Page 1

•

INDUSTRIAL

SEWING

FINEST

QUALITY

STYLES

P260-9/108

P260-9/109

MACHINES

P260-9/1

26

P260-9/139

P260-9/141

CATALOG

NO.

HIGH

SPEED SINGLE

MACHINES

AND

CLASS P26

FOR

GENERAL BARRING

TACKING

0

NEED

LE L

OPERAT

OCKSTITC

IONS

H

P3148

UNION SPECIAL

C H I

CORPORATION

CA

GO

Page 2

Page 3

CONTENTS

DESCRIPTION...

LUBRICATION

...

...............

....

......

....... ........

................

....

...

........

..........

.............. 4

OPERATOR INFORMATION .....................

MACHINE

ADJUSTMENTS ............................ 8-21

INDEX

.....

Page

..

..

3-7

3

Bobbin ..............................

Adjusting Bobbin Winder

Case

Bobbin

Bobbin

Bobbin

Remov.a1

Case

Replacement..................... ... .... 7

Case

Threading

Bobbin Winding..

Description.....

General

Special

Feed

Mechanism Adjustment.. ........................ 14-19

..

................................................

Characteristics..

Features

Driving Gear s...

.................................... 6-7

.. .........................

......................

...

............................. 7

..

..........................

......

...

..................... 3

.................

...

...

....

.......................................... .

Lateral Linkage {Barring and T a eking

...

Machines). .............................

Lateral

Machines).....

Linkage (Button Sewing

...

.................

.......

.....................

Longitudinal Linkage {Barring and

Tacking Machines)..........................

Length of

Tack...

....

..........

..........................

Longitudinal Linkage {Button Sewing

...

Machines)

Timing Lateral

Timing Longitudinal

Width

.....................................................

Feed

......

...

...................... 18, 19

Feed

......................

of Tack....................................

Knife Actuating and Clamp

Lifti~;~g

Safety Interlock ..........................

Tension

Adjustments. .............

Releaser

............

......................

...

...................

..............

...

......... 6

...........

...

...........

...

....

.......

......

..............

...

.......

......

...

...

...

..

..

18,

12-13

....

..

Page

.. 6

...

14

14

17

16

18

18

19

16

..

12

12

Page

Thread

6

Work

Knife Removal and Replacement.. .........

Wiper

.......... .

.......................................

Clamp Foot Lifter ........................

.....

13

........ 13

...

...

..

20

Knife Timing and Positioning ........................ 19-20

Positioning

Timing .......... .........................

3

Lubrication...... .......

Daily Care............................................

3

Week

Machine Threading ...........

Needles

........

...

.............

...

...............................

ly

Care ........................ ....

..........

...

...........................................

.............................. 20

........................... 19

........

............ 4

................

.........

............................

...

..

4

.......... 4

..

5

............ 5

Setting the Needle ............................................ 5

Sewing Meehan

Needle Bar Height ...............................

Positioning Shuttle Driver ....

Shuttle Timing ...

Speed .....................................................

Stop Motion Adjustments ...................

Arm

Shaft ...

Engaging

Starting Lever

Starting Lever

Tripping Linkage

Motion Brake ......

Stop

Thread

Tens

Bobbin Thread

Needle Thread

ism

Adjustments .......

...........

....

...

...........

....

...........

Arm .........

..

....

Arm

............

.........................

..............

Stop

.......

...

..........

...

....

...................

......

............................ 9

...................

...

..............

ion Adjustments .........

..

.................................... ......

..

................

......

.......

...

.. ..............

...

........

..........

...

...........

........

........

................... 4

........

.......

..........

.............

....

......

......

......... 8

..........

........ 10

..............

....................... 7

...

...

...........

8-11

.... 8

..

...

...

..

21

21

21

21

9

11

7

7

2

Page 4

Page 5

DESCRIPTION

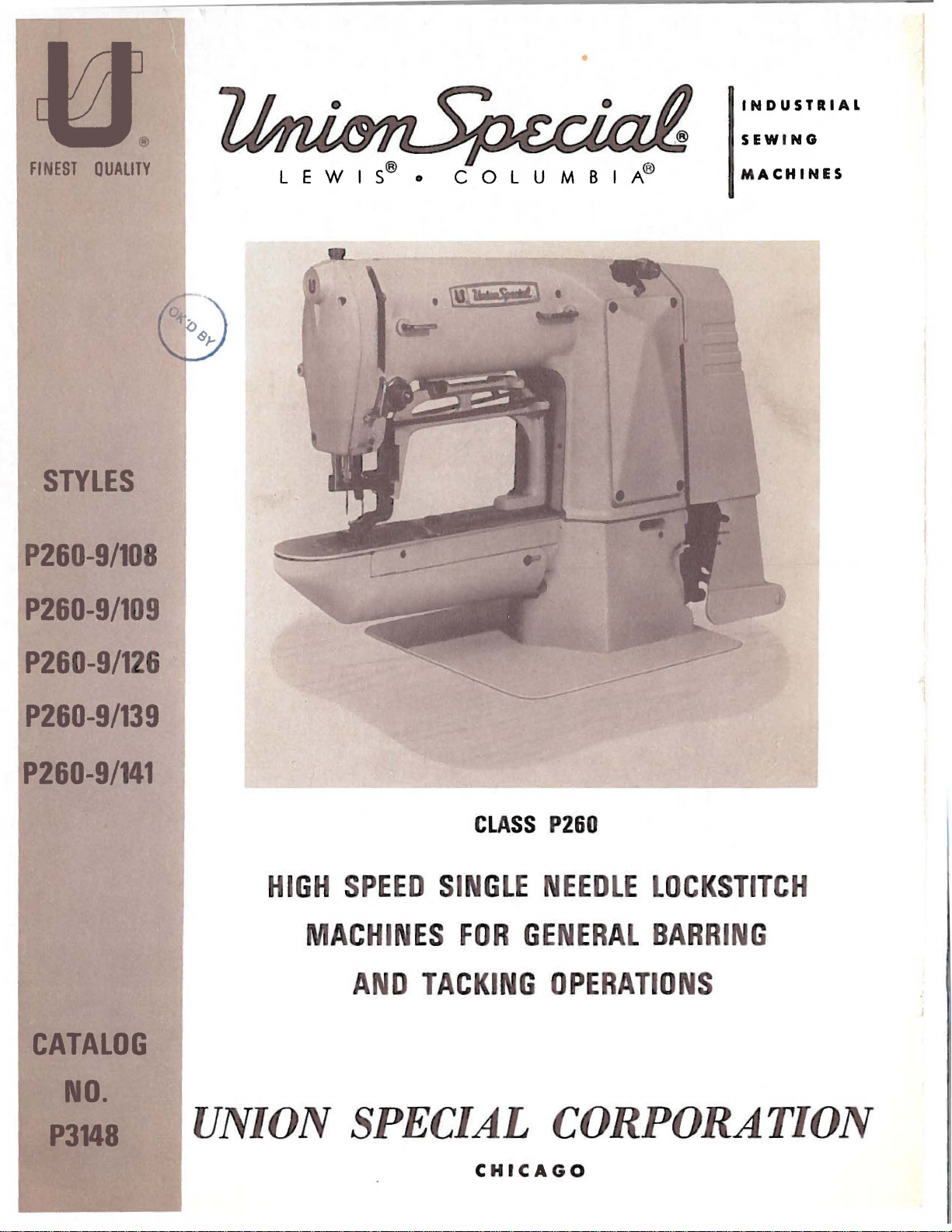

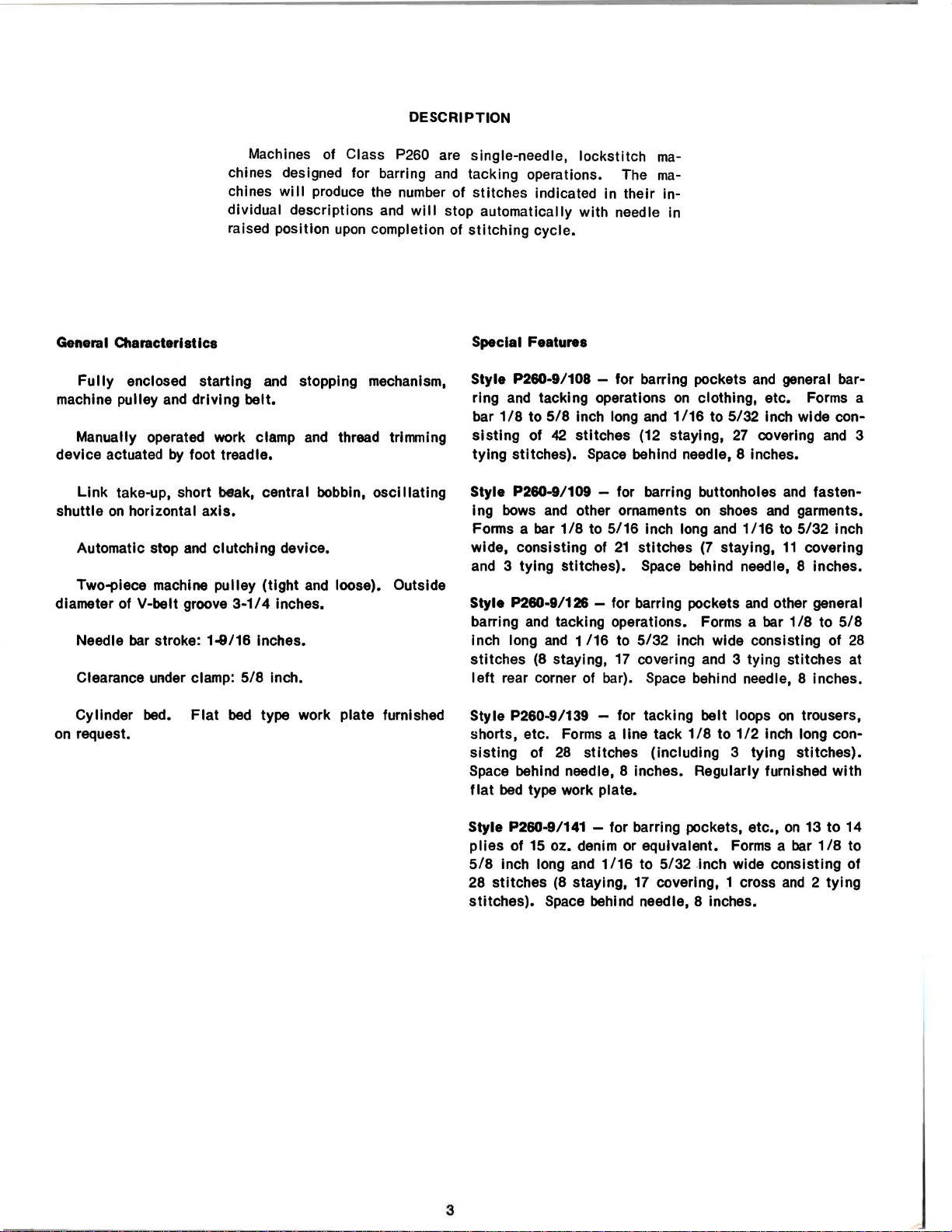

Machines of Class P260 are single-needle, lockstitch

chines designed for barring

chines

dividual descriptions

raised position

General

machine pulley

device actuated

shuttle

diameter of V-belt groove

Characteristics

Fully

Manually operated work clamp

Link

Automatic stop

Two-piece machine pulley (tight

enclosed starting

and

driving belt.

by

foot treadle.

take-up, short beak, central bobbin,

on

horizontal

axis.

and

clutching device.

3-1/4

bar

Needle

Clearance under clamp:

stroke: 1-9/16 Inches.

5/8

will

produce the

upon

and

stopping mechanism,

and

thread trlnvning

and

loose). Outside

inches.

Inch.

and

number

and

completion of

oscillating

of stitches indicated in their In-

will

stop automatically with needle In

ma-

tacking operations. The

stitching

Special Features

Style P260-9/108

ring

bar

sisting

tying stitches).

Style P260-9/109 - for barring buttonholes

1

ng

Forms a bar

wide, consisting of

and

Style P260-9/126 - for barring pockets

barring

Inch long

stitches

left

cycle.

- for barring pockets

and

tacking operations

1/8

to

5/8

Inch long

of

42

stitches (12 staying,

Space

bows

and

other ornaments

1/8

to

5/16

3 tying stitches).

and

tacking operations. Forms a bar

and

1/16

(8

staying, 17 covering

rear corner of bar).

ma-

and

on

clothing, etc. Forms a

and

1/16

to

5/32

27

behind needle, 8 inches.

on

shoes

21

to

5/32

Inch long

stitches

Space

Space

and

1/16

(7

staying,

behind needle, 8 inches.

and

inch wide consisting of

and

3 tying stitches at

behind needle, 8 inches.

covering

general bar-

Inch wide con-

and

and

fasten-

and

garments.

to

5/32

inch

11

covering

other general

1/8

to

5/8

28

3

Flat

bed

Cylinder bed.

on

request. shorts, etc. Forms a line tack

type work plate furnished Style P260-9/139 - for tacking belt loops

sisting

Space

flat

Style P260-9/141 - for barring pockets, etc.,

plies

5/8

28 stitches

stitches).

of

28

stitches (including 3 tying stitches).

behind needle, 8 inches. Regularly furnished

bed

type work plate.

of 15 oz. denim or equivalent. Forms a

Inch long

and

1/16

(8

staying,

Space

behind needle, 8 inches.

1/8

to

to

5/32

.Inch wide consisting of

17

covering, 1 cross

on

1/2

Inch long con-

on

and

trousers,

13

to

bar

1/8

2 tying

with

14

to

3

Page 6

LUBRICATION

For best results, use proper

Oil.

Use

"Type

duce a minimum of stain

D"

Oil

when

on

fabric.

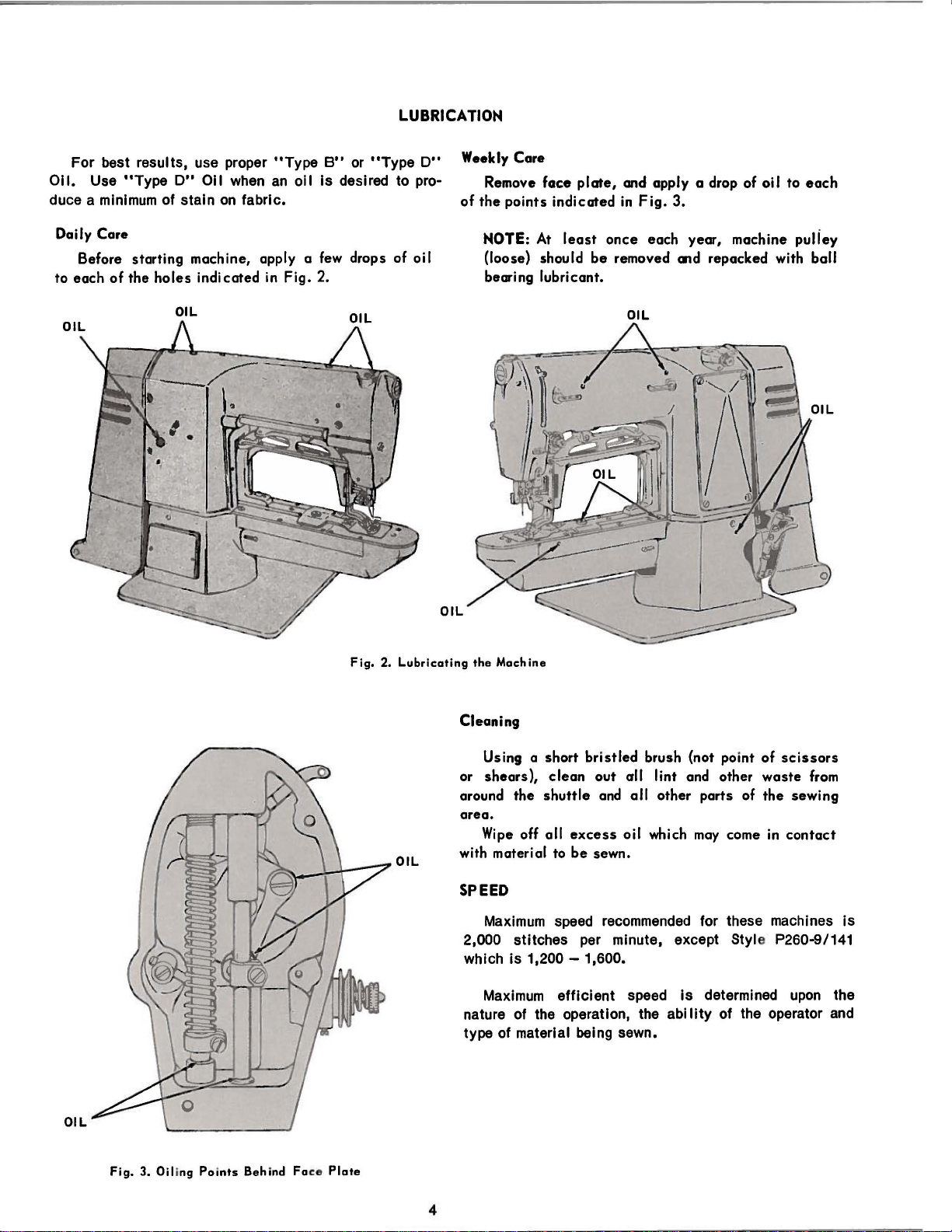

Daily Care

Before starting machine, apply a

to each

of

the

holes

indicated in Fig. 2.

"Type

an

oil

B"

or

"Type

is

desired to pro-

few

drops of oil

D"

Weekly Care

of

Remove

the

NOTE:

face

points indicated

At

(loose) should

bearing lubricant.

plate,

least

and apply a drop of oil to

in

Fig.

3.

once

each year, machine puliey

be

removed

OIL

md

repacked with ball

each

Fig.

2.

Lubricating

OIL

the

Machine

Cleaning

Using a short

or

shears),

around

the

clean

shuttle

bristled

brush {not point of

out all lint and other

and

all

other parts of

scissors

waste

the

sewing

area.

Wipe

off all

with material to

excess

be

sewn.

oil which

may

come

in

contact

SPEED

Maximum

speed

recommended

for these machines

2,000 stitches per minute, except Style P260-9/141

which

is

1,200-

Maximum

nature of the operation, the

type of material being sewn.

1,600.

efficient

speed

is

ability

determined

of the operator

upon

from

is

the

and

OIL

Fig.

3. Oil ing

Points

Behind

Face Plate

4

Page 7

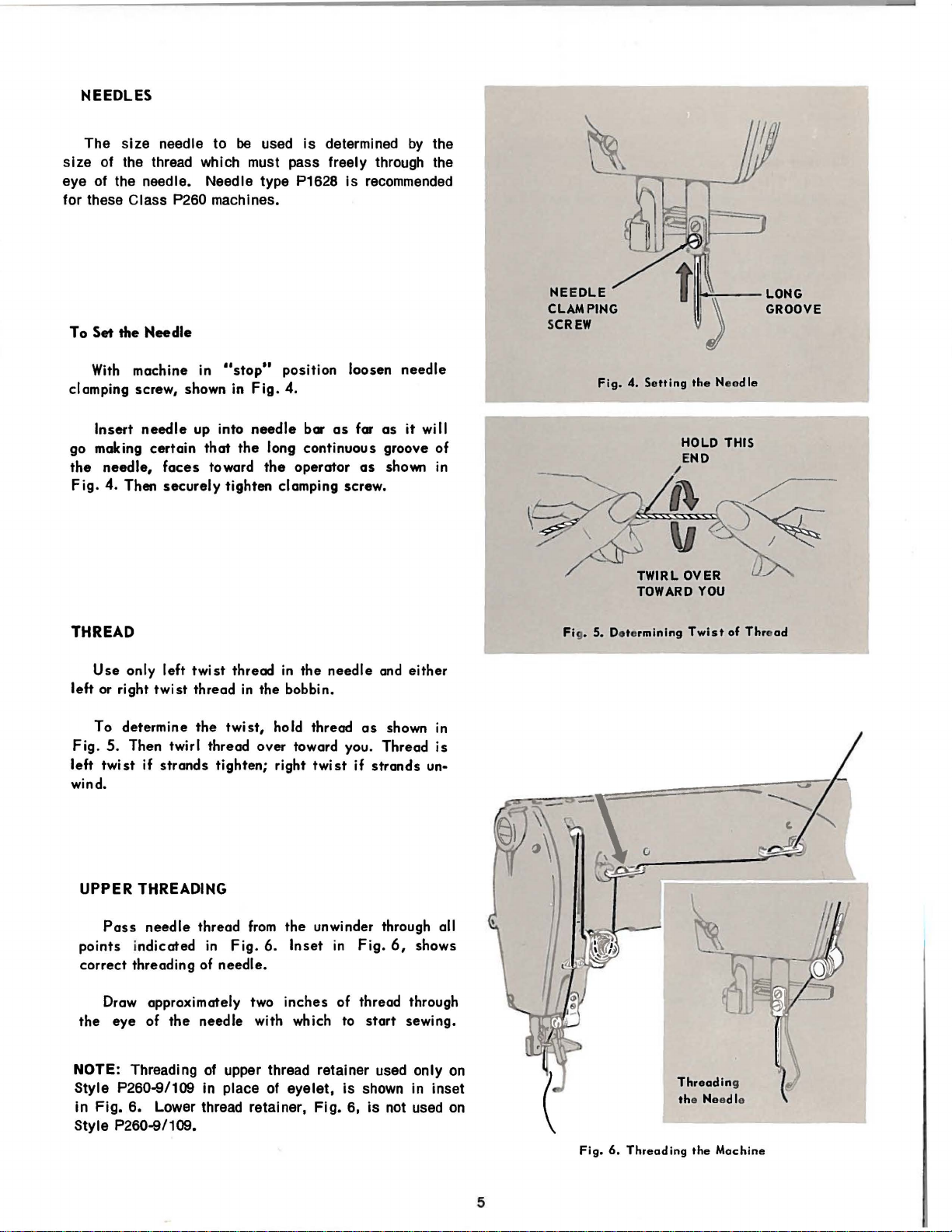

NEEDLES

The size needle to be used

is

determined

by

the

size of the thread which must pass freely through the

is

eye of the needle. Needle type P1628

recommended

for these Class P260 machines.

To Set the

With

clamping screw, shown in

Insert

go making certain

the

Fig.

Needle

machine in 11stop"

needle

needle,

4.

Then

up into

faces

securely

position loosen

Fig.

4.

that

toward

needle

the

bar

as

long continuous groove of

the

operator

tighten clamping screw.

for

as

needle

as

it

shown

will

in

NE E

DLE

CLAMPING

SCREW

Fig.

4.

Setting

TWIRL

TOWARD

1~1:--

the Needle

HOLD THIS

END

/

OVER

YOU

-

LONG

GROOVE

THREAD

Use

only left

left or right

To determine

Fig.

5.

Then twirl thread over toward you. Thread

left

twist

if

twist

strands

twist

thread

thread

the

in

twist,

tighten; right

in

the

the bobbin.

hold thread

twist

needle

if

wind.

UPPER THREADING

Pass

needle

points i

correct

ndicated

threading of

Draw approximately two

the

eye

of

thread

in

from

Fig.

6.

needle.

inches

the

needle with which to

the

unwinder through all

Inset

in

of thread through

NOTE: Threading of upper thread retainer

Style P260-9/109 In place of eyelet,

in

Fig.

6. Lower thread retainer,

Fig.

is

6,

Style P260-9/109.

and either

as

shown

in

is

strands

Fig.

start

used

6,

shows

sewing.

only

un·

shown in inset

is

not

used

on

on

Fi • 5.

Fig.

Determining Twi

Threadin

th

e Needle

6.

Threading

the

st

of

Thread

g

Machine

5

Page 8

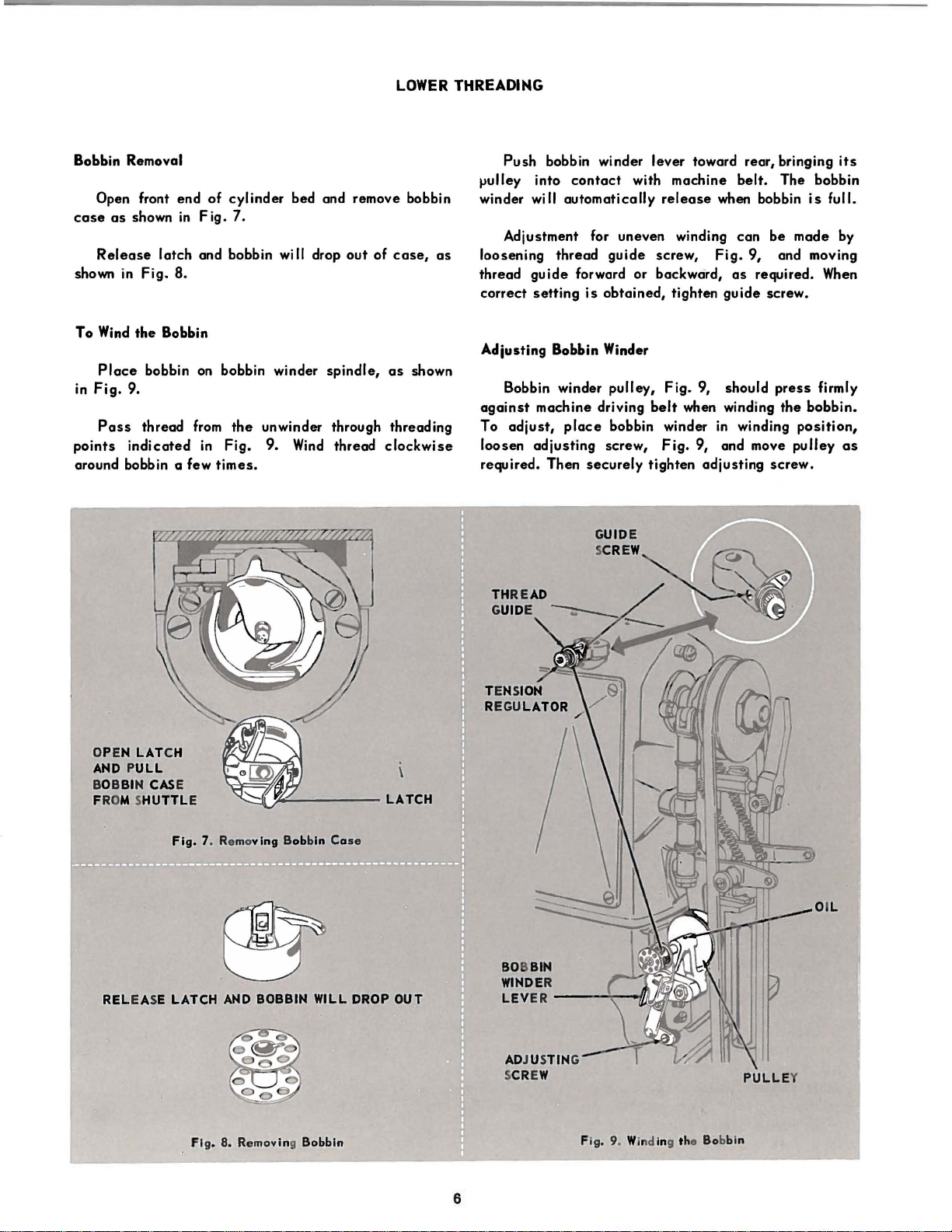

LOWER THREADING

Bobbin Removal

Open

front end

case

as

Release

shown

To

Wind

Place

in

Fig.

Pass

points

shown

in

9.

indicated

latch

Fig.

the

bobbin

thread

in

Fig.

and bobbin

8.

Bobbin

on

from

in

around bobbin a few

of

cylinder

7.

wi

bobbin winder

the

unwinder through threading

Fig.

9.

times.

bed and remove bobbin

II

drop

out

of

case,

as

Wind

spindle,

thread

as

shown

clockwise

Push

bobbin winder lever toward rear, bringing

.,ulley into

winder will

contact

with machine

automatically

release

Adjustment for uneven winding

loosening

thread

correct

thread

guide

setting

guide

forward or backward,

is

obtained,

screw,

Adiusting Bobbin Winder

Bobbin winder

against

To

loosen

machine driving

adjust,

adjusting

required. Then

pulley,

place

bobbin winder

screw,

securely

Fig

belt

Fig.

tighten adjusting

belt.

when bobbin

can

Fig.

as

tighten

guide

. 9, should

when winding

in

winding

9, and move

its

The bobbin

is

full.

be

made by

9, and moving

required.

When

screw.

press

firmly

the

bobbin.

position,

pulley

as

screw.

OPEN

LAT

PULL

BIN CAS

CH

E

Fig.

LATCH

7. Remo

Fig

ving Bob

AND

BOBBIN

. 8. Removing Bobbin Fig. 9. Winding the Bobbin

bin Ca

WILL

se

DROP

OUT

BOBBIN

WINDE

R

LEV

ER

--

AD

J USTING

CR

EW PULL EY

S

AND

BOB

FROM SHUTTLE

REL EASE

6

~:--t/l.i

'::lh~

Page 9

PULL THRE

INTO

UNDER TENSION

SPRING

SLOT

AD

AND

THREAD

PULL

UP

INTO

POSITION

FINGER

Fig. 10. Re

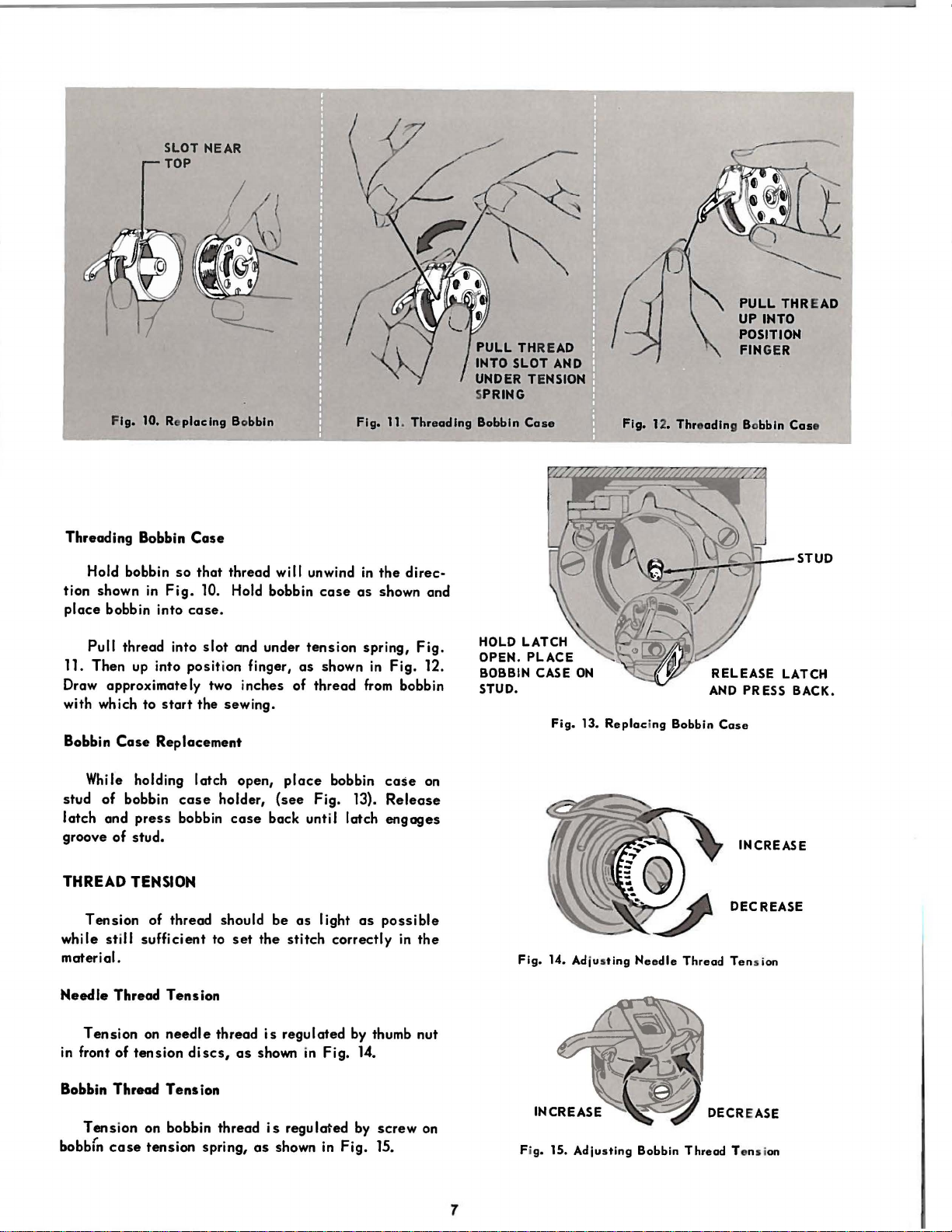

Threading Bobbin

Hold bobbin

tion shown

place

bobbin into

Pull

thread into

11. Then

up

placing Bobbin

Case

so

that thread will unwind

in

Fig.

10. Hold bobbin

case.

slot

and under

into position finger,

case

tension

as

shown

Draw approximately two inches of thread

with which to

Bobbin

While holding latch open,

stud of bobbin

latch and

Case

press

start

the sewing.

Replacement

case

holder,

bobbin

case

place

(see

bobbin

Fig. 13).

back until latch

groove of stud.

Fig. 11.

in

the

as

shown and

spring,

in

Fig. 12.

from

case

Release

engages

Threading

direc·

Fig.

bobbin

on

Bobbin

Case

HOLD

LATCH

OPEN. PLACE

BOBBIN

STUD

CASE

.

Fig.

Fig.

ON

13.

Replacing Bobbin

12. Thre

adin

g Bobbin

RELEASE

AND

PRESS BACK.

Case

INCREASE

Cas

e

STUD

LATCH

THREAD

while still sufficient to

material.

Needle

Tension

in front of

Bobbin Thread

Tens

bobb(n

TENSION

Tension of thread should be

set

the

Thread Tension

on

needle

tension

Tens

ion on bobbin thread

case

tension spring,

thread

discs,

ion

as

is

shown

is

as

shown

as

light

stitch

correctly

regulated

in

Fig.

regulated

in

as

by

14.

by

Fig.

possible

in

the

thumb nut

screw

on

15.

Fig.

14. Adjus

Fig. 15.

7

ting

Adjusting

DECREASE

Needle

Thread

Ten

DECREASE

Bobbin Thread Tens i

s ion

on

Page 10

ARM

SHAFT

STOP MOTION ADJUSTMENTS

ARM

SHAFT

Fig. 16. Stop Motion

LOCK

HUT

Adjustment

1/32 INCH

--

ADJUSTER

(Left Vlow)

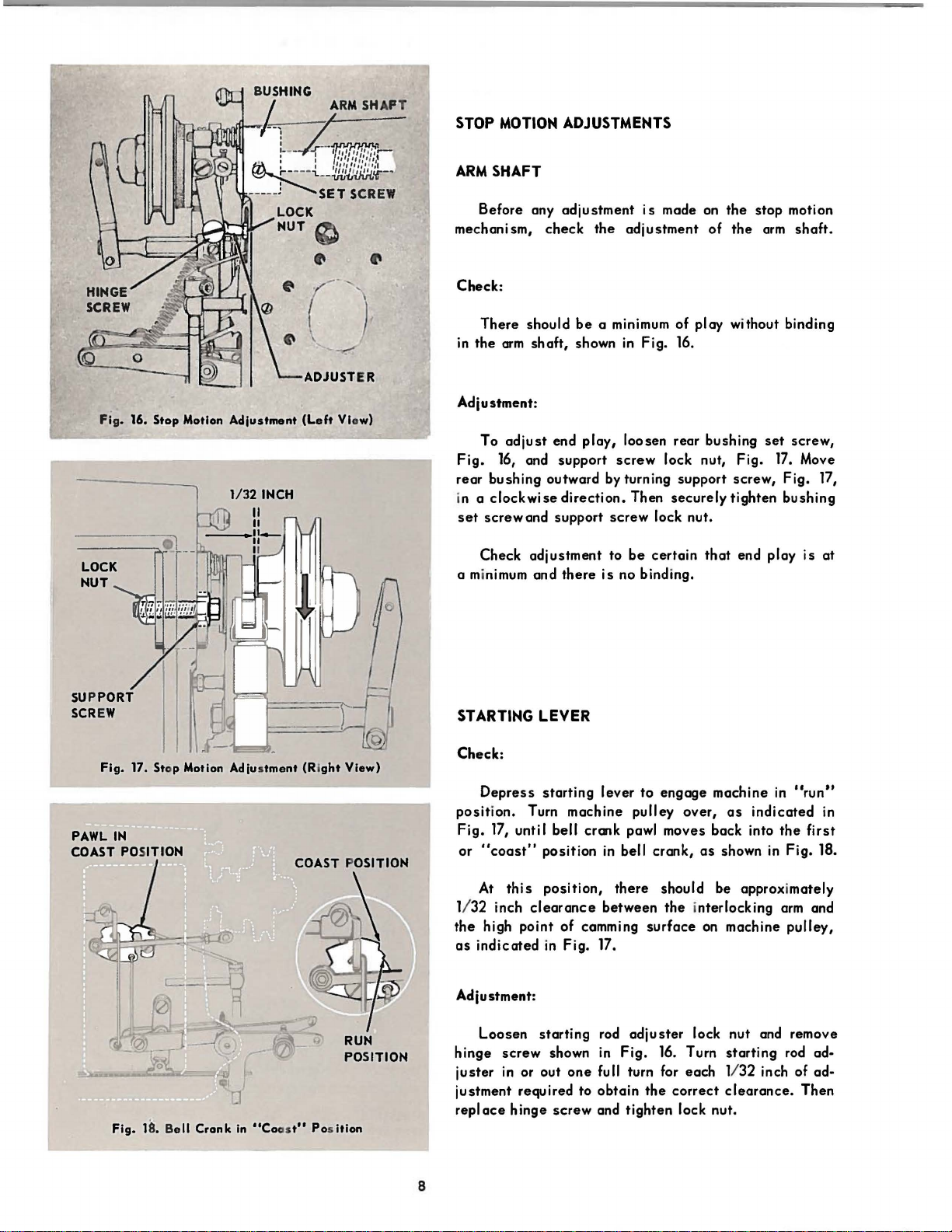

Before any

mechanism,

Check:

There

in

the

arm

Adjustment:

To

adjust

Fig.

16, and support

rear bushing outward by turning support screw,

in a

clockwise

set

screwand

Check

a minimum and

adjustment

check

should

be

shaft,

shown

end

play,

direction.

support

adjustment

there

is

made on

the

adjustment

a minimum of play without binding

in

Fig. 16.

loosen rear bushing

screw

screw

to

is

lock nut,

Then

securely

lock nut.

be

certain

no binding.

of

that

the

stop

the

arm

set

Fig.

tighten

end play

motion

shaft.

screw,

17.

Move

Fig.

bushing

is

17,

at

Fig.

17. Stop Motion Adjus

PAWL

IN

COAST POSITION

Fig.

18. B

ell

Crank

tment

(Ri

ght

in

"Coast" Pos ition

View)

RUN

POSITION

STARTING

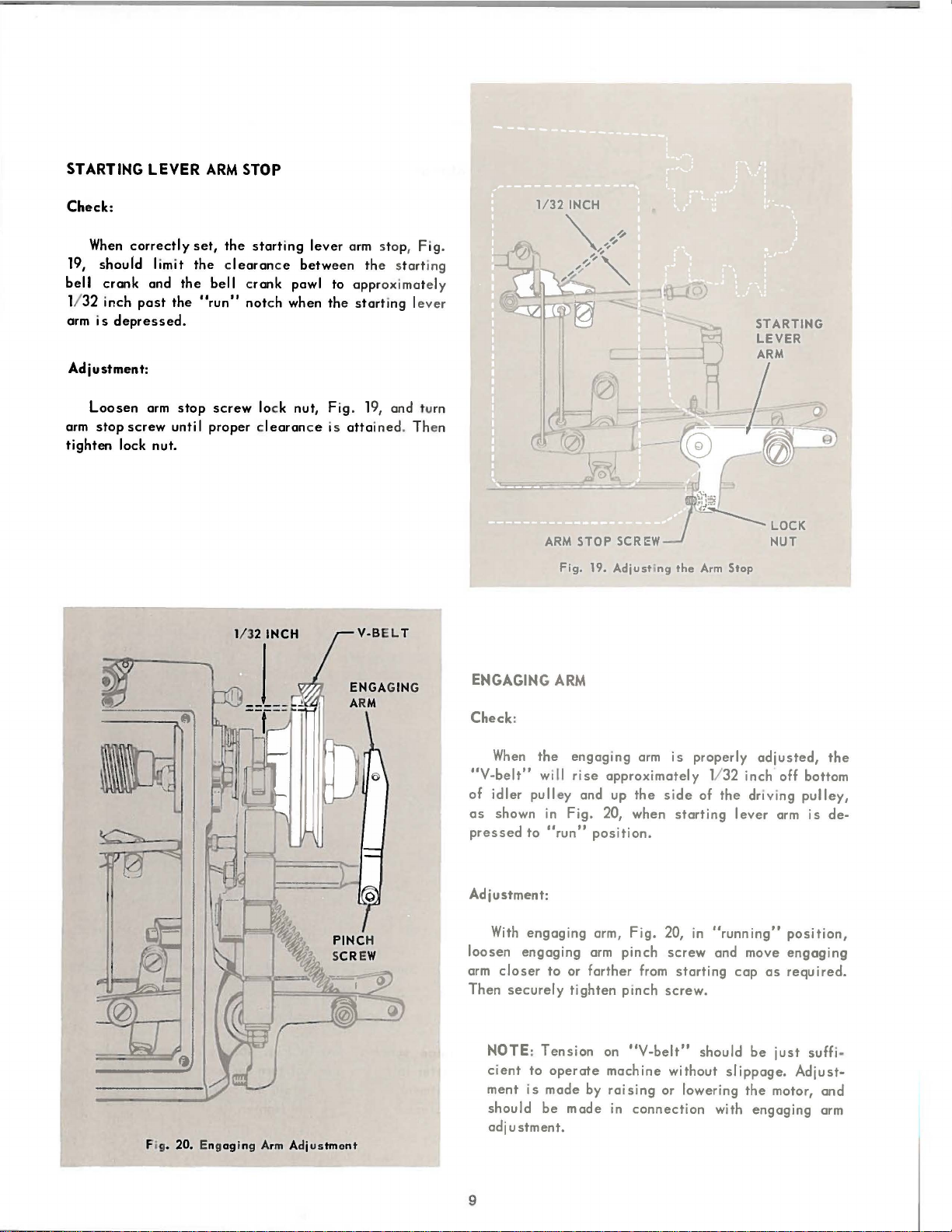

Check:

Depress

position.

Fig.

17, unti I bell crank pawl moves back into

or

"coast"

At

1/32

the

high

as

indicated

Adjustment:

Loosen

hinge

juster

justment required to

replace

LEVER

starting

Turn machine pulley over,

position

this

position,

inch

clearance

point

in

starting

screw

in or out

hinge

shown

screw

lever

to

in

bell

there

between

of

camming

Fig. 17.

rod

adjuster

in

Fig.

one

full turn for each 1/ 32 inch of adobtain

and

tighten

engage

crank,

should be approximately

the

surface

16.

Turn

the

correct

lock nut.

machine

as

as

shown in Fig. 18.

interlocking

on machine

lock nut and remove

starting

clearance.

in

"run"

indicated

the

arm

pulley,

rod ad-

Then

in

first

and

8

Page 11

STARTING

Check:

When

correctly

19,

should

bell

crank

1/

32

inch

arm

is

depressed.

Adjustment:

LEVER

limit

and

past

ARM

set,

the clearan

the

bell crank

the

"run"

STOP

the

start

not

ch when th e st

ing

leve

r arm stop,

ce

betw

een

th e st

pawl to appr oximately

art

ing l

Fig

art

ever

.

ing

Loosen

arm

stop

tighten

arm

screw

lock nut.

stop

screw

unti I proper c

loc k

learan

nut, Fig

ce is

. 19, and tu

atta

ined. Then

rn

ENGAGING

Check:

When

"V-belt"

of

idler

pulley

as

shown

pressed

to

ARM

the

will

in

"run"

Fig.

19.

Adjusting

engaging

rise

approximately 1132 inch off bottom

and up

Fig.

20, when

arm

the

the

is

properly

side

starting

Arm

of

Stop

the

driving

lever

position.

adjusted,

pulley,

arm

is

the

de-

Adjustment:

With

engaging

loosen

arm

Then

engaging

closer

securely

NOTE:

cient

ment

should

to

Tension

to

operate

is

made

be

adjustment.

Fig.

20.

Engaging Arm Adjustment

9

arm,

arm

or

farther

tighten

by

made

Fig.

pinch

from

pinch

on

"V-belt"

machine

raising

in

connection

20,

in

"running"

screw

and move

starting

screw.

should

without

slippage.

or lowering

with

cap

as

be

the

engaging

position,

engaging

required.

just

suffi·

Adjust-

motor,

and

arm

Page 12

STOP

MOTION ADJUSTMENTS

(

CONNECTING

ROD }

ROCK

PINCH

SUPPORT

I

SHAFT

SCREW

SET

SCREW

(continued)

Fi

g.

___ /

21.

Adjusting tho

Tripping

Link

ogo

I

r

--------

1

1-------·

1

I

__

..

,

--

- -

- ----

TRIPPING

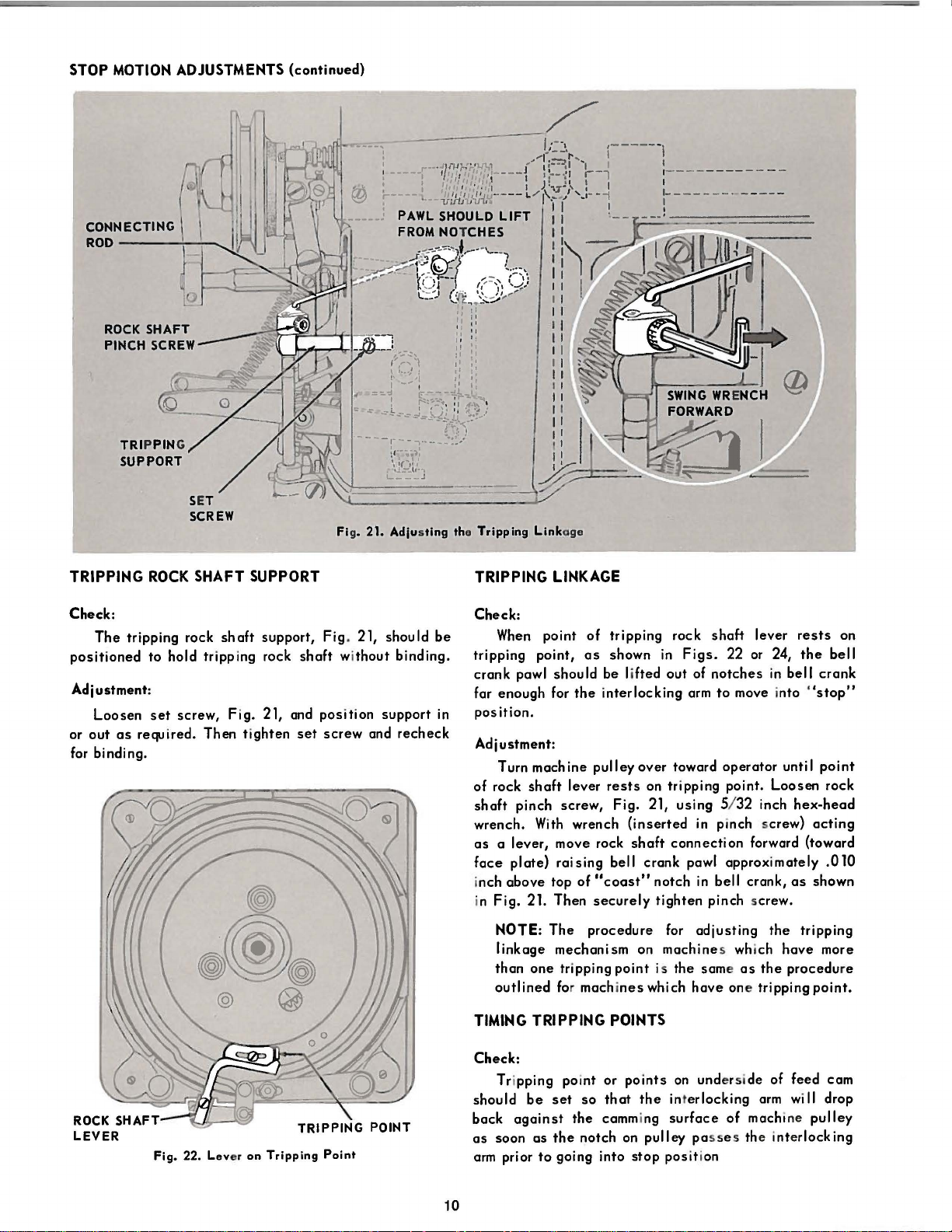

Check:

The

tripping rock

positioned

Adjustment:

Loosen

or

out

as

for binding.

ROCK

SHAFT

to

hold tripping rock

set

screw,

req.~ired.

SUPPORT

shaft

Fig. 21, and

Then

tighten

support,

shaft without

set

Fig

. 21, should

position

screw

binding.

support

and

recheck

be

in

TRIPPING

Check:

When

tripping

crank

far

enough

position.

Adjustment:

Turn

of

rock

shaft

wrench.

as

a lever, move rock

face

inch

above

in

Fig.

NOTE:

linkage

than

outlined for mach i

TIMING

point

point,

pawl

machine

shaft

pinch

With

plate)

21. Then

The

one

TRIPPING

LINKAGE

should

for

screw,

raising

top

mechanism

tripping

of

as

be lifted

the

interlocking

pulley

lever

wrench

of

"coast"

securely

procedure

tripping

shown

rests

Fig.

bell

point

nes

POINTS

rock

in

out

over

toward

on tr ipping point.

21,

using

(inserted

shaft

connection

crank

notch

tighten

for

on

machines wh

is the same

which

shaft

Figs.

22 or 24,

of

notches

arm

to

operator

5/ 32 inch

in

pinch screw)

pawl

approximately

in

bell crank,

pinch screw.

adjusting

have

one tripping

lever

rests

the

in

bell

move into

forward (toward

ich

as

the

until

Loosen

hex-head

as

the

tripping

have

procedu

"stop"

acting

shown

point.

on

bell

crank

point

rock

.010

more

re

Check:

Tr ipping poi

Fig.

22.

Lev

er

on

Tripping

Point

should

back

as

arm

against

soon

prior

be

set

as

the

to

going into

10

nt

so

the

notch

or

points

that

cammi

on

on

undersi de of feed cam

the int

stop

erlocking

ng

surface

pulley passe s the inte

posit

ion

of

arm

mach

wi

II

ine

pulley

rlocking

drop

Page 13

Adjustment:

On

machines

point shown in

and move tripping

or to

the

left

to

more than

be

adjusted

On

point

three

STOP

one

tripping point,

independently.

machines

shown in

tripping point

MOTION BRAKE

CLEARANCE

Check:

The

clearance

Fig.

25, and

proximately

1/

the

32

position.

equipped

Fig.

point

set

equipped

Fig.

with feed

23, loosen tripping

to

the

trip

off

with

24, it

is

screws, then,

between

machine

the

pulley

inch when

right to trip

later.

On

each

tripping

feed

necessary

set

stop

motion

(tight)

the

machine

cams

with tripping

machines

cams

with

to

the

same

should

point

off

point

loosen

as

brake

is

in

screw

sooner,

having

must

tripping

the

above.

shoe,

be

ap-

"run"

Fig.

23.

Tripping

Point

on

Cast

Iron

Cam

Adjustment:

With

machine

stud

set

screw,

the

proper

clearance

screw.

PRESSURE

Check:

The

brake

pressure,

and material being

machine

ning

from

at

excessive

going i

parts.

Adjustment:

Loosen

rurn

adjusting

ward for

adjusting

screw

less

pressure.

in

"run"

Fig.

25, and turn

is

depending

sewn,

should

nto

full

speed;

screw

inward for more

Then tighten p.inch

position,

eccentric

attained.

Then

upon machi

be

adjusted

stop

position

to

avoid damaging

pinch

screw,

loosen

stud

tighten

to

while

Fig.

pressure,

eccentric

unti I

set

ne

speed

prevent

run-

machine

25,

and

or out-

screw.

ECCE

ADJUS

SCREW

NT

TIN

Fig.

RIC S

G

24.

TUD

Tripping

Point

on

Phenolic

Cam

NOTE: Stop motion brake

adjusted

braking power

about

once

due

to

surface.

adjustment

a month,

wear or

to

offset

glazing

should

any

of

the

be

re-

loss

in

braking

Fi

g. 2 • Adjust ing the Sto M

11

otion Brak

Page 14

SAFETY

INTERLOCK

KNIFE

ACTUATING AND CLAMP

TE

LIFT

ING ADJUSTMENTS

NSION

RELE

ASER

Check:

The

safety

vent

the

clamp from

operating

when

the

and will

clamp

Adjustments:

With

knife

cam,

depress

into

running

pinch

screw,

arm with

lifting

taining

that

tighten

screwdriver,

lug

this

the

knife

the

LIFTING

PINCH

interlock,

is

roller

starting

position.

Fig.

against

position

roller

pinch

ARM

SCREW

being

prevent

lifted.

at

lever

26, and

back

of

is

screw.

when

lifted

the

the

clear-out

to

Loosen

lift

as

shown in

of

the

in

against

correctly

while

machine

place

knife

up on

bell

lifting

the

slot

starting

bar

clamp

Fig.

crank.

lug,

the

set,

wi

II

pre-

machine

from running

in

the

feed

bell

crank

driving

lifting

26,

lever

lever

bringing

While main-

make

certain

cam and

then

is

Check:

When

work c I amp is

ment

of

the c lamp

the

need

le

thread

needle thread

Adjust

ment:

Loosen the

and m

ove

the

set sc

screw,

o

sc

and

until

posi

Make

fo

rew.

Fig. 27, and

ut

of th e rock sh aft approx i

rew.

N

ex

t, loos

push upw

ten

sio

n dis cs

tion w

hile

certain

rward shou

.---

- - - -

.

tens

entire

Then

en

the

ard on

tightening

that

lder

on

lifting

raised,

bar,

tens

ion

ion

regulator

regulator

loosen

set

lifting

lifting arm

lifting

just

begin

the

lifting

the

rock

--

the

first

Fig.

27,

discs,

releasing

set

all

the

the lifting

link

so

mately 1/32

pinch

bar,

as

shown in

to

release.

the lifting

arm

is

shaft.

INTERLOCKING

ARM

upward move·

should

tension

screw,

way in.

link

connection

that

it

inch.

screw,

Maintain

arm

pinch

up

against

separate

on

Fig.

27,

Tighten

projects

Tighten

Fig.

26,

Fig.

27,

tliis

screw.

the

LIFTING

BACK

OF

Ll

FTING

LUG

BELL

CRANK

LUG AGAINST

BELL

CRANK

---

-

CLAMP

LEVER

--'

LIFTING---"

DRIVING LEVER

SC

PINCH

REW

~-

--

-NOTCH

Fig.

26.

Adjusting

the Safety Devi

ces

12

Page 15

LIFTING

SCREW

------,

LINK

i-ft

TENSION

DISCS

I

Fig.

28.

Adjusting

Foot

Lifter

CLAMP

BAR

WORK

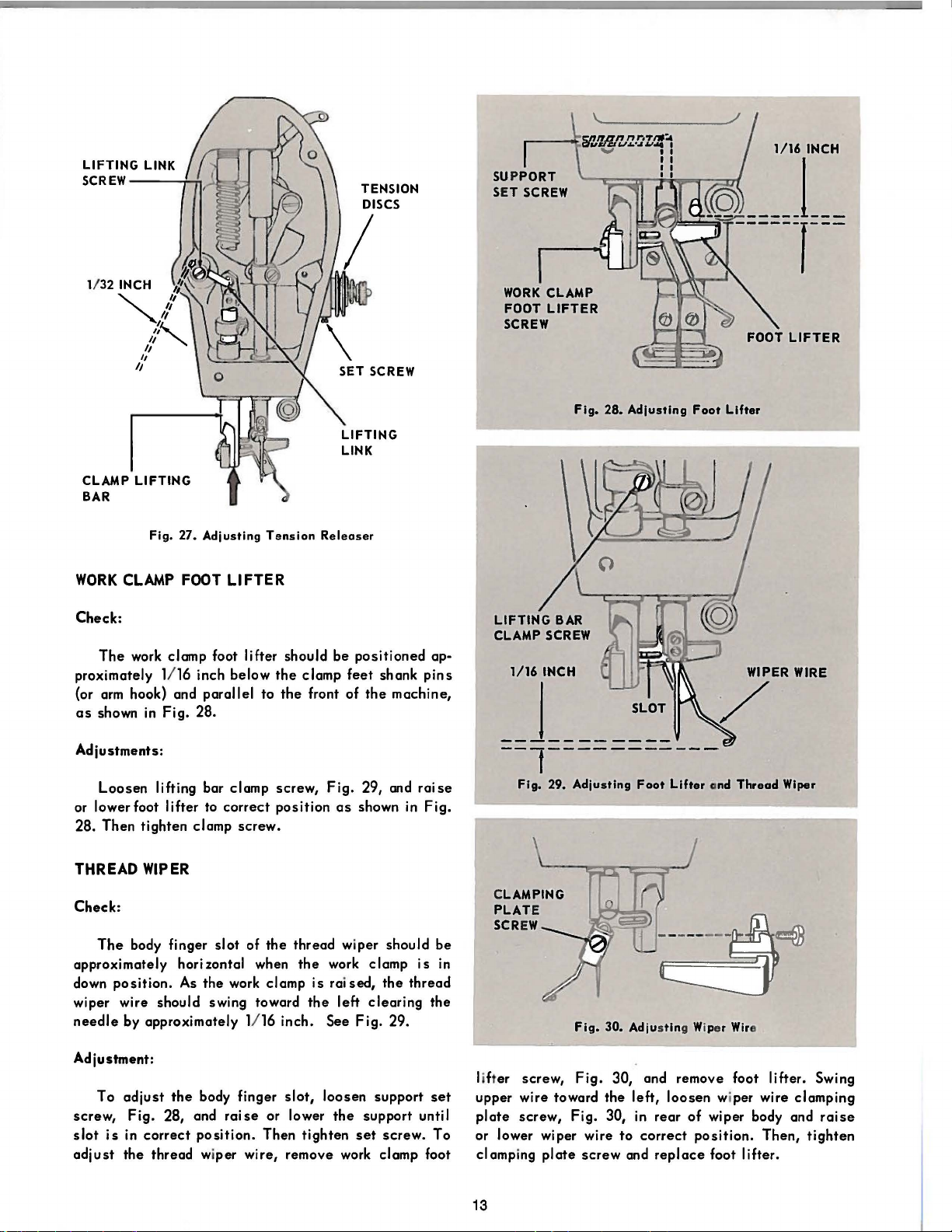

Check:

proximately 1116 inch below

(or

as

Adjustments:

or lowerfoot lifter to

28. Then tighten clamp screw.

THREAD

Check:

LIFTING

Fig.

27.

Adjusting

CLAMP

The

work clamp foot lifter should be

arm

hook) and parallel to

shown

Loosen

FOOT

in

Fig. 28.

lifting bar clamp screw,

WIPER

Tension

LIFTER

correct

the

clamp

the

front of

position

Releaser

positioned

feet

Fig.

as

shown

shank

the

machine,

29, and

in

ap-

pins

raise

Fig.

1/16

INCH

__

j_

__ l __________

______

Fig.

29.

Adjusting

Foot

_

Lifter

_

ond

Thread

Wiper

The

body finger

approximately horizontal when

down

position.

wiper wire should swing toward

needle

Adjustment:

screw,

slot

adjust

by approximately 1116 inch. See

To

adjust

Fig.

28, and

is

in

correct

the

thread wiper wire, remove work clamp foot

As

the

the

body finger

position.

slot

of

the

work clamp

raise

or lower

Then

thread wiper should

the

work clamp

is

raised,

the

slot,

loosen support

the

tighten

the

left

clearing

Fig.

support unti I

set

screw. To

29.

be

is

in

thread

the

set

lifter screw,

upper wire toward the left, loosen wiper wire clamping

plate

screw, Fig. 30,

or lower wiper wire

clamping

13

plate

Fig.

30.

Adjustin

Fig.

30, and remove foot lifter. Swing

to

screw

and

in

rear

correct

replace

g Wiper

Wir

of

wiper body and

position.

foot lifter.

e

Then,

raise

tighten

Page 16

FEED

MECHANISM ADJUSTMENTS

FEED

Check:

marks on

shaft

31, and

driving

DRIVING GEARS

When

the

machine

the

cam supporting

pinion

there

gear

should

gears.

should

be

is

in

be

aligned,

a minimum

stop

position,

gear

and

as

shown in

of

play

the

the

timing

vertical

Fig.

between

Fig.

31.

Alignment

of

Timing

Morks

NOTE:

gear

with

If

for any

are

removed, make

the

timing mark on

reason

with timing mark on pinion

Adjustment:

the

worm

the

be

in

arm

vertical

excessive

the

two

worm

forward

gear

spot

equally

casting

shaft

To remove

worm,

32) and

loosen

move

When

tical

shaft,

32, should

opening

gear

and

aligned.

To remove

pinion

gear

through

loosen

the

Then, by

gear

screw, turn

only

the

gears.

gear

Tighten the

sc

rew.

excessive

and cam supporting

hole

in

center

supporting

means

of the

the

bracket

minimum amount

socket

the

feed cam and supporting

certain

the

supporting

gear.

pi

ay between

screws

and

on

is

properly

set

in

shaft.

screws,

accessible

when

the

pini'on

play

gear

between

of supporting

gear

bracket

"hex"

head on

(which is

of

play

head

screw

they

are

replaced

gear

aligning

worm

gear

and

worm

(see

inset

Fig.

assembled

shown

through

on

in

the

verFig.

side

feed cam supporting

timing marks

vertical

gear,

insert

gear

socket

head

the

eccentric)

exists

between

inside

screw

supporting

supporting

are

shaft

wrench

and

screw.

unti I

the

SHOULD

ACCESSIBLE

BE

EQUALLY

LINKAGES ON BARRING

FEED

AND

TACKING MACHINES:

CENTERING

Check

:

The

wi

II ensure

LATERAL

lateral

that

changed, it will

of

the

throat

plate

Fig. 32. Adjusting t he

Feed

Driving Gea rs

14

FEED

feed

linkage,

when the length

change

needle

in

hole.

size

when corre

of

equally

ctly

bar or

on

both s

adjus

tack

ted,

ide

is

s

Page 17

Adjustment:

First

determine

lation

to

the

be

can

has

returned

been made,

clamping foot,

clamping foot so

the

to

its

e.

g.,

engage

turn pulley over toward

until

needle

over toward

Leave

will

indicate

To

screw

tion feed

across

aligned

At

arm

and

in

Fig.

position.

screw.

pinch

just

punctures

left

side

paper

under the clamp during

the

original

adjust,

loosen

and driving arm pinch screw,

plate

carrier bar so

the

cylinder

with

the

needle).

this

position,

the

driving arm should

33. If

Then

the

necessary,

tighten

position

that

original

position

insert a piece

machine

the

'tight

side

the

paper, then turn pulley

of machine to

position

lateral

pivot driving arm pinch

it

(or

center

lateral

feed

be

move

linkage

the

lateral

of

the

needle

the

feed

carrier

after

adjustment

of paper under

into

"run"

of machine slowly

raise

the

adjustment

of

the

needle.

Fig.

33, and

is

centered

of clamping

rock

shaft

parallel,

to

as

obtain

pivot driving arm

in

re-

bar

position,

needle.

as

this

posi-

laterally

feet

is

driven

shown

this

Next, return feed

(A

check

puncture

the

driving

TO

ADJUST LENGTH

can

hole

arm

Adjustment:

Loosen

and

the

length of

length of

tighten

slide

stud

the

stud

tack,

nut.

NOTE: After this

necessary

to

the

needle

LATERAL

carrier

be

made by lowering

previously

pinch

lateral

toward front of

tack

(across

slide

stud toward rear of machine.

bar to

made in paper.) Then

screw.

OF

TACK

driving

arm

machine

the

bed). To

adjustment

to

adjust

the

feed

carrier

as

instructed

FEED.

its

original

the

position.

needle

into

tighten

stud nut,

Fig.

to

increase

decrease

33,

the

Then

is

made, it may

bar

in

relation

under CENTERING

be

FEED

PLATE

CARRIER

BAR---.

~

:::::!

~

.-----~-PINCH

.-------A

------

LATERAL

DRIVING ARM

S

CREW

DRIVEN

RM

DRIVING

ARM

PIVOT

Fi g. 33. Adjus t ing La tera l F

eed

Link

15

age

Page 18

FEED

LINKAGES

ON

BARRING

AND

TACKING MACHINES

(continued)

DRIVING

PINCH

STUD

----

ARM

SCREW

------

DRIVING

STUD

-+-

---',.

f

ig.

34,

Adjusting

Longitudinal

Feed

Linkag

e

ARM

NUT

CENT~RING

LONGITUDINAL

FEED

With machine

Check:

The

longitudinal feed, when

will

insure

changed,

ward

from

the

the

that

feed

when

plate

throat

the

plate

backward preventing the

width (bight)

moves

the

needle

needle

correctly

same

distance

hole

as

from

striking

adjusted,

of

tack

it

moves

for-

the

is

ley

slowly

not

strike

movement.

TO ADJUST

Adjustment:

while checking to

the

WIDTH

clamping foot.

Adjustment:

Through

loosen

screw,

the

Fig.

backward in

tighten

the

access

longitudinal rock

hole

in

right

shaft

side

of upright arm,

driving arm pinch

34, and move clamping foot forward or

correct

relation to

the

needle.

Then

pinch screw.

re-

Loosen

34, and

to

increase

slide

NOTE: After

necessary

the

GITUDINAL

slide

stud

needle

to

the

stud

the

the

to

as

16

in

"run"

position,

see

that

clamping foot during i

OF

TACK

longitudinal driving

to

the

right (facing rear of machine)

width of

left.

this

adjust

instructed

tack.

Then

adjus

the

tighten

tment

feed

under CENTERING LON-

To

decrease

is

plate

arm

the

FEED.

turn machine pul-

the

ts

stud nut,

stud

made,

in

needle

longitudinal

does

the

width,

nut.

it

may

relation

Fig.

be

to

Page 19

FEED LINKAGES

ON

BUTTON

SEWING

MACHINES

Lateral

adjusted

buttons or when

LATERAL

and longitudinal

when changing

the

hole spacing

FEED

Check:

The

lateral feed linkage, when correctly adjusted,

will

ensure

t,ance on one

moves on

increased

To

Obtain Equal Distance:

Remove cylinder

Insert button to

chine

until

needle

into

that

side

the

other

or

decreased

,.run"

is

just

the

feed plate moves

of

the

side.

as

arm

be

position and rotate machine pulley

above button,

Loosen lateral pivot driving

arm

driving

plate

inder)

so

pinch screw, Fig. 36, and position feed

that

as

button

shown

in

Fig. 36.

is

feeto

linkages should

from

throat

This

two or

in

plate

equal

from

the

buttons change.

the

same

needle

hole

distance

four hole

dis-

as

can be

required.

cover.

sewn into clamp, engage ma-

as

shown

arm

centered laterally

in

Fig. 35.

pinch screw and

(across

cyl-

be

it

At

this

position, the lateral feed rock

arm

and

the

driving

inset,

in

this

arm

Fig. 36.

position. Then tighten the lateral pivot driving

pinch screw.

Next, obtain correct position of

to

holes

in

button

plate

feed

hole

en

the

to bring

button or rear

driving

Fi

g. 35. Needle Position

arm

If

necessary,

should

be

parallel,

move linkage

needle

by

turning machine pulley and moving

needle

hole

arm

pinch screw.

into right rear hole

of two-hole button. Then

ed Above B

utt

shaft

as

to

in

on

driven

shown

obtain

relation

of

four-

tight-

BUTTON

LATERALLY

CENTERED

DRIVING

PINCH

ARM

SCREW

Fig.

36.

Adjusting

Loteral

17

Feed

Linkage

FEED

PLATE

LATERAL

DRIVING

PINCH

SCREW

PIVOT

ARM

ARMS

BE

SHOULD

PARALLEL

STUD

HUT

Page 20

FEED

LINKAGES

ON

BUTTON

LATERAL FEED (continued)

To

Increase

or

Decrease

Distance:

SEWING

MACHINES

LONGITUDINAL

FEED

When

adjusting

machine

When

adjusting

sewing two-hole

lever (lower lever),

as

far

sewing four-hole

lever (lower lever),

machine until

enter

the

left

is

turned.

When

correct

be

locked into

screw.

as

it will go.

position

hand

hole

adjustment

position

Fig.

37.

buttons,

buttons,

is

attained

in

button when

is

by

Adjus

ting

move

Fig.

37,

move

Fig.

37, away

where

attained,

tightening

LATERAL

ADJUSTING

Lev

rs

the

in

toward

the

needle

machine

the

lever

the

hex

LEVER

HINGE

SCREW

lateral

lateral

from

pulley

head

PLATE

the

the

will

can

Check:

The

longitudinal feed, when

will

ensure

tance

moves backward.

or

decreased

To

Obtain

Insert

chine

until

needle

Loosen

gitudinal

feed

plate

(along

At

arm

and

sary,

move linkage

Then

securely

Next,

to

the

and moving feed

hole

of four-hole button or rear

Then

that

forward

Equal

button to

into

"run"

is

arm

rock

so

the

bed) under

this

position,

the

obtain

holes

securely

the

from

This

as

required.

Distance:

just

hinge

shaft

that

driven

tighten

correct

in

the

tighten

plate

feed

the

equal

be

position

above button,

driving

button

the

the

arm

as

required to

the

button by turning machine pulley.

driving arm pinch screw.

To

Increase

or

Decrease

correctly

plate

moves

throat

plate

needle

distance

sewn into clamp,

and

rotate

as

shown in

plate

screw,

is

needle

Fig.

arm

pinch screw. Move

centered

as

shown.

longitudinal rock

should

be

parallel.

obtain

hinge

plate

position

to

the

of

needle

bring

needle

hole

of two-hole

longitudinal rock

Distance:

adjus~ed,

the

same

hole

can

be

increased

engage

machine

38, and

longitudinally

shaft

If

this

position.

screw.

in

into right

dis·

as

ma·

pulley

Fig.

35.

lon·

driving

neces-

relation

rear

button.

shaft

it

With

needle

move

the

longitudinal

Fig.

37, in toward

where

machine

toward

mov

be

needle

the

ement

When

locked

pulley

machine, will

from

correct

into

screw.

TIMING THE

FEED

NOTE: Longitudinal feed timing should

before

making any lateral timing

Check:

The

movement of

ARM

Fig.

38.

Adjusting Long

itudinal

Feed

Linkage

stopped

should not begin

work .

before

18

positioned

adjusting

the

machine until

will

enter

the

is

turned. Movement

the

machine, will

adjustment

position

the

the

needle

to

move until the

over rear

lever

posit

forward

increase

the

decrease

is

obtained,

by tightening

adjustment.

feed bar,

enters

Fig.

the

needle

hole

in button,

(upper lever),

ion

is attained

needle

of

hole

the

feed di

the distance.

the

lever

the

hex

40,

should

work.

Feed

leaves

when

lever in

stance;

can

head

be

set

be

bar

the

Page 21

Fig. 39. Timing Longitudinal

Feed

Longitudinal Timing:

To

time

the

longitudinal feed movement, loosen

the

three

cam mounting

the

cam

counter-clockwise

machine)

to

movement, or

When

correct

the

cam

screws.

speed

clockwise

adjustment

up

the

screws,

(as

feed

in

to

slow down

is

obtained,

Lateral Timing:

To time

lateral rock

to

the

the

down

right to

adjustment

left

feed

speed

the

shaft

(as

viewed

in

up

is

obtained,

I ateral feed movement, I

roller

stud

nut,

from

rear of machine)

relation

to

needle

the

feed movement.

securely

nut.

KNIFE TIMING

Check:

To

check

the

knife timing, turn

to

the

stitch

before

page 20) moves

penetrations

the

machine back

by hand and

to

the

shuttle

When

start

to move toward

space

between

before

observe

thread knife.

correctly

across

the

the

the

on

its

the

motion

timed,

the

heel of

shuttle

the

needle

machine

hinges,

of

the

shuttle

right when

the

driver) comes within 118 inch of

at

the

top

right hand

side

of

the

Fig.

39.

Then

rotate

viewed from bottom of

relation

Fig.

movement,

tighten

thread knife

goes

turn

the

shuttle

the

securely

40.

the

the

hole

into

the

shuttle

thread

the

"pocket"

and

end

to

the

the

movement.

oosen

Move roller

to

or

When

correct

roller

machine

(Fig.

(two

stop).

tight

in re lation

knife will

the

shuttle

of

its

stroke,

needle

tighten

the

slow

to

the

stud

cycle

42,

needle

Tilt

pulley

(the

race.

SL

DOWN

ROLLER

STUD NUT

40. Timing

Fig.

KNIFE

ROLLER----~~~~

HUT

FASTER

Fig. 4

~

~--

1.

Knife Timing

Adjustment:

faster

knife

act

ion

roller

in relation

loosen

toward the left, a s viewed

For

of

the needle

Fig.

41, and move

from

bottom of feed cam.

and

shuttle,

For s lower knife action, loosen

nut and move

roller

toward

the

~STUD

:(C

@ • 0

SPE

Lateral

S

LOW

Feed

------

ER

to

the

knife roll er nut,

the

right.

ED UP

~

the

knife

NUT

movem

roller

ent

19

Page 22

NEEDLE O

THREAD

KNIFE

0

ADJUSTING

BLOCK

Fig.

42.

Knife

Positioning

ADJUSTING

BLOCK

SHUTTLE

0

SCR

EW

KNIFE POSITIONING

Check:

With

machine

in

"run"

until a

the

position

machine

pulley, and

tween

the

the

needle

inside

of

the

NOTE:

last

the

position and turn machine pulley by hand

needle

should be approximately 1/32 inch from

This

two

between

cycle

as

the

shuttle

stitches

tilted

has

needle

thread

thread knife,

setting

back,

engage

the

second

and third

been reached. Continue turning

moves

knife and

down

shuttle

as

should

of machine

also

be checked during

cycle.

Adjustment:

To position

screws,

Fig.

until correct position

making certain

knives,

43, and

that

slide

is

obtained.

the

rack

loosen

the

knife rack along knife bar

Then retighten

is

set

knife bar.

Should there be

excessive

play between

rack and pinion, loosen the two rack

justing block screw, Fig. 43.

forward until

excessive

tighten the three

screws.

play

Then recheck knife

Slide

has

been removed and

starting lever

stitch

in

the

area

thread knife,

shown in

Fig.

two knife rack

screws

firmly

against

the

screws

and ad-

adjusting block

position.

in

be-

the

42.

the

knife

KNIFE

RACK

SCREWS

KNIFE

BAR

--!-

......

0

0

KNIF E

PINION

KNIFE

REMOVAL

AND

REPLACEMENT

Removal:

Tilt

machine back

knife rack

screws,

Fig.

on

its

43, and

hinges.

slide

Remove

rack up

the

out

two

of

engagement with knife pinion. Then remove knife holder

screw

an'd

remove

Position

first

tooth of knife rack with

rack down along knife bar and fasten in

two

screws.

knives.

knives on holder and

first

Then

check

knife

position.

replace

tooth

screw. Mesh

of

pinion.

place

with

Slide

the

Fig.

43. Knife Removal and Re

pla

eement

20

Page 23

SEWING

MECHANISM

ADJUSTMENTS

POSITIONING SHUTTLE DRIVER

Check:

The

to

.002

the

the

needle

to

needle.

shuttle

.010

driver should

with

sufficient

inch)

to

prevent

be

clearance

the

Adjustment:

With

machine

pulley until

using

an

Allen wrench,

screw, Fig. 44.

inner)

set

screw

ing to

correct

set

ing

SHUTTLE

screw.

TIMING

in

needle

Loosen

and move

position.

drive

bar

the

Tighten

is

at

loosen

shuttle

the

position,

bottom of

the

shuttle

Check:

Loop taking

inch

from

bottom of

point should

Fig.

45.

occurs

be

stroke.

at

centerline

when

needle

At

this

of

positioned

shuttle

rotate

shuttle

shaft

driver and bush-

the

shuttle

bar

has

position,

needle,

in

relation

(approximately

point striking

machine

stroke.

Then

driver pinch

bushing (front

shaft

bush-

risen

. 100

the

shuttle

as

shown in

PINCH

SCREW

Fig. 44. Pos

itioni

r---

- SET S

ng

Shuttle Driver

SHA

FT BUSHING

CREW

NOTE: A

inch

at

additional

from

gauge

bottom

charge.

Adjustment:

With

of

needle

stroke,

bar

rotate

Allen wrench, unti I

tioned.

Then

securely

screw.

NEEDLE

BAR

HEIGHT

Check:

Needle

point

1/16

bar height should

is

just

inch)

at

loop taking,

above

Adjustment:

Rotate

shuttle

and

needle

securely

is

loosen

bar until

tighten

shuttle,

at

centerline

needle

for

position

positioned

the

shuttle

the

shuttle

tighten

the

by machine

of

bar pinch

correct

pinch

screw

positioning

is

needle

available

• 100 inch above bottom

driver, by means of

point

is

correctly

the

shuttle

be

set

so

that

needle

see

needle.

position

Fig.

pulley,

screw.

and

eye

(approximately

45.

until point

Remove

Raise

is

obtained.

replace

bar . 100

upon

request

the

posi-

driver pinch

the

shuttle

of

face

plate

or lower

Then

face

plate.

SHUTTLE

AT

CENTER

NEEDLE

Fig.

POINT

OF

---~

45.

Needle

Bor

Height

ond Hook

1/16"

Timing

21

Page 24

NUMERICAL

MACHINE

LIST

OF

P260-9/108

PARTS

NUMBER

171( 830)

DESCRIPTION

Adjustin

Screw

175~830~

176 819

Pinch Screw

Arch

Clamp

Screw

193(804)

Knife Bar Connection

Screw

201(804)

202(819)

Bracket Stud Screw

Clamp

Arch

Screw (2)

209(833)

330( 809)

Needle

Thread Wiper

Finger

418( 804)

423(830)

460(830)

462( 830)

Thread Tension Stud

Stop Screw

Collar

Adjusting Stud

Screw

591(806)

592(805)

691(819)

691(806)

808( 830)

Regulating

Latch Lever Stop Sc

Cover

Throat

Retaining Plate

(4)

808(830~

858(830

896(830~

908(

1053( 806)

1065(830)

1208( 809)

1513(819)

1518( 805)

1519(805)

1521(805~

1560(803

1562(819)

1620(819)

1636(805)

1650( 805)

1655~803~

1662

Rubbing Block Screw

Crank

Cap

Screw

Hinge Screw

803

Knife Screw

Crank

Bushing Screw

Stud

Lock

Arm

Stop

Driving

Screw Stud

Tension

Tension

Housing

Screw

Stop Screw

Screw Stud Nut (2)

Bell

805

Crank Hinge Screw

Nut

1662(805)

Knife

Screw

Pawl

1662~805~

1747 805

2049

2102

2103

2455

2807

Hinge Screw

Screw

Crank

Tension Disc

Tension

Tension Disc

Bumper

washer (4)

2973

2974

2975

5968

10141

13275

13288

15140

15141

lAtch Lever

F\llcrum

Lever

Roller

Tension

Oil Pad

Retaining

Bobbin Case

Bobbin

2973, 2974 and

17825

17828

19448

20197

Knife Holder

Pinion

Slide

Crank

with

125044 and two

896(830)

Oil

23421

23477

Hole

Needle

858(830), 1065(830) and

two

141275( 869)

23500

32376

Bobbin

Retaining

e Screw Pinch

Foot

Lifter

(2)

Foot

Set

Screw

Body

Screw

Set

Screw

(2)

Set

Screw

Plate

Screw (6)

Plate

Screw (4)

Screw

Set

Screw

(2)

Position

Screw

(2)

Nut

Rod

Nut

(2)

Link Screw

Nut

Thumb

Nut

Thumb

Nut

Screw Nut

Stud

Nut

Lock

Nut

Actuating

Lever

Nut

Nut

Lock

Nut

Pin

(2)

Spring

(2)

Separating

Pin

Spring

Washer

(2)

Spring

(felt)

Ring

Latch

Case Hinge Nos.

15140

Stud

Bracket

Block

Connecting

Plug

Bar Crank

Rod

(.leather)

with

Ring

NUMBER

32377

32572

37310

39453

39653

40028-003

43725

50018(806)

50169(819)

50356(804)

50446~803)

rew

50628 809)

50650(803~

51119(805

51381( 805)

51403(869)

51657(805)

51948

51951

52082

Nut

52454

53612(805~

53617(805

53618(805)

55325

55459

63837

68721

68723

125044

131022

140321(830)

140352( 830)

141059(830)

141066(803)

141067(805)

141069(869)

141069(869)

141069(869)

141070(803)

141071(

141075(

141077(

141099(805

819~

803

830 l

141100(850

141101(803

141128(833)

141145(803~

141242(819

141242(819

141245(869)

141275(869)

DESCRIPTION

Shaft

Oscillatin

Slide

Block complete,

Crank

Nos. 19448, 32376 and

141412

Tension

Roller

Washer

Releasin

Screw Stud

(2)

Thread Wiper

g Disc

Body

Finger

Oscillating Rock

Shuttle

Shuttle

Body

Bobbin Case

Shaft

complete, Nos. 591(805),

592(805), 2975, 15141

and 224842

Bracket Screw

Thread Guide Screw

Spindle

Housing Screw

Hinge Screw

Plate

Screw

Cap

Screw

Lever

Arm

Sprin

Screw

Lock

Follower

with

Screw

g Screw

(2)

(2)

Nut

Arm Roller

1521(805) and

225837

Cam

Follower

and Screw Stud

Roller

with

1655(803), 5968 and

37310

(2)

Thread Take-up

Thread

Retainer

Screw Stud

Nut

Sprin

(front)

(2)

g

Swivel Stud Nut

Support Screw

Throat

Plate

Bushing (46

Look

Nut

Needle Hole

drill

needle

hole)

Knife

(shuttle

Arch

Clamp

Arch

Clamp

Arch

Clamp

Oil

Pad

Stop

Rod

(rubber)

Collar

Tripping

Lifting

Set

Link Connection

Foot

Foot

Foot

(felt)

Bumper

( 3)

Screw (4)

Point

thread)

Lifter

(left)

(right)

Screw

(2)

Screw

Locating

Screw (4)

Locking Screw

Arm

Screw ( 3)

Cylinder

Supporting

Screw

Gear

(2)

Bracket

Screw

Supporting

Driving

Drivin

Bushing

Screw Stud

Gear Screw

Block Screw

g Link Screw

Set

Screw

(upper)

(2)

Hinge Screw

Pressure

Adjustin

Sprin

g Screw

g

Bushing (back)

SUpport Screw

Knife Screw

Adjusting

Rook

Block Screw

Adjusting

Screw

(2)

Stud

Set

Tension

Screw

(2)

Crank

Position

Screw

(2)

NUMBER

Worm

141407~869)

141407

869)

Worm

Position

Gear

Screw

Worm

141408(869)

141408(869~

141412(803

141448(803)

Worm

Slide

Knife

Gear

Set

Block Screw

Actuating

Screw

Pawl

141449(803)

141450(803)

141462(803)

141560( 805)

141574(803)

141575(803)

Hinge Screw

Bell

Crank Hinge Screw

Slide

Block Screw

Feed

Plate

Clamping

Spring

(2)

141576(803)

167001

Tension

Arch

Clamp

(universal)

239208

167004

Lifting

141059(830)

167006

Lifting

35:)604(869)

167007

1670')9

Lifting

Arm

Cover

1053(806)

Arm

167012

167013

Arm

Shaft

Shaft

167012

141128(833) 202299,

239374 and

167041

Cylinder

(top)

Screw

167048

167049

167050

167051

167052

167055

167062

Stud

Arm

Shaft

Supporting

Feed

Plate

Feed

Plate

with

two

Driving

Driving

350604(869)

167064

167072

167075

Adjusting

Connecting

Driving

350600(869)

167076

Driving

1519(805), 141075(803) and

239266

167084

Machine

Engaging

167086

167087

Needle Bar

Needle Bar 167086

209(833), 50169(819) and

239376

167088

Needle Bar Connecting Link

271597

167089-001

167089..{)01

Connecting

175(830) and 239277

167143

167144

Starting Bell

Starting Bell

with

51657(803), 53617(805),

167154 and 167155

167145

Startin

141077(830)

167146

Startin

239159, 239307 and two

141099(805) and 214053

167154

Startin

Rod

167155

167157

U7159

Starting

Stop

Rod

Brake Shoe Support

171(830) and 201(804)

DESCRIPTION

Screw

Position

Set

Screw

Screw

Stud

Lever

Screw Stud

Plate

Adjusting

Screw

Screw

Stud

Frame

with

two

Rock

Shaft

with

Arm

with

Link

(front)

with

and 167262

Bushing

Bushing

with

two

Cover

(back)

(back)

53618(805),

239383

Plate

(2)

Busbin

Gear

(·~enter)

Bracket

Carrier

239448

Block complete

Lever

with

Block

Arm

Arm

with

Arm

167075

Pulley

Arm

(loose)

Stud

with

with

50650(803),

and 239385

Stud

with

Crank

Crank 167143

g Lever

with

g Lever 167145

g Lever

Rod

Starting

Adjuster

Swivel

with

Bar

with

with

each

Page 25

NUMERICAL

MACHINE P260-9/108

LIST

OF

PARTS

NUMBER

167160 Swivel

DESCRIPTION

Retaining

Ring

167161 Brake Shoe SUpport

Bracket 167159

with

50446(803), 141101(803),

223812, 239513 and

239557

167162 Tension

167163

Tension complete, Nos.

Release

1560(803), 2103, 32572,

52082, 141576(803),

167173,

270278 and two

2102

167173

Spring

Regulator

two 141245(869)

167181

167182

167183

Tripping

Tripping

Collar

Vertical

Worm

with

Rook

Rook

with

two

Drive

141407(869)

Shaft

Shaft

Shaft

and 141408(869)

167184

167229 SUpport

167234

Vertical

Worm

141407~869~

141408

Gear

869

Drive

w1

th

and

Shaft

Bracket

Pressure

Spring

Tripping Point

167235 Washer (2)

167262

167292

167413 Knife

Thread

Cutter

Adjusting

with

462(830)

Actuating

Stud

Knife

Bracket

Screw and Nut complete,

Nos.

1662(805) and

141448(803)

167414

Ball

Crank Hinge Screw

and Nut complete, Nos.

1662(805) and

141449(803)

167415

Pawl

Hinge Screw

Nut

complete, Nos.

1662(805) and

141450(803)

167416

Collar

with

two

140321(830)

Arch

Clamp

167423

complete,

Nos. 68721, 68723,

141071(819),

167041,

167001,

167051, 167052,

167055, 239202, 239204,

239209, 350605(869),

two

each 202(819),

141575(803), 201711(803)

239206,

239613 and

808(830)

Arm

Stop

167445

167446

Arm

Nos.

Rod

Stop

Rod

complete,

167445, 202342,

239518 and 239519

167447

200056(805)

200084(819)

Interlocking

Rod

167446

two 1518(

131022 and

Arm

with

805),

four

Stop Latch Screw

Arm

Cover

(side)

167157,

three

2807

(4)

200072~803~

200084

200084(819)

200084(850~

200132(819 Thread

200138(805 ICnite

819

Pinch Screw

Arm

Cover

Screw

(2)

Cylinder

Screw

Bracket

Cover

(2)

Set

Guida Screw

(stationary)

(front)

(side)

Screw

Screw

Rod

with

460(830)

Laver

and

five

Stop

Screw

NUMBER

200161( 819)

200294(819)

200299(819)

DESCRIPTION

Position

Screw

Cylinder

Plate

(2)

Cover

(bottom) Screw

Trip

Laver Hinge

(2)

Screw

200308(803~

200333(830

200335(830)

200338( 803)

Hinge Screw

Bushing

Sat

Hinge

Screw

(front-outer)

Screw

Stud

(2)

Sat

Bushing (back)

Set

Screw

200338(803)

200363(830)

200364(830)

200366( 830)

Bushing

Set

Hinge

Hinge Stud

Thread Guard

Screw

Pin

(canter)

Set

Screw

Set

Sat

Screw

Scrlltf

803

819)

Support

Hinge

Pulley

Regulator

Arm

200378(830}

200394(803~

200397(833 Stud

200436(

200442~803)

200582

Screw

200582( 819) Thread

Screw

20ll35(803)

20ll88(

201256(803~

201356(805

201422(803)

201442

201472(803)

803)

Pulley

Collar

Bracket Screw

Screw Stud

Stud Screw

Position

Bushing

Set

201525(805)

201

7ll

( 803)

Screw Stud

Adjusting

Sat

Pin

Set

Set

Screw

Set

Sat

Cover

(2)

Retainer

(2)

Retaining

Set

Screw

(front-inner)

Scrlllf

Screw

Screw

Screw

Screw

Screw

(canter)

Scrlllf

(4)

(lower)

(pin)

Nut

Nut (2)

201

7ll

( 803)

201749( 805)

202005

Bracket Screw

Hinge Screw

Gear Bracket Screw

Nut

Nut

Washer

202299

202342

Oil Packing (wick)

Arm

Hinge Tension

Spring

Hinge

Stud

202423

Packing (wick)

202478 Stop Latch

202603

Adjusting

011

(2)

Trip

Block Screw

washer

202603

Adjustin

g Screw

Washer (2)

203172

204235

204235

210805 Screw washer

Friction

Arm

Position

Cylinder

Pin

(2)

Washer

Pin

Position

(3)

210805 Screw Stud Washer

210957 Thread

Retainer

(lower) Stud

210958

210993

214053

222583

223710

Stud

Collar

Sleeve

Retum

Oil

Pack

Thread

(lower)

Spring

ing

(wick)

Retainer

with

( 2)

200397(833)

2237ll

Thread

(lower)

Retainer

complete, Nos.

210957, 210958, 210993,

223812

223710

Brake Shoe SUpport

and 223844

Spring

223844

'l'hread

(lower)

Retainer

Spring