Page 1

Finest Quality

STYLES

54200A

54200C

54200E

54200F

54200G

54200K

54200N

54200P

54400C

54400E

ADJUSTING

ILLUSTRATED

STREAMLINED

INSTRUCTIONS

PARTS

MULTIPLE

LIST

NEEDLE

AND

MACHINES

•

54400G

54400H

54400J

CATALOG

54400F

NO.

102L

THIRD

EDITION

Page 2

THIRD

•

EDITION

©

1956

©UNION

INFORMATION

SPECIAL

PRINTED

SUBJECT

CORPORATION

1996

TO

ALL

IN

USA

CHANGE

RIGHTS

WITHOUT

RESERVED

NOTICE

IN

ALL

COUNTRIES

..

Page 3

Catalog

No.

102

L

54200

54200

54200

54200

Classes

A

c

E

F

LIST

54200

54200

54200

54200

OF

54200,

STYLES

G

54400

K

54400

N

54400

p

54400

PARTS

54400

A

c

E

F

54400

54400

54400

G

H

J

Third

•

Union

Rights

Copyright

Special

Reserved

UNION SPECIAL

INDUSTRIAL

CHICAGO

Printed

July,

1979

Edition

1956

By

Corporation

in

All

Countries

CORPORATION

SEWING

in

3

MACHINES

U.S.

A.

Page 4

The

Classes

represent

bars

the

filtered

located

drivingmechanism,

Some

the

device

by

able

machines.

and

utmost

upper

precision

It

our

54200

the

driving

in

oil

throw-out

styles

roller,

to

allow

is

our

customers

The

and

54400.

latest

speed

to

the

are

the

methods

constant

following

54200

mechanisms

and

main

device

equipped

to

required

to

and

54400

design

thus

insure a uniformly

insuring

secure

in

production.

reservoir

enables

exposing

with a close

amount

aim

to

all

pages

FOREWORD

streamlined

the

UNION

and

light

Automatic

has

the

the

of

complete

furnish

possible

illustrate

machines

SPECIAL

weight

made

operator

heel

coupled

controlled

elastic

carefully

presser

and

interchangeability'.

economies

and

describe

flat

lubrication,

maintenance

to

disengage

eye

puller,

in

each

prepared

covered

bed

line.

bars

of

eachlooperforeasythreading.

feeding,

from

make

with a pump

simple.

the

with

the

and

garment;

information

the

use

the

parts

by

Light

it

possible

loopers

clutch

an

elastic

All

of

UNION

for

styles

this

weight

for

A

conveniently

mechanism

parts

which

catalog,

needle

to

attain

returning

from

their

metering

are

made

will

SPECIAL

in

Classes

('

in

en-

•

which

will

cooperate

Additional

will

be

furnished

Catalog

Form

In

all

No.

357

manufacturing

catalogs,

45

with

on

request,

N

Adjusting

of

machine

instructions

centers

those

who

containing

Instructions.

for

are

will

desire

information

are

listed

which

in

the

required.

be

found

planning

Specify

relative

below:

Needle

Engineering

adjusting

Union

and

Manual

the

Special

estimating

UNION SPECIAL

to

these

Department

style

representatives,

their

machines

requirements.

CORPORATION

Engineering

Department

and

who

4.

Page 5

IDENTIFICATION

OF

MACHINES

Each

plate

style

on

the

numbers

Example:

only

minor

dard

style

Styles

which

"54200

differs

11

•

This

herein.

54200

etc.,

ting

It

and

are

taken

direction

Streamlined,

Needles

Drive

Looper

Filter

Abreast,

Mechanism,

Throw-out

Type

UNION

machine.

have

"Style

changes

number.

of

machines

from

catalog

can

54400.

of

Enclosed

Oil

SPECIAL

Style

one

54200

are

.Example:

the

applies

also

from

be

All

the

reference

handwheel

Light

Double

for

Simplified

Return

carries

numbers

or

more

A".

made

letters

Special

in a standard

"54200

similar

style

in

number,

APPLICATION

specifically

applied

with

to

operator's

is

toward

STYLES

Type,

Weight

Flat

Presser

Locked

Threading,

Pump,

Oil

a

style

are

number

classified

suffixed,

style

numbers

machine,

AZ".

construction

in

that

OF

to

the

discretion

direction,

position,

the

operator.

OF

MACHINES

Bed,

Independent

Bar

Stitch,

Type

Automatic

Pan

Base

which

as

standard

but

never

contain

a

are

grouped

it

contains

CATALOG

standard

to

such

while

the

as

seated

styles

special

left

Row,

Mechanism,

401.

Loopers

Enclosed

Plate

and

is

stamped

and

contain

the

"Z"

is

under a class

no

of

machines

and

right,

at

the

Four,

Light

Head

Oil

special.

the

letter

suffixed

letters.

machines

front

machine.

Nine

Weight

in

Line

Type

Oiling

Siphon

in

the

Standard

letter

"Z".

to

the

number,

Example:

as·listed

in

Classes

and

Opera-

and

Twelve

Needle

With

Feed,

System,

Assembly.

name

"Z".

When

stan-

/'

back,

Bar

•

54200

children's

to

covered,

LSk-4,

54200

54200

walking

medium

not

folder.

Maximum

54200

54200

54200

overalls.

gauges

54200

imum

A-4

High

heavy

modified.

C-4

E-4

Same

High

covered,

F-4

G-4

K-4

Same

Same

High

Nos.

speed

3/4

skirts,

N

4800

High

inch

jackets

materials;

recommended

Throw

play

suits,

weight

materials.

swing-out

as

54200

Throw

shorts,

to

heavy

children's

weight

equipped

Standard

recommended

as

54200

as

54200

Throw

Right

angle

12-56-12,

R.

P.M.

Throw

wide

Single

rubber

and

where

Machine,

boys'

folder.

Maximum

A-4,

Machine,

materials.

with

gauges

speed

E-4,

E-4,

Unequal

folder,

16-64-16.

Needle

puller

similar

seam

is

speed

for

attaching

trousers,

Body

Standard

recommended

except

for

attaching

play

close

Nos.

suits,

coupled

16,

4800

except

except

Space

close

coupled

Machine

rollers,

garments

primarily

5500

R.

swimming

of

garment

gauges

no

attachment

boys'

Body

of

puller,

21, 24,

R.

P.M.

no

attachment

fitted

with

Machine,

puller,

Seam

Type

equipped

upper

made

straight.

P.M.

woven

Nos.

speed

woven

trousers,

garment

32.

elastic

for

BSc-4.

roller

from

elastic

trunks,

turned

16,

4800

or

elastic

turned

upper

Seam

or

banding

upper

with

driven.

Koratron

Seam

to

etc.,

downwardly,

21, 24,

R.

P.M.

elastic

strip

to

hobby

downwardly,

roller

Type

elastic

strip

metering

denim

roller

Maximum

close

coupled

For

Type

boxer

on

type

medium

32.

Seam

tension.

swimming

jeans,

driven,

LSk-4,

tension.

device.

dungarees

driven.

recommended

puller

seaming

and

durable

401-SSa-1.

shorts,

heavy

elastic

Type

trunks,

etc.,

elastic

swing-out

modified.

Standard

with,

trousers,

press

Max-

not

on

and

5

Page 6

STYLES

OF

MACHINES

(Continued)

54200 P Same

with

imum

54400

children's

Body

Standard

recommended

54400

54400

pajamas,

downwardly,

Standard

,

recommended

54400

54400

54400

stitching

wear,

attachment

gauge

yielding

recommended

A-4

C-4

E-4

F-4

G-4

H-9,

Low

of

Same

Low

Same

Same

-12

and

for

as

Style

section

Throw

play

suits,

garment

gauges

etc,,

gauges

operations

for

or

twelve

Nos.

speed

as

54400

Throw

on

close

Nos.

speed

as

54400

as

54400

Nine

similar

thread

54200 N except

to

the

left

speed

Machine,

boys'

turned

16,

5000

Machine,

light

coupled

16,

4800

E-4,

and

Twelve

on

stand.

needle

5500

trousers,

downwardly,

21,

R.

A-4,

to

medium

21, 24,

R.

E-4,

except

women's

operations

No.

of

R.

for

attaching

24,

P.M.

except

for

attaching

puller,

P.

M.

except

Needle

and

Standard

12.

Maximum

equipped

needle

P.M.

etc.,

elastic

32,

Seam

no

weight

upper

32.

Seam

no

fitted

Machine,

children's

on

light

gauge

with

hole,

,

woven

on

attachments

woven

materials.

attachments

with

Seam

light

not

Type

elastic

roller

Type

elastic

equally

dresses,

to

medium

for

nine

recommended

compensatory

Type

elastic

tomediumweightmaterials.

covered,

LSk-4,

or

Body

driven,

LSk-4,

or

metering

needle

401-SSa-1.

to

boxer

swing-out

modified.

elastic

to

boxer

of

swing-out

modified.

elastic

spaced,

blouses,

weight

speed

strip

garment

strip

device.

for

coats,

material.

No.

16;

4000

presser

type

Maximum

tension.

type

Maximum

tension.

decorative

standard

R.

foot

Max-

shorts,

folder.

shorts,

turned

folder.

beach-

No

P.M.

54400

type

tails.

of

•

the

eye.

except

descriptions

Type

113

133

J-9,

upper

Each

number

The

blade,

Collectively,

The

No.

GS

GS

-12

roller

UNION

denotes

size

measured

standard

Styles

of

Round

struck

080/032, 090/036,

Round

groove,

100/040,

Same

driven.

SPECIAL

number,

the

needle

54200

these

shank,

groove,

shank,

as

54400

the

kind

stamped

in

type

for

K,

54200

needles

ball

eye,

110/044,

H-9,

needle

thousandths

number

all

round

ball

round

has

of

shank,

on

and

Styles

Nand

and

the

point,

eye,

100/040,

point,

spotted,

125/049,

-12,

NEEDLES

the

54200 P which

Description

except

both a type

point,

needle

of

an

inch,

size

number

in

Classes

sizes

available

extra

spotted,

short,

chromium

short,

110/044,

140/054'

length,

shank,

chromium

double

equipped

number

groove,

denotes

midway

represents

54200

and

plated-

and

uses

are

Sizes

double

125/049,

groove,

with

close

and a size

finish,

the

between

the

54400,

needle

listed

below.

groove,

plated

140/054.

spiral

sizes

coupled

number.

and

largest

the

shank

complete

is

Type

Type

080/032,

spiral

-

sizes

groove,

133

puller,

The

other

diameter

GS.

075/029,

090/036,'

de-

and

the

symobl.

113

GS,

The

groove,

struck

To

have

sample

on

label, A complete

needle,

needle

or

orders

the

order

type

promptly

and

size

would

number

read:

and

"1000

6

accurately

should

Needles,

filled,

be

forwarded.

Type

an

113

empty

Use

GS,

Size

package,

description

100/040".

a

Page 7

NEEDLES

{Continued)

Selection

Thread

formation.

ILLUSTRATIONS

Exploded

parts

illustration

tions,

position

used

are

of

the

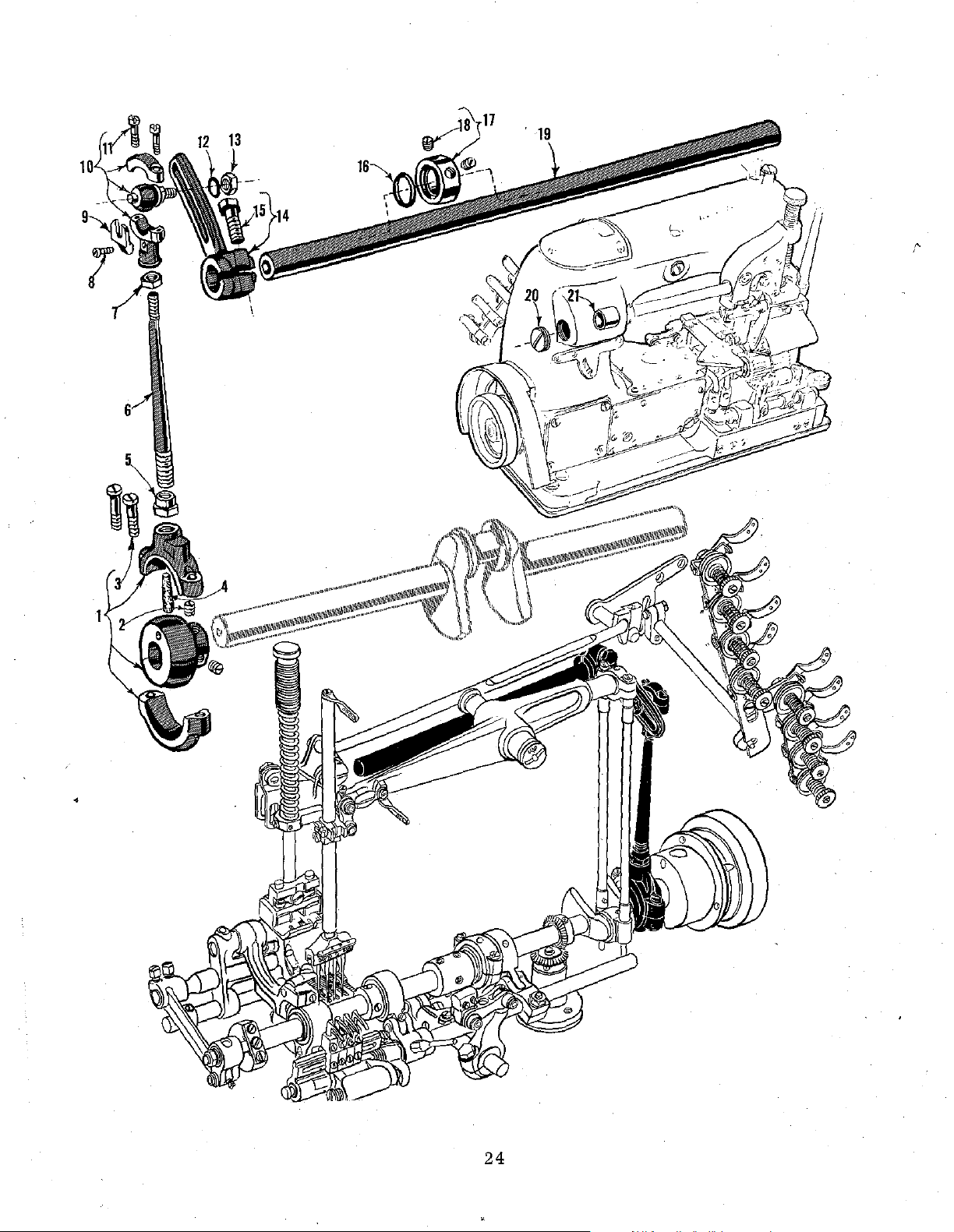

29126

22587

should

This

may

and

The

numbers

of

in

ordering

Those

indicated

main

DE

95

of

catalog

views

be

seen

will

the

that

component

by

sub-assembly.

Puller

the

proper

pass

freely

has

been

of

the

various

in

their

be

found

number

in

the

part

parts.

the

in

parts

fact

Drive

Screw--------------------------------------------------Bearing

needle

through

ORDERING

so

arranged

actual

the

listing

of

pieces

first

Always

column

the

illustration.

of

sub-assemblies,

that

their

Example:

Eccentric

Cap

Screw---------------------------------------

size

is

determined

needle

sections

position

of

required

·are

use

the

descriptions

Assembly------------------------------

REP

AIR

as

to

of

in

the

parts

reference

The

part

eye

in

PARTS

simplify

the

mechanism

the

machine,

in

reference

number

which

are

order

with

the

numbers

indented

the

their

particular

can

by

the

to

ordering

On

number

shown

be

size

produce

are

shown

the

page

part

number,

view

only,

in

the

furnished

under

of

thread

a

good

of

repair

so

opposite

being

and

indicate

should

second

for

the

description

used,

stitch

parts.

that

the

the

descrip-

shown.

the

never

column.

repairs,

be

1

2

2

It

will

listed.

is

catalog,

the

mentioned

the

•

the

only

IDENTIFYING

On

identification

they

USE

The

not

recommended

In

those

parts

illustration.

At

the

illustrations,

the

part

Where

some

All

part

appear.

GENUINE

be

reason

no·

specific

for

in

back

the

smaller

noted

for

cases

the

the

number

letter

numbers

where· a part

various

descriptions,

of

the

which

PARTS

construction

parts,

is

NEEDLES

in

the

this

and

the

usage

book

will

is

known.

stamped

represent

above

is

that

complete

will

machines

will

be

facilitate

permits,

and

on

to

AND

REPAIR

example

the

replacement

sub-assembly

is

common

be

mentioned

are

and

if

necessary,

found a numerical

locating

each

those

distinguish

the

same

that

to

not

part

where

part,

PARTS

the

of

all

in

the

the

same,

the

illustration

is

the

construction

the

part

regardless

eccentric

any

of

should

of

the

description.

the

the

difference

index

stamped

from

and

these

be

ordered.

machines

specific

of

all

and

with

does

similar

of

the

bearing

parts

will

the

description

individually

covered

However,

usage

be

parts

its

part

not

permit,

ones,

catalog

are

not

by

this

when

will

shown

shown

when

number.

in

which

be

in

in

an

Success

genuine

Corporation,

ing

The

UNION

to

the

maximum

in

its

most

the

operation

SPECIAL

subsidiaries

approved

efficiency

of

Needles

and

scientific

and

durability

these

and

authorized

machines

Repair

principles

are

Parts,

distributors.

and

assured.

7

can

made

be

as

furnished

secured

They

with

the

only

by

are

utmost

by

the

Union

designed

the

use

Special

accord-

precision.

of

Page 8

USE

GENUINE

NEEDLES

AND

REPAIR

PARTS

(Continued)

Genuine

parts

is

TERMS

are

insured

insurance.

must

viscosity

sight

ounces.

than

throw-out

diagram,

are

your

guarantee

Prices

forwarded

The

be

Oil

is

gauge

The

an

needles

stamped

are

strictly

at

unless

oil

has

filled

occasional

,before

of

90

filledat.the

on

the

machine

pin,

are

required.

are

with

of

the

the

buyer's

otherwise

OILING

been

to

and

drained

beginning

125

seconds

spring

front

is

almost

drop

looper

packaged

the

Union

highest

net

cash

risk

directed.

AND

cap

of

the

entirely

of

oil

holder

with

Special

quality

and

subject

f. o.

b.

A

THREADING

from

to

at

machine.

the

operate.

100°

in

the

at

both

frame

automatically

labels

in

machine

Fahrenheit.

top

bearings

marked

trademark,

materials

to

change

shipping

charge

INSTRUCTIONS

Use a straight

cover,

The

capacity

locking

and

point.

is

made

before

and

lubricated,

of

the

pin,

~.Genuine

U S

Emblem.

workmanship.

without

shipping,

the

of

retainer

notice.

Parcel

to

cover

mineral

oil

level

the

oil

as

indicated

Each

All

post

shipments

the

and

the

oil

with a Say

is

checked

reservoir

and

no

holder,

trademark

shipments

postage

reservoir

is

oiling

the

in

the

repair

are

and

bolt

at

the

twelve

other

looper

oiling

the

which

reservoir,

reservoir

handwheel.

screw

threaded.

eyes

•

from

A

daily

oil

in

the

has

gone

may

with a little

The

accompanying

Please

in a plane

right

to

check

main

through

making

be

Mter

at

left

•

before

reservoir

too

frequent

drained

draining

gasket

note,

right

the

morning

is

the

machine

at

the

oil,

cement,

drawings

that

the

angles

start

kept

oilings

plug

wipe

needles

to

the

and

also

the

should

between

is

filtered

unnecessary.

screw

hole

re-assemble

show

are

direction

the

in

and

the

inserted

be

made,

two

and

the

main

plug

screw.

manner

of

line

to

red

lines

pumped

Excessive

frame

screw

in

which

in

the

needle

of

feed,

see

that

on

back

oil

directly

dry,

and

the

the

gauge.

into

in

paint

the

holder

are

level

the

main

the

main

under

hole

machine

with

threaded

of

Oil

the

and

is

the

8

Page 9

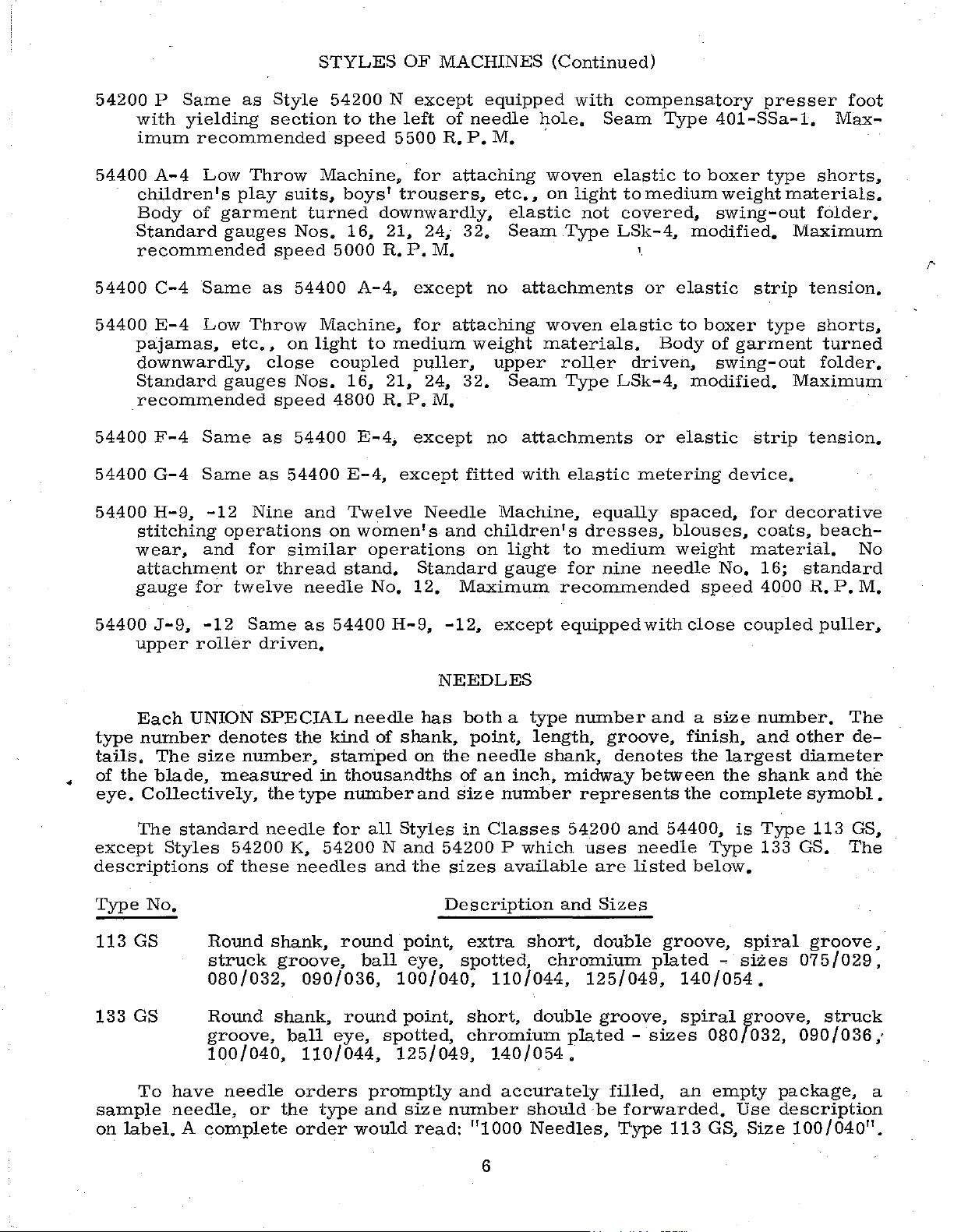

4 NEEDLE MACHINE THREADING.

•

12

NEEDLE MACHINE THREADING.

NOTE: 9

THREADED

NEEDLE

IN

CAUTION!

FILL

BEFORE

MACHINE HAS

BEFORE

MACHINES

ARE

A SIMILAR MANNER

ALL

OIL

STARTING.

SHIPPING .

RESERVOIRS

BEEN

DRAINED

9

Page 10

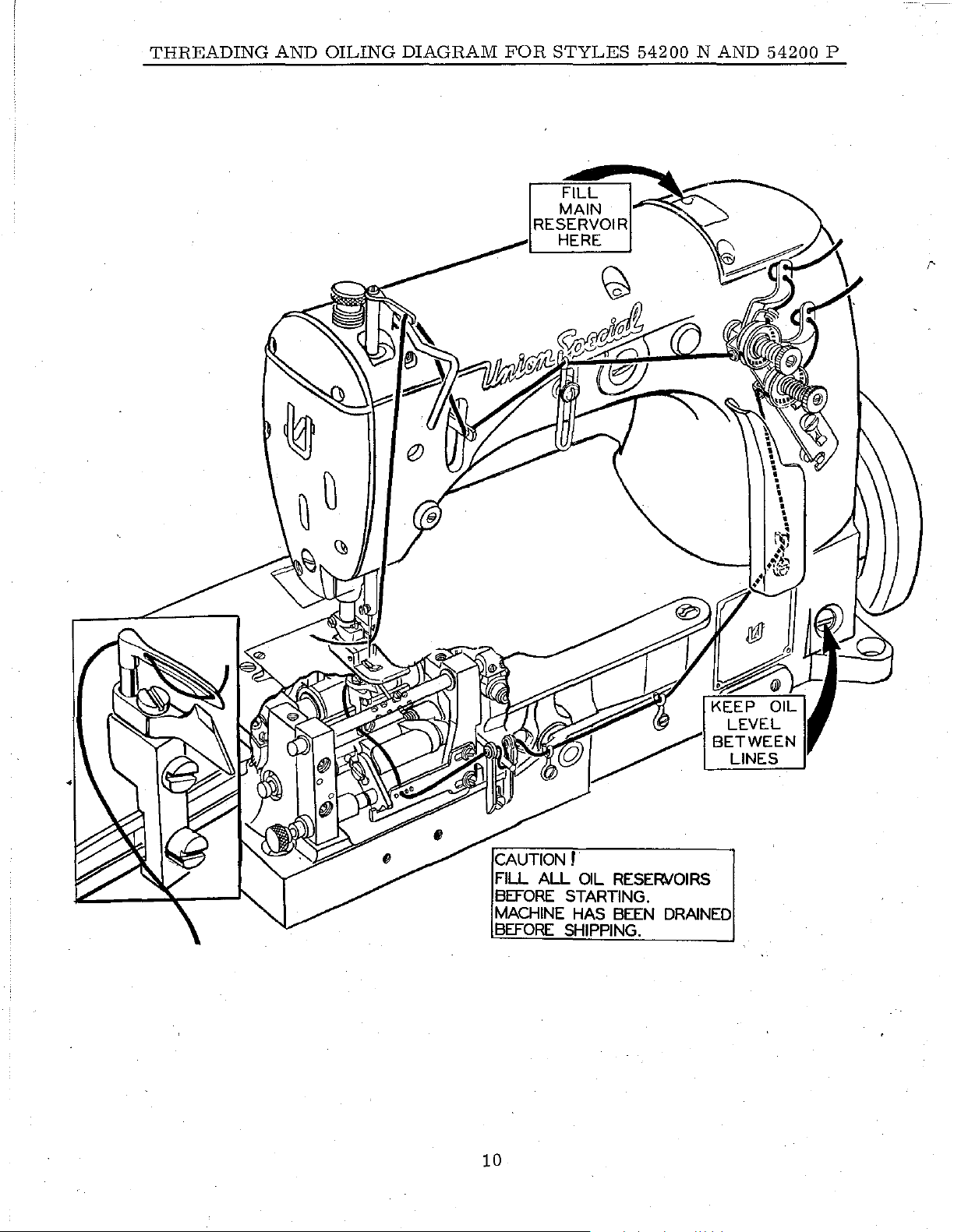

THREADING

AND

OILING

DIAGRAM

FOR

STYLES

54200

NAND

54200

P

!'

CAUTION I

FILL

ALL

BEFORE

MACHINE HAS BEEN DRAINED

BEFORE

STARTING.

SHIPPING.

10

OIL

RESERVOIRS

Page 11

EXPLODED

VIEWS

AND

54200

DESCRIPTION

FOR

MULTIPLE

OF

NEEDLE

PARTS

MACHINES

•

11

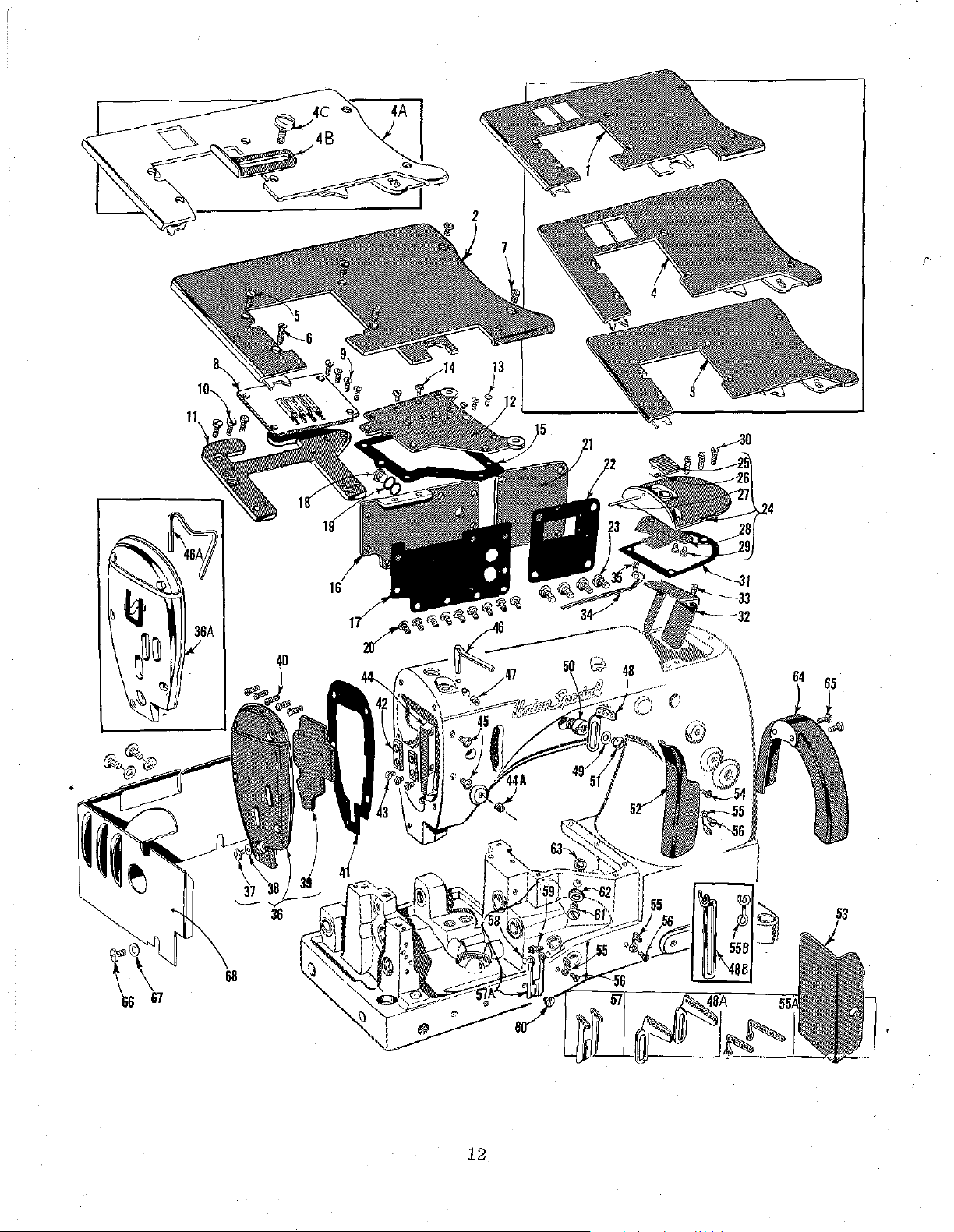

Page 12

!'

12

Page 13

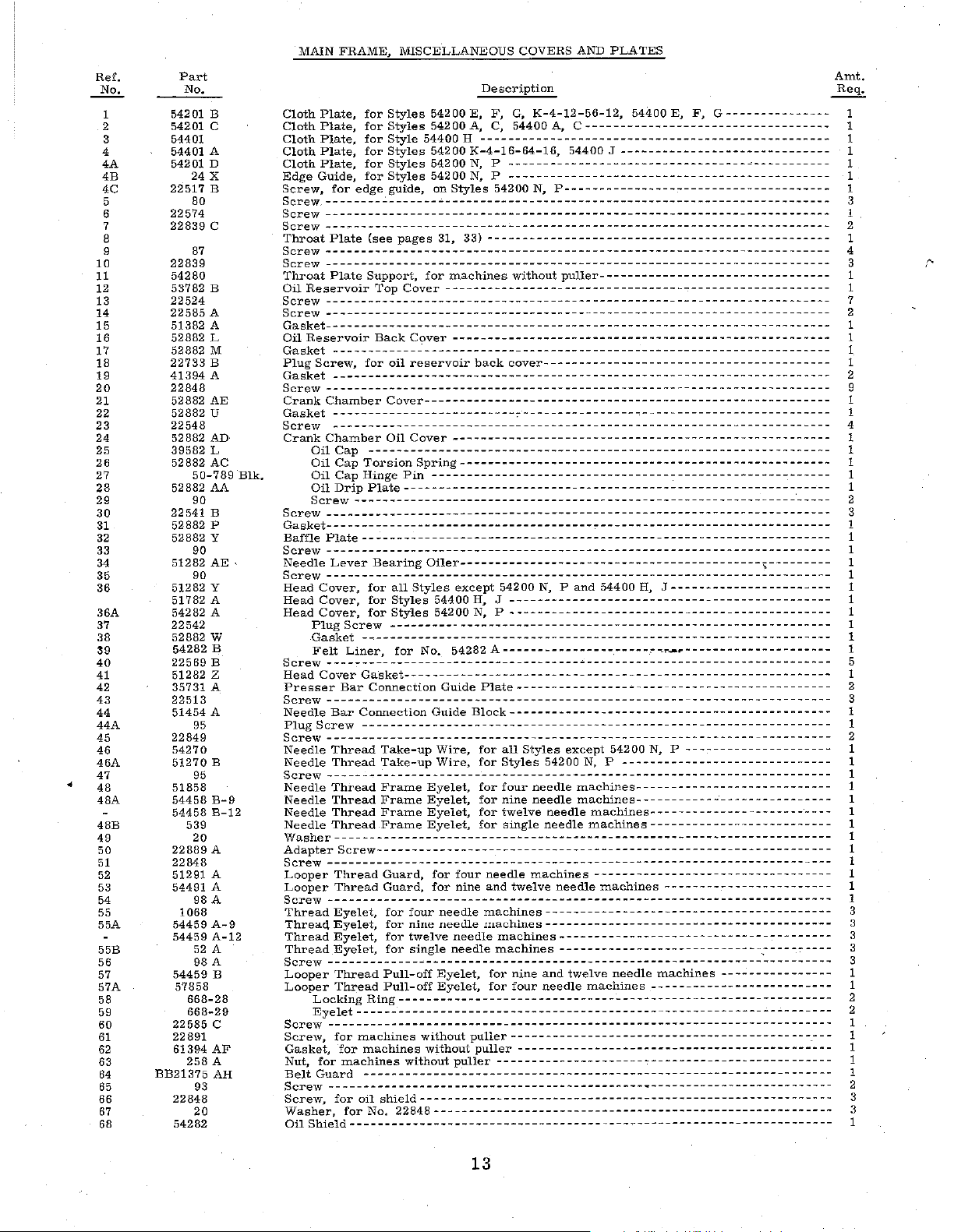

MAIN

FRAME,

Ref.

~

1

2

3

4

4A

4B

4C

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

36A

37

38

39

40

41

42

43

44

44A

45

46

46A

47

•

48

48A

48B

49

50

51

52

53

54

55

55A

55B

56

57

A

57

58

59

60

61

62

63

64

65

66

67

68

Part

No.

54201 B

54201 c

54401

54401

54201 D

24 X

22517

80

22574

22839 c

87

22839

54280

53782

22524

22585

51382

52882

52882 M

22733

41394

22848

52882

52882

22548

52882

39582 L

52882

50-789

52882

90

22541

52882 p

52882

90

51282

90

51282

51782

54282

22542

52882

54282

22569

51282

35731 A

22513

51454

95

22849

54270

51270

95

51858

54458

54458

539

20

22889

22848

51291

54491 A

98 A

1068

54459

54459

52

98 A

54459

57858

668-28

668-29

22585

22891

61394

258

BB21375

93

22848

20

54282

A

B

B

A

A

L

B

A

AE

u

AD

AC

AA

B

y

AE

y

A

A

w

B

B

z

A

B

B-9

B-12

A

A

A-9

A-12

A

B

c

AF

A

AH

Cloth

Plate,

Cloth

Plate,

Cloth

Plate,

Cloth

Plate,

Cloth

Plate,

Edge

Guide,

Screw,

Screw

Screw-----------------------------------------------------------------------Screw------------------------------------------------------------------------

Throat

Screw------------------------------------------------------------------------

Screw

Throat

Oil

Screw

Screw

Gasket-----------------------------------------------------------------------Oil

Gasket

Plug

Gasket

Screw-----------------------------------------------------------------------Crank

Gasket

Screw

Crank

Elk.

Screw

Gasket------------------------------------------------------------------------

Baffle

,

Screw

Needle

Screw-----------------------------------------------------------------------Head

Head

Head

Scre~e_I:-

Head

Presser

Screw-----------------------------------------------------------------------Needle

PlugScrew

Screw-----------------------------------------------------------------------Needle

Needle

Screw----------------------~-------------------------------------------------

Needle

Needle

Needle

Needle

VVasher----------------------------------------------------------------------Adapter

Screw------------------------------------------------------------------------

Looper

Looper

Screw------------------------------------------------------------------------

Thread

Thread.

Thread

Thread

Screw------------------------------------------------------------------------

Looper

Looper

Screw

Screw,

Gasket,

Nut,

Belt

Screw---------------------------------------------~--------------------------

for

--------~-------~------------------------------------------------------

Plate

-----------------------------------------------------------------------Plate

Reservoir

------------------------------------------------------------------------

------------------------------------------------------------------------

Reservoir

-----------------------------------------------------------------------

Screw,

-----------------------------------------------------------------------

Chamber

--------------------------~-------------------------------------------

-----------------------------------------------------------------------

Chamber

Oil

Cap

Oil

Cap

Oil

Cap

Oil

Drip

Screw--------------------------------------------------------------------

------------------------------------------------------------------------

Plate-------------------------------------------------------------------

-----------------------------------------------------------------------Lever

Cover,

Cover,

Cover,

Plug

Screw---------------------------------------------------------------

Gasket

~~~::•

Cover

Bar

Bar

Thread

Thread

Thread

Thread

Thread

Thread

Screw-----------------------------------------------------------------

Thread

Thread

Eyelet,

Eyelet,

Eyelet,

Eyelet,

Thread

Thread

LockingRing-------------------------------------------------------------Eyelet--------------------------------------------------------------------

-----------------------------------------------------------------------for

for

for

machines

Guard

~::~r,fo[o;i£r~.hi;i~48

Oil

Shield---------------------------------------------------------------------

MISCELLANEOUS

for

Styles

54200

for

Styles

for

Style

for

Styles

for

Styles

for

Styles

edge

guide,

(see

pages

Support,

Top

Cover-------------------------------------------------------

Back

Cover

for

oil

reservoir

Cover----------------------------------------------------------

Oil

Cover------------------------------------------------------

--------------------------------------------------------------Torsion

Hinge

Plate-------------------------------------------------------------

for

for

for

-------------------------------------------------------------------

Gasket-------------------------------------------------------------

Connection

-------------------------------------------------------------------

machines

machines

-------------------------------------------------------------------

Spring-----------------------------------------------------

Pin---------------------------------------------------------

Bearing

all

Styles

Styles

Styles

__

f_o!'

__

~~·--

Connection

Take-up

Take-up

Frame

Frame

Frame

Frame

Guard,

Guard,

for

four

for

nine

for

twelve

for

single

Pull-off

Pull-off

without

without

E,

54200

A,

54400 H --------------------------------------------------

54200

K-4-16-64-16,

54200

N, P

54200

N, P ----------------------------------------------

on

Styles

31,

33)

for

machines

------------------------------------------------------

Oiler-------------------------------------------"---------

except

54400

54200

~=:~:~:::::::::

Guide

Guide

Block----------------------------------------------

Wire,

Wire,

Eyelet,

Eyelet,

Eyelet,

Eyelet,

for

four

for

nine

needle

needle

needle

needle

Eyelet,

Eyelet,

puller-------------------------------------------_---

without

puller------------------------------------------------

==:

::::::::::::::::::::::: = ::

COVERS

Description

F,

G,

C,

54400

-----------------------------------'-----------

54200

-------------------------------------------------

without

back

cover-----------------------------------------

54200

H, J ---------------------------------------------N, P ----------------------------------------------

Plate---------------------------------------------

for

all

Styles

for

Styles

for

four

for

nine

for

twelve

for

single

needle

machines----------------------------------

and

twelve

machines----------------------------------------Lnachines

machines---------------------------------------

machines

for

nine

for

four

puller---------------------------------------------

AND

PLATES

K-4-12-56-12,

A, C -----------------------------------

54400

N,

P--------------------------------------

puller---------------------------------

N, P

and

::::::

except

54200

N, P

needle

machines----------------------------

needle

machines----------------------------

needle

needle

needle

-----------------------------------------

-----------------------------.----------

and

twelve

needle

54400

J

------------------------------

54400

H, J

:·::

:::

=

54200

N, P ---------------------

------------------------------

machines--------------------------

machines--------------------------

machines------------------------

needle

machines--------------------------

=:::::

E,

F, G ---------------

-----------------------

:-::::::::::::::::::::::::

machines

----------------

:::::::::::

=:

= = = = :::::

Amt,

Req.

1

1

1

1

1

1

1

3

1

2

1

4

3

1

1

7

2

1

1

1

1

2

9

1

1

4

1

1

_-

_

1

1

1

2

3

1

1

1

1

1

1

1

1

1

1

1

5

1

2

3

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

3

3

3

1

1

2

2

1

1

1

1

1

2

3

3

1

13

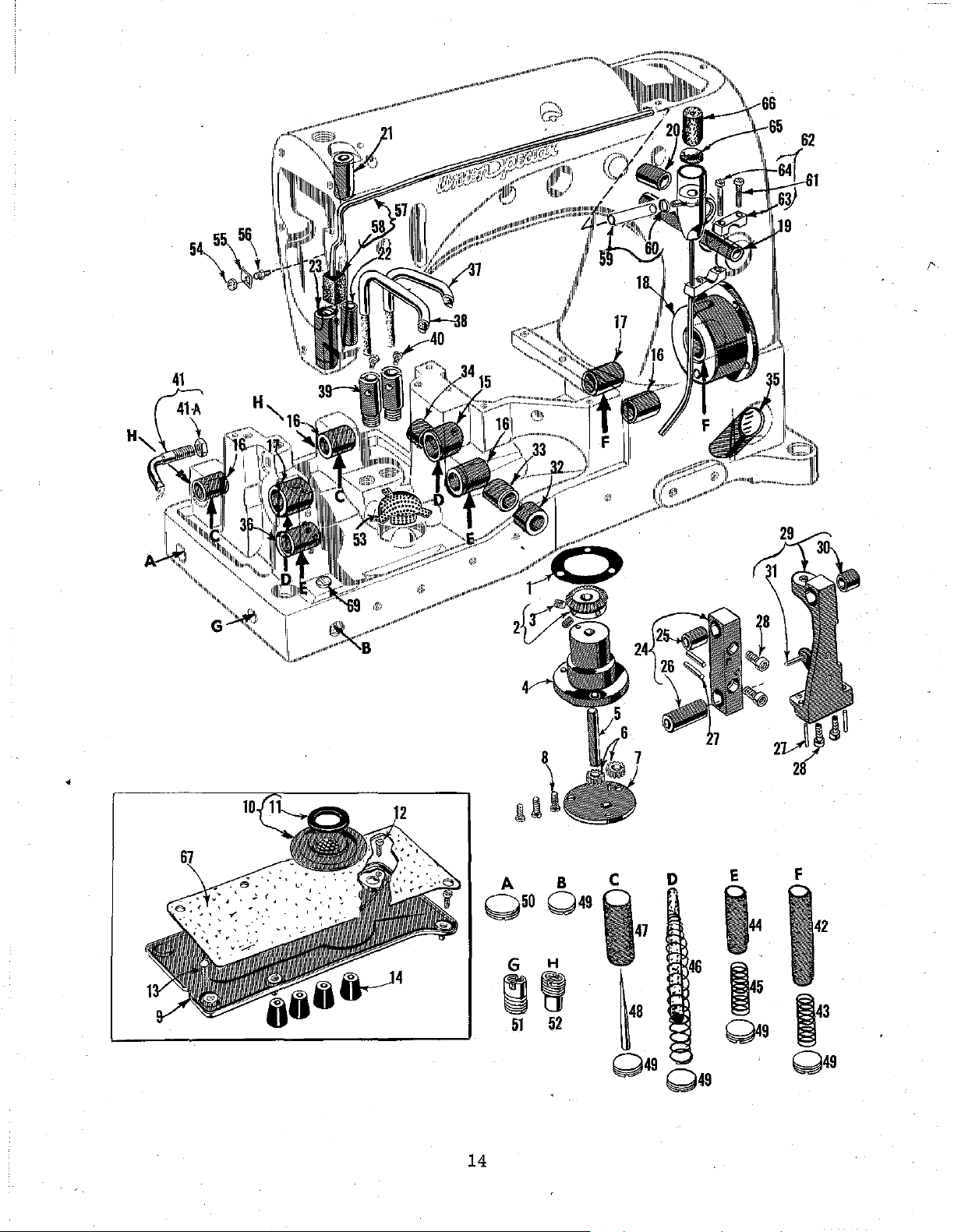

Page 14

!'

•

A.

Q50

6 H

8

Q49

;8

52

51

14

c

E

F

144

i"

Q49

~·

049 049

•

••

Q49

Page 15

MAlN

FRAME,

BUSHINGS

AND

MISCELLANEOUS

OILlNG

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

41A

42

43

44

•

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

Part

No.

643-127

51493

531

51493

51493

51493

51493

22569

51493

51493

51493

22823

22823

51295

51290

52936

52890

52891

21657

52883

51854

51854

51257

54242

61354

51254

667

22652

54242

61354

667

51242

51242

51242

50-648

52944

54244

54293

54293

52894

90

660-136

258 A

666-114

35178

666-65

35178

666-118

666-111

666-179

22571

22539

22889

22889

51493

7947

51294

51294

51294

666-214

51294

21212

22729

51294

51294

22729

666-209

666-201

51493

BQ

AG

D

E

AH

B

BA

BH

BJ

A

B

A

T

c

B

X

R

F

E

AA

c

A

A

B-12

B-8

D

A

B-12

z

R

s

T

N

A

AB

D

D

A

H

D

c

BK

p

R

M

z

A

u

K

B

BG

Elk.

Elk.

Amt.

Description

Gasket

Oil

-------------------------------------------C----------------- 1

Pump

Driven

Gear

--------.:.--------------------------------------

Screw----------------------------------------------------------

Oil

Pump

Oil

Oil

Oil

Screw--------------------------------------------------------------

Base

Filter

Housing

Pump

Driving

Pump

Driving

Pump

Housing

Plate------------------------------------------------------c

Cap

Assembly-------------------------------------------------

Washer,

Screw

Screw--------------------------------------------------------------

Feed

Foot

------------------------------------------------------------

Mo-unting

Main

Rock

Main

Crankshaft

Tension

Needle

Needle

Presser

Retainer

Dowel

Isolator----------------------------------------------------

Shaft

Bushing,

Rock

Shaft

Shaft

Shaft

Bushing,

Bushing

Release

Lifter

Bar

Bar

Lever

Bushing,

Bushing.

Bar

Holder

Bushing,

Bushing,

Pin---------:-------------------------------------------------Screw-------------------------------------------------------------Retainer

Looper

Looper

Looper

Lucite

Looper

Looper

Oil

Oil

Oil

Holder

Bushing

Dowel

Pin-----------------------------------------------------Drive

Drive

Drive

Oil

Gauge

Rocker

Rocker

Tube,

Tube,

Tube

for

for

Holder---------------------------------------~-------------

Screw-------------------------------------------------------------Oil

Tube,

Oil

VVick-----------------------------------------------------------Spring-------------------------------------------------------------Oil

VVick------------------------------------c----------------------Spring-------------------------------------------------------------Oil

VVick------------------------------------------------------------

Oil

VVick------------------------------------------------------------

VVedge

Plug

Plug

Adaptor

Adaptor

Lint

Nut

Oil

Tube

Screw--------------------------------------------------~-----------

Oil

Siphon

Oil

Tube

for

Nut

-------------------c----------------------------------------

Pin----------------------------------------------------------

Screw

Screw

Filter

----------------------------------------------------------------

Felt

---------------------------------------------------------15

---------------------------------------------------------

Plug

Plug

Screen---------------------------------------------------

Clamp

Tube

Lint

Connection

Oil

Siphon

Screw--------------------------------------------------------------

Oil

Siphon

Felt

Felt

Base

Assembly-------------------------------------------------

Upper

Screw----------------~-----------------------------------------

Disc-----------------------------------------------------------

Clamp----------------------------------------------------

Plug-----------------------------------------------------------

Plate

Felt

------------------------------C-------------------- 1

Shaft----------------------------------------------Shaft

Gear------------------------------------------

Cover

rubber-------------------------------------------------

Bushing.

Bushing,

Lever

Bushing--------------------------------------------

Bushing,

Bearing,

upper--------------------------------------------------

lower-------------------------------------------------

Bearing,

--------------------------------------------------------

Lever

Lever

Lever

----------------------------------------------------

Shaft

Shaft

feed

take-up

feed

Screw,

Screw,

-----------------------------------------------------

-----------------------------------------------------

Filter

Connection

-----------------------------------------------------

---------------------------------------------

middle-------------------------------------------

left

and

middle

left

Housing,

upper-------------------------------------------

and

and

Shaft

right---------------------------------

inner

including

Bushing----------------------------------

right.

and

Looper

right--------------------------------

bushing

-------------------------

lower-------------------------------------------

lower-----------------------------------.:..

left------------c----------------------------

right

---------------------------------------

Shaft

Bushing,

Shaft

Bushing,

Shaft

Bushing,

Bushing.

Bushing.

lift

eccentric---------------------------------------

drive

eccentric----------------------------------

crank

link-----------------------------------------

left

end-----------------------------------------

back--------------------------------------------

-------------------------------------------------

front------------------------------middle----------------------------rear-------------------------------

left,

for

left.

machines

for

machines

without

with

-------------------------------------------------

Locking

Ring--------------------------------

puller

puller-------------

----------

Req.

___ 1

--·

______ 1

1

2

1

2

1

3

1

1

2

1

4

1

4

2

1

1

1

1

1

1

1

1

4

4

1

1

1

1

1

1

1

1

1

1

1

2

2

1

1

2

2

2

2

2

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

/'

15

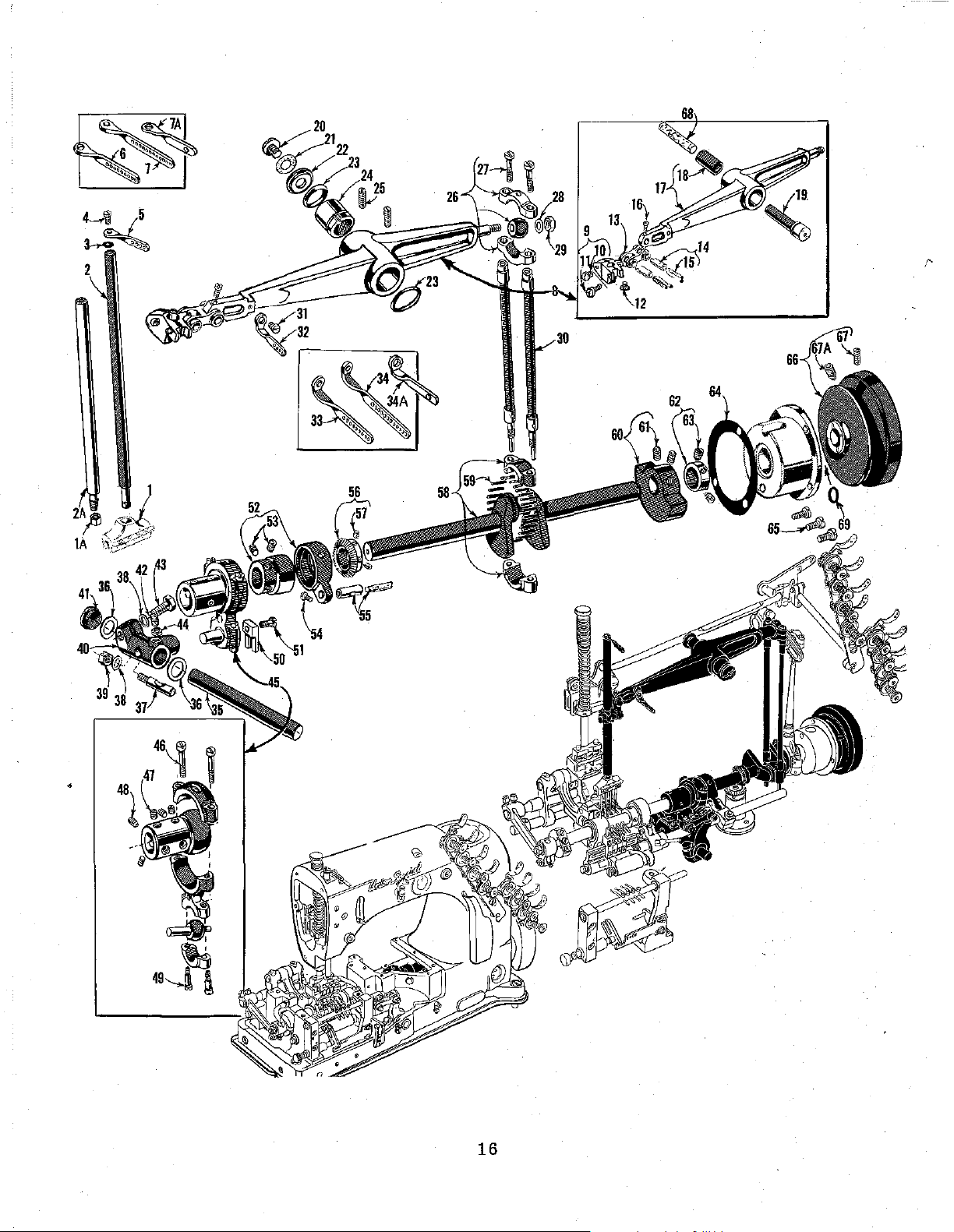

Page 16

!'

16

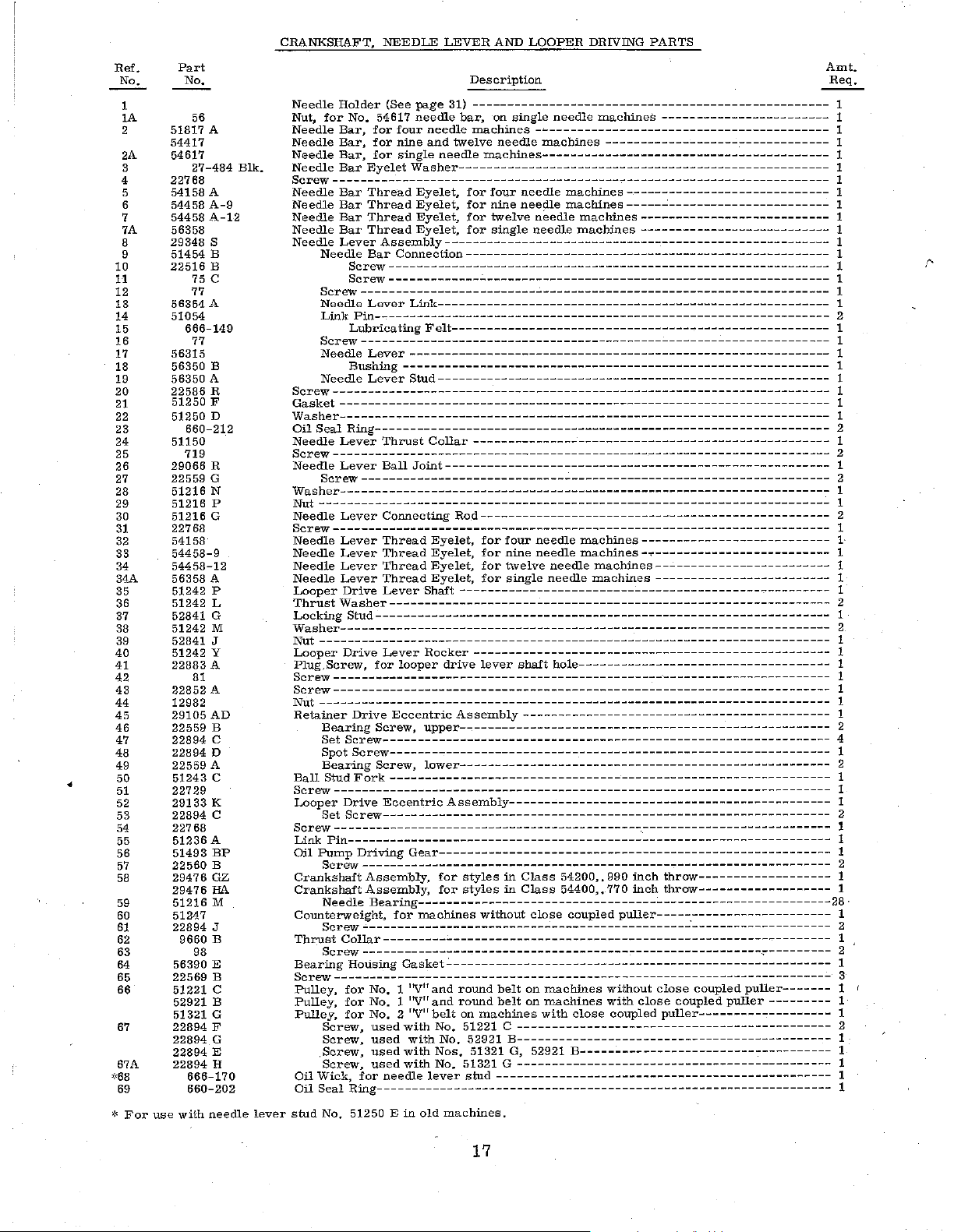

Page 17

CRANKSHAFT, NEEDLE LEVER

Ref.

No.

1

1A

2

2A

3 27-484

4 22768

5

6

7

7A

8

9

10

11

12

13

14

15

16 77

17

18

19

20 22586 R

21

22

23

24

25

26

27

28

29

30

31

32

33

34

34A

35

36 51242 L

37

38

39

40

41

42

43

44 12982

45

46

47

48

49

•

50

51

52

53

54

55

56

57

58

59

60

61

62

63 98

64

65

66 51221 c

67

67A

*68

69

*

For

Part

51817 A

54417

54617

54158 A

54458

54458

56358

29348 s

51454 B

22516 B

56351 A

51054

56315

56350 B

56350 A

51250 F

51250 D

51150

29066 R

22559 G

51216 N

51216 p

51216 G

22768

54158

54458-9

54458-12

56358 A

51242 p

52841 G

51242 M

52841 J

51242 y

22883 A

22852 A

29105 AD

22559 B

22894

22894 D

22559 A

51243 c

22729

29133 K

22894

22768

51236 A

51493

22560 B

29476 GZ

29476

51216 M

51247

22894 J

9660 B

56390 E

22569 B

52921 B

51321 G

22894 F

22894 G

22894 E

22894 H

use

with

No.

56

A-9

A-12

75 c

77

666-149

660-212

719

81

c

c

BP

HA

666-170

660-202

needle

Elk.

Needle

Nut,

Needle

Needle

Needle

Needle

Screw----------------------------------------------------------------------Needle

Needle

Needle

Needle

Holder

for

Bar,

Bar,

Bar.

BarEyeletVVasher-----------------------------------------------------

Bar

Bar

Bar

Bar

Needle

Needle

Screw-------------------------~-----------------------------------------

Needle

Link

Screw------------------------------------------------------------------Needle

Needle

(See page

No. 54617

Thread

Thread

Thread

Thread

Lever

Bar

Screw---------------------------------------------------------------

needle

for

four

for

for

Assembly-------------------------------------------------------

needle

nine

and

single

needle

Eyelet.

Eyelet.

Eyelet,

Eyelet.

Connection----------------------------------------------------

Screw---------------------------------------------------------------

Lever

Pin-----------------------------------------------------------------

Lubricating

Bushing

Link--------------------------------------------------------

Felt------------------------------------------------------

Lever

------------------------------------------------------------

-------------------------------------------------------------

Lever

Stud--------------------------------------------------------

Screw----------------------------------------------------------------------Gasket

VVasher---------------------------------------------------------------------Oil

Screw-----------------------------------------------------------------------

lever

stud

----------------------------------------------------------------------

Seal

Needle

Needle

VVasher----------------------------------------------------------------------

Nut

Needle

Screw----------------------------------------------------------------------Needle

Needle

Needle

Needle

Looper

ThrustVVasher--------------------------------------------------------------Locking

VVasher----------------------------------------------------------------------

Nut

Looper

Plug,Screw,

Screw

Screw----------------------------------------------------------------------Nut

Retainer

Ball

Screw----------------------------------------------------------------------Looper

Screw

Link

Oil

Crankshaft

Crankshaft

Counterweight.

Thrust

Bearing

Screw-----------------------------------------------------------------------

Pulley.

Pulley,

Pulley,

Oil

Oil Seal

Ring-----------------------------------------------------------------

Lever

Thrust

Collar

Lever

Ball

Joint-------------------------------------------------------

Screw-------------------------------------------------------------------

------------------------------------------------------------------------Lever

Connecting

Lever

Lever

Lever

Lever

Drive

Thread

Thread

Thread

Thread

Lever

Eyelet,

Eyelet,

Eyelet,

Eyelet,

Shaft

Stud-----------------------------------------------------------------

-------------------------------------------------------------------------

Drive

Lever

for

Rocker

looper

drive

------------------------------------------------------------------------

-------------------------------------------------------------------------

Drive

Bearing

Set

Spot

Bearing

Stud

Drive

Set

--------------------------------------------.---------------------------

Pin---------------------------------------------------------------------

Pump

Screw-------------------------------------------------------------------

Needle

Screw

Collar

Screw---------------------------------------------------------~---------

for

Screw,

Screw.

Screw.

Screw.

VVick,

No, 51250 E

Eccentric

Screw.

Screw----------------------------------------------------------------

Screw---------------------------------------------------------------

Screw.

upper-----------------------------------------------------

lower-----------------------------------------------------

Fork---------------------------------------------------------------

Eccentric

Assembly----------------------------------------------

Screw----------------------------------------------------------------

Driving

HoUsing

for

for

for

Ring-----------------------------------------------------------------

Gear--------------------------------------------------------

Assembly,

Assembly,

Bearing-----------------------------------------------------------28·

---------------------------------------------

----------------------------------------------------------------

for

machines

for

for

Gasket-------------------------------------------------------

1'V11

No. 1

No. 1

No. 2

used

used

used

used

needle

and round

1'V11

and

1\711

belt

with

No. 51221 C

with

No. 52921

with

Nos. 51321

with

No. 51321 G

lever

in

old

machines.

AND

LOOPER

DRIVING

PARTS

Description

31)

---------------------------------------------------

bar,

on

single

needle

machines

twelve

-"-----------------------------------------

needle

machines

machines

--------------------------------

------------------------

machines-----------------------------------------

for

four

needle

for

nine nee9J.e

for

twelve

for

single

machines----------------------------machines-----------------------------

needle

machines---------------------------

needle

machines

---------------------------

---------------------------------------------------

Rod--------------------------------------------------

for

four

needle

for

nine

for

twelve needle

for

-------------------------------------------.,.---------

single

--------------------------------------------------lever

shaft

machines---------------------------

needle

machines-..,.-------------------------

machines-------------------------

needle

machines

-------------------------

hole------------------------------------

Assembly--------------------------------------------

styles

in

Class

styles

without

in

54200,,990 inch

Class

54400,.770 inch

close

coupled

throw------------------throw-------------------

puller-------------------------

--·----

belt

on

round

machines

belt

on

on

machines

stud

------------------------------------------------

machines

with

---------------------------------------------

B---------------------------------------------

G.

52921

---------------------------------------------

close

without

with

coupled

close

close

coupled

coupled

puller-------------------

B------------------------------------

----------------

puller-------

puller

---------

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

2

1

2

1

1

2

1

1·

1

1

1

1

2

1

2

1

1

1

1

1

1

1

2

4

1

2

1

1

1

2

1

1

1

2

1

1

1

2

1

2

1

3

1 I

1

1

2

1

1

1

1

1

!'

17

Page 18

\

'

'

•

18

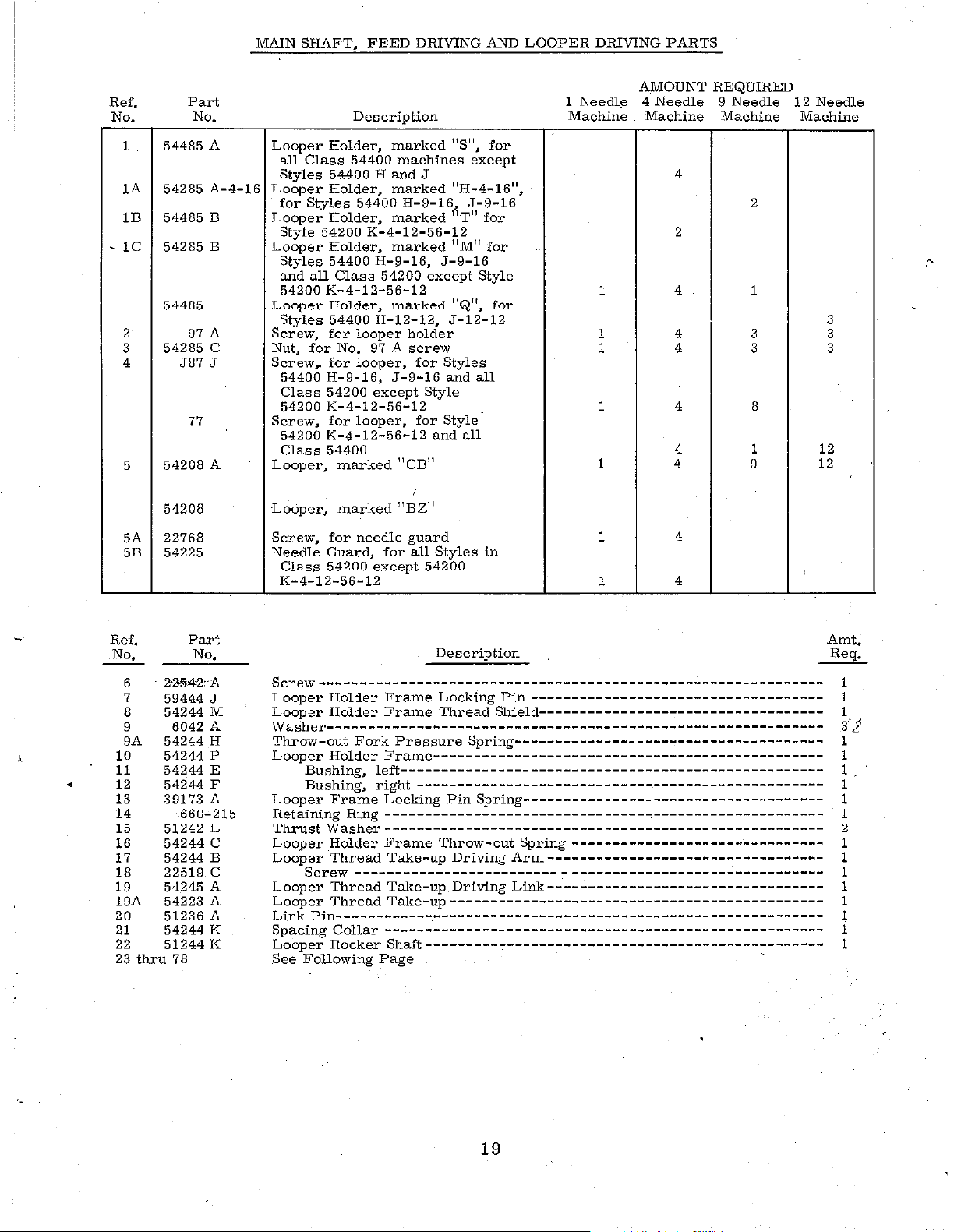

Page 19

MAIN

SHAFT,

FEED

DRIVING

AND

LOOPER

DRIVING

PARTS

Ref.

No.

1

1A

1B

-

1C

2

3

4

5

5A

5B

Part

54485

54285

54485

54285

54485

97 A

54285

J87

77

54208

54208

22768

54225

No.

A

A-4-16

B

B

c

J

A

Description

Looper

all

Styles

Looper

for

Looper

Style

Looper

Styles

and

Holder~

Class

54400

54400 H and

Holder,

Styles

54400

Holder,

54200

Holder,

54400

all

Class

K-4-12-56-12

H-9-16,

54200K-4-12-56-12

Looper

Styles

Screw,

Nut,

Screw,.

54400

Class

54200

Screw,

54200

Class

Looper,

Looper,

Screw,

Needle

Class

Holder,

54400

for

looper

for

No. 97 A

for

looper,

H-9-16,

54200

K-4-12-56-12

for

looper,

K-4-12-56-12

54400

marked 11CB

marked 11BZ

for

needle

Guard,

54200

H-12-12,

except

except

K-4-12-56-12

marked 118

11

machines

J

marked 11H-4-16

H-9-16,

J-9-16

marked 11T

marked

11 M11

J-9-16

54200

except

marked

11

Q

J-12-12

holder

sqrew

for

J-9-16

Styles

and

Style

for

Style

and

all

11

I

11

guard

for

all

Styles

54200

,

for

except

11

for

for

Style

11

,

for

all

in

1

AMOUNT

Needle 4 Needle 9 Needle

Machine

11

,

Machine Machine Machine

4

REQUIRED

12

Needle

2

2

!'

1 4

1

3

1 4

1 4

1

1 4

1

1

4

4

4

4

3

3

3

3

8

1

9

12

12

Ref.

No.

6

7

8

9

9A

10

11

•

12

13

14

15

16

17

18

19

19A

20

21

22

thru

23

Part

No.

~2542'A

59444

6042

J

M

A

H

p

E

F

A

54244

54244

54244

54244

54244

39173

660-215

51242

22519

54245

54223

51236

54244

51244

L

c

B

c

A

A

A

K

K

54244

54244

78

Description

Screw----------------------------------------------~---------------

Looper

Looper

Holder

Holder

Frame

Frame

Locking

Thread

Pin------------------------------------

Shield-----------------------------------

washer-------------------------------------------------------------

Throw-out

Looper

Bushing1 left----------------------------------------------------

Bushing~

Looper

Retaining

Thrust

Looper

Looper

Screw--------------------------------------------------------Looper

Looper

Link

Spacing

Looper

See

Following

Fork

Holder

Frame

Ring

Washer------------------------------------------------------

Holder

Thread

Thread

Thread

Pressure

Frame------------------------------------------------

right

---------------------------------------------------

Locking

--------------------------------~---------------------

Frame

Take-up

Take-up

Take-up----------------------------------------------

Spring--------------------------------------

Pin

Spring-------------------------------------

Throw-out

Driving

Driving

Spring

Arm---------------------------------Link----------------------------------

-------------------------------

Pin------------------------------------------------------------ 1

Collar

Rocker

------------------------------------------------------

Shaft-------------------------------------------------

Page

·

Req.

1

1

1

s·

1

1

1 ,

1

1

1

2

1

1

1

1

1

1

1

f

Amt.

19

Page 20

•

20

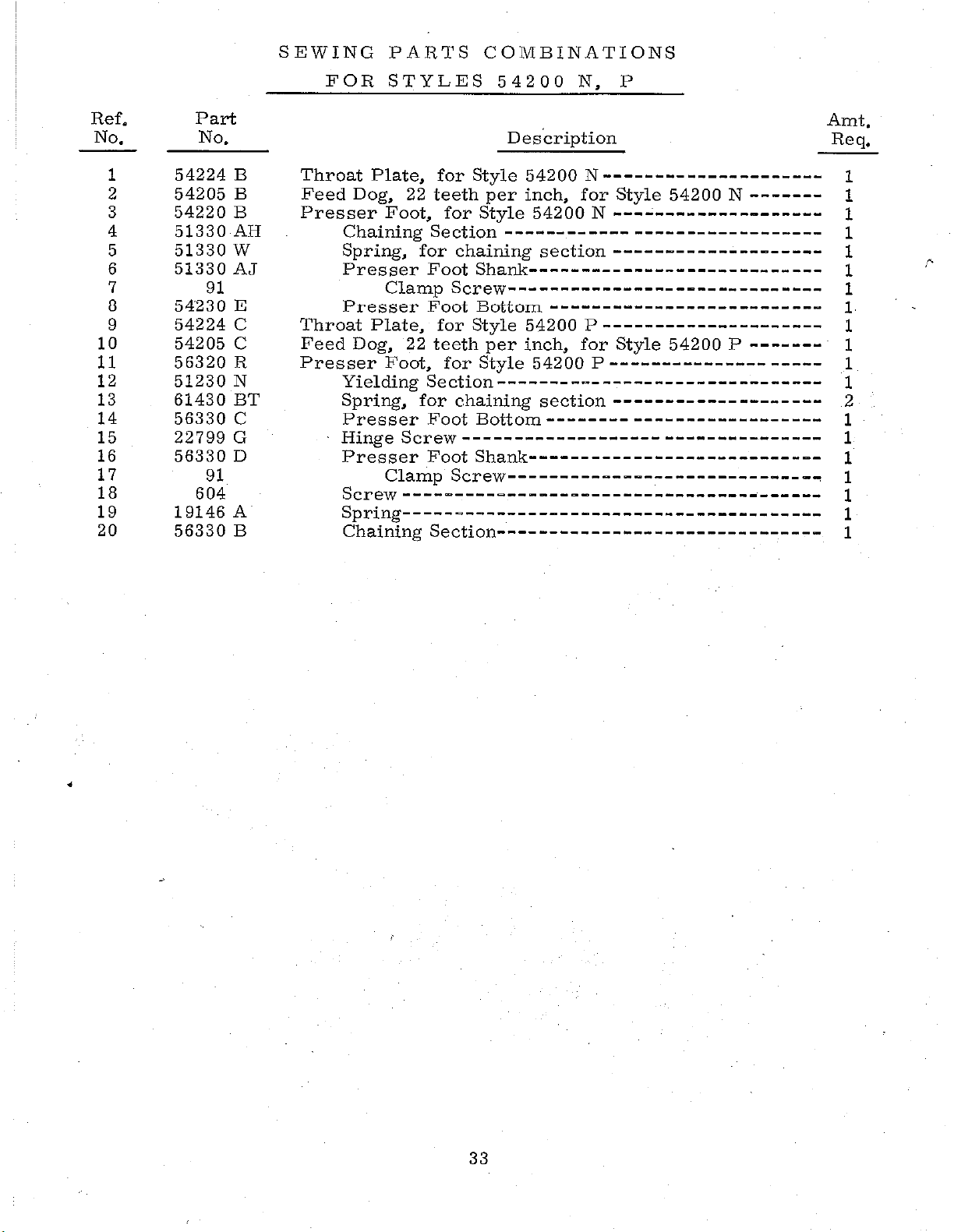

Page 21

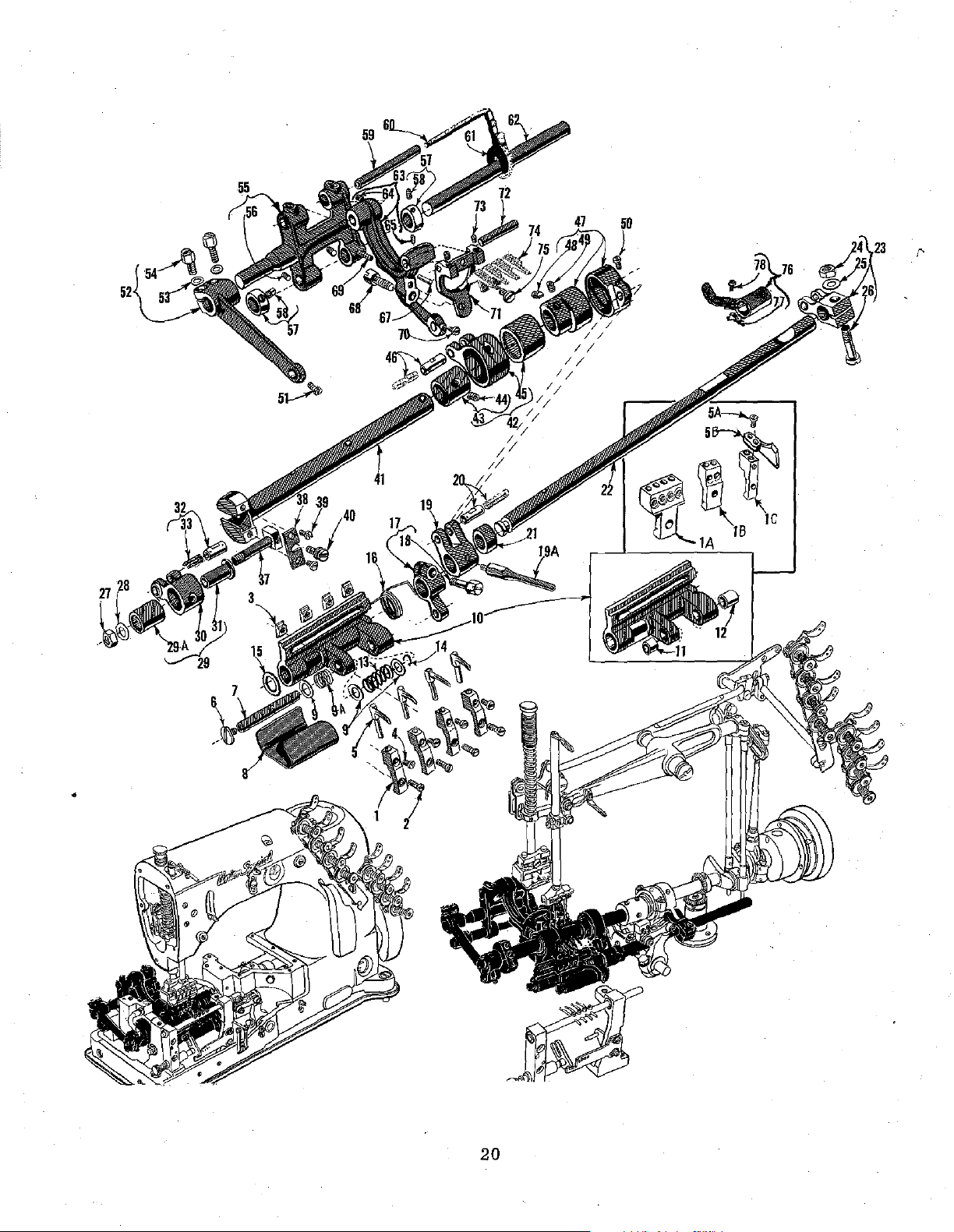

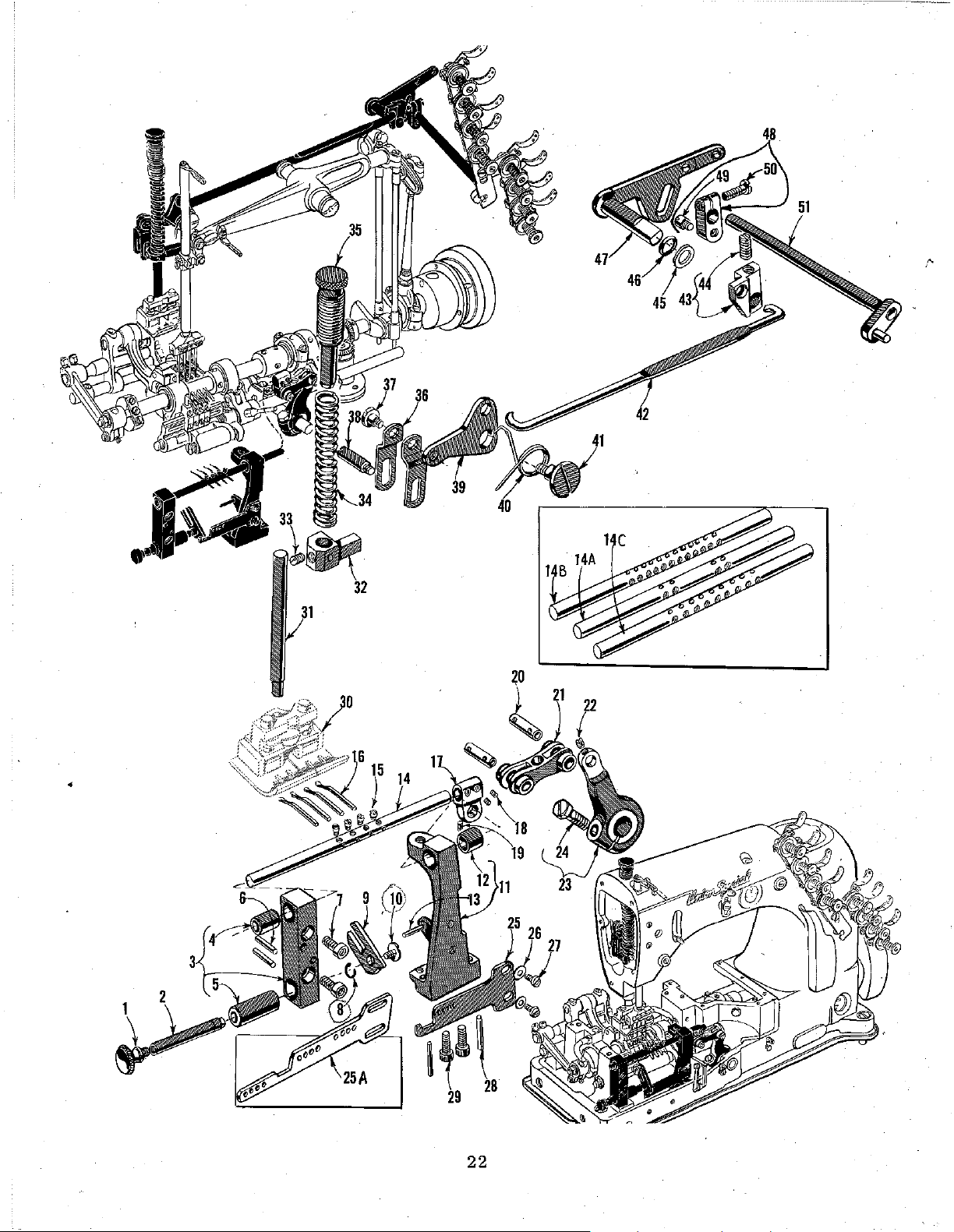

MAIN

SHAFT,

FEED

DRIVING

AND

LOOPER

DRIVING

PARTS

Ref.

No. No.

1

thru

23

24

25 20

26

27

28 20

29

29A

30

31

32

33

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51 77

52

53

54

55

56

57

58 98

•

59

60

61

62

63

64

65

67 667

68 88 F

69 531

70

71

72

73

74

75

76

77

78

Part

22

54244

18

55244

269

51236

660-169

51236

51236

51054

666-149

51236

51236

22768

82

54222

29476

51406

22894

54245

51236

29133

22894

22894

22768

51235

51235

22519

51235

98

482

51134

51134

51134

8

54234

22560

22733

77

54234

54134

22560

HA61 D

54243

54135

J

87

A

G

E

D

F

G

B

KR

D

c

A

J

L

c

A

G

c

c

p

R

B

B

B-20

c

N

B

A

J

Description

See

Preceding

Looper

Nut,

Feed

Feed

54200

Feed

Feed

Feed

Screw

Stitch

Main

Feed

Link

Take-up

Screw

Screw

Feed

Feed

Feed

Feed

Lubricating

Lubricating

Feed

Feed

Dowel

Screw,

Screw

Screw

Feed

Pin---------------------------------------------Screw

Feed

Screw

Looper

Travel

Nut,

for

VVasher--------------------------------------

Locking

left

thread----------------------------------Crank

Crank

G,

Needle

Feed

Feed

Crank

Oil

VVick

Crank

Crank

-------------------------------------------

Regulating

Shaft

Lift

Eccentric, • 062

Screw

Eccentric

Pin-----------------------------------------

Drive

Eccentric

Eccentric

-------------------------------------------

-------------------------------------------

Rocker

VVasher-------------------------------------Screw

Rocker

Screw

Rocker

Screw

Bar

Rocker

Bar----------------------------------------

Screw

Screw

Pin,

for

----------------

-------------------------------------------

Bar

---------------------------------~---------

Dog

------------------------------------------Drive

Nut------------------------------------------

Screw

Page

Drive

locking

Stud

Stud

Link

54400

Bearing------------------------------Crank

Crank

Link

------------------------------------Stud---------------------------------Stud

---------------------------------------

Eccentric

-----------------------------------

Bearing

Eccentric

Spot

Set

Arm---------------------------------

---------------------------------------

-------------------------------------

--------------------------------------Shaft

---------------------------------------

Shaft

Tilting

(See

----------------------------------Felt---------------------------------Felt

Shaft--------------------------------

---------------------------------------

--------------------------------------for

feed

feed

bar-------------------------------

pages

Eccentric

---------------------------------------

Link

stud--------------------------

---------------------------------

VVasher---------------------------

Assembly,

G--------------------------------

Link-----------------------------Link

Pin--------------'----------------

Cap------------------------------

Stud-----------------------------

Assembly----------------------

inch

Screw--------------------------

Screw---------------------------

Collar--------------------------

Guard----------------------------

bar

Extension

31, 33)

~-----------------------

for

all

Ferrule----------------------

throw

---------------------------Assembly-----------------

---------------------------

---------------------.---

Oil

--------------------

------------------------

-----------------------

Slinger-----------------

machines

except

---

Amt.

Req.

1

1

1

1

1

1

{'

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

21

Page 22

22

Page 23

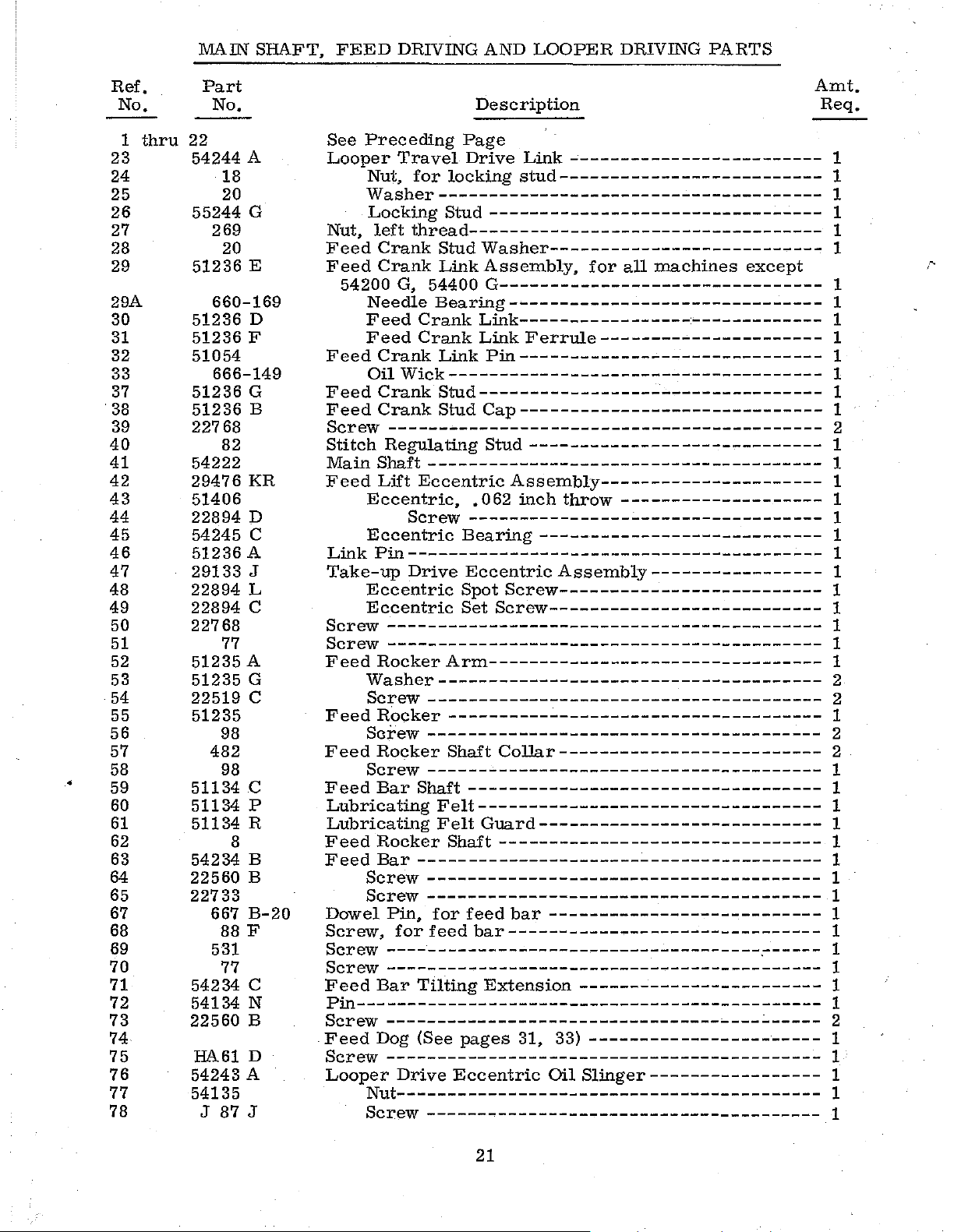

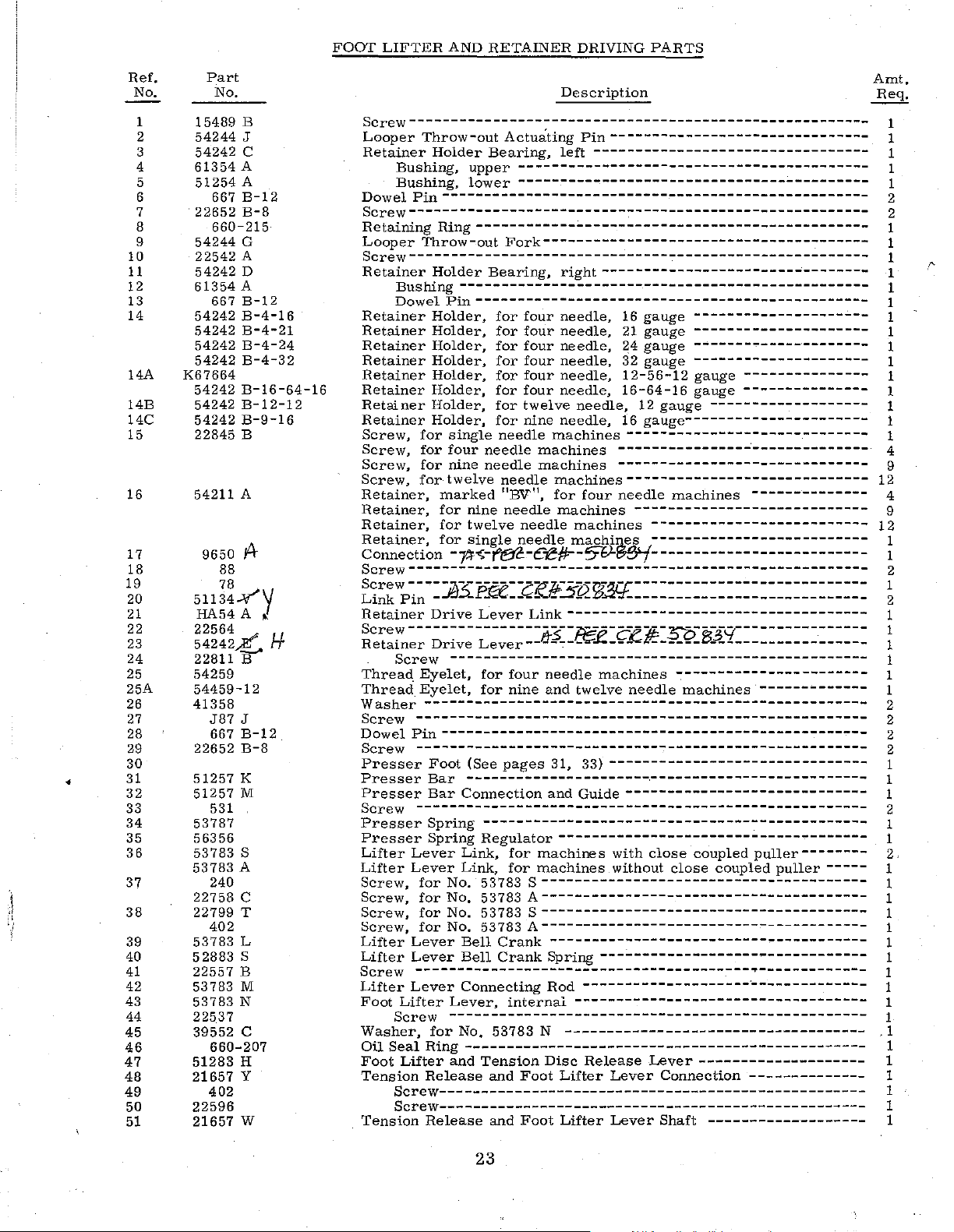

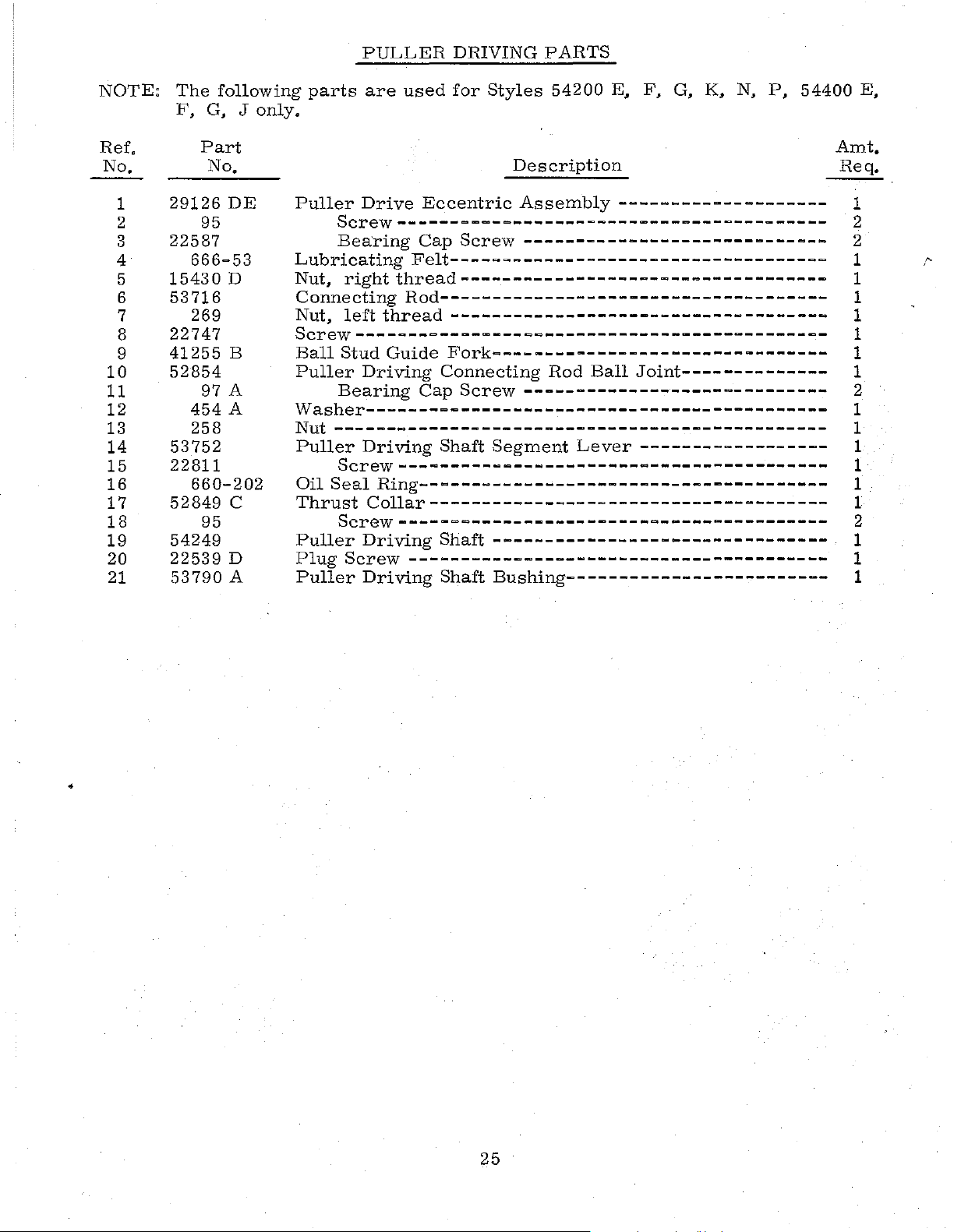

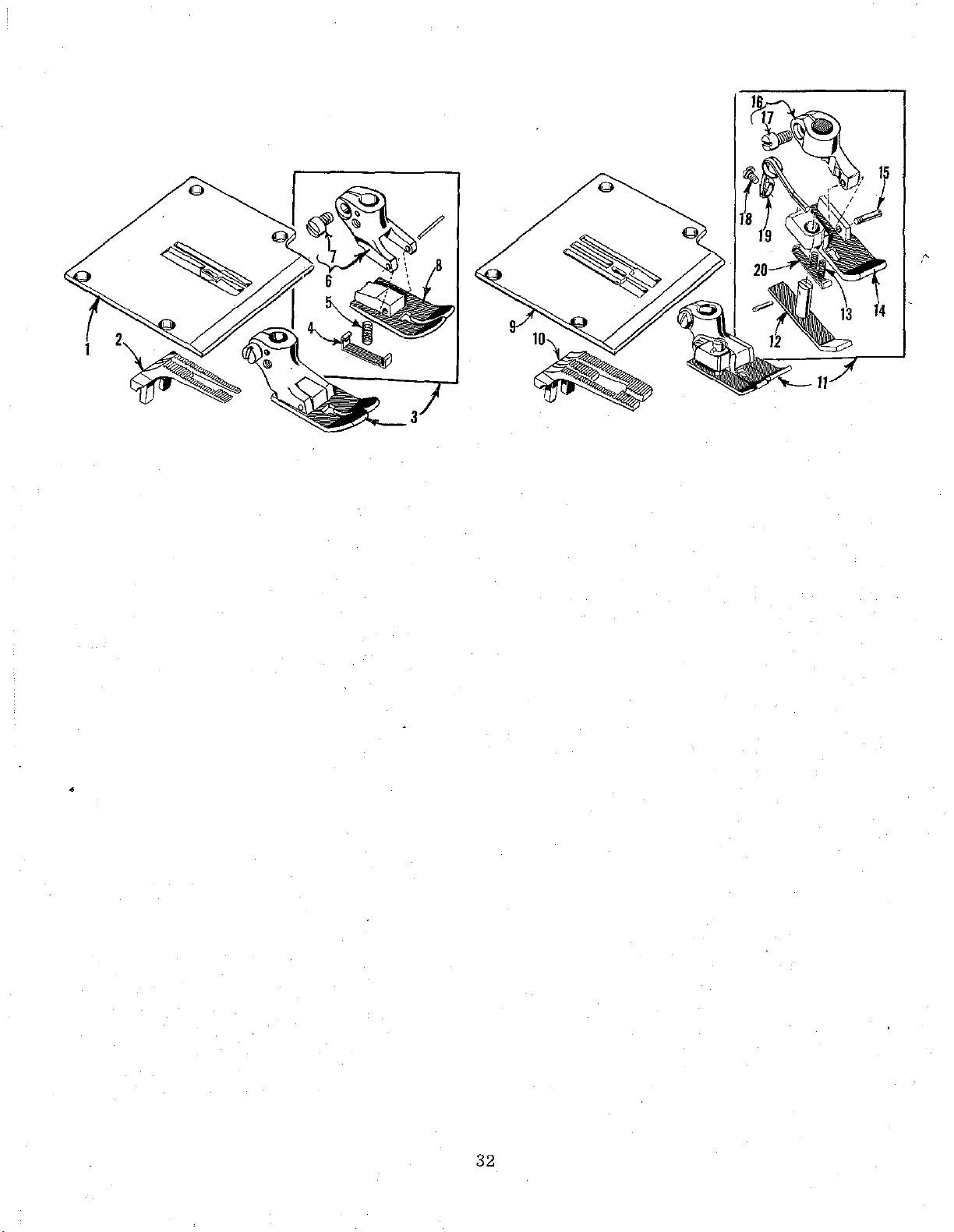

FOOT

LIFTER

AND

RETAINER

DRIVING

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

14A

14B

14C

15

16

17

18

19

20

21

22

23

24

25

25A

26

27

28

39

30

•

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

Part

No.

15489

54244

54242

61354

51254

667

22652

660-215

54244

22542

54242

61354

667

54242

54242

54242

54242

K67664

54242

54242

54242

22845

54211

9650

88

78

51134x-y

HA54

22564

54242£

22811

54259

54459-12

41358

J87

667

22652

51257

51257

531

53787

56356

53783

53783

240

22758

22799

402

53783

52883

22557

53783

53783

22537

39552

660-207

51283

21657

402

22596

21657

B

J

c

A

A

B-12

B-8

G

A

D

A

B-12

B-4-16

B-4-21

B-4-24

B-4-3

2

B-16-64-16

B-12-12

B-9-16

B

A

A-

A •

H

B

J

B-12

B-8

K

M

s

A

c

T

L

s

B

M

N

c

H

y

w

-----

Amt.

Req.

1

1

1

1

1

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

9

12

4

9

12

1

1

2

1

2

1

1

1

1

1

1

2

2

2

2

1

1

1

2

1

1

2,

1

1

1

1

1

1

1

1

1

1

1

,l

1

1

1

1

1

1

Description

Screw-------------------------------------------------------

Looper

Retainer

Dowel

Screw--------------------------~---------------------------

Retaining

Looper

Screw------------------------------------------------------Retainer

Retainer

Retainer

Retainer

Retainer

Retainer

Retainer

Retainer

Retainer

Screw,

Screw.

Screw,

Screw,

Retainer,

Retainer,

Retainer,

Retainer,

Connection

Throw-out

Holder

Bushing,

Bushing.

Pin

---------------------------------------------------

Ring

Throw-out

Holder

Bushing

Dowel

Pin-----------------------------------------------

Holder,

Holder,

Holder,

Holder,

Holder,

Holder,

Holder,

Holder,

for

single

for

four

for

for

twelve

marked 11EV'\

for

for

for

Actuating

Bearing.

upper

lower

------------------------------------------

------------------------------------------

-----------------------------------------------

Fork---------------------------------------

Bearing,

-------------------------------------------------

for

four

for

four

for

four

for

four

for

four

for

four

for

twelve

for

nine

needle

needle

nine

needle

needle

nine

needle

twelve

single

needle

needle

Pin-------------------------------

left

---------------------------------

right---------------------------------

needle.

needle.

needle,

needle,

needle,

needle,

needle,

machines

machines

machines

16

gauge

21

gauge

2.4

gauge

32

gauge

12-56-12

16-64-16

needle,

12

gauge

16

gauge----------------------

---------------.--------------

------------------------------

------------------------------

---------------------

---------------------

-------.,.-----·--------

--------------------gauge

gauge

-------------------

machines----------------------------for

four

machines

needle

machines

machi:u,es

machines

----------------------------

--------------------------

--------------------------

---------------

---------------

--------------

--p<;-f&-C:-It/r-5FJ--&f!fi--------------------------

Screw-------------------------------------------------------

Screw---------------<5u~---~;~;r----------------------------

Link

Pin

-~~~~--~~~~~~V~----------------------------

Retainer

Screw--------------------~-----~-2)()---------------------

Retainer

Thread.

Thread.

VVasher

Screw

Dowel

Screw

Presser

Presser

Presser

Screw

Presser

Presser

Lifter

Lifter

Screw,

Screw,

Screw,

:Screw,

Lifter

Lifter

Screw

Lifter

Foot

VVasher,

Oil

Foot

Tension

Screw

Eyelet,

Eyelet,

Drive

Lever

Drive

Lever

-------------------------------------------------for

for

Link------------------------------------

__

f,J-;?

__

four

nine

c<;;3£._<;;£r-

needle

and

machines

twelve

___

-----------------------

needle

__

8.?..'£

machines

__

--------------

-------------

-----------------------------------------------------

------------------------------------------------------

Pin

---------------------------------------------------

------------------------------------------------------

Foot

(See

Bar

Bar

pages

----------------------.--------------------------

Connection

31,

and

33)

-------------------------------

Guide

-----------------------------

-----------------------------------------------------Spring

Spring

Lever

Lever

for

for

for

for

Lever

Lever

----------------------------------------~-------------

Lever

Lifter

Screw

for

Seal

Ring

Lifter

Release

----------------------------------------------

Regulator

Link,

Link,

No.

No.

No.

No.

Bell

Bell

for

for

53783 S --------------------------------------53783

53783 S ---------------------------------------

53783

Crank

Crank

Connecting

Lever,

internal

-------------------------------------

machines

machines

A---------------------------------------

with

close

without

coupled

close

A---------------------------------------

--------------------------------------

Spring

Rod

-------------------~------------

--------------------·--------------

-----------------------------------

--------------------------------------------------

No.

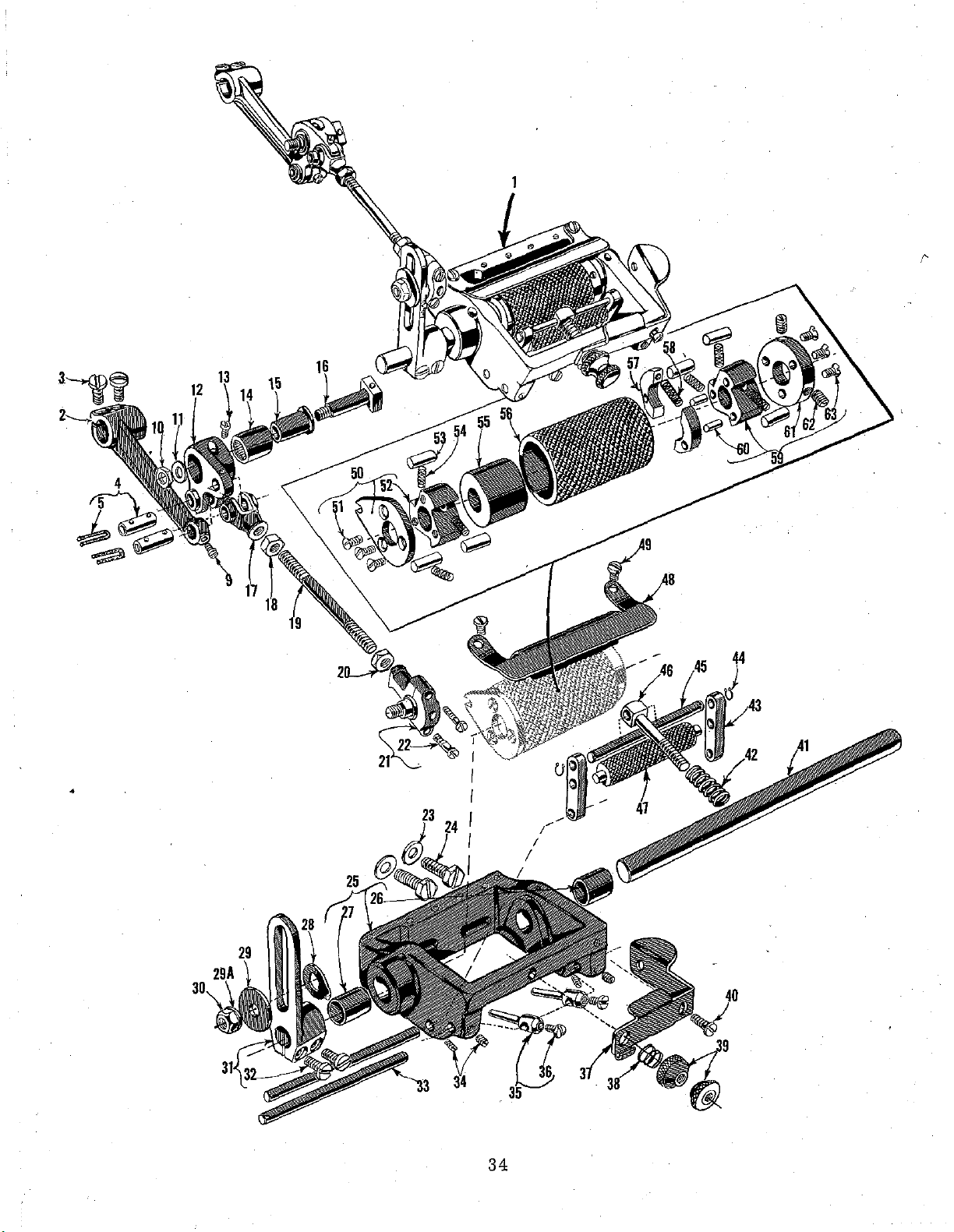

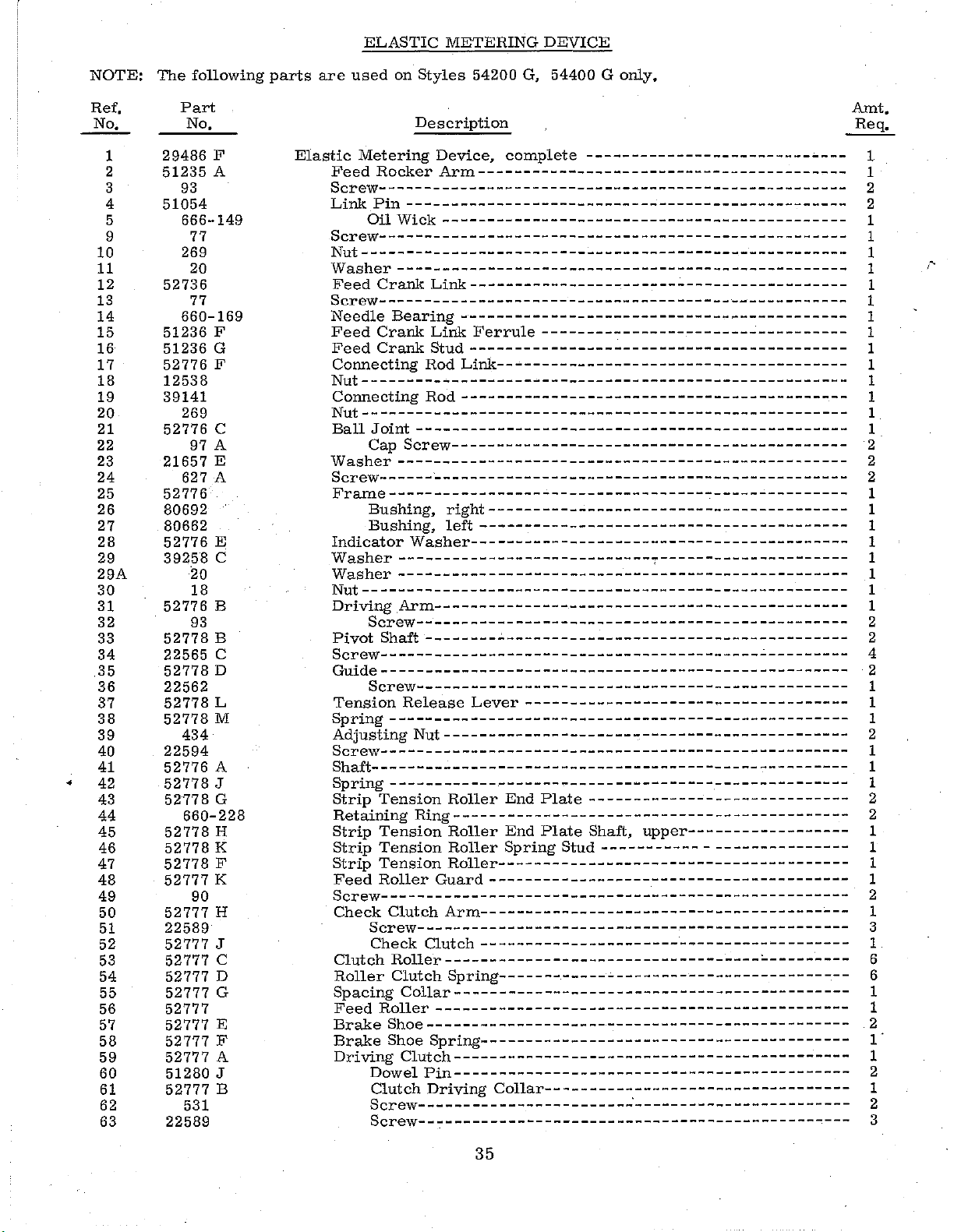

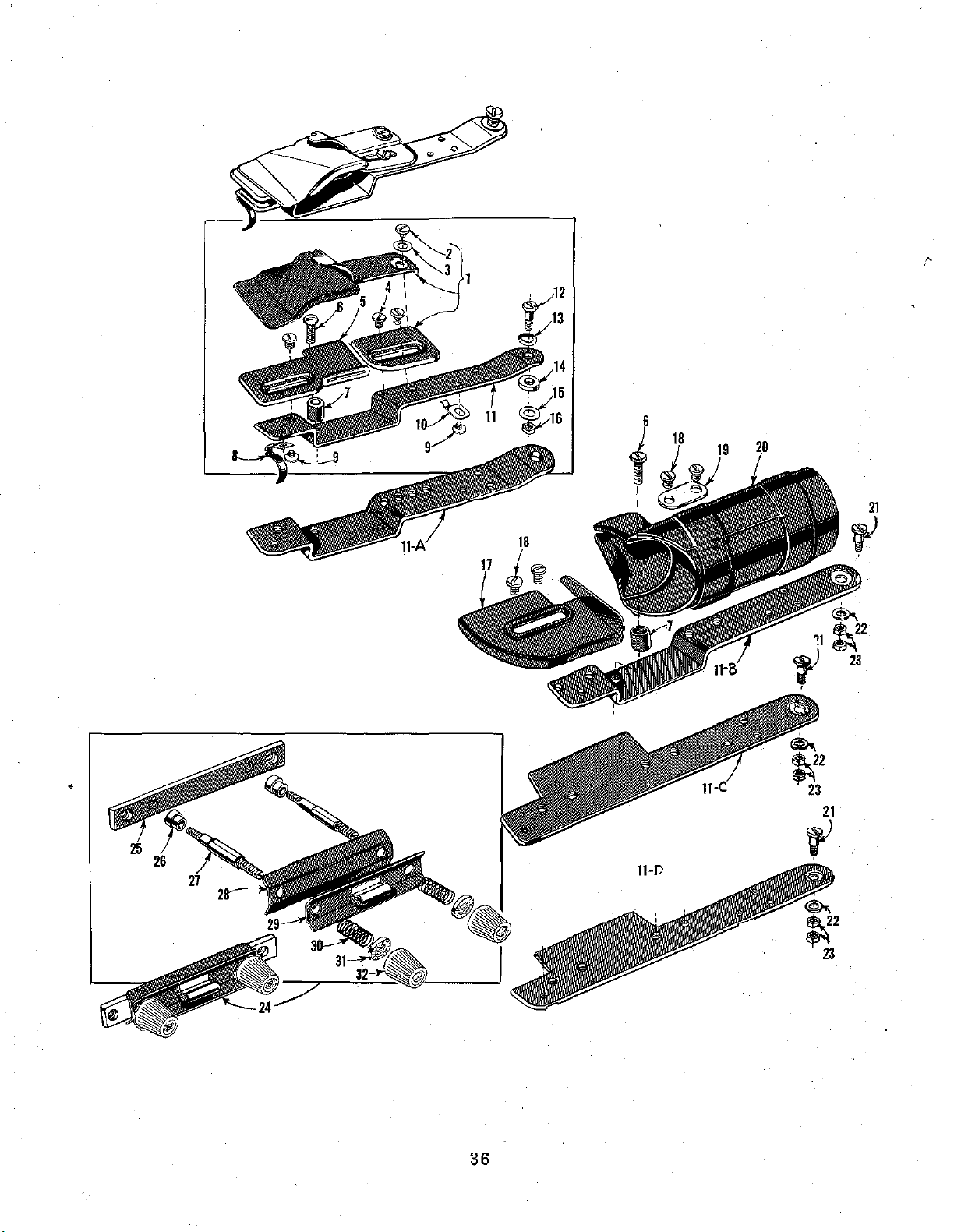

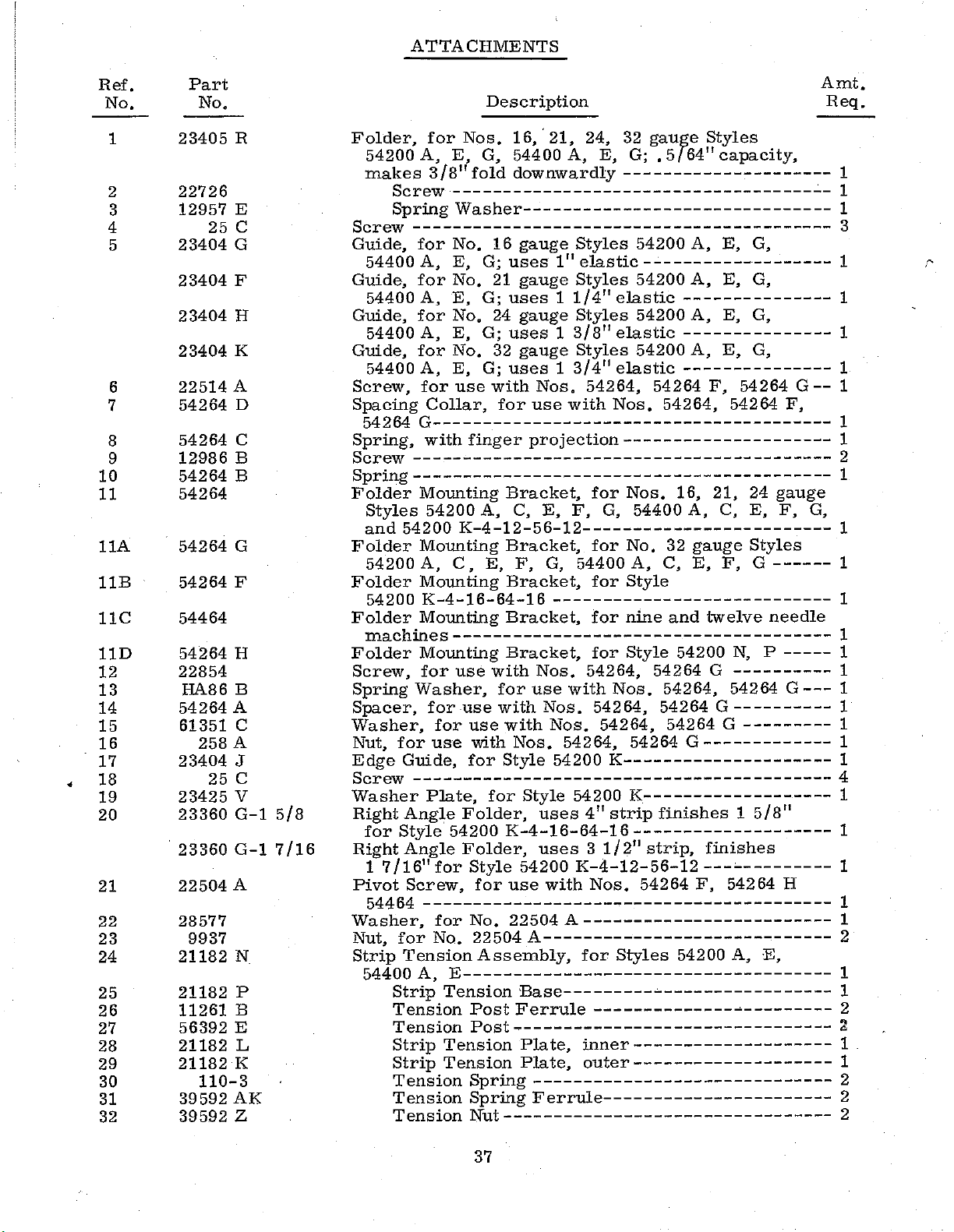

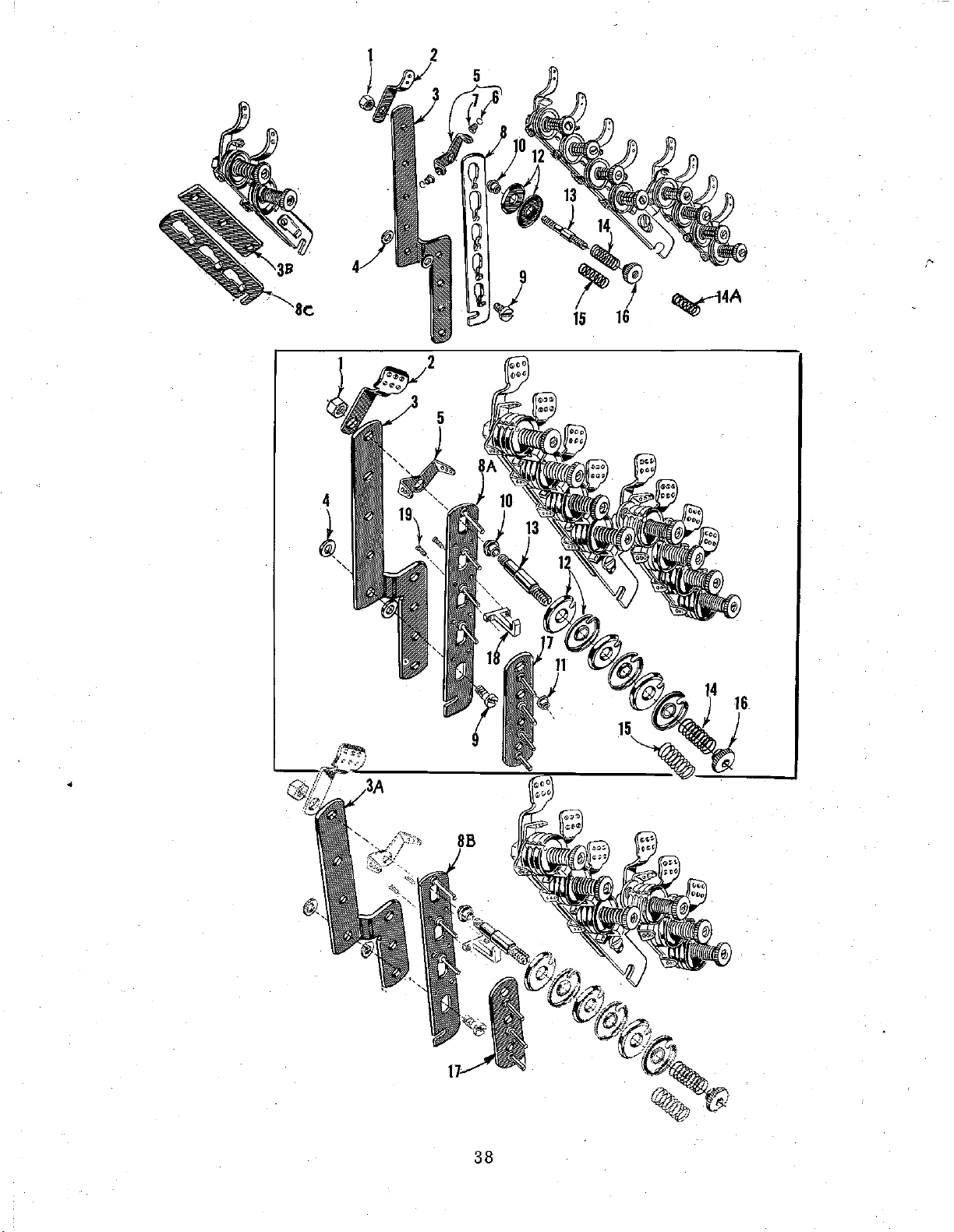

53783 N ------------------------------------