Page 1

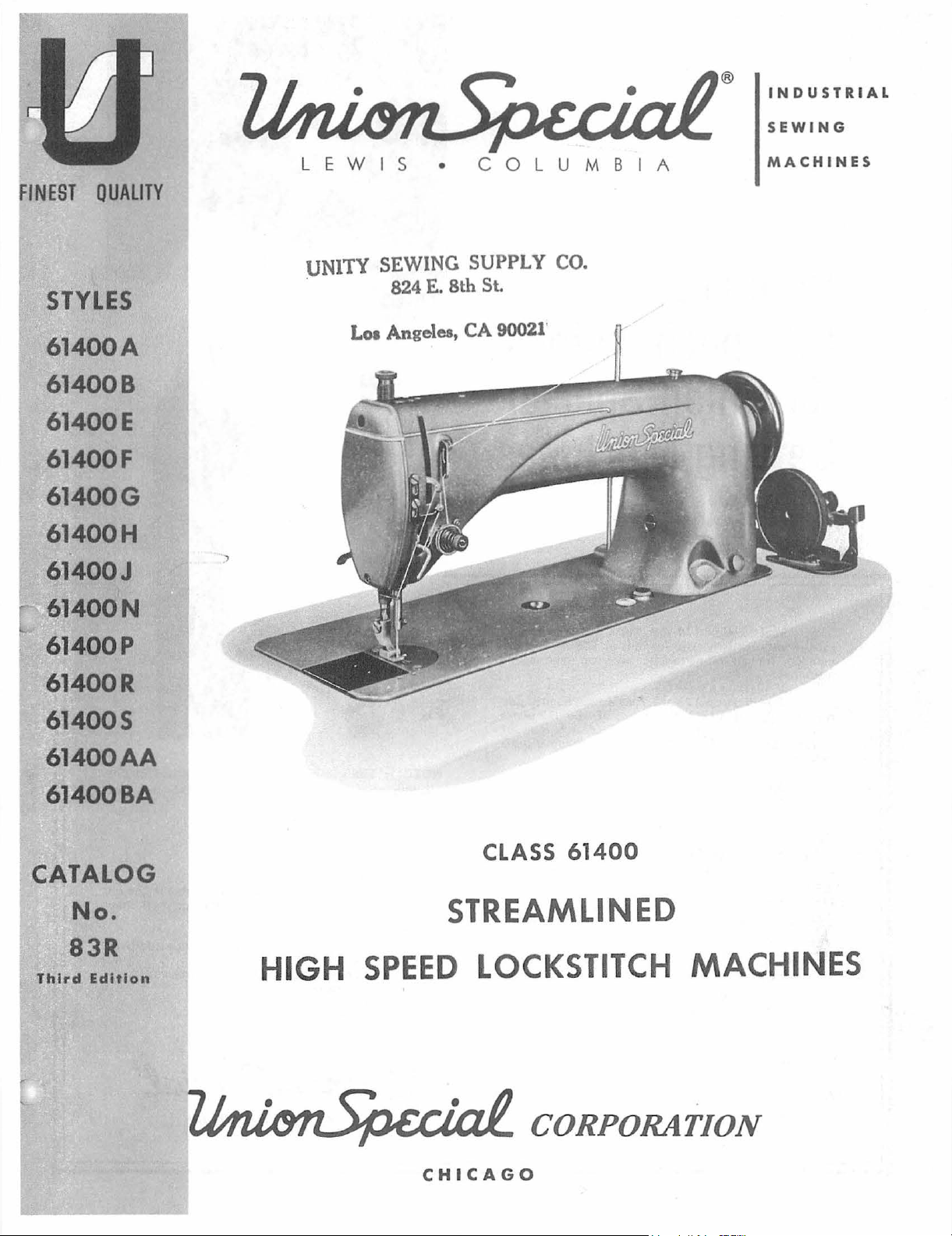

®

INDUSTRIAL

SEWING

FINEST

STYLES

6l400A

614008

61400E

61400F

61400G

61400H

61400J

61400N

QUALITY

LEWI

UNITY

. 824

Loa Angeles,

S •

SEWING SUPPLY

E.

8th St.

COLUMBIA

CA

90021'

MACHINES

CO.

61400P

61400R

61400S

61400AA

61400BA

CATALOG

No.

83R

Third

Edition

HIGH

STREAMLINED

SPEED

CLASS

61400

LOCKSTITCH

MACHINES

CORPORATION

CHICAGO

Page 2

•

Here

Oil

for

are

Specifications

Union

Sewing

Specification

roleum oil,

mended

machines.

roleum

white

1.

For

mount.

roleum

high quality

mi

tters. It

3. Where

used.

UNION

viscosity

for

all

Specification

oil,

viscosity

or

with a maximum

use

where freedom

Specification

oil,

viscosity

Spec

ifi

grease

is sim

No.

3 grease

SPECIAL

SPECIFICATION

Viscosity

Flash

Pour

Color

Neutralization

Viscosi

(D

Compounding

Copper

*A

nline

* Used

S.S.U.

(Min.)

(Max.)

A.S.T.M

ty Index

& D

Min.)

Corrosion

No.

with

Buna N

174

100

oiling

175 specifies a high

100

87

300

cation

100 specifies a general purpose

for

use

ilar

to

commerc

is

NO.

at

lOOoF

. (M

ax.)

No.

(Max.)

(Max.)

Rubber

Special

Machines

specifies a high

seconds

applications

seconds at

A.S.T.M.

from

oil

specifies a high

seconds

not

at

in

ball bearings

ial

obtainable,

174

90-125

350

20

3 3

0.10 0.10

85

None

1A

1

75-225

"0"

Retainers

at

100°F.

on

100°F.,

color

staining

100°F.

N.L.G.I.,

No. 2 may

175 87

90-125

350

20 20

85 85

None

1A

175-225

quality

Recom-

high

quality

number

is

quality

and

grease

300-350

175-225

pet-

speed

pet-

water

of

para-

pet-

trans-

No.

be

350

0.10

None

1A

'

'

NOTE

meeting

essential. These

These

and

separate.

NOTE

sha

1:

The

above classification

1. Ox

idation

2.

Rust

3.

4.

5.

addi

not

ll

not

1. E

2. Ta ckiness

3. Lead soap additives

4. Detergents

fiNUl

0UA;lll1'

inhibitors

Lub

ricity

Anti-oxidants

Film

strength additives

tives

removable

2:

Oils

containing

be used

xtreme

use

of

non-corrosive

is

desirable

may

include:

inhibitors

additives

must

be

completely

by

wick

feeding

the

at

any

pressure

or

adhesive additives

following

time:

additives-corrosive

CORPORATION

additives

soluble

nor

shall they

type

in

oils

but

not

in

the oil

additives

®

Page 3

Catalog

No.

83

R

LIST

61400

OF

PARTS

ADJUSTING

Streamlined

A

61400

61400

61400

B

E

61400

61400

Class

F

G

H

61400

AND

FOR

AND·

61400

Styles

INSTRUCTIONS

OPERATING

Lockstitch

61400

61400

61400

61400

61400

·61400AA

BA

J

N

p

R

s

November,

197

4

Union

Rights

Third

Copyright

Special

Reserved

Edition

19

By

Corporation

in

All

55

CORPORATION

INDUSTRIAL

Printed

SEWING

CHICAGO

in

MACHINES

U.S.A.

Countries

3

Page 4

The

dominating

industrial

lined

lines.

interchangeability.

1.

tional

difficult-to-clean

2.

shaft

eliminates

lubrication

3.

speed

4.

With a stitch

as a means

sewing

Lockstitch

All

parts

Streamlined

design

Simplified

bearings,

all

commonly

Acceleration.

in

an

Push

button

instant

of

idea

machines

machines

are

made

A few

design.

provides

recesses.

oiling.

feed

oil

holes

The

-

control,

length

reference

indicator

FOREWORD

back

of

required

new

of

"Union

in

the

world.

are a pronounced

to

precision

the

outstanding

Pleasing

greater

Automatically

rocker

in

cloth

Streamlined

for

higher

for

quick,

to

predetermine

in

stability

and

feed

plate

below

productive

easy

of

the

appearance,

comparison

Special"

The

new

achievement

gauges

new

features

and

ruggedness,

supplies

lift

bearings

but

also

bed

plate.

Lockstitch

rates

adjustment

stitch

is

to

high

insuring

this

oil

to

does

is

and

of

type,

lengths.

build

speed

along

are:

natural

lower

and

away

brought

lower

stitch

using

the

best

Stream-

these

complete

func-

free

from

main

not

only

with

hand

to

costs.

length.

letters

top

It

is

that

advantages

tain

the

machines,

centers,

will

valuable

parts

An

additional

Union

ready

our

constant

enable

from

operating

for

and

Special

the

customer

the

use

Styles

which

to

in

catalog,

Catalog

representatives

cooperate

aim

to

of

Union

and

adjusting

Class

containing

will

be

No. 45 N

with

furnish

to

secure

Specials.

61400

furnished

Streamlined

will

you

to

carefully

all

possible

The

data

and

information

on

request,

Needle

be

plan

Manual

found

and

Engineering

prepared

following

illustrate

Lockstitch

relative

in

all

estimate

CORPORATION

information

economies

pages

and

describe

machines.

to

these

is

listed

manufacturing

requirements.

Department

below:

and

con-

5

Page 5

APPLICATION

OF

CATALOG

This catalog

applied

as

right

with

and

discretion

left,

machine.

Each

Union'

machine. Style

or

more letters

taining

the

*6

~~

61400

*6140

*614

Styles

sty

1400

00

the letter

le

number

A

B

0 E

F

of

For

Same

Non-adjusted

Same

applies

to

front

Special machine

numbers

suffixed,

11

''Z

are

machines

in

STYLES

Plain

edge

similar

that

OF

plain

seaming,

edge

guide No.

specified.

throat

plat

size).

as

Sty

needle

(Specify

for

as

bar

needle type

as

Style

plain

seaming

house dresses,

only

the

special

and

back,

are

classified

but

never

special.

it

contains

MACHINES

guide

No.

All oth

61303

er

e,

attachments,

le

61400

machine

travel,

61400

to

the

standard

machines

etc.,

are

IDENTIFICATION

carries a sty

as

standard

contain the letter 11Z

in

construction

no letters. Examp

IN

CLASS

1

9164

inch

61203

guides

E

with

and

or

61203

attaching

guides,

A,

except

it

prepared

no

sewing

and

size)

.

E,

except

and

simultaneous

slips,

it

etc. (Specify

styles

taken

in

of

Class

from

OF

le

number

and

are

gro

uped

le:

61400

needle

STREAMLINED

bar

A

and

screw No.

attachments

stitches

has

1

13164

to

receive

parts

included.

includes

sewing

pinking operations

needle

machines

61400.

the

operator

as

All

listed

references

' s

position

MACHINE

which

Sfecial.

1

•

11

61400

is

stamped

Those

Example:

under a class

11

11

61400

•

which

number

LOCKSTITCH

travel.

attaching

are

Columbia

per

inch

Accessories

screw

G26

extra.

inch,

thread

needle

pinking

No.

will

be

(Specify

bar

travel

Accessories

parts and Columbiapinking

on

light

type

and

size).

herein.

to

directions,

while

in

the

name

are

standard

11

A

•

Style

which

No

.

29480

22551

furnished

feed

dog,

number,

.

attachment,

No

.

29480

to

medium

It

can

seated

plate

numbers

differs

AJ

A

or

gratis

presser

needle

1 9 I 64

AJ

attachment

work,

also

be

such

at

the

on

the

have

one

con

from

included

three-way

when

foot,

type

and

inch

included

such

-

.

.

'~

61400

G

*6

1400

H

*

61400

*614

~~61400

*

61400

*6

'~6

J

00

N

P

R

1400

S

1400

AA

Non-adj

bar

(Specify

Same

for

house

Same

pr

Equipped

travel,

shirts, etc.

plate,

Equipped

trave

trave

as

plain

dresses,

as

oduce

l,

usted

l,

needle

Style

seaming

Sty

two

with

for

feed

with

for

machine

plain

61400

le

61400

pred

power

attaching

Accessories

roll

power

attaching

included. (Specify

per

inch,

thread

Same

as

Style

presser

needle

Same

pr

esser

needle

Same

spool

type

as

type

as

pin,

foot,

and

Style

foot,

and siz

Style

two

61400

61400

61400

feed,

type

and

slips,

A,

etermined

er,

guides,

feed

number,

N,

throat

size).

throat

e).

hinge

prepared

no

and

G,

sewing

size).

except

simultaneous

etc.

(Specify

except

stitch lengt

driven

collar

top

bands

No.

stitches

driven top

sleeve

facings

dog, presser

need

except

plate,

P,

except

plate,

A,

except

studs

and

to

receive Lewis

parts

it

includes

needle

equipped

roller

to

29480

AJ

roller

to

le

type

it

has

feed

roller,

it

has

feed

roller,

without

two No.

included.

sewing

pinking

type

with a quick

hs

by

feed

inc

to

shirts

luded.

inch,

dress

per

feed

work

and

foot,

throat

and

size).

1

13164

guides,

1

13164

guides,

accessories.

22585

pinking

Accessories

parts

operation

and

instant

right

and

(Specify

thread

to

rear

dress

plate,

inch

needle

stitches

inch

needle

stitches

A

screws

attachment,

and

Lewis

on

light

No.

to

medium

1 9 I 64

29480

pinking

size).

stitch

change

mechanism

adjustment.

of

needle,

hemming

feed

number,

of

needle,

1 9 I 64

tails

dog,

needle

1 9 I

inch

of

presser

type

64

inch

sport

shirts. Accessories No.

feed

bar

bar

We do

for

roller,

travel.

per

travel.

per

furnish

attachment.

guides,

(Specify

inch, thread

(Specify

inch,

thread

one

inch

needle

AJ

included

attachment,

work

such

that

needle bar

or

dress

foot,

throat

and

size).

needle

29480

stitches

feed

number,

feed

number,

extra

bobbin,

.

as

will

bar

AJ

dog,

dog,

*

61400

*

No

lon

BA

ger

Same

as

spool

pin,

available.

Style

two

61400

hinge

B,

studs

except

and

without

two No.

accessories.

22585

A

-6-

screws

We do

for

furn

ish

attachment.

one

extra

bobbin,

Page 6

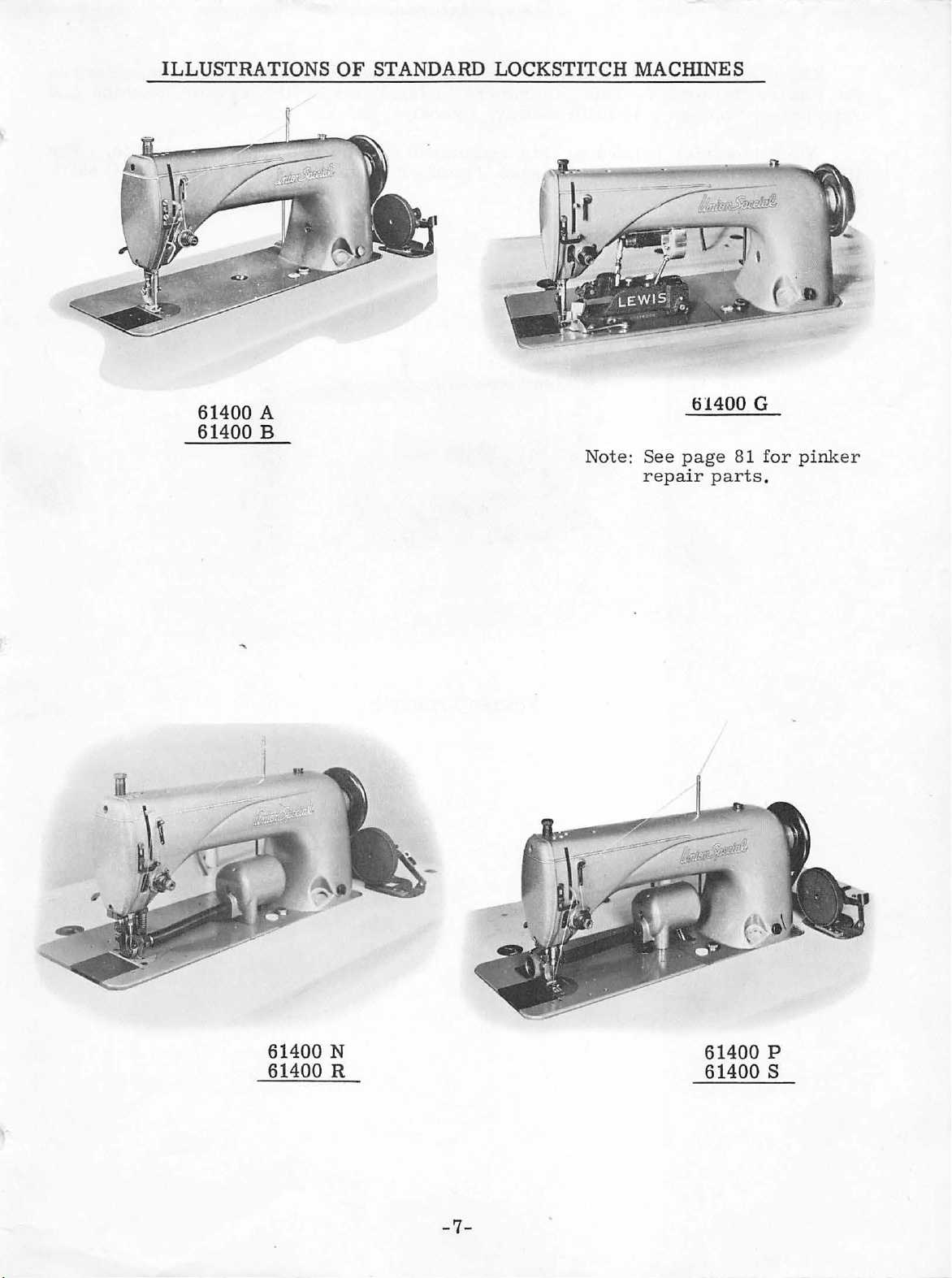

ILLUSTRATIONS

OF

STANDARD LOCKSTI

TCH

MACIDNES

61400 A

61400 B

Note:

See

r epa

tH400 G

page

ir

81 fo r pi

parts.

nker

61400 N

61400 R

-7-

61400 p

61400 s

Page 7

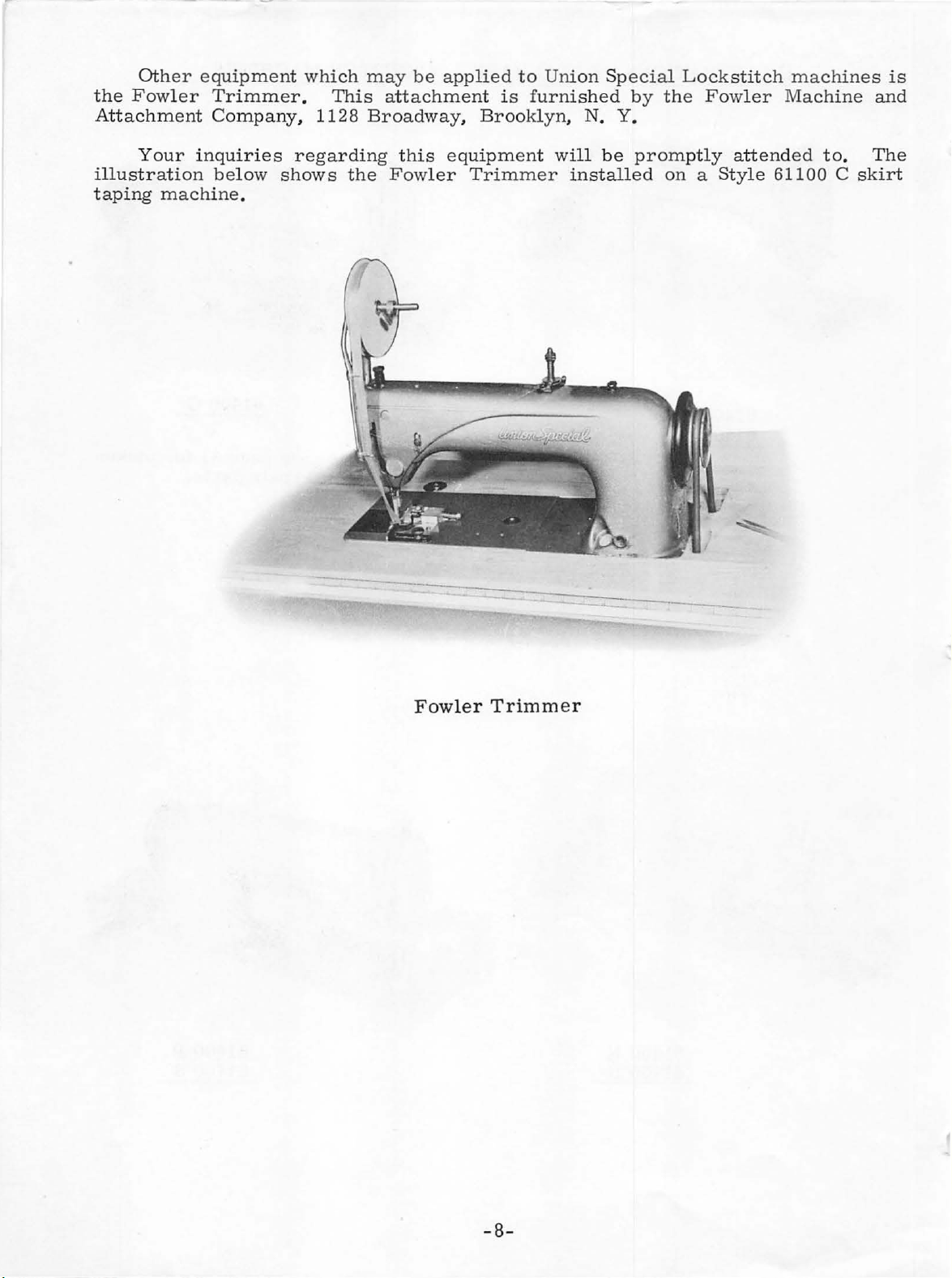

Other

the

Fowler

Attachment

equipment

Trimmer.

Company, 1128 Broadway,

which

This

may

be

attachment

applied

Brooklyn,

to

is

furnished

Union

N. Y.

Special

by

Lockstitch

the

Fowler

machines

Mach

ine

is

and

Your

illustration

taping

machine.

inquiries

below

regarding

shows

the

this

Fowler

equipment

Trimmer

wi

ll

be

installed

promptly

on a Style 61100 C

attended

to.

The

skirt

Fowler

Trimm

er

-8-

Page 8

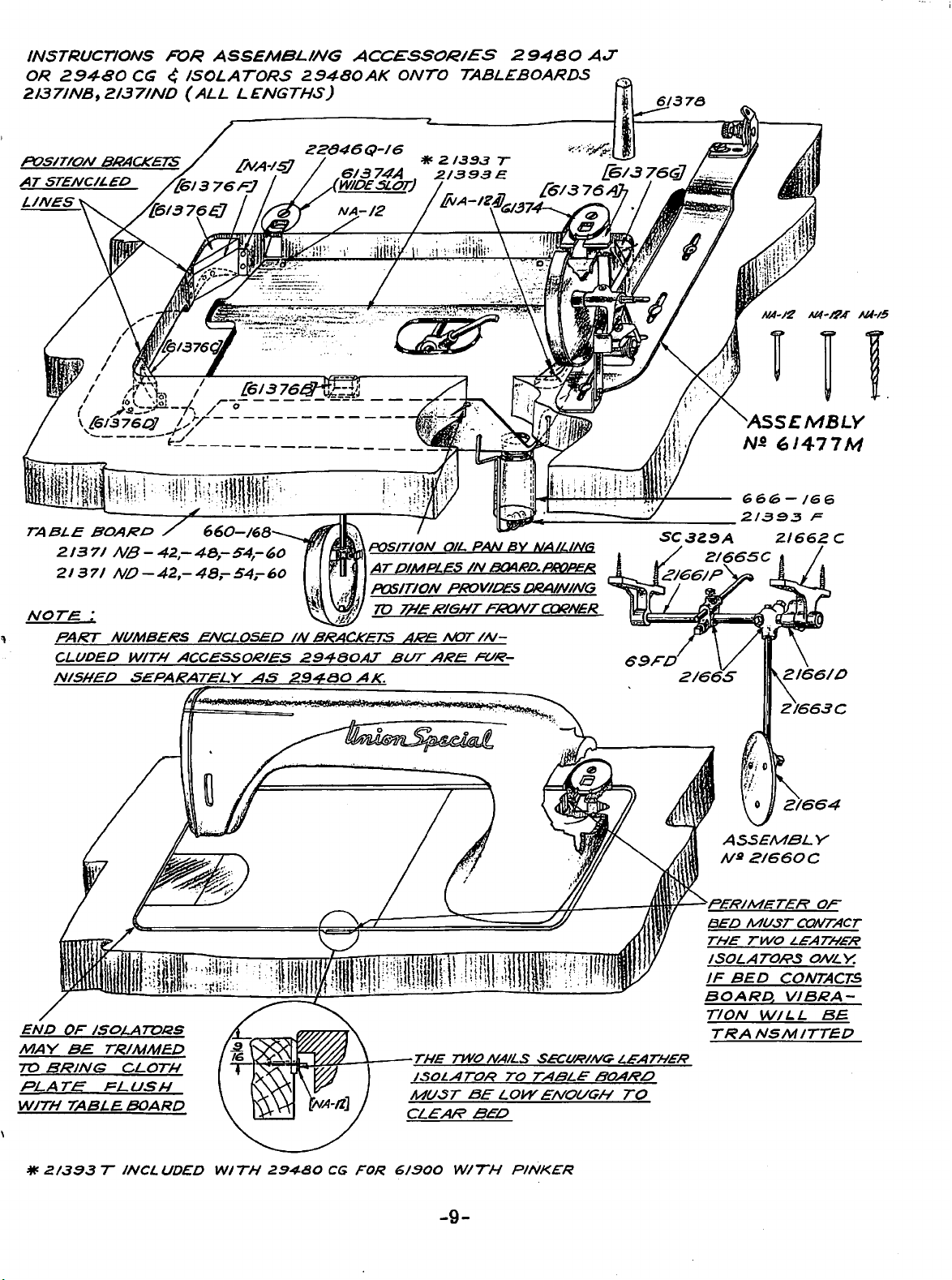

INSTRUCTIONS

OR

29480

FOR

CG

~ISOLATORS

21371NB1ZI.371NO

TABLe

NOTE.;

BOARD

21371

21371

NB-42,-4B~-s4,-6o

N0-42,-48;-54

PART

ASSEMBLING

(ALL

LENGTHS)

1

60

ACCESSORIES

ZS480AK

29480

ONTO

POSITION

AT

1?/MPLES

TABLEBOARD.S

il-lal~~===::::::::2:__

OIL

PAN

BY

NA

IN

~~D.PROPER

/LING

POSITION PROVIDES DRAINING

TO

!He

RIGHT

FI<'OIVTCCY<NER

AJ'

___

SC

32.9A

ASSEMBLY

NS

61471M

666-IG6

21.3

9 3 F

21662

C

END

OF

150/...ATORS

MAY

BE.

rRIMMED

70

BRING

PLATE

WITH

TABLE.

:ttc

2.13S3 T INCLUDED

CLOTH

FLUSH

BOARO

WITH

2!1480

CG

FOR

THE

ISOLATOR

MVST

CLEAR

61.900

TWONAILS

TO

Be

LOW

BED

WITH

PINKER

SECUR/NGL.EATHER

TABLE

ENOVGH

-9-

BOARO

TO

ASSEMBLY

NR21660C

PERIMETER

BED

MUST

rHE

TWO

LEATHER

ISOLATORS

IF

BED

BOARA

TION

TRANSMITTED

CONTACTS

VIBRA-

WILL

Or

CONTACT

ONLY.

BE

Page 9

Each

machine

the machine

those

who handle the machine, the

reaches

and make only the

before

ordinary

ASSEMBLY PARTS

A

bag

of

assembly

screws

are

for

After

Push

slotted

holding

miscellaneous

unpacking the machine

the hinge

so

that a tight

studs

the

customer

parts,

it

leaves

settings

into

fit

can be

the

factory

it

is

ready

customer

to

adapt

consisting

attachments

assemble

position

in the

easily

INSTALLING

is

for

needs

sewed off,

service.

only to

inspected,

Because

place

the machine to the

of one spool pin, one

to

the

bed

plate

the spool pin (K, Fig. 3).

holes

provided

at

made.

o~

it

in

its

material

extra

is

bobbin, two hinge

packed with

the

rear

and

all

the

proper

he

carefully

precaution

wishes

packed. When

position

to

sew.

studs,

each

machine.

of the machine. The

taken by

in

the table

and

studs

two

STANDARD

Also included with

assembly,

one machine

are

indispensable

TABLE

Lockstitch

ACCESSORIES

one

drip

rest

TOPS

machines

each

pan, one

oil

pin, two hinge

when

setting

are

flush with the top of the table.

Standard

Isolated

installation

mounting,

should be

When

possible,

Special

KNEE

PRESS

The knee

Special table

by

punch

boards

center

right

locate

of the

side

assembly

table

tops

are

mounting

of

isolated

felt

pads

driven

horizontally

assembling

so

that

the hinge

care

press

tops

marks

on the

the knee

shaft

parts

mounting

are

furnished

the hinge

studs,

should be taken

is

attached

at

the location

underside.

press

is

8-1/4

inches

of the cut-off. The knee

should

appear

as

in

machine

drain

plates

is

a box of

jar

and

and

clamp

screws,

up the machine.

installed

available

are

not included with table

parts

with the

as

indicated

plates

attached

that

in

table

for

isolated

is

shown

accessories

on the

to the

table

to the machine,

machine

to Union

designated

For

other

so

that

the

from

the

press

(Fig. 2).

standard

spring,

four

tops

prepared

mounting on

in

(Fig. 1).

for

right

end of

tops,

does

not

accessories

one knee

felt

pads

and

with

cut

all

types

tops

and

must

For

table

isolating. The

cut-out

be

sure

to locate

can

swing

contact

the

containing one bobbin

lifter

assembly

necessary

out,

so

of

installations

be

ordered

tops not

nails

that

prepared

and

nails.

the bed plate

separately.

for

these

(Fig. 1).

them

as

accurately

properly

sides

in

of the

the

plate.

cut-out

rubber

These

and

for

isolated

pads

at

any point.

winder

pad,

parts

is

drives.

The

as

DRIP PAN

The

drip

pan

is

Special

on the

furnished

For

set

table

inside

with the

other

table

high enough to

low enough to

machine.

that

it

It

is

directly

tops

at

the indentation

of the

cut-out,

accessories

tops, the

clear

clear

the botton of the

should be

under

attached

laterally

the

to Union

using

(Fig. 1).

drip

pan should be

the knee

base

marks

the

nails

press

located

of the

and

so

machine.

-10-

Fig. 2

Page 10

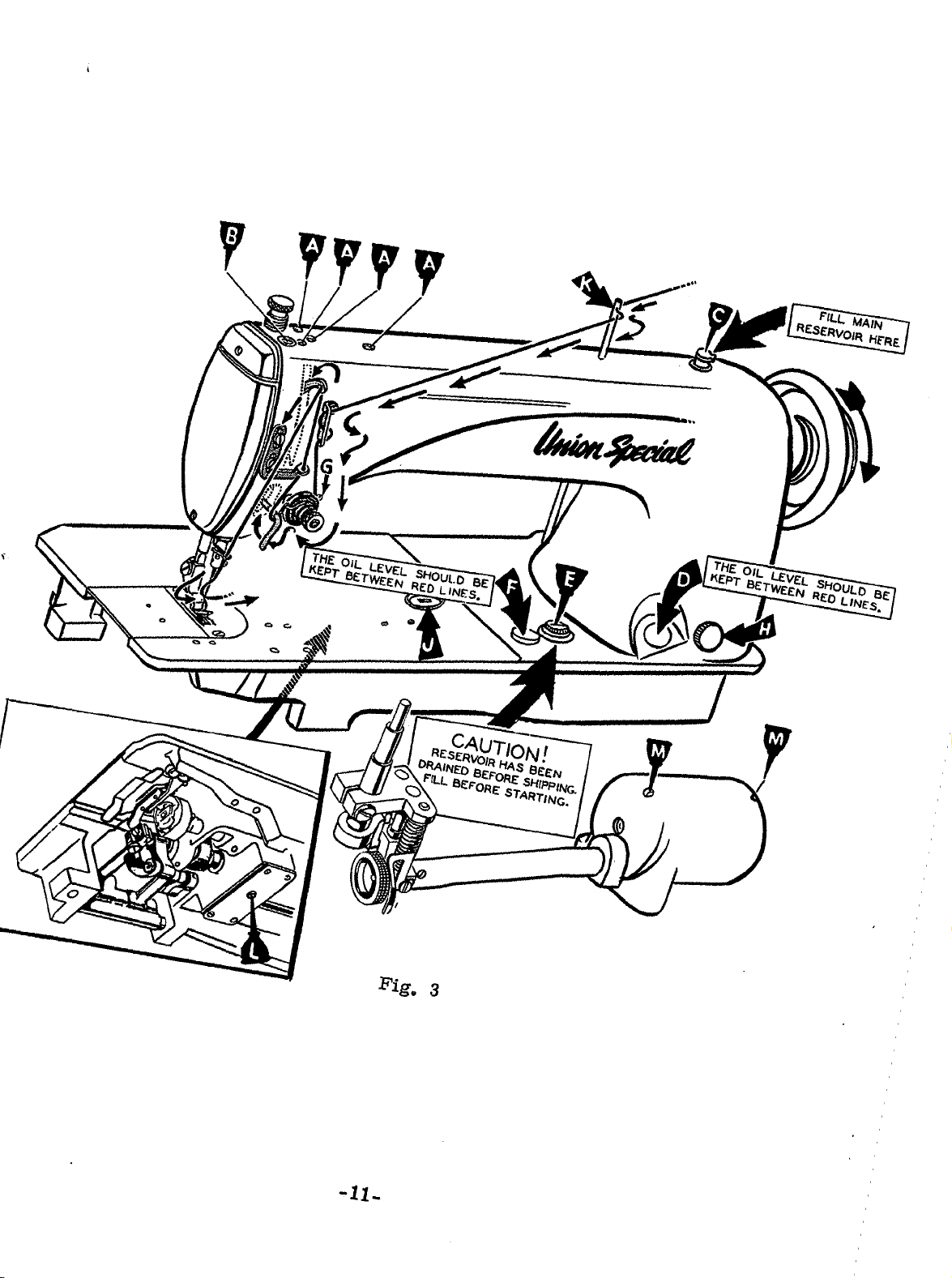

F'tLL MAIN

R£StRVot~

HE"R£

-11

Fig.

..

3

Page 11

BOBBIN WINDER

The

in

front

winder

ther

pressure

scribed

of

has

away

under

bobbin

the

sewing

two

from

against

"Threading

elongated

belt

BELTS

winder

machine

as

the

belt

should

attaching

needed.

to

wind

and

be

secured

belt

and

holes,

The

pulley

the

bobbin.

Winding

INSTALLING

to

the

will

the

which

Bobbin

table

bear

against

allows

of

the

winder,

Re~ulation

'.

(Continued)

top

so

that

the

belt

the

mechanism

when

and

operation

its

when

in

operation

pulley

in

operation.

to

be

of

the

will

be

moved

should

bobbin

located

The

closer

exert

winder

directly

base

to

only

is

of

the

or

far-

enough

de-

These

machines

CAUTION!!

The

oil

the

hook

before

before

oughly

for

several

parts.

out

damage.

shipment

starting

in

has

shaft

gear

accordance

minutes

Full

speed

to

RECOMMENDED

Use a straight

90

to

125

main

equivalent

same

graph

less

seconds

reservoir,

to

Stainless

viscosity

can

be

oil

is

Union

Union

water

as

used

been

case,

and

these

operate.

with

to

operation

OILS

mineral

at

100°

and

hook

Special

white

that

in

the

Special

are

equipped

drained

and

the

reservoirs

Lubricate

instructions

distribute

can

oil

F.

in

shaft

oil

straight

described

hook

oil

specification

to

use

from

the

main

hook

oil

must

machine

and

the

oil

then

to

be

expected

of a Saybolt

hook

oil

gear

reservoir,

case.

specification

mineral

in

the

preceding

reservoir,

No.

either

No. 1

"V"

LUBRICATION

reservoir,

reservoir

be

filled

thor-

run

slowly

the

various

with-

viscosity

This

of

is

No. 174.

oil

of

the

para-

the

stain-

17&.

or

round

belt.

Oils

For

trouble

With

little

oil

in

the

J,

all

sllould

is

the

hole

28604

to

fill

replenished

kept

between

Th"e

kept

The

the

On

hook

between

hook

level

Remove

Styles

and

bring

be

used.

CAUTION! I

Do

shaft

not

gear

conforming

needle

be

needle

included

free

bar

used

bar

with

to

operation,

at

the

and

as

reservoirs.

about

twice a month.

the

lines

on

oil

reservoir

the

lines

shaft

gear

up

to

the

plug

plug

screw

61400 N, 61400

use a compounded

case,

as

these

spec~fication

top

of

only

it

will

the

flow

accessories

The

main

oil

the

its

stroke,

around

out

reservoir

No. 174

machine

the

when

packed

However,

the

gauge

(D).

is

filled

at

on

case

oils

the

gauge

is

filled

screw

and

P,

oil

separate

plug

(F).

at

hole,

check

the

when

the

61400 R, 61400 S,

in

the

hook

and

or

oil

outer

machine

is

the

screw

plug

the

level

oil

froth.

175

may

as

indicated

the

holes

edges

is

with

the

filled

level

(E)

through

and

oil

screw

machine

of

oil

about

holes

reservoir,

also

be

in

(A)

twice

of

the

needle

operated

machine.

oil

should

hole

be

its

level

(L). A quantity

is

tilted

every

(M)

should

feeding

used

in

the

the

diagram

daily.

bar.

at

high

It

contains a sufficient

cup

(C)

checked

should

back

six

be

drive

(Fig.

In

Do

speed. A can

and

from

be

against

months.

oiled

shaft

manually

3).

oiling

hole

not

put

the

supply

time

checked

of

oil

sufficient

the

rest

sparingly

gear

case,

oiled

(B),

oil

into

of

is

to

time'and

twice

pin,

each

places.

very

the

oil,

No.

quantity

usually

daily

to

should

day.

or

hook

·t

-12-

Page 12

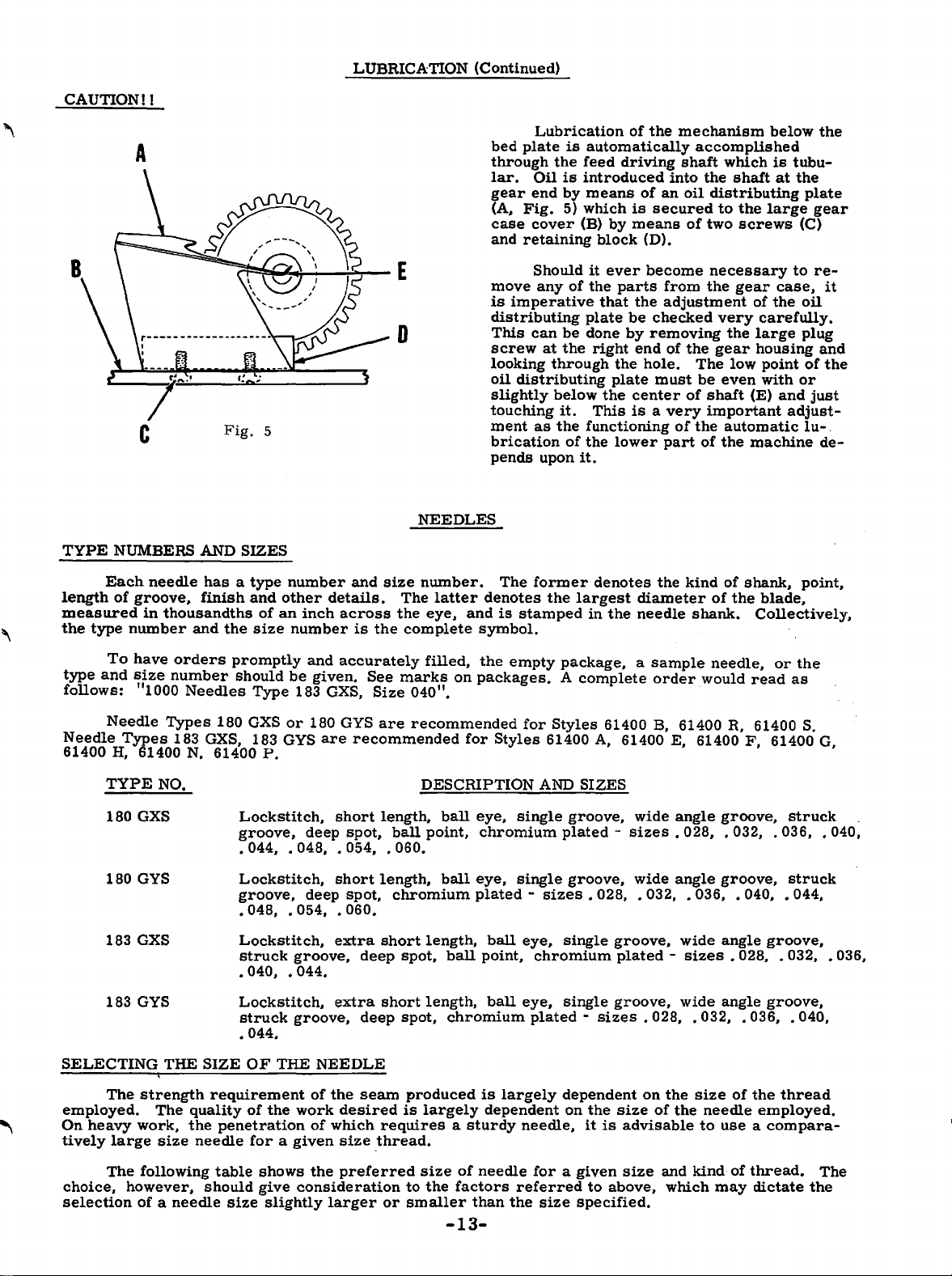

CAUTION!!

LUBRICATION

(Continued)

TYPE

NUMBERS AND

Each

length

of

measured

the

type

A

needle

groove,

in

thousandths

number

Fig.

SIZES

has a type

finish

and

the

5

and

of

size

number

other

an

inch

number

and

details.

across

is

0

size

the

the

NEEDLES

number.

The

latter

eye,

complete

bed

through

lar.

gear

(A,

case

and

move

is

imperative

distributing

This

screw

looking

oil

distributing

slightly

touching

ment

brication

pends

The

denotes

and

is

symbol.

Lubrication

plate

is

the

Oil

is

end

by

Fig.

5)

cover

retaining

Should

any

of

can

be

at

the

through

below

it.

as

the

of

upon

former

the

largest

stamped

of

the

automatically

feed

driving

introduced

means

which

(B)

it

the

plate

done

right

This

by

block

ever

parts

that

by

the

plate

the

of

is

secured

means

(D).

become

the

be

checked

removing

end

hole.

must

center

is a very

functioning

the

lower

it.

denotes

the

diameter

in

the

needle

mechanism

accomplished

shaft

into

an

which

the

oil

distributing

to

of

two

necessary

from

the

adjustment

very

the

of

the

gear

The

be

even

of

shaft

important

of

the

of

kind

automatic

the

of

part

of

shank.

below

is

shaft

at

the

large

screws

gear

case,

of

the

carefully.

large

housing

low

point

with

(E)

and

adjust-

machine

shank,

the

blade,

Collectively,

tubu-

the

plate

gear

(C)

to

reoil

plug

of

or

just

lu-.

point,

the

it

and

the

de-

To

and

h?-ve

S1ze

"1000

type

follows:

Needle

Needle

61400

Types

H,

61400

TYPE

180

GXS

180

GYS

183

GXS

183

GYS

SELECTING

The

strength

employed.

On

heavy

tively

work,

large

orders

number

Types

183

NO.

THE

The

size

promptly

should

Needles

180

GXS,

N.

61400

groove,

groove,

SIZE

requirement

quality

the

penetration

needle

and

be

Type

GXS

or

183

GYS

P.

Lockstitch,

•

044, • 048, • 054, • 060.

Lockstitch,

•

048, • 054, • 060.

Lockstitch,

struck

•

040, • 044.

Lockstitch,

struck

•

044.

OF

THE

of

the

for a given

accurately

given.

183 GXS,

180

GYS

are

short

deep

spot,

short

deep

spot,

extra

groove,

extra

groove,

NEEDLE

of

the

work

desired

of

which

size

See

marks

Size

are

recommended

length,

ball

length,

chromium

short

deep

short

deep

seam

requires a sturdy

.thread.

filled,

040".

the

on

packages. A complete

recommended

for

DESCRIPTION

ball

eye,

point,

ball

chromium

eye,

plated -sizes

length,

spot,

ball

point,

length,

spot,

chromium

produced

is

largely

is

dependent

empty

for

Styles

single

single

ball

eye,

chromium

ball

eye,

plated -sizes

largely

needle,

package, a sample

Styles

61400

AND

61400

A,

SIZES

groove,

61400

wide

plated -sizes

groove,

single

wide

•

028, . 032, • 036,

groove,

plated -sizes

single

groove,

•

dependent

on

the

it

size

is

advisable

on

order

needle,

would

B,

61400

E,

61400 F 61400

angle

groove,

•

028, • 032, . 036,

angle

groove,

wide

angle

wide

028, • 032, • 036, • 040,

the

of

angle

size

the

needle

to

use a compara-

or

the

read

as

R,

61400

S.

I I

struck

struck

• 040, •

044,

groove,

•

028, • 032, • 036,

groove,

of

the

thread

employed.

G

• 040,

The

choice,

selection

following

however,

of a needle

table

should

size

shows

give

consideration

slightly

the

larger

preferred

or

size

to

the

smaller

of

needle

factors

than

for a given

referred

the

size

specified.

-13-

to

size

above,

and

which

kind

of

may

thread.

dictate

The

the

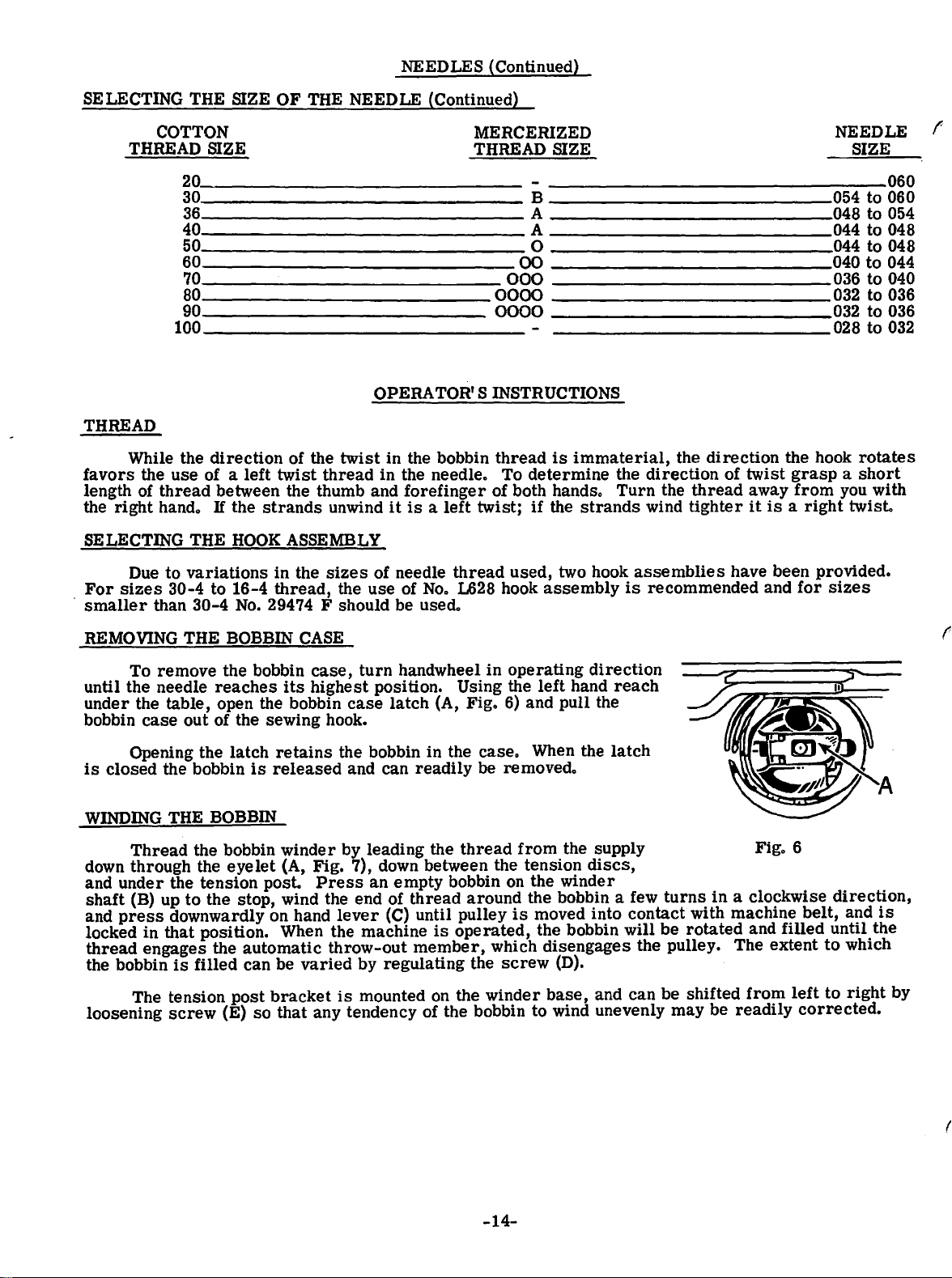

Page 13

NEEDLES (Continued)

OF

SELECTING THE SIZE

THE NEEDLE (Continued)

COTTON MERCERIZED NEEDLE f

THREAD SIZE THREAD SIZE SIZE

20____________________________

30

36

40

50 0 044

60

70

80

90

100 028

THREAD

use

direction

of a

H the

While the

favors

the

length of

the

right

thread

hando

SELECTING THE

Due to

For

sizes

smaller

variations

30-4

than

30-4

to

REMOVING THE

OPERA TOR'S INSTRUCTIONS

left

of the

twist

twist

thread

in the bobbin

in the needleo To

between the thumb and

strands

HOOK

in the

16-4

thread,

No.

29474 F should be usedo

BOBBIN

unwind

ASSEMBLY

sizes

the

use

CASE

it

of needle

forefinger

is a left

thread

of

Noo

L628 hook

B

-------------------054

A 048 to 054

A 044 to 048

00

000

0000

0000

thread

is

determine

of both handso

twist;

if

used,

the

two hook

assembly

immaterial,

the

direction

Turn

strands

wind

assemblies

is

recommended and

the

the

direction

of

thread

tighter

the hook

twist

grasp a short

away

from

it

is a right

have been provided.

for

060

to 060

to 048

040

to

044

036 to 040

032 to 036

032 to 036

to 032

rotates

you with

twisto

sizes

(

To

remove

until the needle

under the table, open the bobbin

bobbin

case

Opening the

is

closed

WINDING

the bobbin

THE BOBBIN

Thread

down through the

and

shaft

and

under

press

the tension post.

(B) up

downwardly on hand

the bobbin

reaches

its

case,

highest

case

out of the sewing hook.

latch

is

the bobbin

eyelet

retains

released

winder

(A, Fig. 7), down between the tension

the bobbin in the caseo When the

and can

by leading the

Press

to

the stop, wind the end of

lever

turn

handwheel

position. Using the

latch

readily

an

empty

thread

(C) until pulley

locked in that position. When the machine

thread

the bobbin

loosening

engages the

is

filled can be

The tension

screw

automatic

post

bracket

(E)

so

throw-out

varied

that

by

is

mounted on the

any tendency of the bobbin to wind unevenly

member,

regulating

in

operating

left

hand

(A, Fig.

6)

and pull the

be removedo

thread

from

the supply

bobbin on the winder

around

is

operated,

the

the bobbin a few

is

moved into

the bobbin will be

which

winder

screw

disengages

(D).

base,

direction

reach

latch

discs,

turns

in

contact

with machine

rotated

the pulley. The extent

and can be shifted

may

be

Figo

6

a clockwise

direction,

belt,

and

and filled until the

to

which

from

left

to

readily

right

corrected.

is

by

-14-

Page 14

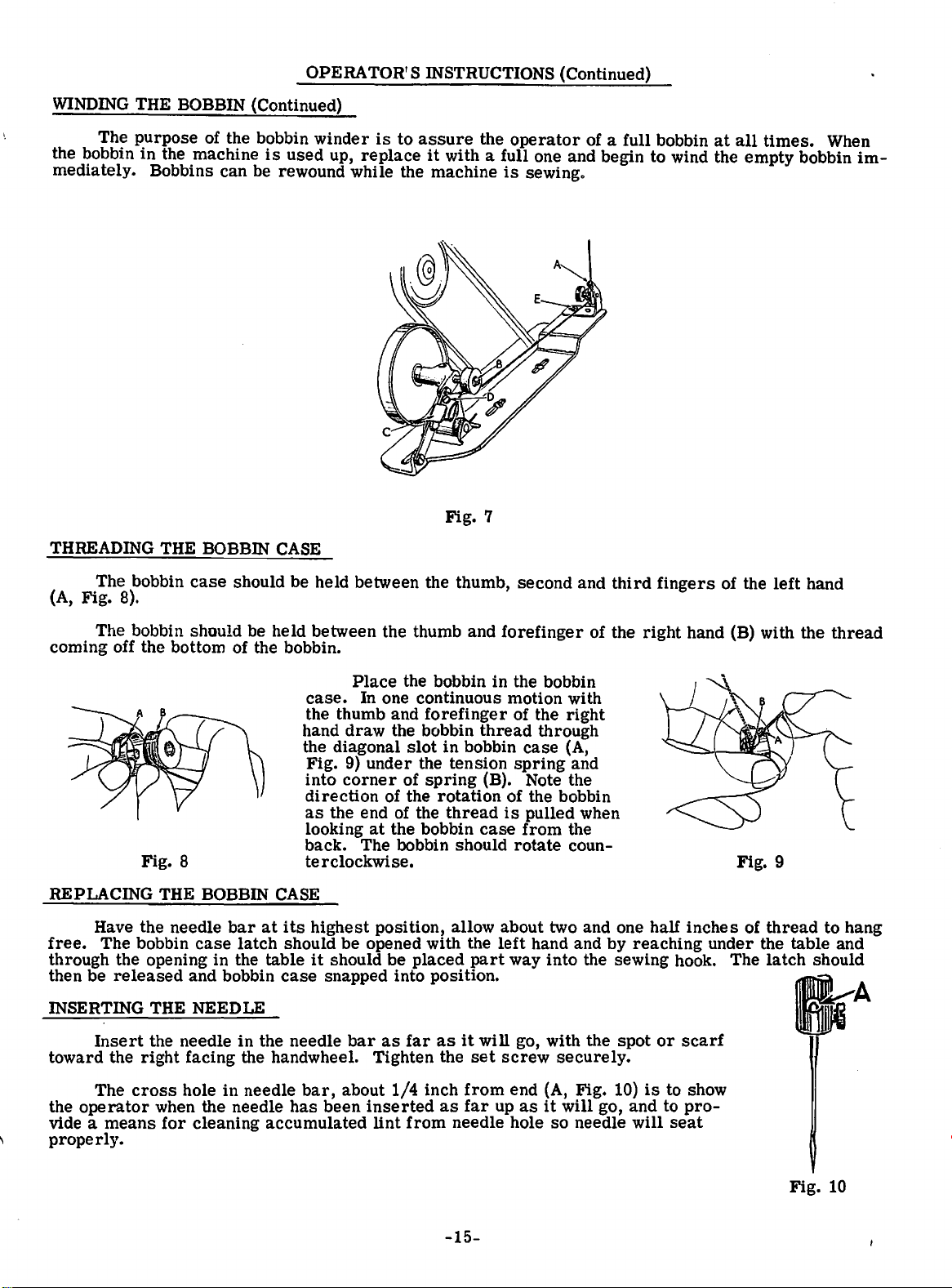

OPERATOR'S INSTRUCTIONS (Continued)

WINDING

the bobbin

mediately. Bobbins

THREADING THE

THE BOBBIN (Continued)

purpose

The

in

the machine

of the bobbin

BOBBIN CASE

is

can

used

be rewound while the machine

winder

up,

is

to

replace

assure

it

the

with a full one and begin to wind the

Fig. 7

operator

is

sewingo

of a full bobbin

at

all

times.

empty

When

bobbin

im-

The bobbin

(A, Fig. 8).

The bobbin should be held between the thumb and

coming off the bottom of the bobbin.

Fig.

REPLACING THE BOBBIN

Have the needle

free.

through the opening

then be

INSERTING THE

toward the

The bobbin

released

Insert

right

case

should be held between the thumb, second and

Place

case.

the thumb and

hand

the diagonal

Fig. 9)

into

direction

as

looking

8

bar

case

latch

in

the table

and bobbin

NEEDLE

the needle

facing the handwheel. Tighten the

in

back. The bobbin should

terclockwise.

CASE

at

its

highest

should

it

case

the needle

In one continuous motion with

draw

under

corner

the end of the

at

position, allow about two and one half

be

opened with the

should be

snapped into position.

bar

as

the bobbin

of the

the bobbin

the bobbin

forefinger

slot

in

bobbin

the tension

of

spring

rotation

thread

placed

far

as

part

it

set

will

third

fingers

forefinger

in

the bobbin

of the

thread

(B). Note the

case

through

case

spring

of the bobbin

is

pulled when

from

rotate

left

hand and by

way into the sewing hook. The

go, with the

screw

of the

right

(A,

and

the

coun-

spot

securely.

right

hand (B) with the

or

inches

scarf

reaching

of the

Fig. 9

of

under

left

hand

thread

thread

the table and

latch

to hang

should

The

the

operator

vide a

properly.

means

cross

hole

in

needle

when the needle

for

cleaning

accumulated

bar,

has

about

been

1/4

inserted

lint

from

inch

from

as

far

needle hole

end (A, Fig. 10)

up

as

it

will

so

needle

-15-

is

to show

go, and to

will

seat

pro-

Fig. 10

Page 15

THREADING THE NEEDLE

OPERA TOR'S INSTRUCTIONS (Continued)

Threading

the needle

PREPARATION

With the

operating

needle

both

direction

thread

threads

diagram

thread

passes

FOR

left

hand hold the end of the needle

until the needle moves

and the bobbin

under the

(Figo

through the needle eye

SEWING

presser

TENSIONS

A

center

perfect

of the

stitch

material

is

one

being sewed. A

threads.

BOBBIN THREAD TENSION

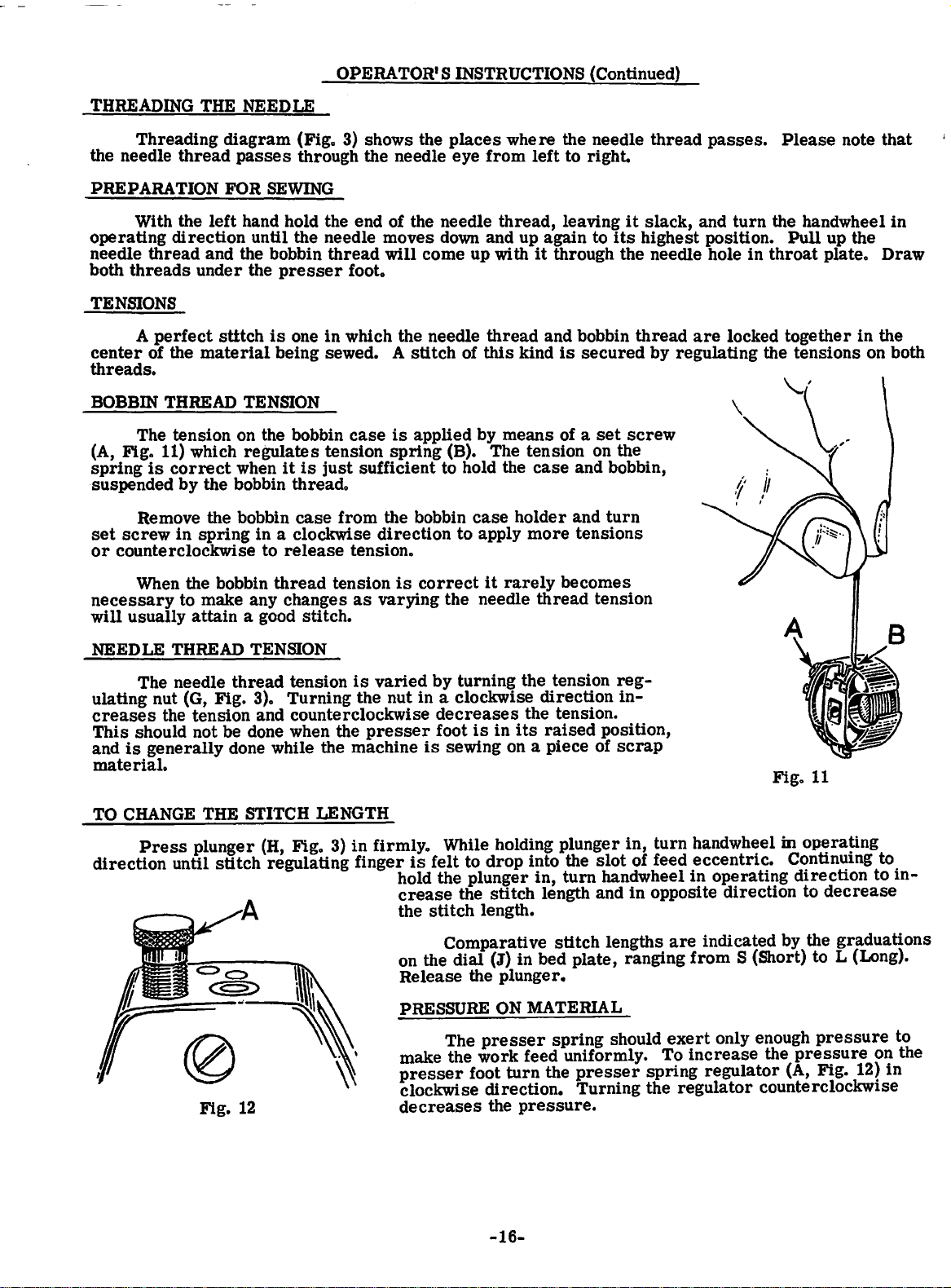

The tension on the bobbin

(A, Fig. 11) which

spring

suspended

is

correct

by

Remove the bobbin

set

screw

or

counterclockwise to

in

When the bobbin

necessary

will usually

to make any changes

attain

regulates

when

it

is

the bobbin thread.

case

spring

in a clockwise

release

thread

a good stitch.

3)

shows the

down

thread

will come up with

footo

in

which the needle

stitch

case

is

tension

just

sufficient to hold the

applied by

spring

from the bobbin

direction

tension.

tension

is

correct

as

varying the needle

places

where the needle

from

left

thread,

and up again to

it

of

thread

this

and bobbin

kind

means

to right.

leaving

it

its

through the needle hole

is

secured

of a

set

screw

(B). The tension on the

case

and bobbin,

case

holder

to apply

it

rarely

more

becomes

thread

and

turn

tensions

tension

thread

slack,

highest position.

thread

passes.

and

turn

the handwheel

in

throat

are

locked together

Please

Pull

up the

plateo Draw

note that

in

the

by regulating the tensions on both

in

NEEDLE THREAD TENSION

The needle

ulating nut

creases

This

and

the tension and counterclockwise

should not be done when the

is

generally

thread

(G,

Fig. 3). Turning the nut in a clockwise direction

tension

done while the machine

material.

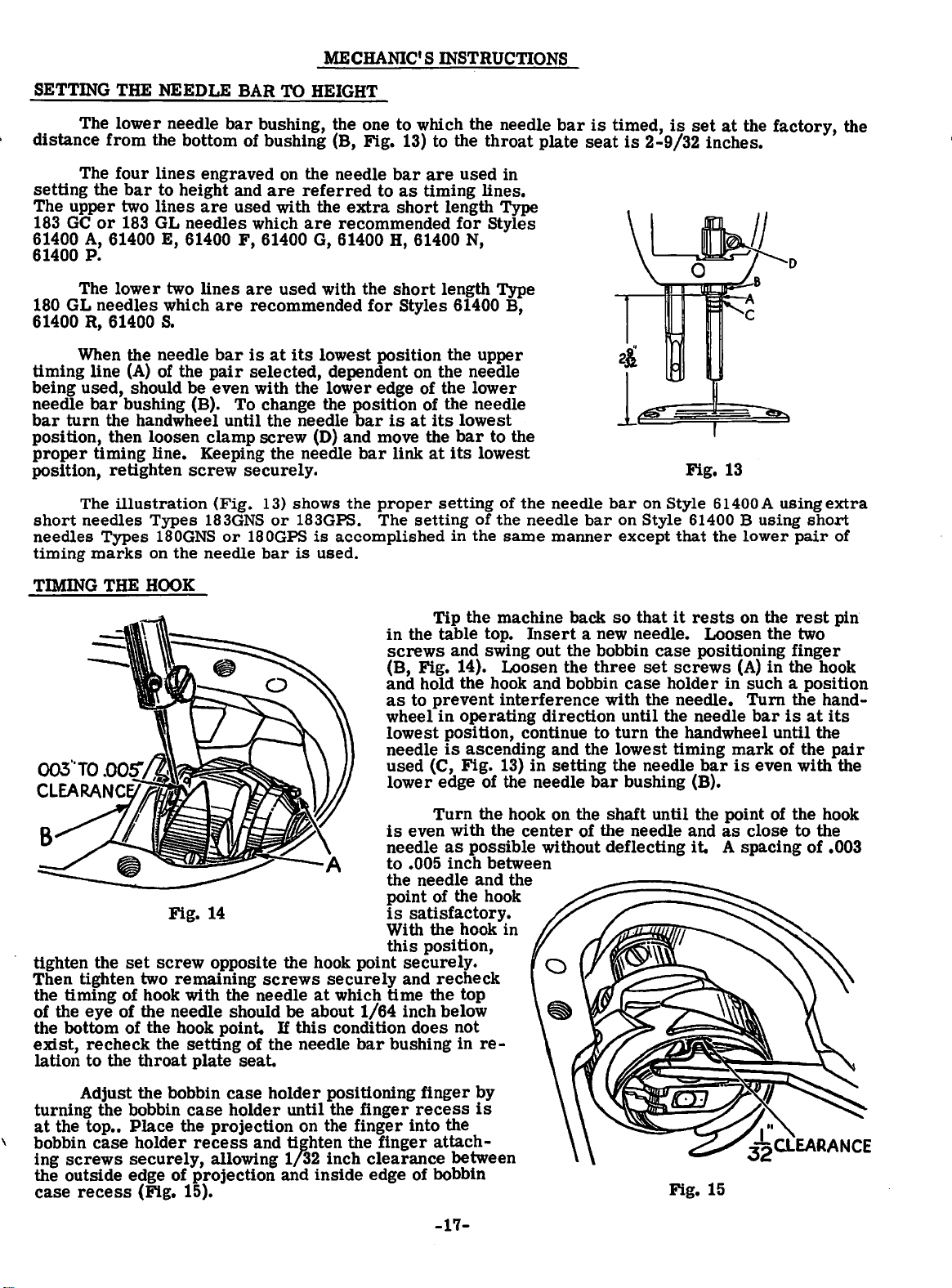

TO

CHANGE

Press

direction

THE STITCH LENGTH

plunger

until

Fig.

stitch

12

(H,

Fig. 3)

regulating finger

is

varied

presser

in

firmly. While holding plunger in,

by turning the tension

decreases

foot

is

is

sewing on a piece of

is

felt to

the tension.

in

its

drop

into the

raised

hold the plunger in, turn handwheel

crease

the

on the

the stitch length and

stitch

length.

Comparative

dial

(1) in bed plate, ranging

stitch

Release the plunger.

PRESSURE

The

ON

MATERIAL

presser

spring

make the work feed uniformly. To

presser

foot

turn

the

presser

clockwise direction. Turning the

decreases

the

pressure.

reg-

in-

position,

scrap

turn

slot

of feed

in

opposite direction to

lengths

should

spring

handwheel

eccentric.

in

operating

in

op~ra~ng

Continuing

direction

decrease

are

indicated by the graduations

from

S (Short) to L (Long).

exert

only enough

increase

regulator

regulator

the

counterclockwise

pressure

pressure

(A, Fig. 12)

to

to

in-

to

on the

in

-16-

Page 16

MECHANIC'S INSTRUCTIONS

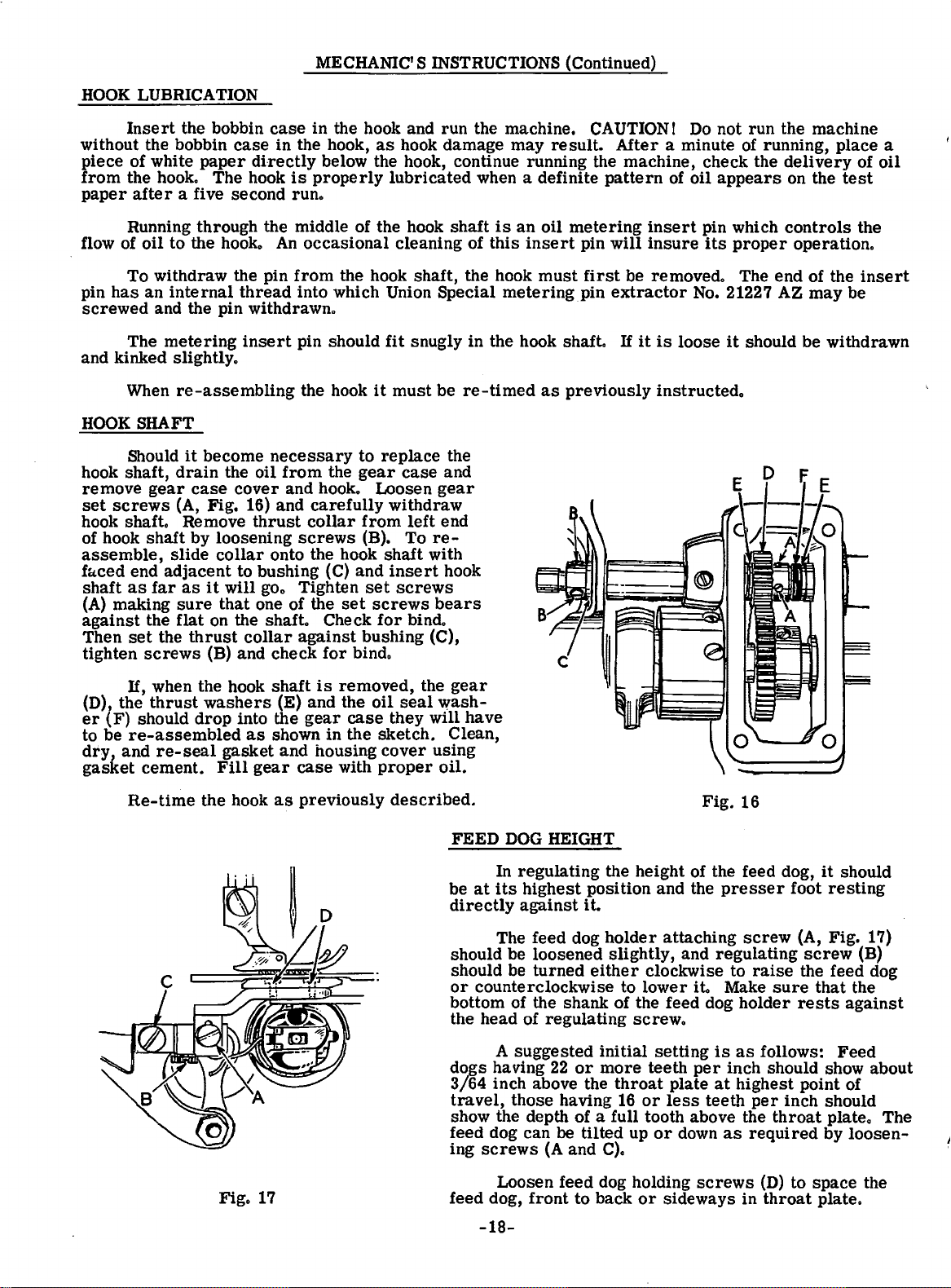

SETTING

distance

setting the

The upper two

183

61400 A, 61400

THE NEEDLE

The lower needle

from

the bottom of bushing (B, Fig.

The four

lines

bar

to height and

lines

GC

or

183

GL needles which

E,

61400

BAR

TO

HEIGHT

bar

bushing, the one to which the needle

engraved on the needle

are

referred

are

used with the

F,

61400 G, 61400 H, 61400 N,

extra

are

recommended

13)

bar

are

to

as

timing lines.

short

to the

used in

length

for

throat

Type

Styles

61400 P.

The lower two

180

GL

needles which

61400 R, 61400

When the needle

timing line

(A) of the

S.

lines

are

bar

pair

are

used

with the

recommended

is

at

its

lowest position the upper

short

for

length Type

Styles 61400 B,

selected, dependent on the needle

being used, should be even with the lower edge of the lower

bar

needle

bar

turn

position, then loosen clamp screw

proper

position, retighten

short

needles

timing

bushing (B). To change the position of the needle

the handwheel until the needle

timing line. Keeping the needle

The

illustration

needles

Types

marks

screw

Types

180GNS

on

the

securely.

(Fig.

183GNS

or

180GPS

needle

13)

or

bar

shows

183GPS.

is

bar

is

at

(D) and move the

bar

link

at

the

proper

The

is

accomplished

used.

setting

its

lowest

bar

its

setting

in

to the

lowest

of

of

the

the

same

plate

the

needle

needle

manner

bar

is

seat

bar

bar

timed,

is

2-9/32

on

on

Style

except

is

set

Fig.

Style

61400 B

that

at

the factory, the

inches.

13

61400 A

the

using

using

lower

D

pair

extra

short

of

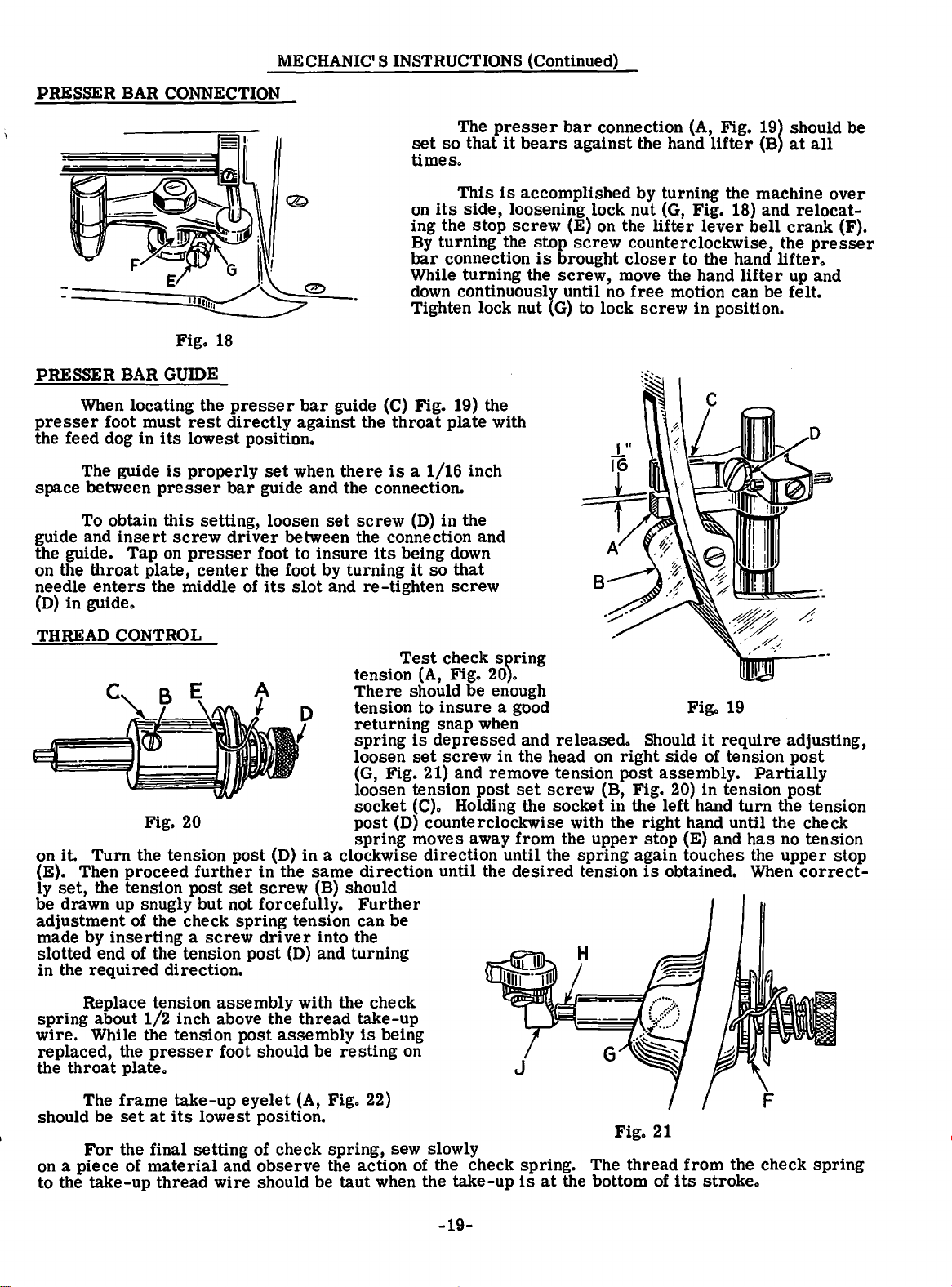

TIMING THE

tighten the

Then tighten two remaining

HOOK

set

Fig.

screw

14

opposite the hook point

screws

the timing of hook with the needle

of the eye of the needle should

the bottom of the hook point.

exist,

lation

recheck

to

the

throat

the setting of the needle

plate seat.

be about

If

this

Tip the machine back

in

the table top.

screws

(B, Fig. 14). Loosen the

and hold the hook and bobbin

as

to

prevent

wheel

lowest position, continue to

needle

used

{C,

lower edge of the needle

Turn

is

even with the

needle

to .005 inch between

the needle and the

point of the hook

is

satisfactory.

With the hook in

this

position,

securely.

securely

at

which time the top

1/64

and

recheck

inch below

condition does not

bar

bushing in

so

that

it

rests

on the

Insert

and swing out the bobbin

interference

in

operating direction until the needle

is

ascending and the lowest timing

Fig.

13)

in

a new needle. Loosen the

case

positioning finger

three

set

screws

case

holder in such a position

with the needle.

turn

the handwheel until the

setting the needle

bar

bushing (B).

bar

(A)

in

Tum

bar

mark

is

even with the

the hook on the shaft until the point of the hook

center

as

possible without deflecting

of the needle and

it.

as

close to the

A spacing of .003

re-

rest

two

the hook

the hand-

is

at

its

of the

pin

pair

Adjust the bobbin

turning the bobbin

at

the top..

bobbin

ing

screws

case

Place

holder

securely,

case

holder

case

holder until the finger

positioning finger by

recess

the projection on the finger into the

recess

and tighten the finger

allowing 1/32 inch

clearance

attach-

between

is

the outside edge of projection and inside edge of bobbin

case

recess

(Fig. 15).

-17-

Fig.

15

Page 17

MECHANIC'S INSTRUCTIONS (Continued)

HOOK

without the bobbin

piece of white

from

paper

LUBRICATION

Insert

the bobbin

paper

the

hooko

after

The hook

a five second

case

case

directly

in

in

the hook and run the machine. CAUTION!

the hook,

below the hook, continue running the machine, check the

is

properly

runo

Running through the middle of the hook

flow of

pin

screwed

oil

to the

To

withdraw the pin

has

an

internal

hooko

thread

and the pin withdrawno

The

metering

insert

An

occasional

from

into which Union Special metering_pin

pin should

and kinked slightlyo

When

HOOK

hook shaft,

remove

set

screws

hook shafto Remove

of hook

assemble,

f~ced

shaft

(A)

making

against

Then

tighten

re-assembling

SHAFT

Should

it

drain

gear

case

(A, Fig. 16) and

shaft

by loosening

slide

end

adjacent

as

far

as

sure

the

flat

set

the

thrust

screws

the hook

become

the oil

cover

necessary

from

the

and

hooko

carefully

thrust

collar

screws

collar

onto the hook

to bushing (C) and

it

will

goo

that

Tighten

one of the

on the shafto Check

collar

(B) and check

against

for

as

hook damage may

lubricated

cleaning of

when a definite

shaft

is

an

this

the hook shaft, the hook

fit

snugly in the hook shaft.

it

must

be

re-timed

to

replace

gear

Loosen

case

the

and

gear

withdraw

from

left

end

Tore-

with

hook

screws

bears

bindo

set

(B).

shaft

insert

set

screws

for

bushing (C),

bind.

result.

oil

insert

must

as

After

pattern

metering

pin

will

first

be removedo The

extractor

Hit

previously

Do

not

run

the machine

a minute of running, place a

delivery

of

oil

insert

insure

is

loose

appears

pin which

its

proper

No.

21227 AZ

it

on the

test

controls

operationo

end

of the

may

should be withdrawn

instructedo

of

the

insert

be

oil

H, when the hook

(D), the

er

to be

dry 1 and

thrust

(F) should

re-assembled

re-seal

drop

gasKet cement.

Re-time

washers

into the

as

gasket

Fill

gear

the hook

shaft

is

removed,

(E) and the

gear

case

shown in the

and

housing

case

with

as

previously

the

oil

seal

gear

wash-

they will have

sketch.

cover

proper

Clean,

using

oil.

described.

FEED

be

directly

should be loosened slightly, and

should be

or

bottom of the shank of the feed dog

the head of regulating screwo

do_gs

3/64

travel,

show the depth of a full tooth above the

feed dog can

ing

Fig.

16

DOG

HEIGHT

In regulating the height of the feed dog,

at

its

highest

against

The feed dog

position and the

it.

holder

attaching

presser

screw

regulating

counterclockwise to

turned

either

clockwise to

lower

ito

Make

raise

holder

A suggested

having

inch above the

those having

screws

(A

initial

22

or

more

throat

16

be tilted up

and

C)o

setting

teeth

plate

or

less

or

is

as

per

teeth

down

follows:

inch should show about

at

highest point of

per

as

required

it

should

foot

resting

(A, Fig. 17)

screw

the feed dog

sure

that

rests

Feed

inch should

throat

plateo The

by

(B)

the

against

loosen-

Figo

17

feed dog,

-18-

front

to back

Loosen feed dog holding

or

screws

sideways in

(D) to

throat

space

plate.

the

Page 18

PRESSER BAR CONNECTION

Fig.

18

MECHANIC'S INSTRUCTIONS (Continued)

The

set

so

that

presser

it

bears

bar

connection (A, Fig. 19) should be

against

times.

This

is

accomplished

on

its

side,

ing the

By turning the

bar

connection

While

loosening lock nut (G, Fig. 18) and

stop

screw

turning

stop

is

the

(E) on the

screw

brought

screw,

down continuously until no

Tighten lock nut

(G) to lock

the hand

lifter

(B)

by turning the machine

lifter

lever

bell

counterclockwise, the

closer

move the hand

free

to

the hand

lifter

motion can be felt.

screw

in

position.

lifter.

at

all

relocat-

crank

presser

up and

over

(F).

PRESSER BAR

When locating the

presser

foot

the feed dog in

The guide

space

between

To obtain

guide and

the guide.

on the

needle

(D)

throat

enters

in guide.

GUIDE

must

its

is

presser

this

insert

Tap

screw

on

plate,

the middle of

rest

presser

directly

bar

against

lowest position.

properly

setting,

presser

center

set

bar

guide

loosen

driver

foot

the foot by

its

when

between the connection and

to

slot

and

set

insure

and

THREAD CONTROL

Fig.

20

on

it.

Turn

(E). Then

ly

set,

the tension

the tension

proceed

further

post

set

post

in

(D)

the

screw

in

a clockwise

same

(B) should

be drawn up snugly but not forcefully.

adjustment

made by

slotted

in the

of the check

inserting a screw

end of the tension

required

direction.

spring

driver

post

tension can be

into the

(D)

and

guide (C) Fig. 19) the

the

there

throat

is a 1/16

plate

inch

with

the connection.

screw

turning

re-tighten

(D)

its

being down

it

Test

in

so

that

screw

check

the

spring

tension (A, Fig. 20).

There

tension to

returning

spring

loosen

(G, Fig. 21) and

loosen tension

socket

post

spring

should

be

insure

enough

a good

snap when

is

depressed

set

screw

in the head on

remove

post

(C)o

Holding the

(D)

counterclockwise with the

moves away

direction

direction

until the

Further

turning

and

released.

tension

set

screw

socket

from

the

until the

desired

right

post

(B, Fig. 20)

in the

upper

spring

again touches the

tension

Figo

19

Should

side

it

require

of tension

assembly.

in

tension

left

hand

turn

right

hand until the check

stop (E) and

is

obtained. When

has

adjusting,

post

Partially

post

the tension

no

tension

upper

correct-

stop

Replace tension

spring

wire.

replaced,

the

should be

about

While the tension

the

throat

The

plateo

frame

set

For

the final

on a piece of

to the

take-up

1/2

presser

at

material

thread

assembly

inch above the

post

foot should be

take-up

its

eyelet

lowest position.

setting

and

wire

of check

observe

should be

with the check

thread

assembly

take-up

is

resting

(A, Fig. 22)

spring,

the

action

taut

being

on

sew slowly

of the check spring. The

when the

take-up

is

at

the bottom of

-19-

thread

from

its

the check

strokeo

spring

Page 19

MECHANIC'S INSTRUCTIONS (Continued)

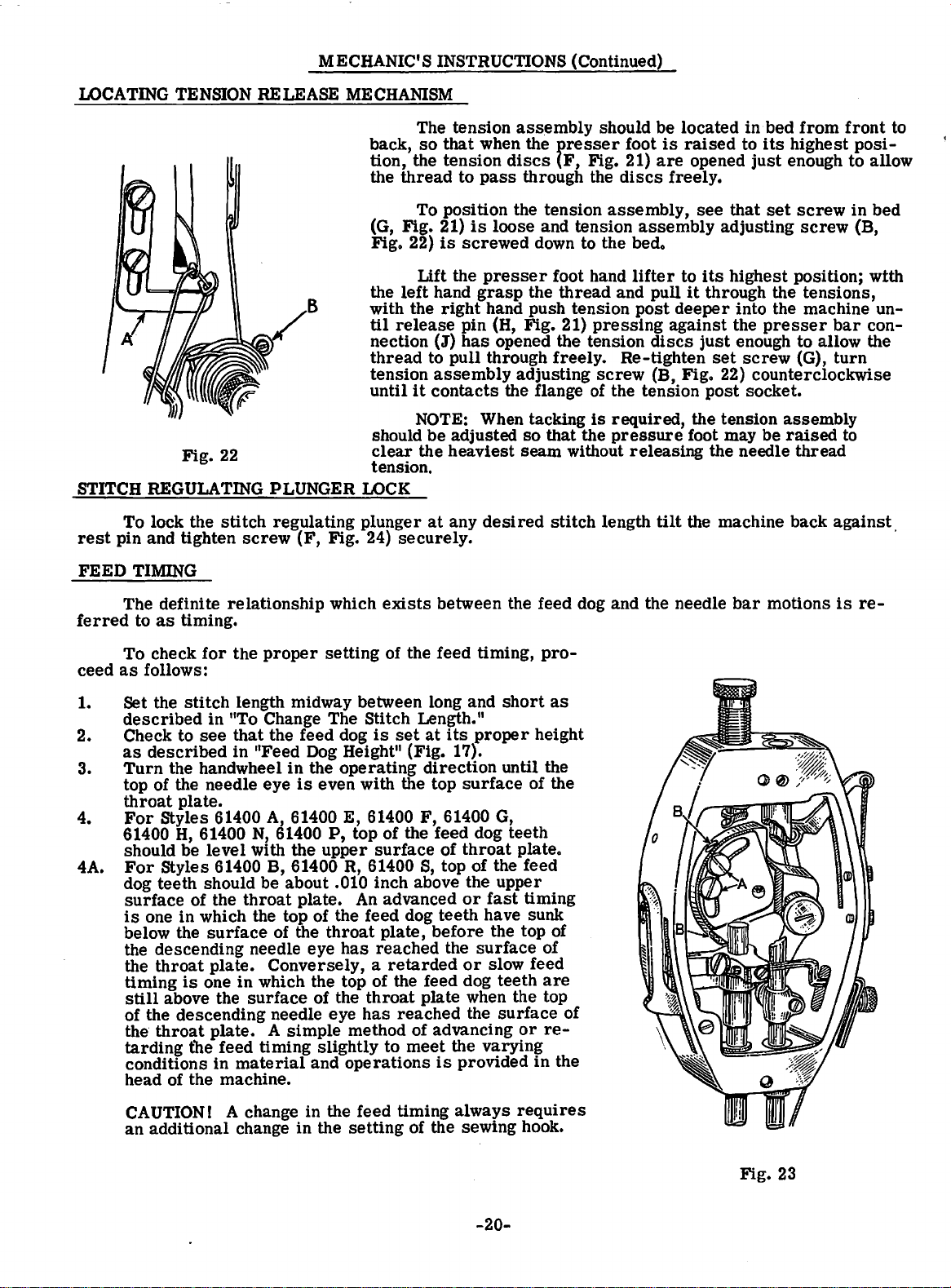

LOCATING

STITCH

rest

REGULATING PLUNGER LOCK

To

lock the

pin

and

TENSION RELEASE MECHANISM

The

Fig.

22

stitch

tighten

regulating

screw

B

(F,

back,

tion, the

the

(G,

Figo 22)

the

with the

til

nection (J)

thread

tension

until

tens1on.

plunger

Fig. 24)

so

that

tension

thread

To

position

Fig.

21)

is

Lift

left

hand

right

release

to

assembly

it

contacts

NOTE: When tacking

should

cle~

be

the

at

securely.

tension

when the

to

pass

is

loose

screwed

the

presser

grasp

hand

pin

(H,

has

opened the

pull

through

the flange of the

adjusted

heaviest

any

desired

assembly

presser

discs

(F,

through the

the

tension

and

down to

foot hand

the

thread

push

tension

Fig.

21)

freely.

adjusting

so

that

seam

without

stitch

should be

Fig. 21)

discs

assembly,

tension

the

and

pressing

tension

Re-tighten

screw

is

required,

the

pressure

length

located

foot

is

raised

are

freely.

assembly

bedo

lifter

to

pull

it

post

deeper

against

discs

(B, Figo 22)

tension

foot may

releasing

tilt

the

opened

see

that

adjusting

its

highest

through

into

the

just

enough

set

post

the

tension

the

needle

machine

in·

bed

from

front

to

its

highest

just

enough

set

screw

screw

position;

the

tensions,

the

machine

presser

to

screw

socket.

(G),

counterclockwise

assembly

be

raised

thread

back

posi-

to

in

(B,

bar

allow the

turn

to

against

to

allow

bed

wtth

un-

con-

·

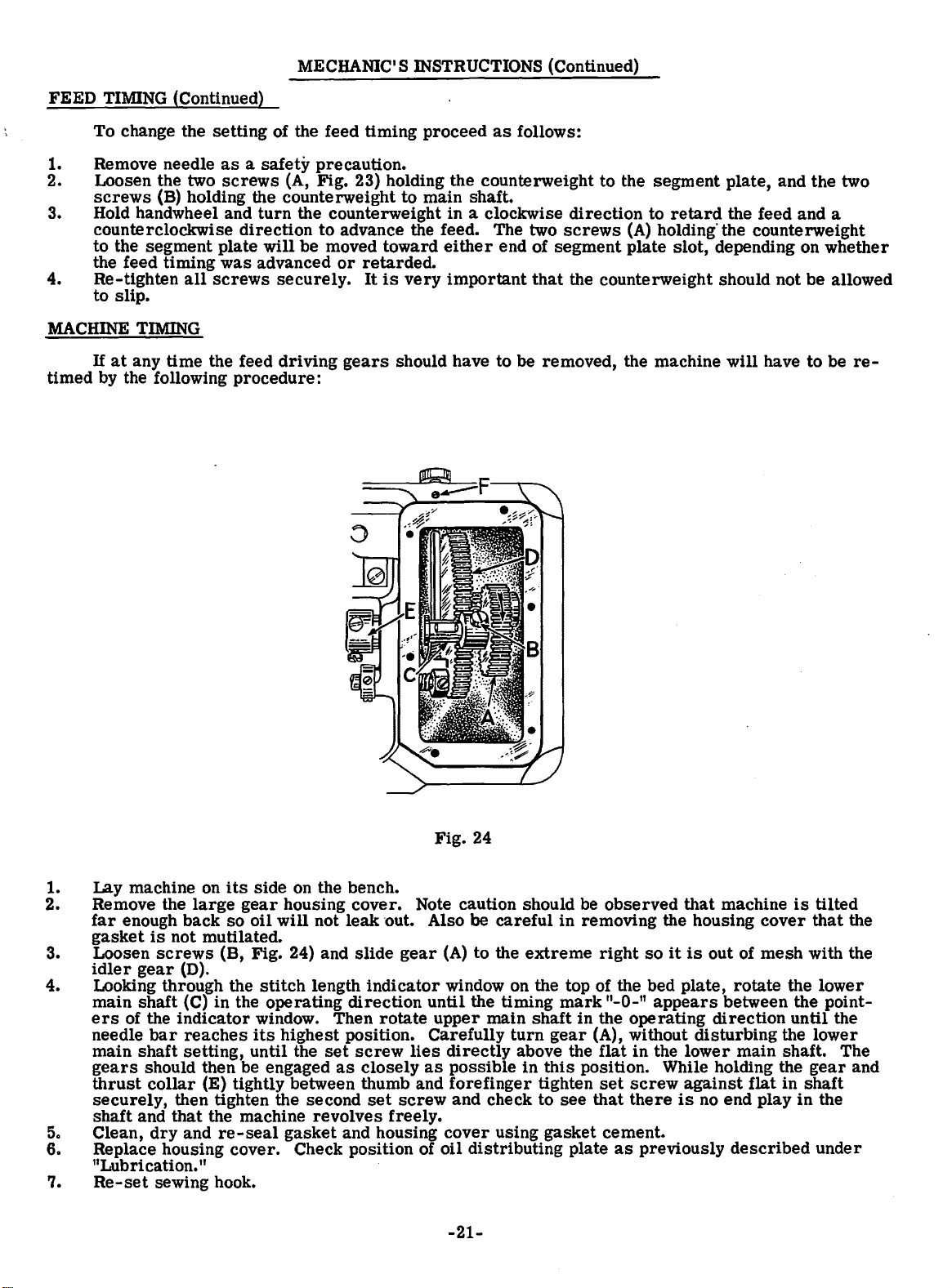

FEED

ferred

ceed

1. Set the

2. Check

3.

4.

4A.

TIMING

The

definite

to

as

To

check

as

follows:

described

as

described

Turn

of

top

throat

For

Styles

61400

should be

For

Styles

dog

teeth

surface

is

one

below the

the

descending

the

throat

timing

still

above the

of the

throat

the·

tarding

conditions

head

of the machine.

relationship

timing.

for

the

proper

stitch

to

the handwheel

the

plate.

H,

in

is

descending

length midway between long

in

"To Change The

see

that

the feed dog

in

"Feed

needle

61400 A, 61400

61400

level

61400

should

of the

which the top of the

surface

plate.

one

plate. A simple

the

feed

in

material

in

eye

N,

61400

With

the

B,

61400 R, 61400

be

about

throat

of the

needle

Conversely, a retarded

in

which the top of the feed dog

surface

needle

timing

which

setting

Stitch

is

Dog Height"

the

operating

is

even

with the top

E,

61400

P,

top

upper

.010

plate.

throat

eye

has

of the

eye

method

slightly

and

operations

An

feed

throat

has

exists

of the

Length."

set

at

(Fig.

direction

F,

of

the

surface

S,

inch

above the

advanced

dog

plate,

reached

plate

reached

of

to

meet

between

feed

its

17).

61400 G,

feed

of

top of the feed

teeth

before

the

advancing

the

is

provided

the feed dog

timing,

and

short

proper

until the

surface

dog

throat

or

surface

or

when the top

the

of the

teeth

plateo

upper

fast

timing

have sunk

the top of

slow

feed

teeth

surface

or

varying

pro-

as

height

of

are

of

re-

in

the

and

the

needle

bar

motions

is

re-

CAUTION I A change

an

additional

change

in

in

the

the

feed

setting

timing

of the

always

sewing

-20-

requires

hook.

Fig.

23

Page 20

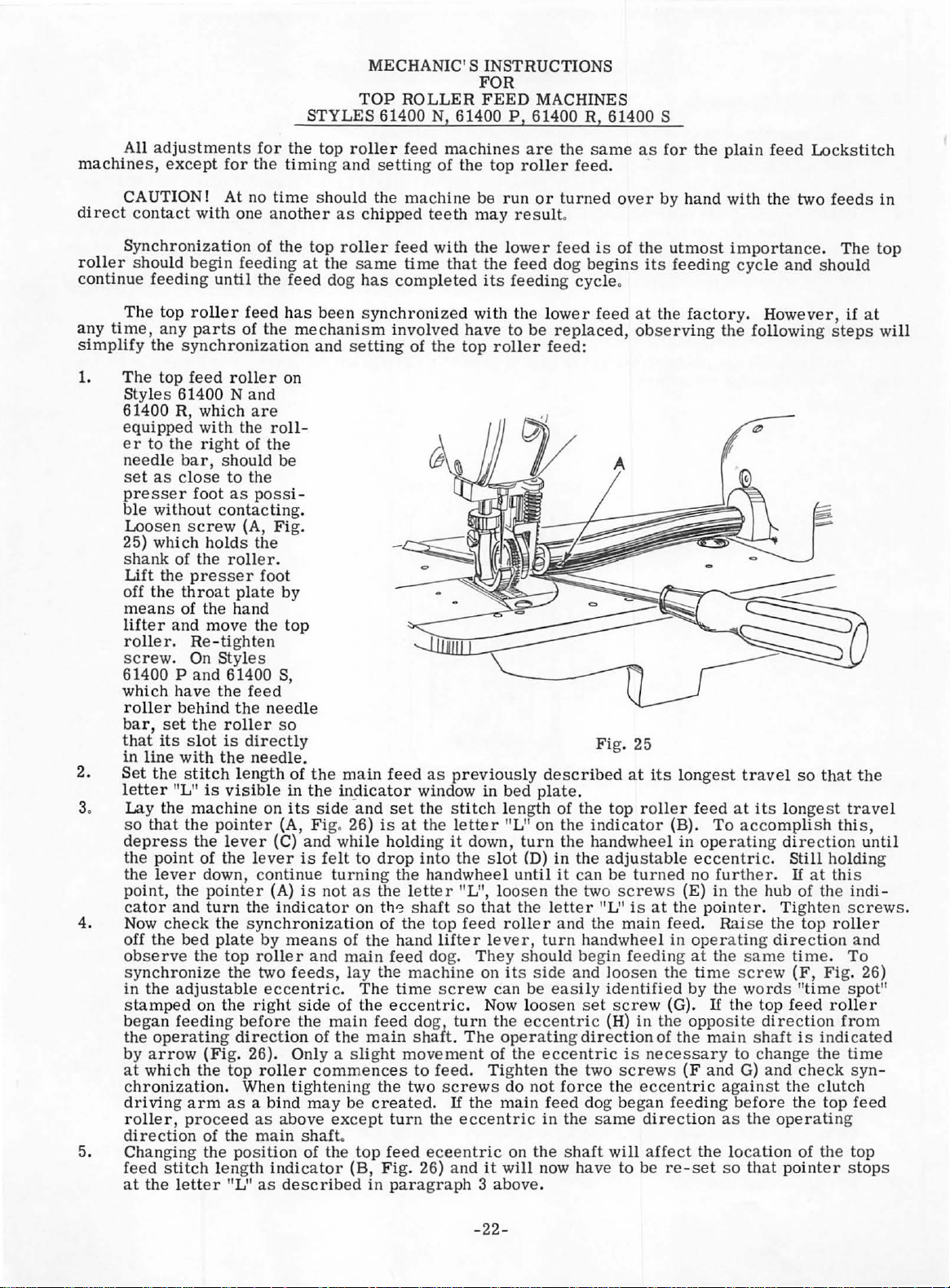

FEED TIMING (Continued)

To

change the

setting

MECHANIC'S INSTRUCTIONS (Continued)

of the feed timing

proceed

as

follows:

1. Remove needle

2. Loosen the two

screws

3. Hold handwheel and

counterclockwise

to

the feed timing

4. Re-tighten

to

MACHINE TIMING

If

timed by the following

(B) holding the counterweight

the

segment

slip.

at

any

time

as a safety

screws

plate

was

all

screws

the feed

direction

procedure:

precaution.

(A, Fig. 23) holding the counterweight

turn

the counterweight

to

advance the feed. The two

will

be

advanced

moved toward

or

securely.

driving

gears

to

main shaft.

in

a clockwise

retarded.

It

is

either

very

important

should have to be removed, the machine

end of

to

the

segment

direction

screws

segment

that

the counterweight should not be allowed

to

retard

(A)

holding· the counterweight

plate

slot,

plate,

the feed and a

depending on

will

and

have to be

the

two

whether

re-

Fig. 24

its

side

1. Lay machine on

2. Remove the

far

enough

gasket

3. Loosen

idler

gear

4. Looking through the

main

shaft

ers

of the

needle

main

shaft

gears

thrust

securely,

shaft

and

5. Clean,

6. Replace housing

"Lubrication."

Re-set

7.

large

back

is

not mutilated.

screws

{D).

(C)

indicator

bar

reaches

setting,

should then be engaged

collar

then tighten the second

that

dry

and

sewing hook.

gear

so

(B, Fig. 24) and

in

the

(E) tightly between thumb and

the machine

re-seal

cover.

on the bench.

housing

oil

will

stitch

operating

window. Then

its

highest

until the

gasket

Check position of

cover.

not

leak

slide

length

direction

position.

set

as

revolves

and housing

·out. Also

gear

indicator

rotate

screw

closely

set

screw

freely.

Note caution should be

lies

be

careful

(A)

to the

window on the top of the bed

until

the timing

upper

Carefully

as

main

directly

possible

forefinger

and check

cover

oil

using

distributing

turn

in

removing the housing

extreme

mark

shaft

in

gear

above the

in

this

position. While holding the

tighten

to

see

gasket

plate

-21-

observed

right

so

it

plate,

"-0-"

appears

the

operating

(A), without

flat

in

the

set

screw

that

there

is

cement.

as

previously

that

machine

cover

is

out of

disturbing

lower

against

no

mesh

rotate

between the point-

direction

main shaft. The

flat

end

play

described

is

tilted

that

the

with the

the

lower

until the

the lower

gear

in

shaft

in

the

under

and

Page 21

ll

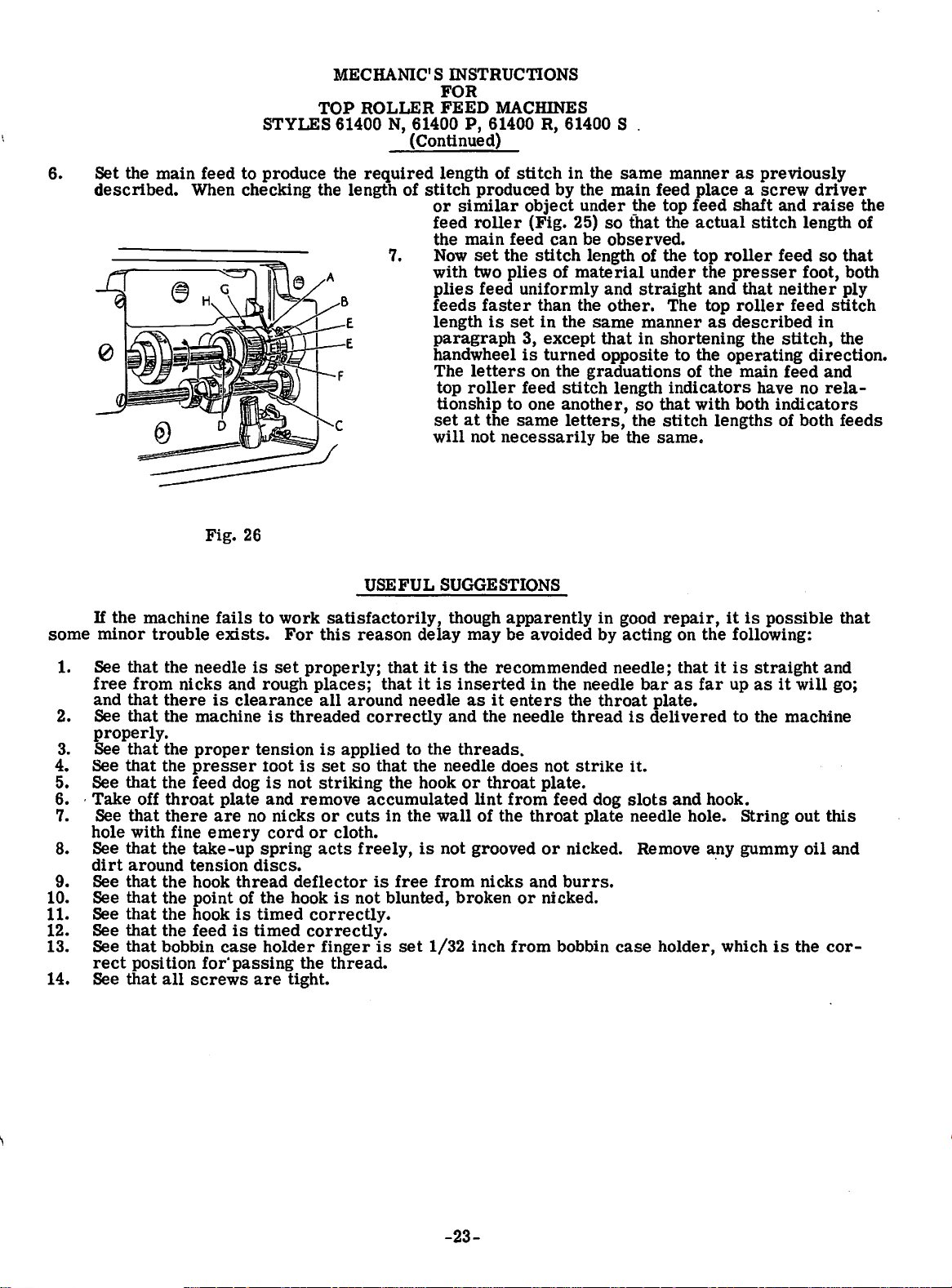

A

machines,

adjustments

except

for

for

the

STYLES

the

top

timing

MECHANIC1 S INSTRUCTIONS

FOR

TOP

ROLLER

61400 N, 61400

roller feed

and

set

ting of

FEED

P,

machines

the

top

MACHINES

61400 R, 61400 S

are

roller

the

feed.

same

as

for

the

plain

feed

Lockstitch

CAUTION! At no

direct

contact

Synchronization

roller

continue

should

feeding

. The top roll

any

hme,

simplify

1.

The

any

the

top

Styles

61400 R, wh

equipped

er

to

the

needle

set

as

presser

ble without

Loosen

25) which

shank

Lift

the

off the

means

lifter

and move the top

roller.

screw

. On Style s

61400 P

which

roller behind

bar,

set

that

its

in

line

2.

Set

the

letter

11

3. Lay the

so

that

depress

the

point

lever

the

point, the

cator

and

Now

4.

check

off the bed

observe

sy

nchronize

in

the

stamped

began

the

operating

by

arrow

at

which

chronization

driving

roller,

direction

5.

Changin

stitch

feed

at

the

with one

another

of the

time

begin

feeding

until

the

er

feed has

parts

of

the

synchronization

feed

61400

with

right

bar,

close

foot

roller

Nand

ich

should

to

as

are

the

of

the

on

roll-

the

be

possi

contacting

screw

of

presser

throat

of

(A,

holds

the

roller.

plate

the hand

Fig.

the

foot

by

Re-tighten

and

the

slot

with

61400 S,

the

feed

the

need

roller

is

directly

the

needle.

so

have

stitch length of

L"

is

visible

machine

the

pointer

the

of the

lev

on

(A, Fig. 26)

er

(C) and while holding

lever

down, continue

pointer

turn

(A)

the

indicator

the synchronization

plate

by

the

top

roller

the two

adjustable

on the

feeding

eccentric. The

right

before

direction

(Fig

. 26). Only a slig

the

top

roller

. When

arm

as a bind

proceed

of the

g the

letter 11V'

as

position

length

above

main

indicator

as descr

should the

as

top

roller

at

the

feed

same

dog

been

mechanism

and

setting

.

le

the

main

in

the

insiicator window

its

side

and

is

felt

to

turning the

is

not

as

on

means

feed

and

side

the

of

of

main

s, lay

of the

main

the

commences

tightening

may

be

except

shaft.

of the

top

(B,

ibed

machine

chipped

feed

time

has

completed

synchronized

involved

of

feed

set