F701-C

WEIGHING CONTROLLER

OPERATION MANUAL

01 Apr. 2015

Rev. 1.16

INTRODUCTION

WARNING

CAUTION

Thank you very much for purchasing our Weighing Controller F701-C.

For good performance, and proper and safe use of the F701-C, be sure to read this instruction

manual and properly understand the contents of it before use. Also, carefully keep this instruction

manual so that it can be referred to at any time.

SAFETY PRECAUTIONS

For safety reasons, please read the following safety precautions thoroughly.

In order to have an F701-C Weighing Controller used safely, notes we would like you to surely

follow divide into " " and " ", and are indicated by the following

documents. Notes indicated here are the serious contents related to safely. Please use F701-C after

understanding the contents well.

INTRODUCTION

WARNING

This sign forewarns the presence of hazards that could result in serious injury or

fatality when incorrectly handled.

CAUTION

This sign forewarns the presence of hazards that could result in personnel injury or

property damage when incorrectly handled.

I

SAFETY PRECAUTIONS

This sign forewarns the presence of hazards

that could result in serious injury or fatality

when incorrectly handled.

Warning on design

Warning on installation

Warning on wiring

WARNING

● For the entire system to function safely when the F701-C becomes faulty or malfunctions,

provide a safety circuit outside the F701-C.

● Before using the F701-C as described below, make sure to consult with our sales personnel.

- Use in environments not described in the operation manual.

- Use greatly impacting human lives and assets, such as medical devices, transport devices

entertainment devices, and safety devices.

● Do not disassemble, repair, or modify the F701-C. Doing so may cause a fire or an electric

shock.

● Do not install in the following environments.

- Places containing corrosive gas or flammable gas.

- Where the product may be splashed with water, oil or chemicals.

● Do not connect a commercial power source directly to the signal input/output terminals.

● Be sure to ground the protective ground terminal.

● The attached AC cable is designed for domestic use in Japan, and its rating is 125V AC, 7A.

For use at voltages exceeding the rating and for overseas use, have a separate AC cable

prepared.

● Before performing the following, make sure that no power is applied.

- Attachment/detachment of connectors of options, etc.

- Wiring/connection of cables to the signal input/output terminals.

- Connection of the earth cable.

● For connection to the signal input/output terminals, check the signal names and pin

assignment numbers, and then carry out wiring properly.

● Be sure to use crimp contacts for connection to the terminal blocks, and do not to connect

bare wires as they are.

● After wiring, be sure to mount the attached terminal block cover. Otherwise, it may cause an

electric shock.

● Do not connect anything to unused terminal(s).

● Before applying power, carefully check the wiring, etc.

II

SAFETY PRECAUTIONS

This sign forewarns the presence of hazards

that could result in serious injury or fatality

when incorrectly handled.

Warning during startup and maintenance

This sign forewarns the presence of hazards

that could result in personnel injury or property

damage when incorrectly handled.

Caution on installation

WARNING

● Use a power supply voltage and load within the specified and rated ranges.

● Do not damage the power cord. Doing so may cause fire or electric shocks.

● Do not touch any signal input/output terminal while applying power. Doing so may cause

electric shocks or malfunctions.

● If the cover of the main body is opened, it may cause an electric shock internally. Even if the

power is off, the internal capacitor is charged. Contact us for internal inspection or repair.

● In the case of smoke, an abnormal smell or strange sound, immediately turn off the power,

and disconnect the power cable.

● Lithium battery use in the F701-C unit.

type: CR14250SE manufactured by Sanyo Electric, or equivalent

Voltage: 3 volts

Capacity: 850 mAh

CAUTION

● Use the F701-C as it is incorporated in a control panel, etc.

● Do not install in the following environments:

- Locations where temperature or humidity exceeds specifications;

- Locations subjected to drastic temperature fluctuations or icing and condensing;

- Outdoors or locations above 2,000m;

- Locations exposed to direct sunlight;

- Locations subject to dust accumulation;

- Locations with poor ventilation;

- Locations with a lot of salt and metal powder;

- Locations where the main unit is subject to direct vibration and shock.

● Take adequate shielding measures when using at the following locations.

- Near a power line.

- Where a strong electric field or magnetic field is formed.

- Where static electricity, relay noise or the like is generated.

● Install the F701-C as far away from devices generating high frequency, high voltage, large

current, surge, etc., as possible. Also, carry out wiring separately from their power lines. Do

not carry out parallel wiring and common wiring.

● Do not use it, broken down.

III

CAUTION

This sign forewarns the presence of hazards

that could result in personnel injury or property

damage when incorrectly handled.

Caution on wiring

Caution during startup and maintenance

Caution during transportation

Caution during disposal

● Tighten the screws for the signal input/output terminals at the specified torque.

If they are loose, shorts, fire or malfunctions may occur.

Tightening torque: 0.5N •m

● For sensors, external inputs/outputs and options, use shielded cables.

● The temporary overvoltage applied to the power should not exceed 1500V.

● For turning on/off the power, be sure to keep intervals of 5 seconds or more.

● After power-on, make sure to warm up the F701-C for at least 30 minutes or more before use.

● If the F701-C is not used by the specified method, its protective performance may be

impaired.

● Maintenance

- When performing maintenance, disconnect the power.

- Do not wipe with a wet rag, or with benzine, thinner, alcohol, etc. Doing so may cause

discoloration or deformation of the F701-C. In the case of heavy contamination, wipe off

the contamination with a cloth after dipping it into a diluted neutral detergent and wringing

it well, and then wipe with a soft, dry cloth.

● When the F701-C is shipped, spacers made of corrugated cardboard are used as

cushioning materials.

Though it is factory-designed so that shocks can sufficiently be absorbed, breakage may

result if shocks are applied when the spacers are reused for transportation. If you send the

F701-C to us for repair, etc., take adequate measures against shocks by using polyurethane

materials, etc., separately.

● If you dispose of the product, handle it as industrial waste.

● Remove the lithium batteries used in the F701-C and make sure to dispose them according

to classification of waste collection.

IV

CONTENTS

CONTENTS

1.APPEARANCE DESCRIPTION .................................................1

1-1.Front Panel .................................................................................................... 1

1-2.Rear Panel ..................................................................................................... 6

2.CONNECTION ............................................................................8

2-1.Load cell Connection ................................................................................... 8

2-1-1.6-wire Connection ........................................................................................ 10

2-1-2.4-wire Connection ........................................................................................ 10

2-1-3.Connecting Load cells in Parallel ............................................................... 11

2-1-4.Sensor Cable ................................................................................................. 11

2-2.Connection of the Power Input Terminals ............................................... 12

2-3.Connection of the Guard Ground ............................................................. 12

2-4.SI/F Connection .......................................................................................... 13

2-5.Connection of the Control Connector ...................................................... 14

2-5-1.Control Connector-Pin Assignment ........................................................... 14

2-5-2.How to Assemble the Connector ................................................................ 15

2-5-3.Equivalent Circuit (Input) ............................................................................. 16

2-5-4.Equivalent Circuit (Output) .......................................................................... 16

3.METHODS OF SETTING .........................................................17

3-1.Setting Procedure ...................................................................................... 17

3-1-1.Method of Selecting a Setting Mode ........................................................... 17

3-1-2.Method of Entering a Setting Value ............................................................ 19

3-2.Setting Mode ............................................................................................... 23

3-2-1.Setting Mode 0 .............................................................................................. 24

3-2-2.Setting Mode 1 .............................................................................................. 26

3-2-3.Setting Mode 2 .............................................................................................. 28

3-2-4.Setting Mode 3 .............................................................................................. 31

3-2-5.Setting Mode 4 .............................................................................................. 33

3-2-6.Setting Mode 5 .............................................................................................. 36

3-2-7.Setting Mode 8 .............................................................................................. 38

4.CALIBRATION .........................................................................41

4-1.Span Calibration ......................................................................................... 41

4-2.Span Calibration Procedure ...................................................................... 42

4-3.Secondary Calibration Procedure (Equivalent Calibration) ................... 43

4-4.Preparation for Calibration ........................................................................ 45

4-4-1.LOCK Release ............................................................................................... 45

4-4-2.Unit ................................................................................................................. 46

4-4-3.Decimal Place ............................................................................................... 46

4-4-4.Capacity ......................................................................................................... 47

V

CONTENTS

4-4-5.Minimum Scale Division .............................................................................. 47

4-4-6.Balance Weight Value .................................................................................. 48

4-4-7.Gravitational Acceleration ........................................................................... 48

4-4-8.1/4 Scale Division ......................................................................................... 50

4-5.Zero Calibration .......................................................................................... 51

4-6.Span Calibration ......................................................................................... 53

4-7.Secondary Calibration (Equivalent Calibration) ...................................... 54

5. FUNCTION SETTINGS .............................................................55

5-1.Display Frequency ..................................................................................... 55

5-2.Subdisplay Selection ................................................................................. 56

5-3.Digital Filter ................................................................................................. 56

5-4.Analog Filter ............................................................................................... 57

5-5.Filter in Stable Condition ........................................................................... 57

5-6.Motion Detection (MD) ............................................................................... 58

5-7.Zero Tracking (ZT) ...................................................................................... 60

5-8.Digital Zero (DZ) ......................................................................................... 61

5-9.Digital Zero Clear ........................................................................................ 62

5-10.Zero Regulation Value ............................................................................. 62

5-11.One-touch Tare Subtraction .................................................................... 63

5-12.One-touch Tare Subtraction Reset ......................................................... 64

5-13.Digital Tare Subtraction ........................................................................... 65

5-14.Restriction of the Tare Subtraction Function ........................................ 66

5-15.Switching Gross Weight/Net Weight Display ........................................ 67

5-16.Reversing Symbol at Discharging Control ............................................ 68

5-17.Invalidation of Function Keys ................................................................. 68

6.DISCHARGING CONTROL MODE ..........................................69

6-1.Feeding Weighing and Discharging Weighing ........................................ 69

6-1-1.Feeding Weighing ......................................................................................... 69

6-1-2.Discharging Weighing .................................................................................. 72

6-1-3.Discharging Mode ........................................................................................ 75

VI

6-2.Simple Comparison Control and Sequence Control ............................... 76

6-2-1.Simple Comparison ...................................................................................... 76

6-2-2.Sequential Control ........................................................................................ 77

6-2-3.Sequence Mode ............................................................................................ 82

6-3.Auto Free Fall Compensation Regulation /

Auto Free Fall Compensation ON/OFF /

Average Count of Auto Free Fall Compensation /

Auto Free Fall Compensation Coefficient ................................................ 83

CONTENTS

6-4.Final / Set Point 2 / Set Point 1 / Compensation / Over / Under ............. 86

6-5.Negative Compensation ............................................................................ 89

6-6.Near Zero / Upper Limit / Lower Limit ...................................................... 90

6-7.Upper/Lower Limit Comparison /

Upper/Lower Limit Comparison Mode /

Near Zero Comparison / Final and Comparison /

Over/Under Comparison Mode ................................................................. 91

6-8.Complete Signal Output Mode / Complete Output Time /

Judging Time / Comparison Inhibit Time / Output Selection 2 .............. 93

6-9.Judging Times / AZ Times / At Start Near Zero Confirmation /

At Start Weight Value Confirmation / Adjust Feeding /

Adjust Feeding Time .................................................................................. 96

6-10.Net Over / Gross Over ............................................................................ 100

6-11.Weight Error / Sequence Error .............................................................. 101

7.STATISTICAL AND ACCUMULATION FUNCTION SETTING AND

OPERATION ...........................................................................102

7-1.Data Display .............................................................................................. 103

7-2.Accumulation Command ......................................................................... 103

7-3.Accumulation Clear .................................................................................. 105

7-4.Auto Accumulation Command ................................................................ 107

8.SYSTEM MODE .....................................................................109

8-1.LOCK (soft) ............................................................................................... 109

8-2.Password .................................................................................................. 109

8-3.Self-Check and Memory Clear ................................................................. 110

9.EXTERNAL INPUT/OUTPUT SIGNALS

(CONTROL CONNECTOR) ....................................................111

9-1.Control Connector-Pin Assignment ....................................................... 111

9-2.Equivalent Circuit (Input) ......................................................................... 112

9-3.Equivalent Circuit (Output) ...................................................................... 112

9-4.External Input Signal ................................................................................ 113

9-4-1.Gross/Net Switching (G/N) <Edge Input> <Level Input> ......................... 113

9-4-2.Digital Zero (D/Z ON) <Edge Input> .......................................................... 113

9-4-3.Tare Subtraction (TARE ON) <Edge Input> .............................................. 114

9-4-4.Tare Subtraction Reset (TARE OFF) <Edge Input> ................................. 114

9-4-5.Hold (HOLD) <Level Input> ........................................................................ 114

9-4-6.Judge <Level Input> ................................................................................... 115

9-4-7.Feed / Discharge <Level Input> ................................................................. 115

9-4-8.Input Signals Used in Sequence Mode ..................................................... 115

VII

CONTENTS

9-4-9.Accumulation command <Edge Input> .................................................... 116

9-4-10.Accumulation Clear <Edge Input> .......................................................... 116

9-4-11.Input Selection .......................................................................................... 117

9-5.External Output Signal ............................................................................. 118

9-5-1.Near Zero ..................................................................................................... 118

9-5-2.Lower Limit, Upper Limit ........................................................................... 118

9-5-3.Stable ........................................................................................................... 118

9-5-4.Weight Error ................................................................................................ 118

9-5-5.Sequence Error ........................................................................................... 119

9-5-6.RUN .............................................................................................................. 119

9-5-7.Accumulation Error .................................................................................... 119

9-5-8.SP1, SP2, SP3 ............................................................................................. 120

9-5-9.Under, Go, Over .......................................................................................... 121

9-5-10.Complete ................................................................................................... 122

9-5-11.Output selection ....................................................................................... 123

10.INTERFACE .........................................................................124

10-1.2-wire Serial Interface (SI/F) .................................................................. 124

10-1-1.Connection ................................................................................................ 124

10-1-2.Auto Print Command ................................................................................ 124

10-2.RS-232C Interface ................................................................................... 125

10-2-1.Communication Specifications ............................................................... 125

10-2-2.Cable .......................................................................................................... 125

10-2-3.Setting Values for RS-232C ..................................................................... 126

10-2-4.Communication Mode .............................................................................. 126

10-2-5.Transmission Format ............................................................................... 128

10-2-6.Communication Format ........................................................................... 129

10-3.BCD Parallel Data Output Interface ...................................................... 137

10-3-1.Control Connector-Pin Assignment ....................................................... 137

10-3-2.Equivalent Circuit (Input) ......................................................................... 137

10-3-3.Equivalent Circuit (Output) ...................................................................... 138

10-3-4.BCD Data Output ...................................................................................... 138

10-3-5.Polarity Output (MINUS) ........................................................................... 138

10-3-6.Over Status Output (OVER) ..................................................................... 139

10-3-7.Print Command Output (P.C) ................................................................... 139

10-3-8.Data Strobe (STROBE) ............................................................................. 139

10-3-9.BCD Data Update Rate Selection ............................................................ 140

10-3-10.Data Hold Input ....................................................................................... 140

10-3-11.Logic Switching Input ............................................................................ 140

10-3-12.Output Selection Input ........................................................................... 140

10-4.D/A Converter ......................................................................................... 141

10-4-1.Name of Each Part .................................................................................... 141

10-4-2.Specifications ........................................................................................... 143

10-4-3.Method of Adjusting the D/A Zero and Gain .......................................... 143

10-4-4.About D/A Resolution .............................................................................. 145

VIII

10-5.RS-485 Communication Interface ......................................................... 146

10-5-1.Communication Specifications ............................................................... 146

10-5-2.RS-485 Connection ................................................................................... 146

10-5-3.Setting Values for RS-485 ........................................................................ 147

10-5-4.Communication Method ........................................................................... 148

10-5-5.Communication Format ........................................................................... 149

CONTENTS

11.OVER SCALE & ERROR .....................................................157

11-1.Over Scale ............................................................................................... 157

11-2.Sequence Error ....................................................................................... 157

11-3.Calibration Error ..................................................................................... 158

12.TROUBLE SHOOTING ........................................................159

13.REPLACEMENT OF THE BACKUP BATTERY ..................166

14.BLOCK DIAGRAM ...............................................................167

15.DIMENSIONS .......................................................................168

16.MOUNTING ON A PANEL ...................................................169

17.SPECIFICATIONS ................................................................170

17-1.Analog Section ....................................................................................... 170

17-2.Display Section ....................................................................................... 171

17-3.Setting Section ....................................................................................... 171

17-4.External Input/Output ............................................................................. 172

17-5.Interface .................................................................................................. 172

17-6.General Performance ............................................................................. 174

17-7.Attachment .............................................................................................. 175

18.THE LIST OF INITIAL SETTING VALUE .............................176

18-1.Setting Mode 0 ........................................................................................ 176

18-2.Setting Mode 1 ........................................................................................ 176

18-3.Setting Mode 2 ........................................................................................ 177

18-4.Setting Mode 3 ........................................................................................ 177

18-5.Setting Mode 4 ........................................................................................ 177

18-6.Setting Mode 5 ........................................................................................ 178

18-7.Setting Mode 8 ........................................................................................ 178

18-8.Calibration Mode (Setting Mode 9) ....................................................... 178

IX

CONTENTS

M E M O

X

1. APPEARANCE DESCRIPTION

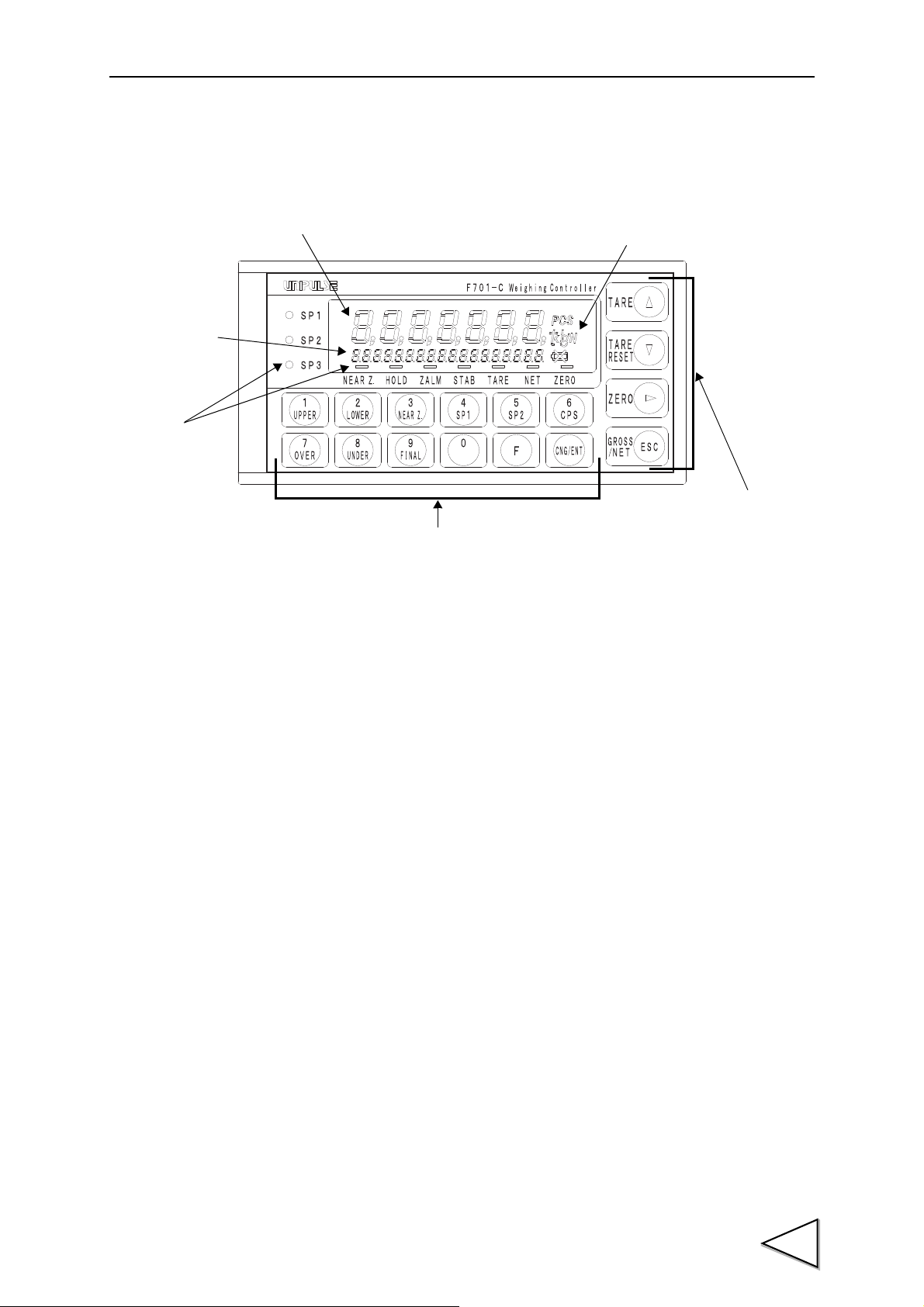

④ Status display

① Main display

⑤ Setting keys

③ Unit indication

⑥ Function keys

② Subdisplay

1-1. Front Panel

1.APPEARANCE DESCRIPTION

① Main display

The following three types are displayed.

(1) Weight value display

Displays the Gross weight or the Net weight.

When error occurred, the display shows error and weight value alternately.

(2) Over scale and error display

Over-scale, sequence errors and calibration errors are displayed.

* Please refer to "11.OVER SCALE & ERROR" on P.157.

(3) Setting value display

Various final discharge setting values and setting values for adjustment, such as Final and Set

Point 2, are displayed.

1

1.APPEARANCE DESCRIPTION

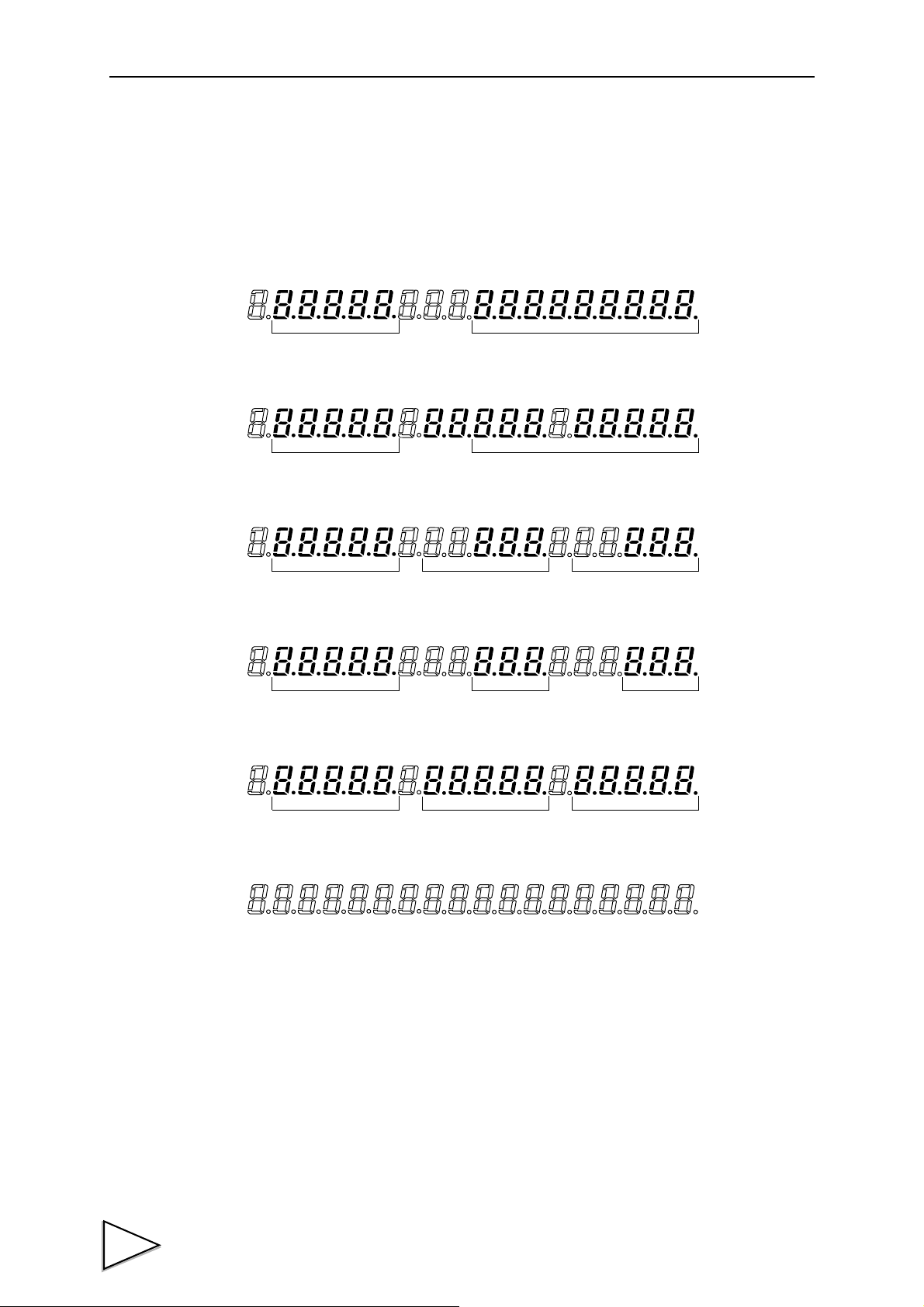

Accumulation Count Accumulation Value

Latest Accumulation Data Accumulation Value

Accumulation Count FinalLatest Accumulation Data

Final UnderOver

Near Zero Lower LimitUpper Limit

② Subdisplay

Weighing data, such as Accumulation Value, and various setting values are displayed by setting.

* Please refer to "- Function Selection" on P.32, "5-2.Subdisplay Selection" on P.56.

(1) Accumulation Count, Accumulation Value

(2) Latest Accumulation Data, Accumulation Value

(3) Accumulation Count, Latest Accumulation Data, Final

(4) Final, Over, Under

(5) Near Zero, Upper Limit, Lower Limit

(6) None

2

1.APPEARANCE DESCRIPTION

NEAR Z.

HOLD

“ ”

ZALM

STAB

“ ”

TARE

“ ”

NET

Accumulation Count Displays the count accumulated by the auto

accumulation command or external input/output signal,

or through RS-232C communication, etc.

Accumulation Value Displays the value accumulated by the auto

accumulation command or external input/output signal,

or through RS-232C communication, etc.

Latest Accumulation Data Displays the latest data accumulated by the auto accumulation

command or external input/output signal, or through RS-232C

communication, etc.

Final Displays the “Final” value set in the setting mode 0-9.

Over Displays the “Over” value set in the setting mode 0-7.

Under Displays the “Under” value set in the setting mode 0-8.

Near Zero Displays the “Near zero” value set in the setting mode 0-3.

Upper Limit Displays the “upper limit” value set in the setting mode 0-1.

Lower Limit Displays the “lower limit” value set in the setting mode 0-2.

③ Unit indication

The unit can select from six types: t, kg, g, N, lb and None.

④ Status display

SP1 Lights when the Set Point 1 signal is ON.

SP2 Lights when the Set Point 2 signal is ON.

SP3 Lights when the Set Point 3 signal is ON.

NEAR Z. Lights when the Near Zero signal is ON. “ ”

HOLD Lights when the weight value is held. “ ”

ZALM Lights when the DZ Regulation Value is exceeded in

Digital zero/Zero tracking operation.

(Such as when any load cell has a problem with its zero point.)

STAB Lights when the weight value is stable. “ ”

TARE Lights when Tare subtraction is performed.

Flashes when the Tare weight is displayed.

NET Lights when the weight value display is Net weight.

Goes out when it is Gross weight.

3

1.APPEARANCE DESCRIPTION

“ ”

ZERO

**

0

0

TARE

0

0

~

1

UPPER

9

FINAL

F

CNG/ENT

TARE

TARE

STAB

TARE

RESET

ZERO - Lights at a true zero point (0±1/4 scale division).

(When the 1/4 scale division display is OFF under

Function Selection in setting mode 3.)

- Lights at a true zero point (0±1/4 scale division),

and at the central point of the scale interval of the indicated

value (indicated value ±1/4 × Min. Scale Division).

(When the 1/4 scale division display is ON under

Function Selection in setting mode 3.)

Flashes when the voltage of the lithium battery for memory backup has

dropped.Replace with a new battery.

For the method of replacement, refer to "13.REPLACEMENT OF THE BACKUP

BATTERY" on P.166.

* The expression “ ” in this instruction manual shows that 「」 on the status display lights,

goes out, or flashes.

⑤ Setting keys

⑥ Function keys

When the key is pressed, the Tare weight is displayed, and

“” flashes.

(When the Tare weight display with the key is valid under

Restriction on the Tare Subtraction Function in setting mode 4.)

To go back to the weight display, press the key again.

Numerical keys to make settings.

Function key to switch the setting mode.

Change/Enter key to confirm setting items and setting values.

Key to perform one-touch Tare subtraction.

“ ” on the status display lights. (In setting mode 0)

However, Tare subtraction is performed only in the following cases

depending on the setting of Restriction on the Tare Subtraction Function

in setting mode 4.

- When the weight value is stable (when “ ” is on).

- When the range of Tare subtraction is 0 < Ta r e ≦ Capacity.

Use as an increment key for setting operation.

Key to reset Tare subtraction. (In setting mode 0)

However, the Tare Weight is not cancelled.

Use as a decrement key for setting operation.

4

1.APPEARANCE DESCRIPTION

ZERO

ZERO

CNG/ENT

ZALM

GROSS

/NET

ESC

GROSS

/NET

ESC

NET

NET

Functioning of the Function keys can be invalidated by setting of

"5-17.Invalidation of Function Keys" on P.68.

When → is pressed, Gross is zeroed

immediately. (In setting mode 0)

However, if this operation is performed with Gross out of

the DZ Regulation Value, “ ” flashes.

(For details of the DZ Regulation Value, refer to

"5-10.Zero Regulation Value" on P.62.)

To discontinue, press the key.

Use to shift setting values for setting operation.

Switch the weight display (Gross/Net). (In setting mode 0)

Pressing on Gross weight display (when “ ” is OFF)

switches to Net weight display, and pressing on Net weight display

(when “ ” is ON) switches to Gross weight display.

However, the display cannot be switched with this key if the switching

Gross weight/Net weight display is set to external input mode under

External Function Selection in setting mode 4.

Use as an ESC key for setting operation.

5

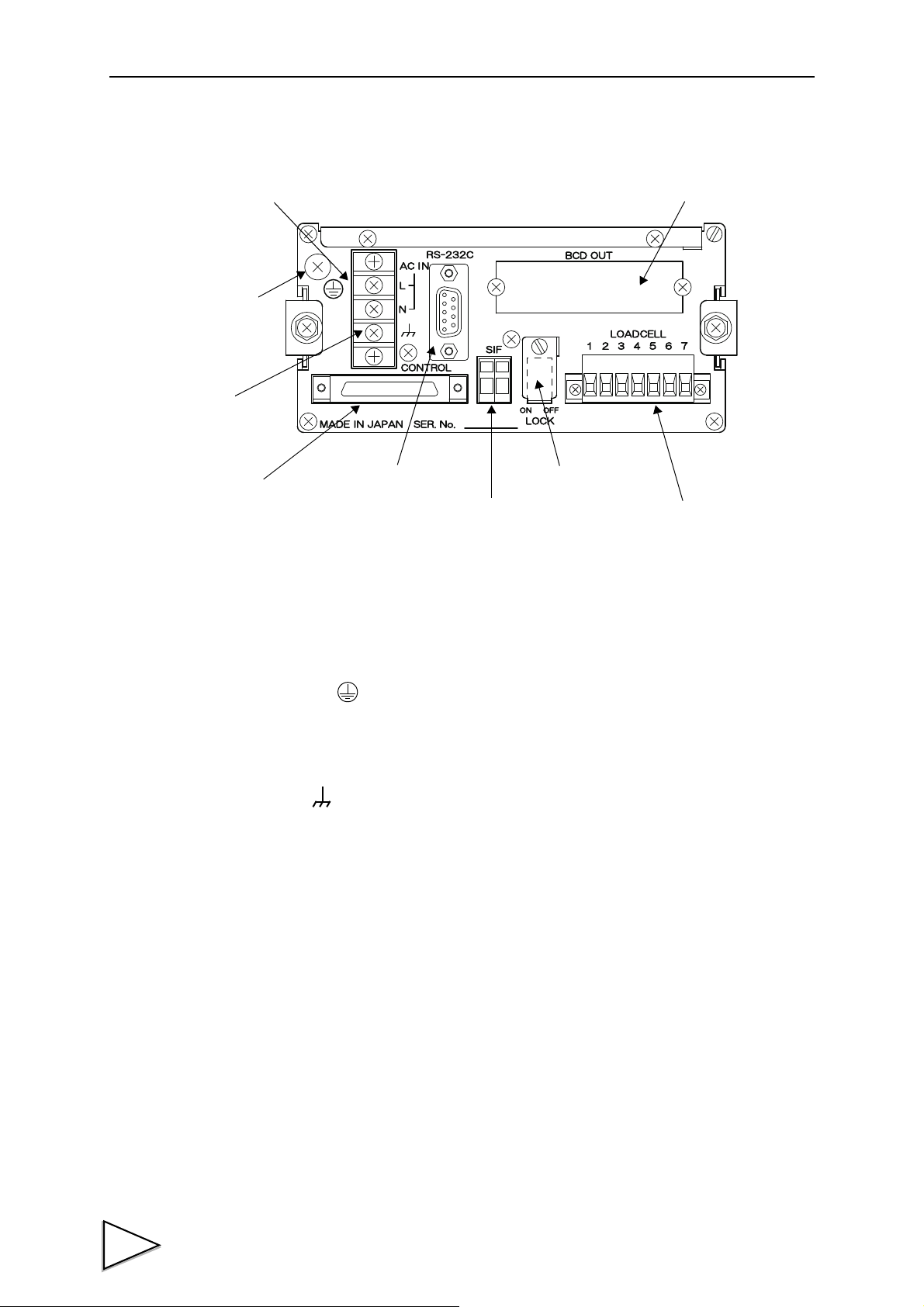

1.APPEARANCE DESCRIPTION

① AC power input terminal block

④ Control connector

⑥ SI/F terminal block

⑦ LOCK switch

⑧ Load cell input terminal block

⑨ Option space

③ Frame ground

⑤ RS-232C connector

② Protective ground

1-2. Rear Panel

① AC power input terminal block

Connect AC power code. The input voltage is 100V ~ 240V AC.

The frequency is 50/60Hz.

② Protective ground

Be sure to ground the protective ground terminal to prevent electric shocks.

③ Frame ground

Please ground the frame ground terminal to prevent failures due to static electricity.

(The frame and the frame ground terminal are conducted.)

It may be better to remove depending on the environment of the installation location.

④ Control connector

This is a connector to input external signals and output control signals. The Input/Output circuit and

6

internal circuit are photocoupler-insulated electrically.

The applicable connector is the following (accessory) manufactured by Fujitsu Component or an

equivalent:

Connector : FCN-361J024-AU

Cover : FCN-360C024-B

1.APPEARANCE DESCRIPTION

⑤ RS-232C connector

RS-232C connector for receiving and transmitting weight data and status information.

The applicable connector is JAE DE-09SN or its equivalent.

⑥ SI/F terminal block

2-wire serial interface is to connect unipulse peripheral equipment such as printer, remote display

or data converter.

⑦ LOCK switch

LOCK switch for avoiding changes of setting value, it prohibits to change setting value while the

switch is ON.

⑧ Load cell input terminal block

This is a terminal block to connect load cell(s).

The applicable terminal block is Osada-manufactured ETB42-07P.

⑨ Option space

One of the following options can be mounted.

- BCD parallel data output interface (BCO)

- D/A converter (DAC)

- RS-485 communication interface (485)

- CC-Link interface (CCL)

7

2.CONNECTION

Load cell terminal block

2. CONNECTION

2-1. Load cell Connection

The voltage application of F701-C is 10V, and the maximum current is 120mA, to which up to four

350Ω load cells can be connected in parallel.

Load cell terminal block pin assignments

Pin No. Signal (6-wire) Signal (4-wire)

1+SIG +SIG

2-SIG -SIG

3+EXC +EXC

4+S

5 -EXC -EXC

6-S

7 SHIELD SHIELD

(Connect 3 to 4)

(Connect 5 to 6)

8

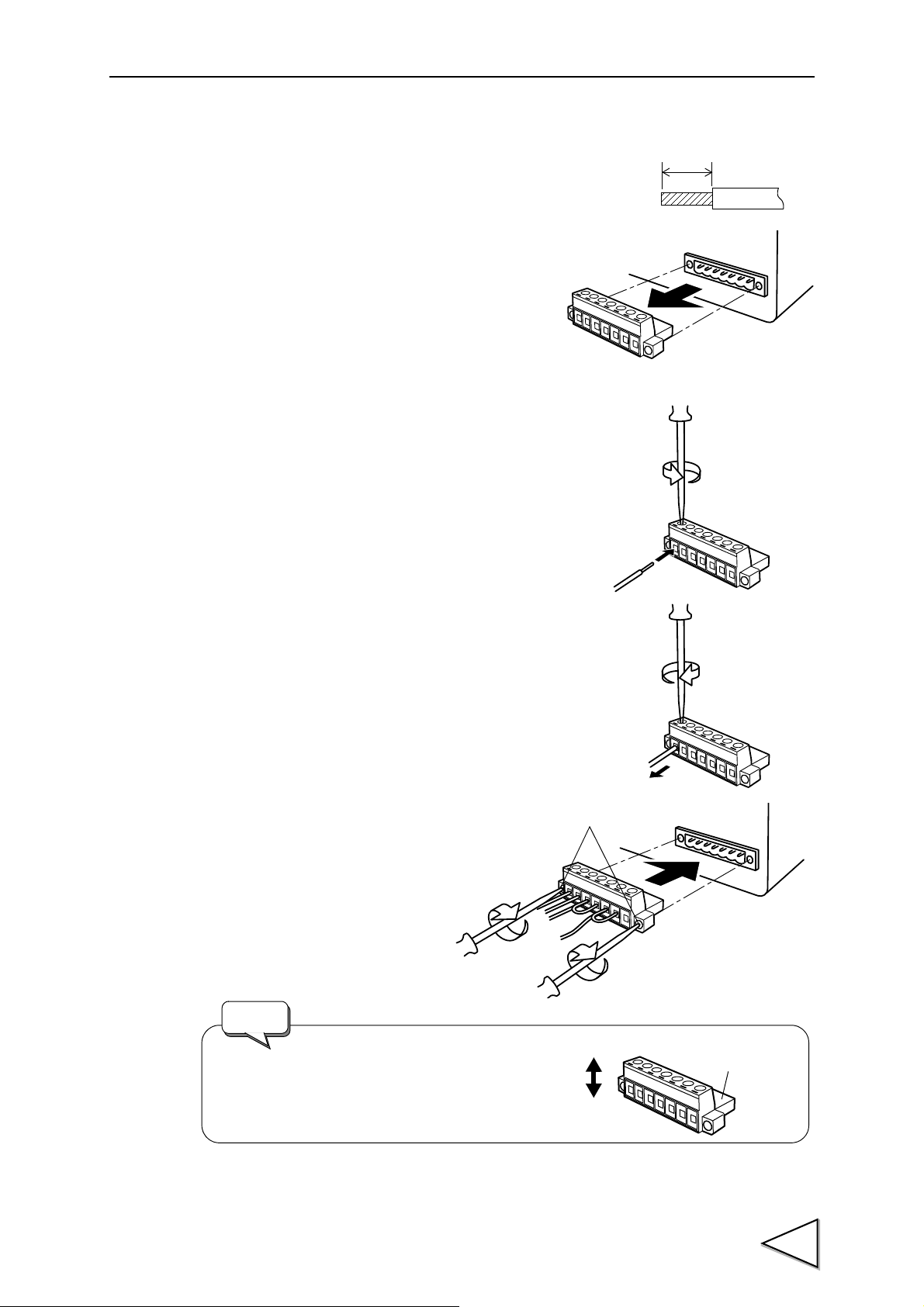

Method of connection

5mm

Hole

Turn

counterclockwise.

Turn

clockwise.

Turn clockwise.

Screws(two)

When mounting the terminal block to the

F701-C body, check its vertical orientation.

(See the illustration on the right-hand side.)

UP

DOWN

Request

Insertion side

1) Peel the sheath of the wire to be connected 5mm.

2) Twist the end to such an extent that it will not become loose.

3) Remove the terminal block from the F701-C body

with a strong pull.

4) Loosen the screw with a screwdriver to open the hole.

A Phillips screwdriver with a shaft diameter of 3 ~ 3.5mm

#1 is recommendable

(precision screwdriver, etc.).

5) Insert the wire into the hole so as not to loosen the end.

2.CONNECTION

6) Tighten the screw with the screwdriver.

7) Lightly pull the wire to check that it is clamped securely.

* Connectable wires are 0.21 ~ 3.31mm

2

(AWG12 ~ 24).

Recommendable tightening torque is 0.5Nm.

8) Insert the wire-connected plug into

the F701-C body, and tighten the

screws (two).

9

2.CONNECTION

+IN

-OUT

-IN

+EXC

+S

-S

-EXC

+SIG

-SIG

SHIELD

+OUT

3

4

6

5

1

2

7

Load cell

+IN

-OUT

-IN

+EXC

+S

-S

-EXC

+SIG

-SIG

SHIELD

+OUT

3

4

6

5

1

2

7

Load cell

These jumpers MUST be connected.

- The load cell excitation voltage of the F701-C is 10V. Heating or breakage may occur

unless the load cells maximum excitation voltage is 10V or more.

- When using the F701-C with the four-wire load cell connected, be sure to connect +EXC

and +S, and -EXC and -S. Even if +S and -S are not connected, normal operation is

performed apparently, but heating or breakage may occur because excessive voltage is

applied to the load cell.

CAUTION

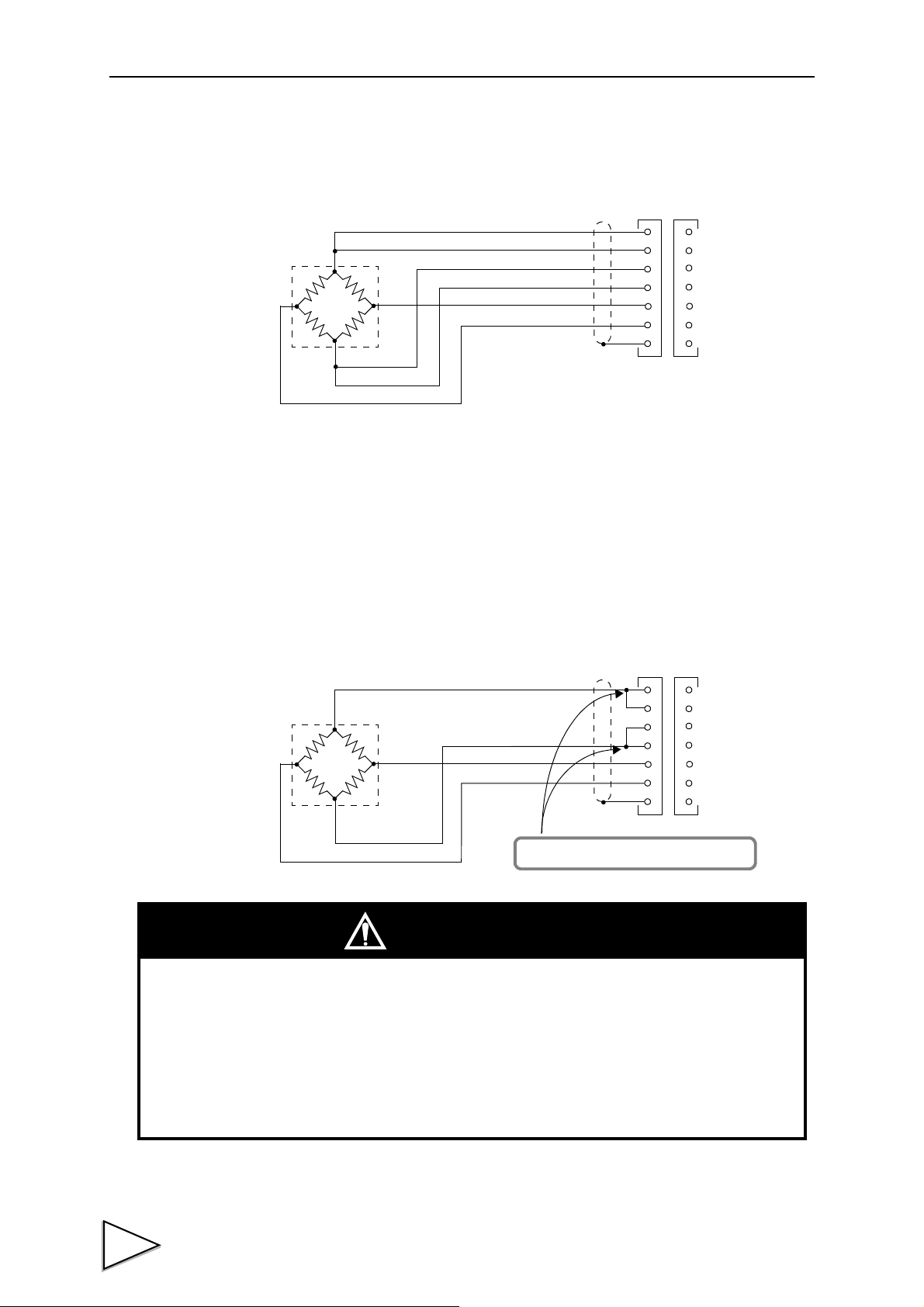

2-1-1. 6-wire Connection

The load cell input of the F701-C is a 6-wire (remote sense) connection. 6-wire shielded load cell

cable should be used and kept separate from AC or other noise generating wire.

* Remote sense lines are used to detect and correct variations in excitation voltage over long cable

runs.

2-1-2. 4-wire Connection

Connect 3 and 4, and 5 and 6 as shown below.

Even 4 and 6 on the terminal block are open, normal operation is performed apparently, but heating

or breakage may occur because excessive voltage is applied to the load cell.

For connection, use the accessory jumper lines.

10

2.CONNECTION

R

R

R

R

R

R

+EXC

-SIG

+SIG

-EXC

+EXC

-SIG

-EXC

+SIG

SHIELD

+S

-S

When connecting several load cells in parallel, load cell capacity should be higher than

expected load to compensate for mechanical shock or eccentric loading.

R

R

The group of “n” parallel load cells

viewed from this device side can be

regarded as a unit load cell the rated

capacity of which is multiplied by “n”

and the sensitivity of which is

unchanged. The averaging resistance (R)

should be 300 to 500Ω, equal in relative

ratio and excellent in temperature

coefficient. No averaging resistance is

needed if load cells with consideration

for parallel connection are used.

Request

2-1-3. Connecting Load cells in Parallel

In some industrial weighing apparatus, two or more load cells may be connected in parallel to form

a hopper scale or track scale. The manner of connection is shown below.

Parallel connection can simply be made by using the optionally available B410 (summing box for

4-point multi load cell).

2-1-4. Sensor Cable

Cable colors of sensors may differ from one manufacturer to another (it may even differ from one

model to another for some products). Refer to the sensor manual (or data sheet) and check signal

names and colors in order to connect the cables correctly.

11

2.CONNECTION

block cover

Within 6mm

AC power cord

Frame

ground

- Connect with no power applied because it may cause an electric shock.

- The attached AC cable is designed for domestic use in Japan, and its rating is 125V AC,

7A. For use at voltages exceeding the rating and for overseas use, have a separate AC

cable prepared.

- Since the F701-C has no power switch, install a breaker.

- Be sure to ground the protective ground terminal to prevent electric shocks.

Do not use other screws than that attached to the main body.

CAUTION

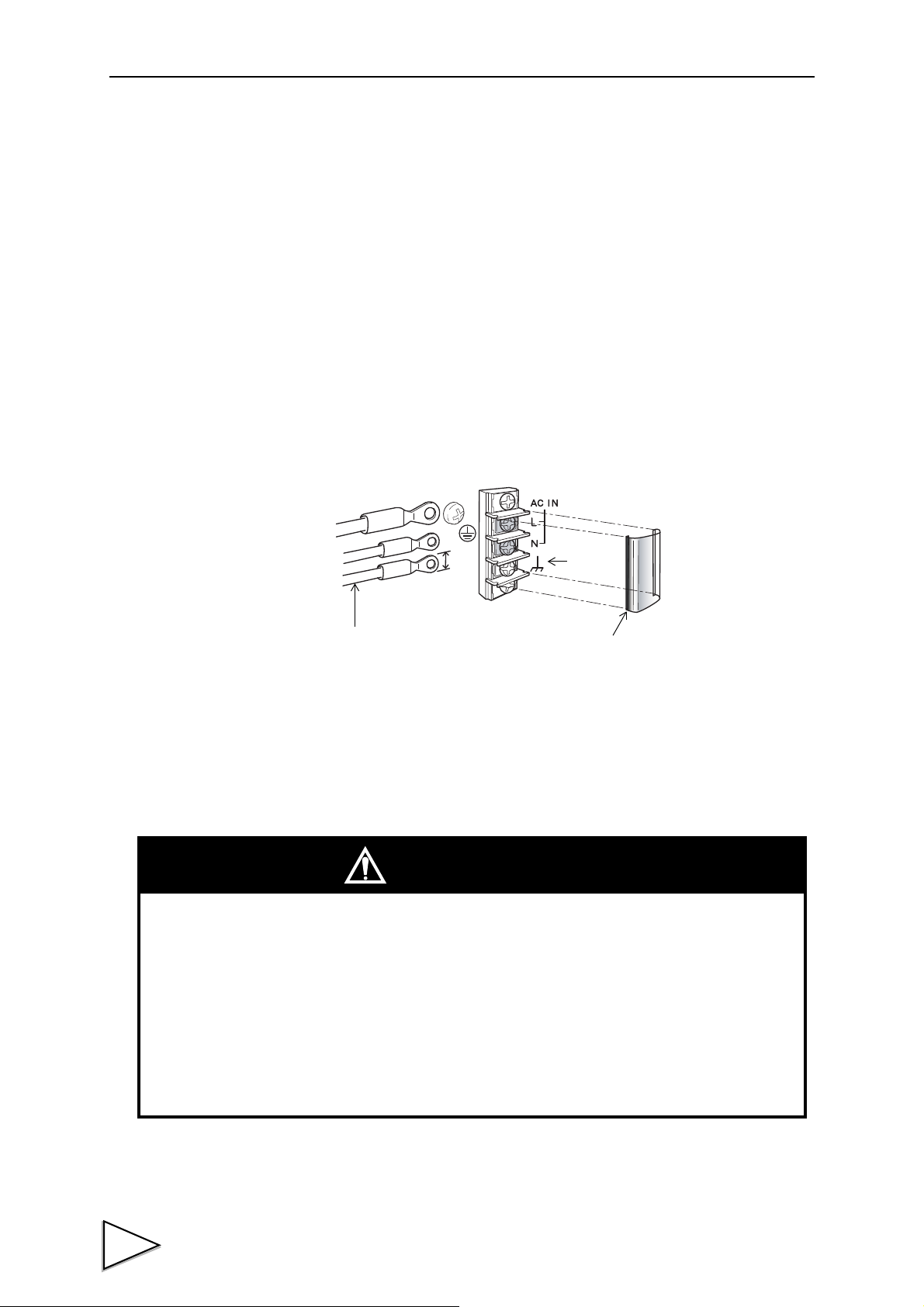

2-2. Connection of the Power Input Terminals

Connect AC power cord. The input voltage is 100V ~ 240V AC.

The frequency is 50/60Hz.

1) Make sure that no power is applied.

2) Remove the terminal block cover.

3) Remove the two screws(M3) of the terminal block, align the crimp contacts with the

screw holes, and then tighten the screws.

4) Mount the terminal block cover.

5) Remove the screws(M4) of the protective ground, align the crimp contacts with the

screw holes, and then tighten the screws.

2-3. Connection of the Guard Ground

The grounding terminal is for prevention of electric shocks.

2

Use an approx. 0.75mm

thick wire, and be sure to ground.

12

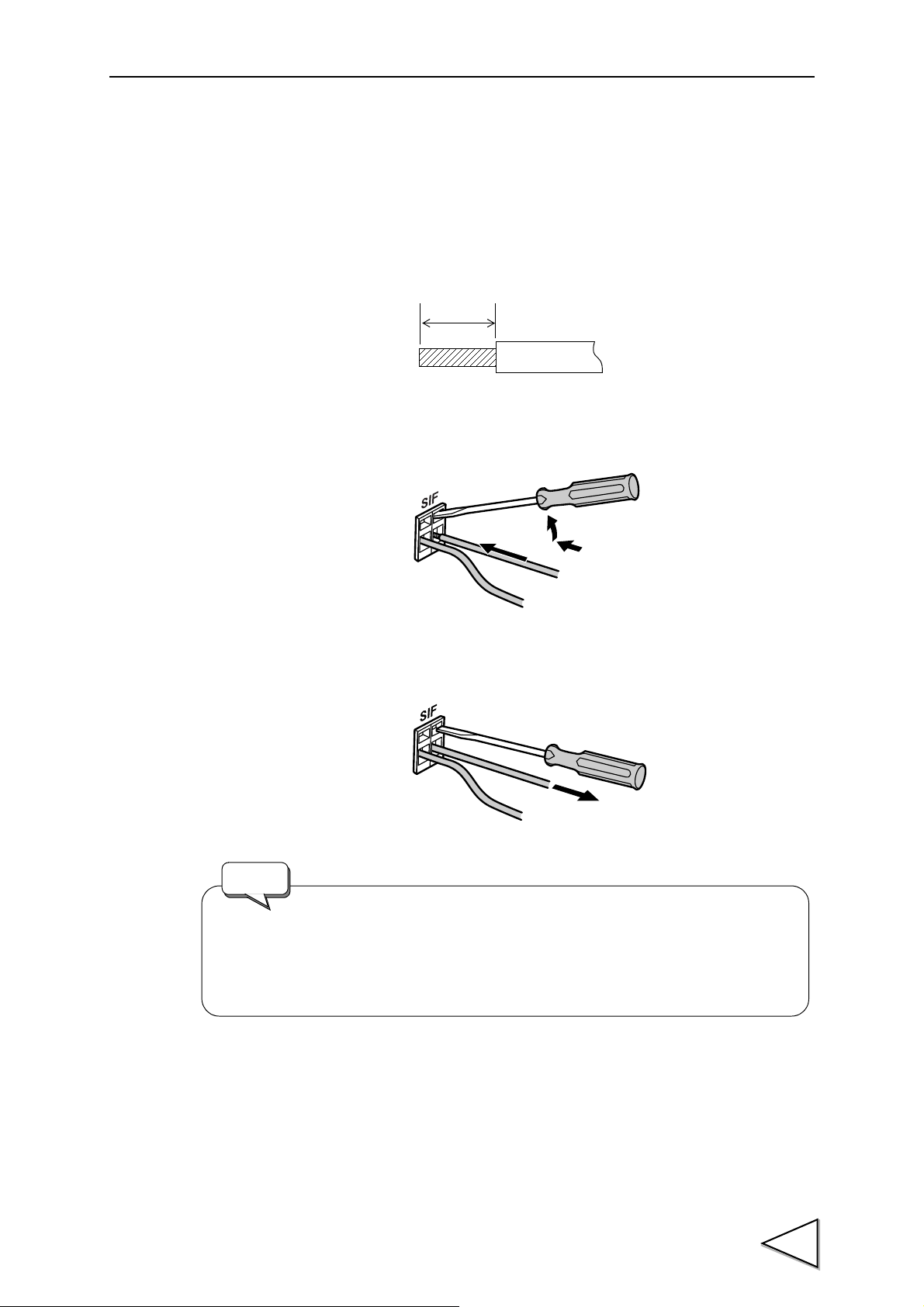

2-4. SI/F Connection

5 to 6mm

- Cable can be from 24 ~ 14AWG (0.2 ~ 2.5mm2).

- It is not necessary to solder the cable wires or to fix a solderless terminal.

- If several cables to be inserted to the same hole, twist those cable wires

together and insert.

Request

The SI/F allows connection of up to three nonpolarized external devices.

As for wire materials, use parallel 2-core cables, cabtyre cables, or the like.

Connect to the cage clamp type terminal block by using the attached mini screwdriver.

1) Strip the casing 0.2in (6mm) on the cable to be connected.

Twist the bare wire to fit the terminal hole.

2) Insert the supplied screwdriver into the upper hole and lift upward.

3) Insert the twisted wires into the lower hole.

2.CONNECTION

4) Pull the screwdriver out from the upper hole.

5) Make sure cable is clamped securely and does not come out with a slight tug.

13

2.CONNECTION

2-5. Connection of the Control Connector

Connect to the control connector (rear panel “CONTROL”).

The applicable connector is the following (accessory) manufactured by Fujitsu Component or an

equivalent:

Connector : FCN-361J024-AU

Cover : FCN-360C024-B

2-5-1. Control Connector-Pin Assignment

For details, please refer to "9.EXTERNAL INPUT/OUTPUT SIGNALS (CONTROL

CONNECTOR)" on P.111.

A1

A2 In G/N B2 In Input Selection 1 *1

A3 In D/Z ON B3 In Input Selection 2 *1

A4 In Tare Subtraction ON B4 In Input Selection 3 *1

A5 In Tare Subtraction OFF B5 In Input Selection 4 *1

A6 Out Near Zero B6 Out Lower Limit

A7 Out SP1 B7 Out Upper Limit

A8 Out SP2 B8 Out Stable

A9 Out SP3 B9 Out Output Selection 1 *2

A10 Out Under B10 Out Output Selection 2 *2

A11 Out Over B11 Out Output Selection 3 *2

A12

* * : The COM (common) terminals are connected inside.

* *1 : Selectable by setting.

* *2 : Selectable by setting. (For details, please refer to "6-11.Weight Error / Sequence Error" on

COM B1

*

COM B12

*

(For details, please refer to "9-4-11.Input Selection" on P.117)

P.101, "6-8.Complete Signal Output Mode / Complete Output Time / Judging Time /

Comparison Inhibit Time / Output Selection 2" on P.93, "9-5-7.Accumulation Error" on

P. 11 9 )

*

*

COM

COM

14

* SP1 turns ON when Weight value ≧ Final - SP1

SP2 turns ON when Weight value ≧ Final - SP2

SP3 turns ON when Weight value ≧ Final - CPS

2-5-2. How to Assemble the Connector

Connector

Pan-head machine screw

M2×8 (short) (two)

Nut M2 (four)

Pan-head machine screw

M2×10 (long) (two)

Washer (two)

Case (two)

Screw (two)

(1) Set the connector and screws (two) into the grooves of the case (one side).

2.CONNECTION

(2) Cover with the other case, and fit the cases.

(3) Tighten the M2×8 pan-head machine screws (two).

Tighten the M2×10 pan-head machine screws (two).

Be aware that washers should be set to the M2×10 pan-head machine screws (two).

15

2.CONNECTION

Vcc

F701-C

Inside

Approx.

COM

Transistor

+12V

Push

Toggle switch Relay

IN

IN

Open OFF

Short ON

- Do not apply external voltage to the signal input circuit.

- The external element is required to withstand Ic=10mA.

- Leakage from the external element is required to be 100μA or below.

switch

IC=6mA

TTL open collector

(ON when IN is HI)

Spark killer

Load

Spark killer

DC Power

Va ri s t o r

Load

AC power

Relay

Ve xt

Output data

Tr

0

OFF

1

ON

F701-C

Inside

Vcc

+12V

COM

Vceo=30V(max)

Ic =120mA (max)

- Use external power source (up to DC30V) for driving relay

(Vext).

- Do not short-circuit the load, such as a coil of relay, that will

break the output transistor.

- Connect a surge absorber or a speark killer to the relay

circuit as shown in the draft so that to reduce noise trouble

and extend the life of relay.

Noise trouble can be reduced, and the relay’s life can be

extended.

- Transistor status

2-5-3. Equivalent Circuit (Input)

A signal is inputted to the signal input circuit by short-circuiting or opening the input terminal and

the COM terminal. Short-circuiting is effected by means of a contact (such as a relay or a switch) or

a noncontact (such as a transistor or an open-collector TTL).

2-5-4. Equivalent Circuit (Output)

The signal output circuit is open-collecter output of a transistor.

16

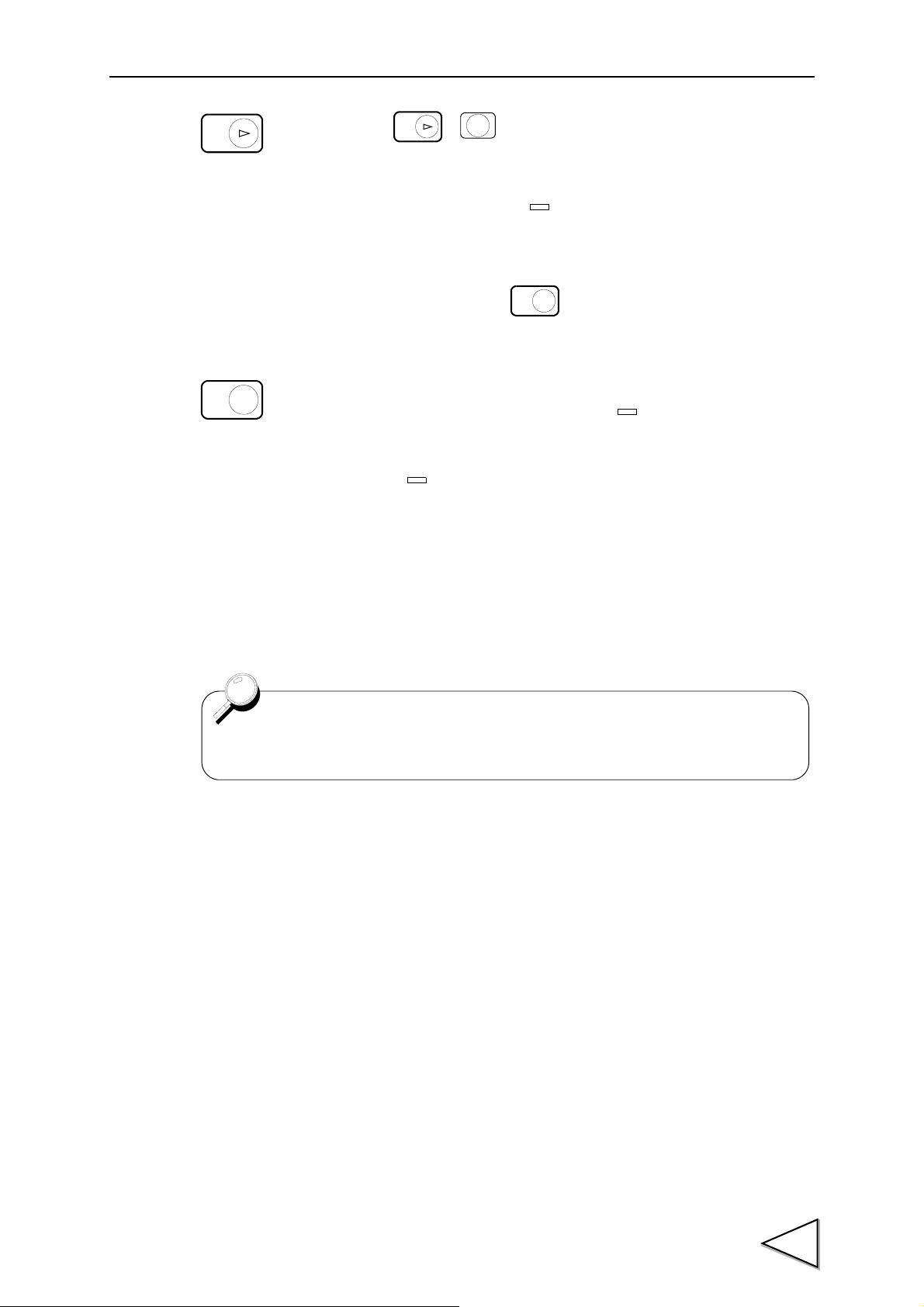

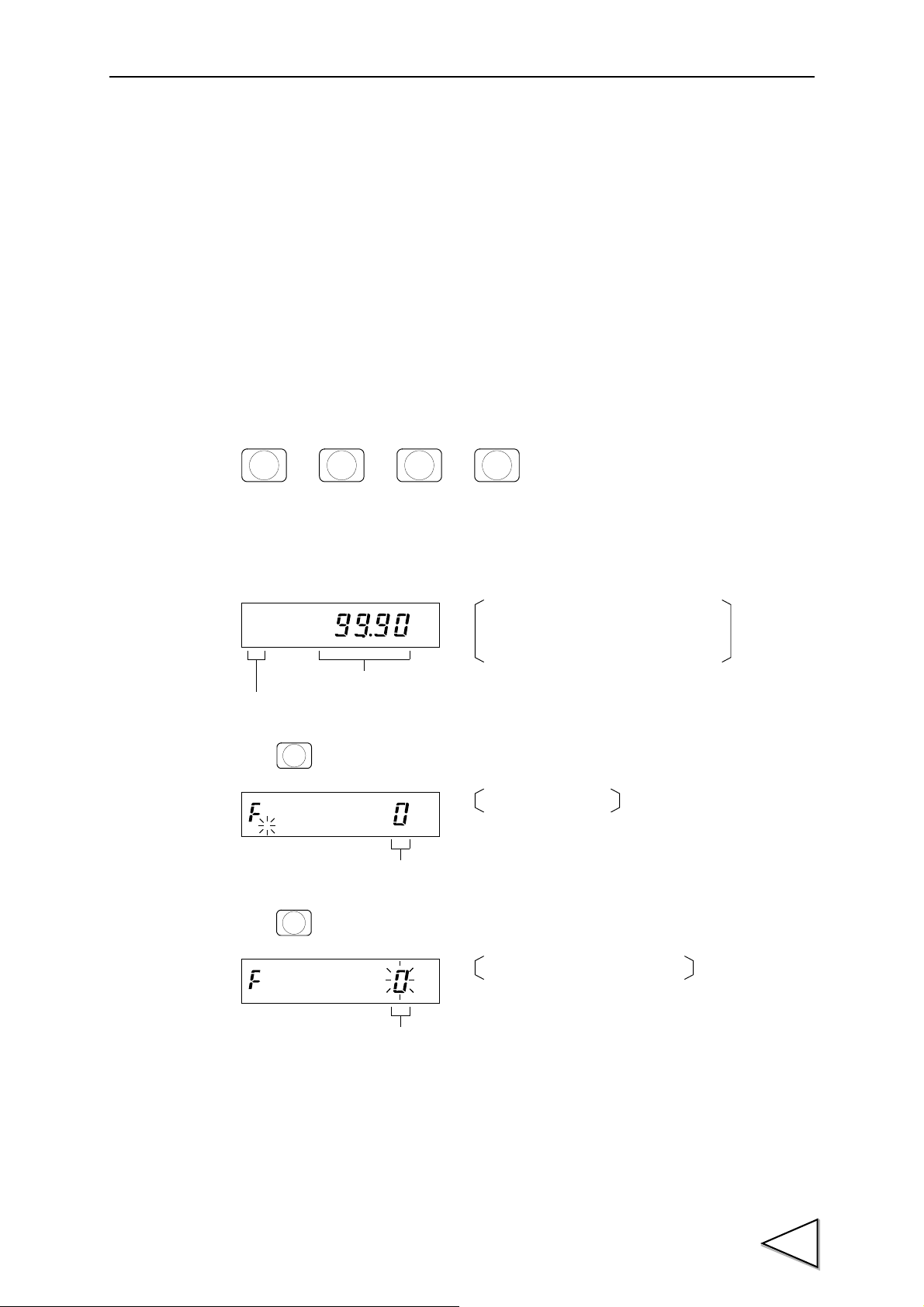

3. METHODS OF SETTING

→→→

F

CNG/ENT CNG/ENT

3

NEAR Z

.

kg

Normally the state is in setting mode 0.

The mode number is not displayed for

mode 0.

Setting mode number

Present weight value

F

kg

,

Setting mode number

The display changes.

,

CNG/ENT

kg

,

Setting mode number

The setting mode number blinks.

,

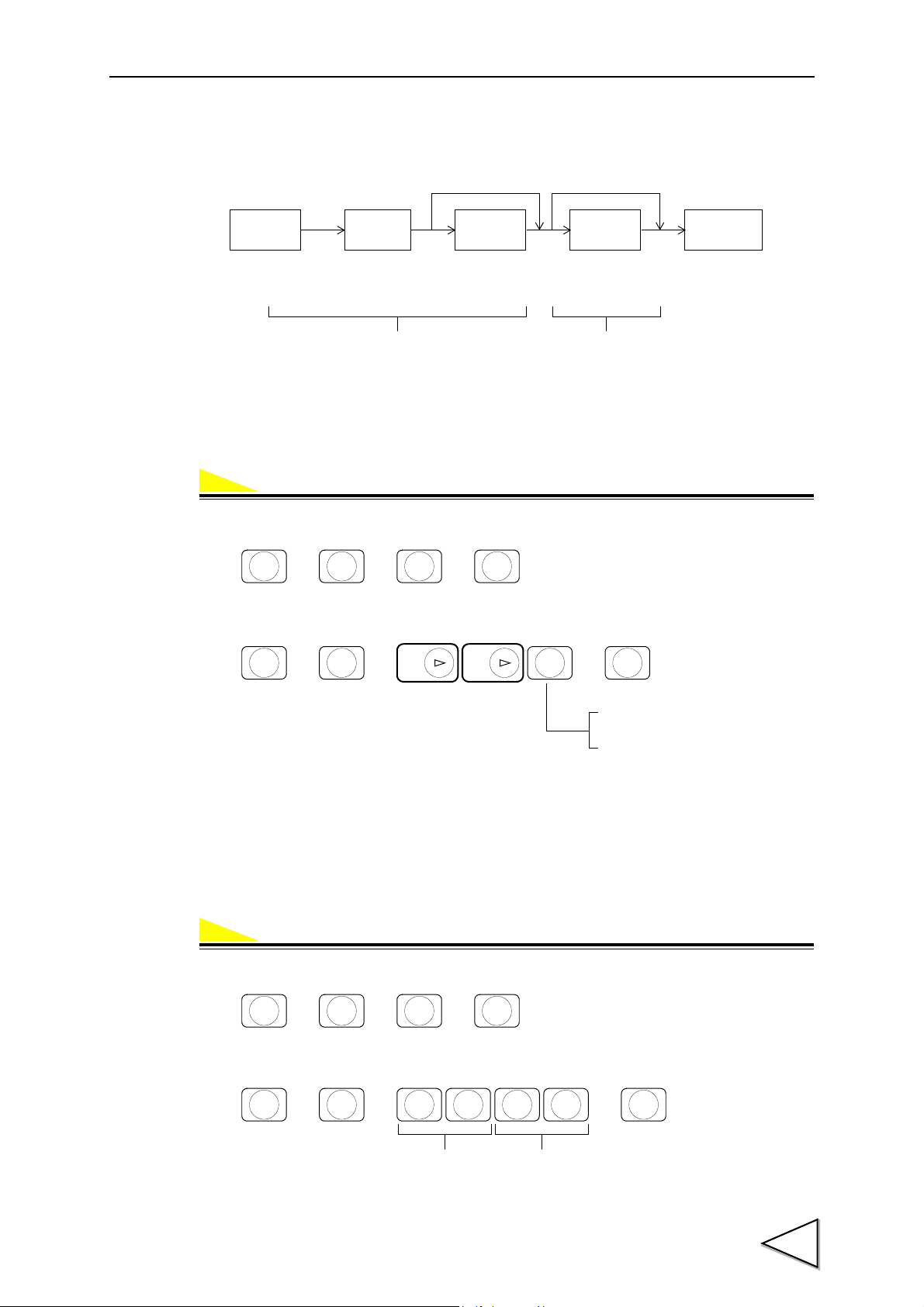

3-1. Setting Procedure

Change settings in the order of “setting mode selection” → “setting item selection” → “setting

value entry”.

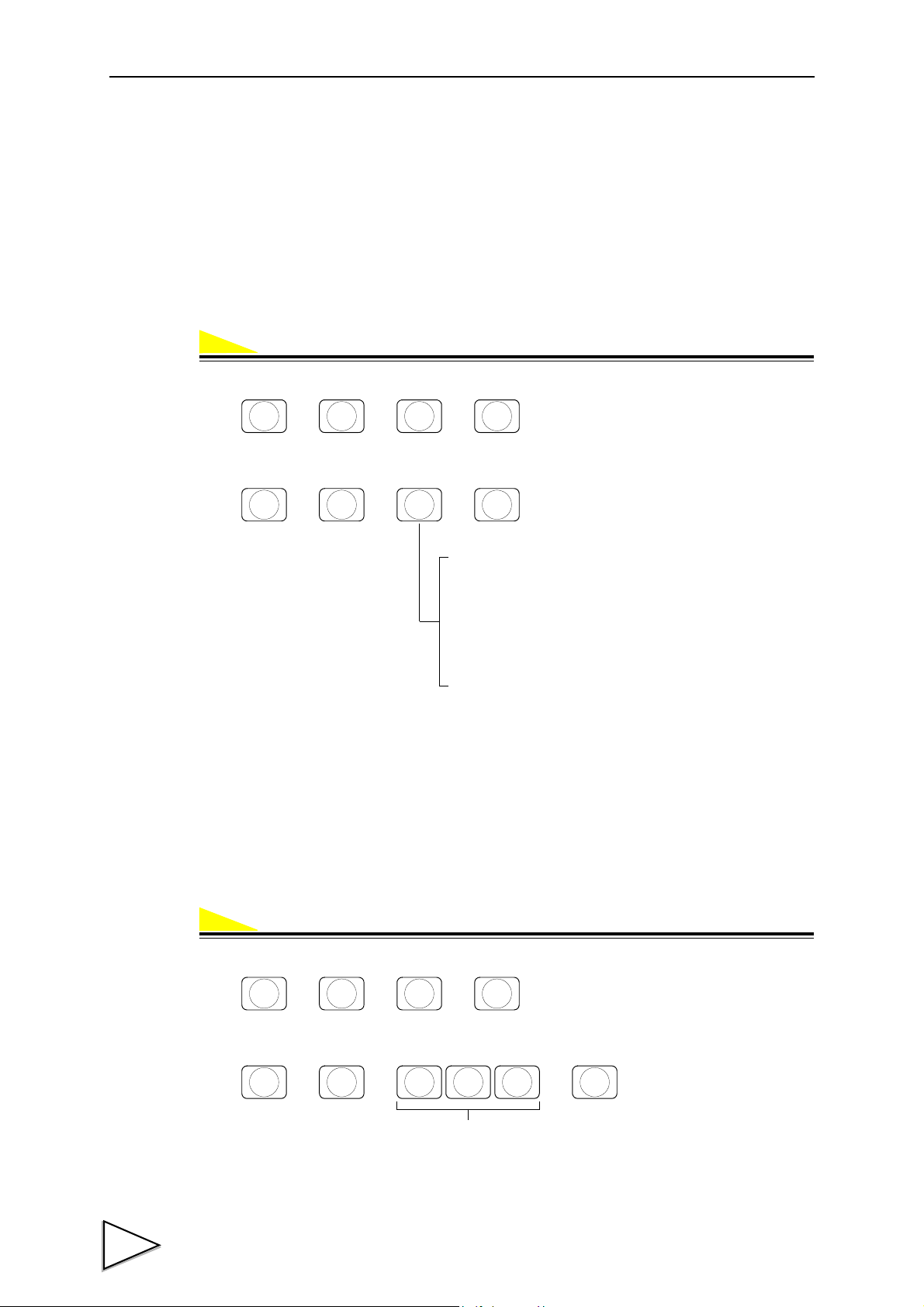

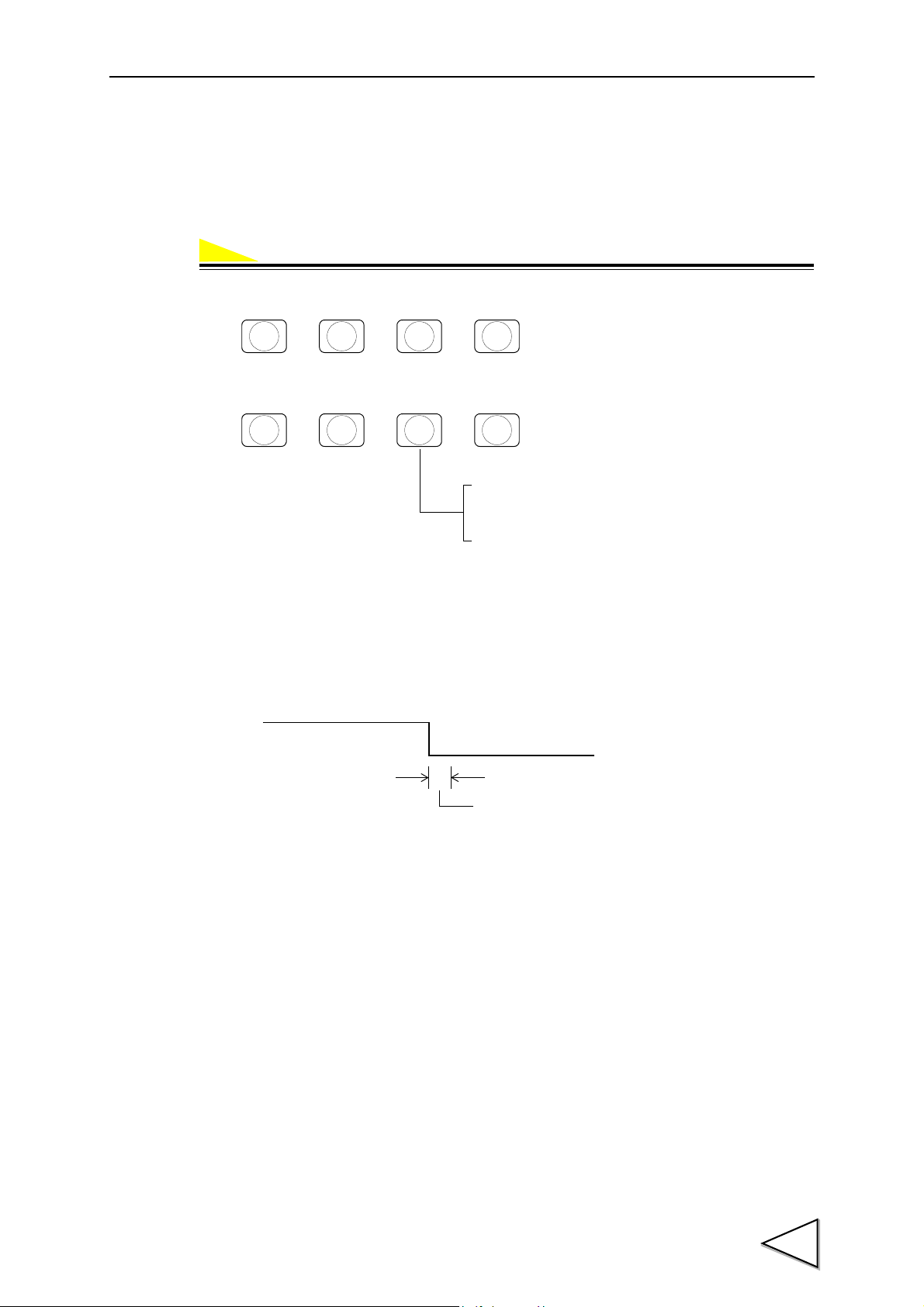

3-1-1. Method of Selecting a Setting Mode

In the text, the method of selecting a setting mode is described as follows:

(Example) For selecting setting mode 3

3.METHODS OF SETTING

This operation can be performed by the following procedure.

1) Press the key when the weight value is displayed.

2) Press the key.

17

3.METHODS OF SETTING

3

NEAR Z

.

kg

,

Setting mode number

The input number blinks.

,

CNG/ENT

Present weight value

The selected setting mode number

Setting mode number

and weight value are displayed

(Setting mode display).

kg

By pressing the key when the setting mode number is displayed, you

can go back to normal display (Setting mode 0).

GROSS

/NET

ESC

3) Select the setting mode number. ( )

4) Press the key.

18

3.METHODS OF SETTING

→→ →

1

UPPER

CNG/ENT CNG/ENT

1

UPPER

kg

,

Present setting value

The setting mode number, setting

Setting mode number

item number, and present setting

Setting item number

value are displayed.

,

CNG/ENT

kg

,

Present setting value

The highest digit of the setting

Setting mode number

value blinks.

Setting item number

,

0

5

SP2

000

kg

,

Setting value

Every time a number is pressed,

Setting mode number

the blinking digit moves to the lower one.

Setting item number

Since the highest digit starts blinking again

after a number is input to the lowest digit,

setting can be redone again and again.

,

CNG/ENT

Present weight value

The display returns to the setting

Setting mode number

mode display.

kg

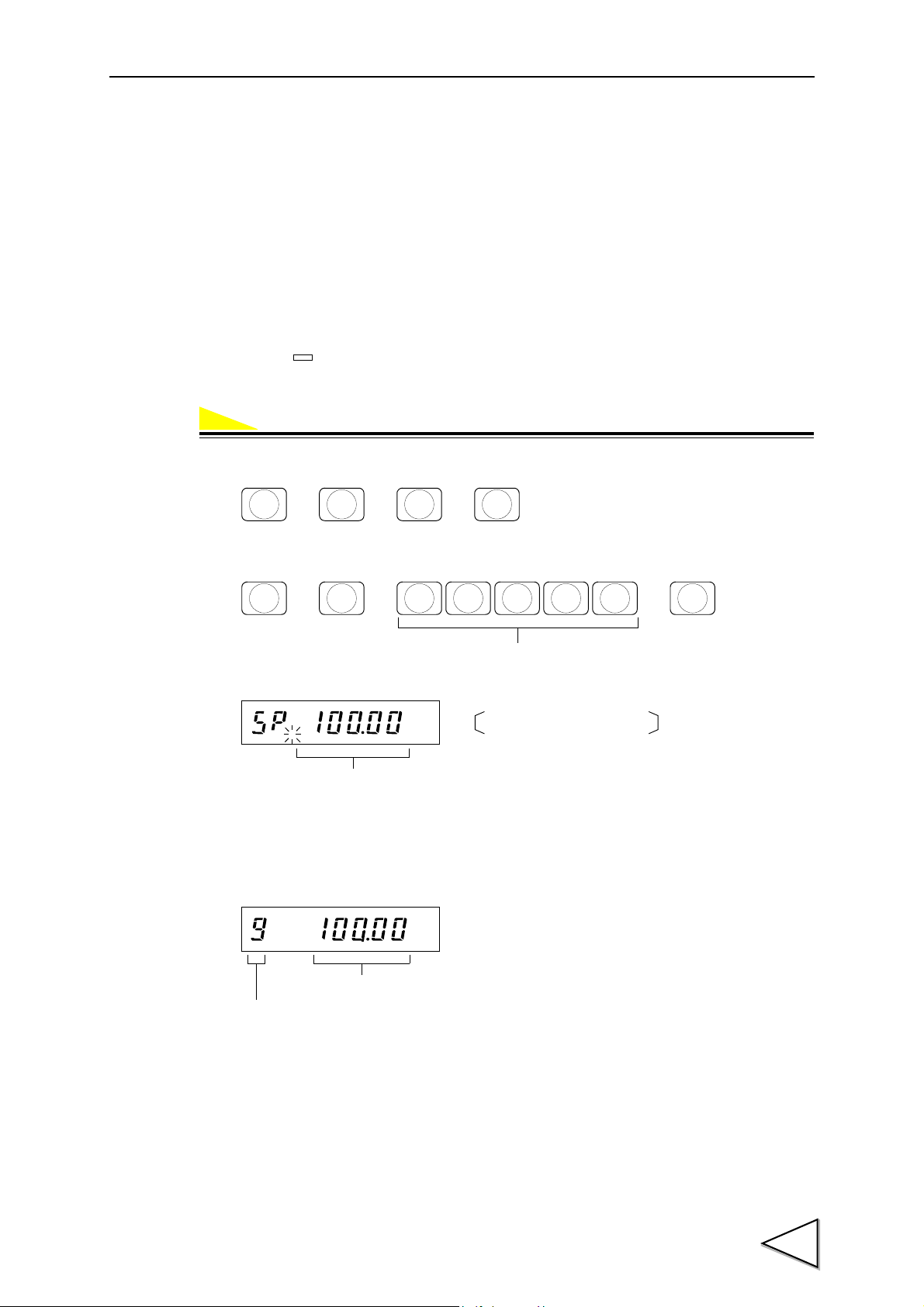

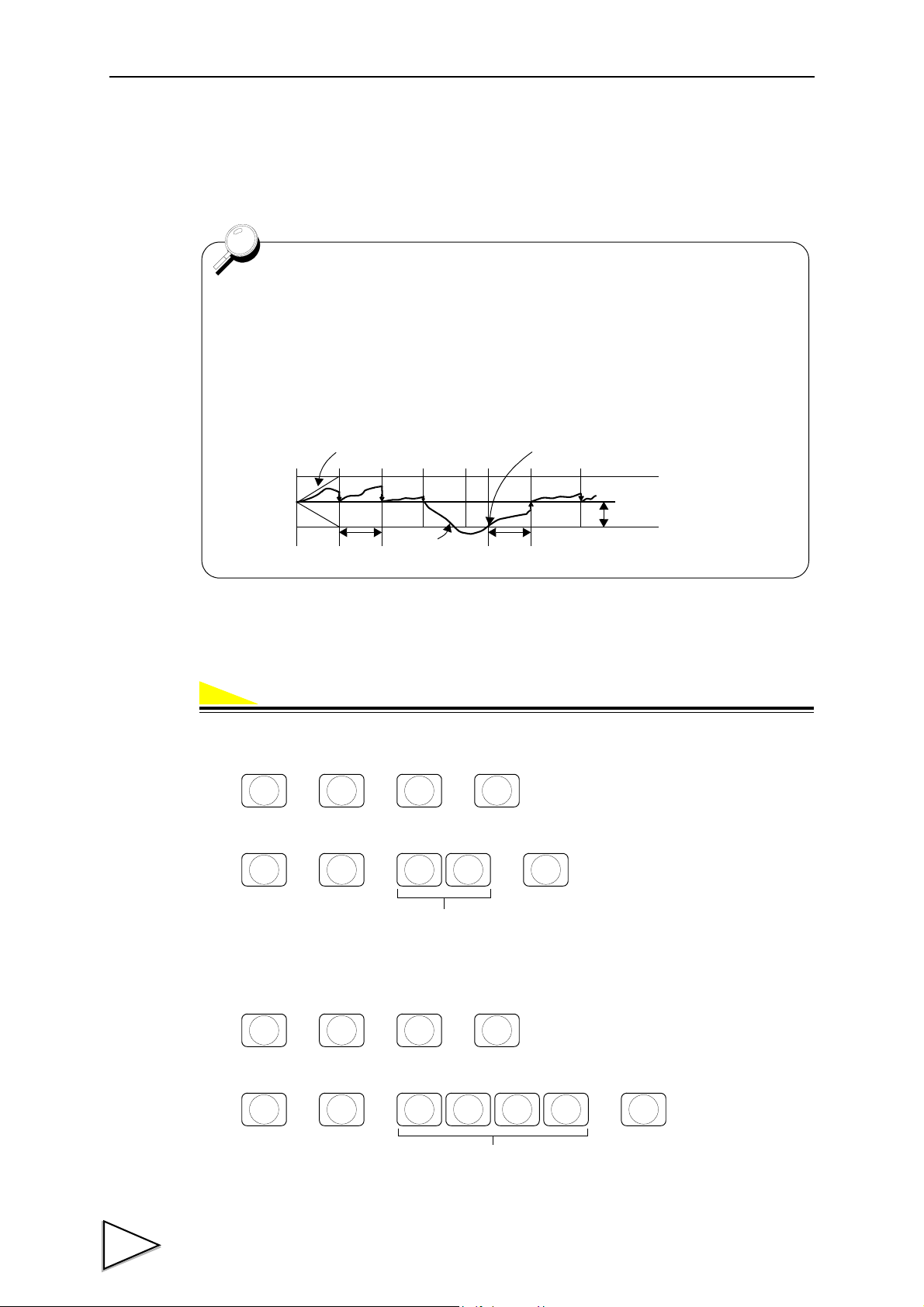

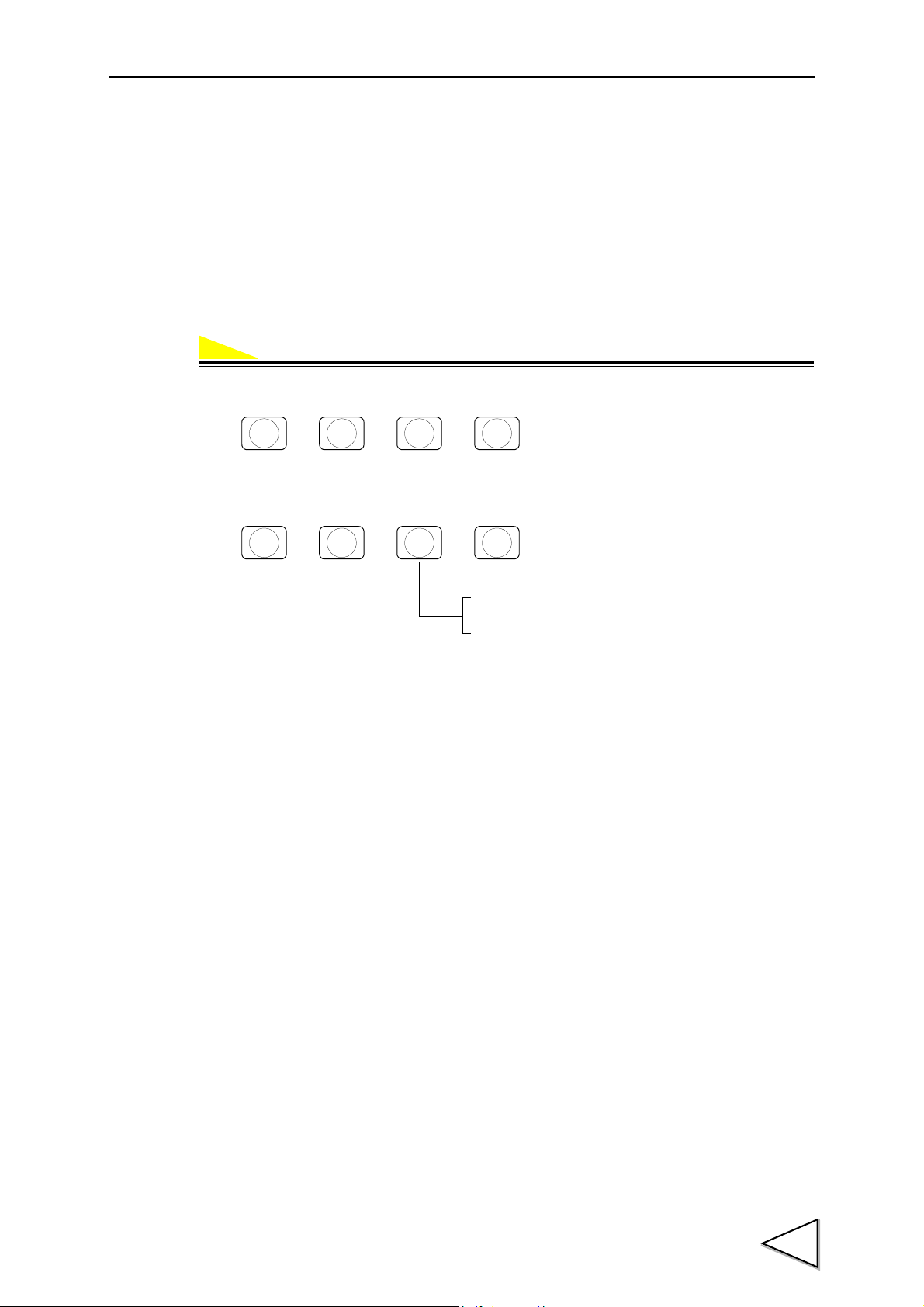

3-1-2. Method of Entering a Setting Value

In the text, the method of entering a setting value is described as follows:

(Example 1) For setting the Balance Weight Value to 50.00kg

(Setting by numerical input: Unsigned)

This operation can be performed by the following procedure.

* However, it is assumed that setting mode 3 has already been selected.

1) Select the setting item.

(Since the setting item number of the Balance Weight Value is 1, press the key.)

2) Press the key.

3) Input the setting value. ( )

4) After the correct setting value is input, press the key to enter the setting value.

19

3.METHODS OF SETTING

→→ →

6

CPS

CNG/ENT CNG/ENT

6

CPS

Present setting value

The setting mode number, setting

Setting mode number

item number, and present setting

Setting item number

value are displayed.

kg

,

CNG/ENT

Present setting value

The highest digit of the setting

Setting mode number

value blinks.

Setting item number

kg

,

003

NEAR Z

.

0

F

Setting value

Every time a number is pressed, the blinking

Setting mode number

digit moves to the lower one.

Setting item number

Since the highest digit starts blinking again

after a number is input to the lowest digit,

setting can be redone again and again.

kg

,

F

Press the key becomes negative setting

value and display the minus sign.

F

Press the key, when minus sign displayed,

becomes positive setting value and will not

display the minus sign.

CNG/ENT

Present weight value

The display returns to the setting

mode display.

kg

(Example 2) For setting the Compensation to -0.30kg

This operation can be performed by the following procedure.

* However, it is assumed that setting mode 0 has already been selected.

1) Select the setting item.

(Since the setting item number of the Compensation is 6, press the key.)

(Setting by numerical input: Signed)

2) Press the key.

3) Input the setting value. ( → )

4) After the correct setting value is input, press the key to enter the setting value.

20

3.METHODS OF SETTING

→→ →

7

OVER

CNG/ENT CNG/ENT

ZERO ZEROZERO

7

OVER

Present setting value

Setting mode number

Setting item number

The setting mode number, setting

item number, and present setting

value are displayed.

kg

,

CNG/ENT

Present setting value

Setting mode number

Setting item number

The highest digit of the setting

value blinks.

kg

,

ZERO

ZERO

ZERO

ZERO

kg

,

Not defined

Setting mode number

Setting item number

1/4 scale division display

Decimal place

Display frequency

ZERO

Subdisplay selection

Every time the key is pressed,

the blinking digit moves to the lower one.

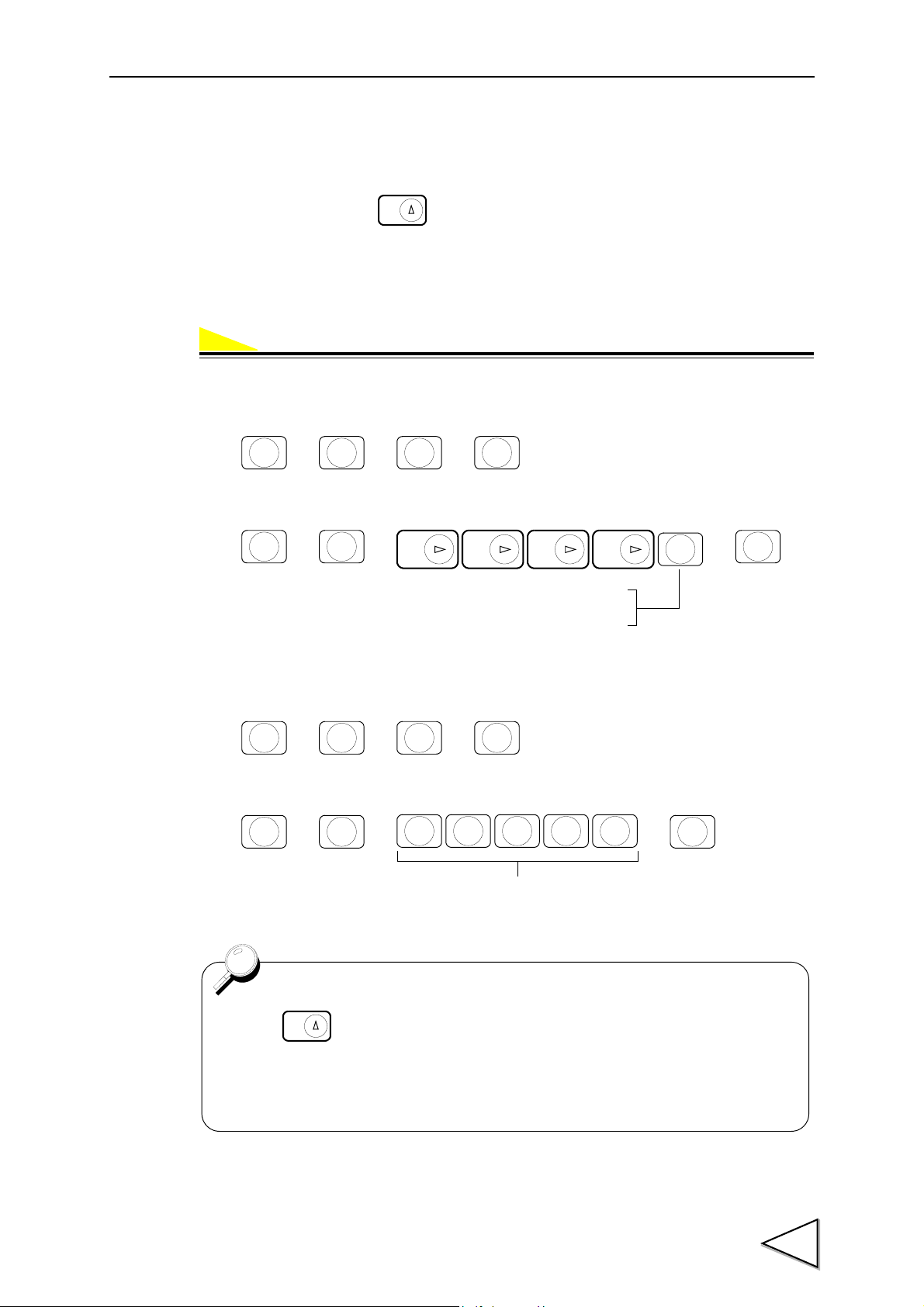

(Example 3) For setting the 1/4 scale division display to OFF (Setting from choices)

This operation can be performed by the following procedure.

* However, it is assumed that setting mode 3 has already been selected.

1) Select the setting item.

(Since the setting item number of the 1/4 scale division display is 7, press the key.)

2) Press the key.

3) Move with the key until the digit you want to set blinks. ( )

21

3.METHODS OF SETTING

0

1/4 scale division display

The blinking digit moves to the lower one.

Setting mode number

Setting item number

Since the blinking digit moves every time

the key is pressed, setting can be

redone again and again.

ZERO

kg

,

CNG/ENT

kg

Present weight value

Setting mode number

The display returns to the setting

mode display.

By pressing the key when the setting item number is displayed (while

changing a setting value after selecting an item), you can exit the item.

(The display returns to the setting mode display.)

GROSS

/NET

ESC

4) Select from choices.

(Since the 1/4 scale division display should be turned off, press .)

5) After the correct choice is input, press the key to enter the choice.

22

3.METHODS OF SETTING

Setting mode 0 Setting mode 1 Setting mode 2 Setting mode 3

Upper Limit

/ P.24

Comparison Inhibit Time

/ P.26

Weighing Function 1

/ P.28

Balance Weight Value

/ P.31

Lower Limit

/ P.24

Judging Time

/ P.26

Weighing Function 2

/ P.28

Capacity

/ P.31

Near Zero

/ P.24

Complete Output Time

/ P.26

Weighing Function 3

/ P.29

Min. Scale Division

/ P.31

Set Point 1

/ P.24

Adjust Feeding Time

/ P.26

Sequence Mode

/ P.29

Net Over

/ P.31

Set Point 2

/ P.24

Auto Zero Times

/ P.26

Function Key Invalid

/ P.30

Gross Over

/ P.31

Compensation

/ P.24

Judging Times

/ P.26

Digital Filter

/ P.30

DZ Regulation Value

/ P.31

Over

/ P.25

Auto Free Fall

Compensation Regulation

/ P.27

Motion Detection

/ P.30

Function Selection

/ P.32

Under

/ P.25

Analog Filter

/ P.27

Zero Tracking Period

/ P.30

Gravitational Acceleration

(area number)

/ P.32

Final

/ P.25

Tare Weight

/ P.27

Zero Tracking Range

/ P.30

Gravitational Acceleration

(acceleration)

/ P.32

1

UPPER2LOWER

3

NEAR Z

.

4

SP1

5

SP2

6

CPS7OVER

8

UNDER

9

FINAL

ZERO

* When each setting mode is selected, the 1 ~ 9 keys function as setting item selection keys.

Setting mode 4 Setting mode 5 Setting mode 8 Setting mode 9

D/A Output Mode

/ P.33

Input Selection

/ P.36

Average Weight

/ P.38

Span Calibration

/ P.53

D/A Zero Output Weight

/ P.33

Output Selection

/ P.36

Max. Value

/ P.38

Equivalent Calibration

/ P.54

D/A Full Scale

/ P.33

CC-Link I/F

Number of occupied station &

Transmission speed

(Refer to separate-volume spec.

)

Min. Value

/ P.38

RS-485 I/F

/ P.33

CC-Link I/F

Station No.

(Refer to separate-volume spec.

)

General Standard Deviation

/ P.38

ID Number

/ P.34

Sample Standard Deviation

/ P.38

RS-232C I/F

/ P.34

Accumulation Count (n)

/ P.38

External Function Selection

/ P.35

Latest Accumulation Data

/ P.38

Setting Value LOCK

/ P.35

Max. - Min. (R)

/ P.39

Restriction on the Tare

Subtraction Function

/ P.35

Option Board

/ P.39

Pass Word

/ P.109

Zero Calibration

/ P.51

1

UPPER

2

LOWER

3

NEAR Z

.

4

SP1

5

SP26CPS7OVER

8

UNDER

9

FINAL

ZERO

3-2. Setting Mode

23

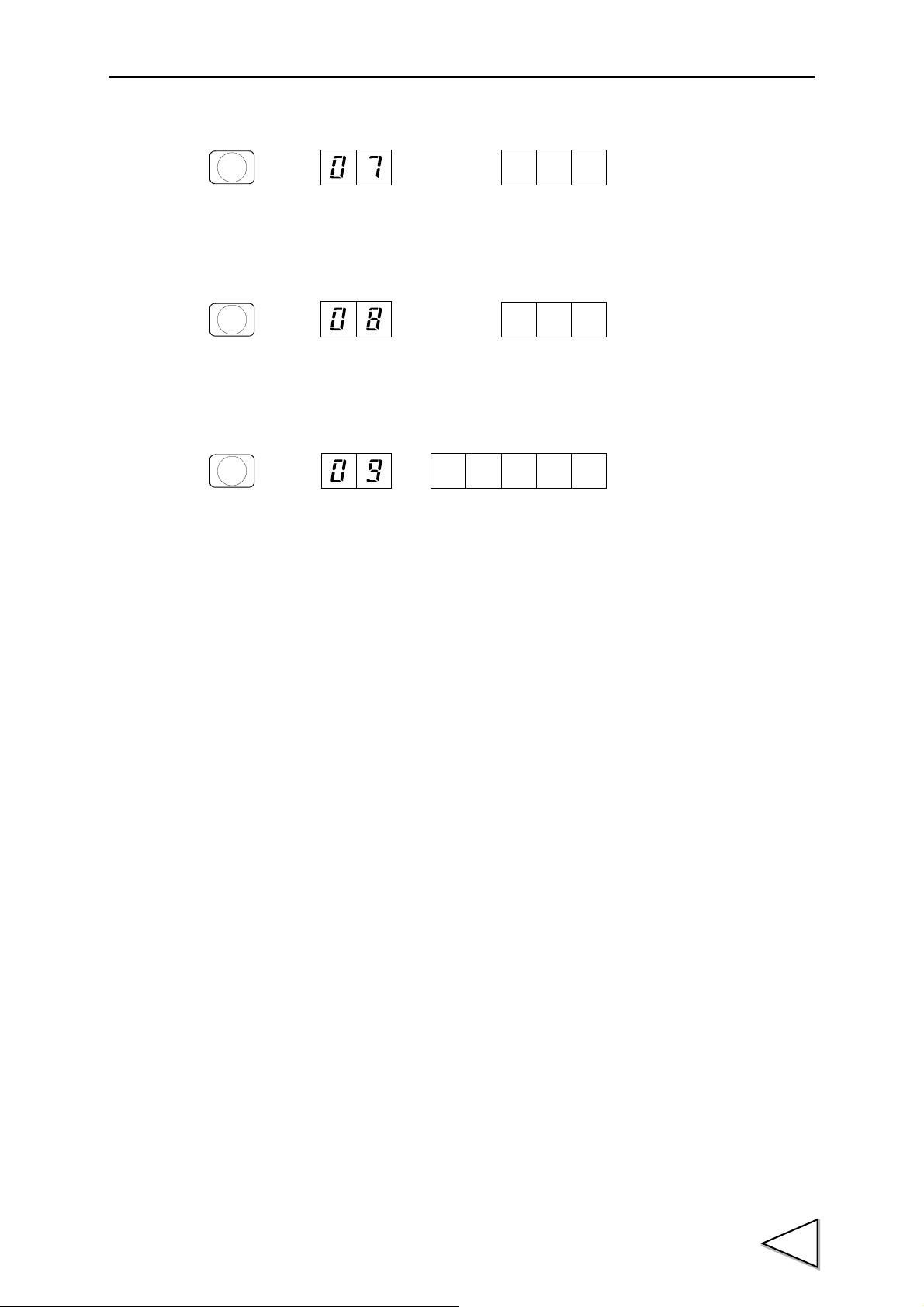

3.METHODS OF SETTING

(0 ~ 99999)

1

UPPER

(0 ~ 99999)

2

LOWER

(0 ~ 99999)

3

NEAR Z

.

(0 ~ 99999)

4

SP1

(0 ~ 99999)

5

SP2

(-9999 ~ 9999)

* If negative setting value, display the sign.

6

CPS

3-2-1. Setting Mode 0

In setting mode 0, setting values for final discharging control are to be set.

- Upper Limit

(For details, please refer to "6-6" on P.90.)

- Lower Limit

(For details, please refer to "6-6" on P.90.)

- Near Zero

(For details, please refer to "6-6" on P.90.)

- Set Point 1

(For details, please refer to "6-4" on P.86.)

- Set Point 2

(For details, please refer to "6-4" on P.86.)

24

- Compensation

(For details, please refer to "6-4" on P.86.)

- Over

(0 ~ 999)

7

OVER

(0 ~ 999)

8

UNDER

(0 ~ 99999)

9

FINAL

(For details, please refer to "6-4" on P.86.)

- Under

(For details, please refer to "6-4" on P.86.)

- Final

3.METHODS OF SETTING

(For details, please refer to "6-4" on P.86.)

25

3.METHODS OF SETTING

.

sec. (0.00 ~ 9.99)

1

UPPER

.

sec. (0.00 ~ 9.99)

2

LOWER

.

sec. (0.00 ~ 9.99)

3

NEAR Z

.

.

sec. (0.00 ~ 9.99)

4

SP1

(0 ~ 99)

5

SP2

(0 ~ 99)

6

CPS

3-2-2. Setting Mode 1

In setting mode 1, output signals for final discharging control and parameters in sequence mode,

etc., are to be set.

- Comparison Inhibit Time

(For details, please refer to "6-8" on P.93.)

- Judging Time

(For details, please refer to "6-8" on P.93.)

- Complete Output Time

(For details, please refer to "6-8" on P.93.)

- Adjust Feeding Time (Effective when selecting sequence mode)

(For details, please refer to "6-9" on P.96.)

- Auto Zero Times (Effective when selecting sequence mode)

(For details, please refer to "6-9" on P.96.)

26

- Judging Times (Effective when selecting sequence mode)

(For details, please refer to "6-9" on P.96.)

- Auto Free Fall Compensation Regulation

(0 ~ 99999)

7

OVER

(0 ~ 3)

8

UNDER

(0 ~ 99999)

9

FINAL

(For details, please refer to "6-3" on P.83.)

- Analog Filter

(For details, please refer to "5-4" on P.57.)

- Tare Weight

3.METHODS OF SETTING

(For details, please refer to "5-13" on P.65.)

27

3.METHODS OF SETTING

Discharging control mode

2 : External selection

1 : Discharging control

0 : Feeding control

Near Zero comparison

4 : ON when |Net weight| ≦ Near Zero

setting value

3 : ON when |Gross weight| ≦ Near Zero

setting value

2 : Comparison OFF

1 : ON when Net weight ≦ Near Zero

setting value

0 : ON when Gross weight ≦ Near Zero

setting value

Final and Over/Under comparison

2 : Comparison OFF

1 : Net weight

0 : Gross weight

Upper/Lower limit comparison

2 : Comparison OFF

1 : Net weight

0 : Gross weight

(For details, please refer to

"6-1-3" on P.75.)

(For details, please refer to

"6-7" on P.91.)

(For details, please refer to "6-7" on P.91.)

(For details, please refer to "6-7" on P.91.)

1

UPPER

* Not defined Complete signal output mode

2 : ON for the complete output time from

when the judging timer has expired

or from when the weight value

becomes stable after the SP3 signal

turns ON.

1 : ON for the complete output time from

when the weight value becomes

stable after the judging timer has

expired.

0 : ON for the complete output time from

when the judging timer has expired.

Over/Under comparison mode

3 : Comparison is made, and the

weight value is held when the

complete output is ON.

2 : Comparison is made when the

complete output is ON.

1 : Comparison is made when the

external judgment input is ON.

0 : Comparison regularly

Upper/Lower limit comparison mode

1 : Comparison is made when the

external judgment input is ON.

0 : Comparison regularly

Accumulation command selection

1 : Auto accumulation

command ON

0 : Auto accumulation

command OFF

(For details, please refer to "6-7" on P.91.)

(For details, please refer to "6-7" on P.91.)

(For details, please refer to "6-8" on P.93.)

(For details, please refer to

"7-4" on P.107.)

2

LOWER

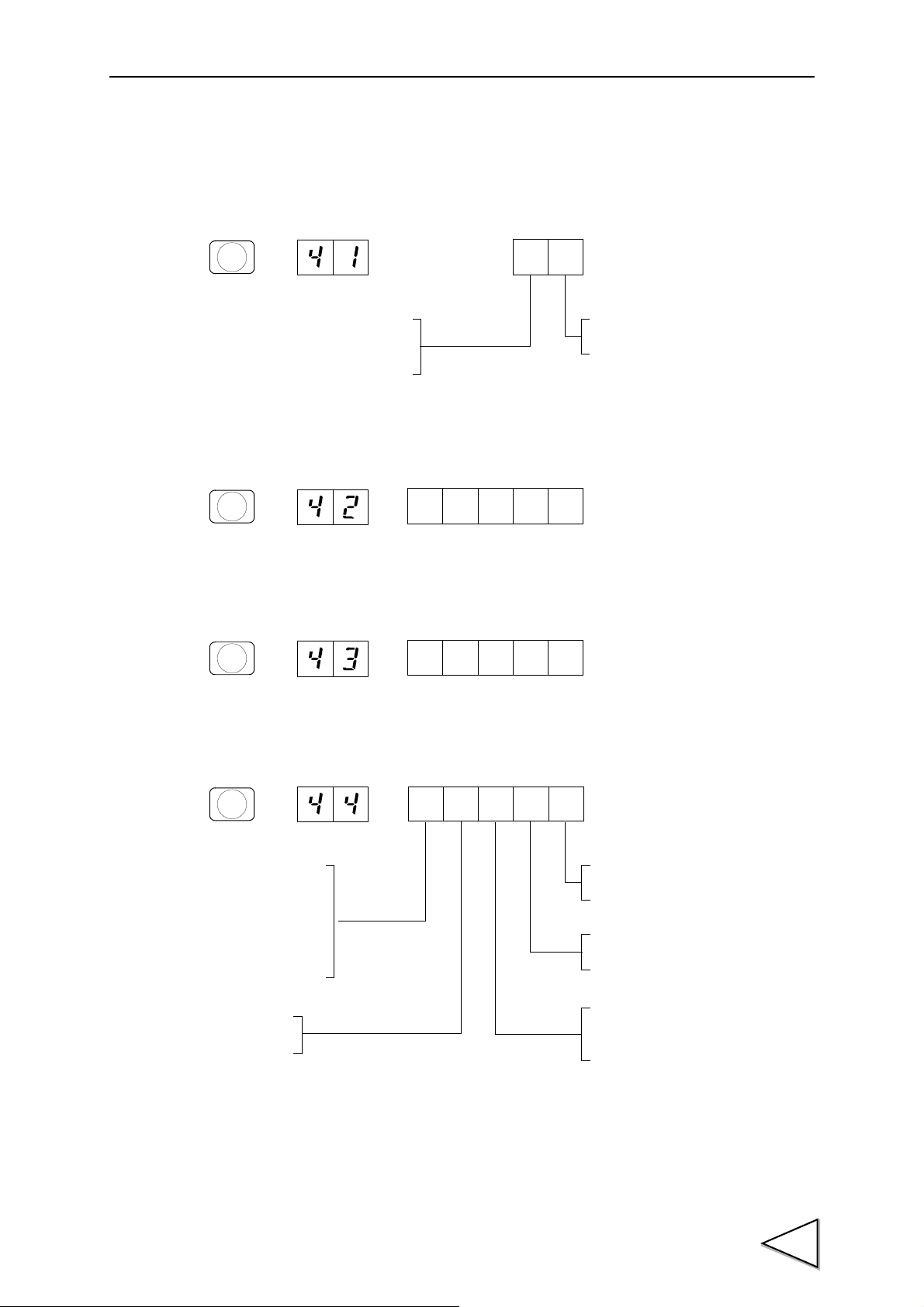

3-2-3. Setting Mode 2

In setting mode 2, the display and internal functions of the F701-C are to be tuned.

- Weighing Function 1

- Weighing Function 2

28

- Weighing Function 3

3 : AFFC. coefficient 1/4

2 : 〃 2/4

1 : 〃 3/4

0 : 〃 1

1 : Digital tare subtraction

ON

0 : Digital tare subtraction

OFF

2 : AFFC. ON

(Communication OP invalid)

1 : 〃 ON

0 : 〃 OFF

Average count of AFFC.

(1 ~ 9)

(For details, please refer to

"6-3" on P.83.)

(For details, please refer to

"5-13" on P.65.)

(For details, please refer to

"6-3" on P.83.)

(For details, please refer to

"6-3" on P.83.)

3

NEAR Z

.

1 : Negative Compensation

Effect

0 : Negative Compensation

Inhibit

(For details, please refer to

"6-5" on P.89.)

1 : Sequence mode

0 : Simple comparison mode

(Sequence control)

1 : At start-time, weight

value check ON

0 : 〃 OFF

1 : Adjust feeding ON

0 : 〃 OFF

(Sequence control)

1 : At start-time,

Near Zero check ON

0 : 〃 OFF

(For details, please refer to

"6-9" on P.96.)

(For details, please refer to

"6-2-3" on P.82.)

(For details, please refer to

"6-9" on P.96.)

(For details, please refer to

"6-9" on P.96.)

4

SP1

3.METHODS OF SETTING

- Sequence Mode

29

3.METHODS OF SETTING

[TARE] key

1 : Valid

0 : Invalid

[GROSS / NET] key

1 : Valid

0 : Invalid

[TARE RESET] key

1 : Valid

0 : Invalid

[ZERO] key

1 : Valid

0 : Invalid

5

SP2

Digital Filter

(0 ~ 256)

6

CPS

Period (sec.) Range

* Set the stability detection parameter.

(0.0 ~ 9.9) (0 ~ 99)

-

.

7

OVER

Period (sec.)

(0.0 ~ 9.9)

.

8

UNDER

Range

(0 ~ 9999)

9

FINAL

- Function Key Invalid

(For details, please refer to "5-17" on P.68.)

- Digital Filter

(For details, please refer to "5-3" on P.56.)

- Motion Detection

(For details, please refer to "5-6" on P.58.)

- Zero Tracking Period

(For details, please refer to "5-7" on P.60.)

30

- Zero Tracking Range

(For details, please refer to "5-7" on P.60.)

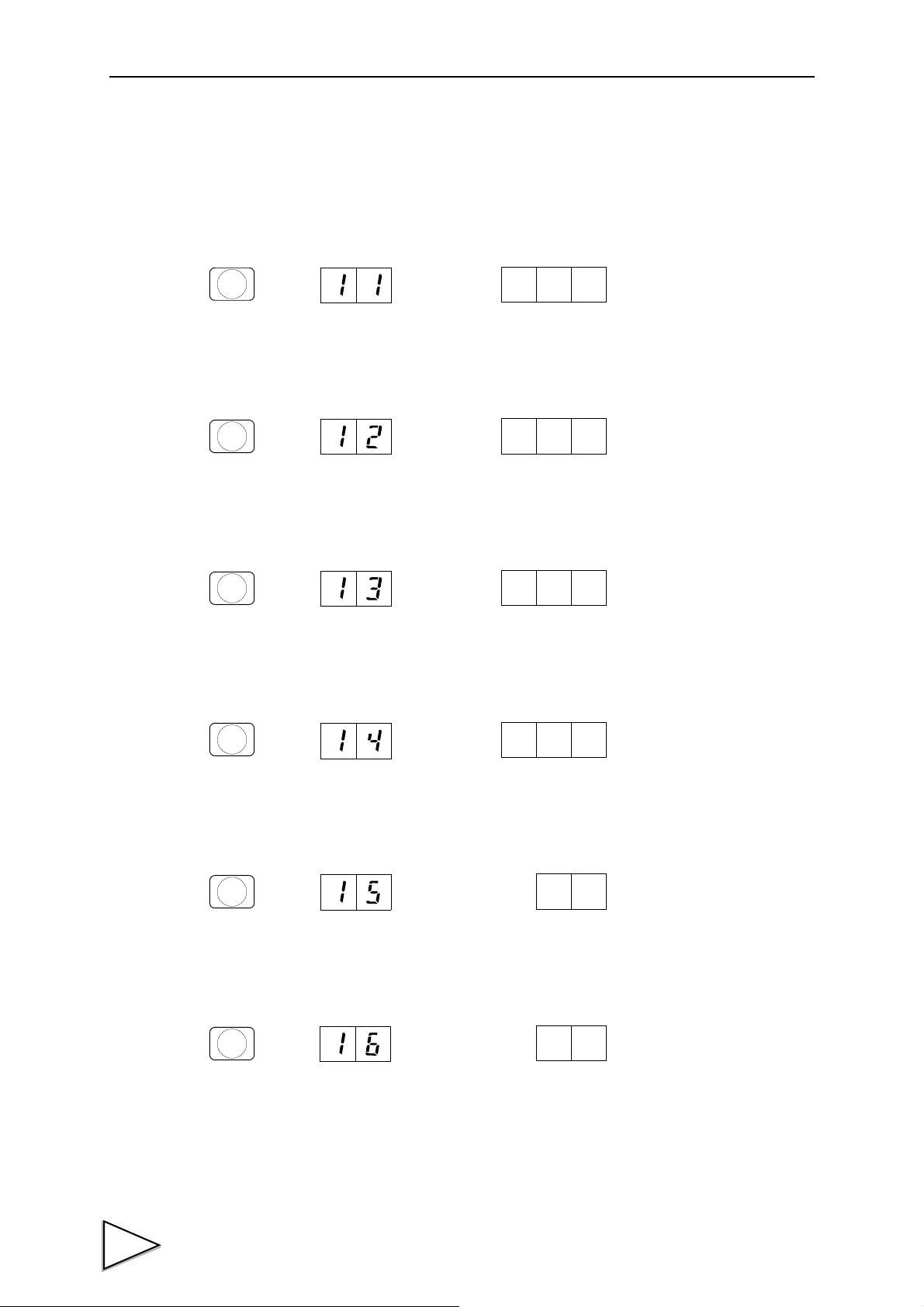

3-2-4. Setting Mode 3

(0 ~ 99999)

1

UPPER

(0 ~ 99999)

2

LOWER

(1 ~ 100)

3

NEAR Z

.

(0 ~ 99999)

4

SP1

(0 ~ 99999)

5

SP2

(0 ~ 9999)

6

CPS

In setting mode 3, setting values relating to initial calibration are to be set.

- Balance Weight Value

(For details, please refer to "4-4-6" on P.48.)

- Capacity

(For details, please refer to "4-4-4" on P.47.)

3.METHODS OF SETTING

- Min. Scale Division

(For details, please refer to "4-4-5" on P.47.)

- Net Over

(For details, please refer to "6-10" on P.100.)

- Gross Over

(For details, please refer to "6-10" on P.100.)

- DZ Regulation Value

(For details, please refer to "5-10" on P.62.)

31

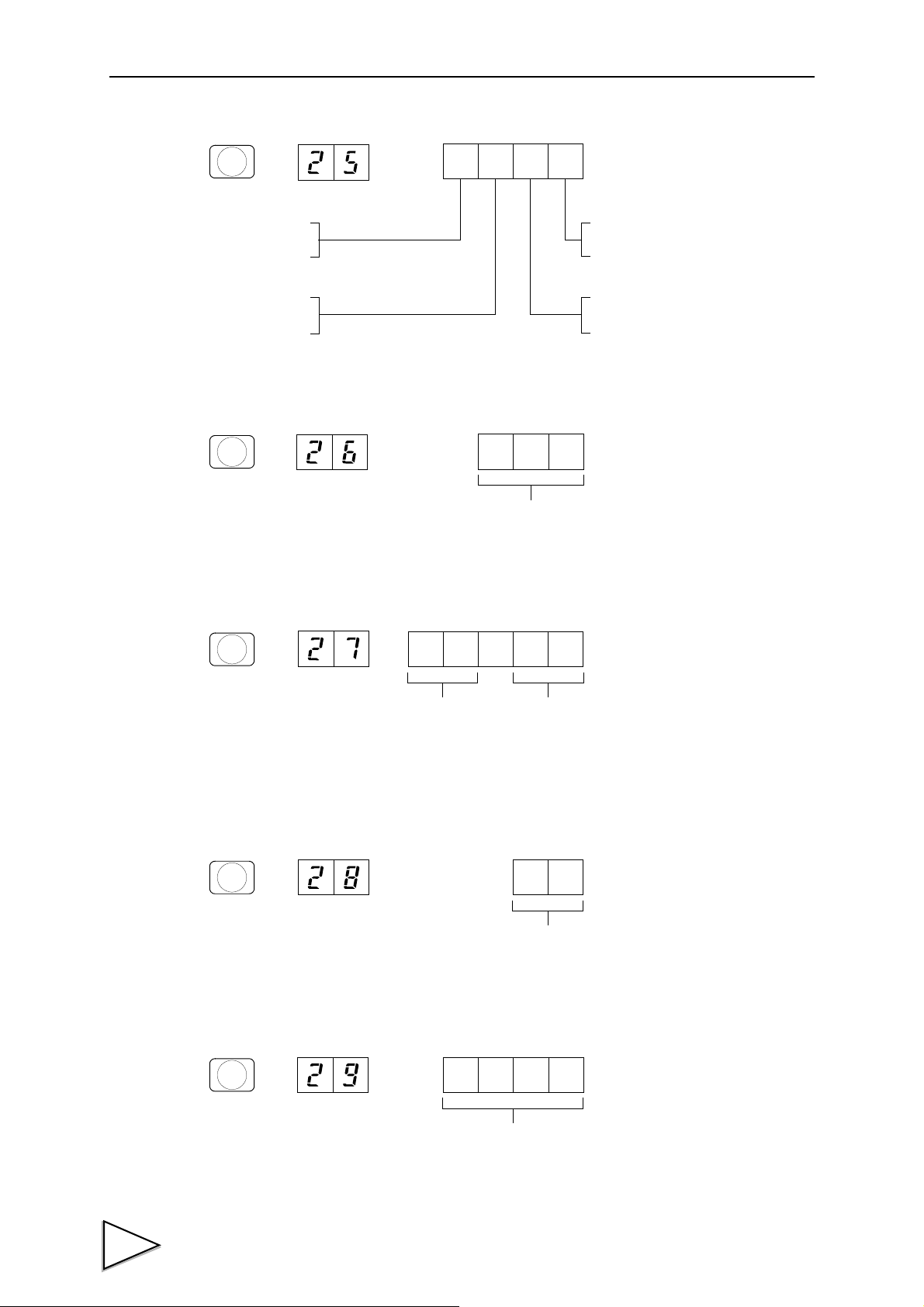

3.METHODS OF SETTING

Display frequency

3 : 25 times/sec.

2 : 13 times/sec.

1 : 6 times/sec.

0 : 3 times/sec.

Decimal place

1/4 scale division display

1 : ON

0 : OFF

(For details, please refer to

"5-1" on P.55.)

(For details, please refer to

"4-4-3" on P.46.)

(For details, please refer to

"4-4-8" on P.50.)

7

OVER

Subdisplay selection

5 : Near Zero /

Upper Limit /

Lower Limit

4 : Final / Over / Under

3 : Accumulation Count /

Latest Accumulation Data /

Final

2 : Latest Accumulation Data /

Accumulation Value

1 : Accumulation Count /

Accumulation Value

0 : None

(For details, please refer to

"5-2" on P.56.)

Unit

5 : N 4 : lb

3 : kg 2 : g

1 : t 0 : None

(For details, please refer to

"4-4-2" on P.46.)

3 :

2 :

1 :

0 :

When using the F701-C for any balance weight to undergo type approval by the

Measurement Law, set the 1/4 scale division display to OFF. If it is set to OFF,

the “zero point” lights only at a true zero point (0±1/4 scale division).

Request

(0 ~ 16)

8

UNDER

(9.700 ~ 9.999)

.

9

FINAL

- Function Selection

- Gravitational Acceleration (Area number input)

(For details, please refer to "4-4-7" on P.48.)

- Gravitational Acceleration (Acceleration input)

(For details, please refer to "4-4-7" on P.48.)

32

3-2-5. Setting Mode 4

Test mode

2 : 20mA fixed output

1 : 4mA fixed output

0 : Tied to the weight value

Output mode

1 : Net weight

0 : Gross weight

1

UPPER

(0 ~ 99999)

2

LOWER

(0 ~ 99999)

3

NEAR Z

.

Baud rate

5 : 38400bps

4 : 19200bps

3 : 9600bps

2 : 4800bps

1 : 2400bps

0 : 1200bps

Terminator

1 : CR+LF

0 : CR

Character length

1 : 8bit

0 : 7bit

Stop bit

1 : 2bit

0 : 1bit

Parity bit

2 : Even

1 : Odd

0 : None

4

SP1

In setting mode 4, setting values relating to communication are to be set.

- D/A Output Mode

(For details, please refer to "10-4-3" on P.143.)

- D/A Zero Output Weight

3.METHODS OF SETTING

(For details, please refer to "10-4-3" on P.143.)

- D/A Full Scale

(For details, please refer to "10-4-3" on P.143.)

- RS-485 I/F

(For details, please refer to "10-5-3" on P.147.)

33

3.METHODS OF SETTING

(0 ~ 9999)

5

SP2

Baud rate

5 : 38400bps

4 : 19200bps

3 : 9600bps

2 : 4800bps

1 : 2400bps

0 : 1200bps

Communication mode

7 : Communication mode 6

6 : Communication mode 5

5 : Communication mode 4

4 : Communication mode 3

3 : Communication mode 2

2 : Communication mode 1

1 : Communication mode 0

(CR + LF)

0 : Communication mode 0

(CR)

Character length

1 : 8bit

0 : 7bit

Stop bit

1 : 2bit

0 : 1bit

Parity bit

2 : Even

1 : Odd

0 : None

6

CPS

- ID Number

(For details, please refer to "10-5-4" on P.148.)

- RS-232C I/F

(For details, please refer to "10-2-3" on P.126.)

34

- External Function Selection

BCD data update rate

7 : 1 times/sec.

6 : 2 times/sec.

5 : 5 times/sec.

4 : 10 times/sec.

3 : 20 times/sec.

2 : 50 times/sec.

1 : 100 times/sec.

0 : 200 times/sec.

At discharging weighing time

1 : Net weight is displayed with

the sign not reversed.

0 : Net weight is displayed with

the sign reversed.

Filter in stable condition

1 : Not insert

0 : Insert (128 times)

Switching Gross weight/Net weight

1 : External input mode

0 : Internal key mode

1 : Checker mode

0 : Stable mode

Motion Detection mode

(For details, please refer to

"5-6" on P.58.)

(For details, please refer to

"5-15" on P.67.)

(For details, please refer to

"5-16" on P.68.)

(For details, please refer to

"5-5" on P.57.)

(For details, please refer to

"10-3-9" on P.140.)

display

7

OVER

8

UNDER

LOCK1

1 : ON

0 : OFF

LOCK2

1 : ON

0 : OFF

One-touch Tare subtraction

1 : Accept only at stable time

0 : Accept regularly

1 : Valid

0 : Invalid

Range of Tare subtraction

1 : 0 < Tare ≦ Capacity

0 : Total range

Prohibition of Tare Weight

1 : Valid

0 : Invalid

Tare Weight display with

the key

0

and digital tare subtraction

ON/OFF when one-touch

tare subtraction is working.

acceptance condition

9

FINAL

3.METHODS OF SETTING

- Setting Value LOCK

(For details, please refer to "8-1" on P.109.)

- Restriction on the Tare Subtraction Function

(For details, please refer to "5-14" on P.66.)

35

3.METHODS OF SETTING

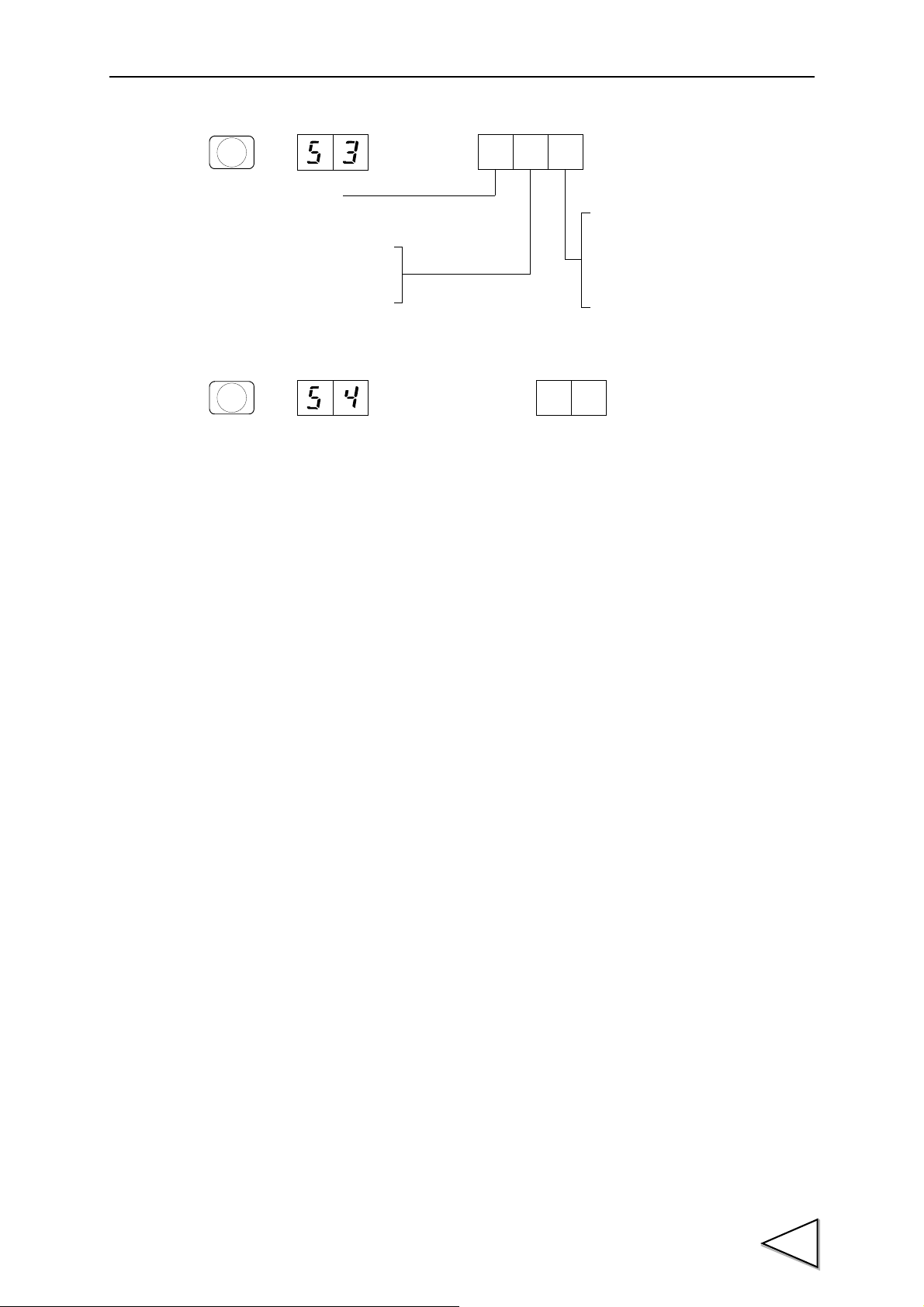

Input selection 1 (B2 pin)

Input selection 3 (B4 pin)

6 : Accumulation Clear

5 : Accumulation Command

4 : Stop

3 : Start

2 : Feed/Discharge

1 : Judge

0 : HOLD

Input selection 2 (B3 pin)

1

UPPER

Input selection 4 (B5 pin)

6 : Accumulation Clear

5 : Accumulation Command

4 : Stop

3 : Start

2 : Feed/Discharge

1 : Judge

0 : HOLD

6 : Accumulation Clear

5 : Accumulation Command

4 : Stop

3 : Start

2 : Feed/Discharge

1 : Judge

0 : HOLD

6 : Accumulation Clear

5 : Accumulation Command

4 : Stop

3 : Start

2 : Feed/Discharge

1 : Judge

0 : HOLD

Output selection 3 (B11 pin)

1 : Accumulation Error

0 : RUN

Output selection 1 (B9 pin)

2 : Weight error

or sequence error

1 : Sequence error

0 : Weight error

Output selection 2 (B10 pin)

1 : Complete output

0 : Go output

2

LOWER

(For details, please refer to

"9-5-7" on P.119.)

(For details, please refer to

"6-11" on P.101.)

(For details, please refer to

"6-8" on P.93.)

3-2-6. Setting Mode 5

- Input Selection

36

(For details, please refer to "9-4-11" on P.117.)

- Output Selection

3.METHODS OF SETTING

Transmission speed

4 : 10M

3 : 5M

2 : 2.5M

1 : 625k

0 : 156k

* Not defined

Number of occupied station

2 : Occupies 4 stations

1 : Occupies 2 stations

0 : Occupies 1 station

3

NEAR Z

(01 ~ 64)

4

SP1

- CC-Link I/F Number of occupied station & Transmission speed

- CC-Link I/F Station No.

37

3.METHODS OF SETTING

(0 ~ 99999)

1

UPPER

(0 ~ 99999)

2

LOWER

(0 ~ 99999)

3

NEAR Z

.

(0 ~ 99999)

4

SP1

(0 ~ 99999)

5

SP2

(0 ~ 10000)

6

CPS

(0 ~ 99999)

7

OVER

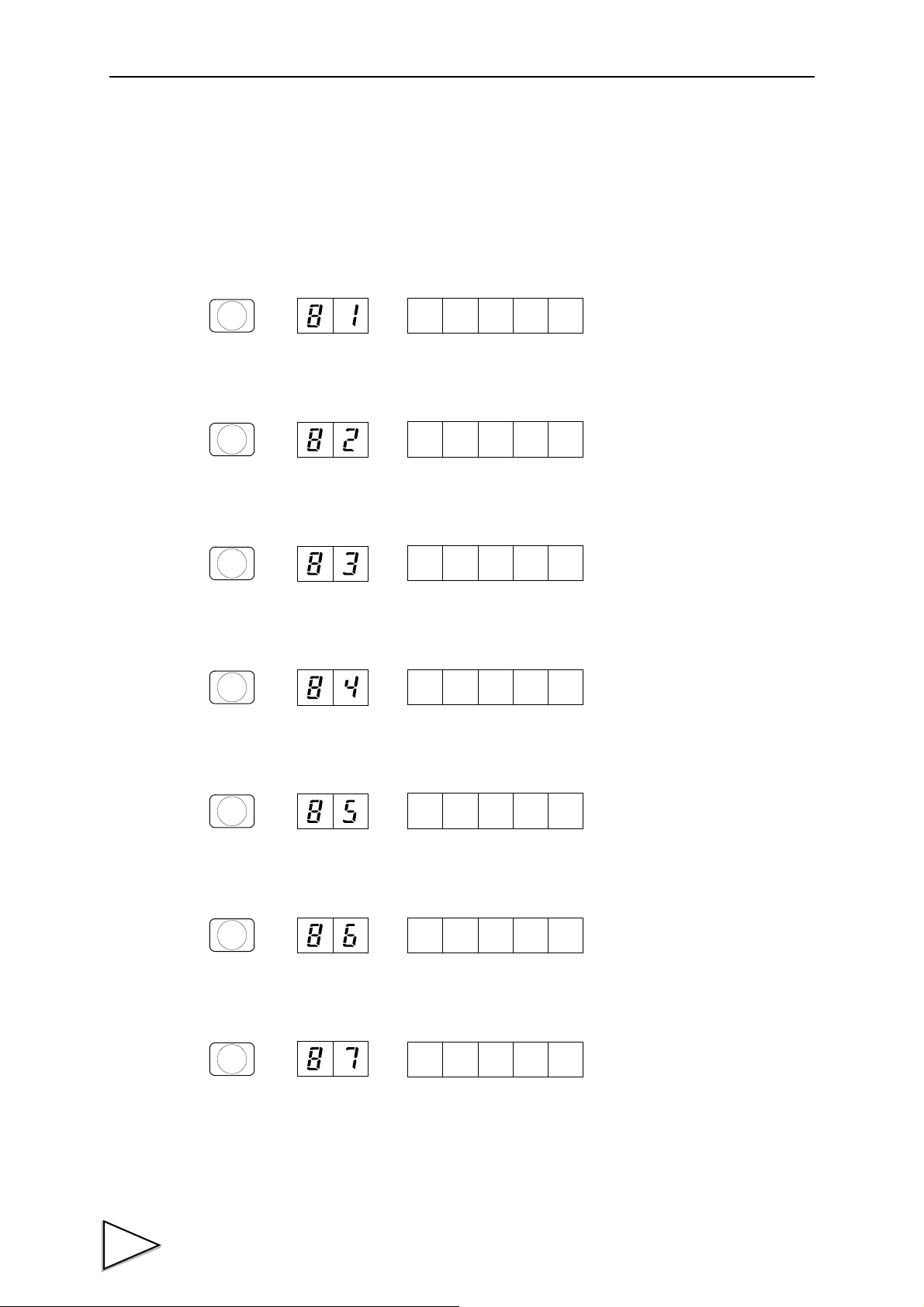

3-2-7. Setting Mode 8

In setting mode 8, statistical data having been accumulated in the F701-C is displayed, including

Average Weight, Max.Value, Min. Value, General Standard Deviation, Sample Standard Deviation,

Accumulation Count, Latest Accumulation Data, Max. - Min.

- Average Weight

- Max. Value

- Min. Value

- General Standard Deviation

- Sample Standard Deviation

- Accumulation Count (n)

38

- Latest Accumulation Data

- Max. - Min. (R)

(0 ~ 99999)

8

UNDER

BCD parallel data

1 : Mounted

0 : Not mounted

output interface

1 : Mounted

0 : Not mounted

D/A converter

1 : Mounted

0 : Not mounted

RS-485 communication interface

9

FINAL

1 : Mounted

0 : Not mounted

CC-Link interface

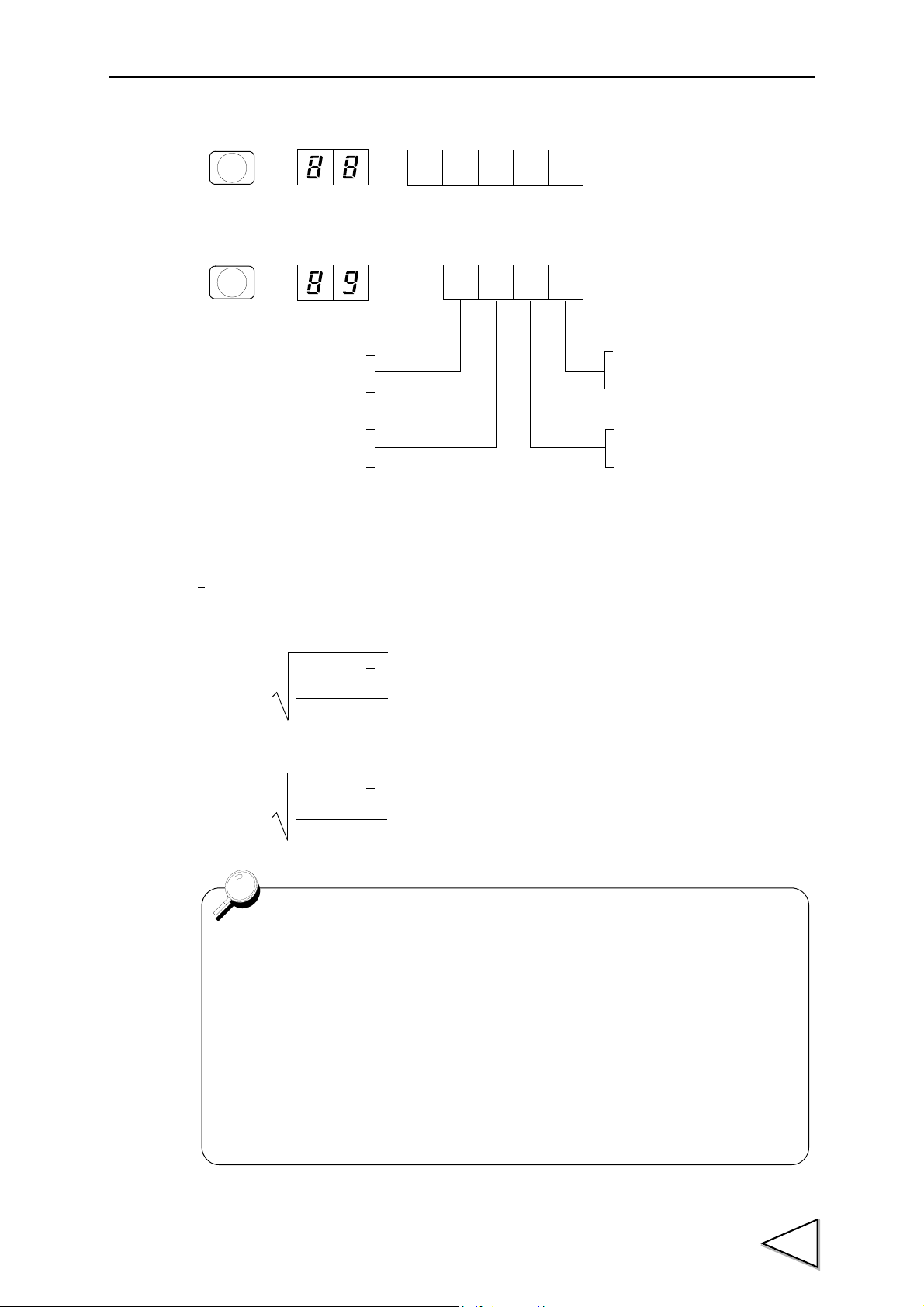

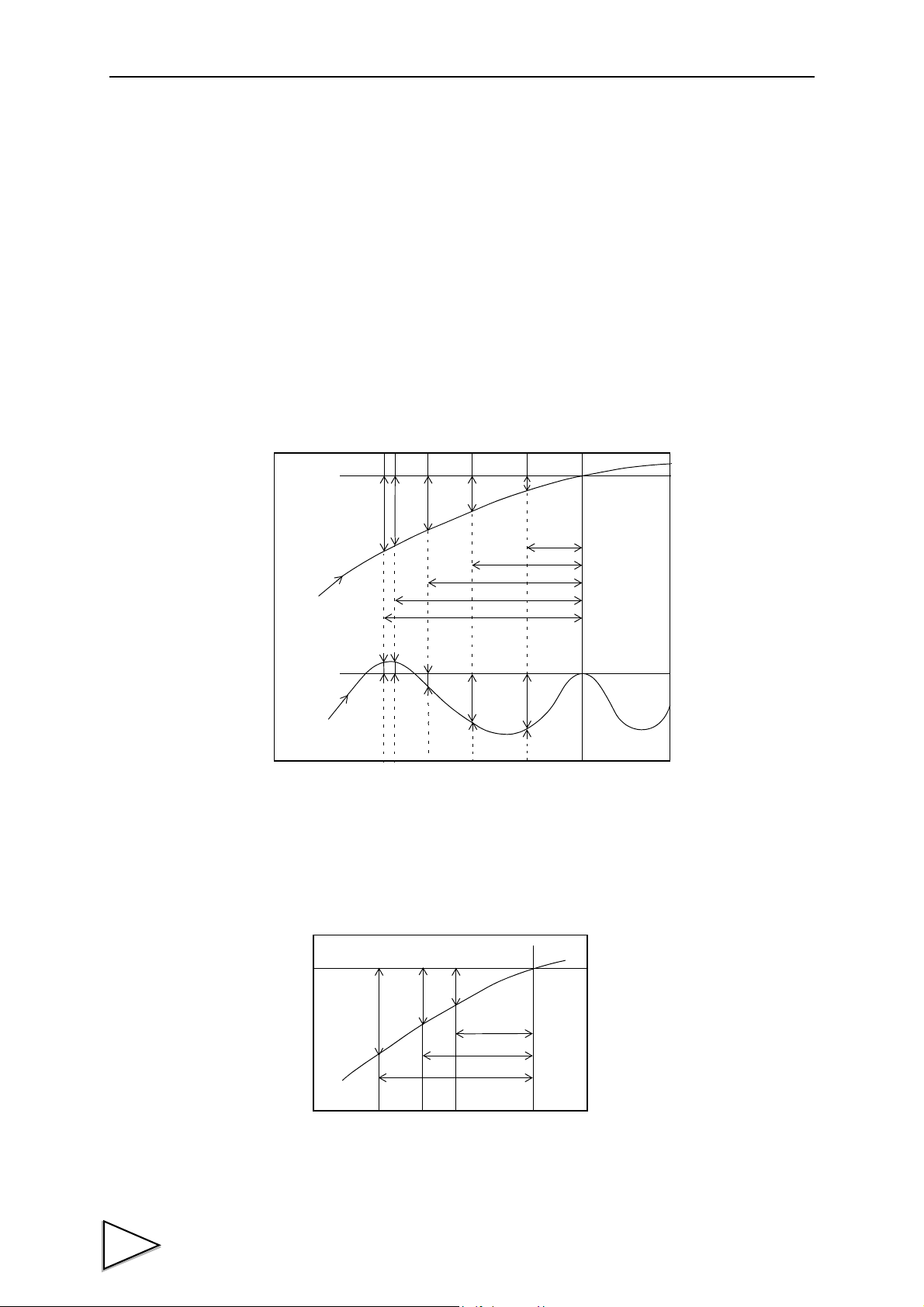

σn =

Σ

n

i=1

n

(

χ

i

-

χ

)

2

Use all the data of the finite population and

find the standard deviation of the population.

σ

n-1

=

Σ

n

i=1

n-1

(

χ

i

-

χ

)

2

Use the sample data among the population and

the standard deviation of the population.

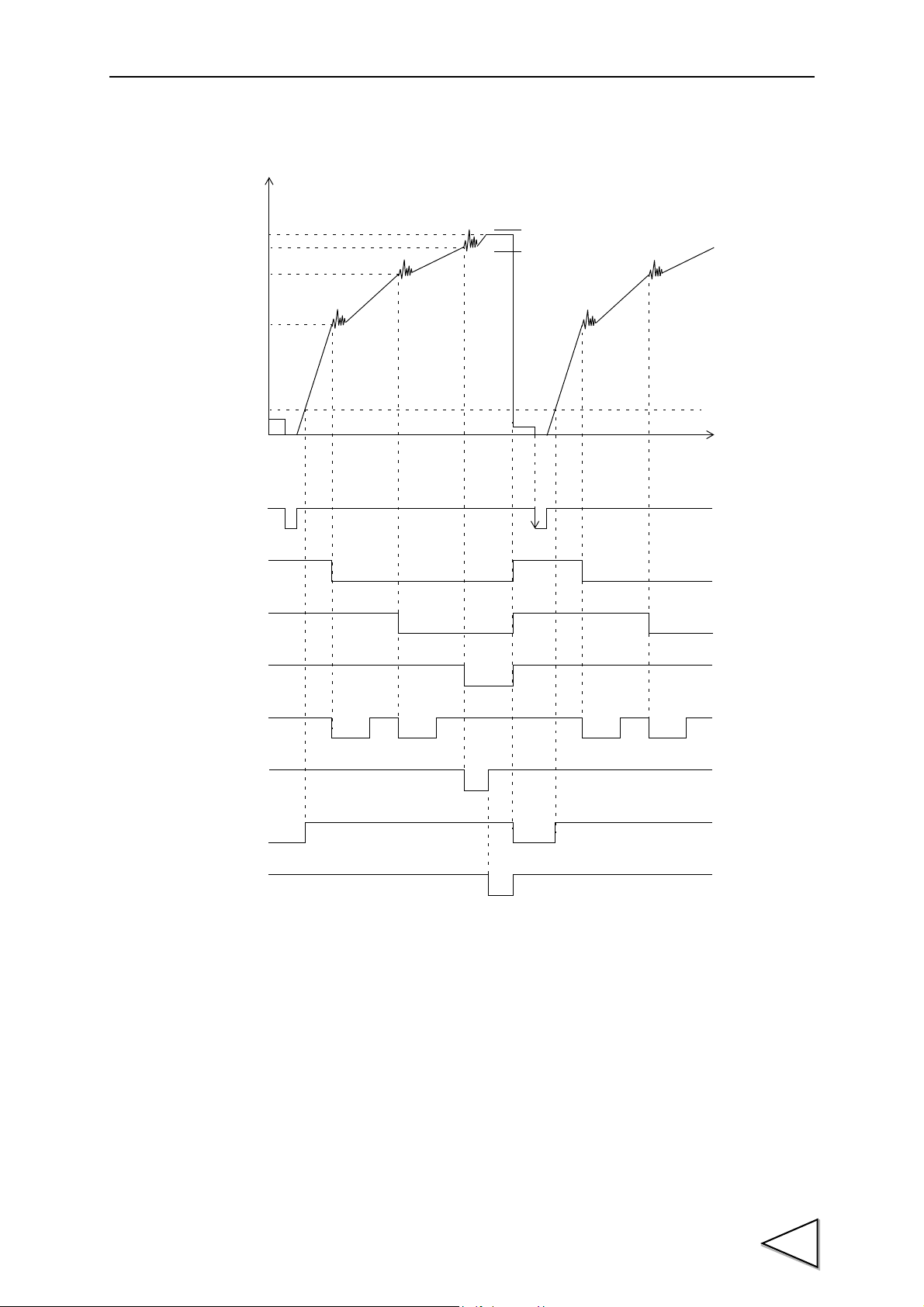

Data taking conditions

- When auto free fall compensation is OFF:

Data is taken when judgment is made.

- When auto free fall compensation is ON:

Data is taken when free fall compensation is made.

(Weighing Function 3 in setting mode 2)

- When the number of Judging Times is 00: No data is taken.

(Judging Time in setting mode 1)

* For judgment and auto free fall compensation, refer to "a) Judging Times"

on P.96.

- Optional Board

● Calculation Formula

3.METHODS OF SETTING

n = accumulation count = count of data

Σχ = accumulation = total amount

= average = accumulation / number of times = Σχ/ n

χ

General Standard Deviation

Sample Standard Deviation

39

3.METHODS OF SETTING

Accumulation clear

Statistical data is cleared by inputting the password “1235”.

(Please refer to "7-3.Accumulation Clear" on P.105.)

【Example】

Times Accumu

(n) lation weighing - Min. S.D. S.D.

Actual Average Max. Min. Max. General Sample

value

(Latest Accumulation Data)

0 0.000 0.000 0.000 0.000 0.000 0.000 error error

1 20.050 20.050 20.050 20.050 20.050 0.000 0.000 error

2 40.090 20.040 20.045 20.050 20.040 0.010 0.005 0.007

3 60.160 20.070 20.053 20.070 20.040 0.030 0.012 0.015

4 80.240 20.080 20.060 20.080 20.040 0.040 0.016 0.018

5 100.260 20.020 20.052 20.080 20.020 0.060 0.021 0.024

6 120.260 20.000 20.043 20.080 20.000 0.080 0.027 0.030

7 140.270 20.010 20.039 20.080 20.000 0.080 0.028 0.030

8 160.250 19.980 20.031 20.080 19.980 0.100 0.033 0.035

9 180.360 20.110 20.040 20.110 19.980 0.130 0.039 0.042

10 200.370 20.010 20.037 20.110 19.980 0.130 0.038 0.041

40

4. CALIBRATION

Connect F701-C to the load cell.....

?

?

?

The display is incorrect.....

100kg

100kg

After calibration.....

The F701-C and load cell

function as a weighing device.

4-1. Span Calibration

Calibration is performed for matching the F701-C to a load cell. For example, it is work to adjust so

that the F701-C accurately displays 100.00kg when an actual load (or weight) of 100kg is applied to

the load cell (balance section) of the weighing apparatus to which the F701-C is connected. This

operation is called Span Calibration.

4.CALIBRATION

41

4.CALIBRATION

Release Calibration LOCK

Decimal Place

Min. Scale Division

Capacity

Balance Weight Value

Zero Calibration

Span Calibration

Zero Calibration

Calibration LOCK

LOCK Switch OFF

LOCK Switch ON

Unit

4-2. Span Calibration Procedure

Follow the steps below to perform Span Calibration.

Release calibration inhibit LOCK by the switch OFF on the rear

panel.

Release Setting Value LOCK which inhibits the calibration.

The displayed unit is set.

Register the position of decimal point.

Register the maximum capacity of the scale.

If the registered value exceeds by 9 scale divisions, display shows

over scale, “ ”.

Register the minimum unit (scale division) of the scale.

Register the value of load (balance weight) for load cell.