Page 1

F

INEST

ST

57

®

QUALITY

YLES

100 c

INDUSTRIAL

SEWING

I

MACHINES

CLASS

57100

CATALOG

No.

T141

M

ADVANCED

FIFTY

FLAT

THOUSAND

BED

HIGH

MACHINES

UNION SPECIAL

CHICAGO

Price

$1.00

SPEED

SERIES

CORPORATION

Page 2

C a t a 1 o g N

( S U P P L E M E N T T 0 C A T A L 0 G N

o.

T 1 4 1 M

I N S T R U C T I 0 N S

F 0 R

A D J U S T I N G A N D 0 P E R A T I N G

L I

S T 0 F P A R T S

F 0 R

S t y 1 e

5 7 1 0 0 c

0.

1 3 1 M )

U n i o n

R i g h t s R e

UNION SPECIAL

INDUSTRIAL

F i r s t E d i t i o n

~

1 9 7 7

b y

S p e c i a 1 C o r p o r a t i o n

s e r v e d i n A 1 1 C o u n t r i e s

CORPORATION

SEWING

CHICAGO

MACHINES

P r i n t e d i n

2

U.

S.

A.

April,

1977

Page 3

IDENTIFICATION

OF

MACHINES

Each

t he m

achi

numb

ers have

Exam

ple

minor

Style

Styl

wh

ich differs from the

5 7100

".

T

used in

not

used

cl

ari

parts.

part

number,

part

or

base

ence

number

This

herein.

in

these

are

given

direction

UNION

ne .

one

: "

Style

cha

nges are made

number.

es

of machi n

his.catalo

conjunction

on

Style

ty,

certain

Opposite

description

is

indicated

part.

in

catalog

It

can

classes.

from

of

handwheel

SPECIAL

Style

57100 C

Example:

g

Always

the

also

the

machine

numbers

or

more

letters

".

are

Special

in a standard

"Styl

e 57100 CZ".

es

similar

style

number,

is a supplement

therewith.

57700 N are

57700 N

the

parts

i l

lustration

and amount

by

indenting

use

the

first

applies

References

column when

specifically

be

applied

to

operator's

is

toward

is

identified

classified

suffixed, but

Style

ma

chi ne , a "Z"

in constructi

in

APPLICATION

to

Catalo

Only

those parts

illustrated

ar

e shown

pages,

required.

its

description

part

number

ordering

to

with

discretion

direction,

position

the

while

operator.

as

number s

on are

that

it contains

OF

g No.

and

in

phantom

parts

in

the

the

such

seated

by a

Style

standard

numb

and sp

never contain

contai

n t he l

is

suffixed

grouped

no

CATALOG

131M.

which

list

ed

are

identified

Any

part

under

second

repair

Standard

to

some

as

right,

are

at

to

the

parts.

at

Second

the

assist

that

description

column,

Style

Special

the

er on a name pl

ecial

t he let

ette

.

r "Z

to

ter "Z".

the

under a class

letters.

Edition,

used

on

Style

back

of

this

in

locating

by a

reference

is a component

never

of

machine

Styles

left,

front,

machine.

Operating

Sta

ndar d

".

\.Jh

en on

standard

numb

Exampl e :

and

57100

book.

th

of

of

the

use

the

as

listed

of

machines

back,

ate

on

Styl

ly

er

''Cla

ss

should

be

C, bu t

For

e 57100 C

number,

another

assembly

refer-

etc.,

Advanced High

Throw,

Driving

Filtered

for

Double

Knee

Work

57100

Needle

Mechanism,

Feed

Disc

Press

Space

C

cord.

gauge.

Oil

Bar

Take-up,

for

to

For

Needle

Standard

Return

and

cording

402-0S-1.

Each

UNION

number

The

size

denotes

number,

blade, measured

and

the

eye.

Collectively,

symbol,

which

Special.

Speed,

Bearing

Single

Feed

Presser

Right

spacing

Type 108

SPECIAL

the

kind

stamped

in

thousandths

is

given

Two

needle,

Needle

Reservoir

Pumps

for

Rocker

Large

Foot

of

~eedle

operations

height

GHS

needle

of

on

on

the

STYLE

One

Bar

Drive,

Head

and

Shafts,

Handwheel

Lifter,

Bar 8 1/4

on

light

or

g

~uge

of

tucking

needle.

has

both a type

shank,

the

the

point,

needle

of

an

type

label

OF

Looper,

Light

Enclosed

Base,

Greased

and

Improved

Equipped

Inches

weight

is

.080

1/8

Maximum

NEEDLES

length,

shank,

inch

or

number

of

all

MACHINE

Plain

Weight

Positive

Needle

and

Sealed.

Belt

with

Disc

(209.6

woven

inch

(2.03

inch

(3.18

recommended

number

groove,

denotes

millimeters,

and

size

needles

Feed

Flat

Presser

Automatic

Bearings

Guard.

Thread

mm).

and

mm)

mm). Seam

speed

and a size

finish

the

number

packaged

Bed

Bar

Lubricating

and

Laterial

Prepared

Tensions,

knitted

or

approximately

6500

and

largest

midway

represents

and

sold

Machines,

and

Needle

Bronze

Looper

Bearings

Travel,

for

Maximum

fabrics,

specification

R.P.M.

number.

other

The

details.

diameter

between

the

by

the

complete

Union

Medium

Bar

System,

use

with

without

No.

5

type

of

the

shank

3

Page 4

The

round

e

needle,

complete

d,

chromium

To

point,

standard

have

or

the

order

extra

plated.

needle

type

would

needle

short,

Available

orders

and

read:

for

double

promptly

size

"1000

NEEDLES

Style

groove,

in

sizes

number

Needles,

(Continued)

57100 C is

struck

080/032, 090/036,

and

accurately

should

be

Type 108

Type 108

groove,

filled,

forwarded.

GHS,

GHS.

ball

Use

Size

It

has a round

eye,

100/040,

an

empty

description

090/036".

ball

110/044,

package,a

point,

on

shank,

spot

t-

125/049.

sampl

label.

e

A

Selection

used.

stitch

needles

for

three-quarters

Thread

formation.

Success

packaged

producing

of

the

should

in

the

highest

of a century.

pass

operation

under

proper

freely

our

quality

needle

of

brand

needles

size

through

UNION

name,~

should

the

SPECIAL

in

materials

be

needle

machines

determined

eye

in

order

can

,

which

and

workmanship

by

be

is

the

to

secured

backed

for

size

of

thread

produce

by a reputation

only

more

a good

by

than

use

of

4

Page 5

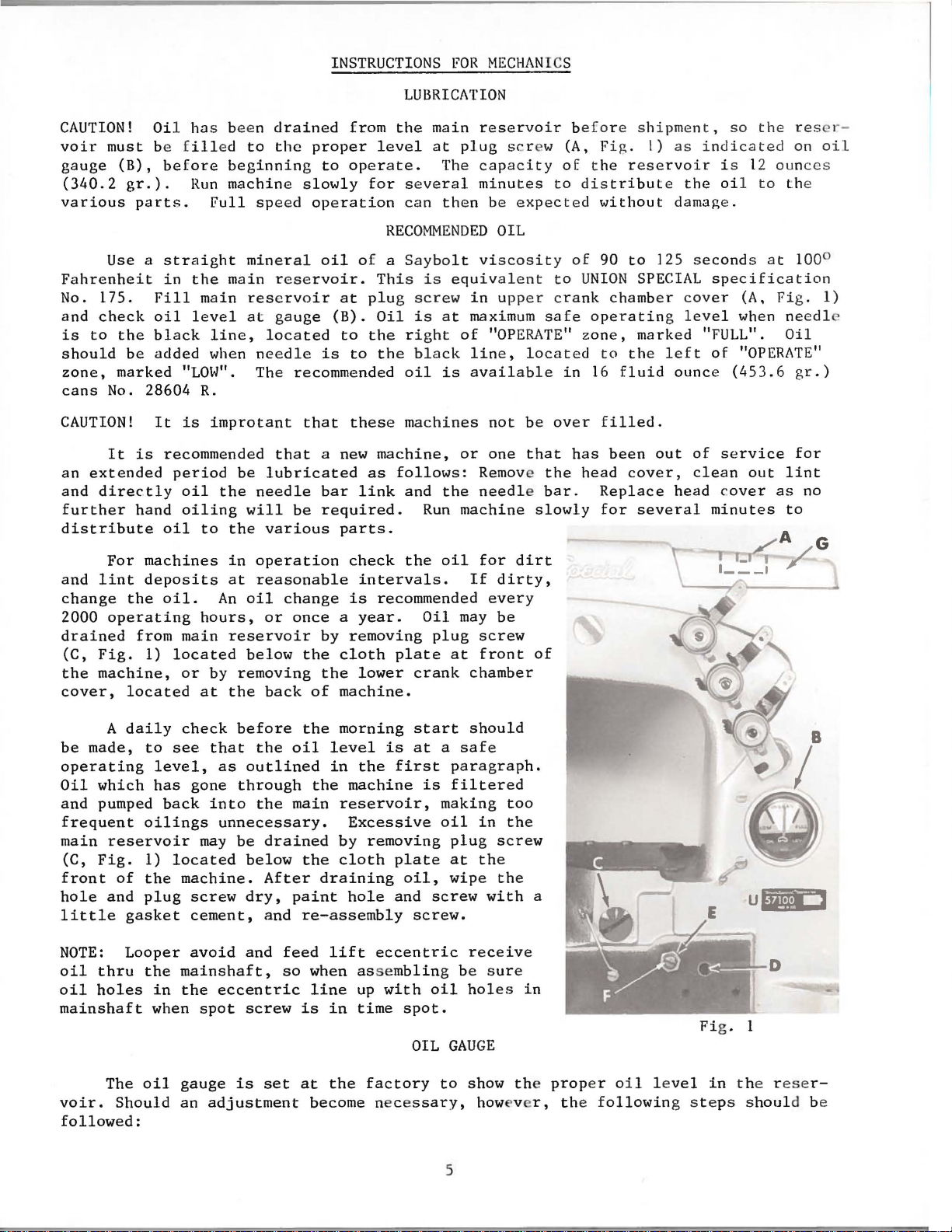

INSTRUCTIONS

LUBRICATION

FOR

MECHANICS

CAUTION!

voir

must

gauge

(340.2

various

Fahrenheit

No. 175.

and

is

should

zone,

cans

CAUTION!

an

and

further

distribute

and

change

2000

drained

(C,

the

cover,

(B),

gr.).

Use

check

to

the

be

marked

No. 28604

It

extended

directly

For

lint

the

operating

Fig.

machine,

located

Oi

l ha s been

be f

ill

before

Run

parts.

a

straight

in

the

Fill

oil

level

black

added

"LOW".

It

is

is

recommended

period

oil

hand

from

oiling

oil

machines

deposits

oil.

main

1)

located

or

at

ed

to

beginning

machine

Full

mineral

main

main

R.

to

hours,

reservoir

at

line,

when

needle

The recommended

improtant

be

the

needle

will

the

in

operation

at

reasonable

An

oil

reservoir

below

by

removing

the

drained

the

proper

slowly

spe

ed

operation

reservoir.

gauge

located

that

that

lubricated

be

various

change

or

once a year.

the

back

of

from

level

to

operate.

for

oil

of a

This

at

plug

(B).

Oil

to

the

is

to

the

these

a new

bar

required.

by

the

machine,

as

link

parts.

check

intervals.

is

recommended

removing

cloth

lower

machine.

the

main

several

can

RECOMMENDED

Saybolt

is

screw

is

right

black

oil

machines

follows:

and

Run

the

Oil

plate

crank

at

The

then

equiv

at

is

the

machine

oil

may

plug

at

plug

in

maximum

of

line,

available

or

If

chamber

reservoir

capacity

minutes

be

OIL

viscosity

alent

upper

"OPERATE"

not

one

Remove the

needle bar.

for

dirty,

every

be

screw

front

scr

ew (A, Fig.

of

to

expected

to

crank

safe

located

in

be

over

that

slowly

dirt

of

b

efo

r e

t he

distribute

without

of

90

UNION

chamber

operating

zone,

to

16

fluid

filled.

has

been

head

Replace

for

shipment, so

I)

as

indicated

reservoir

to

125

SPECIAL

marked "FULL".

the

left

out

cover,

several

i s 12 oun

the oil

damage.

seconds

specification

cover

level

of

ounce

of

service

clean

head

cover

minutes

(453.6

the res -r -

on

ces

to th

e

at

100°

(A,

Fig.

when ne

"OPERATE"

out

Oil

as

edl

gr.)

for

lint

no

to

oil

1)

e

A

be

made,

operating

Oil

which

and

pumped

frequent

main

reservoir

(C,

Fig.

front

hole

little

NOTE:

oil

oil

mainshaft

voir.

followed:

of

and

Looper

thru

holes

The

Should

daily

to

level,

has

back

oilings

1)

the

plug

gasket

the

in

when

oil

check

see

that

as

gone

into

unnecessary.

may

located

machine.

screw

cement,

avoid

mainshaft,

the

eccentric

spot

gauge

an

adjustment

before

the

outlined

through

the

be

drained

below

After

dry,

and

and

feed

so

screw

is

set

the

morning

oil

level

in

the

the

machine

main

paint

reservoir,

Excessive

by

the

cloth

draining

hole

re-assembly

lift

when asse

line

is

at

become nece

in

the

up

time

start

is

at a safe

first

is

removing

plate

oil,

and

screw.

eccentric

mbling

with

spot.

OIL

factory

ssary,

should

paragraph.

filtered

making

oil

in

plug

screw

at

the

wipe

screw

oil

GAUGE

to

5

the

with

receive

be

sure

holes

show the

how v r, the f

too

the

in

a

prop

er oi l l e

ollowin

Fi

vel

in

g s

teps shoul

g. I

the rese

B

I

r-

d be

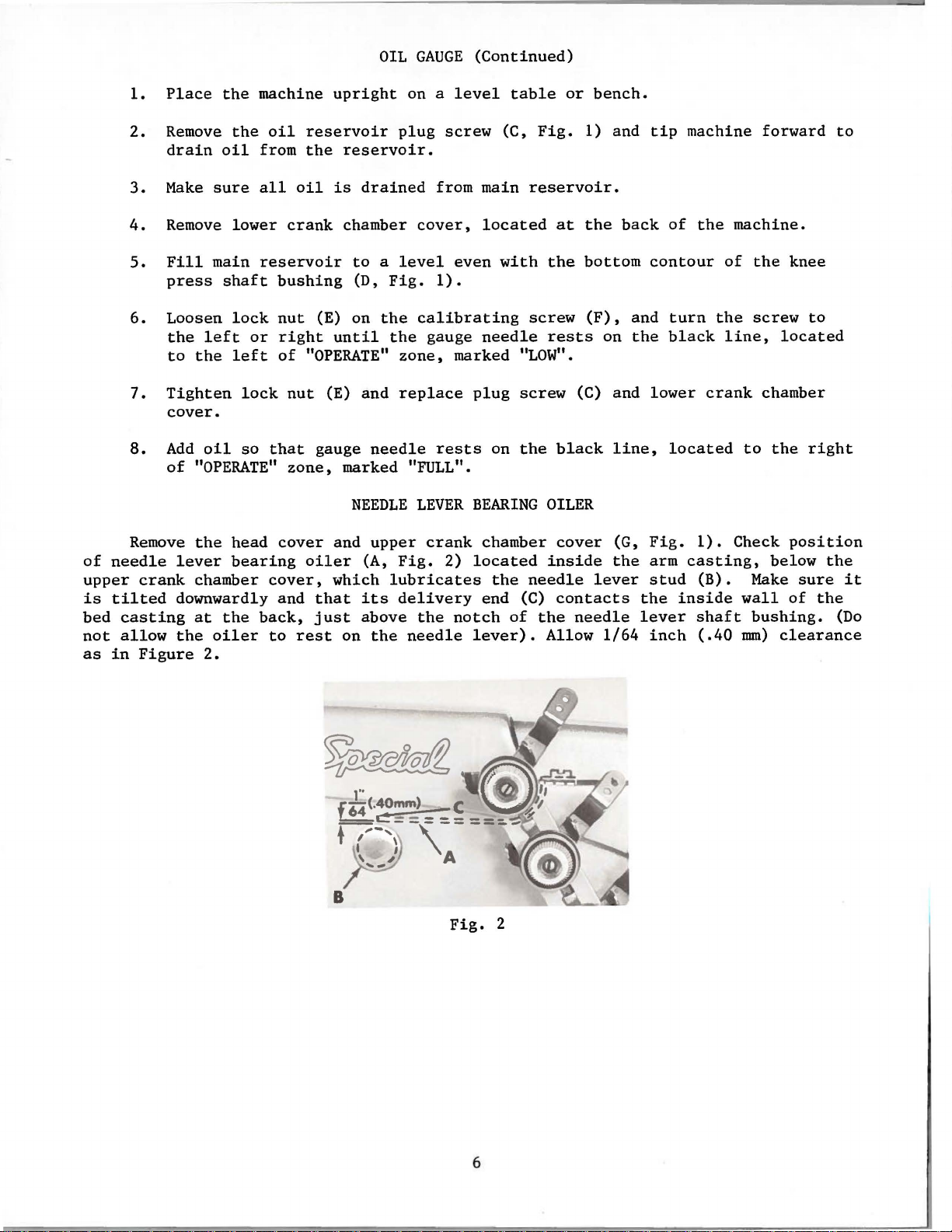

Page 6

1.

2.

3.

4.

5.

6.

7.

8.

Place

Remove

drain

Make

Remove

Fill

press

Loosen

Tighten

cover.

Add

of

sure

main

the

left

to

the

oil

"OPERATE"

the

the

oil

lower

shaft

lock

or

left

lock

so

machine

oil

reservoir

from

the

all

oil

crank

reservoir

bushing

nut

(E) on

right

of

"OPERATE"

nut

that

gauge

zone,

OIL

GAUGE

upright

reservoir.

is

chamber

to a level

(D,

until

(E) and

marked "FULL".

on a

plug

drained

Fig.

the

the

zone,

replace

needle

cover,

calibrating

gauge

(Continued)

level

screw

from main

even

1).

marked

rests

table

(C,

located

with

needle

plug

on

or

Fig.

reservoir.

at

the

screw

rests

"LOW".

screw

the

(C) and

black

bench.

1) and

the

back

bottom

(F),

and

on

the

line,

tip

machine

of

the

contour

turn

black

lower

located

machine.

of

the

line,

crank

forward

the

screw

located

chamber

to

the

to

knee

to

right

of

needle

upper

is

tilted

bed

not

as

in

Remove

crank

casting

allow

Figure

the

head

cover

lever

downwardly and

the

bearing

chamber

at

the

oiler

2.

cover,

back,

to

rest

and

oiler

which

that

just

NEEDLE

upper

(A,

lubricates

its

above

on

the

LEVER

crank

Fig.

delivery

2)

the

needle

Fig.

notch

BEARING

chamber

located

the

needle

end (C)

of

the

lever).

2

OILER

cover

inside

lever

contacts

needle

Allow

(G,

the

1/64

Fig.

arm

stud

the

lever

inch

1).

casting,

(B).

inside

shaft

(.40

Check

below

Make

wall

bushing.

mm)

position

the

sure

of

clearance

it

the

(Do

6

Page 7

FILL

MAIN

RESERVOIR

HERE

Thread

clarity.

The

oil

must

be

and add

filled

oil

zone marked

keeping

refer

the

to

paragraphs

machine

has

been

before

when

needle

"LOW".

main

reservoir

THREADING

as

indicated

drained

starting

is

to

The machine

filled

on

"LUBRICATION"

AND

from

to

the

OILING

above.

the

machine

operate.

black

is

automatically

is

necessary.

and

CAUTION!

FILL

ALL

OIL

BEFORE

MACHINE

BEFORE

DIAGRAM

The

STARTING.

HAS

SHIPPING.

FOR

looper

STYLE

threading

before

Maintain

line

located

lubricated

For

further

"RECOMMENDED

RESERVOIRS

BEEN

DRAINED

57100 C

has

shipping

oil

level

to

the

and

in

left

and no

lubricating

OIL".

FOR

CORRECT

OIL

LEVEL

NEEDLE

SHOULD

OPERATE

Fig.

been ent

the

reservoir

"OPERATE"

of

the

"OPERATE"

oiling

instructions

OF

GAUGE

BE

IN

POSITION

3

arged

position

other

for

than

7

Page 8

ALIGNING

THE

NEEDLE

BAR

Insert

bar

so

that

turn

needle

quired.

tion

left

respect

looper

needle.

to

the

able.

the

direction

the

accomplished

drive

tap

with a small

quired.

plate,

ervoir

rocker

Looper

ring

from

ring

metal

Tighten

Insert

until

side

to

point

If

looper

If

the

looper

rear.

Moving

lever.

To

throat

back

shaft,

drive

between

the

looper

until

contact

move

a new

the

bar

the

the

of

the

the

again

the

point

distance

is

greatest

Moving

of

as

To

move

plate

cover,

toward

lever

it

drive

with

set

needles

(A,

Fig.

clamp

looper

point

looper

motions

the

the

follows:

and

drive

of

right

moves

will

looper

it

in

looper

move

hammer,

stud

support,

then, a light

the

(E,

the

lever

the

of

needles

correspond

4),

screw.

SYNCHRONIZING

in

the

the

looper

needle

point,

to

the

synchronize,

be

the

from

the

when

stud

forward

Fig.

lever

(E) and

bed

the

drive

the

opposite

drive

Loosen

to

driectly

operator,

5)

bed

casting.

rocker

casting.

(Type and

loosen

looper

(B).

then

left,

same. A

eye

pulley

shaft

lever

the

rear

(toward

oil

reservoir

tap

has

the

with the ver tical face

turn

of

on

is

an

shaft

oil

Size as

needle

LOOPER

rocker

(A,

Note

the

direction

clamp

(away

the

operator),

on

all

oil

All

Tighten

bar

AND

Fig.

the

handwheel

and

is

height

variation

the

needle

is

turned

synchronizing

shaft

screw

from

stud

top

the

that

seal

end

by

seal

requi

clamp scr ew (B)

NEEDLE

and

turn

5),

moving

height

even

of

acts

synchronizing

(D)

operator),

is

cover

looper

is

collar

play

compressing

collar

screw

MOTIONS

handwheel

of

in

the

with

the

eye

of

.005

to

the

in

the

stud

the

of

all

that

remove

and

drive

required.

and

must

make

(D).

be

red)

of

to

the

the

eye

reverse

the

left

of

inch

point

operating

(C)

reverse

stud

the

looper

a

light

is

the

cloth

oil

lever

Note:

an

removed

the

"O"

metal

and

the

and

in

left

of

direction

side

the

(.127

of

to

.

is

reres-

"O"

to

align

needle

turn

operating

is

even

the

needle

of

needle

mrn)

the

guard.

bar

until

the

with

is

needle

as

re-

direc-

with

with

right

respect

allow-

To

the

the

check

With

the

the

looper

location

Fig.

of

at

5

the

the

center

extreme

line

right

of

tion

move

over

should

looper

sary,

the

clamp

can

tween

and

er

(Fi

rod

nut

threaded

looper

be

the

lever stud

g.

end

the

right

bearing,

(F,

locate

rocker

loosen

screw.

checked

the

center

center

5).

of

its

travel,

looper

using

Fig.

drive

If

5)

stud.

against

cone

the

clamp

lever

gauge

with a scale.

line

and

should

and

The

(G).

the

be

connec-

gauge

place

left

the

right

If

screw

(E)

is

not

of

the

center

4

1/16

No. 21227

hole

end

of

side

adjustment

(D)

and

as

required.

available,

The

distance

looper

line

of

inch

Fig.

4

CX.

in

g.

•1ge

the

gauge

of

the

is

neces-

reposition

Tighten

se

ttin

be-

rocker

the

loop-

(103.19

Re-

con

mrn)

g

e

8

Page 9

SETTING

THE

LOOPER

Inser t t

er g

au

ge

the center of the two

wh

en the

this

adjustment

recheck the

i s

5/32 inch

loop

Fig.

adjustment.

wo

er

6

new ne

is

at

may

edles

(3.97

needles

its

prove

in

the

mm),

farthest

can

has a left

turn

5/32

nut

vertical

of-feed,

hind

brushes,

the

lock

(G)

wise

ing

Holding

helpful.

set

(B)

be

used

If

the

inch

(D).

The

the

needle

If

screw

as

required.

sets

it

counterclockwise

needle

to

position

adjustment

hand

connecting

(3 . 97

Then

position

looper

if,

needle,

but

adjustment

the

looper

Tighten

seat,

the

looper

the

point

advantageously

mrn)

nut

as

does

(B).

(F,

Fig.

looper

to

of

to the

is

thread)

rod

dimension.

(C).

and

is

set

it

moves

its

point

not

is

6)

Turning

the

lock

type

and

(A,

Fig.

the

right.Looper

in

required,

and

forward

Make

does

not

correctly

to

(A,

pick

at

necessary,

and

turn

stop

to

the

acts

front

screw

size

6)

looper

making

loosen

nut

or

Retighten

sure

bind

the

left,

Fig.

the

stop

screw

rear

the

while

when

as

so

is

(D)

on

backward

the

after

in

line-

7)

rear

loosen

clockand

reverse.

making

setting

specified.The

the

distance

5/32

gauge

this

left

be-

screw

turn-

inch

No.

adjustment.

nut

(C,

connecting

to

both

ball

adjustment.

of

is

obtained

between

(3.97

21225-5/32

Fig.

obtain

nuts,

joint

6)

rod

first

Fig.

loop

mrn),

(it

(E),

the

is

7

and

-

in

Fi

g. 8

1/64

the

pressure

screw.

of the nee

inch

corner

The

(.40

on

dles

may

the

point

rnrn)

be

slightly

heel

of

by

adjusting

SETTING

The

height

is

correct

eye

is

of

the

moving

of

this

loosen

up

or

Care

must

ment

ating

and

retainer

cannot

of the

justment,

right

following conditions

(.40

of

the

and

The loop

direction

the

rnrn)

be

the

looper

1/64

looper,

to

needle.

screw

down

be

as

left

left

(B).

over

obtained

altered

looper

the

when

inch

wh

the

left,

(B)

as

required

taken

needle

the needl

sides

SETTING

er

corner

At

the

by

in

will

loop

HEIGHT

of

the

(.40

en

If

and

and

until

th n have to

er

OF

the

needle

top.of

mrn)

the

point

is even

adjustment

reposition

and

not

to

bar

while

es

are

of

the

THE

LOOPER

loop

r e

prevail:

the

of

the

this

looper,

then the

loosening the

the

point

requir

rocker.

NEEDLE

bar

the

left

below

of

with

is

retighten

disturb

making

to

needle

AND

tainer

(1)

looper

recess

the

from

back

distance

ed

direction

be

BAR

(A,

Fig.

8)

needle's

the

underside

looper,

the

l e

ft

side

necessary,

needle

have

LOOP

are set correctly when the

Turn the handwh

(A,

prong

looper

reset

bar

(A)

screw.

the

align-

this

ad-

equal

slots

Fig.

is

under the

to

which the

clearance on

in

throat

RETAINER

9)

moving

should project

front

set screw (C) and a

with

whil

e r etighte

r espe

(Fi

prong projects

eel

pron

g.

ct

Fig.

plate.

i n the op e

to the

g of the

1/64

9).

ning th

to the

9

both the

right

loop

inch

I f

this

over

pplyin

e

back

r-

g

9

Page 10

(2.)

tainer

and

the

drawn

that

When

there

underside

between

passes

the

looper

should

them.

throu

SETTING

moves

be

a minimum amount

of

the

The

gh

the

THE

LOOPER

to

the

prong,

adjustment

throat

plate

or

AND

LOOP

right

and

of

just

enough

is

made by means

and

bears

RETAINER (Co

passe

s under the

clearan

ce

to perm

against

ntinued)

prong

between the

i t a

piece

of a small

the

top

top

of

screw

of

of

the

the

of

paper

(A,

loop

loop

the

to

Fig.

retainer.

re-

looper

be

10),

Fig.

If

throat

front

dog

CAUTION:

of

(A,

feed

(D)

plate,

teeth,

is

set

looper.

Should

Fig.

rocker

does

10

feed

properly.

See

13)

not

dog

loosen

and

that

it

be

which

to

desired

bind

Set

the

there

teeth

(1.19

and

plate

Adjust

under

this

to

teeth

nut

counterclockwise

there

necessary

hold

after

is

equal

extend

mm)

above

are

parallel

at

high

the

the

feed

setting.

hold

are

position

feed

not

(A, Fig. 12)

is

sufficient

to

the

feed

making

feed

dog

clearance

the

depth

the

with

point

supporting

dog,

Screw

dog

in

parallel

and

to

raise

move

rocker

and

this

the

retighten

adjustment.

SETTING

(A,

of a tooth

throat

the

of

travel.

screw

to

mainta

(D)

is

position.

with

turn

the

space

feed

(B)

onto

THE

Fig.

on

all

plate

throat

(C),

i n

used

the

screw

front

between

dog

to

the

screws.

FEED

11)

in

sides.

or

(B)

teeth.

underside

the

left

feed

Make

DOG

the

throat

See

that

approximately

clockwise

Retighten

or

rocker

sure

of

right,

shaft

the

to

feed

plate

the

lower

nut

feed

(B)

tips

3/64

when

dog

and

loosen

(C),

rocker

of

inch

the

screws

and

so

the

feed

top

move

arm

have

desired

the

feed

loosen

the

feed

rocker

ward

tighten

When

equal

stitch

Should

dog

nut

rocker

and

or

backward

nut.

the

handwheel

clearance

length.

it

be

forward

(E,

Fig.

move

Fig.

12

necessary

13)

arm

to

the

feed

as

needed

is

on

both

or

backward,

which

the

rocker

turned

ends

to

move

clamps

feed

and

re-

for-

in

of

the

the

operating

throat

direction

plate

slots

the

with

Fig.

feed

feed

13

dog

travel

should

set

to

10

Page 11

Set

nut

(F,

ulating

of

the

"S".

toward

(moves

prevent

the

"U"

the

Fig.

stud

cloth

Turning

the

"S")

stitch

destructive

shaped

stitch

13)

1/2

and

turning

plate,

the

screw

and

regulating

key

slot

to

required

turn

the

in

the

clockwise

turning

stud

damage

in

CHANGING

length.

(it

has a left

stitch

head

of

shortens

it

in a counterclockwise

toward

to

the

feed

the

ferrule

This

adjusting

the

main

the

drive

(K).

STITCH

is

hand

shaft

the

"L").

bearing,

LENGTH

accomplished

thread)

screw

stitch

Retighten

on

(G)

(H),

(moves

direction

the

the

located

which

the

Key

by

loosening

end

of

under

is

marked

stitch

lengthens

locknut

screw

the

the

stitch

the

left

with

regulating

the

securely.

(J)

must

lock-

regend

"L" and

stud

stitch

To

engage

NOTE:

rear

operation.

move

screws

withdrawn.

directly

the

sealed

assemble,

end

damage. Check

Feed

contact

A

clearance

possible,

the

needle.

needle

loosen

clockwise

Any

needle

The

nut

(A)

When

part

number 28604

bearings

of

shafts

Dog".

Set

the

the

needle,

To

guard

screw

change

guard

feed

This

(F).

and remove

Loosen

packing

from

reverse

Also

rear

of

yet

until

move

to

rocker

can

Remove

the

are

first,

for

rear

.005

have

as

required,

(F),

raise

in

stitch

setting.

assembly

be

Allen

bearings

tube

P.

replaced

the

twisting

proper

check

needle

of

the

inch

its

the

point

needle

and

turn

it.

length

may

accomplished

feed

rocker

stop

collar

screw

to

avoid

Greased

procedure

adjustment

to

see

SETTING

guard

right

(.127

vertical

guard

and

Retighten

(L) and remove

the

parts

they

slightly

that

(C,

needle

mm)

of

the

forward

retighten

screw

will

require

arm

on

contamination.

bearings

should

described

there

THE

Fig.

is

face

looper

(G)

screw

necessitate

lubrication

as

follows:

(D)

from

right

must

of

REAR

(D)

permissible.

approach

or

clockwise

end

be

are

be

in

when

feed

is

NEEDLE

12)

when

(E),

backward,

screw.

(F)

after

a

Loosen

machine

of

shaft

shaft

clean

Tube

located

pressed

the

entering

dog

no

binding

horizontally

at

within

moving

to

(M).

and

of

in

previous

as

described

GUARD

its

most

It

about

merely

To

raise

lower

guard

corresponding

or

repair

nuts

by

grease

grease

at

flush

the

at

should

to

is

(E,

rocking

(C).

Now,

(N,

P,

with

paragraph.

grease

any

so

that

forward

3/64

the

left,

loosen

or

lower

needle

properly

The

repack

should

can

under

point.

be

guard

after

F,

Fig.

slightly.

shaft

be

Fig.

the

seals

it

point

set

inch

is

screw

needle

set.

change

years

13) and

can

bearings.

be

applied

supplied

13).

casting.

Start

to

prevent

"Setting

does

not

of

as

low

(1.19

even

(F),

guard,

and

counter-

in

of

Loosen

now

If

grease

tapered

the

quite

travel.

as

mm)

with

move

the

re-

be

under

To

of

the

NOTE: A change

rear

needle

The

thread

begins

within

is

its

lever

machine

Retighten

binding

to

1/8

entirely

highest

If

adjustment

screw

and move

at

screw.

in

guard

tension

function

inch

released

position.

(A,

Fig.

any

point.

stitch

setting.

THREAD

as

(3.18

is

tension

After

length

TENSION

release

the

presser

mm)

of

when

the

needed,

14),

located

disc

adjustment

will

RELEASE

is

foot

the

end

presser

loosen

at

separator

there

require

set

of

foot

tension

the

a

correctly

is

raised

its

travel

has

release

back

as

required.

should

11

change

when

to

reached

of

the

be

no

and

in

it

Fig.

A

l.

14

Page 12

The

to

remove

pressed.

lower

surface

presser

plate.

needle

foot

a

setting

presser

surface

If

bar

down

screwdriver

height

the

Also

of

foot

adjustment

on

by

foot

of

presser

there

of

head

opening

resting

is

in

the

to

turning

can

the

presser

foot

should

the

presser

on

is

needed,

the

low

throat

obtain

handwheel

be

removed

SETTING

when

be

in

the

the

throat

position

plate

the

1/16

as

HEIGHT

bar

(A,

the

foot

approximately

bar

connection

bed

when

plate,

turn

handwheel

and

loosen

surface,

inch

so

that

mentioned

(1.59

needle

Fig.

lifter

the

pry

in

OF

PRESSER

15)

1/16

and

foot

with

in

screw

up

presser

mm)

bar

previous

is

set

lever

inch

guide

lifter

the

feed

operating

(C).

setting

is

in

paragraph.

BAR

correctly

(B,

Fig.

(1.59

(B,

Fig.

lever

dog

direction

Then,

bar

connection

and

its

high

14)

mm)

15) and

is

down

while

tighten

position

if

it

is

is

fully

clearance

the

released

below

the

until

holding

and

screw.

possible

debetween

bottom

and

throat

the

presser

guide

Check

and

see

the

with

if

Remove

bar

(A),

be

able

to

be

true

position

the

presser

hole

only

tension

(19.05

in

Regulate

enough

if

to

corded

presser

is

Fig.

mm)

both

not

move

and

with

foot

the

pressure

placed

15

above

needles

already

freely

operate

respect

clamp

foot.

presser

on

on

the

the

attaching

SETTING

(D,

Fig.

in

place.

on

the

presser

the

machine.

to

the

screw.

the

fabric.

the

wise

reverse.

take-up

located

needle

(C),

surface

top

of

needle

when

completed

stroke.

ting

thread

for a larger

the

needle

eyelet

eyelet

Replace

PRESSER

spring

presser

needle

increases

SETTING

Set

the

wire

adjacent

bar

so

that

is

the

bar

the

needle

Lower

for a smaller

loop,

(D)

hole

screw

THE

15) and

Do

not

bar.

This

guide

regulating

foot

This

bar

thread

even

holes

thread

its

thread

so

is

in

the

NEEDLE

needle

(B,

its

with

bar

downward

this

and

loop.

that

is

3/4

(Fig.

PRESSER

put

tighten

will

on

top

the

needles

FOOT

to

the

the

pressure,

THREAD

thread

Fig.

to

the

eyelet

upper

the

in

the

eyelet

has

set-

needle

raise

Set

frame

the

inch

16).

FOOT

presser

Place a piece

allow

of

PRESSURE

screw

feed

knurled

head

of

16),

it

foot

the

clamp

the

the

throat

and

check

(A,

Fig.

the

work

screw,

the

counterclockwise

TAKE-UP

(E) on

screw

of

fabric

presser

plate.

for

16)

uniformly

located

machine.

WIRE

Fig.

to

(F).

foot

clearance

so

that

Turning

AND

FRAME EYE

B

the

presser

It

in

the

to

Now

tighten

it

when a

directly

it

acts

16

the

should

machine

find

its

in

needle

exerts

slight

behind

clock-

LET

12

Page 13

THREADING

Draw t he

iece

p

Pull

to

produce

The

thread

The

(B)

contr~ls

tion.

take-up

The

trol

of

More

and

set

traingle

ed

down

as

the

of f

looper

is

looper

It

(C)

height

the

toward

may

stitches.

looper

loo

per

abric. R

the

needle

uniform

thread

just

sufficient

thread

the

amount

should

and

be

the

and

looper

looper

thread

the

be

wiped

moves

and

needle

efer to

thread

stitches

tension

SETTING

retaining

of

set

laterally

tip

parallel

the

lateral

thread

is

takeup.

under

This

to

can

the

threading

THREAD

through

on

the

should

to

steady

THE

slack

as

the

given

However,

the

be

checked

left.

threads

into

diagram

TENSIONS

the

eyelets

under

be

the

thread.

LOOPER

THREAD

finger

thread

so

with

in

that

the

adjustment

looper

to

blade

the

if

moves

stitch

it

of

by

the

(Fig.

surface

set

so

(A,

Fig.

the

it

is

discs.

of

is

the

looper,

observing

machine

3).

and

set

of

the

that

the

RETAINING

17)

located

system

and

midway

the

retaining

to

the

left.

when

raised

the

too

causing

the

and

the

needle

fabric.

tension

FINGER

can

between

finger

retaining

high,

action

start

on

on

the

be

moved

the

finger

the

triangle

of

the

operating

thread

the

looper

cast-off

to

two

discs

affects

is

looper

skips

looper

on a

tension

support

any

posi-

of

the

con-

raised

thread

or

pull-

thread

the

Fig.

17

13

Page 14

...

···········--------····

..

K

14

Page 15

R

ef.

No.

THREAD

Part

No.

EYELETS, FEED

LOOPER

LIFT

ECCENTRIC,

DRIVING

NEEDLE

AND

LOOPER

Description

ROC

BAR,

KER

HANDWHEEL

PAR

TS

ASSEMBLY,

Amt.

Req.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

2

3

4

5

6

8

9

1

7

56458 A

52170

539

56458

61434

29476

22894 M

57845 B

39543 N

56321

22574

61321

56321 D

56321

22894

57117

52107

29105

22587 K

56343

56343 E

22559 A

56344

29192

51745

57113

15465

22829

G

NM-080

77

J

L

H

AB

56

c

56

GV

56 v

88

AG

c

c

98

719

AD

F

88

258 A

96

Needle

Needle

Needle

Needle

Washer,

Feed

throw------------------------------------------------

Thrust

Handwheel

Needle

Needle

Needle

Screw------------------------------------------------Looper-----------------------------------------------Looper

Looper

Looper

Screw-------------------------------------------------

Bar

Thread

Thread

Thread

Lever

for

Lift

Screw--------------------------------------------Eccentric

Screw-----------------------------------------

Washer

Screw--------------------------------------------Retaining

Handwheel-----------------------------------------

Pulley--------------------------------------------

Screw-----------------------------------------

Bar,

Tapered

Wedge-----------------------------------------Clamp

Drive

Bearing

Ball

Oil

Splasher--------------------------------------

Bearing

Rocker

Set

Screw-----------------------------------------

Stop

Rocker

Looper

Looper

Looper

Screw----------------------------------------Lock

Lock Nut

Thread

needle

Eccentric

Assembly------------------------------------

marked

Stop

Collar-----------------------------------

Lever

Cap

Joint

Cap

Screw----------------------------------------

Rocker

Rocker,

Rocker

Nut------------------------------------------

Screw------------------------------------

Eyelet-----------------------------Take-up

Frame

Link

for

Plate-----------------------------------

Screw,

Guide

Screw,

Frame-----------------------------------

Assembly--------------------------------

Wire

---------------------------Eyelet---------------------------Eyelet----------------------------

guard------------------------------

Assembly,

Assembly---------------------------

feed

Pin---------------------------------

Cone

Cone--------------------------------

bar----------------------------

"EY"-------------------------------

Crank

marked

Assembly---------------------

upper--------------------------

Fork-----------------------------

lower--------------------------

Stud---------------------------

.080

inch

"AE"------------------------

(2.03

l

l

1

l

l

rnrn)

1

1

1

1

2

l

3

1

l

l

2

1

1

l

l

l

1

1

2

l

l

2

l

l

l

l

l

l

1

2

l

l

l

15

Page 16

16

Page 17

PRESSER

FOOT,

AND

THROAT

LOOPER

PLATE,

THREAD

FEED

TAKE-

DOG,

UP

CLOTH

PARTS

PLATE

COVER

R

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

ef.

No

1

2

3

4

5

6

7

8

9

.

Par t

No.

8620

K-1/8

91

8624

K-1/8

28

c

27

v

28

8605 J

57757 A

52904 G

51204

22569 D

69

H

87

u

22768

77

52904 E

50-216

51204 A

73

A

56381-222

22845 B

22760 A

35772

51281

H

AC

Blk.

Desc

ript

i on Re

P

resser

hroat

T

Feed Dog,

Cast-off

Cast-off

Looper

Screw,

Washer,

Screw,

Screw,

Screw,

Retaining

Cast-off

Screw,

Cloth

Foot------------------------------------------

Screw---------------------------------------------

Plate------------------------------------------

Screw,

Loop Re

Screw,

Dowel

Plate

Pivot

Screw-------------------------------------------

Washer-------------------------------------------Cloth

for

adjustin

tainer,

for

loop retainer--------------------------

16

teeth

Support

Wire-----------------------------------------

Thr

ead

for

cast-off

for

for looper

for

retaining

for

cast-off

Finger

Pin-----------------------------------------

Wire

for

cast-off

Screw---------------------------------------

Plate

Plate--------------------------------

Retaining Finger------------------------

cast-off

Support

Support---------------------------------

Cover-------------------------------------

Cover

g

loop

retainer----------------

marked

per inch

support

thread retaining

wire

wire------------------------------

"AY"------------------------

(1.59

plate---------------------

support

fing

Spring--------------------------

plate

er

support

support---------------------Bracket----------------------

mm

screw-------------finger-------------

bracket-----------

per

tooth)-------

Am

t.

q.

-

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

~

-

3

3

1

17

Page 18

Special

Wants

to

Help

\bu

Cut

Maintenance Costs

Union

help

maintenance costs: a record keeping system

spot machines requiring

and a parts

Machine

Repair-prone machines

eat

spot these problems,

variations

system using cards

The

Record" card

plant. When a repair is required, the card is pulled

the file and the repair date, parts used, and

are entered in the spaces provided and the card is refiled.

DAT

Special is offering

pinpoint

and reduce

inventory

Maintenance

up

your

maintenance dollars in short order. To help

of

a simple maintenance record keeping

provided

two

your

abnormally

system

to

Records

or

inexperienced operators can

Union

Special suggests

by

practical systems

sewing machine

high maintenance,

speed routine repairs.

Union

Special.

first system utilizes a "Machine Maintenance

I:

MAKIU I a

NAM

aT•uto'-

(Form

I

PART

MACHINE

I

uaco

237)

for

each sewing machine

MAINTENANCE RECORD

aTTL&

TYP

I N

EID

I.C

I I I

.

...

.

OA

"'

I

S 'I'M

a

«llliALN

aCM,.P'Aft

O

TU

231-

fO~~aintenance

f'<\ad""

Recor

dear

d

to

two

their

..

CO

to

help

from

cost

bAT

I P U RCH

in

COOT

a

f.-

~~-.nn

forelady

Request Card" and gives

the

their

transferred

kept

invaluable tool

Repair

machines require

little

repairs. To alleviate this situation,

recommends

parts

machine they operate.

mechanics can be eliminated with an orderly

inventory

is

spare parts.

machine

parts

considered.

Style 39500 QB

or

foreman fills

time

the repair

cost, and the

to

the permanent "Machine Repair Record"

in

the office.

Whichever system

to

reduce needless maintenance costs.

Part

Inventories

out

it

to

work

is started, the parts used and

completion

is

used, management now has an

While record keeping tells

abnormally

to

help reduce the

that

inventory

system

Excessive machine

of

the

most

no

longer a need

Long

downtime

inventory

is small when the overall savings are

downtime

manufacturers establish a

for

each type

downtime

commonly

to

cannibalize other machines

waits

for

deliveries are avoided and

is

kept

to a minimum.

the

top

of

a "Repair

a mechanic. He fills in

time

. This data is then

management

high maintenance,

caused by routine

Union

Special

of

sewing

and wasted hours by

needed parts. There

The cost

which

formal

in-plant

it

doe

for

of

s

a

-

The

second system is

detailed

information

on repair costs is desired . Two

record cards are used : a

(Form

(Form

234), and a "Machine Repair Record"

233)

. When a machine requires service, the

MACHINE

REPA

IR

RECORD

CARD

MAKER a NA

MC

DATil

...

r:.

u.•

fOlt~

hl'\e

f'<\aC

I

-

~

"

233-:rd

ReP

air

~

Rec

-

normally

- - _ . ,

.._

•a•-

••

used when

•• - ... U O

"Repair Request Card"

.........

:t:w

~~

L

card

I

I

•A'l~~a:

l'J~t>'-f

..

o

IN'IUoffOft

MA

• u e N Aill

MA

E:)!

CINIIIIH

~

a &

lo

I

NU M M&"

REPAIR REQUEST CARD

'r O•OII

G

, a&11"

fo. NO,

I;II

.

NO

.

PART

, • • • N

v--

fOlt~

ai<Re<\

ReP

TIMC

aT

...

Itn:o

11

WC COM

"'-CTII

"'IC:HA

D

N IC: 8 NO

--

·--

_ , _ ·-·---":::" !"; :

..

more

..

lti

AL

I

S USED

234-

uest card

-

1----

Hflfil,--

..,

,._

,.

• • a

..

e~l~ftll

-

-

-

-

-·

f.-

f-

~-

':

Part Number

39520A

39530

3959711

3

9524 B 3/32

or

39524 B 1/B

22524

3

9526

B

3950

5 B

39505

22528

93

11

22797 A

39!!

70

14077

39549

2258

8 A

39508

B

3950811

225646

39551

F

14077

22596

E

21225

1/8

154

GAS

For

free sample copies

and spare part

Presser foot

Presser

Presser foot sti

Throat plate markPd "V-

Throat plate marked "V·

Throat plate screw

Differentoal feed

Matn feed dog marked B. I

Chai

nong

ScrPu•

sJ\

l

s-pat'e

N . .. pper knife clamp stud

Lower

Screw for lower kn ife clamp

Lower looper

Upper loope r marked

Screw for upper looper

Needle clamp stud

Nut

for

Screw

Looper guage

Needles (spec•fy size)

inventory

Description

foot

h.nge

tch

or

feed

t~~-

•

1"\~\...'-"

\)aftS

knofe

needle clamp stud

for

needle droving

popular machines, contact

Representative

or

write direct

Minimum Spare

Parts Per Machine

spr

.ng

tongue marked "OS"

3/32

"

I/8"

dog.

16

teeth per inch

I'

• eth per inch

G

\..\St

"CC"

arm

100

of

the machine record cards

lists

for

your

to

a variety

local

Union

Union

Special.

of

the

Special

I

2

1

I

I

2

I

I

1

2

2

2

4

1

4

1

1

1

2

1

1

2

1

most

Page 19

Here

are

Oil

for

Specifications

Union

Sewing

roleum

mended

machines.

roleum

mount

high

mitters.

3.

used.

Specification

Specification

white

or

1.

For

use

roleum

quality

Where

UNION

oil,

viscosity

for

all

oil,

viscosity

with a maximum

where freedom from

Specification

oil,

viscosity

Specification

grease

It

is

similar

No.

3 grease

SPECIAL

SPECIFICATION

Viscosity S.S.U.

Flash

(Min.)

Pour

(Max.)

Color

A.S.T.M.

Neutralization

Viscosity

(0

Compounding

Copper

*Anline

*Used

Index

& D

Min.)

Corrosion

No.

with

Buna N

174

100

oiling

175 specifies a high

87 specifies a high

300

100

for

to

commercial

is

NO. 174 175 87

at

100°F

(Max.)

No.

(Max.)

(Max.)

Rubber

Special

Machines

specifies a high

seconds

applications

100

seconds at

A.S.T.M.

oil

seconds

use

not

at

specifies a general purpose

in ball bearings and trans-

N.L.G.I.,

obtainable,

90-125

350

20

3

0.10

85

None

1A

175-225

"0"

Retainers

quality

at

100°F.

on

color

staining is para-

100°F.

90-125

0.10

175-225

Recom-

high speed

quality

100°F.,

number

quality

grease

No. 2 may

300-350

350 350

20

1 3

85

None

1A 1A

pet-

pet-

water

of

pet-

No.

be

20

0.10

85

None

175-225

NOTE

1:

The

use

of

non-corrosive additives

meeting above classification is desirable

essential. These

1.

2.

3.

4.

5.

These additives

and

not

separate.

NOTE

2:

shall

not

1.

2. Tackiness

3. Lead soap

4. Detergents

may

Oxidation

Rust

Lubricity

Anti-oxidants

Film

removable

Oils

be used

Extreme

inhibitors

inhibitors

additives

strength

must

containing

at

any

pressure

or

additives

include:

additives

be

completely

by

wick

feeding

the

following

time:

additives-corrosive

adhesive additives

soluble

nor

type

UNION SPECIAL

IIN!SI

QUAIIIY

CORPORATION

in

but

in

the

shall

they

additives

oils

not

oil

Page 20

.,.o

..

...

'

q

WORLD'S

p.llf

FINEST

QUALITY

*

,,

'"

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

maintains sales

facilities throughout the world. These offices

aid

you

in

the selection of the right sewing

equipment for your

Special representatives

tory trained

promptly

tion, there

you. Check with

serve

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

MASS.

YORK, N.

ILL.

and

and

is

a Union Special Representative to

Y.

PA.

particular operation. Union

and

service men

are

able

to serve your needs

efficiently. Whatever your loca-

him

today.

MONTREAL, CANADA

TORONTO,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnGART,

and

service

are

CANADA

ENGLAND

ENGLAND

GERMANY

will

fac-

Representatives

I

ndustrial

UNION SPECIAL

400

N.

FRANKLIN

and

cities

distributors

throughout

CORPORATION

ST.,

In

all

Important

the

world.

CHICAGO,

ILL.

60610

Loading...

Loading...