Page 1

CATALOG

1

33M

F

ourth

STYLES

57800E

57800M

57800N

57800P

57800U

57800V

57800W

Edition

NO.

Adjusting instructions and

illustrated parts list

'

57800X

®

-

-

Class 5 7 800 - Advanced

di

fferential feed, coverseaming machines

Se

rles,

Finest Quality

Page 2

CATALOG

NO.

133

M

ADJUSTING

ILLUSTRATED

ADVANCED

SERIES,

COVERSEAMING

57800

57800

57800

57800

E

M

N

P

Fourth Edition

©

1975, 1979,

INSTRUCTIONS

PARTS

CLASS

LIST

57800

DIFFERENTIAL

MACHINES

STYLES

57800

57800

57800

57800

1981

AND

FOR

FEED

U

V

W

X

Union

Rights

By

Special Corporation

Reserved

Printed in

in

All

U.S.A.

November, l 981

2

Countries

Page 3

IDENTIFICATION

OF

MACHINES

Each

stamped

The

Advanced

er,

UNION

in the

serial

one

spreader,

SPECIAL

machine

style

number

is

high speed,

offset

plate

stamped

medium

matic lubricating system.

(Depending

on

operation).

(209.6mm).

57800

E Three needle,

five

ine. Typical application and

legs of girdles

57800

Standard

M Similar to Style

application light

Gauge

to

medium

No.

For

attaching cuffs in

weight material.

carries a style

affixed to the

in the casting

CLASS

duty,

and

Needle

Maximum

flat

tandem

Type

work

MACHINE

thread interlock

For

on

medium

weight material.

16.

57800

E except

number,

right

at

front

the

DESCRIPTION

bed

machine.

top adjusted

121

GBS.

space to

differential

Maximum

right

STYLES

stitch,

joining panels

offset

one

differential

operation to knitted undergarments

which

on

this

of the machine.

right

Two

rear

and

three needle,

recommended

of

needle bar, 8 1/4 inches

tandem

or

attaching

Seam

differential

specification

feed machine. Typical

class

machine

is

base of machine.

one

loop-

feed, enclosed auto-

speed

elastic

5500

R.P.M.

feed

machto waists

605

LSa-1.

on

57800

N Similar to Style

seaming

57800 P Two

Typical application arm-holes

Fitted with treadle operated

602

BSa-1.

57800

'

U Similar to Style

to knitted undergarments

tension. Standard

l 1/4 inches (19.0, 22.2, 25.4,

57800

V Similar to Style

borders to the leg openings

ation

602

(12.7, 15.9, 19.0, 22.2, 25.4,

57800

W Similar to Style

application ted undergarments

Gauge Nos.

(19.0, 22.2, 25.4,

on

men's

57800

and

boy's knit underwear

E.

Typical application -

needle, four thread interlock

For

of

knitted

attaching

athletic

shirts

flat

intermittent

Standard

Gauge

57800

Gauge

No.

8.

P.

Typical application -

on

light

Nos. 8 and

to

12. Standard finished widths 3/4, 7/8,

31.8mm).

BSb-1.

57800

Standard finished widths

U.

Typical application -

on

briefs

31.8mm).

14

57800

For

attaching

and

sweatshirts.

and

16. Standard finished widths 3/4,

U except three needle,

wide

collarettes

Seam

31.8mm).

on

medium

stitch,

knit

made

from

strip

medium

and

weight material. Constant

similar

1/2,

and

specification

For

weight material.

offset

split

tube borders to

light

tension.

operations.

5/8,

five

split

single operation crotch

differential

feed

necks

machine.

and

weight knitted fabrics.

For

attaching

Seam

specification

collarettes

strip

For

attaching

3/4,

7/8,

split

Seam

1,

specific-

l 1/4 inches

tube

thread machine. Typical

tube borders to knit-

605

7/8,

BSa-1.

1,

1 1/4 inches

Standard

l,

57800

X Similar to

undergarments

57800

and

E.

for

decorative

Typical application -

stitching.

3

For

patch operations

on

knit

Page 4

SAFETY

RULES

A

CAUTION

THIS

TO

PREVENT

-

All

power

justing or replacing parts.

-

Wear

-

All

degrees

safety glasses.

shields

DO

NOT

tamper

Use a straight

F.

SAFETY

PERSONAL

sources to the

and

with safety shields, guards,

This

SYMBOL

INJURY:

guards

mineral oil with a saybolt viscosity of

is

equivalent to

INDICATES

machine

MUST

be

YOUR

MUST

in position before operating

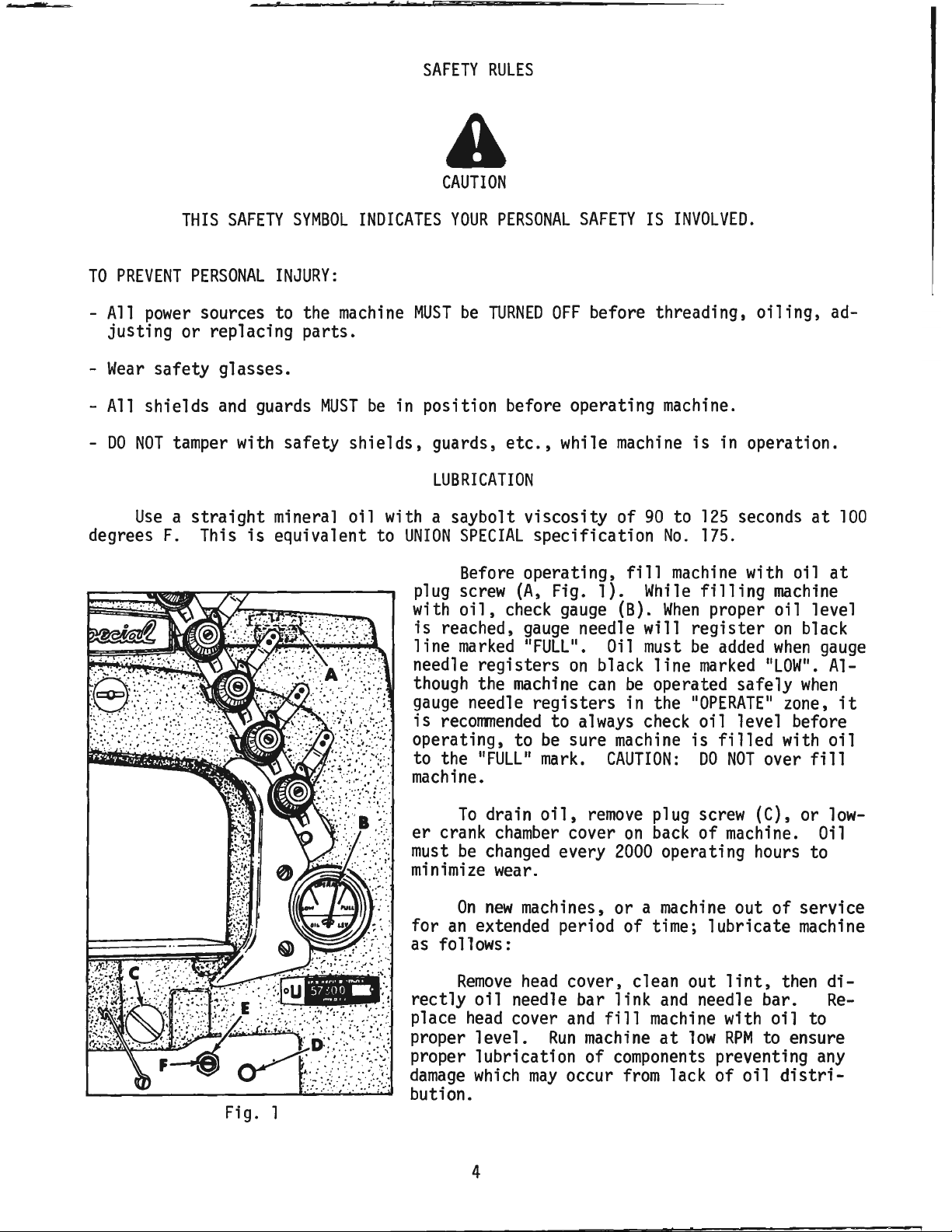

LUBRICATION

UNION

plug

with

is

reached,

line

needle registers

though

gauge

is

recommended

operating, to

to the 11FULL

machine.

PERSONAL

be

TURNED

etc.,

SPECIAL

Before

screw

oil,

check

marked 11FULL

the

needle

OFF

while

specification

operating,

(A,

Fig. 1).

gauge

gauge

machine

11

11

on

registers

to

be

sure

mark.

SAFETY

before threading,

needle will

•

black

can

always

IS

machine

90

fill

While

(B).

Oil

must

be

in the

check

machine

CAUTION:

INVOLVED.

oiling,

machine.

is

in operation.

to

125

seconds

No.

175.

machine

When

register

be

line

operated safely

"OPERATE"

is

with oil

filling

proper oil level

added

marked

oil

filled

DO

machine

on

when

"LOW".

zone,

level before

with

NOT

over

ad-

at

at

black

gauge

Al-

when

oil

fill

100

it

To

Fig. l

drain

er

crank

must

minimize

for

as

rectly

place

proper level.

proper lubrication of

damage

bution.

be

changed

On

new

an

extended period of time; lubricate

follows:

Remove

oil

head

which

4

oil,

chamber

every

wear

.

machines, or a

head

needle bar link

cover

Run

may

remove

cover

cover, clean out

and

fill

machine

occur

plug

screw

on

back

2000

machine

components

from

of

operating

machine

and

needle bar.

at

low

lack of

(C), or

machine.

hours

out of service

lint,

with oil to

RPM

to ensure

preventing

oil

Oil

to

machine

then

any

distri-

low-

diRe-

Page 5

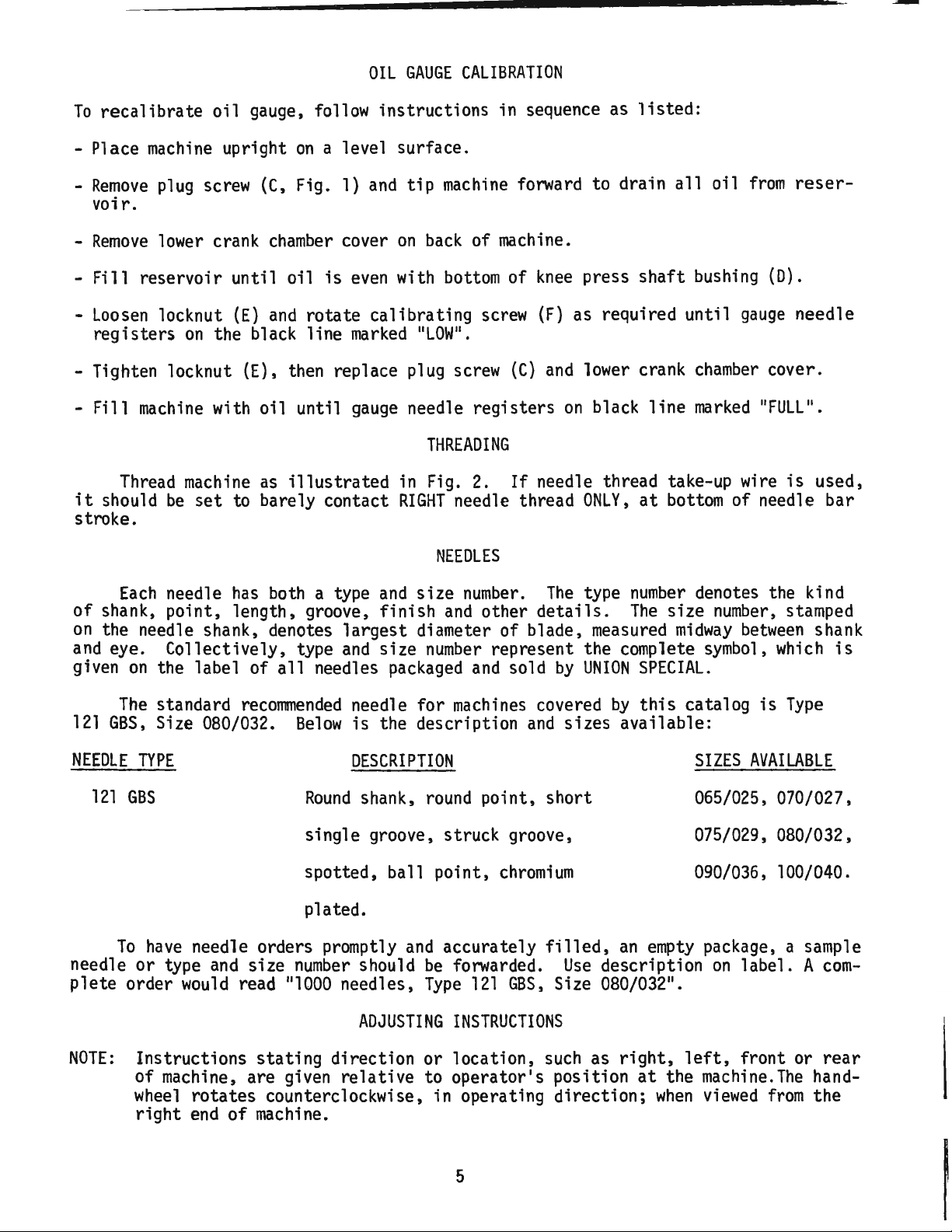

To

recalibrate

OIL

GAUGE

oil

gauge, follow instructions in sequence as

CALIBRATION

listed

:

- Place

-

Remove

machine

plug

screw

upright

(C,

on

Fig.

voir.

-

Remove

-

Fill

-

Loosen

registers on

- Tighten locknut

- Fil l

it

should

lowe

r crank

reservoir until oil

locknut (E)

the black line

(E},

machine

Thread

with oil until

machine

be set

to barely contact

as

chamber

and

then

illustrated

stroke.

Each

of

shank, point, length, groove,

on

the needle shank, denotes

and

eye. Collectively, type

given

needle

on

the label of

has

both

all

a level surface.

1)

and

tip

machine

cover

is

even

on

with

back

bottom

rotate calibrating

marked 11LOW".

replace plug

gauge

screw

needle registers

THREADING

in

Fig.

RIGHT

needl

NEEDLES

a type

needles

and

finish

largest

and

size

packaged

size

number.

and

diameter of blade,

number

forward to drain

of

machine.

of

knee

screw

2.

e thread

other

press

(F)

as required until

(C)

and

lower crank

on

If

needle thread take-up wire

ONLY,

The

type

details.

shaft

black

at

number

The

measured

represent the complete

and

sold

by

UNION

SPECIAL.

all

oil from

bushing

gauge

chamber

line marked

bottom

of

denotes the kind

size

number,

midway

between

symbol,

reser-

(D).

needle

cover.

"FULL

is

needl

e bar

stamped

which

".

used,

shank

is

The

121

GBS,

NEEDLE

121

GBS

To

n

ee

dle

pl

ete order

NOTE:

wheel

standard

Size 080/032.

recommended

Below

TYPE

Round

single groove, struck groove,

spotted, ball point,

plated.

have

needle orders promptly

or

type

and

size

number

would

Instructions

read 111000

stating

of machine, are given

right e

rotates

nd

counterclockwise, in operating direction;

of

machine.

needle for

is

the description

machines

DESCRIPTION

shank,

round

point, short

chromium

and

accurately

should

needles,

ADJUSTING

be

forwarded.

Type

121

GBS,

INSTRUCTIONS

direction or location,

relative

to operator's position

covered

and

sizes

filled,

Use

Size

such

by

this

available:

an

empty

description

080/032

as

right,

at

11

the

when

catalog

SIZES

is

Typ

AVAILABLE

065/025, 070/027,

075/029, 080/032,

090/036, 100/040.

package, a sample

on

label. A

•

left,

front or

machine.The

viewed

from

e

com-

rear

handthe

5

Page 6

Take-up

only right needle thread

at

wire must contact

bottom

of

stroke.

CAUTION: FIii oil reservoir before starting.

Machine has been drained before shipping.

THREADING

Thread

machines

machine

are threaded in a similar

to contact only the

all

Styles except

be

set

to contact

Oil

has

been

filled

before

starting

as

indicated.

RIGHT

57800

BOTH

V-8.

needle threads

drained

to operate. Refer to

AND

OILING

DIAGRAM

Three

manner.

needle thread

On

Style

from

machine

Fig. 2

FOR

CLASS

needle

machine

Needle

when

57800

when

needle bar

V-8,

needle thread take-up wire should

needle bar

before shipping

"LUBRICATION".

6

57800

MACHINES

illustrated,

but

two

thread take-up wire should

is

at

is

at

bottom

and

the reservoir

bottom

of stroke

of stroke.

must

needle

be

set

on

be

Page 7

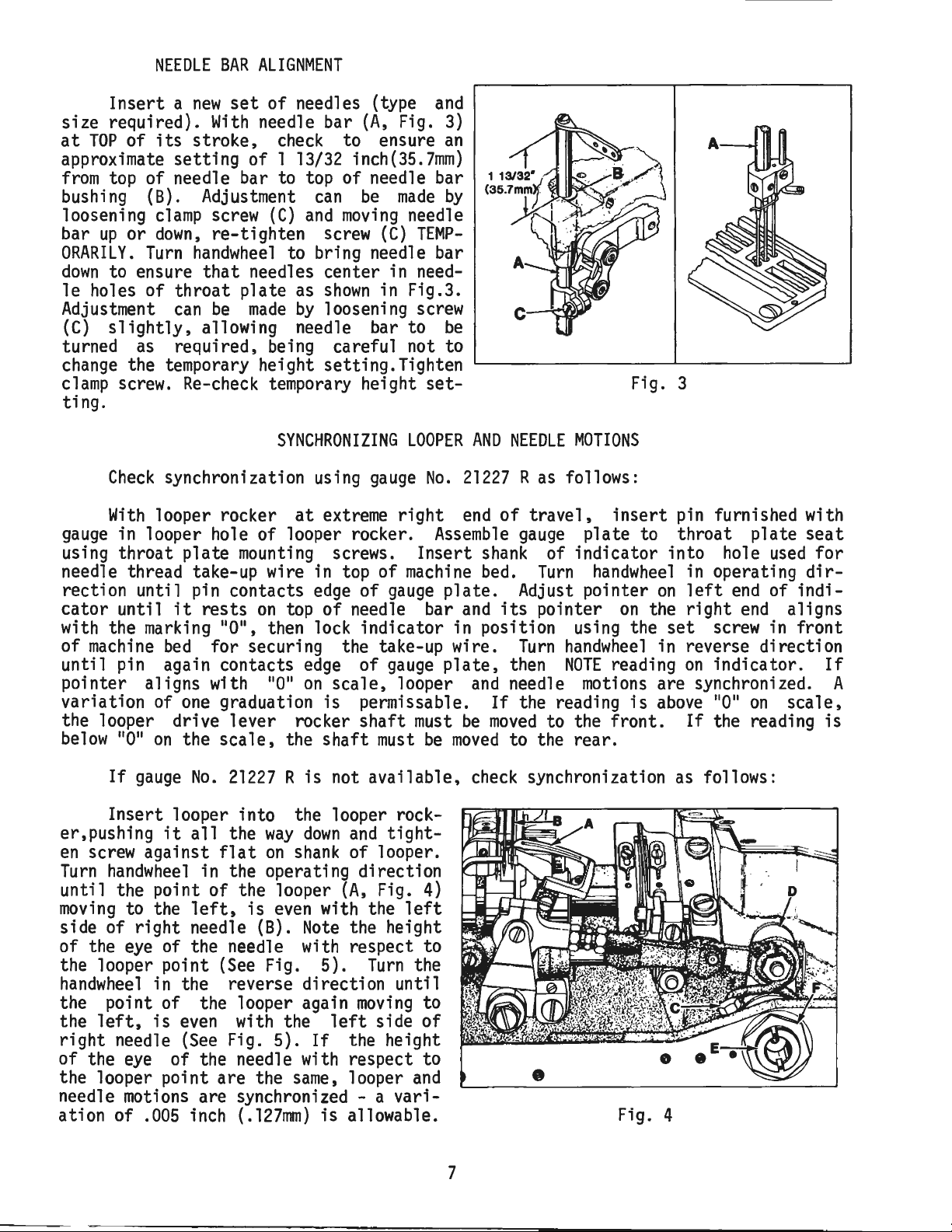

NEEDLE

BAR

ALIGNMENT

Insert a new

size required).

at

TOP

of

its

approximate

from

top

setting

of needle bar to top of needle bar

bushing (B). Adjustment

loosening

up

bar

ORARILY.

down

le

holes of throat plate as

Adjustment

(C)

turned

change

clamp

clamp

or

down,

Turn

to ensure

can

slightly,

as

required, being careful not to

the temporary height setting.Tighten..._

screw.

set

of needles (type

With

needle bar

stroke,

of l 13/32

screw

(C)

re-tighten

handwheel

that

needles center in

be

made

check

can

and

to bring needle bar

by

(A,

to ensure

inch(35.7mm)

be

moving

screw

shown

(C)

in Fig.3.

loosening

allowing needle bar to

Re-check

temporary

height

ting.

SYNCHRONIZING

Check

With

gauge

using throat plate

synchronization using

looper rocker

at

extreme

gauge

in looper hole of looper rocker.

mounting

screws. Insert

needle thread take-up wire in top of

rection until pin contacts

cator until

with the

machine

of

it

rests

marking

bed

on

"O",

for securing the take-up wire.

until pin again contacts

pointer aligns with 110"

variation of

the looper drive lever rocker

below 110

one

graduation

11

on

the scale, the shaft

edge

of

gauge

top

of needle bar

then lock indicator in position using the

edge

on

of

gauge

scale, looper

is

permissable.

shaft

must

and

Fig.

3)

an

made

by

needle

TEMP-

need-

screw

be

____________

set-

LOOPER

right

machine

AND

No.

21227

end

Assemble

shank

bed.

NEEDLE

Ras

of

travel,

gauge

of indicator into hole

Turn

plate. Adjust pointer

and

its

pointer

Turn

plate,

must

be

moved

then

and

needle

If

be

moved

to the rear.

the reading

to the front.

._

______

Fig. 3

MOTIONS

follows:

insert

pin furnished with

plate to throat plate

handwheel

on

handwheel

NOTE

reading

motions

is

in operating

on

left

end

the

right

set

end

screw

in reverse direction

on

indicator.

are synchronized. A

above

11

"0

on

If

the reading

seat

used

for

dir-

of indi-

aligns

in

front

If

scale,

is

_

If

gauge

No.

21227 R is

not available,

check

synchronization

Insert looper into the looper rocker,pushing

en

screw

Turn

handwheel

until the point of the looper

moving

side of right needle (B).

of the

the looper point

handwheel

the point of the looper again

the

left,

right

of

needle

the

the looper point are the

needle

ation of

it

all

the

way

down

and

against

flat

on

shank

of looper.

in the operating direction

(A,

to the

eye

left,

is

even

Note

with the

the height

of the needle with respect to

(See

Fig. 5).

Turn

in the reverse direction until

moving

is

eye

of

motions

.005

even

(See

with the

Fig. 5).

left

If

the height

the needle with respect to

same,

looper

are synchronized - a

inch

(.127ITITI)

is

allowable.

tight-

Fig.

4)

left

the

to

side of

and

vari-

•

7

Fig. 4

as

follows:

Page 8

SYNCHRONIZING

For Proper

the

se

SYNCHRONIZATION of

Looper

two Dimens ions w

& Needle

~

J.

-,:t,LJ.

i...._,,,==--_l·~=----

.3:•,.,,...

1)4

-~

Needl

OPERATING

Directi

~~

-1

e

In

on

3''11

ill

be the same

l

,,

Loop

FRONT of

N

ee

in

REVERSE

Dir

ec

~

er

in

dle

tion

LOOPER

AND

NEEDLE

If

the distance

of

point

is

turned in the operating

the looper

drive lever rocker

slightly

wards

NOTE:

towards the

the

The

Fig. 5

height.

MOTIONS

front

3/64 inch

is

from

shaft

acts

for

(Continued)

the

eye

of

is

greater

direction,

will

rear.

Moving

the reverse.

(l.2111Tl)

final

setting

the needle

when

the

the looper

have

to

be

the

dimension

of needle bar

to

the

handwheel

moved

shaft

shown

to-

in

Fig. 5

0

Fig. 6 .

left

At

side of

inside e

this

dge

time, there should

cone

{A).

of

looper drive lever

Adjust looper drive rocker lever

~

~!18

\tl

~ ~

gauge

If

(C)

against the

be

no

adjustment

clearance

is

left

necessary, loos

as required, then tighten s

shaft

Loosen

drive lever

Union

Special

threaded

er

shaft

usting screw (E).

required to position

screw

(D).

into

(C,

Fig. 4) in looper

A

rod

of

Screw

No.

22870 A can

the looper drive lever rock-

through the center

Tap

or

pull

shaft

for

chronization. Tighten screw

and

remove

shaft.

thrust

rod or

Loosen

screw

lock nut

adjusting screw

used

(F)

(E)

to 6 i

(7cm/kg);re-tighten lock nut

With

travel,

connecting

21227

gauge

sid

e of looper rocker

between

looper

at

extreme

check location of the

rod

bearing using

DC

as

shown

in Fig. 6. Place hole

over threaded stud, then

left

en

crew

ins ide e

clamp

(B).

scr

cone

dge

ew

of

(B)

(A)

and

as follows:

.146-40 thd.

be

of

thrust a

slightly

proper syn-

(C)

securely

to

position

and

TORQUE

n.

lbs.

(F)

securely.

right

gauge and

right

gauge

set

as

end

of

looper

No.

the

shown.

left

reposition

or

dj-

as

of

If

gauge

abl e,

ance be

check

tween

and centerline

should be 4 1/16 inch

in Fig. 6;

right end

Insert a new

required

Fig. 7

wheel

is

Loop

between

and

dimensions

8

in operating direction until looper

at

its

er ga

centerline

point

No.

21227

setting

the cente

of

loop

when

of

looper

travel.

LOOP

ER SE

needle

into

uge

right

extreme

("A"

right end

, Fig. 7) is the dist

of right needle

of

looper (C); see

on

following page.

DC

is

not

avail-

with a scale. Dist-

rline of

rocker

con

er drive lever stud

(103.2mm)

is

at its extreme

as

shown

TTINGS

of

type

and size

needle

seat.Turn

of trave

hand-

l.

anc

(B)

CHART for

e

e

Page 9

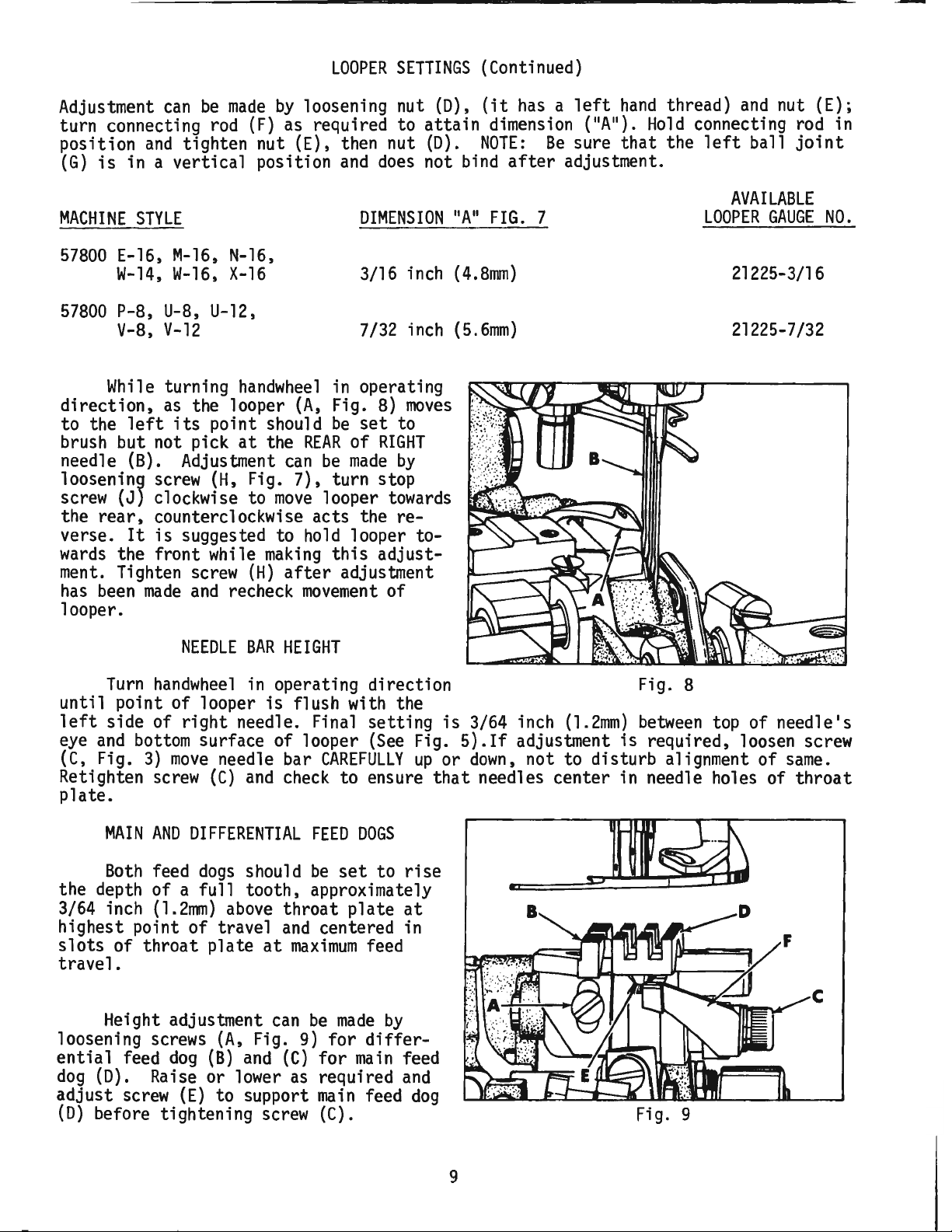

Adjustment

can

turn connecting

position

{G)

is

and

tighten nut (E), then nut

in a vertical position

be

rod

made

(F)

LOOPER

by

loosening nut

as required to

and

does

SETTINGS

(D),

(Continued)

(it

attain

(D).

NOTE:

not bind

has a left

dimension

Be

after

hand

11

(11A

).

Hold

sure

that

adjustment.

thread)

connecting

the

left

and

ball

nut (E);

rod

in

joint

MACHINE

57800

57800

direction,

to the

brush but not pick

STYLE

E-16,

W-14,

P-8,

V-8,

While

left

M-16,

W-16,

U-8,

U-12,

V-12

turning

as

the looper

its

point should

N-16,

X-16

handwheel

at

needle (8). Adjustment

loosenin9

screw

the

rear,

verse.

wards

ment.

has

been

screw

(J}

clockwise to

(H,

Fig. 7), turn stop

counterclockwise acts the re-

It

is

suggested to

the front while

Tighten

made

screw

and

making

(H)

recheck

looper.

NEEDLE

BAR

(A,

the

REAR

can

move

hold

after

movement

HEIGHT

DIMENSION

3/16

7/32

in

operating

Fig.

8)

be

set

of

RIGHT

be

made

looper

towards

looper to-

this

adjust-

adjustment

of

inch

inch

moves

to

by

11

11

A

FIG.

(4.8mm)

(5.6mm)

7

AVAILABLE

LOOPER

GAUGE NO.

21225-3/16

21225-7/32

Turn

until point of looper

left

eye

and

(C,

Fig.

Retighten

handwheel

side of

bottom

3)

screw

in

operating

is

flush with the

right

needle. Final

surface of looper

move

needle bar

(C)

and

check

dir

ection Fig. 8

setting

(See

Fig.

CAREFULLY

up

to ensure

plate.

MAIN

AND

Both

DIFFERENTIAL

feed

dogs

should

FEED

be

set

DOGS

to

rise

the depth of a full tooth, approximately

3/64 inch (l .

highest point of travel

slots

of

21t1n)

above

throat plate

throat plate

and

centered in

at

maximum

at

feed

travel.

Height adjustment

loosening screws

ential

dog

adjust

(D)

feed

(D).

screw

dog

Raise or

(E)

before tightening

(A,

(B)

to support

and

low

can

Fig.

(C)

er

screw

be

9)

for

as

required

main

(C).

made

for

main

by

differ-

feed

and

feed

dog

is 3/64 inch (1.

5).If

or

that

adjustment

down,

not to disturb alignment of

needles center in needle holes of

2mm)

is

between

required, loosen screw

Fig. 9

top

of needle's

same.

throat

C

9

Page 10

MAIN

AND

DIFFERENTIAL

FEED

DOGS

(Continued)

NOTE: A change

rear needle

To

center

feed

dog,

slightly

be

centered

left

as

required, retighten screws.

in

of

main

to

right,

main

guard

feed

feed

(F).

dog

loosen

throat plate

Fig.

10

dog

height will necessitate a

in

throat plate

screws

(A,

slots,

Fig. 10), reposition feed rocker

Loosen

slots

left

to

right,

Loosen

operating direction

tial

the

tial

feed

ance

feed indicator

same

feed

dog

from

screws

(G)

to

so

feed

throat

tighten

Turn

check

feed

dogs

slots.

check

front to

screws

(C)

back

allowing

retighten screws.

screw

(D),

and

(E)

amount

at

should

end

(F)

be

moved

dog

plate,

screws

handwheel

to ensure

and

of

travel.

extreme

have

of throat plate

allowing

differential

forward, rearward or turned

teeth are parallel to

across-the-line-of-feed.

(F).

in operating direction,

ample

both

ends

of the

or

setting

differential

for

(B)

main

rotate

feed

dog

handwheel

to

in

position differenso

both feeds

With

forward

1/32 inch (.8mm)clear-

end

slot.

have

differenof

travel,

Loosen

feed bar

top

of

Re-

clearance

between

of throat plate

The

differential

the selector slide

DIFFERENTIAL

feed

(E)

ratio

is

set

to the desired position.

FEED

by

loosening

accessible through the top of the cloth plate

ential feed selector

and

moving

This

of 2 to

by

hand,

of

its

it

Class of

1,

depending

making

stroke.

back

sure the

slide

(E)

decreases the

machine

on

has

a stretching

the length of

differential

toward

the front increases the

differential

stitch

feed

ratio

dog

This

(A,

thread)

stud

located under the

plate,

which

the

(moves

11

11

S

direction lengthens the stitch(moves

regulating stud

11

Fig.

locknut securely.

RATIO

on

The

the

screw

screw

left

(D,

and

side.

Fig.

selector

Moving

amount

feed. Retighten screw.

of 3/4 to l

set

at

the

clears the

CHANGING

Set the

is

accomplished

Fig.

11)

on

and

turning

in

the

is

marked

screw

clockwise shortens the

stitch

)

and

turning

main

stitch

1/2 turn

the

end

head

regulating stud

up

to a gathering

feed

main

feed

STITCH

to required length.

by

(it

of the

stitch

left

end

of the

with 11L

it

toward

11

in

a counterclockwise

the "L"). Retighten

10)

and

moving

slide

the

of

differential

are

differ-

ratio

dog.

at

Turn

the

machine

back

end

LENGTH

loosening locknut

has a left

stitch

adjusting

hand

regulating

screw

of the cloth

main

shaft (C),

and 11S

11

•

Turning

stitch

toward

the

stitch

(8)

10

Page 11

To

prevent destructive

gage

the 11U

11

shaped

CHANGING

damage

key

slot

STITCH

LENGTH

(Continued}

to the feed drive bearing, the

in

the ferrule

(E}.

Key

screw

(D}

must

en-

NOTE:

needle

Any

needle

At

extreme

guard

change

guard

REAR

(A,

in

stitch

setting.

NEEDLE

forward

Fig.

length will necessitate a corresponding

GUARD

end

of

travel,

12}

must

be

set

horizontally not to contact rear of

needle

inch

as

approach

(B}

with a

(.13mm}.

Guard

possible, yet

approximately 3/64 inch

maximum

should

have

its

clearance of

be

set

vertical face

(1.2mm}

needle point until point of looper

moving

Adjustment

(D},

to the

left,

can

reposition

be

guard

is

made

even

by

loosening

as

required

with the needle.

and

tighten screw.

NOTE:

Adjustment

of rear needle

guard

FRONT

rear

right

.005

as

low

of

(C},

screw

re-

will necessitate checking

NEEDLE

GUARD

Fig.

change

12

main

feed

in the rear

dog

height.

Front needle

left

rear

needle

time.

guard

by

needle

and

left

guard

Forward

as

required

loosening

(F}

should not

screws

NOTE: A change

ting.

The

thread tension release is

as

function

of the

foot

has

If

{A,

Fig.

end

the presser foot

of

reached

adjustment

13},

disc separator

there should

be

guard

towards

side of needle.

or rearward adjustments

and

in

stitch

its

travel

its

is

located

as

required. Retighten screw. After adjustment

no

binding

(E,

Fig.

the path of looper

make

12}

Looper

should

may

be

set

as

(C}

until point of looper passes to the

brush but not pick

contact with rear needle

can

be

made

by

loosening

retighten screws. Height or rotation of

{H},

reposition

length

THREAD

TENSION

and

is

is

as

WILL

required

NOT

require a

and

retighten screws.

change

RELEASE

set

correctly

when

raised to within 1/8 inch

entirely

released

when

highest position.

needed, loosen tension release lever

at

the

back

at

any

of the

point.

machine

and

move

low

as

possible, yet

at

the

guard

or right needle

screws

guard

in front needle

it

begins to

(3.2mm}

the presser

screw

tension

left

needle. Front

(G},

can

be

guard

push

the

at

any

reposition

acquired

set-

11

Fig.

13

Page 12

PRESSER

BAR

HEIGHT

1/16"

(1.6m~

Height

is

correct

ed

by

loosening stop

pressing foot

There

should

(1.6mm)

presser bar connection

14)

and

bed

casting

leased

throat

and

plate

of

presser bar

when

presser foot

collar

lifter

be

clearance

bottom

surface

when

lever

approximately 1/16 inch

between

foot

lifter

presser foot lying

with feed

and

of

dog

plate.

can

be

Adjustment

handwheel

of stroke.

to position needle bar

Loosen

made

screw

while holding presser foot

plate,

guide

clearance

position presser bar connection

as

required to

and

retighten screw.

attain

Set presser bar stop

14)

so

presser foot

spreader

when

raised.

does

not contact

(A,

Fig.

14)

can

be

remov-

(B)

and

de-

(B,

Fig. 13).

lower surface of

guide (C, Fig.

head

below

(D,

down

opening

lever

flat

by

turning

Fig.

on

throat

at

14)

in

is

re-

on

bottom

and

throat

and

specified

collar

(B,

Fig.

Set the arc travel of the spreader point

below,

by

loosening nut

to the desired

rocker shaft

rocker

nut

shaft

(H).

Fig.

amount

Fig.

(G).

arm

14

of arc

15

Adjustment

(J)

to positi

(E,

SPREADER

Fig.

14)

ADJUSTMENTS

(A)

and

moving

to point

the connecting link

travel.

Machine

57800

57800

57800

57800

57800

57800

57800

57800

57800

57800

57800

After

Styles

E-16

M-16

N-16

P-8

U-8

U-12

V-8

V-12

W-14

W-16

X-16

making

tightening nut (E),

arc

of

travel of link

tance

is

made by

on

the connecting link properly.

loosening nut

from

(B)

figure

15

(F)

Spreader

11/16

11

/ l 6 II ( l 7 ,

11/16

9/16

9/16

5/8

9/16

5/8

21 / 32

11

/ 1 6

11 / 16

the travel adjustment

check

the center

(H)

and

moving

to

see

(F)

is

equal

of

the spreader

the spreader

Be

sure to

as

up

or

Arc

11

(17

11

(17.5mm)

11

(14.3nm)

11

(14.3mm)

II

(

15 • 9mm)

11

(14.3mm)

11

(15.9mm)

II

( l 6 •

II

(

17 • 5mm

II ( l 7 •

that

retight

listed

down

Travel

.5mm)

5mm)

7mm)

5mm)

and

re-

the

dis-

)

en

12

Page 13

SPREADER

ADJUSTMENTS

(Continued)

With

and

spreader

travel,

(A,

Fig.

(5.6nun) to the

left

needle. Adjustment

loosening screws (B), reposition spreader

as

required being sure to

spreader holder

on

spreader holder (L) while tightening

screws

(C)

acts

er

holder

Bottom

set

21/64 inch

plate

of

travel,

the

shank

inch

by

loosening

er

as

NOTE:

needle bar

at

point

16)

(B,

as

(See

(.4

to

required

It

these adjustments to

ed

of

should extend

left

Fig.

lower

carrier.

surface

(8.3mm)

Fig. 16).

spreader

of

left

.8mm).

screws

and

may

be

dimensions.

at

extreme

thread carrying notch

of the centerline

carrier

16)

because spreader holder

thrust

of

At

must

needle

Adjustments

(D), reposition spread-

reti

necessary to coordinate

top

of

its

stroke

left

end

of

its

7/32

inch

can

be

made

push

down

(K,

Fig.

collar

spreader should

from

ghten screws.

top

extreme

be

set

by

1/64 to 1/32

attain

by

on

14)

and

for spread-

of

throat

right

to

clear

can

be

specifi-

of

be

end

made

up

Fig.

16

(

'

Stationary thread guide

proximately 3/32 inch

quired.

be

positioned with

the

guide (E).

stroke,

and

the clearance equivalent to the

Type 121

(2.mm).

as required.

ed

by

tric

rotating

the spreader should begin to

left

from

made

tric

Moveable

front

top of thread guide

Timing

as needle bar

bottom

by

against spacing washer

end

of

slot

With

lower surface

needle, approximately

Screw

of

the position of spreader drive eccen-

(A,

Fig.

handwheel

of

loosening screws (B),

needle bar

(H)

spreader travel

17)

stroke.

(2.4mm).

thread eyelet

its

eye

in stationary thread

of

will allow repositioning

on

the crankshaft.

in operating

rises

Adjustment

(E,

directly

at

thread

(E)

should

move

1/8 inch

(C)

Fig.

Attaching

(G)

should

over

bottom

eyelet

have

shank

.080

inch

is

determin-

direction,

to the

(3.8rrm)

can

advance

when

tightening screws

16)

of

(G)

of

a

While

be

or

retard

should

screws

9

be

set

to

clear

(F)

will allow repositioning as

--...;;;,,;,;o1,......

eccentric as required. Thrust eccen-

(B).

right

i;.;..,;;,.......

...,

Fig.

17

needle

__

_,

by

9

ap-

re-

NOTE:

Thread

machine

as indicated in Fig. 2.

13

Page 14

THREAD

TENSION

Pull the thread through the eyelets

tensions

at 4 oz.

thread tension

.---iiiii~

':..

-=-------:::----------

~~

E (85.05

(113.40 gr. )

at

3 oz. (85.05

i~

:#~~1t;~~~~~~~~~~~~

-----ra==='--------""------

Fig.

18

Set the needle thread

mounting

of

screw

(B).

frame

on

Styles

gr.)

on

---,

~~~

=-~,=.,~:Cf::.!~

- -

NEEDLE

THREAD

eyelet

and

set

the

left

and

57800

Styles

E,

M,

57800

Wand

N,

P,

X.

U,

the center needle should

gr.)

and

the

,

sion

at

4 oz.

(113.40

Set the spreader thread tension

ounce

sion.

(28.35

The

gr.)

adjusting nut

on

lever thread eyelet should

the tension

ounce

(14.18

type of thread

all

Styles.

The

ounces

---'

applied

the front of the

on

the spreader thread

gr.)

or

being

looper thread tension

(56.70

at

gr.)

the thread tension located

machine

gauge.

FRAME

(A,

Fig.

EYELET

18)

l inch

center needle thread

Set the

and

V.

right

gr.)

the

be

upper

below

left

needle

On

Style

set

at

3 oz.

needle thread ten-

on

all

Styles.

thread tenthe needle

be

set

so

is

more,

used.

on

(25.41l111)

all

just

depending

This

is

Styles.

above

above

applies to

set

It

the oil

the center

57800

at

1

that

1/2

on

the

at

2

is

on

N

amount

thread

J E

Fig.

19

of looper thread

in

system.

in

the system,

SPREADER

The

"U"

shaped

should

to

eyelet

eyelet

same

be

set

engage

the

(D)

by

makes

bottom

a looser cover thread, lowering

makes a tighter

LOOPER

To

properly control the looper thread,

follow instructions

THREAD

TAKE-UP

eyelet (C, Fig.

to allow the spreader thread

of

the needle lever

1/4 inch

(6.4mm).

cover thread.

THREAD

TAKE-UP

listed

looper thread take-up:

-

Loosen

cast-off

ing

screws

-

Loosen

as

extreme

across the

tighten

eyelets

screws

support plate

slots

- front to back, then tighten

(A).

screws

required,

left

cast-off

screws

(D)

(A,

Fig.

19)

(B)

(C)

and

adjust eyelets

so

when

the looper

the looper thread

support

(C). _

NOTE:

to the front to increase the

or to the rear to decrease the

18)

Raising the

for adjusting the

and

center

in

its

adjust-

(D)

is

at

its

is

taut

plate,

then

Re-position

amount

of

14

Page 15

LOOPER

-

To

adjust looper thread take-up (E), loosen screws (F),

through

til

of looper.

thread take-up.

screws

slot

in

cast-off

needles are descending

At

this

time

If

required,

{F)

be

sure take-up

support

the looper thread should cast

THREAD

and

the

make

is

centered

TAKE-UP

plate.

tip

Turn

of

(Continued)

handwheel

left

needle

the necessary adjustments . Prior to tightening

left

to right in

slot.

-

Loosen

then tighten

screw

(G)

and

screw

center

(G).

cast-off

wire

(H)

in

slot

in

operating direction

is

visible

off

the

cast-off

which

are accessible

on

the underside

high

lobe of looper

support plate

of looper thread take-up,

un-

- Retaining finger

is

set

properly

(J)

when

controls the

it

prevents the looper thread

amount

the looper blade, while looper travels

finger

parallel with the top surface of

centered

screw

take-up

(J),

(L)

slot,

loosen

in

retaining finger adjusting

and

screw

(K)

and

center the retaining finger

then tighten

screw

adjust retaining finger

cast-off

(L).

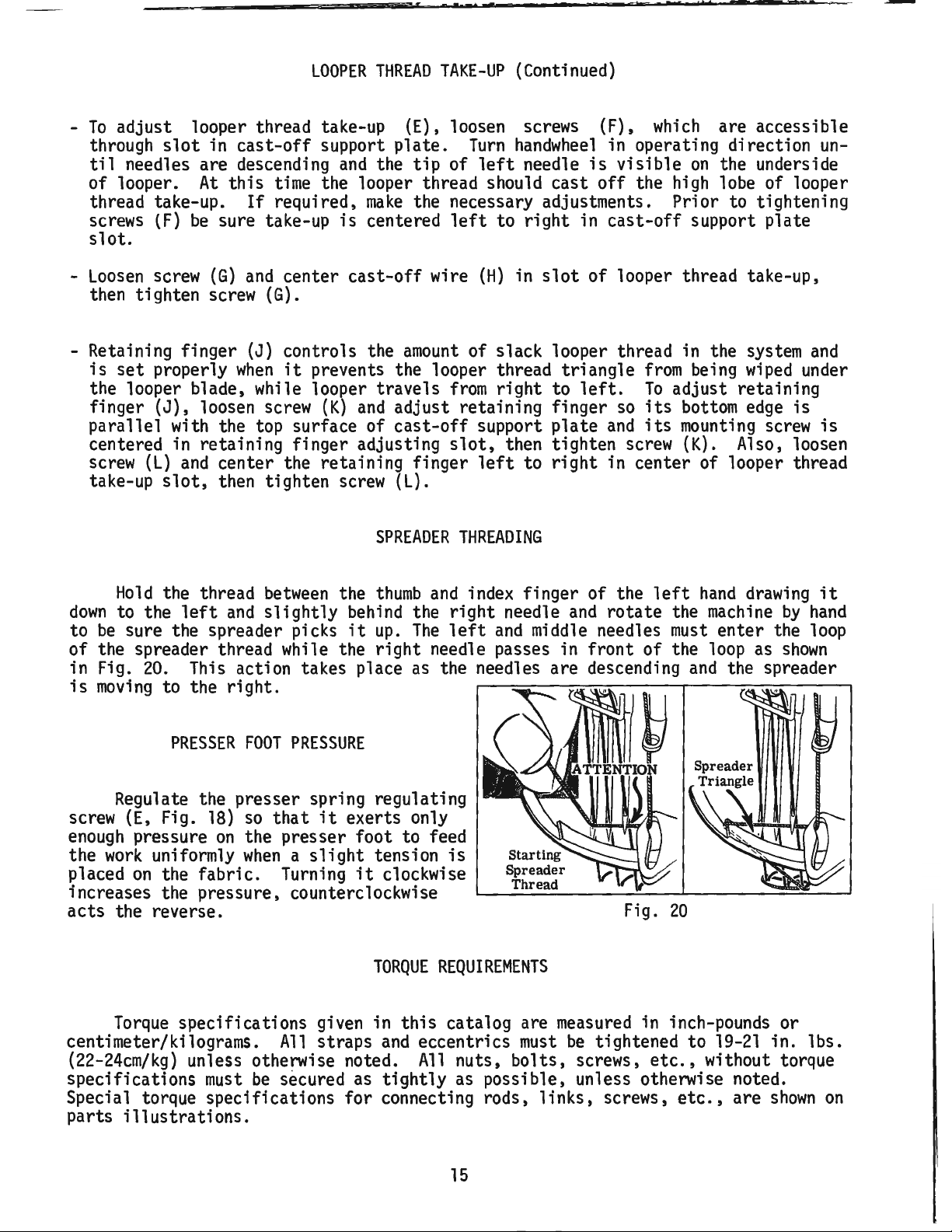

SPREADER

Hold

the thread

down

to

to the

be

sure the spreader picks

left

of the spreader thread while the

in Fig.

is

moving

20.

This action takes place

to the right.

PRESSER

and

FOOT

between

slightly

PRESSURE

the

behind

it

thumb

the right needle

up.

The

right

as

Regulate the presser spring regulating

screw

enough

the

placed

(E,

pressure

work

on

Fig.

18)

on

uniformly

the fabric.

so

that

it

exerts only

the presser foot to feed

when a slight

Turning

tension

it

clockwise

increases the pressure, counterclockwise

acts the reverse.

of slack looper thread in the

from

support

slot,

left

triangle

right

to

left.

plate

then tighten

to

right

from

To

adjust retaining

so

its

bottom

and

its

mounting

screw

(K).

in center of looper thread

THREADING

and

index finger of the

and

left

and

middle

needles

left

rotate

the

must

needle passes in front of the

the needles are descending

and

is

Fig.

20

system

being

wiped

edge

Also, loosen

hand

drawing

machine

enter the

loop

as

the spreader

under

is

screw

by

shown

and

is

it

hand

loop

TORQUE

Torque

centimeter/kilograms.

(22-24cm/kg)

specifications

specifications given in

All

straps

and

unless otherwise noted.

must

be

secured

as

tightly

Special torque specifications for connecting rods,

parts

illustrations.

REQUIREMENTS

this

catalog are

eccentrics

All

nuts,

as

possible, unless otherwise noted.

15

measured

must

bolts,

links,

in inch-pounds or

be

tightened to

screws,

screws,

etc.,

etc.,

19-21

in.

lbs.

without torque

are

shown

on

Page 16

SPECIAL

INSTRUCTIONS

Fig.

21

When

ing

related

sequence

l.

Install 110

adjusting needle lever or replac-

as

needle lever stud

NEEDLE

parts,

listed:

11

rings

LEVER

follow instructions in

(A,

Fig.

(B)

and

(C).

2.

With

needle lever

positioned properly;

through hole in needle lever until

shoulder contacts the needle lever

the

word 11UP

position.

exists

stud

top

3.

(B)

of

Install

machine

pression

push

ring

machine

11

While

in the needle bar

with the front

temper

cups

and

bed.

(D)

in

machine

insert

on

stud

making

is

in the upright

sure

link,

set

bed.

load ring

(F)

onto stud (B), then

cups

through

(E)

21)

onto

thrust

stud

no

secure

screw

and

opening

collar

and

(B)

its

and

binding

in

com-

in

Fig.

Fig.

22

.045" ( 1.14mm)

23

ALIGNING

MAINSHAFT

4.

Install

being careful not to

Compress

ing

thrust

screw

collar

components

(G)

until

(C)

onto stud

damage 110

together

washer

11

by

(H)

against stud (B). Secure stud

position using the rear

bed.

of

5.

To

check

pression,

and

loosen rear

Thrust

-

.007

temper

remove

collar

(C)

inch (.08 -

load ring for proper

screw

set

should spring out

set

(G)

screw

.18mm).

screw

from

in top of

Compress

ring in reverse order, then tighten rear

set

screw.

6.

With

position,

its

stud.

their

of oil will

indented 11UP

install

hook

sets

When

hook

proper positions,the proper

be

lubricating needle lever

TO

CRANKSHAFT

11

on

stud (B)in upright

in

bearing

oil

and

oiler

supply hole

stud are secured in

channeled to stud for

(D).

(B)

ring.

tighen-

bottoms

(B)

in

in top

com-

stud

bed.

.003

load

(J)

so

(K)

of

amount

(B)

As

viewed

couplings

must

align with the

positioned

head

and

the

looking

must

align with the spots in the looper drive crank

laterally

bed

casting

down

flats

with

from

on

crankshaft

.045

as

shown

rear of

inch (1.

in

Fig.

machin

(D)

14nm)

23.

16

e, spot

and

mainshaft (E). Mainshaft

clearance

screws

between

(A,

Fig.

22)

in the

(B)

and

set

screws

must

the right side of

(C)

be

its

Page 17

ALIGNING

MAINSHAFT

TO

CRANKSHAFT

(Continued)

Looper

(.8mm)

are

made,

quence

Tighten spot screws

screws

21

in.

screws

screws

cm/kg), then, torque screws

19 -21

The

in the

with

bed

without touching.

holes

screws

oil

its

casting,

and

drive crank

clearance

it

for

best performance.

(C)

temporarily, to the crankshaft

lbs.

(A)

and

(F)

to

in.

lbs.

oil

between

is

very important

(22 -24

set

screws (C). Re-torque

19 -21

(22 -24

drip

plate

reservoir

tip

in the recessed cut out in the

as

far

It

can

be

adjusted

(B) in top of the

(B,

cm/kg).

in.

(A,

should

to

the

has

Fig.

it

and

mainshaft

that

(A)

temporarily, to the looper drive crank. Tighten s

Loosen

lbs.

(22 -24

(A

and

cm/kg).

Fig. 24)1ocated

be

positioned

left

as possible

elongated

by

loosening (2)

oil

reservoir

22)

must

the couplings

spot

C)

to

mounting

back

cover to position as required, retighten

screws.

be

positioned

(E)

as

and

mainshaft.

shown

are

laterally

in Fig.22.

with 1/32 inch

Once

these

settings

tightened in the following

et

Torque

Fig.

screws

24

B

(F)

G

to

19

se-

-

•

0

17

Page 18

25

21

CAUTION!

Fi

ll

oil

before

starti

Machine

drained

shipping.

reservoir

before

has

ng.

been

.

36

18

Page 19

R

ef.

~

l

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

24A

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

68A

69

70

Part

No.

56382

56382

56382

56382

22829

56382

22848

22524

56382

22548

56382

56382

56382

22733

22541

56382

56382

90

56382

22539

21375

22829

98

98

158

52858

56391

52904

52804

87

22768

52904

50-216

22516

73

22569

69

57757

52958

73

52904

52958

22848

20

51858

22889

22585

95

57844

57858

57844

57892

80665

57892

57892

22542

57844

57944

57944

605

57882

22733

22569

22569

57882

22564

57831

22513

35731

22539

57770

56470

660-617

22894

Y

AB

K

J

AA

L

D

E

M

E

C

B

C

AC

S

AV

A

A

B

Block, clamping,

Plate, oil

Gasket

Cover,

Screw

Cover,

Screw

Screw----------------------------------------------------

Gasket

Screw----------------------------------------------------------

Cover,

Gasket

Gasket--------------------------------------------------------Plug

Screw,

Screw

Cover,

Gasket

Screw-------------------------------------------------------------

Oiler

Plug

Screw------------------------------------------------------

Guard,

Screw

Screw,

Screw,

Eyelet, looper thread,

Eyelet, looper thread, Style

B

E

U

E

A

C

H

B

D

A

G

B

A

C

B

Guard,

Finger,

Support,

Screw

Screw-----------------------------------------------------------------------------------

Support, retaining

Blk.

Pin,

Screw-----------------------------------------------------------------------------------

Screw

Screw-----------------------------------------------------------------------------------

Washer

Support,

Eyelet, take-up, looper

Screw

Wire,

Eyelet, looper

Screw

Washer----------------------------------------------------------------------------------

Eyelet, frame, needle

Plug

Screw,

Screw

Plug

Screw-------------------------------------------------------------------------Plate, mounting, spreader thread

Eyelet,

Guide,

A

F

C-5

B

A

A

B

A

C

C

C

B

B

A

G

Post, spreader

Disc, spreader

Spring, tension,

Nut,

spreader tension

Screw

Guide,

Eyelet,

Guide,

Screw

Cover,

Plug

Screw,

Screw,

Gasket---------------------------------------------------------------------------------Screw

Plate, guide, presser bar connection

Screw

Plate, guide, presser bar connection

Plug

Screw----------------------------------------------------------------Wire,

Wire,

Gasket, needle lever

E

Screw

MAIN

FRAME,

CAST-OFF

PLATE

AND

MISCELLANEOUS

COVERS

Description

oil

drip

drip--------------------------------

plate-------------------

----------------------------------------reservoir, looper drive

-----------------------------------------------------back,

oil

reservoir-----------------------------------------

shaft--------------------------

------------------------------------------

----------------------------------------------------crank

chamber,

lower-------------------------------------------------------------

--------------------------------------------------------

oil

filler----------------

-------------------------------------------------crank

chamber,

upper--------------------------------

-

-------------------------------------------------

----------------------------------------------------------------------------------

and

Baffle Plate

Assembly,

needle lever

belt--------------------------------------------

------------------------------------------

Styles

Styles

57800

57800

E,

M,

Na~ X -------------------------------------------------------

P,

U, V and\W

all

Styles except

--------------------~---------------------------------57800 P ----------------------------------------

--

----------

--

---------------------------------------

-

----------------

-.

---------------------------------------

--

---

-----------------------

------------------------

--

------------------------

--

---------------------------

-

--------------------

-

------------------------------

-

----------------------------

-

------------------------

---

-----------------------

-------------------------

------

-----

-

----------------------------

--------------------

--

--------------------

bearing-----------------------------------

-

---

------------

-

---------------

-----------------------

------------------

---

----------------------

57800 P ----------------------------------------------------

looper thread, Styles

retaining-----------------------------------------------------------------------

57800

E,

M, N and X -------------------------------------

retainer-----------------------------------------------------------------------

----------------------------------------------------------------------------------finger---------------------------------------------------------------

dowel

--------------------------------

--------------------------------

---------------------------------------------------------------------------------cast-off

plate-----------------------------------------------------------------

-

--------------------------------------------------

-

----------------------------------------

thread----------------------------------------------------------

----------------------------------------------------------------------------------cast-off--------------------------------------------------------------------------

thread-------------------------------------------------------------------

----------------------------------------------------------------------------------thread------------------------------------------------------------

adaptor---------------------------------------------------------------------

-----------------------------------------------------------------------------------

eyelet-------------------------------------------------

pull-off,

spreader

spreader

thread-------------------------------------------------------

thread-----------------------------------------------------------------tension-----------------------------------------------------------------tension------------------------------------------------------------------

spreader---------------------------------------------

-

-----------------

post--------------------------------------------------------------

----------------------------------------------------------------------------------thread---------------------------------------------------------------------------

thread--------------------------------------------------------------------------

spreader

----------------------------------------------------------------------------------head-----------------------------------------------------------------------------

and

needle

thread-------------------------------------------------------

Screw-------------------------------------------------------------------------

all

Styles except

Style

57800 E --------------------------------------------------------------------

-----------------------------------------------------------------------------------

-----------------------------------------------------------------------------------

take-up, needle thread,

take-up, needle thread, for

57800 E --------------------------------------------------------

{rear)----~----------------------------------------

(front)--------------------------------------------

-

all

Styles

No.

and

8 gauge, Style

gauges

except

57800

V-8

--------------------

57800 V ----------------------------

------------

eyelet-------------------------------------------------------------

-----------------------------------------------------------------------------------

Amt.

~

l

l

1

l

2

l

9

2

l

4

l

l

l

l

4

l

l

2

l

l

l

2

3

2

l

l

l

-

--

l

l

l

1

l

l

l

l

2

2

l

2

2

l

l

l

l

l

l

l

l

-

---

l

l

l

l

2

1

1

2

1

l

l

2

l

l

3

l

l

2

1

2

l

l

l

1

l

2

19

Page 20

20

Page 21

MAIN

FRAME,

BUSHINGS,

OIL

GAUGE

AND

MISCELLANEOUS

OILING

PARTS

Ref.

No.

l

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

Part

No.

59493

666-214

57849

52883

21657

56390

56390

660-665

22569

57890

56390

63494

63494

63494

660-455

56394

22793

56394

660-221

61256

11635

56394

22772

57894

56342

22539

52942

52942

50-895

56393

666-259

56390

57836

57842

56190

56393

35897

56390

57893

666-214

51257

56354

57846

56393

51154

A

R

X

H

J

B

B

E

K

F

G

B

C

G

B

A

B

D

R

AC

AB

P

B

B

Q

BV

G

AA

C

W

E

Blk.

Description

Oil

Pump

Assembly,

Felt,

intake-----------------------------------Bushing, spreader rocker

Bushing, presser foot

Bushing, release

Washer,

Ring,

thrust---------------------------------------

pilot-------------------

Bearing, needle

base------------------------------

shaft-----------------------

lifter

lever-------------------

lever-------------------------------

--

---------------------

thrust------------------------------Screw-----------------------------------------------Housing, crankshaft

Gasket, bushing

Oil

Gauge

Assembly-----------------------------------

bushing--------------------------

housing------------------------------

Nut---------------------------------------------

Washer,

11011

Connecting

Screw------------------------------------------------

Lever

Ring,

Assembly,

oil

Washer-----------------------------------------------

spring----------------------------------

Ring----------------------------------------

Rod,

oil

gauge----------------------------

oil

gauge

float----------------------

retaining----------------------------------

Nut--------------------------------------------------

Shaft,

Screw------------------------------------------------

Deflector,

oil

gauge

oil

adjusting---------------------------

---------------------------------------

Nut--------------------------------------------------

Screw,

Screw,

Bushing, looper drive lever

Bushing, looper rocker

Felt,

plug---------------------------------thrust

synchronizing

adjusting---------------shaft

(front)------------

shaft-------------------------

base

(front)-----------------------------------

-

-------

Felt-------------------------------------------------

Bushing, mainshaft

Bushing, feed rocker

Bushing, looper drive lever

Bushing, mainshaft,

Felt,

Filter,

base

oil

(rear)------------------------------------

intake----------------------------------Bushing, mainshaft

Oil

Pump

Assembly,

Felt,

intake-----------------------------------Bushing, presser bar

Bushing, needle bar

Bushing, spreader holder

Felt,

oil

attraction---------------------------------

Bushing, needle bar

(left)----------------------------

shaft---------------------------

shaft

(rear)-------------

middle---------------------------

(right)---------------------------

head------------------------------

(lower)-------------------------

(lower)--------------------------

carrier------------

-------

(upper)--------------------------

--

Amt.

~

1

1

2

1

1

4

2

2

3

1

1

1

1

1

1

1

1

1

1

2

l

l

2

1

1

l

1

1

2

l

1

1

2

l

1

1

l

l

l

1

1

l

l

1

1

21

Page 22

:,

:~

1

_____

IN,.

,

I

~

41

40

22

Page 23

CRANKSHAFT,

NEEDLE

LEVER,

NEEDLE

BAR

AND

LOOPER

DRIVING

PARTS

Ref.

~

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

Part

-1i2.:..

52817

E-8

52717

E-12

52817-14

52817-16

27-435

56958

A

22768

22586

R

51250

F

51250

D

660-625

56350

E

56350

F

660-614

29348

AF

56315

A

56350

G

77

56354

D

51254

K

22562

A

22564

660-215

52336

A

W0-3

56350

D

22768

56958

29066

R

22559

G

51216

N

51216

P

56316

61321

L

22574

57821

56321

N

22894

AB

660-202

29476

NZ

51216

M

56316

C

12934

A

22894

C

22894

D

56343

F

22653

L-8

29105

AM

22559

A

56343

E

56343

C

22587

K

57818-8

89

88

B

22738

F

28

B

41076

D

57842

52942

AA

660-202

CL-21

52942

AC

56342

E

56390

H

660-665

56390

J

Blk.

Description

Needle

Needle

Needle

Needle

Lockwasher,

Bar,

Bar,

Bar,

Bar,

marked

marked

marked

marked

needle bar

Eyelet, needle bar

11

"BG-8

, for

No.

"EJ-12", for

"BD-14",

"BD-16

11

, for

for

8 gauge, Styles

No.

12

14

16

gauge,

gauge,

gauge,

No.

No.

57800

P,

E,

U,

M,

Styles

Style

Styles

57800 U and V -----------

57800 W ------------------

57800

and V ---------

N,

Wand X --

eyelet------------------------------------------------

thread----------------------------------------------------

Screw------------------------------------------------------------------------

Screw------------------------------------------------------------------------

Gasket----------------------------------------------------------------------Washer-----------------------------------------------------------------------

Ring,

oil seal

Collar,

Cup,

Load

Lever

thrust,

compression-------------------------------------------------------------

Ring,

Assembly,

Lever,

--------------------------------------------------------------needle

lever-------------------------------------------------

temper------------------------------------------------------------

needle-------------------------------------------------------

needle-----------------------------------------------------------

Bushing------------------------------------------------------------

Screw-------------------------------------------------------------------

Link, needle

Connection, needle

bar--------------------------------------------------------

bar--------------------------------------------------

Screw-------------------------------------------------------------

Screw--------------------------------

Ring,

retaining---------------------------

link-----------------------------------

Pin,

Yarn,

Stud, needle

columbia

lever-----------------

(6

strands)----------------------------

Screw------------------------------------------------

Eyelet, thread, needle

Ball

Joint

Assembly,

lever-------------------------------------------------

needle lever connecting

---------

--------------------------

·

---------

-

---------------------------

---

-----------------

--

---

-------------------------------

------------------------

{upper)-------------------------

----------- -

Screw-------------------------------------------------------------------

Washer--------------------------------------------------------

---

-----------Nut-------------------------------------------------------------------------Connecting

Plate,

Screw-------------------------------------

Handwheel

Pulley----------------------------------

"O"

Ring--------------------------------

Crankshaft

Guide,

Rod,

needle

lever-------------------------------------------------

retaining-------------------------------------------------------------

--

---------------------------------

--------------------------------------------------------------------

Screw------------------------------

----

---------------------------------

---

----------------------------------

-------------------------------------

Assembly,

Bearing,

connecting

needle---------------------------------------------------------

.910

inch

(23.11mm)

throw-------------------------------

rod-------------------------------------------------------Nut-------------------------------------------------------------------------Oil

Pump

Oil

Pump

Screw,

Screw,

Assembly,

set------------------------------------------------------------------spot------------------------------------------------------------------

Coupling, looper drive

Assembly,

head

(See

Ref.

No.

base

{See