Page 1

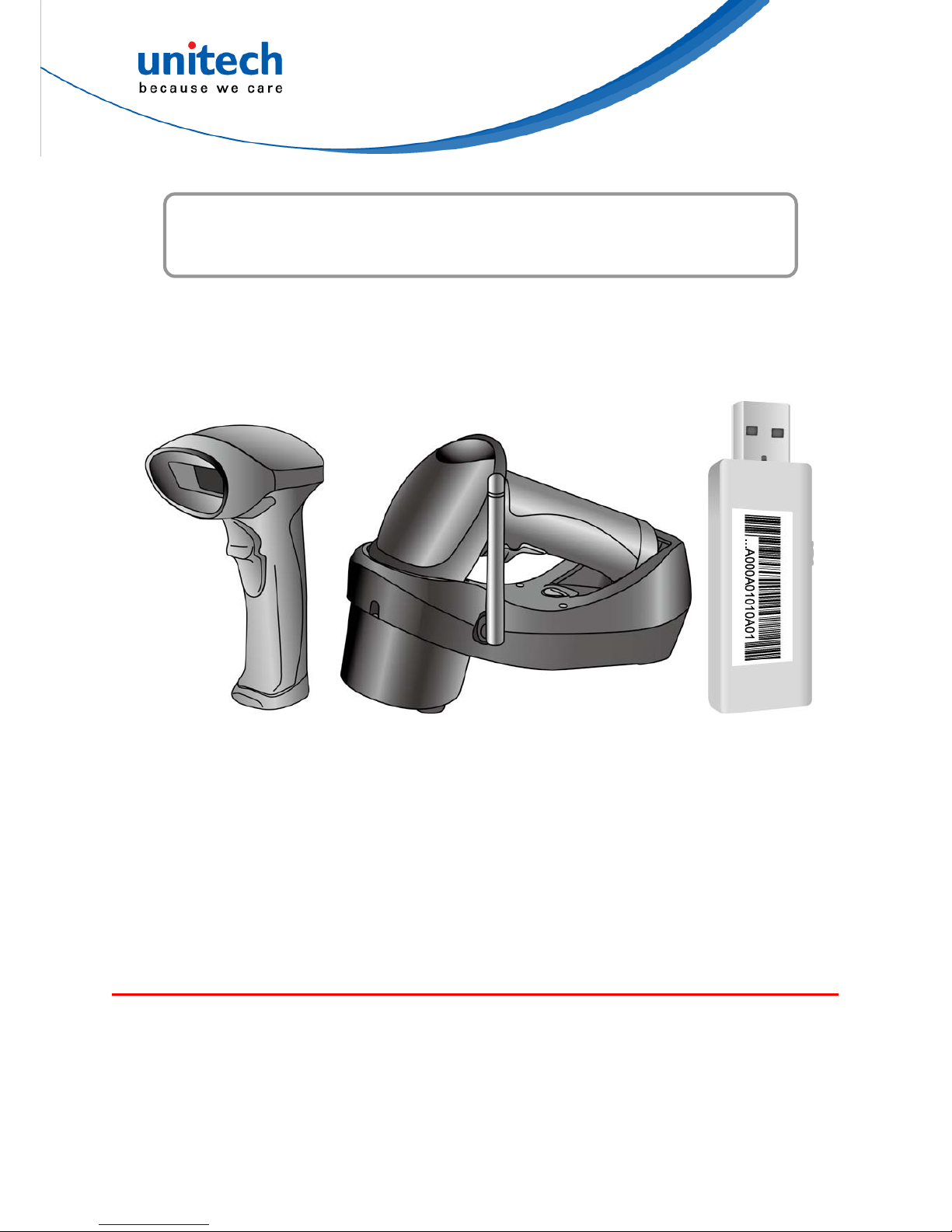

Wireless Scanner

- MS840B/MS840P/MS084 -

User’s Manual

Version 1.3

Page 2

Page 3

i

Preface

About This Manual

This manual explains how to install, operate and maintain the MS840-series wireless scanner.

No part of this publication may be reproduced or used in any form, or by any electrical or

mechanical means, such as photocopying, recording, or information storage and retrieval

systems, without permission in writing from the manufacturer. The material in this manual is

subject to change without notice.

© Copyright 2012 Unitech Electronics Co., Ltd. All rights reserved.

Unitech global website address: http://www.ute.com

Bluetooth is a registered trademark of Bluetooth SIG.

Page 4

ii

Regulatory Compliance Statements

FCC Warning Statement

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to part 15 of the FCC rules. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with

the instructions, may cause harmful interference with radio communications. However, there is

no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference with radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct the interference by

one or more of the following measures:

–Reorient or relocate the receiving antenna.

–Increase the separation between the equipment and receiver.

–Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected.

–Consult the dealer or an experienced radio/TV technician for help.

1. This Transmitter must not be co-located or operating in conjunction with any other antenna

or transmitter.

2. This equipment complies with FCC RF radiation exposure limits set forth for an

uncontrolled environment. To maintain compliance with FCC RF exposure requirements,

avoid direct contact to the transmitting antenna during transmitting.

3. Any changes or modifications (including the antennas) made to this device that are not

expressly approved by the manufacturer may void the user’s authority to operate the

equipment.

FCC Label Statement

This device complies with part 15 of the FCC rules. Operation is subject to the following two

conditions:

1. This device may not cause harmful interference, and

2. This device must accept any interference received, including interference that may cause

undesired operation.

RF Radiation Exposure Statement

For body contact during operation, this phone has been tested and meets FCC RF exposure

guidelines when used with an accessory that contains no metal and that positions the handset

a minimum of 1.5 cm from the body. Use of other accessories may not ensure compliance with

FCC RF exposure guidelines.

Canadian Compliance Statement

This Class B Digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.

Cet appareil numerique de la classe B respecte les exigences du Reglement sur le material

broilleur du Canada.

Page 5

European Conformity Statement

Declaration of Conformity with regards to the R&TTE 1999/5/EC and EMC 89/336/ EEC

directives.

RoHS Statement

This device conforms to RoHS (Reduction Of

Hazardous Substances) European Union

regulations that set maximum concentration limits

on hazardous materials used in electrical and

electronic equipment.

Taiwan NCC Warning Statement

交通部電信總局低功率電波輻射性電機管理辦法 (930322)

根據交通部低功率管理辦法規定:

第十二條 經型式認證合格之低功率射頻電機,非經許可,公司、商號或使用者均不得擅自變更

頻率、加大功率或變更原設計之特性及功能。

第十四條 低功率射頻電機之使用不得影響飛航安全及干擾合法通信;經發現有干擾現象時,應

立即停用,並改善至無干擾時方得繼續使用。前項合法通信,指依電信法規定作業之

無線電通信。

低功率射頻電機須忍受合法通信或工業、科學及醫療用電波輻射性電機設備之干擾。

減少電磁波影響,請妥適使用

Laser Information

The Unitech MS840B/MS840P/MS084 series is certified in the U.S. to conform to the

requirements of DHHS/CDRH 21CFR Subchapter J and to the requirements of IEC 825-1.

Class II and Class 2 products are not considered to be hazardous. The MS840/MS084 series

contains internally a Visible Laser Diode (VLD) whose emissions do not exceed the maximum

limits as set forth in the above regulations. The scanner is designed so that there is no human

access to harmful laser light during normal operation, user maintenance or prescribed service

operations.

The laser safety warning label required by the DHHS/IEC for the MS840B/MS840P/MS084

series' optional laser scanner module is located on the memory compartment cover, on the

back of the unit.

CAUTION! Use of controls or adjustments or performance of procedures other than those

specified herein may result in hazardous laser light. Use of optical instruments with

the scanner, including binoculars, microscopes, and magnifying glasses, with will

increase eye damage.

This does not include eyeglasses worn by the user.

iii

Page 6

iv

Battery Notices

The MS840 is equipped with a Lithium-Ion battery. The battery will discharge after an extended

period of no use.

When the battery is discharged, recharge the unit for some 4.5 hours in order to fully charge

the battery.

Note: To guarantee optimal performance, it is advised that rechargeable batteries be replaced

every year, or when 500 charge/discharge cycles are achieved. It is normal that the

battery balloons or expands beyond one year or the maximum of 500 cycles. Although it

does not cause harm, it cannot be used again and must be disposed of according to the

location's safe battery disposal procedures.

If the performance, of a Lithium-Ion battery, decrease is greater than 20% in, the battery

is at the end of its life cycle. Do not continue to use, and ensure the battery is disposed

of properly.

The length of time that a battery lasts depends on the battery type and how the device is used.

Conserve the battery life by doing the following:

Avoid frequent full discharges because this places additional strain on the battery. Several

partial discharges with frequent recharges are better than a full discharge. Recharging a

partially charged lithium-Ion battery does not cause harm because there is no memory

effect.

Keep the lithium-Ion battery cool. Avoid a hot car. For prolonged storage, keep the battery

at a 40% charge level.

Do not leave the lithium-Ion battery discharged and unused for an extended period

because the battery will wear out and the longevity of the battery will be at least half of the

one with frequent recharges.

Battery charge notice

It is important to consider the environment temperature when the Lithium-Ion battery pack is

charged. Charging is most efficient at normal room temperature or in a slightly cooler

environment. It is essential that batteries are charged within the stated range of 0°C to 40°C.

Charging batteries outside of the specified range could damage the batteries and shorten their

charging life cycle.

CAUTION! Do not charge batteries at a temperature lower than 0°C. This will increase the

internal resistance to cause heat and make the batteries unstable and unsafe.

Please use a battery temperature detecting device for a charger to ensure a safe

charging temperature range.

Storage and safety notice

Although the charged Lithium-Ion battery may be left unused for several months, their capacity

may be depleted due to build up of internal resistance. If this happens they will require

recharging prior to use. Lithium-Ion battery may be stored at temperatures between -30°C to

70°C, however they may deplete more rapidly at higher temperatures. It is recommended to

store batteries at room temperature.

Page 7

v

Warranty

The following items covered under the Unitech Limited Warranty are free from defects during

normal use:

MS840B/MS840P/MS084 – 1-year limited warranty.

Lithium-Ion battery – 6-month limited warranty.

Warranty becomes void if equipment is modified, improperly installed or used, damaged by

accident or neglect, or if any parts are improperly installed or replaced by the user.

Use only the adapter supplied. Using the wrong adapter may damage the unit and will void the

warranty.

Page 8

vi

Page 9

vii

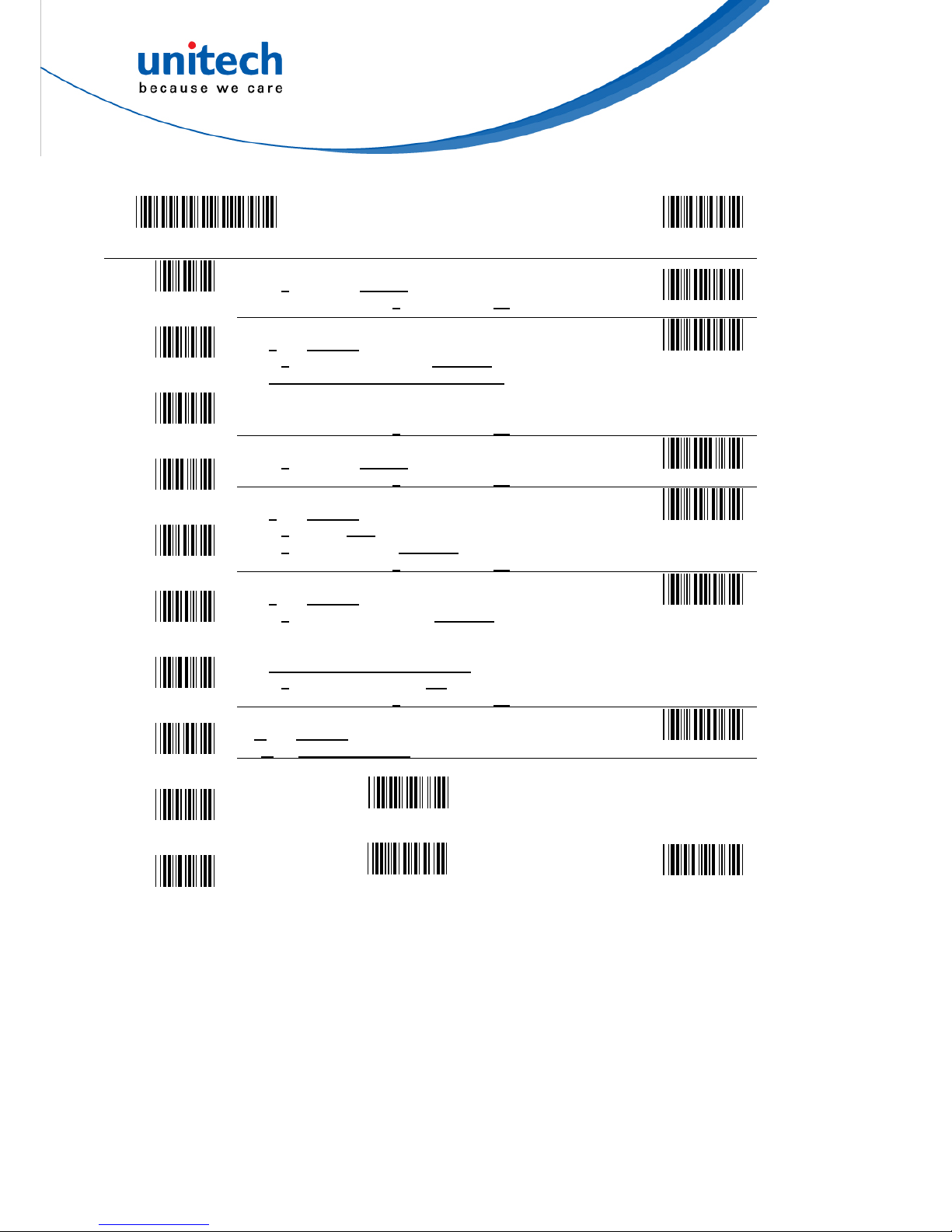

Table of Contents

PREFACE

ABOUT THIS MANUAL..............................................................................................................I

Regulatory Compliance Statements....................................................................................ii

.................................................................................................ii

ment.........................................................................................ii

................................................................................................iii

..iii

Battery charge notice..........................................................................................................iv

Storage and safety notice....................................................................................................iv

Wa

CHAPTE

.............................................................................................................................1

..2

C

ARGING AND CONNECTION.............................................................................7

arging........................................................................................... 7

upport)........................................................................................ 8

Cr g ...........................................................................................11

t SCM support) .........................................................................12

Ch

Dongle Mode, Connection (for MS840P ONLY)................................................................ 14

FCC Warning Statement......................................................................................................ii

FCC Label Statement..........

RF Radiation Exposure Statement.......................................................................................ii

Canadian Compliance State

European Conformity Statement.........................................................................................iii

RoHS Statement.................

Taiwan NCC Warning Statement.........................................................................................iii

Laser Information ..............................................................................................................

Battery Notices .................................................................................................................... iv

rranty................................................................................................................................v

R 1

OVERVIEW...

Introducing the MS840B/MS840P/MS084............................................................................ 1

Package Contents...............................................................................................................

HAPTER 2

BATTERY CH

Cradle Mode, Battery Ch

Cradle Mode, Connection ....................................................................................................8

Cradle Mode (with SCM s

Wall-Mount Installation of a Cradle .....................................................................................9

adle-less, Battery Chargin

Cradle-less, Connection..................................................................................................... 12

Cradle-less Mode (withou

ange between Cradle Mode and Cradle-less Mode.....................................................13

Page 10

viii

Dongle Mode (with SCM support).....................................................................................14

..............................................................................................16

Co r ............................................................................................17

LE

r............................................................................................... 17

LED Indication 18

CHA

BARCODE SETTING............................................................................................................... 19

Barcode Menu Setting........................................................................................................19

Preamble (Prefix) and Postamble (Suffix).........................................................................21

.....22

nager Software ....................................................................... 24

CH

O ..................................................................................................25

e ...................................................................................................26

..................................................................................................27

Qu ..............................................................................................28

..............................................................................................28

Modifier ..............................................................................................29

O-S ......30

Memory Buffer Setting....................................................................................................... 15

Batch Mode.........................

Inventory Mode .................................................................................................................16

nnecting Multiple Scanne

D / Beeper Indication for Scanner................................................................................. 17

LED Indication for Scanne

Beeper Indication for Scanner........................................................................................... 18

for Cradle...................................................................................................

PTER 3

Barcode Length Setting ..................................................................................................... 20

Code ID Setting................................................................................................................... 20

Predefined Labels...............................................................................................................21

Quick Setup....................................................................................................................

Batch Setup......................................................................................................................... 22

Scanner Configuration Ma

APTER 4

UTPUT DATA EDITING.......

Programming ......................................................................................................................26

Programming Sequenc

Preparation........................................................................................................................26

Programming Sheet........

Parameter Entry................................................................................................................27

alifier.................................

Input ID .............................................................................................................................28

Length.................................

Match................................................................................................................................29

..................................

A-String.............................................................................................................................29

tring.......................................................................................................................

Page 11

ix

Examples.............................................................................................................................30

Example 1.........................................................................................................................30

Advanced Features............................................................................................................. 30

APPENDIX A

QUICK SETUP SHEET............................................................................................................33

APPENDIX B

FUNCTION CODES................................................................................................................. 34

Function Codes for PC....................................................................................................... 34

Function Codes for IBM Terminals....................................................................................36

APPENDIX C

SETUP MENU.......................................................................................................................... 37

APPENDIX D

FULL ASCII CHART................................................................................................................46

APPENDIX E

BARCODE TEST CHART .......................................................................................................50

APPENDIX F

WORLDWIDE SUPPORT........................................................................................................51

Example 2.........................................................................................................................30

Page 12

x

Page 13

1

Chapter 1

Overview

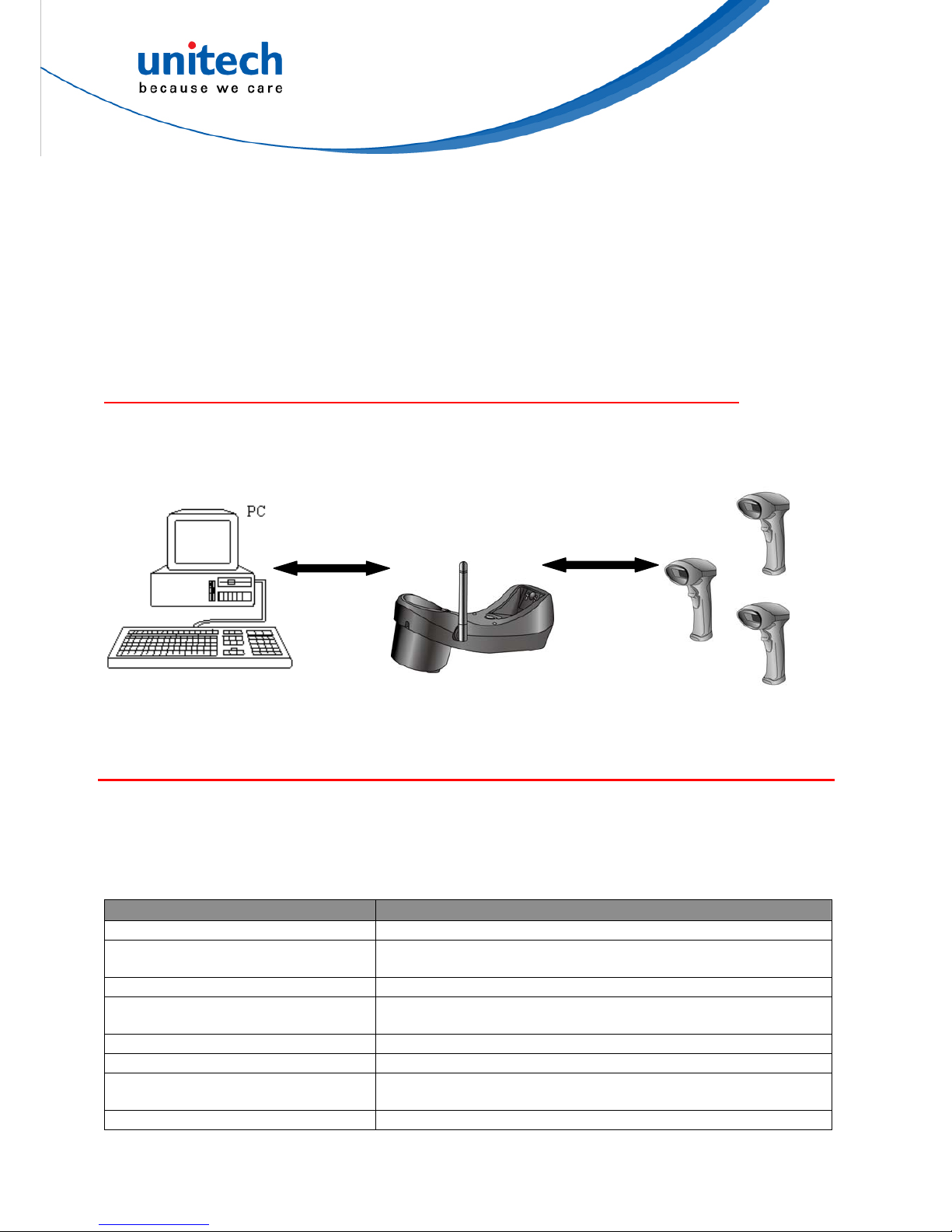

Introducing the MS840B/MS840P/MS084

First of all, thank you for choosing Unitech’s products. This scanner has capability

of precise barcode scanning, reconnecting automatically after off-line in a long

transmitting distance. It not only provides convenient and high efficient performance

but also is well featured with wireless technology.

The cradle (optional) is provided with a charger and a wireless dongle together. The

scanner has a prolonged battery life, being thus able to work continuously for 10

hours while scanning a barcode every 3 seconds in 100 meters of long-range

communication.

You can accelerate productivity, lower cost of ownership, and even enjoy the delight

of move-around freedom. The device is the best scanning partner you can trust.

Thank you for choosing Unitech product.

Features -

Extremely low power consumption

Firmware upgradeable

Supports most popular barcode symbologies, including GS1-128 (EAN-128),

GS1 DataBar (RSS), etc.

Supports 2 scan profiles, Cradle Mode and Cradle-less mode

User feedback via LED indicator and beeper

Beeping tone and duration programmable for Good Read

Up to 3 scanners connected to one base

Up to 4KB of memory buffer for reading when scanner out of range

Capable of transmitting scanned data, emulating a serial cable (Cradle Mode)

or as keyboard input (Cradle-less Mode), to a laptop PC or PDA with wireless

technology

Parameters programmable, including data output format, editing format,

symbologies, etc.

Over 10 hours of operation time

Application -

Warehouse

Pharmacies

Logistics

Retailers

Point of sale (POS)

Inventory Management

Distribution & Transportation

Page 14

2

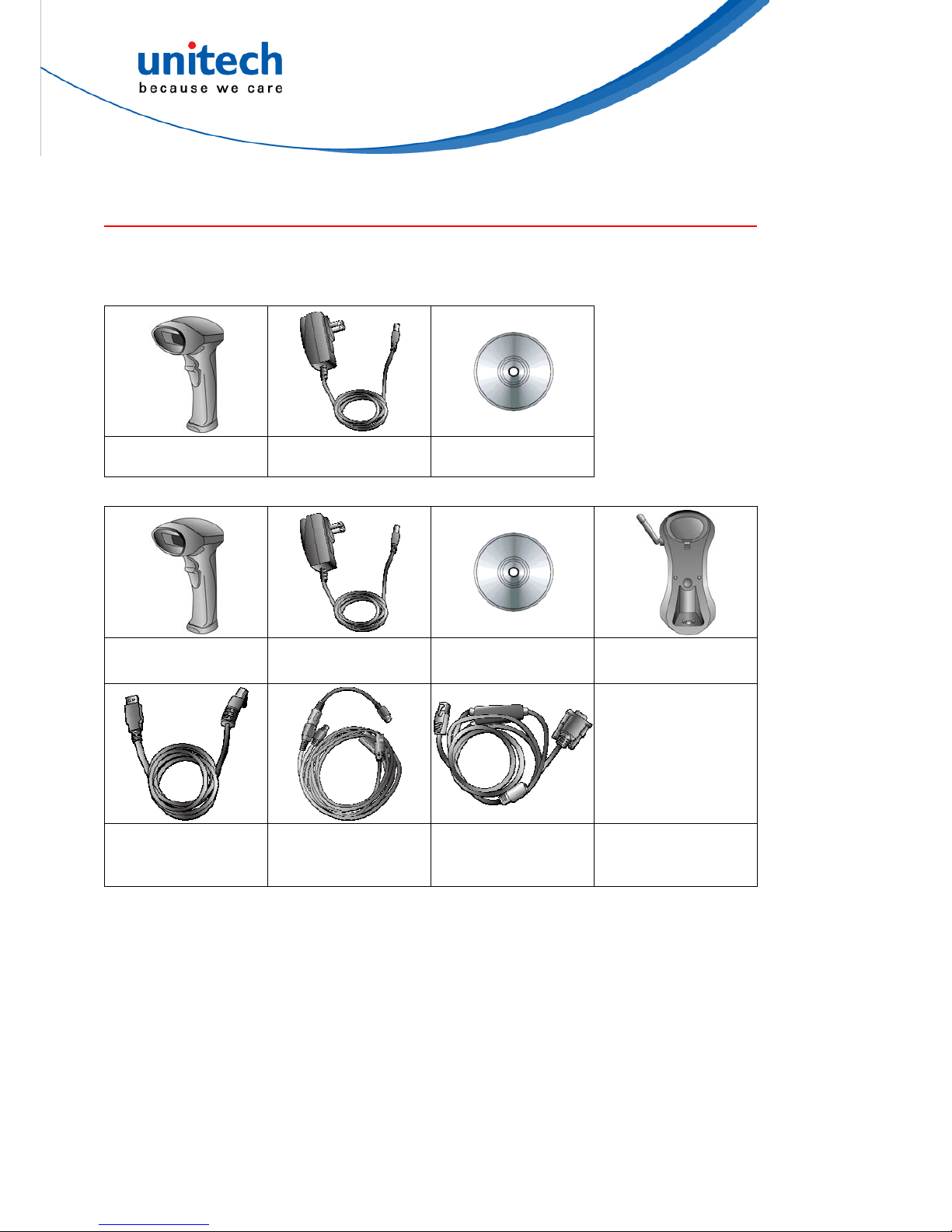

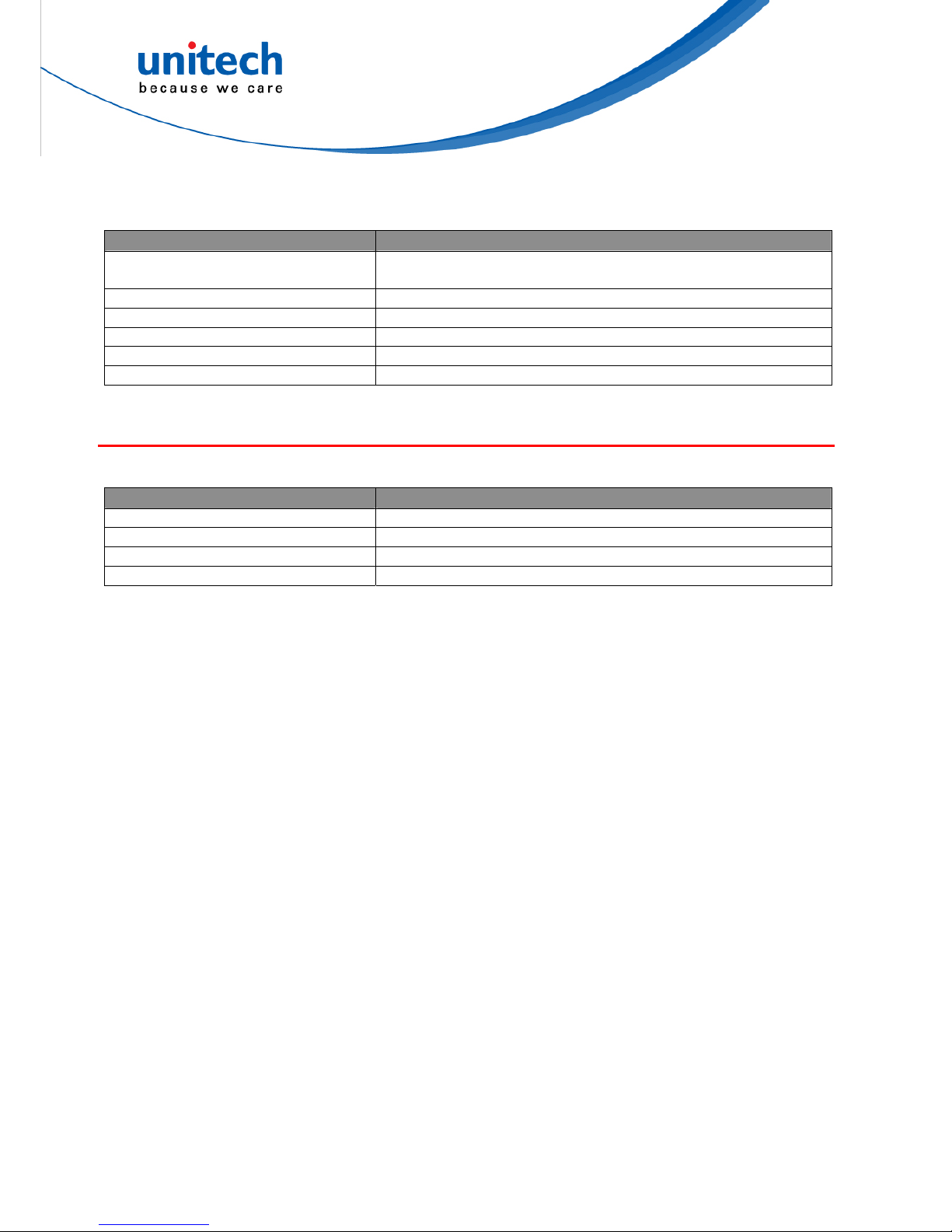

Package Contents

Please make sure the following c S840 package box. If

something is missing or damage r Unitech representative.

a

ontents are in the M

d, please contact you

Scanner-only p ckage (MS840B)

Wireless laser scanner

Power adapter

(1010-601959G)

User's manual CD

Scanner-and-cradle package (MS840B)

Wireless laser scanner

Power adapter

Cradle

(1010-900008G)

User's manual CD

(5000-900007G)

USB Cable

(1550-900040G

PS2 Cable RS232 Cable

)

(1550-900041G) (1550-900042G)

(Optional)

(Optional)

(Optional)

Page 15

Scanner-and-USB dongle package (MS840P)

Wireless laser scanner

Power adapter

(1010-601959G)

USB dongle / USB cable

(1550-900054G)

User's manual CD

Scanner-and-Cradle package (MS840P)

Wireless laser scanner

USB dongle Cradle

(5500-900008G) (5000-900008G)

Power adapter

(1010-601959G)

USB Cable

(1550-600626G)

User's manual CD

Note:

1. The items included in the package may be different, depending on your orde r. Save the box

and packaging material for future use in case you need to store or ship the scanner.

2. ceive and unpack the package at first time, if any item above is lost, please

ealer you bo mediately.

3. mperat ould be °C.

4. Up to 3 scanner devices work with only 1 host PC t dle or wireless receiver, only

for MS840B.

5. The scanner’s default power off (idle mode) time is 1 min.

6. When you use the scanner for the first time, the scanner must be charged continuously for

some 4.5 hours.

When you re

contact the d ught from, im

ure for charging shEnvironment te between 0°C - 40

hrough 1 cra

3

Page 16

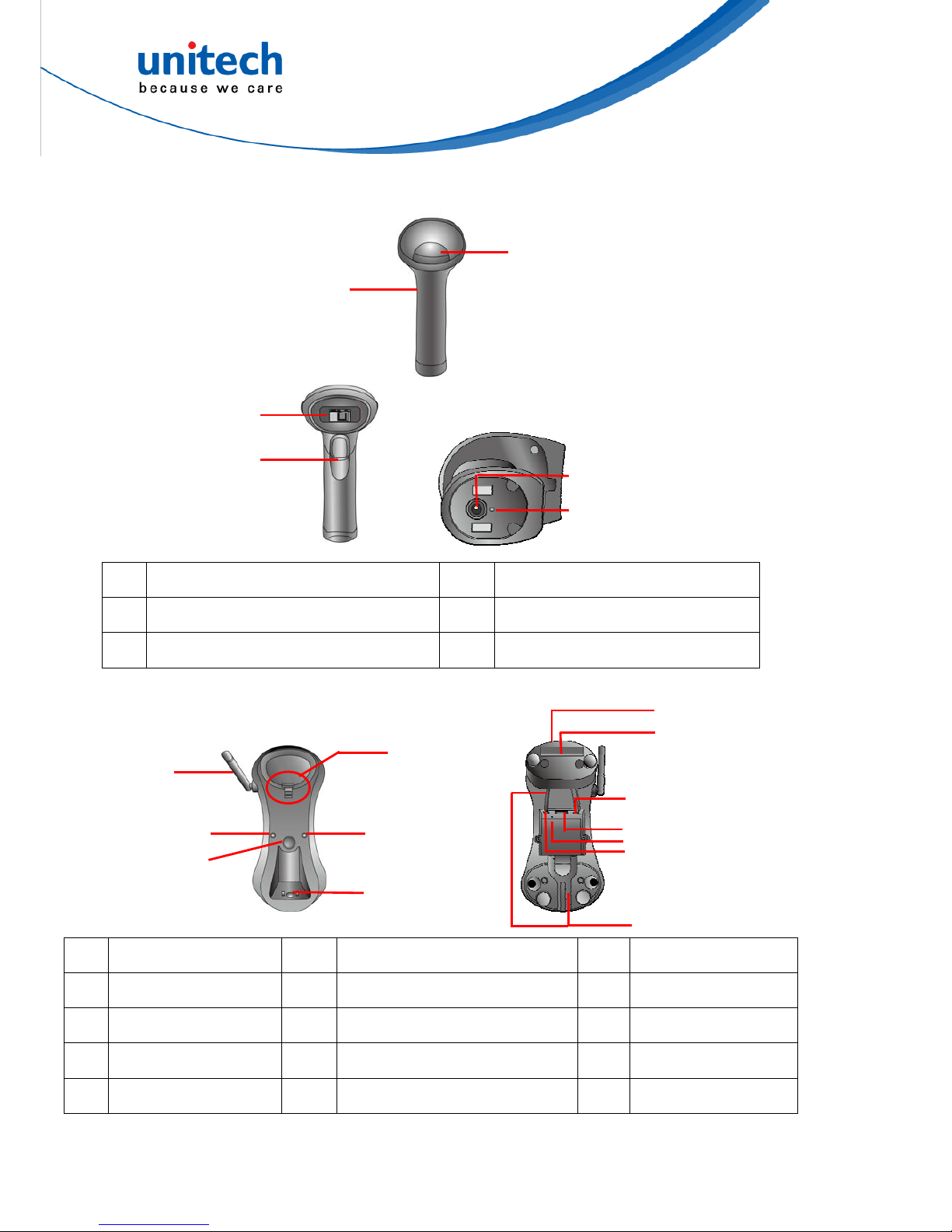

[Scanner Body Aspect]

1

2

3

4

5

6

1 LED indicator 2 Scanner Grip

3 Laser Exit Window 4 Trigger

5 Scanner Contact Points for Charge 6 Reset Pinhole

[Cradle Aspect]

4

1 Antenna 2 Communication S tatus LED 3 Page Button

4 Wedge

Note 1

5 Power LED 6

Cradle Contact Points for

Charge

7 Cradle Foot

Note 2

8 Cradle address barcode 9 Interface Switch

Note 3

10 USB/RS232/PS2 Socket 1 1 Reset Pinhole 12 DC Power Socket (5V)

13 Guidance Groove

Note 4

2

5

3

1

6

10

4

8

7

12

11

13

9

Page 17

Note:

1. If you remove the wedge and flip it upside down, it acts as a clip to hold up the scanner

when the base is mounted to the wall.

2. The cradle f

the antenna;

on the guida

3. When using

(default).

The USB cable can sup

Before changing the swit

Operation in USB COM requires additional driver which is available

http://www.ute.com

oot serves for table mount when being fixed to the upper portion adjacent to

the cradle foot serves for wall mount when being fixed to the lower portion

nce grooves.

RS232 or PS2 cable, the interface switch should be to the left side

port HID (default) or COM port when switch is set to right.

ch;

Disconnect power from cradle,

Disconnect USB cable from cradle

Set the interface switch

Connect USB Cable to cradle

Connect power to cradle

Interface switch, right

USB COM

Interface switch, left

RS232

PS2

USB HID

at

.

In case the USB cable is been used, the cradle will receive power via USB cable. In

order to charge the scanner it is mandatory to connect power supply to cradle

4. wer cord and the

unication cable (U /R

The guidance groove is designed for

comm

arrangement of the po

S232/PS2). SB

5

Page 18

6

Page 19

7

Chapter 2

Battery Charging and Connection

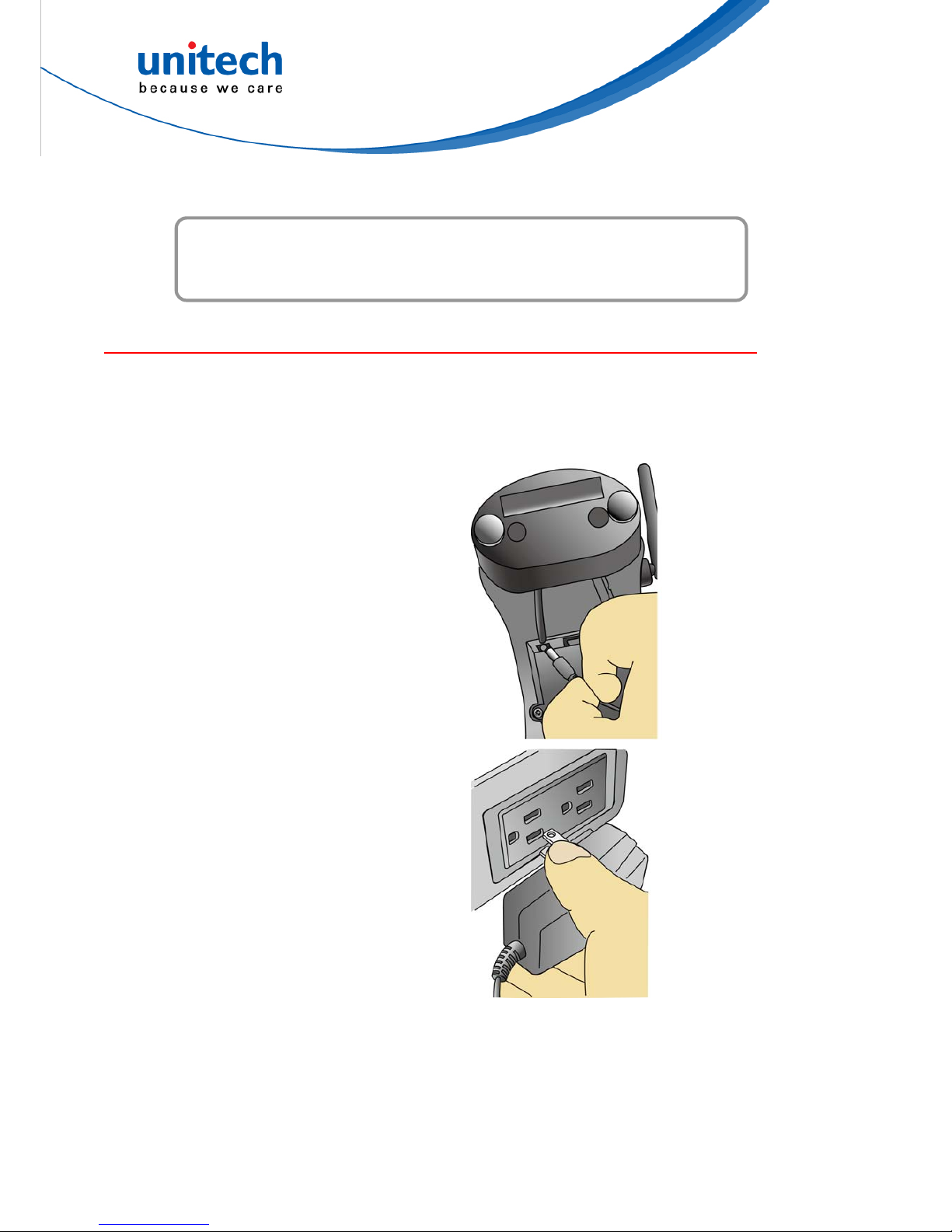

Cradle Mode, Battery Charging

The battery is in advance loaded into the compartment of the scanner and may not

be fully charged before shipment. When you receive the package and use the

MS840 for the first time, you will

Note: It takes approximately 4.5 hours to full

To charge the scanner with a cradle, follow the instructions below:

1. Plug the adapter cable into the power

socket on the bottom of cradle.

need to fully charge the battery.

y charge the battery.

2. Plug the AC adapter cord into an

electrical outlet.

Now, check whether the power LED on

the cradle is bright in solid green and the

communication status LED on the cradle

is bright in solid blue.

Page 20

3. Place the scanner in the cradle. The

scanner LED will be red to indicate

charging. When the scanner is charged,

the LED will turn off.

Cradle Mode, Connection

Cradle Mode (with SCM support)

In order to establish a proper connection between your computer a

through a cradle, we suggest that you follow these step-by-step in

nd a scanner

structions:

S232, or PS2 port of your computer

respectively with a USB cable, RS232 cable, or PS2 cable.

USB cable will operate as HID device (keyboard)

4. Determine that the power LED on the cradle is bright in solid green and the

communication status LED on the cradle is bright in solid blue.

5. By default, the MS840 operates in cradle mode. Thus, by using at most 3

scanners, scan the Cradle Address barcode on the bottom side of the cradle.

should turn off and beep shortly one time with a high tone

e cradle should flash in blue.

7. rrect connection of scanner and

The Cradle Address barcode is on the bottom side of the cradle.

1. Ensure the cradle powered, check the Power LED.

2. Turn on your computer.

3. Connect the cradle to the USB, R

6. The scanner LED

and the communication status LED on th

The Pager button can be used to verify co

cradle.

8

Page 21

Wall-Mount Installation of a Cradle

Before mounting the cradle onto the wall, read

Mounting Kit (Optional article

the instruction made below.

4070-900011G

)

If you want to mount the MS840 cradle onto the wall, an iron plate, two screws, and

two plastic conical anchors are required.

rs

rewdriver.

Iron Plate 2 Screws 2 Plastic Conical Ancho

Before mounting the cradle onto the wall, prepare a screwdriver and read the

step-by-step instructions made below.

Follow the steps below to mount the cradle onto the wall.

Step 1: Loose and remove 2 screws from the stand of cradle by using a sc

Then, remove the stand from the cradle.

Step 2: Move the stand of cradle to the lower portion of the cradle from the upper

Then, secu and to the cradle with 2

.

portion adjacent to the antenna.

screws by using the screwdriver

re the st

9

Page 22

Step 3: Push up and shift out the wedge and then inversely insert the wedge. Note

that the protruding portion is upward.

Step 4: Place the iron plate against the wall, and mark

the 2 screw hole locations with a pen or pencil. Drill

secure

the screw locations somewhat deep. Insert 2 plastic

conical anchors into the screw holes. Attach and

the plate to the wall with the 2 screws.

Step 5: Align the two holes on the bottom surface of the cradle respectively with the

two short pillars of the iron plate for in

Then, push the cradle downwards to

groove.

sertion of the pillars into the holes.

wedge the pillars into the guidance

10

Page 23

Step 6: mpleted, as shown in the figure

below.

The cradle wall-mount installation is co

Cradle-less, Battery Charging

To charge the scanner without a cradle, follow the instructions below:

1. Plug the adapter cable into the power

socket of the foot of scanner.

2. Plug the AC adapter cord into an

electrical outlet.

Now, check whether the scanner LED

will be bright in solid red during

charging.

When the charging is done, the

scanner LED will turn off.

11

Page 24

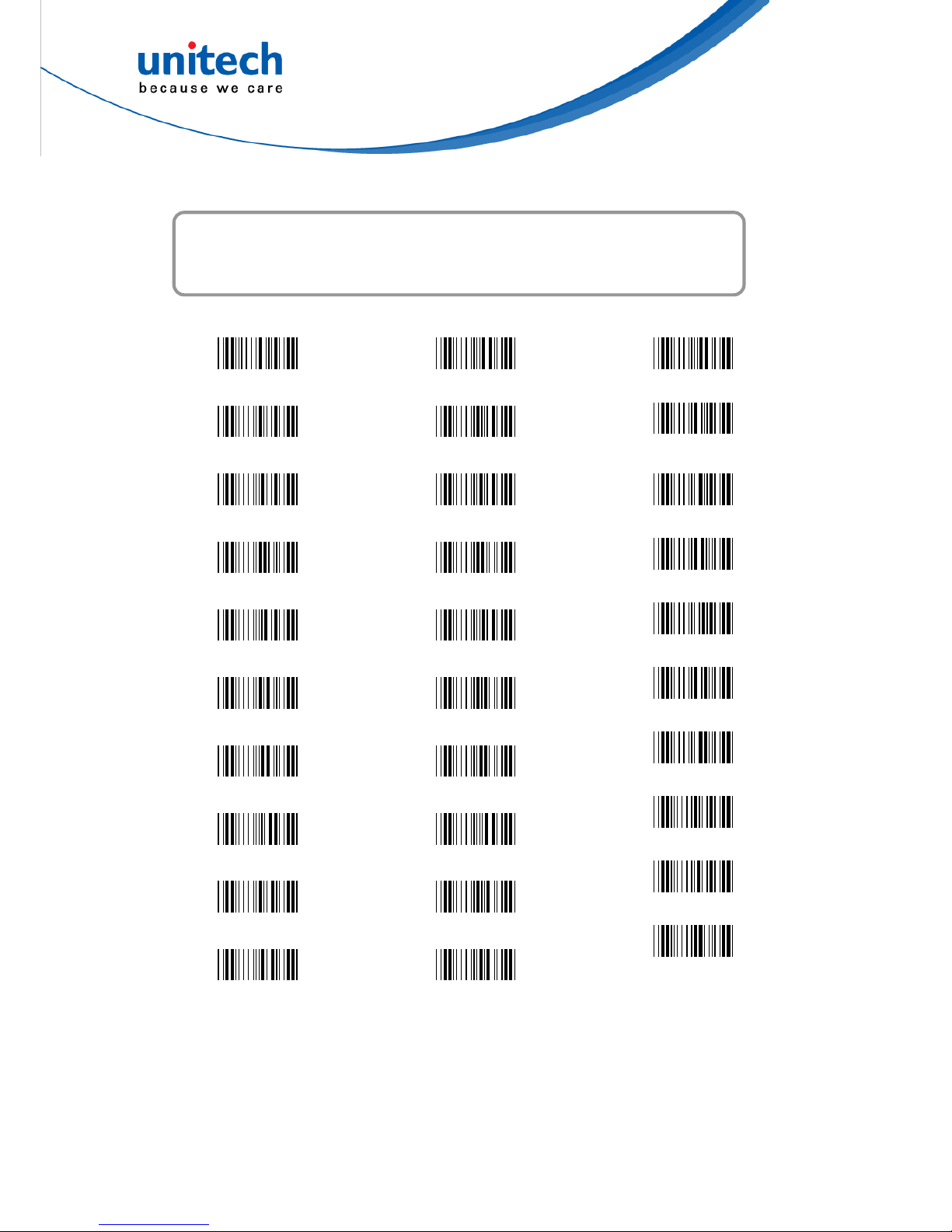

Cradle-less, Connection

Cradle-less Mode (without SCM support)

MS840 can connect directly to a Host with proper supported wireless technology. In

order to establish a proper connection between your Host with wireless technology

and the scanner, we suggest that you follow these step-by-step instructions:

1. Turn on your Host.

2. Change the default cradle-mode to the cradle-less mode b y scanning the

Cradle-less Mode barcode.

3. When the change is successful, the LED indicator of scanner flashes in blue.

4. Make your Host with wireless technology search for the MS840 scanner. When

your Host locates a “HID SCANNER”, select it.

5. The Host should now present a pairing pin and you will be requested to input the

pin code at the Scanner. For inputting the pin code, scan the “Link Keys” barcode

below:

Cradle-less Mode

Link Keys

6. At this step, referring to the barcode table

another you got from your PC; f

below, scan the pin code one after

or example, if you get the pin code “241657”, then

scan the ba – “4” – “1” – “6” – “5” – “7” liste in th e order.

rcodes “2” d in the table

0

8

1

9

2

A

3

B

4

C

5

D

6

E

7

F

12

Page 25

7. After you finish in scanning the pin code, scan the barcode as shown below:

CR($M)

8. When the pairing is successful, the scanner LED is off and has a short beep.

The scanner will operate as HID (keyboard) towards host.

Note: When scanning a wrong character, scan the DLE($P) to erase the

character(s). After scanning the DLE($P) barcode, please re-scan the pairing pin.

DLE($P)

Change between Cradle Mode and Cradle-less Mode

You may make the scanner change between cradle mode and cradle-less mode.

For example, if your scanner operates currently in cradle-less mode and you want

to change the existing mode of the scanner to cradle mode, then scan the Cradle

Mode barcode as shown below:

Cradle Mode

To determine whether your scanner mode is successfully changed, press the Page

button on the cradle; your scanner will have 2 short beeps when you press the

Page button.

For example, if your scanner operates currently in cradle mode and you want to

change the existing mode of the scanner to cradle-less mode, then scan the

Cradle-less Mode barcode as shown below:

Cradle-less Mode

Whenever the scanner enters cradle-less mode, you must pair the scanner with

your PC following step 3 through step 8 at the section called “Crad -less Mode

(without SCM Support)”.

Note: When you successfully connected in Cradle and/or Crade-less, both

addresses are memorized in the scanner. To completely disconnect the

scanner;

1.Scan the Cradle Mode barcode, scan the Delete Address barcode; and

2.Scan the Cradle-less Mode barcode, scan the Delete Address barcode.

le

Delete BT Addr ess

Delete Address

13

Page 26

Dongle Mode, Connection (for MS840P ONLY)

Dongle Mode (with SCM support)

In order to establish a proper connecti en your computer and a scanner on betwe

through a dongle, we suggest that you follow these step-by-step instructions:

1. Turn on your computer or laptop PC.

2. Insert a dongle into a USB port of the

computer or laptop PC.

3. Scan the MAC address of the dongle by

using the MS840B scanner.

4. When being successfully connected to

the dongle, the scanner will beep shortly

one time with a high tone.

You can also connect the MS840B scanner optionally to another dongle by

follow

1. Scan the Disconnection

b

ing the steps made below.

arcode.

14

Page 27

2. Insert another dongle into a

USB port of the computer or

laptop PC.

3. Scan the MAC address of

the dongle by using the

MS840B scanner.

4. When being successfully

connected to the dongle, the

scanner will beep shortly one

time with a high tone.

Memory Buffer Setting

The collected data can be sent back to a host computer one by one via the WPAN

connection as the scanner is set to the Batch Mode, or can be stored in the flash

memory of the scanner being set to the Inventory Mode.

By default, the Batch Mode is enabled for use when the scanner is out of range.

Upon reading a barcode successfully within range, the scanner responds with one

short beep (high tone) and its LED indicator becomes solid green and goes off

f

B transmit buffer, the scanner can ignore the

on reading barcodes until the buffer is full.

d and the scanner is out of range, the scanner will

respond with two short beeps, high-low tone, upon reading a barcode successfully.

When the memory buffer is full, the scanner will respond with one long beep (low

tone) and its LED indicator will become solid red and go off quickly. You are

advised to get back to range.

quickly. However, the host computer may not receive the data immediately i

getting out of range. With the 4 K

transmission status and keep

When the Batch Mode is enable

15

Page 28

MS840 features 2 memory mode

Note: The 4 KB of memory buffer in t

based on

settings: Batch Mode and Inventory Mode

he scanner can hold as many as 256 scans

EAN-13 barcodes. Data will be cleared out once the scanner is not

powered!

Batch Mode

Batch Mode is the default setting. To set the scanner to the Batch Mode, scan the

following barcodes in the order:

ly

connecting to the cradle (Cradle Mode) or a host PC (Cradle-less Mode) in a

specified range, the scanner sends out the data. When the scanner is out of range

of the cradle or the host and keeps trying to re-connect, the scanner will keep the

data in its memory buffer until the buffer is full; when the scanner is again in range

of the cradle or the host, the scanner will sent out the data that it has in the memory

buffer . When the buffer is full and the scanner is out of range, the scanner will

respond with one long beep (low tone) and its LED indicator will become solid red

ised to get back to range.

the scanner keeps the scanned data in its

on the host automatically; you should scan

Read Buffer barcode to order the scanner sent out the memorized data to the Host.

To set the scanner to the Inventory Mode, scan the following barcodes in the order:

Bear in mind the fact that the scanner operating in the inventory mode does not

lly but keeps the data in its memory buffer. If

the data it scanned before, please scan the

Enter Group 6

In the Batch Mode, once you scan a barcode by using a scanner wireless

and go off quickly. You are adv

Inventory Mode

Inventory Mode is the mode in which

memory buffer but not send out the data

send out the scanned data automatica

you want to make the scanner output

Exit

E

1

2

Exit

E

1

1

Enter Group 6

Read Buffer barcode as shown below:

Read Buffer

Note: After scanning the Read Buffer barcode, the data is sent and deleted from

the scanner’s memory buffer.

If you do not output the barcode data, the barcode data is always kept in the

memory buffer. To erase the data from the scanner’s memory buffer, scan the

following barcodes in the order.

Erase Buffe

r

Buffer Erasable

16

Page 29

If you are out of range of the cradle or the host PC when reading out the scanned

data, the scanner will keep the data in its memory buffer until the buffer is full; only

the scanner is within the specified range of the cradle or the host, and you when

scan the Read Buffer barcode the data will be sent.

When the buffer is disabled and the scanner is out of range, the scanner will

respond with one long beep (low tone) and its LED indicator will become solid red

and go off quickly. You are advised to get back to range.

Connecting Multiple Scanner

Up to 3 scanners can be connected to 1 cradle. When data is scanned (at the

time) the cradle will sent the data from one scanner and then the date of the other

scanner. Different Prefix/Suffix per scanner will allow which scanner has sent the

data

same

a will/can

17

If multiple scanners are connected to Host, in cradle-less mode, the dat

ecome mixed up (simultaneous scan).

LbED / Beeper Indication for Scanner

LED Indication for Scanner

The LED lights on the MS840 scanner turn on to indicate the status of the battery, a

successful read of a barcode, or the status of the wireless connection.

MS840 Lights: The status LED turns green, blue, or red to indicate the status of the battery

and scanning.

LED Light State What it means

Red LED flashes per 5 seconds Low battery power

Red LED on

2. Battery charging when the scanner is set

1. Barcode reading when the trigger is pressed

on the cradle

Green LED flashes Successful barcode reading

Blue LED fast blinks and then turns

off

Successful pairing/connection/reconnection (Cradle mode)

Blue LED slow blinks ) Disconnect (out of range

Green LED blinks g mode Entering barcode settin

Green LED on

Exiting barcode setting mode

Battery charging completion

1.

2.

Green and blue LEDs blink Pin code setting (waiting to enter a pin code)

USB Interface

PS2 Interface

RS232 Interface

Wireless connection to cradle

Page 30

Beeper Indication for Scanner

The MS840 uses beeps to give you audio feedback when it performs some

functions. For example, you hear a beep each time you scan a valid barcode.

Beep Sequence What it means

One short beep with a Hi tone 1. Successful barcode reading

2. Pin code setting (waiting to enter a pin code)

One beep with a Hi tone Successful pairing/connection/reconnection (Cradle mode)

3 Hi-Low alarms Disconnect (out of range)

One long beep with a Hi tone Entering barcode setting mode

One short beep with a Hi-Low tone Exiting barcode setting mode

2 short beeps with a Hi tone Page calling

LED Indication for Cradle

The LED lights on the MS840 cradle turn on to indicate the status of the power and

wireless connection.

18

LED Light State What it means

Blue LED blink Connection

Blue LED on sconnection Di

Green LED on Power on

Green LED off Power off

Page 31

19

e confi application. All

e hich is retained

Chapter 3

Barcode Setting

The scanner interface can b gured to fit the user's specific

configuration parameters are stor d in a non-volatile memory, w

even if power is lost.

Barcode Menu Setting

The setup menu in Appendix D contains eight groups:

elay.

* Group and Emulation.

232 Settings

canner port.

netic Reader

e 39, I 2 of 5, S 2 of 5 and Code 32.

* Group 8: Code 128, Code 93, Code 11, Codabar, and MSI.

* Group 9: UPC/EAN, and Delta Distance Code.

* Group 10: Data Editing.

* Group 11: Dump setup.

Setup Procedures

For most parameters, proceed the following steps for the setting:

1. Locate a group that contains the parameter to be changed.

2. Scan the "Enter Group #" label to enter setup mode. The green LED on the

scanner will flash to indicate that setup is in progress.

3. Scan the label (on right hand side) representing the parameter to be changed,

such as B1 label.

4. Scan the labels (number) representing the desired parameter value; for

example, for 05, scan “0” and “5” labels.

5. Repeat steps 3 and 4, if necessary, to change the parameters in the same

group.

6. Scan "Exit" label to end the group setup. The scanner will make two beeps to

end the setup.

* Group 1: Device selection.

* Group 2: Beep and d

3: Keyboard and W

* Group 4: RS* Group 5: S

* Group 6: Mag

* Group 7: Cod

Page 32

20

Barcode Length Setting

The following example illustrates how to set Code 39 with a minimum length of 5

and a maximum length of

* Scan “Enter Group 7”.

Scan “F1” to select Code 39.

Scan “MIN LENGTH” to enter minimum length setting.

um length setting.

20.

*

*

* Scan “0” and “5” to select length 5.

* Scan “MIN LENGTH” to end minimum length setting.

* Scan “MAX LENGTH” to enter maximum length setting.

* Scan “2” and “0” to select length 20.

* Scan “MAX LENGTH” to end maxim

* Scan “Exit” to end setup.

Code ID Setting

Each barcode symbology supported by the s

ow what the label that you’re scanning is, you may

canner has a default ID character

defined below. If you don’t kn

. use this feature to identify

Symbology Pre-Defined

UPC-A A

UPC-E E

EAN-13 F

EAN-8 FF

I 2 of 5 I

S 2 of 5 H

Code 39 M

Codabar N

Code 93 L

Code 128 K

UCC/EAN128 ]C1

MSI O

Code 32 T

Delta Code D

Plessey Code P

Label Code IV,V B

China Postal Code C

Those ID characters can be redefined through setup menu. The following example

shows how to set Code 93 with ID ‘O’ and Code 128 without ID:

* Scan “Enter Group 5”.

* Scan “D2” to select Code ID.

* Scan “1” for "Enable".

* Scan “D3” to define IDs.

* Scan “0” and “9” for selecting Code 93.

* Scan “O” from Full ASCII Table for new ID.

* Scan “0” and "8" to select Code 128.

Page 33

* Scan “NULL” character from Full ASCII Table for none ID.

* Scan “Exit” to end setup.

Preamble (Prefix) and Postamble (Suffix)

Regarding Preamble, the scanner adds the start of text characters before the input

scanner adds the end of text characters after the

ets ‘STX’ as preamble and

II Table.

ble setting.

data; regarding Postamble, the

input data. The following description is an example that s

‘ETX’ as postamble.

* Scan “Enter Group 5”.

* Scan “PP” to start preamble setting.

Table. * Scan ‘STX’ character from Full ASCII

* Scan “PP” to end preamble setting.

ble setting. * Scan “OO” to start postam

* Scan ‘ETX’ from Full ASC

* Scan “OO” to end postam

* Scan “Exit”.

Predefined Labels

The scanner provides three special labels encoded as “/FY”, “/FZ”, and “/F-” in

Code 39 format. T th be defined through the setup

menu. The defi e the same space with “Edit Formula

definition”(See “Output Data Editing”), so you can only use one of the functions.

he output from ese labels can

nition of the labels shar

Label 0 Label 1 Label 2

21

/FY

/FZ

/F-

Here is an example indicating how to define the output of “Label 0” as “START”,

“Label 1” as “ACCEPT”, and “Label 2” as “END”.

* Scan “Enter G

* Scan “B7”

* Scan “0” to de

* Scan “S”, “T”, ” from Full ASCII chart

* Scan “B7” to end “Label 0”

* Scan “1” to define “Label 1”

* Scan “A”, “C”, d “T” from F L ASCII chart

* Scan “B7” to

* Scan “2” to de

* Scan “E”, “N” CII cha

ning “Label 0”, “Label 1”, and “Label 2” listed above will

CEPT”, and “END”, respectively. The characters

an be ASCII characters or Function keys.

f “Label 1”, do the following scan:

roup 3”

fine “Label 0”

“R” and “T “A”,

“C”, “E”, “P” an

end “Label 1”

UL

fine “Label 2”

and “D” from Full AS rt

* Scan “B7” to end “Label 2”

* Scan “Exit” to quit setup

After programming, scan

have the output of “START”, “AC

defined in these labels c

To eliminate the definition o

* Scan “Enter Group 3”

* Scan “B7”

* Scan “1” to choose “Label 1”

Page 34

* Scan “B7” to end

* Scan “Exit” to exit setup

There is only total 24 characters space available for defining these

one of the labels has been defined for the output with 24 characters

three labels. If

, the other two

labels cannot be defined further.

Quick Setup

Appendix A has a quick setup chart, which gives you one-label-for-one-function

up the scanner, locate the label with the convenience to set up the scanner. To set

function you want and scan that label.

Batch Setup

If you need to configure more than one scanner, you may duplicate the settings of

can do this by producing a set of custom

anner, and by scanning these labels

other scanners.

ump Settings” label. Before you scan the label,

bology,

to

t he the

the scanner (master) to the others. You

erived from the master scsetup labels d

configuring the

The following label is called “D

please open a text editor application (such as Notepad, Word, etc.). Scan the

following label and the settings of the scanner will dump to the screen as one or

several ASCII string(s). Use a barcode printing software, select Code 39 sym

and use the string(s) to generate barcode labels. You use this batch setup labels

duplicate setting o t o r scanners.

Dump

3.

F1>”.

”.

PC/AT, you have the following strings:

J8

Settings

If you have settings as follows:

* Device Ty pe is “Keybaordless Wedge”.

digit of UPC-A and EAN-1* Do not send the check

amble as “<* Define Pre

* Define Postamble as “<Tab>

* Define Label 0 as “START”.

When dumping settings on a

...I800C06D51D

08080A0O7C005354

415254.

Print into Code 39 bar code labels:

. . . I 800C06D51DJ8

08080A0O7C005354

415254.

22

Page 35

By scanning the labels from top to bottom sequentially, you may duplicate the rest

settings.

scan them in the same sequence as the one that

ped.

ous

that are different from the default values will be dumped. So

bels produced depends on how many settings being changed

al

evious

Wedge” as Device Type is equivalent to a PC/AT

not

of scanners with the same

The following issues should be observed:

The sequence of the strings that the scanner dumped is important. You have to

print the bar code labels and

the scanner dum

When you scan the batch setup labels to configure a scanner, the previ

settings on that scanner are reset to default and then replaced by the settings

contained in the batch labels.

Only the settings

the number of la

compare to the factory default setting.

The settings can be dumped to a PC or terminal only if that PC or termin

matches the type defined by Device Type of the scanner. The pr

example of “Keyboardless

interface, so you cannot dump that settings to a system which dose

support a PC/AT keyboard interface.

The following label let you dump the settings to a PC/AT regardless what kind of

device has been chosen on the scanner.

Dump Settings On PC/AT

You can adjust the length of the dumped strings by combining multiple strings

ing into multiple strings. The following strings have

listed above:

C005354415254.

from or add any character into the strings and the

t present in the first string.

wercase

characters in dumped strings, change them to upper case.

into one or breaking one str

the same effect as the dumped string

...I800C06D51DJ8080

80A0O7

You cannot delete any charac

first three characters (“...”) mus

ter

All charac ngs are in upper case. If you see loters in dumped stri

23

Page 36

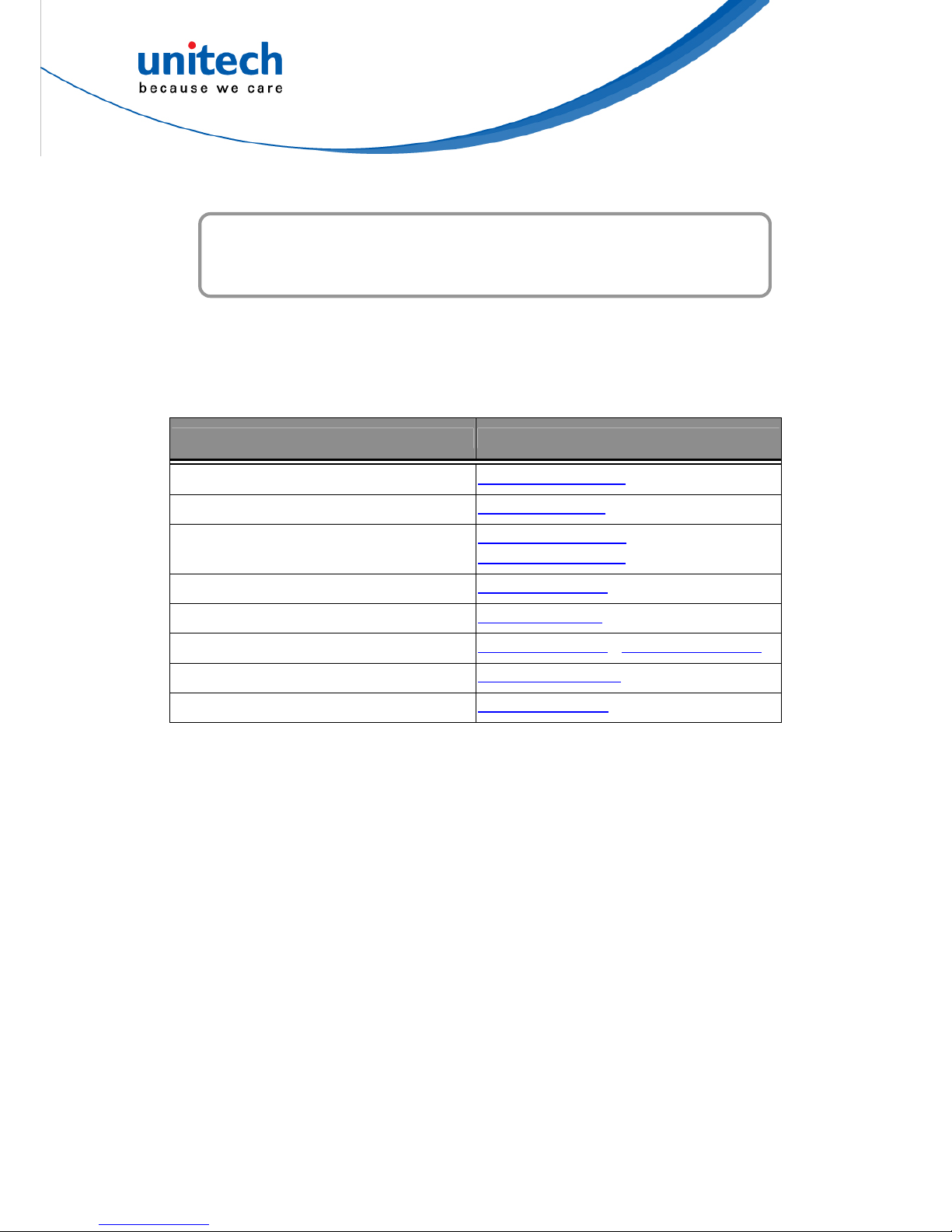

Scanner Configuration Manager Software

Scanner Configuration Manager is a utility program designed for users to

the program from our web site:

configure scanner settings on a computer by using the Microsoft Windows based

operating system. Use this program to define the settings and then download the

parameters to the scanner. Download

http://www.ute.com.

The SCM is for Cradle Mode only.

SCM will be future support for MS840BT

24

Page 37

Output Data Editing

Chapter 4

s removed from this barcode setup manual. It is

anager Software providing a user-friendly

ad the latest program from Unitech’s web site at

ttp://www.ute.com

The Output Data Editing feature wa

implemented to the Scanner Configuration M

interface for easier operation. Please downlo

h . This chapter will mainly describe the concept and feature provided by this

data output feature. The function described here also can be replaced by the “Pre-defined

Labels” function. So if data-editing function is defined, “Pre-defined Labels” will be removed.

They cannot be defined at the same time.

General

The purpose of Data Edit is allowing you to define and modify a data record that comes from

ecoding of a bar code. By using combination of formulas, you can perform the following

nctions on the data received by the scanner:

A. Rearrange the output sequences.

B. Delete characters from the record.

C. Insert characters to the record, including function codes.

D. Duplicate characters in the record.

E. Insert time delay in the record

Formula

Formula is a structure that tells the scanner what and how to process the original data record

to produce the desired output. The wedge allows multiple Formulas, but the number of the

Formulas can be defined depends on the memory size allocated for Data Editing.

Original Data Structure

The original data is the decoded data plus preamble and postamble. The original data structure

is as follow:

Preamble Decoded Data Postamble

d

fu

Formula Structure

A Formula consists of two parts: Qualifier and Modifier. Qualifier is used to verify if the data

record meets the conditions specified and Modifier is processed only if all conditions in

Qualifier are met.

Execution Sequence

If several Formulas were defined, data editing will perform sequentially from the first Formula to

the last Formula. If a Formula is qualified and executed, the further formulas will be ignored. If

none of the Formulas is executed, the data record will be discarded and there will be no output

to the host.

25

Page 38

26

Formula Structure

Programming

Programming Sequence

Each Formula is entered into the reader by the following sequence:

Input_ID tring >> Enter

A Formu (a label in programming sheet). If a field is

optional equence can be entered. But “Enter” must be the

f a formula.

x E).

mming Data Editing, you should know the format of the original data record that

may b y t .

>> Length >> Match >> A-String >> O-String >>...>> O-S

la starts with Input_ID and ends with “Enter”

and missing, the next one in the s

last input o

Preparation

To start the data editing, the following barcode sheets are needed:

-- Programming Sheet. (Setup Sheet in Appendix D).

-- Full ASCII Sheet (Appendi

-- Function Code Sheet (Appendix B or C).

Before progra

e altered b he setup groups

Page 39

27

Programming Sheet

The bold and italicized characters in following sections mean a barcode label on the

Programming Sheet.

Enter

Group 10

Scan this label to start the formula

input.

Group

Default

Erase all formulas.

Review

To see the formulas programmed in

the Wedge. If scanning this label

during a formula input (without

finished by scanning “Enter”), the

current formula will be displayed.

Otherwise, all programmed formulas

will be displayed.

Backspace

Delete the last character

,

Delimiter to separat

g specifier.

character to specify any digit or

ength field input.

For Match field input.

it setup.

r string parameters unless a special function is required.

Parameter Entry

a) Digit Parameters and Numbers

Each digit parameter or number is represented by one to three digits with ‘,’

.

e parameters.

"

Strin

*

Wild

any position.

# Wild character to specify any

letter(A--Z, a--z) or last position

Enter

To end the current formula.

0 to 9 For digit input.

IN_ID

For ID field input.

LEN

For L

MA TCH

O-STR

For O-String input.

+

For O-String input.

put.

-

For O-String in

Exit

Save all formulas and ex

Note: The ' * ', '#' ','" ' and ', 'on Programming Sheet have special meanings as mentioned

above and are different from those represented in Full ASCII chart. Always use

characters in Full ASCII chart fo

as terminator. For

example:

1,

023,

b) String Parameters

A string is a set of characters, wild characters, or sequence of adjacent characters enclosed in

double quotation marks, which are on the Programming Sheet. For example:

"A*B# "

Page 40

28

Here * and # are wild characters on the setup sheet.

Qualifier

The three core are

t ID, Length

nditional fields in the Qualifier:

d Match. Inpu an

Inp

For

Input ID is required correspond to Input ID of a formula in

order to be proces

ID1 to IDi are repre t IDs are available:

0 = Co

1 = Co

4 = UP

5 = UP

6 = I 2

7 = Co

8 = Co

= Co

= S

= MS

All I

There is no limitati IDs to be defined.

Example:

IN

Leng

Forma

in,Max,

arameters: minimum length (Min) and maximum length

When missing, the following fields of current Formula are always processed.

Example:

,48,

ut ID

mat:

IN_ID,ID1, ... ,IDi,

and the original data record must

sed.

sented by digits. The following Inpu

de 39 Full ASCII

de 39 Standard

2 = EA

3 = EA

N 13

N 8

C A

C E

of 5

dabar

de 128

9 de 93

10

2 of 5

11 I

19 = nputs

on on the number of

_ID,0,11,

What is shown above means the original data can be Code 39 or MSI.

th

t:

LEN,M

Length field consists of two length p

(Max). When defined, a formula will be performed if the length of the original data falls between

MIN and MAX.

LEN,9

What is shown above means the length of original data must be within 9 and 48.

Page 41

29

Match

Format:

MA TCH, P0 ,"C0" ,P1, "C1" ,..

atch field (n indicate

.,Pn, "Cn" ,

s a sequential integer number). To define a

re required. The first is character position (Pn) and the second is

means the number of characters, counting from the first

to the one to be positioned in the data record.

...

'E' has p

When Match field is defined, the original data string starts at the position specified by the first

parame compared with string "C". If the match is identical, processing of

current Formula continues.

The pos could be a wild character * for any position or # for the last position

in the or used,

is valid. parameter.

The string p an include * for any digit or # for any letter.

Example

MA TCH,3,"AB",#,"?",

Checks if the original dat 'B' at position '4' and last character is '?'.

10 , " *A*",

first character and "A*" followed at

.

A pair of Pn and Cn forms a M

Match field, two parameters a

a string (Cn). Character position

character

For example, in the following data

BARCODE

'B' has position 1.

'A' has position 2.

osition 7.

ter P and will be

ition parameter P

iginal data. If # is

#-N

Here N is a digit

arameter C c

s:

a has 'A' at position 3,

MA TCH ,

Checks if the original data includes a string with a digit as

position 10

Modifier

Modifier hgas two types of fields: A-String and O-String to define the output contents.

Format:

a string of characters to be added to the output. For example, if the original

string is

e

Note: If '*' on Programming Sheet are included in A-String, one interblock delay defined by

Group 2 will be inserted.

A-Strin

"abc..."

'a', 'b' and 'c' in the string can be any character.

A-String defines

data is:

BCD

and output

BarCoD

"ar", 'o' and 'e' in output string are added strings and can be defined by A-Strings.

Page 42

30

O-String

O-Str , 4, 4,

ut as

code

er of remaining characters counting from P, the remaining

Format:

O-STR , P, N,

O-String always applies to the original data. It contains two parameters. The first is position

parameter (P) that specifies the start output position in the original data. Parameter N tells how

many characters will be included beginning from P.

Example:

Original data is:

Barcode

Then

Gives outp

Note:

-- N can be '#' for all remaining characters from P.

-- If P greater than the length of original data, the O-String will be skipped.

-- If N greater than the numb

characters are included as valid.

Examples

Example 1

If the original data is Code 39 and content is "AA", output "ABC Company", and otherwise

riginal data as it is.

l data is Code 128 and logically divided into:

acters are personal ID,

ters are person's name.

ID first,

aracter,

terblock del

ula will be:

IN_ID,8,O-STR,1,6," **",O-STR,7,#,"<CR>",Enter

racter scanned from Full ASCII Chart.

output the o

IN_ID,0,LEN,2,2 company",Enter

IN_ID,19,O-STR,1,#,Ente

,MATCH,1,"AA","ABC

r

Example 2

If the origina

-- First six char

-- Other charac

The output will be:

-- Personal

ch-- A 'CR'

-- Two in ay,

-- Name,

-- A 'CR' character.

The Form

<CR>

<CR> is a Carriage Return cha

Advanced Features

The O-String has the format:

O-STR,P,N,

Page 43

31

Both param

specified

eters of O-String mentioned above are numbers. But both parameters can be

gs. If N is a string, it becomes a position and the meaning of O-String will be

"Output itio .

e evaluated as

the first position of the original string and search character 'a'.

-- From the position next to 'a' in original data, search for 'b'.

-- ....

-- From the position next to 'i', search for k.

-- If above searches e result of the parameter will be the position where 'k' is

located.

ng, the position evaluation of N is the same as P except that the searching position

ing from P+1.

from the position.

"ab...ik"-M,

.

EVE L MGR ^90010129999999?

5678901234" is account number.

first name.

e

r.

ion date.

ntinel.

desired is:

on Date [CR]

,3,"^"-1,"<CR>",O-STR

r and <CR> is Carriage Return character.

as strin

from pos n P to position N"

If P is defined as:

"ab...ik"

a, b, I, and k can be any character, the position will b

-- Start from

are all found, th

If N is a stri

is start

For both P and N, if string is defined, a value can be added to or subtracted

That following O-Strings:

"ab...ik"+M,

and

are meaningful. M is an integer number

Example:

Suppose the following is a message to be modified:

%B012345678901234^ABEL/ST

In this message:

"%" is start sentinel.

"01234

"^" is a separator

6. "ABEL" is surname.

"/" is a separator.

"STEVE" is

"L" is initial.

l"MGR" is tit

"^" is a separato

001" is expirat"9

"?" is end se

The output sequence

Surname, First Name [CR] Account Number [CR] Expirati

The formula input will be:

IN_ID,0,O-STR,"^"+1,"/"-1,",",O-STR,"/"+1,"<SP>"-1,"<CR>",O-STR

,"^^"+1,4,"<CR>",Enter

Here <SP> is Space characte

Page 44

32

The output of above input will be

ABEL,STEVE[CR]

012345678901234[CR]

9001[CR]

Page 45

Appendix A

Quick Setup Sheet

Scanner Mode

Trigger

Flash

UPC-E

Default

Cut Leading Digit

Send Check Digit

UPC-A Conversion

EAN-8

Default

Cut Leading Digit

Cut Check Digit

33

EAN-13

Default

Cut Leading Digit

Cut Check Digit

ISBN Conversion

Beep

None

Medium

rminator Te

Enter

Field Exit

Scan Code

U.S.

Alt Key

cter Delay Inter-Chara

1 ms

20 ms

Code ID

No

Yes

UPC-A

Default

Cut Leading Digit

Cut Check Digit

Supplement Code

No

Yes

Menu Setup

Enable / Disable

Display Version

Display Version

Factory Default

Factory Default

※ In cradle mode, the cradle is set for functions

necessarily through SCM.

Page 46

Appendix B

Function Codes

Function Codes for PC

F1 (%VA)

F3 (%VC)

F2 (%VB)

F4 (%VD)

F6 (%VF)

F5 (%VE)

F7 (%VG)

F9 (%VI)

F8 (%VH)

F10 (%VJ)

F12 (%VL)

F11 (%VK)

Cursor Right (/FC)

Cursor Up (/FE)

Cursor Left (/FD)

Cursor Down (/FF)

PgDn (/FH)

PgUp (/FG)

TAB (/FI)

Esc (/FK)

Back Tab (/FJ)

Left Enter (/FL)

Right Enter (/FM)

Ins (/FW)

Shift Break (/FS)

Ctrl Break (/FT)

Right Ctrl (/FO)

Shift Make (/FP)

Ctrl Make (/FQ)

Alt Make (/FR)

Alt Break (/FU)

Del (/FX)

34

Page 47

35

F1 (%VA)

F13 (%VM)

F2 (%VB)

F3 (%VC)

F4 (%VD)

F5 (%VE)

F6 (%VF)

F7 (%VG)

F8 (%VH)

F9 (%VI)

F10 (%VJ)

F11 (%VK)

F12 (%VL)

F14 (%VN)

F15 (%VO)

Cursor Left (/FD)

Cursor Right (/FC)

Cursor Down (/FF)

Cursor Up (/FE)

page down (/FH)

page up (/FG)

ins (/FJ)

tab (/FI)

Enter (/FL)

Esc (/FK)

return (/FM)

Option Make (%VP)

Option Brea (%VQ)

k

Control Make (%VR)

Control Break (%VS)

Shift Make %VT)

(

Shift Break (%VU)

Apple Make (%VV)

Apple Brea %VW)

k (

Page 48

36

Reset (/FV)

Function Codes for IBM Terminals

F1 (%VA)

F3 (%VC)

F5 (%VE)

F7 (%VG)

F9 (%VI)

F11 (%VK)

F13 (%VM)

F15 (% O) V

F17 (%VQ)

F19 (%VS)

F21 (%VU)

F23 (%VW)

Home A) (/F

TAB (/FI)

Return (/FM)

Field + (/FP)

Clear(/FR

)

F2 (%VB)

F4 (%VD)

F6 (%VF)

F8 (%VH)

F10 (%VJ)

F12 (%VL)

VN) F14 (%

F16 (%VP)

F18 (%VR)

F20 (%VT)

F22 (%VV)

F24 (%VX)

End (/FB)

Enter (/FL)

Field Exit (/FO)

Field - (/FQ)

Page 49

pendix C

Setup Menu

D.1 Beeps and D

Ap

elays

Group Default

Enter Group 2

Beep Tone:

0 – None

- Low 1 -

2 -- Medium

37

3 -- Hig

- Low to High

5 -- High to Low

h

4 -

A 1

0

1

Interblo

0 -- 0 ms

ck Delay:

1 -- 10 s

- 50 ms

3 -- 100 ms

500 ms

1 seconds

6 -- 3 seconds

- 5 seconds

m

2 4 --

5 - 7 -

2

A 2

3

4

Intercharacter Delay:

0 m 0 -- s

- 1 ms

2 -- 2 m

- 5 ms

4 -- 10

30 s

6 -- 50 ms

7 -- 100 ms

1 -

s

3 -

ms

m 5 --

A 3

5

6

Power Saving Mode:

0 -- 10 minutes

30 inutes

2 -- 60 minutes

3 -- 240 minutes

1 -- m

A

4

7

PharmaCod (Ease on decoding)

0 -- Disable

e

A5

Enable

8

1 --

Reserve

A6

9

Exit

Page 50

D.2 Keyboard Wedge Settings

Enter Group 3

Group Default

Function Code:

0 -- Off

1 -- ON

38

B 1

0

Caps-Lock:

0 – Auto Trace(PC/XT,AT)

1 – ower Case

–Upper Case

L

2

B 2

1

Language (For PC/XT/AT):

0-U.S.

5-Norwegian :-Danish

1 ;-Partial Alt

2-Swiss 7-German <-Japanese

3-S

4-S ode

-U.K. 6-Italian

wedish 8-French

panish 9-Alt Key M

B 3

2

3

Outp ulation:

0 h/Space with Low

ut of Wand Em

—Bar with Hig

1 Space with High —Bar with Low/

B 4

4

Level Duration of Mini Width:

0—200us

1 —600us

B 5

5

Pola ndition:

0

rity of Idle Co

—Low

1 —High

B 6

B

7

Pre-d

0 —Label 1 2—Label 2

( label” section for detail)

efine Label:

—Label 0 1

See “Pre-defined

6

B 8

Use s:

0

number keypad digit

—Disable

1—Enable

7

Exit

8

9

Page 51

D.3 RS232 Settings

Enter Group 4

Group Default

Baud Ra3te:

0 - 1 -- 6

39

00 4 – 4800

00 5 – 9600

200 6 – 19200

38400

2 -- 1

3 – 2400 7 –

C1

Parity:

0 – Even

0

1

3 -- Space

1 – Odd 4 -- None

C2

2

2 – Mark

Data Bit:

– 7

8

0

1 –

C3

3

Handsha edge): king (for serial w

0 – Ignore

1 – RTS Enabled in

Communication

2 – RTS Enable at Power up

3

/ 4 – Special Bell Off / On

C4

4

5

ACK/NAK (for serial wedge):

0 – Off

1 – On

C5

6

BCC Character (for serial wedge):

0 – Off

1 – On

C6

7

Time Out (for serial wedge):

0 -- 1 sec

1 – 3 sec

2 – 10sec

3 – Unlimited

C7

8

9

Data Direction (for Terminal Wedge):

0 – Send to Host

C8

1 – Send to Host and Terminal

2 – Send to Terminal

Define Terminator of RS232 input:

Scan an ASCII code in full ASCII Chart to

select a new RS232 Terminator.

C9

Exit

Page 52

D.4 Scanner Port

Enter Group 5

Group Default

T erminator:

0—Enter

1--Return (on its ypad)

D 1

40

dig ke

r Right C 2--Field Exit o trl

3--None

Code ID: 0 – disa

0

1

ble

1 – Enable

Code ID.

n C de page D.7.

Note: This setting doesn’t affect EAN128

EAN128 has its ow o ID setting on

D 2

2

D 3

Define Code ID

Full :ASCII

St andard

00–Code 39

01–Code 39

02–EAN-13

03–UPC-A

04–EAN-8

05–UPC-E

06–Interleaved 2 of 5

07–Codabar

08–Code 128

09–Code 93

0 - Stand ard 2 of 5

1 - MSI Code

2 - EAN128

3 - Code32 (Italian harmacy)

4 - Delta Code

5 - Label Code

6 - Plessey Code

7 - Code 11(Special)

18 - China Postal code

hiba Code) (Tos

Scan two digits to

choose a code, and

then scan a char. From

full ASCII table to

define ID.

Double Verification:

0 – Off

1~7 – On

3

4

5

D 4

(Verify 1~7 times)

Scanning Mo6de & Trigger Function :

0

–Trigger 1– Flashing 2 –Multis

One Scan 4 –Test

can

Mode

flash Mode 6 –Continuous

nning

3–One Press

5–Old Laser

7–Trigger with Command control sca

Trigger in Flash: 8 -Enabl ed

-, 9-

D 5

7

Disabled

8

Label Type:

0 – Positive

Negative 1 – Positive and

D 6

9

Aim function for long range laser engine:

0—Disable

1—Enable

, Aiming Time: 2—0.5s 3—1s

, 4—1.5s, 5—2s

D 7

Data Length (Two Digits) Send:

0—Disable

1—Enable

D8

Preamble Postamble

PP

OO

Scan ‘PP\OO’ for Pre\Postamble. Sc an characters

ASCII char or Function

from Full

Exit

Page 53

D.5 Operating Modes

41

Enter Group 6

Group Default

Buffer Mode

0— Disabled

1— Inventory Mode

2 — Batch Mode

E1

Reserve

E2

Buffer Transmit delay

0—50ms

1— 100ms 2— 300ms

3— 600ms 4— 1s 5— 2s

6— 3s 7— 5s

E3

Reserve

Reserve

Reserve

Reserve

Reserve

Reserve

0

1

2

3

4

5

6

7

8

9

Exit

Page 54

D.6 Code 39 / I 2 of 5 / S 2 of 5 / Code 32 / EAN128

42

Enter Group 7

Group Default

Code 39:

0/1

--Disable/Enable.

2/

3--Full ASCII/ St an Cdard.

alculate & Send.

t send.

4--Check Digit (CD)

5--CD Calculate, no

6 --CD not Calculate.

7/8

-- Send/No Send Start/Stop

9

/: -- Double labels decoding Off/On

0 - 48 -- Min length 0

/ Max length 48

F 1

I 2 of 5 (ITF):

0/1

--Disable/Enable

2/3

--Fix Le

0

1

ngth On/Off (by first three reads)

4--Ch git (CD) Calculate & Send

5--CD Calculate, not send.

t Calculate

eck Di

6—CD no

it Suppressed.

8--Last Digit Suppressed

9 -- Not Suppressed

7--First Dig

in length 102 - 64 -- M

/ Max length 64

F 2

2

3

4

S 2 of 5 / China Postal Code (Toshiba Code):

0

/1--Disable/Enable

2

/3 -- Fix Length On/Off (by first three reads)

igit (CD) Calculate & Send

5--CD Calculate, not send. 6--CD not Calculate

4--Check D

in length 41 - 48 -- M

/ Max length 48

F 3

5

6

Code 32(Italian pharmacy):

0

/1 -- Disable/Enable

2

/3 -- Leading Character Send / No Send

4

/5 -- Tailing Character Send / No Send

F 4

7

Telepen:

0

/1 – Disable/Enable 2/3 – Standard/Numeric Set

F 5

8

UCC/EAN 128:

0/1

—Disable/Enable

2/

3—Code ID Disable/Enable

Note: If EAN128 be disabled, the EAN128 labels will be

decoded as Code 128

F 6

Define the EAN128 Fields separator:

Scan a ASCII code in full ASCII code chart to select a

new Fields Separator

F 7

Define a separator for double labels:

Scan a ASCII code in full ASCII code chart to select a

new definition of Func1

F8

9

Min Length Max Length

MM

NN

Exit

Page 55

D.7 Code 128 / MSI Code / Code 93 / Codabar/ Label Code

43

Enter Group 8

Group Default

Code 128:

0/1

-- Disable/Enable

1-64 -- Min Length 1

/ Max Length 64

G1

MSI /Plessey Code:

0

/1 -- Disable/Enable

2/3

-- Check Digit Send / No

0

G2

Send

10 4 -- Check Digit Double Module

5 -- Check Digit Module 11 plus 10

6 -- Check Digit Single Module 10

1-16 -- Min Length 1

/ Max Length 16

1

2

Code 93:

0/1

-- Disable/Enable

1-48 -- Min Length 1

/ Max Length 48

G3

3

Code 11: (S pecial)

0

/1 -- Disable/Enable

2/3

-- One / Two Check

G4

Digit

4/5 -- Check Send / No Send

1-48 -- Min Length 1

/ Max Length 48

4

Codabar:

0

/1 -- Disable/Enable

2/3

-- Start & Stop Send / No Send

4 -- Check Digit Calculate & Send

5 -- Check Digit Calculate but not Send

6 -- Check Digit not Calculate

7/8

-- CLSI Format On / Off

3-48 -- Min Length 3

/ Max Length 48

G5

Label Code IV and V:

0

/1 -- Disable/Enable

2/

3 – Checksum send/ No send

5

6

G6

7

Min Length

8

MM

Max Length

NN

9

Exit

Page 56

D.8 UPC / EAN / Delta Code

44

Enter Group 9

Group Default

UPC-A:

0/1

-- Disable/Enable

2

/3 -- Leading Digit Send / No Send

4

/5 -- Check Digit Send / No Send

H1

UPC-E:

0/1

-- Disable/Enable

2

/3 -- Leading Digit Send / No Send

4/5

-- Check Digit Send / No Send

6/7

-- Zero Expansion On / Off

8

/9 – Disable/Enable NSC=1

0

H2

EAN-13:

0/1

-- Disable/Enable

2

/3 -- Leading Digit Send / No Send

4

/5 -- Check Digit Send / No Send

6/7

-- ISBN Enable / Disable

H3

1

2

3

EAN-8:

0/1

-- Disable/Enable

2

/3 -- Leading Digit Send / No Send

4

/5 -- Check Digit Send / No Send

H4

Supplement Code:

0

/1 -- T wo Supplement Code Off / On

2

/3 -- Five Supplement Code Off / On

4 -- Transmitted if Present

5 -- Must Present

.

6/7

-- Space Separator Inserted / Not Inserted

H5

4

5

6

Delta Distance Code:

0

/1 -- Disable/Enable

2

/3 -- Check Digit Calculated / Not Calc

4

ulated

/5 -- Check Digit Send / No Send

H6

Reserved:

H7

7

8

H8

RSS14 Code:

0/1

RSS14 Disable / Enable

2/3

RSS Expanded Disable / Enable

4

/ SS Limited 5 R isableD / Enable

6

/7 Linkage dDigit Not Sen / Send

8

/9 Use UCC/EAN128 ID Off/On

9

Exit

Page 57

D.9 Dump Setup Strings

See the section Batch Setup for how to use the labels below.

Dump Settings

Dump Settings on PC/AT

,Parity = None, Stop=1 Flow Control = None)

(Speed=9600,Databit=8

R

d setting

S232 Interface Keyboard Setting

PC/AT Interface Keyboar

45

Page 58

Appendix D

Full ASCII Chart

Characters in p arentheses represent Code 39 barcode printing

NUL (%U)

SOH ($A)

STX ($B)

DC4 ($T)

NAK ($U)

SYN ($V)

ETB ($W)

CAN ($X)

LF ($J)

VT ($K)

FF ($L)

CR ($M)

SO ($N)

ETX ($C)

EOT ($D)

SI ($O)

EM ($Y)

ENQ ($E)

SUB ($Z)

ESC (%A)

FS (%B)

ACK ($F)

BEL ($G)

BS ($H)

DLE ($P)

DC1 ($Q)

DC2 ($R)

GS (%C)

HT ($I)

DC3 ($S)

46

Page 59

)

(/I)

RS (%D)

4

5

US (%E)

* (/J)

6

SP

+

!

(/A)

,

(/L)

7

”

(/B)

8

-

9

#

(/C)

.

:

(/Z)

/

$

;

(%F)

%

0

< (%G)

& (/F)

1

= (%H)

’ (/G)

2

> (%I)

(

(/H) 3

47

Page 60

48

? (% J)

@ (% V)

A

B

C

D

E

F

G

H

I

U

J

V

K

W

L

X

M

Y

N

Z

O

[

(%K)

P

\

(%L )

Q

]

(%M )

R

^

(%N )

S

_

(%O)

T

Page 61

49

`

(%W)