F350

OPERATION MANUAL

01MAR2015REV.1.04

Introduction

Applications

Introduction

Introduction

Thank you very much for purchasing our Digital Indicator F350.

The F350 is an indicator for various strain gauge sensors that measure pressure, load, torque, etc. Equipped

with ultrahigh-speed peek hold and HI/LO limit comparison functions, the F350 is for general purpose use,

such as an automatic assembly machine and testing machine.

To take full advantage of high performance of F350, thoroughly read this operating manual first before use

and understand the explanations contained herein for correct operating procedures.Also, carefully store

this instruction manual so that it can be referred to at any time.

I

I

Safety Precautions

WARNING

CAUTION

This sign forewarns the presence of hazards

that could result in serious injury or fatality

when incorrectly handled.

Warning on design

Safety Precautions

Safety Precautions

BE SURE TO READ FOR SAFETY

Installation, maintenance and inspection of the F350 should be performed by personnel having technical

knowledge of electricity.

In order to have an F350 Weighing Controller used safely, notes I would like you to surely follow divide

into " " and " ", and are indicated by the following documents.

Notes indicated here are the serious contents related to safely.

Please use F350 after understanding the contents well.

This sign forewarns the presence of hazards that could result in serious injury

or fatality when incorrectly handled.

WARNING

CAUTION

This sign forewarns the presence of hazards that could result in personnel

injury or property damage when incorrectly handled.

WARNING

● For the entire system to function safely when the F350 becomes faulty or malfunctions,

provide a safety circuit outside the F350.

● Since the F350 has no power switch, install a breaker.

● Before using the F350 as described below, make sure to consult with our sales personnel.

- Use in environments not described in the operation manual.

- Use greatly impacting human lives and assets, such as medical devices, transport devices

entertainment devices, and safety devices.

II

II

WARNING

This sign forewarns the presence of hazards

that could result in serious injury or fatality

when incorrectly handled.

Warning on installation

Warning on wiring

Warning during startup and maintenance

● Do not disassemble, repair, or modify the F350. Doing so may cause a fire or an electric

● Do not install in the following environments.

● Do not connect a commercial power source directly to the signal input/output terminals.

● Be sure to ground the protective ground terminal.

● The attached AC cable is designed for domestic use in Japan, and its rating is 125V AC,

WARNING

WARNING

shock.

- Places containing corrosive gas or flammable gas.

- Where the product may be splashed with water, oil or chemicals.

10A. For use at voltages exceeding the rating and for overseas use, have a separate AC

cable prepared.

● Before performing the following, make sure that no power is applied.

- Removal and installation of optional connectors and so forth;

- Wiring and connection of cables to a power input terminal;

- Wiring and connection of cables to a signal I/O terminal;

- Connection to protective grounding terminals.

● For connection to the signal input/output terminals, check the signal names and pin

assignment numbers, and then carry out wiring properly.

● After wiring, be sure to mount the attached terminal block cover. Otherwise, it may cause an

electric shock.

● To take measures against lightning surge, install a lightning surge protector (optionally

available).

● Do not connect anything to unused terminal(s).

● Before applying power, carefully check the wiring, etc.

● Use a power supply voltage and load within the specified and rated ranges.

● Do not damage the power cord. Doing so may cause fire or electric shocks.

● Do not touch any signal input/output terminal while applying power. Doing so may cause

electric shocks or malfunctions.

● If the cover of the main body is opened, it may cause an electric shock internally. Even if the

power is off, the internal capacitor is charged. Contact us for internal inspection or repair.

● In the case of smoke, an abnormal smell or strange sound, immediately turn off the power,

and disconnect the power cable.

III

III

CAUTION

This sign forewarns the presence of hazards

that could result in personnel injury or property

damage when incorrectly handled.

Caution on installation

Caution on wiring

Caution during startup and maintenance

CAUTION

CAUTION

● Use the F350 as it is incorporated in a control panel, etc.

● Do not install in the following environments.

- Locations where temperature or humidity exceeds specifications;

- Locations subjected to drastic temperature fluctuations or icing and condensing;

- Outdoors or locations above 2,000m;

- Locations exposed to direct sunlight;

- Locations subject to dust accumulation;

- Locations with poor ventilation;

- Locations with a lot of salt and metal powder;

- Locations where the main unit is subject to direct vibration and shock.

● Take adequate shielding measures when using at the following locations.

- Near a power line.

- Where a strong electric field or magnetic field is formed.

- Where static electricity, relay noise or the like is generated.

● Install the F350 as far away from devices generating high frequency, high voltage, large

current, surge, etc., as possible. Also, carry out wiring separately from their power lines. Do

not carry out parallel wiring and common wiring.

● Do not use it, broken down.

● Tighten the screws for the power input terminal at the specified torque.

If they are loose, shorts, fire or malfunctions may occur.

Tightening torque: 0.5N •m

● For sensors, external inputs/outputs and options, use shielded cables.

● The temporary overvoltage applied to the power should not exceed 1500V.

● For turning on/off the power, be sure to keep intervals of 5 seconds or more.

● After power-on, make sure to warm up the F350 for at least 30 minutes or more before use.

● If the F350 is not used by the specified method, its protective performance may be impaired.

● Maintenance

- When performing maintenance, disconnect the power.

- Do not wipe with a wet rag, or with benzine, thinner, alcohol, etc. Doing so may cause

discoloration or deformation of the F350. In the case of heavy contamination, wipe off

the contamination with a cloth after dipping it into a diluted neutral detergent and wringing

it well, and then wipe with a soft, dry cloth.

IV

IV

CAUTION

This sign forewarns the presence of hazards

that could result in personnel injury or property

damage when incorrectly handled.

Caution during transportation

Caution during disposal

This sign forewarns the presence of hazards

that could result in serious injury or fatality

when incorrectly handled.

CAUTION

CAUTION

● When the F350 is shipped, spacers made of corrugated cardboard are used as cushioning

materials.

Though it is factory-designed so that shocks can sufficiently be absorbed, breakage may

result if shocks are applied when the spacers are reused for transportation. If you send the

F350 to us for repair, etc., take adequate measures against shocks by using polyurethane

materials, etc., separately.

● If you dispose of the product, handle it as industrial waste.

About the Built-in Lithium Battery

WARNING

● Never disassemble, deform under pressure or throw the battery

into fire.The battery may explode, catch fire or leak.

V

V

Statement of Conformation to EC Directives

)

Overvoltage category II

Pollution degree 2

The combination of the main unit of the F350 and a lightning surge protector

conforms to EN61000-4-5 (lightning surge immunity) in the EMC Directives.

Refer to " Connection of a Lightning Surge Protector (Power Cable)" on page VII

for information regarding lightning surge protector connection.

Point

Statement of Conformation to EC Directives

Statement of Conformation to EC Directives

* The F350 is a CE-compliant product. For use, observe the following.

The F350 Digital Indicator is a CE-marked EC-Directive-conforming product

(by the Council of the European Union).

- Low Voltage Directive EN61010-1:2010

EN62311:2008 (test distance: 0cm)

- EMC Directive EN61326-1:2006

EN55011:2009, A1:2010 Group1, ClassA

EN61000-3-2:2006, A1:2009, A2:2009

EN61000-3-3:2008

EN61000-4-2:2009

EN61000-4-3:2006, A1:2008, A2:2010

EN61000-4-4:2004, A1:2010

EN61000-4-5:2006

EN61000-4-6:2009

EN61000-4-8:2010

EN61000-4-11:2004

When installing, attention should be given to the following.

1. Since the F350 is defined as open type (built-in equipment), be sure to use it as installed

and fixed to a panel, etc.

2. The power cable attached to this product as standard can be used with 100V AC power in

Japan.(Nominal rated voltage: 125V AC)

For using this product in a country outside Japan, use a power cable certified in that

country.

3. For cables other than the power cable (sensor, external input/output, option), use shielded

cables.

Also, mount the attached ferrite core to the strain gauge sensor cable.

VI

VI

Connection of a Lightning Surge Protector (Power Cable)

F350

Lightning surge protector

* MAINTRAB MNT-1D is a registered trademark of

PHOENIX CONTACT.

An EU-outlet-shape AC power cable is required.

CA325AC3P-CEE7/7-B2: CEE7/7 plug cable (2m)

Connection of a Lightning Surge Protector (Power Cable)

Connection of a Lightning Surge Protector

(Power Cable)

Connect a lightning surge protector against lightning surge.

EMC Directive EN61000-4-5 (Lightning Surge Immunity) is met by the F350 body in combination with a

lightning surge protector.

●Lightning surge protector [MAINTRAB MNT-1D]

The lightning surge protector [MAINTRAB MNT-1D] is not included as standard.

In addition, as optional parts, we sell EU-outlet-shape 250V AC withstanding cables (following illustration:

European standard) and lightning surge protectors in pairs (TSU02). For details, contact our sales

department.

RoHS-Compliant Product

The parts and attachments (including the instruction manual, packaging box, etc.) used for this unit are

compliant with the RoHS Directive restricting the use of hazardous substances with regard to adverse

effects on the environment and human body.

What is RoHS?

It is an abbreviation for Restriction on Hazardous Substances, which is implemented by the European

Union (EU). The Directive restricts the use of six specific substances in electric and electronic equipment

handled within EU borders. The six substances are lead, mercury, cadmium, hexavalent chromium, PBB

(polybrominated biphenyls), and PBDE (polybrominated diphenyl ethers).

VII

VII

CONTENTS

CONTENTS

CONTENTS

1 OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-1. Main features of the F350. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1-2. Contents of the package. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

1-3. About connectable devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1-4. Appearance description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 INSTALLATION & CONNECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

■ Front panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

■ Rear panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2-1. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2-2. Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

■ Power input terminal connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

■ Analog input/output connector connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

■ How to remove the terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

■ How to connect and install the terminal block . . . . . . . . . . . . . . . . . . . . . . . . . . 11

■ Attachment of a ferrite core . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

■ Strain gauge sensor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

■ Strain gauge sensor cable coloration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

■ Voltage output connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

■ External I/O connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

■ How to assemble the connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

■ SI/F interface connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3 SETTING MODE CONFIGURATION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-1. Setting mode composition . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

3-2. Key operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3-3. Calling a setting mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

VIII

4 CALIBRATION PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4-1. How to calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

■ Equivalent input calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

■ Actual load calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4-2. Procedure of equivalent input calibration and calibration protect. . . . . . . . . . . . . . . . 24

VIII

CONTENTS

CONTENTS

5 EXPLANATION OF INDICATED-VALUE-RELATED FUNCTIONS . . . . . . . 35

5-1. A/D conversion speed select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

■ A/D conversion speed select setting method . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5-2. Analog filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

■ Analog filter setting method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5-3. Digital filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

■ Digital filter setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5-4. Digital Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

■ Digital Zero / Digital Zero reset by means of keys . . . . . . . . . . . . . . . . . . . . . . 38

■ Digital Zero by means of the external signal "D/Z input". . . . . . . . . . . . . . . . . . 39

5-5. D/Z synchronous mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

■ D/Z synchronous mode setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5-6. Zero Tracking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

■ Zero Tracking setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5-7. Motion Detect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

■ Motion Detect setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

5-8. Display frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

■ Display frequency setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6 EXPLANATION OF COMPARISON FUNCTIONS . . . . . . . . . . . . . . . . . . . . 44

6-1. Calculation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

■ Calculation mode setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

6-2. HI/LO limit comparison of calculated value / ch1 value / ch2 value . . . . . . . . . . . . . . 45

■ HI/LO limit setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6-3. Hysteresis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

■ Hysteresis setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

6-4. Near Zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

■ Near Zero setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6-5. Calculation comparison timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

■ Calculation comparison timing setting method . . . . . . . . . . . . . . . . . . . . . . . . . 48

IX

6-6. Comparison OK output conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

■ Comparison OK output conditions setting method . . . . . . . . . . . . . . . . . . . . . . 49

7 EXPLANATION OF HOLD FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7-1. Hold functions of calculated values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

IX

CONTENTS

CONTENTS

■ Flow of hold measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

7-2. Setting of hold mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

■ Hold mode setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

■ Sample hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

■ Peak hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

■ Bottom hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

■ Average hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

■ Average sample number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

7-3. Setting of hold section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

■ Hold section setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

■ All section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

■ External signal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

■ External signal + time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

7-4. Auto reset function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

■ Auto reset setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8 STANDARD INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

8-1. External I/O. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

■ Connector pin assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

■ About outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

■ About inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

■ About the RUN signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8-2. SI/F(Serial interface) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

■ SI/F Indicated value format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

■ SI/F print . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

9 OPTION INTERFACE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9-1. BCD interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

■ Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

■ Connector pin assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

■ Output data select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

■ Signal timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

■ Logic switching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

■ BCD data hold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

■ Output rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

■ BCD/binary select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

■ Pin assignment at binary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

9-2. RS-232C interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

■ Communication specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

■ Connector pin assignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

■ Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

■ Communication mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

■ Communication conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

■ Delimiter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

■ Communication format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

X

X

CONTENTS

CONTENTS

■ Continuousness / print send mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

9-3. D/A converter output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

■ Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

■ Output data select . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

■ Zero/Full scale setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

■ Adjustment by fixed output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

10 SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

10-1. Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

■ Analog section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

■ Display section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

■ Setting section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

■ External input/output section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

■ Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

■ Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

■ General performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

■ Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

10-2.Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

■ Standard equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

■ Equipped with BCD parallel data output interface option . . . . . . . . . . . . . . . . . 85

■ Equipped with RS-232C interface option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

■ Equipped with D/A converter option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

10-3. F350 block diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

11SUPPLEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11-1.The list of initial setting value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

11-2.Self-check function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

■ Self-check method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

11-3.Setting protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

■ Setting protect setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11-4.Key protect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

■ Key protect setting method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

11-5.Initialize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

■ Initialize setting method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

XI

11-6.Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

11-7.Error/message list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

■ Main numerical display section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

■ Sub numerical display section. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

11-8.Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

XI

CONTENTS

CONTENTS

11-9. About disposal of the lithium battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

■ Removal of the lithium battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

XII

XII

1-1. Main features of the F350

1 OUTLINE

● The F350 is a digital indicator that is capable of two-channel inputs of strain gauge

sensors.

● Calculations, such as addition and subtraction, and comparison judgments are made

by using the input values of two channels. The F350 is also suitable for balance

measurement.

● The F350 is equipped with comparison judgments on the input value of each channel,

and analog voltage output.

● The A/D conversion speed of each channel and the digital processing speed for

calculations and judgments are as high as 3,000 times/sec. It can also be switched to

300 times/sec.

1 OUTLINE

Chapter

1

OUTLINE

● The F350 is equipped with hold functions with respect to calculated values.

(sample, peak, bottom, and average holds)

● The F350's compact size of DIN96×96 realizes space-saving.

● By mounting an optional interface according to the purpose, ease of load control can

be further improved.

1

1

CAUTION

F350 body・・・1 F350 operation manual・・・1

AC input cord・・・1

Conversion plug for

Mini screwdriver for Connector for BCD parallel

(with BCD parallel data output option)

AC input code・・・1

(with D/A converter option)

Ferrite core・・・2

(with unity band)

External input/output

(with solderless terminal)

connector・・・1

terminal block connection・・・1

data output・・・1

1 OUTLINE

Chapter

1

OUTLINE

1-2. Contents of the package

The packaging box contains the following.

Be sure to check them before use.

CAUTION

The attached AC cable is intended for domestic use in Japan, and it is rated as 125V AC, 10A. If it

is used at voltages exceeding the rating or it is used overseas, have a suitable AC cable ready

separately.

2

2

CAUTION

Strain gauge type sensor

(Option)

D/A Converter

Valve, recorder

(Option)

(Option)

Printer Display Various converters

PC

* + .1 * + .1

* + . 11 -

* 1 . &

2 ' # -

%J

%J

(0% '5%

*+.1

<'41

*1.&

F

350

Main status display

Sub status display

Setting key pad

Main numerical display

Sub numerical display

section

section

section

section

1 OUTLINE

1-3. About connectable devices

Chapter

1

OUTLINE

1-4. Appearance description

3

■Front panel

3

CAUTION

In this operation manual, the display status is expressed as follows:

Lighting: Status display section → Black

Numerical display section → White

Blinking: Lighting state + Lines in a radial pattern

Being unlit:Status display section → Gray

Numerical display section → Nothing displayed

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

Lighting

Blinking

Being unlit

Chapter

1

OUTLINE

1 OUTLINE

Main status display section

The status with respect to calculated values is indicated.

HI: Lights when the indicated value is larger than the calculation HI limit.

Indicates that the external output "calculation HI" is ON.

OK: Lights when the indicated value is smaller than the calculation HI limit and larger

than the calculation LO limit.

Indicates that the external output "calculation OK" is ON.

LO: Lights when the indicated value is smaller than the calculation LO limit.

Indicates that the external output "calculation LO" is ON.

PEAK: Blinks during hold detection, and lights when a hold is confirmed.

However, it is always unlit in all section sample hold.

HOLD: Lights during hold detection and when a hold is confirmed.

However, it blinks when hold waiting in all section sample hold.

Main numerical display section

The following display patterns exist.

Indicated value:Displays calculation results during measurements.

Error display: Displays an error message when an error occurs.

Setting value: Displays setting values in setting mode.

Sub status display section

The status with respect to ch1/ch2 values is indicated.

HI: Lights when the indicated value is larger than the ch1/ch2 HI limit.

Indicates that the external output "ch1/ch2 HI output" is ON.

LO: Lights when the indicated value is smaller than the ch1/ch2 LO limit.

Indicates that the external output "ch1/ch2 LO output" is ON.

Sub numerical display section

The following display patterns exist.

Indicated value: Displays ch1/ch2 values during measurements.

Error display: Displays an error message when an error occurs.

Setting value: Displays the mode number and item number at the ch1 display section in

setting mode; the currently-selected weight value may be displayed at the ch2

display section according to the setting item

4

4

CAUTION

FNC

ESC

HI/LO

ZERO

HOLD

Setting key pad

These are keys for commanding settings and operations.

・Use this key to go to a setting mode state.

・Use this key to cancel setting/execution.

・Use this key to go back from a setting mode state to an indication display state.

・Use this key to take a shortcut from an indication display state to HI/LO limit setting.

・

Use this key to go from an indication display state to ch1 or ch2 Digital Zero ready.

・Use this key to execute/release the calculated value hold in an indication display state.

・Use this key to switch between ch1 setting and ch2 setting, etc., in a Digital Zero

ready state or setting item select state.

・Use this key to set whether or not to sign a setting value, when available, in a setting

value input state.

1 OUTLINE

Chapter

1

OUTLINE

・Use this key to select a trailing setting item number in a setting mode state.

・Use this key to select the previous item number in a setting item select state.

・Use this key to increment the numerical value by one in a setting value input state.

・Use this key to select a leading setting item number in a setting mode state.

・Use this key to select the next item number in a setting item select state.

・Use this key to decrement the numerical value by one in a setting value input state.

・Use this key to execute Digital Zero reset in a Digital Zero ready state.

・Use this key to increment the leading setting mode number by one in a setting mode

state.

・Use this key to move the setting digit by one in the lower direction in a setting value

input state.

・Use this key to execute Digital Zero in a Digital Zero ready state.

・Use this key to move to a setting value input state in a setting item select state.

・Use this key to validate the setting value in a setting value input state.

5

5

CAUTION

Options slot

Power input terminal

Protective ground

Signal input/output

Analog input/output

connector

connector

Frame ground

Chapter

1

OUTLINE

1 OUTLINE

■Rear panel

Analog input/output connector

Connect a strain gauge sensor or voltage output.

* For connection, see "

■ Analog input/output connector connection" on page 10.

Signal input/output connector

Connect external input/output signals or SI/F (serial interface).

* For connection, see "

■ External I/O connection" on page 14.

Power input terminal block

Connect an AC input cord.

The input power source is free in the range of 100 to 240V AC (-15%, +10%). The frequency is 50/

60Hz.

* For connection, see "

■ Power input terminal connection" on page 9.

Protective ground

Be sure to ground the protective ground terminal to prevent electric shocks.

Frame ground

6

6

Please ground the frame ground terminal to prevent failures due to static electricity.

(The frame and the frame ground terminal are conducted.)

It may be better to remove depending on the environment of the installation location.

Options slot

One option board can in stall in the option slot.

・BCD parallel data output (BCO)

・RS-232C interface (232)

・D/A converter voltage output (DAV)

・D/A converter current output (DAI)

2 INSTALLATION & CONNECTION

2 I

NSTALLATION & CONNECTION

The following are precautions related to connection to the signal input/output terminal block.

The precautions described here are important for safety.

Make connections after properly understanding the description.

WARNING

● Do not connect commercial power directly to the signal input/output terminals.

● Make connection to the signal input/output terminals with no power applied

because you may receive an electric shock.

● For connections to the signal input/output terminals, carry out wiring properly after

confirming the signal names and pin assignment numbers.

● Use of the F350 is limited to category II specified by EN61010. Overvoltage applied

to the signal input/output terminals should not exceed the value defined to category

II.

● After wiring, make sure to mount the attached terminal block cover. Otherwise, you

may receive an electric shock.

● Turn on the power after carefully checking the wiring, etc.

Chapter

2

INSTALLATION & CONNECTION

● Do not touch the signal input/output terminals while the power is on. Otherwise, you

may receive an electric shock, or a malfunction may occur.

● The F350 conforms with EMC Directives as a product used in industrial

environments (class A). If it is used in living environments, radio disturbance may

occur. In that case, take suitable measures.

CAUTION

● Tighten the terminal screws at specified torque. If the terminal screws are loose,

short-circuiting, fire, or a malfunction may occur.

● Use shielded cables.

7

7

2 INSTALLATION & CONNECTION

92mm

Panel-cut

+1

0

–

Panel thickness

1.6 to 3.2mm

dimensions

92mm

+1

0

–

2-1. Installation

To install the F350 into a control panel, use the following procedure.

1. Make a hole in the panel according to

Chapter

2

INSTALLATION & CONNECTION

the panel-cut dimensions.

2. Remove the screws (two), and remove

the guide rails from both sides.

* Do not use other screws than those installed to

the F350 body.

3. Fit in the F350 from the front of the panel.

4. Install from the rear the guide rails having

been removed from both sides in Step 2,

and fix them with the screws (two).

8

8

2-2. Connection

Within 6mm

Black

White

Green/Yellow

Color description are for the attached

AC input cord.

■Power input terminal connection

Connect an AC input cord. The input power source is free in the range of 100 to 240V AC (-15%,

+10%).

The frequency is 50/60Hz.

Make connections to the terminal block with a solderless terminal within 6mm in diameter as

shown in the illustration so as not to let the tip of the cable spread out.

1. Make sure that no power is applied.

2. Remove the screws (two), and remove

the terminal block cover.

3. Remove the two screws(M3) at

the terminal block

.

2 INSTALLATION & CONNECTION

Chapter

2

4. Align the solderless terminals with

the screw holes, and then tighten

the screws.

L :Black

N :White

5. Install the terminal block cover, and fix it with the screws (two).

6. Remove the screws(M4) of the protective ground, align the crimp contacts

with the screw holes, and then tighten the screws.

:Green/ Yellow

The protective ground is internally connected with frame ground.

*

INSTALLATION & CONNECTION

9

9

Chapter

Loosen.

(Turn

counterclockwise

.)

When installing the terminal block to the F350

body, check its orientation. (See the illustration at

the right.)

Attention

Insert side

Right side

2 INSTALLATION & CONNECTION

■Analog input/output connector connection

Connect a strain gauge sensor or voltage output.

Make connections according to the silk-screen printing on the rear panel of the F350.

●Pin Assignment

12 SHIELD

2

11 -MONITOR(ch2)

10 +MONITOR(ch2)

INSTALLATION & CONNECTION

9 -MONITOR(ch1)

8+MONITOR(ch1)

7 -SIG(ch2)

6+SIG(ch2)

5 -SIG(ch1)

4+SIG(ch1)

3 -EXC*

2 +EXC*

1SHIELD

Compatible connector: ETB42-12P(OSADA CO.,Ltd.) or equivalent

(Connector optional type:CN81)

* EXC is common to ch1 and ch2.

CAUTION

Before connecting a strain gauge sensor, make sure to check the setting of excitation

voltage.

For the setting of excitation voltage, see "4-2 ②Excitation voltage setting" on page

25.

■How to remove the terminal block

1.

Loosen the screws (two) with a screwdriver.

2. Remove the terminal block by giving it a

strong pull.

10

10

2 INSTALLATION & CONNECTION

5mm

Pin No.12

Pin No.1

Adaptable plug ETB42-12P

Tighten.

(Turn clockwise.)

(attachment)

(Turn counterclockwise.)

Loosen.

2KP0Q

2KP0Q

Tighten.

(Turn clockwise.)

Tighten.

(Turn clockwise.)

Sensor cables

F350

A cable is twisted around

a ferrite core.(One roll)

Ferrite core

■How to connect and install the terminal block

Strip 5mm of the covering of the wire to be

1.

connected.

The size of connectable wires is from 0.21 to

3.31mm

2

(AWG12 to 24).

2. Twist the tip to such an extent that it will not spread out.

3. Loosen the screw with a screwdriver to open

the connection hole.

*A Phillips screwdriver 3 to 3.5mm #1 in shaft

diameter is recommended. (Precision screwdriver,

etc.)

4. Insert the wire into the connection hole so as

not to let the tip spread out.

Chapter

2

5. Tighten the screw with the screwdriver.

*0.5Nm of tightening torque is recommended.

6. Lightly pull the wire to make sure that

it is securely clamped.

7. Insert the wire-connected plug into

the F350 body, and tighten the

screws (two).

■Attachment of a ferrite core

It is necessary to twist a power supply cable and sensor cables, such as a load cell, around an

attached ferrite core.

INSTALLATION & CONNECTION

11

11

2 INSTALLATION & CONNECTION

-SIG

-EXC

+EXC

+SIG

SHIELD

+IN

+OUT

-IN

-OUT

5

4

3

2

1

SHIELD

+SIG

-SIG

+IN

+OUT

-IN

-OUT

F350

12

7

6

SHIELD

+SIG

-SIG

12

7

6

-SIG

-EXC

+EXC

+SIG

SHIELD

+

IN

+

OUT

-

IN

-

OUT

F350

+

S

-

S

5

4

3

2

1

+IN

+OUT

-IN

-OUT

+S

-S

Short-circuit +EXC with +S

and -EXC with -S for

connecting a 6-wire straingage sensor.

■Strain gauge sensor connection

■ 4-wire sensor

Chapter

2

INSTALLATION & CONNECTION

■ 6-wire sensor

12

12

2 INSTALLATION & CONNECTION

+

-

External equipment

8 or 10

9 or 11

+ MONITOR1or 2

← F350 Inside Outside →

- MONITOR1or 2

+

-

+

-

+

SIG

-

SIG

A/D

Analog

filter

■Strain gauge sensor cable coloration

Cable colors of sensors may differ from one manufacturer to another (it may even differ from one

model to another for some products). Refer to the sensor manual (or data sheet) and check signal

names and colors in order to connect the cables correctly.

CAUTION

The excitation voltage of the F350 is 2.5V/10V. If the maximum excitation voltage of

the sensor is under 2.5V/10V, heating or damage may result.

■Voltage output connection

The voltage output terminals output analog voltage in proportion to each sensor signal input.

The voltage output is approximately 2V per sensor input of 1mV/V.

It is useful for observing or recording waveforms by connecting a recorder, etc.

・Example) Connection of output equivalent circuit and external instrument.

Chapter

2

・Since the output voltage is taken out in a step prior to A/D conversion of the sensor input signal, it

・Since the ±MONITOR terminals are not insulated from the internal circuit, use two-core shielded

CAUTION

is not synchronized with indicated values processed digitally, such as Digital Zero and digital

filter. Output in synchronization with indicated values requires an optional D/A converter.

twisted pair wires for connection with external equipment, and carry out with as short a wiring as

possible.

● Do not short-circuit. Doing so will cause a failure.

● Do not apply voltage externally. Doing so will cause breakage.

INSTALLATION & CONNECTION

13

13

2 INSTALLATION & CONNECTION

Vceo=30V(max)

Output

Output COM1

Ic=30mA(max)

COM

Input

F350

Sink type

PLC etc.

Plus common connection

A8 ~ A10

B2 ~ B6

A1,A7

B1

DC24V

(Minus common connection)

+24V

0V

A2 ~ A6

COM2

+12V

F350 Inside

IN

IN

・ The external element is required to withstand Ic=10mA.

・ Leakage from the external element is required to be 100μA or below.

B8~12

B7

Open → OFF

Short → ON

Push

Switch

Toggle

Switch Relay

TTL Open Collector

(ON when IN is HI)

■External I/O connection

Details of signal, see "8-1.External I/O" on page 60.

・How to connect external output (Sink type)

Chapter

2

The external output circuit is operated through an open collector. A1(A7) COM1 is the common

terminal. The open collector output capacity is 30mA and the withstand voltage is up to 30V.

INSTALLATION & CONNECTION

●Output Transistor Status

Output Data Tr

・How to connect external input

OFF OFF

ON ON

For driving, have an external power source ready.

(24V DC is shown in the illustration.)

(minus common connection of no-voltage contact input type)

A signal is inputted to the signal input circuit by short-circuiting or opening the input terminal and

the COM2 terminal. Short-circuiting is effected by means of a contact (such as a relay or a switch)

or a noncontact (such as a transistor or an open-collector TTL)

14

14

■How to assemble the connector

Connector

Pan-head machine screw

M2×8 (short) (two)

Nut M2 (four)

Pan-head machine screw

M2×10 (long) (two)

Washer (two)

Case (two)

Screw (two)

RNC[

SI/F

A11

← Inside Outside →

F350

A12

Set the connector and screws (two) into the grooves of the case (one side).

1.

2 INSTALLATION & CONNECTION

Chapter

2

2. Cover with the other case, and fit the cases.

3. Tighten the M2×8 pan-head machine screws (two).

Tighten the M2×10 pan-head machine screws (two).

Be aware that washers should be set to the M2×10 pan-head machine screws

(two).

■SI/F interface connection

Two-wire serial interface (SI/F) for connecting printers and external display from UNIPULSE.

Connect from A11 and A12 of the external input/output connector.

The interface is nonpolarized and up to three external devices can be connected.

Wiring materials should use a two-core parallel cable, cabtyre cable (electric wire with covering

thickened for construction), etc. When a two-core parallel cable or a cabtyre cable is used, the

transmission distance is approximately 30m. When a two-core shielded twisted pair wire is used,

the transmission distance is approximately 300m.

Do not parallel it with AC lines and high-voltage lines. Doing so will cause malfunction.

INSTALLATION & CONNECTION

15

2TKPVGT

&KU

%QPXGTVGT

15

3 SETTING MODE CONFIGURATION

3 SETTING MODE

CONFIGURATION

Indicated value

display

HI/LO limit setting

mode (P21)

5: A/D conversion speed select

(P35)

1: ch1 Digital filter (P37)

1: Motion Detect (P41)

3: Hysteresis (P45)

2: Near Zero (P47)

1: Comparison function

select (P48、P49)

ESC

F3(Mode3)

Ch Operation

F2(Mode2)

Calculation/common Operation

F1(Mode1)

Comparison/hold

FNC

ESC

HI/LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

2: SI/F function select

(P62)

4: D/Z synchronous mode

(P39)

3: Display frequency

(P43)

7: Average sample number

(P53)

6: Detection time (P57)

5: Calculation hold function

select (P50)

2: ch2 Analog filter

2: ch1 Analog filter (P36)

1: ch2 Digital filter

3: ch2 Zero Tracking

3: ch1 Zero Tracking (P40)

3-1. Setting mode composition

Chapter

3

SETTING MODE CONFIGURATION

16

16

3 SETTING MODE CONFIGURATION

F5(Mode5)

Option

BCO DAV/DAI232

2: Communication

condition (P72)

8: Alarm LO limit

(P33)

7: Alarm HI limit

(P33)

6: Digital Zero limit

(P32)

5: ch2 Digital offset

4: ch2 Actual load

calibration

3:ch2 Equivalent input

calibration

2:ch2 Zero calibration

5: ch1 Digital offset

(P31)

4: ch1 Actual load

calibra tion (P30)

3:ch1 Equivalent input

calibration (P28)

1: Calibration function select

(P23)

F9(Mode9)

Protect/initialize

*As for an option setting, a setting item is different depending

F4(Mode4)

Calibration setting

H

I

Ch1Ch 2

OK LO

PEAK

HOLD

HILO

HILO

Ch

1

HILO

H

I

Ch 2

OK LO

PEAK

HOLD

HILO

H

I

Ch1Ch 2

OK LO

PEAK

HOLD

HILO

HILO

2: ch1 Zero calibration

(P27)

Moreover, a set item is not displayed when there is no option.

2: Output rate

(P68)

2: Zero scale value

(P80 )

3: Delimiter

(P72)

3: BCD / binary

select (P68)

3: Full scale value

(P80 )

1: Communication

mode (P71)

1: Output data

select (P66)

1: Output data

select (P79)

4: Password

(P97)

3: Initialize

(P97)

2: Key protect

(P96)

1: Setting protect

(P95)

on the installed option.

Chapter

3

SETTING MODE CONFIGURATION

17

17

3 SETTING MODE CONFIGURATION

Ch

1

H

I

LO

Ch

1

H

I

LO

Selecting a

Select a setting item.

The highest digit blinks to enter setting.

Select the digit you want to set.

Set a setting value.

The setting value is validated.

Go back to setting mode selection.

From the indicated value display,

Selecting a

Selecting a setting

"F2" of setting mode 2

For signing the setting value, when

available, press .

"F9" of setting mode 9

FNC

ESC

Go back to setting mode 1.

・・・

ESC

Go back to the indicated value.

Ch

1

HILO

Ch

1

H

I

LO

For setting values available for ch1 and ch2 individually,

and inputting a

setting value

is displayed. is displayed.

setting mode.

setting item.

"F1" of setting mode 1 is displayed

on the SUB display (ch1 side).

switch with .

If key operation is not performed for one minute or more between the time of pressing

the key and the time of validating with the key, the setting is stopped to go

back to the indicated value display. In that case, the setting value is not saved.

FNC

Point

3-2. Key operation

Chapter

3

SETTING MODE CONFIGURATION

≪Setting procedure≫

18

18

≪Setting mode select state≫

Ch

1

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

Ch 2

H

I

LO

Ch 2

H

I

LO

【Setting mode 1(COP.HLD)】【Setting mode 3(SYS.ch)】【Setting mode 2(SYS.OPR)】

【Setting mode 4(CAL.)】【Setting mode 9(PRT.INI)】【Setting mode 5(OPTION)】

The protect state of each setting mode is visible at a glance.

Protect information

Protect ON

Protect OFF

For the protect setting method, see " ■ Setting protect setting

method " on page 95 .

3 SETTING MODE CONFIGURATION

Chapter

3

SETTING MODE CONFIGURATION

19

19

3 SETTING MODE CONFIGURATION

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

【Normal setting item】

【Normal setting item (with separate

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

Selected ch display

1:ch1

2:ch2

Item number (1 - 9)

Mode number (1 - 5, 9)

【Calibration operation item】

(Zero calibration, equivalent input

Selected ch display

Example) 1 → ch1 selected

Indicated value

Example) ch1 indicated value 99.97

settings on ch1 and ch2)】

calibration, actual load calibration)

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

Ch1 setting value Ch2 setting value

Chapter

3

SETTING MODE CONFIGURATION

≪Setting item select state≫

≪Setting ch switching function≫

For settings available for ch1 and ch2 in a setting item select state, press to switch

between ch1 value setting and ch2 value setting.

20

20

3 SETTING MODE CONFIGURATION

HI/LO

Ch 2

H

I

LO

Ch 2

H

I

LO

LO

Ch 2

H

I

H

I

Ch 2

LO

Ch 2

H

I

LO

Ch 2

H

I

LO

HI/LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

HILO

H

I

Ch

1

OK

LO

PEAK

HOLD

H

I

LO

H

I

Ch

1

OK

LO

PEAK

HOLD

H

I

LO

H

I

Ch

1

OK

LO

PEAK

HOLD

H

I

LO

H

I

Ch

1

OK

LO

PEAK

HOLD

H

I

LO

H

I

Ch

1

OK

LO

PEAK

HOLD

H

I

LO

H

I

Ch

1

OK

LO

PEAK

HOLD

H

I

LO

HI/LO

HI/LO

ESC

Indicated value display

ch1 LO limit

ch1 HI limit

ch2 LO limit

ch2 HI limit

Calculation LO limit

Calculation

Exit the HI/LO limit setting item display

HI/LO

HI limit

state.

≪HI/LO limit setting mode function≫

By pressing on the indicated value display screen, you can enter a HI/LO limit setting

item select state.

Press at the setting value you want to change, and you will go to a setting value input

state.

After inputting the setting value, you will go back to the HI/LO limit setting item state.

Chapter

3

SETTING MODE CONFIGURATION

21

21

3 SETTING MODE CONFIGURATION

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

FNC

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

ESC

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

HILO

While the lowest decimal place on the sub display

(ch2 side) is lit, writing in NOVRAM is in progress.

If the power is turned off at this time, normal writing

cannot be performed.

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

HILO

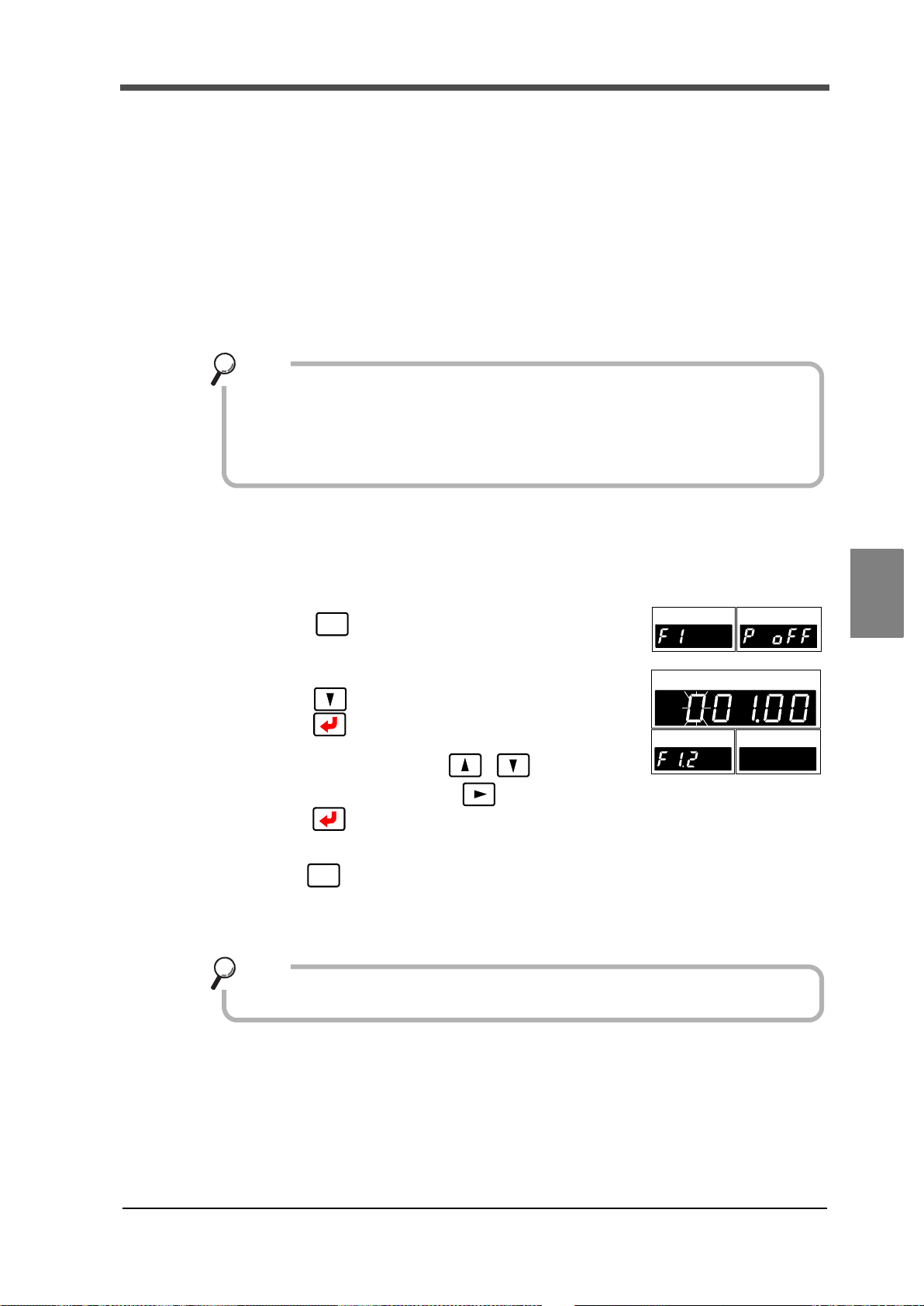

3-3. Calling a setting mode

Example) For changing the ch1 digital filter from "000" to "256"

1. Press from an indicated value display state.

Chapter

3

SETTING MODE CONFIGURATION

2. Go to a setting mode select state.

Press twice to make the mode number "3."

3. Go to a setting item select state.

Press once to select F3-1.

Press .

4. Go to a setting value input state.

Press to move the setting digit.

Press to change the numerical value.

Press to validate it.

The change can be cancelled by pressing .

While a signed setting value is being input, press to select whether or not to sign it.

5. Upon validation, you will go back to the setting item

select state.

22

22

4-1. How to calibration

4 CALIBRATION PROCEDURE

A data sheet will be attached to a strain gauge sensor you buy.

On the data seat, the following values are listed.

Capacity Rated Output

Non-Linearity Hysterisis

Input Resistance Output Resistance

Zero Balance etc.

The Capacity and the Rated Output are necessary values for the equivalent input

calibration. Input these two values to F350.

POINT

"Calibration" refers to an operation whereby matching between the F350 and a strain gauge sensor

is obtained. The F350 uses the two calibration methods as described below.

■Equivalent input calibration

Calibration is performed without an actual load by entering the rated output value (mV/V) and the

capacity (to be indicated) of the strain-gage sensor by the keys. Calibration is easily performed

when no actual load is available.

For example,

for load: 2.001mV/V-100.0kgf

for pressure: 2.002mV/V-10.00kgf/cm

for torque: 2.502mV/V-15.00kgf・m

4 CALIBRATION PROCEDURE

Chapter

4

2

Gain will be automatically decided by registering the values indicated as follows.

■Actual load calibration

This approach provides calibration by applying an actual load to the strain gauge sensor and

inputting the actual load value. This calibration is without little errors and more correct.

CALIBRATION PROCEDURE

Perform either actual load calibration or equivalent input calibration.

23

*

If an actual load cannot be applied, make sure to perform equivalent input calibration

alone.

23

Equivalent input

Actual load

calibration

calibration

Digital offset

⑦

Calibration protect

Min. scale division

a.Equivalent input

Calibration protect

①

④

⑥

⑩

Zero calibration

⑤

Excitation voltage

②

Decimal place

③

Digital Zero limit

⑧

b.Actual load

⑥

Alarm HI and LO limits

⑨

calibration

calibration

Chapter

4

CALIBRATION PROCEDURE

4 CALIBRATION PROCEDURE

4-2. Procedure of equivalent input calibration and

calibration protect

The equivalent input calibration and the calibration protect uses the following procedure :

Turn off the calibration protect that inhibits

calibration.

Set the excitation voltage according to the sensor

used.

Set the decimal place.

Set the desired minimum value of digital increments.

(This step may be omitted if there is no change.)

Set the zero point of the strain gauge sensor in no-

load condition (with the sensor unloaded).

Equivalent input calibration

Register the rated output value of the strain gauge

sensor, and the indicated value of that time.

Actual load calibration

Set the span (gain) point of the strain gauge sensor

with a load applied to the sensor.

The calibrated value can be offset in advance.

(When not using, set "0.")

Set the load limit that allows Digital Zero.

24

Set the HI/LO limit for monitoring overload.

Turn on the calibration protect to prevent

misoperation.

24

①Releasing the calibration protect

Ch

1

Ch 2

H

I

LO

H

I

LO

FNC

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

0 0 0

Calibration protect

0:OFF 1:ON

System protect

0:OFF 1:ON

Work protect

0:OFF 1:ON

《Setting value》

ESC

Turn off the calibration protect that inhibits calibration.

≪Setting value≫

0:OFF Enables rewriting of setting values.

1:ON Disables rewriting of setting values.

◇Calibration protect setting method

1. Select setting mode 9.

Press → five times.

4 CALIBRATION PROCEDURE

2. Set "Calibration protect."

Press once. ⇒ "Setting protect" is displayed.

Press → twice to make the digit of the

calibration protect blink.

Input the setting value with .

(Initial value: 0)

Press to validate it.

3. Press twice to go back to the indicated value

display.

②Excitation voltage setting

Select the bridge voltage (excitation voltage) supplied to the strain gauge sensor.

The bridge voltage can be selected from 2.5V and 10V.

After this setting, make sure to perform calibration.

≪Setting value≫

0:2.5V

1:10V

Chapter

4

CALIBRATION PROCEDURE

25

* Common to ch1 and ch2.

③Decimal place setting

Set the decimal place for load-value-related display, setting items, etc.

≪Setting value≫

0:None

1:0.0

2:0.00

3:0.000

* Calculated values are also synchronized with this setting.

25

4 CALIBRATION PROCEDURE

Ch

1

Ch 2

H

I

LO

H

I

LO

FNC

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

002

Min. scale division

Excitation voltage

0:2.5V

1:10V

Decimal place

0:None

1:0.0

2:0.00

3:0.000

0:1 4:20

1:2 5:50

2:5 6:100

3:10

《Setting value》

ESC

The maximum excitation voltage value of the strain gauge sensor connected to the

F350 should always be larger than the set bridge voltage.

If the excitation voltage of the F350 is larger than the maximum excitation voltage

value of the strain gauge sensor, the strain gauge sensor may heat or break.

④Min. scale division setting

Set the minimum unit (scale interval, scale division) of measurements.

CAUTION

Chapter

4

CALIBRATION PROCEDURE

≪Setting value≫

0:1

1:2

2:5

3:10

4:20

5:50

6:100

* Calculated values are also synchronized with this setting

◇Excitation voltage, decimal place, and min. scale division setting method

1. Select setting mode 4.

Press → three times.

2. Set "Excitation voltage," "Decimal place," and "Min.

scale division."

Press once. ⇒ "Calibration function select"

is displayed.

Press , and the highest digit blinks.

26

26

① Select excitation voltage.

Input the excitation voltage with , and

move to the lower digit with . (Initial value: 0)

② Select decimal place.

Input the decimal place with , and

move to the lower digit with . (Initial value: 2)

③ Select min. scale division.

Input the min. scale division with , and

validate it with .(Initial value: 0).

3. Press twice to go back to the indicted value display.

4 CALIBRATION PROCEDURE

Ch

1

Ch 2

H

I

LO

H

I

LO

FNC

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

HILO

Selected ch display

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

HILO

ESC

⑤Zero calibration

Register the zero point with the sensor unloaded. Also, if there is any initial load, such as a jig, for

measurements, the zero point can be registered with the initial load applied, but the signal input

range needs to be considered as the initial load is subtracted from it.

In addition, there is a way of considering the initial load by using the digital offset. See " ⑦Digital

offset" on page 31.

≪Setting value≫

-3.000~+3.000mV/V

By performing zero calibration, the setting value of zero calibration becomes the sensor output

value (mV/V) of the time when it was executed. The load with which actual load calibration was

performed can be confirmed. However, it stays unchanged when an error occurs.

Chapter

◇Zero calibration setting method (Example: ch1 zero calibration)

1. Select setting mode 4.

Press → three times.

2. Set "Zero calibration."

Press twice. ⇒ "Zero calibration" is displayed.

* For performing ch2 zero calibration, switch with

.

Enter a setting value input state with , and the entire

setting value blinks. (Initial value: 0.000)

Unload the sensor, check the current load value on the sub

display (ch2), and press .

3. Zero calibration is executed.

A message as shown on the right-hand side is displayed.

If zero calibration is not executed normally, the alarm

sounds and an error is displayed.

4

CALIBRATION PROCEDURE

27

4. Go back to the setting item select state.

If zero calibration is executed normally, you will go back

to the setting item select state, and the output (mV/V) of

the time when it was performed will appear.

The example shows that zero calibration was performed at

0.017mV/V.

5. Press twice to go back to the indicated value display.

27

Chapter

Ch

1

Ch 2

H

I

LO

H

I

LO

FNC

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

H

I

LO

Selected ch display

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

4 CALIBRATION PROCEDURE

⑥a.Equivalent input calibration

See the test report of the sensor, and register the rated output value and the value you want to

display at that time (rated capacity value).

Input the rated output value and display value (rated capacity value) successively.

Equivalent input calibration is not executed by simply inputting the rated output value.

≪Setting value≫

Rated output value [mV/V]: -3.000 ~ 3.000 (except 0)

Display value (rated capacity): -19999 ~ 19999 (except 0)

By performing equivalent input calibration, the setting value of actual load calibration becomes the

input rated capacity value.

However, it stays unchanged when an error occurs.

4

CALIBRATION PROCEDURE

◇Equivalent input calibration setting method

(Example: ch1 equivalent input calibration)

1. Select setting mode 4.

Press → three times.

2. Set "Rated output value" of the sensor.

Press three times. ⇒ "Equivalent input

calibration" is displayed.

* For performing ch2 equivalent input calibration,

switch with .

Enter a setting value input state with , and the

highest digit blinks. (Initial value: 3.000)

Check the test report of the sensor in use, and input the

rated output value (mV/V) with .

Move to the lower digits with .

28

28

Press to validate it.

3. Set "Rated capacity value."

Decide the load you want to display at the rated output

value, and input it with .

Move to the lower digits with .

Press to validate it.

* For inputting a negative sign, press

.

4. Equivalent input calibration is executed.

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

If the calibration error()is displayed, take measures according to each

error, and redo calibration. For details, see "11-7 Error/message list" on page 97.

After completion of calibration, make sure to turn on the calibration protect.

Point

A message as shown on the right-hand side is displayed.

If equivalent input calibration is not executed normally,

the alarm sounds.

5. If equivalent input calibration is executed normally,

you will go back to the setting item select state.

4 CALIBRATION PROCEDURE

Chapter

4

CALIBRATION PROCEDURE

29

29

4 CALIBRATION PROCEDURE

Ch

1

Ch 2

H

I

LO

H

I

LO

FNC

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

Selected ch display

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

H

I

LO

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

H

I

LO

HILO

⑥b.Actual load calibration

Apply an actual load, and register the value of the actual load (rated capacity value).

≪Setting value≫

-19999~19999 (except 0)

By performing actual load calibration, the setting value of equivalent input calibration becomes the

sensor output value (mV/V) of the time when it was executed. The load with which actual load

calibration was performed can be confirmed. However, it stays unchanged when an error occurs.

◇Actual load calibration setting method

Chapter

4

CALIBRATION PROCEDURE

(Example: ch1 actual load calibration)

1. Select setting mode 4.

Press → three times.

2. Set "Actual load" of the sensor.

Press four times. ⇒ "Actual load calibration"

is displayed.

* For performing actual load calibration on ch2,

switch with .

Enter a setting value input state with , and the

highest digit blinks. (Initial value: 100.00)

Check the capacity of the actually-applied load, and

input the value with .

* For inputting a negative sign, press

Move to the lower digits with .

Recheck that the load is properly applied on the sub display (ch2 side), and press

to validate it.

.

30

30

3. Actual load calibration is executed.

If actual load calibration is executed normally, a

message as shown on the right-hand side is displayed.

If actual load calibration is not executed normally, the

alarm sounds and an error is displayed.

4. If actual load calibration is executed normally, you will

go back to the setting item select state.

4 CALIBRATION PROCEDURE

Ch

1

Ch 2

H

I

LO

HILO

FNC

H

I

Ch

1

Ch 2

OK

LO

PEAK

HOLD

HILO

H

I

LO

Selected ch display

ESC

⑦Digital offset

This function is to subtract a set value from the indicated value. This function is convenient when

zero cannot be obtained with no load for some reason or for offsetting. When not using, set "0."

(Displayed value)=(Actual indicated value)-(Setting value of digital offset)

≪Setting value≫

-19999~19999

◇Digital offset setting method

1. Select setting mode 4.

Press → three times.

2. Set "Digital offset."

Press five times. ⇒ "Digital offset" is displayed.

* Switch desired ch with

.

Press , and the highest digit blinks.

Input the setting value with .

Move to the lower digits with .

Validate it with .

* For inputting a negative sign, press

.

3. Press twice to go back to the indicated value display.

Chapter

4

CALIBRATION PROCEDURE

31

31

Chapter

Ch

1

Ch 2

H

I

LO

HILO

FNC

H

I