Page 1

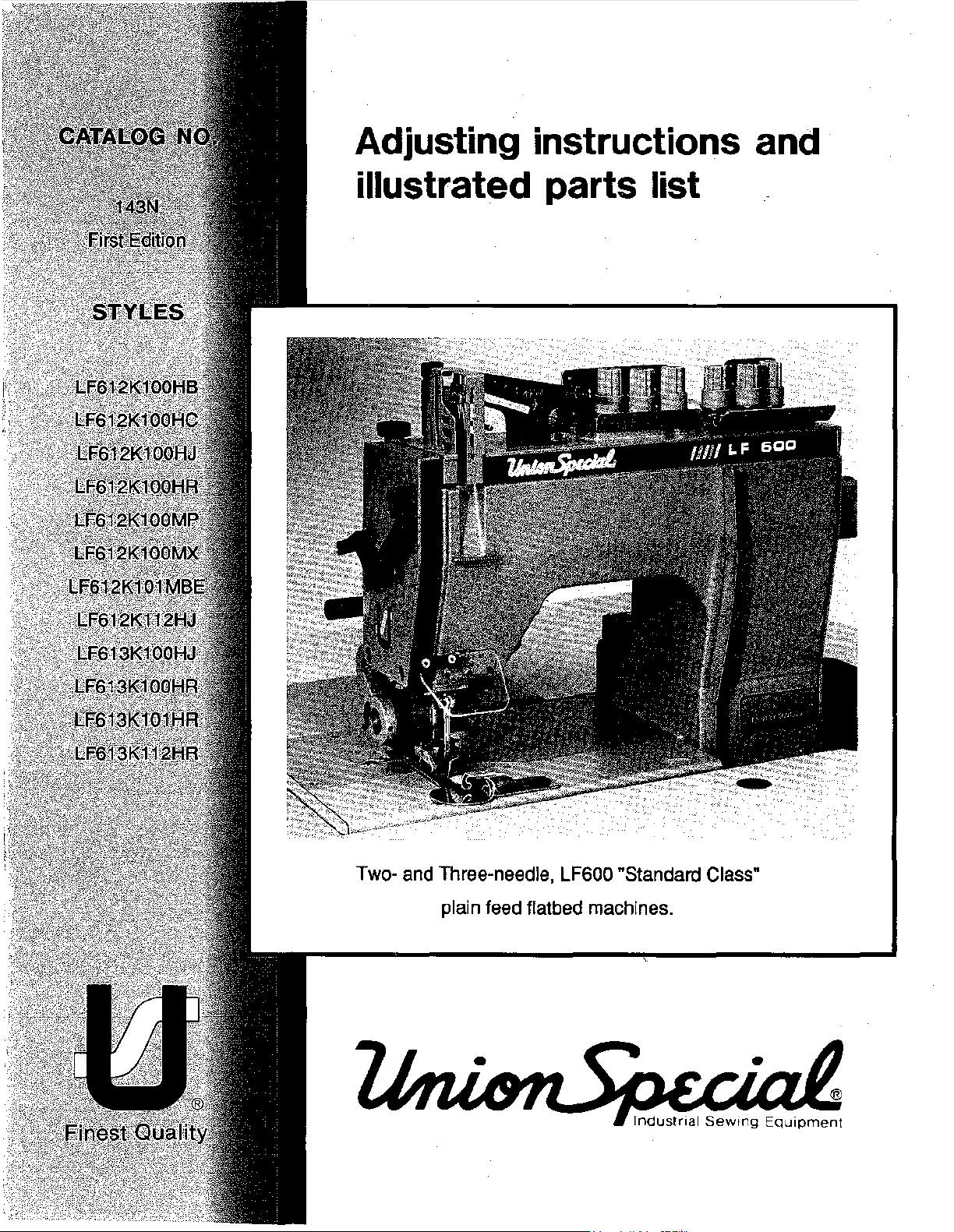

Adjusting instructions and

illustrated parts list

Two- and Three-needle,

plain feed flatbed machines.

LFGOO

"Standard Class"

Page 2

FOREWORD

This technical manual has been prepared to guide you in the maintenance

machine. Careful attention to the instructions for operating and adjusting these machines will enable you

to maintain the superior performance and reliability designed and built into every

machine.

The Adjusting Instruction portion

components related to forming the stitch and completing the functions

illustrate the adjustments using reference letters to point out specific items discussed.

Adjustments are presented in sequence so that a logical progression is accomplished.

performed out

Implementation

productivity by avoiding costly equipment breakdowns. Whenever

or

replace parts on your machine, be sure to insist on genuine UNION SPECIAL Repair Parts. These parts

are designed specifically for your machine and manufactured with utmost precision to assure long lasting

service.

This Catalog has been made on the basis

may incorporate a slight modification

of

sequence may have an adverse effect on the function

of

Preventive Maintenance Schedule can bring about significant improvements in operator

of

this manual explains in detail the proper setting

of

available information. Changes in design and/or improvements

of

configuration in illustrations

CATALOG

N0.143

N

of

your new UNION SPECIAL

UNION SPECIAL

for_

each

of

of

the machine. Figures are used to

Some adjustments

of

other related parts.

it

becomes necessary to make repairs

or

part numbers.

the

LF612KlOOHB

LF612KlOOHC

LF612KlOOHJ

LF612KlOOHR

LF612KlOOMP

LF612KlOOMX

Rights Reserved In All Countries

For

Styles

LF612Kl01MBE

LF612K112HJ

LF613K100HJ

LF613KlOOHR

LF613K101HR

LF613Kll2HR

First Edition

Copyright

Union Special Corporation

1990

By

Printed in U.S.A.

July, 1990

2

Page 3

Each UNION SPECIAL machine is identified

into the

left rear base

Style plate affixed to the right front

of

machine

of

by

a Style number, which

machine. Serial number is stamped into bed casting at the

on

this machine Class, is stamped

NOTE: Instructions stating direction

relative to the operator's position at the machine, unless otherwise noted.

counterclockwise in operating direction as viewed from the right

High speed, maximum performance, double locked stitch, plain feed flatbed machine. Totally enclosed

feed and looper drive mechanism, fully automatic forced feed lubricating system with easily replaceable

oil filter, quick stitch change, independently driven rear needle guard and quick adjustable looper avoid.

LF612K100HB Two needle, HIGH capacity, for seaming trousers and similar garments made

heavy to heavy weight material. Right needle in front. Standard recommended needle

Type

128

GBS, Size 100/040. Available in 7 S.P.I.

The seam produced has two rows of stitching with the strength

is

moved forward

depending on operation.

LF612K100HC Same

LF612K100HJ Two needle, HIGH capacity, for attaching risers to dungarees, piecing sleeves on denim

as

Style LF612KlOOHB except available in 10 S.P.I.

jackets and attaching overall bibs. Includes double lap seam folder 3/32 inch (2.4mm)

capacity. Left needle in front. Standard recommended needle Type 128

125/049.

mended speed

Stitch range 7-14 S.P.I. Standard gauge Nos.

or

location, such as right, left, front

STYLES

at.

a rate

6500 R.P.M., depending on operation.

OF

MACHINES

ONlY.

of

7 S.P.I. Maximum recommended speed 6500 R.P.M.,

or

rear

of

machine, are given

The

handwheel rotates

end

of

machine.

of

medium

Standard gauge No.1 ONI.Y.

of

14 S.P.I., yet the fabric

ONlY.

GAS, Size

16

and

18.

Maximum recom-

LF612K100HR Same

LF612K100MP

LF612K1

LF612K101 MBE Two needle, MEDIUM capacity, for hemming bloomers. Equipped with Close-Coupled

LF612K112HJ

LF613K100HJ Three needle, HIGH capacity, for seaming wind breakers, mackinaws, lumber jacks and

OOMX

Two needle, MEDIUM capacity, for piecing sleeves, joining shoulders and setting sleeves

as

Style LF612K100HJ except Standard gauge No.

S.P.I.

on ordinary quality shirts made with light to medium weight materials. Includes double

lap seam folder 1/16 inch (1.6mm) capacity. Standard recommended needle Type 192

GLS,

Size 75/029. Stitch range 9-20 S.P.I. Standard gauge Nos.

recommended speed

Two needle, MEDIUM capacity for quilting collar bands of shirts and similar garments.

Standard recommended needle Type 192

Standard gauge No. 24 ONLY. Maximum recommended speed 6500 R.P.M., depending

on operation.

Roller Puller. Standard recommended needle Type 192

6-12

S.P.I. Standard gauge No.

depending on operation.

Same as Style LF612K100HJ except-equipped with power"AlR-KLIPP" ® Chain Cutter.

Standard recommended needle Type 128

for similar operations on medium heavy to heavy weight material. Equipped with tractor

6500 R.P.M., depending on operation.

GLS, Size 90/036. Stitch range 14-20 S.P.I.

16

ONLY. Maximum recommended speed 6500 R.P.M.,

GAS, 125/049.

18

ONLY. Stitch range 7-10

12

and 16. Maximum

GLS, Size 80/032. Stitch range

3

Page 4

type presser foot. Includes double lap seam folder 3/32 inch (2.4mm) capacity. Standard

recommended needle Type

gauge Nos. 8 and 9. Maximum recommended speed

128

GAS, Size 125/049. Stitch range 7-10 S.P.I. Standard

6500 R.P.M., depending on operation.

LF613K100HR Three needle, HIGH capacity, for seaming sanforized denim and similar operations on

medium to heavy weight materials. Includes double lap seam folder 1/8 inch (3.2mm)

capacity. Standard recommended needle Type

S.P.I. Standard gauge Nos. 8 and

depending on operation.

9.

128

GAS, Size 125/049. Stitch range 7-14

Maximum recommended speed 6500 R.P.M.,

LF613K101HR Three needle, HIGH capacity, for seaming sanforized denim and similar operations.

Equipped

(3.2mm) capacity. Standard recommended needle Type

range

R.P.M., depending on operation.

with Close-Coupled Roller Puller. Includes double lap seam folder. 1/8 inch

128

GAS, Size 125/049. Stitch

7-10 S.P.I. Standard gauge Nos. 8 and

9.

Maximum recommended speed 6500

LF613K112HR SameasStyleLF613K100HRexcept-equippedwithpower"AIR-KLIPP®" ChainCutter.

®"AIR-KLIPP" is a registered trademark

of

Union Special Corporation.

4

Page 5

SAFETY RULES

A

CAUTION!

THIS SYMBOL INDICATES YOUR PERSONAL SAFETY

PREVENT PERSONAL INJURY:

TO

- All power sources to the machine

replacing parts.

- Wear safety glasses.

- All shields and guards

-

DO

NOT tamper with safety shields, guards, etc., while machine is in operation.

IMPORT ANT: Machine must be in a leveled position.

Oil has been drained from main reservoir before shipment. Use a straight mineral oil with a Say bolt viscosity

of90

to 125 seconds at 100 ° Fahrenheit. This is equivalent to UNION SPECIAL Specification No. 175.

Remove oil filler cap (A, Fig.

MUST be in position before operating machine.

1)

and fill to the TOP line

MUST be TURNED OFF before threading, oiling, adjusting, or

LUBRICATION

of

oil level gauge (B). Replace oil filler cap.

IS

INVOLVED

CAUTION!

To maintain maximum recommended

Preventive Maintenance Schedule. Under no circumstances, should oil remain in the machine for more

than one year. Oil drain plug is located in bottom

At this time, evaluate the contaminated condition

more or less frequently. To replace

cartridge. REMOVE (brass) BY-PASS VALVE

FILTER. Reassemble in reverse manner.

On

new machines, machines that have been out

OR

machines that have been drained

300 R.P.M. for approximately five minutes while paying strict attention to the oil flow

indicator which should rise in the oil filler cap (A) and remain steady while machine is

running. This must be noted to ensure that oil flow indicator is functioning and oil is

circulating. Check oil level while machine is running which

the red lines

of

oil level gauge.

filter, remove four screws (C, Fig.

speed and serviceability

of

oil and refilled .... RUN MACHINE SLOWLY at

of

oil pan. ALWAYS change oil filter when oil is changed.

of

the oil to determine

FROMTOPOFOLDFILTERAND

5

of

service for an extended period

MUST be maintained between

of

these machines, refer to General-

if

the oil filter should be changed

1)

and cover (D); lift out filter

INSTALL IN NEW

of

time

Page 6

LUBRICATION DIAGRAM

•

P100B

PRESSURE

OIL

•

~TfM!~!f@

SIPHON

FILTER

Fig.1

6

RETURN

BY-PASS

Page 7

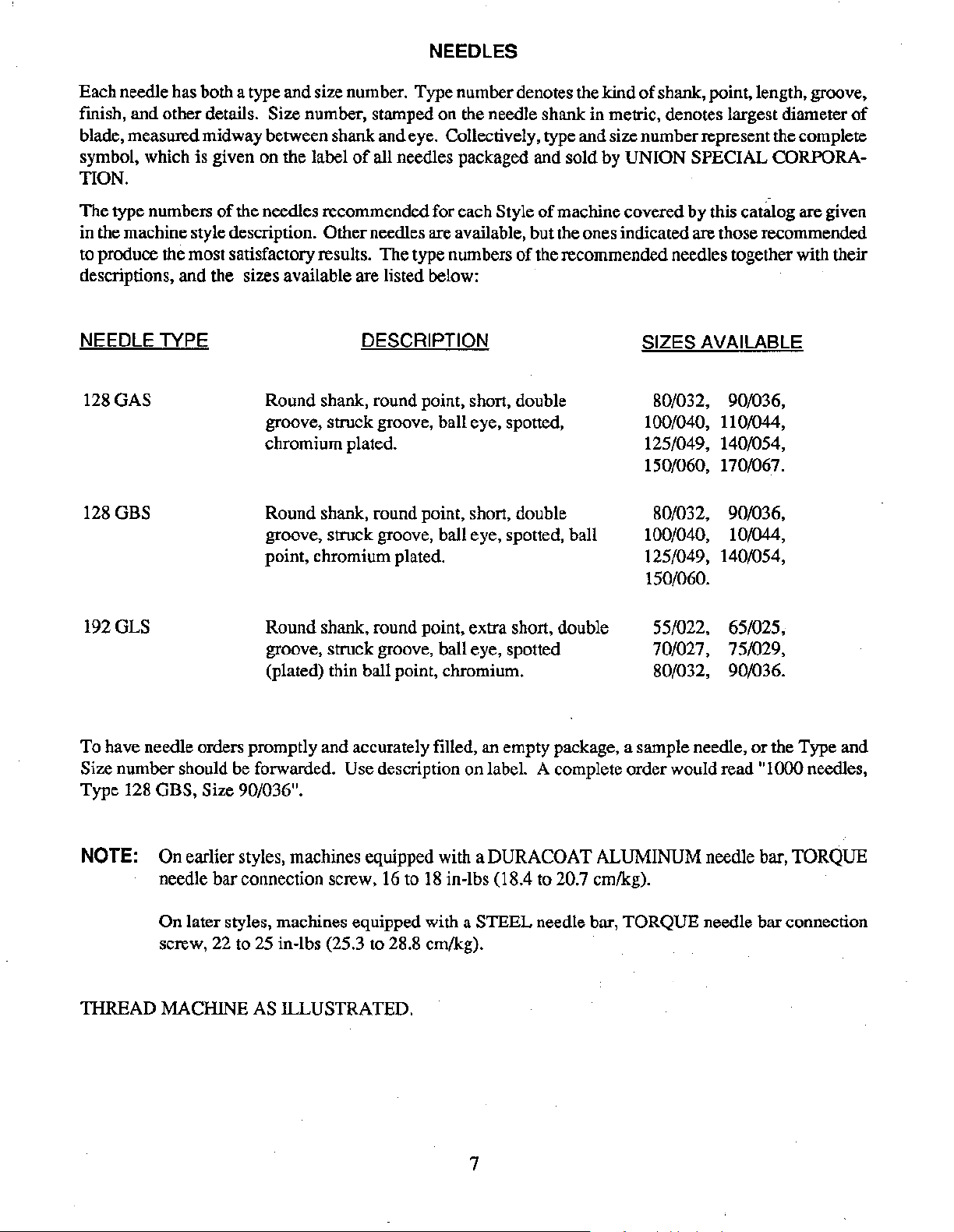

NEEDLES

Each needle has both a type and size number. Type number denotes the kind

fmish, and other details. Size number, stamped on the needle shank in metric, denotes largest diameter

blade, measured midway between shank and eye. Collectively, type and size number represent the complete

symbol, which is given on the label

TION.

The type numbers

in the machine style description. Other needles are available, but the ones indicated are those recommended

to produce the most satisfactory results. The type numbers

descriptions, and the sizes available are listed below:

NEEDLE TYPE

128 GAS

128 GBS

of

the needles recommended for each Style

Round shank, round point, short, double

groove, struck groove, ball eye, spotted,

chromium plated.

Round shank, round point, short, double

groove, struck groove, ball eye, spotted, ball

point, chromium plated.

of

all needles packaged and sold by UNION SPECIAL CORPORA-

of

machine covered by this catitlog are given

of

the recommended needles together with their

DESCRIPTION

of

shank, point, length, groove,

SIZES AVAILABLE

80/032, 90/036,

100/040, 110/044,

125/049, 140/054,

150/060, 170/067.

80/032, 90/036,

100/040, 10/044,

125/049, 140/054,

150/060.

of

192GLS

To have needle orders promptly and accurately filled, an empty package, a sample needle,

Size number should be forwarded.

Type 128 GBS, Size

Round shank, round point, extra short, double

groove, struck groove, ball eye, spotted

(plated) thin ball point, chromium.

Use description on label. A complete order would read

90/036".

55/022, 65/025,

70/027, 75/029,

80/032, 90/036.

or

the Type and

"1

000 needles,

NOTE: On earlier styles, machines equipped with a DURACOAT ALUMINUM needle bar, TORQUE

needle bar connection screw, 16 to

On later styles, machines equipped with a STEEL needle bar, TORQUE needle bar connection

screw, 22 to 25 in-lbs (25.3 to 28.8 ern/kg).

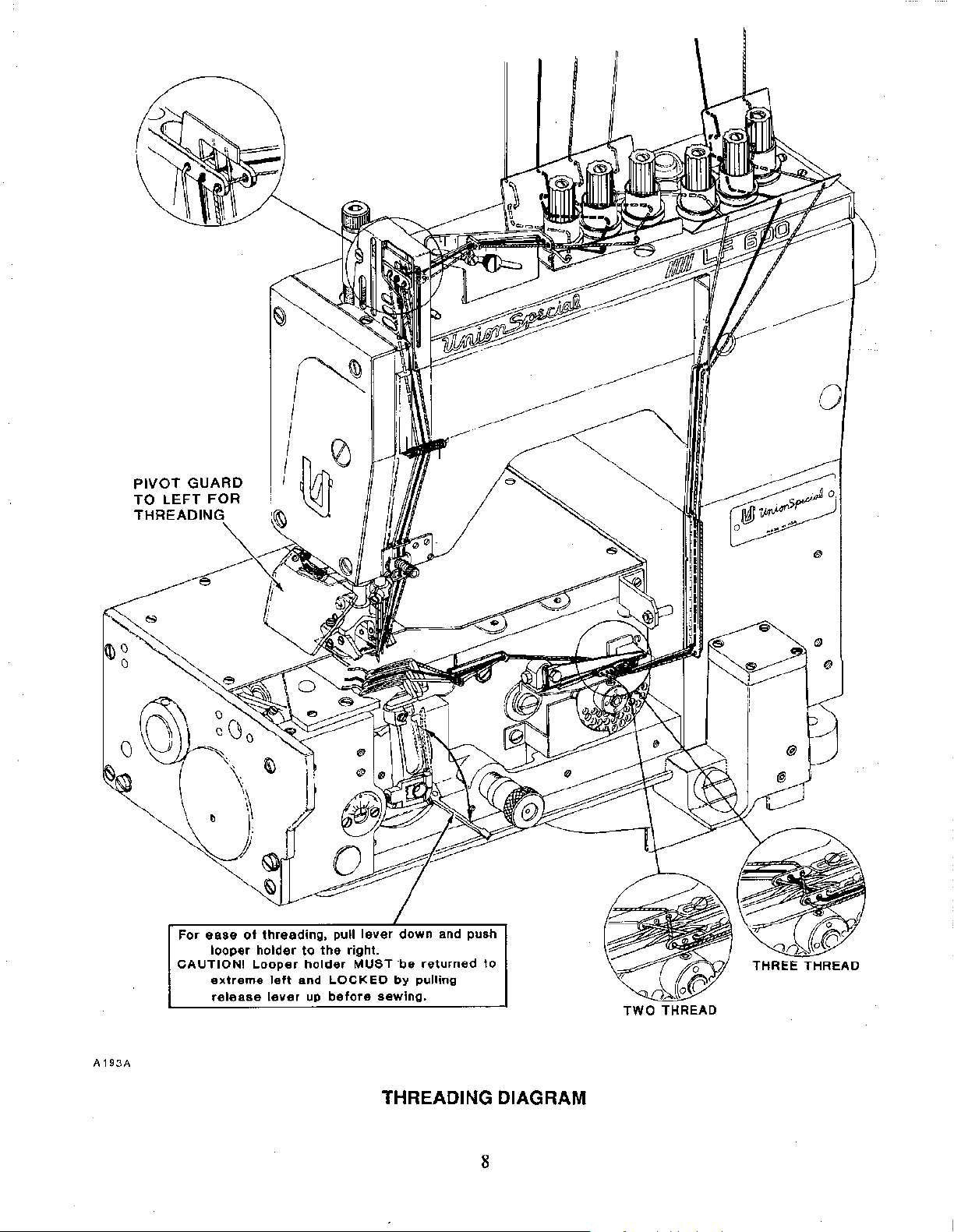

TIIREAD MACHINE AS ILLUSTRATED.

18

in-lbs (18.4 to 20.7 ern/kg).

7

Page 8

PIVOT

TO

LEFT FOR

GUARD

•

For

ease

looper

CAUTION!

extreme

release

of

threading,

holder

Looper

left

lever

to

the

holder

and

up

right.

MUST

LOCKED

before

·be

by

sewing.

returned

pulling

to

TWO

THREAD

A193A

THREADING DIAGRAM

8

Page 9

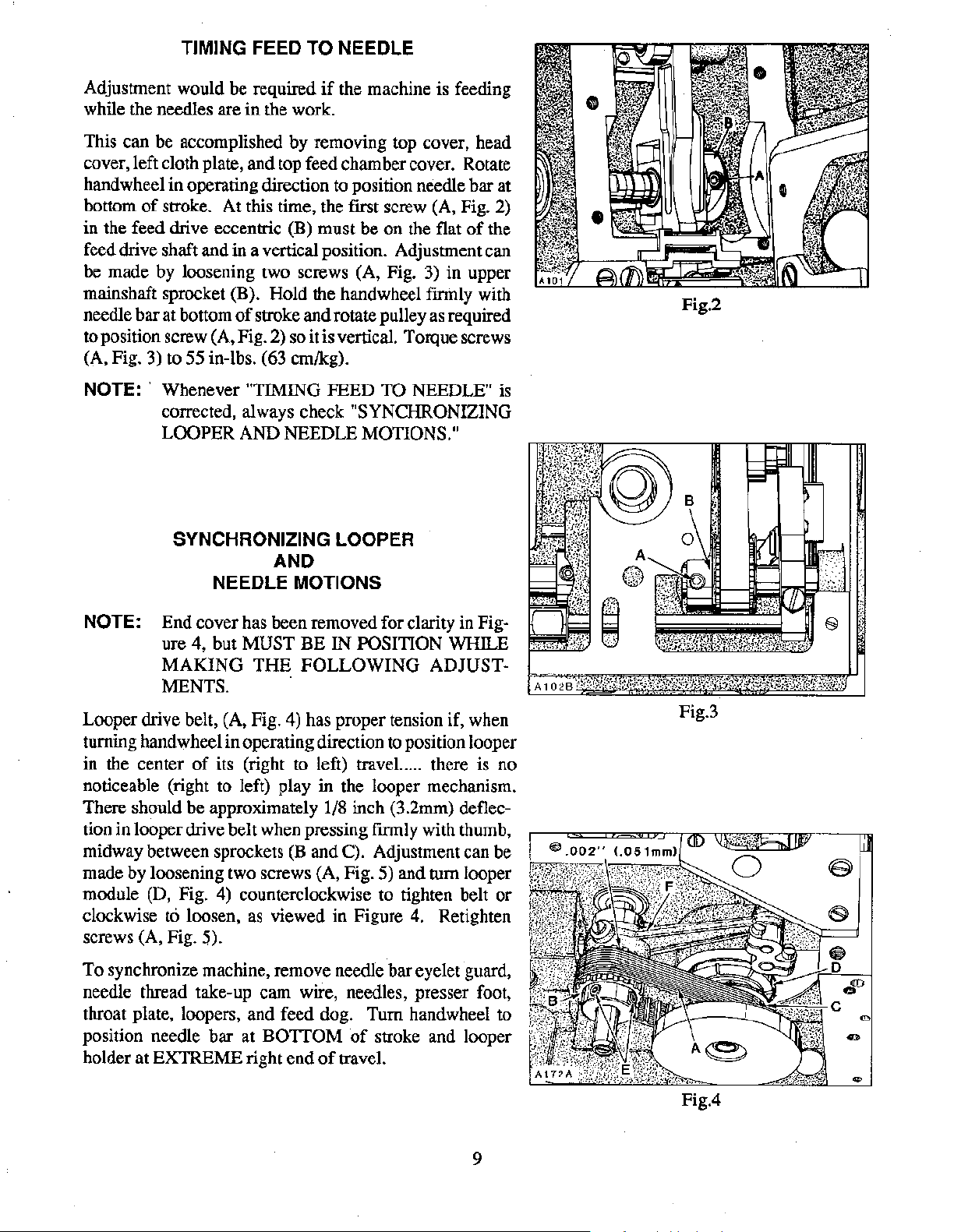

TIMING FEED TO NEEDLE

Adjustment would be required

while the needles are in the work.

This can be accomplished by removing top cover, head

cover, left cloth plate, and top feed chamber cover. Rotate

handwheel in operating direction to position needle bar at

bottom

in the feed drive eccentric (B) must be on the flat

feed drive shaft and in a vertical position. Adjustment can

be made by loosening two screws (A, Fig. 3) in upper

mainshaft sprocket (B). Hold the handwheel

needle bar at bottom

to position screw (A, Fig. 2) so it is vertical. Torque screws

(A, Fig. 3) to 55 in-lbs. (63 em/kg).

NOTE:,

of

stroke. At this time, the first screw (A, Fig. 2)

of

stroke and rotate pulley as required

Whenever "TIMING FEED TO NEEDLE" is

corrected, always check

LOOPER

SYNCHRONIZING LOOPER

AND NEEDLE MOTIONS."

AND

NEEDLE

if

the machine is feeding

"SYNCHRONIZING

MOTIONS

of

the

fmnly with

Fig.2

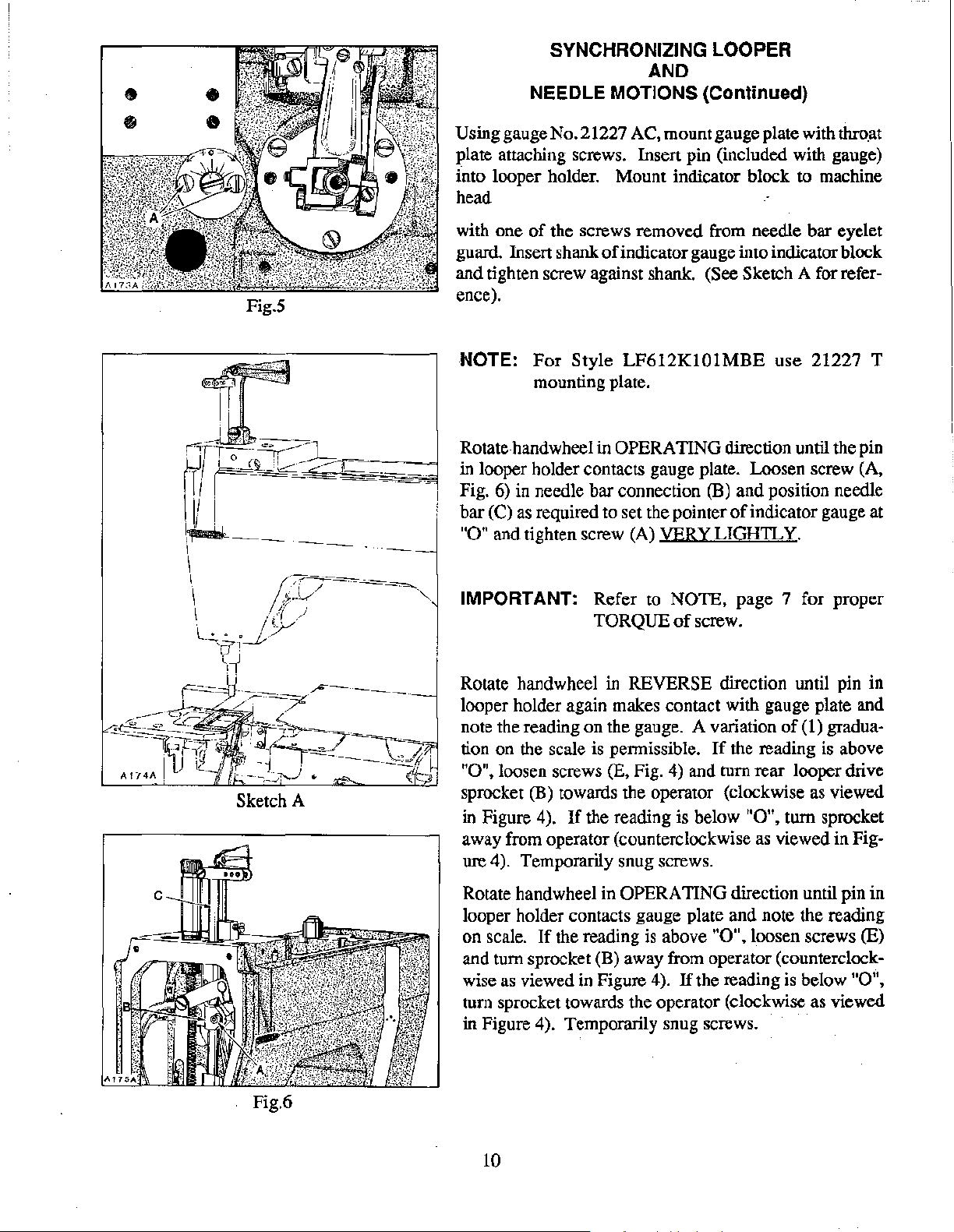

NOTE:

Looper drive belt, (A, Fig. 4) has proper tension if, when

turning hand wheel in operating direction

in the center

noticeable (right to left) play in the looper mechanism.

There should be approximately 1/8 inch (3.2mm) deflection in looper drive belt when pressing

midway between sprockets

made by loosening two screws (A, Fig. 5) and tum looper

module (D, Fig. 4) counterclockwise to tighten belt or

clockwise

screws (A, Fig.

To synchronize machine, remove needle bar eyelet guard,

needle thread take-up cam wire, needles, presser foot,

throat plate, loopers, and feed dog. Tum handwheel to

position needle bar at

holder at

End cover has been removed for clarity in Figure 4, but MUST BE IN POSITION WHILE

MAKING

MENTS.

of

to

loosen,

5).

EX1REME right end

THE

its (right to left) travel...

as

FOLLOWING

,

fmnly with thumb,

(B

and C). Adjustment can be

viewed in Figure

BOTTOM

of

of

stroke and looper

travel.

to

ADJUST-

position looper

..

there is no

4.

Retighten

Fig.3

9

Fig.4

Page 10

SYNCHRONIZING LOOPER

AND

NEEDLE MOTIONS (Continued)

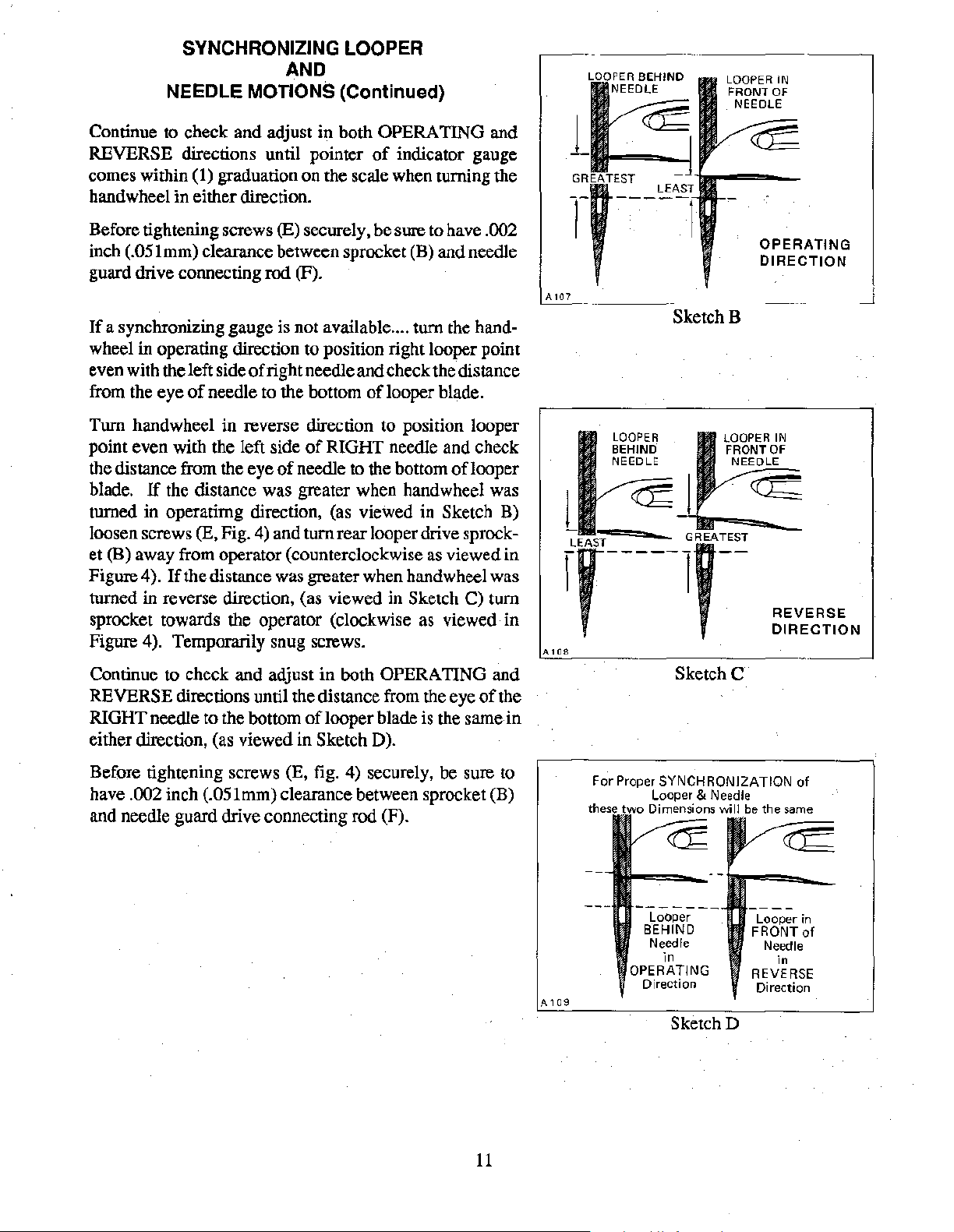

Using gauge No. 21227 AC, mount gauge plate with thro.at

plate attaching screws. Insen pin (included with gauge)

into looper holder. Mount indicator block to machine

head

Fig.S

with one

guard.

and tighten screw against shank.

ence).

NOTE:

Rotate hand wheel in

in looper holder contacts gauge plate. Loosen screw (A,

Fig.

bar

"0"

IMPORTANT: Refer to NOTE, page 7 for proper

of

the screws removed from needle bar eyelet

lnsen

6)

(C)

and tighten screw (A) VERY LIGH1L

shank

of

indicator gauge into indicator block

(See Sketch A for refer-

For

Style

mounting plate.

in needle bar connection (B) and position needle

as

required to set the pointer

LF612Kl01MBE

OPERATING direction until the pin

TORQUE

of

screw.

use

21227 T

of

indicator gauge at

Y.

Sketch A

Fig.6

Rotate handwheel in REVERSE direction until pin in

looper holder again makes contact with gauge plate and

of

note the reading on the gauge. A variation

tion on the scale is permissible.

"0",

loosen screws (E, Fig. 4) and tum rear looper drive

sprocket (B) towards the operator (clockwise as viewed

If

in Figure 4).

away from operator (counterclockwise as viewed in Figure 4). Temporarily snug screws.

Rotate handwheel in

looper holder contacts gauge plate and note the reading

on scale.

and turn sprocket (B) away from operator (counterclockwise

turn sprocket towards the operator (clockwise as viewed

in Figure 4). Temporarily snug screws.

If

as

viewed in Figure 4).

the reading is below

OPERATING direction until pin in

the reading is above

If

the reading is above

"0",

"0",

loosen screws (E)

If

the reading is below

(1) gradua-

tum sprocket

"0",

10

Page 11

SYNCHRONIZING LOOPER

AND

NEEDLE

MOTIONS (Continued)

LOOPER IN

FRONT

OF

NEEDLE

Continue to check and adjust in both OPERATING and

REVERSE directions until pointer

comes within (1) graduation on the scale when turning the

hand wheel in either direction.

Before tightening screws

inch (.051mm) clearance between sprocket (B) and needle

guard drive connecting

If

a synchronizing gauge is not available .... turn the hand-

wheel in operating direction to position right looper point

even with the left side

from the eye

Turn handwheel in reverse direction to position looper

point even with the left side

the distance from the eye

blade.

turned in operatirng direction, (as viewed in Sketch B)

loosen screws

et (B) away from operator (counterclockwise

Figure 4 ).

turned in reverse direction, (as viewed in Sketch

sprocket towards the operator (clockwise as viewed in

Figure 4). Temporarily snug screws.

Continue to check and adjust in both OPERATING and

REVERSE directions until the distance from the eye

RIGHT needle to the bottom

either direction, (as viewed in Sketch D).

of

needle to the bottom

If

the distance was greater when handwheel was

(E, Fig. 4) and turn rear looper drive sprock-

If

the distance was greater when hand wheel was

(E) securely, be sure to have .002

rod (F).

of

right needle and check the distance

of

of

needle to the bottom

of

of

indicator gauge

of

looper blade.

RIGHT needle and check

of

looper

as

viewed in

C) tum

of

the

looper blade is the same in

t[§

~:EATEST

r

A107

LOOPER

BEHIND

NEEDLE

A108

_j

OPERATING

DIRECTION

SketchB

GREATEST

REVERSE

DIRECTION

SketchC

Before tightening screws (E, fig. 4) securely, be sure to

have

.002 inch (.051mm) clearance between sprocket (B)

and needle guard drive connecting rod (F).

A

109

11

For Proper SYNCHRONIZATION

Looper & Needle

Dimensions

-------

Looper

BEHIND

Needle

in

OPERATING

Direction

SketchD

will

in

REVERSE

Direction

of

Page 12

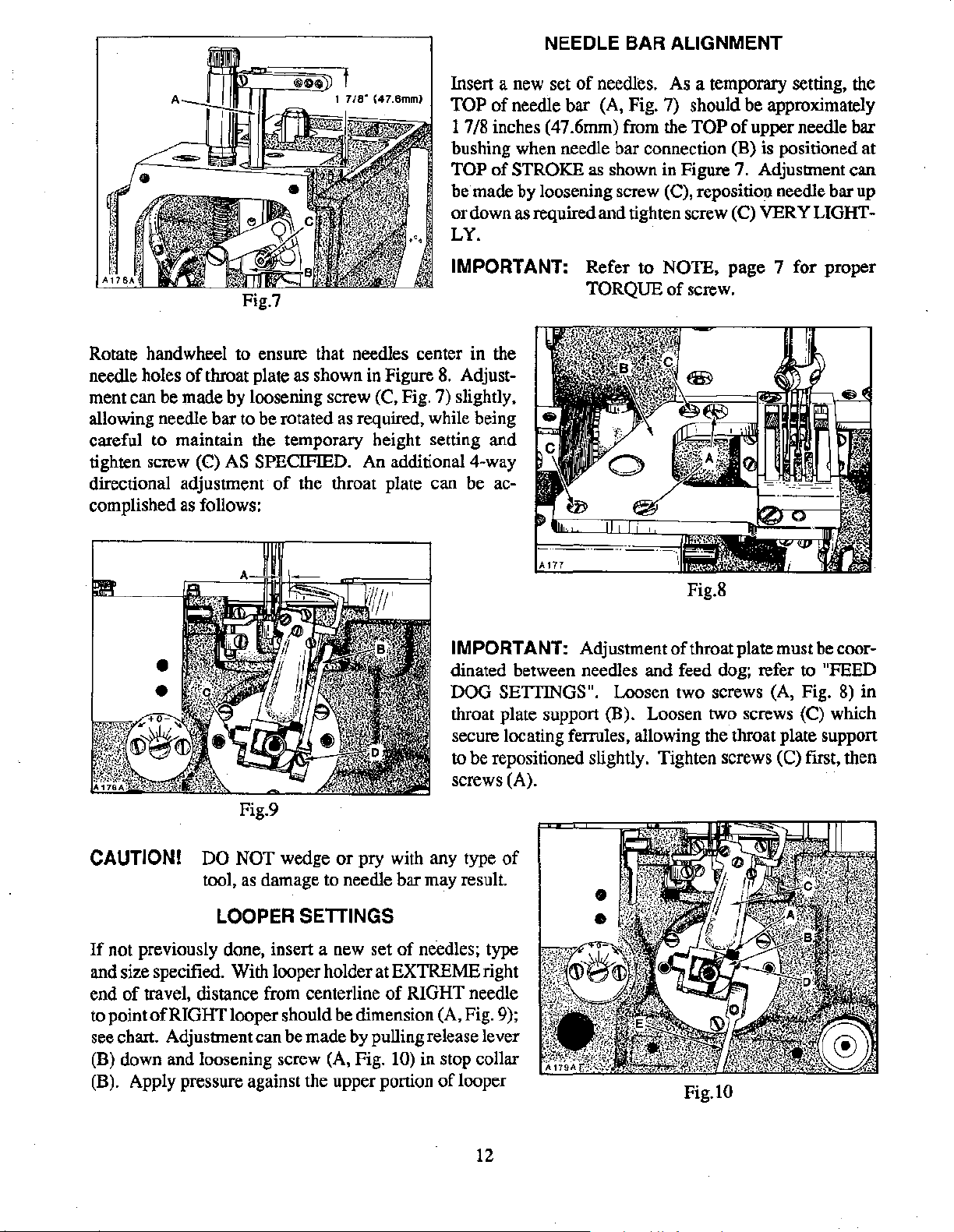

NEEDLE BAR ALIGNMENT

Insert a new set

TOP

of

1 7/8 inches (47.6mm) from the

bushing when needle bar connection (B) is positioned at

TOP

of

be made by loosening screw (C), reposition needle bar up

or down as required and tighten screw

LY.

IMPORTANT: Refer to NOTE,

Rotate handwheel to ensure that needles center in the

needle holes

ment can be made by loosening screw (C, Fig. 7) slightly,

allowing needle bar to be rotated

careful to maintain the temporary height setting and

tighten screw (C)

directional adjustment

complished

of

throat plate as shown in Figure

as

required, while being

AS

SPECIFIED. An additional 4-way

of

the throat plate can be ac-

as

follows:

8.

Adjust-

of

needles. As a temporary setting, the

needle bar (A, Fig. 7) should be approximately

TOP

of

upper needle bar

STROKE as shown in Figure 7. Adjustment can

(C) VERY LIGHT-

page

7 for proper

TORQUE

of

screw.

IMPORTANT: Adjustmentofthroatplatemustbecoor-

dinated between needles and feed dog; refer to

DOG SETTINGS". Loosen two screws (A, Fig. 8)

throat plate support (B). Loosen two screws (C) which

secure locating ferrules, allowing the throat plate support

to be repositioned slightly. Tighten screws (C) first, then

screws (A).

Fig.9

CAUTION!

If

not previously done, insert a new set

and size

end

to point

see chart. Adjustment can be made by pulling release lever

(B) down and loosening screw (A, Fig.

(B). Apply pressure against the upper portion

specified. With looper holder at EXTREME right

of

travel, distance from centerline

of

DO

NOT wedge

tool, as damage to needle bar may result.

LOOPER SETTINGS

RIGHT looper should be dimension (A, Fig. 9);

or

pry with any type

of

needles; type

of

RIGHT needle

10) in stop collar

of

of

looper

Fig.8

"FEED

in

Fig.lO

12

Page 13

LOOPER SETTINGS (Continued)

holder (C) to the

counterclockwise to decrease. Applicable looper gauge can be used advantageously in making this

adjustment Continue to apply pressure against upper portion

collar (B) to its EXTREME CLOCKWISE position and tighten screw (A) securely. Push up release lever

(E)

to

lock looper holder in position. Adjust screw (C, Fig. 9) which incorporates a spring plunger, against

the recess in cam

Pull release lever down and be able to push looper holder to the right, with a snapping motion (making

loopers easily accessible for threading).

pressure against upper portion

in operating position.

In locked position, the release lever should be approximately in line with middle looper as viewed from the

right side

lever as required and retighten screw.

Loopers must also be set so, as they travel to the left behind the needles,

MAXIMUM clearance

loosening screw (A, Fig.

its shaft,

collar (B) to its EXTREME

up in locking position. RECHECK looper gauge.

of

as

required. Apply pressure against upper portion

LEFf

of

looper holder. Adjustment can be made by loosening screw (D, Fig. 9), reposition release

while turning screw (D) in looper holder clockwise to increase looper gauge

of

looper to the

stop collar as required to attain the following conditions:

Push looper holder

of

looper holder to the

of

.002 inch (.051mm). Adjustment can be made by pulling release lever down,

10) in stop collar (B) allowing looper holder to be moved forward

CLOCKWISE position and tighten screw (A) securely and push release lever

LEFf

to

the left, with a snapping motion. Apply

and push release lever up to lock looper holder

of

looper holder to the

LEFf

NOT to touch, but with a

while turning stop

or

LEFf

while turning stop

or

rearward on

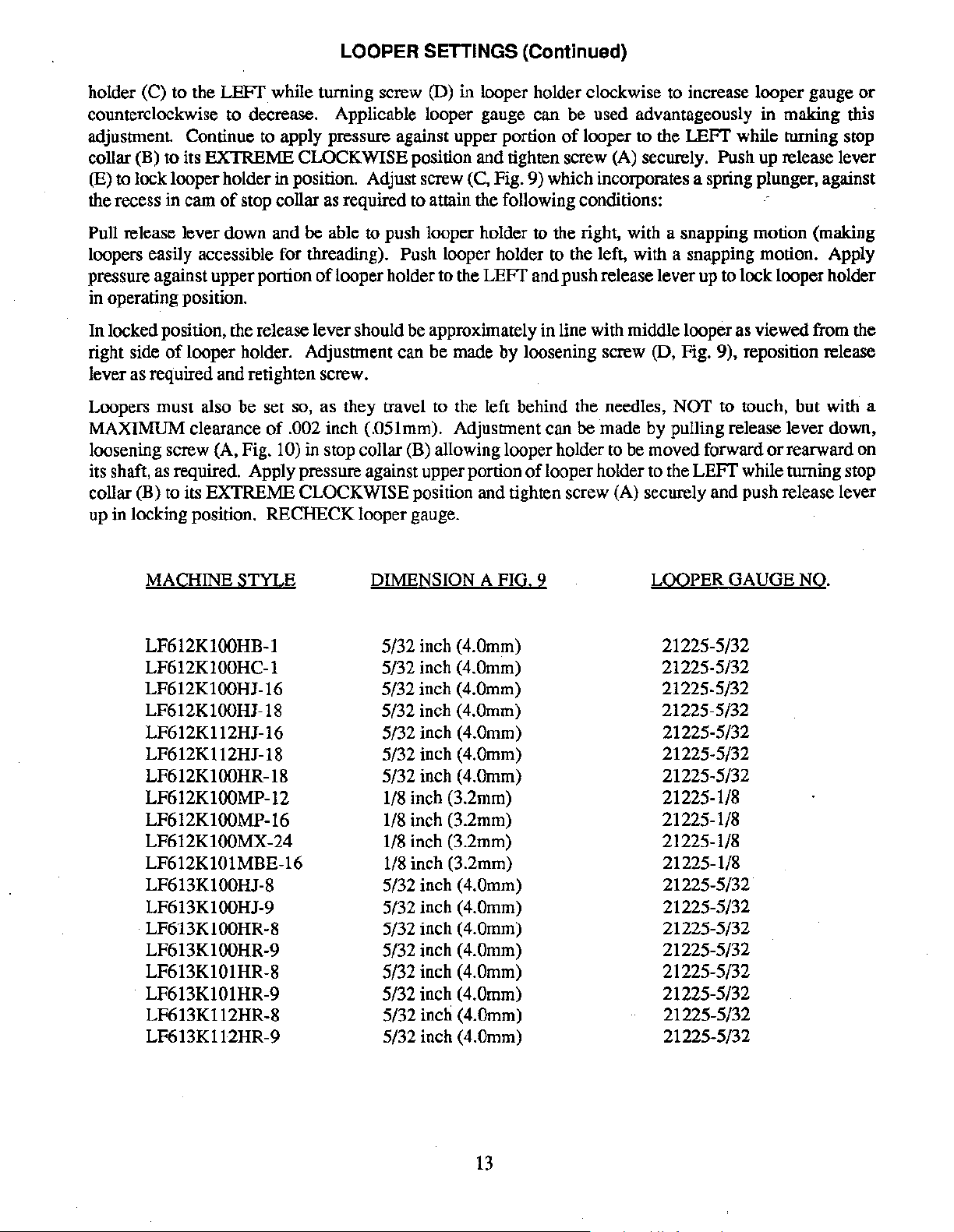

MACHINE

LF612K100HB-1

LF612KlOOHC-1

LF612K100HJ-16

LF612K100HJ-18

LF612K112HJ-16

LF612K112HJ-18

LF612K100HR-18

LF612K100MP-12

LF612K100MP-16

LF612K100MX-24

LF612K101MBE-16

LF613K100HJ-8

LF613K100HJ-9

LF613K100HR-8

LF613K100HR-9

LF613K101HR-8

LF613K101HR-9

LF613K112HR-8

LF613Kll2HR-9

STYLE

DIMENSION A FIG. 9

5/32 inch

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

1/8 inch (3.2mm)

1/8 inch (3.2mm)

1/8 inch (3.2mm)

1/8 inch (3.2mm)

5/32 inch

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

5/32 inch (4.0mm)

(4.0mm)

(4.0mm)

LOOPER GAUGE NO.

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-1/8

21225-1/8

21225-1/8

21225-1/8

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-5/32

13

Page 14

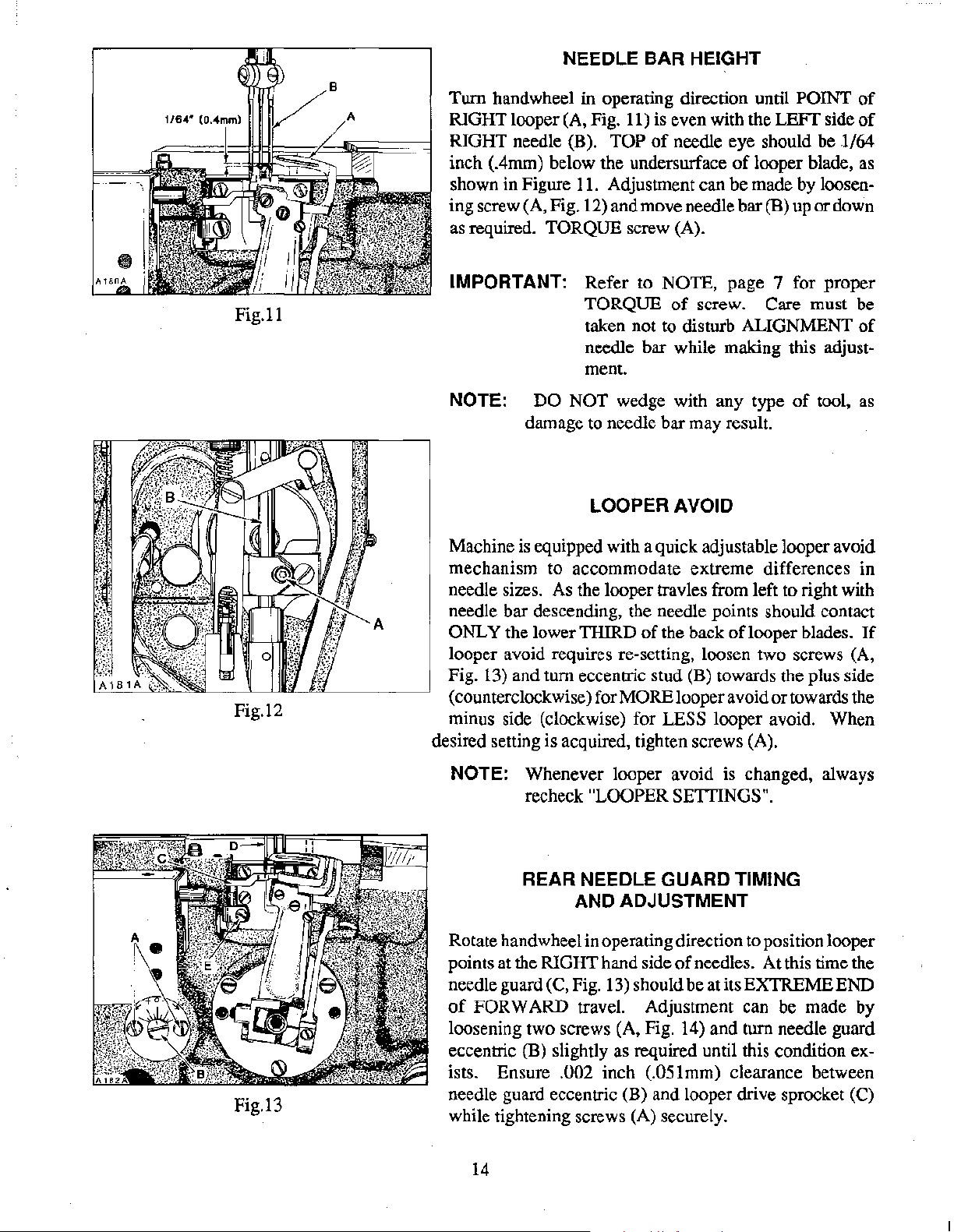

NEEDLE BAR HEIGHT

Fig.ll

Fig.12

Turn handwheel in operating direction until POINT

RIGHT looper (A, Fig. 11) is even with the LEFT side

RIGHT needle (B). TOP

inch (.4mm) below the undersurface

shown in Figure

11.

ing screw (A, Fig. 12) and move needle bar

as

required. TORQUE screw (A).

IMPORTANT: Refer to NOTE, page 7 for proper

TORQUE

of

needle eye should be

of

looper blade, as

Adjustment can be made by loosen-

(B) up or down

of

screw. Care must be

taken not to disturb ALIGNMENT

needle bar while making this adjustment.

NOTE: DO NOT wedge with any type

of

tool,

damage to needle bar may result.

LOOPER AVOID

Machine is equipped with a quick adjustable looper avoid

mechanism to accommodate extreme differences in

needle sizes.

As

the looper travles from left to right with

needle bar descending, the needle points should contact

ONLY the lower THIRD

of

the back

of

looper blades.

looper avoid requires re-setting, loosen two screws (A,

Fig.

13) and turn eccentric stud (B) towards the plus side

(counterclockwise) for

MORE looper avoid or towards the

minus side (clockwise) for LESS looper avoid. When

desired setting is acquired, tighten screws (A).

of

of

l/64

of

as

If

NOTE: Whenever looper avoid is changed, always

recheck

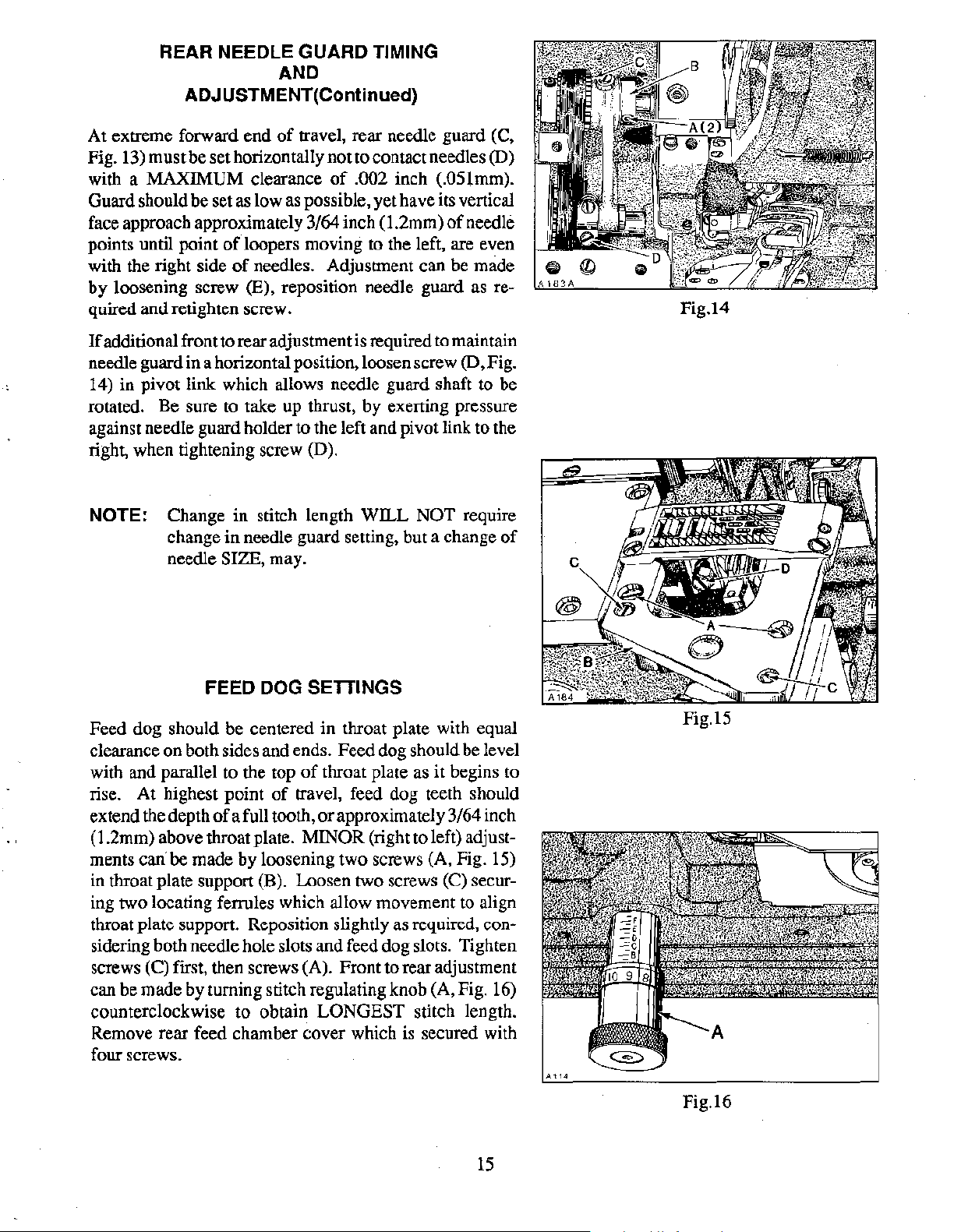

REAR NEEDLE GUARD TIMING

Rotate hand wheel in operating direction to position looper

points at the RIGHT hand side

needle guard (C, Fig.

of

FORWARD travel. Adjustment can be made by

loosening two screws (A, Fig. 14) and turn needle guard

Fig.13

eccentric

ists. Ensure

needle guard eccentric

while tightening screws (A) securely.

(B) slightly as required until this condition ex-

.002 inch (.05lmm) clearance between

14

"LOOPER SETTINGS".

AND ADJUSTMENT

of

needles. At this time the

13) should be at its EXTREME END

(B) and looper drive sprocket (C)

Page 15

REAR NEEDLE GUARD TIMING

AND

ADJUSTMENT(Continued)

of

At extreme forward end

Fig. 13) must be set horizontally not to contact needles

with a MAXIMUM clearance

Guard should be set as low as possible, yet have its vertical

face approach approximately

points until point

with the right side

by loosening screw

quired and retighten screw.

If

additional front to rear adjustment is required to maintain

needle guard in a horizontal position, loosen screw

14) in pivot link which allows needle guard shaft to be

rotated. Be sure

against needle guard holder to the left and pivot link to the

right, when tightening screw (D).

of

loopers moving to the left, are even

of

(E), reposition needle guard

to

take up thrust, by exerting pressure

travel, rear needle guard (C,

(D)

of

.002 inch (.05lmm).

3/64 inch (1.2mm)

needles. Adjustment can be made

of

needle

as

(D, Fig.

re-

Fig.14

NOTE: Change in stitch length WILL NOT require

change in needle guard setting, but a change

needle SIZE, may.

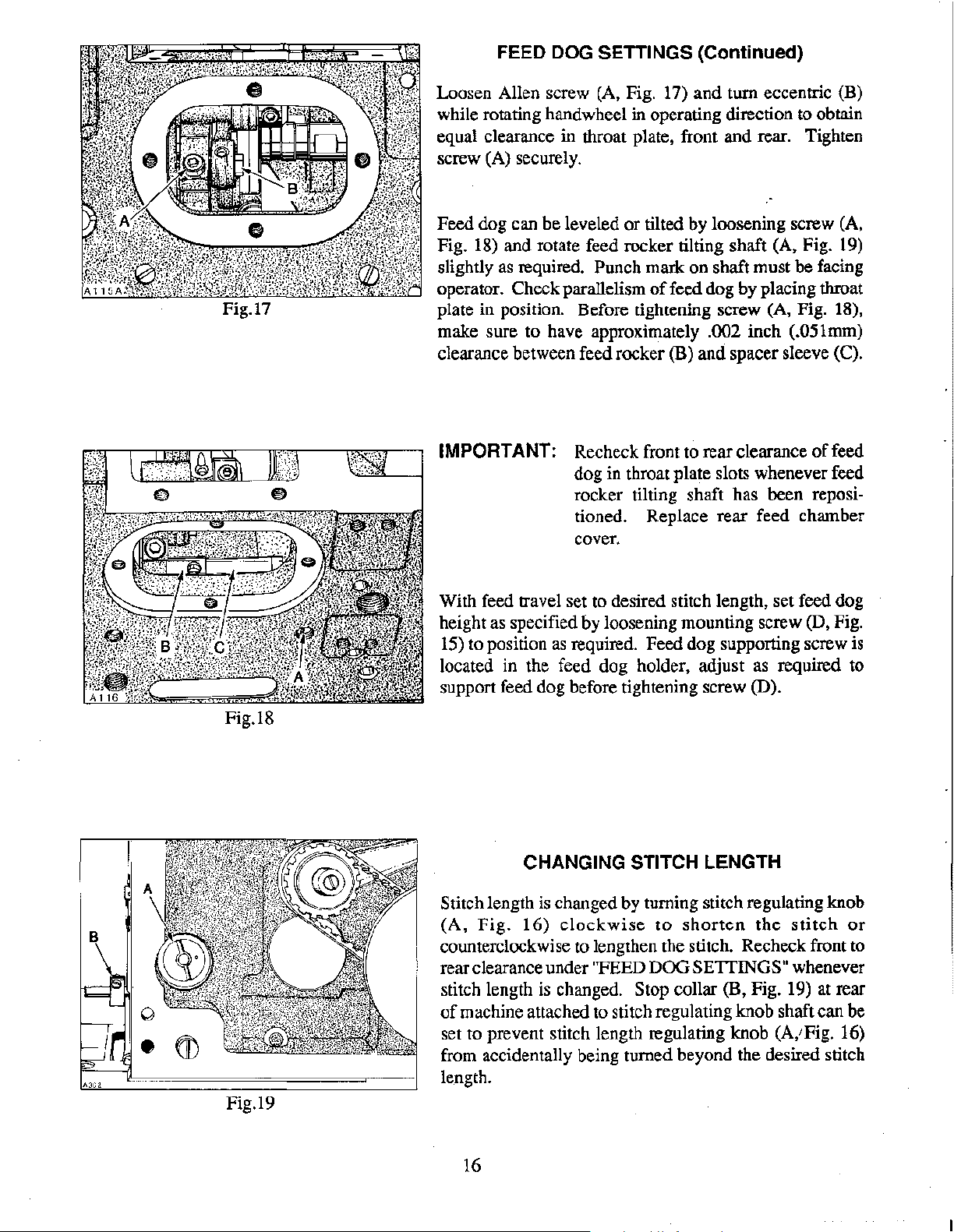

FEED

Feed dog should be centered in throat plate with equal

clearance on both sides and ends. Feed dog should be level

with and parallel to the top

rise. At highest point

extend the depth

(1.2mm) above throat plate.

ments

in throat plate support (B). Loosen two screws

ing two locating ferrules which allow movement to align

throat plate support. Reposition slightly

sidering both needle hole slots and feed dog slots. Tighten

screws

can be made by turning stitch regulating knob (A, Fig. 16)

counterclockwise to obtain LONGEST stitch length.

Remove rear feed chamber cover which is secured with

four screws.

can' be made by loosening two screws (A, Fig. 15)

(C) first, then screws (A). Front to rear adjustment

of

DOG SETTINGS

of

throat plate

of

travel, feed dog teeth should

a full tooth,

or

approximately 3/64 inch

MINOR (right to left) adjust-

as

it begins to

(C) secur-

as

required, con-

of

Fig.15

15

Fig.16

Page 16

FEED DOG SETTINGS (Continued)

Loosen Allen screw (A, Fig. 17) and turn eccentric (B)

while rotating handwheel in operating direction to obtain

equal clearance in throat plate, front and rear. Tighten

screw (A) securely.

Feed dog can be leveled or tilted by loosening screw (A,

18)

Fig.

slightly

operator. Check parallelism

plate in position. Before tightening screw (A, Fig. 18),

make sure to have approximately

clearance between feed rocker

and rotate feed rocker tilting shaft (A, Fig. 19)

as

required. Punch mark on shaft must be facing

of

feed dog by placing throat

.002 inch (.051mm)

(B) and spacer sleeve (C).

Fig.18

Fig.19

IMPORTANT: Recheck front to rear clearance

dog in throat plate slots whenever feed

rocker tilting shaft has been repositioned. Replace rear feed chamber

cover.

With feed travel set to desired stitch length, set feed dog

height as specified by loosening mounting screw

15)

to position

located in the feed dog holder, adjust as required to

support feed dog before tightening screw (D).

Stitch length is changed by turning stitch regulating knob

(A,

Fig.

counterclockwise to lengthen the stitch. Recheck front to

rear clearance under

stitch length

of

machine attached to stitch regulating knob shaft can be

set to prevent stitch length regulating knob

accidentally being turned beyond the desired stitch

from

length.

as

required. Feed dog supporting screw

CHANGING STITCH LENGTH

16)

clockwise

"FEED DOG SETTINGS" whenever

is

changed. Stop collar (B, Fig. 19) at rear

to

shorten

the

of

feed

(D, Fig.

is

stitch

(A,' Fig. 16)

or

16

Page 17

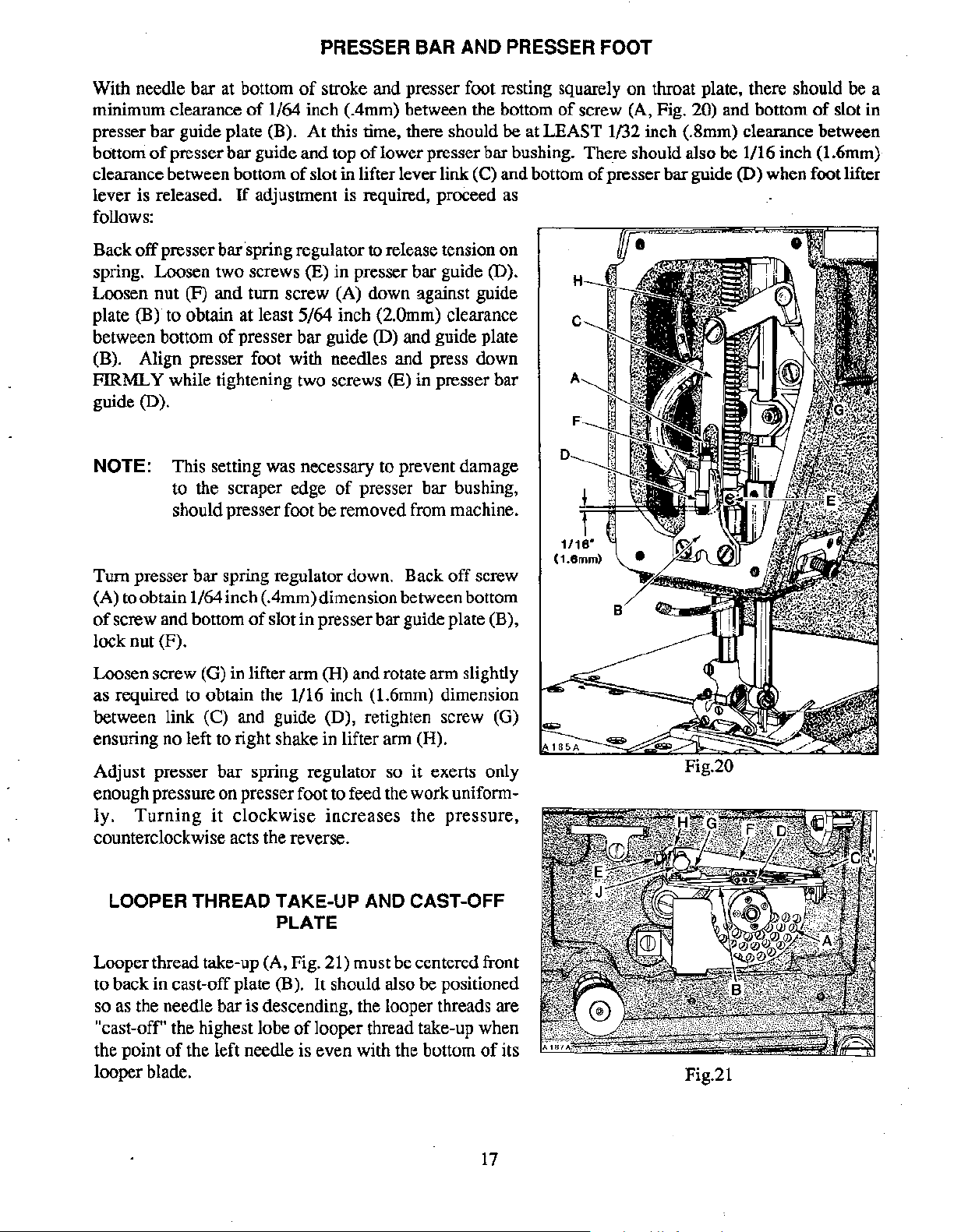

PRESSER BAR AND PRESSER FOOT

With needle bar at bottom

minimum clearance

of

of

stroke and presser foot resting squarely

1/64 inch (.4mm) between the bottom

presser bar guide plate (B). At this time, there should be at

bottom

clearance between bottom

of

presser bar guide and top

of

of

lower presser bar bushing. There should also be 1/16 inch (1.6mm)

slot in lifter lever link (C) and bottom

lever is released. 1f adjustment is required, proceed as

follows:

Back

off

presser bar spring regulator to release tension

on

spring. Loosen two screws (E) in presser bar guide (D).

Loosen nut (F) and turn screw (A) down against guide

(B)

plate

between bottom

to obtain at least 5/64 inch (2.0mm) clearance

of

presser bar guide (D) and guide plate

(B). Align presser foot with needles and press down

FIRMLY while tightening two screws

(E) in presser bar

guide (D).

NOTE: This setting was necessary to prevent damage

to the scraper edge

of

presser bar bushing,

should presser foot be removed from machine.

on

throat plate, there should

of

screw (A, Fig. 20) and bottom

LEAST

1132

inch (.8mm) clearance between

of

presser bar guide

of

(D)

when foot lifter

be

a

slot in

off

Turn presser bar spring regulator down. Back

screw

(A) to obtain 1/64 inch (.4mm) dimension between bottom

of

screw and bottom

of

slot in presser bar guide plate (B),

lock nut (F).

(H)

Loosen screw (G) in lifter arm

and rotate arm slightly

as required to obtain the 1/16 inch (1.6mm) dimension

between link (C) and guide (D), retighten screw (G)

ensuring no left to right shake in lifter arm (H).

Adjust presser bar spring regulator so

it

exerts only

enough pressure on presser foot to feed the work uniformly.

Turning

it

clockwise

increases

the

pressure,

counterclockwise acts the reverse.

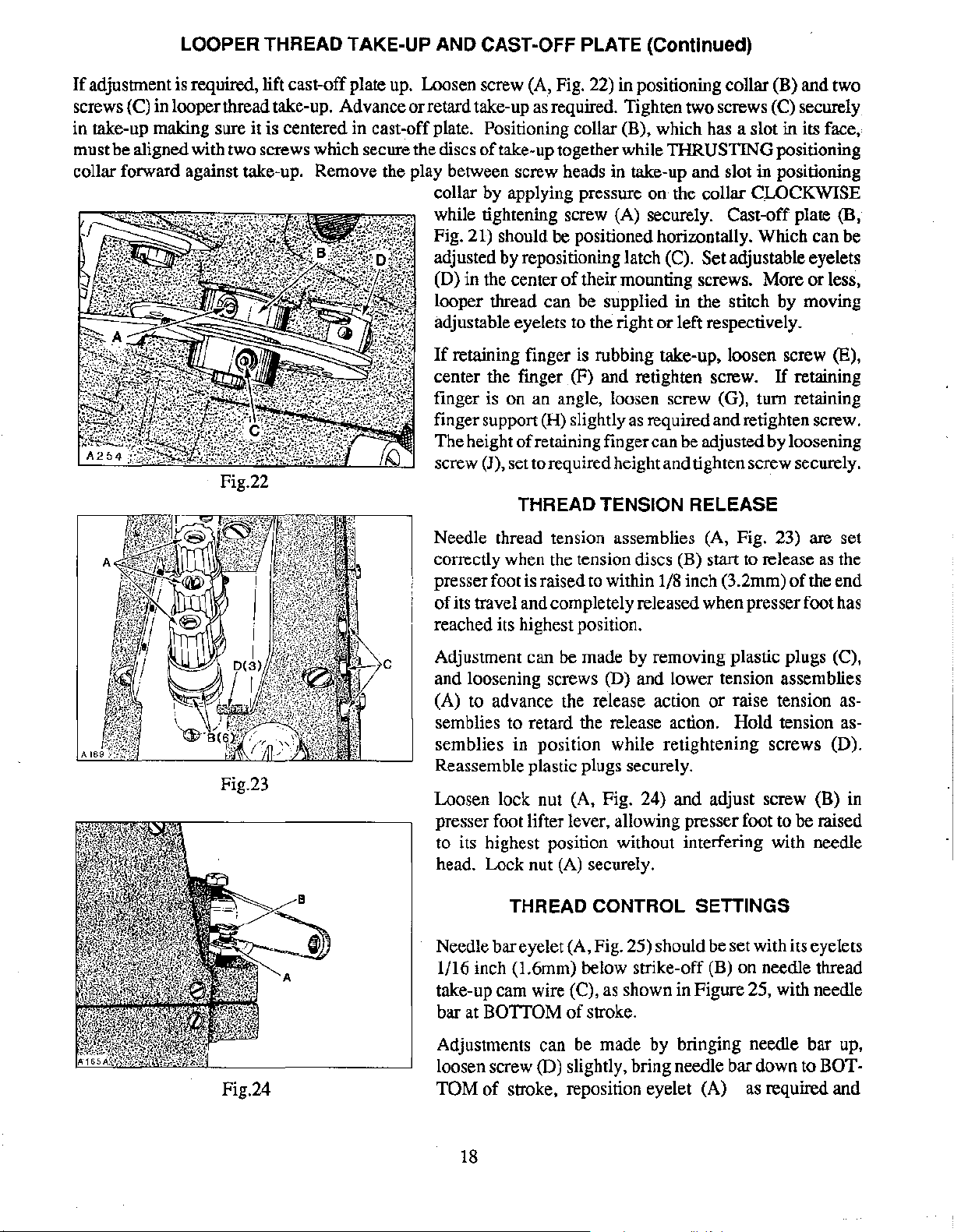

LOOPER THREAD TAKE-UP AND CAST-OFF

PLATE

Looper thread take-up (A, Fig. 21) must be centered front

to back in cast-off plate (B).

It

should also be positioned

so as the needle bar is descending, the looper threads are

"cast-off' the highest lobe

the point

of

the left needle is even with the bottom

of

looper thread take-up when

of

its

looper blade.

1/16"

(1.6mml

Fig.21

17

Page 18

LOOPER THREAD TAKE-UP AND CAST-OFF PLATE (Continued)

If

adjustment is required, lift cast-off plate up. Loosen screw (A, Fig. 22) in positioning collar (B) and two

screws (C) in looper thread take-up. Advance or retard take-up as required. Tighten two screws (C) securely

in take-up making sure it is centered in

cast~off

must be aligned with two screws which secure the discs

plate. Positioning collar (B), which has a slot in its face,

of

take-up together while THRUSTING positioning

collar forward against take-up. Remove the play between screw heads in take-up and slot in positioning

collar by applying pressure on the collar

CLOCKWISE

while tightening screw (A) securely. Cast-off plate (B,

Fig. 21) should be positioned horizontally. Which can be

adjusted by repositioning latch (C).

(D) in the center

of

their mounting screws. More or less,

Set adjustable eyelets

looper thread can be supplied in the stitch by moving

adjustable eyelets to the right or left respectively.

If

retaining finger is rubbing take-up, loosen screw (E),

center the fmger (F) and retighten screw.

If

retaining

finger is on an angle, loosen screw (G), turn retaining

finger support

The height

screw

(J), set to required height and tighten screw securely.

(H) slightly

of

retaining finger can be adjusted by loosening

as

required and retighten screw.

Fig.22

THREAD

TENSION RELEASE

Fig.23

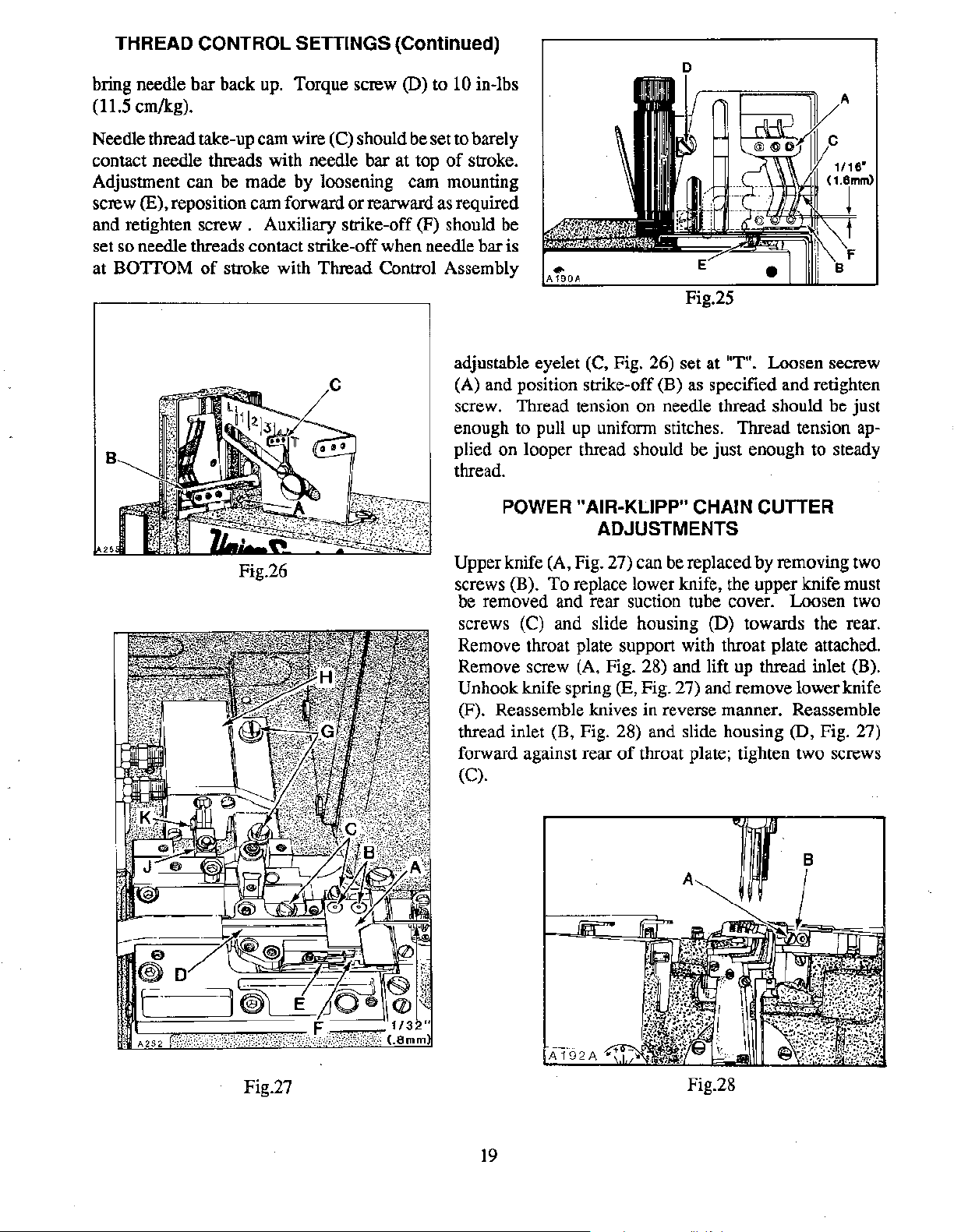

Needle thread tension assemblies (A, Fig. 23) are set

as

correctly when the tension discs (B) start to release

presser foot is raised to within 1/8 inch (3.2mm)

of

its travel and completely released when presser foot has

of

the

the end

reached its highest position.

Adjustment can be made by removing plastic plugs (C),

and loosening screws

(A) to advance the release action

(D) and lower tension assemblies

or

raise tension as-

semblies to retard the release action. Hold tension as-

semblies in position while retightening screws (D).

Reassemble plastic plugs securely.

Loosen lock nut (A, Fig. 24) and adjust screw (B) in

presser foot lifter lever, allowing presser foot to be raised

to its highest position without interfering with needle

head. Lock nut

THREAD

(A)

securely.

CONTROL SETTINGS

Needle bar eyelet (A, Fig. 25) should be set with its eyelets

1/16 inch (1.6mm) below strike-off (B) on needle thread

take-up cam wire (C), as shown in Figure 25, with needle

bar at BOTTOM

of

stroke.

Adjustments can be made by bringing needle bar up,

loosen screw (D) slightly, bring needle bar down to

of

Fig.24

TOM

stroke, reposition eyelet (A) as required and

18

BOT-

Page 19

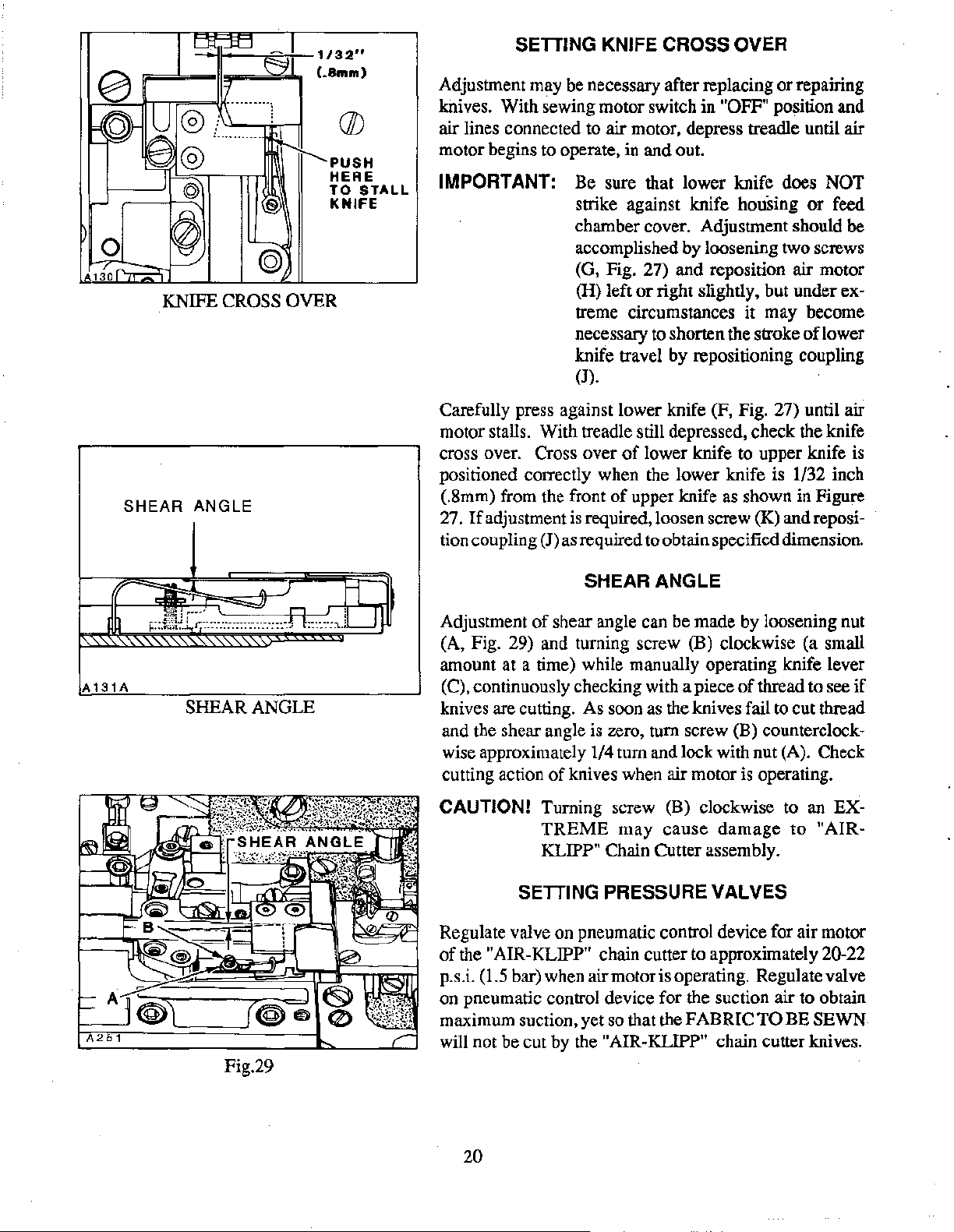

THREAD CONTROL SETTINGS (Continued)

bring needle bar back up. Torque screw (D) to 10 in-lbs

(11.5 em/kg).

Needle thread take-up cam wire

contact needle threads with needle bar at top

(C) should be set to barely

of

stroke.

Adjustment can be made by loosening cam mounting

screw

and retighten screw . Auxiliary strike-off

(E), reposition cam forward

or

rearward as required

(F) should be

set so needle threads contact strike-off when needle bar is

at

BOTTOM

of

stroke with Thread Control Assembly

adjustable eyelet (C, Fig. 26) set at

(A) and position strike-off (B) as specified and retighten

screw. Thread tension on needle thread should be just

enough to pull

plied on looper thread should be just enough to steady

thread.

POWER "AIR-KLIPP" CHAIN CUTTER

Fig.26

Upper knife (A, Fig. 27) can be replaced by removing two

screws

be removed and rear suction tube cover. Loosen two

screws (C) and slide housing (D) towards the rear.

Remove throat plate support with throat plate attached.

Remove screw (A, Fig. 28) and lift up thread inlet (B).

Unhook knife spring (E, Fig. 27) and remove lower knife

(F). Reassemble knives in reverse manner. Reassemble

thread inlet (B, Fig. 28) and slide housing

forward against rear

(C).

(B).

"T". Loosen secrew

up

uniform stitches. Thread tension ap-

ADJUSTMENTS

To

replace lower knife, the upper knife must

(D, Fig. 27)

of

throat plate; tighten two screws

Fig.27

19

Fig.28

Page 20

A130

0

SHEAR

1/32"

(.8mm)

PUSH

HERE

TO

KNIFE

KNIFE CROSS OVER

ANGLE

(//)

STALL

SETIING

Adjustment may be necessary after replacing

knives. With sewing motor switch in

KNIFE CROSS OVER

or

"OFF" position and

repairing

air lines connected to air motor, depress treadle until air

motor begins to operate, in and out.

IMPORTANT: Be sure that lower knife does NOT

strike against knife housing

chamber cover. Adjustment should

or

feed

be

accomplished by loosening two screws

(G, Fig. 27) and reposition air motor

(H) left

treme circumstances

necessary to shorten the stroke

or

right slightly, but under ex-

it

may become

oflower

knife travel by repositioning coupling

(J).

Carefully press against lower knife (F, Fig. 27) until air

motor stalls. With treadle still depressed, check the knife

cross over. Cross over

of

lower knife to upper knife is

positioned correctly when the lower knife is 1/32 inch

(.8mm) from the front

27.

If

adjustment is required, loosen screw

tion coupling (J)

as

of

upper knife as shown in Figure

(K)

and reposi-

required to obtain specified dimension.

A

131A

SHEAR ANGLE

Fig.29

SHEAR ANGLE

Adjustment

of

shear angle can be made by loosening nut

(A, Fig. 29) and turning screw (B) clockwise (a small

amount at a time) while manually operating knife lever

(C), continuously checking with a piece

of

thread to see

if

knives are cutting. As soon as the knives fail to cut thread

and the shear angle is zero, turn screw (B)

counterclockwise approximately 1/4 turn and lock with nut (A). Check

cutting action

of

knives when air motor is operating.

CAUTION! Turning screw (B) clockwise to an EX-

TREME

KLIPP"

SETIING

may

cause

damage

Chain Cutter assembly.

PRESSURE VALVES

to

"AIR-

Regulate valve on pneumatic control device for air motor

of

the "AIR-KLIPP" chain cutter to approximately 20-22

p.s.i.

(1.5 bar) when air motor is operating. Regulate valve

on pneumatic control device for the suction air to obtain

maximum suction, yet so that the FABRIC

TO

BE SEWN

will not be cut by the "AIR-KLIPP" chain cutter knives.

20

Page 21

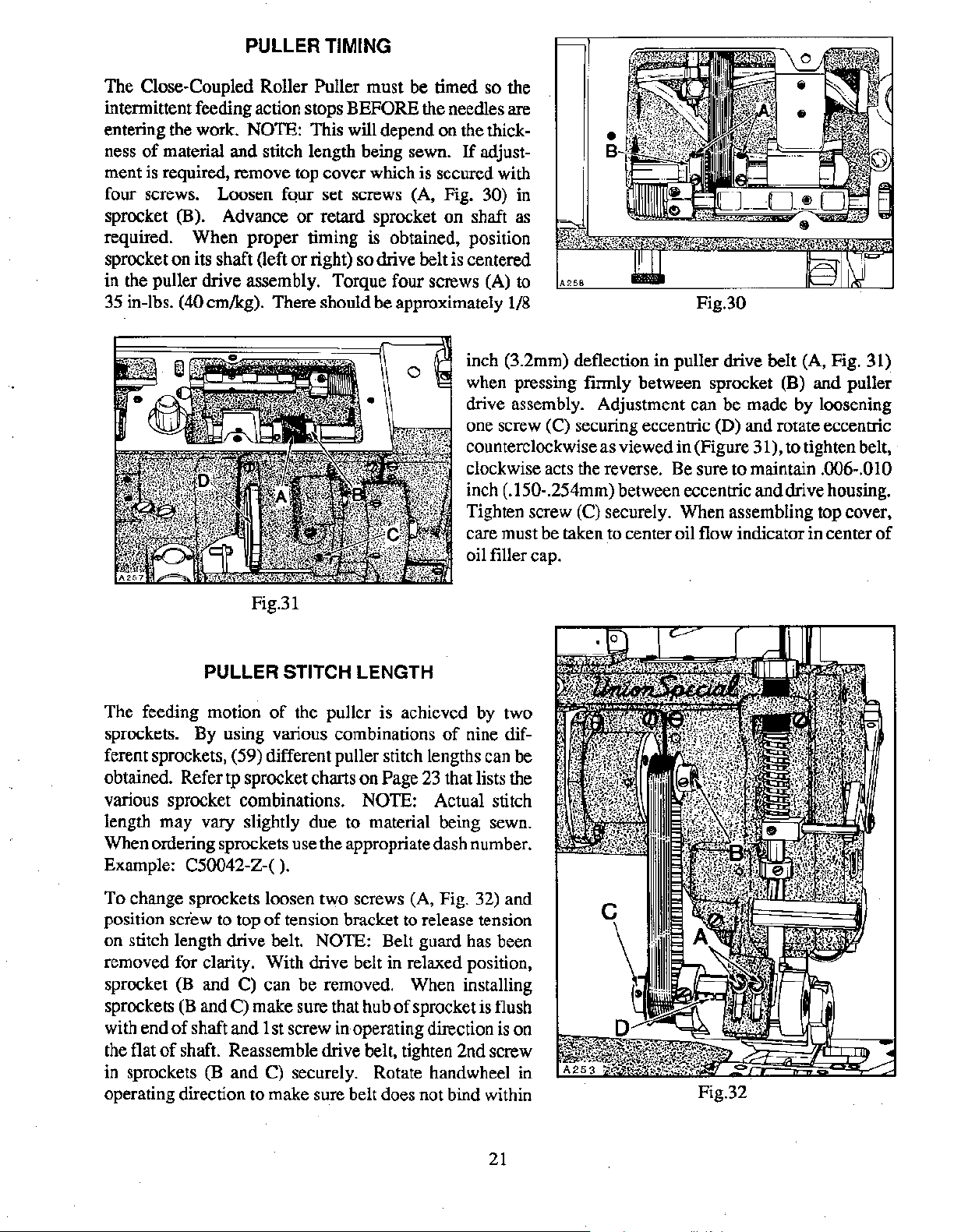

PULLER TIMING

The Close-Coupled Roller Puller must be timed

intermittent feeding action stops

entering the work.

ness

of

material and stitch length being sewn.

NOTE: This will depend on the thick-

BEFORE the needles are

If

so

the

adjustment is required, remove top cover which is secured with

four screws. Loosen four set screws (A, Fig.

sprocket

(B). Advance

or

retard sprocket on shaft as

30) in

required. When proper timing is obtained, position

sprocket

in the puller drive assembly. Torque four screws (A)

35 in-lbs. (40 em/kg). There should be approximately

on

its shaft (left

or

right) so drive belt is centered

to

1/8

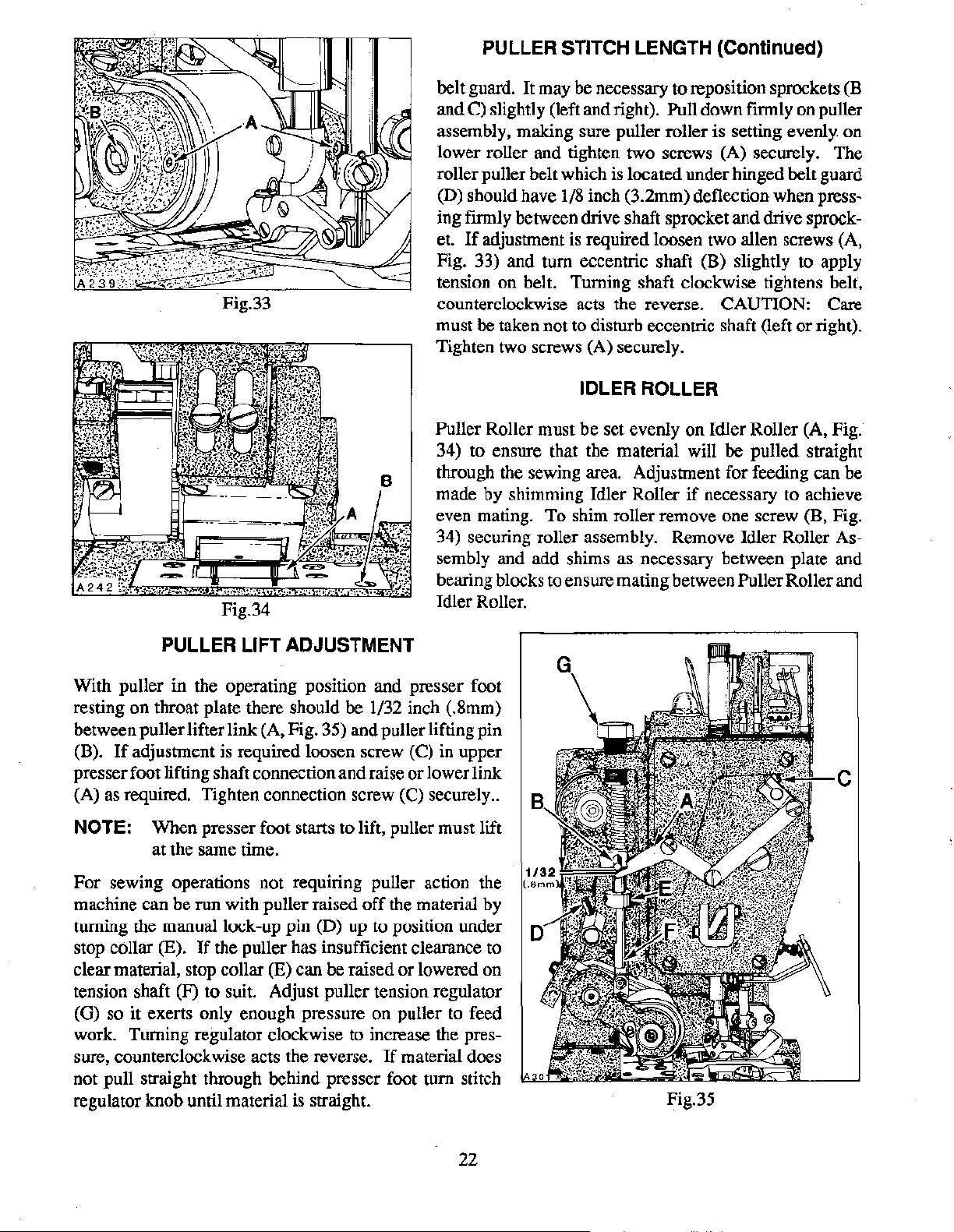

inch (3.2mm) deflection in puller drive belt (A, Fig. 31)

when pressing

drive assembly. Adjustment can be made by loosening

one screw (C) securing eccentric

counterclockwise as viewed in (Figure 31),

clockwise acts the reverse. Be sure to maintain

inch (.150-.254mm) between eccentric and drive housing.

Tighten screw (C) securely. When assembling top cover,

care must be taken to center oil flow indicator in center

oil filler cap.

Fig.30

firmly between sprocket (B) and puller

(D)

and rotate eccentric

to tighten belt,

.006-.010

of

Fig.31

PULLER STITCH LENGTH

The feeding motion

sprockets. By using various combinations

of

the puller is achieved by two

of

nine different sprockets, (59) different puller stitch lengths can be

obtained. Refer

tp sprocket charts on Page

various sprocket combinations.

NOTE: Actual stitch

23

that lists the

length may vary slightly due to material being sewn.

When ordering sprockets use the appropriate dash number.

Example:

C50042-Z-(

).

To change sprockets loosen two screws (A, Fig. 32) and

position

screw to top

on stitch length drive belt.

of

tension bracket to release tension

NOTE: Belt guard has been

removed for clarity. With drive belt in relaxed position,

sprocket (B and

sprockets

with end

the flat

(B

of

of

shaft. Reassemble drive belt, tighten 2nd screw

in sprockets

C) can be removed. When installing

and C) make sure that hub

shaft and 1st screw

(B

and C) securely. Rotate handwheel in

in

of

sprocket is flush

operating direction is on

operating direction to make sure belt does not bind within

Fig.32

21

Page 22

PULLER

STITCH LENGTH (Continued)

Fig.34

belt guard. It may be necessary

and C) slightly (left and right). Pull down

assembly, making sure puller roller

lower roller and tighten two screws (A) securely. The

roller puller belt which is located under hinged belt guard

(D) should have

ing

fmnly

If

adjustment is required loosen two allen screws (A,

et.

Fig. 33) and

tension

counterclockwise acts the reverse.

must be taken not

Tighten two screws (A) securely.

on

1/8

inch (3.2mm) deflection when press-

between drive shaft sprocket and drive sprock-

tum

eccentric shaft (B) slightly to apply

belt. Turning shaft clockwise tightens belt,

to

disturb eccentric shaft (left

to

reposition sprockets (B

firmly

is

setting evenly on

CAUTION: Care

on

or

right).

puller

IDLER ROLLER

Puller Roller must

34) to ensure that the material will

through the sewing area. Adjustment for feeding can be

made by shimming Idler Roller

even mating.

34) securing roller assembly. Remove Idler Roller Assembly and add shims as necessary between plate and

bearing blocks to ensure mating between Puller Roller and

Idler Roller.

be

set evenly

To

shim roller remove

on

Idler Roller (A, Fig.

be

pulled straight

if

necessary to achieve

one

screw (B, Fig.

PULLER LIFT ADJUSTMENT

With puller in the operating position and presser foot

on

resting

between puller lifter link (A, Fig. 35) and puller lifting

(B).

presser foot lifting shaft connection

(A) as required. Tighten connection screw

NOTE:

For

machine can

turning the manual lock-up

stop collar

clear material, stop collar

tension shaft (F)

(G) so it exerts only enough pressure

work. Turning regulator clockwise to increase the pressure, counterclockwise acts the reverse.

not pull straight through behind presser foot

regulator knob until material is straight.

throat plate there should

If

adjustment

When

at

the same time.

sewing operations not requiring puller action the

be

(E).

is

required loosen screw (C) in upper

presser foot starts to lift, puller must lift

run

with puller raised

pin

If

the puller has insufficient clearance to

(E) can be raised

to

suit. Adjust puller tension regulator

(D)

be

1/32 inch (.8mm)

and

raise

or

lower link

(C) securely

off

the material by

up

to position under

or

lowered

on

puller to feed

If

material does

tum

pin

..

on

stitch

Fig.35

22

Page 23

PULLER SPROCKETS COMBINATIONS

This chart shows the stitch length produced by available sprocket combinations. Sprockets furnished

the machines produces approximately 9.2 S.P.I.

appropriate dash number when ordering sprockets-C50042-Z-(

r.<

=

IXl

~

~

z

14.69

-18

-17,

-16,

-15,

SPI

(1.73rnrn) (1.90rnrn)

13.87

SPI

(1.83rnrn)

13.06

SPI

(1.94rnrn)

Roller

13.37

SPI

12.25

(2.07rnrn)

12.62

(2.01rnrn) (2.20rnrn) (2.38rnrn) (2.56rnrn) (2.75rnrn)

11.88

(2.13rnm) (2.53rnrn) (2.53rnrn)

11.14

(2.28rnrn)

11.56

SPI

SPI

10.89

SPI 10.21 SPI

(2.49rnrn)

Puller

NUMBER

11.30

SPI

(2.25rnrn) (2.42rnrn) (2.59rnrn)

SPI

10.67

SPI

10.05

9.42

(2.70rnrn) (2.90rnrn)

If

a different length

Sprocket

OF

STITCHES PER INCH

SPI

SPI 9.91 SPI

SPI

SPI 8.75 SPI

Variations

10.50

SPI

9.34

SPI 8.71 SPI

(2.72rnrn)

).

9.80

SPI

9.25

SPI 8.67 SPI

(2.92rnrn)

8.16

SPI

(3.11rnrn)

is

required, refer to the chart for

9.18

SPI

8.65 SPI

(2. 77rnrn) (2. 94rnrn)

8.16

SPI 7.71 SPI

(2.93rnrn) (3.11rnrn)

8.16

SPI 7.69 SPI 7.26 SPI

(3.11rnrn)

7.65 SPI 7.21 SPI

(3.32rnrn) (3.52rnrn) (3.73rnrn)

(3.30rnrn) (3.50rnrn)

(3.30rnrn)

6.80

SPI

~

<

~

r.<

""

~

u

0

~

=

"'

z

r.<

..

-

Q

=

-14,

-13,

-12,

-11,

9.52

(2.67rnrn) (2.89rnrn) (3.11rnrn) (3.33rnrn) (3.56rnrn)

8.76 SPI

SPI

8.16

(3.11rnrn) (3.35 rnrn) (3.59rnrn) (3.83rnrn)

8.16 SPI 7.62

SPI 7.59 SPI 7.08

7.00

SPI

6.53

(3.63rnrn)

(3.89rnrn)

5.98

(4.24rnrn) (4.53rnrn) (4.81rnrn) (5.09rnrn)

SPI

SPI

SPI

SPI 5.61

7.14 SPI

6.63

6.12

(4.15rnrn) (4.41rnm) (4.67rnrn)

6.72

SPI 6.35

(3.78rnrn)

SPI 6.25 SPI

(4.07rnrn) (4.31rnrn)

SPI

5.76

SPI

5.28

SPI

SPI

SPI

(4.00rnrn)

5.90

SPI

5.44

SPI

4.99

SPI

in

-10,

C50042-Z-10,

A304

-11,

-12, -13,

DRIVE

SPROCKET

-14,

PART

-15,

NUMBER

5.10

SPI

4.81

SPI

4.54

SPI

(4.98rnrn) (5.28rnrn) (5.60rnrn)

-16, -17,

-18

23

Page 24

GENERAL

PREVENTIVE

MAINTENANCE

SCHEDULE

TASK

LF600

Check oil level (sight gauge)

· oil level between

Check pump operation

(oil flow indicator-top

Clean lint and

from

machine

Check that

and

shields

place and being used

Change oil-filter

(housed-on machine

bottom

Change oil (oil

which conforms to

U.S.C.

be used)

Clean lint and

from

cover)

spec

suction screen

(inside bottom cover)

red

dirt

all guards

are

in

175

must

dirt

lines.

of

ann)

AFTER EVERY EVERY EVERY

DAILY FIRST MONTH -3-

MONTH MONTHS

LF600

LF600

LF600

LF600

LF600

LF600

LF600

YEARLY

-6-

MONTHS

LF600

LF600

Check

tension

internal timing belts

Inspect clutch/

position motor,

V-belt,

Check clutch motor

clutch/hrake

adjustment

Clean lint

clutch/positioner

motor

air

Check needles

bent, blunt, sharp

or worn eye or groove

NOTE: SCHEDUllNG IS BASED ON NORMAL WORKING CONDffiONS FREQUENCY OF TASKS DEPENDS

ON MAClllNE DUTY CYCLE

DETERMINED BY PLANT MANAGEMENT

tension

from

passages

on

and

wear

LF600

TIME

LF600

LF600

LF600

AND

PERSONNEL RESPONSIBLE TO PERFORM TASK

LF600

LF600

LF600

24

Page 25

p

191

EXPLODED VIEWS

AND

DESCRIPTION OF PARTS

25

Page 26

16

21

44

50

TORQUE TO

16-18

in.

(18-21

lbs

ern/kg)

9445

51

P186A

26

74

Page 27

OIL PUMP, PAN AND LUBRICATION PARTS

Ref.

Part

No. No.

1 50393

CB

2 22653 B-36

3

50393

CD

4 22571 F

5

50394X

6 C50093 U

7

660-684

8 50393 CE

9

10

11

12

13

14

15

16

17

18

19

20

21

50393 cc

50394X

35036X

22894 c

C50093Z

50393 D

89

50393 c

50393 CP

50393CR

50393 CN

50393AX

50393DC

22 50393 cs

23

24 666-322

25

50393

cu

50393AY

26 50393BB

27

28

29

PI-18

671

F-41

50393

CY

30 50393 v

31

660-310

32 C50094AK

33

34

35

36

37

38

39

W0-3

503940

50393DJ

50394K

RI-37

35093 BL

C50094B

40 C50094AH

41

42

43

44 22720A

45

671

F-41

C50094P

C50094C

41350X

46 35094 A

47

48

50394L

C50094C

Description Req.

Oil Pump Assembly

Screw

-------------------------------4

Housing, pump (pressure side)

Screw,

Connector, tube

Gerotor, 1/4 inch (6.4mm) thick

"0"

Ring

Divider, housing

Housing, pump (syphon

Connector, tube

Collar, (positioning and thrust)

---------------------------

------------------

plug--------------------------

-----------------------

-----------"------

-----------------------------2

------------------------side)-------------------

-----------------------

------------------

Screw-----------------------------

Pin, drive

Shaft, drive

-----------------------------

----------------------------

Screw-----------------------------1

Bushing, oil delivery

Cap, oil indicator

Sleeve, oil indicator

----------------------------

--------------------------Indicator, oil (priority metering valve)

Tube, oil return

-----------------------------

HeadOilReturnAssembly

Spring, tube retainer

Tube, oil return

Felt

--------------------------------2

Tube, oil

Restrictor

-----------------------------

-----------------------------

-----------------------

-----------------

-----------------------

-----------------------

--------------------------

Pin--------------------------------Tee,

union-----------------------------

Tube oilreturn

w'ire

Retainer,

Felt, oil return

(oil tube)

------------------------------

Plug, felt, oil return

-------------------------_______

:_

______

--------------------------Yarn, Columbia, rear needle guard bushing

Tube, oil (looper rocker)

Oil Tube Assembly

Connector, oil (single feed)

Ring, wire

Tube, oil

-----------------------------7

----------------------------Connector, oil (doublefeed)

Tube, oil

union-----------------------------

Tee,

Tube, oil

-----------------------------

----------------------------Connector, oil (single feed)

Screw, oil connection

Washer, fiber

-----------------------------Screw, oil connection

Tube, oil, complete (take-up gear)

Connector, oil (single feed)

------------------------

---------------------------

--------------------

-------------------

--------------------

--------------------------

--------------------------

-------------------

------------.-----------

-----------

(8

strands)---------

Amt.

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

8

2

1

3

49

thru 96

See Following

Page

27

Page 28

21

~

l

TORQUE TO

II

I

16~18

(1

8-21

in.

lbs.

em/kg)

I

P186A

28

Page 29

OIL PUMP, PAN AND LUBRICATION PARTS

Ref. Part

No. No.

1 thru 48

49

660-885

50 258

51

C50094R

52 56393 N

53

50393 AW

54 Rl-37

55

C50093 CJ

56 52393 Q

57

58

59

671

F-41

50393 AV

28619

60 50393 AU

61

50393 BU

62 50393 BA

63

64 50393 AR

65

66

67

68

69

22652A-6

35093F

35093 H

35093 J

97

670E-2

70 50382BH

71

6042 A

72 6524-16

73

820

74 50393 N

75 22571 E

76 22571 J

77 999-211 E

78

C50094 Y

79 660-206

80 C50093

81

C50093

CA

CB

82 50393DM

83 C50093 F

84 22541

85

22586U

86 41350 X

87

88

74E

660-455

89 661-51

90 35039 A

91

i2894

J

92 22841 M

93

50393 BK

94 6042 A

95

RI-37

96 50394 B

Description Req.

See Preceding

Clamp, oil

Page

--------------------------------

Nut-----------------------------------Tube, oil

Spring

Oil Syphon

Bracket,manifold

Screw

Clamp, oil screen

Housing, screen

Screen

Plate, retaining

Screw

Tie, cable (to secure

Gasket, oil pan

Washer

Washer, lock

Screw

Pan, oil

---------------------------------

--------------------------Assembly--------------------------

Ring,

wire-----------------------------

Tube, oil return

Tube,oil

Fitting, oil

Manifold, oil syphon

Ball, steel

Screen, oil

Extension, manifold

--------------------------

-----------------------------

syphon-------------------------

-----------------------

-----------------------------

filter--------------------------

------------------------

----------------------------

----------------------------------1

housing------------------------

-----------------------------

----------------------------------

----------------------

----------------------------------

Ref.

No.

55

to

Ref.

-----------------------------

----------------·-----------------7

------------------------------

----------------------------------

--------------------------------Screw, oil drain plug (magnetic)

Screw, plug

"0"

Ring---------------------------------

Tube, oil

"0"

Filter,

---------------------------------

Ring---------------------------------

oil---------------------------------

By-Pass, oil filter

Gasket

---------------------------------Cover, oil filter

Screw

----------------------------------4

Screw, plug

Washer, fiber

Screw

"0"

"0"

----------------------------------

Ring--------------------------------Ring---------------------------------

Gear, driven (oil pump)

Screw

Stand, oil

Fitting, oil

Washer

Ring, wire

Tube, oil

----------------------------------2

plug------------------------------

--------------------------------

-----------------------------~---

--------------------------------2

---------------------------------

----------------------------

----------------------------

-----------------------------

-------------------------------

------------------------------

-------------------------

No.

93)

------------

-----------------

~-

-----

~------

Amt.

7

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

7

7

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

2

29

Page 30

30

Page 31

MAINFRAME BUSHINGS AND PLUGS

Ref. Part

No. No.

1

2

3

50344K

136A

C067B

4 50393DD

5

50393

cs

6 50393CV

7

50393

cz

8 50393CX

9

10

11

12

13

14

15

16

17

18

19

22733

666-321

661-1

660-739

C50057D

50354E

c5oo93

C50093

cr

AY

50354D

22539 G

666-311

20 C50054D

21

22

23

C50093

604

22586 u

AX

24 41350X

25

50394S

26 820

27 22764 c

28

50390C

29 51-627 BLK.

30

31

50390A

50390

32 50390D

33

34

35

36

37

38

39

51-794BLK.

50355L

98540

22569F

C50093 BG

50344L

50344 v

40 50344X

41

42

43

44

45 35036

46

22894 c

50344 B

50368 B

50344E

AB

671

F-4

47 RM2964-B

48

50339 B

Description Req.

Bushing, lower main shaft

Screw, plug

Plug, cork

Needle Bar

-------------------------------

-------------------------------Oil Collector Plate Assembly

Spring, tube retainer

Tube, oil return

Spring

Plate, oil

------------------------------collector-------------------------

(left)---------------------

----------------

--------------------------

Screw-----------------------------

Felt, oil return

"0"

Ring, for lower needle bar

Seal, oil (presser bar bushing)

Bushing, presser

Bushing, needle bar (lower)

Plug, oil

Plug, oil

Bushing, needle bar (upper)

Screw,plug

Screen, needle bar bushing

Shield, needle bar bushing

Plug, oil

Screw, plug

Screw, plug

Washer, fiber

Plug, steel

Screw,plug

Screw, spot

-----------------------------bushing-----------------

----------------------

bar---------------------------

-----------------------

---------------------------------

---------------------------------

-----------------------

-------------------------------

-----------------------

-----------------------

---------------------------------

-------------------------------4

-------------------------------

------------------------------

--------------------------------

-------------------------------

-------------------------------

Bushing, presser foot lifter lever (right)

Plug

----------------------------------Bushing, presser foot lifter lever (front)

Bushing, presser foot lifter lever (rear)

Bushing, presser foot lifter lever (left)

Plug, aluminum

Bushing, uppermainshaft

threaded------------------------------

Plug,

Screw

----------------------------------1

Plug, aluminum

Bushing, lowermainshaft (right)

· Bushing, take-up shaft (front)

Bushing, take-up shaft (rear)

Screw, plug

-----------------------------

------------------------

-----------------------------

--------------------

----------------------

----------------------

------------------------------Bushing, lowermainshaft (intermediate)

Bushing, needle guard

Bushing, looper rocker (rear)

Bushing, stitch control

Fitting

----------------------------------

shaft-----------------------

----------------------

shaft-----------------------

Gasket----------------------------------

:__

Washer, fiber

__________

-------------------

----------------

--------

--------

-----------------

-----------------

----------------

~-

---------

---------

-----

Amt.

1

2

2

1

2

1

1

1

1

1

1

1

1

1

2

3

1

1

1

1

1

6

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

l

1

1

1

1

31

Page 32

32

Page 33

SAFETY SHIELD, COVERS AND CLOTH PLATES

Ref. Part

No. No.

1

C50095G

2 12934A

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

97127

RM2879-2

C50095E

C50095D

C50095F

50382BN

660-219A

C50082AA

22883 B

22541 c

C50082AW

C50082K

C50082 V

22569M

C50082M

C50082N

22861 c

50382K

22894J

50394 J

C50093

AU

C50082X

50382F

22526H

50382 J

22525 E

22841 N

50382H

87

--------

22839

34 35036AE

35

36

37

38

39

40 50393

41

22587 N

50380

660-939

22799AH

50393 u

AS

225690

42 22517

43

44

45

22541 A

50336L

999-216 c

Description Req.

Safety Shield

Nut

Washer, spring

Rivet

Bracket, mounting

Stud

Shield, safety

Assembly-------------------------

--------------------------------2

--------------------------

-------------------------------

------------------------

--------------------------------

---------------------------

Cover, head, all styles except LF612K101MBE-16,

LF613K101HR-8 and

Pin, roll (stop)

101HR-9

-------------------

---------------------------

Gasket-------------------------------

Screw

Screw,plug

----------------------------------4

----------------------------

Gasket---------------------------------Gasket---------------------------------Cover, head (left rear) for all styles except LF612Kl01MBE-16,

LF613K101HR-8, and 101HR-9

Screw

----------------------------------9

-------------------

Cover, head (right rear) for all styles except LF612Kl01MBE-16,

LF613K101HR-8, and 101HR-9

Gasket

Screw

Cover, top

Plug

Cap, oil filter

Gasket

----------------------------------

----------------------------------4

--------------------------------

Screw

-------------------------------

-----------------------------------

------------------------------

----------------------------------

-------------------

Gasket---------------------------------Screw

Cover

Screw

Screw,

Cover

Screw, for styleLF612K101MBE-16

Throat

Screw

Ferrule, locating

Screw

Support, throat plate, for Style LF612K101MBE-16

Stud, latch spring

Shield,

Screw

Screw

Screw

Ferrule, locating (end cover)

Plug, plastic

---------------------------------

----------------------------------

----------------------------------

adapter------------------------------

----------------------------------

------------------

Plate, see "Sewing Combinations"

----------------------------------

-----------------------------

----------------------------------2

Bumper, rubber

--------------------------

----------------------------

lint--------------------------------

Gromment, rubber

-------------

----------------------------------

----------------------------------4

----------------------------------2

----------------------

-------------------------------

---------------

----------

--

------

--

Amt.

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

4

4

1

1

1

10

1

9

1

1

2

1

2

2

1

1

1

1

- 1

1

2

1

46

thru 70

See Following Page

33

Page 34

34

Page 35

SAFETY SHIELD, COVERS AND CLOTH PLATES

Ref.

No.

1 Thru45

46

47

48 22571 H

49

50 50301 B

51

52

53

54

55

56

56A 50382 u

57

57 A 50382 v

58 22653 B-8

59

59 A

60

61

62

63

64

65

66

67

68

69 51280 K

70

Part

No.

50382A

22894

93

93

50301 B

50394 y

35082F

35082E

50339 B

225690

50382BT

50382EA

50301 R

50301 AD

50301 AE

50382BM

660-896

660-739

22883 B

C50082AA

50301

37-70BLK.

503800

660-939

22570

c

Description Req.

See Preceding

Cover,

Screw (bearing)

Screw

Screw, all styles except LF612K112HJ-16, 112HJ-18,

Screw, for styles LF612K112HJ-16, 112HJ-18, LF613K112HR-8

Support, cloth plate, all styles except LF612Kl12HJ-16

Support, clothplate, for styles LF612Kll2HJ-16, 112HJ-18,

Wrre-----------------------------------1

Gasket

Cover, feed chamber (rear)

Washer, fiber

Screw

Gasket, for all styles except LF612K101MBE-16, LF613Kl01HR-8

Gasket for styles LF612K101MBE-16,

Cover, feed chamber (top) for styles

Cover,feed chamber (top) for styles LF612K101MBE-16,

Screw

Plate, cloth (left) for styles LF612KlOOHB-1, HC-1, HJ-16, HJ-18,

Plate, cloth (left) for style LF612K101MBE-16

Plate, cloth (left) for styles LF613K101HR-8 and lOlHR-9

Cover, head, for styles LF612K101MBE-16, LF613Kl01HR-8

Plate, cloth (right)

Trough, blank, for styles LF612K101MBE-16,

Support, Throatplate, for all styles except LF612K101MBE-16

Screw, for all styles except LF612K101MBE-16

end--------------------------------

----------------------------------1

LF613K112HR-8 and 112HR-9

and 112HR-9

112HJ-18,LF613K112HR-8 and 112HR-9

LF613K112HR-8 and 112HR-9

----------------------------------

---------------------------------and lOlHR-9

and lOlHR-9

HJ-18, HR-18, MP-12, MP-16, MX-24,

HR-8, and HR-9

LF613Kl01HR-8, and lOlHR-9

---------------------------------HR-18, MP-12, MP-16, MX-24,

and HR-9

lOlHR-9

and

Bushing

Seal, oil

Screw, plug

Gasket-------------------------------

and lOlHR-9

Bumper, rubber

Pin,

Page

-----------------------------

-------------------

-----------------------------

--------------2

-------------------

-----------------------

------------------------------

----------------------------LF613K101HR-8,

-----------------------------

LF612K100HB-1, HC-1, HJ-16,

LF613KlOOHJ-8, HJ-9,

----------------------------

-------------------

LF613KlOOHJ-8, HJ-9, HR-8,

-------------------------------

------------

------

-----------------------------

------------------------------

------------------------------

----------------------------

---------------------------LF613K101HR-8,

-----------------------------

----

--------------------------

dowel-----------------------------

------------

Amt.

1

2

4

2

1

1

1

4

4

1

1

1

1

6

1

1

1

1

1

1

1

1

1

1

1

1

2

2

35

Page 36

9

I;

i

"j

TORQUE

16-18

(18-21 em/kg) 7

TO

in.

1bs.

TORQUE

22-25

(25.3-28.8

TO

in.

6

A~

~~

1bs.

em/kg)

8

P19o

36

Page 37

NEEDLE DRIVE (SCOTCH YOKE) AND ASSOCIATED PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

.i

36

37

38

39

40

41

42

43

44

Part

No.

50355 AE

22655 B-7

50355 H

54249D

22596H

22720C

C50094X

41350X

C50093

C067D

50355P

50355

88 B

J80K

22591

35091 A

22894J

660-713

C50036P

22894AD

35093P

660-708

660-680

25

C50055H

22706

50342AC

22651 CD-4

50342AB

22562A

C50021 A

22894

50342R

50342

50342X

35042

50342 y

258

50342U

652-20

50342W

RM2747-3

50342AF

50342AD

652B-24

CJ

T

s

c

c

v

c

Description

Stud, support

Screw

Yoke

Screw

Fitting,

Washer

Tube,

Cork

Scotch Yoke Assembly, all styles except LF612K100MP-12,

Scotch Yoke Assembly, for styles LF612K100MP-12, MP-16,

Flywheel--------------------------------Ring, retaining

Bearing and Collar

Housing, scotch yoke drive

~~lip

Screw

Screw,

Screw,

Sprocket, scotch yoke drive

Flange,

Screw

Handwheel

Beh

Screw, shoulder

Fan,

Roller, idler

Spacer

Nut-----------------------------------B&t

Washer

Arm,

Washer, lock (internal tooth)

Fan,

Roller, idler

Washer, lock (external tooth, 1

----------------------------------

Assembly-----------------------------

Washer

Screw

---------------------------·-------

barbed------------------------------

air---------------------------------

----------------------------------MP-16, MX-24 and 101MBE-16

MX-24and

Screw

Screw

Screw

Screw

Screw

"O"Ring

----------------------------------2

Set-------------------------------locking------------------------------

Screw

sprocket-----------------------------

----------------------------------

Screw

-----------------------------------1

spring--------------------------------

----------------------------------

-----------------------------------1

pivot--------------------------------

spring--------------------------------

------------------------------

------------------------------

------------------------:-------

---------------------------------

101MBE-16

-------------------------------

-------------------------------

-------------------------------

-------------------------------

-----------------------------Assembly----------------------

-------------------------------

-----------------------------

---------------------------------1

-------------------------------

---------,-----------------------

---'--------------------------__:-

-----------------------------

-------------------------------

---------------------------------

-------------------------------

. Req.

-------------------

-----------------------

-----------------------

-----------------------

----------------------

to

4 at base)