Page 1

OILING AND

THREADING

INSTRUCTIONS

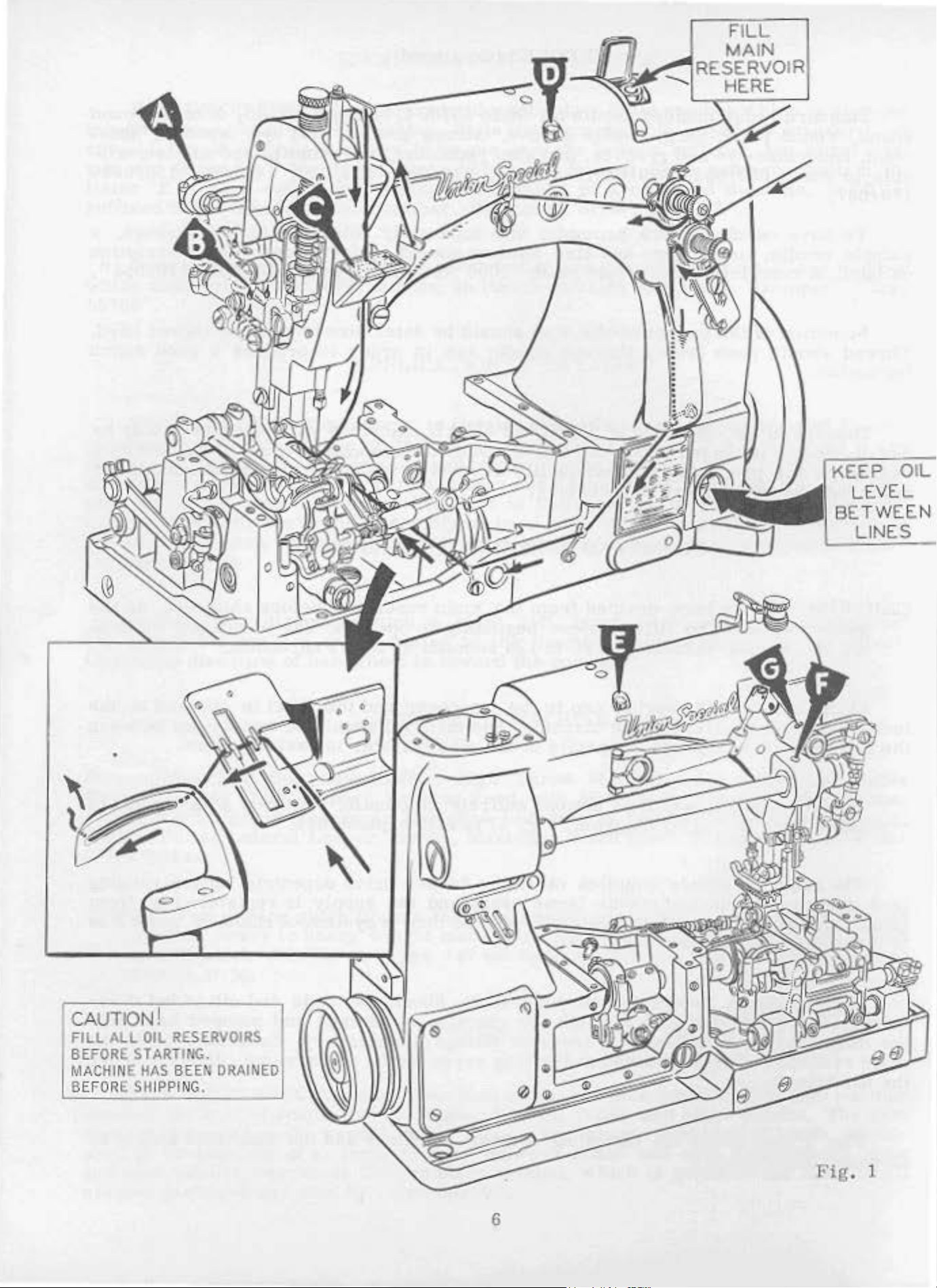

CAUTION!

reservoir

oil

of a Saybolt

Oil

is

lucile

the

manual

feed

gauge

red

The

The

drive

lines

lubrication

oiling.

main

gauge. The

in

the

main

Oil

has

must

filled

on

on

at

the

this

The

reservoir

eccentric

entire

frame

been

be

viscosity

the

front

drained

filled

spring

of

the

before

of

cap

machine.

gauge. Capacity

,

which

oiling

is

almost

diagram

supplies

and

lower

by

this

needle

mechanism

reservoir

from

90

to

in

(Fig.

oil

lever

.

the

main

beginning

125

the

seconds

top

The

of

the

oil

entirely

1)

is

to

the

crank

is

served

reservoir

to

operate.

at J 00°

cover

oil

level

reservoir

and

should

Fahrenheit.

the

is

automatic,

self-explanatory.

looper

and

thru

drive

the

a

eccentric,

supply

system

before

shipment,

Use a straight

level

be

twelve

requires

is

checked

maintained

ounces.

a

upper

is

registered

of

channels

so

mineral

at

between

minimum

running

at

front

and

wicks

the

the

of

A

daily

quired. Oil

the

main

mnin

the

reservoir

handwheel.

Fig.

threaded

check,

which

has

reservoir

may

1

also

shows

accordingly

before

gone

making

be

drained

the

.

the

morning

through

too

frequent

at

the

threading

start, should

the

machine

oilings

plug

of

screw

these

5

is

filtered

urmecessary

in

the

machines

be

main

and

made

and

.

frame,

the

and

oil

added

pumped

Excessive

directly

machines

if

back

oil

into

in

under

should

re-

the

be

Page 2

MAIN

RESERVOI

HERE

KEEP

LE.VE.L

BE

TW

EEN

CAUTION I

FILL

ALL

OIL

RESERVOIRS

BEFORE

MACHINE

B

EFORE SHIPPING.

STARTING.

HAS

BEEN

DRAINED

_j

I

6

Fig

. 1

Page 3

SYNCHRONIZING

LOOPER

AND

NEEDLE

~OTIONS

Check

21227

AC

Insert

gauge plate

the

indicator

pointer

in

the

gauge

top

of

screw

the

pin

the

indicator

scale

in the

rear

NOTE

to

operating

plate

the

and

again

is

allowable.

operating

.

If

t

he

:

If

follows:

Insert

direction

of

the

then

the

turn

left

height

variation

point

of

move

acts

the

until

needle.

and

of

the

of . 005

the

the

looper

reverse.

the

synchronization

as

follows:

the

pin,

on

the

portion

the

right,

and

needle

note

indicator

contacts

will

reading

gauge

the

looper

the

Note

handwh

is

even

eye

looper

which

throat

but

direction

set

the

bar

is

plate

of

the

do

not

until

indicator

and

the

included

gauge

reading.

the

plate.

return

If

the

to

the

reading

direction, the

is

lower,

No.

eel

drive

21227

in

point

the

height

in

the

with

of

the

needle

inch

is

greater

is

lever

Moving

AC

the

of

the

reverse

the

left

allowable.

of

the

of

scat

tighten

the

so

right

lf

same

is

looper

the

is

not

looper

looper,

of

the

side

with

when

rocker

looper

the

looper

with

using

in

the

the

the

pin

in

that

end

Turn

the

the

of

the

motions

reading.

higher

drive lever

rocker

available,

rocker

moving

eye

of

direction

of

the

resp

If

the

ect

the

handwheelis

to

the

drive

and

the

gauge,

throat

need

set

the

le

screw

looper

left

the

pointer

handwhecl

are

1\

on

the

will

have to

synchronization

and

turn

to

the

needle

unt

needle.

to

the

distance

rear.

lever

needle

in

the

plate

thread

at

screws

take

this

rocker

end

of

the

rests

in

in

synchronization,

variation

scale

rocker

when

will

be

the

handwheel

the

left,

with

il

the

looper

If

the

looper

from

turned

~oving

rocker

is

motions.

looper

rocker.

for

-up

time.

wire

Turn

contacts

pointer

at

"0".

the

reverse

of

one

graduation

the

handwheel

have

moved

to

to

may

is

even

respect

to

point

motions

point

the

in

it

in

will

eye

of

the

operating

the

opposite

accomplished

using

gauge

Place

attaching. Place

hole

the

the

rests

Tighten

direction

the

with

handwheel

edge

of

against

the

until

pointer

on

is

turned

be

moved to

the

front.

be

checked

in

the

operating

with

the

synchron

the

the

looper

again

be

the

needle

left

side

point,

moves

ize,

same

to

direction,

direction

as

follows:

No.

the

the

the

the

set

of

the

the

as

to

the

. A

the

Remove

reservoir

drive

as

ing

as

eccentri

far

to

to

the

required

remove

bushing

shoe

thick

shaped

between

bushing

ectly

ism

ly

reposition

(per

.

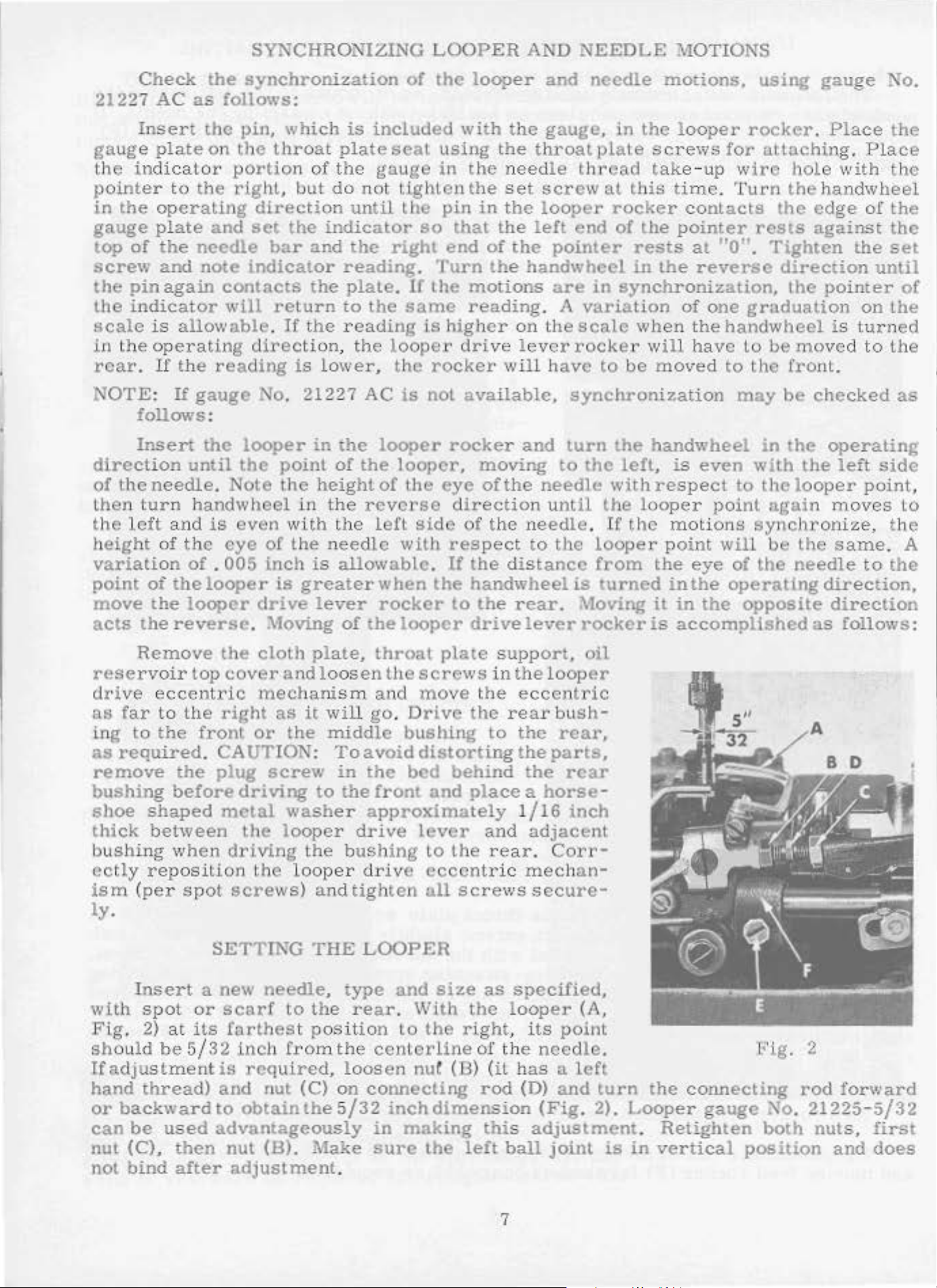

Insert

with

Fig.

should

If

hand

or

can

nut

not

spot

2)

be

adju

stment

thread)

backward

be

(C),

bind

the

top

cover

the

right

front

. CAUTION:

the

plug

before

metal

when

spot

driving

screws)

SETTING

a new

or

scarf

at

its

farthest

5/32

is

and

to

used

advantageously

then

after

nut

adjustment.

cloth

and loosen

c

mechanism

as

it

or

the

screw

driving

washer

the

looper

the

the

looper

needle,

to

inch

from

required,

nut (C)

obtain

the

(B). .Make

plate,

throat

and

will go.

middle

To

avoid

in

the

to

the

front

approximately

d!'ive

bushing

driv

and

tighten

THE

LOOPER

type

the

rear. With

position

the

centerline

loosen

on

connecting

5/32

in

sure

the

screws

move

Drive

bushing

distorting

bed

and

lever

to

e

eccentr

all

and

to

the

nut (B)

inch

dimension

making

the

plate

support,

in

the

the

rear

to

the

eccentric

the

the

behind

place a horse-

1

and

the

rear

ic

scre

size

as

the

ws

specified,

looper

right, its

of

the

(it

has a left

rod

(D)

this

left

ball

oil

looper

bush-

rear,

parts,

the

rear

/16

inch

adjacent

.

Corr-

mechan-

secure-

(A,

point

needle.

and

(Fig.

turn

2).

adjustment.

joint

is

the

connecting

Looper

Retighten

in

vertical

gauge

position

Fig.

'lo.

both

2

rod

forward

21225 -

nuts,

and

5/32

fir:;t

does

7

Page 4

SETTING

THE

LOOPER

(Continued)

The

needle,

looper

when

adjustment

reposition

its

is

necessary

looper

is

set

correctl

point passes

,

as

requi

red and

loo

sen

y

in-line-of-feed, as

as close

screw

retighten

as

possible

(

E,

Fig.

screw

it

without

2)

in

(El.

moves to

the

left

contacting the

looper rock shaft

behind

needle.

arm

the

If

(F).

needle.

(B)

up

all

sides.

above

Height

or

Set

the

if

the

can

supporting

dog

hold

er

ance can

right

or

left, as

Fig

. 3

adjustm

down

See

throat

be

as

feed

that the

set

do

plate

screw

adj

usting sc

be

set by loosen

required

ent is

required

g (A,

tips of

and

by

loosening

(C).

Parallelism

rew

necessary

and

retighten

SETTL.'IG

Fig. 4)

the

are

parallel

feed

(A,

Fig

ing

screws

.

,

loosen

THE

in

the

teeth ex

dog

can

. 5),

(E,

SETTI

NG

The

when

the

er

screw

the

underside

poi

nt

scr

ew (A,

(A).

FEED

throat

plate

tend slightly

with

the

thr

attaching

be

set

by

loosening

as

required

Fig. 4)

and

HEIGHT

height

top

or

or

is

flush

Fig. 3)

DOG

so there

less

oat

plate

screw

and

moving

Fig.

OF

of

the

its

eye

the

looper,

with

and

is

than

at

high

(B)

and

nul (D)

retighten

feed rock

4

NEEDLE

needle

is

1/64

when

the

left

side

move

equal

clear

the depth

point

adjusting

and

rotating

nut. Side

er

BAR

is

correct

inch

the

below

loop

of

the

needle ba

ance

of

a t

ooth

of

trave

feed

dog

feed

clear

(F)

to

the

r

on

l.

-

l\OTE:

and moving

Whenever

feed

End

clea

rocker

rance

feed

the

arm

(G)

can be

rocker

feed

docs

(F)

rocker

not

set by

forward

has

been

bind

looseni

.

ng

or backward as

8

moved,

scre

ws

always

(1-D

In

the

required.

check

feed

to

rock

assure

er

that

arm

the

(G)

Page 5

INITIAL

SETTINGS

OF

UPPE

.R

RUNNING

FEE

D

MECHAN

ISM

The

first

the

turned

NOTE

screw

needle

in

: T

mechanism

centerline

of

the

upper

inch

(Fig.

The

should

(B).

if

required

Th

be

is

top

the

he

Fig

of

6)

bell

set

con

.

feed

inthe

bar

has ris

operating

next

. 5

the link

feed

.

Retighten

crank

all

necting

eccentric

eccentric

en

two

paragraphs

which

pin

drive

lever

the

way

rod

assembly

will

1/4 inch

direction.

can

be lowered

Turn

in

the

r e c t i

needle

bot

tom

While

handwhee

the

upper

driving

Fig.

ing

nut

tance

(C)

and the

rock

nut

(

B).

shaft

ball join

to

the

can

also

should

be

in

aperpendicularposition

from

refer

to

later

handwheel

operating

on

u n t i 1

bar

of

its

is

str

holding

l,

position

feed

l

ever

6)

after

(B)

loosen-

so

the

between

centerline

(D)

t

(A,

Fig.

right

in the

be lengthened

the

at

dis

is

be

bottom

lhe

maximum

to

dithe

the

ok

e.

the

lift

(A,

-

t

he

7/8

7)

slot

located

of its

suit

sewing

.

of the

or

shortened

on

the

stroke

height

conditions

upper

to

main

to

,

setting

the

with

shaft

main

the

of

.

Fig.

feed

6

bell

suit sewing

so

that

shaft

when

handwhee

the top

cranl< l

ever

conditions

the

l

feed

Fig.

As the

from

the

between

8)

e111d

the

be

1 3/32

made

ward

by loosening

or

needle

bottom

the

rear

front

of

inch

rearward

of

of

the

(Fig

7

bar

its

the

upper

. 8).

screw

as

requi

just

stroke,

needle

begins

the distance

bar

feed bar (B)

Adjustment

(C)

in

red

and

to

( ,~

,

should

can

the

upper

retighten

rise

Fig

9

.

be

feed

driving

screw

(C).

lever

Fig

(D)

. 8

and

moving

it for -

Page 6

INITIAL

SETTINGS

OF

UPPER

RUNNING

FEED

MECHANISM

(Continued)

Synchronizing

ing

nut

lever

(B).

Set

contact

ward

point

missible.

its

vertical

needle,

left, is

forward

needle

To

raise

and

wise

er

ly

turn

to

set

the

(A,

Fig.

Retighten

Fig

the

the

rear

of

It

face

until

even

or

backward,

guard

or

screw

9)

. 9

rear

of

travel.

should

approach

the

point

with

as

lower

(E)

and

nut

needle

the

A

be

the

required

the

clockwise

raise. Retighten

.

upper

moving

.

guard

needle

clearance

set

as

within

of

the

needle

merely

needle

screw

feed

with

the

Set

the

ball

the

complished

left

hand

(B).

and

the

Turning

turning

stitch

NOTE:

corr

thread)

.

Any

esponding

setting

f

eed

mechanism

SETTING

(A,

(B)

low

Fig

when

of

.

as

possible,

about

looper

.

To

(C),

move

loosen

and

retighten

guard, loosen

to lower

(D)

after

lower

stud

in

feed

the

upper

CI!ANCI:-JG

stitch

by

screw

It

in a counterclockw

change

to

the

loosening

and

turning

(B)

in

stitch length

change

and

also

synchr

as

.

ll)

at

Its

005

inch

3/64

moving

needle

screw

TllE

horizontally

most

inch

(D),

is

yet

REAR

for-

per-

have

or

to

guard

move

screw

screw

or

counterclock

gu

ard

is

prop

can

be

feed

STITCH

required

locknut

the

clockwise

in the

onization

described

NEEDLE

so

the

the

(D) .

(0)

-

-

accomplished

driving

shaft

LENGTH

length. This

(A.

stitch

Fig.

adJUSting

shortens

ise

direction

will

rear

of

necessitate

needle

the

upper

previously.

GUARD

that

it

does

Fig

by

loosen-

segment

10)

(it

the

lengthens

not

. 10

is

ac-

has

a

screw

stitch

a

guard

running

quite

foot

has

Fig.

reached

11

its

highest

position

SF.TTINC

Set

that

it

point

just

may

past

brush,

needle

meet

needle

needle

screws

required

lower

(J),

screws

'T'he

ly

when

is

raised

travel

.

the

front

barely

of

the

looper

the

left

but

guard

this

guard

should

condition

or

guard

(G) ,

rotate

and

or

rotate

reposition

after guard

TliRE

I\D T ENSION

thread

it

begins

to

within 1/8

and

is

entirely

FRON

T

needle

NEEDL

guard

contacts the

(C),

side

not

pick

be

looper

forward

moving

of

the

at

set

yet

at

or

not

needle

retigh

ten

needle

as

is

tens

ion

to

function

screw

guar

necess

properly

release

inch

released

E GUARD

(F,

needle

(B)

to

needle. The

the

needle. The

as

low

as

contact

any

time.

rearward,

guard

holder

s (G).

d,

loosen

ary

and

set.

RELEASE

is

set

as

the

presser

of

the

when

Fig

.

11)

until

the

left,

looper

possible

the

To

loosen

(H)

To

raise,

screws

retighten

correct-

end

the

presser

so

the

is

front

to

rear

move

as

foot

or

its

10

Page 7

If

adjustment

at

the

back

of the

screw. After

THREAD

is

needed, loosen

machine

adjustment

SE

TT

ING HEIGHT

and

there

TENSION

tension

move

should

OF

tension

be no

PRESSER

RELEASE

release

disc

bindi

separator

ng

BAH

(Co

ntinue

d)

levers crew

as

at

any

poin

(A,

Fig

. 12

),

located

required. Retighten

t.

•

The

it

is

possible

(B,

Fig

mately

t

he

lifter

feed

foot

bar

resting

throat

If

ion unt

Fig

.

3),

su

rfa

ce, pry up

driver

heig

ht

to

. 12)

1/16

(F)

plate

is

inch clearan

link

(D, Fig

when

on

the

.

adjustment

il

the

needle

then

, while hold

pre

to

obtain

of

the

presser

rem

fully

ove

depressed

.

the

foot lifter

throat plate,

is nec

sse

the

bar

r b

1/ 16

essary,

is

ba

the

presser foot

.

ce

be

tween

3)

and the

lever

with

turnha

in

the

ing

presser

ar

connection

inch

setting

r (C, F

Also,

the

stud

is

the feed

ndwheel

low p

osition. Loosen

fo

and

ig.

3)

is

set

when

there

the

foot lif

should

bottom end of the

(E)

locat

ed

in the

released and

dog down below t

in

opera

ot

down

and

guide (H)

ret

into the

piece

(Fig

machines

on

the

with a screw

ighten

Draw

screws

the

machine

of

fabric. Refer

. 1) for m

.

correctly

ter

lever

be

app

roxi

slot

upper

the

presser

ting

throat

scre

direct

ws

pla

.

THR

EADING

looper

and sta

anner

if

-

of

he

-

(G.

te

Fig

and

needle threads

r t operating on

to threading

of

threading

.

12

diagram

th

ese

a

•

I

Set

to

the

need

le

The

tha

t the l

comes

q

uired

finge

r h

the

needle

machine

thread

looper

ooper

up

out of

byl

oos

as

been

Fig

.

13

thread

base and

is desired

SETTING

thread

thread

the

mater

ening

screws (Band

pro

perly

frame

midway

in

the

eyelet

in

stitch

LOOPER

retainer

is

cast-off

ial.

finger

Co-ordinated

set, retighten

(A, F

even

bar thre

is

setting

or rai

(C,

its

mo

unting slot.

or

r a

THR EAD

(A,

Fig

just

C).

after

After

screws.

SETTING

WIRE Al:II

Set

ig.

with t

at

the bottom

se

Fig

. 13)

ise

for

NEEDLE

TI

the

ad

13)

he

eyelet

needle

so

that its

top

of its str

for

it

a

for

small

a l

perpendicular

Lower

les

s .

if

FRA

of

arger loop.

TAKE-UP

. 14) sho

the eye of

positioning

uld

the

can

be

needle

be

looperthreadretainer

THREAD

ME

EYELET

thread take-up

upper sur

the hole

(B)

when

in

the

oke.

er

nee

dle

more

set

so

ac-

TAKE-UP

wire

face

the

needle

needle

Lo

wer

thre

bar

thi

ad loop

is

s

<

Hegulate

that

w

ing

reverse

it

exerts

ork

unif

ormly

it clockwise increases

.

the

only enough

PRESSER

presser

when a slight

FOOT

spring

regula

pressure

tension

the

pressure,

PRESSURE

ting

on the

is

placed

co

11

screw

presser

on

(D,

Fig

foot to feed

the fabr

unterclockwise

. 13)

ic. Tur

acts

so

the

n-

the

Fig

.

14

Page 8

12

Page 9

The

that

parts

are

illustrated

used

on

Style

on

the

53700

preceding

C,

but

not

page

used

and

described

on

Style

be

53700

low

B.

represent

the

parts

•

Those

to

Use

this

Reference

indented

assembly.

Ref.

No.

1 77

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19 51

20

21

22

23

24

25

26

27 51281

28

29

30

parts

Styles

Catalog

catalog.

53754

53754

55235

55235

41336

53720

53726

53753

53726

53705

53724

53770

22799

512

51236

5372 2 A

29476

22559

51 325

51242

21 657 E

22517 B

53701 A

53700

nu

descriptions,

Part

No.

6042

78

376

21-335

236

36

24

shown

No. 100 L

mbers

K

in

Band

phantom

that

J

D

A

E

c

B

E

J

D

B

A

B

E

F

G

•

DD

E

L

U-207

s

views

C.

(Style

are

indicate

Screw,

Upper

Upper

Link

PresserFoot

Top

Lower

Screw,

Throat

Feed

Feed

Main

Crank

Looper

Washer, for

Cloth

Washer

Edge

Screw, for

Cloth

537 00 B)

inside

they

for

Running

Running

L<>cking

Locking

Locking

Pin

-----

Scr~v

Feed

Top

Top

Chain

Spr

Scr~v-

Crank

Ferru

Crank

Shaft

Screw

Plate

Guide--

Plate

-----------

Dog

Feed

Feed

Feed

for

Plate-

Cutting

u1g -

l e

---------

Shaft

--- ---

Needle

--

---------

and

a

link

Stud----Stud

Stud

----

Dog

feed

---------

------

-----------

Link

----

Stud

Assembly

No. 53754 F

Cover

-----------

edge

(not

bearing

for

all

bracket

are

pin

Feed Lift

Feed

-----------

Assembly

Dog

Dog,

Guard-------

shown

component

Description

No.

Lift

--------

Washer

Nut -

------

, 14

dog ----

Knife,

Assembly

------

----------

--------

--------------

guide

------

------

Shank

marked "FH

teeth

---------

------, .

-----------

-------on

no

parts

or

41336 C ---

Driving

Driving

----

----------

---

--

---------

-----marked

------

-----------

990

---

---

-----

picture

reference

not

illustrated

box

------

-------

per

----

on

the

parts

------

Link-------

Lever

-------

----------

---------

----------

------

---------

--

----

inch-

-----------

-------

----------

-----

--------inch

---------

--

-----

------

-------- --------

"--

-----

---------

-------

"L"

-----

-----

----------throw

--------

- -

--------

-----

- -

----

------plate)

numbers

picture

of

a

complete

----------

-----

----------

------

------

-----

------

----------

- -·

----------

----------

-----

-----

-----------

-----------

------

---------

-----

----------

------

---

------

--

-------

-----

-------------

------

--------

--

------

-------

are

common

or

described

plate

---------

----------

---------

------

---------

------

--------

------

----------

----------

--------

--

--------

------

and

-----

-------

----

-- --

-------

----

------

------

------

-------

----

-----

------

part

Amt

--

- -- 1

---

---

- 1

---

--

- - - 1

---

in

have

or

.

Req.

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

2

1

1

1

•

•

'

'

13

Loading...

Loading...