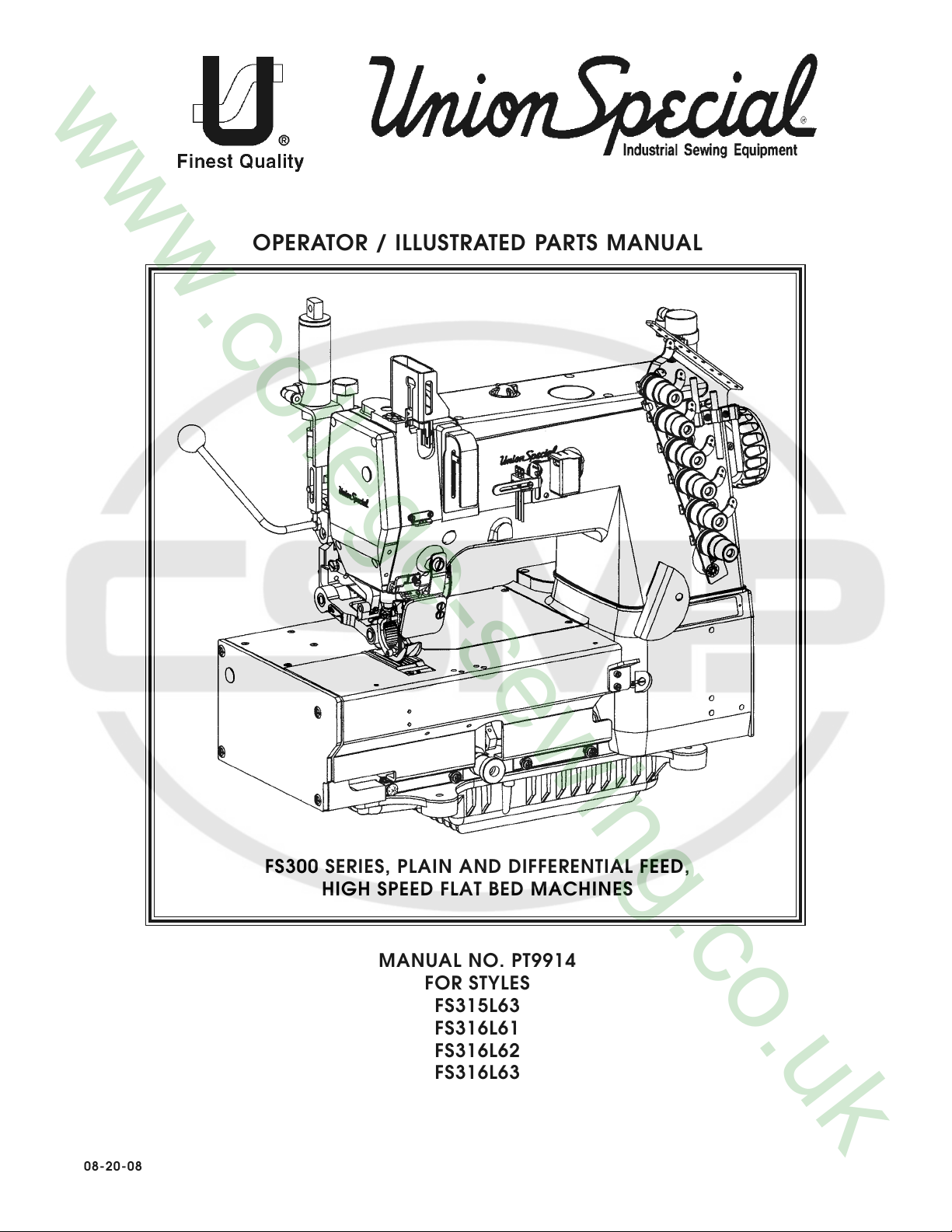

Union Special PT9914 Parts Book

OPERATOR / ILLUSTRATED PARTS MANUAL

08-20-08

FS300 SERIES, PLAIN AND DIFFERENTIAL FEED,

HIGH SPEED FLAT BED MACHINES

MANUAL NO. PT9914

FOR STYLES

FS315L63

FS316L61

FS316L62

FS316L63

Manual No. PT9914 llustrated Parts List for FS300 Series Machines

First Edition Copyright 2000

By

Union Special Corporation Rights Reserved In All Countries

This parts manual has been prepared to assist you in locating individual parts or assemblies on FS300 Series machines.

It can be used in conjunction with Union Special Engineer's Manual EN9424.

It is the desire of Union Special that each machine run at its optimum performance. Parts listed in this manual are

designed specifically for your machine and are manufactured with utmost precision to assure long lasting service.

This manual has been comprised on the basis of available information. Changes in design and/or improvements may

incorporate a slight modification of configuration in illustrations or part numbers.

On the following pages are illustrations and terminology used in describing the parts used on FS300 Series machines.

Printed in U.S.A. Jan. 2000

PREFACE

CONTENTS

PREFACE .................................................................................................................................................................... 2

IDENTIFICATION OF MACHINES ............................................................................................................................... 4

CLASS DESCRIPTION ................................................................................................................................................. 4

STYLE OF MACHINES ................................................................................................................................................. 4

STYLE OF MACHINES CONT. .................................................................................................................................... 5

ILLUSTRATIONS........................................................................................................................................................... 5

IDENTIFYING PARTS ................................................................................................................................................... 5

NEEDLES ..................................................................................................................................................................... 5

SAFETY RULES ............................................................................................................................................................ 6

FS300 SERIES BUILDING BLOCK STYLE DESIGNATION SYSTEM................................................................................ 7

CAUTION AREAS: ...................................................................................................................................................... 8

OPERATOR'S DAILY CHECK LIST:.............................................................................................................................. 9

OPERATING CAUTIONS: ........................................................................................................................................... 9

OPERATING CAUTIONS (CONT.): .......................................................................................................................... 10

OPERATING THE PEDALS: ....................................................................................................................................... 10

LUBRICATION: ......................................................................................................................................................... 11

THREADING THE MACHINE: ................................................................................................................................... 12

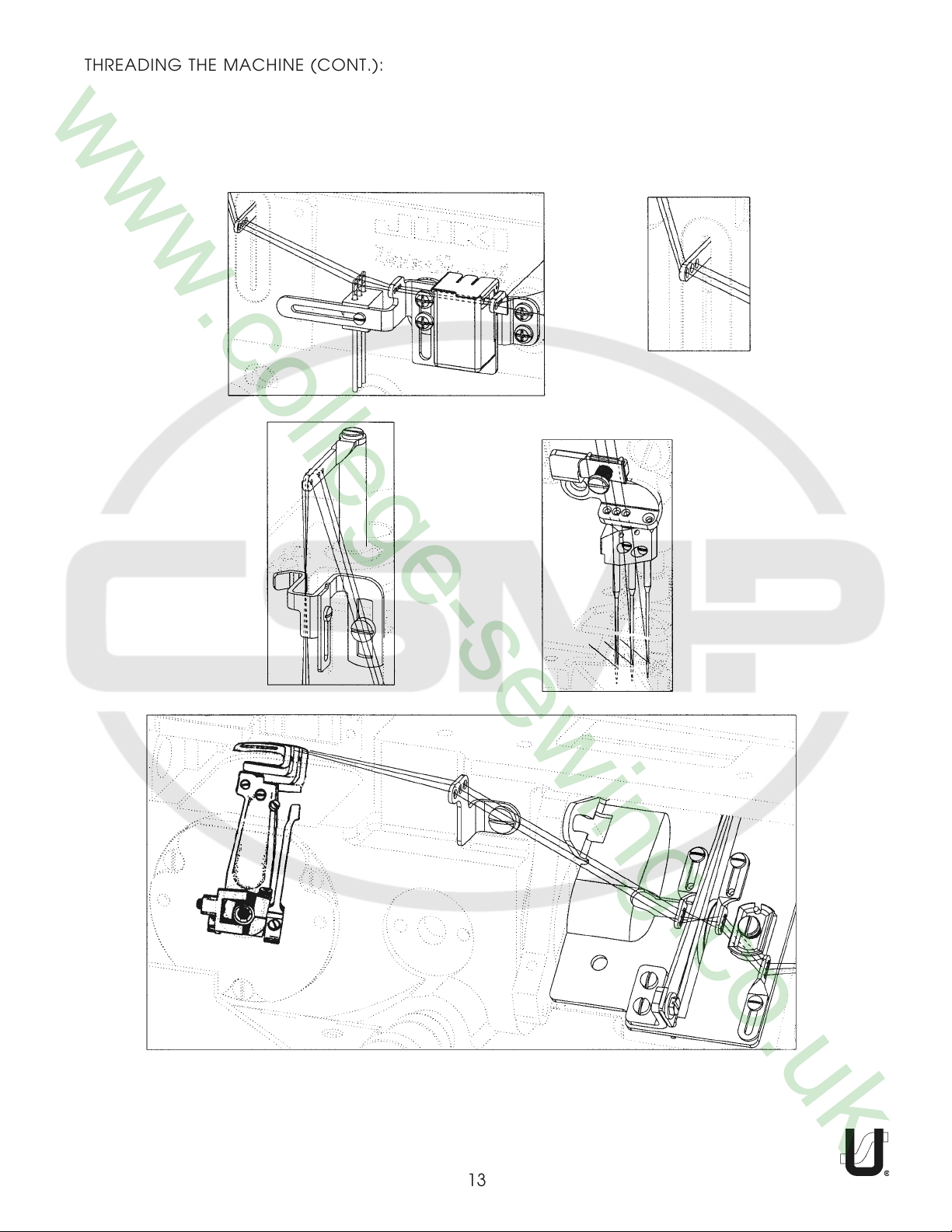

THREADING THE MACHINE (CONT.): .................................................................................................................... 13

THREADING METHODS ........................................................................................................................................... 14

ADJUSTING THE STITCH LENGTH: ........................................................................................................................... 15

PRESSER FOOT PRESSURE AND LIFTER: .................................................................................................................. 15

FEED, NEEDLE LOOPER TIMING:............................................................................................................................. 16

NEEDLE ALIGNMENT: .............................................................................................................................................. 16

LOOPER SETTING:.................................................................................................................................................... 17

NEEDLE BAR SETTING: ............................................................................................................................................. 17

2

REAR NEEDLE GUARD: ........................................................................................................................................... 18

FEED DOG CENTERING AND HEIGHT ABOVE THROAT PLATE: ............................................................................ 18

PRESSER FOOT: ........................................................................................................................................................ 18

LOOPER THREAD TAKE-UP CAM SETTING: ............................................................................................................ 19

THREAD CONTROL: ................................................................................................................................................ 19

PULLER ADJUSTMENTS: ........................................................................................................................................... 20

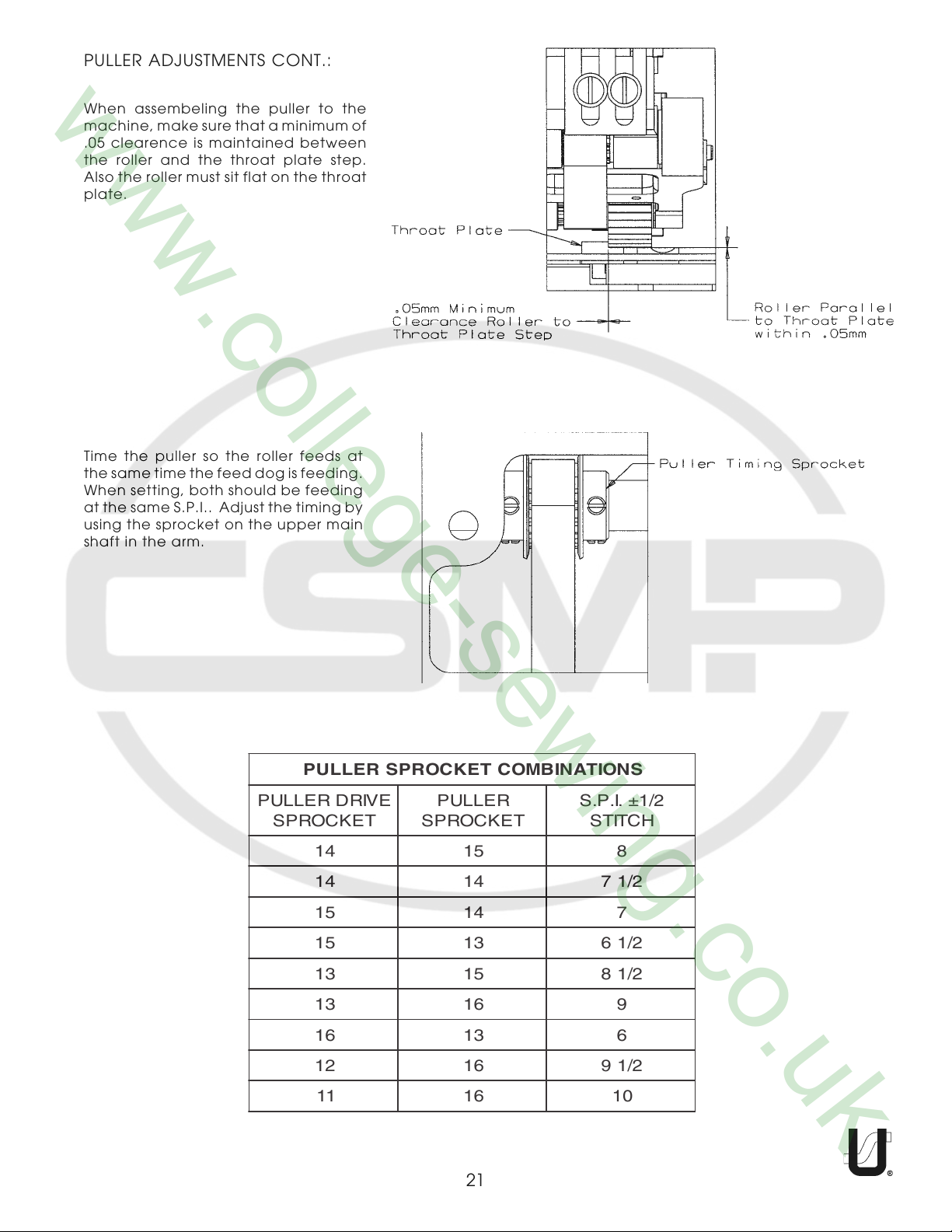

PULLER ADJUSTMENTS CONT.: ............................................................................................................................... 21

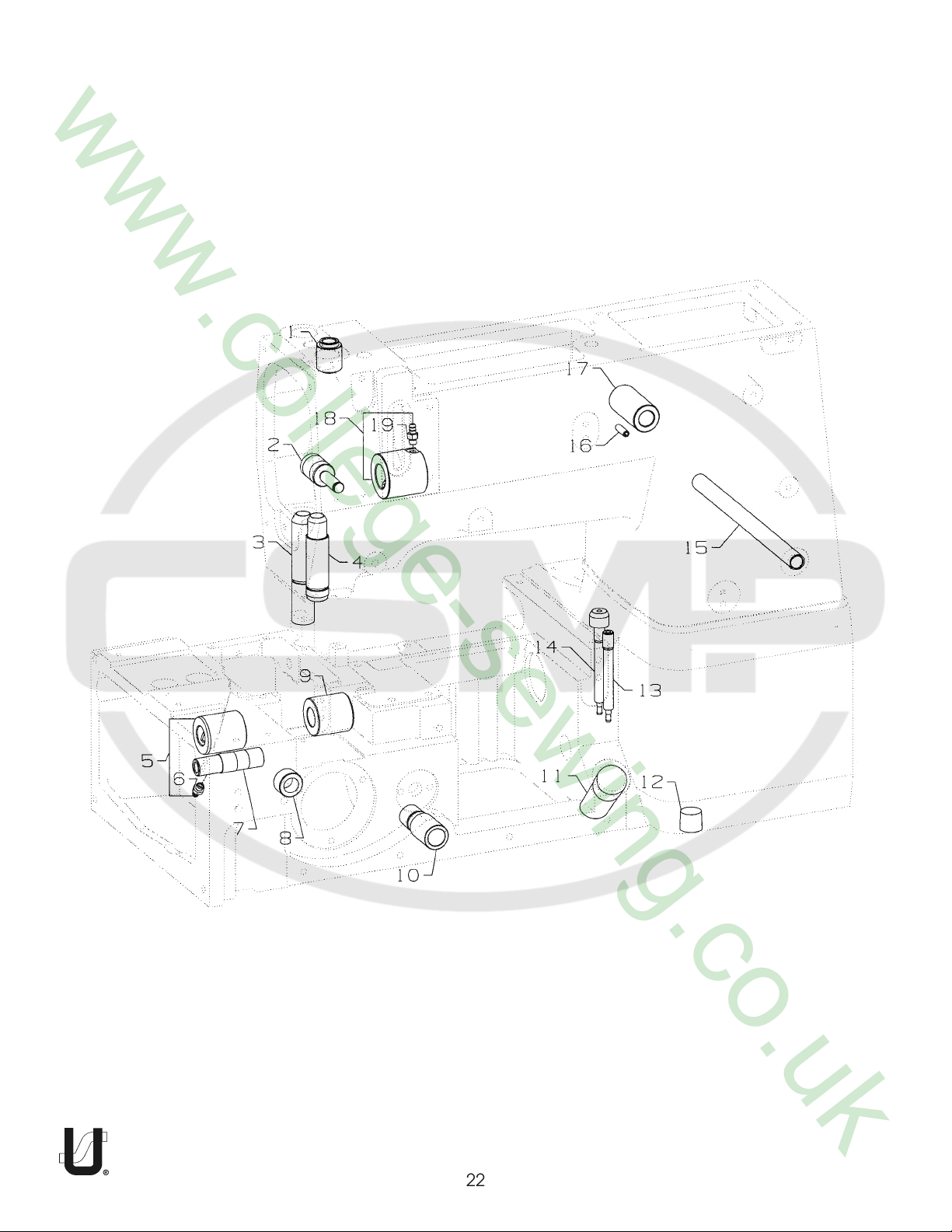

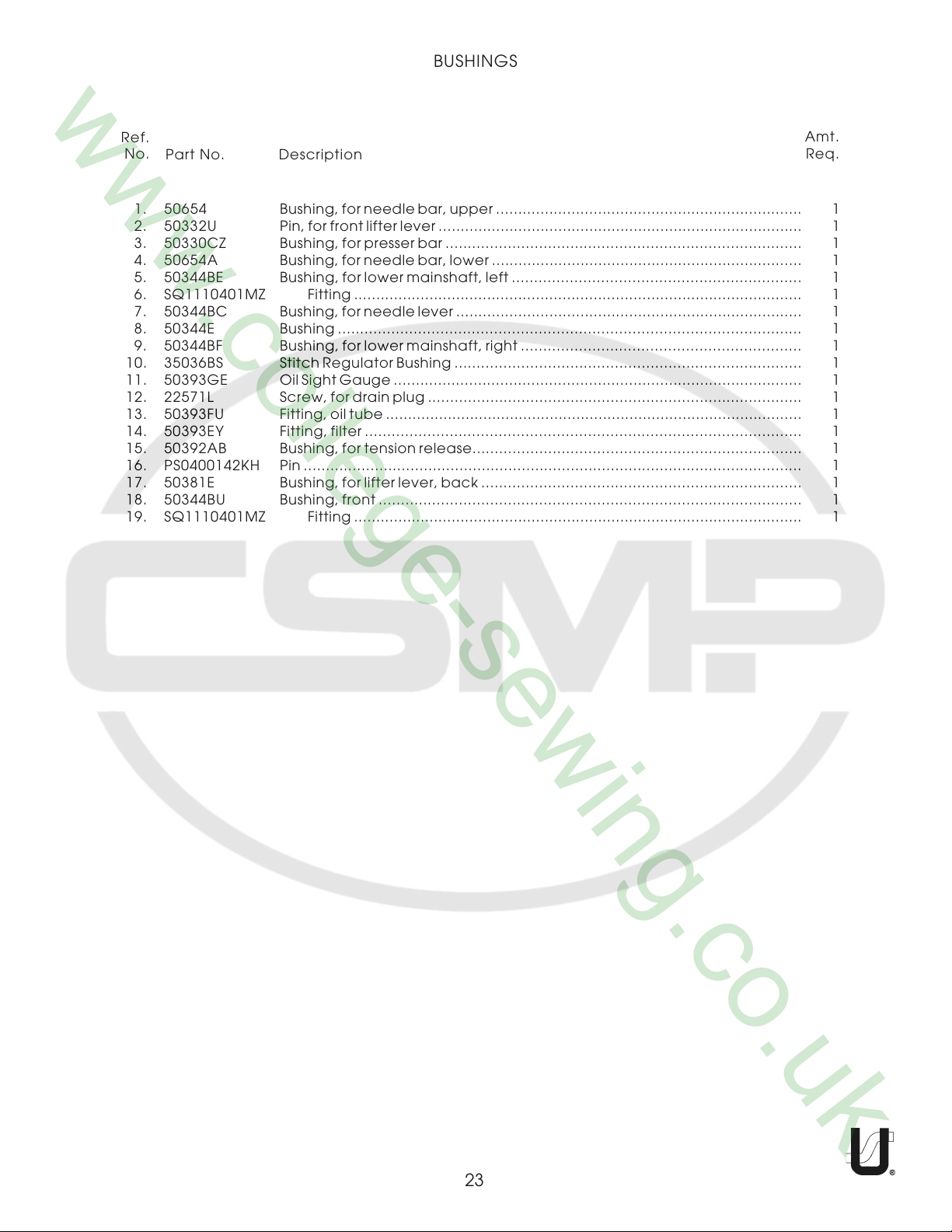

BUSHINGS ................................................................................................................................................................ 23

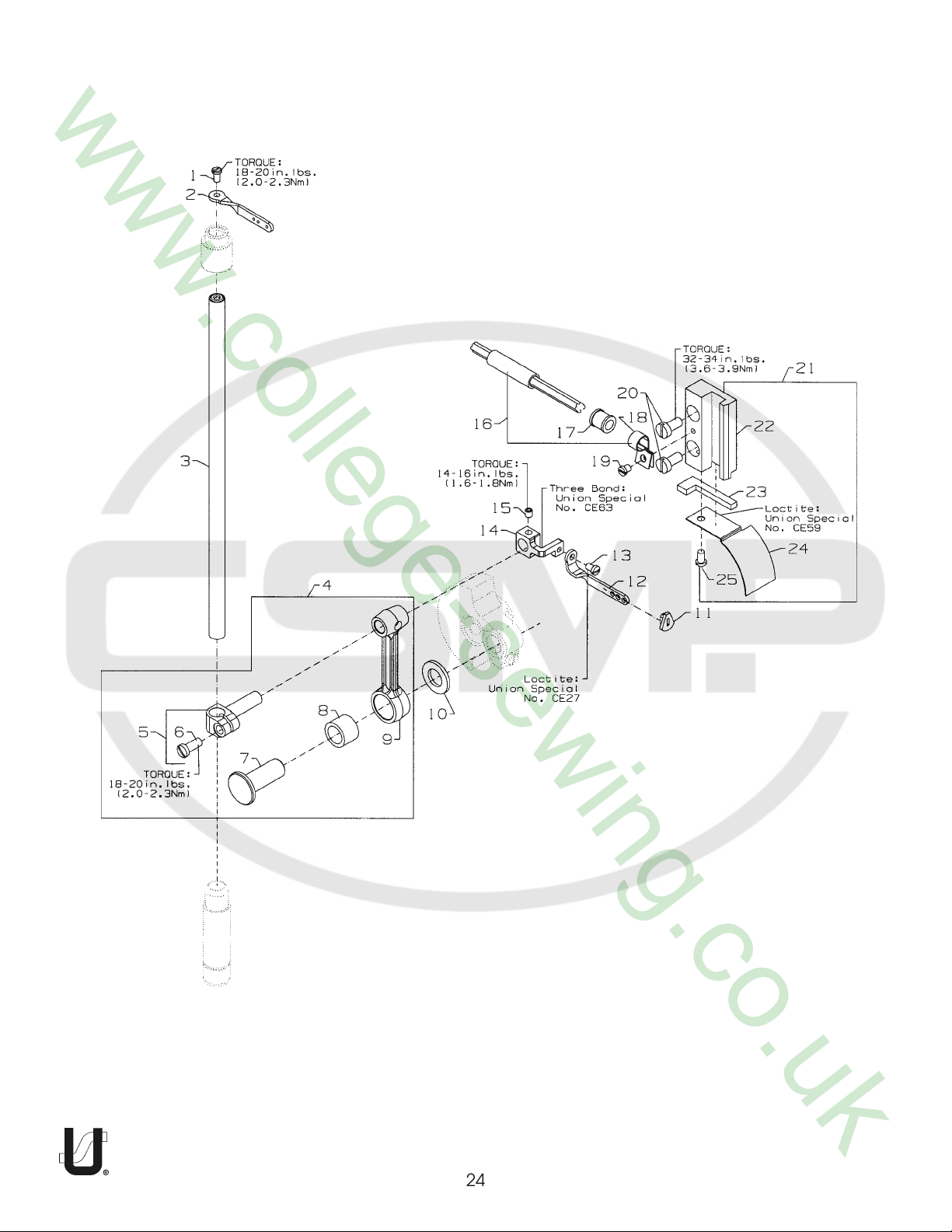

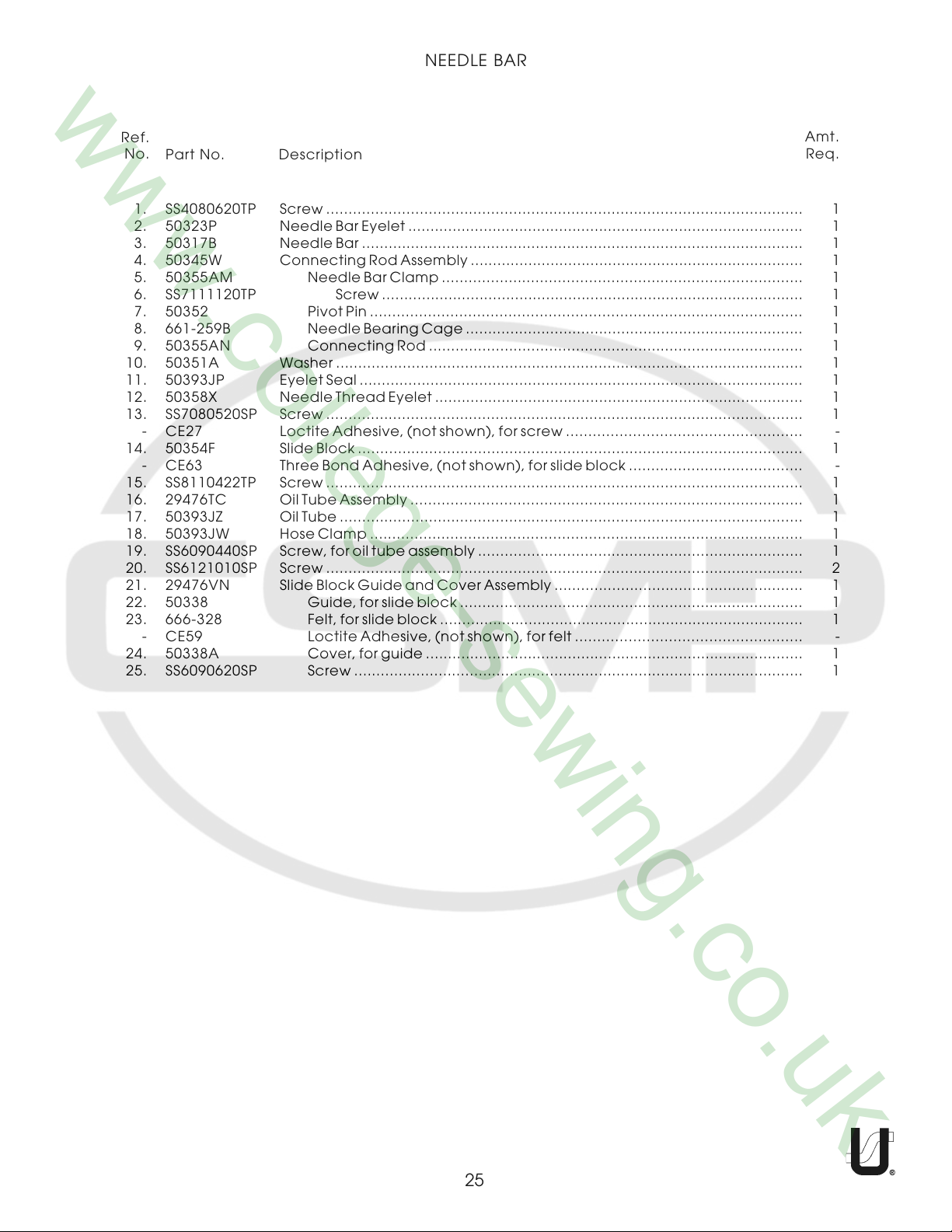

NEEDLE BAR ............................................................................................................................................................ 25

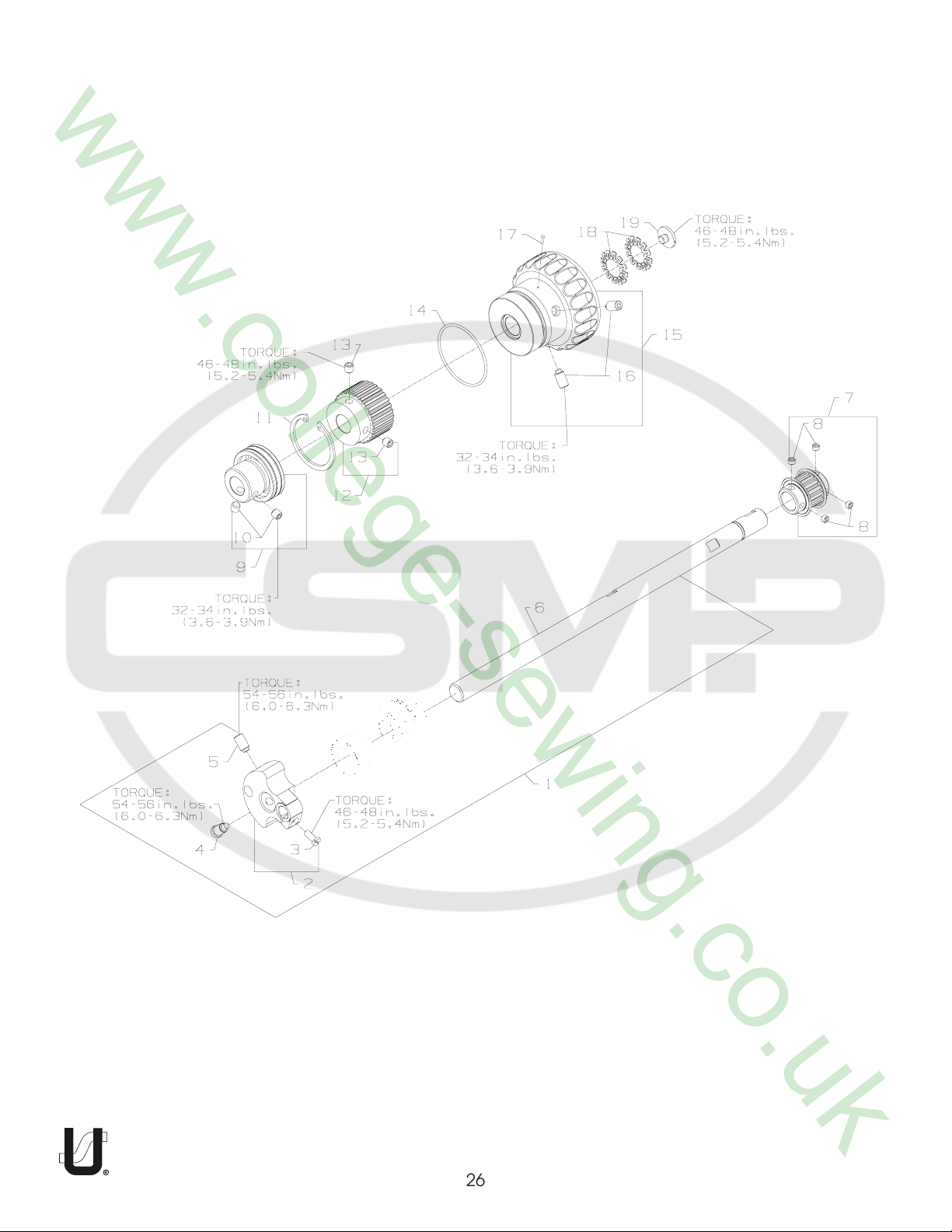

UPPER MAIN SHAFT ................................................................................................................................................. 27

THREAD GUIDE ........................................................................................................................................................ 29

TENSION RELEASE & THREAD TENSION .................................................................................................................. 31

PRESSER FOOT LIFT .................................................................................................................................................. 33

COVERS, UPPER ARM ............................................................................................................................................ 35

LOWER MAIN SHAFT ............................................................................................................................................... 37

LUBRICATION, OIL TUBING & OIL PUMP ................................................................................................................ 39

LOOPER DRIVE ........................................................................................................................................................ 41

NEEDLE GUARD ...................................................................................................................................................... 43

LOOPER THREAD TAKE-UP ..................................................................................................................................... 45

FEED DRIVE MECHANISM FOR PLAIN FEED .......................................................................................................... 47

FEED DRIVE MECHANISM FOR DIFFERENTIAL FEED .............................................................................................. 49

FEED DRIVE MECHANISM FOR PLAIN FEED .......................................................................................................... 51

FEED DRIVE MECHANISM FOR DIFFERENTIAL FEED .............................................................................................. 53

COVERS, LOWER BED............................................................................................................................................. 55

COVERS, LOWER BED............................................................................................................................................. 57

SEWING PARTS ........................................................................................................................................................ 59

FOLDERS .................................................................................................................................................................. 61

PULLER DRIVE ASSEMBLY ........................................................................................................................................ 63

PULLER ASSEMBLY ................................................................................................................................................... 65

PULLER ASSEMBLY ................................................................................................................................................... 67

MISCELLANEOUS PARTS PA1 (USE WITH CC2 CHAIN CUTTER) ........................................................................... 69

MISCELLANEOUS PARTS PA1A (USE WITHOUT CC2 CHAIN CUTTER) .................................................................. 71

TUBING PA1 WITH CHAIN CUTTER ......................................................................................................................... 72

TUBING PA1A WITHOUT CHAIN CUTTER ................................................................................................................ 73

TABLING (EXTRA SEND CHARGE) .......................................................................................................................... 75

PRESSER FOOT LIFTER .............................................................................................................................................. 77

ACCESSORIES ......................................................................................................................................................... 79

NUMERICAL INDEX OF PARTS ................................................................................................................................

NUMERICAL INDEX OF PARTS ................................................................................................................................ 81

80

3

IDENTIFICATION OF MACHINES

Each UNION SPECIAL machine is identified by a style number, which is stamped into the style plate affixed to the

middle of the machine under the tension assembly. The serial number is stamped into the serial number plate affixed

to the right rear base of the machine.

Precision high speed, single needle, plain or differential feed flat bed machines. Totally enclosed feed and looper

drive mechanism, automatic forced feed lubrication system with easily replaceable filter. Main feed has thumbscrew

adjustment and differential feed has lever adjustment and independently driven rear needle guard.

CLASS DESCRIPTION

STYLE OF MACHINES

FS316L61-3H36CC2PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, flat sewing parts, close-

coupled toothed roller puller, pneumatic power "AIR-KLIPP" Chain cutter, pneu

matic assisted presser foot and roller lift, and double lap seam folder with 1/8"

(3.2mm) capacity. For attaching the risers to jeans, seat seaming operations on

jeans, bibs to overalls and piecing sleeves on denim jackets. Seam Specifications

401LSc-3. Recommended needle 128 GAS sizes 140/054 - Stitch range 7-10 S.P.I..

Maximum recommended speed 6000 R.P.M.

FS316L61-3H36PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, flat sewing parts, close-

coupled toothed roller puller, pneumatic assisted presser foot and roller lift, and

double lap seam folder with 1/8" (3.2mm) capacity. For attaching the risers to jeans,

seat seaming operations on jeans, bibs to overalls and piecing sleeves on denim

jackets. Seam Specifications 401LSc-3. Recommended needle 128 GAS sizes 140/

054 - Stitch range 7-10 S.P.I.. Maximum recommended speed 6000 R.P.M..

FS316L62-3H36CC2PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, .040" stepped chaining

sewing parts, close-coupled toothed roller puller, pneumatic power "AIR-KLIPP"

Chain cutter, pneumatic assisted presser foot and roller lift, and double lap seam

folder with 1/8" (3.2mm) capacity. For attaching the risers to jeans, seat seaming

operations on jeans, bibs to overalls and piecing sleeves on denim jackets. Seam

Specifications 401LSc-3. Recommended needle 128 GAS sizes 140/054 - Stitch

range 7-10 S.P.I.. Maximum recommended speed 6000 R.P.M..

FS316L62-3H36PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, .040" stepped chaining

sewing parts, close-coupled toothed roller puller, pneumatic assisted presser foot

and roller lift, and double lap seam folder with 1/8" (3.2mm) capacity. For attaching

the risers to jeans, seat seaming operations on jeans, bibs to overalls and piecing

sleeves on denim jackets. Seam Specifications 401LSc-3. Recommended needle

128 GAS sizes 140/054 - Stitch range 7-10 S.P.I.. Maximum recommended speed

6000 R.P.M..

FS316L63-3H32CC2PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, .070" stepped chaining

sewing parts, close-coupled toothed roller puller, pneumatic power "AIR-KLIPP"

Chain cutter, pneumatic assisted presser foot and roller lift, and double lap seam

folder with 1/8" (3.2mm) capacity. For attaching the risers to jeans, seat seaming

operations on jeans, bibs to overalls and piecing sleeves on denim jackets. Seam

Specifications 401LSc-3. Recommended needle 128 GAS sizes 140/054 - Stitch

range 7-10 S.P.I.. Maximum recommended speed 6000 R.P.M..

FS316L63-3H32PA1 DOUBLE LAP SEAM. Three needle, plain feed, high capacity, .070" stepped chaining

sewing parts, close-coupled toothed roller puller, pneumatic assisted presser foot

and roller lift, and double lap seam folder with 1/8" (3.2mm) capacity. For attaching

the risers to jeans, seat seaming operations on jeans, bibs to overalls and piecing

sleeves on denim jackets. Seam Specifications 401LSc-3. Recommended needle

128 GAS sizes 140/054 - Stitch range 7-10 S.P.I.. Maximum recommended speed

6000 R.P.M..

4

STYLE OF MACHINES CONT.

FS315L63-3H32CC2PA1 Same as FS316L63-3H32CC2PA1 except differential feed.

FS315L63-3H32PA1 Same as FS316L63-3H32PA1 except differential feed.

ILLUSTRATIONS

This manual has been arranged to simplify ordering repair parts. Exploded views of various sections of the mechanism are

shown so that the parts may be seen in their actual position in the machine. On the page opposite the illustration will be

found a listing of the parts with their part numbers, description and the number of pieces required in the particular view

being shown.

Numbers in the first column are reference numbers only, and merely indicate the position of the part in the illustration. The

reference number should never be used in ordering parts. Always use the part number listed in the second column.

Component parts of sub-assemblies which can be furnished for repairs are indicated by indenting their descriptions under

the description of the main sub-assembly. As an example refer to the following text.

5. 50366B Needle Thread Strike-Off Assembly ................................................................................ 1

6. 50358V Needle Thread Strike-Off .................................................................................. 1

7. 50370F Thread Strike-Off Component ......................................................................... 1

8. SS7060310SP Screw, for plate strike-off .................................................................................. 1

When a part is common to all machines covered in this manual, no specific usage will be mentioned in the description.

However, when the parts for the various machines are not the same, the specific usage will be mentioned in the description

and, if necessary, the difference will be shown in the illustration.

*Ref. No. showing no Part No. is for location only. Part is not for sale separately.

A numerical index of all the parts shown in this manual is located at the back. This will facilitate locating the illustration and

description when only a part number is known.

IDENTIFYING PARTS

Where construction permits, each part is stamped with its part number. On some of the smaller parts and on those where

construction does not permit, an identification letter is stamped in to distinguish the part from similar ones.

PLEASE NOTE: Part numbers represent the same part, regardless of which manual they appear. On all orders please include

part number, name and style of machine for which the part was ordered.

For optimum performance use only genuine Union Special replacement parts.

NEEDLES

Each needle has both a type and size number. The type number denotes the kind of shank, point, length, groove, finish

and other details. The size number, stamped on the needle shank, denotes the largest diameter of the blade measured

between the shank and the eye. Collectively, the type number and size number represent the complete symbol which

is given on the label of all needles packed and sold by Union Special.

TYPE DESCRIPTION

128 GAS Short, double groove, struck groove, ball eye, spotted, round point, chromium plated- Sizes available 080/032,

090/036, 100/040, 110/044, 125/049, 150/060.

When changing the needle, make sure it is fully inserted in the needle holder before the screw is tightened.

When ordering needles, please use the complete type and size numbers as printed on the package to ensure prompt and

accurate processing of your order. A complete order should read as follows: "100 needles, type 128 GAS, size 150/060".

5

SAFETY RULES

1. Before putting the machines described in this manual into service, carefully read the instructions. The

starting of each machine is only permitted after taking notice of the instructions and by qualified

operators.

IMPORTANT! Before putting the machine into service, also read the safety rules and instructions from the

motor supplier.

2. Observe the national safety rules valid for your country.

3. The sewing machines described in this instruction manual are prohibited from being put into service until

it has been ascertained that the sewing units which these sewing machines will be built into, have

conformed with the EC Council Directives (89/392/EEC, Annex II B).

Each machine is only allowed to be used as foreseen. The foreseen use of the particular machine is

described in paragraph “STYLES OF MACHINES” of this instruction manual. Another use, going beyond

the description, is not as foreseen.

4. All safety devices must be in position when the machine is ready for work or in operation. Operation

of the machine without the appertaining safety devices is prohibited.

5. Wear safety glasses.

6. In case of machine conversions and changes all valid safety rules must be considered. Conversions

and changes are made at your own risk.

7. The warning hints in the instructions are marked with one of these two symbols:

8. When doing the following the machine has to be disconnected from the power supply by turning off

the main switch or by pulling out the main plug:

8.1 When threading needle(s), looper, spreader etc.

8.2 When replacing any parts such as needle(s), presser foot, throat plate, looper, spreader, feed

dog, needle guard, folder, fabric guide etc.

8.3 When leaving the workplace and when the workplace is unattended.

8.4 When doing maintenance work.

8.5 When using clutch motors without actuation lock, wait until the motor is stopped totally.

9. Maintenance, repair and conversion work (see item 8) must be done only by trained technicians or

special skilled personnel under consideration of the instructions.

10. Any work on the electrical equipment must be done by an electrician or under direction and supervision

of special skilled personnel.

11. Work on parts and equipment under electrical power is not permitted. Permissible exceptions are

described in the applicable sections of standard sheet DIN VDE 0105.

12. Before doing maintenance and repair work on the pneumatic equipment, the machine has to be

disconnected from the compressed air supply. In case of existing residual air pressure, after disconnect-

ing from compressed air supply (i.e. pneumatic equipment with air tank), the pressure has to be

removed by bleeding.

6

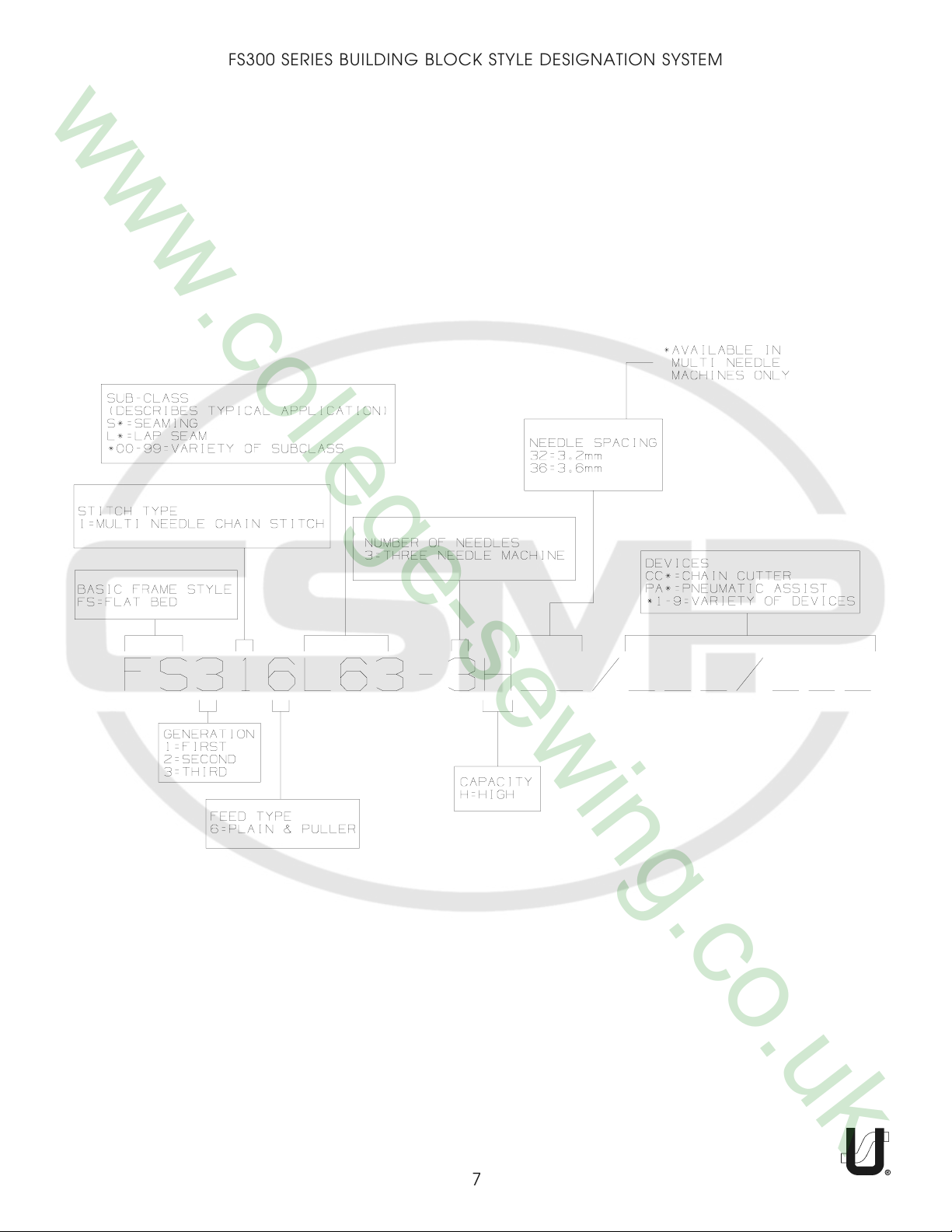

FS300 SERIES BUILDING BLOCK STYLE DESIGNATION SYSTEM

7

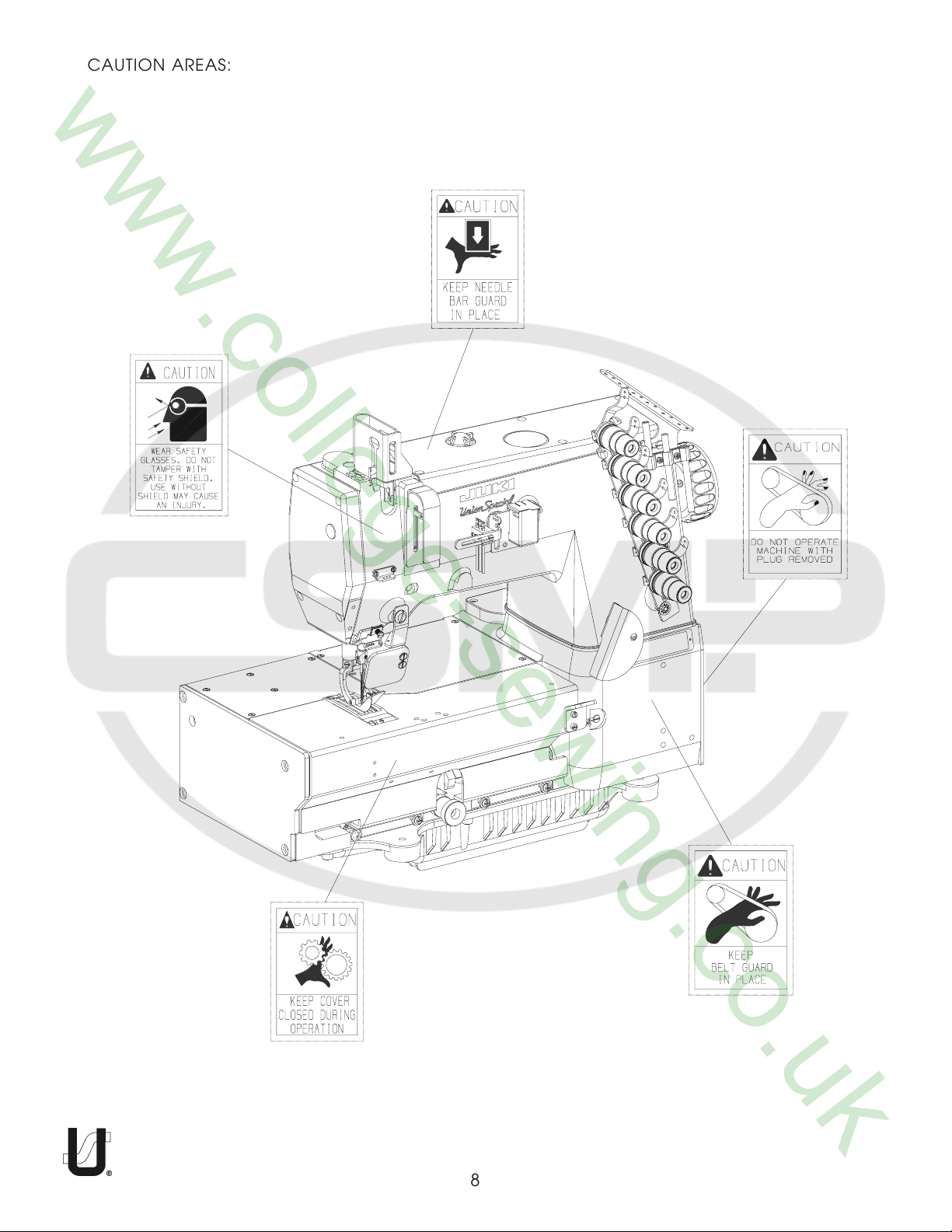

CAUTION AREAS:

8

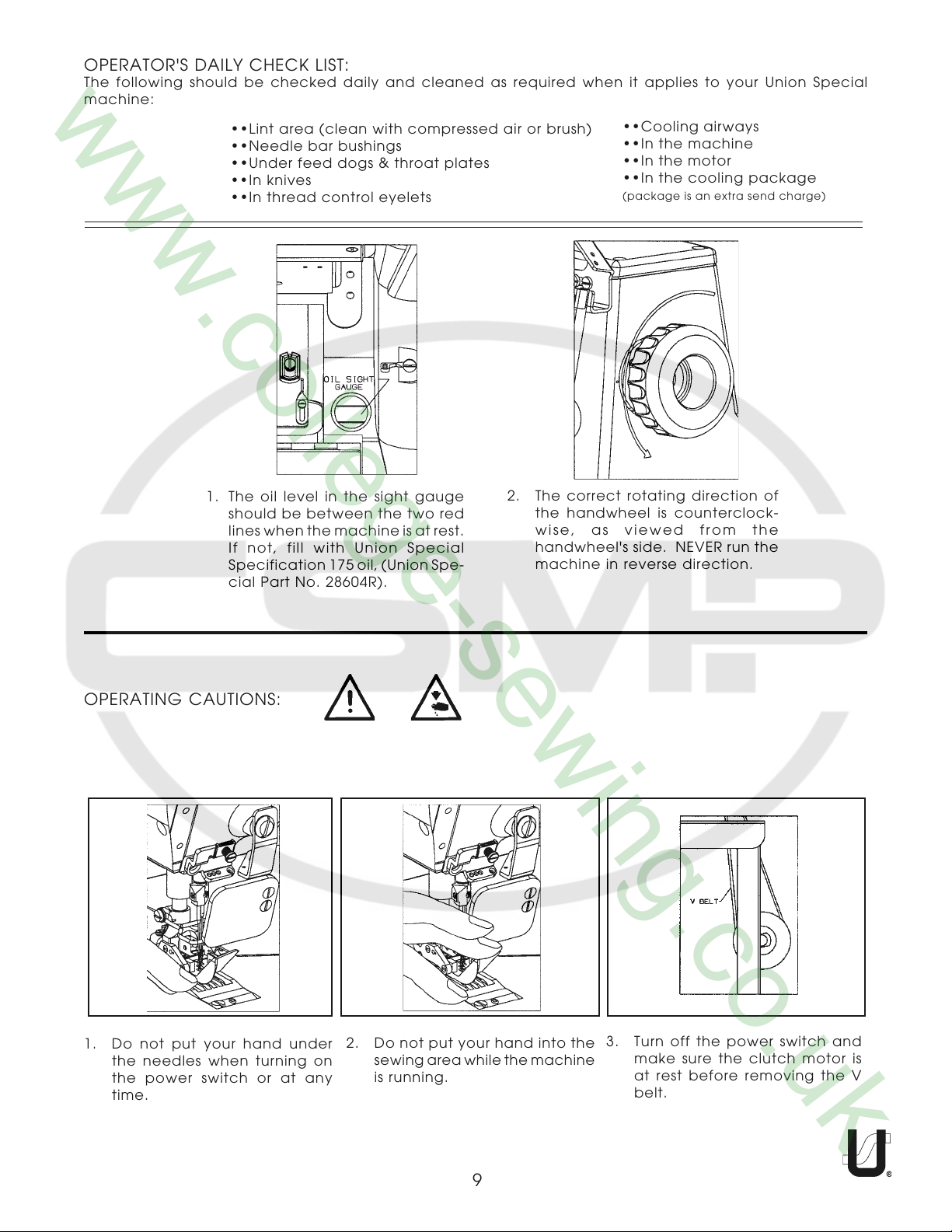

OPERATOR'S DAILY CHECK LIST:

The following should be checked daily and cleaned as required when it applies to your Union Special

machine:

••Lint area (clean with compressed air or brush)

••Needle bar bushings

••Under feed dogs & throat plates

••In knives

••In thread control eyelets

1. The oil level in the sight gauge

should be between the two red

lines when the machine is at rest.

If not, fill with Union Special

Specification 175 oil, (Union Spe-

cial Part No. 28604R).

2. The correct rotating direction of

the handwheel is counterclock-

wise, as viewed from the

handwheel's side. NEVER run the

machine in reverse direction.

••Cooling airways

••In the machine

••In the motor

••In the cooling package

(package is an extra send charge)

OPERATING CAUTIONS:

1. Do not put your hand under

the needles when turning on

the power switch or at any

time.

2. Do not put your hand into the

sewing area while the machine

is running.

3. Turn off the power switch and

make sure the clutch motor is

at rest before removing the V

belt.

9

OPERATING CAUTIONS (CONT.):

4. During operation, do not allow head, hands or any instrument, tool etc. near handwheel, V belt and

motor.

5. Do not operate your machine without the proper belt guard, sewing guards or any other protectors that

have been provided. Doing so is very dangerous.

6. Before inspecting, adjusting, cleaning, threading the head or replacing needles, turn OFF the power

switch. Make sure the flywheel on the motor has stopped, it will be kept running by inertia after turning

OFF the power switch. DO NOT depress the foot pedal while the machine is running or it will cause the

machine to rotate abruptly.

7. Turn OFF the power switch when you leave your machine or in case of a power failure.

8. Do not wipe the machine surface with lacquer thinner.

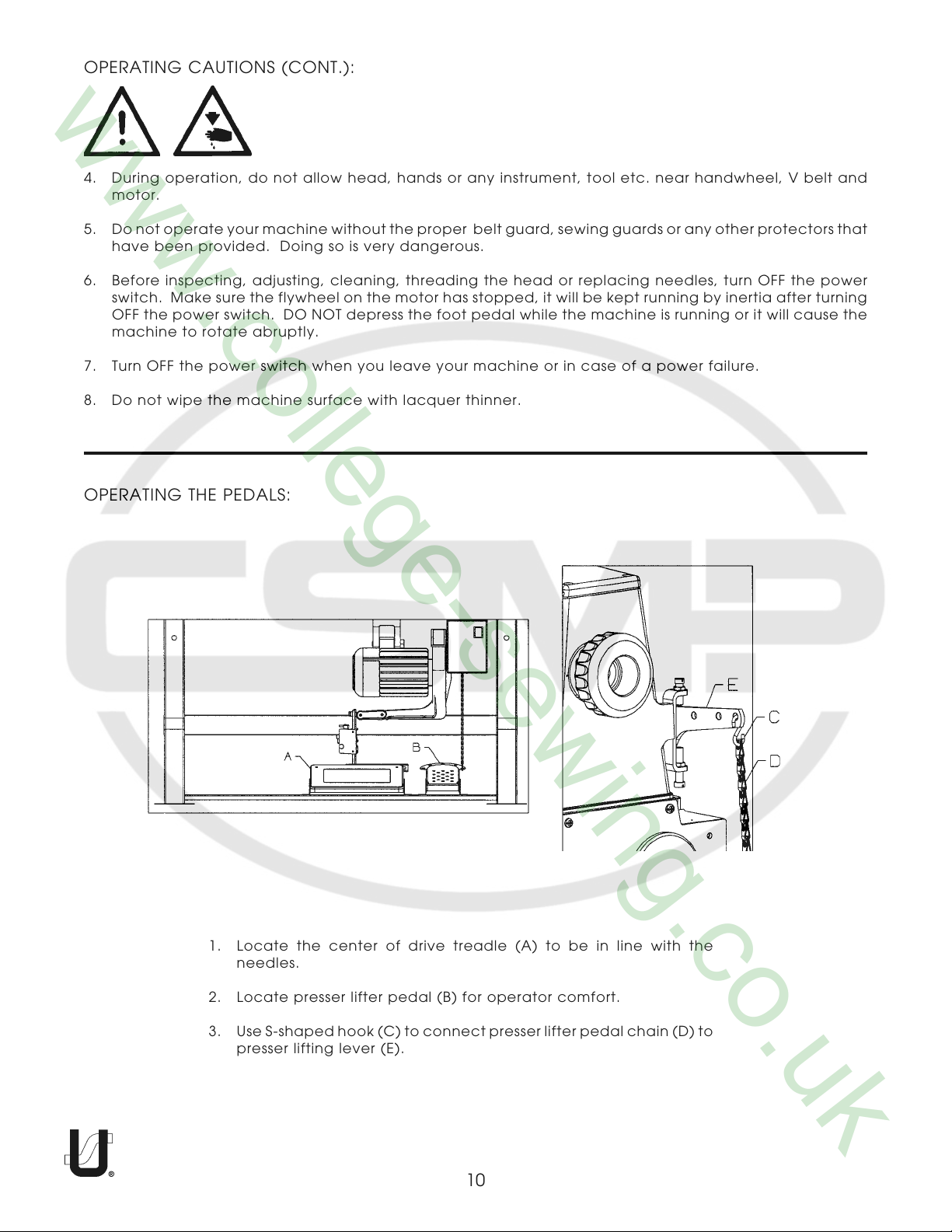

OPERATING THE PEDALS:

1. Locate the center of drive treadle (A) to be in line with the

needles.

2. Locate presser lifter pedal (B) for operator comfort.

3. Use S-shaped hook (C) to connect presser lifter pedal chain (D) to

presser lifting lever (E).

10

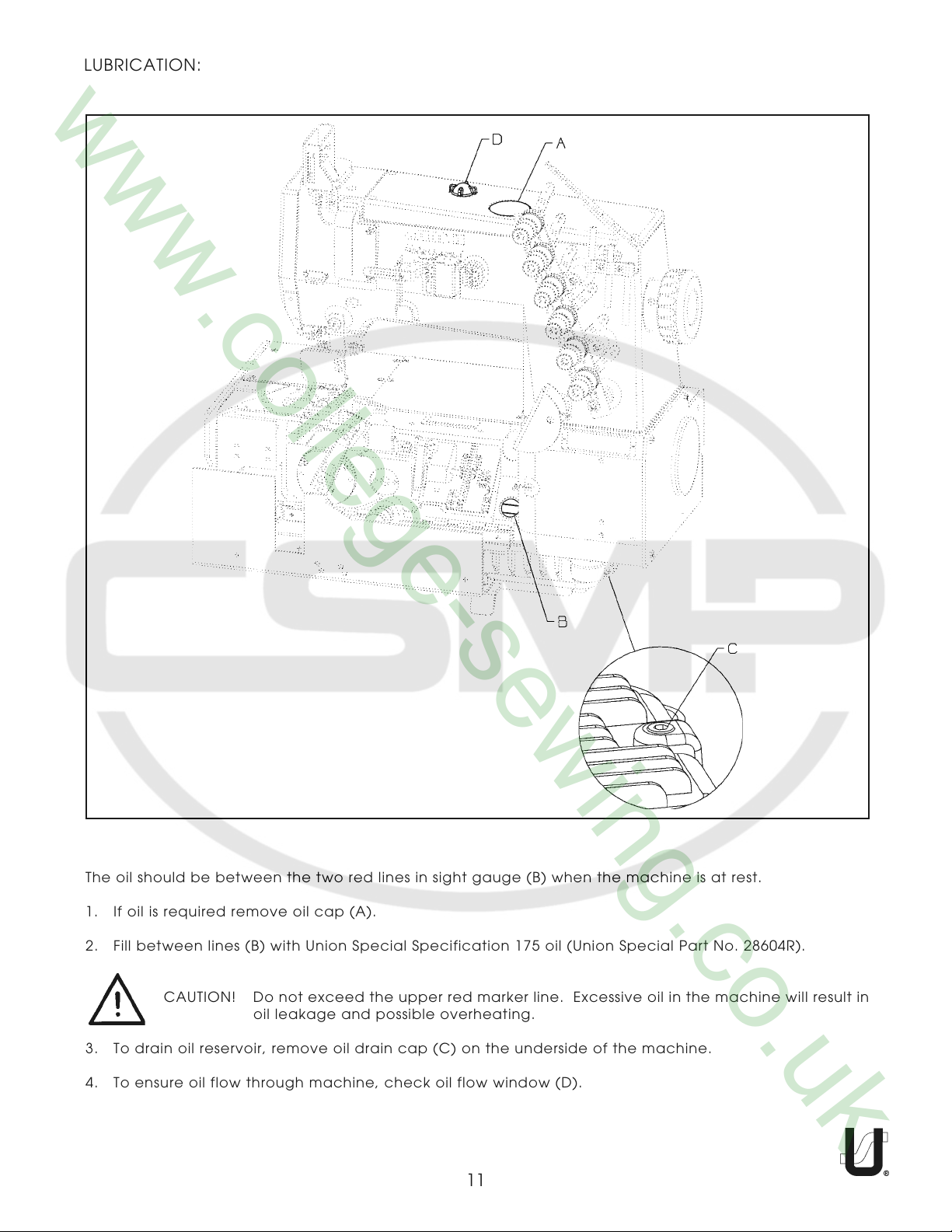

LUBRICATION:

The oil should be between the two red lines in sight gauge (B) when the machine is at rest.

1. If oil is required remove oil cap (A).

2. Fill between lines (B) with Union Special Specification 175 oil (Union Special Part No. 28604R).

CAUTION! Do not exceed the upper red marker line. Excessive oil in the machine will result in

oil leakage and possible overheating.

3. To drain oil reservoir, remove oil drain cap (C) on the underside of the machine.

4. To ensure oil flow through machine, check oil flow window (D).

11

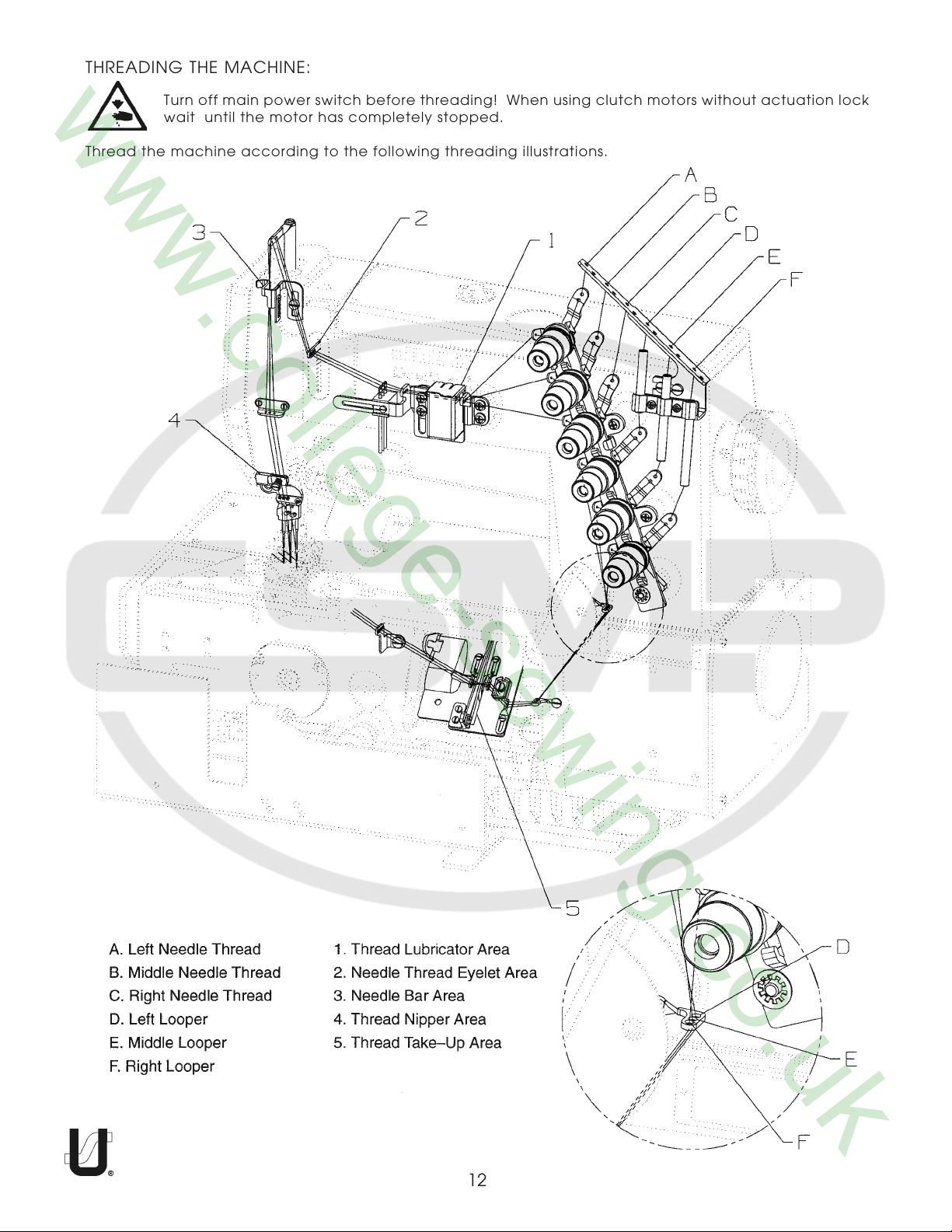

THREADING THE MACHINE:

Turn off main power switch before threading! When using clutch motors without actuation lock

wait until the motor has completely stopped.

Thread the machine according to the following threading illustrations.

12

THREADING THE MACHINE (CONT.):

13

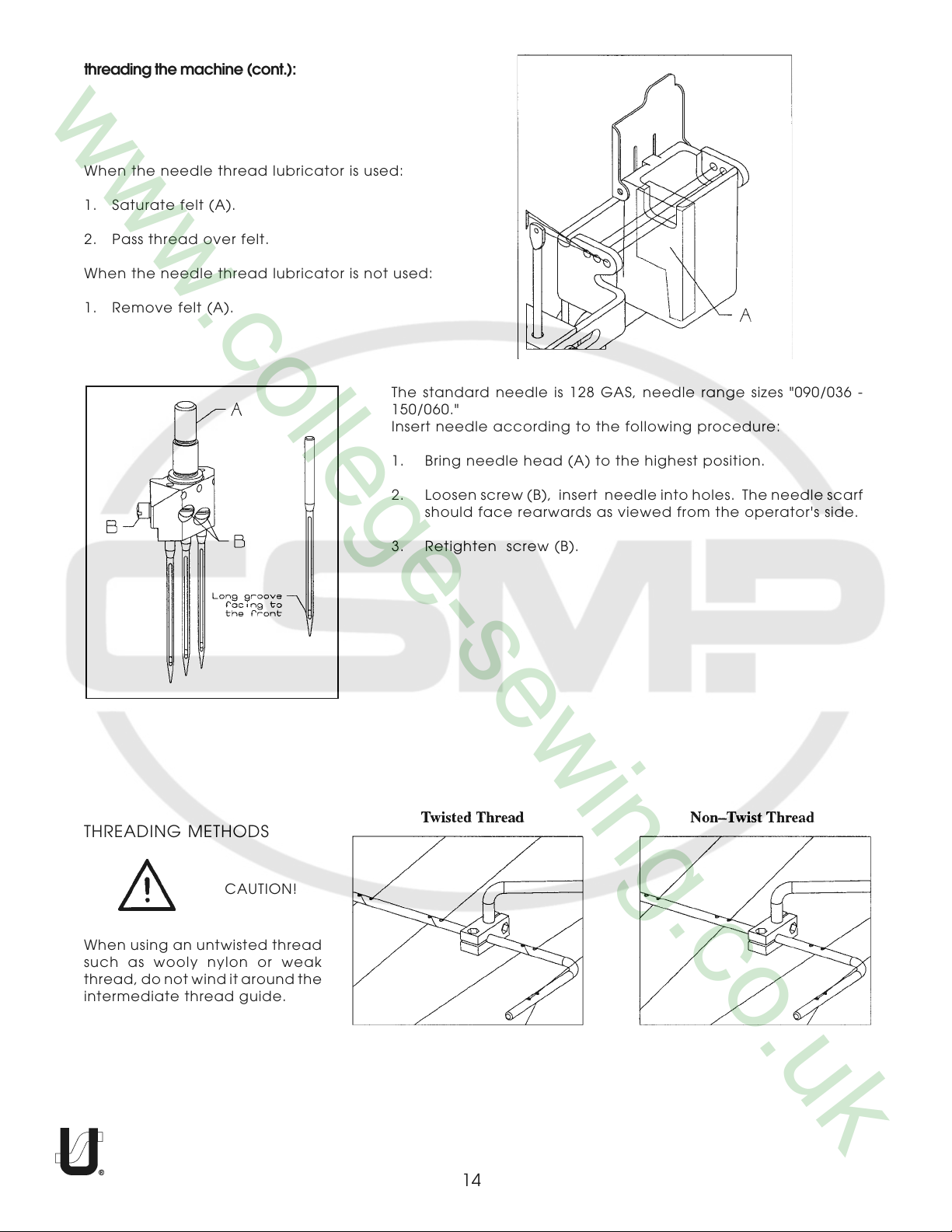

threading the machine (cont.):

When the needle thread lubricator is used:

1. Saturate felt (A).

2. Pass thread over felt.

When the needle thread lubricator is not used:

1. Remove felt (A).

The standard needle is 128 GAS, needle range sizes "090/036 -

150/060."

Insert needle according to the following procedure:

1. Bring needle head (A) to the highest position.

2. Loosen screw (B), insert needle into holes. The needle scarf

should face rearwards as viewed from the operator's side.

3. Retighten screw (B).

THREADING METHODS

CAUTION!

When using an untwisted thread

such as wooly nylon or weak

thread, do not wind it around the

intermediate thread guide.

14

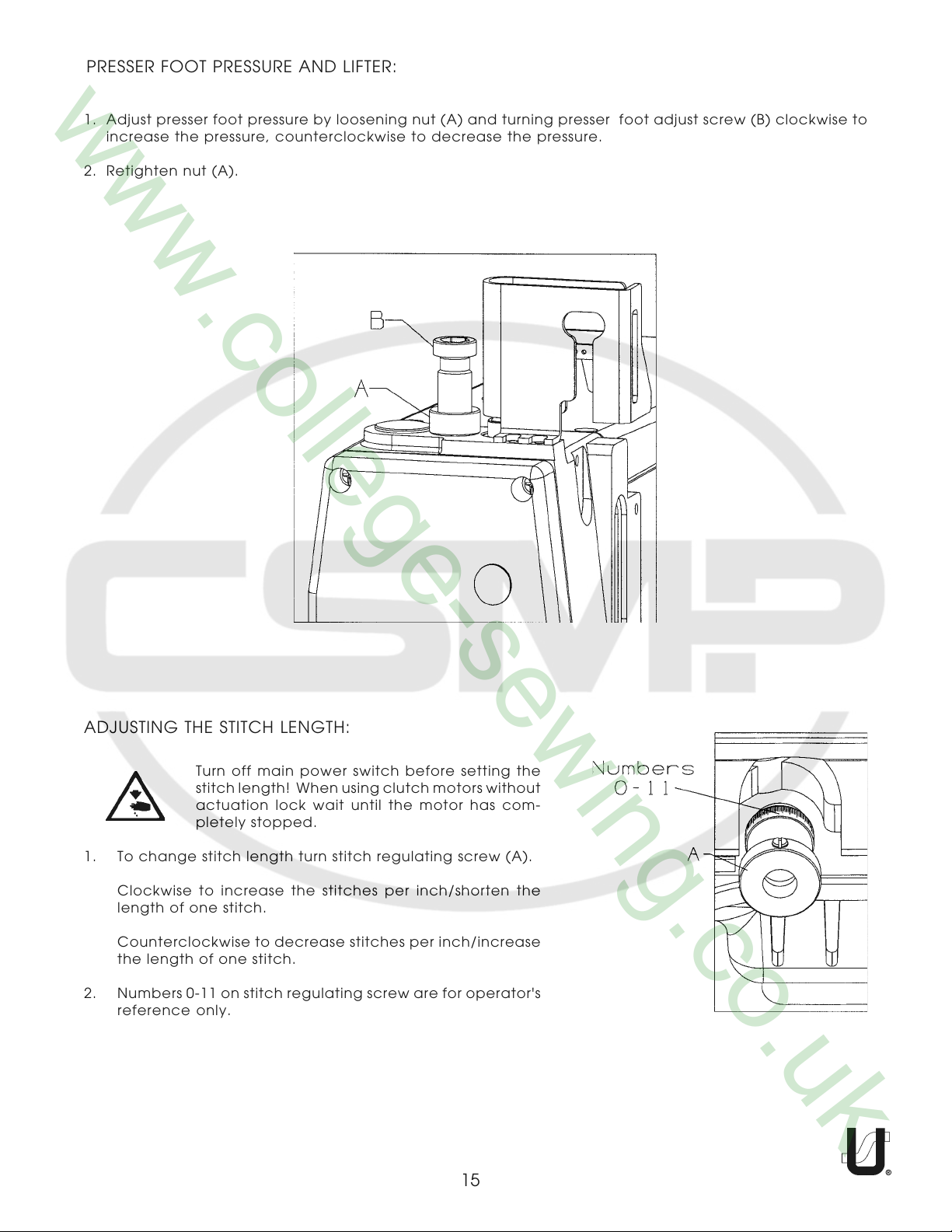

PRESSER FOOT PRESSURE AND LIFTER:

1. Adjust presser foot pressure by loosening nut (A) and turning presser foot adjust screw (B) clockwise to

increase the pressure, counterclockwise to decrease the pressure.

2. Retighten nut (A).

ADJUSTING THE STITCH LENGTH:

Turn off main power switch before setting the

stitch length! When using clutch motors without

actuation lock wait until the motor has com-

pletely stopped.

1. To change stitch length turn stitch regulating screw (A).

Clockwise to increase the stitches per inch/shorten the

length of one stitch.

Counterclockwise to decrease stitches per inch/increase

the length of one stitch.

2. Numbers 0-11 on stitch regulating screw are for operator's

reference only.

15

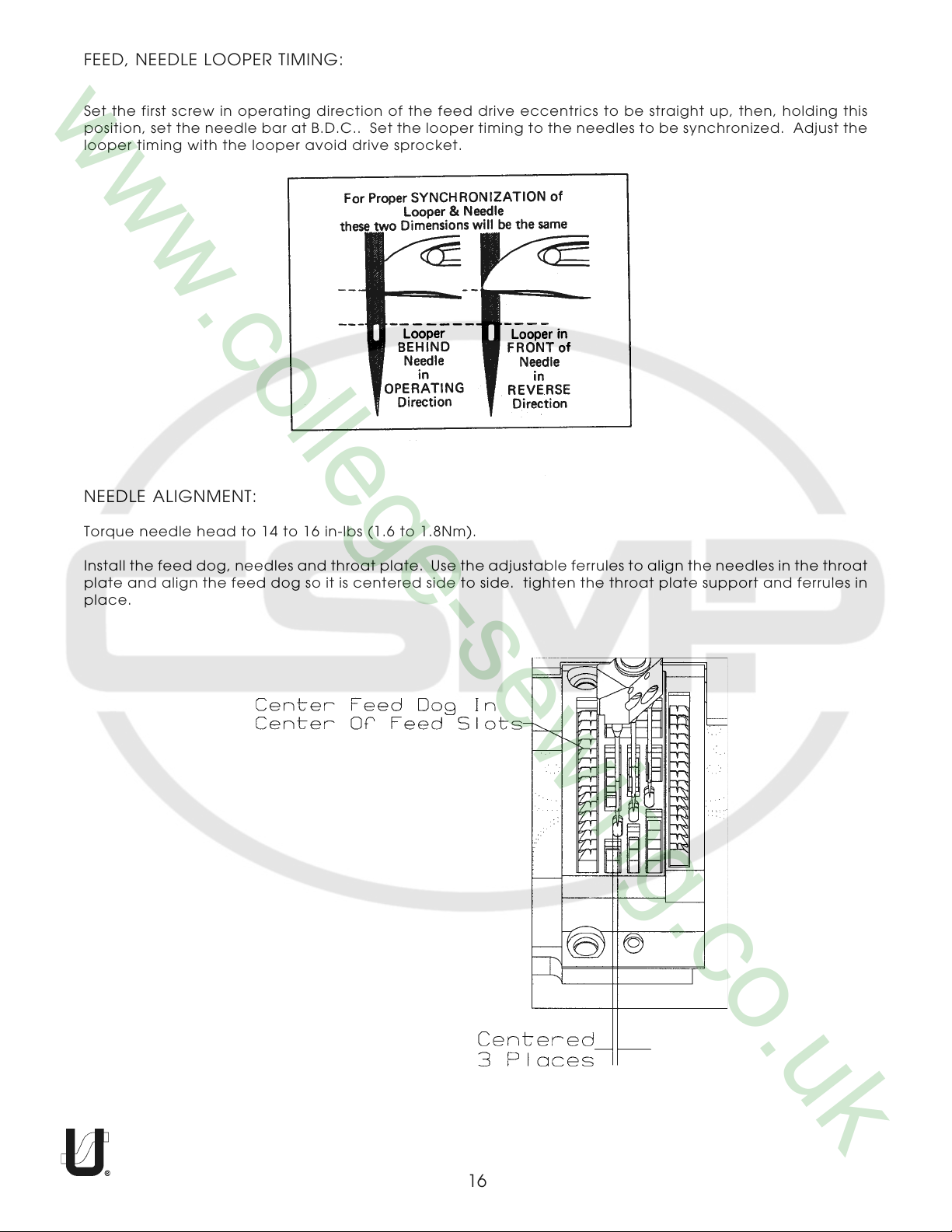

FEED, NEEDLE LOOPER TIMING:

Set the first screw in operating direction of the feed drive eccentrics to be straight up, then, holding this

position, set the needle bar at B.D.C.. Set the looper timing to the needles to be synchronized. Adjust the

looper timing with the looper avoid drive sprocket.

NEEDLE ALIGNMENT:

Torque needle head to 14 to 16 in-lbs (1.6 to 1.8Nm).

Install the feed dog, needles and throat plate. Use the adjustable ferrules to align the needles in the throat

plate and align the feed dog so it is centered side to side. tighten the throat plate support and ferrules in

place.

16

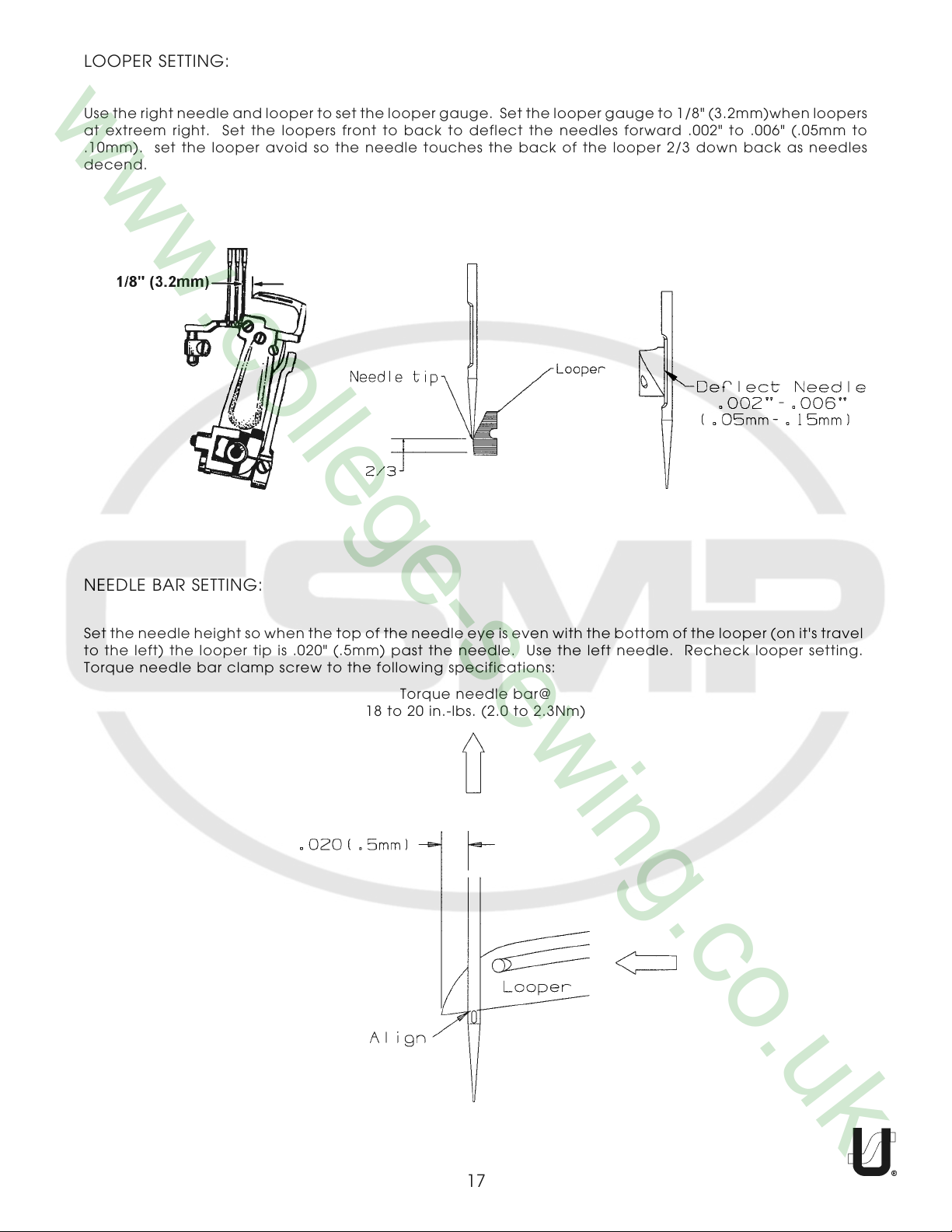

LOOPER SETTING:

Use the right needle and looper to set the looper gauge. Set the looper gauge to 1/8" (3.2mm)when loopers

at extreem right. Set the loopers front to back to deflect the needles forward .002" to .006" (.05mm to

.10mm). set the looper avoid so the needle touches the back of the looper 2/3 down back as needles

decend.

NEEDLE BAR SETTING:

Set the needle height so when the top of the needle eye is even with the bottom of the looper (on it's travel

to the left) the looper tip is .020" (.5mm) past the needle. Use the left needle. Recheck looper setting.

Torque needle bar clamp screw to the following specifications:

Torque needle bar@

18 to 20 in.-lbs. (2.0 to 2.3Nm)

17

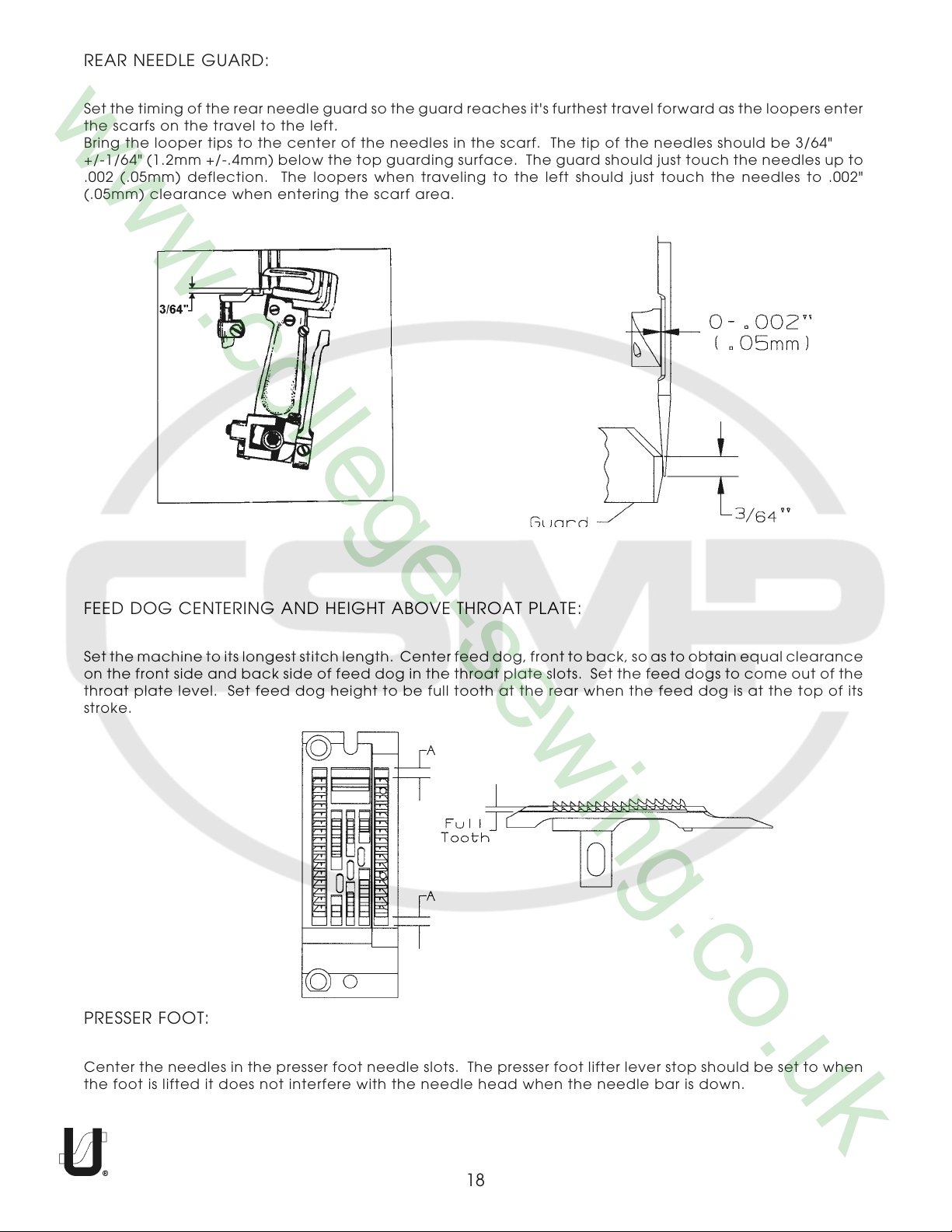

REAR NEEDLE GUARD:

Set the timing of the rear needle guard so the guard reaches it's furthest travel forward as the loopers enter

the scarfs on the travel to the left.

Bring the looper tips to the center of the needles in the scarf. The tip of the needles should be 3/64"

+/-1/64" (1.2mm +/-.4mm) below the top guarding surface. The guard should just touch the needles up to

.002 (.05mm) deflection. The loopers when traveling to the left should just touch the needles to .002"

(.05mm) clearance when entering the scarf area.

FEED DOG CENTERING AND HEIGHT ABOVE THROAT PLATE:

Set the machine to its longest stitch length. Center feed dog, front to back, so as to obtain equal clearance

on the front side and back side of feed dog in the throat plate slots. Set the feed dogs to come out of the

throat plate level. Set feed dog height to be full tooth at the rear when the feed dog is at the top of its

stroke.

PRESSER FOOT:

Center the needles in the presser foot needle slots. The presser foot lifter lever stop should be set to when

the foot is lifted it does not interfere with the needle head when the needle bar is down.

18

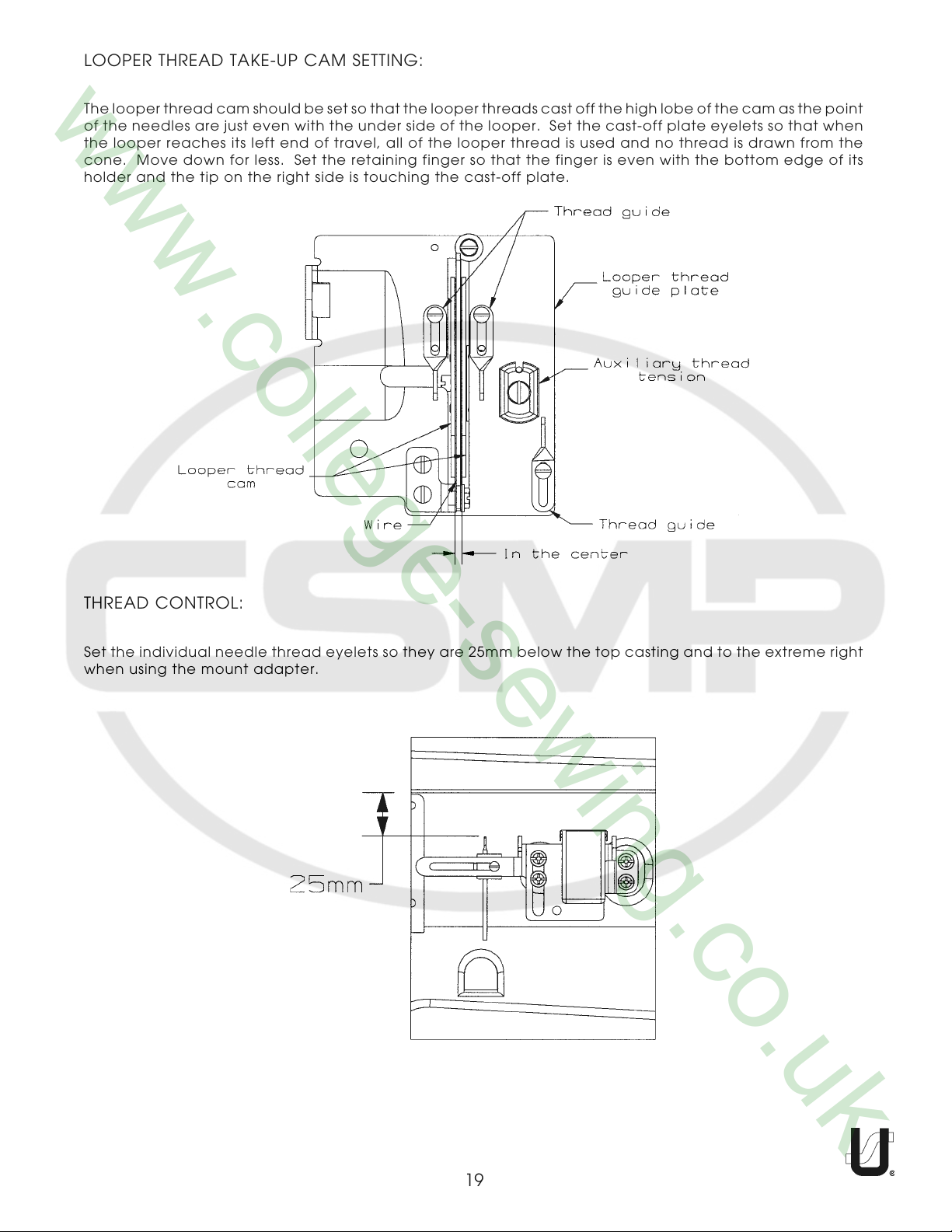

LOOPER THREAD TAKE-UP CAM SETTING:

The looper thread cam should be set so that the looper threads cast off the high lobe of the cam as the point

of the needles are just even with the under side of the looper. Set the cast-off plate eyelets so that when

the looper reaches its left end of travel, all of the looper thread is used and no thread is drawn from the

cone. Move down for less. Set the retaining finger so that the finger is even with the bottom edge of its

holder and the tip on the right side is touching the cast-off plate.

THREAD CONTROL:

Set the individual needle thread eyelets so they are 25mm below the top casting and to the extreme right

when using the mount adapter.

19

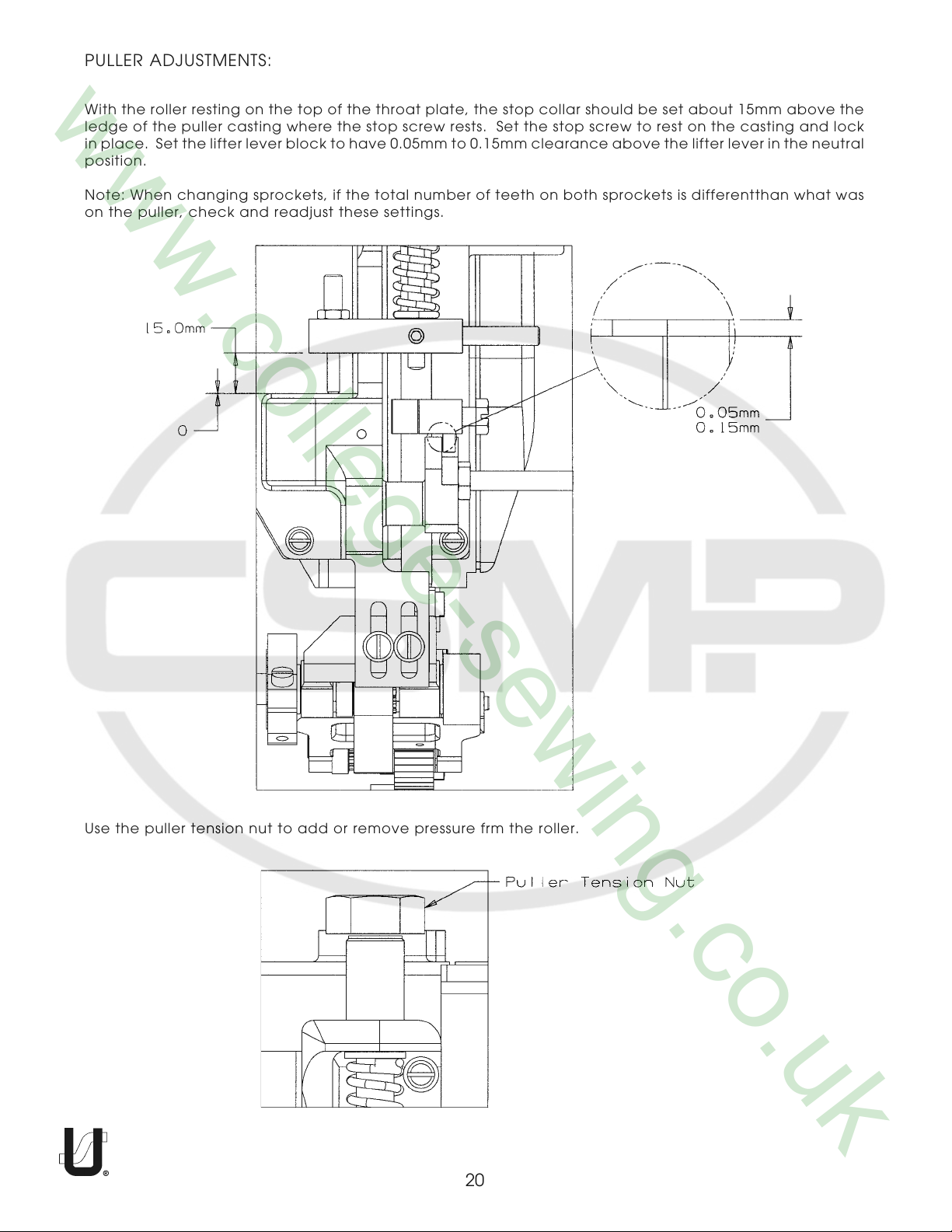

PULLER ADJUSTMENTS:

With the roller resting on the top of the throat plate, the stop collar should be set about 15mm above the

ledge of the puller casting where the stop screw rests. Set the stop screw to rest on the casting and lock

in place. Set the lifter lever block to have 0.05mm to 0.15mm clearance above the lifter lever in the neutral

position.

Note: When changing sprockets, if the total number of teeth on both sprockets is differentthan what was

on the puller, check and readjust these settings.

Use the puller tension nut to add or remove pressure frm the roller.

20

PULLER ADJUSTMENTS CONT.:

When assembeling the puller to the

machine, make sure that a minimum of

.05 clearence is maintained between

the roller and the throat plate step.

Also the roller must sit flat on the throat

plate.

Time the puller so the roller feeds at

the same time the feed dog is feeding.

When setting, both should be feeding

at the same S.P.I.. Adjust the timing by

using the sprocket on the upper main

shaft in the arm.

SNOITANIBMOCTEKCORPSRELLUP

EVIRDRELLUP

TEKCORPS

41518

41412/17

51417

51312/16

31512/18

31619

61316

21612/19

116101

21

RELLUP

TEKCORPS

2/1±.I.P.S

HCTITS

22

BUSHINGS

Ref.

No.

Part No.

Description

Amt.

Req.

1.

50654

2.

50332U

3.

50330CZ

4.

50654A

5.

50344BE

6.

SQ1110401MZ

7.

50344BC

8.

50344E

9.

50344BF

10.

35036BS

11.

50393GE

12.

22571L

13.

50393FU

14.

50393EY

15.

50392AB

16.

PS0400142KH

17.

50381E

18.

50344BU

19.

SQ1110401MZ

Bushing, for needle bar, upper .....................................................................

Pin, for front lifter lever ..................................................................................

Bushing, for presser bar ................................................................................

Bushing, for needle bar, lower ......................................................................

Bushing, for lower mainshaft, left .................................................................

Fitting .....................................................................................................

Bushing, for needle lever ..............................................................................

Bushing ........................................................................................................

Bushing, for lower mainshaft, right ...............................................................

Stitch Regulator Bushing ..............................................................................

Oil Sight Gauge ............................................................................................

Screw, for drain plug ....................................................................................

Fitting, oil tube ..............................................................................................

Fitting, filter ..................................................................................................

Bushing, for tension release..........................................................................

Pin ................................................................................................................

Bushing, for lifter lever, back ........................................................................

Bushing, front ...............................................................................................

Fitting .....................................................................................................

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

23

24

NEEDLE BAR

Ref.

No.

Part No.

Description

Amt.

Req.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

-

14.

-

15.

16.

17.

18.

19.

20.

21.

22.

23.

-

24.

25.

SS4080620TP

50323P

50317B

50345W

50355AM

SS7111120TP

50352

661-259B

50355AN

50351A

50393JP

50358X

SS7080520SP

CE27

50354F

CE63

SS8110422TP

29476TC

50393JZ

50393JW

SS6090440SP

SS6121010SP

29476VN

50338

666-328

CE59

50338A

SS6090620SP

Screw ...........................................................................................................

Needle Bar Eyelet .........................................................................................

Needle Bar ...................................................................................................

Connecting Rod Assembly ...........................................................................

Needle Bar Clamp .................................................................................

Screw ...............................................................................................

Pivot Pin .................................................................................................

Needle Bearing Cage ............................................................................

Connecting Rod ....................................................................................

Washer .........................................................................................................

Eyelet Seal ....................................................................................................

Needle Thread Eyelet ...................................................................................

Screw ...........................................................................................................

Loctite Adhesive, (not shown), for screw .....................................................

Slide Block ....................................................................................................

Three Bond Adhesive, (not shown), for slide block .......................................

Screw ...........................................................................................................

Oil Tube Assembly ........................................................................................

Oil Tube ........................................................................................................

Hose Clamp .................................................................................................

Screw, for oil tube assembly .........................................................................

Screw ...........................................................................................................

Slide Block Guide and Cover Assembly ........................................................

Guide, for slide block .............................................................................

Felt, for slide block ..................................................................................

Loctite Adhesive, (not shown), for felt ...................................................

Cover, for guide .....................................................................................

Screw .....................................................................................................

1

1

1

1

1

1

1

1

1

1

1

1

1

-

1

-

1

1

1

1

1

2

1

1

1

-

1

1

25

26

Loading...

Loading...