Union Special XF511H100MF, XF511H112MF User Manual

CATALOG

142M

NO.

Adjusting

instructions

and

First Edition

STYLES

XF511H100MF

XF511H112MF

illustrated

parts

list

\.

(

Maximum performance

machines

Finest Quality

for

ultra high speed seaming operations

XFSOO

Series flatbed

FOREWARD

This

new

UNION

adjusting these

reliability

The

setting

technical

SPECIAL

designed

manual

has

machine. Careful

machines

will enable

and

built

been

prepared to guide

attention

you

into every

Adjusting Instruction portion of

for

each

of the

components

related to

functions of the machine. Figures are

reference

letters

to point out specific items discussed.

Adjustments are presented in sequence

plished.

Some

adjustments

performed

out

the function of other related parts.

Implementation

ficant

downs.

machine,

designed

assure

improvements

Whenever

be

sure to

specifically

long

lasting

To

simplify indentification of repair

exploded views. A colored

anisms

of the

machine

of

preventative maintenance procedures

in operator productivity

it

becomes

insist

for your

necessary to

on

genuine

machine

service.

insert

in the center of

assembled.

you

in the maintenance of your

to the instructions for operating

to maintain the superior performance

UNION

this

used

of

make

UNION

and

SPECIAL

manual

forming

to

illustrate

so

that

sequence

by

avoiding costly

machine.

explains in detail the proper

the

stitch

and

completing the

the adjustments using

a logical progression

may

have

an

adverse

can

bring about

equipment

repairs or replace parts

SPECIAL

Repair Parts.

These

manufactured with utmost precision

parts,

the

mechanisms

this

are

illustrated

catalog presents the

is

accom-

effect

signi-

break-

on

your

parts are

mech-

and

and

on

to

by

Catalog

XF511H100MF

First

Copyright

Union

Rights

Reserved

Printed

No.

142M

For

Styles

XF511H112MF

Edition

1983

By

Special Corporation

In

All

Countries

In

U.S.A.

Apri

1,

1983

2

Each

UNION

machine,

Serial

SPECIAL

is

stamped

number

is

stamped

IDENTIFICATION OF MACHINES

machine

is

identified

by

a Style

number,

which

on

into the Style plate affixed to the right front of

into

bed

casting

STYLES OF MACHINES

at

the right rear base of

this

Class

machine.

machine.

Super

machine.

fully automatic forced feed lubricating

replaceable oil

high

speed,

Modular

filter,

maximum

performance,

construction,

quick

totally

stitch

medium

sewing

capacity, double locked

enclosed feed

system

with

built-in

change, adjustable feed

driven rear needle guard, quick adjustable looper avoid

XF511HlOOMF

Single needle, plain feed,

low

inertia

presser foot permitting

presser foot pressure for positive feeding

high

XF511Hll2MF

tremely

fabrics

such

ification

Maximum

Same

chain

recommended

as

Style

cutter.

sewing

as

401

SSa-1.

XF511HlOOMF

speeds - for

in trousers,

Type

128

speed

9000

except, equipped with

SAFETY RULES

CAUTION!

long

skirts,

GBS

R.P.M.,

seams

coats, jackets,

needle. Stitch

depending

and

looper drive

and

built-in

and

chaining,

on

light

stitch

mechanism,

oil

cooler, easily

lift,

independently

needle cooler.

light

even

at

to

medium

etc.

range

on

7-10

operation.

Power 11AIR-KLIPP

weight

Seam

S.P.I.

spec-

11

ex-

®

THIS

TO

PREVENT

-

All

power

PERSONAL

sources to the

justing or replacing

-

Wear

safety glasses.

-All

-DO

shields

NOT

tamper

Oil

has

and

with safety shields, guards,

been

SAFETY

guards

drained

SYMBOL

INJURY:

machine

parts.

MUST

from

be

oil with a Saybolt viscosity of

valent to

fill

to

TOP

UNION

SPECIAL

line

of level

specification

gauge

INDICATES

MUST

YOUR

be

TURNED

PERSONAL

OFF

SAFETY

before threading,

in position before operating

LUBRICATION

main

reservoir before shipment.

90

to

(B).

125

seconds

No.

175.

Replace

3

etc.,

filler

while

at

100

Remove

cap.

oil

IS

machine.

machine

degrees

fill

er

INVOLVED

oiling,

is

in operation.

Use a straight

F.

This

cap

(A,

is equi-

Fig.

ad-

mineral

1)

and

LUBRICATION (Continued)

CAUTION!

To

operating continously, the oil

should oil

located in

recommended

When

oil

starting

flow

indicator

to operate

rises

machine,

in

a short period of running time,

properly

lubrication

period

maintain

machine

system

and

RECHECK

maximum

recommended

should not

working

oil level.

and

must

remain

bottom

to

in the

of oil

change

machine

pan.

oil

filter

for

ALWAYS

after

watch

same.

If

this

be

run

the

indicates oil

properly, stop

speed

be

more

and

changed

than

replace

the

first

serviceability of

at

one

oil

oil

flow

for

machine

least

year.

filter

three

time, evaluate the contaminated condition to determine

changed

lift

Replace

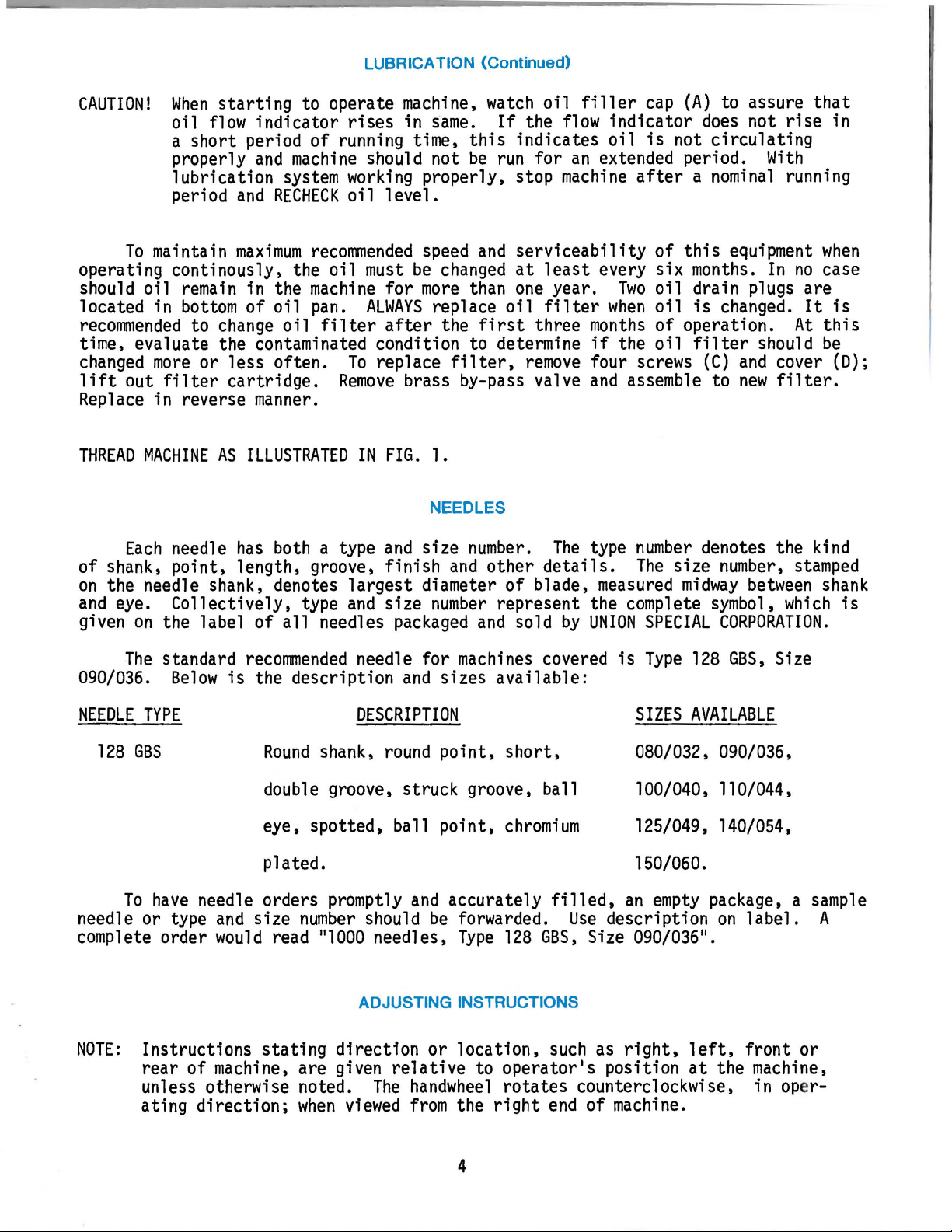

THREAD

of shank, point, length, groove, finish

on

and

given

more

out

in reverse

MACHINE

Each

or less often.

filter

needle

cartridge.

AS

ILLUSTRATED

has

manner.

both

To

Remove

IN

a type

replace

filter,

brass by-pass valve

FIG.

1.

NEEDLES

and

size

number.

and

other

remove

The

details.

the needle shank, denotes largest diameter of blade,

eye. Collectively, type

on

the label of

all

and

needles

size

number

packaged

represent the

and

sold

by

filler

cap

indicator

is

not circulating

an

extended period.

after a nominal

every six

Two

oil drain plugs are

when

months

if

four

and

type

oil

of operation.

the oil

screws

assemble

number

The

size

measured

complete

UNION

SPECIAL

(A)

to assure

does

not

With

this

equipment

months.

is

changed.

filter

(C)

to

should

and

new

In

cover

filter.

denotes the

number,

midway

between

symbol,

CORPORATION.

that

rise

in

running

when

no

case

It

is

At

this

be

(D);

kind

stamped

shank

which

is

The

standard

090/036.

NEEDLE

128

To

Below

TYPE

GBS

have

needle or type

complete

NOTE:

order

Instructions stating direction or location,

rear of

unless otherwise noted.

ating direction;

recommended

is

the description

Round

double

eye, spotted, ball point,

plated.

needle orders

and

size

number

would

machine,

read 111000

are given

when

needle for

and

machines

covered

sizes available:

DESCRIPTION

shank,

round

point, short,

groove, struck groove, ball

chromium

promptly

ADJUSTING INSTRUCTIONS

and

should

needles,

accurately

be

forwarded.

Type

128

filled,

GBS,

such

relative

The

viewed

handwheel

from

to operator's position

rotates counterclockwise, in ope

the

right

end

is

an

Use

description

Size

as

right,

of

machine.

Type

SIZES

128

GBS,

Size

AVAILABLE

080/032, 090/036,

100/040, 110/044,

125/049, 140/054,

150/060.

empty

090/036

package, a

on

label. A

11

•

left,

at

front or

the

machine,

sample

r-

4

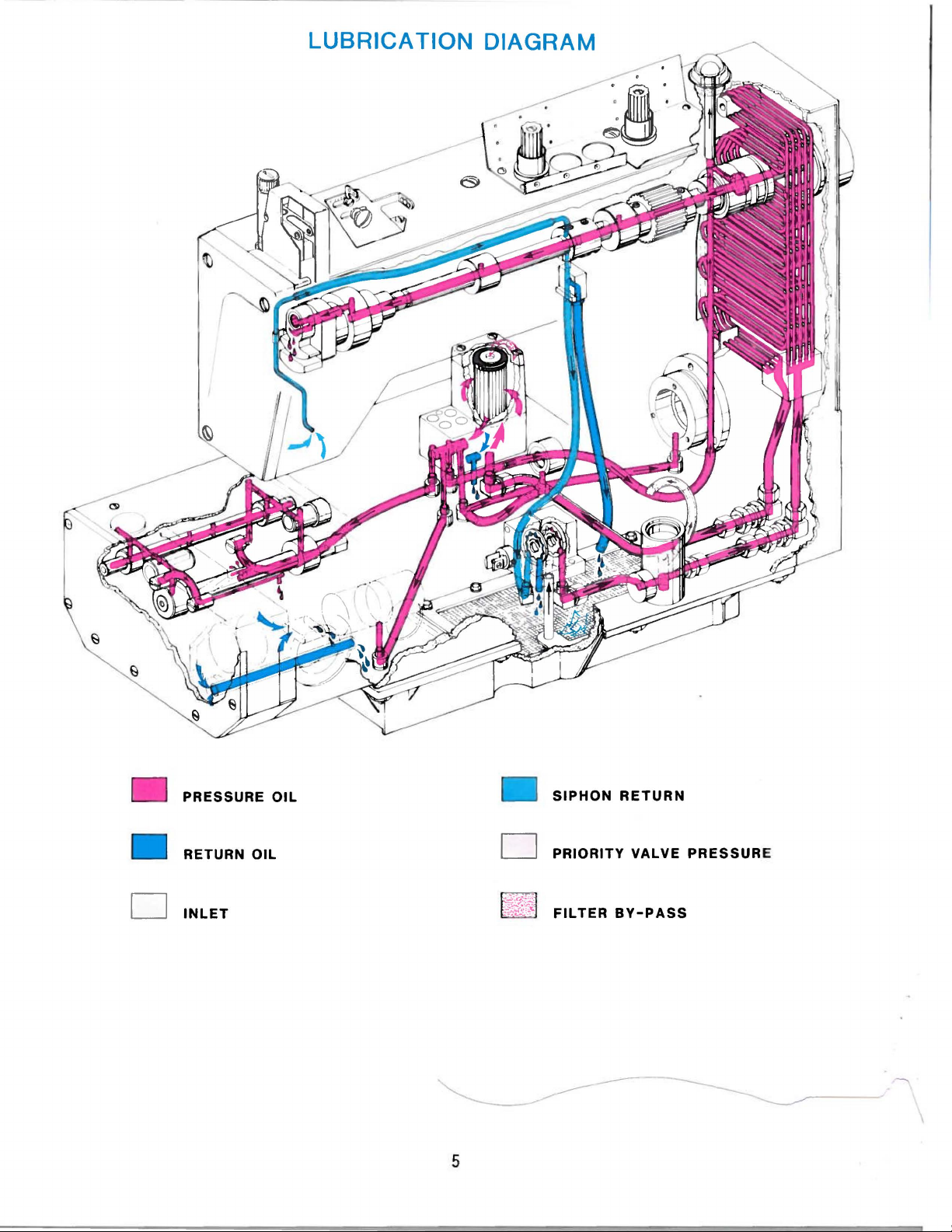

PRESSURE

OIL

SIPHON

RETURN

PRIORITY

FILTER

D

RETURN

INLET

OIL

D

5

VALVE

BY-PASS

PRESSUR

E

Fig.

1

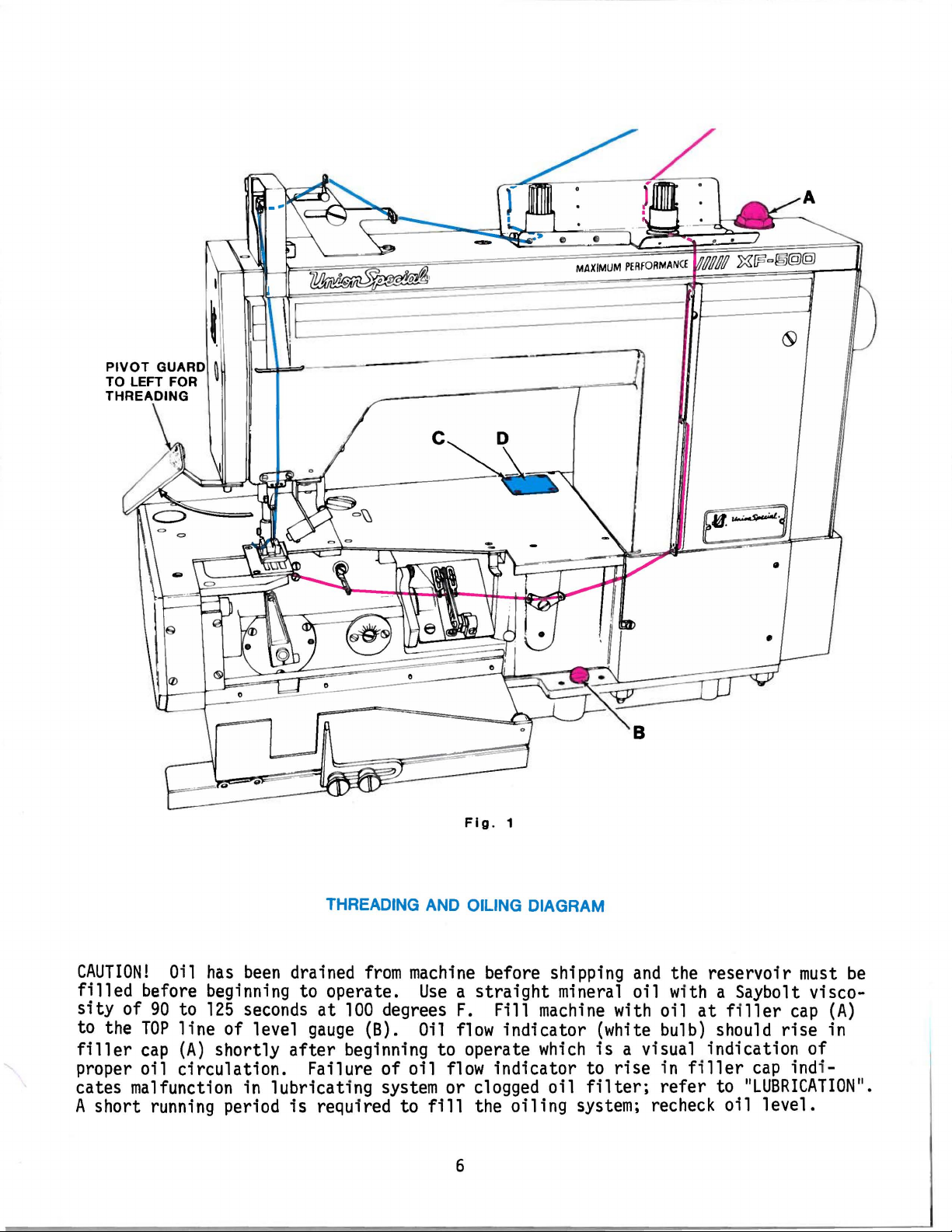

THREADING AND OILING DIAGRAM

CAUTION!

filled

sity

of

to the

filler

proper oil circulation. Failure of oil

cates malfunction in lubricating

A short

Oil

has

been

drained

from

before beginning to operate.

90

to

125

TOP

cap

line

(A)

seconds

of level

shortly

at

gauge

after

100

degrees

(B).

beginning to operate

system

running

period

is

required to

machine

before shipping

Use a straight

F.

Fill

Oil

flow

flow

indicator (white bulb) should

indicator to

or clogged

fill

the oiling system; recheck oil level.

6

mineral oil with a Saybolt visco-

machine

which

oil

and

the reservoir

with oil

is

a visual indication of

rise

filter;

at

in

filler

refer

filler

to

"LUBRICATION".

cap

must

cap

rise

ind

be

(A)

in

i-

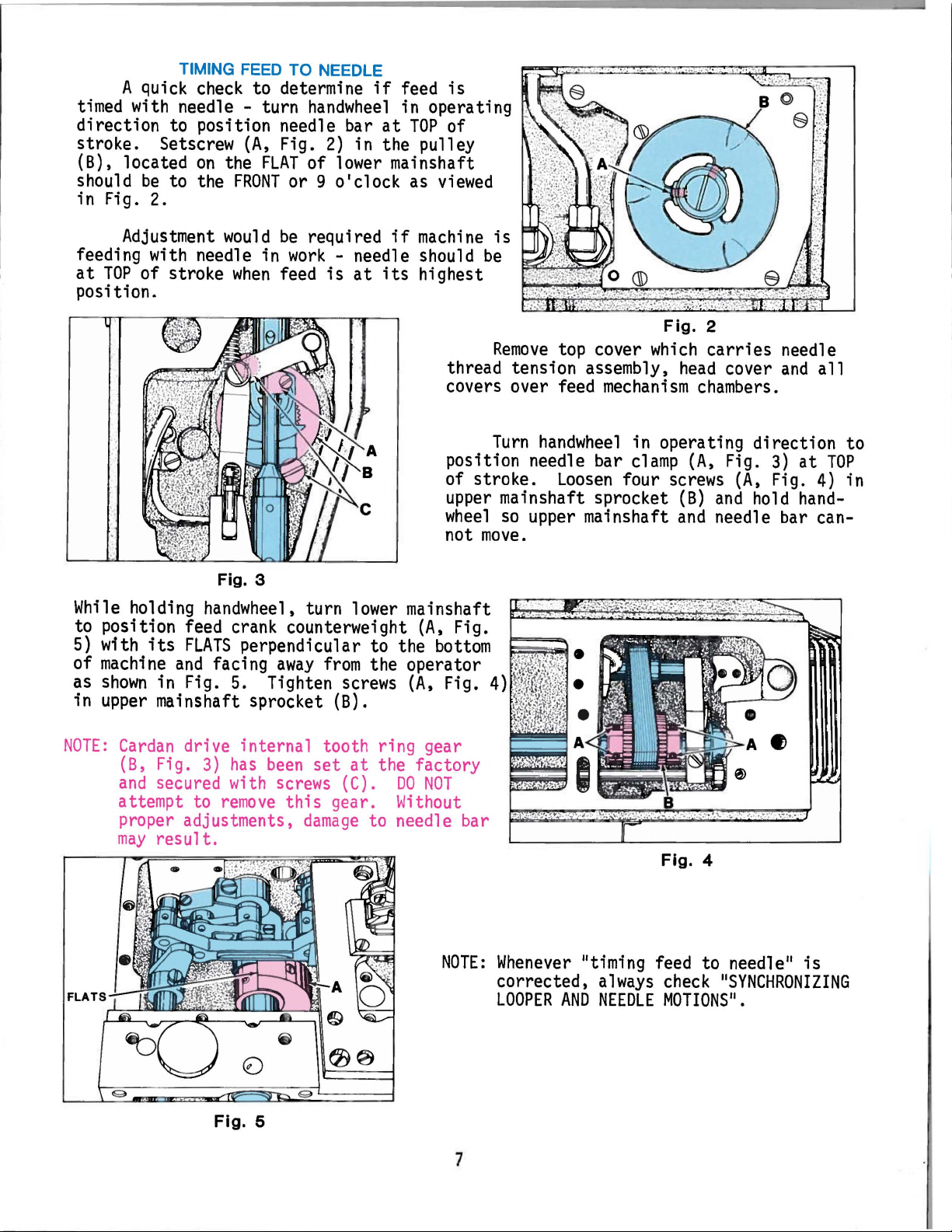

TIMING FEED TO NEEDLE

A

timed

quick

with needle - turn

check

to determine

handwheel

direction to position needle bar

(A,

Fig.

2)

stroke. Setscrew

on

(B), located

be

should

in Fig.

to the

2.

the

FLAT

FRONT

or 9 o'clock

of

in the pulley

lower

if

feed

is

in operating

at

TOP

of

mainshaft

as

viewed

Adjustment

would

feeding with needle in

at

TOP

of stroke

when

position.

Fig. 3

While

to position feed

5)

of

as

in

holding

with

its

machine

shown

upper

in Fig.

mainshaft sprocket (B).

handwheel,

FLATS

and

facing

crank

perpendicular to the

5.

be

required

work

feed

- needle should

is

at

turn

lower

counterweight

away

Tighten

from

screws

if

machine

its

highest

thread tension assembly,

covers over feed

position needle bar

of stroke.

upper

wheel

not

mainshaft

(A,

Fig.

bottom

the operator

(A,

Fig.

is

be

Remove

top cover

mechanism

Turn

handwheel

Loosen

four

mainshaft sprocket

so

upper

mainshaft

move.

4)

Fig.

2

which

carries

head

cover

needle

and

all

chambers.

in operating direction to

clamp

(A,

Fig.

screws

(B)

and

(A,

and

needle bar can-

3)

Fig.

hold

at

TOP

4)

hand-

in

NOTE:

Cardan

(B,

and

attempt to

drive internal tooth ring gear

Fig.

3)

has

been

secured with

screws

remove

proper adjustments,

may

result.

Fig.

5

set

this

damage

at

the factory

(C).

gear.

DO

Without

to needle bar

NOT

NOTE:

7

Whenever

corrected,

LOOPER

AND

"timing

always

NEEDLE

Fig.

4

feed

to needle"

check

"SYNCHRONIZING

MOTIONS".

is

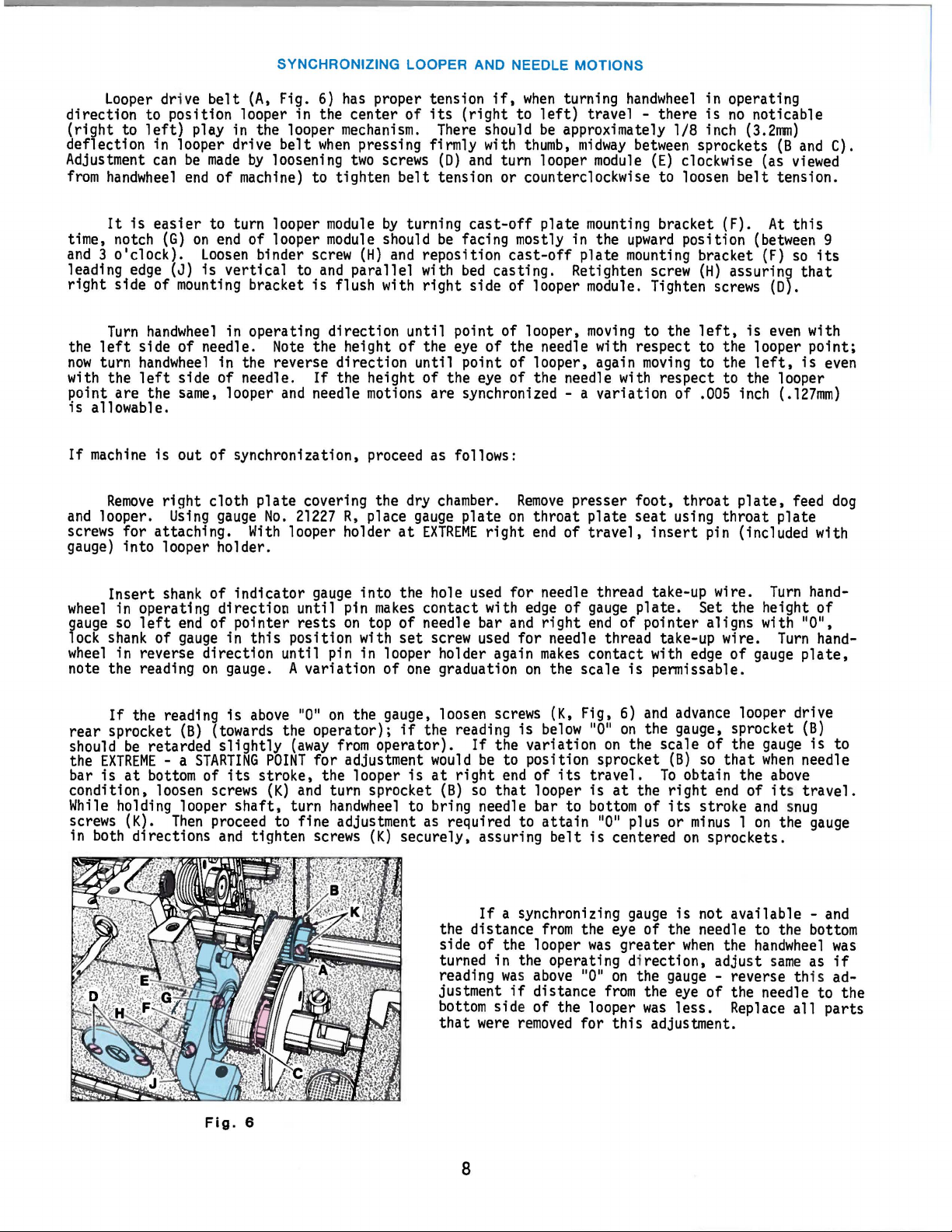

SYNCHRONIZING LOOPER AND NEEDLE

MOTIONS

Looper

dri

ve

belt

(A,

Fig.

6)

has

proper tension

direction to position looper in the center of

(right

deflection in looper drive

Adjustment

from

time, notch

and

leading

right

the

now

with the

point are the

is

If

and

screws

gauge)

to

left)

play

can

be

handwheel

It

is

end

easier

{G)

on

3 o'clock).

edge

side of

Turn

left

turn

(J)

mounting

handwheel

side of needle.

handwheel

left

side of needle.

same,

allowable.

machine

Remove

looper.

is

out of synchronization, proceed

right cloth

Using

for attaching.

into looper holder.

in

the looper

belt

made

by

loosening

of

machine)

to turn looper

end

of looper

Loosen

is

binder

vertical to

bracket

mechanism.

when

pressing firmly with

two

to tighten

module

module

screw

is

(H)

and

parallel with

flush with

screws

belt

by

turning

should

and

in operating direction until point of looper,

Note

the height

of

in the reverse direction until point of looper, again

If

looper

gauge

and

plate

No.

With

looper holder

the height of the

needle

motions

covering the dry

21227

R,

place

at

gauge

if,

when

its

There

(D)

(right

should

and

turn looper

turning

to

left)

be

approximately 1/8 inch

thumb,

midway

handwheel

travel - there

between

module

(E)

clockwise (as

tension or counterclockwise to loosen

cast-off

be

facing mostly

reposition

bed

right

the

casting.

side of looper

eye

of the needle with respect to the looper point;

plate

cast-off

mounting

in

the

plate

Ret

ighten

module.

moving

bracket (F).

upward

mounting

screw

Tighten

to the

position

moving

eye

of the needle with respect to the looper

are synchronized- a variation of

as

follows :

chamber. Remove

plate

EXTREME

on

right

presser foot, throat

throat plate seat using throat plate

end

of

travel,

insert

in operating

is

no

noticable

(3.2mm)

sprockets (Band

viewed

belt

tension.

At

this

(between

bracket

(H)

screws

left,

to the

.005

(F)

assurin9

(OJ.

is

even

left,

inch

(.127mm)

plate,

so

that

with

is

feed

its

pin (included with

C).

9

even

dog

wheel

gauge

lock

wheel

Insert

in

so

shank

in reverse direction until pin in looper holder again

shank

operating direction until pin

left

end

of

gauge

note the reading

If

the reading

rear sprocket

should

the

bar

be

EXTREME

is

at

(B)

retarded

- a

bottom

condition, loosen

While

screws

in

holding looper

(K).

both

directions

Then

of indicator

of pointer

in

this

on

gauge.

is

above

gauge

rests

into the hole

on

top of needle bar

position with

A variation of

"0"

on

the gauge, 1

(towards the operator);

slightly

STARTING

of

its

screws

shaft,

(away

POINT

from

for adjustment

stroke, the looper

(K)

and

turn sprocket

turn

handwheel

proceed to fine adjustment

and

tighten

screws

(K)

makes

operator).

contact with

set

screw

one

graduation

oosen

if

the reading

would

is

at

right

{B)

used

screws ( K,

If

the variation

be

to position sprocket

end

so

that

to bring needle bar to

used

as

required to

securely, assuring

If

a synchronizing

the distance

side of the looper

turned in the operating direction, adjust same as

reading was

justment

bottom

that

side of the looper

were removed

for needle thread take-up wire.

edge

of

and

right

gauge

end

plate. Set the height

of pointer aligns with "0",

for needle thread take-up wire.

makes

on

is

of

looper

above

if

distance

contact with

the scale

Fig,

below

its

"0"

travel.

is

bottom

attain

belt

is

from

the

was

"0"

for

edge

is

permissable.

6)

and

advance

on

the gauge, sprocket

on

the scale of the

(B)

so

To

at

"0"

plus or

centered

gauge

eye

greater

on

from

this

obtain the

the

right

of

its

stroke

minus 1 on

on

is

not available -

of the needle to the

when

the

gauge

the

eye

was

less.

adjustment.

of

1 ooper drive

that

end

sprockets.

the

- reverse th

of the needle to the

Replace

Turn

Turn

gauge

plate,

(B)

gauge

when

needle

above

of its

travel.

and snug

the

handwheel

all

hand-

of

hand-

is

to

gauge

and

bottom

was

if

is

ad-

parts

Fig.

6

8

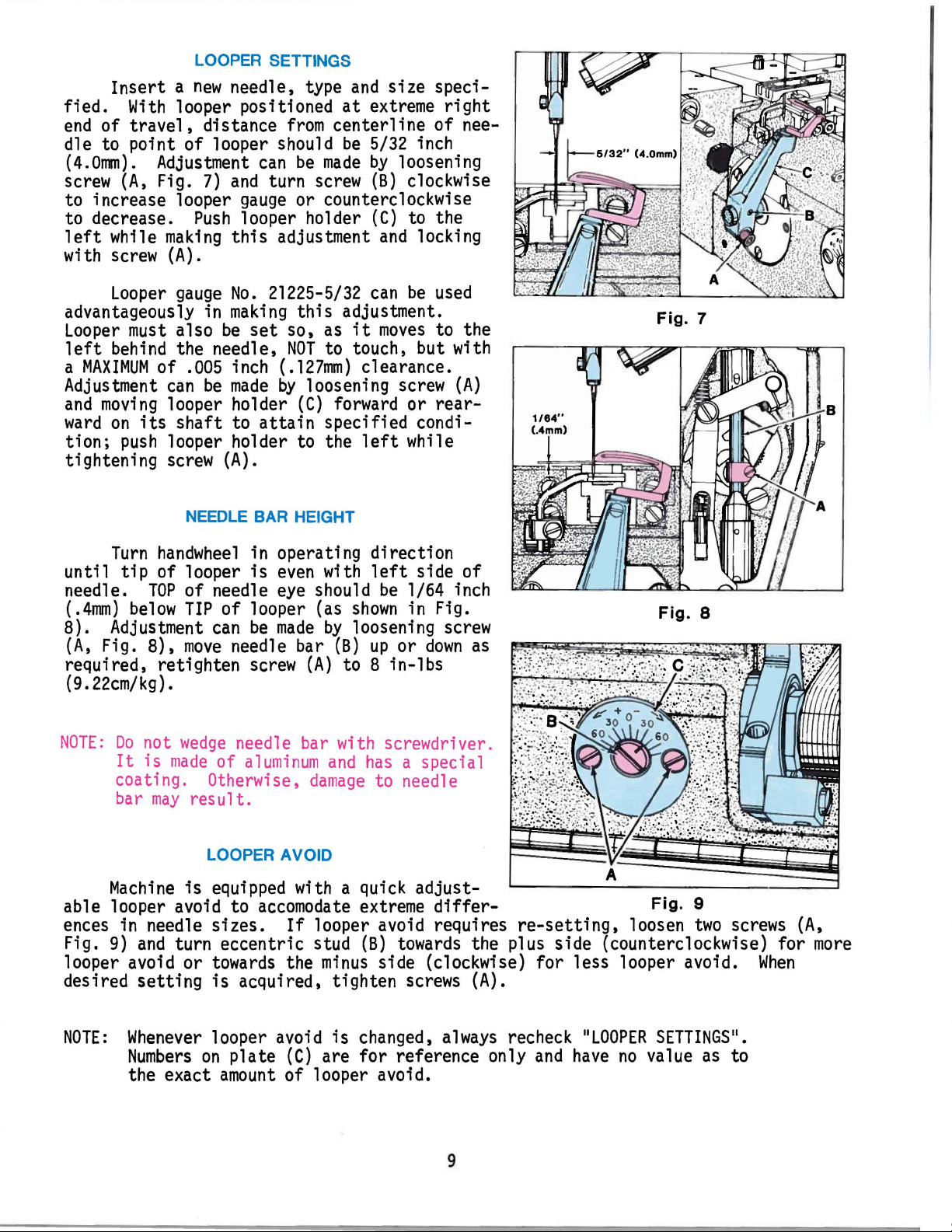

LOOPER SETTINGS

fied.

end

Insert a

With

of

travel,

new

needle, type

looper positioned

distance

from

dle to point of looper should

(4.0mm).

screw

to increase looper

to decrease.

left

while

with

(A,

screw

Adjustment

Fig.

7)

and

gauge

Push

looper holder

making

this

(A).

can

be

made

turn

screw

or counterclockwise

adjustment

and

size speci-

at

extreme

right

centerline of nee-

be

5/32 inch

by

loosening

(B)

clockwise

(C)

to the

and

locking

Looper

gauge

advantageously in

Looper

left

a

Adjustment

and

ward

tion;

tightening

until

needle.

(.4mm)

8).

(A,

must

behind

MAXIMUM

also

the needle,

of

can

moving

on

push

looper holder

its

shaft to

looper holder to the

screw

Turn

handwheel

tip

of looper

TOP

below

Adjustment

Fig. 8),

be

.005

be

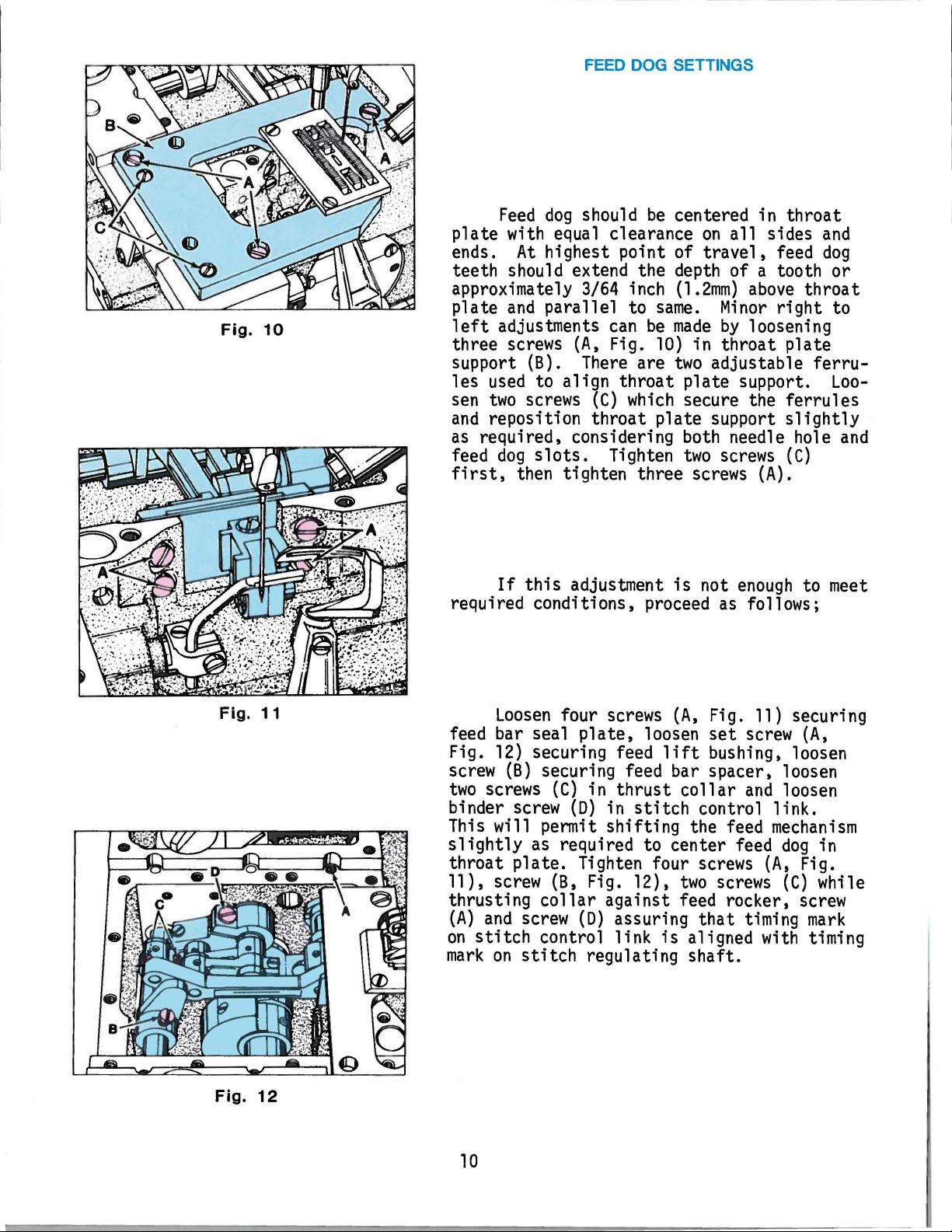

NEEDLE BAR HEIGHT

of needle

TIP

of looper (as

can

move

required, retighten

(9.22cm/kg).

NOTE:

Do

It

not

is

wedge

made

of

coating. Otherwise,

may

bar

result.

No.

21225-5/32

making

set

inch

made

(.127mm)

by

attain

this adjustment.

so,

as

NOT

loosening

(C)

can

be

used

it

moves

to the

to touch, but with

clearance.

forward

screw

or rear-

(A)

specified condi-

left

while

(A).

in operating direction

is

even

eye

should

be

made

needle bar

screw

(A)

with

left

be

shown

by

loosening

(B)

up

or

to 8 in-lbs

side of

1/64 inch

in Fig.

screw

down

needle bar with screwdriver.

aluminum

and

damage

has

a special

to needle

as

Fig.

Fig.

7

8

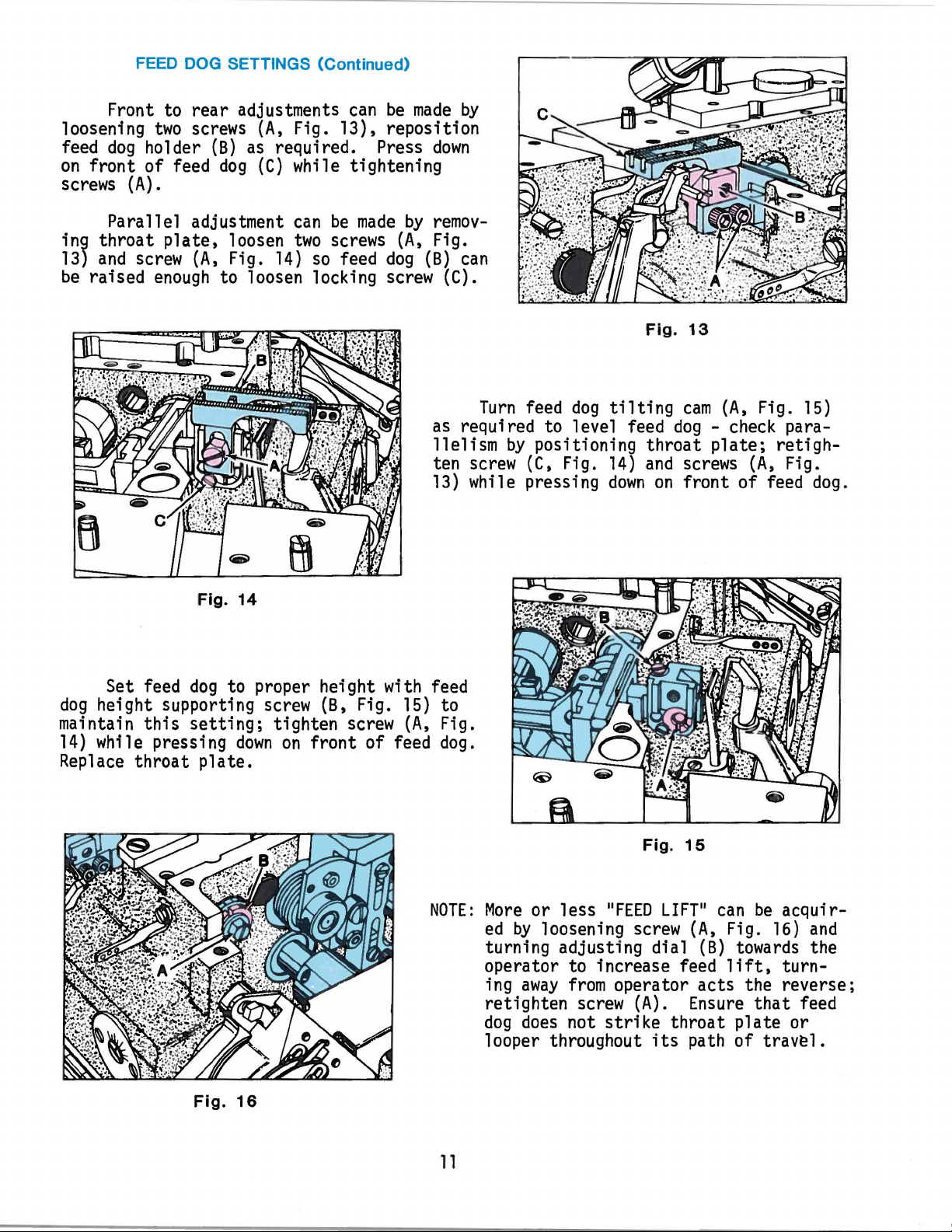

LOOPER AVOID

Machine

able looper avoid to

ences

Fig.

in needle sizes.

9)

and

looper avoid or

desired setting

NOTE:

Whenever

Numbers

the exact

is

equipped

with a quick adjust-

accomodate

If

looper avoid requires

turn eccentric stud

towards

is

acquired, tighten

looper avoid

on

plate

amount

the

minus

is

(C)

are for reference only

of looper avoid.

extreme

differ-

re-setting,

(B)

towards

the plus side (counterclockwise) for

side (clockwise) for less looper avoid.

screws

changed,

(A).

always

recheck 11LOOPER

and

9

have

Fig.

loosen

SETTINGS

no

value

9

two

as

screws

When

...

to

(A,

more

Fig.

10

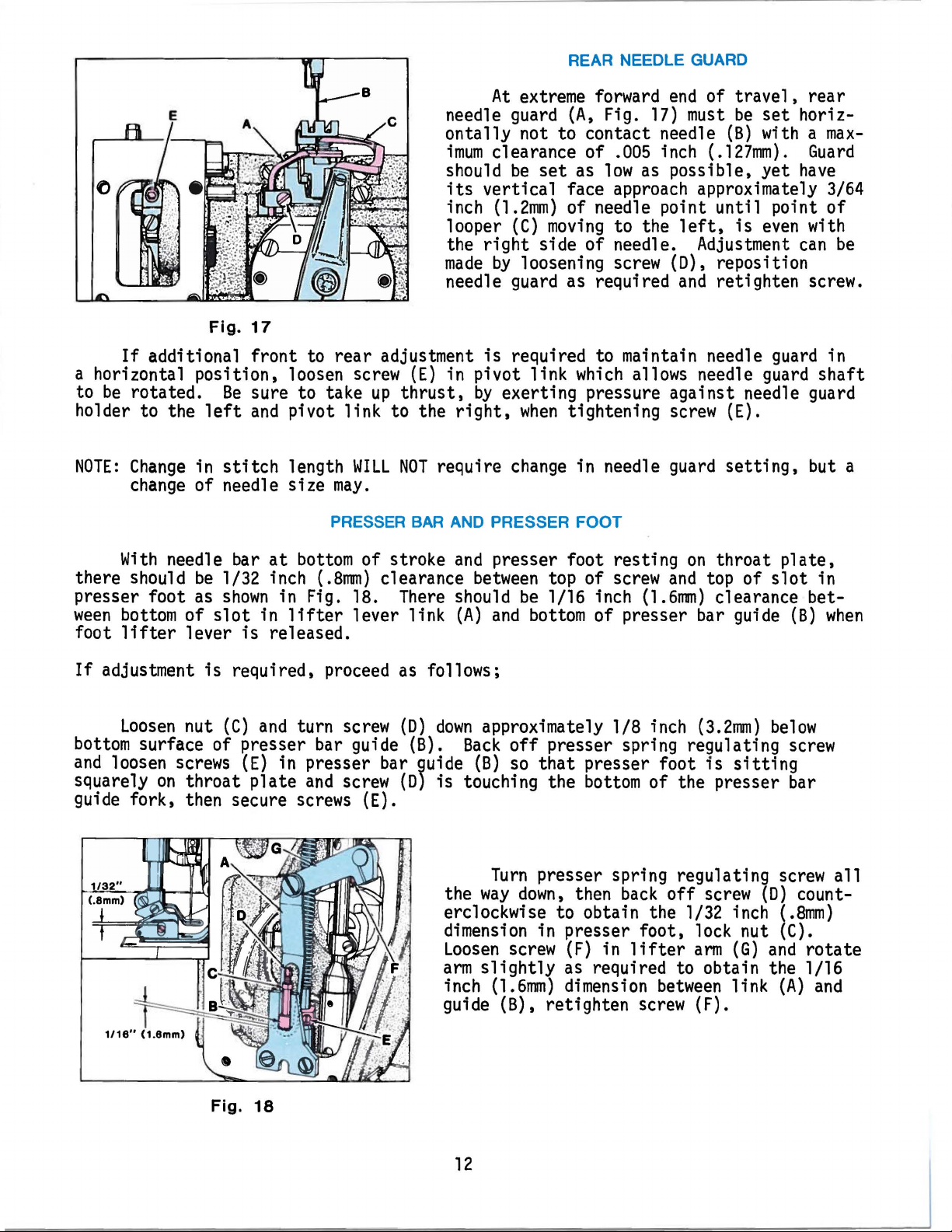

FEED DOG SETTINGS

Feed

dog

should

plate with

ends.

equal

At

highest point of

teeth should extend the

approximately 3/64

plate

left

three

support

les

sen

and

as

feed

first,

and

parallel to

adjustments

screws

used

two

screws

(A,

(B).

There

to align throat plate support.

(C)

reposition throat plate support

required, considering both needle hole

dog

slots.

then tighten three

be

centered in throat

clearance

depth

inch

(1.2mm)

same.

can

be

made

Fig.

10)

are

two

which

Tighten

secure the ferrules

two

on

all

travel,

of a tooth or

above

Minor

by

loosening

in throat plate

adjustable ferru-

screws

screws

(A).

sides

feed

throat

right to

slightly

(C)

and

dog

Loo-

and

Fig.

11

If

this

adjustment

is

required conditions, proceed

Loosen

feed

bar seal

Fig.

12)

screw

two

binder

This

(B)

screws

screw

will permit shifting the feed

slightly

four

screws

plate,

securing feed

(A,

loosen

lift

securing feed bar spacer, loosen

(C)

in thrust

(D)

in

as

required to center feed

collar

stitch

throat plate. Tighten four

11),

screw

thrusting

(A)

and

on

stitch

mark

on

(B, Fig. 12),

collar

screw

against feed rocker,

(D)

control link

stitch

regulating shaft.

assuring

is

two

aligned

not

as

Fig.

set

enough

follows;

11)

screw

to

securing

(A,

bushing, loosen

and

loosen

control link.

mechanism

dog

screws

screws

(A,

(C)

Fig.

screw

that

timing

with

mark

timing

meet

in

while

Fig.

12

10

FEED DOG SETTINGS (Continued)

Front to rear adjustments

loosening

feed

on

screws

dog

front of feed

(A).

Parallel adjustment

in~

throat

13)

and

screw

be

raised

two

screws

holder

plate,

(A,

enough

can

(A,

Fig. 13), reposition

(B)

as

required. Press

dog

(C)

while tightening

can

be

loosen

Fig.

14)

two

so

screws

feed

to loosen locking

be

made

dog

screw

made

by

(A,

by

down

remov-

Fig.

(B)

can

(C).

Turn

feed

dog

as

required to level feed

llelism

ten

13)

by

positioning throat

screw

(C,

Fig.

while pressing

Fig.

tilting

14)

and

down

on

13

cam

(A,

Fig.

dog -check

plate;

screws

front of

(A,

feed

15)

para-

retigh-

Fig.

dog.

Set feed

dog

height supporting

maintain

14)

while pressing

Replace

this

throat plate.

Fig.

14

dog

to proper height with feed

setting;

down

screw

tighten

(8, Fig.

screw

on

front of feed

15)

(A,

to

Fig.

dog.

NOTE:

Fig.

15

More

ed

or less 11FEED

by

loosening

screw

turning adjusting dial

LIFT

(A,

11

(B)

operator to increase feed

away

from

ing

retighten

dog

does

looper throughout

operator acts the reverse;

screw

not

(A).

strike

its

Ensure

throat plate or

path of

can

Fig.

towards

lift,

be

acquir-

16)

and

the

turn-

that

feed

trav~l.

Fig.

16

11

Fig.

17

If

additional front to rear adjustment

a horizontal position, loosen

to

be

rotated.

holder to the

Be

sure to take

left

and

pivot link to the

screw

up

REAR NEEDLE GUARD

At

needle

extreme

guard

forward

{A,

Fig.

ontally not to contact needle

imum

should

its

inch

looper

the

made

needle

(E)

in pivot link

thrust,

right,

clearance of

be

set

vertical face

(1.2mm)

(C)

right

by

guard

is

required to maintain needle

by

exerting pressure against needle

when

of needle point until point of

moving

side of needle.

loosening

as

tightening

.005

as

low

approach

to the

screw

required

which

end

of

travel,

17)

must

be

(B)

inch

as

(.127mm).

possible, yet

approximately 3/64

left,

is

Adjustment

(D),

reposition

and

retighten screw.

allows needle

screw

(E).

rear

set

horiz-

with a

Guard

have

even

with

can

guard

guard

guard

max-

be

in

shaft

NOTE:

there should

presser foot

ween

foot

If

bottom

and

squarely

guide

Change

change

With

bottom

lifter

in

stitch

of needle size

needle bar

be

l/32 inch

as

shown

of

slot

lever

is

adjustment is required,

Loosen

nut

(C)

surface of presser bar guide

loosen

screws

on

throat plate

(E)

fork, then secure

length

WILL

NOT

may.

PRESSER BAR AND PRESSER FOOT

at

bottom

in Fig. 18.

in

lifter

of stroke

(.8mm)

lever link

clearance

There

released.

and

turn

proceed

screw

as

(D)

(B).

in presser bar 9uide

and

screw

screws

{D)

(E).

require

and

should

(A)

change

in needle

presser foot resting

between

and

top of

be

l/16 inch

bottom

screw

of presser bar guide

follows;

down

approximately 1/8 inch

Back

is touching the

the

(B)

Turn

way

off

presser spring regulating

so

that

presser foot

bottom

presser spring regulating

down,

then

back

erclockwise to obtain the

dimension

Loosen

arm

slightly

inch

in presser foot, lock nut (C).

screw

(1.6mm)

(F)

in

lifter

as

required to obtain the l/16

dimension

guide (B), retighten

guard

and

(1.6mm)

setting,

on

throat plate,

top

of

slot

clearance bet-

(3.2mm)

is

below

sitting

of the presser bar

screw

off

between

screw

screw

1/32

arm

(F).

inch

(G)

link

(D)

(.8mm)

and

(A)

but a

in

(B)

when

screw

count-

rotate

and

all

Fig.

18

12

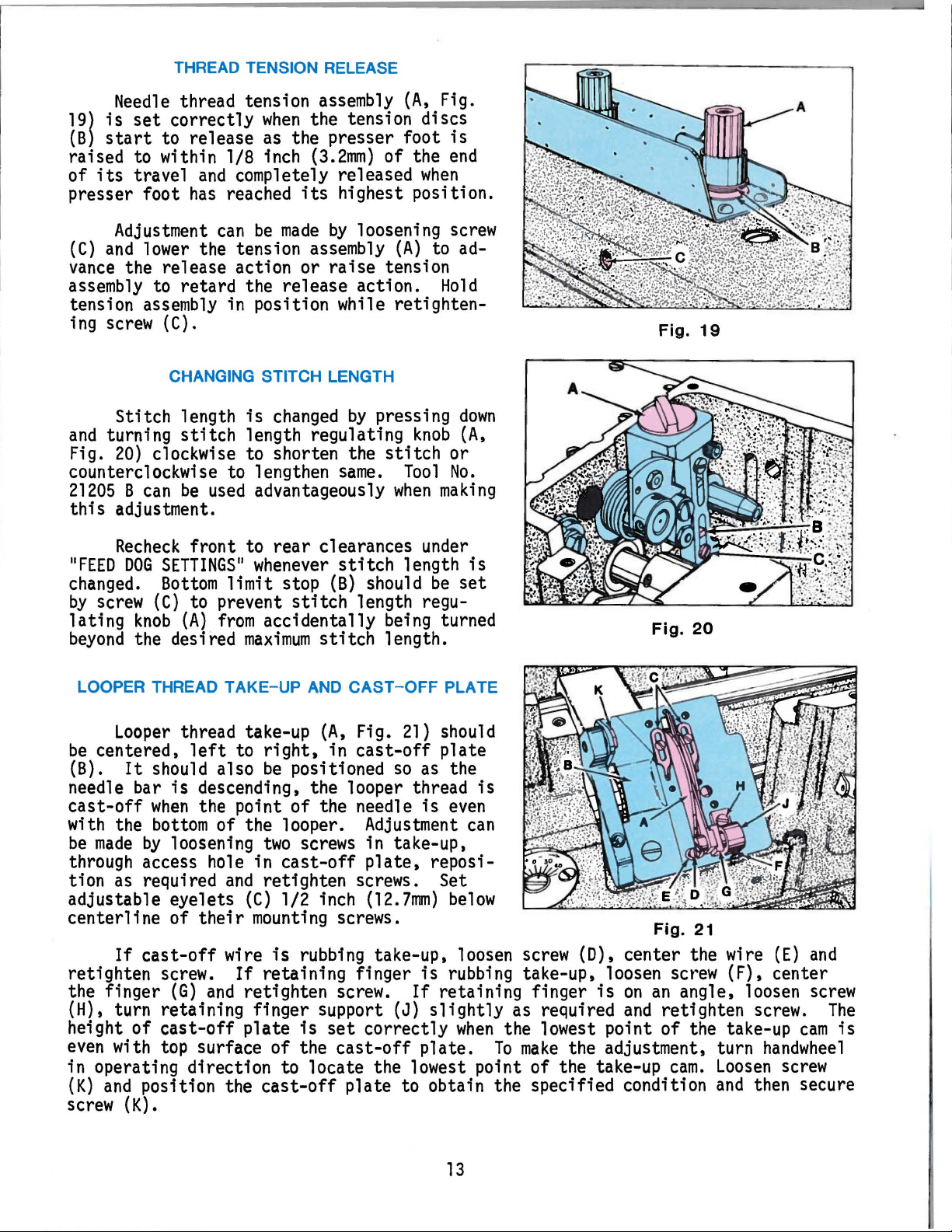

THREAD TENSION RELEASE

Needle

19)

is

(B)

start

raised to within 1/8 inch

of

its

presser foot

Adjustment

(C)

and

vance

the release action or

assembly

tension

ing

screw

Stitch length

and

turning

Fig.

20)

thread tension

set

correctly

to release

when

as

assembly

the tension discs

the presser foot

(3.2mm)

travel

lower

and

completely released

has

reached

can

the tension

be

its

made

assembly

to retard the release action.

assembly

(C).

CHANGING STITCH LENGTH

in position while retighten-

is

changed

stitch

length regulating

clockwise to shorten the

counterclockwise to lengthen

21205 B can

be

used

advantageously

this adjustment.

Recheck

"FEED

DOG

changed.

by

screw

lating

beyond

knob

the desired

front to rear clearances

SETTINGS"

Bottom

(C)

to prevent

(A)

whenever

limit

from

accidentally

maximum

stop (B) should

stitch

stitch

(A,

Fig.

is

of the

end

when

highest position.

by

loosening

raise

(A)

tension

screw

to ad-

Hold

by

pressing

same.

stitch

Tool

when

knob

making

down

(A,

or

No.

under

stitch

length

be

set

length regu-

being

turned

length.

is

Fig. 19

Fig.

20

LOOPER THREAD

Looper

be

centered,

It

(B).

needle bar

cast-off

with the

be

made

should also

is

when

bottom

by

loosening

through access hole in

as

tion

required

adjustable eyelets

centerline of

If

cast-off

retighten screw.

the finger

(H),

turn retaining finger support (J)

height of

even

with

(G)

cast-off

top

TAKE-UP

thread take-up

left

to

AND

(A,

right,

be

positioned

CAST

Fig.

in

cast-off

-OFF

21)

so

as

descending, the looper thread

the point of the needle

of the looper.

two

screws

cast-off

and

retighten screws. Set

(C)

l/2

their

mounting

wire

and

is

rubbing take-up, loosen

If

retaining finger

retighten screw.

plate

is

surface of the

Adjustment

in take-up,

plate,

inch

(12.7mm)

screws.

set

correctly

cast-off

is

is

If

plate.

PLATE

should

plate

the

is

even

can

reposi-

below

screw

(D), center the wire

rubbing take-up, loosen

retaining finger

slightly

when

as required

the lowest point of the take-up

To

make

is

the adjustment, turn

on

and

in operating direction to locate the lowest point of the take-up

(K)

and

screw

position the

(K).

cast-off

plate to obtain the specified condition

Fig.

21

(E)

sct·ew

an

angle, loosen

(F), center

retighten screw.

handwheel

cam.

Loosen

and

then

and

screw

cam

screw

secure

The

is

13

D

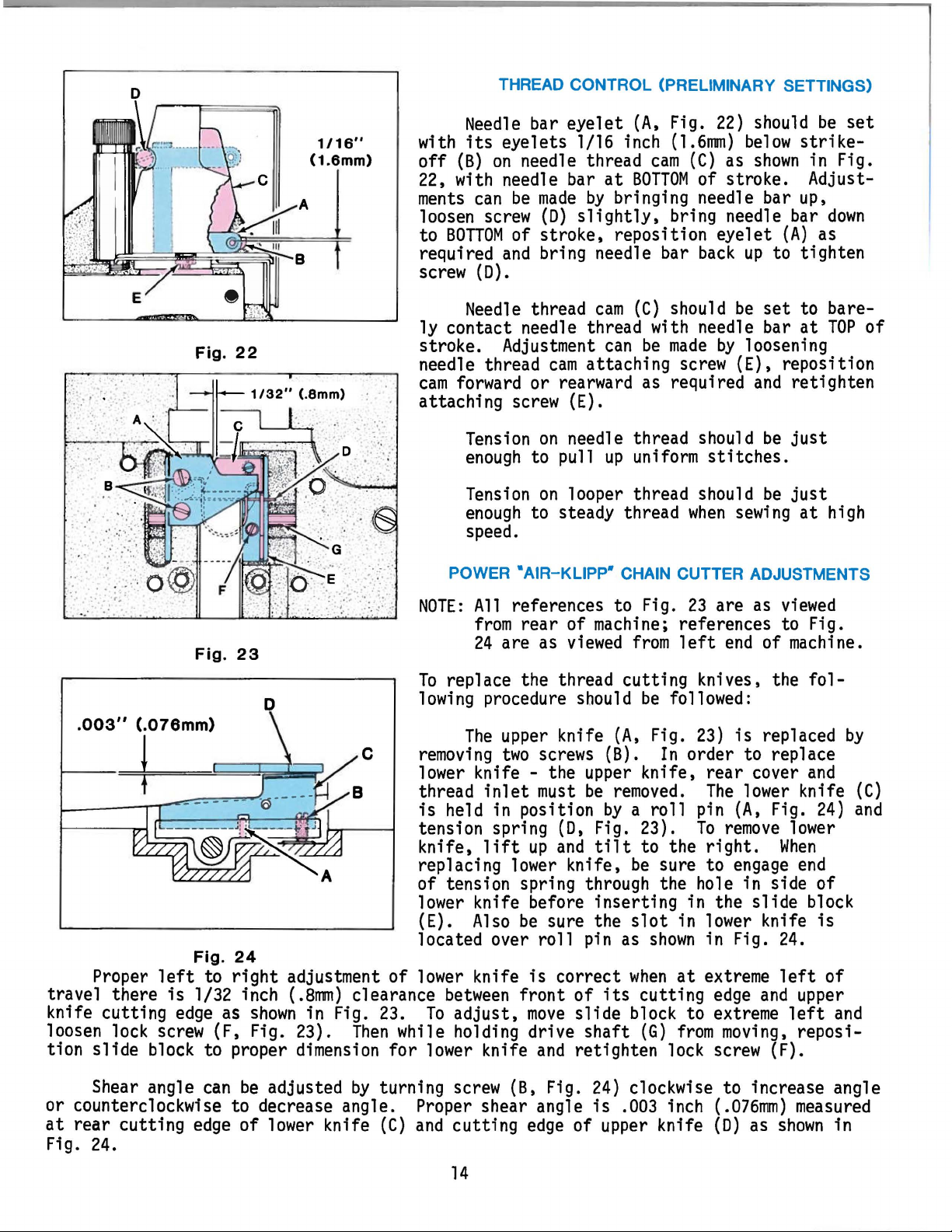

THREAD CONTROL (PRELIMINARY SETTINGS)

Fig.

22

1/16"

(1.6mm)

A

Needle

with

off

22,

ments

its

(B)

with needle bar

can

loosen

to

BOTTOM

required

screw

(D).

Needle

bar eyelet

eyelets 1/16 inch

on

needle thread

be

made

screw

(D)

slightly,

by

{A,

Fig.

(1.6mm)

cam

(C)

at

BOTTOM

of stroke. Adjust-

bringing needle bar

bring needle bar

of stroke, reposition eyelet

and

bring needle bar

thread

cam

(C)

back

should

22)

as

should

below

shown

up

to tighten

be

set

ly contact needle thread with needle bar

stroke.

needle thread

cam

attaching

Adjustment

forward

Tension

enough

Tension

enough

can

cam

attaching

or rearward

screw

(E).

on

needle thread should

to pull

on

up

uniform

looper thread should

to steady thread

be

made

as

required

by

screw

stitches.

when

loosening

(E), reposition

and

be

be

sewing

speed.

POWER

•AIR-KLIPP•

CHAIN CUTTER ADJUSTMENTS

be

set

strike-

in Fig.

up,

down

(A)

as

to bareat

TOP

retighten

just

just

at

high

of

Fig.

23

D

.

003"

(.076mm)

l

Fig.

24

Proper

travel there is 1/32 inch

knife cutting

loosen lock

tion

slide

left

edge

screw

block

to

right

as

shown

(F, Fig. 23).

to proper

adjustment of

(.8mm)

dimension

clearance

in Fig.

Then

23.

while holding drive shaft

for

NOTE:

To

lowing

removing

lower

thread

is

tension spring

knife,

replacing

All

references to Fig.

from

24

rear of

are

as

viewed

machine;

from

23

are

as

viewed

references to Fig.

left

end

of

replace the thread cutting knives, the

procedure should

The

upper

two

knife - the

inlet

knife

screws

must

upper

be

held in position

{D,

lift

up

and

lower

knife,

tilt

be

followed:

{A,

Fig.

23)

(B).

In

order to replace

knife, rear cover

removed.

by

a roll pin

Fig. 23).

To

to the right.

be

sure to

is

The

{A,

remove

engage

replaced

lower

Fig.

When

machine.

fol-

and

knife

24)

lower

end

of tension spring through the hole in side of

lower

(E).

located over roll

lower

To

lower

knife before inserting in the slide block

Also

between

adjust,

knife

knife

be

sure the

is

correct

front

move

and

pin

of

its

slide

slot

as

when

block to

in

shown

at

cutting

{G)

from

retighten lock

lower

in Fig.

extreme

edge

and

extreme

moving,

screw

knife

24.

left

(F).

is

of

upper

left

reposi-

by

(C)

and

and

Shear angle

can

be

adjusted

by

turning

screw

{B,

Fig.

or counterclockwise to decrease angle. Proper shear angle

at

rear cutting

24.

Fig.

edge

of

lower

knife

(C)

and

cutting

14

edge

of

24)

clockwise to increase angle

is

.003

upper

inch

knife

(.076mm)

(D)

as

shown

measured

in

EXPLODED VIEWS

AND

DESCRIPTION OF PARTS

15

Loading...

Loading...