Page 1

STYLES

53700B

53800B

ADJUSTING INSTRUCTIONS AND

ILLUSTRATED PARTS LIST

STREAMLINED

FIFTY THOUSAND SERIES

CATALOG NO.

100L-GR

FIRST EDITION

01/23/09

Page 2

MANUAL NO. 100L-GR ADJUSTING INSTRUCTIONS AND LLUSTRATED PARTS LIST FOR 53700 /53800

SERIES MACHINES

First Edition Copyright 2008

BY

Union Special Corporation Rights Reserved In All Countries

Printed in U.S.A. Jan 2008

FOREWORD

The new streamlined Class 53700 and 53800 machines bring to the automobile upholstery and seat cover industry new

styling, improved lubrication, and light running high speed performance. Enclosed type oiling system for looper drive

eccentric, upper feed driving eccentric, and needle lever crank have substantially increased the speed of these

machines. The almost entirely automatic lubrication system makes maintenance simple. All parts are made by precision

methods insuring complete interchangeability.

It is our constant aim to furnish carefully prepared information which will enable our customer to secure all possible

economies from the use of Union Special sewing machines. The following pages illustrate and describe the parts for the

styles in Classes 53700 and 53800.

Union Special representatives will be found in all manufacturing centers, ready to cooperate with you to plan and estimate

requirements.

2

Page 3

CONTENTS

IDENTIFICATION OF MACHINE .................................................................................................................................................................3

APPLICATION OF CATALOG ...................................................................................................................................................................3

STYLES OF MACHINE ................................................................................................................................................................................3

NEEDLES .................................................................................................................................................................................................... 4

ORDERING REPAIR PARTS ........................................................................................................................................................................4

ORDERING REPAIR PARTS (CONTINUED) ................................................................................................................................................ 5

IDENTIFYING PARTS ................................................................................................................................................................................... 5

USE GENUINE NEEDLES AND REPAIR PARTS ........................................................................................................................................... 5

TERMS ........................................................................................................................................................................................................ 5

OILING AND THREADING ......................................................................................................................................................................... 5

0ILING AND THREADING DIAGRAM ....................................................................................................................................................... 6

SELF-PRIMING HEAD OIL SIPHON ............................................................................................................................................................ 7

INSTALLING AND MAINTENANCE OF OIL SIPHON ................................................................................................................................. 7

INSTRUCTIONS FOR MECHANICS ............................................................................................................................................................ 8

NEEDLE LEVER STUD SETTING ...................................................................................................................................................................8

OILING SYSTEM ......................................................................................................................................................................................... 8

SETTING THE ZIG-ZAG MOTION ............................................................................................................................................................... 8

SPACING NEEDLE IN THROAT PLATE .......................................................................................................................................................8

SETTING THE LOOPER ...............................................................................................................................................................................8

SETTING THE LOOPER (CONTINUED) .......................................................................................................................................................9

SETTING HEIGHT OF NEEDLE BAR ............................................................................................................................................................. 9

SYNCHRONIZING LOOPER AND ............................................................................................................................................................. 9

NEEDLE MOTIONS ..................................................................................................................................................................................... 9

SYNCHRONIZING LOOPER AND ........................................................................................................................................................... 10

NEEDLE MOTIONS (CONTINUED) ..........................................................................................................................................................10

SETTING THE FEED DOG ......................................................................................................................................................................... 10

SETTING THE FEED DOG (CONTINUED) .................................................................................................................................................11

CHANGING STITCH LENGTH .................................................................................................................................................................. 11

SETTING THE NEEDLE GUARD ................................................................................................................................................................. 11

SYNCHRONIZATION OF THE UPPER ROLLER FEED ................................................................................................................................ 12

THREADING .............................................................................................................................................................................................12

SETTING THE LOOPER THREAD TAKE-UP ................................................................................................................................................13

THREAD TENSIONS .................................................................................................................................................................................. 13

PRESSER FOOT PRESSURE ....................................................................................................................................................................... 13

SETTING NEEDLE THREAD TAKE-UP ........................................................................................................................................................ 13

SETTING SPRING RETAINERS ON LOOPER .............................................................................................................................................14

THREAD TENSION RELEASE .....................................................................................................................................................................14

SETTING THE ATTACHMENTS ................................................................................................................................................................... 14

MAIN FRAME, CAST-OFF PLATE, MISCELLANEOUS COVERS AND PLATES ......................................................................................... 17

CLOTH PLATES, CLOTH PLATE COVERS, MISCELLANEOUS AND ATTACHMENTS .............................................................................. 19

MAIN FRAME, BUSHINGS AND MISCELLANEOUS OILING PARTS ........................................................................................................ 21

FOR STYLES 53100B AND C ONLY CLUTCH ASSEMBLY, CLUTCH DRIVE SHAFT GEAR AND HOUSING ASSEMBLY .......................... 23

FOR STYLES 53100B AND C ONLY CLUTCH ASSEMBLY, CLUTCH DRIVE SHAFT GEAR AND HOUSING ASSEMBLY .......................... 25

CRANKSHAFT, NEEDLE LEVER AND LOOPER DRIVING PARTS ............................................................................................................ 27

CRANKSHAFT, NEEDLE LEVER AND LOOPER DRIVING PARTS ............................................................................................................ 29

LOOPER ROCKER AND CONNECTING ROD PARTS ............................................................................................................................ 31

MAIN SHAFT AND FEED MECHANISM ................................................................................................................................................... 33

FOR STYLE 53100E ONLY MAIN SHAFT AND FEED MECHANISM ......................................................................................................... 35

THREAD TENSION AND FOOT LIFTER LEVER PARTS ............................................................................................................................... 37

FEED DOGS, THROAT PLATES AND PRESSER FEET ................................................................................................................................ 39

THREAD STAND, KNEE PRESS AND TAPE REEL PARTS ........................................................................................................................... 41

3

Page 4

IDENTIFICATION OF MACHINE

Each UNION SPECIAL machine is identified by a Style number which is stamped into the name plate on

the machine. Style numbers are classified as standard and special. Those which are standard have one

or more letters suffixed to the class number, but never contain the letter "Z". Example : "53700B". Style

numbers containing the letter "Z" are special. When only minor changes are made in a standard machine,

a "Z" is merely suffixed to the standard style number. Example: "53700BZ".

Styles of machines similar in construction are grouped under a class number which differs from the style

number, in that it contains no letters. Example: “53700”.

APPLICATION OF CATALOG

This catalog applies specifically to the standard Styles of machines as listed herein. It can also be

applied with discretion to some Special Styles of machines in this class.

STYLES OF MACHINE IN CLASSES 53700 AND 53800

Streamlined Enclosed Type Flat Bed, High Throw, Power Driven Upper Running Feed, with Alternating

Presser Foot Action, Lower Feed, Single Reservoir Enclosed Automatic Lubricating System and Filter

Type Oil Return Pump, Lateral Looper Travel, 1 1/2 Inch Needle Travel, Work Space to Right of

Needle, 7 3/4 Inches.

53700B For seaming operations on automobile upholstery and similar articles made from medium

heavy to heavy weight materials, one needle machine, four to seven stitches per inch, seam

specification 401-SSa-1. Maximum recomended speed 3300 R.P.M.

53800B For seaming operations on automobile upholstery, also on fiber, fabric, and plastic auto-

mobile seat covers and for similar operations on medium heavy to heavy weight materials

with or without corded leatherette or plastic piping, two needle machine, four to seven

stitches per inch, seam specification 401-SSa-2. Maximum recomended speed 3300 R.P.M.

NEEDLES

Each UNION SPECIAL needle has both a type number and a size number. The type number denotes the

kind of shank, point, length, groove, finish and other details. The size number, stamped on the needle

shank, denotes the largest diameter of blade measured in thousandths of an inch midway between the

shank and the eye. Collectively, type number and the size number is the complete symbol.

Standard needle for Styles 53700 B, and 53800B is Type 147 GS. It is a round shank, round point, long,

double groove, ball eye, spotted, short point, struck groove, undersize eye and grooves, one step reduction,

chromium plated needle and is available in sizes 080/032, 090/036, 100/040, 110/044, 125/049, 140/054,

150/060, 170/067.

Also available for styles 53700B and 53800B is Type 143GS. It is a round shank, round point, No. 2 bag,

double groove, spotted, chromium plated needle and is available in sizes 140/054, 150/060, 170/067.

To have needle orders promptly and accurately filled, an empty package,a sample needle, or the type and

size number should be forwarded. Use description on label. A complete order would read: "11000

Needles,Type 147 GS, Size 140/054".

Selection of the proper needle size should be determined by the size of thread used. Thread should pass

freely through needle eye in order to produce a good stitch formation.

4

Page 5

ORDERING REPAIR PARTS

ILLUSTRATIONS

This catalog has been arranged to simplify ordering repair parts. Exploded views of various sections of the

mechanism are shown so that the parts may be seen in their actual position in the machine. On the page

opposite the illustration will be found a listing of the parts with their part numbers, descriptions and the

number of pieces required in the partcular view being shown.

Numbers in the first column are reference numbers only and merely indicate the position. of that part in the

illustration. Reference numbers should never be used in ordering parts. Always use the part number listed

in the second column.

Component parts of sub-assemblies which can be furnished for repairs are indicated by indenting their

descriptions under the description of the main subassembly. Example:

23. 29105Q Looper Drive Eccentric Assembly ...................................................... 1

24. 22559B Bearing Cap Screw, upper ..................................................... 2

25. 22894D Eccentric Spot Screw ............................................................ 1

26. 22894C Eccentric Set Screw .............................................................. 1

27. 22559A Bearing Cap Screw, lower ...................................................... 2

It will be noted in the above example that the eccentric and bearing are not listed. The reason is that

replacement of these parts individually is not recommended, so the complete sub-assembly should be

ordered.

In those cases where a parts for the class 53700B and 53800B are not the same the difference will be

shown in the illustrations and descriptions. When a part is used in all machines covered in this catalog no

machine style is mentioned.

At the back of the book will be found a numerical index of all the parts shown in this book. This will facilitate

locating the illustration and description when only the part number is known.

IDENTIFYING PARTS

Where the construction permits, each part is stamped with its part number. On some of the smaller

parts, and on those where the construction does not permit, an identification letter is stamped in to

distinguish the part from similar ones.

Part numbers represent the same part, regardless of catalog in which they appear.

IMPORTANT! ON ALL ORDERS, PLEASE INCLUDE PART NAME AND STYLE OF MACHINE FOR

WHICH PART IS ORDERED.

5

Page 6

USE GENUINE NEEDLES AND REPAIR PARTS

Success in the operation of these machines can be secured only with genuine UNION SPECIAL

Needles and Repair Parts as furnished by the Union Special Corporation, its subsidiaries and

authorized distributors. They are designed according to the most approved scientific principles, and are

made with the utmost precision. Maximum efficiency and durability are assured.

Genuine needles are packaged with labels marked Union Special Genuine repair parts are stamped

with the Union Special trademark, U S Emblem. Each trademark is your guarantee of the highest

quality in materials and workmanship.

TERMS

Prices are strictly net cash and are subject to change without notice. All shipments are forwarded f.o.b.

shipping point. Parcel Post shipments are insured unless otherwise directed. A charge is made to

cover the postage and insurance.

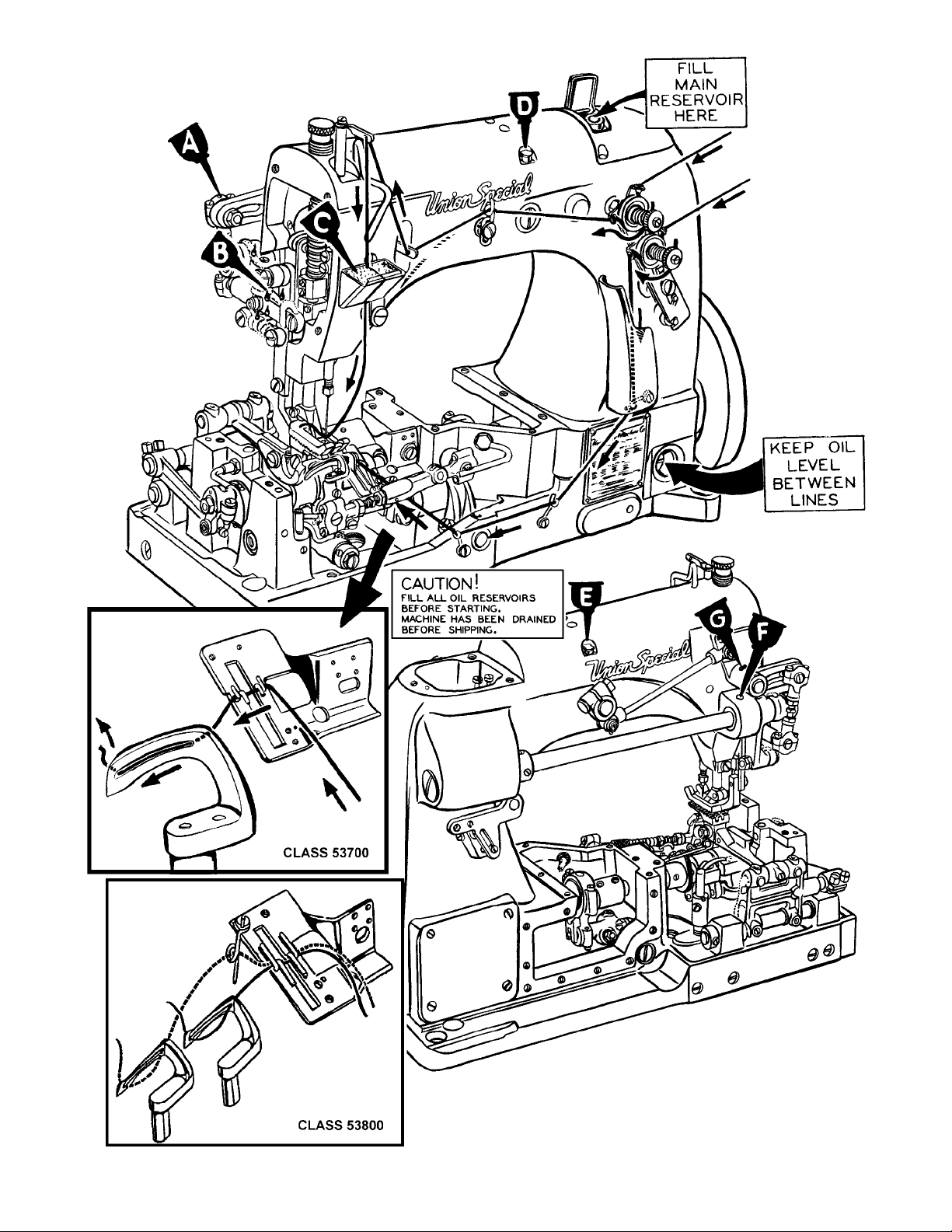

OILING AND THREADING

The oil has been drained from the machine before shipping, and the reservoir must be filled before

beginning to operate. Use a straight mineral oil with a Saybolt viscosity of 90 to 125 seconds at 1000

Fahrenheit.

Oil is filled at the spring cap in the top cover, and the oil level is checked at the sight gauge on the

front of the machine. The oil level should be maintained between the red lines on the gauge. The

capacity of the oil reservoir is 12 ounces.

The lubrication, which is almost entirely automatic, requires a minimum of manual oiling. The oiling

diagram on the opposite page is self-explanatory.

The main reservoir supplies oil to the looper drive eccentric, upper running feed drive eccentric, needle

lever crank: and the supply is registered at the front gauge. The entire lower mechanism is served

through a system of channels and wicks in the main frame by this reservoir.

A daily check before the morning start should be made and oil added if required. Oil which has gone

through the machine is filtered and pumped back into the main reservoir, making too frequent oilings

unnecessary. Excessive oil in the main reservoir may be drained at the plug screw in the main frame

directly under the handwheel.

The accompanying diagram also shows the threading of the single needle Class 53700B machine.

Threading of the two needle Class 53800B machine is substantially the same.

6

Page 7

Fig. 1

7

Page 8

SYNCHRONIZING LOOPER AND NEEDLE MOTIONS

Check the synchronization of the looper and needle motions, using gauge No. T34 and plate No.

21227AD as follows:

Insert the pin, which is included with the gauge, in the looper rocker for 2 needle machine use right

looper. Place the gauge plate on the throat plate seat using the throatplate screws for attaching. Place

the indicator portion of the gauge in the needle thread take-up wire hole with the pointer to the right,

but do not tighten the set screw at this time. Turn the handwheel in the operating direction until the pin

in the looper rocker contacts the edge of the gauge plate and set the indicator so that the left end of

the pointer rests against the top of the needle bar and the right end of the pointer rests at “O”. Tighten

the set screw and note indicator reading. Turn the handwheel in the reverse direction until the pin again

contacts the plate. If the motions are in synchronization, the pointer of the indicator will return to the

same reading. A variation of one graduation on the scale is allowable. If the reading is higher on the

scale when the handwheel is turned in the operating direction, the looper drive lever rocker will have to

be moved to the rear. If the reading is lower, the rocker will have to be moved to the front.

NOTE: If gauge No. 21227AD is not available, synchronization may be checked as follows:

Insert the looper in the looper rocker and turn the handwheel in the operating direction until the point of

the looper, moving to the left, is even with the left side of the needle. Note the height of the eye of the

needle with respect to the looper point, then turn handwheel in the reverse direction until the looper

point again moves to the left and is even with the left side of the needle. If the motions synchronize, the

height of the eye of the needle with respect to the looper point will be the same. A variation of .005

inch is allowable. If the distance from the eye of the needle to the point of the looper is greater when

the handwheel is turned in the operating direction, move the looper drive lever rocker to the rear.

Moving it in the opposite direction acts the reverse. Moving of the looper drive lever rocker is accomplished as follows:

Remove the cloth plate, throat plate support, oil reservoir top

cover and loosen the screws in the looper drive eccentric mechanism and move the eccentric as far to the right as it will go. Drive

the rear bushing to the front or the middle bushing to the rear, as

required. CAUTION: To avoid distorting the parts, remove the plug

screw in the bed behind the rear bushing before driving to the

front and place a horse shoe shaped metal washer approximately

1/16 inch thick between the looper drive lever and adjacent

bushing when driving the bushing to the rear. Correctly reposition

the looper drive eccentric mechanism (per spot screws) and

tighten all screws securely.

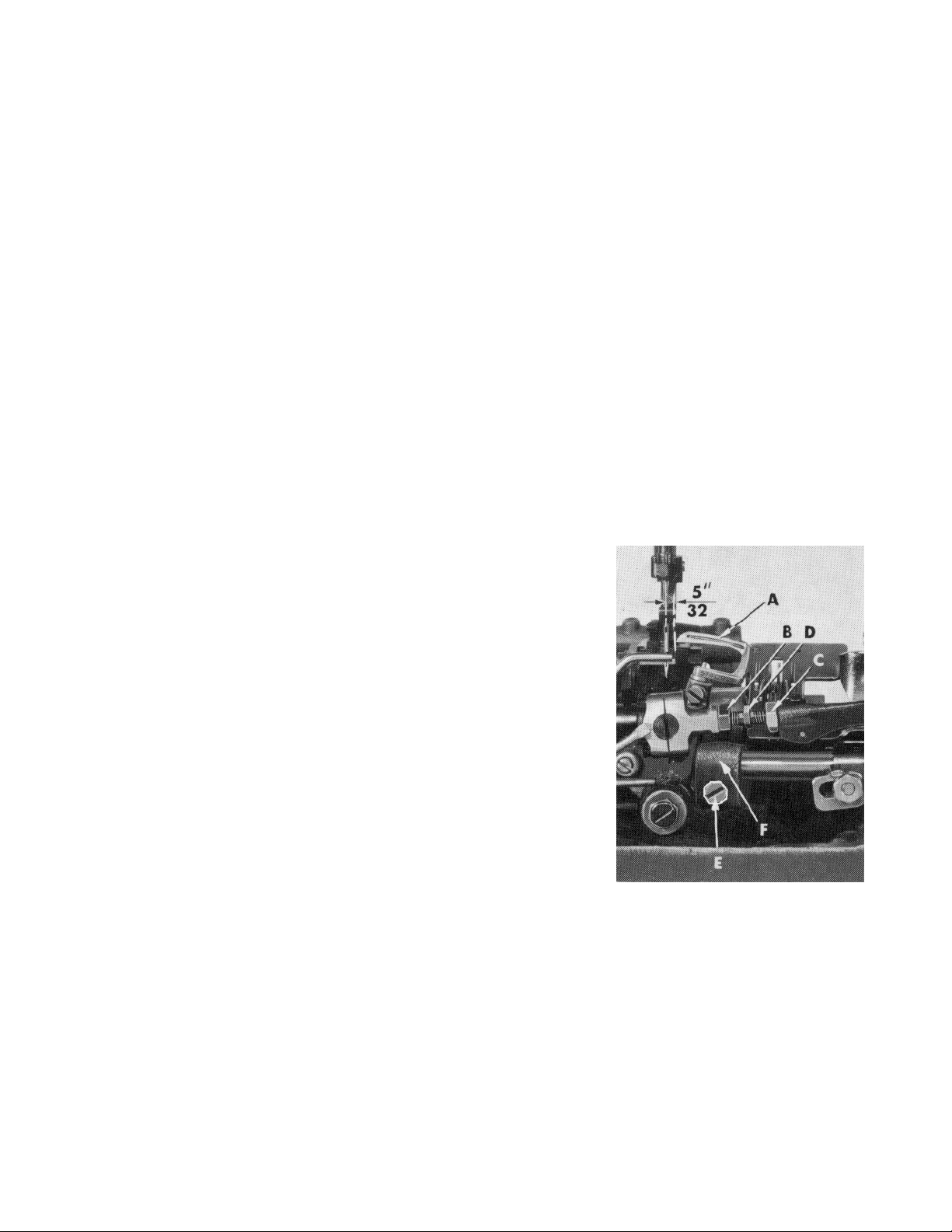

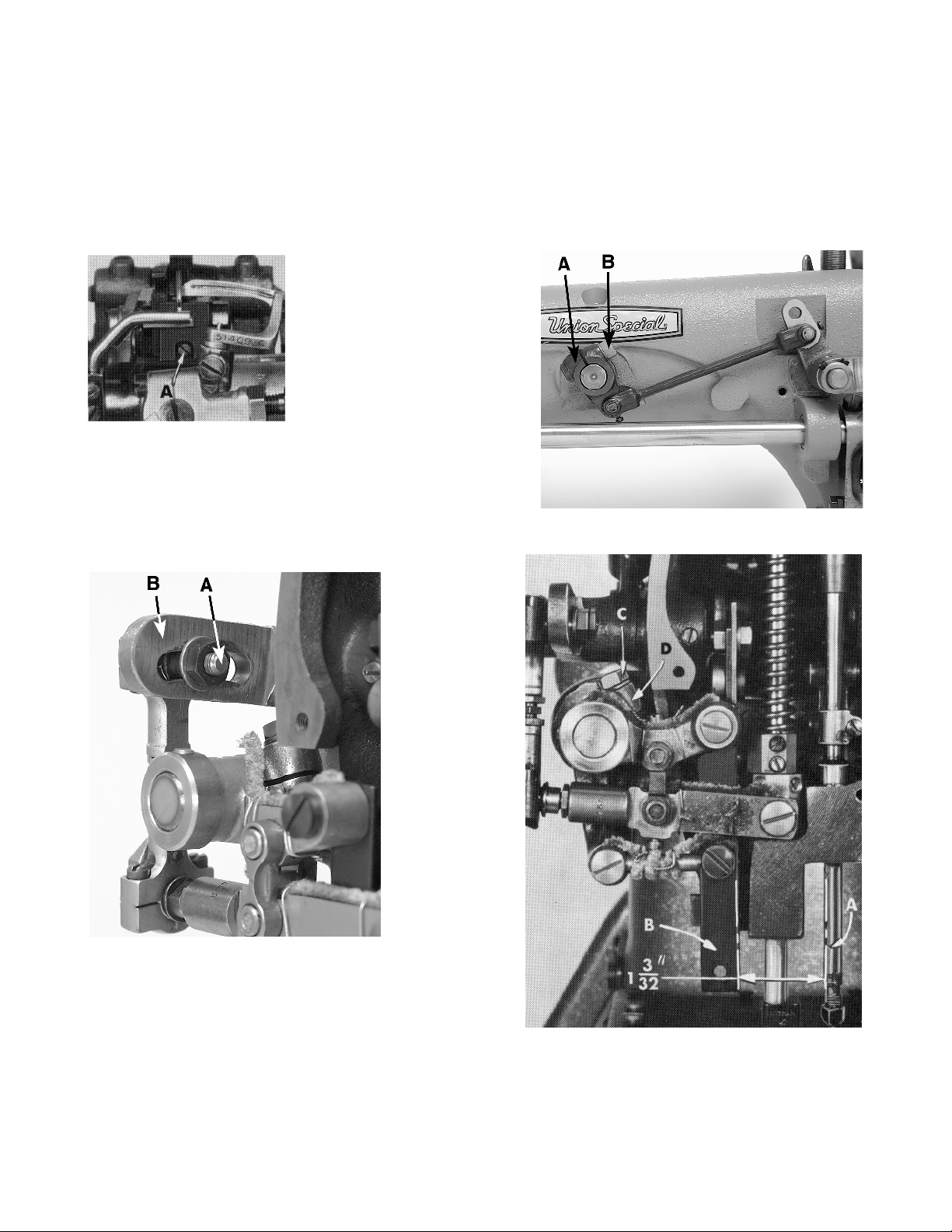

SETTING THE LOOPER

Insert a new needle, type and size as specified, with spot or scarf

to the rear. With the looper (A, Fig. 2) at its farthest position to the

right, its point should be 5/32 inch from the centerline of the

needle. If adjustment is required, loosen nut (B) (it has a left hand

thread) and nut (C) on connecting rod (D) and turn the connecting rod forward or backward to obtain the 5/32 inch dimension

(Fig. 2). Looper gauge No. 21225-5/32 can be used advantageously in making this adjustment. Retighten both nuts, first nut (C),

then nut (B). Make sure the left ball joint is in vertical position and

does not bind after adjustment.

NOTE: For 2 needle 53800, looper gauge should be set using the left needle and looper.

Fig. 2

8

Page 9

SETTING THE LOOPER (CONTINUED)

The looper is set correctly front to back, as it moves to the left behind the needle, when its point passes

as close as possible without contacting the needle (.001-.002). If adjustment is necessary, loosen screw

(E, Fig. 2) in looper rock shaft arm (F), reposition looper as required and retighten screw (E).

Fig. 4

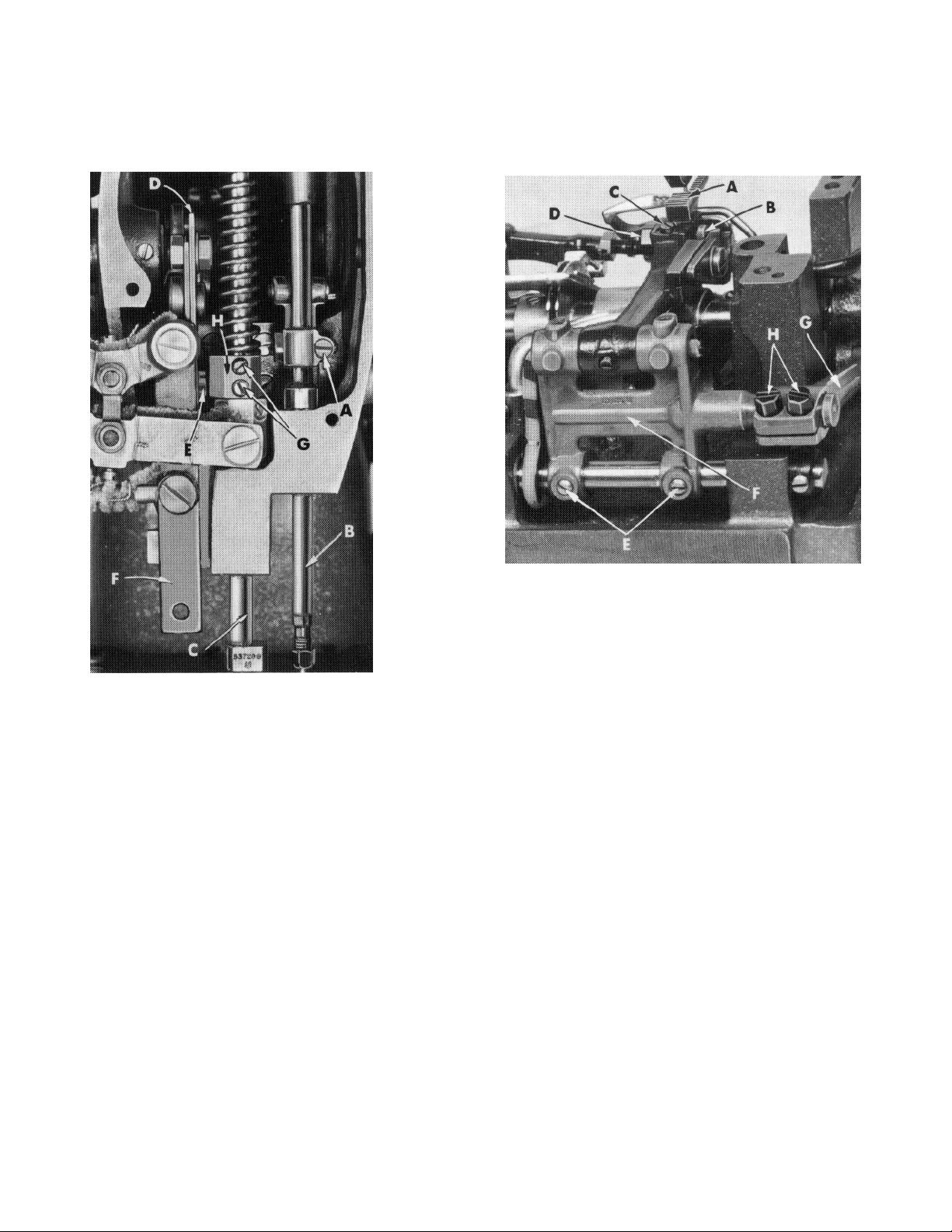

SETTING HEIGHT OF NEEDLE BAR

The height of the needle is correct when the top of its eye is

1/64 inch below the underside of the looper, when the

Fig. 3

looper point is flush with the left side of the needle. If adjustment is necessary, loosen screw (A, Fig. 3) and move needle

bar (B) up or down as required and retighten screw (A).

SETTING THE FEED DOG

Set the feed dog (A, Fig. 4) in the throat plate so there is equal clearance on all sides. See that the tips

of the teeth extend 1/2 to 1 full tooth above the throat plate and are parallel with the throat plate at

high point of travel. Height can be set by loosening feed dog attaching screw (B) and adjusting feed

dog supporting screw (C). Parallelism can be set by loosening nut (D) and rotating feed dog holder

adjusting screw (A, Fig. 5), as required and retighten nut. Side clearance can be set by loosening screws

(E, Fig. 4) and moving feed rocker (F) to the right or left, as required.

NOTE: Whenever the feed rocker has been moved, always check to assure that the feed rocker arm

(G) does not bind.

End clearance can be set by loosening screws (H) in the feed rocker arm (G) and moving feed rocker

(F) forward or backward as required.

9

Page 10

INITIAL SETTINGS OF UPPER RUNNING FEED MECHANISM

The top feed eccentric assembly should be located on the main shaft so that the first screw in the

eccentric will be in a perpendicular position to the mainshaft when the needle bar has risen 1/2"

(12.7 mm) from the bottom of its stroke, with the handwheel turned in the operating direction.

NOTE: Eccentric may need to be advanced or retarded to obtain proper feeding between top and

bottom feeds.

NOTE: The next two paragraphs refer to the maximum height setting of the top feed mechanism

which can be lowered later to suit sewing conditions.

Turn handwheel in the

operating direction until the

needle bar is at the bottom

of its stroke. Loosen nut (B,

Fig.6), and move upper feed

lift driving lever (A) so that

the teeth of the upper feed

dog is 5/32" (7.9mm) for style

53700B and 3/16" to 13/64"

Fig. 5

the throat plate. Then tighten nut (B) securely.

The bell crank lever ball joint (A, Fig. 7) should be in the

center of the upper feed bell crank lever (B). The ball joint

may need to be moved slightly to meet sewing conditions.

(4.8 to 5.2mm) for style

53800B, above the top of

Fig. 6

Fig. 7

As the needle bar just begins to rise from the bottom of

its stroke, the distance between the rear of the needle

bar (A, Fig.8) and the front of the upper feed bar (B)

should be 1 3/32 inch (Fig. 8). Adjustment can be

made by loosening screw (C) in the upper feed driving

lever (D) and moving it forward or rearward as required and retighten screw (C).

10

Fig. 8

Page 11

INITIAL SETTINGS OF UPPER RUNNING FEED MECHANISM (CONTINUED)

Synchronizing the upper feed with the lower feed can be accomplished by loosening nut (A, Fig. 9) and

moving the ball stud in the upper feed driving shaft segment lever (B). Retighten nut.

CHANGING STITCH LENGTH

Set the stitch to the required length. This is accomplished by loosening locknut (A, Fig. 10) (it has a left hand thread) and turning the

stitch adjusting screw (B). Turning screw (B) clockwise shortens the

stitch and turning it in a counterclockwise direction lengthens the

stitch.

NOTE: Any change in stitch length will necessitate a correspond-

ing change in the rear needle guard setting and also

synchronization of the upper running feed mechanism as

described previously.

Fig. 9

Set the rear needle guard (A, Fig. 11) horizontally so that it barely

contact the rear of the needle (B) when at its most forward point of

travel. It should be set as low as possible, yet have its guarding surface

in contact with the needle, until the point of the looper (C), moving to

the left, is even with the needle. To move needle guard forward or

backward, merely loosen screw (D), move needle guard as required

and retighten screw (D) To raise or lower the needle guard, loosen

screw (D; and turn screw (E) clockwise to lower or counterclockwise to

raise. Retighten screw (D) after guard is properly set.

SETTING THE REAR NEEDLE GUARD

SETTING FRONT NEEDLE GUARD

Set the front needle guard (F, Fig. 11) so that it barely

contacts the needle (B) until the point of the looper (C),

moving to the left, is just past the left side of the needle.

The looper may brush, but not pick at the needle. The front

needle guard should beset as low as possible to meet this

condition yet not contact the rear needle guard or looper

at any time. To move needle guard forward or rearward,

loosen screws (G), rotate needle guard holder (H) as

required and retighten screws (G). To raise, lower or rotate

needle guard, loosen screws (J), reposition as necessary

and retighten screws after guard is properly set.

Fig. 10

Fig. 11

THREAD TENSION RELEASE

The thread tension release is set correctly when it begins

to function as the presser foot is raised to within 1/8 inch of

the end of its travel and is entirely released when the

presser foot has reached its highest position.

11

Page 12

THREAD TENSION RELEASE (CONTINUED)

If adjustmentis needed, loosen tension release lever screw (A, Fig. 12), located at the back of the

machine and move tension disc separator as required. Retighten screw. After adjustment there should

be no binding at any point.

SETTING HEIGHT OF PRESSER BAR

The height of the presser bar (C, Fig. 3) is set correctly if it is possible to remove

the presser foot when the foot lifter lever (B, Fig. 12) is fully depressed.

If adjustment is necessary, turnhandwheel in operating direction until the needle

bar is in the low position. Loosen screws (G, Fig. 3), then, while holding presser foot

down on the throat plate surface, pry up presserbar connectionand guide(H) with

ascrewdriver to obtain the 1/16 inch setting and retighten screws.

Fig. 12

THREADING

Draw the looper and needle threads into the machine and start operating on a piece of fabric.

Refer to threading diagram (Fig. 1) for manner of

threading these machines.

SETTING NEEDLE THREAD TAKE-UP WIRE AND

FRAME EYELET

Set the needle thread take-up wire (A, Fig. 13) so

that its upper surface is even with the top of the

hole in the needle bar thread eyelet (B) when the

needle bar is at the bottom of its stroke. Lower this

setting for a smaller needle thread loop or raise it

for a larger loop.

Fig. 13

Set the needle thread frame eyelet (C, Fig. 13) perpendicular to the machine base

and 1/4" above the mounting screw. Lower if more needle thread is desired in the

stitch or raise for less.

SETTING LOOPER THREAD TAKE-UP

The looper thread retainer finger (A, Fig. 14) should be set so that the looper thread

is cast-off just after the eye of the needle comes up out of the material. Coordinated positioning can be acquired by loosening screws (B and C). After looper

thread retainer finger has been properly set, retighten screws.

PRESSER FOOT PRESSURE

Regulate the presser spring regulating screw (D, Fig. 13) so that it exerts only

enough pressure on the presser foot to feed the work uniformly when a slight

tension is placed on the fabric. Turning it clockwise increases the pressure, counterclockwise acts the reverse.

Fig. 14

12

Page 13

EXPLODED VIEWS

AND

DESCRIPTION OF PARTS

13

Page 14

14

Page 15

MAIN FRAME, MISCELLANEOUS COVERS AND PLATES

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

*

*

Part No.

22585A

22524

53782B

51382B

22839C

51281P207

51281AC

22760A

35772H

22845B

80

53701

22570

22839

294

53782E

53780

51280J

51280K

51270B

95

GR-96122A

53724A

53824A18

21396BN

21396AG

22517B

22889A

53758

20

22848

95

35731A

22513D

22528

53753G

605A

53780A

12934A

22539H

22889D

158B

136

53780B

52A

98A

51291A

98A

50-648BLK

20

22848

Description

Screw ............................................................................................................

Screw ............................................................................................................

Oil Reservoir Top Cover .................................................................................

Gasket ..........................................................................................................

Screw ............................................................................................................

Cloth Plate Cover .........................................................................................

Cloth Plate Cover Spring ...............................................................................

Screw ............................................................................................................

Spring Washer ...............................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Cloth Plate ....................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Head Cover ..................................................................................................

Throat Plate Support .....................................................................................

Dowel Pin, lower .....................................................................................

Dowel Pin, upper ....................................................................................

Needle Thread Pull-off Wire ..........................................................................

Screw ............................................................................................................

Lock Washer .................................................................................................

Throat Plate, for Style 53700B ........................................................................

Throat Plate, for Style 53800B ........................................................................

Needle Thread Lubricator ............................................................................

Lubricating Felt .......................................................................................

Screw ............................................................................................................

Adapter Screw ..............................................................................................

Frame Thread Eyelet .....................................................................................

Washer ..........................................................................................................

Screw ............................................................................................................

Set Screw, for upper feed bell crank lever shaft ............................................

Presser Bar Connection Guide Plate .............................................................

Screw ............................................................................................................

Screw ............................................................................................................

Thrust Bracket ...............................................................................................

Screw ............................................................................................................

Throat Plate Support Rod ..............................................................................

Nut ................................................................................................................

Plug Screw ....................................................................................................

Plug Screw ....................................................................................................

Frame Thread Eyelet for Style 53800B ............................................................

Screw ............................................................................................................

Throat Plate Support Rod Bracket .................................................................

Frame Thread Eyelet, for Style 53700B ...........................................................

Screw ............................................................................................................

Looper Thread Guard ...................................................................................

Screw, for looper thread guard ....................................................................

Lucite Oil Guage ...........................................................................................

Washer, for 22848 ..........................................................................................

Screw, for 51282AH .......................................................................................

Amt.

Req.

2

7

1

1

2

1

1

3

3

1

3

1

2

3

3

1

1

2

2

1

1

1

1

1

1

2

1

1

1

1

1

1

2

4

1

1

1

1

1

1

1

3

1

1

3

3

1

1

1

3

3

15

Page 16

16

Page 17

BUSHINGS, OIL TUBES, WICKS AND MISCELLANEOUS COVERS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

Part No.

22541B

52882AD

39582L

52882AC

50-789BLK

52882AA

90

90

52882P

52882Y

22539D

21375BQ

93

52891B

52890C

51242C

21657X

51242R

52944U

52883R

53790A

52894AB

52894AC

53750A

53750B

80689D

51254D

53788A

52890C

51254C

51290T

90

22560B

52894AK

52944T

Description

Screw ............................................................................................................

Crank Chamber Cover, upper ......................................................................

Oil Cap ...................................................................................................

Oil Cap Torsion Spring .............................................................................

Oil Cap Hinge Pin ....................................................................................

Drip Plate ................................................................................................

Screw .....................................................................................................

Screw ............................................................................................................

Gasket ..........................................................................................................

Baffle Plate ...................................................................................................

Plug Screw ....................................................................................................

Belt Guard ....................................................................................................

Screw ............................................................................................................

Main Shaft Bushing Housing, includes bushing ..............................................

Main Shaft Bushing, left and right ..................................................................

Looper Drive Lever Shaft Bushing, front .........................................................

Tension Release Lever Shaft Bushing .............................................................

Looper Drive Lever Shaft Bushing, middle .....................................................

Looper Rock Shaft Bushing, right ...................................................................

Presser Foot Lifter Lever Bushing ....................................................................

Upper Running Feed Drive Rock Shaft Bushing, right .....................................

Oil Tube Holder .............................................................................................

Oil Tube, for feed lift and looper avoid eccentric .........................................

Needle Lever Bushing, front ..........................................................................

Needle Lever Bushing, rear ...........................................................................

Oil Cup ..........................................................................................................

Needle Bar Bushing, lower ............................................................................

Presser Bar Bushing, lower .............................................................................

Upper Running Feed Drive Rock Shaft Bushing, left .......................................

Needle Bar Bushing, upper ...........................................................................

Main Shaft Bushing, middle ...........................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Oil Tube, for looper rocker and left ball joint ..................................................

Looper Rock Shaft Bushing, left .....................................................................

Amt.

Req.

3

1

1

1

1

1

2

2

1

1

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

36. thru 71. See Following page

17

Page 18

18

Page 19

BUSHINGS, OIL TUBES, WICKS AND MISCELLANEOUS COVERS CONTINUED

Ref.

No.

Part No.

1. thru 35. See Previous page

660-136

36.

258A

37.

52936

38.

51242S

39.

52882L

40.

52882AT

41.

52882AE

42.

52882AS

43.

22548

44.

22848

45.

22733B

46.

41394A

47.

22883A

48.

643-127BLK

49.

51493BQ

50.

531

51.

51493AG

52.

51493D

53.

51493BR

54.

22569B

55.

51493AH

56.

51493BH

57.

51493BJ

58.

22823A

59.

22823B

60.

51493AY

61.

51295A

62.

22571A

63.

666-111

64.

666-179

65.

666-118

66.

666-65

67.

35178D

68.

666-114

69.

22889C

70.

51493BK

71.

22848

*

51282AH

*

20

*

Description

Feed Crank Link Oil Tube ..............................................................................

Nut .........................................................................................................

Feed Rocker Shaft Bushing ...........................................................................

Looper Drive Lever Shaft Bushing, rear .........................................................

Oil Reservoir Back Cover ..............................................................................

Gasket ..........................................................................................................

Crank Chamber Cover, lower ......................................................................

Gasket ..........................................................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Gasket ..........................................................................................................

Plug Screw ....................................................................................................

Gasket ..........................................................................................................

Oil Pump Driven Gear ...................................................................................

Screw .....................................................................................................

Oil Pump Housing .........................................................................................

Oil Pump Driving Shaft ..................................................................................

Oil Pump Driving Shaft Gear .........................................................................

Screw ...........................................................................................................

OIl Pump Housing Cover ...............................................................................

Filter Cap Assembly ......................................................................................

Washer, rubber ......................................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Base Plate ....................................................................................................

Mounting Isolator .........................................................................................

Plug Screw ....................................................................................................

Oil Wick ........................................................................................................

Wedge Pin ....................................................................................................

Oil Wick ........................................................................................................

Oil Wick ........................................................................................................

Spring ...........................................................................................................

Oil Wick ........................................................................................................

Plug Screw ....................................................................................................

Lint Filter Screen ...........................................................................................

Screw, for 51282AH ......................................................................................

Oil Shield, end and back ..............................................................................

Washer .........................................................................................................

Amt.

Req.

1

1

2

1

1

1

1

1

4

9

1

2

1

1

1

2

1

1

2

3

1

1

1

2

1

1

4

15

2

2

2

2

4

2

2

1

2

1

2

19

Page 20

20

Page 21

CRANKSHAFT AND UPPER FEED DRIVING ROCK SHAFT PARTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

Part No.

51321G

22894H

22894E

22569B

56390E

660-202

9660B

98

666-53

29126BJ

22587

22894C

15430D

53716

29476DT

22559E

51216

51493BP

22560B

51242P

22729

51243U

29105Q

22559B

22894D

22894C

22559A

52841G

51242Y

51242L

52841J

51242M

51242M

22852A

81

12982

269

22747

41255B

52854

22729C

454A

258

53752

22811

80630C

660-202

52849C

95

52849

29066X

97A

51216N

15430D

Description

"V" Belt Handwheel .......................................................................................

Spot Screw, for round and "V" belt handwheel .......................................

Set Screw, for round and "V" belt handwheel .........................................

Screw, for housing ........................................................................................

Crankshaft Bearing Housing Gasket .............................................................

"O" Ring, for pulley ........................................................................................

Crankshaft Thrust Collar ...............................................................................

Set Screw ...............................................................................................

Lubricating Felt ............................................................................................

Upper Running Feed Drive Eccentric Assembly ...........................................

Bearing Cap Screw ................................................................................

Eccentric Set Screw ...............................................................................

Nut, right thread ...........................................................................................

Top Feed Driving Connecting Rod ...............................................................

Crankshaft Assembly ...................................................................................

Bearing Cap Screw ................................................................................

Needle Lever Connecting Rod ....................................................................

Pump Driving Gear .......................................................................................

Screw .....................................................................................................

Looper Drive Lever Shaft ..............................................................................

Screw ...........................................................................................................

Ball Stud Guide Fork ......................................................................................

Looper Drive Eccentric Assembly .................................................................

Bearing Cap Screw, upper .....................................................................

Eccentric Spot Screw .............................................................................

Eccentric Set Screw ...............................................................................

Bearing Cap Screw, lower ......................................................................

Locking Stud .................................................................................................

Looper Drive Lever Rocker ...........................................................................

Thrust Washer ...............................................................................................

Nut ...............................................................................................................

Washer .........................................................................................................

Washer .........................................................................................................

Clamp Screw ................................................................................................

Spot Screw ...................................................................................................

Lock Nut .......................................................................................................

Nut, left thread .............................................................................................

Screw ...........................................................................................................

Ball Stud Guide Fork ......................................................................................

Upper Running Feed Drive Connecting Rod Ball Joint Assembly ..................

Bearing Cap Screw ................................................................................

Washer .........................................................................................................

Nut ...............................................................................................................

Upper Feed Driving Shaft Segment Lever .....................................................

Clamp Screw .........................................................................................

Nut, left thread .............................................................................................

Oil Seal Ring ..................................................................................................

Upper Running Feed Drive Rock Shaft Thrust Collar ......................................

Set Screw ...............................................................................................

Upper Running Feed Drive Rock Shaft ..........................................................

Needle Lever Connecting Rod Ball Joint ......................................................

Bearing Cap Screw ................................................................................

Washer............................................................................................................

Nut...................................................................................................................

Amt.

Req.

1

1

1

3

1

1

1

2

1

1

2

2

2

1

1

2

1

1

2

1

2

2

1

2

2

3

2

1

1

2

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

1

1

2

1

1

21

Page 22

22

Page 23

FEED ROCKER SHAFT, MAIN SHAFT AND LOOPER ROCKER FRAME ROCKER SHAFT PARTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

Part No.

8

51134P

51134R

51134C

51235

98

482

98

29476RF

51235X

51235G

22519C

77

51054A

666-149

51236M

-269

20

53722

22768

51236B

82

51236G

29476BJ

22894D

51145

PI18

666-82

51236J

77

29476AR

22894D

51145

PI18

666-82

51236J

77

51423C

96

22580D

55244G

51244N

51216N

18

51244L

52470

51244B

22519H

51144

51244

96

98

52444B

52825D

33174B

77

51325

Description

Feed Rocker Shaft ........................................................................................

Lubricating Felt ............................................................................................

Lubricating Felt Guard .................................................................................

Feed Bar Shaft ..............................................................................................

Feed Rocker .................................................................................................

Screw .....................................................................................................

Feed Rocker Shaft Collar .............................................................................

Screw .....................................................................................................

Feed Rocker Arm and Link Assembly ............................................................

Feed Rocker Arm ...................................................................................

Washer ............................................................................................

Screw ..............................................................................................

Set Screw ...............................................................................................

Feed Crank Link Pin ................................................................................

Lubricating Felt ...............................................................................

Feed Crank Link Assembly .....................................................................

Ferrule (Not sold separately)...........................................................

Nut, left thread .............................................................................................

Washer .........................................................................................................

Mainshaft .....................................................................................................

Screw ...........................................................................................................

Feed Crank Stud Cap ...................................................................................

Stitch Regulating Screw ...............................................................................

Feed Crank Stud ..........................................................................................

Feed Lift Eccentric Assembly ...............................................................

Spot Screw .............................................................................................

Feed Lift and Looper Avoid Eccentric Link .............................................

Pin ..........................................................................................................

Lubricating Felt ......................................................................................

Link Pin ...................................................................................................

Screw .....................................................................................................

Looper Avoid Eccentric Assembly ...............................................................

Spot Screw .............................................................................................

Feed Lift and Looper Avoid Eccentric Link .............................................

Pin ..........................................................................................................

Lubricating Felt ......................................................................................

Link Pin ...................................................................................................

Screw .....................................................................................................

Take-up ........................................................................................................

Time Spot Screw .....................................................................................

Set Screw ...............................................................................................

Locking Stud ................................................................................................

Looper Rock Shaft Collar .............................................................................

Washer .........................................................................................................

Nut ...............................................................................................................

Thrust Washer ...............................................................................................

Stop, for looper connecting rod ...................................................................

Looper Rock Shaft Arm .................................................................................

Screw .....................................................................................................

Looper Rock Shaft ........................................................................................

Looper Rocker Frame, for Style 53800B ........................................................

Spot Screw ...................................................................................................

Set Screw .....................................................................................................

Looper Rocker Frame, for Stle 53700B ..........................................................

Looper Needle Guard Holder, for Style 53700B ............................................

Screw .....................................................................................................

Screw .....................................................................................................

Looper Needle Guard, for Style 53700B .......................................................

Amt.

Req.

1

1

1

1

1

2

2

2

1

1

2

2

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

2

1

23

Page 24

24

Page 25

FEED BAR, LOOPER ROCKER AND CONECTING ROD PARTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

Part No.

51134X

22560B

56334E

538

22863

6042A

258

77

22834

53705A

22528

51225

53825

22801

51225W

22585B

53805A

53825

18

52841A

22729C

269

51240D

51241K

56341G

22729C

50-458BLK

12538

53710

73A

51409C

1740

21211

73

73

29192

51213

51745

15465F

22894W

258

22829

51246

51508M18

51909C

29192D

51513

51745

15465F

22894W

258

22829

51242W

22811B

22894H

Description

Feed Bar .......................................................................................................

Set Screw ...............................................................................................

Feed Dog Holder ....................................................................................

Feed Dog Height Adjusting Screw ..........................................................

Feed Dog Holder Adjusting Screw ..........................................................

Washer ...................................................................................................

Feed Dog Holder Nut .............................................................................

Screw ...........................................................................................................

Needle Guard Adjusting Screw ....................................................................

Lower Feed Dog, for Style 53700B .................................................................

Screw ...........................................................................................................

Needle Guard, for Style 53700B ....................................................................

Needle Guard, for Style 53800B ....................................................................

Needle Guard Guide Screw ..................................................................

Washer .........................................................................................................

Screw ...........................................................................................................

Lower Feed Dog, for Style 53800B .................................................................

Needle Guard, for Style 53800B ....................................................................

Nut ...............................................................................................................

Looper Connecting Rod Ball Joint, left .........................................................

Bearing Cap Screw ................................................................................

Nut, left thread .............................................................................................

Looper Connecting Rod, 1 11/32 inches long ..............................................

Looper Connecting Rod Ball Joint, right .......................................................

Spring .....................................................................................................

Bearing Cap Screw ................................................................................

Spring Pin ...............................................................................................

Nut ...............................................................................................................

Looper Needle Guard, for 53700B older models ..........................................

Screw ...........................................................................................................

Looper, for Style 53700B ...............................................................................

Looper Needle Guard Pin ......................................................................

Looper Collar, for Style 53700B .....................................................................

Screw, for Style 53700B .................................................................................

Screw, for Style 53800B .................................................................................

Looper Rocker Assembly, for Style 53700B ....................................................

Looper Rocker .......................................................................................

Looper Rocker Cone Stud ......................................................................

Looper Rocker Cone ..............................................................................

Set Screw .........................................................................................

Lock Nut .................................................................................................

Lock Nut Screw ......................................................................................

Nut ...............................................................................................................

Looper, front, for Style 53800B ......................................................................

Looper, rear, for Style 53800B .......................................................................

Looper Rocker Assembly, for Style 53800B ....................................................

Looper Rocker .......................................................................................

Looper Rocker Cone Stud ......................................................................

Looper Rocker Cone ..............................................................................

Set Screw .........................................................................................

Lock Nut .................................................................................................

Lock Nut Screw ......................................................................................

Looper Drive Lever .......................................................................................

Clamp Screw .........................................................................................

Spot Screw ...................................................................................................

Amt.

Req.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

25

Page 26

26

Page 27

UPPER FEED DRIVE, NEEDLE BAR DRIVE AND PRESSER BAR PARTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

Part No.

53753H

22585S

9937

51770-88

51771

22773A

22773B

22764A

53783D

531

53755A

22787D

J87J

56354D

22598D

9660B

98

53752F

J87J

51054A

666-149

53752D

627A

80557

12934A

53788B

53783C

22560B

41071G

33174B

52889A

53787

22768

56358

Description

Upper Running Feed Bar ...............................................................................

Screw, for upper feed dog ...........................................................................

Nut ...............................................................................................................

Upper Running Feed Bar Spacing Link ..........................................................

Upper Running Feed Bar Link Bushing ...........................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Presser Bar Connection Block .......................................................................

Screw ...........................................................................................................

Upper Running Feed Foot Lifter Link ..............................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Connection Link ...........................................................................................

Screw ...........................................................................................................

Upper Running Feed Drive Rock Shaft Collar ................................................

Screw .....................................................................................................

Upper Running Feed Lifter Drive Link ............................................................

Screw ...........................................................................................................

Link Pin ..........................................................................................................

Lubricating Felt ......................................................................................

Upper Running Feed Driving Lever ...............................................................

Clamp Screw .........................................................................................

Washer ...................................................................................................

Nut ...............................................................................................................

Presser Bar ....................................................................................................

Presser Bar Connection and Guide ..............................................................

Screw .....................................................................................................

Nut ...............................................................................................................

Screw ...........................................................................................................

Presser Bar Bushing, upper and presser spring regulator ..............................

Presser Spring ...............................................................................................

Scew ............................................................................................................

Needle Bar Thread Eyelet, for Style 53700B ...................................................

Amt.

Req.

1

1

3

1

2