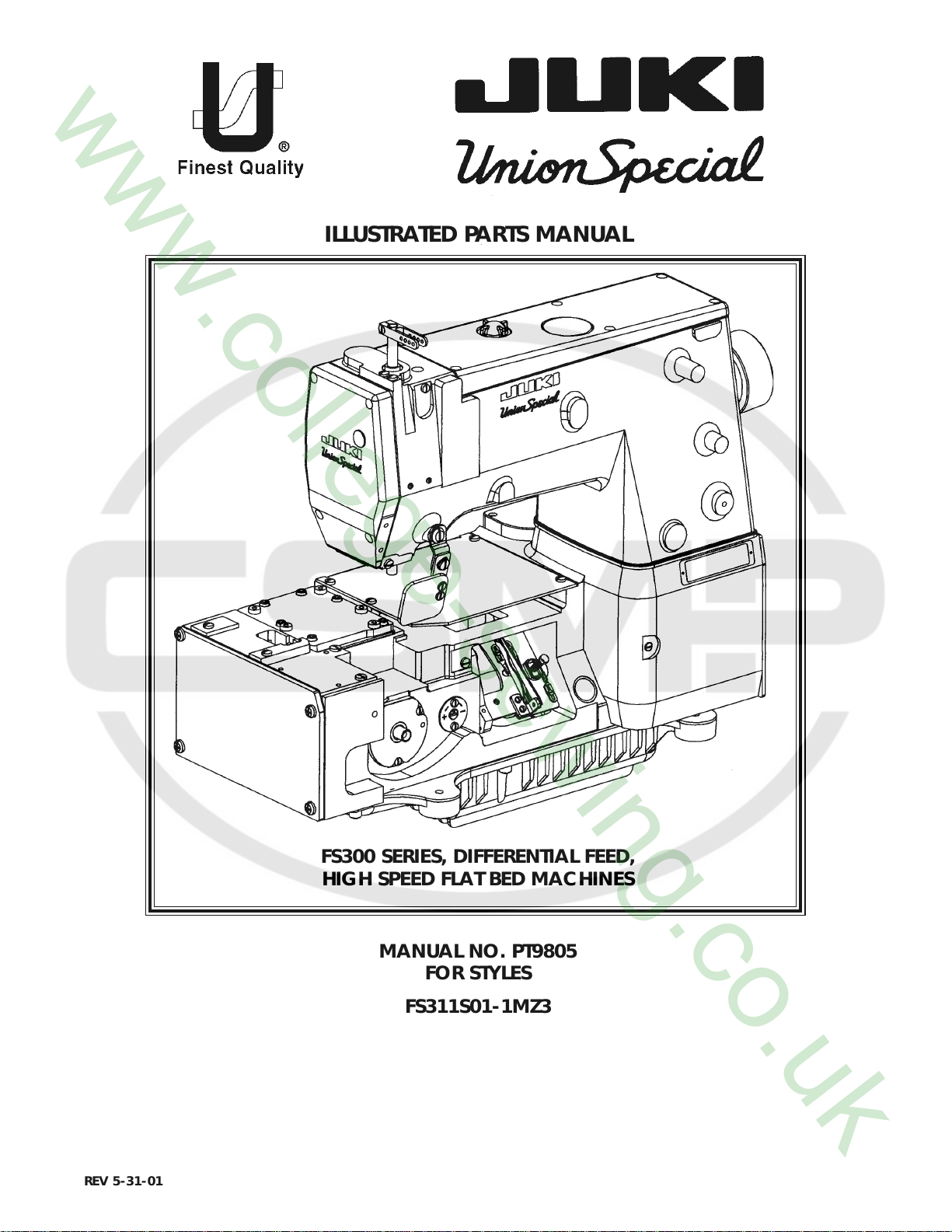

Union Special PT9805 Parts Book

ILLUSTRATED PARTS MANUAL

REV 5-31-01

FS300 SERIES, DIFFERENTIAL FEED,

HIGH SPEED FLAT BED MACHINES

MANUAL NO. PT9805

FOR STYLES

FS311S01-1MZ3

Manual No. PT9805 llustrated Parts List for FS300 Series Machines

Second Edition Copyright 2001

By

Union Special Corporation Rights Reserved In All Countries

This parts manual has been prepared to assist you in locating individual parts or assemblies on FS300 Series machines. It

can be used in conjunction with Union Special Engineer's Manual EN9424.

It is the desire of Union Special that each machine run at its optimum performance. Parts listed in this manual are

designed specifically for your machine and are manufactured with utmost precision to assure long lasting service.

This manual has been comprised on the basis of available information. Changes in design and/or improvements may

incorporate a slight modification of configuration in illustrations or part numbers.

On the following pages are illustrations and terminology used in describing the parts used on FS300 Series machines.

Printed in U.S.A. May 2001

PREFACE

2

CONTENTS

PREFACE ................................................................................................................................................................... 2

SAFETY RULES ............................................................................................................................................................ 4

SAFETY LABLES .......................................................................................................................................................... 5

BUSHINGS.................................................................................................................................................................. 7

NEEDLE BAR .............................................................................................................................................................. 9

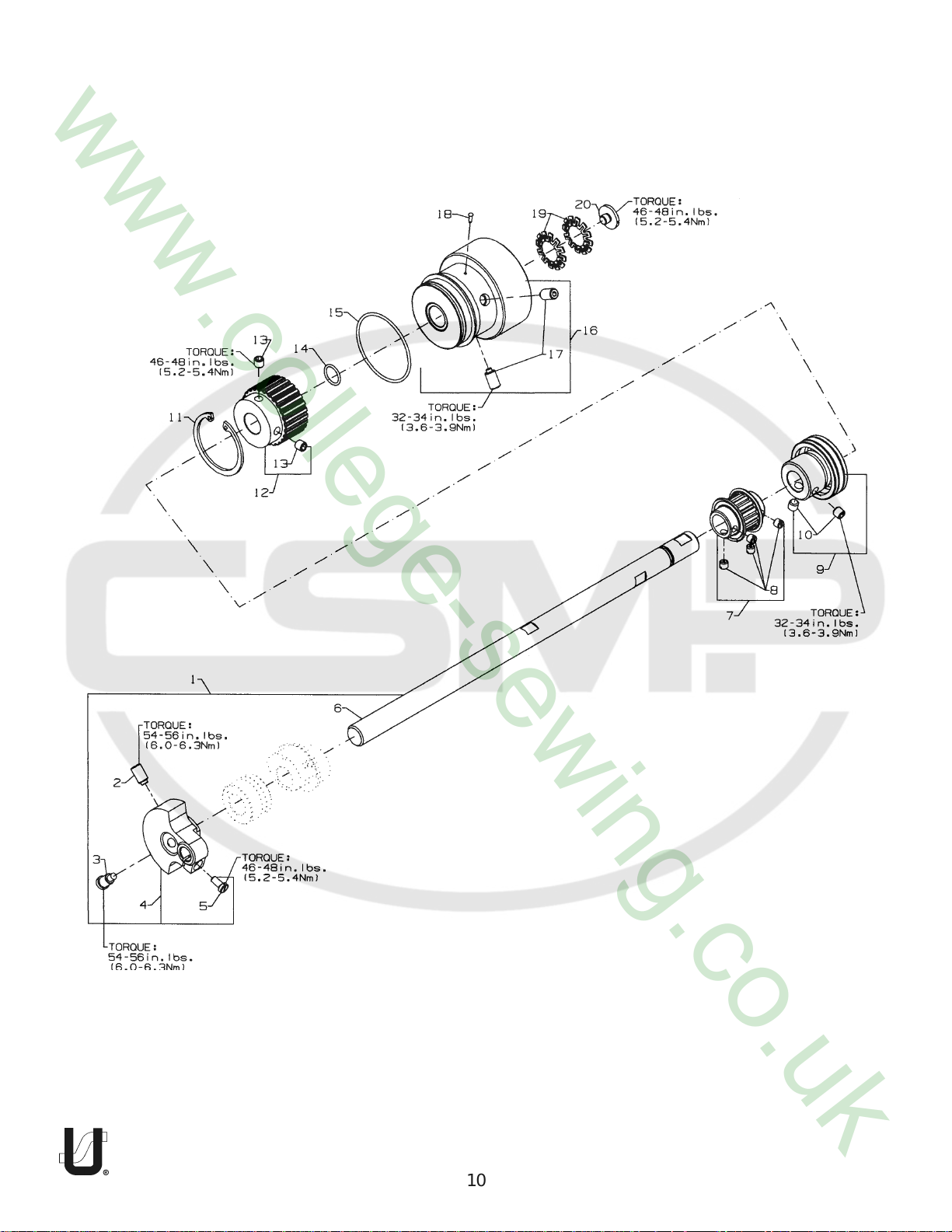

UPPER MAIN SHAFT ................................................................................................................................................ 11

COVERS, UPPER ARM ........................................................................................................................................... 13

LOWER MAIN SHAFT............................................................................................................................................... 15

LUBRICATION, OIL TUBING & OIL PUMP ............................................................................................................... 17

LOOPER DRIVE........................................................................................................................................................ 19

NEEDLE GUARD ...................................................................................................................................................... 21

LOOPER THREAD TAKE-UP ..................................................................................................................................... 23

COVERS, LOWER BED ............................................................................................................................................ 25

PULLER DRIVE ASSEMBLY ....................................................................................................................................... 27

ACCESSORIES ......................................................................................................................................................... 29

NUMERICAL INDEX OF PARTS................................................................................................................................ 30

NOTES ...................................................................................................................................................................... 31

NOTES ...................................................................................................................................................................... 32

NOTES ...................................................................................................................................................................... 33

3

SAFETY RULES

1. Before putting the machines described in this manual into service, carefully read the instructions. The

starting of each machine is only permitted after taking notice of the instructions and by qualified

operators.

IMPORTANT! Before putting the machine into service, also read the safety rules and instructions from the

motor supplier.

2. Observe the national safety rules valid for your country.

3. The sewing machines described in this instruction manual are prohibited from being put into service until

it has been ascertained that the sewing units which these sewing machines will be built into, have

conformed with the EC Council Directives (89/392/EEC, Annex II B).

Each machine is only allowed to be used as foreseen. The foreseen use of the particular machine is

described in paragraph “STYLES OF MACHINES” of this instruction manual. Another use, going beyond

the description, is not as foreseen.

4. All safety devices must be in position when the machine is ready for work or in operation. Operation

of the machine without the appertaining safety devices is prohibited.

5. Wear safety glasses.

6. In case of machine conversions and changes all valid safety rules must be considered. Conversions

and changes are made at your own risk.

7. The warning hints in the instructions are marked with one of these two symbols:

8. When doing the following the machine has to be disconnected from the power supply by turning off

the main switch or by pulling out the main plug:

8.1 When threading needle(s), looper, spreader etc.

8.2 When replacing any parts such as needle(s), presser foot, throat plate, looper, spreader, feed

dog, needle guard, folder, fabric guide etc.

8.3 When leaving the workplace and when the workplace is unattended.

8.4 When doing maintenance work.

8.5 When using clutch motors without actuation lock, wait until the motor is stopped totally.

9. Maintenance, repair and conversion work (see item 8) must be done only by trained technicians or

special skilled personnel under consideration of the instructions.

10. Any work on the electrical equipment must be done by an electrician or under direction and supervision

of special skilled personnel.

11. Work on parts and equipment under electrical power is not permitted. Permissible exceptions are

described in the applicable sections of standard sheet DIN VDE 0105.

12. Before doing maintenance and repair work on the pneumatic equipment, the machine has to be

disconnected from the compressed air supply. In case of existing residual air pressure, after disconnect-

ing from compressed air supply (i.e. pneumatic equipment with air tank), the pressure has to be

removed by bleeding.

4

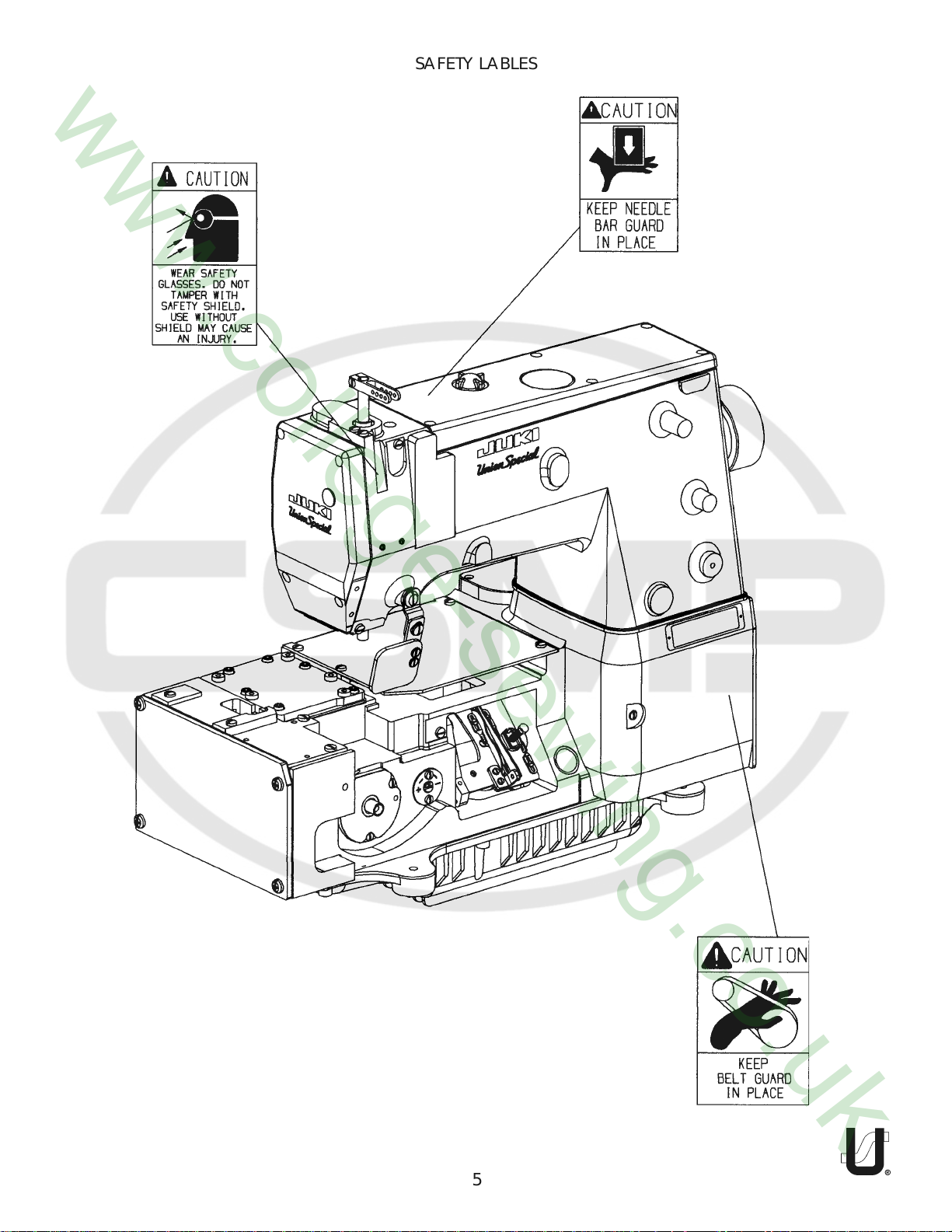

SAFETY LABLES

5

6

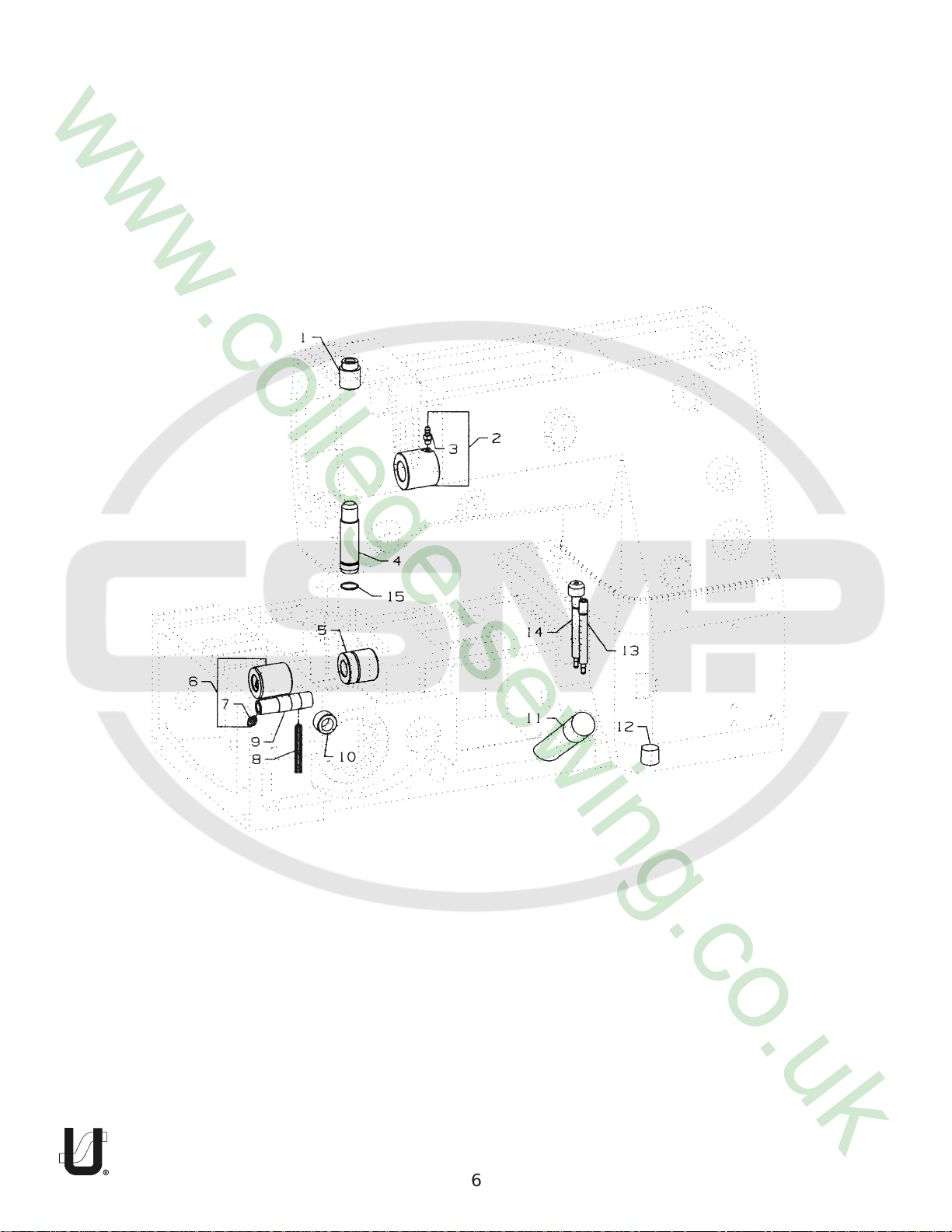

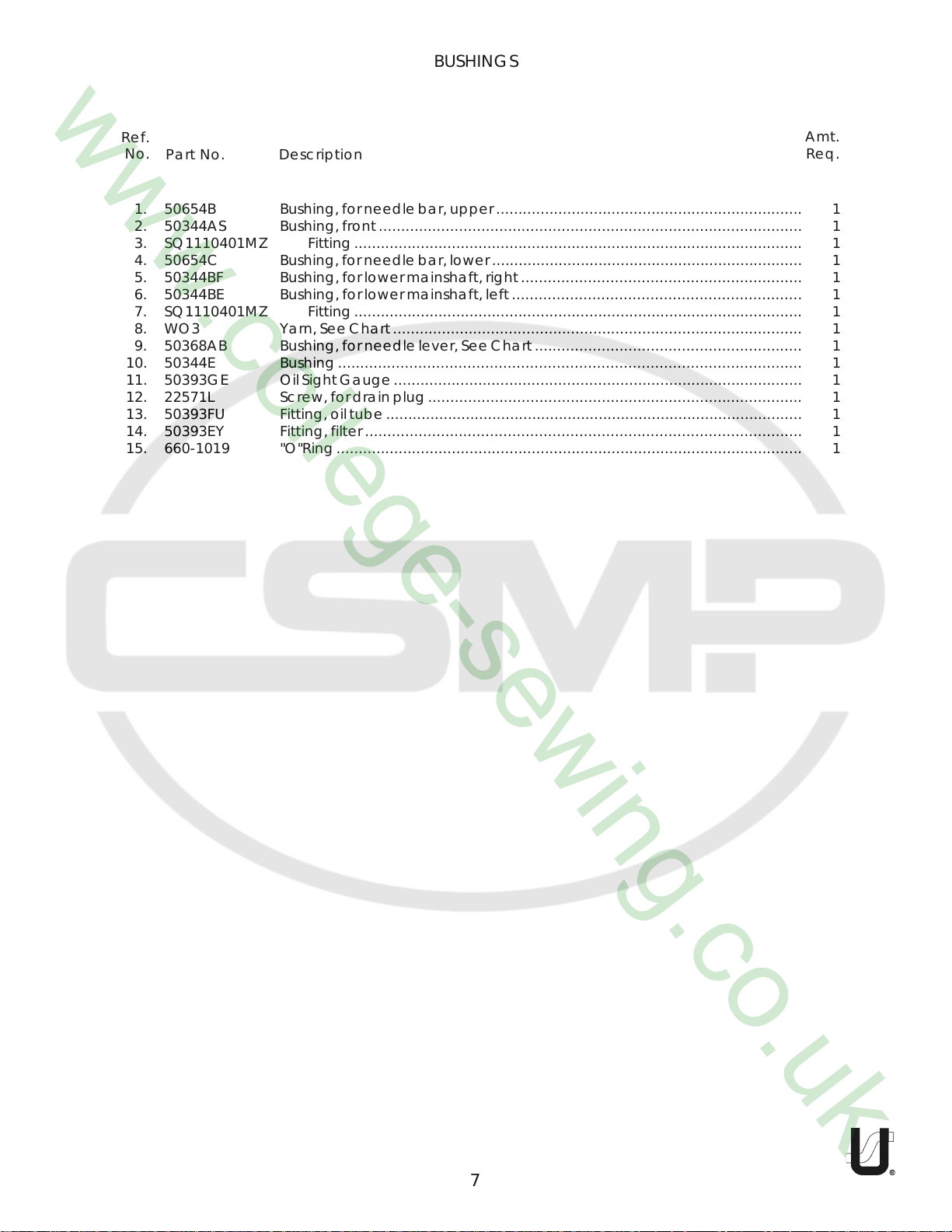

BUSHINGS

Ref.

No.

Part No.

Description

Amt.

Req.

1.

50654B

2.

50344AS

3.

SQ1110401MZ

4.

50654C

5.

50344BF

6.

50344BE

7.

SQ1110401MZ

8.

WO3

9.

50368AB

10.

50344E

11.

50393GE

12.

22571L

13.

50393FU

14.

50393EY

15.

660-1019

Bushing, for needle bar, upper .....................................................................

Bushing, front ...............................................................................................

Fitting .....................................................................................................

Bushing, for needle bar, lower ......................................................................

Bushing, for lower mainshaft, right ...............................................................

Bushing, for lower mainshaft, left .................................................................

Fitting .....................................................................................................

Yarn, See Chart ............................................................................................

Bushing, for needle lever, See Chart ............................................................

Bushing ........................................................................................................

Oil Sight Gauge ............................................................................................

Screw, for drain plug ....................................................................................

Fitting, oil tube ..............................................................................................

Fitting, filter ..................................................................................................

"O"Ring .........................................................................................................

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

7

8

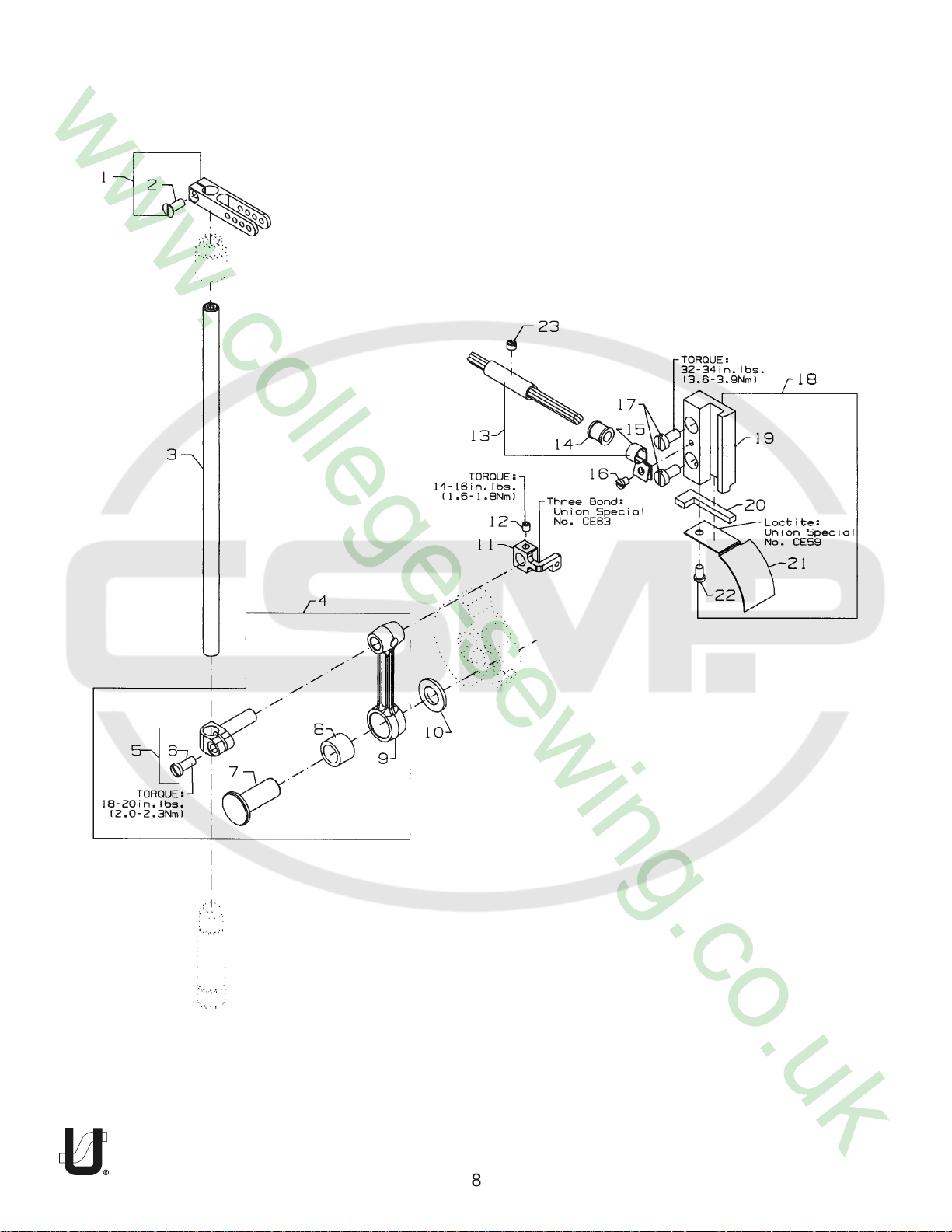

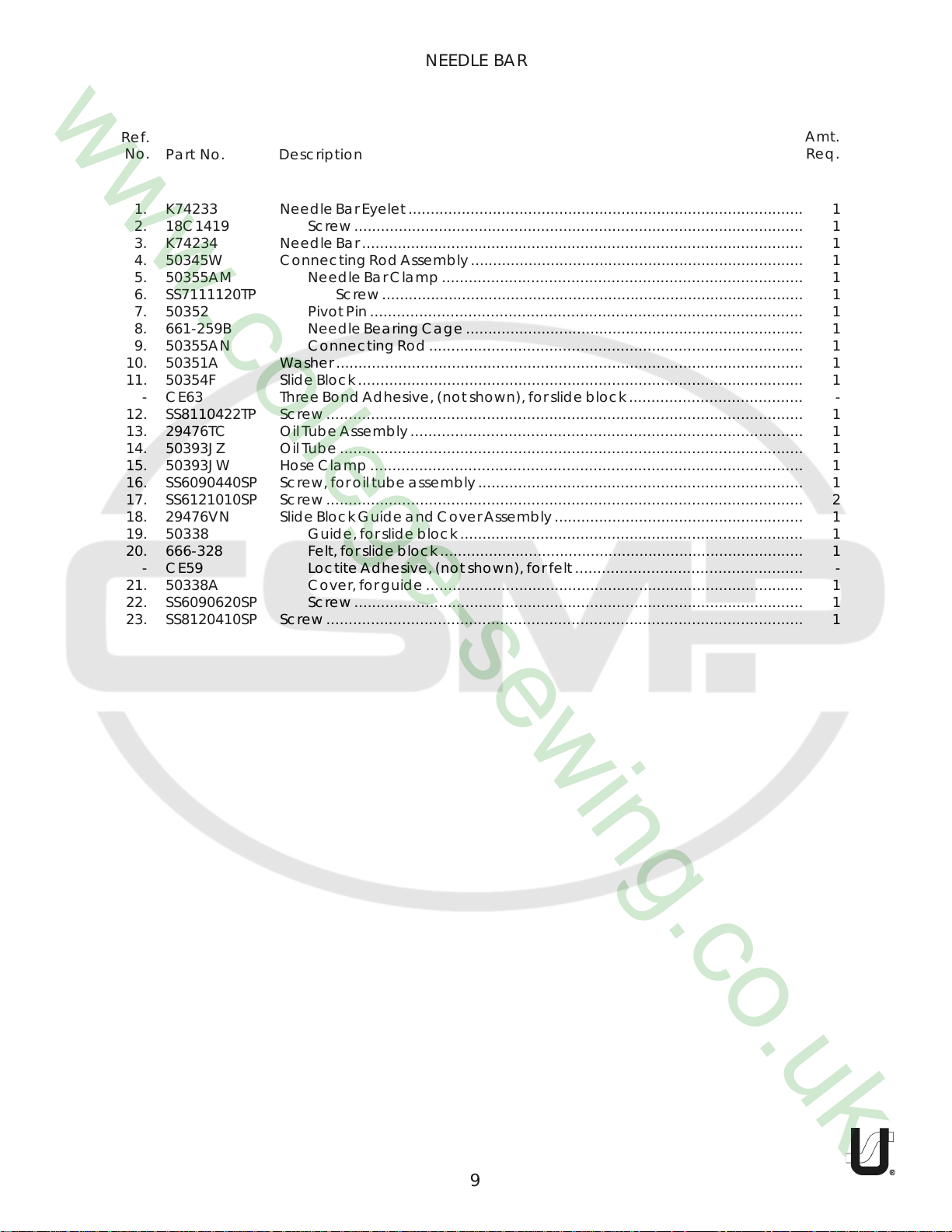

NEEDLE BAR

Ref.

No.

Part No.

Description

Amt.

Req.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

-

12.

13.

14.

15.

16.

17.

18.

19.

20.

-

21.

22.

23.

K74233

18C1419

K74234

50345W

50355AM

SS7111120TP

50352

661-259B

50355AN

50351A

50354F

CE63

SS8110422TP

29476TC

50393JZ

50393JW

SS6090440SP

SS6121010SP

29476VN

50338

666-328

CE59

50338A

SS6090620SP

SS8120410SP

Needle Bar Eyelet .........................................................................................

Screw .....................................................................................................

Needle Bar ...................................................................................................

Connecting Rod Assembly ...........................................................................

Needle Bar Clamp .................................................................................

Screw ...............................................................................................

Pivot Pin .................................................................................................

Needle Bearing Cage ............................................................................

Connecting Rod ....................................................................................

Washer .........................................................................................................

Slide Block ....................................................................................................

Three Bond Adhesive, (not shown), for slide block .......................................

Screw ...........................................................................................................

Oil Tube Assembly ........................................................................................

Oil Tube ........................................................................................................

Hose Clamp .................................................................................................

Screw, for oil tube assembly .........................................................................

Screw ...........................................................................................................

Slide Block Guide and Cover Assembly ........................................................

Guide, for slide block .............................................................................

Felt, for slide block ..................................................................................

Loctite Adhesive, (not shown), for felt ...................................................

Cover, for guide .....................................................................................

Screw .....................................................................................................

Screw ...........................................................................................................

1

1

1

1

1

1

1

1

1

1

1

-

1

1

1

1

1

2

1

1

1

-

1

1

1

9

10

Loading...

Loading...