Page 1

®

INDUSTRIAL

SEWING

FINEST

ST

5290

YL

QUALI

ES

0BF

52900BG

52900BH

52900BL

52900BM

TY

LEWIS

•

COLUMBIA

MACHINES

52900BN

52900BP

52900BR

CATALOG

No.

97N

Second

Edition

SAFETY

FRONT

CLASS

52900

STREAMLINED

HIGH

SPEED

STITCH

DISPOSAL

OF

MACHINES

TRIMM

IN

GS

C H

ICAGO

Page 2

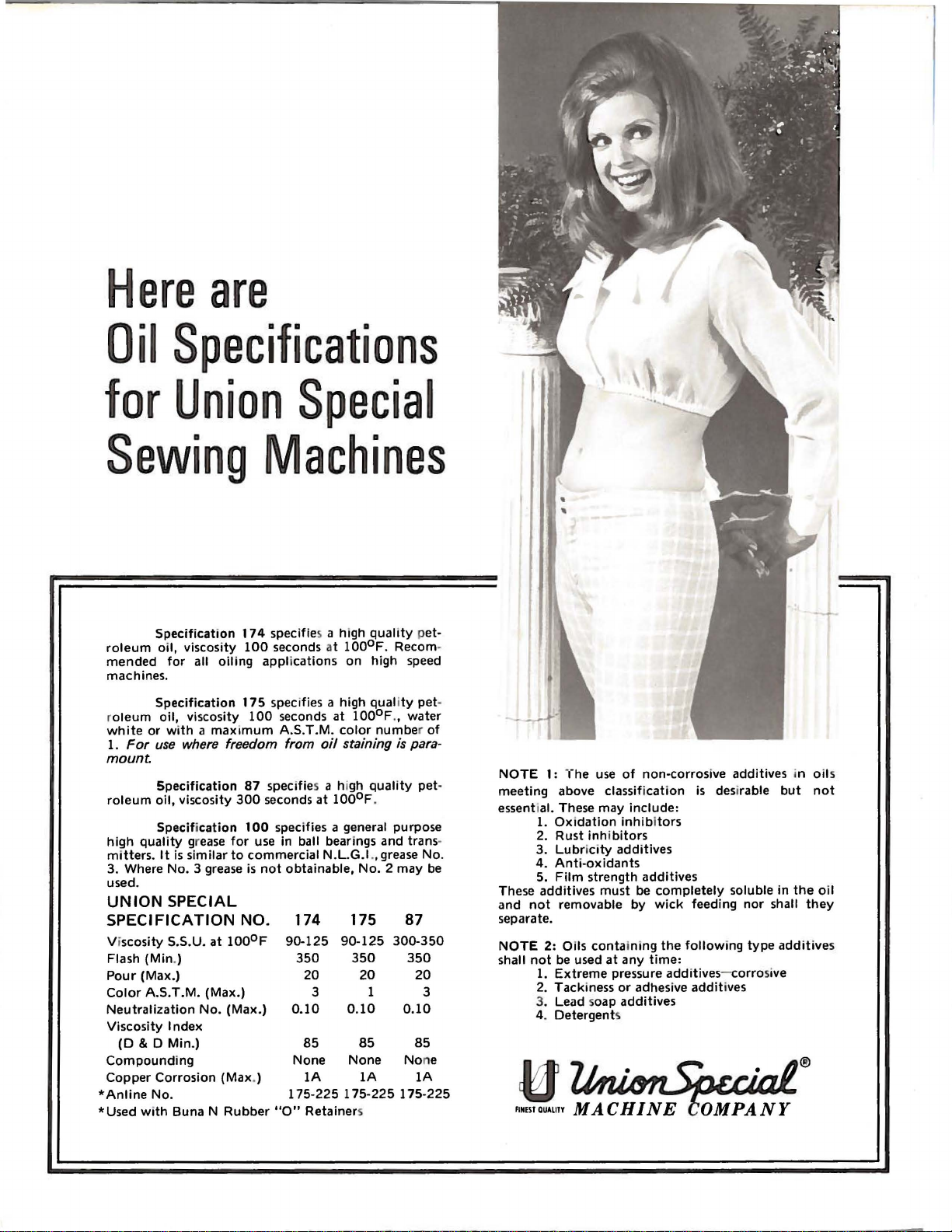

Here

are

Oil

for

Specification

Union

Sewing

roleum

mended

machines.

r

white

1.

mount.

roleum

high

mitters.

3. Where

used.

UNION

Specification

oil, viscosity

for

Specification

oleum

oil,

viscosity

or with a maximum

For

use

where freedom from

Specification

oil,

viscosity

Specifi

quali

ty grease

It

is

similar

No.

SPECIAL

all

3 grease

SPECIFICATION NO.

Viscosity S.S.U. at

Flash

(Min

.)

Pour

(Max.)

Color

A.S.T.M.

Neutralization

Viscosity

(D

Compounding

Copper Corrosi

*Anline No.

*Used with

& D

Index

Min

.)

Buna N

174

100

oiling

175

100

87

300

cation 1 00

for

use in ball bearings and trans-

to

commercial

is

100oF

(Max.)

No.

(Max.)

on

(Max

.)

Rubber

not

s

Special

Machines

specifies a hi

seconds at

appl ications

specifies a high quali

seconds at 1

A.S.T.M.

speci

fie

seconds at

specifies a general purpose

obtainable,

174 175 87

90-125

350

20

0.10

85 85

None

1A

175-225

"0"

gh

qual i

100°F

on

color

oil

staining

s a hi

gh

100°F

N.L.G.I.,

90-125

350 350

3 1 3

0.

None

175-225

Retainers

ty

. Recom-

high speed

ty

00°F

., water

number of

is

quality

.

grease

No. 2 may

300-350

20 20

10

0.

No

1A

175-225

pet-

pet

para-

pet

No.

be

10

85

ne

1A

-

-

NOTE

meeting

essential. These

These additives

and

separate.

NOTE

shall

1:

The

above classificati

1.

Oxidation

2. Rust

3.

Lubricity

4.

Anti-oxidants

5.

Film

not

removable

2:

Oils

not

be

used

1.

Extreme

2.

Tackiness

3. Lead soap

4.

Detergent

use

of

non-corrosive additives in

may

include:

inhibitors

inhibitors

additives

strength

conta

additives

must

be

completely

by

wick

ining

any

time:

or

adhesive

additives

s

the

at

pressure additives-

on

is

feeding

following

additives

desirable

soluble in

nor

type

corrosive

but

the

shall

they

additives

oil

not

oil

s

Page 3

Catalog

No.

9 7 N

LIST

52900

52900

52900

For

BF

BG

BH

Second

OF

Styles

52900

52900

PARTS

52900

BP

BR

Edition

52900

52900

BL

BM

BN

December,

1971

Union

Rights

Copyright

by

Special

Reserved

1960

Machine

in

All

MACHINE COMPANY

INDUSTRIAL

Printed

SEWING

CHICAGO

in

3

MACHINES

U.S.A.

Co.

Countries

Page 4

The

se

latest

improv

ed

FOREWORD

famous

Union

Special "Safety

Stitch",

Class

52900

machin

types

beach

street

and similar garment

smoother

required

type

which

our

The

es off

of g

arments

and

and

New

Increased

It

customers

light

operating.

to

oil

return

returns

is

our

following

er

many

bathrob

hou

se

weight

lift

the

speed

pump,

any

constant

to

pages

advantages

such

es,

dresses,

foot.

excess

secure

as

pants,

kiddies'

nightgowns,

s.

parts and needle

A

new

light

has

been

used

aim

illustrate

in

oil

to

furnish

all

on

slacks,

corduroy

weight

made

conjunction

to

reservoir.

possible

and

possible by

carefully pre

advantages from

describe

s e

aming-overedging

ladies'

overalls,

dungarees,

bearings

presser

with

isolated

the

skirts,

make

bar

design

pared

part

operations

jackets,

sport

ladies•

mechanism

information

s f

shirts,

jeans,

them lig

changes

mounting

the

use

or

Styl

es

on

various

bathing suits,

ladies'

pe

hter

reduces

and

oil

pan

which

of Uni

in Class 52900

dal

running

the

new

base

will

on

blouses,

pushers

pressure

Speci

filter

plat

ena

als .

and

e,

ble

-

front

Union

to

cooperate

disposal

Special

of trim

with

mings.

representatives

you

to

plan

and estimate

will

be

found

requirements.

4

in

all

~

manufacturi

Engineer i

ng cente

MACHINECOMPANY

ng

rs,

Departm

rea

en

dy

t

Page 5

IDENTIFICATION

OF

MACHINE

Each

on

the

machine.

Style

Example:

only

Style

a

5-8

to

extreme

represents

401

and

needle.

herein.

Class.

from

handwheel

numbers

minor changes

number.

The

gauge

gauge

middle

stitch,

finally

This

Reference

the

Union

"Style

distance

number

represents

or

left

right

catalog

It

operator's

a

11/64

12/64

can

is

toward

needle.

distance

Special

Style

have

Example:

one

52900

are

between

measured

a

needle

of

an

or

applies

also

be

to

position

the

3/16

direction

carries

numbers

or

more

BF".

made

distance

Similarly,

of

inch

applied

operator.

Special

in a standard

"Style

the

rows

in

1/64ths

of

of

60 2

1/64

of

from

of

an

APPLICATION

specifically

while

a

Style

are

letters

52900

of

5/64

stitch

1-11-12

an inch

right

inch

with

such

number

classified

suffixed,

Style

machine,

BFZ".

stitches

of

an

inch

and

from

row

from

seated

left

OF

to

the

discretion

as

right,

which

as

numbers

or

between

inch,

from

8/64

gauge

of

at

left

or

on

left

401

needle

CATALOG

standard

to

left,

the

machine.

is

standard

but

never

contain

a"

Z"

going

needle

1/8

inch

tandem

row

of

stitch

of

602

Styles

some

front,

stamped

and

contain

the

is

suffixed

needles

from

(needle

from

needle

401

stitch

to

left

stitch

of

Spe

cial

back,

Operating

in

the

special.

the

letter

is

left

middle

needle

to

machines

machines

"Z".

to the standard

represented

to

right.

for

Style

to

right

of

extreme

etc.,

direction

name

Standard

letter

401

stitch)

needle

52900

row

602

as

in

are

plat

"Z''.

When

by

Thus,

to

BP

of

stitch

right

listed

this

given

of

e

High

Trimmer,

Driving

Stitch,

Otherwise

Filter

Automatic

52900

52900

52900

Speed

Double

Type

BF

garment

material.

Standard

BG

shirts,

pillow

material.

Standard

R.P.M.

BH

n-seams

i

slacks,

corduroy

Se

am

Nos.

Streamlined

Front

Mechanism.

Specified.

Lubrication

Medium

Medium

ladies'

cases

Medium

specification

5-8,

Disposal

Locked

Oil

Return

pockets

Seam

gauge

and

Seam

gauges

and

out-seams

ladies'

overalls,

12-12,

Three

Stitch

One

P u

of

throw

and

for

specification

No.

throw

blouses,

throw

machine

for

specification

Nos.

skirts,

and

401

16-8.

STYLES

Flat

mp

Spreader

5-8

machine

Bed,

of

Trimmings,

Needles,

on

Reservoir

for

machine

similar

only.

street

similar

5-8,

of

light

jackets,

for

similar

and

602-SSa-2.

Maximum

OF

Medium

Left,

for

16-8,

Four

Enclosed

Main

Mechanism,

for

operations

401

Maximum

simult

and

house

operations

401

for

simultaneous

and

bathing

operations

MACHINES

and

Light

Left

Driving

simultaneous

and

and

24-8.

medium

recommend

Weight

Needle

Thread

Me

602-SSa-2.

ane

ous

dresses,

on

602-SSa-2.

Max

suits,

Type

High

Presser

in

Interlock Sti

Automatic

chanism,

Lateral

seaming

on

medium

r e

commended

seaming

shoulder

medium

imum

seamin

weight

beach and bathrob

on lig

ht

128

GAS needle. Standa

ed spe

Throw

Rear,

Looper

recommended

corduroy pant

to

medium weig

ed

Machines,

Bar

Two

tch

Lubricating Sy

Separate

Travel.

and over cdging

to

medium hea

Type

and

to

Type

g a

5000

128

speed

overedging on spor t

pads,

medium heavy weig

128

nd over ed

R. P

Verti

and Needl

Loopers,

on

Rig

ht Unle

st em w

Res e

rvo

vy weig

GAS

5000

co

at

GAS

spe

ging

s,

wash

es, kiddies

ht

m at erial.

rd gauges

.M.

cal

e Bar

Dual

ss

ith

ir

for

on

ht

needle

R. P . M.

lining

needle.

ed

s,

ht

5000

on the

pant s ,

.

'

5

Page 6

STYLES

OF

MACHINES

(Continued)

52900

feed

operations

suits

specification

5-8.

52900

serting

medium

128

speed

52900

and

operations

and

Maximum

52900

ducing

stitch.

ducing

14

602

corduroy.

seaming

jeans.

material.

Standard

BL

Me

mechanism

and

12-12.

BM

Medium

a

to

GAS

4000

BN

High

closing

602-SSa-2.

BP

High

two

Tandem

Type

stitches

overedge

pedal

dium

needle.

on

gauge

throw

for

on

street

for

similar

401

and

16-8.

throw

corded

heavy

R.

throw

on

recommended

throw.

rows

602

per

twill.

men's

Seam

welt

weight

Standard

P.

M.

machine

on

sport

medium

Type

of

needles

stitch.

inch

stitch.

drill.

pushers.

specification

No.

machine

setting

and

house

operations

602-SSa-2.

Maximum

machine

to

furniture

material.

for

shirts.

heavy

147

GS

speed

four

needle.

401

stitching

mounted

The

on

the

401

Designed

etc.

work,

1-11-12

service

and

with

puff

recommended

gauges

side

to

needle.

5000

tandem

stitch

to

For

for

only.

treadle

sleeves.

dresses.

on

Type

with

Seam

Nos.

seaming.

play

heavy

three

1/64

to

handle

inseaming.

and

similar

401

Maximum

shirt

light

128

top

feed

slip

covers

specification

5-8.

pants.

weight

Standard

R.

P.

M.

looper.

inch

left

and

needle

as

compared

materials

semi-dress

operations

and

602-SSa-3.

controlled

backs

nightgowns.

to

medium

GAS

needle.

speed

mechanism

shoulder

heavy

material.

apart

rear

arrangement

side

recommended

5000

and

12-12.

bathrobes.

gauges

tandem

and

of

to 6 stitches

made

seaming.

on

two

pants.

intermittent

to

yokes.

nylon

weight

R.P.M.

for

similar

401

Maximum

seaming.

Seam

Nos.

needle

with a Type

needles

gives

of

medium

Type

blouses.

material.

Standard

for

seaming

and

602-SSk-2.

and

specification

5-8.

machine

seersucker.

front

dungarees.

128

speed

differential

and a variety

bathing

Seam

gauges

and

operations

Type

recommended

sleeve

for

12-12.

602

abreast.

an

equivalent

per

seaming.

to

heavy

GAS

4500

setting

similar

for

overedge

inch

on

denim.

ladies'

weight

needle.

R.

16-8.

P.M.

of

Nos.

in-

on

401

propro-

of

the

seat

52900

throat

press

Standard

Each

kind

denotes

midway

ively.

the

"1000

by

able,

results.

tions.

of

To

empty

The

this

but

BR

Same

plate

material.

needle

shank.

the

largest

between

the

type

have

needle

package.

Needles.

type

numbers

catalog

the

ones

The

type

and

the

as

has • 050

gauges

has a type

point.

the

number

Type

are

indicated

numbers

sizes

Style

Seam

Nos.

length,

diameter

shank

and

orders

or

description

128

of

the

given

in

available

52900

inch

specification

5-8

number

and

size

promptly

GAS,

needles

the

are

of

BH

needle

and

12-12.

groove.

of

the

number

on

Size

machine

those

the

recommended

are

except

holes.

401

Maximum

NEEDLES

and

size

finish

the

blade,

eye.

and

is

is

the

and

accurately

label.

040".

recommended

recommended

listed

A

style

on

next

feed

number.

complete

dog

for

sewing

and

602-SSa-2.

recommended

and

other

measured

stamped

complete

filled.

for

description.

to

needles

page.

has

teeth

garments

Type

The

type

details.

in

thousandths

in

the

needle

symbol.

forward a sample

order

each

produce

together

would

style

Other

of

the

cut

22

made

128

speed

number

The

shank.

read

machine

needles

most

with

their

per

inch

of

durable

GAS

needle.

5000

R.

P.M.

denotes

size

number

of

an

inch,

Collect-

needle,

as

follows:

covered

are

avail-

satisfactory

descrip-

and

the

6

Page 7

Type No.

NEEDLES

(Continued)

De

scription

and

Sizes

128

GAS

147

GS

Selection

Thread

should

ofthe

formation.

ILLUSTRATIONS

This

views

seen

will

be

number

Numbers

the

position

in

ordering

catalog

of

various

in

their

actual

found a listing

of

pieces

in

of

that

parts.

Component

indicated

assembly.

by

indenting

Example:

proper

pass

has

sections

required

the

part

Always

parts

Short.

mium

Long.

point.

double

plated-

double

undersize

plated -sizes

needle

freely

through

ORDERING

been

position

first

of

arranged

of

the

in

the

of

the

parts

in

the

column

in

the

illustration.

use

the

sub-assemblies

their

descriptions

groove.

sizes

groove.

eye

and

032.

size

036. 040. 044,

should

needle

REP

to

mechanism

machine.

with

particular

are

reference

part

number

struck

032,

036, 040.

struck

grooves.

be

eye

AIR

simplify

are

On

their

parts

view

Reference

which

under

groove.

groove.

one

049,

determined

in

order

PARTS

ordering

shown

the

page

numbers.

being

shown.

numbers

numbers

listed

can

the

in

be

description

ball

eye.

044. 049.

ball

eye.

step

reduction.

054. 060, 067.

by

size

to

produce

repair

so

that the

opposite

descriptions

only.

and

should

the

second

furnished

of

parts.

the

merely

never

column.

for

of

the

spotted

054,

060,

spotted

chromium

thread

a

good

Exploded

parts

illustration

indicate

be

repairs

main

chro-

short

used.

stitch

may

and

used

sub-

067.

be

the

are

62

63

64

65

66

It

will

be

The

reason

the

complete

In

those

catalog.

parts

styles

be

mentioned

the

illustration.

this

part

no

for

covered

At

the

book.

number

the

back

This

Where

On

some

of

identification

29476

22587

22729

51243

22559

noted

is

in

that

replacement

the

sub-assembly

cases

specific

where a part

usage

various

on

that

in

the

of

the

will

facilitate

is

known.

the

construction

the

smaller

letter

is

LE

c

A

above

should

will

machines

page

description

book

parts.

stamped

will

will

locating

IDENTIFYING

permits.

Looper

Screw.

Screw--------------------------------

Ball

Screw.

example

of

be

are

and,

be

that

these

be

is

parts

ordered.

common

mentioned

not

be

noted

if

necessary.

found a numerical

the

each

and

on

those

in

to

distinguish

Driving

Lever

upper

Stud

Guide------------------------

lower

the

eccentric

individually

to

all

in

the

the

same.

on

top

of

illustration

PARTS

part

where

is

construction

the

Crank

Assembly

-------------------------

------------------------and

bearing

is

not

recommended,

of

the

machines

description.

(the

specific

page

the

difference

index

and

or)

of

description

stamped

However.

the

specific

all

with

machine

the

its

does

part

from

similar

are

covered

will

be

parts

when

part

not

ones.

------

not

listed.

by

when

style

usage

shown

shown

only

number.

permit,

1

2

1

1

2

so

this

the

or

will

in

in

the

an

7

Page 8

IDENTIFYING

PARTS

(Continued)

Part

numbers

appear.

IMPORTANT!

OF

MACHINE

Success

Union

Special Nee

Company. its

to

the

most

Maximum

efficiency

Genuine

repair

your

parts

guarantee

Prices

forwarded

wis

e di r ecte

f.

represent

ON

FOR

WHICH

USE

in

the

dles

subsidiaries

approved

needles

are

stamped

of

the

are

net

o.

b.

shipping

d.

A

charge

ALL

ORDERS~

PART

GENUINE

operation

and

Repair

and

scientific

and

durability

are

packaged

with

highest

cash

and

point.

is

the

sam

IS

NEEDLES

of

these

Parts as

authorized

principles~

are

the

Union

quality

subject

Parcel

made

to

OILING

part~

PLEASE

ORDERED.

AND

machines

furnished

distributors.

a

assured.

with

labels

Special

in

materials

TERMS

to

change

Post

cover

AND

postag

THREADING

regardless

INCLUDE

REPAIR

can

be

by

They

nd

are

made

marked

trade

and

workmanship.

without

shipments

and

of

PART

PARTS

secured

the

Union

are

with

~

mark.

notice.

are

insuranc

catalog in

NAME

only

Special

design

ed

utmost

Each trade

All shi

insured

unless other-

e.

which

AND

with

STYLE

genuine

Machine

according

precision.

.

Genuine

mark

pme

nt s

they

is

are

The

oil

must

Saybolt

be

viscosity

Oil

is

sight gauge

the

red

lines

The

machine

main

Oil

reservo

r

hand

eser

reservoir

A

daily

which

ir

voir

wheel.

On the

covered

la

en

in

rged for

has

filled

fill

ed

on

on

check

has

making

may

next

been

before

of

at

the

the

is

filled

before

gone

be

page

drained

200

the

front

gauge.

automatically

is

throu

too

drained

is a

this catalog are

clarity.

from

beginning

to

250

seconds

spring cap

of

the

machine.

The

the

to

operatet>

in

capacity

lubr

necessary.

the

morning start

gh

the

machin

frequent

at

the

oilin

plug

gs

picture showing the

threaded.

machine

Use

at

100

the

The

of

ica

should

e is

top

oil

the

ted

filter

Fahrenheit.

cover

level

oil

and

be

unnecessary.

scr

ew

in

Th

e sprea

before

a

and

should

reservoir

no

made

ed

and

the

main

mann

der

and

shipping

straight

the level is

be

is

oiling

and

other

oil

pumped

Excessive

frame directly

er

in whi

loop

er

and

the

mineral

checked

maintained

12

ounces.

than

keeping th

added

back

ch

oil

th

if

into

in

52900

threading

reservoir

oil

with

at

the

between

required.

the

main

the

main

under

the

Styles

has been

a

e

8

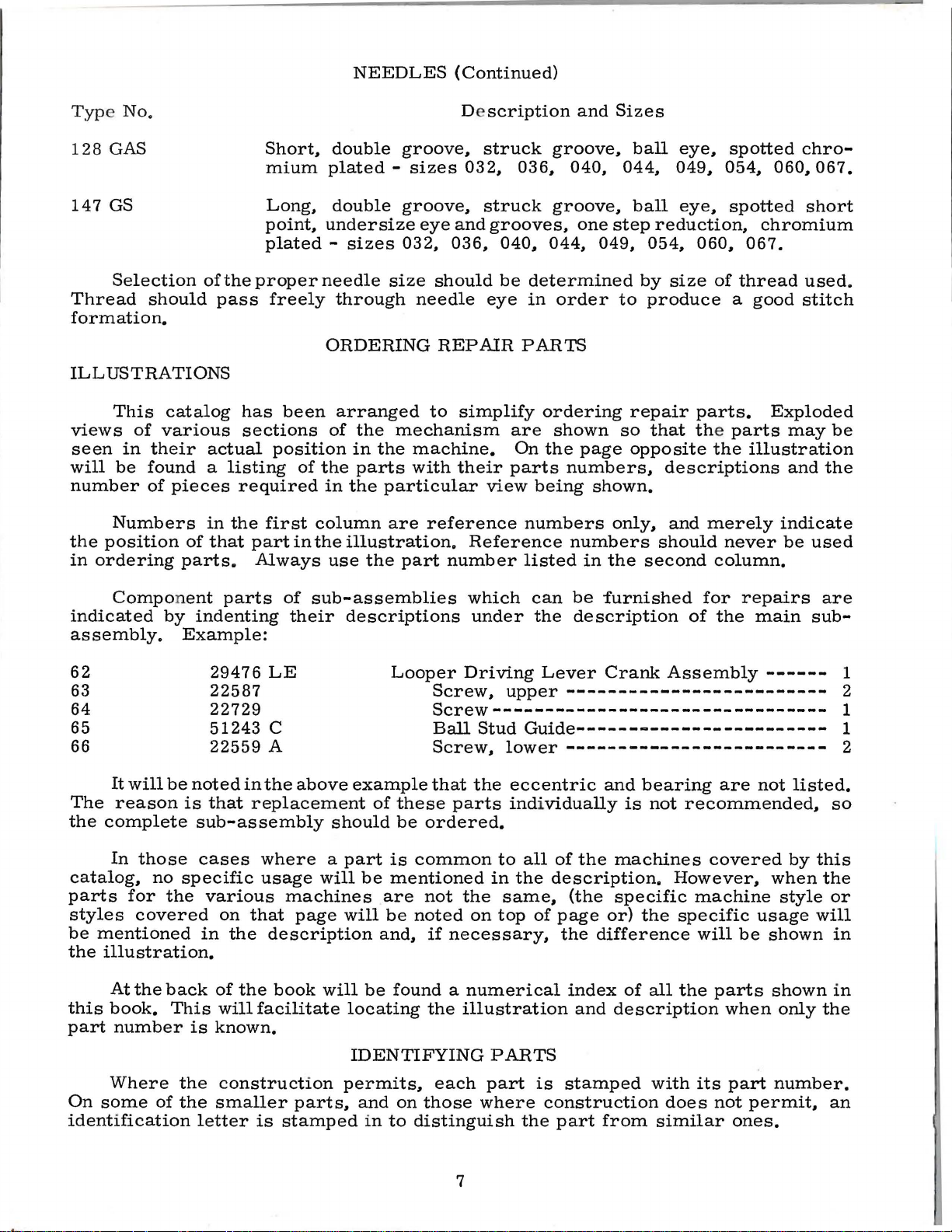

Page 9

THREADING

AND

OILING

DIAGRAM

FOR

STYLES

52900

BF,

BG, BH,

BL,

BM,

BN

FOR

ALL

STYLES

IN

CLASS

52900

FOR STYLE

52900

BP

9

Page 10

10

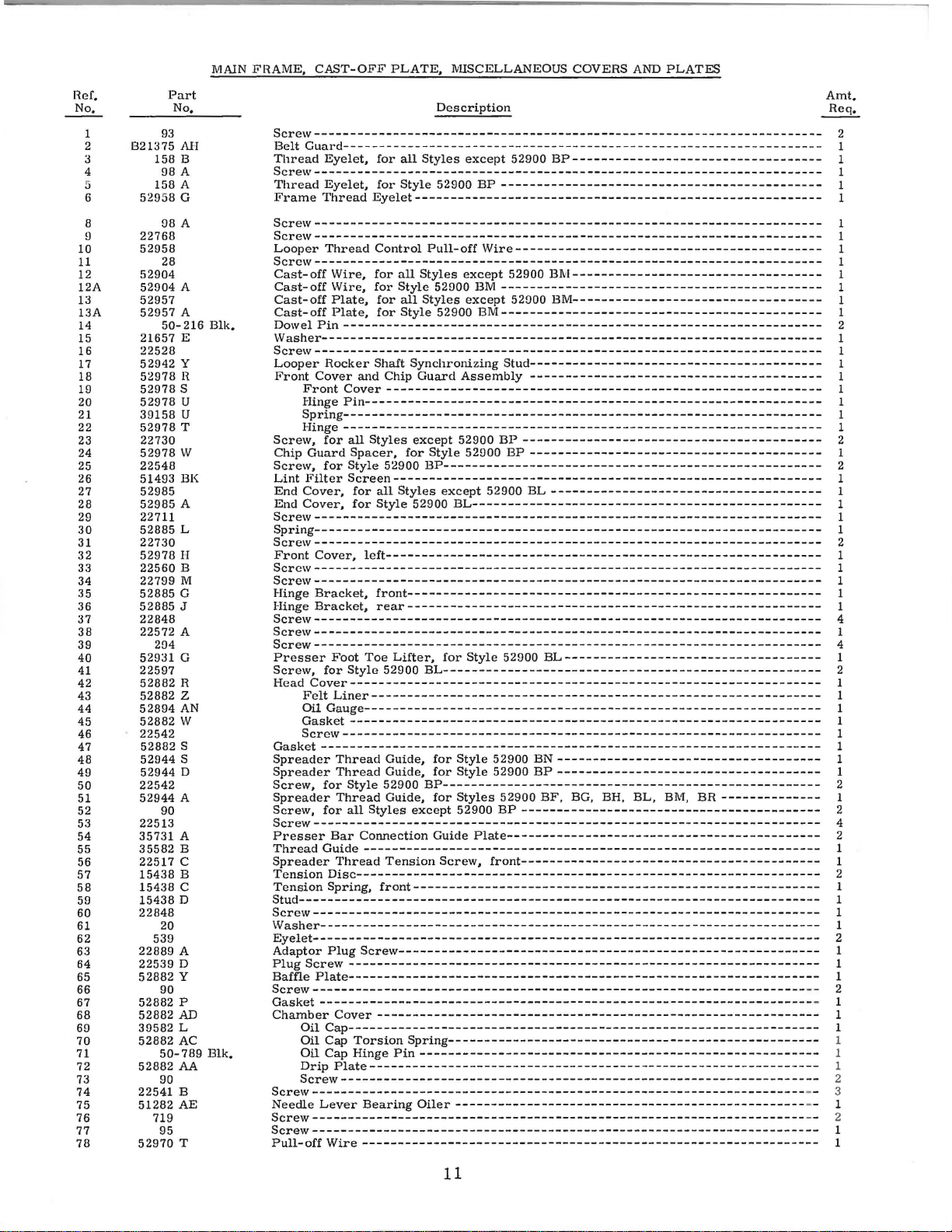

Page 11

Hef,

No,

1

2

3

4

5

6

8

9

10

11

12

12A

13

13A

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

Part

No,

93

821375

158 B

98

158 A

52958 G

08 A

22768

52958

28

52904

52904

52957

52957

50-216

21657 E

22528

52942

52978 H

52978 s

52978 u

39158 u

52978 T

22730

52978

22548

51493

52985

52985

22711

52885

22730

52978

22560 B

22799 M

52885 G

52885 J

22848

22572

204

52931 G

22597

52882

52882 z

52894

52882 w

22542

52882

52944 s

52944 D

22542

52944

90

22513

35731

35582 B

22517 c

15438 B

15438 c

15438 D

22848

20

539

22889

22539 D

52882 y

90

52882 p

52882

39582 L

52882

50-789

52882

90

22541 B

51282 AE

719

95

52970 T

Ali

A

A

A

y

w

BK

A

L

H

A

H

AN

s

A

A

A

AD

AC

AA

MAlN

Blk.

Blk.

FHAME,

CAST-OFF

PLATE,

MISCELLANEOUS COVERS

AND

Description

Screw----------------------------------------------------------------------Belt

Guard-------------------------------------------------------------------

Thread

Eyelet,

for

all

Styles

except

52900

BP-----------------------------------

Screw-----------------------------------------------------------------------

Thread

Frame

Eyelet,

Thread

for

Style 52900

Eyelet---------------------------------------------------------

BP

---------------------------------------------

Screw----------------------------------------------------------------------Screw----------------------------------------------------------------------Looper

Screw-----------------------------------------------------------------------

Cast-off

Cast-off

Cast-off

Cast-off

Dowel

\Vasher---------------------------------------------------------------------Screw----------------------------------------------------------------------Looper

Front

Thread

Pin

Hocker Shaft Synchronizing

Cover

Front

Hinge

Wire,

Wire,

Plate,

Plate,

Control

for

for

for

for

Pull-off

all

Styles

Style 52900

all

Styles

Style 52900

Wire-------------------------------------------

except 52900

BM

---------------------------------------------

except 52000

BJ\.1-----------------------------------

BM-----------------------------------

BM---------------------------------------------

-------------------------------------------------------------------

Stud-----------------------------------------

and Chip

Cover-------------------------------------------------------------

Guard

Assembly

-----------------------------------------

Pin----------------------------------------------------------------

Spring------------------------------------------------------------------Hinge

Screw,

Chip

Screw,

Lint

End

End

-------------------------------------------------------------------

for

all

Guard

Styles except 52900

Spacer,

for

Style 52900

Filter

Screen-----------------------------------------------------------Cover,

Cover,

for

for

for

Style 52000

BP-----------------------------------------------------

all

Styles

Style 52900

except 52900 BL

BL-------------------------------------------------

BP

------------------------------------------

BP

-----------------------------------------

--------------------------------------

Screw----------------------------------------------------------------------Spring----------------------------------------------------------------------Screw----------------------------------------------------------------------Front

Cover,

left------------------------------------------------------------Screw----------------------------------------------------------------------Screw----------------------------------------------------------------------Hinge

Hinge

Bracket,

Bracket,

front----------------------------------------------------------

rear---------------------------------------------------------Scre\v----------------------------------------------------------------------Screw----------------------------------------------------------------------Screw----------------------------------------------------------------------Presser

Screw,

Head

Gasket

Spreader

Spreader

Screw,

Spreader

Screw,

Screw-----------------------------------------------------------------------

Presser

Thread

Spreader

Tension

Tension

Foot

Toe

for

Style 52900

Lifter,

for

Style 52900 BL

------------------------------------

BL-----------------------------------------------------

Cover------------------------------------------------------------------

Felt

Liner---------------------------------------------------------------

Oil

Gauge----------------------------------------------------------------

Gasket

Screw-------------------------------------------------------------------

------------------------------------------------------------------

---------------------------------------------------------------------Thread

Thread

for

Thread

for

Bar

Guide,

Guide,

Style 52900

Guide,

all

Styles except 52900

for

for

BP-----------------------------------------------------

for

Connection Guide

Style 52900

Style 52900

Styles

EN------------------------------------BP

-------------------------------------

52900 BF,

BP

------------------------------------------

BG,

BH, BL, EM, BR

Plate--------------------------------------------

Guide----------------------------------------------------------------

Thread

Tension

Screw,

front-----------------------------------------Disc----------------------------------------------------------------Spring,

front--------------------------------------------------------Stud------------------------------------------------------------------------Screw----------------------------------------------------------------------\Vasher---------------------------------------------------------------------Eyelet----------------------------------------------------------------------Adaptor

Plug

Baffle

Plug

Screw-----------------------------------------------------------

Screw------------------------------------------------------------------

Plate------------------------------------------------------------------

Screw--------------------------------------------------------------------Gasket

Chamber

--------------------------------------------------------------------Cover

Oil

Cap------------------------------------------------------------------

Oil Cap

Oil Cap Hinge

Drip

--------------------------------------------------------------

Torsion

Plate---------------------------------------------------------------

Spring----------------------------------------------------

Pin

--------------------------------------------------------

Screw-------------------------------------------------------------------

Screw---------------------------------------------------------------------

Needle

Lever

Bearing

Oiler------------------------------------------------Screw--------------------------------------------------------------------Screw-----------------------------------------------------------------------

Pull-off

Wire

----------------------------------------------------------------

PLATES

--------------

Amt,

Heq,

--

- 1

-- 3

-- 1

-- 2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

1

2

1

1

1

1

1

4

1

4

1

2

1

1

1

1

1

1

1

1

2

1

2

4

2

1

1

2

1

1

1

1

2

1

1

1

2

1

1

1

1

1

2

1

1

11

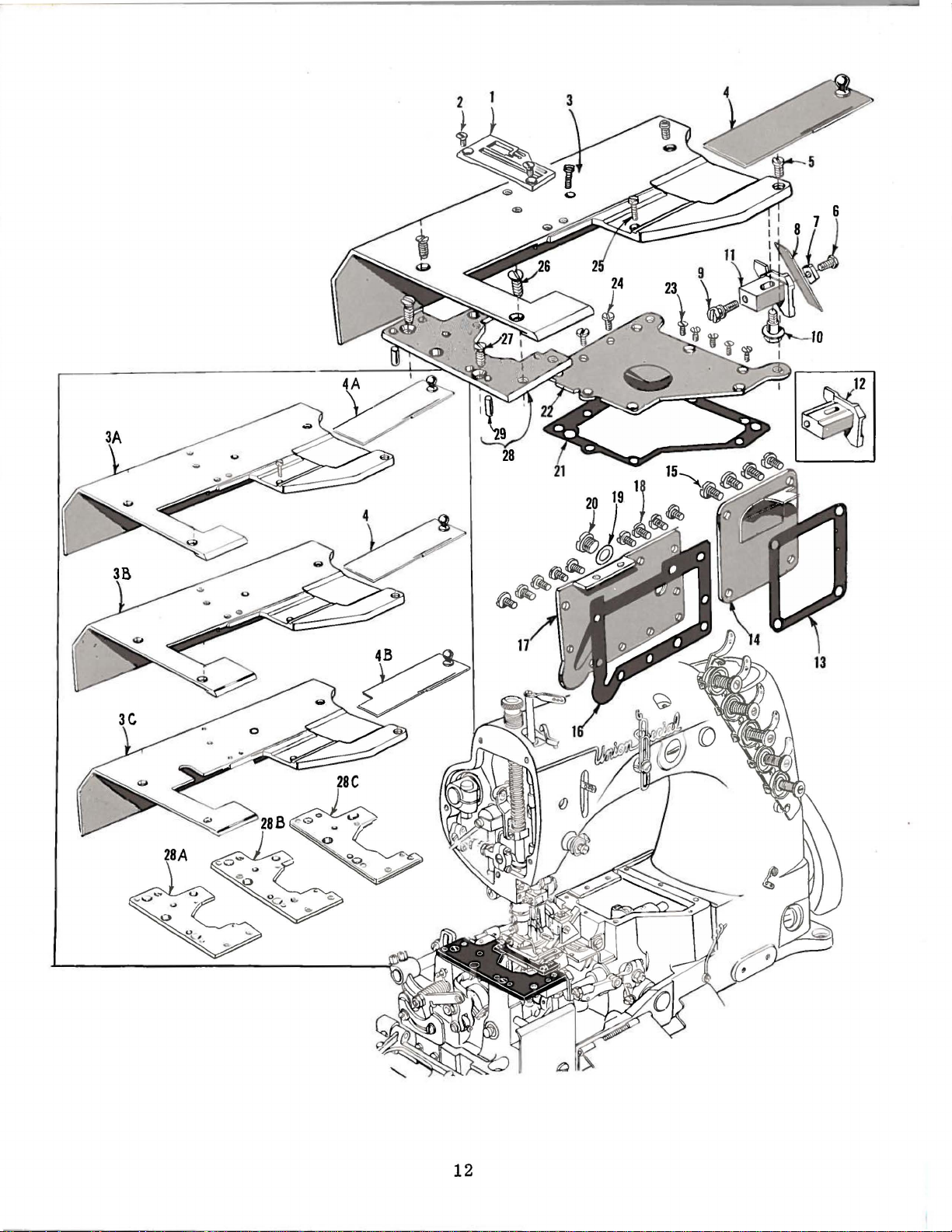

Page 12

12

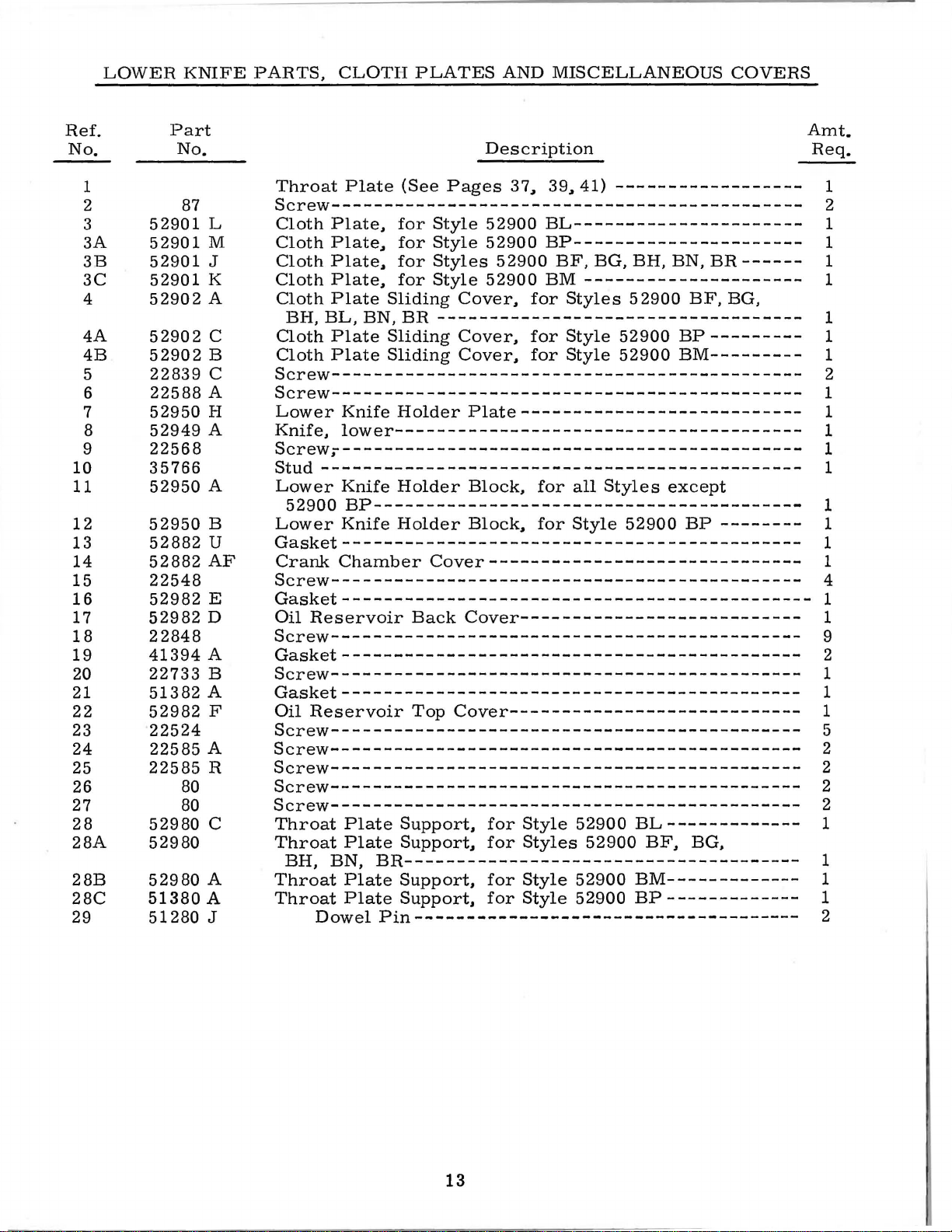

Page 13

LOWER

KNIFE

PARTS,

CLOTH

PLATES

AND

MISCELLANEOUS

COVERS

Ref.

No. No.

1

2 87

3

3A

3B

3C

4

4A

4B

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27 80

28

28A

28B

28C

29

Part

52901

52901

52901

52901

52902

52902

52902

22839

22588

52950

52949

22568

35766

52950

52950

52882

52882

22548

52982

52982

22848

41394

22733

51382

52982

22524

22585

22585

80

52980

52980

52980

51380

51280

L

M

J

K

A

c

B

c

A

H

A

A

B

u

AF

E

D

A

B

A

F

A

R

c

A

A

J

Description

Throat

Screw---------------------------------------------

Cloth

Cloth

Cloth

Cloth

Cloth

BH,

Cloth

Cloth

Screw--------------------------------------------Screw--------------------------------------------Lower

Knife.

Screw;--------------------------------------------

Stud

Lower

52900

Lower

Gasket-------------------------------------------Crank

Screw--------------------------------------------Gasket--------------------------------------------Oil

Screw---------------------------------------------

Gasket-------------------------------------------Screw---------------------------------------------

Gasket--------------------------------------------

Oil

Screw---------------------------------------------

Screw--------------------------------------------Screw--------------------------------------------Screw--------------------------------------------Screw---------------------------------------------

Throat

Throat

BH, BN,

Throat

Throat

Plate

Plate.

Plate

Plate

Plate.

Plate

BL,

Plate

Plate

Knife

lower---------------------------------------

---------------------------------------------Knife

BP-----------------------------------------

Knife

Chamber

Reservoir

Reservoir

Plate

Plate

Plate

Plate

Dowel

(See

Pages

for

Style

..

for

Style

..

for

Styles

for

Style

Sliding

BN,

BR

Sliding

Sliding

Holder

Holder

Holder

Support.

Support

BR--------------------------------------

Support.

Support

Pin-------------------------------------

Cover.

----------------------------------Cover.

Cover.

Cover------------------------------

Back

Top

Cover----------------------------

37

..

39

..

41)

52900

52900

52900

52900

Plate---------------------------

Block.

Block.

Cover---------------------------

for

..

for

for

..

for

BL----------------------

BP----------------------

BF,

BG, BH,

BM

---------------------

for

Styles 5 2900

for

Style

for

Style

for

all

for

Style

Style

Styles

Style

Style

52900

52900

52900

52900

------------------

Styles

BN,

BF,

52900

52900

52900

BP

BM---------

except

BP

BL

-------------

BF.

BG,

BM------------BP

-------------

BR

------

BG,

---------

--------

Amt.

Req.

1

2

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

4

1

1

9

2

1

1

1

5

2

2

2

2

1

1

1

1

2

13

Page 14

14

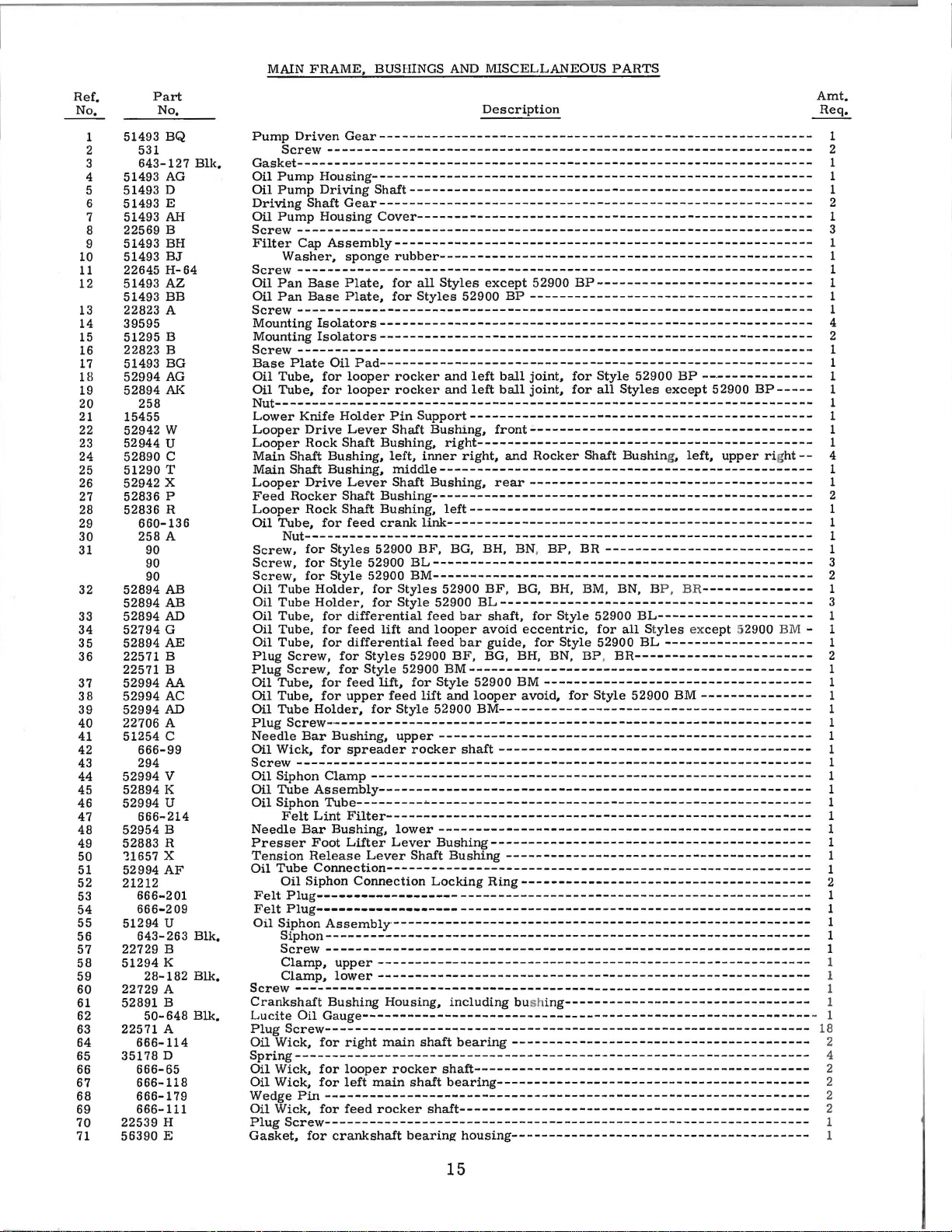

Page 15

MAIN

FRAME,

BUSHINGS AND

MISCELLANEOUS

PARTS

Ref.

~

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

1

2

3

4

5

6

7

8

9

Part

No.

BQ

51493

531

643-127

51493 AG

51493

D

51493

E

51493 AH

22569

B

51493

BH

51493

BJ

22645

H-64

51493

AZ

51493

BB

22823 A

39595

51295

B

22823

B

51493

BG

52994

AG

52894

AK

258

15455

52942

w

52944

u

52890

c

51290

T

52942

X

52836

p

52836 R

660-136

258

A

90

90

90

52894

AB

52894

AB

52894

AD

52794

G

52894

AE

22571

B

22571

B

52994

AA

52994

AC

52994

AD

22706

A

51254

c

666-99

294

52994

v

52894

K

52994

u

666-214

52954

B

52883

R

':!1657 X

52994

AF

21212

666-201

666-209

51294

u

643-263

22729

B

51294

K

28-182

22729

A

52891

B

50-648

22571

A

666-114

35178

D

666-65

666-118

666-179

666-111

22539

H

56390

E

Blk.

Blk.

Blk.

Blk.

Description

Pump

Driven

Screw

Gasket---------------------------------------------------------------------

Oil

Pump

Oil

Pump

DrivingShaftGear---------------------------------------------------------Oil

Pump

Screw

Filter

Washer,

Screw

Oil

Pan

Oil

Pan

Screw

Mounting

Mounting

Screw

Base

Plate

Oil

Tube,

Oil

Tube,

Nut-----------------------------------------------------------------------Lower

Looper

Looper

Main

Shaft

Main

Shaft

Looper

Feed

Rocker

Looper

Oil

Tube,

Nut-------------------------------------------------------------------Screw,

Screw,

Screw,

Oil

Tube

Oil

Tube

Oil

Tube,

Oil

Tube,

Oil

Tube,

Plug

Screw,

Plug

Screw,

Oil

Tube,

Oil

Tube,

Oil

Tube

Plug

Screw-·----------------------------------------------------------------

Needle

Oil

Wick,

Screw

---------------------------------------------------------------------

Oil

Siphon

Oil

Tube

Oil

Siphon

Felt

Needle

Presser

Tension

Oil

Tube

Oil

Fell

Plug------------·-----------------------------------------------------

Felt

Plug------------------------------------------------------------------

Oil

Siphon

Siphon----------------------------------------------------------------Screw

Clamp,

Clamp,

Screw

---------------------------------------------------------------------

Crankshaft

Lucite

Plug

Screw-----------------------------------------------------------------

Oil

Wick,

Spring---------------------------------------------------------------------

Oil

Wick,

Oil

Wick,

Wedge

Oil

Wick,

PlugScrew-----------------------------------------------------------------

Gasket,

Gear----------------------------------------------------------

-----------------------------------------------------------------

Housing----------------------------------------------------------Driving

Housing

--------------------------------------------------------------------Cap

Assembly--------------------------------------------------------

--------------------------------------------------------------------Base

Base

---------------------------------------------------------------------

Isolators---------------------------------------------------------Isolators----------------------------------------------------------

---------------------------------------------------------------------

for

for

Knife

Drive

Rock

Bushing,

Bushing,

Drive

Rock

for

for

for

for

Holder,

Holder,

for

for

for

for

for

Holder,

Bar

for

Clamp-----------------------------------------------------------

Assembly----------------------------------------------------------

Tube-------------------------------------------------------------

Lint

Bar

Foot

Release

Connection---------------------------------------------------------

Siphon

Assembly--------------------------------------------------------

-----------------------------------------------------------------

Bushing

Oil

Gauge------------------------------------------------------------

for

for

for

Pin-----------------------------------------------------------------

for

for

Shaft------------------------------------------------------

Cover-----------------------------------------------------

sponge

Plate,

Plate,

Oil

looper

looper

Holder

Lever

Shaft

Lever

Shaft

Shaft

feed

Styles

Style

Style

differential

feed

differential

for

for

feed

upper

Bushing,

spreader

Filter---------------------------------------------------------

Bushing,

Lifter

upper---------------------------------------------------------lower

right

looper

left

feed

crankshaft

rubber--------------------------------------------------

for

all

Styles

for

Styles

Pad----------------------------------------------------------

rocker

rocker

Pin

Support----------------------------------------------

Shaft

Bushing,

Bushing--------------------------------------------------Bushing,

crank

52900

52900

52900

for

for

lift

Styles

Style

lift,

for

Lever

Connection

----------------------------------------------------------

main

main

rocker

Bushing,

left,

inner

middle-------------------------------------------------Shaft

Bushing,

link-------------------------------------------------

BF,

BL

---------------------------------------------------

BM---------------------------------------------------

Styles

Style

52900

feed

and

looper

feed

52900

52900

for

Style

feed

lift

Style

52900

upper

rocker

lower--------------------------------------------------

Lever

Bushing-------------------------------------------

Shaft

Locking

Housing,

shaft

rocker

shaft

shaft-----------------------------------------------

bearing

except

52900

and

left

and

left

right---------------------------------------------

right,

left----------------------------------------------

BG,

BH, BN,

52900

BF,

BL

bar

avoid

bar

BF,

BG, BH, BN, BP,

BM----------------------------------------------

52900

and

looper

BM------------------------------------------

-------------------------------------------------shaft

Bushing

including bush

bearing----------------------------------------

shaft---------------------------------------------

bearing------------------------------------------

housing----------------------------------------

52900

BP

ball

ball

front--------------------------------------

and

rear

BG, BH,

------------------------------------------

shaft,

eccentric,

guide,

BM

avoid,

------------------------------------------

-----------------------------------------

Ring---------------------------------------

BP-----------------------------

--------------------------------------

joint,

for

for

Style

Style

for

Style

all

Styles

Shaft

Bushin

BR

----------------------------

BM,

BN, B

52900

for

all Styles except

52900

BR------------------------

Style

joint,

Rocker

--------------------------------------

BP,

for

for

------------------------------------

ing---------------------------------

52900

BP

--.-------------

except

P, BR---------------

BL---------------------

BL

--------------------

52900

g,

BM

left,

52900

upper rig

52900

---------------

BP

-----

ht--

BM

Amt.

Req.

- 1

- 1

18

2

2

2

1

1

2

1

1

1

2

1

3

1

1

1

1

1

1

4

2

1

1

1

1

1

1

1

1

4

1

1

2

1

1

1

1

3

2

1

3

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

4

2

1

15

Page 16

16

Page 17

CHANKSHAFT,

NEEDLE

LEVEH

AND

LOOPER

DRIVING PARTS

f.

Part

No.

52944 c

22743

41076 D

52842 A

73

56958

54158

22768

56958

54158 A

652

22768

22586 H

51250 F

51250 D

660-212

51150

660-212

29066

22559 G

51216 N

51216 p

51216 G

52916

18

HA20 A

52052 B

22559 G

666-170

29348 p

51254 H

22562 A

54

78

51054

666-149

77

51215 J

A

51250

51250 E

52921 B

22894 G

660-202

22569 B

c

52951

I-I

22587

52947 A

29126 CR

52951

95

52951 A

660-244

660-246

29476

HW

29476

IIL

51216 i\1

BP

22560 B

52943 L

22894 X

29476

LE

22587

22729 D

51243 c

22729 D

52951 c

52942 A

56343 D

22894 X

He

No.

1

2

3

4

5

6

7

:3

!)

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

:n

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54 52951 B

55

56

57

58 51493

59

60

61

62

63

64

65

66

67

68

69

70

Description

Thread

Scrc\v

Thread

Needle

A

C-9

H.

Needle

Scre\V

Needle

Needle Lever

Screw --------------------------------------------------------------------Needle

Needle

Needle

Screw

Screw

Gasket---------------------------------------------------------------------

\\'

Oil

Needle

Oil

Needle

\V

Nut--------------------------------------------

Needle

Connecting

Nut------------------------------------------------------------------------

\Vashcr

Spreader

\Vick-----------------------------------------------------------------------

Needle

Pulley

Oil

Screw---------------------------------------------------------------------Spacing \Vasher------------------------------------------------------------Screw---------------------------------------------------------------------Counterweight

Spreader Drive

Crankshaft

Crankshaft

Pump

Collar--------------------------------------------------------------------Looper

Spacing

Looper

Collar---------------------------------------------------------------------

Eyelet,

--------------------------------------------------------------------Eyelet,

Bar

Bar

--------------------------------------------------------------------Lever

Bar

Bar

Bar

---------------------------------------------------------------------

---------------------------------------------------------------------

asher

--------------------------------------------------------------------

Seal

Ring

Lever

Sea

l Hing

Lever

Scre\V

asher

--------------------------------------------------------------------

Lever

--------------------------------------------------------------------

Screw------------------------------------------------------------------

Lever

Needle

Screw

Needle

Screw

Link

Lubricating

Screw

Needle

Needle

Needle

--------------------------

Screw

Seal Ring---------------------------------------------------------------

Spreader

Screw--------------------------------------------------------------

Connecting

Needle

Retaining

True-Arc

Needle

Driving

Screw-----------------------------------------------------------------Screw

Driving

Screw,

Screw

Ball

Stud Guide

Screw,

\\'asher

Drive

Screw

for

Style

52900

BP-------------------------------------

for

Assembly

Finger

Thread

Thread

Eyelet

-----------------------------------------------------------------

Hod-------------------------------------------------------------

Connecting

Bar

Bar

-----------------------------------------------------------------

Pin---------------------------------------------------------------

----------------Lever-----------------------------------------------------------

Lever

-----------------------------------------------------------------

Assembly,

Assembly,

Bearing---------------------------------------------------------

----------------------------------------------------------------upper-----------------------------------------------------------

-----------------------------------------------------------------

lower------------------

-----------------------------------------------------------------

Styles

Thread

Eyelet,

Eyelet,

Eyelet,

Eyelet,

Lock

--------------------------------------------------------------Shaft Stop

--------------------------------------------------------------Connecting

Connecting

Assembly------------------------------------------------------

Connection---------------------------------------------------

------------------------------------------------------------Link--------------------------------------------------------

Lever

Stud

----------------------Eccentric

Driving

Rod

Bearing-----------------------------------------------------

Washer

Ring

Gear---------------------------------------

Lever

---------------------------------------------

Lever

52900

BF,

(See

Page

Eyelet

for

Styles

for

Style

for

for

Washer----------------------------------------------

Collar-----------------------------------------------

Hod and

Hod-------------------------------------------------

Hod

Ball

Joint,

Felt

----------------------------------------------------

-

Bushing

------------------------------------------------------

Assembly-------------------------------------------

Eccentric,

Bearing------------------

-------------------------------------------------------

-----------------------------------------------for

Styles

for

Styles

Crank

---------------------------------------------------------

Rocker

Assembly----------------------------------------

Shaft---------------------------------------------

BG, BII, BL, BM, BN,

35)

-------------------------------------------

Support

52900

52900

Styles

Style

Upper

-----------------------------------------------

-----------------------------------------------

-

. 382

52900 BN,

52900

-------------------------------------

BF,

BG,

BP

--------------------------------------

52900

52900

upper-------------------------------------

------------------------------------------

-

BF,

BP

Bearing

-

--------------------------------------

inch

throw-------------------------------

BP,

BF,

BG, BH,

----------------------------------------

BH-----------------

Bl-1,

BL,

BM, BN, BR

BG,

Bl-1,

---------------------------------

Assembly----------------------

-

-------------------------------

. 990

BL,

BL, BM, BN, BR

-

------------------------

inch

throw

BM, BR, • 910

----------------

-

-----------------

----------------

inch

- ----

-----------

------

--·--

-----

throw

-

--

--

--

Amt.

Hcq.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

2

1

1

1

2

1

1

1

1

1

1

2

2

1

1

1

1

1

2

1

3

1

2

1

1

1

2

1

1

1

1

1

1

28

1

2

1

4

1

2

1

1

2

1

1

1

4

17

Page 18

18

Page 19

UPPER

KNIFE AND SPREADER DRIVE MECHANISM

Ref.

No. No.

1

2 55235 D

3

4

5

6 51147

7 95

8

9 52848

10

11

11A CL21

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35 52849 c

36

37

38 52855 G

39

40

41

42

43

44 51292

45

46

47

48 52973

49

50

51

52

53

54

55

56

57

58 52973 v

59

60

Part

52849

52849 B

6042 A

55235 E

15037 A

269

51240 D

18

52848 B

12934 A

258

52973 X

52973 z

52970 E

52973 T

97

52973 s

90

22857 B

52973 Q

22596

52855 A

668-25

668-28

43266

52952 c

55235 D

6042 A

55235 E

660-202

95

22872

95

51292 D

51292 A

51292

109

51292 c

258

52973 L

22811 B

22738 D

53636 c

52973 K

22857 B

22517

22580

60077 K

52973 w

129

22526

c

F-5

u

Description

Spreader

Screw------------------------------------------------------

Rocker

Washer-----------------------------------------------------

Nut

Collar------------------------------------------------------

Screw---------------------------------------------------

Nut

Spreader

Nut,

Spreader

Oil

Wick----------------------------------------------------

Nut,

Spreader

Nut

Nut

Upper

Knife

Knife,

Knife

Screw-----------------------------------------------------Knife

Screw-----------------------------------------------------Screw------------------------------------------------------

Upper

Screw-----------------------------------------------------Spreader

Steel

Locking

Nut

Spreader

Screw---------------------------------------------------

Washer

Nut-----------------------------------------------------

Oil

Ring----------------------------------------------------

Spreader

Screw--------------------------------------------------Screw-----------------------------------------------------Spreader

Screw--------------------------------------------------Tension

Tension

Spreader

Spreader

Tension

Tension

--------------------------------------------------------

Nut

Driving

Upper

Screw---------------------------------------------------

Screw--------------------------------------------------Washer-----------------------------------------------------

Driving

Screw-----------------------------------------------------Screw-----------------------------------------------------Screw------------------------------------------------------

Pin

--------------------------------------------------------

Upper

Upper

Washer-----------------------------------------------------

Screw------------------------------------------------------

Rocker

Shaft

--------------------------------------------------------

--------------------------------------------------------

Connecting Rod

left

thread

Connecting

right

thread--------------------------------------------

Connecting Rod

--------------------------------------------------------

-------------------------------------------------------Knife

Holder

upper------------------------------------------------

Clamp,

Holder

Knife

Thread

Eyelet

--------------------------------------------------------

Thread

Rocker

Thread

Thread

Post

Thread

Thread

Spring,

Nut

Lever

Knife

Lever

Knife

Knife

Shaft

---------------------------------------

Arm

-------------------------------------------

Ball

Joint,

--------------------------------------------Rod-------------------------------------

Ball

Joint,

Lever-------------------------------------------

Block

Block

Lever

Ring--------------------------------------------

-------------------------------------------------

-----------------------------------------------

Driving

Lever

Lever

------------------------------------------

upper------------------------------------------

Clamp------------------------------------

Thrust

Pull-Off

---------------------------------------------

Rock Shaft

Shaft

Pull-Off

Eyelet---------------------------------------

Ferrule---------------------------------------

Tension

Tension

spreader

Link

Adjusting

Lever --...

Link------------------------------------------

Stud

Stud--------------------------------------

Bracket

Eyelet------------------------------

Lever

Oil

Seal

Collar

Arm--------------------------------

Post--------------------------------

Disc--------------------------------

------------------------------------

Nut

--------------------------------

Support

rear----------------------

front----------------------

----------------------------

----------------------------

-------------------------

-----------------------------

Bracket

-----------------------

Amt.

Req.

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

2

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

2

2

2

1

1

1

1

19

Page 20

Page 21

LOOPER

ROCKER

AND

CONNECTING

ROD

PARTS

Ref.

No.

1

2

3

4

5

6

7

8

8A

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

25A

26

27

28

29

30

31

32

33

34

35

36

36A

37

38

39

40

41

42

43

44

45

51244

18

51216

51244

55244

52942

52942

22882

51242

41355

41355

41355

41355

41355

41355

20

18

52941

56341

50-458

18

51240

269

52841

73

73

29192

29192

29192

22829

258

15465

88

52913

73

52913

52913

51745

51244

96

51246

98

22768

51244

22519

18

51144

52808

1740

52909

52909

52909

52909

52908

52908

1740

52910

73 A

Part

No.

L

N

N

G

R

p

A

M

U-4

U-5

U-6

U-7

U-8

U-9

F

G

E

A

G

s

u

A

F

B

A

B

H

E

A

E-16

B-24

D

F-1

D

Blk.

Description

Thrust

Nut-----------------------------------------------------

Washer------------------------------------------------Looper

Locking

Looper

Looper

Shim, . 004

Shim, . 005

Shim, . 006

Shim, . 007

Shim, . 008

Shim, . 009

Washer-------------------------------------------------

Nut----------------------------------------------------Looper

Assembly,

Nut,

Looper

Nut,

Looper

Looper

Looper

Looper

BH,

Looper

Looper

Looper

Spot

Looper

Set

Screw

Looper

Nut----------------------------------------------------Looper

Looper,

Looper,

BH,

Looper,

52900

Looper,

Looper,

Looper,

Looper,

Looper

Screw

Washer

Rocker

Stud

Lever

Drive

Screw

Washer---------------------------------------------

Connecting

Spring---------------------------------------------Spring

right

Connecting

left

thread------------------------------------------

Connecting

Set

Set

Rocker

BM,

Rocker

Rocker

Lock

Nut

LockNut-------------------------------------------Looper

Set

Looper

BR

------------------------------------------------

Screw,

Looper

Looper

Looper

Rocker

Screw----------------------------------------------

Rocker

Screw

-----------------------------------------------

-------------------------------------------------Rocker

Screw

Rocker

front,

Pin-------------------------------------------------

back,

BL,

back,

BG,

back,

back,

middle,

front,

Pin-------------------------------------------------

Needle

----------------------------------------

------------------------------------------

Shaft

Collar-------------------------------

-------------------------------------------Stud---------------------------------------

Lever--------------------------------------

---------------------------------------------inch

thick

-------------------------------as

inch

thick

-------------------------------as

inch

thick

-------------------------------as

inch

thick

-------------------------------as

inch

thick

inch

right----------------------------------------

Pin

------------------------------------------

thread----------------------------------------

Screw,

Screw,

Assembly,

BN,

BR--------------------------------------Assembly,

Assembly,

Screw--------------------------------------

Rocker

Screw---------------------------------------

Rocker,

for

Rocker,

Rocker,

Rocker

Frame-----------------------------------Stud

Shaft

---------------------------------------------Shaft

for

for

BM,

BN,

for

BH,

for

for

for

Guard,

-------------------------------as

thick

-------------------------------as

Rod

Section

Rod----------------------------------Rod

Ball

for

Style

for

all

Cone

---------------------------------

for

Styles

looper---------------------------------

for

Style

for

Style

Cone

Stud-----------------------------

Nut

----------------------------------

Arm---------------------------------

-------------------------------------

all

Styles

No.

5-8

BR

---------

Nos.

12-12

BL,

BM,

No.

24-8

Style

52900

for

Style

Style

52900

for

Joint,

52900

Styles

for

for

for

52900