Page 1

MS100 Bar Code

Pen Reader

Page 2

AdventureJan

Page 3

Improper handling, storage, environmental influences and /or

product modification can lead to problems during use.

This is particularly true if repairs and maintenance work are

not performed by trained personnel.

We reserve the right to make technical modifications in accordance with technological advancements as they occur.

General Advisory

FCC Information

This device has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the device is

operated in a commercial environment. This device generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual,

may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to

cause harmful interference, in which case the user will be

required to correct the interference at his or her own expense.

MS100 Manual

Page 4

TABLE OF CONTENTS

RS232 31. . . . . . . . . . . . . . . . . . . .

Scanner Port 33. . . . . . . . . . . . . . . . . .

Bar Code Symbologies 35. . . . . . . . . . . . . .

Data Editing 40. . . . . . . . . . . . . . . . . .

Function Codes 45. . . . . . . . . . . . . . . . . .

ASCII Chart 46. . . . . . . . . . . . . . . . . .

SPECIFICATIONS 48. . . . . . . . . . . . . . . . .

TROUBLESHOOTING . . . . . . . . . . . . . . . . 50

WARRANTY 53. . . . . . . . . . . . . . . . . . .

BAR CODE TEST CHART 54. . . . . . . . . . . . . .

Keyboard Wedge 30. . . . . . . . . . . . . . . .

SCANNER CONFIGURATION MANAGER 3. . . . . . . .

Device 6. . . . . . . . . . . . . . . . . . . .

Beeps and Delays 6. . . . . . . . . . . . . . . .

Keyboard Wedge 7. . . . . . . . . . . . . . . .

Scanner Port 11. . . . . . . . . . . . . . . . . .

RS232 9. . . . . . . . . . . . . . . . . . . .

Bar Code Symbologies 14. . . . . . . . . . . . . .

Data Editing 22. . . . . . . . . . . . . . . . . .

PROGRAMMING VIA SCANNER INPUT 25. . . . . . . . .

Quick Setup Bar Codes 26. . . . . . . . . . . . . .

Beeps and Delays 29. . . . . . . . . . . . . . . .

Device Selection and Default 28. . . . . . . . . . . .

INTRODUCTION . . . . . . . . . . . . . . . . . . 1

MS100 Manual

Page 5

MS100 Manual 1

INTRODUCTION

The MS100 is a family of pen style bar code readers specifically designed

to be a simple, unobtrusive method of scanning bar codes. The operation

is intuitive - simply swipe the MS100 across the bar code you want to read.

The MS100 comes in four interfaces: PS/2, RS232, USB, and TTL Wand,

described below.

Please note that pen bar code scanners might not recognize a given bar

code on the first swipe. All scanners may take several scans to recognize

a particular bar code, but whereas gun type bar code scanners can make

30 scans per second, making even repeated scans seem instantaneous,

pen scanners can only make one scan per swipe.

MS100

MS100A

The Undecoded (or TTL, or Wand) MS100A requires an external decoder

in order to communicate with your computer. Decoders are built into

Wedge devices and many POS (Point of Sale) keyboards, such as the

Unitech KP3700.

The MS100A cannot be configured via Scanner Configuration Manager.

Any modification of the output data must be done in the external decoder.

Normal Operation

MS100-2

The RS232 (Com Port) interface should only be used when your software

is designed to accept com port input. The MS100-2 has a built-in decoder

and outputs the scanned data in ASCII Code. MS100-2 input requires

special software such as HyperTerminal (Bits per second: 9600, Data bits: 8,

Parity: None, Stop bits: 1, Flow control: None) in order to view the output.

The MS100-2 will require an optional power supply unless your computer’s

com port supplies power (unlikely).

Page 6

MS100 Manual2

MS100-3

The MS100-3 AT keyboard wedge interface has a “Y” interface cable with

an AT male plug on one end and an AT female plug on the other. The

cable end with the male plug is inserted into your computer’s keyboard

port and your keyboard is plugged into the female plug.

The MS100-3 operation should be “plug and play”. The MS100-3 has a

built-in decoder that outputs the scanned data in Scancode keyboard

format. Your computer will treat your MS100-3’s input as it would normal

keyboard input.

Note: If you are using a laptop computer or a USB keyboard (ie. you are

not using an AT keyboard), then your MS100-3 will need to be configured

as a “Keyboardless Wedge” (see “Device” in the “Scanner Configuration

Manager” section.

MS100-3PS2

The PS/2 Keyboard Wedge interface is the most popular and straightforward. The MS100-3PS2 has a “Y” interface cable with a PS/2 male plug

on one end and a PS/2 female plug on the other. The cable end with the

male plug is inserted into your computer’s keyboard port (not the mouse

port!) and your keyboard is plugged into the female plug.

The MS100-3PS2 operation should be “plug and play”. The MS100-3PS2

has a built-in decoder that outputs the scanned data in Scancode keyboard format. Your computer will treat your MS100-3PS2’s input as it

would normal keyboard input.

Note: If you are using a laptop computer or a USB keyboard (ie. you are

not using a PS/2 keyboard), then your MS100-3PS2 will need to be

configured as a “Keyboardless Wedge” (see “Device” in the “Scanner

Configuration Manager” section.

MS100-4

The USB interface is becoming popular and relatively foolproof. Your

MS100-4 uses the standard USB driver that has been included in the

Windows Operating System since Windows 98 SE.

The MS100-4 operation should be “plug and play”. The MS100-4 has a

built-in decoder that outputs the scanned data in HID keyboard format.

Your computer will treat your MS100-4’s input as it would normal keyboard

input.

Note: Mac OS10 users might need to update their USB driver.

Page 7

3

MS100 Manual

The above icons, from left to right, represent download settings

(from computer to scanner), and upload settings (from scanner to

computer). The third icon opens a Test Pad where you can view the

actual scanner output.

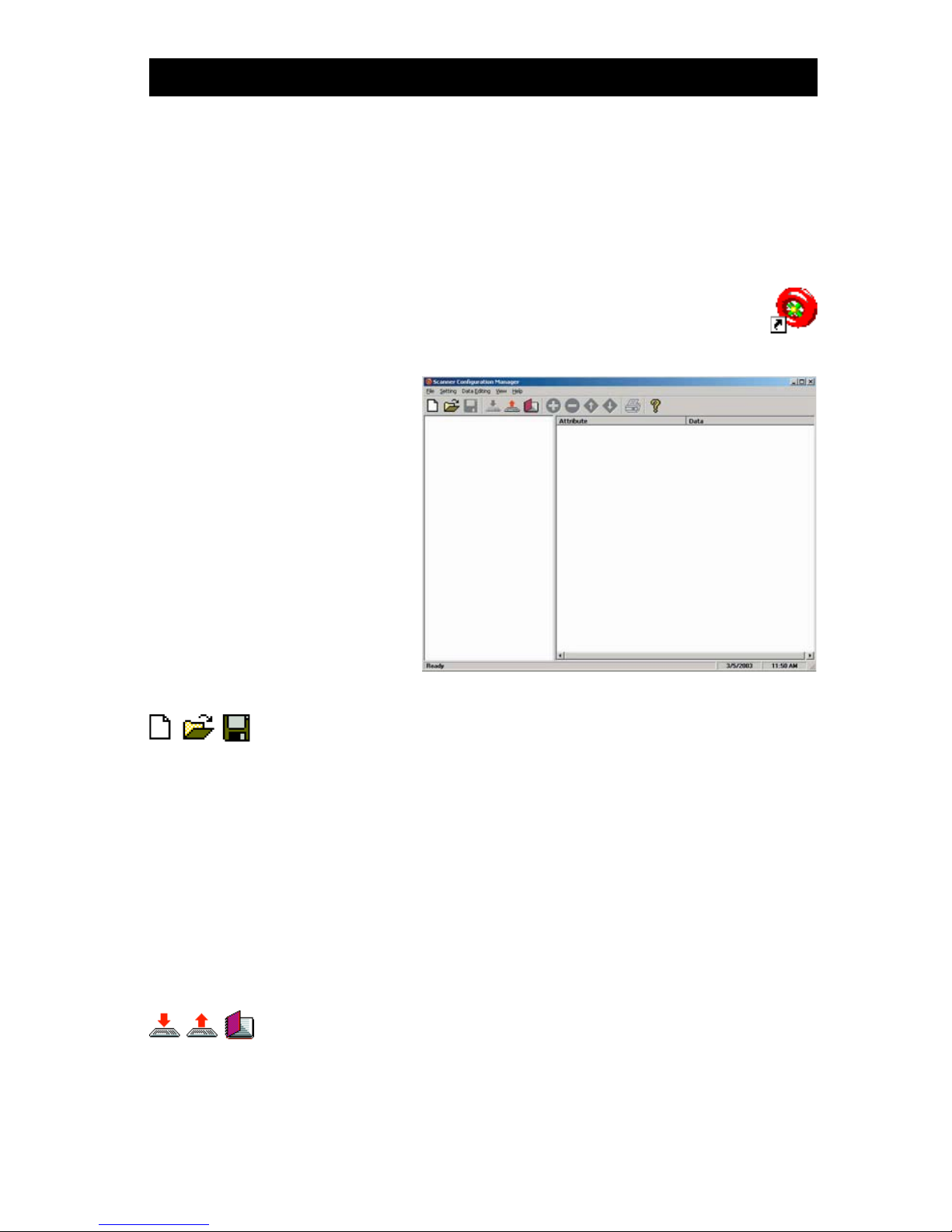

Scanner Configuration Manager software is the simplest and most

foolproof way to configure your scanner settings.

SCANNER CONFIGURATION MANAGER

Above, from left to right, are the standard Windows icons for “New

Document”, Open File”, and “Save File”.

Scanner Configuration Manager saves scanner settings in .cfg files,

so you can have access to a variety of different scanner configurations that you’ve set up.

To reset the scanner back to factory default, click on the “New

Document” icon and download the unmanipulated setting to the

scanner (see below).

After loading and starting SCMSetup.exe the icon to the left

will appear on your desktop:

Start it Up

Click on the SCM icon

and the following screen

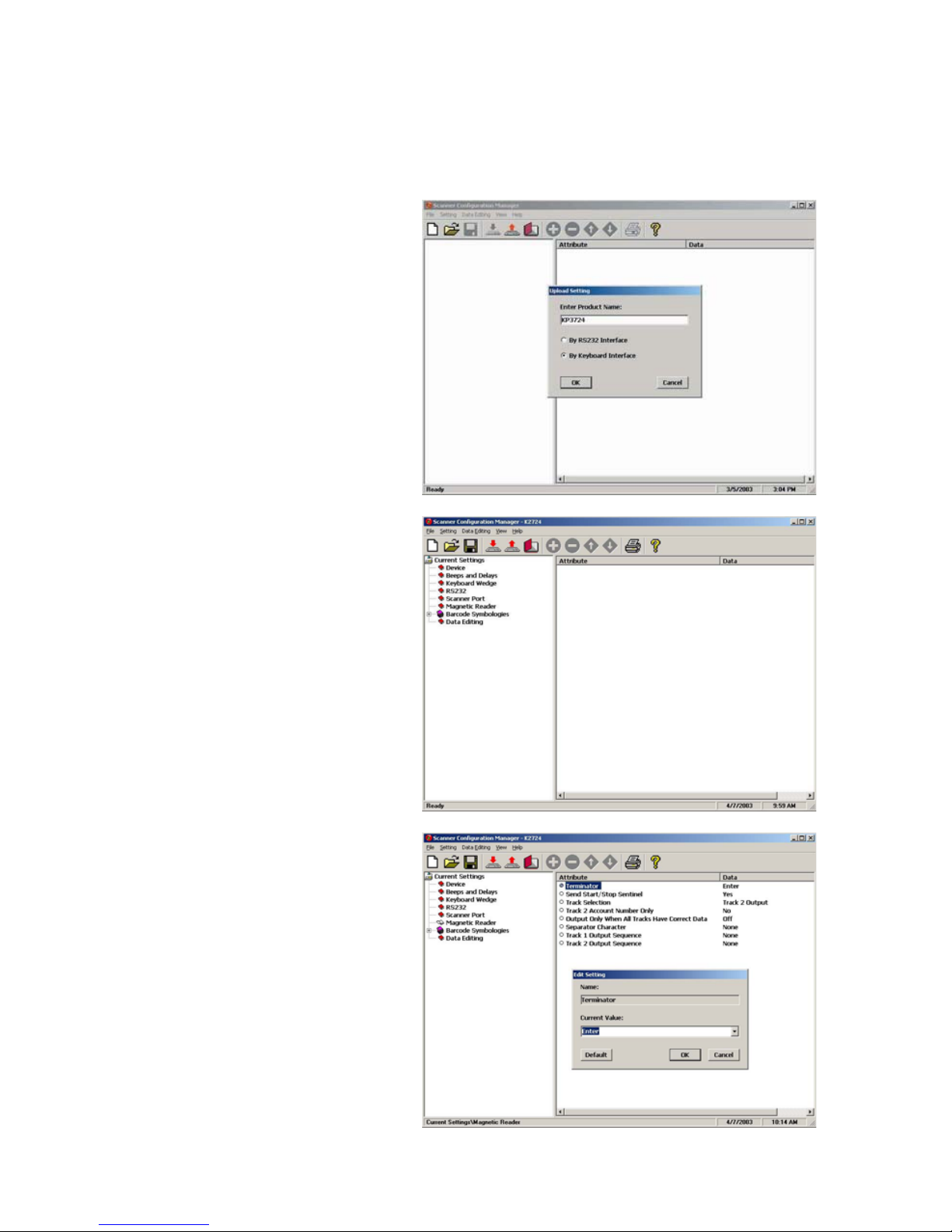

will appear:

As you can see, you are

presented with a blank

work area and a row of

icons across the top.

Following is an explanation of each of the icons:

Page 8

MS100 Manual4

The above four icons are used in the “Data Editing” feature of SCM.

From left to right they are the “Add a Formula” icon, the “Remove a

Formula” icon, and the right-hand two are the “Move Formula” icons

that move selected formulas up or down in relation to each other.

For information on data editing, see page 22.

Click this icon to print a series of bar codes that you can scan in

order to configure your scanner to the current SCM settings.

This option is especially useful if downloading to the scanner is not

an option, like when using an interface adaptor or if Windows NT is

your operating system.

If you can produce PDF files via Acrobat, your SCM configuration

can be sent via e-mail to remote locations where they can be

scanned from a printed PDF file (without having to run SCM).

Help is just a click away.

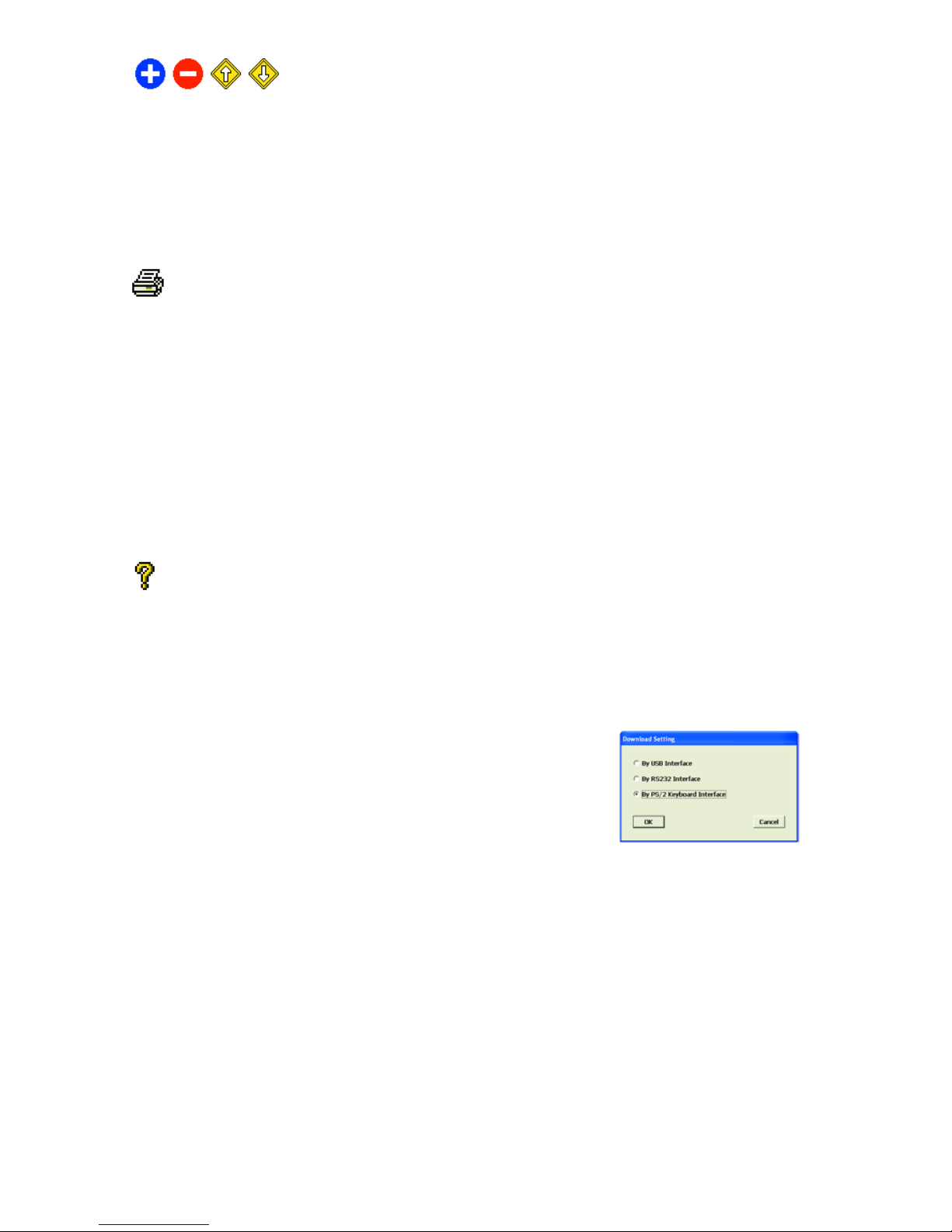

Download to your Scanner

Once you have SCM configured just the way

you want it, click the Download icon (see page

3). The pop-up box to the right should appear:

Select your appropriate interface: USB, RS232,

or PS/2, and then click “OK”.

The green LED on your scanner should blink and you should see the

message “Download completed successfully”. Now your scanner is

ready to use with its new configuration.

If you should get the message “Download to scanner failed”, don’t

dispair. You can still click the “Print” icon (see above) and scan in

the resulting bar codes to configure your scanner.

Page 9

5

MS100 Manual

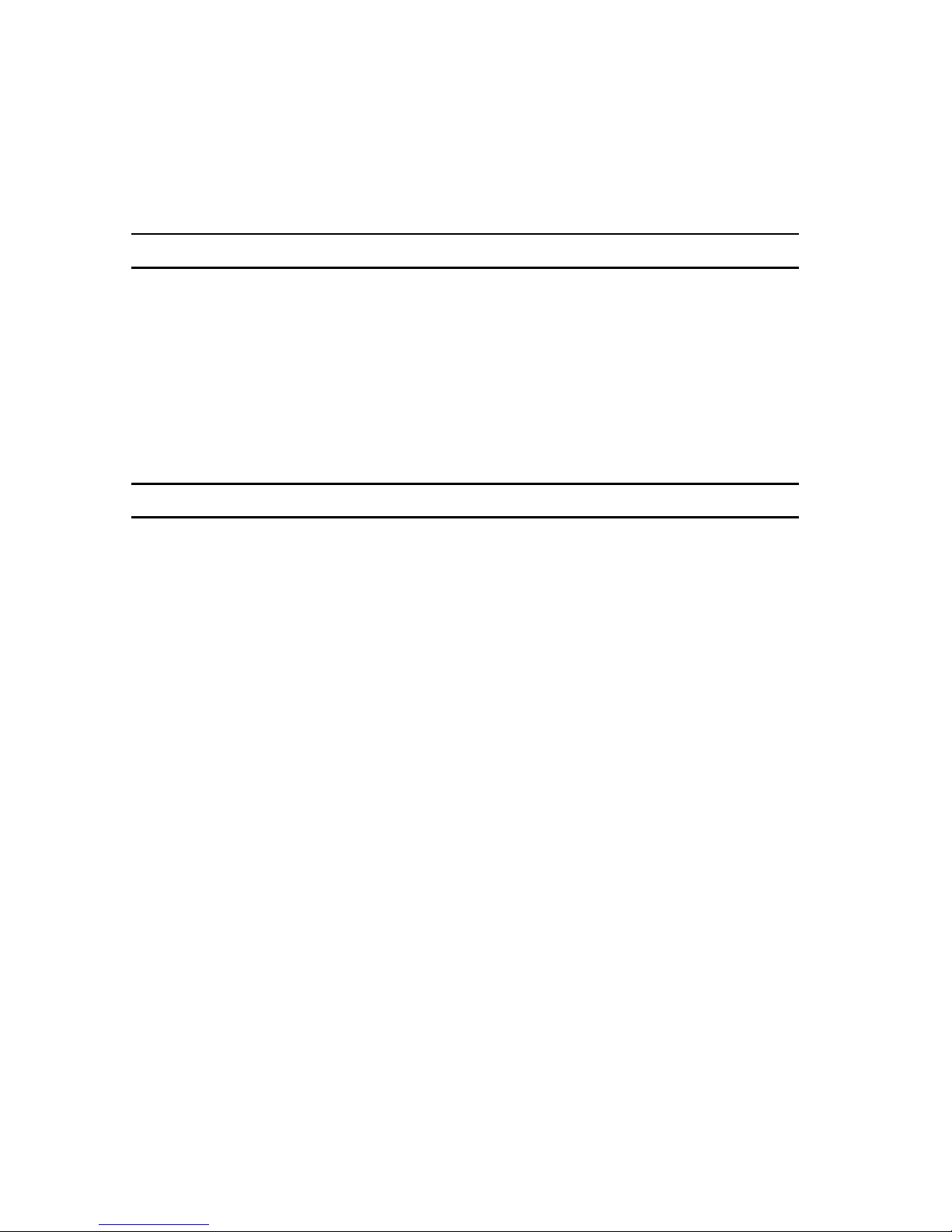

The screen to the left

appears. Click on any of

the selections under

“Current Settings” to view

its “Attributes”.

Click the upload icon (see page 3) and the following pop-up screen

will appear: (alternatively, you can click on the “New Document”

icon, page 3, in which case the second screen will appear)

First Look

Enter the scanner product

number (MS100, for

example).

Make sure the proper

Interface radio button

is selected, and click "OK".

After selecting your configuration settings, click on

the Download icon (see

page 3). The LED on the

top of the scanner will

flash during the download

process. Afterwards, you

will be prompted to do an optional “Quick Test”.

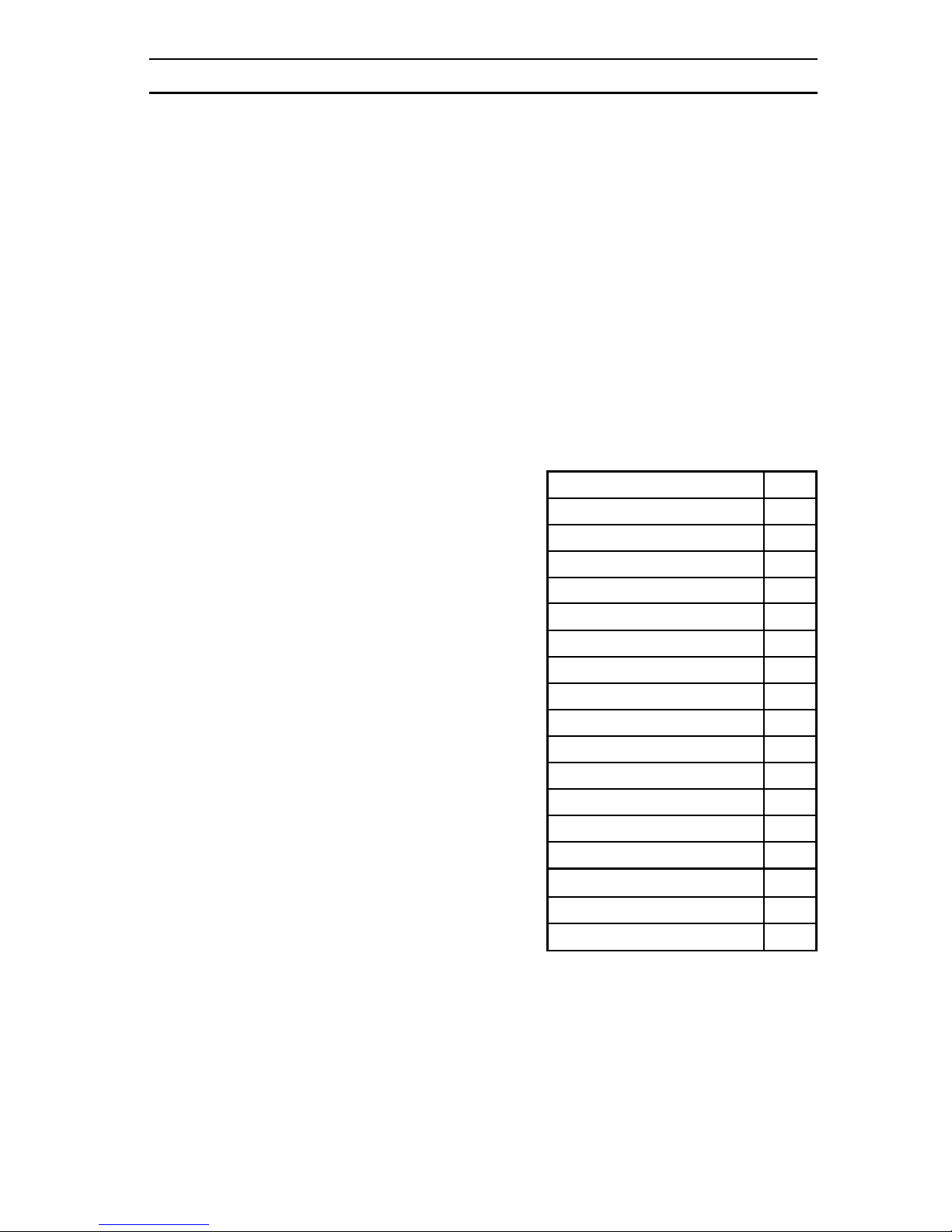

Double-click on any of

the “Attributes” to edit

that attribute. This is

done via a drop-down

menu.

Page 10

6

MS100 Manual

Beep Tone

Select a value from “None” to “High” to set the loudness of the tone,

or select “Low to High” or “High to Low” to set the characteristic of

the tone.

Default is “Medium”.

Intercharacter Delay

Intercharacter Delay is the time duration between data characters

sent from the scanner to the computer. Intercharacter delay is

usually inserted when the data flow must be slowed down for the

benefit of a slower computer.

Default is “1 ms”.

Interblock Delay

Interblock delay is the time duration that can be inserted between

one block of data and another. This function is analogous to the

time duration required between dialing a phone number’s country

code and the phone number itself. The interblock delay can be

inserted via SCM’s Data Editing function (see page 22).

Default is “10 ms”.

Following is a detailed discussion of each of the settings, their

attributes, and the effects each of these will have on data output

from your Unitech scanner.

Settings

The only attribute for the “Device” setting is “Device ID”, which

defines the device to which the scanner is connected (usually a

computer or terminal). Select the setting that most closely describes your device.

The default selection is “01 - IBM PC/AT, PS/2 MOD 40, 60, 80,

USB”, which is appropriate for most PCs.

Device

The three attributes for “Beeps and Delays” are: “Beep Tone”,

“Intercharacter Delay”, and “Interblock Delay”.

Beeps and Delays

Page 11

7

MS100 Manual

Keyboard Wedge

Your Unitech keyboard contains a built in data decoder or “wedge”

that translates raw bar code input into Keyboard Scan Code, with

the result that bar code data exits the scanner as if you had typed

the text.

Seven keyboard wedge parameters are listed below:

Function Code

Function Code determines how function code characters from the

scanner is output.

If Yes is selected, then scanned function codes will output the

same as if their corresponding function keys were pressed.

Scanning an F1 label will pop-up a “Help” box, F3 a “Find” pop-up

box, etc.

•

•

If No is selected, the scanned function codes will output special

character strings defined by Unitech for non-print character

output.

Default is “Yes”.

Caps-Lock

The Caps Lock function determines how the Caps Lock key controls

the case of alphabetical characters. The three options below are

available:

•

Auto Trace automatically determines the Caps Lock key status

and informs the decoder accordingly.

Lower Case manually coordinates the physical state of the Caps

Lock key with the Caps Lock state of the decoder. For example,

if the Caps Lock light is not on, then “Lower Case” should be

selected.

•

Upper Case is the same as Lower Case (above) except that it

applies to the upper case state. If the Caps Lock is on, then

Upper Case should be selected.

Default is “Auto Trace”.

•

Page 12

8

MS100 Manual

Keyboard Wedge, continued

Use Numeric Keypad

The ASCII code for numeric input from the keypad part of the

keyboard is different from that of the upper row of the keyboard

proper. Some accounting programs require keypad input, and for

that reason, the keyboard decoder can output scanned or read

numbers as either keypad or keyboard (upper row) output.

Default is “No”.

Level Duration of Minimal Width

This adjustment refers to the amount of time the wand scanner

requires to recognize an individual bar in a bar code. The choices

are 200 µs (microseconds) or 600 µs.

Default is “200 µs”.

Polarity of Idle Condition

The polarity of the idle condition (while it has no input) of the wand

scanner can be either high or low.

Default is “Low”.

Language

Your Unitech scanner can output characters using eleven different

language sets, including:

Default is “U.S.”

Danish

U.S. English

U.K. English

Norwegian

Swedish

Spanish

Swiss

Alt Key Mode

French

German

Italian

Wand Emulation Output

Wand emulation refers to raw, undecoded bar code data - 0s and

1s. The choice here is whether to assign a 1 (high) to the dark bar

and a 0 (low) to the white space - or vice-versa.

Bar with High / Space with Low

Bar with Low / Space with High

Default is “Bar with High / Space with Low”.

Page 13

9

MS100 Manual

Baud Rate

Baud Rate (bits per second) refers to the speed of the data through

the RS232 port. If the data error rate is unacceptably high, setting

the baud rate lower should help.

Default is “9600 Baud”.

RS232

ACK/NAK

Data characters that are sent from the receiver to the sender in

order to “acknowlege” or “not acknowlege” the receipt of the data

without error. Rarely used these days.

Default is “No”.

Handshaking

Handshaking is the mechanism that controls the speed of data flow

so that a slower receiver of data is not overwhelmed by a faster

sender of data. Selections are: “Ignore”, “RTS (request to send)

Enabled at Power Up”, and “RTS Enabled in Communication”.

Default is “Ignore”

Data Bit

Number of bits per byte that are dedicated to data (minus start/stop

bits).

Default (and the current universal standard) is “8 Data Bits”.

Parity

A technique used to detect data transmission errors by adding an

extra bit to each character. This scheme has been supplanted in

modern communication devices by “error correction”.

Default (and the current universal standard) is “No Parity”.

BCC Character

Block Check Character. An error checking character added for data

integrity.

Default is “No”.

Page 14

10

MS100 Manual

Data Direction

Three options are available for data direction: “Send to Host”,

“Send to Host & Terminal”, and “Send to Terminal”.

Default is “Send to Host”.

Time Out

The ACK/NAK function (see page 9) can be given a limited (ranging

from 1 second to 10 seconds) or unlimited amount of time to operate.

Default is “1 Second”.

RS232, continued

Receive Terminator

A user-definable Receive Terminator can be inserted at the end of

bar code data. Pre-defined receive terminators include:

The above special characters must be bracketed by < > symbols as

shown.

Function codes (F keys, cursor up, Enter, etc.) can also be inserted

via hexadecimal code (accessable in a linked menu) and must

include surrounding brackets (<>).

Letters and numbers should be entered directly by keyboard input

without surrounding brackets (<>).

Default is “None”.

<t>: Tab

•

<r>: Carriage Return

•

<n>: Line Feed

•

<d>: Any Digit

•

<a>: Any Letter

•

<*>: Interblock Delay

•

<“>: “ (quotation marks)

•

<dd>: character in hexadecimal notation

•

<<>: <

•

<>>: >

•

Page 15

11

MS100 Manual

Terminator

The Terminator is a command that follows the input of bar code

data. Four different terminators can be selected here: “Enter”,

“Return (on numeric keypad)”, “Field Exit or Right Control”, or

“None”. Alternative terminators (such as Tab) can be be configured

via the Postamble function (see page 13).

Default is “Enter”

Double Verification

Double Verification enables the scanner to verify the accuracy of the

output by outputting only after a specified number (from 0 to 7) of

identical results. For instance, if 3 is selected, the scanner will not

output the bar code data until it’s obtained 4 identical scan results.

Because the scanner normally scans at a rate of 33 scans per

second (unless it’s a wand), this process should take less than a

fraction of a second, even for higher values.

Default is “0-Off”

Scanner Port

Terminator, Use Code ID, Double Verification, Scanning Mode,

Label Type, Aim Function for Long-Range Engine, Aim Time for

Long-Range Engine, Preamble, and Postamble are the parameters

for Scanner Port configuration.

Use Code ID

The Code ID function can be used to

identify the type of bar code that is

being scanned by inserting an identifying letter (refer to chart at right) at the

beginning of the bar code output.

For example, if the Code ID function is

on, and a bar code string of “54321”

was output as “M54321”, the bar code

would thus be identified as type Code

39.

Default is “No”.

Code 11 / Telpen J

DDelta Code

UPC-A

A

UPC-E E

EAN-13 F

FFEAN-8

I 2 of 5 I

S 2 of 5

H

Code 39 M

Codabar N

Code 93 L

Code 128 K

UCC/EAN128 ]C1

MSI O

Code 32 T

Plessey Code P

Label Code IV, V B

C

Toshiba Code

Page 16

12

MS100 Manual

Aim Function for Long Range Engine

The Aim Function causes a laser scanner to output a “pin-point”

aiming aid for a specified period of time (see below) to enable the

user to more easily scan distant bar code labels. This function can

be toggled on or off.

Default is “No”.

Scanner Port, continued

Label Type

Toggle between reading only Positive and both Positive and Negative bar codes. Reading both positive and negative bar codes can

be useful in the graphics industry when negative images must be

proofed.

Default is “Positive”.

Default is “Trigger”

Scanning Mode

Actual bar code scanning can occur in six different ways:

•

Continuous causes the scanner light to remain on and scan bar

codes as they are presented. Bar codes can be “double

scanned” only after a short interval.

•

Old Laser Flash causes the scanner to flash continuously after

the trigger is pressed and will scan each bar code only once per

presentation. A second trigger press stops the scanning.

•

Test is similar to the Flash setting except that the scanner outputs bar code data in a rapid-fire manner as long as a bar code is

presented to the scanner.

•

One Press One Scan causes the scanner light to remain on

after the trigger is briefly depressed until a bar code is detected

and output.

•

Multiscan allows multiple scans while holding down the trigger.

•

Flashing causes the scanner to flash continuously after the

trigger is pressed until it detects a bar code and outputs the data.

The scanner light will remain on in anticipation of another bar

code for approximately 12 seconds, after which it will begin

flashing again. A second trigger press stops the scanning.

•

Trigger scan causes the scanner light to remain on as long as

the trigger is depressed, whether the bar code is recognized or

not.

Page 17

13

MS100 Manual

Aiming Time for Long Range Engine

The Aiming Time function specifies the duration of the Aim Function

(see previous page). Length of duration can be specified from

500ms to 2 seconds, in half-second increments.

Default is “1 second”.

Postamble

Identical to Preamble (above), but characters are inserted after

scanned data. A common postamble would be to insert a “Tab” in

lieu of an “Enter” terminator (see page 11).

Default is “None”

Scanner Port, continued

The above special characters must be bracketed by < > symbols as

shown.

Function codes (F keys, cursor up, Enter, etc.) can also be inserted

via hexadecimal code (accessable in a linked menu) and must

include surrounding brackets (<>).

Letters and numbers should be entered directly by keyboard input

without surrounding brackets (<>).

Default is “None”

Preamble

Insert a string of characters prior to the actual scanned data.

Pre-defined characters include:

•

<>>: >

<<>: <

•

•

<dd>: character in hexadecimal notation

•

<“>: “ (quotation marks)

•

<*>: Interblock Delay

•

<a>: Any Letter

•

<d>: Any Digit

•

<n>: Line Feed

•

<r>: Carriage Return

•

<t>: Tab

Page 18

14

MS100 Manual

Bar Code Symbologies

Modify the output characteristics of 16 of the most popular bar code

symbologies in current use. Following are the bar code symbologies and their modifiable parameters.

Code 39

Maximum Length defines the maximum length the user will

accept for a valid bar code. Default is “48”.

•

Minimum Length defines the minimum length the user will

accept for a valid bar code. Default is “0”.

•

Send Start/Stop toggles sending or not sending start/stop

sentinels (* in the case of Code 39). Default is “No Send”.

•

Check Digit defines whether or not a check digit (to insure data

accuracy) is calculated, and if so, whether it should be sent or

not. Default is “Not Calculate”.

•

Type toggles Code 39 between Standard and Full ASCII.

Default is “Full ASCII”.

•

Code ID (Full ASCII) is the same as Code ID (Standard), above,

except that the symbology is Full ASCII Code 39.

Default letter is also the letter “M”.

•

Code ID (Standard) is a user-definable identification letter for

Standard Code 39, which is referred to in the “Use Code ID”

function (see page 11). Default is letter “M”.

•

Enabled toggles the ability for the keyboard/scanner to read

Code 39 on or off. Default is “Yes”.

•

Page 19

15

MS100 Manual

Bar Code Symbologies, continued

Standard 2 of 5 / Toshiba Code (China Postal Code)

Maximum Length defines the maximum length the user will

accept for a valid bar code. Default is “48”.

•

Minimum Length defines the minimum length the user will

accept for a valid bar code. Default is “4”.

•

Check Digit defines whether or not a check digit (to insure data

accuracy) is calculated, and if so, whether it should be sent or

not. Default is “Not Calculate”.

•

Fix Length (by first 3 reads) fixes the length of acceptable

subsequent bar code reads from the first three bar codes read.

Useful as a data verification if all bar codes are of a consistent

length. Default is “No”.

•

Toshiba Code ID is the same as S25 Code ID (above), but

instead applicable to Toshiba Code. Default is letter “C”.

•

S25 Code ID is a user-definable identification letter for S 2 of 5,

which is referred to in the “Use Code ID” function (see page 11).

Default is letter “H”.

•

Enabled toggles the ability for the keyboard/scanner to read S 2

of 5 / Toshiba Code on or off. Default is “No”.

•

Interleaved 2 of 5

Enabled toggles the ability for the keyboard/scanner to read I 2

of 5 on or off. Default is “Yes”.

•

Code ID is a user-definable identification letter for I 2 of 5, which

is referred to in the “Use Code ID” function (see page 11).

Default is letter “I”.

•

Fix Length (by first 3 reads) fixes the length of acceptable

subsequent bar code reads from the first three bar codes read.

Useful as a data verification if all bar codes are of a consistent

length. Default is “No”.

•

Check Digit defines whether or not a check digit (to insure data

accuracy) is calculated, and if so, whether it should be sent or

not. Default is “Not Calculate”.

•

Suppress Digit suppresses the output of the first or last bar

code digit. Default is “Not Suppressed”.

•

Minimum Length defines the minimum length the user will

accept for a valid bar code. Default is “10”.

•

Maximum Length defines the maximum length the user will

accept for a valid bar code. Default is “64”.

•

Page 20

16

MS100 Manual

Bar Code Symbologies, continued

Code 128

Enabled toggles the ability for the keyboard/scanner to read

Code 128 on or off. Default is “Yes”.

•

Code ID is a user-definable identification letter for Code 128,

which is referred to in the “Use Code ID” function (see page 11).

Default is letter “K”.

•

Minimum Length defines the minimum length the user will

accept for a valid bar code. Default is “1”.

•

Maximum Length defines the maximum length the user will

accept for a valid bar code. Default is “64”.

•

EAN 128

Field Separator is a user-definable character to insert between

fields. Default is “None”.

•

Enable Code ID determines whether or not to assign a Code ID.

Default is “No”.

•

Code ID is a user-definable identification letter for EAN 128,

which is referred to in the “Use Code ID” function (see page 11).

Default is “None”.

•

Enabled toggles the ability for the keyboard/scanner to read EAN

128 on or off. Default is “No”.

•

Code 32

Enabled toggles the ability for the keyboard/scanner to read

Code 32 on or off. Default is “No”.

•

Code ID is a user-definable identification letter for Code 32,

which is referred to in the “Use Code ID” function (see page 11).

Default is letter “T”.

•

Send Leading Character toggles sending or not sending a

leading (“start bar code”) character. Default is “Send”.

•

Send Tailing Character toggles sending or not sending a tailing

(“stop bar code”) character. Default is “Send”.

•

Page 21

17

MS100 Manual

Bar Code Symbologies, continued

Code 93

Enabled toggles the ability for the keyboard/scanner to read

Code 93 on or off. Default is “Yes”.

•

Code ID is a user-definable identification letter for Code 93,

which is referred to in the “Use Code ID” function (see page 11).

Default is letter “L”.

•

Minimum Length defines the minimal length the user will accept

for a valid bar code. Default is “1”.

•

Maximum Length defines the maximum length the user will

accept for a valid bar code. Default is “48”.

•

MSI / Plessey Code

Enabled toggles the ability for the keyboard/scanner to read MSI

/ Plessey Code on or off. Default is “Yes”.

•

MSI Code ID is a user-definable identification letter for MSI

Code, which is referred to in the “Use Code ID” function (see

page 11). Default is letter “O”.

•

Plessey Code ID is the same as MSI Code ID (above), but

instead applicable to Plessey Code. Default is the letter “P”.

•

Send Check Digit toggles whether or not to send a check digit.

Default is “No Send”.

•

Check Digit Formula defines the formula to calculate the check

digit. Options are: “Double Module 10”, Module 11 Plus 10”, and

“Single Module 10”. Default is “Double Module 10”.

•

Minimum Length defines the minimal length the user will accept

for a valid bar code. Default is “1”.

•

Maximum Length defines the maximum length the user will

accept for a valid bar code. Default is “16”.

•

Page 22

18

MS100 Manual

Bar Code Symbologies, continued

UPC-A

Send Check Digit toggles whether or not to send a check digit.

Default is “Send”.

•

Send Leading Digit toggles sending or not sending a leading

(“start bar code”) digit. Default is “Send”.

•

Code ID is a user-definable identification letter for UPC-A, which

is referred to in the “Use Code ID” function (see page 11).

Default is letter “A”.

•

Enabled toggles the ability for the keyboard/scanner to read

UPC-A on or off. Default is “Yes”.

•

Codabar

Maximum Length defines the maximum length the user will

accept for a valid bar code. Default is “48”.

•

Minimum Length defines the minimum length the user will

accept for a valid bar code. Default is “3”.

•

CLSI Format deletes the start and stop sentinels and outputs the

data with spaces inserted after the 1st, 5th, and 10th characters.

Default is “No”.

•

Check Digit defines whether or not a check digit (to insure data

accuracy) is calculated, and if so, whether it should be sent or

not. Default is “Not Calculate”.

•

Send Start/Stop toggles sending or not sending start/stop

sentinels. Default is “No Send”.

•

Code ID is a user-definable identification letter for Codabar,

which is referred to in the “Use Code ID” function (see page 11).

Default is letter “N”.

•

Enabled toggles the ability for the keyboard/scanner to read

Codabar on or off. Default is “No”.

•

Page 23

19

MS100 Manual

Bar Code Symbologies, continued

EAN-8

Send Check Digit toggles whether or not to send a check digit.

Default is “Send”.

•

Send Leading Digit toggles sending or not sending a leading

(“start bar code”) digit. Default is “Send”.

•

Code ID is a user-definable identification letter for EAN-8, which

is referred to in the “Use Code ID” function (see page 11).

Default is letters “FF”.

•

Enabled toggles the ability for the keyboard/scanner to read

EAN-8 on or off. Default is “Yes”.

•

EAN-13

Bookland EAN toggles whether or not to send the EAN-13 bar

code data in Bookland EAN (ISBN) format. Default is “No”.

•

Send Check Digit toggles whether or not to send a check digit.

Default is “Send”.

•

Send Leading Digit toggles sending or not sending a leading

(“start bar code”) digit. Default is “Send”.

•

Code ID is a user-definable identification letter for EAN-13, which

is referred to in the “Use Code ID” function (see page 11).

Default is letter “F”.

•

Enabled toggles the ability for the keyboard/scanner to read

EAN-13 on or off. Default is “Yes”.

•

UPC-E

Enable NSC=1 allows the output of a UPC-E bar code with a first

digit of “1”. Default is “No”.

•

Zero Expansion adds 0s to the bar code output to change the

output format to UPC-A. Default is “No”.

•

Send Check Digit toggles whether or not to send a check digit.

Default is “No Send”.

•

Send Leading Digit toggles sending or not sending a leading

(“start bar code”) digit. Default is “Send”.

•

Code ID is a user-definable identification letter for UPC-E, which

is referred to in the “Use Code ID” function (see page 11).

Default is letter “E”.

•

Enabled toggles the ability for the keyboard/scanner to read

UPC-E on or off. Default is “Yes”.

•

Page 24

20

MS100 Manual

Bar Code Symbologies, continued

Code 11

Maximum Length defines the maximum length the user will

accept for a valid bar code. Default is “48”.

•

Minimum Length defines the minimum length the user will

accept for a valid bar code. Default is “1”.

•

Send Check Digit toggles whether or not to send a check digit.

Default is “No Send”.

•

Check Digit Number defines the check digit correct result to be

either “1” or “2”. Default is “2”.

•

Code ID is a user-definable identification letter for Code 11,

which is referred to in the “Use Code ID” function (see page 11).

Default is letter “J”.

•

Enabled toggles the ability for the keyboard/scanner to read

Code 11 on or off. Default is “No”.

•

Delta Code

Send Check Digit toggles whether or not to send a check digit.

Default is “Send”.

•

Calculate Check Digit toggles whether or not to calculate a

check digit. Default is “Yes”.

•

Code ID is a user-definable identification letter for Delta Code,

which is referred to in the “Use Code ID” function (see page 11).

Default is letter “D”.

•

Enabled toggles the ability for the keyboard/scanner to read

Delta Code on or off. Default is “No”.

•

Supplement Code (for UPC-E, ISBN, EAN-13)

Insert Space Separator toggles whether or not to output a space

between the main and supplemental bar codes. Default is “No”.

•

Must Present toggles whether or not the supplemental bar code

must be present in order to output data. Default is “Yes”.

•

Five Supplement Code toggles whether the five digit supplemental bar code is to be recognized. Default is “No”.

•

Two Supplement Code toggles whether the two digit supplemental bar code is to be recognized. Default is “No”.

•

Page 25

21

MS100 Manual

Bar Code Symbologies, continued

Label Code IV and V

•

Enabled toggles the ability for the keyboard/scanner to read

Label Code IV and V on or off. Default is “No”.

Send Check Digit toggles whether or not to send a check digit.

Default is “Send”.

•

Code ID is a user-definable identification letter for Code IV and V,

which is referred to in the “Use Code ID” function (see page 11).

Default is letter “B”.

•

Page 26

22

MS100 Manual

Data Editing

Qualifier

The Qualifier section defines the conditions that must be present for

the bar code to be modified, such as what type of bar code it must be

(Code 39, EAN-13, etc.), what length the bar code must be, or what

characters (defined by a match string) the bar code must contain.

When the conditions of the Qualifier are met, the bar code is then

modified according to the rules defined in the “Modifier”, below.

From Original extracts the desired

data from the existing bar code.

The Start Parameter defines the

beginning of the string of data that

is to be output. The start parameter

can either be defined by position

starting from the beginning (“From

Position”), or a specific number of

characters from the end of the string (“From Last Position”), or a

specified number of characters before or after a user-defined character string (“After Matching”).

Modifier

The Modifier section contains three selections: “From Original”,

“Add New”, and “Delete”.

The End Parameter defines the end of the string of data that is to

be output. Three options are available: “Number Of Characters To

Output”, “All Remaining”, and “After Matching”. The first two are

self-explanatory. “After Matching” defines the end as a specified

number of characters before or after a user-defined character string.

Data Editing is a powerful function that can give you tremendous

control over how data is exported from the scanner.

After clicking on “Data Editing” the

data editing icons become active.

Click on the icon with the blue

circle and white plus sign.

The “Define Formula” pop-up box to

the right appears, which is divided

into two sections: “Qualifier” and

“Modifier”.

Page 27

23

MS100 Manual

Data Editing, continued

Delete deletes existing modifier strings.

Move Up / Move Down moves the modifiers up and down

in relation to each other. The top modifier will be performed

first and each one down the list will be performed in sequence. The original data (modified or unmodified) will be

output according to its position in the modifier sequence.

Even if the original bar code data is not modified, if additional characters are to be added (see “Add New”, below) the original Start

Parameter must be defined as From Position “1” and the End

Parameter defined as “All Remaining”, otherwise, none of the

original data will be output.

Add New adds characters (printing and non-

printing) to the data output from the scanner/

reader. These characters can be added before

and/or after the actual scanned data (see “Move

Up / Move Down”, below). Pre-defined characters include:

Characters must be bracketed by < > symbols.

Letters and numbers should be represented in hexadecimal format

(accessable in a linked menu). For instance, the lower-case letter

“t” should be entered as <74> and the numeral 5 should be entered

as <35>.

Function codes (F keys, Cursor up, Enter, etc.) can also be inserted

via hexadecimal code (accessable in a linked menu).

<>>: > (greater than)

•

<<>: < (less than)

•

<dd>: character in hexadecimal notation

•

<“>: “ (quotation marks)

•

<*>: Interblock Delay (data editing)

•

<a>: Any Letter (data editing)

•

<d>: Any Digit (data editing)

•

<n>: Line Feed

•

<r>: Carriage Return

•

<t>: Tab

•

Page 28

24

MS100 Manual

Data Editing, continued

The “Everything Else” Formula

If a formula is entered into the Data Editing area, then all scanned

bar codes will be evaluated according to this formula. If the

scanned bar code does not satisfy the requirements of the Qualifier

(see page 22), then no data is output. Practically speaking, the

scanner has been set up to scan only bar codes that are defined by

the Qualifier. You will not be able to scan other types of bar codes.

The answer to this problem is to end the sequence of formulas with

a formula that has no Qualifier and whose Modifier includes all the

scanned data (starts at position 1 and outputs “all remaining”). An

example of this can be seen as Formula 7 above.

In the example pictured above, a series of formulas are designed to

output all the data in a bar code that follows a series of “0”s. For

instance, if the actual bar code is “000045678”, the desired output

would be “45678” (the original minus all the 0s occurring at the

beginning of the string). If there are six 0s (Formula 1), then the

output starts at the seventh position. If there are five 0s (Formula

2), then the output starts at the sixth position, etc.

If, instead, we were to place the qualifier for two 0s above (before)

the qualifier for six 0s, then the formula stipulating two 0s would

activate even if there were six 0s in the bar code because the

qualifier would stop looking for 0s after it had found two. In this

case, all qualifiers with three or more 0s would be disregarded,

which would not be a desirable result.

Arrange Formulas

After the formulas have

been created, they must

be arranged in the optimum sequence by selecting formulas and using the

“Move Formula” icons (see

page 4). This sequence is

usually according to their

qualifier - from least likely

to occur to most likely to

occur.

Page 29

25MS100 Manual

PROGRAMMING VIA SCANNER INPUT

In addition to the Scanner Configuration Manager software, your

Unitech scanner can also be configured via bar code scanner input,

by scanning in the bar codes on the following pages.

The concept is fairly simple: Parameters are associated together

into groups. For instance, on page 35, “Beep Tone”, “Interblock

Delay”, and “Intercharacter Delay” form a group called “Beeps and

Delays”.

In order to modify a particular parameter, first you must scan an

“Enter Group X” bar code to start the procedure. For instance, to

change the Beep Tone, first you must scan the “Enter Group 2” bar

code. The scanner will emit a triple beep which indicates that the

scanner has entered configuration mode. (The scanner will remain

in configuration mode until the "Exit" bar code has been scanned.)

Then you must scan the bar code of the parameter you’d like to

modify. To modify the Beep Tone, scan the “A1” label.

Then select a number along the left side of the page that corresponds with the modification you wish to make. To set the Beep

Tone to “High”, scan the “3” label. Please note that factory default

settings are printed in bold face.

If you’d like to modify another parameter within the same group,

scan another parameter label now. To change “Intercharacter

Delay”, scan the “A3” label. Then scan the number that corresponds with your requirements.

After you’re finished modifying your selected parameters in “Beeps

and Delays”, scan the “Exit” bar code at the bottom of the page to

end the modification session. The keyboard will emit a double beep

to indicate that it is no longer in configuration mode.

An easy alternative programming method is to simply scan in the

bar codes in the Quick Setup labels on the next page, if appropriate.

Page 30

26 MS100 Manual

Quick Setup Bar Codes

Device Type

USB

IBM Terminal

Keyboardless

Code 39

Wand Emulation

Serial Interface

Terminal Wedge

PC AT (PS/2)

PS/2

Macintosh

Enter

Field Exit

Terminator

Inter-Character Delay

1 ms

20 ms

Trigger

Flash

Scanner Mode Code ID

No

Yes

None

Medium

Beep

U.S.

Alt Key

Scan Code

Page 31

27MS100 Manual

Quick Setup Bar Codes, continued

Default

Cut Leading Digit

Send Check Digit

UPC-A Conversion

UPC-E

Default

Cut Leading Digit

Cut Check Digit

EAN-8

Default

Cut Leading Digit

Cut Check Digit

ISBN Conversion

EAN-13

UPC-A

Default

Cut Leading Digit

Cut Check Digit

Supplemental Code

No

Yes

Menu Setup

Enable / Disable

Display Version

Display Version

Factory Default

Factory Default

Page 32

28 MS100 Manual

Device Selection and Default

28 - Dorio ANSI Keyboard

00 - IBM PC/XT

01 - IBM PC/AT, PS/2 MOD 40, 60, 80, USB etc.

02 - IBM PS/2 MOD 30 (8086) 25, 56, 70, 90

08 - IBM 3196 / 3197

09 - IBM 3476 / 3477

10 - IBM 3191 / 3192 / 3270PC

11 - IBM 3486 / 3487 / 3488

13 - IBM 3471 / 3472 (3179)

15 - IBM 3180

17 - IBM 3151

19 - IBM 5550-5P

20 - IBM 5550-6P

06 - Keyboardless Wedge (PC/AT, Notebook)

03 - Macintosh (ADB Port)

04 - Serial Wedge

35 - Serial TTL Inverted

25 - Terminal Wedge

26 - Wand Emulation (Native Output)

07 - Wand Emulation (with Code 39 output)

32 - DEC VT220/320/420

27 - Dorio PC Keyboard

Device ID Device Type

0

1

2

3

4

5

6

7

8

9

Enter Group 1

Factory Default

Group Default

Exit

Page 33

29MS100 Manual

Beeps and Delays

Interblock Delay: (see page 6)

0 - 0 ms

1 - 10 ms

2 - 50 ms

3 - 100 ms

4 - 500 ms

5 - 1 seconds

6 - 3 seconds

7 - 5 seconds

Beep Tone: (see page 6)

0 - None

1 - Low

2 - Medium

3 - High

4 - Low to High

5 - High to Low

0 - 0 ms

1 - 1 ms

2 - 2 ms

3 - 5 ms

4 - 10 ms

5 - 30 ms

6 - 50 ms

7 - 100 ms

Intercharacter Delay:

(see page 6)

0

1

2

3

4

5

6

7

8

9

Group Default

Enter Group 2

A1

A2

A3

Exit

Page 34

30 MS100 Manual

Keyboard Interface

Caps-Lock: (see page 7)

0 - Auto Trace (PC/AT)

1 - Lower Case 2 - Upper Case

Function Code: (see page 7)

0 - Off 1 - ON

Language (For PC/AT): (see page 8)

9 - Alt Key Mode

Enter Group 3

Group Default

B1

B2

B3

Exit

0

1

2

3

4

5

6

7

8

9

:

0 - Disable 1 - Enable

Use Number Keypad Digits: (see page 8)

B8

0 - U.S.

3 - Swedish

6 - Italian

1 - U.K.

4 - Spanish

7 - German

2 - Swiss

5 - Norwegian

8 - French

: - Danish

Page 35

RS232

Group Default

Enter Group 4

0

1

2

3

4

5

6

7

8

9

C1

Baud Rate:

0 = 300 4 = 4800

1 = 600 5 = 9600

2 = 1200 6 = 19200

3 = 2400 7 = 38400

C2

Parity:

2 = Mark

0 = Even 3 = Space

1 = Odd 4 = None

C3

Data Bit:

0 = 7

1 = 8

C4

Handshaking (for serial wedge)

0 = Ignore

1 = RTS enabled at Power Up

2 = RTS enabled in Communication

C5

ACK/NAK (for serial wedge)

0 = Off

1 = On

C6

BCC Character (for serial wedge)

0 = Off

1 = On

MS100 Manual 31

Page 36

C7

Time Out (for serial wedge)

0 = 1 second

1 = 3 seconds

2 = 10 seconds

3 = Unlimited

C8

Data Direction (for Terminal Wedge)

0 = Send to Host

1 = Send to Host and Terminal

2 = Send to Terminal

RS232, continued

Exit

0

1

2

3

4

5

6

7

8

9

MS100 Manual32

Page 37

33MS100 Manual

Scanner Port

0

1

2

3

4

5

6

7

8

9

Group Default

Enter Group 5

Code ID: (see page 11)

Note: This setting does not affect EAN128

Code ID. EAN128 has its own Code ID

setting on page 11.

0 - disable 1 - Enable

D2

Terminator: (see page 11)

3 - None2 - Field Exit or Right Ctrl

0 - Enter 1 - Return (on keypad)

D1

* Scan two digits to choose a code (symbology), then scan

characters from the Full ASCII table (pages 44 to 47)to define the

code ID.

Define Code ID: (see pages 14 to 21)

01 - Code 39 Standard

00 - Code 39 Full ASCII

02 - EAN-13

04 - EAN-8

05 - UPC-E

06 - Interleaved 2 of 5

07 - Codabar

08 - Code 128

09 - Code 93

03 - UPC-A

10 - Standard 2 of 5

11 - MSI Code

12 - EAN 128

13 - Code 32 (Italian pharmacy)

14 - Delta Code

15 - Label Code

16 - Plessey Code

17 - Code 11 (Special)

18 - China Postal Code (Toshiba Code)

D3

0 - Off 1~7 - On (Verify 1~7 times)

Double Verification: (see page 11)

D4

0 - Trigger 1 - Flashing 2 - Multiscan

3 - One Press One Scan 4 - Test Mode

5 - Old Laser flash Mode 6 - Continuous

Scanning Mode: (see page 12)

D5

Page 38

34 MS100 Manual

Scanner Port, continued

0 - Positive 1 - Positive and Negative

Label Type: (see page 12)

0 - Disable 1 - Enable

Aim Function for Long Range Laser

Engine: (see page 12)

0 - Disable 1 - Enable

Data Length (Two Digits) Send:

A Preamble or Postamble can be inserted

before or after the scanned bar code output

(a Tab, for instance).

To insert a postamble, scan the “Postamble”

(00) bar code, scan your selected postamble

from the Function Code (page 43) or ASCII

Code (pages 44 to 47) charts, and then scan

the “Postamble” (00) bar code once again.

To insert a preamble, follow the

same procedure, but using the “PP” bar code.

0

1

2

3

4

5

6

7

8

9

Exit

D6

D7

D8

PP

Preamble

OO

Postamble

Page 39

35MS100 Manual

Symbologies:

Code 39 / I 2 of 5 / S 2 of 5 / Code 32 / Telpen / UCC/EAN128

Group Default

Enter Group 6

0

1

2

3

4

5

6

7

8

9

:

Standard 2 of 5

China Postal Code (Toshiba Code):

1 ~ 48 - Min. Length 4 / Max. Length 48

6 - Check Digit not Calculate

5 - Check Digit Calculate, not send

4 - Check Digit Calculate & Send

2/3 - Fix Length On / Off ( by first three reads)

0/1 - Disable/Enable

(See next page for Min./Max. Length procedure)

F3

F2

2 ~ 64 - Min. Length 10 / Max. Length 64

Interleaved 2 of 5 (ITF):

0/1 - Disable / Enable

2/3 - Fix Length On / Off (by first three reads)

4 - Check Digit Calculate & Send

5 - Calculate Check Digit, Not Send

6 - Check Digit Not Calculate

7 - Suppress First Digit

8 - Suppress Last Digit

9 - Last Digit Not Suppressed

(See next page for Min./Max. Length procedure)

F1

0 ~ 48 - Min. Length 0 / Max. Length 48

Code 39:

0/1 - Disable / Enable

2/3 - Full ASCII / Standard

4 - Check Digit Calculate & Send

5 - Check Digit Calculate, Not Send

6 - Check Digit Not Calculate

7/8 - Send / No Send Start/Stop

9/: - Double Labels Decoding Off / On

(See next page for Min./Max. Length procedure)

Page 40

36 MS100 Manual

Code 39 / I 2 of 5 / S 2 of 5 / Code 32 / Telpen / UCC/EAN128, continued

0

1

2

3

4

5

6

7

8

9

Exit

MM

Min. Length

NN

Max. Length

To define minimum or maximum acceptable

bar code data length, after scanning the

parameter code (F1, F2, or F3) scan the

“MM” or “NN” to the right, scan the number(s)

to the left, and then scan the “MM” or “NN”

again. Then scan “Exit” as usual.

Define Minimum and Maximum Length

Define a Separator for Double Labels:

Scan from the ASCII Code chart (pages 44 to

47) to select a new separator for double labels

F8

Scan from the ASCII Code chart (pages 44 to

47) to define a new fields separator

Define the EAN128 Fields Separator:

F7

Note: If EAN128 is disabled, EAN128 labels

will be decoded as Code 128

UCC/EAN 128:

0/1 - Disable / Enable

2/3 - Code ID Disable / Enable

F6

2/3 - Standard / Numeric Set

Telepen:

0/1 - Disable / Enable

F5

4/5 - Tailing Character Send / No Send

Code 32 (Italian Pharmacy):

0/1 - Disable / Enable

2/3 - Leading Character Send / No Send

F4

Page 41

37MS100 Manual

Symbologies:

Code 128 / MSI / Code 93 / Code 11 / Codabar / Label Code

0

1

2

3

4

5

6

7

8

9

Group Default

Enter Group 7

G1

0/1 - Disable / Enable

1-64 - Min. Length 1 / Max. Length 64

Code 128:

(See next page for Min./Max. Length procedure)

G2

MSI / Plessey Code:

(See next page for Min./Max. length procedure)

1~16 - Min Length 1 / Max Length 16

6 - Check Digit Single Module 10

5 - Check Digit Module 11 plus 10

4 - Check Digit Double Module 10

2/3 - Check Digit Send / No Send

0/1 - Disable / Enable

0/1 — Disable/Enable

2/3 — One / Tw o Check Digit

4/5 — Check Send / No Send

1-48 — Min Length 1 / Max Length 48

Code 11: (Special)

(See next page for Min./Max. Length procedure)

G4

0/1 — Disable/Enable

1-48 — Min Length 1 / Max Length 48

Code 93:

(See next page for Min./Max. Length

procedure)

G3

Page 42

38 MS100 Manual

Code 128 / MSI / Code 93 / Code 11 / Codabar / Label Code, continued

0

1

2

3

4

5

6

7

8

9

Exit

0/1 - Disable / Enable

2/3 - Checksum send / No send

Label Code IV and V:

G6

To define minimum or maximum acceptable

bar code data length, after scanning the

parameter code (G1 through G5) scan the

“MM” or “NN” to the right, scan the number(s)

to the left, and then scan the “MM” or “NN”

again. Then scan “Exit” as usual.

Define Minimum and Maximum Length

MM

Min. Length

NN

Max. Length

0/1 - Disable / Enable

2/3 - Start & Stop Send / No Send

4 - Check Digit Calculate & Send

5 - Check Digit Calculate but not Send

6 - Check Digit not Calculate

7/8 - CLSI Format On / Off

3 ~ 48 - Min Length 3 / Max Length 48

Codabar:

(See below for Min./Max. Length procedure)

G5

Page 43

39MS100 Manual

Symbologies:

UPC / EAN / Delta Code

0/1 - Disable / Enable

2/3 - Check Digit Calculate / Not Calculate

4/5 - Check Digit Send / No Send

Delta Distance Code:

0/1 - Two Supplement Code Off / On

2/3 - Five Supplement Code Off / On

4 - Transmit if Present

5 - Must be Present.

6/7 - Insert Space Separator / Not Insert

Supplement Code:

0/1 - Disable / Enable

2/3 - Leading Digit Send / No Send

4/5 - Check Digit Send / No Send

EAN-8:

0/1 - Disable / Enable

2/3 - Leading Digit Send / No Send

4/5 - Check Digit Send / No Send

6/7 - Bookland EAN (ISBN) Enable / Disable

EAN-13:

0/1 - Disable / Enable

2/3 - Leading Digit Send / No Send

4/5 - Check Digit Send / No Send

6/7 - Zero Expansion On / Off

8/9 - Disable / Enable NSC=1

UPC-E:

0/1 — Disable/Enable

2/3 — Leading Digit Send / No Send

4/5 — Check Digit Send / No Send

UPC-A:

0

1

2

3

4

5

6

7

8

9

Group Default

Enter Group 8

H1

H2

H3

H4

H5

H6

Exit

Page 44

40 MS100 Manual

Data Editing:

Data Editing allows you to manipulate the bar code data output into a format that

you require by scanning in the bar codes on page 42 in addition to Function Codes

and ASCII Codes on pages 43 to 47.

After scanning the “Enter Group 9” bar code, all the subsequent bar code input

(except character string units) beginning with “IN_ID” must be separated by

scanning comma bar codes, until you scan the final “Enter” followed by the “Exit”

bar code. The “Enter Group 9” and the “Enter” barcodes are not followed by

commas.

Each programming parameter is input according to the following patterns:

Parameters are grouped into Qualifiers and Modifiers.

Qualifiers specify the conditions that must be met in order for data editing to

occur, be it minimum or maximum data length, specific symbologies, or specific

character strings present.

Modifiers modify the data output according to pre-set rules by either removing

specified parts of the data or adding user-defined data.

When programming the keyboard/scanner, qualifiers must precede modifiers.

Input ID - Specific bar code symbologies can be selected for special

treatment. The programming bar codes must be entered in the following

sequence: IN_ID,ID1,ID2,...,IDX, - where “IN_ID” announces that the next

bar code inputs refer to the various bar code symbologies according to their

“Code Type” on page 48. For example, if UPC-A and Code 32 bar codes

are to to be singled out for data editing, the bar code scanning sequence

should be “IN_ID,3,13,”.

Length - Bar codes of specific length can be selected. The programming

bar codes must be entered in the following sequence:

LEN,MIN,MAX, - where “LEN” announces that the next bar code inputs refer

to the minimum and maximum length bar codes allowable. For example, if

we only want data editing to apply to bar codes between 6 and 12 characters long, then the bar code scanning sequence should be “LEN,6,12,”.

Qualifiers:

Match - Bar codes with specific character strings can be selected. The

programming bar codes must be entered in the following sequence:

MATCH,P1,”S1”,P2,”S2”,...,PX,”SX”, - where “MATCH” announces that

the next bar code inputs will define where in the data a specific string will be

located, and what characters the string consists of, surrounded by quotation

marks. For example, if the bar code to be selected requires the string “efgh”

beginning at the 3rd position, the bar code scanning sequence should be

“MATCH,3,”efgh”,”. If we’re looking for “efgh” anywhere within the bar code,

the sequence should be “MATCH,*,”efgh”,”, with the “*” character signifying

that it could be anywhere in the string.

Page 45

41MS100 Manual

Modifiers:

Original Data - Part or all of the original data string can be selected. The

programming bar codes must be entered in the following sequence:

O-STR,P,N, - where “O-STR” announces that the next bar code inputs refer

to where the output should begin and how many characters should be

output.

For example, if 7 characters are to be output beginning with the 4th character, the bar code scanning sequence should be “O-STR,4,7,”. If we want all

the characters after the 4th character output, the sequence should be “O-

STR,4,#,”, with the “#” character signifying that the entire string should be

output. Should you decide that the last two characters should not be output,

the sequence would be “O-STR,4,#-2,”, with “#-2” specifying all remaining

minus 2.

Data Editing, continued

Additional Data - User-specified data can be added by simply surrounding

it with quotation marks. For instance, if you want to follow the original data

with the characters “123”, then simply add ”123”, after the O-STR parameter.

If the additional data is to be added before the original data, then it needs to

precede the O-STR parameter. Additional data can be scanned in from the

Function Code or ASCII Code pages (pages 43 through 47).

Thus, if we want to output just the first five characters only from UPC-A input and

follow it with three “0”s, the scanning sequence would be the following:

Enter Group 9 IN_ID , 3 , O-STR , 1 , 5 , “ 0 0 0 “ , Enter Exit

If we only want to treat UPC-A this way, but still want other symbologies to output

normally, the scanning sequence would be the following:

Enter Group 9 IN_ID , 3 , O-STR , 1 , 5 , “ 0 0 0 “ , Enter

IN_ID , 19 , O-STR , 1 , # , Enter Exit

Finally, end the programming sequence with the “Enter” bar code. Do not follow it

with a comma. If you need to add another formula, do so now by scanning the

“IN_ID” bar code directly, followed by the rest of the second formula’s parameters.

Lastly, scan the “Exit” bar code.

Special Characters

, Comma - Used as a separator between formula parameters, beginning

with the IN_ID parameter and ending with the Enter parameter.

“ Quotation Mark - Used to begin and end a character string. A character

string bounded by quotation marks is treated as a single unit, and would

be written as “abcd”.

* Asterisk - Wild character used to specify any digit or any position.

# Hash Sign - Wild character used to specify any letter or last position.

Page 46

42 MS100 Manual

Data Editing, continued

Code Type:

10 - S 2 of 5

19 - All Inputs

18 - China Postal Code

11 - MSI Code

17 - Code 11(Special)

16 - Plessey Code

15 - Label Code

14 - Delta Code

13 - Code 32

12 - EAN 128

9 - Code 93

7 - Codabar

6 - I 2 of 5

5 - UPC-E

4 - EAN-8

3 - UPC-A

2 - EAN-13

1 - Code 39 Std.

0 - Code 39 Full

8 - Code 128

, - delimiter to separate parameters.

“ - string specifier.

* - specify any digit or any position.

# - specify any letter or all input.

Special Characters in this section:

ID1, ID2, etc. = number for Code ID.

P1, P2, etc. = position.

S1, S2, etc. = string, “abc...”.

P = number or string for start position.

N = number of char. or string to end position.

Input ID: IN_ID,ID1,ID2,...,IDX,

Length: LEN,MIN,MAX,

Match: MATCH,P1,S1,P2,S2,...,PX,SX,

A-String: “abc...”,

O-String: O-STR,P,N,

Formula Format:

0

1

2

3

4

5

6

7

8

9

Group Default

Exit

Enter Group 9

+

-

Review

IN_ID

LEN

MATCH

O-STR

"

*

#

Enter

Backspace

,

Page 47

43MS100 Manual

Function Codes for PC

(Code 39)

(Characters in parentheses represent Code 39 bar code printing)

F1 (%VA)

F4 (%VD)

F7 (%VG)

F10 (%VJ)

Esc (/FK)

Tab (/FI)

Back Tab (/FJ)

Shift Make (/FP)

Shift Break (/FS)

Ctrl Make (/FQ)

Ctrl Break (/FT)

F3 (%VC)

F6 (%VF)

F9 (%VI)

F12 (%VL)

Delete (/FX)

Left Enter (/FL)

Right Enter (/FM)

Page Up (/FG)

Page Down (/FH)

Right Ctrl (/FO)

F2 (%VB)

F5 (%VE)

F8 (%VH)

F11 (%VK)

Cursor Up (/FE)

Cursor Down (/FF)

Cursor Left (/FD)

Cursor Right (/FC)

Insert (/FW)

Alt Make (/FR)

Alt Break (/FU)

Page 48

44 MS100 Manual

ASCII Chart

(Characters in parentheses represent Code 39 bar code printing)

VT ($K)

FF ($L)

CR ($M)

SO ($N)

SI ($O)

DLE ($P)

DC1 ($Q)

DC2 ($R)

DC3 ($S)

DC4 ($T)

NAK ($U)

ENQ ($E)

NUL (%U)

SOH ($A)

STX ($B)

ETX ($C)

EOT ($D)

ACK ($F)

BEL ($G)

BS ($H)

LF ($J)

Tab (%I)

SYN ($V)

ETB ($W)

CAN ($X)

EM ($Y)

SUB ($Z)

FS (%B)

GS (%C)

RS (%D)

US (%E)

Escape (%A)

Space

Page 49

45MS100 Manual

ASCII Chart, continued

(Characters in parentheses represent Code 39 bar code printing)

, (/L)

-

.

/

0

1

2

3

4

5

6

7

8

9

: (/Z)

; (%F)

< (%G)

= (%H)

> (%I)

? (%J)

@ (%V)

! (/A)

" (/B)

# (/C)

$

%

& (/F)

( (/H)

) (/I)

* (/J)

+

` (/G)

Page 50

46 MS100 Manual

ASCII Chart, continued

(Characters in parentheses represent Code 39 bar code printing)

L

M

N

O

P

Q

R

S

T

U

V

W

X

Y

Z

[ (%K)

\ (%L)

] (%M)

^ (%N)

_ (%O)

' (%W)

A

B

E

F

G

H

I

J

K

C

D

Page 51

47MS100 Manual

ASCII Chart, continued

(Characters in parentheses represent Code 39 bar code printing)

a (+A)

b (+B)

c (+C)

d (+D)

e (+E)

f (+F)

g (+G)

h (+H)

i (+I)

j (+J)

k (+K)

l (+L)

m (+M)

n (+N)

o (+O)

p (+P)

q (+Q)

r (+R)

s (+S)

t (+T)

u (+U)

v (+V)

w (+W)

x (+X)

y (+Y)

z (+Z)

{ (%P)

| (%Q)

} (%R)

~ (%S)

Delete (%T)

Page 52

ENVIRONMENTAL

-4° to 158° F (-20° to 70° C)Storage:

Temperature: Operating: 32° to 131° F (0° to 55° C)

Humidity: 20% to 85% RH non-condensing

SPECIFICATIONS

MS100 Manual

48

PERFORMANCE

Resolution: 5 mils (.012mm) min.

Light Source: 660nm Red LED

Depth of field: 0.04” (0.1mm)

Scan rate: 2” (50mm) to 30” (750mm) per second

Print Contrast Ratio: 0.5 min.

Reading Angle: 0° to 45°

0.18mm @ PCR 0.5

Minimum Bar Width: 0.12mm @ PCR 0.9

DECODER

Configuration: Via Scanner Configuration Manager software

(downloadable from www.ute.com) or bar code

setup menus in manual

Data Editing: Almost unlimited

Interfaces:

PS/2, RS232, TTL, USB (see next page for pinouts)

Symbologies: Codabar, Code 11, Code 32, Code 39 (Standard

and Full ASCII), Code 93, Code 128, Delta Code,

EAN-8, EAN-13, Label Code IV and V, MSI Code,

Plessey Code, Standard 2 of 5, UPC-A, UPC-E

MECHANICAL / ELECTRICAL

TTL (Undecoded): 35mA

Weight: 4 oz. (113 grams)

Cord: 45” (114cm) coiled, unstretched

Power consumption: Decoded: 70mA

Voltage: 5 Volts DC

Dimensions: 5.4375” L x 1.25” W

(138mm L x 32mm W)

Page 53

PINOUTS

Pin 1 N/C

Pin 2 TXD (Transmit Data)

Pin 3 RXD (Receive Data)

Pin 4 N/C

Pin 5 GND (Ground)

Pin 6 N/C

Pin 7 CTS (Clear to Send)

Pin 8 RTS (Request to Send)

Pin 9 VCC (+5V DC Input)

RS232 Interface (DB9 female)

1

2

3

45

6

7

89

Data (Connect to PC Data)Pin 1

Reset (Connect to PC Reset)Pin 2

GroundPin 3

+5V DC InputPin 4

Clock (Connect to PC Clock)Pin 5

N/CPin 6

Keyboard Interface (6 pin mini-DIN male)

1

2

3

4

5

6

Pin 4 Ground

Pin 3 Data +

Pin 2 Data -

Pin 1 +5V DC Input

USB Interface (4 pin male)

123

4

Pin 1 N/C

Pin 2 Data

Pin 3 N/C

Pin 4 N/C

Pin 5 N/C

Pin 6 N/C

Pin 7 Ground

Pin 8 N/C

Pin 9 +5V DC Input

TTL (Wand) Interface (DB9 female - squeeze release)

1

2

3

45

6

7

89

MS100 Manual 49

Page 54

TROUBLESHOOTING

MS100 Manual

50

Most problems that you might encounter with your scanner can be

solved using the following procedures:

Test the scanner on other ports. Unitech scanners are built to

the highest standards, and a perceived scanner malfunction may

actually be a malfunction in the host computer.

Test the scanner on the host’s other ports if possible or, in necessary, on other systems to verify that the problem is actually in the

scanner and not in the host computer.

Reset to Factory Default. While the Scanner Configuration

Manager program is active, click the “new file” icon (see page 3)

and the “download to scanner” icon (see page 3) to reset your

scanner back to factory default.

Please note that the factory default interface is specified as PS2/

AT/USB. If you have a different interface, then you will need to

configure that also (see page 6) and then download to the scanner.

Caution: This procedure will erase special configurations that

you would have created.

Try scanning other bar codes. If your scanner can scan other

types of bar code symbologies, but cannot scan your bar codes,

first check to see if your particular bar code symbology is enabled.

If it is, try the scanner on the same bar code type in the Bar Code

Test Chart in the back of this manual. Then, insure that your bar

codes are crisp and clear.

Page 55

MS100 Manual 51

Problems and Solutions

Problem: Scanner doesn’t light up.

If the scanner does not emit a light when plugged

in, check the interface.

If the scanner uses an RS232 interface, you will

very likely need a power supply (5V, 300mA).

Unplug the scanner and plug it back in.

Try the scanner on another port if possible.

Re-boot the computer.

If the scanner still doesn’t light up, try the scanner

on another computer to insure that the fault isn’t in

the original computer.

Problem: Scanner lights up but doesn’t beep.

If the scanner emits a light, but doesn’t beep when

scanning a bar code, try bar codes of different

symbologies. If other types of bar codes scan

properly, then it might be that the scanner is not

configured to scan your particular symbology.

If the scanner can scan other bar codes of the same

symbology, then other parameters (such as minimum/maximum length, etc.) may have to be

adjusted.

Insure that your bar code has been created properly, with crisp edges and start/stop sentinels. For

instance, Code 39 bar codes require asterisk (*)

start/stop sentinels at the beginning and end of the

data string (*123ABC*).

Avoid glossy surfaces or glossy inks for your bar

codes. A glossy black surface may be indistinguishable from a white surface to your scanner. Try

photocopying your bar code and scanning the copy

to determine if glossiness may be a factor.

Page 56

MS100 Manual52

Problems and Solutions

Problem: Scanner Configuration Manager cannot upload or

download.

Scanner Configuration Manager can currently

upload and download only in the Windows operating system (NT excluded).

If you have a different OS, or the download function

doesn’t work, prepare your scanner’s configuration

in SCM in the usual manner, and then, instead of

downloading, click the printer icon (page 4) to print

a series of bar codes that you can then scan into

the scanner to configure it.

Problem: No output from scanner.

If the scanner appears to scan (emits a light and

beeps), but does not output data, try scanning into

a word processor application or Notepad session to

see if it’s a software problem.

Try the scanner on other ports to see if it’s a computer port problem.

If your scanner is connected by RS232 interface,

make sure that the correct com port is selected. If

you’re testing your scanner in HyperTerminal, make

sure that “Bits per second” = 9600, “Data bits” = 8,

“Parity” = None, “Stop bits” = 1, and “Flow control”

= None.

Page 57

53MS100 Manual

Limited Hardware Warranty

The Limited Warranty terms described below are solely applicable to the Customer of Unitech America, Inc’s (afterwards simply referred to as Unitech)

products. This warranty applies to equipment only. All consumables and

accessories are exempted.

Unitech warranties its products to be delivered free from defects in material

and workmanship, from the date of purchase. All equipment except for cables,

batteries, power supplies, and RF cards are warranted for a period of twelve

months (beginning from the month of delivery). Some products may have

longer warranties, but all products (except for cables, batteries, power supplies, and RF cards) carry at least a one year warranty. All cables, batteries,

power supplies, and RF cards external to dedicated Unitech products carry a

ninety day warranty.

During this warranty period Unitech will, at its sole discretion, replace or repair

free of charge any product(s) which, in its opinion, is/are defective. Any merchandise that is to be returned must have a valid Return Merchandise Authorization (RMA) number clearly indicated on the outside of the returned package and on the accompanying packing list. Unitech cannot be held responsible for any package returned without an RMA number. To obtain an RMA

number, please contact Unitech’s Customer Service Department or a Sale

Representative, by telephone (562) 490-9550 or by facsimile (562) 490-0320.

The Customer is responsible for packing the defective product properly, and

for the cost of shipping the defective product to Unitech. Unitech is responsible for the cost of shipping back the product which is repaired or replaced. If

any charges are borne by the Customer, the invoice for the repaired or replaced product(s) will be sent to the Customer based on the Customer’s payment terms.

In the event that the product has been modified without Unitech’s consent or

if the product failure is the result of misuse, abuse, willful neglect or misapplication, Unitech has no obligation to repair or replace the product.

Except as expressly mentioned above, the hardware and accompanying written materials (including the user’s manual) are provided “as is” without warranty of any kind, including the implied warranties of merchant ability and

fitness for a particular purpose, even if Unitech has been advised of that purpose. In no event will Unitech be liable for any direct, indirect, consequential

or incidental damages arising out of the use of or inability to use such product(s),

even if Unitech has been advised of the possibility of such damages.

WARRANTY

Page 58

54 MS100 Manual

BAR CODE TEST CHART

8012 3453

EAN-8

Unitech 128

Code 128

A22357000599876B

Codabar

123456789-0

Code 11

Code 32

AO23399013

Code 93

123ABC

0123456

Delta Code

W E D G E

Code 39

UNITECHE

Code 39 with Check Digit

Page 59

55MS100 Manual

3 045214 834123

EAN-13

06

47669 13716

UPC-A

02123457

99

UPC-E

(01)054123456789(01)659344

EAN 128

1234558

MSI Code

0987654321

Interleaved 2 of 5

9 789576 302398

07200

ISBN 957-630-239-0

Standard 2 of 5

1122334455

10017

Label Code IV

Toshiba Code

20132000400

BAR CODE TEST CHART

Loading...

Loading...