Automated Systems Division

ARGO 42/A

Comelz

Drive Motor & Stepper Drive

Eprom Version B

Instruction Manual

CATPT9910

Union Special Corporation

Automated Systems Division

ARGO 42/A

INSTALLATION

USE

MAINTENANCE

Catalog Part Number

CATPT9910

Eprom B

COMELZ ARGO 42/A 2

INSTALLATION...................................................5

CONNECTING TO MAINS ...................................................................................5

CONNECTION TO THE SEWING MACHINE..................................................5

SYNCHRONIZERS / INSTALLATION AND TIMING .....................................5

INSTALLATION OF ME100 SYNCHRONIZER..........................................................................5

INSTALLATION OF ME200 SYNCHRONIZER

INSTALLATION OF ME300 SYNCHRONIZER

TIMING............................................................................................................................................

“0” reference position without using

the MT800 console ....................................................6

SOCKET PANELS ..................................................................................................7

CZ0 AND CZ1 SOCKET PANELS.................................................................................................7

CZ2 SOCKET PANEL.....................................................................................................................

CZ3 AND CZ4 SOCKET PANELS

NT4 SOCKET PANEL ....................................................................................................................

.................................................................................................7

..........................................................................6

..........................................................................6

6

7

8

THE MT800 CONSOLE .........................................................................................8

PROTECTED ACCESS TO INFORMATION.....................................................8

INSTALLATION SETUP .......................................................................................8

TRANSFER OF THE SETUP THROUGH THE KK195 MEMORY ............................................8

SELECTION AMONG CONFIGURATIONS INCLUDED IN THE “LIBRARY

OF CONFIGURATIONS”..............................................................................................................9

SETUP -01 / machine selection.............................................................................................10

DIRECT PROGRAMMING OF MOTOR CONFIGURATION...................................................10

SETUP -02 / machine parameters........................................................................................10

TIMING (DIRECTION OF ROTATION, NEEDLE POSITIONS)................................................... 11

ROTATION (SPEED, ACCELERATION)....................................................................................... 11

TREADLE .......................................................................................................................................12

COVER PAGES................................................................................................... 13

MOTOR DIAGNOSIS....................................................................................................................... 13

PROTECTED ACCESS SETUP .............................................................................................. 14

SETUP -03 / machine devices................................................................................................14

THREAD TRIMMER....................................................................................................................... 14

COMELZ ARGO 42/A 3

TENSION RELEASE....................................................................................................................... 15

THREAD WIPER............................................................................................................................ 16

PRESSER FOOT LIFTER............................................................................................................... 16

BACK-TACK................................................................................................................................... 16

NEEDLE COOLING....................................................................................................................... 17

CHAIN SUCTION (VENTURI)....................................................................................................... 17

PHOTOCELL........................................................................................................................ 17

SAFETY SWITCH................................................................................................................. 17

STATIONARY BRAKE .................................................................................................................... 18

HP ADLER / JUKI.......................................................................................................................... 18

CUTTER.......................................................................................................................................... 18

STEPPER MOTORS .......................................................................................................................19

AUTOMATION .....................................................................................................19

SETUP –10 / output signals / input signals........................................................................19

PROGRAMMING OUTPUT SIGNALS .......................................................................................19

PROGRAMMING INPUT SIGNALS............................................................................................ 22

CONNECTION OF INPUT DEVICES (M

ICRO-SWITCHES, NPN, PNP).........................................24

USE........................................................................26

CONSOLES AND KEYBOARDS........................................................................26

MT800 CONSOLE.........................................................................................................................26

MT600 CONSOLE.........................................................................................................................

MT100 AND MT400 KEYBOARDS

............................................................................................27

MT500 KEYBOARD.....................................................................................................................

26

27

SEWING PROGRAMMING................................................................................27

STEP PROGRAMMING ...............................................................................................................28

Operations...............................................................................................................................

Sewing mode...........................................................................................................................

Behavior of devices while sewing..........................................................................................29

28

29

COMELZ ARGO 42/A 4

Behavior of devices at the end of the sewing .......................................................................30

Beginning and end of a Step and shift from a Step to the next one

USE OF THE PHOTOCELL .........................................................................................................31

Additional conditions for the use of the photocell

USE OF THE AUTOMATION FUNCTIONS

Importance of the Pause Step ...............................................................................................33

CREATING A PROGRAM BY SELF-TEACHING

PROGRAM MANAGEMENT ......................................................................................................33

Modifying and deleting a Program

Correction of a Program and limitation to correction

Transferring a Program........................................................................................................34

..............................................................................32

......................................................................................34

..............................................................32

....................................................................33

.......................................................34

PROGRAM 000 ......................................................................................................35

PROGRAM INDEX...............................................................................................35

PIECE COUNTING / PRODUCTION CONTROL ...........................................36

USE OF STANDARD COVER PAGES...............................................................37

..................................30

MAINTENANCE.................................................39

TROUBLESHOOTING .................................................................................................................39

ERROR MESSAGES DISPLAYED BY THE MT800 CONSOLE

COMPLETE MOTOR RESET ......................................................................................................40

RUNNING THE MACHINE WITHOUT SYNCHRONIZER

BUILT-IN BACK-UP MEMORY.................................................................................................40

REPLACEMENT OF THE SOCKET PANEL

REPLACEMENT OF THE SYNCHRONIZER

REPLACEMENT OF THE KK66 ELECTRONIC BOARD

REPLACEMENT OF THE FRONT PEDAL

MOTOR REPLACEMENT............................................................................................................41

SOFTWARE UPDATING.............................................................................................................41

..............................................................................40

............................................................................41

........................................................41

PANEL ..................................................................41

..............................................39

......................................................40

EXAMPLES (Sewing Programs)........................42

SM1 STEPPER MOTOR DRIVER ………….. 61

COMELZ ARGO 42/A 5

INSTALLATION

CONNECTING T O MAINS

ARGO is a 220 V single-phase unit and it can be immediately connected to the 220 V single-phase line.

It can also be connected to the 380 V three-phase line by obtaining 220V using any one

case of connection to the 380V three-phase line it is important not to connect the unit between two phases instead of

between any one phase and the neutral wire.

By request Argo is available in 110V model.

Also the ground wire must be absolutely connec

Besides, near the unit there must not be any equipment that has sparking contacts (as lacking the correct protections).

For a good functioning it is necessary to c

housing.

ted for correct functioning of the motor (through the mains socket).

onnect the sewing machine head to the ground screw located on the motor

CONNECTION TO THE SEWING MACHINE

The motor is fixed to the stand through a bracket. Fixing holes comply with both DIN and ASA norms.

The transmission of the motion is effected through a V b

to obtain a correct ratio between the maximum rotation speed allowed on the machine (MAX) and the rated rotation speed

of the motor (4500rpm). A different ratio to the motor speed (max. 6000rpm) reduces performances.

The correct pulley size is given to the technician dur

The correct pulley size can also be calculated u

sing the following formula:

elt, “Z” section. Choose the diameter of the motor pulley (PUL) so as

ing the configuration process of the motor (pag e 11).

of the three phases and the neutral wire. In

(where DV is the pitch diameter of the hand-wheel of the machine):

Pulleys are available with pitch diameters (in mm): 50,

The treadle is connected to the control lever on the main body of A

machine.

To prevent vibrations from moving the motor and loosening the belt, the

securely fastened with the wrench provided with the unit.

58, 63, 67, 71, 75, 80, 85, 90, 95.

RGO, through the rod (extensible) that is usually fitted to the

screws that connect the motor to the bracket must be

SYNCHRONIZERS / INSTALLATION AND TIMING

Besides the traditional optical synchronizer (ME100), other two synchronizer types are available (miniaturized and without

m

echanical parts): one Hall-effect based type (ME200) and one with proximity sensor (ME300). These two types satisfy the need

to eliminate rotating members inside the synchronizer, especially on fast machines.

INSTALLATION OF ME100 SYNCHRONIZER

Just fit the synchronizer to the shaft. No mechanical adjustment is required, as the setting of the “0” reference and the stopping

positions of the machine will be accomplished afterwards in the configuration phase (see Timing paragraph page 11).

COMELZ ARGO 42/A 6

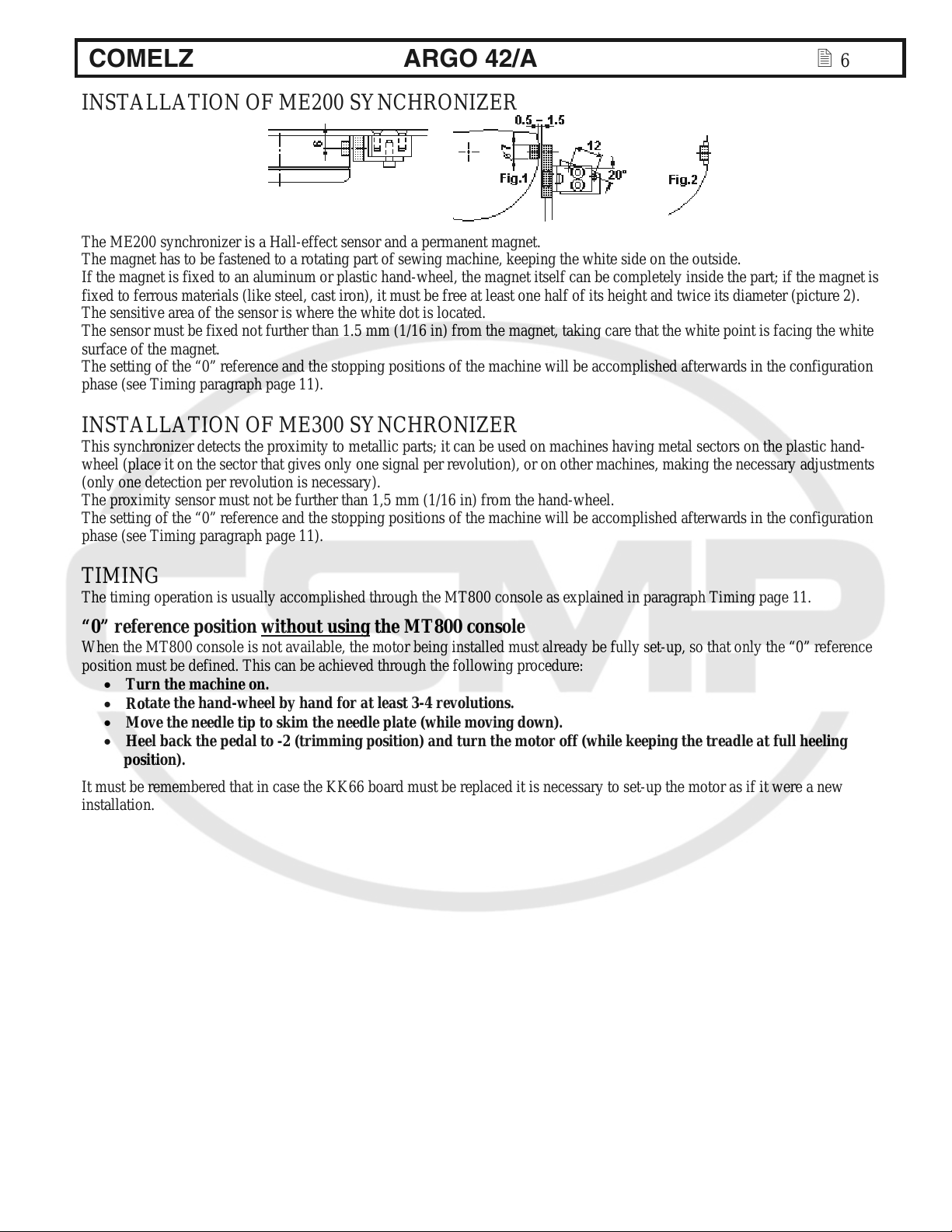

INSTALLATION OF ME200 SYNCHRONIZER

The ME200 synchronizer is a Hall-effect se

The magnet has to be fastened to a rotating part of sewing machine, keeping the white side on the outside.

If the magnet is fixed to an aluminum or plastic hand-wheel, the magnet itself can be completely inside the part; if the magnet is

d to ferrous materials (like steel, cast iron), it must be free at least one half of its height and twice its diameter (picture 2).

fixe

The sensitive area of the sensor is where the white dot is located.

The sensor must be fixed not further than 1.5 mm (1/16 in) from the magnet, taking care that the white point is facing the white

surface of

The setting of the “0” reference and the stopping positions of the machine will be accomplished afterwards in the configuration

pha

the magnet.

se (see Timing paragraph page 11).

INSTALLATION OF ME300 SYNCHRONIZER

This synchronizer detects the proximity to metallic parts; it can be used on machines having metal sectors on the plastic hand-

wheel (place it on the sector that gives only one signal per revolution), or on other machines, making the necessary adjustments

(only one detection per revolution is necessary).

The proximity sensor must not be further than 1,5 mm (1/16 in) from the hand-wheel.

The setting of the “0” reference and the stopping positions of the machine will be accomplished afterwards in the configuration

se (see Timing paragraph page 11).

pha

nsor and a permanent magnet.

TIMING

The timing operation is usually accomplished through the MT800 console as explained in paragraph Timing page 11.

“0” reference position without using the MT800 console

When the MT800 console is not available, the motor being installed must already be fully set-up, so that only the “0” reference

position must be defined. This can be achieved through the following procedure:

• Turn the m

tate the hand-wheel by hand for at least 3-4 revolutions.

• Ro

ve the needle tip to skim the needle plate (while moving down).

• Mo

• Heel

position).

It must be remembered that in case the KK66 board must be replaced it is

installation.

achine on.

back the pedal to -2 (trimming position) and turn the motor off (while keeping the treadle at full heeling

necessary to set-up the motor as if it were a new

COMELZ ARGO 42/A 7

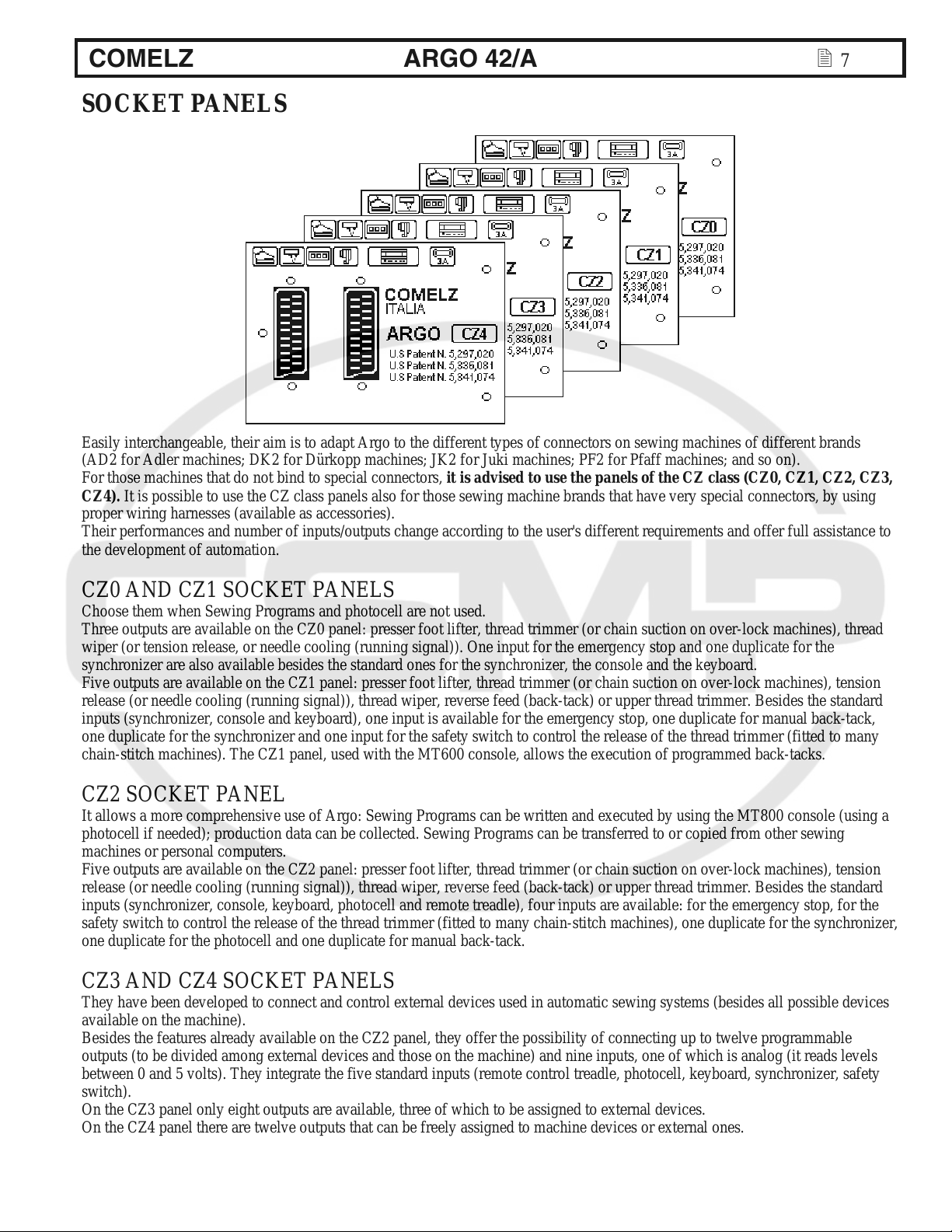

SOCKET PANELS

Easily interchangeable, their aim is to adapt Argo to the different types of connectors on sewing machines of different brands

(AD2 for Adler machines; DK2 for Dürkopp machines; JK2 for Juki machines; PF2 for Pfaff machines; and so on).

For those machines that do not bi

CZ4). It is possible to use the CZ class panels also for those sewing machine brands that have very special connectors, by using

proper wiring harnesses (available as accessories).

Their performances and number of inputs/outputs change according to the user's different requirements and offer full assistance to

th

e development of automation.

nd to special connectors, it is advised to use the panels of the CZ class (CZ0, CZ1, CZ2, CZ3,

CZ0 AND CZ1 SOCKET PANELS

Choose them when Sewing Programs and photocell are not used.

Three outputs are available on the CZ0 panel: presser foot lifter, thread trimmer (or chain suction on over-lock machines), threa

wiper (or tension release, or needle cooling (running signal)). One input for the emergency stop and one duplicate for the

synchronizer are also available besides the standard ones for the synchronizer, the console and the keyboard.

Five outputs are available on the CZ1 panel: presser foot lifter, thread trimmer (or chain suction on over-lock machines), tensio

release (or needle cooling (running signal)), thread wiper, reverse feed (back-tack) or upper thread trimmer. Besides the standard

inputs (synchronizer, console and keyboard), one input is available for the emergency stop, one duplicate for manual back-tack,

one duplicate for the synchronizer and one input for the safety switch to control the release of the thread trimmer (fitted to many

chain-stitch machines). The CZ1 panel, used with the MT600 console, allows the execution of programmed back-tacks.

d

n

CZ2 SOCKET PANEL

It allows a more comprehensive use of Argo: Sewing Programs can be written and executed by using the MT800 console (using a

photocell if needed); production data can be collected. Sewing Programs can be transferred to or copied from other sewing

machines or personal computers.

Five outputs are available on the CZ2 panel: presser foot lifter, thread trimmer (or chain suction on over-lock machines), tensio

release (or needle cooling (running signal)), thread wiper, reverse feed (back-tack) or upper thread trimmer. Besides the standard

inputs (synchronizer, console, keyboard, photocell and remote treadle), four inputs are available: for the emergency stop, for the

safety switch to control the release of the thread trimmer (fitted to many chain-stitch machines), one duplicate for the synchronizer,

one duplicate for the photocell and one duplicate for manual back-tack.

n

CZ3 AND CZ4 SOCKET PANELS

They have been developed to connect and control external devices used in automatic sewing systems (besides all possible devices

available on the machine).

Besides the features already available on the CZ2 panel, they offer the possibility of connecting up to twelve programmable

out

puts (to be divided among external devices and those on the machine) and nine inputs, one of which is analog (it reads levels

between 0 and 5 volts). They integrate the five standard inputs (remote control treadle, photocell, keyboard, synchronizer, safety

switch).

On the CZ3 panel only eight outputs are available, three of which to be assigned to external devices.

On the CZ4 panel there are twelve outputs that can be freel

y assigned to machine devices or external ones.

COMELZ ARGO 42/A 8

NT4 SOCKET PANEL

This socket panel has the same features of CZ4 socket panel plus it has the possibility to be conn ected to one or more external

boxes SM1 for Stepper motor control. See manual “Stepper Motors”.

THE MT800 CONSOLE

This console is the most powerful instrument to access the functions available with ARGO; through it, it is possible to intervene at

any level and on each aspect of the application. It is used by installers, maintenance personnel and by users.

Through the use of the MT800 console, installers define their application precisely and in details, adjust the parameters of the

sewing m

Users, through a simple and exhaustive language, can create and store in memory a great number of Sewing Programs and, during

ope

All available functions, both for configuration and use, are shown by a set of pages and underlying pages, divided into three

gr

oups:

achine, detect malfunctioning and collect operation data.

rations, they can count the pieces and monitor production.

• SETUP -01

• PR

G 000 basic Sewing Programs

/..../SETUP -10 configuration instruments

• PRG

Parameters within pages are selected through the

The value of a parameter is defined through the

• change

• chan

• confirm or

• search for

The

associated to some pages and parameters. The access to and the return from the underlying pages is obtained by pressing the

button.

001/.../PRG 255 Sewing Programs written by the user

buttons.

and buttons that, depending upon the context, are used to:

the numerical value ( to increase, to decrease)

ge the literal content (to insert text)

exclude (

alternatives for the use of devices

and buttons are also used to move through the main pages (starting from the page number). An underlying page is

for YES, for NO)

PROTECTED ACCESS TO INFORMA TION

The machine configuration (set-up), the modification of Sewing Program data and the access to production data fall within

specialized personnel competence. To prevent operators from accidentally altering these data, two 3-digit access codes are

provided (code

Program area; code

The original codes are 000 and they can be changed in Set-up-02 ( see Protected access set-up page 14).

If the codes are set to a value different than 000 it is possible to write into the KK195 memory chip only after entering the PRG

code.

PRG to modify Sewing Programs, for production control or to move from Cover page area to Sewing

STP to move from Sewing Program area to Set-up area).

INSTALLATION SETUP

On the MT800 programming console, at every position of the cursor corresponds a message displayed in the bottom line that will

help you through the programming. Basically, to program Argo, you simply follow the instruction s in the messag e line until the

motor is fully configured.

There are three diffe rent ways to

Transfer of machine configuration from an external KK195 memory chip to the motor.

Selection of machine configuration among several configurations already stored in the motor “library of configurations”.

Direct programming of all the parameters needed (or modification of some parameters stored in the two previous ways).

set-up the motor for the particular machines used:

TRANSFER OF THE SETUP THROUGH THE KK195 MEMORY

By means of a KK195 memory chip it is possible to copy the configuration from an already installed machine and transfer it to a

machine of the same type. When required, at this moment it is also possible to transfer all the Sewing Programs.

To transfer a machine configuration from an external KK195 memory chip to the motor:

- Turn the motor off

COMELZ ARGO 42/A 9

- Plug in the KK195 chip into the right side of the MT800 console

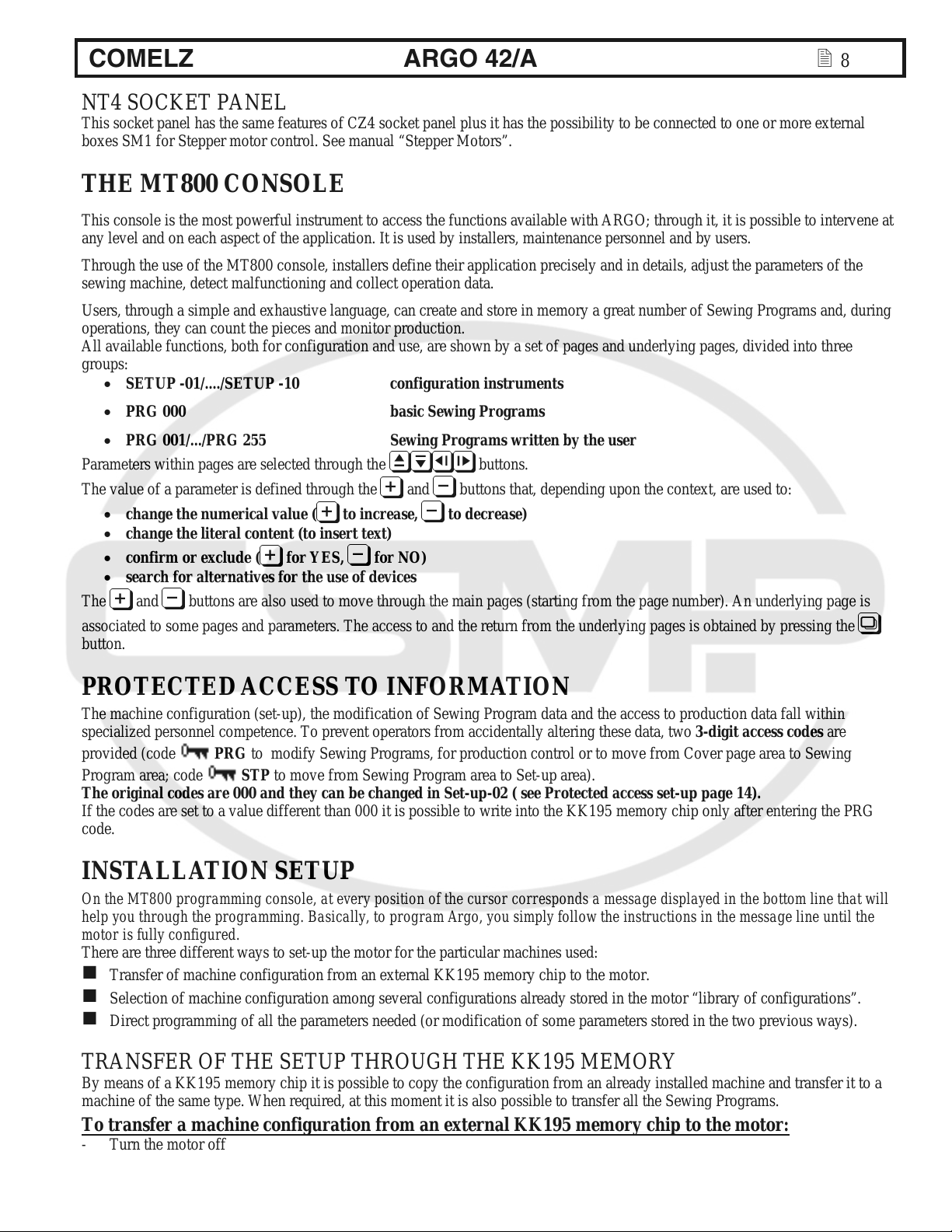

- Turn the motor on and the page to transfer data fro

- Press the

- Then press a second time the

be permanently erased).

- Now will appear the page for needle stopping position setti

button to transfer the configuration to the motor

button to confirm (CAUTION! After the second , the previous motor configuration will

m the KK195 chip to the motor will appear:

ngs and the only necessary adjustment is the setting of the “0”

reference position. See paragraph

If into the KK195 is stored only the machine Set-up (for example with motors equipped with socket panels CZ0 or CZ1), the only

ption available is to transfer the Setup. If into the KK195 are stored the machine Set-up and the Sewing Programs, then three

o

options are presented: transfer of Setup and Sewing Programs in only one operation (suggested option), transfer of Setup only,

transfer of Sewing Programs only.

TIMING (DIRECTION OF ROTATION, NEEDLE POSITIONS) page 11.

To transfer a machine configuration from the motor to an external KK195 memory chip:

- Turn the motor off

- Plug in the KK195 chip into the right side of the MT800 console

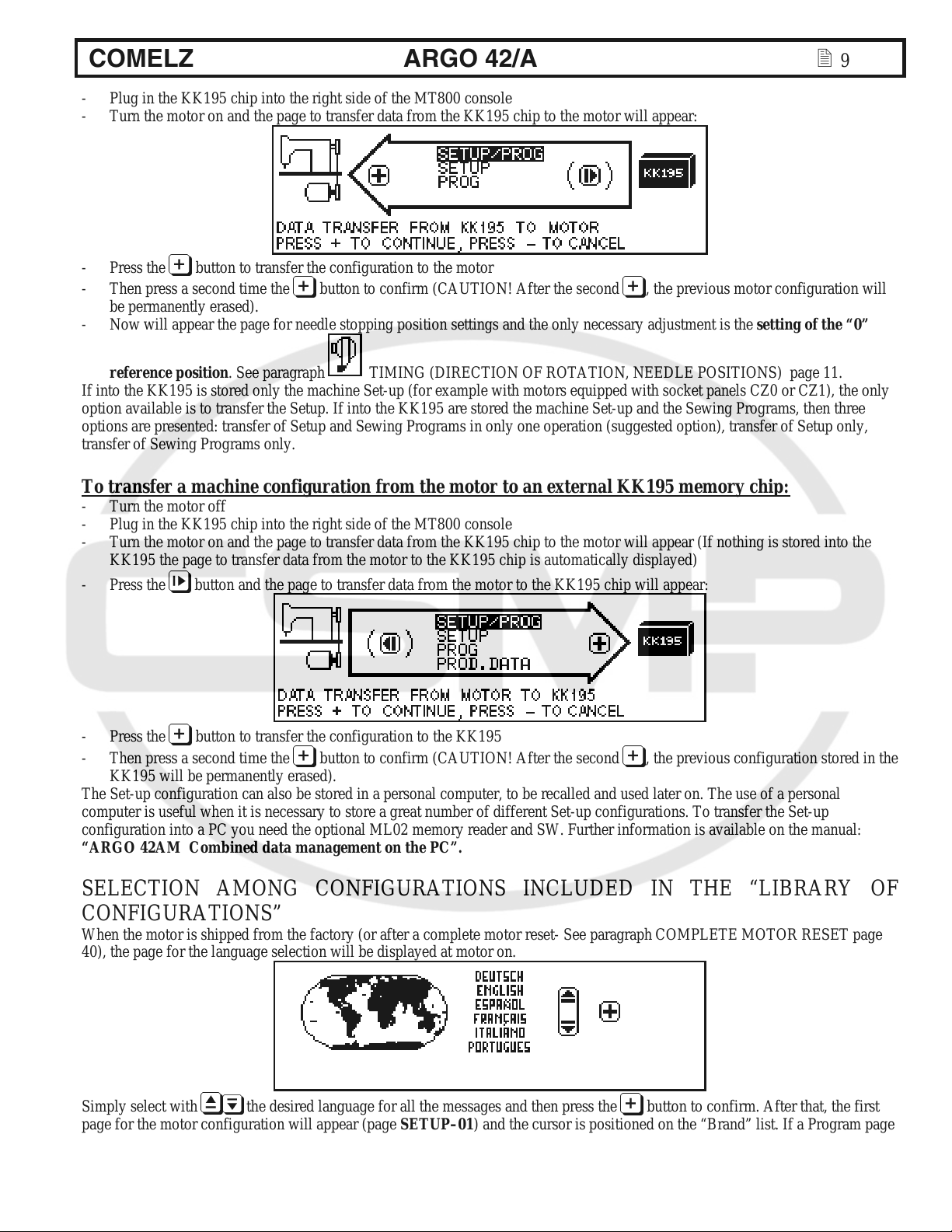

- Turn the motor on and the page to transfer data from the KK195

KK195 the page to transfer data from the motor to the KK195 chip is automatically displayed)

- Press the

- Press the

- Then press a second time the

KK195 will be permanently erased).

The Set-up configuration can also be stored in a personal computer, to be recalled and used later on. The use of a personal

com

puter is useful when it is necessary to store a great number of different Set-up configurations. To transfer the Set-up

configuration into a PC you need the optional ML02 memory reader and SW. Further information is available on the manual:

“ARGO 42AM Combined data management on the PC”.

button and the page to transfer data from the motor to the KK195 chip will appear:

button to transfer the configuration to the KK195

button to confirm (CAUTION! After the second , the previous configuration stored in the

chip to the motor will appear (If nothing is stored into the

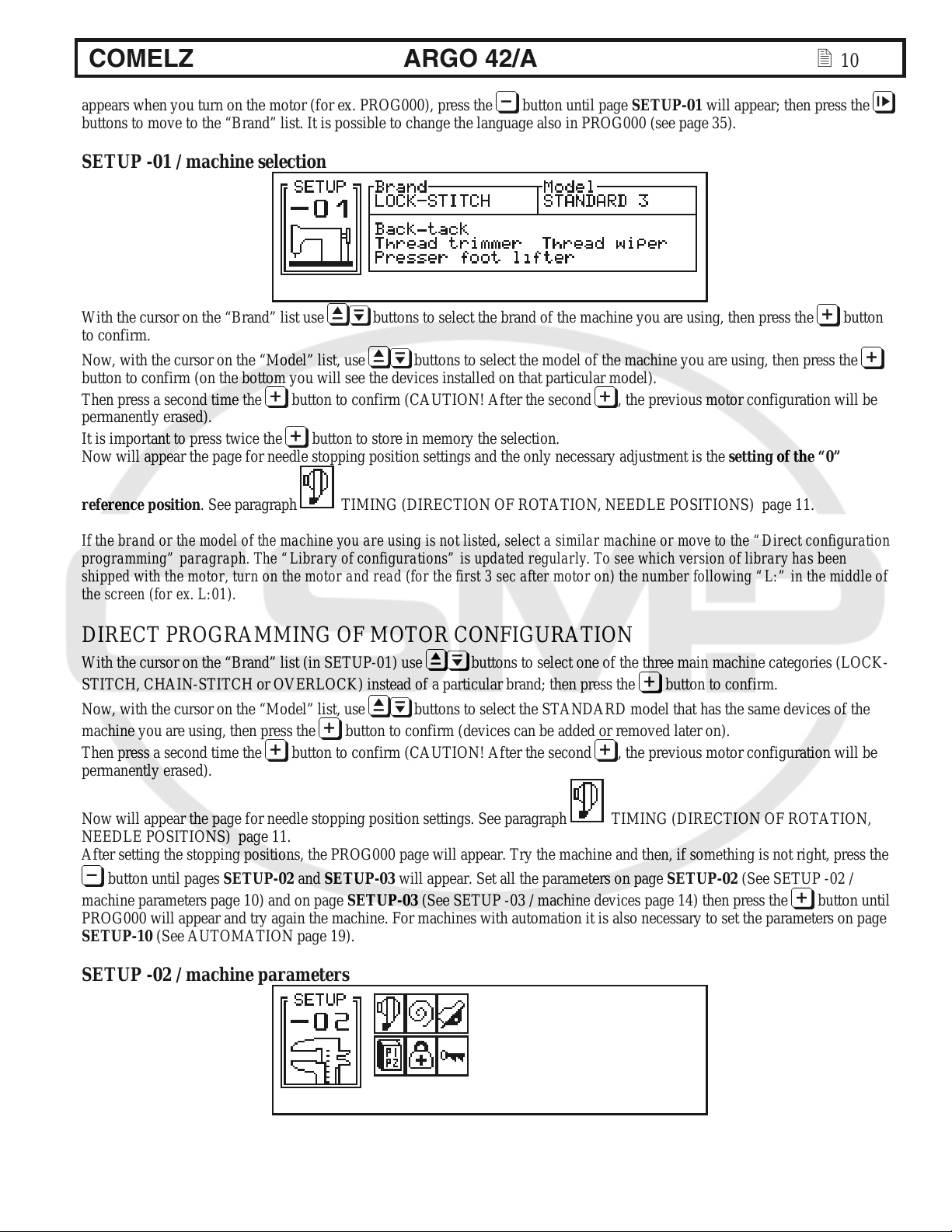

SELECTION AMONG CONFIGURATIONS INCLUDED IN THE “LIBRARY OF CONFIGURATIONS”

When the motor is shipped from the factory (or after a complete motor reset- See paragraph COMPLETE MOTOR RESET page

40), the page for the language selection will be displayed at motor on.

Simply select with

page for the motor configuration will appear (page SETUP–01) and the cursor is positioned on the “Brand” list. If a Program page

the desired language for all the messages and then press the button to confirm. After that, the first

COMELZ ARGO 42/A 10

appears when you turn on the motor (for ex. PROG000), press the button until page SETUP-01 will appear; then press the

buttons to move to the “Brand” list. It is possible to change the language also in PROG000 (see page 35).

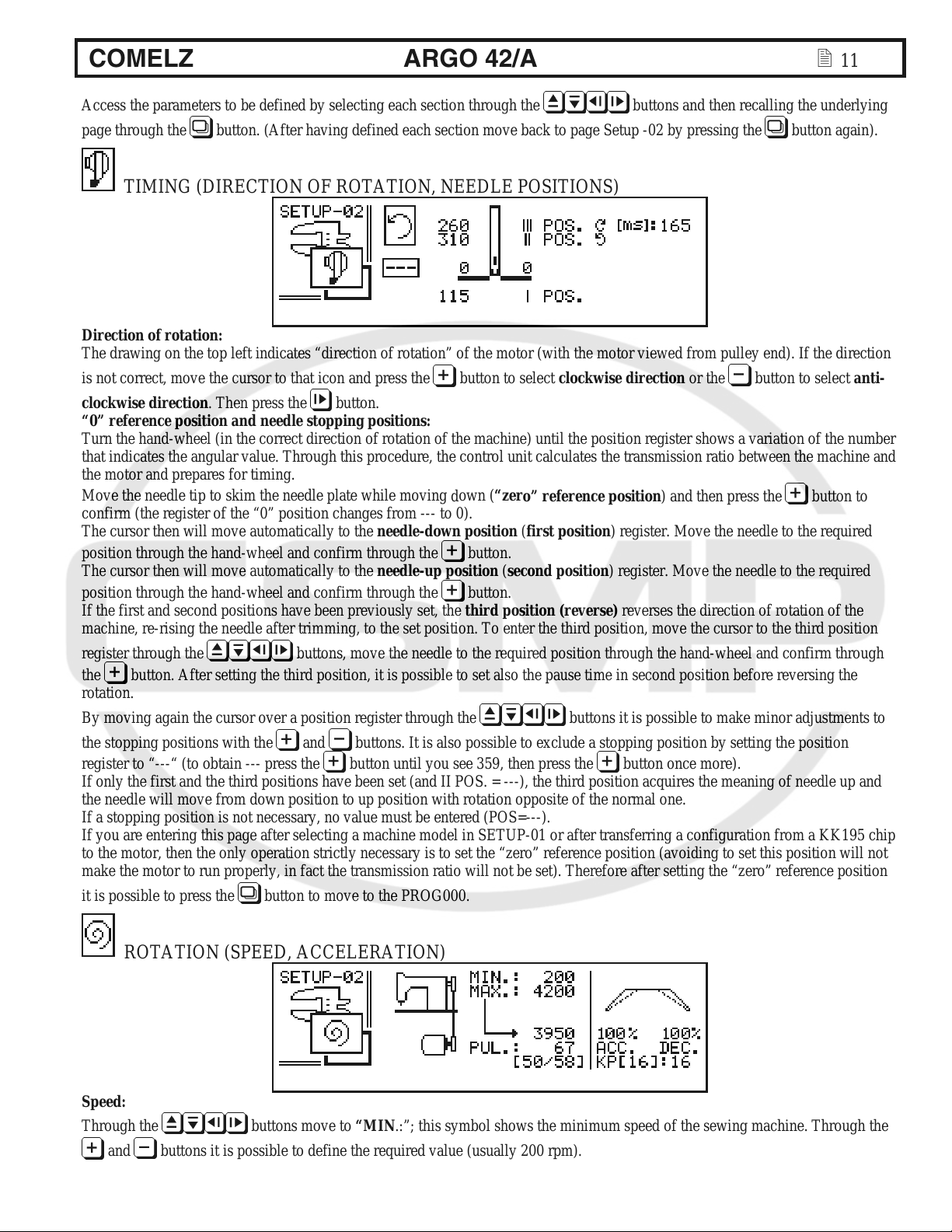

SETUP -01 / machine selection

With the cursor on the “Brand” list use

to confirm.

Now, with the cursor on the “Model” list, use

button to confirm (on the bottom you will see the devices installed on that particular model).

Then press a second time the

button to confirm (CAUTION! After the second , the previous motor configuration will be

permanently erased).

It is important to press twice the

Now will appear the page for needle

button to store in memory the selection.

stopping position settings and the only necessary adjustment is the settin g of the “0 ”

buttons to select the brand of the machine you are using, then press the button

buttons to select the model of the machine you are using, then press the

reference position. See paragraph

TIMING (DIRECTION OF ROTATION, NEEDLE POSITIONS) page 11.

If the brand or the model of the machine you are using is not listed, select

a similar machine or move to the “Direct configuration

programming” paragraph. The “Library of configurations” is updated regularly. To see which version of library has been

shipped with the motor, turn on the motor and read (for the first 3 sec after motor on) the number following “L:” in the middle of

the screen (for ex. L:01).

DIRECT PROGRAMMING OF MOTOR CONFIGURATION

With the cursor on the “Brand” list (in SETUP-01) use

STITCH, CHAIN-STITCH or OVERLOCK) instead of a particular brand; then press the

Now, with the cursor on the “Model” list, use

machine you are using, then press the

Then press a second time the

button to confirm (CAUTION! After the second , the previous motor configuration will be

button to confirm (devices can be added or removed later on).

buttons to select the STANDARD model that has the same devices of the

permanently erased).

Now will appear the page for needle stopping position settings. See paragraph

NEEDLE POSITIONS) page 11.

After setting the stopping positions, the PROG000 page will appear. Try t

button until pages SETUP-02 and SETUP-03 will appear. Set all the parameters on page SETUP-02 (See SETUP -02 /

machine parameters page 10) and on page SETUP-0

3 (See SETUP -03 / machine devices page 14) then press the button until

PROG000 will appear and try again the machine. For machines with automation it is also necessary to set the parameters on page

SETUP-10 (See

AUTOMATION page 19).

buttons to select one of the three main machine categories (LOCK-

button to confirm.

TIMING (DIRECTION OF ROTATION,

he machine and then, if something is not right, press the

SETUP -02 / machine parameters

COMELZ ARGO 42/A 11

Access the parameters to be defined by selecting each section through the buttons and then recalling the underlying

page through the

TIMING (DIRECTION OF ROTATION, NEEDLE POSITIONS)

button. (After having defined each section move back to page Setup -02 by pressing the button again).

Direction of rotation:

The drawing on the top left indicates “direction of rotation” of th

is not correct, move the cursor to th

clockwise direction. Then press the

“0” reference position and needle stopping positions:

Turn the hand-wheel (in the correct direction of rotation of the machine) until the position register shows a variati of the num

that indicates t

the motor and prepares for timing.

Mo

ve the needle tip to skim the needle plate while moving own (“zer

confirm (the register of the “0” position cha

The cursor then will move automatically to the needle-dow position (

position through the hand-wheel and confirm through the

The cursor then will move automatically to the needle-up position (second position) register. Move the needle to the required

position through the and confirm through the

If t

h irst and second positions have been previously set, the third position (reverse) reverses the direction of rotation of the

e f

machine,

register through the

the

rotation.

By moving again the cursor over a position register through the

the stopping positions with the

register to “---“ (to obtain --- press the

If only the first and the third positions have been set (and II POS. = ---), the third position acquires the meaning of needle up and

the needle will move from down position to up position with rotation opposite of the normal one.

If a stopping position is not necessary, no value must be entered (POS=---).

If you are entering this pa after selecting a machine model in

to the motor, then the only operation strictly necessary is to set the “zero” reference position (avoiding to set this position will not

make the motor to run properly, in fact the transmission ratio will not be set). Therefore after setting the “zero” reference position

ossible to press the

it is p

he angular value. Through this procedure, the con

hand-wheel button.

g the needle after trimming, to the set position. To enter the third position, move the cursor to the third position

re-risin

button. After setting the ird po ion, it is possible to set also the pause time in second position before reversing the

ge SETUP-01

at icon and press the

button.

nges from --- to 0).

buttons, move the needle to th osition through the hand-wheel and confirm through

th sit

and buttons. It is also possible to exclude a stopping position by setting the position

button until you see 359, then press the button once more).

button to move to the PROG000.

e motor (with the motor viewed from pulley end). If the direction

button to select clockwise direction or the button to select anti-

trol unit calculates the transmission ratio between the machine and

d o” reference position) and then press the

n first position) register. Move the needle to the required

button.

e required p

buttons it is possible to make minor adjustments to

or after transferring a configuration from a KK195 chip

n ber

o

button to

ROTATION (SPEED, ACCELERATION)

Speed:

Thr

ough the

and buttons it is possible to define the required value (usually 200 rpm).

buttons move to “MIN.:”; this symbol shows the mi nimum speed of the sewing machine. Through the

COMELZ ARGO 42/A 12

Through the buttons move to “MAX.:”; through the and buttons it is possible to define the value that limits

the top speed of the sewing machine. The speed reached by the motor when the machine is turning at top speed is displayed on t

lower line (this is only a reference value and it can not be changed).

Pulley:

The correc

“PUL.:”

If the pulley was correctly chosen, the top speed of the machine is reached when the motor run s at 4500 rpm. If the motor runs

uch faster (6000 rpm) or much slower (less than 3000 rpm) it is advisable to replace the pulley following the suggestion in

m

brackets. After replacing the pulley it is necessary to set again the “zero re rence sition”.

Acceleration:

While accelerating and decelerating, the motor can deliver its full power or a lower power (to comply with the requirements of the

machine). Move to the “ACC.:” and “DEC.:” symbols and, through the

percentage of power utilization

the (the fi

is possible to set a value greater than 100% (between 100% and 150%). Caution! Use values of DEC greater than 100% only if an

extrem

counter may result inaccurate).

Quietness and accu racy when stopping:

In case possible to increase the quietness when stopping by reducing the accuracy (KP<16). Values bigger than

16 ar ince the stopping accuracy has already reached its best.

t choice of the pulley is very important to obtain the best performances from the motor. With the cursor on th

positi

on, enter the diameter of the pulley fitted to the motor (this value is stamped o

fe po

and buttons, define the value that will represe

rst value for acceleration, the second one for deceleration). For the deceleration value it

ely high deceleration is needed (in fact the machine may stop so quickly that the needle can bounce back, and the stitch

of real need, it is

not suggested s

e

the pulley).

n

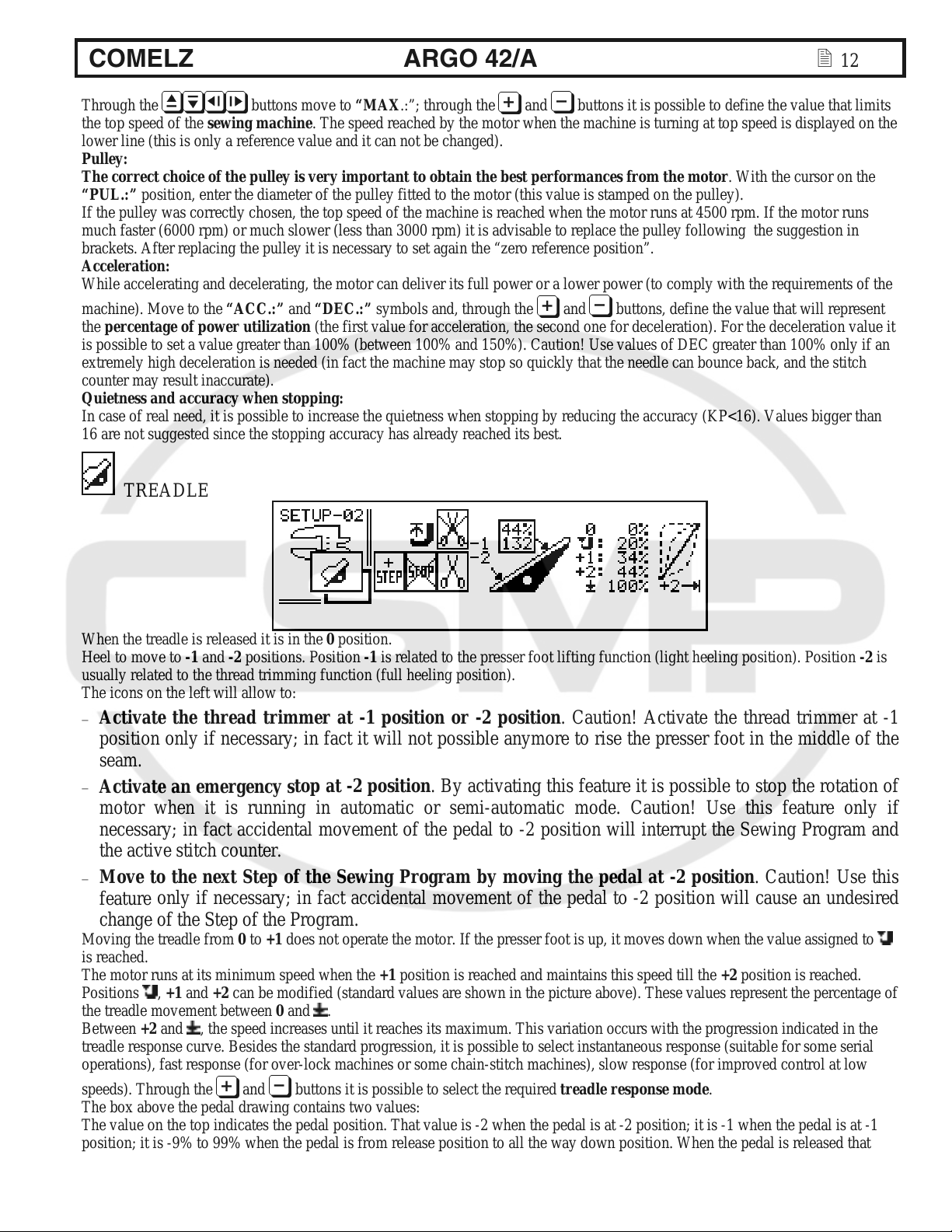

TREADLE

he

e

nt

When the treadle is released it is in the 0 posi

Heel to move to -1 and -2 positions. Position -1 is related to the presser foot lifting function (light heeling position). Position -2 is

us

ually related to the thread trimming function (full heeling position).

Th

e icons on the left will allow to:

− Activate the thread trimmer at -1 position or -2 position. Caution! Activate the thread trimmer at -1

tion.

position only if necessary; in fact it will not possible anymore to rise the presser foot in the middle of the

seam.

− top at -2 position. By activating this feature it is possible to stop the rotation of

Activate an emergency s

motor when it is running in automatic or semi-automatic mode. Caution! Use this feature only if

necessa

ry; in fact accidental movement of the pedal to -2 position will interrupt the Sewing Program and

the active stitch counter.

− Move to the next Step of the Sewing Program by moving the pedal at -2 position. Caution! Use th

feature

only if necessary; in fact accidental movement of the pedal to -2 position will cause an undesired

is

change of the Step of the Program.

Moving the treadle from 0 to +1 does not operate the motor. If the presser foot is up, it moves down when the value assigned to

is reached.

e motor runs at its minimum speed when the +1 position is reached and maintains this speed till the +2 position is reached.

Th

Positions

the treadle movement between 0 and

Between +2 and

operations), fast response (for over-lock machines or some chain-stitch

speeds). Through the

The box above the pedal drawing contains two values:

The value on the top indicates the pedal position. That value is -2 when the pedal is at -2 position; it is -1 when the pedal is at -1

position; it is -9% to 99% when the pedal is from release posit

, +1 and +2 can be modified (standard values are shown in the picture above ). These value s represent the percentage

.

, th peed i reases until it reaches its maximum. This variation occurs with the pre s nc ogression indicated in the

, it is possible to select instantaneous response (suitable for some serial treadle response curve. Besides the standard progression

machines), slow response (for improved control at low

and buttons it is possible to select the required treadle response mode.

io

n to all the way down position. When the pedal is released that

of

COMELZ ARGO 42/A 13

value should be 0%. If not, it is possible to perform little adjustments to the tuning of the pedal by moving the cursor on this

percentage register and pressing the

potentiometers installed on the pedal electronic board KK81.

The value on the botto sition. That value should be below 30 when the pedal is all the way back, it should

o

be ab ut 1 (be n pedal is at rest position; it should be 255 when the pedal all the way down.

08 twee 100 and 115) when the

m indicates the pedal po

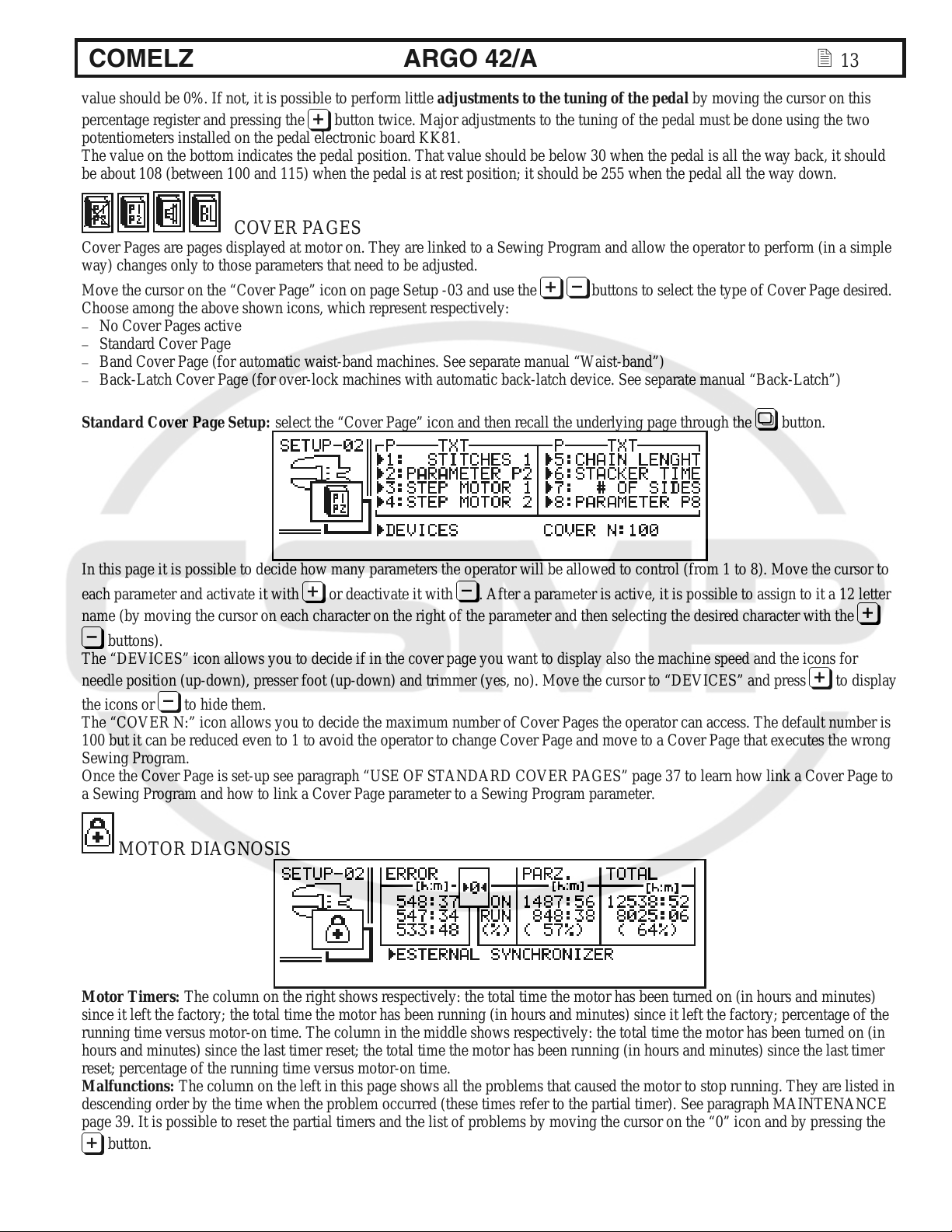

COVER PAGES

Cover Pages are pages displayed at motor on. They are linked to a Sewing Program and allow the operator to perform (in a simple

way) changes only to those

Move the cursor on the “

Choose among the above shown icons, which represent respectively:

− No Cover Pages active

Standard Cover Page

−

−

Band Cover Page (for automatic waist-band machines. See separate manual “Waist-band”)

− Back-Latch Cover Page (for over-lock machines with automatic back-latch device. See separate manual “Back-Latch”)

Standard Cover Page Setup: select the “Cover Page” icon and then recall the underlying pag e through the

parameters that need to be adjusted.

Cover Page” icon on page Setup -03 and use the

button twice. Major adjustments to the tuning of the pedal must be done using the two

buttons to select the type of Cover Page desired.

button.

In this page it is possible to decide how many parameters the operator will be allowed to control (from 1 to 8). Move the cursor to

each parameter and activate it with

or deactivate it with

name (by moving the cursor on each character on the right of the parameter and then selecting the desired character with the

. After a parameter is active, it is possible to assign to it a 12 le

tter

buttons).

The “DEVICES” icon allows you to decide if in the cover page you

needle position (up-down), presser foot (up-down) and trimmer (yes, no). Move the cursor to “DEVICES” and press

the icons or

to hide them.

want to display also the machine speed and the icons for

to display

The “COVER N:” icon allows you to decide the maximum number of Cover Pages the operator can access. The default number is

100 but it can be reduced even to 1 to avoid the operator to change Cover Page and move to a

Sewing

Once aragraph “USE OF STANDARD COVER PAGES” page 37 to learn how link a Cover Page to

a Sew Cover Page parameter to a Sewing Program parameter.

Program.

the Cover Page is set-up see p

i

ng Program and how to link a

Cover Page that executes the wrong

MOTOR DIAGNOSIS

Motor Timers: The column on the right shows respectively: the total time the motor has been turned on (in hours and min utes)

since it left the factory; the total time the motor has been running (in hours and minutes) since it left the factory; percentage of

running time versus motor-on time. The column in the middle shows respectively: the total time the motor h a s been turned on (in

hours and minutes) since the last timer reset; the total time the motor has been running (in hours and minutes) since the last timer

reset; percentage of the running time versus motor-on time.

Ma s: The column on the left in this page shows all the problems that caused the motor to stop running. They are listed in

lfunction

descending order by the time when the problem occurred (these times refer to the partial timer). See paragraph MAINTEN

39. It is possible to reset the partial timers a d the list of problems by oving the cursor on the “0” icon and by pressing the

page

button.

n m

the

ANCE

COMELZ ARGO 42/A 14

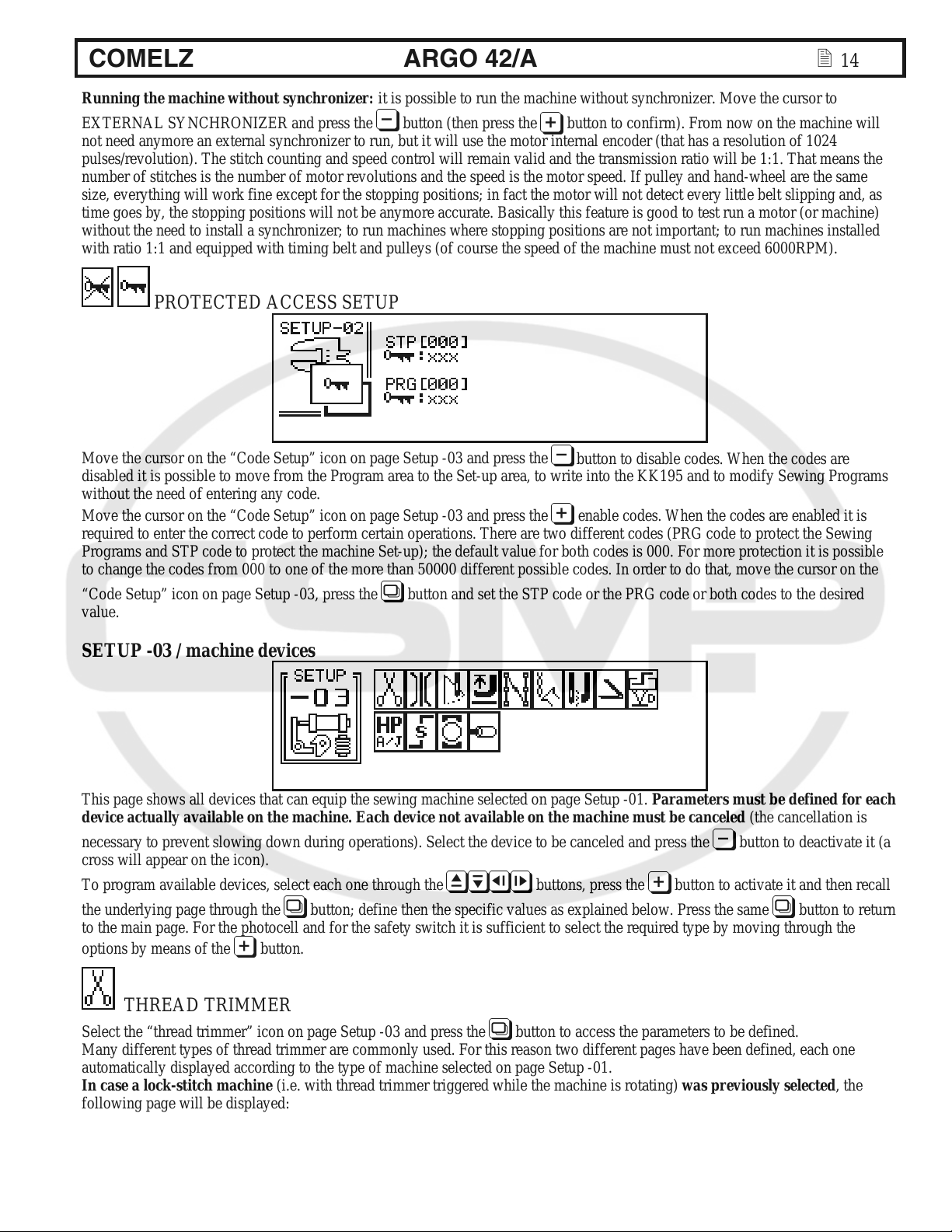

Running the machine without synchronizer: it is possible to run the machine without synchronizer. Move the cursor to

EXTERNAL SYNCHRONIZER and press the

not need anymore an external synchronizer to run, but it will use the motor internal encoder (that has a resolution of 1024

pulses/revolution). The stitch counting and speed control will remain valid and the transmission ratio will be 1:1. That means the

number of stitches is the number of motor revolutions and the speed is the motor speed. If pulley and hand-wheel are the same

size, everything will work fine except for the stopping positions; in fact the motor will not detect every little belt slipping an

ti

me goes by, the stopping positions will not be anymore accurate. Basically this feature is good to test run a motor (or machine)

ou e need to install a synchronizer; to run mac

with t th hines where stopping positions are not important; to run machines installed

ra

with tio ys (of course the speed of the machine must not exceed 6000RPM).

1:1 and equipped with timing belt and pulle

button (then press the

PROTECTED ACCESS SETUP

Move the cursor on the “Code Setup” icon on page Setup -03 and press the

disabled it is possible to move from the Program area to the Set-up area, to write into the KK195 and to modify Sewing Program

without the need of entering any code.

Move the cursor on the “Code Setup” icon on page Setup -03 and press the

required to enter the correct code to perform cert operations. There are two different codes (PRG code to protect the Sewing

Program

to change the codes from 000 to one of the more than 50000 different possible codes. In order to do that, move the cursor on the

“Code Setup” icon on page Setup -03, button and set the STP code or the PRG code or both codes to the desired

val

ue.

s and

STP code to protect the machine Set-up); the default value for both codes is 000. For more protection it is possible

press the

ain

button to confirm). From now on the machine will

button to disable codes. When the codes are

enable codes. When the codes are enabled it is

d, as

s

SETUP -03 / machine devices

This page shows all devices that can equip the se

device actually available on the machine. Each device

necessary to prevent slowing dow during operations). Select the device to be canceled and press the

cross will appear on the icon).

To program available dev es, select

the underlying page through the

to the m for the safety switch it is sufficient to select the required type by moving through the

optio

ain page. For the photocell and

by means of the

ns

ic each one through t

n

button; define then the specific values as explained below. Press the same button to return

button.

wing machine selected on page Setup -01. Parameters must be defined for each

no on the machine must be canceled (the cancellation is

t available

he

buttons, press the button to activate it and then recall

button to deactivate it (a

THREAD TRIMMER

Select the “thread trimmer” icon on page Setup -03 and press the button to access the parameters to be defined.

Many different types of thread trimmer are commonly used. For this reason two different pages have been defined, each one

atically displayed according to the type of machine selected on page Setup -01.

autom

In case a lock-stitch machine (i.e. with thread trimmer triggered while the machine is rotating) was previously selected, the

following page will be displayed:

COMELZ ARGO 42/A 15

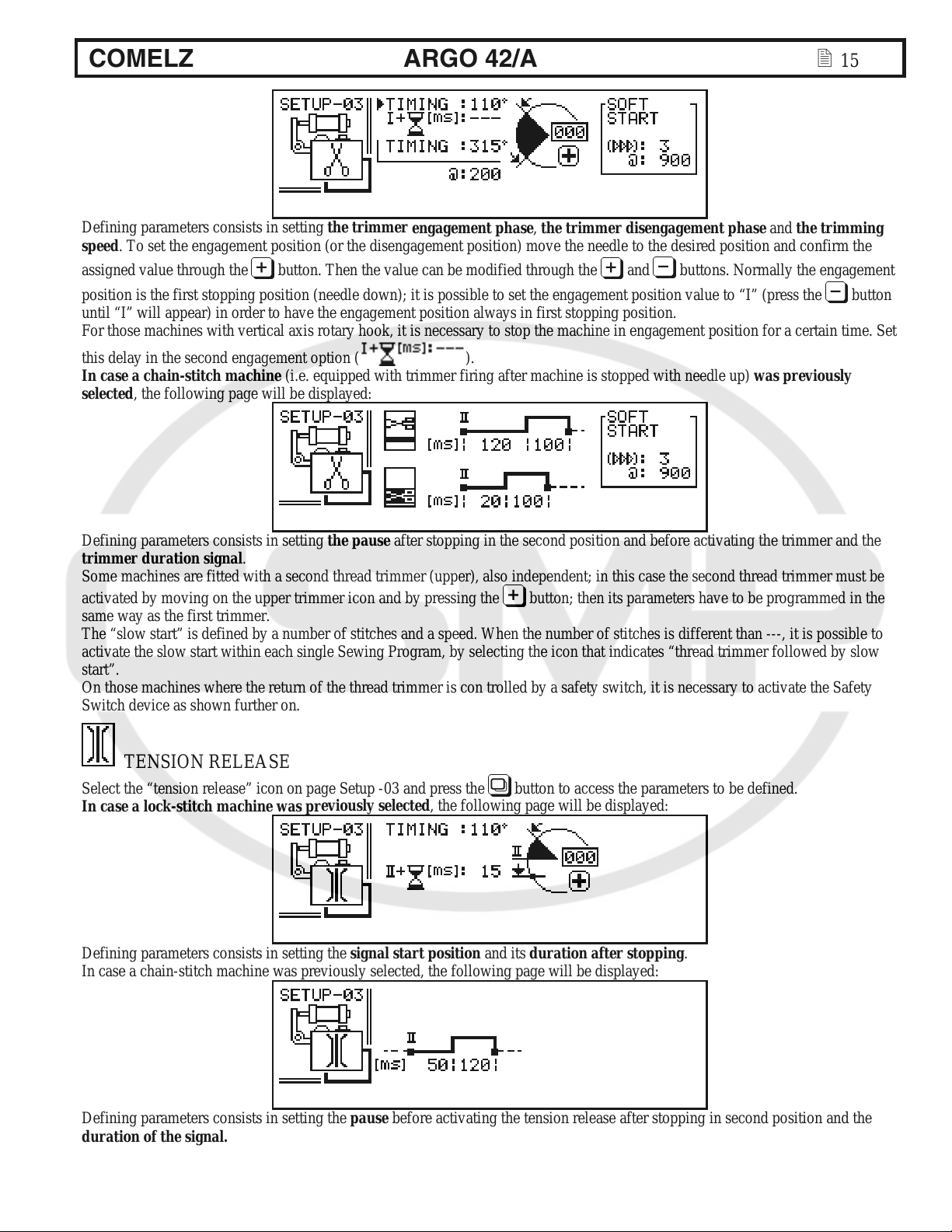

Defining parameters consists in setting the trimmer

speed. To set the engagement position (or the disengagement position) move the needle to the desired position and confirm the

assigned value through the

position is the first stopping position (needle down); it is possible to set the engagement position va lue to “I” (press the

until “I” will appear) in order to have the engagement position always in first stopping position.

For those machines with vertical axis rotary hook, it is necessary to stop t

this delay in the second engagement option (

In case a chain-stitch machine (i.e. eq

selected, the following page will be displayed:

Defining parameters consists in setting the pause after stop

trimmer duration signal.

Some machines are fitted with a second thread trimmer (upper), also

activated by moving on the upper trimmer icon and by pressing the

same way as the first trimmer.

The “slow start” is defined by a number of stitches and a speed. When the number of stitches is different than ---, it is possibl

activate the slow start within each single Sewing Program, by selecting the icon that indicates “thread trimmer followed by slow

start”.

On those machines where the return

Switch device as shown further on.

button. Then the value can be modified through the and buttons. Normally the engagement

uipped with trimmer firing after machine is stopped with needle up) was previously

of the thread trimmer is con trolled by a safety switch, it is necessary to activate the Safety

engagement phase, the trimmer disengagement phase and the trimming

he machine in engagement position for a certain time. Set

).

ping in the second position and before activating the trimmer and the

independent; in this case the second thread trimmer must be

button; then its parameters have to be programmed in the

button

e to

TENSION RELEASE

Select the “tension release” icon on page Setup -03 and press the button to access the parameters to be defined.

In case a lock-stitch machine was pr

Defining parameters consists in setting the s

In case a chain-stitch machine was previously selected, the following page will be displayed:

Defining parameters consists in setting the pause b

duration of the signal.

eviously selected, the following page will be displayed:

ignal start position and its duration after stopping.

efore activating the tension release after stopping in second position and the

COMELZ ARGO 42/A 16

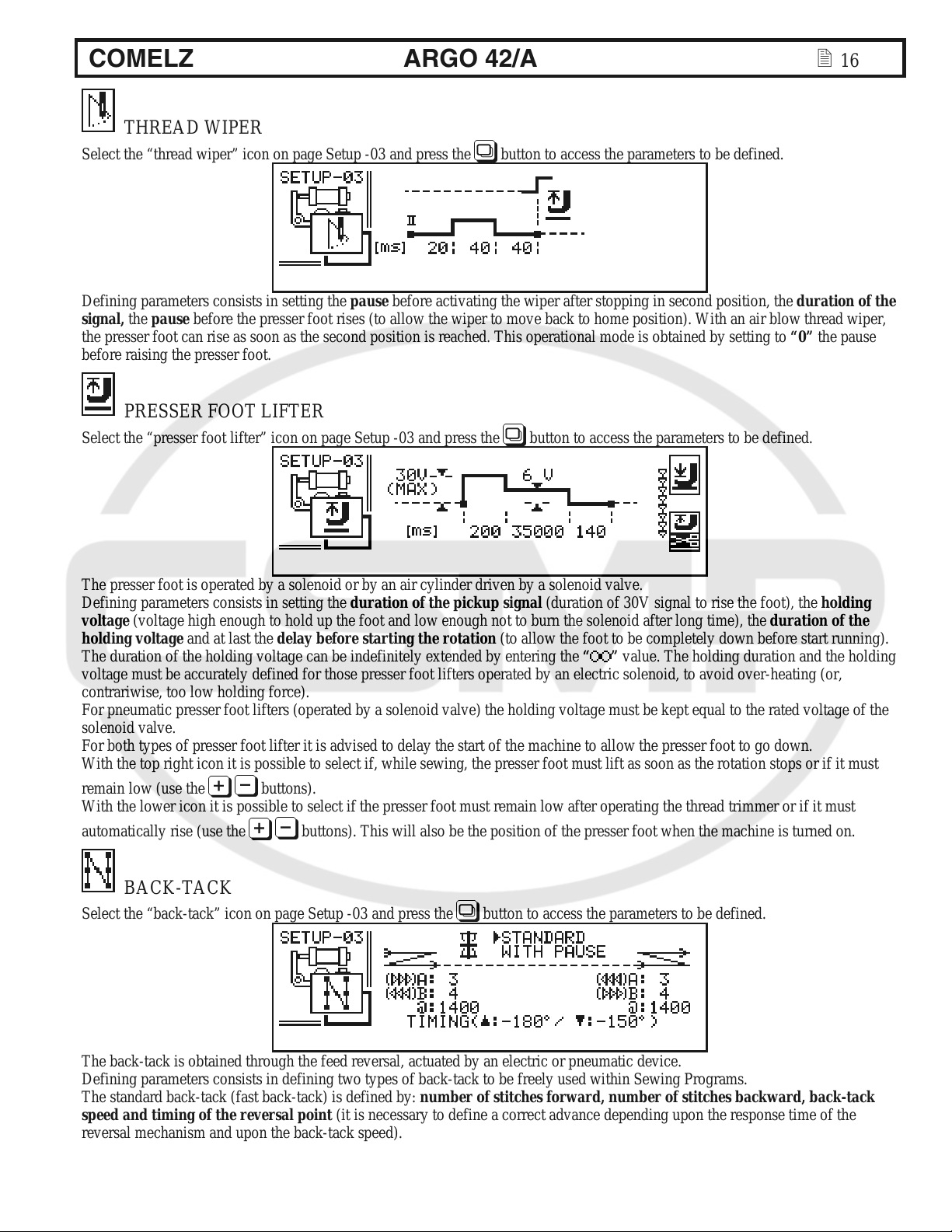

THREAD WIPER

Select the “thread wiper” icon on page Setup -03 and press the button to access the parameters to be defined.

Defining parameters consists in setting the pause b

signal, the pause before the presser foot rises (to allow the wiper to move back to home position). With an air blow thread wiper,

the presser foot can rise as soon as the second position is reached. This operational mode is obtained by setting to “0” the pause

before raising the presser foot.

efore activating the wiper after stopping in second position, the duration of the

PRESSER FOOT LIFTER

Select the “presser foot lifter” icon on page Setup -03 and press the button to access the parameters to be defined.

The presser foot is operated by a solenoid or by an air cylinder driven by a solenoid valve.

Defining parameters consists in setting the duration of th

voltage (voltage high enough to hold up the foot and low enough not to burn the solenoid after long time), the duration of the

holding voltage and at last the delay before starting the rotation (to allow the foot to be completely down before start running).

The duration of the holding voltage can be indefinitely extended by entering the “

voltage must be accurately defined for those presser foot lifters operated by an electric solenoid, to avoid over-heating (or,

contrariwise, too low holding force).

For pneumatic presser foot lifters (operated by a solenoid valve) t

solenoid valve.

For both types of presser foot lifter it is advised to delay the start of the machine to allow the presser foot to go down.

With the top right icon it is possible to select if, while sewing, th

remain low (use the

With the lower icon it is possible to select if the presser foot

automatically rise (use the

buttons).

buttons). This will also be the position of the presser foot when the machine is turned on.

e pickup signal (duration of 30V signal to rise the foot), the holding

” value. The holding duration and the holding

he holding voltage must be kept equal to the rated voltage of the

e presser foot must lift as soon as the rotation stops or if it must

must remain low after operating the thread trimmer or if it must

BACK-TACK

Select the “back-tack” icon on page Setup -03 and press the button to access the parameters to be defined.

The back-tack is obtained through the feed reversal, actuated by an electric o

Defining parameters consists in defining two types of back-tack to be freely used within Sewing Programs.

The standard back-tack (fast back-tack) is defined by : number of stitc

speed and timing of the reversal point (it is necessary to define a correct advance depending upon the response time of the

reversal mechanism and upon the back-tack speed).

r pneumatic device.

hes forward, number of stitches backward, back-tack

COMELZ ARGO 42/A 17

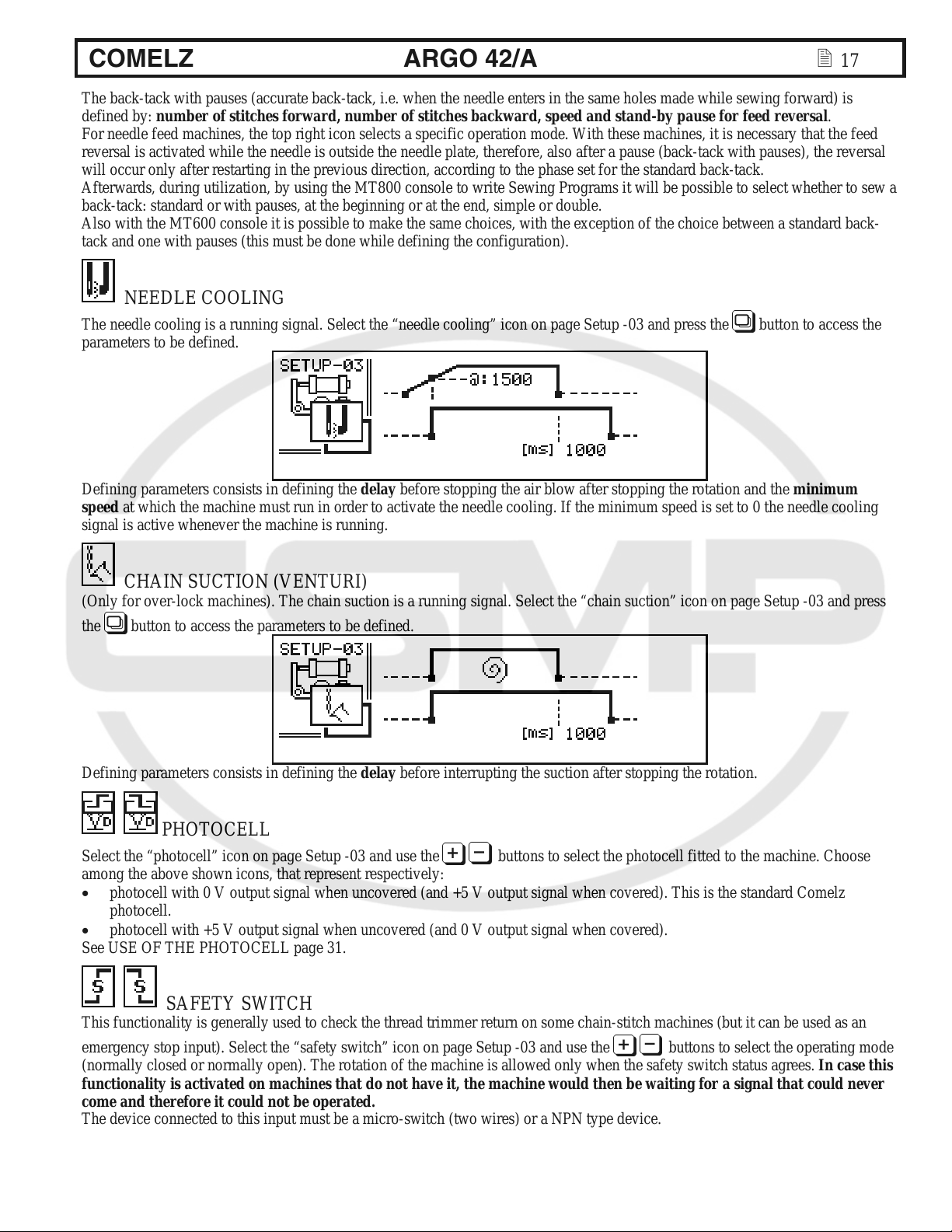

The back-tack with pauses (accurate back-tack, i.e . when the needle enters in the same holes made while sewing forward) is

defined by: number of stitches forward, number of stitches backward, speed and stand-by pause for feed reversal.

For needle feed machines, the top right icon selects a specific operati

reversal is activated while the needle is outside the needle plate, therefore, also after a pause (back-tack with pauses), the reversal

will occur only after restarting in the previous direction, according to the phase set for the standard back-tack.

Afterwards, during utilization, by using the MT800 console to write Sewi

back-tack: standard or with pauses, at the beginning or at the end, simple or double.

Also with the MT600 console it is possible to make the same choices, with the exception of the choice between a standard back-

t

ack and one with pauses (this must be done while defining the config urat ion).

NEEDLE COOLING

The needle cooling is a running signal. Select the “needle cooling” icon on page Setup -03 and press the button to access the

parameters to be defined.

on mode. With these machines, it is necessary that the feed

ng Programs it will be possible to select whether to sew a

Defining parameters consists in defining the delay

speed at which the machine must run in order to activate the needle cooling. If the minimum speed is set to 0 the needle cooling

signal is active whenever the machine is running.

before stopping the air blow after stopping the rotation and the minimum

CHAIN SUCTION (VENTURI)

(Only for over-lock machines). The chain suction is a running signal. Select the “chain suction” icon on page Setup -03 and press

button to access the parameters to be defined.

the

Defining parameters consists in defining the delay

before interrupting the suction after stopping the rotation.

PHOTOCELL

Select the “photocell” icon on page Setup -03 and use the

among the above shown icons, that represent respectively:

• ph

otocell with 0 V output signal when uncovered (and +5 V output signal when covered). This is t he standard Comelz

photocell.

• ph

otocell with +5 V output signal when unc overed (and 0 V output signal when covere d ).

See USE OF THE PHOTOCELL page 31.

buttons to select the photocell fitted to the machine. Choose

SAFETY SWITCH

This functionality is generally used to check the thread trimmer return on some chain-stitch machines (but it can be used as an

emergency stop input). Select the “safety switch” icon on page Setup -03 and use the

(normally closed or normally open). The rotation of the machine is allowed only when the safety switch status agrees. In case this

functionality is activated on machines that do not have it, the machine would then be waiting for a signal that could never

come and therefore it could not be operated.

The device connected to this input must be a m

icro-switch (two wires) or a NPN type device.

buttons to select the operating mode

Loading...

Loading...