Page 1

INDUSTRIAL

INEST

57900H

57900N

QUALI

STYLES

®

TY

Unum~

L E W I

S®

• C 0 L U M B I A®

SEWING

MACHINES

CATALOG

No.

135M

Second

Edition

-

CLASS

ADVANCED

FIFTY

SAFETY

FRONT

DISPOSAL

THOUSAND

STITCH

UNION SPECIAL

57900

HIGH

SPEED

SERIES

MACHINES

OF

TRIMMINGS

CORPORATION

CHICAGO

Page 2

A D

Catalog

INSTRUCTIONS

JUSTIN

No.

135

FOR

G A N D 0 P E

M

RA

TIN

G

57900

Union

Rights

LIST

CLASS

H

Second

Copyright

Special

Reserved

OF

Styles

Edition

By

PARTS

57

9 0 0

57900

1971

Corporation

in

All

Countries

N

UNION SPECIAL CORPORATION

INDUSTRIAL

Printed

SEWING

CHICAGO

in

2

MACHINES

U.S.

A.

October.

1977

Page 3

IDENTIFICATION

OF

MACHINES

on

the

Style

Each

UNION

machine.

numbers

Example:

minor

Style

a

gauge

changes

number.

The

distance

number

Thus. a 5-8

(needle

(3.

18

for

mm)

Styles

which

57900

herein.

in

given

of

differs

11

•

This

catalog

It

this

Class.

from

handwheel

"Style

Example:

gauge

401

from

of

machines

from

can

also

Reference

the

operator's

is

SPECIALmachine

Style

have

57900

are

numbers

one

H".

made

or

more

Special

in a standard

"Style

between

measured

the

in

represents

stitch)

middle

to

middle

needle

similar

the

Style

number.

APPLICATION

applies

be

specifically

applied

to

direction,

position

toward

the

operator.

are

57900

rows

of

1/64ths

a

distance

or

to

extreme

in

construction

with

while

is

identifi

classified

letters

Style

numbers

machine,

HZ".

stitches

of

an

left

needle

in

that

to

the

discretion

such

seated

ed

by a Style

as

suffixed,

or

between

inch

of

(.40

5/64

of

right

needle.

are

it

contains

OF

CATALOG

Standard

to

as

right,

at

standard

but

contain

a

"Z"

mm),

inch

602

grouped

Styles

some

the

machine.

number

never

the

is

suffixed

needles

going

(1.

98

stitch

no

letters.

Special

left,

on a name

and

special.

contain

letter

from

mm)

and

the

"Z".

to

the

is

represented

left

from

8/64

or

under a Class

Example:

of

machines

Styles

front,

of

back,

Operating

plat

Standard

letter

When

standard

to

right.

left

needle

1/8

inch

number

''Class

as

listed

machines

etc.,

direction

e

"Z".

only

by

are

Advanced

mer,

Presser

Rear,

Interlock

System,

Feed

an

Adjustable

High

Front

Bar

Two

Stitch

Filtered

Rocker

Disposal

Loopers,

Preparedfor

Thread

mm).

57900

Tensions.

H

Medium

in-seams

slacks,

corduroy

weightmaterial.

forallgauges

recommended

57900 N High

closing

on

Type

16-8

on

medium

147

gauge

commended

Speed

and

Needle

on

Right,

Oil

Shaft.

Lateral

Cast-off

use

with

Maximum

throw

and

out-seams

ladies'

overalls,

of

speed

throw

machine

sport

to

heavy

GSneedle

machines.

speed

Flat

Bed

of

Trimmings.

Bar

Dual

Stitch,

Single

Return

Looper

Plate

Knee

Press

machine

skirts,

and

Seam

specification

machines.

5500

shirts,

play

weight

for

No.

Standard

5500

R.

STYLES

Machines,

Driving

Reservoir

Pumps

Support,

for

Work

for

of

light

jackets,

for

similar

Standard

R.

P.

for

side

pants.

material.

5-8

P.M.

OF

Needle

Mechanism,

Double

for

Travel,

Large

Presser

Space

to

simultaneous

and

medium

bathing

(401-602)

gauge

M.

seaming,

heavy

gauge

gauges

MACHINES

Medium

and

Bearing

Locked

Stitch

Enclosed

Head

and

Single

Disc

Handwheel

Foot

Right

Lifter,

of

weight

suits,

operations

519-SSa-2.

Nos.

shoulder

bathrobes,

Se

am

specification

and

Type

Nos.

147

5-8,

High

Needle

Three

on

Positive

Base,

Looper

and

Needle

seaming

corduroy

beach

on

medium

5-8,

seaming,

and

GKS

12-12,

Throw.

Bar

Drive,

Needles,

Left

and

Automatic

Wakefield

Thread

Improved

Equipped

Bar 8 1/4

and

overedging

pants,

and

bathrobes,

to

Type

12-12,

16-8.

sleeve setting and

for

similar

{401-602)

needle

16-8.

Vertical

Light

Left

Needle

Four

Lubricating

Bearings

Take-up

Belt

with

Disc

Inches

wash

medium

128

GAS

Maximum

operations

519-SSa-2.

for

Nos.

Maximum

Trim-

Weight

Thread

for

and

Guard.

Type

(209.

on

the

pants,

kiddies'

heavy

needle

12-12,

re-

in

6

3

Page 4

NEEDLES

Each

denotes

number,

in

thousandths

size

number

needles

The

by

this

able,

but

results.

tions,

Type

128

147

and

No.

GAS

GS

UNION

the

kind

stamped

packaged

type

numbers

catalog

the

ones

The

type

the

Round

eye,

ium

140 I 054,

Round

eye,

duction,

1251049,

SPECIAL

of

shank,

on

the

of

an

represent

and

are

given

indicated

numbers

sizes

available

shank,

spotted,

plated-

shank,

spotted,

needle

inch,

the

sold

of

the

in

needle

point,

midway

by

needles

the

are

of

has

length,

shank,

between

complete

Union

Special.

recommended

machine

those

the

are

recommended

recommended

listed

both a type

denotes

symbol,

Description

round

undersize

sizes

1501060,

round

short

point,

eye

0801032,

170 I 067.

point,

point,

chromiumplated-sizes

1401054,

1501060,

groove,

shank

style

description.

below:

short,

and

groove

0901036,

long,

undersize

1701067.

and

size

finish

largest

which

for

to

needles

and

double

double

and

diameter

and

eye.

is

each

produce

together

Sizes

groove,

27%

of

1001040,

groove,

eye

number.

other

Collectively,

given

style

Other

size

and

grooves,

The

details.

of

blade,

on

of

machine

needles

the

most

with

struck

of

needle,

1101044,

struck

the

their

0801032,0901036,1001040,

type

number

The

size

measured

type

label

of

covered

are

avail-

satisfactory

descrip-

groove,

ball

chrom-

1251049

groove,

one

ball

step

110/044,

and

all

re-

147

GKS

To

have

sample

onlabel.

needle,

Acompleteorderwouldread:

Selection

should

pass

Success

use

ofneedlespackaged

a

reputation

more

than

three-quarters

Round

size

ium

needle

or

of

proper

freely

in

the

for

producing

shank,

ball

eye,

plated-

orders

the

type

needle

through

operation

round

spotted,

sizes

promptly

and

size

needle

of

under

our

highes·i:

of a century.

point,

short

0901036,

and

size

number

"1000

is

determined

eye

in

UNION

brand

quality

long,

double

point,

1001040,

accurately

should

Needles,

order

to

SPECIAL

name,

~

needles

groove,

standard

eye

1101044,

filled,

be

forwarded.

Type128

by

the

size

of

produce a good

machines

in

materials

can

®

struck

and

grooves,

1251049,

an

empty

Use

GAS,

Size

thread

stitch

be

secured

•

which

and

workmanship

groove,

1401054.

package,

description

0901036".

used.

formation.

is

backed

over-

chrom-

Thread

only

by

by

for

a

4

'

Page 5

Fig.

1

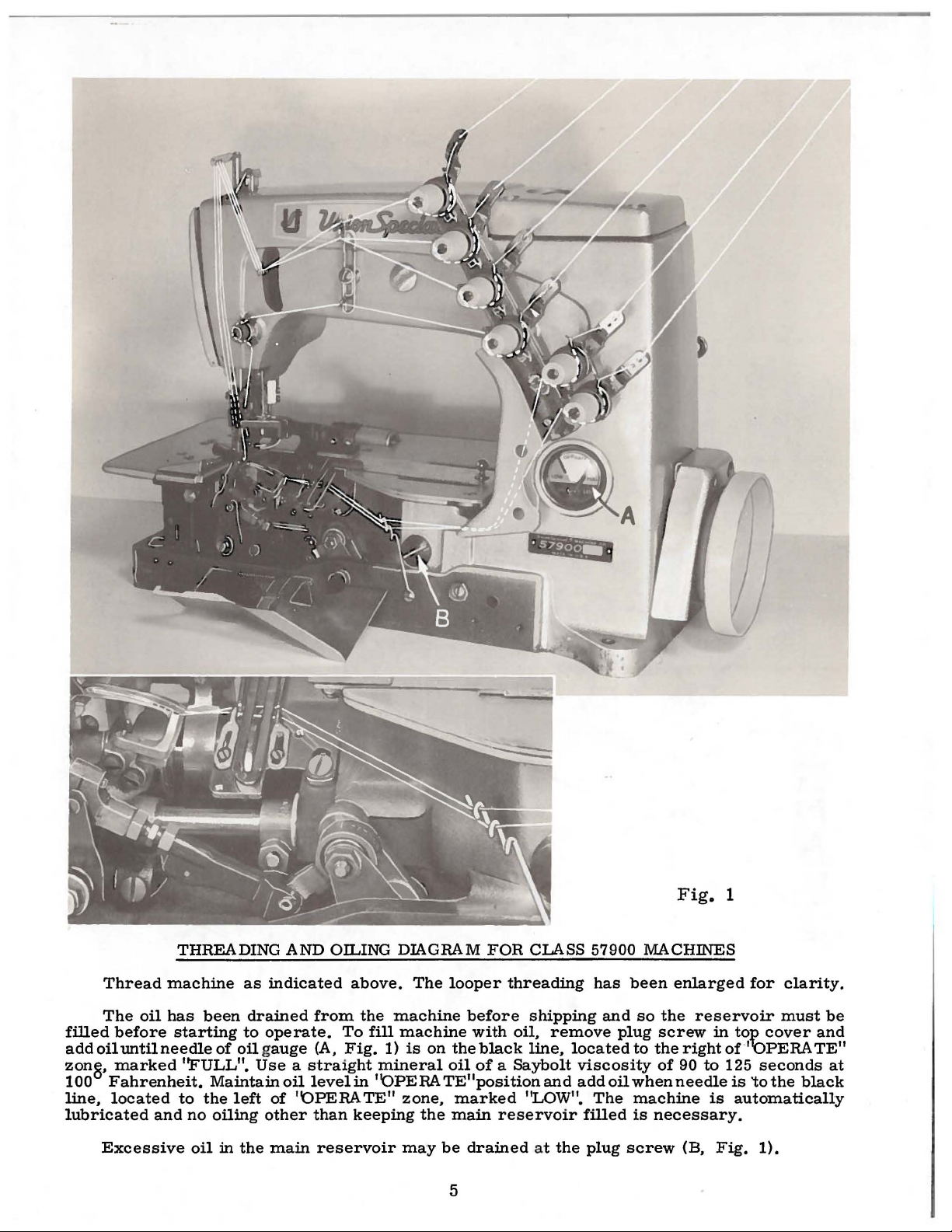

Thread

The

filled

add

zong.

100

line,

lubricated

before

oil

until

marked

Fahrenheit.

located

Excessive

THREADING

machine

oil

has

starting

needle

''FULL".

to

and

no

oil

been

of

oil gauge

Maintain

the

left

oiling

in

the

AND

OILING

as

indicated

drained

to

operate.

Use a straight

other

from

(A,

oil

level

of

''OPERATE"

than

main

reservoir

above.

the

To

fill

Fig.

1)

mineral

in

''OPERA

keeping

DIAGRAM

The

looper

machine

machine

is

on

the

oil

TE"position

zone,

may

the

marked

main

be

FOR

CLASS

threading

before

with

black

of a Saybolt

drained

shipping

oil,

line,

and add

''LOW".

reservoir

at

remove

the

5

57900

has

and

plug

located

viscosity

oil

The

filled

plug

MACHINES

been

enlarged

so

the

reservoir

screw

to

the

right of·''OPERA

of

90

when

needle

machine

is

necessary.

screw

(B,

for

in

top

cover

to

125

seconds

is

'to

is

automatically

Fig.

1).

clarity.

must

the

black

be

and

TE"

at

Page 6

H

VAPOR

~~

SPLASH

OIL

i!

oiL

B

oiL

ACTION

RESERVOIR

FEED

RETURN

SCR

E W

-PASS

WIT

OUTLET

BY

6

H

Page 7

ADVANCED

FLATBED

LUBRICATION

SYSTEM

F i

gure

Letter

A.

B.

c.

D.

E.

F.

G.

Bearing

Crankshaft

and

Needle

Head

ings).

Looper

lever

Opposing

end

vents

shaft

Right

Left

tric

or

crankshaft

lever

area

drive

bearings.

of

mainshaft.

oil

bearing.

mainshaft

main

bearings

Machine

drives,

(all

mechanisms

Helical grooves

leakage

shaft

bearing

located

Area

upper

bearings.

cross

crank,

shaft

Short

from

bearing.

on

and

SUPPLY

ball

straps

bearing.

and

looper

in

groove

right

main-

all

eccen-

mainshaft.

bear-

drive

right

pre-

SYSTEM

Method

Oil

ions

rods.

Oil

supplied

Mist

Oil

(56343

connecting

Oil

splash

Supply

shaft.

Oil

andmeteredby

troduced

right

Amount

shaft

in

of

agitation

on

trough

by

as a result

agitation

E)

drip

in

grooves

supplied

mains

of

controlled

right

end

Lubrication

needle

on

rod.

plate

chamber.

into

as a result

lever

(51282

splash

as a result

bottom

from

lubricant

of

in

of

splash

which

in

right

hollow

felt

plugs.

center

haft

with

mainshaft.

of

extens-

connecting

AE)

which

column

in

column.

of

splasher

of

looper

accumulates

end

of

mainshaft

Oilis

of

shaft

bearing

in

center

by-pass

area.

drive

main-

in-

in

the

area.

hole

is

of

H.

I.

J.

K.

Figure

Letter

L.

M.

Lower

mains

Looper

rocker

per

Right

joint.

Feed

rocker

Machine

Head

Base

haft

rod

looper

rocker

ends

eccentrics.

cone,

shaft

bearings,

ball

joint.

shaft

bearings.

Area

of

connecting

right

rod

shaft

and

and

needle

and

upper

rods

left

looper

left

bearing

RETURN

of

loo-

feed

SYSTEM

Oil

run-out

supplies.

Supplied

shaft

yarn

Oil

to

Self-lubricated

Method

Felt

pump

primed

bearing.

Felt

return

and

accumulates

chamber.

which

as a metering

supplied

lubricating

pad

pad

primed

from

from

of

Return

in

head

located

by

oil

in

base

pump

by

eccentric

hollow

contains 4 strands

from

plate

bearings.

on

from

collects

located

oil

splash

looper

device.

front

(56393 K).

collects

crankshaft

left

on

drip

in

bearing

rocker

base

oil.

Return

crankshaft

oil.

Second

crankshaft

plate

which

looper

drive

of

felt

and

7

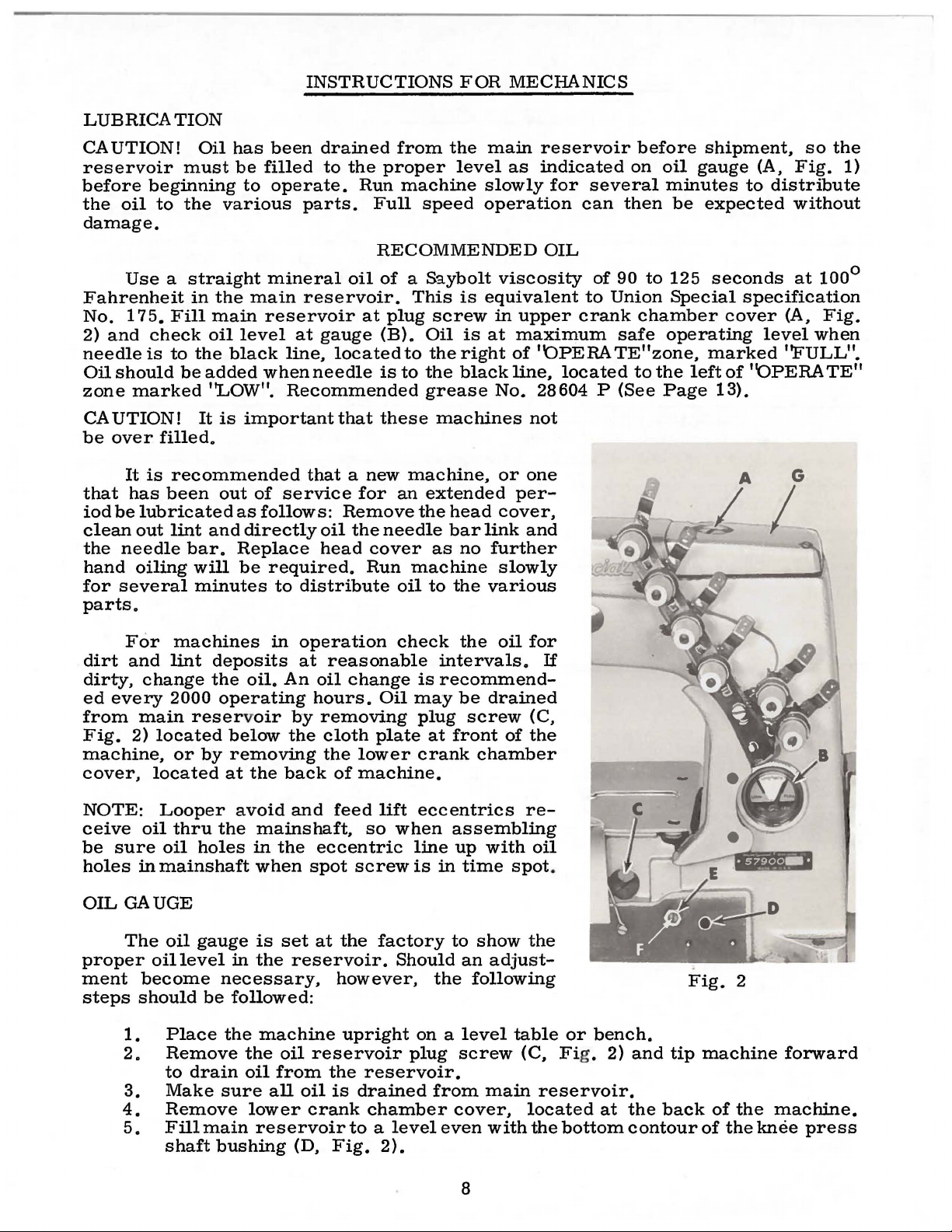

Page 8

LUBRICATION

INSTRUCTIONS

FOR

MECHANICS

CAUTION!

reservoir

before

the

beginning

oil

to

damage.

Use a straight

Fahrenheit

No.

175.

Fill

2)

and

check

needle

Oil

zone

is

should

marked

to

CAUTION!

be

over

that

iod

clean

the

hand

for

filled.

It

is

has

been

be

lubricated

out

needle

oiling

several

recommended

lint

parts.

Oil

must

the

various

in

the

main

oil

the

be

added

''LOW".

It

is

out

and

bar.

will

minutes

has

been

be

filled

to

operate.

mineral

main

reservoir

level

black

line,

when

Recommended

important

of

service

as

follows:

directly

Replace

be

required.

to

drained

to

the

Run

parts.

oil

reservoir.

at

at

gauge

located

needle

that

that a new

for

Remove

oil

the

head

cover

Run

distribute

from

proper

machine

Full

the

level

speed

main

as

slowly

operation

RECOMMENDED

of

a S3.ybolt

This

plug

(B).

Oil

to

is

to

the

grease

these

machine,

an

extended

the

needle

machine

oil

screw

the

machines

head

bar

as

to

viscosity

is

equivalent

in

is

at

right

black

No.

or

cover,

link

no

further

slowly

the

various

upper

maximum

of

line,

per-

reservoir

indicated

for

OIL

crank

''OPERA

located

28604

not

one

and

several

can

then

of

90

to

Union

safe

TE"zone,

P

(See

before

on

oil

minutes

be

to

125

Special

chamber

operating

to

the

Page

shipment,

gauge

to

expected

seconds

specification

cover

marked

left

of

''OPERATE"

13).

so

(A,

Fig.

distribute

without

at

(A,

level

when

''FULL".

the

1)

100°

Fig.

For

dirt

and

dirty,

ed

from

Fig.

change

every

main

2)

machine,

cover,

NOTE:

ceive

be

holes

OIL

oil

sure

in

GAUGE

The

proper

ment

steps

become

should

1.

2.

3.

4.

5.

machines

lint

deposits

the

2000

operating

reservoir

located

or

by

located

Looper

thru

the

oil

holes

mainshaft

oil

gauge

oil

level

be

Place

Remove

to

drain

Make

Remove

Fill

main

shaft

bushing

in

oil.

An

by

below

the

removing

at

the

back

avoid

and

mainshaft,

in

the

when

is

set

in

the

reservoir.

necessary,

followed:

the

machine

the

oil

oil

from

sure

all

lower

reservoir

(D,

operation

at

reasonable

oil

change

hours.

removing

cloth

the

lower

of

machine.

feed

so

eccentric

spot

screw

at

the

however,

upright

reservoir

the

reservoir.

oil

is

drained

crank

chamber

to a level

Fig.

check

is

Oil

may

plug

plate

crank

lift

eccentrics

when

line

is

factory

Should

on a level

plug

2).

the

oil

intervals.

recommend-

be

drained

screw

at

front

of

chamber

assembling

up

with

in

time

to

show

an

adjust-

the

following

screw

from

main

cover,

even

with

for

If

(C,

the

re-

oil

spot

.

the

table

or

bench.

(C, Fig. 2)

reservoir.

located

the

bottom

at

and

tip

the

back

contour

Fig.

2

machine

of

the

of

the

forward

machine.

knee

press

8

Page 9

6.

Loosen

or

of

7.

Tighten

cover.

8.

Add

''OPERATE"

lock

nut

right

until

''OPERATE"

lock

oil

so

that

zone,

(E)

the

zone,

nut

gauge

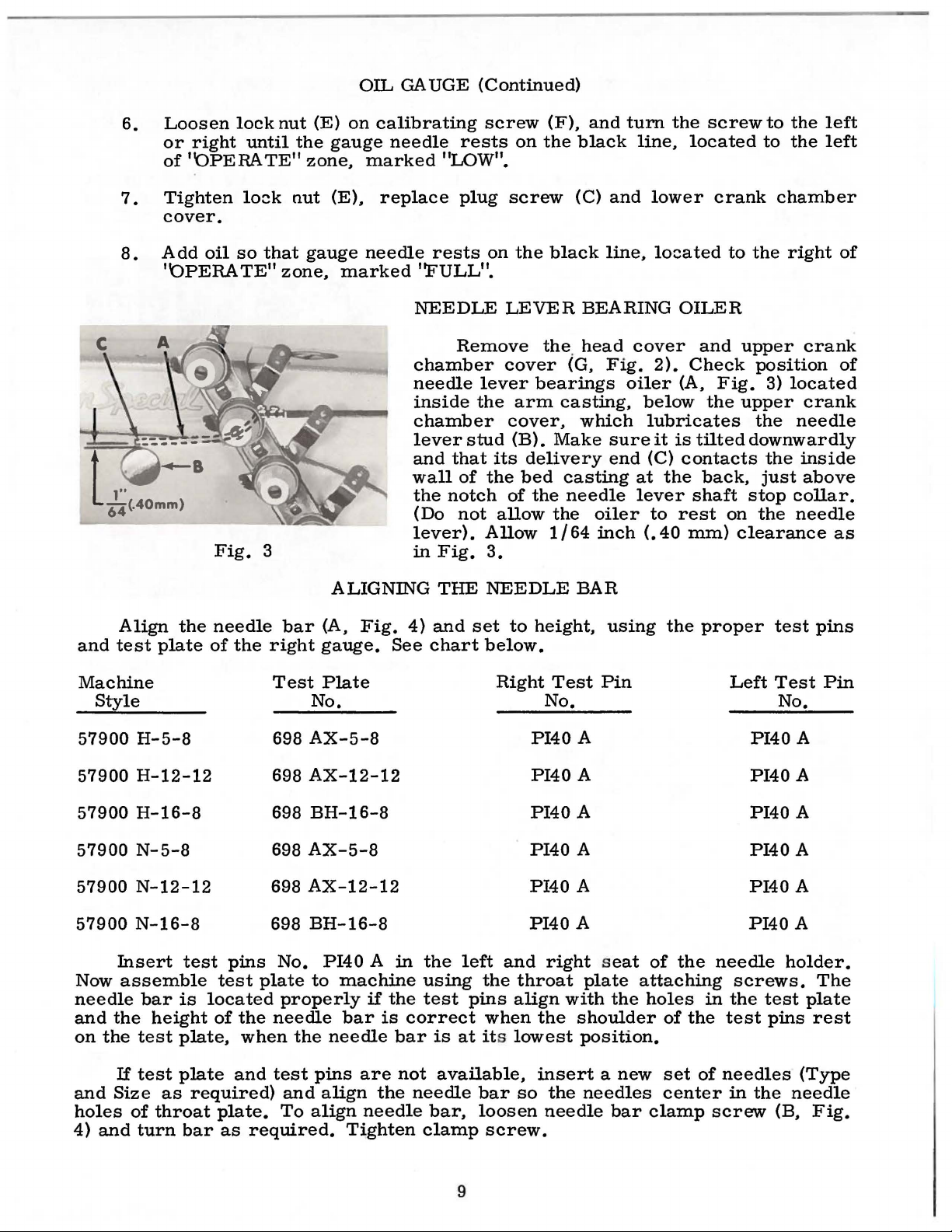

OIL

on

gauge

marked

(E),

needle

marked

GAUGE

calibrating

needle

"LOW".

replace

rests

''FULL".

(Continued)

screw

rests

plug

on

on

screw

the

(F),

the

black

and

black

(C)

and

line,

turn

line,

lower

the

screw

located

located

crank

to

the

to

the

to

the

chamber

right

left

left

of

Align

and

test

Machine

Style

57900

H-5-8

the

plate

Fig.

needle

of

the

3

bar

right

Test

698

ALIGNING

(A,

Fig.

gauge.

See

Plate

NEEDLE

Remove

chamber

needle

inside

chamber

lever

and

that

wall

the

(Do

of

notch

not

lever).

in

Fig.

THE

4)

and

chart

LEVER

cover

lever

the

arm

cover,

stud

(B).

its

the

of

allow

Allow

3.

NEEDLE

set

to

below.

Right

the. head

bearings

casting,

Make

delivery

bed

casting

the

the

1/64

height,

Test

No. No.

AX-5-8

PI40

BEARING

(G,

Fig.

oiler

which

sure

end

needle

oiler

inch

BAR

using

Pin

A

OILER

cover

2).

Check

(A,

below

lubricates

it

is

(C)

contacts

at

the

lever

(.40

to

shaft

rest

mm)

the

and

Fig.

the

tilted

back,

on

clearance

proper

Left

upper

crank

position

3)

located

upper

the

crank

needle

downwardly

the

inside

just

above

stop

collar.

the

needle

test

pins

Test

Pin

No.

PI40

A

of

as

57900

57900

57900

57900

57900

Insert

Now

needle

and

the

on

the

If

and

Size

holes

4)

and

H-12-12

H-16-8

N-5-8

N-12-12

N-16-8

test

assemble

bar

is

height

test

plate,

test

plate

as

of

throat

turn

bar

pins

test

plate

located

of

the

when

and

required)

plate.

as

required.

698

AX-12-12

698

BH-16-8

698

AX-5-8

698

AX-12-12

698

BH-16-8

No.

PI40 A in

to

properly

needle

the

test

pins

and

align

To

align

machine

if

bar

needle

are

the

needle

Tighten

the

is

correct

bar

not

the

using

test

is

at its

available,

needle

bar,

clamp

9

left

the

pins

when

bar

loosen

PI40

PI40

PI40

PI40

PI40

and

throat

align

lowest

so

screw.

right seat

the

insert a new

the

needle

A

A

A

A

A

plate

with

the

shoulder

position.

needles

bar

of

the

attaching

holes

of

set

in

the

of

center

clamp

PI40

PI40

PI40

PI40

PI40

needle

screws.

the

test

needles

in

the

screw

holder.

test

pins

needle

(B,

A

A

A

A

A

The

plate

rest

(Type

Fig.

Page 10

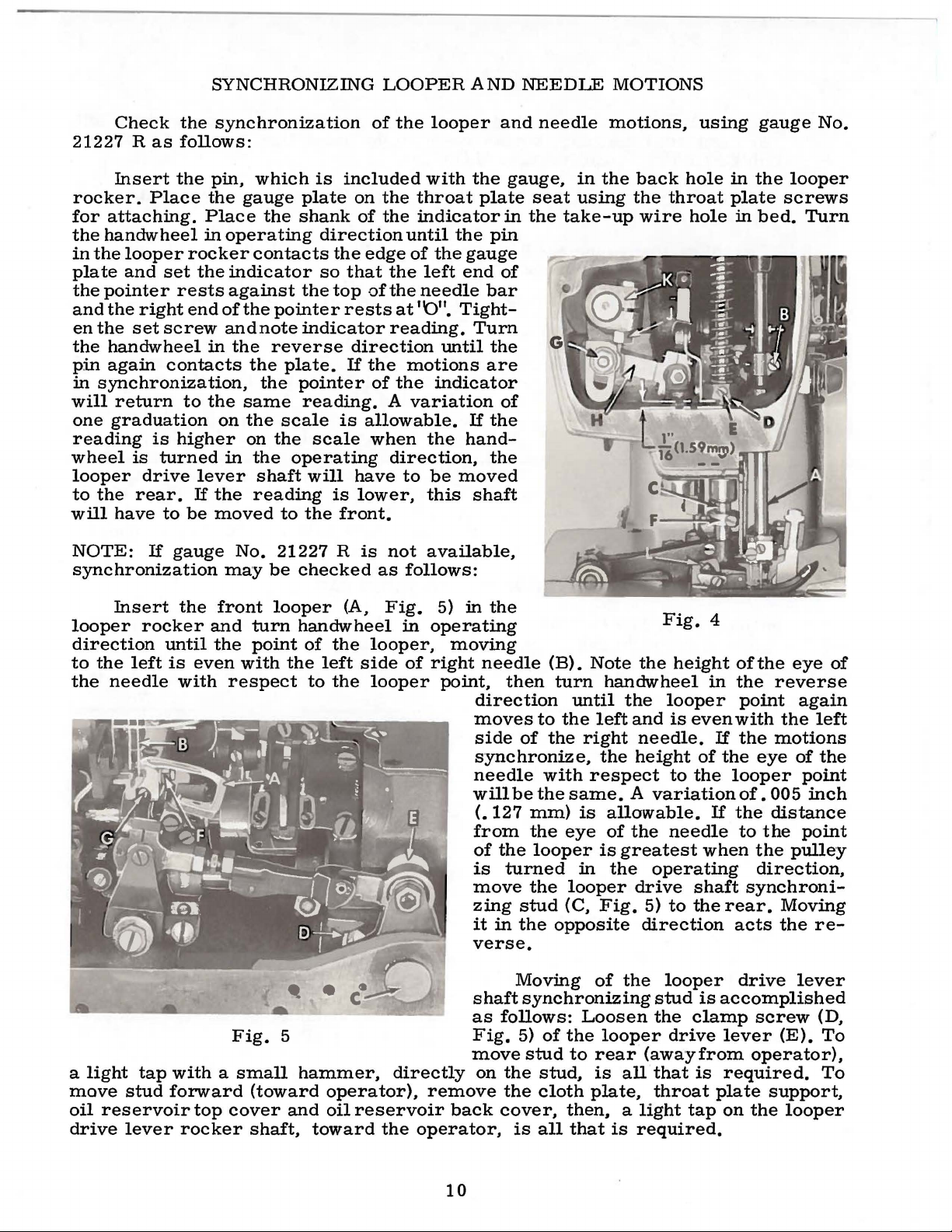

SYNCHRONIZING

LOOPER

AND

NEEDLE

MOTIONS

Check

21227 R as

Insert

rocker.

for

attaching.

the

handwheel

in

the

looper

plate

the

and

en

the

pin

in

will

one

and

pointer

the

the

set

handwheel

again

synchronization,

return

graduation

reading

wheel

is

looper

to

the

will

have

NOTE:

Place

set

right

screw

is

turned

drive

rear.

to

If

the

follows:

the

rocker

rests

end

contacts

to

higher

If

be

gauge

synchronization

synchronization

pin,

which

the

gauge

Place

in

operating

the

plate

shank

contacts

the

indicator

against

of

and

in

the

on

in

lever

the

moved

may

the

the

the

same

the

on

the

reading

No.

the

pointer

note

indicator

reverse

plate.

the

pointer

reading.

scale

the

operating

shaft

to

21227 R is

be

checked

is

included

on

direction

the

so

that

top

rests

direction

If

is

scale

will

is

the

front.

of

the

the

throat

of

the

indicator

until

edge

of

the

left

of

the

needle

at

''0".

reading.

the

motions

of

the

A

variation

allowable.

when

direction,

have

to

lower,

not

as

follows:

looper

with

the

plate

the

pin

the

gauge

end

bar

Tight-

Turn

until

the

are

indicator

If

the

the

hand-

the

be

moved

this

shaft

available,

and

needle

gauge,

seat

in

the

of

of

motions,

in

the

using

take-up

back

the

wire

using

hole

throat

hole

gauge

in

the

plate

in

bed.

No.

looper

screws

Turn

Insert

looper

direction

to

the

left

the

needle

a

light

move

oil

drive

stud

reservoir

lever

the

rocker

until

is

even

with

tap

with a small

forward

top

rocker

front

and

the

with

respect

Fig.

cover

looper

turn

handwheel

point

of

the

5

hammer,

(toward

and

shaft,

(A,

the

left

side

to

the

operator),

oil

reservoir

toward

Fig.

in

looper,

of

looper

directly

the

operator,

5)

in

the

operating

moving

right

needle

point,

direction

moves

side

synchronize,

needle

will

(.

127

from

of

is

move

zing

it

in

verse.

shaft

as

Fig.

move

on

remove

back

(B).

then

turn

until

to

the

of

the

right

with

be

the

same. A variation

mm)

the

the

looper

turned

the

stud

the

is

eye

in

looper

(C,

opposite

Moving

synchronizing

follows:

5)

stud

the

the

cover,

is

Loosen

of

the

to

stud,

cloth

then, a light

all

that

Note

the

handwheel

the

left

and

needle.

the

height

respect

allowable.

of

the

is

greatest

the

operating

drive

Fig.

5)

direction

of

the

stud

the

looper

rear

is

plate,

(awayfrom

all

that

throat

is

required.

Fig.

height

looper

is

even

of

to

the

needle

when

shaft

to

the

looper

is

clamp

drive

is

tap

4

of

the

eye

in

the

reverse

If

the

looper

If

point

with

the

of.

the

to

again

the

motions

eye

of

005

distance

the

the

pulley

point

point

direction,

synchroni-

rear.

acts

drive

Moving

the

lever

accomplished

screw

lever

(E).

operator),

required.

plate

on

support,

the

looper

of

left

the

inch

re-

(D,

To

To

10

Page 11

SYNCHRONIZING

LOOPER

AND

NEEDLE

MOTIONS

(Continued)

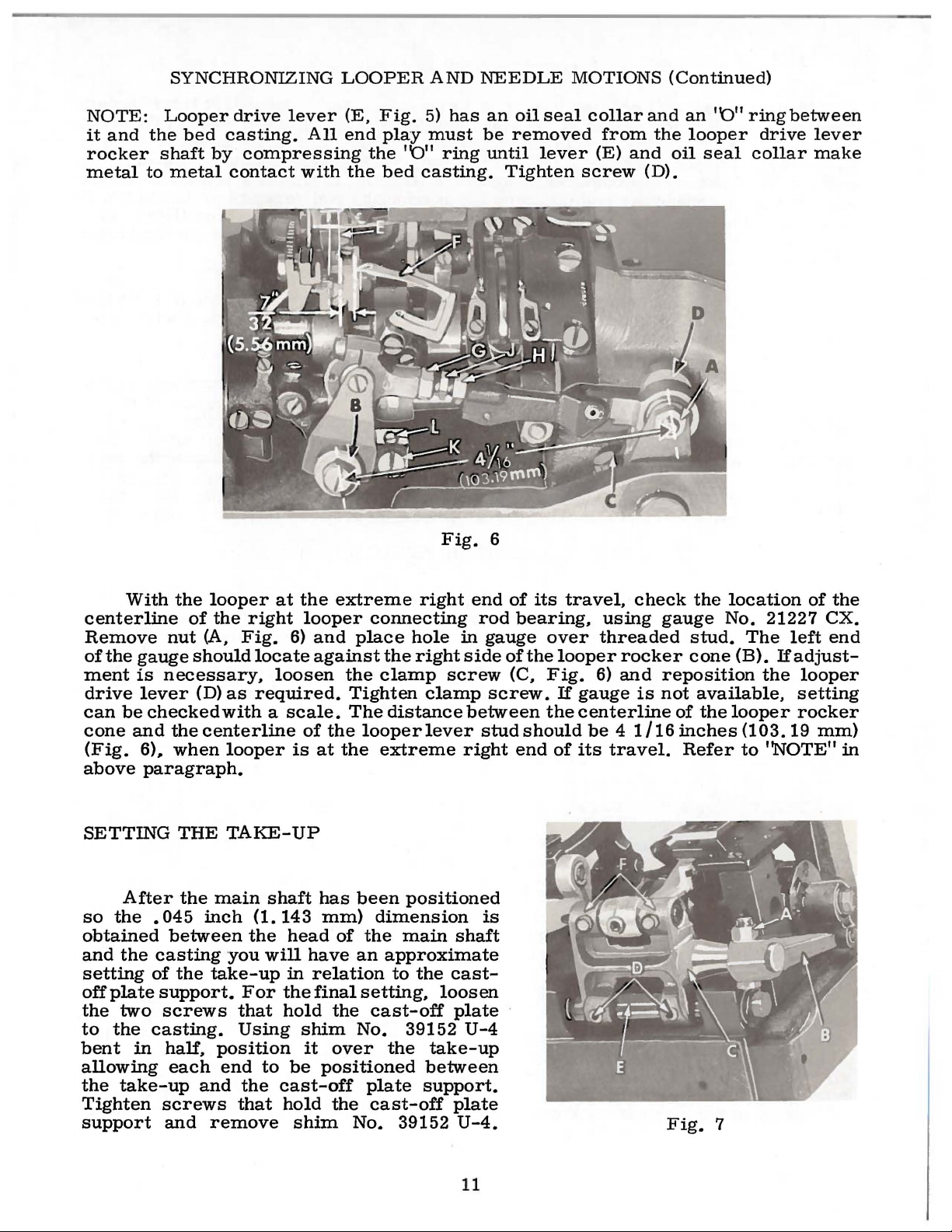

NOTE:

it

and

rocker

metal

Looper

the

shaft

to

metal

bed

drive

casting.

by

compressing

contact

lever

All

with

(E,

end

the

Fig.

play

the

bed

5)

must

''0"

ring

casting.

Fig.

has

an

oil

be

removed

until

Tighten

6

seal

lever

collar

from

(E)

screw

and

and

(D).

the

oil

an

''0"

looper

seal

ring

drive

collar

between

lever

make

With

centerline

Remove

of

the

gauge

ment

drive

can

cone

(Fig.

above

SETTING

so

obtained

and

setting

offplate

the

to

bent

allowing

the

Tighten

support

is

lever

be

checked

and

6)..,

paragraph.

After

the

• 045

the

of

two

the

casting.

in

take-up

the

looper

of

the

nut

(A,

should

necessary,

(D)

with a scale.

the

centerline

when

THE

the

between

casting

the

support.

screws

half,

each

screws

and

looper

TAKE-UP

main

inch

you

take-up

position

end

and

remove

right

Fig.

locate

as

required.

shaft

(1.

the

will

For

that

Using

to

the

that

at

the

looper

6)

and

against

loosen

of

the

is

at

has

143

mm)

head

have

in

relation

the

final

hold

shim

it

be

positioned

cast-off

hold

shim

extreme

connecting

place

the

the

clamp

Tighten

The

distance

looper

the

extreme

been

dimension

of

the

an

approximate

setting,

the

cast-off

No.

over

the

the

plate

cast-off

No.

right

hole

right

screw

clamp

lever

positioned

main

to

39152

39152

shaft

the

cast-

loosen

plate

take-up

between

support.

plate

U-4.

end

of

rod

bearing,

in

gauge

side

of

(C,

screw.

between

stud

right

U-4

end

is

its

travel,

over

the

looper

Fig.

If

the

should

of

check

using

threaded

rocker

6)

and

gauge

centerline

be 4 1/16

its

is

travel.

the

location

gauge

reposition

not

of

Fig.

No.

stud.

cone

(B).

available,

the

looper

inches

Refer

7

21227

The

If

the

(103.

to

''NOTE"

of

CX.

left

end

adjust-

looper

setting

rocker

19

mm)

the

in

11

Page 12

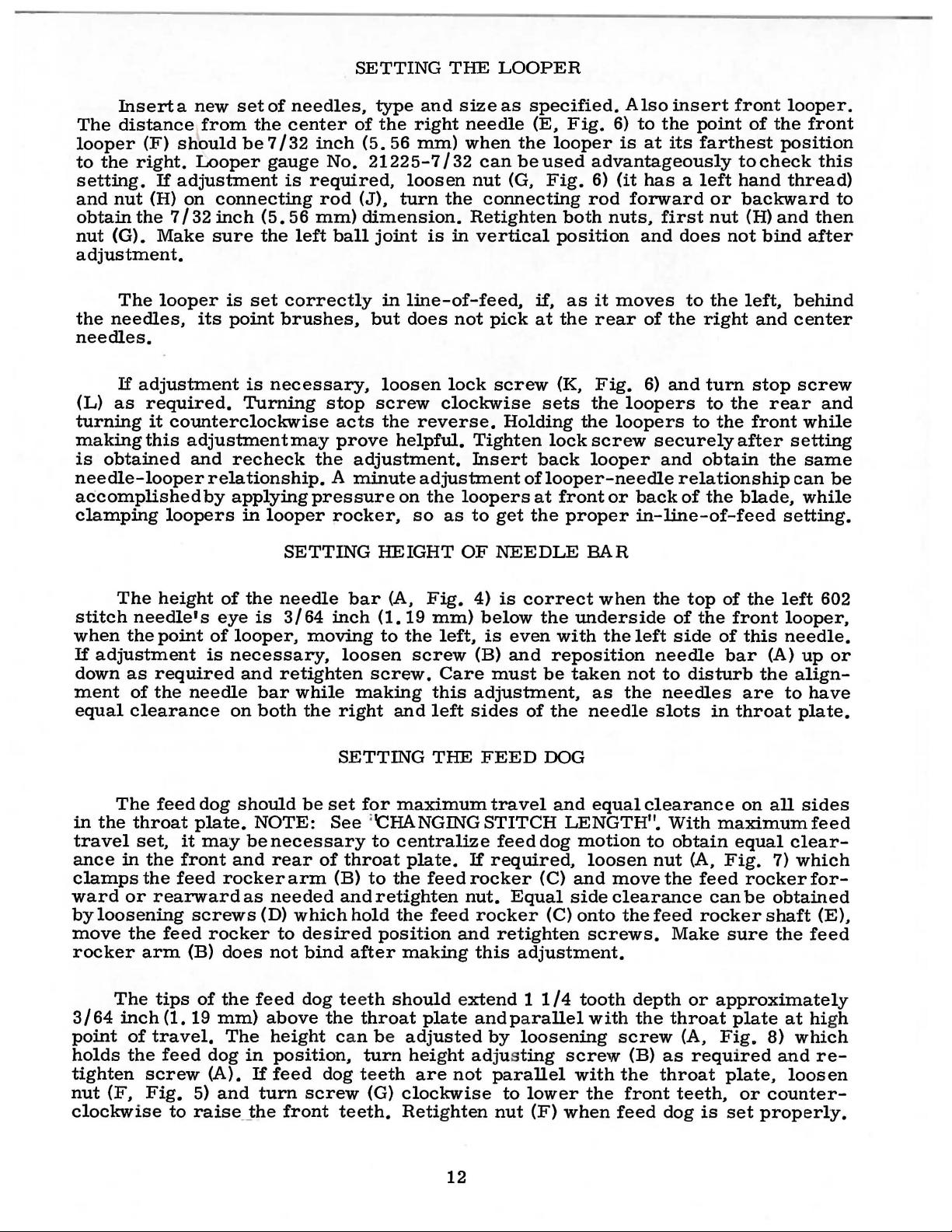

SETTING

THE

LOOPER

Insert a new

The

distance

looper

to

setting.

and

obtain

nut

the

nut

(G).

(F)

should

right.

If

adjustment

(H)

the

7/32

Make

on

adjustment.

The

looper

the

needles.

needles.

If

adjustment

(L)

as

required.

turning

it

counterclockwise

makingthis

is

obtained

needle-looper

accomplished

clamping

loopers

set

of

needles.

from

Looper

the

be

center

7/32

gauge

is

connecting

inch

(5.

56

sure

its

the

is

set

point

is

left

correctly

brushes.

necessary.

Turning

adjustmentmay

and

recheck

relationship.

by

applying

in

looper

SETTING

type

of

the

inch

(5. 56

No.

21225-7/32

required.

rod

(J).

mm)

dimension.

ball

joint

but

stop

screw

acts

prove

the

adjustment.

A

minute

pressure

rocker.

HEIGHT

and

right

mm)

loosen

turn

the

is

in

in

line-of-feed.

does

not

loosen

lock

clockwise

the

reverse.

helpful.

adjustment

on

the

so

as

size

as

needle

when

can

nut

the

beused

(G.

connecting

Retighten

vertical

pick

screw

Holding

Tighten

Insert

of

loopers

to

get

OF

NEEDLE

specified.

(E.

Fig.

looper

6)

is

advantageously

Fig.

6)

(it

rod

both

nuts.

position

if.

as

it

moves

at

the

rear

(K.

Fig.

sets

back

lock

the

the

loopers

screw

looper

looper-needle

at

front

the

or

proper

BAR

Also

to

at

insert

the

its

point

farthest

has a left

forward

first

and

of

6)

loopers

does

to

the

and

or

nut

the

right

turn

to

to

not

the

the

securelyafter

and

obtain

relationship

back

of

the

in-line-of-feed

front

of

looper.

the

position

tocheck

hand

thread)

backward

(H)

and

bind

left.

and

stop

behind

center

screw

rear

front

setting

the

can

blade.

setting.

front

this

to

then

after

and

while

same

be

while

The

stitch

when

If

down

ment

equal

needle's

the

adjustment

as

of

clearance

The

in

the

throat

travel

ance

clamps

ward

by

move

rocker

set.

in

the

the

or

loosening

the

arm

The

3/64

point

holds

tighten

nut

inch

(F.

of

the

screw

Fig.

clockwise

height

eye

point

of

is

required

the

needle

feed

dog

plate.

it

may

front

feed

rearward

screws

feed

rocker

(B)

tips

of

(1. 19

mm)

travel.

feed

dog

(A).

5)

and

to

raise

of

the

needle

is

3/64

looper.

necessary.

and

retighten

bar

while

on

both

should

NOTE:

be

necessary

and

rear

rockerarm

as

needed

(D)

which

to

does

the

not

feed

above

The

height

in

position.

If

feed

turn

__

the

front

bar

inch

moving

loosen

making

the

right

SETTING

be

set

See

of

throat

(B)

and

hold

desired

bind

after

dog tee

the

can be

dog te

screw

teeth.

(A.

Fig.

(1.19

to

the

screw

screw.

and

for

maximum

;'CHANGING

to

centralize

plate.

to

the

retighten

the

position

making

th

should extend 1 1/4

throat

plate

adjusted

turn

height adjus

eth

are

(G)

clockwise

Retighten

4)

mm)

left.

below

is

(B)

Care

this

left

THE

must

adjustment.

sides

FEED

travel

STITCH

feed

If

required.

feedrocker

nut.

feed

rocker

and

retighten

this

and parallel

by

not

parallel

nut

is

correct

the

even

and

with

reposition

be

taken

of

the

DOG

and

LENGTH".

dog

(C)

and

Equal

side

(C)

adjustment.

loosening

ting

screw

to

lower

(F)

when

when

underside

the

left

not

as

the

needle

equal

motion

clearance

to

loosen

move

clearance

onto

the

screws.

tooth

with

depth

the

screw

(B)

with

the

the

front

feed

the

top

of

the

side

needle

to

disturb

needles

slots

With

obtain

nut

(A.

the

feed

feed

rocker

Make

or

throat

(A.

as

required

throat

teeth.

dog

is

of

the

left

front

of

bar

in

throat

maximum

equal

Fig.

this

the

are

on

looper.

needle.

(A)

up

align-

to

plate.

all

sides

clear-

7)

which

have

feed

rockerfor-

can

be

obtained

shaft

sure

the

(E).

feed

approximately

plate

Fig.

plate.

set

at high

8)

and

loosen

or

counter-

properly.

which

re-

602

or

12

Page 13

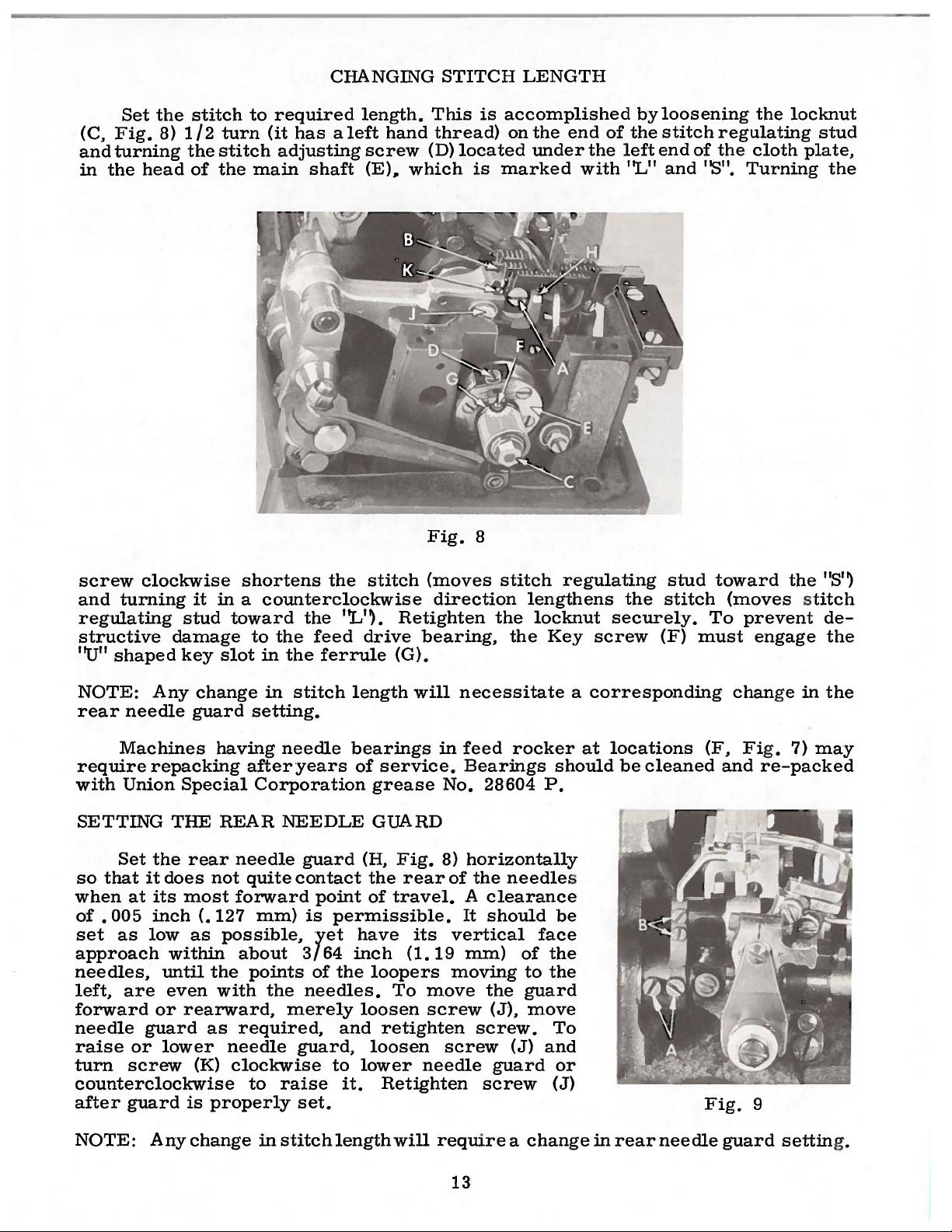

(C.

and

in

Set

Fig.

turning

the

head

the

8)

stitch

1/2

the

of

to

turn

stitch

the

main

required

(it

has a left

adjusting

shaft

CHANGING

length.

hand

screw

(E)

..

which

STITCH

This

is

thread)

(D)

located

is

LENGTH

accomplished

on

the

end

under

marked

the

with

of

by

the

left

"L"

end

loosening

stitch

and

regulating

of

the

''S".

the

locknut

cloth

plate,

Turning

stud

the

screw

and

regulating

structive

''U"

NOTE:

rear

clockwise

turning

shaped

Any

needle

it

stud

damage

key

change

guard

Machines

require

with

SETTING

so

when

of

•

set

approach

needles,

left,

forward

needle

raise

turn

Union

Set

that

at

005

as

are

or

screw

repacking

Special

THE

the

rear

it

does

its

inch

low

not

most

(.127

as

within

until

the

even

or

rearward,

guard

as

lower

(K)

counterclockwise

after

guard

is

properly

shortens

the

stitch

in a counterclockwise

toward

to

slot

in

in

the

the

stitch

the

feed

ferrule

''L''·

drive

length

Retighten

(G).

setting.

having

REAR

needle

forward

possible,

with

needle

clockwise

needle

afteryears

Corporation

NEEDLE

guard

quite

contact

point

mm)

is

yet

about

points

the

3/64

of

needles.

merely

required,

guard,

to

raise

bearings

of

service.

grease

GUARD

(H.

Fig.

the

of

travel.

permissible.

have

inch

the

loopers

To

loosen

and

retighten

loosen

to

lower

it.

Retighten

set.

Fig.

(moves

direction

bearing,

will

in

No.

8)

rear

its

(1.

19

move

screw

needle

8

stitch

the

the

necessitate

feed

rocker

Bearings

28604

horizontally

of

the

needle

A

clearance

It

should

vertical

mm)

moving

the

(J),

screw.

screw

(J)

guard

screw

regulating

lengthens

locknut

Key

a

at

should

P.

s

be

face

of

the

to

the

guard

move

To

and

or

(J)

stud

the

stitch

securely.

screw

(F)

must

corresponding

locations

be

cleaned

toward

the

(moves stitch

To

prevent

engage

chan

ge

(F. Fig. 7)

and

re-packed

Fig.

9

"S'~

de-

the

in

the

may

NOTE:

Any

change

in

stitch

length

will

require a change

13

in

rear

needle

guard

settin

g.

Page 14

Set

the

ward

brush

vertical

of

the

the

but

face

needle.

rightneedle

(A,

Fig.

9),

lower

tighten

or

screws

front

path

not

push

at

rotate

rotate

needle

of

the

pick

at

the

The

front

anytime.

needle

needle

after

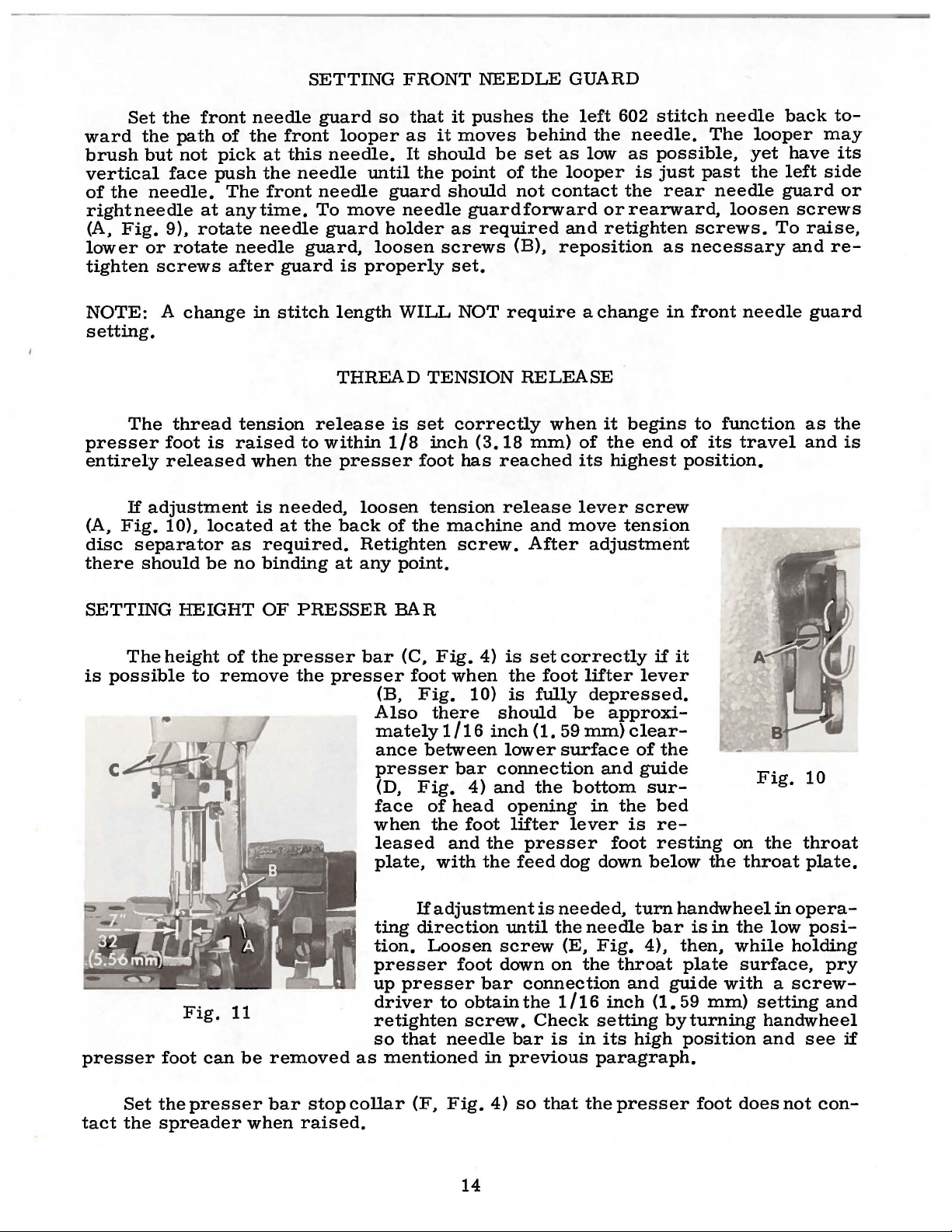

SETTING

guard

front

this

needle.

needle

needle

To

guard

guard,

guard

so

looper

until

move

holder

loosen

is

properly

FRONT

that

as

It

should

the

guard

needle

NEEDLE

it

pushes

it

moves

be

point

of

should

guardforward

as

required

screws

(B),

set.

the

behind

set

the

not

contact

GUARD

left

602

the

needle.

as

low

as

looper

is

the

orrearward,

and

retighten

reposition

stitch

needle

The

possible,

just

past

rear

needle

screws.

as

necessary

looper

yet

the

loosen

To

back

have

left

guard

screws

raise,

andre-

to-

may

its

side

or

NOTE:

A

setting.

The

presser

entirely

If

adjustment

(A,

Fig.

disc

there

separator

should

SETTING

The

is

possible

change

thread

foot

is

released

10),

located

be

HEIGHT

height

to

remove

in

tension

raised

when

is

as

required.

no

binding

OF

of

the

stitch

length

THREAD

release

to

within

the

needed,

at

the

at

PRESSER

presser

the

presser

1/8

presser

loosen

back

of

Retighten

any

bar

(B,

Also

mately

ance

presser

(D,

face

when

leased

plate,

WILL

TENSION

is

set

inch

foot

tension

the

point.

BAR

(C,

Fig.

foot

Fig.

there

between

Fig.

of

the

with

NOT

correctly

(3.18

has

reached

machine

screw.

4)

when

10)

should

1/16

inch

bar

connection

4)

and

head

foot

and

the

the

require a change

RELEASE

when

mm)

release

and

After

is

set

the

foot

is

fully

(1.

lower

the

opening

lifter

presser

feed

it

begins

of

the

its

highest

lever

move

screw

tension

adjustment

correctly

lifter

depressed.

be

approxi-

59

mm)

clear-

surface

of

and

bottom

in

the

lever

is

foot

dog down

lever

guide

in

end

if

it

the

sur-

bed

reresting

below

front

to

of

needle

function

its

travel

position.

on

the

throat

Fig.

the

guard

as

the

and

is

10

throat

plate.

If

presser

Set

tact

the

Fig.

foot

can

the

presser

spreader

1

1

be

when

removed

bar

stop

raised.

ting

tion.

presser

up

driver

retighten

so

as

mentioned

collar

adjustment

direction

Loosen

presser

to

that

needle

(F,

Fig.

foot

bar

obtain

screw.

in

4)

14

is

needed,

until

the

screw

down

on

connection

the

1/16

Check

bar

is

previous

so

that

(E,

turn

needle

Fig.

the

4),

throat

and

inch

setting

in

its

high

paragraph.

the

presser

handwheel

bar

is

in

then,

plate

guide

(1.

59

mm)

byturning

position

foot

in

opera-

the

low

posi-

while

surface,

holding

pry

with a screw-

setting

and

handwheel

and

see

does

not

con-

if

Page 15

The

Nos.

mm)

a

made

5-8

for

scale

by

required

its

arc

loosening

ecting

link

arc

travel

and

16-8

gauge

between

loosening

to

obtain

travel

nut

is

(J)

properly.

No.

the

equal

and

of

the

on

Styles

12-12

two

nut

the

desired

moving

SETTING

spreader

on

extreme

(G,

Fig.

distance

57900

Styles

4)

amount

to

the

spreader

THE

should

Hand

57900

spreader

and

moving

of

the

center

SPREADER

be

set

at

N.

This

Hand

N.

arc

the

arc

travel.

of

rocker

shaft

9/16

inch

setting

should

Measurementis

travel

points.

connecting

Set

the

its

arc.

arm

This

(K)

(14.

29

mm)

be

5/8

made

Adjustment

link

(H)

up

connecting

is

accomplished

to

position

for

gauge

inch

(15.

byplacing

can

or

down

link

so

the

conn-

88

be

as

that

by

With

end

of

its

left

of

the

(A,

Fig.

Retighten

3/32

inch

complished

the

needle

stroke,

centerline

12)

and

screws.

Fig·

(2.

12

38

mm)

by

loosening

bar

the

upper

of

the

rotating

and

in

its

spreader

center

spreader

CAUTION:

thrust

ing

spreader

1/64

Styles.

inch

Style

throat

Adjustment

12)

11)

be

kept

screws

up

position,

needle.

screws

The

and

The

should

close

(C)

point

This

holder

The

collar

(A,

shaft

spreader

to

17 32

The

(8.

33

mm)

57900 H

plate

on

can

position

left

edge

clear

to

the

and

moving

and

the

should

is

(B)

to

spreader

for

the

Fig.

and

inch

bottom

above

and

machine

be

spreader

of

the

top

spreader

extend

7/32

accomplished

position

holder

spreader

12)

be

up

on

the

should

(.

of

40

the

clear

to • 79

spreader

the

27/64

inch

Style

made

by

loosening

as

the

spreader

of

the

right

the

guide

needle

spreader.

(A,

inch

by

the

upper

shaft,

sure

to

spreader

the

mm)

throat

(10.

57900

required.

thread

as

necessary.

Fig.

(5.

11)

56

loosening

spreader

is

also

so

when

push

holder.

left

needle

on

all

should

plate

72

mm)

N ('X",

screws

guide

by

approximately

This

at

mm)

the

tighten-

down

shank

machine

be

on

machine

above

Fig.

(C,

(B,

can

the

left

to

the

screws

point.

lower

on

the

by

21/64

the

12).

Fig.

Fig.

be

ac-

For

best

The

Needle

the

The

The

Needle

The

Pull

tension

Needle

Needle

Looper

nuts

all

results

602

loops

loops

left

needle

401

loops

seam

threads

to

threads

threads

gauges

and

THREAD

the

stitch

do

not

stitch

may

obtain

following

must

may

hang

have

loop

must

may

be

grin

through

the

for

Styles

for

Styles

be

may

be a medium

pulled

or

following

pulled

down

to

be

open

the

proper

conditions

up

as

much

alike.

pull

in

up

between

up

to

tensions:

57900

57900

----·--------------------------------------

spreader

threads---------------------------

TENSIONS

are

desirable:

unpuckered.

as

1/3

slightly.

tight

stitch.

1/64

1/64

inch

eyelets,

H-5-8

H-12-12

and

and

of

to

(.40

per

Fig. 1 and

H-16-8

57900

one

1/32

15

stitch

inch

mm).

-------

N,

and

(.

40

adjust

4

5

2

within

to • 79

the

oz.

(113.40

oz.

(141.

oz.

(56.

this

range

mm).

applicable

gr).

74

gr).

70

gr).

Page 16

Set

eyelet

the

57900

(19.

the

inch

(A,

center

H-12-12

05

mm)

spreader

(12.

mounting

thread

ble

frame

without

stroke.

SETTING

the

401

Fig.

13) 1

of

its

and

on

all

thread

70

mm)

screw.

eyelet

drawing

NEEDLE

stitch

needle

inch

mounting

57900

other

frame

below

Set

the

(C)

thread

AND

thread

(25. 4 mm)

screw

N-12-12;

machine

eyelet

the

center

602

stitch

as

high

on

SPREADER

frame

above

on

Styles

3/4

inch

Styles.

(B).

of

Set

1/2

the

needle

as

possi-

the

down-

THREAD

FRAME

EYELETS

SETTING

TAKE-

Set

Fig.

13)

thread

is

needle

bar

Lower

thread

eyelet

even

bar

has

this

loop,

SETTING

The

is

not

spotted

ing

conditions.

NEEDLE

UP

the

needle

THREAD

WIRE

thread

locatedadjacent

(E)

so

that

with

completed

looper

the

thread

setting

or

raise

LOOPER

thread

on

the

It

is

top

eyelet,

its

for a smaller

THREAD

mainshaft

set

take-up

to

the

its

upper

of

the

holes

when

downward

it

for a larger

TAKE-UP

take-up

(A,

correctly

lobe

clearly

cast-off

determines

Moving

screw

cones,

slots

should

treme

tioning

graph

wire

needle

bar

surface

in

the

needle

stroke.

needle

loop.

Fig.

and

consequently,

when

of

the

take-up

visible

plate

the

support

slots

(C)

moving

causes

just

less

become

position

before

"SETTING

(D,

the

14)

the

looper

below

support

amount

(B)

causes

same;

thread

to

the

securing

THE

when

up

taut

TAKE-

can

be

thread

the

the

underside

(B)

is

of

thread

towards

more

down

to

towards

be

as

left.

Check

support

set

to

is

just

point

adjustable

pulled

the

thread

pulled.

the

loopers

(B)

UP'~

for

Fig.

13

compensate

cast

of

of

the

the

off

left

and

off

by

bottom

to

the

be

The

of

pulled

top

looper

reach

out

right

as

described

final

setting.

for

the

needle

looper.

its

the

take-up.

its

mounting

from

of

its

threads

their

to

left

in

vary-

highest

is

The

setting

the

screw

ex-

posi-

para-

The

401

Fig.

Regulate

enough

is

bar

pressureon

placed

in

the

clockwise

an

independent

the

chain

on

head

acts

and

14

the

presser

the

fabric.

of

the

the

pressure

stopping

the

presserfoot

This

machine.

reverse.

adjusting

chain

stitch

adjustable

looper

the

602

PRESSER

and

thread

thread

into

FOOT

spring regulating screw

to feed the

is

the

knurled screw.

Turning

The

401 stitch

it

screw

cuttin

g.

looper

can

be

the

setting.

PRESSURE

clockwi

chaining

(L, Fig.

thread

positioned

401

stitch

(F.

workuniformlywhen

located

se

increases

4)

16

Fig.

directly

section

for

best

eyelets

to

reduce

system

13)

so

the

of

the

control

(D,

Fig.

or

without

that

it

exerts

a

slight

behind

pressure,

presser

on

14)

put

more

changing

tension

the

needle

counter-

foot has

feeding

are

only

out

Page 17

of

The

the

cutting

throat

edge

plate

ADJUSTING

of

the

(B).

This

lower

can

TRIMMER

knife

be

(A,

accomplished

MECHANISM

Fig.

15)

should

by

be

set

loosening

level

screw

with

(C),

the

move

top

lower

lower

complished

to

When

The

rear.

knife

knife

move

desired

shear

This

up

should

by

knife

angle

adjustment

counterclockwise

screws

screws

blade.

lished

upward

(J).

screw.

knife

turn

NOTE:

bear

(F)

(E).

The

upper

Positioning

by

loosening

or

When

desired

Should

become

eccentric

Upper

against

& (G)

downward

upper

or

down

be

aligned

loosening

to

the

left

position

of

the

and

screw

in

the

knife

should

of

knife

screw

can

position

forward

necessary,

pin

(L)

as

knife

lever

knife

as

required

screw

and

of

knife

lower

can

be

opposite

be

to

(H,

be

accomplished

of

knife

or

rearward

loosen

required.

thrust

lever.

with

(D),

turning

has

knife

made

(G)

clockwise

direction

set

the

left

Fig.

has

Allen

Retighten

bracket

Fig.

and

the

center

turn

it

away

been

should

by

loosening

to

trim

or

right

15).

been

repositioning

head

15

retighten

of

screw

from

screw.

the

(A,

the

obtained,

be

set

at

about 1 degree,

screws

until

will

the

the 1 degree

decrease

full

length

can

be

Positioning

by

loosening

obtained,

screws

Allen

head

(G, Fig. 13)

The

right

Fig.

needle.

16)

operator

retighten

(E)

the

of

its

accomp-

of

knife

screw

retighten

of

upper

(K),

then

screws.

should

toward

screw

and

is

shear

trimming

This

the

acts

the

(D,

yielding

turning

obtained,

angle.

Fig.

edge

can

be

operator

reverse.

Fig.

15).

to

screw

turning

Retighten

16

of

ac-

the

(F)

ORDERING

REPAffi

PARTS

ILLUSTRATIONS

This

views

in

their

found a listing

pieces

catalog

of

various

actual

required

has

sections

position

of

the

parts

in

the

been

in

of

the

arranged

the

machine.

with

particular

to

simplify

mechanism

On

their

view

part

being

are

shown

the

page

number,

shown.

ordering repair

opposite

description,

17

so

that

the

parts.

the parts

illustration

and

Exploded

may

the

number of

be

will

seen

be

Page 18

ORDERING

REPAIR

PARTS

ILLUSTRATIONS

the

position

in

ordering

Numbers

in

of

that

parts.

Component

indicated

assembly.

Ref.

by

Example:

Part

indenting

No. No.

62

63

64

65

66

not

commended,

in

this

the

29105

22559

56343

56343

22587

It

will

listed.

At

the

book.

part

AJ

A

E

c

K

be

noted

The

so

back

This

number

(Continued)

the

first

part

in

Always

parts

of

their

Looper

in

the

reason

the

of

will

is

is

complete

the

book

facilitate

known.

column

the

use

are

reference

illustration.

the

part

sub-assemblies

descriptions

Driving

Bearing

Oil

Ball

Bearing

example

that

Cap

Splasher

Joint

Guide

Cap

shown

replacement

sub-assembly

will

be

found a numerical

locating

Reference

number

which

under

numbers

listed

can

the

only.

numbers

in

the

second

be

furnished

description

Description

Lever

Screw.

Crarik

Assembly

lower----------------------

---------------------------------Fork

S~rew.

above

should

the

--------------------------

upper----------------------

that

the

eccentric

of

these

illustration

parts

be

ordered.

index

individually

of

and

and

merely

should

never

column.

for

of

the

--------------

and

all

the

description

indicate

be

repairs

main

bearing

is

notre-

parts

when

used

are

sub-

Amt.

Req.

1

2

1

1

2

are

shown

only

Where

some

of

the

identification

Part

numbers

appear.

IMPORTANT!

OF

MACHINE

Success

UNION

oration.

to

Maximum

the

SPECIAL

its

most

efficiency

Genuine

parts

is

are

your

stamped

guarantee

the

construction

smaller

letter

is

represent

ON

FOR

WHICH

USE

in

the

operation

Needles

subsidiaries

approved

needles

with

of

parts.

and

stamped

ALL

PART

GENUINE

and

and

scientific

and

durability

are

packaged

the

Union

the

highest

IDENTIFYING

permits.

on

in

the

ORDERS,

each

those

to

distinguish

same

part.

PLEASE

IS

ORDERED.

NEEDLES

of

these

Repair

machines

Parts

authorized

principles.

are

assured.

with

labels

Special

quality

PARTS

part

is

where

the

the

regardless

INCLUDE

AND

as

furnished

distributors.

and

marked

trademark.

in

materials

stampedwith

construction

part

from

of

PART

REPAIR

can

be

PARTS

secured

by

They

are

made

~

U S

Emblem.

and

workmanship.

the

the

are

with

its

part

number.

does

similar

catalog

not

ones.

in

permit,

which

NAMEANDSTYLE

only

Union

designed

utmost

with

Special

oo

.

Genuine

Each

genuine

according

precision.

repair

trademark

On

an

they

Corp-

TERMS

Prices

are

forwarded

otherwise

are

net

f.

directed.

o.

cash

b.

A

charge

and

are

shipping

point.

is

subject

made

to

Parcel

to

cover

change

Post

postage

without

shipments

18

and

notice.

are

insured

insurance.

All

shipments

unless

Page 19

TORQUE

REQUIREMENTS

Torque

a

distance

driver.

amount

All

unless

by

hand

The

(measured

by a lever

etc.

of

straps

otherwise

as

Many

torque

and

tightly

screws

in

inch-pounds)

(in

inches

of

these

will

tighten

eccentrics

noted.

as

requiring a specific

All

possible,

or

devices

the

part

should

other

unless

is a rotating

feet).

nuts,

This

are

to

the

be

tightened

otherwise

torque,

is

accomplished

available,

correct

to

bolts,

screws,

noted.

will

force

which

amount

19-21

be

indicated

(in

pounds)

by a wrench,

when

and

inch-pounds

etc.,

set

no

should

on

the

applied

at

the

tighter.

(22-24

be

picture

through

screw

proper

em/kg)

tightened

plates.

19

•

Page 20

1

l

6

8

9

10

•

CAUTIO~!

Fi

ll oil

rese.

efore starti

b

i\

lachine has

drained bP.fore

s hipping .

.

r m r

ng.

been

20

Page 21

MAIN

FRAME,

CAST-OFF

PLATE

AND

MISCELLANEOUS COVERS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31.

32

33

34

35

36

36A

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

Part

No.

22829

56382

J

56382 K

56382 F

22848

56382 L

22548

56382 D

56382 E

56382 B

56382 M

22733 E

22541

c

56382 c

90

22539 s

52882 y

51282 AE

22894 E

57770

22539 G

57882 E

357

57831

22564 B

57882 B

22569

c

57882

227'

33

c

22513

35731 A

22542

605

A

57944 B

57944 A

57844 A

57944

95

57844 B

57858

57844

57892 A

80665 F

57892

C-5

57892 B

22848

20'

51758

22585

c

539

22889 A