Page 1

Ztn:Um

}pt:cial®

INDUSTRIAL

SEWING

FINEST QUA

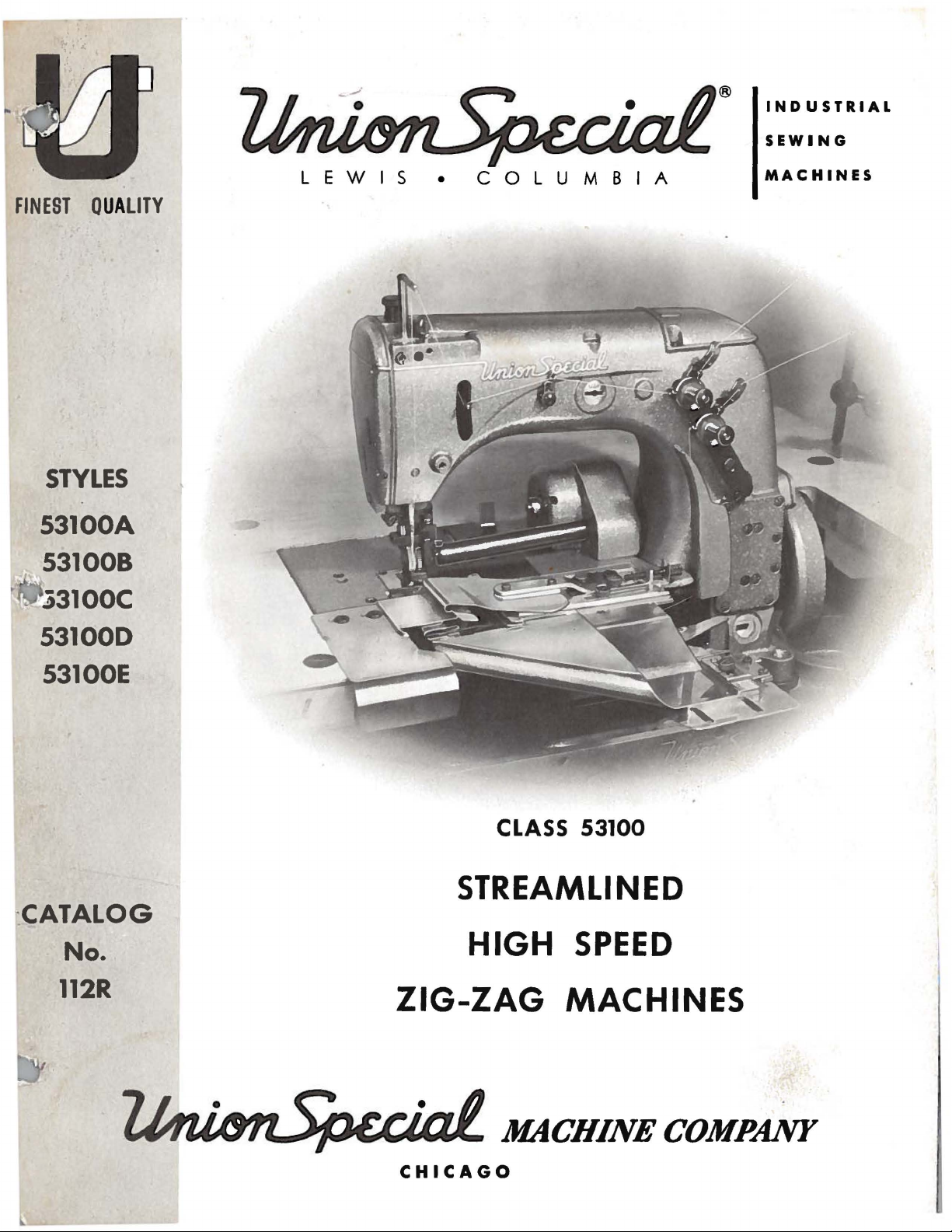

STYLES

53100A

:i3100C

LITY

LEWIS

•

COLUMBIA

MACHINES

531000

53100E

~

CATALOG

No.

112R

CLASS 53100

STREAMLINED

HIGH

SPEED

ZIG-ZAG MACHINES

CHICAGO

Page 2

Aid Plant Layo

ut!

Boos

t Production!

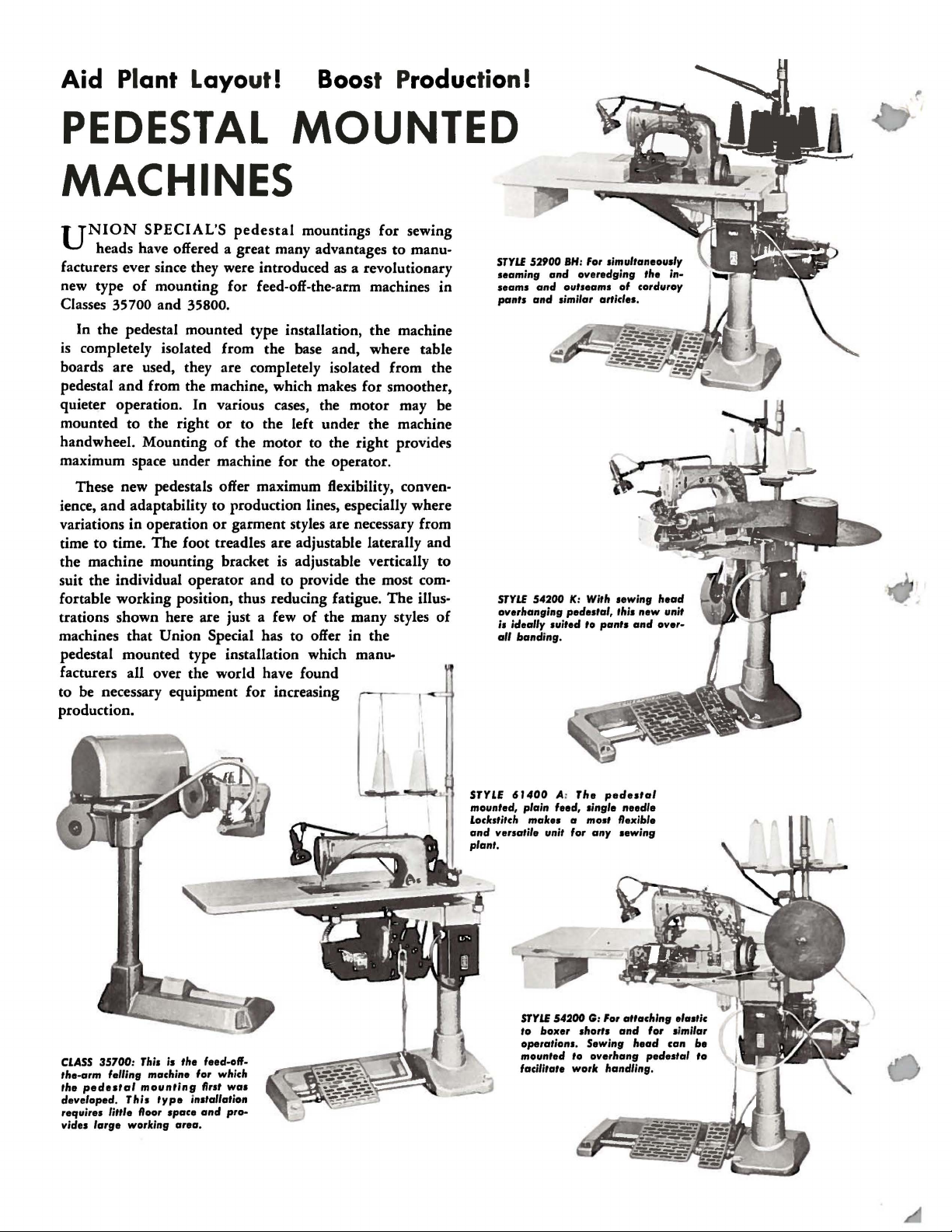

PEDESTAL

MOUNTED

MACHINES

UNION

heads have offered a great many advantages

facturers ever since they were introduced

new type

Classes 35700 and 35800.

In

the

is

completely isolated from the base and, where table

boards are used, they are completely isolated from the

pedestal

quieter operation.

mounted

handwheel. Mounting

maximum space under machine for the operator.

These new pedestals offer maximum flexibility,

ience,

variations

time

to

the machine mounting bracket

suit the individual operator and to provide the most comfortable working position, thus reducing fatigue.

trations shown here are just a few

machines

pedestal mounted type installation which

facturers all over the world have found

to be necessary equipment

production.

SPECIAL'S

pedestal

mountings

for

to

as

a revolutionary

of

mounting for feed-off-the-arm machines

pedestal mounted type installation, the machine

and

from the machine, which makes for smoother,

In

various cases, the

to

the

right

or

to the left under the machine

of

the motor to the

and

adaptability to production lines, especially where

in

time.

operation

The

or

garment styles are necessary from

foot treadles are adjustable laterally and

is

adjustable vertically

motor

right

The

of

the many styles

that

Union Special has to offer in the

manu-

for

increasing

sewing

manu-

in

may be

provide's

conven-

to

illus-

of

STYLE

52900

BH:

For •imultaneou1ly

and

1eaming

1eams

pants

STYLE

overhanging pede1tal, thi•

I• ideally 1uited to

all

banding.

overedging the

and

outseams

and

1imilar articles.

54200 K: With

of

•ewing

pant•

corduroy

head

new

and

over·

in·

unit

CLASS

35700:

Thi1

i1

the

type

feed-off-

llr~t

in1tallation

and

area.

wa1

pro·

the-arm felling machine for which

the

pedutal

developed. This

require•

vides

large

mounting

little floor 1pace

worlcing

STYLE 6 I

mounted, plain feed, •Ingle needle

loclc•titch malce•

and

plant

400

A:

versatile unit for

.

STYLE

54200

to

boxer

operation•. Sewing

mounted

facilitate worlc handling.

The

pedestal

a most flexible

any

•ewing

G:

far

attaching

short•

and

overhang

head

to

ela1tic

for similar

can

pedestal

be

to

Page 3

Catalog

No.

112

R

The

furnished

53100

53100

parts

at

LIST

A

listed

list

First

For

B

53100

OF

Styles

in

prices

Edition

PARTS

53100

53100

E

this

for

D

catalog

repairs

C

are

only.

October,

1966

Union

Rights

Copyright

by

Special

Reserved

1962

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

3

MACHINES

U.S.A.

Co.

Countries

Page 4

the

The

latest

50000

design

series

of

streamlined

Union

Special's

FOREWORD

zig-zag

flat

machines

bed

line.

covered

Class

by

53100

this

catalog

machines

represent

offer

many

advantages

panties,

dresses,

Light

attain

the

bearings

bar

mechanism

Automatic

with

isolated

reservoir,

It

is

our

our

customers

The

following

covered

in

on

various

foundations,

blouses,

weight

utmost

make

bed

presser

in

them

reduces

lubrication

mounting

has

made

constant

to

secure

pages

this

catalog.

operations

children's

jackets

bar

speed

lighter

and

running

pressure

and a new

oil

pan

maintenance

aim

to

furnish

all

illustrate

on a variety

knit

and

pajamas.

and

needle

production.

and

required

filter

base

simple.

carefully

possible

and

describe

of

garments

undergarments,

bar

driving

The

smoother

type

plate,

to

lift

for

operating.

oil

returning

prepared

advantages

the

parts

mechanism

new

light

the

presser

return

information

from

used

such

men's

weight

The

pump,

filtered

the

in

as

nightgowns~

trousers,

make

it

parts

light

weight

foot.

used

in

oil

to the main

which

use

of

Union Spe

all

of

the

slips~

women's

possible

and

to

needle

presser

conjunction

will enabl

cial

s.

machin

es •

e

Union

to

cooperate

Special

with

representatives

you

to

plan

and

will

be

estimate

found

in

all

requirements.

~MACHINE

4

manufacturing cent

Engineerin

g Depa

er s, ready

COMPANY

rtm

nt

Page 5

IDENTIFICATION

OF MACHINE

Each

the

name plate

Standard Style numb

"Z".

only

Style

Styles

which

This

he

rein.

this

from

handwheel

igh Spe

H

Lightweight

EnclosedAutomat

As

sembly.

Union Spec

on the ma

Exampl

minor chan

number.

differ

class.

the operator ' s posi

e: "S

ges are

Exa

of machine

s f

rom

catalo

It

e d Streamlined F lat Bed, S

g applies

can als o

R

efe

r e

is

toward the

P r

esser

ic

Lateral

ial ma

er s

tyl

mple:

the sty

be applied

nce

Lubri

Loop

chin

chin

have one

e 53100 A" .

made

s s i

le

to

direction, such

tion

operator.

Ba

r a

cati

erTra

e is

identifi

e. S

tyle

numb

or

more

SpecialStylenumber

in

a s

tandard

"Styl

e 53100

milar

number,

APPLICATION

specifically

in

construction

in

with

discreti

whil

e seated

STYL

nd Needle

ng System

ES OF MACHINE

ing

ve

l,

WorkSp

that

to

le Ne

, F

ed

by a Style

er s

are

classified

letters suffixed,

machine, a "Z" is

AZ".

ar

e gr

it

contains

OF

CATALOG

the

standard

on

to

as rig

Bar Driving

ilt

ht, lef

at the

edl

e, Me

er

Type

ace

to

no

some

t, front,

machine. Operating direction

dium Thr ow, Zig-Za

Oil Return

Right

number

s

containtheletter

ouped

letter

Styles of

Special

Mechanism,

of Ne

which

as

standard

but

never

suffixed

under a class

s .

Styles

back,

Pump and

edl

e Ba r 7 3/4

is

stamped

and

conta

to

the

Example:

machines

of

machines

etc.,

Sin

gl e

into

special.

in

the

letter

"Z

" .

When

standard

number

"53100".

as

listed

are given

g Ma

chine.

Reservoir

Oil Siphon

Inches.

in

of

5

3100

53100 B

53100 C

53100 D

53100 E

A F orattachin

light

and similar

Can

f

to

No.

lon

inches.

swing-up edge guide

abutt

bottom

together. Attaching

s

weight knit and

material

g

404-LSa-1,

to medi

be used for pur l ed

or

r a ising pres

Power dr

top

g l

leev

ather

s or

234

engt

Same as

Same as

ed

Di

es

ed

to wais

50 L prepa

hs, enteri

Seam

ed

ge

fferential feed

of nightg

in

blou

s wh

sea

g an

um

weig

mat erials

ser f

iven

upper roll

tband

red totake

ng from the

spec

ifi

53100

53

100

sea

ming on

owns,

tiers

ses, bed

woven

ere a large

ms .

FSa

-1

Knee

or

dmitering

ht

knit and

; also

ge stitchin

oot.

B, exce

A,

attach

Seam

of m en's trousers, g

cation 404-LSb-1.

exce

machine.

slips,

of

jackets and

fabrics

percent

pr

SSa-1.

la ce

tonightgowns,

wov

for hemm

g on

s pecifica

er

fee

d. For

wais

tband

rig

ht, and

pt

without

pt fitt

ed to the

slips and gown

F

panties, gath

lace

to slips, dresses and nightg

pajama

of

of the wo

ess

for

en fabrics

ing pane

chil

s r anging fr

folde

d wi

low

or attachi

cotton,

rk calls for int

raising

ls

dren

's

tion 404-LSa-1.

attaching pre-mad

produces

r.

th

open

er

presser bar bushing,

s.

ering either

s. F

ra

pre

slip

s, a

nd pant

of

cotton,

on

two-way stre

knit

und

ivin

g ha

om 1 1/4 to 4 inch

he

toe

"V"

Seam specificatio

ng

lace to neck,

or

operations

yon,

nylon,

ermittently

sser foot.

ra

yon,

erg

arment

e w

nd fell

adin

the garment,

ed effe

gs

of from

type pr

own

on light

da

cron and si

Seam

ies

ma

de from

nylon, dacron

tch foundations.

s . K

nee

press

aistba

s.

or c

nd lini

ct. Folder

es

wide,

1/8

to

esser foot

to

be used f

n 404- F

armhol

la ce

Setting puff

to medium

onti

specifica

Sa-1.

es

or both

mila

nuously

ngs

in

3/4

and

or

and

tio

r

n

5

Page 6

NEEDLES

Each

number

The

measured

Collectively~

Standard

needle

Type

110 GAS

size

for

No.

Union

denotes

number,

in

the

needle

Styles

Special

the

stamped

thousandths

type

53100 B

Round

ball

040, 044.

163 GA

Round

spot,

To

sample

on

label.

Selection

Thread

have

needle,

needle

A

complete

of

should

or

the

pass

proper

formation.

needle

kind

number

for

shank,

eye~

shank,

chromium

orders

the

type

order

freely

has

of

shank~

on

the

of

an

and

Styles

and C is

round

long

round

promptly

and

would

needle

through

both a type

point~

needle

inch,

the

53100

size

A~

Type

shank~

midway

D

110 GAS.

Description

point~

spot~

point~

extra

government,

plated -sizes

and

size

number

read:

size

"1000

should

needle

number

length~

groove~

denotes

between

number

is

and E is

and

short~

chromium

Picoetta,

027~

accurately

should

be

determined

eye

be

Needles~

in

order

and a size

finish

the

largest

the

the

complete

Type

163

Sizes

double

single

029,

filled~

groove,

032, 036.

forwarded.

Type

by

the

to

number.

and

other

diameter

shank

symbol.

GA~

and

groove~

struck

plated

flat

an

empty

Use

110 GAS,

size

of

produce

a

The

type

details.

of

blade

and

the

eye.

the

standard

groove~

-

sizes

blade~

package~

036~

long

description

Size

044".

thread

good

used.

stitch

a

ILLUSTRATIONS

This

catalog

ofvarious

actual

listing

required

Numbers

the

position

in

ordering

sections

position

of

the

parts

in

the

in

of

parts.

in

particular

that

Component

indicated

assembly.

9

10

11

12

13

It

The

reason

the

complete

by

Example:

29476

22559 A

51243 c

22729

22587

will

be

is

indenting

LE

noted

that

sub-assembly

has

been

of

the

the

machine.

with

the

first

part

Always

parts

of

Looper

Screw#

Ball

Screw--------------------------------------------- 1

Screw.

in

the

replacement

ORDERING

arranged

to

mechanismare

On

their

in

part

view

being

column

the

illustration.

are

use

sub-assemblies

their

descriptions

Driving

lower

Stud

Guide-------------------------------------

upper

above

example

of

should

REPAIR

simplify

shown

the

page

numbers,

PARTS

ordering

so

that

opposite

the

descriptions

repair

the

parts

illustration

and

shown.

reference

Reference

the

part

which

under

Lever

Crank

--------------------------------------

numbers

number

can

the

Assembly

only,

numbers

listed

be

furnished

description

------------------

-------------------------------------that

the

these

be

ordered.

parts

eccentric

individually

and

is

parts.

maybe

the

number

and

merely

should

in

the

second

for

of

bearing

not

recommended,

Exploded

seen

will

be

of

indicate

never

column.

repairs

the

main

are

not

views

in

their

found a

pieces

be

used

are

sub-

listed.

so

1

2

1

2

In

catalo

parts

in

the

those

g,

for

description,

no

specific

the

cases

various

where a part

usage

machines

and

will

if

necessary,

are

is

common

be

mentioned

not

the

the

same,

difference

6

to

in

all

of

the

description,

the

specific

will

the

machines

be

usage

shown

covered

however,

will

be

in

the

illustration.

by

this

when

the

mentioned

Page 7

this

part

At

the

book.

number

back

This

is

of

the

will

facilitate

known.

ORDERING

book

will

be

locating

REPAIR

PARTS

found a numerical

the

illustration

(continued)

index

and

of

description

all

the

parts

when

shown

only

in

the

Where

some

of

the smaller

identification

Part

numbers

appear.

IMPORTANT!

OF

MACIDNE

Success in

Special

its

approved

efficiency

Needles and

subsidiaries

scientific

and

Genuine

parts

g

uarantee

are

of

the

construction

letter

FOR

the

and

durability

needles

stamped

the

highest

permits,

parts,

is

and

stamped

represent

ON

ALL

WHICH

USE

operation

Repair

ORDERS,

PART

GENUINE

of

Parts

authorized dis

principles,

are ass

are

packaged

with the

quality

IDENTIFYING

each

on

the

those

in

same

where

to distinguish

part,

PLEASE

IS

ORDERED.

NEEDLES

these

machin

as

furnished

tributor

and

are

made

ured.

with

labels

Union

Special

in

materials

part

AND

es

s.

marked

trade

PARTS

is

stamped

the

construction

regardless

INCLUDE

REPAIR

can

be

by

the

Union

They

are

with the

mark.

and

workmanship.

with its

the

part

PART

secured

Special

designed

utmost

~.

Each

does not

from

of

catalog

NAME AND

PARTS

only

according

precision.

part

similar

in

with

genuine

Machine

Genuine

trade

mark

number.

permit,

which

STYLE

CompanY,,

to

the

Maximum

repair

is

On

an

ones.

they

Union

most

your

Prices

ments

are

unless

The

must

be

viscosity

Oil

is

sight

the

gauge

red

The

main

Oil

reservoir filled

A

daily

which

reservoir,

reservoir

hand

wheel.

are

strictly

forwarded

otherwise

oil

has

filled

of

200

filledat

on

lines

machine

di

been

before

to

the

the

front

on

is

rected.

drained

beginning

250

spring

the

automatically

is

check bef

has

gone through

ore

making too frequent

may

be drai

net

cash

f.

o.

b. shipping point.

A

and

charge

OILING

seconds

cap

of

the

gauge.

from

to

machine.

the

operr;te.

at

100

in

the

The

lubricated,

nece

ssa

ry.

the

morning

the

machine

oilings

ned

at

the

plug

TERMS

are

subject

is

made

AND

THREADING

machine

Fahrenheit.

top

The

capacity

start

should

is

unnecessary.

screw

Parcel

Us

e a s

cover,

oil

and

f

iltered

in

to

to

change

cover

Post

the

without

shipments

postage

before shipping,

level

of

be

traight

and

the

no

made

and

mineral

the

oil

should

oil

oiling,

and

pumped

reservoir

Excessive

the

main

frame

notice.

and

oil

level

be

is

maintained

other

oil

added

bac

directly

All ship-

are

insured

and

ins

urance.

the

reservo

with a Saybolt

checkedat

between

is

12

ounces.

than

keeping

if

required.

k i

nto

the

oil

in

the

under

ir

the

the

main

main

the

On

the

in

this

next page

catalog

is a picture showing

ar e

threaded.

the

The looper

7

mann

er

threading

in

which

has

been

the

53100

enlarg

Styles

ed for

covered

clarity.

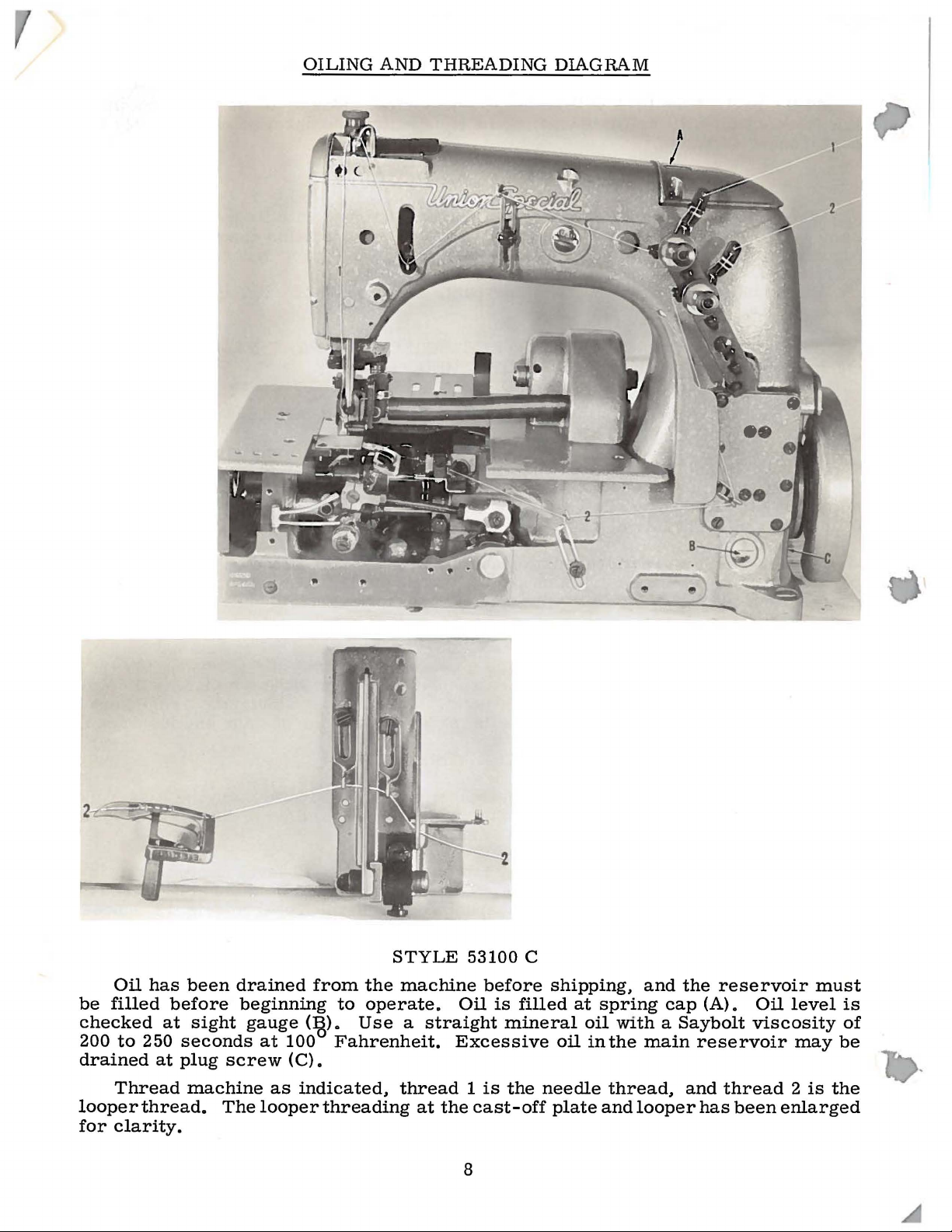

Page 8

OILING

AND

THREADING

DIAGRAM

Oil

be

filled

checked

200

to

drained

Thread

looper

for

clarity.

has

been

before

at

250

seconds

at

plug

machine

thread.

sight

The

drained

beginning

gauge<:%>·

at

100

screw

(C).

as

looper

from

indicated,

the

to

operate.

Use a straight

Fahrenheit.

threading

STYLE

machine

thread 1 is

at

53100

before

Oil

is

Excessive

the

cast-off

8

C

shipping,

filled

mineral

oil

the

needle

plate

and

at

spring

oil

with a Saybolt

in

the

main

thread,

and

looper

the

cap

reservoir

and

reservoir

(A).

has

Oil

viscosity

thread 2 is

been

must

level

may

be

the

enlarged

is

of

Page 9

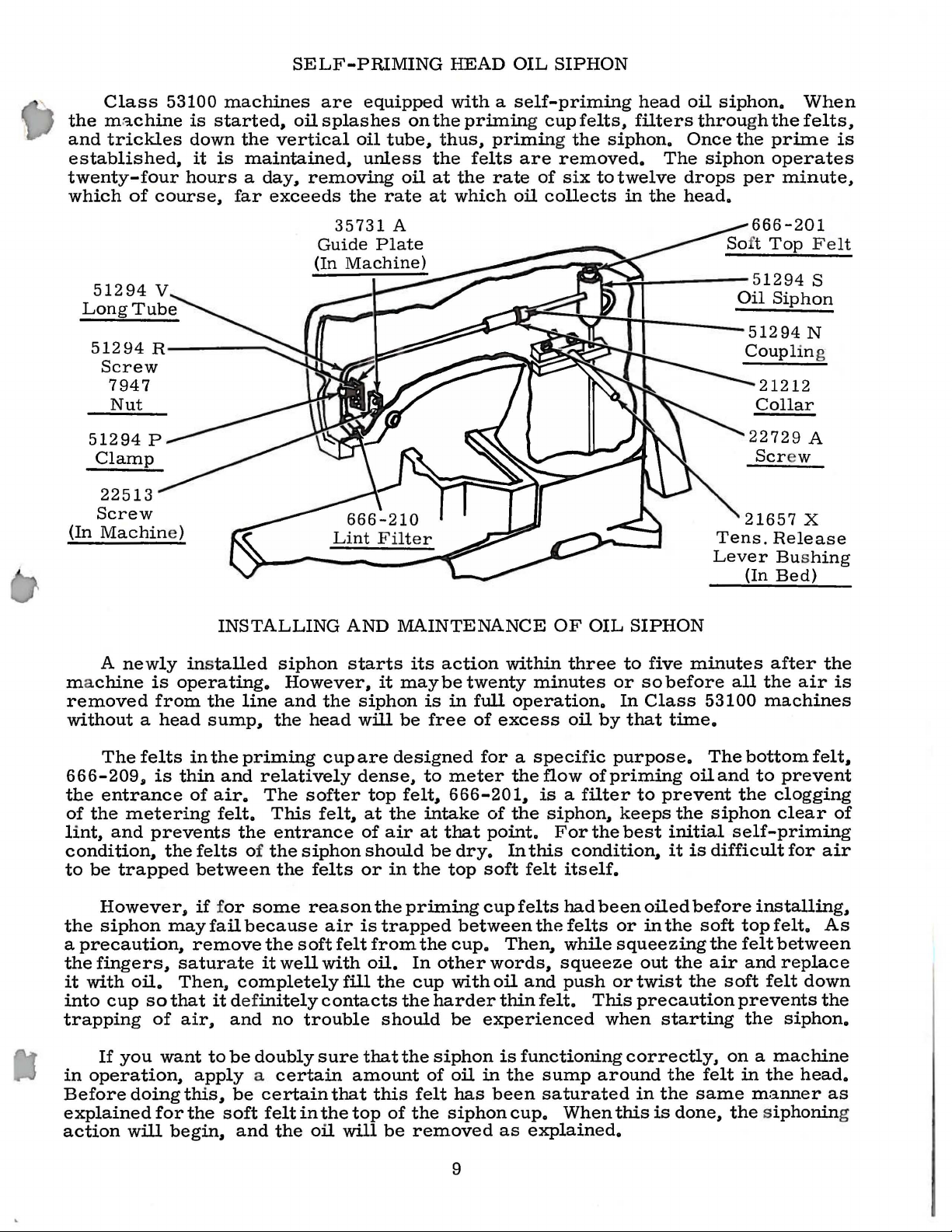

SELF-PRIMING

HEAD

OIL

SIPHON

Class

the

m~chine

and

trickles

established,

twenty-four

which

of

51294

course,

R -

Screw

7947

Nut

51294

p

Clamp

22513

Screw

(In

Machin

53100

machines

is

started,

down

it

is

the

maintained,

hours a day,

far

---

e)

oil

vertical

removing

exceeds

(In

......

are

equipped

splashes

oil

unless

the

35731

Guide

tube,

oil

rate

A

Plate

with a self-priming

on

the

thus,

the

at

at

which

Machine)

';._,~

_.,.-

~=+--"':1rt~~-;fl+l----.:_

priming cup

priming the

felts

the

rate

oil

are

of

collects

head

felts,

filters

siphon.

removed.

six

totwelve

in

~~~----51294

The

the

oil

Once

drops

head.

siphon.

throu

the

siphon

Oil

Tens.

Lever

gh

the

prime

operates

per

minute,

Siphon

512

94

Couplin

21212

Collar

Scr

ew

Release

Bushing

(In

Bed)

When

felts,

is

s

N

g

A

newly ins

m a

chine

removed

is

operating.

from

without a head

The

felts

666-209,

the

entrance

of

the

lint,

condition,

to

be

is

metering

and

prevents

trapped

thin

the

However,

the

siphon

a

precaution,

the

fingers,

it

with

into

cup

trapping

If

you

in

operation,

Before

explained

action

oil.

so

of

want

doing

for

will

may

satur

Then,

that

air,

begin,

INSTALLING

talled

siphon

However,

the

line

and

sump,

in

the

and

of

air.

felt.

felts

between

if for

fail

remove

ate

the

priming

relatively

The

This

the

entrance

of

the

the

some

because

the

it

well

softer

siphon

soft

completely

it def

initely

and

no

trouble

to

be

doubly

apply a certain

this,

the

be

soft

and

certain

felt

in

the

AND

starts

the

head

cup

felt,

felts

reason

air

felt

with

fill

contacts

sure

amount

that

the

top

oil

will

MAINTENANCE

its

action

it

maybe

siphon

will

are

dense,

top

at

of

should

or

the

is

from

oil.

the

that

this

is

be

free

designed

to

felt,

the

intake

air

at

be

in

the

priming

trapped

the

In

cup

the

harder

should

the

siphon

of

felt

of

the

be

removed

in

meter

666-201,

that

top

cup.

other

with

be

oil

has

siphon

within

twenty

full

of

minutes

operation.

excess

for a specific

the

is a filter

of

the

point.

dry.

between

In

soft

cup

this

felt

felts

the

Then,

words,

oil

and

thin

felt.

experienced

is

functioning

in

the

been

cup.

as

explained.

OF

OIL

three

oil

by

flow

ofpriming

siphon,

For

the

condition,

itself.

had

been

felts

while

squeeze

push

This

when

sump

around

saturated

When

SIPHON

to

five

or

so

before

In

Class

that

time.

purpose.

to

prevent

keeps

best

the

initial

it

oiled

or

in

the

squeezing

out

the

or

twist

precaution

starting

correctly,

the

in

the

this

is

done,

minutes

all

53100

The

bottom

oil

and

the

siphon

self-priming

is

difficult

before

soft

top

the

felt

air

and

the

soft

prevents

the

on a machine

felt

in

same

manner

the siphonin

after

the

the

air

machines

felt,

to

prevent

clogging

clear

for

air

installing,

felt.

As

between

replace

felt

down

the

siphon.

the

head.

as

is

of

g

9

Page 10

INSTRUCTIONS

FOR

MECHANICS

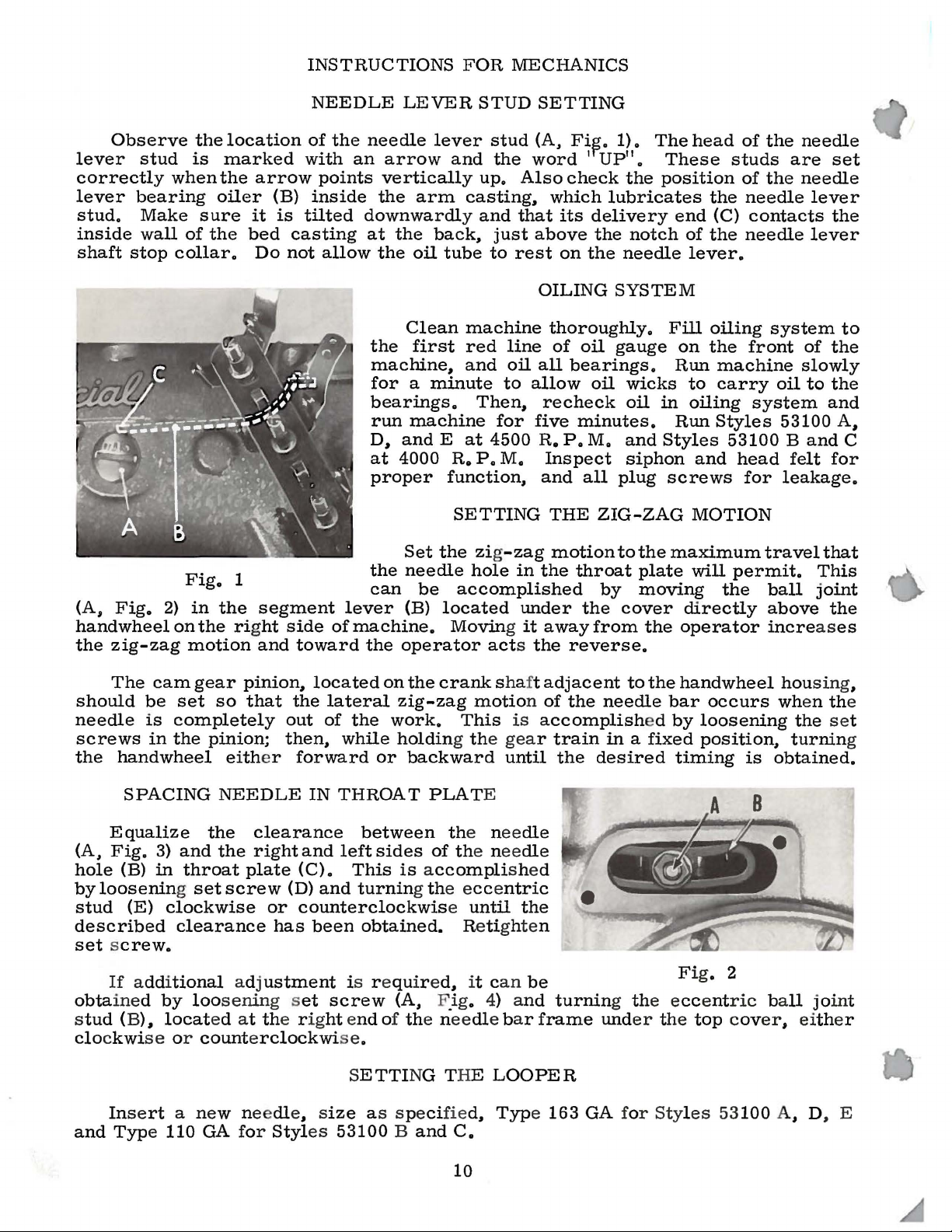

Observe

lever

stud

correctly

lever

stud.

inside

shaft

bearing

Make

wall

stop

the

is

when

sure

of

collar.

Fig.

(A,

Fig.

2)

in

handwheelonthe

the

zig-zag

motion

location

marked

the

oiler

the

bed

1

the

right

with

arrow

(B)

it

is

tilted

casting

Do

not

segment

side

and

toward

NEEDLE

of

the

needle

an

points

inside

downwardly

at

allow

the

machine,

for a minute

bearings.

run

D,

at

proper

the

can

lever

ofmachine.

the

LEVER

lever

arrow

vertically

the

arm

the

back,

the

oil

Clean

first

machine

and E at

4000 R ..

Set

the zig

needle

be

(B)

located

operator

STUD

stud

(A, Fip:.

and

the

word • UP

up.

Also

casting,

and

that

just

above

tube

to

rest

machine

red

line

and

oil

to

allow

Then1 recheck

for

five

4500

P.M.

function,

SETTING

-zag

hole

in

accomplished

under

Moving it

acts the

SETTING

check

which

its

lubricates

delivery

the

on

the

OILING

SYSTEM

thoroughly.

of

oil

gauge

all

bearings.

oil

minutes.

R.

P.M.

Inspect

and

all

THE

ZIG-ZAG

motion

the

throat

by

the

awayfrom

reverse.

1).

The

11

•

the

notch

needle

wicks

oil

and

siphon

plug

to

the

plate

moving

cover

the

head

These

position

the

end

(C)

of

the

lever.

Fill

oiling

on

the

Run

machine

to

carry

in

oiling

Run

Styles

Styles

and

screws

MOTION

maximum

will

the

directly

operator

of

the

studs

of

the

needle

contacts

needle

system

front

system

53100

head

for

travel

permit.

ball

above

increases

needle

are

needle

lever

lever

of

the

slowly

oil

to

the

and

53100

Band

felt

for

leakage.

that

This

joint

the

set

the

to

A,

C

The

cam

should

needle

screws

the

be

is

in

handwheel

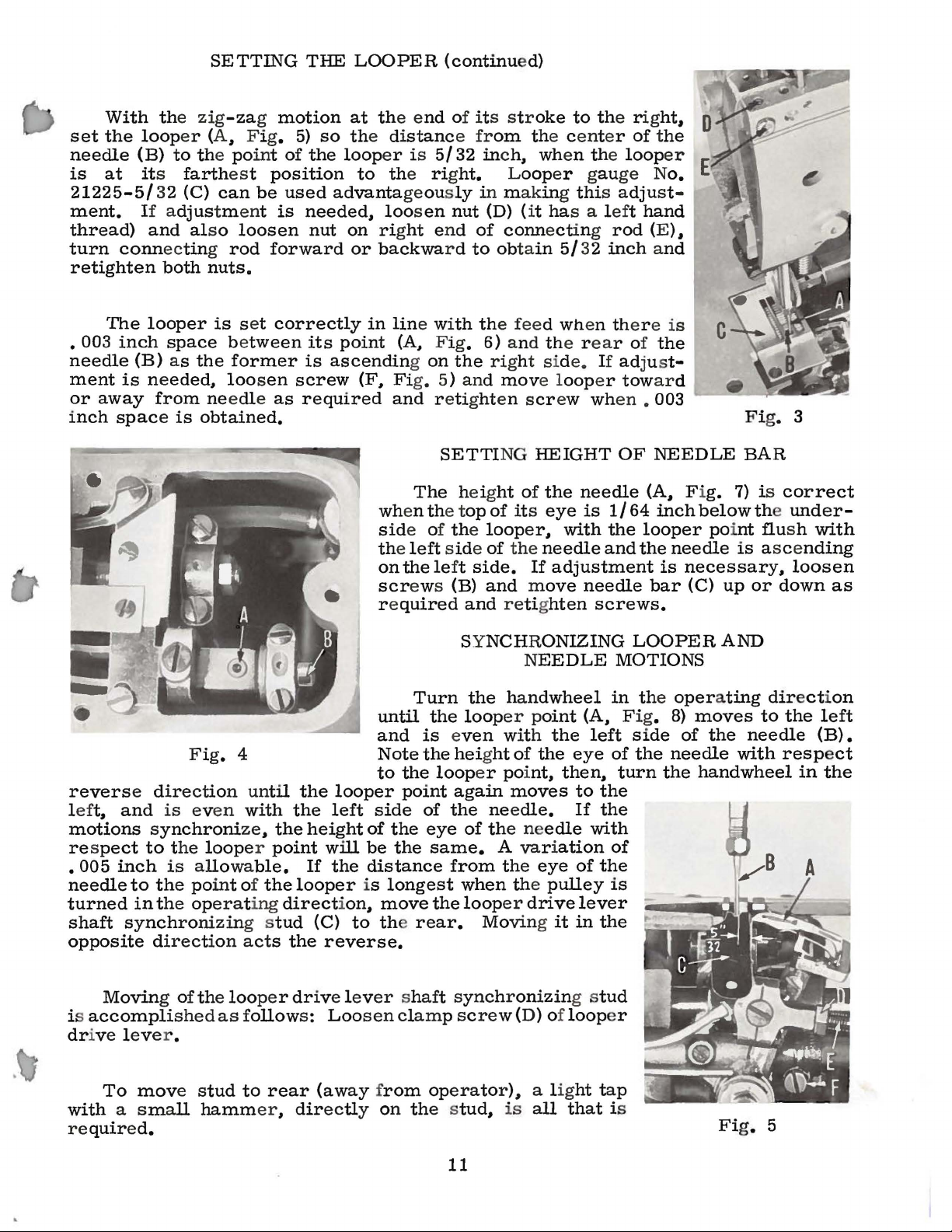

SPACING

Equalize

(A,

Fig.

hole

by

loosening set

stud

(B)

(E)

3)

in

described

set screw.

If

addi

obta

ined by

tud (B),

s

clockwi

se

Insert a ne

and

Typ

e 110 GA for

gear

set

pinion,

so

completely

the

pinion;

eith

NEEDLE

the

and

the

throat

screw

clockwise

clearance

tional

locat

or

adj

loo

sening set

ed at the right end

counterclockwi

w needl

that

the

out

then,

er

forward

clearance

right

plate

and

(C).

(D)

or

counterclockwis

has

ustment

e, s

Styl

located

lateral

of

the

while

or

IN

THROAT

between

left

sides

This

and

turning th

been

obtained.

is r equir e

screw

of the needl

s e.

S

ETTI

ize

a s s pecifie

es

53100 Band

on

the

crank

zig-zag

work.

shaft

motion of

This

is

adjacent

accomplish

holding the gear train

backward

PLAT

th

until

E

e needle

the

of the needle

is accompli

e ecce

e

until

shed

ntr

the

ic

Retighten

d,

it c

an

be

(A, F_ig. 4) a

NG THE

d,

nd

turning th

e bar

frame

LOOPER

Type 163

C.

the

desired

GA for

needle

und

to

the

hand

wheel

bar

occurs

ed

by

loosening

in a fixed

position,

timing

is

Fig. 2

e eccentric ball join

er the

top cover, eith

Styles 53100

hou

sing

wh

en the

the set

turnin

obtained.

er

A, D, E

,

g

t

10

Page 11

SETTING

THE

LOOPER

(continued}

With

set

the

looper

needle

is

at

(B)

its

21225-5/32

ment.

thread}

turn

If

and

connecting

retighten

The

looper

• 003

needle

ment

or

inch

inch

is

away

space

(B)

needed,

the

zig-zag

(A,

to

the

farthest

(C)

can

adjustment

also

both

nuts.

is

space

as

between

the

loosen

from

needle

is

obtained.

Fig.

point

position

be

loosen

rod

forward

set

former

motion

5}

so

of

the

used

is

advantageously

needed,

nut

correctly

its

point

is

ascending on

screw

as

required

at

the

the

distance

looper

to

is

the

loosen

on

right

or

backward

in

line

(A,

(F, Fig. 5)

and

when

side

the

left

on

the

screws

required

end

of

5/32

right.

nut

end

with

Fig.

the

and

retighten

SETTING

The

height

the

top

of

the

side

left

(B)

its

stroke

from

inch,

Looper

in

making

(D)

(it

of

connecting

to

obtain

the

feed

6)

and

right side.

move

of

of

its

looper,

of

the

side.

and

and

retighten

to

the

center

when

this

has a left

5/32

when

the

rear

looper

screw

HEIGHT

the

needle

eye

with

needle

If

adjustment

move

the

the

looper

gauge

adjust-

rod

inch

there

If

adjust-

toward

when

OF

is

1/64

the

and

needle

screws.

right,

of

the

No.

hand

(E),

and

is

of

the

• 003

......____,~""""T-

NEEDLE

(A, Fi

inch

below the

looper poi

the

needle

is

necessary,

bar

(C)

g.

7}

nt

is

up

Fi

BAR

is

or

g. 3

correct

under-

flush

with

ascending

loosen

down

as

reverse

left,

motions

respect

•

005

needle

turned

shaft

opposite

direction

and

is

synchronize,

to

the

inch

to

in

is

the

the

synchronizing stud

direction

Moving

is

accomplished

drive

To

leve

move

r .

with a small

required.

Fig.

4

even

looper

allowable.

point

of

operating

of

the

looper

as

follows:

stud

to

hammer,

until

with

the

point

the

direction,

acts

rear

the

looper

the

left

height

will

If

the

looper

(C)

to the

the

reverse.

drive

lever shaft

Loosen

(away from

directly

Turn

until

and

Note

to

the

point

side

of

the

be

the

distance

is

longest

move

rear.

clamp

on

the stud,

SY

NCHRONIZING

the

the

looper

is even

the

height

loop

er poi

again

of

the

needle.

eye

of

the needle

same.

from

when

the

looper

Moving it

synchronizin

screw

operator),

NEEDLE

handwheel

point

with

of

the

nt,

the

then,

moves

A

variation

the

eye

the

pulley

drive

(D) of

looper

a lig

is

all

that

(A,

left

eye

to

the

If

the

with

of

the

lever

in

the

g s

tud

ht

tap

is

is

LOOPER

MOTIONS

in

the

operating

Fig.

of

turn

side

the

8}

of

needle

the

of

AND

direction

moves

the

to

needle

with

handwheel

Fig.

5

the

left

(B).

respect

in

the

11

Page 12

To

remove

oil

reservoir

and

C

light

toward

SYNCHRONIZING

NEEDLE

move

the

stud

cloth

back

remove

1

tap

the

on

the

the

looper

operator~

LOOPER

MOTIONS

forward

plate~

oil

cover1 and

clutch

drive

drive

is

(continued)

(toward

reservoir

on

housing;

lever

all

that

AND

Styles

rocker

is

operator)

top

cover~

53100

then1 a

shaft,

required.

1

B

Fig.

Reset

throat

the

plate

side

For

in

the

throat

that

the

tips

throat

under

hold

nut

plate

the

feed

If

feed

(A~

Fig.

teeth1 and

when

feed

Should

loosen

feed

screws

rocker

retighten

bind

after

Then1 using

the

end

shaft

6

the

of

needle

zig-zag

will

drive

permit

and

SETTING

Styles

feed

dog

plate

of

at

dog

10)

53100

(B)

the

high

dog~

in

position.

teeth

and

teeth

point

to

are

counterclockwise

dog

is

set

properly.

it

be

necessary

(A1 Fig.

shaft

screws.

making

(C)1 and

Make

this

play

and

its

synchronizing

lever

on

motion

(allow.

needle

A

B

1

there

are

of

travel.

C

parallel

1

so

maintain

not

parallel

turn

screw

to

to

move

11)

which

move

sure

adjustment.

the

between

the

to

maximum

010

to.

hole).

THE

and

is

FEED

D1 set

equal

Adjust

this

(B)

raise

the

hold

feed

that

the

looper

the

looper

shaft

using

015

clearance

with

setting.

with

clockwise

the

front

feed

the

rocker

feed

drive

lever

drive

stud1 tighten

screw

that

the

inch

clearance

DOG

the

feed

on

and

3/64

the

supporting

Screw

the

throat

to

teeth.

dog

to

the

feed

rocker

to

desired

rocker

arm

to

take

lever

(D.,

needle

the

rocker

looper

Fig.

hole

between

dog

(A1 Fig.

all

sides.

inch

above

screw

(D)

is

used

plate1 loosen

lower

the

Retighten

left

or

(B)

onto

position

(D)

does

See

the

(C)

front

nut

right

the

and

not

up

8).

in

9)

to

1

1

Fig.

7

(E)

Should

which

it

be

clamp

necessary

the

feed

Fig.

8

to

move

rocker

the

arm

feed

to

the

forward

retighten

dog

and

depth

Maintain

stop

there

prongs

feed

from

more

may

described

dog

feed

For

so

that

Space

dog

forward

rocker

or

screws.

Style

that

at

of a tooth

this

screw

the

is

equal

and

holding

side

adjustment

be

moved

in

12

or

backward~

and

move

backward

53100

it

is

its

highposition1 it

E1 set

level

above

adjustment

under

feed

the

dog

clearance

the

throat

screws

to

side

for

is

needed1 the

laterally

paragraph

loosen

the

feed

as

needed1 and

the

main

with

the

throat

extends

the

throat

by

means

feed

laterally~

dog

between

plate

this

slots.

and

move

adjustment.

feed

feed

the

same

3.

screws

rocker

feed

plate

plate.

of

holder.

so

that

the

feed

Loosen

dog

dog

1

the

the

If

as

Page 13

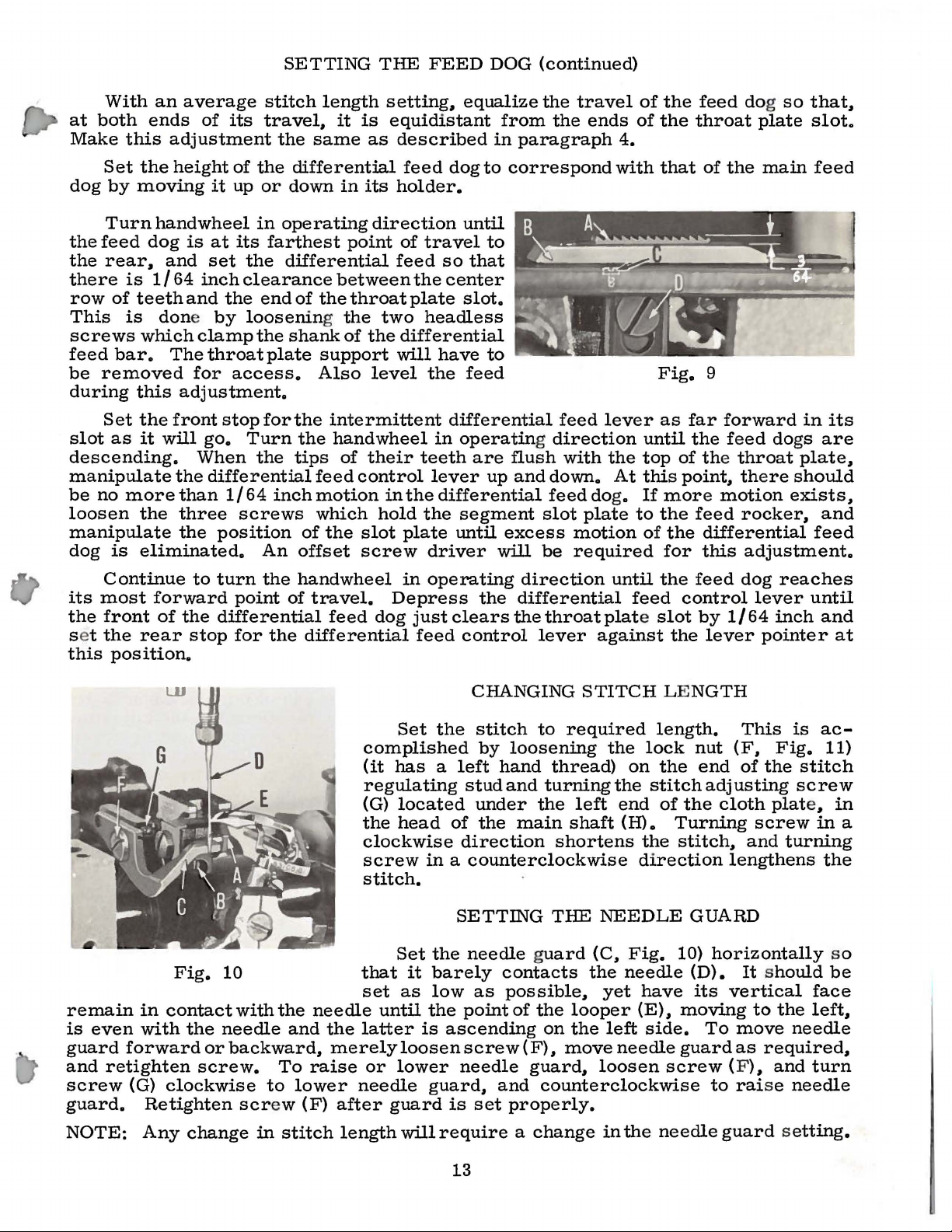

SETTING

THE

FEED

DOG

(continued)

With

at

both

Make

Set

dog

by

Turn

the

feed

the

rear,

there

row

This

screws

feed

be

removed

during

Set

slot

this

the

moving

is

of

teeth

is

bar.

this

the

as

an

ends

hand

dog

1/64

which

it

descending.

manipulate

be

no

more

loosen

the

manipulate

dog

is

eliminated.

average

of

its

adjustment

height

and

done by

it

wheel

is

at

set

inch

and

clamp

of

the

up

in

its

the

clearance

the

end

loosening the

the

Thethroatplate

for

access.

adjustment.

front

will

stop

go.

When

the

differential

than

1/64

three

the

position

Turn

the

screws

stitch

length

travel,

the

same

differential

or

down

operating

farthest

differential

of

the

shank

support

Also

for

the

the

tips

feed

inch

motion

which

of

An

offset

setting,

it

is

equidistant

as

described

feed

in

its

holder.

direction

point

of

feed

between

throat

plate

two

of

the

differential

will

level

intermittent

handwheel

of

their

control

in

the

hold

the

slot

plate

screw

equalize

from

in

paragraph

dog

to

correspond

until

travel

the

so

that

center

slot.

to

......

•

headless

have

the

to

feed

differential

in

operating direction

teeth

lever

are

up

flush

and

differential

the

segment

until

driver

excess

will

the

travel

the

ends

feed

lever

with

down.

feed dog.

slot

plate

motion

be

required

of

the

of

the

4.

with

that

Fig.

as

until

the

top

of the

At

this point, the

If

more motion

to

the

of

the

for

feed dog

throat

of

the

so

plate

main

9

far

forward

the feed dogs

throat

re

should

exists,

feed

rocker,

differential

this

adjustment.

that,

slot.

feed

in

its

are

plate,

and

feed

Continue

its

most

the

front

s et

the

this

position.

remain

is

even

guard

and

retighten

screw

guard.

forward

of

the

rear

in

contact

with

forward

(G)

clockwise

Retighten

to

turn

point

differential

stop

for

with

the

needle

or

backward,

screw.

scr

the

handwheel

of

the

differential

the

and

To

to

lower

ew

(F)

travel.

feed

needle

the

merely

raise

after

in

operating

Depress

dog

justclearsthethroatplat

feed

Set

the

complished

(it

has a left

regulating

(G)

located

the

head

clockwise

screw

in a counterclockwise

stitch.

Set

the

that

it

barely

set

as

low

until

latter

the

is

loosen

or

lower

needle

guard,

guard

direction

the

differential

control

CHANGING

stitch

by

loosening

hand

stud

and

under

of

the

main

direction

SETTING

needle guard

contacts

as

possible,

point

of

ascending

screw

needle

(F),

guard,

and

is

set

properly.

until

the

feed

e

slot

lever

to

turning

the

the

on

against

STITCH

required

the

thread)

left

shaft

shortens

THE

NEEDLE

(C,

the

yet

looper

the

left

move

loosen

length.

lock

on

the

the

stitch

end

of

(H).

the

di

rection

Fig.

needle

have

(E),

side.

needle

LE

screw (F),

counterclockwise

feed

control

by

the

lever

NGTH

nut

end

adjusting

the

cloth

Turning

stitch,

GUARD

10)

horizontally

(D).

its

moving

To

guard

to

dog

reaches

lever

1/64

inch

pointer

This

(F,

of

Fig.

the

is

stitch

screw

plat

screw

and

turning

lengthens

It

s

hould

vertical

to

the

move

as

needle

required,

and

rai

se

needle

until

and

ac-

11)

e,

in

the

s o

be

face

left,

turn

at

in

a

NOTE:

Any

change

in

stitch

length

will

require a change

13

in

the

needle

guard setting.

Page 14

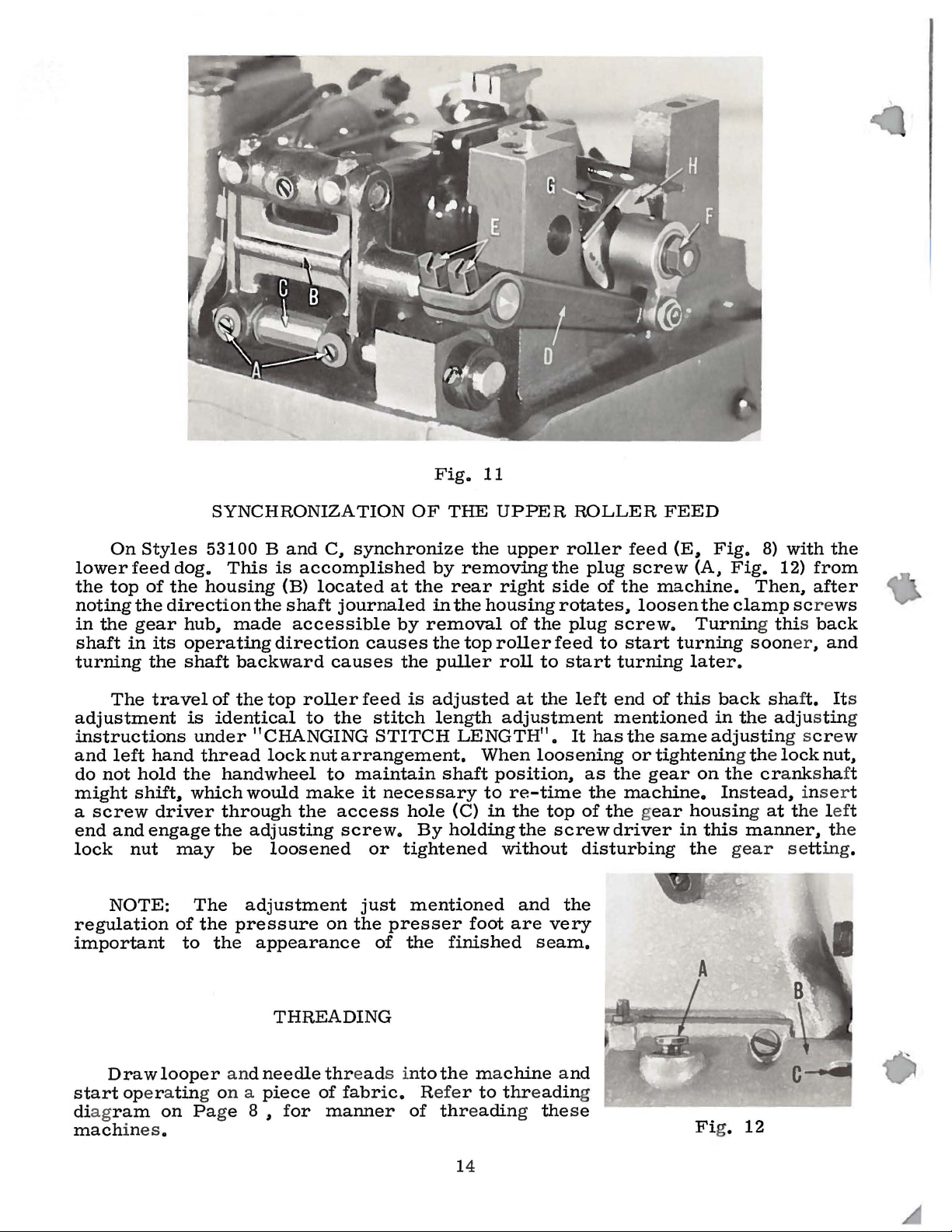

Fig.

11

On

Styles

lower

the

noting

in

shaft

turning

top

the

The

feed

of

the

gear

in

the

travel

its

adjustment

instructions

and

left

hand

do

not

hold

might

a

end

lock

shift,

screw

driver

andengagethe

nut

NOTE:

regulation

important

SYNCHRONIZATION

53100 B and

dog.

the

direction

This

housing

hub,

made

operating

shaft

is

backward

of

the

identical

under

thread

the

handwheel

which

would

through

is

accomplished

(B)

the

shaft

accessible

direction

top

roller

11

to

CHANGING

lock

make

the

adjusting

may

of

to

The

the

the

be

loosened

adjustment

pressure

appearance

C,

synchronize

located

journaled

causes

causes

feed

the

stitch

STITCH

nut

arrangement.

to

maintain

it

access

screw.

or

just

on

the

of

OF

THE

by

at

the

rear

in

the

by

removal

the

the

puller

is

adjusted

length

shaft

necessary

hole

(C)

By

holdingthe

tightened

mentioned

presser

the

finished

UPPER

the

upper

removing

right

housing

of

top

roller

roll

at

adjustment

LENGTH

When

position,

to

re-time

in

the

without

and

foot

are

ROLLER

roller

the

plug

side

of

rotates,

the

plug

feed

to

to

start

the

left

11

•

It

has

loosening

as

the

top

of

screwdriver

disturbing

the

very

seam.

FEED

feed

(E,

screw

the

machine.

loosen

screw.

start

turning

end

of

mentioned

the

same

or

tightening the lock

the

gear

machine.

the gear

Fig.

(A,

the

8)

with

Fig.

12)

Then,

clamp scre

from

after

Turning this back

turning

soon

er 1 and

later.

this

back

in

adjustin

on

shaft. Its

the

adjustin

g screw

the crankshaft

Instead, inser

housing at the left

in

this

manner, the

the

gear

setting

the

ws

g

nut,

t

.

THREADING

Drawlooper

start opera

diagram

machines

tin

on Page 8 ,

.

an

g on a

dneedlethreads in

piece

for

of

fabric.

manner

toth

e ma

R

efer to

of

threading the

14

chine and

threadi

ng

se

Fi

g.

12

Page 15

SETTING

THE

LOOPER

THREAD

TAKE-UP

The

equal

main

compensate

correctly,

off

the

of

the

underside

eyelets

adjustable,

amount

Moving

thread

them

Set

the

its

extreme

been

not

controls

and

it

thread

of

the

to

left.

cast-off

clearance

shaft,

highest

needle

(E),

of

the

to

forward

eyelets

removed

become

the

is

set

triangle

looper

and

for

when

of

the

located

and

thread

eyelets

be

pulled

causes

position

taut.

amount

correctly

when

plate

on

each

consequently,

varying

the

looper

lobe

of

the

(C)

is

clearly

looper

on

their

pulled

to

from

less

so

that,

to

from

from

the

The

of

slack

when

being

the

(A,

Fig.

side.

conditions.

take-up

(D).

the

settin

off

the

the

thread

when

the

left,

looper

retaining finger

thread

it

wiped

looper

13)

The

can

thread

when

visible

The

looper

cast-off

g

determines

by

rear

cones,

the

prevents

causes

to

looper

all

thread,

in

under

moves

should

looper

is

plate,

the

and

be

pulled

the

the

the

from

be

set

It

is

just

the

point

below

thread

take-up.

more

movin

reaches

slack

but

it

system,

looper

the

blade

right

be

set

thread

to

set

cast

the

are

the

g

off.

has

has

(F)

over

take-up

the

take-up

(B)

is

Fig.

not

13

so

that

spotted

A

there

on

is

the

The

stitches

be

just

Regulate

enough

directly

on

the

of

the

tension

on

the

sufficient

pressure

behind

upper

material

Fig.

under

the

presser

the

roller

being

on

the

to

steady

on

needle

feed,

14

needle

surface

spring

the

presser

bar

using

sewn.

THREAD

thread

of

the

fabric.

the

thread.

PRESSER FOOT

regulating

foot

in

the

head

only

located

(C),

above

completed

thread

amount

thread

(Setting

thread

the

TENSIONS

should

to

feed

of

the

enough

SETTING

Set

the

adjacent

so

that

the

frame

tension

this

around

front

be

only

The

tension

PRESSURE

screw

pressure

line

of

retainer

(A,

the

machine.

NEEDLE

needle

its

of

its

downward

eyelet

thread

while

eyelet

the

sufficient

on

the

Fig.

work

thread

to

upper

thread

is

looper

prematurely).

14)

uniformly.

Also, reg

to

insure

THREAD

the

needle

surface

when

stroke.

(D)

so

drawn

the

too

high

to

to

looper

so

that

ulate

the

take-up

projects

the

the

smallest

through

needle

can

be

pulled

produce

thread

it

This

the

uniform

TAKE-UP

(B,

bar

thread

needle

Set

is

descending.

cause

from

uniform

should

exerts

is

Fig.

3/32

the

noticeable

the

the

only

located

pressure

feeding

14),

eyelet

inch

bar

needle

needle

needle

under

has

15

Page 16

The

exert

thread

by

these

spring

only

long

retainers

retainers

enough

enough

SETTING

(A,

pressure

for

the

descending

cannot

on

fly

SPRING

Fig.

or

the

be

15)

needle

pulled

RETAINERS.

on

the

looper

thread,

needle

to

reach a point

to

the

around

left

ON

(B)

of

LOOPER

are

set

the

looper,

where

the

needle.

correctly

to

the

thread

when

retard

released

they

this

that

there

Set

the

the

canvas.

needle.

is

adjustable

the

extreme

guide

and

Styles

seaming.

throat

or

plate.

decreasing

Fig.

is

upper

Adjust

for

53100 D

The

15

3/16

folder

Set

the

the

to

take

narrow

the

extreme

edge

There

the

The

thread

begins

1/8

when

Styles

so

raised,

inch

the

that,

On

to

53100 B

the

Styles

presser

the

body

inch

margin

so

that

body

canvas

waistbands

width,

the

guide

guide

remove

wide

on

the

needle

so

that

to

from 1 3/4

width,

and E are equipped

guide

is

space

should

an

in

between

and

be

out

the

THREAD

tension

function

of

the

presser

when

feed

end

and

the

roller

as

of

foot

C,

presser

SETTING

foot

and

under

53100

as

waistband

Band

possible

ply

penetration

there

conform

is a margin

to

to 4 inches

the

right

remove

the

with a swing-out

set

down

snugly

adjustment

two

abutted

TENSION

release

the

presser

its

reaches

adjust

does

THE

material.

of

the

is

the

width

hand

left

screw

edges.

RELEASE

is

set

foot

is

travel

feed

foot

not

and

is

its

highest

roller

and

the

contact

ATTACHMENTS

C,

setthefolder

and

still

allow

Adjust

canvas

1/32

of

of

wide.

attaching

attaching

edge

against

and

inch

1/4

the

the

lock

to

from

inch

canvas.

To

screw

screw.

guide

stitch

nut

correctly

raised

entirely

position.

lifter

feed

the

presser

as

free

it

laterally

the

left

the

top

to

the

adapt

for

for

abutted

tongue

for

when

to

within

released

On

connection

roller

are

foot.

closetothe

passage

so

of

needle.

edge

right

The

folder

folder

the

for

canvas

edge

in

the

increasing

it

of

of

of

Style

or

ruffling.

right

guide~

ply

the

distance

53100 E

If

will

be

left

from

its

is

set

on

ruffled.

ply

will

edge

equipped

the

right

If

be

to

the

with

side

set

on

ruffled.

front

an

auxiliary

of

the

The

edge

and

left

side

pressure

of

the

16

pressure

against

of

throat

the

and

plate

plate

plate

to

swing-out

against

should

is

19/32

produce

edge

the

swing-out

be

set

inch.

gathering

guide,

edge

so

that

the

the

Page 17

EX

PLOD

ED VIE WS

AND

DESCRIPTIO

CLASS

53100

FOR

ZIG-

N OF PA

ZAG

MACHINE

RTS

S

17

Page 18

18

7

4

7

Page 19

MAIN

FRAME,

CAST-OFF

PLATE,

MISCELLANEOUS COVERS

AND

PLAT

ES

"-

,.

'

' ·

~

'

Ref.

' 2

'-

•.

•

59

60

61

62

63

64

65

66

67

No.

1

lA

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

AB21375 AH

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

Part

No.

50-216 Blk.

21657 E

22528

22768

87

u

52904 E

52804 E

52904 B

22516

52957

c

52958 D

73 A

52904 G

57

WD

15438 c

57

WB

43296

605 A

98A

20

539

53191

51758

93

53182 E

22570 A

93

22570 A

53182 F

53182 G

53182 A

53137

c

22760 B

53137 D

376

22569 B

53182

39582 L

AC

52882

50-789

22564 B

53182 N

53182 B

c

53182

719

22565

53170

53182 D

22565

51294 R

35731 A

51294

p

22513

7947

53182

K

53182 J

53182 L

22569 B

22848

20

51282 AH

53137 A

22889 A

539

20

22848

53182 M

Blk.

Descr iption

Dowel Pi

n--------------------------------------------------------

Washer---------------------------------------------------------Screw

Screw

Screw

Retain

Retaining F

Retaining Fing

Screw

Cast-O

-----------------------------------------------------------

-----------------------------------------------------------

-----------------------------------------------------------

ing Finger

Support Bracket-----------------------------------

inger

Support

------------------------------------------

er--------------------------------------------------

----------------------------------------------------------ff

Support

Plate --------------------------------------------

Eyelet----------------------------------------------------------Scr

ew

-----------------------------------------------------------

ast-Off Wir

C

Nipper

pper

Ni

Nipper S

Thread

Screw, for

Screw

Washer

F

-----------------------------------------------------------

rame Thread

Looper

L

ooper Threa

Scr ew

Cam Gear Fork

B

Screw

Screw

Scr

Cov

-----------------------------------------------------------

el

t G

uard-------------------------------------------------------

-----------------------------------------------------------

-------------------------

ew

-----------------------------------------------------------

er Plate------------------------------------------------------

e-------------

Spr

ing

pr

ing,

ing P

Screw, for

for

late,

ase, for

Spr

Nipper B

Styles 53100 A,

Style

for

-

--------------------------------------

Sty

les 53100 A,

s 53100

Styles

A,

D,

53100

Styles 53100 A,

D,

E

-----------------------------------

D,

E

E-----------------------------

A,

D,

E

-----------------------

D,

E-----------------------

----------------------

---------------------------------------------------------Eyel

et

Thread

d Le

Guard----------

---------------------------------------------

-

ad-In

Eyelet

Frame Support

----------------

------------------------------------Plate

---------------

-

---------------------------------

-

Gasket----------------------------------------------------------Cra

nk Chamber

Needle B

Scr ew

Ne

Scr

Screw

Crank Chamber

Screw

O

il

Baffle

Needle

Screw

Scr ew

Take-Up

Needle

Screw

Screw

Presser

Oil

Screw

Nut--------------------------------------------------------------

ar Fram

-----------------------------------------------------------

edl

e Bar Fr ame Guiqe Plate, rear

ew

-----------------------------------------------------------

-----------------------------------------------------------

lCap-------------------------------------------------------

Oi

Oil

Cap

O

il

Cap

-----------------------------------------------------------

Shi

eld--------------------------------------------------------

Plate------------------------------------------------------

Lever

-----------------------------------------------------------

----------------------------------------------------------Wire----------------------------------------------------

Bar

-----------------------------------------------------------

----------------Bar

Tube

Clamp-----------------------------------------

-------------------------------

Cov

er Gaske

t--------------------------------------

e Guide Plate, fr

Cover---------------------------

Tor sion

Hinge

Bear

Frame

Connect

Spring-----------------------------------------

Pin

---------------------------------------------

ing

Oiler----------------------------------------

Cover------------------------------------------

-

-----------------------------------------

ion Guide

Plate--------------------------------

ont-------------------------------

-------------------------------

-

-

---------------------------

Gasket-----------------------------------------------------------

Cover------------------------------------------------------

Head

Felt

Liner----------------------------------------------------

Screw

Screw

Washer---------------------------------------------------------Oil

Needle

PlugScrew-------------------------Needle

-----------------------------------------------------------

-----------------------------------------------------------

Shi

eld,

end

and

Bar

Frame

Thread

back, for

Guide

Eyelet

---------------------------------------------

Styles

53100 A,

B, C,

Pin---------------------------------------

-

----------------------------

D

Washer----------------------------------------------------------

Screw

EndGasket-------------------------------------------------------

-----------------------------------------------------------

-----------------

-

---------------

-----------------

-

---------

----------------

Amt.

Req.

2

1

1

1

1

1

1

1

1

1

2

3

1

1

1

1

1

1

1

1

1

1

1

2

1

1

10

2

2

1

1

1

1

2

1

1

3

1

1

1

1

2

1

1

1

2

1

1

1

3

1

2

1

3

1

1

1

1

5

3

3

1

2

1

1

1

1

1

19

Page 20

46 47

20

Page 21

CLO

T H

PLATES

,

CL

OT H

PLATE COVERS, MISCELLANE

OUS COVERS AND ATTACHMENT

S

Re

f.

No.

'-1

2

3

4

5

6

'

7

8

9

'

10

., 11

12

'-1

3

14

15

' 16

17

18

19

20

21

22

23

24

' 25

26

27 23425

.......

28

29

30

.........

31

32

33

34

35

' 36

37

38

39

40

41

'-

42

'

43

44

45

46 53101

'-4

7

'

'-4

8

'-49

50

51

'-

52

'53

'-54

55

56 51

57

58

59

60

61 22

62

63

64

65

66 51280

Part

N

25 s

51282

51282

52978

52882

52882

22548

51 4 80 c

51301

22760

3577

2 H

51281

2

284

5 B

512

81 AJ -219

5

1281

25 c

29480

39

531 F

77 A

39

531 B

60

4

39531

53

132 B

53132

22561

531

32

2

2514

23450 L

188

83

72 A

23 4 50 u

23450 M

234 50 p

2345

0 R

90

2345

0 v

23450 N

2

345

0 T

23450

s

53102

22

760

A

35772 H

25 c

23

45

0 w

80

22

845

B

88 D

25

343

s

7 G

39 c

2

228

22585 A

22524

5

378

2 B

382