Page 1

®

INDUSTRIAL

SEWING

F

INEST

STYLES

57700KL

57700KM

QUALITY

LEWIS

•

COLUMBIA

MACHif!:IES

CLASS

ADVANCED

CATALOG

No.

T131KL

FIFTY

FLAT

THOUSAND

BED

WITH

"KLIPP-IT"

CHICAGO

57700

HIGH

SPEED

SERIES

MACHINES

Page 2

(Supplement

Catalo

g

to

No.

Catalog

T131

INSTRUCTIONS

FOR

KL

No.

131

M)

ADJUSTING

LIST

57700

First

AND

OF

CLASS

Styles

KL

OPERATING

PARTS

57700

57700

Edition

KM

Copyri

g

ht

19

71

By

Right

Union

s R e

Special

served

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

Print

SEWING

CHICAGO

e d

in

2

MACHINES

U.S.

Co.

Countries

A.

May.

1973

Page 3

.

U

INDUST ~

IAL

SEWING

EQUI

~

MEN

~

-----------

TECHHICAL

IHFORMATIOH

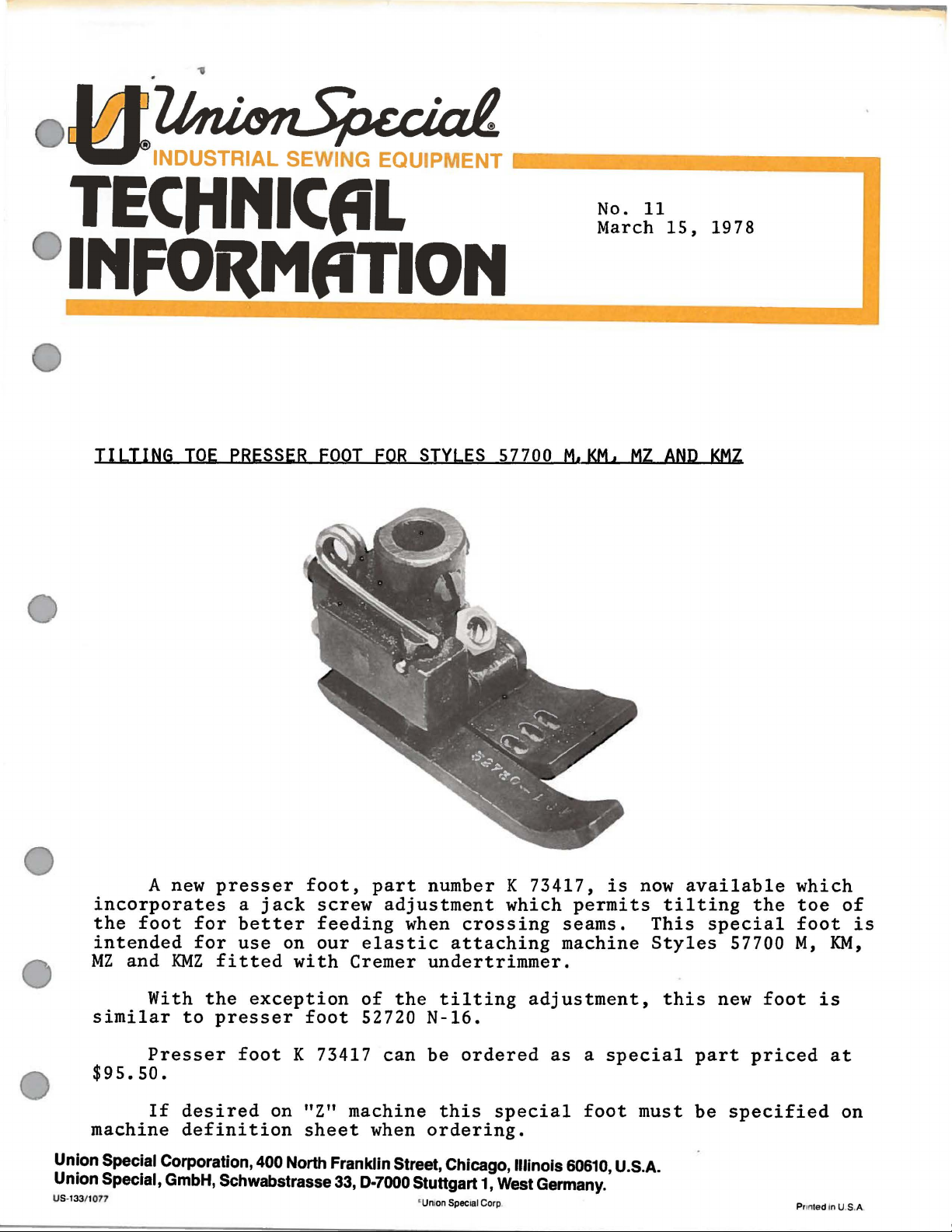

TILTING

TOE

PRESSER

FOOT

FOR

STYLES

57700

No. 11

March

M•KM•

MZ

15,

AND

1978

KMZ

A

new

presser

incorporates

the

foot

intended

MZ

and

KMZ

With

similar

$95.50.

machine

Union Special Corporation, 400 North Franklin Street, Chicago, Illinois

Union

US-133/ t

Special, GmbH, Schwabstrasse 33, D-7000 Stuttgart 1, West Germany.

On

to

Presser

If

desired

definition

for

for

fitted

the

presser

a

better

use

exception

foot

foot,

jack

on

with

foot

K 73417

on "Z"

sheet

part

screw

feeding

our

elastic

Cremer

of

52720

machine

when

number K 73417,

adjustment

when

the

can

crossing

attaching

undertrimmer.

tilting

N-16.

be

ordered

this

ordering.

' Unton Specllll Corp

special

which

machine

adjustment,

as a special

is

permits

seams.

foot

60610,

U.S.A.

now

tilting

This

Styles

this

must

available

the

special

57700

new

foot

part

be

priced

specified

which

toe

of

foot

M,

KM,

is

at

on

Pflnted In U.S.A.

is

Page 4

..

.

Page 5

IDENTIFICATION

OF

MACHINES

Each

the

machine.

numbers

"Style

changes

number.

Union

have

57700

are

Example:

Styles

which

57700

junction

differs

11

•

This

catalog

therewith.

57700 L are

ference

the

part.

number

Any

description

part

column

Advanced

Bearing

number

when

High

Needle

Mechanism,

Filtered

ings

Travel,

pared

for

for

Oil

Feed

Double

use

Tensions,

Special

Style

one

or

KL".

made

of

machines

from

is a supplement

illustrated.

and

part

under

in

the

ordering

Speed,

Bar

Single

Return

Bar

Disc

with

Knee

Maximum

machine

numbers

more

Special

are

letters

Style

in a standard

"Style

57700

similar

the

Style

number,

APPLICATION

Only

that

the

the

parts

At

the

on

the

opposite

is a component

description

second

repair

Two

Drive,

column,

parts.

and

Light

Reservoir,

Pumps

and

for

Feed

Take-up.

Press

Work

Space

is

identified

classified

suffixed,

numbers

machine,

KLZ".

in

construction

to

found

back

page

of

STYLES

Three

Weight

Enclosed

Head

Rocker

Large

for

Presser

to

Right

as

but

contain

a

in

that

OF

Catalog

on

Styles

are

illustrations

the

of

another

the

assembly

never

OF

use

MACHINES

Needle,

Presser

Positive

and

Base,

Shafts,

Handwheel

Foot

of

Needle

by a Style

standard

never

contain

the

"Z"

is

are

it

contains

CATALOO

No.

131 M

57700

part

number

part

the

One

Looper,

Needle

Greased

and

Lifter,

number

and

special.

the

letter

suffixed

grouped

no

letters.

and

KL

and

identifying

and

is

indicated

or

base

reference

Medium

Bar

and

Automatic

Bearings

and

Sealed,

Improved

Equipped

Bar 8 1/4

on a name

Standard

letter

"Z"

to

When

the

"Z".

only

Standard

under a Class

Example:

should

KM,

be

but

the

used

not

parts

description

by

indenting

part.

Always

number

in

Throw,

Needle

Bar

Lubricating

and

Bronze

Lateral

Belt

with

Guard.

Disc

Inches.

plate

on

Style

Example:

minor

Style

number

"Class

in

con-

on

Style

by

re-

identifies

its

use

the

the

first

Needle

Driving

System,

Bear-

Looper

Pre-

Thread

57700

KL

top

similar

gauge

needle.

57700

KM

both

with

knit

Standard

121

Each

denotes

number,

in

thousandths

the

size

needles

Two

and

bottom

operations

Nos.

Maximum

Three

top

and

ends

joined,

garments

gauge

GBS

needle.

Union

the

kind

stamped

of

number

packaged

needle

threads,

12

and

needle

bottom

and

No.

Maximum

Special

of

shank,

on

the

an

inch,

represent

and

machine,

for

on

medium

16.

Seam

recommended

machine.

threads.

to

rayon,

similar

16

only.

needle

point,

needle

shank,

midway

the

complete

sold

by

Union

equipped

with

hemming

to

medium

specification

speed

equipped

for

attaching

silk,

cotton,

operations

Seam

specification

recommended

NEEDLES

has

both a type

length,

groove,

denotes

between

symbol,

Special.

3

"KLIPP-IT"

sides

and

heavy

406-EFa-1

6000

R.

with

elastic

nylon

on

light

speed

and

largest

shank

bottoms

weight

P.

M.

"KLIPP-IT"

bands

and

wool,

to

medium

407-LSb-1

6000

size

finish

R.

number.

and

diameter

and

eye.

Collectively,

which

is

mechanism

of

bathrobes,

woven

fabrics.

inverted.

mechanism

in

garment

flat,

warped

weight

P.

M.

The

other

given

details.

of

blade,

on

that

cuts

Standard

Type

that

lengths

or

material.

inverted.

type

The

measured

the

the

label

both

and

128

GAS

cuts

ribbed

Type

number

size

type

and

of

for

or

all

Page 6

To

sample

on

label.

The

given

i

ndicated

type

numbers

sizes

have

needle,

A

complete

type

in

the

machine

are

available

needle

or

the

numbers

those

of

the

are

listed

NEEDLES

orders

type

order

of

style

recommended

recommended

promptly

and

size

would

the

needles

description.

below:

(Continued)

and

accurately

number

read:

to

needles tog

"1000

recommended

Other

produce

should

Needle

needles

the

ether

filled,

be

forwarded.

s,

for

most

with

an

Type

each

are

satisfactory

their

121 GBS,

style

available,

descriptions

empty

Use

of

package,

description

Size

machine

but

the

results.

and

a

032".

are

ones

The

the

Type

121

128

Thread

formation.

of

reputation

more

No .

GBS

GAS

Selection

should

Success

needles

than

Round

ted,

040.

Round

eye,

060, 067.

of

pass freely

in

the

packaged

for

producing

three-quarters

shank,

ball

shank,

spotted,

the

proper

operation

round

point,

round

chromium

needle

throu

of

under

our

highest

of a century.

Description

point,

chromium

point,

gh

the needle

Union

brand

quality

IDENTIFYING

short,

plated

short,

plated -sizes

size

is

Speci

al

name,

needles in

and

single

-sizes

double

determined

eye

in

machines

~,which

materials

PARTS

Sizes

groove,

groove,

032,

by

order

can

struck

025,

027,

struck

036, 040,

the

size

to

produce a good

be

secured

and

workmanship

groove,

029,

groove,

044,

of

thread

only

is

back

032,

049,

by

ed

spot-

036,

ball

054,

used.

stitch

use

by

for

a

Where

part

number.

letter

Each

it

appears.

IMPORTANT!

STYLE

Prices

ments

unless

construction

symbol

part

OF

MACHINE

are

are

forwarded

otherwise

A

part

which

number

strictly

directed.

permits,

too

small

distinguishes

represents

ON

ALL

FOR

net

f.

o.

ORDERS,

WHICH

cash and

b.

shipping point.

A

each

for

its

it

from

the

PART

char

ge is made

Union

complete

same

TERMS

are subject

Special

another

part,

PLEASE

IS

ORDERED.

Parcel

4

catalog

part

regardless

INCLUDE

to

to

cover

part

chan

Post

is

stamped

stamping

similar

ge

the postage a

in

of

the

PART

without

shipment

with

its catalog

is

identified

appearance.

catalog

NUMBER

notice.

s ar e

nd insurance.

in

All ship-

which

AND

insur

by

ed

a

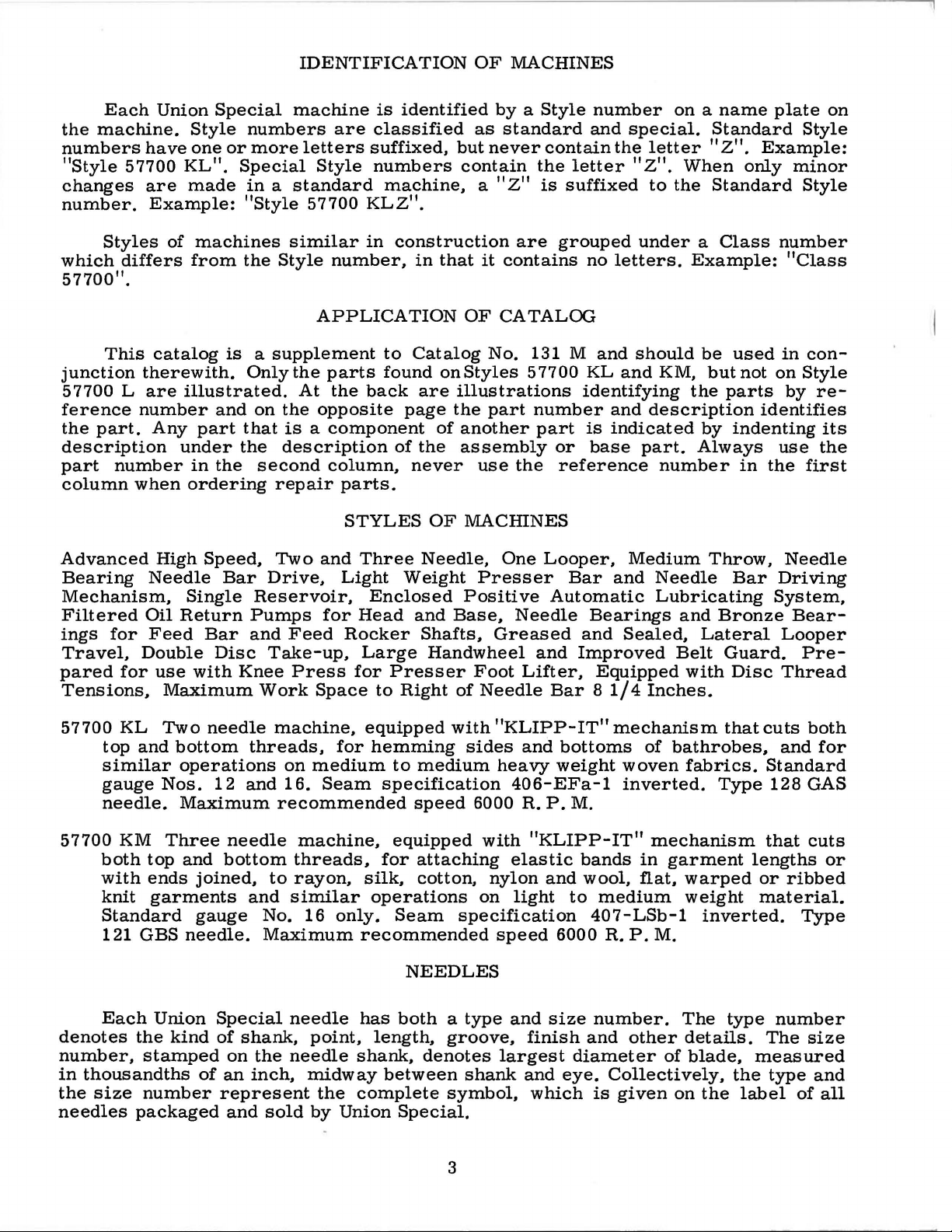

Page 7

Fig.

1

THREADING

Thread

picture

are

threaded

NOTE:

take-up

The

before

until

bolt

andaddoil

and

the

starting

needle

viscosity

no

oiling

Excessive

left

machine

shows

in

The

needle

wire

oil

has

of

of

whenneedleisin

other

of

the

oil

AND

as

indicated.

the

manner

substantially

thread

on

the

needle

been

drained

to

operate.

oil

gauge

90

to

125

than

oil

in

the

gauge.

OILING

in

which a two

the

nearest

bar

from

To

is

in

yellow

seconds

yellow

keeping

main

DIAGRAM

The

same

the

downstroke,

the

fill

machine

band

at

100°

band

the

main

reservoir

FOR

looper

needle

manner.

machine

machine

with

marked

Fahrenheit.

marked

reservoir

may

STYLES

threading

machine

bed

should

before

oil,

remove

"FULL".

"LOW".

filled

be

drained

57700

has

is

casting,

always

shipping

Maintain

The

is

at

been

be

plug

Use a straight

machineis

necessary.

the

5

KL

enlarged

threaded.

which

threaded

and

the

screw

oillevelin

plug

screw

and

KM

MACHINES

for

clarity.

Three

contacts

through

reservoir

in

automaticallylubricated

needle

the

top

cover

mineral

"OPERATE"

in

the

needle

the

must

main

The

right

and add

oil

above

machines

thread

needle.

be

filled

oil

of a Say-

position

frame

to

Page 8

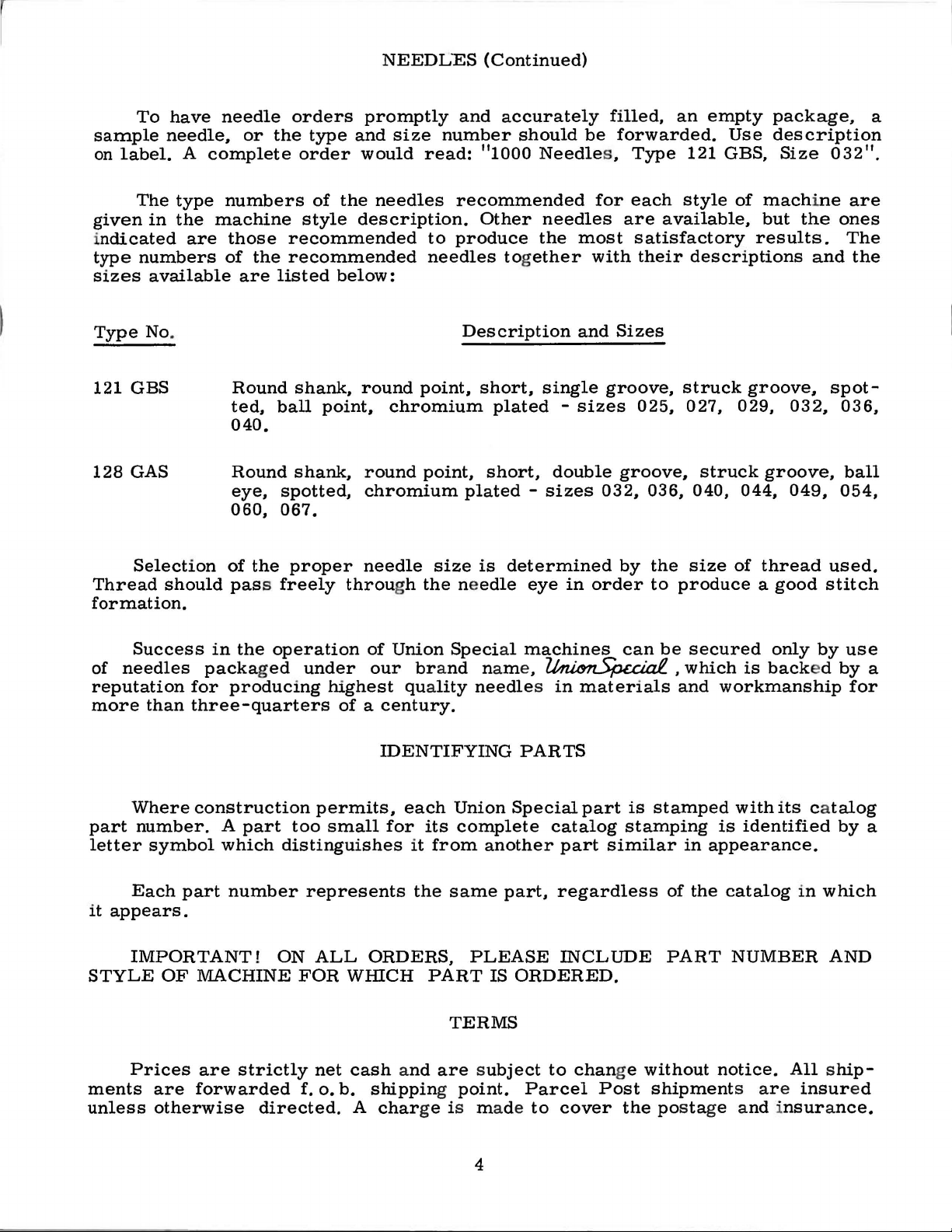

INSTRUCTIONS

LUBRICATION

FOR

MECHANICS

CAUTION!

reservoir

before

the

beginning

oil

to

Oil

must

the

various

damage.

RECOMMENDED

Use a straight

viscosity

renheit

alent

Fill

main

crank

oil

level

level

"Full".

in

yellow

CAUTION!

ines

It

or

one

extended

follows:

lint

and

the

needle

further

machine

tribute

of

in

the

to

Union

reservoir

chamber

at

gauge

when

Oil

needle

should

band

It

not

be

over

is

recommended

that

has

period

Remove

directly

bar.

hand

slowly

oil

to

90

to

main

Special

cover

marked

is

oiling

for

the

has

been

be

filled

to

operate.

OIL

mineral

125

seconds

reservoir.

specification

at

(A,

(B).

is

in

be

added

important

filled.

been

of

the

oil

out

time,

head

the

Replace

will

several

various

drained

to

the

Run

parts.

Full

oil

of a Saybolt

at

This

plug

screw

Fig.

Oil

is

yellow

2)

at

band

when

"Low".

that

these

that a new

of

service

be

lubricated

cover,

needle

head

be

bar

cover

required.

minutes

parts.

from

the

proper

machine

speed

100°

and

is

No.

in

Fah-

equi

174.

upper

check

maximum

marked

needle

mach-

machine,

for

clean

link

as

to

dis-

main

level

slowly

operation

v-

is

an

as

out

and

no

Run

reservoir

as

indicated

for

several

can

before

on

then

shipment,

oil

gauge

minutes

be

expected

(A,

to

A

so

the

Fig.

distribute

without

1)

Oil

may

by

removing

below

NOTE:

receive

the

Looper a void

oil

assembling

line

up

with

screw

is

"Changing

rocker

OIL

Should

sealed

GAUGE

The

oil

an

followed:

1.

Place

2.

Remove

to

be

drained

plug

cloth

plate

thru

be

sure

oil

holes

in

timespot.

Stitch

Length"

greased

gauge

adjustment

the

the

drain

oil

from

screw

at

front

and

the

mainshaft,

oil

holes

in

mainshaft

bearings.

is

set

become

machine

oil

from

main

(C,

Fig.

of

the

feed

lift

in

the

See

paragraph

for

repacking

at

the

factoryto

necessary,

upright

reservoir

the

reservoir.

reservoir

2)

located

machine.

eccentrics

so

when

eccentric

when

spot

on

feed

show

on a level

plug

screw

the

however,

table

(C,

6

proper

the

or

bench.

Fig.

Fig.

oil

level

following

2)

and

in

tip

machine

2

the

steps

reservoir.

should

forward

be

Page 9

3.

4.

5.

6.

7.

8.

Make

Remove

Fill

press

Loosen

or

"LOW".

Tighten

Add

"FULL".

sure

main

shaft

right

oil

all

lower

reservoir

bushing

lock

until

lock

so

that

oil

nut

the

nut

is

crank

(E)

gauge

(E)

gauge

OIL

GAUGE

drained

chamber

to a level

(D,

Fig.

on

calibrating

needle

and

replace

needle

from

cover,

2).

rests

rests

(Continued)

main

even

screw

plug

in

with

in

screw

the

located

the

reservoir.

the

(F),

and

middle

(C).

middle

at

the

bottom

turn

of

the

of

the

back

contour

the

screw

yellow

yellow

of

the

of

band

band

machine.

the

knee

to

the

left

marked

marked

Align

and

test

Machine

Style

57700

KL-12

Fig.

the

plate

3

needle

of

the

bar

right

Test

698

ing

below

wardly

wall

oiler

ALIGNING

(A,

gauge.

Plate

No.

BB-12

NEEDLE

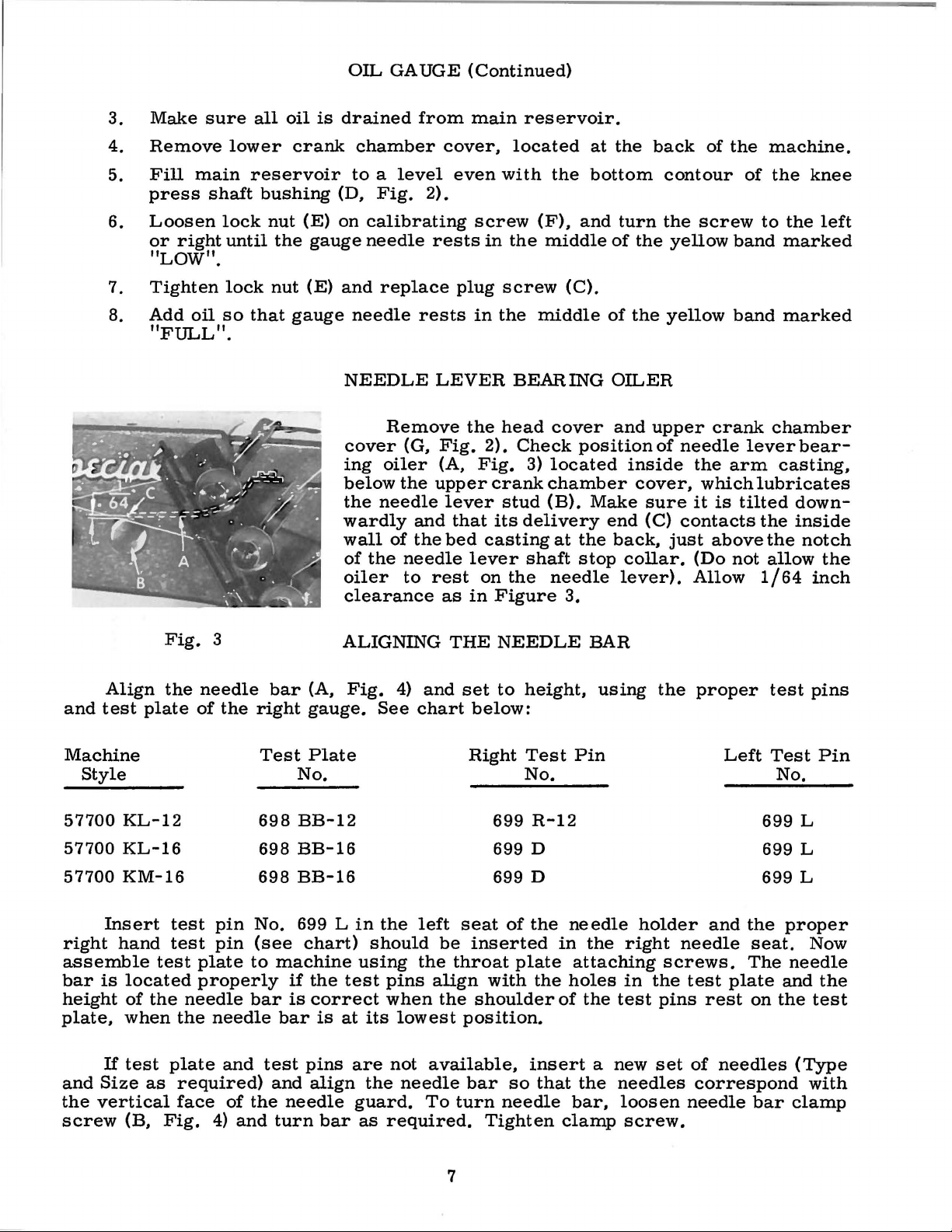

Remove

cover

the

of

clearance

Fig.

oiler

the

needle

of

the

needle

4)

See

(G,

and

the

to

LEVER

Fig.

(A,

upper

lever

that

bed

rest

as

THE

and

chart

the

2).

Fig.

crank

its

casting

lever

on

in

Figure

NEEDLE

set

to

below:

Right

699

BEARING

head

stud

cover

Check

3)

located

chamber

(B).

delivery

at

shaft

the

needle

height,

Test

No.

R-12

3.

OILER

and

positionof

inside

cover,

Make

the

stop

BAR

Pin

end

back,

collar.

lever).

using

sure

(C)

upper

needle

contacts

just

the

crank

the

arm

which

it

is

above

(Do

not

Allow

proper

Left

chamber

leverbear-

casting,

lubricates

tilted

the

the

allow

1/64

test

Test

No.

699

downinside

notch

L

the

inch

pins

Pin

57700

57700

right

assemble

bar

height

plate,

and

the

screw

KL-16

KM-16

Insert

hand

is

located

of

the

when

If

test

Size

as

vertical

(B,

test

test

test

plate

properly

needle

the

plate

required)

face

Fig.

pin

No.

pin

(see

to

bar

needle

and

of

the

4)

and

698

BB-16

698

BB-16

699 L

chart)

machine

if

is

bar

test

and

needle

turn

the

test

correct

is

at

pins

align

bar

in

the

should

using

pins

when

its

are

not

the

guard.

as

required.

left

be

the

align

the

lowest

available,

needle

To

699 D

699 D

seat

inserted

throat

with

shoulder

position.

bar

turn

Tighten

7

of

the

plate

the

insert

so

that

needle

in

of

clamp

needle

the

right

attaching

holes

bar.

the

a

the

in

test

new

needles

loosen

screw.

holder

needle

screws.

the

pins

set

and

the

seat.

The

test

plate

rest

on

of

needles

correspond

needle

bar

699 L

699

L

proper

needle

and

the

(Type

clamp

Now

the

test

with

Page 10

SYNCHRONIZING

LOOPER

AND

NEEDLE

MOTIONS

Insert

wheel

(A,

of

with

in

Fig.

rightneedle

respect

reverse

left

and

motions

with

ation

eye

of

the

pulley

respect

of.

the

looper

Moving

Moving

stud

(D,

rear

is

Fig.

(away

hammer,

move

plate,

oil

drive

is

up

stud,

stud

throat

reservoir

lever

required.

the

end

tighten

the

looperin

operating

5),

moving

(B).

to

the

looper

direction

is

even

until

with

synchronize,

to

the

005

inch

is

needle

is

drive

it

in

turned

shaft

the

opposite

of

the

to

looper

accomplished

5)

of

the

from

directly

on

forward

plate

back

rocker

Then,

play

between

the

looper

the

looper

direction

to

the

Note

until

left

theheight

point,

the

looper

the

left

the

height

looper

point

allowable.

the

in

point

the

of

operating

synchronizing

direction

drive

as

follows:

looper

drive

operator),

the

stud,

(toward

support,

cover,

shaft,

using

operator),

oil

then, a light

toward

the

the

looper

drive

is

then

point

side

of

will

If

the

looper

lever

Loosen

lever.

a

light

is

all

reservoir

the

looper

lever

rocker

the

point

even

with

ofthe

turn

again

of

the

the

eye

be

the

the

distance

direction,

stud

acts

the

shaft

To

tap

that

remove

operator,

drive

drive

on

the

and

turn

of

the

the

left

eye

ofthe

handwheel

moves

right

of

needle.

the

same. A vari-

from

is

greatest

move

(C)

to

the

reverse.

synchronizing

the

clamp

move

with

is

a

required.

the

top

cover

tap

on

the

is

lever

lever

rocker

shaft,

hand-

looper

side

needle

in

to

needle

when

rear.

screw

stud

small

cloth

and

looper

all

that

to

take

using

the

the

If

the

the

to

To

shaft

screw

and

(D,

Fig.

its

Fig.

4

synchronizing

5).

Fig.

5

With

extreme

travel,

the

looper

ing,

21227

Fig.

gauge

The

check

centerline

connecting

using

CX.

5)

over

left

should

right

side

rocker

ment

the

is

clamp

position

1

eve

r (

Tighten

gauge

ting

is

can

scale.

tween

looper

the

rocker

centerline

lever

inches

stud

(Fig.

the

looper

right

the

of

gauge

Remove

and

place

threaded

end

of

locate

of

cone

(F).

necessary,

screw

the

looper

G)

as

clamp

not

available,

be

checked

The

distance

centerline

cone

of

should

6).

at

end

of

location

the

rod

bear-

nut

hole

the

gauge

against

the

looper

If

adjust-

loosen

(D)

andre-

required,

screw.

with

of

and

the

looper

be 4 1/16

the

its

of

right

No.

(E,

in

stud.

the

drive

If

set-

a

be-

the

the

8

Page 11

SETTING

THE

LOOPER

Fig.

6

Insert

right

needle

specified.

3/16

looper

from

(B)

3/16

farthest

er

used

inch,

(A,

the

to

the

inch,

position

gauge

advantageously

adjustment.

for

needle

ting

and

the

various

adjustment

(C)

(it

has a left

nut

(D)

on

the

connecting

ward

ion.

(D),

left

tion

to

obtain

Retighten

then

ball

and

does

ment.

a

new

seat,

If

the

for

example,

Fig.

center

6)

of

point

when

the

to

No.

21225-3/16

Refer

type,

looper

looper

gauge

styles

is

required,

connecting

rod

the

both

nut

(C).

joint

is

not

needle

type

looper

so

the

the

of

the

looper

the

right.

in

to

of

machines.

hand

rod

forward

3/16

inch

nuts,

Make

in

vertical

bind

after

in

and

size

gauge

set

distance

right

needle

looper

is

can

making

chart

gauge

number

loosen

thread)

(E),

or

dim

first

sure

adjust-

the

as

is

the

is

at

its

Loop-

be

this

below-

set-

for

If

nut

and

turn

back-

ens-

nut

the

posi-

Machine

Styles

57700

57700

57700

moves

brushes,

Fig.

screw

KL-12

KL-16

KM-16

The

looper

to

the

but

If

adjustment

6)

and

clockwise

turn

counterclockwise

front

Tighten

adjustment.

while

lock

making

screw

Now

seat.

SETTING

On

is

correct

underside

left

side

dimension

loosen

down

not

to

needle

HEIGHT

Style

of

screw

as

required

disturb

bar

57700

when

the

of

should

the

either

is

left,

does

stop

sets

acts

insert

OF

the

looper

the

left

be

(B,

Fig.

and

alignment

up

Needle

Type

128

128

121

set

correctly

behind

not

pick

is

necessary,

screw

the

the

this

when

NEEDLE

KL,

the

top

(B),

needle.

1/64

4)

retighten

or

down.

GAS

GAS

GBS

the

needle,

at

the

(G)

looper

reverse.

adjustment

setting

another

height

of

its

with

the

inch.

and

If

move

screw.

of

the

in

line-of-feed,

rear

loosen

as

required.

to

the

Holding

is

obtained

needle

BAR

of

the

eye

is

looper

On

Style

adjustment

needle

needle

its

of

rear

may

in

needle

3/64

point

Care

bar

Looper

Setting

3/16

3/16"

point

the

lock

Turning

and

looper

prove

and

the

inch

flush

57700

is

bar

should

when

Gauge

7/32"

11

if,

(A,

Fig.

needle

screw

turning

to

helpful.

recheck

left

needle

(A,

Fig.

below

with

KM,

necessary,

(A)

up

be

taken

moving

as

(B).

(F,

stop

the

the

the

the

this

the

it

7)

it

8)

or

Looper

Number

21225-7/32

21225-3/16

21225-3/16

Fig.

7

Gauge

9

Page 12

SETTING

HEIGHT

OF

NEEDLE

BAR

(Continued)

NOTE:

bar.

right

descending

back

SETTING

(B)

the

approximately

are

travel.

feed

to

hold

and

the

CAUTION:

looper.

The

All

and

of

the

Set

so

there

tips

parallel

Adjust

dog,

feed

If

feed

turn

front

needles

left

looper.

THE

the

of

the

to

screw

teeth.

height

are

sides

needles

FEED

feed

is

maintain

dog

dog

See

dog

equal

teeth

3/64

with

the

in

teeth

(D)

Retighten

that

should

of

must

inch

the

supporting

position.

clockwise

there

be

to

have

needle

be

DOG

(A,

Fig.

clearance

extend

above

throat

this

setting.

are

not

nut

is

right

slots

the

sufficient

if

equal

deflected

plate

parallel

to

when

in

9)

in

on

all

depth

the

screw

Screw

lower

clearance

feed

test

plate

throat

alike

the

throat

sides.

of a tooth

throat

at

high

(C),

with

the

dog

space

plate.

See

plate

point

under

(D)

is

the

front

is

between

and

on

The

on

plate

that

and

used

throat

teeth

set

test

pins

the

the

or

of

the

plate,

and

properly.

underside

were

counterclockwise

used

loosen

of

feed

to

Fig.

nut

dog

align

8

(C,

to

and

needle

Fig.

raise

top

8)

of

Fig.

Should

move

backward,

clamps

the

feed

ward

nut.

CHANGING

length.

by

Fig.

thread)

regulating

stitch

the

the

feed

Set

loosening

rocker

rocker

as

needed

the

This

10)

(it

on

adjusting

9

it

be

feed

dog

loosen

feed

forward

STITCH

stitch

is

the

has

the

end

stud

and

or

rocker

rocker

sure

this

ion

of

stitch

necessary

forward

nut

(E)

which

rocker

and

and

to

accomplished

locknut

a

of

screw

arm

move

or

back-

retighten

LENGTH

required

left

the

turning

hand

stitch

(G)

Should

right,

(B)

to

the

adjustment.

When

the

feed

the

throat

length.

to

or

to

the

(F,

the

lo-

it

loosen

onto

desired

feed

the

dog

be

necessary

screws

the

feed

position

rocker

handwheel

plate

arm

should

slots

(A,

rocker

is

have

with

to

move

Fig.

and

(D)

does

turned

equal

feed

Fig.

the

feed

10)

which

shaft

retighten

(C)

not

bind

in

the

clearance

travel

10

dog

hold

and

move

screws.

after

operating

on

both

set

to

to

the

the

making

direct-

desired

left

feed

feed

Make

ends

10

Page 13

CHANGING

STITCH

LENGTH

(Continued)

cated

marked

stitch

under

with

regulating

lengthens

locknut

be

Start

beari~s

under

securely.

pressed

tapered

to

Setting

the

"L"

the

stitch

Fig.

in

flush

end

prevent

the

left

and

stud

11

of

Feed

end

of

"S".

toward

(moves

with

the

shaft

damage.

Dog".

the

cloth

Turning

the

stitch

casting.

first,

Check

Also

plate

the

'S")

screw

and

in

turning

regulating

Any

change

corresponding

setting.

The

feed

cation

be

10)

(D)

screws

shaft

Allen

or

repair

accomplished

and

remove

from

(A)

(C).

The

screw

bearings.

When

clean

the

can

Greased

If

twisting

and

tube

be

grease

To

for

proper

check

grease

to a void

supplied

bearings

sealed

assemble,

slightly

to

the

head

clockwise

it

stud

in

change

rocker

after

nut

machine

and

remove

shaft

(J)

and

packing

bearings

adjustment

see

that

of

the

main

shortens

shaft

the

in a counterclockwise

toward

stitch

as

follows:

(F).

by

can

remove

the

should

contamination.

under

are

reverse

when

there

the

length

in

the

assembly

years

of

Remove

rocking

stop

now

shaft

bearings,

be

applied

the

part

located

are

the

entering

of

feed

is

no

"L").

will

rear

may

operation.

Loosen

feed

slightly.

collar

be

withdrawn.

(K). Now,

the

Tube

number

at

(L,

replaced

above

the

dog

binding

(H),

which

stitch

(moves

direction

Retighten

necessitate

needle

require

This

nut

(E,

rocker

on

right

Loosen

parts

must

directly

of

2 860 4

M,

Fig.

they

procedure.

grease

as

described

at

any

is

the

guard

lubri-

can

Fig.

arm

Loosen

end

of

repack

be

from

grease

P.

10).

should

sealed

point.

a

SETTING

Set

it

does

at

is

permissible.

its

until

the

loosen

screw.

turn

not

its

most

vertical

the

needle.

screw

To

screw

clockwise

erly

set.

NOTE:

needle

A

guard

SETTING

On

Style

back

set

toward

toward

the

the

THE

the

rear

quite

forward

face

point

To

raise

(G)

to

raise

change

FRONT

the

front

path

REAR

needle

contact

It

should

approach

of

the

move

(F),

move

or

clockwise

it.

in

setting.

NEEDLE

57700

path

needle

of

the

NEEDLE

guard

the

point

looper

needle

needle

lower

Retighten

stitch

KL,

of

set

the

guard

looper

(E,

rear

of

travel.

be

set

within

(B).

guard

guard

needle

to

lower

screw

length

GUARD

the

looper

so

as

GUARD

Fig.

of

the

A

as

low

about

moving

forward

as

guard,

needle

will

require a change

front

as

it

that

it

it

moves

8)

horizontally

right

clearance

as

possible,

3/64

to

the

or

inch

backward,

required

loosen

guard

(F)

after

needle

moves

pushes

behind

needle

of.

of

left,

is

and

screw

or

guard

guard

behind

the

the

so

(A)

005

yet

the

needle,

even

merely

retighten

(F)

counter-

is

prop-

in

so

that

the

left

and

needles.

that

when

inch

have

with

and

rear

it

pushes

needle.

"center

The

On

looper

Style

Fig.

the

12

left

57700

needles",

may

needle

KM,

back

brush

11

Page 14

but

not

vertical

side

of

guard

loosen

To

raise,

tighten

pick

face

the

or

right

screws

lower

screws

at

push

left

SETTING

the

left

the

needle.

needle

(A,

Fig.

or

after

needle.

left

The

at

11),

rotate

guard

FRONT

needle

front

any

needle

is

It

should

until

needle

time.

move

needle

guard,

properly

NEEDLE

be

the

guard

To

move

guard

loosen

set.

GUARD

set

point

should

guard

as

of

the

forward

as

required

screws

(Continued)

low

as

possible,

looper

not

contact

or

and

(B),

is

just

the

backward,

retighten

move

yet

past

rear

guard

have

the

its

left

needle

merely

screws.

and

re-

NOTE:

A

change

setting.

THREAD

The

TENSION

thread

correctlywhen

the

presser

inch

tirely

has

tension

12),

and

of

the

released

reached

If

adjustment

release

located

move

tension

required.

adjustment

at

any

point.

SETTING

The

Fig.

lifter

1/16

(D,

Fig.

lever

down

height

4)

is

lever

inch

4)

is

released

below

HEIGHT

set

clearance

in

tension

it

begins

foot

is

raised

end

ofits

when

its

highest

lever

at

the

back

Retighten

there

should

of

the

correctly

(B,

Fig.

and

the

and

the

throat

stitch

RELEASE

release

to

to

travel

the

presser

position.

is

needed,

screw

of

the

disc

separator

screw.

be

OF

PRESSER

presser

if

12)

is

between

bottom

the

presser

plate.

length

is

function

within

and

is

loosen

(A,

machine

After

no

binding

BAR

bar

it

is

possible

fully

lower

surface

will

NOT

set

as

1/8

en-

foot

Fig.

as

(C,

depressed.

surface

of

head

foot

resting

require

to

remove

of

opening

Also

the

on

a

change

the

presser

there should

presser

in

the

the

throat

in

Fig.

bar

bed

plate,

front

needle

13

foot

when

be

approximately

connection

when

the

with

the

the

and

foot

feed

guard

foot

guide

lifter

dog

If

adjustment

bar

is

in

on

the

throat

driver

to

handwheel

removed

SETTING

Set

the

bar

thread

the

needle

Lower

Set

the

this

needle

attaching

the

low

plate

obtain

so

as

mentioned

needle

eyelet

bar

setting

screw

is

position.

the

that

needle

NEEDLE

(B),

thread

thread

(Fig.

needed,

turn

Loosen

surface,

1/16

inch

pry

setting

bar

in

previous

THREAD

thread

so

that

eyelet

take-up

when

for a smaller

frame

13),

eyelet

on

Style

handwheel

screw

up

is

in

paragraph.

wire

its

upper

the

needle

(E).

presser

and

tighten

its

high

TAKE-UP

(A,

surface

needle

thread

(C)

so

that

57700

KL;

in

operating

Then,

bar

connection

screw

position

WIRE

Fig.

13),

is

bar

has

loop

the

7/8

even

eyelet

inch

THREADING

Draw

piece

of

the

fabric.

looper

Refer

and

to

needle

threads

threading

into

diagram

the

(Fig.

machine

1)

machines.

12

direction

while

and

(E).

AND

holding

Check

see

FRAME

located

with

completed

and

raise

hole

on

Style

and start

for

manner

and

guide

if

presser

adjacent

the

its

it

is

57700 KM.

until

presser

the

foot

with a screw-

setting

by

foot

EYELET

to

the

top

of

the

downward

for a larger

3/4

inch

above

operating

of

threading

needle

down

turning

can

needle

holes

stroke.

loop.

on

these

be

in

the

a

Page 15

be

The

set

looper

to

compensate

thread

for

SETTING

take-up

varying

LOOPER

is

not

spotted

conditions.

THREAD

on

the

It

is

set

is

just

take-up

are

clearly

of

the

in

slot

plate

TAKE-UP

main

correctly

support.

shaft

cast

when

visible

looper.

of

cast-off

when

off

the

This

and

consequently

the

the

highest

points

below

should

plate

looper

of

the

the

underside

be

and

can

thread

lobe

needles

centered

cast-off

of

I

I

I

0 -

1

'----

should

The

39/64

---

be

length

inch

made

(See

---

in

of

Fig.

--

Fig.

ADJUSTMENT

the

following

stroke

14).

14

- ·

--

of

the

Loosen

c

--

sequence:

OF

CUTTING

armature

screw

B

(A,

PRESSER

Regulate

gulating

exerts

presserfoot

ly

when a slight

the

fabric.

located

in

the

clockwise

counterclockwise

With

connections

SOLENOID

shaft

(A,

Fig.

Fig.

23)

FOOT

the

screw

only

directly

head

ADJUSTING

all

14)

when

(D,

enough

to

feedthe

This

is

behind

of

the

increases

MECHANISM

of

disconnected,

STROKE

should

making

PRESSURE

presser

Fig.

pressure

workuniform-

tension

the

knurled

the

machine.

the

acts

"KLIPP-IT"

the

electrical

be

approximately

this

spring

13)

so

that

on

is

placed

screw,

needle

Turning

pressure,

the

reverse.

plug-

adjustments

adjustment

re-

it

the

on

bar

it

f3/"

764

to

be

sure

to

operate

position

(D)

to

the

in

is

that

one

by

right

Fig.

solenoid

direction

the

or

15

spring

left

is

bottoming.

only,

loaded

on

shaft

when

shaft

(B)

Since

actuated,

(B,

to

obtain

13

the

Fig.

desired

armature

its

only

14).

Loosen

C A

of

the

means

dimension.

of

nut

8

Fig.

solenoid

returning

{C)

and

Retighten

16

is

to

move

designed

its

rest

head

nut

(C).

Page 16

The

support

looper

(A,

Fig.

height

15)

should

when

ADJUSTING

be

set

3/64

at

its

extreme

LOOPER

inch

left

position.

HEIGHT

below

the

surface

of

the

throat

plate

With

shaft

pass

required,

retighten

(A,

the

the

needles

Fig.

looper

loosen

screws.

14).

(B)

in

On

the

along

screws

With

ADJUSTING

up-position,

forward

edge

the

(A,

lower

(C)

Fig.

SEVERING

slowly

motion,

for

approximately

17)

reposition

knife

at

the

its

DEVICE

depress

tip

of

lower

extreme

the

7/16

the

lower

knife

left

cutting

knife

inch.

Should

(B)

position,

solenoid

(A,

Fig.

adjustment

as

necessary

cutting

armature

16)

must

be

and

edge

(C)

for

the

of

the

ring

Replace

(E)

.004

needle's

needles.

and

snap

Fig.

threads

Should

rotate

ring

"

18

must

adjustment

connecting

and

tighten

B

be

"X"

be

rod

(F)

lock

nut.

the

should

the

adjustment

knife

be

rechecked

through

and

swinging

looper

Fig.

inch

required,

as

With

lower

be

looper

carrier

The

the

deflect

thread

17

(See

the

knife

approximately.

basic

in.

Fig.

loosen

necessary

looper

in

(A,

Fig.

is

necessary,

bracket

ADJUSTING

adjustment

to

assure

needle

the

looper

As

the

must

17)

at

approximately

thread

be

to

locknut

to

obtain

extreme

004

18)

at

point

that

thread

lower

caught

"X"

12

ga.

16

ga.

the

inch

and

CAREFULLY

KNIVES

outlined

the

loops

(C)

knife

left

(D),

the

left

15

clearance

plate

(G,

lower

(A & B,

by

by

cutting

7/64

5/64

of

"X"

~osition,

f 3 2

Fig.

in

swings

11

11

the

centerline

remove

dimension.

inch.

spring

BEND

17)

Fig.

knife

edge

snap

swing

There

between

(B).

to

suit.

16

must

passes

Fig.

(D)

while

out,

edge

(E),

If

the

19)

the

14

Page 17

the

needle

Should

as

described

threads

correction

for

be

Fig.

ADJUSTING

caught

required

17.

by

cutting

to

meet

KNIVES

edge

this

(F)

condition,

(Continued)

and

drawn

increase

back

dimension

to

the

uR.per

'X"

knife.

slightly

NOTE:

apply

The

figures

to a three

shown

needle

are

machine.

for a two

A

needle

machine,

however,

the

same

would

To

avoid

the

edge

at

point

the

screws

spring

the

upper

lower

Adjustment

(C)

(D).

overlapped

left

interfering

spring.

ment

must

fere

severing

(C).

corner

(G),

as

With

knife

and

repositioning

Retighten

With

end

position

With

of

the

be

taken

with

pinching

of

the

lower

Tip

of

the

reposition

required.

both

knives

knife

reference

the

device

(B)

can

by

with

any

plate

to

feed

(A,

screw.

the

the

knife

(D)

of

the

upper

approximately

be

plate

to

the

adjustment

spring

assure

dog

in

knife

upper

Retighten

in

their

Fig.

21)

made

the

to

Fig.

spring

prevent

front

that

(F)

rest

position

by

hexagonal

(E,

by

Fig.

needle

and

must

18,

face

it

maintaining a minimum

threads

the

plate

cutting

(E)

at

point

knife

screws.

resting

overlap

.

020

loosening

stop

the

at

its

the

looper

of

requiring

Fig.

does

21),

not

(See

edge

and

position,

looper

extreme

the

move-

inter-

Fig.

as

spring

of

(F).

plate

the

inch.

screw

plate

is

from

plate

care

21).

19

the

the

lower

(B)

lower

Adjustment

While

knife

must

knife

of.

in

020

this

(A,

Fig.

be

in

alignment

must

can

be

Fig.

inch

position,

20)

be

overlapped

made

clearance,

by

20

a

clearance

swings

as

shown

loosening

with

out,

by

E

the

of

15

Page 18

.

020-.040

edge

of

the

inch

upper

must

knife

0

ADJUSTING

be

maintained

carrier

J

(H).

KNIVES

between

Forward

(Continued)

the

lower

or

rearward

stop

(G)

repositioning

and

the

corresponding

of

the

upper

E

.020~~

The

22)

must

plate

(C)

upper

1 o

spring

the

spring

after

knife

ope r thread

can

tension

THREAD

HOOKS AND

RELEASE

1

I

A

Fig.

looper

be

clamped

being

(D).

be

regulating

21

thread

(B)

and

severed

Tension

retaining

adjusted

PULL-OFF

TENSION

ADJUSTMENTS

(A,

between

lower

by

on

by

turning

screw

Fig.

the

knife

the

the

plate

(E).

stop

extending

ment

position

(J)

can

will

from

be

stops

lengthen

the

made

as

required

by

Fig.

or

shorten

cloth

loosening

22

after

and

the

thread

seve

ring.

screws

retighten

tails

Adjust-

(K),

re-

screws.

Loosen

23)

in

rear

(C)

tighten

tension

turning

tension

cutting

tension

t h r e

thread.

h o o k ( F ) s o t h a t t

threads

sewing

stitch.

of

in a horizontal

ad

clamp

clamp

the

clamp

disc

eccentric

is

process

discs

Adjust

are

immediately

Adjust

(B)

machine

screw.

separator

released

begins

are

p u 11 e r s

thread

long

thread

screw

located

and

position,

Adjust

(E)

so

as

soon

open

begin

he

enough

on

(A,

at

set

lever

(D)

that

as

and

before

pulling

pull-off

needle

to

start

the

pull-off

Fig.

the

re-

the

by

the

the

that

next

16

Fig.

23

Page 19

THREAD

PULL-OFF

HOOKS AND

TENSION

RELEASE

ADJUSTMENTS

(Continued)

hook

CAUTION:

(G)

so

that

(a)

(b)

(c)

Fig.

the

Observe

cutting

Tension

with

Take

support.

24

looper

to

operation.

disc

no

bind.

care

A

thread

insure

separator

that

pull-offhooks

ADJUSTING

With

moved

wiper

piece

threads.

wiper

observing

threads

the

ing

of

must

its

hook

in

the

not

arc

(A,

and

is

clamped

ample

should

WIPER

the

power

from

solenoid,

of

fabric

Actuate

Fig.

that

must

wiper

of

be

of

the

caught

contact

travel.

when

securely

clearance

move

do

not

THREAD

lead

the

thread

sew

and

the

thread

24)

by

the

needle

deflected

wiper

swing-

by

the

returning

the

needles

of

bottom

re-

on

sever

hand,

by

hook

after

the

freely

a

or

it

pull-off

between

on

thread

(See

Fig.

the

has

hooks

Fig.

25).

presser

been

during

tension

guide

25

The

foot

severed.

the

discs

or

guide

wiper

during

This

screws

8

condition

(A &

B,

Fig.

Fig.

26

can

c

26)

be

accomplished

and

position

the

wiper

the

screws.

be

set

least

the

wiper

through

When

position,

lever

stopped

before

solenoid

be

accomplished

ing

screw

lever

s

crew

lead

assembly.

guard

will

fabric.

Screws

so

possible

wire

its

returning

the

(A,

Fig.

by

stop

the

armature

stops.

as

required,

.

Reconnect

for

by

plate

not

Retighten

as

to

resistance

as

arc

thread

27)

(B)

(C),

thread

loosening

(C)

hook

(D)

offer

it

of

This

by

reposition

retighten

into

should

passes

travel.

to

rest

wiper

must

slightly

of

the

can

loosen-

power

wiper

so

the

to

be

Fig.

27

17

Page 20

4

]~~

6

9~

~~

45

10

11

Page 21

FEED

NEEDLE

DOGS,

BAR,

CLOTH

NEEDLE

PLATE,

BAR

HEAD,

HANDWHEEL

PRESSER

ASSEMBLY

FOOT,

AND

THROAT

MISCELLANEOUS

PLATES,

PARTS

He

No.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

1

2

3

4

5

6

7

8

9

f.

Part

No.

22768

56958

29264

52817-16

52818-8

52842

57720

51430

22840

51430

57730

22799

57724

57705

57780

51280

57725

57725

22801

57725

52724

52724.

22526

22574

57701

56381

22845

22760

35772

51281

56958

51858

51758

23405

22726

12957

57791

56321

61321

22574

56321

56321

22894

29476

29476

22894

27-435

89

88

28

28

91

80

7205

22

660-313

87

25 c

AB

77

A

S-16

B

B

G

c

M-16

D

A

F

M-16

B

M-16

M

A

J

A

B

A

JW

P-12

P-16

c

c

D-219

B

A

H

AC

T

E

L

L

F

K

LK-062

LK-072

AA

Blk.

Description

Screw,

Needle

Needle

Needle

Presser

Throat

Feed

Screw----------------------------------------------------

Throat

Needle

Needle

Looper

Feed

per

Feed

per

Throat

Throat

Well

Screw,

Screw,

Screw,

Cloth

Cloth

Needle

Needle

Needle

Screw,

Folder,

Looper

Handwheel

Looper

Looper

for

needle

Bar

Thread

Bar

Thread

Bar

Assembly,

Needle

Needle

Set

Presser

Tilt

Lock

Presser

Hinge

Dog,

Dowel

Pivot

Dog,

inch-------------------------------------------------

Dog,

inch-------------------------------------------------

Nut

Plate

Plate

Pivot

Screw------------------------------------------------

Spring

Cloth

Screw-----------------------------------------------Spring

Retaining

Screw------------------------------------------------

Handwheel-------------------------------------------Pulley------------------------------------------------

Screw,

Set

Bar,

Bar

Spot

Set

Screw,

Set

Screw,

Needle

Screw,

Foot,

Clamp

Adjusting

Nut

Screw

Plate,

for

Plate

Pin

Guard,

Guard,

Screw

Needle

for

for

Plate,

Plate,

-------------------------------------------------

for

throat

for

cloth

for

cloth

----------------------------------------------Cover

Screw

Washer

Plate

Lever

Thread

Thread

for

No.

for

Style

Washer

Thread

Assembly

Set

Screw

Avoid

Avoid

for

Screw

bar

eyelet

Eyelet,

Eyelet

for

marked

Head

--------------------------------------

Screw

Foot

---------------------------------------------

Foot

for

Style

Support---------------------------------------

for

for

No. 12

No.

for

for

Thread

Frame

Frame

Plate

Eccentric

Eccentric

--------------------------------------------

---------------------------------------

for

for

Thread

for

middle

for

Style

Shank

Screw

--------------------------------------------

Guard

plate

plate

Cover

23405 T ------------------------------------

Guard--------------------------------------

link

-------------------------------------

Screw-----------------------------------

Bottom

-----------------------------------------Style

57700

57700

Style

Style

------------------------------------------

-------------------------------------gauge,

16

gauge,

No.

12

No.

16

plate

-------------------------------------

-------------------------------------

Assembly--------------------------------

------------------------------------------

---------------------------------------Spring-------------------------------

Eyelet,

Eyelet,

Eyelet,

57700

KM---------------------------------

----------------------------------------

--------------------------------------

---------------------------------------

--~-------------------------------------

pin

------------------------------------

-------------------------------

for

Style

57700

Lock

Washer

Style

57700

"BD-16"

outside

No.

Guide

57700

-----------------------------------

57700

57700

gauge,

gauge,

------------------------------------

Assembly,

Assembly,

needles----------------------

52842 G ------------------------

------------------------------

needle

----------------------------------

KM, 16

---------------------------

KM

KM

--------------------------teeth

KM--------------------------KL

---------------------------

Style

Style

Style

Style

for

Style

for

Style

for

Style

---------------------

KM

--------------------------

--------------------------

per

57700

57700

57700

57700

57700

57700

57700

for

Style

for

Style

KM

---------------

-------------------

inch--------------

KL,

16

teeth

KL,

16

teeth

KL

--------------

KL

--------------

KM

------------KM------------KL

-------------

57700

57700

KM

KL

--------

--------

Amt.

Req.

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

3

3

1

1

1

1

2

1

1

1

1

1

1

3

1

1

2

1

1

1

1

19

Page 22

35~

I

I

34~

~)I

33_?~

i

-

~·

!,......

Ll

•

20

Page 23

THREAD

WIPER

AND

KNIFE

ASSEMBLY

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

Part

No.

G29906

22767

96150

998-59

1310109

99650

96707

22738

99646

28 B

60078

99646

99318

43443

99651

99648

99653

22585

94

99648

99652

G21233

99654

92

22729

99649

22849

998-243

99647

G52768

G52771

G52773

22561

G51367

G51352

43443

G51350

G660-210

99314

G52737

96275

G22561

G52749

87 u

G52774

99316

G52770

G52763

G52751

G52769

G52772

96705

G52776

E

A

D

B

z

A

Q

c

c

HE

A

A

KW

KW

KW

A

KE-020

KE

Q

KE

KW

A

KW

KW

KW

KW

KW

KW

KW

KW

Description

Thread

Washer

Upper

Hexagonal

Screw,

Washer, . 008

Connector-------------------------------------------

Nut,

Lower

Retaining

Nut------------------------------------------------Connecting

Retaining

Screw,

Lower

Screw,

Upper

Screw,

Upper

Clamp

Counter

Clamp

Carrier

Spring

Lower

Wiper

Screw,

Washer,

Terminal

Insulating

Mounting

Spring

Screw,

Ball

Screw,

Nut,

Lever

Screw,

Nut,

Bracket,

Thread

Thread

Screw,

Screw,

Thread

Washer----------------------------------------Cable-------------------------------------------

Cable

Screw,

Screw,

Holder------------------------------------------

Screw,

Rotating

Thrust

Nut,

---------------------------------------------

Knife

for

for

No.

Knife

for

Knife

for

Stop

for

Knife

Spring----------------------------------------

Part----------------------------------------

Plate-----------------------------------------

Plate

----------------------------------------------

Stop

Assembly------------------------------

for

No.

998-59----------------------------

for

No.

998-59

--------------------------------------Tube

Bracket--------------------------------

-----------------------------------------for