Unitary products group C*ED060A Series, C*ED090A Series, C*ED120A Series, C*ED180A Series Installation Instruction

INSTALLATION

SINGLE PACKAGE

INSTRUCTION

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CAUTIONS, NOTES AND WARNINGS . . . . . . . . . . 3

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

A Complete Table of Contents on Following Page

WATER COOLED

AIR CONDITIONERS

EMBASSSY SERIES

MODELS C*ED060A, 090A, 120A, & 180A

SAVE THIS MANUAL

035-16734-000 REV A (799) Form 560.20-N1Y

560.20-N1Y 035-16734-000

y

TABLE OF CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

CAUTIONS, NOTES AND WARNINGS . . . . . . . . . . 3

INSPECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

LIMITATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

LOCATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

FOUNDATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

CLEARANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

RIGGING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

UNCRATNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SHIPPING BOLTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

BLOWER ARRANGEMENTS . . . . . . . . . . . . . . . . . . . . . 15

SUPPLY AIR BLOWER ADJUSTMENT . . . . . . . . . . . . .15

DUCT CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 18

SUPPLY AIR DUCTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

RETURN AIR DUCT FLANGE . . . . . . . . . . . . . . . . . . . . 19

INSULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

CONDENSER WATER PIPING . . . . . . . . . . . . . . . . . . .19

PRECAUTIONS AGAINST FREEZING . . . . . . . . . . . . . . . . . .19

DRAIN CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

REFRIGERATION SYSTEM . . . . . . . . . . . . . . . . . . . . . .20

WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

POWER WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

LOW VOLTAGE WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

ACCESSORY WIRING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

WATER REGULATING VALVES . . . . . . . . . . . . . . . . . .21

COOLING TOWER . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

16 CTRL (LOW VOLT) FIELD WIRING DIA. . . . . . 22

17 COOLING TOWER WATER PIPING . . . . . . . . . 24

18 UNIT CONTROL ON WATER FLOW . . . . . . . . 24

19 ALT UNIT CONTROL ON WATER FLOW . . . . 24

LIST OF TABLES

1 APPLICATION DATA . . . . . . . . . . . . . . . . . . . . . 4

2 OPERATING AND SHIPPING WEIGHT . . . . . . . 5

3 PHYSICAL DATA . . . . . . . . . . . . . . . . . . . . . . . . 6

4 COOLING CAPACITY 80°F TO 90°F . . . . . . . . . 7

5 COOLING CAPACITY 100°F TO 110°F . . . . . . . 8

6 CORRECTION FACTORS ALL MODELS . . . . . 9

7 CONDENSER WATER PRESSURE DROP . . . . 9

8 SUPPLY AIR BLOWER PERFORMANCE . . . . 10

9 MINIMUM CLEARANCES CED060 . . . . . . . . . . 14

10 MINIMUM CLEARANCES CED090 & 120 . . . . 14

11 MINIMUM CLEARANCES CED180 . . . . . . . . . . 14

12 SPLY AIR BLWR MOTOR PULLEY ADJ . . . . . 16

13 TUBE HOLE LOCATIONS . . . . . . . . . . . . . . . . 17

14 CFM RATINGS . . . . . . . . . . . . . . . . . . . . . . . . . 17

15 BLOWER MOTOR DRIVE DATA . . . . . . . . . . . 18

16 WATER CONNECTION SIZING . . . . . . . . . . . . 19

17 ELECTRICAL DATA . . . . . . . . . . . . . . . . . . . . . 23

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

ADJUSTING WATER REGULATING VALVE . . . . . . . . .24

LIST OF FIGURES

1 PRODUCT NOMENCLATURE . . . . . . . . . . . . . . 3

2 UNIT DIMENSIONS - CED060 . . . . . . . . . . . . . 11

3 UNIT DIMENSIONS - CED090 & 120 . . . . . . . . 12

4 UNIT DIMENSIONS - CED180 . . . . . . . . . . . . . 13

5 BLOWER ARRANGE CED060, 090 & 120 . . . . 15

6 BLOWER ARRANGE CED180 #1 . . . . . . . . . . . 15

7 BLOWER ARRANGE CED180 #2, #3, & #4 . . . 15

8 TYPICAL MOTOR MOUNTING ASSEMBLY . . 16

9 PROBE LOCATIONS . . . . . . . . . . . . . . . . . . . . 17

10 CFM CURVE . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

11 SUPPLY AIR DUCT CONNECTION . . . . . . . . . 18

12 COILS AND WATER CONNECTIONS . . . . . . . 19

13 RECOMMENDED DRAIN PIPING . . . . . . . . . . . 20

14 ELECTRICAL CONTROL BOX . . . . . . . . . . . . . 21

15 PS FIELD WIRING DIAGRAM . . . . . . . . . . . . . . 22

2 Unitar

Products Group

035-16734-000 560.20-N1Y

y

g

y

y

g

y

y

y

y

y

y

y

y

g

g

g

y

g

g

y

y

g

g

y

g

g

g

g

y

y

C

2

PRODUCT CATEG ORY

C = Single P ackage A ir

C o n d ito n in g U n it

(W a te r C o o le d )

PRODUCT GENERATION

2 = 2nd G eneration

PRODUCT IDENTIFIER

E D = E m bassy Factory

A s s e m b le d U n it w ith

B lo w e r M o to r and D rive

NOM INAL COOLING CAPACITY

FIGURE 1 : PRODUCT NOMENCLATURE

GENERAL

These C2ED Embassy units are water-cooled, single pack-

e air conditioners designed for vertical application and

a

indoor installation onl

conditioned space or in a utilit

. The unit may be installed within the

room.

DE

Installer should pay particular attention to the words: NOTE,

CAUTION and WARNING. Notes

make the installation easier. Cautions

equipment dama

that personal injur

the installation proced ure is not handl ed prop erl

9 0 A

0

060 = 5 Tons

090 = 7-1/2 Tons

120 = 10 Tons

180 = 15 Tons

2 5

INSTALLED HEAT

A = N o t A p p lic a b le

e. Warnings are given to alert the installer

and/or equipment damage may result if

VOLTAG E C O DE

06-208/230-1-60

25-208/230-3-60

46-460-3-60

FAC TO RY

are intended to clarify or

are given to prev ent

.

Models ED060, ED090 and 120 are desi

flow onl

The ED180 is factor

blower section ma

Units ma

return, with suppl

or a combination of these items.

Units are complet el

wired, tested and read

mounted in the blower se cti on. Units less motor and drive or

with alternate motors and drives are not available.

The units require electrical power, duct connections or plenum, condenser wa ter p ipi n

tial support at the point of installation.

Wate r pi pi n

made from either side of unit. Low volta

side onl

Drain connections a r e ma de on the ri

except the ED180, which can be made form either side.

and can not be field converted to horizontal airflow.

assembled f or vertical air flow, but the

be field converted for horizontal airflow.

be installed either with ductwork on supply and

air plenum and return air grille accessor

factory assembled, refr igerant ch arged,

for installation. Motor and drive are

, condensate drai n a nd s ub sta n-

connections an d power wiring entrance can be

.

ned for vertical air-

e entrance on right

ht side only for all units

CAUTIONS, NOTES AND WARNINGS

INSPECTION

Immediately upon receiv ing the unit, it should be inspected

for possible da ma

should be noted on the carrier’s frei

request for inspection b

in writin

.

e during transit. If damage is evident, it

ht bill. A separate

the carrier’s agent should be ma de

LIMITATIONS

1. Units are not suitable for brackish or salt water.

2. Refer to Table 1 for recomm en ded c ond ens er w ater flo w

rate and water temperature rise for coolin

cation.

3. Excessively high GPM and low water temperature may

result in coil freeze up.

4. A water-re

applications; it should be adjusted to maintain a head

pressure of 220 psi

approximatel

5. Excessivel

result in H.P. Cutout trip, 325 PSI.

6. Units are not intended for outdoor installation.

ulating valve is recommended for city water

and a water temperature rise of

20°F.

low GPM and high water temperature may

tower appli-

Products Group 3

Unitar

560.20-N1Y 035-16734-000

y

g

y

g sy

g

g

g

y

g

7. These units should be installed in accordance with:

a. Re

b. Standards for air conditionin

ulations of National Board of Fire Underwriters,

local utilit

or other authorities having jurisdiction.

stems, National Fire

Association Pamphlet # 90.

TABLE 1: APPLICATION DATA

LIMITATION

208/230-1-60 187 252

P

OWER SUPPLY

S

UPPLY AIR

A

IR TEMPERATURE ENTERING

C

OOLING COIL

C

ONDENSER WATER

C

ONDENSER WATER-SIDE WORKING PRESSURE

, V

, CFM

°F

OLTS

, GPM

208/230-3-60 187 252

460-3-60 432 504

C2ED060 1600 2400

C2ED090 2400 3600

C2ED120 3200 4800

C2ED180 4800 7200

Wet Bulb 57 72

Dry Bulb 65 95

C2ED060 4 20

C2ED090 6 30

C2ED120 8 40

C2ED180 12 60

, PSIG

c. National Warm Air Heatin

and Air Conditionin

Association Manuals, which ever is applicable.

d. Wirin

must conform to provisions of National Electrical Code (NFPE Pamphlet # 70) and local ordinances.

MINIMUM

2

20

1

MAXIMUM

150

1

3

L

EAVING CONDENSER WATER TEMPERATURE

1.

Utilization Range “A” in accordance with ARI Standard 110.

2.

The water pressure must be great enough to overcome the pressure drop of the condenser and the condenser water piping.

3.

Although the water side is only leak tested for 150psig, the maximum water-side working pressure of the condenser is 450 psig.

Class 150 fittings in the unit’s condenser water piping are good for 300 psig. For 300 psig applications, a sealing material (Locktite or equivalent) must be applied to all threaded connections to assure a leak-tight installation. The water regulating valve accessories are limited to a maximum 150 psig.

4.

The limitation for entering condenser water temperature will vary with condenser water GPM.

INSTALLATION

4

, °F

ACCESSORIES

60 115

Refer to the following instructions for installation of accessories:

• Form 550.13-N10.1U Electric Heat

THIS PRODUCT MUST BE INSTALLED IN

STRICT COMPLIANCE WITH THE ENCLOSED

INSTALLATION INSTRUCTIONS AND ANY

APPLICABLE LOCAL, STATE, AND NATIONAL

CODES INCLUDING BUT NOT LIMITED TO,

• Form 550.13-N10.2U Suppl

• Form 550.13-N10.3U Return Air Grille

• Form 550.12-N10.7U Hot Water Coil and Non-Freeze

Steam Coil

• Form 560.20-N1.5 W ate r Re

Air Plenum

ulating Valve

BUILDING, ELECTRICAL AND MECHANICAL

CODES.

4 Unitar

Products Group

035-16734-000 560.20-N1Y

y

y

g

g

g

g

g

y

g

g

ging

g

g

y

g

g

g

g

g

g

y

g

g

g

g

g

g

g

y

g

y

g

g

LOCATION

1. Units may be located in the conditioned space or in an

adjacent room. Units ma

must be protected from freezin

2. Units should be installed in an area offerin

power and control wir in

densate trap and pi pin

if required, outdoor air duct if required, and supply

in

not be located outdoors, and

.

proper

, condenser water piping, con-

, overflow if required, heating pip-

and return air.

FOR WINTER SHUTDOWN, RESIDUAL WATER

MUST BE BLOWN FROM THE CONDENSER IF

THE UNIT IS LOCATED IN AN AREA WHERE

THE AMBIENT TEMPERATURE MAY DROP

BELOW 32°F OR IF THE UNIT HAS AN OUTDOOR AIR INTAKE.

3. Supply air may be ducted or distributed with a plenum.

Return air ma

an inlet

be ducted, unducted or returned through

rille. If the unit is to have an outdoor air intake,

it should be located near and outside wall.

Units should be located for ease of service, with adequate

clearance for compressor access, front and ri

drive access, chan

filters, and heating coil service if

required. Refer to respective unit dimension detail (Fi

ht side, fan

ure 2,

3, and 4) for required clearances.

FOUNDATION

1. Units may be placed on the floor or b e elev ated o n a su itable platform.

2. No special foundation or isolation is required for most

applications.

a. Unit incorporates adequate isolation to eliminate

fan, compressor, and condensin

Flexible duct is also recommended.

b. It is not necessar

in

structure.

to bolt unit to the floor or support-

c. Floor or platform must be capable of supportin

operatin

wei

3. For installations requirin

followin

weight of the unit. See Table 2 for unit

hts.

extreme quiet operation, the

precautions should be considered:

a. Locate unit outside the conditioned space.

b. Suppl

and return air ducts should be used, connected to the unit with asbestos cloth collars, and

lined with sound absorbing material.

section vibration.

the

c. Support the unit on a separate floor structure form

that of the conditioned space.

d. Place a non-deteriorating sound isolation pad under

the entire unit base.

CLEARANCE

Clearance must be provided for:

1. Air intake and discharge – with or without ductwork.

2. Condenser water pipin

and connections.

3. Electrical power conne cti on s.

4. Heatin

coil piping and connections, if required.

5. Trapped condensate drain connection.

6. Maintenance and service access. Recommended minimum clearances for units are shown on the unit dimension drawin

are based on standard arran

standard arran

’s Figures 2, 3, and 4. These clearances

ements of units. For non-

ements, allow clearan ce s th at are in line

with the recommended minimum values shown.

RIGGING

1. Lift with slings under the unit.

2. Use spreader bars across the top of the unit to prevent

crushin

3. Avoid possible surface dama

the unit frame and panels.

e by NOT removing the

carton or the skids un til the unit is at or near its final location and soon to be installed.

TABLE 2: OPERATING AND SHIPPING WEIGHT

(LBS.)

MODEL C2ED 060 090 120 180

S

HIPPING WEIGHT

O

PERATING WEIGHT

452 755 809 1115

402 690 744 1040

UNCRATNG

Keep the units in their carton until moved close to point of

installation. Units are mounted on skids and should be

“trucked” to location in a vertical position. Under no circumstances should the

1. Remove the shippin

2. Remove skid from under the unit.

3. Remove front access panel from condenser section.

This is necessar

denser water pipin

blocks.

pin

be “walked” on the corners of the crate.

carton.

for access to the electrical box, con-

and the removal of compre ssor s hip-

Products Group 5

Unitar

560.20-N1Y 035-16734-000

y

TABLE 3: PHYSICAL DATA

DESCRIPTION

Quantity Per Unit

C

OMPRESSOR

(F

ULLY HERMETIC

3-3/4 ton - 2 - 5-Ton 1 - 2 1

10-Ton - - Rows Deep x Rows Wide 3 x 24 3 x 24 3 x 32 4 x 26

Finned Length - inches 30 46 46 54.5

E

VAPORATOR COIL

Face Area - square feet 5.0 7.7 10.2 12.4

Tube (Copper) OD - inches 3/8 3/8 3/8 1/2

Fins (Aluminum) per inch 13 13 13 12

C

ENTRIFUGAL BLOWER

(F

ORWARD CURVE

2

M

OTORS

F

ILTERS

(T

HROWAWAY

)

)

Diameter x Width - inches 10 x 10 15 x 15 15 x 15 18 x 18

Nominal HP Rating

Quantity per Unit

Face Area - square feet 5.6 11.1 11.1 16.7

Quantity Per Unit

C

ONDENSER

(W

ATER COOLED

)

3-3/4 Ton - 2 - 5 Ton 1 - 2 3

Refrigerant-22, lbs. - oz.

O

PERATING CHARGE

System - 1 5-1 4-9 5-14

System - 2 - 4-9 5-14 5-4

1.

The 10-Ton system is wired for first stage operation.

2.

The refer to Table 15 for additional blower motor and drive data.

UNIT MODEL

CED060 CED090 CED120 CED180

3/4

(1@460-3-60)

1-1/2 2 3

16” x 25” x 1” 2 4 4 20” x 20” x 1” - - - 6

12-0

1

1

2

6 Unitar

Products Group

035-16734-000 560.20-N1Y

y

g

TABLE 4: COOLING CAPACITY 80°F TO 90°F

AIR ENTERING

MODEL

CED

060

(1 Phase)

060

(3 Phase)

090

120

180

1.

These capacities are gross ratings. For net capacities, determine the Kw requirements of the supply air blower motor per T able 8.

Convert kW to MBH per the following equation and deduct this equivalent heat from the gross cooling ratings.

BLOWER MOTOR kW x (3.415 MBH / kW) = Blower Motor Heat (MBH)

2.

Compressor kW only. For total unit kW, add the kW requirement of the supply air blower per Table 8.

COOLING COIL TOTAL

TEMP. °F

CFM

86 72

2000

2000

3000

3000

6000

80 67 63 43 4.3 10.4 59 42 4.6 10.0

56 41 57 41 4.2 9.6 54 40 4.5 9.3

68 57 52 40 4.1 8.8 49 39 4.4 8.6

86 72

80 67 63 43 4.1 10.3 59 42 4.4 9.9

74 62 57 41 4.0 9.5 54 40 4.3 9.2

68 57 52 40 3.9 8.7 49 39 4.2 8.5

86 72

80 67 94 65 6.0 10.2 89 63 6.4 9.9

74 62 86 62 5.8 9.4 81 61 6.2 9.1

68 57 77 60 5.7 8.6 73 59 6.1 8.4

86 72

80 67 128 90 8.2 10.5 121 87 8.8 10. 1

74 62 118 87 8.0 9.7 110 84 8.6 9.4

68 57 107 84 7.8 8.9 100 81 8.4 8.6

86 72

80 67 195 139 13.1 10.6 187 135 13.7 10.4

74 62 175 133 12.8 8.7 168 130 13.5 9.5

68 57 154 127 12.6 8.8 149 125 13.3 8.6

COND.

WATER

GPM

15

15

22.5

30

45

1

CONDENSER WATER TEMPERATURE, °F

80 90

TOT.

MBH

69 45 4.4 11.2 65 44 4.7 10.8

69 45 4.2 11.1 65 44 4.5 10.7

102 68 6.2 11.0 97 66 6.6 10.6

139 93 8.4 11.2 132 90 9.0 10.8

211 146 13.4 11.4 203 140 14.0 11.2

SENS.

MBH

Kw

2

WATER

RANGE

°F

TOT.

MBH

SENS.

MBH

Kw

2

WATER

RANGE

°FDB WB

Nominal Ratin

Products Group 7

Unitar

560.20-N1Y 035-16734-000

y

g

TABLE 5: COOLING CAPACITY 100°F TO 110°F

AIR ENTERING

MODEL

CED

060

(1 Phase)

060

(3 Phase)

090

120

180

1.

These capacities are gross ratings. For net capacities, determine the Kw requirements of the supply air blower motor per Table 8.

Convert kW to MBH per the following equation and deduct this equivalent heat from the gross cooling ratings.

BLOWER MOTOR kW x (3.415 MBH / kW) = Blower Motor Heat (MBH)

2.

Compressor kW only. For total unit kW, add the kW requirement of the supply air blower per Table 8.

COOLING COIL TOTAL

TEMP. °F

CFM

86 72

2000

2000

3000

3000

6000

80 67 56 41 4.9 9.7 53 40 5.2 9.4

56 41 51 39 4.8 9.0 48 38 5.1 8.7

68 57 46 38 4.7 8.3 43 37 5.0 8.0

86 72

80 67 56 41 4.7 9.6 53 40 5.0 9.3

74 62 51 39 4.6 8.9 48 38 4.9 8.6

68 57 46 38 4.5 8.2 43 37 4.8 7.9

86 72

80 67 84 61 6.8 9.5 78 58 7.3 9.1

74 62 76 59 6.6 8.8 71 56 7.1 8.4

68 57 68 57 6.5 8.1 64 55 7.0 7.8

86 72

80 67 114 84 9.4 9.7 106 81 10.0 9.3

74 62 103 81 9.2 9.0 96 78 9.8 8.6

68 57 93 78 9.0 8.3 86 75 9.6 7.9

86 72

80 67 175 130 14.4 9.9 158 125 15.1 9.3

74 62 158 126 14.2 9.1 145 122 14.8 8.7

68 57 141 122 14.0 8.4 132 119 14.6 8.1

COND.

WATER

GPM

15

15

22.5

30

45

1

CONDENSER WATER TEMPERATURE, °F

100 110

TOT.

MBH

62 43 5.0 10.5 58 42 5.3 10.1

62 43 4.8 10.4 58 42 5.1 10.0

91 63 7.0 10.2 85 60 7.5 9.8

124 87 9.6 10.4 116 85 10.3 10.0

188 134 14.7 10.6 170 128 15.4 9.9

SENS.

MBH

Kw

2

WATER

RANGE

°F

TOT.

MBH

SENS.

MBH

Kw

2

WATER

RANGE

°FDB WB

Nominal Ratin

8 Unitar

Products Group

035-16734-000 560.20-N1Y

y

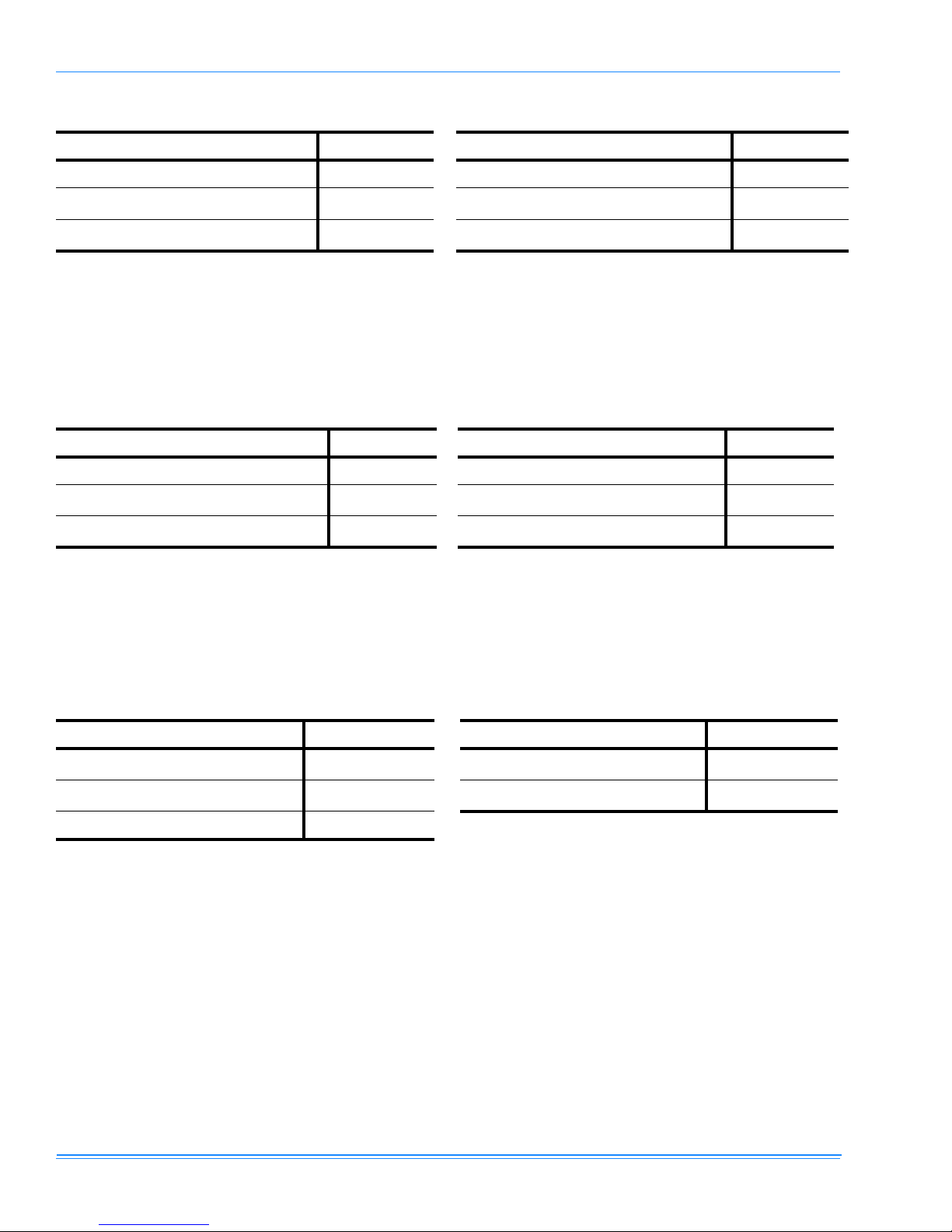

TABLE 6: CORRECTION FACTORS - ALL MODELS

RATING

Total Capacity

Sensible Capacity

Compressor kW

80 90 100 110 120 50 75 100 125 150

0.95 0.98 1. 00 1.01 1.02 0.90 0.96 1.00 1.03 1.05

0.85 0.94 1. 00 1.04 1.07 0.95 0.98 1.00 1.01 1.02

0.97 0.99 1. 00 1.01 1.02 1.10 1.04 1.00 0.97 0.95

% CFM % GPM

TABLE 7: CONDENSER WATER PRESSURE DROP

MODEL

CED060

CED090

CONDENSER

WATE R GPM

10

15

20

15

22.5

30

PRESSURE

DROP PSI

2.0

4.4

8.0

2.4

3.0

4.2

MODEL

CED120

CED180

CONDENSER

WATER GPM

20

30

40

30

45

60

PRESSURE

DROP PSI

2.0

4.4

8.0

2.0

4.4

8.0

Products Group 9

Unitar

560.20-N1Y 035-16734-000

y

y

y

TABLE 8: SUPPLY AIR BLOWER PERFORMANCE

RPM

810

900

1000

1100

1110

655

700

800

880

SP

2

BHP

3

kW

1600

0.45 0.39 0.35

0.64 0.48 0.43

0.87 0.58 0.53

1.12 0.69 0.64

1.15 0.70 0.65

2400

0.49 0.70 0.66

0.60 0.77 0.73

0.92 0.97 0.90

1.18 1. 11 1.04

SP

0.32

0.53

0.77

1.03

1.06

0.41

0.53

0.85

1.11

2

BHP

3

kW

1800

0.46 0.42 0.18 0.53 0.49 0.02 0.61 0.56 - - -

0.56 0.51 0.40 0.64 0.59 0.25 0.73 0.68 0.10 0.82 0.77

0.67 0.62 0.65 0.76 0.71 0.51 0.86 0.81 0.37 0.91 0.90

0.78 0.73 0.92 0.89 0.83 0.79 1.00 0.94 0.66 1.13 1.04

0.79 0.74 0.95 0.90 0.84 0.82 1.02 0.95 - - -

2700

0.78 0.72 0.30 0.87 0.82 0.07 0.96 0.90 - - -

0.85 0.80 0.43 0.95 0.89 0.29 1.06 0.99 0.12 1.17 1.09

1.06 0.99 0.77 1.18 1.10 0.65 1.30 1.21 0.49 1.42 1.32

1.24 1.16 1.03 1.37 1.28 0.91 1.50 1.38 0.77 1.64 1.53

1

SP

CED060

CED090

CFM

2

BHP

4

3

kW

SP

2

BHP

3

kW

SP

2000 2200 2400

3000 3300 3600

2

BHP

3

kW

900

1.24 1.15 1.07

1.18

1.28 1.19 1.10 1.42 1.32 0.98 1.55 1.43 0.84 1.70 1.57

CED120

700

800

900

950

3200

0.49 1.01 0.94

0.84 1.25 1.16

1.18 1.48 1.38

1.37 1.61 1.50

0.34

0.71

1.06

1.26

3600

1.17 1.09 0.14 1.33 1.24 - - - - - -

1.42 1.32 0.53 1.60 1.48 0.30 1.80 1.64 - - -

1.70 1.57 0.91 1.92 1.75 0.70 2.18 1.99 0.43 2.45 2.24

1.86 1.71 1.11 2.12 1.95 0.91 2.39 2.18 0.65 2.67 2.44

4000 4400 4800

CED180

4800

625

700

800

810

0.55 1.54 1.43

0.84 1.83 1.68

1.26 2.38 2.17

1.31 2.44 2.22

1.

Unit resistance is based on a wet evaporator coil and clean filters

2.

Available static pressure in IWG to overcome the resistance of the duct system. Refer to Table 15 for additional motor and drive data.

3.

Motors can be selected to operate into the service factor because they are located in the moving air stream. If maximum air on temper-

0.40

0.70

1.15

1.20

5400

1.79 1.64 0.22 2.08 1.90 0.01 2.41 2.20 - - -

2.12 1.94 0.54 2.43 2.22 0.36 2.77 2.54 0.12 3.12 2.82

2.70 2.47 1.00 3.03 2.74 0.83 3.37 3.05 0.62 3.75 -

2.74 2.52 1.05 3.09 2.80 0.88 3.44 - - - -

6000 6600 7200

ature is exceeded, a service factor of 1.0 must be used.

4.

The CED060A46 has a 1 HP blower motor that can operate 1.15 BHP providing the unit is not equipped with a hot water or steam coil.

RPM range for the standard, fac-

-mounted drive components

tor

Exceeds the BHP limitation of the standard, factor

mounted blower motor.

10 Unitar

Products Group

035-16734-000 560.20-N1Y

y

36-1/8

8-1/2

13-1/4

SUPPLY

AIR

(O U T )

1-23/32 K N O C K O U T

(R em ove only w hen

E le c tric H e a t A c c e s s o ry

1

is used)

3/4

HOT W ATER AND STEAM C O IL

ACC ESSO RIES C AN BE INSTALLED

IN A V E R T IC A L P O S IT IO N B E T W E E N

THE UNIT RETURN AIR OPENING

AND THE DUCT FLANGE

AC CESSO R IES

ELECTRIC H EATER

Add 13" to U nit H eight W hen U sed.

SUPPLY AIR PLENUM

Add 24-3/8" To U nit H eight W hen U sed

DUCT

FLANG E

20

21-3/8

1

1-3/8

2

2-1/4

RETURN

AIR

(IN )

1" N PTI W ATER OU TLET

1" N PTI W ATER INLET

(2" KN O CKO U TS)

(Both Sides of Unit)

ACC ESS PANEL TO

COM PRESSOR AND

ELECTRICAL BOX

32

11-5/8

1-3/32 K N O C K O U T

POW ER W IR ING

(Both Sides of Unit)

11-1/2

22-3/4

BLOW ER M O TO R

AND DRIVE

ACC ESS PANEL

(This side only)

43-1/8

FILTER ACCESS PAN EL

(This side only)

7/8 O.D. DRAIN CO NN.

1-3/8

(M ust be trapped)

1-3/16

1-1/8

7/8 H O LE W ITH B U S H IN G

CONTROL W IRING

2-5/16

(Both Sides of Unit)

2-3/4

2-5/8

9/16

3-3/4

1-1/2

1-7/16

3-1/2

22

All dim ensions are in inches. They are

2

subject to change w ithout notice. Certified

d im e n s io n s w ill b e p r o v id e d u p o n r e q u e s t .

CONDENSER

SECTIO N

7/8 OD AUXILIARY DRAIN CONN.

1-3/8

(M ust be trapped)

3/4

*

Includes flexible sheathing

to route control wiring to

low voltage term inal block

64-1/2

*

FIGURE 2 : UNIT DIMENSIONS - CED060

1.

See Table 9 for Minimum Clearances on page 14.

Products Group 11

Unitar

1

560.20-N1Y 035-16734-000

y

52-1/4

15-3/8

18-7/8

HOT W ATER AND STEAM C O IL

ACC ESSO RIES C AN BE INSTALLED

IN A V E R T IC A L P O S IT IO N B E T W E E N

THE UNIT RETURN AIR OPENING

AND THE DUCT FLANGE

AC CESSO R IES

ELECTRIC H EATER

Add 14-1/4" to U nit H eight W hen U sed.

SUPPLY AIR PLENUM

Add 27-1/2" To U nit H eight W hen U sed

1-23/32 K N O C K O U T

(R em ove only w hen

Electrical H eat A ccessory

is used)

DUCT

FLANG E

23

1-5/8

21-3/8

1-3/8

ACC ESS PANEL TO

COM PRESSORS AND

2

ELECTRICAL BOX

2-1/4

RETURN

AIR

(IN )

1-1/4" N P T I W A T E R O U TLE T

1 -1 /4 " N P T I W A T E R IN L E T

(2" KN O CKO U TS)

(Both Sides of Unit)

48

SUPPLY

AIR

(O U T )

15

1

1-3/32' KN O C K O U T

POW ER SUPPLY

(Both Sides of Unit)

1-1/2

1

16-1/8

FILTER ACCESS PAN EL

(T his side only)

1-3/8

1-3/16

7/8 O.D. DRAIN CO NN.

1-1/8

(m ust be trapped)

7 /8 " H O L E W IT H B U S H IN G

CONTROL W IRING

(Both Sides of Unit)

CONDENSER SECTION

2-5/16

2-1/16

3

3-15/16

3-3/16

25-1/8

2-5/16

2

1-3/8

1-1/8

9/16

*

Includes flexible sheathing

to route control wiring to

low voltage term inal block.

All dim ensions are in inches. They are

subject to change w ithout notice. Certified

d im e n s io n s w ill b e p r o v ided upon request.

5/8

25-7/8

BLOW ER M O TO R

AND DRIVE

ACC ESS PANEL

(This side only)

*

7 /8 O D A U X IL IA R Y

DRAIN CO NN.

(M ust be trapped)

51-1/8

72-1/2

FIGURE 3 : UNIT DIMENSIONS - CED090 & 120

1.

See Table 10 for Minimum Clearances on page 14.

12 Unitar

1

Products Group

035-16734-000 560.20-N1Y

y

60-3/4

19-3/8

21-7/8

1-23/32 KN O C K O U T

(R em ove only w hen E lectric

H eat Accessory is used)

27-5/8

2-3/8

21-1/2

1-1/2

2-3/16

7-1/4

RETURN

AIR

(IN )

1-1/2" NP TI W A T ER O UT LE T

1 -1 /2 " N P T I W A T E R IN L E T

(2 -5/8 " K N O C K O U T S )

(B oth Sides of U nit)

ACCESS PANEL TO

COM PRESSORS AND

ELECTRICAL BO X

56-3/8

SUPPLY

AIR

(O U T )

16-1/2

1-3/32" K N O C KO U T

POW ER W IRIN G

6-1/2

7/8

7/8" H O LE W ITH BU S H IN G

CONTROL W IRING

2-3/4

1

4

2-3/8

1-5/16

3-7/8

2-3/16

16-1/2

31-5/8

2-1/8

18-7/8

32-3/8

BLOW ER M OTO R

AND DRIVE

ACCESS PANEL

(O n opposite side of

unit O N LY w hen the

blower section has

been rotated 180

from position shown)

FILTER ACC ESS P ANEL

Filters can be rem oved

through either side of

the unit.

3-1/8

2-1/2

1-1/4" K N O C KO U T

FOR 7/8 OD DRAIN CON.

(M ust be trapped)

CONDENSER SECTION

*

3-1/8

7/8 OD AUXILIARY DRAIN CONN.

(M ust be trapped)

3/4

9/16

*

Includes flexible sheathing

to ro u te c o n tro l w irin g to

low voltage term inal block.

All dim ensions are in inches. They are

subject to change w ithout notice. C ertified

d im e n s io n s w ill b e p r o v ided upon request.

ACC ESSO RIES

ELECTRIC HEATER

Add 14-1/4" to Unit H eight W hen U sing

10, 16, 26, or 36kW Heater. A dd 21-3/4"

To Unit H eight W hen U sing 72kW Heater.

SUPPLY AIR PLENUM

Add 27" To U nit H eight W hen Used

62-5/8

HOT W ATER AND STEAM C O IL

ACCESSO R IES CAN BE INSTALLED

BETW EEN THE EVAPOR ATOR

SECTIO N AND THE BLO W ER

SECTIO N

84-1/8

FIGURE 4 : UNIT DIMENSIONS - CED180

1.

See Table 11 for Minimum Clearances on page 14.

Products Group 13

Unitar

1

560.20-N1Y 035-16734-000

y

TABLE 9: MINIMUM CLEARANCES - CED060

LOCATION CLEARANCE LOCATION CLEARANCE

Side w/ RTN Air Opening

Side w/ SPLY Air Opening

Side w/ Piping Conn.

1.

Overall dimension of the unit will vary if an electric heater or a supply air plenum is used

2.

Although no clearance is required for service and operation some clearance may be required for routing the power and control wir-

24”

24”

36”

Side Opposite Piping Conn. 12”

1

3

Side w/ Access for PWR & CTRL Wiring

Bottom

ing.

3.

This dimension is required for removal of the coil. Only 26” is required for normal servicing.

4.

Allow enough clearance to trap the auxiliary drain line.

TABLE 10: MINIMUM CLEARANCES - CED090 & 120

LOCATION CLEARANCE LOCATI ON CLEARANCE

Side w/ RTN Air Opening

Side w/ SPLY Air Opening

Side w/ Piping Conn.

1.

Overall dimension of the unit will vary if an electric heater or a supply air plenum is used

2.

Although no clearance is required for service and operation some clearance may be required for routing the power and control

wiring.

3.

This dimension is required for removal of the coil. Only 26” is required for normal servicing.

4.

Allow enough clearance to trap the auxiliary drain line.

24”

24”

52”

Side Opposite Piping Conn. 12”

1

3

Side w/ Access for PWR & CTRL Wiring

Bottom

2

-

4

-

2

-

4

-

TABLE 11: MINIMUM CLEARANCES - CED180

LOCATION CLEARANCE LOCA TION CLEARANCE

Side w/ RTN Air Opening

Side w/ SPLY Air Opening

Side w/ Piping Conn.

1.

If the coil has to be removed, this dimension is required to loosen screws that secure the coil to the unit frame. This dimension will

also be required for blower motor access if the piping connections are made on the opposite side of the unit.

2.

Overall dimension of the unit will vary if an electric heater or a supply air plenum is used

3.

Allow enough clearance to trap the auxiliary drain line

4.

This dimension is required for removal of the coil. Only 26” is required for normal servicing.

24”

24”

61”

Side Opposite Piping Conn.

2

4

Bottom

26

1

”

3

-

14 Unitar

Products Group

035-16734-000 560.20-N1Y

y

g

y

g

g

g

g

g

g

g

g

g

y

y

g

g

y

g

A

A IR IN

PLAIN PANEL

SHO R T PANEL

PLAIN PANEL

BLO W ER

SECTION

NO N -FREEZE STEAM

OR HOT W ATER

HEATING COIL

COIL

SECTION

CO M PRESSO R

SECTION

PLAIN PANEL

RETURN

AIR G R ILLE

(NO FILTERS)

AIR

AIR

ARRANG EM ENT

N O . 4

AIR

)14

ARRANG EM ENT

N O . 3

AIR

AIR

ARRANG EM ENT

N O . 2

SHIPPING BOLTS

Loosen the compressor shipping bolts and ferrule s. Remo ve

shippin

10-15 ft.-lbs.

blocks under the compressor(s). Retighten nuts to

PLAIN PAN EL

PLEN UM

RETURN

IR G R ILLE

(NO FILTERS)

NO N-FREEZE STEAM

OR HOT WATER

HEATING CO IL

PLAIN PAN EL

A IR IN

PLAIN PAN EL

BLO W ER

COIL

CO M PRESSO R

SECTION

FIGURE 5 : BLOWER ARRANGEMENT - CED060,

090 & 120

BLOWER ARRANGEMENTS

Models ED060, 090 and 120 are sh ipped assem bled fo r vertical suppl

Model ED180 is shipped assembled for vertical supply air

(see Fi

one of three-(3) alternate air dischar

7).Convertin

tern is accomplished per the followin

air operation only (See Figure 5).

ure 6) operation and can also be field converted to

e patterns (See Figure

Model ED180 to an alternate air discharge pat-

procedures:

FIGURE 6 : BLOWER ARRANGEMENT - CED180

ARRANGEMENT #1

FIGURE 7 : BLOWER ARRANGEMENTS - CED180

ARRANGEMENTS #2, #3, & #4

1. Remove the panels from the blower sectio n.

2. Remove Phillips machine screws located inside casin

corner an

to

ether.

les which hold coil and blower section

3. Rotate blower section for the air dischar

desired.

4. Refasten coil section to blower section with machine

screws removed in Step 2.

5. Before replacin

nection and Drain connections.

panels, see paragraphs on Duct Con-

6. Replace panels.

Unitar

Products Group 15

SUPPLY AIR BLOWER ADJUSTMENT

The RPM of the supply air blower will depend on the required

CFM, the unit accessories and the static resistances of both

the suppl

e pattern

tion, the RPM for suppl

the blower performance, Table 8.

Knowin

the settin

determined form Table 12.

Each motor pulle

1. A threaded barrel with two flats (or notched recesses

and the return air duct systems. With this informa-

air blower can be determined from

the requi red blo wer RP M and the blo wer m otor H P,

(turns open) for the supply air motor pulley can be

has:

180 de

rees apart.

560.20-N1Y 035-16734-000

y

g

g

g

y

g

g

y

g

g

g

g

y

y

y

y

g

y

y

g

g

y

g

g

y

y

y

g

g

g

y

R

2. A movable flange with one set screw

After the movable flan

ber of “turns open”; the setscrew should be ti

the flat on the barrel to lock the movable flan

the pulle

includes a l o cki ng collar, the locking collar must be

loosened to adjust the settin

e has been rotated to the proper num-

htened against

e in place. If

of the movable flange.

TABLE 12: SUPPLY AIR BLOWER MOTOR PULLEY

ADJUSTMENT

BLOWER RPM

TURNS

OPEN

0

1

2

3

4

1

DRIVE RPM RANGE AND UNIT SIZE

CED060

810-110

RPM

1110 880 950 810

1050 835 900 773

990 790 850 736

930 745 800 699

870 700 750 662

CED190

655-880

RPM

CED120

700-950

RPM

CED180

625-810

RPM

5. All suppl

air motor pulleys are factory set at 2 “turns

open”.

After the supply air blower motor is operating, adjust the

resistanc es in bo t h t he s up pl

balance the suppl

air distribution throu

specifications ma

and the return duct system to balance the

hout the conditioned space. The job

required that this balancing be done b

and the return duct systems to

someone other than the equipment installer.

C (DO NOT LOO SEN)

MOTOR

B

MOTO

MO UNT

A

5

1.

Pulleys can be adjusted in half-turn increments.

Note the followin

1. The suppl

810 655 700 625

:

air CFM must be within the lim itation s shown

in Table 1.

2. All pulleys can be adjusted in half turn increments.

3. The tension of the belt should be adjusted for a deflection of 3/16 of an inch per foot of belt span with and

applied force of 2 to 3 pounds. Movin

mountin

8 turnin

plate makes this adjustment. Refer to Figure

the adjustment bolt (B) moves the motor

the blower motor

mounting plate up or down.

NEVER LOOSEN THE TWO NUTS (C OF FIGURE 8) THIS COULD CAUSE THE MOTOR

MOUNT TO LOOSEN AND BREAK THE BELT.

Two hex nuts (A) have to be loosened to move the

mountin

plate and retighten after the mounting plate

has been moved to the proper position.

4. All pulle

s are factory aligned.

FIGURE 8 : TYPICAL MOTOR MOUNTING

ASSEMBLY

To check the supply air CFM after the initial balancing has

been completed:

1. Drill two 5/16-inch holes in the side panel as shown in

ure 9.

Fi

2. Insert at least 8” of 1/4 inch tubin

holes for sufficient penetration into the airflow on both

sides of the evaporator coil.

NOTE:

The tubes must be inserted and held in a position perpendicular t o the air flow so velo cit

the static pressure readin

CED060 to

et accurate readings.

s. Filters must be removed on the

3. Using an inclined manometer, determine the pressure

drop across a dr

an evaporator coil ma

evaporator coil. Sin ce the moisture on

vary greatly, measuring the pressure drop across a wet coil under field conditions would

be inaccurate. To assure a dry coil, The refrigeration

stem should be de-activated while the test is being

s

run.

4. Knowin

CFM throu

in Fi

the pressure drop across a dry coil, the actual

h the unit can be determined from the curve

ure 10.

If the CFM i s above or below the sp ecified v alue, t he supp l

air motor pulley may have to be re-adjusted. After on hour of

into each of these

pressure will not affect

16 Unitar

Products Group

035-16734-000 560.20-N1Y

y

g

g

g

g

y

0.5

0.4

0.3

0.2

0.1

0.0

70

80

90 100 110

120

130

C U R V E N O . 1 - C E D 1 8 0 U N IT

C U R V E N O . 2 - C E D 0 9 0 & 1 2 0 U N IT

C U R V E N O . 3 - C E D 0 6 0 U N IT

PRESSURE DROP

(IW G )

P E R C E N T N O M IN A L C F M

operation, check the belt and pulleys for tightness and alignment.

FAILURE TO PROPERLY ADJUST THE TOTAL

SYSTEM AIR QUANTITY CAN RESULT IN

EXTENSIVE BLOWER DAMAGE.

B

5/16"

A

EVAPOR ATOR

COIL

AIR

IN

FILTER S

C

5/16"

HOLE

HOLE

FIGURE 10 : CFM CURVE

D

COIL

SECTIO N

TABLE 14: CFM RATINGS

% OF NOMINAL CFM

MODEL

80 90 100 110 120

FIGURE 9 : PROBE LOCATIONS

CFM

After readin

seal up the drilled holes in the side panel. 5/16” dot plu

N029-12880) are available throu

parts order in

TABLE 13: TUBE HOLE LOCATIONS

MODEL

CED060

s have been obtained, remove the tubes and

s (P/

h normal SOURCE ONE

procedures.

DIMENSION

ABCD

9-1/2 2-1/4 19 10-1/4

1

CED060

CED090

CED120

CED180

1.

1600 1800 2000 2200 2400

2400 2700 3000 3300 3600

3200 3600 4000 4400 4800

4800 5400 6000 6600 7200

Filter must be removed on CED060 unit only before readings are taken.

CED090

CED120

CED180

3 3 14 12

3 3 14 12

7 1-3/4 18 13-3/4

NOTE:

Shut down the refrigerant system before taking an

test measurements to assure a dry evaporator coil.

Products Group 17

Unitar

560.20-N1Y 035-16734-000

y

g

g

y

y

y

TABLE 15: BLOWER MOTOR DRIVE DATA

MOTOR

UNIT

MODEL

CED060

CED090

CED120

CED180

1.

All of these motors are 1750 RPM and have a 56 frame inherent protection and permanently lubricated ball bearings. The 3/4 Hp

motor is split phase and has a resilient base and a 1.25 service factor. All of the 3 phase motors have a solid base and a 1.15 service factor.

HP

06

3/4 208/230-1-60

25

46 1 460-3-60 7/8

25

1-1/2

46

25

2

46

25

3 208/230-3-60 625-810 3.4-4.4 7/8 9.5 1 A57 58.3

46

1

POWER

SUPPLY

208/230-3-60

460-3-60

208/230-3-60

460-3-60

BLOWER

RPM

810-110 2.8-3.8

655-880 2.8-3.8 7/8 7.5 1 A36 37.3

700-950 2.8-3.8 7/8 7.0 1 A36 37.3

AJUSTABLE MOTOR PULLEY FIXED BLOWER PULLEY BELT

PITCH

DIA.

(In.)

BORE

(In.)

5/8

PITCH

DIA.

(In.)

6.0 3/4 A32 33.3

BORE

(In.)

DESIG.

LENGHT

PITCH

(In.)

DUCT CONNECTIONS

DO NOT OPERATE A MOTOR ABOVE ITS NOMINAL HP RATING WHEN A UNIT IS EQUIPPED

WITH EITHER A HOT WATER OR A STEAM

COIL ACCESSORY.

NO N -FLAM M ABLE

C O LLA R

SUPPLY AIR

DUCT FLANG E

AIR

OUT

All ducts should be made in accordance with all local and/or

National Codes and in line with

ood duct installation prac-

tices.

Ductwork should be suspended with flexible han

fasten directl

Allow clearance around duct for safet

if an

.

to building or structure.

in handling heater air,

DUCT

FLANGED DUCT

CONNECTIO N

(F IE L D

FABRIC ATED)

BLO W ER GASKET

(BY INSTALLER)

ers. Do not

FIGURE 11 : SUPPLY AIR DUCT CONNECTION

18 Unitar

Products Group

035-16734-000 560.20-N1Y

y

g

g

g

g

y

y

g

g

y

y

g

g

y

y

g

y

g

g

y

y

g

g

g

WATER OUTLET

CONDENSERS

SUPPLY AIR DUCTS

See Figure 11 for suggested method of connecting supply air

ductwork.

Duct should be sized no smaller than the duct flan

es on the

blower sec tion.

Use flexible fiber

lass or plastic cloth collars or other nonflammable materials at the duct connections to minimize the

transmission of noise and vibration.

RETURN AIR DUCT FLANGE

The inlet duct frame connection is shipped on the front of the

unit. When th e return air

frame is not used. Refer to Fi

NOTE:

If return air duct is not used, applicable installation

codes ma

limit the unit to installation only in a single stor

rille is used , the duct connect ion

ure 2, 3 and 4.

area.

INSULATION

Insulation should be applied to ductwork where it passes

throu

h and unconditione d area d uring the cooling season, or

h unheated space during heating season.

thou

Insulation should include vapor barrier to prevent absorption

of moisture b

insulation.

WATER INLET

FIGURE 12 : COILS AND WATER CONNECTIONS

(CED090 SHOWN)

TABLE 16: WATER CONNECTION SIZING

INLET & OUTLET WATER CONN.’S

CED060

(NPT, FEEM

1”

CONDENSER WATER PIPING

1. All internal condenser water piping in these units are

completel

2. Units are arran

(Same side as electrical.) However, knockouts are also

provided in left end panel for pipin

desired. Suppl

rotated to provide for left-hand connections. Inlet water

must alwa

denser (See Fi

3. When local water conditions require it, install strainer in

the suppl

4. It is recommended that a fle xible connect ion be pro vided

between condenser an d supply and return mains if nois e

and vibration transmis si on cou ld be a probl em .

5. Water pipin

can be serviced without shutti n

entire s

(not in series), the stop valves ma

the pressure drop throu

condenser water distribution.

factory assembled.

ed for piping connections on the right.

connections if

and return elbow connections may be

s enter at the lower connection of the con-

ure 12).

line to the condenser.

should include stop valves so that any unit

down and draining the

stem. Since the units will be piped in parallel

be used to equalized

h every parallel circuit for even

CED090

CED120

CED180

1-1/4”

1-1/4”

1-1/2”

PRECAUTIONS AGAINST FREEZING

1. When units are in locations subjec t to freezi n

tures, condenser must be drained durin

shut down.

WA TER MUST BE BLOWN FROM CONDENSER,

AS IT WILL NOT DRAIN COMPLETELY BY

GRAVITY BECAUSE OF THE SPIRAL DESIGN.

A WATER FLOW SWITCH IS RECOMMENDED

ON THE WATER OUTLET CONNECTION

(EXTERNAL TO THE UNIT) TO PREVENT THE

COLLASPE OF THE TUBES INSIDE THE

REFRIGERANT TO WATER HEAT EXCHANGER

DUE TO LACK OF WATER FLOW.

tempera-

Products Group 19

Unitar

560.20-N1Y 035-16734-000

y

y by

y

y

y

g

g

g

g

y

g

g

y

g

g

g

y

g ty

y

g

y

g

g

g

g

y

g

g

y

g

g

g

g

g

g

g

g

g

g

g

g

2. Add glycol to the condenser water for year-round operation.

NOTE:

Adding 40% by weight ethylene glycol to the con-

denser water will:

a. Decrease the unit capacit

b. Increa se the unit power requirement b

c. Increase the condenser water pressure drop b

12%.

DRAIN CONNECTIONS

All drain lines must be trapp ed and lo ca ted so the

exposed to f reezin

Models ED060, 090 and 120 have a 7/8” OD drain line out

ht side of the cabinet. Model ED180 has a 7/8” OD

the ri

steel condensate stub at each end of the drain pan. Seal the

cap at the unused end with a suitable mastic. A plastic ell is

provided with clamp for evaporator drain pan connection.

An emer

Both drain connections mu st b e pi ped to th e dra ina

in accordance with local codes. The drain connection from

the upper pan must be trapped and not connected directl

into the lower drain unless it is done at a level below the unit.

This is to prevent water from backin

If unit drains are connecte d to a co mmon bu ilding drain line, it

is recommended that a flexible connection be provided to

prevent possible transmission of vibration to building.

ency drain connection is located in the bottom pan.

temperatures (See Figure 13).

5%

8%.

will not be

e system

up into the lower pan.

2. Unit is shipped with a full char

Refer to Ph

refri

3. Refri

4. Hi

5. Compressors are hermetic t

6. Schrader t

7. The inlet joints or the liquid line strainer dr

8. Condensers (tube in tube) are manifold for sin

h Pressure Control – Automatic reset type.

protection, have sprin

are equipped with crankcase heaters.

and dischar

dered with 95-5 and serve as pressure relief devices.

inlet and water outlet connections.

sical Data (Table 3) for the respective unit

erant charges.

erant flow controlled by thermo expansion valves.

pe access valves are provided in the suction

e lines for field use.

e of Refrigerant-22.

pe with internal line break

pe isolator s for mounting and

ers are sol-

le water

WIRING

Install ele ctrical wir ing in accordance with the latest Nat ional

Electrical Code (NFPA Standard # 70 and/or local re

tions). The unit must be

codes.

Knockouts are provided in both the left and ri

in the condenser section for electrical entr

. A knockout is provided in the right side panel only for

in

low volta

entr

POWER WIRING

Three knockouts are provided in electrical control box to

access to the power terminal block (See Fi

e wiring entry. Refer to Fig. 2, 3 or 4 for the des ire d

locations.

rounded in accordance with these

ht side panels

of the power wir-

ure 14).

ula-

ain

CONDENSATE

DRAIN

EM ERG ENCY

DRAIN

2 " M IN .

(TYP.)

TRAP

FIGURE 13 : RECOMMENDED DRAIN PIPING

REFRIGERATION SYSTEM

1. Completely assembled, evacuated, charged and leak

tested.

20 Unitar

NOTE:

It is recommended to use the knockout on the same

side of the control box as power wirin

However, on the Model CED060, sin

tom or ri

Route the power wires into the unit throu

knockout provided and into the control box.

Connect power wires to terminal block 1TB in the control box

located near front ri

LOW VOL TAGE WIRING

Route the control wires into t he unit thro u

provided i n the unit ri

sheathin

for isolation from power wirin

Connect wires to terminal block 4TB located on left side of

control box (See Fi

NOTE:

proper connections.

ht side knockout only is available for access.

ht end of unit.

ht side pane l. Run the w ires through

material provided along the back of the control box

existing rear of control box.

ure 14).

Refer to wiring diagram inside control box cover for

entry into the unit.

le phase only, the bot-

h the 1-3/32”

h the 7/8” knockout

Products Group

035-16734-000 560.20-N1Y

y

y

g

g

g

ying

y

g

y

y

y

g

g

y

y

g

g

g

g

y

g

g

y

y

y

g

y

y

y

y

y

g

g

g

g

g

g

L

L

CONTROL BOX

TERMINA

BLOCK

(2TB)

TERMINA

BLOCK

(1TB)

POWER WIRING

KNOCKOUTS

FIGURE 14 : ELECTRICAL CONTROL BOX

(CED090 SHOWN)

ACCESSORY WIRING

If the unit include s an e lectri c heat acces sor

must be provided. Refer to electric heat instruction,

wirin

, separate power

Form 550.13-N10.1U, for additional installation instructions.

Refer to Fi

Table 17 to size the disconnect switch, the power wirin

ure 15 and 16 for field wiring diagrams. Refer to

and

the fuses.

NOTE:

Three phase motor rotations may be incorrect when

unit is first started. Reverse phase (leads L1 and L2) at

blower motor contactor to obtain correct rotation.

WATER REGULATING VALVES

Water regulating valves provide control of quantity of condenser water supplied to the unit under var

tions b

sensing compressor discharge pressure. This

feature is required in s ome ar eas whe re wa ter con serva tion i s

mandated.

Water re

ulating valves are shipped separately for field

installation.

load condi-

Installation of water control valves is accomplished b

front panel of condenser section, breaking water line

in

unions to condenser coils and removin

Factor

installed nipples are removed and replaced with the

water inlet piping.

remov-

nipples and water valve furnished for each condenser, unit is

repiped and capillar

Valves are desi

water pressure-reducin

water inlet line if pressure exceeds 150 psi

is attached to proper discharge line.

ned to operate between 25 and 150 psig. A

valve must be instal led in co nde nser

.

COOLING TOWER

Where water costs are high, or water is not plentiful, an outdoor or indoor forced or i ndu ce d dra ft-co olin

mend for condenser water.

pical piping and wiring arrangements for installing one or

T

more units with pump and coolin

tower as shown in Figures

17, 18 and 19.

1. Fi

ure 17 illustrates the piping including a bleed-off valve

and strainer in the suction line to the pump. The bleedoff is needed to keep the concentration of salts down,

especiall

The b

quantit

in areas having hard water.

-pass is used to permit circulation of a larger

of water over the tower than through the con-

denser. This allows the tower to operate at

without suffering the pressure drip through the

cienc

condenser.

2. Figure 18 shows the suggested wiring arrangement nec to interconnect the units pump and tower fan

essar

motor. The entire s

stem starts and stops automaticall

3. Figure 19 shows an alternate wiring arrangement. Its

room thermostat individuall

controls each unit. The

conditioner control circuit is ener

motor also starts the tower fan. After th e pump is start ed

annually it will continue t o operate until t he stop butt on is

pushed. This arran

be a lon

it mi

run of condenser wa ter p ipi ng exposed so that

ht be heated exce ssively during the off perio ds w ith

ement is suggested where there will

automatic operation.

In each case, the wiring is such that there is water circulation

h the condenser when units are running.

throu

Cooling towers must be selected for the speci fic con diti on s of

each application. Local representatives of coolin

manufacturers will assist in the selection of proper size tower

for each CED installation.

tower is recom-

reater effi-

ized by the pump

tower

Accessor

kits 1WR0413, 1WR0402, and 1WR0403 are

used on the CED060, CED090 and CED120, and CED180

respectivel

Unitar

.

Products Group 21

560.20-N1Y 035-16734-000

y

g

g

y

g

s

T

LINE VOLTAGE POWER SUPPLY*

L1

TER M INAL BLO C K

L2

1TB O N

C2ED UNIT

**

W IRE IN ACCORDANCE W ITH

LOCAL AND NATIO NAL

ELECTRICAL CO DES

FIGURE 15 : POWER SUPPLY FIELD WIRING DIAGRAM

1.

Three-phase units with electric heat require two power supplies. The electric heat power supply and ground wire should be con-

L3

GROUND LUG

C2ED UNIT

ON

1

* P o w e r w ir in g , d is c o n n e c t s w it c h a n d

fusing by field. U se copper conductor

only.

** O nly tw o conductors are required on

the single phase C 2E D 060A 60.

nected directly to the fuse block and ground lug in the electric heat control box. Use copper conductors only. Refer to Table 17 to

size the power wiring, disconnect switch, and fusing.

COOLING ONLY UNITS

RC

Y1

Y2

G

TERM INALS ON

T-S TA T 2TH 04701724

W ITH SU B -BA S E 2TB 04700124

* C 2E D 060 units only have one

cooling stage and can use the

fo llo w in g

Therm ostat

Sub-Base

24-VOLT CONTRO L W IRING

R

Y

0

*

G

TER M IN A L

BLO C K 2TB

O N C 2 E D U N IT

2TH 13700424

2TB 08700124

TERM INALS ON

T-S TA T 2TH 04701524

W ITH SU B -BA S E 2TB 04700324***

* Not required on C 2E D 060 units

(only one-stage cooling).

** N ot required on 10kW heaters

(only one-stage heating).

*** T h is t-s ta t a n d s u b -ba se w ill

cycle the sup ply air blo w e r

m o to r o n e ith e r a c o o lin g o r

heating dem and.

UNITS W ITH ELECTRIC HEAT

24-VOLT CONTRO L W IRING

R

Y1

Y2

W1

W2

G

R

Y

O

*

66

60

**

53

G

JU M PE R

An outdoor jum per can

be wired betw een

term inals 53 and 60 and

7 2 k W h e a te rs .

TER M IN A L

BLOW CK 4TB

ON C2ED UNI

UNITS W ITH STEAM OR HOT W ATER HEAT

TERM INALS ON T-STAT

2TH 04701524 W ITH S U B BAS E 2TG 04700324**

FIGURE 16 : CONTROL (LOW VOLTAGE) FIELD WIRING DIAGRAM

When installing a cooling tower system:

1. Avoid usin

22 Unitar

long runs of pipe exposed to the sun.

R

Y1

Y2

G

W1

W2

TO HOT W ATER OR

STEAM CONTROL

CIRCUIT

2. If freezin

24-VOLT CONTRO L W IRING

*

TER M IN A L

BLO C K 2TB

O N C 2 E D U N IT

R

Y

O

G

B

* C2E D 060 units only have one cooling

stage and can use the follow ing

Therm ostat

Sub-Base

** Th is t-stat a nd sub-base w ill cycle th e

supply air blower m otor on eith er

cooling or heating dem ands.

2TH 13700424

2TB 17700324

is a problem, provisions for draining the system should be made. In addition, it ma

run as much of the pipin

indoors as possible.

be desirable to

Products Group

035-16734-000 560.20-N1Y

y

g

y

g

g

y

g

g

g

g

g

y

y

y

g

TABLE 17: ELECTRICAL DATA

MODEL

CED060

CED090

CED120

CED189

COMPRESSOR SUPPLY AIR BLOWER MOTOR

POWER

POWER

SUPPLY

06 208/230-1-60 1 27.6 125

25 208/230-3-60 1 16.0 90

46 460-3-60 1 7.7 45 0.88 460-3-60 1 1.7 12 15 14 246

25 208/230-60 2

46 460-3-60 2

25 208/230-3-60 2

46 460-3-60 2

25 208/230-3-60

46 460-3-60

QTY RLA LRA

12.8

ea.74ea.

6.0

ea.41ea.

16.0

ea.90ea.

7.7

ea.45ea.

1 34.6 193

1 16.0 90

1 17.3 97 0.90

1 7.7 45 0.88

FACTOR

@ FULL

LOAD

0.99 @ 208 V

0.96 @ 230 V

0.95 @ 208V

0.88 @ 230V

0.94 @ 208V

0.85 @ 230V

0.85 460-3-60 1-1/2 2.6 17 20 12 282

0.95 @ 208V

0.88 460-3-60 2 3.4 23 25 10 320

0.99 @ 208V

0.90 @ 230V

0.95 @ 208 V

0.88 @ 230V

POWER

SUPPLY

208/230-1-60 3/4 5.3 43 50 6

208/230-1-60 3/4 5.3 28 35 10

208-3-60

230-3-60

208-3-60

203-3-60

208-3-60

230-3-60

208-3-60

230-3-60

460-3-60 3 4.8 28 40 10 260

HP FLA

1-1/2

1-1/2

2

2

3

10.0

3

3

10.0

3

5.7

5.2

7.6

6.8

9.6

9.6

UNIT

AMPACITY,

AMPS

42 45 6

47 50 6

70 80 4

MAX.

FUSE

SIZE

AMPS

MIN.

60°C

1

WIRE

,

SIZE

MAX.

WIRE

LENGTH

2

FEET

149 @ 208 V

173 @ 230 V

111@ 208V

130 @ 230V

181 @ 208V

214 @ 230V

162 @ 208V

187 @ 230V

167 @ 208V

188 @ 230V

3

,

1.

Dual element, time delay fuses.

2.

Based on three, 60°C insulated copper conductors in steel conduit.

3.

Based on a 3% voltage drop.

3. In extreme cases where year-round operation is

required, an indoor stora

e take with automatic tem pe ra-

ture control valves will be required

OPERATION

Before starting unit be sure condenser water is available.

Open an

in

Unit is controlled through room thermostat.

Coolin

1. Cool/Heat (When electric heat is used.)

2. Set thermostat s

3. Close power supply disconnect.

4. Move fan switch to “ON”. Evaporator blower motor

stop valves and ma ke s ure coo ling tower is operat-

if this is source of cooling water.

only.

stem switch to “OFF” position. Set

thermostat fan switch to “Auto” position.

should start.

5. Check fan motor for proper rotation and check blower fo r

free runnin

6. Move fan switch to “COOL”. Lower thermostat settin

call for coolin

. No interference should occur.

to

. Evaporator blower should start and System No. 1 compressor will start. Check to be sure that

bottom portion of evaporator coil is

7. Continue to lower thermostat setti n

etting colder.

until second, System No. 2 compress or s tart s (exc ep t CE D0 60, 5-to n unit

that has only one compressor). Check to be sure that

upper portion of evaporator coil is also getting colder.

8. .Check to be sure that there is no unusual noise or vibration as unit operates.

9. Replace an

panels removed for unit installation and

operation check.

10. Set room thermostat at desired space temperature. Unit

will continue to c

1 1. If electric heat is installed on unit – set s

“HEAT” and raise room thermostat until 1 sta

cle as required to maintain conditions.

stem switch to

e of heat

Products Group 23

Unitar

g

y

g

g

P

T O A D D IT IO N A L U N IT S

FIGURE 17 : COOLING TOWER WATER PIPING

T O D R A IN

BLEED VALVE

BY PASS

STRAINER

PUM P

OVER FLOW

COOLING

TO W E R

M AKEU

SUPPLY

comes on. If unit has more than 1 stage of heat, continue raising thermostat until all heat in on.

2TB

R

Y

B

* C ontorl included cooling tow er pum p/fan (24V coil) or other

flow contorl device. 20VA available per unit

24 V TO W ATER FLOW CONTROL*

TO ADDITONAL UNITS*

FIGURE 18 : UNIT CONTROL ON WATER FLOW

ADJUSTING WATER REGULATING VALVE

(IF USED)

The water-regulating valve should be adjusted so that a 15°

to 20° water temperature ran

capacit

. To raise the temperature of the water off the condenser, increase tension on the power sprin

temperature of the water off the condenser, decrease tension

on the power sprin

.

e is held for maximum unit

. To lower the

TO ADDITONAL UNITS*

2TB

R

Y

B

* C ontorl included cooling tow er pum p/fan (24V coil) or other

flow contorl device. 20V A available per unit

24 V

AUXILIARY CONTRO L

(F IE L D S U P P L IE D )

FIGURE 19 : ALTERNATE UNIT CONTORL ON

WATER FLOW

Subject to change without notice. Printed in U.S.A.

Copyright © by Unitary Products Group 1999. All rights reserved. Supersedes: 560.20-N1Y (1282) 560.20-N1Y (799)

YORK 5005 York Norman

Unitary Drive OK

Product North 73069

Loading...

Loading...