CATALOG NO.

31200AQ64Z6

PT0203

First Edition

STYLES

31200AQ64

ADJUSTING INSTRUCTIONS

AND ILLUSTRATED PARTS LIST

04-02-04

31200AQ64

High Speed, Feed Up The Arm, Plain Feed, Two needle, two looper, Side Wheel Cylinder Bed Machine specifi-

cally designed for Taping Shoulders and Collar Seams on Knitwear.

DESCRIPTION OF MACHINE

31200AQ64Z6

NEEDLE TYPE:

SETTING THE NEEDLES:

SETTING OF THE NEEDLE BAR:

LOOPER ADJUSTMENT:

Equipped with top tape reel and Presser Foot with folder for a precut 3/4" (19mm) tape to finish 3/8" (9.5mm).

Seam Spec. 401SSag-3. 6.4mm (16ga) needle spacing only. 4500 R.P.M. Maximum speed.

Same as 31200AQ64 except without presser foot.

128 GJS: Short, double groove, struck groove, thin ball point, spotted, tapered blade reinforcement, chro-

mium plated - sizes 070 / 027, 075 / 029, 080 / 032, 090 / 036.

Before readjusting the machine insert two new needles type 128GJS as far as they will go into the needle bar

head. The long groove must show to the operator. Tighten set screws securely.

To set the needle bar for the correct needle space in line of feed use the assembled needle guard, as the

step of the needle guard is the same as the needle space. The needles should slightly touch the needle

guard. After the setting, check that the needles are in the center of the stitch holes.

Insert the rear looper in the rear looper holder and be sure that the screw rests on the looper flat. The looper

gauge is 13/64"(5.16mm) measured from the center line of the left needle to the looper point with the looper

at the extreme left of its travel. Use of looper gauge 21225 - 13/64" is of advantage. For adjusting the looper

gauge loosen the clamp screw of the rear looper holder and move holder on the looper shaft to obtain

proper setting.

NEEDLE BAR HEIGHT:

Set the needle bar so that the tops of the needle eyes are about 5/64"(2mm) below the looper points when

the points are flush with the right side of the needles on their travel to the right. Watch that the needle bar

does not turn during this adjustment.

LOOPER TO NEEDLE SET:

After setting the needle bar to the correct height, set the loopers front to back to touch but not deflect the

needles at loop taking time

2

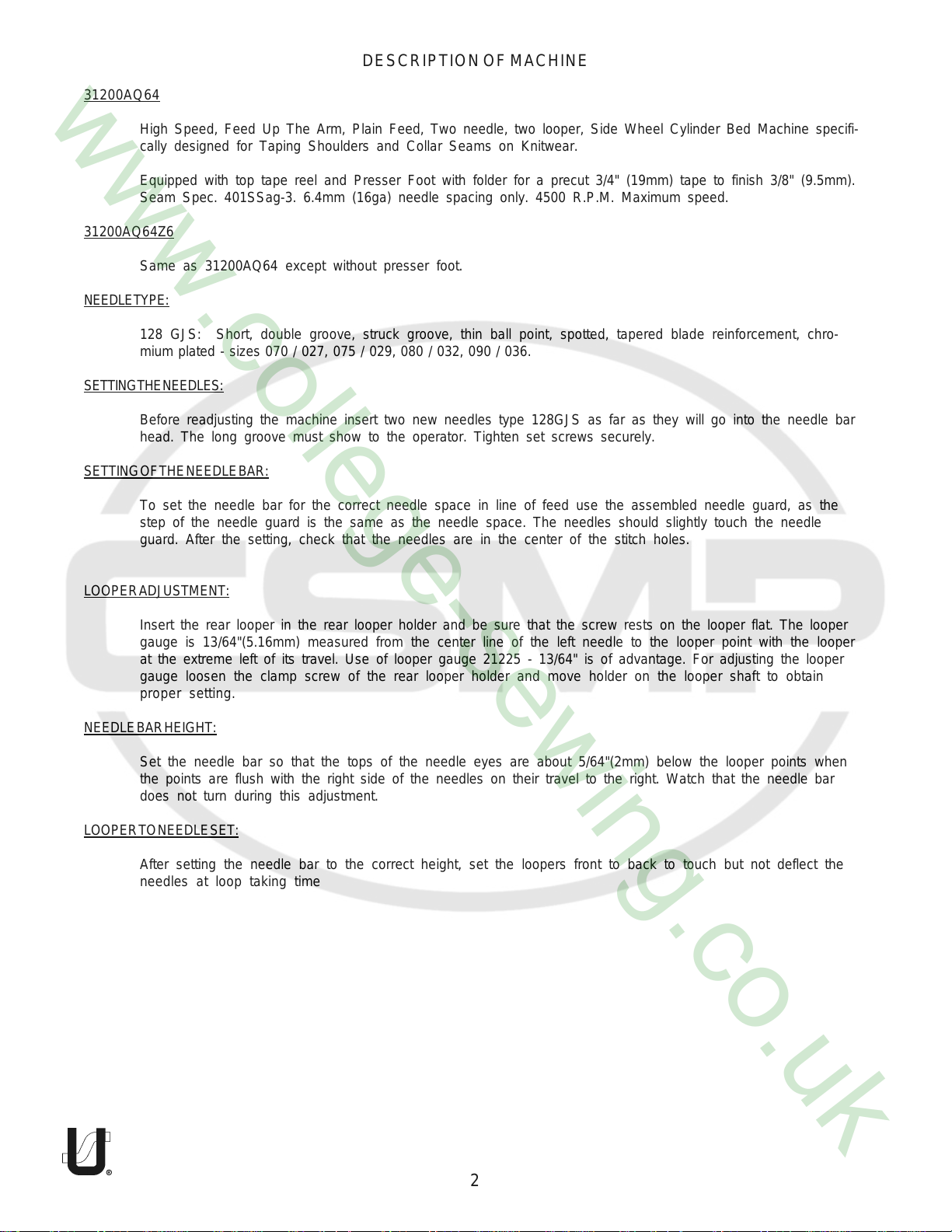

LOOPER AVOID MOTION:

The amount of looper avoid has been set at the factory to approximately .080"

(2.0mm). If it becomes necessary to adjust the amount of avoid it is recom-

mended as a starting point, to have the points of the decending needles

contact the lower 1/3 of the back of the looper blade.

NEEDLE GUARD:

Set the rear guard horizontally so that it barely contacts the needles when at its extreme forward position. It

should be set vertically as low as possible, yet have its guarding surface in contact with the needle until the

points of the loopers moving to the right are even with the right side of needles.

NOTE: Any time you change stitch length you must reset the guard.

After changing the looper avoid motion check the adjustment with respect to

the needle.

After setting the rear looper insert the front looper. The adjustment of both

loopers is the same.

To adjust the looper avoid motion remove cover plate No.31182N

at the rear of the machine. Loosen the nut with wrench No. 21388

(see sketch). To increase the avoid motion the connection link must

be moved downwards and to reduce it upwards. Tighten the nut

and replace the cover plate No. 31182N with the gasket.

FEED DOG SETTING:

The feed dog height is set correctly when the tips of the teeth project ±3/64"(1.2mm) above the throat plate

at its highest position. The height adjustment is made by loosening the set screws No. 22894W and turning the

eccentric stud No. 31139A. After this adjustment tighten set screw. At maximum stitch length adjust feed dog

to have equal clearance at both ends of the slots. Loosen screw on feed dog and move front to back to

obtain proper setting.

PRESSER FOOT:

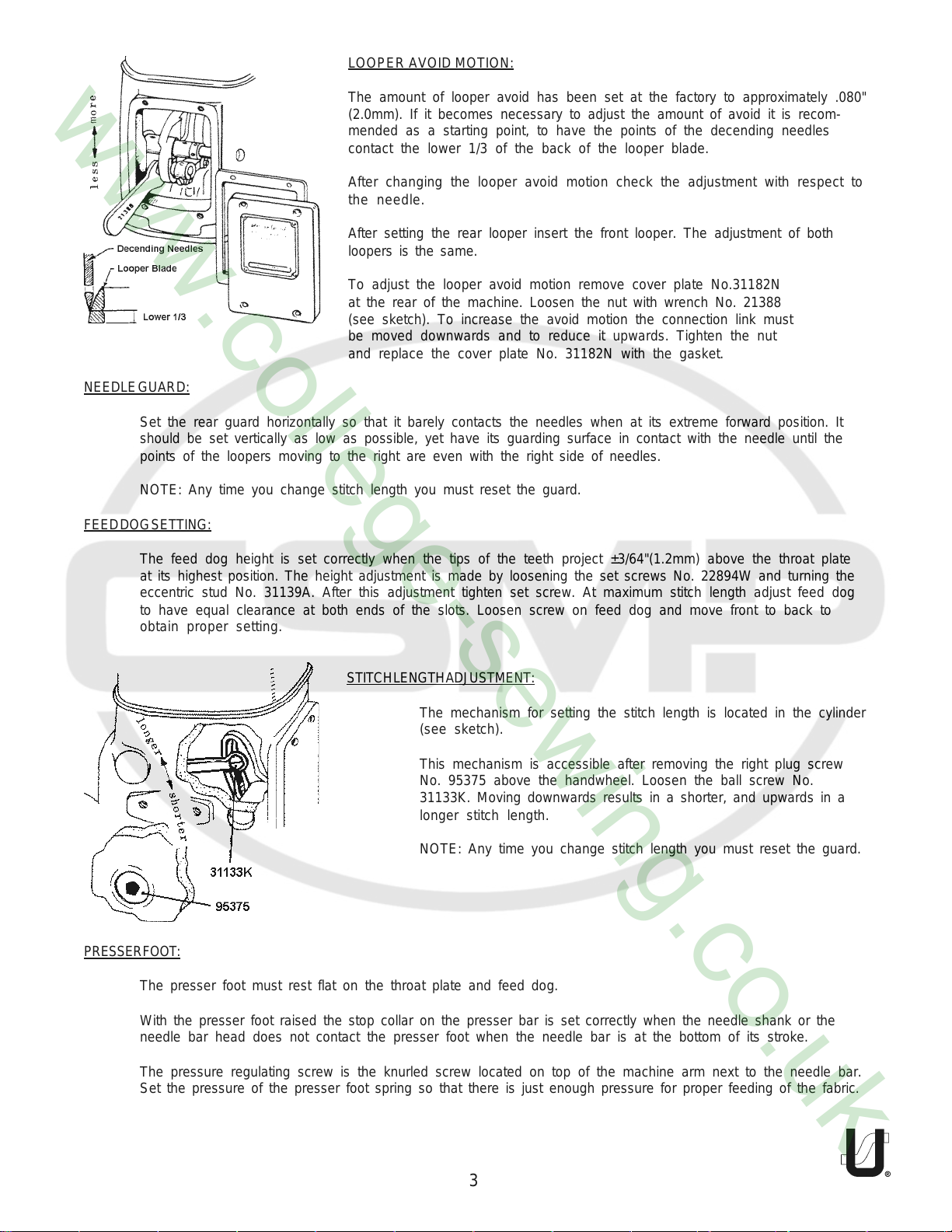

STITCH LENGTH ADJUSTMENT:

The mechanism for setting the stitch length is located in the cylinder

(see sketch).

This mechanism is accessible after removing the right plug screw

No. 95375 above the handwheel. Loosen the ball screw No.

31133K. Moving downwards results in a shorter, and upwards in a

longer stitch length.

NOTE: Any time you change stitch length you must reset the guard.

The presser foot must rest flat on the throat plate and feed dog.

With the presser foot raised the stop collar on the presser bar is set correctly when the needle shank or the

needle bar head does not contact the presser foot when the needle bar is at the bottom of its stroke.

The pressure regulating screw is the knurled screw located on top of the machine arm next to the needle bar.

Set the pressure of the presser foot spring so that there is just enough pressure for proper feeding of the fabric.

3

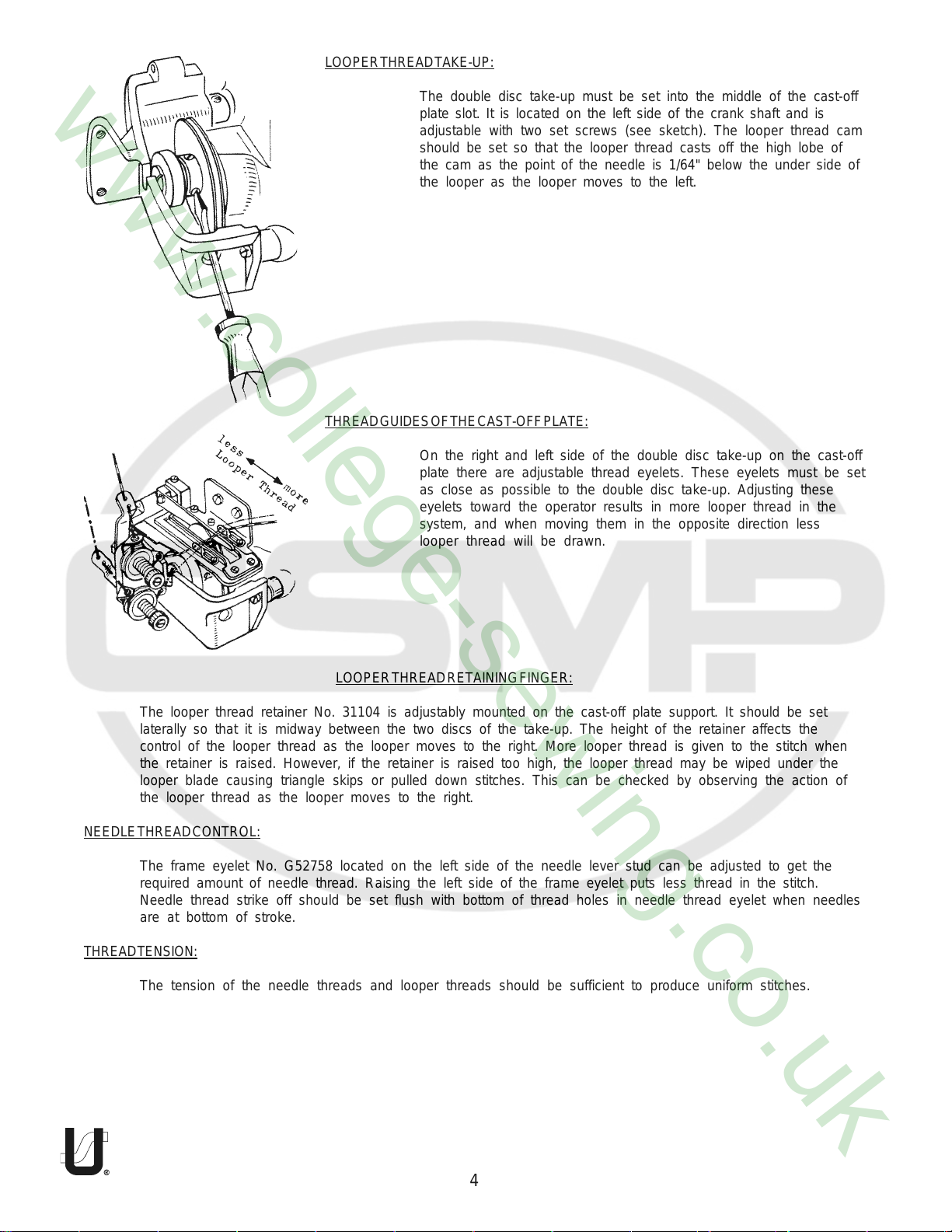

LOOPER THREAD TAKE-UP:

The double disc take-up must be set into the middle of the cast-off

plate slot. It is located on the left side of the crank shaft and is

adjustable with two set screws (see sketch). The looper thread cam

should be set so that the looper thread casts off the high lobe of

THREAD GUIDES OF THE CAST-OFF PLATE:

the cam as the point of the needle is 1/64" below the under side of

the looper as the looper moves to the left.

On the right and left side of the double disc take-up on the cast-off

plate there are adjustable thread eyelets. These eyelets must be set

as close as possible to the double disc take-up. Adjusting these

eyelets toward the operator results in more looper thread in the

system, and when moving them in the opposite direction less

looper thread will be drawn.

The looper thread retainer No. 31104 is adjustably mounted on the cast-off plate support. It should be set

laterally so that it is midway between the two discs of the take-up. The height of the retainer affects the

control of the looper thread as the looper moves to the right. More looper thread is given to the stitch when

the retainer is raised. However, if the retainer is raised too high, the looper thread may be wiped under the

looper blade causing triangle skips or pulled down stitches. This can be checked by observing the action of

the looper thread as the looper moves to the right.

NEEDLE THREAD CONTROL:

The frame eyelet No. G52758 located on the left side of the needle lever stud can be adjusted to get the

required amount of needle thread. Raising the left side of the frame eyelet puts less thread in the stitch.

Needle thread strike off should be set flush with bottom of thread holes in needle thread eyelet when needles

are at bottom of stroke.

THREAD TENSION:

The tension of the needle threads and looper threads should be sufficient to produce uniform stitches.

LOOPER THREAD RETAINING FINGER:

4

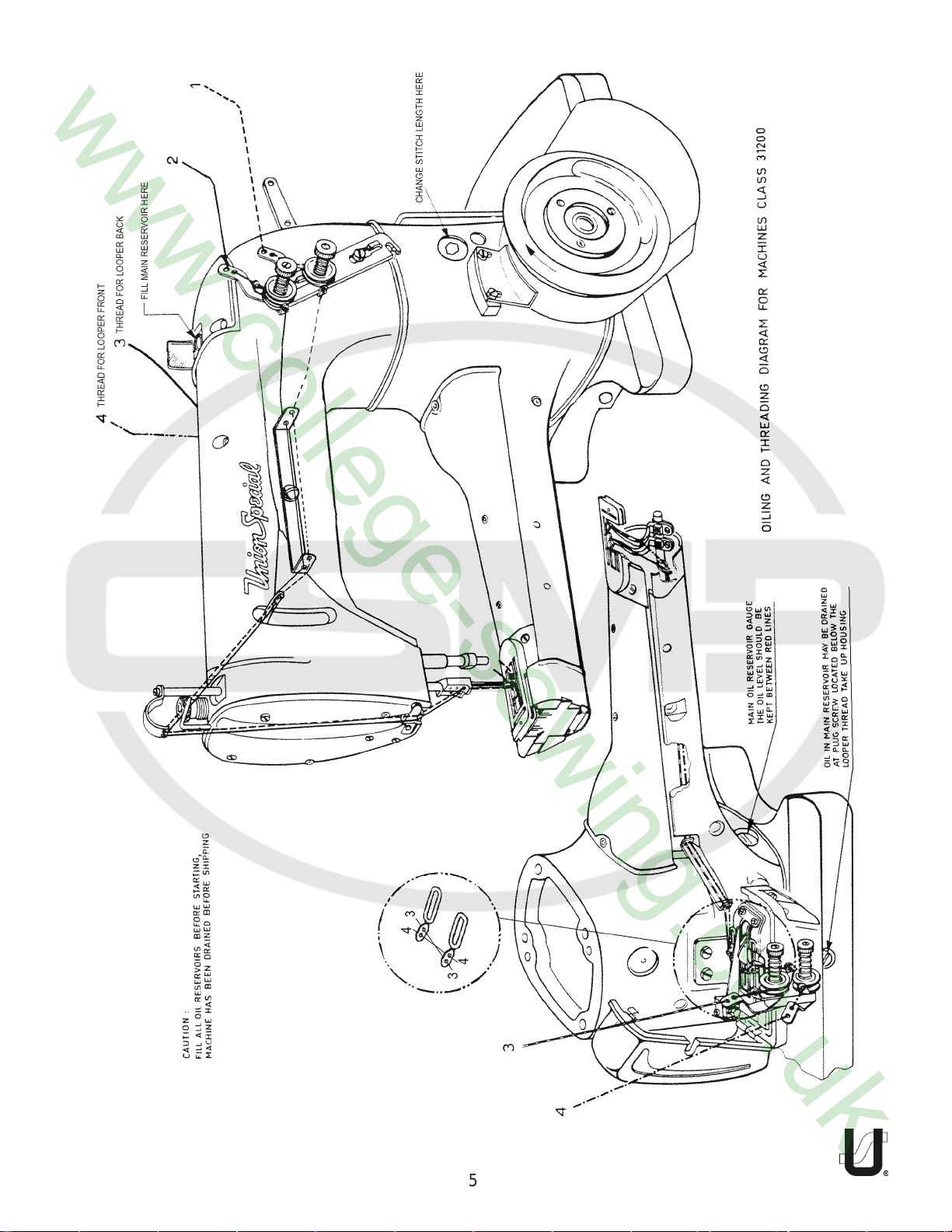

5

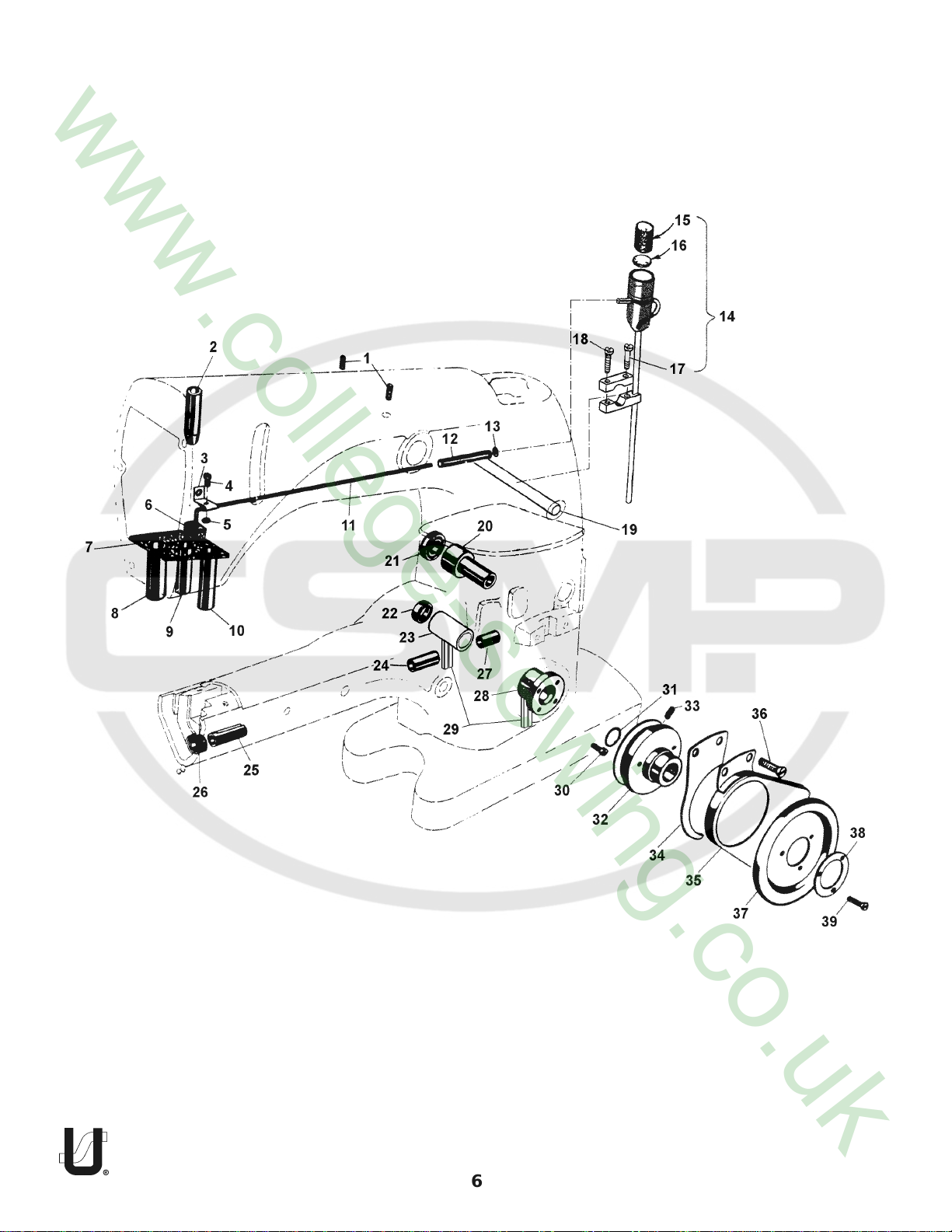

6

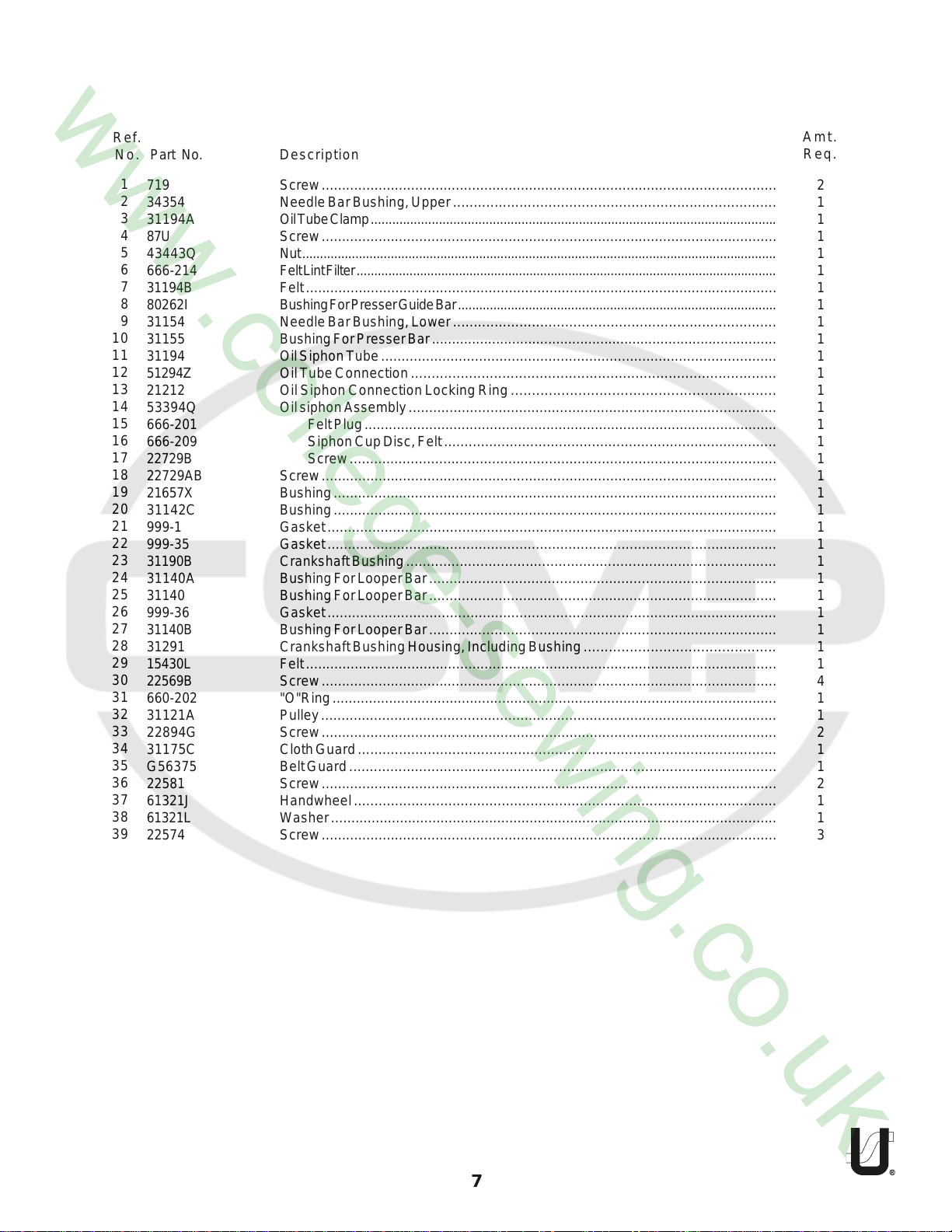

Ref.

No.

Part No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

719

34354

31194A

87U

43443Q

666-214

31194B

80262I

31154

31155

31194

51294Z

21212

53394Q

666-201

666-209

22729B

22729AB

21657X

31142C

999-1

999-35

31190B

31140A

31140

999-36

31140B

31291

15430L

22569B

660-202

31121A

22894G

31175C

G56375

22581

61321J

61321L

22574

Description

Screw ................................................................................................................

Needle Bar Bushing, Upper ..............................................................................

Oil Tube Clamp .................................................................................................................

Screw ................................................................................................................

Nut ......................................................................................................................................

Felt Lint Filter .......................................................................................................................

Felt ....................................................................................................................

Bushing For Presser Guide Bar ..........................................................................................

Needle Bar Bushing, Lower ..............................................................................

Bushing For Presser Bar ......................................................................................

Oil Siphon Tube .................................................................................................

Oil Tube Connection ........................................................................................

Oil Siphon Connection Locking Ring ...............................................................

Oil siphon Assembly ..........................................................................................

Felt Plug ......................................................................................................

Siphon Cup Disc, Felt .................................................................................

Screw .........................................................................................................

Screw ................................................................................................................

Bushing .............................................................................................................

Bushing .............................................................................................................

Gasket ..............................................................................................................

Gasket ..............................................................................................................

Crankshaft Bushing ..........................................................................................

Bushing For Looper Bar .....................................................................................

Bushing For Looper Bar .....................................................................................

Gasket ..............................................................................................................

Bushing For Looper Bar .....................................................................................

Crankshaft Bushing Housing, Including Bushing ..............................................

Felt ....................................................................................................................

Screw ................................................................................................................

"O"Ring ..............................................................................................................

Pulley ................................................................................................................

Screw ................................................................................................................

Cloth Guard ......................................................................................................

Belt Guard ........................................................................................................

Screw ................................................................................................................

Handwheel .......................................................................................................

Washer ..............................................................................................................

Screw ................................................................................................................

Amt.

Req.

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

2

1

1

2

1

1

3

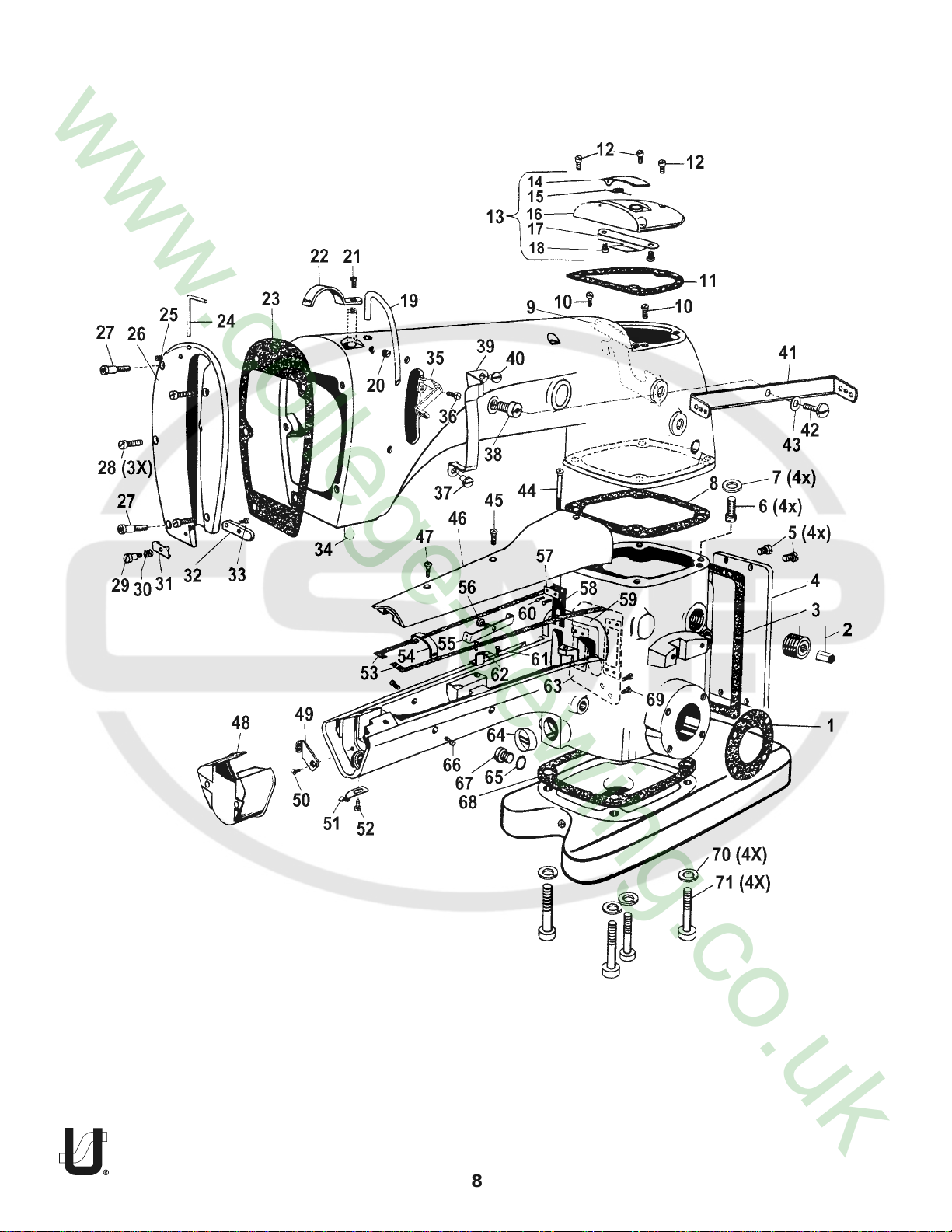

7

8

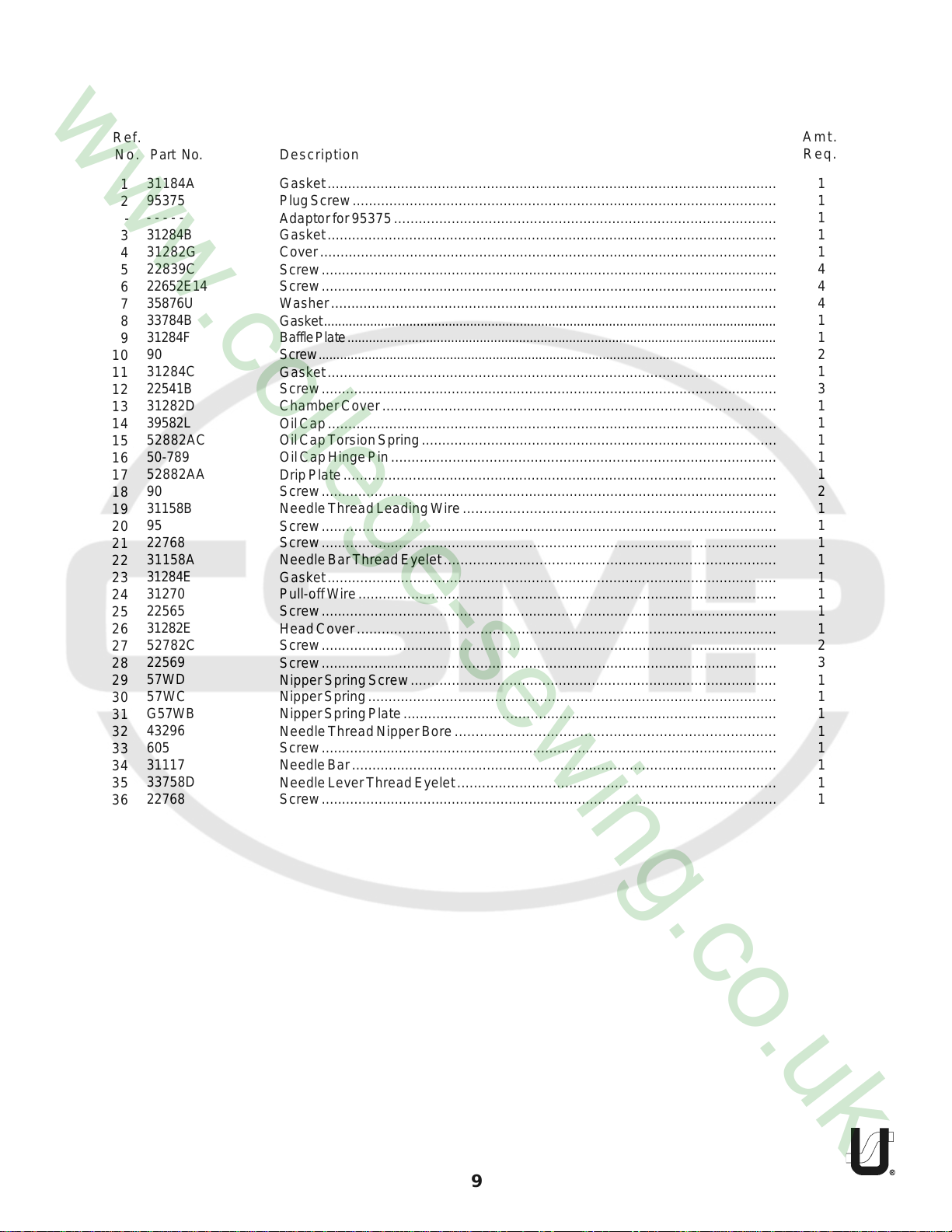

Ref.

No.

Part No.

1

2

-

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

31184A

95375

- - - - -

31284B

31282G

22839C

22652E14

35876U

33784B

31284F

90

31284C

22541B

31282D

39582L

52882AC

50-789

52882AA

90

31158B

95

22768

31158A

31284E

31270

22565

31282E

52782C

22569

57WD

57WC

G57WB

43296

605

31117

33758D

22768

Description

Gasket ..............................................................................................................

Plug Screw ........................................................................................................

Adaptor for 95375 .............................................................................................

Gasket ..............................................................................................................

Cover ................................................................................................................

Screw ................................................................................................................

Screw ................................................................................................................

Washer ..............................................................................................................

Gasket ...............................................................................................................................

Baffle Plate ........................................................................................................................

Screw .................................................................................................................................

Gasket ..............................................................................................................

Screw ................................................................................................................

Chamber Cover ...............................................................................................

Oil Cap ..............................................................................................................

Oil Cap Torsion Spring .......................................................................................

Oil Cap Hinge Pin ..............................................................................................

Drip Plate ..........................................................................................................

Screw ................................................................................................................

Needle Thread Leading Wire ...........................................................................

Screw ................................................................................................................

Screw ................................................................................................................

Needle Bar Thread Eyelet ................................................................................

Gasket ..............................................................................................................

Pull-off Wire .......................................................................................................

Screw ................................................................................................................

Head Cover ......................................................................................................

Screw ................................................................................................................

Screw ................................................................................................................

Nipper Spring Screw .........................................................................................

Nipper Spring ....................................................................................................

Nipper Spring Plate ...........................................................................................

Needle Thread Nipper Bore .............................................................................

Screw ................................................................................................................

Needle Bar ........................................................................................................

Needle Lever Thread Eyelet .............................................................................

Screw ................................................................................................................

Amt.

Req.

1

1

1

1

1

4

4

4

1

1

2

1

3

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

3

1

1

1

1

1

1

1

1

9

10

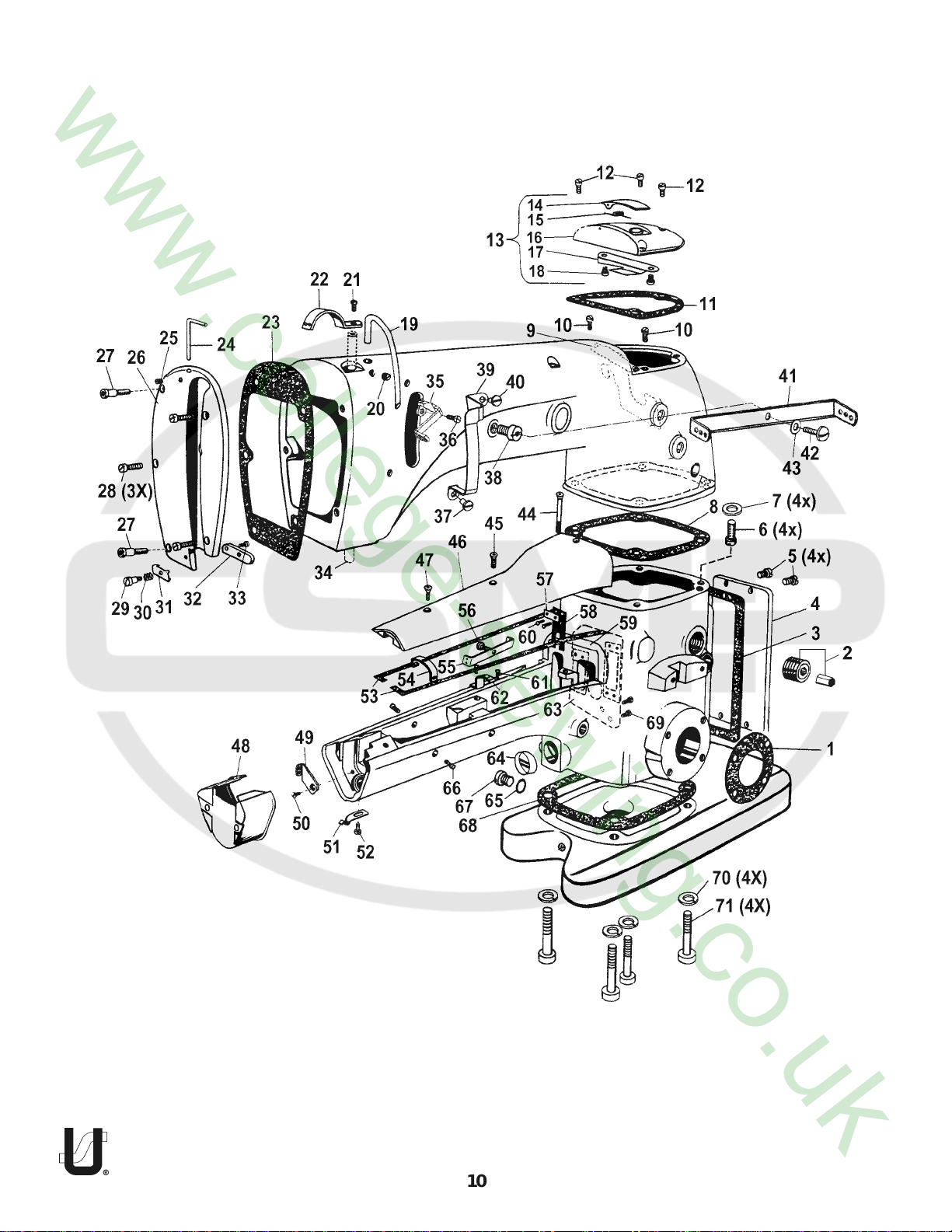

Ref.

No.

Part No.

Description

Amt.

Req.

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

22585A

22889H

31295

22585A

G52758

22848

20

99287

99287B

31182

99287C

31279F

31258E

77K

31263

77L

31184R

31182B

31258D

94

31182K3

31182SK4

33784

96402

22524

31182C

31262B

G50-434

41394A

99242

22733B

31284D

22585A

40C149

22652E24

Screw ................................................................................................................

Screw ................................................................................................................

Needle Lever Eyelet Guard .............................................................................

Screw ................................................................................................................

Thread Eyelet ...................................................................................................

Screw ................................................................................................................

Washer .............................................................................................................

Screw ................................................................................................................

Screw ................................................................................................................

Cylinder Cover .................................................................................................

Screw ................................................................................................................

Cylinder End Cover ..........................................................................................

Thread Eyelet, Front .........................................................................................

Screw ................................................................................................................

Latch Spring .....................................................................................................

Screw .................................................................................................................................

Gasket ..............................................................................................................

Support For Cylinder Cover, Front ...................................................................

Thread Eyelet, Rear ..........................................................................................

Screw ................................................................................................................

Holding-plate ...................................................................................................

Splash-leather ..................................................................................................

Gasket ..............................................................................................................

Rivet ..................................................................................................................

Screw ................................................................................................................

Support for Cylinder Cover, Rear ....................................................................

Baffle Plate .......................................................................................................

Lucite Oil Gauge ..............................................................................................

Gasket ...............................................................................................................................

Screw .................................................................................................................................

Oil Drain Screw ..................................................................................................................

Gasket ..............................................................................................................

Screw ................................................................................................................

Washer .............................................................................................................

Screw ................................................................................................................

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

3

4

4

11

12

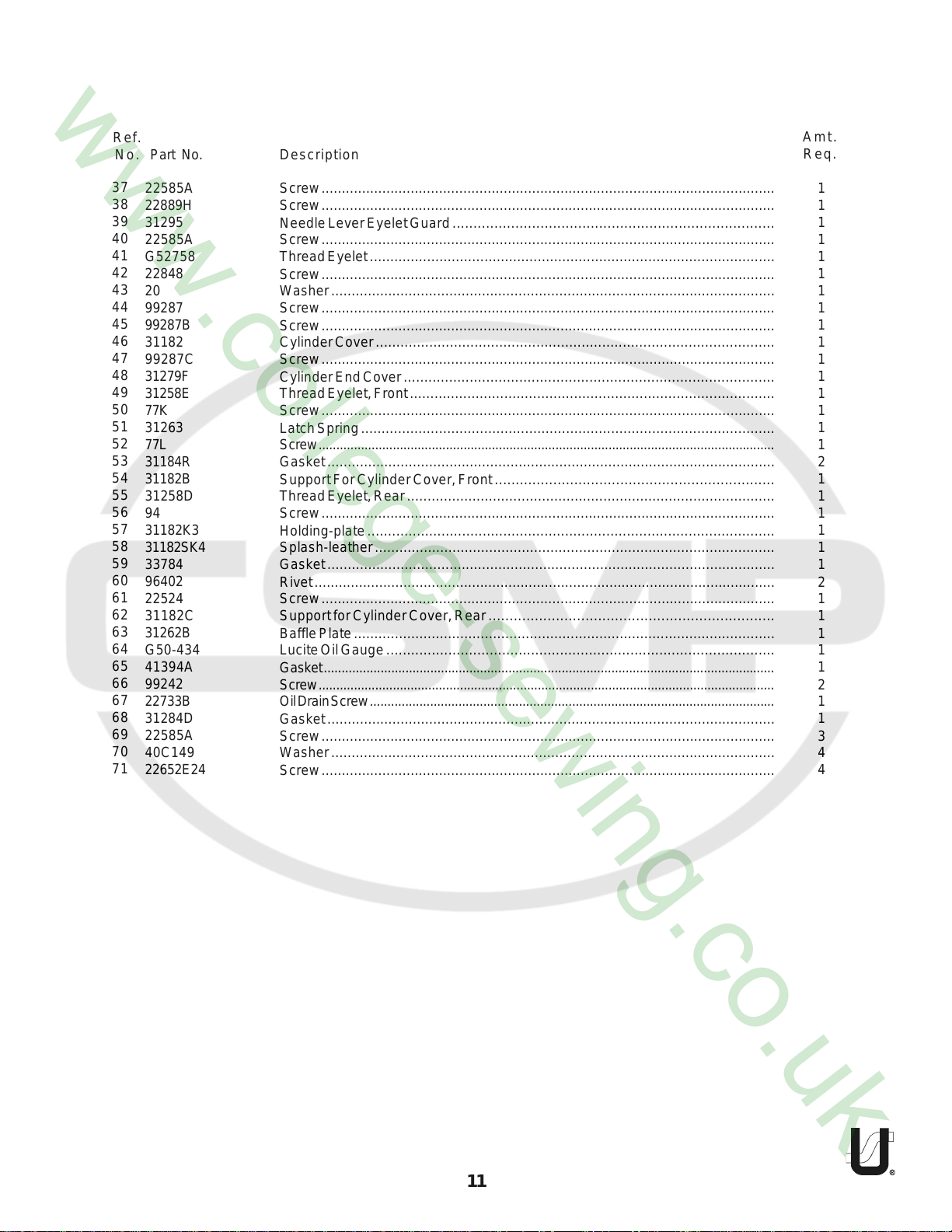

Ref.

No.

Part No.

Description

Amt.

Req.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

22586R

51250V

51250D

660-212

34350

719

29476ZL

660-212

51250E

51254K

22562A

660-215

52336A

22564

56354D

31215B

BP108

77

31247

21233FB

61256G

29476ZK

29066Z

80630C

31116H

22559C

999-39W

31222

22768

33758D

31218A16

22565C

96654

31117

31158A

22768

Screw .................................................................................................................

Gasket ................................................................................................................

Washer ...............................................................................................................

"O"Ring ...............................................................................................................

Bushing ...............................................................................................................

Screw .................................................................................................................

Needle Lever Assembly .....................................................................................

"O"Ring ........................................................................................................

Needle Lever Stud ......................................................................................

Needle Bar Connection .............................................................................

Screw ...................................................................................................

Retaining Ring .............................................................................................

Link Pin .........................................................................................................

Screw ..........................................................................................................

Needle Bar Link ...........................................................................................

Needle Lever ..............................................................................................

Screw ...................................................................................................

Screw ...................................................................................................

Pin, for needle lever ...........................................................................................

Nut, for 31247 .....................................................................................................

Washer ...............................................................................................................

Needle Lever Rod Assembly .............................................................................

Bearing ........................................................................................................

Nut, left thread ............................................................................................

Needle Lever Rod Assembly ......................................................................

Screw ...................................................................................................

Needle Bearing ..........................................................................................

Crankshaft ..................................................................................................

Screw .................................................................................................................

Needle Lever Thread Eyelet ..............................................................................

Needle Holder ...................................................................................................

Screw ..........................................................................................................

Pin ................................................................................................................

Needle Bar .........................................................................................................

Needle Bar Thread Eyelet ..................................................................................

Screw .................................................................................................................

1

1

1

1

1

2

1

1

1

1

1

4

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

2

1

1

1

13

14

Ref.

No.

Part No.

Description

Amt.

Req.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

31139C

258

31146

G29476X

22729C

31139B

35746C

28B

22894C

31206

22559C

31142A

999-1

31244

31142B

22517

31242

12538

31144C

31144B

31144E

77B

31144D

22729

G97A

18

22517

31144G

22733

12538

31209

31207

31248A

22564D

22562A

31248

22564D

22562A

Feed Rocker Arm ...............................................................................................

Nut ......................................................................................................................

Washer ...............................................................................................................

Feed Lift Connection Assembly For Style 31200Q .............................................

Screw ...........................................................................................................

Bearing ........................................................................................................................

Ball Screw ....................................................................................................................

Screw ...........................................................................................................................

Screw ...........................................................................................................

Eccentric .....................................................................................................................

Screw ...........................................................................................................

Bar For Looper Avoid Lever ................................................................................

Gasket ................................................................................................................

Looper Drive Lever And Link Assembly ..............................................................

Link Pin .........................................................................................................

Screw ...........................................................................................................

Looper Drive Lever ......................................................................................

Nut ...............................................................................................................

Ball Screw ....................................................................................................

Bearing ........................................................................................................

Guide Fork ...................................................................................................

Screw ...........................................................................................................

Ball Screw ....................................................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Nut ...............................................................................................................

Screw ..................................................................................................................

Looper Drive Lever .............................................................................................

Screw ..................................................................................................................

Nut ......................................................................................................................

Looper Rear For Class 31200Q ...........................................................................

Looper Front For Class 31200Q ..........................................................................

Looper Holder, Rear ...........................................................................................

Screw ...........................................................................................................

Clamp Screw ..............................................................................................

Looper Holder, Front ..........................................................................................

Screw ...........................................................................................................

Clamp Screw ..............................................................................................

1

1

1

1

2

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

15

16

Ref.

No.

Part No.

Description

Amt.

Req.

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

31244A

75A

31116F

999-38

31116C

22559C

999-40

31106

22894C

31144J

77

39543P

18

12538

G12055P

51054A

666-149

31133H

31133K

999-32

31142P

18

21657E

12538

31142M

22894W

31142Q

88

482C

31133M

999-30

31142E

31275A

Looper Rocker Shaft .........................................................................................

Screw ................................................................................................................

Looper Drive Lever Connection ......................................................................

Needle Bearing ................................................................................................

Feed Drive And Looper Avoid Connection Assembly ....................................

Screw .........................................................................................................

Needle Bearing .........................................................................................

Eccentric ...................................................................................................

Screw ..................................................................................................

Looper Avoid Link .............................................................................................

Screw .........................................................................................................

Washer ..............................................................................................................

Nut ....................................................................................................................

Nut ....................................................................................................................

Looper Avoid Drive Link ....................................................................................

Link Pin ...............................................................................................................

Oil Wick ......................................................................................................

Connection Rod ..............................................................................................

Shoulder Screw .................................................................................................

"O"Ring ..............................................................................................................

Bar, For 31142Q .................................................................................................

Nut ....................................................................................................................

Washer ..............................................................................................................

Nut ....................................................................................................................

Link Pin ...............................................................................................................

Screw ................................................................................................................

Feed Drive And Looper Avoid Drive Lever .......................................................

Screw ................................................................................................................

Collar ................................................................................................................

Adjusting Nut ....................................................................................................

"O"Ring ..............................................................................................................

Stud For Looper Avoid Link ...............................................................................

Washer ..............................................................................................................

1

2

1

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

17

18

Ref.

No.

Part No.

Description

Amt.

Req.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

990-30

31135C

660-221

22894C

660-199

31136A

31234

99305

31225F

31225A

99306

31134L

G41228A

31136E

31136A

999-30

31139A

999-31

22894W

31139C

31146

35746C

258

96275

31135G

31135E

90

CQ200000000

"O"-Ring .............................................................................................................

Feed Rocker Shaft ............................................................................................

"O"-Ring .............................................................................................................

Screw for 31135C ..............................................................................................

Retaining Ring ...................................................................................................

Link Pin ...............................................................................................................

Feed Bar .............................................................................................................................

Screw .........................................................................................................

Holder For Needle Guard .................................................................................................

Needle Guard ...................................................................................................

Screw .........................................................................................................

Spring ..................................................................................................................................

Screw ..................................................................................................................................

Feed Bar Guide .................................................................................................................

Link Pin ...............................................................................................................

"O"-Ring .............................................................................................................

Feed Bar Adjusting Pin ......................................................................................

"O"-Ring .............................................................................................................

Screw For 31139A ..............................................................................................

Feed Rocker Arm ..............................................................................................

Washer ..............................................................................................................

Ball .....................................................................................................................

Nut .....................................................................................................................

Retaining Ring ...................................................................................................

Feed Bar Shaft ...................................................................................................

Feed Rocker ......................................................................................................

Screw ................................................................................................................

Oil Wick ..............................................................................................................

1

1

1

1

4

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

19

20

Ref.

No.

Part No.

Description

Amt.

Req.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

21657W

318

31292

SS7121410TP

22875N

33783H

660-207

33783N

33783M

56356

51256C

34383BA

56383D

22557G

22758C

53783A

33783

88

G402

77

31260

39135

52888B

22562

31260F

31223

22580D

74

31274

31282M

31282H

G43266

51491C

51292D

51292A

51292G

109

51292F2

51292C

95303

31163

95259

96851

31282J

Tension Release Lever Shaft .............................................................................

Screw ................................................................................................................

TensionRelease and Foot Lifter LeverConnection ..........................................

Screw .........................................................................................................

Screw ................................................................................................................

Presser Foot Lifter Lever ....................................................................................

Oil Seal Ring .......................................................................................................................

Presser Foot Lifter Lever, Internal .....................................................................................

Presser Foot Lifter Lever Connecting Rod ......................................................................

Presser Spring Regulator ..................................................................................................

Presser Bar Spring ..............................................................................................

Presser Foot Lifter Lever Bell Crank ...................................................................

Presser Foot Lifter Lever Bell Crank Spring ........................................................

Screw ................................................................................................................

Screw ................................................................................................................

Lifter Lever Link .................................................................................................

Presser Bar Connection ....................................................................................

Screw .........................................................................................................

Screw ................................................................................................................

Screw ................................................................................................................

Presser Bar .........................................................................................................

Presser Bar Guide Bar ........................................................................................

Collar For Presser Foot ......................................................................................

Screw ................................................................................................................

Presser Bar Insert For Style 31200Q ....................................................................

Looper Thread Take-up ....................................................................................

Screw ................................................................................................................

Screw ................................................................................................................

Collar ................................................................................................................

Case For Take-up Complete ............................................................................

Case For Take-up .......................................................................................

Nut ..............................................................................................................

Thread lead in Guide .................................................................................

Tension Thread Eyelet ................................................................................

Tension Post Ferrule ...................................................................................

Tension Post ...............................................................................................

Tension Disc ...............................................................................................

Spring .........................................................................................................

Tension Nut ................................................................................................

Screw .........................................................................................................

Spring .........................................................................................................

Nut ..............................................................................................................

Pin ...............................................................................................................

Cover .........................................................................................................

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

2

2

2

1

1

2

2

2

2

2

4

2

2

2

1

2

1

1

21

22

Ref.

No.

Part No.

Description

Amt.

Req.

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

43266

51491C

51292D

51292A

51292G

109

51292F4

51292C

80557

52892

22598C

21657-3

94

69H

G29389U

31204

22729

53304C

31257

J87J

53304B

28

73A

52958L

22588A

31104

52804E

Nut ....................................................................................................................

Thread Lead-in Guide ......................................................................................

Tension Thread Eyelet .......................................................................................

Tension Post Ferrule ..........................................................................................

Tension Post ......................................................................................................

Tension Disc ......................................................................................................

Tension Spring-Needle .....................................................................................

Tension Nut .......................................................................................................

Washer ..............................................................................................................

Tension Post Support ........................................................................................

Screw ................................................................................................................

Tension Disc Separator .....................................................................................

Screw ................................................................................................................

Washer ..............................................................................................................

Take-up Shield Complete ................................................................................

Cast-off and Retaining Finger Support Bracket .......................................

Screw ..................................................................................................

Cast-off ......................................................................................................

Take-up Shield ...........................................................................................

Screw .........................................................................................................

Cast-off Plate .............................................................................................

Screw .........................................................................................................

Screw .........................................................................................................

Eyelet .........................................................................................................

Screw .........................................................................................................

Retaining Finger ........................................................................................................

Retainer Support .......................................................................................................

1

2

2

2

2

4

2

2

2

1

1

1

2

2

1

1

1

1

1

2

1

2

2

2

1

1

1

23

24

Ref.

No.

Part No.

Description

Amt.

Req.

*1

31220R16

2

31130S

3

31130T

4

31230R16

5

91

6

11940

7

605

8

22524

9

31224Q16

10

31134M

11

31134N

12

22716

13

99293

14

31205Q

* 31220R16 Presser Foot Assembly not supplied

with machine style 31200AQ64Z6

Presser Foot Assembly For Style 31200Q64 .......................................................

Yielding Section, Left .................................................................................

Yielding Section, Right ...............................................................................

Presser Foot Bottom ...................................................................................

Screw .........................................................................................................

Spring .........................................................................................................

Screw .........................................................................................................

Screw ................................................................................................................

Throat Plate ......................................................................................................

Stripper .............................................................................................................

Plate ..................................................................................................................

Screw ................................................................................................................

Screw ................................................................................................................

Feed Dog ..........................................................................................................

1

1

1

1

1

1

1

2

1

1

1

2

1

1

25

26

Ref.

No.

Part No.

Description

Amt.

Req.

1

2

3

4

5

6

21201

12288403

TT17

21388

G43294B

28604R

Screw Driver ......................................................................................................

Thread Tweezers ...............................................................................................

Wrench 9/32" ....................................................................................................

Wrench 3/8" ......................................................................................................

Oil Can ..............................................................................................................

Container of Oil .................................................................................................

1

1

1

1

1

1

27

28

Ref.

No.

Part No.

Description

Amt.

Req.

1

2

21101W4

51295B

Thread Stand............................................................................................................

Mounting Isolator ....................................................................................................

1

4

29

30

Ref.

No.

Part No.

Description

Amt.

Req.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

21177A

22647K24

1349A5

21114W

258

23105B

21182AP

22581

52782C

31282E

22569

31270

22565

31278

753

188D

Tape Reel Tension Spring Complete ................................................................

Thumb Screw .............................................................................................

Spring .........................................................................................................

Spool Pin ...........................................................................................................

Nut ....................................................................................................................

Tape Reel Bracket ............................................................................................

Tape Tension Bracket .......................................................................................

Screw ................................................................................................................

Stud ...................................................................................................................

Head Cover ......................................................................................................

Screw ................................................................................................................

Pull-off Wire .......................................................................................................

Screw ................................................................................................................

Tape Holder Disc ..............................................................................................

Spool Axle Cone ...............................................................................................

Thumb Screw ....................................................................................................

1

1

1

1

3

1

1

2

2

1

3

1

1

2

1

1

31

NUMERICAL INDEX OF PARTS

Part No. Page No. Part No. Page No. Part No. Page No.

109 ........... 21, 23

11940 ........... 25

12288403 ...... 27

12538 ...... 15, 17

1349A5 ......... 31

15430L ......... 7

18 ......... 15, 17

188D ........... 31

20 ............. 11

21101W4 ........ 29

21114W ......... 31

21177A ......... 31

21182AP ....... 31

21201 ........... 27

21212 ............. 7

21233FB ........ 13

21388 ........... 27

21657-3 ......... 23

21657E ........... 17

21657W ........... 21

21657X ........... 7

22517 ............. 15

22524 ........ 11, 25

22541B ........... 9

22557G .......... 21

22559C ..... 13, 15

22559C .......... 17

22562 ............. 21

22562A ..... 13, 15

22564 ............. 13

22564D ........... 15

22565 ........ 9, 31

22565C ......... 13

22569 ........ 9, 31

22569B ........... 7

22574 .............. 7

22580D .......... 21

22581 ........ 7, 31

22585A ........... 11

22586R ........... 13

22588A ........... 23

22598C ........... 23

22647K24 ........ 31

22652E14 ......... 9

22652E24 ....... 11

22716 .............. 25

22729 ......... 15, 23

22729AB ......... 7

22729B ........... 7

22729C ........... 15

22733 ............. 15

22733B ........... 11

22758C ........... 21

22768 ......... 9, 13

22839C ............ 9

22848 ............. 11

22875N ........... 21

22889H ........... 11

22894C ..... 15, 17

22894C .......... 19

22894G ........... 7

22894W .... 17, 19

23105B .......... 31

258 ..... 15, 19, 31

28 ................ 23

28604R ......... 27

28B ............... 15

29066Z ........... 13

29476ZK ......... 13

29476ZL ......... 13

31104 ............. 23

31106 ............. 17

31116C ........... 17

31116F ........... 17

31116H ........... 13

31117 ......... 9, 13

31121A ............. 7

31130S ........... 25

31130T ........... 25

31133H ........... 17

31133K ........... 17

31133M ........... 17

31134L ........... 19

31134M ........... 25

31134N ........... 25

31135C ........... 19

31135E ........... 19

31135G ........... 19

31136A ........... 19

31136E ........... 19

31139A ........... 19

31139B ........... 15

31139C ...... 15, 19

31140 ............. 7

31140A ............ 7

31140B ............ 7

31142A ........... 15

31142B ........... 15

31142C ............ 7

31142E ........... 17

31142M ........... 17

31142P ........... 17

31142Q ........... 17

31144B ........... 15

31144C ........... 15

31144D ........... 15

31144E ........... 15

31144G ........... 15

31144J ........... 17

31146 ....... 15, 19

31154 .............. 7

31155 .............. 7

31158A ....... 9, 13

31158B ............. 9

31163 ............. 21

31175C ............. 7

31182 ............. 11

31182B ........... 11

31182C ........... 11

31182K3 ......... 11

31182SK4 ....... 11

31184A ............. 9

31184R ........... 11

31190B ............ 7

31194 .............. 7

31194A ............ 7

31194B ............ 7

31204 ............. 23

31205Q ........... 25

31206 ............. 15

31207 ............. 15

31209 ............. 15

31215B ........... 13

31218A16 ....... 13

31220R16 ....... 25

31222 ............. 13

31223 ............. 21

31224Q16 ....... 25

31225A ........... 19

31225F ........... 19

31230R16 ....... 25

31234 ............. 19

31242 ............. 15

31244 ............. 15

31244A ........... 17

31247 ............. 13

31248 ............. 15

31248A ........... 15

31257 ............. 23

31258D ........... 11

31258E ........... 11

31260 ............. 21

31260F ........... 21

31262B ........... 11

31263 ............. 11

31270 ......... 9, 31

31274 ............. 21

31275A ........... 17

31278 ............. 31

Part No. Page No.

31279F ........... 11

31282 ............. 31

31282D ............ 9

31282E ....... 9, 31

31282G ............ 9

31282H ........... 21

31282J ........... 21

31282M ........... 21

31284B ............ 9

31284C ............ 9

31284D ........... 11

31284E ............ 9

31284F ............ 9

31291 .............. 7

31292 ............. 21

31295 ............. 11

318 ............... 21

33758D ....... 9, 13

33783

33783H ........... 21

33783M ........... 21

33783N ........... 21

33784 ............. 11

33784B ........... 9

34350 ............. 13

34354 .............. 7

34383BA ......... 21

35746C ...... 15, 19

35876U ............ 9

39135 ............. 21

39543P ........... 17

39582L ............ 9

40C149 ........... 11

41394A ........... 11

43266 ............. 23

43296 .............. 9

43443Q ............ 7

482C .............. 17

50-789 .............. 9

51054A ........... 17

51250D ........... 13

51250E ........... 13

51250V ........... 13

51254K ........... 13

51256C ........... 21

51292A ..... 21, 23

51292C ..... 21, 23

51292D ..... 21, 23

51292F2 ......... 21

51292F4 ......... 23

51292G ..... 21, 23

51294Z ............ 7

51295B ........... 29

............. 21

32

NUMERICAL INDEX OF PARTS

Part No. Page No. Part No. Page No.

51491C ...... 21, 23

52336A ........... 13

52782C ....... 9, 31

52804E ........... 23

52882AA .......... 9

52882AC .......... 9

52888B ........... 21

52892 ............. 23

52958L ........... 23

53304B ........... 23

53304C ........... 23

53394Q ............ 7

53783A ........... 21

56354D ........... 13

56356 ............. 21

56383D ........... 21

57WC ............. 9

57WD ............. 9

605 ........... 9, 25

61256G ........... 13

61321J ............ 7

61321L ............ 7

660-199 ......... 19

660-202 .......... 7

660-207 ......... 21

660-212 ......... 13

660-215 ......... 13

660-221 ......... 19

666-149 ......... 17

666-201 .......... 7

666-209 .......... 7

666-214 .......... 7

69H ............. 23

719 .......... 7, 13

73A ............. 23

74 ............... 21

753 ............. 31

75A ........... 17

77 ..... 13, 17, 21

77B ............. 15

77K ............. 11

77L ............. 11

80262I ........... 7

80557 ............. 23

80630C ........... 13

87U .............. 7

88 ........ 17, 21

88D ........... 31

90 ............ 9, 19

91 ............. 25

94 ......... 11, 23

95 ............. 9

95259 ............. 21

95303 ............. 21

95375 .............. 9

96275 ............. 19

96402 ............. 11

96654 ............. 13

96851 ............. 21

990-30 ........... 19

99242 ............. 11

99287 ............. 11

99287B ........... 11

99287C ........... 11

99293 ............. 25

99305 ............. 19

99306 ............. 19

999-1 ........ 7, 15

999-30 ...... 17, 19

999-31 ........... 19

999-32 ........... 17

999-35 ............ 7

999-36 ............ 7

999-38 ........... 17

999-39W ........ 13

999-40 ........... 17

BP108 .......... 13

CQ200000000 ... 19

G12055P ......... 17

G29389U ......... 23

G29476X .......... 15

G402 ............. 21

G41228A ......... 19

G43266 .......... 21

G43294B ........ 27

G50-434 ........... 11

G52758 ........... 11

G56375 ............ 7

G57WB ............ 9

G97A ............... 15

J87J ............. 23

SS7121410TP ... 21

TT17 ............. 27

33

NOTES

NOTES

Loading...

Loading...