Page 1

H

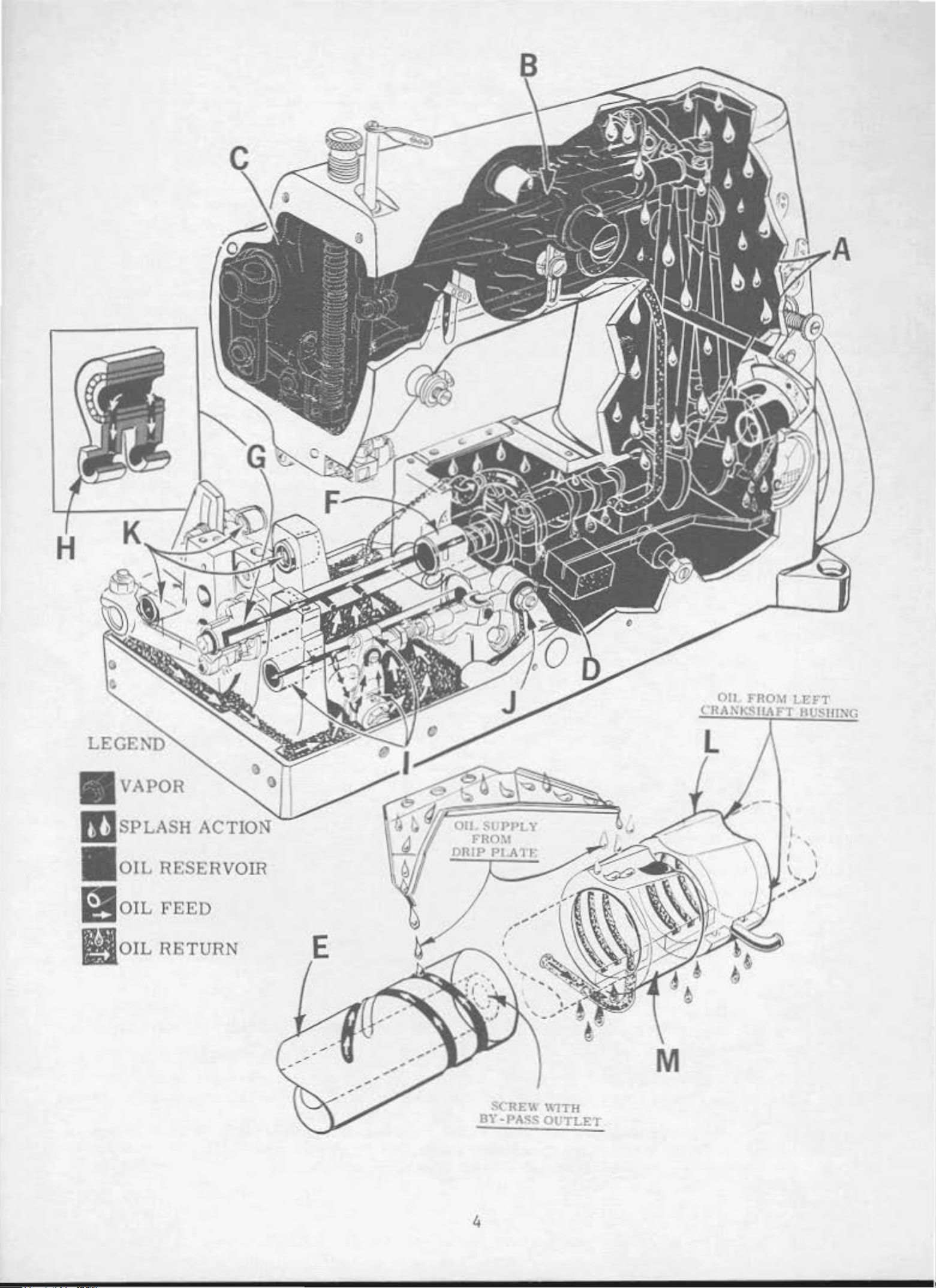

IIJ

VAPOR

sPLASH

ACTION

L RESERVOIR

011.

FRO

DRIP

~~

PPLY

\I

PI.AH'

Oil

FRO"

CR.'\~K~UAFT

LEFT

HIJSHI:-\G

L

I .

' '

I \

I I

.._,.;

, ...

i!l

!!

oiL

oiL

FEED

RETURN E

~("REV.

8\'

·PASS

4

M

\\lTH

OUTLET

Page 2

SETTING

THE

RUFFLF.R

BLADE

blade

With

(A,

A

the

Fig

ruffler

. 16)

arm removed from

to

the

ruffler

(D)

the

the

fles

check: the

ccnterlines

and

(93.66

can

securing

screws

extension

screws

This

aga

with

ruffler

chance

.

As

link

mm)

be made by

(F)

(F) and

adj

in

after

blade

the

pin

screws

ustment

ruffler

arm, which

of

forming

a

preliminary

distan

of

should

See

and

as

required.

inst

the

rufflcr

Fig. 16

loosening

position

locknuts.

ruffler

holder

blade

<'c

between t he

be 3 11/

(r,

may

allation

rig.

be

slanted

. Adjustment

drive

(8),

will mini

setti

rocker

ruffle

Retighten

required

using

square

ru

ng ,

arm

16

locknuts

17)

.

loosen

r arm

~OTE

shaft,

mize

f-

inch

:

screws

to

assemble

(C)

and washer

1

the

ruffler

plate

Fig.

shaft

er

screw

clearance

tion

plate.

screws

until

turn

travel

aligns

ber.

ing

moving t

(B).

foot.

(D) and

The

The

to

(A,

the

the

toward

with

cover

rod

16

Align

Snug

ru

ffler

between

ruf

the

If

adjustment

Fig

descending

upper

.

ass

embly (A,

he

ruffl

up

nut

fler

nee

dles

. 18)

drive

the

the lower

At

this

the

spot

(E)

ann

the

blade

needles

er

blade

Fig.

left

screw

securely

length

lower

(A,

when

in

needle

shaft

position

Fig

descend

is

necessary

the

.

sprocket

. 19)

.

Install

17)

side

(C)

may

part

Fig

ruffler

points

(C)

Retighten

, you

onto

of

in

.

require

of

. 16)

ing

unt

, so

in

the

the

the

"V"

the

should

needle

, remove

drive

are

i l

the

timing

should

slot

rufC!er

the

ruffler

groove

adjustment

ruffler

shaft

even

ruffler

set

be

ruffler

blade

of

arm mechanism and

be timed

points

upper

sprocket

with

screws

belt

of

runs

able

the

arm

crank

the

blade

(A)

to

ru

(A

drive

with

ruffler

to obtain

so

are

.

true

mo

ffl

even

top

ve

er

,

the

drive

th

at

chamber

(B) . Turn

of

is

at

Be

sure

.

the ruffler

dr

left

a

it

with

the

its

Replace

ive

side

shaft,

1/32

the

is

at

the

cover

the

throat

most

that

upper

lever

Fig. 17

of

tighten

inch

its

top

and

upper

dr

(B)

(.

upper fo

closest

of the

loosen

handwheel

plate

forward

crank

ive

without

the

79

sprocket

connect-

mm)

lde

.

point

pressclamp

throat

set

~ow

cham-

r.

posi-

of

•

•

.

...,

Fig.

18

lj

,

f

~

•

:&.-

Fig. 19

I 3

Page 3

If

you

ball

(40

nut

ward

D)

"xist

through

b

lnde

.

joints

mm)

(D)

or

After

in

AT

should

between

(it

backward

the

a 3600

ITS

approximat

from

the

front

and E (See

q

uire

of

needles,

of

required

arm

nut

rod

in

crank

f

lin

hold

get

leadin

terline

setting

its

teeth

blade

so

ruffler

(H)

. With

(A,

the

ruffler

eccentric

g

ratio

ing

the

g edge

with

(See

loosen

Fig

the

I

of

are

u~able

. A good

the

has

a

left

to

making

this

connecting

rotation

HOST

be

ely

Fig

FORI<ARD

set

3/3

2

of

the

. 20) .

th" r u

slightly

th"

needles

Fig. 20A)

nut

blade

the

.

19)

set

drive

to

.

To

set the

handwheel, l

l/

2

to

1

of

the

the

n"edles

SETTING

to

starting

two

ball

hand

obtain

adjustment,

rod.

of

wi

th

to

1/8

needles

Sty

ffler

beyond

.

(H) and

is

set

ruffler

in

its

lever

ob

tai

n a I

oosen

ruffling

ruffler

.

THE

do

this,

point

joints

thread)

the

I

You

th"

POSI

handwheel.

TION,

the tips

inc

h (2 .

on

les

59300 F and G

blade

with

the

centered

If

adjustment

position

properly

drive

lowest

(B),

set

1/2

cra

nk

eccentric,

nut

ratio

blade

RUFFLER

change

would

.

on

19/32

it

should

the

of

its

38

to

Styles

the

point

in

This

is

the

be a centerline

connecting

inch

important

have

ru(fler

teeth

3

.18

59300 C

tips

of

slots

is

ruffler

.

Tighten

connecting

position

the

to

I

ruf-

while

(F) nnd

.

Tighten

remain s

at

lll..AOE

the

is

(40

mm)

re-

the

tu

rn

nut

the

(Conti

centerline

nued)

distance

accomplished

rod

mm)

some

(E),

dimension

that

side

a

play

Fig

adjusting

screw

(F) . Recheck

specified

between

dimension

by

loosening

turn

binding

connecting

.

Tighten

condition

in

the

. 20

(G)

to

assure

dimensi

ons

the

of

I 19/32

nut

rod

nuts

connecting

Fig. 20A

as

required

that

fro

m the

two

inch

(C) and

for-

(C

and

does

not

rod

to

the

cen-

NOTE: As"outlined

should

ruffler

(40

NOTE

using

driv"

rufflcr

If

more

screw

nut

blade

blade

the

be

able

drive

mm)

: A

centerlin"

greater

lever

lever

The

spring

blade

pressure

(H)

cl

(C) .

The

front

when

must

material

to

lever

(J,

.

Tighten

down

ockwise

of

the

ruffle

also

to

in

the

move

without

dimens

ruffling

Fig

. 19) and moving

paragraph

the

ruf

moving

ion

rati

lever

press

is

be

be

ure

at

top

required

.

When

the

ruffler

r

flush

ruffled

on

speed

the

blade

on

.

the

top

fle

as

o

(J)

on

blade

is

explaining

r

drive·

the

outlined

can

be

the

.

ruffler

and

the

not

rufflcr

requir

must

ed

connecting

ruffler

in

obtained

ball

blade

so

great as

spri

be

moving towards

of

the

stripper

how

to

blade

same

paragraph

by

loosening

joint

should

bl

ade,

ng

pressure

parallel

the

blade

ti

me

rod

.

up

assembly

If

in

only

to

push

loosen

has

with

needles

to

the

ruf(ler

in

not

, change I

.

the

the

slot

front

of

be sufficient

the

nut

been

the

. The

ensure

stripper

(G,

l'ig

obtained,

front

teeth

a

positive

blade

the

slot

19/32

ball

the

to

. 19) a

of

the

of

, you

of

inch

joint

ruffler

hold

blade

nd

Lighten

stripper

the

ruffler

pickup

the

the

down

turn

of

.

J 4

Page 4

LOOPER

FRAME

THROW

-OU

T

The

the

used

at

By

loopers

only

the

pulling

actuating

the

left,

frame

the

SURE

er

loopers

to

frame back

before

•

Although

sary

to

procedures

the

needle

looper

when

top

of

looper

pin

the

is

released

push

starting

make

will

lever

f rame throw -

easier

their

the

.

It

needles

stroke

throw-out

(A, Fig

looper

. 21)

holder

tilting

forward.

the

into

to

the

looper

po

siti

operate

machines

adjustments,

help

in

.

can

are

.

to

BE

hold-

on

.

are

the

installing

out

(Fig

. 21)

be

SPECIAL

INSTALLING

properly

following

is

a

convenience

INSTRUCT10NS

THE

assembled

NEEDLE

at

LEVER

the

used

Fig.

21

factory,

to

make

should

threading

it

be

neces-

of

Install

the

lever

needle

tion

until

stud

Haking

dll'

front

ing.

and

needle

through

the

on

damage

screw

until

toms

needle

thrust

lever

insert

the

(B)

sure

bar

link

set

Place

compression

lever

the

needle

the

stud,

"0"

(G)

the

ag~inst

(B) . Then

stud

(ll)

tightening

on

top

of

"0"

lever

col

(D)

the

ring

stud

lar

in

needle

sl:tOulder on

contacts

no

bind

and

screw

the

secure

in

temper

cups

stud

opening

lever

thrust

being

ring

to

on

compress components

securing

the

needle

secure

in

lts

the

the

proper

rear

casting

(A,

(B) and nee

(C) . With t

its

the

the

needle

exists

top

(F)

Fig

proper

lever

needle

with

of

bed

load

onto

. 22) on

he

posi-

stud

lev

er

in

the

the

cast-

ring

the

dle

lever

(E)

(B) and push them

. Then

careful

it

.

washer

the needle

position

set

install

collar

not

Tighten

(H)

lever

bot-

stud

lever

screw

from

(C)

to

by

.

(B)

(0).

nee-

Fig

. 22

As

a

quick

remove

screw

(.076-.178

•

screw

screw

and

the

mm)

against

check

(G) from

needle

.

Compress

the

needle

ro

see

the

lever

lever

if

end

thrust

load

the

of

ring

Stud

the

~ollar

.

temper

needle

(C)

in

reverse

load

lever

15

ring

stud

should

order

(E)

is

(B),

spring

. Then

compressed

loosen

out

from

the

retighten

properly,

rear

set

.003-.007

the

rear

inch

set

Page 5

To

hooks

proper

(B).

needle

portion

the

set

insure

into

the

position

For

proper

lever

falls

screws.

positive

supply

and

alignment,

stud

into

INSTALLING

hole

secured,

(B)

the

until

lubricating

oiling

(K)

loosen

the

of

of

the

proper

indented

THE

the

the

the

hole

NEEDLE

needle

needle

amount

needle

"UP"

(K)

in

LEVER

lever

lever

of

oil

lever

is

in

the

(Continued)

stud

stud

stud

the

needle

is

(B),

(B) .

fed

set

up

position

lever

the

bearing

When

to

the

screws

stud

oiler

located

needle

and

and

rotale

the

(B).

(J)

in

its

lever

stud

the

hook

Retighten

'fhis

of

various

actual

listing

required

Numbers

position

ordering

Component

ed

by

indenting

Example:

catalog

sections

position

of

the

in

the

in

of

thal

parls.

has

of

in

the

parts

particular

the

first

part

Always

parts

of

their

been

arranged

the

mechanism

nachine. On

with

their

view

column

in

the

use

sub

illustration.

the

- asse~blies

descriptions

ORDERING

ILLUSTRATIONS

to

simplify

are

the

part

being

are

part

page

numbers,

shown.

reference

number

which can

under

REPAIR

shown

opposite

Reference

listed

the

description

PARTS

ordering

so

that

repair

the

the

descriptions

numbers

only

numbers

in

the

be

furnished

parts.

parts

may

illustration

and

and

the

numbers

merely

should

second

for

of

the

column.

repairs

main

Exploded views

be

seen

will

:Ln

be found a

of

pieces

indicate

never

be

are

used

indicat-

sub-assembly

their

the

in

.

32 29133

p

33 77

34 22894 c

35 22894 L

It

will

listed.

ed,

no

the

so

the

In

those

specific

various

description

At

the

this

the

book.

part

be

noted

The

reason

complete sub-assembly

cases

usage

machines

and,

bock

This

number

where a

will

if

of

the

will

is

known

Take- up

Drive

Screw- - - - - - - - - - - - - - - - - - -

in

is

Set

Spot

the

that

Screw- - - - - -

Screw - - - - - - - - - - - - - -

above example

replacement

should

part

is

common

be mentioned

are

necessary,

not

book

the

will

same,

the

be

differences

facilitate locatine

.

Eccentric

that

of

be

to

in

the

the

found a

the

Assembly - - - - - - -

the

these

eccentric

parts

ordered.

all

the

description.

specific

will

usage

be

numerical

illustration

and

individually

machines

covered

However, when

will

shown

index

in

of

and

- - - - - 1

bearing

is

not

by

the

are

this

part

be mentioned

the

all

illustration.

the

parts

description

not

recommend-

catalog,

for

in

the

shown

when

in

only

1

1

1

IDENTU"iiNG

Where

some

of

tification

Part

HIPORTANT!

PART

IS

the

the

construction

smaller

letter

numbers

Qi

ORDERED.

pares

is

stamped

represent

ALL

ORDERS,

permits,

each

and on chose where

in

to

distinguish

the

same

part,

PLEASE

INCLUDE

PARTS

part

is

construction

the

regardless

PART

16

stamped

part

of

NA}IE

A,_D

with

does

from

similar

catalog

STYLE

its

not

in

OF

part

which

number.

permit,

ones.

they

MACHINE

an

FOR

On

iden-

appear.

WHICH

Page 6

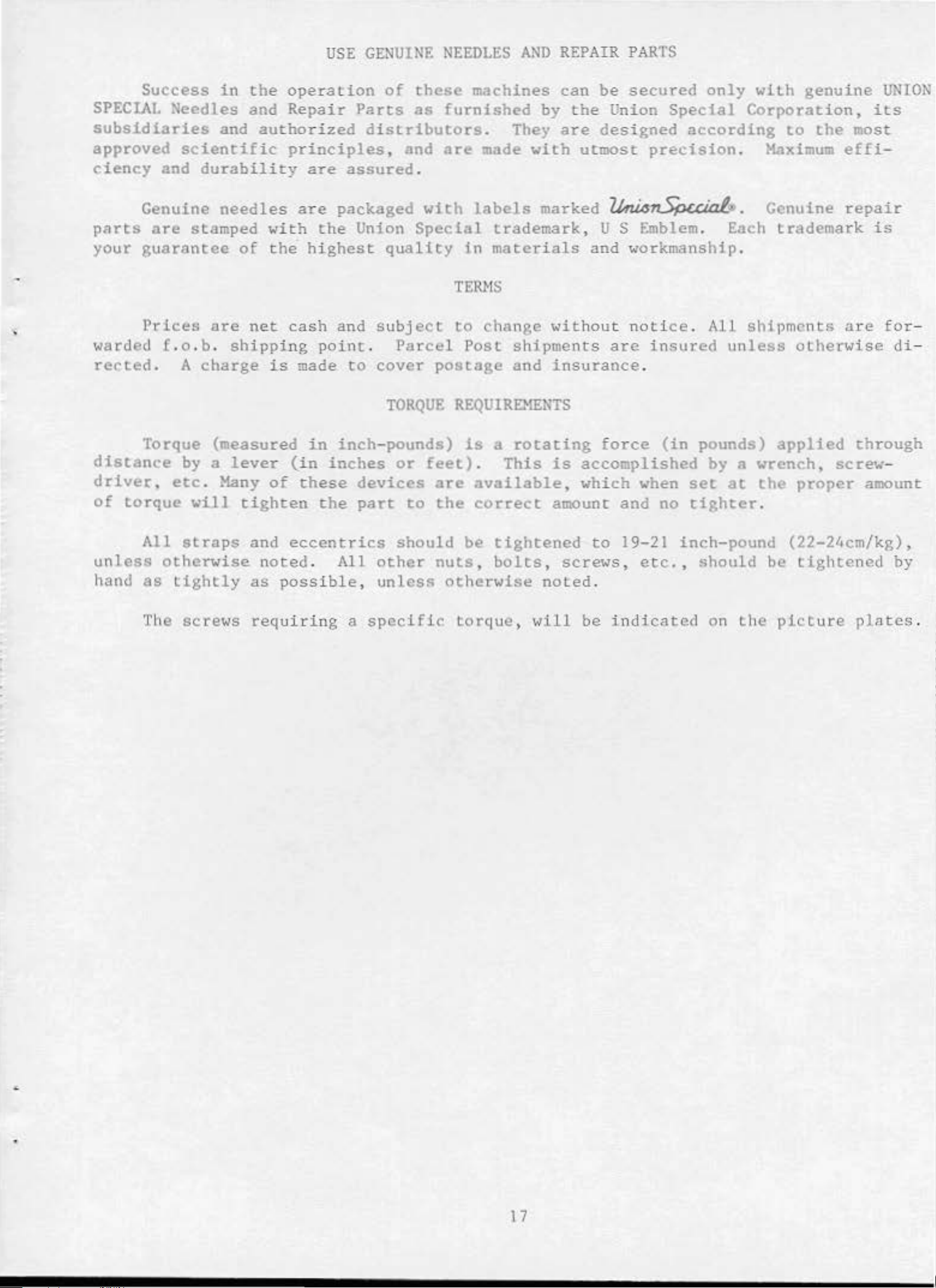

USE

GENUINE

NEEDLES

AND

REPAIR

PARTS

Success

SPECIAl.

Needles

subsidiaries

approved

~iency

scientific

and

Genuine

parts

your

are

guarantee

Prices

warded

re~

ted

f.

o. b.

. A

in

the

and

and

durability

needles

stamped

of

ore

net

shippi

charge

operation

Repair

authorized

principles,

are

are

with

assured.

packaged

the

the· highest

ca

sh and su

ng

point

is

made

to

of

these

Parts

as

distributors.

and

are

with

Union

Special

quality

bject

.

Parcel

cover

postage

TORQUE

machines

furnished

They

made

labels

can

by

are

with

marked

trademark,

in

materials

TERNS

to

cha

Post

nge

shipments

and

wit

insurance

REQUIREI'!ENTS

be

secured

the

Union

designed

utmost

~~-

Special

according

precision.

U S Emblem. Each

and

ho

'.-lOrkmanship.

ut notice. All

are

insured

.

only

unless

wHh

genuine

Corporation,

to

the

~~ximum

Genuine

effi-

repair

trademark

shipments

are

otherwise

UNION

its

most

is

for

di

-

-

Torque (measured

distance

driver,

of

torque

All

unless

hand

as

The

by a

etc.

lever

Many

will

straps

otherwise

Lightly

screws

(in

of

tighten

and

as

req

eccentrics

not

ed. Al l

poss

uirin

in

inch-pounds)

inches

these

the

i bl e ,

g a

or

devices

part

to

should

other

unless

specific

is

a

feet)

are

the

nuts,

.

available,

correct

be

tightened

bolts,

otherwise

torque, will

rotating

This

is

amount

noted

force

(in

accomplished

which

to

when

and

no

19-21

screws, etc.,

.

be

indicated

pounds)

by a

set

wrench,

at

the

tighter.

inch-pound

should

on

be

the

applied

through

screw

proper

amount

(22-24cm/kg),

tightened

picture

plates

-

by

.

1 7

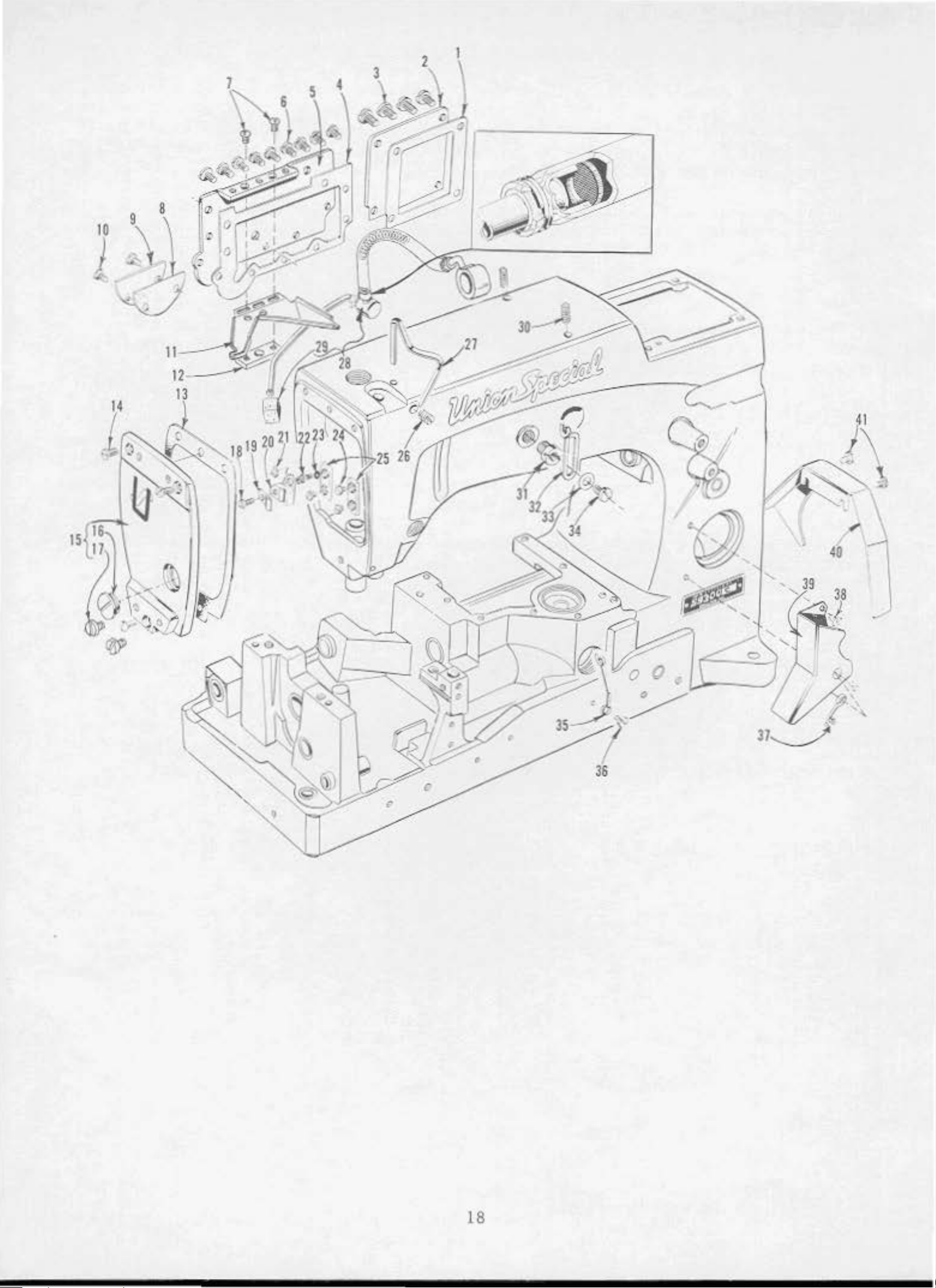

Page 7

10

j

11

t1

l\

~

...

/

40

.

,,

.,

~

\

18

Page 8

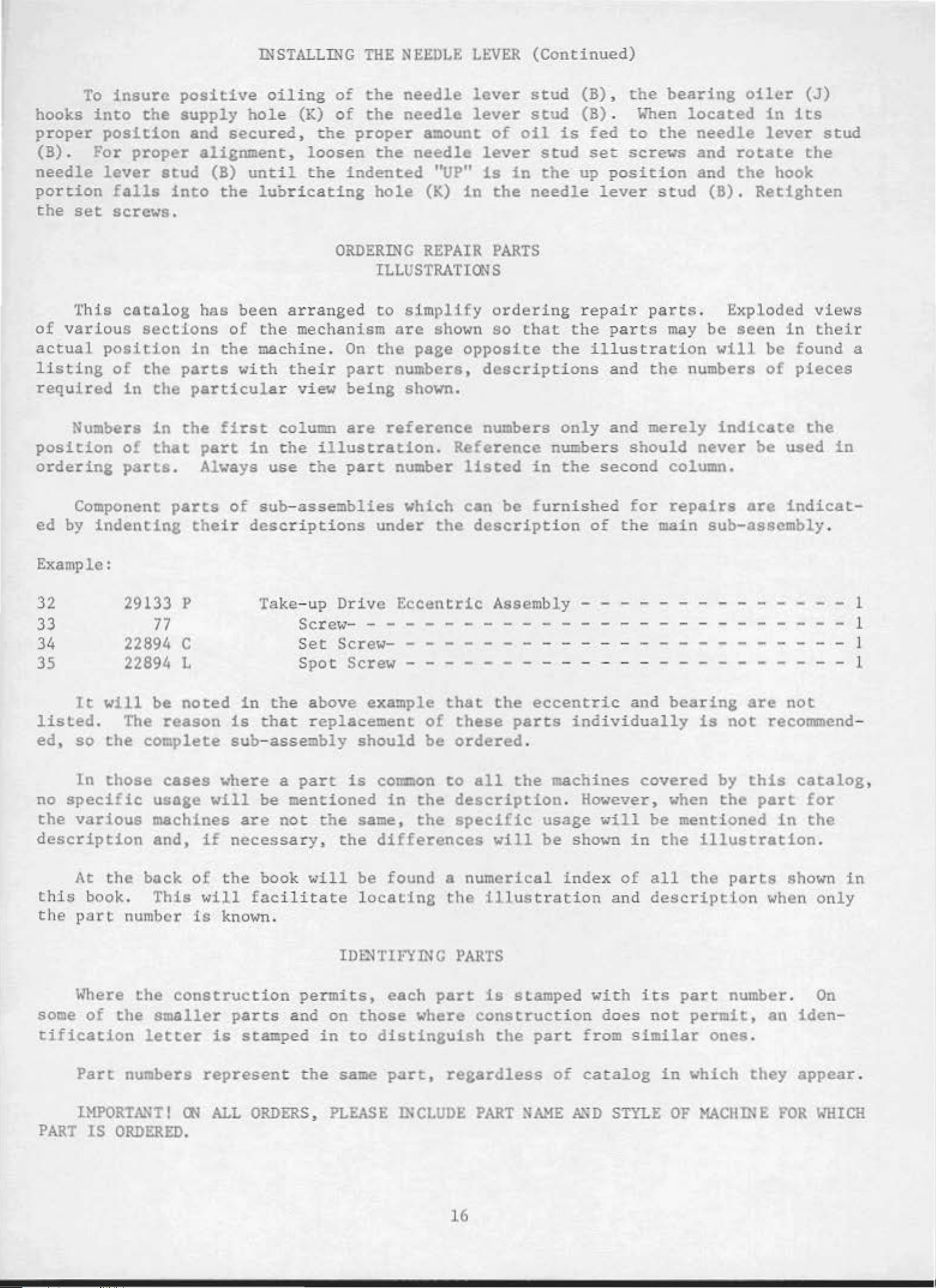

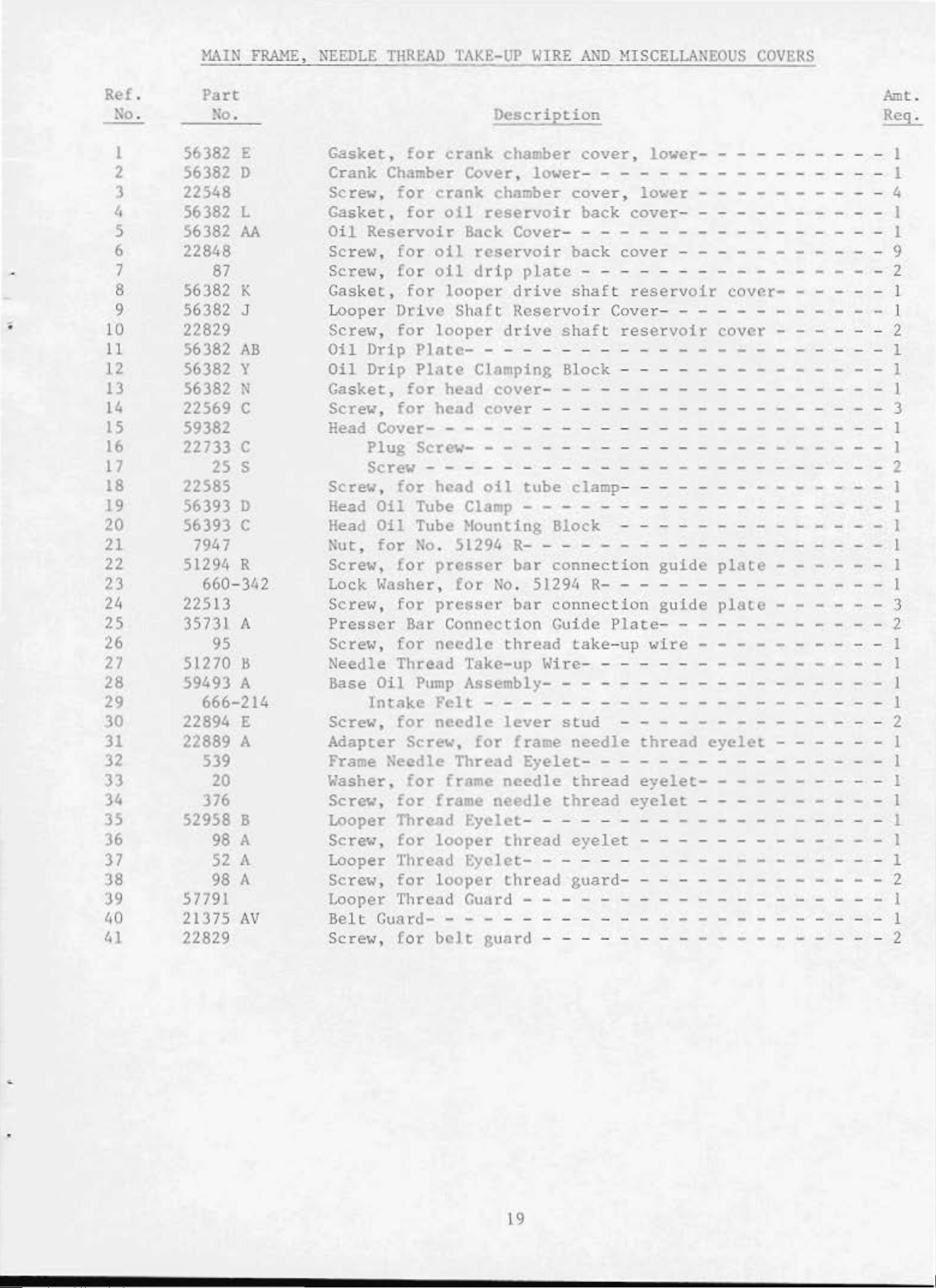

~lAIN

FRAME,

NEEDLE

THREAD

TAKE-UP

WIRE

AND

HISCELLANEOUS

COVERS

Ref.

No.

I

2

3

4

5

6

7

8

9

;

10

11

12

13

14

IS

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

Part

No.

56382 E

56382

D

22548

56382

56382

L

AA

22848

87

56382 K

56382 J

22829

56382

AB

56382 y

56382 N

22569 c

59382

22733

25

c

s

22585

56393 D

56393

c

7947

51294 R

660-342

22513

35731 A

95

51270

ll

59493 A

666-214

22894 E

22889 A

539

20

376

52958 B

98

A

52

A

98 A

57791

21375

AV

22829

Description

Gasket,

for

crank

chamber

Crank Chamber Cover,

Screw,

Gasket,

Oil

Screw,

Screw,

Gasket ,

Looper

Screw,

Oil

Oil

Gasket,

Screw,

Head

for

for

crank

oil

Reservoir

for

oil

for

oil

for

Drive

for

Drip

Drip

for

Cover-

Plug

looper

PlatePlate

for

head

head

- - - - - - - - - - - - - - - - - 1

Screw- - - - - - - - - - - - - - - - - - - - I

chamber

reservoir

Back

Cover-

reservoir

drtp

looper

Shaft

drive

Reservo

drive

- - - - - - - - - - - - - - - - - - - 1

Clamping Block - - - - - - - - - - l

cover-

cover

Screw - - - - - - - - - - - - - - - - 2

Screw,

Head

Head

Nut,

Screw,

Lock

Screw,

Presser

Screw,

Needle Thread

Base

Screw,

Adapter

for

Oil

Oil

for

Tube Clamp - - - - - - - - - - - 1

Tube Hounting Block - - - - - - - - I

No.

for

Washer,

for

Bar Connection Guide

for

Oil

Pump

Intake

for

Screw,

head

presser

presser

needle

oil

51294

for

No

Rbar

bar

thread

Take-up Wire- - - - - - - - - - - - l

Assembly- - - - - - - - 1

Felt

needle

- - - - - - - - - - - - - - - - - 1

lever

for

frame

Frame Needle Thread

Washer,

Screw,

Looper Thread

Screw,

Looper Thread

Screw,

Looper

Be

lt

Screw,

for

for

frame

frame

needle

needle

Eyelet

for

looper

thread

Eyelet-

for

looper

thread

Thread Guard - - - - - - - - - 1

Guard- - - - - - - - - - - - - - - - - - 1

for

belt

guard

lower-

cover,

cover,

- - - - - 1

back

lower-

lower

cover-

- - - I

- - - - - - - - 4

- - - - - - - - I

- - - - - - - - - - - - 1

plate

back

- - - - - - - - - - - - - - 2

shaft

ir

shaft

cover

reservoir

Cove

r-

reservoir

- - - - - - - 9

cover---

-

--

- - - - - - - - - - - I

cover

- - - - 2

- - - - - - - - - - - - - - - 1

- - - - - - - - - - 3

tube

clamp- - - - - - I

- - - - - - - - - - - - - - - - - - 1

connection

. 51294

connection

ta

stud

needle

Eyelet-

thread

thread

R-

- - - - - - - - - - - - - - 1

Plate

ke-

up

- - - - - - - - - - 2

- - - - - - - - - - - - - 1

guide

gu

ide

plale

plate

- - - - 1

- - - - - - 3

- - - - - - - - - - 2

wire

thread

eyelet-

eyelet

- - - - 1

eyelet

- - - - - - - I

- - - - 1

- - - - - - - - - - - - - - - 1

eyelet

- - - - - - - I

- - - - - - - - - - - - - - - - 1

guard

----

- - - - - - - - - - 2

---

-

--

- -

-- --

- - 2

Amt .

Rcq

1

1

.

19

Page 9

16

0

17

18

1S

32

20

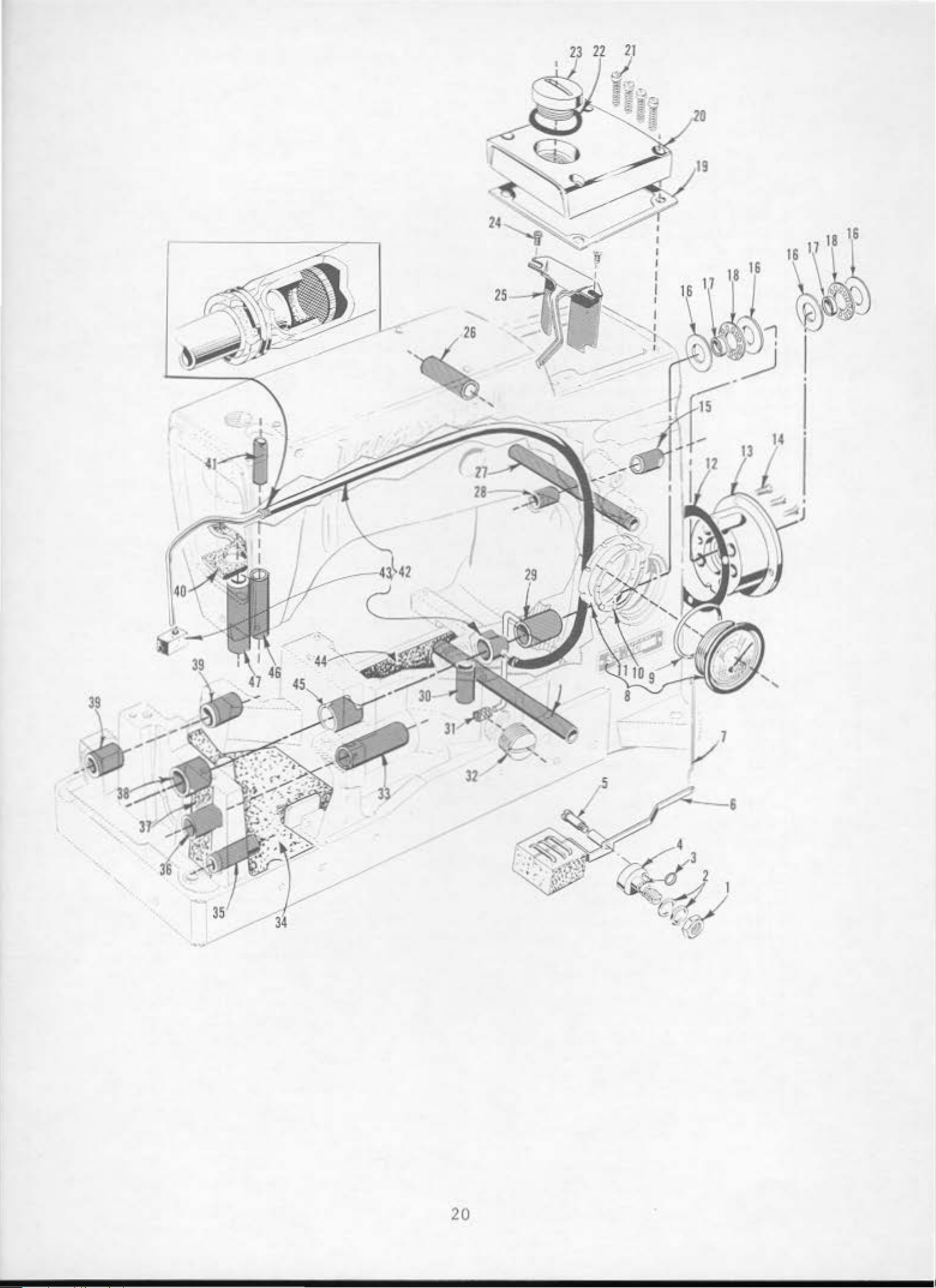

Page 10

~lAIN

FRAHE,

BUSHINGS,

HEAD

OIL

PUMP

OIL

AND

GAUGE,

UPPER

CRANK

MISCELLANEOUS

CHAMBER

OILING

COVER

PARTS

•

•

Ref.

No.

I

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

Part

No

.

11635 B

61256

G

660-221

56394

A

22793

59494

56394

B

63494 K

660-455

63494

G

63494 F

56390 E

57890 B

22569 8

59349 p

56390 H

56390 J

660-665

56382

c

56382 B

22541

c

56382 H

22733 E

90

56382

AC

52883 R

21657 X

59349 Q

56390 G

59451 A

35897

BV

22539 R

59436

56393 X

51254 A

50-895

666-259

56390

57836 B

56393

w

51154 E

56393

1'

56393 L

56393 Q

56190

56354 c

51257 M

8lk

Description

Nut,

Washer,

Oil

Oil

Screw,

Oil

Oil

Oil

for

for

Seal

Gauge

for

Gauge

Gauge

oil

Ring,

gauge

oil

Adjusting

oil

Float

Connecting

Gauge Assembly - - - - - - - - - - - - - - - - 1

11011

Spring

Ring - - - - - - - - - - - - - - - - 1

Washer - - - - - - - - - - - - - - - - I

Nut - - - - - - - - - - - - - - - - - - - - - - - 1

Gasket ,

Crankshaft

Screw,

Ruffler

Thrust

Pilot

Needle

Gasket,

Uppe

r Crank Chamber Cover- - - - - - - - - - - - - - - I

Screw,

Gasket,

Plug

Screw,

assembly

Needle Lever

Presser

Tension

Ruffler

Main

Loop

Oil

Intake

Plug Screw,

Looper Rocker

Machine Base

for

bushing

Bushing Housing - - - - - - - - - - 1

for

bushing

Drive

Shaft

Washer - - - - - - - - - - - - - - - - - - 4

Ring - - - - - - - - - - - - - - - - - - - - 2

Thrust

for

for

for

Screw,

for

Bearing

upper

upper

plug

for

needle

- - - - - - - - - - - - - - - - - - - - - - 2

Beari

Foot

Lifter

Release

Drive

Shaft

Retainer

Shaft

Bushing,

Drive

Filter

for

Shaft

Felt,

Looper Throw-out

Looper Rocker

.

Oil

Main

Feed

Oil

Collector

Shaft

Rocker

Attraclion

Needle

Head

Oil

Intake

}~chine

}~in

Shaft

Bar Bushing, upper

Pump

Base

Shaft

Felt

Bushing,

Shaft

Assembly - -

Felt

Felt,

Bushing,

Needle Bar Bushing,

Presser

Bar Bushing, lower -

adjusting

gauge

for

gauge

adjusting

oil

gauge

Shaf

floa

t - - - - - - - - - - - - - - 1

t

Lever Assembl

Rod

- - - - - - - - - 1

housing

housing

Bushing,

shaft

adjusting

lever

- - - - - - - - - - 1

shaft-

- - - - - - - - - - 2

shaft

- - - I

assembly - - - - - - I

y - - - - - - - - - - - - - - I

-----

-

--

---

---

- - - - - - - - - - - - - - - - 3

right

- - - - - - - - - - - - 1

- - - - - - - - - - - - 2

crank

crank

chamber

chamber

cover

cover

--

---

- - - - - - - 4

screw - - - - - - - - - - - - - - - - 1

upper

lever bearing

ng

crank

Oiler

chamber

oiler

and

Baffle

cover-

and

Plate

- - - - 1

baffle

plate

Assembly - - - 1

Lever Bushing- - - - - - - 1

and

Lifter

Lever

Bushing ,

right

- - - - - - - - - - - - - - - 1

left-

Shaft

Bushing - - - - 2

- - - - - - - - - - 1

Crank Bushing- - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - 1

bed-

Actuating

- - - - - - - -

Bushing ,

front

---

Bushing,

ri

Pi

n Bushing -

left

ght

- -

- -

-

- - - - - - - - - - - 1

- - - 1

- - - - - - - -

Bushing-

Felt-

left

- - - - - - - - - -

- - - - - - -

- - - -

- - - - - rear---

middle

lower

----

-

- - - - - - - - -

- - - I

Arnt.

Req

.

1

I

1

l

1

1

1

2

1

1

l

I

1

1

1

21

Page 11

'Torqu~

19- 21

t.o

1a.

lb•

.

.

34

y, r

'"'

to

'"·

·

lbe.

kg

. 2

(4t,c~;

I

49

-

L..--

22

Page 12

ADVANCED

FLATBED

LUBRICA

TIOK

SYSTEl\l

Figu

Lette

A.

B.

c.

ll.

E.

re

r

Bearing

or

Cl·ankshaft

and

crankshaft

Needle

Head

lever

area

ings).

Looper

lever

drive

bearings.

Opposing

end

of

mainshaft.

vents

shaft

oil

leakage

bE>aring.

Machine

drives,

bearings.

cross

(all

mechanisms

crank,

Helical

Area

upper

shaft

looper

grooves

Short

from

SUPPLY

ball

straps

bearing.

and

bear

drive

in

right

groove

pr

e-

right main-

SYSTEM

-

Method

Oil

ions

of

Lubrica

agitation

on

needle

as

rods.

Oil

supplied

trough

by

(51282

splash

i\llistas a result

Oil

agitation

(56343

E)

connecting

Oil

splash

drip

in

as a result

on

bottom

rod

plate;,

chamber

bon

a

result

lever

of

splash

.

which

.

of

connecting

AE)

in

which

column

in

ofs

of

looper

accumulates

extens-

is

area

column.

plash

er

drive

.

F .

G.

I-1.

I.

J.

Hight

Left

mains

mainshaft

tric bearings

Lower

mainshaft

Looper

rocker

per

Right

joint

ends

eccentrics.

cone,

shaft

rod ball

looper

.

haft

bearing.

bearing

lo

cated on

of

connecting

right

bearings,

joint

.

1·od

and

mainshaft

and

left

and

needle

all

eccen

rods

looper

left

be a ring

loo

.

of

-

Supply

grooves

shaft.

Oil

supplied

and

metered

trodu

ced

right

Amount

shaft

in

Oil

controlled

right

run-

supplies.

Supplied

shaft

yarn

Oil

to

which

as a metering

supplied

lubricating

by

into

mains

of

lubricant

end

of

out

from

from

in

right

from

felt

hollow

plugs.

center

haft

with

mainshaft

eccentric

hollow

contains

device.

from

plate

(56393 I<).

end

of shaft

bearing

in

by-pass

.

looper

4

strands

front

of

main

mainshaft

Oil

is

in-

in

the

area.

center

of

hole

bearing

rocker

of

base

felt

-

•

I<

.

Figure

Letter

L.

i\1!

.

Feed

rocker

Mach

Head

Base

rocker

shaft

ine

Area

shaft

and

bearings.

upp

er

RETURN

feed

SYSTEM

Self -lubrica

Method

Felt

pump

primed

of

pad

located

by

Return

in

bearing.

Felt

retur.n

and

pad

in

pump

primE>d

accumulates

chamber.

ted

head

oil

base

loca

by

splash

bearings.

collects

on

crankshaft

from

left

collects

ted

oil

drip

in

oil.

crankshaft

oil.

on

crankshaft

plate

looper

Return

and

Second

which

drive

5

Page 13

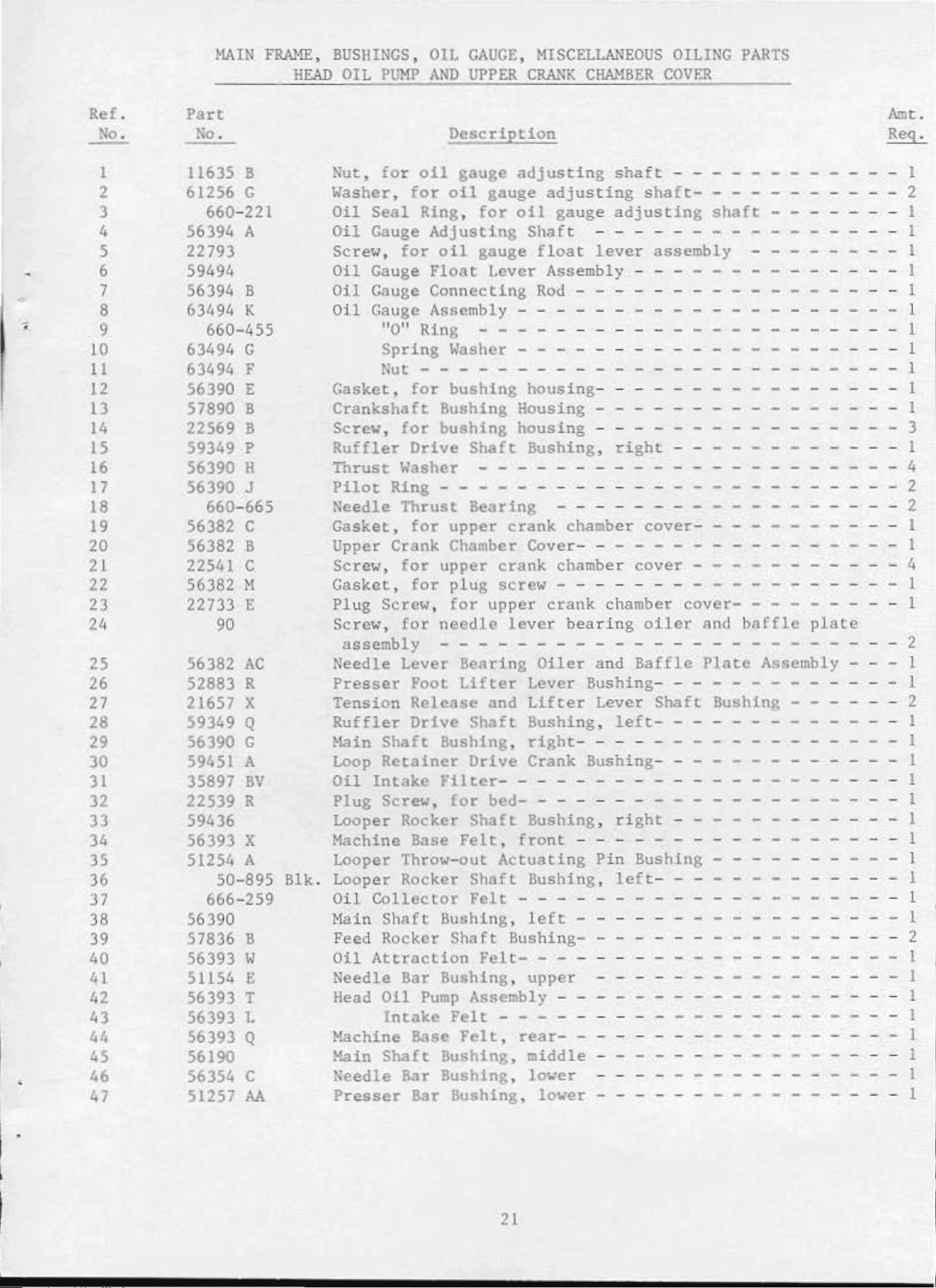

CRANKSHAFT,

NEEDLE

LEVER,

NEEDLE

8AR

AND

PULLEY

<

Ref.

No.

I

2

3

4

5

6

7

8

9

10

I I

I 2

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

Part

No

.

89

98

59318-16

59317-16

50

J- 16

27

- 435 Blk .

56458 A

22768

22586

R

51250 F

51250 D

660-625

56350

E

56350 F

660-614

29348

AF

51254 K

22562 A

22564

660- 215

56354 0

77

52336 A

W0

- 3

56350

D

56315 A

56350 G

22768

59358

A

29066 R

22559 G

51216

N

Amt.

Description

Spot

Screw,

1\eedle

Needle

Needle

Screw,

for

Holder,

Bar,

Stop

Pin

Bar

for

needle

needles-

marked

marked 11FB" - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - 1

Eyelet

Needl e Bar Thread

Screw,

for

needle

holder

- - - - -

- - - 1

- - - - - - - - - - - "DD-16"

- - - - - - - - - - - I

Washer - - - - - - - - - - - - - - - - - I

Eyelet

bar

- - - - - - - - - - - - - - 1

thread

eyelet

- - - - - - I

Req

Screw - - - - - - - - - - - - - - - - - - - - - - - - - - - I

CasketHasher-

Oil

Seal

Needle

Thrust

Temper Load

Needle

- - - - - - - - - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - - - - Ring - - - - - - - - - - - - - - - - -

Lever

\~asher

Thrust

Collar-

- - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - 2

Ring-

- - - - - - - - - - - - - - - - - 1

Lever Assembly - - - - - - - - - - - - -

Needle

~1r

Connection

- - - - - - - - - - -

Screw - - - - - - - - - - - - - -

Screw- - - - - -

Retaining

Needle Bar

Screw-

Link

Pin

Columb

Ring -

Link

- - - - -

- - - -

La

Yar n

(6

strands)

- 4

- - - 1

- - - - - - - - - - -

Needle Lever Stud - - - - - - - - - - - - - - - - - - 1

Needle

Screw,

Needle

for

Lever

Needle Lever

Lever - - - - - - - - - - - - - - - - - - - I

Bushing

needle

Thread

Connecting

- - - - - - - - - - - - - - - - - I

lever

Eyelet

thread

eyelet

- - - - - - - - - 1

- - - - - - - - - - - - - - - 1

Rod

Upper Ball

Joint

Assembly - - - 1

Screw- - - - - - - - - - - - - - - - - - - - - 2

Washer,

for

needle

lever

connecting

rod

upper

ball

joint

.

2

1

2

1

I

I

1

1

2

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

so

51216 p

56316

12934

A

56316 c

29476

51216 M

MD

57847

95

56334 K

59484 D

98

61321 L

22574

57821

56321

22894

:\

AB

660-202

assembly

Nut,

for

assembly

Needle

Nut,

for

Connecting

Crankshaft

Needle

Th

rust

ScrewDrive

Drive

Sprocket,

Sprocket,

Screw-

Retaining

Screw - - - - - - - - - - - - - - - - - - - - - 3

~andwheel

Pulley-

Screw-

"0"

Head

Base

Ring,

Oil

Oil

- - - - - - - - - - - - - - - - - - - - - - - - - l

needle

lever

connecting

rod

upper

ball

joint

- - - - - - - - - - - - - - - - - - - - - - - I

Lever

connecting

Connecting

Rod

rod gui

Rod

Guide-

- - - - - - - - - - - - - I

Assembly, . 910

- - - - - - - - - - - - - - 2

de

- - - - - - - - - - - I

inch

t hrow - - - - - - - - - - I

Bearing - - - - - - - - - - - - - -28

Collar

- - - - - - - - - - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - - - - - - - 2

for

for

- - - - - - - - - - - - - - - - - - - - - - 2

Plate

Styles

Styles

59300 C, F 59300 E, G

-----

---

- I

-

---

- - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - - - 2

for

Pump

Pump

pulley-

Assembly

Assembly

- -

(See

(See

Ref .

Ref .

!':o. 42!':o. 28-

Page

Page

21)-

19)-

- - - - l

-

-

1

1

1

23

Page 14

6

s

,,

-

,.,

(

I o •

l·lioc~.

lll.s.

I<

.•

)

24

Page 15

Ref.

No.

Part

No

~lAIN

.

SHAFT

AN1)

FEED

Description

DRIVING PARTS

Amt

Req

.

.

=

<

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

56335 L

56335 D

98

56334

B

59235 A

22651

CD-4

660-438

41

391

59234

22651

CB-4

22901

22560

B

59234 c

59434 B

22713

20

14077

22900

57834

59305-

HA61

29476

22894

G

16

D

MK

AA

77

39543 N

59222

22891

B

56322 B

51236 A

61341 J

29476

MJ

55235 E

6042 A

55235 D

77

56336 B

56336 c

51054

666-149

269

21657

E

22525 A

56322 c

56336

22798

c

22543 A

660- 269 B

56336 D

-062

Feed Rocker

Feed Rocker

Shaft

Shaft

- - - - - - - - - - - - - - - - - 1

Collar-

- - - - - - - - - - - - - - - I

Screw - - - - - - - - - - - - - - - - - - - - - 2

Feed Bar

Shaft-

- - - - - - - - - - - - - - - - - - I

Feed Rocker - - - - - - - - - - - - - - - - - - - - - - 1

Screw - - - - - - - - - - - - - - - - - - - - - - - 2

Retaining

Washer,

Feed

Bar-

Ring,

for

feed

for

feed

rocker

rocker

shaft

-

shaft

---

-

-- --

- - - - - - - 1

-

---

- - - - - - - - - - - - - - - 1

l

Screw - - - - - - - - - - - - - - - - - - - l

Set

Screw - - - - - - - - - - - - - - - 1

Screw - - - - - - - - - - - - - - - - - - - 2

Feed Bar

Feed Bar

Tilting

Tilting

Extension

Extension

- - - - - - - - - - - - - 1

Pin

- - - - - - - - - I

Screw - - - - - - - - - - - - - - - - - - - 2

Washer- - - - - - - - - - - - - - - - - - - - - 1

Nuc

Feed

- - - - - - - - - - - - - - - - - - - - 1

Dog

Tilt

Eccentric

Screw - - - - - - - - - - - I

Bushing - - - - - - - - - - - - - - - - - - - - 2

Feed Dog- - - - - - - - - - - - - - - - - - - - - - I

Screw,

Feed

Lift

Set

for

feed dog - - - - - - - - - - - - I

Eccentric

Assembly- - - - - - - - - - - - 1

Screw - - - - - - - - - - - - - - - - - 1

Screw - - - - - - - - - - - - - - - - - - - I

Thrust

Main

Link

Washer,

Feed Rocker

Washer,

ShaftScrew - Casket-

Pin,

for

for

for

feed bar

-

---

-

------

- 2

- - - - - - - - - - - - - - 1

- - - 1

feed

feed

Arm

bar

- - - - - - - - - - - - - - -

bar

--- ---

and Feed Crank Link

---

Sub-assembly-

-

2

- - - I

Nut - -

Washer- - - - - - - - - - - - - - - - - - - - - - -

Locking

Stud-

- - - - - - - - - - - - - - - 1

1

Screw - - - - - - - - - - - - - - - - - - • - - - - I

Feed Crank Link Assembly - - - - - - - - - - - 1

Feed Crank Link

Feed Crank Link

Oil

Nut,

Washer,

Screw,

tlain

for

feed

for

for

Shaft

Feed Crank

Screw,

Stitch

Quad

for

Regulating

Ring,

Feed Crank

Pin

Wick- - - - - - - - - - - - - - - - - - 1

crank

feed

main

Head

Stud

feed

shaft

Plate

, marked

crank

stu

crank stud

Screw - - - - - - - - - - - - 1

for

Stud

feed

Insert

crank

Ferrule

- - - - - - - - 1

- - - - - - - - - - - - I

d-

head

- - - - - - - - - - plate-

- - - - - -

- - - - l

- - - 4

- - - "A"

stud-

- - - - - - - - - - - - I

- - - - - - - - - - 1

stud

- - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - - I

I

1

I

1

1

25

Page 16

21

\ ,

41'

...

2

7 5

26

Page 17

TAKE-UP

~~D

LOOP

ER

DRIVE

PARTS

•

Ref.

No

.

1

2 59444

3

4 41358

5 59259 Looper Thread

6 59444 M

7

8

9 53678

10 54244

11 15489

12

13

14

15

16

17

18 59444

19 51242 L

20 54244 R Looper

21

22

23

24

25

26

27

28

29

30 18

31

32 29133

33

34

35

36 54195

37

38 29133

39

'•0

41

42

43 59444

44

45

46 55244

47 51236 A

48

49

so

51

52

53

54

55

Part

~o.

C0-67 E Cork

Looper Rocker

J87

54244

59444

41071

HS82

51225

54244

59444 L

39543

54285

59285-2-16

54208 A Looper,

54244

59444 G Looper

55244

51236 A

22894

22894 L

22768

22894 c

59451 R Looper

J Screw,

Wa

Screw,

c

p

N

J Looper Throw

B

G

w

H

R Washer,

J Looper

c

22

KH

97

A

Loop

Neoprene

1

.-lasher,

Screw,

Nut

Screw,

'.J'asher,

Looper

Collar,

Washe

Nu

Looper

Screw,

Screw,

c Looper

G Locking

20

Link Pin-

p

77

Tak

c

Coupling-

98 Screw -

~I

98

A

18

20 Washer-

Looper

Loope r T

c

Link

22585

57858 Looper

54223 A Looper

59445 A

66~215

6042 A Washer,

59344 Looper

39173 A Looper Frame

c Screw,

Looper

Retaining

Plug,

for

sher,

er

,

t,

Washer-

~ut

e-up Drive

Sc

Set

Spot

Screw

Set

Screw -

Nut

Locking

for

for

Throw-out

Washer,

for

for

for

r,

for

screw

for

for

Throw-out

for

for

Holder

for

Holder

looper

Holder,

marked

for

for

Holder

Holder

-

re

w - -

Screw - - - - - - - - - -

Screw-

Drive

Screw

Retainer

rav

-

Pin

- -

for

Thread

Thread

Thread

for

Holder

for

looper

looper

looper

looper holder

looper

looper

- -

-

looper

Shaft

screw

Eyelet

Fork

for

looper

-out

looper

looper

looper

looper

Stud-

Actuating

No

.

Fork

Frame

Frame

holder

marked

"CB"

~·ramc

Fr

ame

-

- -

- -

-

-

Eccentric

- - -

-

thread

No. J87

throw-out

th

throw-out

HS82

holder

holde

holder

Locking

holder

-

-

--

holder-

Th

Driving

- - -

-

- - - - - -

-

- - -

-

Descr

rocker

-

- - - - -

- - - - - - - - - - -

loope

row-out

Pressure

-

"AAu-

-

-

row-out

-- -

-

ietion

-- ------ --

eyelet

J

r

Pin-

-

-

fr

ame

f rame

r f rame

frame

frame

- - - - - - - - - -

screw-

-

- - - - -

- -

- - -

- - -

-

Assemb

- - - -

- -

- - - -

-

- - - - -

Eccentric

--

- - - -

-

- - - - -

-

Drive

- - - - -

el

Drive

- -

- - -

Stud-

- -

looper

Pull-off

Take-up - - - - - - -

Take-up

Ring-

looper

l'reme

Locking

-

-

-

thread

- - - - -

-

-

- -

Gea

- -

-

Assembly - - - - - - -

- - - - -

r-

- - - - - - - - - -

Link-

-

-

- - - - - - - - - -

- - - - - - - - - - -

- - -

pull-off

Eye

let

Drive

- - - - - - -

holder

Shiel

Pin Spring

frame

d-

shaft-

- - - -

-

-

- - -

-

- -

- -

actuating

throw-out

actuating

- - -

actuating

-

Pin

- - - - -

-

l ocking

locking

Spring

lock

locking

- - -

locking

-

-

--

--

- - - -

Spring

Arm

pin

actuating

pin-

- -

- -

pin

-

- - -

--

pin

- -

pi

n -

- - -

pin-

pi n

- - -

pin

- - - -

-

- - -

--

-

-

- - - - - -

- - -

-

-

- -

- 1

- - -

-

-

- - -

- - - - - - - -

- -

- - -

ly

- -

- -

- - -

-

-- -

-

-

- - -

- - -

--

- - - -

- - - - -

- - - - -

- - - - - -

- - - - - - - -

- - - -

-

- - - - - - - -

- - - -

Link

locking

- - - - - - -

- - - -

- - - - - - - -

- - -

- - -

-

- - -

- -

- -

-- - -

- -

- - -

eyelet-

-

- -

--

- -

- - - - - -

- -

pin

- -

- - -

--

--

- - - - -

---

-

-

- -

--

- -

pin

- -

-

--

- -

-

- 1

-

- -

- - - - -

-

-

- - -

- - - -

-

- 1

-- -

- -

- I

-

-

- - - -

- - - -

- -

--

- - -

-

- - -

-

-

-

- - -

-

- - - -

- -

-

-

- - -

- - -

-

- - -

- -

- - -

----

-

-

- 1

- -

-

- - -

- - -

- -

-

-

-

-

- -

- - -

-

--

- - -

--

--

- -

- -

---

--

- - -

--

-

- -

-- -

-

-

--

- - - -

--

- -

- -

- - -

- - -

--

- -

--

---

--

-

-

- - - 1

-

- - -

-

- - -

--

-

- -

- - -

- 1

- -

- -

- -

- - - 1

-

-

- - - 1

- - 1

-

---

- - -

-

- - -

- - -

-

- - - -

- - - 1

- - - 2

----

- - 1

A.mt

Reg.

1

1

- 2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

-

2

-

1

1

1

-

1

-

1

1

1

1

1

6

- 1

1

- 2

2

1

1

l

1

l

1

1

1

.

27

Page 18

4

3

30

2

2

24 23

28

Page 19

CLOTH

PLATE,

SWINGING

BRACKET

AND

LOOP RETAINER

DRIVING

PARTS

Ref.

No. No.

I 59401 8

Part

2 22839 c

3 22574

4

* 5

* 6

* 7

8 28577

9

10

11 59364

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38 59451

39

40

41

42

43

23425

23443

9937

22504 A

22574 D

59451 F

59451

59451

59482 A

59451 c

666-206

660-337

56382 H

59451 u

22580 E

59493

59451 w

531

59451

627

59324-16

59480 c

59380

51280 J

22839

22524

22585 A

59311

12986 B

54264 c

54264 B

80

25

c

v

B

B

T

88

90

v

18

A

87

0

87 u

Am

Cloth

Screw,

Screw,

Screw,

Screw,

Place

for

for

for

for

Washer Plate

Hemmi

l/6

Washer,

Nut , fo r

Pi

Folder

Sc

Washer,

Loop

Loop

Oil

ng

Attachment,

in

ch (

vot

Screw,

Hounting Swinging

rew,

for

Retainer

Retainer

Reservoir

for

pivot

for

Fulcrum and

Oil

Oil

Gasket

Retainer

Wick,

Seal

for,

for

Ring - - - - - - - - - - - - - - - - - - - 1

Driven

Description

- - - - - - - - - - - - - - - - l

cloth

cloth

cloth

hemming

,

l.

59

pivot

for

loop

loop

Slide

oil

plateplate-

plate

- - - - - - - - - - - - - - - - - 2

attachme

for

hemming

lower, 1

mm)

capacity-

screw

screw-

- - - - - - - - - - - - - 2

folder

retainer

retainer

Holder and

Driving

Top

Cover - - - - - - - - - - - - - - 1

Arm

Block - - - - - - - - - - - - - - - - 1

fulcrum and

reservoir

Gear-

- - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - 2

- - - - - - - - - - - - - - - - - - 1

nt - - - - - - - - - - - - - 2

attachment

/4

inch

- - - - - - - - 1

(6.

35

mm)

hem

turned

- - - - - - - - - - - - - 1

-

---

mounting s

llracket

driving

driving

Driving

- - - - - winging

bracket

--

- - - - - l

- - - - - - - - - - l

arm- - - - - - - - 1

arm - - - - - - - 1

Arm-

- - - - - - - - - I

Crank - - - - - - - - 1

slide

top

block

cover

- - - - - - - 1

-

--

- - - - - 1

Req

up

1

Screw - - - - - - - - - - - - - - - - - - - 2

St

op

Collar

and

Oil

Slinge

r - - - - - - - - - - - - 1

Screw - - - - - - - - - - - - - - - - - - - 2

Screw ,

Retainer

Screw,

Retainer

Nut - - - - - - - - - - - - - - - - - - - - - - - - 1

for

Arm

for

Arm

retainer

Support,

retainer

Support,

arm su

pport

, upper- - - - - - - - - - - 2

upper - - - - - - - - - - - - - - 1

arm

support,

lower- - - - - - - - - 1

lower - - - - - - - - - - - - - - 1

Screw - - - - - - - - - - - - - - - 1

Throat

Screw,

Throat

Throat

Screw,

Screw,

Retainer

Screw,

Lo

op

S

crew,

Scr

ew, for

Latch

Spring

Plate-

for

Plate

Plate

Dowel

Pin

for

for

Holder

for

Retainer,

for

Spring,

Clip,

- - - - - - - - - - - - - - - - - - - - - 1

throat

plate

- - - - - - - - - - - - 3

Support Shim - - - - - - - - - - - 1

Support-

- - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - 2

throat

oil

oil

loop

lalch

for

for

plate

reservoir

Plate

reservo

marked

- - - - - - - - - - - - - - - - - 1

i r

"BY

retainer-

spring

folder

swinging

support

top

to

p cover- - - - - - - - - 3

- - - - - - - - - - 2

cove

r-

- - - - - - - - - - 8

"- - - - - - - - - - - 1

- - - - - - - - - - - 2

- - - - - - - - - - - - - - 1

mounting

bracket,

swinging

(not

shown)- - - - - - - 1

bracket-

I

t.

.

*

Available

•

as

an

extra

send

and

charge

item

29

.

Page 20

2 A

12

~

• •

-

30

Page 21

Ref.

No.

Part

No

STRIPPER

.

BLAD

E,

FOLD

ERS,

BRACKETS

AND

Description

RUFFLER

PARTS

A:nt

Rcq

.

.

I

2

2A

3

4

5

6

7

8

9

10

*1 1

12

13

14

*15

*

16

*l

7

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

45A

59382

s

25

22733 c

59340 c

22882

59340

B

22596

I I 85 L

59340 A

12934

A

22704

23442

B

604

27-527

59340

59303

87

u

2 7-527

22504

59348 A

22798 A

29476

PA

59348

59349

F

605

51236 A

14077

22566 A

59349 D

667 D-16

59349 K

9660 B

98

59349

22

76/1

E

B

12934 A

22517

22704

59347

93

59347

43443

77

A

Q

Q

22704

59348 8

59346

59346 A

Blk

Bl

k.

Head

Strip

Screw,

folder

Stripper

bracket-

Screw, f

Washer,

Stripp

Nut,

Screw,

Hemming

Screw,

.

Washer,

Stripper

Ruffle

Screw, for

T

Screw,

Ru

~ut,

Shoulder

Ruffler

Dowel

SpacerCollar,

Cover-

Screw - - - - - - - - - - - - - - - - - - -

Plug

per

for

bracket

- - -

ScrewBlade

stripper

Blade

- - - - - - - - - - - - - -

Holder

Brac

blade

ket,

upper-

holder

bracket,

- - - - -

upper

- - - - - - - - - - - - - - - -

Holder B

racket,

lower

and

folder

- - - - - - - - - - - - - - - - -

or

er

for

turned

(2. 38

Washer,

ilting

f f

le

Ruffler

Ruffler

Link

for

Pin

strip

for

Bl

No.

ade

No. 22596-

for

hemmlng

Attachment,

down, 1/16

for

stripper

for

No

Blade-

Edge

mm)

Guide,

capacity

for

for

ti

Lever

for

Arm

tilti

Extension

Blade

Rocker

Screw,

Pinscrew

Screw,

Shaft

- - - - - - - - - - - - - - - 1

per

22596

Holder

blade

holder

---

- - - - - - - - - - 2

- -

--

- - - - 4

- - - - - - - - - - - I

- - - - - - - - - - - - - - - - 2

attac

uppe

inch

blade

hment - - - - - - - - - - - - - 2

r,

(1

1/4

.59

inch

mm)

(6. 35

capacity-

mm)

hem

- - - - - - 1

- - - - - - - - - - - - - 2

. 604 - - - - - - - - - - - - - - - - 2

- - - - - - - - - - - - - - 1

for

set

on

ruffles

3/32

inch

- - - - - - - - - - - -

ruffle

No

. 87 U - - - - - 2

ltin

g

- - - - - - - - ng

Holder

for

edge gu

le

ver

lever-

And

Blade

- -

ide

- - -

- - - - Holder

--

Arm Extensionruffle

r

rocker

- - - -

- - - - - - - - I

- - - - - - - - - - 1

- - - - 1

-

- - - - - - - - - I

arm

extension

- - - - - - - - - - - - - - - 1

~o

.

93

- - - - - - - - - - - - - - - 2

for

Bracket,

ruffler

left

shaft

bracket,

left

- - - - - - - - - - 1

- for

ruffler

rock

shaft

-

Screw -

Ruffler

Spot

Locknul - - - - - - - - - - - - - - - - - -

Rocker

A~n,

left

- - - - - - - - -

Screw- - - - - - - - - - - - - - - - -

Screw - - - - - - - - - - - - - - - - - -

Screw,

Rufflcr

Sc

rew,

Ruffler

Nut,

Screw,

Screw,

Ruffler

Ruffler

Ruffler

for

for

for

for

for

rufflcr

Blade

ru(fler

Slade

ruffler

adjusting

rufflcr

Blade

Slade,

Blade,

blade

tension

Tension Plate

blade

Tension

blade

ten

Plate

tension

ruffler

blade-

Support

for

for

- - - - - - - - - - - - - - Styles

Styles

plate

holder

- - - - - - - - sion

Holder

blade

plate

holder

- - - - - - - - -

adjusting

screw-

tension-

- - - - 1

- - - - - - - - - - - 2

59300

59300 F, G- -

C,

E- - - - - - - -

----

- - - 1

2

1

I

and

2

I

1

- 2 Screw,

I

- - - 1

I

---

- - - 1

- - - 1

- - - - 1

- - - I

- - - I

- - - 1

- 1

1

- 2

I

- - - - - 2

1

-

---

- - 1

I

1

1

* Order

~s

on

extra

send and char

ge

item

.

31

Page 22

1

18

17

',

24

~

~

'

;;;; \

\

23

32

Page 23

INSTRUCTIONS

FOR

MECHANICS

CAUTIO:>!

ervoir

oil

ounces

the

Fahrenheit

No

. 175 .

and

is

to

should

zone,

cans

must

gauge

(340.2

various

Use a

check

the

be added when

marked

No.

Oil

be

(8),

parts.

straight

in

Fill

oi.l

black

"LOW".

28604

has

filled

before

gr.)

the

level

main

main

line,

R.

been

.

drained

to

the

beginning

Run

Full

mineral

reservo

at

machine

speed

reservoir

gauge

located

need] e is

The recommended

proper

oil

i r

(B) .

LUSR I CA

from

to

slowly

operation

of

.

at

to

to

the

level

operate.

REC0}1}!ENOF.D

a Snybol t

This

plug

Oil

the

the

main

for

is

screw

is

right

black

oil

TI

0!'1

reservoir

at

plug

The

several

can

at

is

then

011..

viscosity

cqui

in

maximum

of

line,

available

screw

capacity

minutes

be

expected

valent

upper

"OPERATE"

to

crank

safe

located

in

before

(A,

of

of

90

Union Spec

operating

zone,

to

16

shipment,

Fig

.

the

to

distribute

without

to

chamber

marked

the

fluid

so

the

I)

as

indicated

reservoir

d~mage.

125

seconds

in l Sp('cification

cover

level

"FULL"

left

ounce

of

is

the

(A,

when

"OP~:RATE"

(453. 6 gr.)

oil

at

Hg

.

res-

on

12

to

1000

. 1)

needle

Oil

CAUTION!

It

is

an

extended

and

further

distribute

and

change

2000

drained

(C,

the

cover.

lubricated,

drop

ing

throw-out

looper

in

directly

hand

For

lint

the

operating

from main

Fig.

machine,

located

The machine

of

oil

rod,

retainer

the

oili

It

is

important

recommended

period

oil

oiling

oil

machines

deposits

oil.

I)

the

pin,

ng

to

hours,

lorated

or

by removing

at

and no

~t

both

ruffler

looper

holde

diagram

be

lubricated

the

An

is

needle

will

the

in

nt

reservoir

the

vario

operation

reasonable

oil

or

below

back

almost

oiling

ends

rock

holder

r and dr

(See Fi

that

that

be

us

change

once

the

of

entirely

other

of

shaft

these

a new

as

bar

required.

by removing

the

the

link

parts

check

intervals

is

a

year.

cloth

lo-....cr

machine.

than

adjustable

brackets,

frame

iving

g.

2)

machines

mnchinc,

follows:

and

.

the

recommended

plate

crank

automatically

an

locking

nrm

are

not

or

one

Remove

the

Run

oil

.

Oil

plug

occasional

as

required

needle

machine

for

If

every

may

screw

at

front

chamber

connect

the

indicated

looper

pin,

dir

dirty

be

-

and

.

be

over

that

the

bar

slowly

t

,

~

of

filled.

has

head

.

Replace

for

been

cover,

several

out

of

clean

head

.-..,-.£

,

__

-

__

service

out

cover

minutes

,

A

lint

as

to

~

for

no

daily

A

be made,

operating

Oil

and

frequent

main

(C,

front

hole

littl~

which

pumped

reservoir

Fig.

and

to

oili

I)

of

the

plug

gasket

check

see

level,

has

gone

back

ngs

located

machine

screw

cement,

before

that

as

into

unnecessary

may

the

outlined

through

the

be

drained

below

.

dry,

and

the

oil

main

After

paint

level

in

the

.

the

draining

re-assemble

morning

the

machine

reservoir,

Excessive

by removing

cloth

hole

is

first

plate

and

start

at

oil,

screw.

a

safe

paragraph

is

filtered

making

oil

plug

at

wipe

screw

6

should

too

in

the

screw

the

the

with

a

.

Fig.

I

Page 24

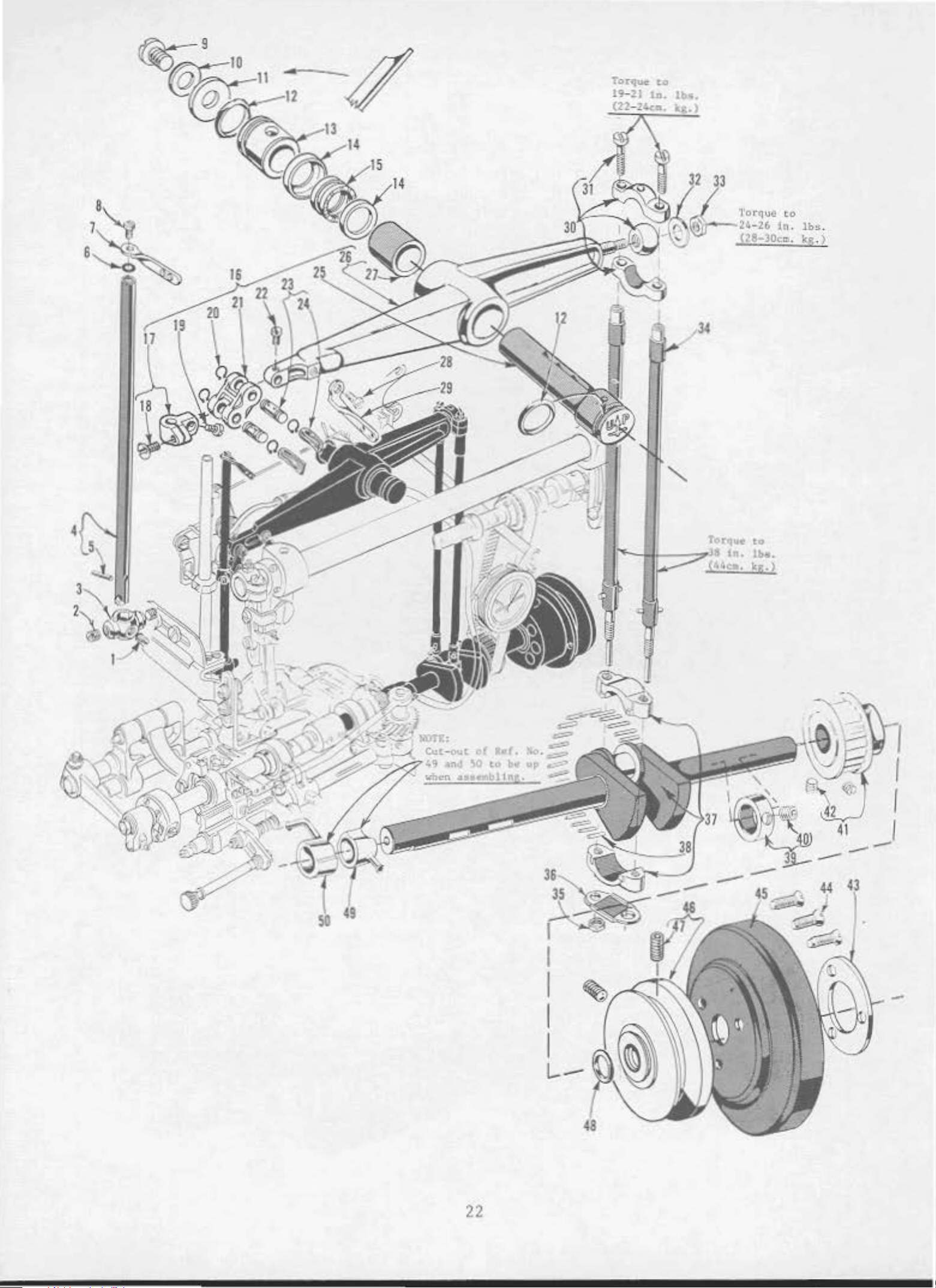

RUFFLER

HECHANISM

AND

COVER

Ref.

No.

I 59349 A

2

3

4

5 55235 E

6

Part

No.

59382

25

59349

6042 A

7 55235 D

8 59349

9 22852 A

10

I I

I 2

13

14

15

16

17

18

19

20

59349 c

667

18

20

59349 J

63439

59336 A

59349

9660 B

98

56334 c

59484

21

98

22651

22

23

24

25

26

27

28

29

30

31

32

33

34

35

5633L,

594

84

22795

59336

660-219

43242 p

59348 c

15037

59349 H

36253 J

59349

52776 v

53678 N

22804

35766

A

s

c

N

D-8

AD

F.

CB-4

H

I'

A

L

BA

p

Ruffler

Ruffler

Scr

ew,

Ruffler

Nut

\,

Blade Rock

Drive Cover - - - - - - - - - - - - - - - - - - I

for

Drive

- - - - - - - - - - - - - - - - - - - - - - 1

1

asher

Locking

Thrust

Screw,

R

uffl

Dowel

Nut,

Hasher,

for

er

Shaft

Pin,

for

ruffler

Washer, for

Ruffler

Drive Lever

Ferrule

Ruffler

Ruffler

Collar,

Feed Crank Stud - - - - - - - - - - - - - - - - I

Blade

for

Screw - - - - - - - - - - - - - - - - - - - - - - - 2

Driven

Driven

Sprocket,

Sprocket,

Screw,

Screw,

T

im

ing

Timing

Ruffler

Ruffler

Roll

Nut,

thread

Ruffler

Kut,

thread

Ruffler

Belt

Belt, for

Adjusting

Drive

Pin,

for

ruffler

- - - - - - - - - - - - - - - - - - - - - - - - - - 1

Shaft

for

ruffler

- - - - - - - - - - - - - - - - - - - - - - - - 1

Drive

Ferrule

Link

Release

Washe

Screw,

Nut , f

Retaining

Lever - - - - - - - - - - - - - - - - - - -

r,

for release

for

or

lin

Amt.

ruffler

Lever,

Description

Shaft-

drive

right

- - - - - - - - - - - - - 1

cover-

- - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - 2

Req

- - - - - - - - - - - - - - - - - - - - - J

Stud-

rufflcr

Bracket,

for

ruffler

- - - - - - - - - - - - - - - - - - - I

for

ruffler

ruffler

shaft

feed

feed

Link,

bracket,

right-

shaft

crank

crank

rear-

dr

ive

leve

right

r,

right

--

- -

-

---