Page 1

®

INDUSTRIAL

SEWING

FI

NEST

CLASS

QUALITY

61

100

LEWIS

•

COLUMBIA

LIST

FOR

OF

STYLES

PARTS

MACHINES

CATALOG

NO.

T

113

L

61100

A

61100

B

61100

c

MACHINE COMPANY

CHICAGO

Page 2

INDUSTRIAL

SEWING

MACHINES

.

• •

Job

variety

why

for

requirements

of

Union Special field representatives make a careful study

requirements before

kind

of

equipment

speed

Union

machines are built to

they stay

ahead when you use

Every

vary-

Purpose!

that's why

Union

specially designed sewing machines,

giving

to install. Plants

Specials have an

do

on

the job

with

Union

you detailed recommendations on the

equipped

important

the job faster

minimum time

advantage. Union Special

...

better

out

Special.

Special builds a

It

is

with modern, high

.. ~ cheaper,

for repairs.

wide

also the reason

of

and

You're

50000

The

thousands

SERIES machines are finding these ultra-modern, streamlined

models to be invaluable aids in cutting costs

boosting production

many machines in the improved

to do a specific job efficiently, quickly,

of

THE

Never before has a general purpose Lockstitch machine been so

thoroughly engineered

requirements! And never has a machine offered more than the new

Union Special

or

heavy weight work . . . for

tacking

NEEDLE

Latest improvements in engineering, manufacturing methods, and

materials have been combined in

Class

62200

with smooth, streamlined, light-running machines

fatigue and strain. It's

throughout the country are praising

these ultra-modern machines!

SIXTY-ONE-FOUR-

and

back stitching

FEED

needle feed Lockstitch machines providing operators

SERIES

manufacturers using Union Special's new

of

a wide variety

61400

for

...

LOCKSTITCH

no

wonder

MACHINES

of

operations

of

products. Each

50000

SERIES is specially designed

and

economically!

LOCKSTITCH

handling modern industrial sewing

a superior machine for light

short

runs

as

well

as

long . . .

for curved seams and straight runs.

MACHINES

Union

Special Class

that

manufacturers

the

superior performance

61800

that

in

50000

and

of

the

for

and

reduce

plants

of

THE

This new development antiquates every machine presently on the

market for use where a curved needle machine

From its handsome, dynamically functional, modern design to its

innermost mechanism, the

duced to accelerate quicker . . .

smoothly

greater

today.

35700-35800

Union Special's popular feed-off-the-arm felling machines are

running, smooth operating machines

sewing head

eliminates feed marking, and presser foot which will lift

lightest touch. Fastl:r fel.iing is certain with Union Special Class

35700-35800

NEW

and

profit than any other like equipment available to users

quietly

CLASS

...

with less maintenance

FEED-OFF-THE-ARM

of

the latest type, new presser bar which practically

feed-otf-thl!-arm machines.

39500

THIRTY-NINE-FIVE

run

OVEREDGER

faster . . . operate more

that

offer great advantages:

1s

recommended.

has been pro-

...

and

yield a

MACHINES

light

at

the

Page 3

Catalog

No.

T113

L

61100

Rights

Union

LIST

A

First

Copyright

Special

Reserved

OF

Styles

61100

Edition

by

PARTS

B

1957

Machine

in

All

61100

Co.

Countries

c

MACHINE COMPANY

INDUSTRIAL

Printed

February,

1970

SEWING

CHICAGO

in

MACHINES

U.S.A.

Page 4

IDENTIFICATION

OF

MACHINE

Each

the

machine.

numbers

"Style

61100

changes

number.

Styles

which

differs

This

It

can

also

references

the

operator's

is

toward

61100

A

Stitch

anism,

Welts,

Union

Special

Style

have

one

or

A".

are

made

Example:

of

machines

from

catalog

be

to

applies

applied

direction,

position

the

operator.

Streamlined,

Regulator,

for

Light

and

Pocket

carries

numbers

more

Special

are

letters

style

in a standard

"61100

AZ".

similar

the

style

number

APPLICATION

specifically

with

discretion

such

while

seated

STYLES

Single

Visible

and

Stitch

Medium

Flaps.

a

style

classified

suffixed,

numbers

machine,

in

as

left

OF

MACHINES

Needle

Weight

Stitch

number

as

but

contain

a

construction

in

that

it

OF

tothe

at

to

and

the

standard

some

right,

machine.

Basting

Indicator,

Material,

Type

101.

which

standard

never

the

"Z"

is

are

contains

CATALOG

styles

special

front

Operating

IN

CLASS

Machine,

Automatic

such

is

stamped

and

contain

letter

suffixed

grouped

no

letters.

of

machines

machines

and

back,

61100

Taupe

Lubrication

as

in

special.

the

letter"

"Z".

to

under

Example:

in

etc.,

direction

Finish,

Basting

the

Standard

When

the

standard

a

as

Class

are

of

Pockets,

name

Z".

plate

Example:

only minor

class

number

"61100

listed

herein.

61100.

taken

of

handwheel

Push

Lower

Pocket

on

style

style

11

All

from

Button

Mech-

61100

B

Topcoats,

61100

C

Dresses,

Each

number

size

number,

measured

tively,

type

Standard

short

length,

plated,

Standard

groove,

available

To

needle,

order

should

Same

Same

Union

denotes

in

number

and

is

struck

in

sizes

have

needle

or

type

as

61100

A,

Overcoats,

as

61100

A,

Ladies 1 Coats,

Special

the

kind

stamped

thousandths

needle

double

groove,

available

needle

groove,

and

for

for

needle

of

on

of

size

Styles

in

Style

spiral

the

sizes

032, 036, 040, 044,

and

read:

orders

size

"1000

promptly

number

Needles,

except

Ladies'

except

etc.

has

shank,

needle

an

inch

number

61100 A and

struck

029,

61100 B is

groove,

should

for

Heavy

Coats

equipped

Seam

Specification

NEEDLES

both a type

point,

length,

shank,

midway

represent

groove,

032,

ball

049, 054.

and

accurately

be

Type

113

Weight

and

similar

with

Tape

number

groove,

denotes

between

the

61100

spiral

groove,

036, 040,

Type

133

eye,

filled,

given.

GS.

See

Size

Material,

Garments.

Reel

101

and a size

finish

the

largest

the

complete

Cis

Type

ball

044, 049,

GS.

It

spotted,

the

!able

040".

for

Taping

LSa-1

and

diameter

shank

symbol.

113 GS.

eye,

054.

is

of

chromium

empty

on

package.

such

as

Coats,

Stitch

Hems

Type

on

(inverted).

number.

other

and

spotted,

short

the

length,

details.

of

the

eye.

It

is

chromium

The

of

plated,

package, a sample

A

complete

Suits,

101.

Skirts,

type

The

blade

Collec-

extra

double

and

is

Selection

should

pass

For

machine.

by a reputation

a

century.

best

They

of

proper

freely

results,

are

for

needle

through

use

only

packaged

producing

size

needle

genuine

under

highest

should

eye

our

quality

be

determined

in

order

Union

brand

needles

to

Special

name,

produce a good

for

by

size

needles

~

more

of

thread

in

the

than

used.

stitch

operation

,

which

Thread

formation.

of

is

backed

three-quarters

this

of

Page 5

IDENTIFYING

PARTS

Where

smaller

is

stamped

All

parts,

part

appear.

Prices

forwarded

unless

otherwise

CAUTION!

The

oil

shipment

thoroughly

the

oil

to

Use a straight

heit

in

both

the

to

distinguish

numbers

are

at

the

has

and

these

in

accordance

the

reservoirs.

construction

and

those

represent

strictly

net

buyer's

directed.

been

drained

reservoirs

various

parts.

mineral

permits,

where

the

part

cash

risk

A

from

with

instructions

oil

This

each

the

construction

from

the

similar

same

TERMS

and

subject

f.

o.

b.

shipping

charge

is

made

LUBRICATION

the

looper

must

Full

be

filled

speed

RECOMMENDED

of a Saybolt

is

equivalent

part

is

ones.

part,

to

change

point.

to

drive

before

and

run

operation

viscosity

to

stamped

does

not

regardless

without

Parcel

cover

the

eccentric

starting

slowly

can

OILS

of

200

Union

Special

with

permit,

postage

to

for

then

to

its

of

the

notice.

Post

and

main

operate.

several

be

expected

250

seconds

oil

part

number.

an

identification

catalog

All

shipments

shipments

and

insurance.

reservoirs

Lubricate

minutes

without

at

specification

in

which

are

to

distribute

100°

On

some

letter

they

are

insured

before

machine

damage.

Fahren-

No.

83.

Oils

conforming

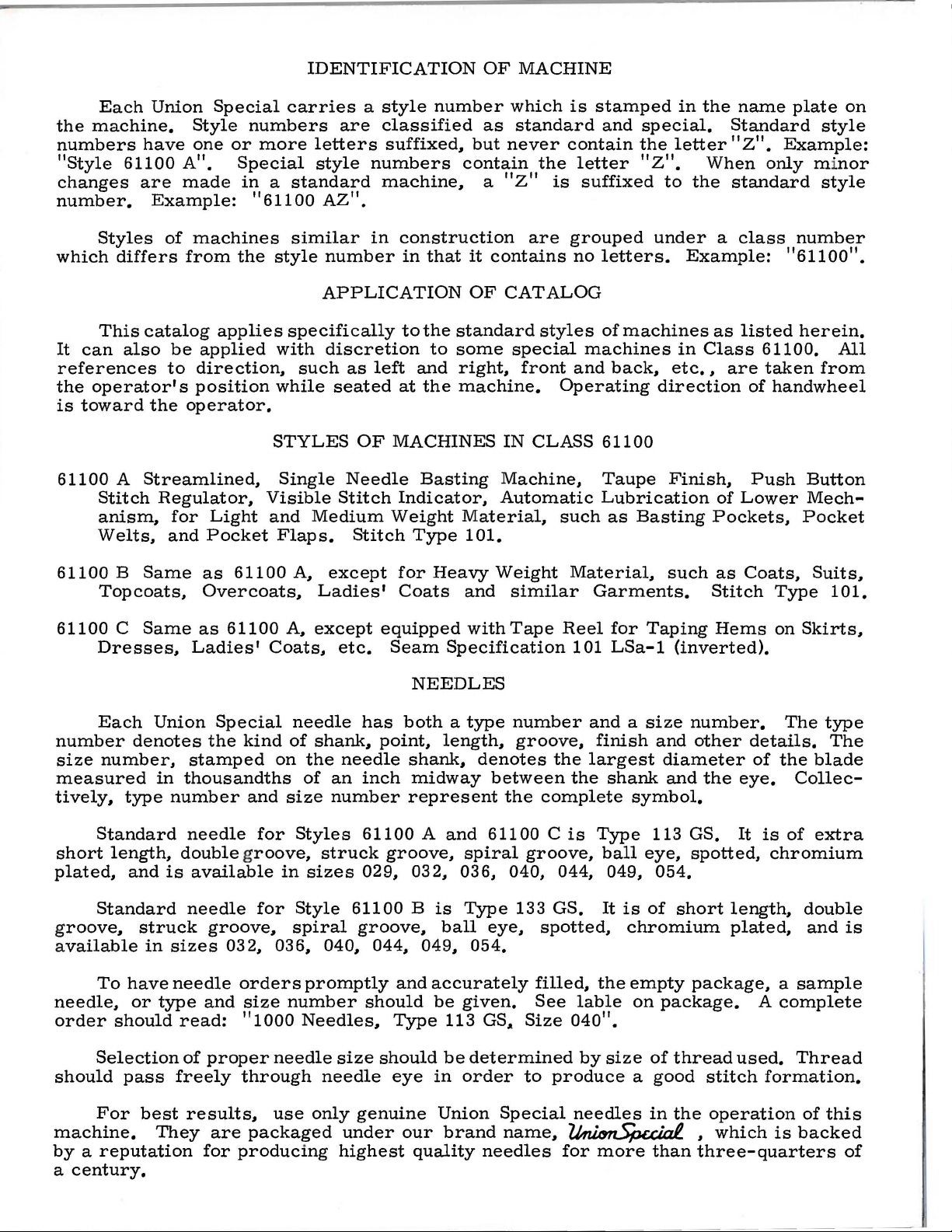

With

daily.

if

on

tric

pin

Both

required.

gauge

In

order

reservoir

and

remove

CAUTION!

Do

not

Lubrication

the

feed

means

(B)

by

of

means

Should

imperative

This

looking

slightly

can

through

below

adjustment,

depends

upon

to

needle

bar

at

reservoirs

The

oil

level

"D".

to

determine

is

functioning,

screw

use a compounded

of

the

mechanism

driving

an

it

be

shaft

oil

distributing

of

two

ever

that

the

done

the

the

as

the

which

screws

become

adjustment

by

removing

hole.

center

functioning

it.

specification

top

of

its

stroke,

are

filled

should

if

the

oil

check

"E"

(Fig.

oil

is

tubular.

plate

(C)

and

necessary

of

the

The

low

of

the

shaft

of

the

No.

through

be

checked

tube

the

2).

in

the

below

(A,

Fig.

retaining

to

the

lar

ge

point

(E)

automatic

83,

mayalso

oil

holes

oil

cup

from

from

oil

the

level

reservoirs

the

bed

plate

Oil

is

introduced

3)

which

block

remove

oil

distributing

plug screw

of

the

and

just

lubrication

be

used

(A

&

B,

Fig.

"C"

and

the

time

main

by

to

time

reservoir

tilting

is

machine

as

these

automatically

into

is

secured

(D).

any

of

the

parts

plate

at

right

oil

distributing plate

touching

of

in

supply

the

to

be

end

it.

the

the

manuallyoiledplaces.

1)

in

top

of

machine

and

to

oils

should

kept

the

back

separate

be

between

looper

against

replenished

drive

accomplished

shaft

the

from

checked

of

This

lower

at

the

large

the

gear

gear

very

the

gear

must

be

is a very

part

gear

housing and

even

of

the

twice

the

lines

eccen-

the

and

froth.

through

end

case

case,

cover

it

carefully.

with

important

machine

rest

by

is

or

Page 6

Fig.

2

E

Fig.

1

A

Fig.

D

E

D

3

Page 7

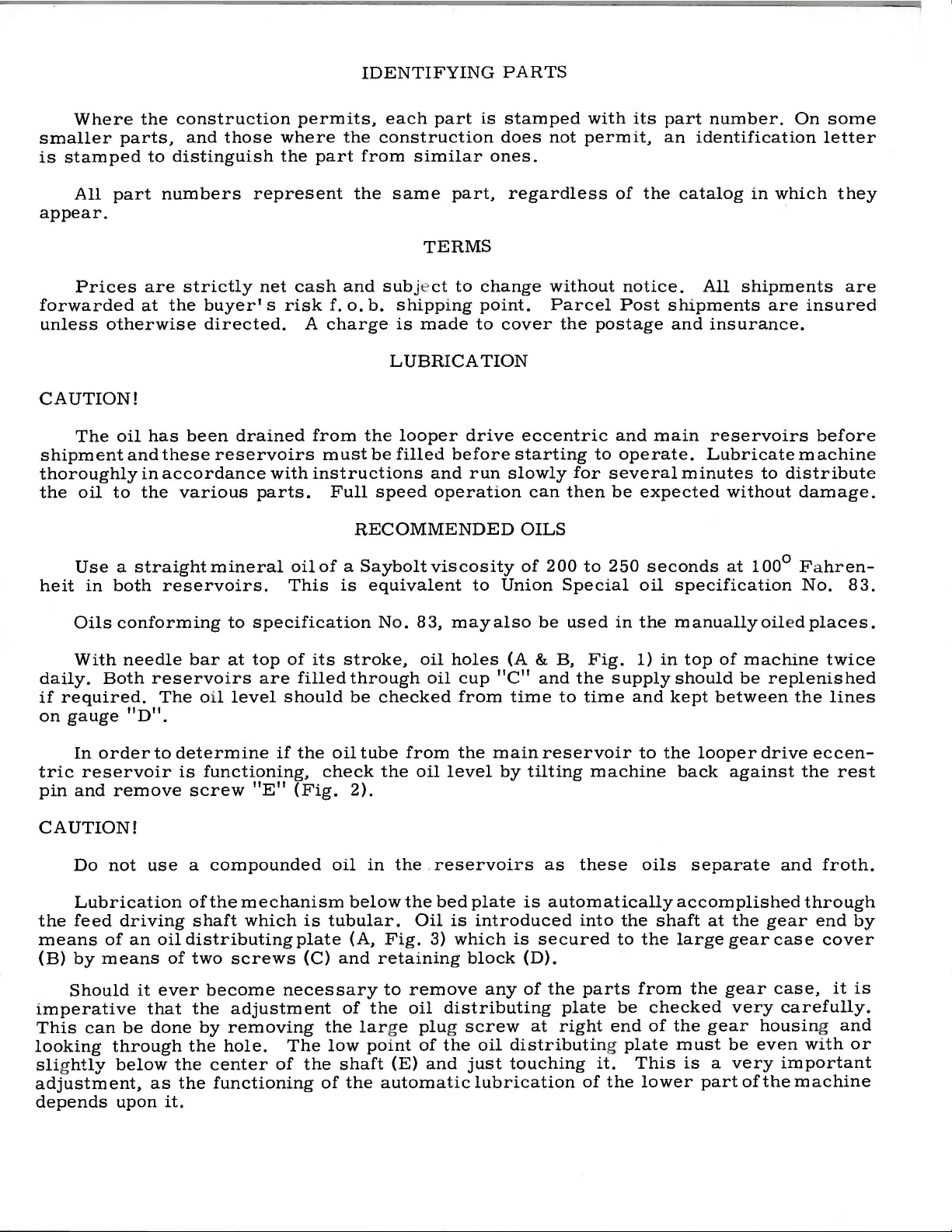

The

following

Following

is a numerical

the

parts

list

are

photographs

list

of

the

parts

of

used

some

of

in

the

this

major

machine.

parts.

Quantities,

part

numbers,

and

descriptions

are

given.

Amt.

Part

1

4

30-56

Blk.

50-552

1

1

1

2

2

1 77

2 88

1

1

1

1

2

2

1 91

2

1

1 93 A

1 95

1

1

1

1

1

1

1

1

2

1

1 161

2

2 376

4 531

1

1

2

2

1

1

2

1

2

2

Blk,

50-558

Blk.

50-568

HA61 D

HA61 D

660-142

660-184

660-190

660-226

660-257

666-20

666-104

668-25

668-29

No,

G26

Blk,

88

88

88

89

90

90

91

93 A

96

96

96

96 A

98

98

107

108

109

110-0

258

652

20

D

A

A

B-

Description

Screw

for

61303

Wood

Plug

for

61132

Plug

for

61132

Plug

for

bed

Oil

Gauge

Screw

for

diate

collar,

Screw

diate

collar,

Screw

bar

Screw

shaft

Screw

Screw

Screw

holder

Screw

Screw

Screw

Looper

Screw

Screw

bar

Screw

Screw

length

Spot

length

Spot

Spot

61137

Screw

Set

Set

61137

Tension

Ferrule

Tension

Tension

Tension

Collar

Nut

on

Screw

plate

Screw

regulating

collar

Lock

lifter

Spring

for

Oil

for

Oil

Nut

Needle

29192

Gasket

Oil

tubes

61393

Oil

shaft

housing

Steel

tension

eyelet

Locking

668-25

interme-

gear

shaft

right

for

interme-

gear

shaft

left

for

presser

guide

for

looper

collar

for

161

for

61438

for

feed

support

for

feed

for

61141

for-61336

Set

Screw

for

61173

for

presser

guide

for

61246

for

stitch

indicator

Screw

for

indicator

Screw

for

Screw

for

B

for

61141

Screw

for

Screw

for

61100

Tube

Tube

Wick

Wick

for

B

Post

Post

Nut

Disc

Spring

for

61445

21114

C

for

throat

for

stitch

shaft

Washer

61368

61193 1

for

bushing

Insert

lever

Cotter

A

Sleeve

Coupling

61193

Bearing

DU

for

22730

for

61293,

B

for

for

thread

Ring

for

stud

main

for

E

C

dog

bar

G

Y

A

stitch

61237

61237

W,

Pin

for

oil

Amt.

1

1

2

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

3

2

1

4

6

2

1

3

1

2

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

Part

No,

719

753

6990

8372

A

8372

A

9937

15037

A

15872

F

21114

21114

w

21171

R

21171

s

21171

u

21171

v

21171 w

21177

A

22528

22539

D

22562

A

22564

B

22569

B

22570

A

22570

A

22570

A

22570

A

22570

B

22574

22576

22581

22585

22585

A

22585

c

22596

D

22597

A

22597

A

22647

K-

24

22712

F

22730

22743

22757

c

22758

B

22758

B

22768

22768

22775

22775

A

22799

M

22799

N

22799

u

22802

A

22817

A

22840

A

Description

Set

Screw

Tape

Axle

61100 c (22576)

Spring

Washer

Washer

Nut

Nut

Spring

lever

Tape

61100

Tape

61100 C (258

Tape

for

Tape

for

Tape

for

Tape

Bracket

(22585

Tape

61100 C (22585

Tape

Spring

Screw

Plug

Screw

connection

Screw

collar

Screw

Screw

Screw

Screw

Screw

Screw

counterweight

Screw

Screw

Screw

Screw

Screw

21171

Screw

Adjusting

61391 D

Screw

Screw

Thumb

21177

Screw

Plug

61282

Plug

61132

Screw

Screw

Screw

Screw

Screw

Screw

foot

Screw

holder

Hand

P in

Screw

Hin

presser

Screw

Stud

Adjusting Screw

resser

p

for

Spool

Support

Cone

for

for

61120

for

51758

for

22874

22845

for

Spool

61391

foot

Disc

for

for

c

Spool

Pin

Heel

Assembly

61100

C

Reel

Support

61100 C (22581)

Tension

61100

C(22858

Tension

for

61100

A)

Guide

Wire

Heel

Tension

for

61100

for

61439

Screw

for

for

needle

stud

for

timing

61437

for

head

for

51758

for

61282

for

61382

for

61394

for

main

for

61321 J

for

753

for

21171 S

for

61151

for

21171

w

for

21171

Screw

for

61445

for

62262

Screw

A

for

61368

Screw

for

A(660-257)

Screw

for

for

61255

for

61267

for

61367

for

feed

for

51236

for

presser

for

feed

support

Lifter

Screw

for

Screw

for

for

61130

foot

61449

61468

foot

ge

61437

A

D

F

D

lifter

for

for

A)

Guide

Guide

for

A) 1

C

base

bar

A

cover

A

J

Q

shaft

V,

U

for

for

F

H

dog

A

dog

F

for

61120

F 1

for

61120

C

C)

C

A

C

Amt,

1

1

1

1

1

2

2

2

1

1

1

1

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Part

No,

22845

D

22845

G

22874

F

22880

22880

22884

22884

22884

22890

22892

22892

22892

22894

c

22894

E

22894

v

29126

BV

29126

CN

29126

DU

29475

K

39151

41064

B

43217

51236

A

51242

M

51292

A

51292

D

51430

F

51491

c

51758

51930

52782

c

61102

61105

61108

A

61120

61120

A

61120

c

61124-068

61130

61130

61130

A

61130

B

61130

c

61130

D

61130

E

61130

F

Description

Stud

for

(15037

Screw

Screw

(9937)

Spot

shaft

Spot

61449

Screw

gear

Screw

shaft

Screw

shaft

Screw

Screw

Screw

Screw

bar

Screw

holder

Screw

Screw

counterweight

Looper

tric

61100

Looper

tric

61100

Feed

tric

Bed

Needle

Looper

Needle

Hinge

61285 G (22768)

Washer

Tension

Tension

Eyelet

Nut

61120

Thread

Frame

Eyelet

22570

Spring

Stud

cover

Bed

Feed

Looper,

Presser Foot

61100 A (22775)

Presser Foot

61100 B (22775)

Presser

61100 c (22775)

Throat

Shank

foot

Shank

foot

Bottom

Bottom,

61120 A (22799

Bottom,

61120 A (22799

Plunger,

61120

Plunger,

61120

Equalizer,

61120 A 22799

61434

A)

for

for

Screw

counterweight

Screw

E

for

for

gear

for

collar

for

for

for

for

connection

for

for

for

Drive

Assembly

A,

Drive

Assembly

B

Drive

Assembly

Slide

Clamp

Drive

Bar

Pin

for

Post

Thread

for

22840 A on

c

Guide

Needle

(8372 A,

A)

for

Screw

on

Slide

Dog

"CV"

(91)

Foot

Plate

for

61120

for

61120

for

right,

left,

A

A

61449

61468

for

for

main

feed

feed

61466

61267

61367

presser

looper

61236

main

61100

Eccen-

Assembly

for

22802

61120

for

61100

(22768)

marked

presser

presser

A

61120

right,

left,

for

E

main

shaft

drive

drive

A

G

shaft

Eccen-

for

C

Eccen-

for

Nut

Shaft

Ferrule

Thread

head

C

for

for

for

(3

76)

for

U)

for

U)

for

for

N)

A

Page 8

Amt.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

Part

61130

61132

61132

61137

61137

61141

61141

61141

61149

61149

61149

61149

61151

61152

61154

61158

61170

61173

61175

61193

61193

61233

61235

61236

61236

61237

61245

61246

61248

61252

61254

61255

61255

61256

61260

61261

No.

G

Bottom

Feed Dri·

(22743)

Feed

c

Oil

Bushin

Feed

Eccentric

Looper

13

Eccentric

61100

Looper

(96 A)

Looper

G

Looper

R

22894

Stitch

tor

(95,

Stitch

A

tor

61100

Stitch Heg

G

Eccentr

Friction

H

stitch reg

eccentric

Take-up

(22585)

Crank

61100

Needle

lower

Presser Bar

tion

(22892)

Needle Thread Gui

Bed

(91 A)

Machine

Oil

drivin

assembly

O

A

N

G

G

I-I

J

I-I

G

A

A

il

Feed

Feed

Feed

Feed

(22894

Looper

Eccentr

61100

(96,

Stitch Reg

Plunger Bindin

Insert

Stitch Regul

A

Plunger

Stitch Reg

Shaft

Crank

61100

Needle

upper

Needle

ting

Needle Bar Link

(22757

Presser

Washer

Feed

Gear

Feed

Intermediate

Description

for

61120

.ri

ng

Shaft

Driving Shaft

Hetainin

for

for

for

Slide

Tube for

Tube

Lifter

Bar

Rocker

Rocker

Stud

Driving Shaft

Driving Shaft

g

g,

left

Drivin

g

Drivin

g

for

B (96,

Drive

C)

Length

96)

Length

Pin

g e

98)

Collar

P in

(2288

98)

Shaft

Bushin

Link (90)

Holder

Indica-

61100

Indica-

61100

c (95,

96)

ulating

ic

Disc

for

ulating

Eyelet

for

B 1

Bar

Bushin

Connec-

61100

Sprin

Hin

ge

feed

ccentric

Coupling

Link

Shaft

Shaft

E)

Drivin

g 1

ic

for

A,

61100

ulatin

atin

Lever

ulat

ing

(531)

for

A,

61100

Bar

Bush

Bar

Connec-

(22562

C)

Spring

4)

Gear

Amt.

C

1

1

1

1

1

g

g,

de

19

A)

A) 1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

B61382

1

1

1

(91,

B

A, 1

B 31

g

Stud

C 1

g 1

g

g

(93

C

ing,

Part

61263

61264

61264

61265

61267

61267

61282

61282

61282

61285

61293

61293

61293

61303

61321

61321

61322

61330

61330

61330

35

61330

61336

61336

61342

61348

61351

61356

61360

61360

61366

61367

61368

61368

61368

61382

61391

61393

No.

Bushing

Intermediate

Intermediate

A

HandLifter

Lifter

G

Sprin

A

Housing Cover,

Gasket

D

Gasket

E

Looper

G

Oil

Plug

N

Oil

u

Ed

E

Handwheel

J

Washer

L

B

Main

Shank

B-

Hinge

B-

Hin

Shank

AI-I

Feed

u

y

Feed

Looper

Stitch Reg

A

Needle

K

Presser

Main

Feed

G

Lifter

c

Lifter

Li

Lifter

A

F

F

H

I-1

H

J

M

D

Oil

B

De

scription

for

driving

intermediate gear

Shaft

(HA61 D)

Shaft

(I-IA61 D)

61100

(22758

(22570

Eccentric

Tube

bar

arm

Tube

Plug

ge

61100A,

(22574)

foot

ge

Bushing

Wi

ck

(88)

Shaft

Gear

Collar

si

on

61100 B (22758

22892)

fter

ting Rod

ting Rod,

(660-142)

oot

Roller

ead

ous

ing

(22570

ain Shaft Counter-

weight

22596

22 8

94

Tube

ma

in

feed

shaft

Gear

Collar, rig

Gear

Collar,

Lever

A,

Pin

for

for

Driving

driving link

for

Guide

Shaft

for

Pin

61120

Pin

for

Rocker

Rocker

(90)

Shaft Coll

Bearing Holler

Sha

(22884)

Driving

Lever

Stud

Lever Link

Lever

Lev

Lift

Cover

D,

V)

bearin

left

(22799

Lin!\ fo

61100

B,

22892)

for

15872

A,

22730)

61382

61282

Strap

for

needle

inside

of

Coupling

for

61100B(G26)

for

61421

for

handwheel

61120

for

presser

C

for

61120

61120

Shaft

Oil

ulatin

g

Sprin

g

ft

Drivin

Shaft

(22 8

84)

Exten-

(652 B

Connec-

er

Connec-

complete

er

Ball

(22712

A)

(22570

F )

(22 569

Cover, rig

B,

22880,

for left

g

left

C

-20)

Crank

C

B,

J

A

ar

g

ht

M )

for

B)

ht

Amt.

r

F

Part

No

61394

61394

61394

61394

61421

61421

61432

61432

61432

61434

6143

61437

61437

61437

61438

61439

61439

61445

61447

61449

61449

61449

61449

61457

61457

61457

61458

61459

61466

61468

61490

61490

62262

81292

p

Q

R

AE

A

B

c

D

4 G

A

B

E

F

I-I

B

A

A

A

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Description

.

Hous

ing

Distributing Plate

Oil

Distributing Pla

Hetainin

(22570

Gasket

Oil

Cup

main

IIandwheel Ass

for

"V" belt

Pull

ey

Feed

Bushin

Feed Dri

B

ushing,

Feed

Oil

Bushing, rig

Feed

22845

Washer

Stitch Reg

A

Eccentric

Collar

B

Stitch Reg

Eccentric

Pin

Stitch Reg

c

Eccentric

(719)

Feed

c

tric

(88)

Feed Dog

(22528)

Feed

Support

22775

Stitch Regulatin

Plunger(22597

Stitch

Plunger

Sprin

Spring for

Stitch Regulating

Pawl

(22845

Stitch Regulatin

P

awl

51242

Stitch

tor

P

resser Bar

P

resser

Regulator

Presser Bar

c

lower

P

resser

ti

on

61100 c (22892)

Presser Bar Gui

(77, 93

Foot

(22890)

Li

fter Lever

Cr

ank

22874

Main Shaft

r

igh

M

ain

Inter

mediate

Shaft

Tension Post

Cov

er

Oil

g Block

A)

for

613

94

filli

ng

e m b

or

No.

ht

left

g

ht

D,

614

34

g

Timin

64

B)

g

P i

vot

g

Hou

sing

cen-

D,

g

A)

g

61149

22880)

g

A,

Indica-

Bushin

Connec-

A,

Lever

Bell

A,

Bushing,

Bush.,

Gear

A)

Q

89,

g

G

de

left

for

reservoir

round

Hub

Driving Shaft

g, rig

ving Shaft

Driving Shaft

Retainin

Bar

(88

D)

for

ulatin

(225

ulatin

ulatin

Driving Ec

Connecting Rod

Holder

Dog

Holder

(88

A)

Reg

ulatin

Lever

g

Collar

G,

(22802

M)

Length

Insert

Spring

Bar

for

61100

A)

Lif

ter

(22817

F )

t

Shaft

(22597

te

ly

1

g,

NOTE:

Numbers

parts.

in

parenthesis

follow

ing

parts'

desc

r ipti

on indicate

the

screws,

nut

s,

etc.

used

to

attac

h or

hold

thes

Page 9

\.)

~

~

~

~

~

~

tN

'

'

~

~

~

~

~

~

\

'a

()

~

\Q

~

~

c:.\1

(1)

~

~

~

Page 10

~I

Page 11

~

~

~

.........

~

j

~~A

~

~

~

"

"\t

~

~

~

~

"

~

~

I

~

'o

(\,

(\J

~

~

"

~

.1

·~

~

~

~

...........

('....

...........

'

~

Page 12

~

~

~

~

"'

~

(J

~

~

'\9

Q(

~

~

"

~

~

~

........;:

'\S

~

('{)

':<'!

~

~

~

~

~

K

~

~

~

~

~

........

~

~

~

\\1

"".:""-

~

~

~

~

:::::

..

Page 13

Page 14

®

FINEST

"t

Handle Union Special and Columbia only.

t Handlo

All

othen

certain

ALABAMA

lloyd

ALABAMA

(Zip Code 36110),

ARKANSAS

Taylor, Tel. 1'011 376·3121.

*CALIFORNIA 90021,

Paul

M.

CALIFORNIA

Robert J.

!CALIFORNIA

Machi

no

COLORADO

leo, '719

CONNECTICUT

Galnot,

FLORIDA

lng Equipm•nt,

FLORIDA

Morgan,

*GEORGIA 30324,

N.E., Morrill M. Arnbroto, Mer

GEORGIA

Hanloy, Tol.

GEORGIA 30030,

Parker, Tel.

GEORGIA 31021,

Tol.

272·~663

GEORGIA

Tol.

Cumming,

GEORGIA 306BO,

Tol

. 867-320B.

*ILLINOIS 60610, CHICAGO,

Koehler, Mgr.,

KANSAS

Rosewood, Cleo C. Smith, Tel .

KENTUCKY

Hinton, Tel. 587·0042.

lOUISIANA

Springs

QUALITY

lewis

and Columbia only.

handlo Union Special# lewis and Columbia with

oxcoptions.

UNITED

3'206,

BIRMINGHAM,

D.

Baldwin, Tel.

36107,

MONTGOMERY,

72203,

LITYLE

Mason, Mgr., Tel. Madl1on

9~110,

Vall, Tel.

9~103,

Ca.,

11

'5

80002,

ARVADA,

Rood

St. , Tol.

06B11,

Tol

.

7~6-3652.

33127,

MIAMI,

Inc

33566,

PLANT

Tol

. 752-1829.

30,29,

COMMERCE,

335-~1.

DECATUR,

377-,559.

DUBLIN,

.

30,01,

GAINESVILLE,

Ga.

WINDER,

Tel

.

6620B,

KANSAS

~0207,

LOUISVILLE,

70~,B.

Drive,

Duane

STATES

732-

833-990~.

Tommy

LOS

SAN

~1,/826·'969

SAN

Minion St.,

DANBUJY,

., Tel.

CITY,

ATLANTA,

BB7-~732.

6~~-6920.

NEW

Bunger,

3223 Wlllow

Hendrix, Tol. 272-6667.

ROCK,

P.O.

ANGELES, 1100

FRANCISCO,

.

FRANCISCO, Apparel City

Tol

Caaoy't Sowing Machlno Sor¥

~2~·6630.

221arnum

2525 N.W. 2nd Avo., Trlrnco Sow·

633-1138.

~6

N. Gordan St. Jamot C.

2120

..

Tol. B7J-9237 .

lakovlow Drlvo, J.

1713 Cavontry Road, Jao V.

1615

Knox

RFD

~8

Fifth Avo., I .

~00

N. Franklin

CITY

(PRAIRIE

HE

2-1705.

P.O.

ORLEANS

Tel. 504/643-2484

SALES

Uth

Stroot, South,

lane

lax

1783, Jamot T.

E.

Plea Blvd.,

5-5828.

3~20-25th

. MArket 1-6660.

Platton lrldgo Road,

St., John W. Janos,

",

Box

7261, Raymond

(SLIDELl)

Sow

Road, Robert W.

John lradborry,

D.

Smith,

St.,

Fred

VILLAGE)

27'

.

INDUSTRIAL

OFFICES

MARYLAND

Fatter,

!MARYLAND

Baltimore

*MASSACHUSETYS

11om

MASSACHUSETTS

Pedenen, Tel,

MASSACHUSETYS

Walter P. Godek, Tel. VanDyke

MICHIGAN

Dr.,

Street

ing

Tam

L.

7351

E.

Pal10

313-5B~·~21

MINNESOTA

louis

MISSISSIPPI 39209, JACKSON, 327 Eastvlow St., Jamlo A.

Boyette, Tel. Fleetwood

1~27

!MISSOURI

915

MISSOURI

Mclaughlin,

631 17), also

!NEW

E.

!NEW

Terrace,

!NEW

W. Whlltan, Tel. Gonovo

NEW

Noll,

NEW

Whoelor, Tol. 518-7B5-6371 .

NEW

bahm,

*NEW

mlnal Bldg.), Clarence L. losenquht, Mgr.,

lng

INEW

Culver

NEW

Candoll,

NORTH

William D. Harrod, Tel. 299·9367.

(Zip Code

OHIO

Equ

0'1~m~~:t~~,

OKLAHOMA

St.,

OREGON, 97220,

:o~;"ts~~~~~~::

PENNSYLVANIA

D.

LEWIS

and

SEWING

AND

2121 ' •

BALTIMORE

Tel

. 727-BA99.

2120~.

BALTIMORE,

St.,

Tel. lETington 9 ·

E. Palm, Mgr.,

Park,

(Tupelo) 3BB01,

Broadway, Tel. VIctor

HAMPSHIRE

Haberman Jr., Tel. Tuxedo

JERSEY

JERSEY

JERSEY

Tol

YORK

YORK

YORK

~-B800.

YORK

YORK 1 "53

CAROLINA

~~109,

lpmont

G.

Canon,

02111,

Tol

. Llborty

02021, CANTON,

828-1412.

02767, TAUNTON, P.O.

~8223,

DETROIT,

0.

55~26,

MINNEAPOLIS, 2800 To•a• Avo.,

Minn., leonard W. Koehler, Tel.

5-1976

Tel. 601/B42·7650

6~105,

KANSAS

631

14,

ST

LOUIS,

Tel.

Chestnut 1-

Jerry

Hicks

.

03060,

NASHUA,

07032,

Jcneph

.

767-~350.

02110,

14502,

Tol

.

Rd

.,

To!.

27~07),

Ca.,

73119,

I.

Wlloy,

NORTH

Logllstl, Tel. 991 -8211 .

07010,

RUTHERfORD,

08091,

WEST

LATHAM,

MACEDON,

916-~693

.

10001,

NEW

YORK,

1~609,

ROCHESTER,

Tol. BUIIor

~gL~~BUS,

1

Tel. 797·2111 .

B-7250.

, UNIONDALE,

lvanhao

3-7~77

27~03,

also Harald E. Miller, Tol.

CLEVELAND,

Tol. 661·5901 .

P.O.

OKLAHOMA

Tol. 6"·2836

PORTLAND,

Phone,

503/771-2159

18105, AllENTOWN, P.O.

COLUMBIA

MACHINES

REPRESENTATIVES

, P.O.

Ia•

2505, Ralph I .

J. Doshow, Inc.,

1838

.

BOSTON

, 179 Lincoln

2·01~7

.

York St.,

RFD,

lax

2-6149

14561 Auburn, John Joyce,

. larry lancaster, P.O .

CITY,

2-9558.

9022 Pallardy Lane, Carl

2368. 8725

2-9698.

ARLINGTON,

8·2178.

BEILIN, P.O.

57 Sylvan Ave., Clarence

3 Jup llor Way, Jamot Hal·

370

A.

873

.

GREENSBORO,

~914

Poarl Rood, Cut &

Box

CITY,

.

19'0 N.E.

12 Raynham,

.

6-U-6236

.

Tullio

Machlnory

Warner (Zip Code

P.O.

Box

,7,

32M

2~6

Sylvan St., Richard

Box

26, Frank A.

71h

Avo

., (Ponn

Tel. Chlcker

J. Adams Co., 1051

llonry

St.,

P.O.

~216

Ponnydale Dr.:

292·073~.

87~.

Lorry

Kolton, Tol.

2226 Sauthwost 53rd

118th Avo.

(Portland)

Ia•

5~2,

~17

St.,

Roy

Horman

Gordon

Anthony

lax

206/62~-

luthot

PENNSYLVANIA

Dootlan, Tol.

W.

PENNSYLVANIA

Mcfadden, Tel.

Wll·

PENNSYLVANIA

Avo., John J . Laftor, Tel. JUnlpor 7·2B20.

T.

*PENNSYLVANIA 19124,

Ave. ,

!PENNSYLVANIA 15670,

R.D. No

Tol

.

Ca.,

Tor

226

Sow

563·35B9,

.

PENNSYLVANIA

M.

51.

Box

A.

E.

·

·

Bender, Tel.

PENNSYLVANIA

Powell, 8.54-80.(0, also f .

SOUTH

CAROLINA

R.

Crisler, Tel. Sunset 7-0B63. P.O.

Carter, Tol.

SOUTH

CAROLINA

Orville

TENNESSEE

John

W.

TENNESSEE

tloroce E. Clinard, Tel. .588-186.5.

TENNESSEE

Lindhorst,

TENNESSEE

M.

felix

*TEXAS

~7~2~,

TEXAS

79926,

Tol. 59B

TEXAS

76106,

walt, Tel.

TEXAS

78213,

13126, Tol.

UTAH

B~105,

Larry F. Rasvall, Tol.

VIRGINIA 2.(006, Roanoke, P.O.

Tel

.

703·3~2·3233,

UNION

BRITISH

Mad

bon Ave., Tel.

MANITOBA,

Bldg.,

*ONTARIO,

~lng

St. Wolf, Tol. Empire 6-2939.

*QUEBEC,

Charlet

WORLD'S

868·8204

18003,

Ben

W.

Merz, Mgr., Tel. Gladstone

. 1,

Box

alto

17567,

25~·~255

W. Gregory,

,

37~21,

Carter

37919,

3B117,

Tel

. Mutual 5-67.50 .

37214,

Blunkall,

752~7,

J.

H.

Muir Mgr

EL

·2928.

FT.

626·3183.

SAN

Dl 2-,924

SALT

FINEST

18015,

UTHLEHEM.

.

BERWICK,

752·2~~2

.

lUll,

CLARKS

PHILADELPHIA,

NEW

26A, W. Dale Spoor,

R. N. Bolos.

REAMSTOWN,

267-6109,

also

17~0~.

YORK,

J.

Bartosfc.

2920~

.

COLUMBIA

.

29607,

GREENVILLE,

Tel

. Cedar 9-5539.

CHATYANOOGA,

615·B92·1~89,

KNOXVILLE,

MEMPHIS,

Tol

DALLAS,

PASO, P.O. Bo• 9573, Edward E.

WORTH,

~695

NASHVILLE,

.

615-25~·7538

6718 Oakbrook Blvd., P.O. Ba•

.,

Tel.

1201 Altamont Dr., Arnold Stlor·

ANTONIO, lorry Gregory, P .0 . Baa

.

LAKE

CITY,

IN

7-6931.

alta

P. C. Eblo.

CANADA

SPECIAL

MACHINE

COLUMBIA,

70

do

N.

BURNABY

MU 3·3917.

WINNIPEG 2, frank Thlorma•,

Arthur St., Tel.

TORONTO

MONTREAL

lalaur

20~.9~3-4933

2B,

Potor fowlor, Mgr.-Rop ., 355

11,

John Catchotto, Mgr.-Rep., 9595

St.

Tol

.

51~/387-7191

QUALITY

*

1212

ea-c

1013 E. 16th

SUMMIT,

ALEXANDRIA,

F.

J. Bartoslc.

P.O.

, P.O.

3905 Groonloaf Avo.,

2517 Woodberry Drlvo,

214/637·5990.

1215

Bo•

Ca. of

2,

St.,

~2B

Wott Gravo

~23~

Macalolloo

5-9800.

(Pittsburgh),

Tol

. (Pittsburgh)

P.O.

Box

176, David

Ia•

B84, Harding T.

lox

~246,

Box

~112,

alta

25 Sir Abbot St.,

1711

Roy

Ja Clrclo,

Dunn Rd., Richard J,

.

!.

13th South

1151,

Tom

Traylor,

Cana~o,

Ltd.

Jomot Murray, 1522

Rm.

201, Whltla

.

.

St .•

Donald

Vlrlyn

J.

S.,lth

Ed

W.

,

St.,

FINEST

QUALITY

WORK

•

•

HIGHEST

PRODUCTION

RATES

•

LOWEST

•

MAINTENANCE

COSTS

Page 15

AFRICA

(TEXTILE & BAG

REPUBliC

Pritchard

72

Commercial

RHODESIA,

Barton

(BAG

ClOSING

ltd.

32

Von

CAPETOWN-Wales

St.

EAST

Nalal-355

at

PIETE~MARITZBURG,

Potgl

etor

Rhodes Str

LUSAKA-W.

Road &

ALGERIA,

Mohamed

ETHIOPIA,

Asfaho

GHANA-ACCRA-crown

3547

IVORY

(L & Cl

KENYA, NAI ROB

Kolnonoo

ganylka

MALAGASY

De

L'Emyme, Bolte

(L & Cl

MAURITIUS, PORT

Machines)

Newton

MOROCCO,

ldrlul

NIGERIA,

Ltd. 9

SUDAN,

305.

MAKING MACHINESI Berzack Bros.,

OF

SOUTH AFRICA-JOHANNESBURG 135

St.

CAPfTOWN-78

Road.

PORT

BULAWAY0--133

Houso~

Corner

MACHINES)

REPUBLIC OF

Brandis

LONDON-33·35

Murchilon.

St.

RHODESIA,

....

t.

SALISBURY-95 VIctoria

& T. Avery

Codrington

ALGIER5--Etablissemont

V.

(L

& q

ASMARA-5.A.

Wooaon

( L & Cl

(l

&

q.

COAST·ABIDJAN-EII.

1-Transcandla,

St.

(P.

O.

and

Zanzibar)

REPUBLIC-TANANARIVE-sac.

Hall,

Geneve, langlois, Ltd., 42 Sir William

St.

CASABLANCA-I. GoluMann

Et

Sakall

Ill

APAPA,

LAGOS-Sunftao

Warohouao

KHARTOUM-Franco

(L & Cl

EliZABETH-277

Sklnley

South

SOUTH

AFRICA-JOKANNESBURG-

St.

BLOMFONTEIN-53

and

Broo Sts.

North Stroot,

PORT

PRETORIA,

BUlAWAYQ-2

(Zamblal

Street.

Caldoronl Africa, Avonuo P.

Industrial Enterprises

Joan Abllo·

lo<

59331

(L & C1

Poatale

1078, 17

LOUIS-(Bao

Road.

(L

& Cl

Pinto (Sudanl Ltd.,

Darllno St.

Fifo St.

Ave.

ELIZABETH-Box

Closing &

ASIA

CAMBODIA, PHOM·

.0.

woth, P

HONG

KONG-G

309.

Marina

INDIA,

CALCUTTA-Parrot

Sovaram Bvsack St. G .

JAPAN,

OSAKA-Kondo

Klla·ku.

Also

all

and

Okayama.

LAOS,

VIETIANE-Donll

PAKISTAN, (WESTI KARACHI·2 (Textile

Trading

AND WEST)

Thomas C.

REPUBLIC

(Talwanl

SINGAPORE

Yono Slak

THAILAND,

Box 23.

VIETNAM,

Trlnh·Minh·Tho. (C &

PENH-Donla

Box

~8

.

(C

. R. Coleman Co. (Hong Konol Ltd.,

Houae,

15

Ill

Branch-TOKYO.

Ashlkago,

Corp.,

OF

Ltd.,

(l

SAIGON-Thai·Binh·Duono

Fukal, Hokkaido,

29

Zoonat Mansion,

(801

closing

Keay,

Ltd

., 15 Baltic

CHINA,

TAIWAN,

16

Non Yang

3-G. R.

St.

BANGKOK-Yip

Coleman (Singoporo Ltd., No. 1·M

Alto

all

& Cl

Ll

Froros, 219

lo

Ll

QuMn

's Road, Control.

s-Ino

P.O.

Post

Box

Sowing Machine,

3·6

Froroa,

P.O. Box

and

Strut,

TAIPEI-G. R.

St.

(L

of

Malaysia.

In

Tool & Ca.,

AUSTRALIA

SOLE DISTRIBUTORS,

Stroot,

SYDNEY

wick

St.,

St.

AGENTS,

Charlick

Ltd.,

LIA

PERTH-Thomsons

LAUNCESTON-Sow

Capron,

2000

Valloy, N.l.

. Branches

MELBOURNE

SOUTH

AUSTRALIA-ADELAIDE-William

London Road, Milo End.

Ply. Ltd.,

Knit Ply. Ltd.,

Carter

at,

789

72-7~

Also

Agent

ltd

/7

DURBAN-

Main Stroot.

SALISBURY-

and

Moffat

St.

Zallran

LADYSMITH,

611.

leander

ZAMBIA-

Comor

ltd.,

Box

Uganda,

Ind.

Clemenceau

lao

& Fila,

P.l.

(l

& Cl

Umega•Cho

Chuo-Ku

133.

Rood.

.. , Scotland

Coleman Co.

Ltd.,

147

Ltd.,

~90

A Beckett

St.

TASMANIA,

St.

(l)

Allwal

Also

House,

Stanley

P.O.

Box

1798

Houte,

Tan·

Et

Cam.

Makino

RINI

(Nioortal

P.O.

lo>

Slao·

Rm.

9/1

163.

N11gata,

(C & Ll

(EAST

P.O.

Ruo.

Kont

Bruna·

AUSTRA·

(L & C1

St.

African Scalo Co. Ply.,

DURBAN-22

VEREENGING-288

Strnt,

ltd

.,

All Amor, 62 Boulevard

Gal,

ltd

,,

College

(Alto

Rue

Knitting Mills

Machine (P.I Ltd.

2~.

ltd.,

Glnza

Nagoya,

Machlnosi-Unlvonal

Mcleod

bag making machines)

Ound

& C)

(L

& Cl

Cono·TY,

Pty.,

BRISBANE--45~

3000--15~

WESTERN

Hay

George

Sales

Agents

for

Ill

For UNION

LEWIS

and

SPECIAL

(C)

COLUMBIA

EUROPE

.

AUSTRIA, VIENNA

O.H.G

., Marf

100

NTNI

&ELGIUM, BRUSSELS--Union Speci

2

of Ameri

ICI

DENMARK,

Sv·lnduatrlon

IORG,

AND SILKEBORG.

FINLAND, HELSINKI -LAUTTASAARI-5uomon Konolllko

Vattuniomenkatu 13. Branches

slalo.

TURKU,

fRANCE,

Franco,

Dlredeur,

Pa<e

Salni·Mour

Alexandre

des

Pensees.

GERMANY,

brik,

G.m.b.H.,

Director.

AT,

.

El

.

BERLIN,

BURG,

GREAT

BRITAIN-(Toxtllo

OADBY

ltd

., Mandervell Road, Industrial

Manager.

Old

St. (A.

BRISTOL,

MILNGAVIE

bar

Avenue. SUB-AGENTS: LONDON, W .

& Son (Sowing Machinery), Ltd., 58

MANCHESTER

Grove

Works,

FAST

15,

GLASGOW S. E.

(Bog Closing

DUNDEE-Thomas

for

entire

GREECE,

trakl St.

ICELAND, REYKJAVIK-Mognus Thoraelrsson, Skolavordustlg

1a

(L &

IRELAND,

Parnell

Mochinet)

Scotland.

ITALY,

I 20121

Va•oso

18.

MALTA,

VALLETTA-Frank Borda & Sons,

Shoot

(l

THE

NETHERLANDS. AMSTERDAM-H. V. Machlnohandol

C. &

H.

ARNHEM, ENSCHEDE, GRONINGEN,

TARO,

TILBURG.

NORWAY,

117,

BERGEN-Biornsonost

PORTUGAL,

de

Forretfer 91A.

SPAIN,

BARCELONA-Rapida,

& Cl

SWEDEN, GOTEBORG

91

. Branch atz BORAS,

and

STOCKHOLM.

SWITZERLAND, URDORf (ZHI

austr

. (L-Buttan.$ewer)

YUGOSLAVIA.

33.

(L

& q

ARGENTINA, BUENOS

San

Jose

BOliVIA-low

inoo

11~0.

BRAZIL,

SAO PAULO--Pancotfura S.A.

ercio,

Alameda, Cleveland,

ALEGRE-Rua

Prlnce

sa

MacKenzie

CHILE, SANTI

Santa

Domi

COLOMBIA, B

30 #12·99.

#3~·54.

IUCARAMANGA-Callo

33/35.

MANIZALES-

MEDELLIN-Carre

COSTA RICA, S

19~9.

(L

DOMINICAN

quoz.

G., Call

A·1061-Naeachustor Holnrlch

ahHfentr

.

51,

Po

•tfoch

ca,

90 Rue

de

Ia Ca•om

COPENHAGEN-Rothonborg

A/S,

HEINING,

PARis-ere. dot

91

KOLN

(NR.

ATHENS-Georges

(L

q.

DUBLIN-(Toxtllo

StrHt

&

MANGLERUD-Jac.

OPORTO-Rost & Janus,

35

Isabel 105; RIO DE JANE

& Cl

Nikolai Plods

KOLDING, ODENSE, RISSKOV·AARHUS

(L

lo

C1

Humollslonkolu

AYe. de

Branches al1

. LYON,

Boutin. TOULOUSE

(L

& C)

STUTTGART

SchwabJtr.

Th. M. Boonstra, Director of

BIELEFELD,

, MUNCHEN,

LEICESTU)-Unlon

LEEDS-60

W.

J.

Brownlee, Manager). SALES OFFICES:

L.

J. Hoard,

(GLASGOWI-Derrick

19-S.

levonthulme.

Aklo• Ltd.

-AIIardice & Co

and

Bog

C. Keay, Ltd., 15 Baltic

Britith Isles.

& Cl

(L

& C)

Thomas C. Keay, Ltd., J5

MILANo-Giovanni

(L

&

Cl

at

7·1.

Machines Union

Ia

Republlqu..._Tha

(!i9)

ULLE

VILLEURBANNE

(HAUTE

(70001-Unlon

33-Dr.

EBINGEN,

OCHTRUP.

Machl

noryi-ENGLAND

Special Machine Company,

Merrion

Street.

19

The Ride. Kingswood, SCOTLAND,

A. Smllh, (Manch01torl Ltd., Park

NORTHER~

186

Covohlll Rood. SCOTLAND,

., 9

Making Machines) SCOTLAND,

Yannakouras-Dimoulla, 30 P•·

Mochlno•l

(log

Clotlng

Cl

VerbHk,

Klovenlenburgwal 77. Offtcos atz

(L

& Cl

Jacob,.n

24. (C &

(l)

S.

A.,

5-Jac.

Jacobsen

lunnegaten

Ill

8902-lourquln & Clo.,

KIRCHE

IM

(73121-

LATIN

0.

onstein & S

Sanliaoo, Chil

11

7.

AGO--lowonalo

ngo I UO. (L

OGOTA-Mocalzodo,

Branches

AN

REPUBLIC,

o Dr. Pedro Urona

AMERICA

AIRES-Pamaco Coa

(Union Special

tewart,

o.

Voluntarios

(C &

Ll

& Cl

at

3~ #17·~ 5

E.

Broalauo

ra

51,

36·18.

JOSE-Enrlquo

SANTA

Machi

S.A.C.,

(L

& Cl

~.(.(,

do Patrlo 533;

ln

lo

BARRANQUILLA-Carrora

(L

DOMINGO--Roberto

al

Machi

o.

Gultavo

23.

TAMPERE·Pionteollisuo·

(L

5 Residence Clteau,.,

Special

K.

Ettote.

R.

Robinson,

Great

Steventon

Conti &

Ll

Succs.

Via Layotona

A/8,

A. Alto In

Jos

of

ne

Company).

-Indultria

Branch

IRO-Rua

Stowart, S.A.C., Callo

Mercan

.

CALl-Carrara 7 #1

r,

Carrera

& Cl

Rod

rigues

19.

(L & C)

Machines;

where

marked.

77,

Spoclalmaddnor

&

(L

LONDON-18~·1B6

W.

laltlc St.,

ltd

A/5,

Scharzor

Schutter

(L)

(C-.rcopt

ne

Corporation

lhlorlo,

Mar.

Ofllcoa

ah

ML·

0/Y,

Cl

Special

t.

do

Semlyen,

(RHONEI

GARONNEI 9 Ruo

FRANKFURT,

Mr.

ROTTERDAM,

Calle

tll,

58

Matchlnonfa·

Schulz, Managing

Sales,

BRANCHES

& C)

and

.

lda

tura

HAM·

LE2

5LN-

J.

C.

Spencer,

48

Cloch·

1-G.

Johnson

Tllchfleld Stroot.

IRELAND-BEL·

Street.

Street-Agent

Blyt~man,

Bag Making

Dundee

Nlpotl,

51/~1

Zachary

SIT·

Enobakkvolon

•• Rua

Iaroe

37.

Molndahvogan

MALMO

Vooel.

8ou lot1h

S.A.C.J.y.

(L

& C)

San

to

Oom·

o Com·

es

at

PORTO

RECIFE-Ru

Alexandre

S.A.,

Carrera

45-B

22

#1

B.~~.

S.,

P.O.

Bo•

Domin·

for

do

ruo

(C)

22~

,

Via

(l

F.

o

3·

ECUADOR,

EL

GUATEMALA,

HONDURAS, SAN

MEXICO,

NICARAGUA,

PANAMA,

PERU,

PUERTO

SURINAM, PARAMARII()......KirpalanJ•s,

URUGUAY,

VENEZUELA,

CYPRUS,

UAN,

IRAQ,

ISRAEL,

JORDAN-Bandar

LEBANON,

SYRIA,

TURKEY,

U.A. R.,

SOLE

HAWAII,

PHILI

WEST

JAMAICA,

TRINIDAD,

GUAYAQUIL-Dlalrlbuldora

S.A., Malocon Simon Bolivar

Avonldo

Potrla

SALVADOR, SAN SALVADOR-Dillrlbuldora

do

El

CIA.,

Box

(L & q

do C.V.,

JARA,

dora

(Aparloclo 2807011 SAN

Royos

#303.

do

Colombia Building, P.

Alfonso Uoarto

Box

St. (L & Cl

Morcodos

Chorro

coupplo

881 P.

2021,

IL

I. Cl

archo

Han Nr.

Tech.

~hubra.

St. AUCKLAND.

Nelson

Islands,

Tahit

CHURCH-90

P.O .

Box

P.O. Box

768.

Salvador,

Colonia Valro.

GUATEMALA-Union

LTDA.,

Sa

Avon ida I

559.

Union

LIMA,

2352.

TEHERAN-Sava Trodlng

BAGHDAD-Sons

DAMAS-landor

DISTRIBUTOR,

i,

Box

602.

PEDRO

TEGUCIGALPA-Carlot

MONTERREY,

Cuauhtemoc

JAL.-Hldaloo

~eclal,

80.

ILl

MANAGUA-Caaa

Ill

PANAMA-International

Brefto--Unltod Agencies, S.A.

U~5·14~7.

RICO, SAN

(L

& Cl

MONTEVIDE0-5toror & Cia.,

1312.

(LI

CARACAS-H.

29.

(LI

NEAR

NICOSIA-Chrltlodoulldos

St.

Ill

O.

lox

1720

Alwlyah.

(L

TEL

AVIV-L.

& Aractlngl,

BEIRUT-Ibrahlm

Hayek.

(L

& Cl

ISTANBUL-.

~6-~7

.

(L & Cl

Colro--Miar

Sub-Agent-A.

(L &

C1

NEW

BRANCH

St.

(LJ

Alto-New

Gilbert

hlands,

and

Tonga.

SUB

Orboll 51.

~0.

(CI

(LI

SAMOA (WESTERNI,

20~.

Ill

PACIFIC

HONOLULU-Aihow,

L &

C).

(Textile

H. S. Gr

PPINE ISLANDS,

723

Inc. ,

CEBU.

(Bog Closing

ay

Co. , 7 59 Puuloa Rd.

2 Malug

ay

(L

& Cl

INDIES

KINGSTON-Mauls

Ill

PORT

C1

AI•-BAIIADO

OF

(L &

12308.

(L

&

C)

(LJ

T"lll

0·~3.

Zona I

SULA-Jacobo

Handal,

N.L.

-Talloroa

Norte 33.5, Branches ah GUAOALA.

~5

y

47,

A.

de

C. V ., Avo., Plno

LUIS

O.

Box

llohrn,

MEXICO,

POTOSI, S. L.

Hontoon, 3A

de

1275.

(L

& Cl

S.

JUAN-Abarca

EAST

. Soray Saodlyoh.

lo

Import &

H.

FIJI

Corp., Avo. lo&arloMohrl

of

0.

O.

Aooplan (IRAQI,

C)

Toubo, Ltd.,

B.P.

R.

Audl &

& Aractlnol, B.P. 1144.

lonmayor,

MahmulpGIG

bport

ka

...

aldllan.

ZEALAND

A.

Tuck & Co., Ltd., 171

AT•

WELLINGTON.

Caledonia,

New

Hebrldet,

·AGENTS, Glondormld,

DUNEDIN-192·196

SUVA-Karl

ISLANDS

Inc., 1892·D

and

MAKATI, IIZAL- Atklns, Kroll & Co .,

Sheet,

{Bu

endia Extension)

FEDERATION,

E.

Parkin, 67

SPAIN-Ackr

lll & Co.,

S,

GRENADA, TOBAGO.

Richard

Branch

at

Union

Gunlor

(L & Cl

E.

Handel,

P.O . Box

Poroz

Zozayo,

D.F.-Distrlbul

P.-J.

Comerclo,

Warohouto

Ltd

.,

17-27

S.A.,

S.A.,

Dr.

Bros. l Ca..

(l & Cl

15

Llllonblom

114"'--Damaa,

Clo.,

11 Ruo

Co

••

6 Rve

S.A.I .l

..

Cook

htonds,

Samoa

Ltd.,

R.

Flolschman,

APIA-$

. C.

Kolakaua

Baa Making

JAMAICA

Church

17

O.

Custer,

QUITO

Special

Hennlno

P.O.

517.

S.A.

Suarez 99·a

do

Calle

N.C.

S.A.,

Banco

(Peru)

Av.

Corp.,

P.O.

Maaodon

Uruouaya,

Paul

94

Trl·

P.O.

Ia>

St.

Syria

Patrl·

(L

& Cl

Abut

Etondl

Adh-

200

Sharlr

Albert

Looo

Bldg.,

Ellice

(American).

CHRIST·

Costlo 51.,

P.O

Percival,

Avo.

Machines)

. Branch

5treet.

Honry

-

&

·

lot

A.

Ill

.

at

St.

Additional

Sales

Agents

for

Ill

LEWIS

and

ICI

COLUMBIA

4·lo&

AUSTRIA IV,

Wiedner

BELGIUM,

Kruldlulnlaan

FRANCE,

Ill

GERMANY,

(C

GREAT

Machine Company, Ltd., 12B- 132

DON,

MANCHESTER,

GLASGOW

IRELAND,

REPUBLIC

223/4

VI

ENNA-fran

Hauptdrasae 36.

BRUSSELS-N.

57a,

PARIS-Societe

KIEFELD-Herbert

.

tie

mach.)

BRITAIN-ENGLAND,

89

leddlngton

105·107A

S2-11

BELFAST

OF IRELAND,

Parnell

Slroet. Ill

t Koerport &

{C)

V.

Mach;nohandol C & H Vorbook,

Buyl Bldg.

Drumrooch Place, Toryglen.

(L)

G.

Amon & Cie.,

Jannsen,

LONDON, E.

Lane. LEED$--60 Morrion Stroot.

Cor,oratlon

1<4-W.

F. Maxwell,

DUBLIN-Wm

Sohne,

t.f

Rue Commlnes

Alto

Linneutr.

C.2-Eostman

Curta

in Road.

Stroot. SCOTLAND,

NORTHERN

20

Todburn Park.

. Blythman,

K.G

ClOY

ltd.,

••

10~

ISRAEL,

TEL

·

Halovy

MEXICO, MEXICO,

Caser, Av. Republic Del S

MOROCCO, CASABLANCA-Durkopp Coudrox,

nona.

St. ICI

(CI

AVIV-Israel

D.f.

Sewing Machi

- Ca1a Dial

alvador

89·93

ne

do

Co.,

Maqulnos

(C)

25

ll

Ruo

Yehuda

Batcu·

Machines

REPUBLIC

OF SOUTH AfRICA,

Sewing Machine Company (Pty.) Ltd., 118 Pre•

St.oot.

Branches

ah

CAPE

ICI

RHODESIA, FEDERATION OF RHODESIA

&ULAWAYO-Afrlcon Sewing Machine Company (Rhodesi

(Pvt.)

Ltd.,

2

leonidas

BORAS-Husqvama,

otan

'27.

(l.

37.

MONTEVIDEO-C.

658·60.

de

SWEDEN,

Katrlnedaltg

I MALMO--Itok

-5TOCXHOL-Brunn

SWITZERLAND,

ttauttr

Slhlttrouo

URUGUAY,

rlocan

TOWN-110

House, 138 Rhodes Ave. (C)

13.

Branches:

Slaktarogatan

ZURICH-Fritz

except

(CI

(Cl

GOTEIORG--Stlgber

sgoton 6·B. (CI

Zollwooor & Sohno, Sol·

Button Sower)

Brande• & Cle .• S A •

JOHANNESBURG-African

Ploln St., DUJI

& NYASALAND,

lndulfrisymasklner

9-0REBRO--Stortogol

Guttlnger

ldent

AN.

A/1-

gsflden

A.G

Call•

a)

19

••

Page 16

\

WORLD'S

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

FINEST

QUALITY

INDUSTRIAL

SEWING

*

UNION

facilities throughout the world. These offices

aid

equipment for your

Special representatives

tory trained

promptly

tion, there

serve you. Check with

you

GA.

MASS.

ILL.

SPECIAL

in

maintains sales

and

the selection of the right sewing

·particular operation. Union

and

service men

and

are

able

to serve your needs

and

efficiently. Whatever your loca-

is

a Union Special Representative to

him

today.

MONTREAL, CANADA

TORONTO,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

MACHINES

service

will

are

fac-

CANADA

ENGLAND

ENGLAND

NEW

YORK,

PHILADELPHIA,

..

400

N.

N.

Y.

PA.

Representatives

industrial

MACHINE

FRANKLIN

and

cities

distributors

throughout

COMPANY

ST.,

CHICAGO,

PARIS, FRANCE

sTunGART,

In

all

the

world.

GERMANY

Important

ILL.

60610

Loading...

Loading...