Union Special 56300V, 56300Y, 56300AV User Manual

INDUSTRIAL

SEWING

F

INEST

S

56

56

QUALITY

TYL

ES

300V

300Y

56300AV

®

MACHINES

CATALOG

I

No.

r ..

T129Y

Second

Edition

FIFTY

BACK

ST

YLE

56300A

ADVANCED

THOUSAND

HIGH

SERIES

WITH

TACKING

-

V

SPEED

MACHINES

MECHANISM

UNION SPECIAL

CHICAGO

CORPORATION

C a t a 1 o g N

(S

u p p 1 e m e n t t o C a t a 1 o g N

o.

T 1 2 9 Y

I N S T R U C T I 0 N S

F 0 R

A D J U S T I N G A N D 0 P E R A T I N G

S T 0 F P A R T S

L I

F o r S t y 1 e s

o.

1 2 9

M)

5 6 3 0 0 v

S e c o n d E d i t i o n

5 6 3 0 0 y

@ 1 9 6 9

5 6 3 0 0

AV

By

U n i o n S p e c i a 1 C o r p o r a t i o n

R i g h t s R e s e r v e d i n A 1 1 C o u n t r i e s

UNION SPECIAL CORPORATION

INDUSTRIAL

SEWING

CHICAGO

MACHINES

P r i n t e d i n

2

U.

S.

A.

February,

1976

IDENTIFICATION

OF

MACHINES

Each Union

the

machine.

numbers

"Style

changes

have

56300 V".

are

Style

one

made

Special

numbers

or

more

Special

in a standard

number. Example: 11Style

which

Styles

differs

of

machines

from

the

style

56300".

This

used

not

in

on

parts

identifies

denting

use

the

column when

This

herein.

Class.

from

handwheel

catalog

conjunction

Styles

by

reference

the

its

part

catalog

It

can

References

the

operator's

is

is a supplement

therewith.

56300 W

number and on

part.

description

number

in

ordering

applies

also

be

to

position

toward

the

are

Any

the

repair

applied

direction,

machine

are

letters

Style

56300 VZ".

similar

number,

APPLICATION

illustrated.

part

under

that

the

second

parts.

specifically

while

operator.

is

identified

classified

suffixed,

numbers

machine,

in

construction

in

to

Catalog

Only

the

the

following

is

description

column,

with

discretion

such

seated

by a Style

as

standard

but

never

contain

a 11Z

the

11

is

are

that

OF

it

contains

CATALOG

No.

At

parts

the

found on

back

page

a component

of

to

never

the

use

Standard

to

as

right,

at

left,

the

and

contain

letter

suffixed

grouped

129 M

is

Fourth

an

the

of

another

the

assembly

the

styles

some

Special

front,

machine.

number on a name

special.

the

"Z".

to

the

Standard

letter

When

only

standard

under a class

no

letter.

Edition

Styles

56300

illustration

part

numbers and

part

or

reference

of

Example:

and

V,

identifying

is

indicated

base

part.

number

machines

machines

back,

Operating

etc.,

direction

plate

Style

"Z".

Example:

minor

Style

number

"Class

should

Y and

AV,

description

by

Always

in

the

as

listed

in

this

are

given

of

on

be

but

the

in-

first

Advanced High Speed

Needle

Mechanism,

Oil

proved

with

(209.6

Bearing

Return

Belt

Disc

nnn).

Single

Pumps

Guard,

Thread

56300 V Medium

dresses,

56300

light

Spec.

Y Medium

es,

to

401-SSa-1.

skirts,

on medium

401-SSa-1.

56300

AV

turns

Medium

of

401-SSa-1.

STYLES

Single

Needle

Bar

Drive,

Reservoir

for

Head and

Prepared

Tensions,

throw

machine

skirts, shirts,

medium

weight

Type 130

throw

weight

glove

machine

hennning

woven

Type 130

throw

machine

fingers.

Type 130

shirts,

GHS

GHS

OF

MACHINES

Needle

Light

Enclosed

Base,

for

Use

Maximum

with

towels,

woven

GHS

with

towels,

materials

needle.

with

For

needle.

IN

Flat

Weight

Positive

Lateral

with

Knee

Work

Space

back-tacking

sheets,

materials

where

needle.

back-tacking

sheets,

where

back

Maximum

four

motion

closing

cotton

Maximum

CLASS

Bed

56300

Machines,

Presser

Automatic

Looper

Travel,

Press

to

Right

mechanism,

curtains

back

Maximum

mechanism,

curtains

tacking

reconnnended

retainer

flannel

recommended

Medium

Bar and

Lubricating

Large

for

Presser

of

Needle

for

and

for

tacking

recommended

for

and

is

required.

speed

to

prevent

gloves.

speed

and High Throw,

Needle

Bar

Driving

Stystem,

Handwheel and Im-

Foot

seaming

similar

is

seaming

for

Lifter,

Bar 8

and/or

required.

speed

pants,

similar

1/4

operations

6500 R.P.M.

operations

Seam

6500 R.P.M.

skipping

Seam

Spec.

6500 R.P.M.

Filtered

Equipped

Inches

hemming

Seam

dress-

Spec.

at

sharp

on

3

Each

number

The

measured

ly,

label

denotes

size

the

of

UNION

number, stamped on

in

type

all

SPECIAL

the

kind

thousandths

number and

needles

packaged and

needle

of

of

the

has

shank,

the

an

inch,

size

NEEDLES

both a type

point,

needle

number

sold

shank,

midway

by

length,

between

is

the

Union

number and a

groove,

denotes

complete

Special.

the

the

shank

symbol,

size

finish

largest

and

number. The

and

other

diameter

the

which

eye.

is

details.

Collective-

given

of

type

blade

on

the

Standard

GHS.

eye,

eye

080/032,

needle,

complete

Thread

tion.

SPECIAL

subsidiaries

proved

and

are

guarantee

It

has a round

spotted,

and

groove

090/036,

To

have

or

order

Selection

should

Success

Needles

scientific

durability

Genuine

stamped

recommended

government,

undersize

needle

the

type

would

of

pass

in

the

and

and

are

needles

with

of

the

shank,

100/040,

orders

and

size

read:

the

proper

freely

USE

operation

Repair

authorized

principles,

assured.

are

packaged

the

Union

highest

needle

short

- one

promptly

through

GENUINE

Parts

Special

quality

for

the

round

110/044, 125/049,

"1000

needle

distributors.

point,

blade

step

number

Needles,

needle

NEEDLES

of

these

as

and

are

with

in

1/8

reduction,

and

should

size

machines

furnished

made

labels

trademark,

materials

machines

short,

inch

140/054.

accurately

be

forwarded.

Type 130

should

eye

in

AND

REPAIR

by

They

are

with

marked~.Genuine

U S Emblem. Each

and workmanship.

covered

double

(3.18

ball

be

can

point,

filled,

GHS,

determined

order

PARTS

be

the

designed

utmost

in

groove,

mm)

less

and empty

Use

Size

to

produce

secured

Union

precision.

this

catalog

struck

than

chromium

description

090/036".

by

size

a good

only

Special

according

trademark

is

Type 130

groove,

standard,

plated -sizes

package, a sample

of

thread

stitch

with

Corporation,

Maximum

genuine

to

ball

width

on

label.

the

most

efficiency

repair

is

your

used.

forma-

UNION

its

parts

of

A

ap-

Where

too

small

distinguish

Part

IMPORTANT I ON

PART

ments

otherwise

IS

ORDERED.

Prices

are

the

construction

for a complete

one

part

numbers

are

forwarded

directed.

represent

ALL

strictly

f.o.b.

A

catalog

from

another

ORDERS,

net

charge

IDENTIFYING

permits,

stamping

the

same

PLEASE

cash

and

shipping

is

made

each

that

part,

INCLUDE

TERMS

are

point.

is

to

part

subject

cover

PARTS

is

stamped

are

identified

similar

regardless

PART

to

Parcel

postage

in

appearance.

of

catalog

NAME

AND

change

Post

shipments

and

with

by

its

letter

STYLE

without

insurance.

part

number.

symbols which

in

which

OF

MACHINE

notice.

are

they

insured

Parts

appear.

FOR

All

unless

WHICH

ship-

4

CL

ASSES

510~

56~

0

CAUTION!

FI~L..Qt

~

8<F~E

MO.CH\Ni HAS BU "l 0

BtFOR

E S

~

~

~

-

~

\ '

··

~~-·

----

CL

ASS

QE

!.ER

\101

.STAA.TING

f<IPPI"l

G.

-

~

/

.56900

.

1:1

)

1'14\o.l£1)

NEEDLE

SHOULD

OPER.IIT€

OF'

GAUGE

BE

IN

POSITION,

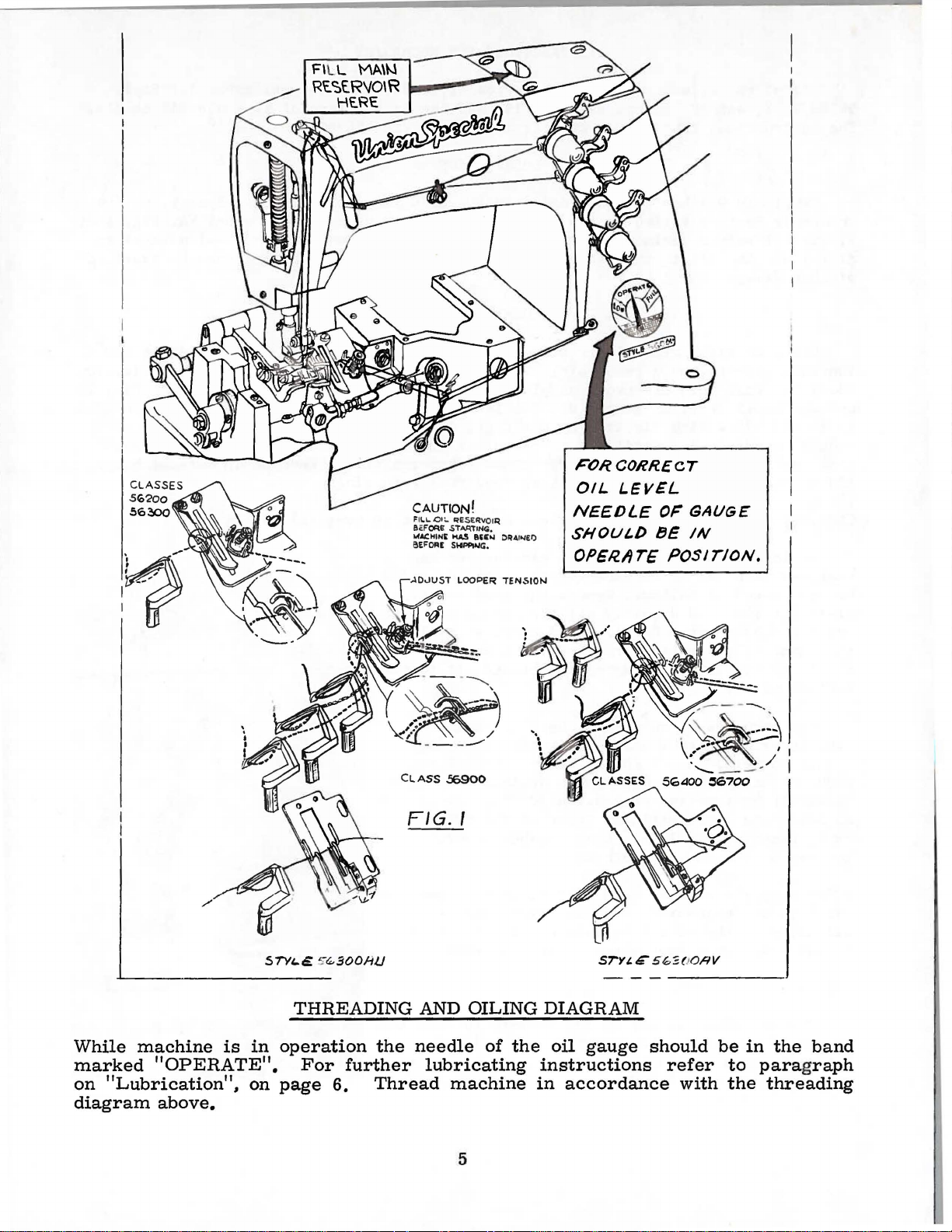

While

marked

on

machine

"OPERATE".

"Lubrication",

diagram

above.

is

THREADING

in

operation

For

on

page

further

6.

FIG.

the

Thread

I

AND OILING DIAGRAM

needle

lubricating

of

the

machine

oil

instructions

in

5

------------

gauge

accordance

should

refer

with

be

to

the

in

'

the

band

paragraph

threading

Loading...

Loading...