Page 1

F395

DYNAMIC FORCE PROCESSOR

Operation Manual

10 Apr. 2012

Rev. 1.12

Page 2

Introduction

We appreciate your kind purchase of F395 Dinamic Force Processor.

To take full advantage of high performance of F395, Thoroughly read this operating

manual first before use and understand the explanations contained herein for correct

operating procedures.

Introduction

Page 3

Safety Precautions

Be sure to read for safety.

In order to have an F395 Dinamic Force Processor used safely, notes I would like you to

surely follow divide into and , and are indicated by the following

documents.Notes indicated here are the serious contents related safely.Please use after

understanding the contents well.

WARNING

CAUTION

WARNING

Misuse may cause the risk of death or serious

injury to persons.

CAUTION

Misuse may cause the risk of injury to persons

or damage to property.

Safety Precautions

Page 4

WARNING

● Use F395 with correct supply voltage.

● Do not carry out the direct file of the commercial power supply to a signal input terminal.

● Carefully check wiring, etc. before applying power.

● Set the correct Excitation Voltage for the sensor. (10V is set when F340A is

dispatched from us.)

● Do not disassemble the main body for modifications or repair.

● Be sure to ground the protective ground terminal.

● When smoke, a nasty smell, or strange sound, please shut off a power supply

immediately and extract a power supply cable.

● Do not install in the following environments.

- Places containing corrosive gas or flammable gas.

- Where the product may be splashed with water, oil or chemicals.

● About the built-in lithium battery

Never disassemble, deform under pressure or throw the battery

into fire.The battery may explode, catch fire or leak.

- Battery

Model: CR14250SE made by SANYO Electric Co., Ltd.

Nominal voltage: 3V

Nominal electric capacity: 850mAh

Safety Precautions

Page 5

Safety Precautions

CAUTION

● Be sure to disconnect the power cable when performing the following.

- Attachment/detachment of connectors of options.

- Wiring/connection of cables to terminal blocks.

- Connection of the ground line.

● Take an interval of more than 5 seconds when repeating ON/OFF.

● For connection to the signal I/O terminal block, wire correctly after checking the signal

names and terminal block numbers.

Also, turn off the power of the main body before connection/wiring to the signal I/O

terminal block.

● Use shielded cables for the connection of strain gauge type sensor, displacement

sensor, External input and output or options.

● Take adequate shielding measures when using at the following locations.

- Near a power line.

- Where a strong electric field or magnetic field is formed.

- Where static electricity, relay noise or the like is generated.

● Do not install in the following environments.

- Where the temperature and/or humidity exceeds the range in the specifications.

- Places with large quantities of salt or iron powder.

- Where the main body is directly affected by vibration or shock.

● Do not use it, broken down.

● When you send F395 by repair etc., please take sufficient measures against a shock.

Page 6

RoHS-compliant product

Please inquire of our sales person about the RoHS-compliance of the option.

The parts and attachments (including the instruction manual, packaging box, etc.) used

for this unit are compliant with the RoHS Directive restricting the use of hazardous

substances with regard to adverse effects on the environment and human body.

What is RoHS?

It is an abbreviation for Restriction on Hazardous Substances, which is implemented by

the European Union (EU). The Directive restricts the use of six specific substances in

electric and electronic equipment handled within EU borders. The six substances are

lead, mercury, cadmium, hexavalent chromium, PBB (polybrominated biphenyls), and

RoHS-compliant product

PBDE (polybrominated diphenyl ethers).

Page 7

Contents

Contents

Per Reading This Instruction Manual ........................................1

1.Outline of the F395 ................................................................2

1-1.What the F395 Can Do: ............................................................................. 2

1-2.Waveform Drawing Procedures ............................................................... 3

1-3.Multi-Hold Procedures .............................................................................. 3

1-4.Hysteresis Procedures .............................................................................. 4

1-5.Hysteresis 2 Procedures ........................................................................... 4

1-6.Waveform Comparison /

Waveform and Displacement Comparison Procedures ......................... 5

1-7.Operation Mode at a Glance ..................................................................... 5

1-8.Standard Interface ..................................................................................... 6

1-9.Waveform Reading .................................................................................... 6

2.Name and Function of Each Part .........................................7

2-1.Front Pane .................................................................................................. 7

2-1-1.Touch Panel Type Color Liquid Crystal Display ........................................ 7

2-2.Rear Panel ................................................................................................ 11

3.Screen Configuration and Setting Methods ......................13

3-1.Screen Flow Chart ................................................................................... 13

3-2.Setting Mode Tree Chart ......................................................................... 15

3-3.Setting Methods ....................................................................................... 17

3-3-1.Specification of Setting Items ................................................................... 17

3-3-2.Unit Setting Method .................................................................................... 18

4.Methods of Connection .......................................................20

4-1.Connection to the Cage Clamp Type Terminal Block .......................... 20

4-1-1.Analog Input / Output Connection ............................................................ 21

Page 8

Contents

4-1-1-1.Analog Input / Output Terminal Pin Assignments .......................................................... 21

4-1-1-2.Strain Gauge Sensor Connection .................................................................................... 22

4-1-1-3.Voltage / Current Type Sensor Connection .................................................................... 23

4-1-1-4.Voltage Output (V-OUT) Connection ................................................................................ 23

4-1-2.SI/F Connection .......................................................................................... 23

4-2.RS-232C Connection ............................................................................... 24

4-2-1.RS-232C Connector .................................................................................... 24

4-2-2.Connector Pin Assignments ..................................................................... 24

4-2-3.Example of Cabling .................................................................................... 24

4-3.Control Connector Connection .............................................................. 25

4-3-1.Connector Pin Assignments ..................................................................... 25

4-3-2.Input and Output Signals ........................................................................... 25

4-3-3.Equivalent Circuit (Input) ........................................................................... 30

4-3-4.Equivalent Circuit (Output) ........................................................................ 30

5.Methods of Calibration ........................................................31

5-1.What is Calibration? ................................................................................ 31

5-2.CH1 Input Calibration and CH2 Input Calibration ................................. 31

5-3.Equivalent Input Calibration Procedures .............................................. 32

5-4.Actual Load Calibration Procedures ..................................................... 33

5-5.LOCK Release .......................................................................................... 34

5-6.Excitation Voltage ................................................................................... 34

5-7.Unit ............................................................................................................ 35

5-8.Increment ................................................................................................. 35

5-9.Decimal Place .......................................................................................... 35

5-10.Zero Calibration ..................................................................................... 35

5-11.Equivalent Input Calibration ................................................................. 36

5-12.Actual Load Calibration ........................................................................ 37

6.Settings and Operations Relating to Indicated Values ....38

6-1.Digital Filter .............................................................................................. 38

6-2.Analog Filter ............................................................................................. 38

6-3.Digital Offset ............................................................................................ 38

6-4.Digital Zero ............................................................................................... 39

Page 9

Contents

7.Measurement Operation Functional Settings ...................40

7-1.Operation Mode ....................................................................................... 40

7-2.Sampling Rate .......................................................................................... 40

7-3.Sampling Reset ........................................................................................ 41

7-4.X/Y-axis Setting by Operation Mode and Input CH .............................. 41

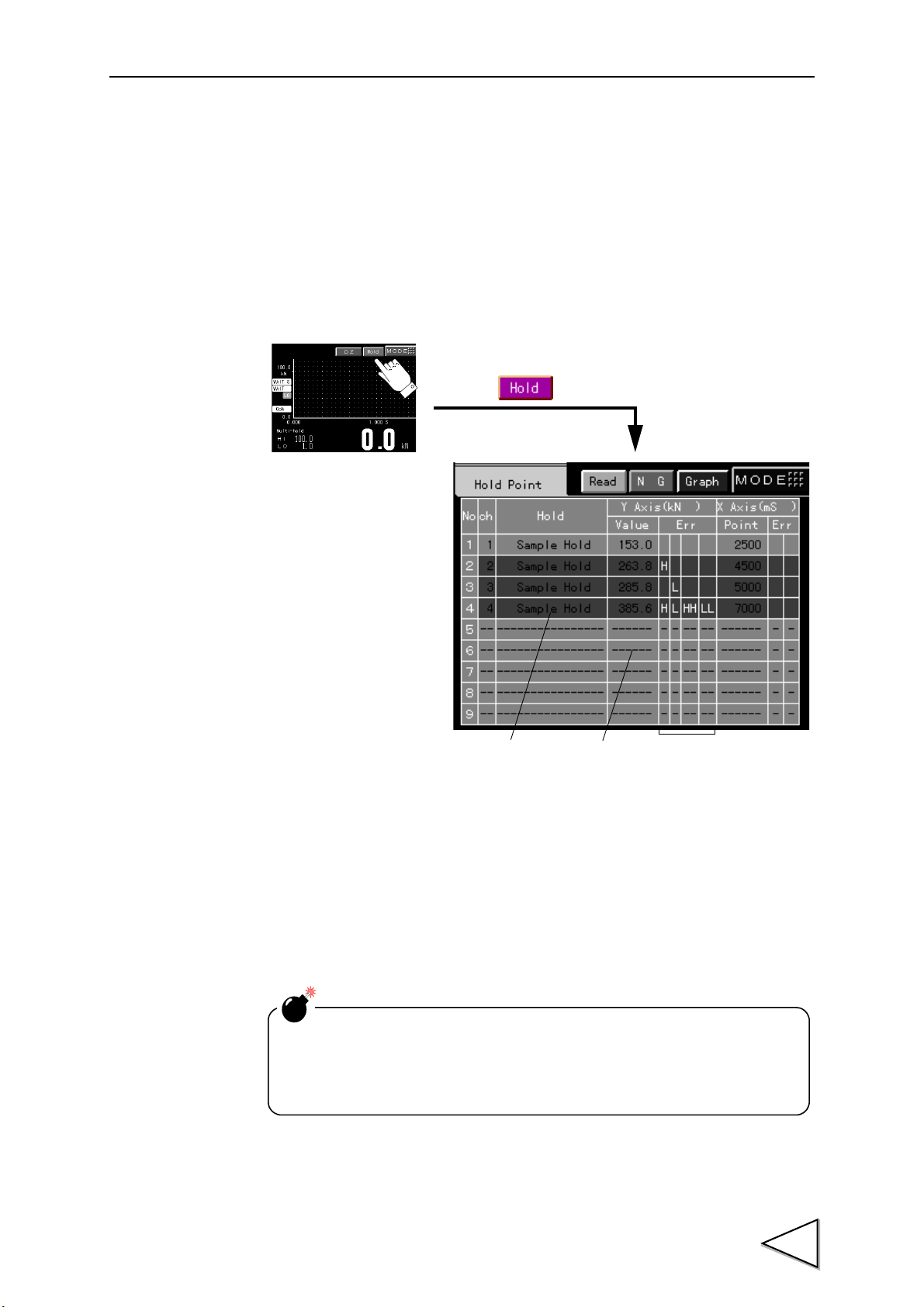

8.Hold Point Display Screen ..................................................42

9.Method of Starting Measurement .......................................43

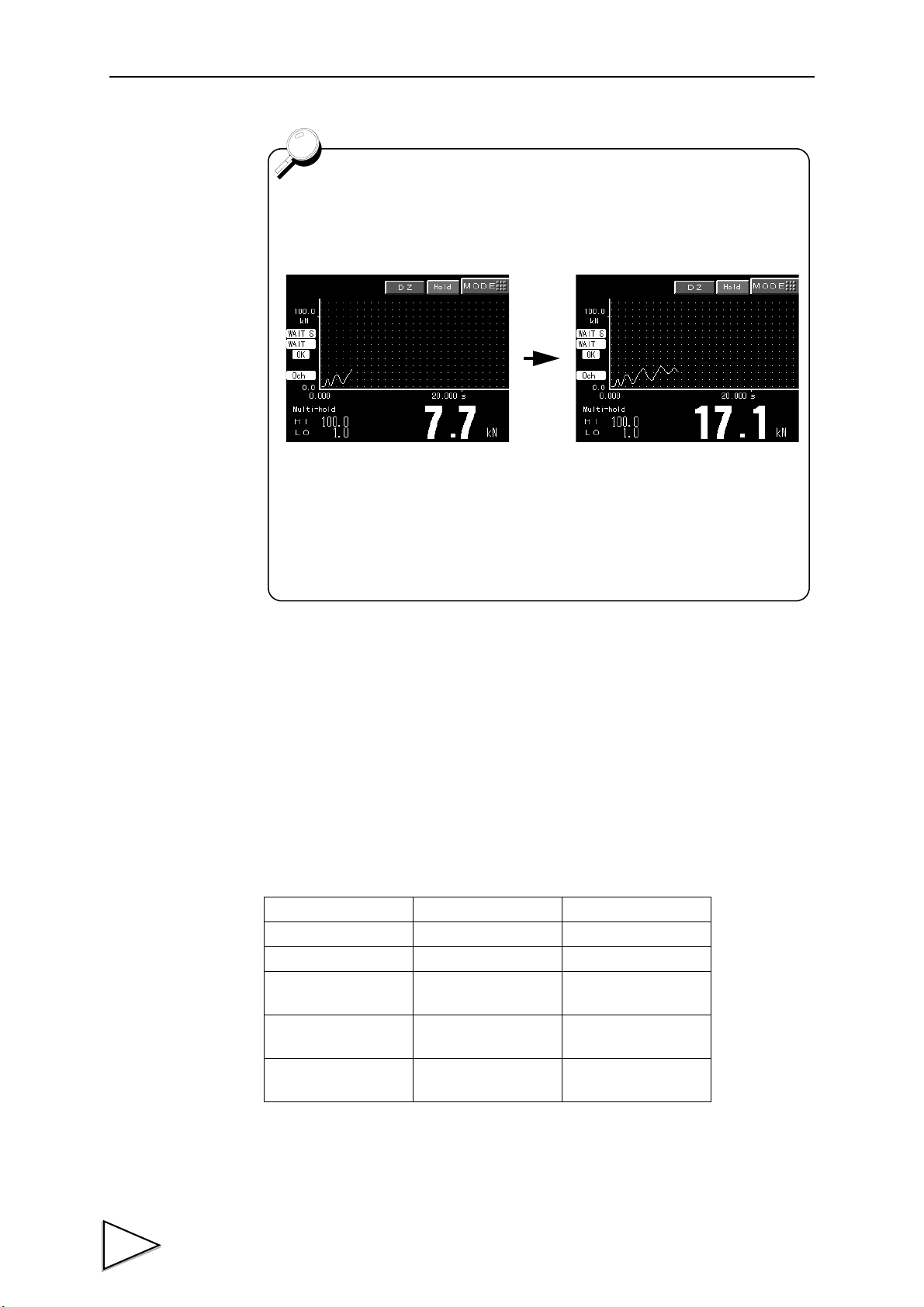

10.Multi-Hold Mode .................................................................47

10-1.Function ................................................................................................. 47

10-2.Setting and Operating Method ............................................................. 47

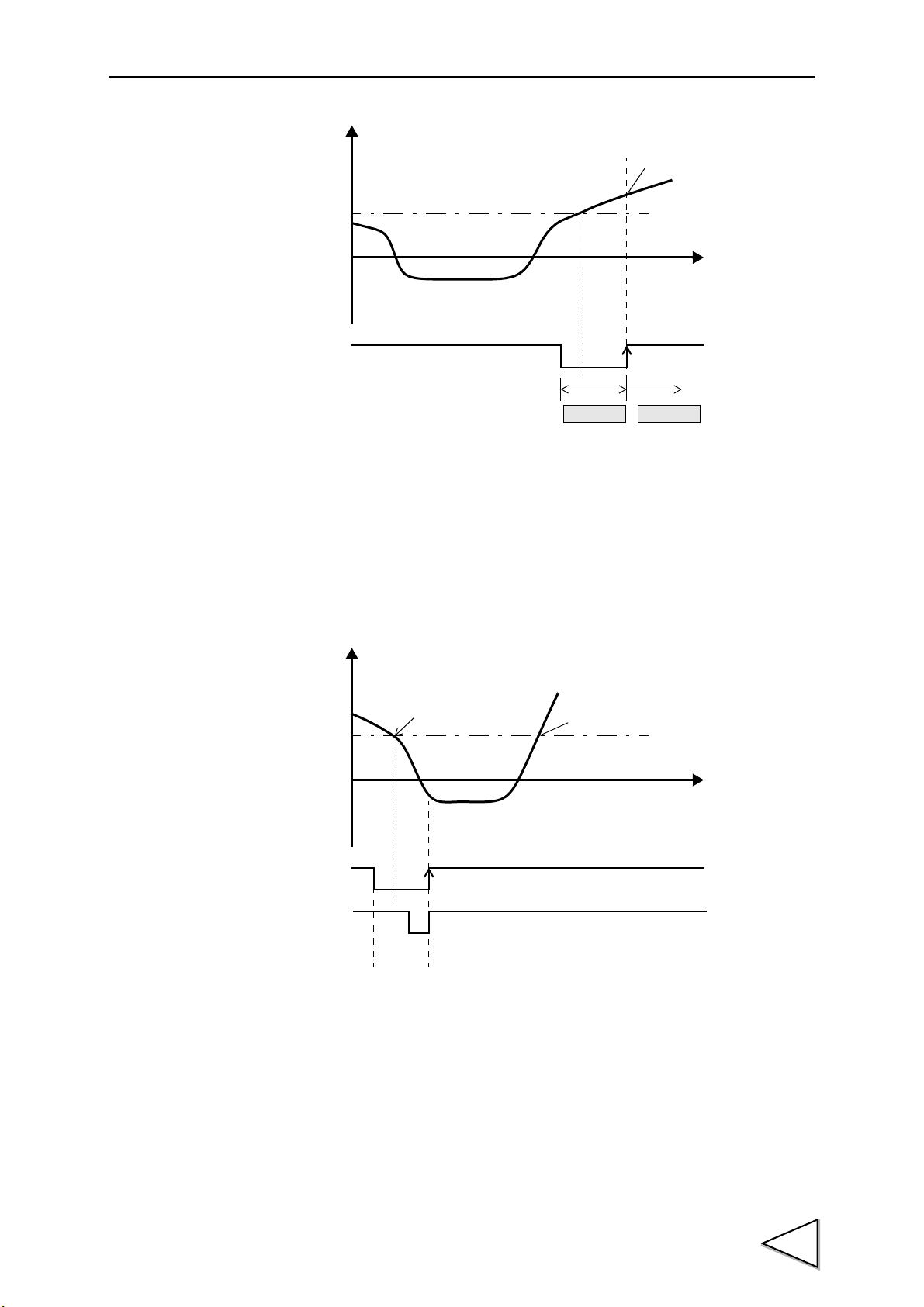

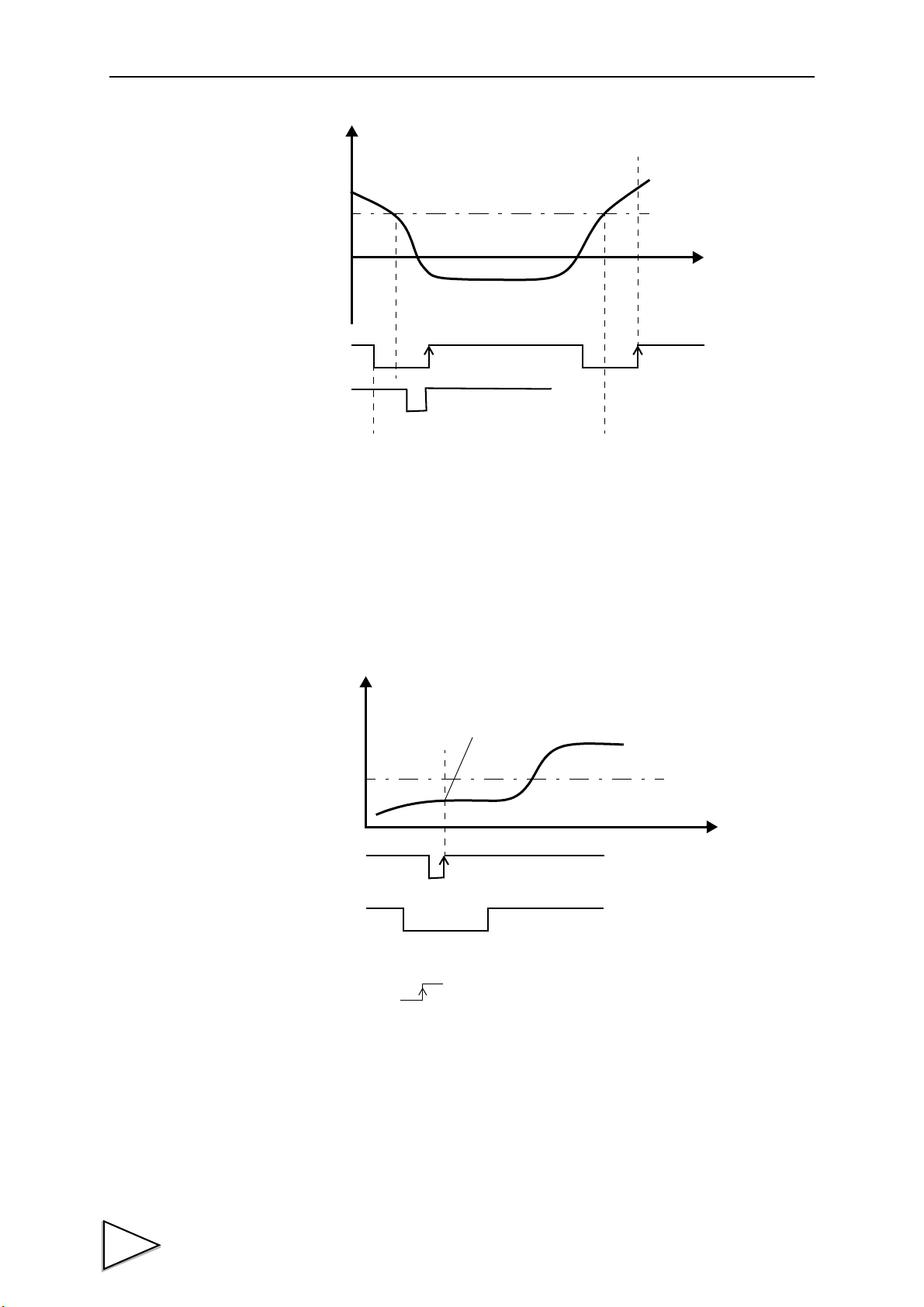

10-3.Hold Functions ...................................................................................... 48

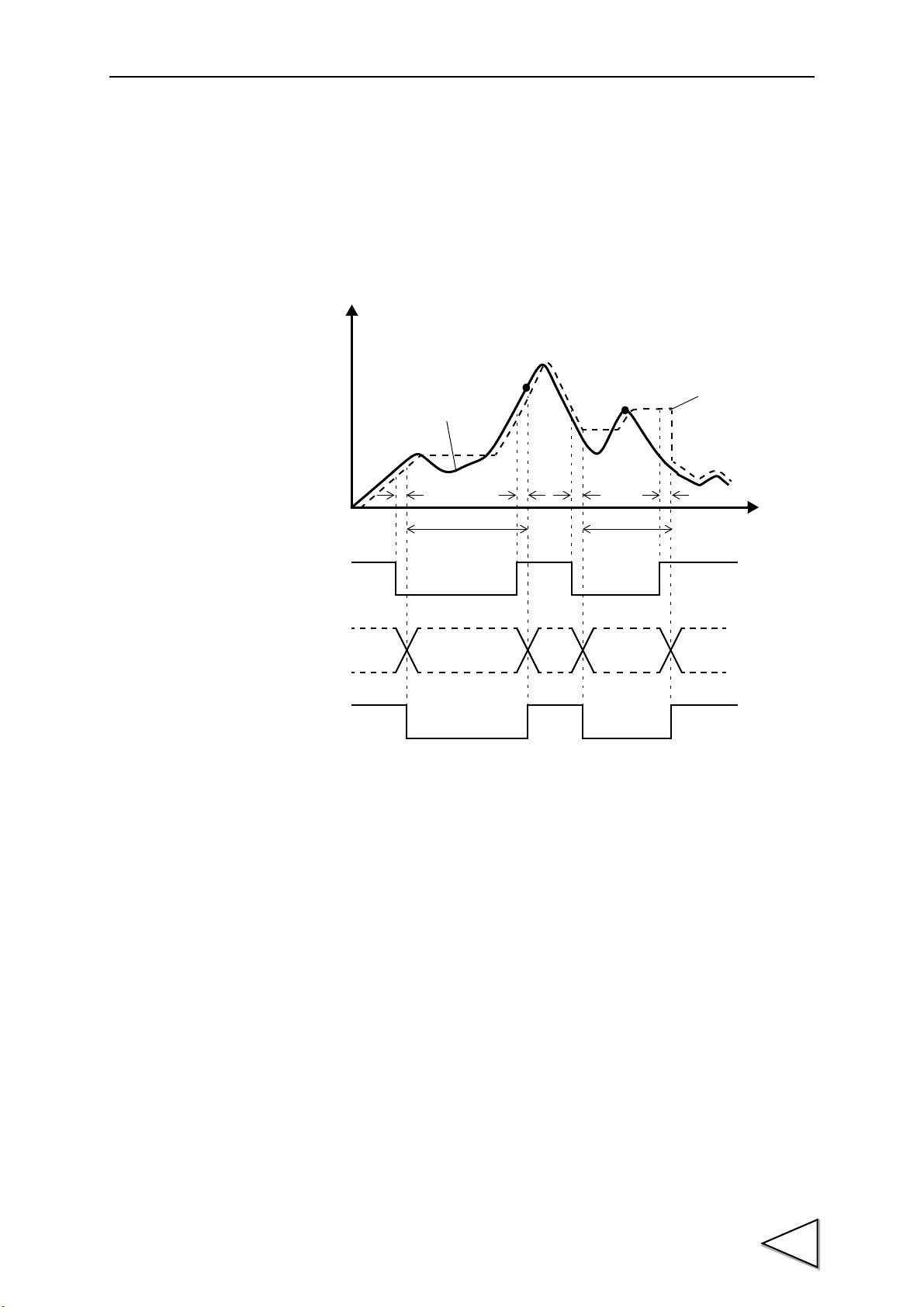

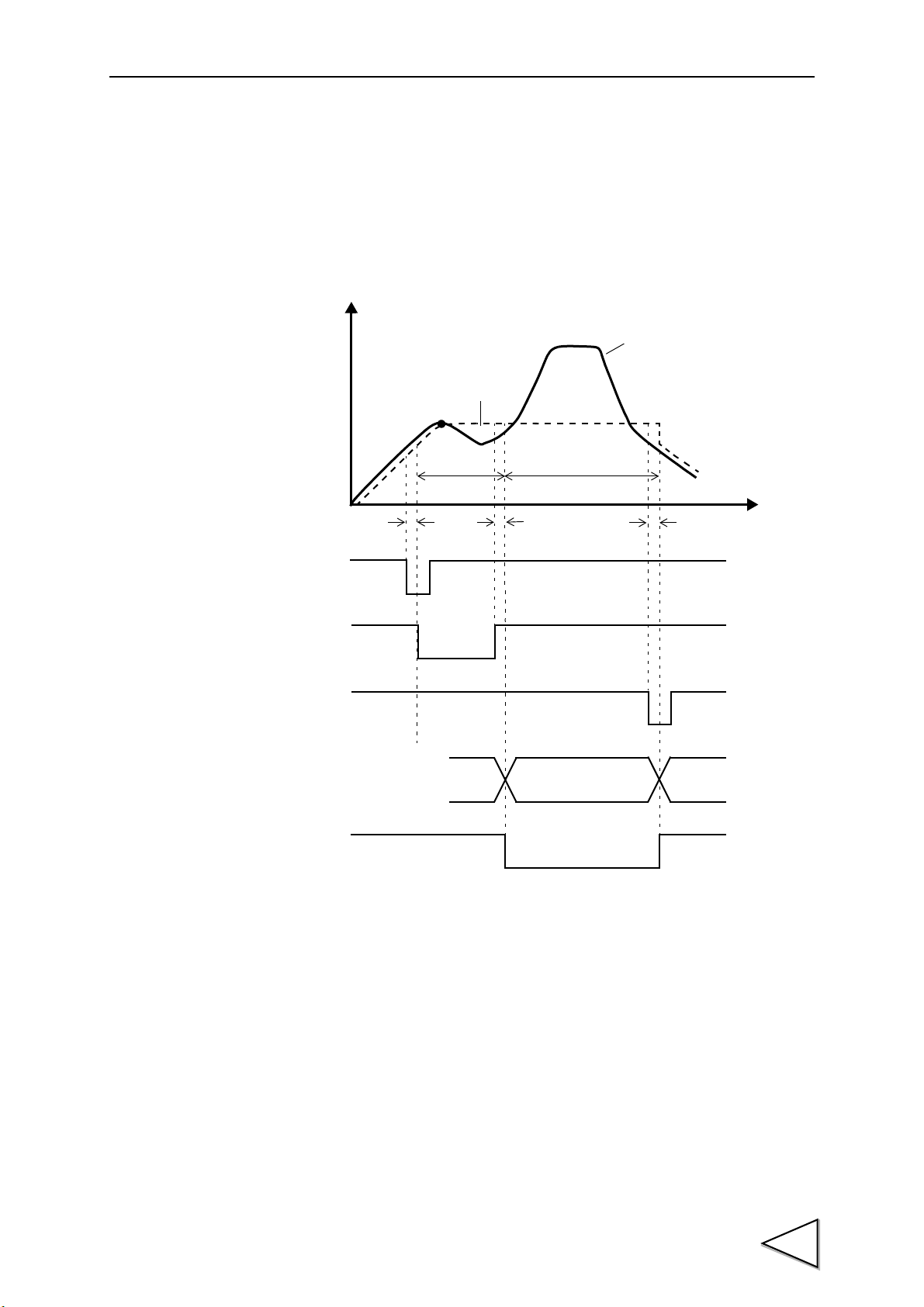

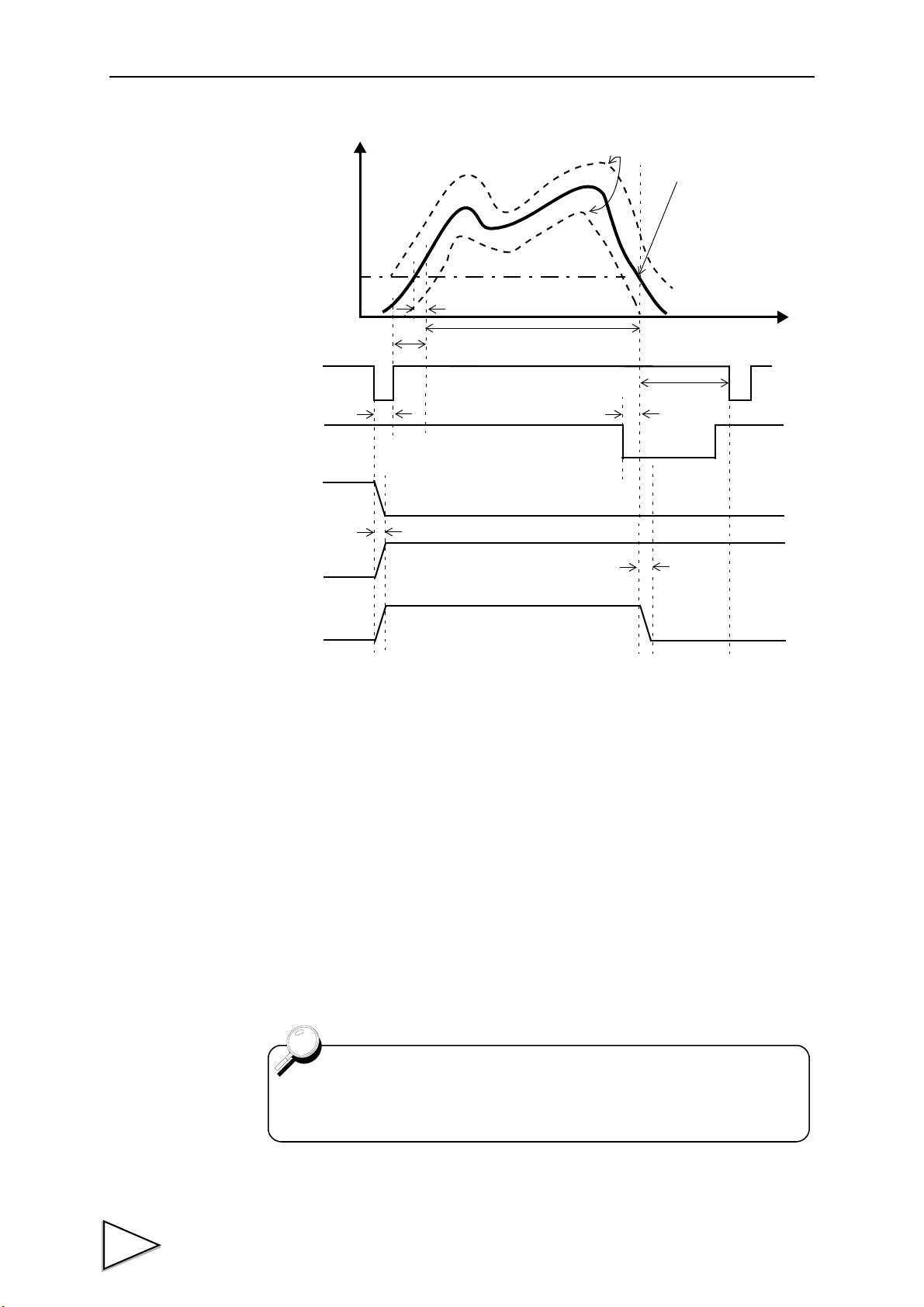

10-3-1.Sample Hold .............................................................................................. 49

10-3-2.Peak Hold .................................................................................................. 50

10-3-3.Valley Hold ................................................................................................ 51

10-3-4.P-P (Peak-to-Peak) Hold ........................................................................... 52

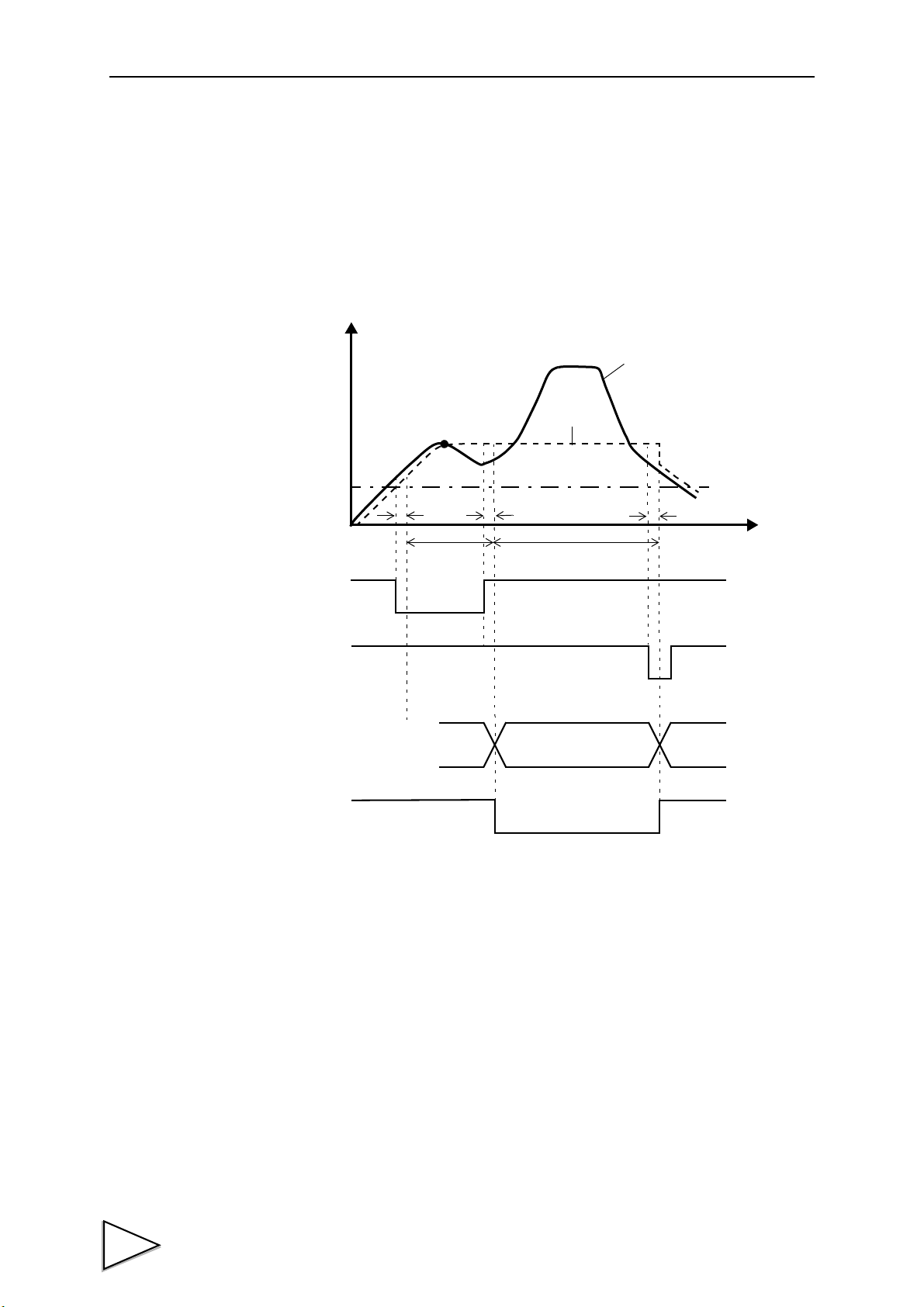

10-3-5.Period Specified Hold (Peak, Valley, P-P) .............................................. 53

10-3-6.Time Specified Hold (Peak, Valley, P-P) ................................................. 54

10-3-7.Time Specified Automatic Hold (Peak, Valley, P-P) .............................. 55

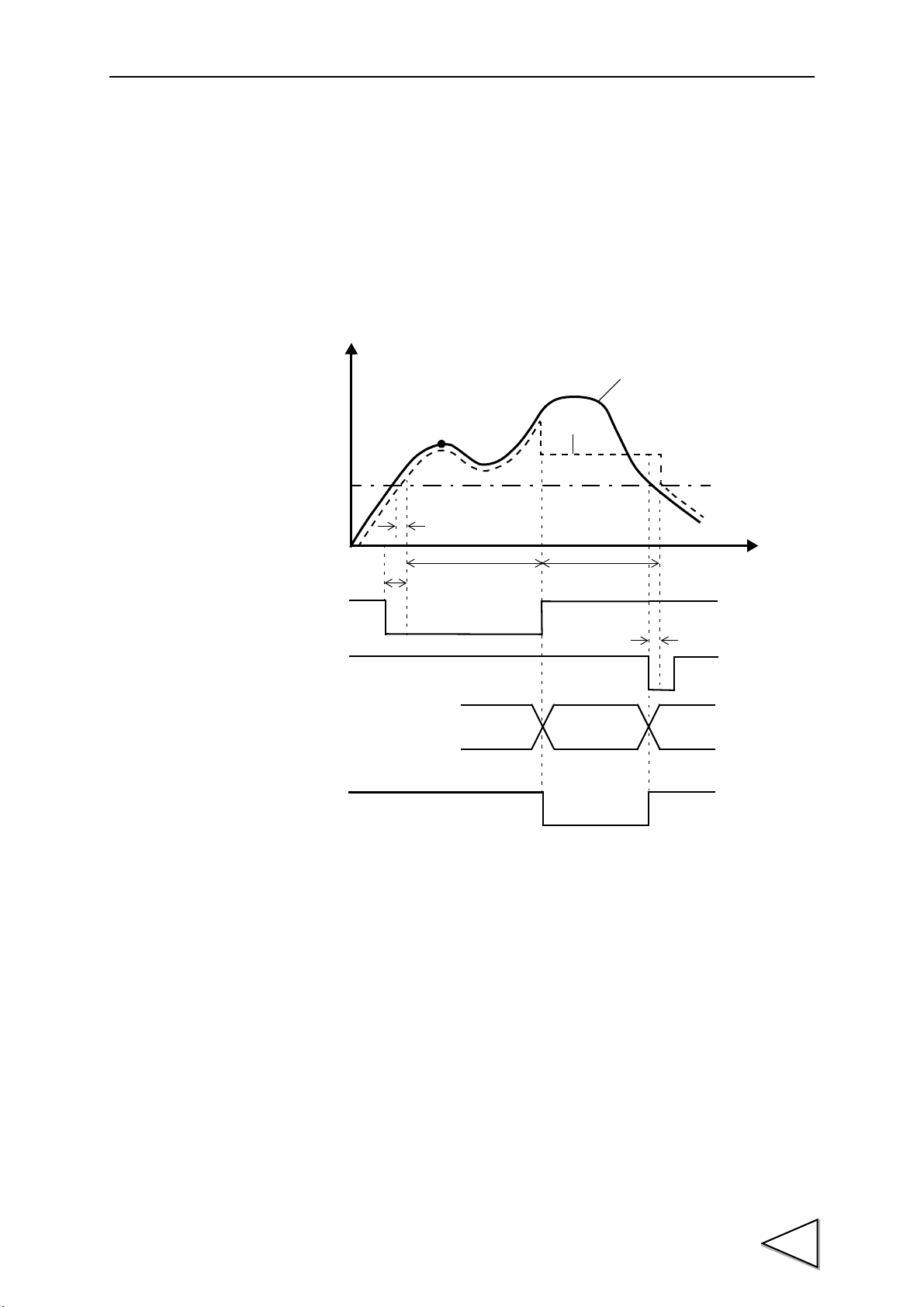

10-3-8.Relative Maximum Value / Relative Minimum Value Hold .................... 56

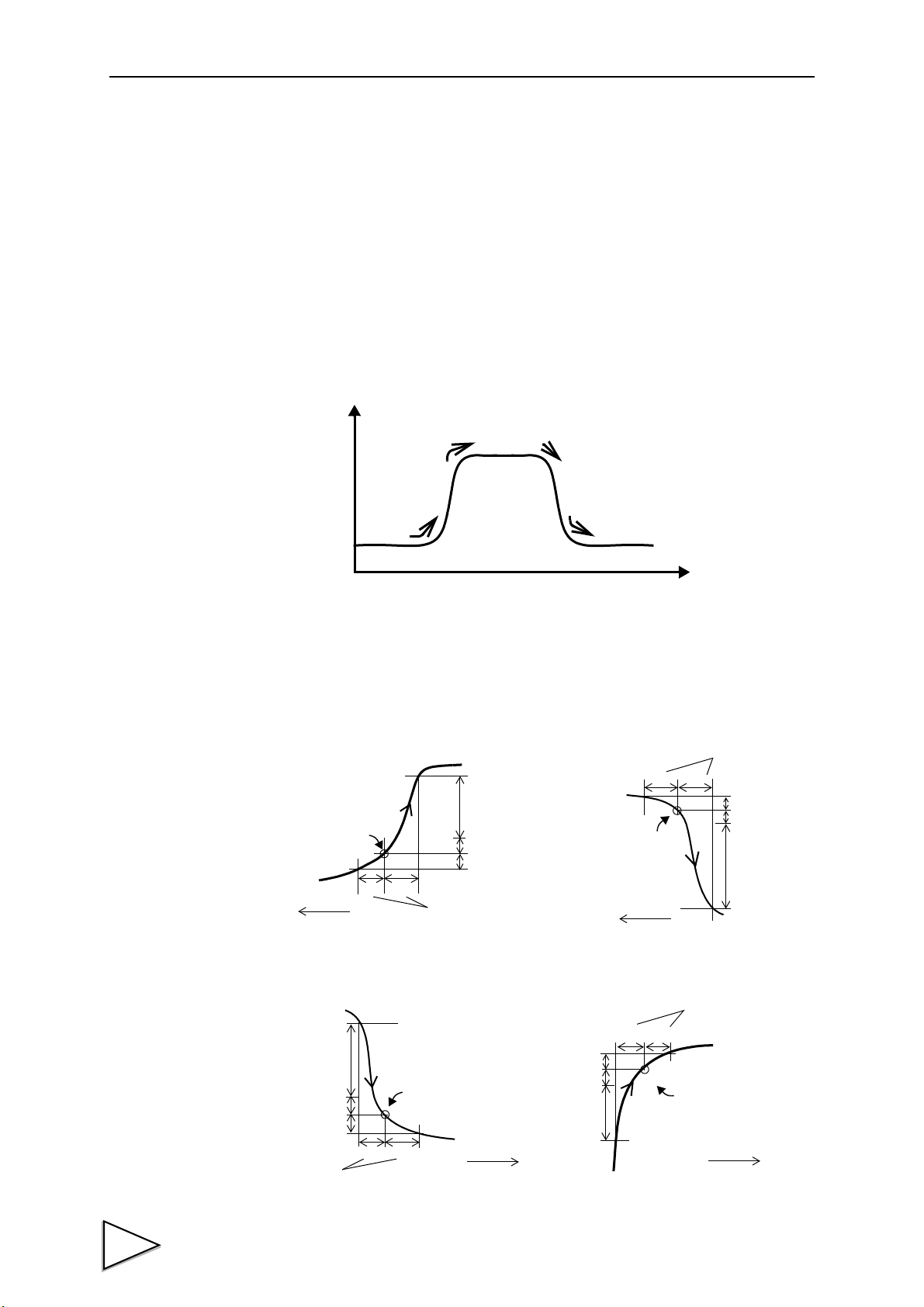

10-3-9.Four Types of Inflection Point Hold ........................................................ 57

10-3-9-1.Inflection Point Hold A ....................................................................................................58

10-3-9-2.Inflection Point Hold B ....................................................................................................59

10-3-9-3.Inflection Point Hold C ....................................................................................................60

10-3-9-4.Inflection Point Hold D ....................................................................................................61

10-3-10.Pulse Hold ............................................................................................... 62

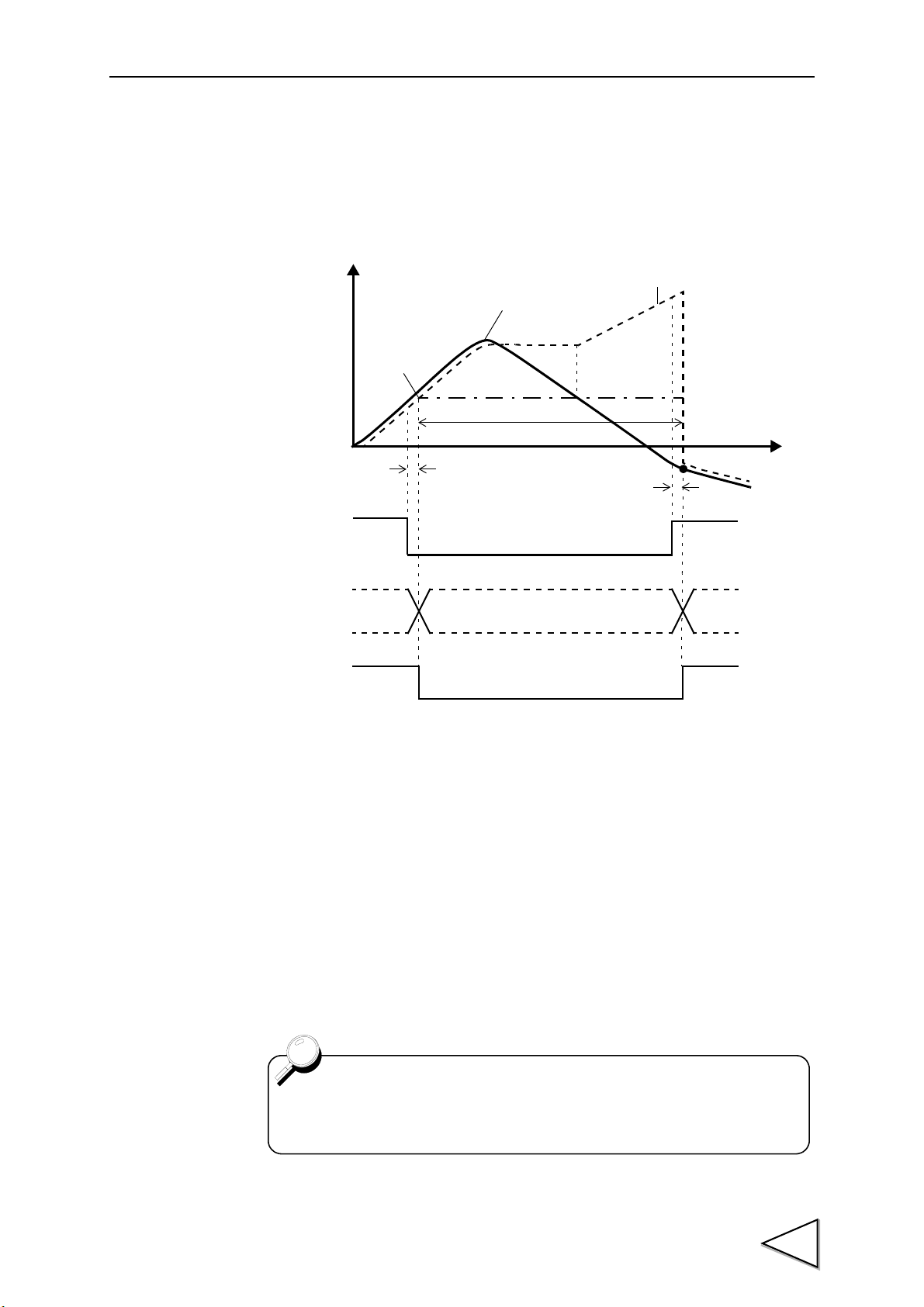

11.Hysteresis Mode ................................................................64

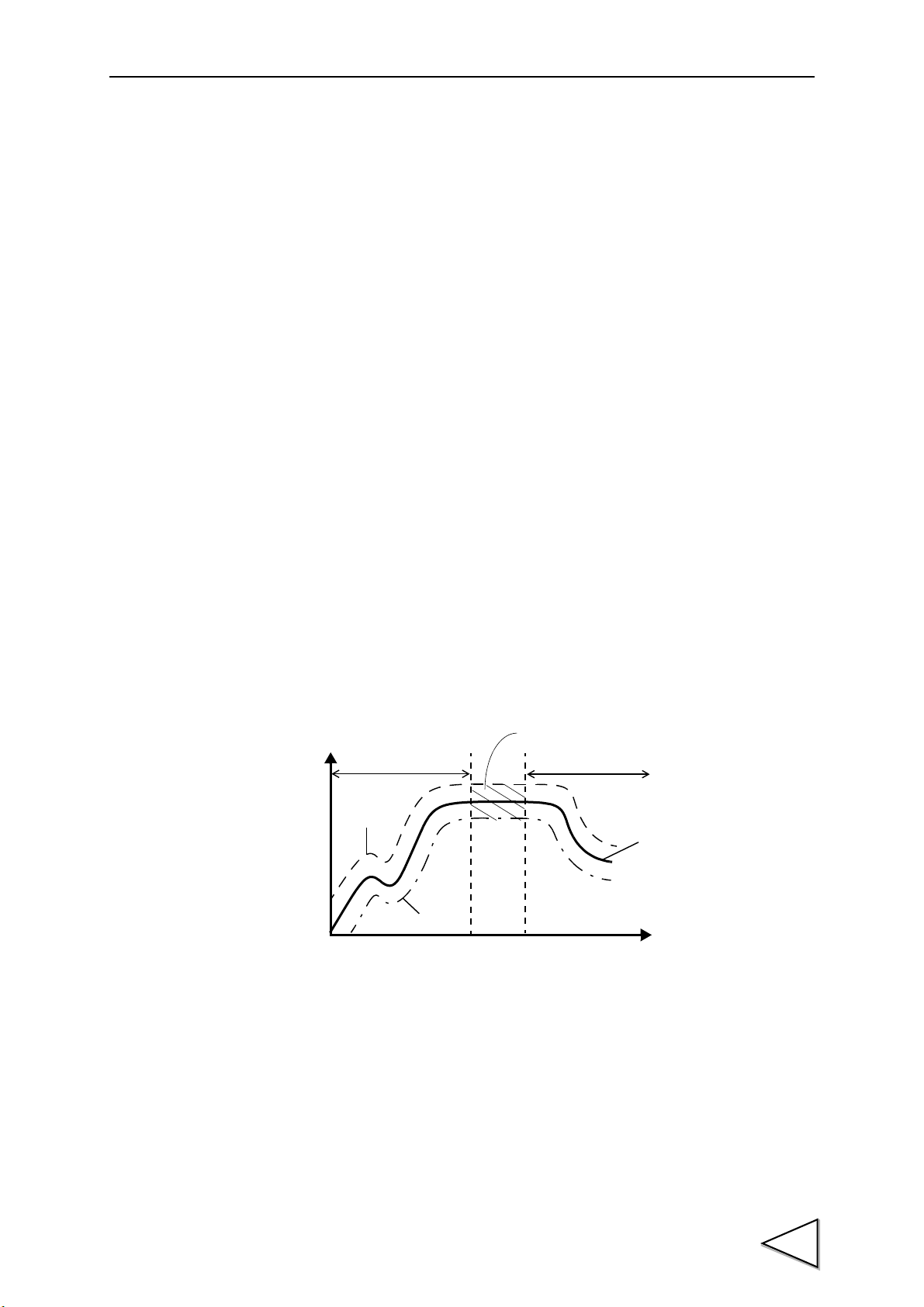

11-1.Function ................................................................................................. 64

11-2.Setting and Operating Method ............................................................. 64

12.Hysteresis 2 ........................................................................65

Page 10

12-1.Function ................................................................................................. 65

12-2.Setting and Operating Method ............................................................. 65

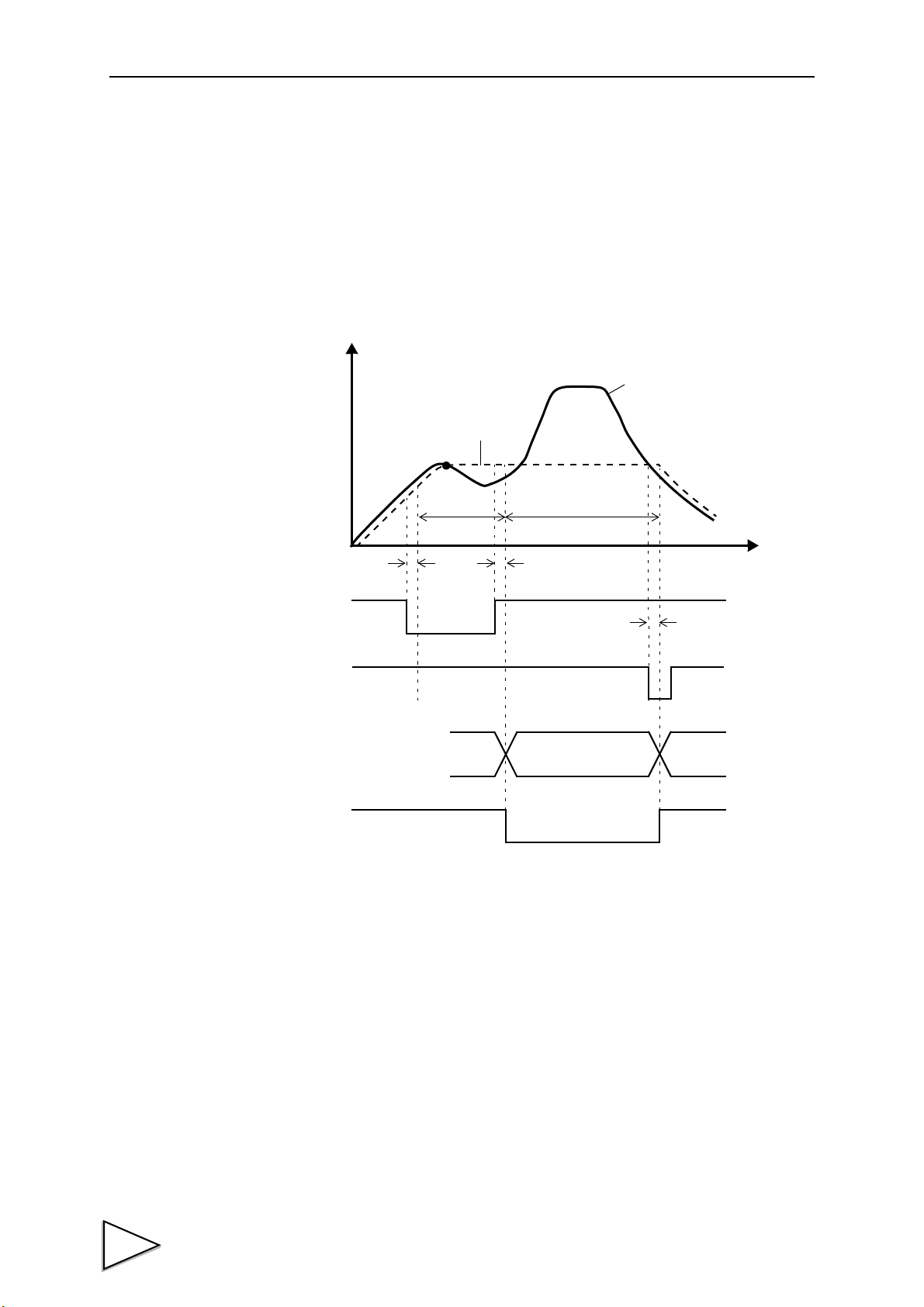

13.Waveform Comparison / Waveform and

Displacement Comparison Mode .....................................68

13-1.Function ................................................................................................. 68

13-2.Setting and Operating Method ............................................................. 68

13-3.Waveform Sampling Procedures ......................................................... 69

13-4.Waveform Comparison Mode ............................................................... 73

13-5.Waveform and Displacement Comparison Mode ............................... 74

13-5-1.Scale of the X-axis .................................................................................... 74

13-5-2.Handling of Sudden Changes ................................................................. 74

Contents

13-5-3.Updating the Amount of Displacement .................................................. 75

13-6.Timing in the Waveform Comparison /

Waveform and Displacement Comparison Mode ............................... 76

13-7.Hold Operation ....................................................................................... 78

13-7-1.Operation and Operating Method ........................................................... 78

13-7-2.Setting Method .......................................................................................... 80

13-8.Un-passing Area Output ....................................................................... 80

13-9.Display After Measurement .................................................................. 81

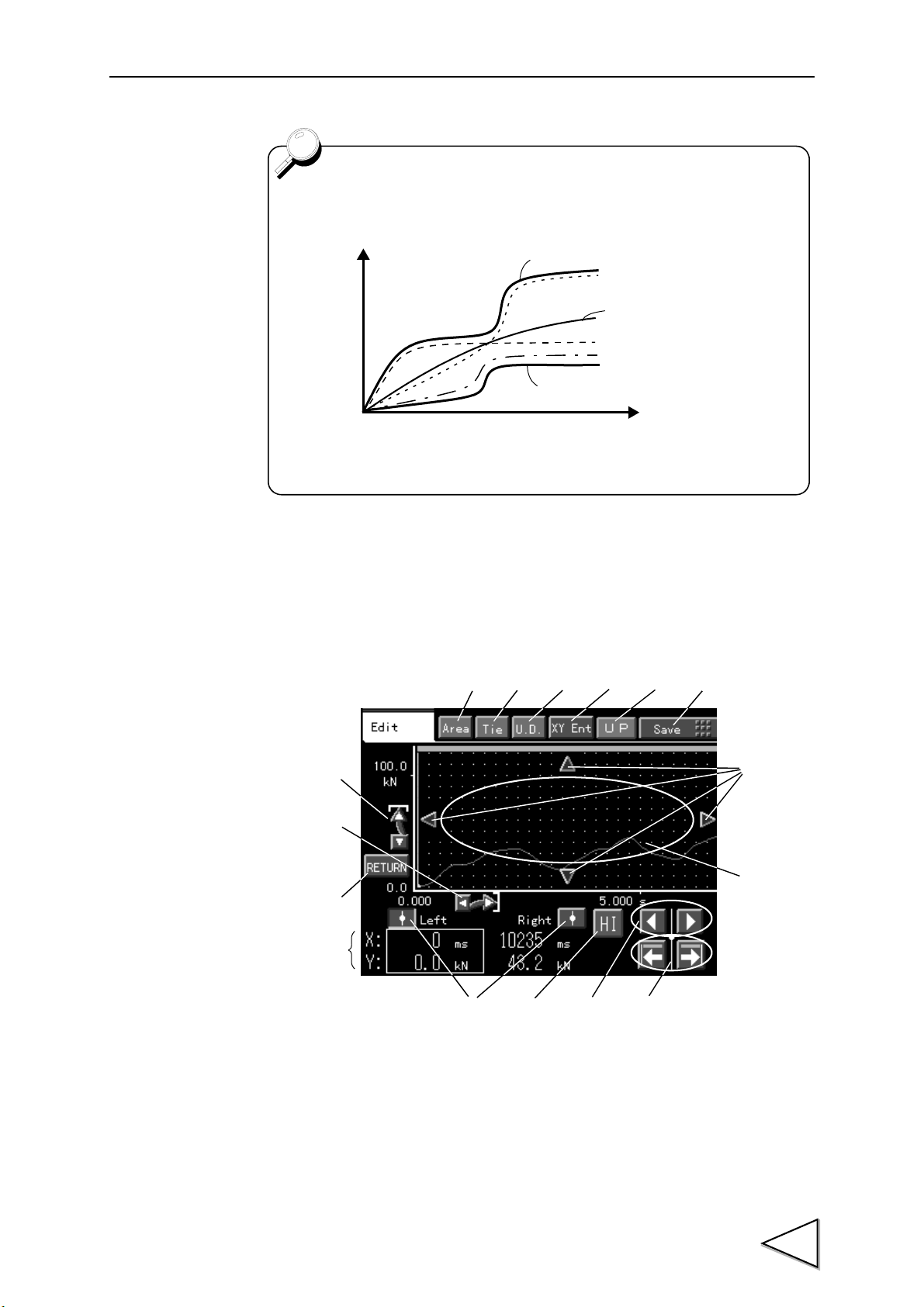

14.Waveform Editing ..............................................................82

14-1.Waveform Call-up .................................................................................. 82

14-2.Waveform Clear ..................................................................................... 82

14-3.Waveform Sampling .............................................................................. 83

14-4.Waveform Editing .................................................................................. 84

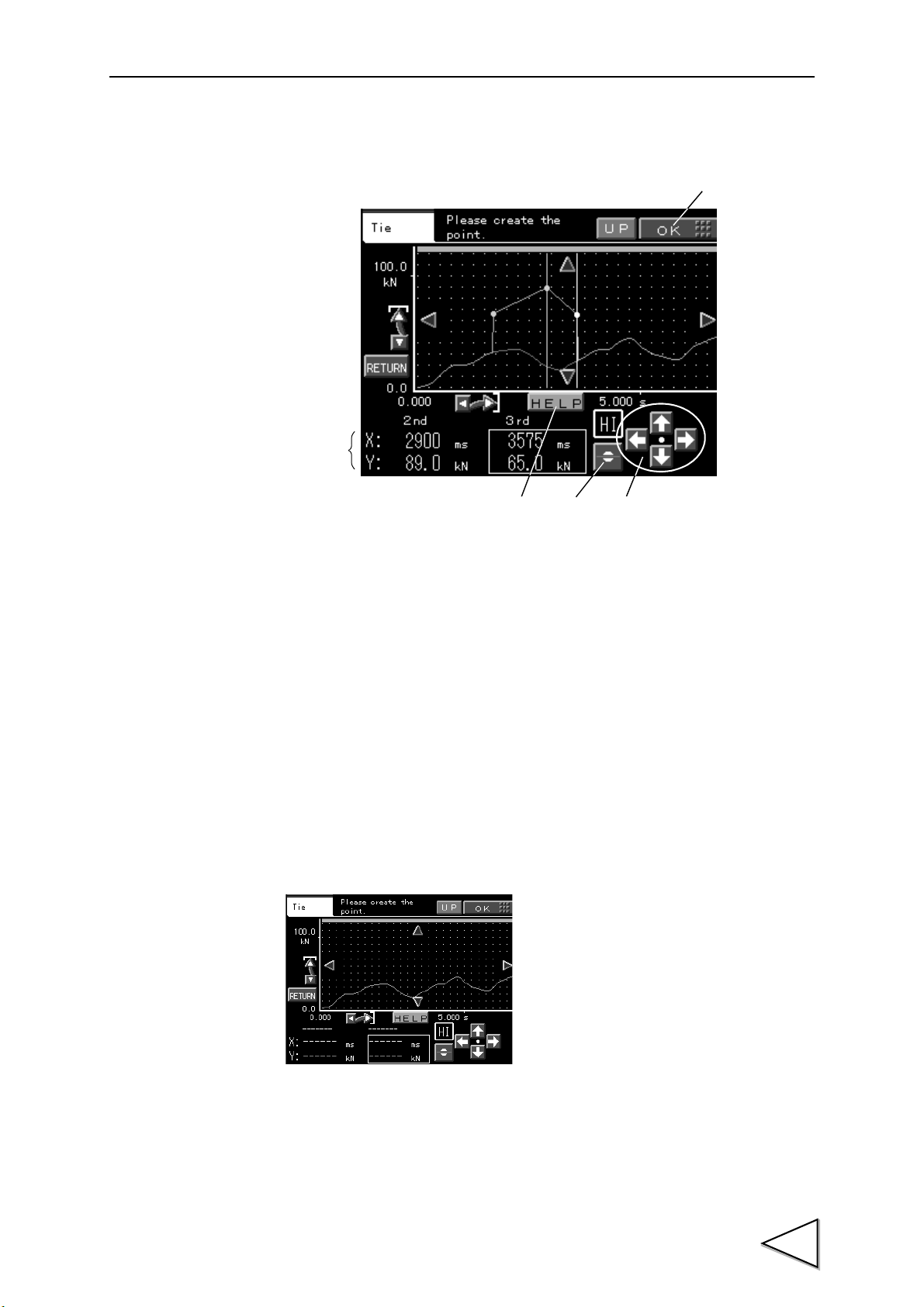

14-4-1.Tie Drawing ............................................................................................... 86

14-4-1-1.Tie Drawing Procedures .................................................................................................. 86

14-4-1-2.About Deletion of Previously Prepared Points .............................................................88

14-4-1-3.About the Help Function ................................................................................................. 88

14-4-2.Shift ............................................................................................................ 89

14-4-2-1.Shift Procedures ..............................................................................................................89

14-4-3.Area Setting .............................................................................................. 90

14-4-3-1.Area Setting Procedures ................................................................................................. 91

14-4-4.Waveform Save ......................................................................................... 91

Page 11

Contents

15.Waveform Reading ............................................................92

15-1.Waveform Reading ................................................................................ 92

15-1-1.Cursor Center Key .................................................................................... 94

15-1-2.Waveform Reading in the Hysteresis / Hysteresis 2 Mode ................... 94

15-1-3.Waveform Reading in the Waveform Comparison / Waveform and

Displacement Comparison Mode ............................................................ 95

15-1-4.Hold Jump Function ................................................................................. 95

15-1-5.Simple Call-up of the Waveform Reading Screen ................................. 96

15-1-6.Display of Hold Point in the Read Waveform ......................................... 96

15-2.Rejected Waveform Reading ................................................................ 96

15-3.Rejected Waveform Clear ..................................................................... 97

15-4.Y-axis Start Point ................................................................................... 97

15-5.Y-axis Scaling ........................................................................................ 97

15-6.X-axis Start Point ................................................................................... 98

15-7.X-axis Scaling ........................................................................................ 98

15-8.Control Signal Display .......................................................................... 99

16.Code Setting .....................................................................100

16-1.Method of Setting the Operation ch ................................................... 100

16-2.Each Setting Item ................................................................................ 103

16-2-1.Channel Number Selection .................................................................... 103

16-2-2.Parameter Copy ...................................................................................... 104

16-2-3.Select Analog CH .................................................................................... 104

16-2-4.Hold Setting ............................................................................................ 105

16-2-5.Auto Code Up / Code Up Point .............................................................. 107

16-2-6.High-Low Relative .................................................................................. 108

16-2-7.High Limit / Low Limit / HI-HI/LO-LO Mode / HI-HI Limit /

LO-LO Limit ............................................................................................ 109

16-2-8.Displacement High-low Mode / Displacement High Limit /

Displacement Low Limit / Displacement Hold High Limit /

Displacement Hold Low Limit ............................................................... 110

16-2-9.Level Axis Select / Waveform Start Level /

Waveform Termination Level / Hold Start Level .................................. 113

16-2-10.Hold Detect Time .................................................................................. 115

16-2-11.Minimum Peak and Valley Difference /

Peak and Valley Detection Rate / Peak and Valley Ordinal .............. 116

16-2-12.Minimum Slope Detection Value / Slope Detection Interval A /

Slope Detection Interval B / Preliminary Slope Detection Point ...... 118

Page 12

Contents

16-2-13.Inhibit Timer .......................................................................................... 119

16-2-14.Hysteresis Interval ................................................................................ 119

16-2-15.Forced-termination Limit ..................................................................... 120

16-2-16.Forced-termination Output .................................................................. 120

16-2-17.Un-passing Area Output ...................................................................... 120

16-3.Graph Confirmation ............................................................................. 121

16-3-1.Items to be Displayed on the Graph of the Present Value and

Input Value .............................................................................................. 122

16-3-2.Minimum Peak and Valley Difference ................................................... 123

16-3-3.Peak and Valley Detection Rate ............................................................ 123

16-3-4.Peak and Valley Ordinal ......................................................................... 124

16-3-5.Minimum Slope Detection Value ........................................................... 124

16-3-6.Slope Detection Interval A ..................................................................... 125

16-3-7.Slope Detection Interval B ..................................................................... 125

16-3-8.Preliminary Slope Detection Point ........................................................ 126

16-3-9.Hysteresis Interval .................................................................................. 126

17.System-related Settings and Operations ......................127

17-1.Set Value Protection ............................................................................ 127

17-2.Display Update Rate ............................................................................ 127

17-3.Backlight .............................................................................................. 127

17-4.Contrast ................................................................................................ 128

17-5.All Parameters Clear ........................................................................... 128

17-6.Self-test ................................................................................................ 128

17-7.Self-test of ROM & RAM / Self-test of NOV-RAM .............................. 131

17-8.Pass Word ............................................................................................ 131

17-9.Switching between Japanese and English ....................................... 131

18.Interface ............................................................................132

18-1.SI/F 2-wire Serial Interface .................................................................. 132

18-2.RS-232C Interface ................................................................................ 133

18-2-1.Communication Specifications ............................................................. 133

18-3.Interface-related Settings ................................................................... 133

18-3-1.Transmission Speed .............................................................................. 133

18-3-2.Character Length .................................................................................... 134

Page 13

Contents

18-3-3.Parity ........................................................................................................ 134

18-3-4.Terminator ............................................................................................... 134

18-3-5.Communication Mode ............................................................................ 134

18-3-6.SI/F Hold Point Transmission ................................................................ 134

18-3-7.SI/F Hold Point ........................................................................................ 134

18-4.RS-232C Format ................................................................................... 135

18-4-1.Writing Set Values .................................................................................. 135

18-4-2.Reading Set Values ................................................................................ 138

18-4-3.Specifying Sampled Waveform Access Channels .............................. 139

18-4-4.Writing Sampled Waveform Data .......................................................... 140

18-4-5.Reading Sampled Waveform Data ........................................................ 142

18-4-6.Writing the Effective Area of the Sampled Waveform ......................... 143

18-4-7.Reading the Effective Area of The Sampled Waveformend of

the Area ................................................................................................... 144

18-4-8.List of Accessible Waveforms by Operation Mode ............................. 145

18-4-9.Reading Indicated Values / Status ........................................................ 146

18-4-10.Commands ............................................................................................ 147

18-4-11.Reading Hold Data ................................................................................ 147

18-4-12.Automatic Transmission Mode ........................................................... 149

19.Error Messages ................................................................150

19-1.Details of Messages ............................................................................ 150

19-2.Method of Checking ADC+OVER / ADC-OVER ................................. 151

20.Block Diagram ..................................................................152

21.Outer Dimensions ............................................................153

22.Mounting to a Panel .........................................................154

23.Specifications ..................................................................155

23-1.Analog Input Section ........................................................................... 155

23-2.Pulse Input Section ............................................................................. 157

23-3.Display Section .................................................................................... 157

23-4.Setting Section .................................................................................... 158

23-5.Input / Output Section ......................................................................... 158

Page 14

Contents

23-6.External Power Supply (Shared with Excitation Voltage) ................ 158

23-7.Interface ................................................................................................ 158

23-8.General Performance .......................................................................... 159

23-9.Option ................................................................................................... 159

23-10.Accessories ....................................................................................... 160

24.Setting Items list ..............................................................161

25.Statement of Conformation to EC Directives ................163

Page 15

Per Reading This Instruction Manual

Per Reading This Instruction Manual

Since various names on the F395 are determined by assuming the X-axis sensor

displacement input, matters relating to the X-axis input may be expressed as

displacement - depending on the description in this instruction manual.

1

Page 16

1. Outline of the F395

Sampling of waveform variation with

displacement for going and return,

detection of points in a waveform such

as an inflection point, and judgment of

differences between going and return

at a given point

(Hysteresis / Hysteresis 2 function);

Connection (P.21 )

Calibration (P.31 )

Settings Relating to Indicated

Value (P.38 )

Reading of Waveform (P.92 )

Measurement Operation

Functional Settings (P.40 )

Multi-Hold, (P.47 )

etc.

Waveform Comparison /

waveform and Displacement

Comparison, (P.68 )

etc.

The procedures from waveform display to uses of the Multi-Hold function and Waveform Comparison

function are as follows:

The Multi-Hold / Hysteresis / Hysteresis 2 / Waveform Comparison / Waveform and

Displacement Comparison functions cannot be used simultaneously.

Carefully read the explanations of "7. Measurement Operation Functional Settings" P40,

"10. Multi-Hold Mode" P47, "11. Hysteresis Mode" P64, "12. Hysteresis 2" P65, "13.

Waveform Comparison / Waveform and Displacement Comparison Mode" P68 and select

function(s) appropriate for the equipment application you use.

Detection of points in a waveform such

as an inflection point

(Multi-Hold function);

Basically, the waveform between the START signal and STOP

signal is graphically drawn.

(Conditional. See "9. Method of Starting Measurement" P43.)

START

STOP

Hysteresis (P.64 )

Hysteresis 2 (P.65 )

etc.

Check to see if the waveform variation

with time and displacement is within a

certain width

(Waveform Comparison / Waveform

and Displacement Comparison

function).

Waveform display of signals from a

strain gauge type sensor;

Strain gauge type sensor

Request

1-1. What the F395 Can Do:

1.Outline of the F395

2

Page 17

1.Outline of the F395

1-2. Waveform Drawing Procedures

The F395 can provide waveform displays of signals from a strain gauge type sensor and

displacement sensor. The waveform display procedures are as follows.

(See "7-4. X/Y-axis Setting by Operation Mode and Input CH" P41.):

1. Connect a strain gauge type sensor (and displacement sensor) with the F395.

(See "4-1-1. Analog Input / Output Connection" P21.)

2. Perform calibration. (See "5. Methods of Calibration" P31.)

3. Set each parameter for waveform display.

(See "9. Method of Starting Measurement" P43, and "16-2-9. Level Axis Select /

Waveform Start Level / Waveform Termination Level / Hold Start Level" P113.)

4. Check to see if a waveform is displayed for the set conditions.

1-3. Multi-Hold Procedures

In the Multi-Hold mode, necessary points are detected in the displayed waveform to

make a judgment such as a High/Low Limit Comparison. Up to 32 channels of Hold

types, High and Low Limits, etc., can be stored, which can be switched by external

signals. The procedures for using the Multi-Hold function are as follows:

1. Check to see if a waveform is displayed in accordance with the waveform drawing

procedures. (See "1-2. Waveform Drawing Procedures" P3.)

2. Select a hold function so that necessary points in the waveform can be held. (See "10-

3. Hold Functions" P48.)

3. Carry out Multi-Hold settings. (See "16-2. Each Setting Item" P103.)

4. Select the channel number(s) you want to control externally. (See "4-3. Control

Connector Connection" P25.)

5. Input T/H and H/M signals in accordance with the selected hold function, and check to

see if operation is performed as set. (See "10-3. Hold Functions" P48.)

3

Page 18

1-4. Hysteresis Procedures

In the Hysteresis mode, go and return waveform variations with displacement are

sampled, and necessary points in the displayed waveforms are detected to perform

controls such as a High/Low Limit Comparison.

This function is almost the same as the Multi-Hold function except for the return

waveform sampling function by hysteresis interval (See "16-2-14. Hysteresis Interval"

P119.), displacement on the X-axis, and the maximum sampling rate of 2kHz.

1. Check to see if a waveform is displayed in accordance with the waveform drawing

procedures. (See "1-2. Waveform Drawing Procedures" P3.)

2. Select a hold function such that necessary points in the waveform can be held. (See

"10-3. Hold Functions" P48.)

3. Carry out Hysteresis settings. (See "11-2. Setting and Operating Method" P64.)

4. Select the channel number(s) you want to control externally. (See "4-3. Control

Connector Connection" P25.)

1.Outline of the F395

5. Input T/H and H/M signals in accordance with the selected hold function, and check to

see if operation is performed as set. (See "10-3. Hold Functions" P48.)

1-5. Hysteresis 2 Procedures

The Hysteresis 2 mode is the same as the Hysteresis mode except for the hold operation.

At the point of displacement where a pulse is input, High/Low Limit Comparison of the

go measured value, and High/Low Limit Comparison of the difference between the go

and return measured values are performed.

1. Check to see if a waveform is displayed in accordance with the waveform drawing

procedures. (See "1-2. Waveform Drawing Procedures" P3.)

2. Carry out Hysteresis 2 settings. (See "12-2. Setting and Operating Method" P65.)

3. Select the channel number(s) you want to control externally.

(See "4-3. Control Connector Connection" P25.)

4. Provide a load to the strain gauge type sensor / displacement sensor, input START and

HOLD 1 ~ 3 signals (See "4-3. Control Connector Connection" P25.), and check to

see if operation is performed as set.

4

Page 19

1.Outline of the F395

1-6. Waveform Comparison /

Waveform and Displacement Comparison Procedures

In the Waveform Comparison / Waveform and Displacement Comparison mode,

waveform variations with time / displacement are sampled, and a High/Low Limit

Comparison is performed based on the sampled waveform.

A sequential comparison can be performed with respect to dynamic waveform

variations.

The procedures for performing a Waveform Comparison / Waveform and Displacement

Comparison are as follows:

1. Check to see if a waveform is displayed in accordance with the waveform drawing

procedures. (See "1-2. Waveform Drawing Procedures" P3.)

2. Carry out Waveform Comparison / Waveform and Displacement Comparison settings.

(See "13-2. Setting and Operating Method" P68.)

3. Select the channel number(s) you want to control externally.

(See "4-3. Control Connector Connection" P25.)

4. Provide a load to the strain gauge type sensor (displacement sensor), input START and

other signals, and check to see if operation is performed as set.

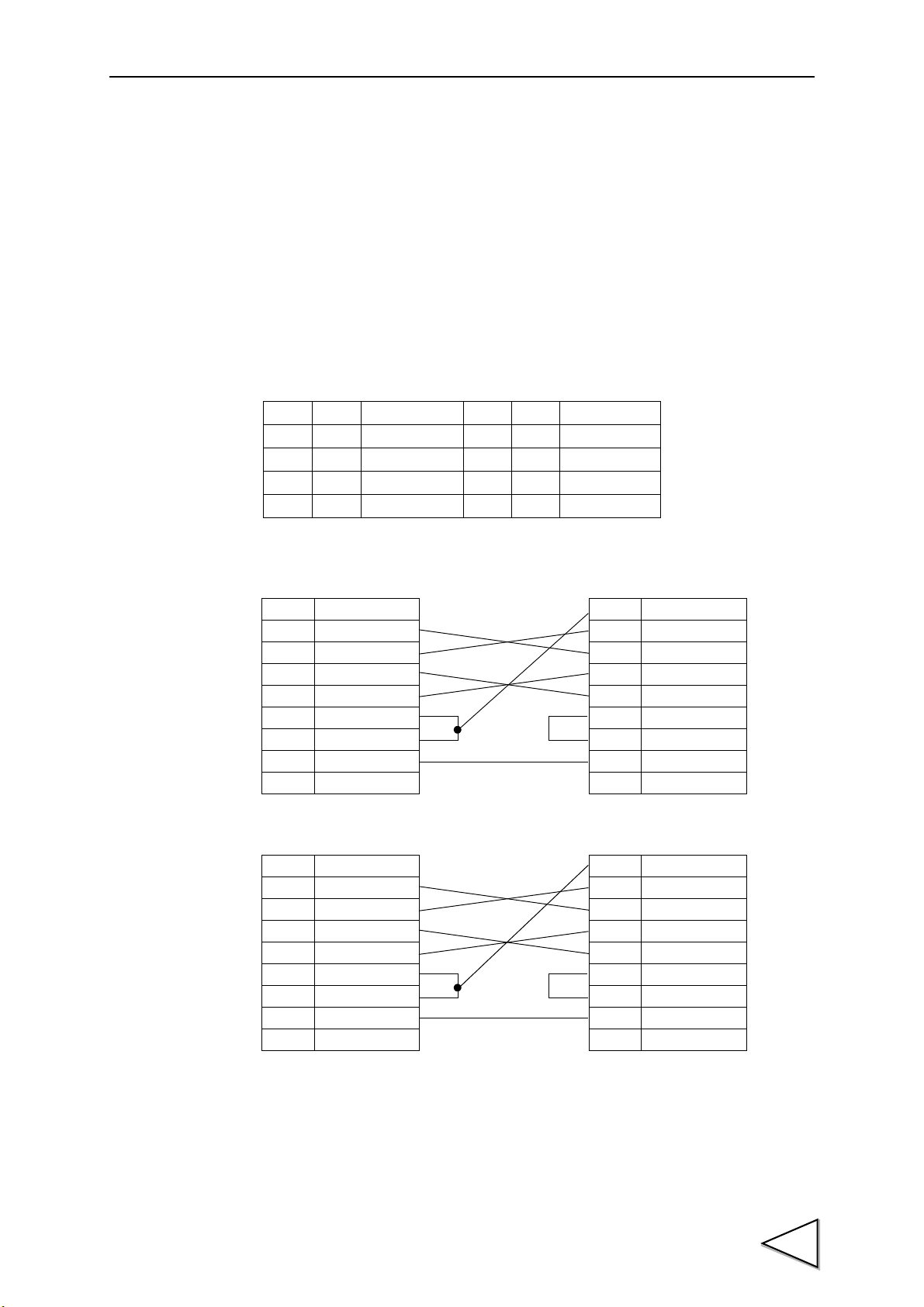

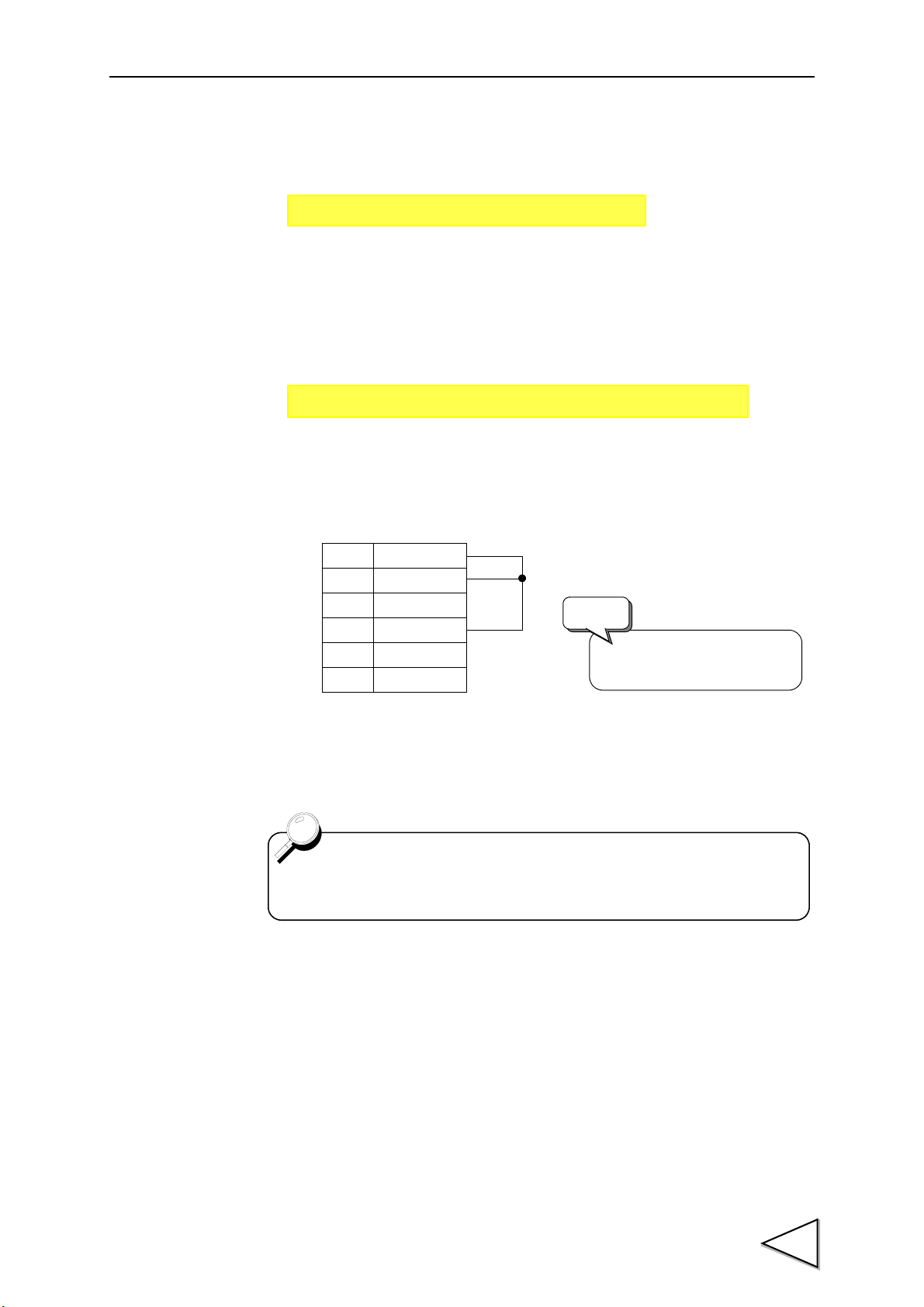

1-7. Operation Mode at a Glance

Operation

mode

Multi-Hold

Hysteresis

Waveform

Comparison

Waveform and

Displacement

Comparison

Usable X-axis Maximum

Time

Sensor

○××

×○○

○××

×○○

Pulse

sampling

rate

4kHz 9 points for all types

2kHz 9 points for all types

4kHz 1 point for three types

2kHz 1 point for three types

Hold

Waveform

comparison

××

×○

○×

○×

Capability

of return

5

Hysteresis 2

×○○

2kHz 3 points for one type

×○

Page 20

1-8. Standard Interface

Status, set values, indicated values, waveform data, etc., can be sent to your PC through

the RS-232C serial interface. Set values and commands can also be sent from the PC to

F395. (See "18-2. RS-232C Interface" P133.)

Also, external equipment such as a printer and large display manufactured by us can be

used by using the SI/F 2-wire serial interface. (See "18-1. SI/F 2-wire Serial Interface"

P132.)

1-9. Waveform Reading

Measured values at sampling points for the latest sampled waveform and NG-

measurement waveforms (rejected waveform reading: four waveforms at maximum) can

1.Outline of the F395

be read.

(See "15-1. Waveform Reading" P92, "15-2. Rejected Waveform Reading" P96, and "15-

3. Rejected Waveform Clear" P97.)

6

Page 21

2.Name and Function of Each Part

Touch panel type

color liquid

crystal display

Power lamp

Shifts to the

2. High and Low Limit

5. Lithium battery

6. Status display

3. X-axis (displacement)

4. Displacement High and

[Main screen]

1. Y-axis display

Performs Digital Zero.

ⅰ

ⅱ

ⅲ

ⅳ

7. Set Operation

8. Control Signal

9. Display of

In the Pulse Hold / Hysteresis 2 mode, the main screen layout is changed to

each specific one.

(See "10-3-10. Pulse Hold" P62, and "12. Hysteresis 2" P65.)

Shifts to the Hold Point

Set Values

section

display section

Low Limit Set Values

alarm

section

Mode display

display

High and Low

Limit Set Values

Display screen.

Mode Setting

Selection screen.

BALM

2. Name and Function of Each Part

2-1. Front Pane

2-1-1. Touch Panel Type Color Liquid Crystal Display

Indicated values and graphs are displayed, and various items are set on this touch panel

type color liquid crystal display.

7

Page 22

[Setting screen]

setting screen with the key displayed in his place.

Returns to the

Setting item

Setting mode name

Setting

Returns to

1) Shifts pages when setting items at the same level

2) Moves to another item at the same level on the item

selection key

previous screen level.

the main screen.

item name

cannot be displayed on one page.

2.Name and Function of Each Part

1. Y-axis display section

・Measured value .....Displays Y-axis measured values such as pressure, and also

・Unit ....................... Displays the unit set with the analog CH set on the Y-axis.

2. High and low limit set values

・Displays the High Limit / Low Limit of the ch (operation ch) set by external input in the

Multi-Hold / Hysteresis mode.

・ Displays the HI-HI Limit / LO-LO Limit of the ch (operation ch) set by external input

in the Waveform Comparison / Waveform and Displacement Comparison mode.

(See "16-2-7. High Limit / Low Limit / HI-HI/LO-LO Mode / HI-HI Limit / LO-LO

Limit" P109.)

displays error messages when measurement errors occur.

(See "7-4. X/Y-axis Setting by Operation Mode and Input CH" P41,

and "19. Error Messages" P150.)

Status Display color

Normal Blue

In sampling White

Hold Green

(See "5-7. Unit" P35, and "16-2-3. Select Analog CH" P104.)

8

Page 23

2.Name and Function of Each Part

WAIT S : Waiting for start.

WAIT 2 : Waiting for the rising edge of start/level.

WAIT L : Waiting for level.

SAMPLE : In sampling.

HIS GO : In hysteresis go sampling

HIS RT : In hysteresis return sampling.

COPY : In waveform copy

STOP : Waiting for start.

3. X-axis (displacement) display section

Displays X-axis measured values such as displacement in the Hysteresis / Hysteresis 2 /

Waveform and Displacement Comparison mode, and also displays error messages when

measurement errors occur.

(See "7-4. X/Y-axis Setting by Operation Mode and Input CH" P41, and "19. Error

Messages" P150)

4. Displacement high and low limit set values

Displays the displacement comparison values of the ch (operation ch) set by external

input in the Hysteresis / Hysteresis 2 / Waveform and Displacement Comparison mode.

Displacement comparison values that are displayed vary depending on the Displacement

High-Low Mode.

(See "16-2-8. Displacement High-low Mode / Displacement High Limit / Displacement Low

Limit / Displacement Hold High Limit / Displacement Hold Low Limit" P110.)

Status Display Color

Thinning-out Yellow

WA RN IN G R ed

Mode Comparison value

Hold Value Displacement Hold High/Low Limit

Peak / Both Displacement High/Low Limit

5. Lithium battery alarm

Displayed when the lithium battery requires replacement. (Normally, nothing is

displayed.)

If this alarm lights, replace the lithium battery in good time. (The life of the lithium

battery is approx. 7 years, which depends on the working environment.) For replacement

of the battery or handling of interchangeable batteries, contact us.

6. Status display section

ⅰ Status display

9

Page 24

2.Name and Function of Each Part

WAIT : In tracking display

DETECT : In hold detection period.

HOLD : In data hold.

NOV : In NOV RAM writing.

HH : Indicated value > HI-HI Limit set value

HI : Indicated value > High Limit set value

OK : Neither of the High and Low Limits is exceeded.

LO : Indicated value < Low Limit set value

LL : Indicated value < LO-LO Limit set value)

Priority : NOV = HH = LL > HI = LO > OK

HI LO

HH LL

OK

or

HI LO

HH HL

OK

or

HOK

or

…

…

Hold judgment

Waveform

comparison

judgment

Displays the ch set by external input (operation ch).

ⅱ Hold status display

ⅲ High and low limits / NOV RAM writing display

Operation mode Status display

Multi-Hold

Hysteresis

Hysteresis 2

Waveform Comparison

Waveform and

Displacement Comparison

ⅳ ch display

7. Set operation mode display

Displays the currently set Operation Mode.

8. Control signal display

Displays the T/H and H/M input status. (See "15-8. Control Signal Display" P99)

9. Display of high and low limit set values

Displays the High and Low Limit Set Values of the ch (operation ch) set by external input in the

Multi-Hold mode. (See "16-2-7. High Limit / Low Limit / HI-HI/LO-LO Mode / HI-HI Limit /

LO-LO Limit" P109), and displays the comparison waveform of the currently set opera-

tion ch in the Waveform Comparison / Waveform and Displacement Comparison mode.

(See "13-1. Function" P68.)

10

Page 25

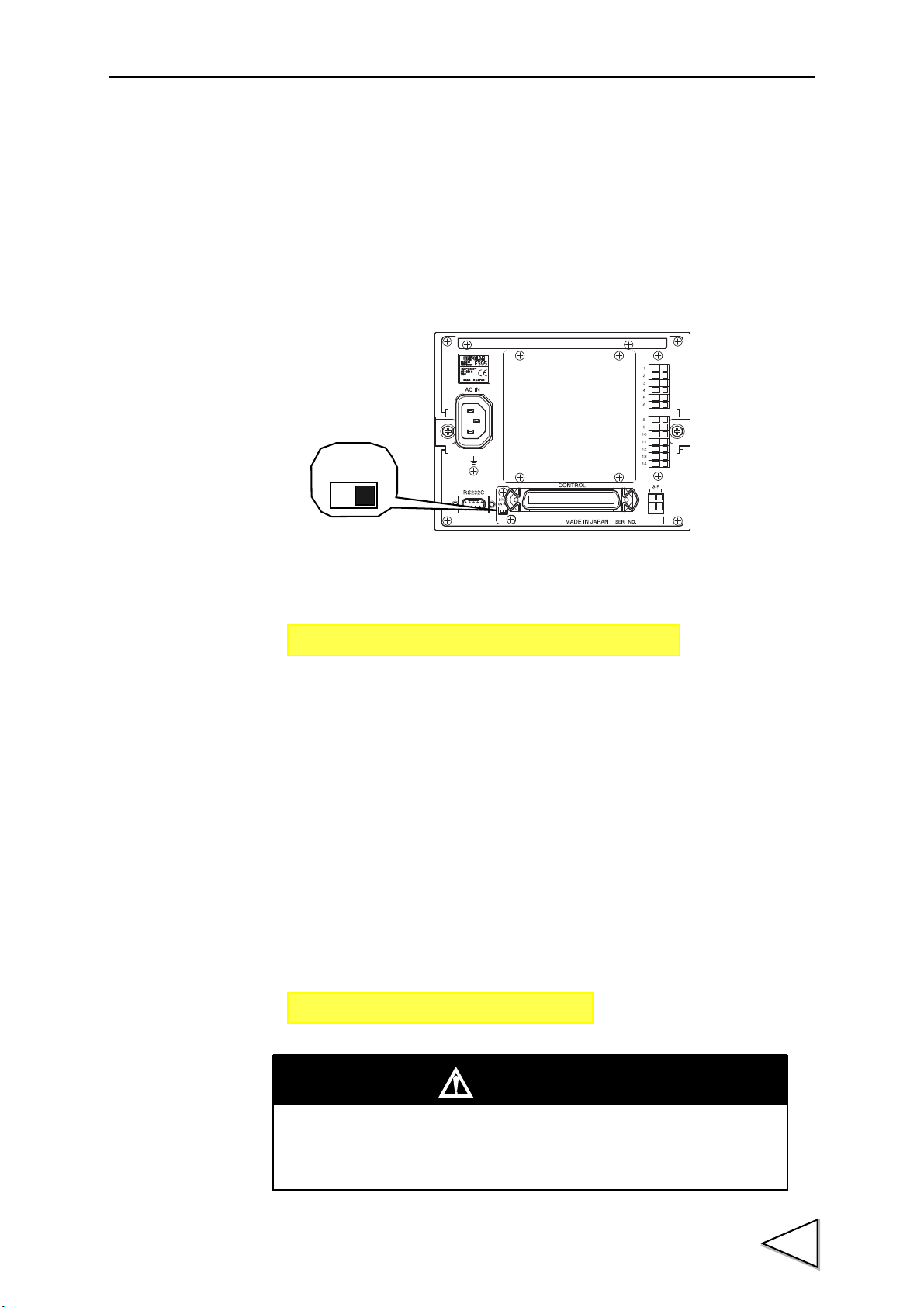

2.Name and Function of Each Part

1. AC power

2. Frame ground

3. RS-232C

connector

4. Calibration

5. Control connector

6. SI/F terminal

7. Analog

8. Optional slot

input connector

LOCK switch

input / output

terminals

2-2. Rear Panel

1. AC power input connector

Connect the attached AC power cord. The input voltage is 100 ~ 240V AC ( ± 10%), and

the frequency is 50/60Hz.

2. Frame ground (F.G)

This is a grounding terminal. Be sure to ground the FG terminal to prevent electric

shocks and failures caused by static electricity.

3. RS-232C connector

This is an RS-232C connector to send and receive measured data and status information.

The applicable plug is OMRON-manufactured XM2D-0901 (cover: XM2S-0913 <with

inch thread #4-40>) or an equivalent.

(See "4-2. RS-232C Connection" P24, and "18-2. RS-232C Interface" P133.)

11

4. Calibration LOCK switch

This is a LOCK switch to prevent calibrated values from being changed by mistake.

Changing of calibrated values is prohibited when this switch is ON. (See "5-5. LOCK

Release" P34.)

Page 26

2.Name and Function of Each Part

5. Control connector

This is a connector to input and output control signals, operation ch settings, etc. The

applicable plug is DDK-manufactured 57-30500 (accessory) or an equivalent.

(See "4-3. Control Connector Connection" P25.)

6. SI/F terminal

This is a serial interface (SI/F) terminal block to connect a UNIPULSE-manufactured

printer, external display, data converter, etc.

(See "4-1-2. SI/F Connection" P23, and "18-1. SI/F 2-wire Serial Interface" P132)

7. Analog input / output terminals

These are terminals for strain gauge type sensor / displacement sensor inputs and voltage

outputs.

(See "4-1-1. Analog Input / Output Connection" P21.)

8. Optional slot

Up to four optional boards can be mounted.

12

Page 27

3.Screen Configuration and Setting Methods

【Main】

【Mode Setting】

【Special】

【Numerical Value Input】

【Selection】

Each mode key

【Execution】

【Set Value Selection】

【Hold Point Display】

or

* Waveform

Waveform Sampling

Reading

Sampling

* Waveform

Reading

Waveform Editing

* Go to Select Rejected Waveform Reading from the selection screen.

Each setting key

Each

setting

key

3. Screen Configuration and Setting Methods

3-1. Screen Flow Chart

13

Page 28

3.Screen Configuration and Setting Methods

【Waveform Reading 【Hold Point for

【Rejected Waveform 【Rejected Waveform

【Basic Setting】

[Code Setting]

Hold Setting key

【Judgment Setting】

【Hold Setting】

Category key

Waveform Reading】Graph】

Reading Selection】 Reading Graph】

Each

setting

key

【Hold Point for Rejected

Waveform Reading】

14

Page 29

Mode set

PAGE1

CH1 CAL.

CH2 CAL.

Operation Mode

Code set

Wave sampling

Read Wave

Communication

Option set

System

System 2

CH2 CAL.

PAGE1

Axis (P41)

EXC. Volt (P34)

Zero CAL. (P35)

Equiv. CAL. (P36)

Actual CAL. (P37)

Digital Flt. (P38)

Analog Flt. (P38)

PAGE2

Decimal Place (P35)

Unit (P35)

Digital Offset (P38)

Increment (P35)

Read Wave

PAGE1

Read Wave (P92)

Read NG Wave (P96)

NG Wave CLR. (P97)

Control Signal (P99)

Y StartPoint (P97)

Y Scale (P97)

X StartPoint (P98)

X Scale (P98)

Communication

PAGE1

Speed (P133)

Data Length (P134)

Parity (P134)

Terminator (P134)

Communication Mode

(P134)

SI/F Hold Trans. (P134)

SI/F Hold Point (P134)

Main

Operation Mode

PAGE1

Operation Mode (P40)

Sample Rate (P40)

CH1 CAL.

PAGE1

EXC. Volt (P34)

Zero CAL. (P35)

Equiv. CAL. (P36)

Actual CAL. (P37)

Digital Flt. (P38)

Analog FIlt. (P38)

Decimal Place (P35)

PAGE2

Unit (P35)

Digital Offset (P38)

Increment (P35)

Wave Sampling

PAGE1

Wave Call (P82)

Clear (P82)

Sampling (P83)

Edit (P84)

3.Screen Configuration and Setting Methods

3-2. Setting Mode Tree Chart

15

Page 30

3.Screen Configuration and Setting Methods

PAGE2

F-T Output (P120)

Auto Code Up (P107)

Code Up Point (P107)

[Basic]

PAGE1

Parameter Copy (P104)

Select CH (P104)

Wave Start Level (P113)

Wave End Level (P113)

Hold Timer ※ (P105)

Inhibit Timer (P119)

Auto Code Up (P107)

Code Up Point (P107)

System

PAGE1

Protect (P127)

Display Rate (P127)

Backlight (P127)

Contrast (P128)

System 2

PAGE1

All Param. CLR. (P128)

Self Test (P128)

ROM-RAM CHK (P131)

NOVRAM CHK (P131)

PASS WORD (P131)

Code Set (Display items vary depending on the selected Operation Mode.)

Multi-Hold Wave Comp. Hysteresis Wave&Displace Hysteresis 2

[Basic]

PAGE1

Parameter Copy (P104)

Select CH (P104)

Wave Start Level (P113)

Wave End Level (P113)

Hold Timer ※ (P105)

Inhibit Timer (P119)

[Basic]

PAGE1

Parameter Copy (P104)

Select CH (P104)

Lv. Axis Select (P113)

Wave Start Level (P113)

Wave End Level (P113)

Hold Timer ※ (P105)

Inhibit Timer (P119)

Hys. Interval (P119)

F-T Limit (P120)

[Basic]

PAGE1

Parameter Copy (P104)

Select CH (P104)

Lv. Axis Select (P113)

Wave Start Level (P113)

Wave End Level (P113)

Hold Timer ※ (P105)

Inhibit Timer (P119)

F-T Limit (P120)

F-T Output (P120)

[Basic]

PAGE1

Parameter Copy (P104)

Select CH (P104)

Lv. Axis Select (P113)

Wave Start Level (P113)

Wave End Level (P113)

Inhibit Timer (P119)

Hys. Interval (P119)

F-T Limit (P120)

F-T Output (P120)

PAGE2

Auto Code Up (P107)

Code Up Point (P107)

PAGE2

DPM Hold HI (P110)

DPM Hold LO (P110)

[Judgment]

PAGE1

HI-LO Relative (P108)

HI Limit (P109)

LO Limit (P109)

HH/LL Mode (P109)

HI-HI Limit (P109)

LO Limit (P109)

DPM HI-LO Mode (P110)

DPM HI (P110)

DPM LO (P110)

[Judgment]

PAGE1

HI-LO Relative (P108)

HI Limit (P109)

LO Limit (P109)

HH/LL Mode (P109)

HI-HI Limit (P109)

LO Limit (P109)

[Judgment]

PAGE1

HH/LL Mode (P109)

HI-HI Limit (P109)

LO Limit (P109)

U. Area Output (P80)

[Judgment]

PAGE1

HH/LL Mode (P109)

HI-HI Limit (P109)

LO Limit (P109)

DPM HI-LO Mode (P110)

DPM HI (P110)

DPM LO (P110)

DPM Hold HI (P110)

DPM Hold LO (P110)

U. Area Output (P80)

PAGE2

DPM Hold HI (P110)

DPM Hold LO (P110)

[Judgment]

PAGE1

HI-LO Relative (P108)

HI Limit (P109)

LO Limit (P109)

HH/LL Mode (P109)

HI-HI Limit (P109)

LO Limit (P109)

DPM HI-LO Mode (P110)

DPM HI (P110)

DPM LO (P110)

* Only the hold setting includes further setting items.

Setting items vary depending on the hold category

selection. For the items in the hold setting, see "16-2-4.

Hold Setting" P105.

Option Set

PAGE1

PUI

ODN

CCL

* For details, see the

attached Option Manual.

16

Page 31

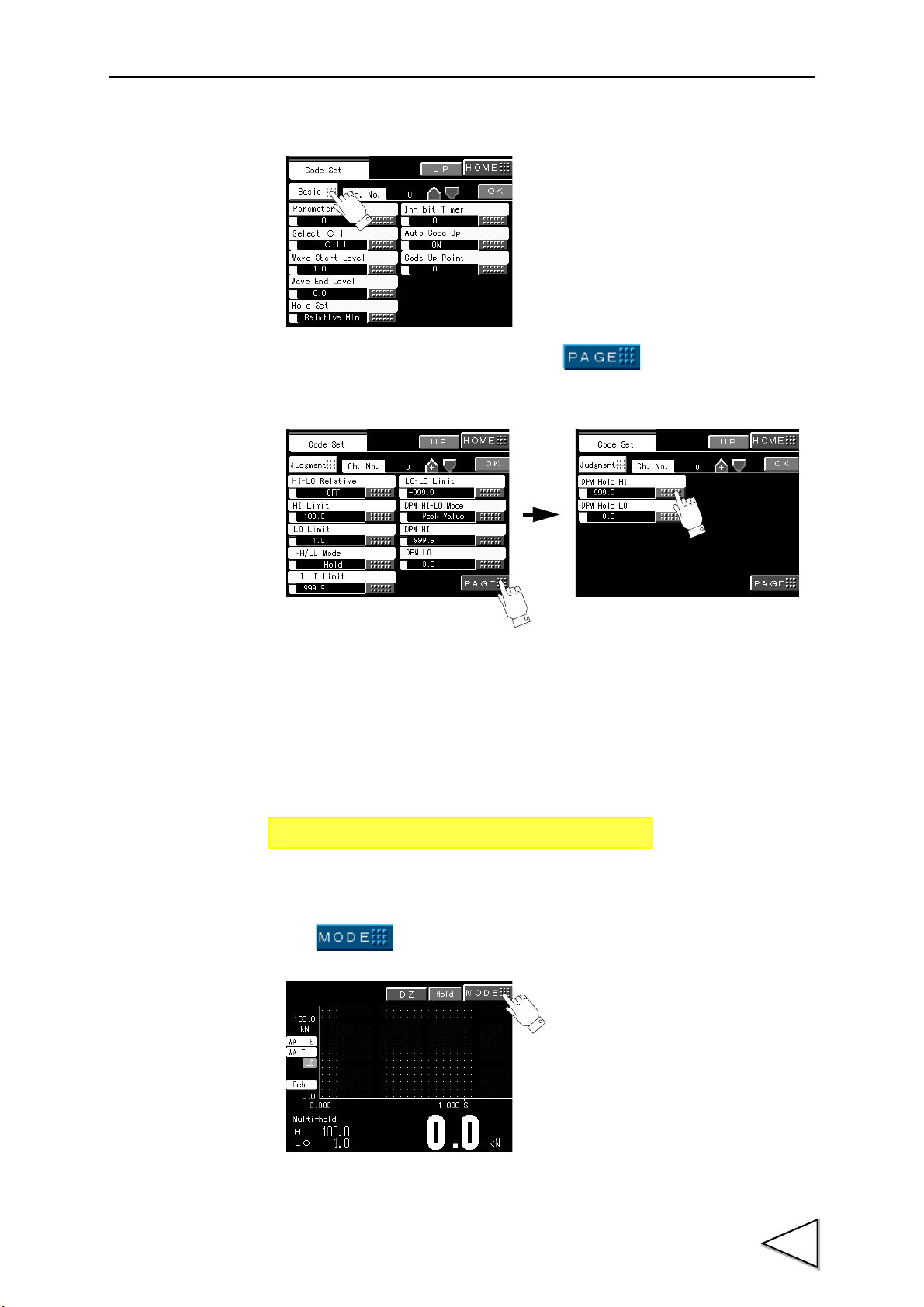

3.Screen Configuration and Setting Methods

MODE → Code Set → Judgment: PAGE → DPM Hold HI

Main

Mode Setting

3-3. Setting Methods

3-3-1. Specification of Setting Items

In this manual, the method of specifying a setting item is described as follows:

Example:

Specifying the "Displacement Hold High Limit" in the "Hysteresis" mode:

This operation can be performed by the following procedures.

1. Press on the main screen.

2. The mode setting screen appears. Select "Code Set".

17

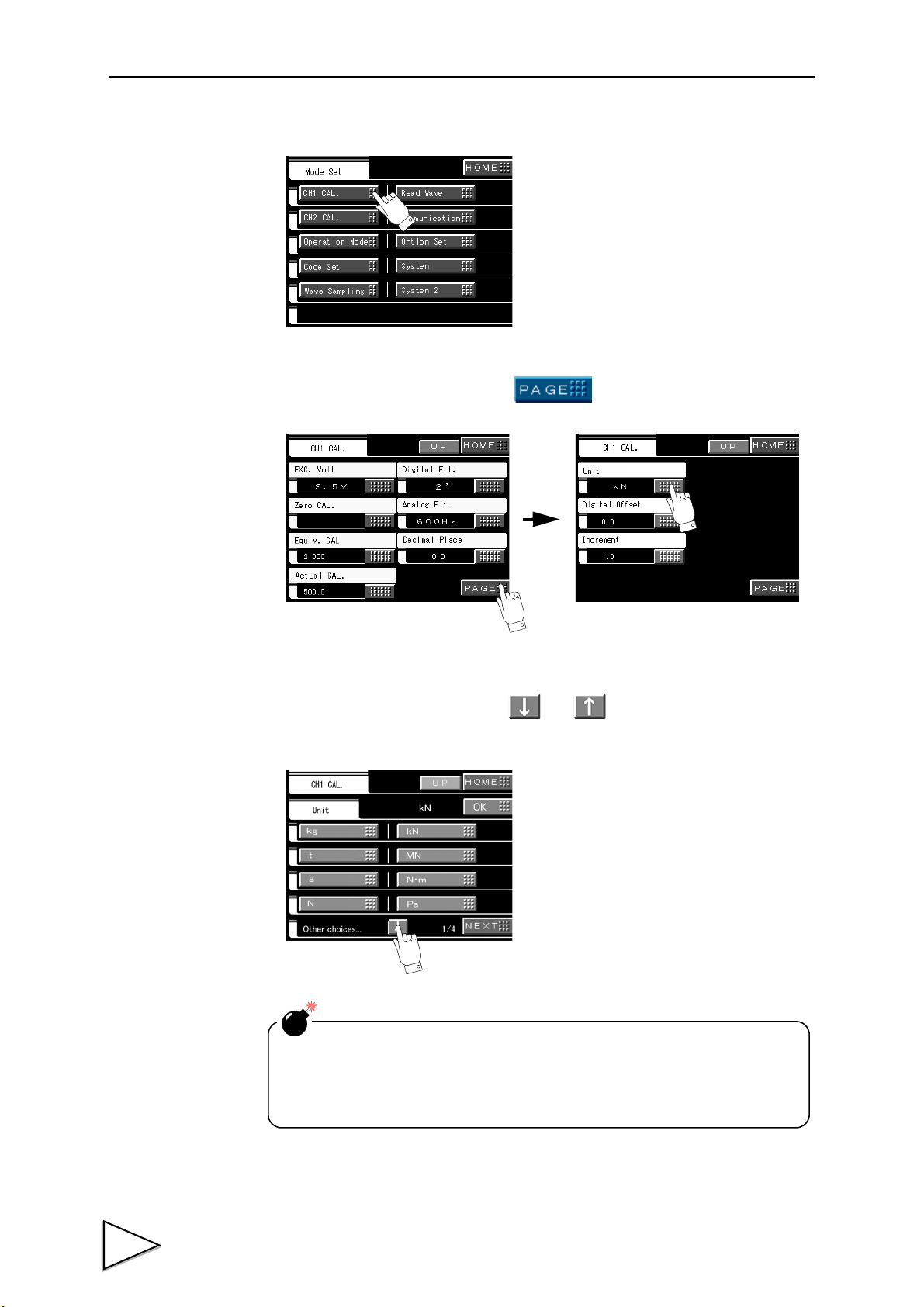

Page 32

3.Screen Configuration and Setting Methods

Code Setting

Page 1 Page 2

MODE → CAL. → PAGE → Unit

CH1

CH2

Main

3. The basic setting screen in code setting appears. Select "Basic".

4. The judgment setting screen appears. Press and select the setting item

("DPM Hold HI" in this case).

3-3-2. Unit Setting Method

In this manual, the method of setting an item with multiple selections is described as

follows:

Example: Setting a "unit"

This operation can be performed by the following procedures.

1. Press on the main screen.

18

Page 33

3.Screen Configuration and Setting Methods

Mode Set

Channel number selection in code setting is an item to select

internal channel number(s), and is not to change operation ch.

Operation ch is changed by external input.

(See "4-3. Control Connector Connection" P25.)

2. The mode setting screen appears. Select "CH1 CAL.".

3. The CH1 CAL. screen appears. Press , and select "Unit".

4. The unit setting screen appears.

Select a desired item by pressing the and keys.

Check that the desired description is displayed at the top, and press OK for entry.

19

Page 34

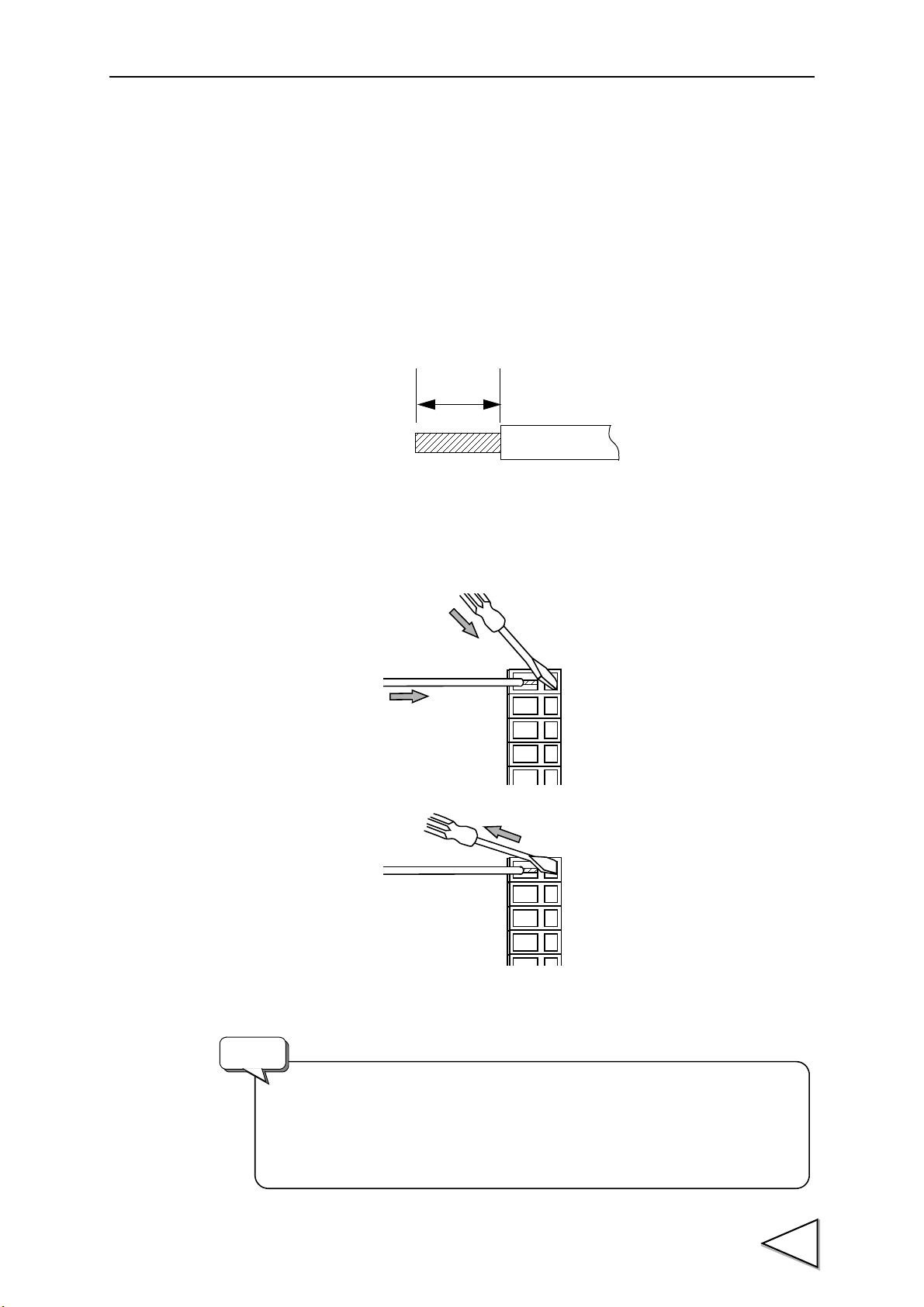

4.Methods of Connection

5 ~ 6mm

・ Wires connectable to the cage clamp type terminal block are

0.2 ~ 2.5mm2.

・ Do not attach crimp contacts to the ends of wires, or solder them.

・ When connecting two or more wires, twist them beforehand.

Request

4. Methods of Connection

4-1. Connection to the Cage Clamp Type Terminal Block

Connect to the cage clamp type terminal block by using the attached mini-screwdriver.

1. Peel the sheath of the wire to be connected 5 ~ 6mm, and twist the end to such an

extent so that it will not become loose.

2. Insert the screwdriver firmly into the hole on the right-hand side while pushing it up

slightly.

3. Insert the wire into the hole on the left-hand side so as not to loosen the end.

4. Withdraw the screwdriver.

5. Lightly pull the wire to check that it is clamped securely.

20

Page 35

4.Methods of Connection

The CH1 and CH2 input sensor specifications (strain gauge/current/

voltage) are factory-shipped settings. For changing the settings,

contact us since modifications are required. CH1 corresponds to a

strain gauge, and CH2 corresponds to voltage as a standard.

Request

4-1-1. Analog Input / Output Connection

4-1-1-1. Analog Input / Output Terminal Pin Assignments

1 FG : Frame ground. Terminal to connect the shield of sensor

connection cabling.

2 + EXC : Terminal to connect a strain gauge type sensor.

3 - SIG : Terminal to connect a strain gauge type sensor or displacement

sensor.

4 - EXC : Terminal to connect a strain gauge type sensor.

5 + SIG : Terminal to connect a strain gauge type sensor or displacement

sensor.

6 V-OUT : Terminal that outputs voltage proportional to sensor input.

The voltage output is approx. 2V per 1mV/V sensor input, and

the load resistance is 5kΩ or more

7 N.C

* 1 ~ 6 are input / output terminals for CH1.

8 V-OUT : Terminal that outputs voltage proportional to sensor input.

The voltage output is approx. 2V per 1mV/V sensor input, and

the load resistance is 5kΩ or more.

9 GND : GND terminal for the V-OUT terminal. (Common to pin 6 and

pin 8.)

10 + EXC : Terminal to connect a strain gauge type sensor.

11 - SIG : Terminal to connect a strain gauge type sensor or displacement

sensor.

12 - EXC : Terminal to connect a strain gauge type sensor.

13 + SIG : Terminal to connect a strain gauge type sensor or displacement

sensor.

14 FG : Frame ground. Terminal to connect the shield of sensor

connection cabling.

* 8 ~ 14 are input / output terminals for CH2. (Pin 9 is common to CH1 and CH2.)

21

Page 36

4-1-1-2. Strain Gauge Sensor Connection

・ For connecting a sensor, be sure to use shielded lines, and separate

wiring from lines with heavy noise (such as wiring of power equipment

and wiring of digital equipment) and AC lines.

・ The analog GND in the F395 is grounded to F.G. Also, when voltage/

current input is specified, the -SIG terminal is at about the same level

as the analog GND. (See "20. Block Diagram" P152.) Carry out wiring

so that unnecessary current will not flow.

Request

+ EXC

- EXC

+ SIG

- SIG

F. G

+ IN

- OUT

- IN

+ OUT

F395

+ EXC

- EXC

+ SIG

- SIG

F. G

+ IN

- OUT

- IN

+ OU T

+ S

- S

F395

Before connecting a sensor, set the excitation voltage, turn off the power, and perform

the following connection. (See "5-6. Excitation Voltage" P34.)

・4-wire sensor

4.Methods of Connection

・ 6-wire sensor

For connecting a 6-wire strain gauge type sensor, short-circuit +EXC and +S, and -EXC

and -S.

22

Page 37

4.Methods of Connection

+ SIG

- SIG

Voltage / current

+

-

F395

Output

type sensor

Within ± 5V/ ± 20mA

V-O UT

GND

External equipment

Load resistance

5kΩ or more

+

-

F395

No displacement sensor (for X-axis measurement) can be

connected when the PUI option is mounted.

Converter

Display

Printer

SI/F

F395

<Example of connection>

4-1-1-3. Voltage / Current Type Sensor Connection

Contact type, overcurrent type, laser type, and other voltage / current type sensors of up

to ± 5V / ± 20mA can be connected. (The analog input option is a factory-shipped

setting.)

4-1-1-4. Voltage Output (V-OUT) Connection

The relationship between sensor type and output voltage is as follows:

Strain gauge 1mV/V ............ Approx. 2.0V

Voltage 5V .............Approx. 5.6V

Current 20mA .............Approx. 5.2V

4-1-2. SI/F Connection

This is a 2-wire serial interface to connect a UNIPULSE-manufactured printer, external

display, etc.

Up to three nonpolarized external devices can be connected. Use parallel two-core

cables, cabtyre cables, and the like for wiring.

23

Page 38

4-2. RS-232C Connection

1

2

RXD

3

TXD

4

DTR

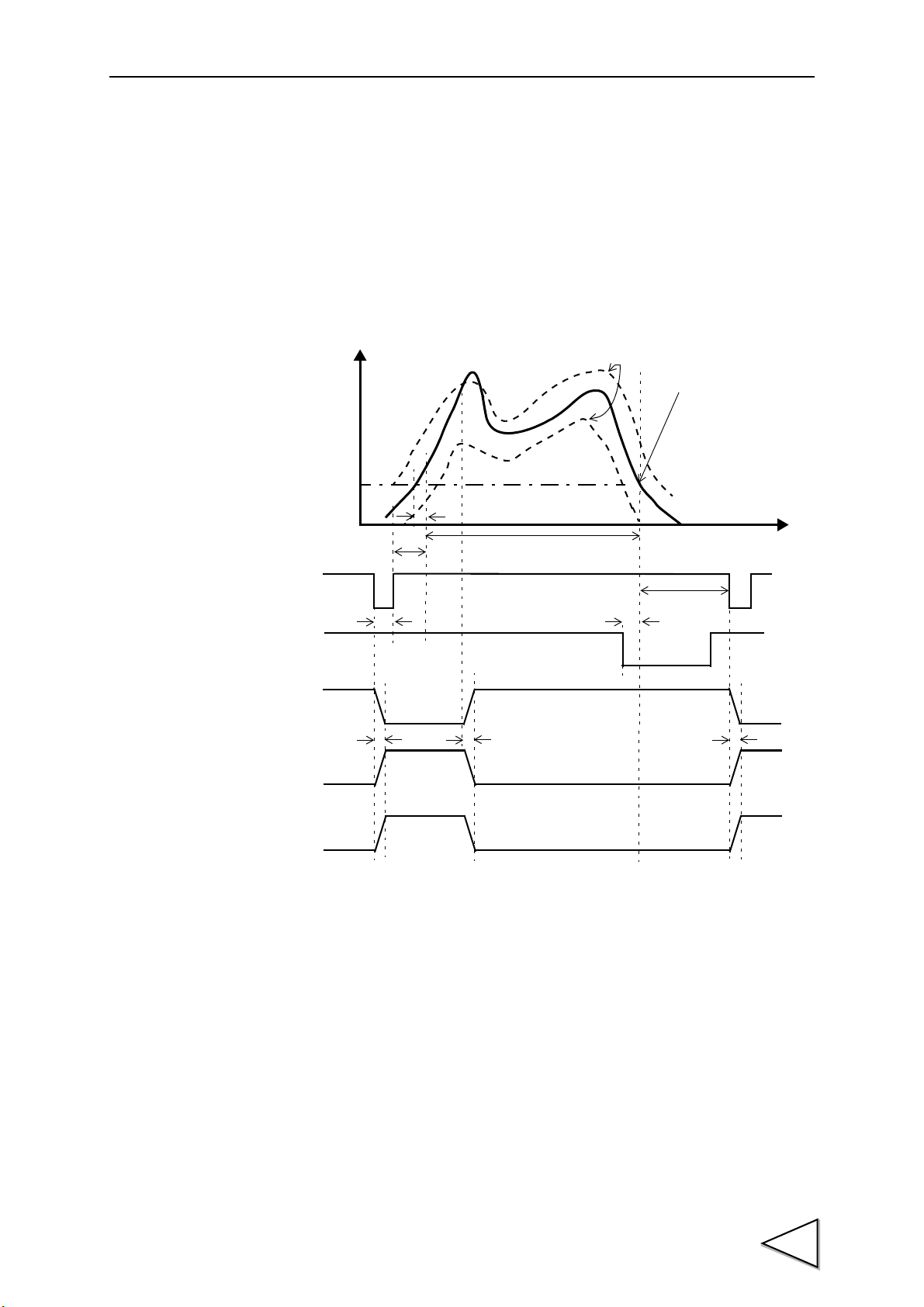

6

DSR

7

RTS

8

CTS

5

GND

9

1

CD

2

RXD

3

TXD

4

DTR

6

DSR

7

RTS

8

CTS

5

GND

9

FG

PC (9-pin)

F395

1

2

RXD

3

TXD

4

DTR

6

DSR

7

RTS

8

CTS

5

GND

9

8

CD

3

RXD

2

TXD

20

DTR

6

DSR

4

RTS

5

CTS

7

GND

1

FG

PC (25-pin)

F395

Cross type cabling

Cross type cabling

4-2-1. RS-232C Connector

The RS-232C connector is a D-SUB 9-pin connector. The applicable plug is OMRON-

manufactured XM2D-0901 (cover: XM2S-0913 <with inch thread #4-40>) or an

equivalent.

4-2-2. Connector Pin Assignments

Applicable plug: D-SUB 9-pin connector

* OMRON-manufactured XM2D-0901 (cover: XM2S-0913 <with inch thread #4-40>), etc.

4.Methods of Connection

16IN

2IN

3OUT

4OUT

5*

RXD

TXD

DTR

GND

7OUT

8IN

9

DSR

RTS

CTS

4-2-3. Example of Cabling

The above connection diagram shows cabling (as an example) when the PC is DTE (data

24

terminal equipment). If the other end of the connection is DCE (data circuit-terminating

equipment) such as a modem, use straight type cabling. Also, recheck the connector

shape and signal lines (pin assignments) of the equipment you use before preparation of

cabling.

Page 39

4.Methods of Connection

4-3. Control Connector Connection

The control connector is a connector to input signals to allow the F395 to function, and

to output control signals from the F395 to external equipment.

The applicable plug is DDK-manufactured 57-30500 (accessory) or an equivalent.

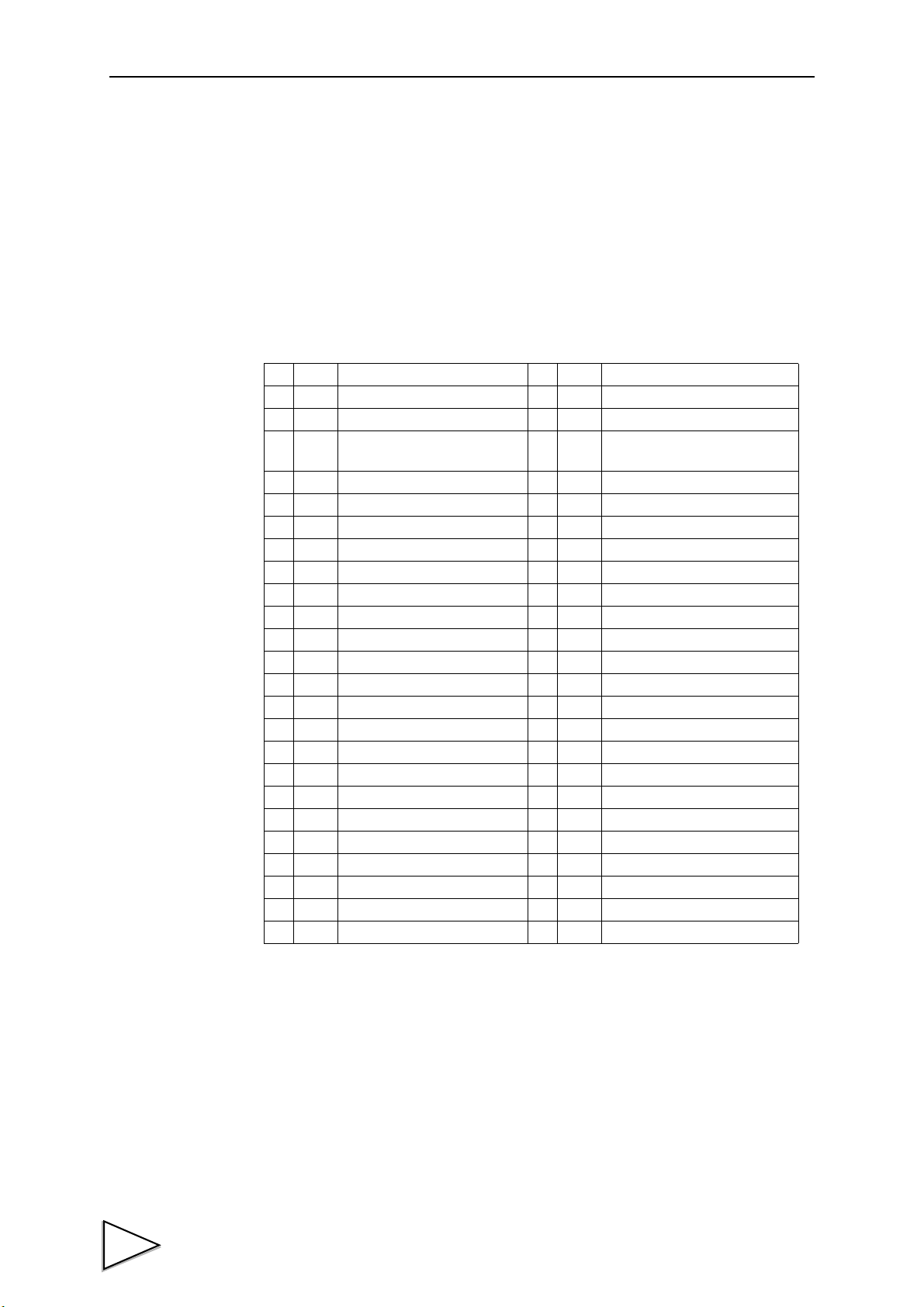

4-3-1. Connector Pin Assignments

1*COM 26*COM

2 IN Display after measurement 27 IN D/Z

3 IN Capture start by external signal 28 IN T/H

4 IN Operation by waveform

termination level

5 IN Prohibit touch panel 30 IN START

6 IN Displacement hold cancel 31 IN STOP

7 IN Backlight ON 32 IN HOLD1

8 IN Select HH/LL 33 IN HOLD2

9 IN Reset auto code up 34 IN HOLD3

10 * COM 35 * COM

11 IN CODE1 36 IN CODE16

12 IN CODE2 37 IN STROBE

13 IN CODE4 38 IN Select output

14 IN CODE8 39 IN N.C

15 * COM 40 * COM

16 * COM 41 * COM

17 OUT LO1 42 OUT OK displacement 1

18 OUT OK1 43 OUT HI displacement 1

19 OUT HI 1 44 OUT LO displacement 2

20 OUT HH/LL 45 OUT OK displacement 2

21 OUT LO 2 46 OUT HI displacement 2

22 OUT OK 2 47 OUT COMPLETE

23 OUT HI 2 48 OUT WARNING

24 OUT LO displacement 1 49 OUT Hysteresis return

25 * COM 50 * COM

29 IN H/M

4-3-2. Input and Output Signals

Input signals

・Display after measurement:

A measured value at the completion of measurement is held when this signal is ON,

and the holding is cancelled when OFF in the Waveform Comparison / Waveform

and Displacement Comparison mode.

(See "13-9. Display After Measurement" P81.)

[Holding of the value is cancelled when the next sampling starts.]

25

Page 40

4.Methods of Connection

・Capture start by external signal:

Sampling is started by the rising edge of the START input irrespective of the

Waveform Start Level when this signal is ON.

(See "9. Method of Starting Measurement" P43

・ Waveform termination level operation:

Sampling is stopped by the Waveform Termination Level when this signal is ON.

(See "16-2-9. Level Axis Select / Waveform Start Level / Waveform Termination

Level / Hold Start Level" P113.)

・Prohibit touch panel:

The touch panel is prohibited when this signal is ON.

・Displacement hold cancel:

The displacement peak value for Displacement High/Low Limit Comparison is

cancelled when this signal is ON. (See "16-2-8. Displacement High-low Mode /

Displacement High Limit / Displacement Low Limit / Displacement Hold High Limit

/ Displacement Hold Low Limit" P110.)

・Backlight ON:

The backlight is lit when this signal is ON. If it is kept ON, the backlight will not go

out.

・Select HH/LL:

Selects operation of HH/LL output (pin 20).

When this signal is OFF: Result of judgment on the currently set operation ch.

When this signal is ON: Accumulated

*1

result of judgment on the pre-switching

operation ch.

・ Reset auto code up:

The Auto Code Up mode is canceled by turning this signal ON after completion of

sampling as follows:

- The operation ch is reset.

- The reference values for High-Low Relative Comparison are cleared.

- Hold reset by T/H and H/M becomes executable.

・ D/Z:

Digital Zero is performed by the ON edge. (See"6-4. Digital Zero" P39.)

・T/H, H/M:

Directs the timing of hold operation. (See "10-3. Hold Functions" P48.)

・ START, STOP:

Directs waveform drawing operation.

(See "9. Method of Starting Measurement" P43)

・HOLD1 ~ 3:

Pulse input 1 ~ 3 for Pulse Hold / Hysteresis 2.

(See "10-3-10. Pulse Hold" P62, and "12. Hysteresis 2" P65.)

Accumulated

*1

: When multiple operation channels are switched, once HI2 / LO2 results,

HI2 / LO2 remains ON, and OK2 turns OFF.

26

Page 41

4.Methods of Connection

A level edge is generated when the input signal (indicated value)

crosses over the Waveform Start Level after the START signal is input.

It is cleared by starting sampling or inputting the STOP signal. (See "9.

Method of Starting Measurement" P43.)

・CODE1 ~ 16:

・STROBE:

・ Select output:

Specifies operation ch for Hold mode, High/Low Limit, Comparison Waveform, etc.

(See "10-2. Setting and Operating Method" P47, "11-2. Setting and Operating

Method" P64, "12-2. Setting and Operating Method" P65, and "13-2. Setting and

Operating Method" P68.)

Changing of operation ch by changing CODE 1 ~ 16 is prohibited when this signal is

ON. (Previous operation ch is maintained.) Use to prevent chattering when changing

operation ch.

Output pin 44 ~ 46 (LO/OK/HI displacement 2) operate when this signal is ON.

- Pin 44/45 "Status" output

Status Pin 44 Pin 45

WAITS / STOP 0 0

WA IT 2 1 0

WA I T L 0 1

SAMP / COPY 1 1

(

For logic, see "4-3-4. Equivalent Circuit (Output)" P30. )

- Pin 46 "Level Edge" output (Present when this signal is ON. Use for level

edge clear, etc.)

When this signal is OFF, output pin 44 ~ 46 result in the operation of LO/OK/HI

displacement 2.

Judgment output signals

The results of High/Low Limit Judgment in each Operation Mode are output.

・LO1, OK1, HI1 : 1) When the Multi-Hold / Hysteresis mode is used.

Outputs the results of judgment of the load with respect to the

high limit / low limit.

2)When the Waveform Comparison / Waveform and Displace-

ment Comparison mode is used.

Outputs the results of judgment of the load with respect to the

high and low limit waveforms.

3) When the Hysteresis 2 mode is used.

Outputs the results of judgment of the load with respect to the

high limit / low limit, and the results of judgment of the

difference between go and return with respect to the hi-hi

limit / lo-lo limit.

27

Page 42

4.Methods of Connection

・HH/LL :1) When the Multi-Hold / Hysteresis mode is used.

Outputs the results of judgment of the load with respect to the

hi-hi limit / lo-lo limit.

2) When the Waveform Comparison / Waveform and

Displacement Comparison mode is used.

Not used. (The output remains OFF.)

・LO displacement 1,: 1) When the Hysteresis / Hysteresis 2 / Waveform and

OK displacement 1, Displacement Comparison mode is used.

HI displacement 1 Outputs the results of judgment of the displacement with

respect to the displacement high limit / displacement low

limit / displacement hold high limit /displacement hold low

limit.

2) When the Multi-Hold / Waveform Comparison mode is used.

Not used. (OK displacement 1 turns ON.)

・LO2, OK2, HI2 : 1) When the Multi-Hold / Hysteresis mode is used.

Outputs the accumulated

*1

results of judgment of LO1, OK1

and HI1 on the previous operation channel at switch-time.

Returns to OK2 when the START signal is turned ON.

2) When the Hysteresis 2 mode is used.

Outputs the accumulated

*1

results of judgment of LO1, OK1

and HI1 with the timing of inputting HOLD1, HOLD2 and

HOLD3.

Outputs the accumulated

*1

results of judgment of LO1, OK1

and HI1 with the timing of judging the difference between go

and return.

Returns to OK2 when the START signal is turned ON.

3) When the Waveform Comparison / Waveform and

Displacement Comparison mode is used.

Outputs the results of judgment of the load with respect to the

hi-hi limit / lo-lo limit.

・LO displacement 2,: 1) When the Hysteresis mode is used.

OK displacement 2, Outputs the accumulated

*1

results of judgment of

HI displacement 2 LO displacement 1, OK displacement 1 and

HI displacement 1 on the previous operation channel at

switch-time.

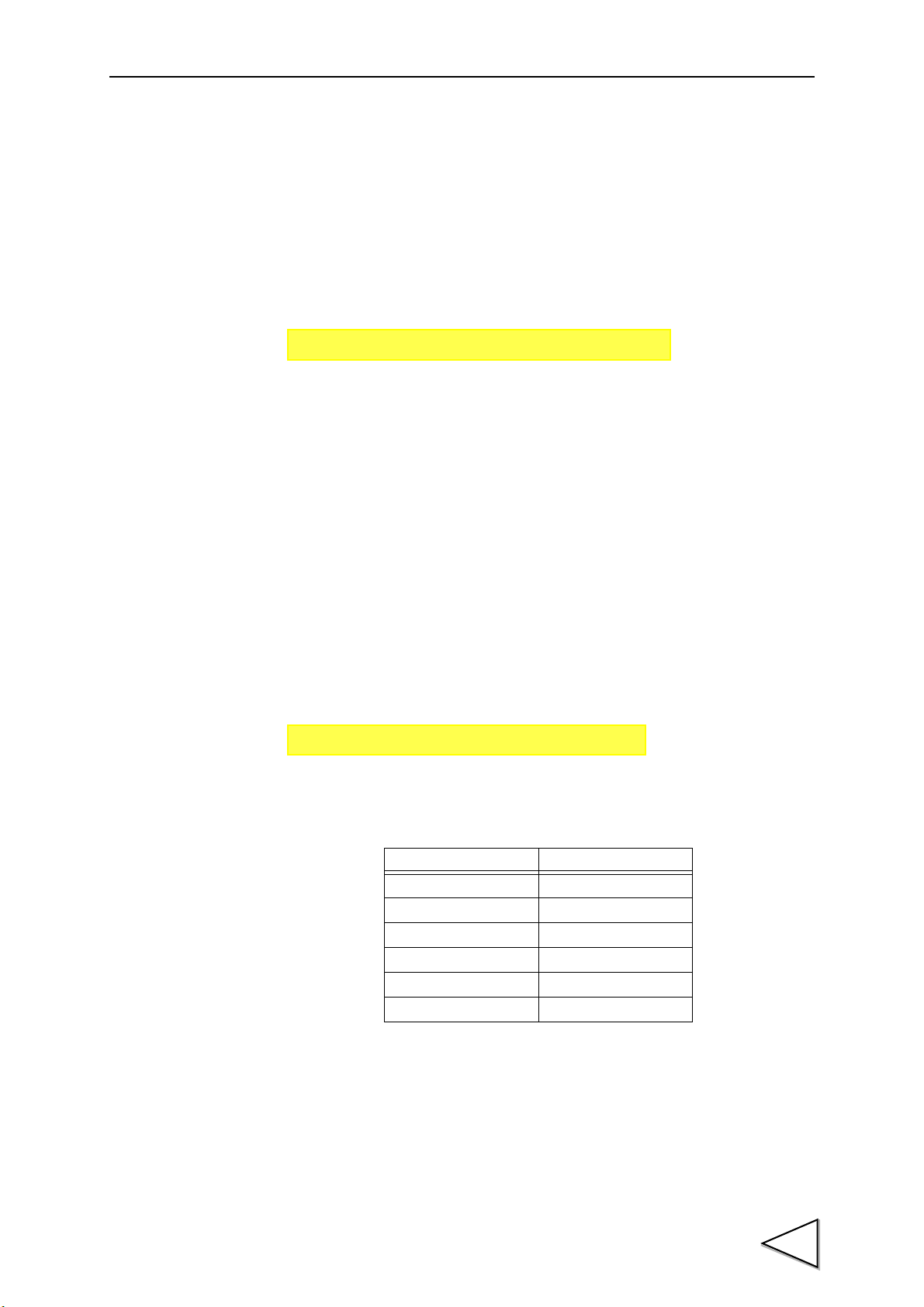

Returns to OK displacement 2 when the START signal is

turned ON.

2) When the Hysteresis 2 mode is used.

Outputs the accumulated

*1

results of judgment of LO

displacement 1, OK displacement 1 and HI displacement 1

with the timing of inputting HOLD1, HOLD2 and HOLD3.

Returns to OK2 when the START signal is turned ON.

28

Page 43

4.Methods of Connection

COMPLETE may be output earlier than each judgment output due to

signal delay in wiring, etc. Do not take in judgment at the ON edge of

the COMPLETE signal.

・COMPLETE :This signal is output upon judgment or hold. Read each output

3) When the Multi-Hold / Waveform Comparison / Waveform

and Displacement Comparison mode is used.

Not used. (OK displacement 2 turns ON.)

4) When the output selection is ON, LO displacement 2, OK

displacement 2 and HI displacement 2 are changed to

“Status” and “Level Edge” outputs. (For details, see “Select

output” P.27.)

signal after confirming that this signal is ON.

(For output timing, see "10-3. Hold Functions" P48, and "13-6.

Timing in the Waveform Comparison / Waveform and

Displacement Comparison Mode" P76.)

・WA R N IN G :

This signal is output when displacement input is used and sampling is thinned out.

(See "13-5. Waveform and Displacement Comparison Mode" P74.)

・ Hysteresis return:

This signal is turned ON when return waveform sampling starts, and is turned OFF

upon completion in the Hysteresis / Hysteresis 2 mode. This signal is turned OFF in

go waveform sampling and in other modes. (See "11-2. Setting and Operating

Method" P64.)

Accumulated

*1

: When multiple operation channels are switched, once HI2 / LO2 results,

HI2 / LO2 remains ON, and OK2 turns OFF.

29

Page 44

4-3-3. Equivalent Circuit (Input)

Inside

IC=

COM

Push swich Toggle swich Relay contact Transistor

+12V

IN

IN

F395

Open: OFF

Short circuit: ON

・ No external voltage should be applied to the signal input circuit.

・ External elements should pass Ic=10mA or more.

・ Leaks of external elements should be 100μA or less.

・The external input circuit is minus (-) common. A circuit of source

type cannot be connected.

6mA

Approx.

TTL open collector output

(ON when IN is

‘

H ’)

Vcc

+12V

COM

F395

・ For the relay driving power supply (Vext), prepare an external power

supply.

・ Do not short-circuit any load (relay coil, etc.); otherwise the output

transistor will be damaged.

・ Connect surge absorbers or spark killers to the relay circuit (coil side and

contact side) as shown in the illustration to minimize surge voltage.

Ve x t

Transistor state

Output data Tr

0OFF

1ON

Vceo=30V(max)

Ic=120mA(max)

Inside

Relay

Spark killer

Load

Spark killer

Load

Varistor

AC power

supply

DC power

supply

Vcc

+12V

The signal input circuit inputs a signal by short-circuiting or opening the input terminal

and COM terminal. Short-circuiting is performed by contact (relay, switch, etc.) or non-

contact (transistor, TTL open collector output, etc.)

4.Methods of Connection

4-3-4. Equivalent Circuit (Output)

The signal output circuit produces transistor open collector output.

30

Page 45

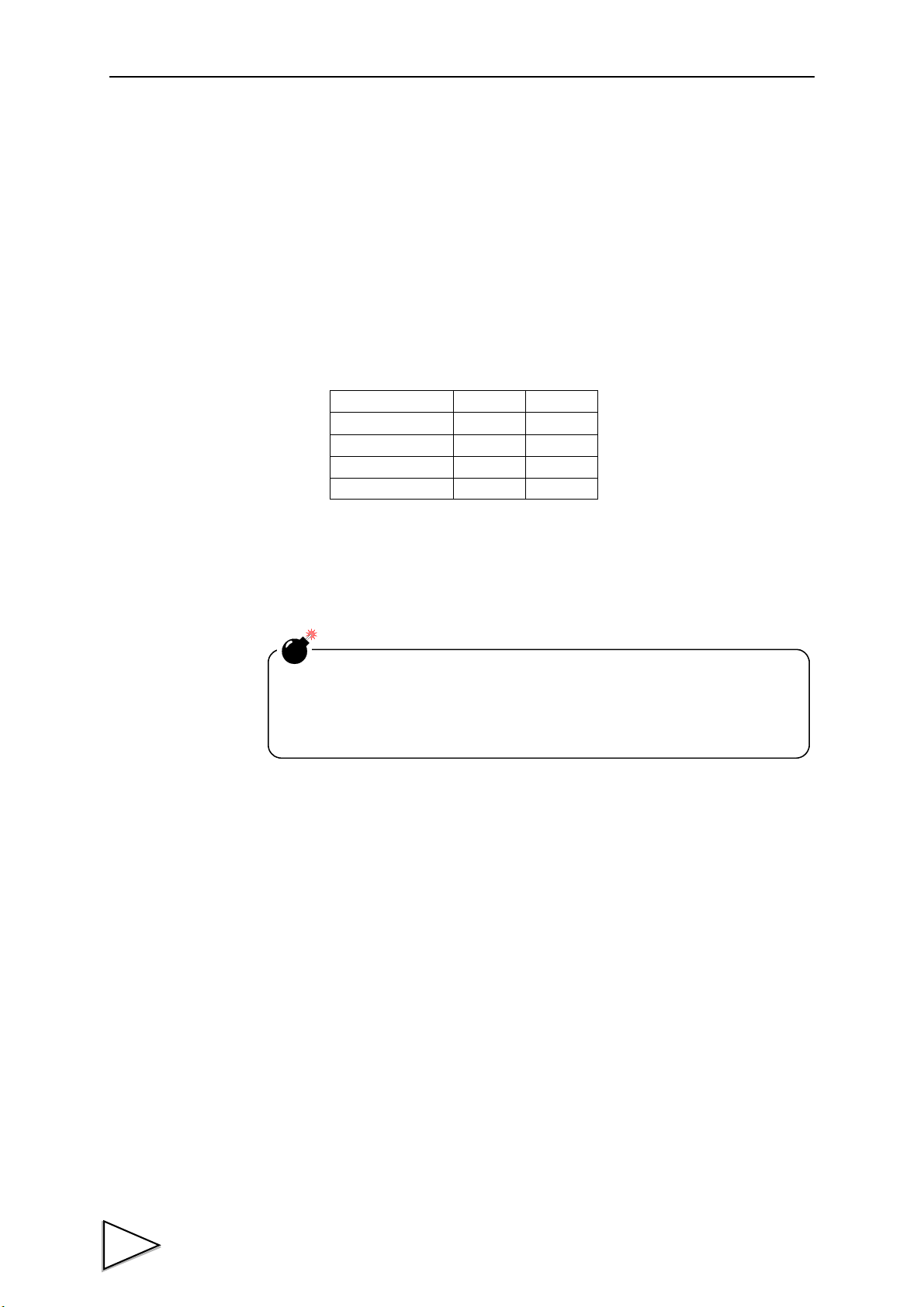

5.Methods of Calibration

+

Rated output value mV/V, V, mA

Indicated value

Strain gauge type sensor

Displacement sensor

In either case of Equivalent Input Calibration and Actual Load Calibration,

set the Excitation Voltage before connecting the strain gauge type sensor.

(See "5-6. Excitation Voltage" P34.)

Request

Strain gauge type sensor

Displacement sensor

Actual load

Displacement

Actual load value (displacement)

5. Methods of Calibration

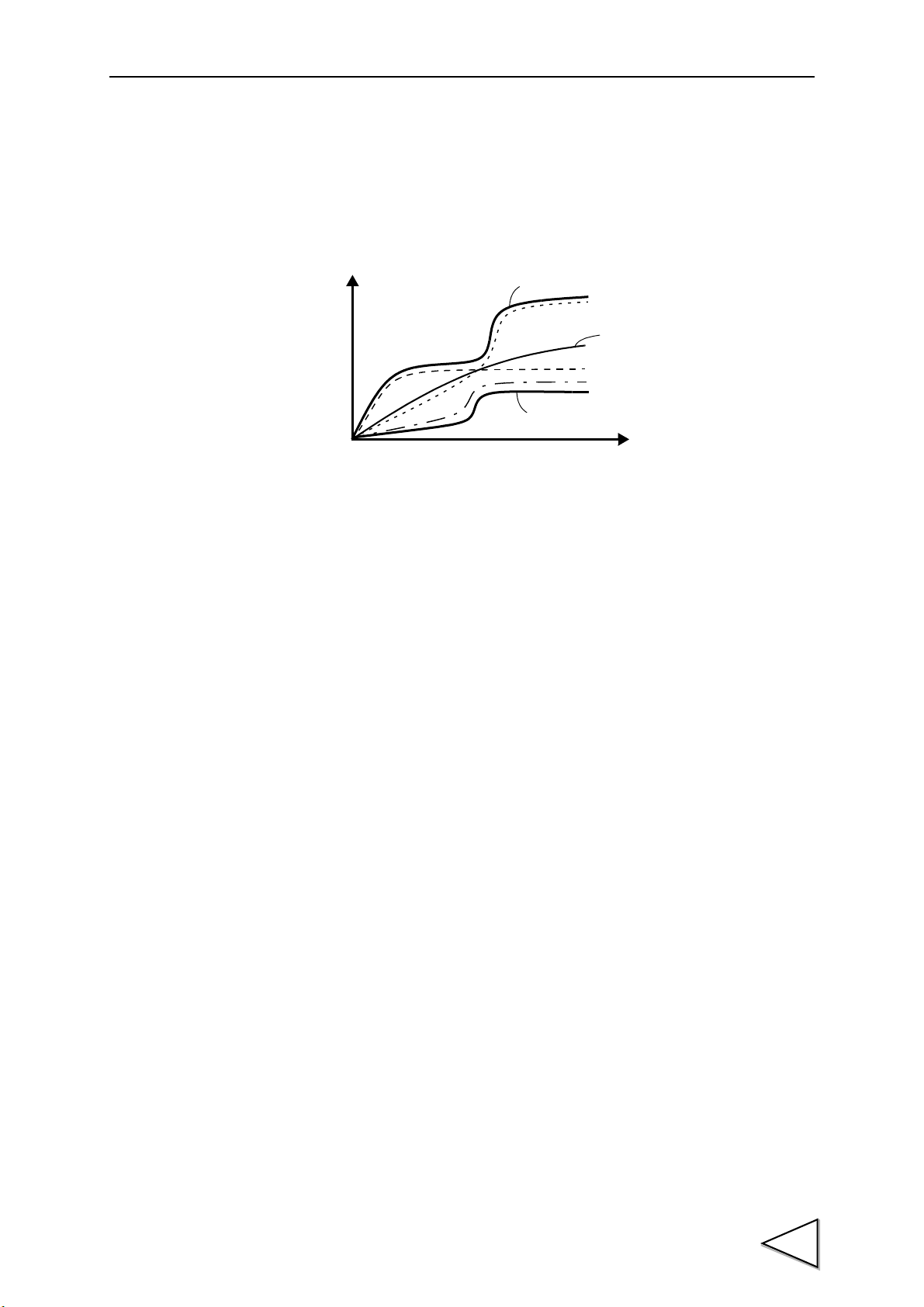

5-1. What is Calibration?

Operation of matching the F395 and sensor is called "Calibration".

For the F395, there are two methods of calibration as follows:

Equivalent input calibration

By this method, calibration is performed by simply inputting the rated output value (mV/

V, V, mA) of the sensor and the indicated value by keypad without using an Actual Load.

Calibration can easily be performed even if an actual load is not prepared.

Actual load calibration

By this method, calibration is performed by giving an actual load (displacement) to the

sensor and inputting the actual load (displacement) by keypad. Accurate calibration with

few errors can be performed.

5-2. CH1 Input Calibration and CH2 Input Calibration

Perform calibration with respect to each of analog input CH1 and CH2. CH2 may be set

for measuring the X-axis (displacement input). (The axis in current use is displayed in

the Axis setting under CH2 Input Calibration.)

31

Page 46

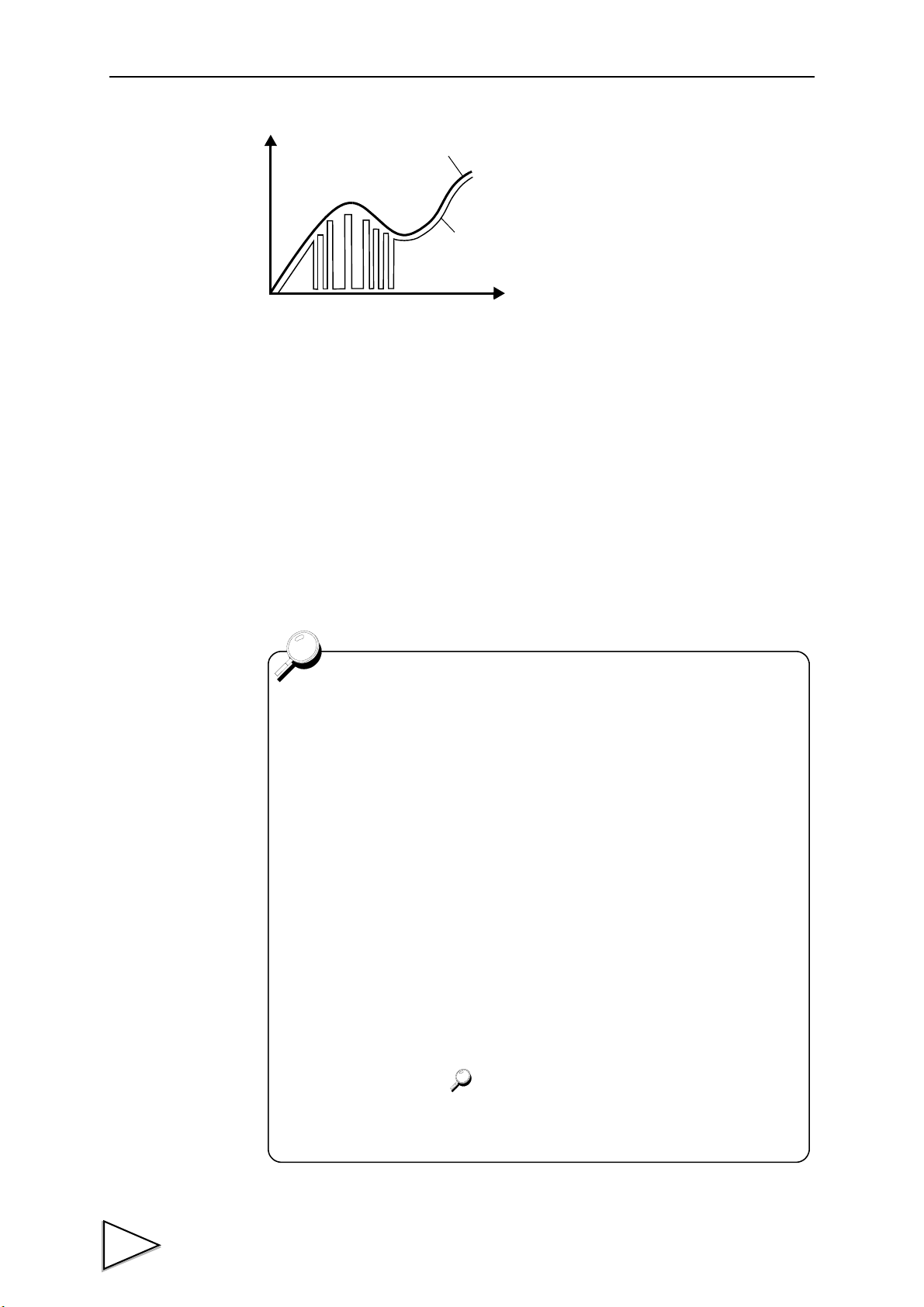

5-3. Equivalent Input Calibration Procedures

Decimal place setting

Set value protection cancel

Unit setting

Set value protection

Zero calibration

LOCK switch OFF

Excitation voltage setting

LOCK switch ON

Equivalent input calibration

Increment setting

Perform equivalent input calibration of the sensor as follows:

Turn off the LOCK switch on the rear panel to unprotect

calibration.

Set the "Set Value Protection" setting to unprotect

calibration.

Select the "Excitation Voltage" from 2.5V/10V.

(Set 2.5V when the input specification is voltage / current.)

Turn off the power, and connect the sensor.

5.Methods of Calibration

Set the "Unit" to be used.

Set the "Decimal Place".

Set the minimum value of the digital changes.

Set the initial zero point.

Set the rated output value of the sensor.

Protect calibration to prevent misoperation.

Turn on the LOCK switch to protect calibration to prevent

misoperation.

32

Page 47

5.Methods of Calibration

Decimal place setting

Increment setting

Set value protection cancel

Unit setting

Set value protection

Zero calibration

LOCK switch OFF

Excitation voltage setting

LOCK switch ON

Actual load calibration

5-4. Actual Load Calibration Procedures

Perform Actual load calibration of the sensor as follows:

Turn off the LOCK switch on the rear panel to unprotect

calibration.

Set the "Set Value Protection" setting to unprotect

calibration.

Select the "Excitation Voltage" from 2.5V/10V.

(Set 2.5V when the input specification is voltage / current.)

Turn off the power, and connect the sensor.

Set the "Unit" to be used.

Set the "Decimal Place".

Set the minimum value of the digital changes.

Set the initial zero point.

Set the span (gain) point of the sensor.

Protect calibration to prevent misoperation.

Turn on the LOCK switch to protect calibration to prevent

misoperation.

33

Page 48

5-5. LOCK Release

LOCK

OFF

MODE → System → Protect → All Unprotect

MODE → CAL. → EXC. Volt

CH1

CH2

The excitation voltage of the F395 is 2.5V/10V. If the maximum

excitation voltage of the sensor is less than 2.5V/10V, heating or

breakage may result.

CAUTION

Calibrated values and set values can be locked to prevent a change due to misoperation.

There are two types of locks: a software lock to be operated from the screen, and a

hardware lock by the switch on the rear panel. For performing calibration, release both

locks.

1. Turn off the LOCK switch on the rear panel. (Hardware lock)

5.Methods of Calibration

2. Set the "Set Value Protection" setting to "All Unprotect". (Software lock)

Now, the locks are released. Upon completion of calibration, hardware lock and software

lock again to prevent misoperation.

5-6. Excitation Voltage

Set the voltage value to be applied to the bridge of the strain gauge sensor. Select as large

a value as possible within the range not exceeding the maximum excitation voltage of the

sensor.

Setting item: 2.5V / 10V

34

Page 49

5.Methods of Calibration

MODE → CAL. → PAGE → Unit

CH1

CH2

MODE → CAL. → PAGE → Increment

CH1

CH2

MODE → CAL.

CH1

CH2

→ Decimal Place

→ PAGE → Decimal Place

MODE → CAL. → Zero CAL.

CH1

CH2

5-7. Unit

Set the measuring unit. Select from the following.

5-8. Increment

Set the minimum value of digital changes.

Setting item: kg / t / g / N / kN / MN / N・m / Pa / kPa / MPa / bar / N/m

/ μm / rad / deg / lb / oz / dyne / psig / ftlb / inlb / inoz / ft / in / None

Setting range: 1 ~ 100 (Not including the decimal point.)

2

/ mm / cm

5-9. Decimal Place

Set the decimal place.

Setting item: 0 / 0.0 / 0.00 / 0.000

5-10. Zero Calibration

Set the initial zero point.

1. Bring the sensor into a zero condition (no-load condition).

2. Press OK under Zero Calibration.

3. For error display, see "19. Error Messages" P150.

35

Page 50

5-11. Equivalent Input Calibration

MODE → CAL. → Equiv. CAL.

CH1

CH2

The strain gauge type sensor comes with a data sheet upon purchase.

Capacity ................... Load/displacement (unit: kN, Mpa, etc.)

Rated Output............ Voltage (unit: mV/V)