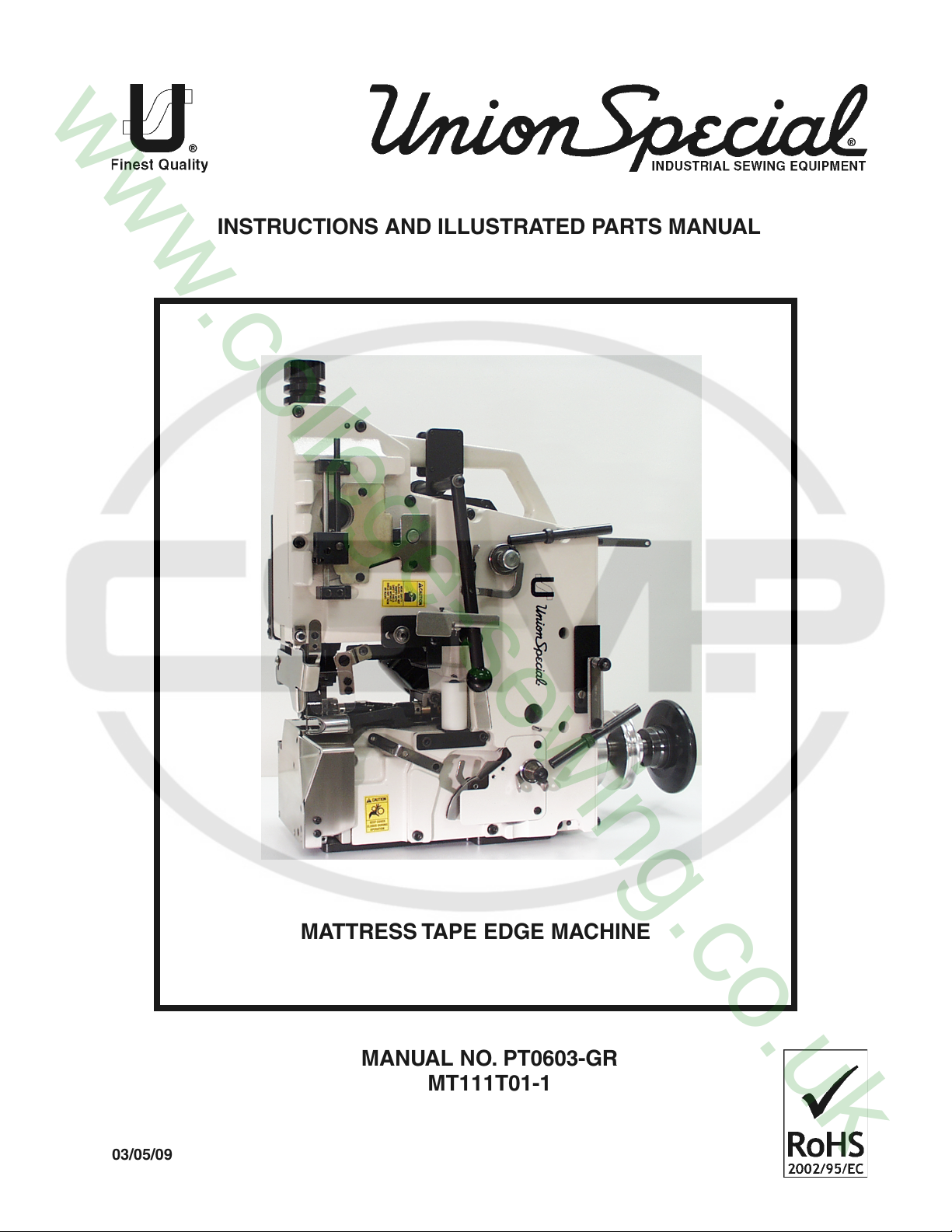

INSTRUCTIONS AND ILLUSTRATED PARTS MANUAL

03/05/09

MATTRESS TAPE EDGE MACHINE

MANUAL NO. PT0603-GR

MT111T01-1

MANUAL NO. PT0603-GR INSTRUCTIONS and ILLUSTRATED PARTS MANUAL for

MT111 SERIES MACHINES

First Edition Copyright 2007

Union Special Machine Company

Rights Reserved in All Countries

This manual has been prepared to simplify ordering spare parts.

Views of various sections of the mechanism are shown so that the parts may be seen in their actual position

in the sewing machine. On the page opposite the illustration will be found a listing of parts with their part

numbers, descriptions and the number of pieces required in the particular view being shown.

Numbers in the first column are reference numbers only, and merely indicate the position of that part in the

illustrations. Reference numbers should never be used in ordering parts. Always use the part number listed in

the second column.

Component parts of subassemblies which can be furnished for repairs are indicated by indenting their

description of the main subassembly.

This manual has been comprised on the basis of available information. Changes in design

and / or improvements may incorporate a slight modification of configuration in illustrations or cautions.

by

PREFACE

On the following pages will be found illustrations and terminology used in describing the parts for your machine.

IMPORTANT: ON ALL ORDERS, PLEASE INCLUDE PART NUMBER, PART NAME AND STYLE OF

MACHINE FOR WHICH PART IS ORDERED.

2

CONTENTS

PREFACE.................................................................................................................................................. 2

SAFETY RULES .......................................................................................................................................... 4

CAUTION AREAS ..................................................................................................................................... 5

IDENTIFICATION OF MACHINES ............................................................................................................. 6

STYLES OF MACHINES ............................................................................................................................. 6

NEEDLES................................................................................................................................................... 6

NEEDLE ORDERING................................................................................................................................. 6

TORQUE REQUIREMENTS ........................................................................................................................ 6

THREADING THE MACHINE .................................................................................................................... 7

INSERTING NEEDLE ................................................................................................................................. 8

STITCH FORMATION ................................................................................................................................ 8

TROUBLE SHOOTING .............................................................................................................................. 8

ADJUSTING THE STITCH LENGTH ............................................................................................................ 9

LUBRICATION ........................................................................................................................................ 10

OIL SPECIFICATION REQUIREMENTS .................................................................................................... 10

OIL FLOW DIAGRAM ............................................................................................................................ 12

NEEDLE / LOOPER SYNCHRONIZATION .............................................................................................. 14

UPPER ROLLER DRIVE PLATE ASSEMBLY .............................................................................................. 15

LOWER ROLLER SETTING....................................................................................................................... 16

UPPER ROLLER AND PRESSER FOOT SETTING ...................................................................................... 16

PRESSER FOOT PRESSURE ..................................................................................................................... 16

NEEDLE BAR SETTING ............................................................................................................................ 17

LOOPER SETTING................................................................................................................................... 17

NEEDLE GUARD SETTING ...................................................................................................................... 18

NEEDLE THREAD CONTROL.................................................................................................................. 18

LOOPER THREAD CONTROL ................................................................................................................ 19

BUSHINGS .............................................................................................................................................. 21

NEEDLE BAR DRIVE ............................................................................................................................... 23

UPPER MAIN SHAFT ............................................................................................................................... 25

CRANKSHAFT ASSEMBLY ...................................................................................................................... 27

LOOPER DRIVE AND NEEDLE GUARD DRIVE ...................................................................................... 29

DRIVE PARTS AND THROAT PLATE SUPPORTS ..................................................................................... 31

PRESSER FOOT LIFT ................................................................................................................................ 33

OIL PUMP............................................................................................................................................... 35

OIL TUBES ............................................................................................................................................... 37

OIL DISTRIBUTOR ASSEMBLY ................................................................................................................. 39

NEEDLE THREAD CONTROL.................................................................................................................. 41

LOOPER THREAD CONTROL ................................................................................................................ 43

FRONT AND LOOPER COVERS ............................................................................................................ 45

COVERS................................................................................................................................................. 47

BACK AND RIGHT COVERS .................................................................................................................. 49

SEWING PARTS ...................................................................................................................................... 51

ACCESSORIES ....................................................................................................................................... 53

NUMERICAL INDEX OF PARTS .............................................................................................................. 60

NUMERICAL INDEX OF PARTS .............................................................................................................. 61

3

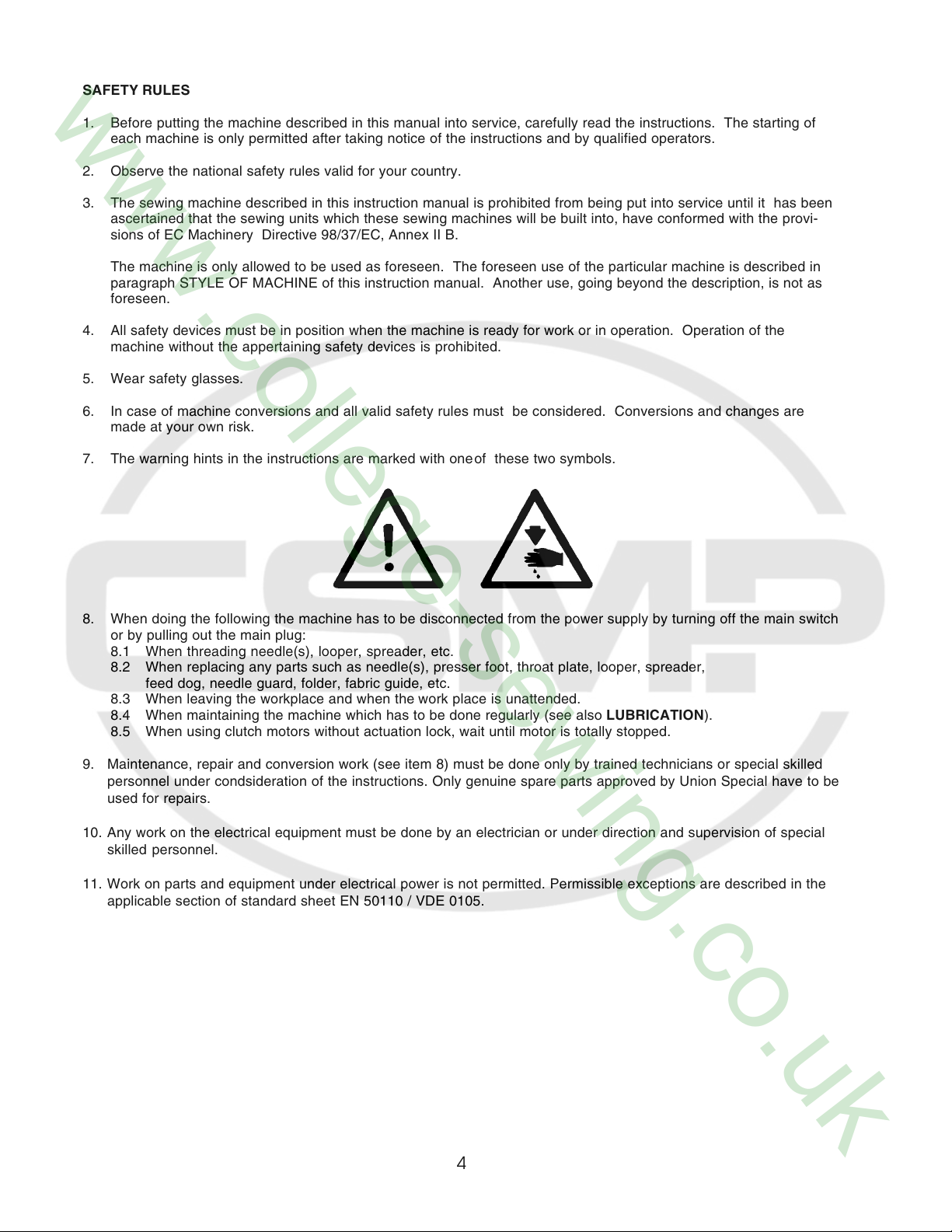

SAFETY RULES

1. Before putting the machine described in this manual into service, carefully read the instructions. The starting of

each machine is only permitted after taking notice of the instructions and by qualified operators.

2. Observe the national safety rules valid for your country.

3. The sewing machine described in this instruction manual is prohibited from being put into service until it has been

ascertained that the sewing units which these sewing machines will be built into, have conformed with the provi-

sions of EC Machinery Directive 98/37/EC, Annex II B.

The machine is only allowed to be used as foreseen. The foreseen use of the particular machine is described in

paragraph STYLE OF MACHINE of this instruction manual. Another use, going beyond the description, is not as

foreseen.

4. All safety devices must be in position when the machine is ready for work or in operation. Operation of the

machine without the appertaining safety devices is prohibited.

5. Wear safety glasses.

6. In case of machine conversions and all valid safety rules must be considered. Conversions and changes are

made at your own risk.

7. The warning hints in the instructions are marked with oneof these two symbols.

8. When doing the following the machine has to be disconnected from the power supply by turning off the main switch

or by pulling out the main plug:

8.1 When threading needle(s), looper, spreader, etc.

8.2 When replacing any parts such as needle(s), presser foot, throat plate, looper, spreader,

feed dog, needle guard, folder, fabric guide, etc.

8.3 When leaving the workplace and when the work place is unattended.

8.4 When maintaining the machine which has to be done regularly (see also LUBRICATION).

8.5 When using clutch motors without actuation lock, wait until motor is totally stopped.

9. Maintenance, repair and conversion work (see item 8) must be done only by trained technicians or special skilled

personnel under condsideration of the instructions. Only genuine spare parts approved by Union Special have to be

used for repairs.

10. Any work on the electrical equipment must be done by an electrician or under direction and supervision of special

skilled personnel.

11. Work on parts and equipment under electrical power is not permitted. Permissible exceptions are described in the

applicable section of standard sheet EN 50110 / VDE 0105.

4

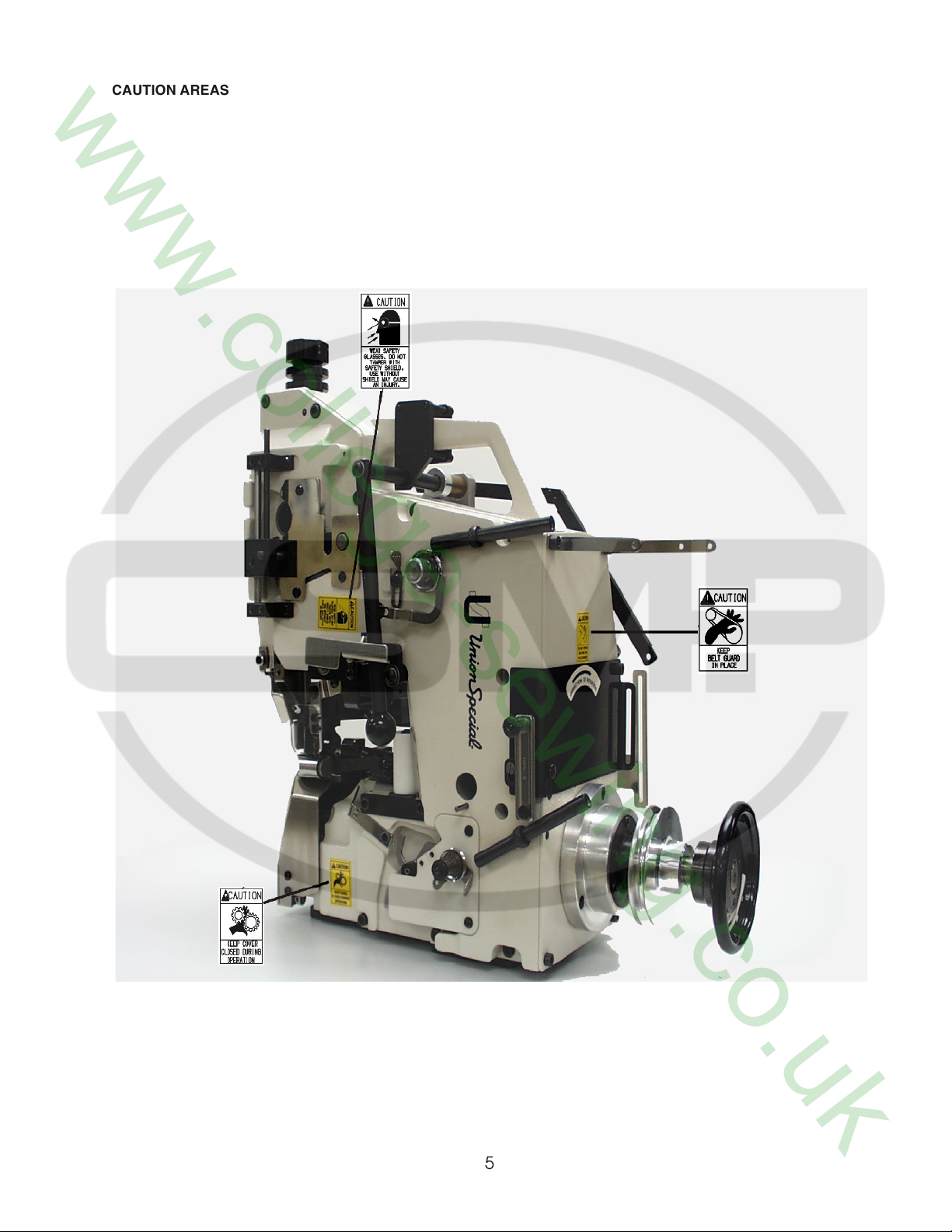

CAUTION AREAS

5

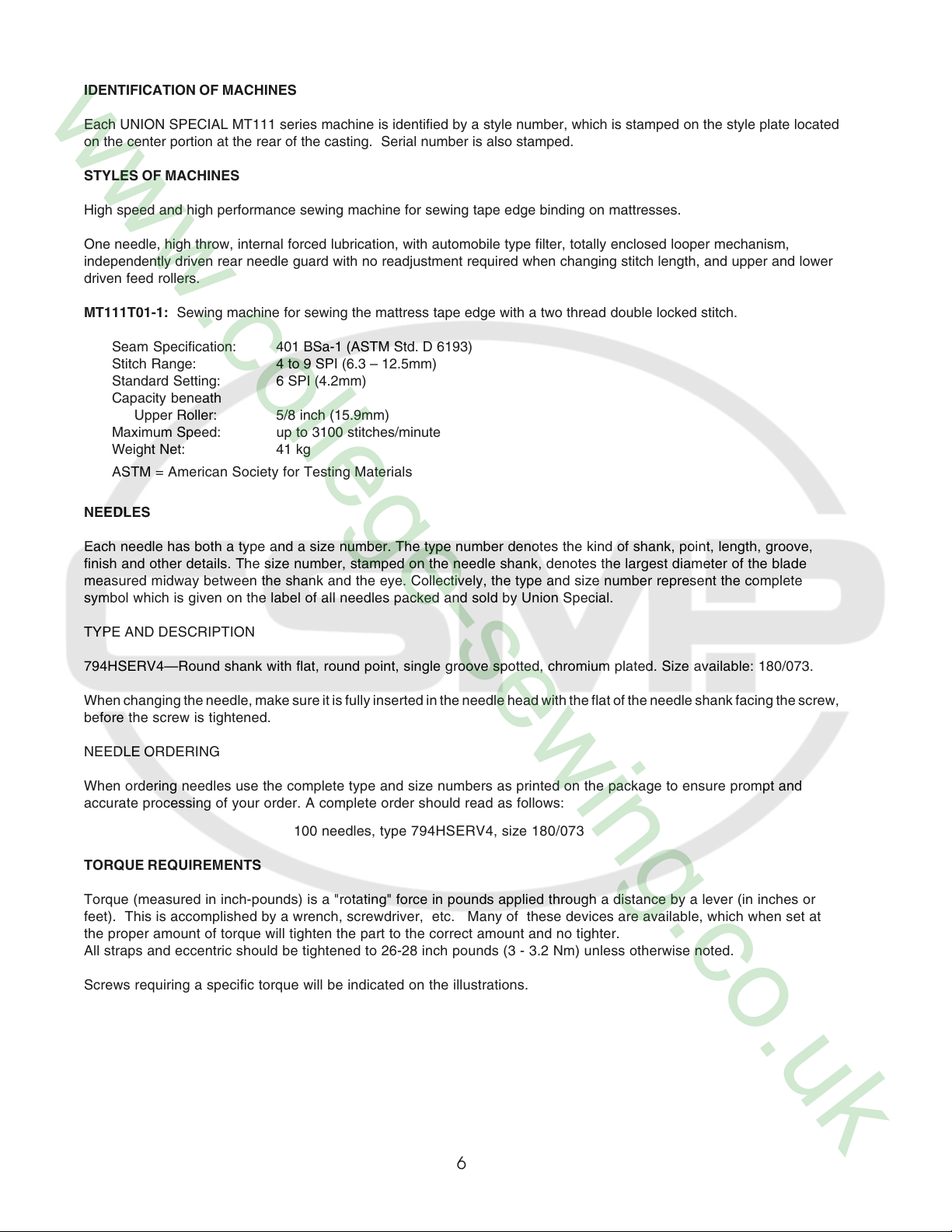

IDENTIFICATION OF MACHINES

Each UNION SPECIAL MT111 series machine is identified by a style number, which is stamped on the style plate located

on the center portion at the rear of the casting. Serial number is also stamped.

STYLES OF MACHINES

High speed and high performance sewing machine for sewing tape edge binding on mattresses.

One needle, high throw, internal forced lubrication, with automobile type filter, totally enclosed looper mechanism,

independently driven rear needle guard with no readjustment required when changing stitch length, and upper and lower

driven feed rollers.

MT111T01-1: Sewing machine for sewing the mattress tape edge with a two thread double locked stitch.

Seam Specification: 401 BSa-1 (ASTM Std. D 6193)

Stitch Range: 4 to 9 SPI (6.3 – 12.5mm)

Standard Setting: 6 SPI (4.2mm)

Capacity beneath

Upper Roller: 5/8 inch (15.9mm)

Maximum Speed: up to 3100 stitches/minute

Weight Net: 41 kg

ASTM = American Society for Testing Materials

NEEDLES

Each needle has both a type and a size number. The type number denotes the kind of shank, point, length, groove,

finish and other details. The size number, stamped on the needle shank, denotes the largest diameter of the blade

measured midway between the shank and the eye. Collectively, the type and size number represent the complete

symbol which is given on the label of all needles packed and sold by Union Special.

TYPE AND DESCRIPTION

794HSERV4—Round shank with flat, round point, single groove spotted, chromium plated. Size available: 180/073.

When changing the needle, make sure it is fully inserted in the needle head with the flat of the needle shank facing the screw,

before the screw is tightened.

NEEDLE ORDERING

When ordering needles use the complete type and size numbers as printed on the package to ensure prompt and

accurate processing of your order. A complete order should read as follows:

100 needles, type 794HSERV4, size 180/073

TORQUE REQUIREMENTS

Torque (measured in inch-pounds) is a "rotating" force in pounds applied through a distance by a lever (in inches or

feet). This is accomplished by a wrench, screwdriver, etc. Many of these devices are available, which when set at

the proper amount of torque will tighten the part to the correct amount and no tighter.

All straps and eccentric should be tightened to 26-28 inch pounds (3 - 3.2 Nm) unless otherwise noted.

Screws requiring a specific torque will be indicated on the illustrations.

6

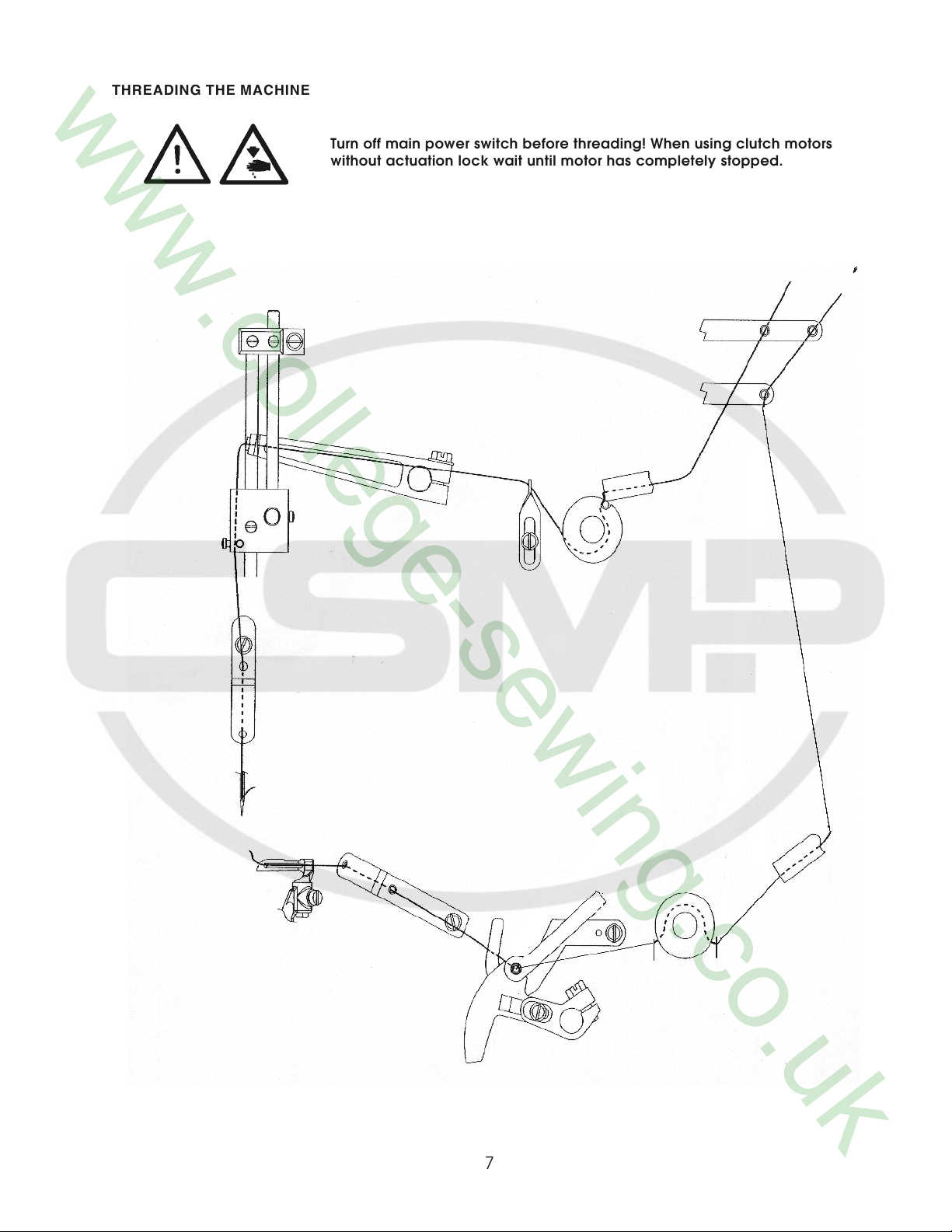

THREADING THE MACHINE

Turn off main power switch before threading! When using clutch motors

without actuation lock wait until motor has completely stopped.

7

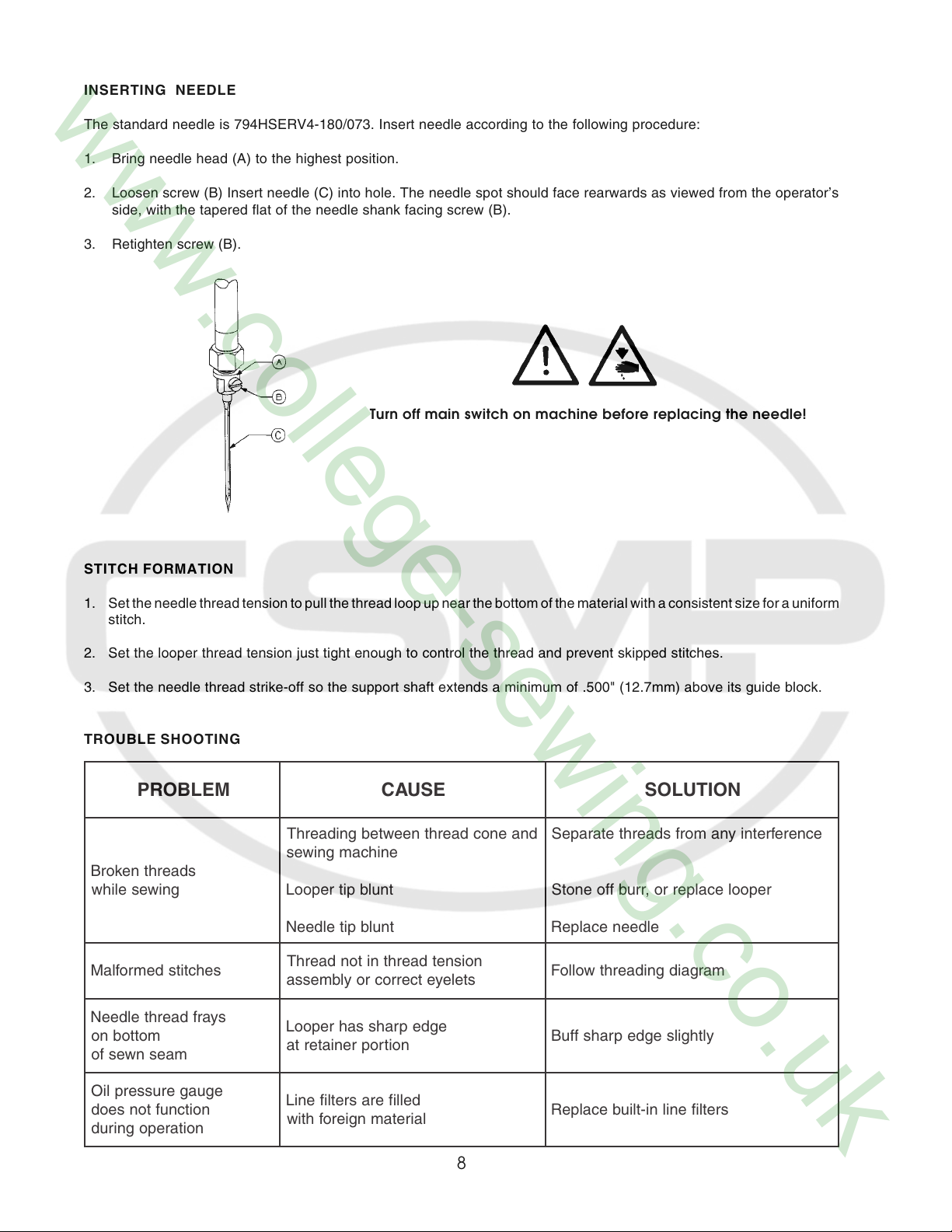

INSERTING NEEDLE

The standard needle is 794HSERV4-180/073. Insert needle according to the following procedure:

1. Bring needle head (A) to the highest position.

2. Loosen screw (B) Insert needle (C) into hole. The needle spot should face rearwards as viewed from the operator’s

side, with the tapered flat of the needle shank facing screw (B).

3. Retighten screw (B).

Turn off main switch on machine before replacing the needle!

STITCH FORMATION

1. Set the needle thread tension to pull the thread loop up near the bottom of the material with a consistent size for a uniform

stitch.

2. Set the looper thread tension just tight enough to control the thread and prevent skipped stitches.

3. Set the needle thread strike-off so the support shaft extends a minimum of .500" (12.7mm) above its guide block.

TROUBLE SHOOTING

MELBORPESUACNOITULOS

dnaenocdaerhtneewtebgnidaerhT

enihcamgniwes

sdaerhtnekorB

gniweselihw

sehctitsdemroflaM

syarfdaerhteldeeN

mottobno

maesnwesfo

eguagerusserpliO

noitcnuftonseod

noitarepognirud

tnulbpitrepooL

tnulbpiteldeeN

noisnetdaerhtnitondaerhT

steleyetcerrocroylbmessa

egdeprahssahrepooL

noitropreniaterta

delliferasretlifeniL

lairetamngierofhtiw

eldeenecalpeR

margaidgnidaerhtwolloF

ylthgilsegdeprahsffuB

repoolecalperro,rrubffoenotS

sretlifenilni-tliubecalpeR

ecnerefretniynamorfsdaerhtetarapeS

8

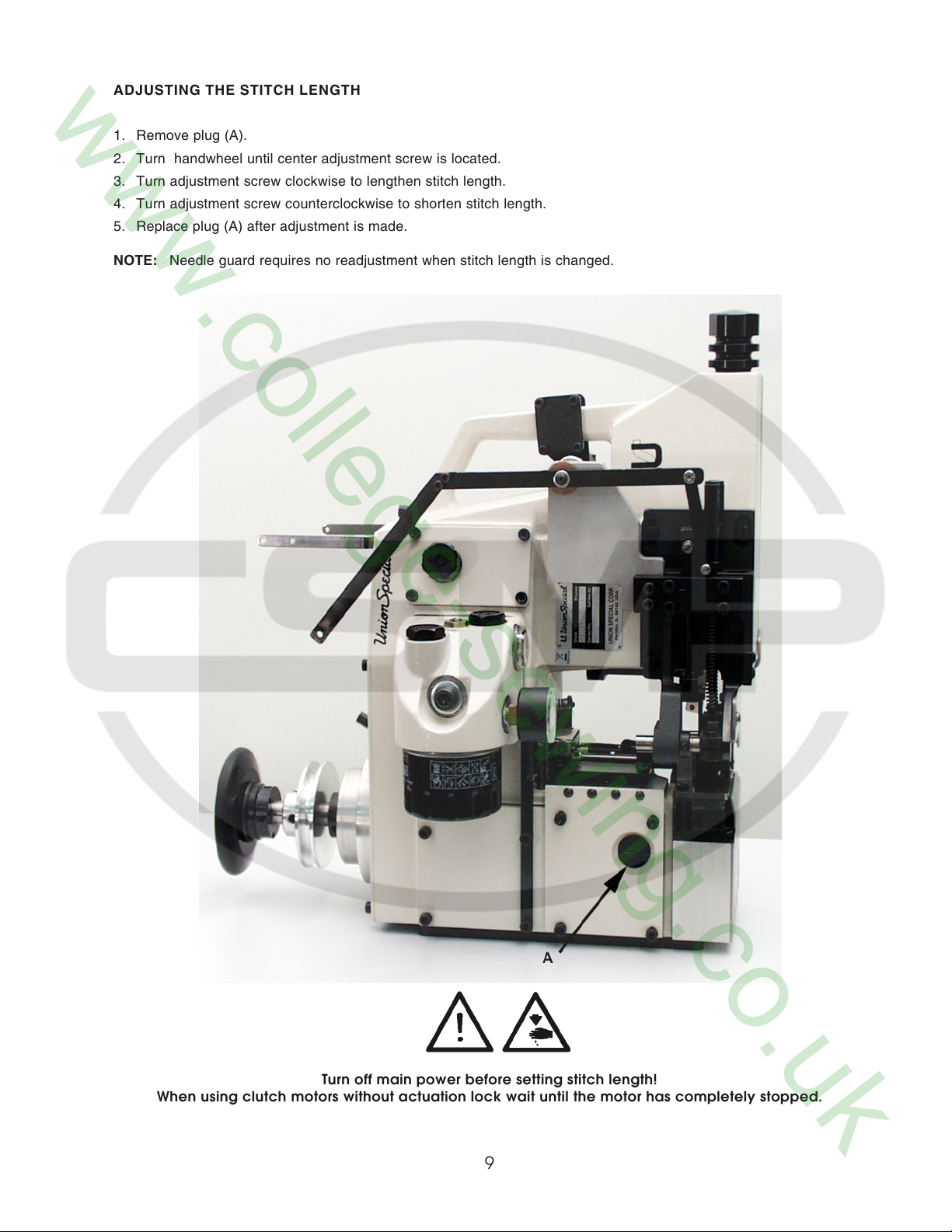

ADJUSTING THE STITCH LENGTH

1. Remove plug (A).

2. Turn handwheel until center adjustment screw is located.

3. Turn adjustment screw clockwise to lengthen stitch length.

4. Turn adjustment screw counterclockwise to shorten stitch length.

5. Replace plug (A) after adjustment is made.

NOTE: Needle guard requires no readjustment when stitch length is changed.

Turn off main power before setting stitch length!

When using clutch motors without actuation lock wait until the motor has completely stopped.

9

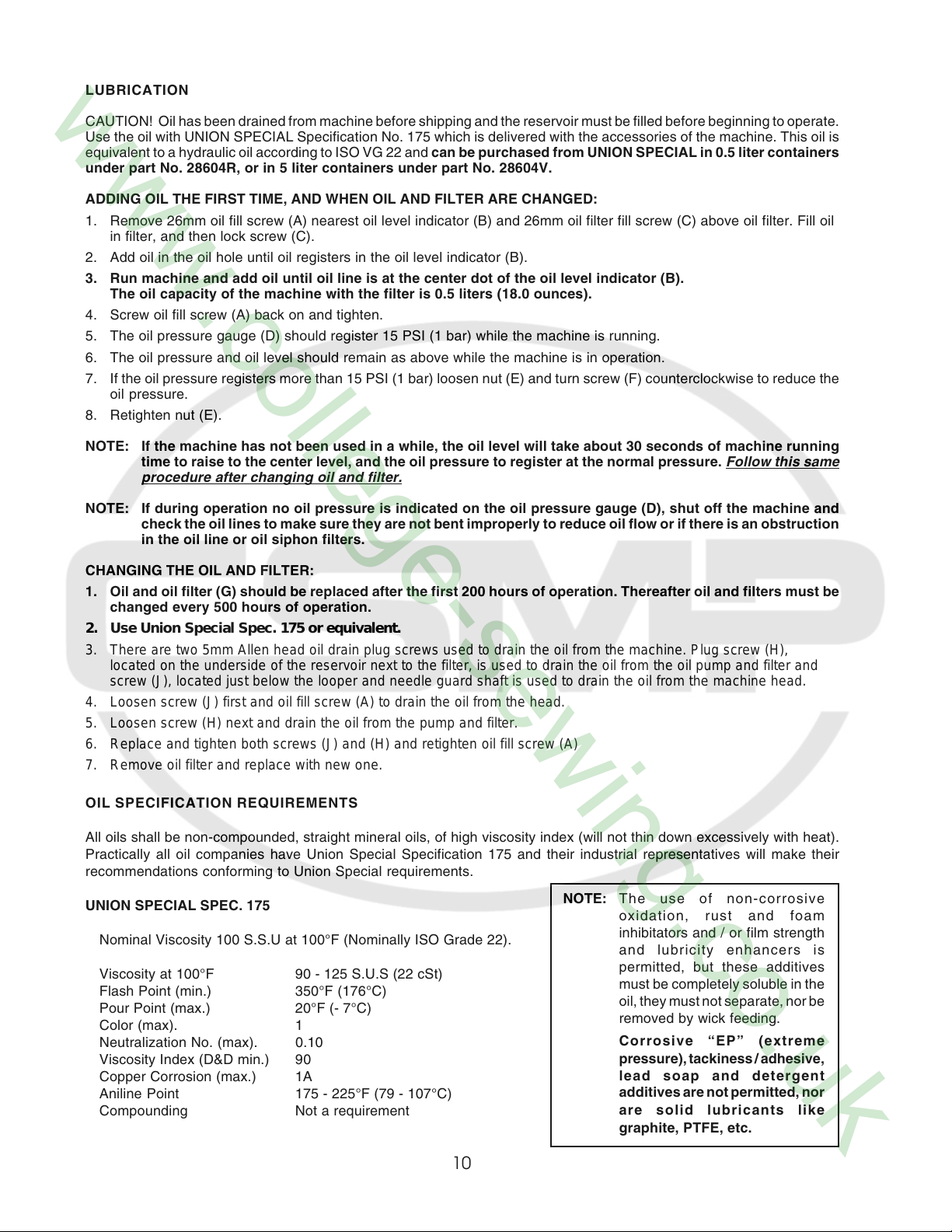

LUBRICATION

CAUTION! Oil has been drained from machine before shipping and the reservoir must be filled before beginning to operate.

Use the oil with UNION SPECIAL Specification No. 175 which is delivered with the accessories of the machine. This oil is

equivalent to a hydraulic oil according to ISO VG 22 and can be purchased from UNION SPECIAL in 0.5 liter containers

under part No. 28604R, or in 5 liter containers under part No. 28604V.

ADDING OIL THE FIRST TIME, AND WHEN OIL AND FILTER ARE CHANGED:

1. Remove 26mm oil fill screw (A) nearest oil level indicator (B) and 26mm oil filter fill screw (C) above oil filter. Fill oil

in filter, and then lock screw (C).

2. Add oil in the oil hole until oil registers in the oil level indicator (B).

3. Run machine and add oil until oil line is at the center dot of the oil level indicator (B).

The oil capacity of the machine with the filter is 0.5 liters (18.0 ounces).

4. Screw oil fill screw (A) back on and tighten.

5. The oil pressure gauge (D) should register 15 PSI (1 bar) while the machine is running.

6. The oil pressure and oil level should remain as above while the machine is in operation.

7. If the oil pressure registers more than 15 PSI (1 bar) loosen nut (E) and turn screw (F) counterclockwise to reduce the

oil pressure.

8. Retighten nut (E).

NOTE: If the machine has not been used in a while, the oil level will take about 30 seconds of machine running

time to raise to the center level, and the oil pressure to register at the normal pressure.

procedure after changing oil and filter.

NOTE: If during operation no oil pressure is indicated on the oil pressure gauge (D), shut off the machine and

check the oil lines to make sure they are not bent improperly to reduce oil flow or if there is an obstruction

in the oil line or oil siphon filters.

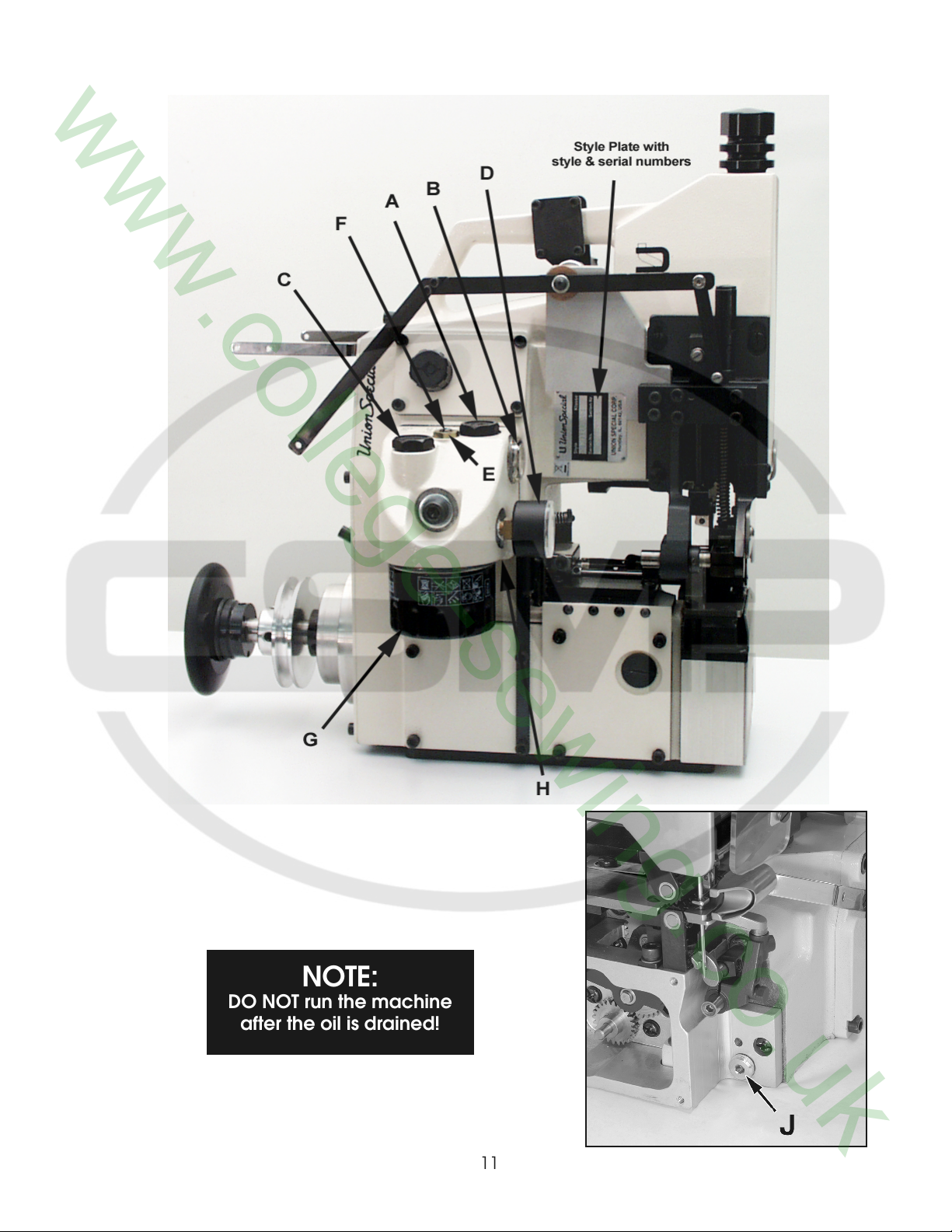

CHANGING THE OIL AND FILTER:

1. Oil and oil filter (G) should be replaced after the first 200 hours of operation. Thereafter oil and filters must be

changed every 500 hours of operation.

2. Use Union Special Spec. 175 or equivalent.

3. There are two 5mm Allen head oil drain plug screws used to drain the oil from the machine. Plug screw (H),

located on the underside of the reservoir next to the filter, is used to drain the oil from the oil pump and filter and

screw (J), located just below the looper and needle guard shaft is used to drain the oil from the machine head.

4. Loosen screw (J) first and oil fill screw (A) to drain the oil from the head.

5. Loosen screw (H) next and drain the oil from the pump and filter.

6. Replace and tighten both screws (J) and (H) and retighten oil fill screw (A)

7. Remove oil filter and replace with new one.

OIL SPECIFICATION REQUIREMENTS

All oils shall be non-compounded, straight mineral oils, of high viscosity index (will not thin down excessively with heat).

Practically all oil companies have Union Special Specification 175 and their industrial representatives will make their

recommendations conforming to Union Special requirements.

Follow this same

UNION SPECIAL SPEC. 175

Nominal Viscosity 100 S.S.U at 100°F (Nominally ISO Grade 22).

Viscosity at 100°F 90 - 125 S.U.S (22 cSt)

Flash Point (min.) 350°F (176°C)

Pour Point (max.) 20°F (- 7°C)

Color (max). 1

Neutralization No. (max). 0.10

Viscosity Index (D&D min.) 90

Copper Corrosion (max.) 1A

Aniline Point 175 - 225°F (79 - 107°C)

Compounding Not a requirement

10

NOTE: The use of non-corrosive

oxidation, rust and foam

inhibitators and / or film strength

and lubricity enhancers is

permitted, but these additives

must be completely soluble in the

oil, they must not separate, nor be

removed by wick feeding.

Corrosive “EP” (extreme

pressure), tackiness / adhesive,

lead soap and detergent

additives are not permitted, nor

are solid lubricants like

graphite, PTFE, etc.

NOTE:

DO NOT run the machine

after the oil is drained!

11

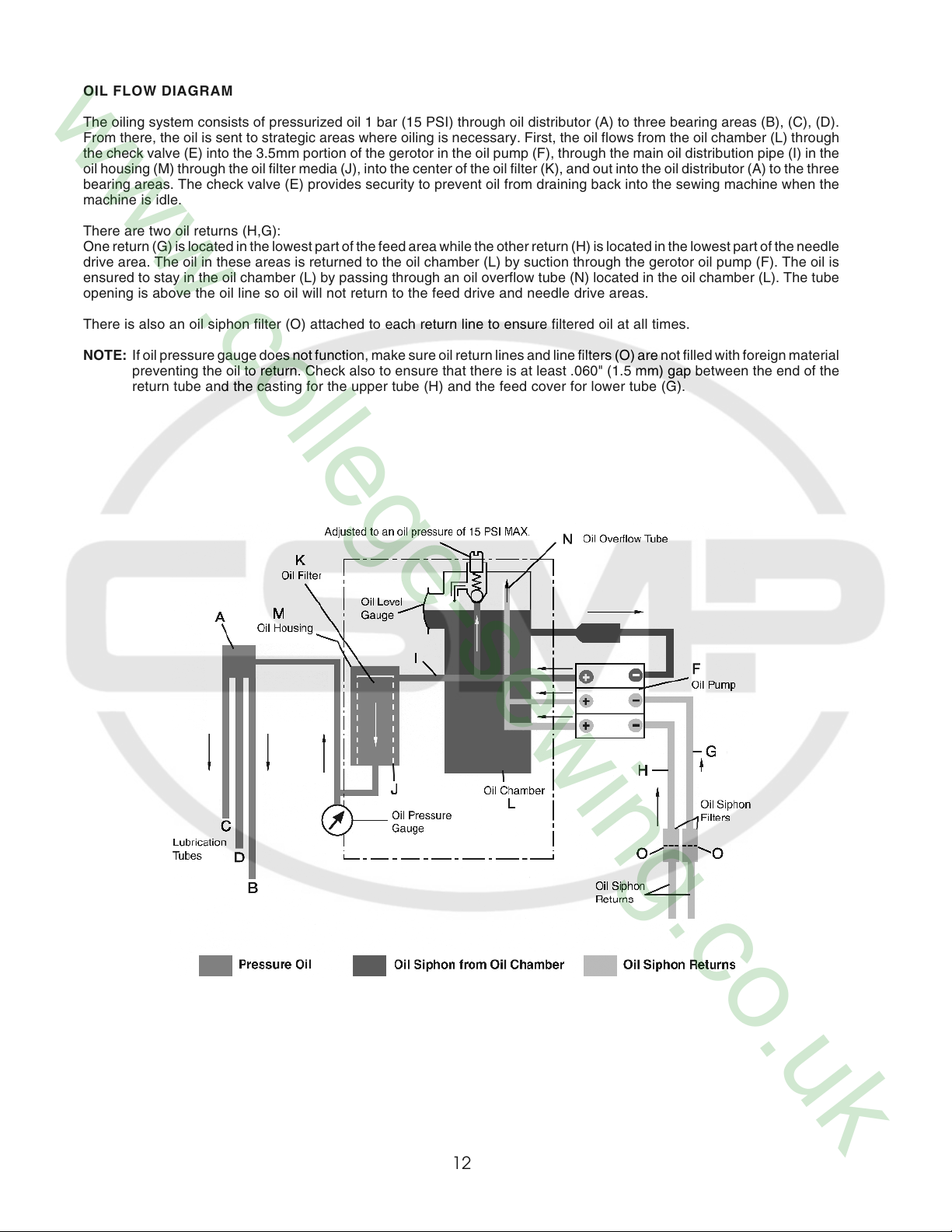

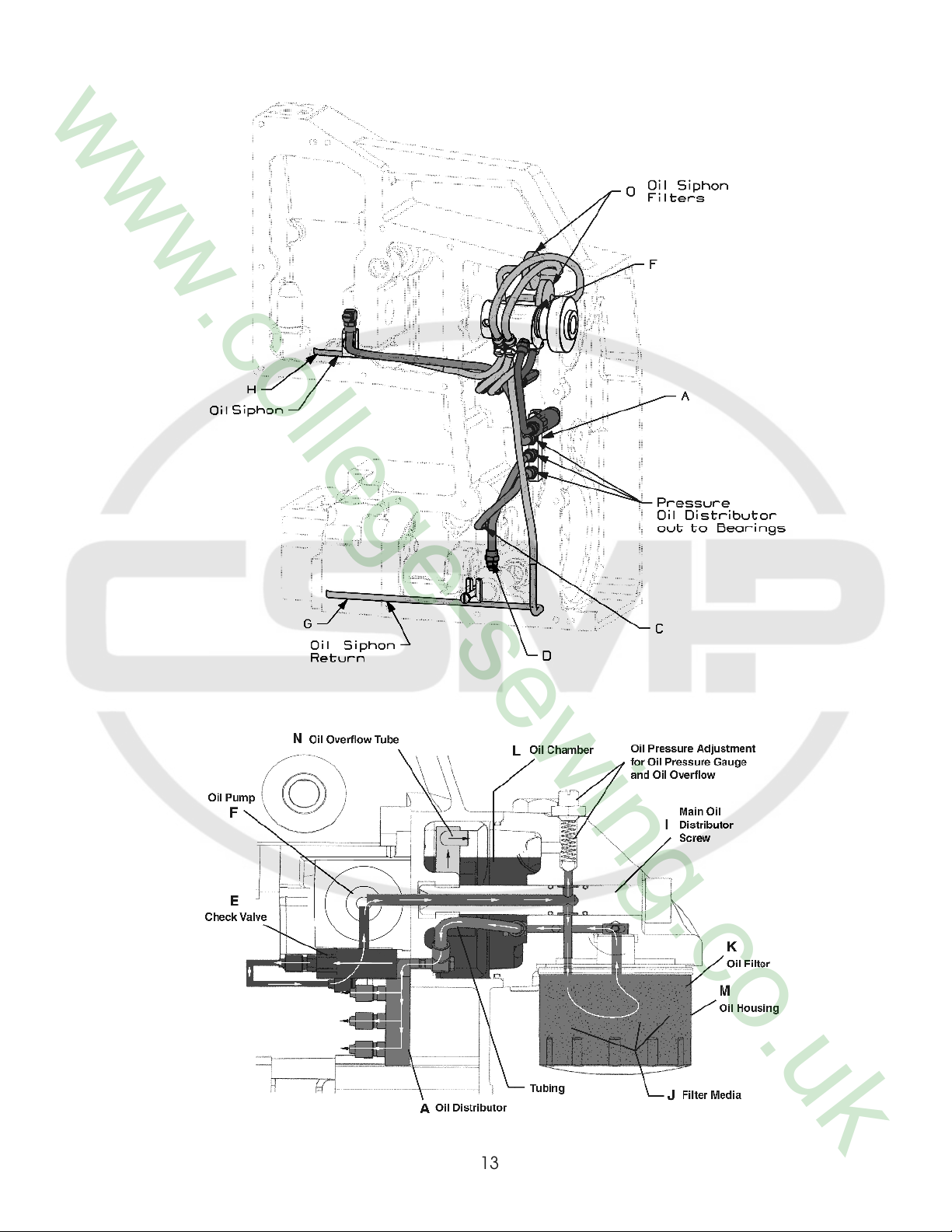

OIL FLOW DIAGRAM

The oiling system consists of pressurized oil 1 bar (15 PSI) through oil distributor (A) to three bearing areas (B), (C), (D).

From there, the oil is sent to strategic areas where oiling is necessary. First, the oil flows from the oil chamber (L) through

the check valve (E) into the 3.5mm portion of the gerotor in the oil pump (F), through the main oil distribution pipe (I) in the

oil housing (M) through the oil filter media (J), into the center of the oil filter (K), and out into the oil distributor (A) to the three

bearing areas. The check valve (E) provides security to prevent oil from draining back into the sewing machine when the

machine is idle.

There are two oil returns (H,G):

One return (G) is located in the lowest part of the feed area while the other return (H) is located in the lowest part of the needle

drive area. The oil in these areas is returned to the oil chamber (L) by suction through the gerotor oil pump (F). The oil is

ensured to stay in the oil chamber (L) by passing through an oil overflow tube (N) located in the oil chamber (L). The tube

opening is above the oil line so oil will not return to the feed drive and needle drive areas.

There is also an oil siphon filter (O) attached to each return line to ensure filtered oil at all times.

NOTE: If oil pressure gauge does not function, make sure oil return lines and line filters (O) are not filled with foreign material

preventing the oil to return. Check also to ensure that there is at least .060" (1.5 mm) gap between the end of the

return tube and the casting for the upper tube (H) and the feed cover for lower tube (G).

12

13

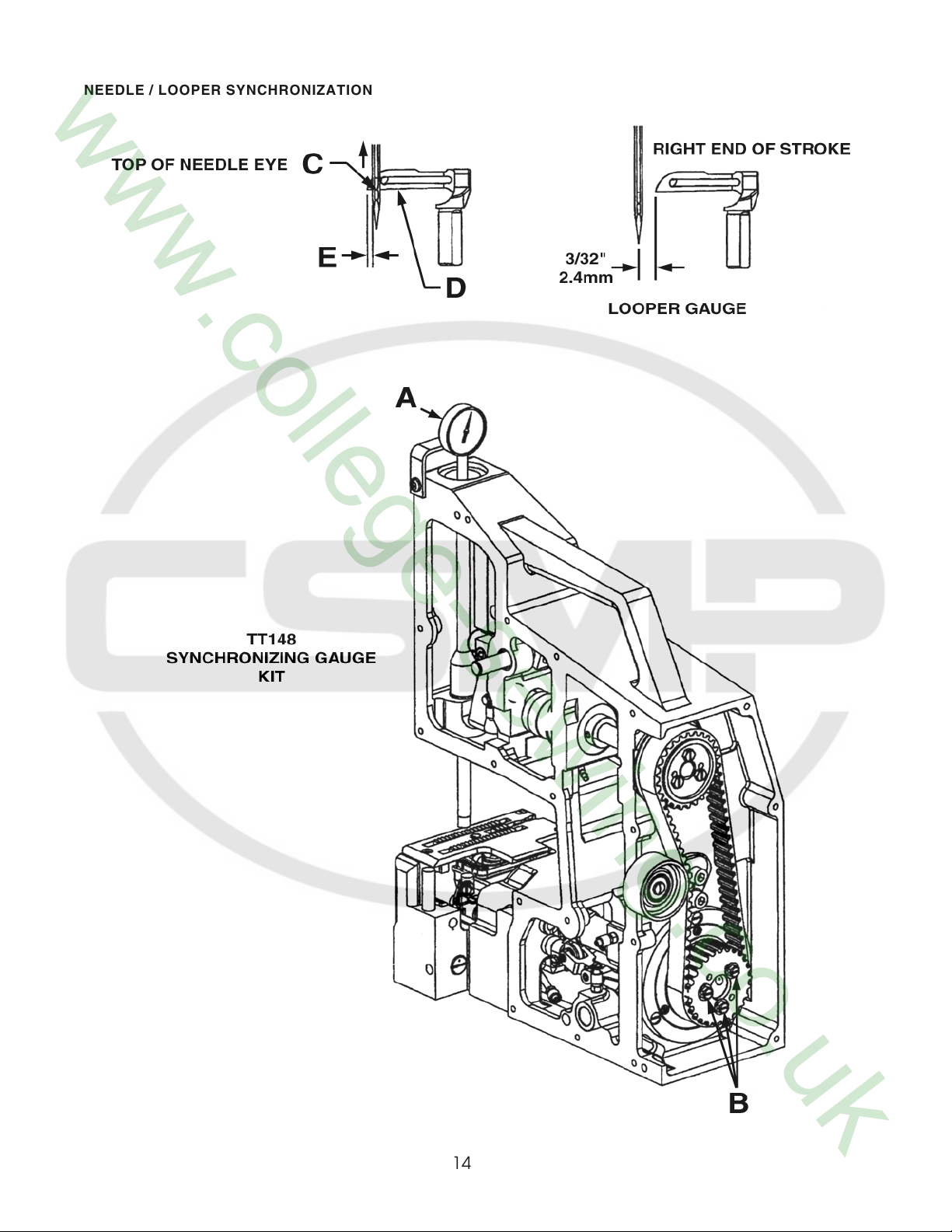

NEEDLE / LOOPER SYNCHRONIZATION

14

1. Synchronize with TT148 Synchronization Gauge Kit

Turn handwheel in clockwise direction until looper shaft is approximately ¼" from the inside of the end cover.

Loosen the looper holder and move the holder to the left until its left edge touches the end cover and lock in

place with its screw.

Turn handwheel until the needle is at the bottom of the stroke and the looper holder is at the farthest position right.

Install the dial indicator (A) on the top of the machine. Set the indicator dial to zero.

Turn the handwheel clockwise until the looper holder touches the end cover. Record the number of revolutions and

final indicator reading.

Turn the handwheel counterclockwise until the looper holder touches the end cover once again. Record the

number of revolutions and final indicator reading. The readings should be the same as above.

The indicator must travel the same distance in the counterclockwise direction, a tolerance of ± .010" (.25mm) is

acceptable.

If the indicator is not the same distance, adjustment can be made by loosening the 3 screws (B) in lower belt

sprocket 10042, and moving slotted sprocket accordingly. If there is a lower number reading of the indicator on

the front travel, turn the slotted sprocket counterclockwise. If there is a lower number reading of the indicator at

the looper rear travel, turn the slotted sprocket clockwise.

After correct adjustment tighten the 3 screws (B) to 100 in lbs. (11.5nm)

Loosen the looper holder and return to its original position.

2. Synchronize without TT148 Synchronization Gauge Kit

If no indicator is available, set the synchronization measuring with a slide caliper or steel ruler.

Set the looper gauge to 3/32" (2.4mm).

Check the synchronization by moving the looper rearward behind the needle scarf. Continue moving the looper to the

left so that the top of the needle eye (C) is flush with the bottom of the looper blade (D). Measure the distance from

the looper tip to the left side of the needle (E).

Move the looper in the opposite direction to where the looper is in front of the needle. Set the top of the needle eye (C)

flush with the looper blade (D), the same as above. Measure the looper point to the left side of the needle. The second

measurement should be approximately 1/64" (0.4mm) less than the first (E).

If the measurement with the looper in front of the needle is less than the rear, turn the slotted sprocket counterclockwise.

If the measurement is less with the looper behind the scarf of the needle, turn the slotted sprocket clockwise.

Tighten the three screws (B) to 100 in. lbs. (11.5Nm).

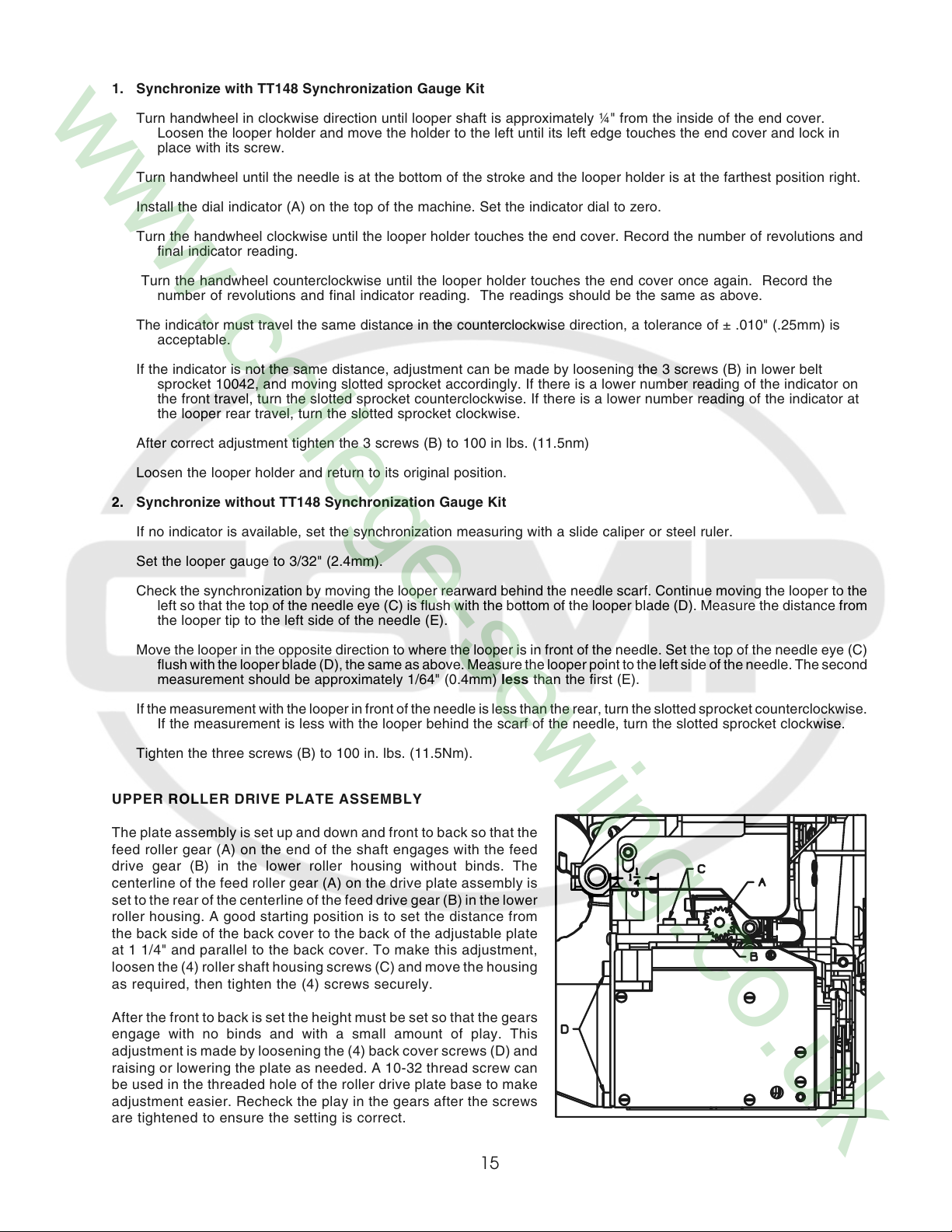

UPPER ROLLER DRIVE PLATE ASSEMBLY

The plate assembly is set up and down and front to back so that the

feed roller gear (A) on the end of the shaft engages with the feed

drive gear (B) in the lower roller housing without binds. The

centerline of the feed roller gear (A) on the drive plate assembly is

set to the rear of the centerline of the feed drive gear (B) in the lower

roller housing. A good starting position is to set the distance from

the back side of the back cover to the back of the adjustable plate

at 1 1/4" and parallel to the back cover. To make this adjustment,

loosen the (4) roller shaft housing screws (C) and move the housing

as required, then tighten the (4) screws securely.

After the front to back is set the height must be set so that the gears

engage with no binds and with a small amount of play. This

adjustment is made by loosening the (4) back cover screws (D) and

raising or lowering the plate as needed. A 10-32 thread screw can

be used in the threaded hole of the roller drive plate base to make

adjustment easier. Recheck the play in the gears after the screws

are tightened to ensure the setting is correct.

15

LOWER ROLLER SETTING

The lower roller should be set left to right so the grooves

in the roller align with the guide wires in the throat plate

when it is against the left bushing in the roller support.

Moving the roller support left or right as needed then

tightening the two screws (A) for the roller support make

this adjustment. The roller is thrust to the left against the

bushing in the support while the drive gear is thrust against

the thrust washer and bushing in the right side of the

support. There should be no shake or bind in the roller after

this adjustment is made.

Note: Keep front edge of roller support parallel with

top edge of casting.

Note: When making this adjustment maintain play in

gears.

UPPER ROLLER AND PRESSER FOOT SETTING

1. Align the upper roller left to right so that it is parallel to the

lower roller; at this time the presser foot will also be

approximately centered to the needle. Set the roller front

to back so the when the roller is raised to its highest

position it does not hit the back of the needle. This

position is generally slightly to the rear of the lower roller.

Tighten the binder screw in the upper roller shank to

secure this position.

2. The presser foot is set with the upper roller in its lowest

position. The front to back position is set so that the

needle is centered in the radius of the presser foot slot.

The height of the presser foot is set so that there is 0.125"

- 0.130" (3.18mm - 3.30mm) between the bottom of the

presser foot and the top of the throat plate. When this

adjustment is made Loctite 222 screw lock must be

applied to the threads of the screws holding the presser

foot to the presser foot shank.

PRESSER FOOT PRESSURE

Turning presser foot presser adjustment screw (A)

clockwise increases the pressure, while counter clockwise

decreases the pressure. Set required force at 16 to 17 lbs.

(75 N).

16

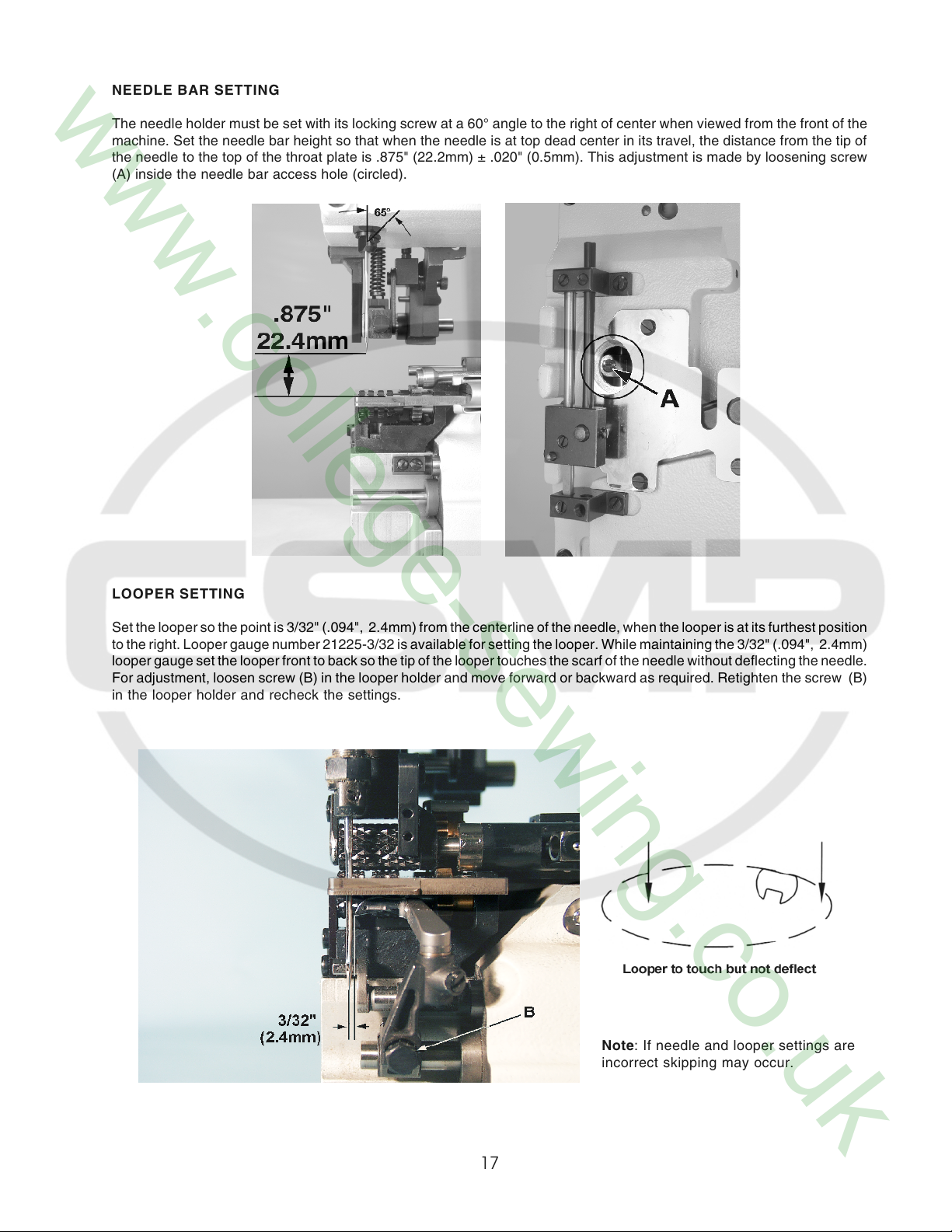

NEEDLE BAR SETTING

The needle holder must be set with its locking screw at a 60° angle to the right of center when viewed from the front of the

machine. Set the needle bar height so that when the needle is at top dead center in its travel, the distance from the tip of

the needle to the top of the throat plate is .875" (22.2mm) ± .020" (0.5mm). This adjustment is made by loosening screw

(A) inside the needle bar access hole (circled).

LOOPER SETTING

Set the looper so the point is 3/32" (.094", 2.4mm) from the centerline of the needle, when the looper is at its furthest position

to the right. Looper gauge number 21225-3/32 is available for setting the looper. While maintaining the 3/32" (.094", 2.4mm)

looper gauge set the looper front to back so the tip of the looper touches the scarf of the needle without deflecting the needle.

For adjustment, loosen screw (B) in the looper holder and move forward or backward as required. Retighten the screw (B)

in the looper holder and recheck the settings.

17

Note: If needle and looper settings are

incorrect skipping may occur.

Loading...

Loading...