Page 1

Page 2

Title Page

I Overview 1

II Configuration 1

III Property 2

IV Instructions about product major components 4

V LCD Display 6

VI Select test method 8

VII Battery installation and check 10

VIII Power on and check battery status 12

IX Function operation instruction 14

X Maintenance 22

XI Warranty 24

XII Certificate 24

XIII Technical Index 25

Appendix: 27

Contents

Page 3

1 2

I Overview

Designed with artificial polarization piezoelectric effect, UT313/UT315

portable vibration meter apply to the normal vibration measurement of

mechanical equipment, especially vibration measurement of the rotating and

reciprocating machinery, widely used in industrial measurement such as

Machine Manufacturing, electric power and metallurgy etc.

II Configuration

home computer One piece

handle accessory machine One piece

9V battery One piece

English manual One

warranty card One piece

long probe One piece

short probe One piece

magnetic chuck One piece

III Property

LCD provides intuitive display of measurement value and measurement

status

Measurable acceleration, velocity, shift

Can select different vibration frequency property

Adopt high-sensitive probe with accurate measurement

Equip with a long and short probe, applicable to measurement in different

occasion

Page 4

3 4

Equip with a magnetic chuck, used to test when it is not convenient to hold.

Low electricity indication function

Automatic power-off function

LCD backlight function

Maximum value display function

USB communication function (only for UT315)

Data hold function

Data storage function

IV Instructions about product major components

power on, and keep pressing,

LCD will hold full display 1

second. Stop pressing, it starts

working, press key POWER

again to power off.

POWER key: press the key until

again to cancel holding data.

maximum value

Key A : Acceleration measurement

Key V : Velocity measurement

Key D : displacement measurement

HOLD key : HOLD data; press it

MAX key : MAX display the

1

2

3

Page 5

2. aP: acceleration indicator

3. Vrms: velocity indicator

4. dp-p: displacement indicator

5. : Backlight indicator

5 6

Key: open or close backlight

READ key: check record data

CLEAR/ key: Delete record data; data upturning, USB communication,

automatic power-off and storage time setting

REC key: data storage

MENU key: menu function set

key: Data down turning, USB communication, automatic power-off and

storage time setting

ENTER key: confirm

LCD (liquid crystal display)

Sensor connecting wire

Probe (long & short probe and magnetic suction pad for option)

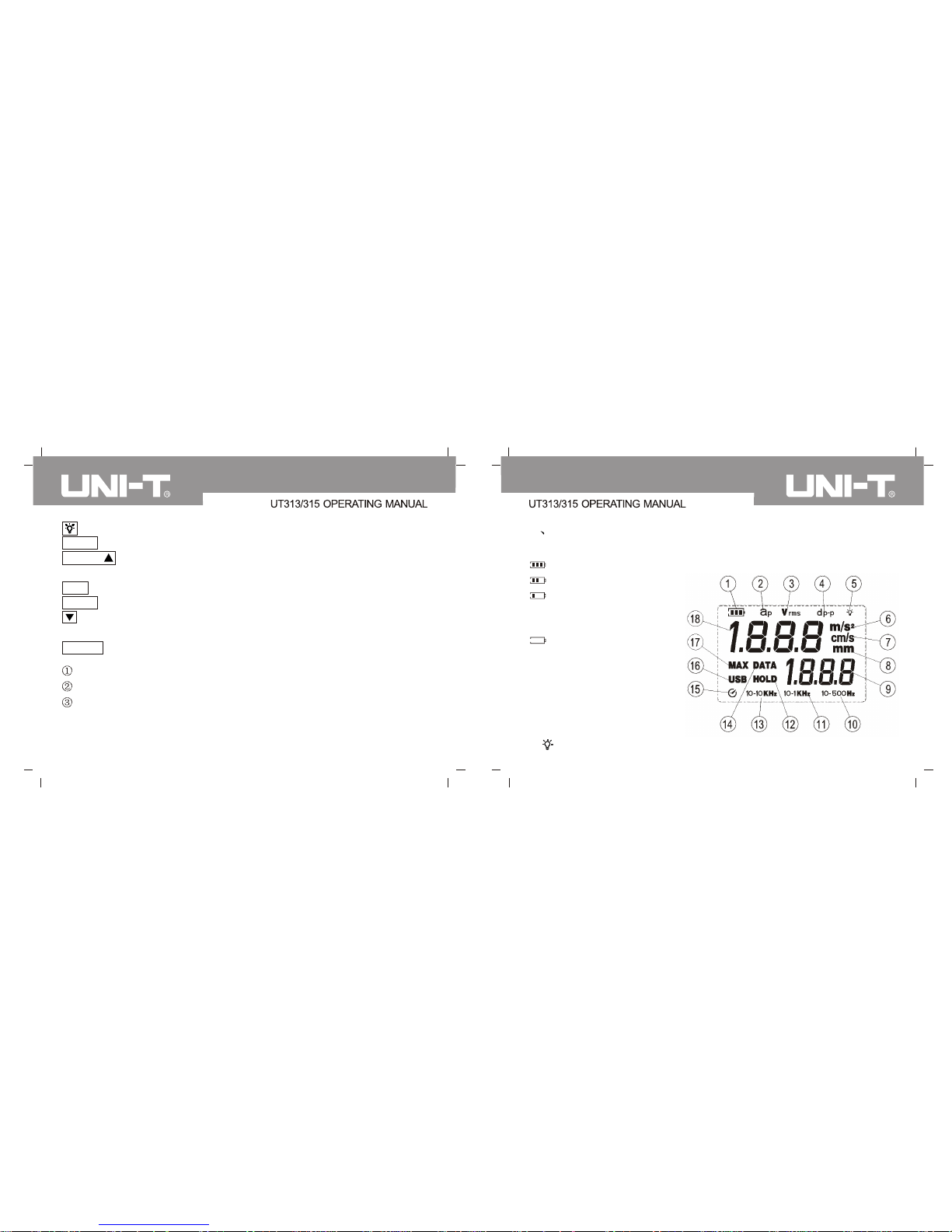

V LCD Display

1. Battery symbol: indicates present remaining electricity. Four grades:

3 bars: sufficient electricity

2 bars: rather sufficient

1 bar: electricity will be

depleting, please replace

battery

Empty: electricity has

depleted, you have to replace

battery. The battery symbol

shall flicker.

Page 6

7 8

6. M/s2: acceleration unit indicator

In velocity measurement, LCD display the velocity unit m/s

7. cm/s: velocity unit indicator

8. mm: displacement unit indicator

9. Data record number display area

10. 10-500Hz: 10Hz-500Hz indicator

11. 10-1kHz:10Hz-1kHz indicator.

12. HOLD: reading hold measurement

13. 10-10kHz: 10Hz-10kHz indicator

14. DATA: data storage indicator

16. USB: USB indicator

17. MAX: maximum value measurement indicator

18. Measurement data value display area

15. : Automatic power-off function indicator

VI Select test method

Please select test method based on real status, four statuses:

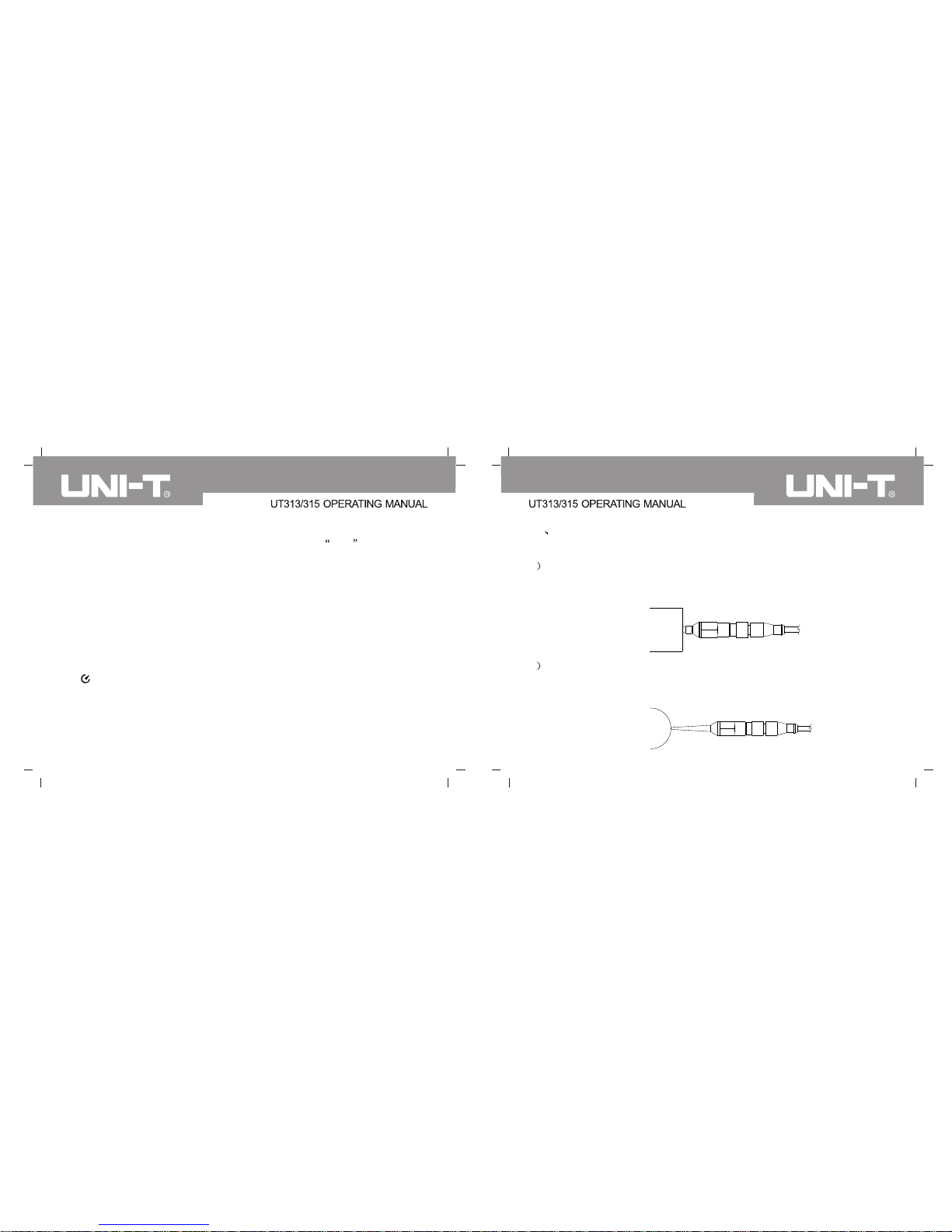

1 Use short(s) probe to measure: it is installed with the machine and

applicable to wide scope vibration measurement; it can acquire effective

response numerical value, as shown in the following illustration

2 Use long (L) probe to measurement: it is an accessory in a package,

mainly used in rather narrow or special object area, with quick response,

as shown in the following illustration

Page 7

9 10

3 Use magnetic chuck to measure: it is an accessory in a package, mainly

used in plain area of iron objects, for instance, elevator etc. as shown in

the following illustration

4 Remove hardware probe to measure: used in plain object surface

measurement to acquire stable data, as shown in the following illustration.

VII Battery installation and check

Install battery:

Hold apparatus, press battery door with right thumb, open battery door from

the arrow-pointed direction, as shown in the following illustration.

Page 8

11

12

2 Put 9V (G6F22 6F22) battery into battery holder correctly, aware of

battery polarity and then close battery holder door, as shown in the

following illustration.

VIII Power on and check battery status;

1 Press POWER key to power on.

As shown in the following illustration:

Press down

Page 9

13

14

2 Press the key until LCD hold full display 1 second, stop pressing it to start

working with fault status being acceleration measurement mode, USB

failure to communicate and automatic power-off status; if LCD screen

displays symbol or , please replace battery timely as

shown in the following illustration.

Press POWER key to power off immediately.

IX Function operation instruction

1 Acceleration measurement:

1 Press key A to enter into acceleration measurement mode with fault

status being acceleration measurement mode m/s2 ,LCD screen shall

display aP; indicators of 10-10kHz and m/s2 are as follows:

2 Use probe to measure object according to the selected way and

measurement result shall display in data value display area of LCD

Page 10

15 16

as shown in the following illustration:

2 Velocity measurement:

1 Press key V to enter into velocity measurement mode and LCD screen

shall display Vrms; indicators of 10-1kHz and cm/s are as follows:

2 Use probe to measure object according to the selected way and

measurement result shall display in data value display area of LCD as

shown in the following illustration:

3 Displacement measurement:

1 Press key D to enter into velocity measurement mode and LCD screen

shall display dp-p; indicators of 10-500Hz and mm are as follows:

Page 11

17 18

2 Use probe to measure object according to the selected way and

measurement result shall display in data value display area of LCD as

shown in the following illustration:

4 Maximum value measurement

Under corresponding measurement mode, press key MAX to enter into

maximum value measurement mode, LCD screen shall display indicator of

MAX and results of maximum under corresponding measurement mode in

the data value display area; press key MAX to cancel maximum value

measurement.

7 Data storage:

Press key REC to enter into manual data storage mode, LCD screen shall

display indicator of DATA and store the present measurement value manually,

DATA signal shall disappear after about 0.5 second; press key REC to

conduct next position data storage. Press REC for a long time to enter into

automatic data storage mode, indicator of DATA on LCD screen shall flicker

continuously, and store the present measurement value automatically

5 Reading holds measurement:

Press HOLD key to enter into reading hold measurement mode, LCD screen

shall display indicator of HOLD and hold the present measurement value in

data value display area on LCD screen.

6 Backlight display:

Press the key to enter into LCD backlight display mode, and LCD

screen shall display indicator , and light up, press key to exit

backlight display.

Page 12

19

20

between the set time intervals (detailed in menu function set). If automatic

record count exceeds the maximum record count 1999, it shall exit data

storage automatically.

8 Check record data

Press key REND to enter into check record data mode, if no storage data,

data value on LCD screen display area display --- data record number

display area display --- and enter into test function after about 0.5 second.

If any storage data, it shall display the last data and record number; press

key to reduce record number and its corresponding storage data; Press

for a long time to automatically reduce them. Press key to increase

record number and corresponding storage data, press it for a long time to

increase them automatically. Press REC to display increase by 100, if record

count is less than 100 or exceed maximum record count 1999, it shall back to

the first record number and corresponding storage value; press REC to back

to the first record number and corresponding storage value. Under the mode,

only the above keys and can be used except for others. Press the key to

exit the mode.

9 Delete record data:

Method1: before start machine, press key CLEAR and POWER in the same

time, stop pressing key POWER until LCD screen display CLR, record

deletion has been completed.

Method2: restore factory setting (detailed in menu function setting)

10 Menu function set:

Press key MENU to enter into menu function set with fault status USB0,

which indicates failure to conduct USB communication, press key or to

change USB setting, LCD screen shall display indicator of USB and USB1

indicates being able to conduct USB communication; Under menu function

set mode, press key READ, LCD display USB1 flickering, after memory data

transmitted to computer, press key ENTER to save and enter into next menu

---set automatic power-off AP01, which indicates automatic power-off function

Page 13

21 22

indicating the automatic power-off function is off, then set AP01.

Press ENTER to save and enter into next menu to record interval

automatically, press automatic add for a long time or press key to reduce

time, press automatic subtraction, time scope of the machine can be set is

0.5-255;Press key ENTER to save and enter into next menu-factory set.LCD

displays DEF? (Press key ENTER to restore factory set USB0, AP01, 60S,

clearing all record data. If press key MENU, it will enter into the original

measurement function. Under menu set mode, if power-off, the menu status

shall be stored automatically and be restored from save status after power-on,

without reset each time).

is open, LCD shall display indicator , and press key or to set AP00,

Able to use short probe s to measure high/low frequency scope

vibration respectively.

Notes:

Long probe L is only applicable to low frequency measurement, when

measurement accelerated and frequency exceeds 1 kHZ, please replace

short probe to measure again.

It will be powered off automatically 3 minutes later if without any operation.

X Maintenance

1 Working environment: UT313/UT315 vibration meter is precision

apparatus required to avoid collision, shock, moisture, strong power,

magnetic field, oil and dust.

2 Replace battery and maintenance

1 in working, LCD screen shall appear symbol , user needs to

replace battery timely in reference to illustration in the manual.

2 please draw out battery to avoid battery weeping, which shall cause

severe damage to the apparatus if you needn't use the test apparatus for

Page 14

23 24

a long time.

3 Don't dismantle the apparatus or try to make any transformation interiorly.

4 Chassis cleaning: alcohol and diluents are erosive to chassis, especially

to LCD window, please

XI Warranty

1 As regard warranty clause, please refer to the provided warranty card.

2 Dismantle of product by user at his discretion, damage after purchase

resulted by improper use and altering of the warranty card and without

voucher may be excluded from such warranty coverage.

XII Certificate

Vibration certificate comply with the following standards:

EN61326-1:2006

Page 15

Battery electricity indication

Storage temperature scope

Working humidity scope

Battery life

Automatic shut-off

LCD backlight shut off time

Working current

Power-off circuit

Power supply

Display refresh period

LCD display

Measurement error

Displacement measurement scope

Velocity measurement scope

Acceleration measurement scope

Vibration collection

Technical parameter

25

26

10HZ ~ 500HZ

XIII Technical Index

Technical index

Piezoelectric accelerometer

0.01cm/s~19.99cm/s (true valid value)

0.001mm~1.999mm (peak peak value)

(5%+2dgts)

Acceleration measurement

frequency scope

10HZ ~ 10kHZ

Velocity measurement frequency

scope

10HZ ~ 1kHZ

Displacement measurement

frequency scope

3 1/2 bit digit display

1 second

9V alkaline battery

1uA

25mA

Press backlight key to shut off

Automatic shut-off after about 3

minutes of non-operation

20 hours of continuous use

Working temperature scope

050

20%RH 80%RH

-20 60

Battery voltage 7V, indicate low

voltage symbol

Dimension

Weight

Elevation

2000 m

0.1m/s ~199.9m/s (peak value)

2 2

Page 16

27 28

Appendix:

a. Mechanical Vibration Rating Table ISO2372

45

Vibration intensity

Applicable to the following machine

Vibration velocity Vrms(mm/s)

Notes:

1) Grade I is small-size electric motor (less than 15kW electric motor); Grade

II is medium-size electric motor (15kW-75kW electric motor); Grade III is

large original electric motor (hard base) ; grade IV is large original electric

motor (plastic base).

2) A, B, C, D is the vibration rating. A is great, B is satisfactory, C is discontent

and D is not allowed. The measurement velocity RMS value shall be on the

orthogonal intersection direction of shell bearing.

b. the maximum allowable vibration for electric motor higher than 1

horsepower NEMA MG1-12.05

3000~4000

25.4

1500~2999 38.1

1000~1499 50.8

63.6

Peak-peak displacement amplitude

Rotating speed

999

Page 17

d. Preformed winding squirrel-cage induction electric motor

50.8

63.6

38.1

50.8

25.4

25.4

Sync rotating speed

720~1499

1500~2999

3000

Peak-peak displacement amplitude ( m)

Plastic support

Rigid support

The standard is formulated by American Petroleum Institute.

29

30

Notes: for AC electric motor, use highest sync rotating speed; for DC electric

motor, use the maximum power rotating speed; and for serial and

multipurpose electric motor, use working rotating speed.

c. the maximum allowable vibration for large electric motor

NEMA MG1-20.52

Peak-peak displacement amplitude

Rotating speed

3000 and higher

25.4

1500~2999

999

50.8

1000~1499

63.6

76.2

The above two standard are formulated by National Electrical Manufacturers

Association (NEMA)

e. ISO/IS2373 the electric quality standard based on vibration speed amplitute

80<H<132 132<H<225 225<H<400

Quality grade

600~3600 1.8 2.8

4.5

N Normal

600~1800

1800~3600

0.71

1.12

1.12

1.8

1.8

2.8

600~1800

1800~3600

0.45

0.71

0.71

1.12

1.12

1.8

R Good

S Special

Rotating speed

Axis height H mm

maximum speed vibration rms(mm/s)

r/min

r/min

Page 18

31

Grade N limit value recommended in the table is only applicable to common

electric motor.

Loading...

Loading...