Page 1

F371

DIGITAL INDICATOR

OPERATION MANUAL

20 Jul. 2011

Rev. 1.18

Page 2

Cautions and Requests for Use

● Do not disassemble the main body for modifications or repair.

● Be sure to use crimp contacts for connection to terminal blocks, and do not to

connect bare wires as they are.

● Be sure to ground the protective ground terminal.

- The main F.G. is indicated by , it must be grounded with the protected

earth.

● Be sure to disconnect the power cable when performing the following.

- Attachment/detachment of connectors of options.

- Wiring/connection of cables to terminal blocks.

- Connection of the ground line.

Cautions and Requests for Use

● Be sure to assort the machine which is supplied by AC power through the ter-

minal in a panel with lock or screws.

● Carefully check wiring, etc. before applying power.

● Take an interval of more than 5 seconds when repeating ON/OFF.

● Take adequate shielding measures when using at the following locations.

- Near a power line.

- Where a strong electric field or magnetic field is formed.

- Where static electricity, relay noise or the like is generated.

● Do not install in the following environments.

- Places exposed to direct sunlight.

- Where the temperature and/or humidity exceeds the range in the

specifications.

- Places containing corrosive gas or flammable gas.

- Places with large quantities of dust, salt or iron powder.

- Where the product may be splashed with water, oil or chemicals.

- Where the main body is directly affected by vibration or shock.

● Set the correct Excitation Voltage for the sensor. (2.5V is set when F371 is

dispatched from us.)

Page 3

Safety Precautions

WARNING

Misuse may cause the risk of death or serious

injury to persons.

Misuse may cause the risk of injury to persons or

damage to property.

CAUTION

Safety Precautions

● Indications for safe use and their meanings

In this manual, precautions for using the F371 digital indicator safely are indicated as

follows. Be sure to follow the precautions given here because they are important

descriptions relating to safety.

Indications and their meanings are as follows:

● Explanation of pictographs

The △ means a caution (or warning).

A specific description is written in the △ .

The illustration on the left-hand side shows "Caution: May explode".

The △ means a caution (or warning).

A specific description is written in the △ .

The illustration on the left-hand side shows a general caution.

Page 4

● About the built-in lithium battery

Never disassemble, deform under pressure or throw the battery

into fire.The battery may explode, catch fire or leak.

- Battery

Model: CR2477-1HF made by Matsushita Battery Industrial Co., Ltd.

Nominal voltage: 3V

Nominal electric capacity: 1000mAh

WARNING

For connection to the signal I/O terminal block, wire correctly after

checking the signal names and terminal block numbers.

Also, turn off the power of the main body before connection/wiring to the

signal I/O terminal block.

CAUTION

Safety Precautions

● About the signal I/O terminal block

Page 5

CONTENTS

CONTENTS

1.APPEARANCE DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . .1

1-1.Front Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1-1-1.Touch Panel Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1-2.Power Lamp . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2.Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1-2-1.AC Power Source Input Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-2.Frame Ground (Functional ground) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

1-2-3.Optional Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.SETTING MODES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2-1.F371 Screen Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

2-2.Setting Modes Tree . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

2-3.About a Setting Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

3.CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3-1.Power Input Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3-2.Load Cell Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

3-3.SI/F Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

3-4.External I/O Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3-4-1.External Output Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-4-2.External Input Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-5.RS-232C Interface Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3-6.Voltage Output Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3-6-1.Connecting to Cage Clamp Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.CALIBRATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

4-1.Equivalent Input Calibration Procedure . . . . . . . . . . . . . . . . . . . . . .17

4-2.Actual Load Calibration Procedure . . . . . . . . . . . . . . . . . . . . . . . . .18

4-3.Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

4-4.Actual Load Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Page 6

CONTENTS

4-5.Equivalent Input Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

4-6.Digital Offset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

4-7.Increment (This step may be omitted if there is no change.) . . . . .24

4-8.Decimal Place . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4-9.Calibration Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

4-10.Calibration Value Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

4-10-1.External Selection of Calibration Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4-11.Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

5.SETTING OF FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5-1.Digital Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

5-2.Digital Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

5-3.Analog Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5-4.Display Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

5-5.Stability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

5-6.Zero Track . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

5-7.Contrast Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5-8.Backlight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5-9.Excitation Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

5-10.Auto Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

5-11.Hold Off Print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5-12.Parameter Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

6.COMPARISON FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . .40

6-1.HI Limit/LO Limit/HI-HI Limit/LO-LO Limit . . . . . . . . . . . . . . . . . . . .41

6-2.Hysteresis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

6-3.Near Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6-4.HI-LO Limit Comparison Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

6-5.HI-LO Limit Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

6-6.Alarm Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Page 7

CONTENTS

7.HOLD FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7-1.Hold Setting --- common --- . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

7-1-1.Hold Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

7-1-2.Hold Detection Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

7-1-3.Auto Start Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7-1-4.Hold Point Shift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

7-2.Hold Setting --- relative maximum and relative minimum --- . . . . .50

7-2-1.Minimum Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7-2-2.Valley Detection Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7-3.Hold Setting --- inflection point --- . . . . . . . . . . . . . . . . . . . . . . . . .52

7-3-1.Minimum Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7-3-2.Interval A and Interval B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7-4.Hold Setting --- mean value --- . . . . . . . . . . . . . . . . . . . . . . . . . . .55

7-4-1.Mean Value Sampling Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

7-5.Hold Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

7-5-1.Sample Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

7-5-2.Peak Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7-5-3.Valley Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7-5-4.Peak-to-Peak (P-P) Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

7-5-5.Relative Maximum and Relative Minimum Hold . . . . . . . . . . . . . . . . . . . . . . . 60

7-5-6.Inflection Point Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

7-5-7.Mean Value Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7-6.How to Specify the Hold Detection Period . . . . . . . . . . . . . . . . . . . .64

7-6-1.All Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

7-6-2.Externally Specified Period Hold

(Peak, Valley , Peak-to-Peak and Mean Value) . . . . . . . . . . . . . . . . . . . . . . . 65

7-6-3.Time Specified Period Hold

(Peak, Valley, Peak-to-Peak and Mean Value) . . . . . . . . . . . . . . . . . . . . . . . . 66

7-6-4.Time Specified Period Hold with Trigger

(Peak, Valley, Peak-to-Peak and Mean Value) . . . . . . . . . . . . . . . . . . . . . . . . 67

8.MULTI-HOLD FUNCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

8-1.About Changing of the Setting CH . . . . . . . . . . . . . . . . . . . . . . . . . .69

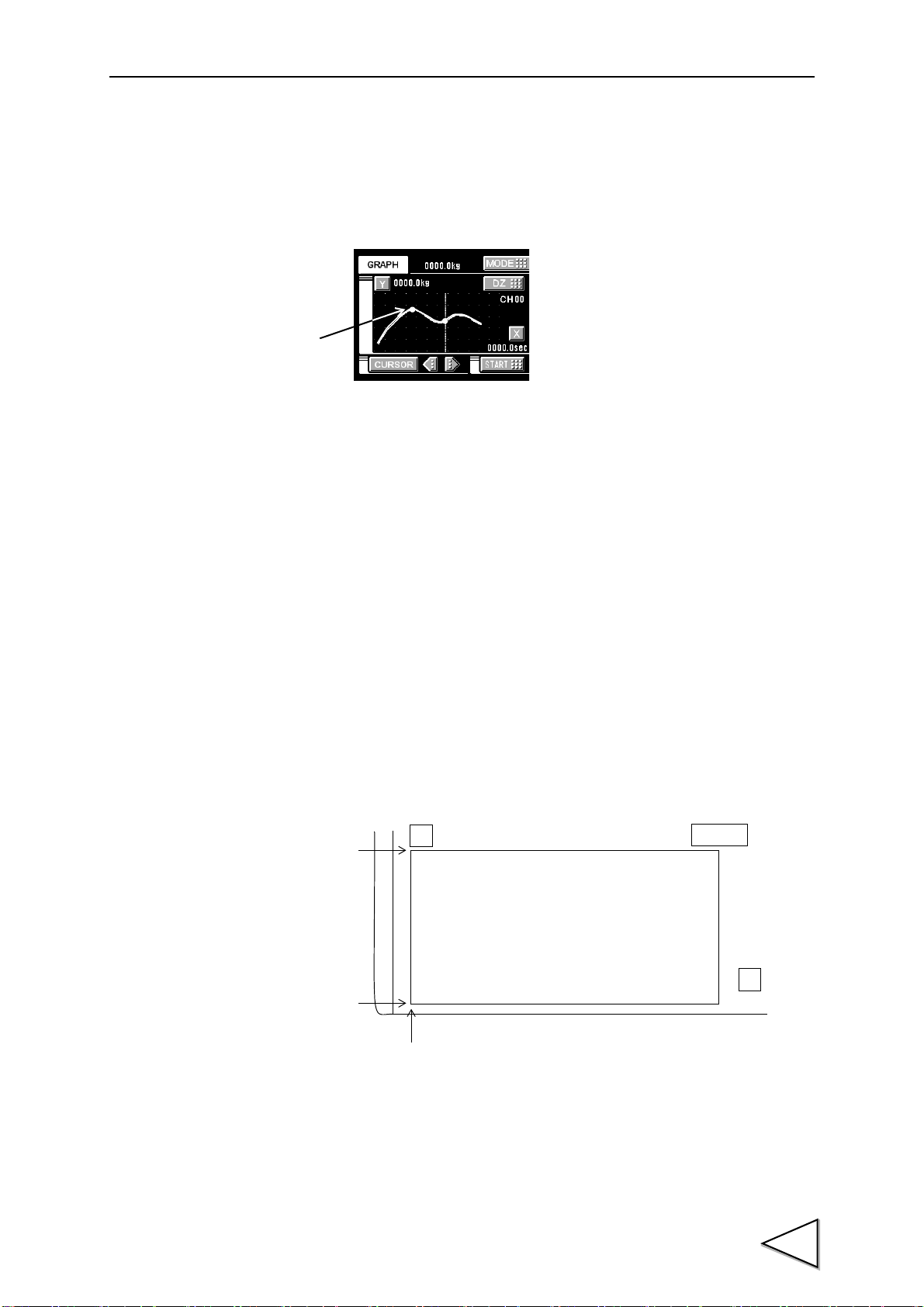

9.WAVEFORM DISPLAY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

9-1.Graphic Display Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

9-1-1.Hold Point Plotting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

9-1-2.X-axis and Y-axis on the Graph Plotting Screen . . . . . . . . . . . . . . . . . . . . . . 71

Page 8

CONTENTS

9-2.Graph Plotting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

9-2-1.Continuous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

9-2-2.External . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

9-2-3.Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9-2-4.External + Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

9-3.Graph Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

9-4.Interval Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

9-5.Graph Start Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

9-6.Level Detection Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

9-7.X Start Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

9-8.Y (Load) Start Point and Y (Load) End Point . . . . . . . . . . . . . . . . . .78

10.VOLTAGE OUTPUT(VOL OUT) . . . . . . . . . . . . . . . . . . . . .79

11.SCREEN LOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

12.EVENT OUTPUT AT THE END OF GRAPH PLOTTING . . . .80

13.RS-232C INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

13-1.Communication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

13-1-1.Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

13-1-2.Connector Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13-1-3.Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

13-2.RS-232C Interface Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

13-2-1.Communication Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13-2-2.Baud Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13-2-3.Character Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

13-2-4.Parity Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13-2-5.Stop Bit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13-2-6.Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

13-3.Communication Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

13-4.Communication Format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Page 9

CONTENTS

14.BCD DATA OUTPUT(OPTION) . . . . . . . . . . . . . . . . . . . . . . .92

14-1.Connector Pin Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

14-2.Logic Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

14-3.BCD Data Hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

14-4.Equivalent Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

14-5.Signal Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

14-6.BCD Data Update Rate Selection . . . . . . . . . . . . . . . . . . . . . . . . .95

14-7.BCD Output Data Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

15.RS-485 COMMUNICATION INTERFACE(OPTION) . . . . . . .96

15-1.Communication Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

15-2.RS-485 connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

15-3.Communication Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

15-4.RS-485 Interface Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

15-4-1.ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

15-4-2.Terminator Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

15-4-3.Communication Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

16.D/A CONVERTER(OPTION) . . . . . . . . . . . . . . . . . . . . . . . .101

16-1.Voltage Zero and Full Scale, Current Zero and Full Scale . . . . .102

16-2.D/A Output Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

16-3.Voltage Output Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

16-4.Current Output Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

17.DC POWER SOURCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

18.ERROR MESSAGES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Page 10

CONTENTS

19.SELF-CHECK AND INITIALIZATION . . . . . . . . . . . . . . . . .107

19-1.Self-Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

19-1-1.Self-Check DSP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

19-1-2.Self-Check MEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

19-1-3.Self-Check KEY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

19-1-4.Self-Check EXT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

19-2.Initialization(All setting value clearances) . . . . . . . . . . . . . . . . . .109

19-3.Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

20.ABOUT JAPANESE/ENGLISH DISPLAY SELECTION . . .110

21.BLOCK DIAGRAM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

22.DIMENSIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

23.INSTALLATION IN A PANEL . . . . . . . . . . . . . . . . . . . . . . .113

24.SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

24-1.Analog Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

24-2.Digital Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

24-3.Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

24-4.Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

24-5.External Input and Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

24-6.General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

24-7.Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .118

25.SETTING ITEM CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

26.CONFORMITY TO EC DIRECTIVES . . . . . . . . . . . . . . . . . .123

Page 11

CONTENTS

Page 12

1. APPEARANCE DESCRIPTION

Touch Panel

Display

Power Lamp

Hold Status Display

Display Change Button

Comparison Status

Indicated Value

Setting Input Screen

Call Button

Digital Zero

Button

Setting Mode

Button

Display

Display

Comparison Display Hold Display Graph Display

1-1. Front Panel

1.APPEARANCE DESCRIPTION

1-1-1. Touch Panel Display

This is the touch panel display for displaying an indicated value and graph set value and

for setting various setting items of the F371. During measurement, a comparison display,

hold display and graph display can be selected according to the function in use.

1-1-2. Power Lamp

This lamp lights when the power to the F371 is on.

1

Page 13

1.APPEARANCE DESCRIPTION

Frame ground

Signal I/O terminal

Optional slot

AC power source

input terminal block

block

1GND

2 VOL OUT

3+SIG

4 -EXC

5-SIG

6+EXC

over

under

1

2

3

4

5

6

terminal block

terminal block

fix screw

fix screw

A1

*

COM1 B1

*

COM2

A2 OUT HH B2 IN CODE0

A3 OUT HI B3 IN CODE1

A4 OUT OK B4 IN CODE2

A5 OUT LO B5 IN CODE3

A6 OUT LL B6 IN T/H

A7

*

COM1 B7

*

COM2

A8 OUT H/E B8 IN H/M

A9 IN D/LOCK B9 IN D/Z

A10 OUT EVENT B10 IN ST/SP

A11 OUT SI/F B11 IN CAL0

A12 OUT SI/F B12 IN CAL1

A1 B1

A12 B1 2

1-2. Rear Panel

Terminal block

Signal input / output connect

2

Page 14

1.APPEARANCE DESCRIPTION

「COMPARISON

FUNCTIONS」

→

page 40

The input for controlling the hold signal.

→ page 47「HOLD FUNCTIONS」

+EXC

-EXC

+SIG

-SIG

See the section on Load Cell Connection page 10 for connection.

VOL OUT

GND

See the section on Voltage Output Connection page 14 for connection.

COM1 The terminal common to output signals.

OK

HI

LO

HH

LL

H/E Outputs the hold end signal.

EVENT Outputs the event signal when graph plotting ends.

The terminal for connecting to a strain-gage sensor.

The voltage output terminal.

→ page 79「VOLTAGE OUTPUT(VOL OUT)」

Outputs the OK signal.

Outputs the HI signal.

Outputs the LO signal.

Outputs the HH signal.

Outputs the LL signal.

→ page 47「HOLD FUNCTIONS」

See the section on External I/O Connection page 12 for connection.

COM2 The terminal common to input signals.

CODE0

CODE1

CODE2

CODE3

T/H

H/M

D/Z The input for digital zero (making the indicated value zero).

ST/SP The graphic display start/stop signal.

CAL0

CAL1

D/LOCK Screen lock input for invalidating key operation on the measurement

See the section on External I/O Connection page 12 for connection.

Selects the CH No. for the multi-hold function.

Calibration value selection input

→ page 68「MULTI-HOLD FUNCTION」

→ page 31「Digital Zero」

→ page 72「Graph Plotting」

Selects the CAL No. for calibration value selecttion function.

→ page 28「External Selection of Calibration Value」

screen (comparison/hold/graph).

SI/F The 2-wire serial interface for coupling a UNIPULSE printer,

external display, etc.

See the section on SI/F Connection page 11 for connection.

3

Page 15

1.APPEARANCE DESCRIPTION

1-2-1. AC Power Source Input Terminal Block

Connect the AC power cord. The input voltage is 100V - 240V AC, and the frequency is

50/60Hz.

1-2-2. Frame Ground (Functional ground)

This is a ground terminal block. Be sure to ground the F.G. terminal to prevent electric

shocks and failures due to static electricity.

1-2-3. Optional Slot

Any one of the following optional boards can be mounted.

• BCD data output F371

• D/A converter

• RS-485

• CC-Link interface

(CC-Link is an abbreviation for "Control & Communication Link".)

• Device Net interface

4

Page 16

2. SETTING MODES

HOME

MODE

UP

Mode keys

Setting keys

HOME

HOME

Set value entry from

the ordinary display screen

UP

[Ordinary display screen]

[Mode selection screen]

[Set value selection screen]

[Set value entry screen]

With the NEXT key on the set value entry screen, the next set value entry screen appears.

2-1. F371 Screen Configuration

2.SETTING MODES

5

Page 17

2.SETTING MODES

ordinary display screen

Mode selection screen

OPERATION

PAGE1

Digital Filter (P32)

Analog Filter (P33)

Display Rate (P33)

Stability (Time) (P34)

Stability (Cnt) (P34)

PAGE2

Zero Track (Time) (P35)

Zero Track (Cnt) (P35)

Contrast1 (P36)

Contrast2 (P36)

Backlight (P36)

PAGE3

Ext Voltage (P36)

Auto Print (P37)

Hold Off Print (P39)

CAL. LOCK (P26)

PARA. LOCK (P39)

COMPARISON

PAGE1

HI_HI Limit (P41)

HI Limit (P41)

LO Limit (P41)

LO_LO Limit (P41)

Hysteresis (P42)

PAGE2

Near Zero (P44)

Comparison Func (P44)

Comparison Mode (P45)

Alarm Mode (P46)

HOLD

PAGE1

Hold Function (P47)

Hold Detect Time (P48)

Auto Start Level (P49)

Minimum Count (P51)

Valley Detect Lv1 (P51)

PAGE2

Minimum Slope (P53)

Interval A (P53)

Interval B (P53)

Hold Point Shift (P49)

Mean Value

Sampling Count (P55)

GRAPH

PAGE1

Graph Function (P75)

Interval Time (P75)

Graph Start Level (P75)

Level Detect Mode (P76)

X Start Point (P77)

PAGE2

Y Start Point (P78)

Y End Point (P78)

2-2. Setting Modes Tree

6

Page 18

2.SETTING MODES

CALIBRATION

PAGE1

Zero Cal. (P19)

Actual Cal. (P20)

Equiv. Cal. (P21)

CAL. Select (P27)

Increment (P24)

PAGE2

Unit (P29)

Decimal Place (P25)

Digital Offset (P23)

OPTION

A setting function changes

by the option.

SYSTEM

PAGE1

All Para. Clear (P109)

SelfCheck DSP (P107)

SelfCheck MEM (P107)

SelfCheck KEY (P108)

SelfCheck EXT (P108)

PAGE2

PASSWORD (P109)

LANGUAGE (P110)

BCD OUTPUT

PAGE1

BCD

Data Update Rate (P95)

BCD

Output Data Selection

(P95)

RS-232C

PAGE1

Communication Modes (P83)

Baud Rate (P83)

Character Length (P83)

Parity Bit (P84)

Stop Bit (P84)

PAGE2

Terminator (P84)

D/AOutput

PAGE1

D/A Output Mode (P103)

D/A Zero Output (P102)

D/A Zero and Full Scale

(P102)

Current Zero Output

(P102)

Current Zero and Full

(P102)

RS-485

PAGE1

Communication Modes(P83

)

Baud Rate (P83)

Character Length (P83)

Parity Bit (P84)

Stop Bits (P84)

PAGE2

Terminator (P84)

ID

(P100)

Terminator resistance

PAGE2

Voltage

Output Selection (P103)

Current

Output Selection (P103)

7

Page 19

2.SETTING MODES

Page 3

↑↑

Mode Page

→→

Setting call

Operation setting

Setting call

Can be changed

by the PAGE

・Operation setting ・Comparison setting

・Hold ・Communication setting

・Calibration ・Graph setting

・System ・Option

Modes are as follows:

Operation setting

button.

PAG E

PAGE

Page 1 Page 2 Page 3

PAG E

2-3. About a Setting Call

In this manual, a setting function call is described as follows.

Calibration Protection

This call can be made by the following procedure.

1)Press the MODE button on the ordinary display screen.

2)The mode setting screen appears. Select the mode.

3)The setting function setting screen appears. Select the function.

8

Page 20

3. CONNECTION

(

Black

)

(

White)

(

Green)

AC

IN

L

N

F. G.

CAUTION

Pay close attention to the wring in case of power on.

(

Red

)

(

Black)

DC IN

+

-

F. G.

CAUTION

Be aware that the voltage drops depending on the wire thickness

and length. Also, never input an AC power source. Doing so will

cause a failure.

3-1. Power Input Connection

AC spec.

Connect AC power code. The input voltage is 100V-240V AC.

3.CONNECTION

The frequency is 50/60Hz.

DC spec.(Depending on the request at the time of order)

Connect the positive (+) side of the power source to the red screw side of the terminal

block on the back of the F371, and its negative (-) side to the black screw side. The input

voltage is 12V-24V DC.

9

Page 21

3.CONNECTION

(+EXC)

(-EXC)

(+SIG)

(-SIG)

(F.G or )

+ IN

- OUT

- IN

+ OUT

A1

B2

A2

B1

F371

(+EXC)

(-EXC)

(+SIG)

(-SIG)

+IN

-OUT

-IN

+OUT

A1

B2

A2

B1

F371

(F.G or )

3-2. Load Cell Connection

・4-wire sensor

・6-wire sensor

Short-circuit +EXC with +S and -EXC with -S for connecting a 6-wire strain-gage

sensor.

10

Page 22

3-3. SI/F Connection

Converter

Display

Printer

SI/F

B10

B11

← Inside Outside →

F371

The 2-wire serial interface has connective ability for coupling a UNIPULSE printer,

external display, etc.

The interface is nonpolarized and up to three external instruments may be connected.

A two-core parallel cable or a cabtyre cable may be used for connection.

3.CONNECTION

11

Page 23

3.CONNECTION

COM1

Spark Killer

Load

F371 Inside

Spark Killer

DC

Var isto r

Load

AC

Relay

Vex t

A3

Supply an external power source for a relay drive

Output Data Tr

0 OFF

1 ON

● Output Transistor Status

power source (Vext).

Power

Supply

Power

Supply

COM2

Push

Switch

Toggle

Switch

Relay

+12V

TTL Open Collector

(ON when IN is HI)

F371 Inside

A6

IN

IN

Open → OFF

Short → ON

- The external element is required to withstand Ic=10mA.

- Leakage from the external element is required to be

100μA or below.

3-4. External I/O Connection

3-4-1. External Output Connection

The external output circuit is operated through an open collector. A3 COM1 is the

common terminal. The open collector output capacity is 30mA and the withstand voltage

is up to 30V.

・Equivalent circuit

3-4-2. External Input Connection

A signal is inputted to the signal input circuit by short-circuiting or opening the input

terminal and the COM2 terminal. Short-circuiting is effected by means of a contact (such

as a relay or a switch) or a noncontact (such as a transistor or an open-collector TTL).

12

Page 24

3-5. RS-232C Interface Connection

Insert

6

7

8

5

4

2

1

3

Metal case

Fit the metal cases into the Din connector,

and cap with the plastic covers.

Plastic cover

Wire connection surface

Side view

Secure with

hardware

Case

F. G

2

TxD

3

RxD

4

DTR

7

GND

GND

5

DTR

4

TxD

3

RxD

2

(CD)

1

(DSR)

6

CTS

8

RTS

7

F. G

TCP8080-01-520

F371

D-sub 9 pin

Personal computer

, etc.

Cabling diagram

CA371-232 (optional)

This connector connects the RS-232C.

Pin No. Signal name

1

2TxD

3RxD

4DTR

5

6

7GND

8

Case F.G.

3.CONNECTION

Example of cabling

The following shows an example of connection between DTE-DTE terminals. This will

require modification depending on the equipment to be connected. For details, see the

instruction manual of the equipment to be connected.

13

Page 25

3.CONNECTION

+

-

F.G o r

External

2

1

SIG

COM

VOL OUT

GND

← F371 inside outside →

equipment

3-6. Voltage Output Connection

The voltage output terminal is an interface to extract analog voltage proportional to

sensor signal inputs.

・ Since the VOL OUT terminal is not insulated from the internal circuit, use a shielded

cable for connection with the external equipment and wire within 2 - 3m.

・ Do not short-circuit. Doing so will cause a failure.

・ Do not apply voltage from the outside. Doing so will cause breakage.

14

Page 26

3-6-1. Connecting to Cage Clamp Terminal Block

5 - 6mm

CAUTION

・Cable can be from 24 to 14AWG (0.2 to 2.5mm2)

・ It is not necessary to solder the cable wires or to fix a solderless terminal.

・If several cables to be inserted to the same hole, twist those cable wires

together and insert.

・If you connect a cable (a load cell, SI/F, external input and output),

please turn off and be sure to perform the power supply of a main part.

The output terminal D/A option and RS-485 option is using the cage clamp system

terminal stand. Please connect in the following procedure.

1.Strip the casing 0.2inch (6mm) on the cable to be connected.

2.Twist the bare wire to fit the terminal hole.

3.Insert the supplied screwdriver into the upper hole and lift upward.

3.CONNECTION

4.Insert the twisted wires into the lower hole.

5.Make sure cable is clamped securely and does not come out with a slight tug.

15

Page 27

4.CALIBRATION

F371

Strain gauge sensor

Rated output value (mV/V)

+

Indicated value

A data sheet is attached to a strain-gage sensor at the time of purchase.

The data sheet provides data including:

capacity load (in kg, t, etc.)

rated output voltage (in mV/V)

non-linearity, hysteresis, input resistance, output resistance

and zero balance.

Enter the capacity and the rated output value required for equivalent

input calibration into the F371.

4. CALIBRATION

Calibration is performed for matching the F371 to a strain-gage sensor. The following

two types of calibration are available for the F371.

◇ Equivalent Input Calibration

Calibration is performed without an actual load by entering the rated output value (mV/

V) and the capacity (to be indicated) of the strain-gage sensor by the keys. Calibration is

easily performed when no actual load is available.

For example, the gain is automatically determined by entering:

2.001mV/V (rated output) - 100.0kg (capacity)

as indicated for a load.

16

Page 28

◇ Actual Load Calibration

Actual

Strain gauge sensor

Indicated value

F371

load

Protection Release

Increment

Input Calibration

Calibration Protection

Decimal Place

Digital Offset

4-9.

4-7.

4-8.

4-5.

4-6.

4-9.

Zero Calibration

4-3.

Value Selection

4-10.

Calibration

Equivalent

Calibration

Apply an actual load to the strain-gage sensor and enter the actual load value by the keys

for calibration. Calibration is accurately performed with reductions in errors.

4-1. Equivalent Input Calibration Procedure

Follow the steps below to perform equivalent input calibration.

4.CALIBRATION

Release the calibration protection.

Set the calibration value No.

(This step may be omitted for use with only one

selection.)

Enter the minimum value of digital increments.

(This step may be omitted if there is no change.)

Determine the decimal point place of the indicated value.

(This step may be omitted if there is no change.)

Set the zero point of the strain-gage sensor in no-load

condition (with the sensor unloaded).

Enter the rated output value and reading of the strain-gage

sensor.

The calibrated value can be offset in advance.

(This step may be omitted if there is no change.)

Turn on the calibration protection for preventing

misoperation.

17

Page 29

4.CALIBRATION

Protection Release

Increment

Load Calibration

Calibration Protection

Decimal Place

Digital Offset

4-9.

4-7.

4-8.

4-4.

4-6.

4-9.

Zero Calibration

4-3.

Value Selection

4-10.

Calibration

Actual

Calibration

4-2. Actual Load Calibration Procedure

Follow the steps below to perform actual load calibration.

Release the calibration protection.

Set the calibration value No.

(This step may be omitted for use with only one

selection.)

Enter the minimum value of digital increments.

(This step may be omitted if there is no change.)

Determine the decimal point place of the indicated value.

(This step may be omitted if there is no change.)

Enter the zero point of the strain-gage sensor with no load

applied to the sensor.

Enter the span (gain) point of the strain-gage sensor with a

load applied to the sensor.

The calibrated value can be offset in advance.

(This step may be omitted if there is no change.)

Turn on the calibration protection for preventing

misoperation.

18

Page 30

4-3. Zero Calibration

How to set

Setting call Page 1

→→

Calibration

Set the zero point in no-load condition.

1)Press the MODE button.

4.CALIBRATION

2)Press the CALIBRATION button.

3)Press the Zero Cal.button.

4)Press OK button after confirming no-load was applied to the sensor.

19

Page 31

4.CALIBRATION

How to set

Setting call Page 1

→→

Calibration

4-4. Actual Load Calibration

Set the actual load value under an actual load.

1)Press the MODE button.

2)Press the CALIBRATION button.

3)Press the Actual Cal. button.

4)Apply an actual load to the sensor, enter the actual load value by the numerical keys

and determine with the OK button.

20

Page 32

4-5. Equivalent Input Calibration

How to set

Setting call Page 1

→→

Calibration

Set the rated output value and reading of the sensor.

Rated output value: 0.000 - 3.000mV/V

Rated value: 00000 - 99999

1)Press the MODE button.

4.CALIBRATION

2)Press the CALIBRATION button.

3)Press the Equiv.Cal. button.

21

Page 33

4.CALIBRATION

4)Enter the rated output of the sensor by the numerical keys and determine with the OK

button. The decimal point is fixed.

5)Enter the rated value by the numerical keys and determine with the OK button.

22

Page 34

4-6. Digital Offset

How to set

- 99999 - 99999

Setting range:

Setting call Page 2

→→

Calibration

By using the digital offset function, the value obtained by subtracting the set value from

the indicated value is displayed.

This function is convenient when zero cannot be obtained with no load for some reason

or for offsetting.

(displayed value)=(actual indicated value)-(offset value)

1)Press the MODE button.

4.CALIBRATION

2)Press the CALIBRATION button.

3)Press the PAGE button to select the page and press the Digital Offset button.

4)Enter the digital offset value by the numerical keys and determine with the OK button.

23

Page 35

4.CALIBRATION

How to set

Setting call Page 1

→→

Calibration

4-7. Increment (This step may be omitted if there is no change.)

Set the increment of the indicated value.

Input range: 001 - 100

1)Press the MODE button.

2)Press the CALIBRATION button.

3)Press the INCREMENT button.

4)Enter the increment by the numerical keys and determine with the OK button.

24

Page 36

4-8. Decimal Place

How to set

Setting call Page 2

→→

Calibration

①

①

②

Set the decimal point place of the indicated value. Selection can be made from

the following.

1)Press the MODE button.

4.CALIBRATION

0, 0.0, 0.00, 0.000, 0.0000

2)Press the CALIBRATION button.

3)Press the PAGE button to select the page and press the DECIMAL PLACE button.

4)Select the decimal place and determine with the OK button.

25

Page 37

4.CALIBRATION

How to set

Setting call Page 3

→→

Calibration

4-9. Calibration Protection

Calibration-related set values can be protected so that they will not be changed

by misoperation. When Cal. Protect is ON, no change can be made while the

alarm sounds.

ON: Protected

OFF: Unprotected

1)Press the MODE button.

2)Press the CALIBRATION button.

3)Press the PAGE button to select the page twice and Press the CAL Lock button.

4)Select the decimal place and determine with the OK button.

26

Page 38

4-10. Calibration Value Selection

How to set

Setting call Page 1

→→

Calibration

By storing up to four calibration values in the memory, the desired calibration value can

be called to switch the indicated value. Setting values that can be switched are as

follows:

Calibration Mode Setting Operation Mode Setting

Zero Calibration Excitation Voltage

Actual Load Calibration

Equivalent Input Calibration

Minimum Slope

Unit

Decimal Place

Digital Offset

4.CALIBRATION

When “Ext Input” is selected, the calibration value can be selected through external

selector signal CAL0 and CAL1.

1)Press the MODE button.

2)Press the CALIBRATION button.

27

Page 39

4.CALIBRATION

B7 COM2

B11 CAL0

B12 CAL1

NOTE

It takes one second at maximum for

the changed calibration value to

become effective. During this time,

the calibration value is indefinable.

Also, the indicated value is

accordingly indefinable.

I/O connector

3)Press the CAL. SELECT button.

4)Select the calibration value from 0 - 3 and determine with the OK button.

4-10-1. External Selection of Calibration Value

With this function, four types of calibration values can be selected with external selector

signals CAL0 and CAL1 (when the calibration value selection setting is external).

Normally, when there is no input to CAL0 and CAL1 (the terminals are open),

calibration value 0 is selected. When each terminal is in the following condition, each

calibration value is selected.

CAL1 CAL0 Calibration value

Open Open alibration value 0

Open Short-circuit alibration value 1

Short-circuit Open alibration value 2

Short-circuit Short-circuit alibration value 3

28

Page 40

4-11. Unit

4.CALIBRATION

Set the unit of the load to be displayed. It can be selected from the following.

Category Unit

Mass

Force

Pressure

Density

Momentum

Viscosity

Length

Speed

Flow rate

kg,Mg,g,mg,μg,t,lb,

dyne,kdyne,oz,TONNE,%

N,kN,MN,mN,μN,Nm,kNm,

MNm,mNm,μNm,

ftlb,inlb,inoz,kgm,gcm

Pa,kPa,MPa,GPa,hPa,mPa,μPa,

bar,mbar,μbar,mmHg,N/m

ftH

2O,inH2O,psia,psig,atm

3

,g/cm3,t/m3,g/ml,g/l,kg/m,mg/m

kg/m

kgm/s,kgm

2

/s,kgm

2

2

,

PaS,mPaS

km,m,cm,mm,μm

m/s,km/h,m/s

2

,rpm

kg/h,kg/min,kg/s,t/h,t/s,t/min,

3

m

/h,m3/min,m3/s,l/h,l/min,l/s

29

Page 41

4.CALIBRATION

How to set

Setting call Page 2

→→

Calibration

Scroll with the and buttons.

Scroll with the and buttons.

* A change of unit does not affect the indicated value (calibration value)

.

1)Press the MODE button.

2)Press the CALIBRATION button.

3)Press the PAGE button to select the page and press the UNIT button.

4)Select the category and determine with the OK button.

5)Select the unit and determine with the OK button.

30

Page 42

5. SETTING OF FUNCTIONS

OK

Cancel

5-1. Digital Zero

The indicated values is forcedly zeroed.

Digital Zero by means of Keys

1)Press the DZ button.

5.SETTING OF FUNCTIONS

2)Press ‘OK’ to perform the digital zero. Press ‘Cancel’ to cancel the digital zero.

31

Page 43

5.SETTING OF FUNCTIONS

How to set

D/Z

OFF

ON

Keep on for 1.0 msec. or more.

Note

Digital zero is reseted in case of power failure. Please set digital zero

again.

Setting call Page 1

→

→

Operation Setting

* See the section on About a

Setting Call page 8 .

Scroll button

Digital Zero by means of Keys

The digital zero may be performed by short circuiting the D/Z to the COM2 on the rear

panel signal I/O terminal block.

5-2. Digital Filter

The digital filter is a function for reducing drifts of the indicated value by means of a

moving average of data converted from analog to digital. The number of the moving

averages can be selected a range between 0 and 512.

With an increase in the number of filterings, the indicated value becomes more stable,

but the response to inputs becomes slower.

The value of a digital filter is scrolled with a button.

Number of settings:OFF, 2, 4, 8, 16, 32, 64, 128, 256, 512

32

Page 44

5-3. Analog Filter

How to set

How to set

Setting call Page 1

→

→

Operation Setting

Setting call Page 1

→

→

Operation Setting

A low-pass filter is provided for filtering input signals from the strain-gage sensor and

canceling noise components.

The cut-off frequency can be selected in a range between 10Hz and 300Hz. With an

increase in the cut-off frequency, the response becomes faster, but noise components

may be indicated.

5.SETTING OF FUNCTIONS

Cut-off frequency: 10Hz, 30Hz, 100Hz, 300Hz

5-4. Display Rate

Enter the rate of rewriting the display.

The display rate can be selected in a range between 1 and 10 times/sec. The internal

operation speed does not change.

33

Page 45

5.SETTING OF FUNCTIONS

How to set

Set

Indicated Value

50msec

Time

Set Period

range

Setting call Page 1

→

→

Operation Setting

CAUTION

When the time is 0.0 sec. and the width is 00 markings, stability is not

detected. At this time, the stable-time digital filter is normally off.

Turning on/off the near zero function is closely related to the auto print

function and HI-LO limit comparison mode.

For details, see the sections on Auto Print page 37 and HI-LO Limit

Comparison Mode page 44 .

5-5. Stability

Enter the parameters to detect stability.

If the difference between the current indicated value and the 50-msec-previously

indicated value is less than the set count and the duration of the condition is more than

the set time, the indicated value is regarded to be stable.

When stability is detected, a digital filter (fixed 32 times) to control instability in weight

value is automatically inserted. This stable-time digital filter differs from the digital filter

setting in the operation mode.

Setting range

- MD (time): 0.1 - 9.9 sec.

- MD (width): 01 - 99

34

Page 46

5-6. Zero Track

How to set

・When displacement of the zero point is within the set count of tracking

and it continues more than the set time, it is automatically made zero by

Zero Tracking function.

・The time (tracking delay) is set in the range of 0.1 - 9.9 sec., and the

band (tracking band) is set in the range of 01 to 99.

If the time is set at 0.0 sec. and the band at 00, the zero tracking function

does not work.

Boundary of zero track

DELAY

Indicated value

+COUNT

-COUNT

BAND

+

0

-

DELAY

Band=count × 2

From the point when it returned within the range,

counting will be resumed.

CAUTION

Since the zero track function works from the calibrated zero point of the

indicated value, it does not work if the indicated value is beyond the

track band. In such a case, obtain the zero point again by zero

calibration.

Setting call Page 1

→

→

Operation Setting

Gradual changes in the zero point due to drifts etc., are automatically tracked for

correction.

5.SETTING OF FUNCTIONS

Setting range

ZT (time): 0.0 - 9.9 sec.

ZT (width): 00 - 99

35

Page 47

5.SETTING OF FUNCTIONS

How to set

How to set

How to set

Setting call Page 2

→

→

Operation Setting

Setting call Page 2

→

→

Operation Setting

Setting call Page 3

→

→

Operation Setting

5-7. Contrast Adjustment

Adjust the contrast of the touch panel display.

Brightness can be adjusted by CONTRAST1.

Screen flickering can be adjusted by CONTRAST2.

5-8. Backlight

The backlight is turned off if no button operation is performed for the set time (minutes).

The backlight is turned on by touching the panel. Setting 00 disables this function.

Setting range: 00 - 99 min.

5-9. Excitation Voltage

Select the bridge voltage to be supplied to the strain-gage sensor.

The bridge voltage is selectable from 10V, 5V and 2.5V.

Be sure to perform calibration after changing this setting.

36

Page 48

5-10. Auto Print

How to set

Setting call Page 3

→→

Calibration

Indicated Value

Near Zero

0

Stable

Near Zero

ON

ON

ON

ON

OFF

OFF

OFF

Autmatic

↑

Hold

1.5Seconds

Time

ON

Hold function……

・Indicatid Value

・SI/F

・Compariosn

+

Sensor input value

Output signal

Printing

The indicated value is automatically printed to the UNIPULSE printer coupled with the

F371 through the SI/F. A print is made when the indicated value is stable. (Set the

stability parameters by the stability operation.)

When Near Zero is OFF, Indicated value is held until Near Zero turns ON after Stability

turned ON.

(Hold will be released when 1.5 sec. is passed after Near Zero is ON.)

・Operation of the indicated value hold function

5.SETTING OF FUNCTIONS

37

Page 49

5.SETTING OF FUNCTIONS

Near Zero

0

Time

Stable

Near Zero

ON

ON

ON

ON

OFF

OFF

OFF

Autmatic

↑

Hold

1.5Seconds

ON

-

Indicated

Sensor input value

Printing

Va l ue

Auto Print is not performed under the following conditions.

・Motion Detect

Time: 0.0 sec. Width: 0.0 of divisions is set.

・Print while hold is released.

When Print is set.

・Hold Mode

When any items except Tracking is selected.

38

Page 50

5-11. Hold Off Print

How to set

How to set

Setting call Page 3

→→

Calibration

Setting call Page 3

→→

Calibration

For the parameters which are protected by parameter protection,

see the section on SETTING ITEM CHART page 119.

At hold-off time, the held value is automatically printed to the UNIPULSE printer

coupled with the F371 through the SI/F.

(The hold is released by the T/H signal off timing when the period setting is all interval

in various hold modes by hold functions, and by the T/H signal of timing when other

periods are set.)

5-12. Parameter Protection

5.SETTING OF FUNCTIONS

Parameters are protected from being changed by misoperation.

39

Page 51

6.COMPARISON FUNCTIONS

Time

Indicated value

HI Limit

LO Limit

HI

LO

OFF

ON

OFF

ON

HI-HI Limit

LL Limit

OFF

ON

OFF

ON

HH

LL

OFF

ON

OK

Va lu e

Va lu e

Va lu e

Va lu e

6. COMPARISON FUNCTIONS

By the comparison function, the HI limit and LO limit values are set, and when the

indicated value exceeds the HI limit, the HI output is turned on, and when the indicated

value falls below the LO limit, the LO output is turned on. Also, HI-HI limit and LO-LO

limit values may be set outside the HI-LO limit comparison. When the indicated value

exceeds the HI-HI limit, the HH output is turned on, and when the indicated value falls

below the LO-LO limit, the LL output is turned on. When the HI, HH, LO and LL

outputs are all off, the OK output is turned on.

<HI/LO output conditions>

HI: indicated value > HI limit value

LO: indicated value < LO limit value

<HH/LL output conditions>

HH: indicated value > HI-HI limit value

LL: indicated value < LO-LO limit value

<OK output conditions>

OK: All conditions of HH, HI, LO and LL are off.

40

Page 52

6-1. HI Limit/LO Limit/HI-HI Limit/LO-LO Limit

How to set

Setting call Page 1

→→

Comparison setting

Press any of the HI-HI, HI, LO and LO-LO buttons at the bottom of the indicated

value display screen to go direct to the entry screen.

Simple setting call

6.COMPARISON FUNCTIONS

About the indicated value display color

The display color can be changed by pressing the indicated value display section. Every

time it is pressed, State 1 and State 2 are changed.

・State 1

The indicated value display color is fixed (yellow).

・State 2

The indicated value display color changes following the comparison status.

OK: green

HI, LO: yellow

HH, LL: red

41

Page 53

6.COMPARISON FUNCTIONS

6-2. Hysteresis

The hysteresis value may be determined so as to allow a margin for timing the turning off

of the HI-LO limit comparison. Normally, it is turned on when the indicated value

exceeds the HI limit and is turned off when the indicated value falls below it. However,

by setting the hysteresis, it is turned off when the indicated value falls below the HI limit

further lowered by the hysteresis value.

This function is effective to prevent chattering in such a case where signals fluctuate

(vibrate) subtly.

〈Comparison conditions〉

- HI limit

ON condition: indicated value>HI limit value

OFF condition: indicated value<=(HI limit value-hysteresis value)

- LO limit

ON condition: indicated value<LO limit value

OFF condition: indicated value>=(LO limit value+hysteresis value)

- HI-HI limit

ON condition: indicated value>HI-HI limit value

OFF condition: indicated value<=(HI-HI limit value-hysteresis value)

- LO-LO limit

ON condition: indicated value<LO-LO limit value

OFF condition: indicated value>=(LO-LO limit value+hysteresis value)

42

Page 54

・ Hysteresis operation

How to set

HI Limit

LO Limit

+

0

Hysteresis Range

Time

HI Output

HI Status Display

LO Output

LO Status Display

OK Status Display

Output ON

Status ON

Output OFF

Status OFF

Status ON Status ON

Output ON

Status ON

Output ON

Status ON

-

Output OFF

Status OFF

Output OFF

Status OFF

Indicated Value

OK Output

(Exsample : HI Output and LO Output and OK output)

Value

Value

Setting call Page 1

→→

Comparison setting

Hysteresis setting value is common to all HI limit value.

6.COMPARISON FUNCTIONS

43

Page 55

6.COMPARISON FUNCTIONS

How to set

How to set

Turning on/off the near zero function is closely related to the auto print

function and HI-LO limit comparison.

For details, see the sections on HI-LO Limit Comparison Mode page 44

and Auto Print page 37 .

Setting call Page 2

→→

Comparison setting

Setting call Page 2

→→

Comparison setting

6-3. Near Zero

By this function, it is detected that the indicated value is near zero.

Near-zero ON:| indicated value | <=near zero set value

Near-zero OFF:| indicated value | > near zero set value

Setting range: 00000 - 99999

6-4. HI-LO Limit Comparison Mode

Set the operating condition of HI-LO limit comparison. Select the condition from the

following.

Continuous :HI-LO limit comparison is performed continuously.

MD :HI-LO limit comparison is performed when the indicated value is

stable. Set the stability parameters by the stability operation.

NZ :HI-LO limit comparison is performed when the indicated value is

not near zero.

Set the near zero parameters by the near zero operation.

MD+NZ :HI-LO limit comparison is performed when the indicated value is

stable and not near zero.

44

Page 56

6-5. HI-LO Limit Output Mode

How to set

The HI limit output is turned on when the indicated value becomes

larger than the set value.

The LO limit output is turned on when the indicated value becomes

smaller than the set value.

COUTION

Even if any mode other than MODE 2 is selected, the name of

each setting does not change. Only the operation differs.

Setting call Page 2

→→

Comparison setting

The number of HI-LO limits can be changed..

Mode HI Limit Operation LO Limit Operation

6.COMPARISON FUNCTIONS

Mode 0

Mode 1

Mode 2

Mode 3 HI-HI Limit

Mode 4 None

HI-HI Limit,HI Limit,

LO Limit,LO-LO Limit

HI-HI Limit,HI Limit,

LO Limit

HI-HI Limit,HI Limit LO Limit,LO-LO Limit

None

LO-LO Limit

HI Limit,LO Limit,

LO-LO Limit

HI-HI Limit,HI Limit,

LO Limit,LO-LO Limit

45

Page 57

6.COMPARISON FUNCTIONS

How to set

Hold values

HI-HI Limit (HH)

HI Limit (HI)

Real-time values

HH

HI

OFF

ON

OFF

HH

HI

OFF

Alarm mode unavailable

Alarm mode available

When the comparison output mode is “mode 0: HI limit operation for

all of HI-HI limit/HI limit/LO limit/ LO-LO limit”, the alarm mode

operation can only be performed with the HI-HI limit.

In a like manner, when the mode is “mode 4: LO limit operation for all

of HI-HI limit/HI limit/LO limit/LO-LO limit”, the alarm mode operation

can only be performed with the low-low limit.

Setting call Page 2

→→

Comparison setting

6-6. Alarm Mode

The comparison target of the HI-HI limit and LO-LO limit set values can be changed

from “hold value” to “real-time value”. By this function, whether or not the indicated

value becomes abnormal during hold can be monitored.

Unavailable : Comparison operation is performed with hold values.

Available : Comparison operation is performed with real-time values.

46

Page 58

7. HOLD FUNCTIONS

How to set

Setting call Page 1

→

→

Hold

By the hold function including sample hold, peak hold, valley hold, peak-to-peak hold,

relative maximum and minimum hold and inflection point hold, a specific point in a

waveform is taken out for HI-LO limit comparison.

The operation of each hold will be described in detail.

7-1. Hold Setting --- common ---

7-1-1. Hold Mode

The F371 includes nine hold modes as shown in the table below.

In the peak, valley, peak-to-peak and mean value modes, period setting is required.

7.HOLD FUNCTIONS

Select all period, external signal, time, or time with trigger.

If you do not use any hold function, be sure to set the hold mode to tracking. (In tracking

condition, hold operation is not performed but input values are always displayed.)

HOLD MODE HOLD PERIOD SETTING

Tracking None

Sample None

Peak

Valley

P-P

Relative maximum

Relative minimum

Inflection Point

Mean value Required

Required

None

There is a section setup.

・ All Period

・ External Signal

・ Time

・ Time with trigger

47

Page 59

7.HOLD FUNCTIONS

How to set

Press the MODE button at the bottom of the indicated value display screen

to go direct to the hold mode entry screen.

Simple setting call

Setting call Page 1

→

→

Hold

Press the TIME button at the bottom of the indicated value display screen

to go direct to the hold detection time entry screen.

Simple setting call

7-1-2. Hold Detection Time

If you set the hold period setting in the hold function setting to Time or Time with

Trigger, set the time.

Setting range: 0.001 - 9.999 sec.

48

Page 60

7-1-3. Auto Start Level

How to set

How to set

Setting call Page 1

→

→

Hold

In each hold mode of relative maximum/relative minimum/inflection

point, if the auto start level is set at 99999, the hold operation starts

only with the period signal H/M without performing level detection.

The actual hold point

t

w

When the hold point shift is set at 8,

the data eight pieces before

the actual hold point is held.

Caution

・This does not work for other holds.

・The retroactive sampling data is held irrespective of the hold

period. If the set numerical value is too large, point(s) out of the

period may be held.

Setting call Page 2

→

→

Hold

If you select the time specified period mode with trigger, or relative maximum, relative

minimum or inflection point hold in the hold mode setting, set the start level.

Setting range: -99999 - 99999

7.HOLD FUNCTIONS

7-1-4. Hold Point Shift

In the “sample hold” and “inflection point hold”, the sampling data is held retroactively

by the numerical value set under hold point shift.

Setting range: -99999 - 99999

49

Page 61

7.HOLD FUNCTIONS

A

B

O

P

Q

2X

X

1.5X 3X

True relative maximum

True relative minimum

Relative

A

X

B

minimum

Relative

maximum

7-2. Hold Setting --- relative maximum and relative minimum ---

If you select the relative maximum and relative minimum hold in the hold function

setting, set the relative maximum and relative minimum value detection parameters

"minimum count" and "valley detection level".

Set referring to the principle of operation only when the value cannot be held

successfully with the factory settings or when further adjustments are required.

Detection of the relative maximum value and relative minimum value

The logic of detecting the relative maximum value and relative minimum value is given

below.

First, when difference X between point

A and point B is larger than the

minimum count, point A is judged to be

the relative maximum value and point B

is judged to be the relative minimum

value.

When difference X between detected

relative maximum value A and relative

minimum value B exceeds the

predetermined detection levels (1.5, 2,

and 3 times), A is displayed in the rela-

tive maximum value hold mode at

respective points O, P and Q and the

value is held.

If the minimum count is too small, when

50

the waveform includes noise as shown

on the left-hand side, the noise is

regarded as the relative maximum value

or relative minimum value and a correct

value may not be held. In such a case,

set the minimum count somewhat large.

Page 62

7-2-1. Minimum Count

How to set

How to set

Setting call Page 1

→

→

Hold

Setting call Page 1

→

→

Hold

Setting range: 0001 - 9999

7-2-2. Valley Detection Level

Level: 1/4, 1/2, 3/4, 1, 1.25, 1.5, 2, 3 times

7.HOLD FUNCTIONS

51

Page 63

7.HOLD FUNCTIONS

D

C

C

AB

a

Input Signal

A : IntervalA

B : IntervalB

D : The amount of change

Inflection point

Held as an inflection point if

D > inflection judgment value.

7-3. Hold Setting --- inflection point ---

If you select the inflection point hold in the hold function setting, set the inflection point

detection parameters "minimum slope", "interval A" and "interval B".

Set referring to the principle of operation only when the value cannot be held

successfully with the factory settings or when further adjustments are required.

Detection of the inflection point

The logic of detecting the inflection point is given below.

Assuming that the remainder obtained by subtracting the amount of change C of the

indicated value over interval A from the amount of change of the indicated value over

interval B is D, when the amount of change D exceeds the inflection point judgment

value, point a is held as an inflection point.

If there are two or more inflection points in the hold period, the point having a larger

change is held.

The inflection point is normally detected by A=B, but it may easily be detected with

A<B where the slope is gradual.

52

Page 64

7-3-1. Minimum Slope

How to set

How to set

Setting call Page 2

→

→

Hold

Setting call Page 2

→

→

Hold

The interval setting is the number of samplings. Since the F371's

sampling speed is 2000 times/sec., one sampling is 0.5msec.

Therefore, setting of the interval at 100 means setting of 50msec.

Load change time

True inflection

point

Inflection

point

Setting range: 00001 - 99999

7-3-2. Interval A and Interval B

Setting range:

- Interval A+Interval B ≦ 1000

- 10 ≦ Interval A(B) ≦ 990

7.HOLD FUNCTIONS

Caution regarding inflection point hold

If the detection interval A and B are set

too short, fine load changes may be

detected as shown in the illustration on

the left-hand side, so that a correct value

cannot be held.

In this case, set the detection interval B

large enough to bring it as close to the

load change time as possible, and also

set the inflection point judgment value

large according to the amount of change

at that time, so that the inflection point

is held at a correct position.

53

Page 65

7.HOLD FUNCTIONS

100

20

10

0

100msecA100msec

B

D = 80

C = 10

①

②

Example of inflection point hold setting

● Example of ideal waveform setting

① Set the load change time (between the inflection point and when the change stops) to

interval B.

In the example, it is set to 200 since it is 100 msec.

② Set the same value as interval B to interval A.

③ Set load D obtained by subtracting load C changing with interval A from the load

changing with interval B to the inflection point judgment value.

In the example, set load change D=80 obtained by subtracting load C=10 changing

with A from load 90 changing with B to the inflection point judgment value.

However, since an inflection point is not judged until load change D exceeds the

inflection point judgment value, actually set the inflection point judgment value a

slightly smaller than D.

● If the inflection point cannot be located successfully

① When holding above the inflection point and

moving downward

1) It is considered that the inflection point

judgment value is small with respect to load

change D. Set the inflection point judgment

value larger.

2) If lowering is insufficient in 1), increase

interval A.

54

② When holding below the inflection point and

moving upward Interval B is too long and the

inflection point judgment value is too large.

Shorten interval B and decrease the inflection

point judgment value.

Page 66

7-4. Hold Setting --- mean value ---

How to set

Setting call Page 2

→

→

Hold

About the maximum mean value detection time

Although the detection period is specified by the H/M signal, etc.,

detection cannot be carried out exceeding the maximum mean value

detection time set according to the mean value sampling count. If the

maximum mean value detection time is exceeded, detection ends

automatically, when the mean value is held.

7-4-1. Mean Value Sampling Count

If the mean value sampling count is set at 2 or more in the mean value hold, the

representative value of the sampling values by the set count (mean value by the count) is

adopted as the sampling data used for mean value calculation.

The maximum mean value detection time with the setting “1” is 5 sec., but the mean

value detection time can be extended by this setting.

Maximum mean value detection time

= Mean value sampling count × 5 [sec.],

where the number of updates of the mean value will decrease.

7.HOLD FUNCTIONS

Number of updates of the mean value

= 2000 / Mean value sampling count [times/sec.]

Setting range: 1 - 999Times

55

Page 67

7.HOLD FUNCTIONS

Indicated Value

t2

t3

t1

Sensor Input Value

Detection・Hold Period

Decide

t

+

T/H

HI-LO Limit

Judging Output

H/E

OFF

ON

OFF

ON

OFF

ON

HOLD

OFF

ON

Button

HOLD

Status Display

Status Display

ONBlink Blink

OFF

PEAK

7-5. Hold Operation

7-5-1. Sample Hold

When the T/H signal is inputted, a desired point is held, and the H/E output is turned on.

Hold of the value continues as long as the T/H signal is on.

t1: A delay time between the instant when the T/H signal is inputted and the instant

t2:A delay time between the instant when the T/H signal is released and the instant

t3:A minimum reset signal width required for releasing the hold

when the indicated value is held

1.0ms (max.)

when the indicated value returns to tracking

1.0ms (max.)

1.0ms (min.)

56

Page 68

7-5-2. Peak Hold

Indicated Value

t2

t3

Sensor Input Value

Detection

t

+

T/H

HI-LO Limit

Judging Output

H/E

Detection

t1t2t1

t3

Note: During the undetermined period, the judging output varies with

fluctuations in the input waveform. However, the H/E output

remains on during the undetermined period. Read the judging

result when the indicated value becomes stable (immediately

before the T/H signal rises).

OFF

ON

OFF

ON

OFF

ON

OFF

ON

Status Display

PEAK

Status Display

ON

Blink Blink

OFF ON

OFF

OFF

OFF

OFF

OFF

HOLD

Button

Undetermind

Period(Note)

Undetermind

Period(Note)

Hold Period

Hold Period

HOLD

The maximum value (peak) in the positive direction of the specified period is held.

The period is specified by the setting of “all period”, “external signal”, “time”, or “time

with trigger”.

7.HOLD FUNCTIONS

(Example) All Period Peak Hold

t1: A delay time between the instant when the T/H signal is inputted and the instant

when the indicated value is held

1.0ms (max.)

t2: A delay time between the instant when the T/H signal is released and the instant

t3:A minimum reset signal width required for releasing the hold

when the indicated value returns to tracking

1.0ms (max.)

1.0ms (min.)

57

Page 69

7.HOLD FUNCTIONS

Indicated Value

t2

t3

Sensor Input Value

Detection

t

+

T/H

HI-LO Limit

Judging Output

H/E

Detection・Hold Period

t1t2t1

t3

Note: During the undetermined period, the judging output varies with

fluctuations in the input waveform. However, the H/E output

remains on during the undetermined period. Read the judging

result when the indicated value becomes stable (immediately

before the T/H signal rises).

OFF

ON

OFF

ON

OFF

ON

OFF

ON

HOLD

Status Display

PEAK

Status Display

ON

Blink Blink

OFF ON

OFF

OFF

OFF

OFF

OFF

HOLD

Button

Undetermind

Period(Note)

Undetermind

Period(Note)

Hold Period

7-5-3. Valley Hold

The maximum value (valley) in the negative direction of the specified period is held.

The period is specified by the setting of “all period”, “external signal”, “time”, or “time

with trigger”.

(Example) All Period Valley Hold

t1: A delay time between the instant when the T/H signal is inputted and the instant

when the indicated value is held

1.0ms (max.)

58

t2: A delay time between the instant when the T/H signal is released and the instant

when the indicated value returns to tracking

1.0ms (max.)

t3:A minimum reset signal width required for releasing the hold

1.0ms (min.)

Page 70

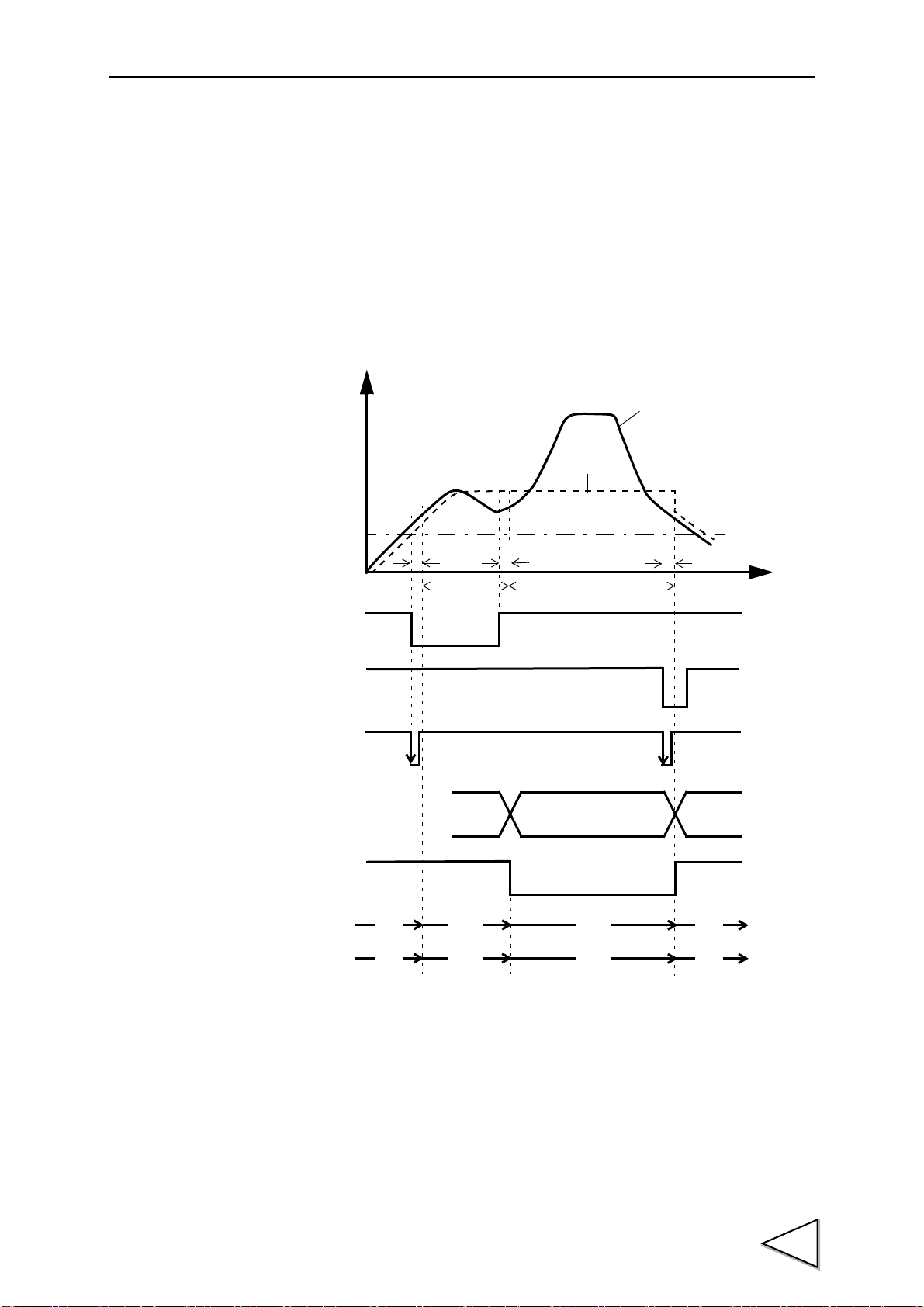

7-5-4. Peak-to-Peak (P-P) Hold

Indicated Value

Sensor Input Value

Detection・Hold Period

Undetermind

t

+

T/H

HI-LO Limit

Judging Output

H/E

t2

t1

t3

Standard Line

(Hold Section Only)

Indicated Value = 0

Indicated Value=0

OFF

ON

OFF

ON

OFF

ON

HOLD

OFF

ON

Button

HOLD

Status Display

PEAK

Status Display

ON

Blink

OFF

OFF

OFF

OFF

Period(Note)

Note: During the undetermined period, the judging output varies with fluctuations in the

input waveform. However, the H/E output remains on during the undetermined

period. Read the judging result when the indicated value becomes stable

(immediately before the T/H signal rises).

The maximum value of the difference between the peak and valley over the specified

period is held.

The period is specified by the setting of “all period”, “external signal”, “time”, or “time

with trigger”.

(Example) All Period Peak-to-Peak (P-P) Hold

7.HOLD FUNCTIONS

t1: A delay time between the instant when the T/H signal is inputted and the instant

when the indicated value is held

1.0ms (max.)

t2: A delay time between the instant when the T/H signal is released and the instant

when the indicated value returns to tracking

1.0ms (max.)

t3:A minimum reset signal width required for releasing the hold

1.0ms (min.)

59

Page 71

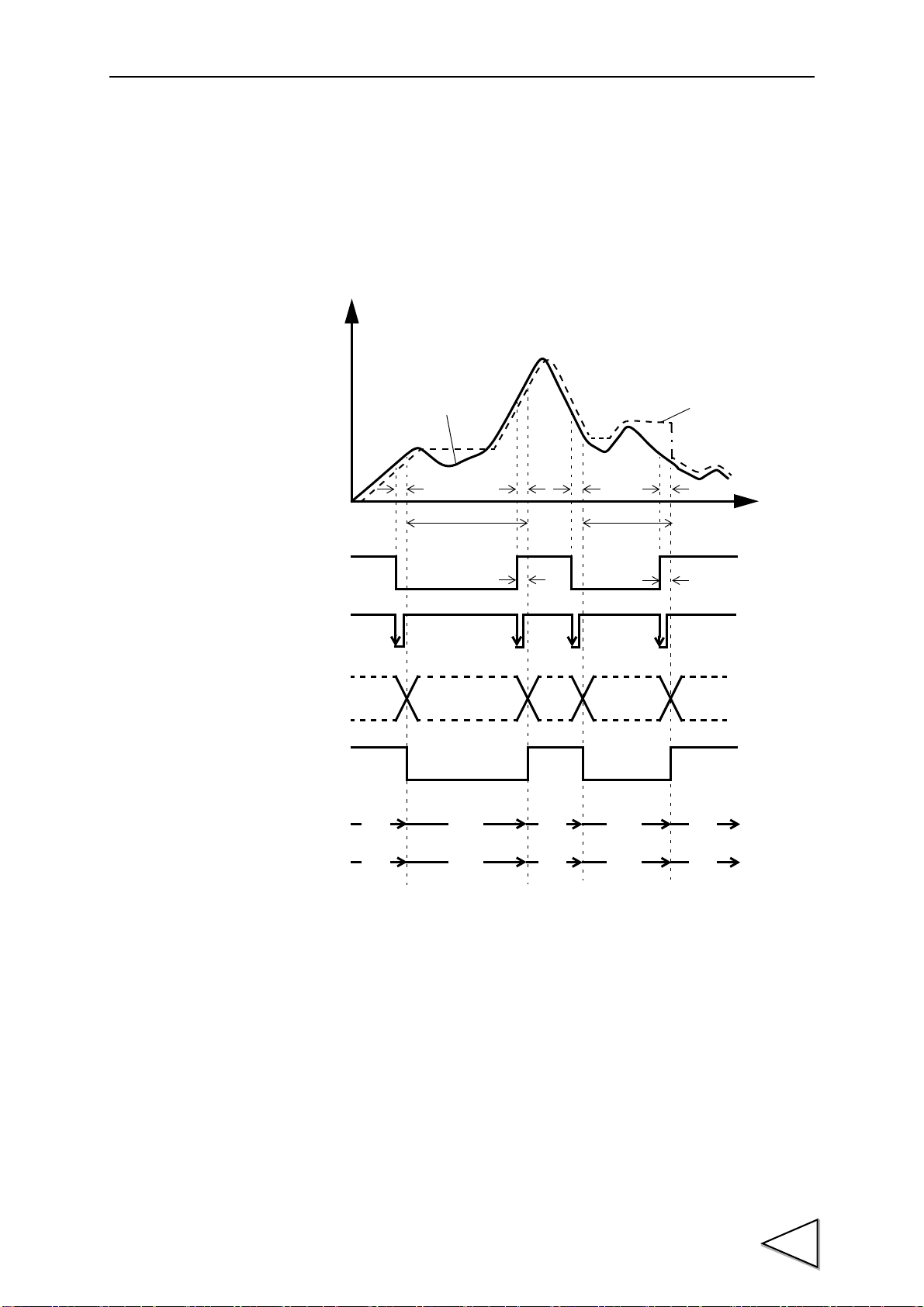

7.HOLD FUNCTIONS

Indicated Value

t3

Sensor Input Value

Detection

t

+

HI-LO Limit

Judging Output

Hold Period

Decide