Page 1

SECOND

EDITION

Finest Quality

~

CATALOG

STYLES

1900

1200

1700

2300A 5800 C

K 2600 A

A 2600 D

A 5600 C

~~

.......

INDUSTRIAL

NO. 58 L

~~®

SEWING

EQUIPMENT

LIST

OF

PARTS

AND

INSTRUCTIONS

Page 2

Page 3

Catalog

No.

58

L

LIST

STYLES

12

0 0

17

0 0

2 3

00

Style

First

OF

IN

and

1900

Edition

PARTS

CLASSES

2600

5600

5800

K

July,

Copyright

Union

Rights

Special

Reserved

UNION SPECIAL

INDUSTRIAL

1976

SEWING

CHICAGO

1927

By

Corporation

in

All

Countries

CORPORATION

MACHINES

Printed

in

1

U.S.A.

Page 4

APPLICATION OF CATALOG

This catalog applies only to the standard styles of machines listed

but

below,

Classes

relative to transmitters

are listed and fully described in Catalog No.

will be furnished gratis on request.

1200

A

1200 c

1200 G

1200 0

1200 Q

1200

AA-%-inch Finished Width

1200

AA-%-inch Finished Width

1200 AC-%;-inch Hem

1200 AD

1700A

1700B

1700 F

1700

G

1700

H

1900 K

2300

A

2300

B

2300M

2300N

can be applied with discretion to the special machines in

1200,

1700, 1900,

2300, 2600,

is

contained in Catalog No.

5600 and 5800. Information

2300

p

29.

45.

These catalogs

Needles

2300Q

R

2300

2600A

2600D

2600 F

2600

G

2600H

2600 J

5600 C-%-inch Binding

5600

C-%

-inch Binding

5800 C-31-inch Finished Width

5800 C-%-inch Finished Width

5800 C-%;-inch Finished Width

5800 H-31-inch Finished Width

5800 H-%-inch Finished Width

5800 H-%-inch Finished Width

5800 J -31-inch Finished Width

IDENTIFICATION

OF

A machine equipped with specified parts and

operation

number evenly divisible

Example:

and SPECIAL.

the letter

(See

made a

number. Example:

is

given a STYLE NUMBER, the symbol for which

1200

A.

Style numbers are classified as STANDARD

Style numbers of standard machines do not include

"Z," while those including

description of Style

"Z"

is

merely suffixed to the respective standard style

1200

by

1200

AZ.

100,

with one or more letters suffixed.

the

Z.) When only minor changes are

Styles of machines similar in construction are grouped and given

a

CLASS NUMBER, the symbol for which is a number evenly

by

100,

divisible

without a letter or letters suffixed. Example:

2

MACHINES

,fitted for a specific

letter

"Z"

is

a

are special.

1200.

Page 5

STYLES

Flat

Bed One Needle Machines, 5}2-inch Space to Right of Needle,

Bed

10 Inches Long, Double Locked Stitch, for Knitted Goods

1200 A For finishing knitted underwear and similar garments;

feed

OF

MACHINES

IN

CLASS 1200

surface on all four sides of needle, Type

121

needle.

1200 C Equipped with split front presser foot No.

wise

same as Style 1200

1200 G For finishing knitted undershirts;

rear of needle, Type

1200 0 _

For

finishing knitted drawers; feed surface

rear of needle, Type

1200 Q

1200

AA

For

jersey seaming; Type

For

attaching collarettes to knitted undergarments; strip

A.

121

needle.

121 needle.

121

needle.

feed

surface

used in long lengths, differential feed, Type

1200 AC For hemming bottoms of step-ins, chemises, union suit

1200 AD

flaps and similar garments, Type

For

dividing a hem

to

permit the subsequent insertion of

101

needle.

65

at

121

A,

at

other-

left and

left and

needle.

an elastic band, thus producing the elastic heading on

101

bloomers and similar garments, Type

1200 Z A special style similar to the standard styles in Class

1200, having several of the standard parts substituted by

corresponding

STYLES

parts or equipped with additional parts.

OF

MACHINES

IN

CLASS 1700

needle.

Flat

Bed One Needle Machines, 5}2-inch Space to Right of Needle,

10 Inches Long for Glove Work

Bed

1700 A

1700 B

1700 F

For

For

Type

---For

pointing gloves, light weight work; Type

121

needle.

pointing gloves, medium and heavy weight work;

121 needle.

closing canton flannel gloves; DOUBLE LOCKED

STITCH, Type 102 needle.

1700 G For closing light weight fabric gloves

chamoisette and similar fabrics,

STITCH, Type

1700 H For closing cotton jersey gloves; DOUBLE LOCKED

STITCH;

1700 Z A special style similar

Type

101

101

needle.

needle.

to

the standard styles in Class 1700,

DOUBLE LOCKED

~ade

from silk,

having several of the standard parts substituted by corresponding parts or equipped with additional parts.

3

Page 6

STYLES

Flat

Bed One Needle Machines, 572-inch Space to Right of Needle,

1900 K For basting clothing, skirts, ladies' suits, dresses and

similar garments; chain stitch, maximum length of stitch

72

inch, gauge attached to cloth plate, Type

1900

Z A special style similar

having several of the standard parts substituted

responding parts or equipped with additional parts.

OF

MACHINES

10

Bed

IN

CLASS

Inches Long

to

the standard styles in Class

1900

140

needle.

1900,

by

cor-

STYLES

Flat

Bed One Needle Machines, Bed

Stitch, Dewees Trimmer, Type

2300

A

For

seaming knitted underwear; minimum width of seam

%J

inch.

2300 B

2300 M For seaming sweaters and other heavy weight materials;

2300 N

2300 P For seaming knitted underwear; tandem differential

2300 Q

2300 R

2300 Z A special style similar to

For

seaming knitted underwear; minimum width of seam

Ys

inch.

minimum width of seam

For

closing toes of stockings; minimum. width of seam

%J

inch.

minimum width of seam

For

seaming knitted underwear; tandem differential

minimum width of seam

For

seaming sweaters and other heavy weight materials;

tandem differential feed, minimum width of seam

having several

responding parts or equipped with additional parts.

OF

MACHINES

ef

the standard parts substituted

IN

CLASS 2300

10

Inches Long, Double Locked

121

Needle

Ys

inch.

%J

inch.

Ys

inch.

the

standard styles in Class

Ys

by

feed,

feed,

inch.

2300,

cor-

STYLES

Flat

Bed One Needle Machines, Bed

2600 A For closing shoes; plain seam, upper and under

Type

2600 D For closing leather shoes; welt seam, using pre-folded

welt, upper and under feed, Type

2600 F For closing shoes, plain seam, under feed only, flat presser

foot,

2600 G For closing shoes; plain seam, under feed only, rolling

presser foot, diameter of roller

501

Type

OF

MACHINES

Stitch, for Shoe and Leather Work

needle.

501

needle.

4

IN

10

Inches Long, Double Locked

1%;

CLASS

501

inches, Type

2600

needle.

501

feed,

needle.

Page 7

STYLES

2600 H For French binding operations on oxfords, pumps, slippers,

sandals and other irregular shaped articles; under feed

only, Type

2600 J For "Gimp" or ornamental stitching on pumps, oxfords

and similar articles; rolling presser foot, diameter of roller

I;!f6

2600 Z A special style similar to the standard styles in Class

having several of the standard

responding parts or equipped with additional parts.

OF

MACHINES

501

inch, Type

needle.

121

needle.

IN

CLASS

parts

2600

(Cont'd)

substituted

by

2600,

cor-

STYbES

Flat

Bed One Needle Machines, Bed

Differential Feed, Double Locked Stitch, Type

5600 C For binding necks and fronts of knitted undershirts.

5600 Z A special style similar

having several of the standard parts substituted

responding parts or equipped with additional parts.

STYLES

Flat

Bed One Needle Machines, Bed

Under Feed, Double Locked Stitch, Type

5800 C For attaching collarettes to knitted undergarments; long

length

5800 H For attaching extension button stays

garments; long length

5800 J For attaching split tube border

chemises and similar garments; long length

5800 Z A special style siinilar to

having several of

responding

OF-MACHINES·IN-eLASS-5600-

10

Inches Long, Tandem

to

the

standard styles in Class 5600,

OF

MACHINES

Miscellaneous Work

cut

edge strip.

cut

the

standard parts substituted

parts or equipped with additional parts.

IN

CLASS 5800

10

Inches Long, Upper and

121

to

edge strip.

to

bottoms of step-ins,

the

standard styles in Class 5800,

·-

121

Needle

by

cor-

Needle for

knitted under-

cut

edge strip.

by

cor-

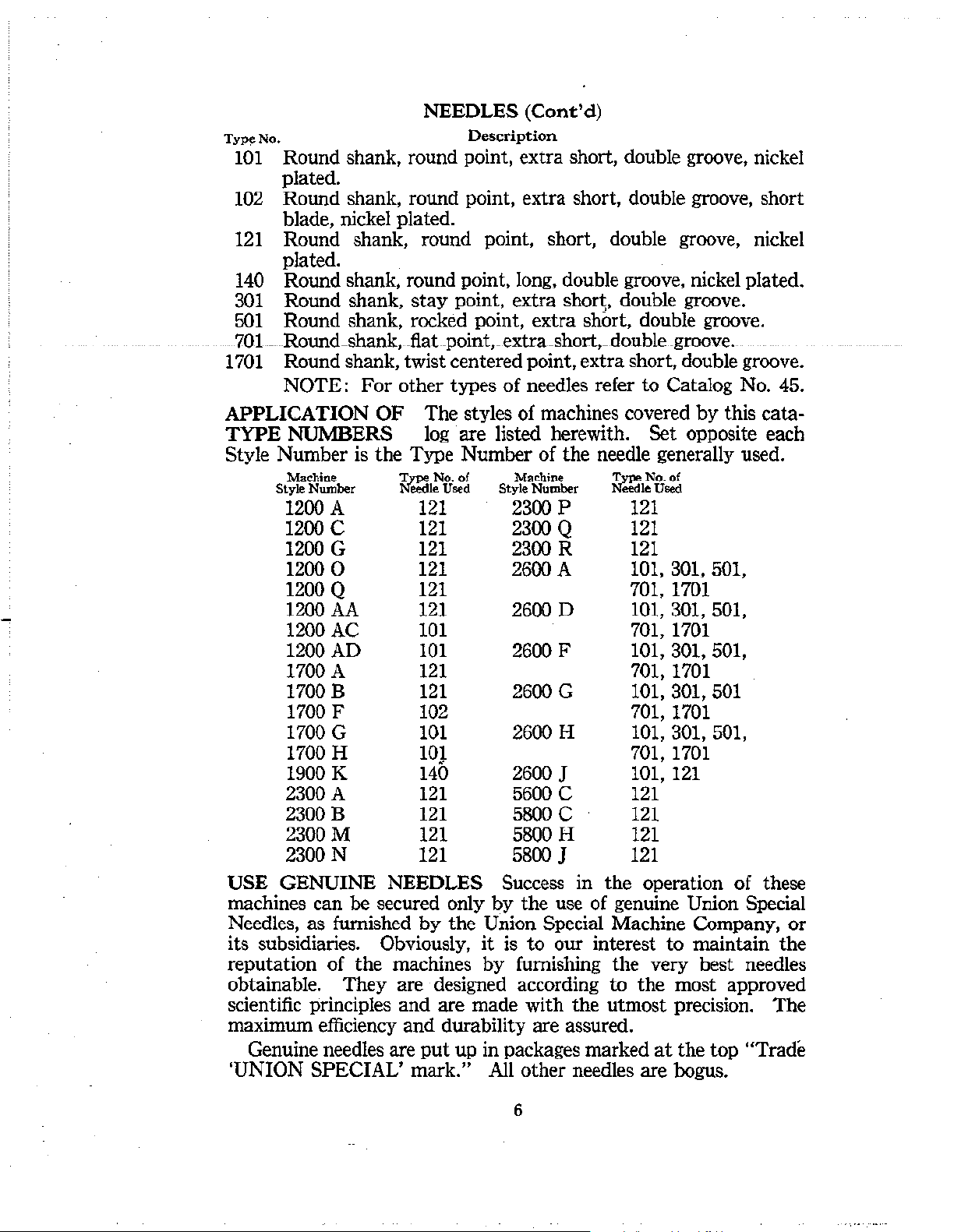

NEEDLES

TYPE

DESCRIPTIONS

length, groove, finish and other details. The latter denotes the

largest diameter of the blade measured in thousandths of

midway between the shank and eye

shank. Collectively, the Type Number and

the complete definition of

covered

posite each Type Number

NUMBER

The Type Numbers of the needles used in

by

this catalog are listed on the following page. Set op-

Each needle has a type number

The former denotes the kind of point, shank,

and

the

needle.

is

the definition of the needles.

5

and

size number.

an

is

stamped on the needle

Size Number represent

the

styles of machines

inch,

Page 8

NEEDLES

Typ~

101

No.

Round shank, round point, extra short, double groove, nickel

Description

plated.

102

Round shank, round point, extra short, double groove, short

blade, nickel plated.

121

Round shank, round point, short, double groove, nickel

plated.

140

301

501

Round shank, round point, long, double groove, nickel plated.

Round shank,

stay

point, extra

Round shank, rocked point, extra short, double groove.

701-Round-shank,.flat.point,

1701

Round shank, twist centered point, extra short, double groove.

NOTE:

For

other types of needles refer to Catalog No.

(Cont'd)

shor~,

..

extra-short,_double

double groove.

...

groove.

45.

APPLICATION

TYPE

Style Number

NUMBERS

is

Machine

Style Number eedle Used Style Number

1200 A

1200 c

1200 G

12000

1200 Q

1200

AA

1200 AC

1200AD

1700A

1700B

1700

F

1700

G

1700H

1900K

2300A

2300B

2300M

2300N

The styles of machines covered

OF

by

this cata-

log are listed herewith. Set opposite each

the Type Number of the needle generally used.

~No.

121

121

121

121

121

121

101

101

121

121

102

101

101

140

121

121

121

121

of

Machine

2300 p

2300Q

2300 R

2600A

2600 D

2600 F 101, 301,

2600G

2600 H

2600 J

5600C

5800C

5800H

5800

J

~No.

le

Used

121

121

121

101,

701,

101,

701,

701,

101,

701,

101,

701,

101,

121

121

121

121

of

301,

1701

301,

1701

1701

301,

1701

301,

1701

121

501,

501,

501,

501

501,

USE GENUINE NEEDLES Success in the operation of these

machines can be secured only

Needles, as furnished

by

its subsidiaries. Obviously,

reputation of the machines

by

the use of genuine Union Special

the Union Special Machine Company,

it

is

to

our interest

by

furnishing the very best needles

obtainable. They are designed according

scientific principles and are made with the utmost precision. The

maximum efficiency and durability are assured.

Genuine needles are

'UNION SPECIAL' mark."

put

up in packages marked

All

other needles are bogus.

6

to

maintain the

to

the most approved

at

the top "Trade

or

Page 9

ORDERING

To

have orders promptly and accurately filled, the

empty package, a sample needle, or the Type and Size Numbers

An

should be given. See marks on package.

intelligible order

would read as follows:

100 Needles Type

121

Size

.040.

ORDERING REPAIR PARTS

PLATES Illustrations of parts similar in appearance and size are

shown in groups.

LIST OF PARTS Turning from the plates to the list of parts,

the definition of each

Always check the symbol against its definition before ordering.

is

not

necessary

When

a.

part

to

is used or can be used in all machines covered by

this catalog, no specific use

For

convenience in ordering, minor parts, such as screws, nuts

and similar articles are repeated after each major part.

(-)

A dash in the "plate number" column of the list of parts

indicates the absence of an illustration.

(0)

A square in the "Symbol to order

the

part

is commercial and can be readily purchased in any ma-

chinists' supply house.

W A double dagger in the "Symbol to order

cates

that

the component parts cannot be furnished separately.

part

and its principal uses will be found.

furnish the plate number.

is

mentioned in the definition.

by"

column indicates

by"

column indi-

It

that

IDENTIFYING PARTS Where the construction permits, each

part

is stamped with its

are stamped with

an

part

number. Some of the smaller parts

identification letter to distinguish them from

parts similar in appearance.

All

part

numbers represent the same

part

regardless of the cata-

log in which they appear.

SUPPLIES

All

supplies, including taps, reamers, belting, belt

hooks, belt fasteners, screw drivers and powdered oil stone will

be promptly furnished.

TERMS Prices are strictly net cash and subject to change with-

out

notice. Express and freight shipments are forwarded

buyer's risk F.O.B. shipping point.

sured unless otherwise directed. A charge

Parcel post shipments are in-

is

made

to

at

the

cover the

postage and insurance.

7

Page 10

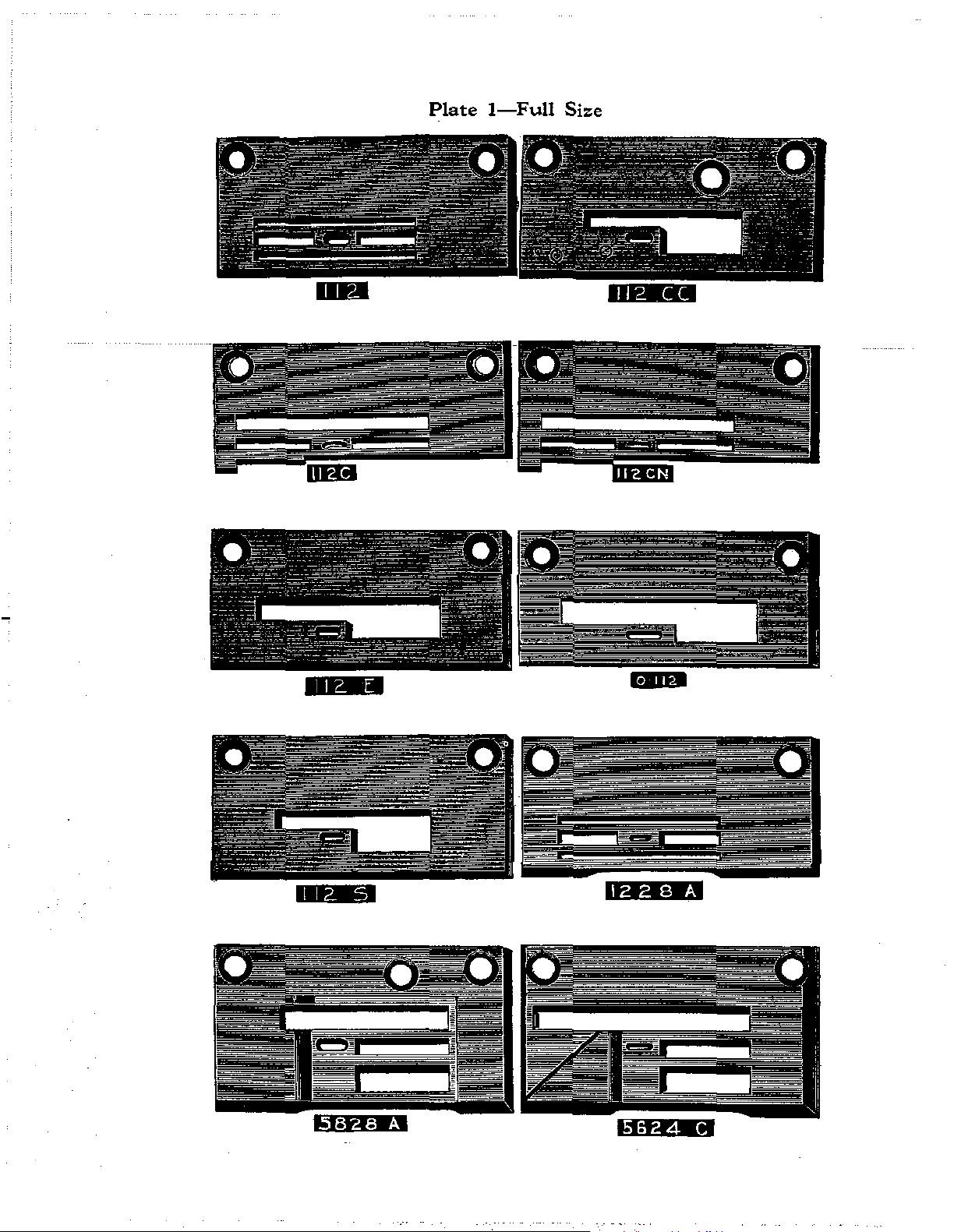

Plate

1-Full

Size

Page 11

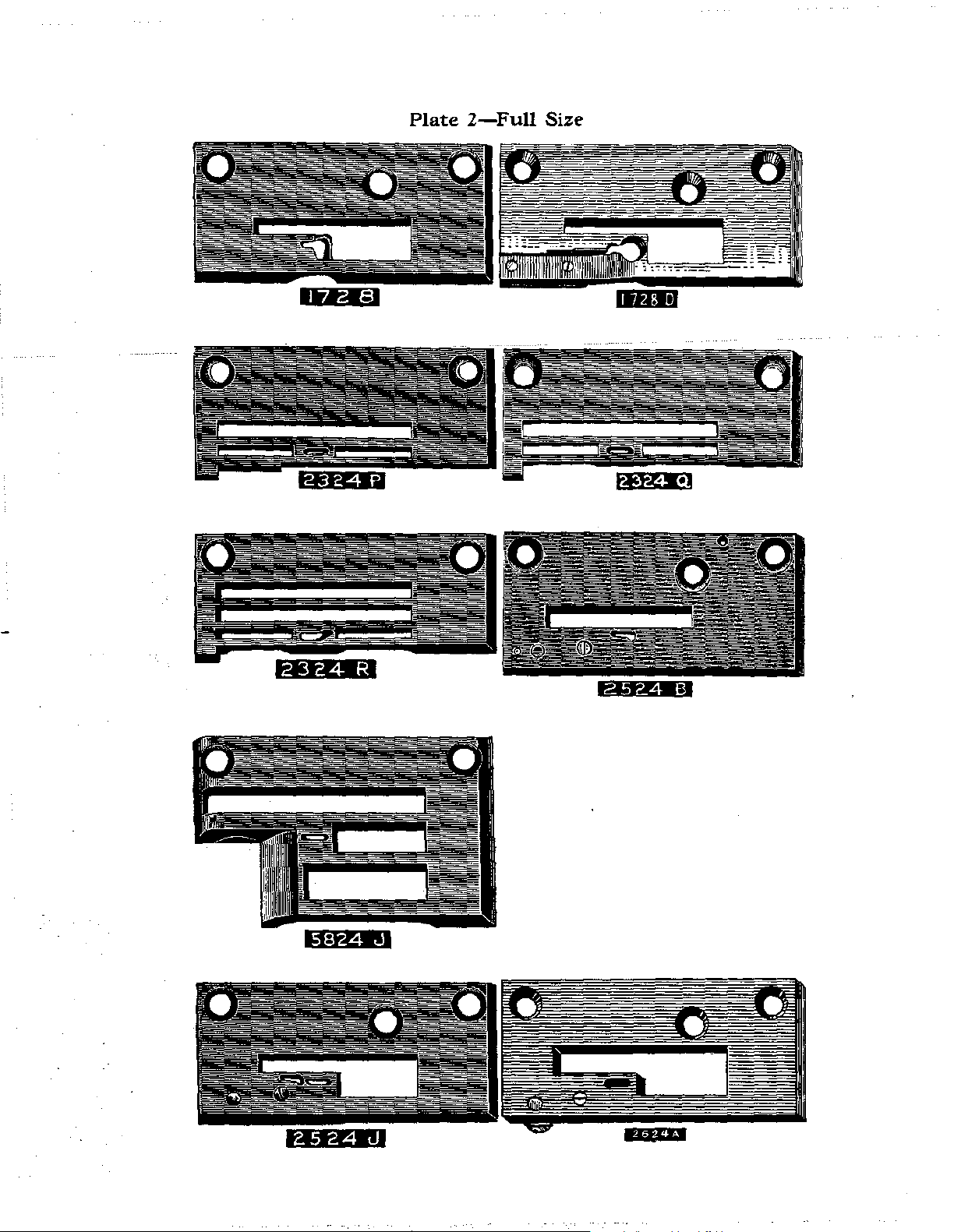

Plate

2-Full

Size

2324

R

Page 12

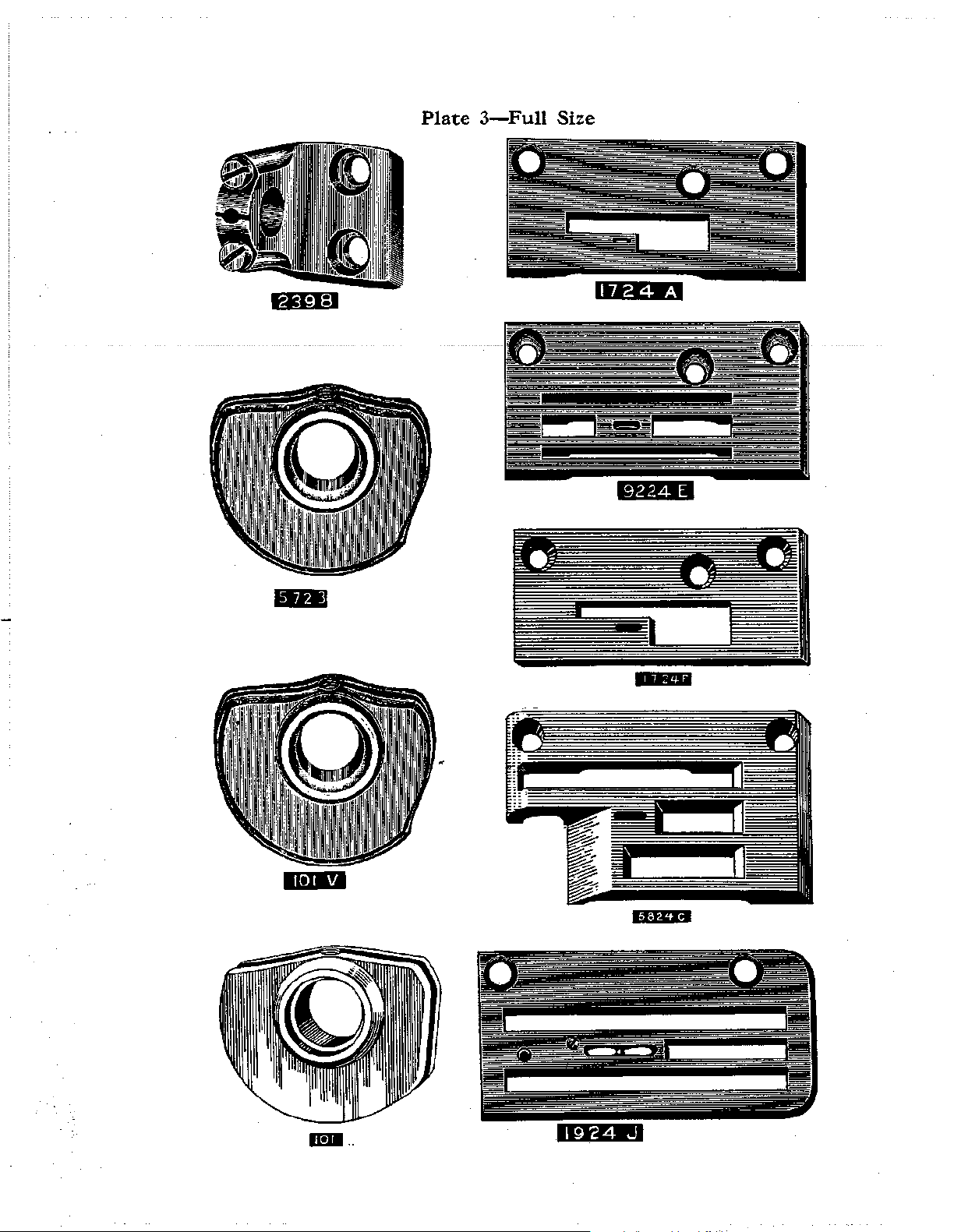

Plate

3-Full

Size

Page 13

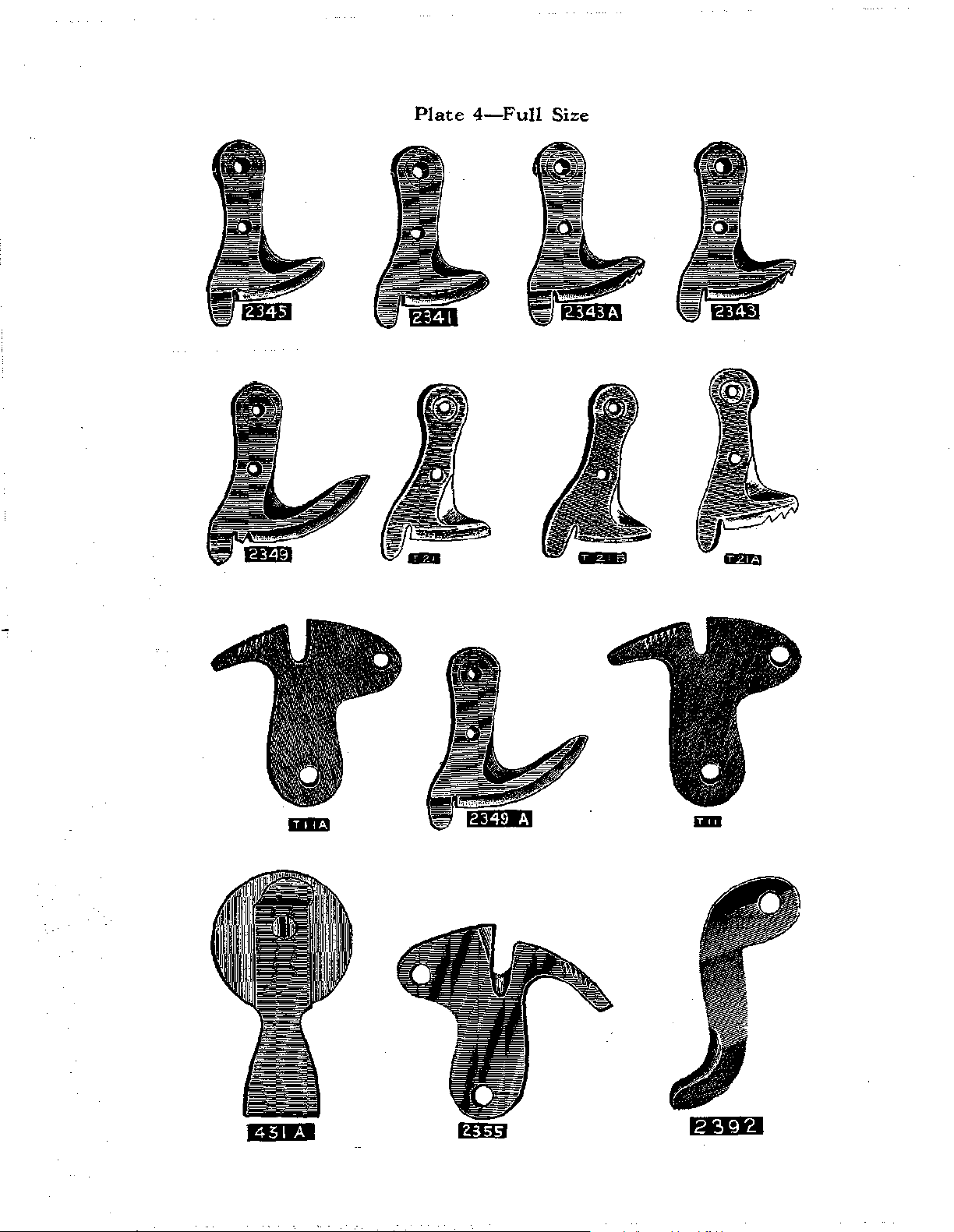

Plate

4-Full

Size

liD

Page 14

Plate

5-Full

Size

Page 15

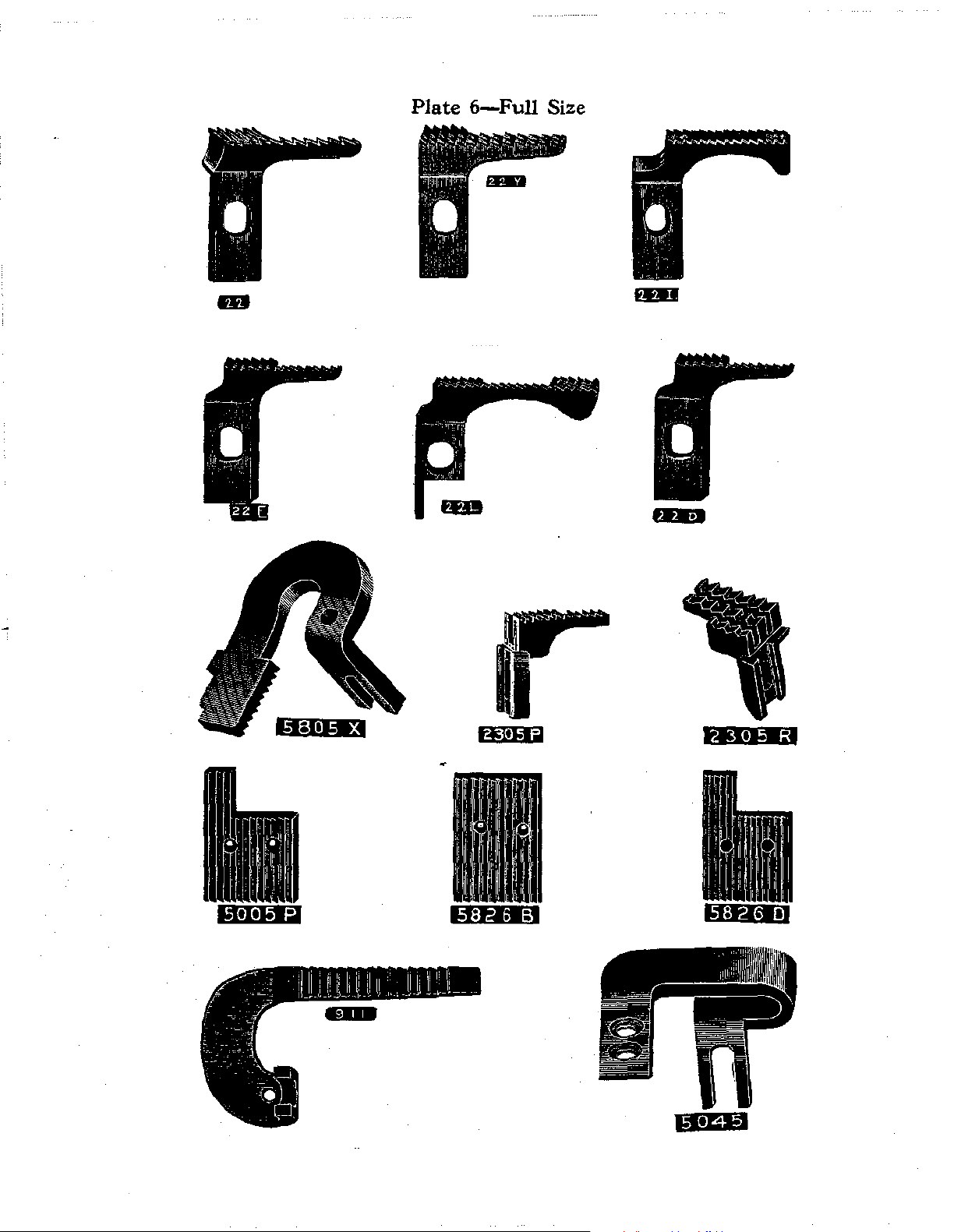

Plate

6-Full

Size

Page 16

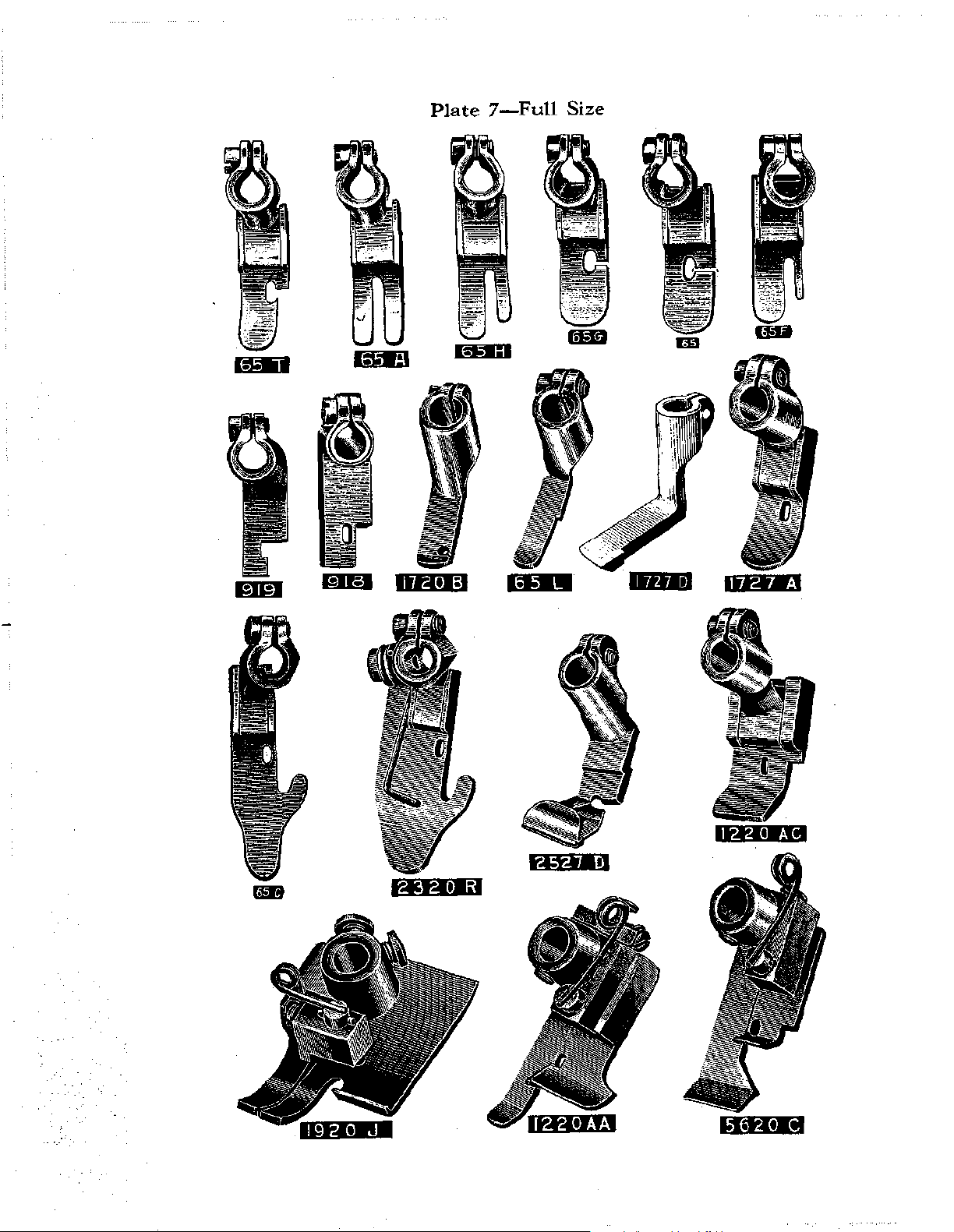

Plate

7-Full

Size

liiUII

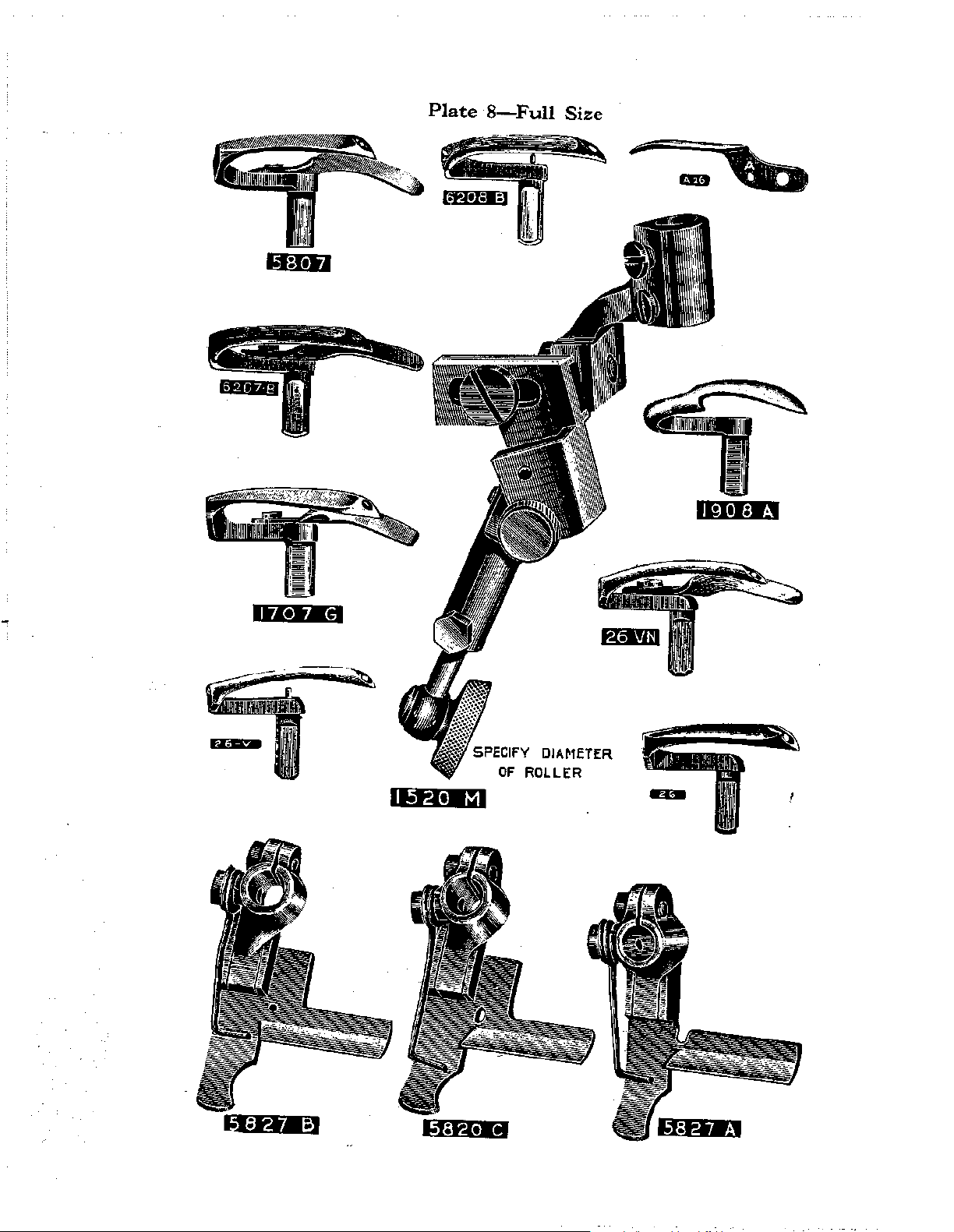

Page 17

Plate

8-Full

Size

OF

ROLLER

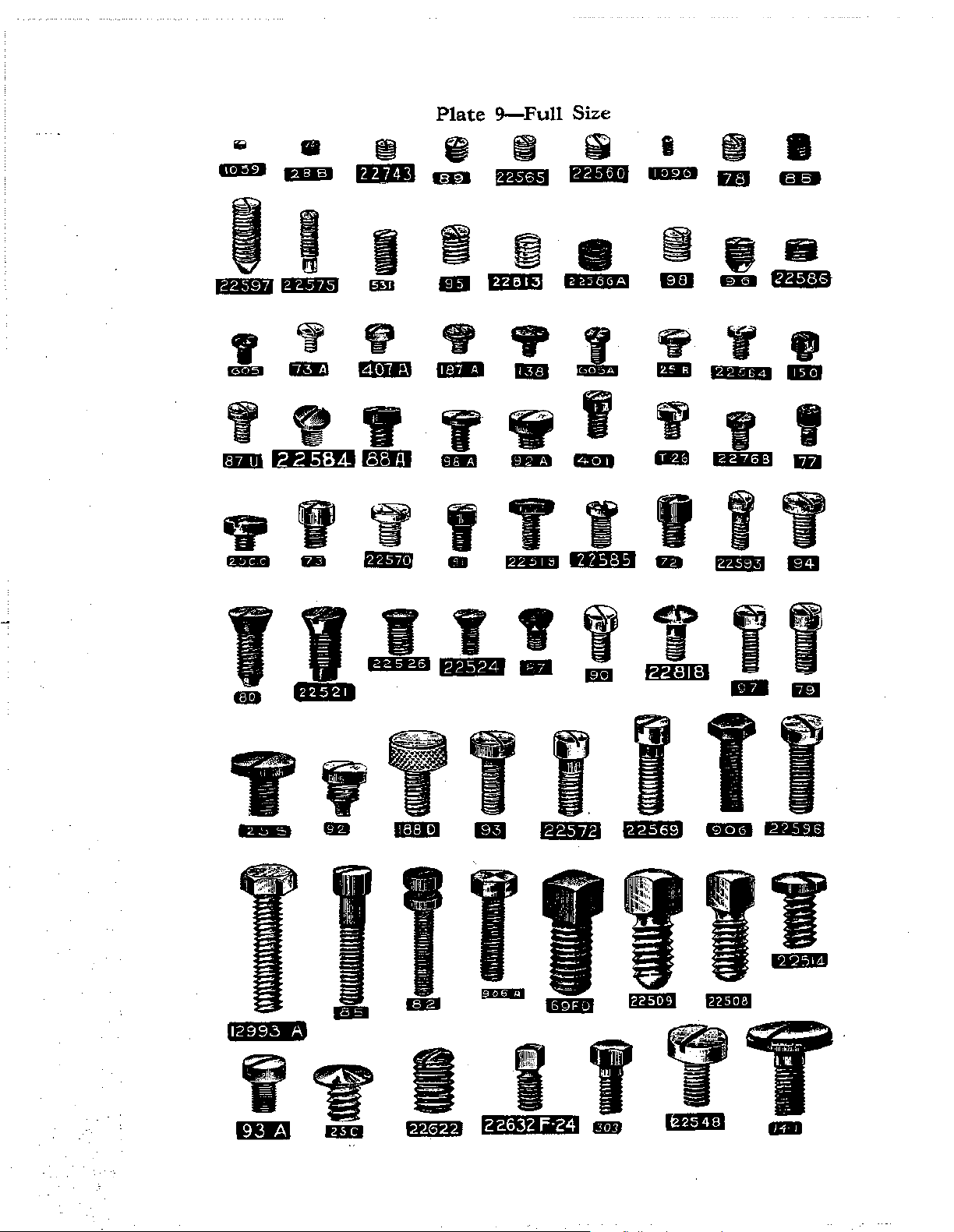

Page 18

Plate

9-Full

Size

iii

mDJ

I

t.IAi#tj t4" ••i

m!S

II

H;l:l

I

mE

"

"

9

UD

f#r..ILi:!l

'

9

fB!D

I

-

~

tijjii

I

lliiD

e

~

I

~

tl'¥1

~

ft;j:IFJ

~

._,

,.,

•.

•

........

,

-

v

lltll!l

.,

tet;I!J

WITIIII

fBiJl

9

miD

y

llmEI

-

..

-

v

DB

..........

~

lmB1

IBiJ t.P.+i:e•

'

I

GI!D

1#!.1~1.1

~

&flil

..

I

~

Bml

t*.Hi:l

~

I;@

•

-

w

...

y

fi

tl4f;@

liD

'

t.P'¥8

..

"

I

m

miJ

'

T¥

5

--

-

.I.~!!

rl-4:11:1

..

''

-

''

.

I

22632 F-24

T

Page 19

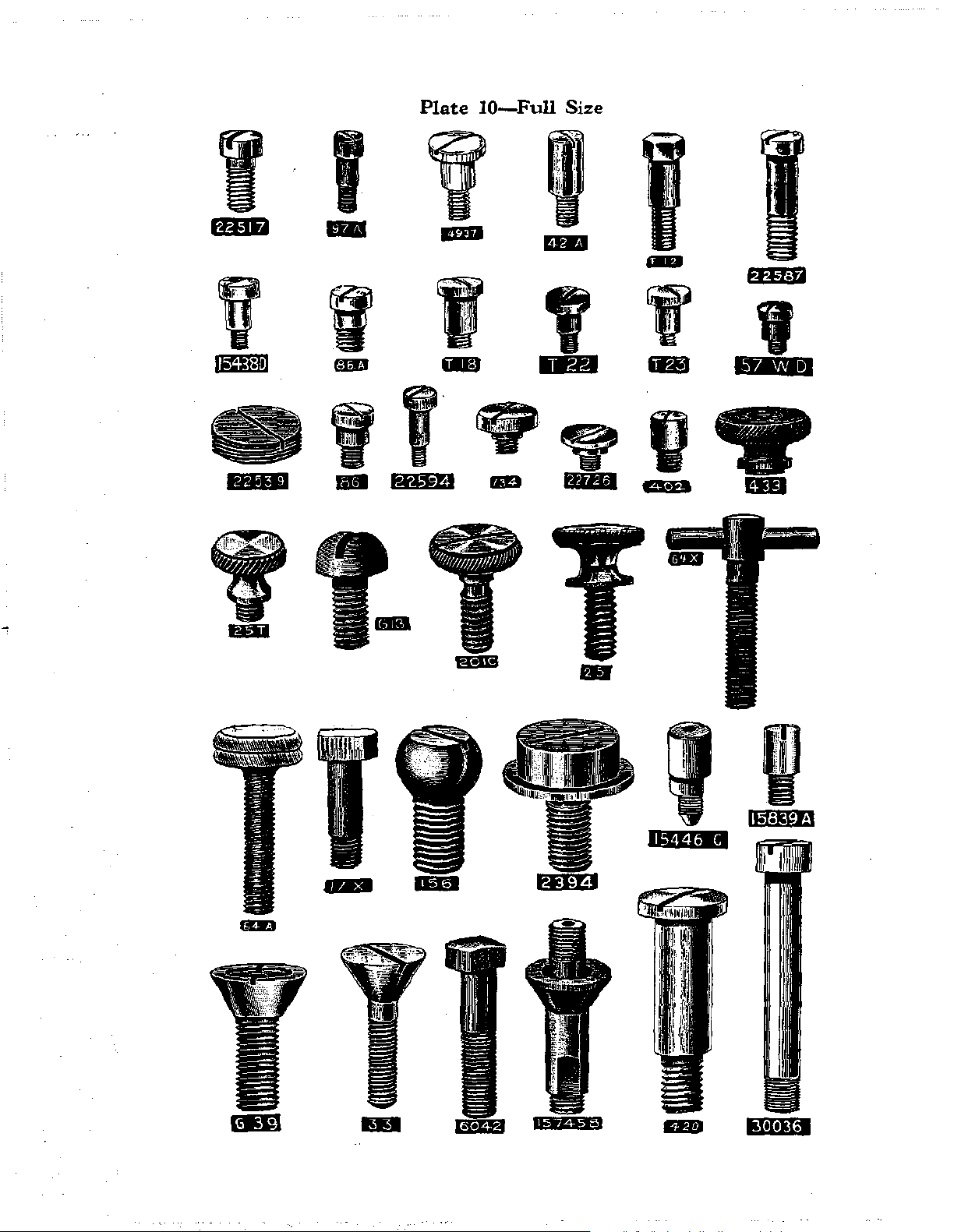

Plate

I I f

rt4-1N

1111

am

10-Full

Size

mB

OlD

.

v

l~il=J•J

.

v

GliB

I

..

·--~--~

'

~"""""

;~~;;;;£,~~~{

~"

lU

.

._,..,.-

,.,__""-~

20\C

i&)

'

.1'4t+ltl

'

.

.

I

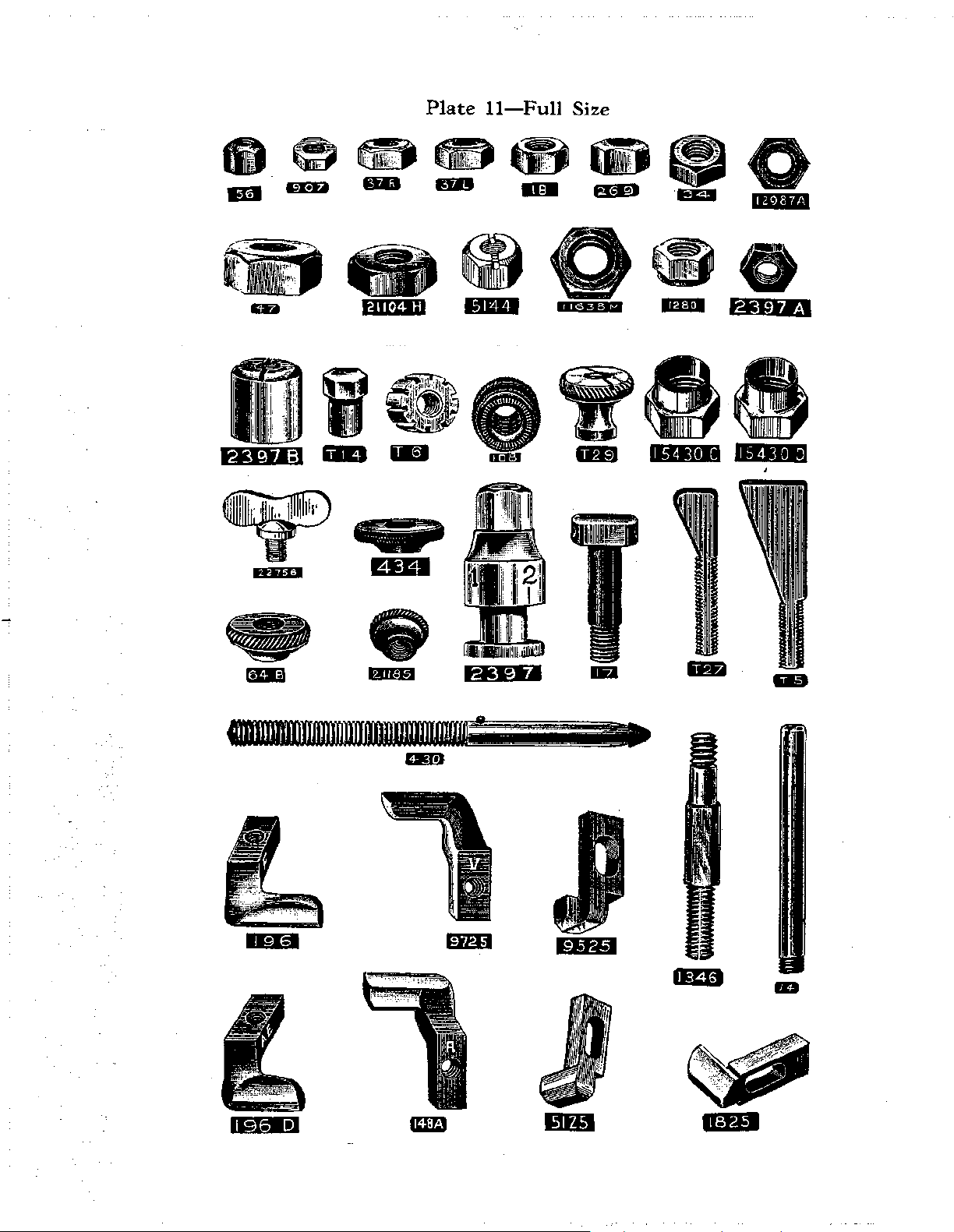

Page 20

Plate

11-Full

MEII

Size

~~~~·

IQ1Ji

..

UI.JI

eiSEJ

Y04t

f1D

eo

·ma

ILjiiep

••+•P·•

0

4jiltlll

'

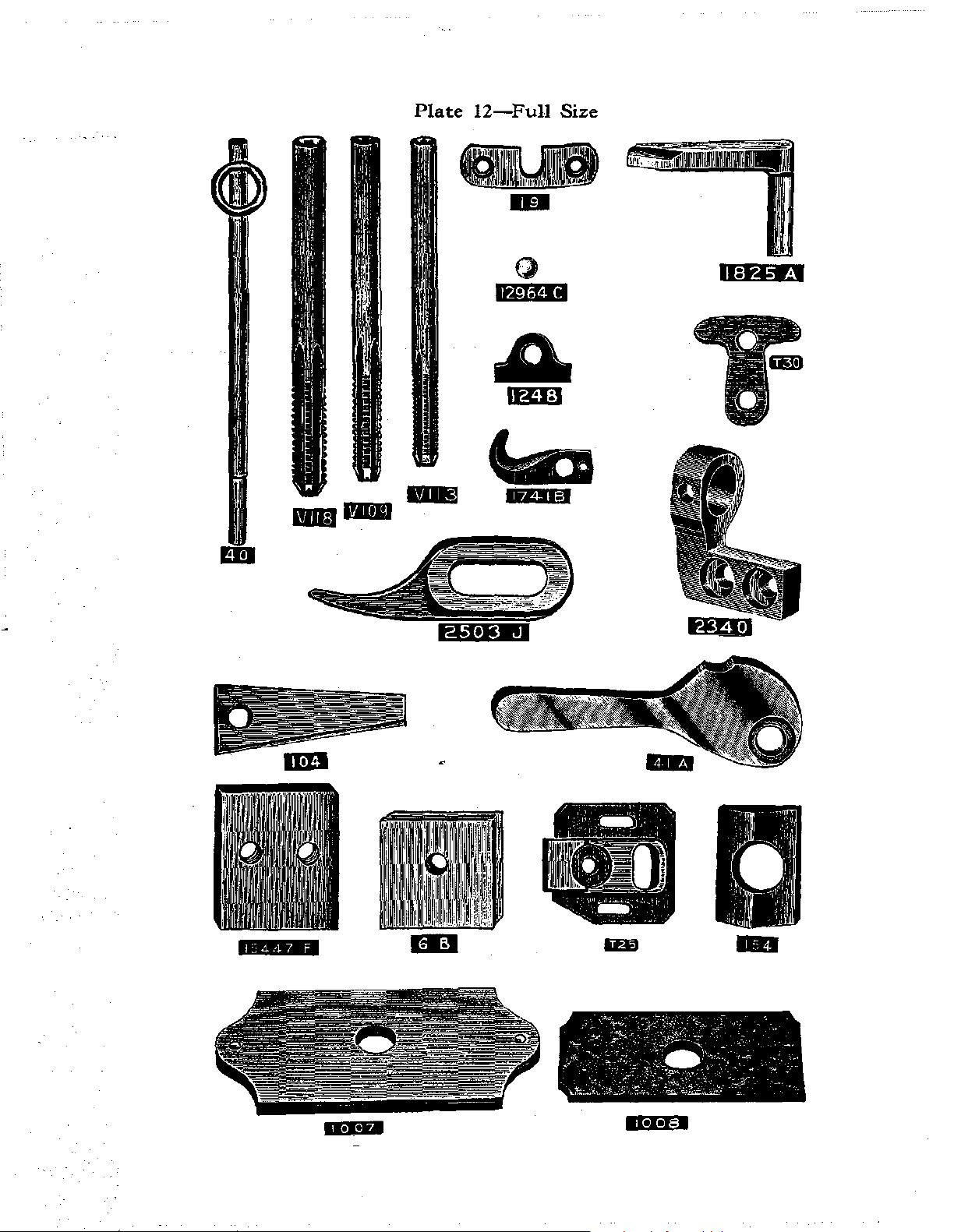

Page 21

Plate

12-Full

··-

Size

lt~I:J

······=·

Page 22

Plate

13-Full

Size

J

...

,.

I

Net;

I

-

c.w••

•••

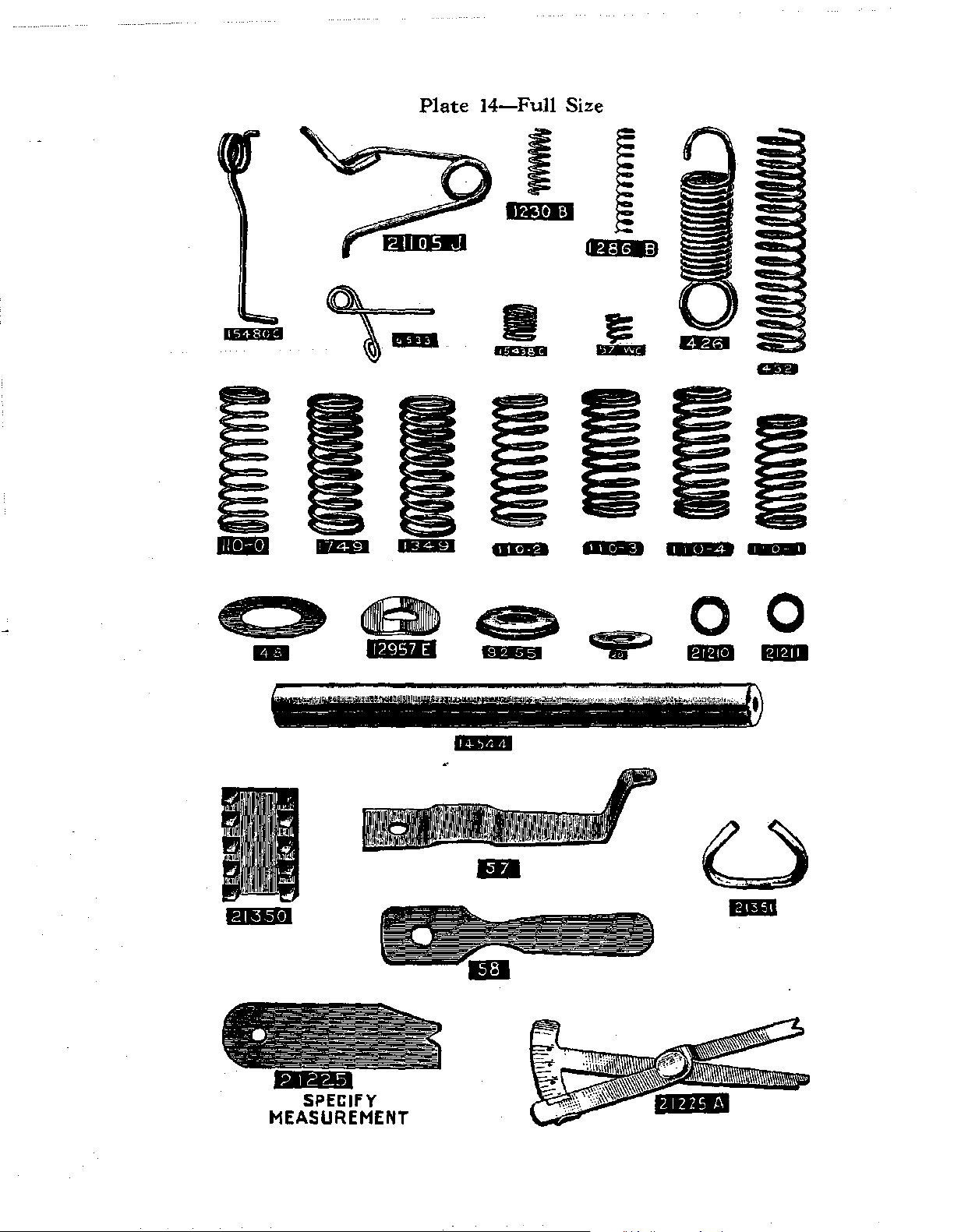

Page 23

••

-$1.:fi13

Plate

14-Full

I

lt41tl:.l

Size

¥&

f=

14

...

....=i=:j:::~

,.,.,.

~

----

.,

...

,

- - - -

..

:.::

...

"~''::~

- -

---=-~~~~-=~

--~-~--

~

•••••

oo

..

"''ii':,::.:.:.i,;,,,,,:l,)

--

-

...

SPECIFY

MEASUREMENT

Page 24

Plate

15-Full

Size

...

,

..•

,

Page 25

Plate

16-Full

Size

l:iWal

-~---

-

W I T

l'E;J

IB

lfJ@ellj

IHiiP-4

.

'

'

'

'

m

i@I:IM

I

I

I

ltd

•

-

Page 26

Plate

17-0ne-half

Size

..

•

I

lliitTiJ

Page 27

....

SPECIFY

MEASUREMENT

Plate

18-0ne-half

,,.,.,

Size

Page 28

".-~

--

--~ j

@iG€@1

'~

Plate

'

,,

19-0ne-half

;

j).

Size

......

23285

A

-7-z

23223

B

I

CID

.

I

t.i!ltiM•J

Page 29

Plate

20-0ne-half

Size

P.:l@ftil

r.41#1•M

Page 30

Plate

21~e-half

Size

6402

F

Page 31

..

,,,,.

Plate

22-0ne-half

Size

Page 32

-

Plate

23-0ne-half

,1

,,

Size

P.JIIIW;i

-

'.1

!I

:-

i

i

li

I'

!I

I

!

ilj

,

,

I

i

!

I

'I

,,

I

I

l#itiH

Page 33

Plate

li+j:ltf

24-0ne-half

.

j

Size

*i¥1*''

I,."Gitell

II

#II#]

Page 34

:::!i!illlii!IUI!!I!Iill!ili!!!lli!fiipllliil!!\llilll!llll!l\ll\lillmlrullm!IUIUIHIII

1

1¥W:I

Plate

25-0ne-third

Size

Specify

Length

Page 35

Plate

26-0ne-fourth

Size

...

,

...

•.:t•l.i

••••

FAt.:Cet.l

t..lt.:lehi

filt.ieiJ

.,.,.,.

q:let-1

f...lt.:.Ceti

Page 36

Plate

27-0ne-fourth

Size

.,

..

,,

23406

G-.!2

t-'II#J#t.l

IWtl:l

Page 37

A

fJIIe(ii!J

----

Plate

t.41Mt4

•

28-0ne-eighth

it~

t41t61;J

Size

'

i

t41Ct§@

t~U·II3

~

.(B!J

-

•

HIC§II4

t.<.tlfill•l

Page 38

Plate

29-0ne-eighth

Size

21118

A

..

,

...•.

Page 39

Plate

30

2375A

Toggle

Grinder

Assembly

1

Page 40

Symbol

to

Order

by

LIST

The

figures in the last column refer only

and are not

to

be used in ordering.

OF

PARTS

to

the plates illustrating the parts Plate

No.

1G

1GC

2

2A

2C

2S

2U

2CU

3

4B

4C

4E

4V

5

T5

6B

6E

T6

7

7C

7G

Cloth Plate, for Styles 1200

1200

Q,

1200 AD, 1700

2600 G, 2600

Cloth Plate, for styles in Class 2300. . . . . . . . . . . . . . . . . . . . .

Cloth

Plate

Cloth

Plate

2600].....

Cloth

Plate

Cloth

Plate

1200 C, 1200 G, 1200

Cloth

Plate

Cloth

Plate

2600G,

Cloth

Plate

Cloth

Plate

Cloth

Plate

Cloth

Plate

Cloth

Plate

Cloth

Plate

Styles

Cloth

Cloth

Cast-off Wire, for Styles 1200

1200 Q, 1700 A, 1700

Cast-off Wire, for Styles

5600 C, 5800 C, 5800 H, 5800

Cast-off Wire for Styles in Class 2300 . . . . . . . . . . . . . . . . . . .

Cast-off Wire for Styles 2600

2600H..........

Cast-off Wire Screw No. 22524.

Main

Main

Lower Toggle Adjusting Wedge, for sryles in Class

Looper Eccentric

Looper Eccentric

Looper Eccentric

Looper Eccentric

Looper Eccentric

Lower Toggle Adjusting Wedge

Feed

2600

Feed Rocker, for Styles 2300

Feed Rocker, floating design, for styles in Classes 1700, 2600,

5800,

1200 AC, 1200 AD, 1900

Feed Rocker Screws No.

1200 A, 1200 C, 1200 G, 1200

~K.~~~~~~~J................

Plate

Plate

Shaft

Shaft Collar Screws No. 95.

Rocker, non-floating design, for

H............................................

also Styles 1200

J......................................

Screws No. 80.

Slide, right, for Styles 1200

...

..

..

.. . .. .. .. ..

Slide Stop, Screw No. 150.

Slide, left; also cloth plate slide, right, for Styles

0,

Slide, right, for styles in Class 2300. . . . . . . . . . .

Slide, right, for Styles 1700

2600

H.....................................

Slide Thumbscrew No.

Hinged Cover

Hinged Cover

Slide, right, for Style 1900

Slide Stop Screw No. 150.

Guard, for styles

Guard

Guard

Collar. . . . . . .

Screw, front, No. 92

Screw, rear, No. 92.

•.

. . .

Fork

Shoe. . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Fork

Shoe Screw No.

Fork.

Fork

Set

Fork

Clamp Screw No. 85.

A,

1200 C, 1200 G, 1200

A,

1700 B, 1700 F, 1700 H, 2600 F,

A,

1200 AC, 1200 AD,

. .

.. .. .. .. .. .. .. .. . ..

1200 Q,1700

Latch.

Latch

in

Classes 1700, 2300; also for

A,

A,

1700

B..........

F,

1700

H,

25

T.

. . . . . . . . . . . . . . . . . . . . . . .

Screw No. 134.

K.

. . . . . . . . . . . . . . . .

0,

1200

Q,

1200 AC,

A.

1200 C, 1200 G, 1200

0,

2600 F,

0,

B..............................

1200

AA,

1200 AD, 1700 G, 2600

J.

. . . . . . . . . . . . . . . . . .

A,

2600 D, 2600

..... . ..

..

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Screws No.

A,

1200 C, 1200 G, 1200

K.

88.

. . . . . . . . . . . . . . . . . . . . . . 13

..

. . . . . . . . . . . . . . . . . 16

94.

72.

Nut.

. . . . . . . . . . . . . . . . . . . .

Styles~

A,

2300 B, 2300

. . . . . . . .

..

. . . . . . . . . . . . . .

M,

F,

F,

2300

0,

2300 . . . . .

J.

2600 G,

2600 G,

N.

. . . m

1200 Q,

..

29

29

.

21

21

21

21

19

21

m

13

13

13

11

11

22

. 27

38

Page 41

So::Jbol

to

derby

LIST OF PARTS

The

figures in the last column refer

and are not

~o

be used in ordering. ·

only

to

the plates illustrating the parts

Plate

No.

·.[

·\

7H

T7

8

I

8-408

8-410

8-413

•

8-416

8-419

8-422

SA

9C

9X

10

10

A Feed

11

T11 Lower Toggle, serrated one side, for Styles

T11 A Lower Toggle, serrated both sides, for

12

T12

13

Feed Rocker Arm, for use with feed rocker No. 7 G

Feed Rocker Arm

Screws No.

93.

Lower Toggle Adjusting Wedge Pin, for styles in Class

Feed Rocker

ground, standard diameter

floating design

Feed Rocker Shaft, standard diameter plus

Feed Rocker Shaft,

Feed Rocker

Feed Rocker

Feed Rocker

Feed Rocker

Feed Rocker Shaft,

design

Feed Bar, for Styles 2300

Feed Bar, for Styles 1200 C, 1200 G, 1200

1200 AD, 1700

2600H

Feed

Bar

Feed

Bar

Styles 1200

1200 AD, 2300

2600

Feed

Bar

Bar

Feed

Bar

styles with non-differential

Shaft, solid, 5

..fo

inches long, hardened and

.407 inch, fur styles with non-

feed

rocker

............................

.001

standard

diameter plus .003 inch

Shaft, standard diameter plus .006 inch

Shaft, standard diameter plus .009 inch

Shaft, standard diameter plus .012 inch

Shaft, standard diameter plus .015 inch

5fi

inches long, for styles with floating

feed

rocker

...................................

A,

2300 B, 2300 M, 2300 N

0,

1200 Q, 1200 AC,

A,

1700 B, 1700

F,

1700

G,

2600

.............................................

Screws No. 88.

Prong and Sponge, for styles in Class 1700; also

A,

1200 C, 1200 G, 1200

A,

2300

B, 2300

G, 2600 H, 2600 J

Prong Screws No.

Prong Sponge

..............................

94.

................................

Shaft, 3-tlr inches long, hardened

feed

0,

1200 Q, 1200 AC,

M,

2300

and

............•..........

2300

2300 N, 2300

P,

2300 Q

..............................

Styles 2300 M, 2300 R

Lower Toggle

Feed Crank Cover, for Style 1700 G

Feed Crank Cover Hinge

Screw, for lower toggles

Feed Crank Cover Spring, for Style 1700 G

Feed Crank Cover Spring Screw No.

Screw No. T12.

Screw No.

................................

.....................

N.

...............

94.

G13 Clamp Screw, for toggle grinder renewable bearing

Tl3

•

Tl3A

14

T14 Lower Toggle Nut, for styles in Class 2300

Lower Toggle Adjusting Bushing, long, for styles in Class

2300

...............................................

Lower Toggle Adjusting Bushing, short, for styles in Class

2300

...............................................

Hinge Screw, forfeed crank cover on Style 1700 G

...............

...

2300

inch

.......

.......

.......

.......

.......

.......

......

F,

2600

G,

N, 2600

F,

ground, for

A,

2300

B,

.........

..........

27

16

23

23

25

22

24

23

4

4

28

10

24

10

16

16

11

11

'

39

Page 42

LIST OF PARTS

Symbol

to

Order

15

16

G16

T16

17

17X

18

T18

19

T19

20

21

T21

T21A

T21 B

22

22D

22E

22 I

22L

22Y

T22

T23

24

24A

24S

25

The figures in the last column refer only

and

are

not

to

by

Feed

Crank Link, for styles in Classes 1200, 1700, 2300, 2600,

5600, 5800..

be used in ordering. No.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

to

the

plates illustrating the parts Plate

Feed Crank Link Shim No. 1248.

Feed Crank Link Screw,

Feed Crank Link

Nut

Feed Crank Link Screw,

H inch long, No. 22569.

No. 7947.

H inch long, No. 79, obsolete.

Feed Crank Link Ferrule. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toggle Grinder Emery Wheel. . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Toggle Grinder Emery Wheel Washer No. G54.

Toggle Grinder Emery Wheel

Trimmer

Trimmer

Feed Crank

5600, 5800.

Pitman

Pitman

Pin, for styles in Class 2300. . . . . . . . . . . . . 16

Pin

Screw No. 77.

Stud, for styles in Classes 1200, 1700, 2300, 2600,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Feed Crank Stud, for Style 1900

Feed

Crank

Trimmer

Feed Crank

2600, 5600,

Feed Crank

Trimmer

2300

Trimmer

Feed Crank

Feed Crank Link

Feed

Stud

Nut;

also for Nos. 36 R, 21168

Pitman

Screw, front, for styles

Stud

Cap, for styles

5800.....

Stud

Cap

Screws No. 77.

Pitman

Bracket, for Styles 2300

N.............................................

Pitman

Crank

Bracket Screws No. 22548.

Stud

Washer; also for No. 21168 A. . . . . . . . . . . . . 14

Pin.

. • . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Link

Pin

Screw No. 77.

Upper Toggle, for Styles 2300 B, 2300

Nut

No. G57

K.

. . . . . . . . . . . . . . . . . . . . . 10

in

Classes 1200, 1700, 2300,

A.

A.

. . . . . . .

in

Class 2300. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

A,

2300 B, 2300

Q.

. . . . . . . . . . . . . . . . 4

Upper Toggle, ! inch long, with three teeth, for styles in

Class

2300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Upper Toggle, for Styles 2300

A,

2300

N,

2300

P.

. . . . . . . . . 4

Upper Toggle Screw No. T22.

Feed Dog, for Style

Feed Dog, for Styles

Feed Dog, for Styles

Feed Dog, for Styles

Feed Dog, for Styles

Feed Dog, for Style

1200 0

1200 G, 1200 Q,1700

1700

1700

1200

2300

................

A,

1700

B,

A,

1200 C, 1200

A,

2300

B,

2600

2300 N . . . . . . . . . . . . . 6

,

..

F,

2600

J..............

AD

. . . . . . . . . . . . 6

H.............................

. . .

..

F,

2600 H 6

Feed Dog Screw No. 93.

Upper Toggle Screw, for styles

Upper Toggle Guide Screw. . .

Gauge, for Styles 1200

Gauge, for Style 1200

Gauge Screws

No.

Gauge, for Styles

A,

0................................

25.

1700

F,

in

Class 2300.. . . . . . . . . . . . . 10

.. .. .. . ..

. . .

.. .. ..

1200 C, 1200 G, 1200

1700 H, 2600

A,

2600

. . . . .

Q.

. . . . . . . .

F.

2600 G

Gauge Screw No. 25 S.

Thumbscrew, for

cloth

plate

gauges......................

15

16

11

11

10

M,

25

. . . . . 6

..

. 10

20

20

20

10

6

6

40

Page 43

so,_mbol

to

derby

LIST OF PARTS

The

figures in the last column refer only

and are not

to

be

used in ordering.

to

the

plates illustrating the parts

Plate

No.

25B

25C

25S

25T

25

T25

cc

Screw, for loop retainer in Styles 2600

2600 G, 2600 H

.....................................

Screw, h inch long, for cloth plate attachments

Screw, for cloth plate slide gauges; also

Thumbscrew, for cloth plate slides

Screw,

for

cloth plate hinged cover; also for Nos. 396 D, 2392.

Upper Toggle Adjusting Block, for styles in

UpperToggle Adjusting Block Guide

26

26

v

'

'

26 VN

A26

T26

27

v

27

X

T27

28

B

29

29

v

Looper, for styles in Class 2300; also Styles

1200G,

12000,

1200Q,1700A, 1700B

Looper, without guard, otherwise same

Looper, with

2600 G, 2600 H

Looper

Set

guard, for Styles 2600

.....................................

Screw No.

73.

Looper Needle Guard, for loopers Nos. 26 VN, 5807, 6207 B

Looper Needle

Guide

Screw, for upper toggle adjusting block, on styles in

Class 2300

Guard

..........................................

Loop Retainer, for Styles 2600

2600H

.............................................

Loop Retainer Screw No.

Loop Retainer Adjusting

Loop Retainer, for

Loop

Retainer

Screw No. 87 U.

Loop Retainer Adjusting

Screw No. 73

A,

25

B.

Screw, h inch long, No.

Style 1900 K

.........................

Screw No. 1096.

Upper Toggle Adjusting Wedge, for styles in

Upper Toggle Adjusting Wedge

Upper Toggle Adjusting Wedge

Adjusting

Screw, h inch long, for loop retainer

Nut

Set Screw No. 22570.

Looper Rocker, hardened, for Style 1900 K

Looper Rocker, hardened, for Styles 1200 AC, 1200 AD,

1700

F,

1700

G, 2600

A,

2600 D, 2600 F, 2600 G, 2600 H

T29 Upper Toggle Adjusting Wedge Nu.t, for styles in Class 2300.

30

Looper Rocker Frame, integral cone, hardened

Looper Rocker Frame

Screw, left, No.

A,

2600 D, 2600

............

for

No.

21163

.......................

Class 2300

Screws

No.

1200

T26.

A,

..................

as

No.

26

VN

A,

2600 D, 2600

A.

2600 D, 2600

F,

Class 2300

No. T29.

...........

...............

............

88.

......

.....

1200

......

2600 G,

28

B.

..•

....

F,

C,

F,

..

9

9

9

10

9

12

8

8

8

8

9

13

13

11

9

25

25

11

22

Looper Rocker Frame Screw, right, No. 98.

Looper Rocker Frame

T30

31

Upper Toggle Guide Screw Washer, for styles in Class 2300

Looper Rock

Shaft,

standard diameter

31-408

31-410

Looper Rock Shaft, standard diameter, plus

Looper Rock Shaft, standard diameter, plus .003 inch

31-413 Looper Rock Shaft, standard diameter, plus .006 inch

31-416 Looper Rock Shaft, standard diameter, plus .009 inch

31-419 Looper Rock Shaft, standard diameter, plus .012 inch

31-422 Looper Rock Shaft, standard diameter. plus .015 inch

G31

Toggle Grinder Frame

Spot Screw No.

3l

inches long, hardened and ground,

.407 inch

...........................

96.

.001

inch

.................................

......

......

......

......

......

......

...

12

23

30

41

Page 44

LIST OF PARTS

Symbol

to

Order by

32

32-408

32-410

32-413

32-416

32-419

32-422

G32

33

G33

34

G34

35

G35

G36

t36

L

t36

R

37 L

37 R

38

38

v

G38 A

G39

40

G40

G41

41

A

The figures in the last colwnn refer only

and are

not

to

be used in ordering.

to

the plates illustrating

the

parts Plate

No.

Looper Rock Shaft, 1 i-inches long, hardened and ground,

standard diameter,

Looper Rock Shaft, standard diameter, plus

Looper Rock Shaft, standard diameter, plus

Looper Rock Shaft, standard diameter, plus

Looper Rock Shaft, standard diameter, plus

Looper Rock Shaft, standard diameter, plus

Looper Rock

Shaft, standard diameter, plus

Toggle Grinder Frame Slide.. .

Looper Rocker Stud, hardened,

.407 inch. . . . . . . . . . . . . . . . . . . . . . . . . . 23

.001

inch

.....

.

..

1h

.. ..

inch

.003 inch

.006 inch

.009 inch

.012 inch

;015

..

. . . . . . .

diameter..........

inch

..

. .

.....

.....

.....

.....

.....

.. ..

.

.

.

.

.

..

. 30

10

Toggle Grinder Frame Slide Adjusting Screw. . . . . . . . . . . . . 30

Looper Rocker

No. 12993

Toggle Grinder Frame Slide

Stud

Nut,

for use

A.

. . . . . . . . . . . . . . . . . .

Gib....

with.;,.

..

. . . . . . . .

..

. . . . . . .

inch stud; also for

..

..

. . . . . . .

.. . ..

. .

..

. . . 30

11

Toggle Grinder Frame Slide Gib Screws No. 22575.

Looper

cOnnecting Rod,

2300, 5800; also Styles 1200

2600

A,

2600 D, 2600

Toggle Grinder

Clamp.................................

Toggle Grinder Clamp Screw No.

Toggle Grinder Clamp

Looper Connecting Rod Ball

Looper Connecting Rod Ball

Looper Connecting Rod Ball

Looper Connecting Rod

Looper Connecting Rod

6i

inches long, for styles in Classes

A,

1200 AD, 1700 G, 1900 K,

F,

2600 G, 2600

Pivot

Pin.

Joint

Joint

Joint

Nut,

left thread. . . . . . . . . . . . . . . . .

Nut,

right thread. . . . . . . . . . . . . . . .

201

H...............

C.

. . . . . . . . . . . . .

Assembly,

Assembly,

left..........

right........

Screws No. 97 A.

..

. . . . . .

..

23

30

30

17

17

11

11

Looper Eccentric, ground, for styles in Classes 2300, 5600;

also Styles 1200 A, 1200 C, 1200 G, 1200

1700 B, 5800 C, 5800

H.

. . . . . . . .

Looper Eccentric, ground, for Styles 1200

1700

F,

1700

H,

2600

J.....

1000 K, 2600

.....

..

..

..

A,

.. .. . .. .. .. .. . ..

0,

1200 Q, 1700

..

. . . .

..

..

..

AA,

2600 D, 2600 F,

.. .. .

A,

. . . . . .

..

1200 AC,

2600

G,

..

....

.. 16

.

16

Looper Eccentric Screw No. 96.

Toggle Grinder

Toggle Grinder

Toggle Grinder

Table. .

Turn

Table Pivot Stud. . . . . . . . . . . . . . . . . . . 10

Turn

Table Pivot

.. . ..

Stud

. . . . . . . . . . .

Nut

No. 11638 M.

..

. . . . . . . . . 30

Turn

Frame Looper Thread Guide, lower, right. . . . . . . . . . . . . . . . 12

Turn

Toggle Grinder

Toggle Grinder

Toggle Grinder Tilting

Hand

Lifter, hardened, for styles

1200A, 1200C, 1200G,

A,

1700

2300

2600

Hand

1700 B, 1700

M,

2300

J,

5600

Lifter

Stud

Table Tilting Block. . . . . . . . . . . . . . . . . 30

Tum

Table Tilting Block Screw No. 96.

Shaft..

P,

2300 Q, 2300 R, 2600 F, 2600 G, 2600 H,

. . . . . . . . . . . . . . . . . . . . . . . . . . 30

in

Class 5800; also Styles

12000,

F,

1700

1200Q, 1200AA, 1200AC,

H,

1900 K, 2300

A,

2300 B,

c......................................

No. 86.

12

tSeePage7

42

Page 45

LIST OF PARTS

Symbol

to

Order

42 A

43

43

c

43 X

G43

G44

G46

47

G47

48

G48

G49

50D

G50

51

G51 A

52 A

G52

53

A

The figures in the last column refer only

by

and are not

Hand

Feed

Lift

also Styles 1700

2300 N

Feed

2600

Feed

Lift

Feed

Lift

Toggle

,Toggle

Toggle

Toggle

Needle Lever

Toggle Grinder Pulley

Toggle

Needle

Toggle Grinder Spindle, hardened

Toggle Grinder Spindle Renewable Bearing, lower,

Needle Bar, hardened

inch, for styles in Classes

also Styles 1200 C, 1200 G, 1200

1200 AC, 1200

Needle

Needle

Toggle

Toggle Grinder Spinclle RenewableBearingCoverScrewsNo.88.

Needle

5800;

1200 AC, 1200 AD, 1900 K

Toggle Grinder Spindle

Toggle

Needle

2300, 5600, 5800;

frame

2600

Thread

Toggle

Toggle

Needle

2300, 5600, 5800;

Needle

2300, 5600, 5800,

1200 Q, 1200 AA, 1200 AC, 1200 AD, 1900

2600 ], No. 22768.

Needle

605A.

to

be used in ordering.

Lifter

Screw Pin, hardened

Eccentric, ground, for styles

A,

1700 B,

............................................

Lift

Eccentric, ground, for Styles 1700

F,

2600 G, 2600

Cam,

hardened

Cam

Screw No. 96.

Grinder

Grinder

Grinder

Grinder

Grinder

Lever

Bar

Bar

Grinder

Bar

also Styles 1200 C, 1200 G, 1200

Grinder

Lever

thread

F,

Eyelet

Grinder

Grinder

Bar

Bar

Bar

Tilting

Tilting

Knife

Turn

Stud

Pulley Screws No. 88.

Stud

Set

Screws, headless, No. 88.

Set

Screws, fillister head, No.

Spindle Renewable Bearing Cover, left

Connection, for styles

Spindle

Thread

eyelet, for Styles 1900

2600 G, 2600 H .

Screw No. 98

Spindle Collar

Spindle Collar Screw

Thread

Thread

Thread

H,

and

Shaft

Shaft

Clamp

Table

Nut.

..............................

.................................

Washer

and

AD

..................................

Cap

Cap

Eyelet, for styles

also Styles 1900 K, 2600 H, 2600 J

Guide, for styles

also Styles 1900

Guide

and

Guide Screw, for Style 1200

to

the plates illustrating the parts

............

in

1700G,

2600 J

Arm

Arm Screw No. 96.

Stop

Spring

............................

ground,

1700, 2300, 2600, 5600, 5800;

2300A, 2300 B, 2300 M,

......................

ground, for Style 1900 K

......................

Screw

Pin

..................

and

ground

standard

0,

in

Classes 1700, 2€00, 5600,

,

Classes 1200, 5600;

Support

............

diameter

1200 Q, 1200 AA,

88

A.

0,

1200 Q, 1200 AA,

.........................

..........................

Screws No. 88.

in

Classes 1200, 1700,

K,

2600

............................

A.

..........................

No.

22560.

in

Classes 1200, 1700,

K,

2600

H,

Screw, for styles h Classes 1700,

Styles 1200 C, 1200

..........

F,

1700

.........

right

A,

2600

2600 J

G,

1200

K,

2600

A,

H,

...

...

.257

.....

and

D,

.....

0,

H,

No.

..

..

Plate

No.

.

10

.

16

.

16

.

16

.

30

.

30

.

16

.

11

.

30

.

14

.

30

.

30

.

23

30

24

30

.

13

.

30

13

43

. i

Page 46

LIST OF PARTS

Symbol

to

Order

The figures in the last column refer only

by

and are

not

to

be used in ordering. ·

to

the plates illustrating the parts Plate

-----------------------------------------------1----

Oiler.

G53

54

G54

G55

56

G56

57

57 WB

we

57

57 WD

G57 A

58

v

59

59

X

60 A

60 A-322

60 A-325

60 A-328

60

A-331

60 A-334

c

60

60

X

60 X-322

60 X-325

60 X-328

60 X-331

60 X-334

61

c

62

62-322

62-325

62-328

62-331

Toggle Grinder Spindle

Needle Lever Link, hardened

Toggle Grinder Emery Wheel Washer

Toggle Grinder Emery Wheel Guard, left

..........................

...........................

.............

...............

Toggle Grinder Emery Wheel Guard Screws No. 531.

Needle Clamp Nut, hardened

Toggle Grinder Emery Wheel Guard,

Toggle Grinder

Emery

Looper Thread Nipper Spring, upper.

Looper Thread Nipper Spring Screw No.

Needle Bar Thread Nipper Plate

Bar

Needle

Thread Nipper Spring. . . . . . . .

..........................

Whee!

Guard Screws

.......................

right

..............

No.

93

...................

90.

.............

A.

Needle Bar Thread Nipper Stud; also for No. 15480 C

Nut

Toggle Grinder Emery Wheel

Looper Thread Nipper Spring, lower.

Looper Thread Nipper Spring Screw No.

Looper Thread Nipper Spring Operating Screw No.

Eccentric Pulley, throw

.461

Eccentric Pulley, throw .634 inch, for Style 1900

......................

...................

90.

97.

inch, for Styles 1200 AC, 1700 F.

K.

Eccentric Pulley Screws No. 22597.

Presser Bar, hardened and ground, standard diameter .319

for

inch,

styles in Classes

Styles 2600 F, 2600

Presser Bar, standard diameter, plus

Presser Bar, standard diameter, plus .006 inch

Presser Bar,

standard

Presser Bar, standard diameter, plus .012inch

Presser Bar, standard diameter, plus .015 inch

1200,

1700, 2300, 5600, 5800; also

G,

2600

H,

2600

diameter, plus

1 .

...............

.003

inch

.009

inch

...........

...........

...........

...........

...........

Presser Bar, hardened and ground, standard diameter .319

A,

inch, for Styles 2600

Presser Bar,

.harden~d

inch, for Style 1900

2600 D

and ground, standard diameter .319

K.

..............................

Presser Bar, standard diameter, plus .003inch

Presser Bar, standard diameter, plus .006 inch

Presser Bar, standard diameter, plus .009 inch

Presser Bar, standard diameter, plus

Presser Bar, standard diameter, plus .015 inch

Presser Bar Connection, for styles in Classes

2600, 5600, 5800

Bar

Presser

Presser

Connection Screw, front, No.

Bar

Connection Screw, rear, No. 88.

....................................

Presser Guide Bar, hardened

E?tyle

.319 inch, for

Presser

Gu.ide

Bar, standard diameter, plus .003 inch

1900 K

Presser Guide Bar, standard diameter, plus

......................

...........

...........

...........

.012

inch

...........

...........

1200, 1700,

77.

and

ground, standard diameter

..........................

.006 inch

Presser Guide Bar, standard diameter, plus .009 inch

Presser Guide Bar, standard diameter, plus .012 inch

:

.....

....

......

2300,

.....

.....

......

......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

No.

30

17

30

30

11

30

14

13

14

10

30

14

18

18

23

23

23

15

23

44

Page 47

Symbol

to

Order

by

The

furores

ana are not to

LIST OF PARTS

in the last column refer only

be used in ordering.

to

the plates illustrating the parts

·.

Plate

No.

62-334

62 A

62 A-322

62 A-325

62 A-328

62 A-331

62 A-334

62

c

62 C-322

62

~325

62

~328

62~1

62

~334

63A

63B

64

64A

64B

64X

65

65 A

65 c

65F

65G

65 H

65L

65T

66

66-531

66-533

66--536

66-539

66--542

Presser Guide Bar,

Presser Guide Bar, hardened

.319 inch, for styles in

2600 A, 2600 D

Presser Guide

Presser Guide Bar,

Presser Guide Bar,

Presser Gtlide

Presser Guide Bar,

Presser Guide Bar, hardened

.319 inch, for styles

1200A, 1200

2600

F,

2600

Presser Guide Bar,

Presser

Presser

Gt1ide Bar,

Gt1ide Bar,

Presser Guide Bar,

Presser Guide Bar,

Presser Spring, for Styles

1700A,

1700B,2300A,2300

standard

diameter, plus .015 inch

and

ground,

Class 5800; also Styles 1200 AD,

....................................

Bar,

standard

standard

standard

Bat,

standard

standard

in

C,

1200

G,

2600 H, 2600 J

standard

standard

standard

standard

standard

diameter, plus .003 inch

diameter, plus .006 inch

diameter, plus .009 inch

diameter, plus .012 inch

diameter, plus .015 inch

and

ground,

Classes 1700, 2300, 5600; also Styles

G,

1200

0,

1200 Q, 1200 AA, 1200 AC,

......................

diameter, plus .003 inch

diameter, plus .006 inch

diameter, plus .009 inch

diameter, plus .012 inch

diameter, plus .015 inch

1200 C, 1200 G, 1200

B,

2300P,

standard

standard

2300Q,

.....

diameter

.....

.....

......

.....

.....

diameter

.....

.....

......

.....

.....

0,

1200 Q,

5600C

....

Presser Spring, for styles in Classes 2800, 5800; also Styles

1200 A, 1200

2300

M,

Presser Spring

Presser Spring

Presser Spring Regulating Screw, for

1700, 2300,

Presser Spring Regulating Screw Lock

Presser Spring Regulating Screw, for Style

Presser Foot, for Style 1200 A

Presser

Foot,

Presser Foot, for Styles

2300

P,

2300 Q

Presser

Foot,

Presser Foot, for

Presser

Presser

Presser

Presser

Main

Foot,

Foot,

Foot,

Foot

Shaft, hardened

inch, for styles

Main

Shaft,

Main

Shaft,

Main

Shaft,

Main

Shaft,

Main

Shaft,

AA,

1200 AC, 1700

2300

N,

Rest

Rest

2600,

2300 R

...................................

Screw No. 88.

5600,

............................

5800

...........................

for Styles 1200 C, 1200

2300

.................

for Style 1200 0

Style

1200 G

for Style 1200 Q

for Style 1700 B

for Style 2600 F

Clamp

Screw No. 91.

and

in

Classes 1200, 1700, 2300, 2600, 5600, 5800

standard

standard

standard

standard

standard

diameter, plus .001 inch

diameter, plus .003 inch

diameter, plus .006 inch

diameter, plus .009 inch

diameter, plus .012 inch

............

ground,

F,

1700

H,

styles

in Classes 1200,

Nut

..............

1900

K.

.........................

AD

................

A,

2300 B, 2300 M, 2300

: .

...................

.........................

.........................

..........................

..........................

,

.............

standard

diameter .530

............

............

.....•.......

............

............

.

1900

.......

K,

N,

.

.

23

.

.

.

.

.

.

23

.

.

.

.

.

25

.

25

24

.

.

10

.

11

.

10

.

7

.

7

.

7

.

7

.

7

.

7

.

7

.

7

25

.

.

.

.

45

Page 48

LIST OF PARTS

Symbol

to

Order

67

68

68B

69 s

0 69

70

70

72

73

73

77

78

79

80

82

84

84 B

85

86

86

87

87

88

88A

89

90

91

92

92

FD

A

A

A

A

u

A

The

figures in the last column refer only

and are

not

to

be

by

Main

Shaft

used_

Sleeve, left, 1

1200, 1700, 5600; also Styles 2300

~~~~~~~a~J

Main

Shaft

Sleeve, right,

Main

Shaft

Thread

Sleeve,

Stand

1H

Pin, 4 inches long, for styles

1700, 2300, 2600, 5600, 5800.

Screw, square head, cup point,

to

inch, t inch long, for

21104

D,

21685, 21693

Looper Eccentric Sponge Holder

in ordering. ·

-fi-

1H

inches long,

F,

to

the plates illusrtating the parts Plate

inches long, for styles

A,

2300 B, 2300

in

Classes

............... w

inches long with

without

. . . . . . . . . . . . . . . . . . . . . . . . . 28

rlf

inch

diameter, 18

thread

21693

stand

seats; also for Nos.

K.

. . . . . . . . . . . . . . . . . . . . 9

and

Sponge. . . . . . . . . . . . . . 24

lug........

lug..........

in

Classes 1200,

threads

Looper Eccentric Sponge Holder Screw No. 93.

Looper Eccentric Sponge

Set

Screw, for looper eccentric

Set

Screw, fillister head, for loopers. . . . . . . . . . . . . . . . . . . . . . 9

..............................

fork......................

Screw, for looper needle guard, also for No. 1742. . . . . . . . . . 9

Screw, for feed

1286A........................

Screw, lower, for needle lever link pin.

Clamp

Screw, for needle

Screw, for cloth

Screw, for regulating length of

Stitch

Regulating Ferrule, for Styles 1200 AA, 2600

2600

D,

5800

J.............................................

Stitch Regulating Ferrule, for styles

also for Styles 1200 A, 1200 C, 1200 G, 1200

2600

crank

stud

plates.

F,

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2600 G, 2600

caps; also for Nos. T16, 21,

...

.. . .. . ..

. . . . . . . . . . . . . . . . . . . 9

rear

guard

in

Style 1200

stitch...........

H,

5600 C, 5800 C, 5800

in

Classes 1700, 2300;

. . . . .

AD.

. . . . . . . . . . 9

0,

1200 Q,

1200 AC, 1200 AD, 2600 J.. . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Clamp

Stud,

Screw, plus size, for

Screw, for

Screw, for needle

Screw, for looper eccentric fork. . . . . . . . . . . . . . . . . . . 9

for

hand

lifters; also for No. 403. . . . . . . . . . . . . . . . . . .

hand

throat

21390 D

...........................

2366 B, 2366

lifters,

plates; also for Nos. 148 A, 196, 196 D, 9725,

thread

E,

5005

take-up

P,

tap

No.

V113............

:................

wire; also for Nos. 27

5805 X, 5826

B,

5826 D, 21607,

21608..............................................

Screw, headless, for feed rockers; also for Nos.

G50, G51

4517, 8648, 15063, 15465

Set

Screw, fillister head, for needle bars; also for No. 6440. . . . 9

Screw, for looper

Screw, for looper

2305 R, 15447

Clamp

A,

61 C, 64, 217, 406 B, 1288, 1917 K, 1920 K,

F,

21113 B, 21161

thread

thread

L,

take-ups..

. . . . . . . . . . . . . . . . . . . . . . 9

nipper springs; also for Nos. 2305

21390

E.

. . . .

.. ..

. . .

Screw, for presser feet. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

30, G47, 50 D,

D.

. . . . . . . . . . . 9

.. ..

. .

.. ..

. .

Screw, rear, for cloth plate guard. . . . . . . . . . . . . . . . . . . . . . . . 9

Screw, front, for cloth plate

guard.

. . . . .

.. . .. .. . ..

..

No.

M,

16

16

.

61

C,

.. ..

. 9

. . . . . 9

A,

H,

16

10

10

X,

P,

..

. . 9

. .

..

. 9

9

9

9

D See page

7.

46

Page 49

LIST OF PARTS

S~bol

to

Order

93

The figures in the last column refer only

by

and are

not

to

be used in ordering. · No.

to

the

Screw, for feed dog in Styles 1200 C, 1200 G, 1200

plates illustrating the parts Plate

0,

1200 Q,

1200AC, 1200AD, 1700A, 1700B, 1700 F, 1700G, 2600F,

93

A

94

95

96

97

97

A

98

98 A

99

100 B

2600 G, 2600 H, 26001 and under feed dog in Styles 2600

2600 D, 5800C,

5650, 5842

Screw, for feed dog in Styles 1200

2300 B, 2300 M, 2300

...

1905 J. 233o,

A,

5800H,

7638

5045,

5800];

A,

15447

N;

also for Nos. G56, 419

15447

also for Nos.

F,

15447

A,

1700 H, 1900

K . . . . . . . . . . . . . . . . . . . . . . . . . 9

7H,

K...

. . . . . . . . . . . . . 9

K,

A,

Screw, for looper eccentric fork shoe; also for Nos.

113, 113

A,

202 A, 404

A,

539, 1825, 1941, 2340, 5132, 9932,

21602..............................................

Screw, for main shaft collar; also for No.

1005.....

Screw, for looper eccentrics; also for Nos. 30, G40, 43,

43

X, G43, 917,

Screw,

H inch long, for supporting feed dogs; also for Nos.

103, 403, 2334, 17158. . . .

58,

2306................................

..

. . . . . . . . . .

..

. .

.. ..

Screw, for looper connecting rod ball joint assemblies. . . . . . 10

Screw, right, for looper rocker frame; also for Nos. 111, 334,

..

482, 2650, 21157.

. . . . . .

Screw, for needle lever thread eyelet; also for No.

Cloth

Plate

Slide, rear, for styles in Class 2300. . . . . . . . . . . .

Thread

Stand

Wire, 16 inches long, for styles in Classes 1200,

1700, 2300, 2600' 5600,

Thread

Stand

Wire Screw, headless,

..

. . . . . . . . . . .

..

. . . . . . . . . .

21632...

5800

. . . . . . . . . . . . . . . . . . . . . . . . . . 27

24

threads

to

A,

70,5150,

2300 A,

911, 912,

13,

104,

. . . . . . . . 9

43

C,

. . .

..

..

. 9

. S

21

inch, No.

9

9

9

22813, obsolete.

Thread

Stand

Wire Screw, square head, 24 threads

to

inch,

No. 22632 F-24.

101

v

101

102

103

•

104

Looper Thread Take-up, for styles in Class 2300; also Styles

1200 A, 1200 C, 1200 G, 1200

2600]

.....

,.......

......... .........

0,

1200 Q, 1700 A, 1700 B,

....

. . . .

..

.....

Looper Thread Take-up, for styles in Classes 5600, 5800; also

Styles 1200 AA, 2600 A, 2600 D. 2600

Looper Thread Take-up Screw No.

Looper

Looper Thread Take-up Eyelet

Looper

Thread

Take-up Eyelet Stand, for styles in Classes

1200,1700,2300,2600,5600,

Thread

1700, 2300,

Take-up Eyelet, for styles in Classes 1200,

2600,5600...............................

5800....

Stand

F,

2600 G, 2600 H

'89.

.........

Screws No. 22596.

.....

...

..

Looper Thread Take-up Eyelet Adjusting Screw No. 97 .

Looper Thread Take-up Eyelet Sprtng, for styles in Classes

1200,1700,2300,2600,5600,5800.

...

...

...

...........

· 3

.

3

24

24

12

Looper Thread Take-up Eyelet Spring Screw No. 94.

105-1!

105-2!

105-3

105-3!

107

Thumbscrew,

Thumbscrew,

Thumbscrew, 3 inches long. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Thumbscrew,

Tension

1t

!nches long, for fastening machine

22

mches long. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3!

.inches long. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

to

table 18

Spring F.errule.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

.,

47

Page 50

LIST OF PARTS

Symbol The figures in the last column refer only

to Order by and are

108

109

V109

110-0

Tension Regulating

Tension Disc, hardened and lapped. . . . . . . . . . . . . . . . . . . . . .

Tap, marked

Tension Spring,

not

to

be

used in ordering.

"J2"

for No. 22526. . . . . . . . . . . . . . . . . . . . . . . .

.022

Nut,

inch diameter wire,

Styles 1200 AD, 1700 G. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

110-1

Tension Spring, .026 inch diameter

on styles in Classes 2300,

110-2

110-3

1200 A,

1700

Style

Tension Spring,

on Styles

No.

Tension Spring,

1200

C,

1200

G,1200

~.

1700 B, 1700 F, 1700 H and

1900

K.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.028

inch diameter

2300

A,

2300

1000...........................................

.040

inch diameter wire,

on Styles 1200 A. 1200

1700B,1700F,1700H,

110--4

111

Tension Spring,

on

Styles

Tension Thread Eyelet, with two eyes,

1200, 1700,

2600

2300,

.048

inch diameter wire,

A,

2€00

2600,

Tension Thread Eyelet Screw No.

112

112 c

112 E

112

0112

112 cc

112

s

CN

Throat Plate,

Throat

Throat

Throat Plate, for Styles

Throat Plate,

Throat Plate,

Throat

Plate,

Plate,

Plate,

for

for

for

for

for

for

Styles

Styles

Style

Style

Style

Styles

1200

1700

2600

Throat Plate Screws No.

113

113 A

Frame Thread Guide, adjustable,

Classes

2300,

5800. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Frame Thread Guide, adjustable, 1 inch long,

1200

A,

1200 C, 1200 G,

1700

A,

1700

B,

1700

F, 1900 K, 5600

Frame Thread Guide Screw No.

Vl13

116

118

118

B

V118

134

137

138

P39A

141

t See page 7.

Tap, marked "Q2",

..;.,.

Wrench,

inch, for needle clamp

Thread Hook,

for

No. 86 A. . . . . . . . . . . . . . . . . . . . . . . . 12

for

looper threads. . . . . . . . . . . . . . . . . . . . . . . . .

Thread Tweezers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tap, marked

Screw,

"X2",

for

cloth plate hinge cover latch. . . . . . . . . . . . . . . . . . .

for

plus size cloth plate screw No. 22521. 12

Needle Thread Controller Lever Eyelet,

2600J...........

...

.. . ....

Screw, for needle thread controller lever eyelet. . . . . . . . . . . . 9

Needle Thread Controller Lever Assembly,

2600

D,

2600

F,

2600

Needle Thread Controller Lever Screw. . . . . . . . . . . . . . . . . . . 9

to

the plates illustrating the parts Plate

knurled........................

for

looper thread on

wire,

for looper thread

2600,

5600,

5800; also Styles

0,

1200Q,

B,

2300

N,

C,

1200 G, 1200

2300M, 2300R, 2600H,

D,

2600

F,

5600,

5800.....................

1200

for

needle thread on

wire,

for

2300

P,

2300

for

0,

1200

for

2600

G.

for

styles in Classes

AA,

1200

AC,

needle thread

Q; also

needle thread

Q,

1200

AC,

2600J...

needle thread

. . . . . . . . . . . . .

98.

1200

A,

1200

C.

. . . . . . . . . . . . . . . . . 1

2300

B,

2300

M.

. . . . . . . . . . . . . . . . . 1

0.

1200

. . . . . . . . .

G,

1200

..

. . . . . . . . . . . . . . 1

Q..................

H. . . . . . . . . . . . . . . . . . . . . . . . . . 1

F.

. . . . . . . . . . . . . . . . . . . . . . . . . 1

2300

A,

2300

N..

. . . . . . . . . . . . . . . . 1

87.

2t

1200

0,

1200

inches long,

Q;

1200

for

AA,

styles in

for

Styles

1200

AC,

C................

22529.

nut.

. . . . . . . . . . . . . . . . . .

for

Styles 1700 H,

G,

...............

2600

H.......................

for

..........

Styles

2600

48

No.

11

13

12

14

14

for

14

14

14

13

1

24

24

20

20

20

10

13

A,

20

Page 51

Symbol

to

Order

by

The

figures in

and are

LIST OF PARTS

the

last column refer

not

to

be

used

in ordering. .

only

to

the

plates illustrating

the

parts

Plate

No.

148 A

150

154

156

161

181

A

187

188D

196

D

196

201C

202A

202 B

213

217

269

303

334

396 D

399

A

400

401

402

403

404

A

406 B

407 A

Throat

Throat

Plate

Needle Guard, hardened, for Styles 2600 A,

2600 D, 2600

Plate

Needle

F,

2600 G, 2600

Guard

H.......................

Screw No. 87.

11

Stop Screw, for cloth plate slides. . . . . . . . . . . . . . . . . . . . . . . . . 9

Needle Lever Buffer,

Needle Lever Ball,

wood

fibre. . . . . . . . . . . . . . . . . . . . . . . • . 12

hardened............................

10

Binding Holder Disc Supporting Collar, for Styles 5800 H,

5600]

...............................

Looper Rocker, hardened,

for

styles in Class 2300. . . . . . . . . 17

Screw, for binding guide adjustments . . . . . . . . . . . . . . . . . . . .

Set

Screw, knurled head, for roller

Throat

Throat

Throat

Screw, for toggle grinder

Needle

Needle

Needle

Plate

Needle Guard, hardened, for Styles 1700

1700 B, 2600

Plate

1700F

Plate

J.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Needle Guard, hardened, for Styles 1200 AC,

......

..

:.......

Needle

Guard

clamp..........................

Thread

1200

AC, 1700

Thread

Thread

1700

H.............................................

Pull-off

F,

Pull-off

and

1700

and

Take-up Wire, for Styles 1200 AC, 1700 F,

H.............................

Take-up Wire

support

.......

.....

Screw No. 87.

Take-up Wire Post, for Styles

,

... , ...........

swinging

........

Post

Screw No. 94.

arm

.........

16

9

. . . . 9

A,

11

11

10

13

13

Needle Thread Take-up Wire Screw No. 87 U.

Looper Rocker, hardened, for

1200

0,

1200 Q, 1700 A, 1700 B, 1700

Needle

2600

Thread

F,

Controller Rack, for Styles 2600

2600 G, 2600

Needle Thread Controller

Trimmer

styles in Class

Stand

Adjusting

2300. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screw, hexagon head, for

Tension

Tension

Welt Gauge Base, for

Welt Gauge Base

W e!t Gauge

Welt Gauge

Welt Gauge

Welt Gauge

Thread

Thread

Eyelet, with one eye, for Style 1900

Eyelet Screw No. 98.

Style 2600

Screws No. 25 CC.

Slide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Slide. Spring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Slide Spring Screw. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Slide Screw Pin, hardened; also for No. 410

Styles 1200 A, 1200 C, 1200 G,

H,

2600

J.

. . . . . . .

A,

2600 D,

H.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Rack

Rod

upper

Screws No.

Lock

feed

bar

D.

. . . . . . . . . . . . . . . . . . . . . 19

88.

Nut,

left thread, for

spring. . . . . . . . . . . . 9

K.

. . . 13

A..

25

11

10

Welt Gauge Slide Lever. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Welt Gauge

Welt Gauge

Welt Gauge

Welt Gauge Slide Lever Stop

Welt Guide,

Welt Guide Screw; also for No.

Welt Guide

Slide Lever

Stud

No. 86.

Slide Lever Screw No. 97.

Slide Lever Stop

adjustable....

Plate.

. . . . . . . . . . . . . . . . . . . . . 19

Plate

Screws No. 94.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

409

A...

. . . . . . . . . . . . . . . . . 9

Height Adjusting Screw No. 88.

49

Page 52

LIST OF PARTS

Symbol

to

Order

409 A

410 A

413

415

B

419 A

420

421

423

424