Page 1

...

FINEST

•

QUA

LilY

INDUSTRI

SEWING

MACHINE$

r

6J

A L

63900

WS 4

PL

AM

2800

1096

Z-900

LAH

-1

/

A D J U S T I N G

LIST

I N S T R U C T I 0 N S

AND

OF

PARTS

-

..

Page 2

'

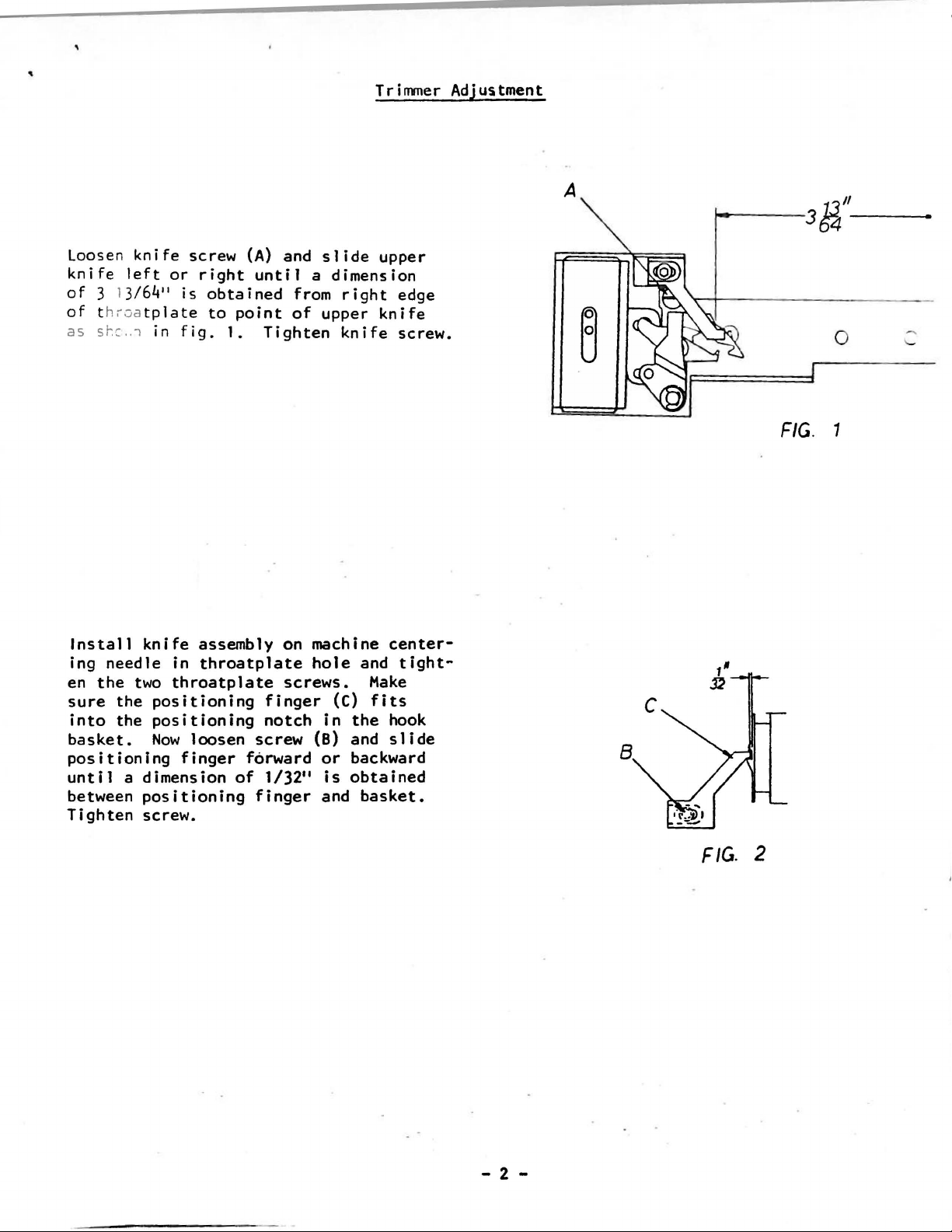

Trimmer Adjustment

A

1J"

36'+---

loosen

knife

of

of

as

Install

ing

en

sure

into

left

3

1

3/6~

throa

st-:c

..

needle

the

the

the

knife

tplate

1 in

knife

two

basket.

positioning

until

between

Tighten

a dimension

positioning

screw.

or

11

screw

right

is

fig.

(A)

until

obtained

to

point

1.

Tighten

assembly on machine

in

throatplate

throatplate

positioning

positioning

Now

loosen

finger

finger

notch

screw

forward

of

1/32

finger

and

slide

a dimension

from

of

right

upper

knife

hole

screws.

(C)

in

(B)

and

or

11

backward

is

obtained

and

upper

knife

center-

and

Make

fits

the

hook

slide

basket.

edge

screw.

tight-

FIG

0

. 1

- 2 -

FIG.

2

Page 3

1.

Rotate

direction

tom

of

its

protective

(B, by

Rotate

of

approximately one

notch

the

notch

opening

handwheel in

until

needle

stroke.

cover

disc

is

centered

(Fig.

4).

Remove

(A)

and loosen

(C)

until

Tighten

Synchronizer

counterclockwise

bar

is

at

the

synchronizer

set

screw

half

over

the

set

turn.

opening

the

shutter

screw.

bot-

Adjustment

FIG.

r

S~TTER

3

2.

Now

is

on

1/8

inch from

Loosen

(D)

until

shutter

caution

notch

rotate

its

up

set

the tab

opening

not

disc.

handwheel

stroke

the

screw

to

change

Tighten

top

(B)

is

(Fig.

until

and

is

of

its

and

turn

centered

4)

while

the

set

screw.

take-up

approxlmatley

stroke.

tab

disc

over

the

using

setting

of

I

rSH

~f\JOTCHEO

'

(SHUTTER

/

.

~

I

U

TTER

sHuTTeR

TAB

FIG.

OPEfJING

DISC

OPeNING

DISC

4

- 3 -

Page 4

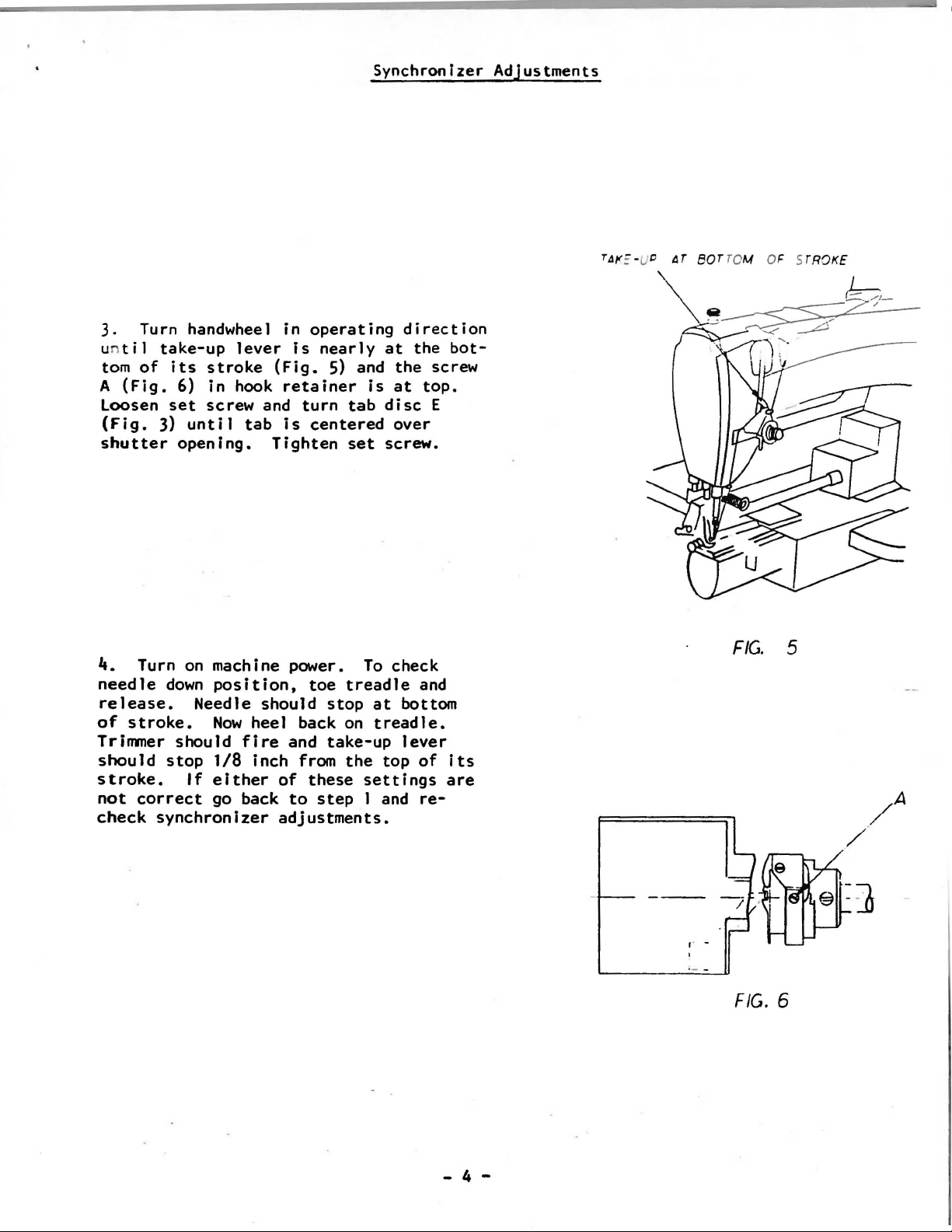

Synchronizer Adjustments

3. Turn handwheel in

u

til

take-up

tom

of

its

A

(Fig.

loosen

(Fig.

shutter

4.

needle

release.

of

stroke.

Trimmer should

should

stroke.

not

check

6) in hook

set

3)

until

opening.

Turn

on

down

stop

If

correct

synchronizer

lever

stroke

screw and

machine power.

position,

Needle should

Now

1/8

either

go

(Fig.

retainer

tab

is

Tighten

heel back

fire

inch from

of

back

adjustments.

operating

is

nearly

5)

turn

centered

toe

stop

and

take-up

these

to

step

at

and

is

at

tab

disc

over

set

screw.

To

check

treadle

at

on

treadle.

the

top

settings

1 and

direction

the

bot-

the

screw

top.

E

and

bottom

lever

of

its

are

re-

FIG.

5

- 4 -

,. -

FIG.

6

Page 5

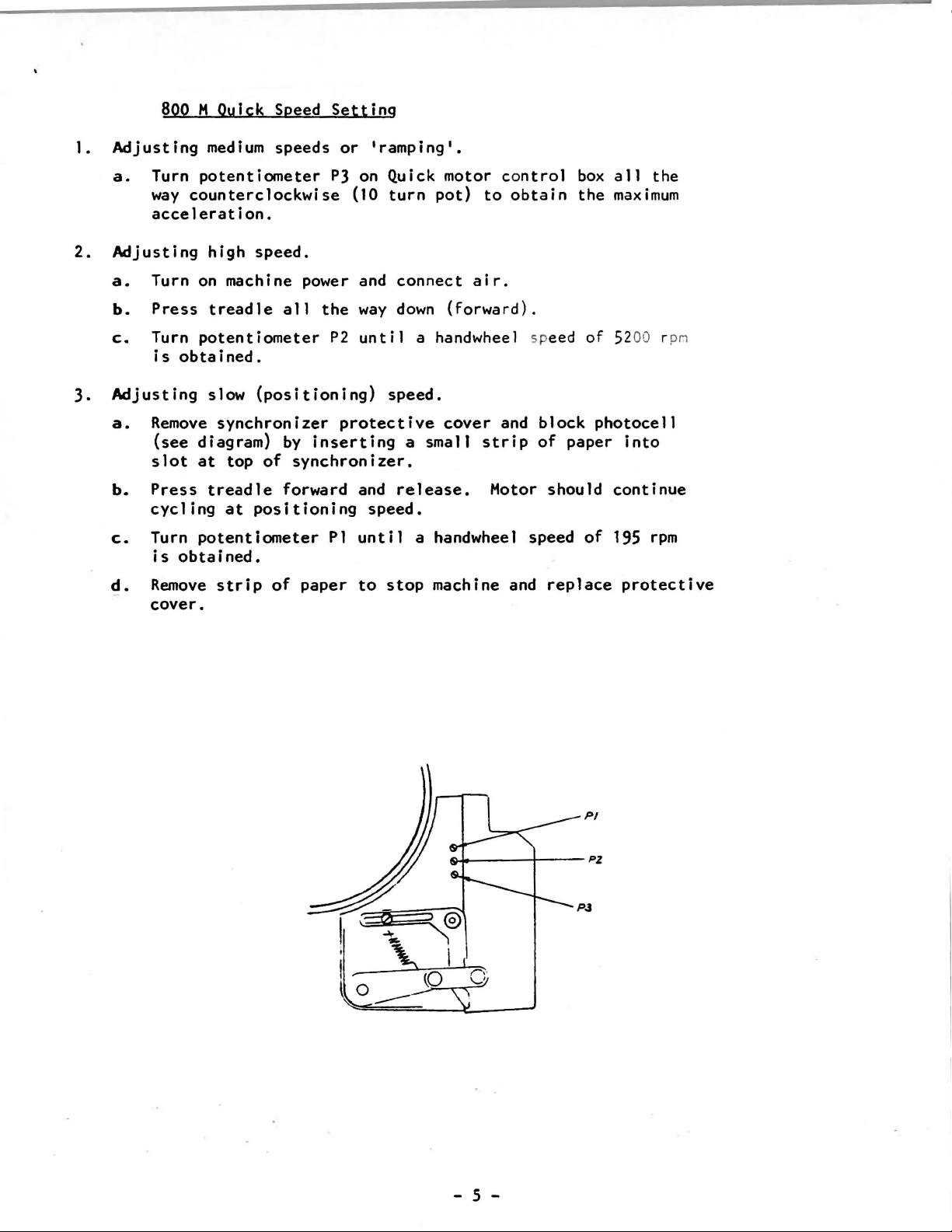

1.

2.

3.

c.

BooM Ouick Speed

Adjusting

a.

Turn

way

acceleration.

Adjusting

a.

Turn

b.

Press

c.

Turn

is

obtained.

Adjusting

a.

Remove

(see

slot

b.

Press

cycling

Turn

is

obtained.

medium

potentiometer

counterclockwise

high

on

machine power and

treadle

potentiometer

slow

synchronizer

diagram)

at

top

treadle

at

potentiometer

speeds

speed.

all

the

(positioning)

by

inserting

of

synchronizer.

forward and

positioning

Setting

or

'ramping'.

PJ on Quick motor

(10

turn

way

P2

until

speed.

protective

speed.

Pl

until

pot)

connect

down

a handwheel speed

a

small

release.

a handwheel speed

air.

(forward).

cover

control

to

obtain

and

strip

Motor

box

the

block

of

paper

should

all

the

maximum

of 5200 rpn

photocell

into

continue

of

195

rpm

d.

Remove

cover.

strip

of

paper

to

stop

machine and

replace

protective

- 5 -

Page 6

SERVICING

INSTRUCTIONS

880M

Assembly/Disassembly

1.

Remove V

2.

Disconnect

3.

Remove

moving

unit

4.

Keep

to

5.

Place

flat

Use

inserting

socket

shaft

brake

clutch

6.

Clean

surfaces

replace

keep

caution

belt

cables

the

three

last

screw,

will

clutch/brake

surface.

not

the

the

clutch/brake

of

of

the

of

the

discs

disc

the

surfaces

should

the

clutch/brake

during

for

projects

plates.

for

and

screws

fall.

Separate

the

solenoid

end

end

bell.

wear.

be

Inspection

guard.

which

housing

disassembly

bell.

of

smooth.

place

beyond

the

attach

located

hand

tilted

disc

housing,

the

electrical

Slide

Put

If

cork

face

or

Replacement:

clutch

approximately

under

sligh':

in

pla

pulley

clutch

and

the

the

end

surfaces

the

outer

plates

If

you

housing

clutch/brake

ly

d·

Jwllv.·a:-.::

ce.

side

facing

solenoid

reassembly

connection

clutch

bell

metal

with

find

and

aside

are

an

nicks

from

smooth

rim,

to

control

120°

apart.

housing so

(pulley side dov.'Tl)

upward,

the

to

ensure

pins

brake

and

inspect

and

discs

oiled

and

gouges

end

into

discs

if

are

rag.

box.

When

that

on a clean

bell.

alignment

the

mating

of

the

the

clutch/

cork

These

on

on

okay.

them,

re-

Note:

and

splined

7.

8.

9.

10.

11.

Thoroughly

dry

rag.

120°.

Apply a

clutch/brake

Reassemble

(part

condition.

certain

Reinstall

cedures

Once

as

Spread

small

No.

that

outlined

reinstallation

outlined

clean

Apply

408.009)

the

grease

the

amount

discs

the

clutch/brake

To

assure

the

clutch/brake

the

grease

move.

and

vent

in

sections

is

cork

faces

(Quick

evenly

of

grease

This

the

stop

proper

holes

discs

completed,

of

No.

over

to

will

discs

washer

operation

are

lined

and

3.,

2.,

the

clutch/brake

051.011)

the

the

brass

assure

making

(part

of

up.

housing

and

check

the

in

3-one

entire

splines

proper

sure

1.

the

No.

the

cooling

by

clutch/brake

discs

inch

cork

reversing

surfaces.

on

which

action.

rubber

250.008)

system,

using a clean,

segments

the

"O"

rings

are

the

clearance

in

good

make

pro-

every

- 6 -

Page 7

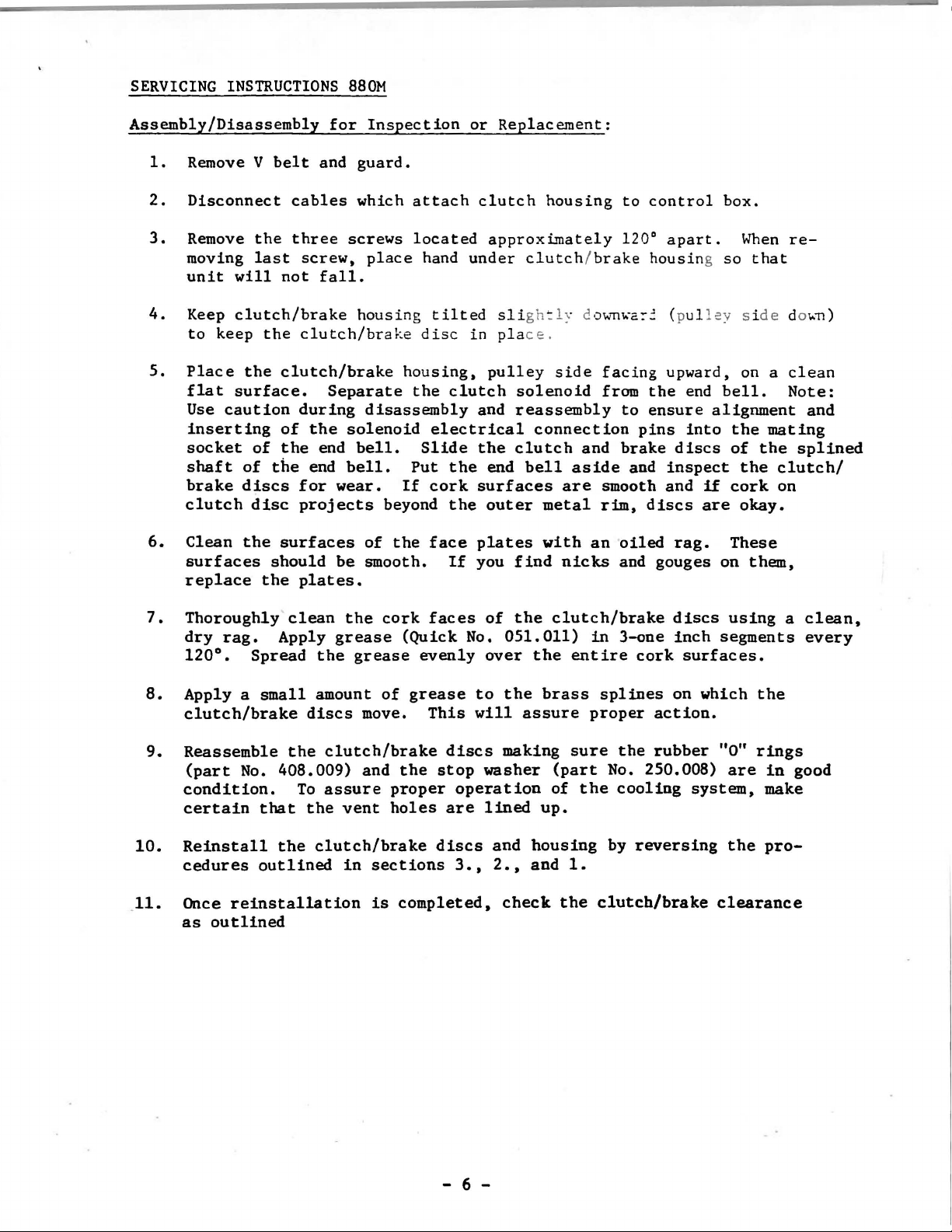

ADJUSTING

THE

CLUTCH/BRAKE

CLEARANCE

1.

Remove

2.

Insert

on

adjusting

of

adjusting

3.

With

has a moderate

4.

Rotate

quired

tool

(120°

fan

cover

adjusting

locked

adjusting

is

the

clutch

(1)

tool

tool

screw

distance

and

in

drag

tool

clearance

by

(4)

turn

(3).

place,

when

(4)

between

turning

into

fan

turn

rotated

and

.5

mm).

counterclockwise.

the

until

fan

fan

cap

bores

with

(2) 120°

nuts

the

(2)

the

[5]

on

tool

clockwise

other

fan

(2).

locks

hand.

counterclockwise

on

the

into

until

end

Exert

pulley

bell.

pressure

the

bores

(6)

Re-

- 7 -

Page 8

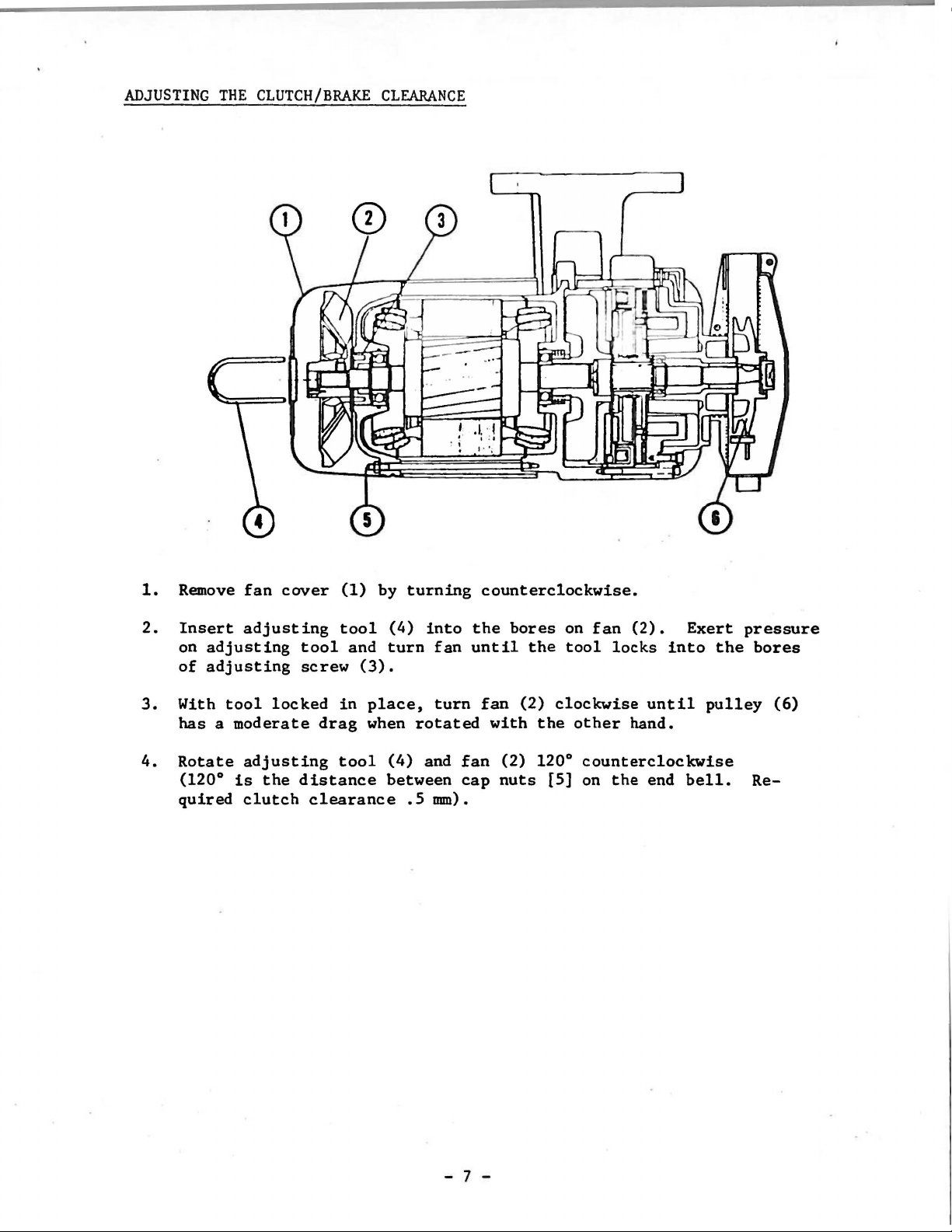

Lubrication

To

prolong

following

1.

Disassemble

as

2.

Remove

3.

Clean

and

flywheel

a

clean,

Mineral

tetrachloride

METAL

cleaning.

4.

Apply 3 segments

(Part

inch

tration,

cork

facing

lubrication

described

clutch

cork

the

metal

and

lint-free

spirits

SURFACES

No.

051.011)

long,

to

life

should

clutch/brake

on

the

and

brake

surfaces

facings

brake

cloth.

solvent

can

be

ONLY

of

about

as

shown

the

cork

and

be

reverse

discs.

of

the

of

surfaces

or

used

to

speed

Quick

one

in

the

surfaces.

increase

performed

assembly

side.

discs

the

'..'ith

Note:

carbon

on

up

grease

illus-

smoothness

annually:

Grease

of

operation,

the

5.

Spread

6.

Install

special

7.

Reassemble

grease

on

splined

grease.

to

evenly

motor

on

shaft

and

both

AFTER

check

cork

lightly

for

surfaces.

coating

clearance

(see

the

above).

splines

with

the

- 8 -

Page 9

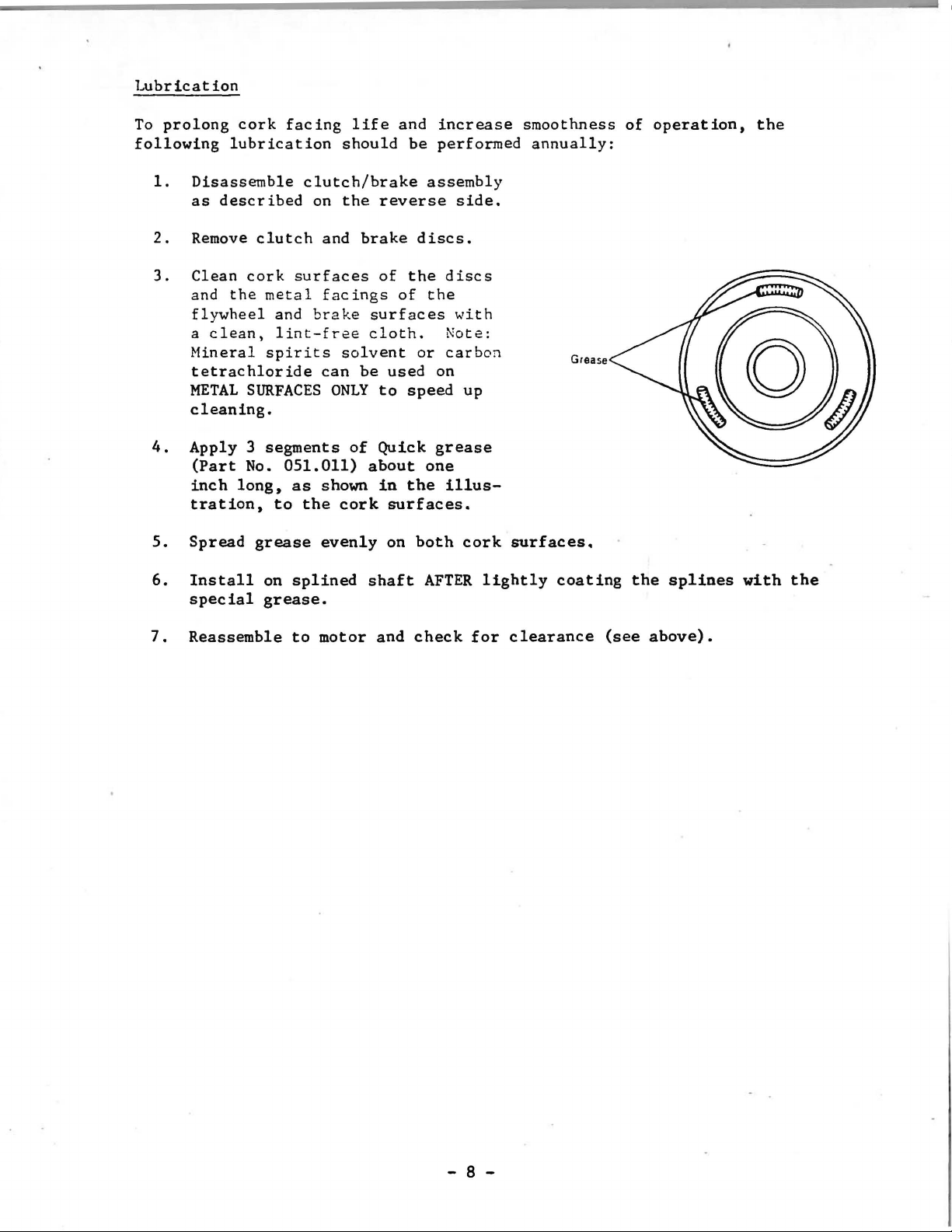

REMOVAL

1.

Turn mac

2.

Unscrew

3.

Unplug

4.

Unscrew

OF

PRINTED

CIRCUIT

hine

main

the 4 screws

flat

ribbon

the 2 screws

BOARD

power

in

cable fron

on the PCB and remove

(PCB)

off.

the corners

PCB,

of

the

motor

board

control

as

shown.

box

cover.

5. Re

6. Connec t

7.

8.

insert

Install

Turn power on

PCB

flat

cover

and tighten

rib

bon

cable

using

and

the 4 screws.

check

with

.

the

t he 2 s

functions.

crews.

Adjust

speeds

if

necessary.

- 9 -

Page 10

ELECTRICAL

The

terminal

connection

three-phase.

diagram

below.

strip

for

of

380

volts

Details

the

of

motor

A.C.

both

is

designed

or

Delta

connection

connections

to

accommodate

are

illustrated

for

220

either

volts

in

the

the

A.C.,

wiring

star

Terminal

WIRING

DIAGRAM

Box

- 10 -

Page 11

SOLENOID

CONNECTIONS

T n

mm~

r

So

lenotd

Sot~notd

H~rncss

610E-287

I

PN=UMATIC CONt,ECTIONS

F~ot

Lift

f'·

t¥t

J.

r.,.,_

w''"

'~~

J

M~·n

Fie!Jui.Jtcr

._IMPORTANT:

retr~ctcd

ro

'c

-

11

-

prc<tcnt

w~t'>t:

tn•

pos' t

lltufc

two

A

f-er

conn~t•ng

ion

1:1c

fore

IJ'ccn~nr

,,,

l•nes.

sm

tritrWT..:or,

carcncr

DDetating

d4md't:.

is

If

rn

JI

..

JyS

·

not,

Page 12

PNEUMATIC

52

DIAGRAM

TRE

:.o_E

At=-• AL

vE

SU~::J_.

~M-IN

0

EG

uL t.

-cq

bOPS/

51

KN=E-OPE.::tA

AtFi

: A_.·£

1----B--

..

EC

P=ESSE;:;

-~~-

FOLDE-=i

I~

=oo~

,...

--· --

•

.J-=

·=.,

-

12

-

Page 13

B0t3BIN COUNTER WIRING DIAGRAM

l

C:loD

Tl

o/11

119 '-)

+

+

1.

Install

chine.

holding

ing

the

other

L_

Operating

a

fully

Set

counter

the

reset

appropriate

three

black

___

_

Instructions

wound

to a value

button

digit

buttons.

bobbin in

of

in

while

by

pressing

ma-

900

by

index-

the

BOBBIN

--

• I

r

~-----------

I

I

t

39011.

RESISTOR

---=---:

______; INDICATOR LAMP

BOBBIN

COUNT

SOLENOID

=00 1

CUT-OFF

RUN-OUT

PPTIONAL}

LI

FT

SWITCH

12VOC

2.

Sew

the

complete bobbin keeping watch

for

when

counter

time

mer

pulses).

3.

Subtract

900

-

of

garments

bobbin.

this

that

~.

Reset

count

5.

-

When

bobbin

on and

when

dle.

button

the

will

a garment

this

figure

that

Also

number

might

to

occur.

the

obtained.

the

run-out

the

presser

the

operator

When

and

this

Install

bobbin

count

the

thread

down

is

completed

resulting

one number each

represents

can be

sewn

subtract a few

account

counter

counter

warning 1

heels

digits

reaches

foot

for

ight

will

back

happens,

new

bobbin.

runs

(counts

count from

the

from a full

cycles

any

variance

to

zero

wU 1 come

not

on

press

the

out.

number

the

the

11ft

the

reset

The

trim-

from

final

_

trea-

-

RESET

BUT

"!

ON

Page 14

@

~

,

'

~-<:.(jj)

Thread

Viper

Assembly

No.

1

2

3

"

s

6

7

8

9

10

11

Qty.

Thread Wiper

1

1

1

2 B.H. Screw 8-32

2

2

2

2

1

10-32

Air

Thread Wiper

118

Nut

Screw .183-32

Washer

Thread Wiper

Set

Description

(Non-Rotating)

Male

Cylinder

lock

8-32

Screw

Connector -

Washer

6-32

Air

Cylinder & Nut

Bracket

Bracket

X

3/8

Clamp

Poly

Part

671-A-15

671-F-17

AS-9-3

AS-9-4

RM-2813-3

RM-27lt7-6

RH-2791-1

22569-J

RM-3293-5

AS-9-5

Rt-:-2808-1

I

12

13

lit Flow Control

15 2

1

1

Thread Wiper

Nut 10.-32

Hale

10-3~1~~nnector

Wire

- Barbed

AS-9-6

651-H

671-37

6]1-F-4

Page 15

@

No.

2

3

IJ

5

6

7

8

9

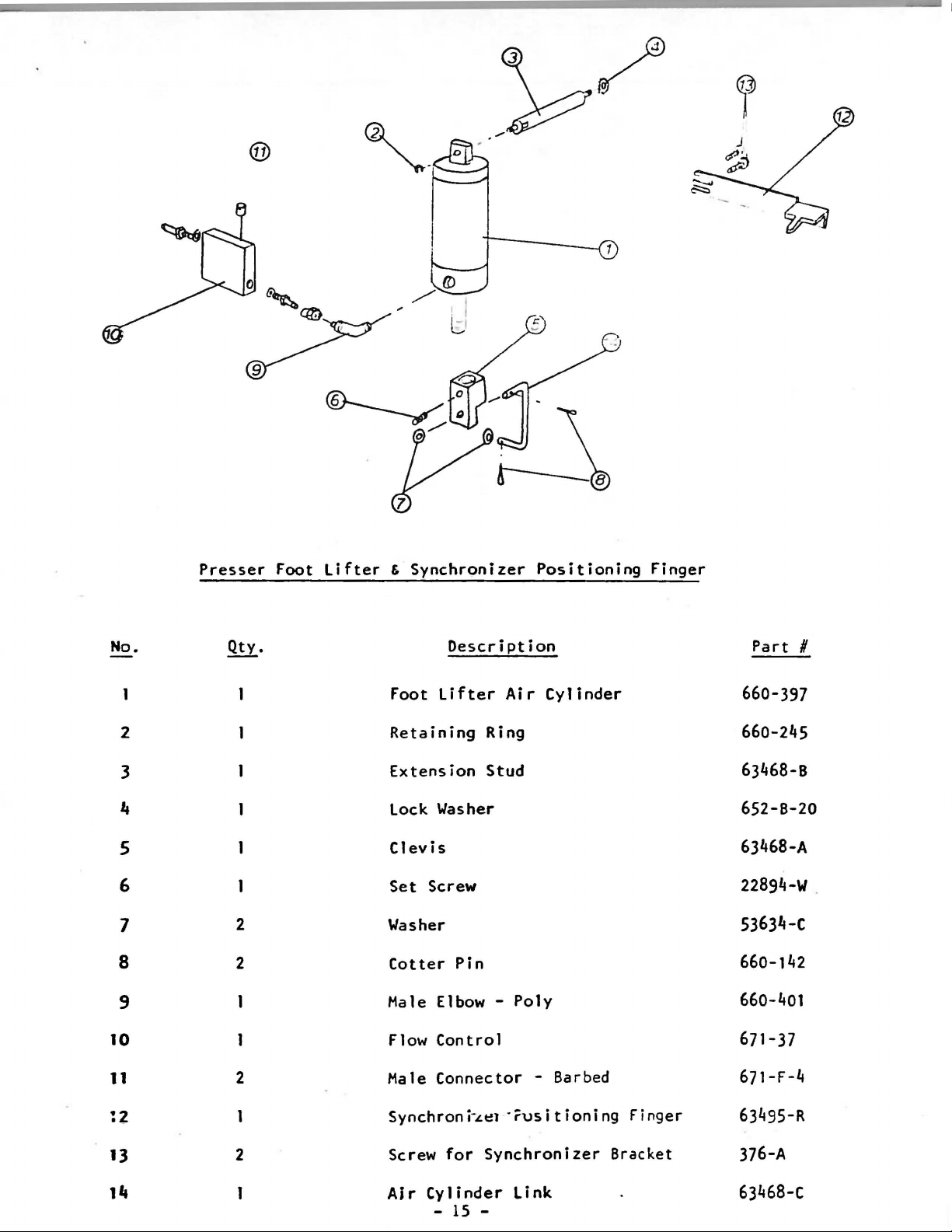

Presser

Qty.

2

2

Foot

Lifter

&

Synchronizer

Description

Foot

Retaining

Extension

lock

Clevis

Set

Washer

Cotter

Male Elbow -

lifter

Ring

Stud

Washer

Screw

Pin

Positioning

Air

Cylinder

Poly

Finger

Part

#

660-397

660-245

63468-B

652-B-20

63468-A

22894-W

53634-c

660-142

660-401

.

10

11

13

2

2

l!J

Flow

Male Connector - Barbed

Synchron

Screw

AJr

Control

i-

.Lt:!t

for

Synchronizer

Cylinder

- 15 -

-·

rus

link

it

ion i

ng

Finger

Bracket

671-37

671-F-4

63495-R

376-A

63468-c

Page 16

Folder

Opener

No.

1

2

3

,

5

Qty.

2

Description

Folder

Folder

Male Elbow

Plunger

Set

Opener Cyl.

Opener

Screw

Air

Cylinder

- Barbed

6/32 X 1/4

Bracket

Part

AS-9-1

671-A-56

RM-3]28-1

AS-9-2

RM-2808-t

#

- 16-

Page 17

_,

I

I

r

e1"rf

J~

No.

·

·a

\

(/

)

..

Qty.

~

~

I

I

l i

'I

I

\

I

I

I

Trimmer,

Tension

Description

Release,

Hemmer

Part

H

2

3

4

5

6

7

1~

8

9

10

11

12

..

3

3

3

Trimmer Assembly

Tension

Throatplate

2

,

,.

_

Throatplate

Hemmer

Adapter

Air

1'"~1"-l<;oc-

1!6

lock

Screw

M

ale

Fe

ma le

Male Elbow Barbed

Release

Assembly

Stud

Tube

fot;<;y

Washer

Connector

Coupling

Assembly

Needle Hole

Screws

A:~

tlDS~

Poly

10-32

10-32

Insert

C;s-r.~~,·-16.)

639-34-ooo

634-27-00

63928-A

22569-C

23564

21237-CK

AS-9-7

~iH3·Z.8'

RM-2747-2

22585-A

671-F-17

671-F-29

671-F-54

13

N/s

1

Check

Conical

Spring

Tension

,

Spring

92-5-J0-1

92-5-25-1

Page 18

No

TRIMMER

.

~

DescriPtion

ASSE)fRLY

Part

Number

l 1 Thr

2

3

4

5

6

7

1

1

1

1

1

8

@

oat Plat e 639-34-5

P

ositioning

Throat

Stationary

Lower

Retaining

Thread

Sc...IZ-C:\-1

Knife

Catcher

Plate

Ring

Fin

Needle

Upper

e r 639-14-50

Hole

Knife

Insert

63928-A

940-34-035

940-34-045

RM

940-34-040

h

~.,

'

3144-3

• _, 4 • s J

C.•

"'

-

18

-

0

0

Page 19

,

CORTA-HILOS

NEUMATICO

. '

PARA

UNION

SPECIAL

63900

,.

...

1ir

1ir-.

F-830

(I

t-:1404J

. · .. ·

639.3A

.·

. · ..

010

far

m~d•l

Ur,IIQN

~P~C'A

..

8~80()

.

·

..

·.

. '

0'140

·

:)/9104

.·.

· . . .

340~

M

• ..

..

Page 20

. ,

·.

TENSOR

NEUMATICO

PARA

UNION

SPECIAL

63900

.. · .. ·

. .

9227

634

1

3~

92

27

27

01

(i)

31

....

922~~·

~

Ia\

~

A...-92 27

9227~u

38-1

.. ·

.. .

Page 21

·~o.

Qty.

Foot

Description

Li

f t

So

1 eno i d

3-Way

-

Part

#

671-~lt

2

3

I

.,

5

6 2

7

8 2

9

10

11

12

2

3

2

2

4

Timmer

Wood

Run

Hex

Male

1/8

Male

Female

1/8

Solenoid -

Screw

#6

x 1

Tee

Nipple

Connector -

NPT

Runn

Tee

Elbow

- Barbed

Connector - Barbed

NPT

Shuttle

Valve

Union Tee - Barbed

Washer

It-Way

11

1/2

671-87

RM-3154-0

RM-2850-0

RM-3287-2

Barbed

671-C-It

- Barbed 671-F-37

RM-3728-1

671-F-It9

671-20

671-F-41

RM-3293-5

I

(f)

-

1Q

-

Page 22

Knee

Press

No.

2

3

4

5 2

6

7

8

9

10

11

~·

3

3

1

2

1

Description

Knee

Press

Hale

Sheet Metal

18

Hale

Knee

3-Way

Knee

Knee

Screw

Doewl

Elbow

Washer

Connector

Press

Manual

Press

Press

Pin

Assembly

- Poly

Screw

- Barbed

Base

Valve

Pad

Rod

Part

2899

660-401

RM-2864-1

RM-3293

671-C-4

AS-7-2

671-85

660-168

AS-7-1

RM-2805-1

667-C-16

#

KP-1

-5

-

20

-

Page 23

z9t/80R

y

I •

s~

•

2l(,O'C

• 1401<:·

.,.,,,

ezu,ue>.,

- 21 -

I

. :

I

I

I

I

' .

Page 24

®~

~--

'

I

)

/

N

o.

1

2

3 1

4

5

6

7

8 2

{)tv.

1

1

1

1

1

1

~

Filter

Bracket

Screw

l.Jasher

Nut

~ale

Treadle

Male

Elbow,

Connector,

I

Descrintion

Regulator

Barbed

Valve

Barbed

Part

29480-WZ

AS-9-8

22642-K-54

RM

211

671-F-47

99683-HC-155

671-f-4

II

3293-2

04-H

9

10

1

1

In-Line

Male Elbow,

Flow

-

22

-

Control

Barbed

671-37

~'1

3728-1

Page 25

Motor, Comp/e[e

997-G-228

•

REF.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

PART

220.014

800.727

402.405

240.001

250.002

800.527

230.001

NUMBER

60.000.032

75.000.103

802.260

60.040.003

250.001

402.405

800.539

60.070.003

801.654

220.012

550.005

550.003

MOTOR,

DESCRIPTION

Motor,

Face

Screw,

Lock Washer

Fan Cover

Fan Cover

Fan

Set

Terminal

Terminal

Screw

Locking

Lock Washer

Screw Cheesehead

Base

Hexagon

Washer

Micro

Micro

RAW

Plate

Screw

Raw

Socket

Plug

Box

Box

Clip

Screw

Fuse

Fuse

Complete

Head

Cover

(6V) 4

(12V) 2

Amp

Amp

AMT.

REQ.

1

1

3

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

•

0-~------------

I

I

I

I

I

I

I

--

~

I

~~-

--

-

--~-

-

-23 -

----~---

2

Page 26

SYNCHRONIZER

-

(ol

O

M-\

•

REF.

NO.

1

2

3

4

5

6

7

PART

NUMBER

250.058

802.250

220.085

801.641

230.177

230.179

230.180

DESCRIPTION

Back Cover

Set

Screw c

Spacer

Hexagon Screw

Tab Washer

Notched

Tab Dis k

for

Disk

Syn h

ronizer

AMT.

REQ.

1

2

1

1

1

1

•

I

c:::I(JJJP a

2

•

-

24

-

Page 27

CLUTCH

ASSEMBLY

(60.050.018)

REF.

NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

PART

NUMBER

75.000.237

250.008

75.000.117

75.000.208

840.715

210.021

220.001

841.332

800.537

402.405

75.000.452

75.000.165

60.110.024

DESCRIPTION

Clutch

Washer,

Brake

Clutch

Disk

Clutch/Brake

Disk

Shaft

Key, Woodruff

Pulley,

V-Belt

Lock !\ut

Retainin

g Ring , Int.

Screw

Lock Washer

Clutch

Brake

Belt

Solenoid

Solenoid

Guard

Complete

AMT.

REQ.

1

1

1

1

1

1

1

1

3

3

1

1

1

11

3

0

-

25

-

Page 28

Control

BOjl

~

I

995-26BH

1)

2)

3)

4)

5)

6)

7)

8)

9)

lla)

b)

C)

11)

12)

13)

238.219

228.114

881.528

888.525

838.315

888.532

546.882

75.888.179

558.187

558.887

558.888

55-.889

.tea

·. 882

241.824

241.823

Control

Spacer

Screw,

Screw,

Washer,

Screw,

Cable

Treadle

Fuse

Micro·Fuse

Micro·Fuse

Micro

Grommet

Spring

Spring

Box

for

Slot

Cheesehead

Serrated

Cheesehead

Clamp

Arm

·Holder

Fuse

-

Ba~ger

Control

Flat

Complete

Assembly

Box

'I

I

Hanger

'1.8

r

l

.•

·'

4

Amp

Allp

Ailp

'

-

26

-

Page 29

RECOMMENDED

SPARE

PARTS

LIST

Throat

Positioning

Throat

Throat

Thread

Stationary

Lower Knife

Thread

Needle

Check

Conical

Rotary

Plate

Plate

Plate

Catcher

Wiper Wire

Thread Guide

Spring

Tension

Hook

Finger

Needle Hole

Screws

Upper

Assembly

Knife

Spring

Insert

639-34-5

639-14-50

63928

22569

A

c

940-34-040

940-34-35

940-34-45

AS

9-6

63970

B

92-5-10-1

92-5-25-1

29474

VA

Bobbins

Quick Motor

Needles

Control

Box

61212

995-268 H

180

GYS

- 100/040

110/044

125/049

140/054

r

-

27

I

-

Loading...

Loading...