Page 1

INDUSTRIAL

SEWING

(B)

Fl

NEST 0 UALITY

STYLES

56300AU

56400C

56600A

C 0 L U M B I A®

MACHINES

...

CATALOG

No.

T129AU

/

/

STYLE 56300AU

ADVANCED

FIFTY

THOUSAND SERIE

DIFFERENTIAL

FLAT

BED

UNION SPECIAL

C H

ICAGO

HIGH SPEED

.

S

FEED

MACHINE

S

CORPORATION

Page 2

C a t a 1 o g N

o.

T 1 2 9 A U

(S U P P

L E M E N T T 0 C A T A L 0 G N

0.

1 2 9

I N S T R U C T I 0 N S

F 0 R

A D J U S T I N G A N D 0 P E R A T I N G

L I S T 0 F P A R T S

F 0 R

Style

56300

AU

56400 c 56600 A

M)

F i r s t E d i t i o n

@ 1 9 7 6

By

U n i o n S p e c i a 1 C o r p o r a t i o n

R i g h t s R e s e r v e d i n A 1 1 C o u n t r i e s

UNION SPECIAL CORPORATION

INDUSTRIAL

P r i n t e d i n

SEWING

CHICAGO

MACHINES

U.

S.

A.

2

April.1978

Page 3

Each

the

machine.

numbers

Example:

minor

Style

changes

number. Example:

UNION

have

"Style

SPECIAL

Style

one

56300

are

numbers

or

more

made

IDENTIFICATION

machine

letters

AU".

in a standard

"Style

is

are

classified

Special

56300

identified

suffixed,

Style

machine,

AUZ".

OF

MACHINES

by a

as

standard

but

numbers

a "Z"

never

contain

Style

contain

is

number on a name

and

special.

the

letter

the

letter

suffixed

to

the

plate

Standard

"Z".

"Z".

When

standard

Styl

only

on

e

Styles

which

"Class

be

56300

trated

56400 W

56600 A

number,

of

the

use

herein.

in

are

direction

differs

This

used

AU,

another

assembly

the

This

these

given

of

machines

from

56300".

catalog

in

conjunction

56400 C and 56600 A,

and

listed

parts

parts.

part

reference

are

number,

part

or

catalog

It

can

classes.

from

of

handwheel

the

is a supplement

at

the

shown

Opposite

description

is

indicated

base

also

the

part.

number

applies

be

References

operator's

similar

style

therewith.

applied

is

STYLES

number,

APPLICATION

back

of

in

phantom

the

illustration

by

Always

in

the

specifically

to

position

toward

OF

in

construction

in

to

Catalog

Only

but

not

this

book.

to

assist

and amount

indenting

use

first

with

MACHINES

column when

discretion

direction,

the

operator.

that

OF

those

used

the

to

while

are

it

contains

CATALOG

No.

parts

on

Styles

For

in

locating

pages,

required.

its

description

part

number

the

Standard

to

such

seated

IN

CLASS

grouped

129

M,

which

56300 W

clarity,

parts

Any

in

ordering

some

as

right,

at

56300

under a class

no

letters.

Fourth

are

certain

the

56300

are

identified

part

under

the

second

repair

Styles

Special

left,

the

machine.

Edition,

used

or

of

on

56400 W

56300 W and

AU,

that

is

the

description

column,

parts.

machines

Styles

front,

number

Example:

and

should

Styles

are

illus-

56400 C and

by a reference

a component

of

never

as

listed

of

machines

back,

Operating

etc.,

Advanced High Speed

Controlled

Weight

Positive

Wakefield

and Improved

Equipped

1/4

8

56300

and

similar

401-SSa-1.

Advanced High Speed

pendent

Bearing

Single

Pumps

Travel,

for

Needle

for

Foot

Intermittent

Presser

Automatic

Bearings

with

Inches

AU

operations

Type 128

Row,

Low

Needle

Reservoir

Head and

Large

Lifter,

Bar 8

1/4

Belt

Single

Differential

Bar

and

Needle

Lubricating

for

Feed Rocker

Guard,

Disc

(209.6

Handwheel and Improved

Type

Medium

Throw,

Bar

Drive,

Enclosed

Base,

Equipped

Inches

Prepared

Thread

mm).

throw

on medium

GBS

needle.

STYLES

Two

Treadle

Wakefield

(209.6

Light

Positive

with

Needle

Bar

System,

Tensions,

machine,

to

Maximum

OF

MACHINES

Needle

Controlled

Weight

Disc

mm).

Flat

Feed,

Driving

Filtered

Shaft,

for

Use

Maximum

for

seaming

heavy

recommended

Flat

Automatic

Bearings

Type

Bed

Presser

Belt

Thread

Bed

Machines,

Needle

Mechanism,

Lateral

with

weight

IN

CLASS

Machines,

Intermittent

Lubricating

for

Guard,

Bearing

Oil

Looper

Knee

Work

side

materials.

Bar and

Feed Rocker

Prepared

Tensions,

Single

Return

Press

Space

and

speed

56400

Left

Needle

Medium

Needle

Pumps

Travel,

for

inseams

6000 R.P.M.

Needle

Differential

System,

Shaft,

for

Work

Throw,

Bar

Reservoir

for

Large

Presser

to

Right

Seam

Bar

Filtered

use

Space

Treadle

Drive,

Enclosed

Head and

Handwheel

Foot

Lifter,

of

Needle

on

knit

Specification

in

Feed,

Driving

Lateral

with

to

trousers

Front,

Needle

Mechanism,

Oil

Looper

Knee

Right

Press

Light

Base,

Bar

Inde-

Return

of

3

Page 4

STYLES

OF

MACHINES

IN

CLASS

56400

(Continued)

5640 0 C

pajamas,

modified.

speed

6000 R.P.M.

Low

etc.,

made from

Type 108

Advanced Hi gh Speed

p ·

ndent

Row,

Low

Throw,

Bearing Needle Bar

Singl

Pumps

Travel,

Needle

garments

ification

Maximum

number

The

measured

ively,

given

for

Foot Lif t e

size

e Rese

56600 A

rvoir

for Head

Larg

e Handwheel and Improved

Bar 8

1/4

Enclosed

and

r,

Equipped

Low

made from light wei

401-LSc-2

recommended

Each

UNION

denotes

number,

in

the

on

the

SPECIAL

the

stamped

thousandths

type

number and

label

throw

machine,

light

GS

needle.

STYLES

Two

Treadle

Drive,

Base,

Inch

throw

Wakefield

es (209.6mm).

machine,

modified.

speed

needle

kind

of

on

of

of

all

for

weight

Standard

OF

MACHINES

Needle

Controlled

Light

Positive

Weight

Automatic

Bearings

with

Disc

for gathering

ght

wov

en fabri

Type 108

6000 R.P.M.

has

both a type

shank,

the

an

the

needles

point,

needle

inch,

size

packaged

setting

woven

gauges

IN

Flat

Bed

Presser

Belt

Type

Thread

GS

NEEDLES

length,

shank,

midway

number

puff

sleeves

fabrics.

nos.

CLASS

56600

Machines,

Intermittent

Bar

Lubricating

for

Feed Rocker

Guard,

Prepared

Tensions,

and

cs and

needle.

similar

Standard

number and a

groove,

denotes

between

represent

and

sold

Seam

12,

16.

Right

Differential

and

Needle

System,

attaching

finish

the

the

shank

the

complete

by

Union

in

house

dresses,

Specification

Maximum

Needle

Bar

Driving

Filtered

Shaft,

for

Work

use

Space

Lateral

with

ruffles

operations.

gauges

size

nos.

number. The

and

largest

and

diameter

the

symbol,

Special.

waists,

401-LSc-2

recommended

in

Front,

Feed,

Ind

Needle

Mechanism,

Oil

Return

Looper

Knee

Press

to

to

Right

body

Seam

8,

12,

of

of

Spec-

16.

type

other

eye.

details.

of

blade,

Collect-

which

e-

is

Standard

shank,

point,

125/049,

round

chromium

140/054,

Standard

has a round

spotted,

needle,

complete

To

have

or

chromium

order

Selection

Thread

should

mation.

Success

UNION

its

approved

and

SPECIAL

subsidiaries

scientific

durability

Genuine

parts

your

are

guarantee

recommended

point,

recommended

shank,

needle

the

type

would

of

pass

in

Needles

are

needles

stamped

of

short,

plated

and

060.

round

plated

orders

and

read:

the

proper

freely

USE

the

operation

and

and

~uthorized

principles,

assured.

are

with

the

the

highest

needle

~ouble

is

available

needle

point,

and

is

promptly

size

number

"1000

needle

through

GENUINE

of

Repair

packaged

Union

quality

for

Style

groove,

for

Styles

extra

short,

available

and

should

Needles,

size

needle

NEEDLES

these

Parts

machines

as

distributors.

. and

are

with

Special

in

56300

struck

in

sizes

56400 C and 56600 A

double

in

sizes

accurately

be

Type 128

should

eye

in

AND

REPAIR

furnished

made

with

labels

trademark,

materials

AU

is

groove,

032,

groove,

036,

filled,

forwarded.

GBS,

be

determined

order

PARTS

can

be

by

They

are

utmost

marked

~

U S Emblem. Each

and

Type 128

ball

90/036,

GBS.

eye,

100/040,

is

struck

040.

an

empty

Use

description

Size

032".

by

to

produce

secured

the

designed

only

Union

according

precision.

workmanship.

It

has a round

spotted,

ball

110/044,

Type 108

groove,

GS.

ball

package, a sample

on

label.

size

of

thread

a good

Special

• Genuine

stitch

with

genuine

Corporation,

to

Maximum

the

efficiency

repair

trademark

It

eye,

A

used.

for-

most

is

. 4

Page 5

IDENTIFYING

PARTS

Where

of

the

smaller

cation

appear.

letter

Part

IMPORTANT!

WHICH

shipments

unless

PART

Prices

otherwise

construction

parts

is

stamped

numbers

represent

ON

IS

ORDERED.

are

strictly

are

forwarded

directed.

and

ALL

permits,

on

those

in

to

the

ORDERS,

net

cash

f.o.b.

A

each

where

distinguish

same

part,

PLEASE

TERMS

and

shipping

charge

is

part

is

construction

the

regardless

INCLUDE

are

subject

point.

made

to

stamped

part

PART

NAME

to

Parcel

cover

with

does

from

of

change

Post

the

its

not

similar

catalog

AND

STYLE

without

shipments

postage

part

permit,

ones.

in

OF

and

number.

an

identifi-

which

they

MACHINE

notice.

are

insured

insurance.

On

FOR

All

some

5

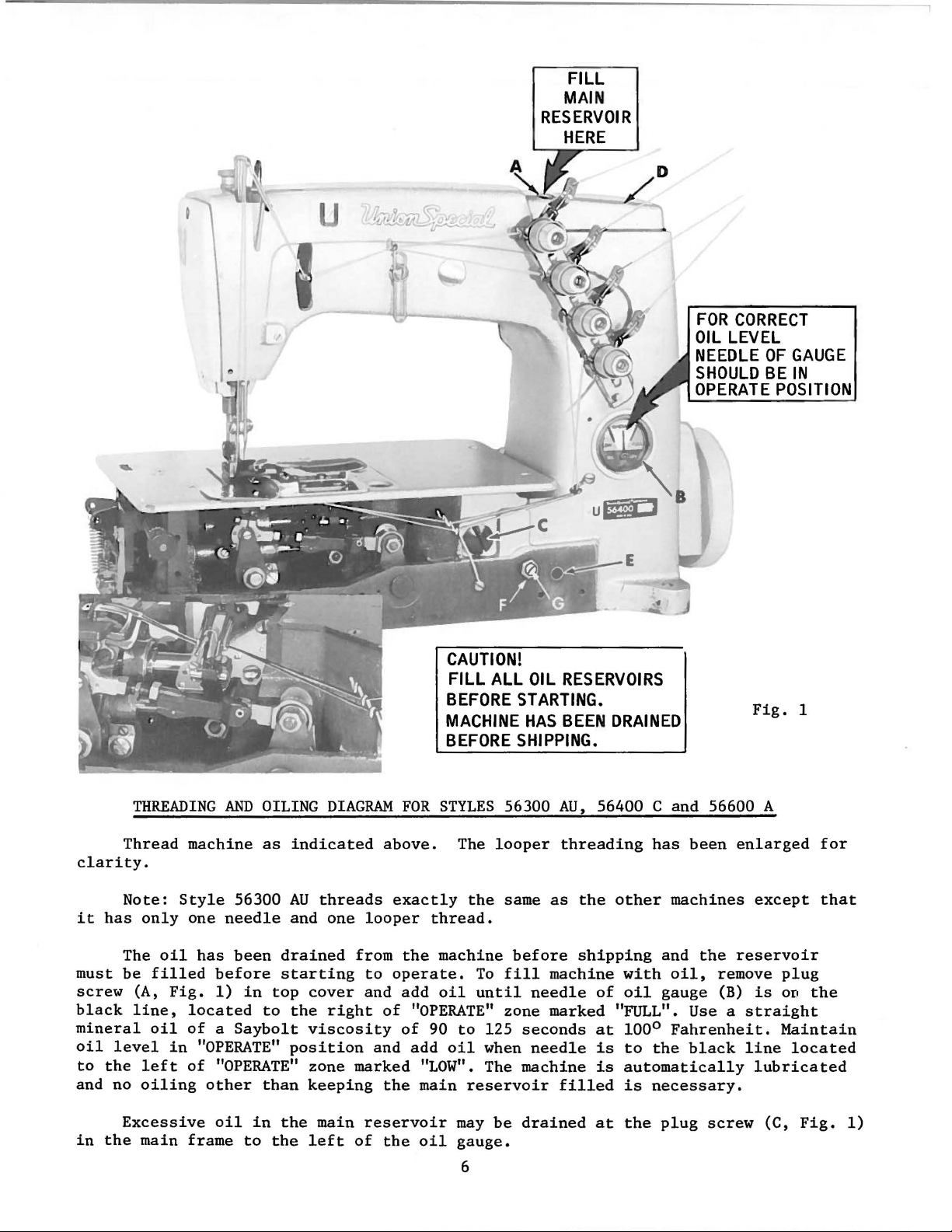

Page 6

-

FILL

MAIN

RESERVOIR

HERE

FOR

CORRECT

OIL

LEVEL

NEEDLE

SHOULD

OPERATE

OF

GAUGE

BE

IN

POSITION

Thread

clarity.

Note:

it

has

The

must

be

screw

black

mineral

oil

level

to

the

and no

THREADING

machine

Style

only

one

oil

has

filled

(A,

line,

oil

left

oiling

before

Fig.

1)

located

of a Saybolt

in

"OPERATE"

of

"OPERATE"

other

AND

OILING

as

56300

needle

been

in

to

than

DIAGRAM

indicated

AU

threads

and

one

drained

starting

top

cover

the

right

viscosity

position

zone marked

keeping

above.

looper

from

to

and

of

and

the

CAUTION!

FILL ALL

BEFORE

MACHINE

BEFORE

FOR

STYLES

exactly

thread.

the

machine

operate.

add

oil

"OPERATE"

of

90

add

oil

"LOW".

main

OIL

RESERVOIRS

STARTING.

HAS

BEEN

SHIPPING.

56300

The

looper

the

same

To

fill

until

zone marked "FULL". Use a

to

125

when

The

reservoir

AU,

threading

as

before

machine

needle

seconds

needle

machine

filled

DRAINED

56400 C and 56600 A

the

other

shipping

with

of

oil

at

100°

is

to

is

automatically

is

has

been

machines

and

the

oil,

gauge

Fahrenheit.

the

necessary.

remove

(B)

black

Fig.

enlarged

except

reservoir

plug

is

on

straight

Maintain

line

located

lubricated

1

for

that

the

in

Excessive

the

main

oil

frame

to

in

the

the

main

left

reservoir

of

the

oil

may

be

gauge.

6

drained

at

the

plug

screw

(C,

Fig.

1)

Page 7

INSTRUCTIONS

LUBRICATION

FOR

MECHANICS

CAUTION!

reservoir

before

the

damage.

Fahrenheit

No.

(D)

needle

Oil

"OPERATE"

cans

CAUTION!

an

and

further

distribute

beginning

oil

to

Use a

175.

and

check

is

should

No. 28604 R.

It

is

extended

directly

hand

Oil

has

must

Fill

be

to

the

various

straight

in

the

main

oil

to

the

black

be

added

zone,

It

marked

is

important

recommended

period

oil

the

oiling

oil

to

been

drained

filled

operate.

parts.

mineral

main

reservoir.

reservoir

level

line,

when

"LOW".

that

be

lubricated

needle

will

the

various

to

at

gauge

needle

that

be

from

the

Run

Full

oil

at

located

The recommended

a new

bar

required.

parts.

the

main

proper

machine

RECOMMENDED

of a Saybolt

plug

(B).

is

these

as

link

level

speed

This

is

screw

Oil

to

the

to

the

machines

machine,

follows:

and

Run

reservoir

as

slowly

operation

equivalent

is

black

the

machine

OIL

viscosity

(A,

Fig.

at

right

oil

not

or

one

Remove

needle

for

maximum

before

indicated

several

can

of

to

1)

of

"OPERATE"

line,

located

is

available

be

over

that

the

bar.

slowly

has

on

then

90

Union

in

upper

safe

filled.

been

head

Replace

for

shipment,

oil

gauge

minutes

be

expected

to

125

Special

crank

operating

zone,

to

the

in

out

cover,

head

several

so

the

(B,

Fig.

to

distribute

without

seconds

specification

chamber

marked "FULL".

left

16

fluid

of

clean

cover

minutes

at

level

of

ounce

service

out

as

1)

100°

cover

when

for

lint

no

to

For

able

operating

NOTE:

assembling

when

be

intervals.

(C,

Fig.

the

lower

Looper

spot

The

reservoir.

followed:

1.

2.

3.

4.

machines

hours.

1)

located

crank

avoid

be

sure

screw

oil

gauge

Should

Place

Remove

to

Make

Remove

the

drain

sure

in

operation

If

dirty,

Oil

may

below

chamber

and

oil

is

in

is

an

adjustment

machine

the

oil

oil

all

lower

change

be

the

cover,

feed

holes

time

set

at

reservoir

from

oil

crank

check

drained

cloth

located

lift

in

the

spot.

the

become

upright

the

reservoir.

is

drained

chamber

the

the

oil.

from main

plate

at

eccentrics

eccentric

OIL

GAUGE

factory

necessary,

on a

plug

screw

from main

cover,

oil

An

at

the

to

level

located

for

oil

reservoir

front

back

receive

line

show

table

(C,

reservoir.

dirt

and

change

of

the

of

machine.

oil

up

with

the

proper

however,

or

Fig.

at

1)

the

lint

is

recommended

by

removing

machine,

thru

oil

oil

the

bench.

and

back

deposits

the

mainshaft,

holes

level

following

tip

machine

of

the

every

plug

or

by

in

in

machine.

at

reason-

2000

screw

removing

so

mainshaft

the

steps

forward

should

when

5.

Fill

6.

main

knee

press

Loosen

the

left

reservoir

lock

or

shaft

nut

right

to a level

bushing

(F) on

until

even

(E,

Fig.

calibrating

the

gauge

1).

needle

7

with

screw

the

(G),

rests

bottom

and

on

contour

turn

the

the

black

of

screw

line,

the

to

Page 8

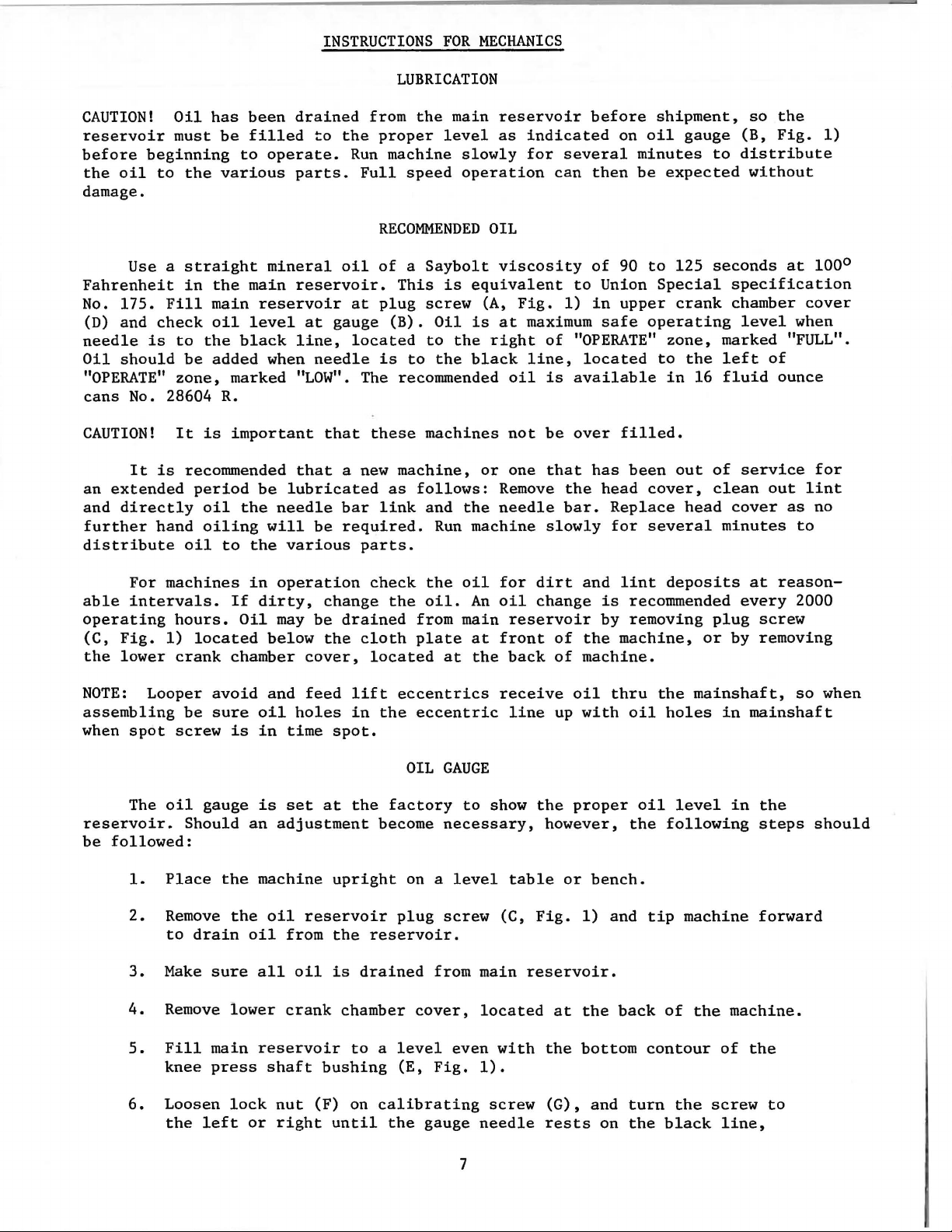

OIL

GAUGE

(Continued)

7.

8.

Remove

chamber

needle

inside

chamber

lever

stud

wardly

the

inside

just

above

stop

collar.

on

the

clearance

located

Tighten

cover.

Add

right

NEEDLE

cover

lever

the

arm

cover,

(B).

and

that

wall

the

needle

as

to

lock

oil

so

of

"OPERATE"

LEVER

the

head

(D,

Fig.

bearing

casting,

which

Make

its

of

notch

(Do

not

lever).

in

Figure

the

left

nut

that

BEARING

cover

1).

oiler

below

lubricates

sure

delivery

the

bed

of

the

allow

Allow

2.

of

(F) and

gauge

zone,

Check

(A,

it

end (C)

casting

needle

the

1/64

ALIGNING

"OPERATE"

replace

needle

rests

marked "FULL".

OILER

and

upper

position

Fig.

2)

the

upper

the

needle

is

tilted

contacts

at

the

lever

oiler

to

inch

THE

(TWO

NEEDLE

zone,

plug

on

crank

of

located

crank

down-

back,

shaft

rest

(.40mm)

NEEDLE

MACHINES)

marked

screw

the

black

BAR

"LOW".

(C) and

line,

lower

located

Fig.

crank

2

chamber

to

the

Align

PI40

A.

See

set

of

needles

correspond

needle

bar

Fig.

the

chart

with

clamp

3

needle

bar

below.

(Type and

the

vertical

screw

(A,

Fig.

3)

with

the

proper

If

test

Size

faces

(B,

Fig.

Machine

56400 C-12

plate

as

required)

3)

of

the

and

Styles

and

turn

test

and

needle

bar

Test

pins

align

guard.

as

698 AP-12

56400 C-16 698 AP-16

56600 A-8 698 H-2

56600 A-12 698

56600 A-16

698

SYNCHRONIZING

Insert

wheel

(A,

Fig.

of

the

with

respect

the

reverse

the

left,

the

motions

with

tion

from

respect

of

the

greatest

tion

move

the

rear.

in

needle

the

operating

4),

moving

(B).

to

direction

and

is

synchronize,

to

.005

inch

eye

of

when

the

the

looper

Moving

looper

direction

to

Note

the

looper

even

the

looper

(.127mm)

the

needle

pulley

it

in

the

until

with

drive

in

reverse.

test

are

the

required.

Plate

H-4

H-4~

LOOPER

the

until

left

the

height

point,

the

the

the

height

point

is

allowable.

to

is

turned

shaft

the

opposite

plate,

not

available,

needle

To

bar

align

Tighten

No.

AND

NEEDLE

looper

rocker

the

is

even

of

the

then

looper

left

side

of

will

be

the

point

in

the

synchronizing

direction

using

so

needle

Test

PI40

PI40

PI40

PI40

PI40

MOTIONS

point

with

eye

turn

point

of

the

eye

the

If

of

the

operating

test

insert

that

needles

bar,

clamp

Pin

screw.

No.

A

A

A

A

A

and

turn

of

the

the

left

of

the

handwheel

again

the

needle.

of

the

same. A

the

distance

looper

stud

acts

pins

a

loosen

hand-

looper

side

needle

in

moves

needle

varia-

is

direct-

(C)

the

No.

new

to

If

to

8

Page 9

SYNCHRONIZING

LOOPER

AND

NEEDLE

MOTIONS

(Continued)

Moving

follows:

(away from

that

is

required.

throat

light

is

screw

If

the

stud

plate

tap

required.

(D)

gauge

is

center

should

of

the

Loosen

operator),

support,

on

the

Note

Fig.

and

reposition

not

available

line

of

be 4 1/16

looper

the

clamp

To

move

looper

Looper

4

the

a

light

oil

drive

drive

the

looper

inch

drive

stud

reservoir

setting

lever

screw

tap

forward

lever

lever

looper

rocker

(103.19mm)

shaft

(D)

of

the

with a small

(toward

top

cover

rocker

drive

can

(G,

be

cone

shaft,

Fig.

ring

end

drive

"O"

seal

the

end

the

ing

Remove

gauge

the

side

adjustment

lever

checked

and

(Fig.

synchronizing

looper

play

ring

bed

of

center

rod

gauge

4).

drive

hammer,

operator),

and

oil

reservoir

toward

4)

has

and

between

must

lever

collar

With

over

of

the

rocker

until

make

casting.

the

its

travel,

line

bearing,

nut

(E,

threaded

should

the

looper

is

(G)

as

with a scale.

center

directly

it

be

looper

necessary,

stud

lever.

the

oil

and

drive

metal

of

Fig.

required.

line

is

remove

operator,

seal

the

removed from

shaft

lever

Tighten

at

check

the

using

4)

stud.

locate

rocker

The

of

accomplished

To

move

on

the

the

back

collar

bed

by

to

metal

screw

the

the

right

gauge

and

The

against

cone

loosen

Tighten

distance

the

stud

stud

cloth

cover,

is

casting.

the

compressing

(G)

and

extreme

location

looper

No. 21227

place

left

(F).

looper

to

is

plate,

then,

all

that

and

an

All

looper

the

contact

(D).

right

connect-

hole

end

the

right

If

the

clamp

clamp

between

lever

as

rear

all

a

"O"

the

oil

with

of

ex.

in

of

screw.

Machine

Style

Fig.

5

Needle

cified.

for

distance

point

the

right.

vantageously

needle

needle

chart

looper

loosen

thread

the

the

nuts,

left

not

Type

SETTING

Insert

example,

of

looper

when

for

connecting

1/8

first

ball

bind

Looper

a

If

the

from

the

is

Looper

machines

setting

needle

gauge

nut

(C,

and

nut

inch

nut

joint

after

Setting

THE

new

needle,

looper

set

the

the

center

looper

at

its

gauge

in

making

set

Type,

number.

Fig.

(D)

on

rod

forward

(3.17mm)

(D),

is

in

adjustment.

Gauge

LOOPER

type

gauge

looper

of

is

1/8

farthest

No.

21225-1/8

this

the

back

the

looper

looper

If

adjustment

5)

(it

connecting

dimension.

then

nut

vertical

and

size

is

1/8

inch

(A,

Fig.

the

needle

inch

has a left

or

(3.17mm), when

position

can

adjustment.

looper

gauge.

gauge

is

rod

backward

Retighten

(C).

Make

position

Looper

as

(3.17mm),

5)

so

(B)

to

be

On

to

the

Refer

setting

required,

hand

(E),

to

sure

and

Gauge

Number

spe-

the

to

the

used

two

right

to

and

turn

obtain

both

does

the

ad-

the

56300

56400 c

56600 A

AU

128

108

108

GBS

GS

GS

9

5/32

1/8

1/8

Inch

Inch

Inch

(3.97mm)

(3.17mm)

(3.17mm)

21225-5/32

21225-1/8

21225-1/8

Page 10

The

behine

the

needle

Fig.

loopers.

other

looper

looper

the

than

in

is

needle,

(B).

6

The same

applying

looper

rocker,

SETTING

set

correctly

its

point

If

turn

stop

the

looper

reverse.

may

prove

recheck

On

(A,

adjustment

screw

to

Holding

helpful.

the

adjustment.

the

two

looper -needle

pressure

so

on

as

in

line-of-feed,

Fig.

(G)

the

rear

looper

needle

relation

the

to

get

THE

6)

brushes,

is

necessary,

as

required.

and

Tighten

machines,

looper

the

LOOPER

turning

to

the

lock

should

at

front

proper

(Continued)

if,

as

it

moves

but

does

not

loosen

Turning

front

screw

now

exist

or

lock

stop

it

counterclockwise

while

when

insert

without

back

of

in-line-of-feed

to

pick

screw

screw

making

setting

the

other

any

blade,

setting.

the

left,

at

the

rear

(F,

Fig.

clockwise

acts

this

adjustment

is

obtained

needles

adjustment,

while

of

5)

and

sets

the

and

and

clamping

The

3/64

with

move

not

or

inch

the

needle

to

down.

The

slots

The main

imately

The

feed

travel.

height

left

disturb

needles

in

throat

3/64

dog

of

(1.19mm)

side

bar

(A)

the

plate.

feed

inch

should

SETTING

the

needles

below

of

up

the

or

the

needle.

down

alignment

are

to

have

SETTING

dog

should

(1.19mm) above

be

centered

HEIGHT

(C,

Fig.

underside

If

as

required

of

the

needle

equal

clearance

THE

be

set

the

in

the

OF

NEEDLE

3)

are

of

the

adjustment

and

bar

on

MAIN

to

throat

slots

rise

FEED

the

plate,

of

BAR

correct

looper,

is

when

with

necessary

retighten

when moving

the

right

DOG

depth

the

at

throat

the

of a full

the

the

,

screw.

the

and

highest

plate

top

looper

loosen

Care

needle

left

tooth,

at

of

point

screw

should

bar

sides

point

maximum

its

or

of

eye

flush

(B)

be

either

of

needle

approxtravel.

feed

is

and

taken

up

Fig.

7

To

screw

dog

at

NOTE:

raise

(A,

specified

A

or

Fig.

change

lower

8) up

height.

of

or

feed

the

main

down

Retighten

dog

height

feed

under

dog,

the

screw

will

loosen

feed

dog

(A).

necessitate

allen

holder

a

setting.

10

Fig.

screw

(B,

check

(A,

Fig.

of

8

7)

the

Fig.

to

rear

7) and

set

the

needle

adjust

feed

guard

Page 11

SETTING

THE

MAIN

FEED

DOG

(Continued)

The main

throat

feed,

(C).

bar

To

as

The

above

of

the

feed

dog

of-feed.

plate

loosen

adjust

required.

differential

the

throat

throat

should

feed

at

maximum

screws

main

plate,

plate

be

dog

should

feed

(C,

Fig.

feed

dog

Retighten

SETTING

feed

at

at

maximum

parallel

have

travel.

7) and

equal

To

position

in-line-of-feed,

nut.

Fig.

THE

DIFFERENTIAL

dog

should

the

highest

feed

to

the

travel.

top

clearance

adjust

9

also

point

surface

be

In

the

feed

loosen

FEED

set

of

travel

addition

of

on

main

dog

to

the

all

as

nut

DOG

rise

and

throat

sides

feed

dog

required.

(A,

Fig.

the

center

to

this

plate

of

feed

slots

across-the-line-of-

Retighten

9) and move

depth

in

the

of a full

the

feed

teeth

across-the-line-

of

in

the

screws

feed

tooth

slots

the

To

raise

the

feed

dog

Loosen

or

backward

ential

alled

screws

NOTE:

through

or

the

feed

with

securely.

Turn

its

throat

These

when

(E,

and

the

Fig.

9).

turning

treadle

These

2~

to 1 depending

hand

its

making

travel

or

lower

at

the

set

screws

as

required.

bar

(D)

the

top

machine

cycle

plate

machines

is

Turning

it

clockwise

machines

on

sure

or

the

the

the

differential

required

to

surface

by

hand

and

does

at

SETTING

have

used.

it

(C,

be

the

counterclockwise

height.

Fig.

The

loosening

rotated,

of

the

to

make

not

forward

THE

an

intermittent

The

differential

decreases

have a stretching

the

length

differential

throat

plate

feed

Retighten

9) and

move

of

so

the

throat

sure

the

contact

end

the

of

DIFFERENTIAL

the

amount

ratio

of

stitch

feed

dog

at

the

forward

dog,

screw.

the

differential

set

screws

differential

plate,

across-the-line-of-feed.

differential

main

its

feed

travel.

FEED

differential

feed

ratio

increases

of

differential

of

3/4

set

at

the

clears

end

loosen

(C)

dog

TRAVEL

feed

is

the

amount

to 1 up

main

the

main

of

its

screw

(B,

feed

will

feed

at

feed

also

dog

dog

back

which

set

by

of

feed.

to a gathering

feed

dog.

feed

travel.

Fig.

bar

(D)

allow

can

be

aligned

has

clearance

end

of

is

activated

turning

differential

Turn

at

the

back

9) and

set

forward

the

differ-

par-

Tighten

its

travel

only

thumbscrew

feed

ratio

machine

end

of

by

of

11

Page 12

ing

stud

damage

slot

in

toward

to

the

the

Fig.

feed

ferrule

10

the"L").

drive

(E).

accomplished

turn

stitch

ing

plate,

marked

shortens

toward

direction

Retighten

bearing,

Set

(it

has a left

regulating

screw

in

with

the

the

locknut

the

Key

CHANGING

the

stitch

by

(B)

located

the

head

"L" and

the

stitch

"S")

lengthens

screw

STITCH

to

required

loosening

hand

stud

and

under

of

the

"S".

(moves

and

turning

the

securely.

{D)

must

LENGTH

the

thread)

turning

the

main

Turning

stitch

it

stitch

To

engage

length.

locknut

on

left

shaft

the

regulating

the

the

end

(C),

screw

This

(A,

end

stitch

of

is

Fig.

10)

of

the

adjust-

the

which

clockwise

stud

in a counterclockwise

(moves

prevent

stitch

destructive

the

"U"

regulat-

shaped

~

cloth

is

key

NOTE:

rear

Any

needle

Set

contact

A

clearance

sible,

yet

needle,

To

move

retighten

NOTE:

Any

Draw

of

fabric.

The

controls

It

should

(C)

and

almost

up.

the

The

affects

to

the

left.

horizontal

stitch

up.

thread

when

However,

triangle

causing

checked

looper

moves

change

guard

the

rear

the

rear

of

have

until

needle

screw.

change

looper

Refer

looper

the

amount

be

set

the

tip

limit

height

the

control

Ordinarily

position.

the

if

triangle

by

observing

to

of

.005

its

the

guard

in

and

to

thread

laterally

parallel

of

and

retainer

the

may

skips

the

in

stitch

setting.

needle

the

inch

vertical

point

merely

stitch

needle

threading

SETTING

cast-off

of

slack

its

the

lateral

of

the

More

retainer

be

wiped

or

the

left.

length

SETTING

guard

right

(.127mm)

face

of

the

loosen

length

threads

THE

thread

so

with

slot

so

looper

it

will

looper

is

raised

is

under

pulled

action

will

THE

REAR

(B,

Fig.

needle

(C) when

is

permissible.

approach

looper

screw

will

THREADING

into

diagram

LOOPER

wire

(A,

in

that

it

the

discs.

that

it

adjustment

thread

be

set

thread

and

raised

the

down

of

the

THREAD

necessitate

NEEDLE

8)

horizontally

within

moving

(D),

require

the

(Fig.

1)

THREAD

Fig.

the

system

is

midway

It

is

barely

of

as

the

in

approximately

is

given

set

toward

too

high,

blade

of

stitches.

looper

TENSIONS

a

GUARD

at

its

It

about

to

the

left,

move

needle

a

change

machine

for

manner

CAST-OFF

11)

located

and

between

usually

clears

the

retainer

looper

to

the

the

the

the

looper,

This

thread

corresponding

so

that

most

should

3/64

forward

be

inch

is

even

guard

in

rear

and

start

of

threading

WIRE

on

the

can

be

moved

the

two

set

toward

the

highest

moves

a

take-

looper

can

be

as

the

change

it

does

point

set

as

(1.19mm)

with

as

required,

needle

operating

cast-off

to

any

discs

of

the

point

in

not

of

travel.

low

as

of

the

needle.

guard

on a

this

support

position.

the

take-up

of

the

Fig.

11

the

quite

pos-

the

and

setting.

piece

mach~ne.

(B)

take-up

to

take-

The

stitches

just

sufficient

tension

on

the

on

the

under

to

steady

needle

surface

the

thread

of

the

thread.

should

fabric.

be

only

Tension

sufficient

on

12

the

to

looper

produce

thread

uniform

should

be

Page 13

The

presser

entirely

If

located

tighten

thread

foot

released

adjustment

at

screw.

the

is

back

After

tension

raised

to

when

the

is

needed,

of

the

adjustment

THREAD

release

within

presser

machine

is

1/8

loosen

there

TENSION

set

correctly

inch

foot

has

tension

and

move

should

RELEASE

(3.17mm)

reached

release

tension

be

no

when

of

its

disc

binding

it

the

highest

lever

begins

end

of

screw

separator

at

any

to

function

its

travel

position.

(A,

Fig.

as

required.

point.

as

and

12),

the

is

Re-

The

remove

Also

between

(E,

when

resting

throat

ion

(F,

plate

screw

en

is

mentioned

only

tension

the

pressure,

the

there

Fig.

the

plate.

If

until

Fig.

surface,

driver

screw.

in

its

Regulate

enough

needle

height

lower

3)

foot

on

adjustment

the

3).

Check

high

in

is

placed

bar

counterclockwise

of

presser

should

surface

and

the

lifter

the

throat

needle

Then,

pry

to

obtain

setting

position

previous

the

pressure

in

the

foot

be

is

while

up

presser

on

the

SETTING

presser

when

approximately

of

bottom

lever

plate,

needed,

bar

presser

the

by

and

paragraph.

on

the

the

head

the

the

presser

surface

is

released

with

turn

is

in

holding

bar

1/16

turning

see

PRESSER

spring

presser

fabric.

of

the

acts

HEIGHT

bar

(D,

foot

1/16

of

the

handwheel

the

low

presser

connection

inch

handwheel

if

presser

regulating

foot

This

machine.

the

reverse.

OF

PRESSER

Fig.

lifter

inch

bar

connection

head

opening

and

the

feed

dog

position.

foot

(1.59mm)

foot

FOOT

is

PRESSURE

to

the

3)

is

lever

(1.59mm)

presser

down

in

operating

Loosen

down

and

guide

setting

so

that

can

screw

feed

the

knurled

Turning

BAR

set

(B,

and

in

below

on

needle

be

(A,

work

screw,

it

correctly

Fig.

12)

clearance

guide

the

bed

foot

the

direct-

screw

the

throat

with

a

and

tight-

bar

removed

Fig.

13)

uniformly

located

clockwise

if

it

is

fully

as

so

that

increases

is

possible

depressed.

Fig.

it

when a

directly

to

12

exerts

slight

behind

the

(B,

Fig.

bar

thread

surface

the

needle

bar

has

this

setting

loop,

the

needle

the

eyelet

the

attaching

Set

the

13),

is

completed

and

raise

SETTING

needle

located

eyelet

even

with

bar

thread

for a smaller

it

thread

hole

is

screw.

NEEDLE

thread

adjacent

(C),

so

that

the

top

eyelet

its

downward

needle

for a larger

frame

3/4

eyelet

inch

THREAD

take-up

to

its

of

the

when

stroke.

loop.

(D)

(19.05mm)

TAKE-UP

wire

the

needle

upper

holes

the

needle

thread

so

that

above

in

Lower

Set

13

WIRE

AND

FRAME

EYELET

~

/

~

~9.05

D

Fig.

13

Page 14

30

33

ft

~

14

Page 15

The

parts

the pnrtll

illustrated

that

nr c u!lcd on

on pa

ges

14,

Style!!

16,

18, 20 and 22, and

56300

AU,

56400 C and 56600

described

A,

but

on

not

this

use

page,

on

page

Styles

17,

19,

56300 W

21

or

and 23

56400

represent

W.

Unless othcrwidc spec

ca

talog.

and 56600

Usc

ports

Reference

they

He

f.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

Catalog

not

are

component

29476

55235 E

6042 A

55235 D

22768 B

56336 B

56336

51054

22801

57822 A

56322 B

22891 B

57847

56323 A

22580 D

29476

22894

29476

22894

57836 E

22768 B

22894

57846 B

52889 A

51256

53688

51617 B

The

parts shown

A.

No.

129 M

illustrated

numbers

Part

No

.

ND

c

666-149

95

NM-062

77

AA

NM-072

77

AA

AA

c

-8

that

parts

51617 B-12

51617 B-16

C-12

51417

32

33

34

35

36

37

38

51417 C-

51418-16

21210

51609

51608 A-8

50

89

98

16

J-16

A

51608 A-12

51608 A-16

39

40

41

42

43

44

45

46

47

48

49

50

51

51204 A

51204 c

77

51204 B

J87 J

22798 A

22569 D

21657 E

51204

56357 B

57841

c

22729

57744

51270 B

51292 F

-2

ifi

ed

in

the

in

phantom

Fourth Edition

or

described

arc

inside a bracket

of a complete

LOOPERS,

Fe

ed Rocker

Nut

Washer

Locking

Screw,

Feed Crank

Feed Crank

Screw,

Main

for

Shaft

GasketOil

Thrust

Collar

Screw - - -

Take-up

Set

Looper Avoid

Screw - - - - - Screw - - - - - - - - - - - - - - - - -

F

eed Lift

Screw - - - - - - - - - - - - - - - - - - Screw - - - - - - - - - - - - - - - - - -

Di

fferential

Screw Screw - - - - - - - - - -

Looper Rocker Cone

Presser

Presser

Presser

Needle

Needle

Needle

Needle

Needle

Spring

Spring

Bar - - - - Bar,

Bar,

Bar,

Bar,

Bar,

Stop

Stop

Screw - - - - - - - - - - - - - - - - - - -

Set

Screw,

Needle

Looper

Looper,

Looper,

Looper,

Looper,

Looper

Holder,

Collar,

back,

front,

front,

front,

Thread

Cast-off

Screw

Cast-off

Screw

Screw

Screw

Washer

Looper

Cast-o

Looper

Thread

f f

Connecting Rod Ball

Screw - - - - - - - - - - - - - Loop r Rocker

Needle

Looper

Thread

Thread

description,

views

and

Style

this

56300 W

catalog.

in

or

part

or

FEED

CRANK,

FEED

Arm

and Feed Crank

- Stud

for

link

Link

Feed Crank

Link

Oil

Wick

take-up

- - - - -

- - - -

Flow Reg

ulating

Screw -

Eccentric

Eccentric

Feed

Connecting

Stud

Regulator

- - - - - - -

marked "DH-8",

marked "DH-12",

marked "DH-16",

marked "CV-12",

marked "CV-16",

Pin-

for

needle

marked

for

Style

for

all

for

No.

for

No.

for

No.

Retaining

and

Retaining

Retainin

Plate

Support

Shaft-

Take-up Wire

Tension

the

parts arc

bearing

for

box on

the

no

reference

56300

picture

used

AU,

on

numbers

and

pla

assembly.

MAIN

LIFT

BARS

SHAFT,

AND

AND

LOOPER

CAST-OFF

LOOPER

AVOID ECC

PLATE

ROCKER

Description

Link

Sub-Assembly

pin

Assembly

Link

Pin

Ferrule-

-

-

Screw -

.062

inch

Assembly,

Assembly,

.072

Rod,

inch

.080

(1.58

(1.83

inch (2.03

Nut-

-

for

No. 8 gauge,

for

No.

12

for

for

for

No.

No.

No.

16

12

16

gauge,

gauge,

gauge,

gauge,

- - - - - - - - - - - - - - -

"D-16",

for

all

gauges,

56600 A - - - - - - -

gauges,

8 gaug

12

16

Finger

g Fing

gauge,

gaug

Finger

er

Style

e,

Style

Style

e,

Style

Holder

Support

56600 A - - - - -

56600 A

56600 A - 56600 A - -

- - - - -

Brack t-- -

- Joint, lef t

- - - - - - - - - (not

Spr

i ng ,

shown)

for

Styles

56400 C and 56600 A

15

all

the

machine

are

common

Style

56400 W for 56400 C a

te

and hove

indente

SHAFT,

ENTRICS,

mm)

Style

Style

Style

Style

Style

Styles

NEEDLE

mm)

throw

throw-

mm)

throw

56600 A

56600 A

56600 A

56400 C

56400 C

56400 C and 56600 A

styles

to

d d

(not

covered

Styles

56300

nd

escriptions,

shown)

in

this

AU,

56400 C

56600

A,

for

indicate

- - - - - - 1

- - - - - 2

all

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

2

1

2

2

1

1

1

1

1

2

Page 16

\

\

'

'\

\

'\

'\

'

'\

'

" '

'\

.-

\

~~

3DA

3DB

~

37

36

16

Page 17

DIFFERENTIAL

FEED

MECHANISM

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

27A

28

29

30

30A

30B

31

32

33

34

35

36

37

38

39

40

41

thru

Part

No.

57835

CL-21

57836 G

56336

J

57836 A

56334 R

55235 E

6042 A

57836 D

57836

c

57836

57834 B

56335 D

98

22894 E

57834 E

22651

CB-4

57834 D

57834 G

22637

P-24

57837 D

57853

57834

c

22593

22593

52953 A

52853

22653 B-14

51235 G

51225 B

51425

AC

51625

52925 D

22635 E-24

CL-21

57834 A

CL-21

90

51236 A

57837 F

22738 B

75

Description

Main Feed Rocker

Oil

Wick- - - - - - - -

Differential

Gather

Differential

Feed

Shaft,

Drive

lower

Rocker

Feed Rocker

Shaft-

Bushing

Bushing

- - - - - - 2

Nut

Washer

Locking

Stud

Main Feed Rocker - - - - -

Bushing

Main Feed Rocker

Collar,

for

lower

Shaft,

main

upper

feed

- - - -

rocker

driving

shaft

Screw - - - - - - - - - - - - - - - - - - - -

Set

Screw,

for

No.

57837 C - - - -

Main Feed Bar - - - -

Screw - Bushing

Bushing

Feed

Differential

Dog

Feed

Oil

Wick

Screw,

Screw,

for

for

Main Feed

Dog

Feed

Feed

Dog

- - - - - - - - - - - -

-

Dog

Height

Adjusting

Feed Bar Guide

Holder

Retainer

main

Dog

Holder,

Holder,

Support

- - -

- - - - - - -

oil

wick

feed

retainer

dog-

- - - -

(See Page 23) - - - - - -

for

Style

for

Styles

Screw

Plate

56300

-

AU

56400 C and 56600 A

Screw - - - - - - - - - - - - - - - - - - - Washer - - - - - - - - - - - - - - - Rear

Needle

Rear

Needle

Rear

Needle

Needle

Guard

Guard,

for

Style

56300

Guard, marked "FT",

Guard, marked "FX",

Holder

- - - - - - - - - -

for

for

AU

- - - - - - - - - Style

Style

56400 C

56600

Screw - - - - - Oil

Wick- - - - -

Differential

Oil

Screw,

for

Differential

Link

Pin

Differential

Feed

Bar

Wick - -

differential

Feed

Dog

feed

(See

Page 23)

- - - - - - - - - - - Driving

Link

Collar-

Screw - - - - - - -

See

Following

Page

- - - - 1

A-

Amt.

Req.

1

1

1

1

1

1

1

1

2

1

3

2

1

1

1

2

2

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

17

Page 18

~~

3DA

308

~

37

36

18

Page 19

DIFFERENTIAL

FEED

MECHANISM

Ref.

No.

1

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

thru

Part

No.

40

57835 B

22758 E

57835 D

57835

c

57837 c

51235 p

258 A

51235 R

56335 R

9663

56335 N

59448

22548

35751 D

51216 N

93

A

69

H

51283 A

9937

20

51235 s

28

56335 M

H

69

57835

EA

12934 A

907

80265

57837

57836

F-40

57836 F-45

57836

F-50

57837 A

22868 B

61341

J

57837 E

22743

Description

See

Preceding

Intermittent

Screw,

for

Differential

Differential

Differential

Thumbscrew,

NutRatchet

- - - - - - - - - - - - - - - - - - - - - Nut-

Bracket,

Screw-

Stop

- - - - - - - - - - - - -

Block

Differential

Screw-

Screw-

-

- Washer - - - - Screw-

- - - - Washer - - - - - Differential

Nut-

- - - - - - - -

Washer - - -

Ratchet

Screw,

Spring

for

Differential

Washer - - - - - - - - - - - - Differential

NutNut-

- - - - -

- - - - - - - - -

Page

Differential

differential

Feed

Feed

Feed

for

adjusting

for

differentifal

Control

Control

Control

Feed Bar

feed

control

Lever

LeverLever

differential

feed

Link

- - - - - -

Bushing

adjusting

- - - - - - - - - - - - Feed

Feed

Stop

Return

Block

Spring

Bracket

- - - - - -

ratchet

Feed

Feed

spring-

Control

Control

Lever-

Indicator-

Driving

lever

Link-

link-

- - - - - 1

- - - - - 1

- - -

- - - - - 1

feed-

screw-

- - - - - - - - - 1

- - - - - - - - - - 1

- - - - - - - - - 1

- - - - - - - - - 2

- - - - - 1

- - - - - 1

- - - - - 1

- - - - - - 1

- - - - - 1

- - - - 1

- - - - - - - 1

- - - - 1

- - - - - - 1

- - - - 1

- - - - 1

- - - - - 1

- - - - 1

- - - - 1

- - - - 1

Washer - - - - - - - - - - - - - - - - Differential

Sliding

Sliding

Sliding

Differential

Differential

Thrust

Driving

Washer,

Link

Screw-

Feed

Block,

Block,

Block,

Feed

Feed

Link

marked "N", • 2540

marked

marked

"P",

"R",

Link

Regulating

for

feed

Guide

- - - - - - - - - -

Sleeve,

.2545

.2550

Sleeve,

bar-

left-

inch

inch

inch

right

Screw -

- - - - - -

- - - - -

(.6

.452

mm)

wide(6.464

(6.477

mm)

mm)

wide-

wide-

- - - - - -

- - - - - - - - - 1

Amt.

Req.

1

1

1

1

2

1

1

1

1

1

1

1

2

- 2

19

Page 20

6

15

7

8

t

20

Page 21

CLOTH

SUPPORT,

PLATES,

ATTACHMENTS

CLOTH

PLATE

AND

COVER,

STRIPPER

THROAT

BLADE

PLATE

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Part

No.

57801

22526

22526 c

22839 E

22839

56401 A

22839

22839

57880

56480

51280

23425 v

23253 F

23253 z

39152 U-4

23233 A

22513

23233

23233 B

51444-12

51444-16

22704

23425

56381-212

56381-207

56381-219

c

c

J

25

c

158 B

A

98

c

v

25

c

Description

Cloth

Screw,

Screw,

Screw,

Screw,

Cloth

Screw,

Screw,

Throat

Throat

Screw,

Washer

Attachment,

Attachment,

Shim,

Looper

Screw,

Attachment,

Stripper

Stripper

Screw,

Washer

Screw,

Cloth

Cloth

Cloth

Plate,

for

for

for

for

Plate,

for

and 56600 A - - - - - - - - - - - - - - - - - - - - - - - - 2

for

Plate

Plate

Dowel

for

Plate,

for

Thread

for

Screw,

Upper

Lower

for

Plate,

for

Plate

Plate

Plate

for

cloth

cloth

cloth

cloth

for

throat

throat

Support,

Support,

Pin-

- - - - - - - - - - - 2

lower

for

lower,

lower,

setting

Eyelet

looper

for

for

upper

Scroll

Scroll

Blade,

Blade,

stripper

for

attachment-

Cover,

Cover,

Cover,

Styles

plate

plate

plate

plate

Style

plate

plate

attachment-

lower

cast-of£

thread

Style

- - - - - - - - - - - - - 1

and

for

for

attachment

for

for

for

56300

on

on

on

on

56400 C - - - - - - - - - - 1

support

support

for

for

attachment

for

Nos.

for

No. 8 gauge,

- - - - - - - - - - - - - - - - - - - - 1

56400 C,

scroll-

Base-

No.

12

No.

16

blade-

Style

Style

Style

AU

and 56600 A - - - - - 1

Styles

Style

Styles

all

Styles

Style

12

plate

eyelet-

gauge,

gauge,

- - - - - - - - - - - - - - - 2

56300

56400 C- - - - - - - - 3

56300

Styles

on

on

56300

56400 C

- - - - - - - - - - - - - 2

and

- - - - - - - - - 1

all

56300

56400 C

56600 A

AU

and 56600 A- - 2

AU

and 56600 A- 1

- - - - - - - - - - - - 2

Styles

Style

- - - - - - - - - - - - - 1

16

Style

gauges-

- - - - - - - - - - 1

Style

Style

- - - - - - - - 1

- - - - - - - - - - - - - 2

AU

56300

56400 C - - - 3

AU

and 56600 A- - 1

(not

gauges,

56600 A- - - - - - 1

56400 C- - - - - 1

56400 C- - - - - - - 1

(not

(not

shown) - - - - 1

(not

shown) - - 1

AU

shown)-

Style

- - - - - - - - - 1

- - - - - - - - - 2

shown)-

- 1

56600 A- 1

- - 1

Amt.

Req.

2

21

Page 22

16

22

Page 23

FEED

DOGS,

ATTACHMENTS

THROAT

AND

PLATES,

STRIPPER

PRESSER

BLADE

FEET,

Ref.

No.

Part

No.

1 56326

2 56305

3 56324 J

4 56320 J

56330 D

5

6

7

91

604

8 19146 A

9 61430

10 56330 B

11

12

13 22799

14

15

16

56330

56330

51426

51405

51424

51424

17

51420

51420

18

19

20

21

22

23

24

51430 B

22765

51430

22799 E

51430

51430

8326 A

8326 - U

24A

25

15226

8305 N

8305

25A

26

15105 B

8324 L-4

8324 L-4

8324 L-2

27

9420 C-4

9420 C-4

9420 C-2

28

29

30

91

22561

23253

23253

31

32

33

28

8344

187 A

87

J

J

BT

AZ

AY

G

AC

AC-12

AC-12

AC-16

AC-12

AC-16

AD

AC-12

AE

B

L

B

y

c

1/2

1/2

Description

Differential

for

Style

Main Feed Dog,

Throat

Plate,

Presser

Presser

Feed Dog, marked "PP",

56300

Foot,

AU

- - - - - - - - - - - -

16

teeth

for

Style

for

Style

Foot

Shank - - - -

per

56300

56300

inch,

AUAU-

16

for

teeth

Style

per

56300

inch,

AU-

- - - - -

- - - - -

Screw - - - - - - - - - Screw,

Spring,

Spring,

Chaining

Yielding

Presser

Hinge

Differential

56400 C,

Main Feed Dog,

all

gauges - - - - - - - - - - - - - -

Throat

Throat

Presser

Presser

Presser

Screw,

Spring,

for

spring

for

yielding

for

chaining

Section

Section

Foot

- - - - - - sectionsection-

- - - - - - -

-

- - - - - - - -

- - - - - - - -

Bottom - - - - - - - - - - -

Screw - - - - - - - - - - - - - all

Plate,

Plate,

Foot,

Foot,

Feed Dog,

gauges-

16

for

for

for

for

16

teeth

per

inch,

- - - - - - - - - -

teeth

No.

No.

No.

No.

per

12

16

12

16

inch,

gauge,

gauge,

gauge,

gauge,

for

Style

Style

Style

Style

Style

56400 C

56400 C

56400 C - - - -

56400 C

Foot Shank-

for

for

spring

plunger

- - -

pin

- - - -

for

56400

- - - - - - 2

Style

C,

Hinge Screw - - - - - - - - - - - - - -

Presser

Foot

Bottom, marked

"B-12",

for

No.

51420 AC-12- - - - - - - - - - - -

Plunger

Differential

Style

Differential

Style

Differential

for

No. 8 gauge,

Main Feed Dog,

Style

Main Feed Dog,

Style

Main Yeed Dog,

Style

Throat

Throat

Throat

Presser

Presser

Presser

Pin

- - - - -

Feed Dog,

16

teeth

per

inch,

for

No.

12

56600 A- - - - - - - - - - - - - - - 1

Feed Dog,

16

teeth

per

inch,

for

No.

16

56600 A- - - - - - - - - - - - - - - - - -