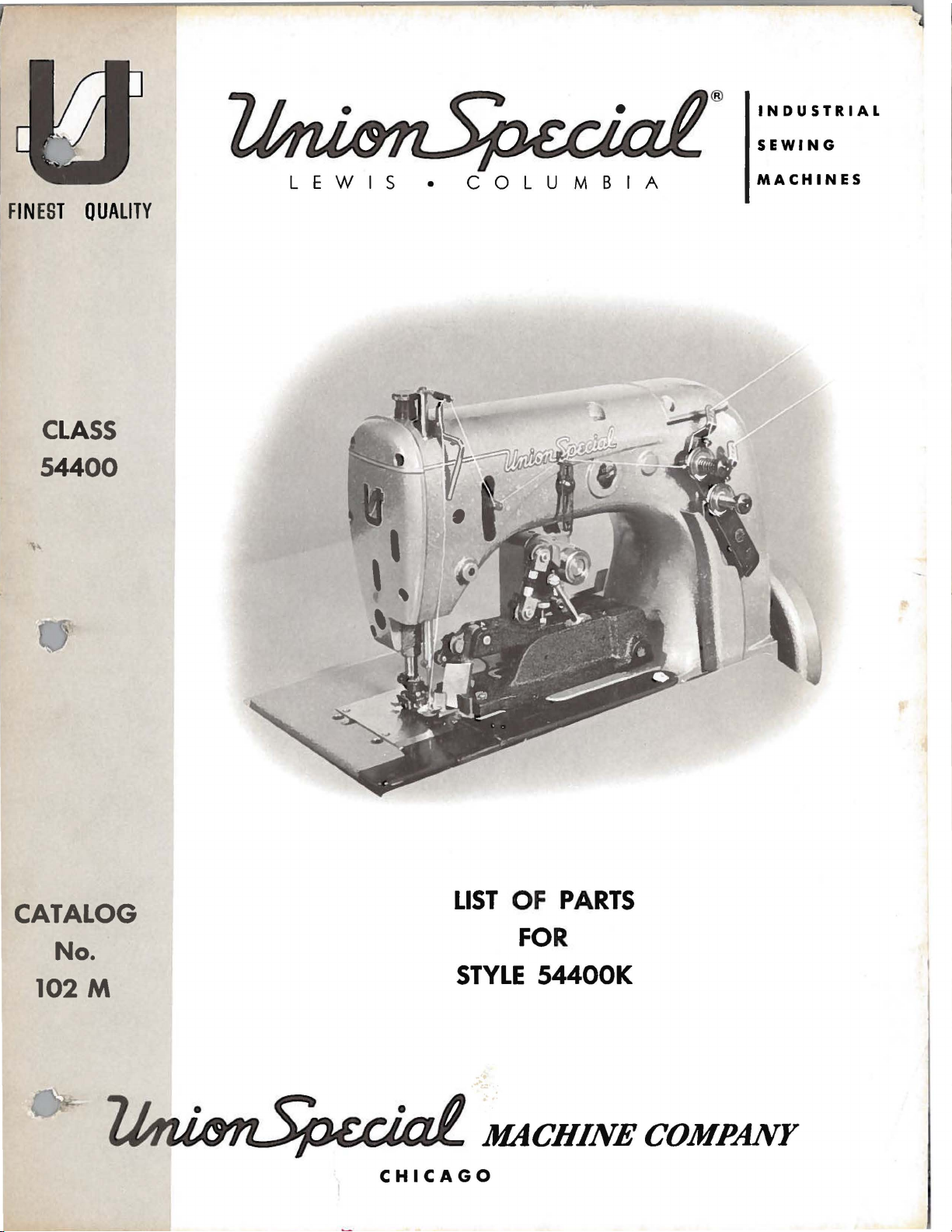

Page 1

®

INDUSTRIAL

5

EWING

FINEST QUALI

CLA

5

44

00

TY

SS

LEWIS

•

COLUMBIA

MACHINES

LIST

OF

PARTS

CATALOG

FOR

No.

102M

STYLE

54400K

MACHINE

CHICAGO

COMPANY

Page 2

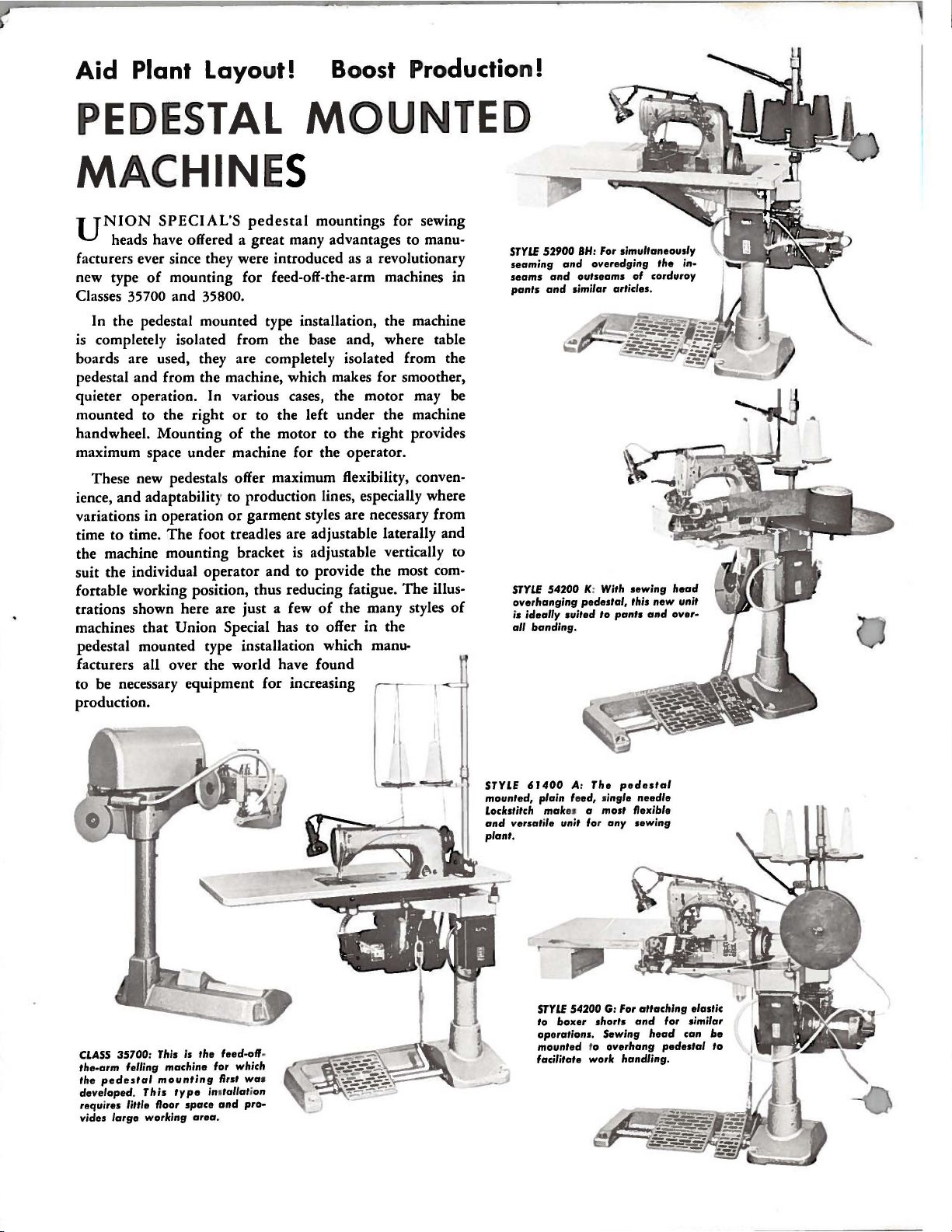

Aid

Plant Layout!

Boost Production!

PEDESTAL

MACHINE

UNION

SPECIAL'S

pedestal

MOUNTED

S

mountings for sewing

heads have offered a great many advantages to manu-

facturers ever since they were introduced

of

new type

Classes

mounting for feed-off-the-arm machines in

35700 and 35800.

as

a revolutionary

In the pedestal mounted type installation, the machine

is

completely isolated from the base and, where table

boards are used, they are completely isolated from the

pedestal and from the machine, which makes for smoother,

quieter operation. In various cases, the motor may be

mounted to the right

handwheel. Mounting

or

to the left under the machine

of

the motor to the right providE's

maximum space under machine for the operator.

These new pedestals offer maximum flexibility,

convenience, and adaptability to production lines, especially where

variations in operation

time to time.

The

the machine mounting bracket

suit the individual operator

fortable working position, thus reducing fatigue.

trations shown here are just a few

or

garment styles are necessary from

foot treadles are adjustable laterally and

is

adjustable vertically to

and

to provide the most com-

The

illus-

of

the many styles

of

machines that Union Special has to offer in the

pedestal mounted type installation which

manufacturers all over the world have found

to be necessary equipment for increasing

production.

STYLE

52900

seaming

seams

and

pants

and

STYLE

54200 K: With

overhanging

ideally suited

is

all

banding.

BH:

For simultaneously

and

overedging

outseams

similar articles.

pedestal,

to

pants

of

corduroy

sewing

this

new

and

the

in·

..

head

unit

over·

CLASS

35700: This is

the-arm

the

developed.

requires little floor

vides

felling machine for which

pedestal

large

mounting

This

working

type

space

the

ino

area.

feed-off-

first was

tallation

and

pro·

STYLE 6 J

mounted, plain feed, single

Lockstitch

and

plant.

---

-

400

mak

versatile unit for any

STYLE

boxer

to

operations.

mounted

facilitate work handling.

A:

The

pedestal

G:

For

shorts

Sewing

overhang

needle

sewing

attaching

and

head

es a most flexible

54200

to

elastic

for similar

can

pedestal

be

to

Page 3

Catalog

(Supplement

to

Catalog

No.

102

No.

M

102

L)

The

furnished

parts

at

LIST

CLASS

listed

list

First

OF

Style

54400

in

prices

Edition

PARTS

54400

K

this

fo

catalog

r

repair

are

s

only.

October,

1963

Union

Rights

Copyright

Special

Re

s e r

by

ved

Mach

in

1961

All

MACHINE COMPANY

INDUSTRIAL

Pr

SEWING

CHICAGO

i nted

in

MACHINES

U.S.A.

3

i n e

Countr

Co.

ie

s

Page 4

IDENTIFICATION

OF

MACHINE

Each

the

name

Standard

letter

When

II

Z

only

standard

Styles

which

differs

This

catalog

therewith.

other

styles

common

locate

the

number,

reference

This

catalog

It

can

also

References

operator's

is

toward

Union

plate

Style

11

Style

Special

on

the

numbers

•

Example: 11Style

minor

changes

number.

of

machines

from the

is a supplement

Only

to

listed

all

parts

in

machines

54400 K parts.

description

numbers.

applies

be

applied

to

direction,

position

the

operator.

while

machine

machine.

have

is

Style

one

54400

are

made

Example: 11Style

similar

style

in

number,

APPLICATION

to

found

Catalog

are

on

No.

Style

listed

Opposite

and

amount

specifically

with

discretion,

such

as

seated

identified

numbers

or

more

11

K

•

Special

in a standard

construction

in

that

Catalog

No.

54400

102

L,

and

the

illustrated

required,

to

the

to

right,

at

the

left,

machine.

by a Style

are

letters

Style

54400

KZ

are

it

contains

OF

CATALOG

102

K,

but

are

illustrated.

other

parts

which

Standard

some

front,

number

classified

suffixed,

numbers

machine,

11

•

grouped

no

letter.

Land

not

should

on

Style

are

page

are

have

style

of

Special

back,

Operating

which

as

standard

but

never

contain

11 Z11

a

is

under a class

Example: 1154400

be

used

54400 A or

For

clarity,

shown

listed

been

in

each

itemized

machine

machines

etc.,

are

direction

is

stamped

and

contain

the

letter

suffixed

in

conjunction

some

phantom

part

as

listed

in

this

given

of

handwheel

special.

number

any

to

by

by

herein.

Class.

from

into

th

11

II

Z

to

the

11

of

the

parts

help

part

detail

the

•

•

Streamlined

in

Line

Light

With

Weight

Mechanism,

Lubricating

Assembly,

54400

K-3/16

uniform

made

specification

54400

54400

54400

and

and

and

K-1/4

with

K-3/8

with

K-5/8

with

Flat

Feed,

Needle

System,

Light

dresses,

of

light

Same

parts

Same

parts

Same

parts

Bed,

Low

STYLE

Throw,

OF

Single

PreparedWithPinkingAttachment,

Presser

Bearing

Weight

For

seaming

to

40

1-SSa-1.

as

furnished

as

furnished

as

furnished

Bar,

Filter

Pulley

slips,

medium

Style

Style

Style

Light

Needle

Type

and

and

half

weight

54400

for

54400

for

54400

for

Weight

Bar

Oil

Return

Prepared

simultaneously

slips,

blouses,

material.

K-3/16exceptpreparedfor

5/16

inch

K-3/16

1/2

inch

K-3/16exceptpreparedfor

3/4

inch

MACHINE

Needle

Drive,

Pump,

width

except

width

width

Machine,

Needle

Single

Oil

for

Oil

pinking

slacks,

Width

of

prepared

of

pink.

of

pink.

With

Looper

FrontDisposalofTrimmin

Bar

Reservoir

Pan

and

Base

Needle

Enclosed

Plate

Shield.

on

women's

robes

of

and

pink

1/4

similar

3/16

inch

pink.

for

3/8

inch

5/8

inch

Bar

and

street

inch.

width

width

width

Traveling

g

Driving

Automatic

Oil

Siphon

dresses,

garments

Seam

of

pink

of

pink

of

pink

s,

NOTE:

Fraction

point

of

denotes

pinking

the

knife.

width

of

pink,

measured

4

from

centerline

of

needle

to

Page 5

NEEDLES

Each

number

The

lade

Collectively,

Standard

shank,

eye,

To

sample

on

label.

Size

Selection

Thread

formation.

This

views

seen

will

be

number

Union

denotes

size

036".

number,

measured

round

spotted,

have

needle,

should

catalog

of

the

in

their

found

of

the

needle

point,

chromium

needle

A

complete

of

various

actual

the

pieces

Special

the

stamped

in

thousandths

type

or

the

the

proper

pass

has

been

listing

required

needle

kind

for

extra

orders

freely

sections

position

of

number

Style

short,

plated -sizes

type

and

order

needle

through

ORDERING

arranged

of

the

in

has

both a type

shank,

on

the

of

an

and

the

54400 K is

double

promptly

size

would

size

to

of

the

in

the

parts

the

particular

point,

needle

number

read

the

simplify

mechanism

machine.

with

length,

shank,

inch,

size

number

Type

groove,

029, 032,

and

accurately

as

should

needle

REPAIR

their

number

midway

113 GS

struck

should

follows:

be

determined

eye

PARTS

the

ordering

are

On

part

view

being

and a size

groove,

denotes

between

is

the

036,

040, 044,

filled,

be

forwarded.

"1000

in

order

shown

the

page

numbers,

shown.

finish

the

the

complete

in

size

groove,

Needles,

by

to

of

repair

so

opposite

number.

and

largest

shank

symbol.

036.

spiral

an

size

produce a good

that

descriptions,

It

049,

empty

Use

of

parts.

the

the

The

other

diameter

and

the

has a round

groove.

054.

package,

description

Type

thread

Exploded

parts

illustration

type

details.

of

eye.

ball

113

GS,

used.

stitch

may

be

and

the

a

&i

ndicate

•

never

column.

catalog,

parts

in

number.

symbol

appears.

OF

Union

Company,

'

to

Maximum

The

In

the

Where

Each

IMPORTANT!

MACHINE

Success

the

numbers

the

position

be

used

those

for

description,

which

Special

most

cases

no

specific

the

various

construction

A

part

distinguishes

part

in

the

Needles

its

subsidiaries

approved

efficiency

in

in

ordering

and,

too

number

ON

FOR

USE

operation

the

of

that

parts.

where

usage

machines

if

necessary,

permits,

small

represents

ALL

WHICH

GENUINE

and

and

scientific

and

durability

first

a

will

for

PART

of

Repair

column

part

in

Always

part

it

ORDERS,

these

is

be

mentioned

are

not

IDENTIFYING

each

its

complete

from

the

IS

NEEDLES

machines

Parts,

authorized

principles

are

are

reference

the

illustration.

use

the

common

the

same,

the

difference

UnionSpecialpart

another

same

PLEASE

ORDERED.

as

distributors.

assured.

to

in

the

PARTS

catalog

part

part

INCLUDE

AND

can

furnished

and

part

all

of

the

description.

specific

will

stamping

similar

regardless

REPAIR

be

secured

made

numbers

The

reference

number

the

be

is

in

PART

PARTS

by

the

They

with

only,

listed

machines

However,

usage

shown

stamped

is

appearance.

only

Union

are

will

in

identified

of

catalog

NAME

by

the

Special

designed

the

utmost

the

and

number

in

the

covered

be

mentioned

illustration.

with

its

by a letter

in

AND

use

of

according

precision.

merely

should

second

by

this

when

Machine

the

catalog

which

STYLE

genuine

it

5

Page 6

USE

GENUINE

NEEDLES

AND

REPAIR

PARTS

(Continued)

Genuine

parts

your

shipments

unless

must

viscosity

gauge

red

than

throw-out

are

guarantee

Prices

otherwise

The

be

Oil

is

on

lines

The

an

occasional

needles

stamped

are

are

oil

has

filled

machine

of

200

filled

the

front

on

the

pin,

before

are

wi

th

of

the

highest

strictly

forwarded

directed.

been

to

at

and

drained

beginning

250

the

spring

of

gauge.

is

almost

drop

the

the

packaged

the

familiar

quality

net

cash

f.

o.

b.

A

THREADING

from

seconds

cap

machine.

The

capacity

entirely

of

oil

looper

holder

with

and

shipping

charge

the

to

operate.

at

100°

in

the

at

both

labels

Union

in

TERMS

top

The

of

automatically

frame

marked

Special

materials

are

subject

point.

is

made

AND

machine

Use a straight

Fahrenheit.

cover

oil

level

the

oil

bearings

locking

~

trade

and

workmanship.

to

Parcel

to

cover

OILING

before

and

the

should

reservoir

lubricated,

of

the

pin,

mark.

change

Post

shipments

postage

shipping,

mineral

level

is

be

maintained

is

12

retainer

are

required.

•

Genuine

Each

without

and

and

oil

checked

ounces.

and

no

holder,

repair

trade

mark

is

no~ll

are insured

insurance.

the

reservoir

with a Saybolt

at

the

sight

between

oiling,

the

the

othe

loope

r

r

NOTE:

knife

lever

on

the

time,

which

reservoir,

reservoir

handwheel.

threaded.

a

and

back

lever

the

A

oil

On

plane

is

to

bearings

daily

it

threaded

attachment.

in

may

has

the

at

front.

All

shaft

check

the

gone

making

may

next

Please

right

moving

and

main

be

well

be

page

angles

from

front

knife

before

reservoir

to

through

too

drained

is a diagram

note,

right

parts

and

rear,

holder

the

is

manually

the

frequent

at

that

the

to

the

to

left.

of

the

also

shaft.

morning

kept

between

oil

machine,

oilings

the

plug

needle

direction

Also

pinking

oil

two

Major

start

the

pinker

is

filtered

unnecessary.

screw

showing

is

inserted

of

line

please

attachment

oil

holes

pinker

should

the

the

two

and

in

the

manner

of

feed,

note,

be

the

and

in

to

be

for

lubricating

oiling

red

main

that

points

made,

lines

other

pumped back

Excessive

frame

in

the

needle

the

spot

the

looper

oiled

to

on

suggested

which

once

are

see

that

the

oil

directly

the

bar

or scarf

is

daily.

both

marked

the

gauge.

points.

into

the

in

the

under

machine

with

the

to

threaded

side

in

level

At

main

eye

the

from

Oi

s of

red

of

this

Oil

main

the

is

in

left,

l

6

Page 7

THREADING

AND

OILING

DIAGRAM

FILL

MAIN

RESERVOIR

HERE

FOR

STYLE

54400

K

CAUTION!

FILL

ALL

OIL

BEFORE

MACHINE HAS

BEFORE

STARTING.

SHIPPING.

7

RESERVOIRS

BEEN

DRAINED

Page 8

8

Page 9

SEWING

PARTS

COMBINATIONS

AND

MISCELLANEOUS

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

16A

17

18

19

20

21

21A

21B

22

23

24

25

26

27

27A

27B

27C

27D

27E

27F

27G

27H

28

29

30

31

32

33

34

35

36

37

38

39

40

41

~

44

45

46

47

A8

49

50

51

52

-

Part

No.

54420

K-5/16

54420

K-3/4

54430 A

91

35730 Y

54430D

54430

B

K-5/16

54430

54430

K-3/4

54430 C

22734

AC

52930

604

22799 A

8-66

408-75

408-79

22798

87

54424

K-3/4

54424

K-3/16

22839

54480

51280 J

HA61 D

54405

K-5/16

54405

K-3/4

54405

K-3/16

54484

N-5/8

54484

N-3/4

12986

B

54264

C

22542

54478

23441 M

475-68

99-143

99-329

21210 A

810 L

18-422

18-353

40-86

54480

A

54484

J

660-237

98A

52 A

54484

P

605

54401 B

22574

80

51493 A Y

51493

BG

51493

BK

54417

A

22819

~

27-484

51258

A

22768

51254

D

51254

C

51270 B

95

539

51493

BH

51493

BJ

Presser

Presser

Presser

Presser

Presser

Screw----------------------------------------------------------Screw

Throat

Throat

Screw

Throat

Screw,

Feed Dog,

Feed Dog, f

Feed Dog,

Knife

Knife

Screw

Sprin

Screw

Chip

Edge

Throat

Swinging

Screw-----------------------------------------------------------

Looper

Knife

Screw

Cloth

Screw

Screw

Oil

Base

Lint

Needle

B-11~:··~---Ey

Needle

Screw

Needle

Needle

Needle

Screw----------------------

Frame

Filter

Description

Foot,

Foot,

Presser

Screw----------------------------------------------------Plunger

Pin---------------------------------------------------------Yield

ing

Presser

Presser

Spacer----------------------------------------------------

Screw----------------------------------------------------Chain

Screw--------------------------------------------------------

Hin

ge

Foot

Foot

Foot

----------------------------------------------------------Plate,

Plate,

----------------------------------------------------------Plate

Dowel

for feed dog

Spacer, for

Space

-----------------------------------------------------------

g, wi

-----------------------

Chute-------------------------------------------------------

Guide

Edge

Guide ----------

Edge Gui

Holder

Washer------------------------------------------------------Screw-------------------------------------------------------Screw-------------------------------------------------------Screw--------------------------------------------------------

Washer-------------------------------------------------------

Plate

Brack

Spring

Thread

Support

----------------------

Plate-------------------------------------------------------

-----------------------------------------------------------

-----------------------------------------------------------

Pan

Base

Plate

Filter

Bar-------------------------------------------------------

Screw--------------------------------------------------------

elet

Lock

Bar

----------------------------------------------------------Bar

Bar

Thread

Needle

Cap

Washer, spo

for

Styles

for

Styles

Foot

Shank--------------------------------------------

Spring------------------------------------------------

Section-----------------------

Foot

Bottom,

Foot

Bottom,

Cutter--------------------------------------------------

Screw

Pin

th fin

Lock---------------------------------------------------

Assembly----------------------------------------------

-------------------------------------------------Guard,

Guard,

Guard,

for

Styles

for

Style

Support----------------------------------------------

----------------------------------------------------

for

Style

or Sty

for Style

------------------------------

Oil

Screen

Eyelet

Bushin

les 54400

Style

r , for

Assembly

Bushin

Styl

ge r

de

Holder---------------------------------------------

Support

et

-------------------------------------------------

Eyelet---------------------------------------------

Block-----------------------------------------------

Plate--------------------------------------

Pad,

----------------------------------------------

Washer-----------------------------------------------

------------------------------------------------

g, lower

g,

Take-u

Thre

ad

nge rubb

54400

54400

for Sty

for

Style

for

Style

54400

54400

----------------------------------------------54400

54400 K-3/16

54400

e 54400 K-5

projection--------------------------------------

---------------------------------------------

Spac

er

felt-------------------------------------------

upp

er

p Wire---------------------------------------

Eyel e

er

K-3/16,

K-3/8,

for

presser

for pre

K-1/4

-

----------------------------------------

----------------------------------------

----------------------------------------

sser

les

54400

54400

54400

K-1/4,

K-3/16

-----------------------------------

K-3/8,

----------------------------------------

t-------------

----------------------------------

K-5/8

/8

-

-----------------------------------

---------------------------------------

-

------------------------------------

-

------------------------------------

1/4

-------------------------

5/8

-------------------------

foot

foot No. 54420

K-3/16, 1/4,

K-5/8

K-5/8 ( 5/8

3/8,

-------------------------------

5/8

(5/8

(3/4

-

No.

(3/4

5/8

----------------------------inch

width

inch

width

-

------------------------

-

---------------------

----------------------54420

K-5/16---------K-3/4

3/8

inch

width

inch

width

----------------------

of

pink)-----------

of

pink)

----------

-------------of

of

-----------

- - -

pink)---pink)

----

-------

-

- - 1

---

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

3

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

9

Page 10

10

Page 11

He f.

No.

Part

No.

1 18-558

2 119-24

119-34

3 21657 E

627

4

5

6

A

29482 A

14-171

7 3-46

8

119-25

9 99-134

10

11

12

13

14

34-26

14-172

18-178

18-544

21-309

15 18-547

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

:l6

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

1012 L

39536

AD

76-18

1003 L

54484

1160 L

18-844

J87 J

18-71

45-248

45-249

40-101

CS231

1776L

46-108

51236 A

53552 p

15037 A

92201

52882 K

22585 H

54484 H

22797

35895 L

531

18

62295 A

54484 K

95

54484 G

29480

DD

29476 LF

652

P-36

39153 G

54484 F

54484 B

54484 A

22733 B

41394 A

22791 G

18

22888 A

54484 E

53139 E

269

54484 D

98

63 54484 M

64 52841 A

65 22729 c

66

67

269

35741 A

68 18

69 22526

70

71

72

73

74

652

N-14

627

652 N-14

54484 H

53138 L

75 22894 X

PINKEH

DHIVING

PAHTS

AND

PINKEH ASSEMBLY

Description

Screw, for

Lower

Lower

Style 54400

(both

VVasher-------------------------------------

Screw,

Pi

nker

Shaft,

Pinker

Upper

Upper Knife

Upper Knife

Shaft, for

Screw, for

Screw,

Knife

Screw,

Nut

Spring

Handle,

Screw,

Pinker Drive

Nut

Kn

Screw, f

Screw,

Throw-o

Knife Throw-out

Tension

Nut

Screw-----------------------------------------------------------------Kn

Li

nk Pin--------------------Conne

N

ut----------------------------

Connecting

Gaske

Scr

ew

Pinke r Drive Lever-------------------------------------------------

Scr

lar------------------------------------------------------------------------

Col

Scr e

Nut

------------------------------------

VVa

sher

Pinker Base

S

Pinker Drive Lever

Pink

er

Housing

Pl

Gask

Pi

Nut

Scre

I

dlerGear

Eccentr ic Bushing

Nut

Pinker Dri

Pink

Lock

Scr ew

Lock

mGa

Shi

Main

Screw

lower

pinker

Pinker

Knife,

Pinker

Knife,

K-3/8

5/8

and

3/4

for

mounting pi

Assembly------------------------------

for

base-------------------------------

knife--------------------------------------------

for

Styles 54400

for

Styles 54400

(1/2

inch width of pink) and

inch width of

nker

assembly-----------------------------------

K-3/16,

K-1/4

1/4,

(5/16

3/8----------------------------

inch width of pink, for

for

Style 54400

pink)--------------------------------------------

-- - - -

-

-------------------------------

-

-----------------------------

-----------------------------

Base---------------------------------------------------------------

Pinker

Knife------------------------

-

----------------------------Holder--------------------------------------------------------Cam

upper

Throw-out----------------

knife

upper

for

upper

Tension

-------------------------------------VVasher

for

for

for

Spring,

leveling

knife

base

holder------------------------------------------knife holder

pinker

shaft-------------------------------------------

knif

e-----------------------------------------

flat--------------

base------------------

------------------------------------------------------------throw-out---------------

shaft-----------------------------------------------

-

---------------------------

---

----------------------------------

~.,.

--------------------------------

-

--------------------------------

--

---------------------------------

Lever---------------------------------------------------------

---------------------------------

ife Ten

sion Adjusting Scre

or

link

pin

for

throw-out

-----------------------------------------lever--------------------------------------------------

w-----------------------------------------------

-

-------------------------------------

ut Lever-----------------------------------------------------------

Lever------------------------------------------------------

VVashe

r,

for

upper knife cam

-----------------------------

throw-out

-

-------------------------------------

-------------------------------

ife Throw-out Link-------------------------------------------------------

-- --

ct

ing

Clevis--------------Stud---------------

----------------------------

--

---------------------------------

-

----------------------------------------------

-----------------------------------------

t------------------------------------------------------------------------

-----------------------------------------------------------------------ew--------------------

w--------------------------------------

-

------------------------------------------------

-

-

----------------------------

------------------

--------------------------------------------------Pla

te

crew-------------------------------------

Gear Drive Housi

, compl

VV

asher

Nut----------------------------------------------------Idler

Bu

shing----------------------------------------------------------------

Pink

ug S

crew----------------

et

-------------------------------------------------

n Screw

---------------------------Shaf

t--------------------------------------

ng Assem

ete

--------------------------------------

bly----------------------------------

-------------------------------------------

Gear Brac

er Drive Hous ing

ket

--------------------------------------

-----------------------------

-

-----------------------·-----------------

---------------------------------------------

-

-----------------------------

-

-------------

-

--------------------------------------------------w-----------------------------------------------

---------------

------

-----------------------------------------------------

S

Ba

Nut, left

Connec

Nu

Screw

VVasher

--------------------------

VV

asher---------------------------------------------

Shaft Gear - -- -- - -------------------------

ving Shaft Gear----------------------

crew----------------------------------

er

Connecting

ll Joint

Scr ew

ti

t, r ight thr

Hod Assembly--

---------------------------------------------

------------------------------------

th

read

---------

ng Hod--------------------------------

ead---------------------------------------

---------------------------

-------------------------------------------

sket- -

--------------------------------------------------

-----------------------

-

---------------------------

---

------------------

-- - - -

-----------------------------------

-- - -

--------------------------

-

-------------------------

-

---------------------------

- --

-------------------------

-

------------------------------

-

--------------------------

-

--------------------------

-

---------------

-

------------

-

-

-------------------------------

--

K-5/8

-

--------

-

-

-------

-

--------------

-

----------------

-

-----------

-----

-

--------

-

-----------

-

-

----------------

--------

------------------

-

----------------

-

-

-------------------

-

--------------------

-

---------

-

--------------

---------------

----------------------

-- -

----

---------------

--------------------

-- -----

-------------

---- ----------------

- - --------------------

-

-----------------

-

----------------

-

-

-----------------

-

----

---------------

-

-----------------

-

--------------

----

---------

-- -

---------

---

---------

--

---

---

-- -

--

-------------

--------------

-- -

Amt.

---

--

-

--

-

----

-

-----

------

-

---

-

--

---

-- 1

- 1

--

- 1

--

- 1

---

- - 1

- - 1

---- - 2

-- - 1

-----

----

---

Heq.

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

2

2

1

1

8

1

1

2

2

1

1

1

1

2

1

1

1

1

1

1

l

1

1

1

1

2

1

1

1

1

1

4

4

1

1

2

11

Page 12

12

Page 13

CRANKSHAFT,

NEEDLE

AND

LOOPER

LEVER,

HOLDER

OIL

SIPHON

PARTS

PARTS,

LOOPER

Ref.

-

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

Part

No.

29476 HA

51216 M

53138

22894

52891 B

52921 B

22894 G

22729 A

51294

51294

22729 B

21212

51294

51294

51294

51294

22652

54242 DA

61354

51134

22845 B

54611

54242

54285

54285 B

54225

22768

54208

54244

54244

54244

54223 A

54245

51236 A

29348

51254

22562 A

51054

51215 J

51250 A

51250 E

51258

22768

29476

51406

22894 D

54245

L

X

660-202

u

K

643-263

666-209

666-201

N

M

666-214

7947

R

p

667

B-12

B-8

B-12

667

A

v

B-4-21

c

97 A

J87

J

A

p

E

F

A

p

H

54

78

666-149

77

KR

c

Description

Crankshaft

Needle

Main

Shaft

Screw------------------------------------------------

Main

Shaft

Oil

Seal

Pulley,

Screw------------------------------------------------

Screw

Oil

Siphon

Clamp,

Screw-----------------------------------------------Siphon------------------------------------------------

Felt

Felt

Locking

Oil

Tube

Oil

Siphon

Felt

Nut------------------------------------------------------

Screw

Oil

Tube

Dowel

Screw

Retainer

Dowel

Bushing

Taper

Screw

Retainer,

Retainer

Nut,

for

Screw

Screw

Looper

Needle

Screw

Looper,

Looper

Bushing,

Bushing,

Looper

Looper

Link

Pin-------------------------------------------------

Needle

Needle

Needle

Screw------------------------------------------------

Link

Screw------------------------------------------------

Needle

Needle

Needle

Screw

Feed

Lift

Feed

Eccentric

Assembly,

Bearing----------------------------------------

Gear

------------------------------------------

Housing----------------------------------------

Ring---------------------------------------------

for

No.

1 "V''

--------------------------------------------------Assembly

upper-----------------------------------------

Plug--------------------------------------------Plug--------------------------------------------Ring,

Lint

--------------------------------------------------Pin------------------------------------------------

---------------------------------------------------

Pin------------------------------------------------

---------------------------------------------------

looper

---------------------------------------------------

--------------------------------------------------Holder,

Guard---------------------------------------------

---------------------------------------------------

marked

Holder

Thread

Thread

Lever

Screw---------------------------------------------

Pin----------------------------------------------

Felt

Needle

Lever

--------------------------------------------------Lift

Spot

for

Connection---------------------------------------

Tube-------------------------------------------

Filter

Clamp-------------------------------------------

Holder

Pin

marked

Holder

Bar

Bar

Lever

Lever

Eccentric

Bearing, rig

--------------------------------------------

----------------------------------------------

------------------------------------------

holder-------------------------------------

marked"

"CB"

Frame-------------------------------------

left------------------------------------------

right

Take-up----------------------------------Take-up

Assembly

Connection--------------------------------Connection

Wick

Lever

Stud-------------------------------------

Eyelet

Eccentric, • 062

Screw

Bearing-------------------------------------

• 770 i

nch

throw----------------------

or

round

--------------------------------------

oil

siphon

---------------------------------------

"BS"

------------------------------------

M"

-------------------------------------

---------------------------------------Driving

-----------------------------------

-----------------------------------------

----------------------------------------Bushing ------------------------------

--------------------------------------

Assembly------------------------------

----------------------------------------

belt-------------------------

connection

ht-----------------------------

-------------------------------

Link

Link

----------------------------

inch

---------------------

-----------------------

throw--------------------

Amt.

Req.

1

28

1

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

13

Page 14

7

14

Page 15

THREAD

STAND, THREAD TENSION PARTS, KNEE PRESS

ASSEMBLY

AND

ACCESSORIES

Ref,

No.

1

2

3

4 21114

5

6

7 21114 A

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39 22598 c

40

41

42

43 21664 F

44

45

46

47 21662 v

48 22650

49

50

51 21662

52

53 22557 A

54 43137 E

55

56 39536

57

58

59

60

61

62

63

64

65

66

67

Part

No,

21101 H-2

258 A

652-16

21114

21104 v

22651 CD-3

22810

21114 T

22651 CD-4

21114 u

652-16

21104 H

21114 D-2

22651 CD-5

21104

21114 H-2

22651

21114 M

21114 L

21114 S-2

21114 M

21114 L

21657-3

52892

43266

51491 c

51292 D

21114 M

21114 L

51292 A

51292 G

109

51292

51292

51292 c

80

557

51493 BC

21660 H

660-219 G

92201

12982

80

21662 R

21662 T

22894 z

21662 w

21664 c

21663 A

660-168

21664

69

21202

21388

116

118B

21388

35

780

258

w

B-24

CD-4

F-5

F-2

CE-

s

AD

FD

AU

B

Amt.

Descript

Thread

Tens

Tension

Nu~-------------------------------------------------------------

Lead-in

Tension

Tens

TensionPost-------------------------------------T

TensionSpring,

Tension

TensionPostNut--------------------------------------------Spacing

Screw---------------------------------

Lifter

Knee

6

S

cre

Socket Wren

W

Th

W

L

Nut, f

Stand,

Nut------------------------------------------------------------Washer

Spool

Spool

Felt

Thread

Screw

Screw----------------------------------------------------------Lead

Screw

Lead

Washer

Nut------------------------------------------------------------Spool

Screw

Thread

EyeletSupport--------------------------------------------------

Screw

Eyelet

Eyelet-------------------------------------------------------

Lead

Eyelet

Eyelet

ion

Eyelet

Eyelet

ion

ensionDisc--------------------------------------------------------

Sprin

Washer--------------------

Link

Press Ass

Roll Pin

Mounting

Screw---------------------------------------------------

Nut-----------------

Screw,

TorsionSpring-----------------

Screw----------------------------------------------------------Knee

Knee

Knee

re

w---------------------------------------------------------

Sc

re

w-----------------------

Sc

Washer

Knee

Spring Washer---------------

racket---------------

B

Wood

Knee

Knee

ee Press Pla

Kn

Screw

w Driver,

re

nch,

rea

d Tweeze

re

nch, _single end,

if

ter

Lever Exte nsion (not s

or 35780

complete----------------------------------------------

------------

Seat Disc

Pin--------------------------------------------------------

Pad

--------------------------------------------------------

Stand

Base

-------------------------------------------------------

Eyelet

Eyelet

Seat

Eyelet

Disc

Post

Thread

Thread

Post Ferrule------------------------------------------------

Press Lif

Press

Pre

Pre

Screw, flat head

Press

Pr ess

singl

Socket

-------------------------------------------------------

Ball

-----------------------------Support------------------------------------------------

-------------------------------------------------------

Stand

Rod------------------------------------------------

-------------------------------------------------------

Locking Rin

-----------------------------------------------------

Locking

----------------------------------------------------

Separator

Support

Gui

Eyelet--------------------------------------------

Locking Ring

----------------------------------------------~-----------

needle----------------

g, looper--------------------------------------------

------------------------

embly------------------------------------------------

------------------------------------

Brack

for

att

aching

Link-------------------------------------------------

ss

Link Connection-- -- -

------------------

ss

Lever---------------------------------------

Plate

Plate

--------------------------

3/1

6 inch round blad e, length over-a

ch, for

e end,

r----------------------------------------------

B (not shown)----

-

--------------------------------------------------

de------------------------------------------------

et

ter Arm

te

3/8

--------------------------------------------

-----------------------------------------------

Ball-------------------------------------------

Split

Socket--------------------------------------

g-------------------------------------------

Ring-------------------------------------------

-----------------------------

------------------------------------------------

---------------------------

-----------------------------------------------

-

-------------------------------------------

----------------------------------------------

--------------------------------

-

1 ·nch long- -

Lever

Cushi

----------------------------------------

9/3

3/8

---------------------------------

on---------------------------

inch hexagon

2 inch opening----------------------------

inch opening

ion

-

--------------------------

-

----------------

- -

-------------

-

-----------------

-

----------------------------

-

------------------------------

-

-----------------------

-

----------------------------

-

--------------------

-

--------------------------------

---------------------------------

-

-----------------------------------

-

-------------------------------

-

---------------

--------------------------------------

hown)--

-------------------------

-------------------

--

-----------

al

nut s

--------------

-----------------

- -----

-----------------------

-

---------------

----- -

ll

9 3

/8

-

--------------

-

----

-

-------

-

----------

-----

-------

---------

-------

----

---

---

-- - - - -- - 1

----

inches ------

-

---------

-

----

-- ----1

-

---

-- - -- - -- 2

Req.

- 1

-- 2

--

-

-- - 2

--

--

-- 1

-- - 1

--

-- 2

-----

-

---

- 1

- 1

- 1

-- 1

--

--

- ---2

-- - 1

---

- 2

--

---

- 1

-- 1

---

- 1

-

---

- 1

-- - 1

-- 1

----- 1

1

4

2

2

2

2

1

1

1

1

2

2

1

1

1

2

1

2

2

2

1

2

1

1

1

2

2

2

2

2

4

2

1

1

1

1

1

1

2

1

1

1

1

1

1

1

15

Page 16

WORLD'S

FINEST

QUALITY

*

INDUSTRIAL

SEWING

MACHINES

,,

UNION

facilities throughout the world. These offices

aid you

equipment for your particular operation. Union

Special representatives

tory trained

promptly

tion, there

serve you.

ATLANTA,

BOSTON,

CHICAGO,

DALLAS, TEXAS

LOS

ANGELES, CAL.

NEW

YORK,

PHILADELPHIA,

SPECIAL

in

and

GA.

MASS.

ILL.

N.

maintains sales

the selection of the right sewing

and

service men

and

are

able to serve your , eeds

efficiently. Whatever your loca-

is

a Union Special Representative to

Check with

Y.

PA.

him

today.

MONTREAL, QUEBEC

BRUSSELS, BELGIUM

LEICESTER

LONDON,

F

PARIS, FRANCE

---

STUTTGART, GERMANY

and

-------

Representatives

Industrial

and

cities

distributors

throughout

In

the

all

Important

world.

service

will

are

fac-

, ENGLAND

ENGLAND

•

400

N.

FRANKLIN

MACHINE

COMPANY

ST.,

CHICAGO,

ILL.

' I

60610

Loading...

Loading...