Page 1

MANUAL

INS9310

SP151H829M032

SP151

SP151H829M040

SP151H830M040

SP161S800M032

SP161S800M040

SP161S800M048C

SP161S900M032C

SP1615900M040C

SP161

SP161

SP161

SP161H829M040

SP161

SP1725800MAAC

SP172S800MACC

SP172S800MADC

SP172S900MACC

SP172S900MADC

SP

172S900MAEC

SP172S800MBDC

SP

172S900MBDC

SP172S9QOHAC

SP172S900HAD

SP172S900HAE

SP

172S9QOP

SP172S900HBE

NO

..

SlYLES

H830M032

S900M048C

H829M032

H830M032

H830M040

;o

ADJUSTING

INSTRUCTIONS

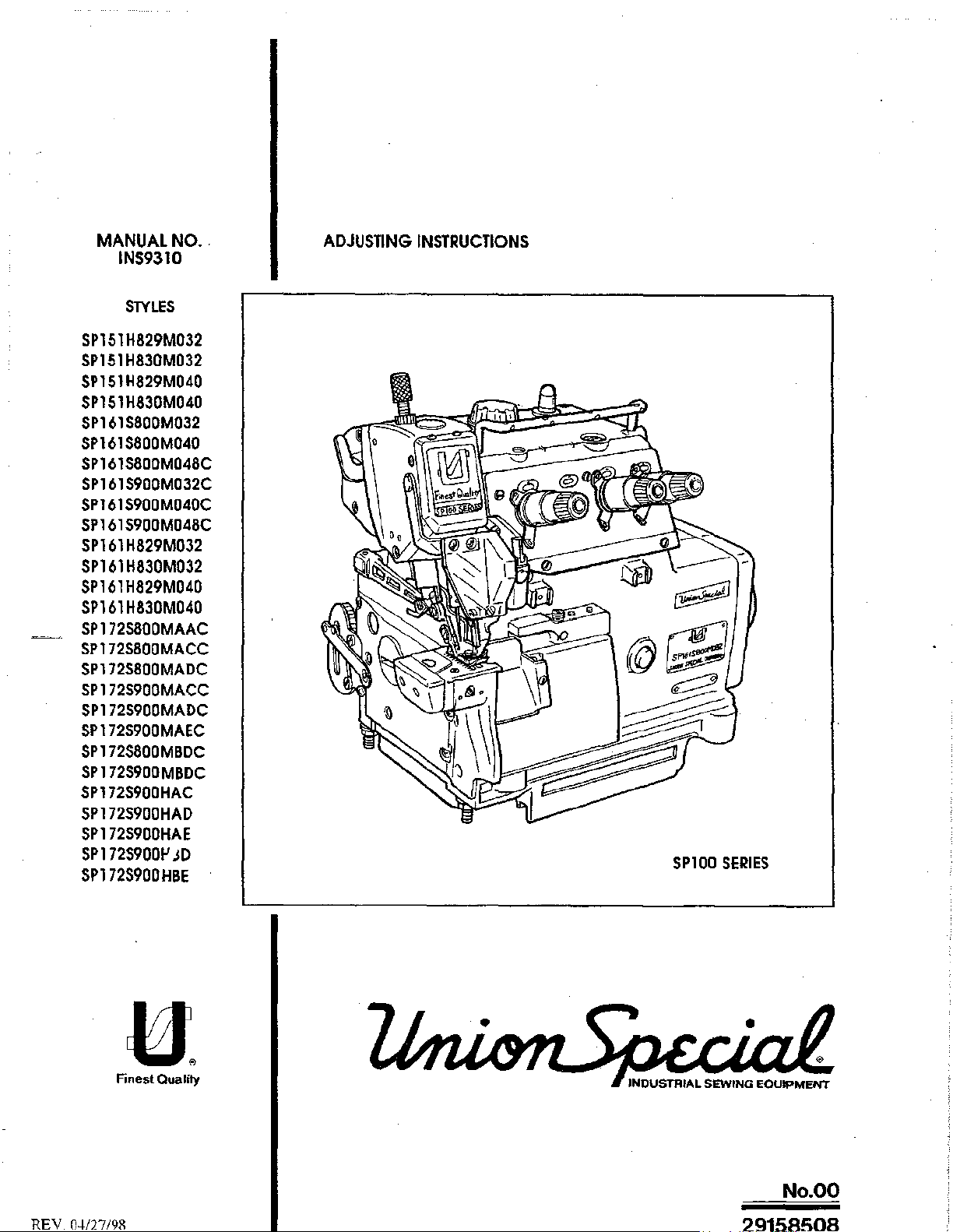

SP100

SERIES

U.

Finest Quality

REV

O-I-/27/9R

No.OO

Page 2

A

SAFETY

RULES

TABLE

OF

CONTENTS

Poge

1-2

BEFORE OPERATION

CAUTIONS

1. INSTALLING

2.

3.

4. INSTALLING THE PEDALS

5. LUBRICATION

6.

7. THREADING THE MACHINE

8.

9.

10. DIFFERENTIAL FEED MECHANISM

11. KNIVES AND OVEREDGE WIDTH

12. SPECIFICATIONS

IN

OPERATION

MOTORPULLEYANDVBELT

ATTACHING THE BELT

ATTACHING NEEDLES

PRESSER FOOT PRESSURE AND

ADJUSTING

•.....

THE

FRAME SUPPORT PLATE

COVER

...•..

•..

THE

STITCH LENGTH

.....•••.

....•

liFTER

.•.

3

3

4

4

5

5

5

6

'

7

7

7

'

'

Page 3

Manual

This

adjusting

conjunction

Tl'lls

manual explains in

the

functions

items

with Union

discussed.

No.

manual

of

the

INS931

has

Special

detail

machine.

0 Adjusting Instructions

First

Edition

Union

Special

Corporation Rights Reserved In All Countries

been

prepared

Illustrated Parts

the proper

Illustrations

lo

seHing

are

used

Printed in

guide

you

Manual

for

each

to

show

Japan

PREFACE

P-RT9311.

for

the

SPI

Copyrightl993

By

October

while

1993

adjusting

the

SP100

of the componenls related

the

adjustments

and

rference letters

00 Series

Series machines. II

to

forming the stitch

are

Machines

used to

eon

and

completing

point

be

out

used

in

specific

Careful oHentlon

are

may

has

a slight

following

Opergfjng

sewing

these

II

8).

putting

each

machine

and

performance

Adjustments

of

sequence

This

manual

incorporate

On

the

machines.

Genergl

The

In

which

Annex

Before

1.

of

IMPORTANT!

to

fhe

instructions for

reliability designed

presented in

have

been

modification

pages

pjrectjons

machines

sewing

the

Before

sequence

an

adverse

comprised

will

be

described

machines

machines

is

only

permitted

pulling

operamg

and

so

effect

on

the

basis

of

configuration in illustraHons

found

iDusiralions

in

this

will

described

into

service

and

built into every Union Special machine.

that a

logical

on

the function

of

available

and

manual

be

built-In

in

this

after

taking

also

adjusting these machines will enable

progression

of

the

information.

fe!TTlinology used

SAFETY

are

manual

read

RULES

prohibited

have

conformed

notice

the

other

or

into

of

safety

is

occomplished.

related

Changes

part

numbers.

in

until

if

service

the

instructions

rules

perfs.

in

design

describing the adjustments for

has

been

ascertained,

with

the

EC

Council

carefully

and

read

and

instruction

you

to

maintain the superior

Some adjustments

the

by

qualified

and/or

from

Improvements

that

the

Directives

instructions.

operators.

the

motor

performed

the

SPlOO

sewing

(89/392/EEC,

The

starting

supplier.

out

may

Series

units

2.

Observe

3.

Each

in

foreseen.

4.

All

the

5.

All

bar

6.

When

threading,

for

clutch

the

machine

paragraph

safety

devices

appertaining

safety

devices

guard,

the

needle

gauge

when

main

motors

notional

is

only

"STYLES

safety

parts

the

power

without

safety

allowed

OF MACHINES"

must

be

in

devices

are

components

break

protection

are

exchanged

operator

by

switching

a start

rules

valid

to

be

position

is

leaves

off

the

inhibitor

used

when

not

of

shield,

(e.g.

the

main

if

for

your

as

foreseen.

of

this

manual.

the

machine

allowed.

the

sewing

handwheel-bell

needle,

workplace,

switch

is

necessory

country.

The

machines:

presser

and

or

disconnecting

to

foreseen

Another

is

ready

Fingerguard,

guard.

loot,

during

wait

unlit

use

use,

for

work

needle

service

the

the

of

going

or

plate,

work,

main

motor

the

particular

beyond

in

operalion.

needle

feed

the

plug.

has

the

lever

dog

machine

On

mechanically

stopped.

machine

description

The

operation

eyelet

guard,

and

bobbin)

must

is

described

is

not

without

needle

during

be

isolated

operated

as

Page 4

7.

Wear

8.

In

changes

safety glasses.

case

of

machine

are

made

conversions

at

your

own

and

risk.

changes

all

valid

safety

rules

must

be

considered.

Convarsions

and

Commissioning

9.

with

EC

10. The

Specjal

11. For

General

warning

Be sure

Operafing

the

or

by

11.1 For

11.2 For

11.3

11.4

11.5

Mgjntengnce

of

regulations.

hints in

to

observe

Pirectjons

following

pulling

When

When

out

threading

replacing

needle

leaving

For

maintenance

using

guard,

the

sewing

the

and

the

machine

the

main

needle(s),

sewing

folder,

the

dutch

Pirectjons

head

instructions

adhere

workplace

work.

has

plug:

tools

fabric

motors

to

looper,

without

is

prohibited

are

these

to

be

disconnected

spreader

such

as

guide

and

until

marked

with

&

Indications

etc.

needle.

etc.

when

the

actuation

such

time

one

of

Danget

and

to

from

the

presser

workplace

lock,

foot,

wait

as

these

the

generally

power

throat

is

unattended.

until

the

two

of

the

entire

symbols.

mjufY

supply

plale.

motor

sewing

fo

opetafive

applicable

by

fuming

looper.

is

stopped

unit

is

found

ot

•etvlee

regulations.

off

the

spreader,

totally.

to

•laff

main

feed

comply

switch

dog.

12.

Maintenance,

skilled

13.

special

Specjgl

14. Work

described

15.

disconnected

from

Stgndards

17. The

personnel

Any

work

on

skilled

Mgiolengnce

on

parts

in

Before

Exceptions

EN292-2 Safety

IEC204-3-1/EN60204-3·1

doing

compressed

ere

sewing

machines

repair

and

under

the

electrical

personnel.

Directions

and

equipment

the

applicable

maintenance

from

the

air

supply

only

allowed

described

of

machinery-basic

conversion

consideration

equipment

under

sections

and

compressed

(e.g.

for

adjusting

in

Electrical

for

works

(see

of

the

must

electrical

of

standard

repair

pneumatic

air

supply.

this

manual

concepts,

sewing

work

work

equipment

machines,

item

8) must

instructions.

be

done

by

tension is

sheet

on

the

In

case

equipment

and

function

are

built

general

of industrial

be

electricians

not

DIN

VDE

pneumatic

of

existing

with

checks

according

principles

units

and

done

permitted.

0105.

residual

air

lank),

machines.

systems.

only

by

troined

or

under

equipment,

air pressure

it has

to

done

by

to

the

following

for

design.

Port 3:

technicians

direction

Permissible

the

machine

after

be

removed

special

skilled

standards:

Particular

and

supervision

exceptions

has

disconnecting

by

personnel.

requirements

or

spe-cial

are

to

be

bleeding.

of

-2-

Page 5

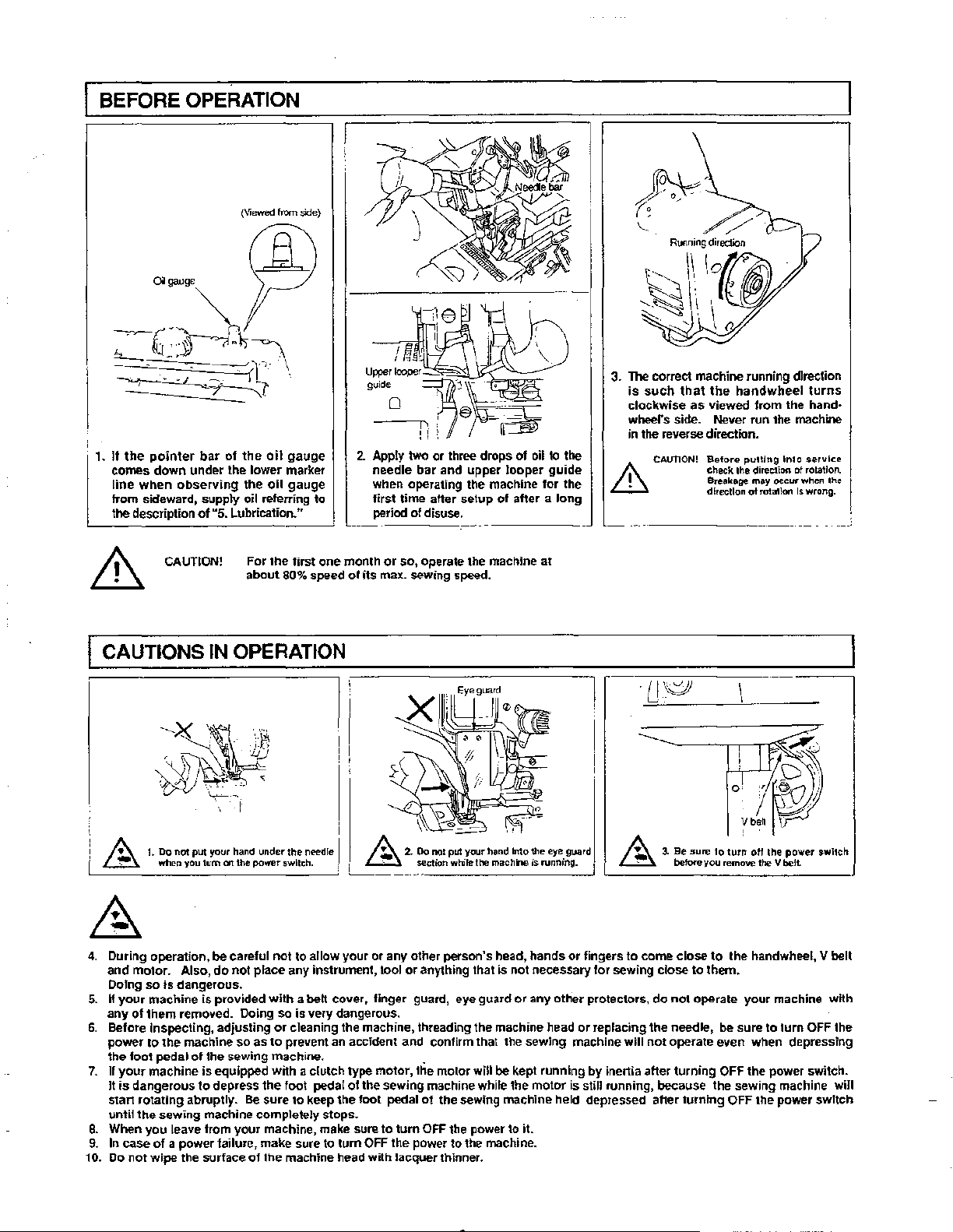

BEFORE OPERATION

(Viewed

from

1.

It

the

pointer

comes

line

when

from sideward,

the

description

bar

of

supply

of

u5.

the

the

oil referring

Lubrication."

down

under the lower marker

observing

oil

oil

side)

gauge

gauge

to

2.

Apply

two

needle

when operating the machine

first

period

or three drollS

bar

time

aHer setup

of

disuse.

and

upper

of

looper

of

after a

oil

to

guide

lor

long

the

the

3.

"IlK!'

correct machine running dlreelion

is

such

that

the

clockwise as viewed from the hand·

side. Never run the machine

wheel's

in

the

reverse direction.

.&

CAUTION!

handwheel

Before

check

lhe

Breaka""

direction

~ulllng

lnlg

direr:tion

may

occur

ol

rol"'lon

ot

turns

$ervlce

rotallon.

when

Is wrong.

lhe

For

lhe

CAUTION!

about

first

80%

CAUTIONS IN OPERATION

:A

~~

4.

5.

6.

7.

8.

9.

10. Do

1.

Do

not

put I"'Ur

hand

when you

tum

During operation,

and

motor. Also,

Doing

so

is

If

your

any

Before Inspecting, adjusting

power

the

If

your

It

is

start

until

When

In case

not

dangerous.

machine

of

them

removed. Doing

to

the

foot

pedal

machine

dangerous

rotating

the

sewing

you

leave from

of a power

wipe

is

machine

of

the sewing machine. .

is

to

abruptly.

machine completely stops.

the surface

under

on

the

po...,r

be

careful

do

not

place any instrument, tool

provided

so

as

equipped

depress

Be

your

failure, make sure to

of

the

switch. .

not

to allow

with

a belt cover,

so

is

or

cleaning the machine, threading the machine head

to

prevent an accident and confirm that the sewing machine

with

a clutch type motor, the motor

the

foot

sure

to keep

machine, make sure to

lhe

machine head with lacquer thinner.

one

month

or

speed

ol

n.....:tle I

'~-~---:"'ction

your

very dangerous.

pedal

olthe

the

tum

so, operate the machine

its max. sewing speed.

A

2.

Oo not

p~

your

han~

while the mac hr...

or

any other person's head,

or

anything that is not necessary

linger

guard, eye guard

sewing machine while the

foot

pedal ot the sewing machine held depressed after

tum

OFF the power

OFF the power to it.

to

the

~~tl1e

or

will

be kept running

machine.

at

~--------.,o

eye guard A

is

running. I

hands

or

any other protectors,

motor

is

~

L_

_______________

fingers

to

lor

sewing

or

replacing the needle,

will

by

inertia after

still running, because the sewing machine will

v~~~

3.

Be"""'

lo

1ur~

oH

before

you

come

close

close

do

not

to

to them.

not

operate

operate even when depressing

turning

be

OFF the power switch.

turning

I he power

remove the V

the handwheel, V belt

sure to

OFF the power

~It

your

machine with

tum

$Wl1C~

J

OFF the

switch

Page 6

1.

INSTALLING THE FRAME SUPPORT PLATE

I)

Attach

plate

blower

0.

case

8.

rubber cushion 0

10

frame support

L

I

0

~----

2) Install

3) Install upper waste chute 0

fram~

support

auach

lower waste

The installation

plate 0 directly

chute

the

9

chutes

of

56mm.

to

the table.

to

the left on

tO

the upper waste chute.

can

be

the

adjusted within a length

table,

and

then

of

2.

MOTOR PULLEY AND V BELT

90.5

85.5

(mm)

-

50Hz

sunken

I

V belt (inch}

Semi-

''"'

40

sunken

40

38

38

38

36

36

35

35

Fully-

''"'

36

34

34

34

32

32

32

30

30

I

Motor

outerdia. (rom)

135.5

125.5

120.5

110.5

100.5

'

~------

Sewing

(s.p.m.)

8500

8000

7500

7000

6500

6000

5500

5000

4500

speed

I

r--

I

I

Motor pulley

outerdia.

'

160.5

!50.5

140.5

130.5

120.5

110.5

100.5

60Hz

V belt

pulley

Semi-

~u11ken

''"

38

38

38

36

36

95.5 35 30

!!5.5

80.5

70.5

35

34

34

4.

(inch)

Fully-

sunken

''"

34

32

32

32

32

30

·w

30

I)

If

the

sewing

spc;:ed

of

the

machine

ex(;eed~

i~

3/4

or

with a clutch motor

W).

2)

UseanMtypeVbel!.

3)

The

sewing speeds obtnined by the use

of

diarnete~

4) Note that the effective diameter

the pulley of the machine head

mm.

7,500

~.p.m.,

the machine

~quipptd

lower, the machine

m<Jtor

lengths.

with a cluu:h molor

HP(550W).Ifitis7,500s.p.m.

is

of

Ill

table

on

the left shows the

pulleys with different

and

V belts with different

equipped

HP(400

of

of

is

50

Page 7

3. ATTACHING THE BELT COVER I I

l

I

i

L-------------------~

Install belt

cover 0 10

the machine head.

I 5. LUBRICATION

0

~~~b,~"'iJI

4. INSTALLING THE PEDALS

'=======;===~

)

(!}

I}

Install

stllning

seen

From

2}

Use

:m

S-shaped

to

presser lifting lever

pedal 0 on

the

operator.

hook 0 to

0.

the

left

connect

and

pre~~er

the

chain

lifter pedal

8 of

the

f)

on

the

presser lifter

right as

pedal

'------~--=---~~--~-

I)

Remo~e

oil

cap 0 . *Checking the cartridge filter

2)

Po(lrJU£<11\\:w

3) Supply oil UJJtilthe pointer

oil gauge

-1'-.

Caution Be careful

LJ..l

4) Remove oil drain cap 8 when dr.tining the oil reservoir.

•

lubrication

I)

Open

cloth

2) Remove plug@),

3}

Infiltrate silicon oil

aft~r

lubricating

Defri;o;

f}

is

observed

else

the

needle

plat~:

c.:o~r

and

al>o

the

needle cooler.

Oil No.2

troubles

cooler

and

supply silicon

into the oil

into

bar

a!mo~t

from

the

not

to

due

supply silicon

the

oil

reservoi[

reoches the upper red marker line when become clogged with dust.

~ide.

exceed

the

to

excessive

upper red marker

lubrication may resuh. wear

" "

'·'

oil

from

section

e.

oiL

felt

if

the

machine

is

started immediately

fine,

r I

~0_~~~:::::l_j

and

1.

After a

long

period

of

us.tge,

If

the

machine

i:;

left

in

this

otatc,

or

pass lhrough can ridge filter 0 ,

out

abnonnally. or a seizure

* Car1ridge filler 0 should nonnally

every

six

months.

and

cleaned

2.

How

to

inspect

the

I) Remove

2) Remove

(Caution) H top cover 0 Is shifted sideward, the

3)

4) Re-inscn canridge filter 0

firot

screw~

it

comes

of[

pointer

Remove cartridge

found

to

be

replace

can

relllm the

(IJld

tighten

car1ridge

oil

di~charging

8.

bar

and

abnonnal, clean

ridge

filter

cover_

Do not forget

them

up.

filter and replace

>crew

and

lift

top

the

cartridge filter may be

filter 0 (IJld

the

0.

into

replacing

cartridge filter 0

the

and

may

or

replaced accordingly.

f).

cover 0 just above

check

relevant components, or

its

to

put back the setscrews

it

dirty oil may

the

machine may

result.

be

checked once

it

oil

n.

If the filter

proper

po-;ition

may

fail

until

amount

damaged.

and

10

is

Page 8

I 6. ATTACHING NEEDLES

SWUcl\-ott main switch

clutch m01ors wl!.hollt attua\101\

stopped

tolall~l

The

standard needle

looper

may

Anach

the

needle.~

I) Bring needle

2)

Loosen

needle clamp screw

the

oper<llor's

3) Tighten

I

7.

THREADING THE MACHINE

Switch-oft

motms

totaHy!

Thread

the

is

be

required

according to the following procedure;

damp

side.

the

needle clamp screw 0 _

mBin

without

machine according

belore

allar::lllng

"0Cx27

to

be

adjusted.

#II."

0 to the highest

8,

and fully

switch

befe>re

actu!lllon

toc:k

to

the threading

You

throadlng!

wait

needles!

to~k

walt

can

If

sewing

po~ition.

until

unHitlla

also

need

insert

Whn

the

motor

chaJt

W~"

use

the Delli

to

the

using

has

g'tven

molor

needle

be

stopl""d

using

has

carried

into

clutch

below.

needle.

ln

this

out

with a finely-adjusted

the

needle

clamp hole

(The

same

chart is

c-ase,

how(;!ver,

on

the

clearance provided between

thread

tension,

with

the

needle recess facing backwards

the

irr~ideofthe

use

looper

the

DCx27 needle.

cover.)

SP172

the

needle and

as

viewed

!he

from

SP161

* How

When

10

thread

lhe

the

needle cooler is used

needle

thread

silicon

oil

tank

When the nee!Je cooler

not

used

1s

lntermcdlal" t'ucad gu;,Je

,,

·~

= \

:\@

\.:::......J.'

~.-----

(Caution)

When using an untwisted

thread such as wooly

thread

or

weak thread, do

not wind it round lhe inter·

mediate

thread

guide.

I

~

nylon

Pass

the

center pawl.

thread under the

Pass

the

thread

center pawl.

above

the

-6-

Page 9

8. PRESSER FOOT PRESSURE

AND LIFTER

9. ADJUSTING THE STITCH LENGTH

I) Adjust the pressure

0 and turning presser

When the adjust screw

increase. When

wi!l decrease. After

without

faiL

2)

To

open

presser

of

the presser

foot

is

turned clockwise,

it

is

turned oounterdockwise,.

lhe

adjustment.

foot

f)

sideward, lower presser

foot

adjust screw

by

loosening tin;t

0.

the

pressure

!he

be

sure to tum nut 0

leverO.

10.

DIFFERENTIAL FEED MECHANISM

pressure

bar

lifting

nut

will

Switch-off main switch before

When

using

clutch

the motor

I) Slowly tum the handwhecl

will

find

a )Xlint at

2) Wnh the above condition maintained, align the desired scale mark on !he

handwheel with

3)

Reset

the

pushbuuon after setting

has

which

mark 8 on

motors

stopped totally!

as

you

keep depressing pushbutton

the

pushbutton goes

the

belt

cover.

the

dial.

I)

Loosen

difft:rential

Move

leverO

for

gathering stitch.

2) When the differential feed adjusting lever is

se1

to graduationS, the machine will perfonn

stretching with a differential

I :0.8. When the lever is set to graduation

0,

the

differential feed ratio between the main

feed dog and the differential

I

:I.

3)

The

maximum

gathering

depending on the adjust-ment

mechanism

graduations beyond

selling

with-out

is 1

actuation

in

farther.

feed

kx:k

up

for stretching stitch

differential

:2.3

(it

of

the

sewing machine). The

0 are used as reference.

the stitch length!

lock

wait until

8,

and

nul

8.

or

down

feed ratio

ked

dog

will

feed

can

ratio

be

set to I :4.5

of

the

in1emal

you

for

of

be

-7-

Page 10

11. KNIVES AND OVEREDGE WIDTH

Switch-oft main switch betore adjusting

of

knives!

actuation

totally!

•

Height

of

Loosen setscrew 8

its

edge

• Height of

lJ:Josen setscrews

knife

knife is

• Dveredge

Ove~edge

parts

slightly larger !han the knife cut width.)

To

change the overedge width:

l)

Loosening setscrew 0 , push lower knife 0

and fix

2) Loosen setscrew 0 and move upper knife 8 as required, then

fix

3)

Lower the llpper knife to

lower

is flush with

the

8 overlaps lower knife 0 by 0.5

at

its lowert point.

widths

widths

or

by using subclass models. (The ovcrcdgc width will

it.

it.

When

using

lock

wait

knife

and

adjust

the

the

throat plate surface.

until

height

clutch

the

motor

or

lower

upper knife

0,

0 and perform adjustment so that upper

IO

I mm when the upper

of

2 through 4.8

mm

are

provided

its

lowest point and loosen

@. Tighten setscrew 0 when the lower knife comes

with the upper knife.

1.

Be

sure

to

tighten

screw

(j)

motors

has

knife 0

by

before

the

height

without

stopped

so

that

changing

the

to

the

left

set~crcw

in

contact

operating

machine.

(caution) knives

• Resharpening the lower

Whefl

figure lefr.

2.Aiter

the

lower knife

knives.

the

completion

cut

a thread to

knife

ha~

become dull, rcsharpen

of

adjustment,

ch~k

for

sharpness

it

as shown in the

make

of

the

the

be

12. SPECIFICATIONS

Sewing

speed

(Ma."<.)

Stitch length

Needle

guagc

Overedge

-=------

Differemial feed

Needle

Presser foot lifl

Presser fool

width

lift

..

ratio

--·

---------------------------------------- ----------------------------------------

·-·---

---------------

c-

SP161

8,500s.p.m. j" 8,000s.p.m.

(exduding

u~u-

..

--

···--

-··~·-:-:--:'-:--=--·-·-

Gathering stitch 2.3 (Max. I :4.5 ), Stretching stitch I :0.8

DC x 27

--~..?-~~---

···--·-

-------------

--"''''cdc"c"c;""•cw~m;c'c'=""~'~::=':cm="'c;c'=''=l-------------1

(Smmlard)

JUKI

New

some

subclass models)

0.8-

3.5

mm

DC

_l

______

Defrix

x 1

may

-------

Oil No. 2

be used

SPI72

2.0,

2.4

mm

~D.•~u-

..

~·-.~.

7mm

Page 11

OfToc~

usr

only

UNION

PRODUCT

(Plea$<

$Ubmit

one

SPECIAL

CORPORATION

INSTALLATION

fl'11m

ea<ll

maoblne lnttalltd and rompltle

REPORT

alllkrms)

Offiu

use only

Adjuster

C11stomer

Address

Telephone Sales Represenmtive

Contact

SURVEY

Rate

each

of

the

items

listM, circle

Highest=

5 (Very SatisfiM):

Date Installed

Machine Style

Serial

Installation

(in hours) Style

Sales

Territory

RATING

one,

Lowest=

number

PROCEDURE

according

5 = Very Satisfied 2 = Dissatisfied*

=Very

4 = Satisfied I

Dissatisfied* (*=Explanation Requested)

EVALUATION

The

A.

carton and packing materials used

are

correct, all accessory items were received

5 4 2 I

Sewing

B.

c.

The

D.

There

E.

All

during initial operation

F.

Machine

The

G.

The

H.

your

machine received in good condition No external parts

5

4

external painted surface was not scratched and showed

4

oil

at

any external part

4

was

no

excessive accumulation

5

of

5

screws and securing devices were tight Adjustable

of

the machine.

4 2

the factory box with only minor adjustment required.

4 2 1

sewed

on

your

operation

5

out

5

of

instruction manual was infonnative and provided clear, easy

4

table stand,

use

of

the machine.

5

motor

and accessory items provided for installing the machine were

5 4 2 I

I.

In

actual operation,

No

unusual vibration was detected at the machine, motor

under

production standards, at

maximum

or

5 4

Please

provide

the

reasons

you

are

not

Item Explanation

Time

to

the

degree

of

satisfaction

I (Very DissatisfiM)

in

good condition.

or

accessories were damaged in shipment.

2 I

no

signs

of

rust at point.

2 I

of

lhe machine.

2 1

pans

were properly secured and did not

1

to

follow instructions.

2 I

of

proper design and suitable for

speed,

the

noise emitted was at acceptable levels.

peripheral devices.

2

satisfied

1

with

this

product.

Inspector

become

1oose

(If

rno~

space

is

rcquiR;d,

please

INSREPF.\1.

WK

Please enter operational

Page 1

data

FPKOOO

usc

back of form.)

on back or form.

Rev. OJI893

Page 12

Needle thread

Looper thread

Stitches per inch

Material

Needle size

Speed

Oil used

(brand & type)

UNION

SPECIAL

PRODUCT

OPERATIONAL

CORPORATION

INSTALLATION

DATA

REPORT

[

Fir

thr""d

•

como labels here ir possible.)

Sewing operation perfonned:

Additional comments:

. .

Threa.d brattd and

(if labels are

Mt

type

furnished}

hg<2

--

Page 13

NOTES

Page 14

NOTES

Page 15

Page 16

WORLDWIDE

SALES

AND

SERVICE

Union Special Corporation maintains sales

out the

WOI1d.

These

offices will aid you in the selection of the right sewing

equipment for

representatives

to serve your needs promptly

there is a

yOIJ

and

quallled

particular operation. Union Special Corporation

service technicians

and

representative to serve you.

Corporate

Office:

are

efticienHy. Whatever your location,

One

Huntley,

Phone: 847•669•5101

Hax:847•669•4454

European Dislribufion Center:

Union Special GmbH

Raiffeisenstrasse 3

0·71696

Tel:

Fax:49•07141•247•100

and

service

fac~ilies

facfory

trained

Union Special Plaza

IL

60142

MOglingen,

and

49•07141•247•0

through·

are

able

Germany

Brussels, Belgium

Charlotte, N.C.

El

Paso,

TX

Hong Kong, China

Huntley,

ll

leicester, England

Lille, France

Miami,

Milan,llaly

FL

M6glingen, Germany

Montreal,

Quebec

Osaka, Japan

Santa

Fe

Springs, CA

Other

Representatives

all parts

of

the

world.

throughout

Finest Quality

Loading...

Loading...