Page 1

CATAL

OG

NO.

Adjusting instructions and

129M

Fif

th Edition

CLASSES

56

200

56300

56400

56500

56700

56900

illustrated parts list

,

..

,

u

Series

hig

h

®

Finest

Quality

500

spe

00 - Advan ced,

ed

, f

la

t b

ed mac

hin

es

Page 2

CATALOG

NO.

129

M

56200

56200

56200

56200

56200

56200

56300

56300

56300

56300

56300

56300

ADJUSTING

ILLUSTRATED

ADVANCED,

FLAT

H

K

L

R

S

W

E

F

G

H

M

N

INSTRUCTIONS

PARTS

SERIES

50000

HIGH

BED

MACHINES

STYLES

56300

56300

56300

56300

56300

56300

56400

56400

56400

56400

56400

56400

R

U

W

X

AH

AL

D

P

R

S

T

W

LIST

SPEED

AND

FOR

56400

56500

56500

56500

56500

56500

56500

56700

56900

56900

56900

56900

X

A

B

C

J

R

U

J

H

J

P

R

Fifth Edition

©1965,

By

Union

Special Corporation

Rights Reserved in

Printed in

March,

2

1982

All

U.S.A.

1982

Countries

Page 3

IDENTIFICATION

OF

MACHINES

Each

ines,

The

Advanced

looper,

R.P.M.

56200

56200

UNION

is

serial

H

K

SPECIAL

stamped

number

high

enclosed automatic lubricating system.

Maximum

Low

ations

and

GS

needle.

Low

made

Type

(19.0, 22.2, 25.4, 28.6,

11/32, 13/32 inch (5.6,

machine

into the

is

speed,

work

throw

a short

throw

with

106

machine.

on

light

machine. Typical application light

GLS

carries

style

stamped

low

or

medium

space to

to

stitch

to

needle.

a Style

plate

in the casting

CLASS

right

Typical application medium

are required.

medium

Uses

affixed to the

DESCRIPTION

throw,

of needle bar 8 1/4 inches

MACHINE

weight

weight materials.

cut

31.8nm)

6.4,

flat

edge

7.1,

number,

at

STYLES

wash

Seam

wide

8.7,

which

the

right

(56200)

bed

machines. Single needle, one

Maximum

and

specification

binding 3/4, 7/8,

and

10.3mm)

on

these Classes of

right

For

wear

For

produces a 7/32, 1/4, 9/32,

front of

rear base of

reconmended

miscellaneous

materials

binding aprons

Seam

specification

finish,

machine.

machine.

speed

(209.6mm).

seaming

where

401

SSa-1.

and

1, l 1/8,

respectively.

mach-

6500

oper-

chaining

Type

dresses

401

1 1/4 inch

101

BSc-1.

#56200

*56200

56200

56200

Advanced

looper, enclosed automatic lubricating system.

bar 8

L

Medium

made

with

401

BSa-1.

inch (15.9, 19.0,

9.5,

11.1mm)

R

Low

throw

in

one

cation

S

Low

throw

W

1/4

woven

light

108

Medium

leather

high

inches

materials, knitted drawer bands, knitted

to

GHS

speed,

throw

operation

401

throw

(209.6mm).

machine.

medium

Type

finish,

machine.

LSe-1.

machine.

medium

needle.

machine.

palm

gloves.

medium

weight materials.

Typical application -

to

medium

126

GS

22.2mm)

respectively.

Typical application -

made

with

Type

Typical application -

Typical application -

Seam

CLASS

or

high

heavy

needle.

wide

and

light

106

GLS

needle.

specification

DESCRIPTION

throw,

For

binding mattress

weight materials.

Uses

selvage

produces a 5/16, 3/8,

to

medium

Seam

flat

specification

401

(56300)

bed

Maximum

edge

For

joining shoulders of

weight materials.

For

miscellaneous operations

shirt

For

seaming

SSa-1.

machines. Single needle,

work

space to

ticks

Seam

specification

binding 5/8, 3/4, 7/8

7/16

fronts

401

cotton flannel

Type

inch

Seam

made

SSa-1.

128

GAS

right

(7.9,

shirts

specifi-

on

with

Type

and

needle.

one

of needle

#Discontinued *Discontinued -

Replaced

In

most

by

Style

instances, replacement parts are available.

56300

M.

3

Page 4

CLASS

DESCRIPTION

(56300

Continued)

56300

56300

56300

56300

E

Medium

thread

throw

machine, equipped with

eyelet,

automatic chain

Typical application -

to

F

medium

128

GBS

Medium

thread

seaming

heavy

needle.

throw

machine, equipped with

eyelet

trousers

and

durable press materials.

needle.

G

Medium

thread

similar

specification

6500

H

High

or

without

Welt

SSk-1

Maximum

throw

machine, equipped with

eyelet.

garments,

401

R.P.M.

throw

machine. Typical application -

rope

guided to the

modified.

MACHINE

For

seaming

weight materials.

Maximum

reconmended

STYLES

thumbscrew

cutter

trousers

Seam

thumbscrew

and

pressure release attachment.

and

specification

speed

6500

adjustable

coats

made

401

R.P.M.

adjustable

frame

with

SSa-1.

frame

a feeding presser foot. Typical application -

and

coats

recommended

Typical application -

made

SSa-1.

welt

made

left

Type

143

of

Type

of

GS

made

with

Seam

specification

speed

medium

128

with

medium

needle.

needle.

medium

6500

thumbscrew

For

to

medium

GBS

needle.

heavy

Seam

Maximum

to

medium

401

SSa-1.

R.P.M.

adjustable

seaming

heavy

trousers,

weight materials.

Maximum

For

seaming

to

heavy

specification

recommended

heavy

Type

frame

recommended

couch

weight materials.

401

speed

needle

medium

Type

needle

For

weight

128

GBS

needle

coats

and

Seam

speed

covers, with

SSa-1

or

6000

401

R.P.M.

56300

56300

56300

*56300

M

High

made

throw

with

BSa-1.

inch (15.8, 19.0

(7.9, 9.5

R.P.M.

N

Medium

thread

seaming

to

medium

(25.4mm)

401

SSa-1.

R

Medium

thread

side

and

on

jackets,

specification

U

6500

Medium

R.P.M.

thread

edge

seaming

similar

width

Seam

ed

isl

specification

speed

machine. Typical application -

medium

Type

and

throw

eyelet

operations

heavy

126

GS

and

11.1mm)

to

needle.

22.2mm)

finish

heavy

weight materials.

Uses

selvage edge binding 5/8, 3/4

wide,

respectively.

machine, equipped with

and

top-grip feed

on

trousers,

mechanism.

slacks,

weight durable press materials.

necessitated

Type

throw

eyelet

machine, equipped with

and

inseams

coats

401

throw

eyelet

machine, equipped with

and

operations

garments

inch

6500

R.P.M.

made

(25.4mm)

by

the top-grip-feed

128

GBS

needle.

Maximum

feeding presser foot. Typical application -

on

trousers,

made

with

SSa-1.

top-grip-feed

on

of

light

back

medium

Type

128

mechanism.

trousers,

to

necessitated

401

SSa-1.

Type

and

produces a 5/16, 3/8

thumbscrew

dress pants, jackets

thumbscrew

and

side

to

medium

GBS

needle.

thumbscrew

slacks,

medium

weight materials.

by

the top-grip-feed

128

GBS

For

binding mattress ticks

Seam

specification

Maximum

recommended

adjustable

frame

Typical application Maximum

mechanism.

recommended

seams

heavy

seam

width

Seam

speed

adjustable

on

coats,

frame

weight materials.

Maximum

adjustable

recommended

frame

Typical application -

dress pants, jackets

needle.

Maximum

and

7/8

and

7/16

inch

speed

6000

needle

For

edge

made

isl

of

inch

light

specification

6500

R.P.M.

needle

For

seaming

sleeve

seams

Seam

speed

needle

For

and

Maximum

seam

mechanism.

recommend-

401

*Discontinued -

In

most

instances, replacement parts

4

are

available.

Page 5

MACHINE

STYLES

(Continued)

56300

*56300

56300

56300

W

Medium

throw

machine, equipped with zipper guiding presser foot for

crossing zipper attached to pants

ing waistbands to men's trousers.

GAS

X

Medium

thread

section to the

operations

made

(25.4mm)

401

AH

Medium

thread

section to the

operations

made

width

Seam

speed

AL

Medium

needle.

throw

eyelet,

of

SSa-1.

throw

eyelet,

of

isl

specification

6500

throw

Maximum

recommended

machine, equipped with

top-grip-feed

left

of needle. Typical application -

on

trousers, slacks, dress pants, jackets

light

necessitated

to

Type

medium

by

128

GBS

weight materials.

machine, equipped with

top-grip-feed

left

of needle. Typical application -

on

trousers, slacks, dress pants, jackets

light

inch

to

medium

(25.4mm)

401

weight durable press materials.

SSa-1.

R.P.M.

machine, equipped with

the top-grip-feed

needle.

necessitated

thread eyelet. Typical application paper garments

range

needle.

is

4 to 7 per inch.

Maximum

and

plastic

recommended

fly.

Seam

speed

Typical application specification

6500

R.P.M.

thumbscrew

mechanism

and

presser foot with yielding

Maximum

mechanism.

Maximum

recommended

thumbscrew

mechanism

Type

by

128

and

presser foot with yielding

the top-grip-feed

GBS

needle.

thumbscrew

For

miscellaneous operations

products requiring a

Seam

specification

speed

6000

R.P.M.

401

401

adjustable

For

and

seam

width

Seam

speed

adjustable

For

~nd

Maximum

adjustable

long

stitch.

SSa-1.

For

attach-

SSa-1.

frame

edge

Type

128

needle

seaming

similar garments

isl

inch

specification

6500

frame

edge

R.P.M.

needle

seaming

similar garments

Maximum

seam

mechanism.

recommended

frame

needle

on

Stitch

Type

128

GAS

Advanced

left

106

mended

needle

GHS

needle. Prepared for

speed

(209.6mm).

56400

56400

56400

D

P

R Typical application -

high

speed,

in

6500

front,

R.P.M.

CLASS

low

throw,

two

loopers, enclosed automatic lubricating system.

use

Maximum

DESCRIPTION

flat

bed

machines.

with

work

knee

space to

MACHINE

To

be

used

with Galkin close-coupled

with machine. Typical application -

serting

to

medium

gauge

Typical

sleeves

erials.

12, 16,

strip

ating

Standard

elastic

in tops

weight materials.

Nos.

12,

16.

application -

of

ordinary quality

Seam

specification

18.

to

at

skirts

neck.

gauge

made

Seam

No.

and

legs

Seam

For

piecing sleeves, joining shoulders,

shirts

401

For

attaching set-on center

with

light

specification -

48.

Maximum

LSc-2.

to

recommended

(56400)

Two

needles, independent

press for foot

right

of

lifter.

needle bar 8 1/4 inches

STYLES

puller.

For

of

knitted undergarments

specification

made

with

Standard

medium

401

LSm-2.

Attachments not furnished

hemming

and

401

light

gauge

weight materials. Starts oper-

Type

speed

Maximum

simultaneously

made

EFg-2.

to

medium

Nos.

plaits

6500

106

and

GHS

R.P.M.

row,

Type

recom-

in-

with

light

Standard

setting

weight mat-

6, 8, 10,

interlining

needle.

*Discontinued -

In

most

instances, replacement parts are available.

5

Page 6

MACHINE

STYLES

(Continued)

56400

56400

56400

56400

S Typical application -

fronts

tions

tion

recommended

of

shirts

at

the neck. Facing

401

LSm-2.

made

speed

Type

6500

T Typical application -

sleeves

materials.

gauge

of

Nos.

extra fine

Seam

8,

specification

10, 12, 16.

W Typical application -

on

operations

where

cation

16.

the majority

401

Maximum

woven

of

LSc-2.

Type

recommended

X Typical application -

to

medium

that

quality

needle. Standard

weight materials.

this

machine

shirts.

can

Seam

gauge

For

folding

with

light

strip

106

GHS

needle. Standard

R.P.M.

For

piecing sleeves, joining shoulders

quality

shirts

Maximum

For

piecing sleeves

shorts

the

106

made

work

GHS

speed

For

quilting

No.

also

be

used

specification

Nos.

24,

CLASS

DESCRIPTION

and

attaching inside button facings

to

medium

guided next

made

401

LSc-2.

weight materials.

to

with

Type

recommended

of

shirts

with

consists

light

of

to

straight

needle. Standard

6500

collar

26

26.

R.P.M.

gauge

for

setting

401

SSa-2

Maximum

bands

is

equipped with a folder

recommended

(56500)

feed

gauge

light

106

GHS

speed

and

medium

gauge

of

shirts

sleeves

or

401

Start

dog.

to

No.

48.

medium

Seam

and

specifica-

Maximum

setting

weight

needle. Standard

6500

R.P.M.

pajamas, joining

weight

seams.

LSc-2.

materials,

Seam

Nos.

8,

made

on

extra fine

Type

speed

specifi-

10, 12,

with

6500

opera-

light

so

106

R.P.M.

to

GHS

Advanced

two

loopers, enclosed automatic

high speed, high throw,

lubricating

needle bar 8 1/4 inches (209.6rnn).

56500

56500

56500

A Typical application -

401

made

SSa-2.

garments

tion

only. Standard

( Formerly

of

known

medium

Type

gauge

as

Style

B Typical application -

medium

Type

gauge

as Style

heavy

130

No.

to

heavy

GS

needle. Available

1 only.

56500

Maximum

N-7).

C Typical application -

medium

Type

gauge

as Style

heavy

130

No.

to

heavy

GS

needle. Available

l only.

56500

Maximum

N-10).

For

130

No.

For

weight materials.

For

weight materials.

flat

bed

MACHINE

seat

heavy

GS

seaming

to

needle. Available

1 only.

56500

N-5).

seaming

for 7 stitches

recommended

seaming

for

recommended

machines.

system.

STYLES

operations

heavy

weight materials.

Maximum

trousers

speed

trousers

10

stitches

speed

Two

needles, independent

Maximum

for 5 stitches

recornnended

and

similar

Seam

specification

per inch only. Standard

6000

and

Seam

R.P.M.

similar

specification

per inch only. Standard

6000

work

on

trousers

speed

garments

garments

R.P.M.

space to

and

Seam

6000

401

(Formerly

401

(Formerly

row,

right

of

similar

specificaper inch

R.P.M.

made

of

SSa-2.

known

made

of

SSa-2.

known

56500

J Typical application -

similar

tion

recommended

garments

401

LSc-2.

speed

made

Type

6000

For

of

medium

128

felling

GS

overalls,

heavy

needle. Standard

R.P.M., depending

6

weight materials.

on

coats,

combination

gauge

Nos.

Seam

16, 18.

suits

specifica-

material or operation.

and

Maximum

Page 7

MACHINE

STYLES

(Continued)

56500

R Typical application -

on

denim

heavy

Standard

on

material or operation.

56500

U Typical application -

medium

or

Type

gauge

Advanced

high speed,

needles abreast,

space

56700

to

J

right

of needle bar 8 1/4 inches

Equipped

folding

fronts of

erials.

tends 1/4 inch

401

LSm-2.

recommended

jackets

and

weight materials.

130

No.

gauge

GS

l only.

No.

18.

heavy

to

heavy

needle. Available for 7

Maximum

CLASS

low

throw,

two

loopers, enclosed automatic lubricating system.

with 11Tru-Front

and

attaching 11Set-on

shirts

and

Starts operation

(6.4mm)

Type

speed

108

6500

For

attaching

risers

to dungarees, piecing sleeves

for attaching overall bibs

Seam

Maximum

For

specification

recommended

seaming

trousers

weight materials.

401

speed

made

Seam

stitches

recommended

DESCRIPTION

flat

bed

machines.

speed

(56700)

Two

6000

(209.6mm).

MACHINE

11

folder. Typical application -

similar

garments

at

neck.

beyond

GKS

needle. Standard

11

center

the

STYLE

plait

made

Plaits

rows

of stitching.

and

of

used

gauge

R.P.M.

made

of

LSc-2.

6000

medium

Type

R.P.M.,

heavy

128

GS

depending

needle.

of durable press material

specification

per

inch

only. Standard

401

SSa-2.

R.P.M.

needles, independent

Maximum

For

one

interlining

light

in

garment

to

Seam

Nos.

56,

medium

strips

weight mat-

lengths

specification

64.

row,

work

operation

to

and

Maximum

to

ex-

Advanced

left

high

needle in front, three loopers, enclosed automatic lubricating system.

recommended

(209.6mm).

56900

H Typical application -

jackets

ion

56900

J Typical application -

heavy

GKS

56900

P Typical application -

medium

Type

56900

R Typical application -

heavy

Standard

speed,

speed

401

to

high

6000

made

LSc-3.

heavy

throw,

R.P.M.

with

Type

weight materials.

needle. Standard

heavy

147

weight

to

heavy

GKS

needle. Standard

denim.

gauge

No.

CLASS

Maximum

DESCRIPTION

flat

bed

work

MACHINE

For

setting sleeves, shoulder

medium

128

For

gauge

For

heavy

GAS

needle. Standard

seaming

No.

attaching

weight materials.

For

seat

Seam

specification

9.

machines.

space to

STYLES

to

heavy

operations

Seam

9.

risers

gauge

No.

seams,

(56900)

Three

right

needles, independent

of needle bar 8 1/4 inches

weight materials.

gauge

on

jackets

specification

to the

Seam

back

specification

9.

outseam

401

or

LSc-3.

inseam

Type

seaming

Seam

Nos.

8, 9.

made

401

LSb-3.

of jeans

on

147

on

denim

specificat-

of

medium

made

401

LSc-3.

jeans

GS

needle.

row,

Maximum

Type

147

with

made

from

7

Page 8

NEEDLES

Each

needle

has

both a type

of shank, point, length, groove,

on

the needle shank, denotes

and

eye.

given

To

Collectively,

on

the label

have

needle orders promptly

of

needle, or the type

A complete order

The

type

by

this

catalog are given in the

are

available,

satisfactory

their

Type

101

descriptions,

No.

GS

would

numbers

but the

results.

and

Round

chromium

106

GHS

Round

ball eye, ball

all

and

of

ones

The

shank,

shank,

largest

type

and

needles packaged

size

number

read: 111000

the needles

indicated are those

type

the sizes available are

round

plated - sizes 022, 025, 027, 080/032, 049, 054.

round

point,

090/036.

and

size

finish

and

diameter of blade,

size

number

and

accurately

should

needles,

recommended

machine

numbers

style

of the

Description

point,

point,

extra

extra

chromium

number.

other

The

type

details.

measured

number

The

size

midway

denotes the kind

represent the complete symbol,

and

sold

be

forwarded.

Type

or

recommended

and

short,

short,

plated -

by

UNION

filled,

106

GHS,

for

each

class

style

description. Other needles

recorrnnended

listed

below:

Sizes

double groove, struck groove,

double groove, struck groove,

sizes

SPECIAL.

an

empty

Use

description

Size 090/036

of

machine

to produce the

needles together with

070/027, 075/029,

number,

stamped

between

which

package, a

on

11

•

covered

most

shank

is

sample

label.

108

108

126

128

128

128

130

GHS

GKS

GS

GS

GAS

GBS

GS

Round

ball eye, ball point, spotted,

shank,

round

point,

extra

short,

chromium

double groove, struck groove,

plated -

sizes

075/029, 080/032, 090/036, 100/040 110/044, 125/049.

Round

oversize ball eye, spotted,

shank,

round

point,

extra

chromium

short,

double groove, struck groove,

plated - sizes 080/032, 090/036,

100/040.

Round

eye,

Round

eye, spotted, undersize

ium

Round

eye, spotted,

shank,

chromium

shank,

round

point,

short,

double groove, struck groove, ball

plated - sizes 080/032, 100/040,

round

point,

eye

short,

and

double groove, struck groove, ball

groove

27%

of

054.

size

of needle,

plated - sizes 090/036, 100/040, 110/044, 125/049, 140/054.

shank,

round

point,

chromium

short,

plated -

double groove, struck groove, ball

sizes

080/032, 090/036, 100/040,

110/044, 125/049, 140/054, 150/060, 170/067.

Round

eye, spotted, ball point,

shank,

round

point,

short,

double groove, struck groove, ball

chromium

plated -

sizes

080/032, 090/036,

100/040, 110/044, 125/049, 140/054, 150/060.

Round

eye, spotted, government,

shank,

round

point,

short,

double groove, struck groove, ball

chromium

plated - sizes 080/032, 090/036,

100/040, 110/044, 125/049, 140/054, 150/060.

070/027,

chrom-

8

Page 9

NEEDLES

(Continued)

Type

143

147

No.

GS

GKS

Round

shank,

spotted,

Round

shank,

chromium

Description

round

point,

plated - sizes 140/054, 150/060, 170/067, 230/090.

round

point, long, double groove, struck groove, oversize ball eye, spotted, short point, standard

chromium

Selection of proper needle size

plated - sizes 090/036, 100/040, 110/044, 125/049, 140/054.

is

Thread should pass freely through needle

formati,'on.

LUBRICATION

Use a straight

degrees

F.

Before operating,

plug screw

with

is

line

needle

though

oil,

check

reached,

marked 11FULL

registers

the

machine

gauge needle

is

recommended

operating,

to

the

to

"FULL"

This

(A,

gauge

registers

be

mark.

mineral oil with a Saybolt viscosity of

is

equivalent to

Fig. 1).

gauge

on

(B).

needle will

11

•

Oil

black

can

to

always

sure

machine

CAUTION:

fill

machine

While

When

must

line

be

operated safely

in the

check

Union

with

filling

machine

proper oil level

register

be

added

marked

on

when

"LOW'.

"OPERATE"

oil

level before

is

filled

DO

NOT

over

machine.

and

Sizes

No.

2 bag, double groove, struck groove,

eye

and

grooves,

determined

eye

in order to

by

size of the thread used.

produce a good

90

to

125

seconds

stitch

Special Corporation Specification

oil

at

black

gauge

Al-

when

zone,

with

it

oil

fill

No.

at

175.

100

To

drain

er

crank

must

be

chamber

changed

minimize wear.

On

new

machines, or a

for

an

extended period of time; lubricate

as follows:

Remove

rectly

place

proper

proper

damage

oil

head

level.

lubrication

which

head

needle bar link

cover

bution.

oil,

remove

cover

every

on

2000

cover, clean.out

and

fill

Run

machine

of

components

may

occur

from

plug

back

screw

of

machine.

(C), or

operating hours to

machine

and

machine

at

out of service

lint,

needle bar.

with

low

RPM

to ensure

oil

then

preventing

lack of

oil

distri-

9

low-

Oil

machine

di-

Re-

to

any

Fig. 1

Page 10

FIii main reservoir

here.

CAUTION:

before

Machine

before

FIii

oll

starting.

has

been

shipping.

reservoir

drained

full

mark

on gauge.

Fig. 2

FOR

Oil

has

been

drained

filled

needle of

lubricated

before

gauge

and

starting

registers

no

oiling other than

Refer to instructions

THREADING

ALL

STYLES

from

EXCEPT

machine

to operate. Maintain oil level in

on

the black

under 11LUBRICATION

AND

OILING

56300

E,F,G,N,R,U,X,AH

before shipping

line

marked

keeping

11

the

and

"CHANGING

DIAGRAM

"LOW".

main

information.

AH

Thread

and

AL.

machine

as

illustrated

above

for

10

all

Styles except

and

the reservoir

"OPERATE"

Machine

reservoir

STITCH

and

AL

zone;

is

filled

LENGTH"

56300

E,F,G,N,R,U,X,

must

add

be

oil

when

automatically

is

necessary.

for additional

Page 11

FIii main reservoir

here.

CAUTION:

before

Machine

before

Fill

oll

starting.

has

been

shipping.

reservoir

drained

CAUTION: Be sure looper connection Is

FIii reservoir

full mark on

up

before

to

gauge.

sewing.

Fig.

2A

FOR

STYLES

Oil

has

been

filled

before

needle of

lubricated

starting

gauge

and

drained

registers

no

oiling other than

from

to operate. Maintain oil level in 110PERATE

on

Refer to instructions under

THREADING

machine

the black

11

LUBRICATION

56300

keeping

AND

OILING

DIAGRAM

E,F,G,N,R,U,X,AH

before shipping

line

marked 11LOW

the

11

and

main

"CHANGING

and

11

reservoir

information.

Thread

machine

as

illustrated

above

for Styles

11

56300

and

AL

the reservoir

•

Machine

11

zone;

is

filled

STITCH

LENGTH"

E,F,G,N,R,U,X,AH

must

add

be

oil

when

automatically

is

necessary.

for additional

and

AL.

Page 12

ADJUSTING

INSTRUCTIONS

NOTE:

Instructions

machine,

of

handwheel

the

right

rotates counterclockwise, in operating direction;

end

stating

are

given

of

machine.

direction or location,

relative

OIL

To

recalibrate oil

- Place

Remove

-

machine

plug

upright

screw

gauge,

(C,

follow instructions in sequence

on

a level surface.

Fig.

1)

and

voir.

-

Remove

-

Fill

-

Loosen

registers

lower

crank

chamber

reservoir until

locknut

on

(E)

and

the black

cover

oil

is

even

rotate calibrating

line

marked 11LOW

- Tighten locknut {E), then replace

- Fill

machine

with oil until

gauge

such

to operator's position

GAUGE

tip

on

with

plug

needle

CALIBRATION

machine

back

of

machine.

bottom

11

screw

of

screw

•

(C)

registers

forward

knee

(F)

as

and

on

as

right,

at

as

to drain

left,

the

listed:

all

press shaft

required until

lower

crank

black line

front or rear

machine.

when

viewed

oil

bushing

The

from

(D).

gauge

chamber

cover.

marked 11FULL

from

reser-

needle

11

•

Fig. 3

Fig. 4

A

NEEDLE

(TWO

AND

Insert a new

size required).

needle bar

(A,

BAR

THREE

NEEDLE

set

Turn

Fig.

3)

ALIGNMENT

MACHINES)

of needles (type

handwheel

down

to bring

to ensure

needles center in needle holes of throat

plate

be

allowing needle bar to

ed. Tighten

as

shown

made

by

SYNCHRONIZING

in Fig.

loosening

clamp

screw.

LOOPER

3.

screw

be

AND

Adjustment

(B)

slightly,

turned

NEEDLE

as

MOTIONS

requir-

Insert looper into the looper rocker,

it

all

the

way

down

and

pushing

screw

handwheel

against

flat

on

in operating direction until

the point of the looper

to the

the

the

looper point

wheel

point

is

(See

left,

right

eye

of the needle with respect to the

is

even

needle (B).

(See

Fig. 5).

with the

in the reverse direction until the

of

looper again

even

with the

Fig. 5).

left

If

the height of the

shank

(A,

Note

the height of

Turn

moving

side of right needle

tighten

of looper.

Fig.

4)

moving

left

side of

the

hand-

to the

left,

eye

the needle with respect to the looper point

are the

synchronized - a variation of

(.127mm)

same,

is

allowable.

looper

and

needle

motions

.005

inch

12

and

that

can

Turn

of

are

Page 13

SYNCHRONIZING

If

the distance

point of

is

turned in the operating direction, the looper

drive

slightly

wards

NOTE:

the

lever

towards the

the

front

The

1/64 inch

Fig. 5

from

the

looper

rocker

is

greater

shaft

rear.

acts the reverse.

(.4mm)

is

for final

eye

will

LOOPER

AND

of the needle to the

when

have

Moving

dimension

setting

the

handwheel

to

be

the

shaft

shown

of needle

bar height.

NEEDLE

moved

to-

in

MOTIONS

(Continued)

For

these

J

1/84'

(.4mm)

-r

Proper

SYNCHRONIZATION of

Looper

two

1Hl

& Needle

Dimensions

--==-

in

OPERATING

Direction

will

Looper

FRONT of

REVERSE

Direction

be

the

Needle

In

same

in

Adjust looper drive rocker lever

Loosen

drive

Union

lever

Special

threaded

er

shaft through the center of

usting screw (E).

required

chronization. Tighten

and

remove

shaft.

thrust

adjusting

(7cm/kg);re-tighten lock nut

With

its

travel,

line

of

ing using

Classes except

21227

21227

looper

gauge

gauge

CX-56

CX-64

lever

(B)

should locate against the

looper rocker

sary,

drive

(D).

loosen

lever

If

checked with a scale.

centerline

which

should

Classes except

be

a 3 5/8 inch

should

be

extreme

screw

(D).

into

to

position

(C,

Fig.

A

rod

Screw

No.

the looper drive lever rock-

Tap

or pull

shaft

screw

rod

or

screw

Loosen

looper

right

gauge

lock nut

check

screw

at

location

(E)

extreme

looper connecting

No.

21227

56700

for Style

for Style

stud

(A,

which

56700

56700

Fig.

over threaded stud.

cone

clamp

(E)

gauge

(C).

screw

as

required

is

not available,

"X"

of stud

be

3 9/16 inch

right

end

(A)

to centerline

4 1/16 inch

56700.

(92.

Style

1nm)

(90.6mm)

of

travel.

4)

in looper

of

.146-40 thd.

22870 A can

for proper syn-

(C)

used

(F)

to position

and

to 6 in.

(F)

right

of

the center-

ex

for

uses

J-56

J-64.

6)

and

If

adjustment

(D), reposition looper

and

dimension

(103.2mm)

56700

and

Style

shaft

as

or

be

thrust

slightly

adj-

as

securely

TORQUE

lbs.

securely.

end

of

rod

bear-

all

gauge

and

No.

No.

Remove

nut

place hole in

The

left

end

RIGHT

side of

is

retighten

setting

is

of

can

from

cone

for

J-56 should

56700

J-64

with looper

follows:

from

of

necesscrew

be

(C)

all

at

Fig. 5

Fig. 6

LOOPER

ified.

(A,

Fig. 7)

Insert a new

If

the looper ga_

so

needle, type

the distance

looper is 5/32 inch

SETTINGS

uge

(4.0mm),

and

size

as

spec-

is

5/32 inch (4.0nm), for example,

from

the center

when

the looper

of

the needle

is

at

its

farthest

13

Fig. 7

set

the looper

(B)

to the point of the

position to the

right.

Page 14

LOOPER

SEITINGS

(Continued)

Looper

On

machines

two

gauge

needle

set

No.

21225-5/32

machines

set

the middle looper to the middle needle,

Refer to chart for needle

ment

is

ing

rod

(4.0mm)

left

ball

required, loosen nut

(F), turn the connecting

dimension. Retighten both nuts,

joint

is

in

vertical

Machine

Styles

56200

56200

56200

56200

56200

56300

56300

56300

56400

56400

56500

56500

56700

56900

56900

56900

56900

H

K,R

L

S

W,

56300

W,AL

E,F,G,N,R,

U,X,AH

H

M

D

P,R,S,T,W,X

A,B,C,U

J,R

J

H

J

P

R

Needle

101

106

126

108

128

128

143

126

106

106

130

128

108

128

147

147

147

(C)

the

Type,

(D)

Type

GS

GLS

GS

GHS

GAS

GBS

GS

GS

GHS

GHS

GS

GS

GKS

GAS

GKS

GKS

GS

can

be

back

looper to the

looper

(it

has a left

rod

forward or

position

used

advantageously in

right

gauge

setting

hand

backward

first

and

nut (E), then nut

does

not bind

Looper

Setting

Inch

1/8

1/8

Inch

5/32

1/8

5/32

5/32

5/32

5/32

1/8

1/8

5/32

5/32

1/8

5/32

7/32

5/32

7/32

Inch

Inch

Inch

Inch

Inch

Inch

Inch

Inch

Inch

Inch

Inch

Inch

Inch

Inch

Inch

making

needle

when

and

looper

thread)

and

setting

gauge

and

on

the looper gauge.

nut

to obtain the 5/32 inch

(D).

after

Gauge

(3.2mm)

(3.2mm)

(4.0mm)

(3.2mm)

(4.0mm)

(4.0mm)

(4.0mm)

(4.0mm)

(3.2mm)

(3.2mm)

(4.0mm)

(4.0mm)

(3.2mm)

(4.0ITITl)

{5.6mm)

(4.0ITITl)

(5.6mm)

adjustment.

this

adjustment.

three needle

number.

(E)

on

Make

Looper

If

connectsure the

Gauge

Number

21225-1/8

21225-1/8

21225-5/32

21225-1/8

21225-5/32

21225-5/32

21225-5/32

21225-5/32

21225-1/8

21225-1/8

21225-5/32

21225-5/32

21225-1/8

21225-5/32

21225-7/32

21225-5/32

21225-7/32

adj-

point

The

(A,

Fig. 8

looper

Fig.

is

8)

set

correctly

clears

and

wise

the

If

turn stop

sets

if,

as

rear

of

needle

adjustment

screw

the looper to the

wise acts the reverse.

this

adjustment

setting

should

flecting

needles

should

sure

is

obtained

On

Style

be

set

as

On

the

and

exist

on

the looper

56200

to barely contact the

looper

two

loopers.

without

looper in looper rocker,

feed

setting.

it

moves

is

necessary, loosen lock screw

(H)

to the

(B)

by

.002 inch (.05lmm).

as

required. Turning stop

rear

Holding

may

prove

and

recheck the adjustment.

W,

looper needle guard (attached to looper)

moves

and

three needle machines,

at

to

The

same

any

adjustment, other than applying pres-

front or

so

looper to the

helpful. Tighten lock

left.

looper - needle relationship

back

as to get the proper

left

and

behind the needle,

turning

front

of needle without de-

insert

of blade, while

(G,

screw

it

counterclock-

front

while

screw

·

the other

clamping

in-line-of-

its

Fig.

clock-

making

when

7)

14

Page 15

the

The

top

height of the needle

of

its

eye

is

1/64 inch (

is

correct

.4mm)

NEEDLE

BAR

when

below

the underside of the looper, with the looper

point

as

flush

shown

C the top of the needle eyes should

with the underside of the looper

looper

point

the needle.

loosen screw

(A)

up

or

care should

bar

either

the 1

oope

with

the

in Fig. 5.

is

flush with the

If

adjustment

(8,

Fig. 3)

down

as

be

taken not to disturb alignment of needle bar

up

or

down.

rs.

left

On

Styles

and

required

The

side of the needle

56500

left

is

necessary, Fig. 9

move

and

retighten screw.

A,

Band

be

even

when

the

side of

needle bar

descending needles

FEED

DOG

SETTINGS

HEIGHT

On

two

must

be

and

three needle machines,

when

moving

deflected alike

the needle

on

the

back

of

plate

feed

travel,

of

Feed

travel

(B)

dog

with

set

tips

(A,

Fig.

equal

clearance

to desired

of feed

9)

dog

should

of a tooth or approximate.ly

plate

support feed

secures feed

extend

"Grip

feed

of the top

and

On

Styles

1/32

Feed"

dog

parallel to

dog

after

dog

in position.

56300

inch

N,U,X,AH

(.8mm)

presser foot feed

left

and

to

right,

bottom

same.

screw

above

and

feeds should

point.

Parallel

clockwise

ly

set,

retighten nut

Right

made

and

by

loosening

slightly

feed rocker shaft

then

sure

not bind

retighten

that

after

adjustment

to

lower

to

front of feed

left

adjustment

screws

move

feed rocker

(C)

screws.

feed rocker

adjustment.

can

(A).

(A,

as

required,

Check

arm

(D)

be

centered in throat

on

all

stitch

sides

length.

and

ends

At

highest point

with

teeth should extend the depth

3/64 inch

Screw

(D)

has

the

the throat plate

dog

in-line-of-feed the

be

made

dog,

can

(1.2mm)

(C)

should

been

tips

of the teeth

must

line

match

by

loosening nut

above

be

loosened

set

which

throat

to

must

and

the

with the

last

lower

teeth

tooth point to

counterclockwise acts the reverse.

be

Fig. 11)

(B)

on

to endoes

(A,

Fig.

10)

and

Fig.

turn

10

screw

When

(B)

proper-

Forward

of feed

dog

loosening nut

feed rocker (B)

or rearward centering

can

be

accomplished

(E,

Fig.

11),

move

as

required

and

by

re-

tighten nut.

15

Fig.

11

Page 16

CHANGING

STITCH

LENGTH

Set the

(F, Fig.

and

stud

plate,

screw

in the

clockwise shortens the

turning

ting stud

age

to the feed drive bearing,

ferrule

NOTE:

Any

rear needle

Machines

may

require repacking

and

repacked with

At

extreme

stitch

11)

1/2 turn

turning

head

it

in a counterclockwise direction lengthens the

toward

to required length.

(it

has a left

stitch

of

main

adjusting

shaft

stitch

the 11L

11

).

Retighten locknut securely.

screw

(H),

key

hand

(G)

which

(moves

screw

(K).

change

in

having

Union

forward

stitch

guard

length will necessitate a corresponding

setting.

needle bearings in the feed rocker

after

years of service. Bearings should

Special Corporation grease

end

of

REAR

travel,

NEEDLE

rear needle

horizontally not to contact rear of needle

(.12711111).

approximately 3/64 inch

left,

the

screw

needle guard, loosen

or

counterclockwise to raise

(F),

Guard

is

even

move

should

be

set

(1.2mm)

with the needle.

needle

guard

screw

as

(F),

it.

as

low

as possible,

of needle point until point

To

move

required,

and

turn

Retighten

This

is

thread)

accomplished

on

the

located under the

is

marked

stitch

(J)

regulating stud

must

engage

No.

GUARD

guard

(D)

with a

maximum

yet

needle

and

screw

screw

guard

retighten screw.

(G)

clockwise to

(F)

after

end

with 11L

stitch

To

prevent destructive

the 11U

at

locations

28604

(C,

have

its

of

forward or

guard

by

loosening locknut

of the

left

11

and 11S

stitch

end

11

toward

(moves

11

shaped

change

(L,

be

throughly cleaned

regulating

of the cloth

•

Turning

the 11S

stitch

key

in the

Fig.

11

regula-

slot

11)

P.

Fig.

10)

must

clearance of

be

set

.005

vertical face approach

looper (E),

backward,

To

raise

lower

is

properly

moving

loosen

or

lower

needle guard

set.

the

)

and

dam-

in

inch

to

NOTE:

Any

Draw

change

in

stitch

THREADING

the looper

length will require a

(FOR

ALL

STYLES

and

needle threads into the

piece of fabric. Refer to threading

machines.

The

stitches

The

bly,

and

just

sufficient

tension

on

the under surface of the fabric.

looper thread tension

the adjusting nut should

on

the needle thread should

is

applied

be

to steady the thread.

THREAD

The

thread tension release

presser foot

entirely

released

is

raised to within 1/8 inch

when

the presser foot

is

EXCEPT

diagram

THREAD

TENSIONS

at

set

so

TENSION

set

correctly

(3.2rrm)

has

change

56300

E,F,G,N,R,U,X,AH

machine

(Fig.

be

only

the

cast-off

that

the tension

RELEASE

when

of the

reached

in rear needle

and

start

2)

for the threading of these

sufficient

to

guard

and

AL)

operating

produce

support tension disc

on

the looper thread

it

begins to function

end

of

its

travel

its

highest position.

setting.

on

a

uniform

assem-

as

the

and

is

is

16

Page 17

If

adjustment

screw

tension

adjustment there should

(A,

Fig. 12), located

disc

separator

is

required, loosen tension release lever

THREAD

as

required. Retighten screw. After

be

at

no

binding

TENSION

the

back

at

PRESSER

RELEASE

of

machine

any

BAR

(Continued)

point.

HEIGHT

and

move

A

'

Height of presser bar

sser

clearance

guide

casting

lying

stroke.

er

ion

and

so

to feed

on

sure, counterclockwise acts the reverse.

(B,

Fig.

foot

and

retighten

that

the

(FOR

foot

Adjustment

Regulate presser spring regulating

can

12).

between

(B,

Fig.

when

flat

on

Loosen

down

guide

it

exerts only

the

fabric.

NEEDLE

ALL

be

removed

There

foot

throat plate with feed

on

as

screw.

work

THREAD

STYLES

should

lower

13)

and

lifter

can

be

screw

throat

Turning

(C,

required to

uniformly

TAKE-UP

EXCEPT

(A,

Fig.

13)

by

depressing foot

be

approximately 1/16 inch

surface of presser bar connection

bottom

lever

made

plate,

enough

it

surface of

is

released

dog

by

turning

Fig.

13)

position presser bar connect-

attain

PRESSER

pressure

when a slight

clockwise increases the pres-

WIRE

56300

E,F,G,N,R,U,X,AH

handwheel

and

while holding press-

specified clearance

on

AND

is

correct

lifter

head

and

below

FOOT

PRESSURE

screw

the presser foot

tension

FRAME

EYELET

when

lever

opeining in

presser foot

throat

to position needle bar

(A,

Fig. 14)

is

and

pre-

(1.6mm)

plate.

placed

AL)

and

bed

Fig.

at

12

bottom

of

Set needle thread take-up wire

its

upper surface

needle bar thread eyelet

its

downward

needle thread loop, or raise

needle thread

3/4 inch

on

all

Styles except

56900

5/8 inch

and

l inch

NOTE:

for

threaded.

H,

on

Style

(25.4mm)

For

56300

see

56300

Refer to threading

the

manner

stroke.

(19.0mm)

J,

P

(15.9mm)

56200

the

E,F,G,N,R,U,X,AH

the following paragraphs.

THREADING

E,F,G,N,R,U,X,AH

is

even

frame

and

above

in

eyelet

above

on

R the eyelet

above

H the eyelet

above

setting

(FOR

which

with the

(C)

Lower

the attaching

Styles

the attaching

the attaching screw.

STYLES

diagram

these

(B,

Fig.

top

of the holes in

when

this

it

(D)

on

and

needle bar

setting

for a larger loop. Set

so

that

56500

is

to

is

to

Styles

and

AL,

AL)

(Fig.

machines

for a smaller

the eyelet hole

screw

J,

be

set

screw

be

set

2A)

are

14),

has

completed

so

that

is

Fig.

14

Fig.

13

17

Page 18

NEEDLE

FOR

THREAD

(STYLES

TAKE-UP

56300

E,F,G,N,R,U,X,AH

WIRE

AND

FRAME

EYELET

and

AL)

Fig.

14A

With

Fig.

14A)

needle bar

so

its

at

the top of

lower extended surface

needle lever thread eyelet hole

vertical surfaces

(See

Fig.

14A).

left

of looper thread take-up (B),

to a

(light).

adjusting plate

only, with nut (E), balance the

inches

thread

inch

Use a sample

needle thread tension,

toward 11L

and

These

are equipped with additional thread handling

___:.i.,j~-----...__,

trol

parts,

ing sequence should

in the following

its

stroke,

is

and

3/4 inch

Set looper thread guide eyelet

outer surface

set

needle thread take-up wire

1 7/16 inch

(19.0mm)

is

3/4 inch

(36.5mm)

above

across the centerlines of

(A,

(19.0rrm)

(See

Fig. 15).

Adjust looper thread tension with nut

minimum

(152.4mm)

is

(25.4mm)

toward 11T

required for controlling the looper thread

Set the thread index eyelet

(D).

Changing

the needle thread tension

stitch

of

sewn

seam

are raveled back, the needle

(C)

so

approximately as long as the looper thread.

difference in lengths

of

the material to

11

to obtain a looser

11

to obtain a

move

thread index eyelet

seam

tighter

is

permissible.

be

sewn.

(longer needle loops)

seam.

Fig.

15

machine

so

the adjust-

manner:

centerline of

Fig.

15)

from

the

(B,

at 113

that

Fig.

11

when

Maintaining

(C)

styles

and

be

(A,

so

its

left

14A)

on

the

6

NOTE:

up

conmade

its

side

Al

this

to

Fig.

16

FEEDING

Remove

spring. Adjust

bar guide

clearance

(C), yet

link

(E)

so

(D)

when

on

stop screw.

PRESSER

FOOT

the presser spring regulator

long

stop

(B)

against

between

that

guide

bed

the guide

is

foot treadle

18

and

presser

screw

casting

pulled

is

(A,

Fig.

16)

in presser

as

required to ensure a

and

top

of

presser bar bushing

up

quickly

by

lifter

activated. Tighten lock nut

lever

Page 19

As

a preliminary

presser

(15.9mm),

foot

throat

regulator

foot

(See

to

presser bar.

plate

nut

so

Fig. 17).

and

{A,

foot bottom line

FEEDING

setting,

the distance

Assemble

With

presser foot resting

feed

dog

down,

Fig.

17)

until the

up

with the centerline of needle,

PRESSER

FOOT

adjust spring regulator nut

from

the top of spring

the feeding presser

press

down

marks

on

spring

on

presser

while keeping the needle in the center of needle

slot,

guide

presser

tighten

to

set

the presser bar,

bar guide

screw

is

resting

(D)

securing presser bar

making

sure stop

on

the

bed

screw

casting.

(Continued)

(B)

to the

on

in

(A,

Fig.

yoke

17)

(C)

on

feeding

is

5/8 inch

Replace presser spring

ulator.

down

until

Turn

presser bar spring regulator

the thread portion

casting.

NOTE:

lationship

probably

guide

ing

throat

less

the

Any

change

to the

was

set

When

plate,

means

not seated against

screw.

the presser foot

that

the foot should

than 1/64 inch

factory,

can

be

Presser foot

resting

on

When

the bare throat

the presser foot

spring bottoms, the

er

bar should not

and

presser spring reg-

screw

is

level with the

in the alignment of needle in

marks

on

the presser foot

the stop

screw

bed

is

(.4mm).

The

readjusted

bottom

of the presser bar

c3sting before lock-

lifted

move

if

off

the bare Fig.

back

only

slightly,

stop

screw

{E,

necessary, should

CHECK

at

back

of needle

slot

should cover

plate.

back

lift

bottom

of the needle

before the feeding foot spring bottoms.

is

raised

slot

by

should

head

re-

-Fig.

17)

this

material

clear

on

the yoke,

dimension

most

of throat plate land

so

that

the needle.

17

which

become

is

set

changed.

the feeding foot

The

main

press-

at

when

The

purpose of the feeding foot

the

same

amount

without pulling

on

the feeding foot spring usually gives a

pull.

pressure will tend to feed the

centimeter/kilograms.

Reducing

Torque

this

pressure will tend to feed the top ply

bottom

specifications given in

All

straps

(22-24cm/kg) unless otherwise noted.

specifications

must

be

secured

as

Special torque specifications for connecting rods,

parts

illustrations.

is

to

the

bottom

good

ply

TORQUE

REQUIREMENTS

this

and

eccentrics

All

tightly

make

the top

ply.

The

matching of

more.

catalog are

nuts,

as

possible, unless otherwise noted.

measured

must

bolts,

be

links,

19

and

bottom

5/8 inch

piles

and

more.

in

tightened to

screws,

etc

screws,

ply of cloth feed

{15.9mm)

setting

a strong feeding

Increasing

this

inch-pounds or

19-21

in.

. , without torque

etc.,

are

shown

on

lbs.

on

Page 20

SPECIAL

INSTRUCTIONS

Fig.

18

When

adjusting needle lever or replac-

ing

related

sequence

1.

as

Install 110

needle lever stud

NEEDLE

parts,

listed:

11

rings

follow instructions in

LEVER

(A,

Fig.

(B)

and

(C).

2.

With

positioned properly;

needle lever

(D)

in

insert

through hole in needle lever until

shoulder contacts the needle lever

the

word 11UP

position.

exists

3.

stud

top of

Install

(B)

machine

pression

push

ring

machine

11

on

While

stud

making

is

in the needle bar

with the front

bed.

temper

cups

and

load ring

(F)

onto stud (B), then

cups

through

bed.

sure

set

18)

onto

thrust

machine

collar

and

stud (B)

its

and

in the upright

no

binding

link,

(E)

secure

screw

and

opening

in

com-

in

•

Fig. 19

.045"

Fig.

( 1.14mm)

20

ALIGNING

4.

Install

being careful not to

Compress

ing

against stud

position using the rear

of

5.

To

pression,

and

Thrust

-

ring in reverse order, then tighten

set

6.

With

position,

its

stud.

their

of

ricating

MAINSHAFT

TO

thrust

collar

(C)

damage

screw

components

(G)

until

{B).

together

washer

Secure stud

set

bed.

check

loosen rear

.007

temper

remove

set

collar

(C)

inch (.08 -

load ring for proper

screw

(G)

screw

should spring out

.18mm).

screw.

in

11

on

stud

bearing

oil

supply hole

and

stud are secured in

indented 11UP

install

hook

sets

When

hook

proper positions, the proper

oil

will

be

channeled to stud for lub-

needle lever

(D).

CRANKSHAFT

onto stud

11011

ring.

by

tighten-

(H)

bottoms

(B)

screw

from

stud (B)

in

top

of

Compress

(B)

in

oiler

(J)

(K)

(B)

in

in top

com-

bed.

.003

load

rear

upright

so

of

amount

As

viewed

couplings

must

align with the

positioned

head

and

must

the

looking

down

from

rear

of

machine, spot

align with the spots in the looper drive crank

laterally

bed

casting as

flats

with

on

crankshaft

.045

inch

shown

(1.14mm)

in Fig.

(D)

20.

and

mainshaft (E). Mainshaft

clearance

20

screws

between

(A,

(B)

the

Fig.

and

right

19)

set

side of

in

the

screws

must

(C)

be

its

Page 21

ALIGNING

MAINSHAFT

TO

CRANKSHAFT

(Continued)

Looper

(.8mm)

tings are

ing sequence for best performance.

screws

__

21

screws

que

24cm/kg), then, torque screws

to

located in the

positioned with

cut

the

It

be

in

to position

screws.

clearance

Tighten spot

in.

screws

19-21

The

out in the

left

has

elongated

adjusted

top

of

drive

made,

(C) temporarily, to the crankshaft

lbs.

(A)

(22-24cm/kg).

and

(F)

in. lbs.

oil

drip plate

as

possible without touching.

by

the

as

Crank

between

it

is

screws

set

screws

to

19-21

(22 -24cm/kg).

oil

reservoir should

its

bed

casting,

mounting

loosening

oil

reservoir

required, retighten

(B,

Fig.

it

and

very

tip

important

(A)

temporarily, to the looper drive crank. Tighten

Loosen

(C).

in.

lbs.

(A,

Fig.

in the recessed

as

holes

(2)

screws

back

19)

mainshaft

spot

Re-tor-

(22

(A

and

21)

be

far to

and

can

(B)

cover

must

that

-

C)

be

positioned

(E)

as

shown

the couplings are tightened in the follow-

and

mainshaft.

laterally

in Fig.

Torque

with 1/32 inch

19.

Once

screws

these

(F)

to

set-

set

19

-

•

Fig.

21

21

Page 22

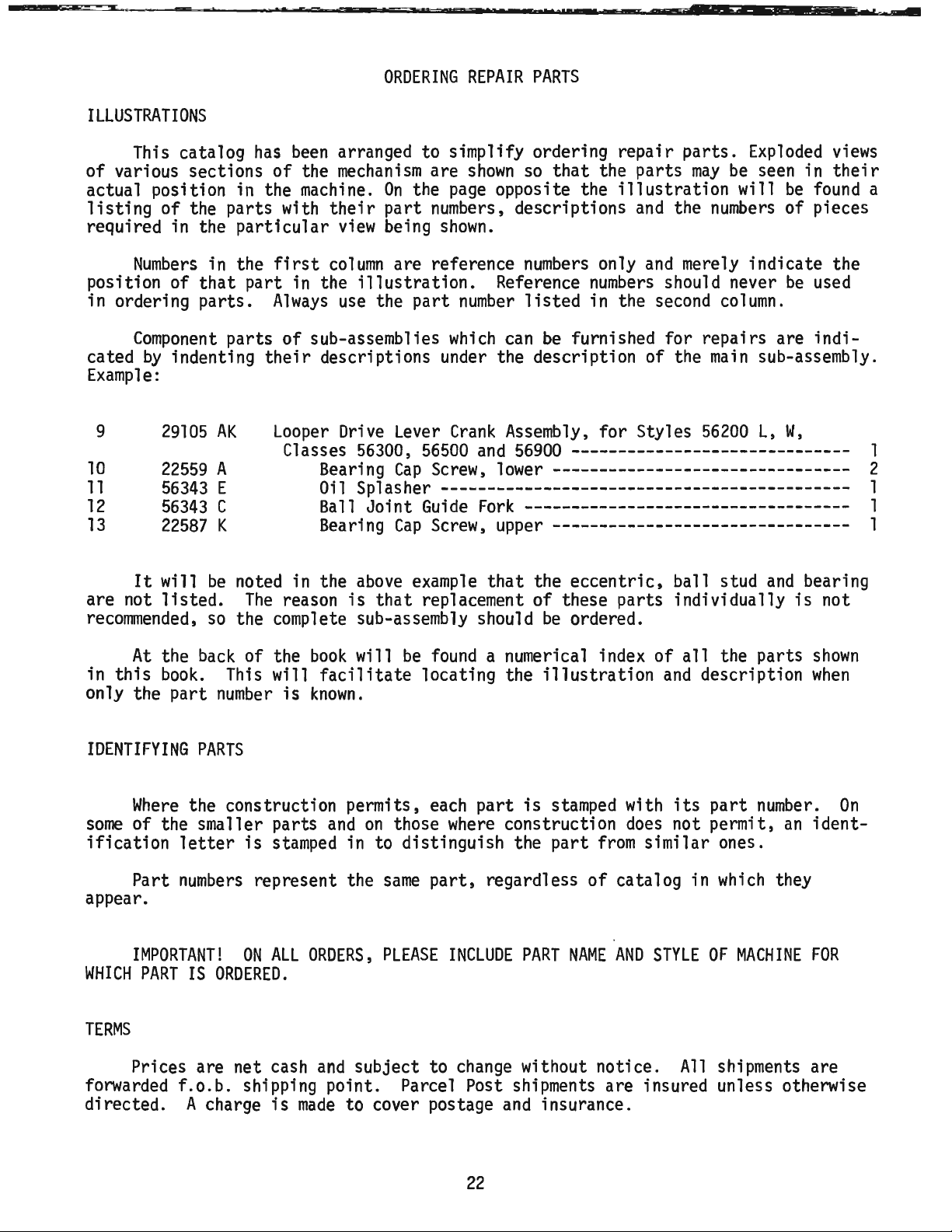

ILLUSTRATIONS

ORDERING

REPAIR

PARTS

This catalog

of

various sections

has

of

actual position in the

listing

required in the

position of

in ordering

cated

of the parts with

particular

Numbers

in the

that

part

parts.

Component

by

indenting

parts

first

Always

their

Example:

9

10

11

12

13

are not

It

29105

22559

56343

56343

22587

will

listed.

recommended,

AK

A

E

C

K

be

so

Looper

noted in the

The

the complete sub-assembly should

been

arranged to simplify ordering

the

mechanism

machine.

their

view

column

in the

of

sub-assemblies

illustration.

use

the

are

shown

On

the

page

part

numbers,

being

shown.

are reference

part

number

which

so

that

opposite the

descriptions

numbers

Reference

listed

can

be

only

numbers

in the

furnished for repairs are

the parts

descriptions under the description of the

Drive

Classes

Bearing

Oil

Ball

Bearing

reason

Lever

56300,

Cap

Crank

56500

Screw,

Assembly,

and

56900

for Styles

------------------------------

lower--------------------------------

Splasher--------------------------------------------

Joint

above

is

Guide

Cap

Screw,

example

that

replacement of these parts individually

Fork-----------------------------------

upper--------------------------------

that

the

eccentric,

be

ordered.

repair

parts.

may

illustration

and

the

numbers

and

merely indicate the

should never

second

main

56200

ball stud

Exploded

be

seen in

will

be

of

be

column.

sub-assembly.

L,

W,

and

views

their

found

pieces

used

indi-

bearing

is

not

a

1

2

1

1

1

At

the

back

in

this

book.

only the part

IDENTIFYING

Where

some

of the smaller parts

ification

Part

PARTS

the construction permits,

letter

numbers

of the

This

number

is

appear.

IMPORTANT!

WHICH

PART

IS

ON

ORDERED.

TERMS

Prices are net cash

forwarded

f.o.b.