Page 1

H

l!!l

M

\'APOR

RESERVOIR

oJL

oiL

FEED

RETURN

E

011

fii;PPL~·

fROM

f>Rifi f11.

ATl

OJI >ROM

f UA:\:K"<ItAPT Bl'SII''\."C

l.EF

I

I '

I \

I I

~.I

~"'

T

IJY

10

nc"lt£\\

•PA.<iS

M

\\tTB

Oi;TL..f:T

Page 2

1{

feed dog

throat

(8)

plate,

clockwise

clockwise

when

feed dog

to

teeth

loosen

to

lower

raise

is

set

are

nut

the

the

front

properly.

SETTING

not

(A,

Fig.9)

front

teeth

THE

para1lel

and

teeth

.

Retighten

FEED

with

turn

, and

DOC

(Continue

th

screw

counter

nut

d)

-

Should

the

hold

(C),

Left

the

and

retighten

doe•

not

When

direction

on

both

travel

set

Should

(E,

Fig.

rocker

forward

Set

nut

gu

of

"S". '

townrd

(moves

(}', Pig

lntl

thP

ng stud and

dot

rur.ntng t he

the

stitch

pr<'vent

the

"II"

it

be

necessary

or

feed

move

screws.

bind

the

the

ends

Lo

right,

rocker

feed

after

handwheel

feed dog

of

desired

it

be

loosen

(B)

roeker

Make

making

the

throat

stitch

necessary

10) which clamps

or

backward

the

stitch

. 10)

1/2

co

turn

turnlng

h

plate,

"S") and

in

scre

turni

w elockwi

regulating

destructive

shaped key

damage co

sloe

to

screws

onto

to

desired

sure

the

this

is

turned

should

have

plate

length

to

the

as

needed and

~~GIXG

required

(it

has a left

the

the

ng

head

it

stud

in

the

move

th~

(A

,

feed

the

feed

adjustment

in

equal

slots

.

move

feed

the

rocker

length

stitch

of

the

se shorte

in

a cou

toward

the

feed

ferrule

[ccd

Fig

. 10) which

rocker

position

rocker

dog

shaft

11nd

arm

to

(D)

.

the

op~rating

clearance

with

{ecd

feed dog forward or backward,

arm

r~ti&hten

STiTCH

.

This

hand

adjusLing

mnln

ns t he

nt

erdorkwtse

the

"

L").

drive

(K).

to

the

LENGTH

is

accomplished by

thread)

scre

~

h n

fl

(11),

lit

i

tch

Retighte

bearing,

feed

nut

.

on

w (G)

which

(moves

directio

the

rocker

the

locat~d

end

is

stll

n

n

the locknut

Key screw

Fig.

9

loosen

and

of

und~

marked

ch

len

.eve

loos~ning

the

stitc

•·

the

wl

Lh

r~gulating

gthens

Lh<'

S<'Curely.

(J)

must engage

nut

the

feed

the

h

left

"L" and

stitc

lockre-

end

stu

d

h

To

NOTE:

rear

Any

ne~dle

Machines

mny

and

require

r~packcd

SETTlNG

Set

(C,

Fig.

that

th~

when

of

inch

It

it

rear

at

cravPl

(.127mm)

should

possible,

face

inch

unt11

approach

(1.19

the

change

tHE

GUARD

th~

9)

does

ot

Ita

. A

be

yet

.. ) of

poinr

in

stitch

guard

having

repacking

with

REAR

rear

setting

needle

after

Union

NEEDLE

needle

horizontally

not

ch~

quite

needle

contact

(D)

most forward

clearance

is

permissible.

set

as

have

within

the

of

tbe

low

its

about

needle

of

vertical

looper

length

.

bearings

years

Special

gunrd

so

point

.005

as

3/64

,

will

of

necPssttate

in

the

service

Corporntion

a

feed

.

~r@nee

rocker

Bearings

No

corresponding

at

locations

should

be

. 2g604 P.

chango

(L,

Plg.

throughly

in

the

10)

cleaned

19

Fig.

10

Page 3

SETTING

THE

REAR

NEEDLE

GUARD

(Continued)

(E),

backwa

screw.

wise

after

NOTE:

moving

rd,

To

to

lower

guard

Any

THREADING

Draw

piece

of

machines.

The

stitches

Pull

ounces

should

should

(85.05gr)

have 5

have

(170.10gr).

to

merely

raise

needle

is

change

the

looper and

fabric.

tension

on

the

the

needle

ounces

4 ounces

T

his

the

left,

loosen

or

lower

is

screw

needle

guard

properly

in

(FOR

set.

sCitch

ALL

STYLES

needle

Refer

on

the

to threading

needle

under surf<:1ce

thread

for

all

Styles,

(141.75gr);

(113.40gr);

will

feel

even

with

(F),

move

guard,

and

coul\terclockwise

length will

EXCEPT

threads

THREAD

thread

of

t he

through the

except

Styles

and

light.

the

needle. To

needle

loosen

require

guard

screw

to

a

move

as

(F),

raise it.

change

needle

required,

and

in

rear

56300 E,F,G,N,R,U,X,AH and

into

diagram

t he machine and

(Fig. 1)

for

the

TENSIONS

should

be

only

sufficient

fabric.

eyelets

Styles

56500

Style

56300 H which

and

set

the

56500 J , 56900 H and 56900 J which

A,

56500 B, 56500 C and 56500 0 which

should

guard

turn

Re

tigh

needle

start

threading

to

needle

have 6

forward

and

retighten

screw

ten

screw

guard

AL)

operating

of

produce

tension

ounces

(G)

clock-

setting.

on a

these

uniform

at

or

(1')

3

The

assembly,

t h

read

T

is

he

presser

entirely

If

located

Retighten

The

correctly

when

ed.

the

Also

clearance

tion

head

leased

with

and

opening

and

the

loope

and t

just

thread

foot

is

released

ad

justment

at

the back

screw

height

if

it

foot

there

between

guide

in

the

feed

r t

hread

he

adjusting

sufficient

tension

raised

when

is

of

.

After

SETTING

of

the

is

possible

lifter

should

lower

(E,

Fig.

the

bed

presse

dog

down

tension

to

is

nut

should

steady

THREAD

release

to

within

is

1/8

the presser

needed, loosen

the

machine and

adjustment there

HEIGHT

presser

lever

be

surface

4)

when the

r

foot

be

low

approximately

OF

bar

to

remove

(B,

Fig

and

the

resting

the

of

foot

applied

the

TENSION

set correctly

inch

foot

tension

at

be

set

thread

(3.17mm)

has

RELEASE

move

should

PRESSER

(D,

. 11)

Fig.

the

is

BAR

presser

fully

1/16

the

presser

bottom

surface

lifter

on

the

throat

throat

plate

the

cast-off

so

that

.

when

reached

release

tension

be no

4)

is

set

fo

depress-

inch (1.

bar

of

lever

plate)

.

the

it

of the

its

highest

lever

disc

binding

ot

59mm)

connec-

the

is

re

-

support tension

tension

begins

end

on

to

fw1ction

of its

the

travel

position.

screw

separator

at

(A,

as

any

Fig.

point.

disc

looper

as

and

11)

,

required.

•

the

is

I

A

If

adjustment

(.

directio

Loosen

down

nect~on

tighten

high

graph

screw

on

pos

.

n

until

the

and

throat

guide

screw

ition

(E,

(F).

and

is

needed,

the

needle

Fig. 4)

plate

. Tben,

surface,

with a screw

Check

see

if

setting

presser

bar

turn

is

while

driver

by

foot

handwheel

in

pry

turning

the

holdi

up

to

can

in

low

position.

ng

presser

presser

obtain

handwheel

be

removed

20

operating

foot

bar

con-

the

1/16

so

as

inc

h (1.59mm)

that

mentioned

needle

Fig

bar is

in

previous

. 11

setting

in

and

its

para

-

Page 4

PRESSER

FOOT

PRESSURE

Regulate

only

enough

tension

the

needle

pressure,

ia

counterclockwise

the

pressure

placed

bar

SETTING

(FOR

Set

needle

the

holes

downward

it

for

hole

is

Styles

Above

the

bnr

in

stroke.

a

larger

3/4

56500

the

attaching

needle

thread

the

inch

J,

(25.40mm) above

presser

on

in

the

ALL

eyelet

needle

Lower

loop.

on

the

head

NEEDLE

STYLES

thread

spring

the

fabric.

(C),

bar

this

Set

presser

of

the

acts

the

THREAD

EXCEPT

take-up

so

thread

setting

the

needle

(19.05mm) above

56900 R and 56900 J

screw

the

attaching

and on

screw.

regulating

foot

Thia

ia

machine.

acrev

to

fe~d

the

Turning

(A,

the

knurled

it

Fig.

work

screw,

clockwise

reverse.

TAKE-UP

WlRE

AND

FRAME

56300 E,P,C,N,R,U,X,AH and

wire(

that

eyelet

the

the

style

for

attaching

B,

Fig.

ita

upper

when

a

smaller

thread

eyelet

56200 H

12),

surface

the

frame

screw on

i~

to

the

located

is

needle

needle

eyelet

all

be

set

eyelet

12)

so

that

uniformly

located

increase~

•

EYELET

AL)

adjacent

even

bar

thread

(D) so

with

has

completed

loop,

that

styles,

5/8

is

to

inch

be

it

when

directly

to

the

and

the

except

(15.88mm)

set

l

exerts

a

slight

the

the

top

of

its

raise

eyelet

on

inch

behind

NOTF.:

For

following

(FOR

STYLES

Refer

the

threaded

manner

.

SETTING

(FOR

STYLES

These

additional

so

the

the

adjusting

following

the

above

paragraphs.

THREADI.NG

56300 E,F,G,N,R,U,X,AK and

to

threading

in

which

NEEDLL

FR.A.'IE

TltREAD

EYELET

56300 E,F,G,N,R,U,X,AH and

aachine

thread

styles

handling

sequence

~~anner:

setting

diagram

these

TAKE-UP

on

Styles

(Fig

machines

WIRE

are

should

equipped

and

control

be

56300 &,F,G,N,R,U,X,AH and

AL)

. lA)

for

are

AND

AL)

vith

parts,

aade

In

AL,

Fig.

ace

12

the

21

Fig.

l2A

Page 5

SETTING

NEEDLE

(FOR

STYLES

THREAD

56300 E, F,

TAKE-UP WIRE

G,

AND

N,

FRAME

R. U,

EYELET

X,

AH

(Continued)

and

AL)

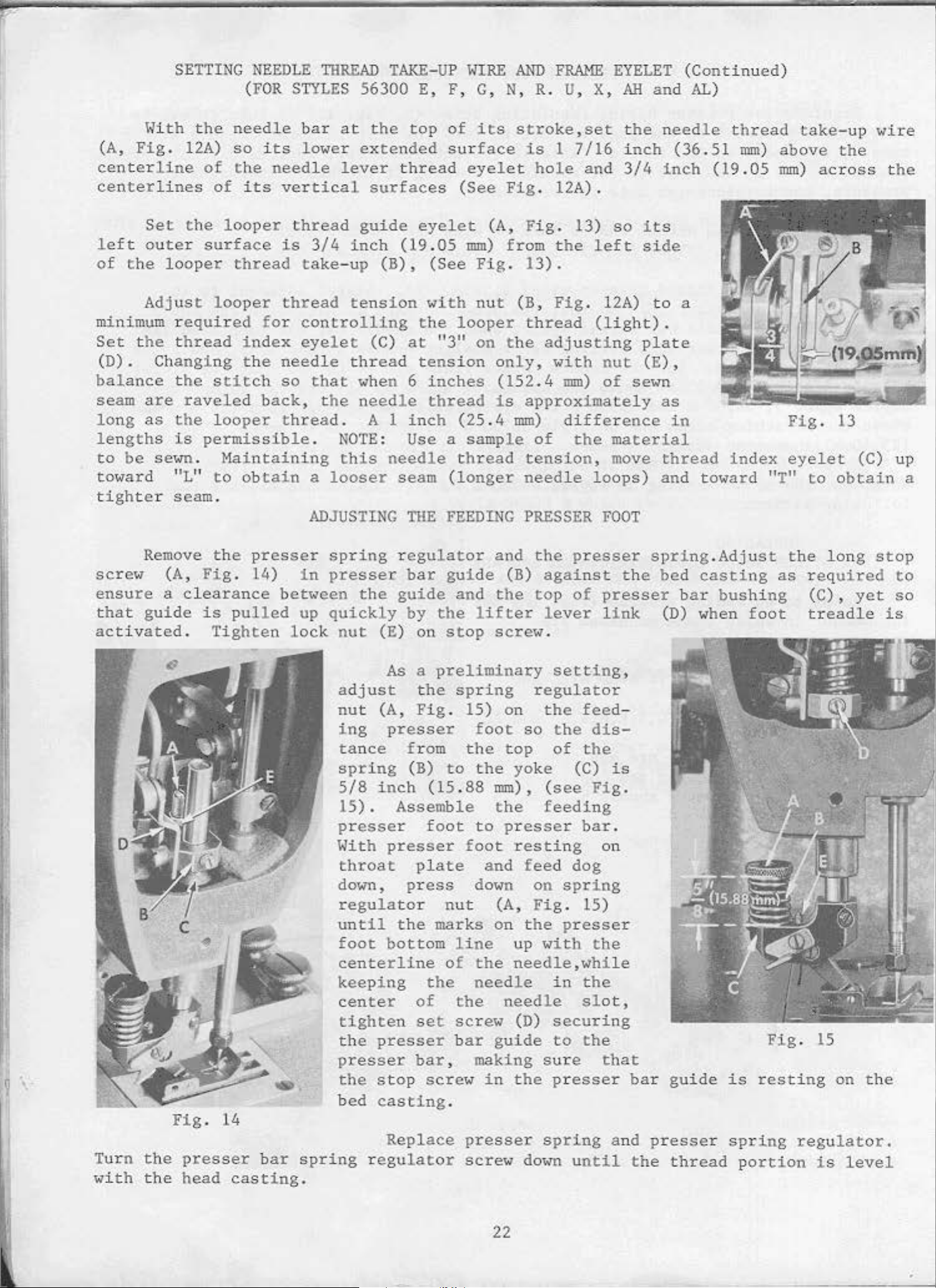

With

(A,

Fig.

centerline

centerlines

Set the

left

outer

of the

Adjust

minimum r

the

12A)

of

of

looper

surface

looper

loo

equired

Set the thread

(D).

bal,ance

seam

long

le

ngths

to

toward

ti

gh

Changing

are

as

be

sewn.

t er

the stit

raveled

the

is

looper thread.

permissible.

Maintaining

"L"

seam.

to

needle

so

the

its

bar

its

lower

needle

vertical

at

lever

thread

is

3/4

inch

thread take-up

per

thread

te

for controlling

index

the

ch

eyelet

needle

so

that

thread

when 6

back, the

NO"!B

this

obta

in

a

looser

ADJUSTING

the

ex

surfaces

guide

nsion

(C) at

top

tended

th

read

eyelet

(19.05

(B),

(See

with

the

of

surface

eyelet

(See

mm)

Fig. 13

nut

looper

"3"

on t

tension

inches

need

A 1

l e

inch

thread

(25.4

: Use a sampl e

needle

seam (

tHE

th~ead

longer

FEEDING

its stro

is

hole

Fig

. 12A) .

(A,

Fig. 13)

from

(B,

thread

he

only,

(152.4

i s

approximately

mm)

of

tension,

needle

PRESSER

ke,set

1

7/16

and

so its

the

left

).

Fig.

adjusting

with

mm)

difference

12A)

(light).

nut

of

the

loops)

material

move

FOOT

the

inch

3/4

side

to

plate

(E),

sewn

need

le

(36.51

inch

a

as

in

thread

and

toward

t h

(19

index

read take-up

mm)

.05

above

mm)

across the

Fig.

13

eyelet

"T"

to

obtain

the

(C)

wire

up

a

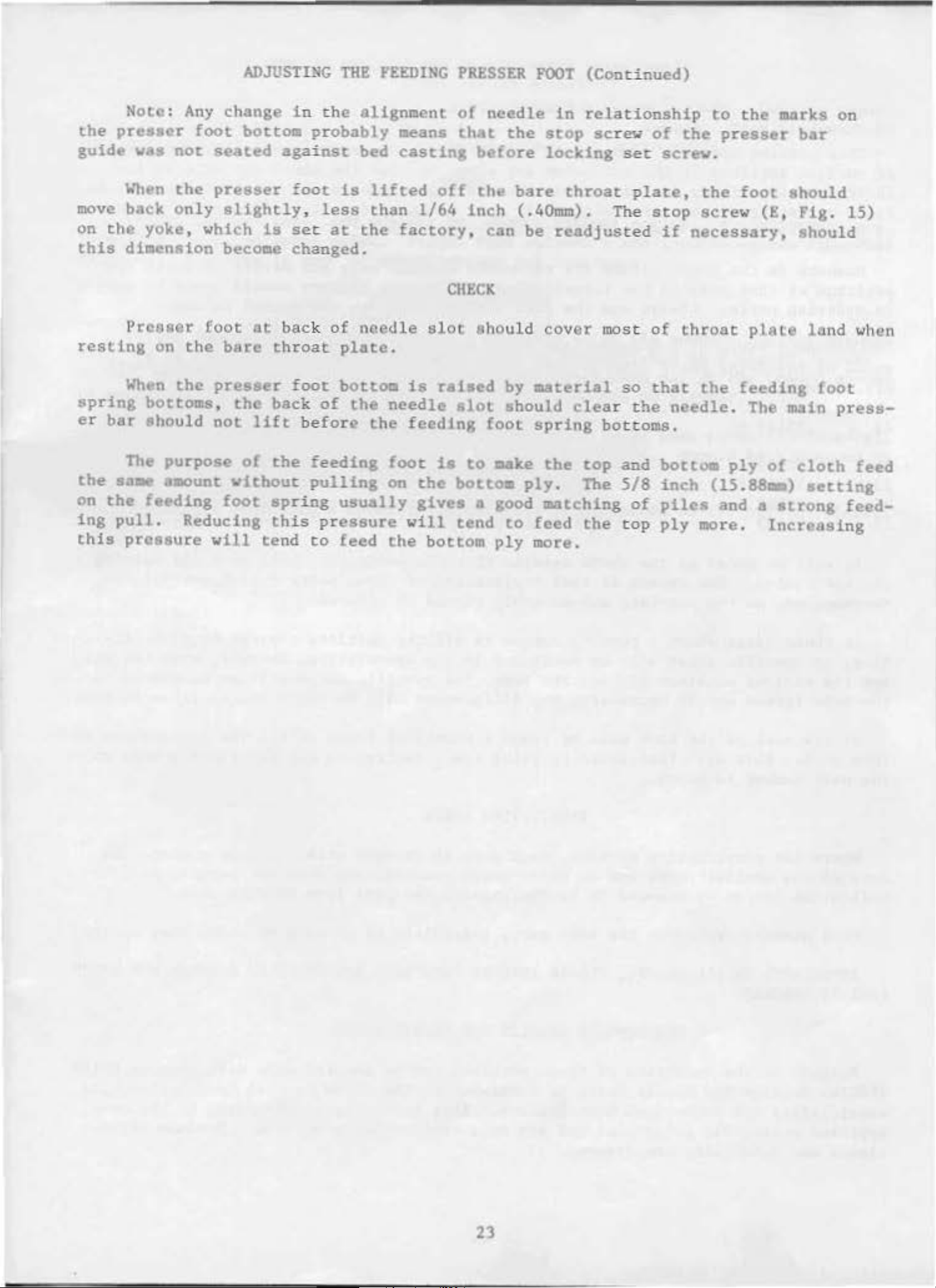

Remove

screw

ensure

that

guide

activated

T

urn

with

the

the

(A,

the

Fi

g.

presser

14)

a clearance

is

pul

.

Tighten

Fig

. 14

presser

head

bar

casting.

in

between

led

up

lock

spring

spring

presser

the

quickly

nut

regu

guide

(E)

bar

by

on

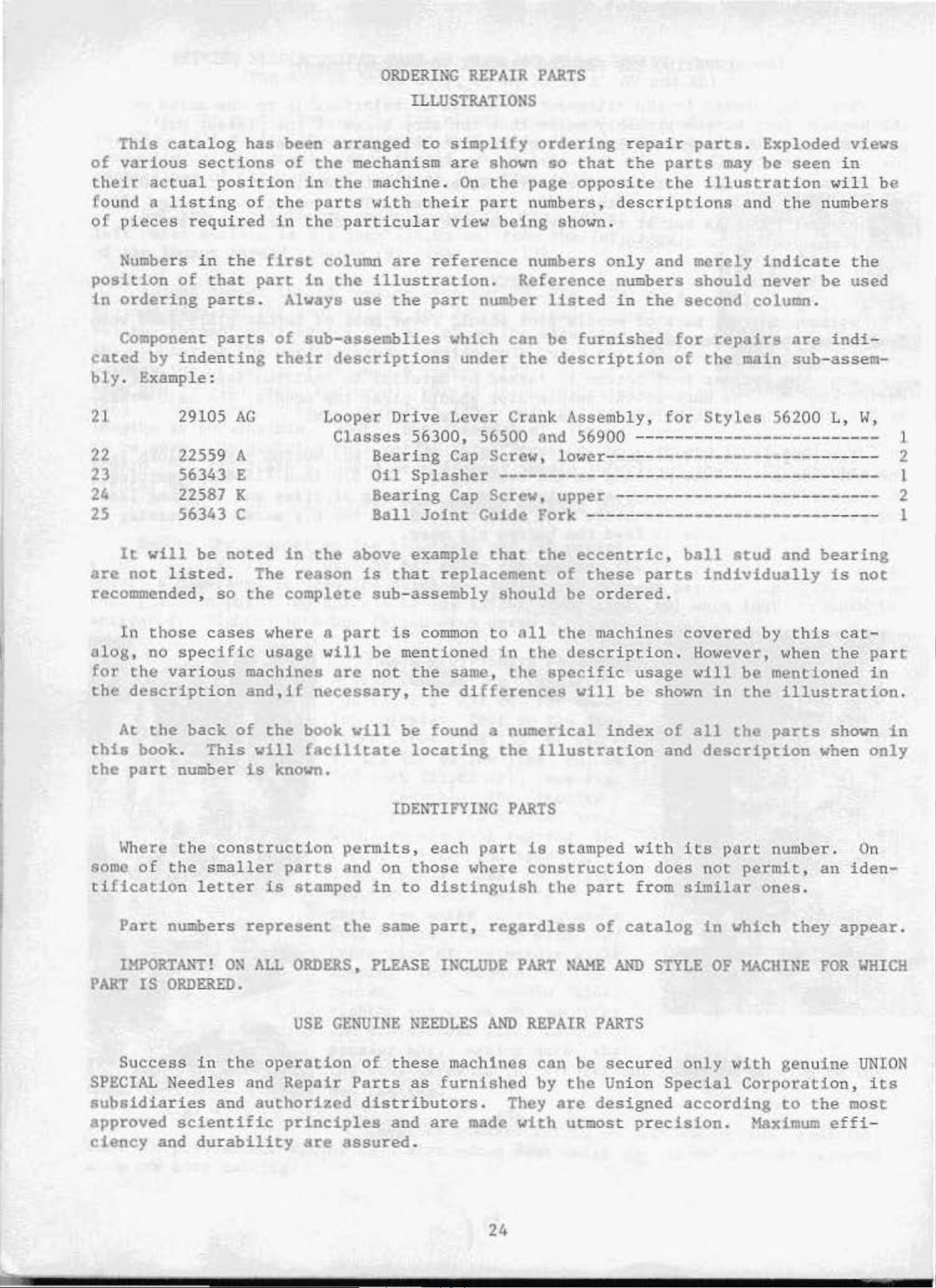

As a

a

dju

st

nut

(A,

ing

ta

nce f r

spring

5/8

15)

presser

With

inch

.

throat

down,

t

Fig

presser

(B)

Assemble

presser

plate

press

regulator

until

foot

the

bottom

centerline

keeping

center

tighten

the

presser

presser

the

stop

of

set screw

bar

bed casting.

R

eplace

regulator

lator

and

guide

and

the

stop

the

lifter

screw

preliminary

he

spring

.

15)

on

foot

om

the

to

the

(15.88

top

mm),

the

foot

to

foot

presser

and

down

nut (A,

marks

on

line

of

the

the

nee

the

bar

dle

needle

guide

, making

screw

in

presser

screw

the presser

(B)

against

top

of

lever lin

.

setting,

regulator

the

so

the

of

feed

dis-

the

yoke (C)

(see

feedi

resting

Fi

ng

bar.

feed dog

on

sp~iog

Fi

g.

15)

the

up

presser

with

the

needle,while

in

the

slot,

(D)

securing

to

the

sure

the

presser

spring

down u

ntil

spring.Adjust

the

bed

presser

k (D) when

-

is

g.

on

that

bar

and

presser

the

guide

thread

casting

bar

as

bushing

foot

Fig. 15

is

resting

spri

ng

portion

the

long

req

uired

(C),

yet

treadle

on

regulator.

i s

level

stop

to

so

is

the

22

Page 6

ADJUSTING

TRB

FEEDING

PRESSER

FOOT

(Con~inued)

Noto:

the

guide

presaer

was

WhPn

move

on

this

back

the

dimension

PrcnAcr

restinQ

WhPn

spring

er

bar

Thu

the

sa~

on

the

ing

this

pull.

pressure

Any

foot

not

the

only

yoke,

which

foot

on

the

the

bottoms,

should

nol

purpose

amount

feeding

Reducing

will

change

bottom

seated

presser

slightly,

in

against

foot

is

set

the

probably

is

less

at

become changed.

at

back of

bare

presser

the

without

foot

lift

of

tend

throat

foot

back

of

before

the

feeding

pulling

spring

this

pressure

to

plote.

bottom

usually

feed

align~enl

means

bed

casting

lifted

than

the

1/64

factory,

of

that

off

CH£CK

naedle

the

needle

the

foot

on

slot

is

raised

slot

feeding

is

to

the

bottom

gives

will

the

tend

bottom

needle

the

bwtore

th~

inch

con

should

by

should

foot

make

a good

to

ply

in

relationship

stop

locking

bare

screw

set

throat

(.40mm). The

be

readjusted

cover

material

mos~

so

clear

spring

tbe

ply.

matching

feed

bottoms.

top

and

The

5/8

of

the

top

more.

of

screw.

plate,

stop

if

of

that

the

needle.

bottom

inch

pileft

ply

to

the

the

presser

the

foot

screw

necessary,

throat

the

plate

feeding

The main

ply

(1S.88

and a

more.

marks on

bar

should

(E,

Fig.

15)

should

land

Coot

pres8-

of

cloth

.. ) aettiog

strong

feed-

Increasing

when

feed

23

Page 7

ORDERING

REPAIR

ILLUSTRATIONS

PARTS

This

of

various

their

found

of

pieces required

Numbe

position

in

ordering

ac t

a

cat

ual

list

rs

of

alog

sec

Component

cated

bly

21

22

23

24

25

by ind

. Example:

29105

22559 A

56343 E

22587 K

56343 c

has

tions

posicion

i ng

in

of

the first

that

parts.

parts

ent

ing

liG

been

of

in

the parts

in

the

part

in

Always

of

sub-assembl

their

arranged

the

Qecbanism are shown

the

machi

with

part

column

the

icular

are

illustration.

use

the

descriptions

Looper

Drive

Classes

Bearing

Oil

Bear

Ball

co

ne.

their

ref

part

ies

simplify

On

the

part

view

baing

erence

number

which

under

Lever

ordering

so

that

page opposite

numbers,

shown .

numbers on

Reference

listed

can

Crank

the

be

furni

description

Assembly,

descrip

numbe

in

56300, 56500 and 56900

Cap

Splasher

ing

Cap

Joint

Scre

w,

lower---------------------

-------------

Screw,

upper

Guide Fork

----------

--------------

repair

the

ly

and

the

shed

-----

parts

parts

t he

tions

merely

rs

should

illustra

. Exploded

may

be

and the

indi

never

second column.

for

of

for

the

Styles

----

repairs

main sub-

---------

tion

562

seen

cate

are

00 L,

----

-------

- -------------------------

-----------------

-------

----

views

in

will

be

numbers

the

be

used

indi

-

assem-

W,

---

----

J

2

l

2

1

It

will

are

not

listed.

recommended,

In t ho

alog,

for

the

this

the

aom~

tificatio

Lhe

descriptio

At

book.

pan:

Where

of

se cases

no

specific

various

the

back

number

the construction

the

n

be

noted

so

n

of

This

smaller

le

tter

in

tbe

The

the

reason

complete

where a

us

age

machines

and,l(

the

will

is

necessary,

book

facilitate

known.

parLs and

is

stomped

above

part

will

arc

will

per.,its

example

is

tha

t r

sub

-asse

is

common

be

mention

not

the

the

be

found a

locating

tDENTIFYINC

,

each part

on those

in

to

dis

chat

the

eplacement

mbly

same,

to

ed

should

all

in

Lhe

the

differences

numerical

the

illustration

PARTS

is

where

tinguish

constructi

eccentric,

of

these

be ordere

the

machines

description

specif

ic

will

index

st

amped

the

pare

parts

d.

us

age

be

shown

of

and

with

on

does not

from

ball

stud

individually

covered

by

. However,

will

all

in

be

the

the

description

it

s p!l

tt

permi

similar

ones

and

bearing

is

this cat-

when

the

mentioned

illustration

parts

shown

when

num

ber.

t,

an

iden-

.

not

pa

in

only

On

r t

.

in

Part

UIPORTA.'IT!

PART

Succe

SPECIAL

subsidia

approved

ciency

numbe

IS

ORDERED.

ss

Needles

ries

scientific

and

rs

represent

Oll

ALL

i n t he o

peratio

and

and

authorized

durability

the

ORDeRS,

USE

GENUINE

n

Repair

Parts

principles

are

assured

same

PLEASE

part,

II>CWDE

NEEDLES

of

these

as

machi

furnished

distributors.

and

are

.

regardless

PART

AND

REPAlR

nes

They

made

with

24

cau

by

are

of

NAME

AND

PARTS

be secur

the

Un

desi

utmost

catalog

STYLE

ed

only with

ion

Special

gned

precision

in

which

OF

MACIIUIE

Corporatio

according

.

Maximum

they

appear.

FOR

genuine

n,

to

the

eff

WHICH

UNtON

it

s

most

i-

Page 8

USE

GENlJINl!

NEBDLES

AND

REPAIR

PARTS

(Continued)

Genuine

parts

your

are

guarantee

Prices

forwarded

directed.

Torque

distance

driver,

or

torque

All

unless

hand

otherwise

as

stamped

are

f

.o.b.

A

(measured

by

a

etc.

will

stra]>S

Ughtly

needles

with

of

net

shipping

charge

lever

Many

of

tighten

and

noted.

as

are

the

the

highest

cash

is

made

in

(in

these

the

eccentrics

possible,

packaged

Union

Special

quality

and

subject

point.

to

cover

TORQUE

inch-pounds)is

inches

or

devices

part

to

should

All

other

unless

with

labels

trademark,

in

materials

to

Parcel

change

Post

post:age

lU!QUIREMENTS

a

rot.ating

feet).

are

the

be

nuts,

This

avai.lable,wbicb

correct

tightened

bolts,

otherwise

marked

and

withou~

shipments

and

insurance.

force

is

accomplished

amount

screws,

noted

ZtrwmSpcci.ab.

U S Emblem.

workmanship.

no

tice.

to

.

are

when

and

19-21

etc.,

insured

(in

set

no

inch-pound

All

pounds)

by

a

at

tighter.

should

Genuine

Each

unless

trademark

sh~pments

otherwise

applied

wrench,

the

proper

screw-

(22-24=/•log),

be

tightened

repair

is

are

through

amount

by

Ute

screws

requiring

a

specific

torque,vill

be

indicated

on

the

picture

plates.

25

Page 9

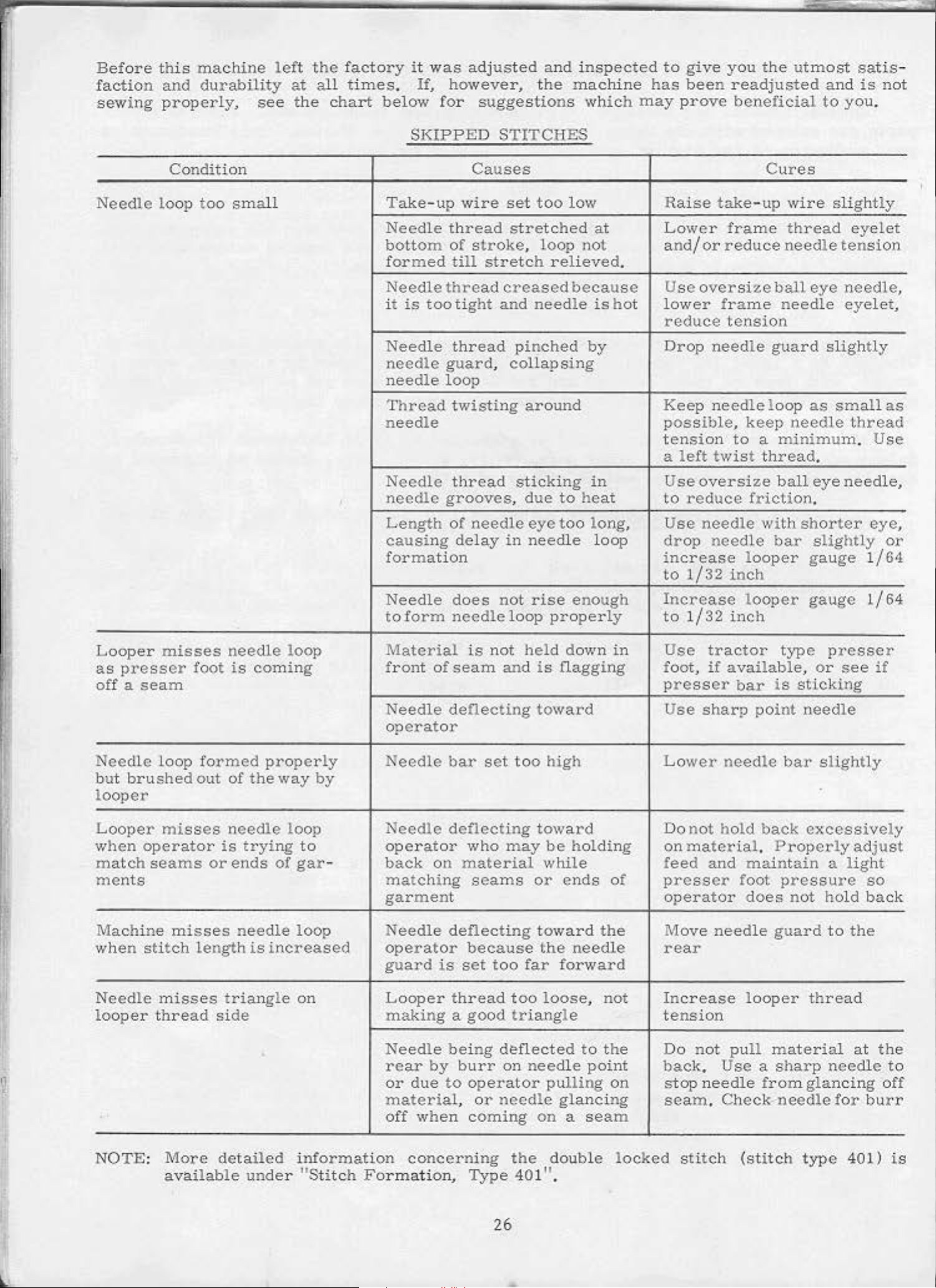

Before

faction

sewing

this

and

machine

durability

properly,

left

see

the

at

all times

the

factory

chart

it

.

If,

below

was

adjusted

however,

for

and

the

suggestions

inspected

machine

which

to

has

may

give

been

prove

you

the

utmost

readjusted

beneficial

and

to

satis

is

you

-

not

.

Needle

Condition

loop

too

small

SKIPPED

Take-up

Needle

bottom

for

med

Needle

it

is

too

Need

le

needle

needle

'

rhread

needle

Needle

needle

STITCHES

Causes

wire

thread

of

till

thread

tight

thread

guard

set

stretched

stroke.

stretch

creased

and

pinched

,

collapsing

too

loop

needle

loop

twisting

thread

around

sticking

grooves, due

low

at

not

relieved.

because

is

by

in

to

heat

hot

Raise

take-up

Lower

and/

Use

lower

or

reduce

oversize

frame

reduce

Drop

Keep

needle

needle

possible,

ten

sion

a

left

twist

Use

oversize

to

reduce

Cures

frame

ball

tension

guard

loop

keep

to

a

minimuJn

thread.

ball

friction.

wire

thread

needle

eye

needle

slightly

as

needle

eye

slightly

eyelet

tension

needle,

eyelet.,

small

as

thread

.

Use

needle,

Looper misses

as

presser

off a seam

Needle

but

brushed

loop

foot

formed

out

looper

Looper

when

m

atch seams

n)ents

misses

operator

needle

is

of

needle

is

or

ends

coming

properly

the

way

trying

of

loop

by

loop

to

gar

Length

causing

formation

Needle

to

form

Material

front

Needle

of

needle

delay

does

needle

is

not

of

seam

deflecting

eye

too

long

in

needle

not

rise

loop

properly

held

and is-nagging

loop

enough

down

in

toward

,

Use

needle

drop

needle

increase

to

1/32

Increase

to

1/32

Use

foot~

tractor

if

available,

presser

Use

sharp

looper

inch

looper

inch

bar

point

with

bar

type

is

shorter

eye,

slightly

gauge 1/64

gauge

1/64

presser

or

see

sticking

needle

or

if

operator

Needle

bar

set

too

high

Lower

needle

bar

slightly

.

Needle

operator

-

back

matching

garment

deilecting

who

on

material

seams

may

or

toward

be

holding

while

ends

or

Do

not

on

material.

feed

and

presser

operator

bold

maintain

foot

does

back

excessive

Properly

pressure

not

adjust

a

light

hold

ly

so

back

Machine

when

Needle

looper

stitch

thread

misses

length

misses

needle

is

triangle

side

loop

increased

on

Needle

operator

guard

Looper

making a good

Needle

rc~

or

is

by

due

deflecting

thread

being

to

material

off

when

NOTE: More

available

detailed

under "Stit

information

ch

Fo

concerning

rmati

on,

because

set

too

far

too

triang

deflected

burr

on

need

operator

,

or

needle

coming

the

Type 401 ".

26

toward

the

the

needle

forward

loose, not

le

to

the

le

point

pulling

on

glancing

on a seam

double

locked

Move

needle

guard

rear

Increase

tension

Do

not

bacl<.

stop

needle

seam. Check· needle

stitch

looper

pull

material

thread

Use a sharp

from

(stitch

glancing

type

to

the

at

needle

for

bux·r

401)

the

to

off

is

Page 10

I

35A

17

L

28

5

6

.)

a

Page 11

itef

•••

1

2

3

4

4A

' 6

••

1

7A

a

9

9A

10

)l

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

lJ

34

35

3SA

36

.,

*38

39

40

4Z

"'

43

44

.,

46

47

48

49

50

5I

52

SJ

54

;;

56

57

58

59

••

61

62

63

64

.,

66

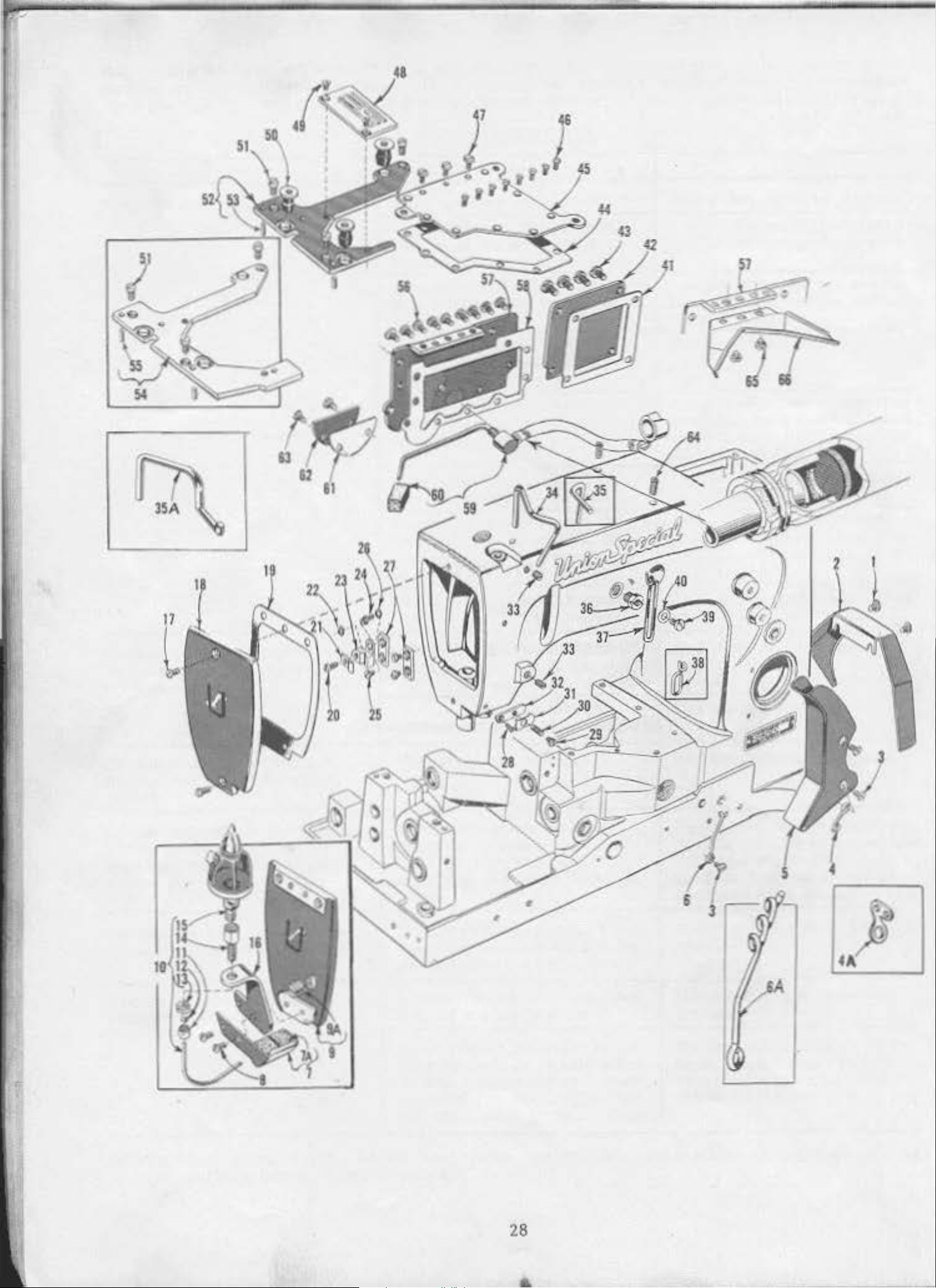

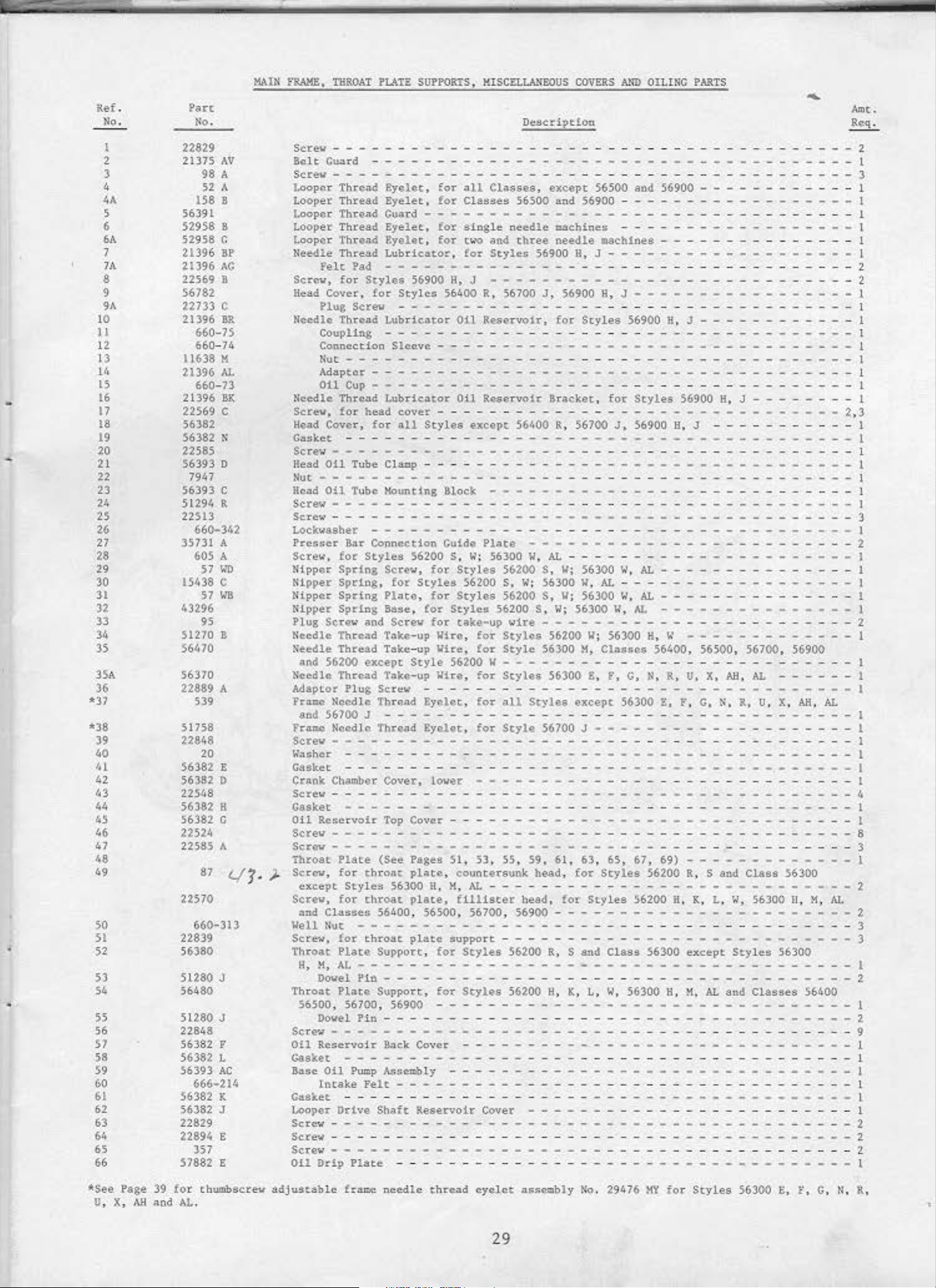

MAD\

t"lUME,

•

22829

1ll75

AV

98 A

>2A

158

B

56391

S29S8

S29S.8

21396

2i396

ZZ5b9 B

.8

c:

Bf

.o\C

56782

22731 c

21396

1!.R

S~tew

Belt

s~.tew

l~o

Looper

l.oopc~;

Looper

toopct

NeMle

Screv,

H~~d

Ncedlo

660-15

660-74

114

38

M

21396

21396

22569

56)82

5638~

22535

56393

5631;13

51294 R

22513

35731 A

l 5it38 c

43296

51270

56470

56370

22389 A

51158

22348

563.82:

56382 D

22.SGS

56382

S633i

2252.4

22585

22570

22839

56380

51280

56480

51280 J

2284S

56382 F

56382: L

56393

56382 K

5(1.382

22829

22894 E

57882 &

A]..

6b0-7l

BK

c

~

0

7947

c

~60.1'2

605

A

57

!;,'!()

Slllll

95

B

539

20

E

I!

c

A

1./j. ).

660-313

J

AC

666-114

J

357

Needle

S~re-w,

~~ad

{;,:wket - - - - - - - - - - - - - -

Sere·•--------l!e8d

Nut·-·-------

llead

Screw

Screw

Lo~kwasher

Prcn::;.er Alar

sere~.

Nipper

totpper

Nipper

titppe.r

Plug

Needle

Needle.

Needle

Adaptor

l"raa.¢ NccdlQ;

f

s~re~

w~~her

G~sket

Crank

Screw

Gasket - - - - - - - - - - - - - - - - - - - - - - - - - - l

Oil

s~rev

S¢rev-----

Throat

Sc~¢W. fo~

Screv.

Vell

Ser~.

th~;on

Throat

Scr~~

Oil

Casket

aue

c~sket

l.ooper

Scr<;loi'

S~rev

ScJ:ew - -

Oil

THROAT

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2

~rd

PLATE

- - - - - - - - - - -

SUPl'ORtS,

lHSCELLA.*EOUS COVERS

D~s~riptton

AND

OlLlNG PARTS

~

• - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - J

p~r

thrc.~~

Thread

1'ht~.n4

Thread

Tht:VId

Thre~d

f'elt?ad

for

Co~er

Plug

Tbcead

Coupltn,s----Connection

Nut

- - - - - - - - - - - - - - - - - - - - - - 1

Adapter

OtlCut>----------

Thread

for

Cove

Oil

Oil

.....

- - - - - - - - - - - - - - - -

F.yel~t.

Eyelet,

0U3Td - - - -

Eyelet,

&yel4t,

LubdetstO!",

·--------------

Styles

,

for

Style~

s~reu

r.

Tube

Tube

- - - - - - - - - - - - - - _

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

L~b~ie~tor

Sleeve

- - - - - - - - - - - -

Lubrie~~or

head

eover

for

~11

Cl.tap

lioiJOtil\8 3loclc - - - - - - - - - - - - - - - 1

for

all

Cl3sses. except

for

Clas~~

... -.............

tor

Slugle

(or

t"''O "'n4

for

5~900

A. J

) 6

400

Oil

- - - - - - - - - - - -

Oll

- - - - - - - - - - - - - - - - - - - - - -

Styles

- - - - - - - -

~xcept

56500

needle

tbt'ee

Style:;

...

- - - • • - - - - - - - - - - - - - - - 2

R,

56700 J , 56900 A. J

~e$ervo1r,

------

-

-------

~$$~TVOIT

56400

------------------

S6l100

...

- -

lr3cket,

------

and

114:e.htne:$

needle

for

R,

56500

56900

- - - - - - - - - - - - - - 1

n.

J -

-----

an4

- -

--

- - - - - - - - - - - - - - - 1

•acl\1M8

----

........

Styles

..

56700

56900

-

----

-

fot

Styles

J,

56900 H. J l

..

- -

....

-

--

-------

...............

....

_ _ _ _ _ _ _

.. .. ..

...

56900

- 1

----- -----

--

-

----

..

-..

..

...

--

u. J

--------1

--

- - - - - - - - - 1

- - - - - - - - - 1

---56900

- -

..

a.

J l

.. -..

.. -..

- - - - - - - - - - 3

- - 1

----

-

..

..

- - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

Conn~t.ion

for

Styles 562

Sp~;ios

Spr1l'8

Spring

Spring

Scr$~

T~~c~d

Thrend

~nd

56200

Thread

Plug

acd S6700 J - - - - - - - - - - - - - - - - - - - - - - - -

ra.IU!.

N~c:dl~ Tbret~d

Screw.

·

for

Pl~tc,

Slsse,

~nd

Sctev

T~ke-up

T~kc-up

ex~ept

'l'~lo:e-up

~rew

Thr~ad

Ct.~ide

00

fo~

Styles

for

Cor

fQr

Uiro.

Wire.

Style

Vir$,

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Eyelet

'£yd.ot.

Pl<~~te

s.

W;

56300

Styles

56200

Style&

S~ylc!l;

tak~~up

for

!or

5&200 w - - - - - - - - - - - - - - - - - - - - - - - - - 1

for

, f(>t'

for

- .. .. ...... - - - - - - - - - - - 2

w.

At

- - - - - - - - - - - - - - - - - - - - 1

56200

s.

56200

..56200 S, W; 5&300

Styl~&

Style

Styl4&

.~11

Scyle

S,

W;

56300

"-'

: 56300

s.

w1re

- - - - - - - - - - - - - - - - - - - - - - 2

56300

Styhs

56700 J

w,

U;

56)00

56200

M.

56300 £ ,

.xcept

W,

AL

- - - - - - - - - - - - - - - 1

AL

- - - - - - - - - - - - - - - - - - 1

W,

AL

- - - - - - - - - - - - - 1

t:.

AL ---

~;

56300

Cl~S$~$

f',

..

H. ~ - - - - - - - - - - - 1

56'00

.

56500.

G.

N,

R.

U,

:<,

56300

r:,

f,

G.~.

- - - - - - - - - - - - - - - l

Ali

56700

,

AL

it,

. 56900

------

U, X,

..

.. - - .. - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - -

- - - - - - - - - - - - -

Cb~mbet

- - - - - - - - - - - -

Renervoir

Cover.

Top

Cover

lov~t

- - -

--------

---------1

- - - - - - - - - - - - - - .. - - l

- - - - - - - - - - - - - - - - - 1

........

- - - .. - - - - - - - - - - - l

______ ______ "

- - - - - - - - - - - -

...............

Plare

<:..x.cept

for

~nd

Cla$~t~

Nut

!or

Pbt@

w.

~.

AL

Dowel P~ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Pht•

565-00,

Dovel

- - • - -~ • ~ .. -..

ltc!;ervo.tr

Oil

Intake

Dt:ive

- - - - - - - - - -

-----

&rip

(See

Pages Sl, 53, 55,

thr.on~

Style~

cbroat

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

throut

pl~t4.

56300 II, X,

plate.,

56400, 56500, 56700,

pLate

SuppQrt, for

- - - - - - - - - - - - - - - • - - .. -~ -

Support.

56700,

- - - - - - - - - - - - - - -

Pump

- - - - - - - - - - - -

Pl8t~

56900

r ·

in

- - - - - - - - - - - - - - - -

b:a~k

~:;cttbty

Pel~

- - - - - - - -

Shi~ft

.......

- - - -

fot:

- - - - - - - -

Co\'cr

Reservoir

..

countersunk

AL

- - - - - - - - - - - - - -

f1111ster

Support

Stylu

- - - - - - - - - - - - - - -

Scybs

- -

- - - -

- - - - -

cover

-----

59,

61,

head

,

bead,

56900

562:00 R, S

54200 H. K,

for

- - - - - - - - - -

-

63,

for

St.)'les

&\d

L,

6~

.

Scyles

Clau

W,

56300

...

67.

69)

56200

56200

S6300 exc

......

H.

------

R, S

and

..

it

...

....... -........

, K, L, '.}, 5.6300

ept

.....

Class

.... -........

.. -..

St)'le~

56300

• - - - - - - - - - -

~.

AL

sud

Classes

- -

..

- -

56300

-----2

-

....

- .. 1

----

- 1

-----1

..

2. 3

..

M.

AL

...

---

•

AL

- I

..

AH.

- - - - - 1

--

11,

- •

5-6400

..

- -

- -

1

I

I

1

l

t

1

1

1

8

3

I

2

2

3

3

1

2

I

2

9

I

1

I

1

l

1

2

2

2

l

A

See

Page

39

f<lt

U,

X,

Ml

and AL.

tbutnbs~rev

adjuSt4hle

h :u:c:

needle thr

ead

eyoJ.ct

29

it$5c::.QJy

No

. 29476

Wi'

for

Styles

56300

t;,

i'

,

G,

1<. R.,

Page 12

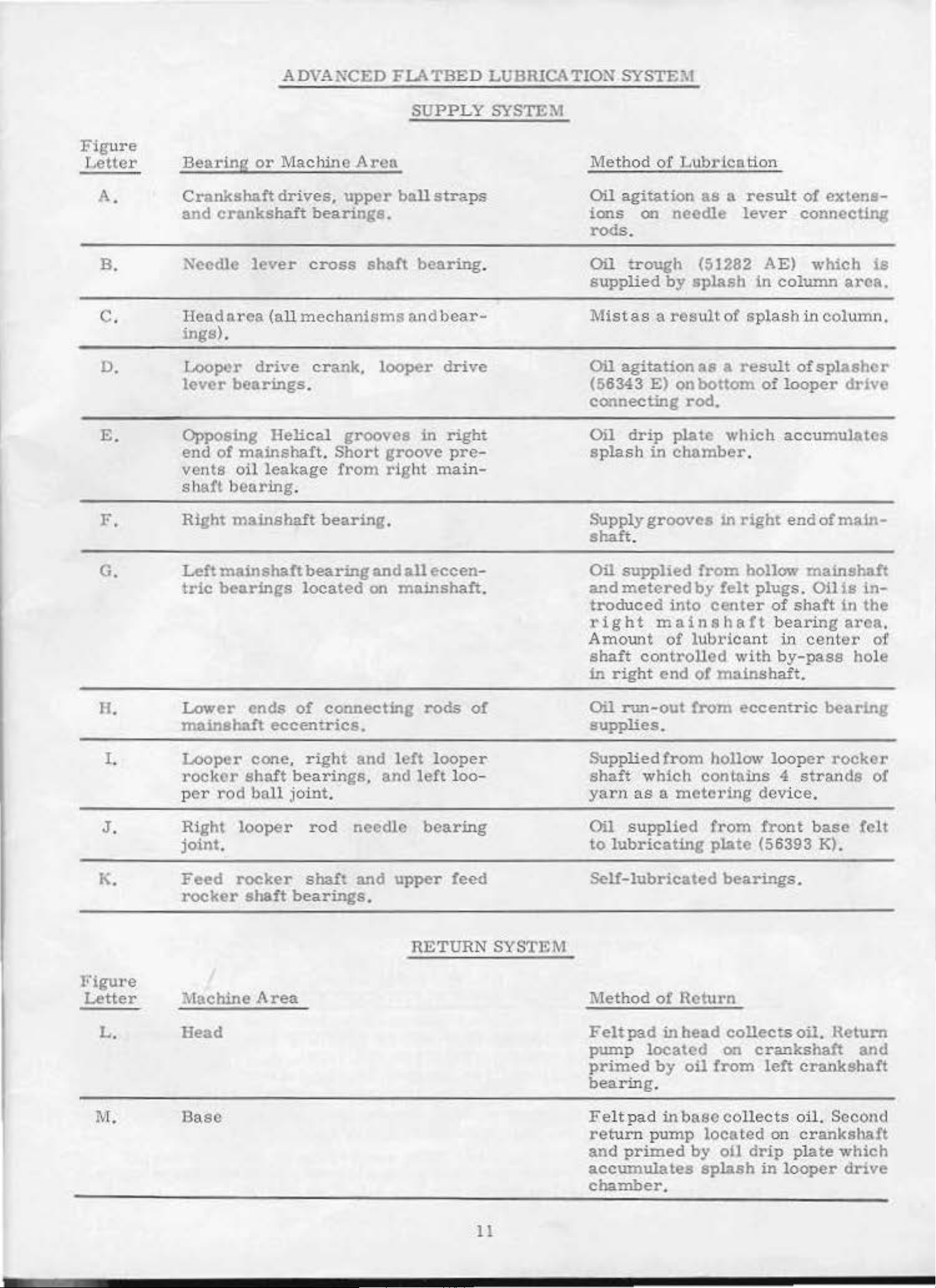

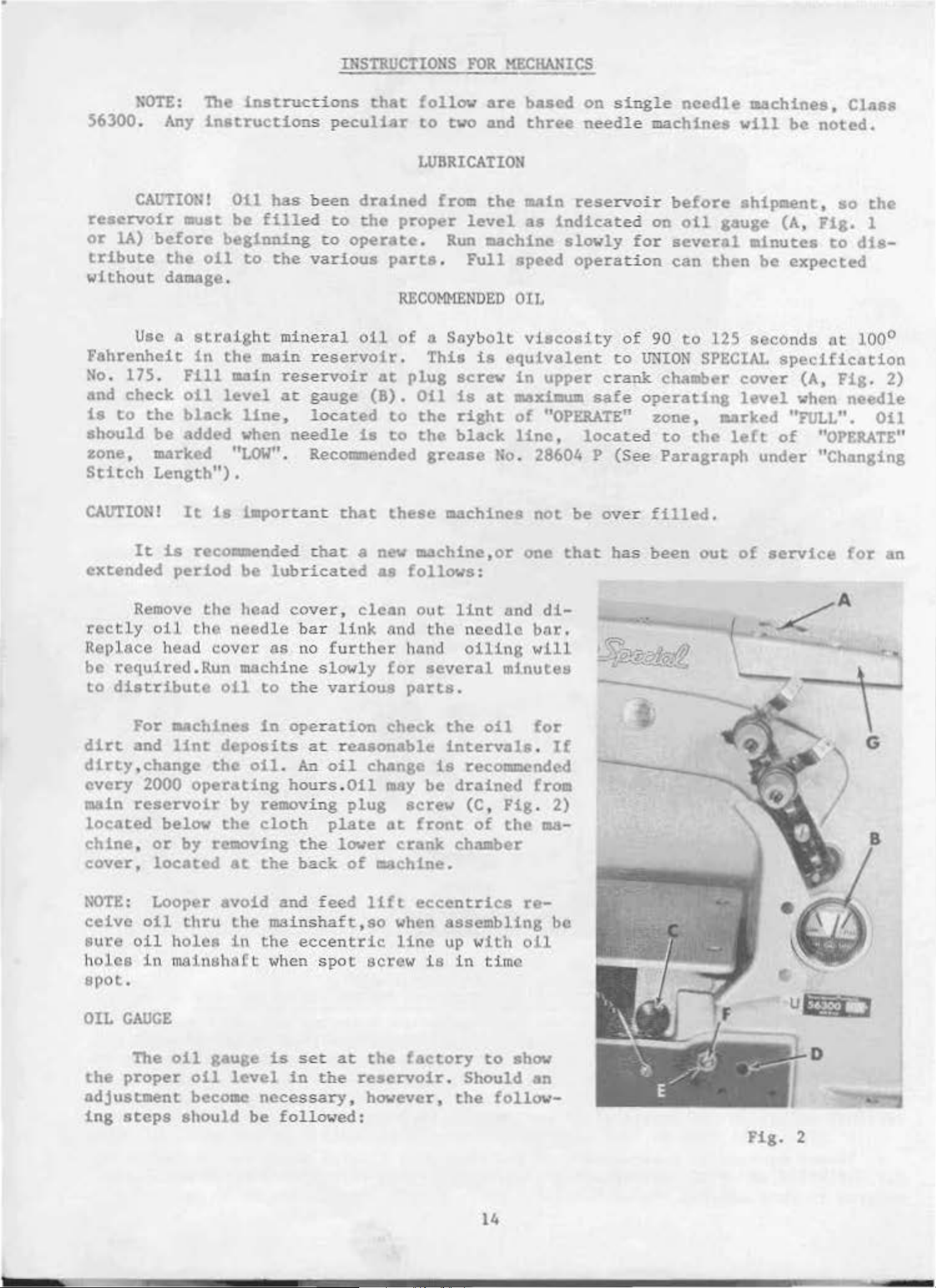

ADVANCED

FLATBED

LUBRICATION

sYSTE:\1

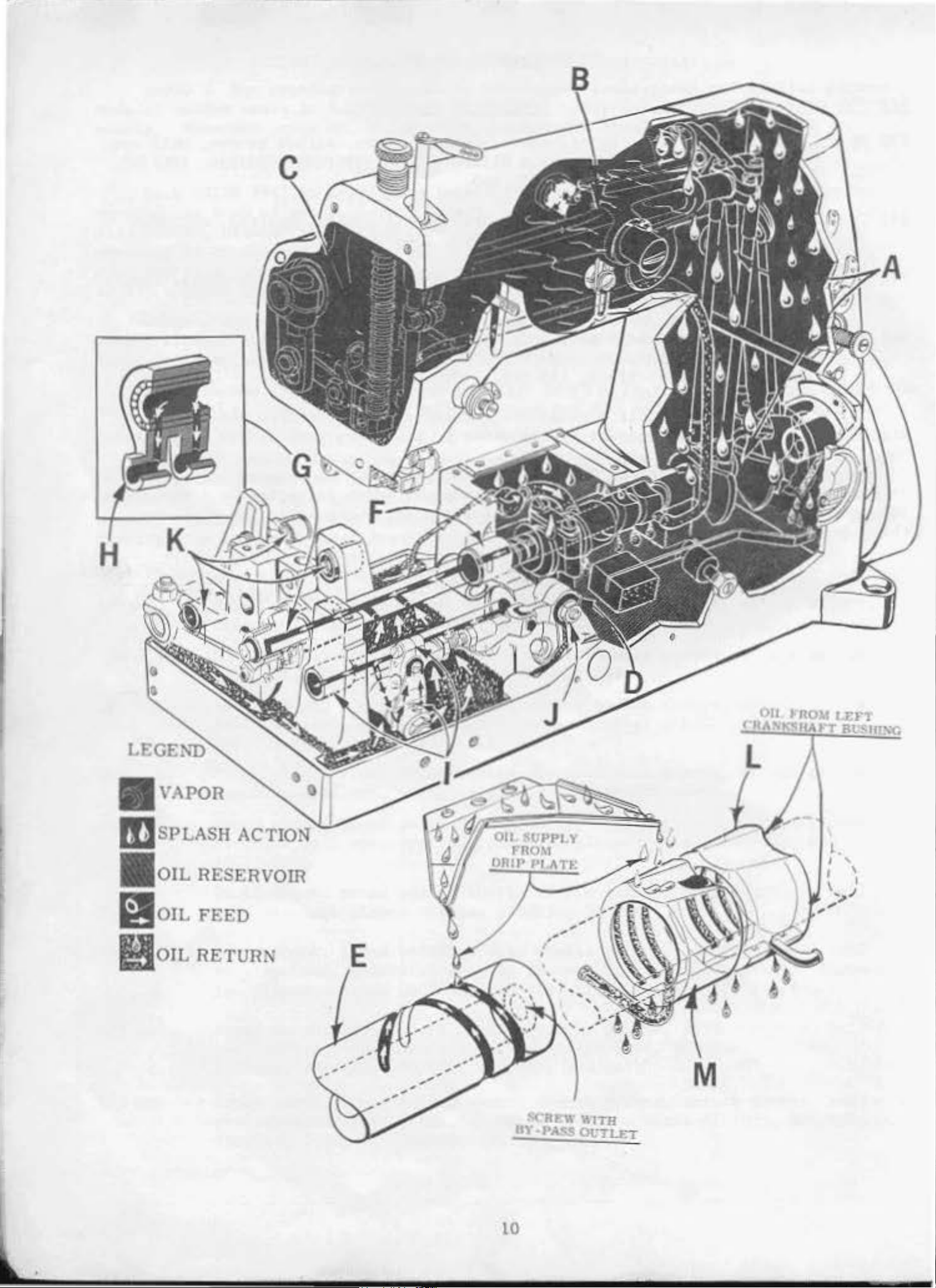

Figure

l

~etter

A.

B.

c.

0.

E.

Bearing

Crankshaft

and

Needle

Head

ings).

Looper

lever

Opposing

end

vents

s

haft

or

crankshaft

lever

area

drive

bearings

of

mainshaft. Short

oil

bearing.

Mach.ine

drives,

bear.inge.

cross

(all

mechanisms

crank,

.

Helical

leakage

Area

upper

shaft

looper

grooves

!rom

SUPPLY

ball

straps

bearing

and

in

groove

right

bear-

drive

right

pre-

main-

SYSTEM

.

Method

Oil

ions

rods

Oil

supplied

Mist as a result

Oil

(56343

connecting

Oil

splash

of

Lubl'lca

agitation

on

needle

.

trough

by

agitation

E)

on

rod.

drip

plate

in

chamber

as a

(51282

splash

as a result

bottom

l:ion

result

lever

AE)

in

of

splash

of

which

.

of

extens-

connect.in8

'vhich

column

in

ofsplasher

looper

accumulates

area.

column.

drive

is

F.

G.

H.

1.

J.

K.

Right

Left

tric

Lower

ma.insha.It

Looper

rocker

per

Right

mainshaft

mainsbaftbearing

bearings

ends

cone,

shaft

rod

ball

looper

joint.

Feed

rocker

rocker

shaft

bearing.

located

of

connecting

eccentrics.

right

bearings,

joint.

rod

sbaft

bearings.

needle

and

on

and

and

all

eccen-

mainshaft.

rods

left

and

upper

looper

left

bearing

o!

loo

-

feed

Supply

shaft

Oil

and

troduced

right

A

mount

shaft

in

Oil

supplies.

Supplied

shaft

yarn

Oil

to

Self-lubricated

grooves

.

supplied

metered

by

into

mains

of

lubrica

controlled

right

lubricat.ing

end

run-out

from

which

as

a

metertng

supplied

of

from

in

right

from

contnins

hollow

felt

plugs.

center

haft

nt

with

mntnshaft.

eccentric

hollow

from

plate

bearings.

end

mainshalt

of

shaft

bearing

in

cen

by-pass

looper

4

strands

device.

front

(56393

of

main-

Oil

is

tn

uca.

ter

bearing

rocker

base

K).

in-

the

of

hole

Of

felt

RETURN

Figul'e

Letter

L.

M.

Machtne

Bead

Base

Area

SYS'l'EM

ll

Method

Feltpad

pump

primed

bearing.

Fe

lt

return

and

accumulates

chamber.

of

in

located

by

pad

in

pump

primed

Return

head

oil

base

collects

on

from

co

located

by

oil

splash

oil.

crankshaft

left

crankshaft

llects

drip

oil.

on

cranksha!t

plate

in

looper

Return

and

Second

which

drive

Page 13

FILL

RESERVOIR

MAIN

23

30

I

•

4

d)O

q;

12

1

'

Page 14

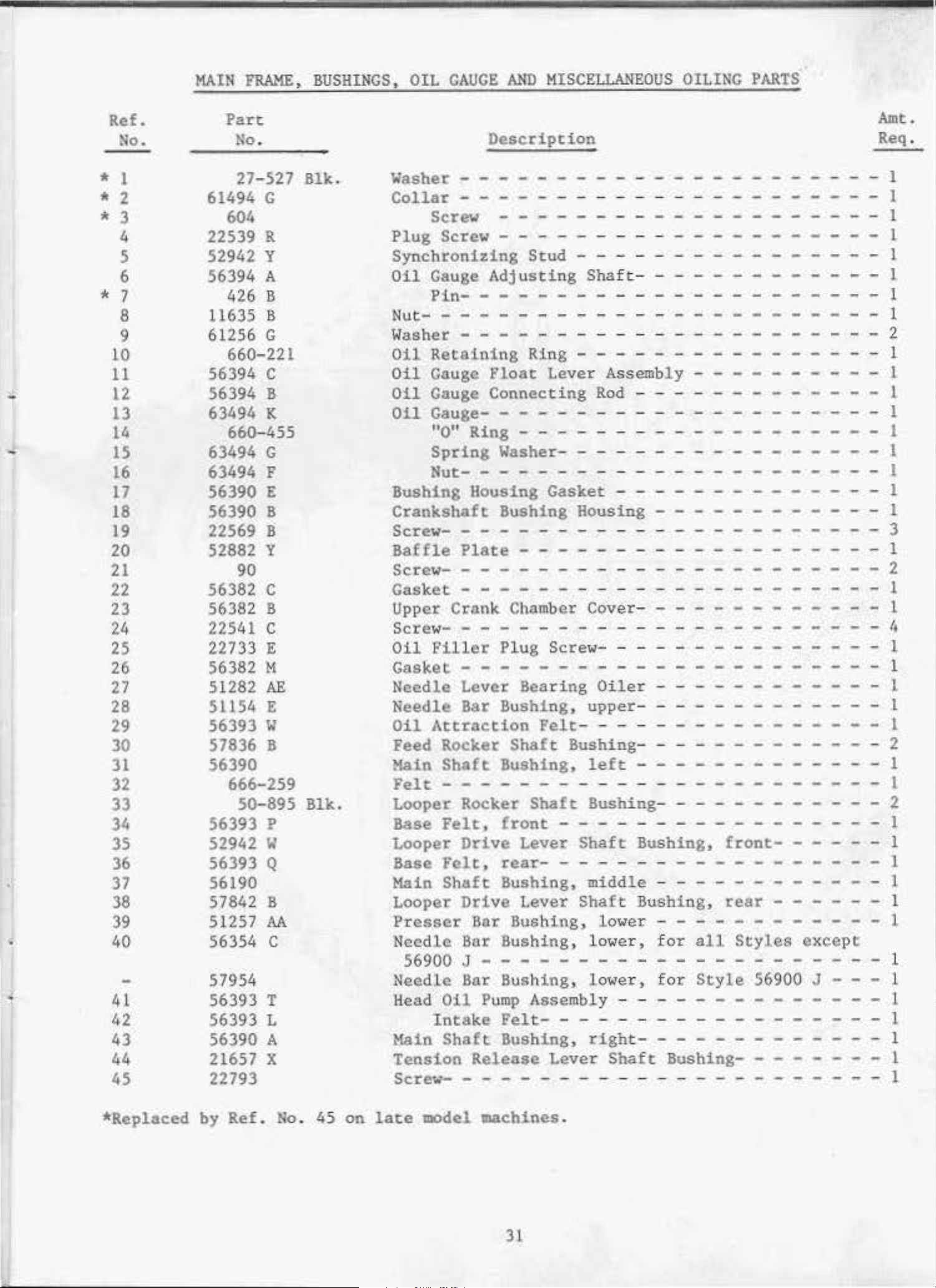

MAIN

FRAME

BUSHIN

,

GS,

OIL

GAUGE

AND

M

ISCE~

~

US

OILING

PARTS

Ref.

No

.

I 27-527

*

2

*

.. 3

Par~

No

61494 G

604

4 22539 R

5

6

* 7

8 11635

9

10

11

12

l3

14

15

16

17

18

19

20

21

22

23

24 22

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

52942 y

563

94

426

61

256 G

660-2

56394 c

56394 B

63494 K

660-4

63494 G

63494 F

56390 E

56390 B

22569 B

52882 y

90

56382 c

56

382 B

54

22733

56382 M

51282

51154 E

56393 w

57836 B

56390

666-259

50..895

56393

52942 w

56393 Q

56190

57842 B

512

57

56354 c

579

54

56393 T

56393 L

563

90 A

21657 X

45 22793

.

A

B

6

1 c

E

AE

p

AA

Blk. Washer

21

55

Bl

k.

Amt.

Descrip~ion

Req

- - - - - - - - - - - - - - - - - - - - 1

Collar

Plug

Synch

Oil

Nut

- - - - - - - - - - - - - - - - - - - - - - 1

Wash

Oil

Oil

Oil

Oil

Bushing Housing Gask

Crankshaft

Sere~-

Baffle

Screw- - - - - - - - - - - - - - - - - - - - - 2

Gas

ket - - - - - - - - - - - - - - - - - - 1

Upper

S

cre

Oil

- - - - - - - - - - - - - - - - - - - - 1

Screw - - - - - - - - - - - - - - 1

Scre

Gauge

Pin-

er

w - - - - - - - - - - - - - - - - I

ronizing

Adjustin

S~ud

g

- - - - - - - - - - I

S h

af~

-

- - - - - - I

- - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - 2

Retaini ng Ri ng - - - - - - - - - - 1

Cauge

Cauge

Float Lever

Assemb

ly

- - - - - - - - l

Connecting Rod - - - - - - - - - 1

Cause- - - - - - - - - - - - - - - - - - - 1

"O"

Ring - - - - - - - - - - - - - - - - - I

Spring

Nut-

Crank Chamb

w- - - - - - - - - - - - - - - - - - - - - '•

Filler Plu

Washe

r-

- - - - - - - - - - - - - - I

- - - - - - - - - - - - - - - - - - - I

et

- - - - - - - - - - - - l

Bushing Rous

- - - - - - - - - - - - - - - - - - - - 3

Plate

- - - - - - - - - - - - - - - 1

er Cover

ing

- - - - - - - - - - - - 1

- - - - - - - - - 1

g Screw- - - - - - - - - - - 1

Gasket - - - - - - - - - - - - - - - - - - 1

Needle Lever

N

eedle

Oil

Bar Bu

Attraction

Feed Rocker

Main

Felt

Shaft

- - - - - - - - - - - - - - - - - - - 1

Looper Rocker

Base

Felt,

Looper Drive Lever

Base

Main

Looper

Pr

Felt,

Shaft

esser

Drive L

Bor

Naedle Bar

56900

J - - - - - - - - - - - - - - - - - - - - - 1

Needle Bnr

Head

011 Pu

Intake

Main

Shaft

Tension Release Lever

Sere

~-

- - - - - - - - - - - - - - - - - - - - - - 1

Bearing

shi

ng, up

Felt

Oiler

per

- - - - - - - - - - l

- - - - - - - - - - - - - l

- - - - - - - - - - - - - - - - 1

Shaft Bushi ng- - - - - - - 2

Bushing,

Shaft

front

rear-

Bushing, m

ever Shaft Bushing,

Bushin

Bush

Bush

mp

Fel

ing,

ing

Assembly - - - - - - - - - - - - - - 1

t-

Bushing, r

left

- - - - - - - - - - - - - 1

Bushi ng- - - - - - - - - - - - 2

- - - - - - - - - - - - - - - - - 1

Shaft

Bushing,

front-

- - - - - l

- - - - - - - - - - - - - - - 1

iddle

- - - - - - - - - - - - l

rear

- - - - - - l

g, lower - - - - - - - - - - - - l

lower,

, l ower,

for all

for

Style

Styles

56900 J

except

--

- - - - - - - - - - - - - - - - - 1

igh

t-

- - - - - - - - - - - - 1

Shaft

Bushing- - - - - - 1

- 1

.

*Replaced

by

Ref. N

o.

45 on

late

model machines.

31

Page 15

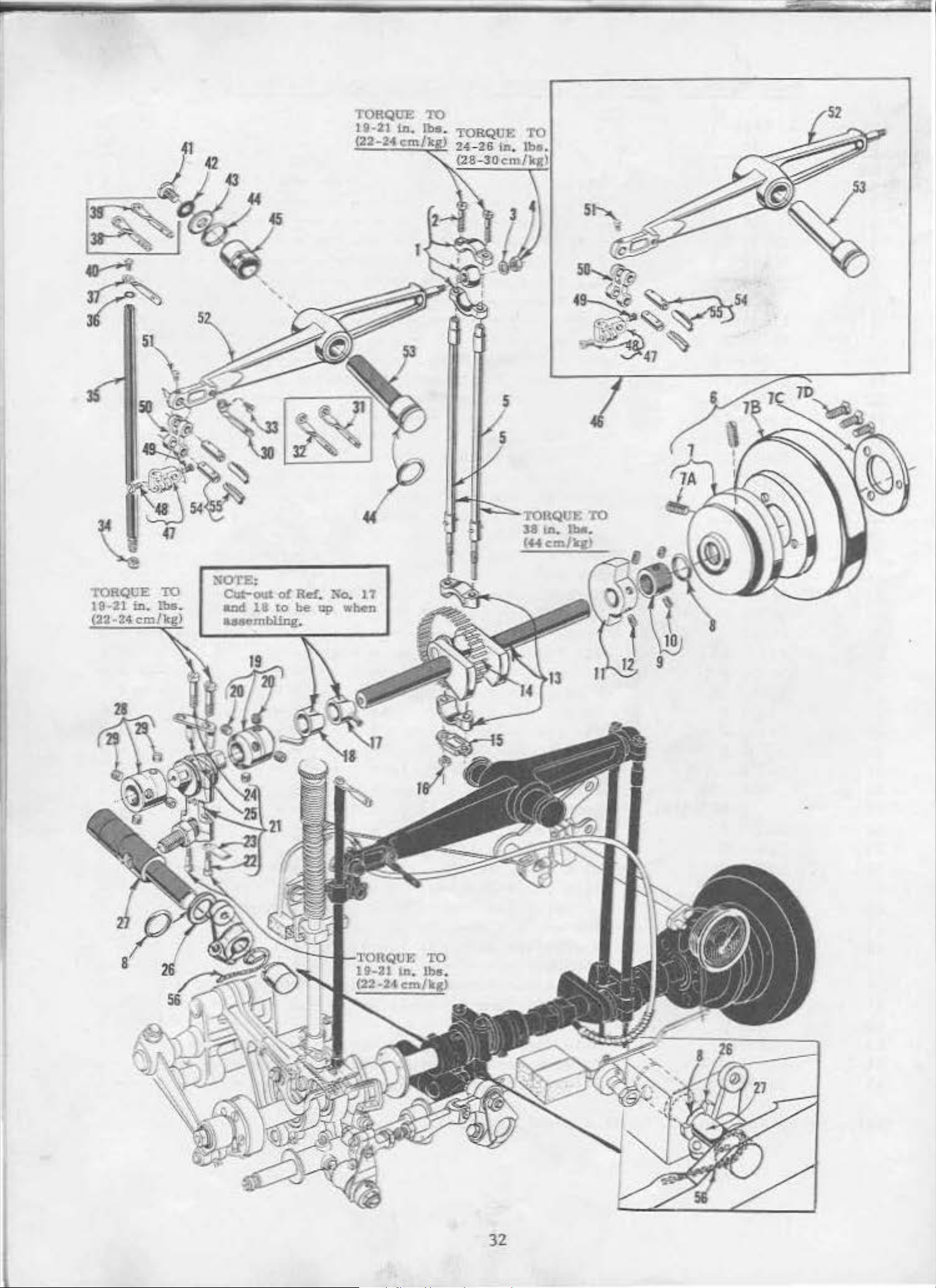

liOTE:

~OU1.

and

18

&Mttmbllng.

~-·

o!

nca

.

to

be

llp

~--

11

*-'

·

wrutn

32

Page 16

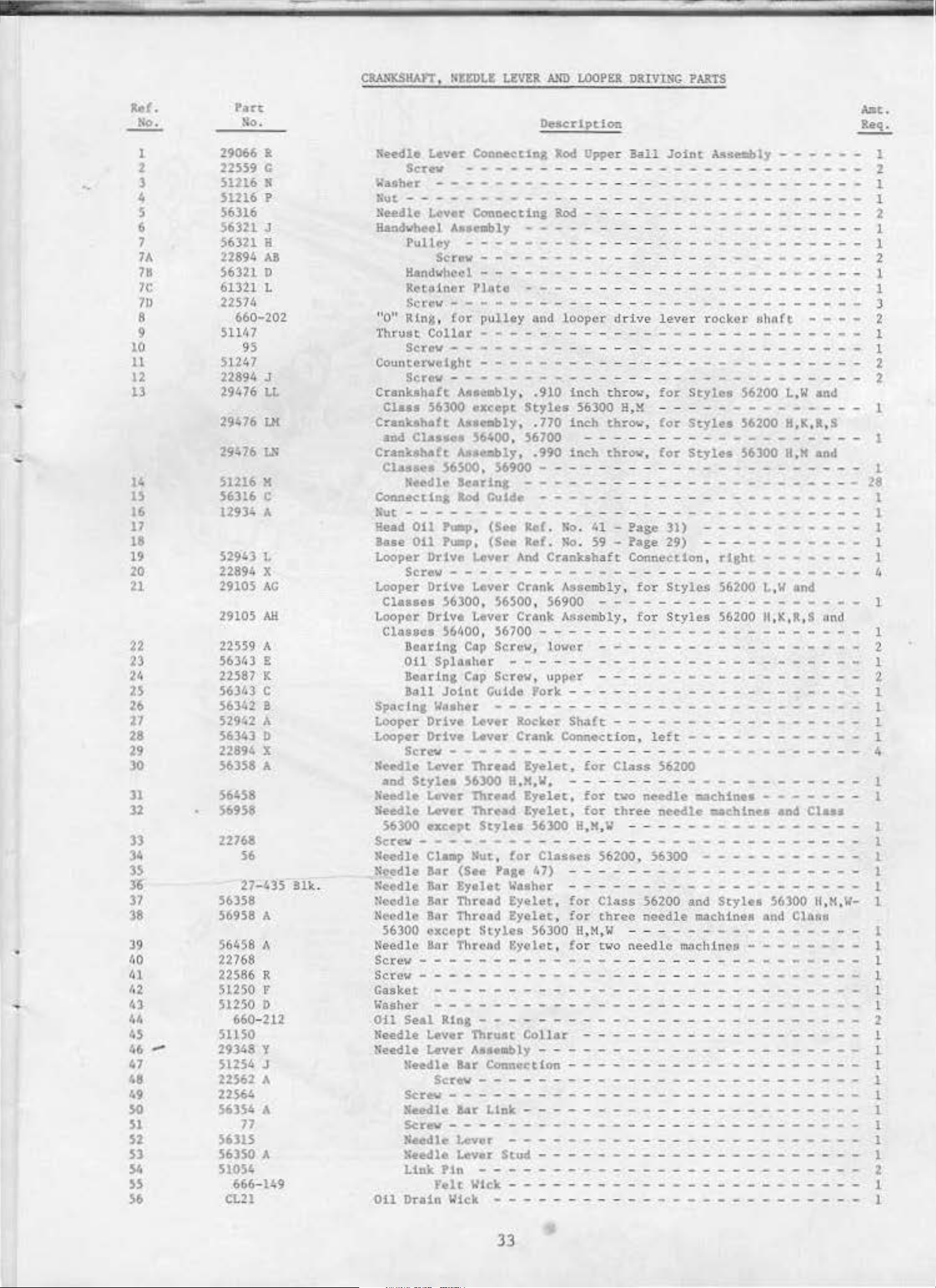

CRASKSI!APT

, K!toLE

~EVER

A.

'ID

LOOPeR

D~IVING

PARTS

-

•

..

a.t.

N.o

•

1

2

l

I.

s

6

7

7A

78

7C

7D

8

9

10

H

12

13

I<

u

16

17

18

19

20

21

22

23

21

,

25

26

27

28

29

lO

ll

3l

n

34

35

36

37

38

39

'·0

41

'•2

'•l

••

45

46

.,

-

..

49

50

51

52

53

S4

5S

56

Pare

No

.

29066 R

22559 G

51216 N

51216

56316

56321

56321 8

22894

56321 D

6U21

l'

J

All

L

22574

660-202

)111

·7

95

51247

22894

29476

29476

2.9476

51216 K

56316 c

U9l!.

52943

22894

29105

29105

22559 A

56343

22587 K

56343 c

56342

52942 A

56343

22894 X

56358 A

56458

J

LL

LM

LN

A

l.

X

AC

AR

E

B

D

)6958

2:2763

56

27-

435

56358

56958

5645

2276

2258

51250 F

SUSO

StlSO

29348

5US4

A

8 A

8

6 R

D

660-212

y

J

22562 A

%2564

56354

56315

56350 A

51054

71

666-

CL21

A

149

B1k.

Du<:r 1 ptlon

Needle

Nut

~eedl.e

H.aftdwheel A•ll!mbly - -

"0

T

h.ruet

Cou

C~an

Class

CraakehAtt

~

Cr:aa~aft

CL&ooca

Coonectin&

Nut - - -

Head

Base

Looper

Looper Drive

C1aaaea

L<~opar

C1a••••

Spacln& Wnlhtr - - - - - - - - - - - - -

LOoper

~ooper

Needle

Aod

Needl~

Seedle

S6300

Screw

~ecdle

~t.oedle.

Needle.

:(ccdle. S.ot T'hro.ad

Needle

56300

Needle. &or

Le:vtr

Scr~

- - - - - - - - - -

~vor

Pulley

Sere"' - .. - - -

Hand'"thC<.'l

R~tbtn~r

SCtc:!V - -

10

Rin$j,

Collar

Sc~~

v

nterwQiSht -

Scr~

v

kaba!t

56300

Cl

..

Nt~edlt:

011 Pu.p,

OU

Drive

Sdra~

Driv•

ConMC.tins

Coa.tw:~ting

- ...... -

loci Upper

- - - - - - - - - - - - - - - - - - - 2

- - - - - - - - - - - - - - - - - - - - - 1

..

-

-- --- - - - - - - - - -- ------

.. -.....

Ploto

......

!ot' pulle

- - - - - - - - - - - - - - - -

- - - - - - - - - - - - - -

.. -..

- - - - - - - - - - - - - - - - - - -~ ..

A••cmbly, .910 inch

•xccpt

~•eobly,

•~•

36400, S6700 - - - - - - - - - - - - .. - - - - - - 1

MJ'l:ubly,

$6~00.

k.arin&

lod

..

Pu.p,

~6900

Outde - - - - - - - - - - - - - - - - - - - - - - 1

- -

..

(S~c

(Seo

Lov•r

- - - - - - - - - - - - - - - - - - - - - - - - -

Lever

$6300, 56500

L•ve-r

-

·--

-

------

- -

- - - - - - - - - - - - - - - - - - - -

y

Ati

d -loo

per dri

- - - - - - - - - - - - - - - - - -

~br~~~

Styles

.

.9'10

110

56300

~neh

tr\eh

throw

throv~ Co~

H,~

- - - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - .. - - - -

- - - - - - - - - - - - - - -

tor.

So. '1-

lte:f.

~

And

Crankshaft

Cr~nk

Assembl

.

59

-?age

y, for S

Page 31) -

, 56900 - - - - - - - - - - - - - - - - - - 1

CrA

nk M$embl

y,

$6400, ,6700 - - - - - - - - - - - - - - - - - - - - - - 1

n

eodna

Oil

Beocin&

Boll

Set~

Styltt

C'p

Sen·v,

Splo8hcr

C4p

Serov.

Joint

Drive

Drive

Lever

Levtr

lAver

•xcept

Cuide 1ork - - - - - - - - - - - - - - - - - - - - 1

Ltvtr

Levtr

- - - - - - - - - - - - - - - - - - -

Thrtad

~6300

H.~,v.

Tl\Tud

Thr~•d

StJle•

lowf'

r - - -

...

- - - - - - - - -

u

pp~r

lockor

C~ank

lyelc:t_,

- - - - - - - - - - - - - - - - - - 1

Shu!t - - - -

Connection, left - - - - - - - - -

for

- - - - - - - - - - - - - - - - - - - - 1

Ey-e:bt.

Eyelet.

56300

for

for

B.~~v

C101ss-

C\tO

three

- - - - - - - - - - - - - - - - - - -

Claap

aar

JSor

&i'lf

C~C~Pt

~ut

(SH

:Sy•lot

Thro•d

Stylqs

'thrend

.

lor

Paat

'-'uhcr

Eydet

Eyelet

~yelc

Cla$$C$

47)

.

.

56300

c,

S6200

- - - - - - - - - - - - -

- - - - - - -

for

Cl~s&

for

tbt'cc

H,M

,W - - - - - - - ..... - - - - - - - 1

f

or

two

needl

aa.u

.Joint

ve

l e

.. -.. .. .. .. .. .. ..

f

or

Aa!U!=bly - - - - - - 1

-

-------

ver roc

Style•

ker ah

..

nrt

- - ..

..

..

56200 L,W and

- - - - - - - - - - - - - - l

,

fo~

Scyle.

Styles

~6200

S6300 II,H

.. -..

- - - - - - 1

----------

29)

--

------

Cona~etion

t

or

Styl

..

- - -

...

S6200

ne~cUe

needle.

.

tyles

es

ti&ht

56200

56200 U,K,R ,S <l

..

- - - - - - - • - - 1

- - - • - - - 1

~.w

- - - - - - - - - - - - - 1

...

- - - - -

...

- - - - - - - - - - - - 1

...

aacbinu

Ncht.nu

--

- - -

- - - - - - - I

aod

- - - - - - - - - - - - - - - - 1

...

- - - - - - - - - - 1

. 56300 - - -

...

- - - - - -

56200 and

need

le

GIOI.chinea

e

mo'l

<:h.Lncs

...

- - - - - - - l

..

- - - - - - 1

..

Styl•a

S6l()() H,M.

•nd

- - - - - - - - I

Screv .. - - - - - M - - - - - - - - - - - - - -

Scr

ew

- - - - - - -

Gasket

Washer

Oil

Seal

tie.edle.

r;

eedle

tludl•

Sc:rtw

Needl~

~rev

Needl•

Nee:dl6 l.Cw•r

Link

011

Dtain

- - - M - - - - -

• -

....

- - - - - - - - - - - - - - - - - - - - - - - - - - l

Rlaj

- - - - - - - - - - - - - - - - - - - - - - - - - - 2

Lf.v~er

IA.ver

'ft1ruu

,\aatll'lb

a..r

Connt-etlon

Screv

- - - - - - - - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - - - - - - - - - - - - - - - - - -

aar

- .. - - - - - - - - - - - - - - - - - - - - - - - - - -

~VOf

Pin

fttlt

......

Wtck

Wick

...

- - - - - - - - - - - - - - - - - - - - - - 1

....

- - -

CQUar

ly

- - - - - - - - - - - - - - - - - - - - - - l

- - - - - - - - - - - - ...... - - - - - l

- - - - - .. - - - - - - - - - - - - - - l

...

- - - - - - - - - - - - - • - l

Ltnk - - - - - - - - - - - - - - - - - - - - - - -

.....

Stud

........

..

..

H.~.l,S

and

..

--

..

- - 4

an4

nd

- - - - 1

... ... ...

...

- - - - 4

Clut

- - - - - l

W-

Cltktl

..

- - - 1

l

1

2

1

2

1

l

3

2

1

1

2

2

18

1

1

1

1

1

1

l

1

l

z

l

1

33

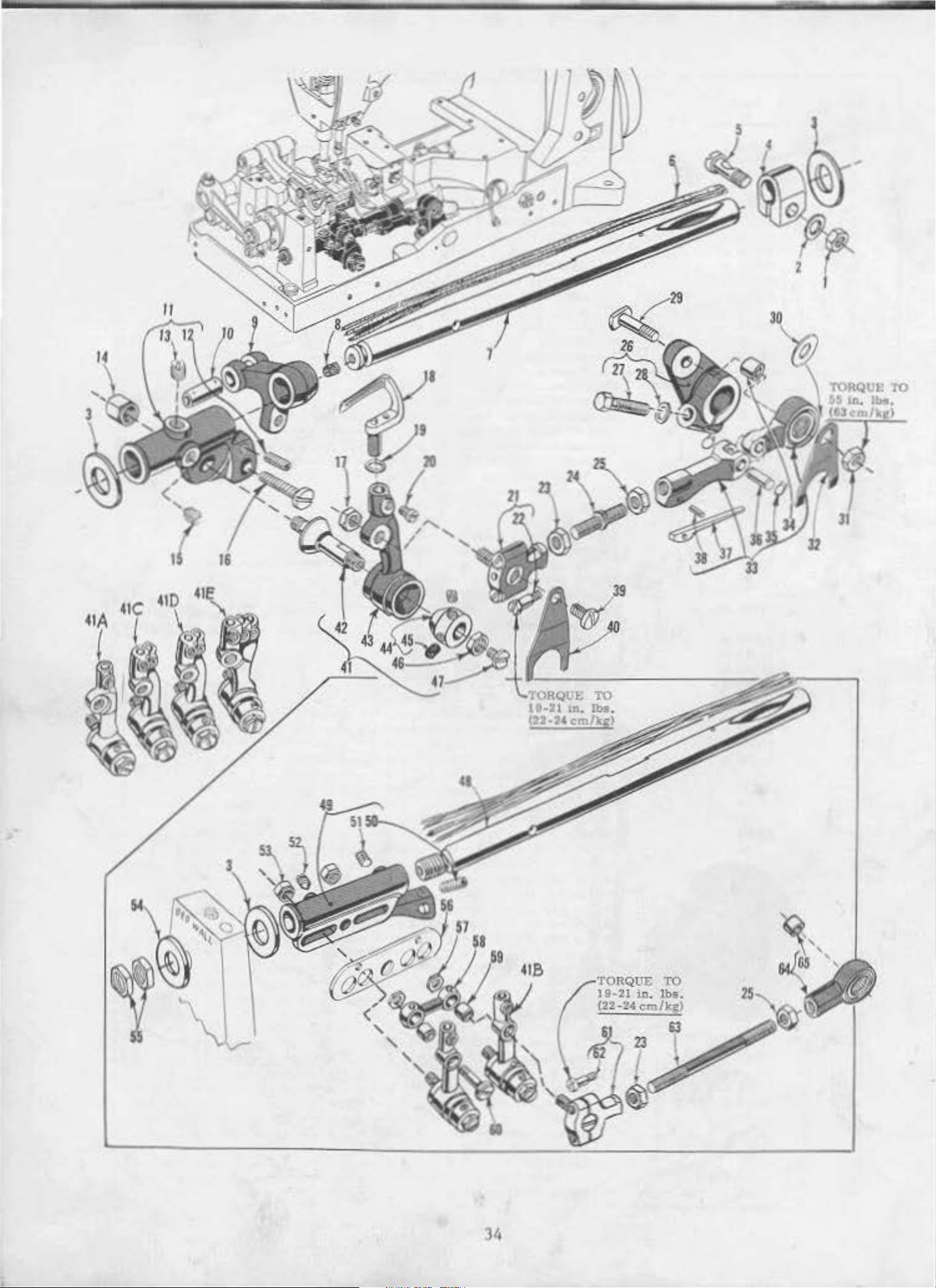

Page 17

14

Page 18

LOOPER

Jt.OCK.tR

AN1>

CO~'XOCtl~

ROD

PARTS

Ref.

~0

.

l

2 5121& N

3 $124.4 l.

4

5

•

J

8

9

10

11

12

13

,.

l5

16

17

18

19

20

;:::wn

22

23

,.

25

26

27

28

29

30

31

J2

~33

34

35

36

31

38

39

;o

toP

42

43

"

.a;

''

48

"

49

so

51

S2

53

''

;;

S6

>J

58

S9

60 12835

61 $7841

62

63

64

6S

P<trc

No.

18

.)1244

55244

tl

G

003

S634G

C067 E

$6"344

512.)6 A

56344 c

B

119

98

512.46

96

2237lo

18

13

57841

22729 (

269

$1,2-"0

1>

512.40 £

18

!l63&2

22882

51242

52942

c

M

!t

20

18

5639'3 X

)6341

$6341

M

f

660-310

56341 R

563U

G

S0-4.58

87"

$6393 J

S174S

15465

F

sa_.

258 A

22829 -

'.i6744 A

567441

119

98

96

1280

56751

.5ll70

.56772

0

-~

56772-M

14077

51770-56

.51770-

6.!,

51771

}.

22729 c

4l047

Z9'•76

56341

LV

F

»lk..

Nu

L, tor

WR$her

Thru$t

Looper

Looper

Columl>b Wool Yilro

t.q,opn aoeJ<er

Cork~lut-----·--·--

Lc>ope~;

Looper

l.oop(l!; R.ochT

l.oop(lr

Screw

Looper

Nuc,

Loop~r

l,..oopor

Screv

l.oopc:r

Nut,

Looper

'(.oop(llr

~ut.,

Looper

Loo~er

Washer

~'ut

t.ooper

J.oop~t

~11

Style$

,

for

all

Style~

~35her

Rocker

S.Ockel:

Rocker

A\'Old

St¢p

Sc~~~

9.ocker

- - - - - - - Roc:k$r

for

(See

C¢llar

- - -

Conn~ecing

Scxe~

left

Connecting

Connecting

ritht

Dr1vi!

S<:te~

Wo1.$h$t

Lever

- - - - - - - - -

..

..

.... -..

Connectins

Coo.Metbl3

- - - - - - - - • - - • - - - - - - - • - - - - - - - - - 2

Shaft

S'bafL

Slwlft

S:t.dt

Link

Pin

ftame,

Scrc:'l.' - - - - - - - -

- - - -

all

P.;~.g9

--

.....

St.ud Nut,

f"l~iltne

St)'lc~

49)

(See

- - - Jt.od

- - - - - - - - - - - - - .. - - - - - - - - - - - - - - -

h>1n<l

~llread

Rod,

Rod,

h~nd

thr'):ui

Lever,

- - - - - - - - - - - - - - -

,...,,.

_ -

Stud

- - - - - - - - - - - - • - - - - - - - - - - ... -

- - - - - - - - - - - - - - - - - -

Rod

Rod

cxcep~

Cl$mp,

C01l3r

(4

,

!or

Are~

for

Loek

except

Psge

marked

56700 J - - - - • - - - - - - - - - - - - - - - 1

e x

cept

56700

for

StUd,

su:a~\ds

- - - - - - -'-- - •

- - - - • ...... - - - - - - - - - - - - - -

• for

... ...

- 8 inche:c

all

Style.G

all

Styl~~ ~xec.pt

...

- - - - - - - - - - - - - - - - - - - - - - - - - - - - all

...

..

...

Secw

S-6700 J - - - - - - - - - - - - • - -

...... - - - - - - - - - - - - - - - - - - - - - - -

49)

- - - -

---

Ball

- - - - - - - - - - - - - - -

for

tor

- -

!~All

Jointed

--

Joint,

811

CUtiH;:

.. .. ..

"A"

...

- - - - - - - - - - - - - - -

JoUle

Sec:t:i.on ll:;!;

re.rrulc: - - - - - -

t

rt~1rc

Hinge

Spring

Spring

Sercw

Looper

Loopttr

J...ooper

Looper

Looper

~

J.«k

Looper

LQQper

Stop

Set

Spot

Ser~

Looper

Looper

!lut

,

for

Looper

Loope:r Re¢k(lr

Nut,

for

Looper

Loop-er Rocket'

l.ooper

Sc~ew,

L0¢?~r

Sore~

LO¢p~r

Loop4r

ferrule

kin~

- - • - - - - - - - - - - - - - .. • - - - - - - - - - - - - - •

Pia

- - - - - - - - - ..

- - - -

l'in

- - - - - - - -

Conne.et1ng: Rod

Rocker

Screw

k

Rocker

Rocker

Screw - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1

R¢cket

Rocker

RoCker

Rock~r

R.oc:ker Linl<

for

Connect-ing~

A~:;cml>ly

Roeker

Rodt~r

Roek$r

- - - - - - - - - - - - - - - - -

Nut; - - - - - - - - - - -

Nuc

Set~

S~w-ft

fraoa,

Scr~

~

- - - - - Stud

Sh~!t

Style

Sp~eing

Sp~eiag

St)'le.

L~ok

Link,

Slyle

...

- - • - - - - - - - - - - - - - -

- - - - - - - - - - - - - - - - - - - - - - - - - - - - • - - - - - - 1

....

- - - - - - - - - - - - - - -

a.&.U

Joint

(Stc

CMn

C01~e

Stud

- - - - - - - - -

(Sec:

Chart;

CQ-1\El

Bdo

- - - - - - - - - -

- - - - - - - - - - - - - - -

,

for

St:yle

to

t

Style

- - - - - -

Nut ,

Thrus

56700 J - - - - - - - - - - - - - -

Pl~te

'Pla:te,

~6700

J - - - - - - - - - - - -

,

for

for No.

f<!nule,

56700

~11

...........

.. -......

tor

Sty!~

t

Coll~r

,

foe

for

No.

56

6-4

for

J - - - - - - - - - -

Jotnt

- • - - - - - - - - - - - - - - - - - - - - .. - - - - - - - - - - - - - - - - - - - 2

Connecting

Cann$CCin~

- - - - - - - - - - - - - - - - - - • - - - - - - - - - - - - - - - - -

Rod,

Rod

for

Scyle

A8seably,

De.scrit'tion

J

---

all

SLy

lea

exc~pt

for

.:~U

Styles

!(Ins)

¢X¢$pt

- -

-----

....

- - - - - - - - - - - -

St-)'ler.

- - - - - - - - - - - - - - -

5.6700 J - - - - - - - • - - - - - - 1

36700 J - - - - - - - - - - - - -

$-XC0PC

- - - - - -

- - - - - - - - - ......

left, !or

Styles

- - - -

---

56700

56700

gauge, Style:

gm.Jg9-,

Style.

,

t i

ex

cept

S640Q - - - -

-

--

011er,

.......

Oilc~,

Bel<>'<>')

• .. •) -

tight

enbly,

- • - - - - - - - -

..

- - - - - - - - - - - - -

left

..

.. -..

- - - - - - - - - - - - -

J - - - - - - - - - - - - - - - - 1

J - - - -

- - -

- - -

56700

.

No. 56

No.

left

5670() J - - - - - - - - - - - -

Sht. !or

J-

right,

for

tauge

64

&d'-!ge. Style

Style

56700 J - - - - -

,

for

Style

56700

E"xcept

... -...

56700 J - - - - - - - - - - -

........

~11

Styles

56700 J and

...

.........

J - .. - - - - - - - - - - - - l

$6700 J - - - - - - -

- - - -

- - - - - - - - -

..

- - - - - - - - - - - - - - - - - - - 1

- - - - - - - - - - - -

except

....

- - - - - - - - - -

Clos.s

..

- - - - - - -

- - - - - - - 1

-----

..

- - - - - - - - - - - - - - - - - - - - 1

- - - - - - - - • - - - - - - - - - - - - - - - 1

r1..gbt,

-

-..

Style

,

Sty!~

..

56700

56700 J - - - - - - - - - - - - - - - - 1

.... -..

Seyle

56700

for

all

..

.. .. - - -

- - - - - - - -

..

- - - - - - - - - - - - - - - -

- - - - - - -

..

- - - - - - - - - - - - - - - - - - - - 2

...

- - - - - - - - - - - -

..

- - - - - - - - - -

S6700 J

.....

- - - - - - - - - - -

56700 J - -

56700 J ..

- - - - - - - - - - - - 2

J - - - -

.. -...

- - - - - - - - - - - - - - - -

56700

J - - - -

J - - - - - - - - - - - - - 1

-- --

..

- - - - - - - - - - - - - - - •

--

.... -..

.........

..

- - - - - - - - - - - - - - - 1

.56700 J - - -

56400 - - 1

- - - - - - - - -

...

.........

--

---

..

Style~ cx~cpt

- - - - - - - - - - - - - - - - l

....

.....

- - - -~ - - - - - - - - - - 1

.. • ..

- - - - - - -

--

..

- 1

- - - - - - - - - - - 2

- -

--

..

- - - - 1

......

--

---

--- ---

...

- .. - - - - - - - - - - 1

- - - 1

-

..

- - - - - - - - 1

......

......

- - - - - - - - l

..

--

- - - - - 1

--

---

- - - - - - 1

.........

- - - - - - - 1

- -

- - -

-

...

---1,2,3

........

- - - - 1

..

---

·1

- - 1

..

- - 1

....

- - - - - - - 1

- - -

• • - - - - - - - - - - - - l

.....

- - - - - - - - - - - - 1

..

.. .. .. - - - - - - - - - 1

- - - - - - - - - - - - 1

--

..

- - - - - - - - - - -

.. -....

..

- - - - - - - - - 1

- - - - - - - - - - - - 1

- - - - - - - - - - - - 1

.,

.. ., - - - - - - - - - 1

.....

..

• -

---

...

- - - - - - - - - 1

.. -..

- - - - - - - - - 1

--•-••1

.56700 J - - - - 1

....

- - - 2

- -

.... • --

...

- - -- 1

- - - -

-·~

-/-

- - - -

........

.. -..

- - - - - -

...

- - - - - - - - - - 1

--

--

..... -...

--

---

.. -..

--

..

• - - - 1

- - 1

..