Page 1

®

INDUSTRIAL

SEWING

F

INEST

S

TYLES

56300F

56300R

QUALITY

LEWIS

•

COLUMBIA

MACHINES

CATALOG

No.

T129F

Third

Edition

WITH

FEEDING

STYLE

ADVANCED

FIFTY

FLAT

INDEXED

THOUSAND

BED

THREAD

AND

PRESSER

CHICAGO

56300

HIGH

F

SPEED

SERIES

MACHINES

RATIO

FOOT

CONTROL

Page 2

(Supplement

Catalog

INSTRUCTIONS

to

No.

Catalog

FOR

T129

No.

F

129M)

ADJUSTING

With

56300

Indexed

Feeding

LIST

CLASS

F

Third

AND

OF

Styles

Thread

and

Presser

Edition

OPE

PARTS

56

3 0 0

56300

Ratio

RATING

R

Control

Foot

Union

Rights

INDUSTRIAL

Copyright

1968,

by

Special

Reserved

Corporation

in

All

CORPORATION

Printed

SEWING

CHICAGO

in

2

MACHINES

U.S.

1970

Countries

A.

April,

1974

Page 3

IDENTIFICATION

OF

MACHINES

Each

the

machine.

numbers

Example:

minor

Style

changes

number.

Styles

which

56300

used

on

differs

11

•

This

in

Styles

catalog

conjunction

56300 F

illustrations

part

tions

numbers

part

or

numbers

identifying

is

indicated

base

part.

and

reference

Union

Style

have

one

"Style

are

Example:

of

machines

from

identifying

and

description

Always

number

Special

machine

numbers

or

more

56300

F".

made

Special

in a standard

"Style

similar

the

style

number,

APPLICATION

is a supplement

therewith.

and R covered

the

parts

description

the

parts

by

identifies

by

indenting

use

the

in

the

first

is

identified

are

classified

letters

Style

56300 F Z".

in

construction

to

Catalog

Only

the

in

Catalog

by

identifies

reference

the

its

description

part

column

as

suffixed,

numbers

machine,

in

that

OF

parts

129

reference

the

part.

numbers

part.

number

when

ordering

by a Style

standard

but

contain

a

are

it

contains

CATALOG

No.

129

found

on

Mare

number

Also

and

Any

part

under

in

the

the

number

and

special.

never

contain

the

"Z"

is

suffixed

grouped

no

letters.

M,

Third

Styles

illustrated.

and

at

at

the

on

the

that

is a component

description

second

repair

column,

parts.

on a name

Standard

the

letter

letter

"Z".

to

the

under a class

Example:

Edition

and

56300 F and

At

the

back

the

top

of

the

back

opposite

are

of

two

page

the

never

plate

Style

"Z"

When

only

standard

number

"Class

should

R,

but

are

two

page

illustra-

the

part

of

another

assembly

use

on

.

be

not

the

the

This

herein.

References

operator's

is

toward

Advanced

Bearing

Mechanism,

Filtered

ings

Travel,

Press

for

for

catalog

It

can

to

position

the

High

Needle

Oil

Feed

Large

Presser

also

direction,

operator.

Single

Return

Bar

Handwheel

Inches.

56300 F Medium

thread

or

tight

ratio

stitch

operations

401-

SSa

-1.

applies

be

while

Speed

Bar

and

Foot

throw

control

on

light

Type

specifically

applied

such

seated

STYLES

Single

Drive,

Reservoir

Pumps

for

Feed

and

Lifter,

machine,

parts,

as

required.

to

128 G BS

with

discretion

as

right,

at

OF

Needle

Light

Enclosed

Head

Rocker

Improved

Maximum

capable

medium

needle.

to

the

to

left,

the

machine.

MACHINES

Flat

Weight

Bed

Presser

Positive

and

Base,

Shafts

Belt

Work

with

For

weight

a

new

of

reducing

seaming

durable

Maximum

Standard

some

front,

Special

back,

Operating

IN

CLASS 5 6300

Machine,

Automatic

Needle

Greased

Guard,

Space

feeding

trousers,

press

recommended

Styles

machines

etc.,

direction

Medium

Bar

and

Bearings

and

Sealed,

Prepared

to

Right

presser

seam

coats

materials.

of

machines

are

Throw,

Needle

Lubricating

and

Lateral

for

Use

of

Needle

foot

pucker,

and

speed

as

listed

in

this

Class

given

from

of

handwheel

the

Needle

Bar

Driving

System,

Bronze

Bear-

Looper

with

Knee

Bar 8 1/4

and

indexed

using a loose

for

similar

Seam

6 500

R.

Spec

P.

M •

.

.

56300 R Medium

thread

or

needle

to

128

ratio

tight

hole.

medium

GBS

stitch

needle.

throw

control

as

For

seaming

weight

Maximum

machine,

parts,

required.

durable

with a new

capable

of

Presser

trousers,

press

coats

materials.

recommended

3

feeding

reducing

Foot

has

and

speed

yielding

for

Seam

6500

presser

seam

similar

R.

pucker,

section

Spec.

P.M.

foot

and

usin

to

the

operations

401-SSa-1.

indexed

g a

left

on

loose

of

light

Type

Page 4

NEEDLES

Each

number

The

size

blade

Union

denotes

number, stamped

measured

Collectively.

is

given

on

Standard

a

round

ball

shank.

point,

060.

To

have

sample

on

label.

needle,

A

Selection

Thread

should

formation.

Success

Union

tion..

the

mum

Special

its

subsidiaries

most

approved

efficiency

Special

the

in

thousandths

the

type

the

label

recommended

round

chromium

needle

or

the

complete

of

the

pass

USE

in

the

operation

Needles

scientific

and

needle

kind

of

number

of

all

needles

point.

plated

orders

type

and

order

proper

needle

freely

GENUINE

and

Repair

and

authorized

durability

has

both a type

shank,

on

the

of

and

point,

needle

an

the

packaged

needle

short.

and

for

double

is

available

promptly

size

would

read:

size

through

NEEDLES

of

these

Parts

principles,

are

assured.

length,

shank,

inch,

size

midway

number

and

Styles

56300 F and R is

groove.

in

and

accurately

number

should

"1000

should

needle

eye

AND

machines

as

furnished

distributors.

and

are

number

groove,

denotes

between

is

sold

by

struck groove,

sizes

032,

be

Needle

be

determined

in

s,

order

REPAIR

can

be

by

They

made

with

and a size

finish

the

the

the

complete symbol,

Union

number.

and

largest

shank

Special.

Type

ball

036,

040,

filled,

an

empty

forwarded.

Type

by

to

produce

128

size

GBS,

PARTS

secured

the

Union

are

utmost

only

Special

designed

precision.

other

diameter

and

128

eye,

044,

Use

of

thread

a

with

according

The

type

details.

the

eye

which

GBS.

It

has

spotted,

049,

054.

package,

description

Size

032

used.

good

stitch

genuine

Corpora-

Maxi-

of

11

to

.

a

•

Genuine

parts

are

guarantee

Where

some

of

the

identification

Part

numbers

appear.

IMPORTANT!

OF

MACHINE

Prices

shipments

unless

otherwise

needles

stamped

of

the

highest

construction

smaller

letter

FOR

are

strictly

are

forwarded

directed.

are

packaged

with

the

quality

permits,

parts

is

stamped

represent

ON

ALL

WHICH

net

f.

with

Union

Special

in

materials

IDENTIFYING

each

and

on

those

in

to

distinguish

the

same

ORDERS,

PART

o.

A

IS

cash

b.

shipping

charge

ORDERED.

and

is

labels

trade

part

where

part.

PLEASE

TERMS

are

point.

made

marked

mark.

and

workmanship.

PARTS

is

stamped

construction

the

part

regardless

INCLUDE

subject

Parcel

to

cover

~.Genuine

Each

with

trade

its

part

does

from

to

chan

Post

postage and

similar

of

catalog

PART

ge

shipments

NAME

without

insurance.

mark

number.

not

ones.

in

AND

are

repair

is

permit,

which

STYLE

notice.

insured

your

On

an

they

All

4

Page 5

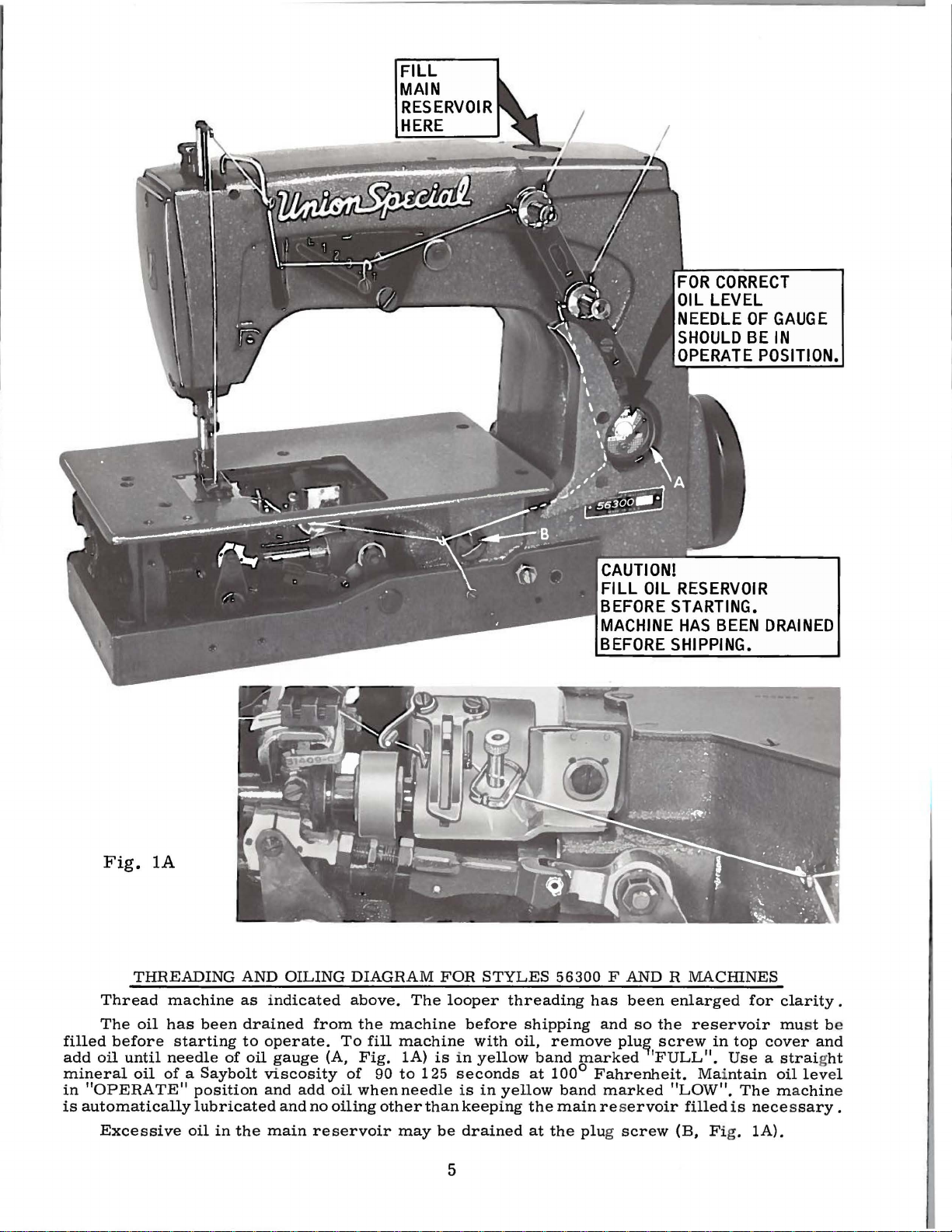

FILL

MAIN

RESERVOIR

HERE

FOR

CORRECT

OIL

LEVEL

NEEDLE

SHOULD

OPERATE

OF

GAUGE

BE

IN

POSITION.

Fig.

THREADING

Thread

The

filled

add

mineral

in

is

before

oil

until

oil

"OPERATE"

automatically

Excessive

lA

machine

oil

has

starting

needle

of a Saybolt

oil

AND

as

been

drained

to

of

oil

position

lubricated

in

the

OILING

indicated

from

operate.

gauge

viscosity

and add

and

no

main

reservoir

DIAGRAM

above.

the

To

fill

(A,

Fig.

of

90

oil

when

oiling

The

machine

machine

lA)

to

125

needle

other

may

FOR

is

than

be

STYLES

looper

before

with

in

yellow

seconds

is

in

keeping

drained

threading

shipping

oil,

remove

band

at

100°

yellow

the

at

the

CAUTION!

FILL

BEFORE

MACHINE

BEFORE

56300

band

main res

F AND R

has

and

marked

Fahrenheit.

marked

plug screw

OIL

been

so

the

plu~

screw

'FULL".

ervoir

RESERVOIR

STARTING.

HAS

BEEN

SHIPPING.

MACHINES

enlarged

reservoir

Maintain

"LOW".

filled

(B, Fig.

for

in

top

Use a straight

The machin

is

DRAINED

clarity.

mu

st be

cover

necessary.

lA).

oil

and

lev

el

e

5

Page 6

INSTRUCTIONS

FOR

MECHANICS

NOTE:

Styles

sewing

the

able

R

covered

Refer

machines

SETTING

This

handling

manner:

With

(A,

Fig.

the

needle

surfaces

Difference

56300 F

parts

adjustment

needle

thread

in

to

threading

are

threaded.

machine

and

control

the

needle

12A)

(See

lever

so

thread

Fig.

between

and R covered

and

the

thread

of

Styles

frame

Catalog

No. 129 M

diagram

NEEDLE

style

parts,

bar

its

lower

THREAD

is

so

at

the

eyelet

12A).

the

Styles

handling

56300 F and R covered

in

Catalog

system,

56300 F and R with

eyelet

are

with

the

the

THREADING

(Fig.

THREAD

1A)

on

TENSIONS

TAKE-UP

equipped

the

top

extended

hole

with

adjusting

of

its

stroke,

surface

and

3/4

disc

sequence

inch

No. 129 M

so

all

No. 29476 MY

same

as

those

following

page 5 for

WIRE

AND

thread

should

set

the

is 1 7/16

across

inch

the

in

(Third

instructions

thumbscrew

for

Styles

exceptions.

the

manner

FRAME

tensions,

be

made

needle

thread

above

center

lines

this

catalog

Edition)

pertaining

56300 F

in

which

EYELET

additional

in

the

take-up

the

centerline

of

its

and

is

in

the

to

adjust-

and

these

thread

following

wire

of

vertical

Fig.

12A

Set

the

-.

Fig.

looper

...

~

13

thread

inch

Fig.

guide

from

13).

Adjust

controlling

eyelet

ing

the

when

is

approximately

ence

~":!':'~

material

in

move

seam

seam.

eyelet

the

(B,

Fig.

needle

11

6

of

lengths

to

thread

(longer

left

looper

the

looper

12A)

thread

sewn

is

be

sewn.

index

needle

(A,

Fig.

side

of

thread

thread

at 113

tension

seam

as

are

long

permissible.

Maintaining

eyelet

(B)

loops)

6

13)

the

tension

11

on

raveled

as

the

up

and

so

its

left

looper

thread

to a minimum

(light).

the

adjusting

only,

balance

back,

looper

NOTE:

this

toward 11L

toward 11T

outer

surface

take-up

required

Set

the

thread

plate

the

thread.

the

(C).

stitch

needle

A 1

Use a sample

needle

thread

11

to

obtain a looser

11

to

obtain a tighter

is

3/4

(B),

(See

for

index

Chang-

so

that

thread

11

differ-

of

the

tension,

Page 7

ADJUSTING

THE

FEEDING

PRESSER

FOOT

Remove

stop

screw

the

bed

casting

the

guide

the

guide

when

stop

screw.

and

is

foot

As a preliminary

nut

(A,

Fig.

from

(See

presser

and

(A,

line

the

screw

bar,

guide

the

Fig.

bar.

feed

Fig.

up

with

needle

(D)

making

is

resting

top

dog

15)

Replace

Turn

the

the

top

presser

of

its

ing.

the

presser

(A,

Fig.

as

the

pulled

treadle

15)

on

of

the

15).

Assemble

With

down,

until

the

centerline

in

the

securing

sure

on

presser

threaded

14)

required

top

of

up

quickly

is

activated.

setting,

spring

in

presser

to

presser

regulator

insure a clearance

bar

by

the

Tighten

adjust

thefeedingpresserfoot

spring

presser

press

the

center

the

that

the

spring

bar

(B)

the

down

marks

of

of

presser

the

stop

bed

casting.

and

spring

portion

tothe

feeding

foot

resting

on

on

the

the

the

needle

bar

screw

presser

regulator

is

level

needle,

bar

guide

bushing

lifter

the

yoke

presser

spring

presser

slot,

guide

in

spring

screw

with

and

lever

lock

spring

so

the

(C)

is

on

throat

regulator

foot

while

tighten

to

the

the

presser

the

the

presser

(B)

against

between

(C),

yet

link

nut

(E)

regulator

distance

5/8

inch,

foot

plate

bottom

keeping

presser

regulator

down

head

until

cast-

so

(D)

on

to

nut

set

bar

.

spring.

Adjust

the

long

NOTE:

ship

to

means

seated

Any

the

that

the

against

Fig.

change

marks

stop

bed

15

in

the

on

the

screw

casting

alignment

presser

of

the

presser

before

throat

less

the

adjusted

changed.

CHECK

most

throat

material

back

main

foot

top

without

on

the

ing

pressure

this

of

needle

foot

locking

When

plate,

than

yoke,

if

Presser

of

throat

plate.

When

so

of

the

presser

spring

The

and

purpose

bottom

pulling

feeding

of

plies

will

pressure

in

relation-

bottom

bar

probably

guide

set

the

presser

the

foot

1/64

which

inch.

is

necessary,

foot

at

plate

the

presser

that

the

needle

bar

bottoms.

of

ply

on

foot

and a strong

tend

to

will

was

screw

should

The

set

back

land

feeding

slot

should

the

of

the

spring

feed

tend

not

.

foot

is

move

stop

at

the

should

of

this

needle

when

foot

bottom

foot

should

not

lift

feeding

cloth

bottom

feed

ply.

usuallygives

feeding

the

top

to

feed

lifted

back

screw

factory,

dimension

resting

spring

clear

before

foot

the

pull.

ply

the

bottom

Fig.

(E,

slot

is

the

is

same

The

a

Reducing

more.

14

off

the

only

slightly,

Fig.

can

become

should

on

the

raised

bottoms,

needle.

the

feeding

to

make

amount

5/8"

good

match-

Increasing

ply

bare

15)

on

be

re-

cover

bare

by

the

The

the

setting

this

more.

7

Page 8

The

parts illustrated

below

56300 F and R with

used

in

and

at

on

Styles

Use

Catalog 129

this catalo

the

top

56300 F and R covered

g.

at

of page 9,

operator

M,

Third

the

bottom

and

controlled

on pag

Edition

of

es

thread

in

Catalo

(Styles

this page

11

and

handling

g No.

56300 F and

and page

13,

represent

parts

129

M,

R)

9,

and

on pages

the

and

Third Edition.

for

all

parts that are us

a fe e

din

parts not

g pr

10

esser

illu

and

foot,

strated

12; des

ed

on

but

or des

cribed

Styles

are

cribed

not

Reference numb

description

Re

f.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13 535

14

1

16

17

Pa

No.

6381-212

5

22760 A

35772

51281

22845 B

1292

5

51292 F-8

109

51292

51292

21657

512

43266

805 57

22598

51292 F-2

514 91

s,

rt

92

92

ind

H

AC

c

G

A

-4

D

c

c

er s

icate t

Cloth

Tension

TensionSprin

Tension

Tensi

Tens

Te

Te

Nut,

VVasher,

Scr

Tension Spri

Lead-in

that are

hey

are

Plate

Screw-------------Spr

Cloth

Screw-------------------------------------------

Te

nsionDisc----------------------------------------------

on

ion Disc Se

nsion

nsion Post

for

ew,

inside a br

component

Cover,

ing

VVa

Plate

Nut-----------------

g,

Post------------Post

Ferrule

Thread Eye

Support

tension

for tension

for

tension post s

ng,

Thread

part

3 5

sher

---------------------------------------

Cover

needle----------------------------------------------

parator---------------------------------------------

let

post------------------------------------------------

post sup

looper----------------------------------------------

Gu i

de,

ack

et

or box

s of a

/16 inch

Spring ----------------------------------------

--------------

----------------

-----------------------------------------------

for

complete

Description

es wi

-

---------------------------------

-

--------------------------------------

-

-----------------------------------------

port-------------------------------------

upport--------------------------------------

Style

on the

de----------------------

-

--------------------------------

563

00

14"o

1

part

-

----------

R (n

picture pl

or asse

ot

shown)

ate

mbly.

-

-------------------

and

- - -

-

-

---------

-

-------------

- - - ------

------------------

o---15

have i

-------

--------

ndented

Am

Req.

1

3

3

1

1

2

1

4

2

2

1

2

1

1

2

1

1

2

t .

1

12~

n#

10

~

9___,

6___.

0

17

•

8

Page 9

THROAT

PLATE,

FEED

DOO

AND

NEEDLE

THREAD

HANDLING

PARTS

Ref.

No. No.

1

2

3

4

5

6

7

8

9

10

11

12

13

Part

56370

51324

51305

22768

56358

29476

22837

56358

98

56358

158

56358

56304

56958

56958

w

w

E

MY

D

A

c

B

B

A

De

scription

Needle

Throat

Feed

Screw,

Looper

Needle

Needle

Needle

Thread

Pl~e------------------------------------------

Dog,

for

Thread

Thread

Screw--------------------------------------------

Washer

Screw--------------------------------------------

Guide

Eyelet--------------------------------------------

Guide

Adjusting

Lever

Bar

Take-up

22

teeth

looper

------------------------------------------

Washer-------------------------------------

Block

Thread

thread

Guide

Cast-off

--------------------------------------

Plate

Thread

Wire---------------------------

per

inch----------------------------

guide

Eyelet----------------------------

Assembly-----------------------

----------------------------------Eyelet

Eyelet

(not

(not

eyelet

shown)

-------------------

shown)

-------------------

-----------------

Amt.

Req.

-

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

11

~

6

10--o

g_J.

8~

2

3

9

'

7

Page 10

17~

18

10

Page 11

FEEDING

GUIDE

(FOR

PRESSER

STYLE

FOOT

56300 F ONLY,

AND

PRESSER

BAR

UNLESS

CONNECTION

OTHERWISE

AND

SPECIFIED)

Re

No.

1

2

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

3

f.

Part

No.

56320

56330

56330

56330

88

22560

22785

56330

56330

41071

56330

51430

56330

52930

604

56330

56330

56330

73

22799

56330

56357

531

402

51430

22840

F

AE

AP

AK

B

AH

AD

G

AU

F

AF

AC

AG

AJ

AX

A

B

AB

A

F

c

Description

Presser

Presser

andR

Foot

Assembly-------------------------------

Presser

Yoke--------------------------------------------

Regulating

Compression

Locking

VVasher

Nut--------------------------------------------Hinge

Chain

Screw,

Connecting

Hinge

Tilting

Screw,

Hinge

Presser

--------------------------------------------Screw

Screw

Locking

Adjusting

Foot

Bushing-------------------------------------

Screw

Screw

Screw

Nut

-----------------------------------------

Screw-------------------------------------

Cutting

for

Pin

Spring

for

Screw-------------------------------------

Foot

Bar

Connection

------------------------------------------

-----------------------------------------Nut

Link,

--------------------------------------

--------------------------------------

--------------------------------------

Nut-----------------------------------

Spring------------------------------

-------------------------------------

Knife

chain

Screw

---------------------------------------

-----------------------------------

tilting

Bottom,

-------------------------------------

Screw----------------------------------

marked'~"

------------------------------

cutting

--------------------------------

spring--------------------------

marked

and

knife

Guide,

-------------------

---------------------

''BS"

----------------

for

Styles

5 6300 F

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

11

Page 12

12

Page 13

FEEDING

PRESSER

FOOT

FOR

STYLE

56300 R ONLY

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

Part

No.

56320

56330

88

22560

22785

56330

56330

41071

56330

51430

52930

604

56330

56330

56330

56330

56330

56330

73

56330

604

22799

56330

56330

H

AK

B

AH

AD

G

AU

F

AC

AF

AG

AN

AP

AJ

AX

A

AR

G

AL

AM

Description

Presser

Foot

Yoke--------------------------------------------

Screw

Screw

Screw

Pressure

Compression

Locking

VVasher

Nut---------------------------------------------

Chain

Screw.

Hinge

Connecting

Presser

Bushing-------------------------------------

Hinge

Tilting

Screw.

Spring.

Screw.

Hinge

Presser

Yielding

Assembly-------------------------------

--------------------------------------

--------------------------------------

--------------------------------------

Regulating

Spring------------------------------

Nut

-------------------------------------

-----------------------------------------

Cutting

for

Screw

Foot

Pin

Spring------------------------------------

for

for

for

Screw-------------------------------------

Foot

Section

Knife

chain

------------------------------------

Screw

Link.

--------------------------------------tilting

yielding

yielding

Bottom.

Nut--------------------------

------------------------------

cutting

--------------------------------

spring--------------------------

---------------------------------

knife

marked

section

section

marked

---------------------

''B"

-------------------

-----------------------

spring

-----------------

''BR"

---------------

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

13

Page 14

BOOST

PRODUCTION

WITH

WORK

UNION

THESE

AIDS

SPECIAL

FROM

PNEUMATIC

conventional

scissor-action

ve

cut.

positi

.,

AIR

FABRIC

signed

for

materi

Style

Class

curls

als

2899

to remove

knit

area.

CHAIN-CUTTER-lor

Class

39500

and

mechanism that makes a clean

Style

2899

••

i

liM

UNCURLER-This

39500

from

top

as

fabric

B-1

39600

A -1

I,

....

•·

machines, uses

and

bollom

passes

is a durable

plies

through

use

unit,

air

sewing

of

on

de-

jets

flat

PNEUMATIC

operated

machines all

simply by knee-

CHAIN

CUTTER-

small

pneumatic

for

installation

36200

Flatseamers. Style 2899A-6

FOOT

loot lifter

ows

the

touc

cha

as an accessory

lor

operator

hin

g an

The

above

in

cutter

LIFTER-The

use

on Class 395

to raise

actuating

photo

that

unit

the

shows

is

available

on

air-

foot

switch.

the

Class

00

KNIFE

GRINDER

type knives, is

nates defect i

sharpens

simple

and easy

ve

garments caused by

straight

to

operate,

dull

®

AMCO

IIHIST

QUA

UIY

wheel

nsuring

i

ELECTRONIC

to

move

better

the

needle up

control,

NEEDLE

or

uniform

POSITIONER&

down

quality

CORPORATION

or

angle

elimi-

knives.

• • .

this

allows the

and increased

HEAT

DISPELLER-Union

unit

(arrow)

oil

temperature

qu ores o

l.

Style

eliminate

the

opera

tor

production.

is an effecto

where heavy duty service re-

2899

E-1

necessity

to keep

ve

of

reaching

both

Special's aux

means

for

for

han

ds

on

ilia

reducing

the

hand-

the

work,

ry

Page 15

Helpful,

cient

machine sewed

Sales

esting,

obligation

authoritative

types

Promotion

illustrated

are the

of

equipment

article

Department.

bulletins

following

information

for

is

available

Among

that

:

on the

making

are available

from

virtually

Union

the

many

most

effi-

Special's

inter-

without

any

HERE

ARE

HELPFUL

No.

240,

"Men's,

No.

249,

"Rainwear"

No.

250,

"Men's

No.

251, "Service

No.

252,

"Men's

No.

253, "Overalls, Coveralls, and Dungarees"

No.

254,

"Men's

No.

256,

"Knit

No.

259,

"Men's

No.

260,

"Work

No.

262,

"Cotton,

Bags"

No. 263,

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No.

No. 740,

No.

No.

No. 1105,

"Columbia

ing Machines"

No.

"Men's

264,

"Men's

265,

"Women's

266,

"Women's

26

7,

"Corsets, Girdles, Brassieres"

268,

"Children's

269,

"Mattresses,

Upholstery"

271,

"Awnings,

273,

"Curtains & Drapes"

610,

"Kiipp-it"

710,

"MCS

730,

"MCS

Hemmer"

"MCS

750,

"Fusing

1100,

stitch,

1500,

Women's,

Dress Shi

Shirts

Shorts

Knit

Outerwear"

Sports

Gloves"

Burlap,

Clothing"

Women's,

ForMation

Automatic

Automatic

Presses"

"Lewis

"Button

"Alteration

Blindstitch,

Machines"

Sewers-

Blindstitch,

Children's

rts"

and

Pants"

and Pajamas"

Underwear"

Shirts"

Jute,

and

Children's

Wear"

Wear

And

High

Wear"

Slip

Covers,

Canopies, Tents,

Unit"

Dual

Saddle Sti

Department

Underfront

Rib-Knit

Chainstitch,

Ticket

tch,

Furniture

Tackers"

Footwear"

Multiwall

Jackets"

Fashion"

Tarps"

Cuff

Machine"

Lock·

and

Tie

Machines"

Paper

Shirt

Clos-

BULLETINS

TO

SEWING

HELP

PROBLEMS

YOU

and

CATALOGS

SOLVE

®

fiNEST QU

ALITY

CORPORATION

Page 16

,..o

..

...

'

Cl

WORLD'S

,.,lf

FINE

ST

QU

ALITY

*

INDUSTRIAL

SEWING

MACHINES

UNION

SPECIAL

facilities throughout

aid

you

in

the selection of the right sewing

equipment for your

Special representatives

trained

tory

promptly

tion,

there

and

and

is

a Union Special Representative

serve you. Check with

'ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS ANGELES, CAL.

NEW

PHILADELPHIA,

GA.

MASS.

ILL.

YORK, N. Y.

PA.

maintains sales

the

world. These offices

particular operation. Union

and

service men

are

able

to serve your needs

efficiently.

Whatever

him

today.

MONTREAL, CANADA

TORONTO,

BRUSSELS, BELGIUM

LEICESTER,

LONDON,

PARIS, FRANCE

STUnGART,

and

service

are

your loc

CANADA

ENGLAND

ENGLAND

GERMANY

will

fac-

ato

Representatives

industrial

and distributors

cities

throughout

in

the

all

important

world.

CORPORATION

400

N.

FRANKLIN

ST.,

CHICAGO,

ILL.

60610

Loading...

Loading...