Page 1

' .

DESCRIPTION

Cylinder

bed machines P300P300-2/406

type

weight

401

on a

fabrics.

preform

wide

high

OF

speed,

variety

MACHINES

2/201,

double

of

medium and heavy

General Features Sp.,c:iol

MACHIN

Cylinder b

work to be

ed

overhangs base, allowing

stitched.

tubular

Two

P300-2/206 and

locked

Features

stitch

of

Individual

E P300-2/201

needles,

two

loopers.

Mo

•

c:hinu

Sliding cover

Arm

shaft

encloses elliptical

is

mounted

with

and rea r.

Belt driven

bed sha

ft

is

at rear and needle bearing

Machine bose

gloss,

Face

oil

·sump jar.

pla

te i s hinged

also

serves as o

to

oiling.

All

chin

threading

e.

is

done on

bed.

boll

bearing

mounted in

in

Iron

!.

drip

faci l

itate

operator's

in

front

boll

pan

bear

with

ing

a

threading and

side

of

mo·

Combination of needle feed and drop feed prevents

the

terial

even l

Maximum

MA

Tw

Pul

tinuous

Length of

f

slipping

and

of the upper and

assists

in

y.

CHINE

stitch

P300-21206

length:

o needles, two loopers.

ler

Feed-Combination of needle feed and con-

close

or 9 stitches

coupled

st

itch

per

: 4

inch).

to

two

or

4 per

gear

12 per

lower

more

Inch.

driven

inch

plies

plies

puller

being fed

feed.

(regularly

of ma-

fitted

Vibrat ing

Ne

edle

needle

spreader

looper thread toke·up is

bor

connecting

bor

rock

driving

needle bearings.

Needle bar stroke:

Presser

Bed

wide. Top

Space at right

bar

lift:

Dimen~ions:

of

3/ 8

bed

of

link,

frame

needle bar

driving

connection ore

i-1/4 inche

s.

inch.

16·3

/4

inches long, 7 inches

is 7 in

need

ches above

le

bar:

10

non·winding.

rock

conne~tion

all

mounted on

frame,

and

table.

inches.

Made

In

gauges from

ard guages are 1

inches.

MA

CHI

NE P300-2/406

Four nee

Puller

tinuous

Length

for

9 s

dles,

Feed -Co

close

of stitch: 4 to

titches

Standard guages

3/6,

3/6

Inch,

3/16

inch,

four

loop

ers

mbination

coupled gear

12

per

inch).

are

1/2,

5/16,

1/2,

1/2

Inch

1-3/8

.

of

needle

driven

per

inch

5/16.

Inch and

to 2 inch

es.

inches and 1-

feed and con -

puller

(regul

5/1

6

feed.

arly

Inch,

1/4,

Stand-

1/2

fitted

3/8,

1.

1/4

Space at

inch

es.

Federal

3

left

stitch

of

needl e bar to edge

type 401.

of

bed: 2·1/ 4

Inch. Minimum

needles

is

3/16

spacing

inch.

between

any

two

adjacent

Page 2

'

CRANK PINCH

SCREW

\

\

I

•

{?.)

FEED

CRANK

LIFTING

I,..

\9'J

!I

I

Fig.

2;

/.

I

23.

FEED LIFTING

ROCK

~·

SHAFT

~

~

'---.

71

I " '

~

lL

:

Cl

,

~

~

'

. )..

\

SLIT

"

-

:\

"'

Fee

d Bar Height Setting

POSITION

SCREW

I

11

lL

J.

li

"'

(.l

11

11.\

1=

~~~

''

!J

'-

TIMING

FLAT

FEED

BAR

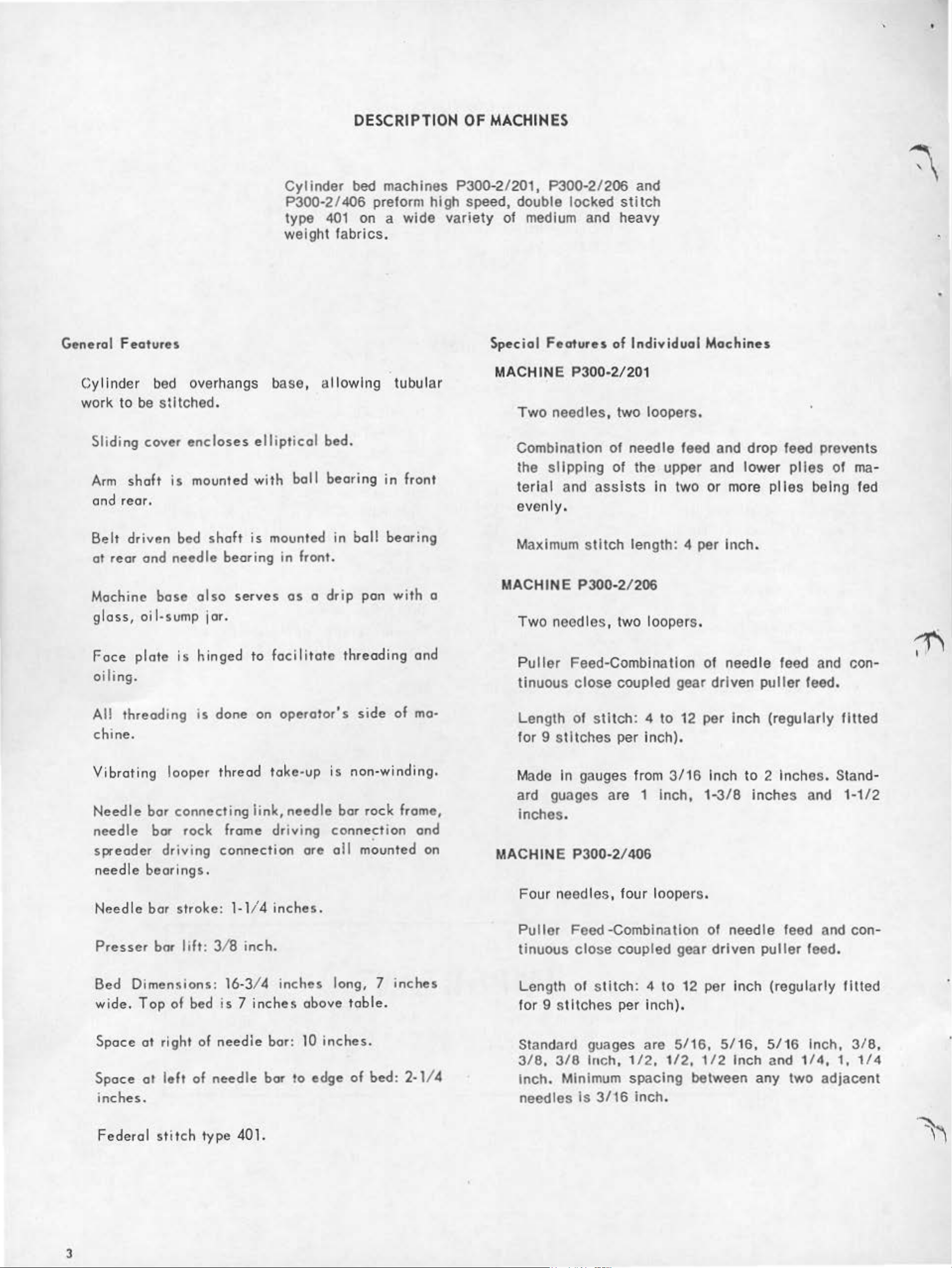

When

the f

flat

feed l

the rock shaft spot correctly

a

feed I

on feed

If adjustment is required, first

Th

lig

n sl

HEIGHT

feed bar

eed

lifting

lift

ifting

en loosen feed l

ifti

rock

it

of feed

ng sha

SETTING

is

crank

ing rock shaft as shown In

shaft

lifting

ft.

Re-tighten crank pinch screw.

at

P300·2/

correct height, the

Is

aligned

crank position screw engages

•

ift

ing crank pinch screw and

crank

with

201

with

be

the timing

Fig

sure that the

timing fl

slit

. 23.

at

In

on

FEED

DOG

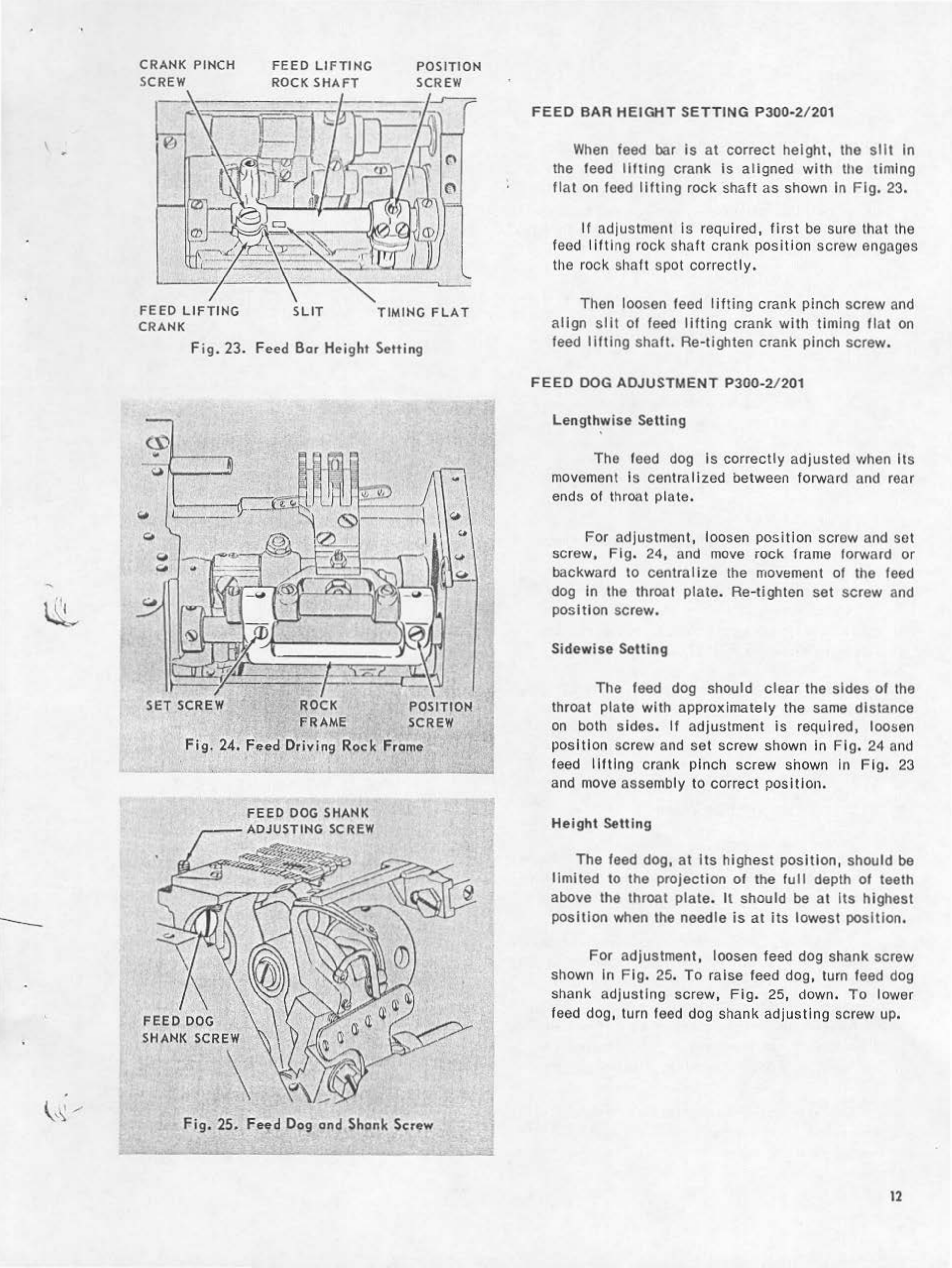

Lengthwise Setting

ADJUSTMENT

P300-2/

201

.

The feed dog

movement Is centralized between forward and rear

ends of throat plate.

For adjustment, loosen

scr

e

w,

Fig.

b

ack

ward to centralize the movement

dog in the throat plate. Re-tighten

posit

Sidew

ion screw.

is

e Setting

24,

and

is

correctly

move

adjusted

position

rock frame forward

screw a

set

wh

of

the feed

screw

en

nd

Its

set

or

and

SET

SCREW ROCK

FRAME

Fig.

24.

Feed

FEED

,---ADJUSTING

Drivi~~

DOG SHANK

w

SCREW

POSITION

SCREW

Rack Frome

Q)

..

J

The f

at

thro

on

position

feed l

and

He

limited

above the throat

position

shown

plate

both sides.

ifting

move

ight Setting

The feed dog,

to

For a

In

eed

with

screw a

crank pinch screw shown In

assembly

the projection

when the needle

dju

stment, loosen feed dog shank screw

Fig

. 25.

dog should

approximately the

If

adjustment

nd

set

screw shown

to

correct

at

its

highest posi

of

plate.

To

It

is

raise feed dog, turn feed dog

clear

is

posit

the

should be at

at

its

the sides

same

requ ired, loosen

in

Fig.

I on.

tion,

full

depth

Its

lowest position.

of

distance

24 and

Fig.

should be

of

teeth

highest

the

23

FEED

SHANK SCREW

DOC

Fig.

25.

Feed

Dog

and

Shonk Screw

st

shank adju

feed dog, turn feed dog shank

ing screw,

Fi

g.

25, down.

adjust

ing screw up.

To

lower

12

Page 3

,·

\

LOOPER

TIMING

FEED

LIFT

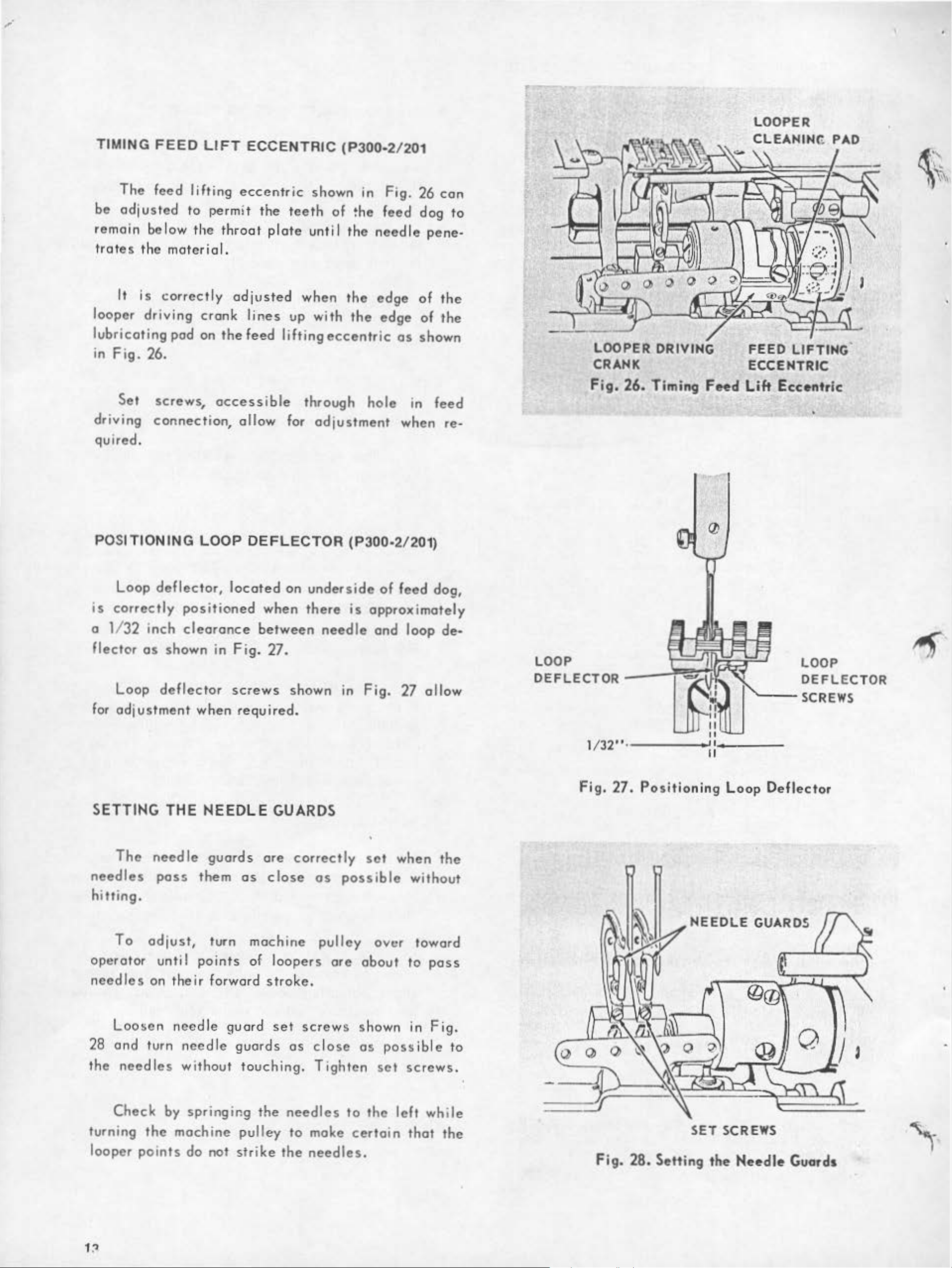

The feed lifting

be

adjusted

remain be low the

trate

looper

s the

It

is

driv

lubricating

on

Fig.

Set

26.

screws,

to

permit the

materia

correctly

ing

crank lines

pod on

accessible

throat

l.

the

driving connection,

ECCENTRIC

eccentric

teeth

plate

adjusted

when the

up with

feed

lift

ing

through hole in

allow

for

(P300·2/201

shown

of

~he

in

Fig.

feed

26

dog

con

to

until the needle pene-

edge

the

edge

eccentric

of

the

of the

os shown

feed

adjustment

when re-

LOOPER DRIVING

CRANK

Fig.

26.

Timing

FHd

FEED

ECCENTRIC

Lift

LIFTING.

Eccentric

•

I

•

quired .

POSITIONING

Loop

is

correc

o

1132 inch

flector

Loop

for

adjustment

deflector,

tly

positioned

clearance

os

shown in

deflector

LOOP

located

when

DEFLECTOR

on

when

between

Fig.

screws

27.

shown

required.

(P300·2/201)

underside

there

is

needle

on

Fig. 27

of

feed

dog,

opprox imotely

and loop de-

allow

"---

LOOP

DEFLECTOR

SCREWS

SETTING

The

needles

hitting.

To

opera

adjust,

tor unti I points of loopers

needles

Loosen

28

and

the

turn

needles

THE

needle

poss

on

their

needle

needle

without

NEEDLE

guards

them

as

GUARDS

ore

close

turn machine

forward

gua

stroke.

rd

set

guards

touching.

correctly

as

possible

pulley

ore

screws

os c l

ose

Tighten

set

when

without

over toward

about

shown

as

set

to

in

possible

screws.

the

pass

Fig.

to

Fig.

27.

Positioning

Loop

NEEDLE

Deflector

GUARDS

Check

turning

looper

by

the

machine

points

springing

pulley

do

nat

strike

the

needles

to

moke

the

needles.

to

the

certain

left

thot the

while

Fig.

28.

SET

Setting

SCREWS

the

N ..

edle

Guards

Page 4

5/8"

___

L

__

__

T

__

_

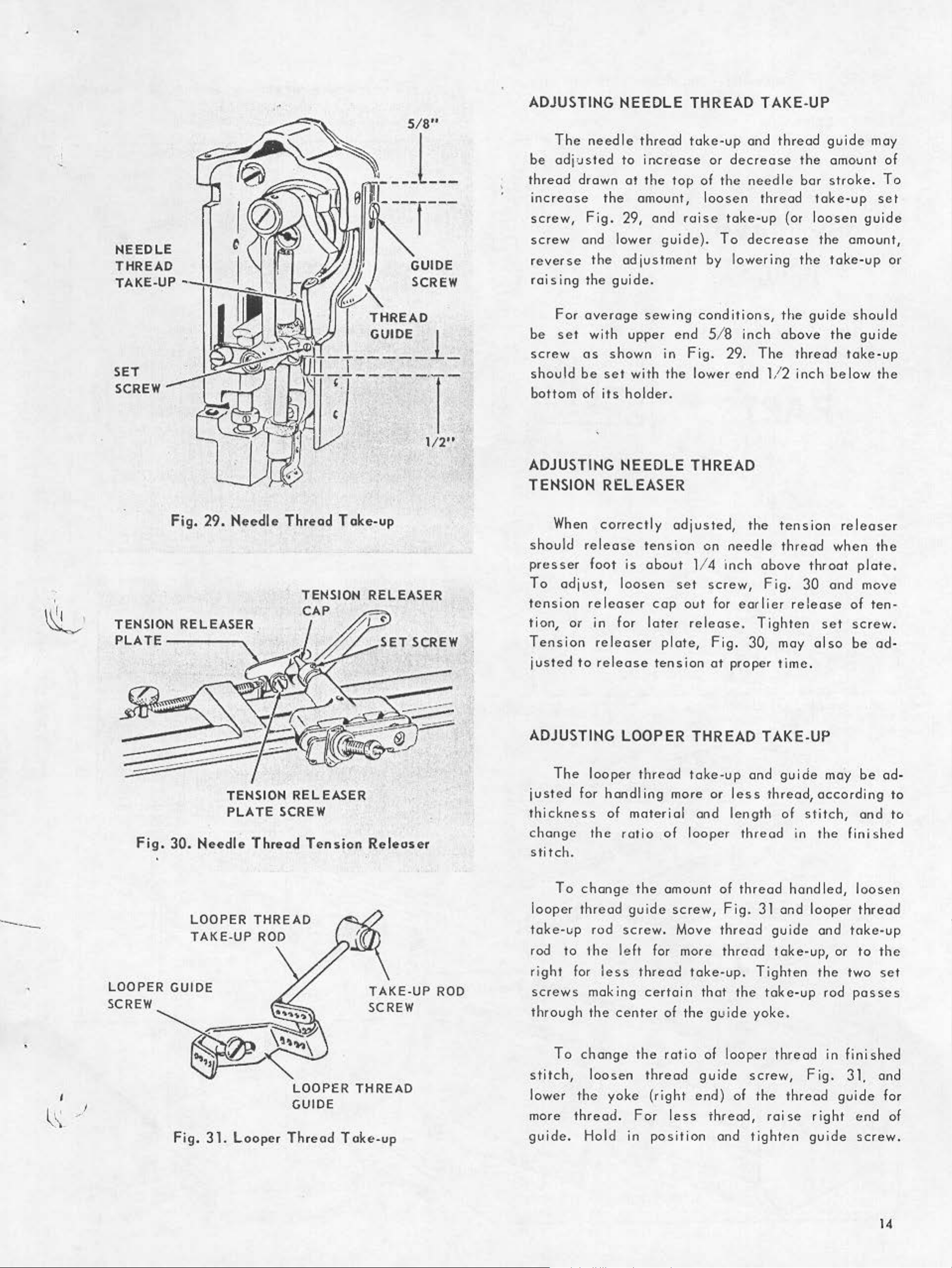

ADJUSTING

T

he

need

be

adjusted

thread

increase

drown

the

NEEDLE

le

thread

to

incr

ease

at

the

top

amount, l

THREAD

toke-up

or

of

oosen

and

decrease

the

TAKE-UP

thread

the amount

need

le

thread

bar

guide

stroke

take-up

may

of

. To

set

NEEDLE

THREAD

TAKE-UP ·-H-._!_

SET

SCREW

GUIDE

SCREW

THREAD

GUIDE 1

-----

-----~-

'

-

1/2"

screw,

screw

reverse

raisi

For

be

screw

shou

bottom

ADJUSTING

TENSION

F i

and l

ng the

overage

set

os

ld

be

of its

g.

the

with

shown

set

RELEASER

29,

and

ower

ad j

ustment

guide.

sew

upper end

with

hold

er.

NEEDLE

ro i

se

guide}.

by l

ing

conditions,

in

Fig.

the

lower

THREAD

take-up

To

decrease

owe

5/8 inch above

29.

end

(or l

ring

The

1/2 inch

the

the

thread

gui

oosen

the

amount,

take-up

de

the

tok

be

low

gui

de

or

should

gui

de

e-up

the

'

~

·

TENSION RELEASER

PLATE---~

Fig.

29.

Needle

TENSION

PLATE

Thread

TENSION RELEASER

CAP

RELEASER

SCREW

Toke-up

SET

SCREW

When

should

presser

To

tension

lion,

Tension

ADJUSTING

j

thi

adjust, loosen

or

j

usted

The

usted

ckness

correctly

rel

ease

foot is

releaser

in fo r

releaser

to rel

looper

for

handling

of

adjusted,

tension

about

cop

later

pl

ease tension

LOOPER

thread

mater

114 i

set screw,

out

release.

ate,

THREAD

take-up

more

ial

and length

the

on

need

nch

for

earlier r

Fig. 30, may a l

at

proper

and

or less

tension

le

thread

above

Fig.

elease

T i

ghten

time

TAKE-UP

gui

thread,

of

rel

when

throat pl

30

and

set

so

.

de

ma"y

acco

stitch,

easer

the

ate.

move

of

ten

screw.

be

ad

be

ad-

rdi

ng

and

-

-

to

to

----

•

Fig.

LOOPER GUIDE

SCREW

30.

Needle

LOOPER THREAD

TAKE-UP

Thread

ROD

LOOPER THREAD

GUIDE

Tension

Releaser

TAKE-UP

SCREW

ROD

c

hange the

stitch.

To

change

l

ooper

t

oke-up rod

rod to

r

ight

screws

th

rough

stitch,

lower

more

thread guide scr

the

for

making

the

T a

change the rat

loosen

the

thread.

rot io

le

less

cente

yoke

of looper

the

amount

ew,

screw.

ft

thread tak

certa

thread

Fo

Move

for more thr

in

that the

r of

the

gui

io of looper

guide

(right end} of the thr

r l

ess

th

thread

of thread

F i

g.

thread

ead

e-up.

de

read

in

hand led, loosen

31 and

guide

toke-up, or to

Tighten

toke-up

yoke.

thread

screw,

, roi

looper thread

Fig.

ead

se right

the

and

the

rod

in fini

guide

finished

toke-

two

posses

31. and

shed

end

up

the

set

for

of

Fig.

31.

Looper

Thread

Toke-up

guide.

Hold

in

posit

ion and tight

P.n

gu

ide

screw

.

Page 5

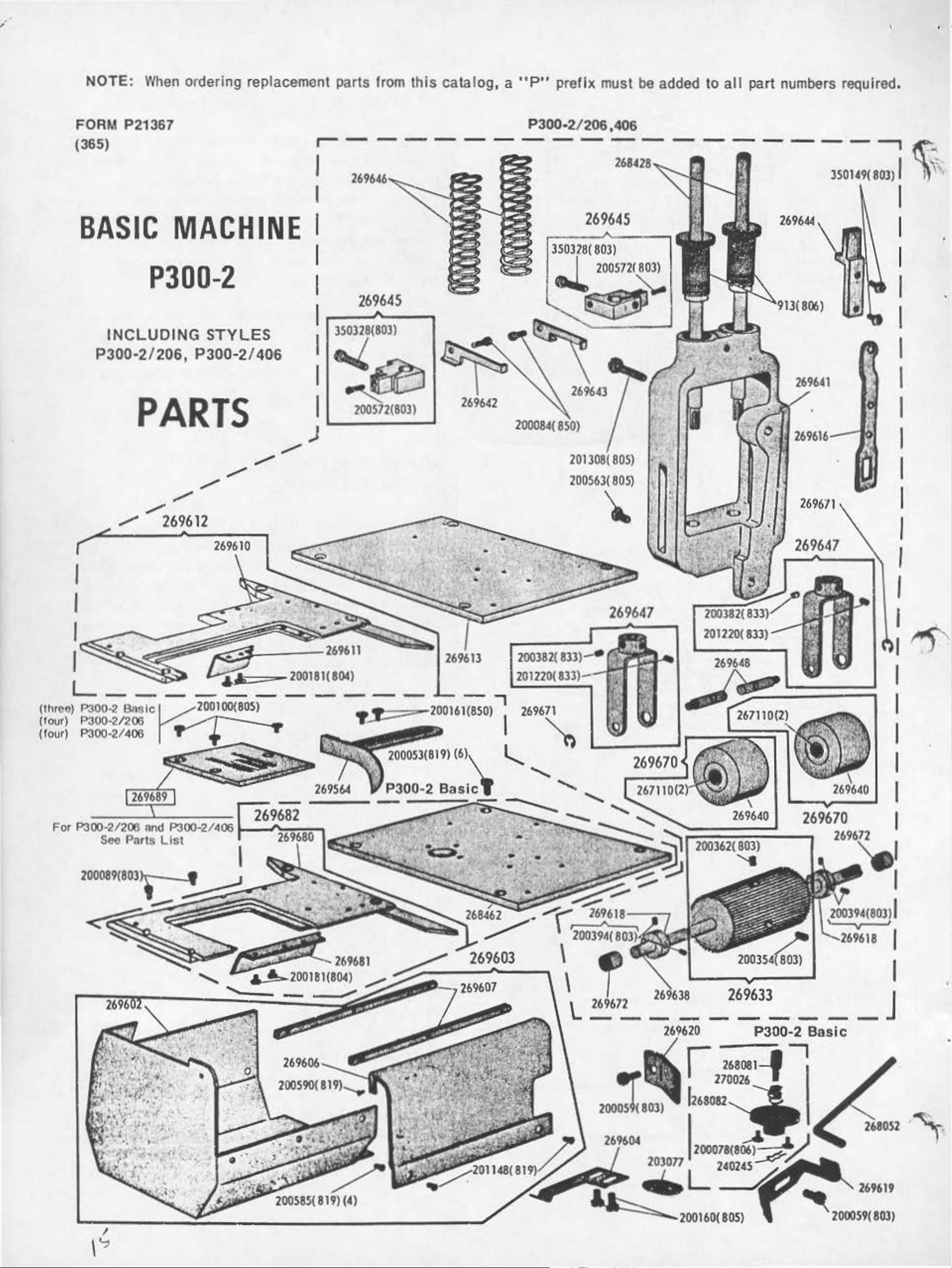

NOTE:

When

ordering replacement parts from

this

catalog, a

"P"

prefix must

be

added to

all

part numbers required.

FORM

(365)

P21367

BASIC

PJ00-2

INCLUDING

P300·2/206,

PARTS

/

/

MACHINE

STYLES

P300·2/406

/

/

/

/

/

269612

P300·2/206

~------------------~

I

I

269645

I

350328(

803)

I

..l2005721~

1

269645

~

:

350328(803

)

l~tb

269642

200084(

850)

2013108{

200S63(

\.

)

I

200S72(803)

,406

269644

269641

•

80S)

80S)

269671

269610

•

•

-

•

269647

201220(833)-

":/'

-,

"'"'

'

• • •

• • • •

•

..

-r:

\

~-

169618

J,'-

-2691·3_8

r

~:

-2~3~

P300·2

-26-808-1--::.'

270026

- - - J

Basic

..,

2680S2

-

~

.

I

,

~

~

2000S9(

269619

803)

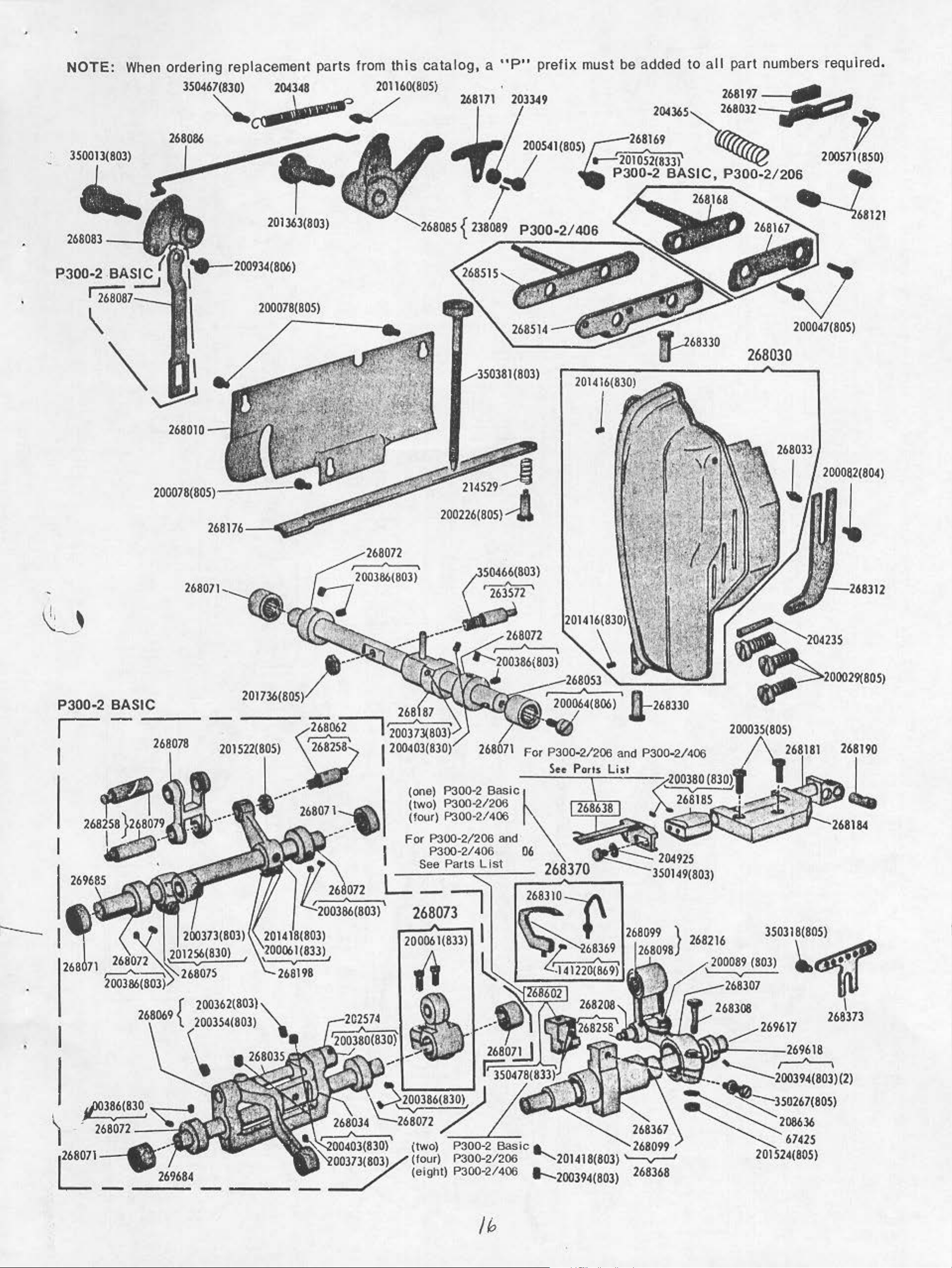

Page 6

'

NOTE:

350013(803)

268083--

P.

300·2

I

When

BASIC

ordering replacement parts from

350467(830)

204348

~~../'

201363(803)

1

200078(805)

this

201160(805)

catalog, a "P"

!__..-3:10381

(803)

prefix

must be added

204365

~68330

to

all

part numbers required,

200571

268030

.,

(850)

P300·2

I

I

BASIC

--

268010

268071

268078

----

201

522(805)

200226(805)--!

For P300·2/206 and P300-2/406

See

Ports

200082(804)

L

ll-268330

200035(805)

268190

List

•

I

(one) P300·2

(two) P300-2/206

(four)

For

I

1"300·2/406

1"300·2/206

P300·2/406

See

Parts L

Basic

and·

06

ist

f~~L--,

~2c

(833)

268073

,..--J..__,

200061(833)

I

I

..

268638

l

350318(805)

268216

268308

I~

) .

r807l

268072

-

(four) P300·2/206

(e

-

P300·2 Basic

ight) P300-i2/406

/h

a.

......._201418(803)

..._

200394

(

803

)

268367

268099

'--v--'

268368

67425

201 524(805)

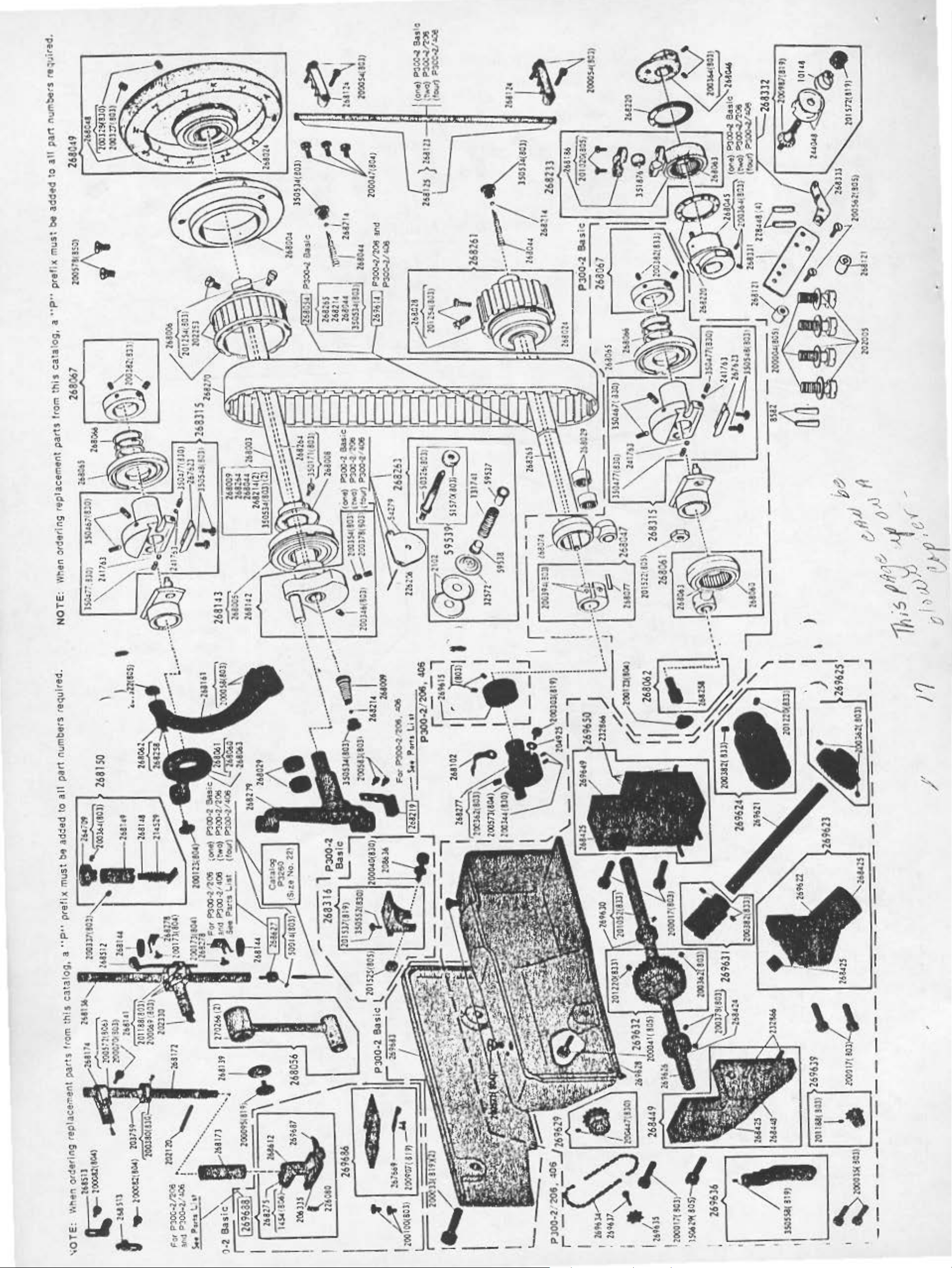

Page 7

~

"

"

"'

.

iL

"'

w

1-

0

z

..

'!l

E

'

-

I

L

•

•

•

.

/"'-

-

-

-.._

,

I

.

·

~

.

iL

"'

Page 8

'

NOTE:

When

ordering

replacement

paris

fron,

this

catalog, a "P"

prefix

must be added to all part numbers required.

j

·

~

'5

rj

MIJMitU

1454(806)

DUCRII'TIOH

Pressor

Pinch

2102 M•ecUe

Dloc(2)

C.to1ot

3260

H...tlo(62a57)

22

asn Arm

10148

32572

50014(803)

SOJ26(803)

51S70(10ll

54279

59537

59538

59539

67425

131T41

141220(869)

20000 4(80

200029(805)

200033

(819

200035(805)

200047(804)

200047(805)

200053(119)

200054(803)

200058(803) H

200059(803)

200059(803)

200064(806)

200069(803)

:j00070(803)

200078(805)

200082(804)

200089(803)

200089(103)

20009

.5(

a 19)

200100(805)

200123(104)

Loa,.,

Spring

Needle

Releosi

He•dl•

Needle

Stud

Heedl•

Thvmb

H••dl•

Th.r•od

H•edle

Sp~ln•

Heedle

SfWIIIg

Needle

Stod 503:16(803)

51570(803)

Loop.r

Clamping

Wo.her

Ne•dle

Sp.fng

Heedle

S)

Ar"" Screw(<4)

Ann Head Screw(3)

)

Bed

Sc

Spreoder

Scrow(2)

Arm

&•oring

Scr•w(l)

Heedle

8reclcet

Bed

Looper

Clo~r~p

Otlvlng

Scrow(2)

Looper

(on

Sc,..w

L.oop.r

(on

Screw

Looper

wp

He•dle

Stu.cl

Pr••••r

8roc:ket

ArM

Scrow(l)

Heedl•

Screw(l)

Sod

Screw(:Z)

Looper

Hinge

N"dl•

Link

Tltreoot

H••~ll•

Driving

Scr•w

..

rew

dle

Bed)

S.cl)

Rod

NUMERICAL

Fool

Shank

Screw

Thr

Position

Thteod

Threocl T

"9

Set

Threod

Th

Nvt

lhreod

tuJd•

Thr•od T ena

Bwahlng

Thteo4 T •naion

Bvddng

Thread

Conler

Thteod

Gvorcl

Side

(2)

Shah

(bock)

Thread T en•

Screw(

Plate

Throod

Screw(4)

&or

Arm

Thr•od

T.,reod

Thteod

S.t

8or

Pinch

Bor

Pinch

Side

Thread

Ploto

Conlet

Pin

8or

Cop

Plot•

8or Rock

Conn.ctlon

(P300-2

.. d Tonalon

51&o

Pln(2)

Tension

en•ion

01

ac

Screw

Tenafon

Tension

reod

T•nalOf'l

(do

...

(front)

(bock)

Tension

wit!>

Cronic

Stud Nut

Tension

S.t

Cover (back)

(P300-2

Bor

BeorlnSJ

Boll

Housing

2)

Scrow(6)

Tvb•

Rock

Pinch

Guide

(on

front)

Guide

(un.d•r

Co"•'

cover)

Tak•·

Scre-w

Connecting

S<:rew(2)

Guld•

Screw

Guide

(loft)

Cronic

Pinch

Connecting

Wnher

Scr.-w

Sc•ew

Ho.

ble)

iOf'l

Scre-w

Basic)

lon

From•

Scr•w

Frome

Cop

LIST

OF

PARTS

HUMBER

:1)0

160(805)

Bast

c)

200161(850)

200173(804) H

200181(804)

200226(805)

20030:U19)

200327(803)

l')0328(8J£1 )

200337(803)

2003~4(830)

200346(803) H

200354(803)

200362(8C3) Loop41r

200364(803)

200364(803)

200364(803)

200373(8031

200378(803)

200380(830)

200380(830)

200382(833)

200386

(80

3)

200386(803)

200 39 4(

80

3)

200394(803)

200403(830)

200541(805)

200562(805)

200S11(8SO)

200572(806)

200573(80~)

MACHIN.

ES

DE5CRIPTI()oj

Sod

(olllptlcol)

Co"'••

Screw(

Ed,.

felt

Bed

Guord

Pre

S"'pport

Looper

Oil

Machine

Scr

M.o

Poairion

He•dl•

Fu;~me

st

L.oop41r Drivi"O Cronk

Position

Set

Heedlo

Positlun

S.t

H

Frome

C"p

Spreader

fcce.ntric

bnl

Spreader

Eccentric

Spreoder Orlving

Cronk Poa

Needle

Position

Screw

Preuer

Collar

Spreader

Guide

..

dle

Holder

Plate

••••

Hole

ew

chi

-no

••

".

..

dl•

Screw

Screw

.. dle

S•t Screw

onco

Lock

2)

Screw(2)

Spring

Screw(l)

8or

Ollin9

Sc:ru.{:2)

(left)

Bot

Sprint

S.cr•w

Dr l

v•no

Co"•'

P"'ll•r

Pvlley

Screw

Oor

Rock

Regulottng

Set

S<:r

Screw(l)

Sor

Cronk

6or

Crou"

Screw

Drlvln~

Sor

Rock

Re\lulatlr~v

Driv

Covnt•r·

~et

Sc,.w'(l)

Driving

Set

1tlon

Bar

Cronk

Screw

Bor

Set

S<:rew

Hold•r

~

Cronk

S.cr•w

Set

Stud

ew

Cronk

Stud

ing

Screw(2)

Scr•w

Check

Stop

Set

5crow( 2)

Heed1e

Frome

Ecce-ntric

Oi.c

S•t

Bed

Colla•

(P300~120G

Spread•r

Shoft

Screw(4)

Loop41r

Collar

Looper

Shoft

Screw

Spreoder

Cronk

Needle

A:el•oaing

Looper

Brocket

fou

Spring

Pres

&rocltet Adlu•ting

Screw

Loop•r

Oil

8or

Ro-e:k

Dri ving

Adjwsting

Spring

Screw{2)

Shall

Collar

S.t

Set

Plot•

sef

Stop

Col

Thrust

Set

Screw(2)

Driving

Corrler

S.t

Screw(

Corrler

Screw

Driving

Screw

Thread

Plote

Ttweocl

Screw(2)

Lock

Screw(:Z)

Bar

Driving Cronk

Scr•w

lor

,

406)

Set

S~ft

Check

Ten•lon

Tens ion

Gui

de

Rock

2)

Sctew

P300-2

HUMBER

200578(850)

200583(803)

200585(819)

200590(819)

2009

Basic,

07

(819)

OE5CRIPTIOH

Loop.r

(top

Suew(2)

.... die Bor

Frome

Screw(2)

Sed

Slide

Bed (elliptical)

Section

(upper)

Loop

Screw(2)

200934(806)

Poot

L.ink

200987(819) L..oop•r

Stud

201020(805)

201052(833)

201148(819)

20 1160(

20118~803)

80

201254(8031

20125.(803)

Spr•od

Connection

Sc.r

Heedt.

Releuur

Screw

Bed

S.ction

(lower)(2)

5)

foot

\prini

Hc.edle Threocl

(on Heedle

Conne>c:ting

Set

Arm

Oeh

Screw(:Z)

Bed

B•lt

Screw(2}

201363(803)

H

201416(830)

201418(803)

201

522(805)

Face

Scr.w(2)

Looper

S.t

Need

c~nnection

....

201524(805)

201572(819)

201736(805)

202005 Arm

202120

202253

202330

203077

203349

203759

204235

Looper

Spr•ad

Shah

Li

lum

8eh

Stud

P300-2/206

Threod

of

Arm)

Btodtet

Rock

Threod

(elliptical)

Bor

Screw(4)

(front)

Dell~ctor

(P300-2

Lift

er L.l

Hinge

er

ew(l)

(elliptical)

Lifter

Screw

~hoft

Pulley

Shoff

Pulley

Foot Lift

in

ge

Plate

Screw

le Bor A:od::

Frome

Looper

Clotn

pinog

Thumb

Scre-w Stu.d

Screw

Foot

Lifter

nk

Stop

S

..

Pul1•y

Flon\)e{2)

Needle

Oil

Bed (•lliptlcol)

Lock Spring

Woahor

Needle

Releosino

Woaher

Pt••s•r

Colla,

Arm

Heod

Screw

Thread

Driving

Cop

Thread

Cop

(front)

L..ev•r

Sc:rew

8or

S

Connection

Set

Connection

S•t

er

Lever

Scr•w

Hinge

Carrier

Dtl'l

lng

Hlno•

Carrier

Stud

Thr•od

Hut

er Driv

Wosher(4)

Llfling

Pin

oh

Conn

Spting

Bor

Conn•ctinv

Pocking

Threod

Plote

Bor

with

200380(830)

Position

£ye

u~oJ)

Screw

Stop

AND

Guide

Guide

Cover

CovM

Screw

Basic)

ftinv

T•nslon

T•nsion

Set

Cov•

Screw

Guide

Set

Shaft

Stu.d

Cronk

Nvt

Tension

ing

Rock

Hut

ection

(wid.)

Cover

Tension

~crew

P300-2/406

HUMBER

204348

204365

204925

204925

206335

208636

214529

214529

2260

226206

228448

238ll89

2

41763

2~•048

263572

264709 H

267623

267669

268003

268004 Arm

268005

268006 Arm

268008

268009

268010

268024 Arm

268024

268028

2611029

268029

268030

Pin

2611032

80

DESCRIPTION

Foot

liher

Spring

Heedle

R•l•••••

Loo

per

Oil

Hole

Washer

Sp

reader

Pressor

Pin

(P300-:1

Looper

Woahor

H

..

dfe

Fro"M

Stud

Spring

Pr••••r

Cvahion

Pressor

Spring

He•dle

A:eleo.ainv P in

Machin•

Lever

Thteocl

Sptlnt

Dtl

vlnt

Co,..•

Scrow

Fool

Holder

8or

Rod

Revwllllng

lor

Spring

Spring

Fool

(P300

Threod T enaio

Locating

(4)

Needle

Aeleuing

H

..

Dti"lnt;a

Friction

Set

(b.o

L.vope1

Di 1.c(2)

Spreader

Shah

Pocking

..

frnme

Cop

Needle

Driving

Friction

Loop

(P300

Arm

268009.

268264.

2682

(bock)

Arm

(

ftont)

Belt

ooch

Thread T ensio

Plot•

dle

&or

Rock

fcc•ntrlc

Plote

Screw

u )

dle

with

Poclunt

(2)

Thread

Driving

Scr•w

Stvd

(wick)

Bor

Rock

R•gvlotln;

200364(803)

Bor

Rodt

Eccentt

Plot•

Defl

ect

-2 t3ns

Shoft

with

2680+'.

twe; e

14 ond

Shoft

Shaft

Shoh

Pviley

20

350534(803

Boll

Hou.lng

Boll

Connection

with

125.(803)

202253

Arm

S.,oft Oil

with

350171(803)

Arm

Shoh

Boll

Arm

Sid•

Shoft

B.oring

Bed

~hoh

Beoring

8ed

Shoft

S.h

011

Spring

Pull•y with

(front)

Covef

Boll

(bock'

Boll

Connection

20125<1(803)

Bed

Shoh H ..

Beoring(l)

Hoedle

H

..

foce

268033

cllle

Plote

Bor

Rock

8eotlne(

with

ond

two

201416(830)

face

Plate

Lock

Tenai

Ctonlt

Screw

Wast

..

tinge

Basic)

Set~

Plate

-2

Basic

Pin

Fron

Screw

T•n•io

Rock

Oil

•c

or

I c )

och

6eorins:

Beorinc

lwo

Sling.,

Stop

two

dle

2)

Spring

N

Stv•

Stud

Fro

~n

ond

fralfteo

.

!9

Page 9

NOTE:

When

ordering replacement parts

from

this

catalog, a

"P"

prefix must

be

added to

all

part numbers required.

NUMBER

268033

268044

26804S

268046

268048

268049 Machine

268052

268053

268054 Bed

268056 H

268060

268061

268062

2611063

268063

2611065

268066

268067

268071

268072

268083

268085

268086

268087

268098

DESCRIPTION

Foee

Arm

Boll

S.d

Boll

Spreader

Eccentric

200364(803)

Spreader

Ec:centrlc:

balance

l00364(803)

Mochine

(aluminum

costing)

(outside

~oove

200327(803) ond 268125 Lool)4'r Threcrd

200328(830)

with

Looper

Rod

Spreod•

Shoft

Link with

270266

,..

Needle

Frome Driv i

Connection

Needle

Frome

Connection

with

Needle

FroMe

Connection

Stud

Needle

Frome

Connection

Be

Spreader

Connect

Bearing

Needle

From•

Eccentric

Oi

Needle

Frome

Eccentric

Disc

Needle

From•

Eccentric

Disc

with

Spreodttr Dri

Rock

Beor

Spreoder

Shaft

200386{803)(2)

foot

238089

Foot L lfter

Foot Lifter

Link ( P300·2

Looper

Plate

Shah

Sptlng

Shaft

Spring

26802~

with

Shaft

268044, 268214, 268142

268265, 350534(803), 200346(803),

(P300-2

..

dle

268063

Orlvfng

with

Driving

orin;

Orivino

sc

Spring

Drivi

Sprin9

two 200382(833)

Shah

ino(2}

Collar

Foot Lifter

Lifter

Cotmectlon

Lock

OH

(rear)

011

Driving

with

Driving

Counter·

with

Pulley

alloy

for

diam

2. 9 in,)

Pulley

Thread T oke·up

Driving

200064(806)

with

8aslc)

Bor

Connecting

two

&or

Rcxk

ng

Bor

Driving

8or

268258

Bor Rock

Needle

Driving

ion

Needle

Bar Rock

Adiu•tlng

Bar Rock

[)d,.ing

Adjustin~t~

Sor

ng

Ad j

Needle

Driving

Driving

St'ud

Stop

Stop

two

two

"V"

belt

of

belt

with

2680.48 268136

Rock

Rock

268060

Rock

Hinge

Rock

usting

Collar

ving

Rock

with

two

Bell

Crank

L•ver

Lever

Lifting

with

Rod

Basic)

NUMBER DESCRIPTION NUMBER

268099

268099

268102

268121

268121

268123

268124

268139

268141

2681~3

268144

2611148

268149

268150 H

268161

2681

67

2681

66

268169

268171

2611172

268173 Pr

26817~

268176

268181

26818~

26818S

268136 Spr•Qder Drivi

268137

268190

268197

Loo~r

S.orlng-(2)

Loop•r

Connection

Bearing

Looper

Oil Hole

Loopo~r

Tension

Spacing

Needle

Brocket

Collor(2)

Looper

with

Looper

Clomp(2) 268233

Thr•ad

Needle

Needle

Connecting

Woaher

Needle

Connectin9

201188(803), 202330

ond

Needle

200354(803) ond

200378(803) 268028 wHh

Needle

2611142

Needle B-tu

Felt(2)

Heedle

Frome

Stud

Needle

From•

Stud

..

Fro•

Stud

2US29, 264709, wi

2681~8

Nudle

Frame Dri

with

Needle

S

rack

Need

Rele

Hud

Re

201052(833)

Ne~dle

Releasing

(Adi

Presser

Presser

Brodtet wit

200070(803) ond

200572(806)

Presser

Spreod•r

Spreader

Spreader

200380(830)

Connection

201020(805)

Spreader

Cronk

l00373(803) ond

200403(830)

Spreader

Foe.

SprinQ

Carrier

Driving

Driving

Heedle

Needle

Crank

268208

268214

268214

Cover

Thread

Broc:lt:et

Collor(2)

Thread

Spacing

Thread

two

2681 25

Thread

Bushln~t~(2)

Bar

Bar

Bar

two

200069(803)

Bor

Bor

wHh 268005

Bor

Regulating

Bar Rock

Reouloting

Sleeve

dl•

8or

·ne

R•gulotlng

complete,

ond 268149 (1?300-2

Bor

two 200058(803)

Thread Ten

el (P300-2

le

Thread

aser

le

Thr•od

leour

Thread

ustoble)

Bor

esser

Bar

Sor

Bor Spr i

with

Plate

Plate

Tension

Tube

Tube

Tube

Link

Cop

Stud with

Cronk

Cronk

Oilin~t~

Rock

Rock

Rod

ving

(P300·2.

Cop

Plate

Guide

h

Bor

Bar

Holder

with

Drivi

Orlvlf'g

Lock

with

e

Arm

Basic,

Tension

Tension

wl th

Ten•ion

Bushino

ng

Bearing

with

ng

two

ng

Pfn

Basic,

268216

268219

268220

2682S8

268258

268261

268263

268264 Arm

26826S

268270 Arm

268Z75

268277

sion

268278

200)

268279

206) Frome

268307

263308

268310

268312

268315

268330

268331

two

'

268332

268333

268367

268368

DESCRIPTION NUMBER D!SC:RIP'TIOM

Looper

Crank

268258

Arm

Boll

Bed

Ball

LoojM'r

Corrler

Hinge

Shah

sn2

Shah

S/32

Driving

Pin

with

011

Stop

in,

diom,(2)

Oil

Stop

in, diom.

268369

268370

268373

Leo,.,

Loo..-r

Guard

261310 on4 268369

Loo.-

(on

wltl.

....

Needle

CtMftplete.

Tlweod Golde

Bed

at

L..,.r)

141220(169)

Connection 268098

with

268099

Neoo

(P300

Spreader

Wosher(2)

le

Bar

Rock

Frame

Eccentric

Spreader

Connection

with

351876

Looper

Hinge

Pocking

He•dle

Frome

Connection

Stlld Oil

(w

Bed

Belt

Needle

T.,nsion

32572, 59537,

59538, 59539,

1317

Rod

Bed

Rod (wood)

s.lt

neopre

Pressor Foot

Looper

Cra,..k

200573(80.4)

200344(830)

Ne•d

Felt

He~dle

Looper

with

Looper

Clamping

Needle

Nudle

(on

Need

Fro~

with

241763. 350467(830),

350477(830)

350548(803)

Face

Stod(2) L

Looper

Bracket

Looper

complete,

200987(819).

201572(819)

244048

Looper

Thread

Looper

Looper

268367

268099

Thread

-2 BasiC)

Driving

Thrust

Driving

268063

Corriet

Pin

(wick)

Bor Rock

Driving

Pocking

iclt)

Shaft

.. 1 ond

Shah

(wood)

Shoft

Shoh

th

Arm

Connectior'

Pulley

Thread

complet•,

Oil

(reinforced

ne)

1454(806)

Basic}

Orlvi.ng

with

le Bo r

Holder(2)

Bor Rock

Co,ier

200089(803)

CarritH'

Stud

Guard

Thr.,od

Head)

le

Sor

Drivi

267623,

Plate

Thret'ld

Thread

10U8

Thr•od

Guide

Cartier

Corder

with

Guide

268186

ond

Cronk

011

Hin99

26802~

two

2102

Oil

Control

Control

Conhection

Shahk

200362(803),

and

two

Oiling

Cronk

Cronk

Guide

Rock

ng

Flange

two

•och

ond

Hing•

Tension

Tension

and

two

T..,sion

two

268462

268512

288513

268514

268515

268602

268612

288627

268638

269564

269602

269603

269604

269606

269607

269610

269611

269612

269613 Oed

2696 14

269615

269616 F

269617 Looper

269616

269619 L ooper T

269620

269680 Bed Plate

269681

Boo

Plate

(P300·2

Needle

(on

Need

Connecting

Needle

(on

side

Need

350478(833) (P300·?.

Spreader

le

Br

acket

Neoole

Releas~

Looper

Pr

e5sor

Heel

Neoole

50014(803) (P300-2

(P300-2

Bed

Cover

Bed

complete,

200590(8t9),

269610,269611,

Sp,.ng

Edoo Guido

(elliptical)

(elliptical)

269602, 269606,

••

,h

201

269607

200S8S(

Bed

(elllptlcol)

Lock

S.d

(elliptical)

Set::tlon (front}

Sed

(elliptical)

Slide

Bed

Plate

(P300·2/206,406)

Bed Plat

(P300·2/206,406)

Bed Plate (left)

Guord compl

two

200

(P

300-2/206,

Plate

(

P300-2/206,

Bed

Shall

268044,

2~6265,

(P300·2/206.

Bed

Shaft

Collar

200386(803).

(P300·2/206,

oot

ink

Loopet

Colla

200394(803)

(on

Bed

(right)

Basic)

Thread C'-..lde

le

Bar

Stud)

Thread Gui

of

Am1)(2)

Thread

(P300·2/406)

Thread Tension

r

(P300-2/406)

Holder

Foot Plate

(P300-2

Holder

with

Basic)

with

Lock

148(819),

ond

fow

819)

Spring

Bcu(2)

(left)

e (l

eft)

ete,

161 (804)

(right)

with

268214,

350534,(803)

Thrust

with

two

Lifter Lifti

(P300-?./206. 406)

Carrier

Carr1er

r w i

th

two

hread Gui

) (on front)

Looper Thread Guide

(on Bed) (under cover)

(left)

(P300-2 Basic)

Bed

Plate (left)

(P300·2

Basic)

de

Tension

with

with

Point

Stud

C-ovet'

two

Cov"

Cover

Cover

Guard

and

and

406)

406)

406)

406)

ng

Shaft

Shaft

de

Guard

,

'

two

Basic)

Basic}

Basic)

,

'

_____

i' 268044

·

~

•

~

lq

Page 10

'

•

NOTE:

When

ordering

replacement

parts

from

this

catalog,

a

"P"

prefix

must

be

added

to

all

part

numbers

required.

I

IIUMI!R

269682

289683

269687

269688

DUCRIPTIOII

Bed

Plate (lefl)

<>uard

269680.

complete.

269681

r.nd

and

two 200181(804)

(P300-2 Basic)

Bed Side Cover (back)

(P300-2 Basic)

Pressor

(P300-2 Basic)

Pressor Foot (spring

hinge

ne

ed

206335.

268275,

269687

Foot

Plate

d)

complete.

lc

hOI

e,

226080

.

268612

( P300-2 Basic)

40

and

HUMIIER

269689

270266

350013(803)

350149(803)

350171(803)

350267(805)

350318(805)

OESCRIPTIOH

Throat Plate.

269686 (

Heedle

Connecting Link

H

.. dle

Foot

Cronk

Spreader

Arm

Sllnoer Set

\..OUjMt

Looper

(on

Bed

Scr

ew

PJ00-2 Basi c)

8or

8eoriru~(2)

Lifter

Sl\oh

Bell

HlrulJ•

Screw

Screw

Oil

Screw

Holder

Threod

ot

L.oo~r)

lor

Screw

Guide

HUMBER

350381(803)

350466(803)

350467(830)

350467(830) Pr

350477(830) H

DESCRIPTIOH

Preuer

A

Spteocfet

Rock

Shtcl ""'hh

Heedle

frame

S•t

Adjuatlng

Screw

Frome

Ecc•ntrlc

Plate

Screw(2)

dlntint

Shoh

Bar Rock

Orlvlnt flong

Screw(2)

e•••r

..

dle

Bor

Otiving

Screw

Bor

Spting

Scr

ew

Dtlvlnt

Screw

263572

Bor

Spring

Screw

Rock

Fflc:tlon

Set

Set

HUMBER

350.78(833)

350478(833)

350534(803)

350534(803)

e

350548(803)

351876

DESCRIPTIOH

Looper

Screw

Looper

Arm

Boll Suew

Bed

Boll

Heedle

Frome

Eccentric

Plote

Spreader

Roclil

St~o~d

Adlw •

Set

Shah

Shoh

Oil

(2)

011

Screw

Bar

Orivlng

Friction

Suew(2)

Or~vlna

Shoft

Boll

Roll•r

ting

Screw

Rock

Screw

Stop

Stop

I

STANDARD

4AUGU

l/4"

711''

...

J

,l/

.f'" 2681

l~l/1'"

1/1/2"

l*l/4 ..

:r·

114, 1/.f, u

S/H,

S/16, S/16u

....

FiTTtHGS

LOOPER

HOLDER

26al05

:::;~

,

OL.'.

ROC

I(

FRAME

THREAD

2612$$

8AR

GUIDE

HEEDLE

HOLDER

P3D0-21206

2611S4

I

2&110$

261106

07

261107 241261 2681 S7

260212

261211

2612U

261256

261261

261)04

2611S4

2611 S6

268157

2681>J

-

P3

D0-2/406

26906> 2691lt

269065

26tUI

269191

269192 2692)1

CCOM.PLf:TU

I

FOOT

··~l,·~·

--

269)74

269)74

26U74

269.51'1

269.517

26Un

SPREADER

26&176

26a:J76

268311 269S98

268378

268373 26,611

261178

261179

,..,,.

26tl'l7

2:69).42

2693.42

THROAT

PLATE

»9S97

21696$1

269597

269$91

269597

16tSt1

.

26fU2

-

HUMIIER

:100040(130)

-1(133)

200061(133)

•

200071(806)

200100(101)

J>Oill(SO.)

2003$4(103)

,,

' '-!}' lOOJ62110lJ

J>Ol7l(IG3

200310(130)

lit.

118,

J/1''

1/2,

112,

1/r'

1/.C, I, 1/.C" 269065

26906S

269065

DfSCRIPTIOH

F-.1

Screw

feed

Sftoft

Sc,ow(l)

F •

Shoh

Screw(2)

f••d

Socic•t

Conn•ctlon

)

.ct

f••d

Fe

ed

f•ecf

f'roftll•

fee.cf

Fra-.

feecl

Hlne-t

(2)

F

..

d

C.llar

Dot

5h...,k 200312(133)

Drl•lng

Cronk

L

lftlng

Cronk

R•oulatJno

Scr•w(2)

Ooo

Orlvino

Driving

Pa•ltion

o,a.,lng

S.t

Lifting

Pin

lor

S.t

Roell

Pinch

Rock

PInch

St~o~d

Screw(2)

Cop

Scr•w

Rock

Scr•w

Rock

Screw

Link

Se1

Scr••

Hinge Pin

Screw

2691)11

249UI

2691)1

-

P300·2

HUMBER DESCRIPTIOH

fe•d

Ad

l~o~

• tino

Collor

200386(130) F

200386(803)

200)94(803)

200403(830) F

201256(830)

201411(803)

20\522(805

201522(105) F

.. d Ori.,ino

Shah

Screw(

Feed

Roclc

Set

Screw(

Fud

Set

Scr•w(2)

..

d

Screw(2)

fe

ed

Pinch

F

.. d Lifting Ro.ck

Shoh

Scr

ew

)

feed

Connection

""'

.. d Lifting

Connection

Stvd

Basic

Orl•lno

S•t

Collar

.C)

Llhing

Shoft

Lifting

Bor

Set

Lifting

Scr••

Crank

Driving

Hut

Ecc•ntric

Oi•c

Screw(2)

Roe-k

Set

Collar

.C)

Eccentric

Cronk

Position

Hinge Stud

Hino

269192

269193 269240

26919]

DROP

FEED

PARl"S

HUMBER

201525(805)

Sprino

201

537(819)

202574 F

208636 F

U0245

241763

267623

268034 F

e

268035

26Ul1

269240 269342 269598

169342 2:696$2

2693-42

269~·

-- -

DESCRIPTIOH

Fu4

Screw

A

Do9

F

.. d Ooo

dl~o~

•t ln

Lodt

g

Shonk

H~o~t

Shonk

Scr

ew

H••

.. d Bar

Ca

ll

or

200

380(830)

..

d Dog

Screw

F

..

d

Reuainlng

F

.. d Otlvlno

Eccenttlc

Plate

PQcklno

Feed

£cc•ntrlc Fricti

Plate

.. d 8or

200373(803)

200•03(830)

F

..

d Bcu Hi

Pin

Hlno•

with

Shonk

Washer

Reg~o~luting

Spring

Friction

Screw

Orl•ln~

(bro

with

Set

..

o•d

nge

Lock

Pin

Stud

Screw

)(

2)

on 268063

two

HUMBER

268047

268060 F

268061 F

268062 F

268062

268065

DESCRIPTIOH

F

..

d Llfti

Eccentr

268077

200394(803)

..

d Oriv l

Conn•cllon

.. d Drivino

Connection

wllh

268063

.. d Dd.ino

Cann•ctlon

with

26a2S8

Feed Ll't

Connection

With 268::158

Fe•d

Connect

Beorint

Feed

Ec:nntfic:

Oitc

Orh•lnt

Orh•ino

no

ic

with

and

two

no

268060

Hlno•

ln o

Hino

ion Heedl

Adjustint

Stud

e Stud

e

J.O

Page 11

•

NOT

HUMBER

268066

E:

Wh

DESCRIPTION

Fe•d

Ecc.ntrlc Adj

Oi

268067 F

Ecc

Disc

whh

268069

268071

268071

268072

F

Frome

ond

F

Shoft H ..

F

Shoft

F

Shah

200386(830)(2)

268072 F

Shoft

200386(

en ordering replacement parts from

Orl

vino

.c

Srtrlno

.. d Orlvlno

ent

ric

Acfiuating

Spring

two

200382(833)

nd

Or l

vino

with

200362(803)

.. d Driving

dltt

.. d Lihlno

Needle

.. d D,l.,ing

Collar with

.. d Lifting

Col

lor

803

)(2)

usting

Coilor

Rock

200J54(803)

Rod

e

Beoring(2)

Rodt

B•oring(2

Rock

two

Rod~

with

two

HUMBER DE

268

073

268074

268075 F

268077

268078 F

)

26

8079

268081 F

268082

SCRIPT

f•ed

Shofl

200061(833)

Food

Connection

.. d Liftlno

with

201256(830)

F

.. d Llftino

Ecc

Pod

.. d l..lhino

F

.. d Liftin

Honoe

268258(2)

.. d Regulotino

F•ed

Sock

this

ION

Orlvino

Cron\

L.ihino

200373(803)

erot

rlc

(wood)

Pin wit

Reovlotino

et

with

Cronk

Lubricotint

Li n~

g

Lin~

cata log, a

Roc~

r

....

ond

h

Srud

Stud

o

268198

2682S8

2682~8

2682~8

268315

268316 F

"P"

HUMBER

prefix

DESCRIPTION

F

.. d L.lhlno Roc:\

Shoh

20U18(803)

100061(833)

Food

Connection

011

F..,od L.Htlno

Connection

Stud

(wick)

Fttttd

Hi

Pocld

F

w

241763.

3S0477(83U)

lSOS48(8031

.. d Ooq

101537(819)

3SOS52(830)

must

Pocklno {wic

Cron\

Or

lv l

be

wl m

and

no

Hin

added

two

o•

Stud

k)

Hlno•

Oil

Poddnv

Llhlno Linlc

noe

Pin

Oil

no (

....

lclc)(2)

.. d Driving Flonge

hh

26

7623,

two

eoc"-

3~467(830).

..,4

S.hon

lc with

ond

to

all part numbers required.

HUMBER

269684

26968S

269686

270026

3~467(830)

3~477(830)

3~548(803)

3~552(830)

DESCRIPTION

Feed

Shoft

F

Shah

Food

hole,

ond

•••

Stud

F

S•t

E

Plot•

Scrttw(2)

Eccentric F

P

Adjustint

Orl• l

.. d Lihlno

Dog,

with 267669

two

200907(81 9)

269689

F

..

d Rogu l

Sprint

.. d Orlvlno

Screw(:Z:)

Feed Orlvln

cc

entr

ic Friction

Screw

Ftted

Orl wlnt

late Screw(2)

Fee~

Dov

s.fotonl.

Scnw

nt

40

otlnt

t

ricti

Rodt

Roc"

no•~llo

Flange

'

S.t

on

\

~

P300·2/206,

HUMBER DESCRI

913(806)

200017(803)

200017(803)

20003~803)

20004 1(805)

200084(8~)

200354(803)

Puller F ..

(upper)

A

djustint Screw(2)

Puller F .. d Cross

Shaft

Puller F ..

Shaft

Pvller

(lo

w•r)

Sproclc

Scr•w(2)

Pull•r

Shoh

(lo

wer)

Puller

(upper)

Arm Scre¥1{2) 201220!833)

Puller F .. d Roll

(lowt~r)

Screw

200362(803) Pullll)r

Shoh

S

crew(2)

200362(803)

200362(803)

200378(803)

200382(833)

200382(833)

200382(833)

200394(803)

200447(130)

200S63(80S) P

200571(804) P

Pvller F ..

$t\oh

Screw

Pull•r F .. d Ro

(lo

w.,) Set

Puller F ..

Shoh

Screw(:2)

Puller

Shah

Puller F .. d Driving

Shoh Worm

Screw(:Z:)

Puller F .. d Roll

(uppttr)

Scr

P

vll

(lower)

Sttt

Puller

Shoh

Scr

ull

(upper)

Sc

uw

ull

Shah

(upp ..

PTION

d Roll 200572(803)

Sor

Spri n g ( uppfl'r)

B•ocket

d Otl.,.ing

Brocket

Feed

et

Feed Drlvi

Cover

Fe..d

Fe•d

Worm

Worlft Geor

Collar

Worm

ew(l)

er P .. A Roll

Screw(~)

Sprocltet Set

ew

er f

(lower)

et

Co•e r Screw

Roll

Cho

ln Idle..

6r4c.

Screw

Rol l

Bar

Lifter

Posit

ion

Crou

Ceor

cl

Orivln9

Screw

cf

Driving

Set

Feed

Fe•cl Orl•ln

fe.d Otl

Crou

Set

Set

Brocll:et

Shoh

..

8or

Coll

d

Roll

8rocltet

)(2)

Screw(2)

Screw(3)

lt.t

n9

Set

Set

ll

Screw

S•t

ar

g

ving

HUMBER OESCR1PTIOH HUMBER

Puller

Brodcer Adjusting

Screw(2l

201052(833)

201158(803)

201220(833)

201220(8

33)

201308(80$)

2

32866

232866

267110

268424

Puller F .. d Driving

Shaft

S•t

Puller F ..

(lo

Sproc

Puller

Shah

Screw

Pulle-r

Sho

Position

Puller

(upper)

Position

Puller Ftted

(upre

Screw

Pull•r

Shoft

P

in(2)

Pufl

Shoft

Po•itlon

Puller

(upper) H

a .

Pullet Feed

Sh

200378

268425 P

268425

268428

2684~8

uller

Shoh

8eorln9(l)

Puller

S

hoh

B•orlnvU)

Puller F .. d Roll

(upper)

Pull.,

Shah

268449 Pulltlf' F

S.,_oh

168

269618

269621

Puller

(l

ower)

wloh

Puller Feed

Sha h

Feed

Sor

Thru•t

Screw

wer)

Shoft

litet Set

Feed

Worm

Feed

ft Worm

Fud

Brocket

r)

Bar

(upper)

Fe

Broc

er

Feed

Broc

Ffted

oring(.4)

oh

Collar

(403)

Feed

Httedle

Feed

Heedl•

8or(2)

F~ed

8roclt

..

Brac

448

with

Feed

Shaft

Owo

Screw

Sc:rttw(2)

• d

Pln(.C)

..

200394(803)(2)

406

Roll

Po• i tion

Collar

ct

Roll

Screw

Cro

u

Position

Driving

Gear

Roll

Roll

8rockttt

Cro

n

ket Pos

ket

'CI

with

Otivi"9

et

d OrivinQ

h t

ition

Orivin

Roll

Ie

Dri

Crou

Orl.,.lng

268~25

Roll

Crou

9

ving

two

C411or

PULLER

269622

269623

269624 P

269625

269626

269628

269629

269630

269631

2

6963

269633 Pv

269634 P

269635

269636

269637

26

9638

2o9639

~

FEED

2

I·

PARTS

DESCRIPTION

Puller F .. d Crou

Shoff

Puller

Shoff

whh

Sl-to

200382(833)

Brocket

Feed

Cro

Broclcttt

two

ull•r F .. d Cro

h Woof!

269622

26842.$

whh

ond

n 269641

u

201220(833)

Puller

Shah Wo""

owo 200

Puller

Shah

Puller

Shaft

Pvller

Shoft

2004A7(U

Pulle

Shoh

wioh 201052(833)

Puller

Shoh

200382!833)

9

Pul:er

Sl.oh

200362(803)

Feed

362(803)

Feed

Feed

Cove

Ff!fld

Sproc"et

r

F~ed

Thrust Coll

Feed

Worm

stitches

Feed

WOf"'

Cros

Geor

Otlvln9

Otivln9

r

Otlvlng

))

Dr i

Driving

with

Uo•

per

Dr i

Geor

ond

s

with

with

ving

er

two

inch)

ving

with

2C1220(833) (loo 9

titchu

s

ller

wloh

20

036

uller

flower)

Pu

ller Feed

(

low

Idler Sproc:l..et

Pull"'

(lowttr)

Iefier

Bracket

per

Inch)

Feed

20035~(803)

Roll

(low•r)

ond

2(803)

Feed Roll

Chain

Roll

er)

Chain

Fud

Sproc

Roll

Choif"'

kttt

with

350558(819) A

Pull•r F .. d Roll

(lower)

Sproc

Pvller

(lower)

Puller

(lo

Sprncket

l..et Pin

wer)

Cho

ln

lcll

F•ed

Fu d Roll

Roll

S.hoft

Shah

whh

er

20 1188(803)

HUMBER

269640

2169642

216964J

269644

269645

269646

269647

260648

269649

2696SO

269670

269671

269672

3S0149(80l)

350328(803)

3~SS8(819)

3~29(805)

DESCRIPTION

Puller

Feed

Roll

(uppo•)(2)

Puller F .. d Roll

(upper)

Pull"' F ..

(upper) l

Arm Cl

PuUer Feed

tuppe

rm

A

Puller

(upper)

Arm 81ocll

Puller

(upper)

8ra

200572(803)

eft

r)

(ritJo.t)

Feed

Feed

clcet

Bar

or

)

8or

8or

Bor

with

8roclun

cf

Roll

Lift

Roll

Lift

Roll

Lifter

Roll

Position

ond

er

.,

350328(803){2)

Puller

(vppttr)

Puller

(upp•r)

200382(833)

Fud

Roll

8or

S.,rlno(2)

Feed

Roll

Brocket

ond

with

201220(833)(2)

Pullttr

(upper)

Puller

Shoh

P

Shaft

w

Beor

Puller

(upper)

two

Puller

(uppe

Reta

Puller

(lowe

89oring(2)

Puller F .. d Roll

(vpper)

Puller F .. d Roll

(uppe.r) B

Brocket

Pvller

(fo

Sprocket

Puller F .. d Drl•lnt

Shah

(lower)

Feed

Feed

8roc:ltet

vller F•e4 Orl••n9

Brocket

ith

268~25

in9

26711

r) Shoft

in

inQ R lno(2)

t) S

rm

Oloc\

wet"

) Cfoaln lcller

Brocllet Scr

Roll

Shah(2)

O..ivino

(rioh

269

(

Heedltt

on

leh,

Fud

Ro

ll

2696.40

Fud

Fud Roll

hoh

8-or

ar

Pinch

Feed Roll

Pin

with

0(:2)

Roll

Needle

lifter

Screw(2)

Position

Sc:rew(l)

Set

Screw

ew

,

t)

6~9

'

"

·

~

'

•

II

Page 12

'

BED PINS

MACHINE

BED

CUSHIONS

PINS

Fig.

2.

Installation

' ; .

. .

~

.

,.4--

MACHINE CUSHIONS

MACHINE BASE

''

FCIOT. LIFTER

.

LEVER

OIL

DRAIN JAR

IHST

drain

1 or.

pi

wi

ALLA

Fasten

jar

Set

ns

Connect

th

machine

into

cha

TION

machine

aligned

machine cushions

foot lifter lever

in

furnished

LUBRICATION

These

machines

wi

th

onto

bose

machine

for this

hove

to

hole

on

table with hole

in

table.

bose

as

to

purpose.

automatic oiling

Attach

by i

nsert

shown

foot lifter

for oil

oi l

dra

in

ing

bed

in F ig. 2.

trP.ad le

system

, ;

.

-"

'

Fig.

3.

Foot

Lifter

Lev'er

consisting

shaft

centrifugal

to all

oti ng.

ports

reservoar s.

Oi I

which

princi

holes

in

contact

of

o

oct

force,

ple

bear

ore

hollow

as

reservoirs.

through

ings

provided

which

arm

small

when

ore

shaft

the

for l

not

and

Oi l

jets

machine is oper

ubricat

lubricated

hollow

is

delivered

in

the

ing

from t

bed

shafts,

movab

by

·

le

he

4

Page 13

• •

P486·72

•

Supplement

Parts

Chart

to

Form P21367

SAME

LIST

AS

OF

PARTS FOR

P300·2/201

BASIC MACHINE P300·2 WITH

MACHINE

THE

FOLLOWING

EXCEPTIONS

•

267821

267825

267829

Feed Dog

056).

When

Feed Dog

and

1-1/4"

Feed Dog

with

with

two 268318

ordering

two 268318

state

gauge {code 116).

with

two 268318

and

four 200172(804)

gauge .

and

four 200172(804)

When

and

four 200172(804) 15TPI

orderiug

15TPL

15TPI

state

1146

1146

gauge.

11460

N.H.

for

N.H. for

N.H. for

7/8"

1"

1-3/8"

gauge (code

gauge.(code 100)

gauge

268105

268106

268107

268136

268255

268256

{code 124)

and

Looper Holder

1-1/2"

with

gauge {code 132).

four 350478(803) for

7/8"

gauge.

Looper Holder

Looper Holder

124)

and

Needle

Needle

1-1/2"

Bar.

Bar

Rock Frame Thread Guide

with

with

four 350478(803) for

four 350478(803) for

gauge (code 132). ·

1"

1-1/4"

When

for

gauge.

Needle Bar Rock Frame Thread Guide for

When

ordering state gauge.

gauge (code 056).

gauge (code 100).

gauge (code 116)

ordering

7/8"

1"

gauge (code 100).

state

gauge.

gauge.(code 056).

When

When

1-3/8"

When

When

ordering

ordering

state

state

gauge.

gauge (code

ordering

state

ordering state gauge.

•

268268

268154

268156

269574

269577

268376

Needle Bar Rock Frame Thread Guide for

124)

and

Needle Holder

Needle Holder

Pressor

(code

Pressor

gauge (code 124) and

Spreader

1-1/2"

Foot

100).

Foot

with

gauge (code 132).

with

with

two 50014(830)

two 50014(830) for

(hinged, compensating)

When

ordering

state

gauge.

(hinged, compensating)

1-1/2"

two 268162 for

gauge

7/8"

When

for

7/8"

1"

!146D

1146D

(code

gauge (code 056).

1-1/4"

gauge (code 116)

ordering state gauge.

gauge (code 056).

gauge (code 100).

N.H.

N.H.

132).

for

7/8"

for

1-1/4"

When

gauge (code 056) and

ordering state gauge.

When

When

gauge (code 116)

ordering state gauge.

1-3/8"

When

ordering

gauge (code

state

ordering state gauge.

1"

1-3/8"

gauge.

gauge

268378

267858

NOTE:

When

Spreader

1-1/2"

Throat

ordering replacement parts

with

gauge (code 132).

Plate

two 268162 for

for

7/8"

gauge.(code 056).

from

1-1/4"

When

this catalog, a

ordering state gauge.

gauge (code 116)

~~

When

"P"

1-3/8"

ordering

prefix must be added to

state

gauge (code 124)

gauge.

and

all

part numbers required.

Page 14

'

267859

267860

268382

268333

268332

268132

Throat

Plate for

1"

gauge (code

100)

gauge.

Throat

Plate

for

1-3

/8"

gauge (code 124) and

state gauge.

Looper

and

TWO

Needle Guard complete nos. 268310

EACH OF

THE

FOLLOWING PARTS

Looper Thread Tension Thread Guide.

Looper Thread Tension complete, nos.

Looper Thread Tube.

and

1-1/4

" gauge (code 116).

1-1/2"

and

gauge (code 132).

ARE

USED

268380.

10148, 141432(819), 201572(819)

When

When

and

ordering state

ordering

•

two 244048.

226206

54279

268263

269564

Needle Thread Tension Releasing

Needle Thread Tension Thread Guide (double).

Needle Thread Tension complete nos. 32572, 59537, 59538, 59539, 131741

Edge Guide.

200161(850) Edge Guide Screw

NOTE:

The standard gauges are

order.

THE

(2)

Pin.

FOLLOWING PARTS ARE NOT USED

1-1/4-

1-3/8

and

1-1

/2.

The

7/8

and 1 are furnished

and

two 2102.

on

specian

~

NOTE:

When

ordering

replacement

parts

from

this catalog, a

"P"

prefix

must

be

added

to

all

part

numbers

required.

Page 15

•

Complete

Before Operation

Use U

ter

white

sity

heit

end

as

conne

ily

shown in

ol

.

Arm

of

shown

Needle bar connecting

cti

accessible

Lubrication

nion

90

shaft

machine

in

ng

Fig.

Special

straight

to

125 seconds at 1

reservoir

Fig

stud

mineral o

pulle

. 4.

and needle bar beari

for lubri

4.

of

Machine

Oi

l, Specificat

il

Is

filled

y or at end

1 i

nk

cat

ion under face

is

Necessary

ion

175, a wa-

of a saybolt v

00

degrees fahren-

through

of

needle

needle bearings,

oil

ngs

hole at

bar

are rea

pla

isco-

crank

d-

te as

INJECT OIL

THROUGH

OR

NEE

MACHINE

DLE

TWIC

BAR

.E OAIL

PULLEY

CRANK

OIL

OI

L

Needle bar ro

ricated

thr

r

ck

ough oil h

01

frame needle

ole

in dicated

.

'

--

OIL

bea

in

ring

Fig.

s are

5.

lub-

Fig.

4.

Arm

OIL

Shaft

Reurvalr

OIL

L

J~t<r

~

~

~

Nee

dle Feed

f-\(

0 •

""""'~

OIL

Ma

chines

~

~~-d

Fig.

5.

lubricating

the

Machine

Bed

looper

oil

hole

shaft

driving

ot e

Puller

reservo ir is

crank

nd

oil

of

bed shaft conn e

OIL OIL

Feed Machines

fil

led thr ough hole under

hole

cover, Fig. 6, or through

ction

belt

pulley.

INJECT OIL

TWICE

Fig. 6. Bed Shaft

5

DAILY

-~

Resetvoir

1

Moving parts under bed may be lubricated through

surf

holes in bed

Other moving parts in contact

of

machine are provided

lubrication

A machine

ed twice daily

cat

.

ace or by removing bed

und

er bed and at rear

'"

conti

.

with oil

nuo

us

hole

use should be lubri-

s for

efficient

plates.

Page 16

CLEANING

SPEED

Using

sheers),

loop

ers, from

of the

Wipe

the

short

remove

throat

extet

bristled

lint

between

plate

ior

of

brush

or

and

machine

(not

other

the fe

from

point

waste

ed

rows

other

with o soft

of

from

end

operating port

•

~

I~

sc

around

unde

cloth

l.>

0

·- ·

issors

rsi

.

-

or

the

de

s.

Maximum

stitches

material

New

s

titche

the

NEEDL

sizes

s per

first

Use

ranging from 14

speed

per

sewn

machines

100

ES

Union Special Nee

minute. Operating

and

minute

hours of

lor

ope

rati

should

less

operation

to

on performed.

25.

thes

run

then

dles,

e mac

speed

at

maximum

.

Catalog

hines

a

speed

is

4500

depends

of

speed

P3

2GO,

on

500

lor

in

-MACHINE P300

-2

MEEDL

SCARF

BI~

S!C

EY

E

.E

MACHINE

--

.

-

P300-2

MOVE

&AR

HIGHEST

MEEDLE

TO

.

/206

POIMT

~

Size of needle for an operation

by

size

Orders for needles should

qu

ired , catalog number and size number.

For

100

SETTING

Turn

needle

of thread used and type of material sewn.

specify

Ex

ample:

Needl

bor

es,

THE

machine

is

NEEDLE

ot

Cata log P-{32

pulley

its

highest

over

60,

toward

position.

is

determined

quanti

Size 22

operator

Loosen

ty

r

e-

unti I

needle

UP

AS

AS

POSSIBLE

FAR

~

MACHINE

Fig.

7.

Sotting

HOLD

~-

P300

the

THIS E

-2/

406

He~dle

MD

set

high

of

shown in

THREAD

the loop

scr

ew. Inse

os

needle

Left

Either

it

will

in

Fig.

twist

left

ers .

rt

need

go

with

line

7.

thread

or

with

ri

shou

ght

le up i

needle

horizontal

ld

twiSt

nto

scorl

be

thr

needle

used

ead

to

!eft

machine

in the

may

be

hol

der

end

arm,

needles.

eye

used

a s

os

in

TWIRL OVER

TOWARD

•

.)

Fig.

8.

Determining

the

YOU

Thread

Twist

Thread

indi

cat

ed

in

with

thread,

thread, stran

thumb

strands

twist

Fig.

and

ds

is

determoned

8.

Twirl thre

fore finger

will

will unwind or

of

wind

by

hoiding thr

ad

over towa

right hond.

tighter.

separate.

If

ead

If left twist

right

rd

as

you

twis

6

t

Page 17

THREADING