Page 1

LCR Meter LCR-1000 series

Operation Manual V1.0

BENCHTOP

LCR METER

Page 2

I

CONTENTS

SAFETY INSTRUCTION ........................................................................................................................... III

1. PRODUCT INTRODUCTION ............................................................................................................. - 1 -

1-1. Description ................................................................................................................................. - 1 -

1-2. Features ..................................................................................................................................... - 1 -

1-3. Front Panel Introduction ............................................................................................................. - 1 -

1-4. Rear Panel Introduction ............................................................................................................. - 4 -

2. PANEL OPERATION .......................................................................................................................... - 5 -

2-1. <MEAS DISPLAY> ..................................................................................................................... - 5 -

2-2. <BIN DISPLAY> (not available for LCR-1010) .......................................................................... - 9 -

2-3. <MEAS SETUP> ...................................................................................................................... - 10 -

2-4. <SYSTEMS SETUP> ............................................................................................................... - 10 -

2-5. <COMM SETUP> ..................................................................................................................... - 11 -

2-6. <ABOUT SYSTEM> ................................................................................................................. - 11 -

2-8. Data Storage ............................................................................................................................ - 12 -

2-8. <INTER Files List> and <EXT Files List> ................................................................................ - 12 -

3. SPECIFICATIONS ............................................................................................................................ - 15 -

3-1. Measurement Range ................................................................................................................ - 15 -

3-2. Accuracy ................................................................................................................................... - 15 -

4. HANDLER INTERFACE ................................................................................................................... - 19 -

4-1. Pin Definition ............................................................................................................................ - 19 -

4-2. Time Sequence of Interface Signal .......................................................................................... - 20 -

4-4. Schematic Diagram of Interface Signal ................................................................................... - 21 -

5. MAINTENANCE ............................................................................................................................... - 25 -

5-1. Inspection ................................................................................................................................. - 25 -

5-2. Fuse Replacement ................................................................................................................... - 25 -

6. TECHNICAL SPECIFICATIONS ...................................................................................................... - 26 -

Page 3

II

Use of Operation Manual

Please read through and understand this Operation Manual before operating the product. After reading, always

keep the manual nearby so that you may refer to it as needed. When moving the product to another location,

be sure to bring the manual as well.

Calibration Notification

We notify that the LCR meters included in this manual are in compliance with the features and specifications

as stated in this manual. Before shipment, the LCR meter has been calibrated in factory. The calibration

procedures and standards are compliant to the national regulations and standards for electronic calibration.

Warranty

We guarantee that the LCR meter has been passed strict quality check. We warrant our LCR meter’s

mainframe and accessories in materials within the warranty period of one year. We guarantee the free spare

parts for products which are approved defective in this period. To get repair service, please contact with your

nearest sales and service office. We do not provide any other warranty items except the one being provided

by this summary and the warranty statement. The warranty items include but not being subjected to the hinted

guarantee items related to tradable characteristics and any particular purpose. We will not take any

responsibility in cases regarding to indirect, particular and ensuing damage, such as modifications to the circuit

and functions by the users, repairing or component replacement by the users, or damage during transportation.

For product improvement, the specifications are subject to change without prior notice.

Page 4

III

SAFETY INSTRUCTION

This chapter contains important safety instructions that you must follow when operating the LCR meter and

when keeping it in storage. Read the following before any operation to insure your safety and to keep the best

condition for the LCR meter.

Safety Symbols

The following safety symbols may appear in this manual or on the LCR meter:

WARNING

Identifies conditions or practices that could result in injury or loss of life.

CAUTION

Identifies conditions or practices that could result in damage to the LCR

meter or to other properties.

DANGER

High voltage

ATTENTION

Refer to the manual

Protective conductor terminal

Earth (ground) terminal

Chassis ground terminal

Safety Guidelines

General Instruction

Do not place heavy objects on the casing.

Avoid serious impact or improper handling to prevent damage to the LCR meter.

Preventive measures for releasing static electricity should be taken when

connecting the LCR meter.

Do not block the air ventilation holes on the two sides and on the back of the

chassis.

Do not disassemble the LCR meter unless you are professionals.

Power supply

AC Input voltage: 110V/220V±10%, 50/60Hz

Connect the protective grounding conductor of the AC power cord to an earth ground

to avoid electrical shock.

Fuse

Make sure the correct type of fuse is installed before power up.

Replace the AC fuse with the same type and rating as the original fuse.

Disconnect the power cord before fuse replacement. Make sure the cause of fuse

blowout is fixed before fuse replacement.

Cleaning

Disconnect the power cord before cleaning.

Use a soft cloth dampened in a solution of mild detergent and water. Do not spray

any liquid.

Do not use chemicals or cleaner containing harsh material such as benzene,

toluene, xylene, and acetone.

Operation

environment

Location: indoor, no direct sunlight, dust free, almost non-conductive pollution.

Relative humidity: <80%

Altitude: <2000m

Temperature: 0℃ ~ 40℃

Storage

environment

Location: indoor

Relative humidity: <70%

Temperature: 10℃ ~ 70℃

Page 5

1. PRODUCT INTRODUCTION

1-1. Description

The LCR-1000 series are high precision LCR meter with basic accuracy 0.1% and maximum measurement

frequency 10kHz, 100kHz and 200kHz. The 5-digit 4.3-inch TFT LCD display gives easy reading. The RS-232

interface facilitates in remote control and analysis of measurement results. With its fast measurement speed,

wide frequency range and low cost, the LCR7000 series are widely used in R&D, IQC, online quality control

and automatic test system.

1-2. Features

32-bit core processor

5-digit 4.3-inch TFT LCD display

2 signal source output impedance: 30Ω, 100Ω

100 sets memories for internal storage/save

500 memories for U disk storage/save, supports FAT16 and FAT32 files

Save the last parameter settings before power off

Standard interface: RS-232, HANDLER, USB HOST

Optional interface: USB DEVICE, GPIB

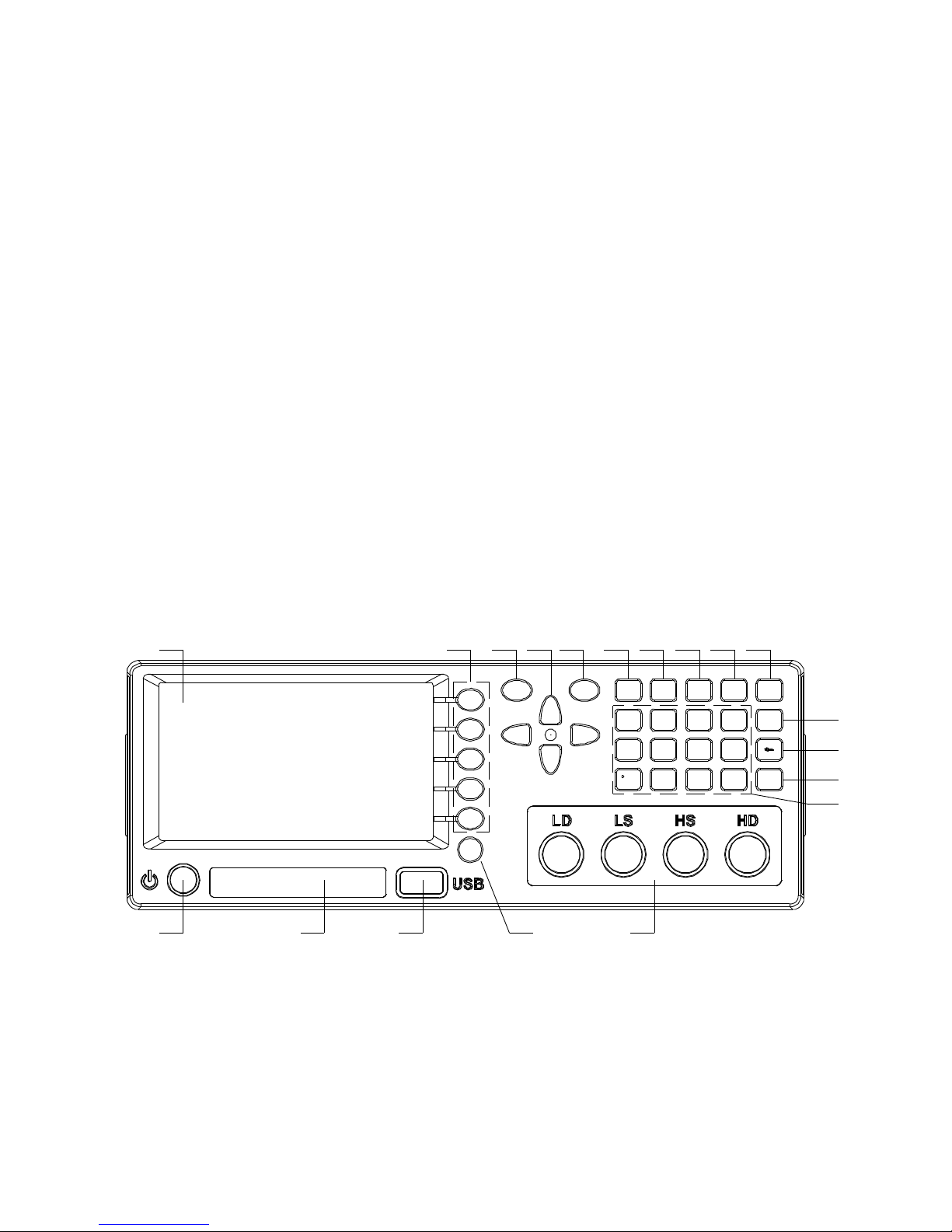

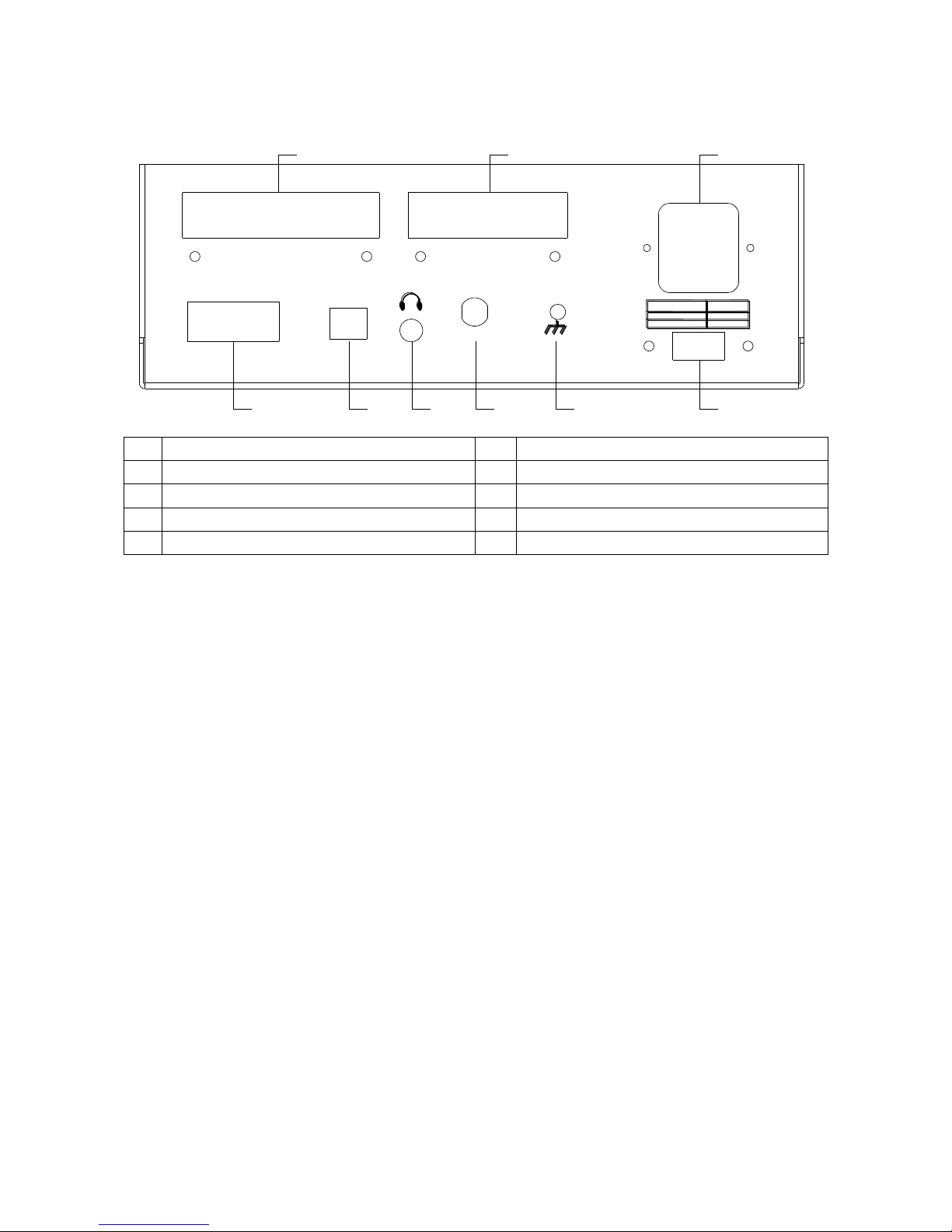

1-3. Front Panel Introduction

PASS FAI L

MEAS SETUP SYSTEM FILE TRI G

4

GHI

10

5

JKL

6

MNO

2

ABC

3

DEF

7

PQRS

8

TUV

9

WXYZ

+/-

ESC

OK

TOOL

1 2 3 54

6 7 9 8 10 11 12 13 14 15

16

17

18

19

1) Power switch

Page 6

Press to power ON or OFF the LCR meter.

2) Name label

It shows brand and model number.

3) USB HOST interface

Connect U flash disk to save or load the file.

4) [TOOL]

Make a short press to this key, the menu soft key area shows corresponding menus. Make a short

press again, the menus disappear.

Make a long press (>1 second) to this key, the LCR meter panel is locked. Other keys (except

TOOL key) are locked, no response to press.

Make a long press again to this key, the LCR meter panel is unlocked. All keys response to press.

When the LCR meter is controlled by RS232, the LCR meter front panel is locked by default. Make

a long press to this key again to unlock the front panel.

5) Measurement terminals: LD, LS, HS, HD

4-teminal test lead is used to connect 4-terminal test fixture or cable to measure DUT.

It is recommended to use the test lead attached to the LCR meter. Using self-made test lead or test

lead from other suppliers may cause error in measurement results.

6) LCD display

4.3-inch TFT LCD displays measurement results and conditions.

7) Soft keys

Five soft keys are used to select parameters. The corresponding function of each soft key has been

displayed on its left (the right part of LCD). The function definition varies with different pages.

8) CURSOR keys

This key is used to move the cursor on the LCD displayed page. When the cursor moves to a zone,

the corresponding zone will be lightened.

9) PASS indicator

Page 7

The indicator lights on to show that the test result has passed.

10) FAIL indicator

The indicator lights on to show that the test result has failed.

11) [MENU]

Five soft keys are used to select parameters. The corresponding function of each soft key has been

displayed on its left (the right part of LCD). The function definition varies with different pages.

When the LCD display the <MEAS DISPLAY> page and the cursor key moves to <MEAS

DISPLAY>, press [MEAS] key to display the measurement results in full screen.

12) [SETUP]

Press this key to enter measurement parameter setup page.

13) [SYSTEM]

Press this key to Enter system setup page.

14) [FILE]

Press this key to enter file management page.

15) [TRIG]

When the trigger mode is set to MAN mode, press this key to trigger the LCR meter.

16) [ESC]

ESCAPE key.

17) [ ]

BACKSPACE key is used delete the last numeric of the input value.

18) [OK]

This key is used to end the input of data, and confirm and save the data displayed on the inputting

line.

19) Number keys

These keys are used to input data to the LCR meter. The key consists of numerical keys [0] to [9],

decimal point [.] and [+/-] key.

Page 8

1-4. Rear Panel Introduction

EXT

RS-232C

HANDLER

USB

RATI NG FUSE

¡ «110V/ 60Hz 30VA

¡ «220V/ 50Hz 30VA

T1.0AL 250V

T0.5AL 250V

FOOT. C

1 2 3 4 5 6

789

1

RS-232C interface

6

Voltage selector

2

USB device interface

7

Power socket

3

Headset interface

8

EXT extension interface

4

FOOT.C foot switch interface

9

HANDLER interface

5

GND screw

Page 9

2. PANEL OPERATION

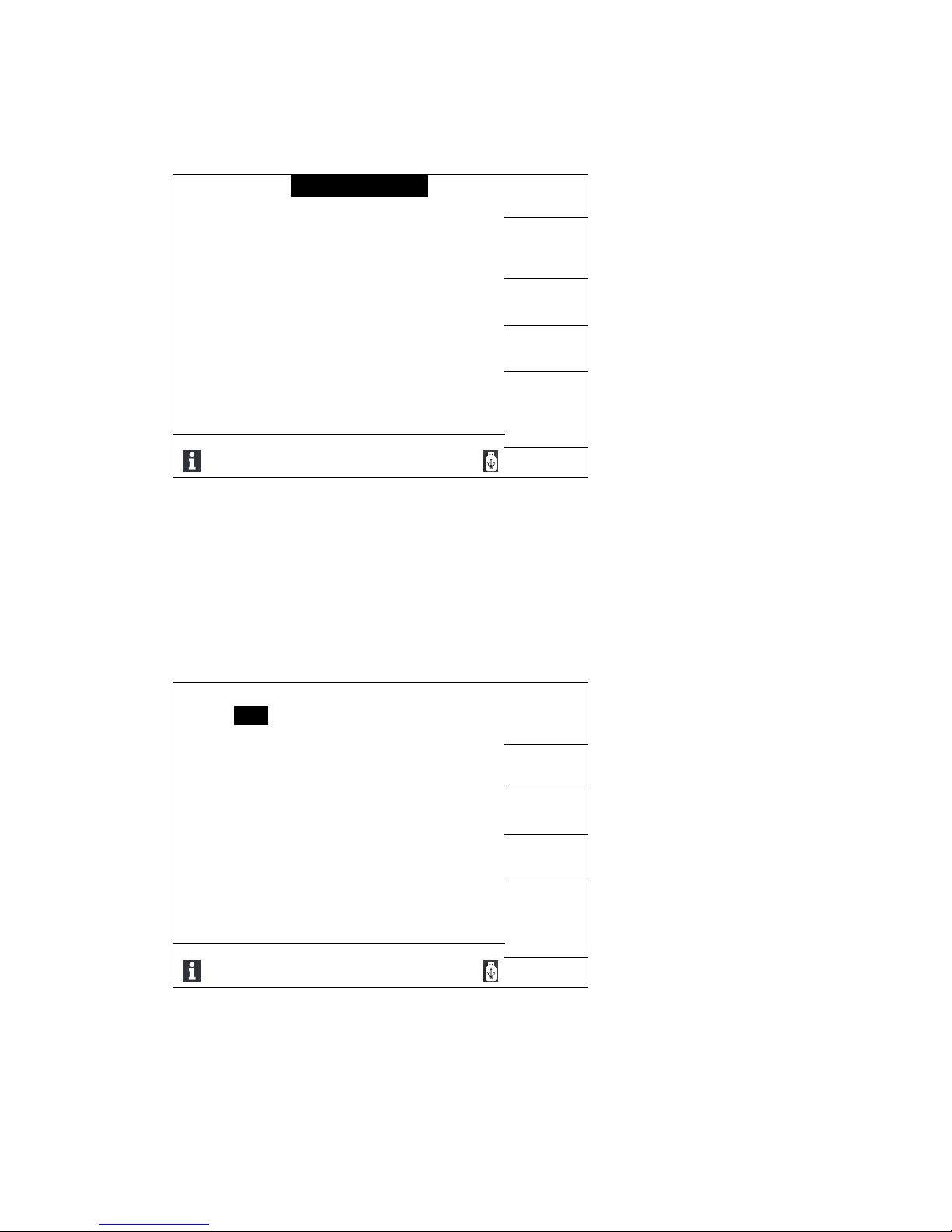

2-1. <MEAS DISPLAY>

Press [MEAS] key, the <MEAS DISPLAY> page will be displayed on screen as shown below:

< MEAS DISP >

MEAS

FUNC : Cp-D

RANGE : AUTO

DISP

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

BIN

/

Cp : -0.0015p F

D : 0.3697

DISP

Vm:OFF Im:OFF

QUICK

CLEAR

Use softkeys to select

2-1-1. MEAS DISP

In <MEAS DISP> page, use the four direction keys (▲▼◄►) to move cursor to choose of FUNC, FREQ,

LEVEL, RANGE, SPEED, COMP. Pressing [QUICK CLEAR] softkey can make quick clear to all parameters.

Test parameter

When parameter “Cp-D” of FUNC is selected, other test parameters are display in the right side of the screen.

Each parameter can be selected by its softkey. There are test parameters of Cs-D, Cp-D, Ls-Q, Lp-Q, Rs-Q,

Rs-D, Rp-Q, Rp-D, R-X, Zs-θ, Zs-r.

< MEAS DISP >

Cs-D

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

Cp-D

/

Cp : -0.0015p F

D : 0.3697

Ls-Q

Lp-Q

Vm:OFF Im:OFF

MORE

1/4

Use softkeys to select

Page 10

Range mode (not available for LCR-1010)

There are four range modes to choose from: Auto, Hold, Increase +, Decrease -

< MEAS DISP >

AUTO

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

HOLD

/

Cp : -0.0015p F

D : 0.3697

INCR +

DECR _

Vm:OFF Im:OFF

Use softkeys to select

Test frequency

Different models have different test frequency points. Press increase or decrease key to choose the last or the

next frequency points.

LCR-1010: 100Hz,120Hz,1kHz,10kHz

LCR-1030: 100Hz,120Hz,1kHz,10kHz, 20kHz, 30kHz

LCR-1200: 40Hz, 50Hz, 60Hz, 75Hz, 100Hz, 120Hz, 150Hz, 200Hz, 250Hz, 300Hz, 400Hz, 500Hz, 600Hz,

750Hz, 800Hz, 1kHz, 1.5kHz, 2kHz, 2.5kHz, 3kHz, 4kHz, 5kHz, 6kHz, 7.5kHz, 10kHz, 12kHz,

15kHz, 15.7kHz, 16.2kHz, 20kHz, 25kHz, 30kHz, 40kHz, 50kHz, 60kHz, 66.6kHz, 75kHz, 100kHz,

120kHz, 150kHz, 200kHz (38 points)

< MEAS DISP >

INCR + +

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

INCR +

/

Cp : -0.0015p F

D : 0.3697

INCR +

DECR Vm:OFF Im:OFF

DECR - -

Use softkeys to select

Speed

Speed can be set at fast, medium or slow.

When test frequency ≥1kHz:

Fast: max.30 times/second

Medium: 10 times/second

Slow: 3 times/second

Page 11

< MEAS DISP >

FAST

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

MED

/

Cp : -0.0015p F

D : 0.3697

SLOW

Vm:OFF Im:OFF

Use softkeys to select

Test level

Test level of LCR-1010 and LCR-1030 can be choose from 0.1V, 0.3V, 1V.

Test level of LCR-1200 can be set from 0.05V to 1V.

< MEAS DISP >

1V

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

0.3V

/

Cp : -0.0015p F

D : 0.3697

0.1V

INCR +

Vm:OFF Im:OFF

DECR -

Use softkeys to select

Comparator

Comparator can be set ON or OFF. Press <BIN DISP> softkey to enter bin display for more details.

< MEAS DISP >

ON

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

OFF

/

Cp : -0.0015p F

D : 0.3697

BIN

DISP

Vm:OFF Im:OFF

Use softkeys to select

Page 12

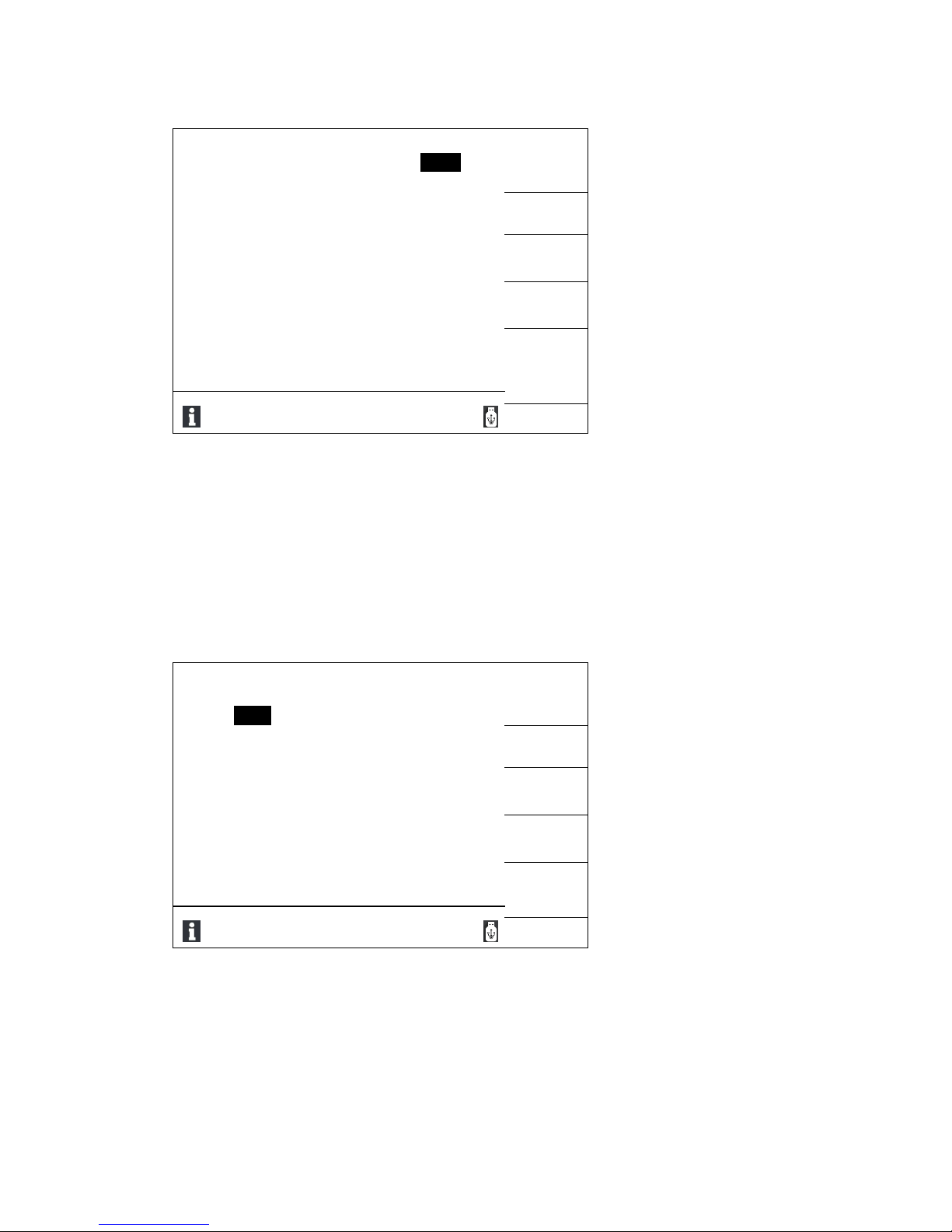

Parameter area

In parameter area, the test parameter and its value are displayed.

Font size of the parameters can be set as small size of large size by pressing [FONT] softkey.

Parameter value display can be turn on or off by pressing [DISP] softkey.

Deviation can be set as OFF, ABS or % by pressing [DEV] softkey.

< MEAS DISP >

FONT

SMALL

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

DISP

OFF

/

Cp : -0.0015p F

D : 0.3697

DEV

OFF

Vm:OFF Im:OFF

Use softkeys to select

Parameter area

In parameter area, the test parameter and its value are displayed.

Font size of the parameters can be set as small size of large size by pressing [FONT] softkey.

Parameter value display can be turn on or off by pressing [DISP] softkey.

Deviation can be set as OFF, ABS or % by pressing [DEV] softkey.

< MEAS DISP >

FONT

SMALL

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

DISP

OFF

/

Cp : -0.0015p F

D : 0.3697

DEV

OFF

Vm:OFF Im:OFF

Use softkeys to select

Page 13

Monitored Voltage and Current

Vm and Im are monitored voltage and current of the DUT respectively. When Vm or Im is selected, it can be

set ON or OFF.

< MEAS DISP >

ON

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

OFF

/

Cp : -0.0015p F

D : 0.3697

Vm:OFF Im:OFF

Use softkeys to select

2-2. <BIN DISPLAY> (not available for LCR-1010)

Press [BIN DISP] key in the pay of <MEAS DISP>, the <BIN DISPLAY> page will be displayed on screen as

shown below:

< BIN DISP >

MEAS

COMP : OFF

AUX : OFF

COUNT : OFF

SETUP

NOMINAL: 0.0000pF

MODE : ABS

BIN

LOW [ ]

HIGH [ ]

COUNT

1 2 3 2nd AUX : OFF

OUT :

BIN

DISP

\

Cp: -0.0009p F

BIN:

D : 0.0033

QUICK

CLEAR

Use softkeys to select

COMP: Set comparator ON or OFF

AUX: Set auxiliary ON or OFF

COUNT: Set counting ON or OFF

NOMINAL: Input nominal value via numeric keys or softkeys. It is reference value of main parameter range.

Deviation is for main parameters only. There are 3 operations to Deviation: OFF, ABS or %.

ABS (Absolute Deviation): The absolute deviation is the currently measured value minus preset nominal

value. Its calculation formula is: ⊿ABS = X – Y.

X is the currently measured value. Y is preset nominal value.

% (percentage deviation): The percentage deviation is the percentage of the difference between the

currently measured value and the preset nominal value. Its calculation formula is: ⊿% = (X – Y)/

Y×100[%]

X is the currently measured value. Y is preset nominal value.

Page 14

2-3. <MEAS SETUP>

Press [SETUP] key, <MEAS SETUP> page will be displayed on screen as shown below:

< MEAS SETUP >

MEAS

SETUP

ResSource

:

30Ω

AVERAGE

: 1

RangeDwe I I

:

0 ms

TrigSource

:

INT TrigDelay

:

0 ms

TrigEdge

:

RISING

Handler

:

CLEAR

PulseWidth

:

1 ms

Use softkeys to select

ResSource

Set internal resistance source at 30Ω or 100Ω

AVERAGE

Set average number of times between numbers 1 to 255. Input numbers by numeric keys

or soft key “+” and “-”.

RangeDwe I I

Set range delay time between 0ms to 6000ms. Input numbers by numeric keys or soft key

“+” and “-”.

TrigSource

Set trigger source as INT or EXT.

TrigDelay

Set trigger display time between 0ms to 6000ms. Input numbers by numeric keys or soft

key “+” and “-”.

TrigEdge

Set trigger edge as RISING or FALLING.

Handler

Set comparator to CLEAR, HOLD, PULSE.

PulseWidth

Set pulse width between 1ms to 9999ms.

2-4. <SYSTEMS SETUP>

Press [SYSTEM] key, <SYSTEMS SETUP> page will be displayed on screen as shown below:

< SYSTEM SETUP >

SYSTEM

Theme

TRAD-BLUE

SETUP

Language

:

英语

COMM

Key Tone

:

ON SETUP

ToneSour

:

MASTER

ABOUT

PassTone

:

OFF

SYSTEM

FailTone

:

TWO SHORT

SYSTEM

ParaSave

:

AUTO SAVE

DEBUG

PassWord

:

OFF

Use softkeys to select

Theme

Set display theme to BLUE, BLACK or GREEN.

Language

Set language as English or Chinese

Key Tone

Turn on or off key tone.

Page 15

ToneSour

Set tone source as MASTER, EAR PHONE or ALL.

PassTone

Set pass tone OFF, or set pass tone as LONG tune, SHORT tune, TWO SHORT tunes.

FailTone

Set fail tone OFF, or set fail tone as LONG tune, SHORT tune, TWO SHORT tunes.

ParaSave

Set parameter save mode as AUTO SAVE, AUTO LOAD, or NO SAVE.

PassWord

In this page, press corresponding softkeys to choose different functions:

1) Set password OFF

2) Lock system: when setting password to lock system, all files are protected and

password is required during power on

3) Lock file: it means protecting files.

4) Modify password: the default password is 0010 for LCR-1010, 0030 for LCR-1030 and

0200 for LCR-1200.

5) Save to USB flash disk: The password can be save to USB flash disk. The password

file name is “0010.STA” for LCR-1010, “0030.STA” for LCR-1030, “0200.STA” for LCR-

1200. Plug USB flash disk into USB HOST, when a password is required during power

on, the LCR meter automatically detects the password file and read it to get password.

2-5. <COMM SETUP>

Press [COMM SETUP] softkey, <COMM SETUP> page will be displayed on screen as shown below:

< COMM SETUP >

SYSTEM

Bus Mode

:

RS232C

SETUP

BaudRate

:

9600

COMM

Data Bit

: 8

SETUP

Stop Bit

: 1

ABOUT

Parity

:

None

SYSTEM

Tx Term

:

LF GpibAddr

:

08 CMD Type

:

SCPI

Use softkeys to select

Bus Mode

Set bus mode as RS232C, GPIB, USBTMC or USBCDC.

BaudRate

Use “+” or “-” to choose baud rate from 4800, 9600, 19200, 38400, 115200.

Baud rate is only for bus mode RS232C.

Data Bit

Set data bit as 6, 7 or 8.

Stop Bit

Set stop bit as 1 or 2.

Parity

Set parity as NONE, ODD, or EVEN.

Tx Term

Set end of text term as LF, CR or LFCR.

In response to ASCII code, LF is 0x0A and CR is 0x0D.

This is only end of text term when the LCR meter is returning data to PC.

GpibAddr

Set GPIB address between 0 to 31. Input numbers via numeric keys or softkeys.

This is only for bus mode GPIB.

CMD Type

Please refer details to Programming Manual.

2-6. <ABOUT SYSTEM>

Press [ABOUT SYSTEM] softkey, the <ABOUT> page will be displayed on screen as shown below:

Page 16

< ABOUT >

Reset

Factory

Model number:

: Serial number

:

GL-817-02333

Firmware version

:

1.8.1

Hardware version

:

1.0.1

Update

License

:

Registered

EXIT

Use softkeys to select

Reset

Press the softkey to restart the LCR meter.

Factory

Press the softkey to return to factory setup. Password is required.

Update

Press the softkey to update firmware through USB flash disk.

EXIT

Press the softkey to exit and return to <SYSTEM SETUP> page.

2-8. Data Storage

The measurement data can be stored to USB flash stick. In <MEAS> page, press [TOOL] key to enter into

data storage menu.

< MEAS DISP >

PrtSc

FUNC : Cp-D

RANGE : AUTO

FREQ : 1 kHz

SPEED : SLOW

LEVEL : 1.00V

COMP : OFF

SAVE

DATA

/

Cp : -0.0015p F

D : 0.3697

SINGLE

SHORT

SINGLE

OPEN

Vm:OFF Im:OFF

Use softkeys to select

There are three formats for data storage: <A>,<B> [,<COMP>]

A and B are measurement results for main parameter and secondary parameter respectively. The

measurement results are stored in the way of scientific notation.

<COMP> is comparator results. LCR-7010 dose not have handler function.

COMP

Description

COMP

Description

0

Fail

3

BIN 3pass

1

BIN 1 pass

4

AUX fail

2

BIN 2 pass

5

No comparator

2-8. <INTER Files List> and <EXT Files List>

The parameter settings can be saved into the internal non-volatile memory. When same parameter settings

Page 17

are needed in the next measurement, user can easily upload parameter settings from the internal non-volatile

memory. No need to make settings again.

Press [File] key, the <Files List> page will be displayed. Press [File] key again to switch between internal and

external files lists.

< INTER Files List >

LOAD

I:\

Page: 1

NO File

STORE

1

2

DEL

3 4

FIND

5 6

COPY TO

E:

7

Use softkeys to select

< EXT Files List >

LOAD

I:\

Page: 1

File/Folder

STORE

DEL

PARENT

DIR

COPY TO

I:

Press / to page, FILE to change I/E !

Use softkeys to select

Operation steps:

1. Read existing files

1) Use ▲ and ▼ keys to choose files. Or Input numbers to choose corresponding file, and then press

[OK] key to confirm.

2) Use ◄ and ► keys o choose pages.

2. Save parameter to files

1) Move cursor to file number. Press [STORE] softkey to save parameter to the selected file.

2) Press [YES] softkey to continue, or press [NO] softkey to cancel operation.

3) If press [YES] softkey in step 2, input file name via numeric keys and then press [OK] to confirm. If the

file name already exists, press [Continue] softkey to cover the existing file of press [ESC] to cancel

operation.

3. Upload parameters from existing files

1) Press [File] key to switch to internal or external files list.

Page 18

2) Move cursor to the file name to be uploaded from, or input file name directly.

3) Press [LOAD] softkey.

4) Press [YES] softkey to upload file.

4. Copy file to USB flash disk

1) Plug USB flash disk into USB host.

2) Move cursor to the file name to be copied, or input file name directly.

3) Press [YES] softkey to copy.

4) If the file name already exists, press [Continue] softkey to cover the existing file of press [ESC] to

cancel operation.

Page 19

3. SPECIFICATIONS

3-1. Measurement Range

With 100Ω source resistance, there are five ranges: 31.6Ω, 100Ω, 1kΩ, 10kΩ, 100kΩ.

With 30Ω source resistance, there are six ranges: 10Ω, 30Ω, 100Ω, 1kΩ, 10kΩ, 100kΩ.

The effective measurement range is listed as below.

Table 3-1 Effective measurement range

with 100Ω source resistance

Table 3-2 Effective measurement range

with 30Ω source resistance

No.

Resistance

Effective mea.range

No.

Resistance

Effective mea.range

0

100kΩ

100kΩ-100MΩ

0 100 kΩ

100kΩ-100MΩ

1

10kΩ

10kΩ-100kΩ

1 10 kΩ

10kΩ-100kΩ

2

1kΩ

1kΩ-10kΩ

2 1 kΩ

1kΩ-10kΩ

3

100Ω

50Ω-1kΩ

3 100Ω

100Ω-1kΩ

4

30Ω

0Ω-50Ω

4 30Ω

15Ω-100Ω

5 10Ω

0Ω-15Ω

3-2. Accuracy

3-2-1. Accuracy of │Z│, L, C,R, X

The accuracy (A

e

) of │Z│,L,C,R,X is shown as below:

Ae= ±[A+(Ka+Kb+Kf)×100+KL]×K

c

[%]

A: Basic measurement accuracy (Refer to Fig.3-1)

K

a

:Impedance scaling factor (Refer to table 3-4), impedance <500Ω

K

b

:Impedance scaling factor (Refer to table 3-4), impedance >500Ω

K

c

:Temperature factor (Refer to table 3-5)

K

f

:Calibration interpolation factor (Refer to table 4-6)

K

L

:Cable length factor (Refer to table 4-7)

Note: Choose only Ka or Kb, depending on resistance value. For others, input zero.

Condition for L, C, X accuracy: D

x

(D measured value)≤0.1

Condition fo R accuracy: Q

x

(Q measured value)≤0.1

When Dx≥0.1, for L, C and X, its accuracy factor Ae shall be multiplied by

2

1xD

When Qx≥0.1, for R, its accuracy factor Ae shall be multiplied by

2

1xQ

Page 20

3-2-2. Accuracy of D

The accuracy De of D is calculated according to: De=

100

eA

The above formula is valid only when D

x

≤0.1.

When Dx>0.1, De shall be multiplied by (1+D

x

).

3-2-3. Accuracy of Q

The accuracy Qe of Q is calculated according to: Qe =

ex

ex

DQ

DQ

1

Here Qx is the measured value of Q. D

e

is the accuracy of D.

The above formula is valid only when Qx×D

e

<1.

3-2-3. Accuracy of θ

The accuracyθe of θ is calculated according to: θe =

100

180 eA

[deg]

3-2-4. Accuracy of Rp

When Dx (the measured value of D) ≤0.1 The accuracy of R

p

is calculated according to:

Rp =

ex

epx

DD

DR

[]

Here, R

px

is the measured value [] of R

p

. Dx is the measured value of D. D

e

is the accuracy of D.

3-2-5. Accuracy of Rs

When Dx (the measured value of D) ≤0.1 The accuracy of R

s

is calculated according to:

Rse = Xx×D

e

[]

Xx = 2πfLx=

xfC

2

1

Here, Xx is the measured value [S] of X. Cx是is the measured value [F] of C. Lx is the measured value [H] of L.

D

e

is the accuracy of D. f is measured frequency.

Page 21

Basic measurement accuracy (Fig.3-1)

In Fig.3-1, the basic accuracy A can be selected by below method:

0.1 (a smaller value): When VS=1V, measurement speed is accuracy of medium and slow speed.

0.2 (a larger value): When VS=1V, measurement speed is accuracy of fast speed.

Page 22

When measuring level correction level ArB (Refer to table 3-3), select measuring accuracy A according to

Fig.3-1, the basic accuracy after level correction is A multiplied by Ar. Here, V

S

is voltage of test signal.

Table 3-1

Test Signal Voltage

V

S

Accuracy Correction Factor

Ar

0.1V

2.5

0.3V

1.5

1V

1

Table 3-4 Impedance Scaling Factor Ka and K

b

Speed

Frequency

K

a

(Zm<500)

K

b

(Zm>500)

Medium

Slow

fm100Hz

)

100

1)(

200

1)(

101

(

3

msm fVZ

)

100

1)(

70

1)(101(

9

ms

m

fV

Z

100Hzfm

≤100kHz

)

200

1)(

101

(

3

sm VZ

)

70

1)(101(

9

s

m

V

Z

fm100kHz

)

200

2)(

101

(

3

sm VZ

)

70

1)(103(

9

s

m

V

Z

Fast

fm100Hz

)

100

1)(

400

1)(

105.2

(

3

msm fVZ

)

100

1)(

100

1)(102(

9

ms

m

fV

Z

100Hzfm

≤100kHz

)

400

1)(

105.2

(

3

sm VZ

)

100

1)(102(

9

s

m

V

Z

fm100kHz

)

400

2)(

105.2

(

3

sm VZ

)

100

1)(106(

9

s

m

V

Z

Note:

fm: measured frequency, [Hz]

Zm: measured impedance of DUT, []

Vs: voltage of test signal, [mV

rms

]

Table 3-5 Temperature Factor K

c

Temperature (℃)

5 8 18 28 38

K

c

6 4 2 1 2

4

Table 3-6 Calibration Interpolation Factor Kf

Test frequency

Kf

Typical frequency (Direct calibration)

0

Non-typical frequency (Interpolation

calibration)

0.0003

Note: So far frequency points of all models are typical frequencies.

Table 3-7 Cable Length Factor

Test frequency

Cable Length

0m

1m

2m

Page 23

0.1Vrms ,0.3Vrms

0

2.510-4(1+0.05fm)

510-4(1+0.05fm)

1Vrms

0

2.510-3(1+0.016fm)

510-3(1+0.05fm)

Note: fm: measured frequency, [Hz]

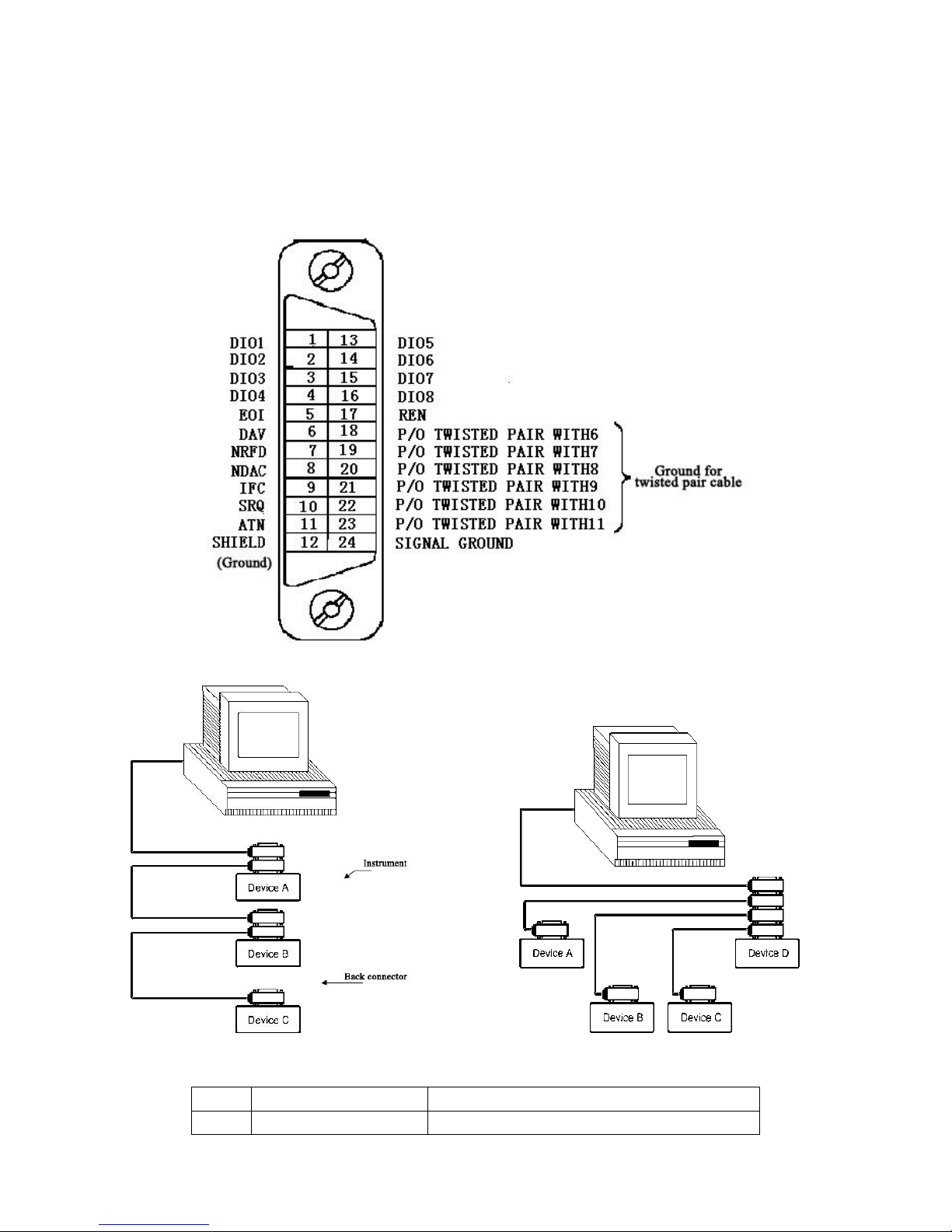

4. HANDLER INTERFACE

The HANDLER interface is used to output comparator results to industrial computer (IPC), so as to realize automatic

comparator test.

4-1. Pin Definition

Fig.4-1 Pin definition

Pin No.

Signal

Description

1

2

3

10

11

/P1

/P2

/P3

/NG

/AUX

Comparator result output.

All signals are collector outputs with built-in pull-up resistor. Pul-up power source

can be internal +5V power source or exteran power source EXTV (default at

EXTV).

Resistance of the built-in pull-up resistor is 4.7kΩ.

12,13

/EXT.TRIG

Rising edge of this signal triggers measurement. Pulse width≥1μs. Low level drive

current approx. 5-10mA.

16,17,18

+5V

Internal +5V power output: Normally it is not recommended to use internal power

source. If the internal power source must be used, please make sure the signal’s

current is less than 0.3A and ensure the signal is well shielded from interference.

27,28

EXTV

External DC power source input for comparator signal.

If using internal +5V power source, please reset the internal jumper connection.

30

/IDX

/IDX is valid after A/D conversion is finished.

When the signal is valid, the automatic tester will allow the next component to move

into measuring position. The currently measured result will be output when /EOM

is valid.

31

/EOM

End Of Measurement: the signal is valid when the measured results and comparing

Page 24

results are valid.

34,35,36

COM

Reference ground for external power source EXTV.

When using internal +5V power source for the HANDLER interface signal output,

reference ground of the LCR meter is connected with COM.

4-2. Time Sequence of Interface Signal

Fig.4-3 Time sequence chart

Time

MIN Value

MAX Value

T1: Trigger pulse width

T2: Delay time of starting measurement

T3: Trigger waiting time after /EOT output

1us

200us

0us

Display time + 200us

---

Page 25

4-4. Schematic Diagram of Interface Signal

If using internal +5V power source: connect pin 1 to pin 2 of J205; and connect pin 1 to pin 2 of J204.

If using external EXTV power source: connect pin 2 to pin 3 of J205; and connect pin 2 to pin 3 of J204.

5. REMOTE CONTROL

The LCR meter is available with RS232C interface and USB HOST as standard. GPIB is an optional interface.

5-1. RS232C Interface

The RS232C interface of this LCR meter is not strictly based on international RS232 standards. Only the

minmal subset as table 5-1 is available.

Table 5-1 Fig.5-1 Connection illustration

Signal

Abbreviation

Connector’s Pin number

Send data

TXD

2

Receive data

RXD

3

Ground

GND

5

5-3. Description to GPIB Interface

The GPIB (IEEE488) interface is a universal intelligent instrument bus interface. The LCR meter can be

connected with computer or other intelligent instruments through GPIB interface to construct an automatic test

system with other instruments. Maximum 15 units of instruments can be connected to one bus at the same

time. The LCR meter adopts IEEE488.2 standards. The command system is open. User can control the LCR

meter by sending commands.

TIPS:

Page 26

1. In one bus system, the connecting cable of each unit shall be less than 2 meters. Total cable length shall

be less than 20 meters.

2. Maximum 15 units can be connected to one bus.

3. There is no rule on how to connect cables. However, it is recommended to impose four back connectors

on one instrument.

Fig.5-2 GPIB Connector and Pinout

Figt.5-3 Superimposition of two back connectors Figt.5-4 Superimposition of four back connectors

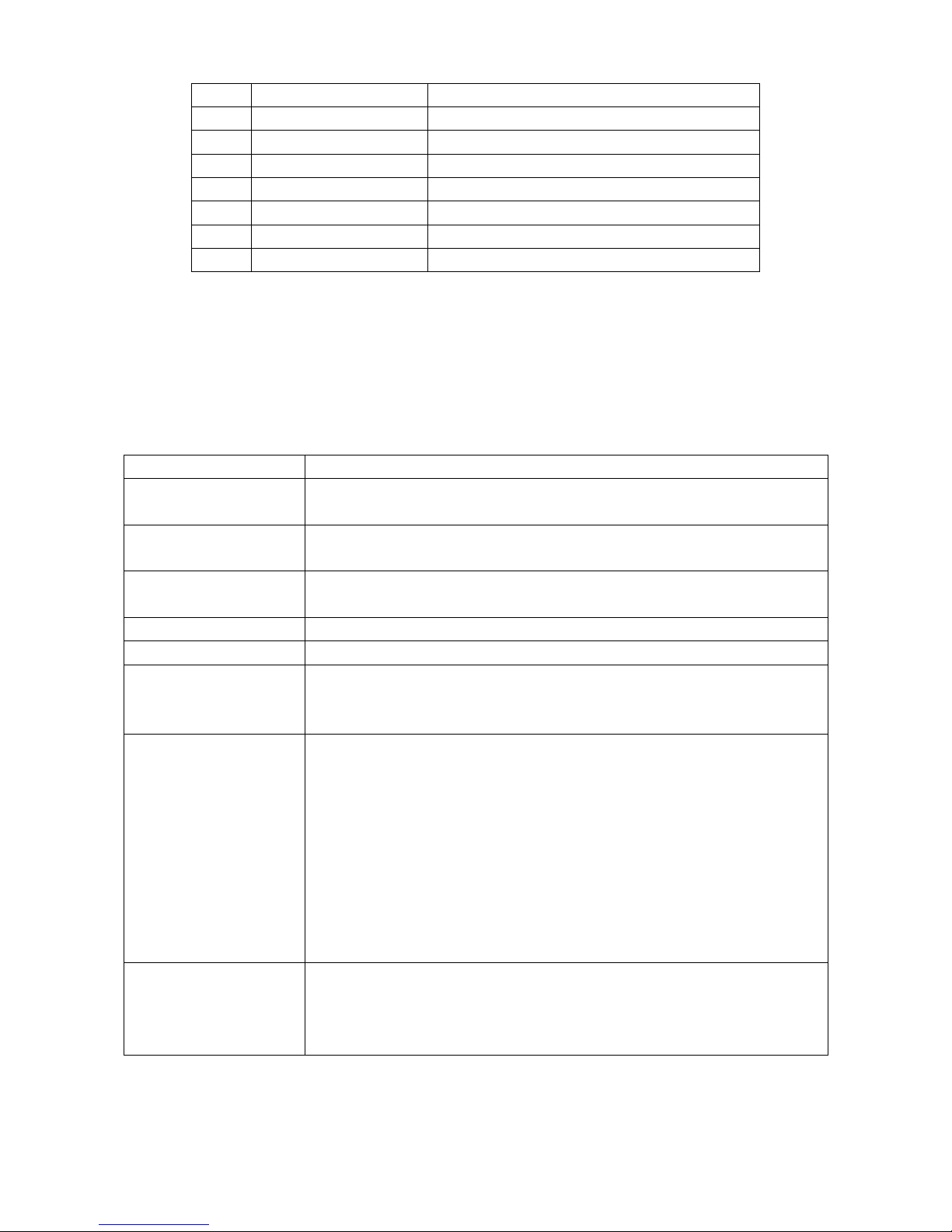

Connector’s function:

Code

Function

Description

SH1

Data source contact

Three line connection

Page 27

AH1

Receiver communication

Three line connection

T5

Speak function

Send instrument information

L4

Listen function

Receive instrument information

SR1

Service request

Demand service

RL1

Remote/local switch

Switch between remote control and local control

DC1

Reset instrument

Send CLEAR signal

DT1

Trigger instrument

Send trigger signal

C0

Control function

Send control signal

5-3-1. GPIB Address

GPIB address can be set between numbers from 0 to 31. Please refer to [SYSTEM] menu for details of

interface setup.

5-3-2. GPIB Bus Function

Commands

Description

AORT I/O (IFC)

Stop all bus actions. Stop receiving instrument’s data. Reset the interface to

idle state.

CLEAR LOCKOUT/

SET LOCAL

Prepare the instrument for remote control.

DEVICE CLEAR

(SDC or DCL)

Clear the selected instrument, or clear all instruments.

LOCAL LOCKOUT (LLO)

Lock local commands. Carry out this command.

REMOTE

Set the instrument to remote control mode.

SPOLL

This is Serial naming command, which is used to configure the bus address

status byte. 8 bytes are used to mask and read to determine the operating

status of the instrument.

SERVICE REQUEST

When the series instrument requests the controller to perform a task, the

instrument will send SRQ (service request) signal. SRQ signal is considered as

an interrupt that tells the controller to be prepared for data transmission or there

is an error condition. When the series instrument sends the SRQ service

request signal, it also sets the status byte to 6 bits. The 6 bits are RQS request

service bits, sometimes as a status bit when concatenated with the naming

command. When the series instrument serializes, it clears the RQS (Request

Service) bit and the SRQ line. Each byte of the status byte initiates an SRQ

service request. The user can mask the status byte to determine which one

caused the series instrument to set the SRQ line. See "Status Bytes" for details.

TRIGGER (GET)

Trigger bus commands. This command can be sent to the selected instrument

or all the instruments as the listener. The series instruments must first be

assigned to the listener and then set the bus trigger mode to trigger mode before

sending the trigger message

5-4. USB HOST

The USB HOST can be used to control the LCR meter It is in compliance with USMTMC-USB488 and USB2.0

Page 28

protocols. When using USBTMC interface, user can write commands via Labview to control the instrument.

In the first time of connecting the instrument to computer via USB cable, the computer will reminds of “Find

New Device” and then pop up installation windows. Follow the installation instructions and install the USB

driver successfully. A “USB Test and Measurement Device” will be found in the Device Manager.

Page 29

6. MAINTENANCE

6-1. Inspection

Inspect the LCR meter at regular intervals so that it maintains its initial performance for a long time.

Check the input power cord for damage of the vinyl cover and overheating of the plug and cord stopper.

Check the terminal screws and binding posts for loosening.

6-2. Fuse Replacement

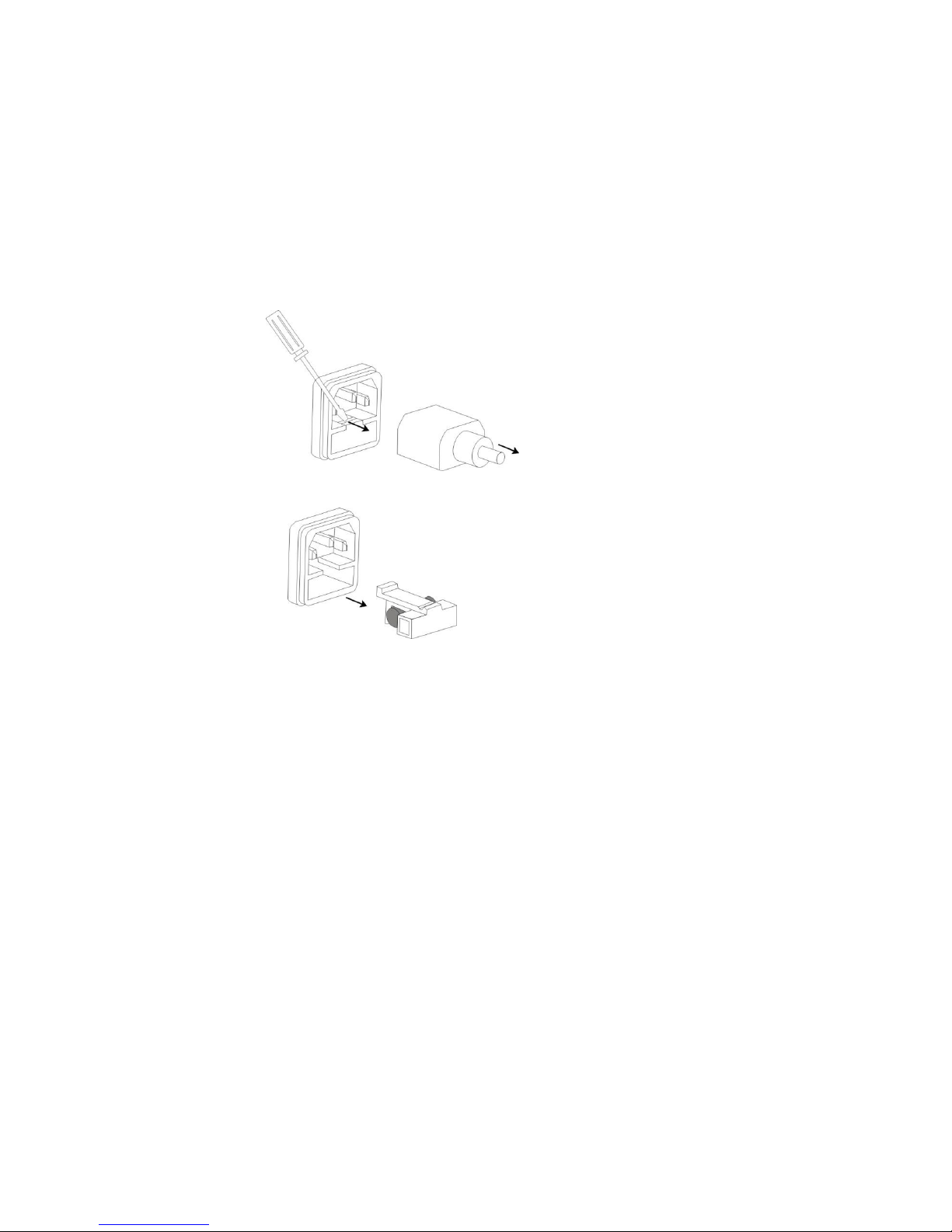

Step

1) Take off the power cord and remove the fuse socket using a minus driver.

2) Replace the fuse in the holder.

Fuse rating: T1.0/250V for 110Vac input, T0.5/250V for 220Vac input.

Page 30

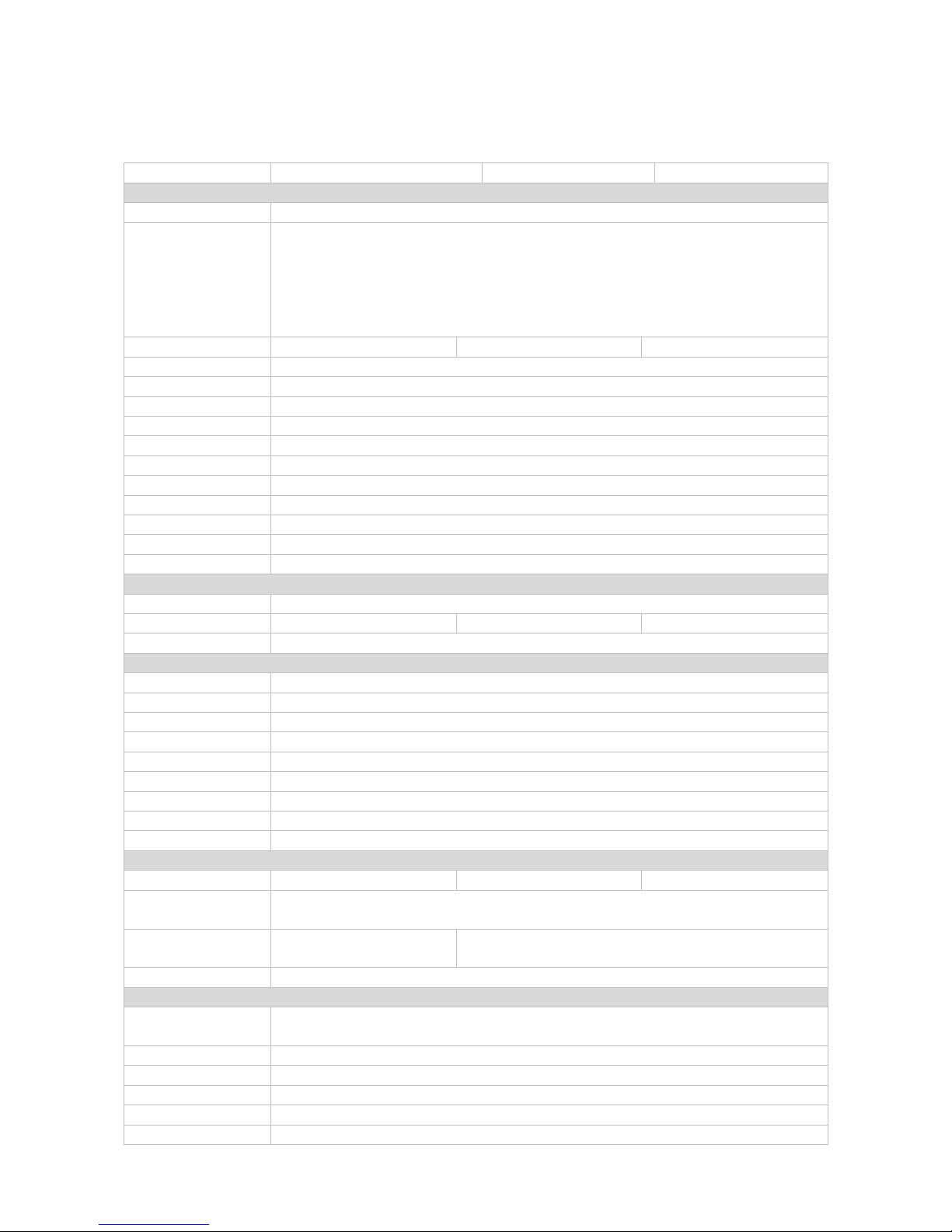

7. TECHNICAL SPECIFICATIONS

The specifications apply when the LCR meter is powered on for at least 30 minutes under regulated

temperature.

Model

LCR-1010

LCR-1030

LCR-1200

Measurement function

Test parameter

| Z|, |Y|, C, L, X, B, R, G, D, Q, θ

Test signal frequency

LCR-1010: 100Hz,120Hz,1kHz,10kHz

LCR-1030: 100Hz,120Hz,1kHz,10kHz, 20kHz, 30kHz

LCR-1200: 40Hz, 50Hz, 60Hz, 75Hz, 100Hz, 120Hz, 150Hz, 200Hz, 250Hz, 300Hz, 400Hz,

500Hz, 600Hz, 750Hz, 800Hz, 1kHz, 1.5kHz, 2kHz, 2.5kHz, 3kHz, 4kHz, 5kHz, 6kHz, 7.5kHz,

10kHz, 12kHz, 15kHz, 15.7kHz, 16.2kHz, 20kHz, 25kHz, 30kHz, 40kHz, 50kHz, 60kHz,

66.6kHz, 75kHz, 100kHz, 120kHz, 150kHz, 200kHz (38 points)

Basic accuracy

0.15%

0.1%

0.1%

Equivalent circuit

Series, Parallel

Mathematical function

Absolute Deviation and Percentage Deviation

Range mode

Auto, Hold, Manual Selection

Trigger mode

Internal, Manual, External, BUS

Measurement speed

Fast: max.30, Medium: 10, Slow: 3 (times/second) (≥1kHz)

Average times

1-255

Delay time

0-60s, step 1ms

Calibration function

Open circuit, Short circuit, Load

Measurement terminal

5-terminal

Display mode

Direct, Δ, Δ%, V/I (monitoring test voltage and current)

Display

5 digit 4.3-in LCD display

Measurement signal

Output impedance

30Ω, 100Ω

Test level

0.1V, 0.3V, 1V

0.1V, 0.3V, 1V

0.1V, 0.3V, 0.5V, 1V

Test level accuracy

5%

Measurement display range

|Z|, R, X

0.01m Ω - 99.999 MΩ

|Y|, G, B

0.0001µS - 99.999 S

C

0.0001 pF - 9.9999 F

L

0.0001 µH - 999.99 H

D

0.0001 - 9.9999

Q

0.0001 - 99999

θ (DEG)

-179.99º -179.99 º

θ (RAD)

-3.14159 - 3.14159

Δ%

-999.99% - 999.99%

Comparator and interface

Comparator

N/A

4-bin comparator

5-bin comparator

Memory

100 sets memories for internal parameter settings storage/save

500 sets for U disk parameter settings storage/save

Standard interface

Standard: RS232, USB

HOST

Standard: RS232, USB HOST, HANDLER

Optional interface

USB device, GPIB

General

Operating

environment

0°C - 40°C, ≤80%RH

Power source

110/220V±10%, 47~63Hz

Power consumption

≤30VA

Accessories

4-terminal Kelvin test clip leads, RS232 cable, power cord, operation manual

Dimensions

265W*100H*340D mm

Weight

Approx.3.5kg

Page 31

Loading...

Loading...