Page 1

INDUSTRIAL

SEWING

SlYLES

59400K

59400R

C 0 L U M B I

A®

MACHINES

8

TALOG

No.

136M

Second

Edition

CL

ASS 594

ADVANCED

FIFTY

LOOPER

THOUSAND

IN-LINE-OF-FEED

FLAT BED

WITH

··

UNION SPECIAL

PINKING

C HICA

00

HIGH SPEED

SERIES

MACHINES

ATTACHMENT

CORPORATION

GO

Page 2

C a t a 1 o g N

o.

1 3 6 M

I N S T R U C T I 0 N S

F 0 R

A D J U S T I N G A N D 0 P E R A T I N G

L I S T 0 F P A R T S

F o r S t y 1 e s

5 9 4 0 0 K 5 9 4 0 0 R

S e c o n d E d i t i o n

@ 1 9 7 1

b y

U n i o n S p e c i a 1 C o r p o r a t i o n

R i g h t s R e s e r v e d i n A 1 1 C o u n t r i e s

UNION SPECIAL CORPORATION

INDUSTRIAL

SEWING

CH IC A

MACHINES

GO

P r i n t e d i n

U.

S. A.

2

~

-----

----

September,l975

Page 3

IDENTIFICATION

OF

MACHINES

Each Union

the

machine.

numbers

ample:

minor

Style

which

"Class

herein.

in

given

of

handwheel

Traveling

Trimmings.

Bearing

System,

Belt

have

"Style

changes

number. Example:

Styles

differs

59400".

This

this

Class.

from

Advanced High Speed

Needle

Filtered

Guard. Equipped

Style

one

of

catalog

It

can

the

is

in

Line

Light

Special

numbers

or

more

59400 K".

are

made

machines

from

the

applies

also

be

Reference

operator's

toward

With

Weight

Bar

Drive,

Oil

Return

with

machine

are

letters

Special

in a standard

"Style

similar

style

specifically

applied

to

position

the

operator.

Single

Feed,

Presser

Single

Disc

is

classified

suffixed,

Style

59400 KZ".

in

number,

APPLICATION

with

direction,

STYLES

Needle

Equipped With

Bar and Weight

Reservoir

Pump

for

Type

identified

as

but

numbers

machine,

construction

in

that

OF

CATALOG

to

the

discretion

such

as

while

Thread

seated

OF

MACHINES

Flat

Bed

Pinking

Enclosed

Head and

Tensions.

by a Style

standard

never

contain

a "Z"

it

Standard

right,

Needle

Base,

is

are

grouped

contains

to

some

at

the

Machine,

Attachment,

Positive

Large

number on a name

and

special.

contain

the

suffixed

Styles

Special

left,

machine.

Bar

the

letter

under a Class

no

letter.

front,

Low

Throw, With Looper

Driving

Automatic

Handwheel and Improved

Standard

letter

"Z".

to

the

of

machines

Styles

back,

Operating

Front

Mechanism,

Example:

Disposal

plate

"Z".

When

Standard

number

as

of

machines

etc.,

direction

Lubricating

on

Style

Ex-

only

listed

are

of

Needle

59400

neously

slips,

where

tion

401-SSa-1.

59400

width

width

width

simultaneously

half

material.

Type 133

width

width

of

59400

of

59400

of

59400

slips,

59400

of

59400

of

K-3/16

pinking

blouses,

back-tacking

K-1/4

pink

K-3/8

pink

K-5/8

pink

R-3/16

Width

GS

R-1/4

pink

R-3/8

pink

Equipped

on women's

robes

Type 133

Same

and

with

Same

and

with

Same

and

with

Equipped

pinking

blouses,

of

needle.

Same

and

with

Same

and

with

and

is

required.

as

parts

as

parts

as

parts

on women's

robes

pink

Maximum

as

parts

as

parts

with

slacks,

similar

GS

needle.

Style

Style

Style

3/16

Style

Style

59400

furnished

59400

furnished

59400

furnished

with

and

similar

inch

recommended

59400

furnished

59400

furnished

reverse

street

garments

Width

Maximum

K-3/16,

K-3/16,

K-3/16,

upper

slacks,

(4.76

R-3/16

R-3/16

feed

dresses,

made

of

pink

for

5/16

for

1/2

for

3/4

driven

street

garments

mm).

speed

except

for

5/16

except

for

1/2

mechanism,

uniform

of

light

3/16

inch

recommended

except

except

except

close-coupled

5500 R.P.M.

inch

prepared

inch

prepared

inch

inch

Seam

(12.70

prepared

(19.05

dresses,

made

specification

prepared

inch

prepared

(12.70

(7.94

of

(7.94

for

dresses,

to

(4.76

speed

mm)

mm)

mm)

puller,

uniform

light

mm)

mm)

seaming

medium

for

for

for

for

for

weight

mm).

5500 R.P.M.

1/4

width

3/8

width

5/8

width

for

dresses,

to

medium

401-SSa-1.

1/4

width

3/8

width

and

simulta-

slips,

material

Seam

inch

of

inch

of

inch

of

inch

of

inch

of

specifica-

(6.35

pink.

(9.52

pink.

(15.88

pink.

seaming and

weight

(6.35

pink.

(9.52

pink.

half

mm)

mm)

mm)

slips,

mm)

mm)

3

Page 4

STYLES

OF

MACHINES

(Continued)

59400

width

to

number

The

measured

ively,

the

round

chromium

needle,

A

used.

stitch

of

NOTE:

point

Each Union

size

label

Standard

point,

To

complete

Selection

R-5/8

pink

of

denotes

number,

the

plated

have

or

Thread

formation.

and

Fraction

pinking

the

in

thousandths

type

of

all

needle

short,

needle

the

type

order

of

should

Same

Special

number and

needles

and

would

as

with

stamped

denotes

knife.

kind

for

double

is

orders

and

the

pass

parts

available

read:

proper

Style

needle

of

on

of

packaged

Styles

size

59400

furnished

the

has

shank,

the

needle

an

inch,

the

size

groove,

promptly

number

"1000

needle

freely

R-3/16

width

59400 K and R

in

through

of

NEEDLES

both a type

point,

shank,

midway

number

and

sold

struck

sizes

and

should

Needles,

size

except

for

3/4

pink,

length,

between

is

by

groove,

032,

accurately

be

Type 133

should

the

prepared

inch

measured

number and

groove,

denotes

the

the

complete

Union

is

Type 133

spiral

90/036,

filled,

forwarded.

be

determined

needle

eye

for

5/8

(19.05

Special.

GS,

mm)

width

from

centerline

size

number. The

finish

the

largest

shank

GS.

groove,

100/040, 110/044,

an

Use

Size

in

order

and

and

symbol,

It

empty

description

036".

by

inch

other

diameter

the

which

has a round

ball

package, a sample

the

to

produce

of

eye.

eye,

size

(15.88

pink.

of

details.

of

Collect-

is

spotted,

049,

on

of

needle

type

blade

given

shank,

054.

label.

thread

a good

mm)

on

Success

of

needles

reputation

more

than

in

the

operation

packaged

for

three-quarters

under

producing

of

Union

our

brand

highest

of a century.

name,

quality

Special

~

needles

machines

in

materials

can

,

be

secured

which

and

only

by

is

backed

workmanship

by a

use

for

4

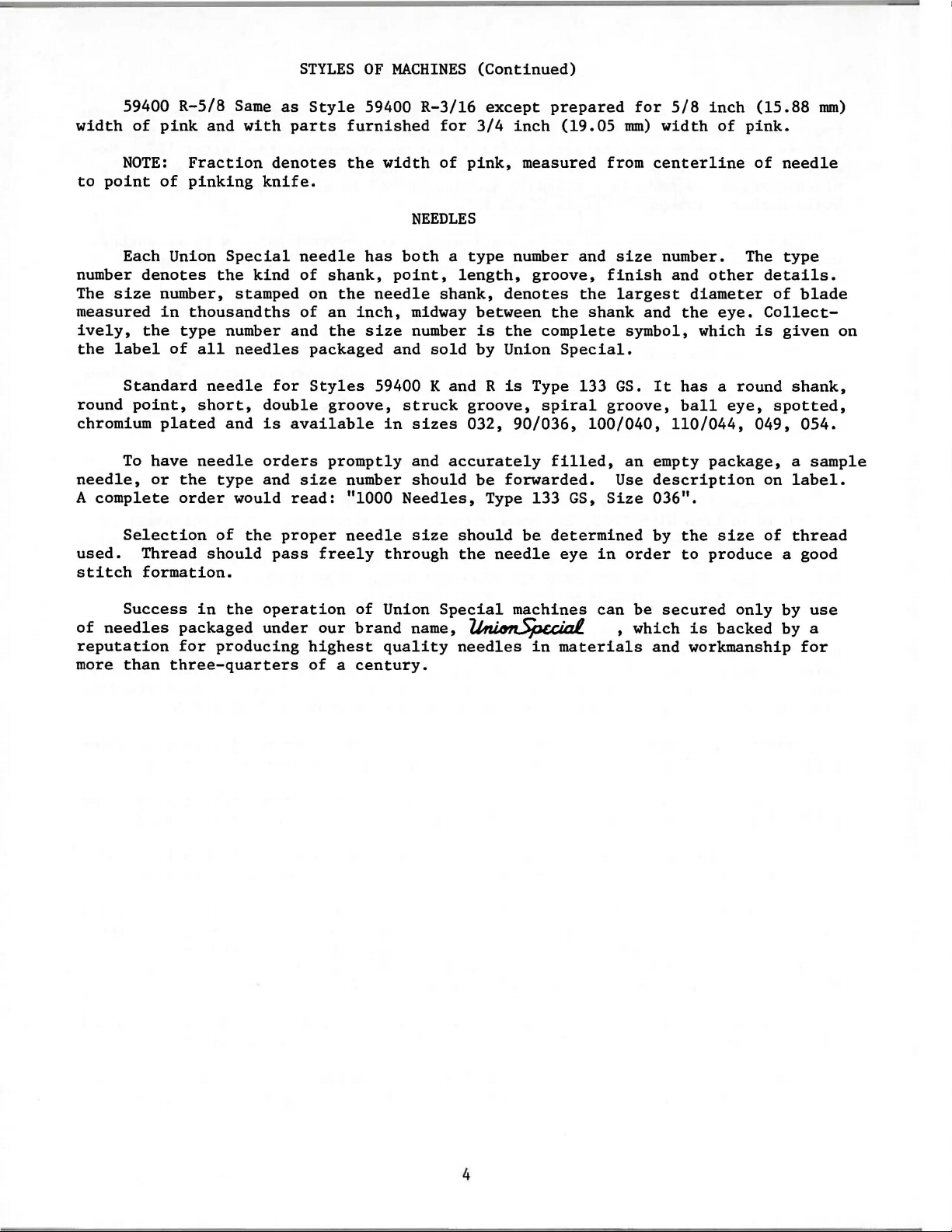

Page 5

FILL

MAIN

RESERVOIR

HERE

While

marked

"OPERATE".

BRICATION"

THREADING

machine

is

For

and

"RECOMMENDED

AND

in

operation

further

CAUTION!

FILL

ALL

BEFORE

MACHINE

BEFORE

OILING

lubricating

OIL".

OIL

RESERVOIRS

STARTING.

HAS

BEEN

SHIPPING.

DIAGRAM

the

needle

DRAINED

FOR

STYLES

of

the

instructions

59400 K

oil

refer

gauge

FOR

CORRECT

OIL

LEVEL

NEEDLE

SHOULD

OPERATE

AND

R

should

to

paragraph

OF

GAUGE

BE

IN

POSITION

be

in

on "LU-

Fig.

the

1

band

Thread

needle

direction

to

left.

is

inserted

of

Also

machine

in

in

line-of-feed,

note

that

accordance

the

needle

the

the

looper

bar

spot

with

with

or

is

the

threading

the

scarf

to

threaded

5

eye

in a plane

the

from

diagram

left,

back

and

to

above.

at

right

is

threaded

front.

Note

angles

that

to

from

the

the

right

Page 6

H

~~

. OIL

VAPOR

SPLASH

ACTION

OIL RESERVOIR

FEED

OIL

FROM

CRANKSHAFT

,.,

LEFT

BUSHING

k

I '

, \

\ I

~.I

BoiL

RETURN

SCREW

BY-PASS

6

WITH

OUTLET

M

Page 7

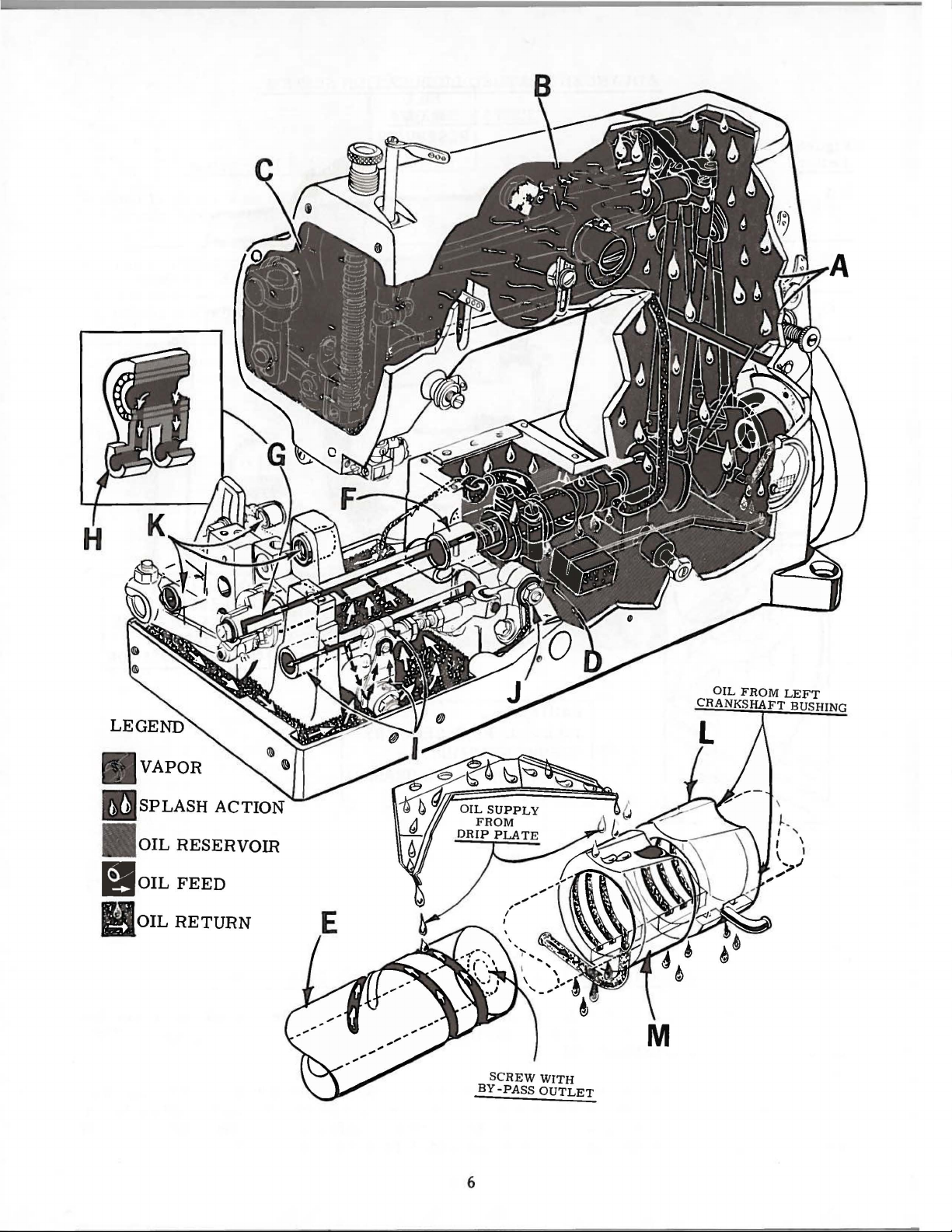

ADVANCED

FLATBED

LUBRICATION

SYSTEM

Figure

Letter

A.

B.

c.

D.

E.

F.

G.

Bearing

Crankshaft

and

Needle

Head

ings).

Looper

lever

Opposing

end

vents

s

haft

R1ght

Left

tric

or

crankshaft

lever

area

drive

bearings.

of

mainshaft.

oil

bearing.

mainshaft

main

bearings

Machine

drives,

(all

mechanisms

Helical

leakage

shaft

bearing and

located

Area

upper

bearings.

cross

crank,

shaft

grooves

Short

from

bearing.

on

SUPPLY

ball

bearing.

and

looper

in

groove

right

all

eccen-

mainshaft.

straps

bear-

drive

right

pre-

main-

SYSTEM

Method

Oil

ions

rods.

Oil

supplied

Mist

Oil

(56343

connecting

Oil

splash

Supply

shaft.

Oil

andmeteredby

troduced

right

Amount

shaft

in

of

Lubrication

agitation

on

trough

as a result

agitationas a result

E)

drip

in

grooves

supplied

controlled

right

needle

by

splash

on

bottom

rod.

plate

chamber.

from

into

mains

of

lubricant

end

of

as a result

(51282

lever

AE)

in

of

splash

of

which

in

right

hollow

felt

plugs.

center

mainshaft.

haft

with

of

bearing

of

extens-

connecting

which

column

looper

accumulates

end

shaft

in

by-pass

area.

in

column.

ofsplasher

drive

of

main-

mainshaft

Oilis

in

area.

center

hole

is

inthe

of

H.

I.

J.

K.

Figure

Letter

L.

M.

Lower

mainshaft

Looper

rocker

per

rod

Right

joint.

Feed

rocker

Machine

Head

Base

looper

rocker

shaft

ends

eccentrics.

cone,

shaft

bearings,

ball

joint.

bearings.

Area

of

connecting

right

rod

shaft

and

and

needle

and

upper

rods

left

looper

left

bearing

RETURN

of

loo-

feed

SYSTEM

Oil

run-out

supplies.

Supplied

shaft

yarn

Oil

to

lubricating

Self-lubricated

Method

Felt

pump

primed

bearing.

Feltpad

return

and

accumulates

chamber.

from

which

as a metering

supplied

of

Return

pad

in

head

located

by

oil

inbasecollects

pump

primed

from

eccentric

hollow

contains 4 strands

from

plate

bearings.

on

from

located

by

oil

splash

looper

device.

front

(56393

collects

crankshaft

left

on

drip

in

base

K).

oil.

crankshaft

oil.

crankshaft

plate

looper

bearing

rocker

of

felt

Return

and

Second

which

drive

7

Page 8

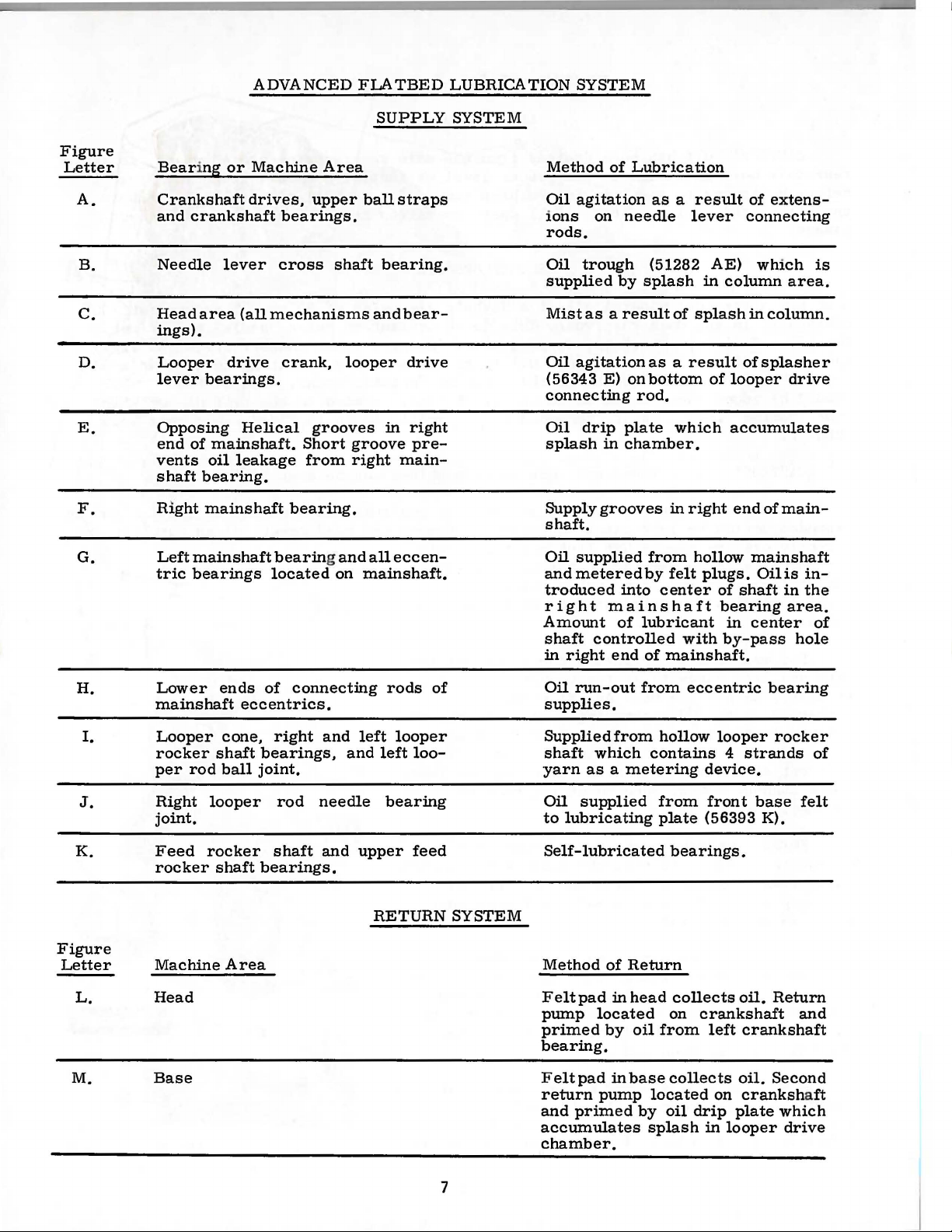

INSTRUCTIONS

LUBRICATION

FOR

MECHANICS

CAUTION!

reservoir

before

the

beginning

oil

damage.

Use a

Fahrenheit

No.

175.

check

and

is

to

the

should

zone,

28604

be

marked

R.

CAUTION!

It

extended

directly

bar.

several

ing

Replace

will

minutes

parts.

For

dirt

and

If

dirty,

commended

drained

screw

at

crank

(C,

front

chamber

machine.

Oil

must

be

to

the

various

straight

in

the

Fill

main

oil

level

black

added when

"LOW".

It

is

recommended

period

oil

be

the

head

be

required.

machines

lint

deposits

change

every

2000

from main

Fig.

of

2)

the

machine,

cover,

has

been

filled

to

operate.

to

parts.

mineral

main

reservoir.

reservoir

at

gauge (A).

line,

located

needle

The recommended

is

important

that

lubricated

needle

cover

bar

as

Run

to

distribute

in

operation

at

the

oil.

operating

reservoir

located

or

located

drained

the

proper

Run

machine

Full

RECOMMENDED

oil

of a Saybolt

This

at

plug

Oil

to

the

is

to

that

a new

link

no

machine

machine,

as

follows:

and

further

slowly

oil

to

check

reasonable

An

oil

change

hours.

by removing

below

the

by

removing

at

the

from

speed

screw

is

right

the

black

oil

these

the

hand

the

the

intervals.

Oil

cloth

back

the

level

slowly

operation

OIL

is

equivalent

in

at

maximum

of

line,

is

available

machines

or

Remove

needle

oil-

for

various

oil

is

re-

may

plug

plate

the

lower

of

main

as

indicated

reservoir

for

viscosity

upper

"OPERATE"

located

not

one

that

the

for

be

several

can

then

of

to

Union

crank

safe

operating

zone,

in

16

be

has

head

before

on

oil

gauge (A,

minutes

be

expected

90

to

125

Special

chamber

marked "FULL".

to

the

left

fluid

over

been

cover,

ounce

filled.

out

clean

shipment,

to

distribute

tithout

,.

seconds

specification

cover

level

(B,

when

of

"OPERATE"

cans

of

service

out

I

••

..---

L

---

..J

so

Fig.

at

Fig.

No.

lint

the

2)

100°

2)

needle

Oil

for

and

B

7

G

an

NOTE:

eccentric

assembling

lines

screw

up

is

The machine

lubricated,

drop

of

arm,

upper

looper

throw-out

locking

NOTE:

ment

shaft

to

front

lubricating

receive

be

with

in

oil

and

pin,

All

be

oiled

The

take-up

sure

oil

time

spot.

is

and no

between

lower

pin,

are

required.

moving

twice

and

rear,

both

sides

oil

oil

holes

almost

oiling

the

retainer

drive

thru

holes

in

loop

and

parts

daily.

also

of

and

the

mainshaft,

in

the

mainshaft

entirely

other

than

retainer

arm

looper

of

the

Oil

oil

two

lever

bearings

feed

lift

eccentric

when

automatically

an

occasional

driving

supports,

holder

frame

pinking

knife

oil

lever

holes

so

spot

attach-

and

8

when

the

for

knife

Fig.

2

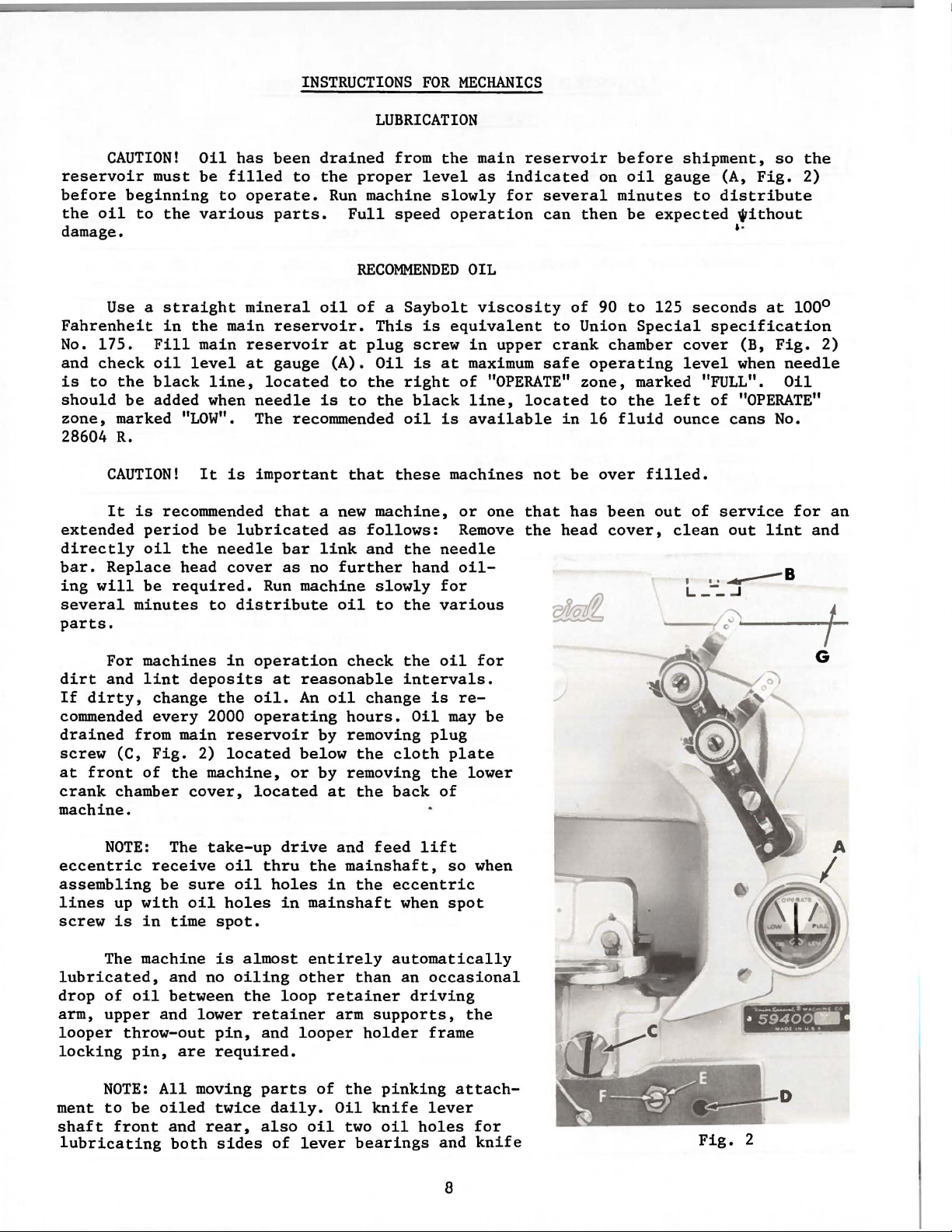

Page 9

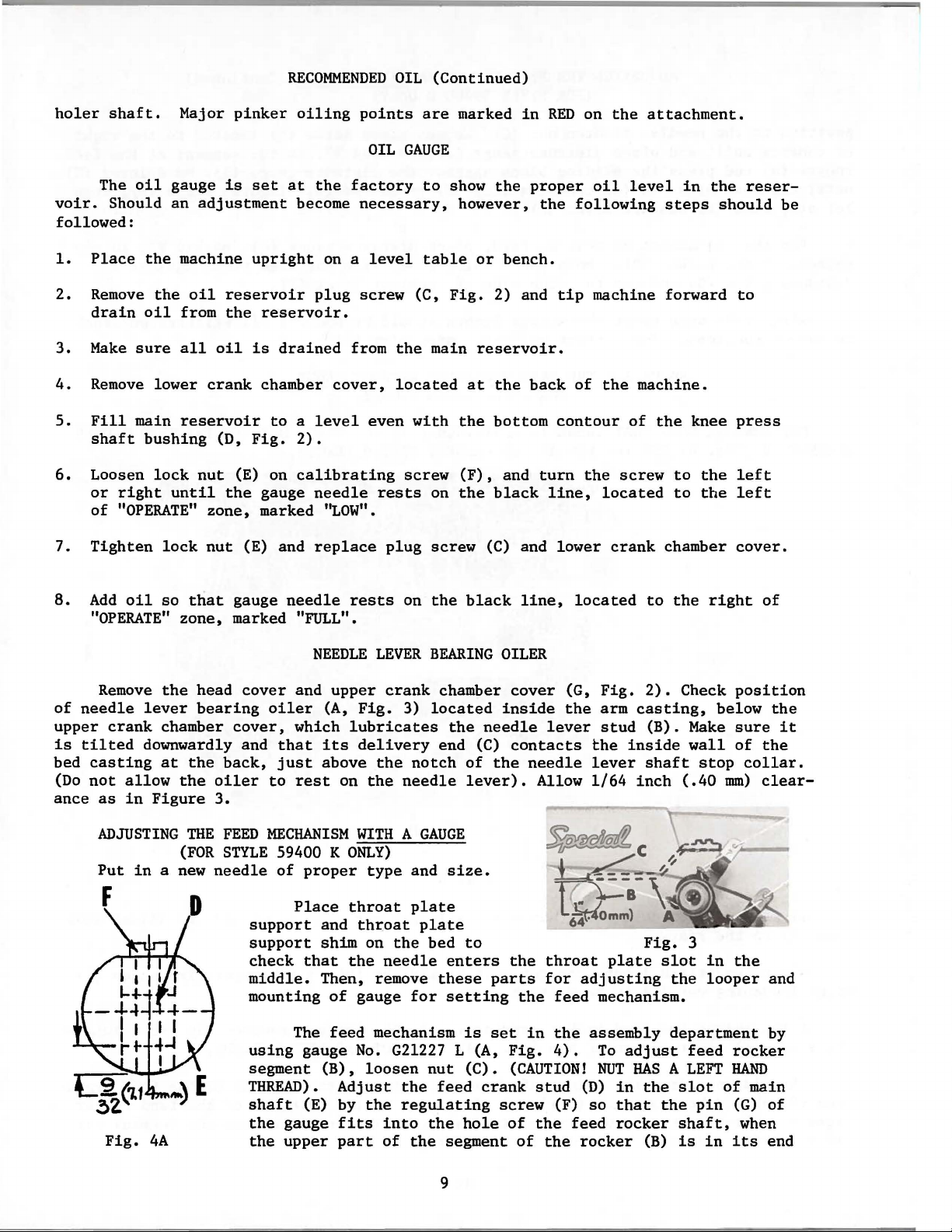

RECOMMENDED

OIL

(Continued)

haler

voir.

followed:

1.

2.

3.

4.

5.

6.

7.

shaft.

The

Should

Place

Remove

drain

Make

Remove

Fill

shaft

Loosen

or

right

of

"OPERATE"

Tighten

oil

gauge

an

the

the

oil

sure

lower

main

bushing

lock

until

lock

Major

machine

from

all

reservoir

pinker

is

adjustment

oil

reservoir

the

oil

crank

(D,

nut

(E) on

the

zone,

nut

set

at

upright

reservoir.

is

drained

chamber

to a level

Fig.

gauge

marked

(E) and

oiling

become

2).

calibrating

needle

points

the

factory

necessary,

on a

plug

screw

from

cover,

"LOW".

replace

OIL

level

even

GAUGE

the

located

screw

rests

plug

are

to

table

(C,

main

with

on

screw

marked

show

the

however,

or

bench.

Fig.

2) and

reservoir.

at

the

the

bottom

{F),

and

the

black

(C) and

in

RED

proper

the

back

turn

line,

on

oil

following

tip

machine

of

the

contour

the

located

lower

the

attachment.

level

machine.

of

screw

crank

in

steps

forward

the

knee

to

the

to

the

chamber

the

reser-

should

to

press

left

left

cover.

be

8.

Add

"OPERATE"

of

needle

upper

is

tilted

bed

casting

(Do

not

ance

oil

so

Remove

crank

as

ADJUSTING

Put

Fig.

the

lever

chamber

downwardly and

at

allow

in

Figure

in a new

4A

that

zone,

head

bearing

the

the

THE

(FOR

gauge

marked "FULL".

cover,

back,

oiler

3.

FEED

STYLE

needle

needle

cover

and

oiler

which

that

just

to

rest

MECHANISM

59400 K

of

proper

Place

support

support

check

middle.

mounting

using

segment

THREAD).

shaft

the

the

that

The

gauge

(E) by

gauge

upper

rests

NEEDLE

upper

(A,

lubricates

its

above

on

ONLY)

throat

and

shim

the

Then, remove

of

feed

No.

(B),

Adjust

fits

part

on

LEVER

crank

Fig.

3)

delivery

the

the

needle

WITH A GAUGE

type

throat

on

the

needle

gauge

mechanism

G21227 L (A,

loosen

the

the

regulating

into

of

the

BEARING

chamber

located

the

end

notch

and

size.

plate

plate

bed

enters

these

for

setting

nut

feed

the

the

segment

black

OILER

needle

(C)

of

the

lever).

to

parts

is

set

(C).

crank

screw

hole

line,

cover

inside

contacts

(G,

the

lever

needle

Allow

located

Fig.

arm

stud

the

lever

1/64

~

l~~

£t.'omm)

the

throat

for

the

feed

in

the

Fig.

4).

(CAUTION!

stud

(F)

of

the

of

the

plate

adjusting

mechanism.

assembly

To

NUT

(D)

in

so

that

feed

rocker

rocker

to

the

2).

Check

casting,

(B).

Make

inside

inch

shaft

wall

stop

(.40

c

----

Fig.

3

slot

the

department

adjust

HAS A LEFT

the

(B)

slot

the

shaft,

is

feed

pin

right

position

below

sure

of

collar.

mm)

in

the

looper

rocker

HAND

of

(G)

when

in

its

of

the

it

the

clear-

and

by

main

of

end

9

Page 10

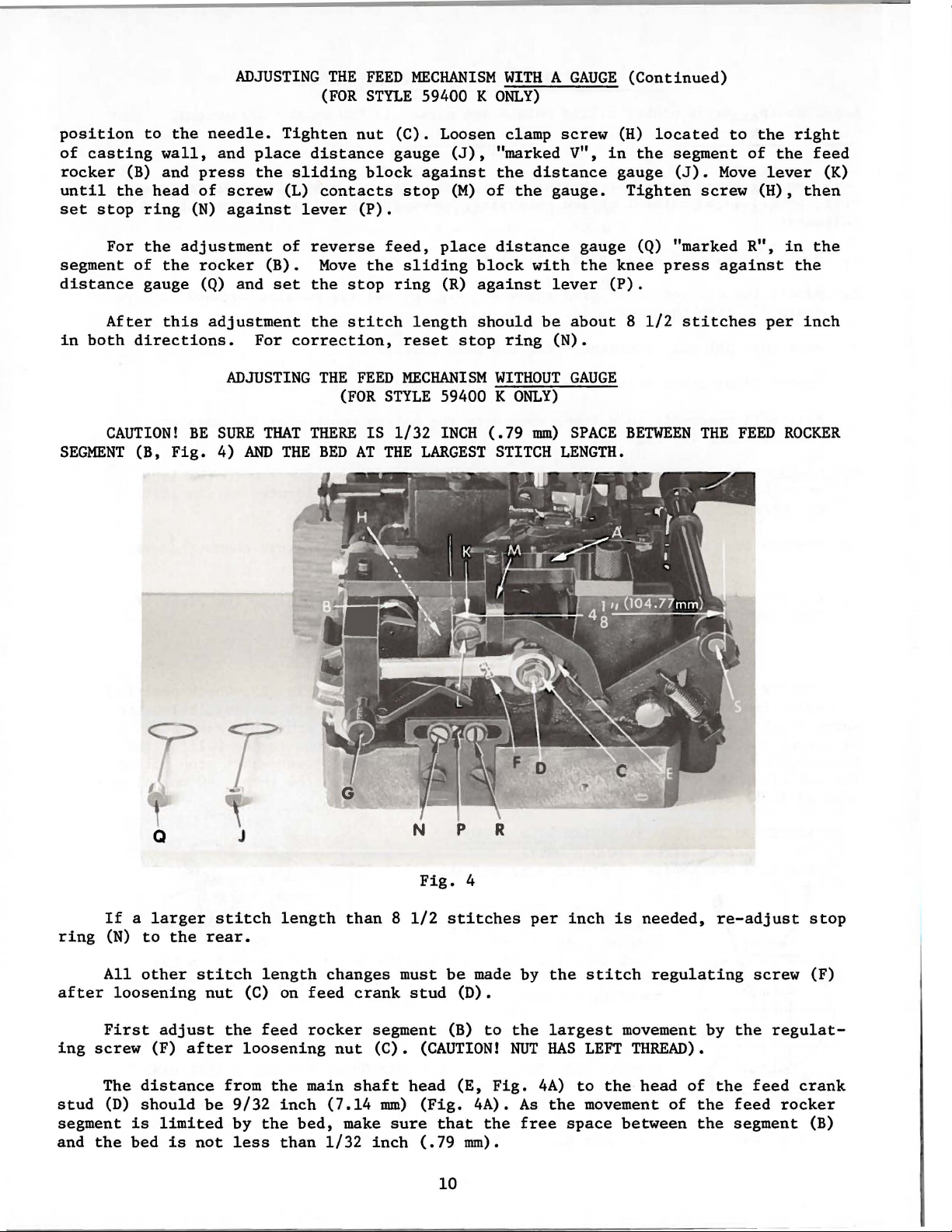

ADJUSTING

THE

(FOR

FEED

MECHANISM

STYLE

59400 K

WITH A GAUGE

ONLY)

(Continued)

position

of

casting

rocker

until

set

segment

distance

in

SEGMENT

(B)

the

stop

For

After

both

CAUTION!

to

the

needle.

wall,

and

head

ring

the

of

the

gauge (Q) and

this

directions.

(B,

and

press

of

screw

(N)

against

adjustment

rocker

adjustment

ADJUSTING

BE

SURE

Fig.

4)

place

the

(B).

For

THAT

AND

Tighten

distance

sliding

(L)

contacts

lever

of

reverse

Move

set

the

the

correction,

THE

THERE

THE

BED

nut

block

(P).

the

stop

stitch

FEED

(FOR

IS

AT

(C).

Loosen clamp

gauge

stop

feed,

sliding

ring

reset

MECHANISM

STYLE

1/32

THE

(J),

against

(M)

place

(R)

length

stop

59400 K

INCH

LARGEST

"marked V",

the

distance

of

the

distance

block

against

should

with

be

ring

WITHOUT

ONLY)

(.79

mm)

STITCH

screw

gauge.

lever

about 8 1/2

(N).

GAUGE

SPACE

LENGTH.

(H)

located

in

the

segment

gauge

Tighten

gauge (Q) "marked R",

the

knee

(P).

BETWEEN

(J).

screw

press

stitches

THE

to

the

of

Move

against

lever

(H),

per

FEED

right

the

feed

(K)

then

in

the

the

inch

ROCKER

r

p

N

Fig.

must

stud

segment

(C).

(CAUTION!

head

mm)

(Fig.

sure

inch

(.79

stitches

be

(B)

that

10

If a larger

ring

after

ing

stud

segment

and

(N)

All

First

screw

The

(D)

the

Q J

to

the

other

loosening

adjust

(F)

distance

should

is

limited

bed

is

stitch

rear.

stitch

nut

after

be

not

length

(C)

the

feed

loosening

from

9/32

by

less

the

the

length

on

feed

rocker

main

inch

bed,

than

than 8 1/2

changes

crank

nut

shaft

(7.14

make

1/32

R

4

made by

(D).

to

(E,

Fig.

4A).

the

mm).

per

the

NUT

As

free

the

largest

HAS

4A)

the

inch

stitch

LEFT

to

the

movement

space

is

needed,

regulating

movement by

THREAD).

head

of

of

the

between

the

re-adjust

screw

the

regulat-

the

feed

feed

segment

stop

(F)

crank

rocker

(B)

Page 11

(B)

is

(6.35

ing

block

this

screw

the

stop

the

lower

pin

of

For

adjusting

in

mm)

pin,

(L) and

ring

For

adjusting

5/16

its

end

diameter

and

the

set

the

the

(N)

part

of

inch

ADJUSTING

the

sliding

position

(e.g.

upper

lever

shaft

against

segment

(7.94

the

end

reverse

mm)

(FOR

to

a

drill

of

(K),

(S)

is 4 1/8

lever

(B).

diameter

THE

block

the

the

so

feed

Move

FEED

MECHANISM

STYLE

turn

needle.

of

1/4

segment.

that

the

inches

(P).

place a pin

the

and

59400 K

handwheel

Loosen

inch

When

distance

(104.77

sliding

set

the

WITHOUT

ONLY)

dia.

the

of

block

stop

GAUGE

until

screw

or

6.35

sliding

between

mm).

5/16

inch

with

ring

the

(H),

place a pin

mm

dia.)

block

outer

Tighten

(7.94

the

(R)

(Continued)

top

part

of

between

is

pressed

edges

knee

against

of

screw

mm)

press

diameter

the

the

of

the

the

(H)

against

lever

segment

1/4

inch

slid-

against

head

and

set

in

of

the

(P).

After

in

both

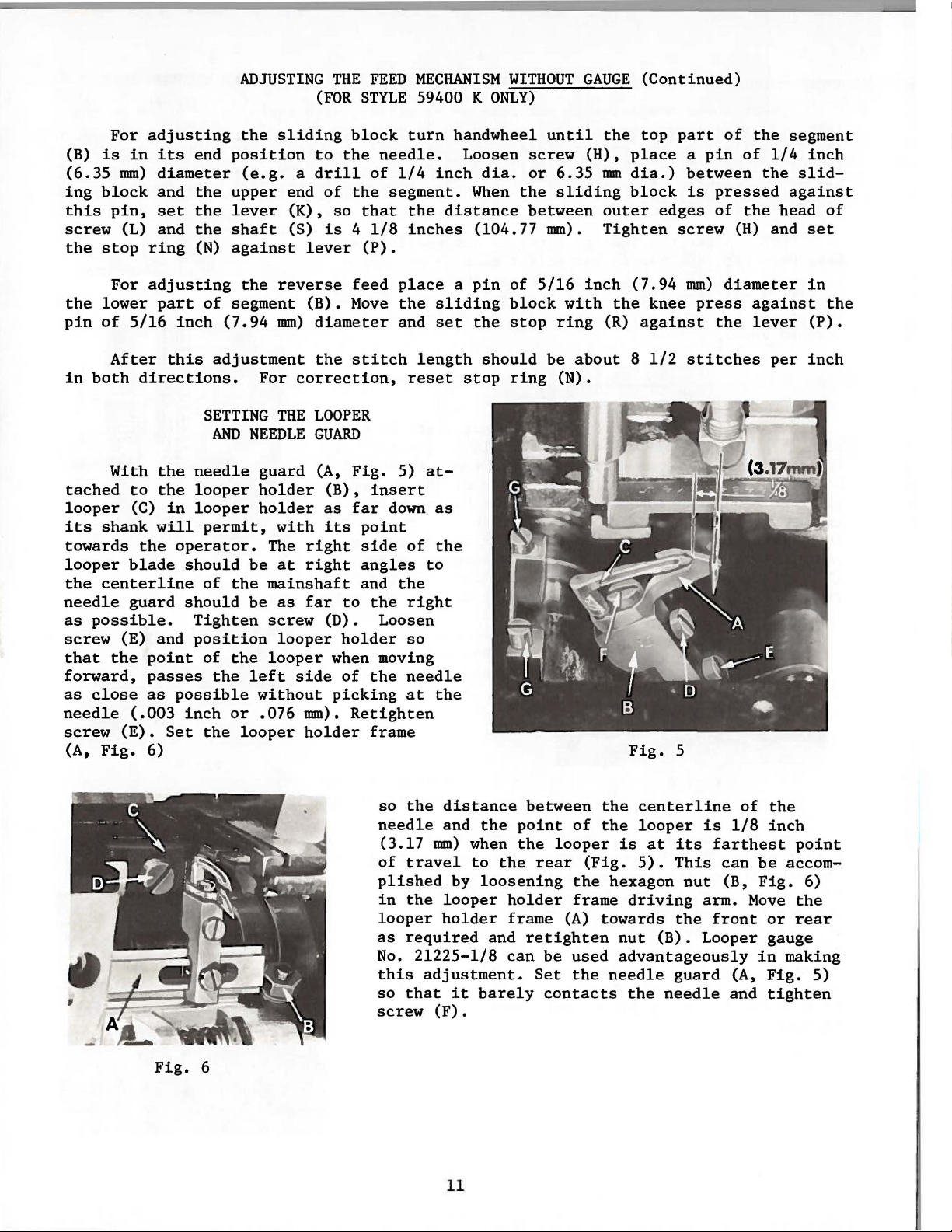

With

tached

looper

its

shank

towards

looper

the

centerline

needle

as

possible.

screw

that

forward,

as

needle

screw

(A,

(E) and

the

close

(E).

Fig.

this

directions.

the

to

the

(C)

in

will

the

operator.

blade

guard

(.003

should

should

point

passes

as

possible

inch

Set

6)

Tighten

adjustment

SETTING

AND

NEEDLE

needle

looper

looper

permit,

be

of

the

be

position

of

the

the

left

or

the

looper

the

For

correction,

THE

LOOPER

GUARD

guard

holder

holder

The

mainshaft

screw

looper

without

.076

(A,

with

right

at

right

as

far

looper

side

mm).

holder

stitch

reset

Fig.

5)

(B),

insert

as

far

down. as

its

point

side

of

angles

and

the

to

the

right

(D).

Loosen

holder

when moving

of

picking

Retighten

so

the

needle

at

frame

so

the

needle

(3.17

of

travel

plished

in

the

looper

as

required

No.

this

so

that

screw

length

at-

the

to

the

mm)

21225-1/8

adjustment.

(F).

should

stop

distance

and

the

when

to

by

loosening

looper

holder

and

it

barely

ring

between

point

the

the

holder

frame

retighten

can

Set

be

about 8 1/2

(N).

of

looper

rear

(Fig.

the

frame

(A)

be

used

the

contacts

stitches

Fig.

the

the

is

hexagon

driving

towards

nut

advantageously

needle

the

5

centerline

looper

at

its

5).

This

nut

the

(B).

guard

needle

of

is

1/8

farthest

can

(B,

arm.

Move

front

Looper

(A,

and

per

the

inch

point

be

accom-

Fig.

the

or

rear

gauge

in

making

Fig.

tighten

inch

6)

5)

Fig.

6

11

Page 12

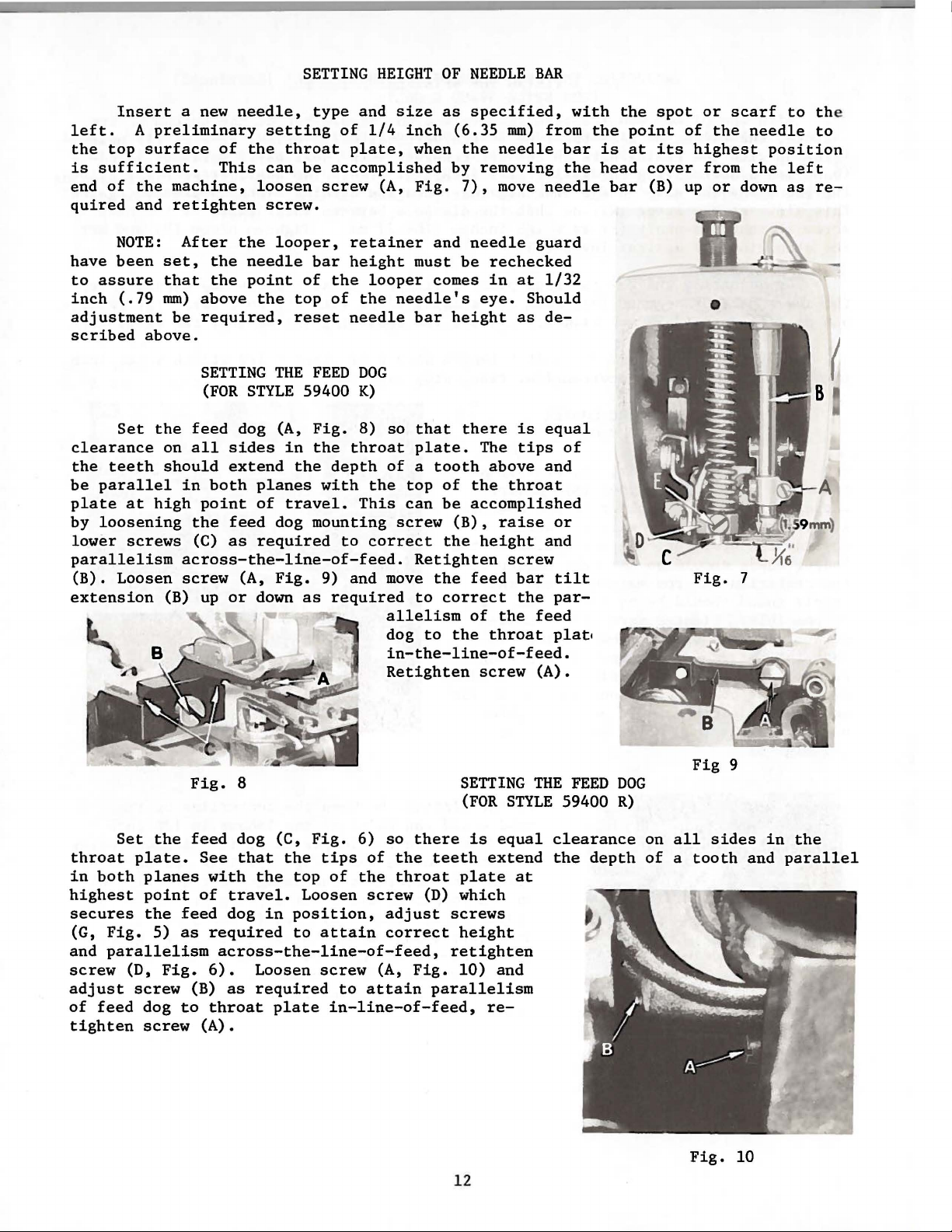

SETTING

HEIGHT

OF

NEEDLE

BAR

Insert

left.

the

is

end

quired

have

to

inch

adjustment

scribed

clearance

the

be

plate

by

lower

parallelism

(B).

extension

A

top

surface

sufficient.

of

the

and

NOTE:

been

assure

(.79

above.

Set

teeth

parallel

at

loosening

screws

Loosen

a

new

needle,

preliminary

machine,

retighten

After

set,

mm)

the

on

should

high

the

that

the

above

be

required,

SETTING

(FOR

feed

all

in

both

point

the

(C)

across-the-line-of-feed.

screw

(B)

up

of

the

This

the

needle

point

STYLE

dog (A,

sides

extend

feed

as

(A,

or

setting

throat

can

be

loosen

screw.

looper,

of

the

top

reset

THE

59400

in

the

planes

of

travel.

dog

required

Fig.

down

as

type

and

of

1/4

plate,

accomplished

screw

bar

the

of

FEED

Fig.

the

depth

with

mounting

9) and

required

(A,

retainer

height

looper

the

needle

DOG

K)

8)

so

throat

of a tooth

the

This

to

correct

move

allelism

dog

in-the-line-of-feed.

Retighten

size

as

inch

when

Fig.

and

must

comes

needle's

bar

that

plate.

top

of

can

be

screw

the

Retighten

the

to

correct

to

specified,

(6.35

by

height

(B),

the

mm)

the

needle

removing

7),

move

needle

be

rechecked

in

at

eye.

Should

as

there

is

The

tips

above

the

throat

accomplished

raise

height

screw

feed

bar

the

of

the

throat

screw

with

from

bar

the

needle

guard

1/32

de-

equal

of

and

or

and

tilt

par-

feed

plat•

(A) .

the

is

head

bar

the

point

at

spot

its

cover

(B)

or

of

the

highest

from

up

or

•

Fig.

scarf

needle

the

down

7

to th

to

position

left

as

re-

8

A

e

(

Set

throat

in

both

highest

secures

(G,

Fig.

and

parallelism

screw

adjust

of

feed

tighten

the

plate.

planes

point

the

5)

(D,

screw

dog

screw

feed

as

Fig.

to

Fig.

8

feed

dog (C,

See

that

with

of

required

6).

(B)

throat

(A).

the

travel.

dog

across-the-line-of-feed,

Loosen

as

required

the

top

in

position,

to

plate

Fig.

tips

of

Loosen

attain

screw

to

in-line-of-feed,

6)

so

of

the

screw

adjust

correct

(A,

attain

there

the

teeth

throat

(D)

Fig.

parallelism

SETTING

(FOR

STYLE

is

equal

extend

plate

which

screws

height

retighten

10)

and

re-

12

THE

at

FEED

DOG

59400

clearance

the

R)

depth

Fig

on

all

sides

of a tooth

Fig.

9

10

in

and

the

parallel

Page 13

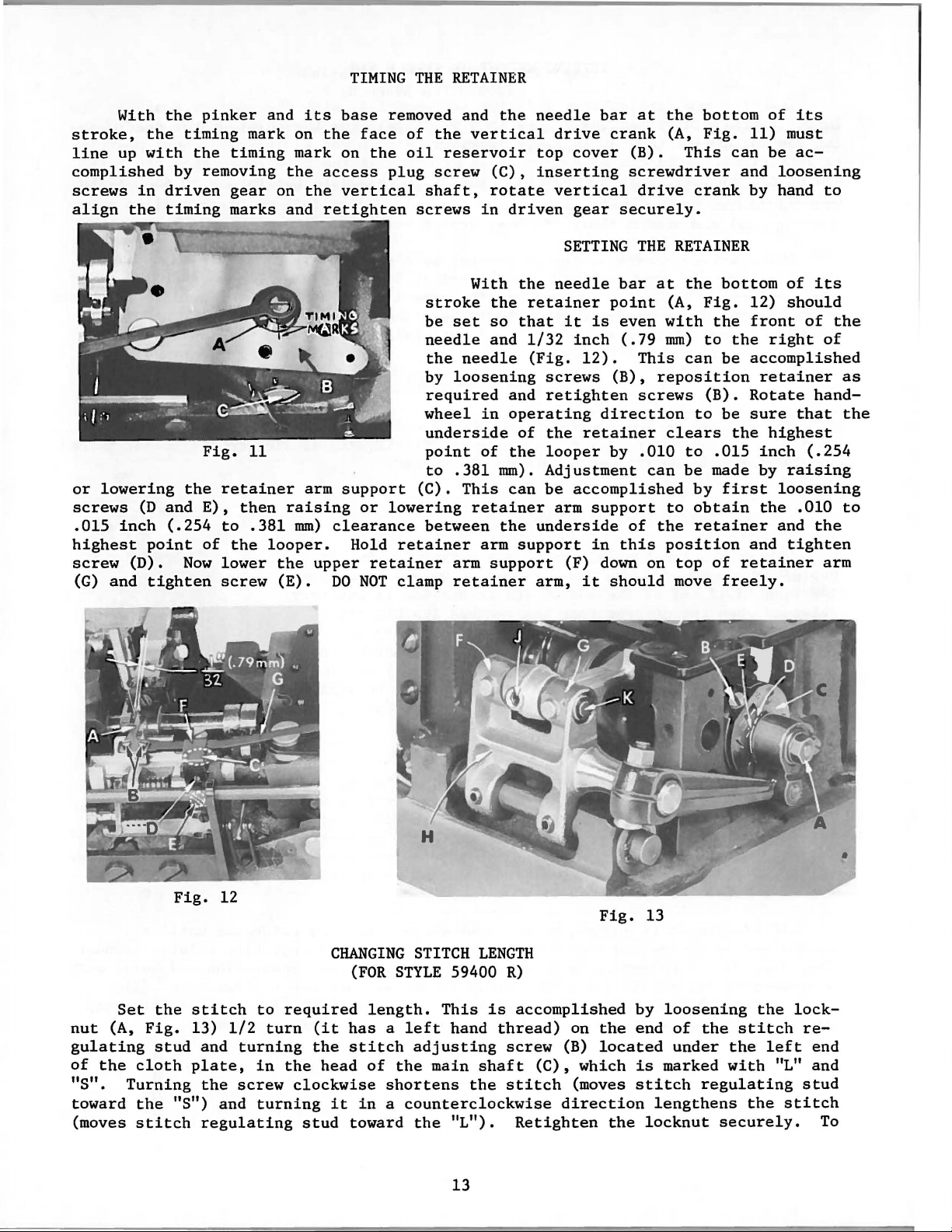

TIMING

THE

RETAINER

With

stroke,

line

complished

screws

align

or

lowering

screws

.015

highest

screw

(G)

up

inch

and

the

with

in

the

(D

point

(D).

tighten

the

pinker

timing

the

by

removing

driven

timing

Fig.

the

and

E),

(.254

of

Now

and

mark on

timing

gear

marks

11

retainer

then

to

.381

the

looper.

lower

screw

its

mark on

the

on

the

and

arm

raising

mm)

the

upper

(E).

base

the

face

the

access

vertical

retighten

support

or

clearance

Hold

retainer

DO

NOT

removed and

of

the

vertical

oil

reservoir

plug

screw

shaft,

screws

With

stroke

be

set

needle

the

needle

by

loosening

required

wheel

underside

point

to

(C).

lowering

between

retainer

clamp

of

.381

This

retainer

arm

arm

retainer

the

(C),

rotate

in

driven

the

the

so

that

and

and

in

operating

of

the

mm).

can

the

support

support

needle

drive

top

cover

inserting

vertical

gear

SETTING

needle

retainer

it

1/32

inch

(Fig.

12).

screws

retighten

the

retainer

looper

Adjustment

be

accomplished

arm

underside

(F) down on

arm,

it

bar

at

crank

(B).

screwdriver

drive

securely.

THE

bar

point

is

even

(.79

This

(B),

screws

direction

by

.010

support

of

in

this

should

the

bottom

(A,

Fig.

This

crank

RETAINER

at

the

(A,

Fig.

with

mrn)

to

can

reposition

(B).

to

clears

to

can

be

by

to

obtain

the

retainer

position

top

move

of

11)

can

be

and

by hand

bottom

12)

the

front

the

right

be

accomplished

retainer

Rotate

be

sure

the

highest

.015

inch

made by

first

the

and

of

retainer

freely.

its

must

ac-

loosening

to

of

its

should

of

the

of

as

hand-

that

the

(.254

raising

loosening

.010

to

and

the

tighten

arm

Fig.

12

Set

nut

(A,

gulating

of

the

"S".

toward

(moves

Turning

the

Fig.

stud

cloth

the

stitch

stitch

13)

and

plate,

the

"S")

regulating

1/2

turning

screw

and

to

required

turn

in

the

clockwise

turning

CHANGING

(FOR

(it

has a left

the

stitch

head

it

stud

toward

of

in a counterclockwise

STITCH

STYLE

length.

adjusting

the

shortens

the

59400

This

hand

main

"L").

13

LENGTH

R)

is

accomplished

thread)

screw

shaft

the

stitch

Retighten

(C),

direction

on

(B)

which

(moves

Fig.

13

by

the

end

located

is

stitch

the

locknut

loosening

of

the

under

marked

regulating

lengthens

securely.

stitch

the

with

the

the

left

lock-

"L"

stitch

re-

end

and

stud

To

Page 14

CHANGING

(FOR

STITCH

STYLE

LENGTH

59400

(Continued)

R)

prevent

the

"U"

The

and

lubricated

(J,

Fig.

When

directly

the

part

sealed

assemble,

grease

up

should

begins

1/8

released

position.

lease

machine

position

screw

bearings

seals

The

a good

be

The

to

inch

lever

(A)

destructive

shaped

needle

13) and remove

packing

from

number 28604

tension

stitch

barely

thread

function

(3.17

when

If

next

the

assuring

key

once a year.

the

start

to

THREAD

mm)

the

adjustment

screw

to

tension

slot

bearings

bearings,

tube

are

tapered

prevent

on

and

sufficient

tension

as

of

presser

(A,

the

that

damage

in

(F &

shaft

to

avoid

P.

Greased

replaced

end

damage.

the

needle

to

avoid

TENSION

release

the

presser

the

end

foot

is

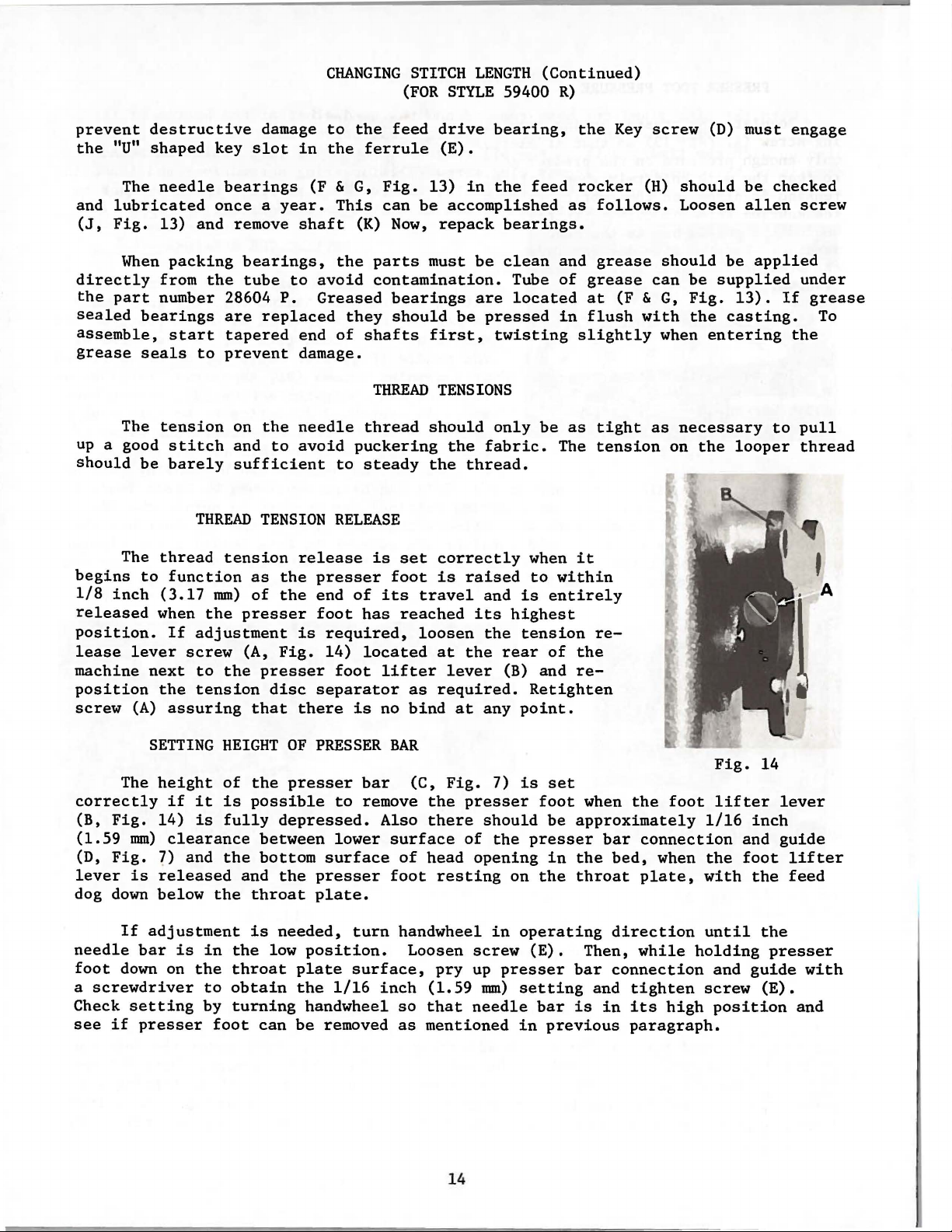

Fig.

presser

disc

separator

there

to

the

the

ferrule

G,

Fig.

This

of

RELEASE

required,

14)

foot

can

(K)

the

parts

contamination.

they

shafts

THREAD

thread

puckering

to

steady

is

of

its

has

located

lifter

is

no

feed

Now,

bearings

should

foot

drive

(E).

13)

be

accomplished

repack

must

first,

TENSIONS

should

the

the

set

correctly

is

travel

reached

loosen

at

lever

as

required.

bind

in

be

are

be

pressed

fabric.

thread.

raised

and

its

the

the

at

any

bearing,

the

feed

bearings.

clean

Tube

located

twisting

only

be

when

to

is

entirely

highest

tension

rear

of

(B) and

Retighten

point.

the

rocker

as

follows.

and

grease

of

grease

at

in

flush

slightly

as

tight

The

tension

it

within

rethe

re-

Key

(F &

with

screw

(H)

Loosen

should

can

G,

when

as

necessary

on

(D) must

should

be

be

supplied

Fig.

the

entering

the

be

checked

allen

applied

13).

casting.

to

looper

engage

screw

under

If

grease

To

the

pull

thread

The

correctly

(B,

Fig.

(1.59

(D,

lever

dog

needle

foot

a

Check

see

mm)

Fig.

is

down

If

bar

down

screwdriver

setting

if

SETTING

height

if

it

14)

is

clearance

?)

and

released

below

adjustment

is

in

on

the

to

by

presser

HEIGHT

of

the

is

possible

fully

the

and

the

throat

is

the

throat

obtain

turning

foot

OF

PRESSER

presser

depressed.

between

bottom

the

presser

plate.

needed,

low

position.

plate

the

handwheel

can

be

bar

to

remove

Also

lower

surface

turn

surface,

1/16

removed

inch

BAR

(C,

Fig.

the

there

surface

of

head

foot

resting

handwheel

Loosen

pry

(1.59

so

that

as

mentioned

14

7)

presser

should

of

the

opening

on

in

screw

up

presser

mm)

needle

is

set

foot

when

be

approximately

presser

in

the

the

throat

operating

(E).

setting

bar

in

Then,

bar

is

previous

the

bar

connection

bed,

plate,

direction

while

connection

and

tighten

in

its

paragraph.

foot

when

high

Fig.

lifter

1/16

and

the

foot

with

until

holding

and

screw

position

14

lever

inch

guide

the

the

presser

guide

(E).

lifter

feed

with

and

Page 15

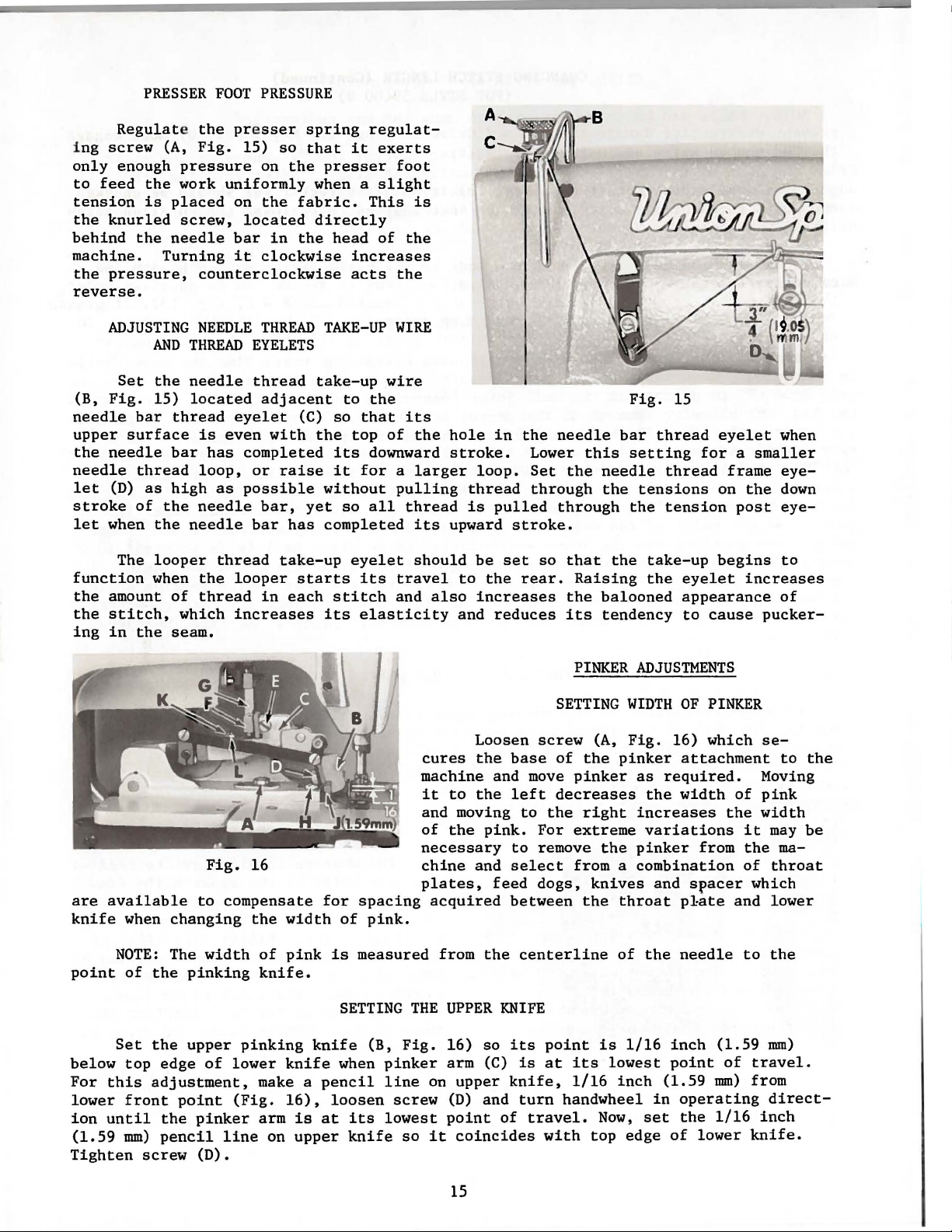

PRESSER

Regulate the pre

i ng

screw

only

enough

to

feed

the

tension

the

behind

machine.

the

reverse.

is

knurled

the

pressure,

FOOT

(A,

Fig.

15)

pressure

work

uniformly

placed

screw,

needle

Turning

on

located

bar

it

counterclockwise

PRESSURE

sser

spring

so

that

on

the

presser

when a

the

fabric. This

directly

in

the

clockwise

regulat-

it

head

increases

acts

exerts

foot

slight

is

of

the

the

A

C

~~

~~1~

D

ADJUSTING

Set

(B,

Fig.

needle

upper

the

needle

needle

let

(D)

stroke

let

when

The

function

the

amount

the

stitch,

ing

in

are

available

knife

when

AND

the

15)

bar

thread

surface

bar

thread

as

high

of

the

the

looper

when

of

the

seam.

changing

NEEDLE

THREAD

needle

located

is

has

loop,

as

needle

needle

thread

the

thread

which

Fig.

to

THREAD

EYELETS

thread

adjacent

eyelet

even

completed

or

possible

bar

looper

increases

16

compensate

the

with

raise

bar,

has

take-up

in

each

width

(C)

starts

TAKE-UP

take-up

to

so

the

top

its

it

without

yet

so

completed

eyelet

stitch

its

for

of

WIRE

wire

the

that

its

of

the

downward

for a larger

pulling

all

thread

its

should

its

travel

and

also

elasticity

cures

machine

it

and moving

of

necessary

chine

plates,

spacing

pink.

acquired

hole

stroke.

loop.

thread

is

pulled

upward

be

to

the

increases

and

reduces

Loosen

the

and

to

the

the

pink.

and

feed

in

the

Lower

Set

through

stroke.

set

rear.

base

move

left

to

to

select

between

needle

the

through

so

that

Raising

the

its

PINKER

SETTING

screw

of

pinker

decreases

the

right

For

extreme

remove

from a

dogs,

the

bar

this

needle

the

the

balooned

tendency

WIDTH

(A,

Fig.

the

pinker

the

knives

throat

Fig.

15

thread

setting

thread

tensions

the

tension

take-up

the

ADJUSTMENTS

as

required.

the

increases

variations

pinker

combination

and

eyelet

for a smaller

on

begins

eyelet

appearance

to

cause

OF

PINKER

16)

which

attachment

width

from

spacer

p1ate

frame

the

post

increases

pucker-

se-

Moving

of

pink

the

width

it

may

the

of

which

and

when

eye-

down

eye-

to

of

to

be

ma-

throat

lower

the

NOTE:

point

Set

below

For

this

lower

ion

until

(1.59

Tighten

mm)

The

of

the

the

top

edge

adjustment,

front

the

pencil

screw

width

pinking

upper

of

point

pinker

(D).

pinking

lower

(Fig.

line

of

pink

knife.

knife

make a

16),

arm

is

on

upper

is

SETTING

knife

when

pencil

loosen

at

measured

(B,

pinker

line

screw

its

lowest

knife

THE

Fig.

so

from

UPPER

16)

arm

on

upper

(D)

point

it

coincides

the

KNIFE

so

{C)

and

of

its

knife,

centerline

point

is

at

turn

handwheel

travel.

with

15

its

1/16

top

of

is

1/16

lowest

inch

Now,

edge

the

inch

point

(1.59

in

set

of

needle

(1.59

of

mm)

operating

the

1/16

lower

to

the

mm)

travel.

from

direct-

inch

knife.

Page 16

SETTING

THE

UPPER

KNIFE

(Continued)

NOTE:

When

Grind

edges

asmuch

of

the

It

back

of

Generally

is

sharpened.

ball

very

(A,

the

the

stud

Fig.

lower

lightly

"V".

upper

tighten

contact

knife.

obtain

edges

(J)

securely.

has

been

Knife".

Knife

resharpening

the

ends

should

be

as a rough

lower

knife.

should

the

knife.

(F)

to

16)

allowing

knife

so

Grind

knife

of

the

so

Now

equal

the

is

lower

the

gently

spacing

opening

removed from

can

be

the

of

the

knife

stoned

be

the

When

keen

or

burred

noted,

Do

not

lower

resharpening

disconnect

removal

(J).

The

only a slight

top

surface

positioned

knife

point

of

holding

the

press

between

of

the

Replace

pinker

the

sharpened

upper

only.

and

smooth,

edge

also,

that

change

SETTING

knife

the

does

ball

of

knife

may

amount

only.

so

that

screws

upper

the

lower

the

lower

on

pinker

on

knife,

DO

will

the

this

THE

not

is

necessary,

joint

the

pinker

be

of

When

its

knife

knife

cutting

knife.

the

machine

base

both

do

NOT

free

not

ends

ends

not

GRIND

from

last

of

angle.

LOWER

require

connection

attachment.

sharpended

metal

replacing

holding

(J)

securely.

is

just

moving

edges

Now

after

and

its

and

can

destroy

THE

SIDES.

all

long

and

the

knife

KNIFE

sharpening

loosen

on

is

removed.

the

screw

is

below

it

to

of

the

tighten

assuring

support.

be

the

burrs.

may

screw

rod

the

lower

at

Bring

the

right

upper

the

Recheck

reversed.

"V"

After

This

damage

are

on

every

(E,

assembly

Remove

side

of a wheel.

DO

NOT

knife

the

top

the

top

surface

or

knife

lower

that

shape

grinding,

is

the

an

angle

time

Fig.

(G).

screws

grind

be

of

cutting

left

as

and

knife

all

"Setting

of

the

important

cutting

with

the

upper

16)

and

Remove

(H)

which

Touch

the

sure

its

that

slot.

edges

of

the

required

the

inside

holding

foreign

The Upper

knife.

the

in-

edge

the

knife

back

screw

inside

the

Do

into

lower

to

screws

matter

out

hold

it

of

not

The

screw

(K,

cutting

is

to

be

necessary

driven

shaft

tion

gear

to

of

pressure

Fig.

16)

clean,

noted

a

that

to

obtain a clean

(B).

obtain

this

shaft

applied

which

slight

to

Fig.

While

desired

is

SPRING

is

increase

insure

on

locked

cut

PRESSURE

the

cutting

in

of

long

knife

should

8

ON

edges

position

pressure

life,

be

used.

UPPER

will

when

its

inch

the

this

various

timing,

cover

the

facilitate

17 (A,

holding

timing

not

changed

the

of

the

while

handwheel,

upper

knife.

making

KNIFE

is

controlled

by

nut

generally

only

the

The

the

upward

(1.59

lower

timing

located

machine.

Fig.

advance

Be

this

adjustment.

by

(L).

If

the

remedy

minimum amount

TIMING

machine

point

should

of

THE

the

travel)

mm)

above

knife.

may

types

remove

improve

of

work.

the

on

the

Slight

Rotate

loosening

17)

in

the

or

retard

careful

that

the

Allen

knives

the

fault.

of

PINKER

start

upper

is

approximately

the

top

variations

the

To

upper

top

crank

right

handwheel

of

screws

hub

of

the

pinker

the

Be

certain

Socket

are

not

pressure

to

feed

knife

surface

operation

obtain

chamber

end

slightly

the

pinker

drive

lateral

that

It

(in

1/16

of

of

on

this

of

posi-

both

16

Page 17

TIMING

THE

PINKER

(Continued)

screws

ion

should

The

the

main

the

puller

adjusted

not

build

enough

This

to

puller

adjusted

can

reposition

tighten

(A)

are

take

puller

feed

drive

to

do most

up

upper

be

accomplished

driving

screws

Fig.

by

the

securely

place

ADJUSTING

mechanism

dog

starts

eccentric

between

feed

roller

the

connecting

segment

(A

and

18 mechanism. The

following

while

of

the

B).

tightened

machine

PULLER

must

to

feed.

located

the

feeding

presser

travel

by

loosening

link

lever

roller

mately

bracket

screw

(G)

spring

vent

tension

(B).

the

overthrow.

and

feed

pressure

pressure

method:

before

MECHANISM

be

timed

This

on

so

foot

to

keep

(C)

(E)

as

With

presser

3/16

casting.

(G)

securely.

The

(A,

the

on

The more

more

cause

by

overcoming

is

required

"Clutch

roller

pressure

of

can

running

feeding.

(FOR

to

start

can

be

the

mainshaft.

when

and

puller

reposition

the

the

screw

in

the

bar

inch

Fig.

the

spring

the

The

roller

the

be

sewing

the

material

(A,

mechanism

(4.76

Brake"

19)

from

spring

inside

proper

checked

the

machine.

STYLE

its

accomplished

puller

Fig.

clutch

to

obtain

collar

Adjustment

collar

has

overthrowing

is

nut

is

exerted

to

the

59400

feeding

The

at

slow

rollers.

taut

18)

driving

in

(F,

mm)

above

is

set

just

regulated

is

tightened

pressure

backspring

clutch

spring

and

R)

by

puller

speed

when

and/or

segment

desired

its

Fig.

the

can

be

as

required,

properly

enough

on

the

can

NOTE:

cycle

advancing

down

18)

or

with

at

mechanism

the

There

sewing

shoulder

amount

position,

should

feed

made by

when

pressure

backfeeding.

nut

to

compress

roller

become

No

cutting

the

same

or

should

material

should

at

slow

screw

lever

roller

retighten

(D)

of

feed,

be

loosening

the

on

and

to

prevent

too

excessive

act-

time

retarding

be

does

be

just

speed.

(B)

or

re-

the

feed

approxi-

mounting

screw

tension

it

to

pre-

The

locknut

the

spring

Raise

screw

plate

machine

as

the

rotate

seconds

er

does

nuts

tension

obtained.

the

to

obtained.

(B,

same

compress

the

(H,

Fig.

(K).

in

running,

screw

90°

in

with

not

Fig.

on

the

If

procedure

clutch

18).

Now

run

hole

direction

the

have

19)

spring

the

the

spring

off

Remove

the

machine

pick

or a pencil

roller

any

should

roller

except

out a point

of

in

movement

be

until

moves

until

the

lower

stop

line.

feed

the

under

loosened

the

too

the

nuts

the

roller

screw

full

speed;

on

This

in

approximately

up

position.

full

and

proper

fast,

should

proper

(J)

from

the

point

speed,

reset

setting

then

be

setting

17

and

loosen

support

while

roller

should

If

the

with

is

follow

tightened

is

the

3

then

such

to

roll-

the

less

4

Fig.

19

Page 18

ADJUSTING

PULLER

MECHANISM

(FOR

STYLE

59400 R

Continued)

CAUTION!

Fig.

pull

stroke.

dering

position

quired

19)

are

Should

the

(C,

Fig.

The

the

loopers

released

ILLUSTRATIONS

This

sections

ing

of

material

19)

looper

By

tilting

catalog

repair

of

in

the

parts

in

the

more

easier.

pulling

the

the

The

machine

locked

clockwise

parts.

particular

together

or

less

through

frame

looper

the

ORDERING

has

mechanism

machine.

with

and/or

pressure

uniformly,

to

increase

throw-out

It

can

throw-out

loopers

REPAIR

been

arranged

Exploded

are

On

their

view

clutch

even

during

on

LOOPER

(Fig.

be

used

forward.

PARTS

views

shown

the

page

part

number,

being

should

the

the

upper

turn

pressure

FRAME

THROW-OUT

20)

only

when

actuating

to

simplify

of

various

so

that

opposite

description,

shown.

never

adjusting

puller

the

feed

or

counterclockwise

is a convenience

the

pin

or-

the

parts

the

be

of

roller

roller

needles

(A),

the

may

illustration

and

run

unless

the

mechanism

presser

used

are

looper

be

seen

the

both

machine.

spring

to

decrease.

to

make

at

the

holder

Fig.

in

will

number

be

be

threading

top

their

found a

of

pieces

nuts

regulator,

of

20

(B,

required

their

frame

is

actual

listre-

to

of

Numbers

position

ordering

Component

dicated

bly.

not

commended,

in

only

by

Example:

Ref.

No. No.

41 29476

42 22894

43

It

will

listed.

At

the

this

book.

the

in

of

that

parts.

indenting

be

The

so

back

part

number

the

parts

Part

noted

the

This

first

part

Always

77

reason

of

in

of

their

MK.-080

AA

in

complete

the

will

is

column

the

use

sub-assemblies

descriptions

the

is

that

sub-assembly

book

facilitate

known.

are

illustration.

the

part

Description

Feed

for

Spot

Screw

example shown

replacement

will

be

IDENTIFYING

reference

number

which

under

Lift

Styles

locating

Eccentric

Screw

-------------------------------

should

found a

numbers

Reference

listed

can

be

the

description

59400 K

above

of

that

these

be

ordered.

numerical

the

illustration

PARTS

in

furnished

Assembly,

and R --------------

parts

only,

numbers

the

second

the

eccentric

individually

index

and

merely

should

column.

for

of

the

of

all

and

indicate

never

repairs

main

be

are

sub-assem-

Amt.

~

1

1

and

bearing

is

the

parts

description

not

used

in-

are

re-

shown

when

the

in

Where

some

identification

appear.

of

Part

the

the

smaller

numbers

construction

parts,

letter

is

represent

permits,

and on

stamped

the

those

in

same

each

where

to

distinguish

part,

18

part

is

the

regardless

stamped

construction

the

of

part

the

with

from

its

does

similar

catalog

part

not

in

number.

permit,

ones.

which

On

and

they

Page 19

IDENTIFYING

PARTS

(Continued)

IMPORTANT I ON

WHICH

Union

it

approved

ciency

parts

trademark

are

wise

a

driver,

of

PART

Success

Special

subsidiaries

and

Genuine

are

Prices

forwarded

directed.

Torque

distance

torque

IS

ORDERED.

in

Needles

scientific

durability

needles

stamped

is

your

are

f.o.b.

(measured

by a lever

etc.

Many

will

ALL

ORDERS,

USE

GENUINE

the

operation

and

Repair

and

authorized

principles,

are

assured.

are

packaged

with a reproduction

guarantee

net

cash

A

charge

of

tighten

shipping

in

(in

these

of

and

are

is

made

inch-pounds)

inches

devices

the

part

PLEASE

of

distributors.

and

the

point.

TORQUE

to

INCLUDE

NEEDLES

these

Parts

are

with

of

highest

TERMS

subject

Parcel

to

cover

REQUIREMENTS

is a rotating

or

feet).

are

the

PART

AND

REPAIR

machines

as

furnished

They

made

with

labels

available,

correct

the

familiar

quality

to

change

Post

postage

This

marked

NAME

AND

PARTS

can

be

secured

by

the

Union

are

designed

utmost

in

without

shipments

and

is

accomplished

which when

amount and no

precision.

~

Union

materials

insurance.

force

notice.

(in

STYLE

only

Special

according

•

Special

and

are

insured

pounds)

by a

set

at

tighter.

OF

MACHINE

with

Genuine

workmanship.

All

the

genuine

Corporation,

to

Maximum

trademark.

shipments

unless

applied

wrench,

proper

FOR

the

effi-

repair

Each

other-

through

screw

amount

most

All

unless

by hand

The

straps

otherwise

as

tightly

screws

and

eccentrics

noted.

as

possible,

requiring

All

a

should

other

unless

specific

be

nuts,

torque,

tightened

bolts,

otherwise

will

to

screws,

noted.

be

indicated

19-21

etc.,

inch-pounds

should

on

be

the

(22-24

tightened

picture

em/kg)

plates.

19

Page 20

FILL

MAIN

RESERVOIR

CAUTION'

Fill

oil

before

re~ervo

start

Machine

dr~ined

sh1ppin

beforeeen

g.

i

r

·

has1~g.

20

Page 21

MAIN

FRAME,

AND

NEEDLE

MISCELLANEOUS

THREAD

COVERS

TAKE-UP

WIRE

Ref.

No.

Part

No.

1 22829

2

3

4

21375

98

52

AV

A

A

5 56391

6 22539 R

7 52958 B

8 22848

9

20

10 539

11

12

22889 A

95

13 22513

14 35731 A

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

660-342

51294

R

7947

56393

c

56393 D

22585

22569

c

56382

56382 N

357

57882 E

51270 B

95

63494 B

22894 E

51282

52882

AE

y

56382 w

90

56382 c

56382 B

22541 c

22733 E

56382 M

39 56382 E

40

41

42

43

44

45

46

47

56382 D

22548

56382

L

56382 F

22848

56382 K

56382 J