Page 1

F381A/F388A

DeviceNet I/F

OPERATION MANUAL

01FEB2015REV.3.02

Page 2

Introduction

Remote I/O communications regularly exchange data between the master and slave.

Communications are carried out at the timing of occurrence of events by message

functions.

Ref erence

DeviceNet is a registered trademark of ODVA (Open DeviceNet Vendor Association).

SYSMAC CS/CJ Series is a registered trademark of OMRON Corporation.

About copyrights and trademarks

The DeviceNet I/F option is an interface for controlling the F381A/F388A with PLC.

By using DeviceNet, the F381A/F388A can be controlled directly from the PLC, resulting in substantial

reductions in wiring.

The supported functions include reading of the present indicated value and status, commands such as D/Z,

waveform functions, reading and writing of set values, etc.

(* Since set values and waveforms are read and written by message functions, use a master that supports

them.)

Parameters such as a slave are to be set at the front of the F381A/F388A. Also, there is no need to set the

baud rate of the F381A/F388A since it automatically follows the master.

In this document, outputs refer to signals from the master to the slave (F381A/F388A), and inputs refer to

signals from the slave (F381A/F388A) to the master.

Introduction

I

Page 3

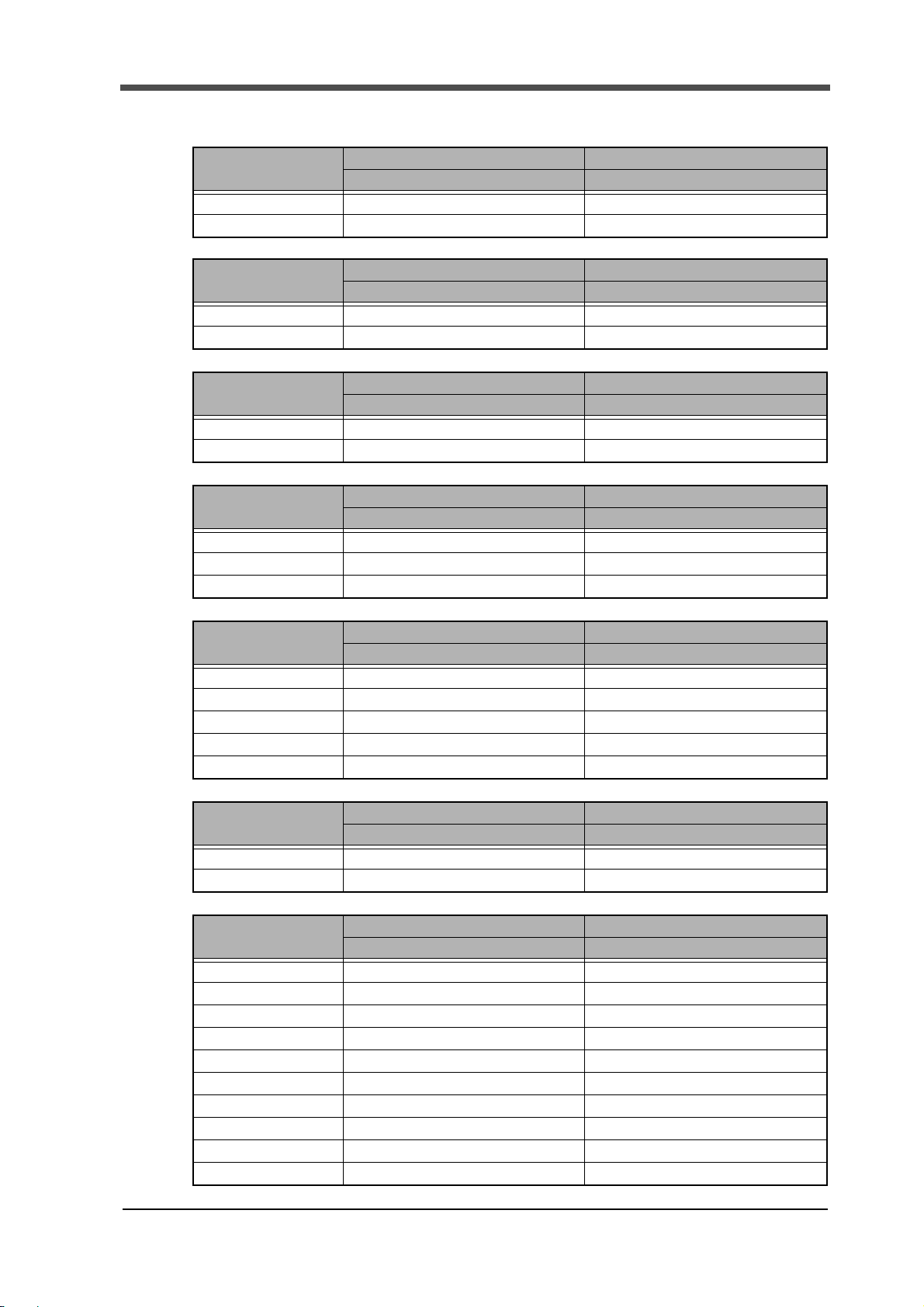

Contents

Contents

1. Part names. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. F381A/F388A setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3. Communication connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

4. Status LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

5. About remote I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

6. I/O format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6-1. I/O format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

■ Input data (F381A/F388A → Master) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

■ Output data (Master → F381A/F388A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

6-2. About input data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

6-3. About output data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

7. About message communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

8. Message communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

8-1. Communication format . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

■ Reading set values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

■ Writing set values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

■ Reading set values(all). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

■ Writing set values(all) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

■ Reading measurement range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

■ Reading waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

■ Writing waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

■ Reading hold results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

■ Reading Wave No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

■ Writing Wave No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

■ Error response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

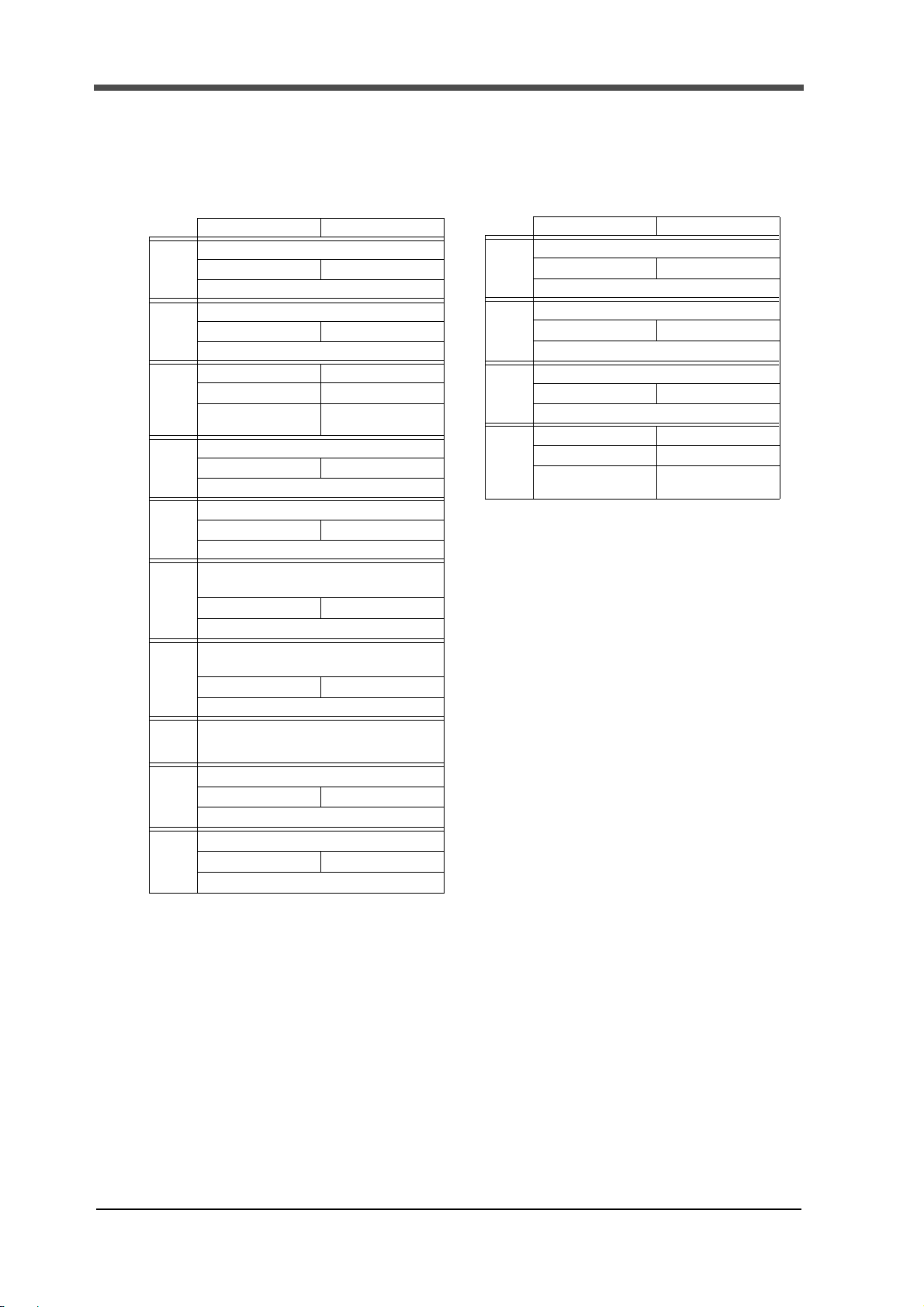

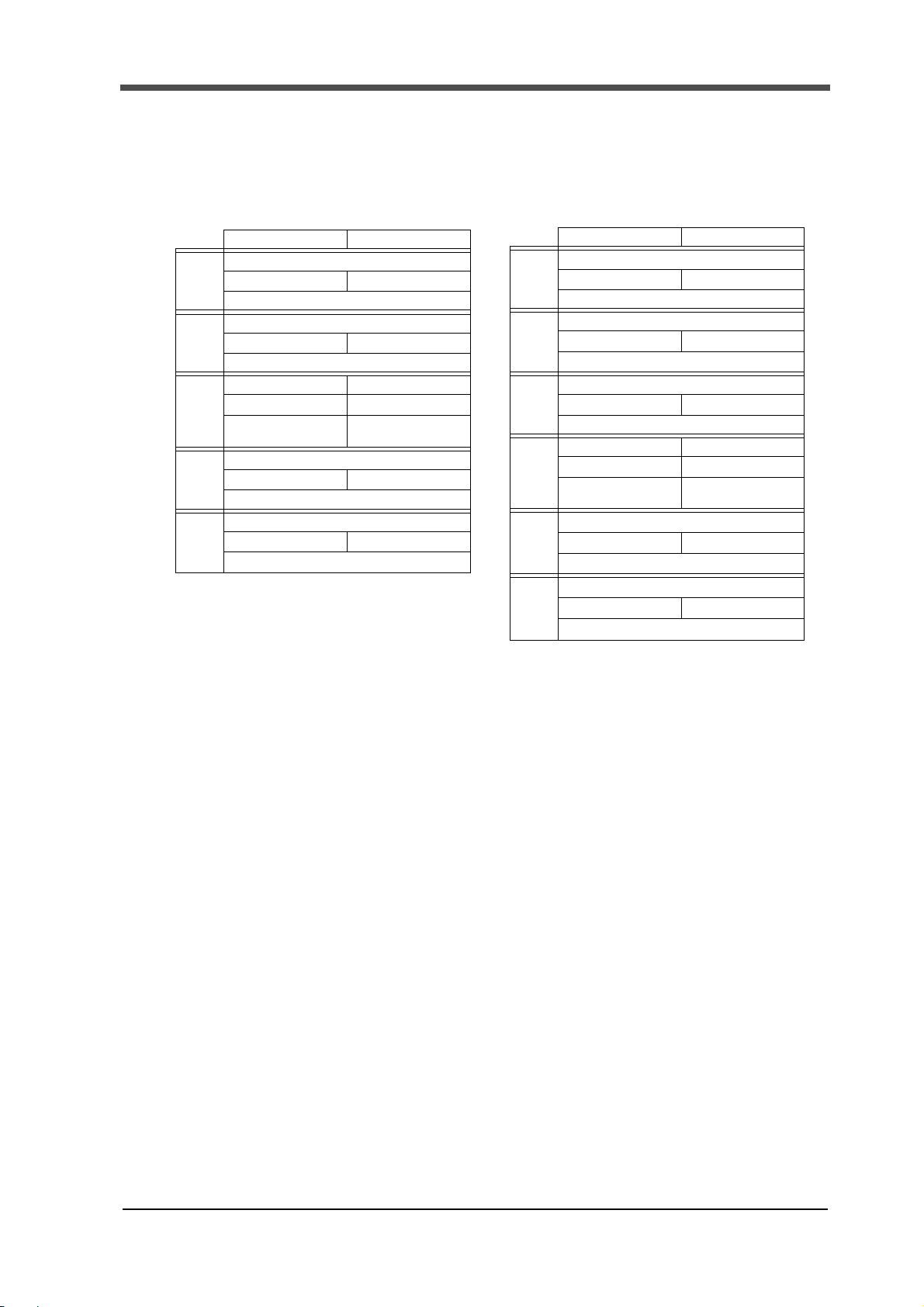

8-2. List of set value commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

II

Page 4

Contents

■ Read and write various settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

■ All read & write set values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

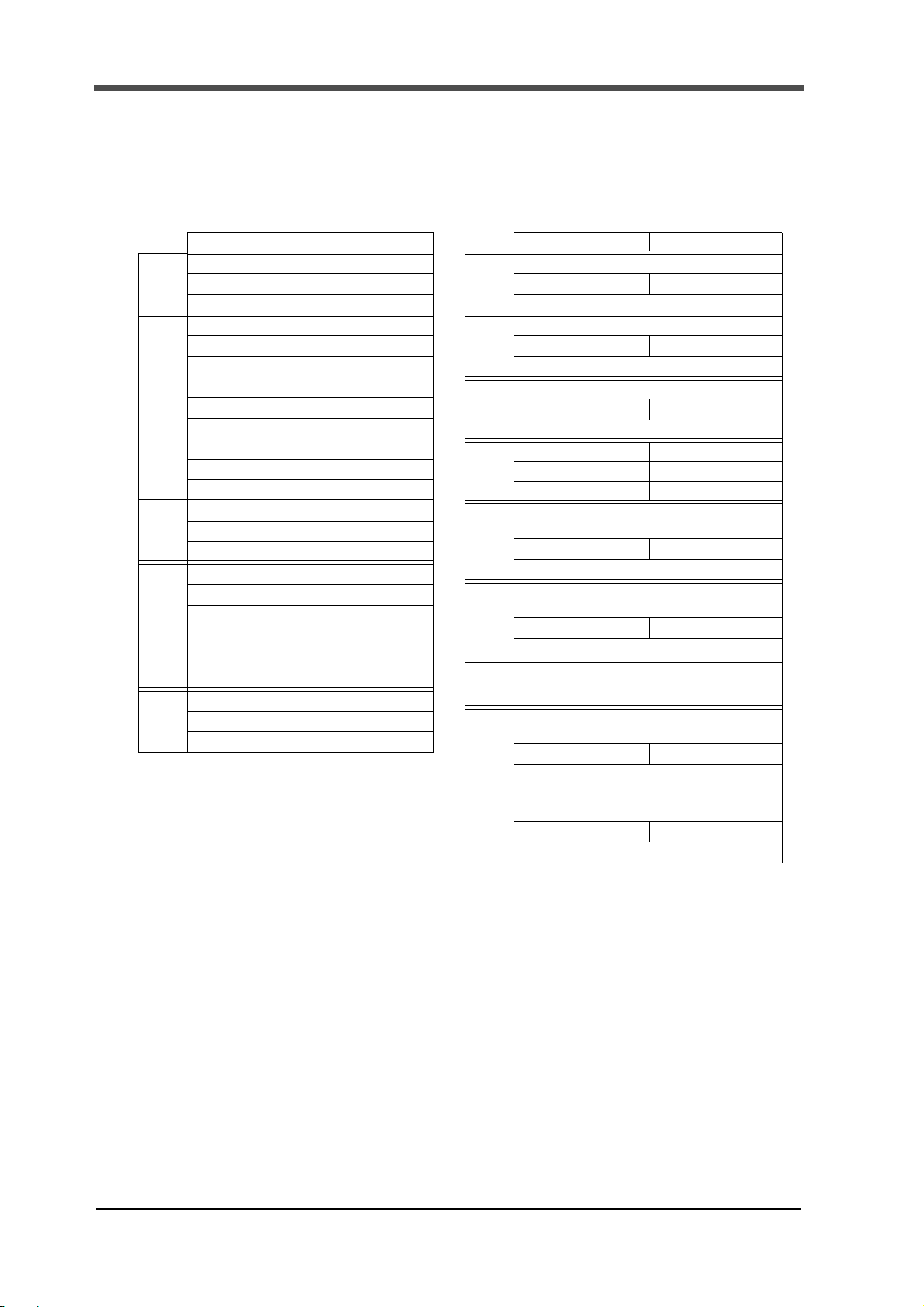

■ Unit setting list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

9. A sample program of message communications using . . . . . . . . . . . . . . . . 26

9-1. Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

9-2. The representative case of each message in a sample program. . . . . . . . . . . . . . . . 29

■ Reading set values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

■ Writing set values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

■ Reading set values(all). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

■ Writing set values(all). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

■ Reading measurement range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

■ Reading waveform . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

■ Writing waveform. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

■ Reading the hold results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

■ Reading Wave No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

■ Writing Wave No. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

■ Error response. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

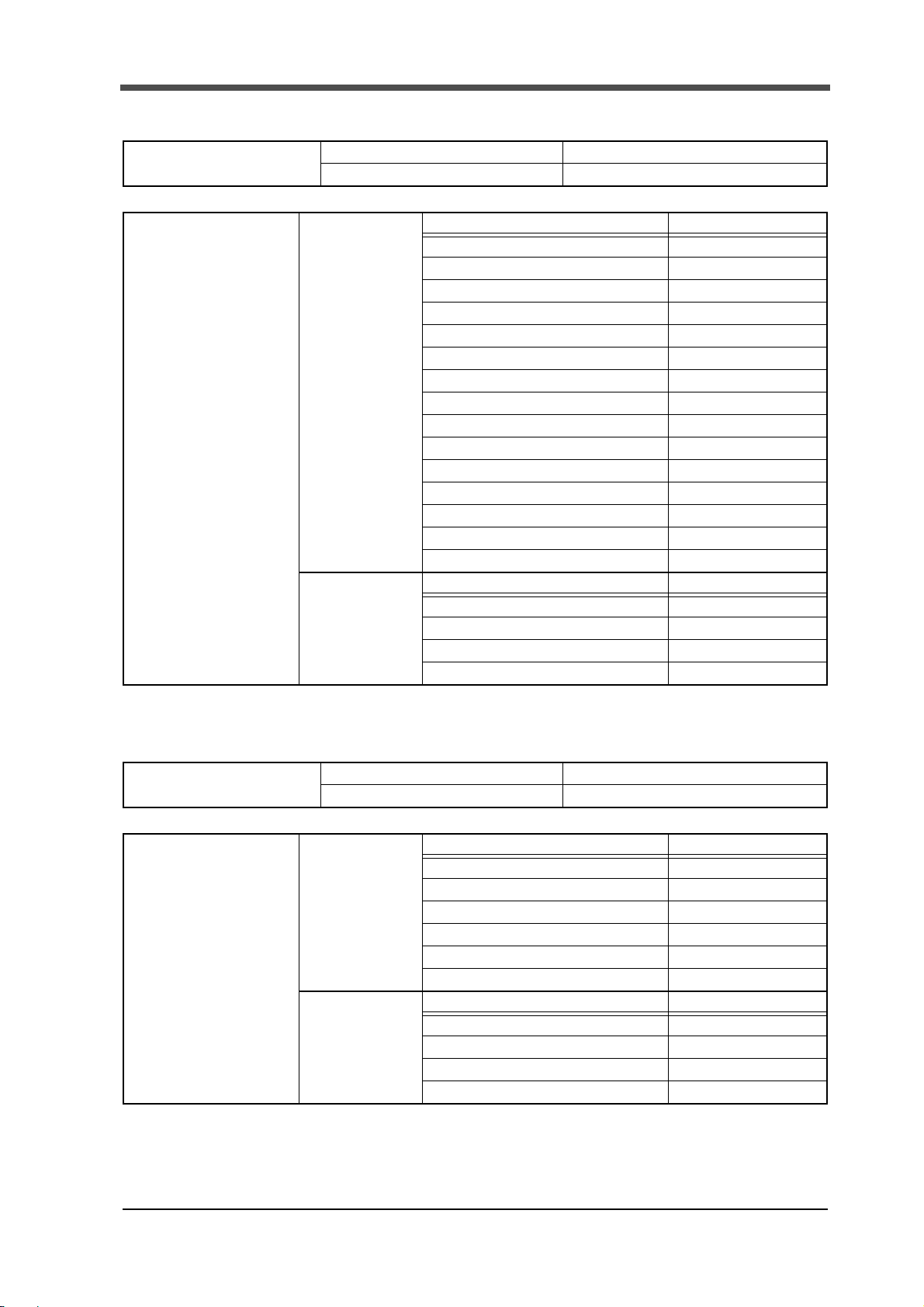

10.Device profiles and object implementation. . . . . . . . . . . . . . . . . . . . . . . . . . 40

■ Device profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

■ Implementation of objects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

■ Expression of EDS file and the explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

■ Names of alternatives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

11.Outside dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

III

Page 5

Contents

M E M O

IV

Page 6

1. Part names

Operation

Status LED

Communication

connector

Status LED

Indicating the communication status.

(See "4.Status LED" on page3.)

Communication connector

The Connector for connecting DeviceNet.

(See "3.Communication connector" on page2.)

2. F381A/F388A setting

1.Part names

Main screen→Setting→First Setting→Option setting→DeviceNet

Node address (Initial value, 0): 0 to 63

Input select 1 (Initial value, Ext. input): Network, Ext. input

Input select 2 (Initial value, Ext. input): Network, Ext. input

Major revision (Initial value, 1): 1 to 2

Explanation for setting

Node address:Setting the node adress.

Input select1 to 2: Select whether input signals of the F381A/F388A are directed by the

control connector (Ext. input) or by DeviceNet (Network).For each

setting, select the following signal.

Input select 1..........Load Digital Zero, DPM Positioning, Start, Stop, Hold, Reset, Backlight

On, Prohibit Touch Panel

Input select 2..........Work 1, Work 2, Work 4, Work 8

Major revision: Set major revision of the F381A/F388A as a device.

Use at “1”. (Do not change.)

* Setting of the communications speed is note required.

1

Page 7

3.Communication connector

When many parameters are displayed via a configurator, etc., it takes time to

access; therefore, an EDS file that supports only 0ch is available for setting on

each ch.

Point

Red

White

Blue

Black

Name Type of signal

Black Power code -side (V-)

Blue Communication data

Low side

(CAN L)

― Shield

White Communication data High side (CAN H)

Red Power code +side (V+)

Alarm codes

The alarm codes appearing at the lower right of the DeviceNet setting

screen are as shown in the table below.

List of alarm codes

Code Status

0 Normal status

1 to 10 Internal hardware failure

11 Node address overlap

13 Network power failure

Correspondence between major revision and an EDS file

EDS

file

F381.eds 1 116 Only 0ch Approx. 30 sec.

F388.eds 1 115 Only 0ch Approx. 30 sec.

Major

revision

setting

Number

of

parameters

3. Communication connector

Remarks

Time to read via a

configurator

(at 500kbps)

Prepare a 24V DC power supply.

The relationship between each signal line and color chip is as follows.

The applicable plug is a PHENIX CONTACT-manufactured MSTB2.5/5-STF-5.08AUM

(accessory) or equivalent.

2

Page 8

4. Status LED

All input and output signals are of positive logic.

1: ON

0: OFF

The operations are the same as those of the I/O signals of

the main body. For details, refer to the F381A/F388A Operation Manual.

Point

Communication status is displayed by LED.

MS:Indicating the F381A/F388A status.

MS (Module status) LED Status

4.Status LED

Red Turns ON

Red Blinks

Green Blinks

Green Turns ON

NS:Indicating the Network status.

NS (Network status) LED Status

Red Turns ON

Red Blinks

Green Blinks

Green Turns ON

5. About remote I/O

The F381A/F388A can send status and indicated values through DeviceNet with a delay of approx.

100msec compared with external I/O signals of the main body (in simple remote I/O

communications).

Furthermore, the delay time is affected by the cycle time of the communications, scan time of the

PLC, etc.

Therefore, for cases where the speed is severe, use the control connector of the main body, and not

via communications.

In a line manner, since input signals such as the D/Z command also cause a delayed time when used

via communications, use the control connector for cases requiring speed.

Input signals (F381A/F388A → Master) are output to communications and the control connector in

parallel irrespective of settings of the main body.

For output signals. (Master → F381A/F388A), communications or the control connector can be

selected on a block-by-block basis.

Trouble

Trouble

Trouble

Normal

Bus OFF, Node Address Overlap

Communication Time-out

Waiting for Connection establishment

Normal

3

Page 9

6.I/O format

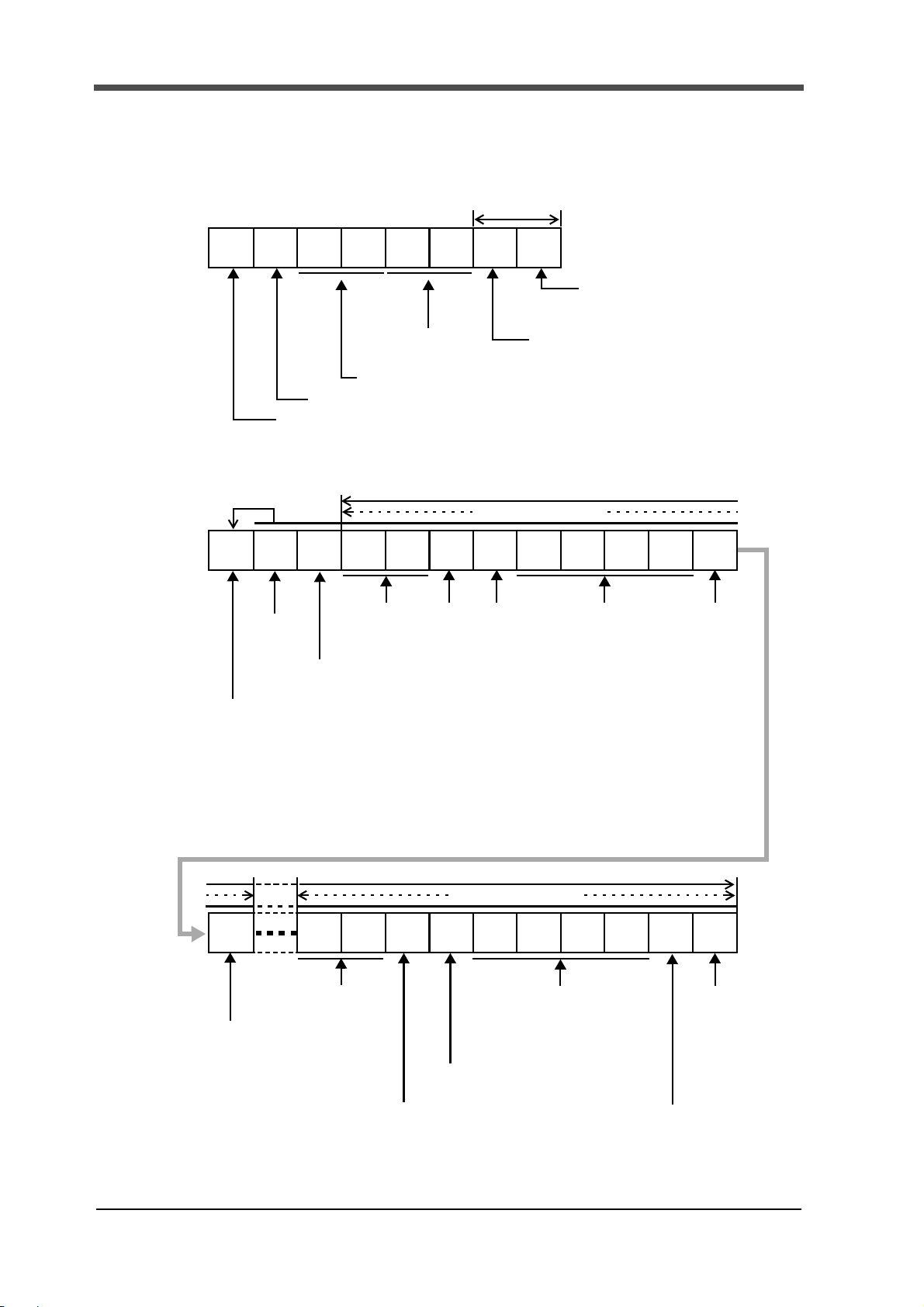

■Input data (F381A/F388A→Master)

■Output data (Master→F381A/F388A)

ch B15 B14 B13 B12 B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 B0

n+0

Load (Signed 16 bit binary)

n+1

DPM (Signed 16 bit binary)

n+2

SD

OK

DPM

OK

Load

OK

Run

Compl-

ete

Wave Result

Overload

Hold Result

DPM Load

HI OK LO HI OK LO HI OK LO

n+3

Work Display Measurement Status

8421

Reset

ON

Compl-

ete

Wai t

Cal.

Sampl-

ing

Wait

Lv.

Wait

OFF

Wai t

St.

ch B15 B14 B13 B12 B11 B10 B9 B8 B7 B6 B5 B4 B3 B2 B1 10

n+0

Work Prohibit

Touch

Panel

Back-

light

ON

Reset Hold Stop Start

DPM

Position

ing

Load

Digital

Zero

8421

* If speed is required, use the control connector on the main unit.

Effective only when Input Select 1 is Network.Effective only when Input Select 2

is Network.

6. I/O format 6-1.I/O format

4

Page 10

6-2.About input data

Load ・displacement

The data of the currently indicated value is stored. If the indicated value is held, the held value is

displayed.

* If the X-axis of the waveform is time, the displacement value becomes 0.

6.I/O format

Range

・Hold Result (Load/DPM)

・Overload

・Complete

・Wave Result

Load:-9999~9999、Displacement:-9999~320000

Use it for acquiring judgment results by using the hold function. If displacement needs to be

judged, also use DPM. It is not used if the hold function is not used. Hold results are output.

LO: Turns ON when the hold result falls below the LO limit, and the output is held.

HI: Turns ON when the hold result exceeds the HI limit, and the output is held.

OK: Turns ON when judgment is made during measurement and the LO and HI outputs are

not ON after completion of the measurement. OK will not turn ON if no hold is made

for the specified Number of Use Sections.

* Please fetch the inputs in synchronization with the Complete of n+2.

Use Overload to stop the equipment in case of emergency due to the excess load applied to the

sensor. Irrespective of the measurement status, it turns ON at the Overload. It turns OFF, when

the Overload is released.

Use it for recognizing the completion of measurement. It turns ON when the measurement is

completed.

Use it for acquiring judgment results by using the waveform comparison function. It is not used

if the waveform comparison function is not used. Waveform comparison results are output.

LO: Turns ON when the waveform comparison result falls below the LO limit, and the

output is held.

HI: Turns ON when the waveform comparison result exceeds the HI limit, and the output is

held.

OK: Turns ON when the Compare Area is passed through during measurement and the LO

and HI outputs are not ON after completion of the measurement. OK will not turn ON if

the measurement does not reach the Compare Area or the Reference Point of Relative

Comparison when Relative Comparison is made.

* Please fetch the inputs in synchronization with the Complete of n+2.

・Load OK

Use it for recognizing the abnormality of the load sensor. It is normally ON. It turns OFF with a

sensor error (sensor ±error), or display error (±OVER), or when load exceeds the Overload or

when the Load-Digital-Zeroed value exceeds the Digital Zero Limit. It also turns OFF when the

Start, Reset, or Load Digital Zero signal is ON.

・DPM OK

Use it if the X-axis of the waveform represents displacement. It is not used when the X-axis of

the waveform represents time. It turns OFF when measuring points of 10 data or more are

skipped because the pacing of displacement is too fast. It also turns OFF when the Start, Reset,

or DPM Positioning signal is ON.

5

Page 11

6.I/O format

Measurement status

・Run

Use it for confirming that the CPU is running normally.

When the CPU is running normally, switching between ON and OFF is done about every 0.5

sec. If it is ON or OFF for a few seconds, there may be something wrong.

・SD OK

Normally use it if the SD card slot option is used. It turns OFF with a memory card error*

when the measurement start input OFF →ON is ignored because a measurement waveform is

not saved in time while being saved automatically*

signal is ON.

*1 It does not turn ON until the error is cleared.

*2 It is reset by starting measurement being saved in time.

Displays the present measurement status.

Wait St............... The Start signal input is waited for. Input the Start signal. Measurement can

also be started by pressing the Start key.

Wait Off .............It is waited for that the Start signal input is turned OFF. Turn OFF the Start

signal.

Wait Lv. .............It is waited for that load or displacement crosses the Measurement Start Level.

Apply load to the sensor so as to cross the Measurement Start Level.

Sampling........... Measurement is in progress. The measurement is stopped when the

Measurement Stop Condition is met.

* During measurement, the present measurement waveform is not displayed.

Calculating ....... Judgment is being prepared.

Complete.......... Measurement is completed. The measurement waveform is displayed.

Reset On .......... It is waited for that the Reset signal is turned OFF.

2

. It also turns OFF when the Start or Reset

1

, or

Work display

The currently used work No. is output. During measurement, the work No. used for measurement is

output.

6-3.About output data

Load Digital Zero

Perform Digital Zero by unloading the load sensor before measurement to simply adjust the

deviation of the zero point of the load by temperature drift, etc. The load is zeroed by turning the

signal from OFF to ON. As long as the signal is ON, the Load OK output is kept OFF.

* Digital zero value is cleared when the power supply is turned on.If you want to

maintain digital zero value, please do zero calibration instead.

DPM Positioning

Use it for adjusting the zero point of displacement just before measurement start.

It is not used if the X-axis of the waveform represents time or the zero point of displacement does

not need to be adjusted. By turning the signal from OFF to ON, displacement is brought to the DPM

Positioning set value, and the internal counter of the pulse input is cleared. As long as the signal is

ON, the DPM OK output is kept OFF.

6

Page 12

7.About message communications

Start

Use it for starting measurement. By turning the signal from OFF to ON when the Start signal input

is waited for, a “Wait Off” state is brought about, and the Hold Result, Wave Result, Complete,

Load OK, and DPM OK outputs are turned OFF. By turning the signal from ON to OFF, a “Wait

Lv.” State is brought about, or the measurement is started according to the Measurement Start

Condition.

Stop

Use it for stopping measurement. By turning the signal from OFF to ON during measurement, the

measurement is stopped.

Hold

Use only for using the section control function by External Input. It is not used if the hold function

is not used or Change of Section is made by Setting. By turning the signal from OFF to ON, the

hold section is changed.

Reset

Use it for releasing some errors, etc., in emergencies. Irrespective of the measurement status, by

turning the signal from OFF to ON, the Hold Result, Wave Result, Load OK, and DPM OK outputs

are turned OFF, and a “Wait St.” state is brought about. If the Reset signal is turned from OFF to

ON during measurement, the measurement is forcedly stopped and the measurement data is

annulled. For keeping the data, check the data after completion of the measurement, and then turn

the Reset signal from OFF to ON.

Prohibit Touch Panel

Use it for controlling so as to prevent touch panel operations. As long as the signal is ON, no operation

can be performed with the touch panel.

Backlight On

Use it for controlling the backlight externally. By turning the signal from OFF to ON, the backlight

lights up. As long as the signal is ON, the backlight stays ON.

Work

Use it for using two or more work Nos. It is not used if only work No. 0 is used. Specify work

No(s). to be used before measurement.

7. About message communications

By using message communications, the following can be read and written.

Be aware that the setting range varies depending on the settings of the main unit.

* For message communications, a master that can carry out message communications and CPU unit

need to be combined.

・Set value: Read / Write / Read (all) / Write (all)

・Measurement range: Read

・Waveform: Read / Write

・Hold result: Read

・Wave No.: Read / Write

7

Page 13

8.Message communication

* For class ID, instance ID, attribute ID, and data, see List of set value commands

" ■ Read and write various settings" on page 17.

* Received data in normal condition is shown. For received data in abnormal

condition, see "Error response" on page16.

Point

00H 0EH 00H 71H 00H 70H 67H

Node address (Node0)

Service code(Various setting reading)

Class ID (Hold setting)

Instance ID (work1、section2)

Attribute ID (Use hold)

Service data(1byte)

06H 00H 8EH 02H 00H 00H 00H

Receiving number of bytes(6byte)

Node address (Node0)

Service code+80H(Various setting reading)

Data(00000002H:PEAK)

Service data(4byte)

LL LH HL HH

8. Message communication

8-1.Communication format

■Reading set values

Example) Reading Use Hold in Hold Setting (work 1, section 2)

●Sending data(Master→F381A/F388A)

●Receiving data(F381A/F388A→Master)

8

Page 14

■Writing set values

00H 10H 00H 71H 00H 70H 67H

Node address (Node0)

Service Code(Various setting writing )

Class ID (Hold setting)

Data

Service data(5byte)

LL LH HL HH

02H 00H 00H 00H

(00000002H:Peak)

Instance ID (work1、section2)

Attribute ID(Use hold)

02H 00H 90H

Receiving number of bytes(2byte)

Node address (Node0)

Service Code+80H(Various setting writing )

00H 32H 00H 6FH 00H 6EH

Node address (Node0)

Service code(Various setting all reading)

Class ID (Measurement start condition setting)

Instance ID (work1)

12H 00H B2H 01H 00H 00H 00H

Receiving number of bytes

Node address (Node0)

Service code+80H (Various setting all reading)

Data4

Service data

LL LH HL HH

2CH 01H 00H

(0000012CH:300)

Data1measurement start condition

00H

LL LH HL HH

(00000001H:External Input + Load)

Measurement end level

(The number of bytes of service data+2

(Example is18byte))

(differs according to the class ID specified at send-time(Example is16byte))

Example) Writing Use Hold in Hold Setting (work 1, section 2)

●Sending data(Master→F381A/F388A)

●Receiving data(F381A/F388A→Master)

8.Message communication

■Reading set values(all)

Example) Reading all measurement start condition settings (work 1)

●Sending data(Master→F381A/F388A)

●Receiving data(F381A/F388A→Master)

9

Page 15

8.Message communication

00H 33H 00H 6FH 00H 64H 01H

Node address (Node0)

Service code (Various setting all writing )

Service data

00H 00H

Data1 measurement start condition

LL LH HL HH

(00000001H:External Input + Load)

00H

Class ID (Measurement start condition setting)

Instance ID (work0)

2CH 00H 00H

Data4 measurement end level

LL LH HL HH

(00000012H:300)

01H

(It changes with Class ID to specify. (Example is16byte))

02H 00H B3H

Receiving number of bytes(2byte)

Node address (Node0)

Service code+80H(Various setting all writing )

00H 34H 00H 82H 00H 64H

Node address (Node0)

Service code(Reading measurement range)

Class ID (0082H fixed)

Instance ID (0064H fixed)

■Writing set values(all)

Example) Writing all measurement start condition settings (work 0)

●Sending data(Master→F381A/F388A)

●Receiving data(F381A/F388A→Master)

■Reading measurement range

Example) Reading the measurement range

●Sending data(Master→F381A/F388A)

10

Page 16

8.Message communication

06H 00H B4H 00H 00H FFH 07H

Receiving number of bytes(6byte)

Node address (Node0)

Service code+80H (Reading measurement range)

Service data(4byte)

Data1 start of the range

LHLH

(0000H:0(Data number ))

data range:0 ~ 2047

Data2 end of the range.

(07FFH:2047(Data number ))

data range:0 ~ 2047

00H 35H 00H 82H 00H 64H 64H

Node address

Service code

Service data(6byte)

00H 00H 00H 1FH 00H

LHLHLH

(Node0)

(Reading

Class ID (Measured waveform)

・0082H(130):Measured waveform

・0083H(131):Comparison waveform (upper limit)

・0084H(132):Comparison waveform (lower limit)

・0085H(133):Comparison waveform (upper limit) used

for measurement

・0086H(134):Comparison waveform (lower limit) used

for measurement

Data3Data1 Data2

Instance ID

・0064H(100):work0

・006EH(110):work1 ~

00 FB H (2 50 ):work15

* Specify 0064H if a measurement

waveform or comparison waveform

used for measurement is specified

to class ID.

Data1(load)

・0064H(100):load

・0065H(101):Displacement(Time)

Data2 start of the range

(0000H:0(Data number )

data range:0 ~ 2047

* Data range should be as the start of the

range ≦ the end of the range.

* The end of the range - the start of the range

≦ 31.

Data3 end of the range.

(001FH:31(Data number )

data range:0 ~ 2047

waveform)

●Receiving data(F381A/F388A→Master)

■Reading waveform

A waveform is an array of up to 2048 (data No. 0 - 2047) load data. The data of the waveform can

be read by specifying the data No. range to read.

However, the amount of load data that can be handled in one message communication is up to 32.

The waveform is divided into 64 (32×64 = 2048), and the waveform is read 64 times.

* The range to read can be specified as narrowed by reading the measurement range.

(Depending on usage, all of 2048 may not be used for measurement.)

* The time required to read one waveform (load) (2048 data) is approximately 4 seconds.

・Measurement conditions:

CPU unit: SYSMAC CS1G CPU42-V1 (manufactured by OMRON)

Master unit: DeviceNet master unit CS1W-DRM21 (manufactured by OMRON)

Master and slave (F381A/F388A) one-to-one, 500kbps

No processing other than waveform read

Example) Reading a measurement waveform (load in the range of 0 - 2047)

① Read the measurement waveform in the range of 0 - 31.

●Sending data(Master→F381A/F388A)

11

Page 17

8.Message communication

42H 00H B5H FFH FFH 01H 00H

Receiving number of bytes

Service code+80H

Service data(differs according to the range specified at send-time

03H 00H 04H 00H

(The number of bytes of service data +2

LH LHLH

LH

Load:2nbyte Displacement(Time):4n (n=1 ~ 32(Example is n=32))

Node address

(Node0)

(Reading waveform)

Data1

Waveform data of the start of

the range(FFFFH:-1)

data range:-9999 ~ 9999

Data2

Waveform Data of the start of

the range+1(0001H:1)

data range:-9999 ~ 9999

Data1 Data2

Data n - 1Data n

Data n - 1

Waveform data of the end of

the range-1 (0003H:3)

data range:-9999 ~ 9999

Data n

Waveform data of the end of

the range.(0004H:4)

data range:-9999 ~ 9999

(Example is 66byte))

82H 00H B5H 00H 00H 00H 00H

Receiving number of bytes

Service code+80H

Service data(differs according to the range specified at send-time

1FH 00H 00H 00H

(The number of bytes of service data + 2

Load:2nbyte Displacement(Time):4n (n=1 ~ 32(Example is n=32))

Node address

(Node0)

(Reading waveform)

Waveform data of the start of the

range(00000000H:0)

data range:

・Time:0 ~ 51175

・Displacement(reference; front):

0 ~ 10235

・Displacement(reference; back):

-10235 ~ 0

Data1

Data n

Waveform data of the end of the

range.(0000001FH:31)

data range:

・Time:0 ~ 51175

・Displacement(reference; front):

0 ~ 10235

・Displacement(reference; back):

-10235 ~ 0

LL LH HL HH LL LH HL HH

(Example is 130byte))

●Receiving data(F381A/F388A→Master)

・When load is specified to data 1 of send data

・When Displacement is specified as data 1 of sending data

② Change the range and repeat ①. (the start of the range~last:32~63、64~95、…、

2016~2047)

12

Page 18

8.Message communication

00H 36H 00H 83H 00H 64H 64H

Node address

Service code

Service data (6byte)

00H 00H 00H 64H 00H

LHLHLH

(Node0)

(Writing waveform)

Class ID(Comparison waveform upper limit)

・0083H(131):Comparison waveform (upper limit)

・0084H(132):Comparison waveform (lower limit)

Data3Data1(0064H fixed)

Data2

Instance ID(Work 0)

・0064H(100):Work 0

・006EH(110):Work 1

~ 00FBH(250):Work 15

Data number specification

(0000H:0(Data No.))

Data range:0 ~ 2047

Load(0064H:100)

Data range:-9999 ~ 9999

02H 00H B6H

Receiving number of bytes(2byte)

Node address (Node0)

Service code +80H(Writing waveform)

■Writing waveform

A comparison waveform upper limit (lower limit) is an array of 2048 (data No: 0 - 2047) load data.

The comparison waveform is written by specifying data Nos. and load, and one piece of load data is

rewritten in one message communication. Therefore, for rewriting all of one waveform, writing

operation is to be performed 2048 times.

Example) Rewriting the comparison waveform upper limit (work 0)

① Writing to data No. 0 of the comparison waveform upper limit (work 0)

●Sending data(Master→F381A/F388A)

●Receiving data(F381A/F388A→Master)

② Change the start of the range and repeat ①. (Data number specification:1、2、…、

2047)(Load:as desired)

13

Page 19

8.Message communication

00H 40H 00H 8CH 00H 64H 65H

Node address (Node0)

Class ID (008CH fixed)

Data2 section last(section 5)

Service data (2byte)

69H

data range:65H(100)section1 ~

Instance ID

Data1 Section head(section1)

data range:65H(100)section 1 ~

Service code (Writing waveform)

69H(105)section5

* The data range should be as

the start of the range ≦ the end of the range.

69H(105) section 5

(0064H fixed)

Section head (section1)

02H C8H 00H 01H 03H B0H 00H 00H04H 01H 02H

34H 00H C0H FFH FFH 01H 01H

Node address

01H 00H

LL LH HL HH

2CH

LL LH HL HH

Service data (10n byte n=1 ~ 5 (Example is n=5))

Receiving number of bytes

(Number of bytes of Service data+2

(Node0)

Service code +80H

(Reading the hold results)

00H 01H

LH

Data1

Hold value(load)(FFFFH:-1)Data range:-9999 ~ 9999

Data2

Existence of load Data(Existent)

・0:None ・1:Existent

Data3

Load judging (OK)

・0:Unused ・1:OK・2:HI・3:LO・4:H/L・5:NG

Data4

Hold value(Time or displacement )(0000012CH:300 (Example is

displacement)

)Data range:・Time:0 ~ 51175

・Displacement(reference; front):0 ~ 10235

・Displacement(reference; back):- 10235 ~ 0

Data5

Existence of Displacement Data(Existent)

・0:None ・1:Existent

Data1 Data2 Data3 Data4 Data5

Displacement judging(HI)

・0:Unused 3:LO

・1:OK 4:H/L

・2:HI 5:NG

Data6

Data6

Data5

Data4

Hold value(Time or displacement )

(000004B0H:1200

(Example is displacement))

Data3

Data2

LH

Data1

Hold value(load)

Load judging (HI)

(00C8H:200)

Load judging (LO)

Existence of load data

(Existent)

Existence of displacement data

(Existent)

(Example is 52byte))

Section head (section1)

Section last (section5)

■Reading hold results

Example) Reading the hold results of section 1 to section 5 (X-axis: displacement)

●Sending data(Master→F381A/F388A)

●Receiving data(F381A/F388A→Master)

14

Page 20

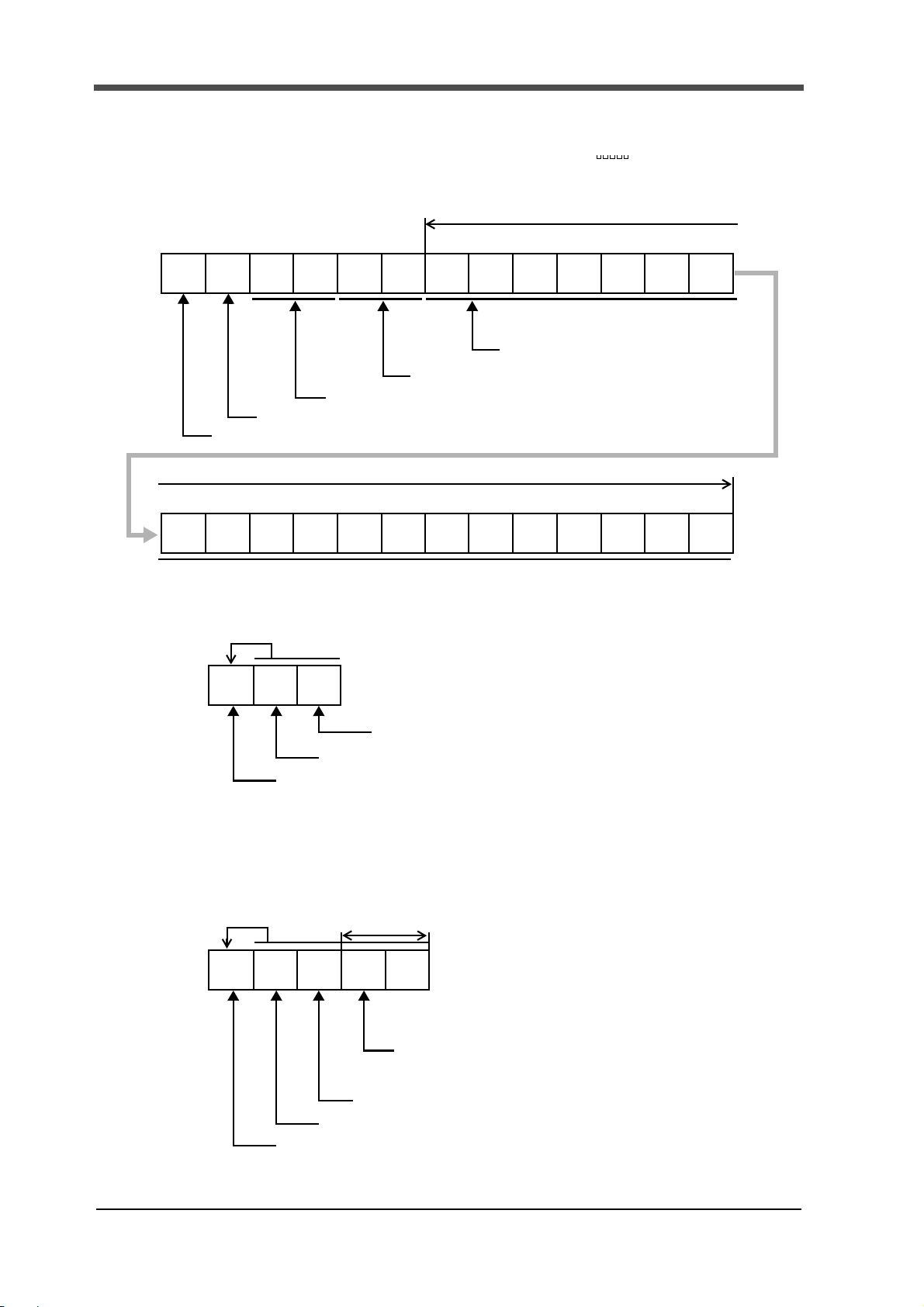

■Reading Wave No.

00H 44H 00H 96H 00H 64H

Node address (Node0)

Service code (Reading Wave No.)

Class ID (0096H fixed)

Instance ID (0064H fixed)

109 12 1114 1316151817 2019 th byte

16H 00H C4H

30H 32H 32H 31H

Data

30H 31H35H

Service data(20 byte fixed)

Receiving number of bytes(22byte)

Service code +80H (Reading Wave No.)

33H

214 36 587 th byte

'0' '2' '2' '1' '5' '0' '1' '3'

Node address (Node0)

data range:0、20 ~ 7E、80 ~ FCH

30H 5FH 30H 30H 30H 30H 20H 20H 20H31H 20H

'0' '_' '0' '0' '0' '0' ' ' '1' ' ' ' ' ' ' ' '

20H

Example) Reading the Wave No. (when "20120531_000001 " is set)

●Sending data(Master→F381A/F388A)

●Receiving data(F381A/F388A→Master)

8.Message communication

15

Page 21

8.Message communication

'0' '2' '2' '1' '5' '0' '1'

7 10 9 12 11 14 13 16 15 18 17 20 19 th byte

00H 45H 00H 96H 00H 64H 30H 32H 31H32H

Service data(20 byte fixed)

Node address (Node0)

Class ID (0096H fixed)

35H

214 36 58th byte

Service code (Writing Wave No.)

33H 30H 5FH 30H 30H 30H 30H 31H 20H20H 20H

'3' '0' '_' '0' '0' '0' '0' ' ' '1' ' ' ' ' ' ' ' '

20H

30H 31H

20H

Instance ID (0064H fixed)

Data

data range:20 ~ 7E、80 ~ FCH

02H 00H C5H

Receiving number of bytes(2byte)

Node address (Node0)

Service code +80H(Writing Wave No.)

04H 00H 94H 16H FFH

Receiving number of bytes(4byte)

Node address (Node0)

Service code (94H fixed)

Service data(2byte)

Error number

Error number

・16H: Class ID is wrong.

Instance ID is wrong.

・08H: Instance ID is 00.

Service code is wrong.

・20H: Service code is 80H or more.

・14H: Attribute ID is wrong.

・15H: Large number of service data

・13H: Small number of service data

・10H: Writing was attempted with the lock applied.

Writing was attempted during measurement.

Write data is wrong (out of range).

■Writing Wave No.

Example) Writing the Wave No. (for setting "20120531_000001 ")

●Sending data(Master→F381A/F388A)

●Receiving data(F381A/F388A→Master)

■Error response

Common to received data

●Receiving data(F381A/F388A→Master)

16

Page 22

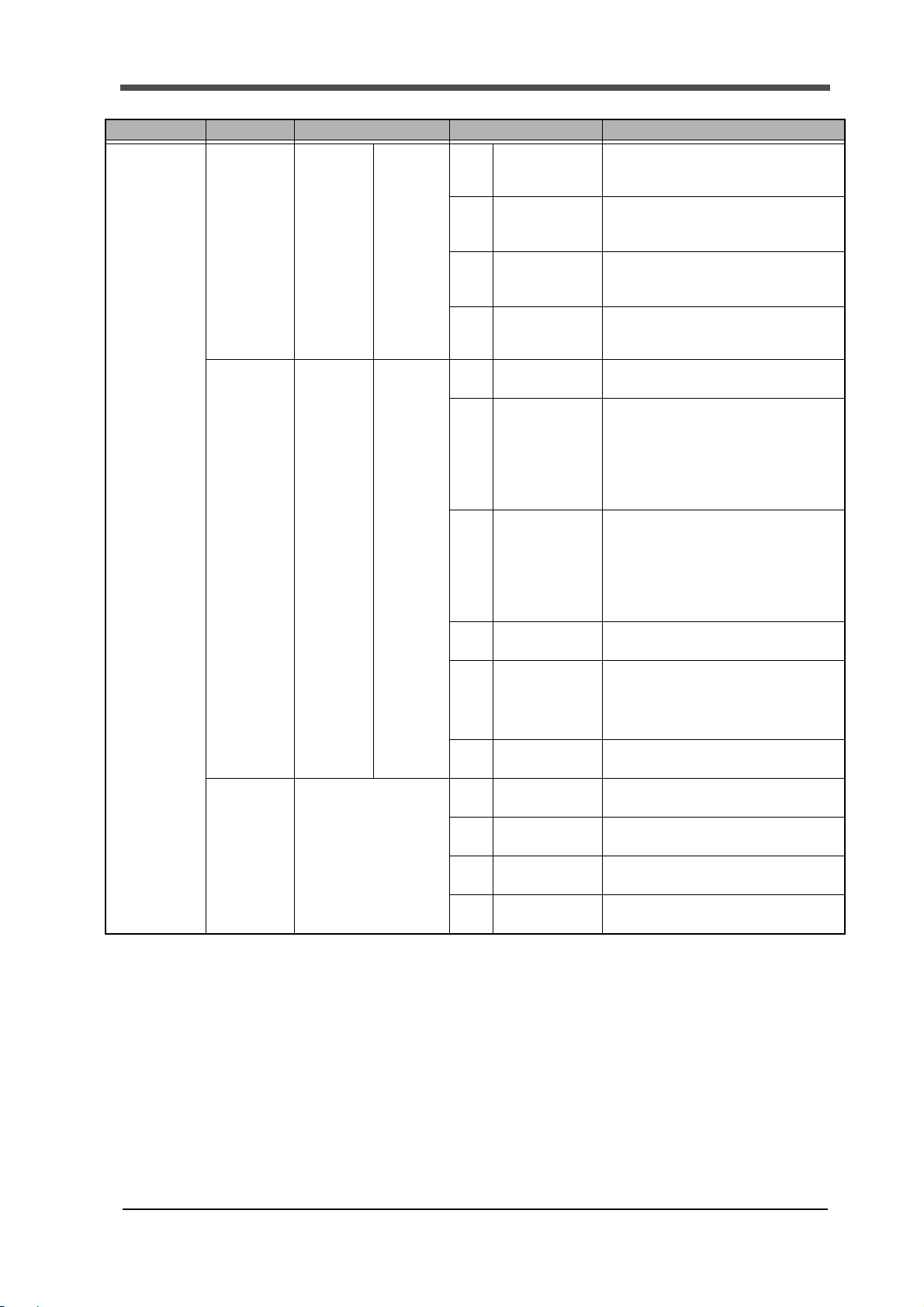

8.Message communication

( ① F381A ② F388A)

8-2. List of set value commands

■Read and write various settings

Service code Class ID Instance ID Attribute ID Input range (display range)

・Read V

Settings

Get Attribute

Single

0EH

・Write

Settings

Set Attribute

Single

10H

arious

Var i o us

Y- a xi s

Setting

0065H (101)

0064H (100) 64H

(100)

65H

(101)

66H

(102)

68H

(104)

69H

(105)

6AH

(106)

6BH

(107)

6CH

(108)

6DH

(109)

6EH

(110)

①Exc. Voltage

②Input Select

Unit

Decimal Place

Equiv. Cal.

(rated output)

Equiv. Cal.

(rated capacity)

Overload 0 to 9999

Increment

Analog Filter

Digital Filter 0, 2 to 999 [Times]

DZ Limit 0 to 9999

①0:2.5 1:10 [V]

②0:±10V 1:±20mA

See "■Unit setting list" on page 24.

0:01:0.0

2:0.00 3:0.000

①-9.999 to 9.999 [mV/V]

②-99.99 to 99.99 [V, mA]

-9999 to 9999

0:11:2

2:53:10

0:10 1:30

2:100 3:300 [Hz]

17

Page 23

8.Message communication

Service code Class ID Instance ID Attribute ID Input range (display range)

Read Various

・

Settings

Get Attribute

Single

0EH

・Write

Var i o u s

Settings

Set Attribute

Single

10H

X-axis

Setting

(DPM)

0066H (102)

Communication

Setting

0067H (103)

0064H (100) 64H

(100)

65H

(101)

66H

(102)

67H

(103)

68H

(104)

6AH

(106)

6BH

(107)

6CH

(108)

6DH

(109)

6EH

(110)

6FH

(111)

0064H (100)

64H

(100)

65H

(101)

66H

(102)

67H

(103)

68H

(104)

69H

(105)

6AH

(106)

6BH

(107)

Time/DPM

Change

Phase Select

Wave Reference

Unit

Decimal Place

Equiv. Cal.

(number of pulses)

(voltage value)

Equiv. Cal.

(displacement

value)

Measure Length

DPM Positioning -9999 to 32000

Analog Filter

(Only ①)

Digital Filter 0, 2 to 999 [Times]

Speed

Data Bit

Parity Bit

Stop Bit

Delimiter

Header

Flow Control

Com. Mode

0:Time

1:Displacement

0:A/B-Phase

1:Only A-Phase

0:Front 1:Back

See "■Unit setting list" on page 24.

0:01:0.0

2:0.00 3:0.000

Standard 1 to 1000000

When the voltage input option is used

-9.999 to 9.999 [V] (Only ①)

-99999 to 99999

Time/Displacement Change; Time

0:0.5 1:1.0 2:2.0

3:5.0 4:10.0 [s]

Time/Displacement Change;

Displacement

0:2000 1:4000 2:6000

3:8000 4:10000

0:10 1:30

2:100 3:300 [Hz]

0:1200 1:2400

2:4800 3:9600

4:19.2k 5:38.4k [bps]

0:71:8 [bit]

0:None 1:Even

2:Odd

0:11:2 [bit]

0:CR 1:CR+LF

0:None 1:STX

0:Off

1:RTS/CTS Control

0:Normal

1:Hold Point Mode

18

Page 24

8.Message communication

Service code Class ID Instance ID Attribute ID Input range (display range)

Read Various

・

Settings

Get Attribute

Single

0EH

・Writ e

Va r i ou s

Settings

Set Attribute

Single

10H

System

0068H (104)

Option

Measurement

Start

Condition

Setting

006FH (111)

Display

Range Setting

0070H (112)

0064H (100) 64H

(100)

65H

(101)

66H

(102)

67H

(103)

68H

(104)

69H

(105)

0064H (100)

006EH (110)

to

00FBH (250)

0064H (100)

006EH (110)

to

00FBH (250)

Work 0

Work 1

to

Work 15

Work 0

Work 1

to

Work 15

64H

(100)

65H

(101)

66H

(102)

67H

(103)

64H

(100)

65H

(101)

66H

(102)

67H

(103)

Backlight

(ON Time)

Language

Work P r o t e c t

First Protect

Contrast 100 (Bright) to 170 (Dark)

Backlight

(Bright → Dark)

Start Condition

Start Level

Stop Condition

Stop Level

Y Start Point -10000 to 10000

Y End Point

X Start Point

X End Point

0 to 99 [minute]

0:Japanese

1:English

0:Not Protect

1:Protect

0:Not Protect

1:Protect

0 to 99 [minute]

0: Only External Input

1: External Input + Load

2: External Input + Displacement

(2 can be set only when the X-axis of

the waveform represents displacement.)

External Input + Load: -9999 to +9999

External Input + Displacement:

-9999 to +32000

0: Only Forced-Stop

1: Load 2: Time

3: Displacement 4: Displacement Stop

(3 and 4 can be set only when the X-axis of

the waveform represents displacement.)

Load: -9999 to +9999

Time: 0.1 to 10.0 [second]

Displacement: -9999 to +32000

Displacement Stop: 0.1 to 10.0 [second]

Y-axis Start Point +

0:25 1:50 2:100 3:200

4:300 5:400 6:500

7:1000 8:2000 9:3000

10:4000 11:5000

12:10000 13:20000

Time or displacement (Front)

0 to 2000 (× Measurement Length/2000)

Displacement (Back)

-2000 to 0 (× Measurement Length/2000)

Time or displacement (Front)

X-axis Start Point +

0:25 1:50 2:100

3:200 4:400 5:600

6:800 7:1000 8:1200

9:1400 10:1600 11:1800

12:2000 13:2200

(× Measurement Length/2000)

Displacement (Back)

X-axis Start Point +

0:

-25 1:-50 2:-100

3:-200 4:-400 5:-600

6:-800 7:-1000 8:-1200

9:-1400 10:-1600 11:-1800

12:-2000 13:-2200

(× Measurement Length/2000)

19

Page 25

8.Message communication

Service code Class ID Instance ID Attribute ID Input range (display range)

Read Various

・

Settings

Get Attribute

Single

0EH

・Writ e

Var i ou s

Settings

Set Attribute

Single

10H

Hold Setting

0071H (113)

0065H (101)

0066H (102)

0067H (103)

0068H (104)

0069H (105)

006FH (111)

0070H (112)

0071H (113)

0072H (114)

0073H (115)

to

00FFH (255)

Work 0 (Sct 1)

Work 0 (Sct 2)

Work 0 (Sct 3)

Work 0 (Sct 4)

Work 0 (Sct 5)

Work 1 (Sct 1)

Work 1 (Sct 2)

Work 1 (Sct 3)

Work 1 (Sct 4)

Work 1 (Sct 5)

to

Work 15 (Sct 5)

64H

(100)

65H

(101)

67H

(103)

68H

(104)

69H

(105)

6AH

(106)

6BH

(107)

6CH

(108)

6DH

(109)

6EH

(110)

6FH

(111)

Change of Sct.

(common to all

work)

Use Sct. 1 to 5

Use Hold

Sct. Start-End

(start point)

Note1)

Sct. Start-End

(end point)

Note1)

Load HI/LO Limit

(HI) Note1)

Load HI/LO Limit

(LO) Note1)

DPM HI/LO

Limit

(HI)

Note1)

DPM HI/LO

Limit

(LO)

Note1)

Start Load -9999 to 9999

Load Difference 1 to 19998

0: External Input 1: Setting

(0 can be set only

when the time or displacement (Front))

0: Always 1: Sample

2: Peak 3: Bottom

4: Peak to Peak

5: Relative Maximum

6: Relative Minimum

7: Inflection Point

8: Average

9: End Displacement

Time or displacement (Front)

0 to 2047 (× Measurement Length/2000)

* However, End point of the previous section

≦Start point≦End point

Displacement (Back)

-2047 to 0 (× Measurement Length/2000)

* However, End point of the previous section

≧Start point≧End point

Time or displacement (Front)

0 to 2047 (× Measurement Length/2000)

* However, Start point≦End point

≦Start point of the next section

Displacement (Back)

-2047 to 0 (× Measurement Length/2000)

* However, Start point≧End point

≧Start point of the next section

-9999 to +9999

* Setting HI limit < LO limit is unacceptable.

-9999 to +9999

* Setting HI limit < LO limit is unacceptable.

Waveform Reference; Front

0 to 2047 (× Measurement Length/2000)

Waveform Reference; Back

-2047 to 0 (× Measurement Length/2000)

* When End Displacement in Use Hold

is selected; -9999 to 32000

* Setting HI limit < LO limit is unacceptable.

Waveform Reference; Front

0 to 2047 (× Measurement Length/2000)

Waveform Reference; Back

-2047 to 0 (× Measurement Length/2000)

* When End Displacement in Use Hold

is selected; -9999 to 32000

* Setting HI limit < LO limit is unacceptable.

20

Page 26

8.Message communication

Service code Class ID Instance ID Attribute ID Input range (display range)

Read Various

・

Settings

Get Attribute

Single

0EH

・Write

Various

Settings

Set Attribute

Single

10H

Hold Setting

0071H (113)

Waveform

Comparison

Setting

0072H (114)

Calibration

0078H (120)

0065H (101)

0066H (102)

0067H (103)

0068H (104)

0069H (105)

006FH (111)

0070H (112)

0071H (113)

0072H (114)

0073H (115)

to

00FFH (255)

0064H (100)

006EH (110)

to

00FBH (250)

0064H (100) 64H

Work 0 (Sct 1)

Work 0 (Sct 2)

Work 0 (Sct 3)

Work 0 (Sct 4)

Work 0 (Sct 5)

Work 1 (Sct 1)

Work 1 (Sct 2)

Work 1 (Sct 3)

Work 1 (Sct 4)

Work 1 (Sct 5)

to

Work 15 (Sct 5)

Wor k 0

Wor k 1

to

Wor k 15

70H

(112)

71H

(113)

72H

(114)

73H

(115)

64H

(100)

65H

(101)

66H

(102)

67H

(103)

68H

(104)

69H

(105)

(100)

65H

(101)

66H

(102)

67H

(103)

0: 1/4 1: 1/2 2: 3/4

Rate

Ordinal 1 to 15 [Times]

Interval AB (A) 1 to 999 (× Measurement Length/2000)

Interval AB (B) 1 to 999 (× Measurement Length/2000)

Relative

Compare Area

(start point)

Note1)

Compare Area

(end point)

Note1)

Compare Margin 0 to 999

Relative Point

(X-axis)

Relative Point

(Y-axis)

Zero Cal. (load) Fixed at 0

Zero Cal.

(displacement)

Actual Cal. (load) -9999 to 9999

Actual Cal.

(displacement)

3: 1 4: 1.25 5: 1.5

6: 1.75 7: 2 8: 3 9: 4[Times]

0:Off 1:On

Time or displacement (Front)

0 to 2047 × Measurement Length/2000

* Setting Start point > End point is unacceptable.

Displacement (Back)

-2047 to 0 × Measurement Length/2000

* Setting Start point < End point is unacceptable.

Time or displacement (Front)

0 to 2047 × Measurement Length/2000

* Setting Start point > End point is unacceptable.

Displacement (Back)

-2047 to 0 × Measurement Length/2000

* Setting Start point < End point is unacceptable.

Time or displacement (Front)

0 to 2047 (× Measurement Length/2000)

Displacement (Back)

-2047 to 0 (× Measurement Length/2000)

-9999 to 9999

Fixed at 0

-9999 to 32000

21

Page 27

8.Message communication

Note1)

Please change other set values beforehand so that the setting range

becomes the maximum when a set value to which other settings influence the

setting range is written in.

Example 1 When you write the Load HI Limit value in.

Please write -9999 in the Load LO Limit value beforehand.

Example 2 When you change the Section Start-End.

Please write 2047(Time or Displacement (Front)) and -2047(Displacement

(Back)) in of the start point and the end point in all sections beforehand in

order of End Point of Section 5, Start Point of Section 5, End Point of

Section 4, …… End Point of Section 1 and Start Point of Section 1.

Please write in the value to be set in order of Start Point of Section 1, End

Point of Section 1, Start Point of Section 2, …… Start Point of Section 5

and End Point of Section 5.

Point

22

Page 28

■All read & write set values

8.Message communication

Service code Class ID Instance ID

・All Read Various

Settings

32H

・

All Write

Settings

33H

Var i o us

Y-axis Setting

0065H (101)

X-axis Setting

(DPM)

0066H (102)

Communication

Setting

0067H (103)

System

0068H (104)

Option

Measurement

Start Condition

Setting

006FH (111)

Display Range

Setting

0070H (112)

0064H (100) 0 40 40 0

0064H (100) 0

0064H (100) 0 32 32 0

0064H (100) 0 20 20 0

0064H (100)

006EH (110)

to

00FBH (250)

0064H (100)

006EH (110)

to

00FBH (250)

Wor k 0

Wor k 1

to

Wor k 15

Wor k 0

Wor k 1

to

Wor k 15

Number of bytes

of service data

All read All write

sending receiving sending receiving

44 (F381A)

40 (F388A)

016160

016160

Number of bytes

of service data

44 (F381A)

40 (F388A)

0

Hold Setting

0071H (113)

Waveform

Comparison

Setting

0072H (114)

0065H (101)

0066H (102)

0067H (103)

0068H (104)

0069H (105)

006FH (111)

0070H (112)

0071H (113)

0072H (114)

0073H (115)

to

00FFH (255)

0064H (100)

to

0073H (115)

Wor k 0 (S ct 1)

Wor k 0 (S ct 2 )

Wor k 0 (S ct 3 )

Wor k 0 (S ct 4 )

Wor k 0 (S ct 5 )

Wor k 1 (S ct 1)

Wor k 1 (S ct 2 )

Wor k 1 (S ct 3 )

Wor k 1 (S ct 4 )

Wor k 1 (S ct 5 )

to

Wor k 1 5 (S ct 5 )

Wor k 0

to

Wor k 15

060600

024240

23

Page 29

8.Message communication

■Unit setting list

* Numbers are values of input range.

Also, “0” results in no unit.

①F381A

Weight Force Pressure Length Angle Other

1 μg 11 μN 24 μPa 41 μm 48 rad 51 g/cm

2 mg 12 mN 25 mPa 42 mm 49 ° 52 kg/m

3 g 13 N 26 Pa 43 cm 50 deg 53 t/m

4 kg 14 kN 27 hPa 44 m 54 g/l 88 μA

5 Mg 15 MN 28 kPa 45 km 55 g/ml 89 mA

6 t 16 μNm 29 MPa 46 in 56 mg/m 90 A

7 lb 17 mNm 30 GPa 47 ft 57 kg/m 91 kA

8 dyne 18 Nm 31 N/m

2

58 kgm/s 92 μV

9 kdyne 19 kNm 32 μbar 59 kgm

10 oz 20 MNm 33 mbar 60 kgm

21 ftlb 34 bar 61 mPas 95 kV

22 inlb 35 mmHg 62 Pas 96 Ω

23 inoz 36 inH

O 63 m2/s 97 kΩ

2

37 ftH2O 64 mm/s 98 MΩ

38 psia 65 m/s 99 W

39 psig 66 mm/min 100 kW

40 atom 67 cm/min 101 MW

68 m/min 102 VA

69 m/h 103

70 km/h 104 °F

71 m/s

72 rpm 106 kJ

73 Hz 107 MJ

74 kHz 108

75 MHz 109 l

76 kg/s 11 0 m

77 t/s 111

78 kg/min 11 2 ‰

79 t/min 113 ppm

80 kg/h 11 4 pH

81 t/h 115 gcm

82 m

83 m3/min 117 TONNE

84 m

3

85 l/s

3

86 l/min

3

2

2

2

3

/s 116 kgcm

3

/h

87 l/h

/s 93 mV

94 V

105 J

℃

%RH

3

%

24

Page 30

8.Message communication

② F388A

Weight Force Pressure Length Angle Other

1 μg 11 μN 28 μPa 45 μm 52 rad 55 g/cm

2 mg 12 mN 29 mPa 46 mm 53 ° 56 kg/m

3 g 13 N 30 Pa 47 cm 54 deg 57 t/m

4 kg 14 kN 31 hPa 48 m 58 g/l 92 μA

5 Mg 15 MN 32 kPa 49 km 59 g/ml 93 mA

6 t 16 μNm 33 MPa 50 in 60 mg/m 94 A

7 lb 17 mNm 34 GPa 51 ft 61 kg/m 95 kA

8 dyne 18 Nm 35 N/m

2

62 kgm/s 96 μV

9 kdyne 19 kNm 36 μbar 63 kgm

10 oz 20 MNm 37 mbar 64 kgm

21 ftlb 38 bar 65 mPas 99 kV

22 inlb 39 mmHg 66 Pas 100 Ω

23 inoz 40 inH

24 Ncm 41 ftH

O 67 m2/s 101 kΩ

2

O 68 mm/s 102 MΩ

2

25 gcm 42 psia 69 m/s 103 W

26 kgcm 43 psig 70 mm/min 104 kW

27 kgm 44 atom 71 cm/min 105 MW

72 m/min 106 VA

73 m/h 107

74 km/h 108 °F

75 m/s

76 rpm 110 kJ

77 Hz 111 MJ

78 kHz 11 2

79 MHz 113 l

80 kg/s 11 4 m

81 t/s 11 5

82 kg/min 116 ‰

83 t/min 11 7 ppm

84 kg/h

85 t/h

86 m

87 m

88 m3/h

3

89 l/s

3

90 l/min

3

3

/s

3

/min

2

91 l/h

2

/s 97 mV

2

98 V

109 J

℃

%RH

%

3

25

Page 31

9.A sample program of message communications using

9. A sample program of message communications

using

OMRON-manufactured PLC and CS1 is shown.

Messages are transmitted when the execution condition (4.00 = 1) is met as sending FINS

commands and send data are stored in advance (D000 and later, D100 and later).

Received data is stored in D200 and later.

This sample program has been created by the following conditions:

・CPU unit: SYSMAC CS1G CPU42-V1 (manufactured by OMRON)

・Master unit: DeviceNet master unit CS1W-DRM21 (manufactured by OMRON)

・Master node address: 63

・Slave (F381A/F388A) node address: 0

・Number of send data: 9H, stored in D000

・Number of received data: 136D: Set the maximum number of received data in

consideration of error messages.

・Sending FINS command data: D000 and later

・Send data storage area: D100 and later

・Received data storage area: D200 and later

・Service code: '0EH (reading of various set values)

・Class ID: '0071H: (Hold Setting)

・Instance ID: '0070H (work 1, section 2)

・Attribute ID (service data): '67H (Use Hold)

26

Page 32

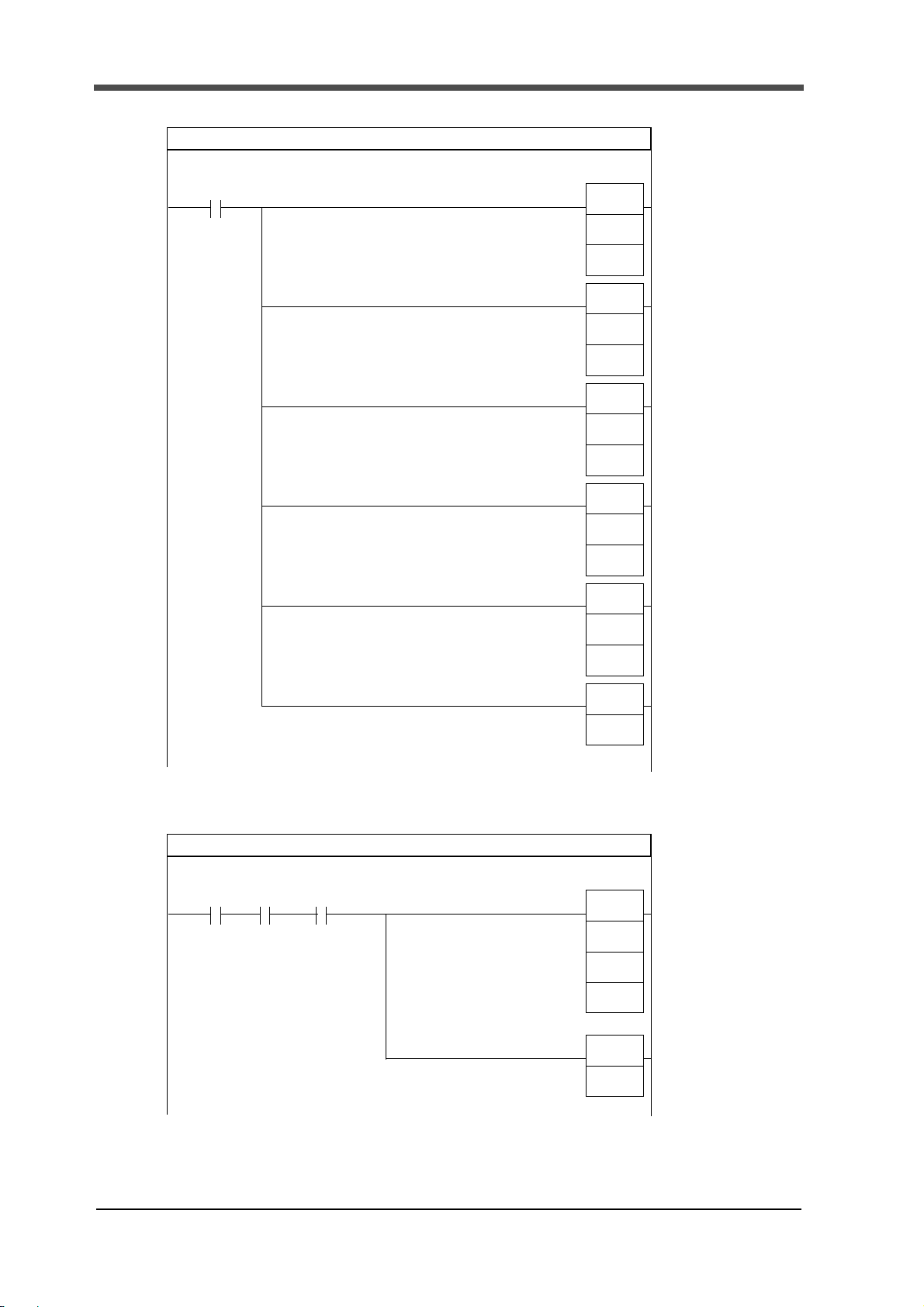

9-1.Program

* 1

P_First_Cycle

D29999

of sending data

* 2

receiving data

Target network

address = 0

(Home network address)

Target

node address

=

3FH、(63

)

Target machine

Response required,

communications port,

number of retransmissions

Response monitoring time

Communications initial setting 1

A200.11

Operation start

BSET

(071)

#0

D0

MOV

(021)

#9

D0

MOV

(021)

&136

D1

MOV

(021)

#0

D2

MOV

(021)

#3FFE

D3

MOV

(021)

#0000

D4

MOV

(021)

#0064

D5

0

0

1Cycle ON

address = FEH

Number of bytes

Number of bytes of

Network-connected unit

Example)Reading set values

9.A sample program of message communications using

"Reading set values" is mention as an example.

About the program of the contents of other message communications, it is possible to correspond

by changing D000 and D100 or subsequent ones.(Please refer to "9-2The representative case of

each message in a sample program" on page 29.)

27

Page 33

9.A sample program of message communications using

* 3Description of

P_First_Cycle

Node address = 00、

Service code = 0EH

Class ID = 0064H

Instance ID

Attribute ID

Communications initial setting 2, Command data

A200.11

Operation start

MOV

(021)

#2801

D100

MOV

(021)

#000E

D101

MOV

(021)

#0071

D102

MOV

(021)

#0070

D103

MOV

(021)

#6700

D104

SET

4.00

1

8

Command code

= 0064H

= 64H

1Cycle ON

sending data

Execution condition

= 2801H fixed

(as desired)

Explicit Send message

4.00

Network

CMND

(490)

D100

D200

ASL

(025)

4

2

15

Send message

D0

Online

A202.00 1511.00

communications state

executable

Execution

condition

28

Page 34

9.A sample program of message communications using

Retry

4.01

MOV

(021)

A203

D6

ASR

(026)

4

3

20

A202.00 A219.00

END

(001)

4

25

Network Network

communications communications

executable execution error

* Received data in normal condition is shown. For received data in abnormal

condition, see " ■ Error response" on page 40.

Point

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 09H

9byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 0EH

Node0

Various setting

reading

D102

Class ID

00H 71H

Hold setting

D103

Instance ID

00H 70H

Work1、section2

D104

Attribute ID

---

67H

00H

Use hold ---

Receiving data(Master(F381A/F388A)→CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 06H

6byte

D203

Node address Service code

00H 8EH

Node0

Various setting

reading

D204

Data :Use hold(LL、HH)

02H 00H

00000002H:Peak

D205

Data :Use hold(HL、HH)

00H 00H

9-2.

The representative case of each message in a sample

program

■Reading set values

Example) Reading Use Hold in Hold Setting (work 1, section 2)

29

Page 35

9.A sample program of message communications using

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 0DH

13byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 10H

Node0 Various setting writing

D102

Class ID

00H 71H

Hold setting

D103

Instance ID

00H 70H

Work1、section2

D104

Attribute ID DATA(LL)

67H 02H

Use hold

00000002H:PEAK

D105

DATA(LH、HL)

00H 00H

D106

DATA(HH)

---

00H

00H

---

Receiving data(Master(F381A/F388A) → CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 02H

2byte

D203

Node address Service code

00H 90H

Node0 Various setting writing

■Writing set values

Example) Writing Use Hold in Hold Setting (work 1, section 2)

30

Page 36

9.A sample program of message communications using

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 08H

8byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 32H

Node0

Various setting all

reading

D102

Class ID

00H 6FH

Measurement start condition setting

D103

Instance ID

00H 6EH

Work1

Receiving data(Master(F381A/F388A)→ CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 12H

18byte

D203

Node address Service code

00H B2H

Node0

Various setting all

reading

D204

Data1:Measurement start condition

(LL、LH)

01H 00H

00000001H:External Input + Load

D205

Data1:Measurement start condition

(HL、HH)

00H 00H

・

・

・

・

・

・

D210

Data4:Measurement end level (LL、LH)

2CH 01H

0000012CH:300

D211

Data4:Measurement end level (HL、HH)

00H 00H

■Reading set values(all)

Example) Reading all measurement start condition settings (work 1)

31

Page 37

9.A sample program of message communications using

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 18H

24byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 33H

Node0

Various setting all

writing

D102

Class ID

00H 6FH

Measurement start condition setting

D103

Instance ID

00H 64H

Work0

D104

Data1:Measurement start condition

(LL、LH)

01H 00H

00000001H:External Input + Load

D105

Data1:Measurement start condition

(HL、HH)

00H 00H

・

・

・

・

・

・

D110

Data4:Measurement end level (LL、LH)

2CH 01H

0000012CH:300

D111

Data4:Measurement end level (HL、HH)

00H 00H

Receiving data(Master(F381A/F388A) → CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 02H

2byte

D203

Node address Service code

00H B3H

Node0

Various setting all

writing

■Writing set values(all)

Example) Writing all measurement start condition settings (work 0)

32

Page 38

9.A sample program of message communications using

Receiving data(Master(F381A/F388A) → CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 06H

6byte

D203

Node address Service code

00H B4H

Node0

Reading

measurement range

D204

Data1:Measurement start condition(L、H)

00H 00H

0000H:0

D205

Data2:End of the range(L、H)

FFH 07H

07FFH:2047

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 08H

8byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 34H

Node0

Reading

measurement range

D102

Class ID

00H 82H

0082Hfixed

D103

Instance ID

00H 64H

0064Hfixed

■Reading measurement range

Example) Reading the measurement range

33

Page 39

9.A sample program of message communications using

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 0EH

14byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 35H

Node0 Reading waveform

D102

Class ID

00H 82H

Measured waveform

D103

Instance ID

00H 64H

D104

Data1:(L、H)

64H 00H

load

D105

Data2:Start of the range(L、H)

00H 00H

0

D106

Data3:End of the range.(L、H)

1FH 00H

31

Receiving data(Master(F381A/F388A) → CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 42H

66byte (2n+2)

D203

Node address Service code

00H B5H

Node0 Reading waveform

D204

Data1:

Waveform data of the start of the range(L、H)

FFH FFH

FFFFH:- 1

D205

Data2:

Waveform data of the start of the range+1(L、H)

01H 00H

0001H:1

・

・

・

・

・

・

D234

(D203

+n-1)

Data n-1:

Waveform data of the end of the range-1(L、H)

03H 00H

0003H

D235

(D203

+n)

Data n:

Waveform data of the end of the range(L、H)

04H 00H

0004H

* n:1 ~ 32 "End of the range." - "Start of the range" + 1

■Reading waveform

Example) Reading Measured waveform(Load、Range 0~31)

34

Page 40

9.A sample program of message communications using

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 0EH

14byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 36H

Node0 Writing waveform

D102

Class ID

00H 83H

Comparison waveform upper limit

D103

Instance ID

00H 64H

Work0

D104

Data1:(L、H)

64H 00H

Load

D105

Data2:Start of the range(L、H)

00H 00H

0

D106

Data3:Load(L、H)

64H 00H

0064H:100

Receiving data(Master(F381A/F388A) → CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 02H

2byte

D203

Node address Service code

00H B6H

Node0 Writing waveform

■Writing waveform

Example) Rewriting the comparison waveform upper limit (work 0)

35

Page 41

9.A sample program of message communications using

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 0AH

10byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 40H

Node0

Reading the hold

results

D102

Class ID

00H 8CH

008CH fixed

D103

Instance ID

00H 64H

0064H fixed

D104

Data1:Section head Data2:Section last

65H 69H

Section1 Section5

■Reading the hold results

Example) Reading the hold results of section 1 to section 5 (X-axis: displacement)

36

Page 42

9.A sample program of message communications using

High Low

・

・

・

・

・

・

D224

(D199

+5n)

Data1:Hold value(Load)(L、H)

C8H 00H

00C8H:200

D225

(D200

+5n)

Data2:Existence of

load Data

Data3:Load judging

01H 03H

Existent LO

D226

(D201

+5n)

Data4:

Hold value(Time or displacement )(LL、LH)

B0H 04H

000004B0H:1200

D227

(D202

+5n)

Data4:

Hold value(Time or displacement )(HL、HH)

00H 00H

D228

(D203

+5n)

Data5:

Existence of

Displacement Data

Data6:

Displacement judging

01H 02H

Existent HI

* n:1 ~ 5 "Section last" - "Section head" + 1

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 34H

52byte(10n+2)

D203

Node address Service code

00H C0H

Node0

Reading the hold

results

D204

Data1:Hold value(Load)(L、H)

FFH FFH

FFFFH:- 1

D205

Data2:

Existence of load Data

Data3:Load judging

01H 01H

Existent OK

D206

Data4:

Hold value(Time or displacement )(LL、LH)

2CH 01H

0000012CH:300

D207

Data4:

Hold value(Time or displacement )(HL、HH)

00H 00H

D208

Data5:

Existence of

Displacement Data

Data6:

Displacement judging

01H 02H

Existent HI

・

・

・

・

・

・

Section

last

Section

head

Receiving data(Master(F381A/F388A)→CPU)

37

Page 43

9.A sample program of message communications using

Receiving data(Master(F381A/F388A)→ CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 16H

22byte

D203

Node address Service code

00H C4H

Node0 Reading Wave No.

D204

2th byte 1th byte

30H 32H

'0' '2'

D205

4th byte 3th byte

32H 31H

'2' '1'

D206

6th byte 5th byte

35H 30H

'5' '0'

D207

8th byte 7th byte

31H 33H

'1' '3'

D208

10th byte 9th byte

30H 5FH

'0' '_'

D209

12th byte 11th byte

30H 30H

'0' '0'

D210

14th byte 13th byte

30H 30H

'0' '0'

D211

16th byte 15th byte

20H 31H

' ' '1'

D212

18th byte 17th byte

20H 20H

' ' ' '

D213

20th byte 19th byte

20H 20H

' ' ' '

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 08H

8byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 44H

Node0 Reading Wave No.

D102

Class ID

00H 96H

0096H fixed

D103

Instance ID

00H 64H

0064H fixed

■Reading Wave No.

Example) Reading the Wave No. (for setting "20120531_000001 ")

38

Page 44

9.A sample program of message communications using

Receiving data(Master(F381A/F388A) → CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 02H

2byte

D203

Node address Service code

00H C5H

Node0 Writing Wave No.

Sending data(CPU → Master(F381A/F388A))

High Low

D000

Number of bytes of sending data

00H 1CH

2byte

D100

Command code

28H 01H

FINS Command

D101

Node address Service code

00H 45H

Node0 Writing Wave No.

D102

Class ID

00H 96H

0096H fixed

D103

Instance ID

00H 64H

0064H fixed

D104

2th byte 1th byte

30H 32H

'0' '2'

D105

4th byte 3th byte

32H 31H

'2' '1'

D106

6th byte 5th byte

35H 30H

'5' '0'

D107

8th byte 7th byte

31H 33H

'1' '3'

D108

10th byte 9th byte

30H 5FH

'0' '_'

D109

12th byte 11th byte

30H 30H

'0' '0'

D110

14th byte 13th byte

30H 30H

'0' '0'

D111

16th byte 15th byte

20H 31H

' ' '1'

D112

18th byte 17th byte

20H 20H

' ' ' '

D113

20th byte 19th byte

20H 20H

' ' ' '

■Writing Wave No.

Example) Writing the Wave No. (for setting "20120531_000001 ")

39

Page 45

10.Device profiles and object implementation

Receiving data(Master(F381A/F388A) → CPU)

High Low

D200

Command code

28H 01H

FINS Command

D201

Completion code

00H 00H

Normal end:(refer to FINS Command)

D202

Number of bytes of receiving data

00H 04H

4byte

D203

Node address Service code

00H 94H

Node0 94H fixed

D204

Error code

16H FFH

Error number

FFH fixed

■Error response

Example) Class ID is wrong.(Error number:16H)

10.Device profiles and object implementation

(①F381A ②F388A)

■Device profiles

General data Corresponding Specification for DeviceNet

Vender ID 135

Device type Generic device type No:0

Produce code

Physical

conformance

data

Current consumption by net work About 30mA (at DC24V)

Connector type The open plug type

With or without insulation for physical layer The use of insulation

Supported LED Module

MAC ID setting Setting by touch panel

Default MAC ID 00

Transmission baud rate setting Not available (Automatic follow-up to the master.)

Supported baud rate 125kbit/s, 250kbit/s, 500kbit/s

Predefined master/ slave connection set Group 2 only server

Support for dynamic connection (UCMM) Not available

Fragmentation of explicit message Available

Communication

data

40

Vo l u m e 1 Release2.0

Vo l u m e 2 Release2.0

①9 ②16

Network

Page 46

10.Device profiles and object implementation

■Implementation of objects

Identity object (01H)

Object class Attribute Not supported

Service Not supported

Object

instance

Attribute ID description GET SET Value

1 Vendor ○

2 Device type ○

3 Product code ○

4 Revision

5 Status (bits supported) ○

6 Serial number ○

7 Product name

8 State

Configuration Consistency Value

9

10 Heartbeat Interval

Service DeviceNet service Parameter option

05H Reset

0EH Get_Attribute_Single

○

○

Not available

Not available

×135

×0

×

×

× bit 0 only

× Each unit

×

××

××

××

(Varying depending on the set value.)

①F381

②F388

Message router object (02H)

Object class Attribute Not supported

Service Not supported

Object instance Attribute Not supported

Service Not supported

Addition of vendor-specific

specification

Not available

①9 ②16

01, 02H or 02, 02H

41

Page 47

10.Device profiles and object implementation

DeviceNet objects (03H)

Objects class Attribute ID description GET SET Value

1 Revision ○

Service DeviceNet service Parameter option

0EH Get_Attribute_Single

Not available

× 02H

Object

instance

Attribute ID description GET SET Value

1 MAC ID ○○

2 Baud rate ○○

3 BOI ○

4 Bus-off counter ○

5 Allocation information ○

6 MAC ID switch changed

7 Baud rate switch changed

8 MAC ID switch value

9 Baud rate switch value

Service DeviceNet Service Parameter option

0EH Get_Attribute_Single

10H Set_Attribute_Single

4BH Allocate Master/

Slave_Connection Set

4CH Release Master/

Slave_Connection Set

××

××

××

××

Not available

Not available

Not available

Not available

Assembly object (04H)

Object class Attribute Not supported

Service Not supported

× 00H

×

×

Object

instance

100

Object

instance

101

42

Section Information Max. number of instances

Instance type Static I/O 1

Attribute Description GET SET Value

1 Number of Members in List

2 Member List

3 Data ○○

Service DeviceNet service Parameter option

0EH Get_Attribute_Single

10H Set_Attribute_Single

Section Information Max. number of instances

Instance type Static I/O 1

Attribute Description GET SET Value

1 Number of Members in List

2 Member List

3 Data ○

Service DeviceNet service Parameter option

0EH Get_Attribute_Single

××

××

Not available

Not available

××

××

×

Not available

Page 48

10.Device profiles and object implementation

Connection object (05H)

Object class Attribute Not supported

Service Not supported

Max. number of active

connections

1

Object

Instance

Section Information Max. number of instances

1

Instance type Explicit Message 1

Production

trigger

Transport type Server

Transport class 3

Attribute ID description GET SET Value

Service DeviceNet service Parameter option

Cyclic

1 State ○

2 Instance type ○

3 Transport class trigger ○