Page 1

STYLES

53100A

53100B

53100C

53100D

53100E

ADJUSTING INSTRUCTIONS AND

ILLUSTRATED PARTS LIST

CLASS 53100

STREAMLINED HIGH SPEED ZIG-ZAG

MACHINES

CATALOG NO.

112R-GR

FIRST EDITION

06/10/08

Page 2

MANUAL NO. 112R-GR ADJUSTING INSTRUCTIONS AND LLUSTRATED PARTS LIST FOR 53100 SERIES MACHINES

First Edition Copyright 2007

BY

Union Special Corporation Rights Reserved In All Countries

Printed in U.S.A. Jan 2007

FOREWORD

The 5000 series streamlined zig - zag machines covered by this catalog represent the latest design of the UNION SPECIAL

flat bed line. Class 53100 machines offer many advantages on various operations on a variety of garments such as

nightgowns, slips, panties, foundations, children's knit undergarmrnts, men's trousers, women's dresses, blouses, bed jakets

and pajamas.

Light weight presser bar and needle bar driving mechanism make it possible to attain the utmost in speed and production.

The new light weight parts and needle bearings make them lighter running and smoother operating. The light weight presser

bar mechanism reduces pressure required to lift the presser foot.

Automatic lubrication and a new filter type oil return pump, used in conjunction with isolated mounting oil pan base plate,

for returning filtered oil to the main reservoir, has made maintenance simple.

It is our constant aim to furnish carefully prepared information which will enable our customers to secure all possible

advantages from the use of UNION SPECIAL machines. The following pages illustrate and describe the parts used in all of

the machines covered in this catalog.

Union Special representatives will be found in all manufacturing centers, ready to cooperate with you to plan and estimate

requirements.

CONTENTS

IDENTIFICATION OF MACHINE .................................................................................................................................................................3

APPLICATION OF CATALOG ...................................................................................................................................................................3

STYLES OF MACHINE ................................................................................................................................................................................3

NEEDLES .................................................................................................................................................................................................... 4

ORDERING REPAIR PARTS ........................................................................................................................................................................4

ORDERING REPAIR PARTS (CONTINUED) ................................................................................................................................................ 5

IDENTIFYING PARTS ................................................................................................................................................................................... 5

USE GENUINE NEEDLES AND REPAIR PARTS ........................................................................................................................................... 5

TERMS ........................................................................................................................................................................................................ 5

OILING AND THREADING ......................................................................................................................................................................... 5

0ILING AND THREADING DIAGRAM ....................................................................................................................................................... 6

SELF-PRIMING HEAD OIL SIPHON ............................................................................................................................................................ 7

INSTALLING AND MAINTENANCE OF OIL SIPHON ................................................................................................................................. 7

INSTRUCTIONS FOR MECHANICS ............................................................................................................................................................ 8

NEEDLE LEVER STUD SETTING ...................................................................................................................................................................8

OILING SYSTEM ......................................................................................................................................................................................... 8

SETTING THE ZIG-ZAG MOTION ............................................................................................................................................................... 8

SPACING NEEDLE IN THROAT PLATE .......................................................................................................................................................8

SETTING THE LOOPER ...............................................................................................................................................................................8

SETTING THE LOOPER (CONTINUED) .......................................................................................................................................................9

SETTING HEIGHT OF NEEDLE BAR ............................................................................................................................................................. 9

SYNCHRONIZING LOOPER AND ............................................................................................................................................................. 9

NEEDLE MOTIONS ..................................................................................................................................................................................... 9

SYNCHRONIZING LOOPER AND ........................................................................................................................................................... 10

NEEDLE MOTIONS (CONTINUED) ..........................................................................................................................................................10

SETTING THE FEED DOG ......................................................................................................................................................................... 10

SETTING THE FEED DOG (CONTINUED) .................................................................................................................................................11

CHANGING STITCH LENGTH .................................................................................................................................................................. 11

SETTING THE NEEDLE GUARD ................................................................................................................................................................. 11

SYNCHRONIZATION OF THE UPPER ROLLER FEED ................................................................................................................................ 12

THREADING .............................................................................................................................................................................................12

SETTING THE LOOPER THREAD TAKE-UP ................................................................................................................................................13

THREAD TENSIONS .................................................................................................................................................................................. 13

PRESSER FOOT PRESSURE ....................................................................................................................................................................... 13

SETTING NEEDLE THREAD TAKE-UP ........................................................................................................................................................ 13

2

Page 3

SETTING SPRING RETAINERS ON LOOPER .............................................................................................................................................14

THREAD TENSION RELEASE .....................................................................................................................................................................14

SETTING THE ATTACHMENTS ................................................................................................................................................................... 14

MAIN FRAME, CAST-OFF PLATE, MISCELLANEOUS COVERS AND PLATES ......................................................................................... 17

CLOTH PLATES, CLOTH PLATE COVERS, MISCELLANEOUS AND ATTACHMENTS .............................................................................. 19

MAIN FRAME, BUSHINGS AND MISCELLANEOUS OILING PARTS ........................................................................................................ 21

FOR STYLES 53100B AND C ONLY CLUTCH ASSEMBLY, CLUTCH DRIVE SHAFT GEAR AND HOUSING ASSEMBLY .......................... 23

FOR STYLES 53100B AND C ONLY CLUTCH ASSEMBLY, CLUTCH DRIVE SHAFT GEAR AND HOUSING ASSEMBLY .......................... 25

CRANKSHAFT, NEEDLE LEVER AND LOOPER DRIVING PARTS ............................................................................................................ 27

CRANKSHAFT, NEEDLE LEVER AND LOOPER DRIVING PARTS ............................................................................................................ 29

LOOPER ROCKER AND CONNECTING ROD PARTS ............................................................................................................................ 31

MAIN SHAFT AND FEED MECHANISM ................................................................................................................................................... 33

FOR STYLE 53100E ONLY MAIN SHAFT AND FEED MECHANISM ......................................................................................................... 35

THREAD TENSION AND FOOT LIFTER LEVER PARTS ............................................................................................................................... 37

FEED DOGS, THROAT PLATES AND PRESSER FEET ................................................................................................................................ 39

THREAD STAND, KNEE PRESS AND TAPE REEL PARTS ........................................................................................................................... 41

IDENTIFICATION OF MACHINE

Each UNION SPECIAL machine is identified by a Style number which is stamped into the name plate on

the machine. Style numbers are classified as standard and special. Standard Style numbers have one or

more letters suffixed, but never contain the letter “Z”. Example: “Style 53100 A”. Special Style numbers

contain the letter “Z”. When only minor changes are made in a standard machine, a “Z” is suffixed to the

standard Style number. Example: “Style 53100 AZ”.

Styles of machines similar in construction are grouped under a class number which differs from the style

number, in that it contains no letters. Example: “53100”.

APPLICATION OF CATALOG

This catalog applies specifically to the standard Styles of machines as listed herein. It can also be

applied with discretion to some Special Styles of machines in this class. Reference to direction, such

as right, left, front, back, etc., are given from the operator’s position while seated at the machine.

Operating direction of handwheel is toward the operator.

STYLES OF MACHINE

High Speed Streamlined Flat Bed, Single Needle, Medium Throw, Zig-Zag Machine. Lightweight

Presser Bar and Needle Bar Driving Mechanism, Single Reservoir EnclosedAutomatic Lubricating

System, Filter Type Oil Return Pump and Oil Siphon Assembly. Lateral Looper Travel, WorkSpace to

Right of Needle Bar 7 3/4 Inches.

53100A For attaching and mitering lace to nightgowns, slips, and panties made from light to medium

weight knit and woven fabrics of cotton, rayon, nylon, dacron and similar materials; also for

hemming panels on two-way stretch foundations. Can be used for purl edge stitching on

children’s knit undergarments. Knee press for raising presser foot. Seam specification 404LSa-1.

53100B Power driven upper roller feed. For attaching pre-made waistband linings to tops or to

waistband of men’s trousers, giving hand felled effect. Folder No. 23450L prepared to take

waistbands ranging from 1 1/4 to 4 inches wide, in long lengths, entering from the right, and

produces headings of from 1/8 to 3/4 inches. Seam specification 404-LSb-1.

53100C Same as 53100B, except without folder.

53100D Same as 53100 A. except fitted with open toe “V” type presser foot and swing-up edge

guide attached to the lower presser bar bushing, to be used for abutted edge seaming on

slips and gowns. Seam specification 404-FSa-1.

53100E Differential feed machine. For attaching lace to neck, armholes and bottom of nightgowns,

slips, panties, gathering either the garment, lace or both together. Attaching tiers of lace to

slips, dresses and nightgowns. Setting puff sleeves in blouses, bed jackets and pajamas.

For operations on light to medium weight knit and woven fabrics of cotton, rayon, nylon,

dacron and similar materials where a large percent of the work calls for intermittently or

continuously gathered seams. Knee press for raising presser foot. Seam specification 404LSa-1, FSA-I or SSa-1.

3

Page 4

NEEDLES

Each UNION SPECIAL needle has both a type number and a size number. The type number denotes the

kind of shank, point, length, groove, finish and other details. The size number, stamped on the needle

shank, denotes the largest diameter of blade measured in thousandths of an inch midway between the

shank and the eye. Collectively, type number and the size number is the complete symbol.

Standard needle for Styles 53100 A, D and E is Type 163 GAS and the standard needle for Styles 53100

B and C is Type 110 GAS.

Type No. Description and Sizes

110 GAS Round shank, round point, extra short double groove, struck groove, ball

eye long spot government, chromium plated - sizes 090/036, 100/040,

110/044: 125/049.

163 GAS Round shank, round point, Picoetta, single groove, struck groove, flat

blade, long spot, chromium plated - sizes 070/027, 075/029, 080/032,

090/036, 100/040, 110/044, 125/049.

To have needle orders promptly and accurately filled, an empty package,a sample needle, or the type and

size number should be forwarded. Use description on label. A complete order would read: "11000

Needles,Type 110 GAS, Size 110/044".

Selection of the proper needle size should be determined by the size of thread used. Thread should pass

freely through needle eye in order to produce a good stitch formation.

ORDERING REPAIR PARTS

ILLUSTRATIONS

This catalog has been arranged to simplify ordering repair parts. Exploded views of various sections of the

mechanism are shown so that the parts may be seen in their actual position in the machine. On the page

opposite the illustration will be found a listing of the parts with their part numbers, descriptions and the

number of pieces required in the partcular view being shown.

Numbers in the first column are reference numbers only and merely indicate the position. of that part in the

illustration. Reference numbers should never be used in ordering parts. Always use the part number listed

in the second column.

Component parts of sub-assemblies which can be furnished for repairs are indicated by indenting their

descriptions under the description of the main subassembly. Example:

9. 29476LE Looper Driving Lever Crank Assembly ............................................... 1

10. 22559A Screw, lower ......................................................................... 2

11. 51243C Ball Stud Guide ..................................................................... 1

12. 22729 Screw .................................................................................. 1

13. 22587 Screw, upper ......................................................................... 2

It will be noted in the above example that the eccentric and bearing are not listed. The reason is that

replacement of these parts individually is not recommended, so the complete sub-assembly should be

ordered.

In those cases where a part is common to all of the machines covered by this catalog, no specific usage

will be mentioned in the description, however, when the parts for thevarious machines are not the same,

the specific usage will be mentioned in the description, and if necessary, the difference will be shown in

the illustration.

4

Page 5

ORDERING REPAIR PARTS (CONTINUED)

At the back of the book will be found a numerical index of all the parts shown in this book. This will facilitate

locating the illustration and description when only the part number is known.

IDENTIFYING PARTS

Where the construction permits, each part is stamped with its part number. On some of the smaller

parts, and on those where the construction does not permit, an identification letter is stamped in to

distinguish the part from similar ones.

Part numbers represent the same part, regardless of catalog in which they appear.

IMPORTANT! ON ALL ORDERS, PLEASE INCLUDE PART NAME AND STYLE OF MACHINE FOR

WHICH PART IS ORDERED.

USE GENUINE NEEDLES AND REPAIR PARTS

Success in the operation of these machines can be secured only with genuine UNION SPECIAL

Needles and Repair Parts as furnished by the Union Special Corporation, its subsidiaries and

authorized distributors. They are designed according to the most approved scientific principles, and are

made with the utmost precision. Maximum efficiency and durability are assured.

Genuine needles are packaged with labels marked Union Special Genuine repair parts are stamped

with the Union Special trademark, U S Emblem. Each trademark is your guarantee of the highest

quality in materials and workmanship.

TERMS

Prices are strictly net cash and are subject to change without notice. All shipments are forwarded f.o.b.

shipping point. Parcel Post shipments are insured unless otherwise directed. A charge is made to

cover the postage and insurance.

OILING AND THREADING

The oil has been drained from the machine before shipping, and the reservoir must be filled before

beginning to operate. Use a straight mineral oil with a Saybolt viscosity of 90 to 125 seconds at 1000

Fahrenheit.

Oil is filled at the spring cap in the top cover, and the oil level is checked at the sight gauge on the

front of the machine. The oil level should be maintained between the red lines on the gauge. The

capacity of the oil reservoir is 12 ounces.

The machine is automatically lubricated, and no oiling, other than keeping the main reservoir filled is

necessary.

A daily check before the morning start should be made and oil added if required. Oil which has gone

through the machine is filtered and pumped back into the main reservoir, making too frequent oilings

unnecessary. Excessive oil in the main reservoir may be drained at the plug screw in the main frame

directly under the handwheel.

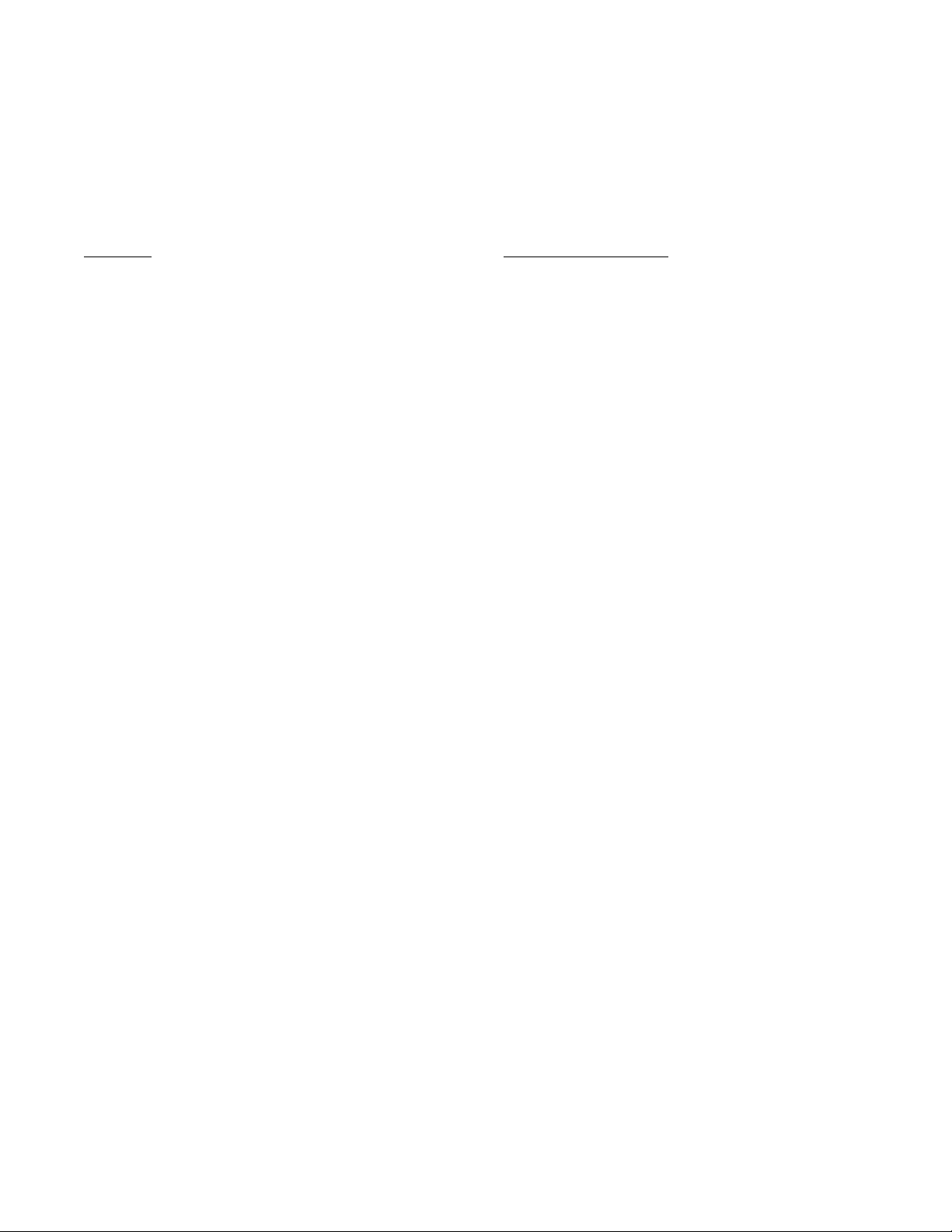

On the next page is a picture showing the manner in which the 5310O Styles covered in this catalog

are threaded. The looper threading has been enlarged for clarity.

5

Page 6

0ILING AND THREADING DIAGRAM

STYLE 53100 C

Oil has been drained from the machine before shipping, and the reservoir must be filled before beginning

to operate. Oil is filled at spring cap (A). Oil level is checked at sight gauge (B). Use a straight mineral

oil with a Saybolt viscosity of 90 to 125 seconds at 10 Fahrenheit. Excessive oil in the main reservoir may

be drained at plug screw (C).

Thread machine as indicated, thread 1 is the needle thread, and thread 2 is the looperthread. The looper

threading at the cast-off plate and looper has been enlarged for clarity.

6

Page 7

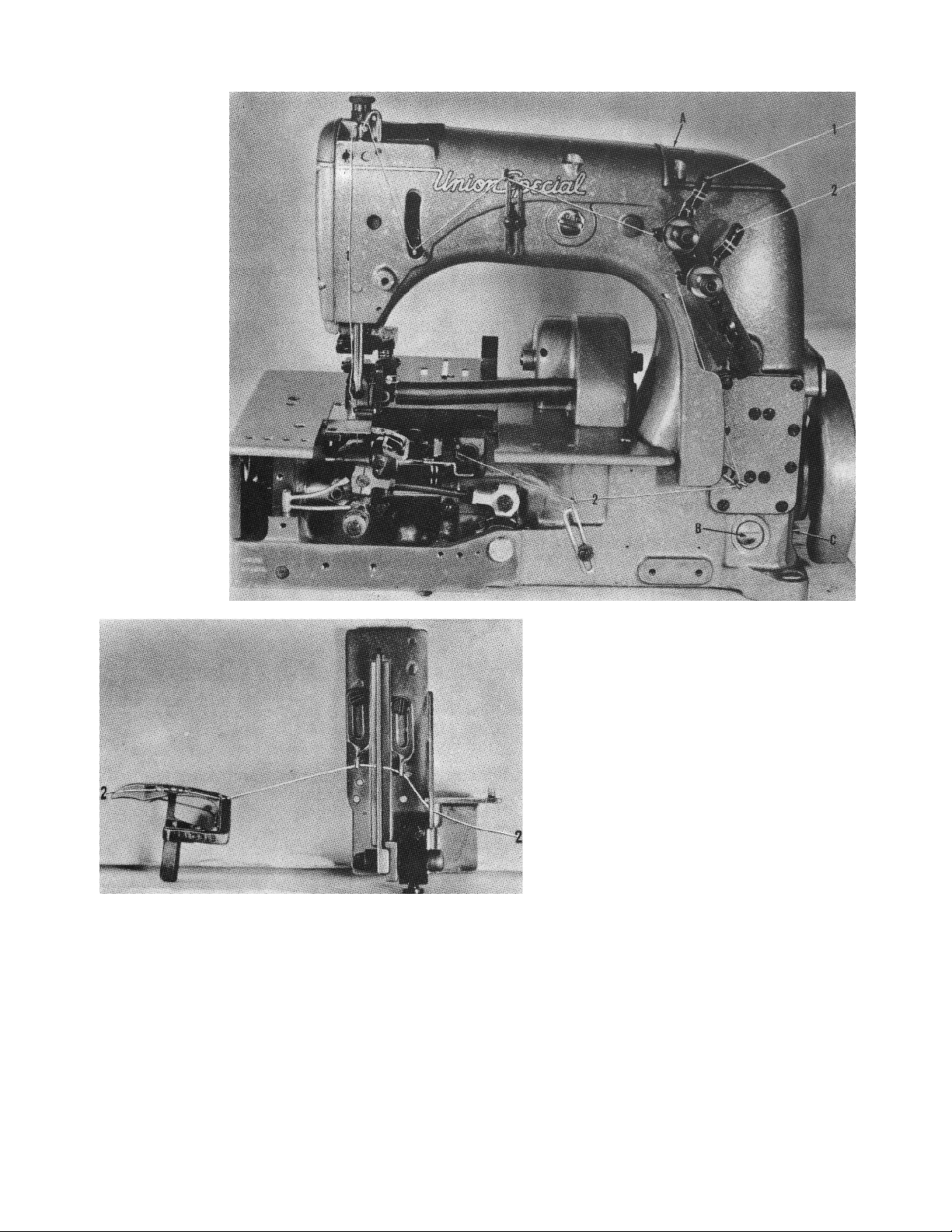

SELF-PRIMING HEAD OIL SIPHON

Class 53100 machines are equipped with a self-priming head oil siphon. When the machine is started, oil

splashes on the priming cupfelts, filters through the felts, and trickles down the vertical oil tube, thus,

priming the siphon. Once the prime is established, it is maintained, unless the felts are removed. The

siphon operates twenty-four hours a day, removing oil at the rate of six to twelve drops per minute, which

of course, far exceeds the rate at which oil collects in the head.

INSTALLING AND MAINTENANCE OF OIL SIPHON

A newly installed siphon starts its action within three to five minutes after the machine is operating.

However, it maybe twenty minutes or so before all the air is removed from the line and the siphon is in full

operation. In Class 53100 machines without a head sump, the head will be free of excess oil by that time.

The felts in the priming cup are designed for a specific purpose. The bottom felt, 666-209, is thin and

relatively dense, to meter the flow of priming oil and to prevent the entrance of air. The softer top felt, 666201, is a filter to prevent the clogging of the metering felt. This felt, at the intake of the siphon, keeps the

siphon clear of lint, and prevents the entrance of air at that point. For the best initial self -priming condition,

the felts of the siphon should be dry. In this condition, it is difficult for air to be trapped between the felts

or in the top soft felt itself.

However, if for some reason the priming cup felts had been oiled before installing, the siphon may fail

because air is trapped between the felts or in the soft top felt. As a precaution, remove the soft felt from

the cup. Then, while squeezing the felt between the fingers, saturate it well with oil. In other words, squeeze

out the air and replace it with oil. Then, completely fill the cup with oil and push or twist the soft felt down

into cup so that it definitely contacts the harder thin felt. This precaution prevents the trapping of air, and

no trouble should be experienced when starting the siphon.

If you want to be doubly sure that the siphon is functioning correctly, on a machine in operation, apply a

certain amount of oil in the sump around the felt in the head. Before doing this, be certain that this felt

has been saturated in the same manner as explained for the soft felt in the top of the siphon cup.

When this is done., the siphoning action will begin, and the oil will be removed as explained.

7

Page 8

INSTRUCTIONS FOR MECHANICS

NEEDLE LEVER STUD SETTING

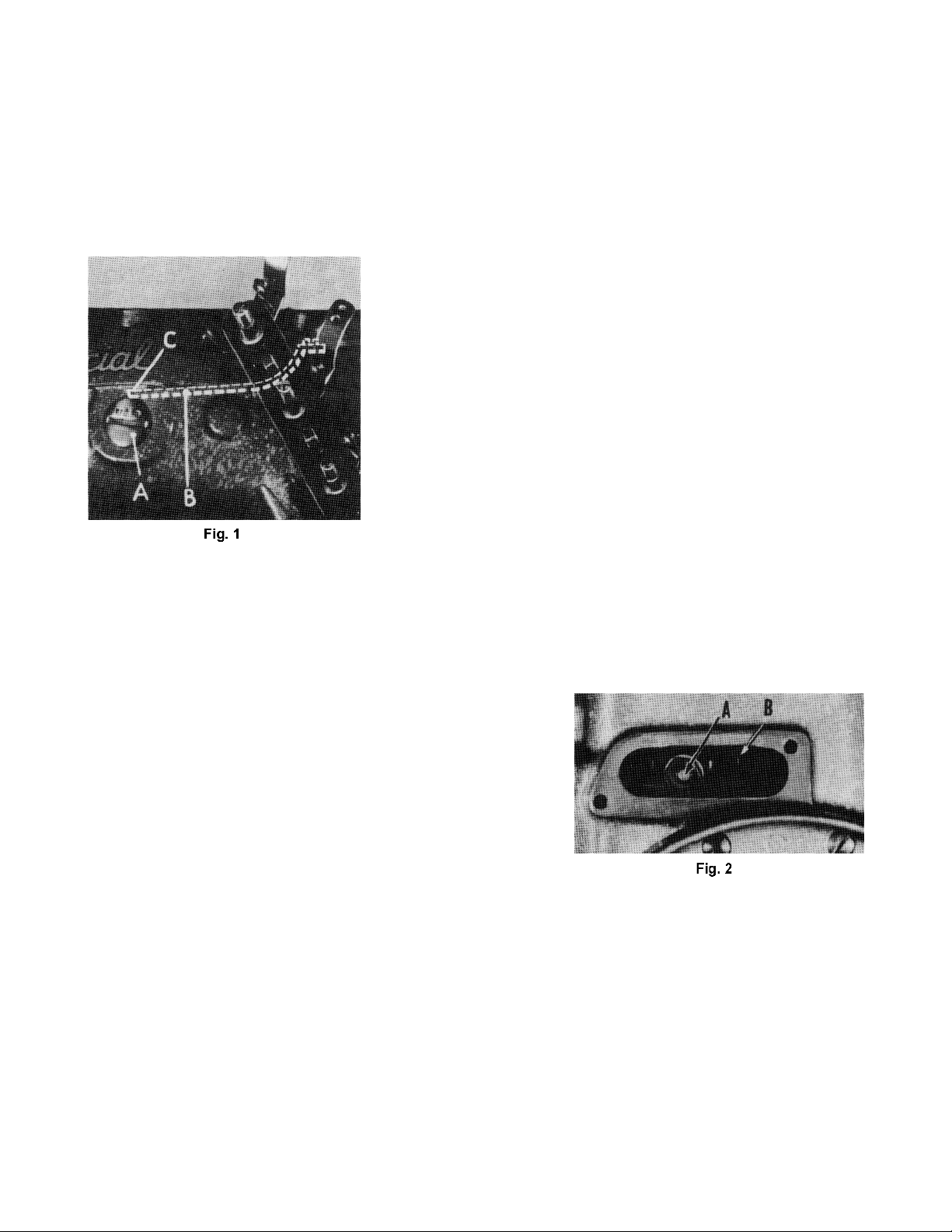

Observe the location of the needle lever stud (A, Fig. 1). The head of the needle lever stud is marked with

an arrow and the word “UP”. These studs are set correctly when the arrow points vertically up. Also check

the position of the needle lever bearing oiler (B) inside the arm casting, which lubricates the needle lever,

stud. Make sure it is tilted downwardly and that its delivery end (C) contacts the inside wall of the bed

casting at the back, just above the notch of the needle lever shaft stop collar. Do not allow the oil tube to

rest on the needle lever.

OILING SYSTEM

Clean machine thoroughly. Fill oiling system to the first red line of

oil gauge on the front of the machine, and oil all bearings. Run

machine slowly for a minute to allow oil wicks to carry oil to the

bearings. Then, recheck oil in oiling system and run machine for

five minutes. Run Styles 53100A, D, and E at 4500 R. P.M. and

Styles 53100B and C at 4000 R.P.M. Inspect siphon and head felt

for proper function, and all plug screws for leakage.

SETTING THE ZIG-ZAG MOTION

Set the zig-zag motion to the maximum travel that the needle hole

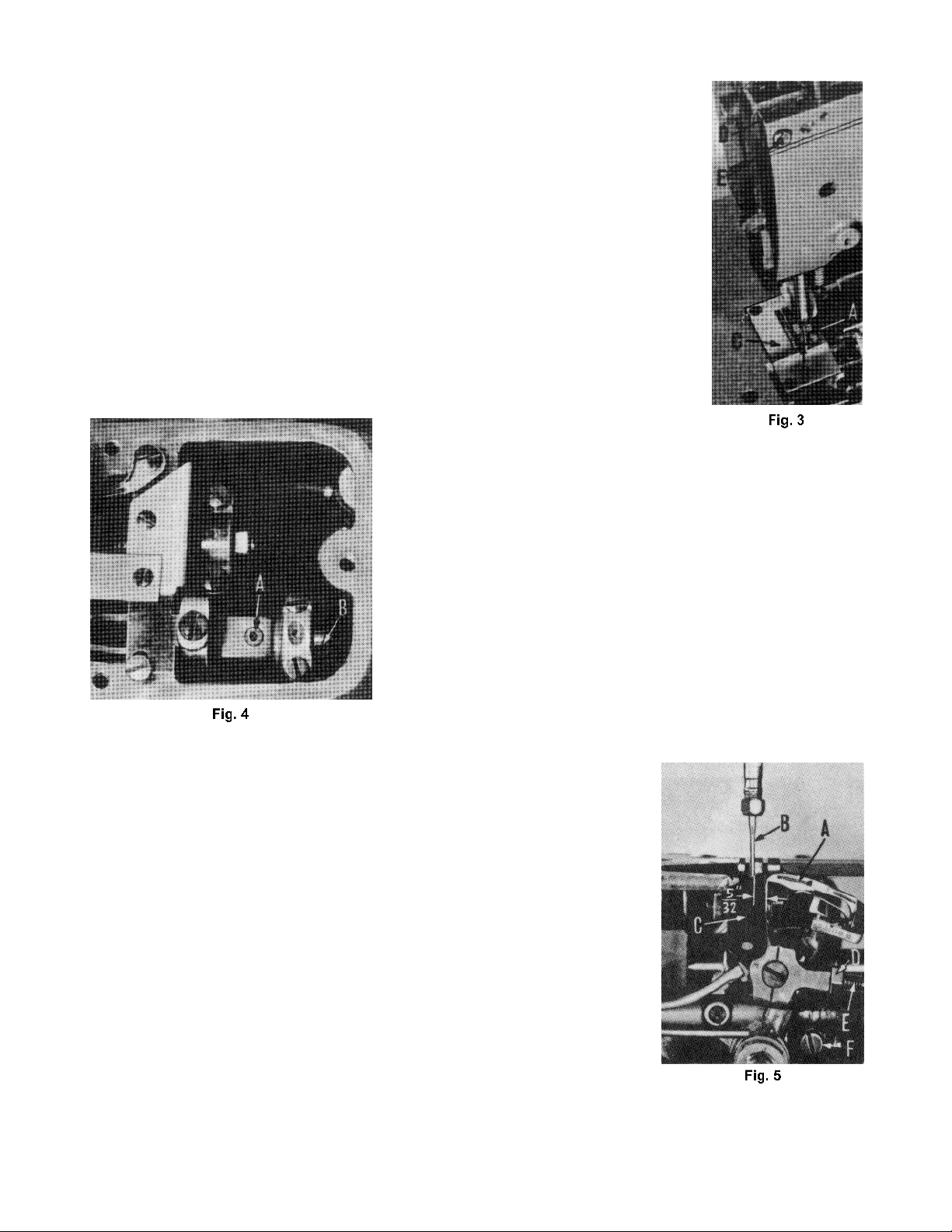

in the throat plate will permit.This can be accomplished by moving

the ball joint (A, Fig. 2) in the segment lever (B) located under the

cover directly above the handwheel on the right side of machine.

Moving it away from the operator increases the zig-zag motion

and toward the operator acts the reverse.

The cam gear pinion, located on the crank shaft adjacent to the handwheel housing, should be set so that

the lateral zig-zag motion of the needle bar occurs when the needle is completely out of the work. This is

accomplished by loosening the set screws in the pinion; then, while holding the gear train in a fixed position,

turning the handwheel either forward or backward until the desired timing is obtained.

SPACING NEEDLE IN THROAT PLATE

Equalize the clearance between the needle (A, Fig. 3) and the

right and left sides of the needle hole (B) in throat plate (C). This

is accomplished by loosening set screw (D) and turning the

eccentric stud (E) clockwise or counterclockwise until the

described clearance has been obtained. Retighten set screw.

If additional adjustment is required, it can be obtained by

loosening set screw (A, Fig. 4) and turning the eccentric ball

joint stud (B), located at the right end of the needle bar frame

under the top cover, either clockwise or counterclockwise.

SETTING THE LOOPER

Insert a new needle, size as specified, Type 163GA for Styles 53100A, D, E and Type 110 GA for

Styles 53100B and C.

8

Page 9

SETTING THE LOOPER (CONTINUED)

With the zig-zag motion at the end of its stroke to the right, set the looper (A, Fig.

5) so the distance from the center of the needle (B) to the point of the looper is 5/

32 inch, when the looper is at its farthest position to the right. Looper gauge No.

21225-5/32 (C) can be used advantageously in making this adjustment. If

adjustment is needed, loosen nut (D) (it has a left hand thread) and also loosen

nut on right end of connecting rod (E), turn connecting rod forward or backward

to obtain 5/32 inch and retighten both nuts.

The looper is set correctly in line with the feed when there is .003 inch space

between its point (A, Fig. 6) and the rear of the needle (B) as the former is

ascending on the right side. If adjustment is needed, loosen screw (F, Fig. 5) and

move looper toward or away from needle as required and retighten screw when

.003 inch space is obtained.

SETTING HEIGHT OF NEEDLE BAR

The height of the needle (A, Fig. 7) is correct when the top of its

eye is 1/64 inch below the underside, of the looper, with the

looper point flush with the left side of the needle and the needle

is ascending on the left side. If adjustment is necessary, loosen

screws (B) and move needle bar (C) up or down as required and

retighten screws.

SYNCHRONIZING LOOPER AND

NEEDLE MOTIONS

Turn the handwheel in the operating direction until the looper

point (A, Fig. 8) moves to the left and is even with the left side

of the needle (B). Note the height of the eye of the needle with

respect to the looper point, then, turn the handwheel in the

reverse direction until the looper point again moves to the left, and is even

with the left side of the needle. If the motions synchronize, the height of the

eye of the needle with respect to the looper point will be the same. A

variation of .005 inch is allowable. If the distance from the eye of the needle

to the point of the looper is longest when the pulley is turned in the operating

direction, move the looper drive lever shaft synchronizing stud (C) to the

rear. Moving it in the opposite direction acts the reverse.

Moving of the looper drive lever shaft synchronizing stud is accomplished

as follows: Loosen clamp screw (D) of looper drive lever.

To move stud to rear (away from operator), a light tap with a small hammer,

directly on the stud, is all that is required.

9

Page 10

SYNCHRONIZING LOOPER AND

NEEDLE MOTIONS (CONTINUED)

To move stud forward (toward operator), remove the cloth

plate, oil reservoir top cover, oil reservoir back cover, and on

Styles 53100B and C, remove the clutch drive housing; then,

a light tap on the looper drive lever rocker shaft, toward the

operator, is all that is required.

Then, using the looper drive lever to take up the end play

between the looper drive lever rocker shaft and its

synchronizing stud, tighten the looper drive lever on the shaft

using screw (D, Fig. 8).

Reset the zig-zag motion to maximum that the needle hole in

throat plate will permit (allow . 0 10 to . 0 1 5 inch clearance

between the side of needle and needle hole).

SETTING THE FEED DOG

For Styles 53100 A, B, C and D, set the feed dog (A, Fig. 9) in the throat plate (B)

so there is equal clearance on all sides. See that the tips of the teeth are parallel

with and 3/64 inch above the throat plate at high point of travel. Adjust the

supporting screw (C), under the feed dog, to maintain this setting. Screw (D) is

used to hold feed dog in position.

If feed dog teeth are not parallel with the throat plate, loosen nut (A. Fig. 10) and

turn screw (B) clockwise to lower the front teeth, and counterclockwise to raise the

front teeth. Retighten nut when feed dog is set properly.

Should it be necessary to move the feed dog to the left or right, loosen screws (A,

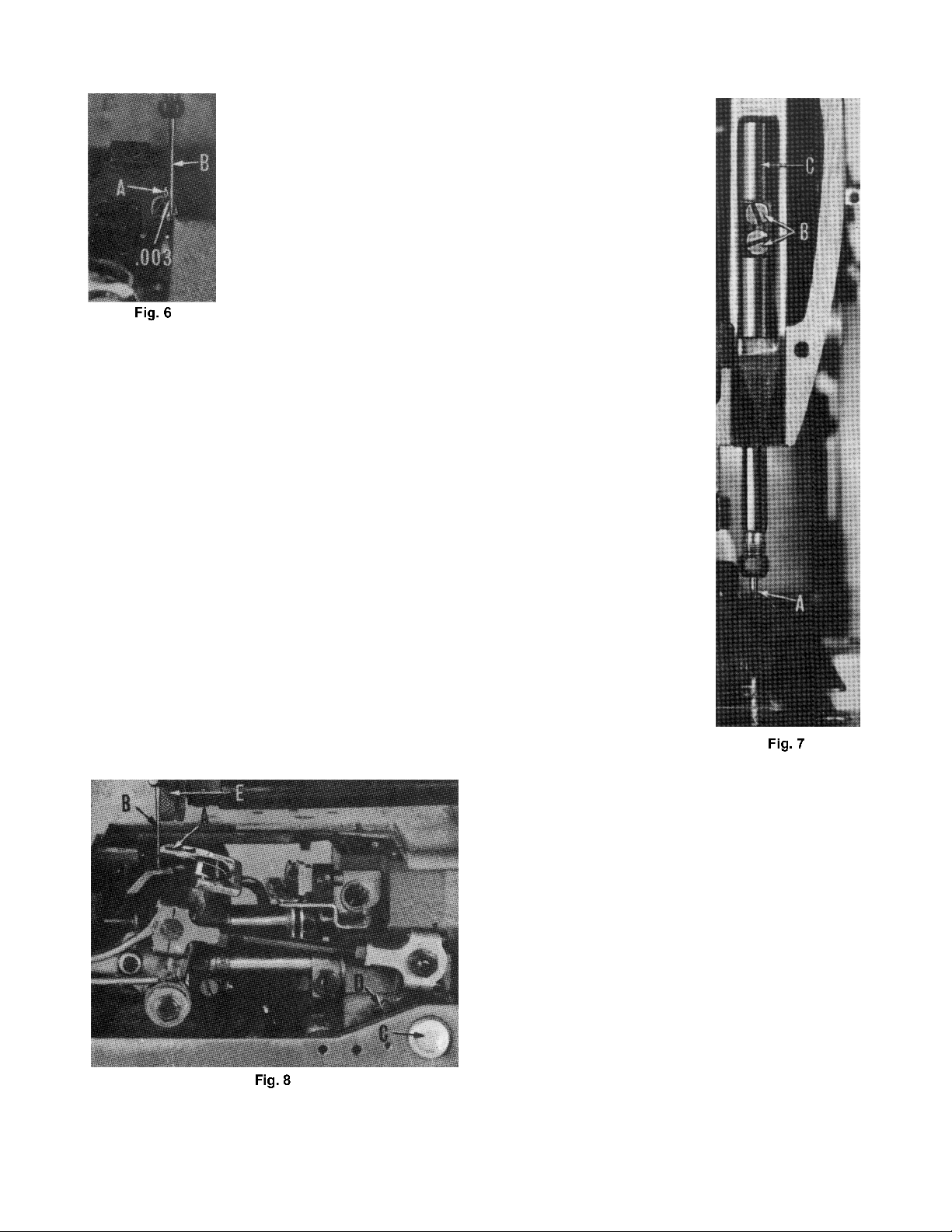

Fig. 1 1) which hold the feed rocker (B) onto the feed rocker shaft (C), and move

feed rocker to desired position and retighten screws. Make sure that the feed

rocker arm (D) does not bind after making this adjustment.

Should it be necessary to move the feed dog forward or backward, loosen screws

(E) which clamp the feed rocker arm to the feed rocker and move the feed rocker

forward or backward as needed, and retighten screws.

For Style 53100E, set the main feed dog so that it is

level with the throat plate, and that at its high position,

it extends the depth of a tooth above the throat plate.

Maintain this adjustment by means of the stop screw

under the feed dog holder.

Space the feed dog laterally, so that there is equal

clearance between the feed prongs and the throat

plate slots. Loosen feed dog holding screws and move

feed dog from side to side for this adjustment. If more

adjustment is needed, the feed dog may be moved

laterally the same as described in paragraph 3.

10

Page 11

SETTING THE FEED DOG (CONTINUED)

With an average stitch length setting, equalize the travel of the feed dog so that, at both ends of its travel,

it is equidistant from the ends of the throat plate slot. Make this adjustment the same as described in

paragraph 4.

Set the height of the differential feed dog to correspond with that of the main feed dog by moving it up or

down in its holder.

Turn handwheel in operating direction until the feed dog is

at its farthest point of travel to the rear, and set the

differential feed so that there is I/ 64 inch clearance

between the center row of teeth and the end of the throat

plate slot. This is done by loosening the two headless

screws which clamp the shank of the differential feed bar.

The throat plate support will have to be removed for

access. Also level the feed during this adjustment.

Set the front stop for the intermittent differential feed lever as far forward in its slot as it will go. Turn the

handwheel in operating direction until the feed dogs are descending. When the tips of their teeth are flush

with the top of the throat plate, manipulate the differential feed control lever up and down. At this point, there

should be no more than 1/ 64 inch motion in the differential feed dog. If more motion exists, loosen the three

screws which hold the segment slot plate to the feed rocker, and manipulate the position of the slot plate

until excess motion of the differential feed dog is eliminated. An offset screw driver will be required for this

adjustment.

Continue to turn the handwheel in operating direction until the feed dog reaches its most forward point of

travel. Depress the differential feed control lever until the front of the differential feed dog just clears the

throat plate slot by I/ 64 inch and set the rear stop for the differential feed control lever against the lever

pointer at this position.

CHANGING STITCH LENGTH

Set the stitch to required length. This is accomplished by

loosening the lock nut (F, Fig. 11) (it has a left hand thread) on

the end of the stitch regulating stud and turning the stitch

adjusting screw (G) located under the left end of the cloth plate,

in the head of the main shaft (H). Turning screw in a clockwise

direction shortens the stitch, and turning screw in a

counterclockwise direction lengthens the stitch.

SETTING THE NEEDLE GUARD

Set the needle guard (C, Fig. 10) horizontally so that it barely

contacts the needle (D). It should be set as low as possible, yet

have its vertical face remain in contact with the needle until the

point of the looper (E), moving to the left, is even with the needle

and the latter is ascending on the left side. To move needle

guard forward or backward, merely loosen screw (F), move needle guard as required, and retighten

screw. To raise or lower needle guard, loosen screw (F), and turn screw (G) clockwise to lower needle

guard, and counterclockwise to raise needle guard. Retighten screw (F) after guard is set properly.

NOTE: Any change in stitch length will require a change in the needle guard setting.

11

Page 12

SYNCHRONIZATION OF THE UPPER ROLLER FEED

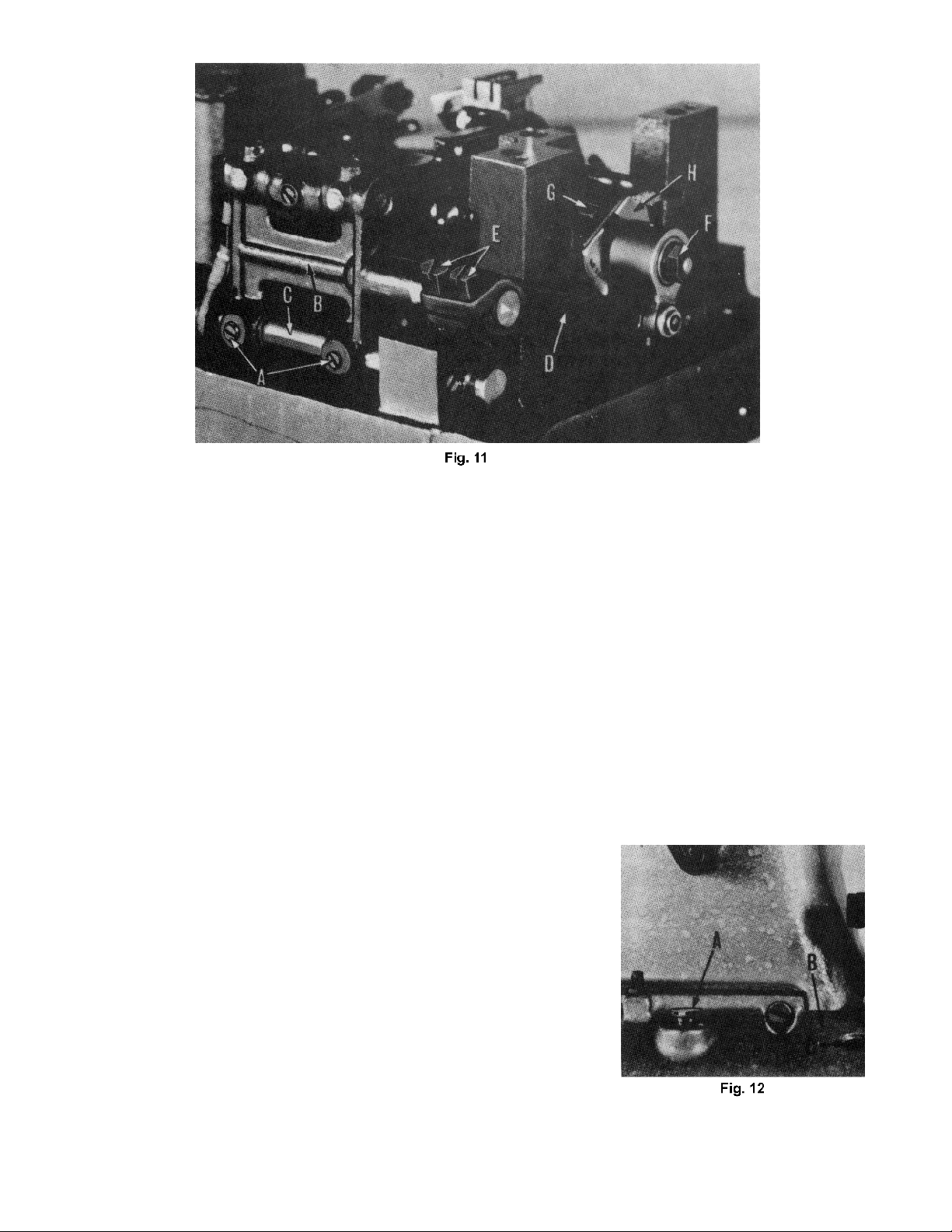

On Styles 53100B and C, synchronize the upper roller feed (E, Fig. 8) with the lower feed dog. This is

accomplished by removing the plug screw (A, Fig. 12) from the top of the housing (B) located at the

rear right side of the machine. Then, after noting the direction the shaft journaled in the housing

rotates, loosen the clamp screws in the gear hub, made accessible by removal of the plug screw.

Turning this back shaft in its operating direction causes the top roller feed to start turning sooner, and

turning the shaft backward causes the puller roll to start turning later.

The travel of the top roller feed is adjusted at the left end of this back shaft. Its adjustment is identical

to the stitch length adjustment mentioned in the adjusting instructionsunder ”CHANGING STITCH

LENGTH”. It has the same adjusting screw and left hand thread lock nut arrangement. When loosening

or tightening the lock nut, do not hold the handwheel to maintain shaft position, as the gear on the

crankshaft might shift, which would make it necessary to re-time the machine. Instead, insert a screw

driver through the access hole (C) in the top of the gear housing at the left end and engage the

adjusting screw. By holding the screw driver in this manner, the lock nut may be loosened or tightened

without disturbing the gear setting.

NOTE: The adjustment just mentioned and the regulation of the

pressure on the presser foot are very important to the

appearance of the finished seam.

THREADING

Draw looper and needle threads into the machine and start

operating on a piece of fabric. Refer to threading diagram on Page

8, for manner of threading these machines.

12

Page 13

SETTING THE LOOPER THREAD TAKE-UP

The cast-off plate (A, Fig. 13) should be set over the take-up so that there is equal clearance on each

side. The looper thread take-up (B) is not spotted on the main shaft, and consequently, can be set to

compensate for varying conditions. It is set correctly, when

the looper thread is just cast off the highest lobe of the

take-up when the point of the needle (C) is clearly visible

below the underside of the looper (D). The looper thread

eyelets (E), located on the cast-off plate, are adjustable,

and their setting determines the amount of thread pulled off

by the take-up. Moving the eyelets to the rear causes more

thread to be pulled from the cones, and moving them

forward causes less thread to be pulled off. Set the eyelets

so that, when the looper reaches its extreme position to the

left, all the slack has been removed from the looper thread,

but it has not become taut. The retaining finger (F) controls

the amount of slack thread in the system, and it is set

correctly when it prevents the looper thread triangle from

being wiped under the blade of the looper when the looper

moves from right to left.

THREAD TENSIONS

The tension on the needle thread should be only sufficient to produce uniform stitches on the under

surface of the fabric. The tension on the looper thread should be just sufficient to steady the thread.

PRESSER FOOT PRESSURE

Regulate the presser spring regulating screw (A, Fig. 14) so that it exerts only enough pressure on the

presser foot to feed the work uniformly. This is located directly behind the needle bar in the head of the

machine. Also, regulate the pressure on the upper roller feed, using only enough pressure to insure

the uniform feeding of the material being sewn.

SETTING NEEDLE THREAD TAKE-UP

Set the needle thread take-up (B, Fig. 14), located adjacent

to the needle bar thread eyelet (C), so that its upper surface

projects 3/32 inch above the line of thread when the needle

bar has completed its downward stroke. Set the needle

thread frame eyelet (D) so the smallest noticeable mount of

thread is drawn through the needle thread tension while the

needle is descending. (Setting this eyelet too high can cause

the needle thread around the looper to be pulled from under

the front retainer prematurely).

13

Page 14

SETTING SPRING RETAINERS ON LOOPER

The spring retainers (A, Fig. 15) on the looper (B) are set correctly when they exert only enough pressure

on the needle thread, around the looper, to retard this thread long enough for the descending needle to

reach a point where the thread released by these retainers cannot fly or be pulled to the left of the needle.

THREAD TENSION RELEASE

The thread tension release is set correctly when it begins to function as

the presser foot is raised to within I/ 8 inch of the end of its travel and

is entirely released when the presser foot reaches its highest position.

On Styles 53100B and C, adjust feed roller lifter connection so that,

when the presser foot and the feed roller are raised, the feed roller does

not contact the presser foot.

SETTING THE ATTACHMENTS

0n Styles 53100B and C, set the folder as close to the presser foot as

possible and still allow free passage of the body and waistband

material. Adjust it laterally so that there is 3/16 inch margin on the under

ply of the canvas to the left of needle. Set the upper folder so that the needle penetration is 1/32 inch from

the top edge of the canvas. Set the body guide so that there is a margin of 1/4 inch to the right of needle.

Adjust the canvas guide to conforrn to the width of the canvas. The folder is adjustable to take waistbands

from 1 3/4 to 4 inches wide. To adapt folder for the extreme narrow width, remove the right hand attaching

screw for the canvas guide and for the extreme wide width, remove the left attaching screw.

Styles 53100D and E are equipped with a swing-out edge guide for abutted edge seaming. The edge guide

should be set down snugly against the stitch tongue in the throat plate. There is an in and out adjustment

screw and lock nut for increasing or decreasing the space between the two abutted edges.

Style 53100E is equipped with an auxiliary pressure plate to produce gathering or ruffling. If set on the

right side of and against the swing-out edge guide, the right ply will be ruffled. If set on the left side of

and against the swing-out edge guide, the left ply will be ruffled. The pressure plate should be set so

that the distance from its edge to the front edge of the throat plate is 19/32 inch.

14

Page 15

EXPLODED VIEWS

AND

DESCRIPTION OF PARTS

FOR

CLASS 53100 ZIG - ZAG MACHINES

15

Page 16

16

Page 17

MAIN FRAME, CAST-OFF PLATE, MISCELLANEOUS COVERS AND PLATES

Ref.

No.

1.

1A.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

67.

Part No.

50-216BLK

21657E

22528

22768

87U

52904E

52804E

52904B

22516

52957C

52958D

73A

52904G

57WD

15438C

57WB

43296

605A

98A

20

539

53191

51758

93

53182E

21375BQ

22570A

93

22570A

53182F

53182G

53182A

53137C

22760B

53137D

376

22541B

53182

39582L

52882AC

50-789BLK

22564B

53182N

53182B

53182C

719

22565

53170

53182D

22565

51294R

35731A

51294P

22513

7947

53182K

53182J

53182L

22569B

22848

20

51282AH

53137A

22889A

539

20

22848

53182M

Description

Dowel Pin ......................................................................................................

Washer ..........................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Retaining Finger Support Bracket .................................................................

Retaining Finger Support ..............................................................................

Retaining Finger ............................................................................................

Screw ............................................................................................................

Cast-Off Support Plate ..................................................................................

Eyelet ............................................................................................................

Screw ............................................................................................................

Cast-Off Wire ................................................................................................

Nipper Spring Screw, for Styles 53100A, D, E ..................................................

Nipper Spring, for Styles 53100A, D, E .............................................................

Nipper Spring Plate, for Styles 53100A, D, E ....................................................

Thread Nipper Base, for Styles 53100A, D, E ...................................................

Screw, for Styles 53100A, D, E ........................................................................

Screw ............................................................................................................

Washer ..........................................................................................................

Frame Thread Eyelet .....................................................................................

Looper Thread Guard ...................................................................................

Looper Thread Lead-In Eyelet .......................................................................

Screw ............................................................................................................

Cam Gear Fork Frame Support Plate .............................................................

Belt Guard ....................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Cover Plate ...................................................................................................

Gasket ..........................................................................................................

Crank Chamber Cover Gasket .....................................................................

Needle Bar Frame Guide Plate, front ............................................................

Screw ............................................................................................................

Needle Bar Frame Guide Plate, rear .............................................................

Screw ............................................................................................................

Screw ............................................................................................................

Crank Chamber Cover .................................................................................

Oil Cap ...................................................................................................

Oil Cap Torsion Spring .............................................................................

Oil Cap Hinge Pin ....................................................................................

Screw ............................................................................................................

Oil Shield .......................................................................................................

Baffle Plate ...................................................................................................

Needle Lever Bearing Oiler ...........................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Take-Up Wire .................................................................................................

Needle Bar Frame Cover ..............................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Presser Bar Connection Guide Plate .............................................................

Oil Tube Clamp .............................................................................................

Screw ............................................................................................................

Nut ................................................................................................................

Gasket ..........................................................................................................

Head Cover ..................................................................................................

Felt Liner .................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Washer ..........................................................................................................

Oil Shield, end and back, for Styles 53100A, B, C, D .......................................

Needle Bar Frame Guide Pin .........................................................................

Plug Screw ....................................................................................................

Needle Thread Eyelet ...................................................................................

Washer ..........................................................................................................

Screw ............................................................................................................

End Gasket ...................................................................................................

Amt.

Req.

2

1

1

1

1

1

1

1

1

1

2

3

1

1

1

1

1

1

1

1

1

1

1

2

1

1

10

2

2

1

1

1

1

2

1

1

3

1

1

1

1

2

1

1

1

2

1

1

1

3

1

2

1

3

1

1

1

1

5

3

3

1

2

1

1

1

1

1

17

Page 18

18

Page 19

CLOTH PLATES, CLOTH PLATE COVERS, MISCELLANEOUS AND ATTACHMENTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

Part No.

25S

51282AJ

51282AK

52978G

52882AS

52882AE

22548

51480C

51301D

22760A

35772H

51281AC

22845B

51281AJ-219

51281T-219

25C

29480BZ

39531AR

77A

39531B

604

39531C

53132B

53132A

22561

53132

23425V

22514

GR-23450L

188D

8372A

23450U

23450M

23450P

23450R

90

23450V

23450N

23450T

23450S

53102

22760A

50368E

25C

23450W

53101

80

22845B

88D

25S

23437G

22839C

22585A

22524

53782B

51382B

52982E

52982D

22848

41394A

22733B

222D

87

87

22839

51280AA

Description

Screw ............................................................................................................

Oil Shield, front, for Styles 53100A, C, D, E ......................................................

Spring .....................................................................................................

Hinge Pin .................................................................................................

Gasket, for Styles 53100A, D, E ......................................................................

Crank Chamber Cover, for Styles 53100A, D, E ..............................................

Screw, for Styles 53100A, D, E ........................................................................

Throat Plate Support, for Style 53100E ...........................................................

Cloth Plate, for Styles 53100A, D, E ................................................................

Screw, for Styles 53100A, D, E ........................................................................

Washer, for Styles 53100A, D, E ......................................................................

Cloth Plate Cover Spring, for Styles 53100A, D, E ...........................................

Pivot Screw, for Styles 53100A, D, E ................................................................

Cloth Plate Cover, for Style 53100E ...............................................................

Cloth Plate Cover, for Styles 53100A, D .........................................................

Screw, for Style 53100E ..................................................................................

Auxiliary Presser Plate Assembly, for Style 53100E ..........................................

Operating Lever .....................................................................................

Screw ...............................................................................................

Shaft Collar .............................................................................................

Screw ...............................................................................................

Spring .....................................................................................................

Auxiliary Pressure plate Bracket ..............................................................

Pressure Plate Shaft ................................................................................

Screw .....................................................................................................

Auxiliary Pressure Plate ...........................................................................

Washer Plate .................................................................................................

Screw, for Style 53100B ..................................................................................

Waistband Folder, complete, for Style 53100B ..............................................

Screw .....................................................................................................

Washer ...................................................................................................

Lower Scroll, adjustable .........................................................................

Folder Base .............................................................................................

Adjustable Waistband Guide, lower .......................................................

Adjustable Support, for waistband guide, lower ....................................

Screw .....................................................................................................

Adjusting Screw ......................................................................................

Adjustable Waistband Guide, upper ......................................................

Top Scroll Support, adjustable ................................................................

Top Scroll ................................................................................................

Cloth Plate Cover, for Styles 53100B, C ..........................................................

Screw ............................................................................................................

Washer ..........................................................................................................

Screw ............................................................................................................

Edge Guide, for Style 53100B ........................................................................

Cloth Plate, for Styles 53100B, C ....................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Folder Support Bracket, for Style 53100B .......................................................

Screw ............................................................................................................

Screw ............................................................................................................

Screw ............................................................................................................

Oil Reservoir Top Cover .................................................................................

Gasket ..........................................................................................................

Gasket ..........................................................................................................

Oil Reservoir Back Cover ...............................................................................

Screw ............................................................................................................

Gasket ..........................................................................................................

Screw ............................................................................................................

Throat Plate (See Page 37) ............................................................................

Screw, for Styles 53100B, C ............................................................................

Screw, for Styles 53100B, C ............................................................................

Screw, for Styles 53100A, D, E ........................................................................

Screw ............................................................................................................

Throat Plate Support, for Styles 53100A, B, C, D .............................................

Amt.

Req.

2

1

2

1

1

1

4

1

1

3

3

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

1

2

1

5

5

1

1

1

1

4

1

1

1

1

1

2

2

2

1

1

3

1

2

1

1

2

2

7

1

1

1

1

9

2

1

1

1

1

2

3

1

19

Page 20

20

Page 21

MAIN FRAME, BUSHINGS AND MISCELLANEOUS OILING PARTS

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

Part No.

GR-53193

643-127BLK

52393H

22569B

22823A

51295A

22823B

51493AY

51493BG

51493BH

51493BJ

22560B

52894AK

51493BK

52942W

52944U

52890C

51290T

52942X

52794G

52894AB

52894AB

90

90

52936

22597

52944T

660-136

258A

51257AA

666-210

51294V

666-214

52894AD

52894AE

22729AB

51294Z

21212

666-201

666-209

GR-51294S

22729B

51294K

52883R

21657X

52891B

50-648BLK

52942Y

22889C

22889D

666-114

35178D

22571A

666-65

666-118

666-111

666-179

22539H

56390E

Description

Oil Pump Assembly .......................................................................................

Gasket ..........................................................................................................

Oil Pump Intake Housing ...............................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Mounting Isolator .........................................................................................

Screw ...........................................................................................................

Oil Pan Base Plate .........................................................................................

Base Plate Felt Pad .......................................................................................

Filter Cap Assembly ......................................................................................

Washer, sponge rubber .........................................................................

Screw ...........................................................................................................

Oil Tube, for looper rocker and left ball joint .................................................

Lint Filter Screen ...........................................................................................

Looper Drive Lever Shaft Bushing, front ........................................................

Looper Rock Shaft Bushing, right ..................................................................

Main Shaft Bushing, left and inner right .........................................................

Main Shaft Bushing, middle ..........................................................................

Looper Drive Lever Shaft Bushing, rear .........................................................

Oil Tube, for feed lift and looper avoid eccentric .........................................

Oil Tube Holder, for Styles 53100A, B, C, D .....................................................

Oil Tube Holder, for Style 53100E ...................................................................

Screw, for Styles 53100A, B, C, D ...................................................................

Screw, for Style 53100E .................................................................................

Feed Rocker Shaft Bushing ...........................................................................

Screw, for Style 53100E .................................................................................

Looper Rocker Shaft Bushing, left .................................................................

Oil Tube, for feed crank link ..........................................................................

Nut .........................................................................................................

Lower Presser Bar Bushing .............................................................................

Oil Attraction Felt .........................................................................................

Oil Siphon Tube .............................................................................................

Felt Lint Filter ...........................................................................................

Oil Tube, for differential feed bar shaft, for Style 53100E ...............................

Oil Tube, for differential feed bar guide, for Style 53100E .............................

Screw ...........................................................................................................

Oil Tube Connection ....................................................................................

Oil Siphon Connection Locking Ring ......................................................

Felt Plug ........................................................................................................

Felt Plug ........................................................................................................

Oil Siphon Assembly .....................................................................................

Screw .....................................................................................................

Upper Clamp .........................................................................................

Presser Foot Lifter Lever Bushing ...................................................................

Tension Release Lever Shaft Bushing ............................................................

Main Shaft Housing, including bushing .........................................................

Lucite Oil Gauge ..........................................................................................

Looper Rocker Shaft Synchronizing Stud ......................................................

Adapter Plug Screw .....................................................................................

Adapter Plug Screw .....................................................................................

Oil Wick ........................................................................................................

Spring ...........................................................................................................

Plug Screw ....................................................................................................

Oil Wick ........................................................................................................

Oil Wick ........................................................................................................

Oil Wick ........................................................................................................

Wedge Pin ....................................................................................................

Plug Screw ....................................................................................................

Crankshaft Bearing Housing Gasket .............................................................

Amt.

Req.

1

1

1

3

2

4

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

3

1

3

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

4

15

2

2

2

2

1

1

21

Page 22

22

Page 23

FOR STYLES 53100B AND C ONLY

CLUTCH ASSEMBLY, CLUTCH DRIVE SHAFT GEAR AND HOUSING ASSEMBLY

Ref.

No.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

12A.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

Part No.

29476JD

53139H

22729C

18

41331G

51236F

269

53139K

660-169

269

20

29476JF

53139B

51236G

51236B

22768

82

53139

53139A

269

53139E

53139D

22888A

53139F

53139C

98

39153G

12982

22791D

41394A

22733B

22861B

22548

258

53139Z

53139AC

22561

22768

40-107

53139AB

53139AD

53139AE

53139AH

51239AA

51239AB

22747B

43443Q

Description

Clutch Drive Connecting Rod Assembly ......................................................

Clutch Drive Ball Joint ............................................................................

Screw ...............................................................................................

Nut .........................................................................................................

Connecting Rod ....................................................................................

Ferrule ....................................................................................................

Nut .........................................................................................................

Crank Strap ............................................................................................

Needle Bearing ......................................................................................

Nut ...............................................................................................................

Washer .........................................................................................................

Clutch Drive Shaft Gear and Housing Assembly ...........................................

Clutch Drive Shaft ..................................................................................

Feed Crank Stud ....................................................................................

Feed Crank Stud Cap .............................................................................

Screw .....................................................................................................

Screw .....................................................................................................

Clutch Drive Shaft Gear .........................................................................

Bushing ............................................................................................

Nut .........................................................................................................

Idler Gear Eccentric Bushing .................................................................

Idler Gear ...............................................................................................

Screw .....................................................................................................

Idler Gear Bracket ..................................................................................

Clutch Drive Shaft Gear .........................................................................

Screw ...............................................................................................

Nut .........................................................................................................

Nut .........................................................................................................

Pin ..........................................................................................................

Gasket ...................................................................................................

Screw .....................................................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Nut ...............................................................................................................

Roller Feed Shaft Guard ...............................................................................

Feed Roller Stripper ......................................................................................

Screw ...........................................................................................................

Screw ...........................................................................................................

Washer .........................................................................................................

Feed Roller Lifter ...........................................................................................

Feed Roller, fine knurl ...................................................................................

Feed Roller, fifty teeth ..................................................................................

Feed Roller, coarse knurl ..............................................................................

Feed Roller Block ..........................................................................................

Bushing ..................................................................................................

Screw .....................................................................................................

Nut .........................................................................................................

Amt.

Req.

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

4

3

1

1

1

1

1

1

1

1

1

1

1

1

1

1

45. thru 90. See Following page

23

Page 24

24

Page 25

FOR STYLES 53100B AND C ONLY

CLUTCH ASSEMBLY, CLUTCH DRIVE SHAFT GEAR AND HOUSING ASSEMBLY

Ref.

No.

Part No.

1. thru 44. See Previous page

45.

53139AA

46.

50-799BLK

47.

88

22874

48.

12987A

49.

53139AG

50.

51239G

51.

22894T

52.

61339F

53.

660-239

54.

22580

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

67.

68.

69.

70.

73.

74.

75.

76.

77.

78.

79.

80.

81.

82.

83.

84.

85.

86.

87.

88.

89.

90.

6042A

29476JE

53139Y

460

88

53139W

22892C

53139L

53139N

53139P

53139M

11638M

54278Y

54278W

54274P

54274N

719

61351C

22894H

53139X

22651CB4

605

53139R

54274H

54274L

29480KP

54274J

54274H

53139S

53139V

53139U

538

53139T

22593

52882AS

55A.

67A.

Description

Roller Feed Mounting Bracket ......................................................................

Nut ...............................................................................................................