Union Special PT0701 GR Parts Book

CATALOG NO.

PT0701-GR

First Edition

STYLES

56100Z28B

56100Z30B

56100Z31B

INSTRUCTIONS AND

ILLUSTRATED PARTS LIST

06-30-09

CLASS 56100 - ADVANCED SERIES,

BAG SEAMING MACHINES

CATALOG NO. PT0701-GR

ADJUSTNG INSTRUCTIONS AND

ILLUSTRATED PARTS LIST FOR

CLASS 56100

ADVANCED SERIES

BAG SEAMING MACHINE

STYLE

56100Z28

56100Z30

56100Z31

First Edition

© 2007

PRINTED 2007 IN USA

INFORMATION SUBJECT TO

CHANGE WITHOUT NOTICE

© Union Special Corporation

ALL Rights Reserved in All

Countries

2

IDENTIFICATION OF MACHINES

Each UNION SPECIAL machine carries a Style number, which on this Class machine is stamped into the

style plate affixed to the right front of machine.

The serial number is stamped in the casting at the right rear base of machine.

Reference to directions, such as right, left, front or rear, are given relative to the operator’s position while

seated at the machine.Operating direction of the handwheel is counterclockwise, as viewed from the

right end of machine.

CLASS DESCRIPTION

Advanced upper and lower feed, single needle, flat bed machine with needle bearing assembly for left

mainshaft bushing. High throw, needle bearing needle bar drive, light weight presser bar and needle bar

driving mechanism, enclosed automatic lubricating system, filtered oil return pumps for head and base,

lateral looper travel.

MACHINE STYLE

56100Z28B Short looper travel with short looper. For seaming heavy poly and multi-wall paper bags.

Single needle two threads. Seam specification 401SSa-1. Stitch range 3 ½ to 6. Sewing

capacity up to 15/64” (6mm). Presser foot has filler cord guide. Maximum recommended

speed 3800R.P.M. Recommended speed for machines operating on a duty cycle of 50% or

more is at least 10% less than maximum.

56100Z30B Long looper travel with long looper and spreader. For seaming heavy poly and multi-wall

paper bags. Single needle, one or two threads. Machine comes with spreader for one

thread and looper for two thread operations. Seam specification 101 SSa-1 & 401SSa-1. .

Stitch range 3 ½ to 6. Sewing capacity up to 15/64” (6mm). Presser foot has filter cord

guide and tape slot. Maximum recommended speed 3800R.P.M. Recommended speed

for machines operating on a duty cycle of 50% or more is 10% less than maximum.

56100Z31B Same as 56100Z30B except with small cloth plate cover and no thread stand. For use

in automatic bag seaming systems.

NEEDLES

Each needle has both a type and size number.The type number denotes the kind of shank, point, length,

groove, finish and other details. The size number, stamped on the needle shank, denotes largest diameter

of blade, measured midway between shank and eye. Collectively, type and size number represent the

complete symbol, which is given on the label of all needles packaged and sold by UNION SPECIAL.

Recommended needle is Type 947GA. It has a round shank, round point, No. 2 bag length, double

groove, spotted, short point, chromium plated, and is available in sizes - 200/080.

Selection of proper needle size is determined by size of thread used. Thread should pass freely through

needle eye in order to produce a good stitch formation.

To have needle orders promptly arid accurately filled, an empty package,a sample needle, or the type

and size number should be forwarded. Use description on label. A complete order would read: “1000

Needles, Type 947GA, Size 200/080”.

3

Fig 1

THREADING AND OILING DIAGRAM

For 401 stitch, thread machine as indicated above. The looper threading has been enlarged for clarity.

For 101 stitch, thread machine using needle thread only.

The oil has been drained from the machine before shipping and the reservoir must be filled before starting

to operate. Maintain oil level between the two red lines and add oil when oil level drops below the

bottom red line. The machine is automatically lubricated and no oiling other than keeping the main

reservoir filled is necessary. For further lubricating instructions refer to paragraph on “LUBRICATION”.

4

SAFETY RULES

THIS SAFETY SYMBOL INDICATES YOUR PERSONAL SAFETY IS INVOLVED.

TO PREVENT PERSONAL INJURY:

- All power sources to the machine MUST be TURNED OFF before threading, oiling, adjusting or replacing

parts.

- Wear safety glasses.

- All shields and guards MUST be in position before operating machine.

- DO NOT tamper with safety shields, guards, etc., while machine is in operation.

Use a straight mineral oil with a Saybolt viscosity of 90 to 125 seconds at 100 degrees F. This is equivalent

to UNION SPECIAL Specification No. 175.

Before operating, fill machine with oil at plug screw (A, Fig. 2).

While filling machine with oil, check gauge (B). When proper

oil level is reached, the oil level should appear in the center

between the two red lines on gauge (B). It is recommended to

always check oil level before operating to be sure machine is

filled between the lines. CAUTION: DO NOT over fill machine.

CAUTION

LUBRICATION

To drain oil, remove plug screw, at right, in front, below

handwheel or lower crank chamber cover on back of ma-

chine. Oil must be changed every 2000 operating hours to

minimize wear.

On new machines, or a machine out of service for an ex-

tended period of time; lubricate machine as follows:

Remove head cover, clean out lint, then directly oil needle bar

link and needle bar. Replace head cover and fill machine with

oil to proper level. Run machine at low RPM to ensure proper

lubrication of components preventing any damage which may

occur from lack of oil distribution.

Fig 2

5

SYNCHRONIZING LOOPER AND NEEDLE MOTIONS

Synchronization is the most important adjustment

involving the needle and looper motion relation,

because it maintains the needle-looper relation at

both the needle loop taking time, as well as when

the needle enters the looper triangle. This adjust-

ment is best made using synchronization gauge set

TT34.

Remove the throat plate, feed dog, looper and

needle thread take-up wire, (also called strike-off

wire). Fig 3 Using gauge set TT34, re-attach the

throat plate (A) to the throat plate support with the

throat plate screws. Insert the pin (B) into the hole

for the looper and tighten with its screw. Turn the

handwheel in operating direction, (towards the

operator), until the pin lightly touches the right

edge of the throat plate. Insert the indicator (C)

into the hole for the needle thread take-up wire,

and move it up or down until the pointer (D) on the

indicator reads at "0", and then tighten the screw.

Now turn the handwheel in opposite of operating

direction (away from the operator), until the pin

again lightly touches the right edge of the plate. If

the machine is synchronized the pointer on the

indicator should again read "0". If the pointer is

above or below the "0", the machine is out of

synchronization. A variation of one line is allowable.

To synchronize the machine the following proce-

dure should be followed. Thread screw (F) (99271),

from gauge kit TT34, into the looper drive lever

rocker shaft through the center of the thrust adjust-

Fig 3

"0" (Fig. 3A). Loosen screw (E) in the looper drive lever and pull screw (F), (99271), slightly toward the

operator. Retighten screw (E) in the looper drive lever and recheck the synchronization as outlined

above. Repeat as necessary to obtain proper synchronization.

If pointer on the indicator reads below the "0", (Fig. 3B). Loosen screw (E) in the looper drive lever and tap

screw (F), (99271), slightly away from the operator. Retighten screw (E) in the looper drive lever and

recheck the synchronization as outlined above. Repeat as necessary to obtain proper synchronization.

If synchronization gauge set TT34 is not available, the following procedure can be used.

ing screw.

If the pointer (D) on the indicator reads above the

Fig 3A

6

SYNCHRONIZING LOOPER AND NEEDLE MOTIONS (CONTINUED)

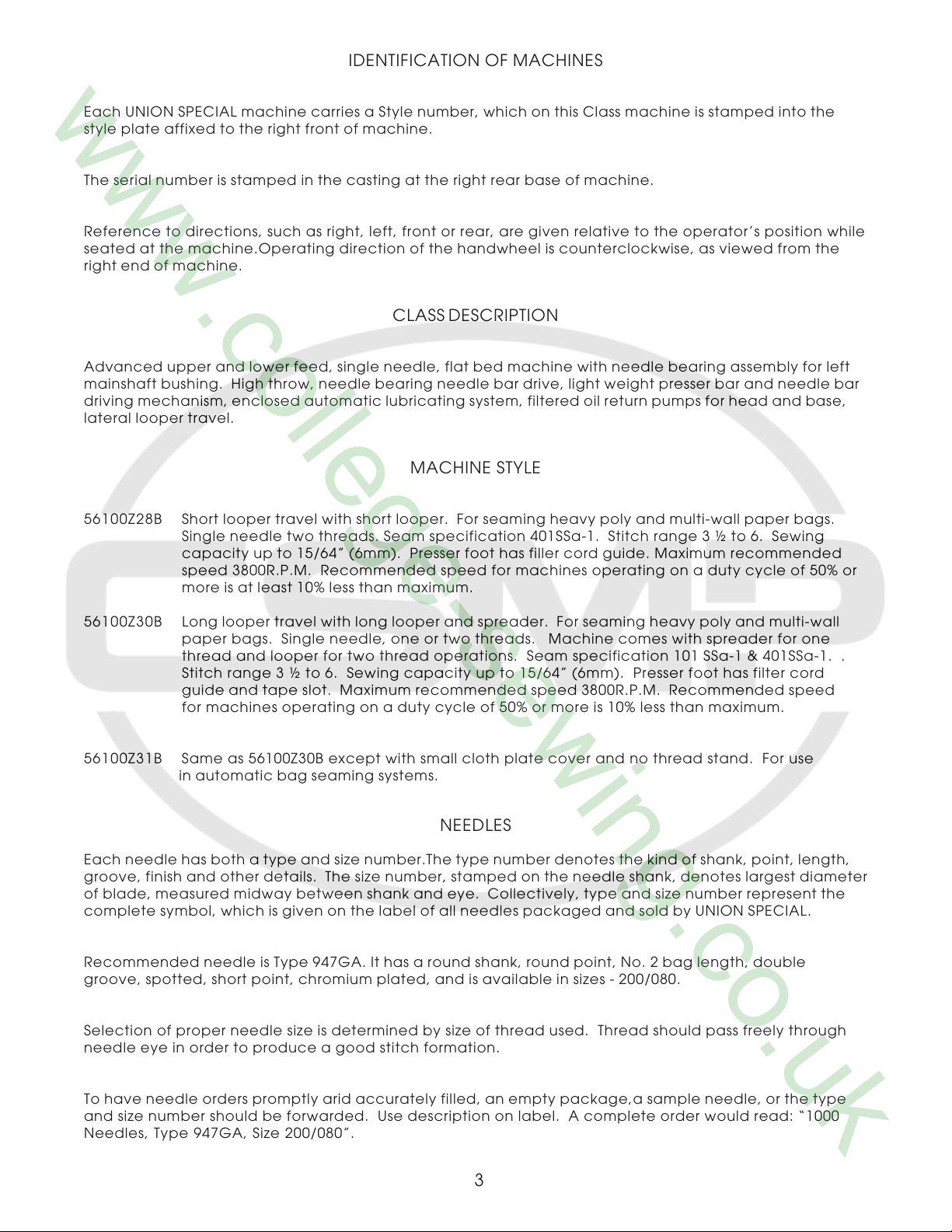

Fig 3B

Turn handwheel in the operating direction until the

point of the looper (A, Fig. 4) moving to the left, is

even with the left side of needle (B). Note the height

of the eye of the needle with respect to the looper

point (See Fig. 4A). Turn the handwheel in the re-

verse direction until the point of the looper again

moving to the left, is even with the left side of needle

(See Fig. 4A). If the height of the eye of the needle

with respect to the looper point are the same,

looper and needle motions are synchronized - a

variation of .005 inch (.127mm) is allowable. If the

distance from the eye of the needle to the point of

the looper is greater when the handwheel is turned

in the operating direction, the looper drive lever

rocker shaft will have to be moved slightly towards

the rear. Moving the shaft towards the front acts the

Fig 4

NOTE: The 1/64 inch (.4mm) dimension shown in Fig. 4A is

reverse.

for final setting of needle bar height.

Fig 4A

Fig 5

Adjust looper drive rocker lever shaft as follows:

Loosen screw (C, Fig. 4) in looper drive lever (D). A rod of .146-

40 thd. or Union Special Screw No. 99271 can be threaded into

the looper drive lever rocker shaft through the center of thrust

adjusting screw (E). Tap or pull slightly as required to position

shaft for proper synchronization. Tighten screw (C) securely and

remove rod or screw used to position shaft.

Loosen lock nut (F) and TORQUE thrust adjjusting

screw (E) to 6 in. lbs. (7cm/kg); re-tighten lock nut

(F) securely.

With the looper at extreme right end of travel,

check location of the right looper connecting rod

bearing using gauge No. TT35. Place large hole of

gauge over threaded stud (A, Fig. 5). The left end

of gauge should locate against the RIGHT side of

looper rocker cone (B). If adjustment is necessary,

loosen clamp screw (C) and reposition looper drive

lever (D) as required, then tighten screw (C).

If gauge is not available, check setting with a

scale. Distance between the centerline of rocker

cone and centerline of looper drive lever stud

should be 4 1/16 inch (103.2mm) as shown in Fig. 5

when looper is at its extreme right end of travel.

7

LOOPER AND LOOPER NEEDLE GUARD SETTINGS

Insert a new needle, type and size specified. Looper

gauge is 5/32 inch (4.Omm) which is the distance from

point of looper (A, Fig. 6) to centerline of needle (B)

when looper is at extreme right end of its travel. Looper

Fig 6

While turning handwheel in operating direction and the looper (A, Fig. 7) moves to the

left, its point should be set to pass the rear of the needle (B) with .003" to .005" (.08 to

.13mm) clearance. Adjustment can be made by loosening screw (G, Fig. 6), turn stop

screw (H) clockwise to move looper towards the rear, counterclockwise acts the

reverse. It is suggested to hold looper towards the front while making this adjustment.

Tighten screw (G) after adjustment has been made and recheck movement of

looper.

gauge No. 21225-5/32 (C) is available for this setting.

Adjustment can be made by loosening nut (D),(it has a

left hand thread) and nut (E); turn connecting rod (F) as

required to attain specified dimension. Hold connecting

rod in position and tighten nut (E), then nut (D). NOTE: Be

sure that the left ball joint is in a vertical position and

does not bind after adjustment.

Fig 7

Looper needle guard (attached to looper), 56100Z28B only, should be set with the

looper point set to the centerline of the needle, set front guard 0.005" to 0.010" (0.13

to 0.25 mm) away from looper.

NEEDLE BAR HEIGHT

Turn handwheel to position point of looper (A, Fig. 8) 0.20" (0.5mm) past the left

side of needle (B). At this time the top of the eye of the needle (B) should be

even with the under side of the looper (A). To make adjustment, loosen screw (C

Fig. 15) and move needle bar (A) up or down as required.

SETTING 101 STITCH RETAINER

56100Z30B & 56100Z31B

The 101 stitch retainer is used to hold open the needle loop as the looper moves

to the right so that the needle can enter the loop to form the 101 stitch. To set

the retainer.

Remove the throat plate and set the retainer (A, Fig 9) so that the tip is

approximately 3/32” (2.4mm) from the front of the needle hole in the throat plate

and tighten screw (B). The retainer may need to be move in or out slightly if

skipping or malformed stitches occur while sewing.

Fig 8

Attach the throat plate and looper/spreader to the machine. Turn the

handwheel in operating direction until the looper moving to the right is directly

under the tip of the retainer (Fig. 9A). Adjust the retainer tip up or down with

screw (C, Fig 9B) so that there is .003” to .005” (0.10mm to 0.13mm) clearance

between the top of the looper/spreader and the bottom tip of the retainer and

then tighten screw (C).

8

Fig 9A

Fig 9B

Fig 9

Feed dog (A, Fig. 10) should be centered in throat plate (B)with

equal clearance on all sides and ends with feed travel set to

desired stitch length. At highest point of travel, tips of feed dog

teeth should extend the depth of 3/64" above throat plate and

parallel to same. Screw (C) should be set to support feed dog

after screw (D) has been loosened which secures feed dog in

position.

Parallel adjustment can be made by loosening nut (A, Fig. 11) and

turn screw (B) clockwise to lower front of feed dog, counterclock-

wise acts the reverse. When properly set, retighten nut (A).

Right to left adjustment can be made by loosening screws (G, Fig.

12) and slightly move feed rocker (H) on feed rocker shaft (J) as

required, then retighten screws. Check to ensure that feed rocker

arm (K) does not bind after adjustment.

Forward or rearward centering of feed dog can be accomplished

by loosening nuts (L, Fig. 12), move feed rocker (H) as required and

retighten nut.

SETTING THE UPPER FEED DOG

Set the up upper feed dog so at it lowest position the teeth will just con-

tact the lower feed dog teeth (A, Fig 10A). To make this adjustment,

loosen nut (C) and turn screw (B) up or down as required. Lock nut (C)

after adjustment has been made.

Note: It may be necessary to raise the upper feed dog for thick materials

or if tearing of the tape occurs.

FEED DOG SETTINGS

Fig 10

Fig 10A

SETTING THE UPPER FEED DOG LIFT LEVER

With the upper feed dog at its lowest position, set the lift lever so the there

is approximately 1/32” clearance between the top of the lift lever and the

bottom of the feed dog heel. (D, Fig 10A) To make this adjustment loosen

screw (E) and move the lift lever up or down as required.

9

Fig 11

CHANGING STITCH LENGTH

Set the stitch to required length.This is

accomplished by loosening lock nut

(A, Fig.12) 1/2 turn, (it has a left hand

thread) on the end of the stitch

regulating stud and turning stitch

adjusting screw (B) located under the

left end of the cloth plate in the head

of the mainshaft (C), which is marked

with “L” and “S”. Turning the screw in

a clockwise direction shortens the

stitch (moves stitch regulating stud

toward the “S”) and turning it in a

counterclockwise direction lengthens

the stitch (moves stitch regulator stud

toward the “L”). Retighten the lock

nut securely. To prevent destructive

damage to the feed drive bearing,

key screw (D) must engage the “U”

shaped key slot in ferrule (E).

LUBRICATING FEED BAR SHAFT

Fig 12

Grease fittings have been added to

both ends of feed bar shaft (F, Fig 12).

It is advisable to add #2 bearing

grease at these points every month

using grease gun AS60-187. A can of

grease can be ordered under part

number GR18.

REAR NEEDLE GUARD

Rotate handwheel in operating direction to position

looper point to just enter the scarf of needle. At this time

the needle guard (A, Fig 13) should be at its extreme end

of forward travel. Set the guard front to back as close as

possible without touching the needle. Guard should be

set as low as possible, yet have its vertical face ap-

proach above the needle point 1/32" +1/64" (0.8mm

+0.4mm). To move the needle guard forward or back-

ward, loosen the screw (B), move needle guard as

required, and retighten screw. To raise or lower needle

guard, loosen screw (B), and turn screw (C) clockwise to

lower needle guard or counterclockwise to raise it.

Retighten screw (B) after guard is properly set.

NOTE: Any change in stitch length will require a

change in rear needle guard setting.

Fig 13

10

THREADING

Draw looper and needle threads into the machine and start

operating on a piece of fabric. Refer to threading diagram

(Fig. 1) for manner of threading this machine.

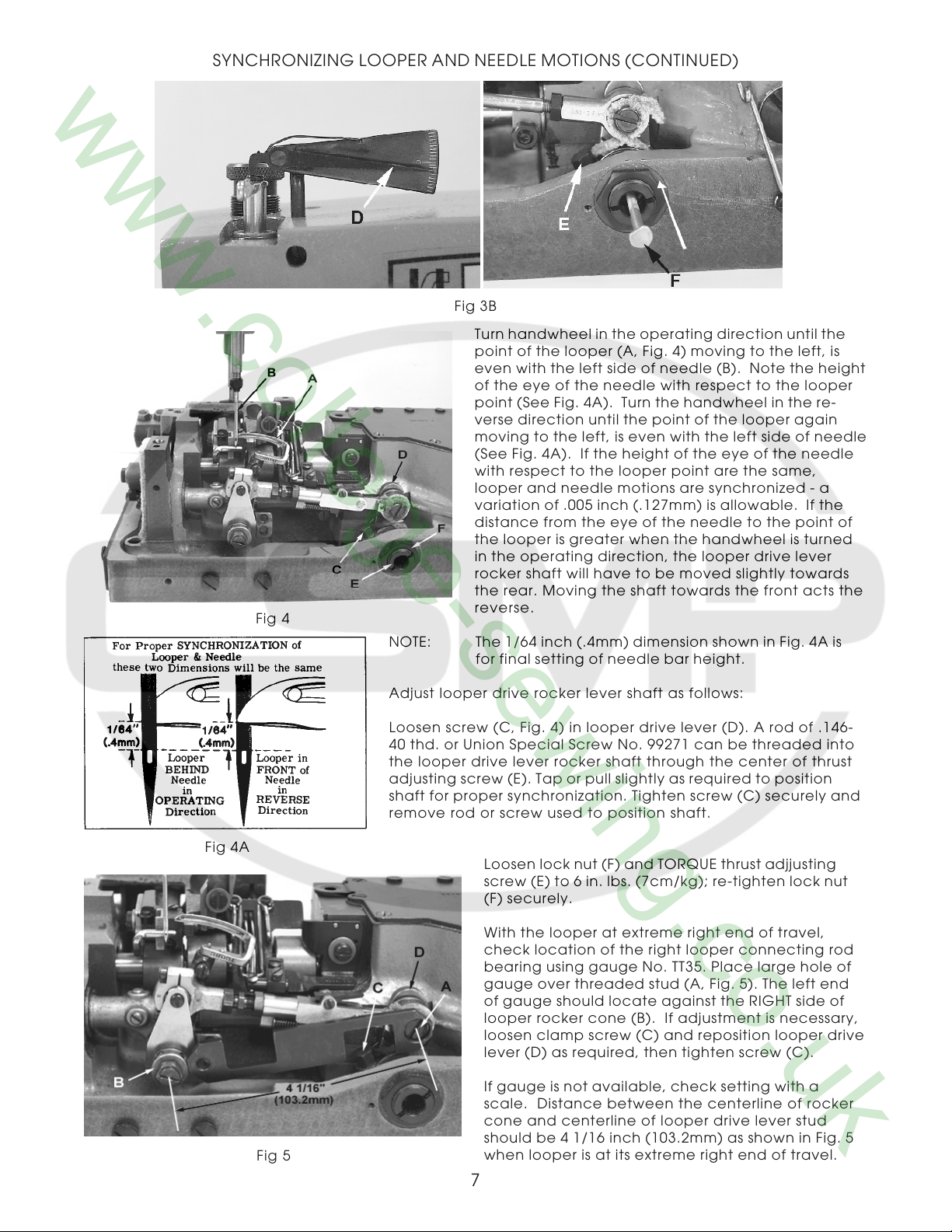

Looper thread cast-off wire (A, Fig. 14) located on the take-up

shield (B) controls the amount of slack thread in the system

and can be moved to any position. It should be set laterally so

that it is midway between the two discs of take-up (C) and the

tip parallel with the discs.

It is usually set toward the take-up to almost the limit of its slot

so that it barely clears the highest point of the take-up. The

height and lateral adjustment of the retainer affects the

control of looper thread as looper moves to the left. Ordi-

narily it will be set in approximately a horizontal position. More

looper thread is given to the stitch when the retainer is raised

and set towards the take-up. However, if the retainer is raised

too high, the looper thread triangle may be wiped under the

blade of the looper, causing traingle skips or pulled down

stitches. This can be checked by observing the action of the

looper thread as the looper moves to the left.

LOOPER THREAD CAST-OFF WIRE

Fig 14

THREAD TENSIONS

Tension on the needle thread should be only sufficient to produce

uniform stitches on the under surface of the fabric. Tension on the

looper thread should be just sufficient to steady the thread.

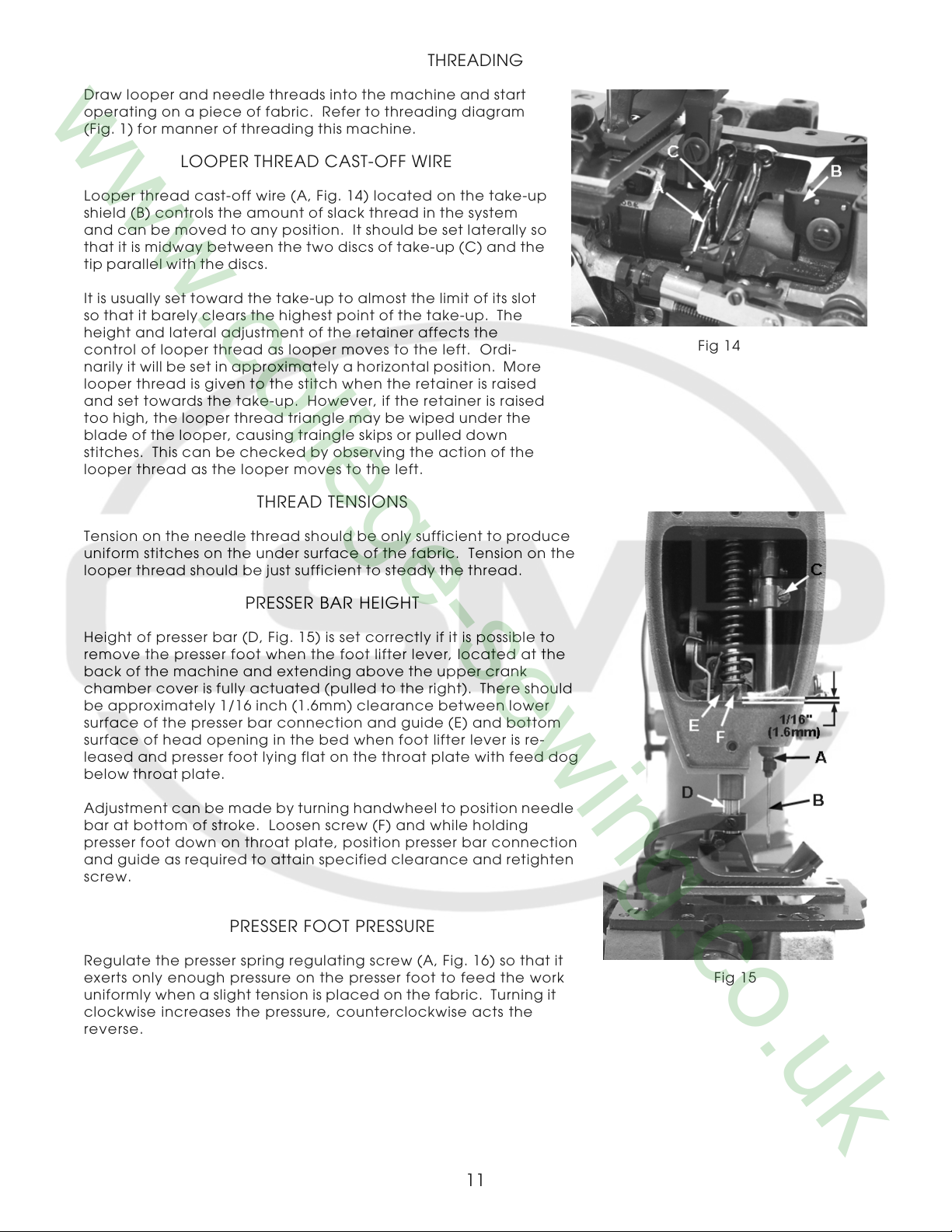

PRESSER BAR HEIGHT

Height of presser bar (D, Fig. 15) is set correctly if it is possible to

remove the presser foot when the foot lifter lever, located at the

back of the machine and extending above the upper crank

chamber cover is fully actuated (pulled to the right). There should

be approximately 1/16 inch (1.6mm) clearance between lower

surface of the presser bar connection and guide (E) and bottom

surface of head opening in the bed when foot lifter lever is re-

leased and presser foot lying flat on the throat plate with feed dog

below throat plate.

Adjustment can be made by turning handwheel to position needle

bar at bottom of stroke. Loosen screw (F) and while holding

presser foot down on throat plate, position presser bar connection

and guide as required to attain specified clearance and retighten

screw.

PRESSER FOOT PRESSURE

Regulate the presser spring regulating screw (A, Fig. 16) so that it

exerts only enough pressure on the presser foot to feed the work

uniformly when a slight tension is placed on the fabric. Turning it

clockwise increases the pressure, counterclockwise acts the

reverse.

Fig 15

11

Loading...

Loading...