Page 1

STYLE

577008

INDUSTRIAL

SEWING

MACHINES

CL

ASS

ADVANCED

TALOG

No.

131L

FIFTY

DIFFERENTIAL

FLAT

THOUSAND

BED

UNION SPECIAL

C H I C

57700

HIGH

MACHINES

CORPORATION

AGO

SPEED

SERIES

FEED

Page 2

(Supplement

Catalog

to

INSTRUCTIONS

No.

Catalog

FOR

131

L

No.

131

M)

ADJUSTING

LIST

CLASS

First

AND

OF

Style

57700

Edition

OPERATING

PARTS

57700

B

Copyright

by

Union

Rights

Special

Reserved

UNION SPECIAL

INDUSTRIAL

Printed

SEWING

CHIC

in

2

1971

Corporation

in

All

CORPORATIO

MACHINES

A

GO

U.S.

A.

Countries

N

May,

1979

Page 3

IDENTIFICATION

OF

MACHINES

Each

on

the

machine.

numbers

••style

changes

number.

which

57700".

junction

are

number

part.

description

number

when

Advanced

Medium

Needle

Lubricating

and

Lateral

Guard.

Rotary

have

57700

are

Styles

differs

This

therewith.

illustrated.

and

Any

in

ordering

Throw,

Bar

Bronze

Looper

Prepared

Thread

UNION

Style

one

B".

made

Example:

of

machines

from

catalog

At

on

the

part

the

High

that

under

second

repair

Speed,

Needle

Driving

System,

Bearings

Travel,

Tensions,

SPECIAL

numbers

or

more

Special

in a standard

"Style

the

Style

is a supplement

Only

the

opposite

is a component

the

description

column,

parts.

Two

Mechanism,

Filtered

for

for

use

machine

are

letters

Style

57700

similar

number,

APPLICATION

the

parts

back

Bearing

are

page,

never

STYLE

Needle,

Oil

Feed

Single

with

Maximum

Bar

Disc

Knee

is

identified

classified

suffixed,

numbers

machine,

BZ".

in

construction

in

that

to

Catalog

found

illustrations

the

part

of

of

the

assembly

use

OF

One

Looper,

Needle

Single

Return

and

Take-up,

Press

Work

as

but

never

contain

a

"Z"

it

contains

OF

CATALOG

No.

on

Style

numbers

another

the

reference

MACHINE

Bar

Drive,

Reservoir,

Pumps

Feed

Space

for

for

Rocker

Large

Presser

to

by a Style

standard

contain

the

letter

is

suffixed

are

grouped

no

131 M

57700 B but

identifying

part

or

Differential

Head

Right

and

and

is

base

number

Light

Enclosed

Shafts,

Handwheel

Foot

of

number

and

special.

the

letter

"Z".

to

the

under a Class

letters.

should

not

the

parts

descriptions

indicated

part.

and

Needle

Always

Feed

Weight

Positive

Base,

Greased

Lifter,

in

Flat

Presser

and

Bar

on a name

Standard

"Z".

When

Example:

on

by

the

Needle

only

Standard

be

used

Style

by

reference

identifies

indenting

use

first

Bed

Machine,

Automatic

and

Improved

Equipped

8 1 f 4

plate

Style

Example

minor

Style

number

"Class

in

con-

57700

the

its

the

part

column

Bar

and

Bearings

Sealed

Belt

with

Inches

:

L

.

.

57700 B Offset

perpendicular

similar

gauge

Maximum

Each

denotes

number,

in

thousandths

size

number

packaged

The

is

Type

needle.

Type

121

No.

GS

No.

UNIONSPECIALneedle

the

kind

stamped

represent

and

standard

121 GS.

differential

to

the

operations

12

only.

recommended

of

shank,

on

the

of

an

inch,

the

sold

by

Union

recommended

Below

Round

chromiumplated080/032, 090/036,

feed

wale

on

medium

Seam

point,

needle

midway

complete

Special.

is

the

shank,

machine

or

parallel

to

specification

speed

description

6000

has

length,

shank,

between

symbol,

needle

round

NEEDLES

both a type

for

attaching

with

the

wale

medium

R.

P.M.

groove,

denotes

shank

which

for

and

Description

point,

availableinsizes

100/040, 110/044,

heavy

406-BSb-1.

and

finish

largest

and

is

the

machine

sizes

short,

size

eye.

given

available

and

double

long

length

to

knitted

weight

Type

number.

and

other

diameter

Collectively,

on

the

covered

Sizes

groove,

065/025, 070/027,

125/049,

rib

knit

undergarments

material.

121 GS

The

details.

of

blade,

label

of

of

by

the

recommended

struck

140/054.

strip

Standard

needle.

type

The

measured

the

type

all

this

groove,

075/029,

cut

and

number

size

and

needles

catalog

3

Page 4

To

have

sample

on

label. A complete

needle,

needle

or

orders

the

order

type

NEEDLES

promptly

and

would

size

read:

(Continued)

and

number

"1000

accurately

should

needles,

filled,

be

forwarded.

Type

an

empty

121 GS,

Use

Size

package,

description

080/032".

a

Selection

should

Success

use

of

needles

a

reputation

more

than

of

pass

freely

in

packaged

for

producing

three-quarters

proper

through

the

operation

needle

size

needle

of

under

our

highest

of a century.

is

determined

eye

UNION

brand

quality

in

order

SPECIAL

name,

needles

by

the

size

to

produce a good

machines

~®

in

materials

of

can

and

thread

used.

stitch

be

secured

,

which

workmanship

Thread

formation.

only

is

backed

by

by

for

4

Page 5

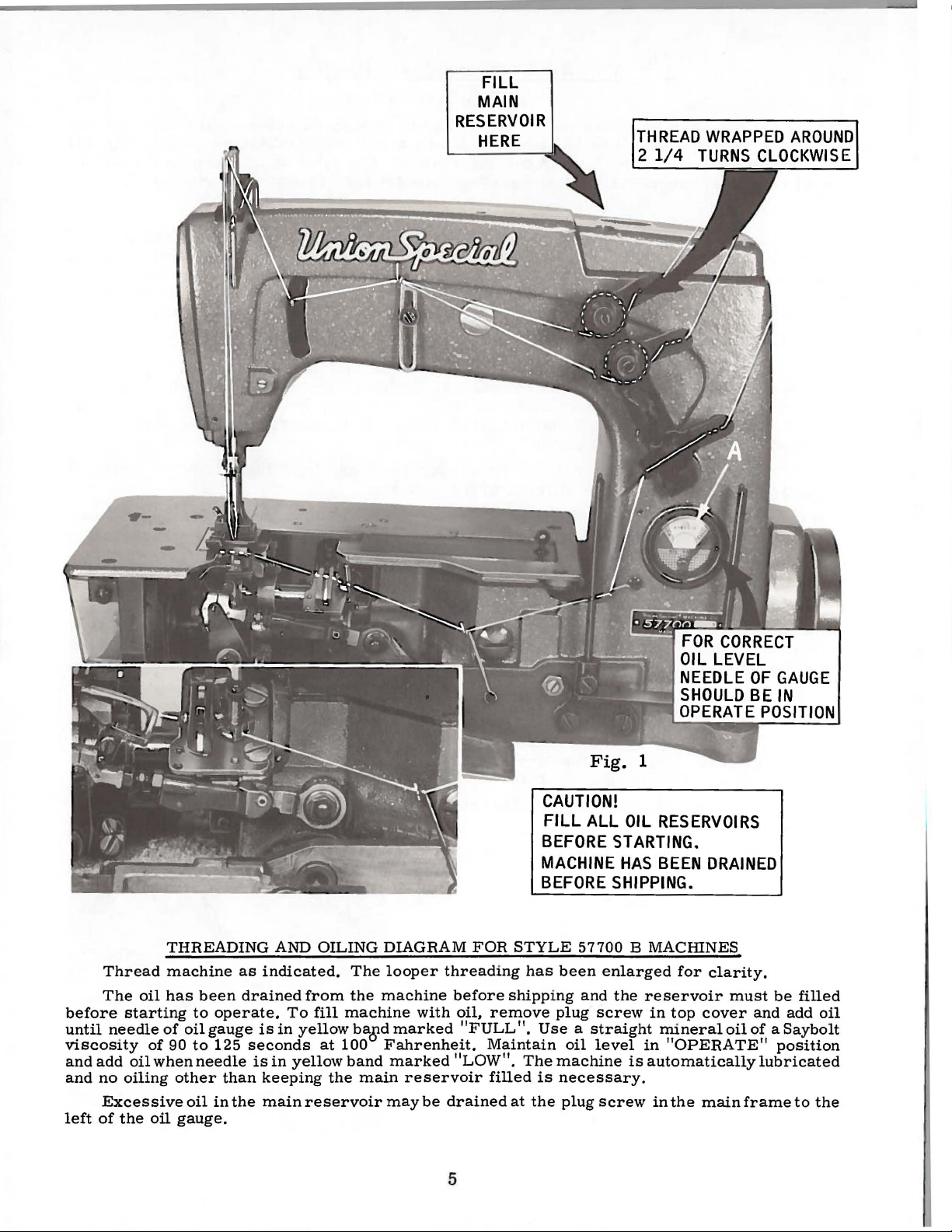

FILL

MAIN

RESERVOIR

HERE

THREAD

2

1/4

WRAPPED

TURNS

CLOCKWISE

AROUND

CAUTION!

FILL

BEFORE

MACHINE

BEFORE

Thread

The

before

until

needle

viscosity

and

add

and

no

Excessive

left

of

the

THREADING

machine

oil

has

starting

of

of

90

oil

when

oiling

oil

been

to

oil

gauge

to

needle

other

oil

gauge.

operate.

125

than

in

as

indicated.

drained

is

seconds

is

keeping

the

main

AND

To

in

in

yellow

OILING

from

fill

machine

yellow

at

100

band

the

reservoir

DIAGRAM

The

looper

the

machine

baBd

Fahrenheit.

marked

main

may

with

marked

reservoir

be

FOR

threading

before

oil,

remove

"FULL".

Maintain

''LOW".

filled

drained

STYLE

has

been

shipping

plug

Use a straight

The

machine

is

necessary.

at

the

plug

5

ALL

57700

and

oil

OIL

RESERVOIRS

STARTING.

HAS

BEEN

SHIPPING.

B MACHINES

enlarged

the

reservoir

screw

level

screw

in

mineral

in

is

automatically

in

DRAINED

for

clarity.

must

top

cover

oil

"OPERATE"

the

main

frame

be

filled

and

add

oil

of a Saybolt

position

lubricated

to

the

Page 6

INSTRUCTIONS

LUBRICATION

FOR

MECHANICS

CAUTION!

reservoir

before

the

beginning

oil

to

Use a straight

Fahrenheit

No.

17

5.

Fill

and

check

band

marked

CAUTION!

It

is

an

extended

and

directly

further

hand

distribute

Oil

may

located

NOTE:

below

Looper

assembling

spot

screw

Oil

has

been

must

the

be

to

various

filled

operate.

parts.

mineral

in

the

main

main

oil

level

reservoir

at

"Full".

It

is

important

recommended

period

oil

oil

be

oiling

to

the

be

the

needle

will

the

various

drained

cloth

avoid

be

is

sure

in

oil

timespot.

drained

to

Full

reservoir.

gauge

Oil

should

that a new

lubricated

be

from

plate

and

feed

holes

the

Run

from

proper

machine

speed

the

operation

RECOMMENDED

oil

of a Saybolt

This

at

plug

screw

(B).

Oil

is

at

be

added

that

these

as

bar

link

required.

when

machines

machine~

follows:

and

Run

parts.

at

in

main

lift

the

reservoir

front

eccentrics

eccentric

of

the

main

level

slowly

viscosity

is

equivalent

in

upper

maximum

needle

or

Remove

the

needle

machine

machine.

receive

lines

reservoir

as

indicated

can

OIL

not

one

by

for

several

then

be

of

90

to

Union

crank

level

is

in

yellow

be

over

that

has

the

bar.

Replace

slowly

removing

oil

thru

up

with

oil

before

on

oil

minutes

expected

to

125

Special

chamber

when

band

filled.

been

head

for

cover,

several

plug

the

holes

shipment,1 so

gaug

e

(A

to

distribute

without

seconds

specification

cover

needle

(A,

is

marked

out

of

service

clean

head

cover

minutes

screw

(C,

mainshaft,

in

mainshaft

~

Fig.

damage

at

100°

Fig.

in

yellow

"Low".

out

as

Fig.

so

when

when

the

1)

.

2)

for

lint

no

to

2)

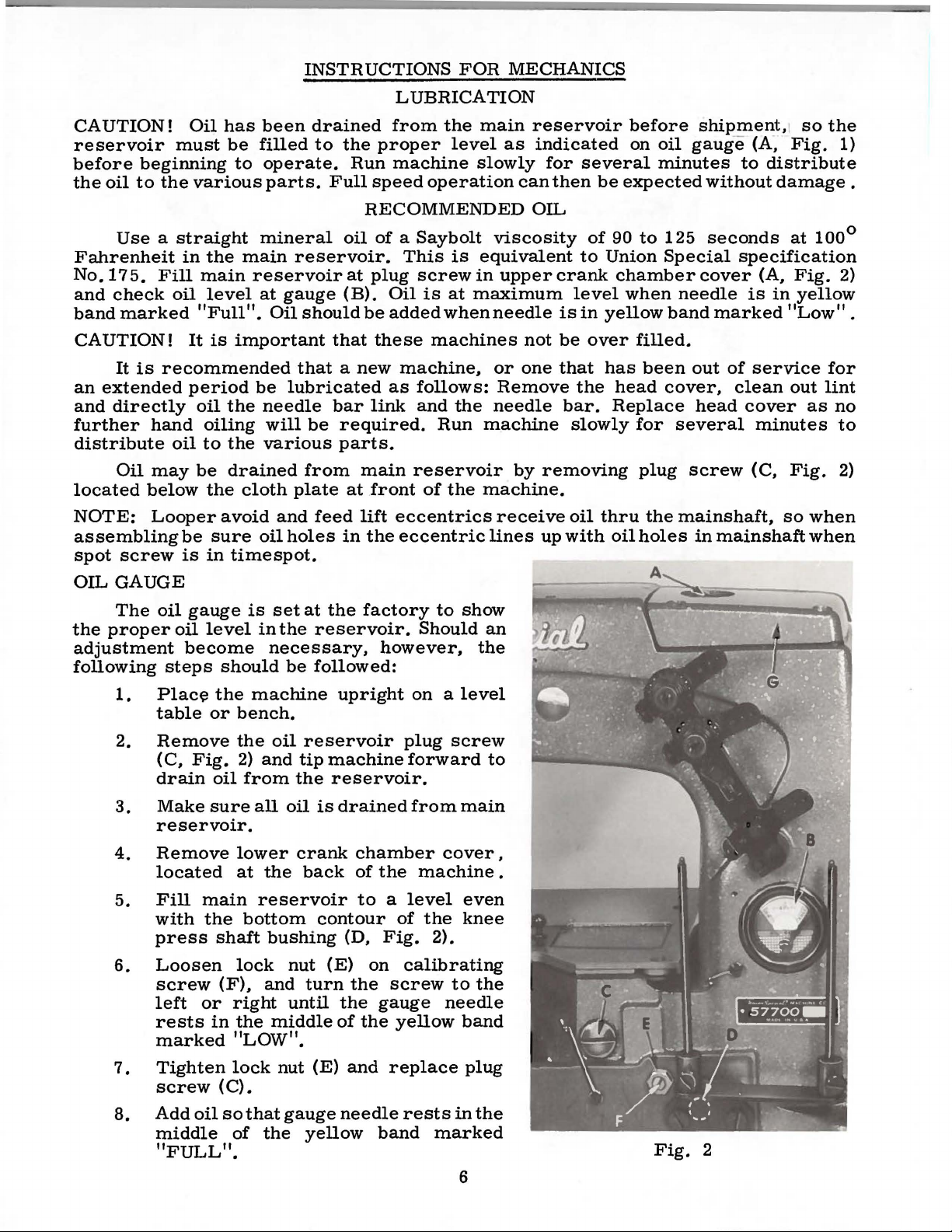

OIL

GAUGE

The

the

proper

adjustment

following

1.

2.

3.

4.

located

5.

with

press

6.

left

rests

oil

gauge

oil

level

become

steps

Place

table

should

the

or

Remove

(C,

Fig.

drain

Make

oil

sure

reservoir.

Remove

Fill

main

the

shaft

Loosen

screw

(F),

or

in

marked

is

set

in

the

necessary,

be

machine

bench.

the

oil

2)

and

from

all

oil

lower

at

the

reservoir

bottom

bushing

lock

nut

and

right

the

until

middle

"LOW".

at

the

reservoir.

followed:

upright

reservoir

tip

machine

the

reservoir.

is

drained

crank

back

contour

(D,

(E)

turn

the

the

of

factory

Should

however,

on a level

plug

forward

from

chamber

of

the

machine

to a level

of

the

Fig.

on

2).

calibrating

screw

gauge

the

yellow

to

show

screw

main

cover,

even

knee

to

needle

band

an

the

to

•

the

7.

8.

Tighten

screw

Add

middle

oil

lock

(C).

so

of

that

the

nut

gauge

yellow

(E)

and

needle

band

replace

rests

marked

plug

in

the

"FULL".

6

Fig.

2

Page 7

NEEDLE

LEVER

BEARING

OILER

height,

Insert

holder

Now

assemble

the

throat

located

test

plate

the

shoulder

the

needle

Fig.

using

the

test

and

test

plate

properly

and

the

of

is

at

3

proper

pin

No. 699 L

pin

test

attaching

if

the

height

the

its

lowest

test

No. 699

plate

No. 698

test

of

test

pins

pins

in

the

R-12

in

BB-12

screws.

pins

align

the

needle

rest

position.

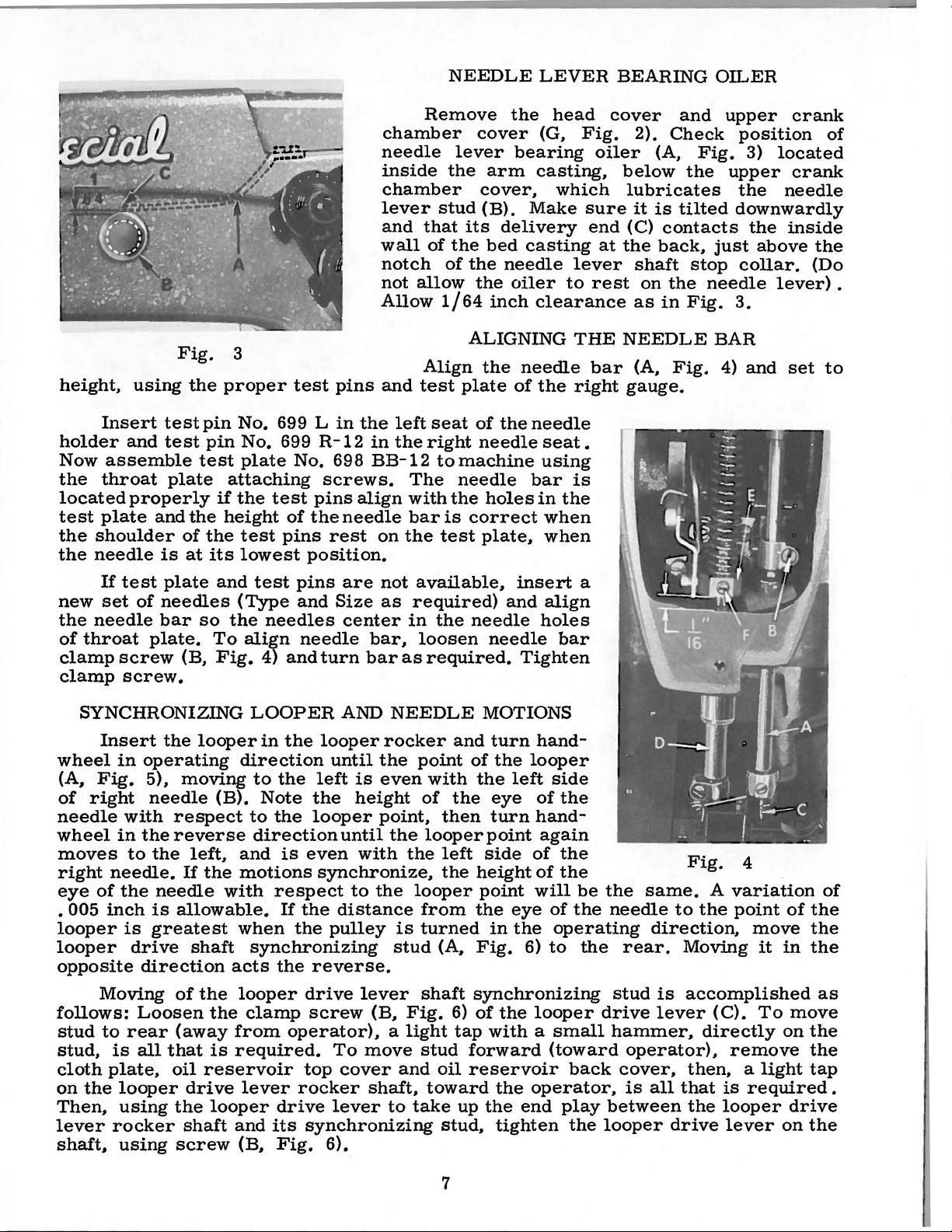

Remove

chamber

needle

inside

chamber

lever

and

that

wall

of

notch

not

allow

Allow

Align

and

test

left

seat

the

right

to

The

with

bar

on

the

cover

lever

the

arm

cover,

stud

(B).

its

delivery

the

bed

of

the

the

1/64

inch

ALIGNING

the

plate

of

the

needle

machine

needle

the

holes

is

correct

test

plate,

the

(G,

bearing

casting,

Make

casting

needle

oiler

clearance

needle

of

the

needle

seat.

using

bar

in

when

when

head

Fig.

which

sure

end

lever

to

rest

THE

bar

right

is

the

cover

2).

oiler

below

lubricates

it

(C)

at

the

shaft

as

NEEDLE

(A,

gauge.

and

Check

(A,

is

tilted

contacts

back,

on

the

in

Fig.

Fig.

the

stop

needle

Fig.

upper

position

3)

located

upper

the

needle

downwardly

the

inside

just

above

collar.

lever).

3.

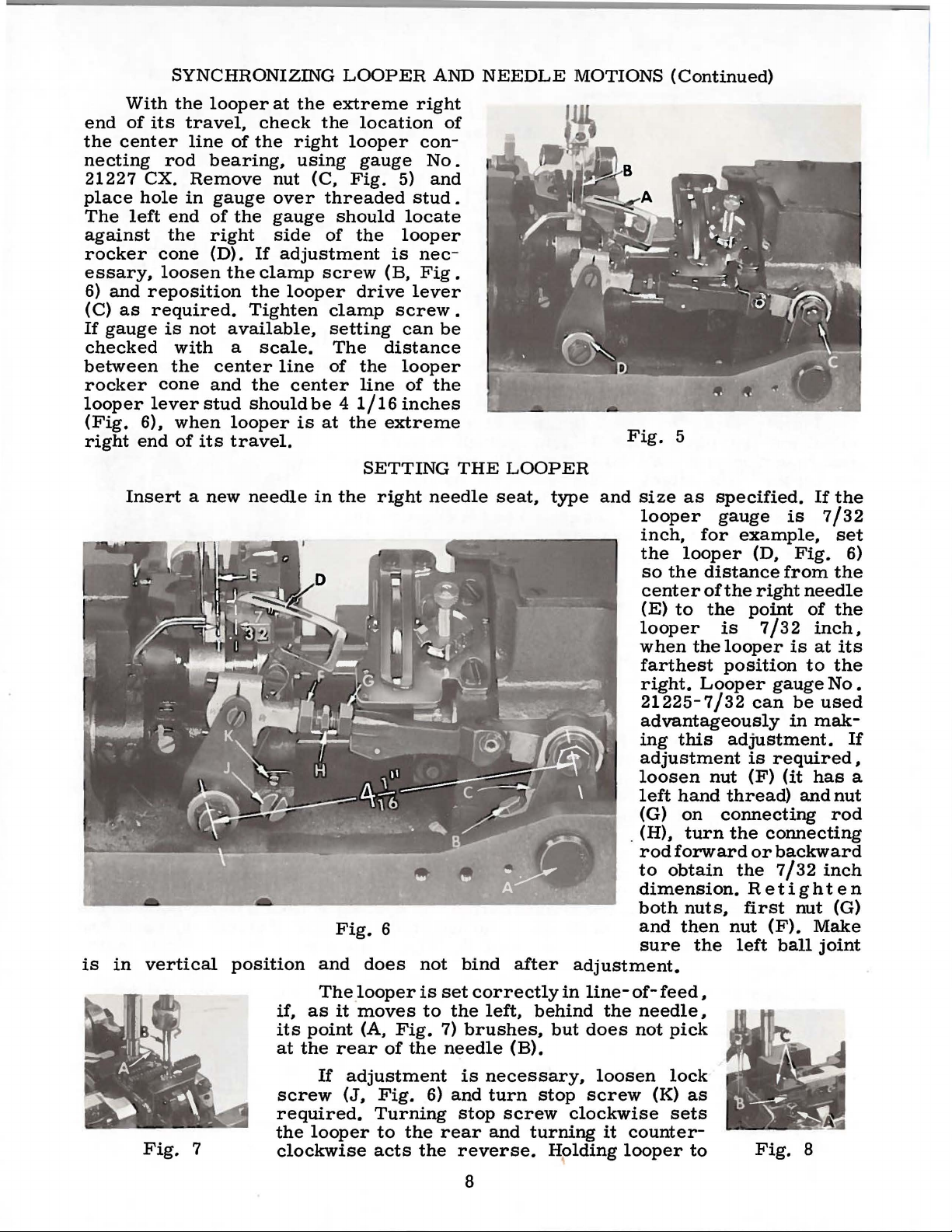

BAR

4)

and

set

crank

of

crank

the

(Do

to

If

test

plate

new

set

of

needles

the

needle

of

throat

clamp

clamp

bar

plate.

screw

screw.

(B,

SYNCHRONIZING

Insert

wheel

(A,

Fig.

of

right

needle

wheel

moves

right

eye

• 005

needle.

of

inch

looper

looper

opposite

Moving

follows:

stud

to

stud,

cloth

on

is

plate,

the

Then,

lever

rocker

shaft,

the

in

operating

5),

needle

with

in

the

to

the

the

needle

is

is

greatest

drive

direction

Loosen

rear

all

looper

using

using

moving

respect

reverse

If

allowable.

of

(away

that

oil

drive

the

shaft

screw

and

(Type

so

the

To

Fig.

looper

direction

(B).

left,

the

and

motions

with

when

shaft

acts

the

looper

the

from

is

required.

reservoir

lever

looper

and

(B,

test

pins

are

and

Size

needles

align

4)

and

LOOPER

in

the

center

needle

turn

AND

looper

until

to

the

left

Note

to

direction

the

is

the

looper

until

even

synchronize,

respect

If

the

the

to

distance

pulley

synchronizing

the

reverse.

drive

clamp

screw

operator), a light

To

top

cover

rocker

drive

its

Fig.

lever

synchronizing

6).

not

as

bar,

bar

NEEDLE

rocker

the

is

even

height

point,

the

with

the

is

stud

lever

(B,

move

and

shaft,

to

available,

required)

in

the

loosen

as

required.

and

point

with

of

the

then

looper

the

left

the

looper

from

turned

(A,

shaft

Fig.

6)

tap

stud

oil

toward

take

up

stud,

insert

and

align

needle

needle

holes

bar

Tighten

MOTIONS

turn

hand-

of

the

looper

the

left

side

eye

of

the

turn

hand-

point

side

height

point

the

in

Fig.

again

of

of

will

eye

the

6)

the

the

of

the

operating

to

synchronizing

of

the

looper

with a small

forward

reservoir

the

the

tighten

(toward

back

operator,

end

play

the

a

be

the

needle

the

stud

drive

hammer,

between

looper

Fig.

same.

to

direction,

rear.

Moving

is

accomplished

lever

operator),

cover,

is

then, a light

all

that

the

drive

4

A

variation

the

point

move

(C).

directly

remove

is

required.

looper

lever

it

To

of

the

the

in

the

move

on

the

the

tap

drive

on

the

of

as

7

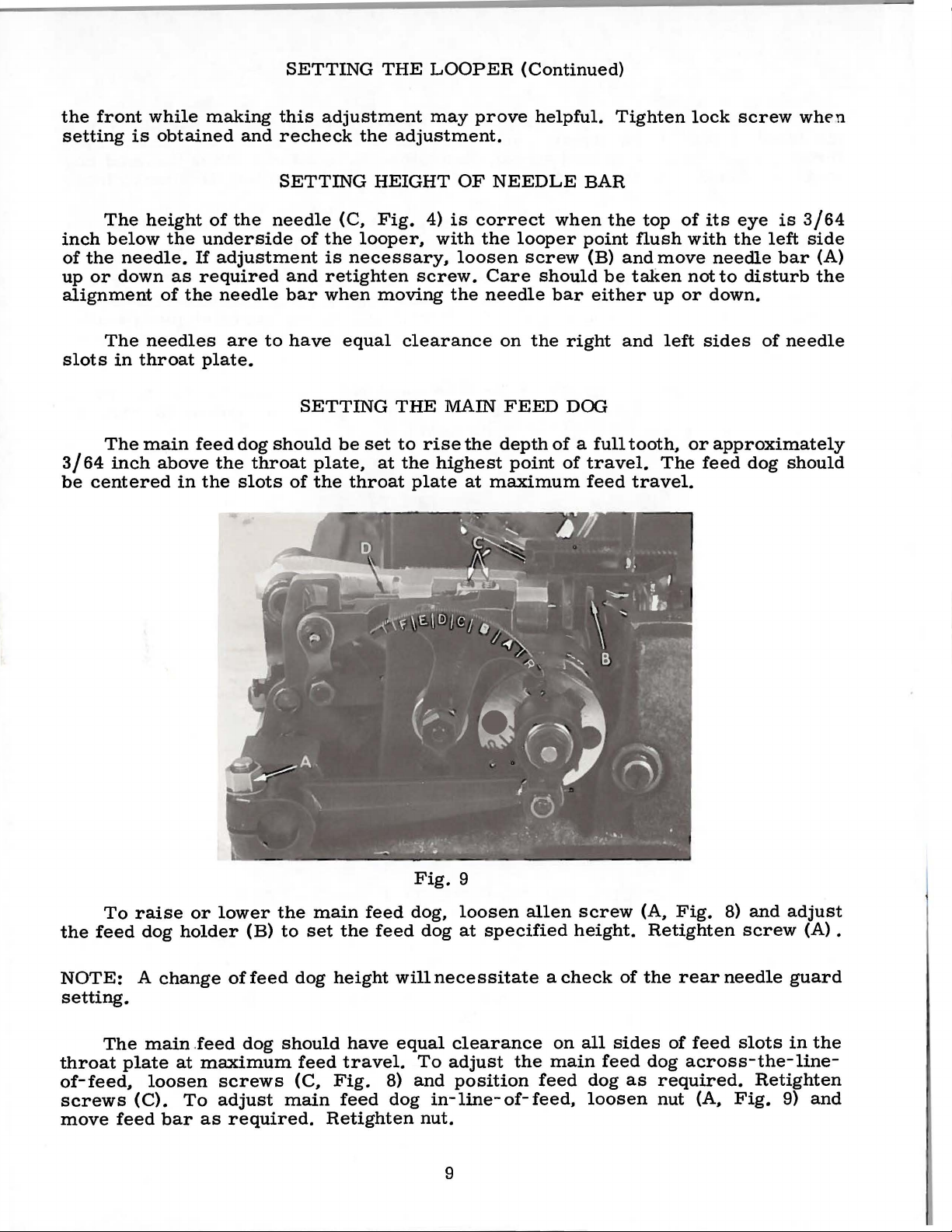

Page 8

SYNCHRONIZING

LOOPER

AND

NEEDLE

MOTIONS

(Continued)

With

end

of

its

the

center

necting

21227 CX.

place

The

against

rocker

essary,

6)

(C)

If

checked

between

rocker

looper

(Fig.

right

is

hole

left

cone

loosen

and

reposition

as

required.

gauge

cone

lever

6),

end

Insert a new

in

vertical

the

travel,

line

rod

Remove

in

end

the

is

not

with

the

when

of

its

looper

check

of

the

bearing,

gauge

of

the

right

(D).

If

the

clamp

the

Tighten

available,

a

scale.

center

and

the

stud

should

looper

travel.

needle

position

at

the

extreme

the

right

using

nut

over

gauge

side

adjustment

looper

line

center

is

looper

(C,

Fig.

threaded

should

of

screw

clamp

setting

The

of

be 4 1/16

at

the

in

the

Fig.

and

right

location

con-

gauge

5)

stud

locate

the

looper

is

nec

(B,

Fig

drive

the

line

SETTING

does

lever

screw.

can

distance

looper

of

inches

extreme

right

6

not

of

No.

and

.

.

be

the

THE

needle

bind

LOOPER

seat,

type

after

Fig.

and

size

looper

inch,

the

so

center

(E)

looper

when

farthest

right.

21225-7/32

advantageously

ing

adjustment

loosen

left

(G)

. (H),

rod

to

dimension.

both

and

sure

adjustment.

5

as

specified.

gauge

for

looper

the

distance

of

to

the

the

Looper

this

nut

hand

on

turn

forward

obtain

nuts,

then

the

is

example,

(D,

Fig.

from

the

right

point

is

looper

position

can

adjustment.

is

(F)

thread)

connecting

the

or

the

Retighten

first

nut

left

needle

7/32

is

gauge

be

in

required

(it

and

connecting

backward

7/32

nut

(F).

ball

If

the

7/32

set

the

of

the

inch,

at

its

to

the

No

used

mak-

has

nut

rod

inch

(G)

Make

joint

6)

•

If

,

a

The

Fig.

7

if,

as

it

its

point

at

the

rear

If

adjustment

screw

required.

the

clockwise

(J,

looper

looper

moves

(A,

is

to

Fig.

of

the

Fig.

Turning

to

acts

6)

the

the

set

correctly

the

7)

brushes,

needle

is

and

stop

rear

reverse.

8

in

left,

necessary,

turn

(B).

screw

and

behind

but

stop

turning

Holding

line-

clockwise

the

does

loosen

screw

it

looper

of-

needle,

not

counter-

feed,

pick

lock

(K)

sets

as

to

Fig.

8

Page 9

the

front

setting

while

is

obtained

making

and

SETTING

this

adjustment

recheck

THE

the

adjustment.

LOOPER

may

prove

(Continued)

helpful.

Tighten

lock

screw

whE'n

The

inch

below

of

the

needle.

up

or

down

alignment

The

slots

in

The

3/64

be

inch

centered

height

the

as

of

the

needles

throat

main

above

in

of

the

underside

If

adjustment

required

needle

are

plate.

feed

dog

the

throat

the

slots

SETTING

needle

of

the

is

and

retighten

bar

when

to

have

SETTING

should

plate,

of

the

HEIGHT

(C.

Fig.

looper,

necessary,

moving

equal

clearance

THE

be

set

to

at

the

throat

4)

is

with

screw.

the

MAIN

rise

highest

plate

OF

NEEDLE

correct

the

loosen

Care

needle

on

the

depth

at

maximum

looper

screw

should

the

FEED

point

BAR

when

the

point

(B)

be

bar

either

right

DOG

of a full

of

travel.

feed

top

flush

and

move

taken

up

and

tooth,

The

travel.

of

or

left

its

eye

with

the

left

needle

not

to

disturb

down.

sides

or

approximately

feed

of

dog

is

3/64

side

bar

(A)

the

needle

should

Fig.

9

To

the

feed

NOTE:

raise

dog

A

or

holder

change

lower

(B)

of

feed

the

to

dog

main

set

height

the

feed

feed

dog,

will

loosen

dog

at

specified

necessitate a check

allen

setting.

The

throat

of-feed,

screws

move

feed

main .feed

plate

at

loosen

(C).

bar

To

dog

maximum

screws

adjust

as

required.

should

feed

(C,

main

Retighten

have

travel.

Fig.

feed

equal

8)

dog

clearance

To

adjust

and

position

in-line-of-feed,

nut.

9

the

on

main

feed

screw

height.

of

all

sides

feed

dog

loosen

(A,

Fig.

Retighten

the

rear

of

dog

as

required.

nut

8)

and

adjust

feed

screw

needle

slots

(A) •

guard

in

across-the-line-

Retighten

(A,

Fig.

9)

the

and

Page 10

The

the

throat

throat

should

To

the

feed

differential

plate,

plate

be

parallel

raise

dog

at

or

at

SETTING

feed

at

the

maximum

to

the

lower

the

required

dog

highest

feed

top

the

differential

height.

THE

should

point

travel.

surface

DIFFERENTIAL

also

be

set

to

of

travel

In

addition

of

the

feed

Retighten

and

throat

dog,

screw.

FEED

rise

the

center

to

this

plate

loosen

DOG

depth

the

across-the-line-of-feed.

screw

in

teeth

of a full

the

feed

of

(B,

Fig.

tooth

slots

the

feed

9)

and

above

of

the

dog

set

Loosen

or

backward

ential

with

securely.

NOTE:

through

the

feed

the

throat

bar

top

Turn

its

cycle

plate

set

screws

as

required.

(D)

surface

machine

at

to

and

the

(C,

The

be

rotated,

of

the

by

hand

does

not

forward

Fig.

throat

9)

loosening

so

to

make

contact

end

and

the

plate,

the

of

its

move

of

differential

sure

travel.

the

differential

set

screws

across-the-line-of-feed.

the

differential

main

feed

(C)

feed

dog

dog

at

will

feed

back

feed

also

can

be

dog

end

bar

(D)

allow

aligned

Tighten

has

of

its

forward

the

differ-

parallel

screws

clearance

travel

or

The

selector

ible

through

selector

it

back

This

of 2 to

by

hand,

its

stroke.

differential

slide

the top

slide

decreases

Class

1,

depending

making

SETTING

(B)

to

(B)

toward

the

of

machine

sure

feed

ratio

the

desired

of

the

cloth

the

differential

has a stretching

on

the

length

the

differential

THE

is

front

Fig.

DIFFERENTIAL

set

by

position.

plate

increases

feed.

of

stitch

feed

10

loosening

The

on

the

Retighten

ratio

set

dog

10

screw

left

the

at

clears

FEED

screw

side.

amount

screw.

of

the

the

and

Moving

3/4

main

main

RATIO

(A,

Fig.

selector

of

differential

to 1 up

feed

feed

10)

and

moving

slide

the

to a gathering

dog.

at

are

differential

and

Turn

the

back

the

access-

feed

moving

ratio

machine

end

of

Page 11

(A,

Set

Fig.

the

11)

stitch

(it

has a left

to

the

CHANGING

required

hand

thread)

Turning

turning

the

with

stud

"L"

setting

STITCH

length.

and

screw

it

in a counterclockwise

stitch.

an

"S"

toward

lengthens

the

stitch

This

turning

The

and

the

LENGTH

is

accomplished

(B)

clockwise

head

an

"L",

"S"

shortens

the

stitch.

to

the

the

stitch

of

the

moving

Retighten

required

by

adjusting

shortens

mains

the

the

stitch

length.

loosening

the

direction

haft

(C)

stitch

and

locknut

locknut

screw

stitch

lengthens

is

regulating

toward

marked

(C)

(B).

and

after

the

needle

permissible.

within

left,

needle

NOTE:

feed

back

The

be

needle

left

needle

or

guard

needle

after

(D)

about

is

even

guard

Adjustment

dog

height.

Set

the

toward

looper

set

as

low

until

needle.

guard

backward,

as

required

guard,

guard

Fig.

11

when

It

should

3/64

with

as

required,

SETTING

front

the

path

may

as

possible,

the

point

The

or

right

merely

loosen

is

properly

at

its

inch

the

of

needle

of

brush

of

front

and

screws

most

be

set

of

the

needle.

and

the

rear

FRONT

guard

the

looper

but

not

yet

the

looper

needle

needle

loosen

retighten

set.

NOTE:

corresponding

and a check

so

that

forward

as

low

needle,

To

move

retighten

needle

NEEDLE

so

pick

have

guard

at

any

screws

screws.

(H),

move

Any

SETTING

Set

the

it

point

as

until

needle

that

as

it

at

its

is

just

should

time.

(G,

guard

change

change

of

the

THE

rear

needle

does

possible,

guard

it

moves

the

vertical

To

not

of

the

point

guard

screw.

will

GUARD

pushes

left

past

not

To

move

Fig.

raise,

and

in

in

feed

REAR

quite

travel.

yet

of

necessitate

the

behind

needle.

face

the

left

contact

guard

10)

lower

retighten

stitch

the

dog

height.

guard

contact

A

have

the

merely

left

the

needle

It

push

side

the

forward

move

or

length

rear

NEEDLE

clearance

its

looper

the

screws

needle

(C,

Fig.

the

vertical

loosen

a

needle

should

left

of

the

rear

needle

rotate

(E),

check

.

will

necessitate

guard

GUARD

10)

rear

of

face

moving

screw

setting

horizontally

of

the

right

. 005

Fig.

approach

(F).

of

the

inch

to

move

main

12

the

a

is

NOTE:

setting.

presser

released

located

Retighten

A

The

thread

foot

when

If

adjustment

at

screw.

change

is

the

the

back

in

stitch

tension

raised

presser

is

of

After

length

THREAD

release

to

within

foot

needed,

the

machine

adjustment

WILL

is

set

1/8

has

reached

loosen

there

NOT

TENSION

correctly

inch

and

of

its

tension

move

should

11

require a change

RELEASE

when

the

end

highest

release

tension

be

no

it

begins

of

its

position.

lever

disc

separator

binding

in

front

to

travel

screw

at

any

needle

function

and

is

(A,

Fig.

as

required

point.

guard

as

the

entirely

12),

.

Page 12

The

remove

Also

inch

the

Fig.

opening

is

released

the

below

in

operating

is

in

then,

throat

connection

obtain

screw.

so

that

see

mentioned

the

there

clearance

presser

4)

and

in

throat

the

If

adjustment

the

while

plate

the

Check

needle

if

presser

height

presser

should

bar

the

the

and

plate,

throat

direction

low

position.

holding

surface,

and

1 I

16

in

previous

of

the

between

connection

bottom

bed

when

the

with

plate.

is

presser

guide

inch

setting

bar

is

foot

SETTING

presser

foot

when

be

approximately

lower

surface

the

foot

presser

the

feed

needed,

until

pry

with a screwdriver

setting

by

in

its

can

paragraph.

the

Loosen

foot

up

turning

high

be

bar

the

surface

and

lifter

foot

resting

turn

handwheel

needle

screw

down

presser

and

handwheel

position

removed

HEIGHT

foot

guide

dog

retighten

(D,

of

Fig.

lifter

1 I 16

(E,

head

lever

down

bar

(F)

on

the

bar

and

of

on

to

as

OF

PRESSER

4)

lever

,

is

set

(B,

BAR

correctly

Fig.

12)

Fig.

if

is

13

it

is

fully

possible

depressed.

to

Thread

machine

Fig.

14

as

indicated

THREADING

in

Fig. 1 and

The

rotary

eyelets

the

sufficient

under

off

nut

The

the

thread.

tension

and

right

surface

The

support

should

spring

looper

SETTING

needle

2 1 I 4

set

the

needle

tension

of

looper

tension

be

set

must

thread

EYELET

start

THREAD

thread

left

thread

to

the

thread

disc

just

still

should

THE

NEEDLE

AND

operating

is

times.

needle

tension

produce

fabric.

tension

assembly,

below

have

be

TAKE-UP

on a piece

TENSION

to

be

wrapped

Pull

the

thread

uniform

is

applied

the

end

free

length.

just

sufficient

THREAD

thread

tension

at

2 1 I 2

stitches

and

of

the

The

FRAME

WIRE

of

fabric.

around

through

at 2 ounces;

ounces

on

at

the

the

adjusting

tension

tension

to

steady

the

the

the

castpost

the

or

•

on

Set

the

mounting

Top

of

take-up

when

loop,

needle

reverse

needlethread

screw

bar

for

(B).

wire

is

more

(C)

at

frame

Lower

to

the

bottom

loop.

be

for

even

eyelet

more

with

of

its

hole

needle

top

stroke.

12

(A,

of

Fig.

thread

holes

Lower

13)

in

in

314

the

the

this

inch

stitch,

needle

setting

abovethe

raise

thread

for

less

center

for

less

eyelet

needle

of

•

(D)

Page 13

The

looper

consequently,

when

of

plate

pulled

slots

assembly

cast-

as

the

the

left

assembly

causes

off

the

looper

off

plate

looper

needle

by

to

thread

can

be

thread

is

(B)

the

take-up.

more

the

reaches

thread

bottom

assembly

SETTING

take-up

set

to

is

clearly

is

adjustable,

Moving

to

of

is

its

extreme

LOOPER

(A,

compensate

just

cast

visible

the

be

pulled

the

screw

set

correctly

Fig.

for

off

the

below

and

its

cast-off

from

slots

position

'I'HREAD

14)

is

not

varying

highest

the

underside

setting

plate

the

cones,

causes

when

to

the

the

TAKE-

spotted

conditions.

lobe

of

the

of

determines

assembly

and

less

looper

left.

UP

on

the

take-up

the

looper.

the

to

the

moving

thread

thread

main

It

is

when

amount

top

the

to

be

just

shaft

set

correctly

the

The

cast-off

of

of

the

cast-off

pulled.

becomes

and,

point

thread

screw

plate

The

taut

Regulate

enough

is

placed

wise

acts

the

pressure

on

the

the

reverse.

presser

on

the

fabric.

PRESSER

spring

presser

Turning

FOOT

regulating

foot

to

it

clockwise

feed

PRESSURE

screw

the

increases

(E,

work

Fig.

13)

uniformly

the

pressure,

so

that

it

exerts

when a slight

counterclock-

only

tension

13

Page 14

9

'

',,

',

',

I

---·~

I

I

.

I

I

I

I

'

I

I

'

26

14

Page 15

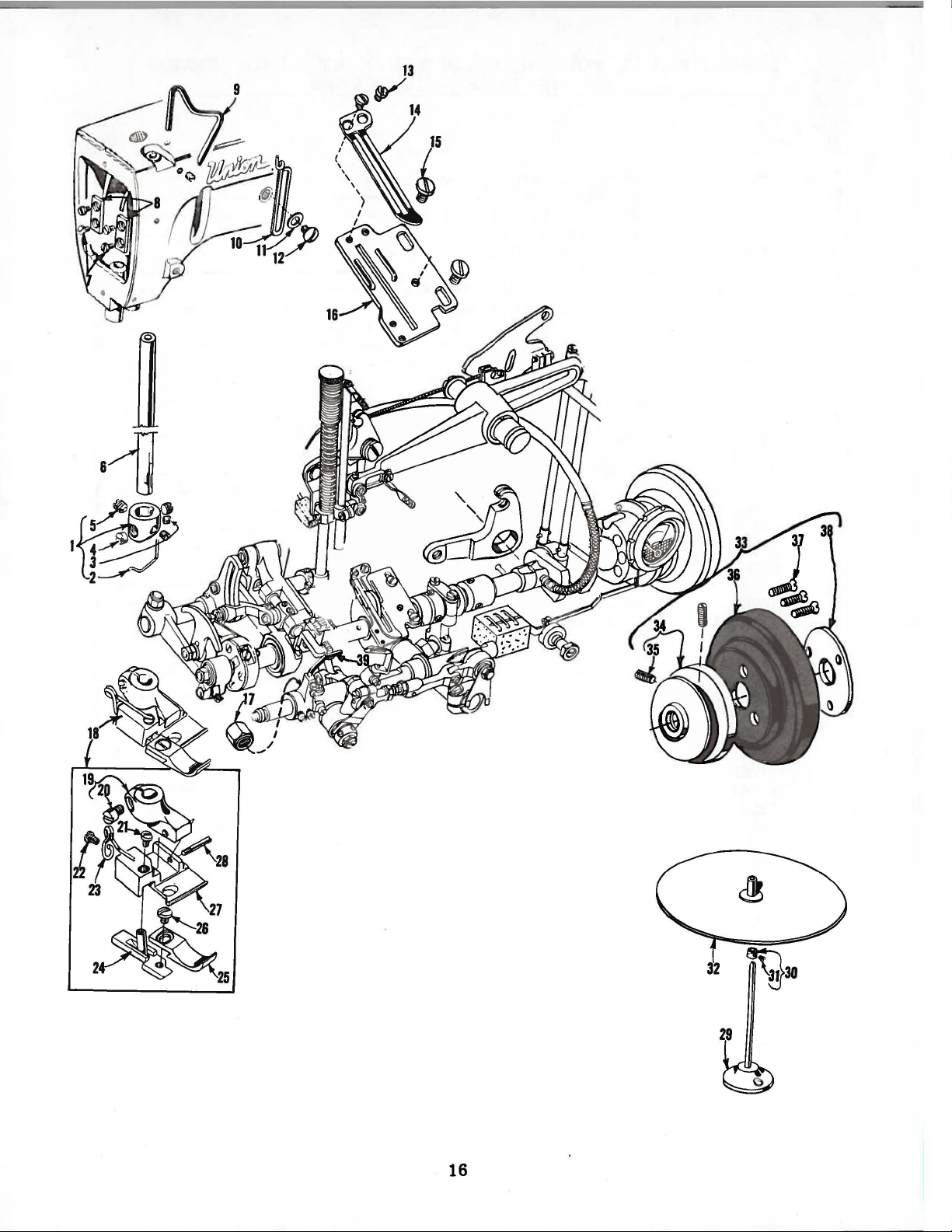

THROAT

PLATE,

FOLDER,

AND

MISCELLANEOUS

FOLDER

SUPPORT,

COVERS

STRIP

TENSION

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18"

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

Part

No.

22839

660-313

87

90

25

25

T38

90

20

188

A-12

c

E

c

D

s

cc

v

K

J

R-5/8

D

D

E

57724

22526

57801 A

22839

22839

57802 A

22526

57764 A

23432

52864 N

23425

57764 B

22564

57885 A

43281

57880

51280

57882 G

22848

57882 c

22848

57885

23406

22848

57864

22548

23439

23439

Description

Screw,

Well

Screw,

Throat

Screw,

Cloth

Screw,

Screw,

Cloth

Screw----------------------------------------------

Screw,

Folder

Screw---------------------------------------------Screw----------------------------------------------

Folder

Folder

Screw----------------------------------------------

Washer

Folder

Screw----------------------------------------------

Hinge

Hinge

Screw---------------------------------------------Throat

Front

Washer,

Screw,

Support

Screw---------------------------------------------Swinging

Folder

Screw----------------------------------------------

Clamp

Screw----------------------------------------------

Strip

for

throat

Nut

-------------------------------------------

for

throat

Plate----------------------------------------

for

cloth

Plate

Plate

Pin

Bracket

Dowel

Cloth

Tension---------------------------------------

Screw-----------------------------------------Adjustable

-----------------------------------------

for

cloth

for

cloth

Sliding

for

cloth

Support

Clamp--------------------------------------Support

Plate

Support

------------------------------------------

Plate

for

Post----------------------------------------

---------------------------------------------

Plate,

Support

Pin

Guard-----------------------------------

for

front

front

Cover

plate

plate

plate

plate

plate

plate

Platform

Bracket

--------------------------------------Hinged

Spring

------------------------------------cloth

cloth

Hinge--------------------------------

for

folder

Pin

support

------------------------------

-------------------------------

-------------------------------

-------------------------------

Cover

----------------------------------

----------------------------

-------------------------------

-----------------------------

------------------------------

Bracket

--------------------------------

--------------------------------

guard

guard--------------------------

support

-----------------------

-----------------------

------------------------

bracket

---------------

Amt.

Req.

2

2

2

1

2

1

1

2

1

2

1

1

1

2

1

1

2

1

1

1

1

1

2

1

2

1

1

1

1

2

1

1

2

1

2

1

2

2

15

Page 16

16

Page 17

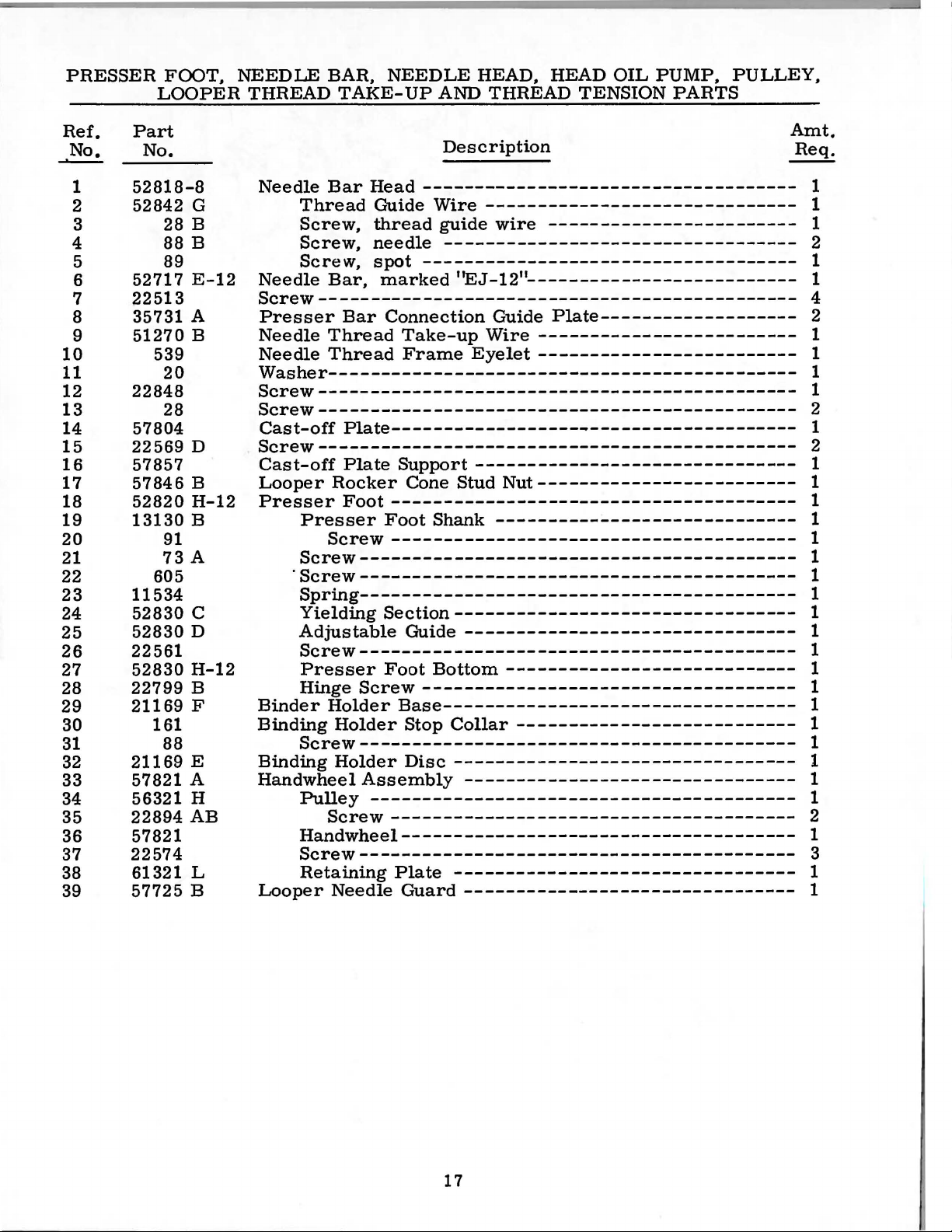

PRESSER

FOOT,

LOOPER

NEEDLE

THREAD

BAR,

TAKE-UP

NEEDLE

AND

HEAD,

THREAD

HEAD

TENSION

OIL

PUMP,

PARTS

PULLEY,

Ref.

No.

_._

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

Part

No.

52818-8

52842

52717

22513

35731 A

51270

22848

57804

22569

57857

57846

52820

13130

11534

52830

52830

22561

52830

22799

21169

21169

57821 A

56321 H

22894

57821

22574

61321 L

57725

28 B

88

89

539

20

28

91

73

605

161

88

G

B

E-12

B

D

B

H-12

B

A

c

D

H-12

B

F

E

AB

B

Description

Needle

Needle

Screw----------------------------------------------

Presser

Needle

Needle

Washer--------------------------------------------Screw---------------------------------------------Screw----------------------------------------------

Cast-off

Screw----------------------------------------------

Cast-off

Looper

Presser

Binder

Binding

Binding

Handwheel

Looper

Bar

Head

Thread

Screw,

Screw,

Screw,

Bar,

Thread

Thread

Presser

Screw

Screw------------------------------------------

·Screw-----------------------------------------Spring-----------------------------------------Yielding

Adjustable

Screw------------------------------------------

Presser

Hinge

Holder

Screw------------------------------------------

Pulley

Screw--------------------------------------Handwheel-------------------------------------Screw-----------------------------------------Retaining

Guide

thread

needle

spot

Bar

Plate---------------------------------------

Plate

Rocker

Foot

Screw

Holder

Holder

Assembly

-----------------------------------------

Needle

-----------------------------------Wire

------------------------------------

marked

Connection

Take-up

Frame

Support

Cone

---------------------------------------

Foot

Section---------------------------------

Foot

Shank

---------------------------------------

Guide

Bottom

------------------------------------

Base----------------------------------

Stop

Disc

Plate

Guard

------------------------------

guide

----------------------------------

wire

''EJ-12"--------------------------

Guide

Wire

Eyelet

-------------------------------

Stud

-----------------------------

--------------------------------

Collar

---------------------------------

--------------------------------

---------------------------------

--------------------------------

------------------------

Plate-------------------

-------------------------

-------------------------

Nut-------------------------

----------------------------

---------------------------

Amt.

Req.

1

1

1

2

1

1

4

2

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

3

1

1

17

Page 18

18

Page 19

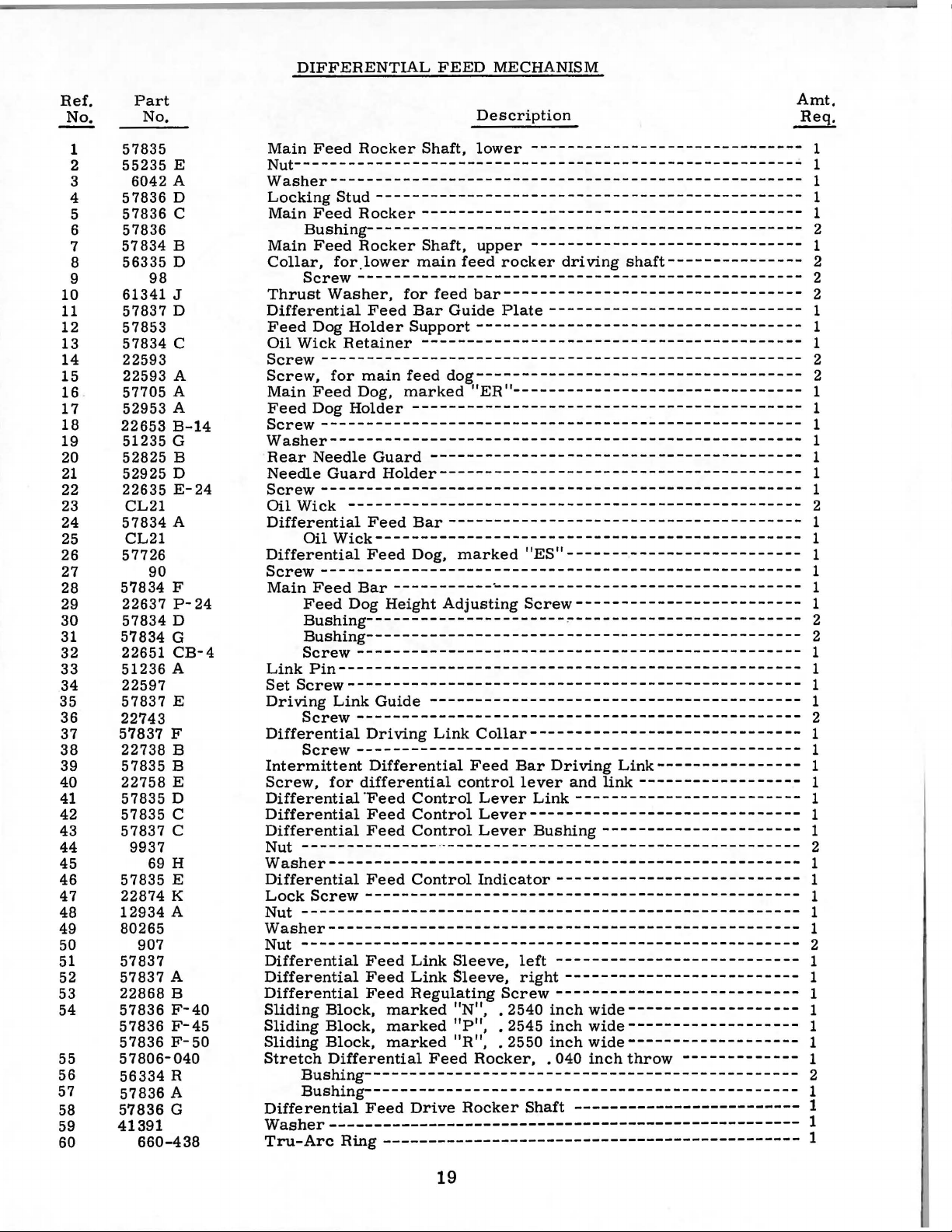

DIFFERENTIAL

FEED

MECHANISM

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 51235 G

20

21

22

23

24

25

26 57726

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

Part

No.

57835

55235

6042 A

57836

57836

57836

57834

56335

98

61341 J

57837

57853

57834

22593

22593 A

57705 A

52953 A

22653

52825

52925 D

22635

CL21

57834

CL21

90

57834 F

22637

57834

57834

22651

51236

22597

57837

22743

57837

22738

57835

22758

57835

57835

57837

9937

69 H

57835

22874 K

12934

80265

907

57837

57837

22868

57836

57836

57836

57806-040

56334

57836

57836

41391

660-438

E

D

c

B

D

D

c

B-14

B

E-24

A

P-

24

D

G

CB-4

A

E

F

B

B

E

D

c

c

E

A

A

B

F-40

F-45

F-50

R

A

G

Description

Main

Feed

Nut-------------------------------------------------------VVasher---------------------------------------------------Locking

Main

Bushing------------------------------------------------

Main

Collar,

Screw------------------------------------------------Thrust

Differential

Feed

Oil

VVick

Screw

Screw,

Main

Feed

Screw

VVasher----------------------------------------------------

Rear

Needle

Screw----------------------------------------------------Oil

VVick

Differential

Oil

Differential

Screw-----------------------------------------------------

Main

Feed

Bushing----------------------~-------------------------

Bushing------------------------------------------------

Screw

Link

Pin---------------------------------------------------

Set

Screw--------------------------------------------------

Driving

Screw-------------------------------------------------

Differential

Screw

Intermittent

Screw,

Differential-Feed

Differential

Differential

Nut

---------------

VVasher---------------------------------------------------Differential

Lock

Screw

Nut

-------------------------------------------------------

VVasher---------------------------------------------------Nut

-------------------------------------------------------

Differential

Differential

Differential

Sliding

Sliding

Sliding

Stretch

Bushing------------------------------------------------

Bushing------------------------------------------------

Differential

VVasher----------------------------------------------------

Tru-Arc

Rocker

Stud-----------------------------------------------

Feed

Rocker------------------------------------------

Feed

Rocker

for_lower

VVasher,

Feed

Dog

Holder

Retainer

----------------------------------------------------for

main

Feed

Dog,

Dog

Holder-------------------------------------------

-----------------------------------------------------

Needle

Feed

Block,

Block,

Block,

Guard

Guard

-------------------------------------------------Feed

VVick

-----------------------------------------------

Feed

Bar

Dog

-------------------------------------------------

Link

Guide

Driving

------------------------------------------------Differential

for

differential

Feed

Feed

Feed

------------------------------------------------

Feed

Feed

Feed

Differential

Feed

Ring

Shaft,

Shaft,

main

for

Bar

Support------------------------------------

------------------------------------------

feed

marked

Holder----------------------------------------

Bar

Dog,

-------

Height

Control

Control

Control

Control

Link

Link

Regulating

marked

marked

marked

Feed

Drive

----------------------------------------------

lower

upper

feed

feed

bar---------------------------------

Guide

dog------------------------------------

"ER"--------------------------------

-----------------------------------------

--------------------------------------marked

----·----

Adjusting

----------------------------------------Link

Collar------------------------------

Feed

control

Lever

Lever------------------------------

Lever

·

·--------------------------------------Indicator---------------------------

Sleeve,

Sleeve,

"N",

"P",

"R",

Rocker, . 040

Rocker

------------------------------

------------------------------

rocker

Plate----------------------------

Screw--------------------------. 2540

. 2545

. 2550

driving

"ES"--------------------------

------------------------------

Screw-------------------------

Bar

Driving

lever

left

right--------------------------

and

Link------------------------Bushing----------------------

---------------------------

inch

inch

inch

Shaft

-------------------------

shaft---------------

Link----------------

link------------------

wide------------------wide------------------wide------------------inch

throw

-------------

Amt.

Req.

1

1

1

1

1

2

1

2

2

2

1

1

1

2

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

2

2

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

1

1

19

Page 20

Torque

19-21

(22

-24cm.

in.

to

lbs.

kg .

20

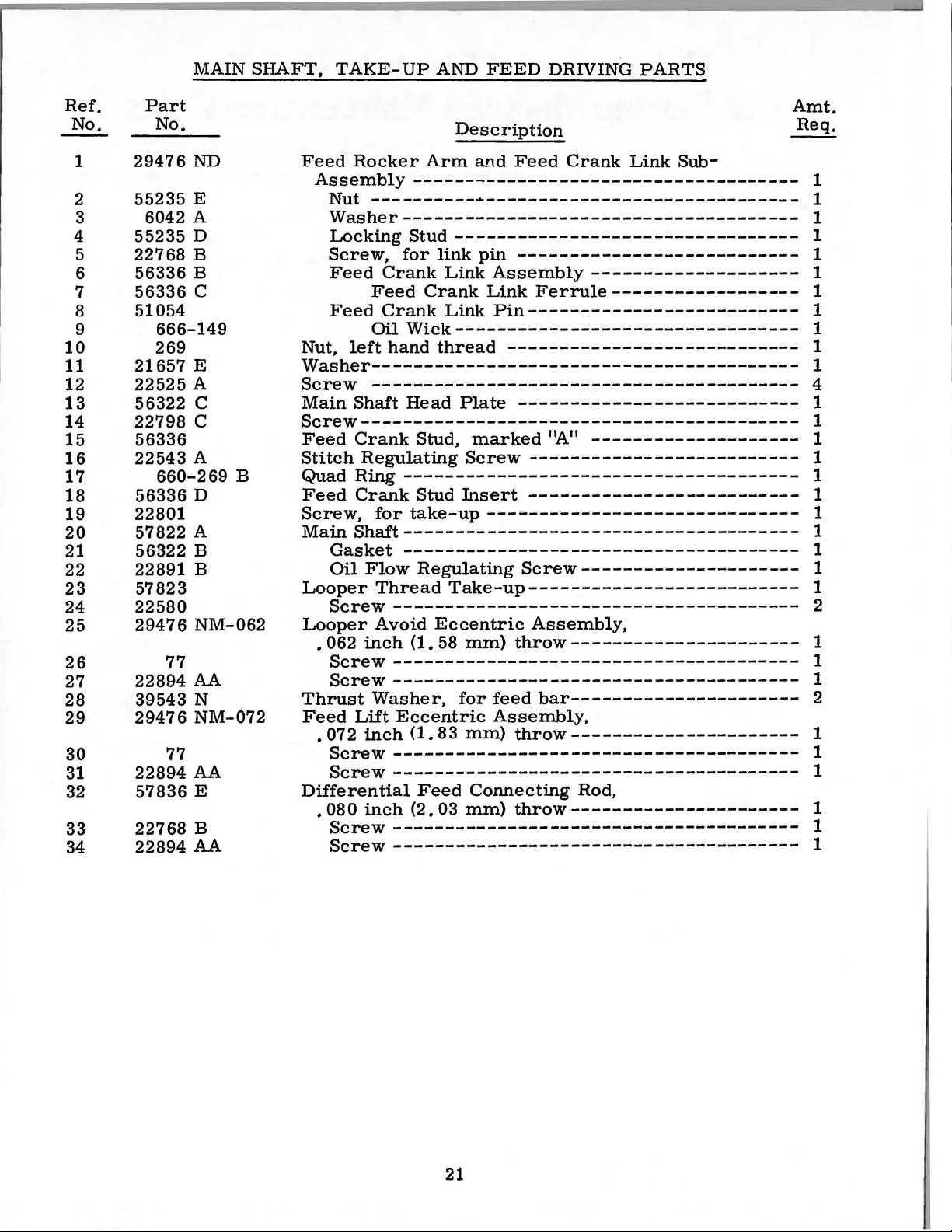

Page 21

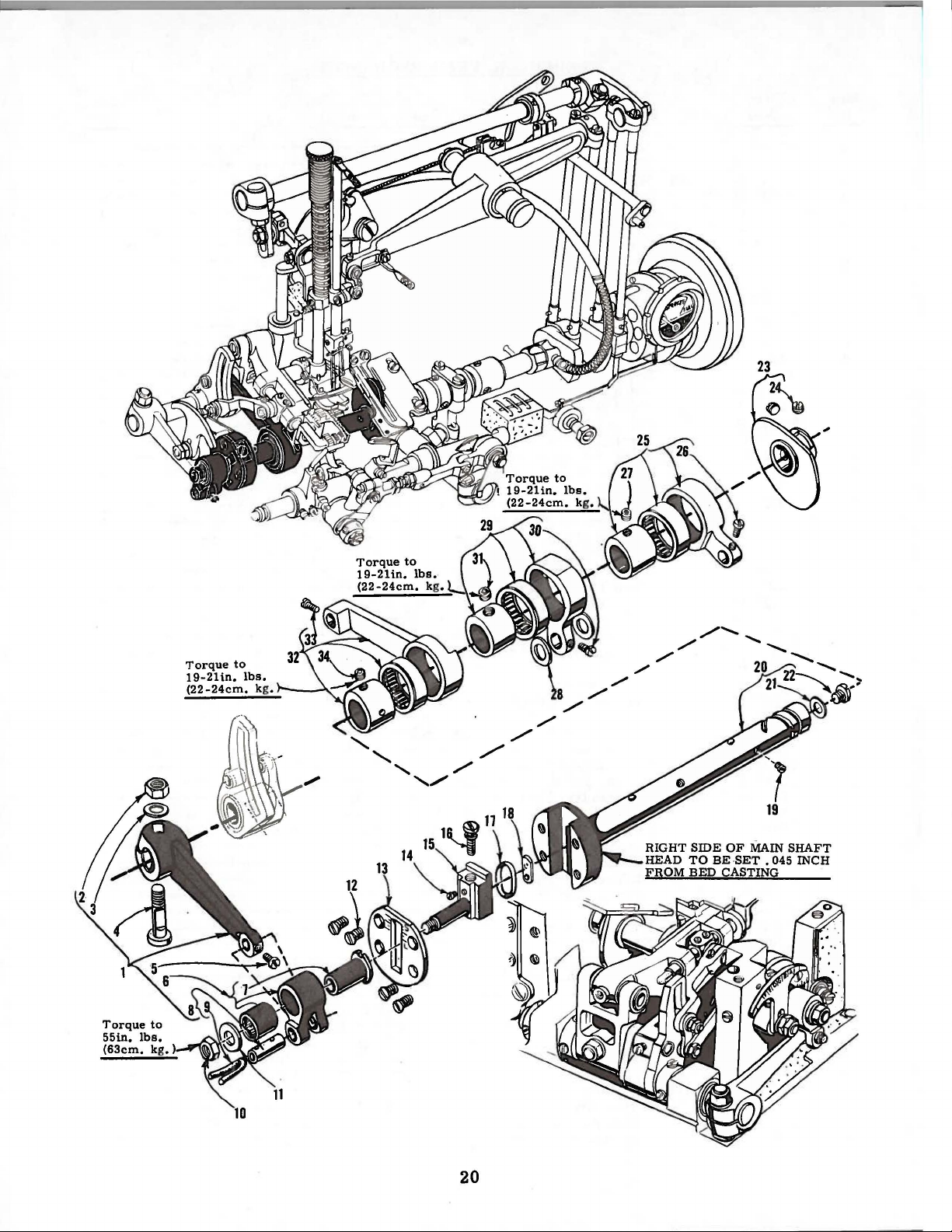

MAIN

SHAFT,

TAKE-UP

AND

FEED

DRIVING

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

Part

No.

29476

55235

6042 A

55235

22768

56336

56336

51054

21657

22525

56322

22798

56336

22543

56336

22801

57822

56322

22891

57823

22580

2947 6 NM-062

22894

39543

29476

22894

57836

22768

22894

ND

E

D

B

B

c

666-149

269

E

A

c

c

A

660-269

D

A

B

B

77

AA

N

NM-072

77

AA

E

B

AA

B

Description

Feed

Nut,

VVasher-----------------------------------------

Screw

Main

Screw-----------------------------------------Feed

Stitch

Quad

Feed

Screw,

Main

Looper

Looper

Thrust

Feed

Differential

Rocker

Assembly

Nut

----------~------------------------------

VVasher-------------------------------------Locking

Screw,

Feed

Feed

Feed

Oil

left

-----------------------------------------

Shaft

Crank

Regulating

Ring

Crank

for

Shaft--------------------------------------

Gasket

Oil

Flow

Thread

Screw

Avoid

• 062

.

•

inch

Screw

Screw

VVasher,

Lift

072

inch

Screw

Screw

080

inch

Screw

Screw---------------------------------------

Arm

-------------------------------------

Stud

for

Crank

Crank

Crank

VVick

hand

Head

Stud

-------------------------------------Stud

take-up

--------------------------------------

Regulating

---------------------------------------

(1.

---------------------------------------

--------------------------------------Eccentric

(1.

---------------------------------------

---------------------------------------

Feed

(2.

---------------------------------------

a!'\d

Feed

---------------------------------

link

pin

---------------------------

Link

Link

thread

Eccentric

58

83

03

Assembly

Link

Pin--------------------------

---------------------------------

----------------------------

Plate

'

Screw

Insert

Take-up--------------------------

mm)

for

mm)

Connecting

mm)

---------------------------

marked

------------------------------

throw----------------------

feed

Assembly,

throw----------------------

throw----------------------

Crank

--------------------

Ferrule------------------

'~"

--------------------

--------------------------

--------------------------

Screw---------------------

Assembly,

bar----------------------

Rod,

Link

Sub-

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

2

1

1

1

1

1

1

21

Page 22

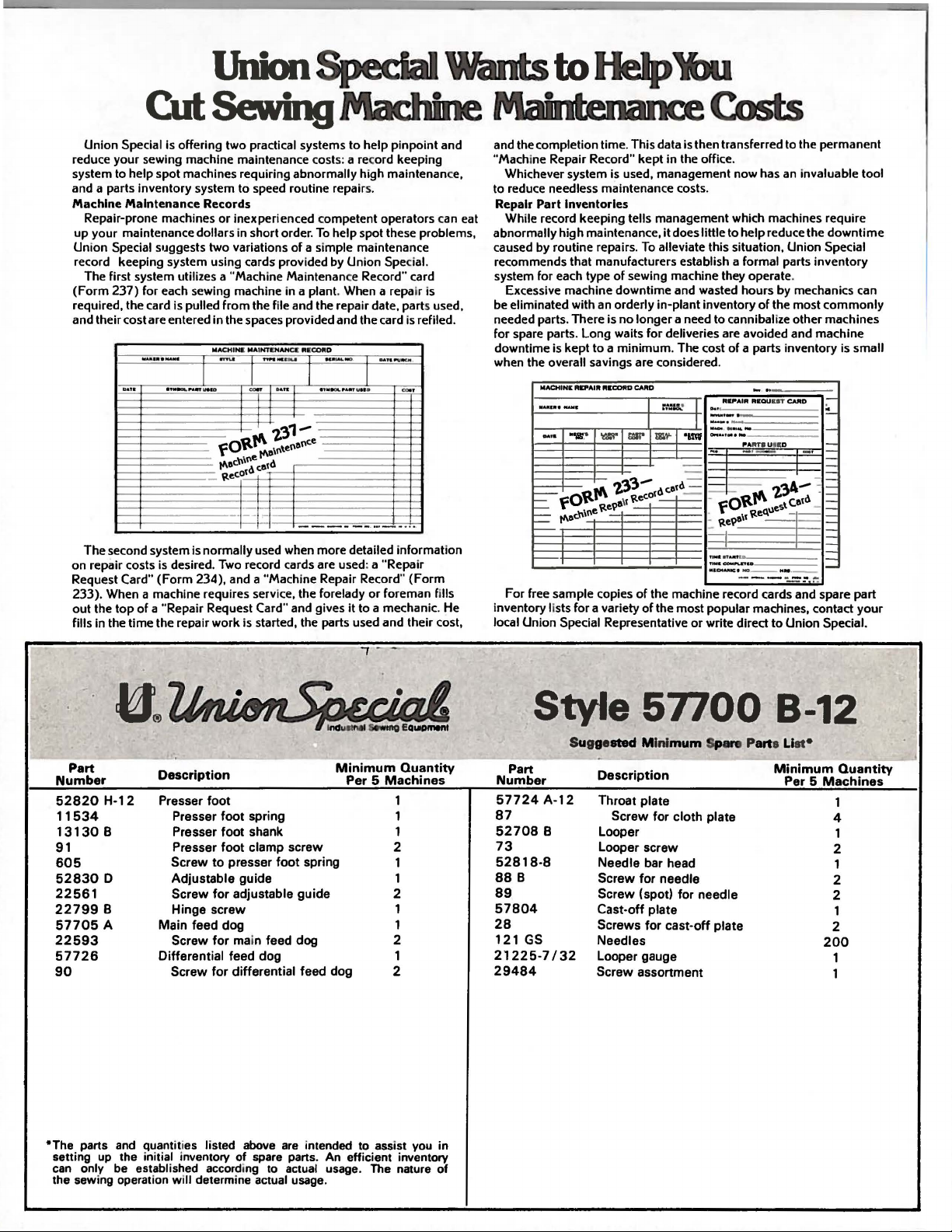

Union Special is offering two practical systems

reduce your sewing machine maintenance cost

system to help spot machines requiring abnormally high maintenanc

and a parts inventory system to speed routine repairs.

Machine Maintenance Records

Repair-prone machines

up your maintenance dollars in short order.

Union Special s•Jggests two variations

record keeping system using cards provided by Union Special.

The first system

(Form

237) for each sewing machine in a plant. When a repair is

required, the card is pulled

and their cost are entered in the spaces provided and the card

.......

-

DATI"

.,....._~ln'U.I

or

inexperienced competent operators can

of

utilizes a "Machine Maintenance Record'' card

from

the file and the repair date, parts used,

MACHIN&

MAIN"RNAHCC ... COfiiO

~

......

....

I

J J

.

O

fOttt'\

1'\Dc"\';;' ce!d

~ec:OI

...

-

2'31-

~el\el\ce

1'\D\1\

--

The second system is normally used when more detailed information

on repair costs

Request Card"

233). When a machine requires service, the forelady

out

the top

fills in the time the repair

is

desired. Two record cards are used: a "Repair

(Form

234), and a "Machine Repair Record"

of

a "Repair Request Card'' and gives

work

is started, the parts used and their cost,

to

help pinpoint and

s:

a record keeping

To

help spot these problems,

a simple maintenance

is

refiled.

...

, .

..,

--

-·

.,.,....._, • .,.u••

-

--

it

_ .

I

•

-·

.....

·-

(Form

or

foreman fills

to a mechanic. He

and the completion time. This data

"Machine Repair Record" kept

e,

Whichever system is used, management now has

to reduce needless maintenance costs.

Repair

Part

While record keeping tells management which machines require

eat

abnormally high maintenance,

caused by routine repairs.

recommends that manufacturers establish a formal parts inventory

system for each type

Excessive machine downtime and wasted hours by mechanics can

be eliminated with

needed parts. There is

for spare parts. Long waits for deliveries are avoided and machine

downtime is kept

when the overall savings are considered .

Inventories

~INit

REPAIR RltCORD CARD

of

sewing machine they operate.

an

orderly in-plant inventory

no

longer a need to cannibalize other machines

to a minimum

-··-·

..

"'1111

.'

mil"

'llr:l"

1'\

=

fOlt

=

1'\0c"\1\e

-

For free sample copies

inventory lists for a variety

local Union Special Representative

1.'3'3- d catd

~e~\1

~eeo'

of

is

then transferred to the permanent

in

the office.

it

does little

To

alleviate this situation, Union Special

. The cost

L'::&IJ..'

-I

-

..:::=

the machine record cards and spare part

of

the most popular machines, contact

to

of

RPAIR

h•

I

-·-·

I

--·

-

..

..

"im'

"""_

o..·-·-·-

-

, _

__ -z'3A-

- fOttt'\ t

.

~

e9a\l

,

....

..

....,.

TJMII-PLPU

M&CMA·III;· NO--·-·--

-

or

write direct

help reduce the

of

the most

a parts inventory is small

-

..

ftiEQU

UT

~ART8 UIE

-·-

~e~\les

-----

to

an

invaluable tool

downtime

commonly

-

CAftD

~

-_

D

-

-·

:

=

catd

-

=

=

-

I

-

-

-

Union Special.

your

Part

Number

52820

11534

13130

91

605

52830

22561

22799

57705

22593

57726

90

*The parts

setting up the initial inventory of spare parts. An efficient inventory

can

the sewing operation

H-12

8

D

8

A

only be established according to actual usage. The nature

and

Description

Presser

Presser

Presser

Presser

Screw

Adjustable

Screw

Hinge

Main

Screw

Differential

Screw

quanttto

es

will

foot

foot

spring

foot

shank

foot

clamp

to

presser

for

screw

feed

dog

for

feed

for

listed above

determine actual usage.

foot

guide

adjustable

main feed dog

dog

differential

are

Minimum

Per 5 Machines

screw

spring

guide

feed dog

intended to assist you in

Quantity

1

1

1

2

1

1

2

1

1

2

1

2

of

Style

Part

Number

57724

87

52708

73

52818-8

88

89

57804

28

121

21225-7/32

29484

A-12

8

B

GS

Su

gge

sted Mini

Description

Throat

Screw

Looper

Looper

Needle bar head

Screw

Screw

Cast-off plate

Screws for

Needles

Looper gauge

Screw

57700

mum

Spar.

P

plate

for

cloth

plate

screw

for

needle

(spot)

for

needle

cast-off

assortment

plate

B-12

arts

Li

st•

Minimum

Per 5 Machines

Quantity

1

4

1

2

1

2

2

1

2

200

1

1

Page 23

Helpful,

cient

machine sewed

Sales

esting,

obligation

authoritative

types

of

Promotion

illustrated

are

information

equipment

article

is available

Department.

bulletins

the

following

for

making

from

Among

that

are available

:

on

the

virtually

Union

the

many

most

Special

without

effi-

any

inter-

HERE

ARE

HELPFUL

No. 240,

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No. 265,

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

"Columbia

ing Machines"

No.

"Men's,

249,

"Rainwear"

250,

"Men's

251,

"Service

252,

"Men's

253,

"Overalls,

254,

"Men's

256,

"Knit

259,

"Men's

260,

"Work

262,

"Cotton,

Bags"

263,

"Men's

264,

"Men's

"Women's

266,

"Women's

267,

"Corsets, Girdles, Brassieres"

268,

"Children's

269, "Mattresses,

Upholstery"

271,

"Awnings,

273,

"Curtains & Drapes"

610,

"Kiipp-it"

710,

"MCS

730,

"MCS

Hemmer"

740,

"MCS

750,

"Fusing

1100,

"Lewis

stitch,

1105,

"Button

Blindstitch,

1500,

"Alteration

Women's,

Dress

Shirts

Shorts

Coveralls, and Dungarees"

Knit

Outerwear"

Sports

Gloves"

Burlap, Jute,

Clothing"

Women's,

Wear"

Wear

Canopies, Tents,

ForMation Uni

Automatic

Automatic

Presses"

Blindstitch,

Machines"

Sewers-Ticket

Children's

Shirts"

and

Pants"

and Pajamas"

Underwear"

Shirts"

Children's

And

Wear"

Slip

Covers,

Dual

Rib-Knit

Chalnstitch,

Saddle

Stitch,

Department

and

High

Furniture

t"

Underfront

Tackers"

Machines"

Footwear"

Multiwall

Jackets"

Fashion"

Tarps"

Cuff

Machine"

Lock·

and

Tie

Paper

Shirt

Clos-

BULLETINS

TO

SEWING

HELP

PROBLEMS

YOU

and

CATALOGS

SOLVE

UNION SPECIAL

H

NIST QUAl

RY

CORPORATION

Page 24

WORLD'S

FINEST

,

QUALITY

*

-.'

..

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

and

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your particular operation. Union

Special representatives

tory trained

promptly

tion, there

serve you.

ATLANTA,

BOSTON, MASS. TORONTO,

CHICAGO,

DALL

AS,

LOS

NEW

PHILADELPHIA,

GA.

TEXAS

ANGELES,

YORK, N.

and

and

efficiently. Whatever your loca-

is

a Union Special Representative to

Check with

ILL.

CAL.

Y.

PA. STUnGART,

are

and

service men

able

to

serve your needs

him

today.

MONTREAL, CANADA

BRUSSELS,

LEICESTER,

LONDON,

PA

RIS,

FRANCE

service

will

are

fac-

CANADA

BELGIU

ENGLA

ENGLA

GERMANY

M

ND

ND

Representatives

Industrial cities

UNION SPECIAL

400

N.

FRANKLIN

and

distributors

throughout

ST.,

In

all

Important

the

world.

CORPORATION

CHICAGO,

ILL.

60610

Loading...

Loading...