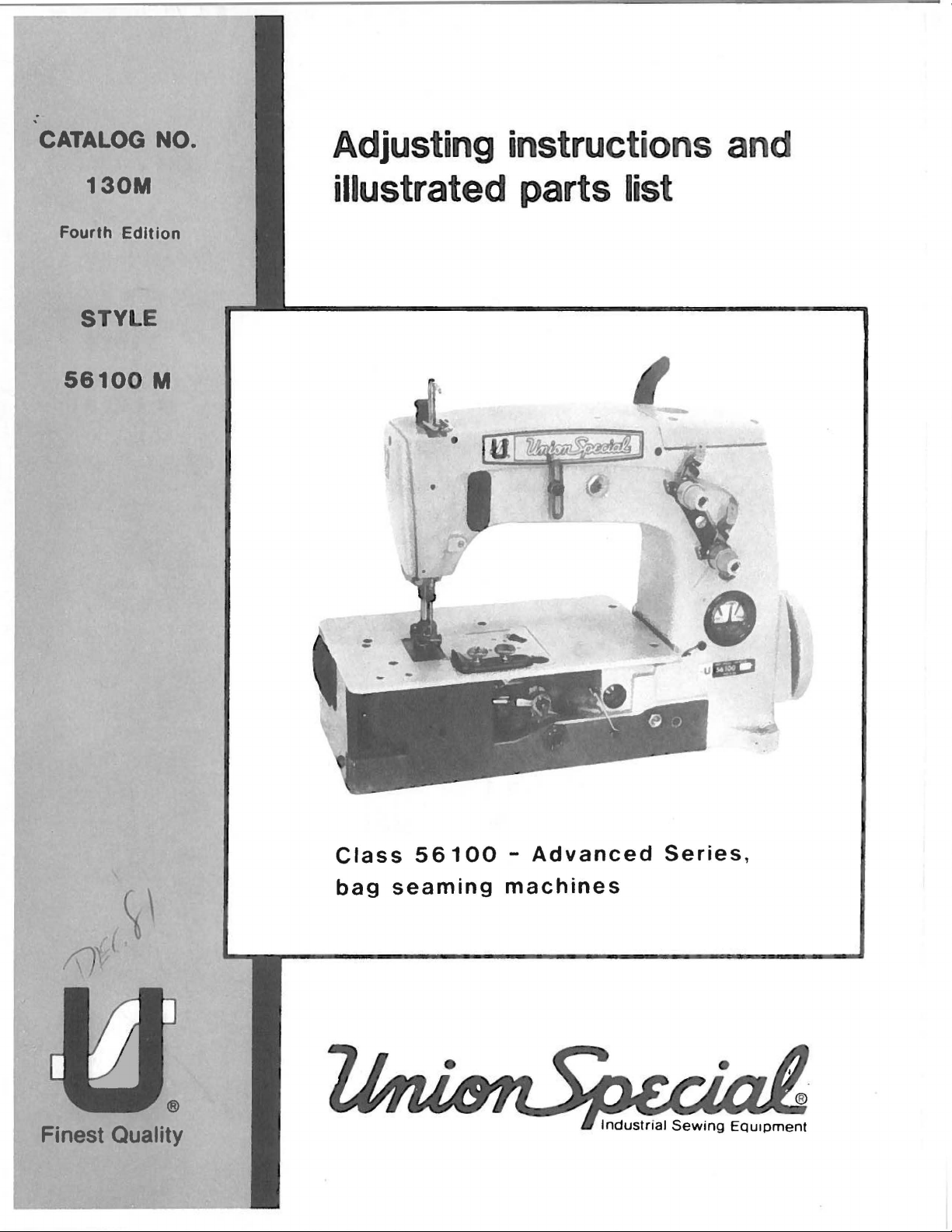

Page 1

CATALOG NO.

Adjusting instructio s and

130M

Fourth

STY

58100

illustrated parts list

Edition

LE

M

Class

bag

56100

seaming

-

Advanced

machines

\

I

®

Finest Quality

Series,

Page 2

CATALOG

NO.

130M

ADJUSTING

ILLUSTRATED

INSTRUCTIONS

PARTS

CL.ASS

ADVANCED

BAG

SEAMING

STYLE

Fourth

© 1965'

56100

Edition

By

Union

Special Corporation

LIST

56100

SERIES

MACHINE

M

1981

AND

FOR

Rights

Reserved

December.

2

in

All

1981

Countries

Page 3

IDENTIFICATION

OF

MACHINES

Each

stamped into the

The

Reference to

the

wheel

Advanced

needle bar drive,

ed

al looper

56100

UNION

serial

SPECIAL

style

number

is

directions,

machine

plate

stamped

such

carries

operator•s position while seated

is

counterclockwise,

as

high speed, single needle,

automatic

travel.

light

lubricating

Maximum

weight presser bar

system,

work

M Typical application medium

specification

to 5

machines

weight burlap bags.

401-SSa-1.

S.P.I.

and

6500

operating

on

R.P.M.

a duty cycle of

a Style

affixed to the

in the casting

as

right,

viewed

CLASS

left,

at

the machine.Operating direction of the hand-

from

DESCRIPTION

flat

bed

filtered

space to

right

MACHINE

For

seaming

Stitch

Maximum

sewing

range 3 1/2 to 7;

recommended

at

number,

right

at

front

the

front

the

right

which

right

or

end

machine.

and

needle bar driving

oil

return

of

pumps

needle bar, 8

STYLE

medium

and

large

speed

more

50%

than 5

or

more

on

this

of machine.

rear

rear,

of

High

base of

are given

machine.

throw, needle bearing

for

head

l/4

size

set

at 3 l/2

6000

S.P.I.

is

R.P.M.

Recommended

10%

less than

Class

machine

machine.

relative

mechanism,

and

base,

inches

cotton,

light

S.P.I.

sewing

maximum.

is

to

enclos-

later-

(209.6mm).

and

Seam

at 3 l/2

speed

for

NEEDLES

Each

needle

shank, point, length, groove,

the needle shank, denotes

and

eye. Collectively, type

given

on

the label

Recommended

point,

is

No.

2

available in sizes - 054, 200/080, 230/090, 250/100.

Selection of proper needle

should pass freely through needle

To

have

needle, or the type

complete order

has

both a type

and

finish

largest

and

size

of

all

needles

needle for Style

bag

length, double groove, spotted, short point,

size

eye

needle orders promptly

and

would

size

read: 111000

number

Needles,

size

number.The

and

other

details.

diameter of blade,

number

packaged

56100 M is

is

represent the complete symbol,

and

sold

Type

determined

in order to produce a

and

accurately

should

be

forwarded.

Type

144

type

measured

by

UNION

144

G.

by

size

filled,

G,

Size 200/080

number

The

denotes the kind

size

number,

midway

SPECIAL.

It

has a round

chromium

of thread used.

good

an

Use

stitch

empty

description

package,a sample

11

•

stamped

between

shank,

plated,

formation.

on

shank

which

round

and

Thread

label.

of

on

is

A

3

Page 4

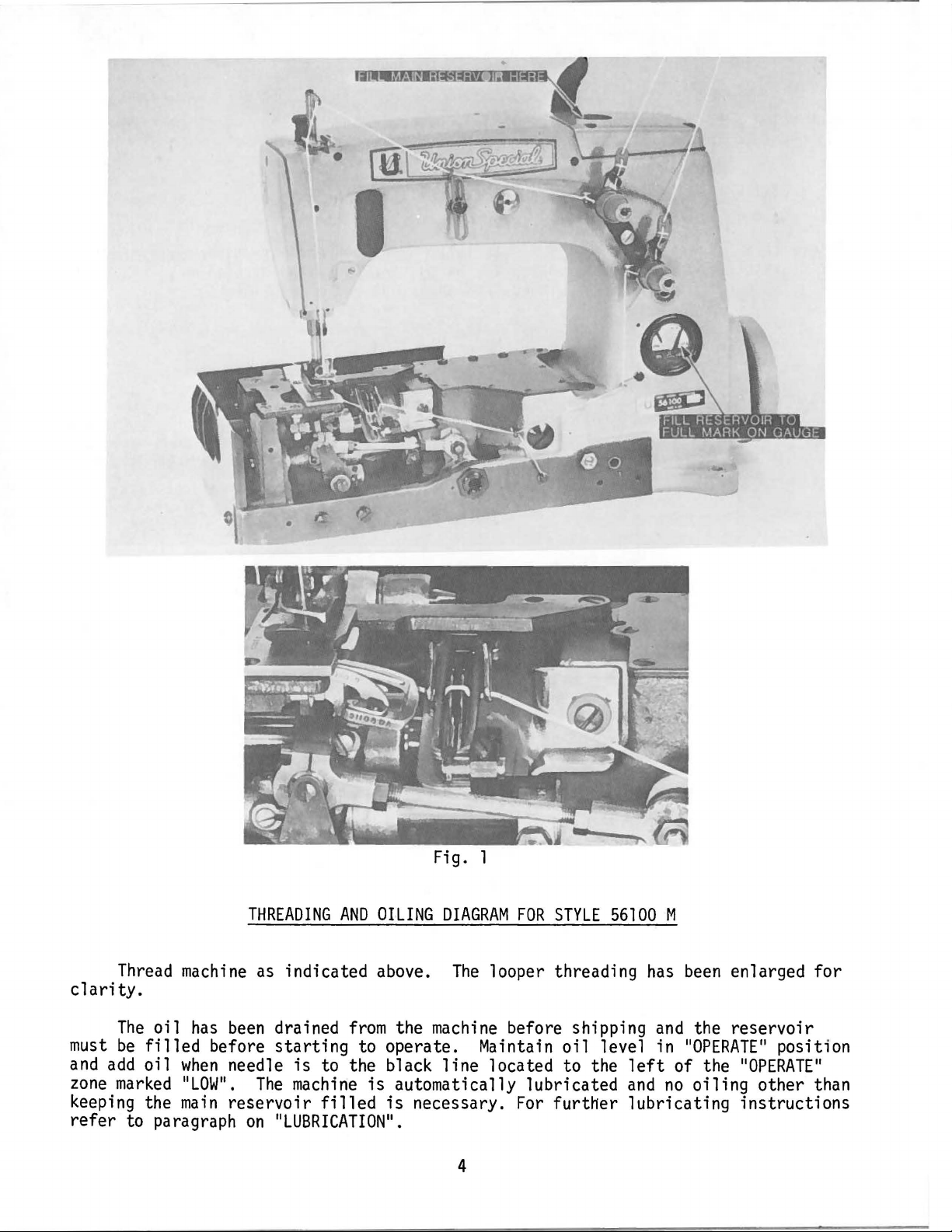

•

Fig. 1

Thread

machine

THREADING

as

indicated above.

AND

OILING

DIAGRAM

The

FOR

looper threading

STYLE

clarity.

The

oil

has

been

must

and

zone

be

filled

add

oil

marked

keeping the

refer

to paragraph

before

when

''LOW

main

drained

starting

needle

11

•

The

is

machine

reservoir

on 11LUBRICATION

from

the

machine

to operate. Maintain

to the black

is

automatically lubricated

filled

is

11

line

necessary.

•

4

before shipping

oil

located to the

For

further

56100

level in 110PERATE

M

has

been

and

the reservoir

left

of the 110PERATE

and

no

oiling

lubricating

enlarged for

11

other than

instructions

position

11

Page 5

TO

PREVENT

-

All

justing

-

Wear

-

All

THIS

SAFETY

PERSONAL

power

sources to the

or replacing

safety glasses.

shields

and

guards

SYMBOL

INJURY:

machine

parts.

MUST

SAFETY

RULES

A

CAUTION

INDICATES

be

in position before operating machine.

YOUR

MUST

PERSONAL

be

TURNED

SAFETY

OFF

before threading,

IS

INVOLVED.

oiling,

ad-

-DO

NOT

tamper

Use a straight

degrees

F.

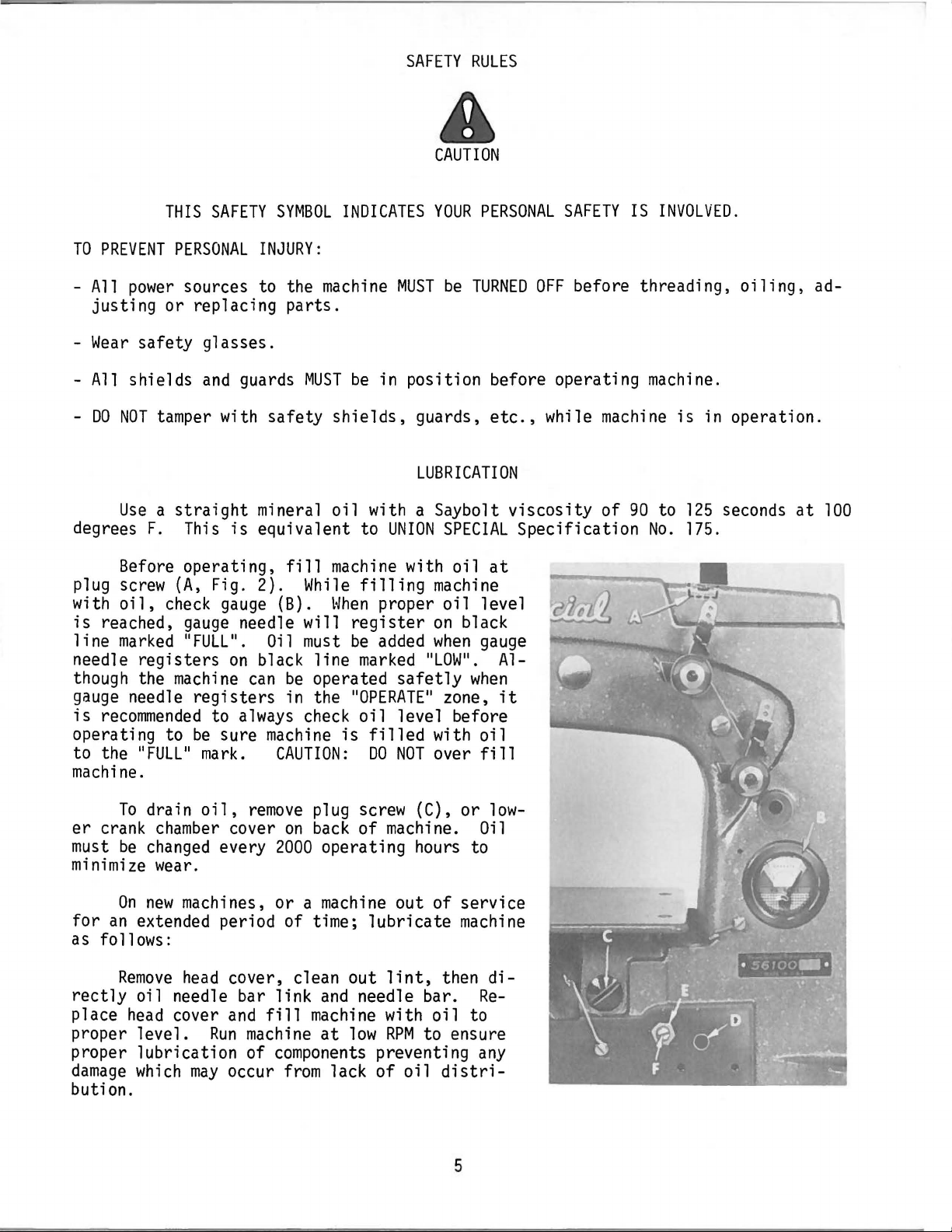

Before operating,

plug

screw

with

oil,

is

reached,

line

marked 11FULL

needle

though

gauge

is

needle

recommended

(A,

check

registers

the

machine

operating to

to the 11FULL

machine.

To

drain

er

crank

must

minimize

be

changed

chamber

wear.

with safety

This

is

Fig. 2).

gauge

gauge

needle will

11

•

on

registers

to

always

be

sure

11

mark.

oil,

cover

every

shields,

mineral

oil

equivalent to

fill

machine

While

(B).

When

register

Oil

black

can

must

be

be

line

operated

in the 110PERATE

check

machine

is

CAUTION:

remove

plug screw (C), or

on

back

2000

operating hours to

guards,

LUBRICATION

with a Saybolt

UNION

filling

proper

added

marked 11LOW

oil

filled

DO

SPECIAL

with

oil

machine

oil

on

black

when

11

safetly

11

when

zone,

level before

with

NOT

over

of machine.

etc.,

viscosity

Specification

at

level

gauge

•

Al-

it

oil

fill

low-

Oil

while

machine

of

90

to

No.

is

in operation.

125

seconds

175.

at

100

On

new

for

machines, or a

an

extended period of time;

machine

lubricate

out of service

machine

as follows:

Remove

rectly

place

head

proper level.

proper lubrication of

damage

which

head

cover, clean out

oil needle bar link

cover

and

Run

fill

machine

components

may

occur

from

and

needle bar.

machine

at

low

lack

lint,

with

RPM

then

oil

to ensure

preventing

of

oil

distri-

di-

Re-

to

any

bution.

5

Page 6

To

recalibrate

oil

gauge, follow

OIL

GAUGE

CALIBRATION

instructions

in sequence

as

listed:

- Place

-

Remove

machine

plug

screw

upright

(C,

on

a level surface.

Fig.

2)

and

tip

machine

voir.

Remove

Fill

-

-

Loosen

registers

lower crank

chamber

reservoir until

locknut

on

(E)

and

the black

oil

rotate

line

cover

is

even

on

with

back

calibrating

marked 11LOWU.

of machine.

bottom

screw

- Tighten locknut (E), then replace plug screw

-

Fill

machine

with

oil

until

gauge

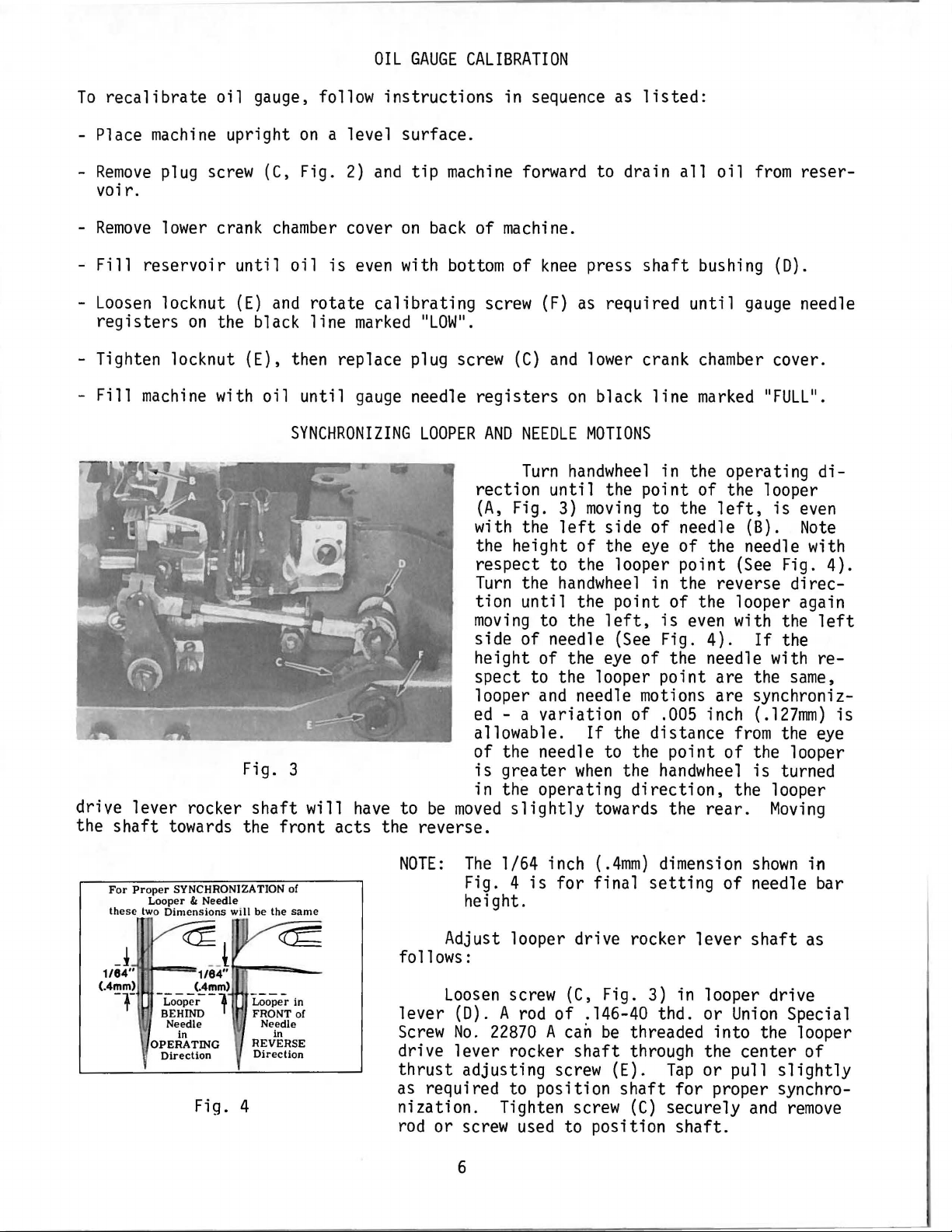

SYNCHRONIZING

needle

LOOPER

registers

AND

rection

(A,

with the

the height

respect to the looper point

Turn

tion

moving

side of needle

height of the

spect to the looper point are the

looper

edallowable.

of the needle to the point

Fig.

3

is

in the operating

drive lever rocker

the

shaft

towards the front acts the reverse.

shaft

will

have

to

be

moved

forward to drain

of

knee

press

(F)

as

required

(C)

and

lower crank

on

black

NEEDLE

Turn

Fig.

the

until

to the

MOTIONS

handwheel

until

3)

left

the point of the looper

moving

side of needle (B).

of

the

handwheel

the point of the looper again

left,

(See

eye

and

needle motions are synchroniz-

all

shaft

until

line

in the operating

to the

eye

of the needle with

in the reverse direc-

is

even

Fig.

of the needle with

a variation of .005 inch

If

the distance

greater

when

the

handwheel

direction,

slightly

towards the

oil

from

bushing

gauge

chamber

reser-

(D).

needle

cover.

marked 11FULL

left,

is

even

Note

(See

Fig. 4).

with the

4).

If

the

same,

(.127mm)

from

of

the

the looper

is

turned

the looper

rear.

Moving

11

•

di-

left

re-

eye

is

For

Prop

Looper

these

two Dimensions

er SYNCHRONIZATION of

& Needle

will be the

NOTE:

same

The

1/64 inch

Fig. 4

height.

is

for final

Adjust looper drive rocker

J

1/84"

(.4mm)

-r

~

-f~~~-l

Needle Needle

OPERATING

Di

1/84"

(.4mm)

in

rection

Fig. 4

J

~

~

----

Looper

in

FRONT of

in

REVERSE

Direction

follows:

Loosen

lever (D). A

Screw

No.

screw

rod

of .146-40 thd. or

22870 A can

drive lever rocker

thrust

as

adjusting screw (E).

required to position

nization. Tighten screw

rod

or

screw

6

used

(.4mm)

dimension

setting

(C,

Fig.

3)

be

threaded into the looper

shaft

through the center of

shaft

{C)

to position

shown

of

needle bar

lever

shaft

in looper drive

Union

Tap

or pull

for

proper synchro-

securely

slightly

and

shaft.

in

as

Special

remove

Page 7

SYNCHRONIZING

LOOPER

AND

NEEDLE

MOTIONS

(Continued)

Loosen

justing

re-tighten

of

looper connecting

No.

place hole of

The

st

(B).

clamp

drive lever

screw

ting with a

centerline

inch

ified.

which

(A,

looper

Looper

for

loosening nut

and

quired to

connecting

(E), then nut (D).

left

does

lock nut

screw

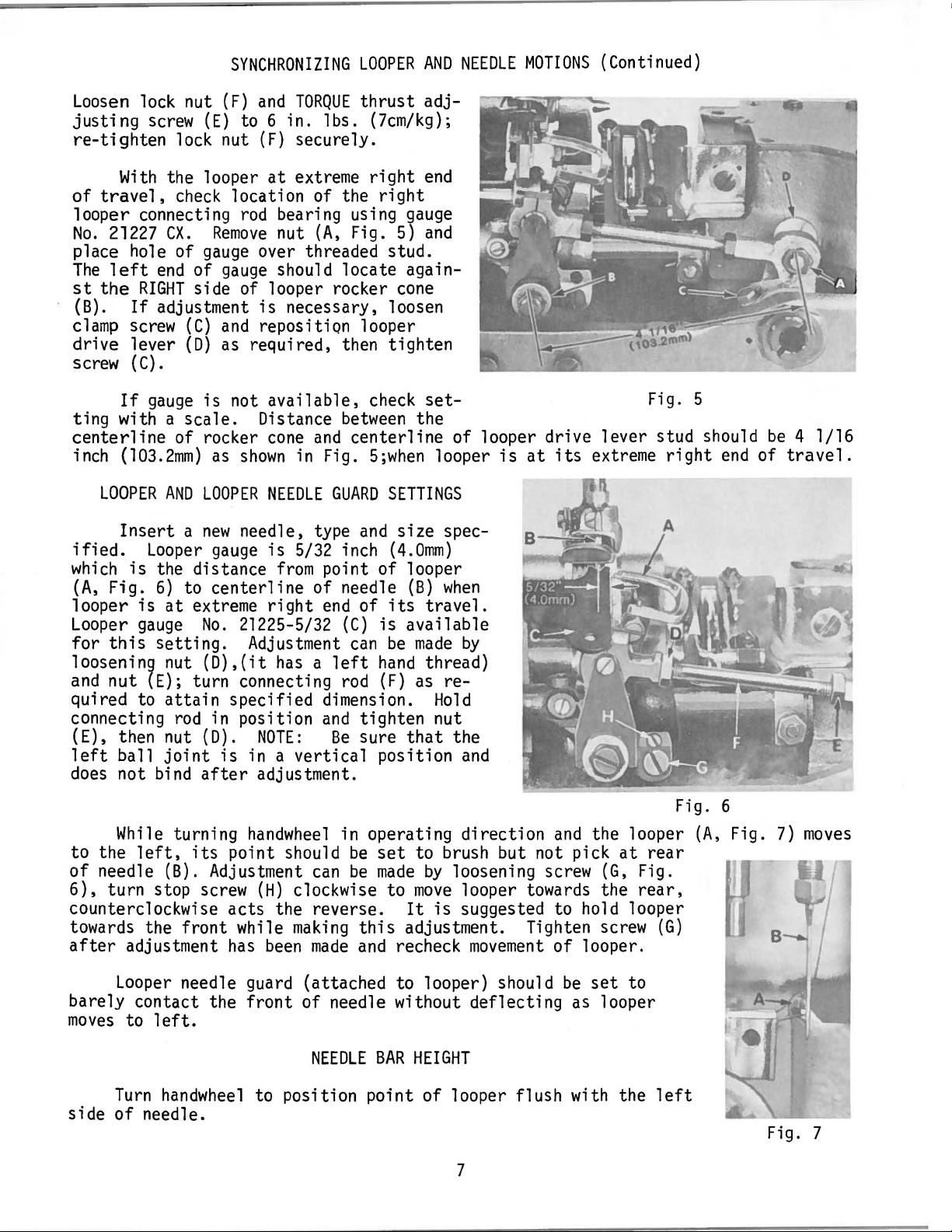

With

travel,

21227

left

the

If

LOOPER

Insert a new

Fig.

this

nut (E); turn connecting

ball

not bind

the looper

check

ex.

end

RIGHT

If

adjustment

screw

(C).

gauge

of rocker

(103.2mm)

AND

Looper

is

the distance

6)

is

at

gauge

setting.

attain

rod

joint

(F)

(E)

to 6 in. lbs. (7cm/kg);

lock nut

location of the

rod

Remove

gauge

of

gauge

side of looper rocker

(C)

and

(D)

as required, then tighten

is

not

scale.

as

shown

LOOPER

needle, type

gauge

to

centerline

extreme

No.

21225-5/32

(D),(it

specified dimension.

in position

is

after

and

TORQUE

(F)

securely.

at

extreme

bearing using

nut

over threaded stud.

should locate again-

is

necessary, loosen

reposition looper

available,

Distance

cone

in

NEEDLE

is

5/32 inch

from

of needle

right

Adjustment

has a left

NOTE:

in a

vertical

adjustment.

thrust

right

right

(A,

Fig.

5)

cone

check

between

and

centerline

Fig.

5;when

GUARD

point of looper

end

rod

and

Be

SETTINGS

and

size

(4.0mm)

of

its

(C)

is

can

be

hand

(F)

tighten nut

sure

position

adj-

end

gauge

and

set-

the

of looper drive lever stud should

looper

spec-

(B)

when

travel.

available

made

as

that

by

thread)

re-

Hold

the

and

is

at

its

extreme

Fig. 5

right

end

be

of

4 1/16

travel.

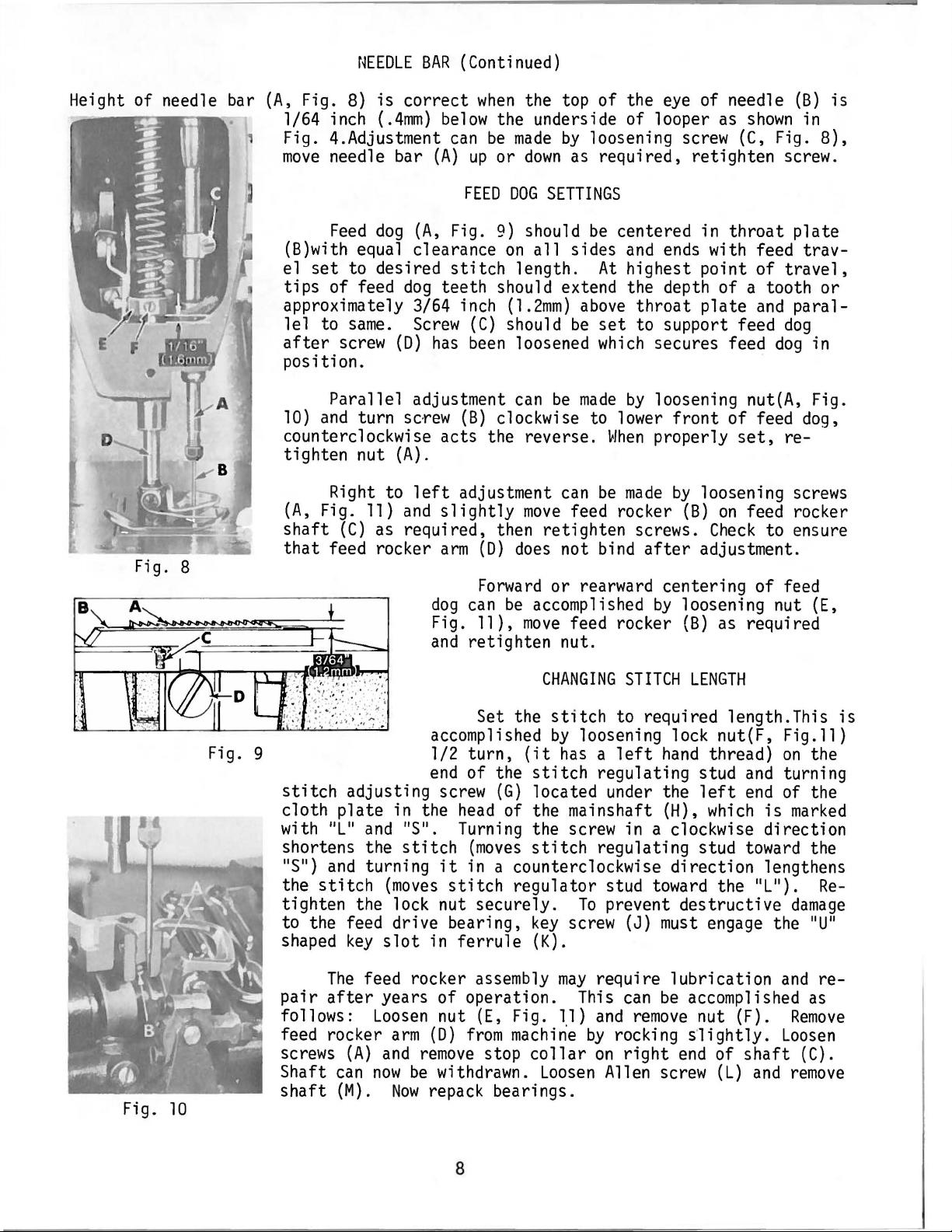

While

to the

of

needle (B). Adjustment

6),

turn stop screw

counterclockwise acts the reverse.

towards the front while

after

barely contact the

moves

side

adjustment

Looper

to

Turn

of

turning

left,

needle.

its

needle guard (attached to looper) should

left.

handwheel

handwheel

point should

(H)

clockwise to

making

has

been

front

to position point

in operating direction

be

can

be

made

of needle without deflecting as looper

NEEDLE

set

made

this

and

BAR

to brush but not pick

by

loosening screw

move

It

is

adjustment. Tighten screw

recheck

HEIGHT

of

looper flush with the

and

looper towards the

suggested to hold looper

movement

7

of

the looper

(G,

looper.

be

set

at

to

Fig. 6

rear

Fig.

rear,

(G)

left

(A,

Fig.

7)

moves

Fig. 7

Page 8

NEEDLE

BAR

(Continued)

Height of needle bar

Fig. 8

(A,

Fig.

8)

is

correct

1/64 inch

(.4mm)

Fig. 4.Adjustment

move

needle bar

Feed

dog

(A,

(B)with equal clearance

el

set

to desired

tips

of feed

dog

approximately 3/64 inch

lel

to

after

same.

screw

Screw

(D)

below

can

(A)

Fig.

stitch

when

up

FEED

the top of the

the underside of looper

be

made

or

down

DOG

SETTINGS

9)

should

on

all

length.

teeth should extend the depth of a tooth

(1.2mm)

(C)

should

has

been

loosened

position.

Parallel adjustment

10)

and

turn sc·

rew

(B)

can

be

clockwise to lower

counterclockwise acts the reverse.

tighten nut

Right to

(A,

Fig.

shaft

that

(C)

feed rocker

(A).

left

adjustment

11)

and

slightly

as

required, then retighten screws.

arm

dog

can

Fig. 11),

and

retighten nut.

move

(D)

does

Forward

be

accomplished

move

or rearward centering of feed

eye

by

loosening screw

of needle

as

shown

(C,

(B)

in

Fig.

as required, retighten screw.

be

centered in

sides

be

and

At

highest point of

above

throat

set

to support feed

which

made

by

When

can

be

made

feed rocker

not bind

after

feed rocker

ends

secures feed

loosening nut(A, Fig.

front

properly

by

(B)

by

loosening nut

(B)

throat

with feed

plate

trav-

travel,

plate

and

paral-

dog

dog

of feed dog,

set,

re-

loosening screws

on

feed rocker

Check

to ensure

adjustment.

as

required

is

8),

or

in

(E,

Fig.

Fig. 9 1/2 turn,

stitch

cloth plate in the

with 11L

shortens the

11

S

the

adjusting screw

11

and 11S

11

)

and

turning

stitch

11

stitch

(moves

tighten the lock nut securely.

to the feed drive bearing,

shaped

pair

follows:

feed rocker

screws

Shaft

shaft

key

slot

The

feed rocker assembly

after

years of operation. This

Loosen

arm

(A)

and

remove

can

now

be

(M).

Now

10

CHANGING

Set the

accomplished

end

of the

(G)

head

of the mainshaft (H),

• Turning the screw in a clockwise direction

(moves

it

in a counterclockwise direction lengthens

stitch

in

ferrule

stitch

by

(it

has a left

stitch

located under the

stitch

regulator stud

key

screw

(K).

may

nut

(E,

Fig.

11)

(D)

from

machine

stop

collar

withdrawn.

Loosen

STITCH

LENGTH

to required length.This

loosening lock nut(F,

hand

thread)

regulating stud

left

and

end

which

regulating stud

toward

To

prevent destructive

(J)

must

require

can

and

by

rocking s·

on

right

lubrication

be

accomplished

remove

end

nut (F).

lightly.

Allen screw

toward

the 11L

engage the 11U

of

shaft

(L)

and

Fig.ll)

on

turning

of the

is

marked

11

).

damage

and

Remove

Loosen

(C).

remove

the

the

Re-

11

re-

as

repack bearings.

is

8

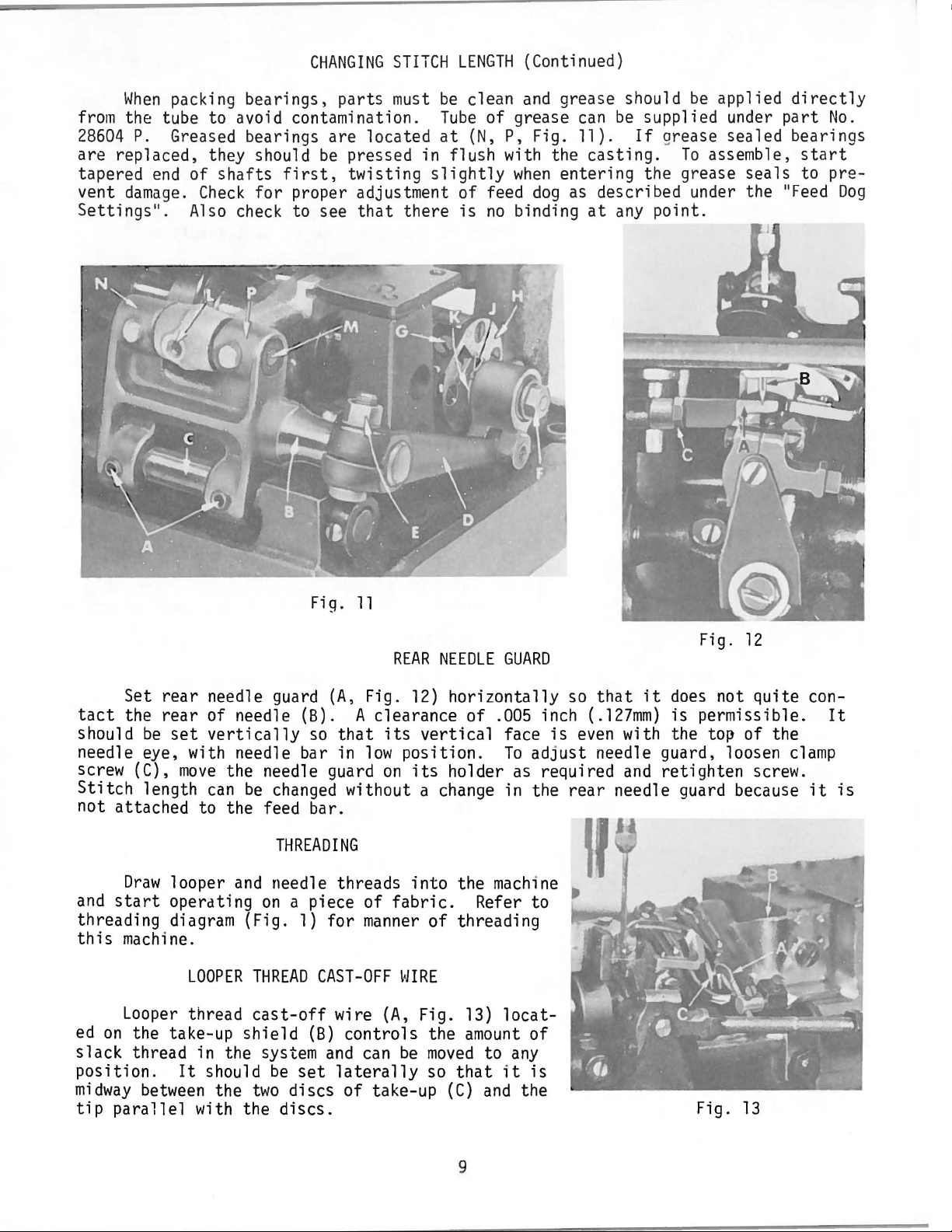

Page 9

CHANGING

STITCH

LENGTH

(Continued)

When

from

the tube to avoid contamination.

28604

are

replaced, they should

tapered

vent

damage.

Settings

packing bearings,

P.

Greased bearings are located

end

of

shafts

•

Check

Also

11

parts

be

first,

for

proper adjustment

check to see

must

be

clean

Tube

at

(N,

and

grease should

of grease

P, Fig. 11).

pressed in flush with the

twisting

that

slightly

there

of

is

when

feed

no

binding

entering the grease

dog

be

applied

can

be

supplied under

If

grease sealed bearings

casting.

To

assemble,

seals

as

described under the 11Feed

at

any

point.

directly

part

No.

start

to pre-

Dog

Fig.

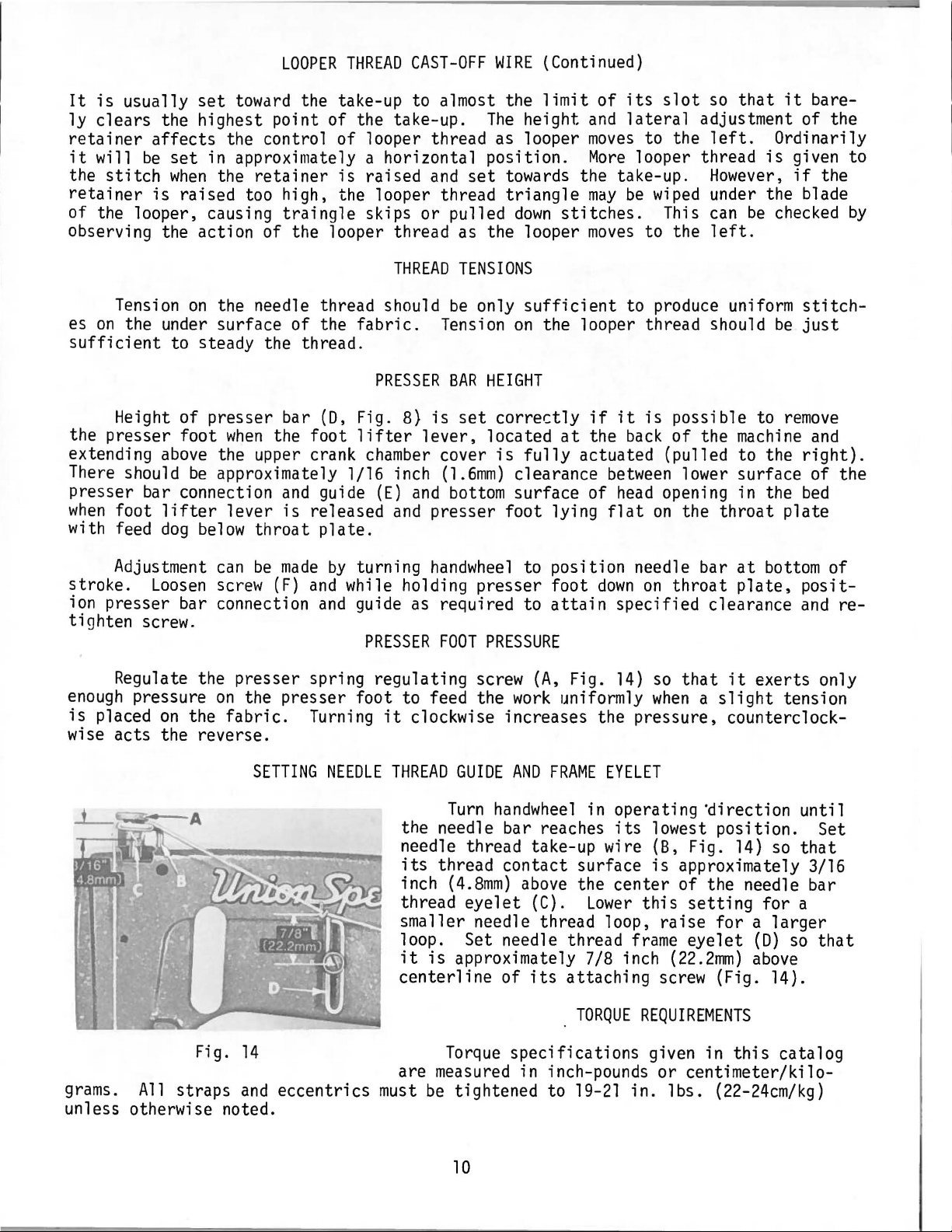

Set

rear

tact

the

should

be

needle guard

rear

of needle (B). A clearance of .005 inch

set

vertically

so

(A,

that

needle eye, with needle bar in

screw (C),

Stitch

move

length

the needle guard

can

be

changed without a change in the

not attached to the feed bar.

THREADING

Draw

and

start

threading diagram (Fig.

this

machine.

Looper

ed

on

slack

position.

midway

tip

parallel

looper

operating

and

needle threads

on

a piece of

1)

LOOPER

thread

the take-up

THREAD

cast-off

shield

thread in the system

It

between

should

the

with the

be

two

set

discs

discs.

for

CAST-OFF

wire

(B)

and

laterally

11

REAR

Fig.

its

low

position.

on

fabric.

manner

WIRE

(A,

controls

can

be

of

take-up

NEEDLE

12)

horizontally

vertical

its

holder

into

the

Refer to

of

threading

Fig. 13)

the

amount

moved

so

that

(C)

GUARD

face

To

as

machine

locat-

of

to

any

it

and

the

so

is

even

adjust

required

rear

is

that

it

(.127mm)

Fig.

does

is

permissible.

not

12

quite

with the top of the

needle guard, loosen

and

retighten

screw.

needle guard because

Fig.

13

con-

clamp

it

It

is

9

Page 10

It

is

usually

ly

clears

retainer

it

will

the

stitch

retainer

be

set

towdrd

the highest point of the take-up.

affects

set

when

is

raised too high, the looper thread

the control of looper thread as looper

in approximately a horizontal position.

the

retainer

of the looper, causing

LOOPER

traingle

THREAD

CAST-OFF

WIRE

the take-up to almost the

The

height

is

raised

and

set

towards the take-up.

triangle

skips or pulled

down

(Continued)

limit

stitches.

observing the action of the looper thread as the looper

of

its

and

lateral

moves

More

may

be

moves

slot

so

that

adjustment of the

to the

left.

looper thread

However,

wiped

This

to the

under the blade

can

be

left.

it

bare-

Ordinarily

is

given to

if

the

checked

by

THREAD

Tension

es

on

the under surface of the

sufficient

on

the needle thread should

to steady the thread.

fabric.

PRESSER

Height of presser bar

the presser foot

extending

above

There should

when

the foot

the upper crank

be

approximately l/16 inch

presser bar connection

when

with feed

stroke.

foot

lifter

dog

Adjustment

Loosen

lever

below

can

screw

throat

be

(F)

ion presser bar connection

and

is

released

made

and

(D,

Fig. 8)

lifter

chamber

guide

(E)

and

and

plate.

by

turning

while holding presser foot

and

guide

as

tighten screw.

PRESSER

Regulate the presser spring regulating screw

enough

is

pressure

placed

on

the

on

the presser foot to feed the

fabric.

Turning

it

clockwise increases the pressure, counterclock-

wise acts the reverse.

TENSIONS

be

Tension

BAR

is

set

lever,

cover

(l.6mm)

only

sufficient

on

the looper thread should

HEIGHT

correctly

located

is

fully

clearance

at

bottom surface of

presser foot lying

handwheel

required to

FOOT

to position needle bar

attain

PRESSURE

(A,

Fig.

work

uniformly

to produce uniform

be

if

it

is

the

possible to

back

of

the

remove

machine

actuated (pulled to the

between

head

flat

down

lower surface of the

opening in the

on

the

throat

at

bottom

on

throat

plate,

plate

specified clearance

14)

so

that

it

exerts only

when a slight

tension

stitchjust

and

right).

bed

of

positand

re-

SETTING

NEEDLE

THREAD

GUIDE

Turn

AND

FRAME

handwheel

the needle bar reaches

needle thread take-up wire (8, Fig.

its

thread contact surface

inch

thread

(4.8mm)

eyelet

above

(C).

smaller needle thread loop,

loop. Set needle thread

it

is

approximately 7/8 inch

grams.

All

Fig.

straps

14

and

eccentrics

centerline

are

measured

must

be

Torque

tightened to

of

its

specifications

in inch-pounds or centimeter/kilo-

unless otherwise noted.

10

EYELET

in operating

its

lowest position. Set

is

~irection

14)

so

until

that

approximately 3/16

the center of the needle bar

Lower

this

raise

frame

setting

for a larger

eyelet

(22.2mm)

for a

(D)

above

so

attaching screw (Fig. 14).

TORQUE

19-21

REQUIREMENTS

given in

in.

lbs.

this

(22-24cm/kg)

catalog

that

Page 11

All

nuts,

tightly

bolts,

as

possible, unless otherwise noted. Special torque specifications

necting rods,

screws,

links,

etc.,

screws,

TORQUE

REQUIREMENTS

without torque

etc.,

are

shown

(Continued)

specifications

on

part

illustrations.

must

be

secured

of

as

con-

When

adjusting needle lever or replacing related

sequence as

l.

Install

needle lever stud

(C).

2.

With

positioned properly;

through hole

parts,

follow

listed:

"0"

rings

needle lever

in

needle lever until

instructions

(A,

Fig.

(B)

and

(D)

in

machine

insert

shoulder contacts the needle lever

the

3.

word

position.

exists

stud

top of

Install

ring

"UP"

on

stud

While

making

in the needle bar

{B) with the

machine

front

bed.

temper load ring

and

cups

through opening in

is

sure

set

SPECIAL

INSTRUCTIONS

NEEDLE

in

15)

onto

thrust

collar

and

stud (B)

its

and

in the upright

no

binding

link,

secure

screw in

(E)

and

compression

machine

LEVER

cups

bed.

(F)

onto stud

Fig.

15

(B),

then

push

4.

Install

Compress

thrust

collar

components

against stud (B). Secure stud

bed.

5.

To

check

compression,

stud

top of

spring out

.

18mm).

temper

(B)

and

bed.

Compress

remove

loosen

Thrust

.003-

load ring

.007 inch

load ring in reverse

order, then tighten

6.

With

oiler

supply hole

and

positions,

will

indented

upright

(J)

position,

so

"UP"

its

(K)

stud are secured in

the proper

be

channeled to stud

on

install

hook

of stud.

cating needle lever

As

couplings

must

align with the

viewed

must

looking

down

align with the spots in the looper drive crank (B)

flats

(C)

onto stud (B) being careful not to

together

for

screw

rear

collar

rear

{G)

set

(C)

set

stud (B) in

bearing

sets

in

When

their

amount

for

(D).

ALIGNING

from

on

crankshaft

by

tighening screw

(B)

in position using the rear

(G)

until washer

proper

from

screw in

should

(.08-

screw.

oil

hook

proper

of

oil

lubri-

MAINSHAFT

TO

CRANKSHAFT

rear of machine, spot screws

(D)

and

mainshaft (E).

Fig.

(A.

damage

(H)

set

screw

16

Fig.

16)

and

set

"0"

ring.

bottoms

in

in

screws

top of

the

(C)

ll

Page 12

ALIGNING

MAINSHAFT

TO

CRANKSHAFT

(Continued)

Fig.

.045"

17

( 1. 14mm)

•

Mainshaft

with

the

right

casting

be

positioned

(.8mm)

(E)

as

tings are

the couplings are tightened

ing sequence

must

.045

inch

side

as

Looper

be

positioned

(1.14mm)

of

its

head

shown

in Fig. 17.

drive crank (8, Fig.

laterally

clearance

shown

made,

between

in Fig. 16.

it

is

very important

for

best performance.

Tighten spot screws

laterally

clearance

and

the

16)

with l/32 inch

it

and

mainshaft

Once

(A)

these

in

the follow-

temporarily,

to the looper drive crank. Tighten

screws

and

21

screws

screws

em/kg), then, torque screws

19-21

(C)

mainshaft.

in.

lbs.

(A)

and

(F)

to

in.

temporarily, to the crankshaft

Torque

(22 -24

set

19 -21

lbs.

(22-

screws

em/kg).

(F)

Loosen

screws (C). Re-torque

in.

lbs.

24cm/kg)

(22 -24

(A

and

.

between

bed

must

setthat

set

to

19

spot

C)

to

-

Fig.

18

CD

•

ed

·

in the

tioned with

out in the

as

possible without touching.

elongated

usted

of the

tion

The

oil

drip plate

oil

reservoir should

its

tip

bed

casting,

mounting

by

loosening (2) screws

oil

reservoir

as

required, retighten screws.

holes

{A,

in the recessed cut

as

far

and

back

cover to posi-

Fig.l8)

be

posi-

to the

It

has

can

be

(B)

in top

locat-

left

adj-

12

Page 13

Before

this

satisfaction

and

is

not

to you.

machine

and

sewing

left

the factory

durability

at

all

it

times.

properly, see the chart

was

below

adjusted

If,

however,

for

and

inspected to give

the

machine

suggestions

which

has

been

may

you

the utmost

readjusted

prove

beneficial

Needle

Condition

loop

too

small

SKIPPED

Frame

set

Needle

bottom

formed

The

because

needle

Needle

needle thread guide

too

low

thread stretched

of

till

needle thread creased

it

is

thread pinched

STITCHES

Causes

stroke,

stretch

is

too

Raise

guide

at

Lower

loop not and/or reduce needle tension

relieved

Use

tight

and

lower

Cures

frame

slightly.

frame

oversize ball

frame

hot reduce tension

by

Drop

needle

needle guard, collapsing

needle loop

Thread

twisting a

round

Keep

needle

needle possible,

tension to a

left

twist thread

Needle

needle grooves,

thread

sticking

due

to heat

in

Use

lubricant

I

needle thread

thread eyelet

eye

needle

guard

loop

keep

eyelet,

slightly

as

small

needle thread

minimum.

on

thread

needle,

as

Use

a

Looper

misses needle loop

as presser foot

off a seam

Needle

but brushed

·

by

Looper

when

match

Needle

loop

formed

out of the

looper

misses needle loop

operator

seams

or

misses

looper thread

is

coming

properly

is

trying to

ends

triangle

side

way

on

Needle

to

Material

front

Needle

does

not

form

needle loop properly

is

not held

of

seam

deflecting

operator

Needle

Needle

erator

back

matching

bar

set

deflecting

who

may

on

material while feed

seams

garment

Looper

thread too loose, not Increase looper thread

making a good

Needle

the rear

point or

pulling

being deflected to

by

burr

due

to operator

on

material,

needle glancing

coming

on a seam

rise

and

is

towards

too high

toward

be

holding

or

ends

triangle

on

needle back.

off

when

enough

Increase looper

to 1/32 inch

down

in

See

if

presser bar

flagging ing

Use

sharp point needle

op-

Lower

Do

on

needle bar

not hold

material. Properly adjust

and

maintain a proper

of feeding pressure

operator

does

tension

Do

not pull material

Use

stop needle

or

off

seam.

burr

gauge

is

l/64

stick-

slightly

back

excessively

on

foot

so

not hold

at

back

the

a sharp needle to

from

glancing

Check

needle

for

NOTE:

More

detailed information concerning the double locked

available under "Stitch Formation,

Type

401".

13

stitch

(stitch

type

401)

is

Page 14

ILLUSTRATIONS

ORDERING

REPAIR

PARTS

This catalog

views

in

be

of various sections of the

their

actual

found a listing

has

been

position

of the

of pieces required in the

Numbers

position

ordering

Component

cated

ly.

48

49

50

51

52

by

Example:

29105

22587

56343

56343

22559

It

will

ing are not

not

recommended,

At

in

this

book.

only the

in the

of

that

parts.

parts

indenting

AK

K

c

E

A

be

listed.

the

back

This will

part

number

first

part

in the

Always

of sub-assemblies

their

Crank

noted in the

The

so

the complete sub-assembly should

of

the

is

arranged to simplify ordering

mechanism

in the machine.

parts

with

particular

column

are reference

illustration.

use

the

part

descriptions

their

view

number

are

shown

On

the

page

part

numbers,

being

shown.

numbers

Reference

listed

which

can

be

under the description

Assembly, looper driving

Screw,

beari~g

Guide, ball

Splasher,

Screw, bearing

reason

book

above

will

example

is

be

facilitate

cap

(upper)

joint--------------------------------------

oil

-----------------------------------------cap

(lower)

that

that

replacement

found

a numerical index of

locating the

the

illustration

known.

repair

so

that

opposite the

descriptions

only,

numbers

in the second

furnished

parts.

the

parts

illustration

and

and

merely

should never

column.

for

repairs

of

the

main

Exploded

may

the

indicate

be

are

sub-assemb-

lever------------------------

-----------------------------

-----------------------------

eccentric,

of

these

be

ordered.

ball

parts

all

and

description

stud,

and

individually

the

parts

be

used

seen

will

number

the

in

indi-

1

2

1

1

2

bear-

is

shown

when

some

Where

of the smaller

the construction permits, each

identification

Part

numbers

pear.

IMPORTANT!

WHICH

PART

IS

Success in the operation of these machines

UNION

sidiaries

proved

cy

SPECIAL

scientific

and

durability

and

Prices are net cash

forwarded

wise

directed.

f.o.b.

parts,

letter

is

represent the

ON

ALL

and

on

stamped

ORDERS,

IDENTIFYING

those

in to

same

PLEASE

where

distinguish

part,

INCLUDE

PARTS

part

is

stamped with

construction

regardless

PART

the

part

of

NAME

its

does

not permit,

from

similar

catalog in

AND

STYLE

part

OF

ORDERED.

USE

repair

parts

authorized

principles,

GENUINE

as

furnished

distributors.

and

are

REPAIR

by

They

made

with utmost

PARTS

can

be

secured only with genuine

the

Union

Special Corporation,

are designed according to the

precision.

Maximum

are assured.

TERMS

and

subject to change without

notice.

All

shipping point. Parcel Post shipments are insured unless

A charge

is

made

to cover postage

and

insurance.

number.

an

ones.

which

they ap-

MACHINE

its

FOR

sub-

most

ap-

efficien-

shipments are

other-

On

14

Page 15

EXPLODED

VIEHS

AND

DESCRIPTION

OF

PARTS

15

Page 16

®~

54~

58

-

_,

21

16

Page 17

MAIN

FRAME,

CAST-OFF

PLATE

AND

MISCELLANEOUS

COVERS

Ref.

10

ll

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

*48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

*

No.

l

2

3

4

5

6

7

8

9

For

old Style

Part

No.

22829

21375

98

52

22593

51158

51104

50-216 Blk.

51157

21657

22528

J87 J

77

51204

51104

51204

22798

51204

52958

25

51482

22569

56382

56382

56382

22585

56393

7947

56393

35731

51294

660-342

22513

95

660-694

22889

539

20

22848

22894

56382

56382

22548

56382

56382

22524

22585

22839

51124

87

56180

51280

22570

56168

51125

906

22829

56382

56382

59493

666-214

22848

56382

56382

56382

56382

22524

AV

A

A

D

F

H

E

c

H

A

A

B

s

A

c

A

N

D

c

A

R

A

E

E

D

H

G

A

D

B

J

A

E

J

A

AA

L

y

AB

56180

Screw

----------------------------------------------------------------------Guard,

Screw

Eyelet,

Screw

Eyelet, take-up

Wire,

Pin,

Support,

Washer

Screw

Screw

Screw

Support, auxiliary

Cast-off,

Support,

Screw

Wire,

Eyelet,

Screw

Guard

Screw

Cover,

Gasket

Screw

Clamp,

Nut

Block,

Plate,

Screw

Lockwasher

Screw

Screw, plug

belt

-----------------------------------------------------------------

----------------------------------------------------------------------frame

looper thread

-----------------------------------------------------------------------

-------------------------------------------------------------

cast-off

dowel

---------------------------------------------------~----------

------------------------------------------------------------------

cast-off

----------------------------------------------------------------------

-----------------------------------------------------------------------

-----------------------------------------------------------------------

-----------------------------------------------------------------------

auxiliary---------------------------------------------------------

cast-off

----------------------------------------------------------------------cast-off

frame

--------------------------------------------------------------

looper thread

-----------------------------------------------------------------------

-----------------------------------------------------------------------

----------------------------------------------------------------------head

Felt-------------------------------------------------------------------

-----------------------------------------------------------------

----------------------------------------------------------------------

-----------------------------------------------------------------------

head

oil

tube

------------------------------------------------------------------------head

oil

tube

presser bar connection guide

-----------------------------------------------------------------------

------------------------------------------------------------------

-----------------------------------------------------------------------

-----------------------------------------------------------------

Gasket, needle lever eyelet

Screw, adapter

Eyelet,

Washer

Screw

Screw, needle lever

Gasket

frame

----------------------------------------------------------------------

-----------------------------------------------------------------------

----------------------------------------------------------------------

--------------------------------------------------------------

needle thread

Cover, lower crank

Screw

----------------------------------------------------------------------Gasket

Cover, top

Screw

Screw

Screw,

Throat Plate

Screw

Support,

Screw

---------------------------------------------------------------------oil

reservoir

-----------------------------------------------------------------------

----------------------------------------------------------------------throat

plate

----------------------------------------------------------------

-----------------------------------------------------------------------

throat

Pin,

plate

dowel

-------------------------------------------------------------

-----------------------------------------------------------------------

Holder, needle guard

Guard, needle

Screw

Screw

----------------------------------------------------

---------------------------------------------------------------

------------------------------------------------------------------

Cover, looper drive

Gasket

Pump

Screw

Cover, back,

Gasket

Block, clamping

Plate,

Screw

A,

use

----------------------------------------------------------------------

Assembly,

Felt

oil,

-------------------------------------------------------------------

-----------------------------------------------------------------------

oil

reservoir

----------------------------------------------------------------------

-------------------------------------------------------------

oil

drip

-------------------------------------------------------------

-----------------------------------------------------------------------

countersunk

head

Description

-------------------------------------------------

wire

------------------------------------------------------

cast-off-------------------------------------------------

wire

------------------------------------------------------

-------------------------------------------------

--------------------------------------------------------

mounting

-----------------------------------------------

-----------------------------------------

----------------------------------·

·

--------------

-------------------------------------------------

thrust

chamber

collar

and

stud

----------------------------------

---------------------··----------------------------

----------------------------------------------------

support

-------------------------------------------------

-------------------------------------------------------

--------------------------------------------------------

·

shaft

---------------------------------------------------

-------------------

base----------------------------------------------------

--------------------------------------------------

screw

No.

80.

Amt.

~

2

l

2

l

2

2

l

2

l

1

l

2

l

l

1

1

l

l

l

2

1

2

l

l

1

l

l

l

l

2

l

l

3

l

l

l

l

l

l

2

l

l

4

l

l

8

3

3

l

2

l

2

l

l

l

l

2

l

l

l

l

9

l

l

l

l

2

17

Page 18

16

\

1~1\_

lp

l

~

-l

I

18

Page 19

MAIN

FRAME,

BUSHINGS,

OIL

GAUGE

AND

MISCELLANEOUS

OILING

PARTS

Ref.

No

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

\

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

.

22

22539

56394

11635

61256

56394

56394

63494

63494

63494

56390

57890

22569

56390

56390

56382

56382

56382

22541

22733

56382

56301

22839

56381-219

51281

35772

22760

22845

22848

51282

56170

51154

56393

56393

56393

56154

51257

57836

56390

56193

52942

56190

57842

35897

56390

21657

Part

No.

793

R

A

B

660-221

G

c

B

K

660-455

G

F

E

B

B

H

660-665

J

AC

90

c

B

c

E

M

c

24

X

25

AC

H

A

B

80

20

AH

E

95

w

T

.L

AA

B

666-259

50-895

A

w

B

BV

G

X

Blk.

Description

Screw

Screw, plug

Shaft,

Nut

"0"

Washer

Float

Rod,

Gauge

Gasket

Housing, crankshaft bushing, includes bushing

Screw

Washer,

Bearing, needle,

Ring,

Plate,

Screw

Gaske

Cover, upper crank

Screw

Screw, plug

Gasket

Cloth Plate

Screw

Guide,

Screw

Cover, cloth

Screw

Screw

Washer

Shield,

Wire, needle thread take-up

Bushing, needle bar (upper)

---------------------------------------------------

---------------------------------------------

oil

gauge

adjusting

------------------------------

----------------------------------------------------Ring

------------------------------------------------

--------------------------------------------------

Assembly,

oil

gauge

Assembly,

Ring,

Washer,

Nut

------------------------------------------------

oil

gauge

connecting

oil

-------------------------------------

oil

------------------------------------------

spring

-------------------------------------

-------------------------------

-------------------------------

--------------------------------------------------

-----------

--------------------------------------------------thrust

pilot

oil

-----------------------------------------thrust

---------------------------------

---------------------------------------------

and

baffle

-----------------------------------

---------------------------------------------------

t -

------------------------------------------------chamber

------------------------------

---------------------------------------------------

---------------------------------------------

------------------

-

-------------------------------

---------------------------------------------

--------------------------------------------------edge

---------------------------------------------

---------------------------------------------------

plate

Spring

Wa

Screw

Screw

---------------------------------------------

sher, spring

----------------------------------------------

----------------------------------------------

--------------------------------------

-------------------------------------

---------------------------------------------------

---------------------------------------------------

--------------------------------------------------

oil,

end

and

back-------------------------------

-----------------------------

-----------------------------

Screw -·--------------------------------------------------

Pad,

felt

Pump

Bushing, needle bar (lower)

Bushing, presser bar (lower)

Bushing, feed rocker

Bushing, mainshaft

Felt

Bushing, looper rocker

Felt,

Bushing, looper drive

Bushing, mainshaft (intermediate)

Bushing, looper drive lever

Filter,

Bushing, mainshaft (inner

Bushing, tension release

------------------------------------·-----------

Assembly,

Fe

l t

oil,

head--------------------------------

-----------------------------------------------

-----------------------------

----------------------------

shaft

(left)

------------------------------

-------------------------------

---------------------------------------------------machine

base

shaft

(front)

lever

----------------------------

-----------------------------shaft

(front)

---------------

-----------------------

oil

intake

shaft

-------------------------------------right)

lever

(rear)

----------------

------------------------

shaft

--------------------

Amt.

~

1

1

1

1

1

2

1

1

1

1

1

1

1

3

4

2

2

1

2

1

1

4

1

2

1

2

1

2

1

1

3

3

1

3

3

3

1

1

1

1

1

1

1

1

1

2

· 1

1

2

1

1

1

1

1

1

1

19

Page 20

~~

2

6

0 9

78

'

0

10

11

12

~11

TORQUE

19-21

in.

(22-24

em/kg)

TO

Ibs.

1

~

13

NOTE:

C

ut-out

and

aRse

43

mblin

to

in

Ref.

be

up

No.

when

9

42

20

Page 21

CRANKSHAFT,

NEEDLE

LEVER

AND

LOOPER

DRIVING

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

Part

No.

56

51217

27-435

56358

22768

22586

51250

51250

660-625

56350

56350

660-614

29348

77

56354

51254

22562

22564

52336

W0-3

660-215

56350

29066

22599

51216

51216

56316

22574

61321

57821

56321

22894

660-202

57847

95

51247

22894

29476

51216

51216

51216

56316

12934

22894

22894

56343

22653

29105

22587

56343

56343

22559

52942

660-202

56390

660-665

56390

56342

CL-21

52942

56342

c

R

F

D

E

F

AF

D

K

A

A

D

R

G

N

p

L

N

AB

J

LN

M-625

M-626

M-627

c

A

c

D

F

L-8

AK

K

c

E

A

AA

H

J

E

AC

D

Blk.

Description

Nut

----------------------------------------------------------------Needle

Washer,

Eyelet, needle bar thread

Screw

Screw

Gasket

Washer

"0"

Collar, needle

Cup,

Ring, temper load

Lever Assembly, needle

Ball

Washer

Nut

Connecting

Screw

Plate,

Handwheel

Pulley

"0"

Collar,

Counterweight

Crankshaft Sub-Assembly, .990 inch

Guide, connecting rod

Nut

Pump,

Pump,

Screw,

Screw, spot

Coupling

Crank

Shaft, looper drive rocker

"0"

Washer,

Bearing, needle

Ring,

Lever, looper

Wick,

Screw,

Nut

Bar

----------------------------------------------------------

needle bar

---------------------------------------------------------------

---------------------------------------------------------------

--------------------------------------------------------------

--------------------··----------

Ring

-------------------------------------------------··----------

compression

Screw

Link, connecting

Connection, needle bar

Screw

Pin,

Ring,

Stud, needle

joint,

Screw

-----------------------------------------------------------------

Screw

Ring

Screw

Screw

Bearing, needle,

Bearing, needle, .0626 inch

Bearing, needle,

-----------------------------------------------------------------

Screw

Screw, bearing

Guide, ball

Splasher,

Screw, bearing

Ring

-----------------------------------------------------------------

----------------------------------------------------------

Screw

----------------------------------------------------------

link

Yarn

retaining

needle

----------------------------------------------------------

-------------------------------------------------------------Rod,

--------------------------------------------------------------retaining

-----------------------------------------------------------

--------------------------------------------------------------

----------------------------------------------------------

------------------------------------------------------------

thrust

----------------------------------------------------------

----------------------------------------------------------

oil,

head

oil,

base

set

----------------------------------------------------------

---------------------------------------------------------

------------------------------------------------------------

----------------------------------------------------------

Assembly, looper driving

------------------------------------------------------------

thrust

pilot

oil

---------------------------------------------------------

-----------------------------------------------------------

thrust

eyelet

lever

----------------------------------------------------

---------------------------------------------------

-----------------------------------------------------

------------------------------------------------------

-----------------------------------------------------lever

lever

needle

----------------------------------------------------

------------------------------------------------------

-------------------------------------------------------

(See

(See

cap

joint

oil

-------------------------------------------------cap

-----------------------------------------------------thrust

drive,

synchronizing adjusting

-------------------------------------------

-------------------------------------------

-------------------------------

thrust-----------------------------------------

----------------------------------------------

-----------------------------------------------

-----------------------------------------

------------------------------------------------

--------------------------------------------(upper)

lever

.0625 inch

.0627

-----------------------------------------------

Ref.

No.

Ref.

No.

(upper)

---------------------------------------------(lower)

------------------------------------------

----------------------------------------------

marked "D''

------------------------------------

----------------------------------------

(25.15mm)

(1.588mm)

(1.590mm)

inch

(1.593mm)

43

Page

19)

60

Page

17)

lever

--------------------------------

-------------------------------------

-------------------------------------

-------------------------------------

-------------------------------

throw-----------------diameter----------------diameter----------------diameter-----------------

---------------------------

---------------------------

Amt.

~

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

1

1

2

2

4

1

1

2

1

1

2

3

1

1

1

2

1

1

2

1

2

1

28

28

28

1

1

1

1

2

2

2

2

1

2

1

1

2

1

1

4

2

2

1

1

1

1

21

Page 22

22

Page 23

LOOPER

ROCKER

AND

CONNECTING ROD

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

Part

No.

51244

51216

18

51244

55244

W0-3

57744

C067

56344

51236

56344

719

98

51246

96

22874

29192

51745

56313

15465

88

258

22829

56393

87

57841

22729

269

35741

18

20

18

29476

56341

52942

56342

22882

51242

73

51108

73

51110

18

N

N

L

G

E

B

A

c

v

F

A

J

u

c

A

LV

F

R

E

c

M

DA

A

D

Descri p

Collar, looper rocker

Washer

Nut

Washer,

Stud

Yarn

----------------------------------------------------

----------------------------------·--------------------thrust

----------------------------------~---------

------------------------------------------------------

----------------------------------------------Shaft, looper rocker

Cork

Arm,

Pin, link

Nut

Screw, spot

Screw, lock

Rocker

-----------------------------------------------------looper rocker

-------------------------------------------------

Frame,

looper rocker

Screw, stop

Screw,

set

------------------------------------------

-------------------------------------------

-------------------------------------------------------

-----------------------------------------------

-----------------------------------------------

Assembly, looper

Stud, rocker

cone

Rocker, looper,

Cone,

Nut,

Screw

Oiler,

Screw

Ball

-----------------------------------------------------

Joint,

Screw

Nut,

left

ConneGting

Nut,

right

Washer

Nut

-------------------------------------------------------

looper rocker

Screw

check

-------------------------------------------

-------------------------------------------

------------------------------------------------

looper connecting rod ball

looper connecting rod

------------------------------------------------

hand

thread

Rod,

looper

hand

thread

----------------------------------------------------

Bearing Assembly, looper connecting rod

Ferrule

----------------------------------------------

Stud, looper lever

Lever, looper

Screw

Washer

Screw, looper

Looper

Screw

----------------------------------------------------

-----------------------------------------------------

drive,

------------------------------------------------

-----------------------------------------------

---------------------------------------------

Guard, looper needle

Nut

-------------------------------------------------------

tion

shaft-

--------

----------------

--------------------------------------

shaft

----------------------------------

--------------------------------------

-----------------------------------

------------------------------------

marked 11S

11

---------------------------

----------------------------------

joint

(left)

(left)

------------------

-------------------------------------

------------------------------------

------------------------------------

(right)

---------------------------------------marked 110

11

---------------------------

--------------------------------------

Amt.

~

--

----

1

1

1

2

1

as required

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

------------

1

1

1

2

1

1

1

1

1

--------~--

1

1

1

1

1

1

1

1

1

1

1

23

Page 24

24

Page 25

MAINSHAFT

AND

FEED

DRIVING

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

Part

No.

29476

55235

6042

55235

77

56336

56336

51054

660-149

21657

269

22525

56322

22798

56336

660-269

56336

22543

56122

51-173

56322

22891

29476

22894

77

39543

29476

22894

77

56123

22764

22580

56334

22651

56334

22637

22863

6042

258

56335

98

56335

56334

56335

660-359

22651

660-438

41391

61341

22528

51105

51236

MJ

E

A

D

B

c

E

A

c

c

B

D

B

A

Blk.

B

B

NM-140

AA

N

NM-096

AA

c

D

N

CB-4

L

P-24

c

A

A

D

L

B

G

CD-4

J

G

A

Descri ption

Feed

Rocker

Nut

Washer

Stud, locking

Screw

Arm

and

Feed

---------------------------------------------

------------------------------------------

-----------------------------------

-------------------------------------------

Link, feed crank

Ferrule, feed crank link

Pin, link

Washer

Nut,

Screw

Plate,

Screw

-----------------------------------------------

left

-----------------------------------------------mainshaft

------------------------------------------------

Stud, feed crank,

Ring,

Insert,

Screw,

quad

feed crank stud

stitch

Mainshaft

Plug,

Gasket

Screw

Eccentric

Screw

Screw

Washer,

feed bar

Eccentric

Screw

Screw

---------------------------------------

Wick,

thread

oil

----------------------------------

------------------------------------head

marked 11A

--------------

regulating

-------------------------------------------oil

---------------------------------------

------------------------------------------

-------------------------------------------

Assembly,

feed

-------------------------------------------

------------------------------------------thrust

Assembly,

looper avoid

-------------------------------------------

-------------------------------------------

Take-up, looper thread

Screw, spot

Screw,

Feed

Bar

Screw

Holder, feed d

set

---------------------------------------------

-------------------------------------------

-------------------------------------

--------------------------------------

og

Screw, height adjusting

Screw, holder adjusting

Washer

Nut

------------------------------------------

---------------------------------------------

Collar, feed rocker

Screw

Shaft, feed rocker

Shaft, feed bar

Rocker, feed

-------------------------------------------

-----------------------------------

--------------------------------------

-----------------------------------------

Bearing, needle, with seal

Screw

Ring, retaining

Washer

Washer,

Screw, feed

Feed

Dog,

Pin,

link

-------------------------------------------

--------------------------------------

----------------------------------------------feed bar

marked 11RD

-------------------------------------

dog

--------------------------------------

11

--------------------------------------------

Amt.

~

Crank

Link

Sub-Assembly

1

1

1

1

1

--------------------------------

-------------------

1

1