Page 1

F381A/F388A

CC-Link I/F

OPERATION MANUAL

01FEB2015REV.3.01

「CC-Link Ver.1.10」

Page 2

Introduction

Introduction

This document describes the standard specifications of the CC-Link I/F that links a PLC and F381A/

F388A.

By using the CC-Link I/F, the F381A/F388A can be controlled directly from the PLC, so that wiring can

be substantially reduced.

Readers this document should have basic knowledge of the programming of the PLC and basic knowledge

of the CC-Link I/F.

The F381A/F388A with CC-Link I/F can be linked with general-purpose PLC as a remote device station

corresponding to the CC-Link Ver. 1.10.

(CC-Link is an abbreviation for Control & Communication Link.)

Functions provided by the F381A/F388A CC-Link

● Setting of wave No.

Wave No. can be assigned.

It can be changed by inputting a set value, and turning on the relay of Request flag 1.

(See "●Setting change of wave No."on p.5.)

● For changing the current set value

The setting can be changed by using the general-purpose area "data".

It can be changed by inputting the setting item (command) and a set value, and turning on the relay of

Request flag 2. (The R/W relay should be off.)

(See "●Setting change by using the general-purpose area "data""on p.6.)

Note

) Items that can be changed are only those entered in the "Command list" on p.11.

● For checking the current set value

The set value can be read by using the general-purpose area "data".

It can be read by inputting the setting item (command), and turning on the relay of Request flag 2.

(The R/W relay should be on.)

(See "●Request to read set value(s) by using the general-purpose area "data""on p.7.)

Note

) Items that can be read are only those entered in the "Command list" on p.11.

● Display of indicated values, hold values and wave No.

The remote register R → M (F381/F388→ PLC) allows display of indicated values, hold values and wave

No. (See"Remote resister R → M (F381A/F388A → PLC)"on p.7.)

The indicated values are updated at approx. 200Hz, and the hold values are updated after completion of

sampling.

Note

) Start the next sampling after completion of updating.

● About status information

Status information on the same items as I/O can be obtained.

The status information is displayed in the relay domain of the remote station.

(See "Remote input (F381A/F388A → PLC)" on p.19.)

● About direction of operations

Operations on the same items as I/O can be directed by using the relay domain.

Turn on/off the corresponding bit in the relay domain.

(See "Remote output (PLC → F381A/F388A)" on p.17.)

I

Page 3

Contents

Contents

1. Part names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. F381A/F388A setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3. Communication connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4. Status LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

5. PLC address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6. Address map . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

■ Data domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

■ Unit setting list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

■ About remote input/output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

■ Relay domain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

7. Setting procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

■ Setting of wave No. by using Request flag 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

■ Setting by using the general-purpose area "data" and "command",

and Request flag 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

■ Reading set value(s). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

■ Sample of ladder program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

8. Outside dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

II

Page 4

1. Part names

Operation

Status LED

Communication

connector

When the above setting is changed, the communications between the F381A/

F388A and PLC are reset so that the ones stop momentarily.

Point

Status LED

Displays the status of communication.

(See "4.Status LED" on p.4.)

Communication connector

Connector for CC-Link interface.

(See "3.Communication connector" on p.3.)

2. F381A/F388A setting

1.Part names

Main screen→Setting→First Setting→Option setting→CC-Link

Baud rate (Initial value, 10M): 156k, 625k, 2.5M, 5M, 10M

Station No. (Initial value, No.1): No.1 to 61

Input select 1 (Initial value, Ext.input): Network, Ext.input

Input select 2 (Initial value, Ext.input): Network, Ext.input

Explanation for setting

Baud rate : Deciding network speed

Station No. : Setting slave station number

Input select1 to 2 : Select whether input signals of the F381A/F388A are directed by the

control connector (Ext. input) or by CC-Link (Network). For each setting,

select the following signal.

Input select 1..........Load Digital Zero, DPM Positioning, Start, Stop, Hold, Reset, Backlight

On, Prohibit Touch Panel

Input select 2..........Work 1, Work 2, Work 4, Work 8

* The number of stations occupied is fixed at 4.

1

Page 5

2.F381A/F388A setting

0: Normal 1: Error

0: Normal 1: Error (Changed from the power-on-time setting)

0: Normal 1: Error (Changed from the power-on-time setting)

Station No. switch setting error

0: Normal 1: Error

Baud rate switch setting error

Station No. setting switch change error

Baud rate switch change error

0: Normal 1: CRC Error

0: Normal 1: Error

CRC error

Time over error

0: Normal 1: Time over error

Channel carrier detection

0: Sufficient 1: Not sufficient for the station

0: Sufficient 1: Not sufficient for the station

Y data or RWw data error

0: Sufficient 1: Not sufficient for the station

Y data error

RWw data error

Settings of Mitsubishi (general-purpose) PLC CPU unit.

When you use Mitsubishi (general-purpose) PLC MELSEC-Q series, set up master

station network parameters as follows.

・CC-Link mode setting: Remote net Ver. 1 mode.

・Station type: Remote device station

(Station information settings → Station type)

・Occupied station: 4 station

Point

Alarm codes

At the lower right of the CC-Link setting screen, communication

conditions and PLC CPU status are displayed.

Code Status

Alarm code 1 0 0 0 0

Alarm code 2 0 0 0

Alarm code 3 0 0 0

PLC CPU STOP / RUN Displays the PLC CPU status (STOP or RUN).

--- / ERR Displays "---" when the PLC CPU is normal, and "ERR"

when it is abnormal.

2

Page 6

3. Communication connector

Name Signal type

DA Signal line DA side

DB Signal line DB side

DG Signal line Ground

SLD Shield

FG Frame Ground

・Pick up the plug and operate the lever with a thumb.

・For the protection from the damage, do not operate

the lever without removing the plug.

When the F381A/F388A is a unit at both ends, terminator resistance must be

installed. (Confirm with the CC-Link specifications.) At this time, when the DA and

DB signal lines and resistance are to be connected to the connector, be aware

that poor contact may result if the nipping conditions differ between the leg of the

resistance and signal lines. There is a possibility of abnormal operation.

Attention

SLD and FG are connected inside.

Suitable plug for the connection is the Plug made by WAGO CO., Ltd. or equivalent one. (Accessories)

CAUTION

3.Communication connector

3

Page 7

4.Status LED

4. Status LED

LED expresses the Status of Communication.

LED Light ON Light OFF Blinks

RUN

SD

RD

ERR

5. PLC address

The F381A/F388A is the remote device stations (occupies four fixed stations).

Prevent overlapping addresses.

At the master station, the addresses assigned to the remote stations changes according to Station No.

・Normal ・Reset Action

・No Communication

・Transmitting ----- -----

・Receiving ----- -----

・Setting Error

・CRC Error

・Fault

・Normal

-----

-----

Station No.

1

2

3

Therefore, the address data of the F381A/F388A also changes according to Station No.

The following address map is in the state of Station No.1.

Remote

RX0000 RY0000 RWw0000 RWr0000

00E0H 0160H 01E0H 02E0H

RX0020 RY0020 RWw0004 RWr0004

00E2H 0162H 01E4H 02E4H

RX0040 RY0040 RWw0008 RWr0008

00E4H 0164H 01E8H 02E8H

6. Address map

■Data domain

Remote resister M → R (PLC → F381A/F388A)

Use the remote register M → R (PLC → F381A/F388A) for the following purposes.

・『Setting change of wave No.』(See p.5)

・『Setting change by using the general-purpose area "data"』(See p.6)

・『Request to read set value(s) by using the general-purpose area "data"』(See p.7)

input

Remote

output

Remote resister

M→R R→M

4

Page 8

6.Address map

Using

Request flag 2

Using

Request flag 1

Station

1

2

3

4

Buffer

Address

01E0H RWw0000

01E1H RWw0001

01E2H RWw0002

01E3H RWw0003

01E4H RWw0004

01E5H RWw0005

01E6H RWw0006

01E7H RWw0007

01E8H RWw0008

01E9H RWw0009

01EAH RWw000A

01EBH RWw000B

01ECH RWw000C

01EDH RWw000D

01EEH RWw000E

01EFH RWw000F

Device

M→R

Content

MSB LSB

Unused

16bit

Unused

16bit

Wave No.

Wave No.

Wave No.

General-

purpose

area

1st byte

8bit

3rd byte

8bit

5th byte

8bit

7th byte

8bit

9th byte

8bit

11th byte

8bit

13th byte

8bit

15th byte

8bit

17th byte

8bit

19th byte

8bit

Section No.

8bit

Command

2nd byte

8bit

4th byte

8bit

6th byte

8bit

8th byte

8bit

10th byte

8bit

12th byte

8bit

14th byte

8bit

16th byte

8bit

18th byte

8bit

20th byte

8bit

Work No.

8bit

16bit

Data

32bit

L

H

Explanation for remote resister M → R

● Setting change of wave No.

Use for setting wave No. (Request flag 1)

Setting range: ASCII code (20 to 7E), Shifted JIS code (80 to FCH)

* How to write wave No.

1. Input wave No. to the address for 20 bytes so that the first byte becomes Hi byte.

* Input 20H to unused bytes.

2. Change the remote output "Request flag 1"

3. After checking that the remote input "Response 1"

(*1)

from 0 to 1.

(*2)

changes from 0 to 1, change

the remote output "Request flag 1" from 1 to 0.

4. Set the remote output "RM data change" to 1.

5. Check that the specified wave No. is stored in the remote register "wave No."

(response)

(*3)

.

5

Page 9

6.Address map

・If a value exceeding the setting range is input, the setting is not changed.

・Set values should be two’s-complement.

Input a negative set value as follows:

Example: Inputting -1234

Decimal number : -1234

Hexadecimal digit : 65536 - 1234 = 64302 = FB2E(H)

・For checking the changed value after a setting change, make a request to read

set value(s) by using the general-purpose area "data". (See p.7)

Point

● Setting change by using the general-purpose area "data"

* How to write set value(s)

*1: See "Remote output (PLC → F381A/F388A)"on p.17.

*2: See "Remote input (F381A/F388A → PLC)"on p.19.

*3: See "Remote resister R → M (F381A/F388A → PLC)"on p.7.

For changing any setting, use the general-purpose area "data". General-purpose area

"command" and general-purpose area "data" comprise one set. Input the command

setting item you want to change to the general-purpose area "command", and input a set value in

the general-purpose area "data". By turning off R/W

relay of Request flag 2

(*2)

, the input setting is written in the F381A/F388A.

(*2)

in the relay domain and turning on the

(*1)

of the

1. Input the command of the set value to write to the general-purpose area "command."

2. Input the work No. to write to the general-purpose area "work No."

Range: 0 to 15

3. Input the section to write to the general-purpose area "section No."

Range: 1 to 5

4. Set the remote output "R/W" to 0.

5. Input the value to write to the general-purpose area "data."

6. Change the remote output "Request flag 2"

7. After checking that the remote input "Response 2"

the remote output "Request flag 2"

(*2)

8. The response is stored in the remote input "R/W" (response)

purpose area (response)

(*4)

.

9. Check the contents of the general-purpose area (response)

*1

: See "Command list"on p.11.

*2: See "Remote output (PLC → F381A/F388A)"on p.17.

*3: See "Remote input (F381A/F388A → PLC)"on p.19.

*4: See "Remote resister R → M (F381A/F388A → PLC)"on p.7.

* If any number not in the command list is set to the general-purpose area "command",

Response 2 will turn on, but FFFFH is written in the general-purpose area "command"

(response).

(*2)

from 0 to 1.

from 1 to 0.

(*3)

changes from 0 to 1, change

(*3)

and general-

(*4)

.

6

Page 10

6.Address map

● Request to read set value(s) by using the general-purpose area "data"

For reading any set value, use the general-purpose area "data". General-purpose area

"command" and general-purpose area "data" comprise one set. Input the command

setting item you want to read to the general-purpose area "command". By turning on R/W

the relay domain and turning on the relay of Request flag 2

specified by the general-purpose area "command" is replied to the general-purpose area

(response). Upon receipt of the reply, Response 2

* How to read set value(s)

(*3)

turns on.

(*2)

, the set value of the item

(*1)

1. Input the command of the set value to read to the general-purpose area

"command."

2. Input the work No. to read to the general-purpose area "work No."

Range: 0 to 15

3. Input the section to read to the general-purpose area "section No."

Range: 1 to 5

4. Set the remote output "R/W" to 1.

of the

(*2)

in

5. Change the remote output "Request flag 2"

6. After checking that the remote input "Response 2"

the remote output "Request flag 2"

(*2)

7. The response is stored in the remote input "R/W" (response)

purpose area (response)

(*4)

.

8. Check the contents of the general-purpose area (response)

*1

: See "Command list"on p.11.

*2: See "Remote output (PLC → F381A/F388A)"on p.17.

*3: See "Remote input (F381A/F388A → PLC)"on p.19.

*4: See "Remote resister R → M (F381A/F388A → PLC)"on p.7.

* If any number not in the command list is set to the general-purpose area "command",

Response 2 will turn on, but FFFFH is written in the general-purpose area "command"

(response).

General-purpose area "data"

General-purpose area "command"

Use for a setting change and setting readout by using the general-purpose data area.

(See "Command list"on p.11.)

(*2)

from 0 to 1.

from 1 to 0.

(*3)

changes from 0 to 1, change

(*3)

and general-

(*4)

.

Remote resister R → M (F381A/F388A → PLC)

Use the remote register R → M (F381A/F388A → PLC) for the following purposes.

・『Setting change by using the general-purpose area "data"』(See p.6)

・『Request to read set value(s) by using the general-purpose area "data"』(See p.7)

Measurement values are displayed on an item-by-item basis.

(See "Explanation for remote resister R → M"on p.9.)

7

Page 11

6.Address map

Data changes

according to

the remote

output "RM

data change"

・When the remote output "RM data change" is OFF

Stat ion

1

2

3

4

Buffer

Address

02E0H RWr0000

02E1H RWr0001

02E2H RWr0002

02E3H RWr0003

02E4H RWr0004

02E5H RWr0005

02E6H RWr0006

02E7H RWr0007

02E8H RWr0008

02E9H RWr0009

02EAH RWr000A

02EBH RWr000B

02ECH RWr000C

02EDH RWr000D

02EEH RWr000E

02EFH RWr000F

Device

R→M

Content

MSB LSB

Load

Present

value

Displacement (0 for time)

16bit

16bit

Load

Section 1

Displacement (Time)

16bit

16bit

Load

Section 2

Displacement (Time)

16bit

16bit

Load

Section 3

Displacement (Time)

16bit

16bit

Load

Section 4

Displacement (Time)

16bit

16bit

Load

Section 5

Displacement (Time)

16bit

16bit

* Presence or absence of valid hold data

16bit

Command

16bit

General-

purpose area

(response)

Data

32bit

L

H

8

Page 12

Stat ion

Data changes

according to

the remote

output "RM

data change"

1

2

3

4

・When the remote output "RM data change" is ON

Buffer

Address

02E0H RWr0000

02E1H RWr0001

02E2H RWr0002

02E3H RWr0003

02E4H RWr0004

02E5H RWr0005

02E6H RWr0006

02E7H RWr0007

02E8H RWr0008

02E9H RWr0009

02EAH RWr000A

02EBH RWr000B

02ECH RWr000C

02EDH RWr000D

02EEH RWr000E

02EFH RWr000F

Device

R→M

MSB LSB

Present

value

Wave No.

(

response)

Wave No.

response)

(

Wave No.

response)

(

* Presence or absence of hold value

General-

purpose area

(response)

Content

Displacement (0 for time)

1st byte

3rd byte

5th byte

7th byte

9th byte

11th byte

13th byte

15th byte

17th byte

19th byte

Load

8bit

8bit

8bit

8bit

8bit

8bit

8bit

8bit

8bit

8bit

Command

Data

6.Address map

16bit

16bit

2nd byte

8bit

4th byte

8bit

6th byte

8bit

8th byte

8bit

10th byte

8bit

12th byte

8bit

14th byte

8bit

16th byte

8bit

18th byte

8bit

20th byte

8bit

16bit

16bit

L

H

32bit

Explanation for remote resister R → M

● Present value

The currently indicated value (displacement, time) data is stored. If the indicated value is held,

the hold value is displayed.

* If the X-axis of the waveform represents time, the value of displacement becomes 0.

Range Load: -9999 to 9999, Displacement: -9999 to 32000

● Section1 to Section5

These are valid when the remote output "RM data change" is 0.

Hold value(s) (load, time or displacement) of Section1 to Section5 is stored.

If there is any valid hold value in a section, "1" is stored in the bit of "Presence or absence of

hold value." If there is no valid hold value, "0" is stored in the bit of "Presence or absence of

hold value," and "0" is stored in the hold value.

Range Load: -9999 to 9999, Time: 0 to 51175 (ms), Displacement: -9999 to 32000

9

Page 13

6.Address map

Under the following conditions, the specified command is not accepted, but FFFFH is

written in the general-purpose area "command" (response).

Setting change

・Made during measurement

・With the general-purpose area "data" outside the input range

・With no setting item corresponding to the general-purpose area "command"

・With the general-purpose area "section No." or "work No." outside the input range

Setting read

・With no setting item corresponding to the general-purpose area "command"

・With the general-purpose area "section No." or "work No." outside the input range

Point

* How to read a hold value

● Wave No.

● Presence or absence of hold value

1. Check that the remote input "Complete" has changed from 0 to 1.

2. Set the remote output "RM data change" to 0.

3. Check that there is a valid hold value in the section you want to read by "Presence

or absence of hold value", and if any, read the hold value.

This is valid when the remote output "RM data change" is 1.

The currently-set wave No. is stored.

If there is valid data for the hold value in a section, "1" is stored in the bit corresponding to each

section. If there is no valid data, "0" is stored in the bit corresponding to each section, and "0" is

stored in the hold value.

・Presence or absence of hold value

Bit Corresponding section Bit Corresponding section

B0 Section1 B10

B1 Section2 B11

B2 Section3 B12

B3 Section4 B13

B4 Section5 B14

B5 B15

B6

B7

B8

B9

● General-purpose area "command" (response)

When setting is updated or set value(s) is read by using the general-purpose area "data", the

specified general-purpose area "command" is written in the general-purpose area "command"

(response).

● General-purpose area "data" (response)

When set value(s) is read by using the general-purpose area "data", the read set value(s) is

written.

10

Page 14

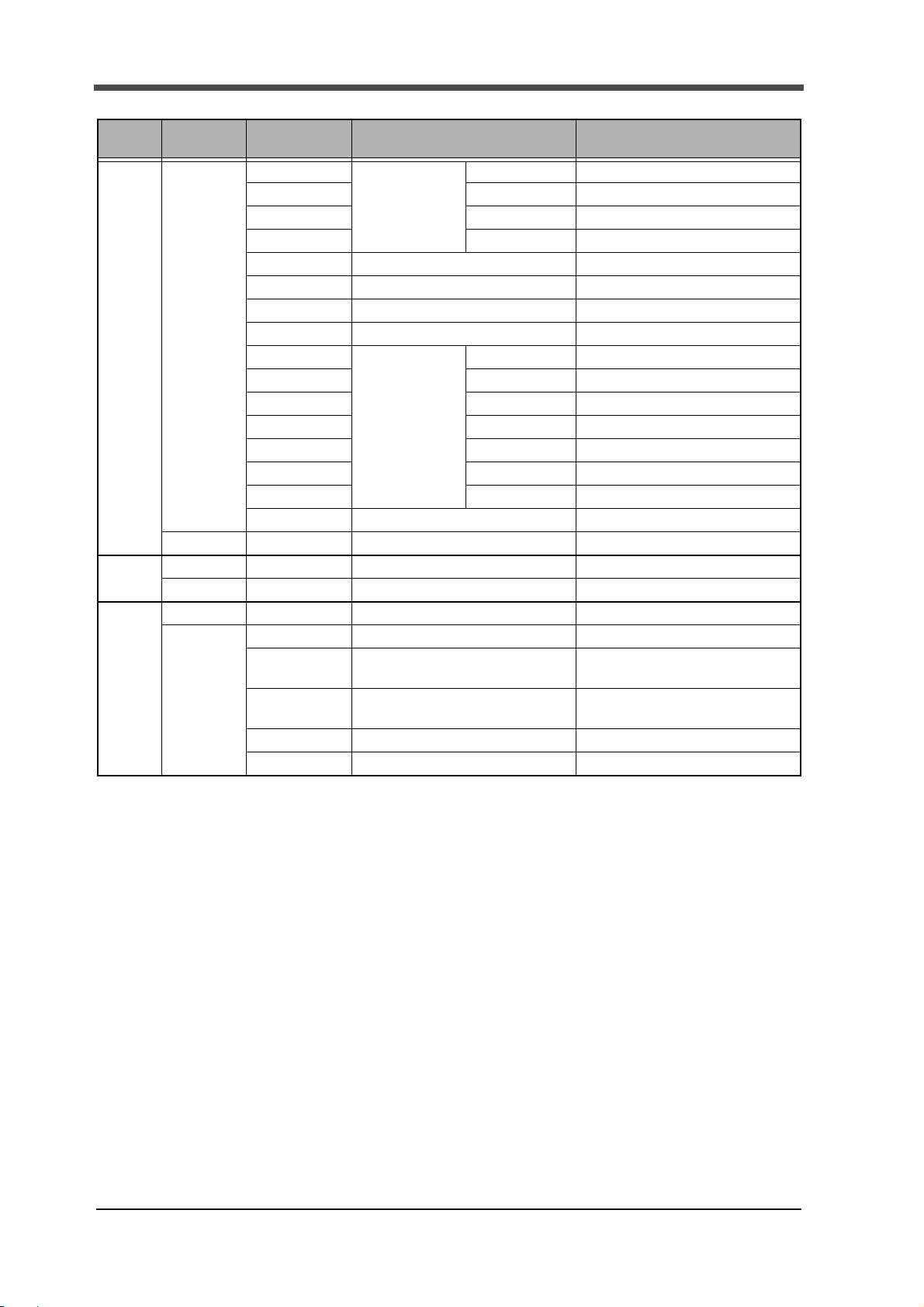

Command list

( ① F381A ② F388A)

6.Address map

Classification of items Setting item

First

Setting

Y-ax is

Setting

X-axis

Setting

(Displacement)

Communication

Setting

①Exc. Voltage

②Input Select

Unit 101

Decimal Place 102 0: 0 1: 0.0 2: 0.00 3: 0.000

Equiv. Cal.

(rated output)

Equiv. Cal.

(rated capacity)

Overload 106 0 to 9999

Increment 107 0: 1 1: 2 2: 5 3: 10

Analog Filter 108

Digital Filter 109 0, 2 to 999 [Times]

DZ Limit 110 0 to 9999

Time/DPM Change 200 0: Time 1: Displacement

Phase Select 201 0: A/B-Phase 1: Only A-Phase

Wave Reference 202 0: Front 1: Back

Unit 203

Decimal Place 204 0: 0 1: 0.0 2: 0.00 3: 0.000

Equiv. Cal.

(number of pulses)

(voltage value)

Equiv. Cal.

(displacement value)

Measure Length 208 Time/Displacement Change; Time

DPM Positioning 209 -9999 to 32000

Analog Filter

(Only ①)

Digital Filter 211 0, 2 to 999 [Times]

Speed 300 0: 1200 1: 2400 2: 4800

Data Bit 301

Parity Bit 302 0: None 1: Even 2: Odd

Stop Bit 303

Delimiter 304 0: CR 1: CR+LF

Header 305 0: None 1: STX

Flow Control 306 0: Off 1: RTS/CTS Control

Com. Mode 307 0: Normal 1: Hold Point Mode

Command

(RWw000D)

100

104

105 -9999 to 9999

206 Standard

207 -99999 to 99999

210

Data area input (output at read-time) range

①0: 2.5 1: 10 [V]

②0: ±10V 1: ±20mA

See "■Unit setting list" on page 15.

①-9.999 to 9.999 [mV/V]

②-99.99 to 99.99 [V, mA]

0: 10 1: 30 2: 100 3: 300 [Hz]

See "■Unit setting list" on page 15.

1 to 1000000

When the voltage input option is used

-9.999 to 9.999 [V] (Only ①)

0: 0.5 1: 1.0 2: 2.0 3: 5.0 4: 10.0 [s]

Time/Displacement Change; Displacement

0: 2000 1: 4000 2: 6000

3: 8000 4: 10000

0: 10 1: 30 2: 100 3: 300 [Hz]

3: 9600 4: 19.2k 5: 38.4k [bps]

0: 7 1: 8 [bit]

0: 1 1: 2 [bit]

(Input:RWw000E to 000F)

(Output:RWr000E to 000F)

11

Page 15

6.Address map

Classification of items Setting item

First

Setting

Settings

by

work

[Work

0 to 15]

System

Setting

Measurement

Start

Condition

Setting

Display

Range

Setting

Backlight

(ON Time)

Language 401 0: Japanese 1: English

Work Protect 402 0: Not Protect 1: Protect

First Protect 403 0: Not Protect 1: Protect

Undefined 404 100 to 170

Backlight

(Bright→Dark)

Start Condition 1100 0: Only External Input

Start Level 1101 External Input + Load: -9999 to +9999

Stop Condition 1102 0: Only Forced-Stop

Stop Level 1103 Load: -9999 to +9999

Y Start Point 1200 -10000 to 10000

Y End Point 1201 Y-axis Start Point +

X Start Point 1202 Time or displacement (Front)

X End Point 1203 Time or displacement (Front)

Command

(RWw000D)

400 0 to 99 [minute]

405 0 to 99 [minute]

Data area input (output at read-time) range

1: External Input + Load

2: External Input + Displacement

(2 can be set only when the X-axis of

the waveform represents displacement.)

External Input + Displacement: -9999 to +32000

1: Load 2: Time

3: Displacement 4: Displacement Stop

(3 and 4 can be set only when the X-axis of

the waveform represents displacement.)

Time: 0.1 to 10.0[second]

Displacement: -9999 to +32000

Displacement Stop: 0.1 to 10.0[second]

0: 25

5: 400 6: 500 7: 1000 8: 2000

10: 4000 11: 5000 12: 10000 13: 20000

0 to 2000 (× Measurement Length/2000)

Displacement (Back)

-2000 to 0 (× Measurement Length/2000)

X-axis Start Point +

0: 25 1: 50 2: 100 3: 200 4: 400

5: 600 6: 800 7: 1000 8: 1200 9: 1400

10: 1600 11: 1800 12: 2000 13: 2200

(× Measurement Length/2000)

Displacement (Back)

X-axis Start Point +

0: -25 1: -50 2: -100 3: -200 4: -400

5: -600 6: -800 7: -1000 8: -1200

10: -1600 11: -1800 12: -2000 13: -2200

(× Measurement Length/2000)

(Input:RWw000E to 000F)

(Output:RWr000E to 000F)

1: 50 2: 100 3: 200 4: 300

9: 3000

9: -1400

12

Page 16

6.Address map

Section

1 to 5

Classification of items Setting item

Settings

by

work

[Work

0 to 15]

Hold Setting Change of Sct.

(common to

all work)

Use Sct. 1301 1 to 5

Use Hold 1303 0: Always 1: Sample 2: Peak 3: Bottom

Sct. Start-End

(start point)

Note1)

Sct. Start-End

(end point)

Note1)

Load HI/LO Limit

(HI limit) Note1)

Load HI/LO Limit

(LO limit) Note1)

DPM HI/LO Limit

(HI limit)

Note1)

DPM HI/LO Limit

(LO limit)

Note1)

Start Load 1310 -9999 to 9999

Load Difference 1311 1 to 19998

Rate 1312 0: 1/4 1: 1/2 2: 3/4 3: 1 4: 1.25

Ordinal 1313 1 to 15 [Times]

Interval AB (A) 1314 1 to 999 (× Measurement Length/2000)

Interval AB (B) 1315 1 to 999 (× Measurement Length/2000)

Command

(RWw000D)

1300 0: External Input 1: Setting

1304 Time or displacement (Front)

1305 Time or displacement (Front)

1306

1307

1308 Waveform Reference; Front

1309 Waveform Reference; Front

Data area input (output at read-time) range

(Input:RWw000E to 000F)

(Output:RWr000E to 000F)

(0 can be set only

when the time or displacement (Front))

4: Peak to Peak 5: Relative Maximum

6: Relative Minimum 7: Inflection Point

8: Average 9: End Displacement

0 to 2047 (× Measurement Length/2000)

* However, End point of the previous section

Displacement (Back)

-2047 to 0 (× Measurement Length/2000)

* However, End point of the previous section

≧Start point≧End point

0 to 2047 (× Measurement Length/2000)

* However, Start point≦End point

≦Start point of the next section

Displacement (Back)

-2047 to 0 (× Measurement Length/2000)

* However, Start point≧End point

≧Start point of the next section

-9999 to +9999

* Setting HI limit < LO limit is unacceptable.

-9999 to +9999

* Setting HI limit < LO limit is unacceptable.

0 to 2047 (× Measurement Length/2000)

Waveform Reference; Back

-2047 to 0 (× Measurement Length/2000)

* When End Displacement in Use Hold is selected;

-9999 to 32000

* Setting HI limit < LO limit is unacceptable.

0 to 2047 (× Measurement Length/2000)

Waveform Reference; Back

-2047 to 0 (× Measurement Length/2000)

* When End Displacement in Use Hold is selected;

-9999 to 32000

* Setting HI limit < LO limit is unacceptable.

5: 1.5 6: 1.75 7: 2 8: 3 9: 4 [Times]

≦Start point≦End point

13

Page 17

6.Address map

Point

Note1)

Please change other set values beforehand so that the setting range

becomes the maximum when a set value to which other settings influence the

setting range is written in.

Example 1 When you write the Load HI Limit value in.

Please write -9999 in the Load LO Limit value beforehand.

Example 2 When you change the Section Start-End.

Please write 2047(Time or Displacement (Front)) and -2047(Displacement

(Back)) in of the start point and the end point in all sections beforehand in

order of End Point of Section 5, Start Point of Section 5, End Point of

Section 4, …… End Point of Section 1 and Start Point of Section 1.

Please write in the value to be set in order of Start Point of Section 1, End

Point of Section 1, Start Point of Section 2, …… Start Point of Section 5

and End Point of Section 5.

Classification of items Setting item

Settings by

work

[Work

0 to 15]

Waveform

Comparison

Setting

Calibration Zero Calibration (load) 2000 Fixed at 0

Relative

(common to all work)

Compare Area

(start point)

Note1)

Compare Area

(end point)

Note1)

Compare Margin 1403 0 to 9999

Relative Point

(X-axis)

Relative Point

(Y-axis)

Zero Calibration

(displacement)

Actual Load Calibration

(load)

Actual Load Calibration

(displacement)

Command

(RWw000D)

1400 0: Off 1: On

1401 Time or displacement (Front)

1402 Time or displacement (Front)

1404 Time or displacement (Front)

1405 -9999 to 9999

2001 Fixed at 0

2002 -9999 to 9999

2003 -9999 to 32000

Data area input (output at read-time) range

(Input:RWw000E to 000F)

(Output:RWr000E to 000F)

0 to 2047 × Measurement Length/2000

* Setting Start point > End point is

unacceptable.

Displacement (Back)

-2047 to 0 × Measurement Length/2000

* Setting Start point < End point is

unacceptable.

0 to 2047 × Measurement Length/2000

* Setting Start point > End point is

unacceptable.

Displacement (Back)

-2047 to 0 × Measurement Length/2000

* Setting Start point < End point is

unacceptable.

0 to 2047 (× Measurement Length/2000)

Displacement (Back)

-2047 to 0 (× Measurement Length/2000)

14

Page 18

6.Address map

■Unit setting list

* Numbers are values of input range.

Also, “0” results in no unit.

- ①F381A

Weight Force Pressure Length Angle Other

1 μg 11 μN 24 μPa 41 μm 48 rad 51 g/cm

2 mg 12 mN 25 mPa 42 mm 49 ° 52 kg/m

3 g 13 N 26 Pa 43 cm 50 deg 53 t/m

4 kg 14 kN 27 hPa 44 m 54 g/l 88 μA

5 Mg 15 MN 28 kPa 45 km 55 g/ml 89 mA

6 t 16 μNm 29 MPa 46 in 56 mg/m 90 A

7 lb 17 mNm 30 GPa 47 ft 57 kg/m 91 kA

8 dyne 18 Nm 31 N/m

2

58 kgm/s 92 μV

9 kdyne 19 kNm 32 μbar 59 kgm2/s 93 mV

10 oz 20 MNm 33 mbar 60 kgm

21 ftlb 34 bar 61 mPas 95 kV

22 inlb 35 mmHg 62 Pas 96 Ω

23 inoz 36 inH

37 ftH

O 63 m2/s 97 kΩ

2

O 64 mm/s 98 MΩ

2

38 psia 65 m/s 99 W

39 psig 66 mm/min 100 kW

40 atom 67 cm/min 101 MW

68 m/min 102 VA

69 m/h 103

70 km/h 104 °F

71 m/s

72 rpm 106 kJ

73 Hz 107 MJ

74 kHz 108

75 MHz 109 l

76 kg/s 110 m

77 t/s 111

78 kg/min 112 ‰

79 t/min 11 3 ppm

80 kg/h 11 4 pH

81 t/h 115 gcm

82 m

83 m

84 m3/h

3

85 l/s

3

86 l/min

3

87 l/h

2

94 V

℃

2

105 J

%RH

%

3

/s 116 kgcm

3

/min 117 TONNE

3

15

Page 19

6.Address map

- ②F388A

Weight Force Pressure Length Angle Other

1 μg 11 μN 28 μPa 45 μm 52 rad 55 g/cm

2 mg 12 mN 29 mPa 46 mm 53 ° 56 kg/m

3 g 13 N 30 Pa 47 cm 54 deg 57 t/m

4 kg 14 kN 31 hPa 48 m 58 g/l 92 μA

5 Mg 15 MN 32 kPa 49 km 59 g/ml 93 mA

6 t 16 μNm 33 MPa 50 in 60 mg/m 94 A

7 lb 17 mNm 34 GPa 51 ft 61 kg/m 95 kA

8 dyne 18 Nm 35 N/m

2

62 kgm/s 96 μV

9 kdyne 19 kNm 36 μbar 63 kgm

10 oz 20 MNm 37 mbar 64 kgm

21 ftlb 38 bar 65 mPas 99 kV

22 inlb 39 mmHg 66 Pas 100 Ω

23 inoz 40 inH

24 Ncm 41 ftH

O 67 m2/s 101 kΩ

2

O 68 mm/s 102 MΩ

2

25 gcm 42 psia 69 m/s 103 W

26 kgcm 43 psig 70 mm/min 104 kW

27 kgm 44 atom 71 cm/min 105 MW

72 m/min 106 VA

73 m/h 107

74 km/h 108 °F

75 m/s

76 rpm 110 kJ

77 Hz 111 MJ

78 kHz 11 2

79 MHz 113 l

80 kg/s 11 4 m

81 t/s 115

82 kg/min 116 ‰

83 t/min 117 ppm

84 kg/h

85 t/h

86 m

87 m

88 m3/h

3

89 l/s

3

90 l/min

3

/s

3

/min

3

2

91 l/h

2

/s 97 mV

2

98 V

109 J

℃

%RH

3

%

16

Page 20

6.Address map

・All input/output signals are

positive-logic.

1: ON 0: OFF

・Operation is the same as the input/

output signals of the main unit.

For details, refer to the F381A/F388A

operation manual.

Point

■About remote input/output

The F381A/F388A can send status and indicated values through the CC-Link with a delay of

approx. 200msec compared with the external input/output signals of the main unit.

The delay time is further affected by the communications cycle time, PLC scan time, etc.

Therefore, use the control connector of the main unit, not through communications, for severe-

speed cases.

Since a delay time also arises when input signals such as the D/Z command are used through

communications in a like manner, use the control connector for severe-speed cases.

*1:Measuring environment

CPU unit A1SCPU

Cable length 5m

Baud rate 10Mbps

Occupied station 4

Number of units connected 1

(*1)

■Relay domain

Remote output (PLC → F381A/F388A)

Use the remote output (PLC → F381A/F388A) for the following purposes.

・Turning on/off the relays of Request flag 1, Request flag 2 and R/W.

・Directing operations corresponding to items.

・ Switching work No.

Stati on

1 0160H

Buffer

address

Remote

output

RY0000

RY0001

RY0002

RY0003 R/W Read: ON Write: OFF

RY0004

RY0005

RY0006

RY0007

RY0008 RM data change

RY0009

RY000A

RY000B

RY000C

RY000D

RY000E

RY000F

Request flag 1

Request flag 2

Request flag 3

Content Remarks

Reserved signal

Wave No.: ON Hold result: OFF

17

Page 21

6.Address map

Station

1 0161H

2

3

4

Buffer

address

0162H

0163H

0164H

0165H

0166H

0167H

Remote

output

Content Remarks

RY0010 Load Digital Zero

RY0011 DPM Positioning

RY0012 Start

RY0013 Stop

RY0014 Hold

RY0015 Reset

RY0016 Backlight ON

RY0017 Prohibit Touch Panel

RY0018

RY0019

RY001A

RY001B

RY001C

RY001D

RY001E

RY001F

RY0020

RY0021 2

RY0022 4

Work change

(for operation)

RY0023 8

RY0024

RY0025

RY0026

RY0027

RY0028

RY0029

RY002A

RY002B

RY002C

RY002D

RY002E

RY002F

:

:

:

:

:

Valid when the setting of "Input Select 1"

of the F381A/F388A is

"Communications."

1

Valid when the setting of "Input Select 2"

of the F381A/F388A is

"Communications."

18

Page 22

Stati on

1

Remote input (F381A/F388A → PLC)

Information of each item is displayed to remote input (F381A/F388A → PLC)

Buffer

address

00E0H

00E1H

Remote

input

RX0000

RX0001

RX0002

RX0003 R/W (Response)

RX0004

RX0005

RX0006

RX0007

RX0008 RM data change (

RX0009

RX000A First Protect

RX000B Work Protect

RX000C

RX000D B1

RX000E

RX000F B1

RX0010

RX0011 OK

RX0012 HI

RX0013

RX0014 OK

RX0015 HI

RX0016 Overload

RX0017

RX0018

RX0019 OK

RX001A HI

RX001B Complete

RX001C Run

RX001D Load OK

RX001E DPM OK

RX001F SD OK

Response 1

Response 2

Response 3

Y-axis Decimal Place

X-axis Decimal Place

Hold Result

Wave Resu l t

Content Remarks

Response)

B0

B0

LO

Load

LO

DPM

LO

Reserved signal

Please fetch the inputs

in synchronization

with the Complete of RX001B.

Please fetch the inputs

in synchronization

with the Complete of RX001B.

6.Address map

19

Page 23

6.Address map

Station

2

3

4

Buffer

address

00E2H

00E3H

00E4H

00E5H

00E6H RX0070

00E7H

Remote

input

RX0020

RX0021 2

RX0022 4

RX0023 8

RX0024

RX0025

RX0026

RX0027

RX0028

RX0029 Wait Off

RX002A Wait Lv.

RX002B Sampling

RX002C Wait Cal.

RX002D Complete

RX002E Reset On

RX002F

::

::

::

::

RX007A Error Status Flag

RX007B Remote READY

:

RX007F

Content Remarks

1

Work Display

(for operation)

Wait St.

Measurement

Status

:

Turns on if there is a load error or

displacement error.

Turns on if the error status flag is off

after initialization.

20

Page 24

7. Setting procedure

Request 1

(RY0000)

Response 1

(RX0000)

Wave No.

(RWw0002 to RWw000B)

ON

ON

OFF

OFF

(The upper row of signal level is ON, the lower row of signal level is OFF.)

Request 2

(RY0000)

Response 2

(RX0000)

R/W

(RY0003)

ON

ON

OFF

OFF

(The upper row of signal level is ON, the lower row of signal level is OFF.)

General-purpose area "data"

(RWw000E, RWw000F)

General-purpose area "Section No.", "Work No."

(RWw000C)

General-purpose area "Command"

(RWw000D)

R/W (Response)

(RX0003)

General-purpose area "Command" (Response)

(RWr000D)

■Setting of wave No. by using Request flag 1

Use Request flag 1 for writing wave No.

After specifying the set value in the wave No., the set value is written at the ON edge of Request

flag 1 when all of Request flag 1 to 3 and Response 1 to 3 are off.

RWw0002 to RWw000B correspond to wave No.

Note

) Turn off the Request flag 1 bit after checking that Response 1 is on.

7.Setting procedure

■Setting by using the general-purpose area "data" and "command", and Request flag 2

Use Request flag 2 for reading and writing set value(s).

Operation is performed at the ON edge of Request flag 2 when all of Request flag 1 to 3 and

Response 1 to 3 are off.

RWw000E and RWw000F correspond to the general-purpose area "data."

RWw000D corresponds to the general-purpose area "command."

RWw000C corresponds to the general-purpose area "section No." and general-purpose area "work No."

Note) Turn off the Request flag 2 bit after checking that Response 2 is on.

For writing set value(s), turn off "R/W."

21

Page 25

7.Setting procedure

Request 2

(RY0000)

Response 2

(RX0000)

R/W

(RY0003)

ON

ON

OFF

OFF

(The upper row of signal level is ON, the lower row of signal level is OFF.)

General-purpose area "Section No.", "Work No."

(RWw000C)

General-purpose area "Command"

(RWw000D)

R/W (Response)

(RX0003)

General-purpose area "Command" (Response)

(RWr000D)

General-purpose area "data" (Response)

(RWr000E, RWr000F)

■Reading set value(s)

For reading set value(s), turn on R/W.

The set value of the specified channel number is outputted.

After checking that Response 2 turns on, read the general-purpose area "data" (response).

) Turn off the Request flag 2 bit after checking that Response 2 is on.

Note

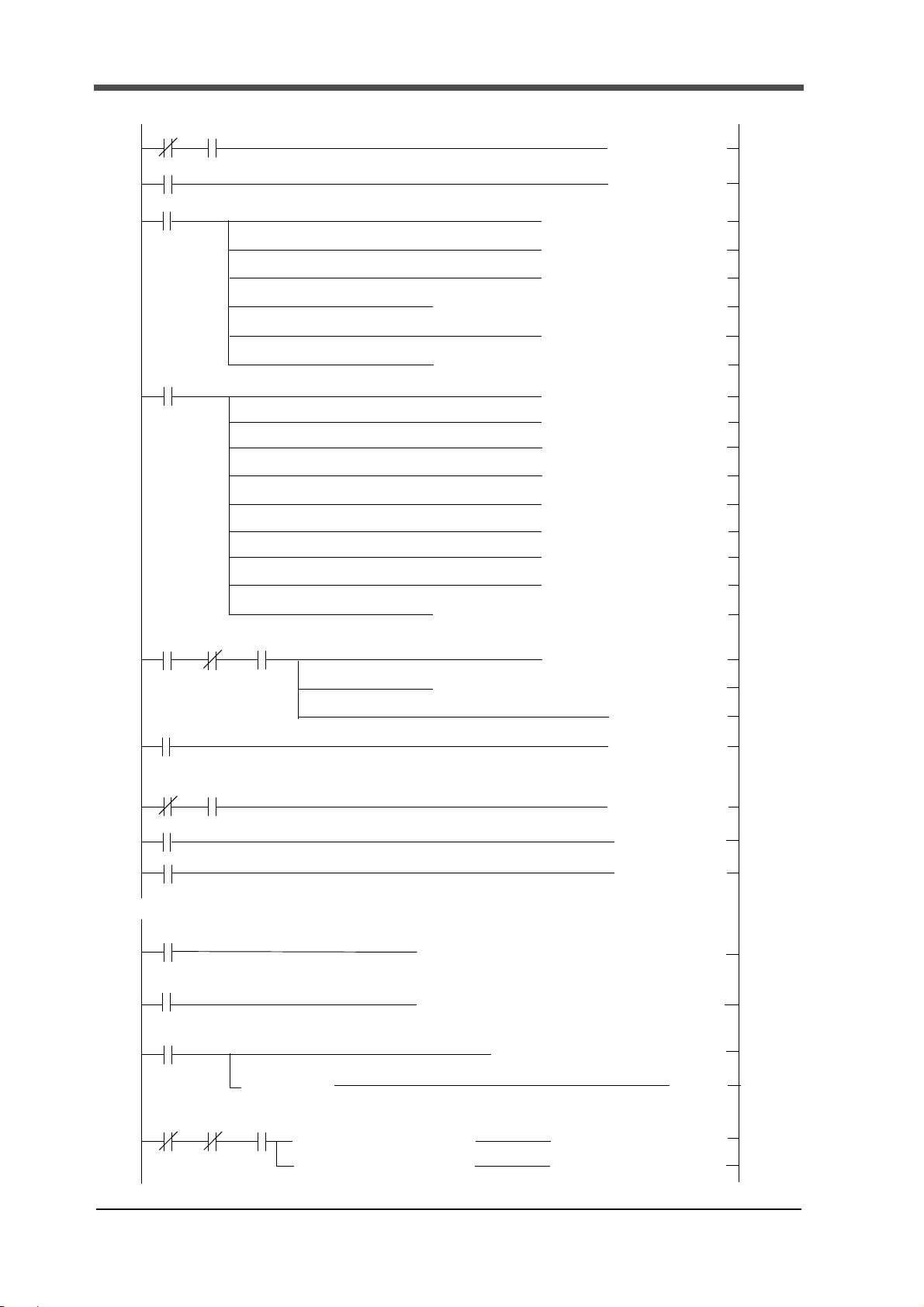

■Sample of ladder program

Rewriting Load HI/LO Limit (HI limit) to CODE No.0 by Request flag 2, the Load HI/LO Limit

(HI limit)

「In detail refer to CC-Link System Master/Local Module Type AJ61QBT11/A1SJ61QBT11 User’s

22

are increased from 0 to 9999 in succession.

Use CPU :A1SH

Station No. :1

Slot of Master :3 (The relay area to be used is X60 ~ X7F and Y60 ~ Y7F.)

Manual」

The following is a sample ladder program to change Load HI/LO Limit (HI limit) of work No.

2, section 1 using request flag 2.

After a value is written in Load HI/LO Limit (HI limit) , Load HI/LO Limit (HI limit) is read,

and the written value and read value are compared, and if they agree, the writing value is

incremented by 1, and it is repeated up to 9999, which is followed by 0.

Note) Set Load HI/LO Limit (LO limit) of work No. 2, section 1 to 0 or less in advance.

Page 26

7.Setting procedure

Initial setting

D300 = 9999

D300 = D300+1

After confirming Request flag 2 response OFF, writes the value of D300 into

After confirming Request flag 2 response ON, turns OFF Request flag 2.

After confirming Request flag 2 response OFF, requests reading out

After confirming Request flag 2 response ON, reads out the value (D302)

Compares D300 with D302

Sequence completion

"0" is substituted for D300

Yes

No

When Conform to

When Not conform to

FLOW

then turns Request flag2 OFF.

Load HI/LO Limit (HI limit).

Load HI/LO Limit (HI limit).

0~123 row Initial setting for Communication speed

96 row Remote device F381A/F388A occupies 4 stations of PLC start from station 1.

125 row RX PLC read value from F381A/F388A

135 row RWr PLC read value from F381A/F388A

145 row Copying Reguest flag 2 response to M200

202 row Writing Load HI/LO Limit (HI limit)

274 row Reading Load HI/LO Limit (HI limit)

308 row Copying read value to D302

337 row When each value coinsides with proceeds to 159 row.

350 row Data Initialization

23

Page 27

7.Setting procedure

X6FX60

M9038

1 cycle

D12

H1401

[MOV ]

96

X60

M1

M0

M9038

M0

M1

D0

D1

D2

K3

D3

K

1

D4

D5

D6

D7

D8

D10

D11

K8

K1

Y60

M2

[PLS

[SET

K1

K3

K1

D0

K0

D3

H0

H0

H0

H0

H0

H0

H0

H0

D4

D12

[RST

[SET

[PLS

[MOV

[MOV

H1

[MOV

[MOV

[MOV

[MOV

[MOV

[MOV

[MOV

[MOV

H10

H20

H6

H6

H6

H6

[TO

[TO

[TO

[TO

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

]

X6F

M1

X60 X6F

0

5

7

46

114

116

*<1device connected

>

[MOV

]

H6

[MOV

D9

*<Remote device F381A/F388A occupies 4

M1

1 cycle ON

M2

M3

M3

Y66

[SET

[SET

]

]

121

123

*

Up to here Initial setting for communication

(M200

D200H0E0H6

[FROM

]

D216H2E0H6

[FROM ]

M9036

M9036

[= D400 H4 ]

125

135

*<RX PLC read value from F381A/F388A >

ON at all times

ON at all times

*<

RWr PLC read value from F381A/F388A >

D200H4[WAND

]

M9036

ON at all times

)

Request flag 2 response

145

H8

D400

H10

]

H1 [+

]

[D= K9999 D300 ]

[D<>

K9999

D300

*<D300 =9999 , D300←0

>

159

D300

[DMOV

]

D300

M200 M9038 M100

Request

1 cycle

K0

stations of PLC start from station 1

>

flag 2

response

ON

ON

24

Page 28

D208

M100

M101

H0FFF7

[RST

[SET

]

]

H10D232H1E0H6

[TO ]

M200 M9038 M100

202

Request

1 cycle

ON

]

*<R /W

relay

OFF

>

D246D300 [MOV ]

[WAND

D247D301[MOV ]

D245K1306[MOV ]

*<(

Load HI/LO Limit (HI limit)

>

*<Reguest flag 2 ON

>

D208H4[WOR ]

H8D208

H160

[TO

]

*<To

M101

>

H6

*

M100

Sequence(Wiriting Load HI/LO Limit (HI limit)

)

M200 M9038 M101

255

*<When Reguest flag 2 response turns ON

Request

1 cycle

ON

*<To

M103

>

M103[SET ]

M101[RST

]

H8D208

H160

H6[TO

]

D208

H0FFFB

][WAND

*

M101 Sequence

*<

R/W relay Turns ON

>

D208H8

[WOR

]

274

M200 M9038 M103

Request

1 cycle

*<Load HI/LO Limit (HI limit)

>

D245K1306

[MOV

]

*<Reguest flag 2 ON

>

H8D208H160H6[TO ]

*<To

M104

>

]

]

M103[RST

M104[SET

D208H4

[WOR

]

*

M103 Sequence(Reading Load HI/LO Limit (HI limit)

)

D244H102[MOV ]

*<Work no. 2 Section 1

>

*<Work no. 2 Section 1

>

D244H102

[MOV

]

ON

flag 2

response

flag 2

response

flag 2

response

Reguest flag 2 goes OFF.

>

7.Setting procedure

25

Page 29

8.Outside dimensions

1 cycle

M105[RST ][ = D300 D302 ] [ = D301 D303 ]

337

*<To M100

>

M100[SET ]

M105

*

M105 Sequence(Comparing values

)

M9038

M100[SET ]

M101[RST ]

M102[RST ]

M103[RST ]

M104[RST ]

M105[RST ]

D300K0[DMOV ]

1 cycle ON

350

364

[END ]

*

Initialization

D303D231

[MOV

]

M104[RST

M105[SET

D302D230[MOV ]

M200 M9038 M104

Request

*<When Reguest flag 2 response turns ON

H8D208H160H6[TO ]

*<To M105

>

]

]

308

D208

H0FFFB

][WAND

*

M104 Sequence

ON

flag 2

response

Reguest flag 2 goes OFF.

>

ࠉ ࠉ

ࠉ

ࠉ

ࠉࠉ

8. Outside dimensions

26

Loading...

Loading...