Page 1

Installation of the TCP1

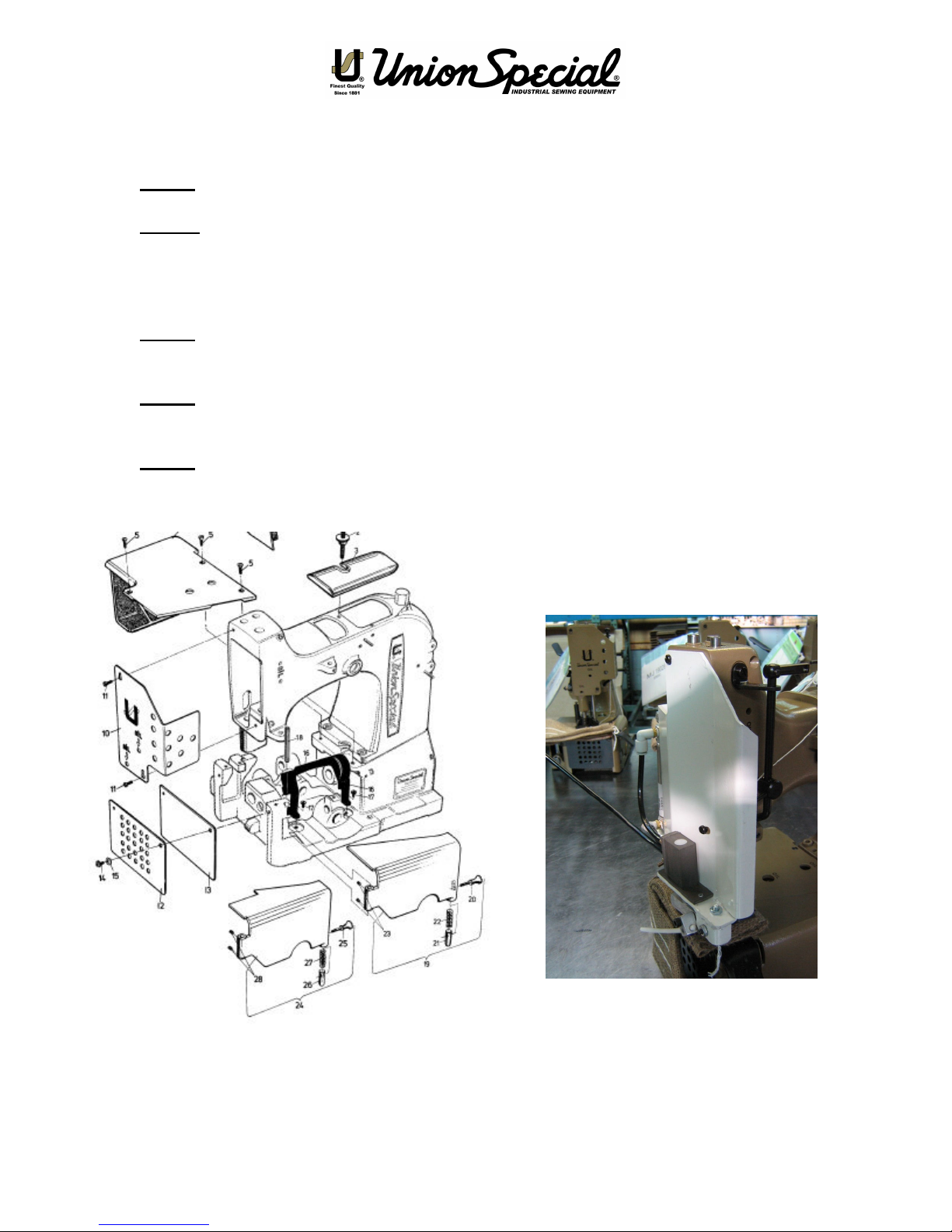

Step 1: Remove face cover # 80887A (#10 below)

Step 2: Attached TCP1 with same screws from face cover (#below). Tighten securely

into place.

Note: position the TCP1 so that the air cylinder is on the left hand side of the sewing

head.

Step 3: Attach air filter/regulator where best suited for operation. Make sure that the

tubing is NOT pinched and clear of moving parts.

Step 4: You will need to supply air and fittings for filter/regulator with ¼” port size NPT

with following specs: Max air pressure: 150 psi, 125 deg F, 18 cfm air supply

Step 5: Once system is installed, adjust pressure on regulator by turning the dial.

Counter clockwise rotation to decrease pressure, clockwise to increase.

Set at 40-60 psi

Page 2

Operation of the TCP1

1. The pusher arm starts in the DOWN position. When the bag is fed into the

machine, the bag will activate the air cylinder which will retract the wand.

2. When the bag passes the wand, the pusher arm returns to the DOWN position

pushing the chain into the knives.

3. Adjusting the wand can be done in 2 ways:

a. Wand Length – loosen allen screw and adjust wand in or out.

b. Position of the Wand – move to adjust contact with the bag and wand,

make adjustment in small increments.

Maintenance of TCP1

1. Air supply should be as free from moisture and inert material as possible, this will

increase the filter life

a. Filter should be drained (manually done) before water level is sump reaches

filter baffle (the black plastic below the filter)

b. Recommend the filter element be replaced once a year when used regularly

throughout the year or every other year with seasonal use.

2. Place 2 drops of sewing machine oil on air cylinder shaft (point closest to the cylinder

body) once a week during regular operation. Always disconnect air supply before

attempting to service any component.

3. Occasionally check tubing and unit for air leaks.

For a video of the unit, go to our website: www.unionspecial.com

Union Special, LLC

1 Union Special Plaza

Huntley, IL 60142

P: 847-669-4500

E: bags@unionspecial.com

Loading...

Loading...