Page 1

®

I N

DUSTRIAL

SEWING

NEST

OUAMTY

STYLES

600AA

600AB

600AD

LEWIS

•

COLUMBIA

MACHINES

CLASS

54600

STREAMLINED

ATALOG

No.

20AM

NEEDLE

C

HI

HIGH

SINGLE

FEED

CA

G O

SPEED

NEEDLE

MACHINES

Page 2

Catalog

INSTRUCTIONS

No.

FOR

120

AM

ADJUSTING

LIST

54600

AA

CLASS

Styles

54600

First

AND

AND

OF

FOR

Edition

OPERATING

PARTS

54600

54600

AD

AB

Union

Rights

Copyright

by

Special

Reserved

19

Machine

in

All

7 2

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CH

ICAGO

in

2

MACHINES

U.S.

Co.

Countries

A.

May.

1972

Page 3

IDENTIFICATION

OF

MACHINES

Each

lhe

name

Standard

letter

"Z".

to

which

"Class

herein.

this

from

handwheel

Streamlined

Double

Needle

System,

With

to

When

the

standard

Styles

This

Class.

the

Feed

Right

"Z".

differs

54600''.

It

Disc

Bar

Filter

of

Union

plate

Style

catalog

can

operator's

is

and

Special

on

numbers

Example:

only

Style

of

machines

from

also

Reference

toward

Flat

Take-up,

Driving

Type

Looper

Needle

machine

the

machine.

"Style

minor

applies

Bed,

changes

number.

the

be

applied

to

position

the

Single

Needle

Mechanism,

Oil

Throw-out

Bar 7 3/4

is

identified

Style

have

similar

style

direction,

operator.

one

54600

are

Example:

in

number,

APPLICATION

specifically

with

while

STYLES

Needle,

Bearing

Single

Return

Pump

for

Inches.

numbers

or

more

AB".

made

construction

discretion

such

seated

Special

in a standard

"Style

in

OF

to

the

as

OF

MACHINES

Independent

Crankshaft,

Reservoir

and

Simplified

by a Style

are

classified

letters

54600

that

CATALOG

Standard

to

right,

at

the

Oil

suffixed,

Style

are

it

contains

some

left,

machine.

Row,

Enclosed

Siphon

Threading,

number

numbers

machine,

ABZ".

grouped

Styles

Special

front,

Needle

Light

Assembly,

which

as

standard

but

never

contain

a

under a class

no

letters.

of

machines

Styles

back,

Operating

Feed,

Weight

Automatic

Maximum

Presser

Loopers

is

stamped

and

contain

the

"Z"

is

Example:

as

of

machines

etc. , are

direction

High

Lubricating

Work

into

special.

the

letter

suffixed

number

listed

in

given

of

Throw,

Bar

and

in

Line

Space

54600

54600

54600

number

The

blade

Collectively,

It

standard,

double

plated

AA

medium

401-BSa-1.

inch

wide

recommended

AB

Edge

a

"U"

401-SSa-1.

AD

Edge

a

box

mum

Each

denotes

size

number,

measured

The

standard

has a round

groove,

and

For

For

guide,

type

For

guide,

type

recommended

Union

ball

is

binding

weight

Type

and

produces

speed

miscellaneous

hinged

feed

dog

Type

miscellaneous

hinged

feed

dog.

Special

the

kind

stamped

in

thousandths

the

type

recommended

shank,

eye,

available

width

struck

on

work.

130

GHS

5000

presser

with

130

GHS

presser

Seam

speed

needle

of

number

round

of

groove,

in

sizes

mattresses

Machine

needle.

5/16,

seaming

no

seaming

shank,

on

eye

3/8

R.

P.M.

foot

feed

directly

needle.

foot

specification

5000

and

point,

R.

has

both a type

point,

the

needle

of

an

the

needle

and

spotted,

032,

and

general

has

and

operations

with a yielding

Maximum

operations

with a yielding

P.M.

NEEDLES

inch,

size

for

short

groove

036,

Uses

7/16

in

401-SSa

length,

shank,

number

machines

length,

ball

040,

throw-out

selvage

front

number

midway

undersize

point,

044,

purpose

binder.

edge

inch

finish

on

light

recommended

on

light

groove,

denotes

is

to

section

of

the

needle.

to

section

-1.

Type

and

between

the

complete

in

Class

short

with a one

government

049, 054.

seaming

Seam

binding

respectively.

medium

behind

Seam

speed

medium

behind

130

GHS

size

number.

finish

the

54600

blade

largest

the

1/ 8 inch

and

shank

specification

5/8,

weight

the

specification

5000

weight

the

needle.

other

diameter

and

symbol.

is

Type

step

point,

on

light

3/4

and

Maximum

materials.

needle

R.

P.M.

materials.

needle

Maxi-

The

details.

the

130

GHS.

less

reduction,

chromium

to

7/8

and

and

type

of

eye.

than

3

Page 4

To

sample

on

label.

have

needle,

A

complete

needle

or

orders

the

type

order

NEEDLES

promptly

and

size

would

and

number

read:

(Continued)

accurately

should

"1000

Needles,

filled,

be

forwarded.

Type

an

130

empty

Use

GHS,

package,

description

Size

036

a

11

•

Selection

Thread

formation.

Success

Union

Special

Company,

to

the

most

Maximum

Genuine

repair

your

parts

guarantee

Prices

are

forwarded

insured

insurance.

of

should

in

its

subsidiaries

approved

efficiency

needles

are

are

at

unless

the

proper

pass

USE

the

operation

Needles

and

are

stamped

of

the

strictly

the

buyer's

otherwise

needle

freely

GENUINE

and

and

scientific

durability

packaged

with

highest

net

cashand

directed.

size

through

NEEDLES

of

these

Repair

authorized

principles

the

quality

risk

f. o.

should

needle

Parts

are

assured.

with

Union

in

TERMS

subject

b.

A

be

eye

AND

machines

as

furnished

distributors.

and

the

labels

Special

materials

to

shipping

charge

determined

in

order

REPAIR

can

are

made

marked

trade

and

change

point.

is

made

by

size

to

produce

PARTS

be

secured

by

Union

They

with

~

mark.

are

the

Each

workmanship.

without

Parcel

to

notice.

Post

cover

of

thread

a

only

with

Special

designed

utmost

trade

All

shipments

the

postage

used.

good

stitch

genuine

Machine

according

precision.

.

Genuine

mark

shipments

are

and

is

The

must

be

filled

viscosity

Oil

is

sight

the

gauge

red

lines

The

than

an

occasional

throw

is

Oil,

-out

required.

A

daily

which

reservoir,

reservoir

handwheel.

The

threaded.

a

plane

at

left.

oil

has

been

before

of

90

to

125

filled

machine

on

on

at

the

the

the

front

is

drop

pin

and

looper

check

has

before

gone

making

may

be

drained

accompanying

Please

right

note

angles

drained

beginning

seconds

spring

of

gauge.

almost

of

holder

the

through

too

frequent

drawing

that

to

the

OILING

from

at

cap

the

machine.

The

entirely

oil

morning

the

at

the

the

needle

direction

the

to

operate.

100°

in

the

capacity

at

both

frame

machine,

oilings

plug

shows

AND

THREADING

machine

Use a straight

Fahrenheit.

top

cover

The

oil

of

the

oil

automatically

bearings

locking

start

is

pin,

should

filtered

unnecessary.

screw

is

inserted

of

the

line

in

manner

of

before

and

level

reservoir

lubricated,

of

the

as

be

made

and

the

main

in

in

the

feed

shipping

mineral

the

oil

should

retainer

indicated

and

pumped

Excessive

frame

which

needle

and

is

and

oil

level

be

is

is

maintained

12

ounces.

and

holder,

in

oil

added

back

directly

these

holder

threaded

the

reservoir

with a Saybolt

checked

between

no

oiling,

the

looper

oiling

oil

if

into

in

diagram,

required.

the

the

under

machines

with

the

eye

from

right

at

the

other

main

main

the

are

in

to

4

Page 5

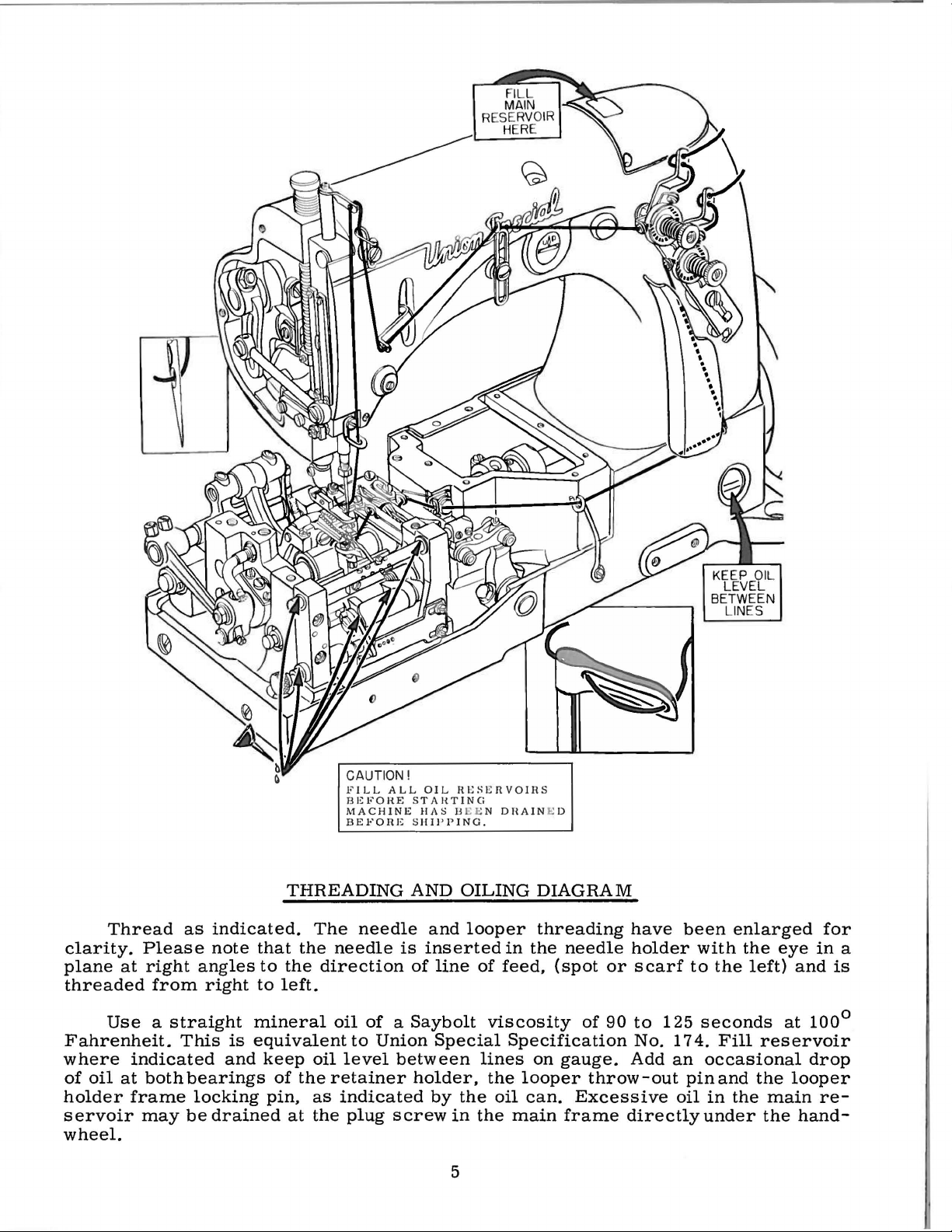

CAUTION!

FILL

ALL

BEFORE

MACHINE

BEFORE

OIL

RESERVOIRS

STAHTING

HAS BEEN DHAIN

SHII'PING.

E D

Thread

clarity.

plane

Please

at

right

threaded

Use a straight

Fahrenheit.

where

of

holder

servoir

oil

indicated

at

both

frame

may

from

This

as

indicated.

note

angles

right

is

and

bearings

locking

be

drained

THREADING

The

that

the

to

the

direction

to

left.

mineral

equivalent

keep

of

pin,

at

oil

the

as

the

retainer

needle

needle

oil

to

level

indicated

plug

AND

OILING

and

is

inserted

of

line

of a Saybolt

Union

Special

between

holder,

by

the

screw

in

looper

in

of

feed,

viscosity

Specification

lines

the

looper

oil

the

main

DIAGRAM

threading

the

(spot

on

gauge.

can.

wheel.

5

needle

or

of

90

throw

Excessive

frame

have

holder

scarf

to

125

No.

174.

Add

an

-out

oil

directly

been

enlarged

with

to

the

seconds

Fill

occasional

pin

and

in

the

under

the

eye

left)

at

reservoir

the

main

the

for

in

and

is

100°

drop

looper

re-

hand-

a

Page 6

INSTRUCTIONS

FOR

MECHANICS

ing

for

system

leaks.

Fig.

and

run

SETTING

NEEDLE

1

machine

THE

five

for

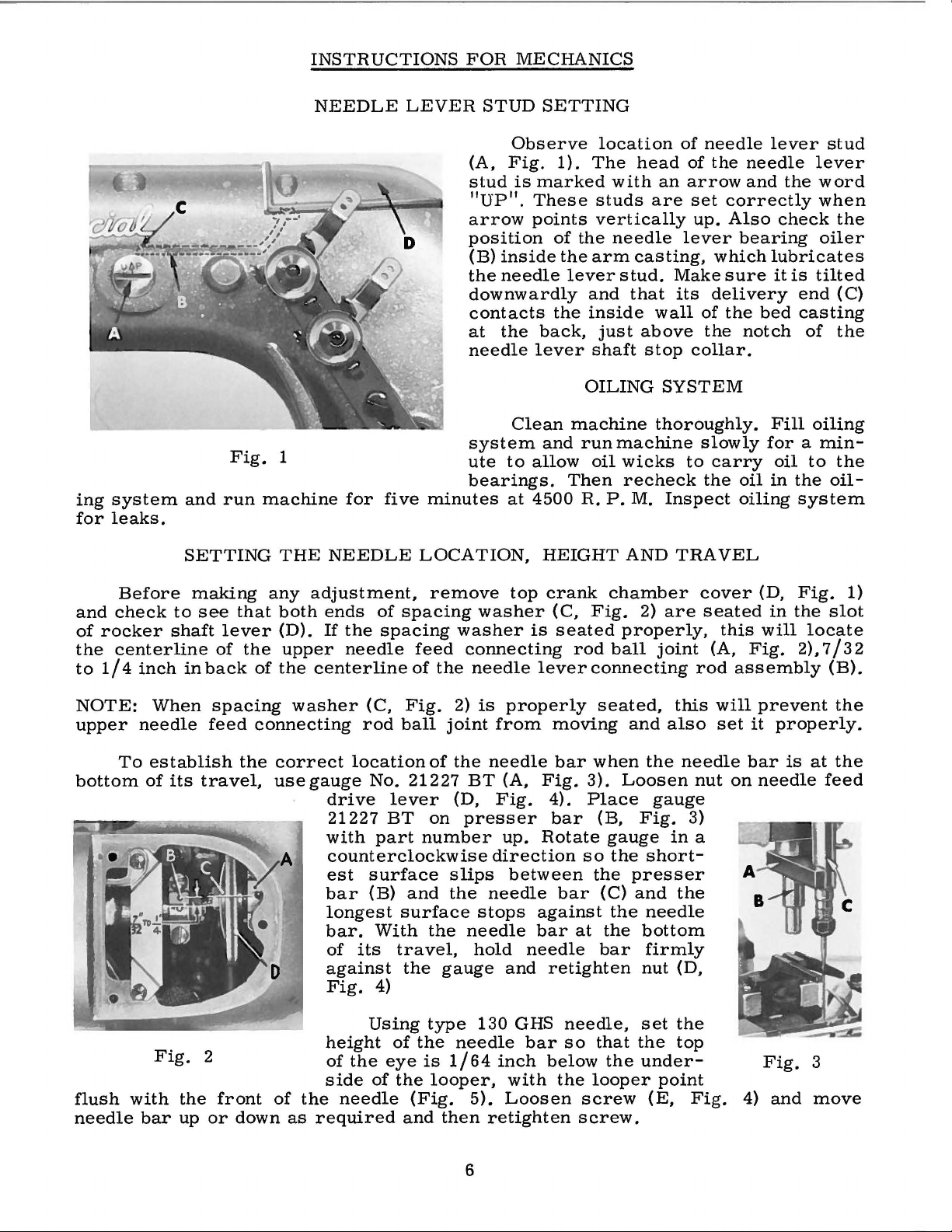

NEEDLE

LEVER

minutes

LOCATION,

STUD

(A,

stud

"UP".

arrow

position

(B)

the

downwardly

contacts

at

needle

system

ute

bearings.

SETTING

Observe

Fig.

is

marked

These

points

inside

needle

the

back,

lever

Clean

and

to

allow

at

4500

HEIGHT

location

1).

The

with

studs

vertically

of

the

needle

the

arm

lever

and

the

inside

just

shaft

OILING

machine

runmachine

oil

Then

R.

P.M.

head

an

are

casting,

stud.

that

wall

above

stop

SYSTEM

thoroughly.

wicks

recheck

Inspect

AND

of

needle

of

the

arrow

set

correctly

up.

Also

lever

Make

its

collar.

to

TRAVEL

bearing

which

sure

delivery

of

the

the

slowly

carry

the

oil

oiling

lever

needle

and

the

check

lubricates

it

is

end

bed

casting

notch

Fill

for a min-

oil

in

the

system

stud

lever

word

when

the

oiler

tilted

(C)

of

the

oiling

to

the

oil-

Before

and

check

of

rocker

the

centerline

to

1/4

NOTE:

upper

To

bottom

flush

needle

to

shaft

inch

When

needle

establish

of

its

Fig.

with

bar

making

see

of

in

back

spacing

feed

travel,

2

the

front

up

or

any

that

lever

the

of

connecting

the

down

adjustment,

both

(D).

upper

the

centerline

washer

correct

use

gauge

of

the

as

required

remove

ends

If

drive

21227

with

counterclockwise

est

bar

longest

bar.

of

against

Fig.

height

of

side

of

the

spacing

needle

(C,

rod

location

No.

part

surface

(B)

With

its

4)

Using

the

eye

of

needle

spacing

feed

of

Fig.

ball

21227

lever

BT

number

and

surface

travel,

the

type

of

the

is

the

(Fig.

and

the

2)

joint

of

the

(D,

on

slips

the

the

gauge

needle

1/64

looper,

then

top

washer

washer

connecting

needle

is

properly

from

needle

BT

(A,

Fig.

presser

up.

direction

between

needle

stops

needle

hold

130

5).

needle

and

GHS

bar

inch

with

Loosen

retighten

crank

(C,

is

seated

rod

lever

moving

bar

Fig.

4).

bar

Rotate

bar

against

bar

at

retighten

needle,

so

below

the

screw.

chamber

Fig.

connecting

when

3).

Place

so

the

looper

screw

2)

properly,

ball

seated,

and

Loosen

(B,

Fig.

gauge

the

presser

(C)

and

the

the

bottom

bar

nut

set

that

the

the

under-

the

gauge

short-

needle

firmly

(E,

are

joint

this

also

needle

3)

in

the

(D,

the

top

point

Fig.

cover

seated

this

(A,

rod

will

set

nut

a

(D,

in

will

Fig.

assembly

prevent

it

properly.

bar

is

on

needle

Fig.

4)

and

Fig.

the

locate

2),

7/32

at

feed

3

move

1)

slot

(B).

the

the

6

Page 7

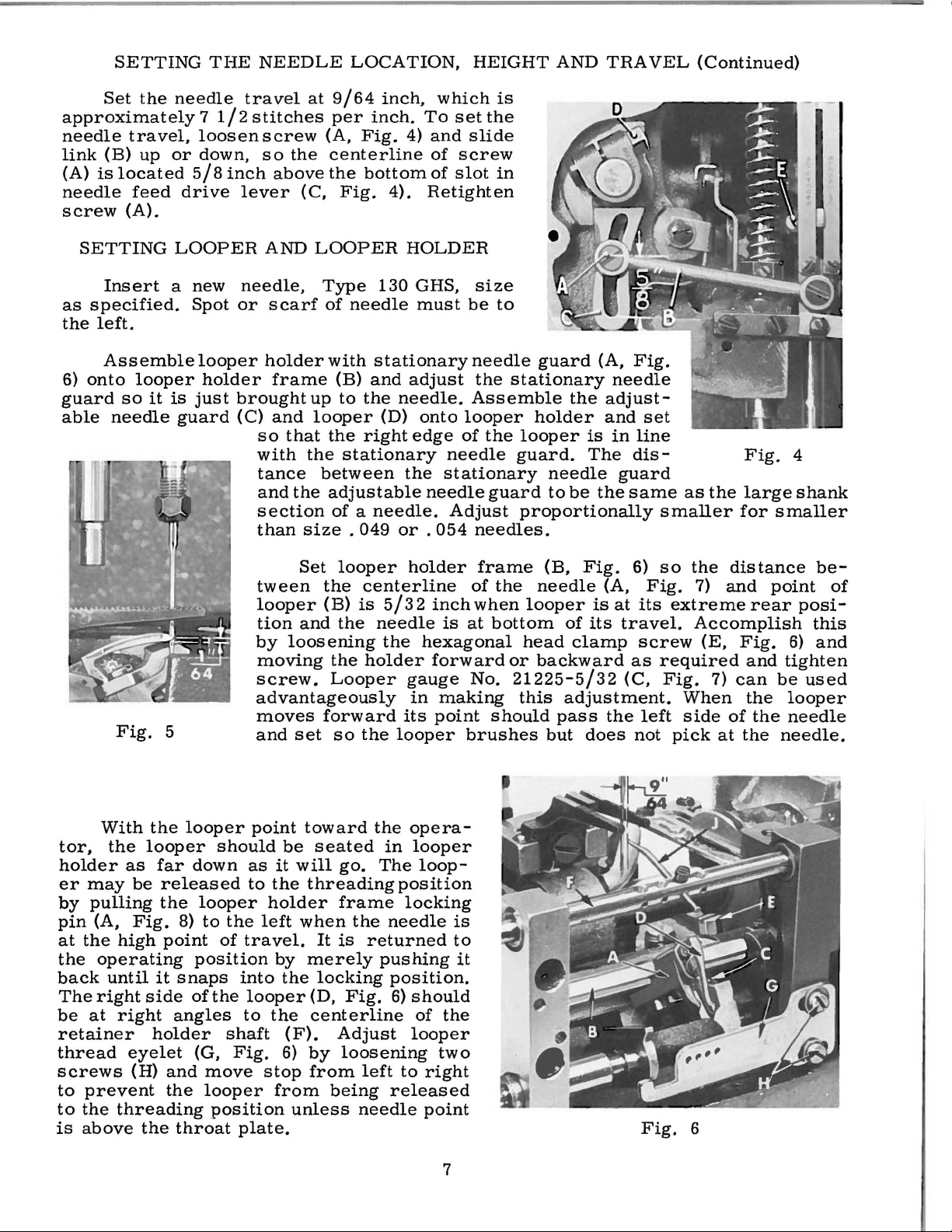

SETTING

Set

the

approximately

needle

link

(A)

needle

screw

travel,

(B)

is

located

(A).

up

feed

or

THE

needle

7

1/2

loosenscrew

down,

5/8

inch

drive

lever

NEEDLE

travel

stitches

so

the

above

at

9/64

per

(A,

centerline

the

(C,

Fig.

LOCATION,

inch,

inch.

Fig.

bottom

4).

which

To

4)

and

of

of

Retighten

HEIGHT

is

set

the

slide

screw

slot

in

AND

TRAVEL

(Continued)

SETTING

Insert

as

specified.

the

left.

Assemble

6)

onto

guard

able

needle

Fig.

looper

so

it

LOOPER

a new

Spot

looper

holder

is

just

guard

5

AND

needle,

or

scarf

holder

brought

(C)

so

with

tance

and

section

than

tween

looper

tion

by

moving

screw.

advantageously

moves

and

LOOPER

Type

of

with

frame

up

and

looper

that

the

between

the

adjustable

size . 049

Set

the

(B)

and

loosening

forward

set

the

of a needle.

the

Looper

so

130

needle

stationary

(B)

and

to

the

needle.

(D)

right

stationary

or . 054

looper

centerline

is

5/32

the

needle

the

holder

its

the

looper

HOLDER

GHS,

must

adjust

onto

edge

the

needle

holder

hexagonal

gauge

in

size

be

needle

the

Assemble

looper

of

needle

stationary

Adjust

needles.

frame

of

inch

when

is

at

forward

No.

making

point

brushes

to

guard

stationary

holder

the

looper

guard.

needle

guard

the

bottom

should

to

proportionally

(B,

needle

looper

head

or

backward

21225-5/32

this

pass

but

(A,

Fig.

needle

the

adjust-

and

set

is

in

line

The

dis-

guard

be

the

same

Fig.

of

clamp

adjustment.

does

is

its

(A,

at

travel.

as

(C,

the

6)

Fig.

its

screw

left

not

as

the

smaller

so

the

7)

extreme

Accomplish

(E,

required

Fig.

When

side

pick

7)

at

Fig.

large

for

smaller

distance

and

point

rear

Fig.

and

can

be

the

of

the

the

needle.

4

shank

be-

of

posi-

this

6)

and

tighten

used

looper

needle

With

tor,

holder

er

may

by

pulling

pin

(A,

at

the

the

operating

back

The

right

be

at

retainer

thread

screws

to

prevent

to

the

is

above

the

the

looper

as

far

be

released

the

Fig.

high

point

until

it

side

right

holder

eyelet

(H)

the

threading

the

looper

down

looper

8)

to

position

snaps

of

angles

(G,

and

move

looper

throat

point

should

as

to

holder

the

left

of

travel.

into

the

looper

to

shaft

Fig.

stop

position

plate.

be

it

will

the

by

the

the

(F).

6)

from

unless

when

toward

seated

go.

threading

frame

the

It

is

returned

merely

locking

(D,

Fig.

centerline

Adjust

by

loosening

from

left

being

needle

the

opera-

in

looper

The

loop-

position

locking

needle

pushing

position.

6)

should

of

looper

to

right

released

point

is

to

it

the

two

7

Fig.

6

Page 8

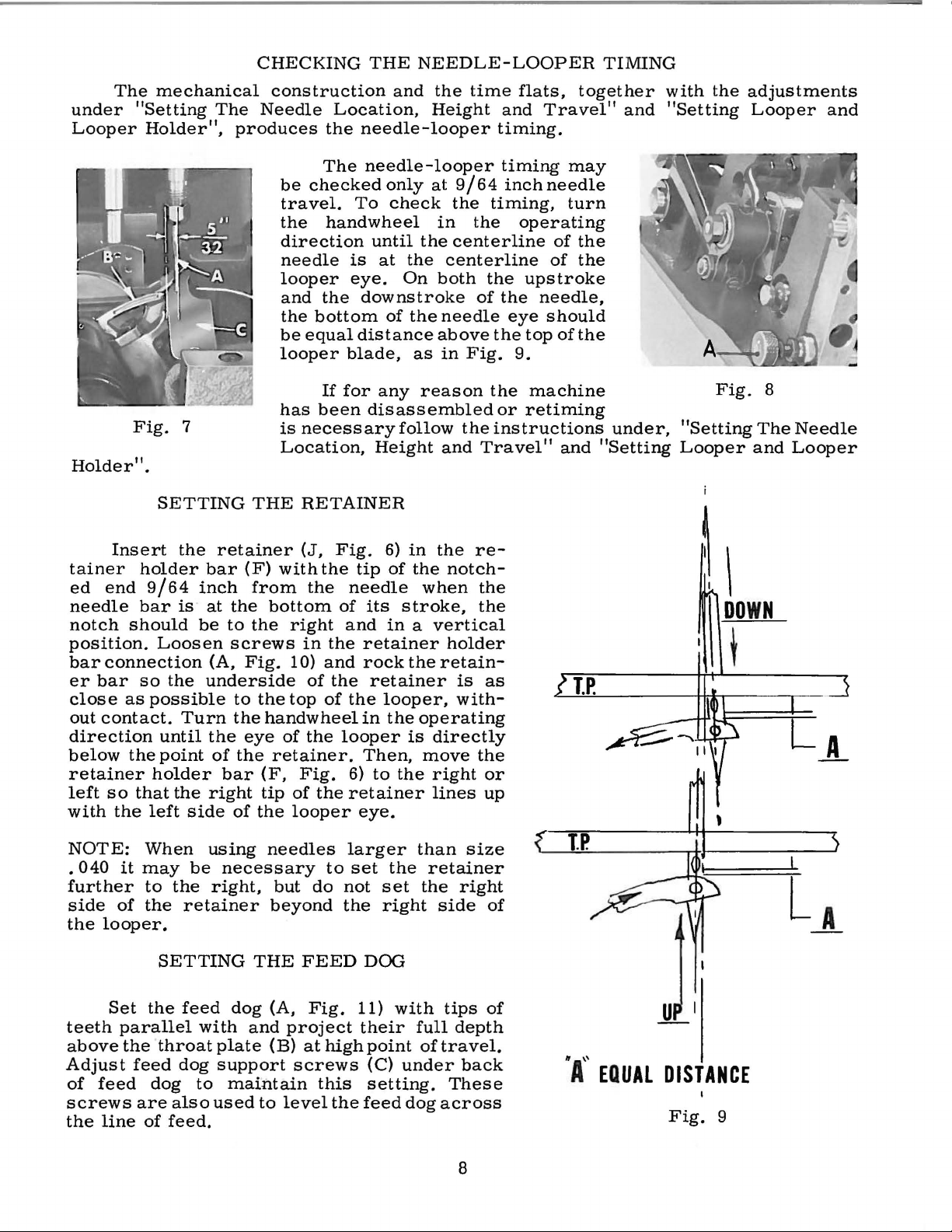

The

under

Looper

Fig.

Holder".

mechanical

"Setting

Holder",

7

CHECKING

The

Needle

produces

construction

Location,

the

needle-looper

The

be

checked

travel.

the

direction

needle

looper

and

the

be

equal

looper

has

is

necessary

Location,

To

handwheel

is

eye.

the

downstroke

bottom

distance

blade,

If

for

been

THE

needle-looper

disassembled

and

only

check

until

at

the

On

of

the

as

any

follow

Height

NEEDLE-

the

Height

at

9/64

the

in

the

centerline

centerline

both

needle

above

in

Fig.

reason

the

and

LOOPER

time

flats,

and

timing.

timing

inch

timing,

the

operating

the

upstroke

of

the

eye

the

top

9.

the

machine

or

retiming

instructions

Travel"

together

Travel"

may

needle

turn

of

the

of

the

needle,

should

of

the

and

TIMING

and

under,

"Setting

with

the

"Setting

Fig.

"Setting

Looper

adjustments

Looper

8

The

and

and

Needle

Looper

Insert

tainer

ed

end

needle

notch

position.

bar

er

close

out

direction

below

retainer

left

with

NOTE:

.

040

further

side

the

should

connection

bar

as

contact.

the

so

the

it

of

looper.

SETTING

the

holder

9/64

bar

is

Loosen

so

the

possible

Turn

until

point

holder

that

the

left

side

When

may

to

the

the

retainer

retainer

bar

(F)

inch

at

the

be

to

screws

(A,

Fig.

underside

to

the

the

eye

of

the

bar

right

of

using

be

necessary

right,

THE

from

the

RETAINER

(J,

with

the

bottom

right

in

10)

of

the

top

handwheel

of

the

retainer.

(F,

Fig.

tip

of

the

the

looper

needles

but

do

beyond

Fig.

the

of

and

the

and

the

of

looper

retainer

larger

to

not

the

6)

in

tip

of

the

needle

its

stroke,

in a vertical

retainer

rock

the

retainer

the

looper,

in

the

is

Then,

6)

to

the

eye.

set

the

set

right

the

re-

notch-

when

operating

directly

move

right

lines

than

retainer

the

holder

retain-

is

with-

the

size

right

side

the

the

as

or

up

of

~

I

DOWN

t

Set

teeth

above

Adjust

of

feed

screws

the

line

SETTING

the

parallel

the

throat

feed

dog

are

also

of

feed.

feed

with

dog

to

THE

dog

and

plate

support

maintain

used

to

FEED

(A,

project

(B)

screws

level

Fig.

at

high

this

the

DOG

11)

with

their

point

(C)

setting.

feed

full

of

under

dog

across

tips

of

depth

travel.

back

These

8

.A,,

EQUAL

DISTANCE

Fig.

9

Page 9

To

tooth

(D,

clockwise

verse

direction

Normal

when

feed

tilt

feed

Fig.

and

setting

is

at

dog

11)

screw

of

two

is

all

high

SETTING

in

line

down,

(B)

screws

teeth

point

of

turn

THE

feed

screw

FEED

and

(A,

counterclockwise.

to

raise

of

level

lift.

with

move

Fig.

front

throat

DOO

front

12)

Re-

tooth.

plate

(Continued)

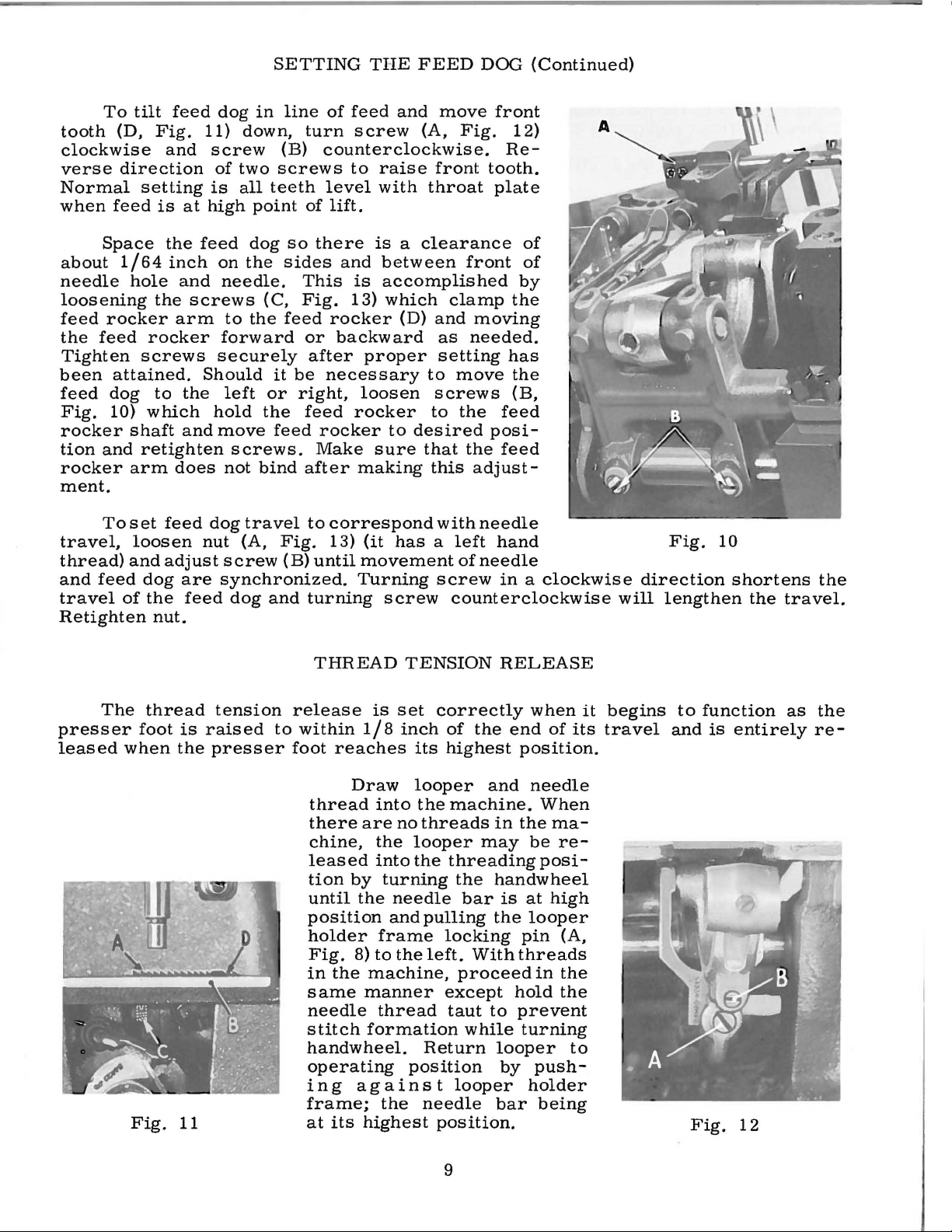

Space

about

1/64

needle

loosening

feed

rocker

the

feed

Tighten

been

feed

Fig.

attained.

dog

10)

rocker

tion

and

rocker

ment.

To

travel,

thread)

and

feed

travel

of

Retighten

the

inch

hole

and

the

arm

rocker

screws

to

the

which

shaft

and

retighten

arm

does

set

feed

loosen

and

adjust

dog

are

the

feed

nut.

feed

on

dog

the

needle.

screws

to

(C,

the

forward

securely

Should

left

hold

the

move

screws.

not

bind

dog

travel

nut

(A,

screw

synchronized.

dog

so

sides

feed

it

or

feed

Fig.

(B)

and

there

and

This

Fig.

rocker

or

backward

after

be

necessary

right,

feed

rocker

Make

after

to

correspond

13)

until

turning

THREAD

is a clearance

between

is

accomplished

13)

which

(D)

and

as

proper

setting

to

loosen

rocker

sure

making

to

desired

screws

to

that

this

with

(it

has a left

movement

Turning

screw

screw

TENSION

of

front

of

by

clamp

the

moving

needed.

has

move

the

(B,

the

feed

posi-

the

feed

adjust-

needle

hand

of

needle

in a clockwise

counterclockwise

RELEASE

direction

will

Fig.

10

lengthen

shortens

the

travel.

the

The

presser

leased

thread

foot

when

Fig.

is

the

11

tension

raised

presser

release

to

within

foot

thread

there

chine,

leased

tion

until

position

holder

Fig.

in

same

needle

stitch

handwheel.

operating

in

frame;

at

is

1/8

reaches

Draw

into

are

the

into

by

turning

the

frame

8)

to

the

machine,

manner

thread

formation

g a g a

the

its

highest

set

correctly

inch

of

the

its

highest

looper

the

machine.

no

threads

looper

the

may

threading

the

needle

and

bar

pulling

locking

the

left.

With

proceed

except

taut

while

Return

position

ins t looper

needle

position.

when

end

of

position.

and

needle

When

in

the

rna-

be

re-

posi-

handwheel

is

at

high

the

looper

pin

(A,

threads

in

the

hold

the

to

prevent

turning

looper

by

push-

holder

bar

being

its

to

it

travel

begins

to

and

Fig.

function

is

entirely

12

as

the

re-

9

Page 10

the

looper

is

threaded

The

thread

and

from

for

is

threaded

right

THREAD

the

looper

from

to

left.

TENSION

enters

back

to

from

front.

RELEASE

the

back

The

needle

(Continued)

of

The

on

mainshaft

looper

up,

when

inch

below

eyelets

able

(Fig.

NOTE:

pulled

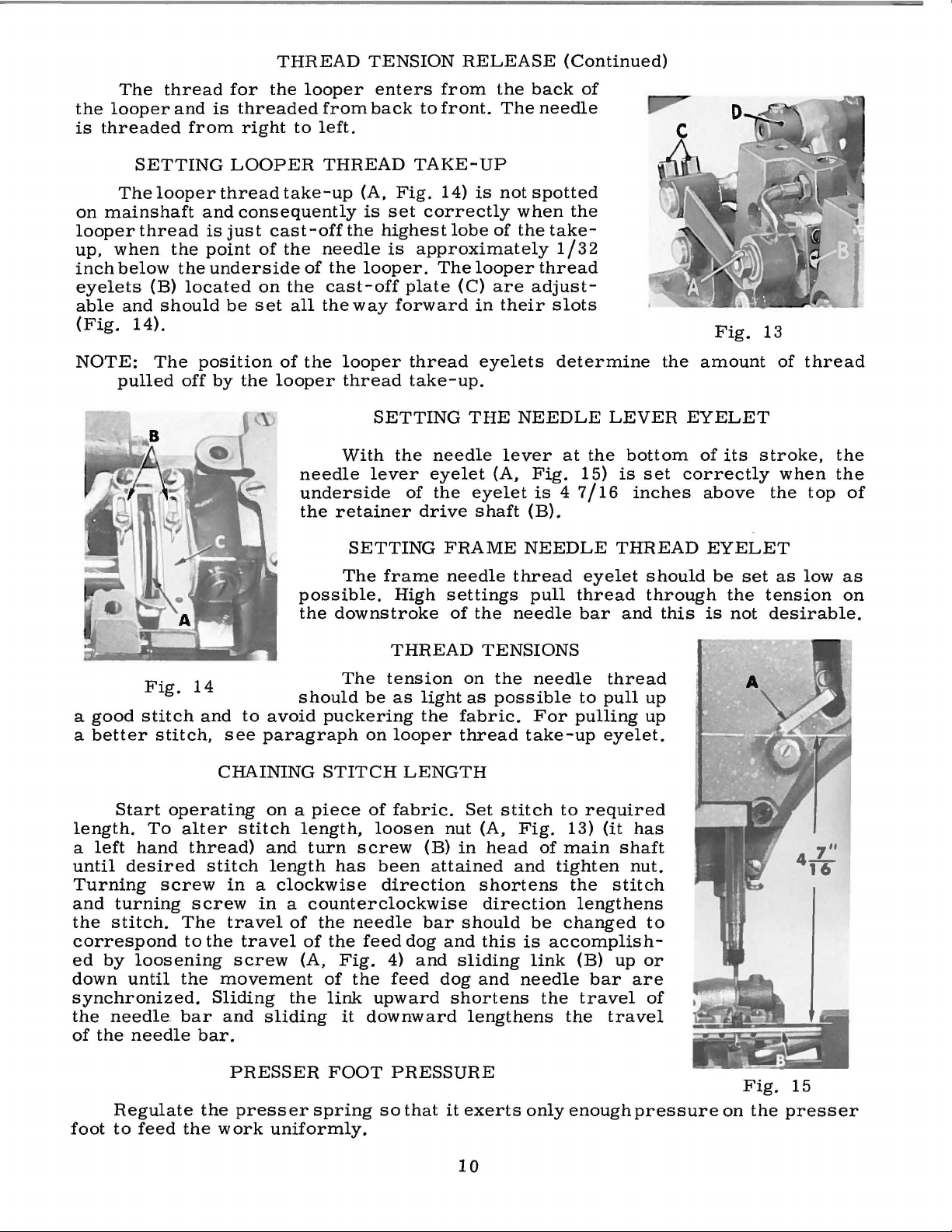

SETTING

looper

thread

the

the

(B)

located

and

should

14).

The

off

LOOPER

thread

and

consequently

is

just

point

underside

be

set

position

by

the

take-up

cast-off

of

the

on

the

all

of

looper

needle

underside

the

possible.

the

THREAD

the

needle

of

the

cast-off

the

way

the

looper

thread

With

retainer

SETTING

The

downstroke

TAKE-

(A,

Fig.

is

set

highest

is

approximately

looper.

plate

forward

thread

take-up.

SETTING

the

lever

of

drive

frame

High

UP

14)

is

correctly

lobe

The

looper

(C)

in

eyelets

THE

needle

eyelet

the

eyelet

shaft

FRAME

needle

settings

of

the

not

spotted

when

of

the

are

adjust-

their

NEEDLE

lever

(A,

Fig.

(B).

NEEDLE

thread

pull

needle

the

take-

1/32

thread

slots

determine

at

the

15)

is 4 7/16

eyelet

thread

bar

the

LEVER

bottom

is

set

inches

THREAD

should

through

and

this

Fig.

amount

EYELET

of

its

correctly

above

EYELET

be

set

the

is

not

13

of

thread

stroke,

when

the

top

as

low

tension

desirable.

the

the

of

as

on

Fig.

a

good

a

better

length.

a

left

until

Turning

and

the

correspond

ed

down

synchronized.

the

of

foot

stitch

stitch,

Start

turning

stitch.

by

needle. bar

the

Regulate

to

operating

To

hand

desired

screw

loosening

until

needle

feed

14

and

see

CHAINING

alter

thread)

stitch

in a clockwise

screw

The

travel

to

the

the

movement

Sliding

and

bar.

PRESSER

the

the

work

The

tension

should

to

avoid

paragraph

on a piece

stitch

travel

screw

presser

length,

and

turn

length

in a counterclockwise

of

of

(A,

the

sliding

spring

uniformly.

be

puckering

on

STITCH

of

loosen

screw

has

been

direction

the

needle

the

feed

Fig.

of

the

link

it

downward

FOOT

upward

so

4)

THREAD

on

as

light

looper

LENGTH

fabric.

dog

and

feed

PRESSURE

that

the

fabric.

thread

Set

nut

(B)

in

attained

bar

should

and

sliding

dog

shortens

it

exerts

as

lengthens

TENSIONS

the

needle

possible

For

take-up

stitch

(A,

head

shortens

direction

this

and

to

Fig.

of

and

tighten

be

is

accomplish-

link

needle

the

only

thread

to

pull

pulling

eyelet.

required

13)

(it

main

the

changed

the

enough

shaft

stitch

lengthens

(B)

up

bar

travel

travel

up

up

has

nut.

to

or

are

of

pressure

on

Fig.

the

15

presser

10

Page 11

IDENTIFYING

PARTS

Where

some

identification

appear.

OF

ILLUSTRATIONS

of

actual

listing

required

of

Part

IMPORTANT!

MACHINE

This

various

the

the

smaller

numbers

catalog

sections

position

of

the

in

the

construction

letter

FOR WI-

in

parts

parts

is

stamped

represent

ON

ITCH

has

been

of

the

the

machine.

with

particular

permits,

and

the

ALL

ORDERS,

PART

ORDERING

arranged

mechanism

their

part

view

on

those

in

to

same

IS

On

numbers,

being

each

distinguish

ORDERED.

to

are

the

shown.

part

where

part,

PLEASE

REPAIR

simplify

shown

page

is

stamped

the

construction

the

part

regardless

INCLUDE

PARTS

ordering

so

that

opposite

descriptions

from

PART

repair

the

parts

the

illustration

with

of

and

its

does

similar

catalog

NAME

parts.

may

the

number

part

number.

not

permit,

ones.

in

which

AND

Exploded

be

seen

will

in

be

of

On

an

they

STYLE

views

their

found

pieces

a

Numbers

position

ordering

indicated

assembly.

46

47

48

49

are

recommended,

catalog,

parts

in

the

of

parts.

Component

by

29105

22559

22894

22559

It

will

be

not

listed.

In

those

no

for

the

description,

in

the

the

part

Always

parts

indenting

Example:

AD

B

c

A

noted

The

so

the

cases

specific

various

first

in

in

reason

where a part

usage

and

column

the

illustration.

use

the

of

sub-assemblies,

their

Retainer

Bearing

Set

Bearing

the

above

is

complete

will

machines

if

necessary,

are

reference

Reference

part

number

descriptions

Drive

Screw----------------------------------------

that

sub-assembly

be

are

Eccentric

Screw,

Screw,

example,

replacement

is

common

mentioned

not

the

the

difference

same,

numbers

numbers

listed

which

under

upper----------------------------lower-----------------------------

that

can

the

Assembly---------------------

the

of

these

should

to

all

in

the

the

will

only

should

in

the

second

be

furnished

description

eccentric,

parts,

be

ordered.

of

the

machines

description,

specific

be

usage

shown

and

merely

never

column.

for

of

the

ball

stud

individually,

covered

however,

will

be

in

the

indicate

be

used

repairs

main

and

when

mentioned

illustration.

are

sub-

bearing

is

not

by

this

the

the

in

1

2

5

2

At

the

this

part

book.

number

back

This

is

known.

of

will

the

book

facilitate

will

locating

be

found a numerical

the

illustration

11

index

and

description

of

all

the

parts

when

shown

only

in

the

Page 12

12

Page 13

I~

c

r.

N

o.

~

;)

'I

5

6

7

u

9

10

11

12

Li

14

15

16

17

18

19

20

21

22

2:)

24

25

26

27

2B

29

30

31

32

33

34

35

:)6

:n

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62 95

63

64

65

66

67

68

69

70

1-'nrt

No.

54601

22H:W

54681

5

4681

:

1577~

n560

22845

80

22574

22562

22562

22U39

54680

22U48

22n:)

41:)94

22585

22524

22541

53782

52882

39582

52882

50-789

52882

90

51382

22548

52882

52882

51282

52882

90

52882

93

B21375

98

52 A

51291

52958

54282

20

22848

294

22572

54682

54682

54682

52882

52882

35731

2

251:1

22569

12934

54682

54637

22528

54658

98

22517

53137

22848

20

539

22889

22784

22891 A

54670

719

c

A

II

A

Fl

A

1:1

A

A

13

B

AD

L

AC

AA

A

AE

u

AE

p

y

AI-I

A

A

B

A

B

A

L

iVI

A

c

A

c

B

c

A

A

F

A

A

F

Blk.

!\'lAIN

FHA

ME,

MISCELLANEOUS

Cloth

Plate----------------------------------------------------------

Screw,

Cloth

Screw,

Screw,

Throat

Screw,

Screw,

Screw,

Throat

Screw,

Plug

Gasket,

Screw,

Screw,

Screw,

Oil

Crank

Gasket,

Screw,

Crank

Gasket,

Needle

Gasket,

Screw,

Baffle

Screw,

Belt

Screw,

Looper

Looper

Frame

Oil

Washer,

Screw,

Screw,

Screw,

Head

Head

Oil

Gasket,

Presser

Screw,

Screw,

Nut,

Needle

Guide

Needle

Needle

Screw,

Screw,

Pin,

Plug

Screw,

Washer,

Frame

Adaptor

Screw,

Screw,

Needle

Screw,

for

cloth

Plate

Spring

\Vasher

Screw-----------------------------------------------------------

Screw-----------------------------------------------------------

for

for

Plate

for

for

for

Plate

for

Screw----------------------------------------------------------

for

for

for

for

.Reservoir

Chamber

Oil

Cap

Oil

Cap

Oil

Cap

Oil

Drip

Screw-----------------------------------------------------------

for

lower

Chamber

for

Lever

for

for

Plate

for

Guard

for

Thread

Thread

Looper

Shield

.Reservoir

-----------------------------------------------------------

for

for

for

for

Cover

Felt

Liner

Cover

for

Bar

for

guide

for

stud

Bar

Stud

Bar

Thread

for

for

for

needle

Screw,

for

for

Needle

Screw,

for

for

Thread

for

plate------------------------------------------------

Cover

----------------------------------------------------------

cloth

cloth

throat

throat

throat

oil

oil

oil

upper

baffle

belt

----------------------------------------------------------

thread

oil

head

head

presser

Frame

Support

Frame

lower

needle

frame

needle

needle

needle

Assembly-------------------------------------------

---------------------------------------------------------

plate-----------------------------------------------plate------------------------------------------------

(See

Page

25)

plate,

plate,

plate

Support-------------------------------------------------

reservoir

plug

screw

reservoir

reservoir

crank

Top

Cover,

--------------------------------------------------------Torsion

Hinge

Plate---------------------------------------------------

oil

reservoir

crank

Cover,

lower

Bearing

upper

plate

--------------------------------------------------------guard-------------------------------------------------

Eyelet

Guard

Thread

oil

shield------------------------------------------------

shield-------------------------------------------------

cover------------------------------------------------

cover

---------------------------------------------------------

------------------------------------------------------

Gasket---------------------------------------------------

Back

oil

reservoir

Connection

stud

No.

22528

Eyelet,

needle

bar

for

bed--------------------------------------------------

needle

frame

Thread

for

Take-up

lever

Styles

Style

support----------------------------------------

back

----------------------------------------------top

top

chamber

Cover

Pin------------------------------------------------

crank

crank

eyelet

support---------------------------------------------

Guard

---------------------------------------------------

Guide

bar

thread

bar

---------------------------------------------

upper-----------------------------------------

Spring-------------------------------------------

top

chamber

lower-----------------------------------------

chamber

Oiler-------------------------------------------

chamber

-----------------------------------------------

and

------------------------------------------------

-----------------------------------------------Eyelet------------------------------------------

-----------------------------------------------

Cover

back

Guide

bar

connection

C---------------------------------------------

---------------------------------------------

Stud

lower------------------------------------------

thread

frame

frame

thread

needle

Eyelet------------------------------------------

frame

take-up

frame

Wire------------------------------------------

stud

COVEHS

Description

-------------------------------------------54600

54600

cover

cover------------------------------------cover-------------------------------------

cover-----------------------------------cover------------------------------------

looper

--------------------------------------------

-----------------------------------------

pin---------------------------------------

--------------------------------------------

thread

needle

pivot

------------------------------------------

AB,

AA

-----------------------------------

cover---------------------------------

cover-------------------------------cover--------------------------------

thread

cover----------------------------------Plate-----------------------------------

guide

eyelet----------------------------------

eyelet----------------------------------

eyelet

thread

wire----------------------------------

pin----------------------------------

AND

PLATES

AD---------------------------

--------------------------------

guard------------------------

plate---------------------------

-------------------------------eyelet--------------------------

A

mt.

Heq.

1

2

1

1

3

3

1

3

1

1

4

4

:)

1

9

1

2

2

7

3

1

1

1

1

1

1

2

1

4

1

1

1

1

2

1

2

1

3

1

1

1

1

3

3

2

1

1

1

1

1

1

2

4

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

13

Page 14

A B

c

D

F G

~

~~

54

55

_;or

56

58

~51

~55

€il55

59

lso

~55

160

.

s2 sJ

61

1

~

14

Page 15

Bel'.

Nu.

1

2

:~

4

5

6

7

8

!)

10

11

12

1:3

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

I-'

art

N

o.

5149:~

BQ

5~H

643-127

5149:~

AG

5149:3 D

5149:3 E

51493

Ail

50-294

22569

5149:3

51493

22645

51493

B

1311

B.J

H-64

BG

2282:3 A

51295

22823

5149:3

52944

5149:3

51242

51242

A

B

AY

T

BK

z

H

52936

52890

51290

51242

22571

54293

c

T

s

B

A

90

52894

AB

51257

AA

660-136

258

A

666-217

54694

666-218

22569

c

20

54694

A

666-99

22706

51294

A

N

21212

52883

H

666-201

666-209

22729

51294

22729

51294

21657

52891

A

u

B

K

X

B

50-648

56:390 E

225:39

22571

H

A

666-111

666-179

666-118

666-65

35178

D

666-114

22889

22889

D

c

MAIN

Blk.

FHk.

Blk.

FHAME,

Oil

Gasket,

Oil

Oil

Oil

Oil

Screw,

ilter

F

Screw, oil

Base

Screw,

ounting

M

Screw,

Oil

Looper

Lint

Looper

Looper

Feed

middle

Main

upper

!\lain

Looper

Plug

Feed

Screw,

Oil

Presser

Oil

Head

Horizontal

Screw,

Washer,

Oil

Oil

Wick,

Plug

Oil

Presser

Felt

Felt

Screw,

Oil

Siphon

Tension

Crankshaft

Lucile

Crankshaft

Plug

Plug

Oil Wick,

Wedge

Oil Wick,

Oil

Wick,

Spring,

Oil

Wick,

Adaptor

Adaptor

BUSIJINGS

AND

MISCELLANEOUS

OILING

PAWl'S

Description

Pump

Pump

Pump

Driving Shaft

Pump

Driven

Screw -----------------------------------------------------

for

oil

Gear---

pump

---

-------------------------------------

housing------------------------------------1-Iousing----------------------------------------------Driving

Housing

Pin

-------------------------------------------------------

for

oil

Cap

Assembly--------------------------------------------

\Vasher,

pan

Plate

Felt:-------------------------------------------------

oil

pan

Shaft------------------------------------------

Gear-------

Cover

pump

housing

-

-----------------------------------

---------------------------------------cover

-------------------------------

rubber--------------------------------------------

assembly

assembly

----------------------------------------

----------------------------------------

Isolator-----------------------------------------------

oil

pan

Pan Assembly----

Hocker

Filter

Drive

Drive

Hocker

and

Shaft

left

Shaft

Drive

Screw,

Lift

for

Tube

Bar

Tube,

assembly-----------------------------------------

-

------------------------------------------

Shaft

Bushing,

left--------------------------------

Screen----------------------------------------------

Lever

Lever

Shaft

right

Bushing,

and

Bushing,

Lever

for

Eccentric

oil

Holder

Bushing,

for

feed

Shaft

Shaft

Bushing

Bushing,

Bush

and

front--------------------------

ing,

middle

Looper

------------------------

Hocker

---------------------------------------------left,

inner

right

and

Hocker

right--------------------------------------------

middle-------------------------------------Shaft

Bushing,

rear

--------------------------

bed--------------------------------------------

Oil

Tube-------------------------------------

tube----------------------------------------------

-----------------------------------------------lower-------------------------------------

crank

link

assembly

---------------------------

Shaft

Shaft

Nut--------------------------------------------------------

Oil

Attraction

Siphon

Siphon

Tube

Priming

for

oil

for

oil

Clamp-------------------------------------------------

for

upper

Felt

Oil

tube

tube

-----------------------------------------

Tube---------------------------------------

Block, felt

----------------------------------

clamp----------------------------------------

clamp

rocker

--------------------------------------

shaft

bushin

g,

left

---------------------

Screw-----------------------------------------------------

Tube

Connection---------------------------------------------

Locking

Plug

Disc

Sere~

Clamp,

Oil

Screw,

Screw,

Hing

Foot Lif

-----------------------------------------------

ter

Lever

Bushing-------------------------------

------------------------------------------------------

------------------------------------------------------

for oil

Helease

siphon

Assembly

·

----------------------------------------------------upper

Bushing Housing,

Gau

ge

Bearing

for

assembly-----------------------------------

--------------------------------------------

----------------------------------------------

Lever

Bushing ----------------------------------

including bus hi

----------------------------------------------Housing

Gasket-------------------------------

bed---------------------------------------------

for bed---------------------------------------------13

for

feed

rocker

shaft-----------------------------------

ng---------------------

Pin-----------------------------------------------------

for main s

for

looper

for

oil

for main s h

Plug

Screw

Plug

Screw---------------------------------------------

haft

bush

ing

left

and

rocker shaft

bushing

middle

-------------------------

-------------------

wick---------------------------------------------

aft

bush

ing

right

and

inner

right---------------

---------------------------------------------

Bushing,

Bushing,

A

Hc

2

2

4

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

mt.

q.

1

2

1

1

1

2

1

1

3

1

1

1

1

1

4

1

1

1

1

1

1

4

4

1

1

1

1

1

1

15

Page 16

/

/

/

/

/

/

.,......

I

I

I

I

I

~.-.-----

~~~ /~//1

I

I

I

I

/

16

Page 17

l~ef.

No.

2

:i

4

5

G

7

H

9

10

11

12

l:i

14

15

16

17

l!l

19

20

21

22

2:i

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

Part

No.

56

54617

27- 4!H

56351:!

2276B

CL21

225!!6 B

51250

51250

660- 2

51150

29066

22559

51216N

51216

51216

lB

54652

52952

22559

52916

52951

29126

660-246

52951

52951

546:~8

95

294 76

51216

54647

88 F

52921

22894

G

22569

660-202

52891

B

51236

A

51493

BP

22560

B

29133

N

22894

c

22768

22729

51243

c

29105

AD

22559

B

22!l94 c

22559

A

12982

51242

p

51242

L

52841

G

51242

1\11

52841

J

51242

y

51242

L

A

22883

51242

M

81

22852

A

29348

X

54654

97

H7A

54654

c

28

22839

A

54615

51250

E

54658

22768

F

I)

12

H

G

p

G

B

G

c

Dll

B

A

l\1 z

1\11

B

B

13Lk.

CHANI<SHAFT,

Needle

Needle

Washer,

Needle

Screw

Oil

Plug

Gasket,

Washer,

Oil

Needle

Needle

Washer,

Nut,

Needle

Nut,

Spacer

Needle

Needle

Thrust

Needle

Crankshaft

Counterweight-------------------------------------------------------------

Screw--------------------------------------------------------------------

Pulley--------------------------------------------------------------------

Screw,

Oil

Cr

Link

Oil

Looper

Screw,

Ball

Retainer

Lock

Looper

Thrust

Locking

Washer

Nul,

Looper

Thrust Was

Plug

Washer,

Spot Scr

Clamp

Needle

Needle

Screw,

CLamp

Bar,

for

Bar

for

Wlck,

Seal

Seal

ankshaft

Pump

Screw---------------------------------------------------------------Needle

Needle

for

Sc1·ew,

for

for

Hing,

Lever

Lever

Screw--------------------------

for

for

needle

Lever

for

ball

Washer,

Feed

Screw-----------------------------------

Feed

\Vasher,

Feed

Tru-Arc

Retaining

Connecting

Eccentric, . 100

Screw----------------------------------------------------------------

Needle

Screw----------------------------------------------------------------

Screw---------------------------------------------------------------Screw----------------------------------------------------------------

Screw----------------------------------------------------------------

Bearing

Set

Bearing

Ball

Assembly, . 990

for

crankshaft

Ring,

Bushing

Pin,

for

Driving

Drive

for

ball

Stud

Guide

Drive

Screw-------------------------------------------------------------

Nut,

for

Drive

Washer------------------------------------------------------------

Stud--------------------------------------------------------------

------------------------------------------------------------------

for

locking stud-------------------------------------------------------

Drive

her------------------------------------------------------------

Screw

---------------------------------------------------------------

for

ew,

Screw,

Lever

Joint

Screw-----------------------------------------------------------Screw------------------------------------------------------------

Guide

Screw------------------------------------------------------------

Lever,

Lever

Lever

for

needle

NEEDLE

Nut---------------------------------------------------------

marked

needle

Eyelet------------------------

needle

ball

for

needle

needle

Stop

Connecting

needle

Connecting

joint

Connecting

Drive

Drive

Ring---------------------------------------------------------

Washer------------------------------------------------------

Bearing--------------------------------------------------------28

looper

Eccentric

Screw,

Screw,

screw

Lever

Lever

looper dri

for

for

Assembly----------------------------------------------------

Assembly---------------------------------------------------

Washer-----------------------------------------------------

Thread

"EE"

bar

bar

joint

needle

lever

lever

for

needle

Collar

lever

lever----------------

assembly------------

for

ball

Connecting

for

crankshafi

Eccentric

Hod

Bearing------------------------------------------------

inch

for

pulley---------------------------------------------------

Housing,

drive

Gear

stud

guide

Fork-------------------------------------------------------

Eccentric

upper--------------------------------------------------

lower--------------------------------------------------

No.

Shaft

Hocker------------------------------------------------

looper

looper dri

including bushing----------------------------------------

Stud----------------------------------------------------lever

LEVER

-------------------------------------------------

eyelet----------------------------------------------

eyelet------------

'assembly

lever

stud-------------

stud--------------

lever

-----------------------------

Hod

-----------------------

Hod-------------

joint

Rod

Ball

throw---------------------------------------------

inch

bushing

eccentric

---------------------------------------------------Assembly, . 312

fork----------------------------------------------

Assembly-----------------------------------------

81-------------------------------------------------

--------------------------------------------------

ve

lever

drive

lever rocker------------------------------------

ve

Eyelet------------------------------------------------

thread

AND

LOOPEH

Description

- -

-------

stud-------

stud------

Assembly---

assembly--------

Joint,

Rod------------------------------------------

---------------------------------------------

Assembly--------------------------------------

throw---------------------------------------

housing---------------------------------------

including

assembly--------------------------------

rocker---------------------------------------

lever

rocker----------------------------------

eyelet----------------------------------------

----------

--

------ - -

--

-------

---

- - - -

--

-

-------------------------------------

- -

--------------

--

-

-----

upper------

bushing-------------------------------

inch

DRIVING

- ------------

-------------

--

----------------

-

---

--------

---

- -

-- --

----------

-

--------------------------

------

--

- - -

---------

-

-----------------------------

-

-

----------------------------

throw---------------------------

PARTS

-

--------------

------------------------

---------

- -

---

- - - - -

-

--------------------

---

- -------------------

----

------------------------

----------

-------------

--

- -

------

--

-------------

------------------

--------

-----

---

- -

--------

------------------

- - -

------------

--

------

- -

----

---

A

mi.

Hcq.

1

1

1

1

1

1

1

1

1

2

1

1

2

2

1

1

1

2

2

1

1

1

1

1

1

2

1

2

1

2

3

1

1

1

1

2

1

2

1

1

1

1

2

5

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

1

1

1

1

1

1

1

17

Page 18

18

Page 19

NEEDLE

FEED

PARTS,

CAST-OFF

PLATE,

NEEDLE

BAR

AND

NEEDLE

HEAD

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

Part

No.

52849

51147

95

52951

54637

55235

6042

55235

51771

22758

54637

43139

61985

54654

22593

54637

61341

52849

22539

52952

55235

6042

55235

54617

22528

21657 E

54657

54604

52958

52904

c

D

E

A

D

H

c

A

A

D

F

c

95

660-202

D

c

D

A

E

56

50-216

28

A

73

D

G

Blk.

Description

Needle

Rocker

Thrust

Needle

Ferrule,

Screw,

Link

Nut,

Needle

Ball

Screw,

Needle

Washer,

Rocker

Oil

Plug

Needle

Needle

Needle

Screw,

Washer,

Dowel

Cast-off

Cast-off

Screw,

Screw,

Looper

Cast-off

Feed

Shaft

Screw----------------------------------------

Washer,

Feed

Nut

Washer

Locking

for

---------------------------------------------

for

Bar

Stud

for

Bar

Shaft

Screw----------------------------------------

Seal

Screw,

Feed

Locking

Washer

Nut

Bar,

Clamp

for

Pin,

for

for

Thread

Rocker

Collar

Drive

------------------------------------------

--------------------------------------

Stud----------------------------------

for

link----------------------------------

link

link--------------------------------------

Frame

Guide-----------------------------------

ball

Frame---------------------------------

for

needle

Oil

Ring,

------------------------------------------

for

Support

Plate-------------------------------------

Wire-------------------------------------

for

for

Rocker

Stud----------------------------------

-------------------------------------marked

Nut---------------------------------

cast-off

cast-off

for

cast-off

cast-off

eyelet

Take-up

Shaft

-------------------------------

for

needle

Lever,

-----------------------------------

Pivot

stud

guide--------------------------

bar

Seal

rocker

bed-------------------------------

Shaft

"EE"--------------------------

support

support

Plate

plate---------------------------

and

--------------------------

feed

left----------------------

Pin------------------------

frame

Collar------------------------

shaft----------------------

Lever,

plate

support

-----------------------------

cast-off

Eyelet

rocker

----------------------

right

-------------------

plate

plate----------------

wire------------------

---------------------

shaft

--------------

------------------

---------

Amt.

Req.

1

1

2

1

1

1

1

1

2

2

1

1

1

2

4

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

2

3

2

1

19

Page 20

20

Page 21

Hd.

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

48

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70