Page 1

INDUSTRIAL

SEWING

FINEST

P300-

P300-0/

P300-0/401

QUA

S

TYLES

0/1

LITY

94

201

MACHINES

CATALOG

NO.

P21323

SINGLE

DOUBLE

GENERAL

STITCHING

TO

&

MULTIPLE

LOCKED

HEAVY

CLASS

NEEDLE,

STITCH

OPERATIONS

WEIGHT

P300-0

UNION SPECIAL CORPORATION

Form

P21323

Rev. (566)

CHICAGO

"'

NEEDLE

MACHINES

MATERIALS

ON

FEED

FOR

MEDIUM

Page 2

CONTENTS

DESC~

INSTALLATION

LUBRICATION

Description

Feed

Feed

Feed

Installation

Loop

Looper, Positioning

Lubrication

I PTION.

Genera

Special

Height

Lengthwise

Sidewise

Timing

Lengthwise

Sidewise

Timing

Arm

Bed

Other

I Charocteri

Features

Bar,

Dog,

Roll,

Deflector

Height

Centralizing

....•.......••....•••.......•....••

.••.•.•......•..•••••..•..••....•.

Pressure

..•.......•..•••••••.•..•...•.....

•.•.•.•..•..•.•.•••••..........•.••

....•..•.••.••.•.••••..•..•........

Shaft

Shaft

Points

............••.••...•.•........

..•••......••••...•..•...•....

......•.....••••.............

of

Machine

.....•..•.•••••..•.••..•.....

Setting

Setting

••.••.••..•.••.••..•.........••

Setting

Setting

.••..••..•..•..•••••..•.•...•.••..

...•..•.•..•.•.•••......•.......•.

•..........•••.•.•..••••.......

......••.....•..•...•....

sties

..•.•.......•..••..•..

•.•...••••••..•......•.....

.....•••....•.....••..•.

........................

..•..•...•••.•........•...

...........................

•.•..••.••.•.•..•..•.....•

.....•.••.•..•.....•.•..

•..•..•.••••.•........•....

•. 5

12

12

12

12

12

.

13

13

•

14

.14

14

15

3

4

IHDEX

3

3

3

9

4

5

5

5

5

OPERATOR

ADJUSTMENTS

Needles

Setting

Needle Bar, Height

Needle Bar, Position

Needle Guard,

Presser

Presser

Speed

•.•.•..••.•.....•.•.•••.•.•••...•••.••..

Stitch Length

Spreader, Position i

Lengthwise Setting

Sidewise and Height Setting

Toke-up, Adjustment

Looper Thread

Needle Thread

Tension

Releaser

Threading

Upper

Lower

INFORMATION

............................

•.•....••..•.........•.••.••.....•••..

•...•.••.••..•..•........••••..•••..

•.•.••..•..•....•...••..••••

••.•.•...•....••.•...•••••

.•......•...••...•••.•..•..•••..

Bar, Height

Foot, Pressure

.•..•.••.••....•..•....••.••.••.•.••.•

...•.•..••.•.••..•.•..••..•.••.••

.•..•......••.•..•..••..••..••..••••

.•.....••.•.....•.....•.•..••.••.••••

••••.•••....••.••..••••••.••••...•••

•..••••.....•..•....•..••••

......................

.•.••..•..•.•..••.•..••.•••.•••.

ng

••.•.•.....•••.•..••••••••

•.......•..•..•.•••..•••

.•..•..•.........••.•..•••

.••.•..••.•.•.•••.•••.•.••••

.•..••••....•.••.•...••..•••

..................

..•...•......••••

S-8

8-17

6

6

14

13

15

11

8, 9

5

.10

16

16

16

17

17

17

8

17

7

7

7

Page 3

DESCRIPTION

Machines

feed, two thread

general

and heavy

These machines are

or

multiple

ing, binding,

perform outstanding work

automotive upholstery, tents,

and a

variety

General

Belt

ball

bearings.

Belt

Semi-automatic

pacity

cates

Presser

lifter

which

Space

Special Features

Style

P300-0/194

One needle

Alternating

trol.

Stitch

Needle

Clearance under presser feet,

Anti-reversing

of

Class

chainstitch

stitching

weight.

Characteristics

driven

driven

oi I reservior

all

principal

at

length, 4

bar stroke, 1-7/ 16

operations

needle

stitching

welting,

of other products .

arm

bed

shaft.

lubricating

bearings.

foot

is

also

releases the needle thread tension.

right

of

and

one looper.

pressers

to

mechanism.

P300-o are

available

lap seam

on

shaft

mounted in front and rear

in

upper and lower

raised by a treadle operated foot

needle, 10

with

12 per inch.

high

speed, needle

machines designed for

on

materials

for

operations such as seam-

felling,

trousers,

tarpaulins,

system

inches.

pneumatic pressure con-

inches.

1/2

single

work

seat covers

with

shafts

inch.

of

medium

needle

etc.,

they

clothing,

large ca-

lubri-

Machine P300-0/201

Two

needles and two loopers.

Stitch

length, 4 to 12 per inch.

Needle bar stroke,

Clearance under pressure foot,

Gauges (Needle Spacing):

in

steps of

Standard gauges,

1/2 inch,

inches.

Machine P300-o/401

Four needles

Stitch

Needle bar stroke,

Clearance under presser foot,

Gauges (Needle

between

Standard gauges,

5/16

inch inch-1 inch-

1/32

5/8

inch,

length, 4 to 12 per inch.

outside

inch -

3/8

5/16

inch,

1/4

1-1/4

inch.

3/16

3/4

and

four loopers.

1-1

Spacing):

needles.

1/4

inch -

1/2

inch

inch.

inch,

I 4 inches.

inches.

3/16

inch,

1-1/4

3/4

inch

5/16

-1/2

3/8

1/4

3/8

inch

-1/4

inch,

inch

inch.

inch

to

2 inches

inch,

3/8

inches and

inch.

to

2 inches

Inch

-1/4

3/8

inch-

-1/2

inch,

inch,

1-1/2

inch,

3/8

1/4

3

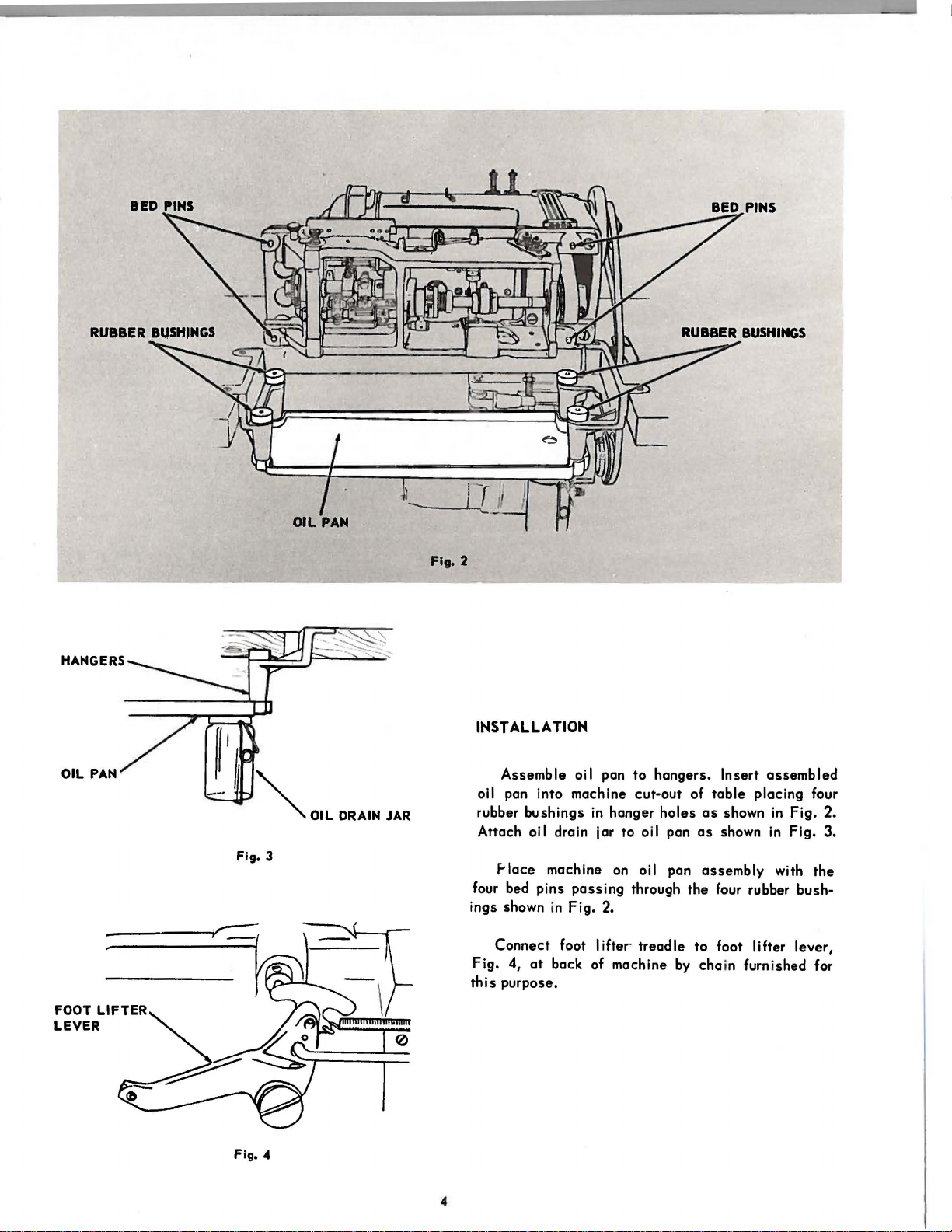

Page 4

HANGERS

OIL

PAN

Fig. 3

Fig. 2

INSTALLATION

oil pan into

rubber

Attach

four bed

ings shown in

Assemble

bushings

F-lace machine on oil pan

oil pan

machine

in

oi I drain jar

pins

passing

Fig.

2.

to

cut-out

hanger

to

oi I pan

through

hangers.

holes

Insert

of

table

as

shown

as

shown in

assembly

the

four rubber

assembled

placing

in

Fig.

Fig.

with

bush-

four

2.

3.

the

FOOT LIFTER

LEVER

Fig.

Connect

Fig.

4,

this

purpose.

4

4

foot I ifter·

at

back of machine

treadle

to

by

foot I i fter

cha

in

lever,

furnished

for

Page 5

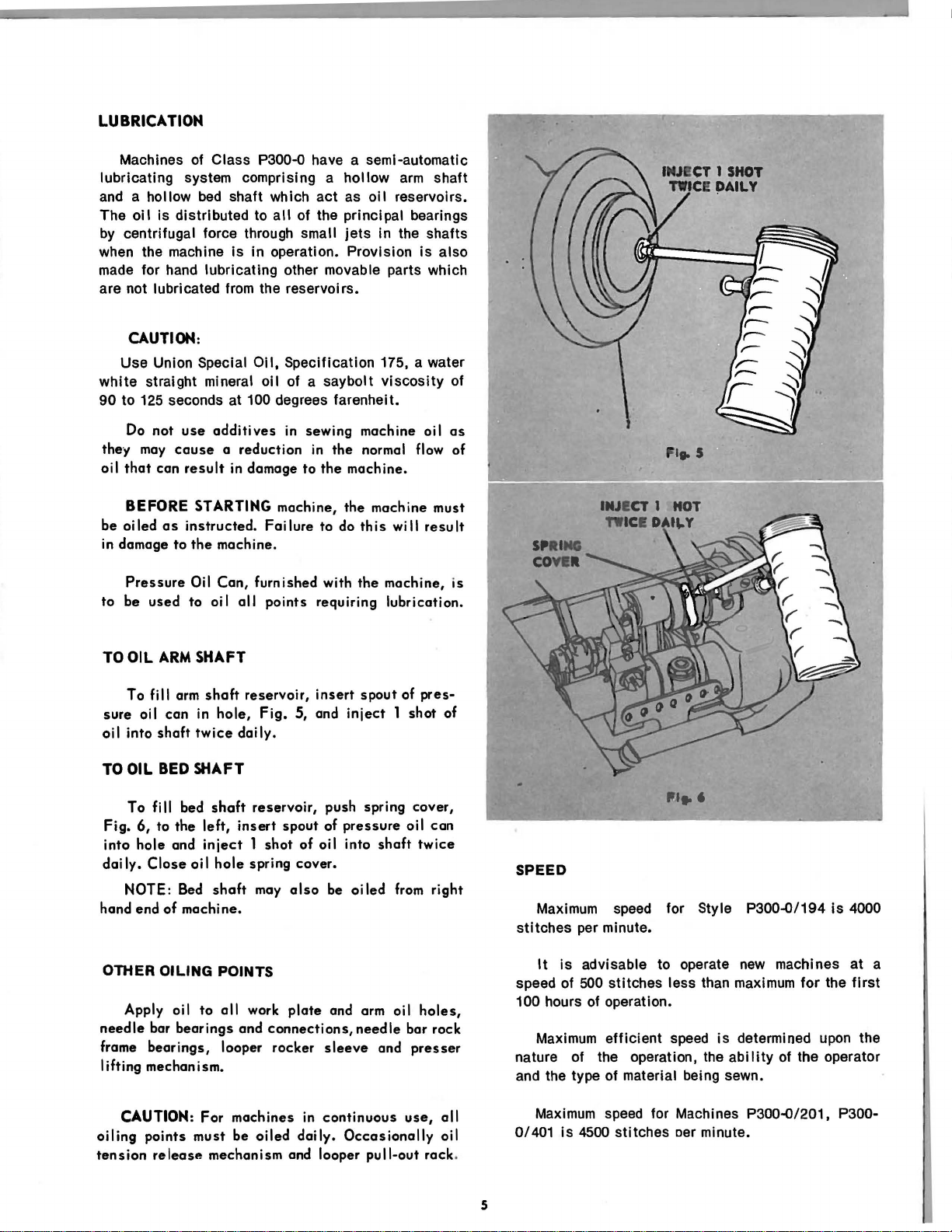

LUBRICATION

Machines of Class P300-o have a semi-automatic

lubricating system comprising a

and

a hollow

The

oil

by

centrifugal force through small

when the machine

made

for hand lubricating other movable parts which

are not lubricated from the reservoirs.

bed

shaft which

is distributed to

is

in

all

operation. Provision

hollow

act

as

of the principal bearings

jets

arm

oil

reservoirs.

in the shafts

CAUTION:

Use

white

90

to

Do

the-y

oil

that

Union Special

straight mineral

125

seconds at 100 degrees farenheit.

not

use

may

cause a reduction

can

result

Oil,

oil

additives

in damage

Specification 175, a water

of a saybolt

in

sewing

in

the

to

the

viscosity

machine oil

normal flow of

machine.

is

shaft

also

of

as

, ... s

BEFORE

be

oiled

as

in damage

to

Pressure

to

be

used

TO OIL

sure

oi

To

oil

I into

ARM

fi

II

can

shaft

TO OIL BED

To fill bed

Fig.

6,

to

the

into

hole

and

daily.

Close

NOTE: Bed

hand end

of

STARTING machine,

instructed.

the

machine.

Oil

Can,

to

oil

Failure

furnished with

all

points

SHAFT

arm

shaft

reservoir,

in

hole,

Fig.

twice

daily.

SHAFT

shaft

reservoir,

left,

insert

spout

inject 1 shot

oil

hole

spring cover.

shaft

may

also

machine.

the

machine

to

do

this

the

machine,

requiring

insert

spout

5, and

inject 1 shot

push spring cover,

of

pressure

of

oil into

be

shaft

oiled

must

wi

II

result

is

lubrication.

of

pres-

of

oil

can

twice

from

right

SPEED

Maximum

stitches per minute.

speed

for Style P300-0/194

is

4000

It

OTHER OILING POINTS

Apply oil

needle

frame

bar

bearings,

to

all

bearings

looper

work

and

lifting mechanism.

CAUTION: For

oiling

tension

points

release

machines

must

be

mechanism and looper

plate

connections,

rocker

in

oiled

daily.

and arm oil

needle

sleeve

and

continuous

Occasionally

pull-out

holes,

bar rock

presser

use,

all

oil

rack

.

5

is

speed of

100 hours

Maximum

nature of the operation, the

and the type of material being sewn.

Maximum

is

0/401

advisable to operate

500

stitches less than

of

operation.

efficient

speed

4500

stitches oer minute.

speed

for Machines P300-Q/201, P300-

new

machines at a

maximum

is

determined upon the

ability

for

the

of

the operator

first

Page 6

NEEDLES

Machines P300-Q/201, P300-0/401 use Needles,

Catalog

P3260 (62 x 57).

MOVE

TO

HIGHEST

POINT

LOOSEN

SCREW

For heavier weight material, needle Catalog

4112 (62x59)

needle bar must

13.

P300-0/194 use Needles, Catalog P4112

for medium heavy work or Catalog

for medium

The

by

the

through

Orders for

quired,

To

Set

The

light

size

size

the

eye

size

number and

Needle

may

work.

of

the

of

the

of

needles

also

be

used. In

be

adjusted as instructed

needle

thread

the

need I

should

catalog

to

be

used

which must

e.

specify

number.

this

P3260 (62 x 57)

is

determined

pass

quantity

P-

case, the

on

page

(62

x 59)

freely

re-

MOVE

TO

HIGHEST

SCARF OF NEEDLE

TOWARD

POINT

LEFT

Fig.

Turn machine pulley over toward

until

the

needle

bar

is

at

its

highest

the

point,

operator

as

shown

in Fig. 7.

Loosen

chines

machines,

Insert

it will go making

needle

LOOSEN

SCREWS

or

needle

as

needle

faces

needle

shown

toward

set

screw

clamping

in

Fig.

into

needle

certain

the

on

screws

on multiple

7.

bar or clamp

that

the

left,

as

single

scarf

shown

needle

needle

as

far

of

in

Fig.

ma-

as

each

7.

THREAD

left

twist

or

right

twist

Either

used

in

the

needles

7

Rough or uneven

through

with

the

needle

successful

and loopers.

thread,

eye

with

operation of

or

difficulty

the

thread

thread

machine.

which

wi

II

may

be

passes

interfer

6

Page 7

THREADitolG

Upper

Threading

THE

MACHINE

Turn machine pulley over toward operator until

needle

points

correct

needle

bar

is

at

its

highest

Pass

thread

indicated

threading

from unwi nder through

in

Fig.

of

needle.

Draw approximately two

eye

with which

to

start

point.

8. See

inches

sewing.

insert,

of

thread

thread

Fig.

ing

8,

for

through

Single and

threaded as shown

thread passes through thread tension

Machines of Class

Pressers are equipped

front

of

the arm. The needle thread must pass through

the lubricator.

multiple

in

Fig.

needle machines are

8. Make

P300-Q

with

having

a thread

certain

device.

lubricator

all

that each

Alternating

on

Fig.

8

Lower

Open front

turn machine

bar

is

LOOP!R

RACK

THROW-OUT

ROD

Move

looper throw-out

throw-out

This

will

ingand

loopers

Threading

LOOP

! R

AR

LOCKING

THROW-OUT

PLUNG

! R

ROD

Pass

GE

points

of thread through looper

sewing.

7

Threading

pulley

at

its

highest

loopers

rack

place

prevent

are

returned

The

Loopers

thread

as

indicated.

table

section,

remove bed

over toward operator unti I

point.

out of sewing

gear

locking plunger rod and looper

rod,

Fig.

8, out

loopers

in

accidental

to

sewing

position

as

far

pos

ition for·

operation of

position.

from unwinder through

Draw approximately

eye

with which

slide

by

as

possible.

easier

machine

threading

two

to

and

needle

pulling

thread·

until

inches

start

Page 8

TENSION

PRESSURE

MORE

TENSION

LESS

TENSION

Fig. 9

Fig.

10

LOOPER

THREADS

Tension

while

still

material.

Needle

screw,

To

Thread

regulate

indicated

IMPORTANT:

only when

Looper

screws,

To

Thread

regulate

as

Alternating

on

thread

sufficient

Tension

needle

in

Fig.

Regulate

pre~ser

foot

Tension

looper

indicated

in

Pressers:

should

to

set

thread

is

down.

thread

Fig.

be

the

9,

as

needle

tension,

10,

light

stitch

tension,

may be

thread

as

may

as

possible

correctly

turn thumb

required.

tension

turn thumb

be

required.

in

Pressure

sible

while

still

Presser

screw,

screw

To

Foot

regulate

Fig.

11,

to

increase

pressure. When

tighten

lock

screw.

on

material

sufficient

Pressure

presser

at

correct

should

foot

rear

of

pressute;

feeding

THUMB

be

to

insure

pressure,

machine.

loosen

pressure

SCREW

as

light

correct

loosen

Tighten

to

is

LOCK

SCREW

as

pos-

feeding.

lock

thumb

decrease

attained,

To

loosen

see

tighten

To

decrease

loosen

When

screw.

increase

lock

Fig.

lock

lock

correct

Then

screw,

12.

screw.

pressure,

screw,

tighten

pressure,

When

correct

Then

then

pressure

the

then

loosen

upper

loosen

tighten

pressure

tighten

tighten

is

attained,

lock

lower lock nut

upper lock

is

attained,

the

lower

lock

upper lock nut•

lower lock

tighten

nut.

and

nut,

nut.

and

nut.

lock

Fig.

11

8

Fig.

12

Page 9

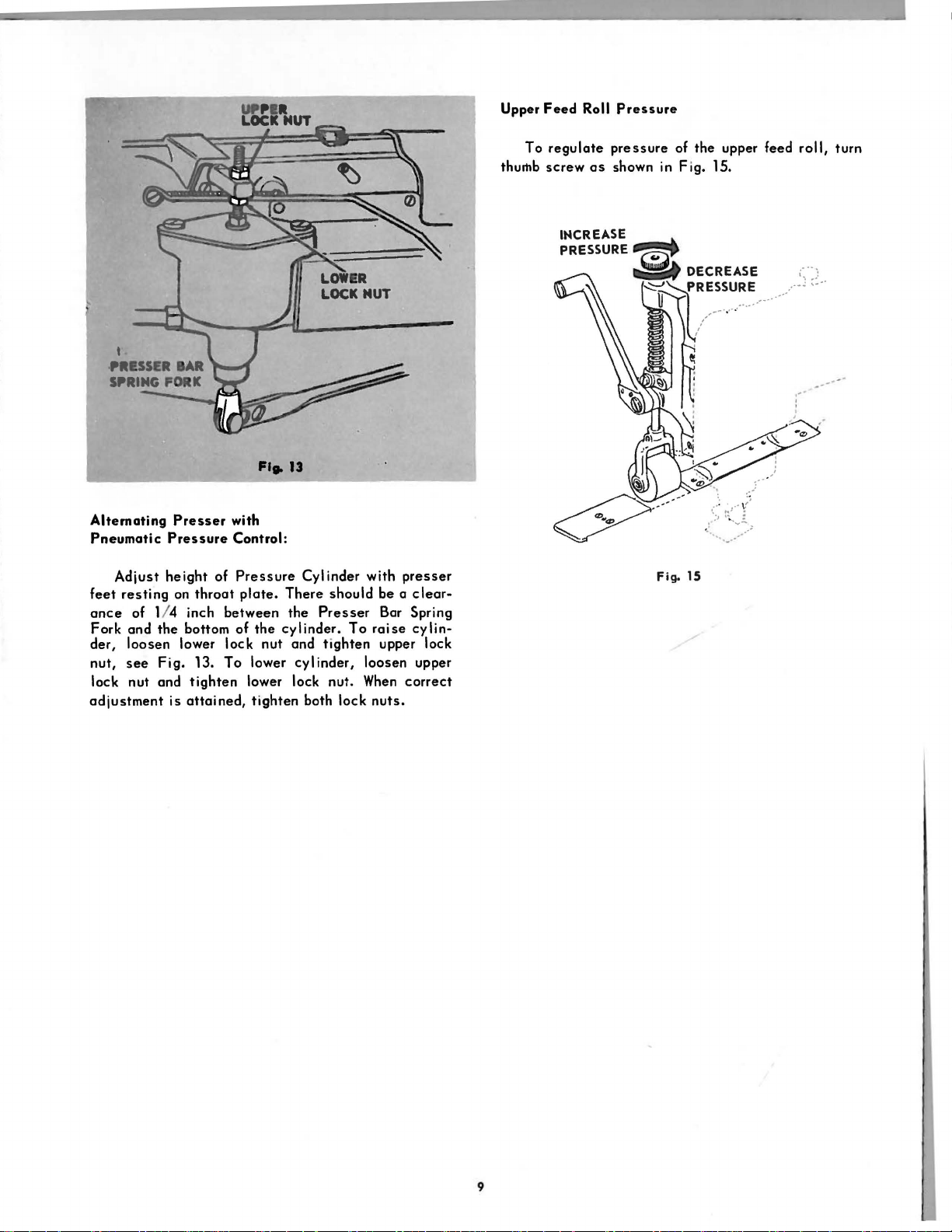

Upper

To

thumb

Feed

Roll

Pressure

regulate

screw

INCREASE~

PRESSURE~

pressure

as

shown in

of

the

upper feed

Fig.

15.

b

~

..

DECREASE

~~RESSURE

u

/.---····

'

.....

··

roll,

turn

;~·)

•....

-·····-~

.-

,.··

_

...

-·

-

·

Alternating

Pneumatic

Adjust

feet

resting

ance

Fork

der,

nut,

lock nut and

adjustment

Pressure

height

of 1/ 4 inch

and

the

loosen

see

Fig.

is

Presser

on

throat

bottom

lower

13.

tighten

attained,

with

Control:

of

Pressure

plate.

between

of

the

lock

nut

To

lower

lower lock nut.

tighten

Cylinder

There

should

the

Presser

cylinder.

and

tighten

cylinder,

both

To

lock

with

presser

be a

clear-

Bar Spring

raise

cylin-

upper lock

loosen

When

correct

nuts.

upper

Fig. 15

··

..

~._

.

....

-··"

9

Page 10

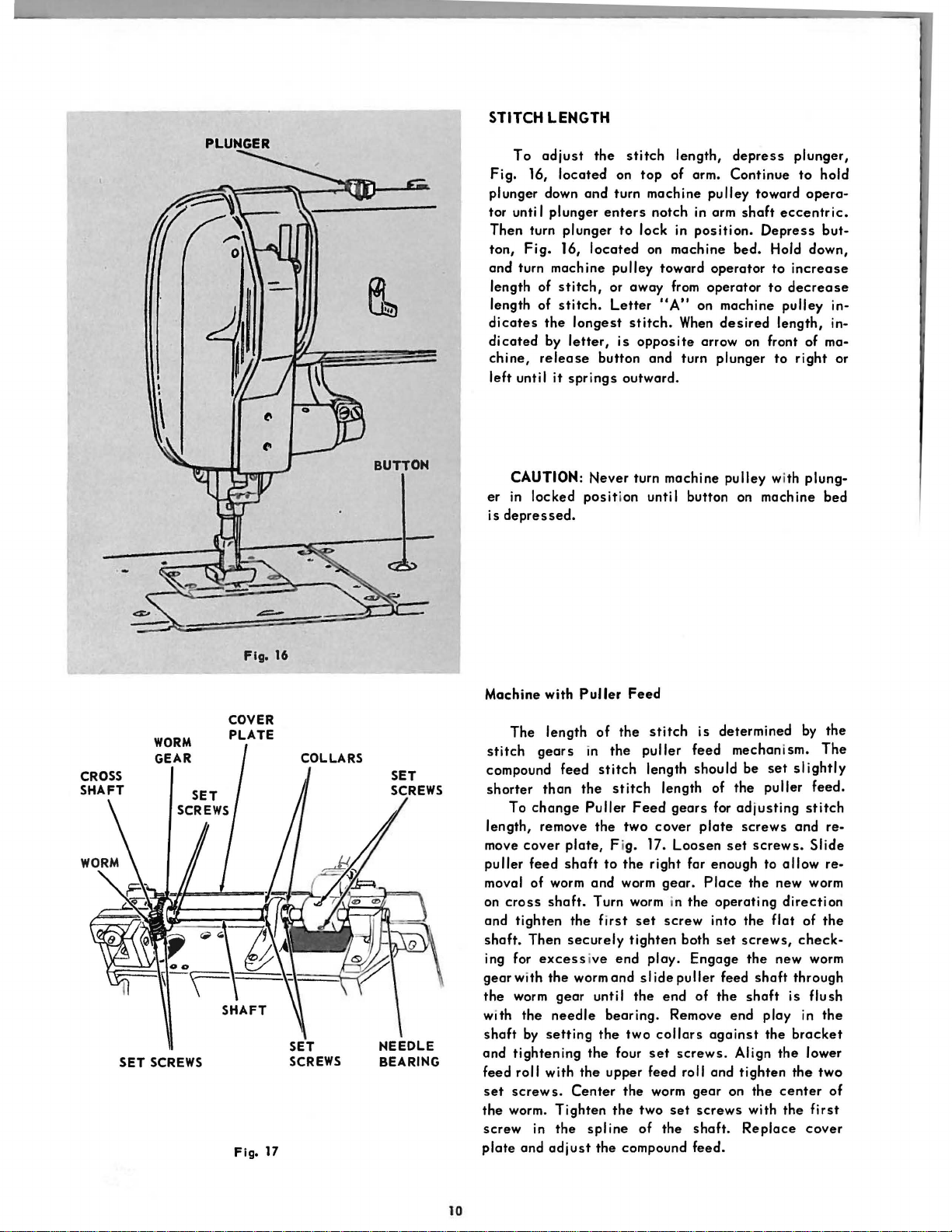

PLUNGER

STITCH LENGTH

To

adjust

Fig.

16,

plunger down

tor unti I

Then

turn

ton,

Fig.

and turn machine

length of

length of

dicates

dicated

chine,

left

the

by

release

unti I

located

and

plunger

plunger

16,

stitch,

stitch.

longest

letter,

it

springs

the

located

button

stitch

on

turn machine

enters

to

pulley toward

or away from

Letter

is

outward.

length,

top

of arm.

notch in arm

lock in

on machine

"A"

stitch.

opposite

and turn plunger

depress

Continue

pulley

position.

operator

on machine

When

arrow on front of ma-

toward

shaft

bed.

operator

desired

eccentric.

Depress

Hold down,

to

increase

to

decrease

pulley

length,

to

plunger,

to

hold

opera-

but-

in·

in-

right

or

SET

WORM

GEAR

SCREWS

Fig.

COVER

PLATE

Fig.

17

16

SET

SCREWS

BUTTON

NEEDLE

BEARING

CAUTION:

er

in

locked

is

depressed.

Machine with

The

length

stitch

compound feed

shorter

length, remove

move

puller

moval of worm

on

and

shaft.

ing for

gearwith

the

with

shaft

and

feed

set

the worm.

screw

plate

gears

than

To

change

cover

feed

cross

shaft.

tighten

Then

excessive

the

worm

gear

the

needle

by

setting

tightening

roll

with

screws.

Tighten

in

the

and

adjust

plate,

shaft

the

securely

Center

Never

turn

posit

ion

Puller

wormand

the

Feed

of

the

in

the

stitch

the

stitch

Puller

spline

Feed

the

two

F ig. 17.

to

the

and

worm

Turn worm in

first

set

tighten

end

unti I

the

bearing.

the

two

the

four

upper

the

the

the

compound

machine

until

stitch

puller

length

length of

gears

cover

Loosen

right

gear.

screw

ploy.

slide

puller

end

Remove

collars

set

screws.

feed roll

worm

two

set

of

the

pulley

button on

is

determined

feed

should

for

plate

set

far

enough

Place

the

operating

into

both

set

Engage

feed

of

the

end

against

and

gear

on

screws

shaft.

feed.

with

machine

by

mechanism.

be

set

slightly

the

puller

adjusting

screws

the

the

screws,

the

shaft

Align

tighten

with

Replace

screws.

to

allow

new worm

direction

flat

new worm

shaft

is

play

the

the

the

center

the

and

check-

through

in

bracket

the

plung·

bed

the

The

feed.

stitch

re-

Slide

re-

of

the

flush

the

lower

two

of

first

cover

10

Page 11

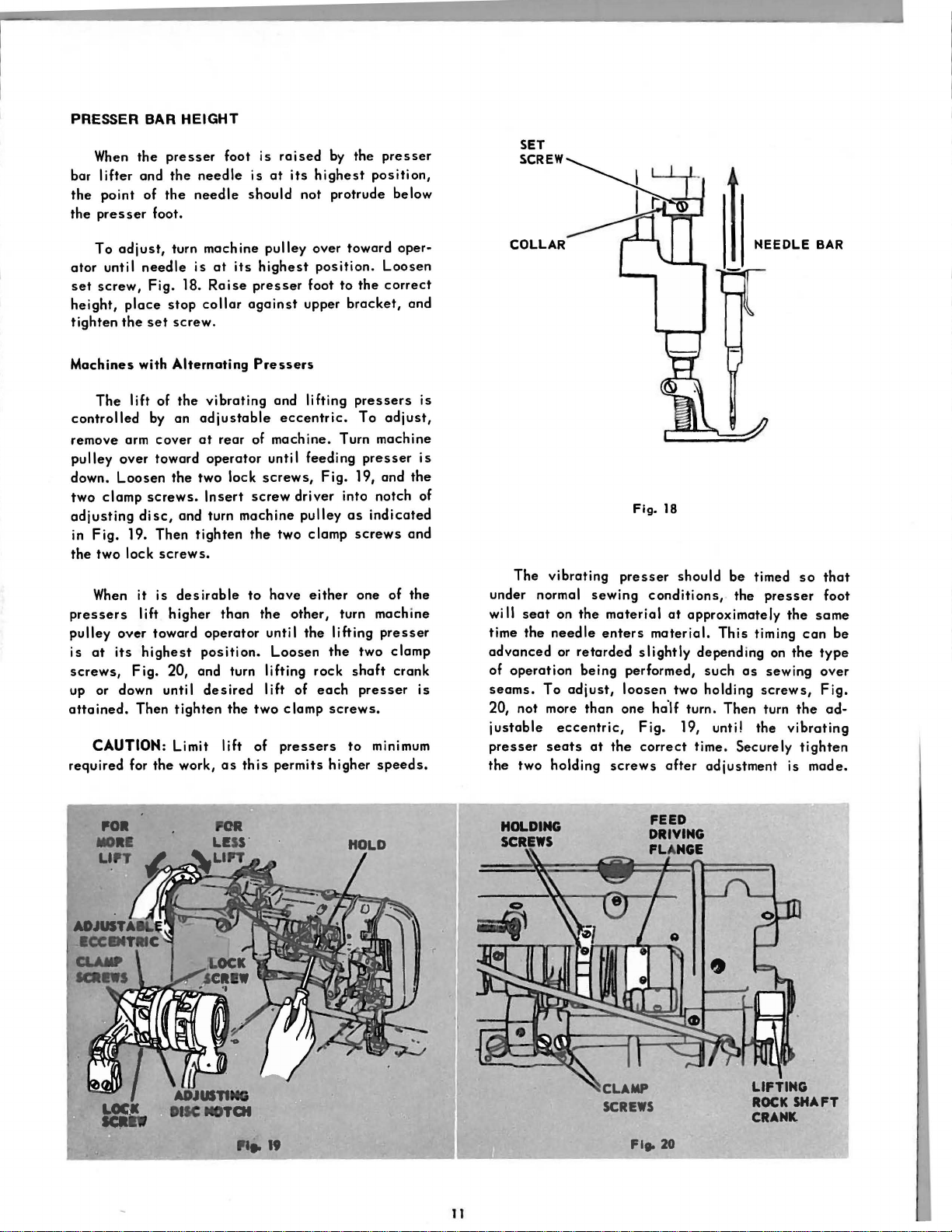

PRESSER

When

bar

lifter

the

point

the

presser

BAR

the

and

of

presser

the

the

foot.

HEIGHT

foot

needle

needle

is

raised

is

at

should

by

the

presser

its

highest

not protrude below

position,

To

adjust,

ator

until

set

screw,

height,

tighten

Machines

controlled

remove arm

pulley

down.

two

adjusting

in

the

pressers

pulley

is

screws,

up or down unti I

attained.

required

place

the

The

over

Loosen

clamp

Fig.

two

When

over

at

its

CAUTION: Limit

needle

Fig.

set

with

lift

by an

screws.

disc,

19.

lock

it is

lift

highest

Fig.

Then

for

of

cover

toward

Then

screws.

toward

the

turn

18.

stop

screw.

Alternating

the

the

and turn

desirable

higher

20, and turn

tighten

work,

machine

is

at

its

Raise

collar

vibrating

adjustable

at

rear

operator

two

lock

Insert

machine

tighten

than

operator

position.

desired

the

lift

as

this

pulley

highest

presser

against

Pressers

and

eccentric.

of

machine.

until

screws,

screw

the

two

to

have

the

until

Loosen

lifting

I ift of

two

clamp

of

pressers

permits

over

position.

foot

upper

lifting

feeding

driver

pulley

clamp

either

other,

the

rock

each

toward

to

the

bracket,

pressers

To

Turn

machine

presser

Fig.

19, and

into notch of

as

indicated

screws

one of

turn

machine

lifting

the

two

shaft

presser

screws.

to

minimum

higher

speeds.

oper-

Loosen

correct

and

adjust,

the

and

the

presser

clamp

crank

is

is

is

COLLAR NEEDLE

Fig.

18

The

vibrating

under normal

wi

II

seat

on

time

the

needle

advanced

of

seams.

20, not more

justable

presser

the

or

operation

To

eccentric,

seats

two

holding

adjust,

presser

sewing

the

material

enters

retarded

being

than

at

the

screws

should

conditions,

at

material.

slightly

performed,

loosen

one

two

ha'lf turn.

Fig.

correct

after

be

timed

. the

approximately

This

timing

depending

such

as

holding

Then

19, unti! the

time. Securely

adjustment

so

presser

the

can

on

the

sewing

screws,

turn

the

vibrating

tighten

is mode.

BAR

that

foot

some

be

type

over

Fig.

ad-

,o.

IIIORI

HOLDING

SCREWS

un

tt:t.

DISC

IIOTOI

.....

19

II

SCREWS

Fl•

20

LIFTING

ROCK

SHAFT

CRANK.

Page 12

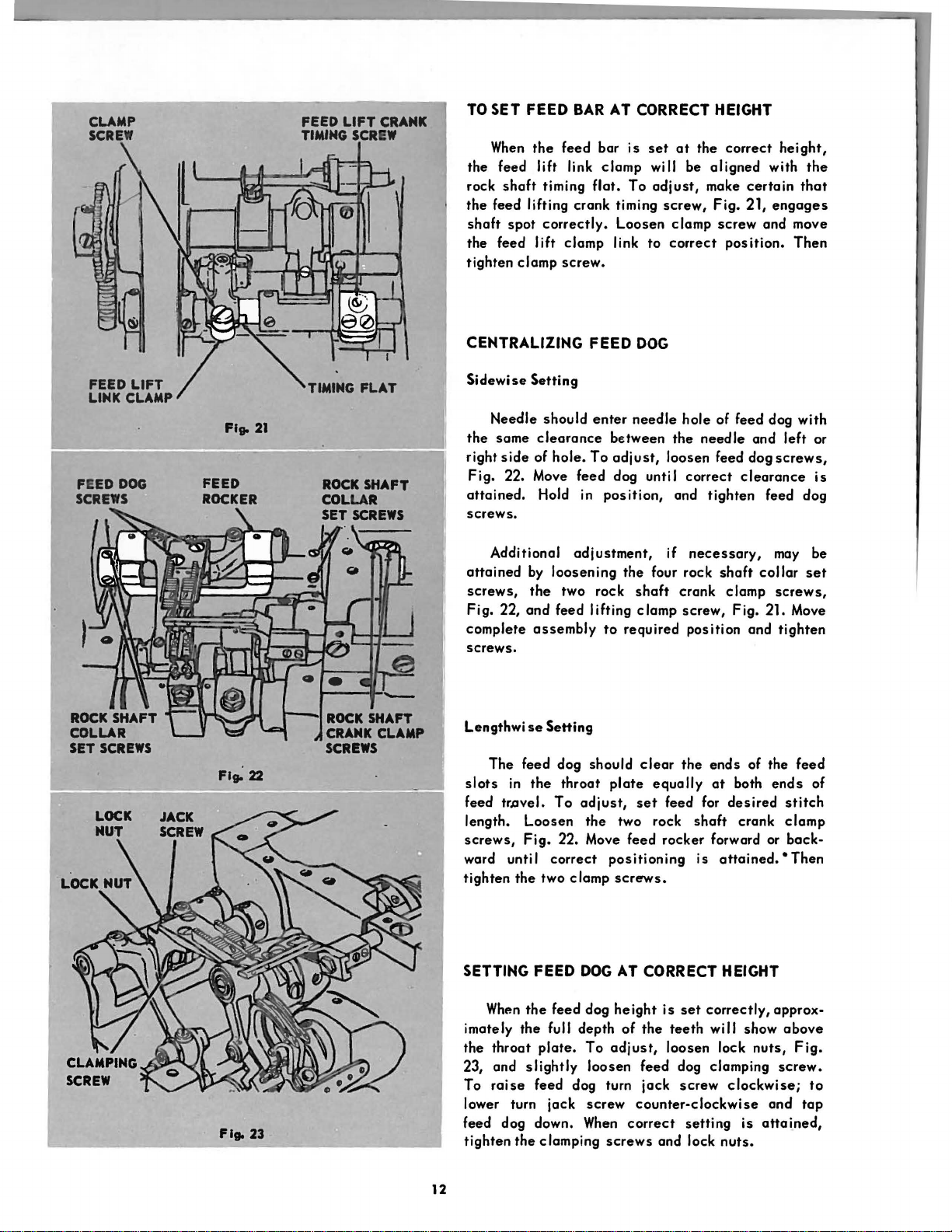

CLAMP

SCREW

FEED

TIMING

LIFT

SCREW

CRANK

TO

SET FEED BAR

When

the

feed

the feed lift link

rock

shaft

timing flat.

the

feed lifting crank timing

shaft

spot

correctly.

the feed

tighten

lift

clamp

clamp

screw.

AT

CORRECT HEIGHT

bar

is

set

at

clamp

To

will

be

adjust,

screw,

Loosen

link

to

clamp

correct

the

aligned

make

Fig.

screw

correct

with

certain

21,

engages

and

position.

height,

the

that

move

Then

FEED

LINK

FEED

DOG

SCREWS

LIFT

CLAMP

FEE

D

ROCKER

TIMING

FLAT

CENTRALIZING FEED

Sidewise

the

right

Fig.

attained.

Setting

Needle

same

side

should

clearance

of

hole.

enter

between

To

adjust,

22. Move feed dog unti I

Hold in

position,

screws.

Additional

attained

screws,

Fig. 22,

complete

and

adjustment,

by

loosening

the

two rock

feed

assembly

lifting

to

screws.

Lengthwise

The

slots

feed

length.

screws,

ward unti I

tighten

Setting

feed dog should

in

the

throat

tr.ovel.

To

Loosen

Fig.

22. Move

adjust,

the

correct

the

two

clamp

plate

positioning

screws.

DOG

needle

hole

the

loosen feed dog

correct

and

if

necessary,

the four rock

shaft

crank

clamp

screw,

required

clear

position

the

equally

set

feed for

two rock

feed

rocker

of feed dog with

needle

and

clearance

tighten

feed dog

may

shaft

collar

clamp

Fig. 21. Move

and

ends

of the

at

both

ends

desired

shaft

crank

forward or

is

attained.

left

or

screws,

is

be

set

screws,

tighten

feed

of

stitch

clamp

back-

• Then

SETTING FEED

When

the

feed dog

Flto 23

imately

the

23, and

To

lower turn

feed dog down.

tighten

12

the

throat

plate.

slightly

raise

feed dog turn

the clamping

full depth

jack

DOG

To

loosen

screw

When

screws

AT

CORRECT HEIGHT

height

adjust,

of

the

is

set

teeth

loosen

feed dog clamping

jack

screw

counter-clockwise

correct

setting

and lock

correctly,

will show

lock

nuts,

clockwise;

is

nuts.

approx-

above

Fig.

screw.

to

and

tap

attained,

Page 13

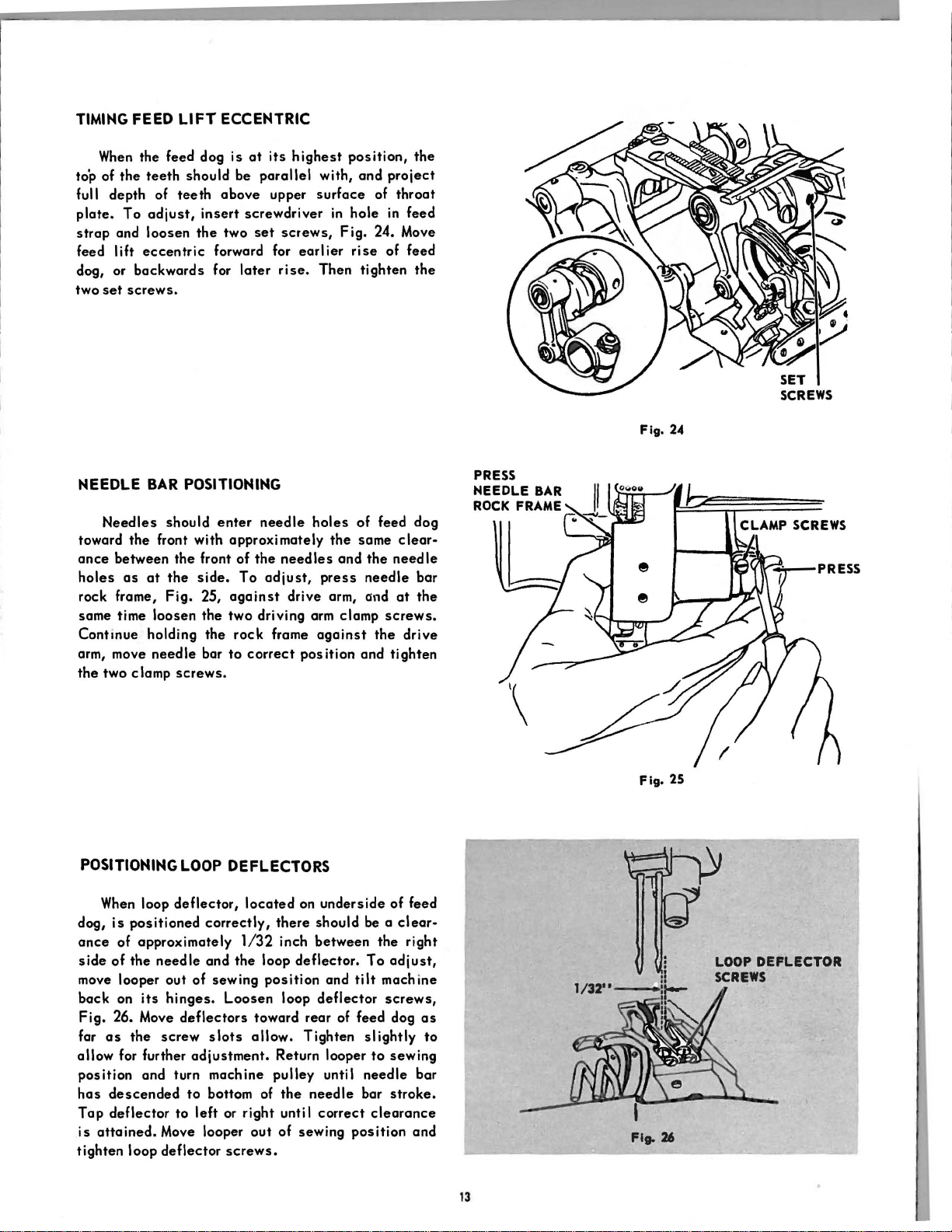

TIMING

to'p

full depth of

plate.

strap

feed

dog, or

two

FEED LIFT ECCENTRIC

When

the feed dog

of

the

teeth

To

adjust,

and

loosen

I ift

eccentric

backwards

set

screws.

should be

teeth

above

insert

the

two

forward for

for

is

at

its

parallel

upper

screwdriver

set

screws,

later

rise.

highest

with,

surface

earlier

Then

position,

and

in

hole

Fig.

rise

tighten

the

project

of

throat

in

feed

24. Move

of

feed

the

Fig. 24

NEEDLE

toward

ance

holes

rock frame,

same time

Continue

arm, move

the

BAR

Needles

the

front with

between

as

at

loosen

holding

needle

two clamp

should

the

the

Fig.

POSITIONING

When

loop

deflector,

dog,

is

positioned

ance

of

approximately

side

of

the

needle

move looper out

back

on

its

hinges.

Fig.

26. Move

far

as

the

screw

allow

for further

position

has

Tap

is

tighten

and turn machine

descended

deflector

attained.

Move looper

loop

deflector

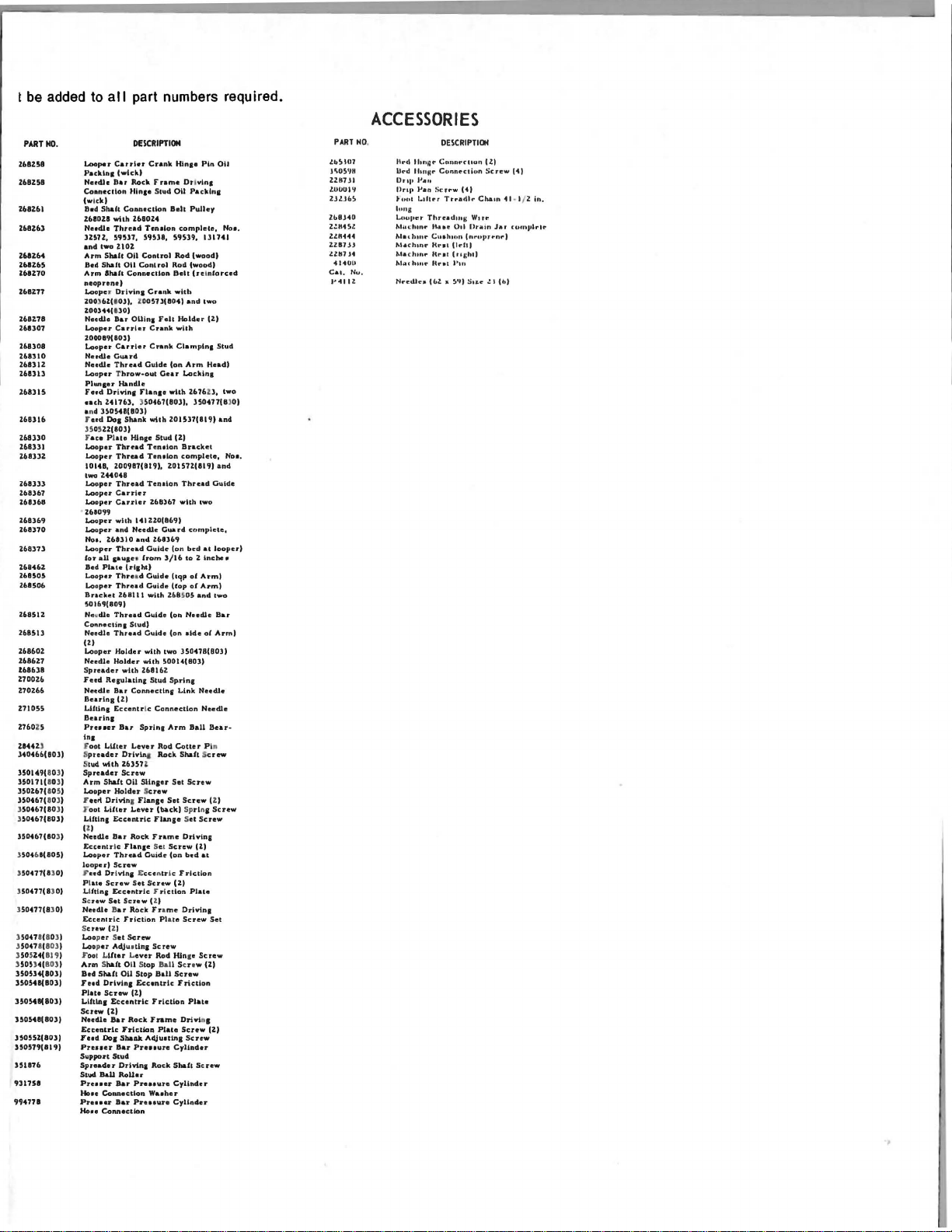

POSITIONING

enter

approximately

front of

side.

25,

the

the

bar

screws.

LOOP

correctly,

and

of

deflectors

adjustment.

to

bottom of

to

left

the

To

against

two

driving arm clamp

rock

to

correct

DEFLECTORS

located

1/32

the

sewing

Loosen

toward

slots

allow.

or

right

out

screws.

needle

loop

holes

needles

adjust,

frame

position

pulley

press

drive

against

posit

on

underside

there

should

inch

between

deflector.

and

loop

deflector

rear

Tighten

Return looper

until

the

needle

until

correct

of

sewing

of

feed

the

same

and

the

needle

arm,

and

screws.

the

ion and

be

o

the

To

tilt

machine

screws,

of feed dog

slightly

to

needle

bar

clearance

position

dog

clear-

needle

bar

at

the

drive

tighten

of

feed

clear-

right

adjust,

as

to

sewing

bar

stroke.

and

Fig.

Fig.

25

26

13

Page 14

LOOPER

HOLDER

1/16

..

Sidewise

When

of

the

the

forward

chine

pulley

side

the

screw,

correct

the

looper

SETTING

Setting

the

looper

looper

stroke

center

Fig.

27, and

clearance

holder

LOOPER CARRIER

CLAMP

just

until

of

NUT

is

clears

of

the

the

the

tap

is

attained.

screw.

correctly

looper

needle.

Fig. 27

the

looper.

holder

THE

positioned,

scarf

of

To

adjust,

point

is

Loosen

to

left

Then

securely

LOOPER

the

the

needle

turn ma-

directly

looper

or

right

tighten

AT

point

on

oppo-

holder

until

CORRECT

clearance

Fig.

To

looper

attained.

two

chines,

just

just,

needle,

looper

screws.

Lengthwise

Height

DISTANCE

Move

looper

between

28,

which

adjust,

set

CAUTION:

clears

to

Hold in

screws.

make

with

loosen

slightly

of

Needle

loosen

left

the

looper

Setting

FROM

to

heel

should

the

or

right

position

On

single

certain

scarf

point

the

two

to

left

and

Bar

Fig.

28

NEEDLE

extreme

of

be

two

until

that

of i

ts

directly

set

or

right.

Setting

forward

looper

approximately

looper

and

and

the

respective

screws,

position.

and

loop

set

correct

securely

multiple

point

of

needle.

opposite

Fig.

Then

tighten

Check

deflector,

1116

screws.

clearance

tighten

needle

each

To

center

28,

and

the

inch

Turn

is

the

ma-

looper

ad-

of

turn

set

.

When

correctly

be

Fig.

29

NEEDLE

CLAMP

~

BAR

SCREWS)!~

I

j~

'

..

\

~

Fig. 30

directly

the

center

needle

pulley

To

ing

nut,

until

needle.

To

needle

as

far

ing

screws,

to

correct

clamping

when

is

adjust

Fig.

looper

Then

adjust

is

as

possible.

screws.

opposite

of

the

opposite

the

tighten

inserted

Fig.

position.

14

the

looper

looper,

29.

point

needle

set,

the

the

center

clearance

timing

the

Move

carrier

is

directly

clamping

bar,

up

into

Loosen

30,

and

Then

point

timing

loosen

first

the

the

raise

securely

of

the

looper

of

the

needle,

above

the

mark L T on

arrow on

looper

carrier

forward or

opposite

nut.

make

needle

two

needle

or lower

tighten

eye

machine

the

backward

center

certain

bar

or

bar

needle

should

and

of

arm.

c Iamp-

clamp

clamp-

the

at

the

of

that

bar

two

Page 15

TIMING LOOPER DRIVING CRANK

When

the

looper driving crank

the

point

of the looper will

the

needle

and backward

To

forward

screw,

at

adjust

stroke,

Fig.

the

same

strokes

when point of looper

loosen

31.

Loosen

(left) approximately

crank timing

correct

set

screw.

When

stroke,

screw

screw

adjustment

point

of

reverse

the

(right) and

looper

of

1/8

(right). Continue

is

adjustment

tightening

pass

distance

the

on both

looper.

looper driving crank

looper crank timing screw

turn, and tighten looper

made. Then

passes

higher on backward

by loosening timing

timing screw (left).

is

properly timed,

above

passes

to

the

the

forward

higher on

adjust

securely

eye

of

set

unti I

tighten

TIMING

(RIGHT)

DRIVING

SET

SCREW

SCREW

CRANK

SETTING THE

When

pass

as

touching.

operator until

pass

the

point,

the

needle

close

To

adjust,

the

needles

NEEDLE

guards

as

points

on

GUARDS

are

properly

possible

to

turn machine pulley over toward

of

the

their

forward

looper timing mark L T on

pulley should be approximately

arrow on machine arm.

screws,

needles

screws.

and turning

the

Fig

32. Turn

as

possible

Check

by

springing

the

maching pulley

looper points do not

Loosen

needle

guards

without touching. Tighten

the

stroke

set,

they should

the

needles

without

loopers are about

strokes.

1/8

inch above the

needle

as

needles

to

make

the

needles.

At

the

machine

guard

close

to

the

certain

to

to

this

set

t4le

set

left

that

Fig.

31

NEEDLE

SET

SCRE

GUARD

W

15

Page 16

Fig.

SPREADER

SET

--

~

33

SCREWS

HOLDER

'

-l

SPREADER

4

-

Flg.U

POSITIONING

Sidewise

spreader

SPREADER

DRIVING

ROCK SHAFT

and

When

looper on

••••

The

point

opposite

looper.

The

clearance

looper should

thickness

SPREADER

Height

Setting

its

of

the

top of

between

be

of ordinary

forward stroke

spreader

thread

approximately

should

groove

spreader

paper.

is

be

at

left

point and

the double

passing

exactly

side

of

To

adjust,

set

screws,

correct

setscrews.

Lengthwise

stroke

clearance

mately

Fig.

correct

CHANGING MOVEMENT

adjusted

normal

generally

hinges,

screws,

centric

crease

When

driving

strap

ceeding

position.

Setting

When

the

is

even

between

1/16

inch. To

34,

and

position.

The

sidewise

for

sewing

conditions,

used.

loosen

Fig.

flange

movement, or to right to

correctly

eccentric

and

tighten

information regarding

loosen

Fig.

33. Move

Hold

point

of

with the point of the

the

adjust,

move

spreader

Then

movement

under abnormal

maximum

To

adjust,

the

two ·

35,

and

screws.

positioned,

screws

flange

the

two

spreader

spreader

in

position

the

needle

two points should be

loosen

forward or backward

tighten

the

Move

spr'eader

OF

SPREADER

of

the

spreader

tilt

machine back on

spreader

two

spreader

eccentric

decrease

tighten the two

first, hold flange

screws.

positioning

and

and

on

its

spreader,

spreader

screw.

spreader

conditions.

movement

driving

driving

to

Then refer

of

holder

holder

tighten

left

movement.

spreader.

the

downward

the

approxi·

screw,

may be

Under

is

its

eccentric

ec·

to

in·

spreader

against

to

pre·

to

to

SPREADER DRIVING

ECCENTRIC

SCREWS

FLANGE

Fig. 35

16

CAUTION:

allow

driving rock

centric

eccentric

sufficient

ball

When

strap.

ball

increasing

clearance

shaft,

Fig.

They should not touch when

stud

is

sidewise

35, and

in

its

between

left

highest

movement,

spreader

side

of

position.

ec-

Page 17

ADJUSTING NEEDLE THREAD TAKE-UP

The

needle

be

adjusted

thread drawn

To

increase

screw,

screw

reverse

raising

Fig.

and lower the guide. To

the

the

thread

to

increase

at

the top of

the

amount,

36, and

adjustment

guide.

take-up

raise

and thread guide may

or

decrease

the

needle

loosen

by lowering the

thread take-up

take-up

decrease

or

the

loosen

the

amount of

bar

stroke.

guide

amount,

take-up

set

or

5/8"

GUIDE

THREAD GUIDE

SCREW

For

average

set

be

screw.

lower

ADJUSTING NEEDLE THREAD TENSION RELEASER

should

the

tension

set

out for

lease.

the

rect

the

sidewise

with upper end

The

end

When

release

presser

when

screw,

earlier

Hold

tension

time after making the

tension

sewing

thread

1/2

inch below

correctly

tension

foot

presser

Fig . 37,

release

in

posit

releaser

releaser

to

correct

take-up

adjusted,

is

raised

foot

and

ion and

not

plate

position.

conditions,

5/8

inch above

should be

the

bottom of

the

on

the

needle

and allow full

is

down. To

move

tension

of

tension

tighten

release

above

adjustments,

screw

Then tighten screw.

the

guide should

set

tension

thread when

adjust,

releaser

or

in

for later re-

set

screw. Should

tension·

and

the

with

its

holder.

releaser

adjusted

at

the

move

guide

the

loosen

cap

cor•

loosen

plate

\--.;..;......;---TAKE-UP

Fig.

36

TENSION RELEASER

PLATE

NEEDLE THREAD

ADJUSTINGLOOPER THREAD TAKE-UP

The

looper

justed

for hand I ing more or

thickness

change

stitch.

To

looper

thread

take-up

right for

making

the

To

stitch,

lower

more

Hold in

of material and length of

the

change

thread

take-up

certain

center

change

loosen

the

thread.

position

thread

ratio

the amount of thread handled,

rod

less

of

yoke or right

take-up

of looper

guide

rod screw. Move thread guide and

to

the

left for more thread or

thread.

that

the

guide yoke.

ratio

of

thread guide

For

less

and

and guide

less

thread,

thread

screw,

take-up

tighten

Fig.

Tighten the two

rod

looper

thread,

thread

screw,

end

of thread guide for

raise

guide screw.

according

stitch,

in

the

38, and looper

passes

Fig.

end of

may

finished

in

finished

38, and

be

ad-

to

and

to

loosen

to

the

screws

through

guide.

17

Fig. 37

LOOPER THREAD

,

TAKE-UP

....

ROD

Page 18

Page 19

Cat.

No.

P51

173

STYLES

P300-0/194, P300

PARTS

LIST

-0/

201,

P300-0/401

Page 20

Page 21

UNION

SPECIAL

NOTE:

~

200 125(833)

..-

Z68169~

268168-

268603

268344

r

l--

201.C16(830)

268030

•~ns~

200029(805)

200100(803)

200053(819)

fi

268618

268318

200172(805)_..

(4

~

167416

268071

268368

<1

268.

1•

267

Jl

I

i

Page 22

Page 23

added

8029

to

all

part numbers required.

200078(805)

~

268010

268176--

-

--

• ....,._

I'

226206

200064(806)

71

268367

{

8368 268099(2)

200362(803)

268061

398812

268051

Page 24

Page 25

268315

~

-

.

~

\4L350477(830)

\241763

.____

267623

350548(803)

r-

q

350534(803)

268049

~

£1

200054(803)

268064

3::::1(803)

268044

l

268123

.

l.t,

200054(803)

200562(805)

Page 26

Page 27

NOTE: When

ordering

replacement

NUMERICAL

parts

from

this

LIST

catalog,

OF

a

"P"

prefix

must

PARTS FOR BASIC MACHINE

be

added

to

all

part

numbers

required.

PART

NO.

1454

(830)

2102

8582

10148

32572

32825 Spreader Driving Rock

32835

32835

32848

50169(809)

50326(803)

51570 (830)

54279

59537

59538

59539

67425

131741

140306 (869)

140321 (830)

140321 (830)

140321 (830)

141432 (819)

141478 (869)

141494 (869)

141495 (830)

156695

167188

167416

167416

DESCRIPTION

Presser

Screw

Needle

Disc

Arm

Looper

Spring

Needle

Releasing

Shaft Screw Stud

Packing

Feed

complete, Nos,

268065, 268066, 268067

and 268315

Needle

Driving

complete,

268065, 268066, 268067

and 268315

Arm

(Front)

Looper Thread Guide (top

of

Needle

Stud

Needle

Thumb Nut

Needle

Thread

Needle Thread

Spring Bushing (Front)

Needle

Spring Bushing

Needle

Stud 50326 (803) with

51570 (830)

Looper

Clamping Stud Washer

Needle

Spring

Feed Lifting Cronk

Screw

Feed

Collar

Feed

Collar

Spreader Driving Rock

Shaft

Looper

Stud

Needle

(Bock)

Needle

(Front)

Feed

Spreader Driving

Pin

Face

Plate

Feed

Collar

140321 (830)

Feed

Collar

140321 (830) (2)

Foot

Shank

Thread

(2)

Position

Thread

Thread

Driving

Shaft Boll

Arm)

Thread

Thread

Thread

Guide (double)

Thread

Thread

Carrier

Thread

Driving Rock Shaft

Set Screw (4)

Lifting Rock Shaft

Set Screw (4)

Collar Set Screw (4)

Thread

Guard Set Screw

Dog Shonk Screw

Plate

Driving Rock Shaft

with two

Lifting Rock Shaft

with two

Tension

Pin

Tension

Tension

Disc

(Wick)

Bar Rock Frame

Eccentric

Bracket

Guard Set Screw

Oi

Eccentric

268064,

Nos,

268064,

Bearing

Screw (2)

Tension

Tension

Tension

Tension

Tension

(Back)

Tension

Crank

Tension

Tension

Eccentric

Lock Spring

(2)

(2)

I

Pinch

Pinch

PART

NO.

167416

200004 (805)

200029(805)

200035 (805)

200047 (804)

200047(805)

200053 (819)

200054 (803)

200058 (803)

200059

(8

05)

200061

(833)

200061 (833)

200061

(8

33)

200064 (806)

200070 (803)

200078 (805)

200078 (806)

200082 (804)

200085(803)

200089 (803)

200095 (819)

200098 (806)

200100 (803)

200100 (805)

200125

(8

33)

200138 (804)

200172 (805)

200173 (804)

200226 (805)

200303(819)

200327 (803)

200328 (8:Jl)

200337 (803)

200344 (830)

200346

(80

3)

DESCRIPTION

Spreader Driving Rock

Shaft

Collar

140321 (830) (2)

Arm

Screw

Arm

Head Screw

Spreader Bar Bearing

Screw

Arm

Shaft Ball Bearing

(Back)

Needle

Bracket

Bed

Plate

Looper Thread

Clamp Screw (4)

Needle

Driving

Screw (2)

Looper

Screw

Feed

Crank

Feed

Crank

Needle

Stud

Looper

Rod

Set Screw

Presser

Bracket

Arm

Side Cover Screw

Feed

Socket Screw (2)

Needle

Screw

Looper Carrier Shaft

Bushing (Left)

Plate

Looper Cprrier Crank

Hinge

Needle

Link Cop Washer Screw

Looper Throw•out Safety

Latch

Screw

Feed

Throat

Needle Set Screw

Bed

Plate

Screw

Loop Deflector Screw (2)

Needle

Holder Screw (2)

Presser

Support Screw

Looper Driving Crank Oil

Hole Cover Screw

Machine

Machine

Screw

Needle

Regulating Stud

Set

Screw

Looper Driving Cronk

Position

Needle

Screw

with two

(4)

(3)

(2)

Housing Screw (3)

Thread

Thread

Driving Rock. Shaft

Pinch

Lifting Rock Shaft

Pinch

Pinch

Thread

Regulating Stud

Thread

(3)

Screw (2)

Pin

Bar

Spring Brocket

(2)

Dog

Plate

(4)

Bar

Bar Rock Frome

Bar Crank Set

Tension

Screw

(2)

Screw (8)

Tube

Bar Rock

Arm

Pinch

Guide

Screw

Screw (2)

Bar

Connecting

Screw (2)

T ake•up

Bar Guide

Pinch

Screw

Guide

Position

Pinch

Connecting

Screw (2)

Screw

Slide Spring

Oiling

Bar Spring

Pulley

Pulley

Screw (2)

Frame

(2)

Screw

(3)

Felt

Set Screw

Position

Sleeve

(3)

PART HO.

200354 (803)

200354 (803)

200354 (803)

200362

(803)

200 362

(8

30)

200362(830)

200362 (830)

200364 (803)

200364 (803)

200364(803)

200364 (830)

200373 (803)

200373 (803) Spreader Driving Cronk

200378 (803)

200380 (803)

200380 (830) Spreader Holder Set

200382 (833)

200382 (833)

200394 (803)

200403 (830)

200403 (830)

200444 (803)

200541 (805)

200562 (805)

200571 (850)

200572(806)

200573 (804)

200578 (850)

200582(803)

DESCRIPTION

Feed

Driving Rock

Position

Looper Carrier Shaft

Bushing

Screw (2)

Needle

Position

Looper Driving Crank

Set

Feed

Set Screw

Looper Carrier Shaft

Bushing Set Screw (2)

Looper Throw•out Gear

Set Screw (2)

Looper Throw•out

Locking

Screw

Needle

Regulating Stud Cap

Set Screw

Spreader Driving

Eccentric

Spreader Driving

Eccentric

Set

Feed

Pin

Position

Needle

Position

Screw

Presser

Collar

Screw (2)

Feed

Adjusting

Collar

Needle

Driving Eccentric:

ing

Set Screw

Feed

Set Screw (2)

Feed

Spreader Driving Crank

Set

Looper Throw•out

Locking

Screw

Needle

Releasing

Looper

Bracket

Face

Screw

Presser

Bracket Adjusting Screw

Looper Driving Crank Oil

Stop Screw

Looper Thread Guide (top

of

Needle

Thread

Screw

Position

Bar Crank

Screw

Screw

Driving Rock

Plunger

Set Screw

Bar Rock

Set Screw

Counterbalance

Screw (2)

Lifting Link Hinge

Set Screw

Screw

Bar Crank

Screw

Bar

Set Screw

Driving Eccentric:

Disc

Set Screw (2)

Bar

Disc

Spring

(2)

Lifting

Bar Set Screw (2)

Screw

Plunger

Thread

Plate

Thread

Screw

Plate

Lock Spring

(2)

Bar Guide

Arm)

Bracket Screw (2)

Bar

Rock

Guide Screw (2)

Frame

Frame

Gear

Stop

Frame

(2)

Check

Stop

Spring

Rock Frome

Adjust•

Collar

Eccentric:

Gear

Stop

Tension

Screw

Tension

(2)

Frame

Page 28

NOTE:

200934 (806)

201020

201052

201160 (805)

201185 (804)

201185

20l188(803)

201188 (803)

201254(830)

201254 (830)

201363 (803)

201416 (830)

20.t418 (803)

201477 (803)

201522 (805)

201522 (005)

201522 (805)

201524 (805)

201525 (805)

201537

201553(804)

201572 (819)

201620 (804)

201736 (805)

202005

202120

202120

202253

202330

203349

PART

When

NO.

(805)

(833)

(804)

(819)

ordering

DESCRIPTION

Foot

lifter

Hinge

Screw

Spreader

Connection

Needle

Thread

Releaser

Foot

Lifter

Screw

Eye

Feed

Driving

Cap

Screw

Needle

Driving

Bar

Connection

Screw

Feed

Bar

Collar

Set

Needle

Needle

Stud)

Arm

Belt

Bed

Pulley

Foot

Thread

Bar

Set

Shaft

Pulley

Shaft

Set

lifter

Screw

Face

Plate

Set

Screw

Feed

lifting

Crank

Position

Looper

Throw•out

locking

Plunger

Bushing

Feed

Driving

Hinge

Stud

Feed

lifting

Hinge

Stud

Needle

Driving

Stud

Nut

Looper

Bar

Connection

Carrier

Clamping

Feed

Dog

Lock

Nut

Feed

Dog Shank

Adjusting

looper

Throw•aut

Rod Thumb

looper

Thread

Thumb

Nut

Looper

Throw•out

locking

Plunger

Nut

Spreader

Shaft

Arm

Presser

Driving

Screw Stud

Screw

Bar

Pin

Foot

lifter

Stop

Pin

Arm

Shaft

Belt

Pulley

Flange

(2)

Needle

Stud

Needle

Rei

Bar

Oi I Packing

Thread

easing

Washer

replacement

lifting

Driving

Cap

Screw

Tension

Cap

Set

Lever

Connection

Rock

Frame

.

Hinge

Pin

Screw

Guide

Connecting

Screw

Connection

Set

Screw

Connection

Screw

(2)

Lever

Hinge

(2)

Rock

Screw

Screw

Connection

Nut

Connection

Nut

Rock

Frame

Crank

Stud

Nut

Shank

Screw

Screw

Lock

Nut

Tension

Thumb

Rock

Nut

Washer (4)

lever

lifting

Connection

Spring

Connecting

(Wick)

Tension

PI

ate

Screw

parts

NUMERICAL

Link

(2)

Screw

Spring

Cap

(on

(2)

Belt

Hinge

Stud

Shaft

Gear

Hinge

Nut

Rack

Gear

Stop

Link

from

LIST

PART

203759

204235

204348

204365

204925

204925

206335

208636

208636

214529

214529

226080

226206

228448

238089

240245

241763

241763

244048

248423

250265

259470

264709

267623

267623

267933

268003

268004

268006

268009

268010

268017

268022

268024

this

NO.

catalog,

OF

a

PARTS

"P"

FOR BASIC

DESCRIPTION

Presser

with

Arm

Foot

Needle

Releaser

Looper

Hole

Spreader

Presser

Feed

Bar

200380(803)

Head

lifter

Thread

Spring

Driving

Cover

Screw

Foot

Dog Shank

Washer

Looper

Holder

Washer

Needle

Bar

Regulating

Presser

Cushion

Presser

Needle

Bar

Spring

Foot

Thread

Releasing

Machine

Needle

locating

Thread

Releasing

Feed

Regulating

Retaining

Feed

Friction

Screw

Needle

Driving

Friction

Screw

Looper

Disc

Foot

Cotter

looper

locking

Feed

with

Needle

Spring

Driving

Plate

Packing

Bar

Eccentric

Plate

Packing

Thread

(2)

lifter

Pin

Throw•out

Plunger

Bar

Hinge

201188 (803)

Bar Rock

Regulating

200364 (803)

Feed

Driving

Friction

Needle

Driving

Plate

Bar

Eccentric

Plate

Feed

lifting

Arm

Shaft

and

Shaft

Housing

Shaft

with two

Shaft

(Front)

Side

Plate

Plate

Shaft

with

Ball

Connection

Oil Stop

Cover

268044, 268264 two

268214

Arm

(Back)

Arm

Pulley

201254 (830)

Arm

Spring

Arm

Bed

268022 and four

200138(804)

Bed

Arm

(Back)

prefix

Stop Co

Position

Lever

II

Pin

Spring

Tension

Crank

Screw

Washer

Washer

Hinge

Pin

Screw

Screw

Rock

Frame

Stud

Spring

Spring

Plate

Spring

Ten~ion

Pin

Stud

Tension

Plate

Pin

Stud

Eccentric

Screw

(Brass)

Rock

Frame

Screw

(Brass)

Tension

lever

Rod

(2)

Gear

Spring

Pin

Collar

Frame

Stud

Cap

Eccentric

Rack

Frame

Friction

Rock

Shaft

268009,

each

350534 (803)

Bearing

each

and

202253

Ball

Slide

with

Slide

Spring

Bearing

Ball

must

be

added

MACHINE

PART

(4)

(2)

(2

(2)

)

268024

268028

268029

268030

268032

268033

268035

268044

268044

268045

268046

268047

268048

268049

268051

268052

268053

268054

268055

268060

268060

268061

268061

268062

268062

268062

268063

268063

268063

or

Oi I 268029

Set

Set

with

Belt

two

to

NO.

all

part

Hinge

Needle

Driving

Stud

Needle

Needle

Driving

Spreader

Connection

numbers

required.

DESCRIPTION

Bed

Shaft

Bed

Pulley

201254 (830)

Bed

Bearing

Needle

Needle

Face

and

Face

Face

Feed

Arm

Spring

Bed

Ball

Shaft

Connection

with two

Shaft

Needle

(2)

Bar

Rock

Bearing

Plate

with 268033

two 201416 (830)

Plate

lock

Plate

lock

Bar

Hinge

Shaft

Oi

I Stop

(Rear)

Shaft

Oi I Stop

Spring

Spreader

with

200364 (803)

Spreader

Counterbal

200 364

Feed

1 566

(8

lifting

Driving

95

and

Driving

once

30)

Eccentric

with 268077 and

200394 (803)

Machine

Pulley

(Aluminum Alloy

for

"V"

Belt

(Outside

Diam.

of

Belt

2.9

In,)

and

200328 (830)

Machine

with

268024

looper

looper

Groove

with 200327

Pulley

Thread

Thread T ake•up

Rod

Spreader

Shaft

Bed

268214, 268265

350534 (803)

Needle

link

Feed

Need

Driving

Feed

268060 wi

Need

Driving

268060 wi

Feed

Hinge

Feed

Driving

with

Shaft

with

Bar

with

twa

Drivi

ng

I e

Bar

Connection

Driving

th

I e

Bar

Connection

th

Driving

Stud

lifting

Stud

200064 (806)

Connecting

270266

Connection

Rock

Connection

268063

Rock

268063

Connection

with

Connection

with

Bar Rock

Connection

with

268258

Feed

Driving

Connect

Bearing

Bar

Rock

Connection

Bearing

Driving

Need

Bearing

Frame

(2)

Spring

Stud

Pin

Ba

Ball

Eccentric

two

Eccentric

with

two

two

Casting)

(803)

268048

Guide

Rock

268044,

and

Frame

Frame

268258

268

258

Frame

Hinge

Frame

Needle

I e

Bearing

Belt

II

ion

Page 29

NOTE:

When

ordering

replacement

NUMERICAL

parts

from

this

catalog, a "P"

LIST

OF

PARTS

FOR

prefix

BASIC

must

be

MACHINE

added

to

all

part

numbers

required.

PART NO.

268064

268064

268065

268065

268066

268066

268067

268067

268069

268070

268071

268071

268071 Spreader Driving Rock with 32848

268073

268074 Feed Lifting

268075

268077

268078

268079

268081

268082

268083

268085

268086

268087

268094

268096

268098

268099

268099

268102 Looper Driving Crank Oil

268111

DESCRIPTION

Feed

Driving

Needle

Driving

Feed Driving

Adjusting

Needle Bor Rock Frame 268124

Driving

Adjusting

Feed

Driving

Adjusting

Needle

Driving

Adjusting

Feed

Driving

Adjusting

Collar

200382 (833)

Needle

Driving

Adjusting

Collar

200382 (833)

Feed

Driving Rock Frame

with 200354 (803) and

200362 (830) 202330 and two

Feed

Driving Rock Shaft 200061 (833)

Feed

Driving Rock Shaft

Needle

Feed

Lifting

Needle

Shaft Needle

Feed

Driving Rock Shaft

Crank with two

200061 (833)

Feed

Lifting Crank with 268150

140306 (869) and 200373

Feed

Lifting

Lubri

eating

Feed

Lifting Link

Feed

Lifting Link Hinge

Pin with 268258

Feed

Regulating Stud 268162 Spreader

Feed Regulating Stud

Socket

Foot

Lifter

Foot

Lifter

238089

Foot

Lifter

with two 248423

Foot

Lifter

Looper Carrier Shaft with

Bushings

Looper Carrier Shaft

Bushing (Left)

Plate

Looper Driving

Looper

Bearing (2)

Looper Driving

Connection

Bearing

Hole Cover

Looper

(top

of

Eccentric

Bar Rock Frame

Eccent'i

Eccentric

Bar Rock

Eccentric

with two

Bar Rock Frame

Eccentric

with two

Bearing (2)

Bearing

Carrier

Thread

Arm)

c 268121

Eccentric

Disc

Disc

Eccentric

Disc

Spring

Frame

Disc

Spring

Eccentric

Disc

Spring

Disc

Spring

Rock Shaft

(2)

Bearing

Connection

Eccentric

Pad

(Wood)

(2)

Bell Crank

Lever

with

Lever

Rod

Lifting

Needle

Link 268171

Position

Connection

Needle

Guide

Bracket

(2)

PART NO. DESCRIPTION PART

Looper

268121

Needle

268123

268126

268127

268129

268131

268132

268133

268139

268141

268142

268143

268144

268148

268149

268161

268167

268168 Needle Thread

268169

268172

268173

268174

268176

268181

268184

268185

268186

Presser

.Bracket with 200070 (803)

and 200572 (806)

Presser

Spreader Bar

Spreader Bar Bearing

Spreader Holder with

200380 (830)

Spreader Driving

201020 (805)

Thread

Bracket

Bracket

Looper

Looper Thread Tube

Clamp

Looper

with

Looper

Locking

Looper

Rod

Looper

Safety Latch

Looper

Safety Latch Spring

Looper Throw-out

Safety

Bracket

Needle

Link Cap Washer

Needle

Stud with

Needle

200346 (803), 200354

and

Needle

Needle

Needle

Regulating Stud

Needle

Regulating Stud Sleeve

Needle

Regulating Stud complete,

Nos.

268148 and 268149

Needle Bar Rock Frame

Driving

200058 (803)

Needle

Bracket 268264

Releaser

Needle

Releaser

201052 (833)

Needle

Releasing

(adjustable)

Presser

Presser

Connection with two

Spacing

Thread

Spacing Collar

Thread

(2)

Throw•out Gear

two

Throw-out Gear

Throw•out Rack 268214

Throw•out

Throw•out

Latch

Bar Connecting

Bar Connecting

Bar Crank with

200378 (803)

Bar Crank 268142

Bar Oiling

Bar Rock Frame

Bar Rock Frame

Bar Rock Frame

214529, 264709, 268261

Arm

Thread

Thread

Thread

Bar

Bar Bushing

Bar Guide

Bar Spring

Tension

Collar

Tension

Tube

200362(830)

Plunger

Spring

201188 (803),

Felt

with two

Point

Tension

Tension

Tension

Cap with

Tension

Plate

(2)

(803)

two

NO.

268187

(2)

268190

268198

268208

268214

268216

268219

268220

268233

268258

268258

268258

268258

(2)

268258

268263

268265

268270

268275

268277

268278

268291

268307

268308

268310 Needle Guard

DESCRIPTION

Spreader

with 200373(803) and

200403 (830)

Spreader Driving

Feed

Crank with

and two 200061 (833)

Looper Carrier Crank

Hinge

Arm

5/32

Bed

Looper Driving

Connection 268098 with

268099

Needle

Thread Guide

Spreader Driving

Eccentric

(2)

Spreader Driving

Connection 268186 with

268063 and 351876

Feed

Hinge Stud

(Wick)

Feed

Hinge Stud Oil

(Wick)

Feed

Pin

Looper Carrier

Hinge

(Wick)

Needle

Driving Connection

Hinge Stud

(Wick)

Bed Shaft Connection

Belt

268024

Needle

complete, Nos. 32572,

59537, 59538, 59539,

131741 and two 2102

Arm

(Wood)

Bed Shaft

(Wood)

Arm

Belt

Presser

1454 (830)

Looper

200362 (830), 200573 (804)

and two

Needle

Holder (2)

Feed

and

Looper Carri

200089(803)

Looper Carri

Clamping Stud

Driving Crank

Lifting Rock

Pin

Shaft

ln.

Di

Shah

Bar Rock

Driving

Lifting Connection

Lifting Link

Oil

Packing

Pin

Bar Rock Frame

Pulley

Thread

Shaft

Shaft Connection

(reinforced

Foot Shank with

Driving Crank with

200344 (830)

Bar

Bar with 200373 (803)

two

200403 (830)

Pin

Shaft

201418 (803)

with 268258

Oi

I Stop Ball

am.

(2)

Oil Stop Ball

Frame

Thrust

Washer

Connection

Oil

Packing

Packing

Hinge

(Wick) (2)

Crank

Oil

Packing

Oil

Packing

268028 with

Tension

Oi

I Control

Oi

I Control Rod

neoprene)

Oiling

Felt

er

Crank with

er

Crank

Rod

Page 30

NOTE:

When

ordering replacement parts from

NUMERICAL

this

LIST

catalog, a

OF

"P"

prefix

must

PARTS FOR BASIC MACHINE

be

added to

all

part numbers required.

PART

NO.

268312

268513

268602

268603

268611

268612

268313 Looper Throw-out Gear

268314 Looper

268315 Feed Driving

268315

268316

268318

268330

268331

268332

268333

268344

268367

268368

268373

268380

268382

268402

268462

268495

268505

268506

268512

DESCRIPTION

Needle Thread Guide (on

Arm

Head)

Needle Thread Guide (on

Side

of

Arm)

(2)

Looper Holder with two

350478 (833)

Needle

Bar with