Page 1

INDUSTRIAL

SEWING

FINEST

QUALITY

CLASSES

61800

62200

®

C 0 L U M B I A®

MACHINES

S

TYLE

61800

STREAMLINED

CATALOG

NEEDLE

No.

101

/

•

LO

/

/

/

/

VERTICAL

CKSTITCH

UNION SPECIAL

C

HI

CAGO

CA

.

FEED

HOOK

MACHINES

CORPORATION

J

Page 2

Catalog

INSTRUCTIONS

No.

FOR

101

R

Streamlined,

ADJUSTING

Vertical

61800

61800

61800

618

0 0

61800

LIST

CLASSES

Hook,

61800

D

H

CA

DA

HA

c

62200

62200

AND

and

OF

FOR

61800,

Needle

Styles

OPERATING

PARTS

62200

Feed

62200

62200

62200

62200

KA

LA

G

H

62200

62200

Lockstitch

K

L

GA

HA

Machin

e s

Rights

Copyright

Union

Reserved

First

Special

Edition

1960,

by

Corporation

in

All

1968

Countries

UNION SPECIAL CORPORATION

INDUSTRIAL

Printed

SEWING

CHICAGO

in

U.S.A.

2

MACHINES

May,

1980

Page 3

IDENTIFICATION

OF

MACHINES

Each

into

special.

tain

letter

suffixed

Styles

which

"Class

This

herein.

in

these

are

direction

Streamlined

Feed

with

Enclosed

Manual

Hook

UNION

the

name

Standard

the

letter

"Z

".

to

differs

61800".

catalog

It

Classes.

given

and

Drop

Locking

Automatic

Head

Mechanism.

plate

"Z

When

the

Standard

of

machines

from

can

also

from

of

handwheel

STYLES

Flat

Feed.

Device.

Lubrication.

SPECIAL

on

Style' numbers

".

Example:

only

the

applies

be

Reference

the

operator's

Bed

Rotary

Lubricating

Maximum

machine

the

minor

Style

similar

Style

APPLICATION

specifically

applied

is

toward

OF

Lockstitch

External

Separate

is

machine.

have

"Style

changes

number.

in

construction

number.

with

to

directions.

position

the

MACHINES

Machines.

Hook.

Needle

System

Work

Vertical

Space

identified

Style

discretion

operator.

Reservoir

r:tumbers

one

or

61800

are

made

Example:

in

that

OF

to

the

while

IN

CLASS

Hook

Thread

for

to

by a Style

more

C".

Special

in a standard

"Style

are

it

CATALOG

Standard

to

some

such

as

seated

61800

Light.

Main

Right

Medium

Shaft.

Tension

Driving

for

Automatic

of

are

classified

letters

Style

61800

grouped

contains

Styles

Special

right.

at

AND

Thumb

Mechanism.

Needle

number

suffixed,

under a Class

no

left.

the

and

Mechanism.

Bar

which

as

numbers

machine,

CZ

".

letters.

of

machines

Styles

front.

machine.

62200

Heavy

Screw

Lubrication

Stitch

10

is

standard

but

never

contain

of

back.

Operating

Duty.

Regulator

One

Reservoir

Automatic

Inches.

stamp

a

number

Example:

as

machines

of

ed

and

con-

the

"Z"

listed

etc

Needle

or

Rotary

is

••

*

*

*

*

61800

61800

61800

61800

61800

61800

C

seaming

hinged

180

ommended

D

waistbands

compensating

24-3

Specify

H

seaming

the

is

speed

CA

head.

DA

head.

HA

head.

Single

operations

bottom

GXS

use

maximum

or

Single

cord

needle

Single

operations

of

4000

Same

Same

Same

Needle

presser

180

speed

Needle

of

trousers

presser

is

maximum

Needle

heavy

usable

R.

P.M.

as

Style

as

Style

as

Style

Machine

on

light.

foot.

GYS

needle.

4000

R.

Machine

foot.

type

and

Machinewithmanuallubricationforhead.

on

medium

threads;

thread

61800

61800

61800

P.M.

and

usable

size.

equipped

size.

c.

D.

H.

with

manual

medium

24-3

Specify

with

manual

similar

to

compensate

thread

Maximum

and

Type

except

except

except

lubrication

and

cord

is

needle

operations;

size.

medium

with

hinged

182

equipped

equipped

equipped

heavy

maximum

lubrication

for

Type

recommended

heavy

GAS

weight

type

equipped

uneven

180

weight

bottom

needle.

with

with

with

for

head.

materials;

usable

and

size.

for

head.

thickness

GXS

speed

materials.

presser

Maximum

automatic

automatic

automatic

for

miscellaneous

equipped

thread

with

or

formiscellaneous

size.

Maximum

for

top

stitching

double

of

materials.

180

GYS

4

000

R.

requiring

foot.

lubrication

lubrication

lubrication

16-4

recommended

needle.

with

Type

rec•

action

P.M.

cord

for

for

for

*

DISCONTINUED

- In

repair.

most

instances,

component

parts

can

3

be

ordered

for

customer

Page 4

*

62200

STYLES

G

Two

seaming

and

other

medium

Type

gauges

ommended

and

180

Nos.

OF

Needle

operations

foundation

heavy

GXS

or

8,

12,

speed 4 000

MACHINES

Machine

on

garments,

weight

180

16,

work

articles.

GYS

20,

R.

P.M.

with

IN

CLASS

manual

shirts,

jackets.

needle.

24,

overalls,

24-3

Specify

28

and

61800

lubrication

shop

cord

32.

AND

work

coats.

is

needle

Specify

62200

for

head,

pants.

aprons

maximum

type

gauge.

(Continued)

for

miscellaneous

dungarees,

and

similar

usable

and

thread

size.

Maximum

corsets

light,

size.

Standard

rec-

* 622

*

62200

*

62200

62200

62200

00

H

Two

operations

canvas.

cord

Nos.

4000

along

taping

reel

wide

180

4000

machine

with

No.

head.

head.

is

12,

R.P.M.

K

furnished

tape

GYS

R.P.M.

L

positive

12

GA

HA

Two

Two

Same

Same

Needle

on

upholstery

maximum

16,

Needle

the

edges

top.

bottom,

and

needle.

Needle

for

only.

as

as

Machine

overalls.

usable

20,

24,

Machine

and

with

finishes

Standard

Machine

chaining

chaining

Maximum

Style

Style

and

similar

28

and

when

gore

machine.

5/16

on

short

parts.

recommended

62200

62200

with

manual

western

thread

32.

with

turning

seams

Folder

inch

gauge

with

operations

Type

G,

except

H.

except

type

items

size.

Specify

manual

corners,

and

wide.

No.

manual

180GXS

lubrication

dungarees,

requiring

Type

gauge.

lubrication

reinforcement

has

Seam

12

only.

lubrication

such

speed

equipped

equipped

the

182

GAS

Maximum

while

1/32

inch

Specification

Maximum

as

or

180GYS

4000

with

with

for

head,

jackets,

use

of

needle.

for

head,

taping

seams

capacity.

for

hemming

needle.

R.

P.M.

automatic

automatic

for

miscellaneous

medium

heavy

recommended

brassieres,

recommended

head,

pockets.

thread.

Standard

for

quality control

on

~orsets.

takes

301-LSk-2.

general

Standard

lubrication

lubrication

weight

16-4

gauges

speed

and

for

Tape

5/8

inch

Type

speed

utility

Equipped

gauge

for

for

622

00

KA

Same

head.

622 00

denotes

number,

sured

number

packaged

sample

on

*

DISCONTINUED

LA

head.

Each

To

label.

Same

UNION

the

stamped

in

thousandths

represent the

and sold

have

needle,

Acomplete

kind

needle

as

Style

as

Style

SPECIAL

of

shank.

on

the

of

complete

by

Union

orders

or

the

type

order

-

In

most

repair.

62200

622 00

needle

point,

needle

an

wouldread:"lOOONeedles,

instances,

K,

L,

has

length.

shank.

inch

across

symbol,

Special.

promptly

and

size

except

except

NEEDLES

both a type

number

component

groove.

denotes

the

which

and

accurately

4

equipped

equipped

should

and

largest

eye.

is

parts

with

with

finish

Collectively,

given

automatic

automatic

size

number. The

and

diameter

on

filled, an

be

forwarded.

Type

can

lubrication

lubrication

other

the

180GXS, size

be

details.

of

the

label

empty

ordered

the

type

Use

type

number

Th

blade,

and

of

all needles

p:tckage

description

090/036".

for cus

for

for

e s

ize

mea-

size

, a

tomer

Page 5

The

by

this

able,

but

results.

criptions,

type

catalog

the

The

and

numbers

are giv

ones

indicated

type

numbers

the

siz

NEEDLES

of the needles r e

en

in the

machine styl

are thos

e r e

of the r e

es

available

are

(Continued)

commendedfor

e de

scription.

commend

commend

listed

ed

ed

below:

each

to

produce

needles

style

of

Other

the

together

machine

needles

most

with

covered

are

avail-

satisfactory

their

des-

Type

180

180

182

No.

GXS

GYS

GAS

Selection

should

Success

use

of

a

reputation

more

than

Where

Parts

which

Round

groove,

chromium

125/049, 140/054,

Round

groove,

-

140/054,

Round

groove,

125/049,

of

pass

needles

freely

in

packaged

for

three-quarters

the

too

small

distinguish

shank,

wide

plated-

shank,

wide

sizes

075/029,

150/060.

shank,

struck

140/054,

proper

needle

through

the

operation

under

producing

construction

for a complete

one

part

Description

round

angle

point,

groove,

sizes

150/060.

round

angle

point,

groove,

080/032,

round

point,

groove,

150/060,

size

needle

of

our

highest

is

eye

UNION

brand

quality

of a century.

IDENTIFYING

permits,

catalog

from

another

and

lockstitch,

struck

075/029,

lockstitch,

struck

090/036,

lockstitch,

deep

spot,

170/067.

determined

in

order

SPECIAL

name,

needles

each

part

stamping

that

is

Sizes

short

groove,

080/032,090/036,

short

groove,

deep

100/040,

long

chromium

by

size

to

produce a good

machines

~

in

materials

PARTS

is

stamped

are

identified

similar

in

appearance.

length,

deep

length,

spot,

length,

plated-

of

thread

can

be

,

and

with

ball

spot,

eye,

ball

100/040,

ball

eye,

chromium

110/044,

ball

eye,

sizes

used.

stitch

formation.

secured

which

is

workmanship

its

part

by

letter

single

point,

110/044,

single

plated

125/049,

single

110/044,

Thread

only

backed

number.

symbols

by

by

for

Part

numbers

appear.

IMPORTANT!

Prices

forwarded

wise

ploded

be

directed.

This

views

seen

catalog

in

blackened

the

illustration

scriptions

are

f.

o.

their

area

and

net

b.

A

of

various

where

will

the

represent

ON

ALL

OF

MACHINE

cash

shipping

charge

has

been

actual

the

be

number

the

same

ORDERS,

PLEASE

FOR

and

subject

point.

is

made

Parcel

to

cover

ORDERING

ILLUSTRATIONS

arranged

sections

position

parts

fit

of

in

to

the

the

in

found a listing

of

pieces

part,

WHICH

TERMS

to

change

Post

the

REPAIR

simplify

mechanism

machine.

the

assembled

of

the

required

regardless

INCLUDE

PART

IS

without

shipments

postage

PARTS

the

ordering

are

Small

machine.

parts

in

with

the

of

the

catalog

PART

NAME

ORDERED.

notice.

are

insured

and

insurance.

of

shown

so

keyline

On

their

part

particular

All

repair

that

views

the

numbers,

view

in

which

AND

STYLE

shipments

unless

other-

parts.

the

parts

show

page

opposite

being shown.

they

are

Exmay

by

de-

a

5

Page 6

ILLUSTRATIONS

(Continued)

Numbers

the

position

in

ordering

Component

indicated

assembly.

Ref.

No.

50

51

It

will

listed.

mended,

Basically,

needle

for

is

by

when

be

the

machine,

the

changed.

this

catalog,

the

mentioned

illustration.

in

of

parts.

by

indenting

Example:

Part

No.

51239

22729

be

noted

The

reason

so

the

standard

In

parts

in

the

first

that

part

parts

L

c

in

complete

Classes

while

machine

those

no

specific

for

the

the

column

in

the

Always

of

sub.,.assemblies

their

Ball

the

is

that

61800

Class

cases

various

description,

descriptions

Joint

Screw,

above

replacement

sub-assembly

and

are

where a part

usage

are

reference

illustration.

use

the

part

Feed

example

62200

62200

the

machines

and

Ball

is a two

same.

will

if

Driving

be

numbers

Reference

number

which

under

Description

Joint

that

of

should

are

the

In

is

mentioned

are

necessary,

can

Connection,

Connection-------------------

the

these

be

same

needle

some

common

not

numbers

listed

be

the

description

bearing

parts

ordered.

except

machine;

cases,

to

in

the

same,

the

only,

furnished

individually

all

the

difference

and

should

in

the

upper-----------

and

the

Class

therefore,

the

quantity

the

machines

description.

the

specific

merely'

never

second

for

of

the

ball

is

61800

will

indicate

be

used

column.

repairs

main

stud

not

is a single

all

requirement

However,

usage

be

shown

are

sub-

Amt.

Re

1

2

are

not

recom-

parts

covered

will

q.

in

At

the

this

catalog.

the

part

number

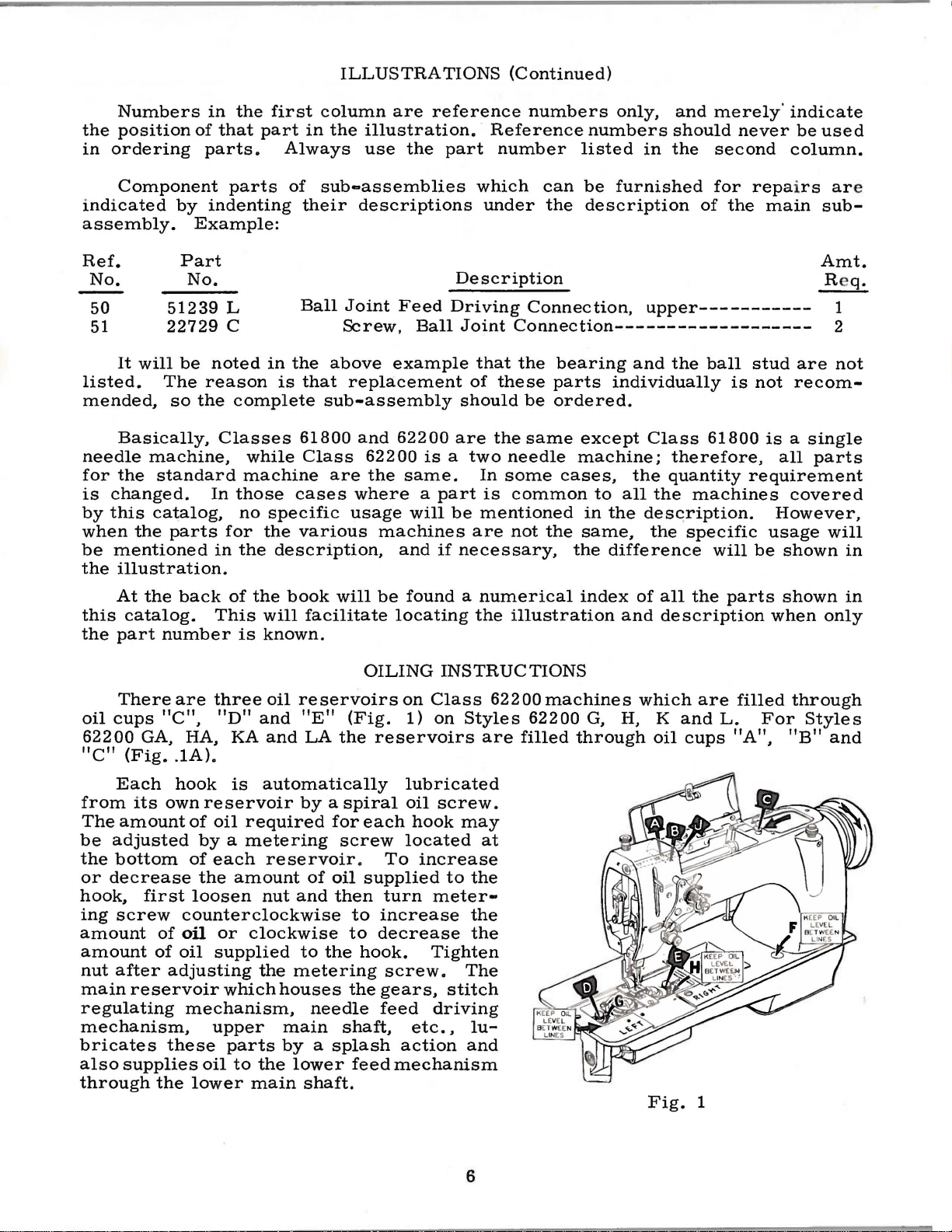

There

oil

cups

62200

"C"

Each

from

The

be

adjusted

the

bottom

or

decrease

hook,

ing

screw

amount

amount

nut

after

main

regulating

mechanism,

bricates

also

through

"C",

GA, HA, KA

(Fig

•.

its

own

amount

first

of

of

reservoir

these

supplies

the

back

are

1A).

hook

oil

adjusting

of

the

book

This

three

reservoir

of

oil

by a metering

of

each

the

loosen

counterclockwise

oil

supplied

mechanism.

upper

oil

lower

will

is

known.

oil

"D"

and

and

is

automatically

required

reservoir.

amount

nut

or

clockwise

the

which

parts

to

the

main

houses

main

by a splash

will

facilitate

OILING

reservoirs

"E"

by a spiral

and

to

metering

lower

LA

the

for

screw

of

oil

then

the

needle

shaft.

(Fig.

each

supplied

to

to

hook.

the

shaft,

feed

be

found a numerical

locating

on

1)

reservoirs

lubricated

oil

hook

located

To

increase

turn

increase

decrease

screw.

gears,

feed

etc.,

action

mechanism

the

INSTRUCTIONS

Class

on

Styles

are

screw.

may

at

to

the

meter-

the

the

Tighten

The

stitch

driving

lu-

and

illustration

62200

machines

62200

filled

index

G, H, K

through

of

and

all

the

description

which

Fig.

oil

are

and

cups

1

parts

filled

L.

"A",

shown

when

For

"B"

in

only

through

Styles

and

6

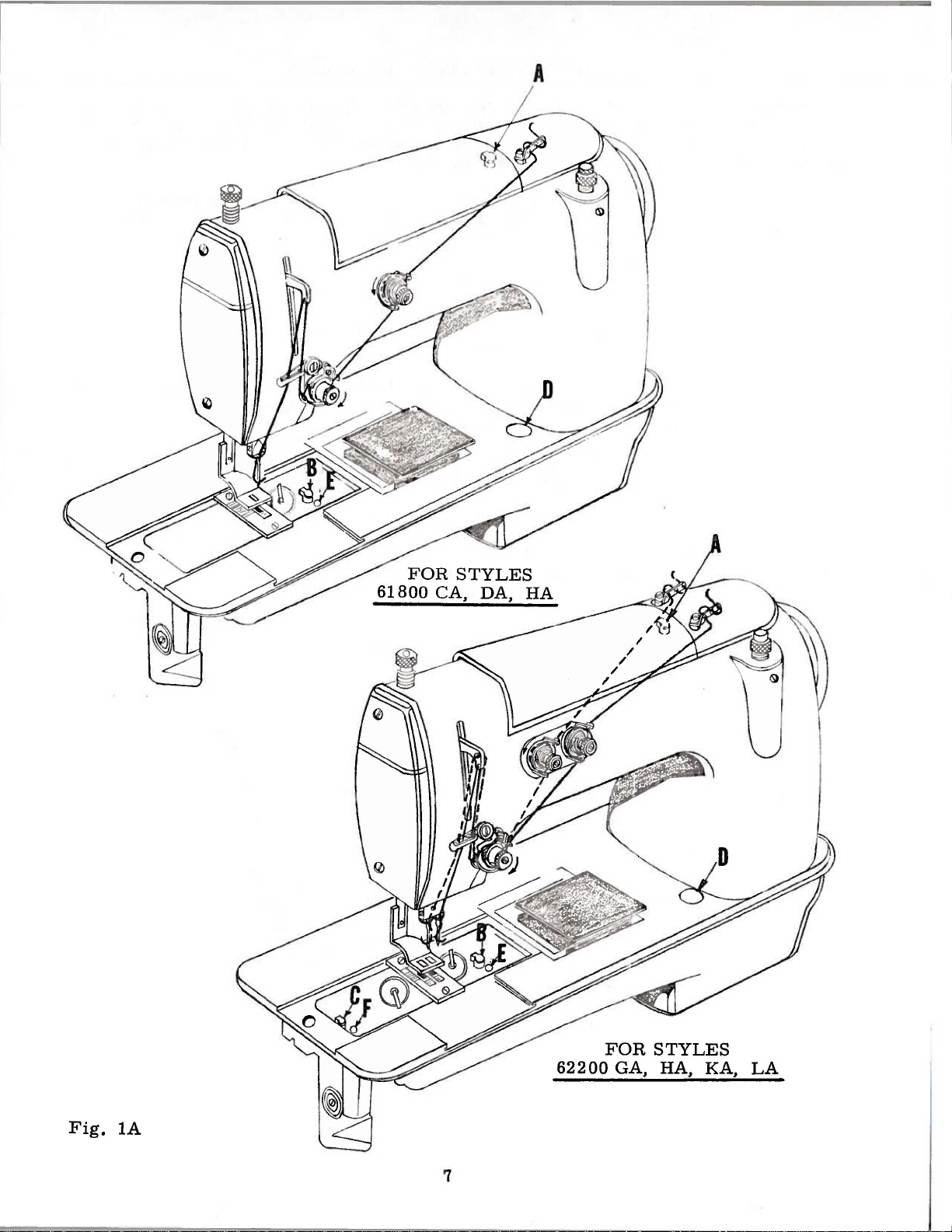

Page 7

A

FOR

61800

STYLES

CA,

DA,

HA

62200

Fig.

lA

7

FOR

GA,

STYLES

HA,

KA,

LA

Page 8

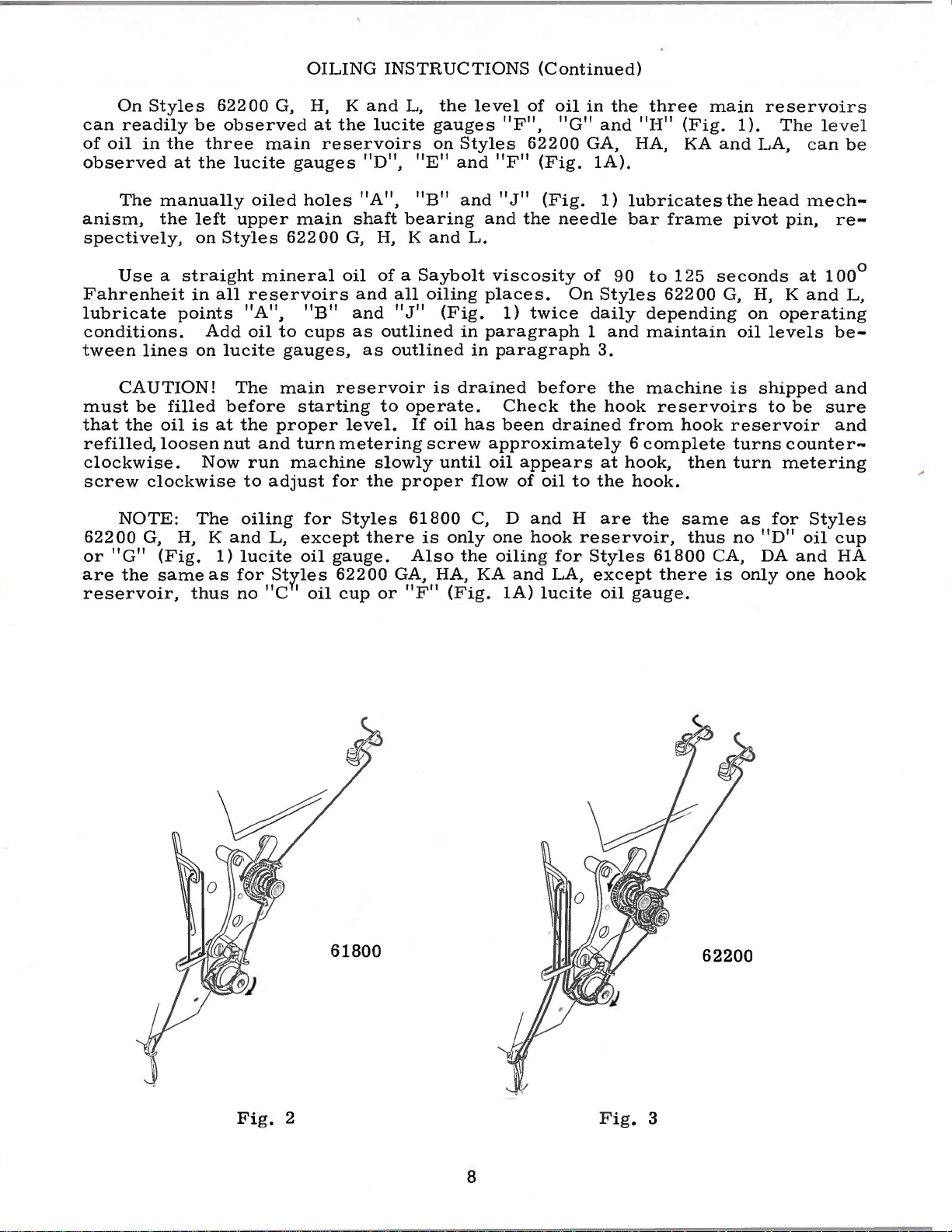

On

Styles

can

readily

of

oil

in

observed

The

anism,

spectively,

62200

be

the

three

at

the

manually

the

left

on

Styles

G,

observed

main

lucite

oiled

upper

OILING

H,

at

reservoirs

gauges

holes

main

62200

INSTRUCTIONS

K

and

L,

the

lucite

"D",

"E"

"A", "B"

shaft

G,

H,

bearing

K

the

gauges

on

Styles

and

and

and

L.

level

"F",

"F"

"J"

and

(Continued)

of

oil

in

''G"

62200

(Fig.

the

GA,

1A).

(Fig.

needle

the

and

"H"

HA,

1)

lubricates

bar

three

frame

main

(Fig.

KA

1 ).

and

the

pivot

reservo

Th

e l

evel

LA, can

head

mech-

pin,

irs

be

re-

Use a straight

Fahrenheit

lubricate

conditions.

tween

must

that

refilled,

clockwise.

screw

62200

or

are

reservoir,

lines

CAUTION!

be

the

loosen

clockwise

NOTE:

G,

"G"

the

(Fig.

same

points

filled

oil

H,

in

all

Add

on

is

at

Now

The

K

as

thus

reservoirs

"A",

oil

lucite

The

before

the

nut

run

to

oiling

and

1)

lucite

for

no

mineral

"B"

to

cups

gauges,

main

starting

proper

and

turn

machine

adjust

for

L,

except

oil

St:rr1es

"C ' oil

oil

of a Saybolt

and

and

as

outlined

as

reservoir

to

level.

metering

slowly

for

the

Styles

there

gauge.

62200

cup

or

all

oiling

"J"

(Fig.

outlined

is

operate.

If

oil

screw

until

proper

61800

is

only

Also

GA,

HA,

"F"

(Fig.

viscosity

places.

1)

twice

in

paragraph

in

paragraph

drained

Check

has

been

approximately

oil

appears

flow

the

of

C, D

one

oiling for

KA

and

1A)

before

drained

oil

and

hook

LA,

lucite

of

90

On

Styles

daily

1

and

3.

the

the

hook

at

hook,

to

the

H

are

reservoir,

Styles

except

oil

to

125

62200

depending

maintain

machine

reservoirs

from

6

hook.

gauge.

hook

complete

the

same

61800

there

then

thus

seconds

G,

H,

on

oil

is

shipped

reservoir

turns

turn

as

no

"D"

CA,

is

DA

only

at

100°

K

and

operating

levels

to

be

sure

counter

metering

for

Styles

oil

and

one

hook

L,

be-

and

and

..

cup

HA

61800

Fi

g. 2 F ig . 3

8

62200

Page 9

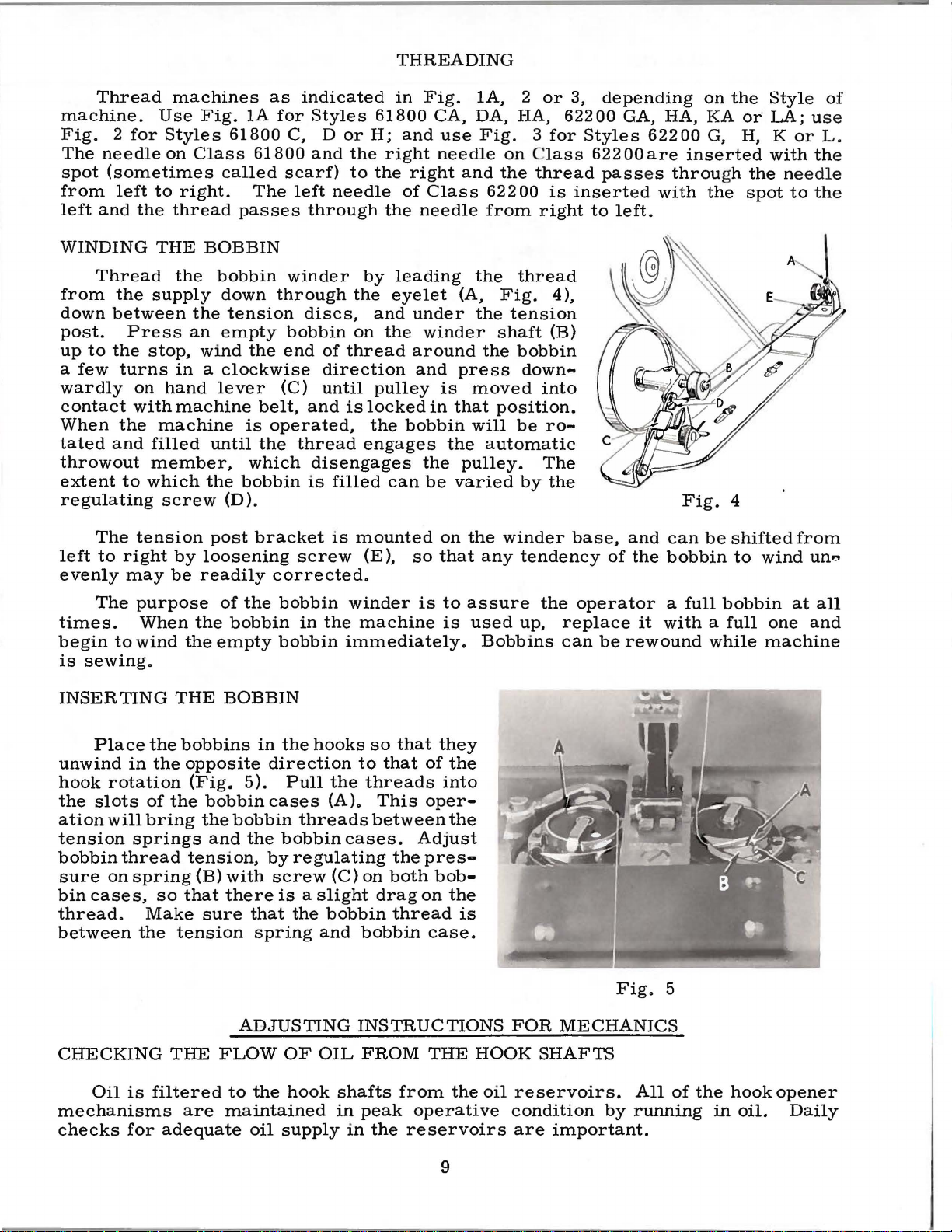

THREADING

Thread

machine.

Fig.

The

spot

from

left

2

for

needle

(sometimes

left

and

the

WINDING

Thread

from

down

post.

up

a

wardly

contact

When

tated

to

few

the

between

Press

the

turns

on

with

the

and

throwout

extent

to

regulating

The

tension

left

to

right

evenly

may

machines

Use

Fig.

Styles

on

61800

Class

called

to

right.

thread

THE

the

supply

an

stop,

passes

BOBBIN

bobbin

down

the

tension

empty

wind

in a clockwise

hand

lever

machine

machine

filled

until

member,

which

screw

the

(D).

post

by

loosening

be

readily

as

1A

for

C, D

61800

scarf)

The

winder

through

bobbin

the

end

(C)

belt,

is

operated,

the

which

bobbin

bracket

corrected.

indicated

Styles

or

and

the

to

left

needle

through

the

discs,

on

of

thread

direction

until

and

is

thread

disengages

is

filled

is

mounted

screw

in

61800

H;

and

right

the

right

of

the

needle

by

leading

eyelet

and

under

the

around

and

pulley

locked

the

bobbin

engages

can

(E),

so

Fig.

CA,

use

needle

and

Class

(A,

winder

press

is

in

that

the

the

pulley.

be

varied

on

the

that

1A, 2

DA,

HA,

Fig.

on

the

622 00

from

the

thread

Fig.

the

tension

shaft

the

bobbin

down-

moved

position.

will

be

automatic

by

winder

any

tendency

or

3,

62200

3

for

lass

thread

is

right

4),

(B)

into

ro-

The

the

base,

depending

GA,

Styles

622

pass

insert

to

left.

of

00

ed

and

the

HA,

62200

are

es

throu

with

Fig.

can

bobbin

on

the

KA or·

G,

H,

inserted

gh

the

4

be

shifted

to

Style

LA;

K

with

the

spot

wind

of

use

or

L.

the

needle

to

the

from

un.,.

The

purpose

times.

begin

is

sewing.

to

When

wind

INSERTING

Place

unwind

hook

the

slots

ation

tension

bobbin

sure

bin

cases,

thread.

between

the

in

rotation

of

will

bring

springs

thread

on

spring

Make

the

CHECKING

THE

bobbins

the

the

so

tension

THE

of

the

bobbin

the

empty

BOBBIN

opposite

(Fig.

bobbin

the

bobbin

and

tension,

(B)

with

that

there

sure

ADJUSTING

FLOW

the

bobbin

bobbin

in

the

direction

5).

cases

the

bobbin

by

screw

is a slight

that

spring

OF

winder

in

the

immediately.

hooks

Pull

the

(A).

threads

cases.

regulating

(C)

the

bobbin

and

OIL

is

to

assure

machine

is

used

Bobbins

so

that

they

to

that

of

the

threads

This

between

into

oper-

the

Adjust

the

pres-

on

both

bob-

drag

on

the

thread

bobbin

is

case.

INSTRUCTIONS

FROM

THE

HOOK

the

up,

FOR

SHAFTS

operator

replace

can

be

Fig.

a

it

with a full

rewound

5

MECHANICS

full

bobbin

while

at

all

one

and

machine

Oil

is

mechanisms

checks

for

filtered

adequate

are

to

the

hook

maintained

oil

supply

shafts

in

peak

in

the

from

the

operative

reservoirs

9

oil

reservoirs.

condition

are

important.

by

All

of

running

the

in

hook

oil.

opener

Daily

Page 10

ing

from

CHECKING

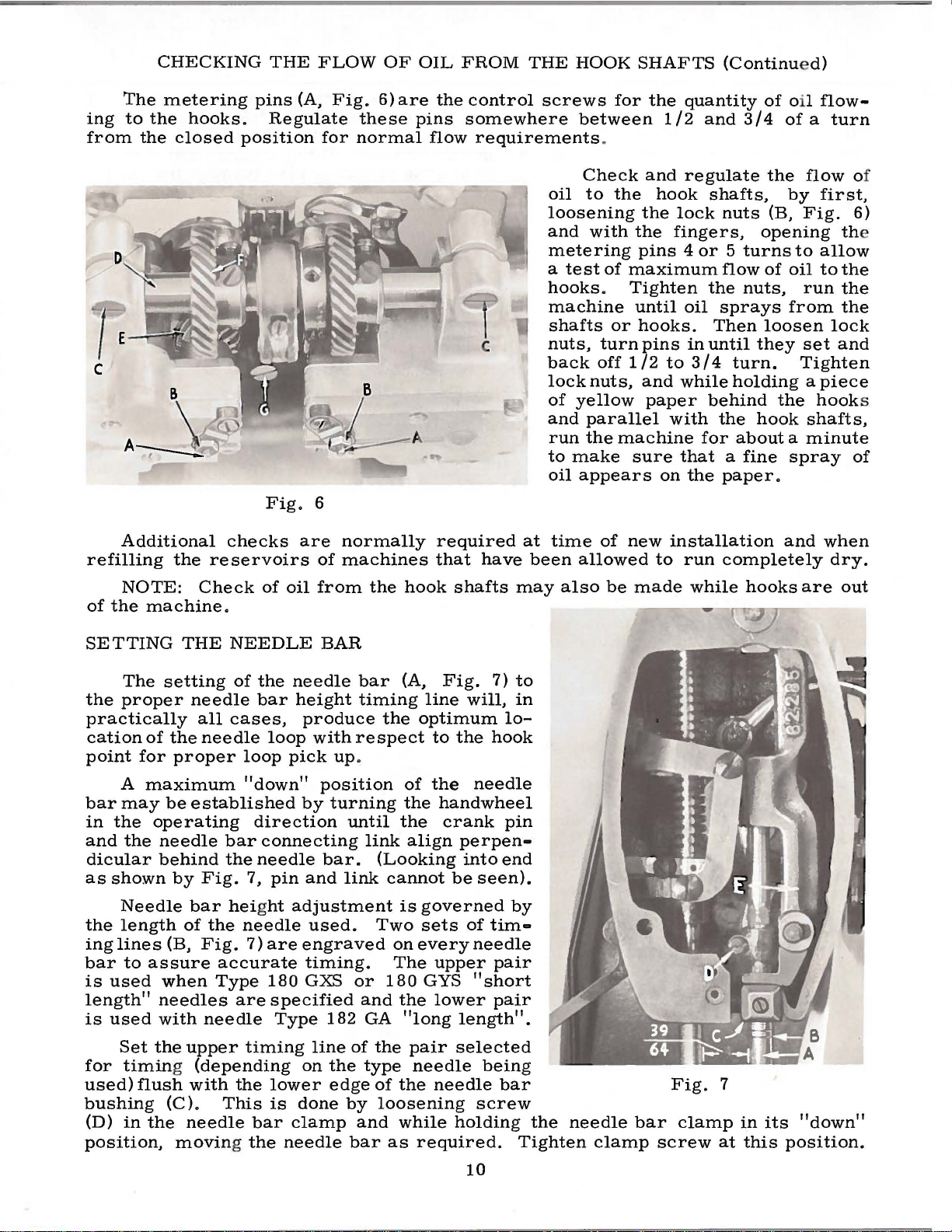

The

metering

to

the

the

closed

hooks.

THE

pins

(A,

Regulate

position

FLOW

Fig.

these

for

normal

OF

6)

are

OIL

the

pins

flow

FROM

control

somewhere

requirements

THE

screws

HOOK

for

between

.

SHAFTS

the

quantity

1/2

and

(Continu

of oil

3/4

ed)

flow-

of a turn

Additional

refilling

NOTE:

of

the

machine.

the

reservoirs

Check

Fig.

checks

of

are

oil

6

normally

of

machines

from

the

required

that

hook

have

shafts

oil

loosening

and

metering

a

hooks.

machine

shafts

nuts,

back

lock

of

and

run

to

oil

at

time

been

may

Check

to

with

test

off

nuts,

yellow

parallel

the

make

appears

allowed

also

and

regulate

the

hook

the

lock

the

fingers,

pins 4 or 5 turns

of

maximum

Tighten

until

or

hooks.

turn

1/2

machine

sure

of

new

be

made

oil

pins

in

to

3/4

and

while

paper

with

that a fine

on

the

installation

to

run

while

for

the

flow

shafts,

nuts

flow

the

sprays

Then

until

turn.

holding a piece

behind

the

about a minute

paper.

completely

by

(B,

Fig.

opening the

to

of

oil

nuts,

they

hook

hooks

run

from

loosen

set

Tighten

the

shafts,

spray

and

are

first,

allow

to

the

the

the

lock

and

hook

when

dry.

out

of

6)

s

of

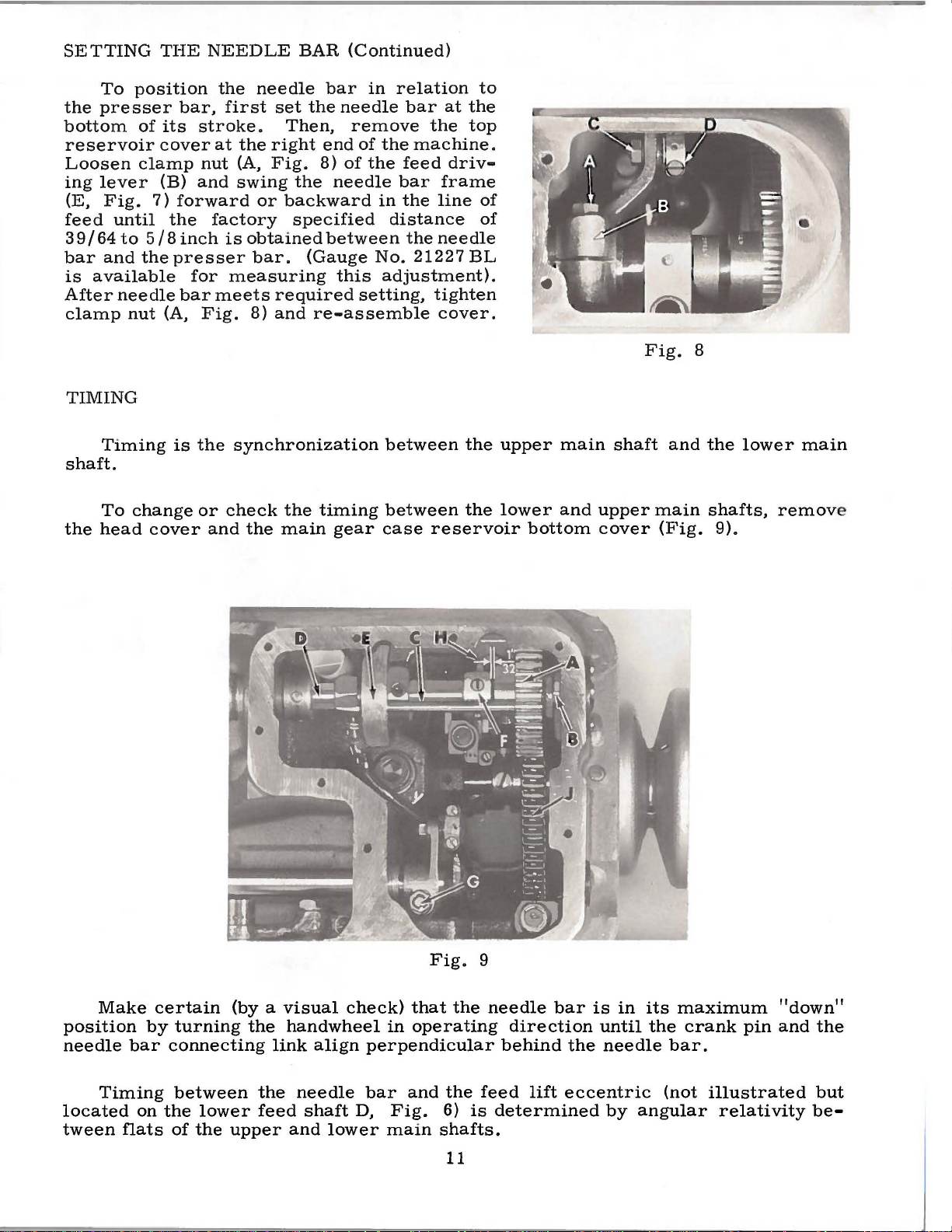

SETTING

The

the

proper

practically

cation

point

A

bar

may

in

the

and

the

dicular

as

shown

Needle

the

length

ing

lines

bar

to

is

used

length"

is

used

Set

for

timing (depending

used)

bushing

(D)

in

position,

THE

setting

needle

all

of

the

for

proper

maximum

be

established

operating

needle

behind

by

bar

of

(B,

assure

when

needles

with

the

upper

flush

with

(C).

the

needle

moving the

NEEDLE

of

cases,

needle

loop

"down"

bar

the

Fig.

height

the

needle

Fig.

accurate

Type

are

needle

timing

the

This

the

needle

bar

height

produce

loop

with

pick up.

by

direction

connecting

needle

7,

pin

and

adjustment

used.

7)

are

engraved

timing.

180

GXS

specified

Type

line

on

lower

is

done

bar

clamp

needle

BAR

bar

timing

respect

position

turning

until

link

bar.

182

the

edge

(Looking

link

Two

or

and

GA

of

the

type

of

by

and

bar

(A,

Fig.

line

the

optimum

to

of

the

the

handwheel

the

crank

align

cannot

is

governed

sets

on

every

The

upper

180

GYS

the

lower

"long

pair

needle

the

needle

loosening

while

as

required.

7)

will,

lo-

the

hook

needle

pin

perpen•

into

end

be

seen).

of

tim-

needle

pair

"short

pair

length".

selected

being

bar

screw

holding

to

in

by

the

Tighten

needle

clamp

bar

Fig.

clamp

screw

7

at

in

this

its

"down"

position.

10

Page 11

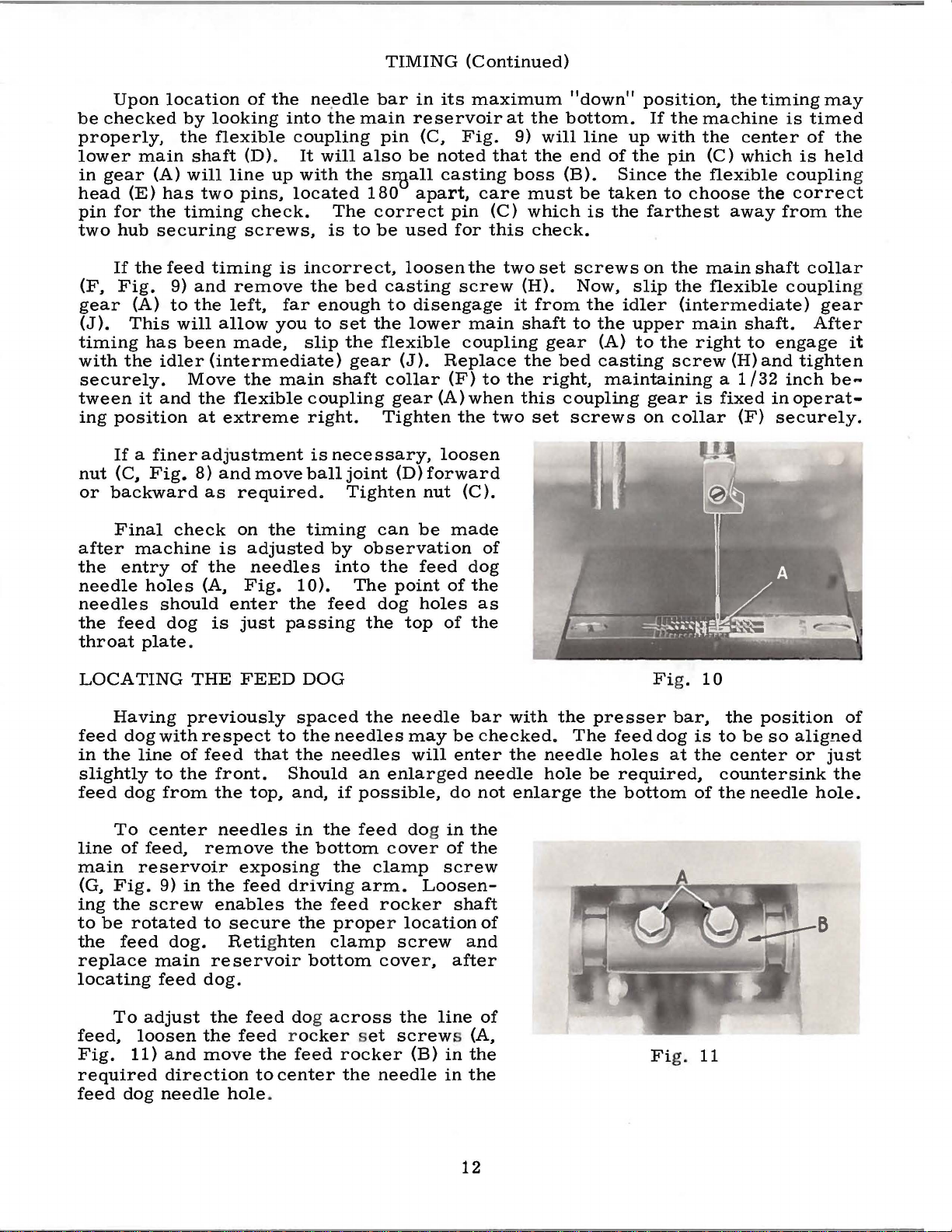

SETTING

To

position

the

presser

bottom

reservoir

Loosen

ing

lever

(E,

Fig.

feed

3 9 I 64

bar

is

After

clamp

until

to

and

available

needle

nut

THE

of

its

cover

clamp

(B)

7)

forward

the

5 I 8

the

presser

(A,

NEEDLE

the

bar,

stroke.

at

nut

and

factory

inch

for

bar

meets

Fig.

needle

first

is

set

Then,

the

right

(A,

Fig.

swing

obtained

measuring

or

backward

bar.

required

8)

and

the

specified

BAR

(Continued)

bar

in

the

needle

remove

end

of

8)

of

the

needle

between

(Gauge

this

setting,

re-assemble

relation

bar

at

the

the

machine.

feed

driv-

bar

frame

in

the

line

distance

the

needle

No.

21227

adjustment).

tighten

cover.

to

the

top

of

of

BL

TIMING

Timing

shaft.

To

the

head

is

change

cover

the

synchronization

or

check

and

the

main

the

timing

gear

between

between

case

reservoir

the

the

upper

lower

bottom

main

and

shaft

upper

cover

Fig.

main

(Fig.

and

8

the

shafts,

9).

lower

remov

main

e

Make

position

needle

Timing

located

tween

certain

by

bar

on

flats

(by a visual

turning

connecting

between

the

lower

of

the

upper

the

handwheel

link

the

feed

align

needle

shaft

and

check)

in

perpendicular

bar

D,

lower

main

Fig.

that

operating

and

Fig.

9

the

the

feed

6)

is

shafts.

11

needle

behind

determined

bar

direction

lift

is

in

until

the

needle

eccentric

by

its

maximum

the

crank

bar.

(not

angular

"down"

pin

and

illustrated

relativity

the

but

be-

Page 12

TIMING

(Continued)

Upon

be

checked

properly,

lower

in

head

pin

two

(F,

gear

(J).

gear

(E)

for

hub

If

Fig.

This

main

the

(A)

timing

with

the

securely.

tween

ing

nut

or

it

position

If

a

(C,

backward

Final

after

the

machine

entry

needle

needles

the

feed

throat

plate.

location

by

the

shaft

(A)

will

has

the

timing

securing

feed

9)

and

to

the

will

has

been

idler

Move

and

finer

Fig.

8)

check

of

holes

should

dog

of

the ne.

looking

flexible

into

coupling

(D).

line

up

two

pins,

located

check.

screws,

timing

is

remove

left,

allow

far

you

made,

(intermediate)

the

main

the

flexible

at

extreme

adjustment

and

move

as

required.

on

the

is

adjusted

the

needles

(A,

Fig.

is

enter

just

the

passing

edle

the

main

It

will

with

the

The

is

to

incorrect,

the

bed

enough

to

set

slip

the

gear

shaft

coupling

right.

is

necessary,

ball

joint

Tighten

timing

by

into

10).

The

feed

bar

in

its

reservoir

pin

(C,

also

be

noted

s:sall

180

casting

apart,

correct

be

used

loosen

casting

to

disengage

the

lower

flexible

(J).

Replace

collar

gear

(F)

(A)

Tighten

loosen

(D)

forward

nut

can

be

observation

the

feed

point

dog

the

holes

top

of

of

maximum

Fig.

that

care

pin

(C)

for

this

the

two

screw

main

coupling

to

when

the

two

(C).

made

of

dog

the

as

the

at

9)

boss

(H).

it

shaft

the

the

this

"down"

the

bottom.

will

the

end

(B).

must

which

check.

set

from

gear

bed

right,

coupling

set

screws

position,

If

the

machine

line

up

with

the

of

the

pin

Since

be

taken

is

the

screws

Now,

the

to

the

(A)

casting

idler

to

farthest

on

the

slip

upper

to

the

screw

the

choose

the

(intermediate)

main

right

maintaining a 1/32

gear

on

is

collar

the

center

(C)

which

flexible

away

main

shaft

flexible

shaft.

to

(H)

fixed

(F)

timing

is

of

is

coupling

the

correct

from

collar

couplin

engage

and

tighten

inch

in

operat-

securely.

may

timed

the

held

the

gear

After

be

g

it

...

LOCATING

Having

feed

dog

with

in

the

line

slightly

feed

line

main

(G,

ing

to

be

the

replace

locating

feed,

Fig.

required

feed

dog

To

center

of

feed,

reservoir

Fig.

the

screw

rotated

feed

To

adjust

loosen

11)

dog

to

from

9)

main

feed

and

direction

needle

THE

previously

respect

of

feed

the

front.

the

needles

remove

in

the

enables

to

dog.

Retighten

reservoir

dog.

the

the

move

hole

FEED

DOG

spaced

to

the

needles

that

the

needles

Should

top,

the

exposing

feed

secure

and,

driving

in

the

bottom

the

the

if

the

feed

proper

clamp

bottom

feed dog

across

feed rocker set

the

feed

rocker

to

center

the

.

the

needle

may

will

an

enlarged

possible,

feed dog

cover

clamp

arm.

Loosen-

rocker

location

screw

cover,

the

screw

(B)

needle

bar

be

enter

do

in

the

of

the

screw

shaft

and

after

line

s (A,

in

the

in

the

with

checked.

the

needle

not

enlarge

of

of

the

The

needle

hole

be

the

presser

feed

holes

required,

bottom

Fi

dog

Fi

g.

bar,

at

g.

10

the

is

to

be

the

center

countersink

of

the

needle

11

position

so

aligned

or

hole.

8

of

just

the

12

Page 13

The

correct

timing between

the

hook

the

flat,

intended

operating

timing

the

hook

for

the

direction.

position

the

hook

screw

opening

flat on

of

opener

on

finger

the

the

the

hook

shaft

TIMING

hooks

finger

shaft

will

be

is

the

on

and

out

THE

their

flat.

of

first

HOOKS

shafts

the

If

time

one

hook

the

with

visible

is

of

is

governed

wrong

the

great

hook

hook.

as

the

importance.

by

the

position

screw

The

hook

is

timing

is

placed

screw

turned

The

of

on

in

The

while

back

obtain

Fig.

the

and

this

12

needle

needle

forth

condition.

and

the

guard

across

Fig.

hooks,

shortest

turn

the

Lock

in

Loosen

gears

shaft

(E,

without

Visually

spots

face

operating

the

needle

until

flush

time,

needle

lower

with

the

eye.

hook

is

just

the

needle.

12

illustrates

it

is

recommended

stitch

stitch

position

the

Fig.

check

their

direction

bar.

timing

the

hook

point

should

brushing

length.

regulator

by

tightening

two

6)

so

turning

position

respective

When

line

bottom

point

the

The

hook

accomplished

(C,

required.

shown).

the

stitch

the

regulator

To

do

this,

(B)

counterclockwise

lockscrew

screws

the

the

on

hooks

driving

of

each

will

gears.

the

hooks.

to

obtain a maximum

this

has

been

(of

the

pair

of

the

lower

should

be

approximately

needle

be

needle

approximately

(A)

guard

Adjustment

by

Fig.

6),

and

(Note:

regulator.

loosen

of

turn

needles.

Now,

reached,

selected)

needle

. 003

as

the

may

of

the

loosening

moving

Two

be

turned

lockscrew

as

(A).

the

freely

turn

"down"

bar

inch

hook

be

hooks,

the

screws

For

far

as

hook

shaft

with

Make

handwheel

continue

(B,

bushing.

1 I 32

apart

point

bent

right

the

saddle

hook

in

back

timing

to

produce

(A)

possible.

pinion

the

hook

sure

their

position

to

Fig.

7)

At

inch

above

(Fig.

is

rotated

slightly

or

left,

screws

saddles

are

the

and

in

of

turn

is

this

13)

to

is

as

not

When

positioned,

the

needle

its

properly

driven

gear

Whenever it

initial

the

in

timed

timing,

timing

paragraph

position.

the

bar

screw

Fig.

saddles

the

hooks

(B,

timed

(E,

Fig.

the

1.

13

and

their

may

be

Fig.

14).

position,

6).

is

necessary

hook

against

need

the

Automatically,

driving

timed

To

maintain

tighten

for a hook

only

flat

by

the

be

on

the

After

the

retaining

the

back

last)

should

directly

the

driving

tremely

and

minimum

gears

using

permanently

set

screws on

to

replaced

the

hook

hook

be

the

screws

the

hook

be

at

important

have

the

removed

on

shaft

retains

saddle

screws

shaft

centered

the

gear

been

timing

the

the

as

its

13

are

first

driving

on

gear

faces.

and

if

gear

correctly

marks

the

hook

hook

after

shaft

described

correctly

is

correctly

tightened,

and

the

the

the

maximum

sound

on

in

shaft

this

with

the

gear

hook

The

hook

are

located

(tightening

clamp

(F,

shaft

alignment

shaft

gear

to

be

Fig.

and

screws

Fi

g. 6)

looking

of

is

exlife

gained.

14

Page 14

SETTING

THE

FEED

DOG

HEIGHT

Place

approximate

above

of

travel.

Height

screw

bottom

To

make

screw

the

lever

1 I

16

inch

take

up

the

opener

screw

imately . 005

of

the

the

(G,

edge

Fig.

(B)

any

(C)

hook

the

throat

adjustment

this

on

to

setting.

and

basket.

throat

height

plate

Fig.

of

the

16

adjustment,

the

opener

the

proper

vertical

finger

move

inch

of

the

16)

in

feed

~

The

end

drive

the

away

Retighten

plate

(Fig.

is

finger

in

feed

15)

accomplished

the

feed

dog

rests.

dog

to

by

turning

wise.

screw

recti

on.

ADJUSTING

Place

Turn

finger

While

tightly

make

the

cam

loosen

lever

position

screw

play

that

shaft.

opener

from

the

the

dog

teeth

at

bar

the

To

in

the

is

at

in

this

against

this

surface

to

(D)

may

Now

finger

cam

screw.

machine.

is . 050

the

highest

by

on

which

Raise

desired

the

screw

lower

the

the

handwheel

adjustment.

the

and

obtain

is

it,

opposite

THE

opener

its

maximum

position,

the

on

clamp

swing

used

exist

loosen

approx-

surface

HOOK

the

point

turning

the

height

clock-

turn

finger

in

hook

the

to

in

The

inch

the

feed

the

di

...

OPENER

the

point

the

opener

basket

The

basket

FINGER

(A,

Fig.

operating

of

travel

finger

(E).

opener

for a length

Fig.

17)

direction

should

Loosen

finger

15

in

from

should

the

machine.

until

the

be

screw

of

1 I

needle.

moved

(C)

contact

16

inch.

the

to

ADJUSTING

Fig.

18

THE

FOOT

ulator

machine

amount

presser

thumbscrew

sure,

to

foot

to

the

plate.

The

while

feed

With

should

118

inch

presser

PRESSURE

presser

(B.

Fig.

head,

of

pressure

foot.

in

clockwise

the

work

the

hand

rest

should

bar

spring

18)

controls

Turning

counterclockwise

uniformly

lifter

securely

be

connection

reg-

atop

maintained

the

the

on

the

the

turning

is

in

down

on

as

required.

the

14

direction

increases

position

throat

between

the

presser

it.

(A,

plate.

the

Fig.

foot

17

decreases

Only

presser

enough

Fig.

18)

Approximately

rests

the

bar

on

foot

pressure

presser

guide

the

throat

pres-

1116

and

Page 15

CHECK

The

the

needle

stop

is

Loosen

locknut

position

for

first

barrel

1 I 8

inch

thread

SPRING

take-up

thread

at

the 9 o•

screw

(D)

to

for

the

sewing

should

movement

passes

ADJUSTMENT

spring

barrel

should

(C)

make

barrel

clock

and

position

turn

this

adjustment.

should

trials.

be

adjusted

of

the

around

the

(A,

Fig.

be

set

so

as

barrel

(A)

be

Ultimately,

so

that

check

spring

6 o1clock

19),

which

that

the

lower

shown

(B,

immediately

This

recommended

approximately

the

take-up

there

is

(E)

position

about

as

of

controls

spring

Fig.

behind

correct

spring

1/16

the

needle

the

19).

to

hook.

Test

tension

raised

(F)

and

may

4 o1 clock

ment

of

to

with

will

is

no

pressure,

above

locknut

depend

fabric.

Machine

age,

feed

on

tack,

and

circle

off

check

to

insure

released.

be

position

made

suggested

Fig.

tack,

at

material

spring

set

so

from

(D).

upon

20

should

all

tension

a

good

that

for

the

and

turning

position.

Final

weight

POSITIONING

position

ADJUSTMENT

thread

spring

Fig.

Fig.

sew

in

line

speeds.

without

(E).

returning

The

take-up

the

head

first

take-up

sewing

pressure

the

check

and

Set

spring

type

the

parallel

By

sewing

tension

pressure,

19)

12)

continuously

of

feed

Styles

thread

There

snap

spring

slot

slants

trials.

screw

Maintain

pressure

of

thread

OF

front

FOR

trials,

(A,

and

set

to

required

without

tack,

and

622 00 L

breakage.

should

when

be

spring

adjusting

from

the

This

screw

(F)

position

counterclockwise

this

adjustment

adjustment

and

weight

THE

frame

with

FRONT

needle

the

cloth

CONTINUOUS

adjust

Fig.

position

the

stitch

the

20),

barrel

length

specifications.

thread

across

and

LA

the

must

enough

screw

10

adjust-

EYELET

thread

plate.

needle

check

break-

line

is

to

of

eyelet

SEWING

(A,

(B,

of

sew

(G,

Fig.

Fig.

19

19)in

its

lowest

SETTING

(FOR

The

on

the

loosening

(D)

right

The

maximum

release

The

the

tension

release

NOTE:

done

together,

release

THE

STYLES

tension

tension

screw

or

left

tension

travel.

sleeve

tension

discs.

arm

The

sleeve

NEEDLE

61800

release

release

(C)

as

release

forward

release

(B)

to

setting

because

will

TENSION

CA,

DA,

pin

arm

and

moving

required.

is

This

is

or

pin

This

the

rear

adjustment

of

if

the

still

not

RELEASE

HA,

62200

(A,

Fig.

(B).

This

the

Tighten

to

be

actuated

accomplished

backward

(A)

should

is

for

less

the

tension

tension

give

the

GA,

HA,

21)

should

adjustment

tension

screw

when

by

until

exert

made

proper

only

by

pressure

release

release

proper

arm

tension

KA

and

be

centered

is

made

release

the

presser

loosening

setting

enough

loosening

and

to

sleeve

is

and

too

release.

LA)

sleeve

screw

has

pressure

screw

the

front

the

far

15

by

foot

tension

back

is

(C)

been

(E)

for

any

Fig.

raised

and

rotating

attained.

to

release

and

moving

more

release

rotation

21

2/3

to

the

the

the

pressure.

arm

of

the

3/4

of

tension

thread

tension

should

tension

its

in

be

Page 16

16

Page 17

MAIN

FRAME

BUSHINGS,

COVERS,

PLATES

AND

HEAD

OILING

PARTS

Ref.

No.

1

2

3 57

4

5 57 WD

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22·

23

24

24A

25

26

27

28

29

30

31

32

33

34

to

61

Part

No.

22564

62271

15438

22569

62282

62282

22569

62285

62285

62294

62282

22569

62282

61271

62271 G

62282

62282

62282

22569

22569

62290

62284

62292

62284

62294

22564

62251 E

B

F

WB

c

K

D

B

J

666-258

666-138

A

D

B

294

c

D

E

B

88

666-117

A

M

B

666-257

A

666-256

Screw,

Needle

Nipper

Needle

Screw,

Screw,

Head

Screw,

Needle

Needle

Oil

Oil

Top

Screw,

Top

Screw,

Screw,

Needle

Needle

Eyelet

Eyelet

Top

Top

Top

Screw,

Screw,

Main

Plug

Oil

Needle

Tension

Needle

Head

Oil

Oil

Screw,

Take-up

See

Cover----------------------------------------

Sound

61800

61800

Wick

Felt

Tube,

HA,KA,

Cover,

Cover

Cover

Cover,

Cover

Shaft

Screw,

Cup

H,

62200

Oil

HA,

Siphon

62200

Siphon

62200

62200

GA, HA,

following

Description

Needle

Thread

Plate---------------------------------------

Thread

Nipper

Head

Top

Bar

C, D, H,

Bar

CA, DA, HA,

------------------------------------------

------------------------------------------

Top

Top

Top

Thread

Thread

Mounting

Mounting

Top

Top

Thread

Nipper

Nipper

Plate--------------------------------

Cover---------------------------------

fusulator---------------------------------

Cover

Frame

62200

Frame

for

Styles

and

LA----------------------------------

hinged

Cover

Latch

Cover,

Hinge

right-----------------------------------

Gasket,

Cover,

Cover,

Bushing

-----------------------------------

Cover,

Lead-in

Lead-in

Sleeve,

Sleeve,

-----------------------------------

for

synchronizer

Nipper

Base--------------------------

Spring

and

Top

Pivot

Pivot

---------------------------------

Latch

right,

right,

right

right,

right,

---------------------------------

Pin

G, H, K

Pin

62200

61800

----------------------------

Eyelet,

Eyelet,

for

for

----------------------------

Base-------------------

------------------------

Cover

GA, HA,

CA, DA, HA,

for

for

Class

Class

for

for

Hinge--------------Bushings,

and

L-------------------

Bushings,

KA

Class

Class

Class

Class

mounting

61800

62200

for

Class

for

Class

61800-------------62200--------------

61800

62200

-------------------------------------------

Feed

Feed

62200

GA,

GA,

Take-up

GA, HA,

Rock

Release

G,H,K

Rock

Attraction

GA,

Intake

HA,

Intake

HA,

Shield,

KA

and

page

Shaft

Pin

and L ---------------------------Shaft

HA,

Tube,

KA

Felt,

KA

Shield,

KA

for

LA

Bushing,

Bushing,

Bushing,

Felt,

and

and

and

Styles

for

KA

and

LA----------------------

for

Styles

LA

--------------------------

for

Styles

LA

--------------------------

for

Styles

LA

--------------------------

61800

-------------------------------

right

for

left

Styles

61800

CA, DA,

Styles

61800

61800

61800

for

Styles

for

Styles

and

LA---------

62200

bracket

--------------61800

----------------

CA,

CA, DA,

CA, DA,

G,

A,

------------

-----------61800-------62200--------

------------

------------

C,

CA,

DA,

DA,

HA,

HA,

HA,

62200

holes

D,

HA,

Amt.

Req.

1

1

1

1

1

2

1

1

6

2

2

1

1

1

1

1

1

1

2

1

2

1

2

1

1

1

2

1

1

- 2

1

1

1

1

1

1

1

2

1

NOTE:

'~".

the

use

of

these

parts

are

recommended

17

when

sewing with

nylon

thread.

J

Page 18

18

Page 19

MAIN

FRAME

BUSHINGS,

COVERS,

PLATES

AND

HEAD

OILING

PARTS

Ref.

No.

to

33

1

34

35 61893

36 62294

37

38

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

Part

No.

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

61893 A

56393

56393

660-356

22849

62236

50-568

22539

62232

61882

62232

62232

62232

25

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62202

62232

62232

62202

62202

62202

62202

62282

62282

22569

G-98

G-97

G-96

G-94

G-92

G-90

G-88

G-86

G-84

G-80

G-76

c

G

A

c

D

B

F

D

A

c

F-125

F-124

F-123

F-122

F-121

F-120

F-119

F-117

F-115

F-113

F-111

F-107

F-103

c

A

N

T

R

s

G

F

c

Blk.

See

preceding

Bed

Slide,

Bed

Slide,

Bed

Slide,

Bed

Slide,

Bed

Slide,

Bed

Slide,

Bed

Slide,

Bed

Slide,

Bed

Slide,

Bed

Slide, rig

Bed

Slide,

Head

Oil

Screw,

Feed

Oil Sig

Plug

Lower

Shim

Lower

Lower

Screw,

Bed

Bed

Bed

Bed

Bed

Bed

Bed

Bed

Bed

Bed

Bed

Bed

Bed

Lower

Bed

Gasket,

Bottom

Screws,

Oil

62200

GA, HA, KA

62200

Class

62200

GA, HA,

Oil

Oil

Porex

Head

Tube

GA,

Rocker

ht

Screw,

Main

and

Main

Main

Lower

Slide,

Slide,

62200---------------------------------------

Slide,

Slide,

Slide,

Slide,

Slide,

Slide,

Slide,

Slide,

Slide,

Slide,

Slide,

Main

Lower

Slide,

except

Friction

Friction

Retaining

Cover

Description

page

right,

right,

right,

right,

right,

rignt,

right,

right,

right,

right,

Pump

Tube--------------------------------------Tube

Filter

Oil

Clamp,

Oil

Tube

HA,

Gauge

Oil

Main

Bed

Slide,

left,

left,

left,

left,

left,

left,

left,

left,

left,

left,

left,

left,

left,

Main

front,

Bottom

Bottom

for

No. 8

for

No. 12

for

No. 16

for

Nos.

for

Nos.

for

No. 40

for

No.

for

No. 56

for

No.

ht,

for

No. 80

for

No.

Assembly,

KA

and

Spring---------------------------------

-----------------------------------

Pump--------

for

Styles

and

LA

------------------------------

Clamp,

KA

and

Rock

Shaft

-------------------------------------

Feed

Rocker

Shaft

Shaft

Shaft

Shaft

Bushing,

Seal

Gasket

Bushing,

Bushing

Shaft

front,

for

No. 8

for

Class

for

No.

for

No.

for

No.

for

No.

for

No. 32

for

No.

for

No.

for

No.

for

No.

for

No. 80

for

No.

Bushing

Shaft

Style

Spring,

Slide,

Sprin

Cover-------------------------------

-------------------------------------Cover-------------------------------

for

all

62200 K

Bed

Bed

g,

Bushir.

Bed

gauge---------------------

gauge------gauge--------------------

20

and

24

gauges

28

and

32

gauges

gauge-----

48

gauge-------------------gauge-----

64

gauge-------------------gauge--------------------

96

gauge--------------------

for

Styles

LA

-------------~------------

-

-------------------------

61800

for

Styles

LA---------------------------

Bushing----------------------

Rock

Shaft

right

---------------------------inner

Sleeve,

Bushing------------------------

and

Attachments

gauge

61800

16

gauge

20

gauge

24

gauge---------------------

28

gauge--------------------gauge

40

gauge

48

gauge

56

gauge---------------------

64

gauge

gauge---------------------

96

gauge

Sleeve,

-----------------------

Styles

Slide,

Slide,

in

------------------------front

Slide,

61800

CA,

DA,

61800

Hole

--------------------right----------------

right---------------

Class

and

front

62200-----------

No. 12 g

---------------------

---------------------

---------------------

---------------------

---------------------

---------------------

--------------------left-----------------

Class

-----------------

------------------

front

----------------

-

------------

-----------

-----------

-

--------------

-

--------------

CA,

DA,

HA,

62200

CA, DA, HA,

-------------

------------auge

61800

and

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

HA,

1

1

1

1

1

- - 1

1

3

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

11

NOTE:

these

parts

are

recommended

when

''A",

the

use

of

19

sewing

with

nylon

thread.

Page 20

20

Page 21

Re

f.

No.

l

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

55

A

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70